Mizerak P5423W2 User Manual

W e striv e t o ensur e tha t ou r product s ar e o f th e highes t quality

an d fre e o f manufacturin g defect s o r missin g parts . Howev e r , if

yo u hav e an y problem s wit h you r ne w product,

D O NO T RETUR N I T T O TH E S T ORE ,

pleas e contac t u s tol l fre e @:

1-86 6 -556-2757

F AX : 1-866-873-3531

pooltables@escaladesports.com

O r writ e to:

Escal a d e Spor t s

Cust o me r Servi c e Depa r tme n t

P .O . Bo x 8 8 9

Evansvill e I N 47706

Please

Whe n contactin g Escalad e Sport s pleas e provid e you r mode l numbe r , d at e

cod e (i f a pplicable ) an d par t n umbe r i f requestin g a replacemen t part . T hes e

number s ar e locate d o n th e product , packaging , an d t hi s owner s m anual .

Y ou r Mode l Numbe r _____ _ ________ _ ______

Dat e Cod e ________________________

hav e you r mode l numbe r whe n inquirin g abou t parts.

P5423W

2-P5423W- -WJ

Purchase Date ________________________

PLEASE RETAIN THIS INSTRUCTION MANUAL FOR FUTURE REFERENCE

All Rights Reserved.

©

201 2 Escalad e Sports

1

Fo r Custome r Servic e Cal l 1-866-556-2757

CAUTION

THE SPRAY ADHESIVE USED FOR APPLYING PLAYFIELD CLOTH IS EXTREMELY FLAMMABLE AND UNDER

PRESSURE

CHILDREN

AREA MUST BE WELL VENTILATED

To ensure safety, do not attempt to assemble system without followinginstructions carefully. Proper and complete assembly, use, and supervision is essential for

proper operation and to reduce the risk of accident or injury.Ahigh probability of serious injury exists if this system is not installed, maintained, and

operated properly.

! CAREFULLY READ CAUTIONS ON SPRAY ADHESIVE CONTAINER ! KEEP OUT OF THE REACH OF

! DO NOT USE OR STORE NEAR HEAT SOURCE , FLAMES , SPARKS OR WHEN SMOKING !

. OPEN DOORS AND WINDOWS WHEN USING SPRAY ADHESIVE .

WORK

READ AND FOLLOW ALL ASSEMBLY, OPERATION, AND

SAFETY INSTRUCTIONS CAREFULLY. AT LEAST TWO

ADULTS ARE NEEDED TO PUT THIS TABLE

TOGETHER.

Tools Needed: (Not Included)

Philips Screwdriver

•

• Putty Knife

• Needle Nose Plyers

• Tape Measure

• Sanding Block

• Scissors or Sharp Knife

• Adjustable Wrench

• Small Hammer

• Carpenters Level

• Ratchet with socket

• 12mm Socket or End Wrench

NOTE: This table adds weight to any floor. Be sure floor can withstand this kind of weight.

If floor sags, table will be impossible to level.

All Rights Reserved.

©

2012 Escalade Sports

2

For Customer Service Call 1-866-556-2757

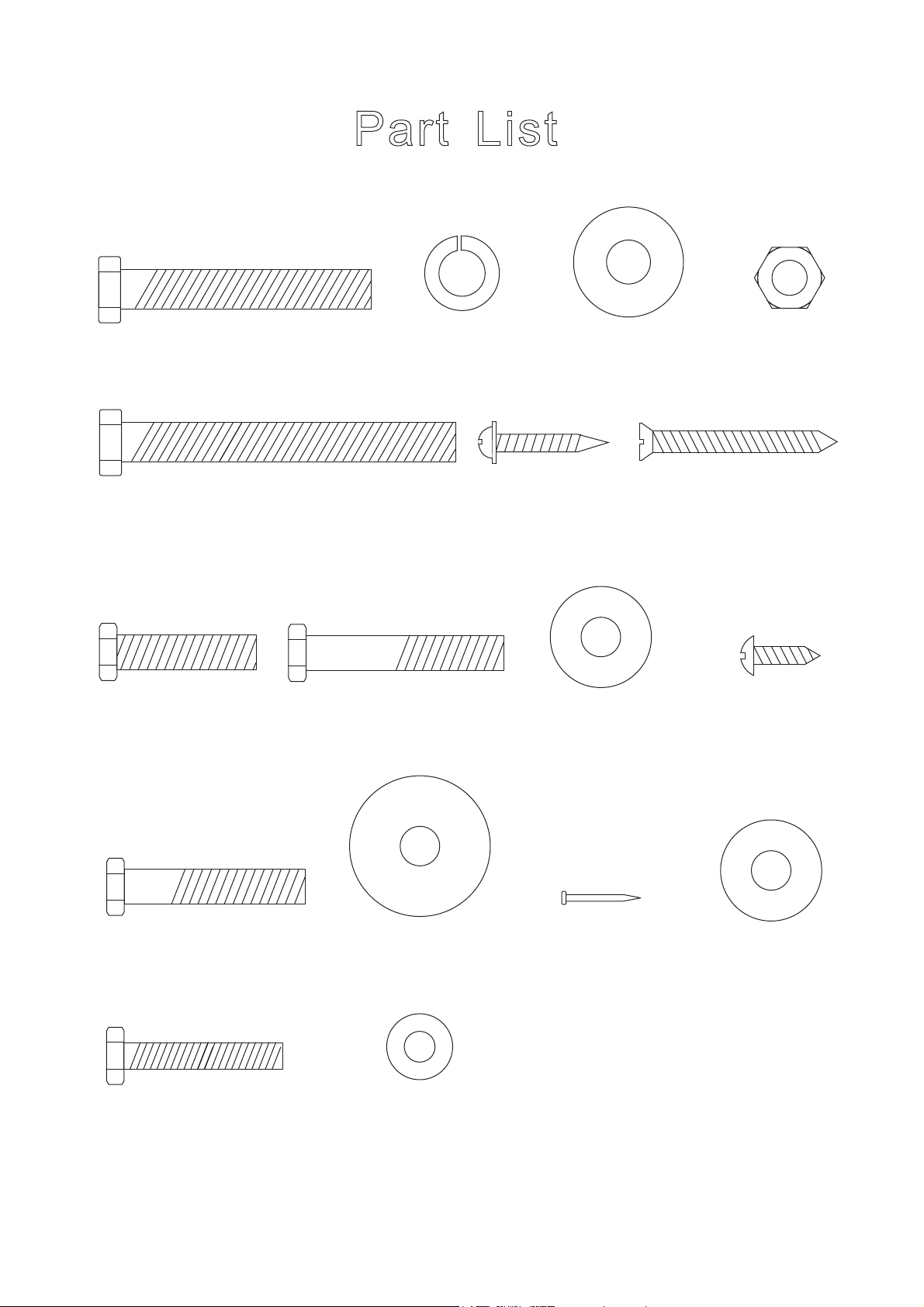

Pa r t Li s t

(To Scale)

H1 - 3/8” x 2-1/4” Bolt

(8 pcs)

H5 - 3/8” x 3” Bolt

H8 - 5/16” x 1-1/4” Bolt

(8 pcs)

(8 pcs)

H2 - 3/8” Lock

Washer (16 pcs)

H9 - 5/16” x 1-3/4” Bolt

(12 pcs)

H3 - 3/8” x 25mm

Flat Washer (32 pcs)

H6 - WP/4 x 1”

Phillips Washer

Head Screw

(12 pcs)

H10 - 5/16” x 23mm

Flat Washer (12 pcs)

H4 - 3/8” Hex Nut

(16 pcs)

H7 - F5 x 1-3/4”

Phillips Flat Head Screw

(16 pcs)

H11 - T4 x 15mm

Phillips Round Head

Screw (24 pcs)

H12 - 5/16” x 1-5/8” Bolt

(18 pcs)

H16 - 1/4” x 1-1/2” Bolt

(4 pcs)

All Rights Reserved.

©

201 2 Escalad e Sports

H13 - 5/16” x 32mm

Flat Washer (18 pcs)

H17 - 1/4” x 15mm

Flat Washer (4 pcs)

3

H14 - Pocket Nail

(36 pcs)

Fo r Custome r Servic e Cal l 1-866-556-2757

H15 - 5/16” x 23mm

Flat Washer

(8 pcs)

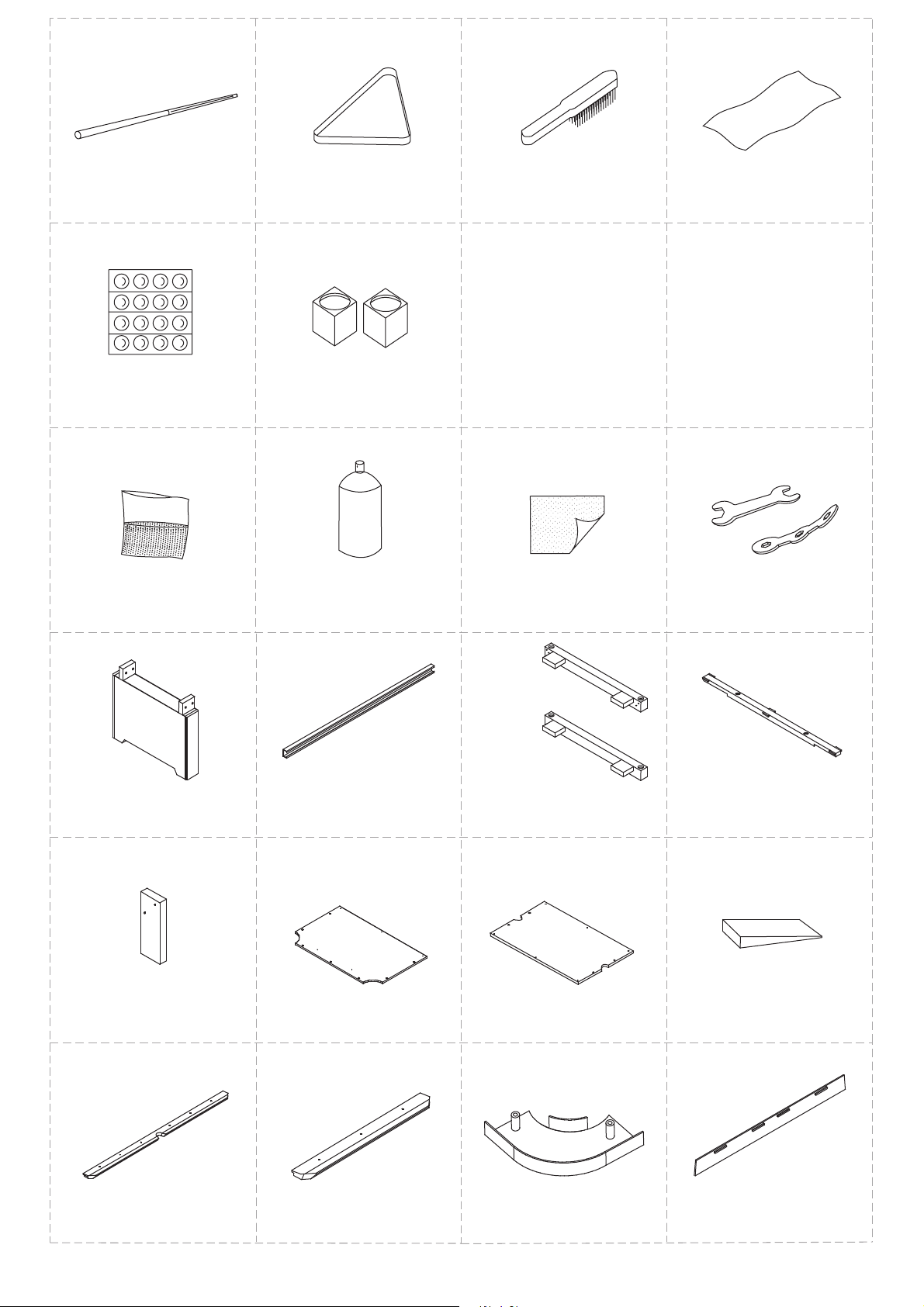

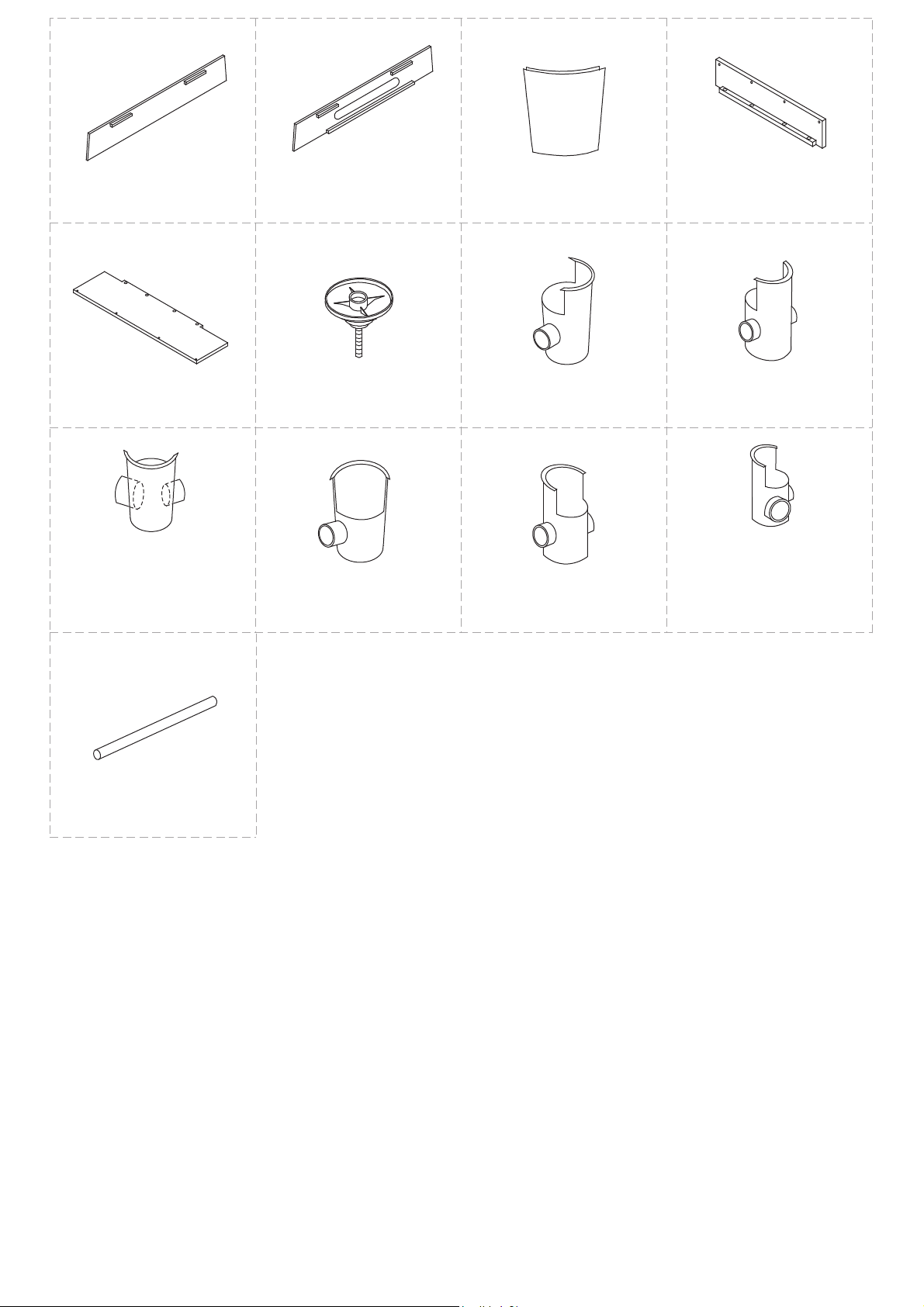

A1

A2

A3

A4

Cu e Stic k

A5

Billiar d Bal l

T1

Playfield Grout Kit

2 Pcs

1 Se t

1 Pc

T riangl e

1 P c

A6

Cue Chalk

2 Pc s

T2

Playfield Cloth to Playfield

- Spray Adhesive 1 P c

Playfield Cloth Brush

1 P c

T3

Sand Paper for Dried Grout

1 Pc

Playfield Cloth

1 P c

T4

Wrench

1 Set

P1

P5

P9

Leg

2 Pcs

End Board

2 Pcs

P2

Main Metal Beam

2 Pcs

P6 - Slatron

P6S - Slate

End Play Bed

2 Pcs

P10

P3A

NOTE: For P5

Installation.

P3B

NOTE: For P16

Installation.

End Slat

2 Pcs

P7 - Slatron

P7S - Slate

Middle Play Bed

1 Pc

P11

P4

Middle Slat

2 Pcs

P8

Shim

8 Pcs

Can also use playing cards (not included)

or Slate / Slatron Shims

P12

Side Top Rail

2 Pcs

All Rights Reserved.

©

201 2 Escalad e Sports

End Top Rail

2 Pcs

Corner Cap

4 Pcs

4

Fo r Custome r Servic e Cal l 1-866-556-2757

Side Apron

2 Pcs

P13

P14

P15

P16

End Apron

1 Pc

P17

Ball Return Tray Board

1 Pc

P21

Right Corner Pocket

NOTE: Attach this pocket on

same end as P14 Apron with

Ball Return Opening

1 Pc

End Apron with Ball

Return Opening

1 P c

P18

Leg Leveler

4 Pcs

P22

Left Corner Pocket

1 Pc

Corner Post

4 Pcs

P19

Right Corner Pocket

1 Pc

P23

Left Middle Pocket

1 Pc

Ball Return

Support Board

1 Pc

P20

Right Middle Pocket

1 Pc

P24

Left Corner Pocket

NOTE: Attach this pocket on

same end as P14 Apron with

Ball Return Opening

1 Pc

P25

Ball Return Tube

4 Pcs

All Rights Reserved.

©

201 2 Escalad e Sports

5

Fo r Custome r Servic e Cal l 1-866-556-2757

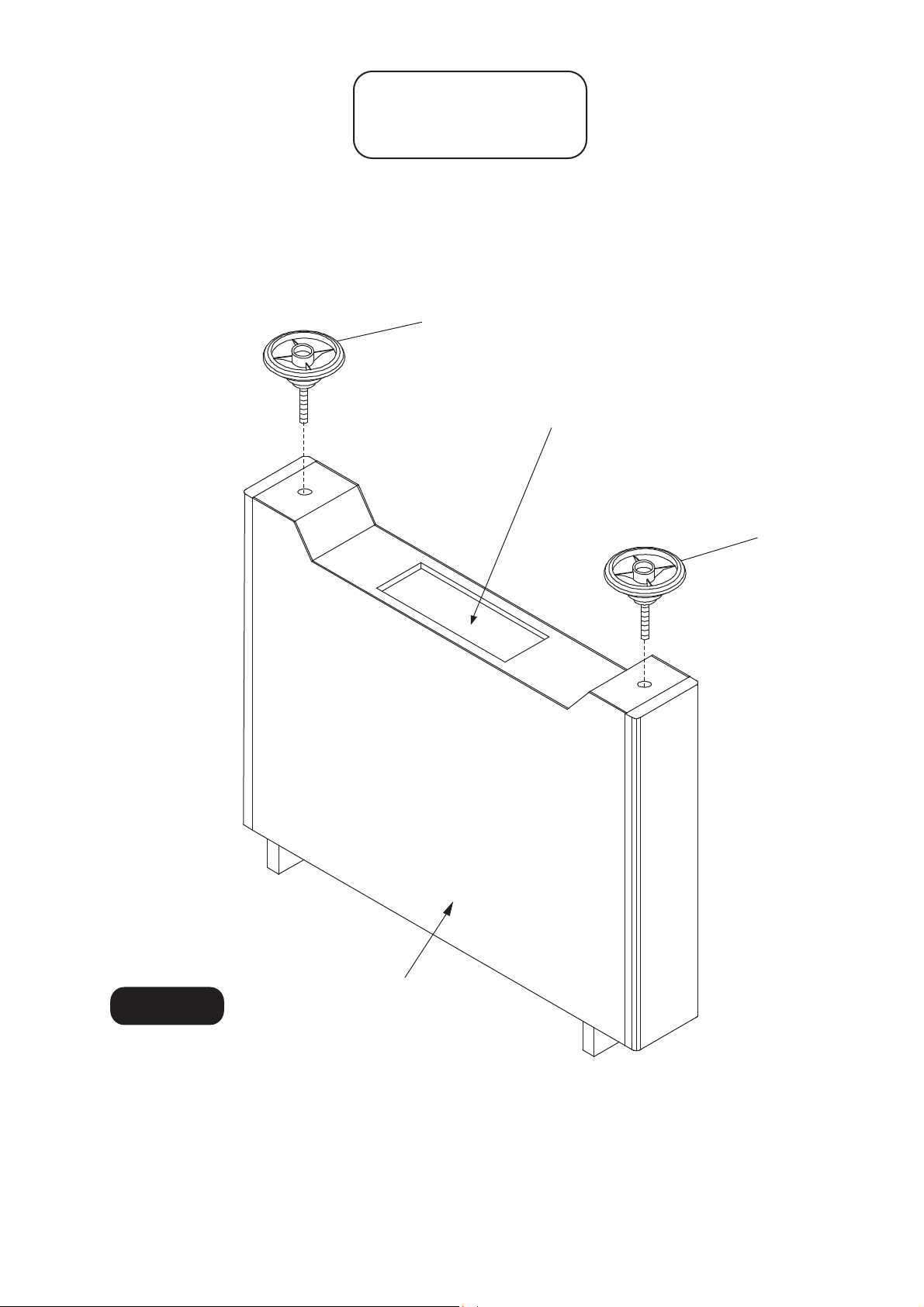

P ARTS REQUIRED:

2 pcs - P1 Leg

4 pcs - P18 Leg Leveler

ST E P 1 :

Thread P18 Leg Levelers into P1 Leg as shown in Figure 1. .

P18

Note: Remove Parts Box, Leg Levelers,

Plastic Pockets and Spray Glue from

inside both Legs.

P18

Figure 1

All Rights Reserved.

©

201 2 Escalad e Sports

P1

6

Fo r Custome r Servic e Cal l 1-866-556-2757

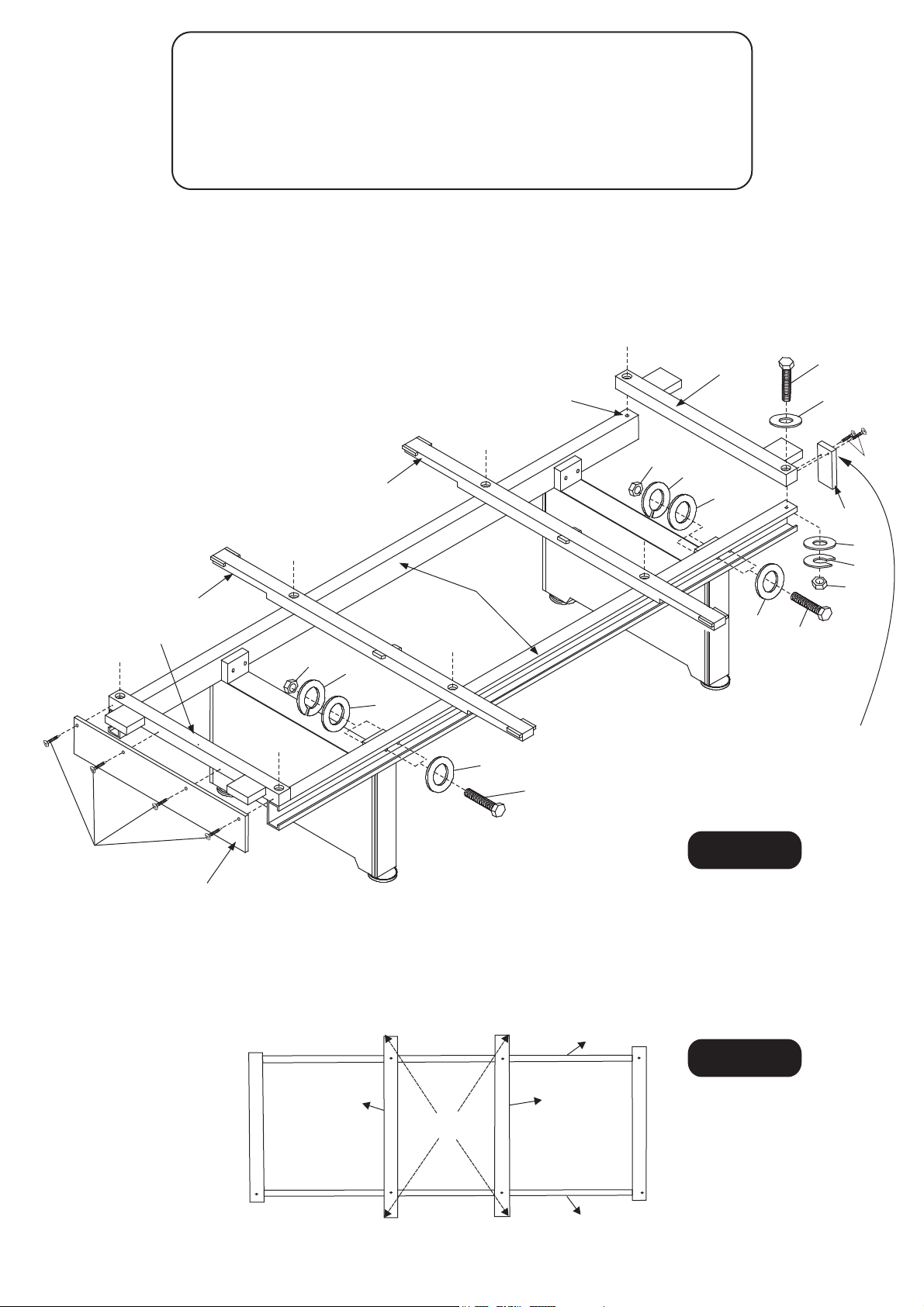

PARTS REQUIRED:

8 pcs - H1 Bolt

16 pcs - H2 Lock Washer

32 pcs - H3 Washer

16 pcs - H4 Hex Nut

8 pcs - H5 Bolt

8 pcs - H6 Screw

2 pcs - P2 Main Metal Beam

2 pcs 2 pcs - P4 Middle Slat

2 pcs - P5 End Board

1 pc 1 set - T4 Wrench

P3A & P3B End Slat

P16 Ball Return Support Board

ST E P 2 :

Attach each P2 Main Metal Beam to P1 Leg assembly as shown Figure 2 using H1 Bolts, H3 Washers,

H2 Lock Washers and H4 Hex Nuts. Use the T4 Wrench to assemble the hardware. Do not tighten

hardware at this time. Place P3 A and P3B End Slats and P4 Middle Slats across P2 Main Beams and

attach using H5 Bolts, H3 washers, H2 Lock Washers and H4 Hex Nuts as shown in Figure 2.

Attach P5 End Boards to P3A End Slat using pre-drilled pilot holes with H6 Screws as shown in Figure 2.

Attach P16 Ball Return Support Board to P3B End Slat using pre-drilled pilot holes with H6 Screws as

shown in Figure 2.

IMPORTANT NOTE:

Make sure holes are located on the

top of both P2 Main Metal Beams.

P3A

H5

H3

H6

P3B

P4

P16

H4

H2

P4

H3

P2

H3

H1

H4

H2

H3

H3

H1

Note: P5 End Boards must be

flush or slightly lower than top

of P3A End Slats.

Figure 2

H6

P5

H3

H2

H4

STEP 3:

Square up P4 Slats by measuring diagonally as show in Figure 3. Diagonal measurements should be

the same within 1/8". If the frame is not square, adjustment can be made by moving table beams P2 in

opposite directions. Once the frame is square, tighten all hardware.

P2

Figure 3

P4

P2

Fo r Custome r Servic e Cal l 1-866-556-2757

All Rights Reserved.

©

201 2 Escalad e Sports

P4

SAME

DIMENSION

7

Loading...

Loading...