Page 1

MiX 4000

Installation Guide

Page 2

Table of Contents

1 Introduction ................................................................................................................................ 3

1.1 Glossary Terms .................................................................................................................. 3

1.2 MiX 4000 Hardware Features .......................................................................................... 3

1.3 MiX 4000 Power Requirements ....................................................................................... 4

2. Safety .......................................................................................................................................... 4

2.1 Installer Requirements ....................................................................................................... 4

3. Prior to Installation .................................................................................................................... 5

3.1 Preparing the SIM card ...................................................................................................... 5

3.2 Inserting of SIM card .......................................................................................................... 5

3.3 Configuration of unit ........................................................................................................... 5

3.4 Installation Steps ................................................................................................................ 6

4. Installation .................................................................................................................................. 6

4.1 During installation ............................................................................................................... 6

4.2 Positioning of product components ................................................................................. 6

4.3 General Wiring Requirements .......................................................................................... 8

4.4 Harnesses and connectors ............................................................................................. 10

4.5 Wiring and Connections .................................................................................................. 14

4.6 Code Plug Socket Installation ........................................................................................ 17

4.7 Signal Inputs...................................................................................................................... 18

4.8 Power Outputs .................................................................................................................. 19

4.9 Serial Communication ...................................................................................................... 21

4.10 CAN ................................................................................................................................. 21

4.10.1 Overview ..................................................................................................................... 21

4.10.2 Tools and Inspection need for CAN Installation ................................................... 21

4.10.3 Wire lengths ............................................................................................................... 22

4.10.4 CAN jumper settings ................................................................................................. 22

4.10.5 When must the 120 Ohm terminating resistor be in the circuit?........................ 25

4.10.6 General Rules for CAN terminating resistors ....................................................... 25

4.10.7 When must the RD/WR Jumpers be in the circuit? ............................................. 26

4.11 DLD and DTCO ............................................................................................................. 27

4.11.1 D-8 ............................................................................................................................... 27

4.11.2 Connect CAN to DTCO ............................................................................................ 27

4.11.3 K-line ........................................................................................................................... 28

4.12 Bluetooth ........................................................................................................................ 28

5. After Installation ................................................................................................................ 28

5.1 Beep codes ........................................................................................................................ 28

5.2 LED flash codes................................................................................................................ 29

5.3 Testing Installation ........................................................................................................... 30

6. Troubleshooting ....................................................................................................................... 30

7. Routine Maintenance.............................................................................................................. 31

8. MiX 4000 Specifications ......................................................................................................... 31

8.1 Technical description ....................................................................................................... 31

8.2 Auxiliary inputs/outputs.................................................................................................... 32

2 | Page

Page 3

8.3

Inserting a Backup Battery .............................................................................................. 33

1 Introduction

The MiX 4000 is a high end Fleet product that incorporates the latest market trends.

1.1 Glossary Terms

ABBREVIATION DESCRIPTION

BT

DLD

DTCO

GPS

GSM

GND

RX

TX

WiFi

BT

Bluetooth

Download Device

Digital Tachograph

Global Positioning System

Global System for Mobile Communications

Ground (0V)

Receive

Transmit

Local Area Wireless Computer Network

Bluetooth

1.2 MiX 4000 Hardware Features

Digital/Analog Inputs

Frequency Inputs

Tacho Inputs

Ignition input

CAN

GNSS

GSM

Serial Ports

K-line and D8

Bluetooth

Accelerometer

Positive drive

Tamper detection

Code Plug

There are 2 analogue inputs can be configured to monitor any device that

generates a change in voltage, e.g. seat belts, headlights, refrigeration units,

temperature sensors, emergency lights, doors, PTO, UDS, trailer coupling

etc. Disconnection of these inputs can be detected using open-wire detect.

There are 2 x frequency/pulse inputs for integration with legacy sensors exist

It is possible to configure any of the 4 existing inputs listed above

(Digital/Analogue and Frequency) as tacho inputs

Used to monitor the ignition switch status. Maximum 36V input, impedance >

100kOhm. The unit is able to detect when the Ignition gets connected or

disconnected. Disconnection of this input can be detected with open-wire

detect.

The system has 2 x CAN inputs that support J1939 and OBDII CAN as a

minimum. Configuration of the termination resistor and the transmit disable

can be done either with jumpers (for safety critical installs) or via software

settings.

GPS and Glonass available

3G UMTS/HSDPA/HSUPA Characteristics

2x RS232 serial ports (with flow control)

K-line interface for Digital Tachograph (DTCO D8 input)

Support Bluetooth V4 and CSA2

3-axis ±2g /±4g / ±8 g / ±16 g dynamically selectable full-scale and is

capable of measuring acceleration with output data rates from 1 Hz to 5 kHz

4 x Positive drive with open-load detect and current sense diagnostics, 1x

with 1.5A current limit and 3x with 250mA current limit

Tamper detection when the housing is opened (covers removed). Shorting,

cutting, or unplugging any of the external antennas can also be detected.

Standard FM code plug circuit (Optional: 5V aux output)

Only Blue Driver plug supported.

3 | Page

Page 4

Internal Back up battery

Buzzer and LED

RF Transceiver

RTC

1.3 MiX 4000 Power Requirements

The MiX 4000 is designed for use in 12V or 24V vehicles. Special vehicles and working machines with

voltages above 33V will require a voltage converter to facilitate the required power supply input.

2. Safety

2.1 Installer Requirements

Installation should only be undertaken by a vehicle technician with comprehensive occupation

specific knowledge. Installation by an unqualified technician may adversely affect the operating

reliability of the vehicle and could endanger other road users.

A basic knowledge of vehicle electrical and mechanical systems is required to successfully install

the Fleet Manager system.

The system should only be installed by a suitably qualified vehicle technician with a basic knowledge

of the operation of computers.

Installation technicians should attend a training course to acquire the skills needed for installation,

configuration and operation of the Fleet Manager system.

An internal battery provides power for more than 8 hours if the supply from

the vehicle’s battery is removed.

A Buzzer is available to warn the driver and to provide feedback of the

vehicle’s status. 2 x LEDs at the back provide feedback on the status of the

unit.

433 or 915 MHz RF transceiver

Real time clock with coin-cell battery

Installers should consult the vehicle manufacturer’s documentation for the specific vehicle make and

model prior to undertaking an installation.

Installers should pay particular attention to the location of fuel systems, hydraulic systems,

compressed air systems and other electrical and mechanical systems, which may have a bearing on

the installation.

Installers should pay attention to any changes to the vehicle’s systems or settings, which should be

noted prior to the installation.

Installers should not smoke or make use of naked flames, which could cause a fire in or near the

vehicle.

After installation, verify that no interference is caused to the vehicle’s electrical system. Check dashboard

warning lights and error messages. Should any error conditions exist, remove the installed unit and contact

MiX Telematics for assistance.

2.1.1 Tools

Standard technical equipment and appropriate tools for use with vehicles are required to install

the MiX 4000.

Vehicle specific tools may be required for the removal of consoles and covers.

Supporting tools

o Multi-meter

2.1.2 Secure the workplace

Remove the ignition key from the vehicle’s ignition lock.

4 | Page

Page 5

Ensure that the vehicle’s engine cannot be unintentionally started during the installation.

Short-circuiting the vehicle’s electrical system may result in fire, explosion of the battery and/or

damage to other electrical systems.

Electrical shock from high voltage batteries must be avoided, as this may lead to death or injury.

The negative terminal of the vehicle’s battery should be disconnected before commencing

installation. If the vehicle has additional batteries, it may be necessary to disconnect the

negative terminals of these batteries too.

2.1.3 Precautions

2.1.3.1 ESD

Prior to touching the PCB, inserting a new SIM or replacing the battery, always take ESD precautions:

Either use an earthed wrist strap or touch a known earth point (or negative potential in the

vehicle) prior to handling the unit

If the PCB must be handled, avoid direct contact with any of the components and handle it by

only touching the edges of the PCB

3. Prior to Installation

3.1 Preparing the SIM card

Before inserting the SIM card determine if the SIM needs to be secured with a unique PIN

If a PIN secured SIM is required

Ensure that the SIM is configured as “PIN required”

Ensure that the PIN is set as either 0000 or 00000

The MiX 4000 will change the PIN to a unique number that it calculates for the device

The SIM is then locked to the device and will be PUK locked if inserted in another device

If an unsecured SIM is required

Ensure the SIM is configured as “PIN not required”

The MiX 4000 will leave the SIM with this configuration

This SIM can be moved to a different device without risk of it being PUK locked

3.2 Inserting of SIM card

In order to insert the SIM card, the following steps must be followed:

Observe ESD precautions as prescribed in section 2.1.3

The SIM card is accessible from the back panel.

Insert the SIM card as indicated by the engraved symbol on the housing plastic.

3.3 Configuration of unit

The MiX 4000 is configured with default fleet settings during commissioning. Via the MiX Fleet Manager

software interface it is possible to make over the air changes to some settings.

5 | Page

Page 6

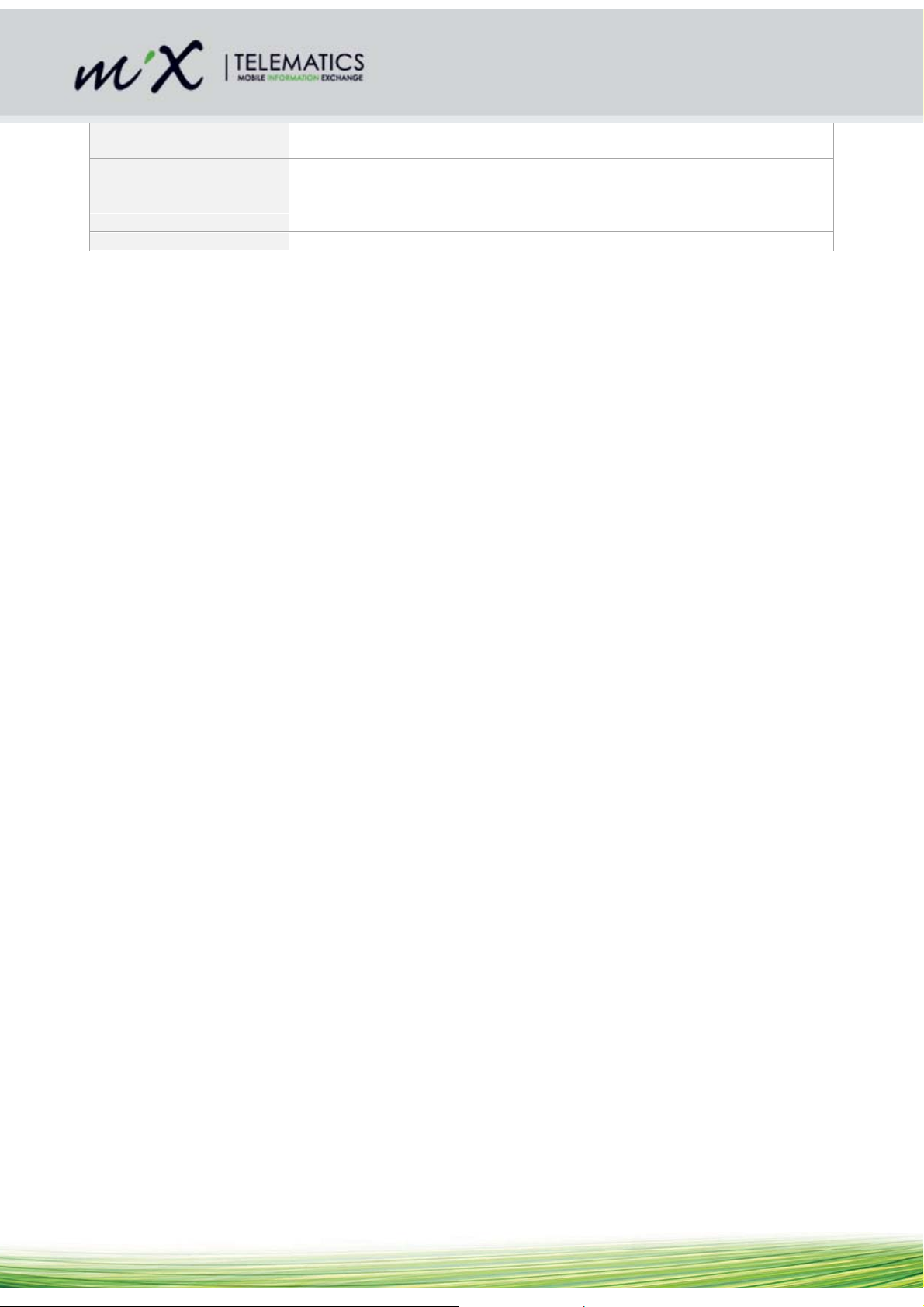

3.4 Installation Steps

Step Action Software Tools

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

11)

12)

On the MiX 4000, the unit maintains an on-board odometer. This starts at 0 km from the factory. An offset

can be sent from the MiX Telematics Fleet Manager user interface to align the odometer value on the MiX

4000 unit with the vehicle odometer at install time using the Bluetooth installation tool. An updated value can

be sent at any time over the air from Dynamix to realign these two values.

4. Installation

Ensure the SIM is correctly prepared (refer to section 3.1) None

Insert the SIM card (refer to ESD precautions in section 3.2). The

SIM card orientation is illustrated in section 3.1

Configure the unit as described in section 3.3 Dynamix

Configure Bluetooth if applicable (section 4.12) Bluetooth Installation Tool

Install harness None

Install code plug socket None

Install GPS antenna None

Connect power and signal inputs None

Test Installation Verify that the unit reports

Test GSM observing the LED flashing sequence (see section 5.2) None

Test GPS observing the LED flashing sequence (see section 5.2) None

Install unit

None

to the Back End

4.1 During installation

Should it be necessary to remove seats, covers or other components, care should be taken to avoid

accidental damage and/or disconnection of cables.

All components should be checked for damage prior to being installed into the vehicle.

For small installation openings, a drill should be used.

For larger openings, a conical milling cutter, compass saw or file should be used.

All rough edges should be trimmed.

Careful attention must be paid to the manufacturers’ safety regulations for all tools used.

Oils and fuels must be collected in appropriate containers and disposed of in accordance with

the law.

4.2 Positioning of product components

Installers should ensure that the components of the product do not influence or hamper the functioning of

the vehicle’s systems.

Care should be taken to ensure that the product’s components do not get damaged during

installation.

Ensure that sufficient space is available for all components of the product, prior to

commencing the installation.

6 | Page

Page 7

Should the bracket be used to fix the unit to the vehicle, make sure that the unit and bracket

are securely clipped together. Add a cable-tie around the complete housing and bracket

assembly for a more secure mounting it required.

Avoid installing in known high-temperature areas, such as parts of the engine bay or near

major heat sources.

o Operating range (with backup battery): -20°C to +60°

o Operating range (without backup battery): -20°C to +80°

o Battery will only charge in the range 0°C to +45°C

Ensure that the unit and harness are secured to prevent the harness vibrating differently to

the unit at the harness connectors.

Correct orientation of the unit is important to ensure good GPS reception if the internal GPS

antenna is being used (it is not a problem if the external antenna is used). In this case where

the internal antenna is used, the unit should be mounted with the top side (with

MiXTelematics engraved) facing up, and the label side down. Additionally, it is advisable to

install the unit in a location where the GPS view of the sky is relatively unobstructed by metal.

Most vehicle boots for example, may form a metal cage which prevents GPS reception. Under

the vehicle bonnet will also not give good performance.

Engraved side facing up

Please note that the voltage of the external relay is rated to the vehicle voltage specification.

Do not run a 12V relay at 24V. The Relay Specifications are:

o Coil current rating: < 250 mA

o Coil Voltage Rating: Must match the vehicle battery supply

Please pay attention to the routing course of cables and wiring.

Do not install the product in or near the location of mechanical or electrical airbags.

Do not install the GSM antenna onto any cable or metal parts (it only applies to optional

external GSM).

Do not drill into supporting or stabilizing braces or beams.

7 | Page

Page 8

4.3 General Wiring Requirements

Note the product’s wire gauge cross-sectional area. If the wire gauge cross-section is reduced, current

density increases which may cause the wiring to overheat.

Cables should be routed in existing channels and should not be routed parallel to ignition cables

or other cables subject to high current.

Cables should be fixed with cable-ties or adhesive tape.

Do not route cables over moving parts or too close to the high voltage areas (like the spark

plugs)

Do not fix cables on the steering column.

Ensure that the cables are not exposed to pulling, pressure or shearing deformation.

If the cables are routed through drilled holes, rubber grommets or similar protection should be

used.

Suitable cable-strippers should be used to strip insulating material from cables and cable-

strippers should be adjusted to suit the wire gauge being stripped, to avoid damaging or

separating the wire strands.

Cables should only be connected using solder or suitable crimping lugs.

A proper crimping tool should be used on all crimping lugs.

Careful attention must be paid to the manufacturers’ safety regulations for all tools used.

Insulate all exposed wires to prevent short-circuits. Use good quality adhesive tape or heat

shrink (provided).

Connections to vehicle power supply must be installed with a fuse (check if the main harness is

fitted with a fuse).

Be aware that short-circuiting may be caused by faulty connections and crushed or damaged

cables.

Short-circuiting the vehicle’s electrical system may result in fire, explosion of the battery and/or

damage to other electrical systems. To prevent this, all connections carrying current must be

soldered and insulated correctly. Other connections such as the speed signal, RPM signal,

brake light or clutch switch can be made with crimping lugs.

Incorrect connections can lead to short circuits. Connections should only be made in

accordance with the vehicle’s wiring diagram.

Current and voltage should be measured with a multi-meter or diode test lamp.

The use of inadequate test equipment may result in damage to control devices or other

electrical systems.

Route the harness in such a way as to prevent water condensation that may form on the cable

from running into the unit. This can be achieved by having the harness at a lower point just

before it connects to the unit. If the back plate is lower than the rest of the unit, water can

accumulate inside the unit with no way to escape and invalidates the IP54 rating. The unit

should also never be exposed to direct water spray and jets.

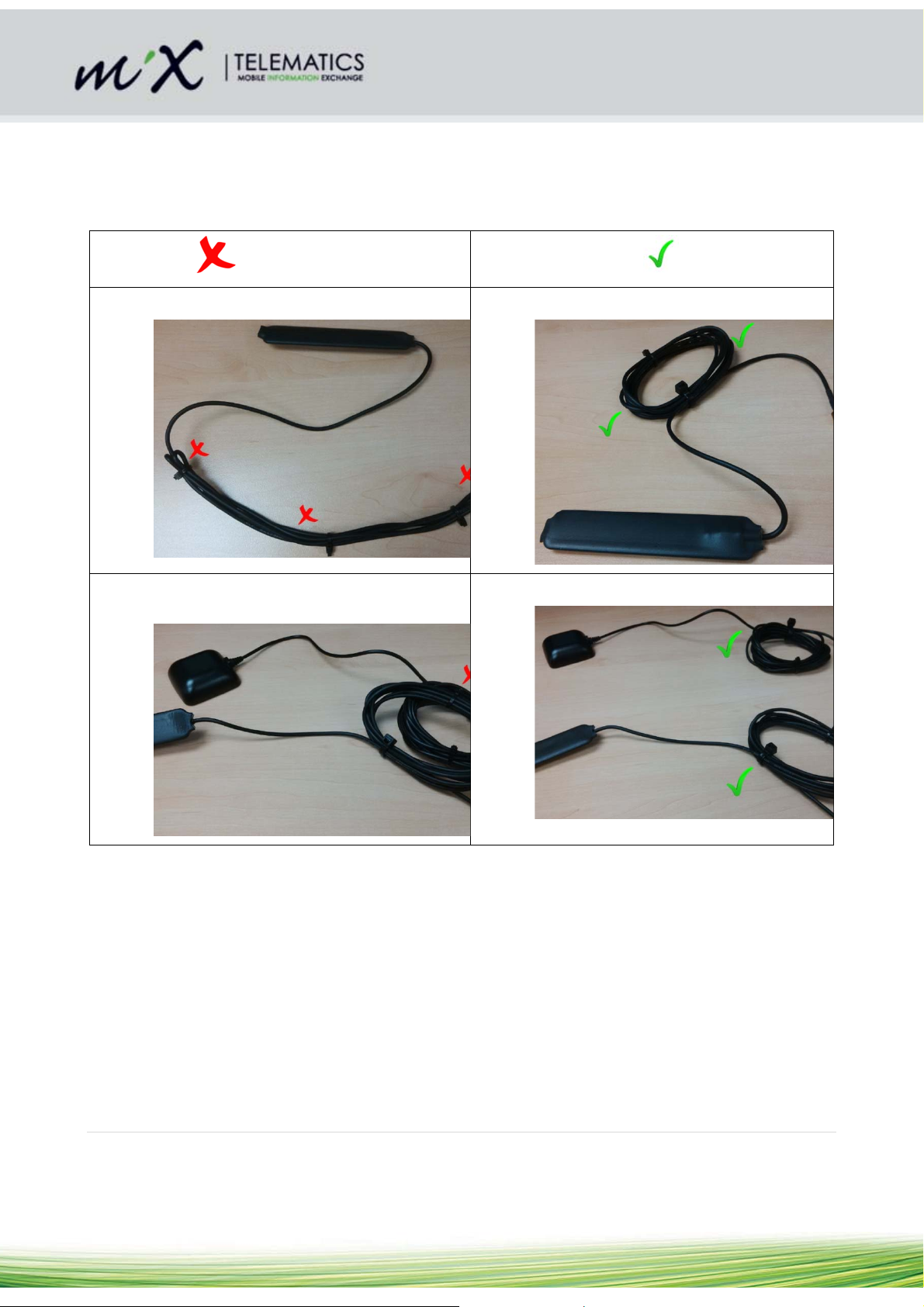

Shortening of antenna wires:

o It would be better to circle/coil excess wires. Avoid sharp bends at the zig/zags. Take

care not to tie coax wires too tight. The coax should not be squeezed or pinched. Using

the broadest possible cable tie.

o The best place to circle/coil the wires is about 300 mm in line from the antenna.

8 | Page

Page 9

o If the GSM and GPS antennas are both coiled, they should be spaced apart.

o Refer to section 4.4.7 for more detailed GPS wiring instructions

o Refer to section 4.4.8 for more detailed GSM wiring instructions

Avoid

Avoid sharp corners and bends: Use rounded bends:

Avoid coupling between 2 different pieces of

wire:

Recommended

Separate coiled wires where possible:

9 | Page

Page 10

4.4 Harnesses and connectors

Please read the “Safety” section of this document before installing the vehicle harness.

Confirm which of the harnesses will be used in the install as the wire colours will differ depending on the

harness selected. All connector diagrams are shown from the back (wiring side) of the harness.

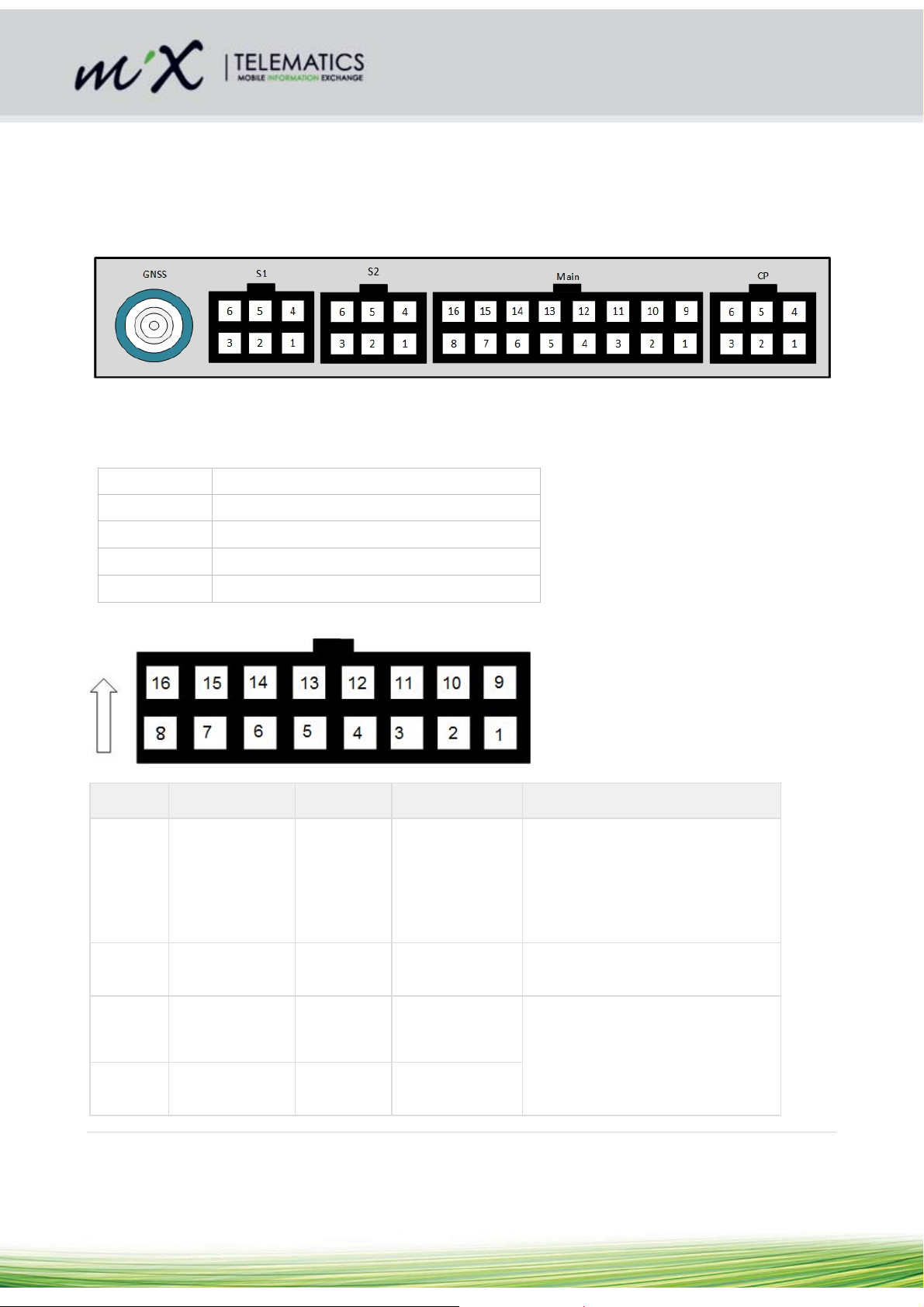

Below is the front view of the MiX 4000.

The pin lay-out and wire colours of the various harness options as well as detailed tables describing pin

functions are shown below.

4.4.1 Harness Part Numbers

440FT0982

440FT0930

440FT0931

440FT0933

440FT0945

4.4.2 Main Harness

Connector viewed from the back (wiring side) of harness (440FT0982)

PIN Color Name Function Application Information

MiX 4000 Main Harness

Code Plug Harness CP2

Serial Harness SR1

GLONASS/GPS External GPS Antenna

Code Plug Socket Harness CP1

1 RED BAT+ Vehicle battery + Connect to vehicle battery +12V to

+24V.

Must be protected with the provided

7.5 amp slow blow fuse, or a similar

one already present in the vehicles

wiring.

2 BLACK IGN Ignition input Connect to vehicle ignition switch.

Must be protected with a 1 amp fuse

3 WHITE/VIOLET ANALOG1 Analogue input 1 Maximum signal voltage = 38V.

Do not connect signals from

unsuppressed inductive sources

4 WHITE/RED ANALOG2 Analogue input

2

such as relay coils (where severe

voltage spikes can be generated)

10 | Page

Page 11

PIN Color Name Function Application Information

5 DARK GREEN FREQ1 Frequency 1 Frequency Input

Maximum signal voltage level = 38V

6 BLUE/WHITE FREQ2 Frequency 2

7 RED/BLUE POSD3 Positive Drive 3 Load current must not exceed 250

mA

Output controlled by MiX 4000 and

selected in Vehicle Properties of

front end user software

8 BROWN/BLUE POSD4 Positive Drive 4 Load current must not exceed 250

mA

Output controlled by MiX 4000 and

selected in Vehicle Properties of

front end user software

9 BROWN GND Ground Connect directly to vehicle ground.

Do not tap into an existing ground

wire carrying high current.

10 RED/WHITE CP-5V-

OUT

11 YELLOW CAN1 P CAN1 High 1st CAN Bus: Used to monitor

12 GREEN CAN1 N CAN1 Low

13 GRAY K-LINE K-Line serial

14 YELLOW/GREEN BUZZOUT Buzzer Output Provides warning sounds

15 YELLOW/BLACK CAN2 P CAN2 High 2nd CAN Bus: Used to monitor

16 GREEN/BLACK CAN2 N CAN2 Low

Code Plug 5V

Out

signal

Can deliver nominal 100 mA

supported CAN bus

Serial communication to DTCO

supported CAN bus

11 | Page

Page 12

4.4.3 Code Plug Harness CP2

Connector viewed from the back (wiring side) of harness (440FT0930)

Pin Colour

(Prim/Sec)

1 White CP Clock Code Plug Clock

2 Red/White CP 5V Code Plug 5V

3 Green CP Data Code Plug Data

4 Red (Twisted with white) LED Code Plug LED

5 NC Not connected

6 Black/White GND Ground

4.4.4 Serial Harness SR1

Connector viewed from the back (wiring side) of harness (440FT0931)

Pin Colour

(Prim/Sec)

Name Function Application Information

Name Function Application

Information

1 Yellow TXD RS-232 Transmit

2 White RXD RS-232 Receive

3 Blue RTS Ready to send

4 Green CTS Clear to send

5 Red POSD1 Positive Drive 1

Load current must

not exceed 1.5 A.

Suitable for driving

capacitive loads

such as Rovi

terminals.

Output controlled

by MiX 4000 and

selected in Vehicle

12 | Page

Page 13

Pin Colour

(Prim/Sec)

6 Brown GND Ground

4.4.5 MiX 4000 Serial Harness 2 (use Serial Harness SR1)

Connector viewed from the back (wiring side) of harness (440FT0931)

Pin Colour

(Prim/Sec)

1 Yellow TXD RS-232 Transmit

2 White RXD RS-232 Receive Also used for

Name Function Application

Information

Properties of front

end user software

Name Function Application

Information

communication to

DTCO D8 line

3 Blue RTS Ready to send RTS looped to CTS

4 Green CTS Clear to send RTS looped to CTS

5 Red POSD2 Positive Drive 2

6 Brown GND Ground

Load current must

not exceed 0.25 A

Output controlled

by MiX 4000 and

selected in Vehicle

Properties of front

end user software

13 | Page

Page 14

4.4.6 GSM, GNSS and BT Antennas

The GSM, GNSS and BT all have internal antennas. The GNSS has an external antenna option as well to

allow for cases where better reception is required. Thus, fitting the external antenna is optional. The system

detects automatically whether an external antenna is fitted or not. It can also detect tampering, like an

external antenna disconnect or a short. In the case where there is no external antenna or in the case of

tampering, the system will automatically switch to the internal antenna.

For deep installs with a lot of metal obstruction it is recommended to use the external antenna.

Refer to the picture in section 4.4 showing the positions of the connectors for the external antennas.

The Unit contains an internal GSM antenna and should be mounted m ore than 20cm away from the human

body under normal operating conditions.

4.4.7 GNSS antenna connection

For best results when the unit cannot be mounted with a good view of the sky, the external GNSS antenna

should be used. Mount the GNSS antenna horizontally where the least metal (or any conductive)

obstruction between the antenna and the satellites will occur. The top side of the antenna is the rounded

side. For best results place the antenna on a metal surface facing towards the sky (see picture

below). Mount as far away from any radio signal or wire bundles as possible.

a) Avoid pinching the coaxial cable or bending it sharply (zigzags).

b) It would be better to circle/coil excess wires. Take care not to tie coax wires too tight. Using the

broadest possible cable tie (refer to section 4.3).

c) The best place to circle/coil the wires is about 300 mm in line from the antenna.

4.4.8 GSM antenna (internal)

The standard product only has an internal GSM antenna.

4.5 Wiring and Connections

4.5.1 Positioning the MiX 4000 Unit in the vehicle

Note: Please follow the instructions, regarding the positioning of product components, as contained in the

“Safety” section, of this document, section 4.2.

The MiX 4000 must be installed inside the passenger compartment or the driver cabin, to

protect it from possible damage by water, solvents, fuel or other environmental factors.

14 | Page

Page 15

The MiX 4000 should not be installed in or near the ventilation, heating system, or hot surfaces

which may cause it to overheat or be damaged by condensed water vapour.

The MiX 4000 should be installed in a position where it will not be subjected to pressure, impact

or excessive vibration. Uneven surfaces, where the box can be deformed or damaged should be

avoided.

Select the installation position carefully before proceeding with the installation.

Mark and drill the required holes.

Route cables from the unit to the appropriate senders within the vehicle. Additional information

can be found in the “Harness Installation” section of this document.

4.5.2 Starter Interrupt

The MiX 4000 requires an external relay for the interruption of the vehicle’s starter circuit. The relay required

should be adequately rated for the purpose intended. Please note that a 30A or 40A (contact rating) relay

should be selected. A standard 5 PIN automotive relay manufactured by a reputable supplier (e.g. Bosch)

would be adequate. The correct relay operating voltage is required; failure to do so may damage the relay.

24V relays will not function correctly in 12V applications and 12V relays will be damaged when used at 24V.

To connect the relay, it only needs to be plugged into the relay socket on the Main Harness. The two 2mm²

black wires represent the two sides of the relay contacts that are controlled via the driver ID Plug. Cut the

wires as short as possible, where higher current will be interrupted via the relay.

Also use a cable-tie to secure the relay through the mounting ear (5mm hole) to the main harness, or where

possible an M5 lock-nut and bolt is to be used to secure the relay to the vehicle. Ensure that the relay wires

have enough play on them not to strain the relay terminal crimps connecting the relay to the wires.

It is not necessary to use a relay with a build in protective diode, because the MiX 4000 has built in

protection already. Positive drive/relay outputs are protected against shorts to ground and battery positive

and the system can detect these faults. See simplified connection diagram below:

15 | Page

Page 16

16 | Page

Page 17

4.6 Code Plug Socket Installation

Note: Please follow the instructions, regarding the positioning of product components, as contained in the

“Safety” section of this document 4.2.

The Code Plug Socket must be installed inside the passenger compartment or the driver cabin,

to protect it from possible damage by water or other environmental factors.

The Code Plug Socket should not be installed in or near the ventilation or heating systems,

which may cause damage to it due to overheating.

The Code Plug Socket should be installed in a position where it will not be subjected to

pressure, impact or excessive vibration.

Select the installation position carefully before proceeding with the installation.

Mark and drill or cut the required hole. Hole size = 13/16” or 20 mm

Remove the mounting clip from the socket.

Remove the protection film from the adhesive surface of the foam ring and press it firmly against

the back of the interface.

Insert the socket into the mounting hole and slide the mounting clip into position.

17 | Page

Page 18

4.7 Signal Inputs

4.7.1 Digital Inputs

The MiX 4000 is equipped with 2 digital/analog inputs (I1-I2), which can be used to monitor digital signals.

When the voltage threshold is crossed, an event is triggered. The voltage threshold and the hysteresis are

set in software. Please refer to the “Specifications” and “Harness Installation” sections, of this document, for

more details. The external inputs and ignition line are protected from typical vehicle transients and can be

directly connected to most vehicle inputs between 0 and 38V (37.95V). The input impedance is >200 kΩ.

Typical connections are shown below:

Note: There is no internal pull-up resistor in the MiX 4000 so observe the correct wiring configurations

shown below for switching to ground or switching to vehicle supply.

18 | Page

Page 19

4.7.2 Ignition Input

The MiX 4000 includes a dedicated ignition input that must be wired if the starter interrupt immobilizer

functionality is required. The input should be connected to the ignition signal on the vehicle. The MiX 4000

will automatically compensate for a 12 or 24V vehicle supply and no configuration is required. For a typical

connection, see below:

Note: If a minimal install is being performed and the vehicle’s ignition wire is not available the MiX 4000 can

use its internal accelerometer and GNSS measurements of the vehicle’s power supply to determine trip start

and stop conditions. If this configuration is required it is important to configure the unit correctly see 3.3

below. For improved trip start/end plotting accuracy on the MiX Telematics Fleet Manager user interface, it

is recommended that the wired ignition configuration be used.

4.8 Power Outputs

4.8.1 Positive Drive

The Positive Drive output supplies power to MiX 4000 accessories. There are in total 4 Positive Drives.

This output is controlled by the MiX 4000 and is configured in the Vehicle Properties of

the Fleet Manager Application software.

Access to these outputs is described in section 4.4.

Do NOT connect an external voltage to the positive drive line.

Positive drive 1 can drive at least 1.5A and is suitable for powering up capacitive loads such as a Rovi

terminal, while the remaining drives can manage 250 mA each. These circuits are protected against over

current and voltage. Should “Positive Drive 1” be occupied already and it is necessary to drive more

peripheral devices (e.g. Rovi, Mix Display, etc.) that draw more than 250 mA at any stage, it is advisable to

make use of an alternative relay to ensure reliable functionality.

Below is a functional block diagram that describes how to wire such a device.

19 | Page

Page 20

Please refer to the Starter Interrupt section 4.5 of this document, for more details.

20 | Page

Page 21

4.9 Serial Communication

The MiX 4000 is equipped with two RS232 external serial ports. Refer to section 4.4 for details of the wiring.

The serial ports can be used to connect to external peripherals.

Serial 1 does RTS/CTS flow control, and is paired with POSD1, so it is suitable for connection to Rovi

terminals and other devices that use more power. It is normally enabled, even when the vehicle is out of trip

Serials 2 does also have RTS/CTS flow control, and is paired with POSD2. It is suitable for general purpose

use, however, sometime after the vehicle is out of trip these ports may be disabled to reduce power

consumption. It is intended for general purpose use or as a D8 input for DTCO use. It is normally enabled,

even when the vehicle is out of trip

All serial ports are capable of up to 115200 baud operation.

4.10 CAN

4.10.1 Overview

Installation of MiX 4000 CAN-bus should only be carried out by trained installers:

Improper connection of the MiX 4000 to the vehicle’s CAN-bus may cause interference with the

vehicle’s normal operation.

The MiX 4000 is already loaded with compatible device drivers.

The unit still needs to be configured for the vehicle in which it will be installed, and the vehicle ID and

odometer still need to be configured. Specifically, the MiX 4000 may not record any CAN data until it

is configured.

After installation, verify that no interference is caused to the vehicle’s electrical system. Check dashboard

warning lights and error messages. Should any error conditions exist, remove the MiX 4000 installation and

contact MiX Telematics for assistance.

Colour coding of the wires are shown in section 4.4.2:

o CAN1 Interface wires are designated by a green and a yellow wire, connected to pins 9 and

10 on the Main Harness

o CAN2 Interface wires are designated by a green/black and a yellow/black wire, connected to

pins 16 and 15 on the AUX1 Harness.

o The convention is that the wire with the color closer to white in the spectrum (lighter color) is

CAN-H and the wire with the color closer to black in the color spectrum (darker color) is CANL.

o This means that the Green wire is CAN-L and the Yellow wire is CAN-H. The two wires should

always be twisted together and if they are not already twisted, they should be twisted together.

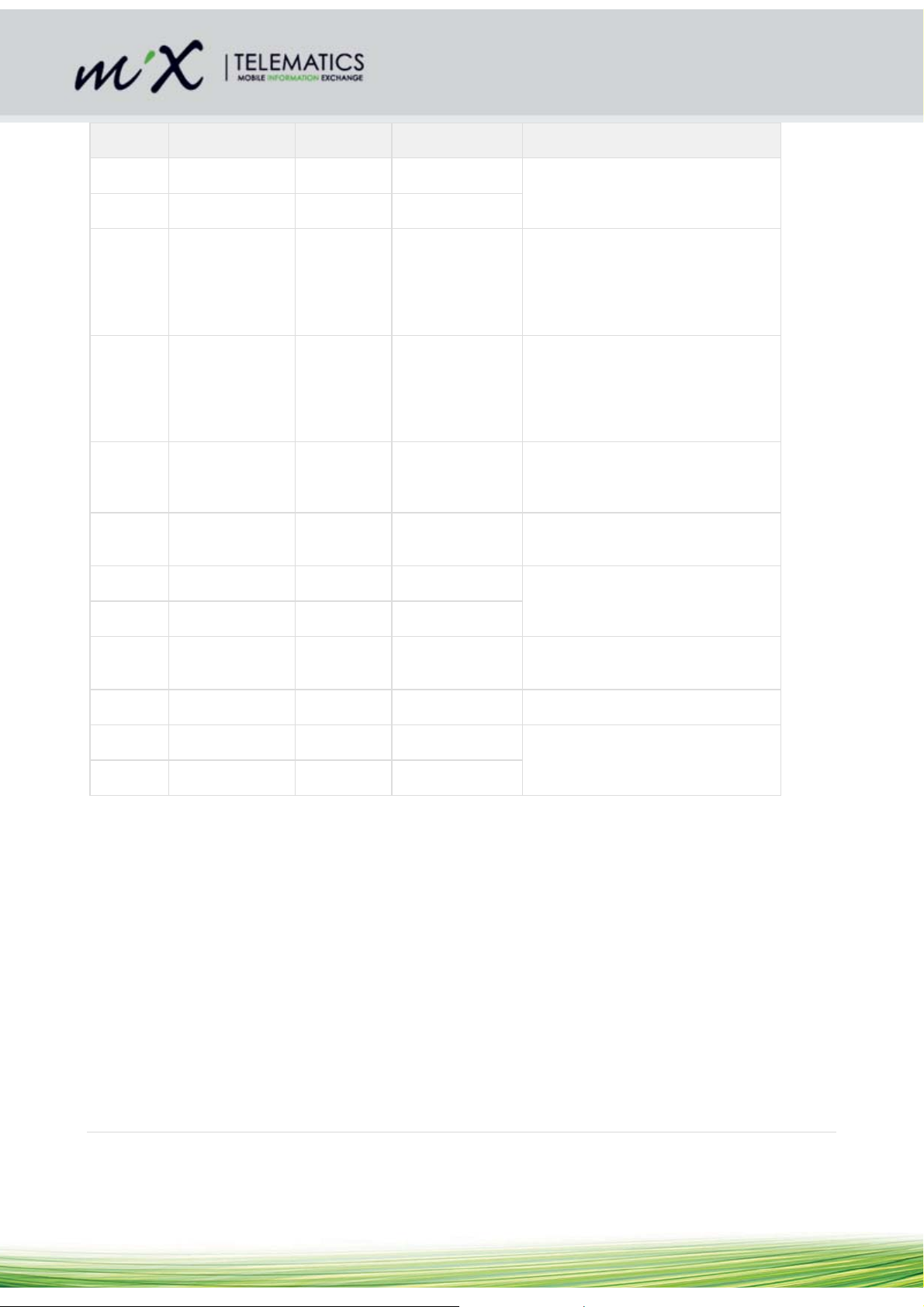

The MiX 4000 has a total of 4 Jumpers on the main PCB (SW3) to set the Read/Write or "Listen Only"

mode and the Terminating Resistor (120 Ohm) of each CAN interface (see Figure 1).

4.10.2 Tools and Inspection need for CAN Installation

Supporting tools

Multi-meter

Oscilloscope

Laptop with CAN to USB interface (for example Vector CANcaseXL, IXXAT)

Identify possible CAN busses by looking for twisted pair wires in the vehicle.

With the vehicle’s ignition turned on, measure the voltages relative to ground on each of the wires using a

multi-meter.

21 | Page

Page 22

For CAN, the voltage readings of the two wires should be very similar (usually 2.5V), with CAN-H likely to

read only slightly higher than CAN-L.

Using an oscilloscope, the actual data signal can be probed.

With a properly configured 3

CAN Baud rates of 250kb/s (SAE J1939) and 500kb/s are the most common.

4.10.3 Wire lengths

The CAN stub wires between the MiX 4000 and the vehicle’s bus should be no longer than 1m. Excessive

wire length may cause interference with the vehicle’s normal operation.

4.10.4 CAN jumper settings

Warning: It is very important to ensure that these jumper settings are correct at installation time. If these

jumpers are set incorrectly it is possible that when a new configuration or script is downloaded to the MiX

4000, it could bring down the CAN bus of the vehicle and interfere with the operation of the vehicle.

Conduct ESD precautions as described in section 3.1.4

Refer to Figure 1 and Table 1 below:

rd

party CAN tool, like the Vector CANcaseXL, the actual data can be recorded.

Figure 1 Position of jumpers on the PCB

22 | Page

Page 23

Setting 1 (FACTORY

DEFAULT)

All Jumpers inserted

120 Ω Termination under

software control

RD/WR or "Listen Only"

mode is under software

control

When all SW1 jumpers are inserted, both CAN1 and CAN2 interfaces

are set for:

- 120 Ω termination is under software control (i.e. the software can

switch the 120 Ω resistor in or out of the circuit)

- RD/WR or "Listen Only" mode is under software control (i.e. the

software can transmit messages on the CAN bus)

Setting 2

All jumpers removed

NOT Terminated (120 Ω)

"Listen Only" mode

When all SW1 jumpers are removed, both CAN1 and CAN2 interfaces

are set for:

- 120 Ω termination is disabled (i.e the 120 Ω termination resistor is

removed from the circuit and cannot be switched in by software)

- "Listen Only" mode (i.e. the software cannot transmit any messages)

23 | Page

Page 24

Setting 3

Jumpers 3-4 and 7-8 inserted

120 Ω Termination is

under software control

"Listen Only" mode

When SW1 jumpers 3-4 and 7-8 are inserted, both CAN1 and CAN2

interfaces are set for:

- 120 Ω termination is under software control (i.e. the software can

switch the 120 Ω resistor in or out of the circuit)

- "Listen Only" mode (i.e. the software cannot transmit any messages)

Setting 4

Jumpers 1-2 and 5-6 inserted

NOT Terminated (120 Ω)

RD/WR or "Listen Only"

mode is under software

control

When SW1 jumpers 1-2 and 5-6 are inserted, both CAN1 and CAN2

interfaces are set for:

- RD/WR or "Listen Only" mode is under software control (i.e. the

software can transmit messages on the CAN bus)

- 120 Ω termination is disabled (the 120 Ω termination resistor is

removed from the circuit and cannot be switched in by software)

Table 1 CAN Jumper settings

24 | Page

Page 25

4.10.5 When must the 120 Ohm terminating resistor be in the circuit?

A properly terminated CAN bus will have a DC resistance of approximately 60 Ω (one 120 Ω

terminating resistor at each end).

By measuring the DC resistance on the vehicle bus between CAN-H and CAN-L, before the MiX

4000 is connected, an installer can determine whether additional termination is required.

If the resistance measures 60 Ω, no further termination is required.

If it measures 120 Ω, then additional termination must be configured.

To configure additional termination the jumper must be fitted and the termination resistor enabled in

the software

See table below for a diagram of a CAN bus that is correctly terminated and how the 60 Ω is

calculated

Incorrectly terminating CAN bus

DC Resistance

Calculation

R

=

total

1/(1/R1+1/R2)

R1 = 120 Ω

and R2 = 120 Ω

R

=

total

1/(1/120+1/120)

R

= 60 Ω

total

Correctly terminated CAN bus with 120 Ω

resistors at both ends

with 120 Ω resistors at both end

and a node that puts another 120

Ω resistor in circuit

If you measure less than 60 Ω

(e.g. 40 Ω), then it means the CAN

Bus is already incorrectly

terminated and loaded by another

120 Ω resistor (R3).

In this case DO NOT ATTEMPT to

connect to this CAN bus under

any circumstance and seek the

advice of the owner to determine

why the CAN bus is incorrectly

terminated.

R

= 1/(1/R1+1/R2+1/R3)

total

R1 = 120 Ω and R2 = 120 Ω and R3

= 120 Ω

R

= 1/(1/120+1/120+1/120) =

total

40 Ω

4.10.6 General Rules for CAN terminating resistors

A properly terminated CAN bus will have a DC resistance of approximately 60 Ω (one 120 Ω

terminating resistor at each end). By measuring the DC resistance on the vehicle bus between CANH and

CANL, before the MiX 4000 is connected, an installer can determine whether additional termination is

required. If the resistance measures 60 Ω, no further termination is required. If it measures 120 Ω, then

additional termination must be configured. To configure additional termination, the jumper must be fitted and

the termination resistor enabled in the software.

Typically, a bus showing 120Ω before installation will only have one node on it, and will not be safety

critical. Examples of this might be a DTCO bus or many of the OBDII connections.

A bus showing 40 Ω before installation may indicate triple termination which can cause CAN errors

and failure. If this is the case it is best to advise the customer and ensure this error is corrected by removing

the offending unit or termination before MiX 4000 installation.

25 | Page

Page 26

For non-safety-critical CAN bus installations, it is recommended to leave the jumper fitted and

configure the termination resistor to OFF or ON in software, as needed, as this allows the maximum

flexibility.

For safety-critical CAN bus (e.g. so-called “hot bus”) installations where a hard disconnect must be

guaranteed and physical safety is needed, the 120Ω termination jumper must be removed. This will

guarantee that termination resistors cannot be accidentally enabled by software, potentially disrupting the

CAN bus. Note that permission from the customer to connect to a safety critical CAN bus should always be

obtained.

If the installer is in doubt as to the safety critical nature of the CAN bus, the jumper must be left off.

After installation of the MiX 4000 and configuration of the termination resistance the CAN bus should

measure as 60Ω, with the unit powered on, if not, the settings should be checked.

Note that the MiX 4000 terminating resistor automatically disconnects from the CAN bus if the MiX

4000 unit loses power.

4.10.7 When must the RD/WR Jumpers be in the circuit?

For non-safety-critical CAN bus installations, it is recommended to leave the transmit enable jumper

fitted and configure the transmit enable to OFF or ON in software, as needed, as this allows the

maximum flexibility.

For OBDII connections the RD/WR (transmit enable jumper) must be fitted, since OBDII is a

request/response protocol and requires the MiX 4000 to transmit messages on the CAN bus.

For safety-critical CAN bus (e.g. so-called “hot bus”) installations where guaranteed, physical safety

is needed, the transmit enable jumper must be removed. This will guarantee that transmissions

cannot be accidentally enabled by software, potentially disrupting the CAN bus.

Note that permission from the customer to connect to a safety critical CAN bus should always be

obtained.

If the installer is in doubt as to the safety critical nature of the CAN bus, the jumper must be left off.

Some FMS gateways requires an acknowledgement ("ACK") on the physical layer and the RD/WR

(transmit enable jumper) must be fitted for the CAN chip to be able to assert the "ACK" bit in the

header, otherwise the host will stop transmitting any CAN messages. (See diagram below). Note

that no messages are transmitted on the CAN bus, the messages are just acknowledging, so this is

a safe mode.

26 | Page

Page 27

4.11 DLD and DTCO

The MiX 4000 also satisfies the need for Remote DTCO Download functionality by incorporating CAN, D8

and K-line communication. The main functionality is the ability to remotely download DTCO data as well as

the D8 status change for the Hours of Service solution.

This functionality allows the user to perform the following:

• Synchronise download schedules

• Authenticate remote tachograph cards

• Transfer downloaded files to back-office archiving systems

• Receive updated firmware and configuration settings

4.11.1 D-8

The D8-line is a free running data interface for fleet management systems. The DTCO information (like

date, time, currently selected driver and co-driver activity (hours of service), speed of vehicle etc.) are sent

on this communication line. The receive line of Serial Port 2 is used for the D8-line. The pin numbers of the

serial port are shown in sections 4.4.5. Connect to pin 2 (of Serial Port 2 on MiX 4000 PCB) to pin 8 of the

brown DTCO D-connector.

4.11.2 Connect CAN to DTCO

Refer to section 4.10.1 on CAN. One of the available CAN busses (normally CAN #2) can be routed to the

DTCO CAN. The Yellow and Green wires must be routed to DTCO C (red) connector pin 5 (Yellow/black)

(CAN-H) and 7 (Green/black) (CAN-L). See pictures below.

27 | Page

Page 28

4.11.3 K-line

Connect the DTCO K-line to pin 13 of the Auxiliary 1 Harness (see sections Error! Reference source not

found.).

4.12 Bluetooth

The Bluetooth can be used as a serial cable replacement in order to connect to Rovi, Android Tablets or

other IVD devices.

5. After Installation

5.1 Beep codes

The MiX 4000 has an output that drives a buzzer. The buzzer is not included inside the enclosure but is part

of the 10-wire main harness. If any of the other reduced wire count main harnesses are installed beep codes

will not be audible.

The following beep codes will apply when a harness with an external buzzer is installed:

• Triple beep when an over speeding, harsh braking, harsh acceleration or harsh cornering event

occurs

• Continuous slow beeping at trip start for the duration of the user configured driver ID prompt period

(When a valid driver ID is inserted two short beeps will sound and the slow prompt beeps will stop – Default

driver ID prompt period is set to zero seconds, disabling the driver ID prompt)

This setting is under Software Configuration control, so the behaviour will depend on the configuration

settings.

28 | Page

Page 29

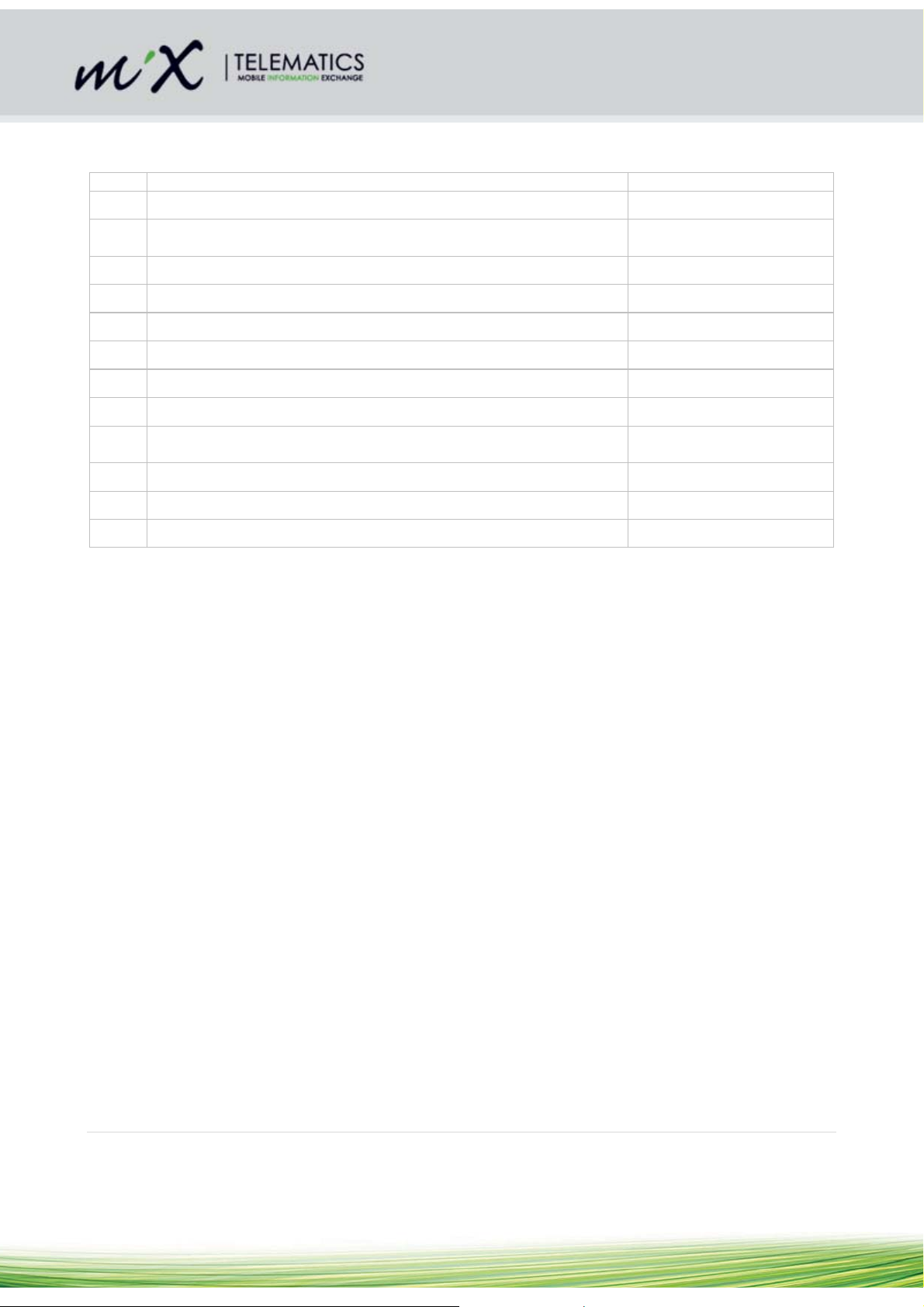

5.2 LED flash codes

The MiX 4000 has 2 LEDs for diagnostic purposes. Refer to the Figure 2 below.

Figure 2 Picture indication the sequence and position of diagnostic LEDs

5.2.1 GPS LED flash codes (GREEN)

Out of trip (2 second repeat cycle, LED mostly OFF)

Out of trip with no GPS lock

Out of trip with 2D GPS lock

Out of trip with 3D GPS lock

In trip (1 second repeat cycle, LED mostly ON)

In trip with no GPS lock

In trip with 2D GPS lock

In trip and GPS has acquired 3D lock. The

MiX 2310i will subsequently be able to report

accurate GPS points.

2 second repeat

2 second repeat

2 second repeat

Continuous

1 second repeat

1 second repeat

GREEN LED: One short ON

blip once every two seconds

GREEN LED: Two short ON

blips every two seconds

GREEN LED: Three short ON

blips every two seconds

GREEN LED: Toggles

ON/OFF in quick succession

continuously

GREEN LED: 50% ON and

50% toggling ON/OFF in quick

succession every second

GREEN LED: Mostly ON

followed by two short OFF

blips every second

5.2.2 GSM LED flash codes (RED)

No communication settings received (LED mostly ON)

GSM OFF

GSM ON, searching for network*

SMS only

1 second repeat

2 second repeat

RED LED: OFF

RED LED: Mostly ON with some

OFF time once every second

RED LED: Almost completely

ON with one short OFF blip once

every two seconds

29 | Page

Page 30

GPRS ready

GSM Connected

Communication settings received (LED mostly OFF)

GSM OFF

GSM ON, searching for network

SMS only

GPRS ready

GSM Connected

5.3 Testing Installation

1 second repeat

2 second repeat

2 second repeat

2 second repeat

2 second repeat

2 second repeat

RED LED: Almost completely

ON with three short OFF blips

once every two seconds

RED LED: Almost completely

ON with two short OFF blips once

every two seconds

RED LED: OFF

RED LED: Mostly OFF with

some ON time once every

second

RED LED: Almost completely

OFF with one short ON blip once

every two seconds

RED LED: Almost completely

OFF with three short ON blips

once every two seconds

RED LED: Almost completely

OFF with two short ON blips

once every two seconds

5.3.1 Test Drive

Disarm the system by inserting the blue plug into the Code Plug socket.

Wait for the audible signal.

Remove the plug.

Start the engine.

Carry out a test drive.

5.3.2 Closing Steps

Check all relevant vehicle functions.

Explain the functions of the MiX 4000 system to the user.

6. Troubleshooting

Supporting Documentation can be found at:

Confluence Link: MiX 4000 Home Page

The audible and visual information generated by the MiX 4000 is described are in sections 5.1 and 5.2 of

this document.

Symptom Probable Cause Action

Unit does not

switch ON (LED

does not flash)

No battery voltage applied to

MiX 4000.

Check the voltage supply to the MiX 4000

Ensure the connectors are properly fitted

Check fuse if applicable

30 | Page

Page 31

GPS does not get

lock

GSM unable to

register on

network

(see GSM LED

flash codes in

section 5.2)

Orientation of the unit is

incorrect

Location of unit is limiting

good GPS reception (internal

antenna)

Location of the GPS antenna

is limiting good GPS

reception (external antenna)

No SIM card inserted or SIM

inserted the wrong way round

Automatic commissioning is

not possible on the GSM

network selected

GSM network is out of range

Mount the unit with the rounded surface

facing up, and the label side down.

Install the unit in a location where the GPS

view of the sky is relatively unobstructed by

metal or conductive parts. Refer to section

4.4.7

If this is not possible t may be necessary to

install the external GPS antenna

Check the installation of the external GPS

antenna and ensure that the antenna is

facing towards the satellites view of the sky

is relatively unobstructed by metal or

conductive parts

Refer to section 3.1 for the correct SIM card

orientation. Alternatively replace the SIM

card

Use a serial configuration harness and the

Configuration software to manually program

APN and server settings for the unit

Check coverage of chosen GSM network

using coverage map or a cell phone on the

same network

If the MiX 4000 fails to detect a MiX

approved GSM antenna it will switch to

internal antenna operation.

7. Routine Maintenance

Item Maintenance Period

Please ensure that the Code Plug Socket is kept clean and free of dust and dirt.

1)

This part is available as an accessory if it needs to be replaced.

The internal battery needs to be replaced when a replacement message is

2)

generated. Replace the battery if it is swollen.

8. MiX 4000 Specifications

8.1 Technical description

Refer to the MiX 4000 Product Fact Sheet for more details.

Monthly

Back End

Warning

Message

31 | Page

Page 32

8.2 Auxiliary inputs/outputs

2 x Configurable

Analogue or Digital

Inputs

(I1 to I2)

1 x Speed Input

1 x RPM Input

4 x RS232 Serial

Interface

2 analogue or digital inputs can be configured to monitor any device that

generates a change in voltage. E.g. seat belts, headlights, refrigeration units,

temperature sensors, emergency lights, doors, PTO, UDS, trailer coupling

etc.

Voltages are measured in the range of 0 – 38V (37.95V) in steps of

approximately 9.3 mV and 0 - 4.95 V in steps of 1.2 mV

Do not connect signals from unsuppressed inductive sources such relay

coils (where severe voltage spikes can be generated)

F1 input can measure speed pulses. The input impedance is 100 kΩ.

Frequencies of up to 20 kHz can be measured.

Maximum signal voltage level = 38V (37.95V)

Disconnection of this input can be detected using open-wire detect.

F2 input can measure RPM pulses. The input impedance is 94 kΩ.

Speed and RPM calibration sensitivity is configurable.

Frequencies up to 20 kHz can be measured.

Maximum signal voltage level = 38V (37.95V)

Disconnection of this input can be detected using open-wire detect.

This can be connected to any RS232 serial device.

2 x CAN Interface

1 x Positive Drive

3 x Positive Drive

1 x K-line

1 x D8

Ignition input

This can be connected to a J1939 CAN bus, termination resistors and

transmit disable can be configured by jumpers (for safety-critical installs) or

by settings.

Positive Drive output is used to power external devices at a current up to

1500 mA. Disconnection of loads can be detected using open-load detect.

Positive Drive outputs are used to power external devices at currents up to

250 mA. Disconnection of loads can be detected using open-load detect.

DTCO K-line

The D8-line is a free running data interface for fleet management systems.

The DTCO information (like date, time, currently selected driver and codriver activity (hours of service), speed of vehicle etc.) is sent on this

communication line. The receive line of Serial Port 2 is used for the D8-line.

The ignition input is used only to monitor the vehicle’s ignition line state, and

can measure up to 38V (37.95V). Disconnection of this wire can be

detected with open-wire detect.

32 | Page

Page 33

8.3 Inserting a Backup Battery

A special space below the PCB is provided to fit the backup battery. The backup battery is ordered

separately. It comes with a piece of foam fitted on the one side. This foam ensures that the battery fits tight

and does not rattle. Refer to the steps below for fitting the battery:

1) Remove the back cover

2) Make use of a folded piece of paper between the foam and the enclosure and insert the battery by sliding

it in.

3) Fully insert the battery (it is important not damage the wire connection below the orange foil).

33 | Page

Page 34

4) Insert the battery connector into the socket on the PCB. Note that it is a keyed connector. Ensure the

battery connector is fully inserted.

5) Remove the paper by pulling it out while pressing gently against the battery.

34 | Page

Page 35

6) Fold the battery wire lead in the open space to the right of the battery.

35 | Page

Loading...

Loading...