Mityvac MV6412, MV6400, MV6410, MV6840, MV6842 User Manual

FLUID DISPENSING SYSTEM

MODELS MV6400,

MV6410, MV6412, MV6840, MV6842

USER’S MANUAL

Have a technical question?

Americas:

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday – Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs, and instructions

for product use.

Need service parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

MARCH 2015 Form 801193 Section - MV97-1E

It is the responsibility of the user of this equipment to read this user’s manual entirely,

and understand the safe and proper use and application of this equipment.

Specications:

Reservoir Capacity (w/ pump): 5 quarts/1.2 gallons/4.5 liters

Maximum Pressure: 25 psi/1.7 bar/170 kPa

Page Number - 2 Form 801193

TABLE OF CONTENTS

Service Parts & Accessories .........................................3

Principal of Operation ...............................................4

Applications ........................................................4

Precautions .........................................................4

Instructions for Use .................................................5

Fluid Dispensing ....................................................5

Pressure Brake Bleeding ............................................6

Refilling Sealed Automatic Transmissions ...........................7

Spanish .............................................................8

French .............................................................15

German ............................................................22

Warranty ...........................................................30

Form 801193 Page Number - 3

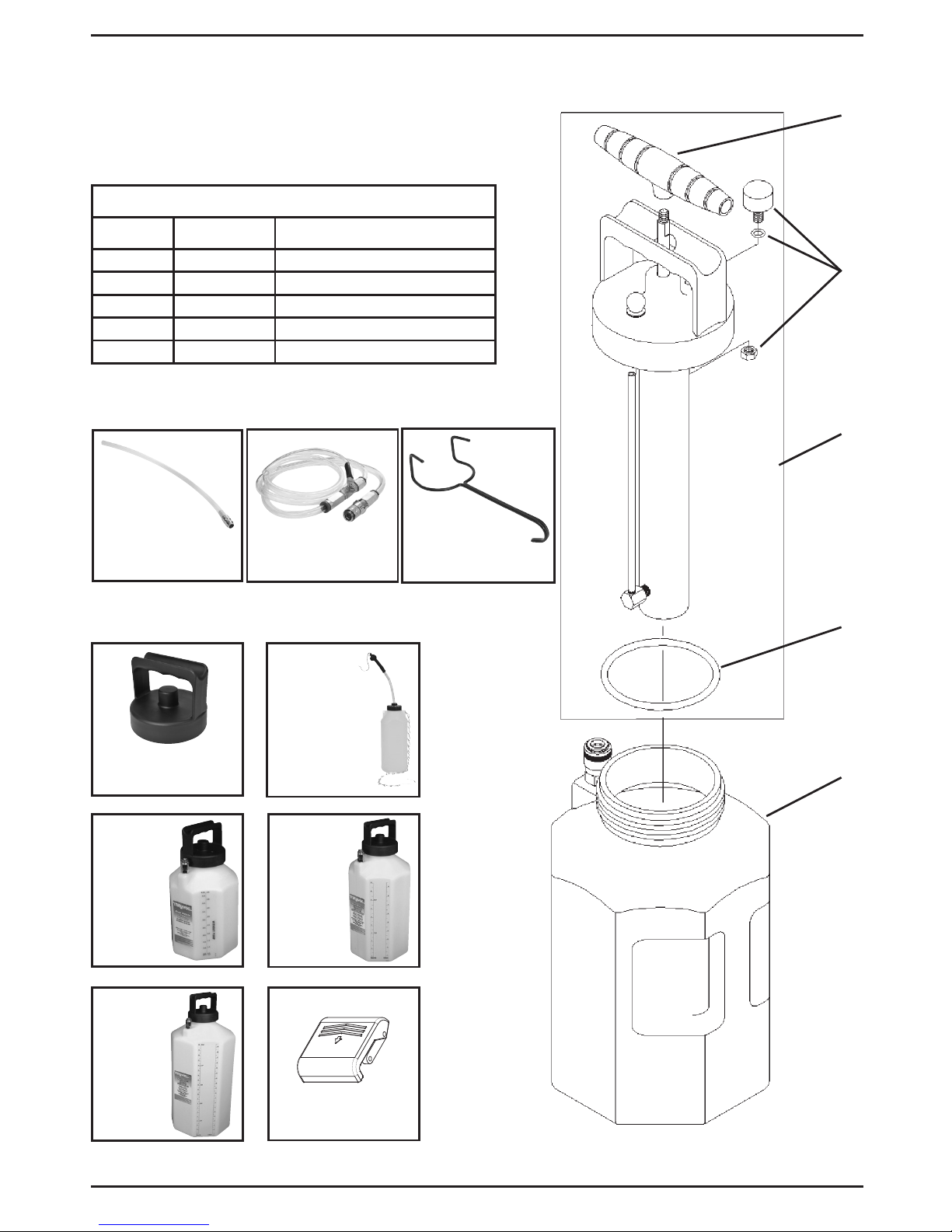

MVA575

Fluid Dispensing

Hose

MVA570 –

Fluid Dispensing

Wand

SERVICE KITS

Ref. No. Part No. Description

1 801230 Lid w/ Pump Assembly

2 801229 1-gallon Reservoir

3 801233 Lid Gasket

4 801234 Pressure Gauge

5 822561 Pump Handle

SERVICE PARTS & ACCESSORIES

3

1

2

5

4

STANDARD ACCESSORIES

OPTIONAL ACCESSORIES

MVA572 –

2.5 Gal. Reservoir

MVA6839 –

Pressure

Bleed Reservoir

MVA571 –

Fluid Storage Lid

MVA576 –

1.2 Gal. Reservoir

MVA573 –

5 Gal. Reservoir

822753 –

Hanging Hook

804789 – Latch

Page Number - 4 Form 801193

This equipment is designed and intended for use as a

means to dispense fluid. It utilizes a manual pressure

pump to build pressure in the reservoir. The pressure

forces fluid to dispense out of the reservoir through a

fluid pickup tube. The output of the fluid pickup tube

is connected to a quick-change coupler, to which a variety of accessories can be attached to control or direct

the flow of fluid according to the intended application.

The equipment should never be operated above a

safe level of pressure depending on the application. A

gauge is installed to indicate the pressure in the reservoir, and should be observed regularly to ensure the

pressure remains at or below what is recommended

for the application.

Applications

This equipment is intended for filling reservoirs with

fluids such as engine coolant, motor oil, or wiper,

automatic transmission, brake or power steering fluid.

However, with the proper accessories it can safely

be used to pressure bleed hydraulic brake or clutch

systems, or refill or top-off sealed automatic transmissions.

Precautions

This equipment is designed for servicing a variety

of vehicles in a safe, convenient manner. However,

differences in vehicle makes and models may make it

impossible to use this equipment as it is intended. Do

not attempt to force the use of this equipment on an

application for which it is not designed to perform.

The procedures documented in this manual are to

serve as guidelines for the use of this equipment. In

addition to these guidelines, always follow the manufacturer’s recommended procedures when servicing

each unique vehicle.

The use of this equipment is simple and straightforward if you follow the instructions. However, always

keep in mind that you are working with a system that

may be under pressure, with fluid that is just waiting

to be expelled. When operating this equipment,

use common sense, and always stop to think before

disconnecting a hose or other component.

• This equipment is intended only for professional use

by personnel trained in performing the service functions for which it is has been designed.

• Read carefully and understand all instructions prior

to using this equipment.

• Always wear eye protection and proper clothing

when operating this equipment

• Do not attempt to modify the pressure relief valve

to alter its performance. If pressure in the reservoir

ever exceeds 23 psi (1.6 bar), return it to an authorized service center for repair or replacement.

• Some fluids, including brake fluid, are corrosive,

and proper care should be taken to protect painted

surfaces and skin from exposure.

• Do not use this equipment with gasoline or other

flammable liquids, or with fluids at temperatures

above 175° Fahrenheit (80° Celsius).

• Consult and follow the vehicle manufacturer’s recommended procedure when using this equipment

to perform automotive service.

PRINCIPAL OF OPERATION

Form 801193 Page Number - 5

Fluid Dispensing

1. Unscrew the lid w/ pump from the reservoir, and

fill to desired level with clean fluid.

Note:There are two scales of volume on the res-

ervoir. One scale indicates the volume when the

lid w/ pump is removed and one when the lid w/

pump is installed. Be sure to note the appropriate

scale.

CAUTION: If fluid is added above the MAX FILL line,

the reservoir will overflow when the lid w/ pump is

installed.

2. Reinstall the lid w/ pump onto the reservoir.

3. Connect the fluid dispensing hose or other accessory to the quick-connect coupler extending from

the reservoir. Ensure the coupler sleeve snaps

forward to lock the

connection.

Note: Depending on the application, the shutoff

valve installed in the fluid dispensing hose may be

left open or closed. If left open, fluid will begin to

flow as soon as the pump is operated. If closed,

pressure will build in the reservoir as indicated on

the gauge.

4. While observing the pressure gauge, operate the

pump to build pressure in the reservoir to the

desired level, or until the desired amount of fluid

has been dispensed.

Note: A built-in pressure relief valve is designed to

open and maintain maximum pressure between

17 and 23 psi (1.2 and 1.6 bar).

Continual operation of the pump is not required

to maintain fluid flow. Fluid will continue to flow

as long as there is pressure in the reservoir and the

shutoff valve is open.

WARNING: Do not exceed 25 psi (1.7 bar) pressure

in the reservoir. The relief valve should prevent

this, but if it fails and the pressure exceeds 25 psi,

immediately discontinue use and send the unit to

an authorized service center for repair or replacement.

5. Once the proper amount of fluid has been dispensed, close the shutoff valve and bleed off the

pressure by tilting the pressure relief knob located

on the lid.

6. Depending on the type of fluid and future intended use, you may store the remaining fluid from the

reservoir. Otherwise empty the reservoir, clean it

with denatured alcohol or a common household

cleaner, and store it properly.

INSTRUCTIONS FOR USE

Page Number - 6 Form 801193

The Mityvac Fluid Dispensing System is appropriate

for use as a pressure bleeder for hydraulic brake and

clutch systems. Additional accessories and adapters

may be required and are available from Mityvac for

performing this function.

WARNING: Hydraulic/brake fluid is hazardous and corrosive. Take precautions to protect painted surfaces

and skin from exposure, and read and follow the fluid

manufacturer’s warnings and instructions.

1. Park the car, set the parking brake, and turn off the

engine.

2. Open and secure the hood.

3. Locate the brake or clutch master cylinder and

remove the cap.

4. Extract as much used hydraulic fluid from the

master cylinder reservoir as possible, and refill it

with new fluid.

5. Select the appropriate master cylinder pressure

bleed adapter and install it securely onto the

master cylinder reservoir.

6. Before adding fluid to the Dispenser, connect the

fluid dispensing hose to the female quick-connect

coupler extending from the reservoir. Ensure the

coupler sleeve snaps forward to lock the connection.

7. Connect the other end of the fluid dispensing hose

to the male quick-connect coupler on the master

cylinder pressure bleed adapter. Ensure the coupler sleeve snaps forward to lock the connection.

8. Ensure the shutoff valve is open, and operate the

manual pump to pressurize the system to 10 psi

(0.7 bar).

9. Watch the pressure gauge to ensure there are no

leaks. If the pressure drops, relieve the remaining

pressure in the system by tilting the pressure relief

knob located on the lid, remove and retighten the

lid from the dispensing reservoir and the adapter

on the master cylinder reservoir, and recheck the

system for leaks.

WARNING: Serious injury and/or equipment

damage can occur if the lid is removed from the

dispensing unit or the adapter from the master cylinder, without first relieving the system pressure.

10. Once you’ve proven all connections are secure

and the master cylinder adapter does not leak,

remove the lid w/ pump from the dispensing unit

and add up to 2 quarts (2 liters) of a manufacturer’s

recommended new hydraulic fluid from a sealed

container.

11. Reinstall the lid w/ pump and tighten it securely.

12. Consult a service manual to determine the recommended bleed pressure and the proper bleeding

sequence for the vehicle being serviced.

13. Observing the pressure gauge, operate the pressure pump to achieve the recommended pressure.

14. Connect the bleed reservoir to the bleed screw of

the first cylinder to be bled.

15. Open the bleed screw. Allow fluid to flow out until

only clear new fluid with no visible air bubbles is

streaming from the screw, and then re-tighten the

bleed screw to the manufacturer’s recommended

torque.

16. Perform the same procedure on all remaining

bleed screws. Operate the pressure pump as

required to maintain adequate pressure.

Note: Do not allow the dispensing unit and master

cylinder reservoir to run dry. Use the pressure

relief valve to relieve the pressure and add new

fluid if necessary.

17. Once bleeding is complete, relieve the pressure

in the reservoir and master cylinder by tilting

the pressure relief knob located on the lid of the

dispensing unit.

18. Close the fluid dispensing hose shutoff valve, and

carefully remove the adapter from the master

cylinder, being careful not spill any brake fluid.

19. Extract excess fluid or top-off the master cylinder

as required, and replace the cap.

20. Dispose of any hydraulic fluid remaining in the

Dispenser. Do not store hydraulic fluid in the reservoir. Clean the dispensing unit with denatured

alcohol and store it properly.

21. Test the brake or clutch system for leaks before

driving the car.

The Mityvac Fluid Dispensing System is appropriate for

use to refill or top-off sealed automatic transmissions.

Additional accessories and adapters may be required

and are available from Mityvac for performing this

function.

PRESSURE BRAKE BLEEDING

Form 801193 Page Number - 7

1. Unscrew the lid w/ pump from the reservoir, and

fill to desired level with new vehicle manufacturer’s recommended transmission fluid.

CAUTION: Lifetime “sealed” transmissions require

the use of special manufacturer recommended

fluids. Use of any other fluids may cause severe

damage to the transmission and void the manufacturer’s warranty.

Note: There are two scales of volume on the res-

ervoir. One scale indicates the volume when the

lid w/ pump is removed and one when the lid w/

pump is installed. Be sure to note the appropriate

scale.

CAUTION: If fluid is added above the MAX FILL line,

the reservoir will overflow when the lid w/ pump is

installed.

2. Reinstall the lid w/ pump onto the reservoir.

3. Connect the fluid dispensing hose to the reservoir

using the quick-connect coupler. Ensure the coupler sleeve snaps forward to lock the connection.

Note: The shutoff valve installed in the fluid

dispensing hose may be left open or closed. If left

open, fluid will begin to flow as soon as the pump

is operated. If closed, pressure will build in the

reservoir as indicated on the gauge.

4. Select the appropriate ATF refill adapter for the application and connect it to the output of the fluid

dispensing hose.

5. Insert or connect the ATF refill adapter to the

transmission.

6. While observing the pressure gauge, operate the

pump to build pressure in the reservoir to the

desired level, or until the proper amount of fluid

has been dispensed.

Note: Check the vehicle’s service manual to deter-

mine the proper method to check the transmission

fluid level. Failure to follow the manufacturer’s

recommended procedure could result in underor over-filling the transmission, causing severe

transmission damage.

The pressure relief valve is designed to open and

maintain maximum pressure between 17 and 23

psi (1.2 and 1.6 bar).

Continual operation of the pump is not required

to maintain fluid flow. Fluid will continue to flow

as long as there is pressure in the reservoir and the

shutoff valve is open.

WARNING: Do not exceed 25 psi (1.7 bar) pressure

in the reservoir. The relief valve should prevent

this, but if it fails and the pressure exceeds 25 psi,

immediately discontinue use and send the unit to

an authorized service center for repair or replacement.

7. Once the proper amount of fluid has been

dispensed, close the shutoff valve on the fluid dispensing hose and bleed off the pressure by tilting

the pressure relief knob located on the lid.

8. Depending on the type of fluid and future

intended use, store or empty the remaining fluid

from the reservoir.

9. Clean the unit with denatured alcohol or common

household cleaners, and store it properly.

REFILLING SEALED AUTOMATIC TRANSMISSIONS

SISTEMA DE DISTRIBUCIÓN DE FLUIDO

MODELOS MV6400,

MV6410, MV6412, MV6840, MV6842

MANUAL DEL USUARIO

¿Tiene dudas técnicas?

América:

Si tiene dudas, o necesita servicio técnico, póngase en

contacto con nuestros técnicos de servicio capacitados

llamando al:

1-314-679-4200 ext. 4782

De lunes a viernes de 7:30 de la mañana a las 4:15 de la

tarde, hora del Centro. Visite nuestro sitio web en www.

mityvac.com para ver nuevos productos, catálogos e

instrucciones de uso del producto.

¿Necesita piezas de servicio?

Para pedir piezas de repuesto o servicio, visítenos en

línea en www.mityvacparts.com

o llame al teléfono gratuito 1-800-992-9898.

MARZO 2015 FORMULARIO 801193 Sección - MV97-1E

El usuario de este equipo tiene la responsabilidad de leer este manual del usuario en su

totalidad, y entender el uso seguro y apropiado y la aplicación de este equipo.

Especicaciones:

Capacidad del depósito (con bomba): 5 cuartos de gal/1,2 galones/4,5 litros

Presión máxima: 25 lb/pulg2/1,7 bares/170 kPa

Formulario 801193 Número de página - 9

TABLE OF CONTENTS

Piezas de Repuesto y Accesorios ..................................10

Principio de Operación ............................................11

Aplicaciones .......................................................11

Precauciones .......................................................11

Instrucciones de Uso ...............................................12

Distribución de Fluido .............................................12

Purga de Frenos de Presión ........................................13

Relleno de Transmisiones Automáticas Selladas ...................14

Garantía ............................................................30

Número de página - 10 Formulario 801193

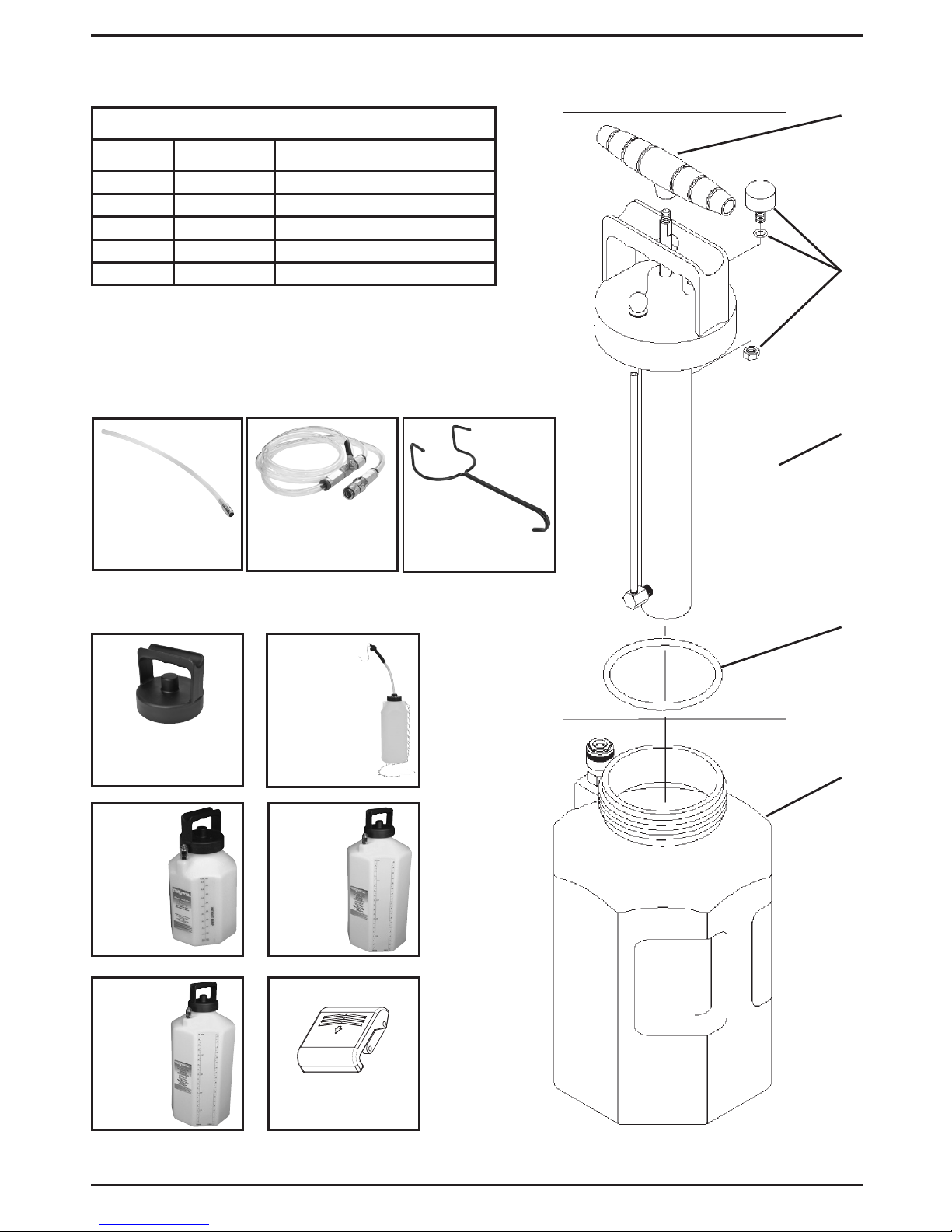

MVA575 –

Manguera de distri-

bución de uidos

MVA570 –

Varilla de distribución

de uido

JUEGOS DE SERVICIO

N° de ref. N° de pieza Descripción

1 801230 Tapa con conjunto de bomba

2 801229 Depósito de 1 galón

3 801233 Empaquetadura de la tapa

4 801234 Manómetro

5 822561 Palanca de la bomba

PIEZAS DE REPUESTO Y ACCESORIOS

3

1

2

5

4

ACCESORIOS ESTÁNDAR

ACCESORIOS OPCIONALES

MVA6839 –

Depósito de

purga de presión

MVA571 –

Tapa de almace-

namiento de uido

MVA576 –

Depósito de

1.2 galones

MVA572 –

Depósito

de 2.5 galones

MVA573 –

Depósito de 5

galones

822753 –

Gancho colgante

804789 – Pestillo

Loading...

Loading...