Page 1

USER’S MANUAL

Have a technical question?

Americas:

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday – Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs, and instructions

for product use.

Need service parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

FLUID DISPENSING SYSTEM

MODELS MV6400,

MV6410, MV6840

Specifications:

Reservoir Capacity (w/ pump): 5 quarts/1.2 gallons/4.5 liters

Maximum Pressure: 25 psi/1.7 bar/170 kPa

It is the responsibility of the user of this equipment to read this user’s manual entirely,

and understand the safe and proper use and application of this equipment.

OCTOBER - 2010 Form 801193 Section - 97-1

Page 2

TABLE OF CONTENTS

Service Parts & Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Principal of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Instructions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fluid Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pressure Brake Bleeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Refilling Sealed Automatic Transmissions . . . . . . . . . . . . . . . . 7

Spanish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

French . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

German . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page Number - 2 Form 801193

Page 3

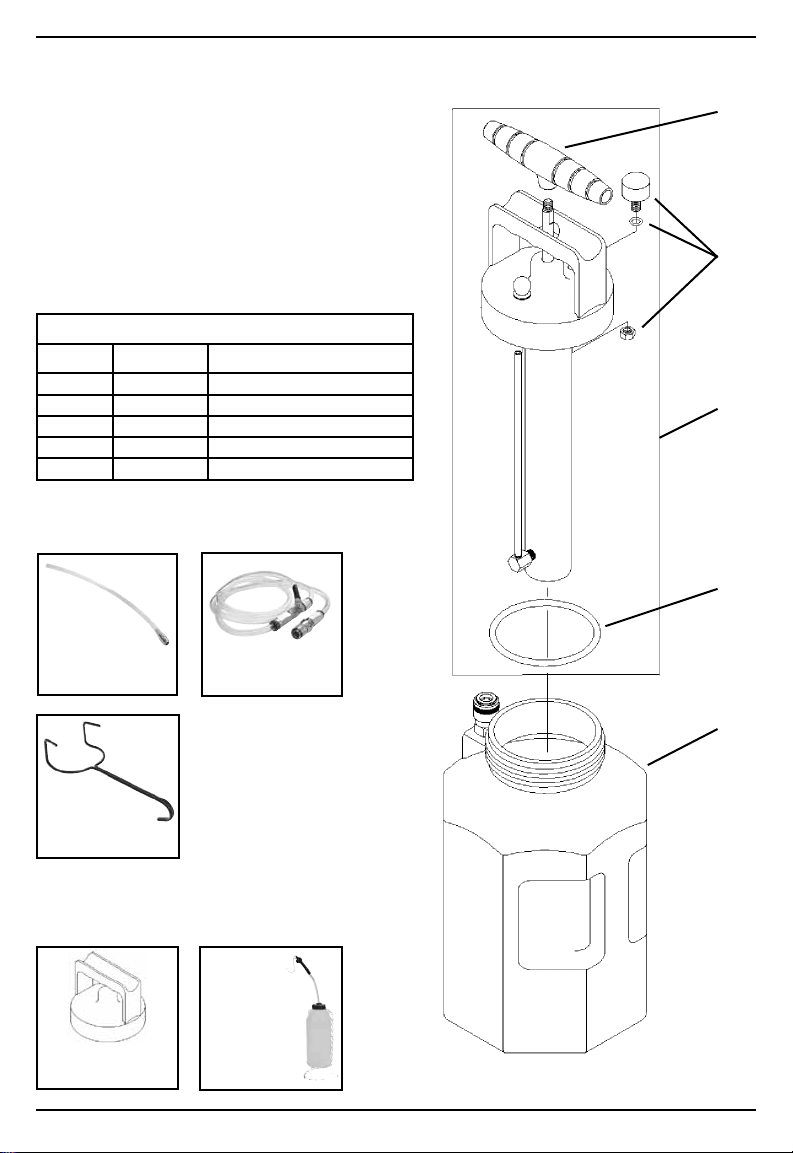

SERVICE PARTS & ACCESSORIES

SERVICE KITS

Ref. No. Part No. Description

1 801230 Lid w/ Pump Assembly

2 801229 1-gallon Reservoir

3 801233 Lid Gasket

4 801234 Pressure Gauge

5 822561 Pump Handle

STANDARD ACCESSORIES

5

4

1

3

MVA570 –

Fluid Dispensing Wand

MVA575 –

Fluid Dispensing Hose

2

822753 –

Hanging Hook

OPTIONAL ACCESSORIES

MVA6839 –

MVA571 –

Fluid Storage Lid

Form 801193 Page Number - 3

Pressure Bleed

Reservoir

Page 4

PRINCIPAL OF OPERATION

This equipment is designed and intended for use

as a means to dispense fluid. It utilizes a manual

pressure pump to build pressure in the reservoir.

The pressure forces fluid to dispense out of the

reservoir through a fluid pickup tube. The output

of the fluid pickup tube is connected to a quickchange coupler, to which a variety of accessories

can be attached to control or direct the flow of

fluid according to the intended application.

The equipment should never be operated above a

safe level of pressure depending on the application. A gauge is installed to indicate the pressure

in the reservoir, and should be observed regularly

to ensure the pressure remains at or below what is

recommended for the application.

Applications

This equipment is intended for filling reservoirs

with fluids such as engine coolant, motor oil, or

wiper, automatic transmission, brake or power

steering fluid. However, with the proper accessories it can safely be used to pressure bleed hydraulic brake or clutch systems, or refill or top-off

sealed automatic transmissions.

Precautions

This equipment is designed for servicing a variety

of vehicles in a safe, convenient manner. However, differences in vehicle makes and models

may make it impossible to use this equipment as

it is intended. Do not attempt to force the use of

this equipment on an application for which it is not

designed to perform.

The procedures documented in this manual are to

serve as guidelines for the use of this equipment.

In addition to these guidelines, always follow the

manufacturer’s recommended procedures when

servicing each unique vehicle.

The use of this equipment is simple and straightforward if you follow the instructions. However,

always keep in mind that you are working with a

system that may be under pressure, with fluid that

is just waiting to be expelled. When operating

this equipment, use common sense, and always

stop to think before disconnecting a hose or other

component.

• This equipment is intended only for professional

use by personnel trained in performing the service functions for which it is has been designed.

• Read carefully and understand all instructions

prior to using this equipment.

• Always wear eye protection and proper clothing

when operating this equipment

• Do not attempt to modify the pressure relief

valve to alter its performance. If pressure in the

reservoir ever exceeds 23 psi (1.6 bar), return

it to an authorized service center for repair or

replacement.

• Some fluids, including brake fluid, are corrosive,

and proper care should be taken to protect

painted surfaces and skin from exposure.

• Do not use this equipment with gasoline or other

flammable liquids, or with fluids at temperatures

above 175° Fahrenheit (80° Celsius).

• Consult and follow the vehicle manufacturer’s

recommended procedure when using this

equipment to perform automotive service.

Page Number - 4 Form 801193

Page 5

INSTRUCTIONS FOR USE

Fluid Dispensing

1. Unscrew the lid w/ pump from the reservoir,

and fill to desired level with clean fluid.

Note:There are two scales of volume on the

reservoir. One scale indicates the volume

when the lid w/ pump is removed and one

when the lid w/ pump is installed. Be sure to

note the appropriate scale.

CAUTION: If fluid is added above the MAX

FILL line, the reservoir will overflow when the

lid w/ pump is installed.

2. Reinstall the lid w/ pump onto the reservoir.

3. Connect the fluid dispensing hose or other

accessory to the quick-connect coupler extending from the reservoir. Ensure the coupler

sleeve snaps forward to lock the

connection.

Note: Depending on the application, the

shutoff valve installed in the fluid dispensing

hose may be left open or closed. If left open,

fluid will begin to flow as soon as the pump is

operated. If closed, pressure will build in the

reservoir as indicated on the gauge.

4. While observing the pressure gauge, operate

the pump to build pressure in the reservoir to

the desired level, or until the desired amount of

fluid has been dispensed.

Note: A built-in pressure relief valve is de-

signed to open and maintain maximum pressure between 17 and 23 psi (1.2 and 1.6 bar).

Continual operation of the pump is not re-

quired to maintain fluid flow. Fluid will continue

to flow as long as there is pressure in the

reservoir and the shutoff valve is open.

WARNING: Do not exceed 25 psi (1.7 bar)

pressure in the reservoir. The relief valve

should prevent this, but if it fails and the pressure exceeds 25 psi, immediately discontinue

use and send the unit to an authorized service

center for repair or replacement.

5. Once the proper amount of fluid has been dispensed, close the shutoff valve and bleed off

the pressure by tilting the pressure relief knob

located on the lid.

6. Depending on the type of fluid and future

intended use, you may store the remaining

fluid from the reservoir. Otherwise empty the

reservoir, clean it with denatured alcohol or

a common household cleaner, and store it

properly.

Form 801193 Page Number - 5

Page 6

PRESSURE BRAKE BLEEDING

The Mityvac Fluid Dispensing System is appropriate for use as a pressure bleeder for hydraulic

brake and clutch systems. Additional accessories

and adapters may be required and are available

from Mityvac for performing this function.

WARNING: Hydraulic/brake fluid is hazardous and

corrosive. Take precautions to protect painted

surfaces and skin from exposure, and read and

follow the fluid manufacturer’s warnings and

instructions.

1. Park the car, set the parking brake, and turn off

the engine.

2. Open and secure the hood.

3. Locate the brake or clutch master cylinder and

remove the cap.

4. Extract as much used hydraulic fluid from the

master cylinder reservoir as possible, and refill

it with new fluid.

5. Select the appropriate master cylinder pressure bleed adapter and install it securely onto

the master cylinder reservoir.

6. Before adding fluid to the Dispenser, connect

the fluid dispensing hose to the female quickconnect coupler extending from the reservoir.

Ensure the coupler sleeve snaps forward to

lock the connection.

7. Connect the other end of the fluid dispensing

hose to the male quick-connect coupler on

the master cylinder pressure bleed adapter.

Ensure the coupler sleeve snaps forward to

lock the connection.

8. Ensure the shutoff valve is open, and operate

the manual pump to pressurize the system to

10 psi (0.7 bar).

9. Watch the pressure gauge to ensure there are

no leaks. If the pressure drops, relieve the

remaining pressure in the system by tilting the

pressure relief knob located on the lid, remove

and retighten the lid from the dispensing reservoir and the adapter on the master cylinder

reservoir, and recheck the system for leaks.

WARNING: Serious injury and/or equipment

damage can occur if the lid is removed from

the dispensing unit or the adapter from the

master cylinder, without first relieving the

system pressure.

10. Once you’ve proven all connections are secure

and the master cylinder adapter does not leak,

remove the lid w/ pump from the dispensing unit and add up to 2 quarts (2 liters) of a

manufacturer’s recommended new hydraulic

fluid from a sealed container.

11. Reinstall the lid w/ pump and tighten it securely.

12. Consult a service manual to determine the

recommended bleed pressure and the proper

bleeding sequence for the vehicle being serviced.

13. Observing the pressure gauge, operate the

pressure pump to achieve the recommended

pressure.

14. Connect the bleed reservoir to the bleed screw

of the first cylinder to be bled.

15. Open the bleed screw. Allow fluid to flow out

until only clear new fluid with no visible air

bubbles is streaming from the screw, and then

re-tighten the bleed screw to the manufacturer’s recommended torque.

16. Perform the same procedure on all remaining

bleed screws. Operate the pressure pump as

required to maintain adequate pressure.

Note: Do not allow the dispensing unit and

master cylinder reservoir to run dry. Use the

pressure relief valve to relieve the pressure and

add new fluid if necessary.

17. Once bleeding is complete, relieve the pressure in the reservoir and master cylinder by

tilting the pressure relief knob located on the

lid of the dispensing unit.

18. Close the fluid dispensing hose shutoff valve,

and carefully remove the adapter from the

master cylinder, being careful not spill any

brake fluid.

19. Extract excess fluid or top-off the master cylinder as required, and replace the cap.

20. Dispose of any hydraulic fluid remaining in

the Dispenser. Do not store hydraulic fluid in

the reservoir. Clean the dispensing unit with

denatured alcohol and store it properly.

21. Test the brake or clutch system for leaks

before driving the car.

Page Number - 6 Form 801193

Page 7

REFILLING SEALED AUTOMATIC TRANSMISSIONS

The Mityvac Fluid Dispensing System is appropriate for use to refill or top-off sealed automatic transmissions. Additional accessories and

adapters may be required and are available from

Mityvac for performing this function.

1. Unscrew the lid w/ pump from the reservoir,

and fill to desired level with new vehicle manufacturer’s recommended transmission fluid.

CAUTION: Lifetime “sealed” transmissions

require the use of special manufacturer recommended fluids. Use of any other fluids may

cause severe damage to the transmission and

void the manufacturer’s warranty.

Note: There are two scales of volume on the

reservoir. One scale indicates the volume

when the lid w/ pump is removed and one

when the lid w/ pump is installed. Be sure to

note the appropriate scale.

CAUTION: If fluid is added above the MAX

FILL line, the reservoir will overflow when the

lid w/ pump is installed.

2. Reinstall the lid w/ pump onto the reservoir.

3. Connect the fluid dispensing hose to the reservoir using the quick-connect coupler. Ensure

the coupler sleeve snaps forward to lock the

connection.

Note: The shutoff valve installed in the fluid

dispensing hose may be left open or closed. If

left open, fluid will begin to flow as soon as the

pump is operated. If closed, pressure will build

in the reservoir as indicated on the gauge.

4. Select the appropriate ATF refill adapter for the

application and connect it to the output of the

fluid dispensing hose.

5. Insert or connect the ATF refill adapter to the

transmission.

6. While observing the pressure gauge, operate

the pump to build pressure in the reservoir to

the desired level, or until the proper amount of

fluid has been dispensed.

Note: Check the vehicle’s service manual to

determine the proper method to check the

transmission fluid level. Failure to follow the

manufacturer’s recommended procedure

could result in under- or over-filling the transmission, causing severe transmission damage.

The pressure relief valve is designed to open

and maintain maximum pressure between 17

and 23 psi (1.2 and 1.6 bar).

Continual operation of the pump is not re-

quired to maintain fluid flow. Fluid will continue

to flow as long as there is pressure in the

reservoir and the shutoff valve is open.

WARNING: Do not exceed 25 psi (1.7 bar)

pressure in the reservoir. The relief valve

should prevent this, but if it fails and the pressure exceeds 25 psi, immediately discontinue

use and send the unit to an authorized service

center for repair or replacement.

7. Once the proper amount of fluid has been

dispensed, close the shutoff valve on the fluid

dispensing hose and bleed off the pressure by

tilting the pressure relief knob located on the

lid.

8. Depending on the type of fluid and future intended use, store or empty the remaining fluid

from the reservoir.

9. Clean the unit with denatured alcohol or common household cleaners, and store it properly.

Form 801193 Page Number - 7

Page 8

MANUAL DEL USUARIO

¿Tiene dudas técnicas?

América:

Si tiene dudas, o necesita servicio técnico, póngase

en contacto con nuestros técnicos de servicio

capacitados llamando al:

1-314-679-4200 ext. 4782

De lunes a viernes de 7:30 de la mañana a las 4:15

de la tarde, hora del Centro. Visite nuestro sitio web

en www.mityvac.com para ver nuevos productos,

catálogos e instrucciones de uso del producto.

¿Necesita piezas de servicio?

Para pedir piezas de repuesto o servicio, visítenos

en línea en www.mityvacparts.com

o llame al teléfono gratuito 1-800-992-9898.

SISTEMA DE DISTRIBUCIÓN DE

FLUIDO MODELOS MV6400,

MV6410, MV6840

Especificaciones:

Capacidad del depósito (con bomba): 5 cuartos de gal/1,2 galones/4,5 litros

Presión máxima: 25 lb/pulg2/1,7 bares/170 kPa

El usuario de este equipo tiene la responsabilidad de leer este manual del usuario en su

totalidad, y entender el uso seguro y apropiado y la aplicación de este equipo.

OCTUBRE - 2010 FORMULARIO 801193 Sección - 97-1

Page 9

TABLE OF CONTENTS

Piezas de Repuesto y Accesorios . . . . . . . . . . . . . . . . . . . . . 10

Principio de Operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Aplicaciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Precauciones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Instrucciones de Uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Distribución de Fluido . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Purga de Frenos de Presión . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Relleno de Transmisiones Automáticas Selladas . . . . . . . . . . 14

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Formulario 801193 Número de página - 9

Page 10

PIEZAS DE REPUESTO Y ACCESORIOS

JUEGOS DE SERVICIO

N° de ref. N° de pieza Descripción

1 801230 Tapa con conjunto de bomba

2 801229 Depósito de 1 galón

3 801233 Empaquetadura de la tapa

4 801234 Manómetro

5 822561 Palanca de la bomba

ACCESORIOS ESTÁNDAR

5

4

1

3

MVA570 –

Varilla de distribución

de fluido

MVA575 –

Manguera de distribución

de fluidos

2

822753 –

Gancho colgante

ACCESORIOS OPCIONALES

MVA571 –

Tapa de almacenamiento

de fluido

Número de página - 10 Formulario 801193

MVA6839 –

Depósito de purga

de presión

Page 11

PRINCIPIO DE OPERACIÓN

Este equipo está diseñado y tiene como finalidad

ser utilizado como medio de distribuir fluido. Utiliza una bomba de presión manual para aumentar

la presión en el depósito. La presión fuerza la

distribución del fluido del depósito por una tubería

de recogida de fluido. La salida de la tubería de

recogida de fluido está conectada a un acoplador

de cambio rápido, al que se puede conectar una

variedad de accesorios para controlar o dirigir el

fluido según la aplicación prevista.

No se debe hacer funcionar el equipo por encima

de un nivel de presión seguro dependiendo de la

aplicación. Hay un manómetro instalado para indicar la presión en el depósito, y debe observarse

con frecuencia para asegurarse de que la presión

sea menor o igual que la recomendada para la

aplicación.

Aplicaciones

Este equipo está diseñado para llenar depósitos

con fluidos como refrigerante de motor, aceite

de motor o fluidos de lavaparabrisas, transmisión

automática, frenos o servodirección. Sin embargo,

con los accesorios adecuados puede usarse con

seguridad para purgar la presión de los sistemas

de freno o embragues hidráulicos o para rellenar o

llenar por completo transmisiones automáticas.

Precauciones

Este equipo está diseñado para efectuar el servicio en una variedad de vehículos de modo seguro

y conveniente. Sin embargo, las diferencias de

marcas y modelos de los vehículos puede hacer

que sea imposible usar este equipo de la forma

prevista. No intente forzar el uso de este equipo en

una aplicación para la que no esté diseñado.

Los procedimiento documentados en este manual

deben servir como guías para el uso de este

equipo. Además de estas guías, siga siempre los

procedimientos recomendados del fabricante al

realizar el servicio en cada vehículo.

El uso de este equipo es sencillo y directo si sigue

las instrucciones. No obstante, debe tener siempre

en cuenta que está usando un sistema que puede

estar sometido a presión, con fluido a la espera de

ser expulsado. Al operar éste equipo use el sentido común y párese siempre a pensar antes de

desconectar una manguera u otro componente.

• Este equipo está previsto para el uso profesional

solamente por personal capacitado para realizar

las funciones de servicio para la que se ha

diseñado.

• Lea con cuidado y entienda todas las instruccio-

nes antes de usar este equipo.

• Lleve siempre protectores para los ojos y ropa

adecuada al hacer funcionar este equipo.

• No intente modificar la válvula de alivio de pre-

sión para alterar su rendimiento. Si la presión en

el depósito es mayor que 23 lb/pulg

2

(1,6 bares),

devuélvela a un centro de servicio autorizado

para ser reparada o reemplazada.

• Algunos fluidos, incluidos el fluido de frenos, son

corrosivos y se deben tomar las medidas apropiadas para proteger las superficies pintadas y

la piel contra la exposición.

• No use este equipo con gasolina u otros líquidos

inflamables, o con fluidos a temperaturas superiores a 175 °F (80 °C)

• Consulte y siga el procedimiento recomendado

del fabricante al usar este equipo a fin de realizar

el servicio automotriz.

Formulario 801193 Número de página - 11

Page 12

INSTRUCCIONES DE USO

Distribución de fluido

1. Desatornille la tapa con la bomba del depósito

y llene al nivel deseado con fluido limpio.

Nota: Hay dos escalas de volumen en el

depósito. Una escala indica el volumen

cuando se quita la tapa con la bomba y otra

cuando está instalada la tapa con la bomba.

Asegúrese de observar la escala apropiada.

PRECAUCIÓN: Si se agrega fluido por encima

de la línea MAX FILL (llenado máximo), el

depósito rebosará al instalar la tapa con la

bomba.

2. Vuelva a instalar la tapa con la bomba en el

depósito.

3. Conecte la manguera de distribución de fluido

u otro accesorio en el acoplador de conexión

rápida que se extiende desde el depósito.

Asegúrese de que el manguito del acoplador

vuelva por resorte hacia adelante para trabar la

conexión.

Nota: Dependiendo de la aplicación, la válvula

de corte instalada en la manguera de distribución de fluido puede dejarse abierta o cerrada.

Si se deja abierta, el fluido comenzará a fluir

tan pronto como se haga funcionar la bomba.

Si está cerrada, la presión aumentará en el

depósito según se indica en el manómetro.

4. Mientras observa el manómetro, haga funcionar la bomba para aumentar la presión en

el depósito al nivel deseado, o hasta que se

distribuya la cantidad deseada de fluido.

Nota: Una válvula de alivio de presión inte-

grada está diseñada para abrirse y mantener la

presión máximas entre 17 y 23 lb/pulg2 (1,2 y

1,6 bares).

No se requiere la operación continua de la

bomba para mantener el caudal de fluido.

El fluido seguirá fluyendo siempre que haya

presión en el depósito y esté abierta la válvula

de corte.

ADVERTENCIA: No sobrepase una presión

de 25 lb/pulg

2

(1,7 bares) en el depósito. La

válvula de alivio debe impedir esto, pero si no

lo hace y la presión sobrepasa las 25 lb/pulg2,

deje de usar de inmediato y envíe la unidad

a un centro de servicio autorizado para su

reparación o reemplazo.

5. Una vez que se distribuya la cantidad apropiada de fluido, cierre la válvula de corte y

purgue la presión inclinando la perilla de alivio

de presión ubicada en la tapa.

6. Dependiendo del tipo de fluido y del uso previsto para el futuro, podrá almacenar el fluido

restante en el depósito. De lo contrario, vacíe

el depósito, límpielo con alcohol de quemar o

limpiador casero común y guárdelo de forma

apropiada.

Número de página - 12 Formulario 801193

Page 13

PURGA DE FRENOS DE PRESIÓN

El sistema de distribución de fluido Mityvac es

apropiado para usar como purgador de presión

para los sistemas de freno y embrague hidráulicos. Tal vez sean necesarios otros accesorios y

adaptadores y estén disponibles de Mityvac para

realizar esta función.

ADVERTENCIA: El fluido hidráulico de frenos es

peligroso y corrosivo. Tome precauciones para

proteger las superficies pintadas y la piel contra la

exposición, y lea y siga las advertencias e instrucciones del fabricante del fluido.

1. Estacione el automóvil, conecte el freno de

estacionamiento y apague el motor.

2. Abra y sujete el capó.

3. Localice el cilindro maestro del freno o embrague y quite la tapa.

4. Extraiga tanto fluido hidráulico usado del

depósito del cilindro maestro como sea posible y vuelva a llenarlo de fluido nuevo.

5. Seleccione el adaptador de purga de presión

del cilindro maestro e instálelo seguramente en

el depósito del cilindro maestro.

6. Antes de agregar fluido al distribuidor, conecte

la manguera de distribución de fluido al

acoplador hembra de conexión rápida que se

extiende desde el depósito. Asegúrese de que

el manguito del acoplador vuelva por resorte

hacia adelante para trabar la conexión.

7. Conecte el otro extremo de la manguera de

distribución de fluido en el acoplador de conexión rápida macho, en el adaptador de purga

de presión del cilindro maestro. Asegúrese

de que el manguito del acoplador vuelva por

resorte hacia adelante para trabar la conexión.

8. Asegúrese de que la válvula de corte esté abierta, y haga funcionar la bomba manual para

someter el sistema a presión a 10 lb/pulg2 (0,7

bares).

9. Observe el manómetro para asegurarse de

que no haya fugas. Si baja la presión, alivie la

presión restante en el sistema inclinando la

perilla de alivio de presión ubicada en la tapa,

quite y vuelva a apretar la tapa del depósito de

distribución y el adaptador en el depósito del

cilindro maestro y vuelva a comprobar si hay

fugas en el sistema.

ADVERTENCIA: Se pueden producir lesiones

graves y daños en el equipo si se quita la tapa

de la unidad de distribución o el adaptador del

cilindro maestro, sin aliviar primero la presión

del sistema.

10. Una vez que se haya probado que todas las

conexiones estén seguras y el adaptador del

cilindro maestro no tenga fugas, quite la tapa

con la bomba de la unidad de distribución y

agregue hasta 2 cuartos de galón (2 litros) de

fluido hidráulico recomendado por el fabricante de un recipiente sellado.

11. Vuelva a instalar la tapa con la bomba y apriétela bien.

12. Consulte el manual de servicio para determinar

la presión de purga recomendada y la secuencia de purga adecuada para el vehículo cuyo

servicio se esté efectuando.

13. Mientras observa el manómetro, haga funcionar la bomba de presión para lograr la presión

recomendada.

14. Conecte el depósito de purga al tornillo de

purga del primer cilindro que vaya a purgar.

15. Abra el tornillo de purga. Deje salir el fluido

hasta que salga solamente fluido nuevo

transparente sin burbujas de aire visibles del

tornillo, y después vuelva a apretar el tornillo

de purga al par de apriete recomendado por el

fabricante.

16. Realice el mismo procedimiento en todos los

tornillos de purga restantes. Opere la bomba

de presión según sea necesario para mantener

una presión adecuada.

Nota: No deje que se agote la unidad de

distribución y el depósito del cilindro maestro.

Use la válvula de alivio de presión para aliviar

la presión y agregar fluido nuevo según sea

necesario.

17. Una vez terminada la purga, alivie la presión en

el depósito y el cilindro maestro inclinando la

perilla de alivio de presión ubicada en la tapa

de la unidad de distribución.

18. Cierre la válvula de corte de la manguera de

distribución de fluido y quite cuidadosamente

el adaptador del cilindro maestro, teniendo

cuidado de no derramar fluido para frenos.

19. Extraiga el fluido excesivo o rellene por completo el cilindro maestro según sea necesario y

vuelva a colocar la tapa.

20. Deseche cualquier fluido hidráulico restante en

el distribuidor. No almacene fluido hidráulico

en el depósito. Limpie la unidad de distribución

con alcohol para quemar y guárdela de forma

apropiada.

21. Pruebe el sistema de freno o embrague para

ver si hay fugas antes de conducir el automóvil.

Formulario 801193 Número de página - 13

Page 14

RELLENO DE TRANSMISIONES AUTOMÁTICAS SELLADAS

El uso del sistema de distribución de fluido

Mityvac es apropiado para rellenar o llenar por

completo las transmisiones automáticas selladas.

Tal vez sea necesario usar accesorios y adaptadores adicionales y están disponibles en Mityvac

para realizar esta función.

1. Desatornille la tapa con bomba del depósito

y llene hasta el nivel deseado con fluido de

transmisión recomendado nuevo del fabricante

del vehículo.

PRECAUCIÓN: Las transmisiones “selladas”

durante toda la vida útil requieren el uso de

fluidos especiales recomendados por el fabricante. El uso de cualquier otro fluido puede

ocasionar daños importantes en la transmisión

y anular la garantía del fabricante.

Nota: Hay dos escalas de volumen en el

depósito. Una escala indica el volumen

cuando la tapa con bomba está quitada y la

otra cuando la tapa con bomba está instalada.

Asegúrese de observar la escala apropiada.

PRECAUCIÓN: Si se agrega fluido por encima

de la marca MAX FILL (llenado máximo),

el depósito rebosará al instalar la tapa con

bomba.

2. Vuelva a instalar la tapa con bomba en el

depósito.

3. Conecte la manguera de distribución de fluido

en el depósito usando el acoplador de conexión rápida. Asegúrese de que el manguito del

acoplador vuelva por resorte hacia adelante

para trabar la conexión.

Nota: La válvula de corte instalada en la

manguera de distribución de fluido puede

dejarse abierta o cerrada. Si se deja abierta,

el fluido empezará a fluir tan pronto como se

haga funcionar la bomba. Si está cerrada, la

presión aumentará en el depósito según se

indica en el manómetro.

4. Seleccione el adaptador de relleno de fluido de

transmisión automática apropiado para la aplicación y conéctelo a la salida de la manguera

de distribución de fluido.

5. Inserte o conecte el adaptador de relleno de

fluido de transmisión automática en la transmisión.

6. Mientras observa el manómetro, haga

funcionar la bomba para aumentar la presión

en el depósito hasta el nivel deseado o hasta

distribuir la cantidad apropiada de fluido.

Nota: Consulte el manual de servicio del ve-

hículo para determinar el método correcto para

comprobar el nivel de fluido de la transmisión.

De no seguir el procedimiento recomendado

por el fabricante podría resultar en un llenado

insuficiente o excesivo de la transmisión, ocasionando daños importantes en la transmisión.

La válvula de alivio de presión está diseñada

para abrir y mantener la presión máxima entre

17 y 23 lb/pulg2 (1,2 y 1,6 bares).

No es necesario hacer funcionar la bomba de

forma continua para mantener el caudal de

fluido. El fluido seguirá fluyendo siempre que

haya presión en el depósito y la válvula de

corte esté abierta.

ADVERTENCIA: No sobrepase la presión de

25 lb/pulg2 (1,7 bares) en el depósito. La válvula de alivio debe impedir esto, pero si no lo

hace y la presión sobrepasa 25 lb/pulg2, deje

de usar de inmediato y envíe la unidad a un

centro de servicio autorizado para reparación

o reemplazo.

7. Una vez que se distribuya la cantidad apropiada de fluido, cierre la válvula de corte en la

manguera de distribución de fluido y purgue la

presión inclinando la perilla de alivio de presión

ubicada en la tapa.

8. Dependiendo del tipo de fluido y el uso previsto en el futuro, almacene o vacíe el fluido

restante del depósito.

9. Limpie la unidad con alcohol para quemar o

limpiadores caseros comunes y guárdela de

forma apropiada.

Número de página - 14 Formulario 801193

Page 15

MANUEL D’UTILISATION

Pour toute question technique :

Amériques :

En cas de questions ou de besoin d’assistance

technique, prière d’appeler nos techniciens

d’entretien spécialisés au :

1-314-679-4200, poste 4782

Lundi – vendredi, 7 heures 30 à 16 heures

15 (heure normale du centre des Etats-Unis)

Visiter notre site Web à www.mityvac.com

pour des nouveaux produits, catalogues et

instructions d’utilisation de nos produits.

Pour toute pièce de rechange :

Pour commander des pièces de rechange, nous

rendre visite en ligne à www.mityvacparts.com

ou nous appeler sans frais au 1-800-992-9898.

SYSTÈME DE DISTRIBUTION

DE FLUIDE MODÈLES MV6400,

MV6410, MV6840

Caractéristiques

Contenance du réservoir (avec pompe) : 4,5 litres/5 quarts/1,2 gallon

Pression maximum : 1,7 bar/170 kPa/25 psi

Il incombe à l’utilisateur de ce matériel de lire le présent manuel en totalité et de veiller à bien

comprendre la façon correcte d’utiliser le matériel en toute sécurité.

OCTOBRE - 2010 DOCUMENT 801193 Section - 97-1

Page 16

TABLE DES MATIÈRES

Pièces de Rechange et Accessoires . . . . . . . . . . . . . . . . . . . 17

Principe de Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Précautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Mode D’Emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Distribution de Fluide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Purge Sous Pression d’un Circuit de Freinage . . . . . . . . . . . . 20

Remplissage des Transmissions Automatiques Scellées . . . 21

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page numéro - 16 Document 801193

Page 17

PIÈCES DE RECHANGE ET ACCESSOIRES

KITS D’ENTRETIEN

Repère N° Ref. N° Description

1 801230 Couvercle à pompe

2 801229 Réservoir de 3,8 l (1 gal.)

3 801233 Joint de couvercle

4 801234 Manomètre

5 822561 Poignée de pompe

ACCESSOIRES STANDARD

5

4

1

3

MVA570 – Lance de

distribution de fluide

MVA575 – Flexible de

distribution de fluide

2

822753 –

Crochet de suspension

ACCESSOIRES EN OPTION

MVA571 – Couvercle de

réservoir de stockage

de fluide

Document 801193 Page numéro - 17

MVA6839 –

Réservoir de purge

sous pression

Page 18

PRINCIPE DE FONCTIONNEMENT

Ce matériel est conçu pour être utilisé comme

moyen de distribution de fluide. Il utilise une

pompe à main pour pressuriser le réservoir. La

pression force le fluide à circuler hors du réservoir

dans un tube de prise de fluide. La sortie de ce

tube est branchée à un raccord rapide auquel

peuvent être reliés divers accessoires permettant

de contrôler ou diriger la circulation du fluide en

fonction de l’application désirée.

Ne jamais faire fonctionner ce matériel au-dessus

d’une pression sans danger qui est fonction de

l’application. Il est pourvu d’un manomètre indiquant la pression dans le réservoir qu’il convient

d’observer régulièrement pour s’assurer que

la pression reste au niveau recommandé pour

l’application ou en dessous.

Applications

Ce matériel est destiné au remplissage de réservoirs avec des fluides tels que liquide de refroidissement, huile moteur, liquide lave-glace, huile à

transmission automatique, liquide de frein ou fluide

de servo-direction. Il peut toutefois être utilisé

en toute sécurité avec des accessoires adaptés

pour purger sous pression les circuits de freinage

hydraulique ou d’embrayage à commande hydraulique, ou pour remplir les transmissions automatiques scellées ou faire l’appoint.

Précautions

Ce matériel est conçu pour l’entretien commode

en toute sécurité de divers véhicules. Toutefois,

les différences qui existent entre les marques et

modèles de véhicules peuvent empêcher d’utiliser

ce matériel comme prévu. N’essayer en aucun cas

de s’en servir dans une application pour laquelle il

n’est pas conçu.

Les marches à suivre décrites dans cette notice

sont destinées à servir de conseils d’utilisation de

ce matériel. Outres ces conseils, toujours suivre

les recommandations du constructeur de chaque

véhicule particulier pour en effectuer l’entretien.

Ce matériel est simple à utiliser, à condition de

suivre les instructions. Toutefois, ne jamais oublier

que l’on travaille avec un système qui risque d’être

sous pression et de contenir du fluide qui ne

demande qu’à être expulsé. Lorsqu’on se sert de

ce matériel, faire preuve de bon sens et toujours

prendre le temps de réfléchir avant de débrancher

un flexible ou un autre accessoire.

• Ce matériel est destiné uniquement à un us-

age professionnel par du personnel formé à

l’exécution des fonctions d’entretien pour lequel

il est conçu.

• Lire attentivement et veiller à bien comprendre

toutes les instructions avant de se servir de ce

matériel.

• Toujours porter des lunettes de protection et

des vêtements adaptés pour faire fonctionner ce

matériel.

• Ne pas essayer de modifier le clapet de

décharge pour ajuster son fonctionnement. Si

jamais la pression dans le réservoir dépasse 1,6

bar (23 psi), renvoyer le matériel à un centre de

réparation agréé pour faire réparer ou remplacer

le clapet.

• Certains fluides, y compris le liquide de frein,

sont corrosifs ; prendre les précautions appropriées pour ne pas y exposer les surfaces

peintes ni la peau.

• Ne pas utiliser ce matériel avec de l’essence

ou d’autres liquides inflammables, ni avec des

fluides dont la température est supérieure à

80 °C (175 °F)

• Consulter et respecter les marches à suivre

recommandées par le constructeur du véhicule

quand on utilise ce matériel dans des opérations

d’entretien automobile.

Page numéro - 18 Document 801193

Page 19

MODE D’EMPLOI

Distribution de fluide

1. Dévisser le couvercle à pompe du réservoir et

remplir de fluide propre jusqu’au niveau désiré.

Remarque : le réservoir comporte deux

graduations de volume, dont l’une indique

le volume lorsque le couvercle à pompe est

enlevé et l’autre lorsque ce couvercle est en

place. Veiller à observer la graduation appropriée.

ATTENTION : si on ajoute du fluide au-dessus

du repère MAX FILL (remplissage maxi), le

réservoir débordera quand on met le couvercle

à pompe en place.

2. Remettre le couvercle à pompe sur le réservoir.

3. Brancher le flexible de distribution de fluide

ou un autre accessoire au raccord rapide qui

dépasse du réservoir. S’assurer que le manchon du raccord s’emboîte vers l’avant pour

verrouiller le branchement.

Remarque : suivant l’application, le robinet

de coupure posé sur le flexible de distribution

de fluide peut rester ouvert ou fermé. S’il reste

ouvert, le fluide commence à circuler dès que

la pompe est actionnée. S’il est fermé, la pression montera dans le réservoir comme indiqué

sur le manomètre.

4. Tout en observant le manomètre, actionner

la pompe pour faire monter la pression dans

le réservoir jusqu’au niveau désiré ou jusqu’à

ce que la quantité désirée de fluide ait été

distribuée.

Remarque : un clapet de décharge incorporé

est conçu pour s’ouvrir et maintenir la pression

maximum entre 1,2 et 1,6 bar (17 et 23 psi).

Il n’est pas nécessaire d’actionner constam-

ment la pompe pour maintenir le débit de

fluide. Le fluide continue à circuler tant que le

réservoir est pressurisé et que le robinet de

coupure est ouvert.

AVERTISSEMENT : ne pas dépasser une

pression de 1,7 bar (25 psi) dans le réservoir.

Le clapet devrait l’empêcher mais s’il ne fonctionne pas et que la pression dépasse 1,7 bar

(25 psi), arrêter immédiatement de se servir du

matériel et l’envoyer dans un centre de réparation agréé pour faire réparer ou remplacer le

clapet.

5. Une fois que la quantité correcte de fluide a

été distribuée, fermer le robinet de coupure et

dissiper la pression en basculant la manette de

décharge qui se trouve sur le couvercle.

6. Suivant le type de fluide et son utilisation

prévue, on peut stocker le restant de fluide

dans le réservoir. Sinon, vider le réservoir,

le nettoyer avec de l’alcool dénaturé on

un produit nettoyant ménager courant et

l’entreposer comme il convient.

Document 801193 Page numéro - 19

Page 20

PURGE SOUS PRESSION D’UN CIRCUIT DE FREINAGE

Le système de distribution de fluide Mityvac

peut être utilisé pour purger sous pression les

circuits de freinage hydraulique et d’embrayage

à commande hydraulique. D’autres accessoires

et adaptateurs peuvent être nécessaires et sont

disponibles auprès de Mityvac pour effectuer cette

opération.

AVERTISSEMENT : le liquide de frein hydraulique

est dangereux et corrosif. Prendre des précautions pour ne pas y exposer les surfaces peintes

et la peau ; lire et respecter les avertissements et

instructions du fabricant du fluide.

1. Garer la voiture, serrer le frein de stationnement et couper le contact.

2. Ouvrir et bloquer le capot.

3. Localiser le maître-cylindre de freinage ou

d’embrayage et enlever le bouchon.

4. Extraire autant d’huile hydraulique usée que

possible du réservoir de maître-cylindre et le

remplir d’huile fraîche.

5. Choisir l’adaptateur de purge sous pression

de maître-cylindre qui convient et le mettre

solidement en place sur le réservoir du maîtrecylindre.

6. Avant d’ajouter du fluide au distributeur,

brancher le flexible de distribution de fluide

au raccord rapide femelle qui dépasse du

réservoir. S’assurer que le manchon du raccord s’emboîte vers l’avant pour bloquer le

branchement.

7. Brancher l’autre extrémité du flexible de

distribution de fluide au raccord rapide mâle

de l’adaptateur de purge sous pression du

maître-cylindre. S’assurer que le manchon du

raccord s’emboîte vers l’avant pour bloquer le

branchement.

8. S’assurer que le robinet de coupure est ouvert

et actionner la pompe à main pour pressuriser

le système à 0,7 bar (10 psi).

9. Observer le manomètre pour s’assurer qu’il n’y

a pas de fuite. Si la pression baisse, dissiper la

pression restant dans le système en basculant

la manette de décharge qui se trouve sur le

couvercle, enlever et resserrer le couvercle du

réservoir de distribution et de l’adaptateur du

réservoir de maître-cylindre puis contrôler de

nouveau l’étanchéité du système.

AVERTISSEMENT : des blessures et/ou

dégâts matériels graves peuvent se produire

si le couvercle est enlevé du distributeur ou

l’adaptateur du maître-cylindre sans dépres-

Page numéro - 20 Document 801193

surisation préalable du système.

10. Une fois que l’on s’est assuré que tous

les branchements sont assujettis et que

l’adaptateur de maître-cylindre ne fuit pas,

enlever le couvercle à pompe du distributeur

et ajouter jusqu’à 2 litres (2 quarts) d’huile

hydraulique recommandée par le constructeur

contenue dans un bidon hermétique.

11. Remettre le couvercle à pompe en place et

bien le serrer.

12. Consulter un manuel d’entretien pour déterminer la pression de purge recommandée et

la séquence de purge adaptée au véhicule en

cours d’entretien.

13. Tout en observant le manomètre, actionner la

pompe de pressurisation pour obtenir la pression recommandée.

14. Raccorder le réservoir de purge à la vis de

purge du premier cylindre à purger.

15. Ouvrir la vis de purge. Laisser le fluide

s’écouler jusqu’à ce que seul du fluide frais

translucide sans bulles d’air visibles s’écoule

de la vis puis resserrer celle-ci au couple

recommandé par le constructeur.

16. Procéder de la même façon sur toutes les

autres vis de purge. Actionner la pompe de

pressurisation selon le besoin pour maintenir

une pression suffisante.

Remarque : ne pas laisser le distributeur ni le

réservoir du maître-cylindre s’assécher. Utiliser

le clapet de décharge pour dissiper la pression

et ajouter du fluide frais si nécessaire.

17. Une fois la purge terminée, dissiper la pression

dans le réservoir et le maître-cylindre en basculant la manette de décharge qui se trouve

sur le couvercle du distributeur.

18. Fermer le robinet de coupure du flexible de

distribution de fluide et retirer avec précaution

l’adaptateur du maître-cylindre, en faisant attention de ne pas renverser de liquide de frein.

19. Extraire l’excédent de fluide ou faire l’appoint

dans le maître-cylindre selon le besoin et

remettre le bouchon en place.

20. Mettre au rebut toute huile hydraulique restant

dans le distributeur. Ne pas stocker d’huile

hydraulique dans le réservoir. Nettoyer le

distributeur à l’alcool dénaturé et le ranger

comme il convient.

21. Contrôler l’étanchéité du circuit de freinage ou

d’embrayage avant de conduire la voiture.

Page 21

REMPLISSAGE DES TRANSMISSIONS AUTOMATIQUES SCELLÉES

Le système de distribution de fluide Mityvac peut

être utilisé pour remplir les transmissions automatiques scellées ou faire l’appoint. D’autres accessoires et adaptateurs peuvent être nécessaires et

sont disponibles auprès de Mityvac pour effectuer

cette opération.

1. Dévisser le couvercle à pompe du réservoir et

remplir celui-ci jusqu’au niveau désiré d’huile

à transmission fraîche recommandée par le

constructeur du véhicule.

ATTENTION : les transmissions « scellées

» à vie exigent des huiles spéciales recommandées par le constructeur. L’emploi de

toute autre huile peut endommager gravement la transmission et annuler la garantie du

constructeur.

Remarque : le réservoir comporte deux gradu-

ations de volume, dont l’une indique le volume

lorsque le couvercle à pompe est enlevé et

l’autre lorsque ce couvercle est en place.

Veiller à observer la graduation appropriée.

ATTENTION : si on ajoute de l’huile au-dessus

du repère MAX FILL (remplissage maxi), le

réservoir débordera quand on met le couvercle

à pompe en place.

2. Remettre le couvercle à pompe sur le réservoir.

3. Brancher le flexible de distribution de fluide au

raccord rapide du réservoir. S’assurer que le

manchon du raccord s’emboîte vers l’avant

pour verrouiller le branchement.

Remarque : le robinet de coupure posé sur

le flexible de distribution de fluide peut rester

ouvert ou fermé. S’il reste ouvert, l’huile commence à circuler dès que la pompe est actionnée. S’il est fermé, la pression montera dans le

réservoir comme indiqué sur le manomètre.

4. Choisir l’adaptateur de remplissage d’huile à

transmission automatique correspondant à

l’application et le raccorder à la sortie du flexible de distribution de fluide.

5. Introduire l’adaptateur de remplissage d’huile à

transmission automatique dans la transmission

ou le raccorder à celle-ci.

6. Tout en observant le manomètre, actionner

la pompe pour faire monter la pression dans

le réservoir jusqu’au niveau désiré ou jusqu’à

ce que la quantité correcte d’huile ait été

distribuée.

Remarque : consulter le manuel d’entretien du

véhicule pour déterminer la méthode correcte

de vérification du niveau d’huile à transmission.

Le non-respect de la marche à suivre recommandée par le constructeur pourrait conduire

à un remplissage insuffisant ou excessif de la

transmission, ce qui l’endommagerait gravement.

Le clapet de décharge est conçu pour s’ouvrir

et maintenir la pression maximum entre 1,2 et

1,6 bar (17 et 23 psi).

Il n’est pas nécessaire d’actionner constam-

ment la pompe pour maintenir le débit d’huile.

L’huile continue à circuler tant que le réservoir

est pressurisé et que le robinet de coupure est

ouvert.

AVERTISSEMENT : ne pas dépasser une

pression de 1,7 bar (25 psi) dans le réservoir.

Le clapet devrait l’empêcher mais s’il ne fonctionne pas et que la pression dépasse 1,7 bar

(25 psi), arrêter immédiatement de se servir du

matériel et l’envoyer dans un centre de réparation agréé pour faire réparer ou remplacer le

clapet.

7. Une fois que la quantité correcte d’huile a été

distribuée, fermer le robinet de coupure du

flexible de distribution de fluide et dissiper la

pression en basculant la manette de décharge

qui se trouve sur le couvercle.

8. Suivant le type d’huile et son utilisation prévue,

entreposer le réservoir ou vider l’huile qui reste

dedans.

9. Nettoyer le distributeur avec de l’alcool

dénaturé ou un produit nettoyant ménager

courant et le ranger comme il convient.

Document 801193 Page numéro - 21

Page 22

BENUTZERHANDBUCH

Haben Sie technische Fragen?

Wenn Sie Fragen haben oder technische

Dienstleistungen benötigen, wenden Sie sich

bitte an unsere technischen Fachkräfte unter:

+1 314 679 4200 Durchwahl: 4782

Montag bis Freitag, 7:30 bis 16:15 Uhr Central

Standard Time

Neue Produkte, Kataloge und Anleitungen finden

Sie auch auf unserer Website unter www.mityvac.

com.

Benötigen Sie Wartungsteile?

Ersatz- und Wartungsteile können über unsere

Website www.mityvacparts.com bestellt werden.

Oder rufen Sie uns an: +1 800 992 9898.

FLÜSSIGKEITSAUSGABE-

SYSTEM MODELLE MV6400,

MV6410, MV6840

Technische Daten:

Behälterkapazität (mit Pumpe): 5 Quarts / 1.2 Gallonen / 4,5 Liter)

Maximaler Druck: 1,7 bar/170 kPa/25 psi

Der Benutzer ist dafür verantwortlich, dieses Handbuch völlig zu lesen und den sicheren

und vorschriftsmäßigen Gebrauch dieses Gerätes zu verstehen.

OKTOBER - 2010 Formular 801193 Section - 97-1

Page 23

INHALTSANGABE

Wartungsteile & standardzusatzgeräte . . . . . . . . . . . . . . . . . . 24

Betriebsprinzip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Applikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Vorsichtsmassnahmen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Gebrauchsanweisungen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Flüssigkeitsausgabe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Bremsendruckentlüftung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Auffüllen versiegelter automatischer getriebe . . . . . . . . . . . . . 29

Standardgewährleistung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Formular 801193 Seite - 23

Page 24

WARTUNGSTEILE & ZUBEHÖR

SERVICE KITS

Ref. Nr. Part No. Beschreibung

1 801230 Baugruppe: Deckel und Pumpe

2 801229 1 Gallone Behälter

3 801233 Deckeldichtung

4 801234 Druckmessgerät

5 822561 Pumpenhandgriff

STANDARDZUSATZGERÄTE

5

4

1

3

MVA570 –

Flüssigkeitsausgaberohr

MVA575 –

Flüssigkeitsausgabeschlauch

2

822753 –

Hängehaken

AUF WUNSCH ERHÄLTLICHE ZUSATZGERÄTE

MVA6839 –

MVA571 –

Flüssigkeitslagerungsdeckel

Seite- 24 Formular 801193

Druckentlüftungs-

behälter

Page 25

BETRIEBSPRINZIP

Dieses Gerät ist für die Ausgabe von Flüssigkeiten

gebaut und vorgesehen. Es benutzt eine manuelle

Druckpumpe zum Aufbau von Druck im Behälter.

Der Druck veranlasst die Ausgabe von Flüssigkeit

aus dem Behälter durch ein Flüssigkeitsaufnahmerohr. Die Ausflussöffnung des Flüssigkeitsaufnahmerohrs ist mit einem Schnellwechselanschluss verbunden, an den je nach gewünschter

Applikation zur Kontrolle oder Lenkung des

Flüssigkeitsstroms eine Reihe von Zusatzgeräten

angeschlossen werden können.

Das Gerät darf niemals bei einem höheren Druck

als dem Sicherheitsstand für den jeweiligen Verwendungszweck betrieben werden. Ein Messgerät ist eingebaut, das den Druck im Behälter

anzeigt. Es sollte regelmäßig geprüft werden,

um sicherzustellen, dass der Druck auf dem für

die Applikation empfohlenen Wert oder darunter

bleibt.

Applikationen

Dieses Gerät hat den Zweck, Behälter mit Flüssigkeiten zu füllen wie z.B. Motorkühlmittel oder

Scheibenwischer-, automatische Getriebe-,

Brems- oder Servolenkungsflüssigkeit. Mit Hilfe

der angemessenen Zusatzgeräte kann es aber

auch gefahrlos zur Druckentlüftung von hydraulischen Brems- oder Kupplungssystemen verwendet werden, oder um versiegelte automatischen

Getriebe zu füllen oder nachzufüllen.

Vorsichtsmassnahmen

Dieses Gerät ist dazu vorgesehen, eine Reihe von

Fahrzeugen auf sichere und praktische Weist zu

warten. Verschiedenheiten der Fahrzeugmarken

und Modelle können es jedoch unmöglich machen, das Gerät wie vorgesehen zu verwenden.

Man darf nicht versuchen, das Gerät zu einer Applikation zu zwingen, für die es nicht vorgesehen

ist.

Die in diesem Handbuch beschriebenen Maßnahmen sollen als Richtlinien für die Verwendung des

Gerätes dienen. Zusätzlich zu diesen Richtlinien

bei der Wartung jedes individuellen Fahrzeugs immer den Empfehlungen des Herstellers folgen.

Die Benutzung des Gerätes ist einfach und unkompliziert, wenn man den Bedienungs-anweisungen folgt. Man muss sich aber immer bewusst

sein, dass man mit Systemen arbeitet, die unter

Druck stehen können und mit Flüssigkeiten, die

nur darauf warten, ausgestoßen zu werden. Bei

der Benutzung des Gerätes gesunden Menschenverstand walten lassen und immer anhalten und

denken, bevor man einen Schlauch oder eine

andere Komponente löst.

• Dieses Gerät ist nur für den beruflichen Ge-

brauch durch Personen gedacht, die in den

Funktionen, für die es gebaut wurde, geschult

sind.

• Vor Gebrauch des Gerätes alle Instruktionen

sorgfältig lesen und verstehen.

• Bei der Verwendung des Gerätes immer einen

Augenschutz und angemessene Kleidung tragen.

• Keinesfalls versuchen, das Überdruckventil zu

bearbeiten, um seine Leistung zu ändern.

Sollte der Druck im Behälter jemals 23 psi (1,6

bar) überschreiten, so muss es zur Reparatur

oder zum Austausch zu einem autorisierten

Kundendienstzentrum gebracht werden.

• Manche Flüssigkeiten, darunter auch die

Bremsflüssigkeit, sind korrosiv, und es muss

angemessene Vorsicht angewandt werden, um

Berührung mit lackierten Oberflächen und der

Haut zu vermeiden.

• Dieses Gerät darf nicht mit Benzin oder anderen

entzündbaren Flüssigkeiten benützt werden,

oder mit Flüssigkeiten, deren Temperatur höher

als 175° Fahrenheit ist (80° Celsius).

• Das vom Hersteller empfohlene Verfahren lesen

und befolgen, wenn dieses Gerät zur Fahrzeugwartung benützt wird.

Formular 801193 Seite - 25

Page 26

GEBRAUCHSANWEISUNGEN

Flüssigkeitsausgabe

1. Deckel mit Pumpe vom Behälter abschrauben

und ihn bis zum gewünschten Stand mit sauberer Flüssigkeit füllen.

Hinweis: Auf dem Behälter sind zwei Volu-

menskalen angezeigt. Eine Skala zeigt das

Volumen bei entfernter Baugruppe von Deckel

und Pumpe, die andere, wenn Deckel und

Pumpe eingebaut sind. Sicherstellen, dass die

richtige Skala benutzt wird.

VORSICHT: Wird Flüssigkeit über die MAX

FILL Linie hinaus nachgefüllt, so läuft der Behälter über, wenn Deckel und Pumpe installiert

werden.

2. Deckel und Pumpe wieder auf dem Behälter

anbringen.

3. Den Flüssigkeitsausgabeschlauch oder ein anderes Zusatzgerät mit dem Schnellverbindungsanschluss verbinden, der aus dem Behälter

herausragt. Sicherstellen, dass die Hülse des

Schnellverbindungsanschlusses nach vorn

schnappt und die Verbindung sichert.

Hinweis: Je nach Verwendungszweck kann

das Absperrventil im Flüssigkeits-ausgabeschlauch offen oder geschlossen sein. Bleibt es

offen, so beginnt der Flüssigkeitsstrom, sobald

die Pumpe betrieben wird. Ist es geschlossen,

so baut sich im Behälter Druck auf, wie das

Druckmessgerät anzeigt.

4. Das Druckmessgerät im Auge behaltend die

Pumpe betreiben, um im Behälter einen Druck

der gewünschten Stärke aufzubauen oder

bis das gewünschte Flüssigkeits-volumen

ausgegeben worden ist.

Hinweis: Ein eingebautes Druckentlastungs-

ventil öffnet sich und hält den maximalen

Druck zwischen 17 und 23 psi (1.2 und 1,6 bar)

Es ist nicht notwendig, die Pumpe kontinuierlich zu betreiben, um den Flüssigkeits-strom

aufrecht zu erhalten. Die Flüssigkeit fährt fort

zu strömen, solange im Behälter Druck besteht

und das Absperrventil offen ist.

WARNUNG: 25 psi (1,7 bar) Druck im

Behälter nicht überschreiten. Das Druck-entlastungsventil sollte das verhindern, aber wenn

es versagt und der Druck 25 psi überschreitet,

den Betrieb sofort abbrechen und die Einheit

zur Reparatur oder zum Austausch an ein

autorisiertes Kundendienstzentrum schicken.

5. Wenn die richtige Flüssigkeitsmenge ausgegeben worden ist, das Absperrventil schließen

und durch Kippen des Druckentlastungsschalters am Deckel den Druck ablassen.

6. Je nach Art der Flüssigkeit und der geplanten zukünftigen Verwendung kann man

die im Behälter verbleibende Flüssigkeit

aufbewahren. Sonst den Behälter leeren,

mit Brennspiritus oder einem gewöhnlichen

Haushaltreinigungsmittel säubern und auf die

vorgeschriebene Weise aufbewahren.

Seite- 26 Formular 801193

Page 27

BREMSENDRUCKENTLÜFTUNG

Das Mityvac Flüssigkeitsausgabesystem eignet

sich als Druckentlüfter für hydraulische Bremsund Kupplungssysteme. Weitere Zusatzgeräte

und Adapter werden möglicherweise benötigt und

sind zur Durchführung dieser Funktion von Mityvac

erhältlich.

WARNUNG: Hydraulische Flüssigkeit ist

gefährlich und korrosiv. Vorsichtsmaßnahmen

treffen, um lackierte Oberflächen und die Haut vor

Berührung damit schützen und die Warnungen

und Instruktionen des Flüssigkeitsherstellers lesen

und befolgen.

1. Das Fahrzeug parken, die Parkbremse einlegen und den Motor abstellen.

2. Die Haube öffnen und sichern.

3. Den Brems- oder Kupplungshauptzylinder

finden und den Deckel entfernen.

4. Aus dem Hauptzylinderbehälter möglichst viel

der benutzten Hydraulikflüssigkeit entfernen

und mit neuer Flüssigkeit füllten.

5. Den richtigen Entlüftungsadapter für den

Hauptzylinder wählen und sicher auf dem

Hauptzylinderbehälter anbringen.

6. Bevor Flüssigkeit in den Ausgeber gefüllt wird,

den Flüssigkeitsausgabeschlauch mit dem

weiblichen Schnellanschluss, der aus dem

Behälter ragt, verbinden. Sicherstellen, dass

die Schnellanschlusshülse nach vorn schnappt

und die Verbindung sichert.

7. Das andere Ende des Flüssigkeitsausgabeschlauchs mit dem männlichen Schnell-verbindungsanschluss am Hauptzylinder verbinden.

Sicherstellen, dass die Anschlusshülse nach

vorn schnappt und die Verbindung sichert.

8. Sicherstellen, dass das Absperrventil geschlossen ist, und die Handpumpe betätigen,

um das System unter einen Druck bis zu 10 psi

(0.7 bar) zu setzen.

9. Das Druckmessgerät beobachten, um sicherzustellen, dass keine Leckstellen vorhanden

sind. Wenn der Druck fällt, den restlichen

Druck durch Kippen des Druckentlastungsschalters am Deckel aus dem System

ablassen. Den Deckel vom Ausgabebehälter

und den Adapter am Hauptzylinderbehälter

entfernen, wieder festziehen und das System

wieder auf Leckstellen prüfen.

WARNUNG: Schwere Verletzung und/oder

Geräteschaden können erfolgen, wenn der

Deckel von der Ausgabeeinheit oder der

Adapter vom Hauptzylinder entfernt wird, ohne

dass man zuerst den Systemdruck ablässt.

10. Wenn feststeht, dass alle Verbindungen sicher

sind und der Hauptzylinderadapter nicht leckt,

den Deckel mit der Pumpe von der Ausgabeeinheit entfernen und bis zu 2 Quarts (2 Liter)

einer vom Hersteller empfohlenen Hydraulikflüssigkeit aus einem versiegelten Behälter

nachfüllen.

11. Den Deckel mit der Pumpe wieder einbauen

und sicher festziehen.

12. In einem Wartungshandbuch nachschlagen,

um den empfohlenen Nenndruck und die richtige Entlüftungsreihenfolge für das gewartete

Fahrzeug festzustellen.

13. Das Druckmessgerät im Auge behaltend die

Druckpumpe betätigen, um den empfohlenen

Druck zu erzielen.

14. Den Entlüftungsbehälter mit der Entlüftungsschraube des ersten zu entlüftenden Zylinders

verbinden.

15. Die Entlüftungsschraube öffnen. Flüssigkeit

auslaufen lassen, bis nur noch klare, neue

Flüssigkeit ohne sichtbare Luftblasen aus

der Schraube kommt, dann die Entlüftungsschraube wieder zum vom Hersteller empfohlenen Drehmoment festziehen.

16. Dieses Verfahren an allen übrigen Entlüftungsschrauben wiederholen. Die Druckpumpe

betätigen, wie benötigt, um den angemessenen Druck aufrecht zu erhalten.

Hinweis: Die Ausgabeeinheit und den Haupt-

zylinderbehälter nicht trocken laufen lassen.

Nötigenfalls mit Hilfe des Druckentlastungsventils den Druck senken und neue Flüssigkeit

nachfüllen

17. Ist die Entlüftung beendet, den Druck im

Behälter und Hauptzylinder durch Kippen des

Druckentlastungsschalters am Deckel der

Ausgabeeinheit ablassen.

18. Das Flüssigkeitsausgabeabsperrventil

schließen und vorsichtig den Adapter vom

Haupt-zylinder abnehmen. Vorsichtig vorgehen, um keine Bremsflüssigkeit zu verschütten.

Formular 801193 Seite - 27

Page 28

BREMSENDRUCKENTLÜFTUNG

19. Überschüssige Flüssigkeit entfernen oder den

Hauptzylinder nachfüllen, wie nötig, und die

Kappe wieder anbringen.

20. Jegliche übrige Hydraulikflüssigkeit in der

Ausgabeeinheit entsorgen. Hydraulik-flüssigkeit nicht im Behälter aufbewahren. Die

Ausgabeeinheit mit Brennspiritus reinigen und

aufbewahren, wie empfohlen.

21. Das Brems- oder Kupplungssystem auf Leckstellen prüfen, bevor das Fahrzeug gefahren

wird.

AUFFÜLLEN VERSIEGELTER AUTOMATISCHER GETRIEBE

Das Mityvac Flüssigkeitsausgabesystem eignet

sich zum Auffüllen oder Nachfüllen versiegelter

automatischer Getriebe. Weitere Zusatzgeräte

werden möglicherweise benötigt und sind zur

Durchführung dieser Aufgaben von Mityvac

erhältlich.

1. Deckel und Pumpe vom Behälter abschrauben

und ihn bis zum gewünschten Wert mit neuer,

vom Fahrzeughersteller empfohlener Getriebeflüssigkeit füllen.

VORSICHT: Auf Lebenszeit „versiegelte“

Getriebe benötigen spezielle, vom Hersteller

empfohlene Flüssigkeiten. Die Verwendung

anderer Flüssigkeiten kann zu schweren

Beschädigungen des Getriebes führen und

die Garantie des Herstellers null und nichtig

machen.

Hinweis: Auf dem Behälter befinden sich zwei

Skalen. Eine Skala zeigt das Volumen nach

Entfernung von Deckel und Pumpe, die andere, wenn Deckel und Pumpe eingebaut sind.

Sicherstellen, dass die richtige Skala beachtet

wird.

VORSICHT: Wird Flüssigkeit über die MAX

FILL Linie hinaus eingefüllt, so fließt der Behälter über, wenn Deckel und Pumpe installiert

werden.

2. Deckel und Pumpe wieder auf dem Behälter

anbringen.

3. Mit Hilfe des Schnellverbindungsanschlusses den Flüssigkeitsausgabeschlauch am

Behälter anbringen. Sicherstellen, dass die

Anschlusshülse nach vorn schnappt und die

Verbindung sichert.

Hinweis: Das Absperrventil im Flüssigkeit-

sausgabeschlauch kann offen gelassen oder

geschlossen werden. Bleibt es offen, so

beginnt die Flüssigkeit zu fließen, sobald die

Pumpe betätigt wird. Ist es geschlossen, so

baut sich im Behälter ein Druck auf, wie vom

Druckmessgerät angezeigt.

4. Den angemessenen ATF Nachfülladapter

für den Verwendungszweck wählen und ihn

mit dem Auslass des Flüssigkeitsausgabeschlauches verbinden.

5. Den ATF Nachfülladapter in das Getriebe

einführen oder mit ihm verbinden.

6. Das Druckmessgerät ihm Auge behalten und

die Pumpe betätigen, um im Behälter Druck

bis zum gewünschten Wert aufzubauen – oder

bis die richtige Flüssigkeitsmenge ausgegeben

worden ist.

Hinweis: Das Fahrzeugwartungshandbuch

zurate ziehen, um die richtige Methode zur

Prüfung des Getriebeflüssigkeitsstandes

festzustellen. Nichtbefolgen des vom Hersteller

empfohlenen Verfahrens könnte dazu führen,

dass das Getriebe überfüllt oder zu wenig

gefüllt wird, was schweren Getriebeschaden

zur Folge haben kann.

Das Druckentlastungsventil öffnet und schließt

sich und hält den Maximaldruck zwischen 17

und 23 psi (1,2 und 1,6 bar).

Es ist nicht nötig, die Pumpe kontinuierlich zu

betätigen, um den Flüssigkeitsstrom aufrecht

zu erhalten. Die Flüssigkeit fließt weiter, solange der Behälter unter Druck steht und das

Absperrventil offen ist.

WARNUNG: Einen Druck von 25 psi (1,7

bar) im Behälter nicht überschreiten. Das

Druckentlastungsventil sollte dies verhindern,

aber wenn es versagt und der Druck 25 psi

überschreitet, den Gebrauch des Gerätes

sofort abbrechen und die Einheit zur Reparatur

Seite- 28 Formular 801193

Page 29

AUFFÜLLEN VERSIEGELTER AUTOMATISCHER GETRIEBE

oder zum Ersatz an ein autorisiertes Kundendienstzentrum schicken.

7. Ist die richtige Flüssigkeitsmenge ausgegeben,

das Absperrventil am Flüssigkeits-ausgabeschlauch schließen und den Druck durch Kippen des Druckentlastungsschalters am Deckel

ablassen.

8. Je nach Art der Flüssigkeit und in der Zukunft

geplanter Verwendung die im Behälter übrige

Flüssigkeit aufbewahren oder ausleeren.

9. Das Gerät mit Brennspiritus oder einem

gewöhnlichen Haushaltreinigungsmittel säubern und auf die empfohlene Weise aufbewahren.

Standardgewährleistung von Lincoln Industrial

BESCHRÄNKTE GEWÄHRLEISTUNG

Lincoln gewährleistet, dass das von Lincoln gefertigte und gelieferte Gerät für einen Zeitraum von einem (1) Jahr frei von

Material- und Verarbeitungsmängeln ist, ausschließlich aller von Lincoln veröffentlichten speziellen, erweiterten oder beschränkten Garantien. Wenn während der Gewährleistungsfrist festgestellt wird, dass ein Gerät fehlerhaft ist, wird es nach

eigenem Erachten von Lincoln kostenlos repariert oder ersetzt.

Diese Gewährleistung setzt voraus, dass ein befugter Vertreter von Lincoln festgestellt hat, dass das Gerät fehlerhaft ist.

Für eine Reparatur oder einen Ersatz muss das Gerät innerhalb der Gewährleistungsfrist frachtfrei mit dem Kaufbeleg an

ein autorisiertes Gewährleistungs- und Dienstleistungscenter von Lincoln geschickt werden.

Diese Gewährleistung erstreckt sich nur auf den ursprünglichen Käufer. Diese Gewährleistung gilt nicht für Geräte,

die durch Unfälle, Überlastung, Missbrauch, unsachgemäßen Gebrauch, Nachlässigkeit, falsche Installation oder

scheuernde oder ätzende Materialien entstanden oder Geräte die von einer nicht von Lincoln bevollmächtigten Person

verändert oder repariert wurden. Diese Gewährleistung erstreckt sich nur auf Geräte, die genau gemäß der schriftlichen

Spezifikationen und Empfehlungen von Lincoln oder dessen bevollmächtigten Fachpersonals installiert, betrieben und

gewartet wurden.

DIESE GEWÄHRLEISTUNG IST AUSSCHLIESSLICH UND TRITT ANSTELLE ALLER ANDERER STILLSCHWEIGENDEN ODER AUSDRÜCKLICHEN GARANTIEN, EINSCHLIESSLICH, ABER NICHT OHNE EINSCHRÄNKUNG, DER

GEWÄHRLEISTUNG FÜR MARKTGÄNGIGKEIT ODER DER EIGNUNG FÜR EINEN BESTIMMTEN ZWECK.

Lincoln übernimmt keinerlei Verantwortung für mittelbare oder Folgeschäden. Die Haftung von Lincoln für Ansprüche

für durch den Kauf, Weiterverkauf oder Gebrauch beliebiger Geräte von Lincoln entstandener Verluste oder Schäden

übersteigt auf keinen Fall den Kaufpreis. In manchen Gerichtsbarkeiten ist der Ausschluss oder eine Beschränkung für

mittelbare bzw. Folgeschäden unzulässig; daher triff dieser Ausschluss möglicherweise nicht auf Sie zu.

Diese Garantie verleiht Ihnen bestimmte Rechte. Abhängig von der Gerichtsbarkeit haben Sie eventuell auch andere

Rechte.

Kunden, die sich nicht in der westlichen Hemisphäre oder Ostasien befinden, können ihre Gewährleistungsrechte bei

Lincoln GmbH & Co. KG, Walldorf, Deutschland erfragen.

Kontaktinformationen für Lincoln Industrial Für ein Service-Center von Lincoln Industrial in Ihrer Nähe rufen Sie bitte eine

der folgenden Nummern an oder besuchen Sie unsere Website.

Kundendienst: 314-679-4200 Website: lincolnindustrial.com

Amerika:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Telefon +1.314.679.4200

Fax +1.800.424.5359

Formular 801193 Seite - 29

Europa/Afrika:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Deutschland

Telefon +49.6227.33.0

Fax +49.6227.33.259

Asien/Pazifik:

No. 3 Tampines Central 1

#04-05, Abacus Plaza.

Singapore 529540

Tel +65.6588.0188

Fax +65.6588.3438

Page 30

Lincoln Industrial Standard Warranty/ Garantía Estándar de Lincoln Industrial/ Garantie standard Lincoln Industrial

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship for a period of one (1) year following the

date of purchase, excluding therefrom any special, extended, or limited warranty published by Lincoln. If equipment is determined to be defective during this warranty

period, it will be repaired or replaced, within Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain repair or replacement, you must

ship the equipment, transportation charges prepaid, with proof of purchase to a Lincoln Authorized Warranty and Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from accident, overload, abuse, misuse, negligence,

faulty installation or abrasive or corrosive material, equipment that has been altered, or equipment repaired by anyone not authorized by Lincoln. This warranty applies

only to equipment installed, operated and maintained in strict accordance with the written specifications and recommendations provided by Lincoln or its authorized

field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or damages arising out of the sale, resale or use of

any Lincoln equipment shall in no event exceed the purchase price. Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages,

therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany, for your warranty rights.

Lincoln Industrial Contact Information:

To find Lincoln Industrial’s Nearest Service Center call the following numbers, or you may also use our web site.

Customer Service: 314-679-4200 Web site: lincolnindustrial.com

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

GARANTÍA LIMITADA

Lincoln garantiza que los equipos fabricados y suministrados por Lincoln carecen de defectos de material y mano de obra durante un periodo de un (1) año a partir de

la fecha de compra, excluyendo a partir de la misma cualquier garantía especial, ampliada o limitada publicada por Lincoln. Si se determina que un equipo tiene algún

defecto durante este periodo de garantía, será reparado o reemplazado, a discreción única de Lincoln, sin cargo alguno.

Esta garantía está condicionada a la determinación de un representante autorizado de Lincoln de que el equipo es defectuoso. Para su reparación o sustitución, usted

tiene que enviar el equipo, con los gastos de transporte pagados por anticipado y con una prueba de la compra, a un Centro de Servicio y Garantía Autorizado de

Lincoln dentro del periodo de garantía.

Esta garantía se extiende solo al comprador al por menor original. Esta garantía no se aplica a los equipos dañados a causa de un accidente, sobrecarga, abuso, uso

indebido, negligencia, instalación defectuosa o materiales abrasivos o corrosivos, equipos que hayan sido alterados, o equipos reparados por cualquier persona que

no haya sido autorizada por Lincoln. Esta garantía solo se aplica a los equipos instalados, operados y mantenidos en estricta conformidad con las especificaciones y

recomendaciones por escrito proporcionadas por Lincoln o su personal de campo autorizado.

ESTA GARANTÍA ES EXCLUSIVA Y ES EN LUGAR DE A CUALQUIER OTRA GARANTÍA, EXPRESA O IMPLÍCITA, INCLUIDAS, AUNQUE SIN LIMITARSE A LAS

MISMAS, LA GARANTÍA DE COMERCIABILIDAD O GARANTÍA DE IDONEIDAD PARA UN FIN PARTICULAR.

En ningún caso deberá ser responsable Lincoln de los daños fortuitos o emergentes. La responsabilidad de Lincoln por cualquier reclamación de pérdidas o daños que

surjan de la venta, reventa o utilización de cualquier equipo de Lincoln no deberá exceder en ningún caso el precio de compra. Algunas jurisdicciones no admiten las

exclusiones o limitaciones de los daños fortuitos o emergentes y, por lo tanto, puede que la anterior limitación o exclusión no se aplique a su caso.

Esta garantía le proporciona derechos legales específicos. Usted puede tener también otros derechos que varían de una jurisdicción a otra.

Los clientes no ubicados en el Hemisferio Occidental o el Este de Asia: pónganse en contacto con Lincoln GmbH & Co. KG, Walldorf, Alemania, para conocer sus

derechos de garantía.

Información de contacto de Lincoln Industrial:

Para buscar el Centro de Servicio Lincoln Industrial más cercano, llame a los siguientes números, o también puede visitar nuestro sitio web.

Atención al Cliente 314-679-4200 Sitio Web: lincolnindustrial.com

Américas:

One Lincoln Way

St. Louis, MO 63120-1578

EE.UU.

Teléfono +1.314.679.4200

Fax +1.800.424.5359

GARANTIE LIMITÉE

Lincoln garantit l'appareillage fabriqué et fourni par Lincoln contre les défauts de matières et de fabrication pendant une période d'un (1) an à compter de la date

d'achat, excluant toute autre garantie spéciale, prolongée ou limitée rendue publique par Lincoln. S’il est déterminé, dans les limites de cette période de garantie, que

l’appareillage est défectueux, il sera réparé ou remplacé gratuitement, à la seule discrétion de Lincoln.