Page 1

USER’S MANUAL

Have Technical Questions?

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday - Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs and instructions for

product use.

Need Service Parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

VACUUM BRAKE BLEEDER

MODEL MV6830

SPECIFICATIONS

Reservoir Capacity: 1.9 quarts

(1.8 liters)

Bleed Tube Length: 72 in. (1830 cm)

Evac Tube Length: 48 in. (1220 cm)

Working Pressure: 60 to 150 psi

(4.1 to 10.3 bar)

Air Consumption: 4.3 scfm @ 90 psi

(2.0 l/s @ 6.2 bar)

Vacuum

@ 30 psi (2.0 bar): 6.5 in. hg (22 kpa)

@ 60 psi (4.1 bar): 16.5 in. hg

(56 kpa)

@90 psi (6.2 bar): 26.5 in. hg

(90 kpa)

@150 psi (10.3 bar): 27 in. hg (91 kpa)

Fill Rate

@ 30 psi (2.0 bar): 24.5 oz/min

(725 ml/min.)

@ 60 psi (4.1 bar): 49.5 oz/min

(1460 ml/min.)

@90 psi (6.2 bar): 70.5 oz/min

(2095 ml/min.)

@150 psi (10.3 bar): 70.5 oz/min

(2095 ml/min.)

APRIL - 2005

Form 822844

Section

- MV26

Page

- 1B

Page 2

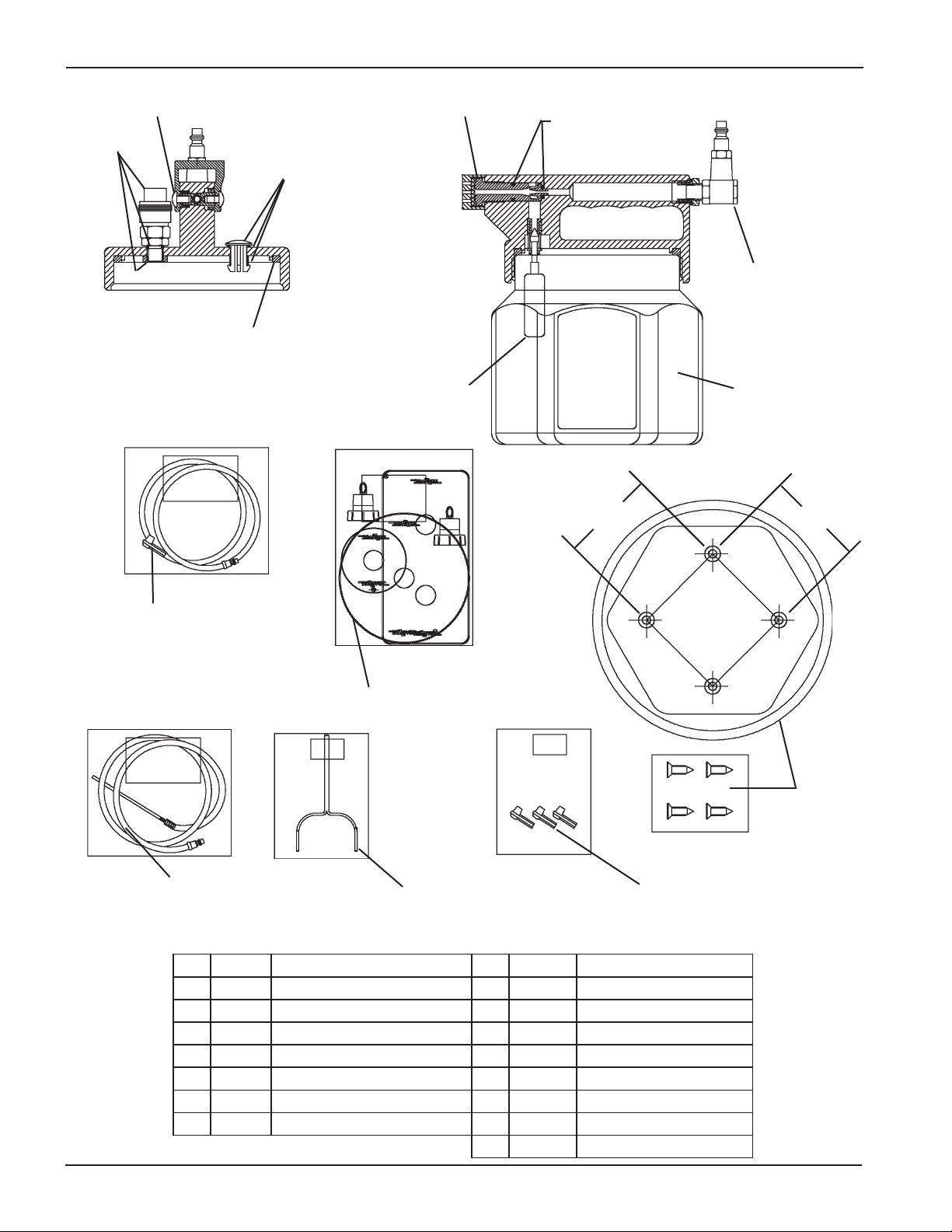

3

6

7

9

10

8

5

12

3.0

2

14

15©

3.0

4

© Indicates change

Page Number - 2

11

13

1

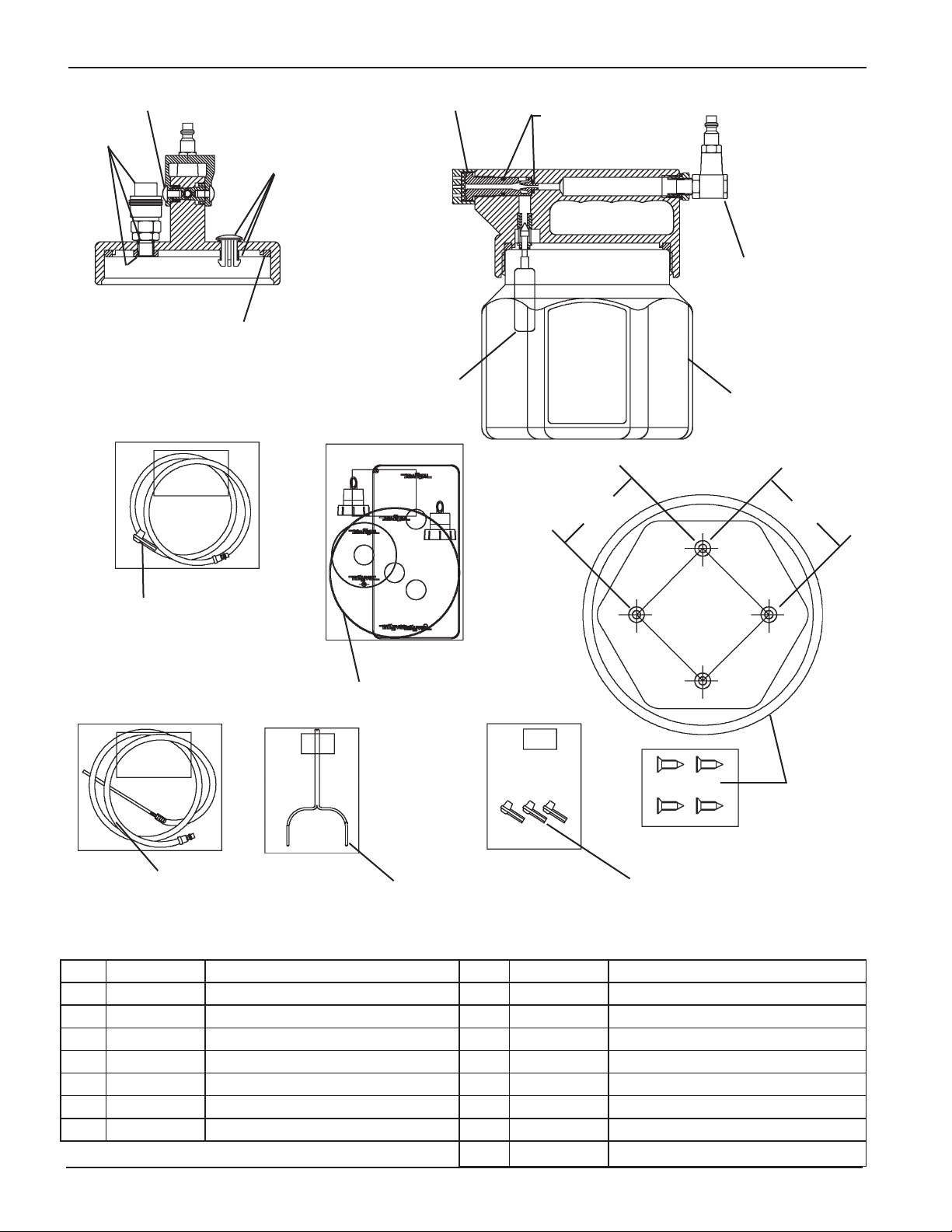

BRAKE BLEEDER

KIT COMPONENTS

Item Part No. Description Item Part No. Description

1 822664 BRAKE BLEEDING ADAPTER 8 822705 O-RING KIT

2 822694 BLEEDING TUBE KIT 9 822706 RESERVOIR GASKET KIT

3 822700 VALVE KIT 10 822709 MUFFLER KIT

4 822701 BASE KIT 11 822722 SUCTION TUBE KIT

5 822702 COUPLER SWIVEL KIT 12 822731 FLOAT KIT

6 822703 COUPLER KIT 13 822753 HOOK KIT

7 822704 VENT KIT 14 MVA6825 FLUID REFILL KIT

15© 822842 RESERVOIR

Form 822844

Page 3

Important Precautions

• Always read carefully and understand instructions prior to using this equipment

• Brake fluid is highly corrosive. Wear gloves and

approved safety goggles at all times, and prevent contact of the fluid with painted surfaces.

• Consult and follow the vehicle manufacturer’s

recommended procedures when servicing any

hydraulic system.

• Do not use this unit with flammable liquids or

with fluids at temperatures above 175° Fahrenheit (80° Celsius).

• Properly dispose of old fluids, and replenish hydraulic systems with new brake fluid from freshly

opened containers.

• Do not attempt to pressurize the bleeder/evacuator. It is designed for vacuum use only.

• This unit is equipped with an automatic shut-off

device that will prevent fluid from entering the

compressed air stream and ejecting through the

exhaust. However, if the unit is continuously operated when the reservoir is full, residual pressure will allow the reservoir to completely fill with

fluid, creating the potential for spillage when the

lid is removed. To prevent this situation, empty

or turn the unit off prior to filling the reservoir

completely full.

©

The screws included in Base Kit 822701 are

•

provided to secure the base to a work surface.

Do not use the screws to attach the base to the

reservoir.

Principal of Operation

This unit is designed for use as a vacuum brake or

clutch bleeder, or fluid evacuator. It utilizes compressed air between 60 psi (4.1 bar)and 150 psi

(10.3 bar), and a venturi system, to build vacuum

in the reservoir. By attaching the proper accessory

to the coupler located on the top of the unit, the

vacuum can be used to drain brake fluid from a hydraulic system such as the brake or clutch systems

on an automobile. It can also be used to evacuate a variety of fluids from reservoirs including the

master cylinder or those for power steering fluid or

engine coolant.

An automatic master cylinder refill kit is included

with this unit. It is conveniently designed for use

with a standard bottle of brake fluid, to maintain an

adequate fluid level in the master cylinder while the

hydraulic system is bled. Instructions are included

with the kit for its use.

Instructions for Bleeding Brakes

IMPORTANT: This unit is designed for servicing a

variety of vehicles in a safe, convenient manner.

However, options such as load sensors or antilock brakes, available on many automobiles, may

require additional steps or equipment to perform a

proper service job. The procedures below are to

serve as guidelines for the use of this equipment,

in addition to these guidelines, always follow the

manufacturer’s recommended procedures when

servicing each unique vehicle.

Removing old fluid from the brake master cylinder

1. Properly park the vehicle on level ground and

turn the engine off.

2. Clean the exterior of the master cylinder and

master cylinder cap to prevent dirt from entering

the master cylinder when the cap is removed.

3. Remove the cap from the master cylinder reser

voir.

4. Connect clean, regulated (60 psi (4.1 bar) to 150

psi (10.3 bar)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

5. Connect the appropriate end of the evac tube

assembly to the female quick disconnect coupler located on top of the vacuum bleeder.

6. Insert the other end of the evac tube assembly

into the master cylinder fluid reservoir, and push

the vacuum bleeder throttle forward to start the

vacuum (allow a few seconds for vacuum to

build in the bleeder reservoir before suction occurs). While evacuating the old fluid, stir it up to

break loose and remove any sludge that has accumulated on the bottom and walls of the master

cylinder.

7. Once all fluid is removed, turn off the bleeder

and refill the master cylinder with new manufac

turer’s recommended brake fluid.

© Indicates change

-

-

Form 822844

Page Number - 3

Page 4

Vacuum bleed brake lines and wheel

brake cylinders

Note: Prior to bleeding, ensure the master cylinder

is full of new manufacture’s recommended brake

fluid. An automatic master cylinder refill kit is

included with the vacuum bleeder to maintain the

level of new fluid in the master cylinder during the

brake bleeding process. Follow the instructions included with the kit to prevent air from being sucked

into the master cylinder pistons, brake lines, and

wheel cylinders while bleeding the brakes. Additional automatic refill kits are available from Mityvac.

1. Properly position the vehicle for safe convenient

access to the brake bleed screw located on

each wheel brake cylinder.

2. Make sure that all bleed screws are clean.

indicate a malfunction. To prevent or reduce this

introduction of air, coat the bleed screw threads

with silicon grease prior to bleeding.

7. Keep the bleed screw open until new fluid is

visibly flowing through the bleed tube (typically

20 to 30 seconds).

8. Close the bleed screw firmly, without over tight

ening, prior to removing the bleed screw adapter

or shutting off the bleeder.

Note: It is important to ensure that the bleed

screw adapter remains connected to the bleed

screw, and the bleeder is still pulling a vacuum

while the bleed screw is closed. This prevents

air from being sucked back into the wheel cylinder from around the bleed screw threads, before

the bleed screw is tightened and sealed.

-

3. Connect clean, regulated (60 psi (4.1 bar) to

150 psi (10.3)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

4. Connect the appropriate end of the bleed tube

assembly to the female quick disconnect coupler located on top of the vacuum bleeder.

Note: Consult the vehicle manufacturer’s guide-

lines for the proper wheel bleeding sequence

and vacuum bleeding procedure.

5. Slip the bleed screw adapter located on the op

posite end of the bleed tube assembly, over the

nipple of the bleed screw.

6. Operate the vacuum bleeder by pushing the

throttle forward (allow a few seconds for vacuum to build in the bleeder reservoir before suction occurs), and with the appropriate wrench,

loosen/open the bleed screw slightly, until fluid

is visibly draining through the bleed hose and

into the reservoir.

Note: During the bleeding process, as brake

fluid is being vacuumed through the bleed

screw, air will also be sucked into the bleed tube

from around the bleed screw threads. This can

give the misconception that air is bleeding from

the lines, however it is normal and does not

Note: If an automatic refiller such as the one

provided with this unit, is not used, be sure to

periodically check the level and top off the brake

fluid in the master cylinder.

Instructions for bleeding hydraulic

clutch system

IMPORTANT: This unit is designed for servicing a

variety of vehicles in a safe, convenient manner.

However, hydraulic clutch systems vary between

vehicles, in design, in components, and even the

location and design of the bleed screw. Due to

these differences, the following procedures are to

-

serve only as a guideline for the use of this equipment. In addition to these guidelines, always follow

the manufacturer’s recommended procedures

when servicing each unique vehicle.

Removing old fluid from the clutch master cylinder

1. Properly park the vehicle on level ground and

turn the engine off.

2. Clean the exterior of the master cylinder and

master cylinder cap to prevent dirt from entering

the master cylinder when the cap is removed.

3. Remove the cap from the master cylinder reser

voir.

-

Page Number - 4

Form 822844

Page 5

4. Connect clean, regulated (60 psi (4.1 bar) to 150

psi (10.3 bar)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

5. Connect the appropriate end of the evac tube

assembly to the female quick disconnect coupler

located on top of the vacuum bleeder.

6. Insert the other end of the evac tube assembly

into the master cylinder fluid reservoir, and push

the vacuum bleeder throttle forward to start the

vacuum (allow a few seconds for vacuum to

build in the bleeder reservoir before suction occurs). While evacuating the old fluid, stir it up to

break loose and remove any sludge that has accumulated on the bottom and walls of the master

cylinder.

7. Once all fluid is removed, turn off the bleeder

and refill the master cylinder with new manufac

turer’s recommended brake fluid.

-

Vacuum bleed clutch master cylinder,

slave cylinder, and hydraulic lines

Note: Prior to bleeding, ensure the master cyl-

inder is full of new manufacture’s recommended

brake fluid. An automatic master cylinder refill kit

is included with the vacuum bleeder to maintain

the level of new fluid in the master cylinder during

the clutch bleeding process. Follow the instructions included with the kit to prevent air from being

introduced into the master cylinder pistons, slave

cylinder, and fluid lines while bleeding the hydraulic

clutch system. Additional automatic refill kits are

available from Mityvac.

1. Properly position the vehicle for safe convenient

access to the clutch bleed screw located on the

slave cylinder.

4. Connect the appropriate end of the bleed tube

assembly to the female quick disconnect coupler located on top of the vacuum bleeder.

Note: Consult the vehicle manufacturer’s guide-

lines for the proper clutch vacuum bleeding

procedure.

5. Slip the universal bleed screw adapter located

on the opposite end of the bleed tube assembly,

over the nipple of the bleed screw.

6. Operate the vacuum bleeder by pushing the

throttle forward (allow a few seconds for vacuum

to build in the bleeder reservoir before suction

occurs), and with the appropriate wrench, loosen/open the bleed screw slightly, until fluid is

visibly draining through the bleed hose and into

the reservoir.

Note: During the bleeding process, as brake

fluid is being vacuumed through the bleed

screw, air will also be sucked into the bleeder

hose from around the bleed screw threads. This

can give the misconception that air is bleeding

from the lines, however it is normal and does

not indicate a malfunction. To prevent or reduce

this introduction of air, coat the bleed screw

threads with silicon grease prior to bleeding.

7. Keep the bleed screw open until new fluid is

visibly flowing through the bleed hose.

8. Close the bleed screw firmly, without over tight

ening, prior to removing the bleed screw adapter

or shutting off the bleeder.

Note: It is important to ensure that the bleed

screw adapter remains connected to the bleed

screw, and the bleeder is still pulling a vacuum

while the bleed screw is closed. This prevents

air from being sucked back into the slave cylinder from around the bleed screw threads, before

the bleed screw is tightened and sealed.

-

2. Make sure that the slave cylinderbleed screw is

clean.

3. Connect clean, regulated (60 psi (4.1 bar) to 150

psi (10.3 bar)) compressed air to the male quick

disconnect nipple attached to the swivel air

inlet, located on one end of the vacuum bleeder

handle.

Form 822844

Note: If an automatic refiller such as the one

provided with this unit, is not used, be sure to

periodically check the level and top off the brake

fluid in the master cylinder.

Page Number - 5

Page 6

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material

and workmanship for a period of one (1) year following the date of purchase, excluding there from any

special, extended, or limited warranty published by Lincoln. If equipment is determined to be defective

during this warranty period, it will be repaired or replaced, within Lincoln’s sole discretion, without charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain repair or replacement, you must ship the equipment, transportation charges

prepaid, with proof of purchase to a Lincoln Authorized Warranty and Service Center within the warranty

period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equip

ment damaged from accident, overload, abuse, misuse, negligence, faulty installation or abrasive or

corrosive material, equipment that has been altered, or equipment repaired by anyone not authorized by

Lincoln. This warranty applies only to equipment installed, operated and maintained in strict accordance

with the written specifications and recommendations provided by Lincoln or its authorized field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE WARRANTY OF MERCHANTIBILITY OR WAR

RANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any

claim for loss or damages arising out of the sale, resale or use of any Lincoln equipment shall in no event

exceed the purchase price. Some jurisdictions do not allow the exclusion or limitation of incidental or

consequential damages, therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co.

KG, Walldorf, Germany, for your warranty rights.

Lincoln Industrial Contact Information

To find Lincoln Industrial’s Nearest Service Center call the following numbers, or you may also use our

website.

Customer Service 314-679-4200

Website lincolnindustrial.com

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Page Number - 6

Europe/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

Asia/Pacific:

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

© Copyright 2005

Printed in USA

Web site:

www.lincolnindustrial.com

Form 822844

Page 7

Mode d’emploi

Vous Avez des Questions Techniques ?

Si vous avez des questions ou vous avez

besoin de support technique, merci de bien

vouloir appeler nos techniciens au :

1-314-679-4200 poste 4782

Du lundi au vendredi de 7:30 à 16:15 CST

Allez sur notre site Internet www.mityvac.

com pour voir les nouveaux produits, les

catalogues et les modes d’emploi.

Vous Avez Besoin de Pièces

Détachées ?

Pour commander des pièces de rechange

ou des pièces détachées, allez sur notre

site Internet www.mityvacparts.com ou

appelez notre numéro vert au 1-800-992-

9898.

APPAREIL DE PURGE

DES FREINS A VIDE

MODELE MV6830

Caractéristiques Techniques

Capacité du Réservoir : 1,8 litres

(1,9 quarts)

Longueur du Tuyau

de Purge : 1.830 cm

(72 pouces)

Longueur du Tuyau

d’Evacuation : 1.220 cm

(48 pouces)

Pression d’utilisation : 4,1 – 10,3 bars

(60 – 150 psi)

Consommation d’Air :

à 6,2 bars (90 psi) : 2,0 l/s (4,3 scfm)

Vide

à 2,0 bars (30 psi) : 22 kpa (6,5 pouces hg)

à 4,1 bars (60 psi) : 56 kpa (16,5 pouces hg)

à 6,2 bars (90 psi) : 90 kpa (26.5 pouces hg)

à 10,3 bars (150 psi) : 91 kpa (27 pouces hg)

Taux de Remplissage

à 2,0 bars (30 psi) : 725 ml/min (24,5 oz/min)

à 4,1 bars (60 psi) : 1.460 ml/min

(49,5 oz/min)

à 6.2 bars (90 psi) : 2.095 ml/min

(70,5 oz/min)

à 10.3 bars (150 psi) : 2.095 ml/min

(70,5 oz/min)

Formulaire 822844

Page Numéro - 7

Page 8

3

10

8

6

7

5

9

12

15©

3.0

3.0

2

14

4

11

13

1

APPAREIL DE PURGE DES FREINS

COMPOSANTS DE KIT

Pièce Code Article Description Pièce Code Article Description

1 822664 KIT ADAPTATEUR DE VIS DE PURGE 8 822705 KIT JOINT TORIQUE

2 822694 TUYAU DE PURGE 9 822706 KIT JOINT STATIQUE DE RESERVOIR

3 822700 KIT VALVE 10 822709 KIT D’ECHAPPEMENT

4 822701 KIT BASE 11 822722 TUYAU D’EVACUATION

5 822702 KIT COUPLEUR JOINT ARTICULE 12 822731 KIT FLOTTEUR

6 822703 KIT COUPLEUR 13 822753 KIT CROCHET

7 822704 KIT PRISE D’AIR 14 MVA6825 KIT DE REMPLISSAGE DE FUIDE

© Indique le changement

15© 822842 RÉSERVOIR

Formulaire 822844Page Numéro - 8

Page 9

Importantes Mesures de Sécurité

• Toujours lire soigneusement et comprendre les instructions avant d’utiliser l’équipement.

• Le liquide de frein est extrêmement corrosif. Porter

des gants et des lunettes de sécurité tout le temps.

Eviter que le liquide soit en contact avec des surfaces

peintes.

• Consulter et suivre les procédures recommandées par

le fabricant du véhicule lors de l’entretient du système

hydraulique.

• Ne pas utiliser cet équipement avec des liquides

inflammables ou des fluides ayant une température

supérieure à 80º Celsius (175º Fahrenheit).

• Disposer des fluides usagés de façon correcte et remplir les systèmes hydrauliques avec du liquide de frein

neuf provenant de containeurs ouverts récemment.

• Ne pas essayer de pressuriser l’appareil de purge/

l’évacuateur. Il est conçu pour le vide uniquement.

• Cet équipement est équipé d’un interrupteur automatique qui empêche le fluide d’entrer dans le jet d’air

comprimé et d’être refoulé par l’échappement. Cependant, si cet équipement fonctionne de manière continue, lorsque le réservoir est plein, la pression résiduelle

permettra au réservoir de se remplir complètement de

fluide, créant un problème de déversement potentiel

lorsque le couvercle est enlevé. Pour empêcher que

cela arrive, vider ou éteindre l’équipement avant que le

réservoir soit plein.

©

Les vis incluses dans le kit bas 822701 sont fournies

•

pour fixer la base à une surface de travail. N’utilisez

pas les vis pour attacher la base au réservoir.

Principes d’Utilisation

Cet équipement est conçu pour purger les freins ou

l’embrayage ou vidanger les fluides. Il fonctionne avec de

l’air comprimé entre 4,1 bars (60 psi) et 10,3 bars (150

psi), et un système venturi, pour créer le vide dans le réservoir. En attachant certains accessoires au coupleur situé

en haut de l’unité, le vide peut être utilisé pour drainer des

fluides d’un système hydraulique tel qu’un système de

freinage ou d’embrayage d’une voiture. Il peut aussi être

utilisé pour vidanger une variété de fluides d’un réservoir,

y compris le maître-cylindre ou le fluide de servo-direction

ou le liquide de refroidissement.

Mode d’Emploi pour Purger les Freins

Important : Cet équipement est conçu pour vous aider

à entretenir une variété de véhicules d’une façon sure

et aisée. Cependant, certaines options, telles qu’un

capteur de charge ou un système de freinage antiblocage, disponibles sur beaucoup de voitures, peuvent

nécessiter certaines procédures additionnelles. Les

procédures ci-dessous sont là pour vous aider à utiliser

cet équipement, en plus de celles-ci, toujours suivre les

procédures recommandées par le fabricant de chaque

véhicule.

Enlever les fluides usagés du

maître-cylindre de freinage.

1. Garer le véhicule sur un terrain plat et éteindre le

moteur.

2. Nettoyer l’extérieur du maître-cylindre et le bouchon

du maître-cylindre afin de prévenir que de la

saleté entre dans le maître-cylindre lorsque que le

bouchon est enlevé.

3. Enlever le bouchon du réservoir du maître-cylindre.

4. Connecter l’air comprimé propre et régularisé (entre

4,1 bars (60 psi) et 10,3 bars (150 psi)) au mamelon

male à déconnexion rapide attaché au joint articulé

d’admission d’air situé près de la poignée de

l’appareil de purge à vide.

5. Connecter le tuyau d’évacuation au coupleur

femelle à déconnexion rapide situé sur le dessus de

l’appareil de purge à vide.

6. Insérer l’autre bout du tuyau d’évacuation dans le

réservoir de fluide du maître-cylindre et pousser

la mollette de l’appareil de purge à vide en avant

pour commencer le vide (cela prendra quelques

secondes afin que suffisamment de vide soit généré

dans le réservoir avant que l’aspiration se produise).

Lors de la vidange du fluide usagé, remué-le afin

de détacher et d’enlever toutes les boues qui se

sont accumulées sur le fond et les parois du maîtrecylindre.

7. Lorsque tous les fluides sont vidangés, éteindre

l’appareil de purge et remplir le maître-cylindre

avec du liquide de frein neuf recommandé par le

fabricant.

Cet équipement comprend un kit de remplissage automatique du maître-cylindre. Il a été conçu pour accommoder

les bouteilles de liquide de frein afin de maintenir un

niveau de fluide adéquat dans le maître-cylindre lors de la

purge du système hydraulique. Le mode d’emploi est joint

avec le kit.

© Indique le changement

Formulaire 822844

Page Numéro - 9

Page 10

Purger par le vide les conduites de frein

et les cylindres de roue

Note : Avant de purger, s’assurer que le maîtrecylindre est rempli avec du liquide de frein

neuf recommandé par le fabricant. Un kit de

remplissage automatique du maître-cylindre est

joint avec l’appareil de purge afin de maintenir un

niveau de fluide adéquat dans le maître-cylindre

lors de la purge des freins. Suivre les instructions

jointes avec le kit afin d’empêcher l’air d’être aspiré

dans les pistons du maître-cylindre, les conduites

de frein, et les cylindres de roue lors de la purge

des freins. Les kits de remplissage automatique

sont disponibles chez Mityvac.

1. Positionner le véhicule pour accéder à la vis

de purge de frein située sur chaque cylindre de

roue.

2. S’assurer que toutes les vis de purge sont

propres.

3. Connecter l’air comprimé propre et régularisé

(entre 4,1 bars (60 psi) et 10,3 bars (150 psi))

au mamelon male à déconnexion rapide attaché

au joint articulé d’admission d’air situé près de la

poignée de l’appareil de purge à vide.

4. Connecter le tuyau d’évacuation au coupleur

femelle à déconnexion rapide situé sur le

dessus de l’appareil de purge à vide.

Note : Se référer aux recommandations du

fabricant du véhicule pour les procédures de

purge à vide.

5. Glisser l’adaptateur de vis de purge situé de

l’autre coté du tuyau de purge sur le mamelon

de la vis de purge.

6. Faire fonctionner l’appareil de purge à vide en

poussant la mollette en avant (cela prendra

quelques secondes afin que suffisamment de

vide soit généré dans le réservoir avant que

l’aspiration se produise). Ouvrir/desserrer

légèrement la vis de purge avec une clé jusqu’à

ce que du fluide soit drainé par le tuyau de

drainage et dans le réservoir.

Note : Durant la procédure de purge, au même

moment que le liquide de frein est aspiré par

la vis de purge, de l’air sera aussi aspiré dans

le tuyau de purge autour du filet de la vis de

purge. Cela peut donner la fausse impression

que de l’air fuit des conduites. Ceci est normal

et n’indique pas un mauvais fonctionnement.

Pour prévenir ou réduire cette introduction d’air,

graisser les filets des vis de purge avec du

silicone avant de purger.

7. Garder la vis de purge ouverte jusqu’à ce

que du fluide neuf coule du tuyau de purge

(généralement entre 20 et 30 secondes).

8. Fermer la vis purge sans la serrer trop fort

avant de retirer l’adaptateur de vis de purge ou

éteindre l’appareil de purge.

Note : S’assurer que l’adaptateur de vis de

purge reste connecté à la vis de purge, et que

l’appareil de purge continue à aspirer lorsque la

vis de purge est fermée. Cela prévient que de

l’air soit aspiré dans le cylindre de roue autour

du filet de la vis de purge avant que la vis soit

serrée et fermée hermétiquement.

Note :

automatique (comme celui fournit avec

cet équipement) n’est pas utilisé, vérifier

périodiquement le niveau et compléter le niveau

de liquide de frein dans le maître-cylindre.

Si un système de remplissage

Mode d’emploi pour purger un

système d’embrayage hydraulique

Important : Cet équipement est conçu pour vous

aider à entretenir une variété de véhicules d’une

façon sure et aisée. Cependant, les systèmes

d’embrayage hydraulique varient d’un véhicule à

un autre au niveau du design, des composants,

et de l’emplacement et du design de la vis de

purge. Du fait de ces différences, les procédures

ci-dessous ne sont là que pour vous aider à utiliser

cet équipement. En plus de celles-ci, toujours

suivre les procédures recommandées par le

fabricant de chaque véhicule.

Enlever les fluides usagés du maîtrecylindre d’embrayage

1. Garer le véhicule sur un terrain plat et éteindre

le moteur.

2. Nettoyer l’extérieur du maître-cylindre et le

bouchon du maître-cylindre afin de prévenir

que de la saleté entre dans le maître-cylindre

lorsque que le bouchon est enlevé.

3. Enlever le bouchon du réservoir du maîtrecylindre.

Page Numéro - 10 Formulaire 822844

Page 11

4. Connecter l’air comprimé propre et régularisé

(entre 4,1 bars (60 psi) et 10,3 bars (150 psi))

au mamelon male à déconnexion rapide attaché

au joint articulé d’admission d’air situé près de la

poignée de l’appareil de purge à vide.

5. Connecter le tuyau d’évacuation au coupleur

femelle à déconnexion rapide situé sur le dessus

de l’appareil de purge à vide.

6. Insérer l’autre bout du tuyau d’évacuation dans

le réservoir de fluide du maître-cylindre et

pousser la mollette de l’appareil de purge à vide

en avant pour commencer le vide (cela prendra

quelques secondes afin que suffisamment de

vide soit généré dans le réservoir avant que

l’aspiration se produise). Lors de la vidange

du fluide usagé, remué-le afin de détacher

et d’enlever toutes les boues qui se sont

accumulées sur le fond et les parois du maîtrecylindre.

7. Lorsque tous les fluides sont vidangés, éteindre

l’appareil de purge et remplir le maître-cylindre

avec du liquide de frein neuf recommandé par le

fabricant.

Purger par le vide le maître-cylindre

d’embrayage, le cylindre asservi, et les

conduites hydrauliques

Note : Avant de purger, s’assurer que le maîtrecylindre est rempli avec du liquide de frein neuf

recommandé par le fabricant. Un kit de remplissage

automatique du maître-cylindre est joint avec

l’appareil de purge afin de maintenir un niveau

de fluide adéquat dans le maître-cylindre lors de

la purge de l’embrayage. Suivre les instructions

jointes avec le kit afin d’empêcher l’air d’être aspiré

dans les pistons du maître-cylindre, le cylindre

asservi, et les conduites de fluide lors de la purge

du système hydraulique d’embrayage. Les kits de

remplissage automatique sont disponibles chez

Mityvac.

1. Positionner le véhicule pour accéder à la vis

de purge de l’embrayage située sur le cylindre

asservi.

2. S’assurer que la vis de purge du cylindre asservi

est propre.

3. Connecter l’air comprimé propre et régularisé

(entre 4,1 bars (60 psi) et 10,3 bars (150 psi))

au mamelon male à déconnexion rapide attaché

au joint articulé d’admission d’air situé près de la

poignée de l’appareil de purge à vide.

4. Connecter le tuyau d’évacuation au coupleur

femelle à déconnexion rapide situé sur le

dessus de l’appareil de purge à vide.

Note : Se référer aux recommandations du

fabricant du véhicule pour les procédures de

purge à vide de l’embrayage.

5. Glisser l’adaptateur de vis de purge universel

situé de l’autre coté du tuyau de purge sur le

mamelon de la vis de purge.

6. Faire fonctionner l’appareil de purge à vide en

poussant la mollette en avant (cela prendra

quelques secondes afin que suffisamment de

vide soit généré dans le réservoir avant que

l’aspiration se produise). Ouvrir/desserrer

légèrement la vis de purge avec une clé jusqu’à

ce que du fluide soit drainé par le tuyau de

drainage et dans le réservoir.

Note : Durant la procédure de purge, au même

moment que le liquide de frein est aspiré par

la vis de purge, de l’air sera aussi aspiré dans

le tuyau de purge autour du filet de la vis de

purge. Cela peut donner la fausse impression

que de l’air fuit des conduites. Ceci est normal

et n’indique pas un mauvais fonctionnement.

Pour prévenir ou réduire cette introduction d’air,

graisser les filets des vis de purge avec du

silicone avant de purger.

7. Garder la vis de purge ouverte jusqu’à ce que

du fluide neuf coule du tuyau de purge.

8. Fermer la vis purge sans la serrer trop fort

avant de retirer l’adaptateur de vis de purge ou

éteindre l’appareil de purge.

Note : S’assurer que l’adaptateur de vis de

purge reste connecté à la vis de purge, et que

l’appareil de purge continue à aspirer lorsque la

vis de purge est fermée. Cela prévient que de

l’air soit aspiré dans le cylindre asservi autour

du filet de la vis de purge avant que la vis soit

serrée et fermée hermétiquement.

Note :

automatique (comme celui fournit avec

cet équipement) n’est pas utilisé, vérifier

périodiquement le niveau et compléter le niveau

de liquide de frein dans le maître-cylindre.

Si un système de remplissage

Formulaire 822844

Page Numéro - 11

Page 12

La Garantie Standard de Lincoln Industrial

GARANTIE LIMITEE

Lincoln garantit que l’équipement qu’il fabrique et fournit est sans vice de matériau ou de fabrication

durant une période d’un (1) an après la date d’achat, sauf si cet équipement est sous garantie spéciale,

prolongée ou limitée publiée par Lincoln. Si l’équipement s’avère défectueux durant la période de

garantie, celui-ci sera réparé ou remplacé, à la discrétion de Lincoln, sans frais.

Cette garantie ne s’applique que si un représentant autorisé de Lincoln juge que l’équipement est

défectueux. Pour faire réparer ou remplacer votre équipement, vous devez l’expédier tous frais de port

payés, avec preuve de date d’achat, au centre de service après-vente autorisé Lincoln durant la période

de garantie.

Cette garantie ne couvre que l’acheteur originel. Elle ne couvre pas tout équipement endommagé durant

un accident, surcharge, abus, négligence, installation défectueuse ou matériaux abrasifs ou corrosifs.

Cette garantie ne couvre pas tout équipement qui a été altéré ou réparé par toute personne qui ne soit

pas autorisée par Lincoln. Cette garantie ne s’applique qu’à l’équipement installé et utilisé suivant les

recommandations écrites de Lincoln ou de son personnel autorisé itinérant.

CETTE GARANTIE EST EXCLUSIVE ET TENANT POUR TOUTE

OU TACITES, Y COMPRIS, MAIS NON LIMITE A, LA GARANTIE DE QUALITÉ MARCHANDE OU LA

GARANTIE D’APTITUDE POUR UNE RAISON PARTICULIERE.

Lincoln n’est en aucun cas responsable pour les dommages accessoires ou indirects. La responsabilité

de Lincoln ne peut excéder le prix d’achat en cas de perte ou de dommages du à la vente, revente ou

utilisation de l’équipement. Certaines juridictions n’acceptent pas d’exclusion ou de limitation sur les

dommages accessoires ou indirects, aussi les limitations ou exclusions ci-dessus ne vous concernent

pas forcement.

Cette garantie vous donne des droits précis reconnus par la loi. Certaines juridictions peuvent vous

donner d’autres droits.

Pour les clients qui ne se trouvent pas dans l’Hémisphère de l’Ouest ou l’Est de l’Asie : Merci de bien

vouloir contacter Lincoln GmbH & Co. KG, Walldorf, Allemagne pour faire valoir votre garantie.

S AUTRES GARANTIES EXPRESSES

Contacter Lincoln Industrial

Pour trouver votre centre de service après-vente Lincoln Industrial le plus proche, appeler un des

numéros suivants, vous pouvez aussi aller sur notre site Internet.

Service Après-Vente 314-679-4200

Site Internet lincolnindustrial.com

Amériques: Europe/Afrique: Asie/Pacifique: Copyright 2004

One Lincoln Way Heinrich-Hertz-Str 2-8 25 Int’l Business Park Imprimé aux USA

St. Louis, MO 63120-1578 D-69183 Walldorf #01-65 German Centre

Page Numéro - 12 Formulaire 822844

Page 13

VAKUUM BREMSENTLÜFTUNGSGERÄT

BENUTZERHANDBUCH

Haben Sie technische Fragen?

Wenn Sie Fragen haben oder technische Unterstützung benötigen,, wenden Sie sich bitte an unseren geschulten Kundendienst.

Tel: 1-314-4200 Apparat 4782

Montag-Freitag, 7:30 bis 16:15 Zentralamerikanische Zeit.

Besuchen Sie unsere Website bei

www.mityvac

neusten Produkte, Kataloge und Gebrauchsanweisungen zu erfahren.

Brauchen Sie Ersatzteile?

Um Ersatzteile oder Wartungsbedarf

zu bestellen, wenden Sie sich online

an uns unter www.mityvacparts.com

oder rufen Sie uns gebührenfrei an

unter Nr. 1-800-992-9898.

, um alles über unsere

MODELL MV6830

TECHNISCHE DATEN

Behälterkapazität 1.9 Quarts (1,8 l)

Entlüftungs/Absaugschlauch 72 Zoll (1830 cm)

Länge Absaugschlauch 48 Zoll (1220 cm)

Arbeitsdruck 60 – 150 Psi (4.1-10.3 bar)

Luftverbrauch 4.3 scfm @ 90 ps

Vakuum

@ 30psi (2.0 bar) 6.5 in. hg (22 kpa)

@ 60 psi (6,2 bar) 16.5 in. hg, (56 kpa)

@ 90 psi (4.1 bar) 26.5 in. hg, (90 kpa)

@ 150 psi (10.3 bar) 27 in. (91 kpa)

Füllrate

@ 30 psi (2.0 bar) 24.5 oz/min

(725 ml/min.)

@60 psi (4.1 bar) 49.5 oz/min

(1460 ml/min.)

@ 90 psi 6 (6.2 bar) 70.50 oz/min,

(2095 ml/min.)

@ 150 psi (10.3 bar) 70.5 oz/min

2095 ml/min,)

(2.0l/s @ 6.2 bar)

Formular 822844

Seite - 13

Page 14

3

10

8

6

7

5

9

12

15©

3.0

2

14

11

13

1

KOMPONENTEN DES

BREMSENENTLÜFTUNGSSATZES

Nr. Teilnr. Beschreibung Nr. Teilnr.

1 822664 ENTLÜFTUNGSSCHRAUBEN-ADAPTERSATZ 8 822705 O-RINGSATZ

2 822694 ENTLÜFTUNGSSCHLAUCHEINHEIT 9 822706 BEHÄLTERDICHTUNGSSATZ

3 822700 VENTILSATZ 10 822709 SCHALLDÄMPFERSATZ

4 822701 UNTERTEILSATZ 11 822722 ABSAUGSCHLAUCHEINHEIT

5 822702 ANSCHLUSSDREHSATZ 12 822731 SCHWIMMERSATZ

6 822703 ANSCHLUSS-SATZ 13 822753 HAKENSATZ

7 822704 ENTLÜFTUNGSSATZ 14 MVA6825 FKÜSSIGKEITSNACHFÜLL-SATZ

© Zeigt Änderung an

15© 822842 VORRATSBEHÄLTER

Beschreibung

3.0

4

Seite - 14

Formular 822844

Page 15

Wichtige Vorsichtsmaßnahmen

• Vor der Benutzung dieses Gerätes immer die

Bedienungsanleitungen sorgfältig lesen und

verstehen.

• Bremsflüssigkeit ist sehr korrosiv. Immer Handschuhe

und einen anerkannten Augenschutz tragen und

verhindern, dass Bremsflüssigkeit mit lackierten

Oberflächen in Berührung kommt,

• Die vom Fahrzeughersteller vorgeschriebenen

Verfahren zur Wartung eines Hydrauliksystems

befolgen.

• Dieses Gerät nicht mit feuergefährlichen

Flüssigkeiten oder Flüssigkeiten mit Temperaturen

über 175° Fahrenheit (80° Celsius) benutzen.

• Verbrauchte Flüssigkeiten vorschriftsmäßig

entsorgen und Hydrauliksysteme immer mit

Bremsflüssigkeit aus neu geöffneten Behältern

auffüllen.

• Nicht versuchen, das Entlüfter- / Absauggerät unter

Druck zu setzen. Es ist nur zur Verwendung unter

Vakuumbedingungen bestimmt.

• Diese Einheit ist mit einem automatischen

Absperrgerät ausgestattet, das verhindert, dass

Flüssigkeit in den Druckluftstrom eindringt und

durch den Auspuff ausgespritzt wird. Wird das Gerät

jedoch dauernd mit vollem Behälter betrieben, so

füllt sich der Behälter durch den Restdruck völlig mit

Flüssigkeit, wodurch beim Anheben des Deckels die

Gefahr des Überlaufens entsteht. Um diese Situation

zu verhindern, entleert man das Gerät oder schaltet

es ab, bevor der Behälter völlig gefüllt wird.

©

Die Schrauben, die im niedrigen Installationssatz

•

822701 eingeschlossen sind, werden zur Verfügung

gestellt, um die Unterseite an eine Arbeit Oberfläche

zu befestigen. Benutzen Sie nicht die Schrauben, um

die Unterseite zum Vorratsbehälter anzubringen.

Betriebsprinzip

Diese Einheit ist als Vakuumgerät zum Entlüften von

Bremssystemen oder Kupplungen oder als Flüssigkeitsabsauggerät zu benutzen. Sie arbeitet mit Druckluft zwischen 60 (4.1 bar) und 150 Psi (10,3 bar) und

erzeugt mittels eines Venturisystems ein Vakuum im Behälter. Durch Anbringen des angemessenen Zusatzteils

am Anschluss am Oberteil des Gerätes kann man das

Vakuum dazu benutzen, Bremsflüssigkeit aus einem Hydrauliksystem abzulassen, z. B. aus dem Brems- oder

Kupplungssystem eines Automobils. Es kann auch dazu

benutzt werden, verschiedene andere Flüssigkeiten aus

Behältern abzusaugen, einschließlich des Hauptzylinders oder derjenigen, die als Servo-lenkungsflüssigkeiten oder als Motorkühlmittel benutzt werden.

formt, dass er mit der Standardflasche für Bremsflüssigkeit benutzt werden kann, so dass der vorschriftsmäßige

Flüssigkeitsstand im Hauptzylinder erhalten bleibt,

während das Hydrauliksystem entlüftet wird. Bedienungsanleitungen werden mit dem Satz mitgeliefert.

Anweisungen zum Entlüften von Brem-

sen

WICHTIG: Dieses Gerät ist für die sichere und prak-

tische Wartung einer Anzahl verschiedener Fahrzeuge

bestimmt. Als Option erhältliche Zusatzgeräte wie z.

B. Belastungssensoren oder Antiblockiersysteme, die

für viele Automobile erhältlich sind, können zusätzliche

Verfahrensschritte oder die Verwendung zusätzlicher

Werkzeuge nötig machen, um eine vorschriftsmäßige

Wartung durchzuführen. Die unten beschriebenen

Verfahren sind als Richtlinie zur Verwendung dieses

Gerätes zu verstehen. Zusätzlich zu diesen Richtlinien

müssen bei der Wartung eines bestimmten Fahrzeugs

immer die vom Hersteller empfohlenen Verfahren befolgt

werden.

Entfernen der verbrauchten Flüssigkeit aus

dem Hauptzylinder der Bremse

1. Das Fahrzeug vorschriftsmäßig auf einer ebenen

Fläche parken und den Motor abschalten.

2. Die Außenseite des Hauptzylinders und

des Zylinderdeckels reinigen, damit kein

Schmutz in den Zylinder eindringen kann,

wenn der Deckel entfernt wird.

3. Deckel vom Hauptzylinderbehälter entfernen.

4. Druckregulierte Luft (60 psi (4.1 bar) bis 150 psi (10,3

bar)) an den männlichen Schnellanschlussnippel am

drehbaren Lufteinlass anschließen. Dieser befindet

sich am Handgriffende des Entlüftungsgerätes.

5. Das zutreffende Ende des Absaugschlauchs mit dem

weiblichen Schnellanschluss verbinden, der sich

oben am Vakuumentlüftungsgerät befindet.

6. Das andere Ende der Absaugschlauch-einheit in

den Hauptzylinder-flüssigkeitsbehälter einführen

und das Vakuumentlüftungsventil vorwärtsschieben,

um den Aufbau des Vakuums zu beginnen (ein

paar Sekunden abwarten, bis das Vakuum sich

im Entlüftungsbehälter aufgebaut hat und der

Saugvorgang beginnt). Während die verbrauchte

Flüssigkeit abgesaugt wird, muss sie umgerührt

werden, um jegliche Festbestandteile, die sich auf

dem Boden und an den Wänden des Hauptzylinders

festgesetzt haben, abzulösen und zu entfernen.

7. Ist alle Flüssigkeit entfernt, so schaltet man das

Entlüftungsgerät ab und füllt den Hauptzylinder mit

frischer, vom Hersteller empfohlener Flüssigkeit auf.

Ein automatischer Hauptzylinder-Auffüllsatz wird mit

dieser Einheit mitgeliefert. Er ist praktischerweise so ge-

Formular 822844

© Zeigt Änderung an

Seite - 15

Page 16

Vakuumentlüftung der Bremsleitungen und

Radbremszylinder.

Hinweis: Vor der Entleerung sicherstellen, dass der

Hauptzylinder mit frischer, vom Hersteller empfohlener

Flüssigkeit gefüllt ist. Ein automatischer Auffüllsatz für

den Hauptzylinder wird mit dem Vakuumentlüftungsgerät

mitgeliefert, damit der Flüssigkeitsstand im

Hauptzylinder während des Entlüftungsvorganges

aufrechterhalten werden kann. Die Anweisungen, die

mit dem Satz geliefert werden, müssen befolgt werden,

damit während der Entleerung der Bremsen keine

Luft in die Hauptzylinderkolben, Bremsleitungen und

Radzylinder eindringen kann. Zusätzliche automatische

Auffüllsätze sind von Miryvac erhältlich.

1. Das Fahrzeug so abstellen, dass die Bremsentlüftungsschraube an jedem Radbremszylinder

praktisch und bequem erreichbar ist.

2. Sicherstellen, dass alle Entlüftungsschrauben sauber

sind.

3. Saubere, druckgeregelte (60 psi (4,1 bar) bis

150 psi (10,3 bar)) Luft an den männlichen

Schnellanschlussnippel am drehbaren Lufteinlass

anschließen. Dieser befindet sich am Handgriffende

des Entlüftungsgerätes.

4. Das zutreffende Ende des Entlüftungsschlauches mit

dem weiblichen Schnellanschluss verbinden, der sich

oben am Entlüftungsgerät befindet.

Hinweis: Die Richtlinien des Fahrzeugherstellers

zurate ziehen für die richtige Reihenfolge der

Radentlüftung und die Vakuumentlüftungsmethode .

5. Den Entlüftungsschraubenadapter, der sich am

entgegengesetzten Ende der Entlüftungsschl

aucheinheit befindet, über den Anschluss der

Entlüftungsschraube schieben.

6. Das Vakuum-Entlüftungsgerät nun in Betrieb

nehmen, indem das Drosselventil nach vorn

geschoben wird (ein paar Sekunden abwarten, bis

das Vakuum sich im Behälter aufgebaut hat und

der Saugvorgang beginnt). Mit dem passenden

Schraubenschlüssel die Entlüftungsschraube leicht

lockern/öffnen, bis man Flüssigkeit durch den

Entlüftungsschlauch und in den Behälter fließen

sieht.

Hinweis:

Bremsflüssigkeit durch die Entlüftungsschraube

abgesaugt wird, wird entlang den Gewinden der

Schraube auch Luft in den Entlüftungsschlauch

gesaugt Dies kann zu dem Trugschluss führen, dass

Luft aus den Leitungen entweiche. Dies ist jedoch

ein normaler Vorgang und nicht das Anzeichen eines

Fehlers. Um das Eindringen von Luft zu vermindern

oder zu vermeiden, kann man die Gewinde der

Entlüftungsschraube vor dem Vorgang mit Siliconfett

bestreichen.

BeimEntleerungsvorgang, während

7. Die Entlüftungsschraube offen lassen, bis

man sieht, dass frische Flüssigkeit durch den

Entlüftungsschlauch fließt (normalerweise 20 bis 30

Sekunden).

8. Die Entlüftungsschraube fest, aber nicht zu fest

anziehen, bevor der Entlüftungsschraubenad

apter abgenommen oder das Entlüftungsgerät

abgeschaltet wird.

Hinweis:

Entlüftungsschraubenadapter mit der Schraube

verbunden bleibt und das Entlüftungsgerät noch

ein Vakuum erzeugt, während die Schraube

geschlossen wird. Dadurch wird verhindert, dass Luft

vom Schraubengewinde zurück in den Radzylinder

gesaugt werden kann, bevor die Schraube

festgezogen und abgedichtet ist.

Hinweis: Wenn kein automatisches Auffüll-gerät,

wie das mit dieser Einheit mitgelieferte verwendet

wird, sicherstellen, dass der Flüssigkeitsstand

regelmäßig geprüft und dass die Bremsflüssigkeit im

Hauptzylinder jeweils nachgefüllt wird.

Es ist wichtig, sicherzustellen, dass der

Anweisungen zur Entlüftung hydrau-

lischer Kupplungssysteme

WICHTIG: Dieses Gerät hat den Zweck, eine Reihe von

Fahrzeugen auf sichere, praktische Weise zu warten.

Hydraulische Kupplungssysteme können jedoch je nach

Fahrzeug im Design, in den Komponenten und sogar

in der Lage und Konstruktion der Entlüftungsschraube

verschiedene sein. Aufgrund dieser Unterschiede

sind die folgenden Verfahren nur als Richtlinie zur

Verwendung des Gerätes anzusehen. Zusätzlich zu

diesen Richtlinien müssen deshalb bei der Wartung

jedes einzelnen Fahrzeuges immer die vom Hersteller

empfohlenen Verfahren befolgt werden.

Absaugen verbrauchter Flüssigkeit vom Hauptzylinder der Kupplung

1. Das Fahrzeug vorschriftsmäßig auf einer ebenen

Fläche parken und den Motor abschalten.

2. Die Außenseite des Hauptzylinders und des

Zylinderdeckels reinigen, damit kein Schmutz in den

Zylinder eindringen kann, wenn der Deckel entfernt

wird.

3. Deckel vom Hauptzylinderbehälter entfernen.

Seite - 16

Formular 822844

Page 17

4. Druckregulierte Luft (60 Psi (4.1 bar) bis 150 psi (10,3

bar)) an den männlichen Schnellanschlussnippel

am drehbaren Lufteinlass anschließen. Dieser

befindet sich am Handgriffende des VakuumEntlüftungsgerätes..

5. Das zutreffende Ende des Entlüftungs-schlauchs mit

dem weiblichen Schnellanschluss verbinden, der sich

oben am Entlüftungsgerät befindet.

6. Das andere Ende der Absaugschlauch—einheit

in den Hauptzylinderflüs-sigkeitsbehälter

einführen und das Vakuumentlüftungsdrosselventil

vorwärtsschieben, um die Erzeugung des Vakuums

zu beginnen (ein paar Sekunden abwarten, bis das

Vakuum sich im Behälter aufgebaut hat und der

Saugvorgang beginnt). Während die verbrauchte

Flüssigkeit abgesaugt wird, muss sie umgerührt

werden, um jegliche Festbestandteile, die sich auf

dem Boden und an den Wänden des Hauptzylinders

festgesetzt haben, abzulösen und zu entfernen.

7. Ist alle Flüssigkeit entfernt, so schaltet man das

Entlüftungsgerät ab und füllt den Hauptzylinder mit

frischer, vom Hersteller empfohlener Flüssigkeit.

Vakuumentlüftung des KupplungsHauptzylinders, Folgezylinders und der

Hydraulikleitungen

Hinweis: Vor der Entlüftung sicherstellen, dass der

Hauptzylinder mit frischer, vom Hersteller empfohlener

Flüssigkeit gefüllt ist. Ein automatischer Auffüllsatz

für den Hauptzylinder wird mit dem Entlüftungsgerät

mitgeliefert, damit der Flüssigkeitsstand im

Hauptzylinder während des Absaugvorganges

aufrechterhalten werden kann. Die Anweisungen, die

mit dem Satz geliefert werden, müssen befolgt werden,

damit während der Kupplungsentleerung keine Luft

in die Hauptzylinderkolben, den Folgekolben und

die Hydraulikleitungen eindringen kann. Zusätzliche

automatische Auffüllsätze sind von Mityvac erhältlich.

1. Das Fahrzeug so abstellen, dass die Kupplungsentlüf

tungsschraube am Folgezylinder sicher und praktisch

zu erreichen ist.

2. Sicherstellen, dass die Folgezylinderentlüftungsschraube sauber ist.

3. Saubere, druckgeregelte (60 psi (4,1 bar) bis

150 psi (10,3 bar)) Luft an den männlichen

Schnellanschlussnippel am drehbaren Lufteinlass

anschließen. Dieser befindet sich am Handgriffende

des Vakuumentlüftungsgerätes.

4 Das zutreffende Ende des Entlüftungsschlauchs mit

dem weiblichen Schnellanschluss verbinden, der sich

oben am Entlüftungsgerät befindet.

Hinweis: Die Richtlinien des

Fahrzeugherstellers zurate ziehen für die richtige

Vakuumentlüftungsmethode der Kupplung.

5. Den Entlüftungsschraubenadapter, der sich am

entgegengesetzten Ende der Entlüftungsschl

aucheinheit befindet, über den Anschluss der

Entlüftungsschraube schieben.

6. Das Entlüftungsgerät nun in Betrieb nehmen, indem

die Vakuumentlüftungs-drossel nach vorn geschoben

wird (ein paar Sekunden abwarten, bis das Vakuum

sich im Behälter aufgebaut hat und der Saugvorgang

beginnt). Mit dem zutreffenden Schraubenschlüssel

die Entlüftungsschraube leicht lockern/öffnen, bis

man Flüssigkeit durch den

7. Entlüftungsschlauch und in den Behälter fließen

sieht.

Hinweis: Bei der Entlüftung, während,

Bremsflüssigkeit durch die Entlüftungsschraube

abgesaugt wird, wird entlang den Gewinden der

Schraube auch Luft in den Entlüftungsschlauch

gesaugt Dies kann zu dem Trugschluss führen, dass

Luft aus den Leitungen entweiche. Es ist jedoch ein

normaler Vorgang und nicht das Anzeichen eines

Fehlers. Um das Eindringen von Luft zu vermindern

oder zu vermeiden, kann man die Gewinde der

Entlüftungsschraube vor dem Vorgang mit Siliconfett

bestreichen.

8. Die Entlüftungsschraube offen lassen, bis

man sieht, dass frische Flüssigkeit durch den

Entlüftungsschlauch fließt.

9. Die Entlüftungsschraube fest, aber nicht zu fest,

anziehen, bevor der Entlüftungs-schraubenadapter

abgenommen oder das Entlüftungsgerät

abgeschaltet wird.

Hinweis: Es ist wichtig, sicherzustellen, dass der

Entlüftungsschraubenadapter mit der Schraube

verbunden bleibt und das Entüftungs- gerät noch ein

Vakuum erzeugt, während die Entlüftungsschraube

geschlossen wird. Dadurch wird verhindert, dass Luft

vom Schraubengewinde zurück in den Radzylinder

gesaugt werden kann, bevor die Schraube

festgelegen und abgedichtet ist.

Hinweis: Wenn kein automatisches Auffüll-gerät, wie

das mit dieser Einheit mitgelieferte verwendet wird,

sicherstellen, dass der Flüssigkeitsstand regelmäßig

geprüft wird und dass die Bremsflüssigkeit im

Hauptzylinder jeweils nachgefüllt wird.

Formular 822844

Seite - 17

Page 18

Standard Garantie der Firma Lincoln Industrial

EINGESCHRÄNKTE GARANTIE

Lincoln gewährleistet, dass die von Lincoln hergestellten und gelieferten Produkte für ein (1) Jahr nach dem

Kaufdatum frei von Material- und Verarbeitungsfehlern sind, ausschließlich anderer, spezieller, erweiterter

oder eingeschränkter von Lincoln veröffentlichter Garantien. Wenn sich während dieser Garantieperiode

ein Gerät als fehlerhaft herausstellt, so wird es nach Ermessen der Firma Lincoln kostenlos repariert oder

ersetzt.

Diese Garantie beruht auf der Entscheidung eines von Lincoln autorisierten Vertreters, dass der Gegen

stand tatsächlich defekt ist. Um eine Reparatur oder einen Ersatz zu erhalten, muss das Gerät mit vorausbezahlter Fracht und mit dem Kaufnachweis innerhalb der Garantieperiode an ein Lincoln Authorized Warranty and Service Center (von Lincoln autorisiertes Garantie- und Kundendienstzentrum) schicken.

Diese Garantie erstreckt sich nur auf den ursprünglichen Käufer. Sie erstreckt sich nicht auf Geräte, die

durch Unfall, Überladung, Misshandlung, falsche Verwendung, Nachlässigkeit, falsche Installierung oder

scheuerndes oder korrosives Material beschädigt worden sind, oder auf Geräte, die von anderen Personen

als autorisiertem Personal von Lincoln verändert oder repariert worden sind. Diese Garantie betrifft nur

Geräte, die unter genauer Einhaltung der schriftlichen Spezifikationen und Anordnungen der Firma Lincoln

oder deren autorisiertem Außenpersonal installiert, betrieben und gewartet wurden.

DIESE GARANTIE IST EXKLUSIV UND STEHT AN STELLE ALLER ANDEREN GARANTIEN, AUS

GESPROCHENER SOWIE AUCH STILLSCHWEIGEND ANGENOMMENER, EINSCHLIESSLICH, ABER

NICHT BESCHRÄNKT AUF, DIE GARANTIE DER VERKÄUFLICHKEIT ODER EIGNUNG FÜR EINEN

BESTIMMTEN ZWECK.

In keinem Falle soll Lincoln haftbar gehalten werden für Zufalls- oder Nachfolgeschäden. Die Haftbarkeit der

Firma Lincoln für jeglichen Verlust oder Schäden, die durch den Verkauf, Wiederverkauf oder die Verwend

ung ihrer Geräte entstanden sind, soll auf keinen Fall den Kaufpreis übersteigen. Einige Gerichtsbarkeiten

erlauben den Ausschluss oder die Einschränkung der Haftpflicht für Zufalls- oder Nachfolgeschäden nicht,

die oben beschriebene Einschränkung oder der Ausschluss betrifft Sie also möglicherweise nicht.

-

-

-

Diese Garantie verleiht Ihnen bestimmte legale Rechte. Sie können – je nach der Jurisdiktion, in der Sie

leben – noch andere Rechte haben.

Kunden, die nicht in der westlichen Hemisphäre oder Ostasien leben: Bitte wenden Sie sich an Lincoln

GmbH & Co. KG, Walldorf, Germany, um Ihre Garantierechte zu erfahren.

Lincoln Industrial Kontaktinformation

Um das nächste Lincoln Kundendienstzentrum zu finden, rufen Sie bitte die folgende Nummer an oder

benutzen Sie unsere Website.

Kundendienst: + 314-679-4200

Website: lincolnindustrial.com

Amerikas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Seite - 18

Europa/Afrika:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

Asien/Pazifischer Raum

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

© Copyright 2005

Gedruckt in USA

Web site:

www.lincolnindustrial.com

Formular 822844

Page 19

MANUAL DEL USUARIO

¿Desea hacer preguntas

técnicas?

Si desea hacer preguntas o requiere

servicio técnico, póngase en contacto

con nuestros técnicos de servicio capacitados, llamando al:

1-314-679-4200 ext. 4782

Lunes a viernes, de 7:30 de la mañana

a 4:15 de la tarde, Hora Central Estándar

Visite nuestro sitio web en www.mitywac.com para obtener información

sobre nuevos productos, catálogos e

instrucciones para las aplicaciones de

los productos.

MODELO DE PURGADOR DE

FRENO VACÍO MV6830

¿Necesita piezas de

repuesto?

Para pedir piezas de repuesto, visítenos

en línea en www.mityvac.com o llame

gratuitamente al 1-800-992-9898.

ESPECIFICACIONES

Capacidad del depósito: 1,9 cuartos de galón

(1,8 litros)

Longitud del tubo de

purga: 72 pulg (1.830 cm)

Longitud del tubo de

evacuación: 48 pulg (1.220 cm)

Presión de trabajo: 60 a 150 lb/pulg2

(4,1 a 10,3 bares)

Consumo de aire: 4,3 pie3/min a 90 lb/pulg2

(2,0 l/s a 6,2 bares)

Vacío

a 30 lb/pulg2 (2,0 bares): 6,5 pulg Hg (22 kpa)

a 60 lb/pulg2 (4,1 bares): 16,5 pulg Hg (56 kpa)

a 90 lb/pulg2 (6,2 bares): 26,5 pulg Hg (90 kpa)

a 150 lb/pulg2 (10,3 bares): 27 pulg Hg (91 kpa)

Velocidad de llenado

a 30 lb/pulg2 (2,0 bares): 24,5 onzas/min

(725 ml/min.)

a 60 lb/pulg2 (4,1 bares): 49,5 onzas/min

(1.460 ml/min.)

a 90 lb/pulg2 (6,2 bares): 70,5 onzas/min

(2.095 ml/min.)

a 150 lb/pulg2 (10,3 bares): 70,5 onzas/min

(2.095 ml/min.)

Forma 822844

Página - 19

Page 20

3

10

8

6

7

5

9

12

3.0

15

3.0

2

14

4

11

13

1

COMPONENTES DEL JUEGO DE PURGADOR DEL FRENO

Artículo N° de pieza Descripción Artículo N° de pieza Descripción

1 822664 JUEGO DE ADAPTADOR DE TORNILLO DE PURGA 8 822705 JUEGO DE JUNTA TÓRICA

2 822694 CONJ. DE TUBO DE PURGA 9 822706 JUEGO DE EMPAQUETADURA DEL DEPÓSITO

3 822700 JUEGO DE VÁLVULA 10 822709 JUEGO DE SILENCIADOR

4 822701 JUEGO DE BASE 11 822722 CONJ. DE TUBO DE EVACUACIÓN

5 822702 JUEGO DE UNIÓN GIRATORIA DEL ACOPLAMIENTO 12 822731 JUEGO DE FLOTACIÓN

6 822703 JUEGO DEL ACOPLAMIENTO 13 822753 JUEGO DE GANCHO

7 822704 JUEGO DE VENTILACIÓN 14 MVA6825 JUEGO DE RELLENO DE FLUIDO

15 822842 DEPÓSITO

© Indica el cambio

Página - 20

Forma 822844

Page 21

Precauciones importantes

• Lea siempre detenidamente y entienda las instrucciones antes de usar este equipo.

• El fluido de frenos es muy corrosivo. Lleve puestos

guantes y gafas de seguridad aprobadas en todo

momento, e impida el contacto del fluido con las

superficies pintadas.

• Consulte y siga los procedimientos recomendados

por el fabricante del vehículo al efectuar el servicio

de cualquier sistema hidráulico.

• • No use esta unidad con líquidos inflamables ni con

fluidos a temperaturas superiores a 175° F (80°C).

• Deseche debidamente los fluidos usados y rellene

los sistemas hidráulicos con fluido de frenos nuevos

procedente de recipientes recientemente abiertos.

• No trate de someter a presión el purgador/evacuador. Está diseñado para usar con vacío solamente.

• Esta unidad está equipada con un dispositivo de

cierre automático que impide la entrada de fluido

en la corriente de aire comprimido y su salida por el

escape. Sin embargo, si la unidad se hace funcionar continuamente cuando el depósito esté lleno,

la presión residual dejará que el depósito se llene

completamente de fluido, creando la posibilidad de

un derrame cuando se quite la tapa. Para impedir

esta situación, vacíe o apague la unidad antes de

llenar completamente el depósito.

Los tornillos incluidos en el kit bajo 822701 se pro-

•

©

porcionan para asegurar la base a una superficie de

trabajo. No utilice los tornillos para unir la base al

depósito.

Principio de operación

Esta unidad está diseñada para usar como freno de

vacío o purgador de embrague o evacuador de fluido.

Utiliza aire comprimido entre 60 y 150 lb/pulg2 (4,1 y

10,3 bares) y un sistema venturi para hacer vacío en

el depósito. Al conectar el accesorio debido al acoplamiento ubicado en la parte de arriba de la unidad, el

vacío se puede usar para drenar el fluido de frenos de

un sistema hidráulico como los sistemas de freno o embrague de un automóvil. También se puede usar para

evacuar una variedad de fluido de depósitos incluido el

del cilindro maestro o los de fluido de servodirección o

refrigerante de motor.

Se incluye un juego de relleno automático de cilindro

maestro con esta unidad. Está diseñado convenientemente para usar con un cilindro estándar de fluido de

freno para mantener un nivel adecuado de fluido en el

cilindro maestro mientras se purga el sistema hidráulico.

Se incluyen las instrucciones para su uso con el juego.

Instrucciones para la purga de frenos

IMPORTANTE: Esta unidad está diseñada para efec-

tuar el servicio de una variedad de vehículos de una

manera segura y conveniente. Sin embargo, opciones

como los sensores de carga o los frenos antibloqueo

disponibles en muchos automóviles, pueden requerir

pasos o equipos adicionales para efectuar un servicio

apropiado. Los procedimientos siguientes son guías

para el uso de este equipo. Además de estas guías siga

siempre los procedimientos recomendados por el fabricante al efectuar el servicio en cada vehículo.

Eliminación del fluido usado del cilindro

maestro del freno.

1. Estacione debidamente el vehículo sobre una superficie horizontal y apague el motor.

2. Limpie el exterior del cilindro maestro y la tapa del

mismo para impedir la entrada de polvo en el cilindro

maestro cuando esté destapado.

3. Quite la tapa del depósito del cilindro maestro.

4. Conecte aire comprimido limpio, regulado [60 a 150

lb/pulg2 (4,1 a 10,3 bares)] al niple macho de desconexión rápida conectado a la entrada de aire giratoria,

ubicada en un extremo de la palanca del purgador de

vacío.

5. Conecte el extremo correspondiente del conjunto

de tubo de evacuación al acoplamiento hembra de

desconexión rápida ubicado en la parte de arriba del

purgador de vacío.

6. Introduzca el otro extremo del conjunto del tubo

de evacuación en el depósito de fluido del cilindro

maestro y empuje hacia adelante el regulador del

purgador de vacío para empezar a formar el vacío

(deje que pasen unos pocos segundos para que se

forme vacío en el depósito del purgador antes de que

se produzca la succión. Mientras se evacua el fluido

usado, agítelo para desprenderlo y elimine los lodos

que se hayan acumulado en el fondo y las paredes

del cilindro maestro.

7. Una vez que se haya eliminado todo el fluido, apague

el purgador y rellene el cilindro maestro con fluido de

freno nuevo recomendado por el fabricante.

© Indica el cambio

Forma 822844

Página - 21

Page 22

Purga de vacío de las tuberías del freno y los

cilindros de los frenos de las ruedas.

Nota: Antes de purgar, asegúrese de que el cilindro

maestro esté lleno de fluido de freno nuevo recomendado por el fabricante. Se incluye un juego de relleno automático del cilindro maestro con el purgador de vacío

para mantener el nivel de fluido nuevo en el cilindro

maestro durante el proceso de purga del freno. Siga

las instrucciones incluidas en el juego para impedir que

se absorba aire en los pistones del cilindro maestro, las

tuberías del freno y los cilindros de las ruedas al purgar

los frenos. Se dispone de juegos de relleno automático

adicionales de Mityvac.

1. Coloque debidamente el vehículo para proporcionar

un acceso seguro y conveniente al tornillo de purga

del freno ubicado en cada cilindro del freno de las

ruedas.

2. Asegúrese de que todos los tornillos de purga estén

limpios.

3. Conecte aire comprimido limpio, regulado [60 a 150

lb/pulg2 (4,1 a 10,3 bares)] al niple macho de desconexión rápida conectado a la entrada de aire giratoria,

ubicada en un extremo de la palanca del purgador de

vacío.

4. Conecte el extremo correspondiente del conjunto de

tubo de purga al acoplamiento hembra de desconexión rápida ubicado en la parte de arriba del purgador

de vacío.

Nota:

5. Deslice el adaptador del tornillo de purga ubicado en

6. Haga funcionar el purgador de vacío empujando el

Nota:

Consulte en las guías del fabricante del vehículo la secuencia de purga apropiada de las ruedas y

el procedimiento de purga de vacío.

el extremo opuesto del conjunto del tubo de purga,

sobre el niple del tornillo de purga.

regulador hacia adelante (deje que pasen unos pocos segundos para que se forme vacío en el depósito

del purgador antes de que se produzca la succión)

y con la llave apropiada, afloje/abra ligeramente el

tornillo de purga hasta que vea drenar el fluido por la

manguera de purga al depósito.

Durante el proceso de purga, a medida que

se absorbe el fluido de frenos mediante un vacío por

el tornillo de purga, el tubo de purga aspira también

aire de los alrededores de las roscas del tornillo de

purga. Esto puede dar la idea equivocada de que

se purga aire de las tuberías. Sin embargo esto es

normal y no indica un funcionamiento defectuoso.

Para impedir o reducir la entrada de aire, recubra

las roscas del tornillo de purga con grasa de silicona

antes de la purga.

7. Mantenga abierto el tornillo de purga hasta que se

vea circular el fluido nuevo por el tubo de purga (típi

camente 20 a 30 segundos).

8. Cierre bien el tornillo de purga, sin apretarlo excesivamente, antes de quitar el adaptador del tornillo de

purga o cerrar el purgador.

Nota:

Nota:

Es importante asegurarse de que el adaptador

del tornillo de purga permanezca conectado al tornillo de purga y que el purgador siga produciendo un

vacío mientras el tornillo de purga esté cerrado. Esto

impide que el cilindro de la rueda aspire aire de los

alrededores de las roscas del tornillo de purga antes

de que se apriete y se selle el tornillo de purga.

Si no se usa un rellenador automático, como

el incluido con esta unidad, asegúrese de comprobar

periódicamente el nivel y rellene el fluido de frenos

en el cilindro maestro.

-

Instrucciones para purgar el sistema

hidráulico del embrague.

IMPORTANTE: Esta unidad está diseñada para efectuar

el servicio de una variedad de vehículos de una manera

segura y conveniente. Sin embargo, los sistemas de

embrague hidráulicos varían de un vehículo a otro en

diseño, en componentes, e incluso en la ubicación y

diseño del tornillo de purga. Debido a estas diferencias,

los procedimientos siguientes deben utilizarse solamente como guía para el uso de este equipo. Además

de estas guías, siga siempre los procedimientos recomendados por el fabricante al efectuar el servicio en

cada vehículo.

Eliminación de fluido usado del cilindro maestro del

embrague.

1. Estacione debidamente el vehículo sobre una

superficie horizontal y apague el motor.

2. Limpie el exterior del cilindro maestro y la tapa del

mismo para impedir la entrada de polvo en el cilindro

maestro cuando esté destapado.

3. Quite la tapa del depósito del cilindro maestro.

4. Conecte aire comprimido limpio, regulado [60 a

150 lb/pulg2 (4,1 a 10,3 bares)] al niple macho de

desconexión rápida conectado a la entrada de aire

giratoria, ubicada en un extremo de la palanca del

purgador de vacío.

5. Conecte el extremo correspondiente del conjunto

de tubo de evacuación al acoplamiento hembra de

desconexión rápida ubicado en la parte de arriba del

purgador de vacío.

Página - 22

Forma 822844

Page 23

6. Introduzca el otro extremo del conjunto del tubo

de evacuación en el depósito de fluido del cilindro

maestro y empuje hacia adelante el regulador del

purgador de vacío para empezar a formar el vacío

(deje que pasen unos pocos segundos para que se

forme vacío en el depósito del purgador antes de que

se produzca la succión. Mientras se evacua el fluido

usado, agítelo para desprenderlo y elimine los lodos

que se hayan acumulado en el fondo y las paredes

del cilindro maestro.

7. Una vez que se haya eliminado todo el fluido,

desactive el purgador y rellene el cilindro maestro

con fluido de freno nuevo recomendado por el

fabricante.

Purga de vacío del cilindro maestro del embrague,

cilindro secundario y tuberías hidráulicas.

Nota: Antes de purgar, asegúrese de que el

cilindro maestro esté lleno de fluido de freno nuevo

recomendado por el fabricante. Se incluye un juego de

relleno automático del cilindro maestro con el purgador

de vacío para mantener el nivel de fluido nuevo en

el cilindro maestro durante el proceso de purga del

embrague. Siga las instrucciones incluidas en el juego

para impedir que se absorba aire en los pistones del

cilindro maestro, cilindro secundario y tuberías de

fluido al purgar el sistema de embrague hidráulico. Se

dispone de juegos de relleno automático adicionales de

Mityvac.

1. Coloque debidamente el vehículo para proporcionar

un acceso seguro y conveniente al tornillo de purga

de embrague ubicado en el cilindro secundario.

2. Asegúrese de que el tornillo de purga del cilindro

secundario esté limpio.

3. Conecte aire comprimido limpio, regulado [60 a

150 lb/pulg2 (4,1 a 10,3 bares)] al niple macho de

desconexión rápida conectado a la entrada de aire

giratoria, ubicada en un extremo de la palanca del

purgador de vacío.

4. Conecte el extremo correspondiente del conjunto

de tubo de purga al acoplamiento hembra de

desconexión rápida ubicado en la parte de arriba del

purgador de vacío.

6. Haga funcionar el purgador de vacío empujando

el regulador hacia adelante (deje que pasen unos

pocos segundos para que se forme vacío en el

depósito del purgador antes de que se produzca

la succión) y con la llave apropiada, afloje/abra

ligeramente el tornillo de purga hasta que vea drenar

el fluido por la manguera de purga al depósito.

Nota:

7. Mantenga abierto el tornillo de purga hasta que se

8. Cierre bien el tornillo de purga, sin apretarlo

Nota:

Nota:

Durante el proceso de purga, a medida que se

absorbe el fluido de frenos mediante un vacío por el

tornillo de purga, la manguera del purgador aspira

también aire de los alrededores de las roscas del

tornillo de purga. Esto puede dar la idea equivocada

de que se purga aire de las tuberías. Sin embargo

esto es normal y no indica un funcionamiento

defectuoso. Para impedir o reducir la entrada de

aire, recubra las roscas del tornillo de purga con

grasa de silicona antes de la purga.

vea circular nuevo fluido por la manguera de purga.

excesivamente, antes de quitar el adaptador del

tornillo de purga o cerrar el purgador.

Es importante asegurarse de que el adaptador

del tornillo de purga permanezca conectado al

tornillo de purga y que el purgador siga produciendo

un vacío mientras el tornillo de purga esté cerrado.

Esto impide que el cilindro secundario aspire aire de

los alrededores de las roscas del tornillo de purga

antes de que se apriete y se selle el tornillo de

purga.

Si no se usa un rellenador automático, como

el incluido con esta unidad, asegúrese de comprobar

periódicamente el nivel y rellene el fluido de frenos

en el cilindro maestro.

Nota:

5. Deslice el adaptador del tornillo de purga universal

Forma 822844

Consulte en las guías de fabricante del

vehículo el procedimiento de purga de vacío de

embrague apropiado.

ubicado en el extremo opuesto del conjunto del tubo

de purga, sobre el niple del tornillo de purga.

Página - 23

Page 24

Garantía estándar de Lincoln Industrial

GARANTÍA LIMITADA

Lincoln garantiza que los equipos fabricados y suministrados por Lincoln carecen de defectos de materiales

y fabricación durante un (1) año contado a partir de la fecha de compra, excluyéndoles de cualquier garantía

especial, extendida o limitada publicada por Lincoln. Si se demuestra que los equipos son defectuosos durante

este período de garantía, se repararán o remplazarán, a discreción de Lincoln, de forma gratuita.

Esta garantía está condicionada por la determinación de un representante autorizado de Lincoln de que el equipo

es defectuoso. Para obtener su reparación o reemplazo, debe enviar los equipos, gastos de transporte pagados de

antemano, con la prueba de compra a un centro de garantías y servicio autorizado de Lincoln dentro del período de

la garantía.

Esta garantía se extiende solamente al comprador original que haya efectuado la compra a un minorista. Esta

garantía no se aplica a equipos dañados por accidente, sobrecarga, abuso, uso indebido, negligencia, instalación

defectuosa o material abrasivo o corrosivo, o a equipos reparados o alterados por cualquier persona que no esté

autorizada por Lincoln para reparar o alterar los equipos. Esta garantía se aplica solamente a equipos instalados,

operados y mantenidos estrictamente según las especificaciones escritas y recomendadas proporcionadas por

Lincoln o su personal de planta autorizado.

ESTA GARANTÍA ES EXCLUSIVA Y REEMPLAZA CUALQUIER OTRA GARANTÍA, EXPLÍCITA O IMPLÍCITA,

INCLUIDA LA GARANTÍA DE COMERCIALIZACIÓN O GARANTÍA DE IDONEDAD PARA UNA CIERTA

FINALIDAD, PERO SIN LIMITARSE A LAS MISMAS.

En ningún caso Lincoln será responsable de daños emergentes o concomitantes. La responsabilidad de Lincoln

ante cualquier reclamación por pérdida o daños que sean consecuencia de la venta, reventa o uso de equipos

suministrados no debe en ningún caso exceder el precio de compra. Algunas jurisdicciones no permiten la

exclusión o limitación de daños emergentes o concomitantes, por lo que es posible que no se aplique a su caso

la limitación o exclusión anterior. Esa garantía le da derechos legales específicos. También puede tener otros

derechos que varían según la jurisdicción. Clientes que no estén ubicados en el Hemisferio Occidental o en el

Lejano Oriente: Póngase en contacto con Lincoln GmbH & Co. KG, Walldorf, Alemania, para obtener información

sobre sus derechos de garantía.

Información de contacto de Lincoln Industrial

Para encontrar el centro de servicio más cercano de Lincoln Industrial, llame a los números siguientes o también

puede visitar nuestro sitio web.

Servicio al cliente 314-679-4200

Sitio web lincolnindustrial.com

Américas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Página - 24

Europa/África:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

Asia/Pacífico:

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

© Copyright 2005

Hecho en USA

Web site:

www.lincolnindustrial.com

Forma 822844

Loading...

Loading...