Mityvac MV5545E User Manual

USER’S MANUAL

Have a technical question?

Americas:

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday – Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs, and instructions

for product use.

Need service parts?

To order replacement or service parts, visit us

online at www.mityvacparts.com or call toll free

1-800-992-9898.

Europe/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

www.lincolnindustrial.de

FST PRO FUEL SYSTEM TESTER

MODEL MV5545E

Asia/Pacific:

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

For a French or Spanish version of this

manual go to www.MityvacFST.com.

APRIL - 2009 Form 824262 Section - MV92-1

Contents

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Components, Service Parts, and Accessories . . . . . . . . . . . . . . . . 4

Standard Kit Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fuel System Test Adapters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Bypass Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Proper Use, Care, and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Setup and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Determining Where to Install the FST . . . . . . . . . . . . . . . . . . . . . . . . .9

Inline Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Alternative Connection Locations . . . . . . . . . . . . . . . . . . . . . . . . . .9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Testing and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Return Fuel Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Returnless Fuel Systems (Mechanical) . . . . . . . . . . . . . . . . . . . . . . 16

Returnless Fuel Systems (Electronic) . . . . . . . . . . . . . . . . . . . . . . . .18

Fuel visualization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Pressure Leakdown Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Disconnecting the FST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Appendix C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Appendix D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Page Number - 2 Form 824262

Safety Precautions

WARNING!

MV5545E must be operated by qualified service technicians.

CAUTION

If personal injury or material damage occurs as a result of inappropriate operation, e.g. if safety instructions are ignored, or resulting

from incorrect use, no claims or legal actions may be taken against

Lincoln.

The use of this service tool requires the exposure of highly

flammable gasoline. To prevent fires, explosions and/or severe

injury , always apply extra precautions when diagnosing or

working on fuel systems.

The FST Pro is designed for servicing a variety of vehicles in a

safe, convenient manner. However, fuel delivery systems vary

widely between makes and models of vehicles, potentially requiring additional steps or equipment to perform a proper service job.

The procedures outlined in this manual are to serve as guidelines

for the use of this equipment. In addition to these guidelines,

always follow the manufacturer’s recommended

procedures when servicing each unique vehicle. Use common

sense in the application of this tester and do not attempt to force

a test on a fuel system for which this equipment is not designed to

perform.

Specifications

Maximum Flow Capacity:

3.8 liters/min. (1 gal./minute) gasoline/petrol (.73 specific gravity)

225 liters/hour (60 gal./hour) gasoline/petrol (.73 specific gravity)

3.5 liters/min. (0.9 gal./minute) diesel (.85 specific gravity)

205 liters/hour (55 gal./hour) diesel (.85 specific gravity)

Maximum Rated Pressure: 8 bar (120 PSI) (800 kPa)

This tester is designed for use on gasoline/petrol or diesel engines

only . It is safe for use with gasoline and most gasoline additives,

including alternative/flex fuels that contain high levels of ethanol.

• Always read carefully and understand instructions prior to using this equipment

• Wear safety glasses at all times

• Operate the vehicle only in a well ventilated area, and away

from potential sources of flame or ignition.

• Prior to starting an engine, make sure all components of the

tester, body parts, and personal clothing are clear of rotating

engine components

• Avoid burns by remaining cautious of engine parts that may

become hot when the engine is running

• Never leave a vehicle unattended while testing

• Check and secure all fuel system connections before

starting the vehicle or activating the fuel pump

• Wear gloves and protective clothing to avoid the contact of

fuel on skin. If contact occurs, immediately wash the area and

perform necessary first aid

• Always keep a fire extinguisher on hand when performing fuel

related diagnostics. Make sure the extinguisher is rated for fuel,

electrical and chemical fires

• Avoid spilling fuel on hot engine parts. Clean-up any fuel spills

immediately after they occur

Form 824262 Page Number - 3

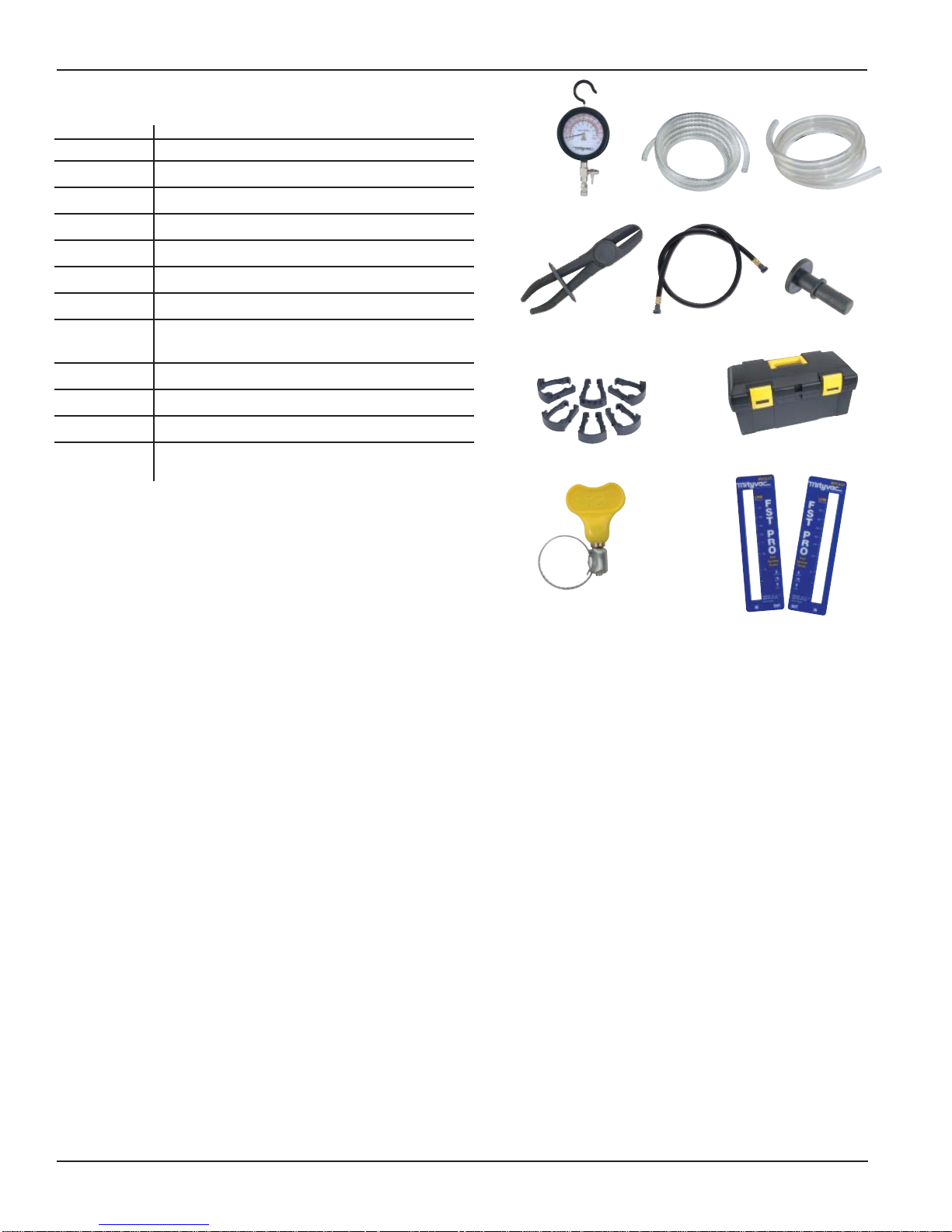

Kit Components and Accessories

Part Number Description

824266 High Pressure Gauge (0 to 8 bar scale)

824265 Low Pressure Gauge (-1 to 3 bar scale)

824149 Pressure Relief Hose (3mm ID x 1.8 m long)

824148 Bypass Hose (6.5 mm ID x 1.8 m long)

824144 Scissor Hose Clamps (Qty 2)

824147 Flowmeter Hose (9.5 mm ID x 1.2 m long)

824173 Hose Plug (Qty 2)

824143 Gasoline/Petrol Flowmeter Faceplates

(Liters/Minute) includes front and back plate

824183 Wing-Style Hose Clamp (Qty 4)

824172 Quick-connect Replacement Clips (Qty 6)

824267 Storage Case

MVA528 Diesel Flowmeter Faceplates (Liters/Minute)

includes front and back plate

824266/824265

824144

824172

824183

824149 824148

824147

824143/MVA528

824173

824267

Page Number - 4 Form 824262

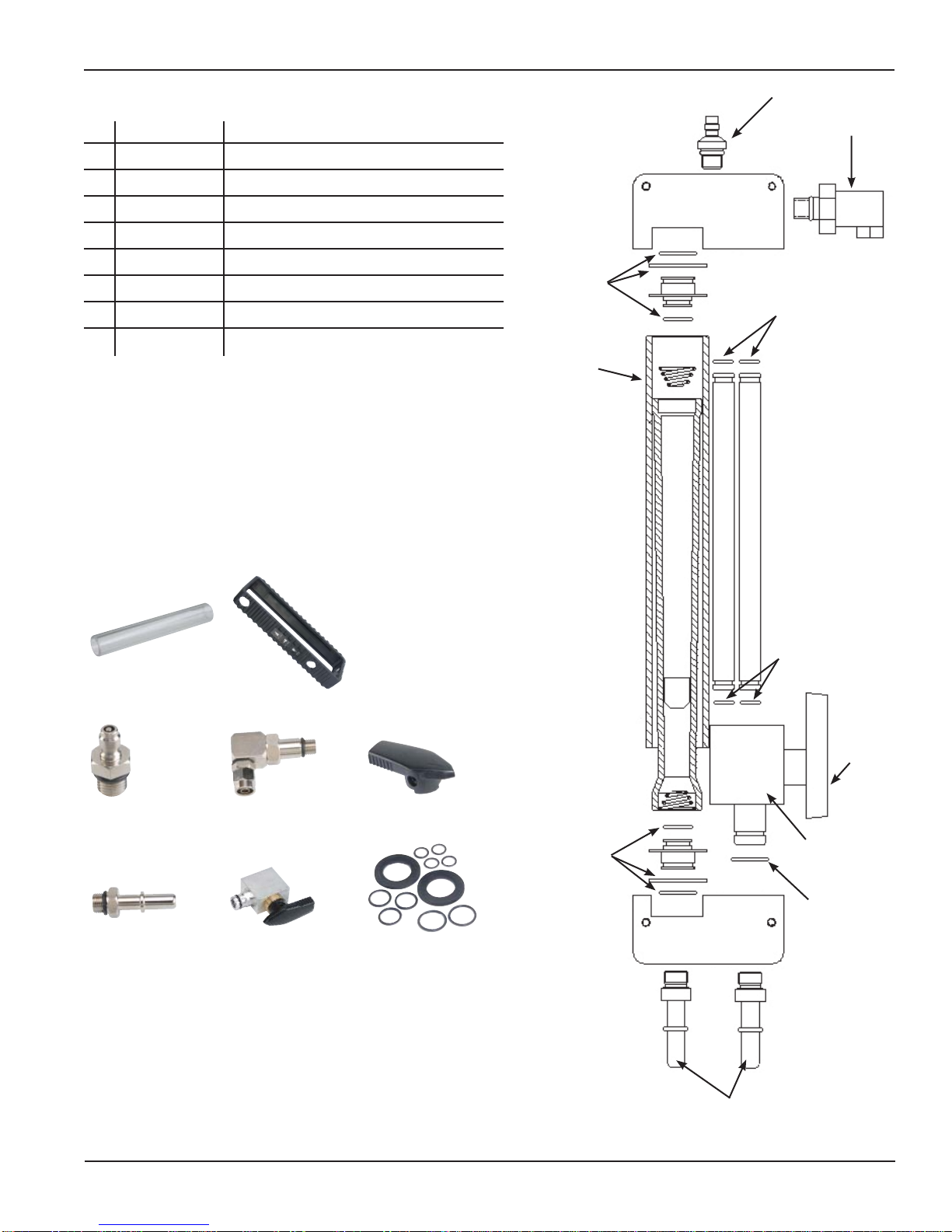

Flowmeter Parts

Part Number Description

1 824182 Flow Tube Shield

2 824177 Male Quick-Connect Fitting

3 824176 Bypass Port

4 824175 Flow Control Valve Knob

5 824174 Flowmeter Inlet/Outlet Connector (Qty 2)

6 824146 Flow Control Valve

7 824145 Flowmeter Seal Kit

824181 Flowmeter Boot

2

3

7

7

1

824182

824174

824181

824176824177

824146

824175

824145

10

4

7

6

7

Form 824262 Page Number - 5

5

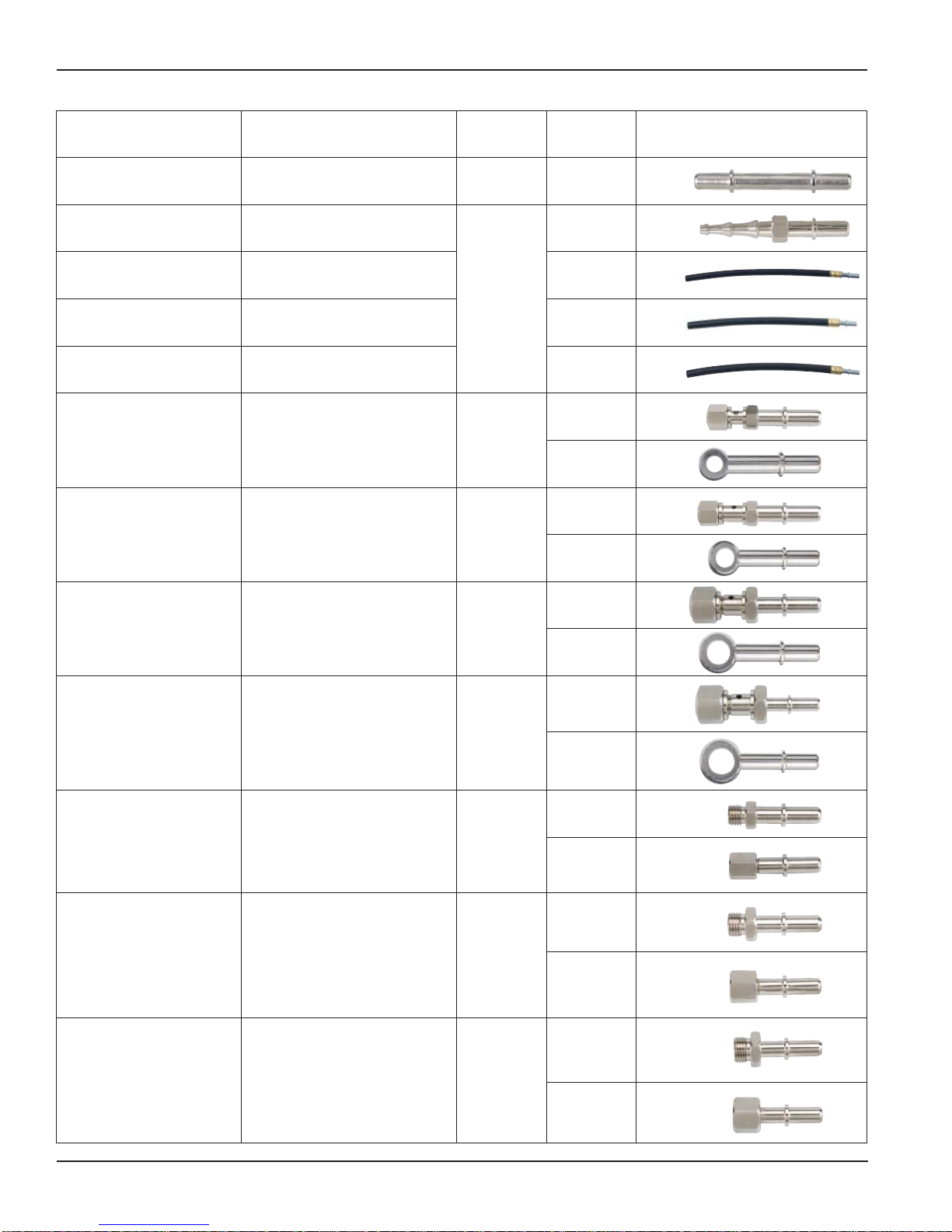

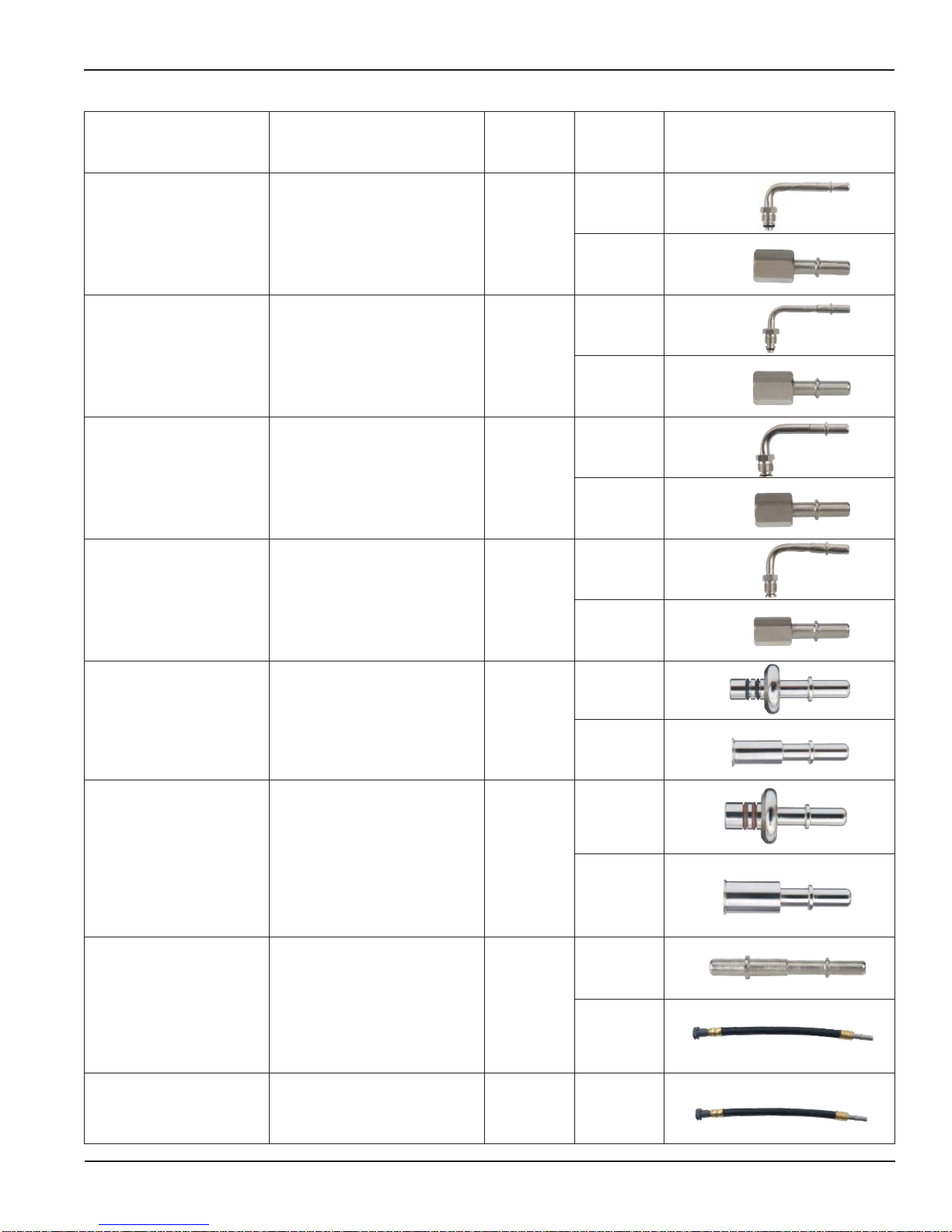

Fuel System Test Adapters

Description Applications Order No.

3

⁄8" Quick-change Adapter GM, Chrysler, Jeep/Eagle MVA512 1

1

⁄4" - 3⁄8" Barbed

Flex Hose Adapter

1

⁄4" Flex Hose Adapter

Vehicles with 1⁄4", 5⁄16"

or 3⁄8" rubber to steel

hose connection

Vehicles with 1⁄4" rubber

to steel hose connection

Reference

MVA505

5

⁄16" Flex Hose Adapter

3

⁄8" Flex Hose Adapter

M8 x 1.0

Banjo Adapter

M10 x 1.0

Banjo Adapter

Vehicles with 5⁄16" rubber

to steel hose connection

Vehicles with 3⁄8" rubber

to steel hose connection

Toyota MVA530

Toyota MVA531

No.

16

16A

16B

16C

13B

13C

14B

14C

M12 x 1.25

Banjo Adapter

M14 x 1.5

Banjo Adapter

M12 x 1.5

Ball Nose Adapter

M14 x 1.5

Ball Nose Adapter

M16 x 1.5

Ball Nose Adapter

Toyota, Lexus, Geo, Honda, Acura,

Hyundai, Mazda, Daihatsu, Chrysler

imports

European vehicles

with CIS fuel system

European vehicles

with CIS fuel system

European vehicles

with CIS fuel system

15B

MVA532

15C

23A

MVA533

23C

12A

MVA517

12B

10A

MVA518

10B

11A

MVA519

11B

Page Number - 6 Form 824262

Fuel System Test Adapters

Description Applications Order No.

M16 x 1.5 Adapter GM Vortec MVA520

M14 x 1.5 Adapter GM Vortec MVA521

3

⁄8" Flare Nut Adapter

5

⁄16" Flare Nut Adapter

Carbureted & early

fuel injected systems

Carbureted & early

fuel injected systems

MVA522

MVA523

Reference

No.

3A

3B

4A

4B

6A

6B

5A

5B

7A

3

⁄8" Spring Lock Adapter Ford fuel injection systems MVA524

7B

8A

1

⁄2" Spring Lock Adapter Ford fuel injection systems MVA525

8B

2B

5

⁄16" Quick-Change Adapter GM, Chrysler, Jeep/Eagle MVA526

2A

10mm Quick-Change Adapter Diesel MVA534 24

Form 824262 Page Number - 7

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Page Number - 8 Form 824262

Setup and Installation

Determining Where to Install the FST

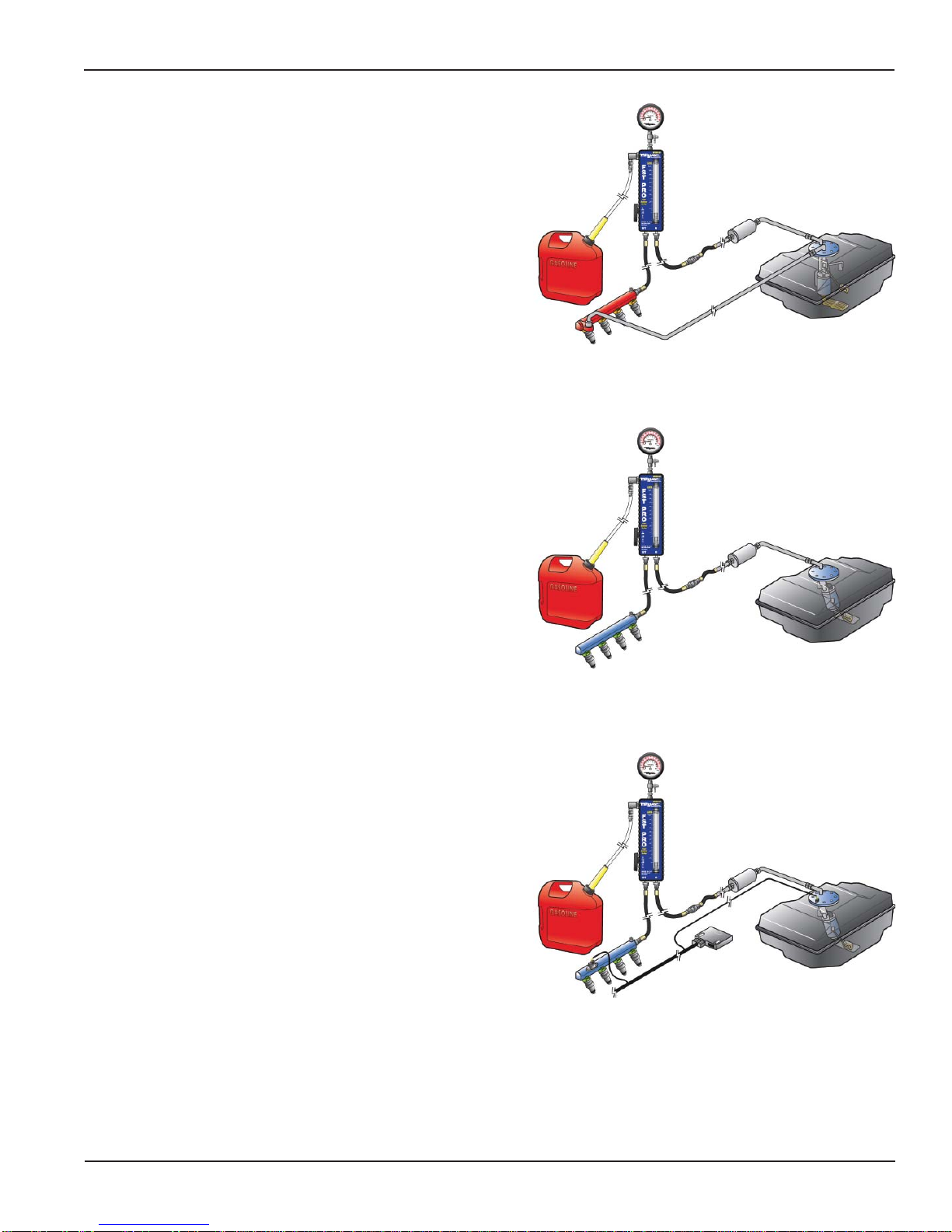

Inline Connection

Regardless of the type of fuel delivery system, the FST Pro is most effective at diagnosing malfunctions when connected inline with the flow

of fuel. The initial installation should be made at an access point along

the fuel supply line, as close as possible to the fuel rail (Figs. 5, 6 and

7). At this location, the fuel pressure and flow measured by the tester

will most accurately represent the conditions within the fuel rail. Due to

some engine compartment layouts and connector locations, it may be

necessary to connect the tester directly after the in-line fuel filter, which

may be located in the engine compartment, under the frame, or near

the fuel tank. In this case, be sure to carefully inspect the fuel supply

line between the tester and fuel rail for any irregularities such as leaks,

crimps, or kinks, as these may cause a false diagnosis based on the

tester readings.

Alternative Connection Locations

Connecting the FST inline as instructed above for the initial test,

ensures the most accurate fuel system diagnosis. However, in some

instances it may be beneficial to connect the tester at alternative locations to more accurately pinpoint the exact cause of a malfunction.

Performing additional diagnostics at different connection locations is

detailed in the Testing and Diagnostics section of this manual.

Fig. 5

Fig. 6

Fig. 7

Form 824262 Page Number - 9

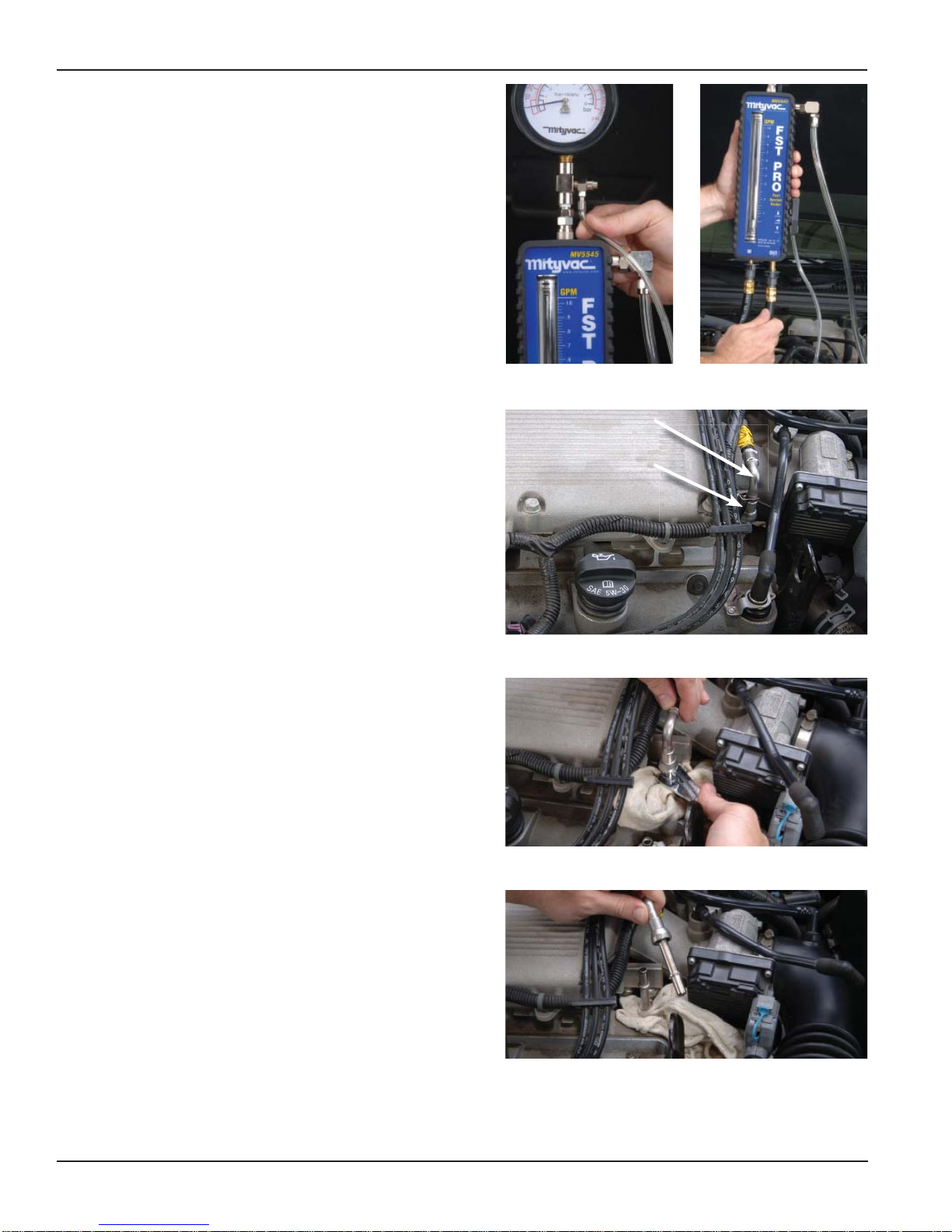

Installation

Once the installation point has been determined, follow the instructions

below to setup the tester prior to disconnecting the fuel line.

1. Place the vehicle transmission in park or neutral, apply the parking

brake, and turn the key off.

2. Hang the pressure gauge under the vehicle hood or other appropriate location.

3. Connect the flowmeter to the pressure gauge using the female

push-to-connect coupler extending from the bottom of the gauge,

and the male connector located on top of the flowmeter. Make sure

the quick-connect sleeve snaps forward to lock the connection.

NOTE: The flowmeter should hang vertically for the most accurate

fuel flow measurement.

4. Connect the 3 mm clear pressure relief hose to the barb extending

from the push-button pressure relief valve located just under the

gauge (Fig. 8).

5. Place the free ends of the bypass hose and pressure relief hose

into an approved gasoline fuel container. Secure hoses in fuel

container as necessary to prevent spills.

6. Connect one end of each 3/8" inlet and outlet connection hoses to

the bottom fittings on the FST flowmeter (Fig. 9).

7. Follow the vehicle manufacturer’s recommended procedure to

relieve the pressure from the vehicle fuel delivery system.

8. Locate the fuel supply line to the engine’s fuel rail, and select the

best location to disconnect the supply line and install the FST

(Fig. 10). If uncertain of the proper connection point, see the

previous section entitled Determining Where to Install the FST.

For additional assistance, consult the vehicle manufacturer’s

service information, or refer to the Types of Fuel Delivery Systems

section earlier in this manual.

If the engine has a cover, it will most likely have to be removed to

gain appropriate access.

9. Remove or disconnect any obstacles required to gain access to

the connection, and place shop towels under and around the connection to absorb fuel from the disconnected line.

T o minimize fuel spillage and reduce the amount of time the fuel

line is disconnected, try to identify the type of connection before

disconnecting the fuel line, and have the required FST connection

adapter(s) readily available (see Selecting and Installing Adapters

above). Also, identify the inlet and outlet hoses to the tester, and

keep them convenient.

10. Follow the vehicle manufacturer’s service information for the

proper method to disconnect the fuel line. Special wrenches or

disconnect tools may be required (Fig. 1 1).

WARNING: Avoid spilling fuel on hot engine parts. Clean-up any

fuel spills immediately after they occur.

1 1. Install the appropriate adapter into the fuel supply line extending

from the tank (Fig. 12).

Fig. 9Fig. 8

Fuel Line

Connection Location

Fig. 10

Fig. 11

Page Number - 10 Form 824262

Fig. 12

Loading...

Loading...