Page 1

USER’S MANUAL

Have Technical Questions?

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday - Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs and instructions for

product use.

Need Service Parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

Digital Diesel Compression Tester

MODEL MV5536

SPECIFICATIONS

Max. Pressure : 1000 PSI (69 Bar)

(6,900 kPa)

www.mityvac.com

AUG - 2005 Section

Form 822857

- MV38

Page

- 1

Page 2

Mityvac offers glow plug and injection adapters for the

following applications.

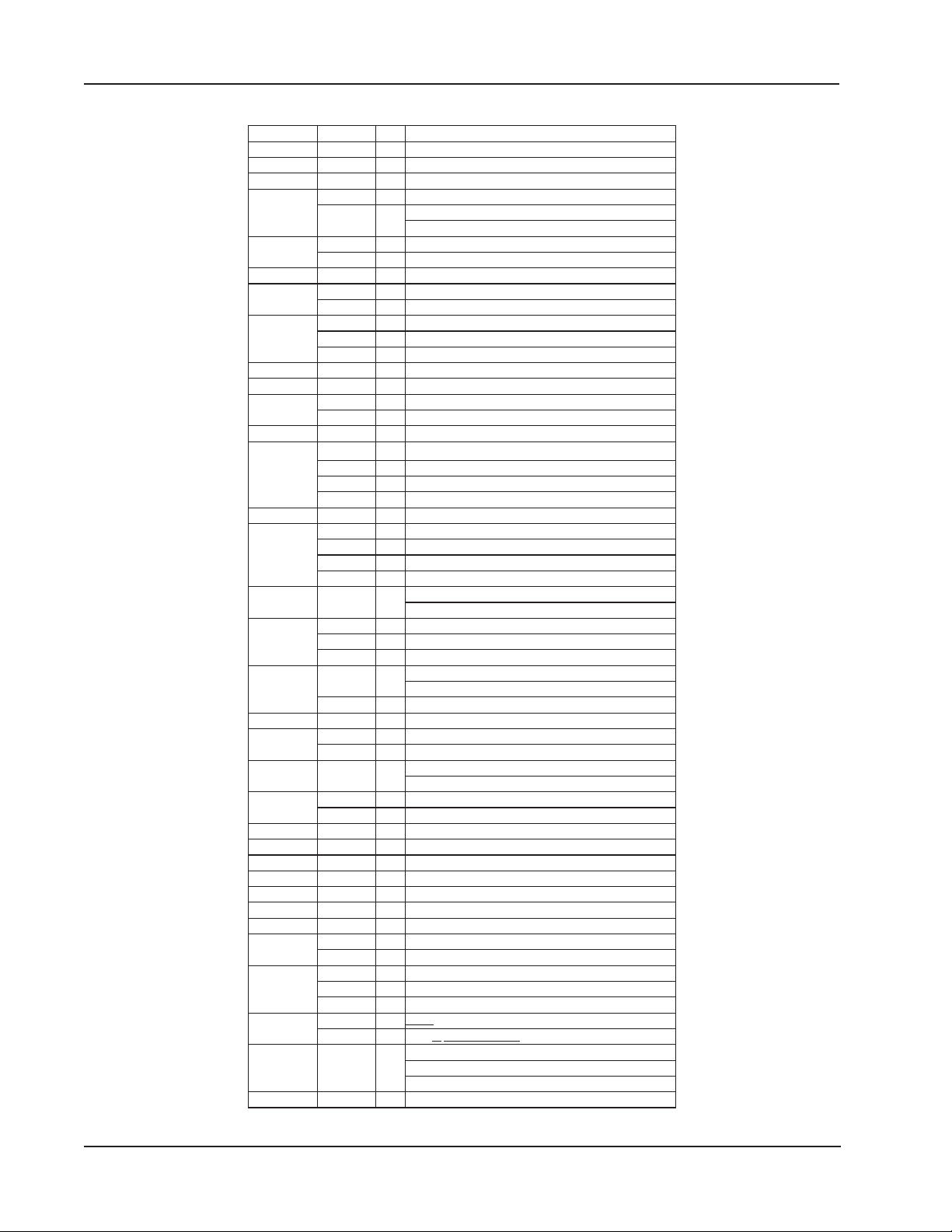

Manufacturer Adapter No Type Model/Engine

AIlis-Chalmers MVA5620 I 6000, 7000, 10000, 11000

Audi MVA5622 I All U.S. models

BMW MVA5613 GP 2.4L

MVA5619

J. I. Case

Caterpillar

Cheverolet MVA5614 GP 1.8L, 2.2L LUV/Isuzu

Cummins/Case

Cummins

Detroit Diesel MVA5621 I 53, 71, 92, 11_0_, 149, V53, V71

Deutz MVA5613 GP Most models

Dodge

Fiat Allis MVA5620

Ford

Ford/Mazda MVA5612 GP 2.0L & 2.21- Ford products including Ranger

GM

IHC MVA5620 I

Isuzu

John Deere

Kubota MVA5612 GP Some models

Lincoln

Mack MVA5620 I

Mercedes

Mitsubishi MVA5612 GP 2 & 3 cylinder engines, some Fuso

Navistar MVA5618 I DT360, DT466, 9.0L, 312, 360, 414, 436,& 446 cid up to 1997

Nissan MVA5612 GP 2.2L & Medium UD truck

Onan MVA5620 I DSL, MDSL

Perkins MVA5620 I 4.203, 4.236, 4.248, 6.354, 8.540

Peugeot MVA5613 GP 12.3L & 2.5L (1978-86)

Scania MVA5620 I DN11, DS11

Toyota

Volkswagen

Waukesha

White Farm MVA5620 1

Wisconsin MVA5620 1 340, 350, 430, 660, 670, 750, 860, 1000

I - Injector Adapter

GP - Glow Plug Adapter

MVA5620

MVA5619

MVA5616

MVA5602

MVA5617 I C series, 8.31

MVA5623

MVA5615

MVA5622

MVA5602

MVA5601

MVA5620 Tractor engines

MVA5612

MVA5603

MVA5605

MVA5603

MVA5604

MVA5613

MVA5611 GP Duromax 6600

MVA5614

MVA5611

MVA5612

MVA5619

MVA5620

MVA5613

MVA 5612 GP Mark VII, Continental w/Volvo engines

MVA5622

MVA5613

MVA5614

MVA5612

MVA5622

MVA5613

MVA5606

MVA5619

MVA5620 I 180DLC, 190D, 195D, 197D

I 70 Series, 188 & 207 cid w/pencil type injector

70 & 90 series, 1570, 2470, 2480 4890 engines w/non-pencil

I

type injector

I 1100 & 3208 series pencil type injector

I D336, 1674, 1676, 3406, 3408, 3412

I B series, 2,9L, 3.9L, 5.9L

I NH855, V6, V8, V12, 903 V8, L10

I V-185, V-210, V-225, V-555, VT-255, VT-_55_5

I 6BT, 4_.02” bore, 5.9L

I 5.9L, 12V Cummins (1989-1998)

I 5.9L, 24V Cummins (1998-2005)

1 8035-02-300, 8035-02-301, 8035-02-302, 8045-02, 8045-03

GP Escort, Lynx, Tempo, Topaz (1984-85)

GP Navistar 6.9L & 7.3L through 1994

GP Navistar 7.3L Power Stroke

GP 4.3L & 5.7L (1978-85)

GP 6.2L & 6.51- V8

GP W4, W7, W7HV (GMC Trucks)

D361, DT361 D429, DT429, DV462, DV550, DVT550, DT573,

DV573, DVT573, 361, 407

GP 1.8L, 2.2L

GP 6.6L

GP NPR, KS, NGR (Trucks)

Pencil Injector - Early 300, 400, 500 Series & 276, 404, 531 CID

I

engines

I 404, 466, 453, 619

GP 2.4L Mark VII, Continental (1984-85)

END 405, 457, 475, 510, 605, 672, 673, 674, 711, 864 & ENDT

1673, 675, 676, 865, 866

I Cars & trucks w/24 mm ports

GP ‘2500_ 30 300 Turbo, 350 Turbo

GP 1.8L

GP 2.2L

I All except 1.61- & 1.9L TDI

GP 1.6L

GP 1.91- TDI

I D155D

66, 77, 88, 99, 166, 177, 188, 199, 550, 660, 770, 880, 950,

1550, 1555, 1600, 1650, 16555, 1750, 17555, 1800, D2000,

2300, 3000

Page Number - 2 Form 822857

Page 3

Current Unit Indication –

Displays current unit of

measure. Available units of

measure include PSI, Bar, or

kPa. Current unit of measure

is maintained when unit is

cycled off and on.

On/Unit/Off Button

– Pressing this button

when unit is off, turns

unit on. Pressing and

releasing this button

while the unit is on, advances the current unit

of measurement forward.

Pressing and holding

this button for 3 seconds

while unit is on, turns

unit off. Tester automati

cally shuts off after six

(6) minutes of non-use.

Compression values are

maintained when unit is

cycled off and on.

Cylinder Advance Button

– Pressing this button advanc-

es the cylinder number by one.

If the pressure in the hose assembly is not relieved by pressing the Pressure Relief Button

or disconnecting the hose at

the quick disconnect junction,

the values for current max and

stored max for the new cylinder

will reflect the stored hose pressure.

-

Current Pressure Indication –

Displays the maximum compression value for the indicated

cylinder until the Pressure Relief

Button is pressed. This is the

measurement of the residual

pressure maintained in the hose

assembly by the Schrader valve.

Cylinder # Indication – Displays cylinder number related

to current and maximum compression values being displayed. Number is advanced

by pressing the Cylinder Button

Maximum Compression Indication

- Displays maximum

compression value for

the indicated cylinder. Holds the value

until the Clear Button

is pressed. Value is

stored electronically.

Clear Button

- Clears maximum

compression value

shown for indicated

cylinder. Clears

values for all cylinders and returns to

cylinder 1 if held for

3 seconds.

Pressure Relief Button

– Pressing this button relieves

the residual pressure in the tester hose assembly. The value

indicated for the Current Pressure will return to zero, but the

Maximum Compression value

will be maintained electronically

until the Clear Button is pressed.

Page Number - 3Form 822857

Page 4

Always read instructions carefully prior to use.

Safety Information

• Read and understand all safety precautions and operating instructions contained in this manual.

• Always wear eye protection when performing a compression test.

• Do not exceed the maximum rating of the tester; 1000

psi (69 bar) (6,900 kPa)

• Prior to testing, set the gearbox to neutral on all vehicles

or machinery having a standard transmission, or park for

automatic transmissions.

• Prior to engaging ignition, ensure that the fuel supply is

disabled using manufacturer’s recommended method.

• Make sure that all connections are secure prior to testing.

• Take precautions to avoid contact with hot engine surfaces.

Included in this Kit

• Digital Diesel Compression Tester comprising of test

gauge with rubber boot, 15” (375 mm) long, high pressure hose, and 90° female quick release swivel coupler.

• Custom molded case

• User’s Manual (English, French, Spanish and German)

Functional Overview

The Mityvac Digital Diesel Compression Tester is designed

for testing the compression produced in the cylinders of a

diesel engine. It can measure, display, and store compression values of up to 1,000 psi (69 bar) (6,900 kPa) for up to

12 cylinders.

When using this tester to perform a compression test on a

cylinder, the current peak compression value is displayed

in larger numbers at the center of the LCD. This value

is automatically transferred to memory, and displayed in

smaller numbers at the bottom right of the display. When

the pressure relief button is depressed, the current compression reading returns to zero, but the peak value is

retained in memory and continues to be displayed in the

bottom right corner of the LCD. Repeated tests can be

run on the same cylinder, and the new current peak value

will be displayed by the larger numbers. This new peak

value will not be retained in memory unless it surpasses

the value of the previous test, or the CLEAR button was

pressed to erase the old value from memory.

Peak compression values can be stored for up to 12 cylinders. Each value is displayed on the LCD along with the

cylinder number. During and/or after completion of testing

all cylinders, the peak values can be reviewed by pressing the CYLINDER button to scroll through the memory.

Individual peak values can be erased from memory by

pressing the CLEAR button when the appropriate cylinder

and value are displayed. Pressing the CLEAR button for 3

seconds at any time will clear the memory for all cylinders

and return the display to cylinder 1.

Before Running a Compression Test

• To achieve accurate results, the engine should be run

until it reaches normal operating temperature, prior to

testing. Testing should be completed before the engine

cools.

• Ensure battery(s) are fully charged to provide power for

adequate cranking speed. Check engine manufacturer’s specifications to determine if a minimum cranking

speed is required. It is recommended that a charger be

connected, or a backup or auxiliary battery be used to

maintain required cranking speed.

Performing a Compression Test

Diesel engines utilize either a direct or indirect fuel injection system. Direct injection engines inject fuel directly into

the cylinder, while indirect injection engines use a small

pre-combustion chamber. Spark plugs are not required for

either type of diesel engine. Instead, the high compression

achieved in a diesel engine cylinder heats the air, which

ignites the fuel. However, a cold diesel engine requires a

means to preheat the air in the cylinder, pre-combustion

chamber or manifold, to facilitate starting. This is most often accomplished with a glow plug. Depending on whether

the engine has a glow plug, and its location, will determine

whether a glow plug adapter or injector adapter is required

for compression testing. The best way to determine the

type of adapter to use, and the appropriate test method is

to consult a service manual. A full line of glow plug and

injector style test adapters for most makes and models of

vehicles and heavy equipment are available from Mityvac.

Testing with Glow Plug Adapter

Prior to starting a compression test, consult manufacturer’s

specifications and/or appropriate service manual to determine the correct procedure for performing the compression

test. Familiarize yourself with the proper specifications and

any unique testing procedures, and follow the recommended procedures for removing and installing the glow plugs.

1. Put the vehicle in neutral or park, and set the parking

brake.

2. Run the engine to normal operating temperature.

3. Ensure the battery has a full charge and/or connect a

charger or auxiliary battery.

4. Thoroughly clean the area around each glow plug to

eliminate any chance of dirt or contamination entering

the engine.

5. Remove the glow plugs, label them by cylinder number,

and protect them from damage.

6. Disable the fuel supply system.

7. Select the appropriate glow plug adapter and install it

into cylinder 1.

8. Turn on the compression tester

UNIT/OFF button. Press and hold the CLEAR button

for at least three (3) seconds to clear the memory and

return the current cylinder indication to cylinder 1.

9. Check to see that the proper unit of measure, PSI, BAR,

or KPA, is displayed in the lower left corner of the LCD.

If not, press the ON/UNIT/OFF button until the desired

unit of measure is indicated.

10. Connect the tester to the glow plug adapter installed in

cylinder 1.

by pressing the ON/

Page Number - 4 Form 822857

Page 5

11. While watching the gauge, crank the engine and count

the compression strokes by listening to one of the adjacent cylinders. Watch for the pressure to peak around

6 to 10 strokes, then stop cranking. Make note of the

number of strokes required to reach peak compression.

12. Press the pressure relief button on the side of the tester

to release the pressure.

13. Disconnect the gauge and remove the glow plug

adapter.

14. Install the glow plug adapter in cylinder 2, and recon

nect the tester.

15. Advance the cylinder number shown on the tester LCD

to 2 by pressing the CYLINDER button.

16. Repeat the compression test on cylinder 2 and all

remaining cylinders. Be sure to crank the engine the

same number of strokes for each cylinder, and to ad

vance the cylinder number shown on the tester.

17. After completing the test on all cylinders, remove the

tester and adapter, and replace the glow plugs.

18. The peak compression value for each cylinder can be

viewed by scrolling through the cylinders using the CYLINDER button.

-

-

Testing with Injector Adapter

Prior to starting a compression test, consult manufacturer’s

specifications and/or appropriate service manual to determine whether the test should be performed while cranking

or running. Familiarize yourself with the proper specifications and any unique testing procedures, and follow the

recommended procedures for removing and installing the

injectors.

note the length of running time until maximum pressure

is reached.

11. Press the pressure relief button on the side of the tester

to release the pressure.

12. Disconnect the gauge and remove the injector adapter.

If required, reinstall the injector before proceeding.

13. Install the injector adapter in cylinder 2, and reconnect

the tester.

14. Advance the cylinder number shown on the tester LCD

to 2 by pressing the CYLINDER button.

15. Repeat the compression test on cylinder 2 and all

remaining cylinders. Be sure to crank the engine the

same number of strokes for each cylinder, or to run the

engine for the same amount of time, and to advance the

cylinder number shown on the tester.

16. After completing the test on all cylinders, remove the

tester and adapter, and reinstall injector(s).

17. The peak compression value for each cylinder can be

viewed by scrolling through the cylinders using the

CYLINDER button.

18. Follow manufactures instructions for analyzing the

results.

1. Put the vehicle in neutral or park, and set the parking

brake.

2. Thoroughly clean the area around each injector to eliminate any chance of dirt or contamination entering the

engine.

3. Run the engine to warm it to normal operating temperature.

4. If the test is to be performed while cranking, ensure the

battery has a full charge and/or connect a charger or

auxiliary battery.

5. Follow the manufacturer’s recommended procedure for

disabling the fuel supply and removing the injector(s).

6. Select the appropriate injector adapter and install it into

cylinder 1.

7. Turn on the compression tester by pressing the ON/

UNIT/OFF button. Press and hold the CLEAR button

for at least three (3) seconds to clear the memory and

return the current cylinder indication to cylinder 1.

8. Check to see that the proper unit of measure, PSI, BAR,

or KPA, is displayed in the lower left corner of the LCD.

If not, press the ON/UNIT/OFF button until the desired

unit of measure is indicated.

9. Connect the tester to the injector adapter installed in

cylinder 1.

10. While watching the gauge, crank or run the engine as

specified by the manufacturer. If cranking, count the

compression strokes by listening to one of the adjacent

cylinders. Watch for the pressure to peak around 6 to

10 strokes, then stop cranking. If running the engine,

Page Number - 5Form 822857

Page 6

Contacting Lincoln Industrial Corp.

Lincoln Industrial Corporation,

One Lincoln Way,

St. Louis, MO 63120

Phone: (314) 679-4200 Ext. 4410

Fax: (800) 424-5359

E-mail: custserv@lincolnindustrial.com

For technical questions, please contact our Technical Ser

vice Department:

Phone:(314) 679-4200 Ext 4782

Fax: (314) 679-HELP (4357)

E-mail: techserv@lincolnindustrial.com

Visit our Web Site at: www.mityvac.com

TO AVOID PERSONAL INJURY AND/OR VEHICLE

DAMAGE:

While some precautions are specified in this manual,

and should be noted to avoid personal injury or vehicle

damage, it is not possible for these cautions to cover all

conceivable ways in which service or testing might be

done, or all possible hazardous consequences of each

way, nor could Lincoln possibly know or investigate all

such ways. It is therefore the responsibility of anyone

using this manual or any other Mityvac product, to satisfy

him or herself completely that neither personal safety nor

vehicle safety will be jeopardized by the service methods

selected. Any such injury or damage is entirely the user’s

responsibility. This device is not to be used in any man

ner on the human body.

-

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship for a period

of one (1) year following the date of purchase, excluding therefrom any special, extended, or limited warranty published by Lincoln. If

equipment is determined to be defective during this warranty period, it will be repaired or replaced, within Lincoln’s sole discretion, with

out charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain

repair or replacement, you must ship the equipment, transportation charges prepaid, with proof of purchase to a Lincoln Authorized War

ranty and Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive material, equipment that has been altered, or equipment

repaired by anyone not authorized by Lincoln. This warranty applies only to equipment installed, operated and maintained in strict ac

cordance with the written specifications and recommendations provided by Lincoln or its authorized field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTIBILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or damages arising

out of the sale, resale or use of any Lincoln equipment shall in no event exceed the purchase price. Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages, therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany, for your

warranty rights.

Lincoln Industrial Contact Information

-

-

-

To find Lincoln Industrial’s Nearest Service Center

Call one of the following numbers, you may also use our Website

Customer Service 314-679-4200

Website: lincolnindustrial.com

Page Number - 6 Form 822857

Page 7

MANUEL D’UTILISATION

Questions techniques ?

Si vous avez des questions ou avez

besoin d’assistance technique,

contacter nos techniciens qualifiés à :

1-314-679-4200, poste 4782

Lundi à vendredi, 7h30 à 16h15 heure

du centre des Etats-Unis.

Rendez visite à notre site web à www.

mityvac.com pour découvrir nos nouveaux produits, obtenir des catalogues

ou des instructions d’utilisations pour

nos produits.

Besoin de pièces ?

Pour commander des pièces de rechange ou des pièces consommables,

rendez-nous visite en ligne à www.

mityvacparts.com ou appelez gratuitement +1-800-992-9898.

Compressiomètre numérique pour

moteurs diesel

MODELE MV5536

DONNEES TECHNIQUES

Pression maximale : 69 bar (6 900

kPa ; 1000 psi)

www.mityvac.com

Page Number - 7Form 822857

Page 8

Mityvac offre des adaptateurs de bougie de préchauffage et d’injecteur pour les

utilisations suivantes

Constructeur N° d’adaptateur Type Modèle / moteur

Allis-Chalmers MVA5620 I 6000, 7000, 10000, 11000

Audi MVA5622 I Tous les modèle américains

BMW MVA5613 BP 2,4 l

J.I. Case

Caterpillar

Chevrolet MVA5614 BP 1,8 l, 2,2 l LUV/Isuzu

Cummins/Case

Cummins

Detroit Diesel MVA5621 I 53, 71, 92, 110, 149, V53, V71

Deutz MVA5613 BP Majorité des modèles

Dodge

Fiat Allis MVA5620

Ford

Ford/Mazda MVA5612 BP 2,0 l et 2,2 l produits Ford, y compris Ranger

GM

IHC MVA5620 I D361, DT361 D429, DT429, DV462, DV550, DVT550, DT573, DV573, DVT573, 361, 407

Isuzu

John Deere

Kubota MVA5612 BP Certains modèles

Lincoln

Mack MVA5620 I END 405, 457, 475, 510, 605, 672, 673, 674, 711, 864 et ENDT 673, 675, 676, 865, 866

Mercedes

Mitsubishi MVA5612 BP moteurs à 2 et 3 cylindres, certains Fuso

Navistar MVA5618 I DT360, DT466, 9,0 l, 312, 360, 414, 436 et 446 cid jusque 1997

Nissan MVA5612 BP 2,2 l et camions moyens UD

Onan MVA5620 I DS l, MDS l

Perkins MVA5620 I 4,203, 4,236, 4,248, 6,354, 8,540

Peugeot MVA5613 BP 2,3 l et 2,5 l (1978-86)

Scania MVA5620 I DN11, DS11

Toyota

Volkswagen

Waukesha

White Farm MVA5620 I 66, 77, 88, 99, 166, 177, 188, 199, 550, 660, 770, 880, 950, 1550, 1555, 1600, 1650, 16555, 1750,

Wisconsin MVA5620 I 340, 350, 430, 660, 670, 750, 860, 1000

I = Adaptateur d’injecteur

BP = Adaptateur de bougie de préchauffage

MVA5619

MVA5620

MVA5619

MVA5616

MVA5602

MVA5617

MVA5623

MVA5615

MVA5622

MVA5602

MVA5601

MVA5620

MVA5612

MVA5603

MVA5605

MVA5603 BP 4,3 l et 5,7 l (1978-85)

MVA5604

MVA5613

MVA5611

MVA5614

MVA5611

MVA5612

MVA5619

MVA5620 I 404, 466, 453, 619

MVA5613

MVA5612

MVA5622

MVA5613

MVA5614

MVA5612

MVA5622

MVA5613

MVA5606

MVA5619

MVA5620 I 180D lC, 190D, 195D, 197D

I 70, 188 et 207 cid avec injecteurs de type crayon

I Séries 70 et 90, moteurs 1570, 2470, 2480, 4890 avec injecteurs type non crayon

I Séries 1100 et 3208 avec injecteurs type crayon

I D336, 1674, 1676, 3406, 3408, 3412

I Série B, 2,9 l, 3,9 l, 5,9 l

I Série C, 8,3 l

I NH855, V6, V8, V12, 903 V8, L10

I V-185, V-210, V-225, V-555, VT-255, VT-555

I 6BT, alésage de 4,02 in, 5,9 l

I 5,9 l, 12V Cummins (1989-1998)

I 5,9 l, 24V Cummins (1998-2005)

I 8035-02-300, 8035-02-301, 8035-02-302, 8045-02, 8045-03

I Moteurs de tracteurs

BP Escort, lynx, Tempo, Topaz (1984-85)

BP Navistar 6,9 l et 7,3 l jusque 1994

BP Navistar 7,3 l Power Stroke

BP 6,2 l et 6,5 l V8

BP W4, W7, W7HV (camions GMC)

BP Duromax 6600

BP 1,8 l, 2,2 l

BP 6,6 l

BP NPR, KS, NGR (camions)

I Injecteurs crayon – premiers moteurs des séries 300, 400, 500 et 276, 404, 531 CID

BP 2,4 l Mark VII, Continental (1984-85)

BP Mark VII, Continental avec moteurs Volvo

I Voitures et camions avec orifices de 24 mm

BP 250, 300, 300 Turbo, 350 Turbo

BP 1,8 l

BP 2,2 l

I Tous sauf 1,6 l et 1,9 l TDI

BP 1,6 l

BP 1,9 l TDI

I D155D

17555, 1800, D2000, 2300, 3000

Page Number - 8 Form 822857

Page 9

Indication de la pression

courante – Affiche la valeur de

compression maximale pour le

cylindre indiqué, jusqu’à la pression sur le clapet de décharge.

C’est la mesure de la pression

résiduelle maintenue dans le

tuyau par la vanne Schrader.

Touche de marche et

arrêt – Quand l’appareil

est éteint, appuyer sur

cette touche pour mettre

l’appareil en marche.

Quand l’appareil est

en marche, appuyer

momentanément sur

cette touche pour

faire avancer l’unité

de mesure. Quand

l’appareil est en marche,

appuyer sur cette touche pendant 3 secondes

pour éteindre l’appareil.

Le compressiomètre

s’éteint automatiquement après 6 minutes

sans utilisation. Les

valeurs de compression

sont maintenues quand

l’appareil est éteint et

remis en marche.

Touche d’avance de cylindre

– Appuyer sur cette touche

pour avancer d’un numéro de

cylindre. Si la pression dans

le tuyau n’est pas relâchée

en appuyant sur le bouton du

clapet de décharge ou en débranchant le tuyau au raccord

rapide, les valeurs maximales

courantes et les valeurs

maximales enregistrées pour

le nouveau cylindre reflètent

la pression enregistrée dans

le tuyau.

Indication de l’unité active – Affiche

l’unité de mesure active. Les mesures

peuvent être affichées en bar, kPa ou

psi. L’unité active est maintenue quand

l’appareil est éteint et remis en marche.

Indication du numéro du

cylindre – Affiche le numéro du

cylindre pour lequel les valeurs

de compression courante et

maximale sont affichées. Le

numéro avance en appuyant sur

le bouton de cylindre.

Indication de

compression

maximale – Af-

fiche la valeur de

compression

maximale pour le

cylindre indiqué.

Maintient cette valeur jusqu’à la pression sur le bouton

d’effacement

(CLEAR). La valeur

est enregistrée

électroniquement.

Touche

d’effacement de la

mémoire – Efface la

valeur de compression maximale affichée pour le cylindre

indiqué. Efface les

Clapet de

décharge – Ap-

puyer sur ce bouton

pour décharger la

pression résiduelle

dans le tuyau du

compressiomètre.

La valeur de pression courante indiquée est remise à

zéro, mais la valeur

de compression

maximale est maintenue électroniquement jusqu’à la

pression sur le bouton d’effacement.

valeurs pour tous les

cylindres et retourne

au cylindre n° 1, si

maintenu pendant 3

secondes.

Page Number - 9Form 822857

Page 10

Il faut toujours lire les instructions avec soin avant utilisation.

Sécurité

• Il faut lire et comprendre toutes les précautions de sécurité

et les instructions d’utilisation contenues dans ce manuel.

• Il faut toujours porter de la protection des yeux pendant

l’exécution de l’essai de compression.

• Il ne faut pas excéder la pression maximale du compressiomètre, 69 bar (6 900 kPa) (1000 psi)

• Avant l’essai, mettre la boîte de vitesses au point mort pour

tous les véhicules ou engins avec une boîte mécanique et

sur Park pour les boîtes automatiques.

• Avant d’engager l’allumage, vérifier que l’alimentation de

carburant est désarmée, en utilisant la méthode recommandée par le constructeur.

• Avant l’essai, vérifier que tous les branchements sont bien

faits.

• Il faut prendre des précautions pour éviter le contact avec

les surfaces chaudes du moteur.

Ce que comprend ce kit

• Un compressiomètre numérique pour moteur diesel comprenant un manomètre avec un embout en caoutchouc, un

tuyau de haute pression de 38 cm (15 in), et un coupleur

rapide femelle.

• Mallette moulée sur mesure

• Manuel d’utilisation (anglais, français, espagnol et alle

mand)

-

Généralités fonctionnelles

Le compressiomètre numérique Mityvac pour moteurs diesel

est conçu pour mesurer la compression produite dans les

cylindres d’un moteur diesel. Il peut mesurer, afficher et enregistrer les valeurs de compression maximales de 69 bar (6 900

kPa) 1 000 (psi) d’un maximum de 12 cylindres.

Quand ce compressiomètre est utilisé pour faire un essai de

compression sur un cylindre, la valeur de pointe courante est

affichée en grands chiffres au centre de l’affichage à cristaux

liquides. Cette valeur est automatiquement transférée dans la

mémoire et affichée en petits chiffres au coin inférieur droit de

l’affichage. Quand l’opérateur appuie sur le bouton du clapet

de décharge, la lecture courante de compression retourne à

zéro, mais la valeur de pointe est retenue dans la mémoire et

est toujours affichée dans le coin inférieur droit de l’affichage

à cristaux liquides. Il est possible de répéter les essais sur le

même cylindre et la nouvelle valeur de pointe courante est affichée en grands chiffres. Cette nouvelle valeur de pointe n’est

pas retenue dans la mémoire à moins qu’elle soit supérieure à

la valeur de l’essai précédent, ou si l’opérateur a appuyé sur la

touche CLEAR pour effacer l’ancienne valeur dans la mémoire.

Il est possible de sauvegarder les valeurs de pointe de compression pour un maximum de 12 cylindres. Chaque valeur est

affichée sur l’affichage à cristaux liquides, ainsi que le numéro

du cylindre. Pendant ou après l’exécution de l’essai de tous

les cylindres, il est possible d’examiner les valeurs de pointe

en appuyant sur la touche CYLINDER pour faire défiler les renseignements de la mémoire. Pour effacer les valeurs de pointe

individuelles, appuyer sur la touche CLEAR quand le cylindre

et la valeur appropriés sont affichés. Appuyer sur la touche

CLEAR pendant 3 secondes à n’importe quel moment pour

effacer toutes les valeurs pour tous les cylindres et retourner

au cylindre n° 1.

Avant de faire une mesure de compression

• Pour obtenir des résultats précis, le moteur doit avoir fonctionné pour atteindre sa température de fonctionnement

normale, avant l’essai. Les mesures doivent être faites

avant que le moteur ne se refroidisse.

• Vérifier que les batteries sont complètement chargées afin

de fournir la puissance nécessaire pour obtenir une vitesse

de lancement adéquate. Vérifier les spécifications du

constructeur du moteur pour déterminer si une vitesse de

lancement minimale est nécessaire. Il est recommandé de

brancher un chargeur ou d’avoir des batteries d’appoint afin

de maintenir la vitesse de lancement nécessaire.

Mesure de compression

Les moteurs diesel utilisent un système d’injection directe ou

indirecte. Les moteurs à injection directe injectent le carburant

dans le cylindre, alors que les moteurs à injection indirecte

utilisent ne petite chambre de pré-combustion. Les deux types

de moteur diesel n’utilisent aucune bougie d’allumage. A leur

place, la compression élevée obtenue dans les cylindres du

moteur diesel chauffe l’air qui, à son tour, allume le carburant.

Cependant, un moteur diesel froid doit avoir un moyen de

préchauffer l’air des cylindres, les chambres de pré-combus

tion ou la tubulure, pour faciliter le démarrage. Généralement,

ceci est accompli au moyen d’une bougie de préchauffage. La

présence d’une bougie de préchauffage et son emplacement

déterminent l’utilisation d’un adaptateur de bougie de préchauffage ou d’un adaptateur d’injecteur pour faire la mesure

de compression. Consulter le manuel de réparation pour déterminer quel est le meilleur type d’adaptateur à utiliser, ainsi

que la meilleure méthode de mesure. Une gamme complète

d’adaptateurs pour bougies de pré-chauffage et pour injecteurs

pour la majorité des marques et des modèles de véhicules et

gros engins est offerte par Mityvac.

-

Mesure avec l’adaptateur de bougie de préchauffage

Avant de commencer la mesure de compression, consulter

les spécifications du constructeur ou le manuel de réparation approprié pour déterminer la procédure correcte à suivre

pour mesurer la compression. Il faut se familiariser avec les

spécifications et toute méthode de mesure unique et suivre les

procédures recommandées pour la dépose et la repose des

bougies de préchauffage.

1. Mettre le véhicule au point mort ou sur Park et serrer le

frein de stationnement.

2. Faire tourner le moteur pour l’amener à sa température de

fonctionnement normale.

3. Vérifier que la batterie est complètement chargée ou

brancher un chargeur ou une batterie d’appoint.

4. Nettoyer soigneusement les alentours de chaque bougie de

préchauffage pour éliminer la possibilité d’entrée de saleté

ou contamination dans le moteur.

5. Déposer les bougies de pré-chauffage, les marquer avec le

numéro du cylindre et les protéger des dommages.

6. Désarmer le système d’alimentation de carburant.

7. Sélectionner l’adaptateur de bougie de préchauffage ap

proprié et l’installer dans le cylindre n° 1.

8. Appuyer sur la touche de marche et arrêt (ON/UNIT/OFF)

pour mettre en marche le compressiomètre. Appuyer pen

dant au moins 3 secondes sur la touche CLEAR pour effacer la mémoire et ramener l’indicateur du cylindre courant

au cylindre n° 1.

-

-

Page Number - 10 Form 822857

Page 11

9. Vérifier que l’unité de mesure correcte, BAR, KPA ou

PSI, est affichée au coin inférieur gauche de l’affichage à

cristaux liquides. Si ce n’est pas le cas, appuyer sur la

touche de marche-unité-arrêt (ON/UNIT/OFF) jusqu’à

l’affichage de l’unité de mesure désirée.

10. Brancher le compressiomètre sur l’adaptateur de bougie

de préchauffage installé sur le cylindre n° 1.

11. Tout en observant le manomètre, faire tourner le moteur

et compter les courses de compression en écoutant un

des cylindres adjacents. Observer la pression maximale,

autour de 6 à 10 courses, et arrêter alors le lancement.

Noter le nombre de courses nécessaires pour obtenir la

compression maximale.

12. Appuyer sur le bouton de clapet de décharge sur le côté

de l’instrument afin de faire tomber la pression.

13. Débrancher le manomètre et déposer l’adaptateur de

bougie de pré-chauffage.

14. Installer l’adaptateur de bougie de préchauffage sur le

cylindre n° 2 et recommencer la mesure.

15. Appuyer sur la touche CYLINDER pour faire avancer

l’affichage au cylindre n° 2.

16. Répéter l’essai de compression pour le cylindre n° 2 et

tous les autres cylindres. Prendre soin de faire tourner

le moteur du même nombre de courses pour chaque

cylindre et d’avancer le numéro du cylindre affiché sur le

compressiomètre.

17. Après avoir fait la mesure sur tous les cylindres, enlever

le compressiomètre et l’adaptateur et remettre les bougies en place.

18. Il est possible d’afficher la valeur maximale de compres

sion pour chaque cylindre en faisant dérouler les cylindres

à l’aide de la touche CYLINDER.

9. Brancher le compressiomètre sur l’adaptateur d’injecteur

installé sur le cylindre n° 1.

10. Tout en observant le manomètre, lancer ou faire tourner le

moteur selon les spécifications du constructeur. En cas de

lancement, compter le nombre de courses de compression

en écoutant un des cylindres adjacents. Observer la pression maximale, autour de 6 à 10 courses, et arrêter alors

le lancement. En cas de moteur en marche, noter la durée

nécessaire pour atteindre la pression maximale.

11. Appuyer sur le bouton de clapet de décharge sur le côté

de l’instrument afin de faire tomber la pression.

12. Débrancher le manomètre et déposer l’adaptateur

d’injecteur. Si nécessaire, reposer l’injecteur avant de

continuer.

13. Installer l’adaptateur d’injecteur sur le cylindre n° 2 et

recommencer la mesure.

14. Appuyer sur la touche CYLINDER pour faire avancer

l’affichage au cylindre n° 2.

15. Répéter l’essai de compression pour le cylindre n° 2 et

tous les autres cylindres. Prendre soin de faire tourner le

moteur du même nombre de courses pour chaque cylindre

ou de faire tourner le moteur pendant la même durée et

de faire avancer le numéro du cylindre sur le compressiomètre.

16. Après avoir fait la mesure sur tous les cylindres, enlever le

compressiomètre et l’adaptateur et remettre les injecteurs

en place.

17. Il est possible d’afficher la valeur maximale de compres-

sion pour chaque cylindre en faisant dérouler les cylindres

-

à l’aide de la touche CYLINDER.

18. Suivre les instructions du constructeur pour analyser les

résultats.

Mesure avec l’adaptateur d’injecteur

Avant de commencer la mesure de compression, consulter les

spécifications du constructeur ou le manuel de réparation approprié pour déterminer si la mesure doit être faite en lançant

le moteur ou quand celui-ci tourne. Il faut se familiariser avec

les spécifications et toute méthode de mesure unique et suivre

les procédures recommandées pour la dépose et la repose

des injecteurs.

1. Mettre le véhicule au point mort ou sur Park et serrer le

frein de stationnement.

2. Nettoyer soigneusement les alentours de chaque injecteur

pour éliminer la possibilité d’entrée de saleté ou contamination dans le moteur.

3. Faire tourner le moteur pour l’amener à sa température de

fonctionnement normale.

4. Si la mesure doit être faite pendant le lancement, vérifier

que la batterie est complètement chargée ou brancher un

chargeur ou une batterie d’appoint.

5. Suivre la procédure recommandée par le constructeur

pour désarmer l’alimentation de carburant et déposer les

injecteurs.

6. Sélectionner l’adaptateur d’injecteur approprié et l’installer

dans le cylindre n° 1.

7. Appuyer sur la touche de marche et arrêt (ON/UNIT/OFF)

pour mettre en marche le compressiomètre. Appuyer pen

dant au moins 3 secondes sur la touche CLEAR pour effacer la mémoire et ramener l’indicateur du cylindre courant

au cylindre n° 1.

8. Vérifier que l’unité de mesure correcte, BAR, KPA ou PSI,

est affichée au coin inférieur gauche de l’affichage à cris

taux liquides. Si ce n’est pas le cas, appuyer sur la touche

de marche-unité-arrêt (ON/UNIT/OFF) jusqu’à l’affichage

de l’unité de mesure désirée.

-

-

Page Number - 11Form 822857

Page 12

Pour contacter Lincoln Industrial Corp.

Lincoln Industrial Corporation,

One Lincoln Way,

St. Louis, MO 63120

Tél. : (314) 679-4200, poste 4410

Fax : (800) 424-5359

Courriel : custserv@lincolnindustrial.com

En cas de question d’ordre technique, contacter le service

technique à :

Tél. : (314) 679-4200, poste 4782

Fax : (314) 679-4357 (HELP)

Courriel : techserv@lincolnindustrial.com

Rendez visite à notre site web à : www.mityvac.com

POUR EVITER DES BLESSURES ET LES DOMMAGES

DU VEHICULE

Bien que certaines précautions soient spécifiées dans ce

manuel afin d’éviter les blessures et les dommages du vé

hicule, il n’est pas possible de prévoir toutes les manières

possibles de réparation ou d’essais, ni tous les risques

possibles associés à chaque manière, et Lincoln ne peut

connaître ni rechercher toutes ces manières. Chaque utilisateur de ce manuel ou de tout autre produit Mityvac doit

donc s’assurer que la sécurité personnelle et la sécurité du

véhicule ne sont pas mises en cause par les méthodes de

réparation sélectionnées. Toute blessure ou tout dommage

est donc la responsabilité de l’utilisateur. Cet appareil ne

doit pas être utilisé d’une manière quelconque sur le corps

humain.

-

Garantie standard de Lincoln Industrial

GARANTIE LIMITEE

Lincoln garantit l’équipement fabriqué et fourni par Lincoln contre tout défaut de matériau et de fabrication pendant une période

d’un (1) an à compter de la date d’achat, à l’exclusion de toute garantie spéciale, étendue ou limitée publiée par Lincoln. Si,

pendant la période de garantie, il est déterminé que l’équipement est défectueux, il sera réparé ou remplacé, à la seule discrétion

de Lincoln, gratuitement.

Cette garantie est sujette à la détermination, par un représentant agréé de Lincoln, que l’équipement est défectueux. Pour obtenir une réparation ou un remplacement, vous devez expédier l’équipement, port payé, avec la preuve d’achat, à un centre de

réparation et de garantie agréé de Lincoln, pendant la période de garantie.

Cette garantie n’est offerte qu’à l’acheteur au détail initial. Cette garantie n’est pas applicable à de l’équipement endommagé par

un accident, une surcharge, des abus, une mauvaise utilisation, de la négligence, une mauvaise installation, une exposition à

des produits abrasifs ou corrosifs, ni à de l’équipement modifié ou réparé par quiconque pas autorisé par Lincoln. Cette garantie

ne s’applique qu’à de l’équipement installé, utilisé et maintenu en stricte conformité aux normes et recommandations écrites

fournies par Lincoln ou son personnel sur place agréé.

CETTE GARANTIE EST EXCLUSIVE ET REMPLACE TOUTE AUTRE GARANTIE, EXPRIMEE OU SOUS-ENTENDUE, Y

COMPRIS MAIS PAS LIMITEE A LA GARANTIE DE VENDABILITE OU D’APTITUTE A UNE UTILISATION PARTICULIERE.

En aucun cas, Lincoln ne peut être tenue responsable des dommages indirects ou secondaires. La responsabilité de Lincoln

pour toute réclamation de sinistre ou dommage provenant de la vente, la revente ou l’utilisation de l’équipement de Lincoln ne

peut dépasser le prix d’achat. Certaines juridictions ne permettent pas l’exclusion ni la limitation des dommages indirects ou

secondaires, il est donc possible que la limitation ou exclusion ci-dessus ne s’applique pas à un cas spécifique.

Cette garantie donne des droits spécifiques à l’acheteur. L’acheteur peut également avoir d’autres droits qui varient en fonction

de la juridiction.

Clients à l’extérieur de l’hémisphère occidental ou de l’Asie orientale : contacter Lincoln GmbH & Co. KG, Walldorf, Germany,

pour obtenir les droits selon la garantie.

Comment contacter Lincoln Industrial

Pour trouver le centre de réparation de Lincoln Industrial le plus proche

Appeler les numéros suivants ou rendre visite à notre site web.

Service après-vente +1 314-679-4200

Site web : lincolnindustrial.com

Page Number - 12 Form 822857

Page 13

BENUTZERHANDBUCH

Haben Sie technische Fragen?

Wenn Sie Fragen haben oder tech

nischen

Kundendienst brauchen, wenden Sie

sich

bitte an unsere geschulten Kundendiensttechniker unter:

1-314-679-4200 Apparat 4782

Montag – Freitag, 7:30 – 16:15

Mittelamerikanische Zeit

Besuchen Sie unsere Website

www.mityvac.com, um Information

über neue Produkte, Kataloge und

Gebrauchsanweisungen zu erhalten.

Brauchen Sie Ersatzteile?

Zur Bestellung von Ersatz- oder

Wartungsteilen besuchen Sie uns bitte

bei www.mityvacparts.com oder rufen

Sie gebührenfrei 1-800-992-9898 an.

-

Digitales Druckprüfgerät für

Dieselmotoren

Modell MV5536

Spezifikationen

Max. Druck: 1000 PSI (69 Bar) (6.900

kPa)

www.mityvac.com

Page Number - 13Form 822857

Page 14

Mityvac bietet Glühkerzen- und Einspritzdüsenadapter für die folgenden

Anwendungen an

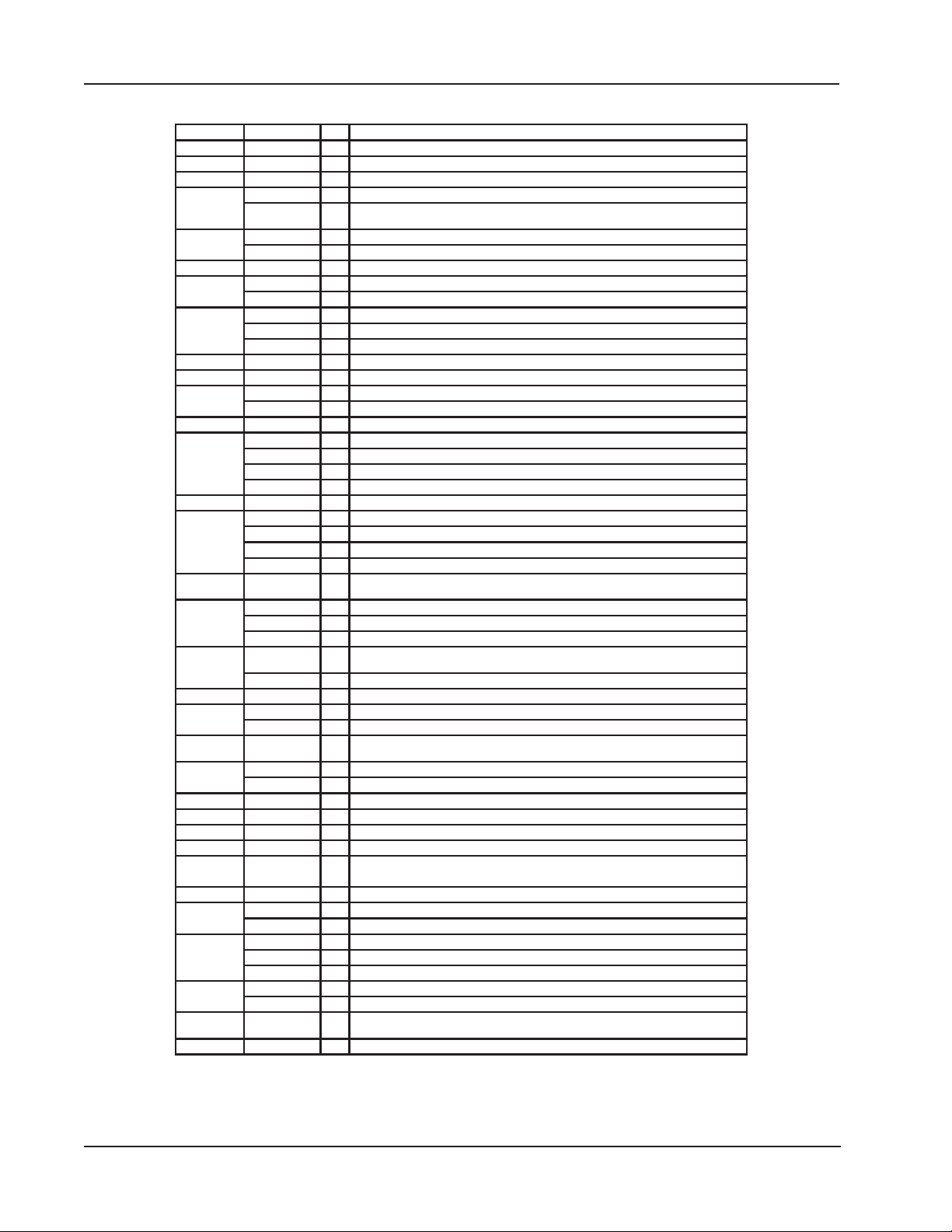

Hersteller Adapter No Typ Modell/Motor

Allis-Chalmers MVA5620 I 6000, 7000, 10000, 11000

Audi MVA5622 I Alle U.S. Modelle

BMW MVA5613 GP 2.4L

MVA5619 I 70 Serie, 188 & 207 cid m/ bleistiftartiger Einspritzdüse

J. I. Case MVA5620 I

Caterpillar MVA5619 I 1100 & 3208 Serie, bleistiftartige Einspritzdüse

MVA5616 I D336, 1674, 1676, 3406, 3408, 3412

Cheverolet MVA5614 GP 1.8L, 2.2L LUV/Isuzu

MVA5602

Cummins/Case

Cummins

Detroit Diesel MVA5621 I 53, 71, 92, 110, 149, V53, V71

Deutz MVA5613 GP Die meisten Modelle

Dodge

Fiat Allis MVA5620

Ford

Ford/Mazda

GM

IHC

Isuzu

John Deere MVA5619 I

Kubota MVA5612 GP Einige Modelle

Lincoln

Mack MVA5620 I

Mercedes

Mitsubishi MVA5612 GP 2 & 3 Zylinder Motoren, einige Fuso

Navistar MVA5618 I DT360, DT466, 9.0L, 312, 360, 414, 436,& 446 cid bis 1997

Nissan MVA5612 GP 2.2L & mittelgroßer UD Lastwagen

Onan MVA5620 I DSL, MDSL

Perkins MVA5620 I 4.203, 4.236, 4.248, 6.354, 8.540

Peugeot MVA5613 GP 2.3L & 2.5L (1978-86)

Scania MVA5620 I DN11, DS11

Toyota

Volkswagen

Waukesha

White Farm MVA5620 I

Wisconsin MVA5620 I 340, 350, 430, 660, 670, 750, 860, 1000

I - Einspritzdüsenadapter GP - Glühkerzenadapter

MVA5617

MVA5623

MVA5615

MVA5622

MVA5602

MVA5601

MVA5620 I Traktormotoren

MVA5612

MVA5603

MVA5605

MVA5612

MVA5603

MVA5604

MVA5613

MVA5611

MVA5620

MVA5614

MVA5611

MVA5612

MVA5620 I 404, 466, 453, 619

MVA5613

MVA5612

MVA5622

MVA5613

MVA5614

MVA5612

MVA5622

MVA5613

MVA5606

MVA5619

MVA5620

70 & 90 Serie, 1570, 2470, 2480, 4890 Motoren mit nicht-bleistiftartiger

Einspritzdüse

I B Serie, 2.9L, 3.9L, 5.9L

I C Serie, 8.3L

I NH855, V6, V8, V12, 903 V8, L10

I V-185, V-210, V-225, V-555, VT-255, VT-555

I 6BT, 4.02” Bohrung, 5.9L

I 5.9L, 12V Cummins (1989-1998)

I 5.9L, 24V Cummins (1998-2005)

I 8035-02-300, 8035-02-301, 8035-02-302, 8045-02, 8045-03

GP Escort, Lynx, Tempo, Topaz (1984-85)

GP Navistar 6.9L & 7.3L bis Ende Baujahr 1994

GP Navistar 7.3L Power Stroke

GP 2.0L & 2.2L Ford Produkte einschließlich Ranger

GP 4.3L & 5.7L (1978-85)

GP 6.2L & 6.5L V8

GP W4, W7, W7HV (GMC Lastwagen)

GP Duromax 6600

I D361, DT361 D429, DT429, DV462, DV550, DVT550, DT573,

DV573, DVT573, 361, 407

GP 1.8L, 2.2L

GP 6.6L

GP NPR, KS, NGR (Lastwagen)

Bleistiftartige Einspritzdüse - Frühe 300, 400, 500 Serien & 276, 404, 531

CID Motoren

GP 2.4L Mark VII, Continental (1984-85)

GP Mark VII, Continental m/ Volvo Motoren

END 405, 457, 475, 510, 605, 672, 673, 674, 711, 864 & ENDT 673, 675,

676, 865, 866

I Personen- und Lastwagen m/ 24 mm Bohrungen

GP 250, 300, 300 Turbo, 350 Turbo

GP 1.8L

GP 2.2L

I Alle außer 1.6L & 1.9L TDI

GP 1.6L

GP 1.9L TDI

I D155D

I 180DLC, 190D, 195D, 197D

66, 77, 88, 99, 166, 177, 188, 199, 550, 660, 770, 880, 950, 1550, 1555,

1600, 1650, 16555, 1750, 17555, 1800, D2000, 2300, 3000

Page Number - 14 Form 822857

Page 15

Fortlaufende Einheitsanzeige -

Zeigt die augenblickliche

Maßeinheit an. Die zur Verfügung stehenden Maße sind PSI,

Bar oder kPa. Die augenblickliche Maßeinheit bleibt erhalten,

wenn das Gerät an- und ausgeschaltet wird.

Ein/Gerät/Aus-Taste –

Wird diese Taste gedrückt,

wenn das Gerät abgeschaltet ist, so schaltet

es sich ein. Drücken und

Freigeben dieser Taste,

während das Gerät an ist,

rückt die augenblickliche

Maßeinheit vorwärts.

Drücken und Halten dieser Taste für 3 Sekunden,

während das Gerät an

ist, schaltet es aus. Das

Prüfgerät schaltet sich

automatisch aus, wenn

es sechs (6) Minuten

lang nicht benutzt wurde.

Die Druckwerte bleiben

erhalten, wenn die Einheit

aus- und eingeschaltet

wird.

Zylindervorwärts-Taste –

Drückt man auf diese Taste, so rückt die

Zylindernummer um einen Schritt vorwärts.

Wird der Druck in der Schlauchbaugruppe

nicht durch Drücken der Druck-entlastungstaste oder durch die Trennung des

Schlauchs an der Schnelltrennverbindung

entlastet, so zeigen die Werte für das

augenblickliche Maximum und das gespeicherte Maximum für den neuen Zylinder

den gespeicherten Druck im Schlauch.

Fortlaufende Druckanzeige -

Zeigt den Spitzendruckwert für den

bezeichneten Zylinder, bis die Druckausgleichtaste gedrückt wird. Dies

ist der verbleibende Druck, der durch

das Schraderventil in der Schlauchbaugruppe aufrechterhalten wird.

Druckentlastungstaste –

Wird diese Taste gedrückt,

so wird der verbleibende

Druck in der Schlaucheinheit

des Prüfgeräts entlastet.

Der Wert für den augenblick

lichen Druck kehrt zu Null

zurück, aber der maximale

Druckwert bleibt elektronisch gespeichert, bis die

Löschtaste gedrückt wird.

Anzeige der Zylindernummer -

Zeigt die Nummer des Zylinders

an, für den die augenblicklichen

und maximalen Druckwerte

gezeigt werden. Die Nummer

rückt weiter, wenn die Zylinder

taste gedrückt wird.

Spitzendruckanzeige –

Zeigt den maximalen

Druckwert für den

angezeigten Zylinder.

Hält diesen Wert, bis die

Lösch-taste gedrückt

wird. Der Wert wird elektronisch gespeichert.

Löschtaste -

Löscht den maximalen

Druckwert, der für den bezeichneten Zylinder gezeigt

wird. Löscht die Werte für

alle Zylinder und kehrt zu

Zylinder 1 zurück, wenn sie

für drei Sekunden gehalten

wird.

-

-

Page Number - 15Form 822857

Page 16

Vor Gebrauch immer die Anweisungen aufmerksam lesen.

Sicherheitshinweise

• Alle Vorsichtsmaßnahmen und Bedienungsanweisungen in

diesem Handbuch lesen und verstehen.

• Bei der Durchführung eines Drucktests immer einen Augenschutz tragen.

• Die maximalen Nennwerte des Prüfgerätes, 1000 PSI (69

bar) (6.900 kPa) nicht überschreiten

• Vor der Prüfung bei allen Fahrzeugen mit Standardgetriebe

das Getriebe auf Neutral schalten, für automatisches Getriebe auf Parken schalten.

• Vor Einschalten der Zündung sicherstellen, dass die Treibstoffzufuhr mit der vom Hersteller empfohlenen Methode

abgestellt worden ist.

• Vor der Prüfung sicherstellen, dass alle Verbindungen

sicher sitzen.

• Vorsichtsmaßnahmen treffen, um Kontakt mit heißen Motorteilen zu vermeiden

In diesem Satz enthalten

• Digitales Druckprüfgerät für Dieselmotoren, bestehend

aus der Prüfanzeige mit Gummischuh, 15 Zoll (375 mm)

langem Hochdruckschlauch und 90° weiblichem Schnelltrennschwenk-anschluss.

• Geformter Tragekoffer der üblichen Art.

• Benutzerhandbuch (Englisch, Französisch, Spanisch und

Deutsch.

Funktionsübersicht

Das Mityvac Digitale Druckprüfgerät für Dieselmotoren hat den

Zweck, den Druck zu prüfen, der in den Zylindern eines Dieselmotors erzeugt wird. Es kann Druckwerte bis zu 1.000 PSI (69

Bar) (6.900 kPa) für bis zu 12 Zylinder messen, anzeigen und

speichern.

Bei der Verwendung dieses Gerätes für einen Zylinderdruck

test wird der augenblickliche Spitzendruck in größeren Zahlen

in der Mitte der Flüssigkristallanzeige dargestellt. Dieser Wert

wird dann automatisch gespeichert und in kleineren Zahlen

unten rechts auf der Anzeige dargestellt.

Wird die Druckentlas tungstaste gedrückt, so stellt sich die

momentane Druckanzeige auf Null zurück, aber der Spitzenwert bleibt gespeichert und wird weiterhin unten rechts auf der

Anzeige dargestellt. Es können wiederholte Prüfungen am

gleichen Zylinder vorgenommen werden, und der neue momentane Spitzendruck wird wieder in großen Zahlen gezeigt.

Dieser neue Spitzenwert wird nicht im Speicher aufbewahrt,

ausgenommen er übersteigt den Wert des vorigen Tests, oder

die LÖSCHEN-Taste wurde betätigt, um den alten Wert aus

dem Speicher zu löschen.

Es können Spitzendrücke für bis zu 12 Zylinder gespeichert

werden. Jeder Wert wird auf der Anzeige zusammen mit der

Zylindernummer gespeichert. Während und/oder nach Durchführung der Prüfung aller Zylinder können die Spitzenwerte angesehen werden, indem man die ZYLINDER-Taste drückt und

durch den Speicher scrollt. Individuelle Spitzenwerte können

gelöscht werden, indem man die LÖSCHEN-Taste betätigt,

während der entsprechende Zylinder und sein Wert gezeigt

werden. Drückt man die LÖSCHEN-Taste zu irgendeiner Zeit

für 3 Sekunden, so werden alle Zylinderangaben im Speicher

gelöscht, und die Anzeige kehrt zu Zylinder 1 zurück.

Vor der Durchführung einer Druckprüfung

• Um genaue Resultate zu erzielen, muss der Motor vor Beginn

der Prüfung laufen, bis er die normale Betriebstemperatur

erreicht. Der Test muss beendet sein, bevor der Motor ab

gekühlt ist.

• Sicherstellen, dass die Batterie(en) voll geladen ist/sind, um

Strom für die richtige Anlassgeschwindigkeit zu liefern. Im

Motorhandbuch des Herstellers nachsehen, ob eine Mindestanlass-geschwindigkeit verlangt wird. Es wird empfohlen, ein

Ladegerät anzuschließen oder eine Zusatzbatterie zu benutzen, um die erforderliche Anlassgeschwindigkeit aufrecht zu

erhalten.

Durchführung einer Druckprüfung

Dieselmotoren haben entweder ein direktes oder ein indirektes

Treibstoffeinspritzsystem. Bei Motoren mit direktem System wird

der Treibstoff direkt in den Zylinder eingespritzt, während bei

Motoren mit indirektem System eine kleine Vorverbrennungs

kammer benutzt wird. Zündkerzen werden für beide Typen von

Dieselmotoren nicht benötigt. Stattdessen erhitzt der hohe Druck

im Dieselmotorzylinder die Luft, die den Treibstoff entzündet.

Ein kalter Dieselmotor benötigt jedoch eine Vorrichtung zum

Vorwärmen der Luft im Zylinder, der Vorverbrennungskammer

oder dem Einlasskrümmer, um das Starten zu erleichtern. Dies

wird meist mit einer Glühkerze erreicht. Es hängt davon ab, ob

der Motor eine Glühkerze besitzt und wo diese angebracht ist,

ob ein Glühkerzenadapter oder ein Einspritzdüsenadapter für die

Druckprüfung benötigt wird. Die beste Methode, festzustellen,

welcher Adapter benutzt werden muss und welches die beste

Prüfmethode ist, besteht darin, in einem Handbuch nachzuschlagen. Ein volles Angebot von Glühkerzen- und Einspritzdüsenadaptern für die meisten Modelle und Arten von Fahrzeugen und

schweren Maschinen ist durch Mityvac erhältlich.

Der Test mit einem Glühkerzenadapter

Vor Beginn des Tests in der Spezifikationsliste des Herstellers

und/oder dem entsprechenden Handbuch nachlesen, welches

das korrekte Verfahren zur Durchführung der Prüfung ist. Ma-

chen Sie sich mit den richtigen Spezifikationen und mit speziellen

Prüfverfahren vertraut und folgen Sie den Empfehlungen für die

Entfernung und den Einbau der Glühkerzen.

1. Das Fahrzeug auf Neutral oder Parken schalten und die Park-

bremse betätigen.

2. Den Motor bis zum Erreichen der normalen Betriebstempera

tur laufen lassen.

3. Sicherstellen, dass die Batterie voll geladen ist und/oder ein

Ladegerät oder eine Zusatzbatterie anschließen.

4. Den Bereich um jede Glühkerze sorgfältig einigen, um jede

Möglichkeit zu vermeiden, dass Schmutz oder andere Verun

reinigungen in den Motor eindringen.

5. Die Glühkerzen entfernen, mit der Zylindernummer versehen

und vor Schaden bewahren.

6. Das Treibstoffzufuhrsystem abschalten.

7. Den richtigen Glühkerzenadapter wählen und in Zylinder 1

installieren.

8. Das Druckprüfgerät durch Drücken der EIN/GERÄT/AUS-

Taste einschalten. Die LÖSCHEN-Taste drücken und

wenigstens 3 (drei) Sekunden halten, um den Speicher zu

leeren und von der momentanen Zylinderangabe zu Zylinder

1 zurückzukehren.

9. Sehen, ob die richtige Maßeinheit, PSI, BAR oder KPA

in der rechten unteren Ecke der Anzeige dargestellt ist.

Wenn nicht, die EIN/GERÄT/AUS-Taste drücken, bis die

gewünschte Maßeinheit gezeigt wird.

-

-

10. Das Prüfgerät mit dem Glühkerzenadapter in Zylinder 1

verbinden.

Page Number - 16 Form 822857

-

-

Page 17

11. Die Anzeige beobachten, den Motor anlassen und die

Druckhübe zählen, indem man auf einen der benachbarten Zylinder horcht. Wenn der Druck nach etwa 6 bis

10 Hüben seinen Spitzenwert erreicht hat, stoppen. Die

Anzahl der Hübe bis zum Erreichen des Spitzendrucks

notieren.

12. Die Druckentlastungstaste an der Seite des Prüfgerätes

drücken, um den Druck zu entlasten.

13. Das Anzeigegerät trennen und den Glühkerzen- adapt

er entfernen.

14. Den Glühkerzenadapter in Zylinder 2 anbringen und das

Prüfgerät wieder anschließen

15. Die Zylindernummer auf der Anzeige des Prüfgeräts durch

Drücken der ZYLINDER-Taste auf 2 vorrücken.

16. Den Drucktest für Zylinder 2 und alle übrigen Zylinder

wiederholen. Sicherstellen, dass der Motor jedesmal mit

der gleichen Anzahl von Hüben pro Zylinder angelassen

wird und dass die Zylindernummer auf der Anzeige jeweils

vorgerückt wird.

17. Wenn alle Zylinder geprüft worden sind, Prüfgerät und

Adapter entfernen und die Glühkerzen wieder einbauen.

18. Man kann den Spitzendruck für jeden Zylinder ansehen,

indem man mit der ZYLINDER-Taste durch die Zylinder

scrollt.

Prüfung mit dem Einspritzdüsenadapter

Vor Beginn des Tests in der Spezifikationsliste des Herstellers

und/oder dem entsprechenden Handbuch nachlesen, ob der

Test beim Anlassen oder bei laufendem Motor durchgeführt

werden soll. Machen Sie sich mit den richtigen Spezifikationen

und speziellen Prüfverfahren vertraut und folgen Sie den

Empfehlungen für die Entfernung und den Einbau der Einspritzdüsen.

11. Die Druckentlastungstaste an der Seite des Prüfgerätes

drücken, um den Druck zu entlasten.

12. Das Anzeigegerät trennen und den Düsenadapter entfernen.

13. Den Düsenadapter in Zylinder 2 anbringen und das Prüfgerät wieder anschließen.

14. Die Zylindernummer auf der Anzeige des Prüfgeräts durch

Drücken der ZYLINDER-Taste auf 2 vorrücken.

15. Den Drucktest für Zylinder 2 und alle übrigen Zylinder

wiederholen. Sicherstellen, dass der Motor jedesmal mit

der gleichen Anzahl von Hüben pro Zylinder angelassen

wird und dass die Zylindernummer auf der Anzeige jeweils

vorgerückt wird.

16. Wenn alle Zylinder geprüft worden sind, das Prüfgerät

und den Adapter entfernen und die Einspritzdüsen wieder

einbauen.

17. Man kann den Spitzendruck für jeden Zylinder ansehen,

indem man mit der ZYLINDER-Taste durch die Zylinder

scrollt.

18. Zur Analyse der Resultate den Anweisungen des Herstellers folgen.

1. Das Fahrzeug auf Neutral oder Parken schalten und die

Parkbremse betätigen.

2. Den Bereich um jede Düse gründlich reinigen, um jede

Möglichkeit zu vermeiden, dass Schmutz oder andere Kontaminationen in den Motor eindringen.

3. Den Motor laufen lassen, bis er die normale Betriebstem

peratur erreicht hat.

4. Wenn der Test beim Anlassen durchgeführt wird, sicherstel

len, dass die Batterie voll geladen ist und/oder ein Ladegerät

oder eine Zusatzbatterie anschließen.

5. Beim Abschalten der Treibstoffzufuhr und der Entfernung

der Düse(n) den Empfehlungen des Herstellers folgen.

6. Den richtigen Düsenadapter wählen und in Zylinder 1 an

bringen.

7. Das Druckprüfgerät durch Drücken der EIN/GERÄT/AUSTaste einschalten. Die LÖSCHEN-Taste drücken und für

wenigstens 3 (drei) Sekunden halten, um den Speicher zu

leeren und die momentane Zylinderanzeige auf 1 zu stellen.

8. Nachsehen, ob die richtige Maßeinheit, PSI, AR oder KPA in

der unteren linken Ecke der Anzeige dargestellt ist. Wenn

nicht, die EIN/GERÄT/AUS-Taste drücken, bis sich die

gewünschte Maßeinheit zeigt.

9. Das Prüfgerät mit dem in Zylinder 1 angebrachten Düsen

adapter verbinden.

10. Die Anzeige beobachten, den Motor anlassen oder laufen

lassen, wie vom Hersteller angegeben. Während des An

lassens die Druckhübe zählen, indem man auf einen der

benachbarten Zylinder horcht. Wenn der Druck nach etwa

6 bis 10 Hüben seinen Spitzenwert erreicht hat, stoppen.

Die Anzahl der Hübe bis zum Erreichen des Spitzendrucks

notieren.

-

-

-

-

-

Page Number - 17Form 822857

Page 18

Lincoln Industrial Corp. Kontaktinformation.

Lincoln Industrial Corporation

One Lincoln Way

St. Louis, MO 63120

Tel: (314) 679-4200, Apparat 4410

Fax: (800) 424-5359

E-Mail: custserv@lincolnindustrial.com

Für technische Fragen wenden Sie sich bitte an unsere Technische Kundendienstabteilung:

Tel: (314) 679-4200 Apparat 4782

Fax: (314) 679-HELP (4357)

E-Mail: techserv@lincolnindustrial.com

Besuchen Sie unsere Website: www.mityvac.com

ZUR VERMEIDUNG VON PERSONENVERLETZUNGEN

UND/ODER SCHADEN AM FAHRZEUG:

Einige Vorsichtsmaßnahmen sind zwar in diesem Handbu

ch erwähnt und müssen beachtet werden, um Personenverletzungen oder Fahrzeugschaden zu verhindern.

Diese Vorsichtsmaßnahmen können aber unmöglich alle

Kundendienstmethoden oder Testmethoden behandeln,

oder alle möglichen damit verbundenen gefährlichen

Konsequenzen. Lincoln kann auch unmöglich alle diese

Methoden kennen oder untersuchen. Es ist daher die

Verantwortung der Person, welche dieses Handbuch oder

irgendein anderes Mityvac Produkt benutzt, sich völlig

davon zu überzeugen, dass durch die gewählte Methode

weder die Sicherheit von Personen noch die Sicherheit des

Fahrzeugs gefährdet wird. Für jegliche solche Verletzung

oder Beschädigung ist ausschließlich der Benutzer verantwortlich. Dieses Gerät darf keinesfalls am menschlichen

Körper benutzt werden.

-

STANDARDGARANTIE DER FIRMA LINCOLN

BESCHRÄNKTE GARANTIE

Die Firma Lincoln garantiert, dass von Lincoln hergestellte und gelieferte Produkte für eine Zeitspanne von einem (1) Jahr nach

dem Verkaufsdatum frei von Material- und Verarbeitungsfehlern sind, ausschließlich aller speziellen, verlängerten oder beschränkten von Lincoln veröffentlichen Garantien. Stellt sich während dieser Garantieperiode heraus, dass ein Produkt fehlerhaft ist,

so wird es gemäß Lincolns ausschließlicher Entscheidung kostenlos repariert oder ersetzt.

Diese Garantie beruht auf der Voraussetzung, dass ein von Lincoln autorisierter Vertreter das Produkt als fehlerhaft bezeichnet.

Für Reparatur oder Ersatz muss der Kunde das Produkt auf seine Kosten, zusammen mit dem Kaufbeweis, innerhalb der Garantiezeit an ein von Lincoln autorisiertes Garantie- und Kundendienstzentrum schicken.

Diese Garantie bezieht sich nur auf den ersten Käufer. Sie gilt nicht für Produkte, die durch Unfall, Überbelastung, Missbrauch,

falschen Gebrauch, Vernachlässigung, falsche Installierung oder scheuerndes und korrodierendes Material beschädigt wurden,

oder für Produkte, welche von Personen, die nicht von Lincoln autorisiert waren, geändert oder repariert wurden. Diese Garantie

gilt nur für Geräte, die in genauer Übereinstimmung mit den schriftlichen, von Lincoln oder seinem autorisierten Personal am

Standort gelieferten Anweisungen und Empfehlungen installiert, betrieben und gewartet werden.

DIESE GARANTIE IS EXKLUSIV UND STEHT ANSTELLE ALLER ANDEREN GARANTIEN, SEIEN SIE AUSDRÜCKLICH

GEGEBEN ODER STILLSCHWEIGEND ANGENOMMEN, EINSCHLIESSLICH DER GARANTIE FÜR HANDELSÜBLICHKEIT

ODER BRAUCHBARKEIT FÜR EINEN BESTIMMTEN ZWECK, JEDOCH NICHT BESCHRÄNKT AUF DIESE.

In keinem Fall ist Lincoln haftbar für Zufalls- oder Nachfolgeschäden. Die Haftbarkeit der Firma Lincoln für Schadensersatzansprüche für Verluste oder Schäden, die sich durch den Verkauf, Wiederverkauf oder die Verwendung eines Produktes von

Lincoln ergeben, kann in keinem Fall den Kaufpreis übersteigen. Manche Gerichtsbarkeiten erlauben den Ausschluss oder die

Begrenzung des Schadensersatzanspruches für Zufalls- oder Nachfolgeschäden nicht, daher kann es sein, dass die oben

erläuterte Begrenzung oder der Ausschluss für Sie nicht gilt.

Diese Garantie gibt Ihnen spezielle Rechte. Sie besitzen möglicherweise noch andere Rechte, die je nach Gerichtsbarkeit verschieden sein können.

Kunden, die sich nicht in der westlichen Hemisphäre oder Ostasien befinden: Bitte wenden Sie sich an Lincoln GmbH & Co. KG,

Walldorf, Deutschland, wenn Sie Fragen über Ihre Garantierechte haben.

Lincoln Industrial Kontaktinformation

Um das nächstgelegene Kundendienstzentrum zu finden,

rufen Sie die folgende Nummer an. Sie können auch unsere Website benutzen

Kundendienst: USA 314-679-4200

Website: lincolnindustrial.com

Page Number - 18 Form 822857

Page 19

MANUAL DEL USUARIO

¿Tiene preguntas técnicas?

Si tiene dudas, o requiere servicio

técnico, póngase en contacto con

nuestros técnicos de servicio capacitados llamando al:

1-314-679-4200 ext. 4782

Lunes a viernes de 7:30 am a 4:15 pm,

hora central estándar

Visite nuestro sitio web en www.

mityvac.com para obtener información

sobre nuevos productos, catálogos e

instrucciones pare el uso del producto.

¿Necesita piezas de reparación?

Para pedir piezas de repuesto o servicio, visítenos en www.mityvac.com o

llame de forma gratuita al 1-800-992-

9898.

Probador de compresión digital

para motores diesel

MODELO MV5536

ESPECIFICACIONES

Presión máxima: 69 bares (1000

lb/pulg2) (6900 kPa)

www.mityvac.com

Page Number - 19Form 822857

Page 20

Mityvac ofrece adaptadores de bujías incandescentes y de inyección para las

siguientes aplicaciones.

Fabricante

Allis-Chalmers MVA5620 I 6000, 7000, 10000, 11000

Audi MVA5622 I Todos los modelos de EE.UU.

BMW MVA5613 BI 2.4L

J.I. Case MVA5619 I Motores de la Serie 70, 188 y 207 pulg3 de cilindrada con inyector tipo lápiz

Caterpillar MVA5619 I Series 1100 y 3208 con inyector tipo lápiz

Chevrolet MVA5614 BI 1.8L, 2.2L LUV/Isuzu

Cummins/Case MVA5602 I Serie B, 2.9L, 3.9L, 5.9L

Cummins MVA5623 I NH855, V6, V8, V12, 903 V8, L10

Detroit Diesel MVA5621 I 53, 71, 92, 110, 149, V53, V71

Deutz MVA5613 BI La mayoría de los modelos

Dodge MVA5602 I 5.9L, 12V Cummins (1989-1998)

Fiat Allis MVA5620 I 8035-02-300, 8035-02-301, 8035-02-302, 8045-02, 8045-03

Ford MVA5620 I Motores de tractor

Ford/Mazda MVA5612 BI Productos Ford de 2.0L y 2.2L incluido el Ranger

GM MVA5603 BI 4.3L y 5.7L (1978-85)

IHC MVA5620 I D361, DT361 D429, DT429, DV462, DV550, DVT550, DT573, DV573, DVT573, 361, 407

Isuzu MVA5614 BI 1.8L, 2.2L

John Deere MVA5619 I

Kubota MVA5612 BI Algunos modelos

Lincoln MVA5613 BI 2.4L Mark VII, Continental (1984-85)

Mack MVA5620 I END 405, 457, 475, 510, 605, 672, 673, 674, 711, 864 y ENDT 673, 675, 676, 865, 866

Mercedes MVA5622 I Automóviles y camiones con lumbreras de 24 mm

Mitsubishi MVA5612 BI Motores de 2 y 3 cilindros, algunos de Fuso

Navistar MVA5618 I DT360, DT466, 9.0L, 312, 360, 414, 436 y 446 pulg3 de cilindrada hasta 1997

Nissan MVA5612 BI 2.2L y camión UD intermedio

Onan MVA5620 I DSL, MDSL

Perkins MVA5620 I 4.203, 4.236, 4.248, 6.354, 8.540

Peugeot MVA5613 BI 2.3L y 2.5L (1978-86)

Scania MVA5620 I DN11, DS11

Toyota MVA5614

Volkswagen MVA5622

Waukesha MVA5619

White Farm MVA5620 I

Wisconsin MVA5620

I – Adaptador de inyector

BI – Adaptador de bujía incandescente

N° de

adaptador Tipo Modelo/Motor

MVA5620 I

MVA5616

MVA5617

MVA5615 I V-185, V-210, V-225, V-555, VT-255, VT-555

MVA5622 I 6BT, calibre de 4.02” , 5.9L

MVA5601 I 5.9L, 24V Cummins (1998-2005)

MVA5612

MVA5603

MVA5605 BI Navistar 7.3L Power Stroke

MVA5604

MVA5613 BI W4, W7, W7HV (Camiones GMC )

MVA5611 BI Duromax 6600

MVA5611 BI 6.6L

MVA5612 BI NPR, KS, NGR (Camiones)

MVA5620 I 404, 466, 453, 619

MVA5612 BI Mark VII, Continental con motores Volvo

MVA5613 BI 250, 300, 300 Turbo, 350 Turbo

MVA5612

MVA5613 BI 1.6L

MVA5606 BI 1.9L TDI

MVA5620 I 180DLC, 190D, 195D, 197D

Motores de las Series 70 y 90, 1570, 2470, 2480, 4890 con inyectores que no son de tipo

lápiz

I D336, 1674, 1676, 3406, 3408, 3412

I Serie C, 8.3L

BI Escort, Lynx, Tempo, Topaz (1984-85)

BI Navistar 6.9L y 7.3L hasta 1994

BI 6.2L y 6.5L V8

Inyector tipo lápiz – Primeros motores de las Series 300, 400, 500 y motores de 276, 404,

531 pulg3 de cilindrada

BI 1.8L

BI 2.2L

I Todos con excepción del 1.6L y 1.9L TDI

I D155D

66, 77, 88, 99, 166, 177, 188, 199, 550, 660, 770, 880, 950, 1550, 1555, 1600, 1650,

16555, 1750, 17555, 1800, D2000, 2300, 3000

I 340, 350, 430, 660, 670, 750, 860, 1000

Page Number - 20 Form 822857

Page 21

Indicación actual de la unidad – Muestra la unidad de

medición actual. Entre las

unidades de medición disponibles se incluyen lb/pulg2,

bares o kPa. La unidad de

medición actual se mantiene

cuando la unidad se apaga y

se enciende repetidamente.

Indicación de presión actual -

Muestra el valor de compresión máximo para el cilindro

indicado hasta que se oprima

el botón de alivio de presión.

Ésta es la medida de la presión

residual mantenida en el conjunto de manguera por medio

de la válvula Schrader.

Indicación del cilindro

número - Muestra el número

del cilindro relacionado con

los valores de compresión

reales y máximos indicados.

Se hace avanzar el número

oprimiendo el botón Cilindro.

Botón de encendido/

unidad/apagado – La

unidad se enciende

al oprimir este botón

cuando esté apagada.

Al oprimir y soltar este

botón con la unidad

encendida se hace

avanzar la unidad

actual de medición en

una unidad. La unidad

se apaga al oprimir sin

soltar este botón durante 3 segundos con

la unidad encendida.

El probador se apaga

automáticamente

después de seis (6)

minutos sin usarse.

Los valores de compresión se mantienen

cuando la unidad se

apaga y se enciende

repetidamente.

Botón de avance del cilindro – Al oprimir este botón

se hace avanzar el número

del cilindro en una unidad.

Si no se alivia la presión

del conjunto de manguera

oprimiendo el botón de

alivio de presión o desconectando la manguera del

empalme de desconexión

rápida, los valores para

el máximo actual y el

máximo almacenado para

el cilindro nuevo reflejarán

la presión acumulada de la

manguera.

Indicación de compresión máxima

– Muestra el valor de

compresión máximo

para el cilindro indicado. Mantiene al

valor hasta oprimir el

botón Borrar. El valor

se guarda electrónicamente.

Botón Borrar – Borra el valor

de compresión máximo mostrado para el cilindro indicado.

Borra los valores de todos los

cilindros y vuelve al cilindro 1 si

se mantiene oprimido durante

3 segundos

Botón de alivio de presión – Al

oprimir este botón se alivia la

presión residual en el conjunto

de manguera del probador. El

valor indicado para la presión

actual volverá a cero, pero el

valor de compresión máximo

se mantendrá electrónicamente

hasta oprimir el botón Borrar.

Page Number - 21Form 822857

Page 22

Lea bien siempre las instrucciones antes de usarla.

Información de seguridad

• Lea y entienda todas las precauciones de seguridad y las

instrucciones de operación contenidas en este manual.

• Protéjase siempre los ojos al realizar la prueba de compre

sión.

• No exceda la norma máxima del probador; 69 bares (1000

lb/pulg2) (6900 kPa)

• Antes de realizar la prueba, ponga la caja de engranajes

en neutro en todos los vehículos y máquinas que tengan

una transmisión estándar o en estacionamiento si tienen

transmisiones automáticas.

• Antes de poner el motor en encendido, asegúrese de

desactivar el suministro de comestible usando el método

recomendado por el fabricante.

• Asegúrese de que todas las conexiones estén fijas antes

de la prueba.

• Tome precauciones para evitar el contacto con las superfi

cies calientes del motor.

-

-

Se incluye lo siguiente en este juego

• Probador de compresión digital para motores diesel

formado por un manómetro de prueba con una funda de

goma de 375 mm (15”) de largo, manguera de alta presión

y acoplamiento giratorio hembra de desconexión rápida de

90°.

• Estuche moldeado especial

• Manual del usuario (inglés, francés, español y alemán)

Generalidades de funcionamiento

El probador de compresión digital Mityvac para motores diesel

está diseñado para comprobar la compresión producida en

los cilindros de un motor diesel. Puede medir, mostrar y

almacenar valores de compresión de hasta 69 bares (1000

lb/pulg2) (6900 kPa) para un máximo de 12 cilindros.

Al usar este probador para realizar una prueba de compresión en un cilindro, el valor de compresión máximo actual

se muestra en números grandes en el centro de la pantalla

LCD. Este valor se transfiere automáticamente a la memo

ria, y se muestra en números más pequeños en la esquina

inferior derecha de la pantalla. Al oprimir el botón de alivio de

presión, la lectura de compresión actual vuelve a cero, pero

se retiene el valor máximo en la memoria y sigue mostrándose

en la esquina inferior derecha de la pantalla LCD. Se pueden

realizar pruebas repetidas en el mismo cilindro y se mostrará

el nuevo valor máximo actual en números más grandes. Este

valor máximo nuevo no se retendrá en la memoria a menos

que sobrepase el valor de la prueba anterior, o se oprima el

botón BORRAR para borrar el valor anterior de la memoria.

Se pueden guardar valores de compresión máximos para un

máximo de 12 cilindros. Cada valor se muestra en la pantalla

LCD junto con el número del cilindro. Durante y después de

completar las pruebas de todos los cilindros, se pueden revisar

los valores máximos oprimiendo el botón CILINDRO para

recorrer la memoria.

Se pueden borrar los valores máximos individuales de la

memoria oprimiendo el botón BORRAR cuando se muestren el

cilindro y el valor apropiados. Al oprimir el botón BORRAR du

rante 3 segundos en cualquier momento se borrará la memoria

para todos los cilindros y volverá la pantalla al cilindro 1.

-

Antes de realizar la prueba de compresión

• Para lograr resultados precisos, el motor se debe poner

en marcha hasta que alcance la temperatura de operación

normal antes de la prueba. Se deben completar las pruebas antes de que se enfríe el motor.

• Asegúrese de que las baterías estén completamente car

gadas para suministrar corriente con el fin de obtener una

velocidad de arranque adecuada. Compruebe las especificaciones del fabricante del motor para determinar si se

requiere una velocidad de arranque mínima. Se recomienda conectar el cargador o usar una batería de reserva o

auxiliar para mantener la velocidad de arranque requerida.

Realización de la prueba de compresión

Los motores diesel usan un sistema de inyección de combustible directa o indirecta. Los motores de inyección directa

inyectan el combustible directamente en el cilindro, pero los

motores de inyección indirecta usan una pequeña cámara de

precombustión. No se necesitan bujías para ninguno de los