Mityvac MV5532 User Manual

USER’S MANUAL

Have Technical Questions?

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday - Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs and instructions for

product use.

Need Service Parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

Digital Compression Tester

MODEL MV5532

SPECIFICATIONS

Max. Pressure : 300 PSI (20 Bar) (2,000 kPa)

www.mityvac.com

AUG - 2005 Section

Form 822856

- MV37

Page

- 1

2

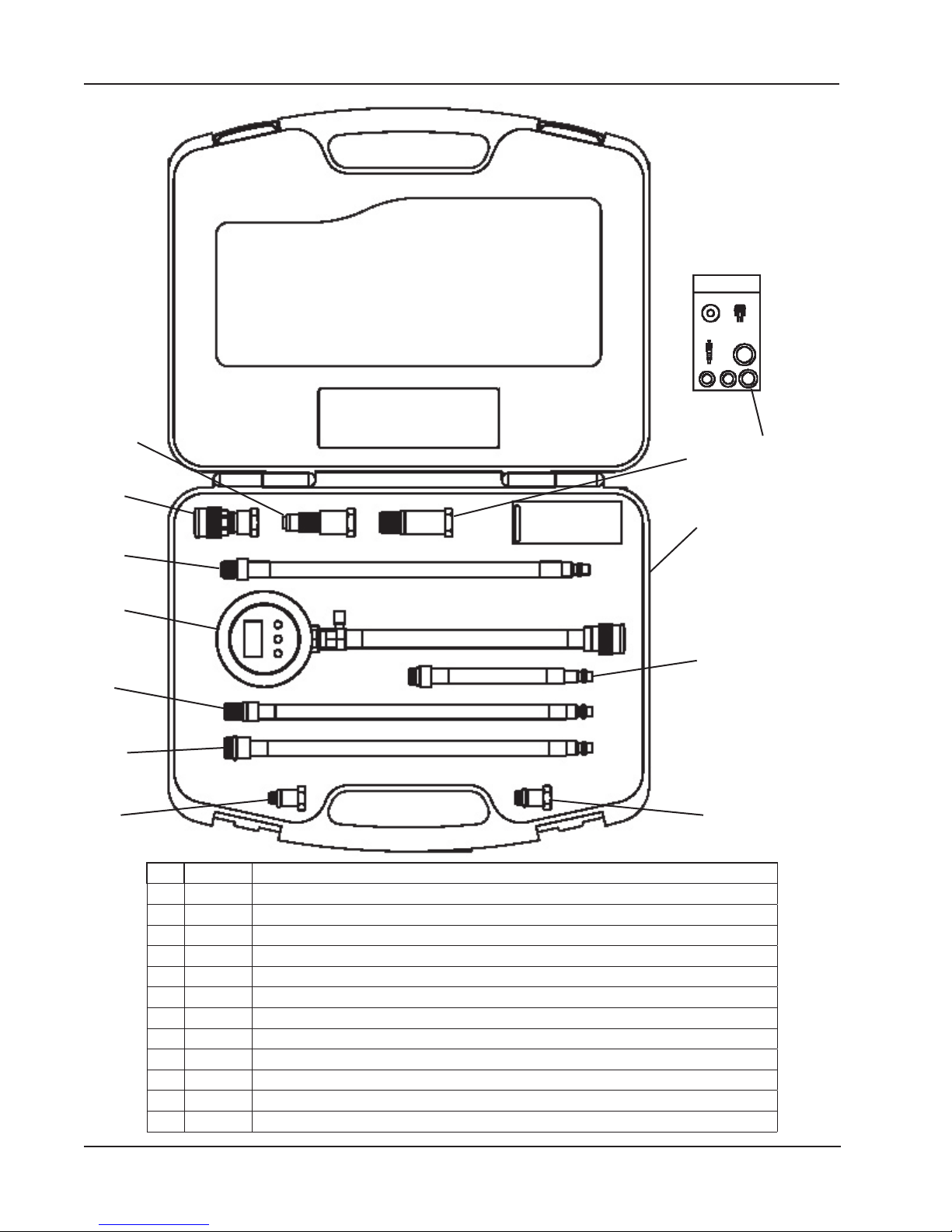

10

9

12

8

11

4

1

5

3

6

Item Part No. Description

1 823620 Compression Tester

2 MVA5506 14 mm long reach thread x 12” (305 mm) long

3 MVA5509 18 mm standard reach thread x 12” (305 mm) long

4 MVA5504 14 mm standard reach thread x 12” (305 mm) long

5 MVA5508 14 mm standard reach thread x 6” (150 mm) long

6 MVA5501 10 mm male thread x 14 mm standard reach female thread

7 MVA5502 12 mm male thread x 14 mm standard reach female thread

8 MVA5503 18 mm long reach male thread x 14 mm standard reach female thread

9 MVA5507 16 mm male thread for Ford Triton engines x 14 mm standard reach female thread

10 MVA5510 Air Hold Adapter

823621 Custom Molded Case

11

12 823441 Field Service Kit

Page Number - 2 Form 822856

7

Current Unit Indication –

Displays current unit of

measure. Available units of

measure include PSI, Bar, or

kPa. Current unit of measure

is maintained when unit is

cycled off and on.

On/Unit/Off Button

– Pressing this button

when unit is off, turns

unit on. Pressing and

releasing this button

while the unit is on, advances the current unit

of measurement forward.

Pressing and holding

this button for 3 seconds

while unit is on, turns

unit off. Tester automatically shuts off after six

(6) minutes of non-use.

Compression values are

maintained when unit is

cycled off and on.

Cylinder Advance Button

– Pressing this button advanc-

es the cylinder number by one.

If the pressure in the hose assembly is not relieved by pressing the Pressure Relief Button

or disconnecting the hose at

the quick disconnect junction,

the values for current max and

stored max for the new cylinder

will reflect the stored hose pres

sure.

Current Pressure Indication –

Displays the maximum compression value for the indicated

cylinder until the Pressure Relief

Button is pressed. This is the

measurement of the residual

pressure maintained in the hose

assembly by the Schrader valve.

Pressure Relief Button

– Pressing this button relieves

the residual pressure in the tester hose assembly. The value

-

indicated for the Current Pressure will return to zero, but the

Maximum Compression value

will be maintained electronically

until the Clear Button is pressed.

Cylinder # Indication – Displays cylinder number related

to current and maximum compression values being displayed. Number is advanced

by pressing the Cylinder Button

Maximum Compression Indication

- Displays maximum

compression value for

the indicated cylinder. Holds the value

until the Clear Button

is pressed. Value is

stored electronically.

Clear Button

- Clears maximum

compression value

shown for indicated

cylinder. Clears

values for all cylinders and returns to

cylinder 1 if held for

3 seconds.

Page Number - 3Form 822856

Always read instructions carefully prior to use.

Safety Information

• Read and understand all safety precautions and operating instructions contained in this manual.

• Always wear eye protection when performing a compression test.

• Do not exceed the maximum rating of the tester; 300 psi

(20 bar) (2,000 kPa)

• Prior to testing, set the gearbox to neutral on all vehicles

or machinery having a standard transmission, or park for

automatic transmissions.

• Prior to engaging ignition, ensure that the fuel supply is

disabled using manufacturer’s recommended method.

• Make sure that all connections are secure prior to testing.

• Take precautions to avoid contact with hot engine surfaces.

Included in this Kit

• Digital Compression Tester comprising of test gauge with

rubber boot, 10” (250 mm) long, high pressure hose, and

female quick release coupler.

• (4) - Extended hose compression test adapters:

o 14 mm standard reach thread x 6.5” (165 mm) long

o 14 mm standard reach thread x 12” (305 mm) long

o 14 mm long reach thread x 12” (305 mm) long

o 18 mm standard reach thread x 12” (305 mm) long

• (4) - Plug style compression test adapters:

o 18 mm long reach male thread x 14 mm standard

reach female thread

o 16 mm male thread for Ford Triton engines x 14 mm

standard reach female thread

o 10 mm male thread x 14 mm standard reach female

thread

o 12 mm male thread x 14 mm standard reach female

thread

• Air Hold Adapter

• Custom blow-molded case

• Field service kit

the value of the previous test, or the CLEAR button was

pressed to erase the old value from memory.

Peak compression values can be stored for up to 12 cylinders. Each is displayed on the LCD along with the cylinder number. During and/or after completion of testing all

cylinders, the peak values can be reviewed by pressing the

CYLINDER button to scroll through the memory. Individual

peak values can be erased from memory by pressing the

CLEAR button when the appropriate cylinder and value are

displayed. Pressing the CLEAR button for 3 seconds at

any time will clear the memory for all cylinders and return

the display to cylinder 1.

How to Perform a Comression Test

Precautions & Diagnostic Notes:

WARNING: DO NOT use the ignition switch during the

compression test on fuel-injected vehicles. Use of a

remote starter switch to crank the engine is recommended. Fuel injectors on many late model vehicles

are triggered by the ignition switch during the cranking

mode, this could result in a fire hazard or contamination of the engine’s oil with fuel.

An engine in good operating condition will produce a

certain amount of pressure in each cylinder. Normally,

the cylinders should be within 10 percentage points of

one another and within the manufacturer’s specifications.

The pressure should rise smoothly on each stroke of the

engine, until it reaches a peak.

If the pressure reading fails to rise, or it remains the same

for several strokes of the engine and begins to rise, the

likely cause of the problem is a sticking valve.

If two adjacent cylinders show pressure readings of 20 or

more pounds below the other cylinder readings, suspect a

blown head gasket.

Functional Overview

The Mityvac Digital Compression Test Kit can perform wet

and/or dry compression tests to determine the pressure

produced in the cylinders of a gasoline engine. It can

measure, display, and store compression values of up to

300 psi (20 bar) (2,000 kPa) for up to 12 cylinders. It can

also be used as a tool for pressurizing an engine cylinder

to hold the valves closed while performing repairs.

When using this tester to perform a compression test on a

cylinder, the current peak compression value is displayed

in large numbers at the center of the LCD. This value

is automatically transferred to memory, and displayed in

smaller numbers at the bottom right of the display. When

the pressure relief button is depressed, the current compression reading returns to zero, but the peak value is

retained in memory and continues to be displayed in the

bottom right corner of the LCD. Repeated tests can be

run on the same cylinder, and the new current peak value

will be displayed by the large numbers. This new peak

value will not be retained in memory unless it surpasses

Page Number - 4 Form 822856

If a cylinder shows a pressure reading of 15 PSI (1 bar)

(100 kPa) or more pounds higher than the other cylinders,

the probable cause is carbon build-up inside the cylinder.

The Mityvac Digital Compression Test Kit can perform two

tests: the dry compression test and the wet compression

test. The result of performing these tests will provide an

indication of the condition of the piston rings, cylinders, and

valve-train.

Dry Compression Test Procedures:

1. Refer to the appropriate service manual for the compression specifications specific to the engine you are testing.

2. Start engine and allow engine to run until it reaches normal operating temperature (usually about 15 minutes.)

Turn engine OFF.

3. Install an auxiliary starter switch in the starting circuit.

4. While wearing eye protection, use compressed air to

carefully remove dirt and debris from the area around

the spark plugs.

5. Remove spark plugs one at a time, marking the number

of the cylinder they were removed from, and place them

on a clean flat surface. This will aid you in identifying

problem cylinders by allowing the comparison of spark

plug appearance to the compression level of a given

cylinder.

NOTE: When testing engines with two spark plugs

per cylinder, it is only necessary to remove the

spark plugs located on the exhaust side.

6. On vehicles with standard distributors, disconnect the

coil wire (high tension lead) from the distributor cap and

secure it to a suitable ground, or disable the ignition by

disconnecting the positive (BAT) terminal from the igni

tion coil.

7. On vehicles with a distributorless ignition (DIS), disable

the ignition system by removing the electronic ignition

(control) module fuse, or disconnect the crank angle

sensor.

NOTE: Refer to the appropriate service manual to

determine which fuse or component to temporarily

remove or disconnect.

8. Remove air cleaner from carburetor or throttle body and

secure throttle linkage in wide-open throttle (WOT) position.

NOTE: NEVER place anything inside the throttle

body; internal damage to the engine could result.

On vehicles equipped with port fuel injection,

remove throttle linkage covers (as necessary) and

secure throttle linkage in the wide-open throttle

(WOT) position.

9. Crank engine several times to ensure removal of any for

eign matter that may have fallen into the cylinders during

preparation for test.

10. Select the appropriate test adapter and thread it into the

spark plug hole of cylinder 1 until the o-ring on the adapter seats firmly (do not tighten with a wrench).

11. If required, thread a test adapter with a hose onto the in

stalled adapter until the o-ring seats firmly (do not tighten

with a wrench).

12. Connect the test gauge to the opposite end of the test

adapter hose.

13. Turn the tester on by pressing the ON/UNIT/OFF button.

14. Press and hold the CYLINDER button for at least three

(3) seconds to clear the memory and return the cylinder

indicator to “CYL# 1”.

15. While watching the test gauge, crank the engine as least

five (5) compression strokes or until the pressure reading

stops increasing (the peak compression value will auto

matically be stored in memory).

16. Relieve the pressure in the tester by pressing the pres

sure relief button.

17. Disconnect the gauge and remove the test adapter(s)

from cylinder 1.

18. Install the test adapter(s) into cylinder 2 and reconnect

the gauge.

19. Advance the cylinder number shown on the tester LCD to

2 by pressing the CYLINDER button.

20. Repeat the compression test on cylinder 2 and all remaining cylinders. Be sure to advance the cylinder number on

the tester for each cylinder.

-

21. After testing all cylinders, review the values of each cyl

inder by pressing the CYLINDER button to scroll through

the results.

22. If any of the cylinder readings are found to be low or

uneven, perform wet compression test.

23. When compression test is complete, return the spark

plugs to their respective cylinders and the throttle and

ignition components to their normal positions.

Wet Compression Test Procedure

The wet compression test is a way to remove the influence

of worn piston rings, pistons and cylinders from the compression test. After completing the dry compression test,

squirt approximately one teaspoon of engine oil into the

spark plug holes and crank the engine several times to seal

the piston rings. Repeat the dry compression test outlined

above. NOTE: If the readings during the wet compression

test are greater, then air is leaking around worn or damaged piston rings. If the reading is approximately the same

for both wet and dry tests then the valves, valve lifters or

the camshaft lobes are worn. Any low reading of cylinder

compression indicates worn or damaged parts.

Small Engine Compression Testing

The Mityvac Digital Compression Test Kit has two (2)

adapters, 10mm and 12mm, that allow it to be used on

small engines such as those found on lawn mowers, chain

saws and line trimmers. To use these adapters:

-

1. Disconnect the spark plug wire and remove the spark

plug.

2. Thread the appropriate size adapter onto the compres

sion tester main hose end until the o-ring seats (do not

use a wrench to tighten).

-

3. Thread the assembly into the cylinder spark plug hole

until the o-ring on the adapter seats firmly (do not use a

wrench to tighten).

4. Ensure the spark plug is grounded to the cylinder head

or is insulated in a way that will prevent an electric

shock hazard.

5. Crank the engine over using the pull cord (or starter if

electric) a minimum of 5 revolutions. This will allow the

cylinder to build sufficient compression to be measured.

6. Refer to the manufacturer’s data to determine the cor

rect reading

-

Using the Pressure Hold Adapter

The Mityvac Professional Compression Tester comes with

a pressure hold adapter. This adapter is used to perform

valve seal replacement on an engine without removing the

cylinder head(s). To use the adapter:

1. Remove the spark plug from the desired cylinder.

2. Select the appropriate extension hose that will fit the

spark plug hole.

3. Using the valve core tool (from the field service kit in-

cluded), remove the valve core from the end of the hose

and lay it aside.

-

-

-

Page Number - 5Form 822856

4. Thread the extension hose into the spark plug hole

until the o-ring seats; do not use pliers or a wrench to

tighten.

5. Attach the Air Hold Adapter to the extension hose.

6. Attach a shop air hose to the Air Hold Adapter, this will

maintain air pressure in the cylinder to hold the valves

closed while performing repairs. (It may be necessary

to rotate the engine until all valve are closed and air is

holding in the cylinder)

Note: Air Hold quick connector does not come with a

compressed air line fitting to adapt to your air source.

This will have to be purchased separately to fit your

system.

Contacting Lincoln Industrial Corp.

Lincoln Industrial Corporation,

One Lincoln Way,

St. Louis, MO 63120

Phone: (314) 679-4200 Ext. 4410

Fax: (800) 424-5359

E-mail: custserv@lincolnindustrial.com

For technical questions, please contact our Technical Service Department:

Phone:(314) 679-4200 Ext 4782

Fax: (314) 679-HELP (4357)

E-mail: techserv@lincolnindustrial.com

Visit our Web Site at: www.mityvac.com

TO AVOID PERSONAL INJURY AND/OR VEHICLE

DAMAGE:

While some precautions are specified in this manual,

and should be noted to avoid personal injury or vehicle

damage, it is not possible for these cautions to cover all

conceivable ways in which service or testing might be

done, or all possible hazardous consequences of each

way, nor could Lincoln possibly know or investigate all

such ways. It is therefore the responsibility of anyone

using this manual or any other Mityvac product, to satisfy

him or herself completely that neither personal safety nor

vehicle safety will be jeopardized by the service methods

selected. Any such injury or damage is entirely the user’s

responsibility. This device is not to be used in any man

-

ner on the human body.

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship for a period

of one (1) year following the date of purchase, excluding therefrom any special, extended, or limited warranty published by Lincoln. If

equipment is determined to be defective during this warranty period, it will be repaired or replaced, within Lincoln’s sole discretion, with

out charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain

repair or replacement, you must ship the equipment, transportation charges prepaid, with proof of purchase to a Lincoln Authorized War

ranty and Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive material, equipment that has been altered, or equipment

repaired by anyone not authorized by Lincoln. This warranty applies only to equipment installed, operated and maintained in strict ac

cordance with the written specifications and recommendations provided by Lincoln or its authorized field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTIBILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or damages arising

out of the sale, resale or use of any Lincoln equipment shall in no event exceed the purchase price. Some jurisdictions do not allow the

exclusion or limitation of incidental or consequential damages, therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany, for your

warranty rights.

Lincoln Industrial Contact Information

-

-

-

To find Lincoln Industrial’s Nearest Service Center

Call one of the following numbers, you may also use our Website

Page Number - 6 Form 822856

Customer Service 314-679-4200

Website: lincolnindustrial.com

MANUEL D’UTILISATION

Questions techniques ?

Si vous avez des questions ou avez besoin

d’assistance technique, contacter nos techniciens qualifiés à :

1-314-679-4200, poste 4782

Lundi à mardi, 7h30 à 16h15 heure du centre des Etats-Unis.

Rendez visite à notre site web à www.

mityvac.com pour découvrir nos nouveaux

produits, obtenir des catalogues ou des

instructions d’utilisations pour nos produits.

Besoin de pièces ?

Pour commander des pièces de rechange

ou des pièces consommables, rendez-nous

visite en ligne à www.mityvacparts.com ou

appelez gratuitement +1-800-992-9898.

Compressiomètre numérique

MODELE MV5532

DONNEES TECHNIQUES

Pression maximale : 20 bar

(2 000 kPa ; 300 psi)

www.mityvac.com

Page Number - 7Form 822856

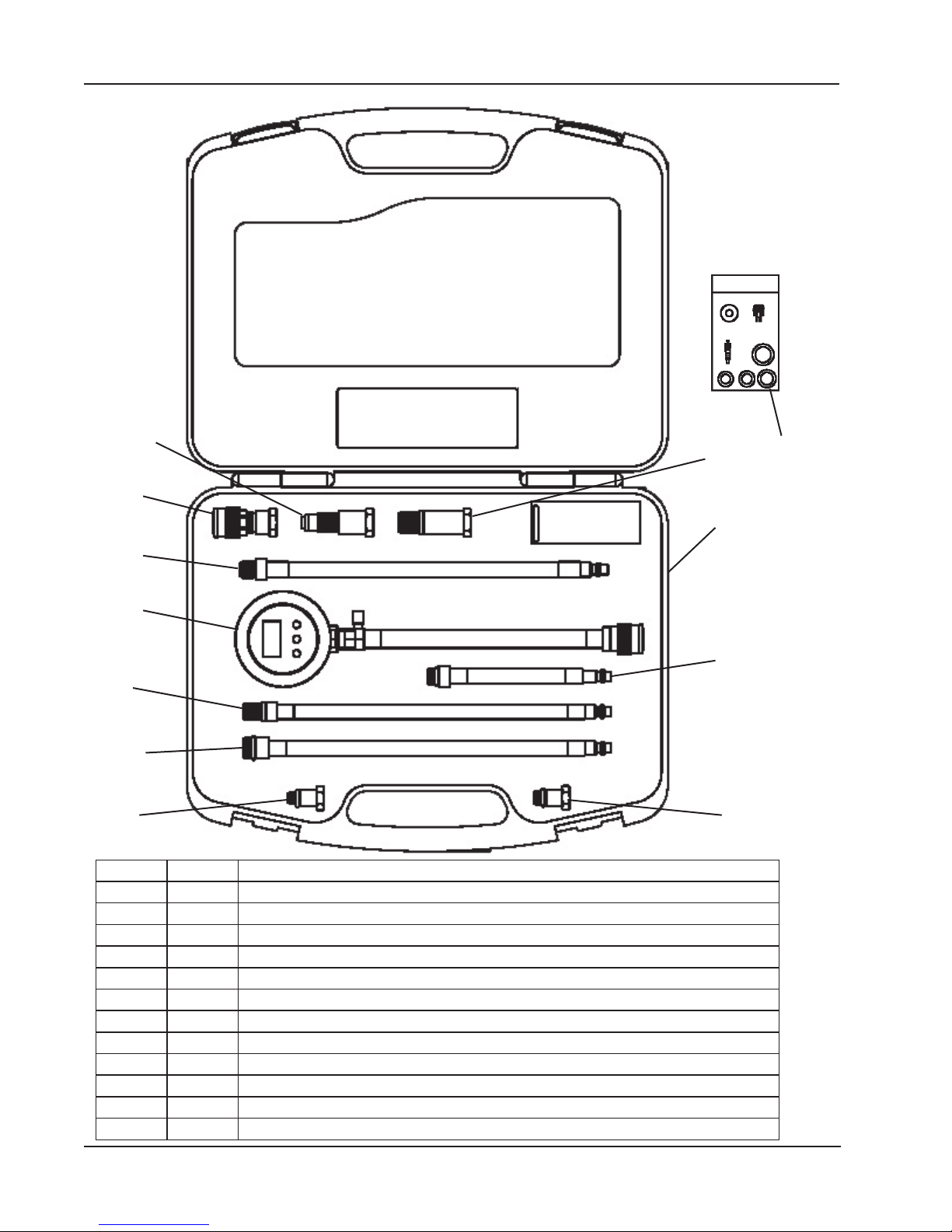

2

10

9

12

8

11

4

1

5

3

6

Référence N° de cat. Description

1 823620 Compressiomètre

2 MVA5506 Filet long de 14 mm x 305 mm (12 in) de long

3 MVA5509 Filet standard de 18 mm x 305 mm (12 in) de long

4 MVA5504 Filet standard de 14 mm x 305 mm (12 in) de long

5 MVA5508 Filet standard de 14 mm x 150 mm (6 in) de long

6 MVA5501 Filet mâle de 10 mm x filet femelle standard de 14 mm

7 MVA5502 Filet mâle de 12 mm x filet femelle standard de 14 mm

8 MVA5503 Filet mâle long de 18 mm x filet femelle standard de 14 mm

9 MVA5507 1Filet mâle de 6 mm pour les moteurs Triton de Ford x filet femelle standard de 14 mm

10 MVA5510 Adaptateur de maintien d’air

11

12 823441 Kit de réparation sur place

823621 Mallette moulée sur mesure

Page Number - 8 Form 822856

7

Loading...

Loading...