Page 1

NOVEMBER- 2006 Form 822954 Section - MV44-1

COOLING SYSTEM AIREVAC KIT

MODEL MV4535

USER’S MANUAL

Have a technical question?

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday – Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs, and instructions for

product use.

Need service parts?

To order replacement or service parts, visit us

online at www.mityvacparts.com or call toll free

1-800-992-9898.

SPECIFICATIONS

Vacuum Air Pressure Requirements:

Min Pressure: 90 psi

(6.2 bar) (600 kPa)

Max Pressure: 120 psi

(8.3 bar) (830 kPa)

Vacuum threads for

air line connection: 1/4" NPT

Page 2

Page Number - 2 Form 822954

Table of Contents

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Applications and Basics of Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Vacuum Leak Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Refill/Airlock Elimination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Page 3

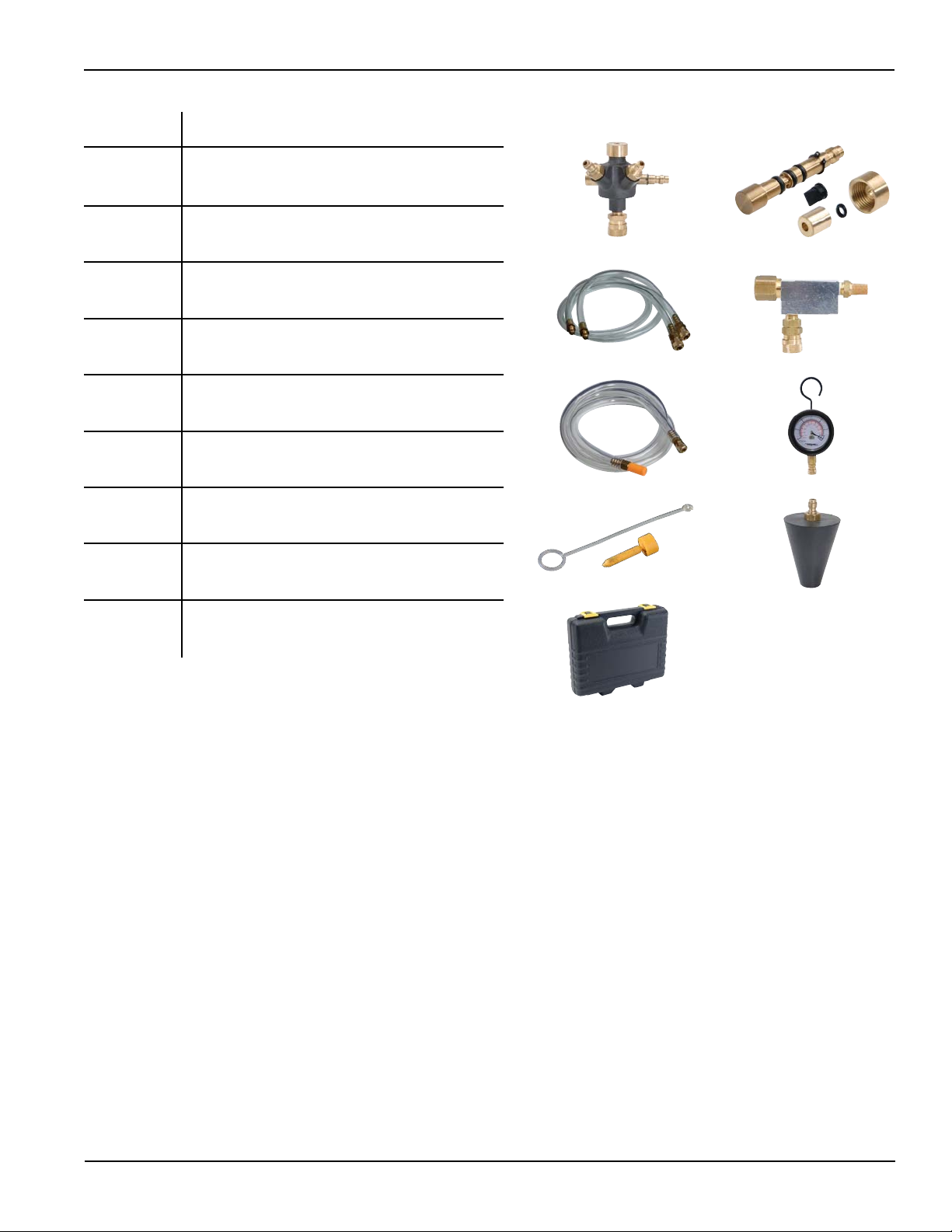

Service Parts

Part Number Description

823032 Valve Coupler

823033 Valve Coupler Repair Kit

823035 Extension Hose

823038 Venturi Vacuum

823039 Refill Hose

823041 Vacuum Gauge

823043 Plug and Tether

MVA300 Universal Evac Adapter

823052 Custom-Molded Case

Form 822954 Page Number - 3

823033

823032

823038823035

823041823039

MVA300823043

823052

Page 4

Page Number - 4 Form 822954

Vacuum Leak Test System Refill/Airlock Elimination

Vacuum Gauge

Venturi Vacuum

Extension Hose

(optional)

Extension Hose

(optional)

Valve Coupler

Universal Vacuum Adapter

Radiator

Coolant Bottle

Refill Hose

Venturi Vacuum

Extension Hose

(optional)

Valve Coupler

Universal Vacuum Adapter

Radiator

Coolant Bottle

Coupler Plug

Coupler Plug

Page 5

Applications & Basics of Testing

The MV4535 Cooling System AirEvac Kit includes equipment

to perform a vacuum leak test on an automotive cooling system

that has been drained of fluid, and then to refill it quickly

without trapping air. All tests are performed with the engine

off, and when the cooling system is cool and drained of fluid.

Cooling system leaks and airlocks are a common cause of

overheating, and can be quickly diagnosed and eliminated

using the MV4535 AirEvac Kit. Although a pressure test is

most commonly used to diagnose a cooling system leak,

using vacuum is convenient because it can be performed

in conjunction with a vacuum refill. Both functions are

performed using a compressed air operated vacuum to

remove all air from a vehicle’s cooling system, and then

monitor it to determine if there are any leaks. If no leaks

are present, the vacuum is used to automatically draw in

new fluid, and fill the system without trapping air.

Precautions

This equipment is designed for servicing a variety of vehicles

in a safe, convenient manner. However, differences in cooling

systems may make it impossible to perform some of the tests

indicated in these instructions on every vehicle. The procedures

documented in this manual are to serve as guidelines for the

use of this equipment. In addition to these guidelines, always

follow the manufacturer’s recommended procedures when

servicing each unique vehicle. Do not attempt to force a test

on a cooling system for which this equipment is not designed

to perform.

Performing cooling system tests using the MV4535 is simple

and straightforward if you follow the instructions. However,

always keep in mind that you are working with a system that

may be full of cold or hot fluid that is under pressure and just

waiting to be expelled. If you are testing an engine that is hot

and/or pressurized, always stop to think before removing a cap

or disconnecting a hose or other component.

Always read carefully and understand instructions prior to using

this equipment.

Always wear eye protection when removing radiator or coolant

bottle cap, or when performing any cooling system test.

Never remove the radiator or coolant bottle cap, or attempt to

pressurize the cooling system of a vehicle that is overheated.

Always allow system to cool prior to attempting to perform any

cooling system related test procedure.

Basics of Testing

When deciding where to connect this test equipment to the

cooling system, first look for the radiator and determine if it

has a fill neck and pressure cap. This is common on about

half of US manufactured vehicles, and almost all Asian

manufactured vehicles, and would be the first choice for

connecting. If the radiator is closed and inaccessible, then

the connection will be made through a coolant bottle. Some

automotive cooling systems utilize a coolant overflow bottle

that is not part of the sealed system. Attempting to test the

cooling system through this bottle will not connect you into

the sealed system, and will simply vent the required test

vacuum to the atmosphere. This type of overflow bottle is

easily recognized because it typically utilizes a snap-on style

cap or a threaded cap that is open to atmosphere. A test

connection should be made through a radiator or coolant

bottle with a bayonet or threaded style of cap, designed to

maintain a specific pressure in the cooling system.

Universal Cooling System Adapter

The MV4535 includes a cone shaped universal adapter for

connecting the test equipment to a radiator or coolant bottle.

After removing the cooling system pressure cap from the

radiator or coolant bottle, the universal adapter will slip easily

into the neck. The adapter does not need to be forced to form

a seal. Once vacuum is applied, it will be sucked securely into

the neck, and will form an airtight seal. Once the vacuum is

relieved, the adapter can be easily withdrawn from the neck.

Form 822954 Page Number - 5

Page 6

Vacuum Leak Test

For diagnosing:

Cooling system leaks

Notes

This equipment uses a venturi vacuum to perform a vacuum leak

test. The venturi requires clean, dry, high pressure air between 90

and 120 psi (5.5 - 10 bar) (550 - 1000 kpa) to create the vacuum.

Prior to testing, install a male quick-change air nipple with 1/4" NPT

male thread to the venturi.

The altitude at which the vacuum test is performed can significantly

affect the ability of the venturi to produce a vacuum. As the altitude

increases, the maximum vacuum the venturi can create will decrease.

This is normal and should not be considered a malfunction.

It is recommended that the cooling system be drained of coolant

prior to performing a vacuum leak test and automatic refill.

When connecting components using quick-connects, make sure

the sleeve snaps forward to lock the connection.

Set-up & Procedure:

1. Properly position the vehicle for service access to the radiator

or coolant bottle. Turn on the heater and set it to its highest

temperature setting.

2. Ensure the cooling system is cool and not pressurized. Carefully

remove the radiator or coolant bottle pressure cap (Fig. 1).

3. Insert the Universal Radiator Adapter into the neck of the radiator

or coolant bottle (Fig. 2).

4. Install the Valve Coupler onto the Universal Radiator Adapter

using the quick-connect. Make sure the quick-connect sleeve

snaps forward to lock the connection (Fig. 3).

Note: It may be more convenient to install an Extension Hose

between the adapter and the coupler.

5. Install the Coupler Plug into the top of the Valve Coupler and

tighten the threaded cap securely to form an airtight seal (Fig. 4).

6. Connect the Vacuum Gauge to the male quick-connect labeled

“Gauge” extending from the Valve Coupler.

Note: It may be more convenient to install an Extension Hose

between the coupler and the gauge (Fig. 5).

7. Connect the Venturi Vacuum to the male quick-connect labeled

“Pressure/Vacuum” extending from the Valve Coupler (Fig. 6).

Note: It may be more convenient to install an Extension Hose

between the coupler and the vacuum.

8. Ensure the Shuttle Valve on the Valve Coupler is shifted to the

“Closed” position (Fig. 7).

9. Connect clean, dry, regulated compressed air between 90 and

120 psi (6.2 and 8.3 bar) (600 and 830 kPa) to the Venturi

Vacuum by means of the previously installed air nipple (Fig. 8).

Page Number - 6 Form 822954

Fig. 2

Fig. 4

Fig. 6

Fig. 3

Fig. 5

Fig. 7

Fig. 8

Fig. 1

Page 7

Form 822954 Page Number - 7

10. Turn on the compressed air. The vacuum will make a hissing

noise as the high pressure air passes through it. If the cooling

system is not empty, it is normal that some fluid may be expelled

from the venturi exhaust.

11. Allow the vacuum to pull air from the cooling system until the

gauge indicates 24 to 26 in Hg (1.6 to 1.8 bar) (81 to 88 kPa)

or the value stops increasing (Fig. 9). This should only take about

1 to 2 minutes during which time it is normal for the radiator

hoses to collapse.

12. Once the proper vacuum is achieved, disconnect the Venturi

Vacuum from the Valve Coupler before turning off the air or

disconnecting the air hose (Fig. 10). Turning off the air or

disconnecting the air hose prior to disconnecting the venturi

from the valve coupler, will allow air to reenter the system.

13. Watch the gauge for at least 30 seconds. The vacuum reading

will remain steady if the system does not have a leak. If the

cooling system has a leak, the vacuum will drop.

14. If the cooling system has a leak, it should be located and

repaired prior to testing, and the system re-evacuated.

15. If no leak is detected and no further repairs are required,

the vacuum may be used to quickly refill the system without

trapping air. See the following section for the proper procedure

to refill the cooling system with new coolant. Otherwise, shift

the Shuttle Valve on the Valve Coupler to the “Open” position to

relieve the vacuum.

16. Disconnect components, clean and store them properly.

System Refill/Airlock Elimination

Set-up & Procedure:

Follow steps 1 through 15 of the procedures for the

Vacuum Leak Test.

1. If there are no leaks in the system, do not open the Shuttle Valve.

2. Connect the Refill Hose to the Shuttle Valve using the

quick-connect coupler (Fig. 11).

3. Place the opposite end of the Refill Hose into a supply of coolant

adequate enough to completely refill the cooling system (Fig. 12).

4. Place the coolant supply at a level even with the radiator or

coolant bottle, or higher.

5. Shift the Shuttle Valve to the “Open” position, allowing the

vacuum to pull the coolant into the system (Fig. 13).

6. If the system does not completely refill, reapply the vacuum and

repeat the refill procedure.

7. Once the refill is complete, disconnect the components, clean,

and store them properly.

8. Top off the radiator or coolant bottle if necessary, and replace

the cap properly.

Fig. 9

Fig. 10

Fig. 13

Fig. 12Fig. 11

Page 8

Page Number - 8 Form 822954

Lincoln Industrial Standard Warranty

LIMITED WARRANTY

Lincoln warrants the equipment manufactured and supplied by Lincoln to be free from defects in material and workmanship for a

period of one (1) year following the date of purchase, excluding therefrom any special, extended, or limited warranty published by

Lincoln. If equipment is determined to be defective during this warranty period, it will be repaired or replaced, within Lincoln’s sole

discretion, without charge.

This warranty is conditioned upon the determination of a Lincoln authorized representative that the equipment is defective. To obtain

repair or replacement, you must ship the equipment, transportation charges prepaid, with proof of purchase to a Lincoln Authorized

Warranty and Service Center within the warranty period.

This warranty is extended to the original retail purchaser only. This warranty does not apply to equipment damaged from accident,

overload, abuse, misuse, negligence, faulty installation or abrasive or corrosive material, equipment that has been altered, or equipment

repaired by anyone not authorized by Lincoln. This warranty applies only to equipment installed, operated and maintained in strict

accordance with the written specifications and recommendations provided by Lincoln or its authorized field personnel.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

In no event shall Lincoln be liable for incidental or consequential damages. Lincoln’s liability for any claim for loss or damages arising

out of the sale, resale or use of any Lincoln equipment shall in no event exceed the purchase price. Some jurisdictions do not allow

the exclusion or limitation of incidental or consequential damages, therefore the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights. You may also have other rights that vary by jurisdiction.

Customers not located in the Western Hemisphere or East Asia: Please contact Lincoln GmbH & Co. KG, Walldorf, Germany, for your

warranty rights.

Lincoln Industrial Contact Information:

To find Lincoln Industrial’s Nearest Service Center call the following numbers, or you may also use our website.

Customer Service 314-679-4200 Website: lincolnindustrial.com

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Europe/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

Asia/Pacific:

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

© Copyright 2006 www.lincolnindustrial.com Printed in Taiwan

Page 9

NOVEMBRE - 2006 Formulaire 822954 Section - MV44-1

LE KIT AIREVAC DU SYSTÈME DE

REFROIDISSEMENT MV4535

MANUEL D’UTILISATION

Avez-vous besoin d’un renseignement technique?

Pour toute question ou pour demande de service

technique, veuillez vous adresser à nos techniciens

spécialisés au numéro suivant:

1-314-679-4200 poste 4782

du lundi au vendredi, de 7 h 30 à 16 h 15, heure

normale du Centre des États-Unis

Visitez notre site web: www.mityvac.com pour les

nouveaux produits, les catalogues et les modes

d’emploi de produit.

Avez-vous besoin de pièces de service?

Pour commander des pièces de rechange ou de service,

utilisez notre site web : www.mityvacparts.com

ou téléphonez sans frais au numéro 1-800-992-9898.

SPÉCIFICATIONS

Exigences de vide/pression :

Pression min: 600 kPa (90 psi) (6,2 bar)

Pression max: 830 kPa (120 psi) (8,3 bar)

Filets de vide pour raccord

de conduite d’air: 1/4 po. NPT

Page 10

Nombre de pages - 10 Formulaire 822954

Table des matières

Pièces de rechange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Schémas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Applications et essentiel des tests . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Test de fuite de vide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Remplissage du système / Élimination du bouchon d’air . . . . . . . . 15

Garantie. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 11

Formulaire 822954 Nombre de pages - 11

823033

823032

823038823035

823041823039

MVA300823043

823052

Pièces de rechange

N° de catalogue Description

823032 Coupleur de vanne

823033 Kit de réparation de coupleur de vanne

823035 Tuyau de rallonge

823038 Vide à tube de Venturi

823039 Tuyau de remplissage

823041 Manovacuomètre

823043 Bouchon et filin

MVA300 Adaptateur de système de

refroidissement universel

823052 Mallette moulée sur mesure

Page 12

Nombre de pages - 12 Formulaire 822954

Test de fuite de vide Remplissage du système / Élimination du

bouchon d’air

Manovacuomètre

Vide à tube

de Venturi

Tuyau de rallonge

(optionnel)

Tuyau de rallonge

(optionnel)

Coupleur de vanne

Adaptateur de vide universel

Radiateur

Réservoir de liquide

de refroidissement

Tuyau de remplissage

Vide à tube de Venturi

Tuyau de rallonge

(optionnel)

Coupleur de vanne

Adaptateur de vide universel

Radiateur

Réservoir de liquide

de refroidissement

Bouchon de coupleur

Bouchon de

coupleur

Page 13

Applications et essentiel des tests

Le kit AirEvac du système de refroidissement MV4535 comprend l’équipement pour effectuer un test de fuite de vide sur

un système de refroidissement d’automobile qui a été vidangé,

puis de le remplir rapidement sans piéger d’air. Tous les tests

sont réalisés avec le moteur à l’arrêt et lorsque le système de

refroidissement est froid et a été vidangé.

Les fuites du système de refroidissement et les poches d’air

sont une cause fréquente de surchauffe et peuvent facilement

et rapidement être diagnostiquées et éliminées en utilisant le kit

AirEvac MV4535. Bien qu’un test de pression soit utilisé

habituellement pour diagnostiquer une fuite du système de

refroidissement, le vide est d’une utilisation pratique parce que

le test peut être effectué conjointement avec le remplissage au

moyen du vide. Les deux fonctions sont effectuées en utilisant

un vide à commande pneumatique pour éliminer tout l’air du

système de refroidissement du véhicule, puis en le surveillant

pour déterminer s’il y a des fuites. S’il n’y a pas de fuite, le vide

sert à amener automatiquement du nouveau liquide et à remplir

le système sans piéger d’air.

Précautions

L’équipement de test a pour but d’effectuer les procédures

de service pour une variété de véhicules sans danger et

facilement. Cependant certains des tests indiqués dans ces

directives peuvent ne pas pouvoir être exécutés sur tous les

véhicules à cause des différences entre les systèmes de

refroidissement. Les procédures figurant dans ce manuel

sont destinées à servir de directives pour l’utilisation de

cet équipement. Outre ces directives, suivez toujours les

procédures recommandées par le constructeur pour le service

de chaque véhicule. N’essayez pas de forcer un test sur un

système de refroidissement pour lequel cet équipement n’est

pas prévu.

L’exécution de tests de système de refroidissement en utilisant

le MV4535M est simple et facile à condition de suivre les directives. Cependant, n’oubliez pas que le système peut être rempli

de liquide froid ou chaud sous pression, prêt à être expulsé. Si

vous exécutez un test sur un moteur qui est chaud et/ou sous

pression, réfléchissez toujours avant de retirer un bouchon ou

de déconnecter un tuyau ou une autre pièce.

Lisez toujours attentivement et comprenez les instructions

avant d’utiliser l’équipement.

Portez toujours des lunettes de protection pour retirer le

bouchon du radiateur ou de la bouteille de liquide de

refroidissement, ou en effectuant un test quelconque du

système de refroidissement.

Ne retirez jamais le bouchon du radiateur ou de la bouteille de

liquide de refroidissement et n’essayez pas de mettre sous

pression le système de refroidissement d’un véhicule qui est

surchauffé.

Liassez toujours le système refroidir avant d’exécuter une procédure de test en rapport avec le système de refroidissement.

Tests

Pour décider où établir la connexion avec le système de

refroidissement, regardez d’abord le radiateur et déterminez

s’il a un goulot de remplissage et un bouchon à soupape de

pression. Cette configuration est habituelle sur environ la moitié

des véhicules fabriqués aux États-Unis et presque sur tous les

véhicules fabriqués en Asie, et est l’emplacement de premier

choix pour établir la connexion. Si le radiateur est fermé et

inaccessible, la connexion doit se faire par la bouteille de

liquide de refroidissement. Certains systèmes de refroidissement utilisent une bouteille de trop-plein de liquide de

refroidissement qui ne fait pas partie du système étanche. Si

vous essayez de tester le système de refroidissement par cette

bouteille, la connexion avec le système étanche ne se fera pas

et cela aura pour résultat de faire passer simplement le vide du

test dans l’atmosphère. Ce type de bouteille de trop-plein se

reconnaît facilement au bouchon encliquetable ou au bouchon

fileté ouvert vers l’atmosphère. Il n’existe pas d’adaptateurs

pour convenir à ce type de bouteille de trop-plein de liquide de

refroidissement. La connexion pour exécuter le test doit se faire

par un radiateur ou une bouteille de liquide de refroidissement

avec un modèle de bouchon à baïonnette ou fileté fabriqué

spécialement pour maintenir une pression spécifique dans le

système de refroidissement.

Adaptateur de système de refroidissement universel

Le MV4535 comprend un adaptateur universel en forme de

cône pour connecter l’équipement de test à un radiateur ou à

une bouteille de liquide de refroidissement. Lorsque le bouchon

à soupape de pression du radiateur ou de la bouteille de liquide

de refroidissement a été retiré, l’adaptateur universel peut se

glisser facilement dans le goulot. L’adaptateur ne nécessite pas

d’être forcé pour former un joint étanche. Lorsque le vide est

appliqué, l’adaptateur est aspiré dans le goulot et forme un

joint étanche. Lorsque le vide est relâché, l’adaptateur peut

facilement être retiré du goulot.

Formulaire 822954 Nombre de pages - 13

Page 14

Test de fuite de vide

Pour diagnostiquer:

Fuites du système de refroidissement

Remarques

Cet équipement utilise un vide venturi pour réaliser un test de fuite de

vide. Le venturi nécessite de l’air propre, sec et à haute pression entre

550 et 1000 kpa (90 et 120 psi) (5,5 et 10 bar) pour créer le vide.

Avant de tester, installez un raccord d’alimentation en air comprimé

mâle à changement rapide avec un filetage mâle de 1/4 po. NPT

au venturi.

L’altitude à laquelle le test est exécuté peut influer beaucoup sur

la capacité du venturi à produire un vide. Le vide maximum que

peut créer le venturi diminue en fonction de l’augmentation de

l’altitude. Ceci est normal et ne doit pas être attribué à un mauvais

fonctionnement.

Il est recommandé de vidanger le système de refroidissement avant

d’exécuter un test de fuite de vide et un remplissage automatique.

Lorsque vous connectez les composants à l’aide de raccords

rapides, assurez-vous que le manchon s’encliquète pour verrouiller

la connexion.

Configuration et procédure:

1. Positionnez correctement le véhicule pour pouvoir accéder au

radiateur ou à la bouteille de liquide de refroidissement. Activez

le réchauffeur et réglez-le à sa température la plus haute.

2. Assurez-vous que le système de refroidissement est froid et qu’il

n’est pas sous pression. Retirez avec précaution le bouchon à

soupape de pression du radiateur ou de la bouteille de liquide de

refroidissement (Fig. 1).

3. Introduisez l’adaptateur de radiateur universel dans le goulot du

radiateur ou de la bouteille de liquide de refroidissement (Fig. 2).

4. Installez le coupleur de valve sur l’adaptateur de radiateur

universel en utilisant le raccord rapide. Assurez-vous que

le manchon du raccord rapide s’encliquète pour verrouiller

la connexion (Fig. 3). Remarqu: il peut être plus pratique

d’installer un tuyau de rallonge entre l’adaptateur et le coupleur.

5. Installez la fiche de coupleur dans le haut du coupleur de valve

et vissez solidement le bouchon fileté pour former un joint

hermétique (Fig. 4).

6. Connectez le manomètre au raccord rapide mâle appelé “Gauge

(Jauge)” en saillie du coupleur de valve. Remarque: il peut être

plus pratique d’installer un tuyau de rallonge entre le coupleur et

la jauge (Fig. 5).

7. Connectez le vide venturi au raccord rapide mâle appelé

“Pressure/Vacuum (Pression/Vide)” en saillie du coupleur de

valve. Remarque: il peut être plus pratique d’installer un tuyau de

rallonge entre le coupleur et le vide (Fig. 6).

8. Assurez-vous que la valve à deux voies sur le coupleur de valve

est en position fermée (Fig. 7).

9. Connectez de l’air comprimé propre, sec, régulé entre 600 et 830

kPa (90 et 120 psi) (6,2 et 8,3 bar) au vide venturi au moyen du

raccord d’alimentation en air installé précédemment (Fig. 8).

Nombre de pages - 14 Formulaire 822954

Fig. 2

Fig. 4

Fig. 6

Fig. 3

Fig. 5

Fig. 7

Fig. 8

Fig. 1

Page 15

Formulaire 822954 Nombre de pages - 15

10. Activez l’air comprimé. Un sifflement se fera entendre parce que

l’air à haute pression passe à travers le vide et sort par le tuyau

de vidange. Si le système de refroidissement n’est pas vide, il est

normal que du liquide soit expulsé par l’échappement venturi,

11. Laissez le vide expulser l’air du système de refroidissement

jusqu’à ce que la jauge indique 81 à 88 kPa (24 à 26 po. Hg)

(1,6 à 1,8 bar) ou que la valeur cesse d’augmenter (Fig. 9). Ceci

doit durer environ 1 à 2 minutes pendant lesquelles il est normal

que les tuyaux souples du radiateur s’affaissent.

12. Une fois le vide correct obtenu, déconnectez le vide venturi du

coupleur de valve avant de désactiver l’air ou de déconnecter le

tuyau à air (Fig. 10). Si l’air est désactivé ou si le tuyau à air est

déconnecté avant de déconnecter le venturi du coupleur de

valve, l’air reviendra dans le système.

13. Observez la jauge pendant au moins 30 secondes. Le relevé de

vide restera immobile s’il n’y a pas de fuite dans le système. Si le

système de refroidissement fuit, le vide diminuera.

14. Si le système de refroidissement fuit, la fuite doit être localisée et

le système réparé avant de réaliser les tests et le système doit

être re-évacué.

15. Si aucune fuite n’est détectée et s’il n’y a pas d’autres réparations à faire, le vide peut être utilisé pour remplir rapidement le

système sans piéger d’air. Voir les sections suivantes où figure la

procédure à suivre pour remplir le système de refroidissement

avec du nouveau liquide de refroidissement. Autrement, mettez la

valve à deux voies sur le coupleur de valve en position ouverte

pour relâcher le vide.

16. Déconnectez les composants, nettoyez-les et rangez-les.

Remplissage du système / Élimination du

bouchon d’air

Configuration et procédure:

Suivez les étapes de 1 à 15 des procédures de test de fuite de vide.

1. S’il n’y a pas de fuite dans le système, n’ouvrez pas la valve à

deux voies.

2. Connectez le tuyau de remplissage à la valve à deux voies en

utilisant le coupleur à raccord rapide (Fig. 11).

3. Placez l’extrémité opposée du tuyau de remplissage dans une

quantité suffisante de liquide de refroidissement pour remplir

complètement le système de refroidissement (Fig. 12).

4. Placez le liquide de refroidissement d’approvisionnement au

même niveau ou à un niveau plus élevé que le radiateur ou la

bouteille de liquide de refroidissement.

5. Mettez la valve à deux voie en position ouverte, ce qui permet au

vide d’amener le liquide de refroidissement dans le système (Fig. 13).

6. Si le système ne se remplit pas complètement, réappliquez le

vide et répétez la procédure de remplissage.

7. Lorsque le remplissage est terminé, déconnectez les composants,

nettoyez-les et rangez-les.

8. Ajoutez du liquide de refroidissement au radiateur ou à la

bouteille de liquide de refroidissement si nécessaire et remettez

le bouchon.

Fig. 9

Fig. 10

Fig. 13

Fig. 12Fig. 11

Page 16

Nombre de pages - 16 Formulaire 822954

Garantie standard de Lincoln Industrial

GARANTIE LIMITÉE

Lincoln garantit que l’équipement fabriqué et fourni par Lincoln est exempt de défauts de matériel et de fabrication pendant une

période d’un (1) an à compter de la date d’achat, à l’exclusion de toute garantie spéciale, étendue ou limitée publiée par Lincoln.

S’il est déterminé que l’équipement est défectueux pendant cette période de garantie, Lincoln le réparera ou le remplacera, à sa

seule discrétion et sans frais.

Cette garantie est offerte à condition que la détermination de la défectuosité de l’équipement soit faite par un représentant agréé de

Lincoln. Pour obtenir une réparation ou un remplacement, vous devez expédier l’équipement, frais de transport payés à l’avance, avec

preuve d’achat à un Centre de garantie et de service agréé par Lincoln pendant la période de garantie.

Cette garantie est offerte à l’acheteur d’origine uniquement. Cette garantie ne s’applique pas à l’équipement endommagé par accident,

surchage, abus, mauvais traitement, négligence, installation défectueuse ou matériel abrasif ou corrosif, équipement qui a été modifié

ou équipement réparé par une personne non agréée par Lincoln. Cette garantie s’applique uniquement à l’équipement installé, utilisé et

entretenu conformément aux spécifications et recommandations fournies par Lincoln ou par son personnel itinérant agréé.

CETTE GARANTIE EST EXCLUSIVE ET EST FOURNIE AU LIEU DE TOUTES AUTRES GARANTIES, EXPLICITES OU IMPLICITES,

Y COMPRIS, MAIS SANS S’Y LIMITER, LA GARANTIE DE COMMERCIALISATION OU LA GARANTIE D’APTITUDE À UN BUT

PARTICULIER.

En aucun cas Lincoln ne sera tenu responsable pour les dommages indirects ou consécutifs. La responsabilité de Lincoln pour

toute réclamation ou perte ou dommage survenant à la suite de la vente, de la revente ou de l’utilisation d’un équipement Lincoln

quelconque ne pourra en aucun cas dépasser le prix d’achat. Certaines juridictions n’autorisent pas l’exclusion ou la limitation de

dommages indirects ou consécutifs, par conséquent, la limitation ci-dessus peut ne pas s’appliquer à votre cas.

Cette garantie vous confère des droits légaux spécifiques, Vous pouvez également avoir d’autres droits qui varient selon la juridiction.

Clients en dehors de l’hémisphère de l’ouest ou de l’Asie de l’est : veuillez contacter Lincoln GmbH & Co. KG, Walldorf, Allemagne,

pour vos droits de garantie.

Informations pour contacter Lincoln Industrial :

Pour trouver le centre de service le plus proche Lincoln Industrial, composez le numéro suivant ou utilisez notre site web.

Service clientèle 314-679-4200 Website: lincolnindustrial.com

Ameriques:

One Lincoln Way

St. Louis, MO 63120-1578

États-Unis

Télé. +1.314.679.4200

Téléc. +1.800.424.5359

Europe/Afrique :

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Allemagne

Télé. +49.6227.33.0

Téléc. +49.6227.33.259

Asia/Pacific:

25 Int’l Business Park

#01-65 German Centre

Singapour 609916

Télé. +65.562.7960

Téléc. +65.562.9967

© Copyright 2006 www.lincolnindustrial.com Imprimé à Taïwan

Page 17

NOVIEMBRE - 2006 Formulario 822954 Sección - MV44-1

EL JUEGO AIREVAC DE SISTEMAS

DE ENFRIAMIENTO MV4535

MANUAL DEL USUARIO

¿Tiene alguna duda técnica?

Si tiene dudas, o requiere servicio técnico, póngase en

contacto con nuestros técnicos de servicio capacitados

llamando al:

1-314-679-4200 ext. 4782

Lunes a viernes de 7:30 am a 4:15 pm, hora central

estándar

Visite nuestro sitio web en www.mityvac.com para

obtener información sobre nuevos productos, catálogos

e instrucciones para el uso del producto.

¿Necesita piezas de reparación?

Para pedir piezas de repuesto o servicio,

visítenos en www.mityvac.com o llame de

forma gratuita al 1-800-992-9898.

ESPECIFICACIONES

Requisitos de presión de aire de vacío:

Presión mínima: 6.2 bares

(90 lb/pulg

2

) (600 kPa)

Presión máxima: 8.3 bares

(120lb/pulg

2

) (830 kPa)

Roscas de vacío para

la conexión de la

tubería de aire: NPT de 1/4"

Page 18

Página Número - 18 Formulario 822954

Tabla de materias

Piezas de repuesto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Esquemas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Aplicaciones y fundamentos de las pruebas . . . . . . . . . . . . . . . . . . . 21

Prueba de fugas de vacío . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Relleno del sistema/eliminación de bolsas de aire . . . . . . . . . . . . . . 23

Garantía . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 19

Formulario 822954 Página Número - 19

823033

823032

823038823035

823041823039

MVA300823043

823052

Piezas de repuesto

Número de pieza Descripción

823032 Acoplamiento de válvula

823033 Juego de reparación de acoplamientos de válvula

823035 Manguera de extensión

823038 Vacío de venturi

823039 Manguera de relleno

823041 Calibre compuesto

823043 Tapón y atadura

MVA300 Adaptador universal de sistemas

de enfriamiento

823052 Caja especial moldeada

Page 20

Página Número - 20 Formulario 822954

Prueba de fugas de vacío Relleno del sistema/eliminación de bolsas

de aire

Manómetro Compuesto

Vacío de venturi

Manguera

de extensión

(opcional)

Manguera

de extensión

(opcional)

Acoplamiento de válvula

Adaptador de vacío universal

Radiador

Botella de refrigerante

Manguera

de relleno

Vacío de venturi

Manguera

de extensión

(opcional)

Acoplamiento de válvula

Adaptador de vacío universal

Radiador

Botella de refrigerante

Tapón de

acoplamiento

Tapón de

acoplamiento

Page 21

Aplicaciones y fundamentos de las pruebas

El juego AirEvac de sistemas de enfriamiento MV4535 incluye

equipos para efectuar una prueba de fugas de vacío en un

sistema de enfriamiento automotriz que haya sido drenado de

fluido, y después llenarlo rápidamente sin atrapar aire. Todas

las pruebas deben realizarse con el motor apagado, y cuando

el sistema de enfriamiento esté frío y drenado de fluido.

Las fugas y bolsas de aire del sistema de enfriamiento son una

causa común del recalentamiento, y pueden diagnosticarse de

forma rápida y sencilla y eliminarse usando el juego AirEvac

MV4535. Aunque las pruebas de presión son las usadas

más comúnmente para diagnosticar fugas del sistema de

enfriamiento, el uso de vacío es conveniente porque puede

efectuarse junto con un relleno de vacío. Ambas funciones se

efectúan usando un vacío operado por aire comprimido para

eliminar todo el aire de un sistema de enfriamiento del vehículo,

y después supervisarlo para determinar si hay fugas. Si no hay

fugas, el vacío se usa para extraer automáticamente el fluido

nuevo, y llenar el sistema sin atrapar aire.

Precauciones

Este equipo está diseñado para efectuar el servicio de una

variedad de vehículos de una manera segura y conveniente.

No obstante, las diferencias en sistemas de enfriamiento

puede hacer imposible que se realicen algunas de las

pruebas indicadas en estas instrucciones en cada vehículo.

Los procedimientos documentados en este manual deben

servir de guía para el uso de este equipo. Además de estas

guías, siga siempre los procedimientos recomendados por el

fabricante al efectuar el servicio en cada vehículo exclusivo. No

trate de forzar una prueba en un sistema de enfriamiento para

el que este equipo no esté diseñado.

La realización de pruebas de enfriamiento usando el MV4535

es sencilla y directa si sigue las instrucciones. No obstante,

debe tener siempre en cuenta que está trabajando con un

sistema que puede estar lleno de fluido frío o caliente a

presión y esperando a ser expulsado. Si está probando un

motor que esté caliente o a presión, párese siempre a pensar

antes de quitar una tapa o desconectar una manguera u otro

componente.

Lea siempre detenidamente y entienda las instrucciones antes

de usar este equipo.

Lleve siempre los ojos protegidos al quitar la tapa del radiador

o de la botella de refrigerante, o al efectuar cualquier prueba

del sistema de enfriamiento.

No quite nunca la tapa del radiador o de la botella de refrigerante ni trate de someter a presión el sistema de enfriamiento

de un vehículo recalentado.

Deje siempre que se enfríe el sistema antes de tratar de

efectuar cualquier procedimiento de prueba relacionado

con el sistema de enfriamiento.

Fundamentos de las pruebas

Al decidir dónde conectar este equipo de prueba al sistema de

enfriamiento, primero fíjese en el radiador y determine si tiene

un cuello de llenado y una tapa de presión. Esto es común en

casi la mitad de los vehículos fabricados en EE.UU., y en casi

todos los vehículos fabricados en Asia, y sería la primera

opción para conectar. Si el radiador está cerrado y es

inaccesible, entonces la conexión se hará por medio de una

botella de refrigerante. Algunos sistemas de enfriamiento automotrices utilizan una botella de rebose de refrigerante

que no forma parte del sistema sellado. Al tratar de probar el

sistema de enfriamiento mediante esta botella no le conectará

al sistema sellado, y simplemente descargará el vacío de

prueba requerido a la atmósfera. Este tipo de botella de rebose

se reconoce fácilmente porque utiliza típicamente una tapa

encajada a presión o una tapa roscada que se abre a la atmósfera. Se debe efectuar una conexión de prueba a través de un

radiador o botella de refrigerante con una tapa tipo

bayoneta o roscada, diseñada para mantener una presión

específica en el sistema de enfriamiento.

Adaptador universal de sistemas de enfriamiento

El MV4535 incluye un adaptador universal en forma de cono

para conectar los equipos de prueba a un radiador o botella

de refrigerante. Después de quitar la tapa de presión del

sistema de enfriamiento del radiador o botella de refrigerante,

el adaptador universal se deslizará fácilmente dentro del cuello.

El adaptador no necesita forzarse para formar un sello. Una vez

que se aplique el vacío, se absorberá con seguridad en el cuello,

y formará un sello hermético al aire. Una vez que se alivie el

vacío, el adaptador puede quitarse fácilmente del cuello.

Formulario 822954 Página Número - 21

Page 22

Prueba de fugas de vacío

Para diagnosticar:

Fugas del sistema de enfriamiento

Notas

Este equipo usa un vacío de venturi para efectuar una prueba de

fugas de vacío. El venturi requiere aire comprimido de alta presión

limpio y seco entre 5.5 y 10 bares (550 – 1.000 kPa) (90 y 120

lb/pulg

2

) para producir un vacío.

Antes de efectuar las pruebas, instale un niple de aire macho de

cambio rápido con una rosca macho NPT de 1/4" al venturi.

La altitud a la que se efectúa la prueba de vacío puede afectar

significativamente la capacidad del venturi de producir un vacío.

A medida que aumenta la altitud, puede disminuir el vacío

máximo que puede producir el venturi. Esto es normal y no

debe considerarse como un funcionamiento erróneo.

Se recomienda drenar el refrigerante del sistema de enfriamiento

antes de efectuar una prueba de fugas de vacío y un relleno

automático.

Al conectar componentes, usando conexiones rápidas, asegúrese

de que el manguito salte hacia delante para trabar la conexión.

Configuración y procedimiento:

1. Coloque debidamente el vehículo para el acceso de servicio al

radiador o botella de refrigerante. Encienda el calentador y fíjelo

en su ajuste de temperatura máximo.

2. Asegúrese de que el sistema de enfriamiento esté frío y no a

presión. Quite con cuidado la tapa de presión del radiador o de

la botella de refrigerante (Fig. 1.

3. Inserte el adaptador de radiador universal en el cuello del

radiador o botella de refrigerante (Fig. 2).

4. Instale el acoplador de válvula en el adaptador de radiador

universal usando la conexión rápida. Asegúrese de que el

manguito de conexión rápida salte hacia adelante pata trabar la

conexión (Fig. 3). Nota: Tal vez sea más conveniente instalar una

manguera de alargamiento entre el adaptador y el acoplador.

5. Instale el tapón del acoplador en la parte superior del acoplador

de la válvula y apriete bien la tapa roscada para formar un sello

hermético al aire (Fig. 4).

6. Conecte el manómetro de vacío a la conexión rápida macho

“Gauge” (manómetro) que se extiende desde el acoplador de

válvula. Nota: Tal vez sea más conveniente instalar una manguera

de alargamiento entre el acoplador y el manómetro (Fig. 5).

7. Conecte el venturi de vacío a la conexión rápida macho

“Pressure/Vaccum” (presión/vacío) que se extiende desde el

acoplador de válvula. Nota: Tal vez sea más conveniente instalar

una manguera de alargamiento entre el acoplador y el vacío (Fig. 6).

8. Asegúrese de que la válvula de lanzadera en el acoplador de

válvula esté desplazada a la posición cerrada (Fig. 7).

9. Conecte aire comprimido regulado limpio y seco entre 6,2 y 8,3

bares (600 y 830 kPa) (90 y 120 lb/pulg

2

) al vacío de venturi por

medio del niple de aire instalado anteriormente (Fig. 8).

continua en la página siguiente

Página Número - 22 Formulario 822954

Fig. 2

Fig. 4

Fig. 6

Fig. 3

Fig. 5

Fig. 7

Fig. 8

Fig. 1

Page 23

Formulario 822954 Página Número - 23

Prueba de fugas de vacío continuación

10. Conecte el aire comprimido. El vacío producirá un ruido

silbante a medida que el aire a alta presión atraviesa y sale por la

manguera de drenaje. Si el sistema de enfriamiento no está vacío,

es normal que parte del fluido pueda ser expulsado por el escape

del venturi.

11. Deje que el vacío extraiga aire del sistema de enfriamiento hasta

que el manómetro indique 1.6 a 1.8 bares (81 a 88 kPa) (24 a 26

pulg de Hg o el valor deje de aumentar (Fig. 9). Esto sólo debe

llevar aproximadamente 1 a 2 minutos durante los cuales es

normal que se colapsen las mangueras del radiador.

12. Una vez que se logre el vacío apropiado, desconecte el vacío del

venturi del acoplador de la válvula antes de desconectar el aire o

la manguera de aire (Fig. 10). Al desconectar el aire o la

manguera de aire antes de desconectar el venturi del acoplador

de la válvula, se permitirá la reentrada de aire en el sistema.

13. Observe el manómetro durante al menos 30 segundos. La

lectura de vacío permanecerá constante si el sistema no tiene

fugas. Si el sistema de enfriamiento tiene fugas, el vacío bajará.

14. Si el sistema de enfriamiento tiene fugas, se deben localizar

y reparar antes de las pruebas, y se debe volver a evacuar

el sistema.

15. Si no se detecta ninguna fuga y no es necesario efectuar

reparaciones adicionales, el vacío puede usarse para rellenar

rápidamente el sistema sin atrapar aire. Vea en la sección

siguiente el procedimiento adecuado para rellenar el sistema de

enfriamiento con nuevo refrigerante. De lo contrario, desplace la

válvula de lanzadera por el acoplador de la válvula a la posición

abierta a fin de romper el vacío.

16. Desconecte los componentes, límpielos y guárdelos

debidamente.

Relleno del sistema/eliminación de bolsas de aire

Configuración y procedimiento:

Siga los pasos 1 a 15 de los procedimientos para la prueba de fugas

de vacío.

1. Si no hay fugas en el sistema, no abra la válvula de lanzadera.

2. Conecte la manguera de relleno a la válvula de lanzadera usando

el acoplador de conexión rápida (Fig. 11).

3. Coloque el extremo opuesto de la manguera de relleno en un

suministro de refrigerante suficientemente adecuado para rellenar

completamente el sistema de enfriamiento (Fig. 12).

4. Ponga el suministro de refrigerante al mismo nivel que el

radiador o la botella de refrigerante, o más alto.

5. Desplace la válvula de lanzadera a la posición abierta, dejando

que el vacío extraiga el refrigerante en el sistema (Fig. 13).

6. Si el sistema no se rellena completamente, vuelva a aplicar el

vacío y repita el procedimiento de relleno.

7. Una vez que se complete el relleno, desconecte los

componentes, límpielos y guárdelos debidamente.

8. Rellene el radiador o botella de refrigerante si es necesario, y

vuelva a colocar la tapa.

Fig. 9

Fig. 10

Fig. 13

Fig. 12Fig. 11

Page 24

Página Número - 24 Formulario 822954

Garantía estándar industrial de Lincoln

GARANTÍA LIMITADA

Lincoln garantiza que los equipos fabricados y suministrados por Lincoln carecen de defectos de materiales y fabricación durante un

(1) año contado a partir de la fecha de compra, excluyéndoles de cualquier garantía especial, extendida o limitada publicada por

Lincoln. Si se demuestra que los equipos son defectuosos durante este período de garantía, se repararán o remplazarán, a discreción

de Lincoln, de forma gratuita.

Esta garantía está condicionada por la determinación de un representante autorizado de Lincoln de que el equipo es defectuoso. Para

obtener su reparación o reemplazo, debe enviar los equipos, gastos de transporte pagados de antemano, con la prueba de compra a

un centro de garantías y servicio autorizado de Lincoln dentro del período de la garantía.

Esta garantía se extiende solamente al comprador original que haya efectuado la compra a un minorista. Esta garantía no se aplica a

equipos dañados por accidente, sobrecarga, abuso, uso indebido, negligencia, instalación defectuosa o material abrasivo o corrosivo,

o a equipos reparados o alterados por cualquier persona que no esté autorizada por Lincoln para reparar o alterar los equipos. Esta

garantía se aplica solamente a equipos instalados, operados y mantenidos estrictamente según las especificaciones escritas y

recomendadas proporcionadas por Lincoln o su personal de planta autorizado.

ESTA GARANTÍA ES EXCLUSIVA Y REEMPLAZA CUALQUIER OTRA GARANTÍA, EXPLÍCITA O IMPLÍCITA, INCLUIDA LA GARANTÍA

DE COMERCIALIZACIÓN O GARANTÍA DE IDONEDAD PARA UNA CIERTA FINALIDAD, PERO SIN LIMITARSE A LAS MISMAS.

En ningún caso Lincoln será responsable de daños emergentes o concomitantes. La responsabilidad de Lincoln ante cualquier

reclamación por pérdida o daños que sean consecuencia de la venta, reventa o uso de equipos suministrados no debe en ningún caso

exceder el precio de compra. Algunas jurisdicciones no permiten la exclusión o limitación de daños emergentes o concomitantes, por

lo que es posible que no se aplique a su caso la limitación o exclusión anterior.

Esa garantía le da derechos legales específicos. También puede tener otros derechos que varían según la jurisdicción.

Clientes que no estén ubicados en el Hemisferio Occidental o en el Lejano Oriente: Póngase en contacto con Lincoln GmbH & Co. KG,

Walldorf, Alemania, para obtener información sobre sus derechos de garantía.

Información de contacto de Lincoln Industrial:

Para encontrar el centro de servicio más cercano de Lincoln Industrial, llame a los números siguientes o también puede visitar nuestro

sitio web.

Servicio al cliente: 314-679-4200 Sitio web: lincolnindustrial.com

Américas:

One Lincoln Way

St. Louis, MO 63120-1578

EEUU

Teléfono +1.314.679.4200

Fax +1.800.424.5359

Europa/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Alemania

Teléfono +49.6227.33.0

Fax +49.6227.33.259

Asia/Pacifico:

25 Int’l Business Park

#01-65 German Centre

Singapur 609916

Teléfono +65.562.7960

Fax +65.562.9967

© Copyright 2006 www.lincolnindustrial.com Impreso en Taiwán

Loading...

Loading...