Page 1

BRAKE BLEEDING KIT

Model 07205

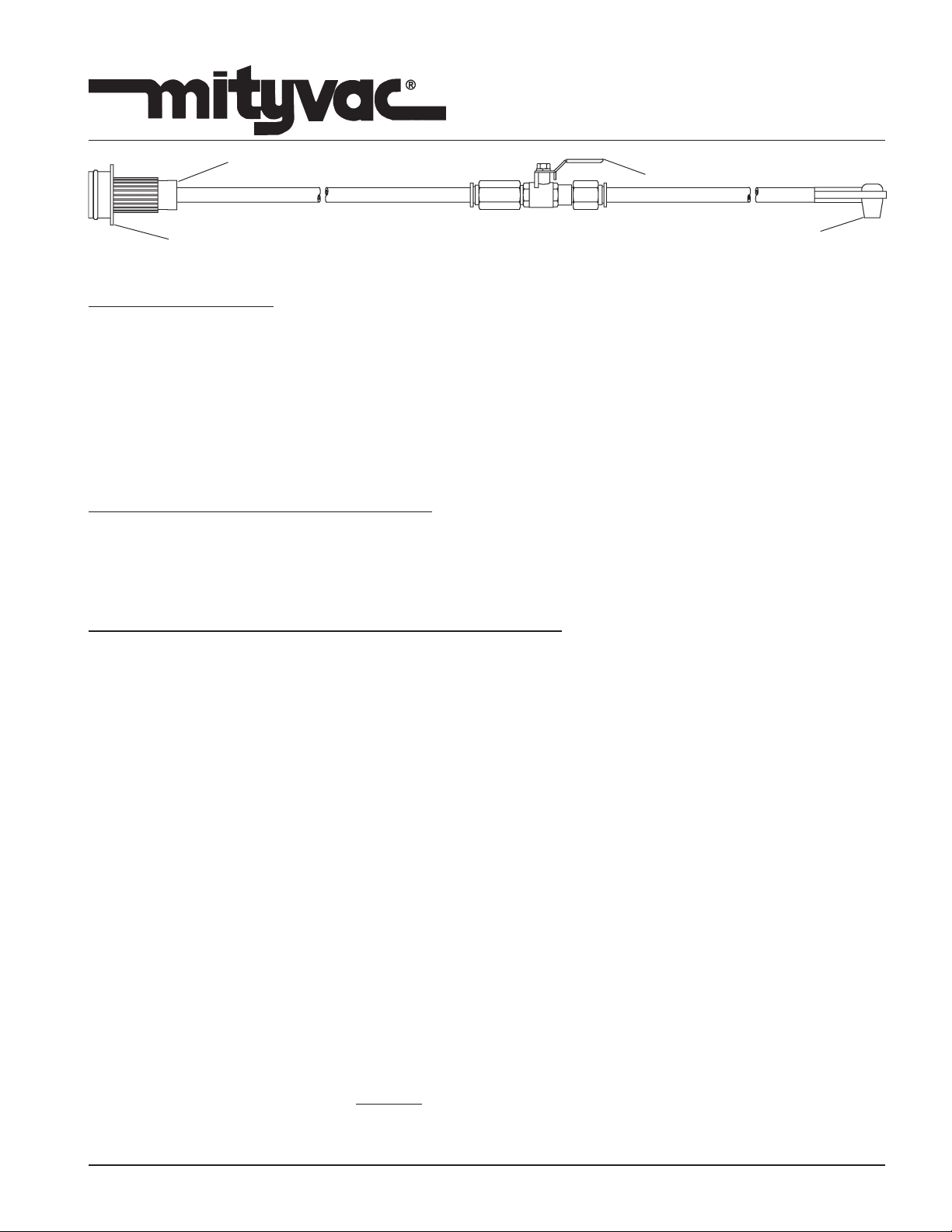

Rubber Connector

Tank Connector

Always read instructions carefully before use.

Instructions for Setup:

1.Connect the reservoir tank connector of the Brake Bleeding Kit to the reservoir tank of the Fluid Evacuator.

2. Fluid Evacuators with an attached main suction tube will need to have the tube capped to allow a

vacuum.

3.Turn the flow control valve to the “OFF” position. (Handle of valve will be turned 90 degrees from hose).

4. Develop a vacuum in the Fluid Evacuator reservoir tank, consult your Fluid Evacuator Manual for

instructions.

Control Valve

Brake Bleeding Adapter

DIRECTIONS

Bleeding Brakes with the Fluid Evacuator

Using the Fluid Evacuator and the Brake Bleeding Accessories Kit provides a simple, clean and quick

method for bleeding air from brake systems. The creation of vacuum in the reservoir tank of the Fluid

Evacuator causes brake fluid to be drawn into the reservoir tank. Usually one or two applications are

sufficient at each wheel to ensure that all air is evacuated.

The following brake bleeding procedure is recommended:

1. Ensure master cylinder reservoir is full of the specified fluid and new, clean fluid is available to top off

the reservoir during bleeding procedure. Ensure all bleeder fittings are clean at the start of the bleeding

procedure.

NOTE: Keep master cylinder full.

2. Bleed system in the following order:

A . Master cylinder (if equipped). See the Bench Bleeding Procedure below if a new or rebuilt master

cylinder is being installed.

B. Bleeder screw on combination valve (if equipped).

C. Wheel cylinders and calipers in succession beginning with the wheel closest to the master cylinder

and working to the farthest one.

3. Place wrench on the nut of the bleeder screw.

4. Connect the brake bleeding adapter onto the bleeder screw.

5. Open the flow control valve by turning it to the “OPEN” position.

6. Open the bleeder ‘screw slightly , only enough to cause fluid to flow into the bleeder hose and continue

into the Fluid Evacuator (usually 1/4 to 1/2 turn).

7. After evacuating, approximately 1/4 of the master cylinder reservoir’s capacity , tighten nut of bleeder

screw. Refill the master cylinder, and proceed to the next wheel. Repeat all previous steps on all of the

remaining wheels.

NOTE:A tiny stream of bubbles may be noted in the bleeder hose after the bleeding procedure. This is

caused by air seeping around the threads of the loosened bleeder screw and is drawn through the

fitting by the suction created by the Fluid Evacuator. Once the air has been removed from the

system these tiny air bubbles

present at the external surface of the bleeder fitting and not in the system. If desired, bleeder-fitting

threads may be sealed with Teflon® tape to help eliminate this condition.

DO NOT jeopardize the bleeding operation since they are only

Form 822666OCT 2003

Section

- MV16

Page

- 1

Page 2

Bleeding Anti-Lock Brake Systems

.

Always refer to the vehicle’s owner manual or the appropriate service manual for manufacturer’s brake

bleeding procedure. The front brakes on most anti-lock brake systems may be bled in the conventional

manner. Most hydraulic pump/pressure accumulator units are fitted with a bleeder valve, which must be

bled when the system has lost fluid or is being replaced. Some vehicles require that the system be

pressurized when the rear brakes are bled. Acura, Ford and General Motors require a bleeding

procedure, which uses specialized equipment.

Bench Bleeding System

Whenever a master cylinder has been removed from a vehicle or a new one is being installed, the

master cylinder must be bench bled. Failure to bench bleed is the main reason for unsuccessful master

cylinder replacement. Bench bleeding greatly decreases the chance that any air will be caught in the

cylinder upon reinstallation. Most manufacturers include a bench bleeding kit with new or remanufactured

master cylinders. If this kit was not included with the replacement part to be installed, consult with your

retailer prior to installing the new or rebuilt master cylinder on the vehicle.

Americas:

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Item Description Part No

1 Brak e B l eeding A dapt er * 822559

2 Plast i c Adapt er 822597

* Consists of three adapters

Europe/Africa:

Heinrich-Hertz-Str 2-8

D-69183 Walldorf

Germany

Phone +49.6227.33.0

Fax +49.6227.33.259

25 Int’l Business Park

#01-65 German Centre

Singapore 609916

Phone +65.562.7960

Fax +65.562.9967

Asia/Pacific:

© Copyright 2003

Printed in USA

Web site:

www.lincolnindustrial.com

Page Number - 2

Form 822666

Loading...

Loading...