Page 1

Users Manual

www.mityvac.com

Users Manual

English / Spanish / French / German

©

© Indicates change

Page 2

ENGLISH

CONTENTS

The Pump..................................................4

The Automotive Vacuum System...............6

Diagnosing Mechanical Engine

Conditions........................................8

Positive Crankcase Ventilation

System...........................................10

Exhaust Gas Recirculation (EGR)...........10

Spark Delay Valves (SDV)......................15

Electrical/Vacuum Solenoid ....................16

Thermal-Controlled Vacuum

Switching Valves............................16

Brake .....................................................17

Frnech Section .......................................48

German Section .....................................48

Spanish Section......................................70

These pumps are not approved for use with combustable

materials such as gasoline, kerosene, or diesel fuel.

Serious injury or damage may occur if pump is used with

these fluids.

TO AVOID PERSONAL INJUR Y AND/OR VEHICLE DAMAGE:

While some precautions are specified in this manual, and should be noted to avoid

personal injury or vehicle damage, it is not possible for these cautions to cover all

conceivable ways in which service or testing might be done, or all possible

hazardous consequences of each way, nor could Lincoln possibly know or

investigate all such ways. It is therefore the responsibility of anyone using this

manual or any other Mityvac® product, to satisfy him or herself completely that

neither personal safety nor vehicle safety will be jeopardized by the service

methods selected. Any such injury or damage is entirely the user’s responsbility.

This device is not to be used in any manner on the human body.

© Copyright 2003 by Lincoln Industrial, Inc

All rights reserved. This volume may not be reproduced in whole or part in any form

without written permission from the publisher.

TRADEMARK NOTIFICATION

Mityvac® SilverlineYM and Dual ConverterTM are all trademarks of Lincoln Industrial

Printed in Taiwan

Page Number - 2

Form 822378

Page 3

Form 822378

Page Number - 3

Page 4

THE PUMP

The vacuum pump is an extremely

versatile service tool that can be used to

test a variety of automotive systems and

perform a number of useful tasks.

Though the pump has obvious uses for

testing various vacuum motors, control

valves and vacuum sources, its applications don’t end there. Almost any part or

system that requires proper sealing,

pressure or vacuum to operate can be

tested with the vacuum pump. The pump

and its accessories also transfer fluids,

help to bleed brakes and aid in other

tasks. The pump also meets diagnostic

tool requirements when such tools are

specified for some state vehicle inspection programs.

This section will describe the pump, give

specifications, tell how to use the pump

and provide some service tips to help

you keep your pump in tip-top shape.

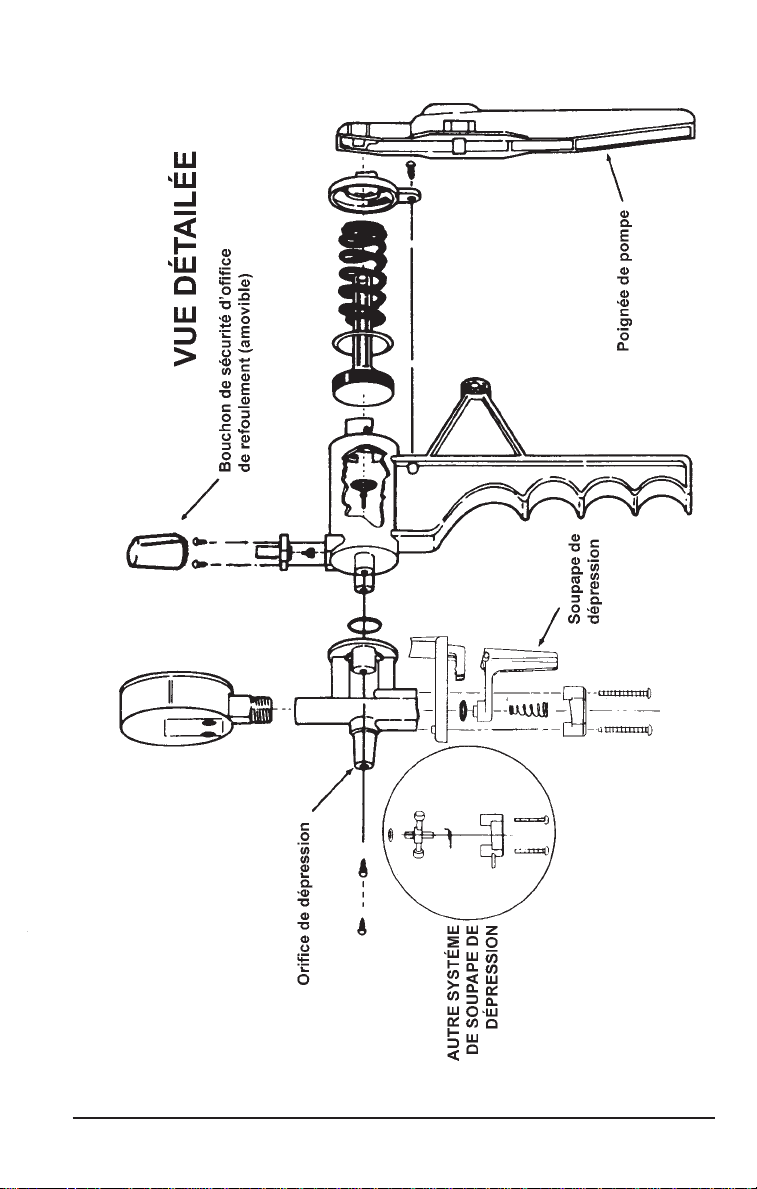

DESCRIPTION

The hand held vacuum pump is simple,

accurate, easy to use and has many

applications. Although the pump comes in

several different versions, the basic unit

consists of a pump body, moveable

handle, vacuum gauge, vacuum fitting

and a safety capped pressure fitting. The

pump is easily held in your hand, and

when the handle is squeezed, a vacuum

is drawn at the vacuum fitting. If the

vacuum of the pump is connected to a

closed container or system, the gauge

will show the vacuum level. If the

pressure fitting is attached to the

container or system, a pressure will be

generated but will not show on the

gauge. If it is desired to read the amount

of pressure, a separate pressure gauge

is available.

V ACUUM RELEASE

There are two basic methods of releasing vacuum at the pump. The first method

is the Trigger Vacuum Release. It is a

straight lever, which must be pulled

straight back to release the vacuum. This

action allows air to enter the system,

thus relieving the vacuum.

The second method is a spring action

rotary release. By slowly turning the

vacuum release tee, the vacuum can be

gradually released. By turning the tee

quickly, the vacuum will be released

quickly.

SAFETY CAP

The small cap on the pressure fitting is

pressed on with a friction fit. It can be

removed with a twisting pull. The cap is

used to prevent any fluids (brake fluid,

etc.), which may have accidentally been

pulled into the pump, from squirting into

the user’s eyes. For this reason, the cap

should always be in place when using

the pump, except when using the

pressure fitting. The pump will last for

many years when cared for properly.

See PROPER CARE in this section.

SPECIFICATIONS

Application Measurement

Maximum Vacuum

At Sea Level Approx. 23-25” Hg.

Stroke V olume

Standard 1 cu. in.

Repairable 1 cu. in.

Superpump 2 cu. in.

Silverline 1 cu. in.

Maximum Pressure

Unassisted

Standard 7 psi.

Repairable 12 psi.

Superpump 7 psi.

Silverline 15 psi.

Assisted

Standard 16 psi.

Repairable 95 psi.

Superpump 12 psi.

Silverline 30+ psi.

Gauge accuracy

15-20 in. HG. 3%-2%-

3% of full

range.

MAINTENANCE KITS are available only

for repairable pumps, which have been

assembled with visible screws. Nonrepairable pumps have been chemically

sealed and cannot be opened without

damaging the pump. Except for lubrication, no repairs should be attempted on

these units. See LUBRICATION in this

section.

Page Number - 4

Form 822378

Page 5

USING THE PUMP

The vacuum pump is simple to use. In

most cases, the pump is either attached

directly to a component, used in place of

a vacuum line or connected into a

vacuum circuit with a tee connector. The

pump can be operated as a test instrument in three ways:

1) When vacuum is desired for a test,

the movable handle of the pump is

simply squeezed with your hand, as

in clenching your fist. Continue

strokes until desired vacuum is

indicated on the gauge.

2) The pump can be connected into a

vacuum circuit and used to measure

existing amounts of vacuum, just as

any vacuum gauge would be used.

When used this way, do not pump the

handle, or incorrect readings may

result.

3) The pump can also be used as a

pressure pump by removing the

safety cap and connecting to the

pressure fitting. When the pump

handle is released from the closed

position, pressure is created.

Additional pressure can be applied

manually pushing in the piston pump

rod.

CAUTION: Always be sure the safety

cap is in place unless the pressure

fitting is being used. Other sections of

this manual outline specific uses for

the pump.

test instrument. Do handle it carefully!

Don’t drop or handle roughly as the gauge

accuracy may be affected. Don’t lay on

hot manifold or expose to direct flame.

Don’t leave plastic pump in a hot car as it

may warp. Care for your pump and it will

give you years of trouble free service.

LUBRICATION

The factory installed lubricant is silicone

oil and should provide very long service.

If you find it necessary to lubricate your

pump, use silicone oil. If unavailable, you

may use DOT 5 (not DOT 3) siliconebased brake fluid or a salad vegetable oil.

Do not use petroleum based fluids or

spray lubricants (WD-40, motor oil, etc.),

as these will damage the pump.

PROPER CARE

Your pump is a sturdily built, precision

Form 822378

Page Number - 5

Page 6

THE AUTOMOTIVE

VACUUM SYSTEM

This manual deals with vacuum, how it is

used in various automotive systems and

how the vacuum pump can be used to

test and diagnose these systems. This

section discusses what vacuum is, how

it is measured, where it comes from on

an automobile, the system for distributing

and using vacuum, and some troubleshooting basics.

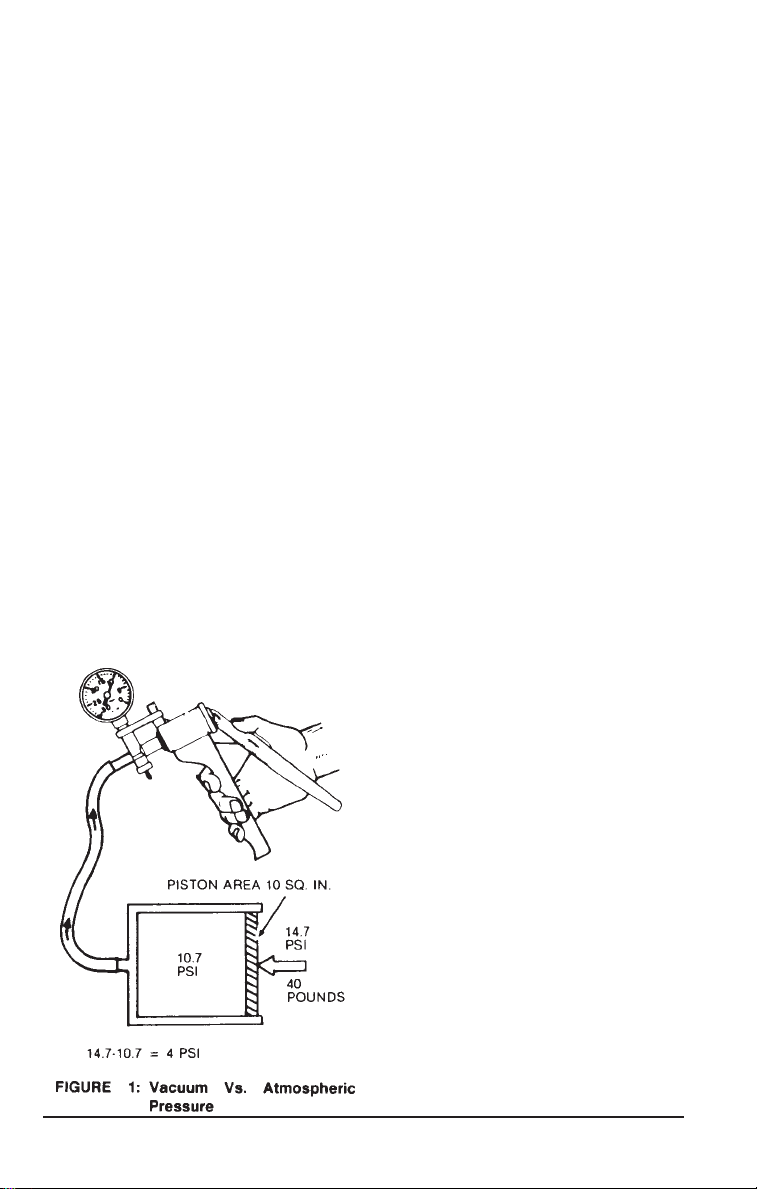

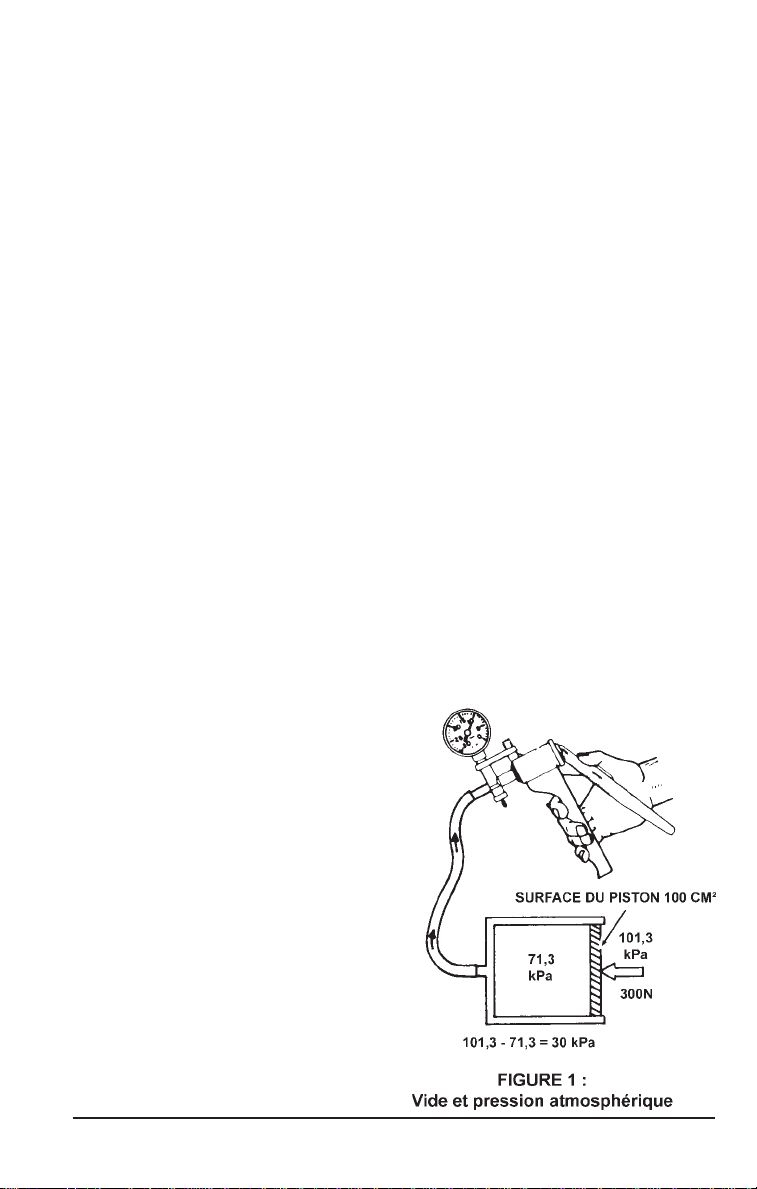

WHA T IS VACUUM?

Put simply, vacuum is empty space, and

may exist as either a total or partial

vacuum. Vacuum does not, of itself,

create power. Rather, power for vacuum

devices depends on the presence of

atmospheric pressure. The atmosphere

exerts a pressure of 14.7 pounds per

square inch (psi) on everything at sea

level. If a portion of the air is removed

from one side of a diaphragm (partial

vacuum), the atmospheric pressure will

exert a force on the diaphragm. The

force is equal to the pressure difference

times the diaphragm area (FIGURE 1).

Generally, the less air (greater vacuum)

in a given space, the more the atmosphere tries to get in and the more force

is created.

HOW IS VACUUM

MEASURED?

In the United States, vacuum is commonly

measured in inches of Mercury (“Hg). It

may also be measured in centimeters of

Mercury (cm Hg) and kiloPascals (kPa).

Atmospheric pressure will support a

column of Mercury in a manometer gauge

about 30 inches high or about 76cm high.

This is the barometric pressure in “ Hg

which varies as the weather changes.

Vacuum readings in “ Hg are really

negative pressure readings. For example, 30” Hg vacuum would be a complete

vacuum. Half of a complete vacuum

would be 15” Hg. A gasoline engine at

idle usually pulls about 16-22” Hg

vacuum. On deceleration, because the

throttle is closed, the vacuum will

increase. The pump will pull about 25” Hg

as indicated on its vacuum gauge which

is calibrated in both “ Hg and kPa.

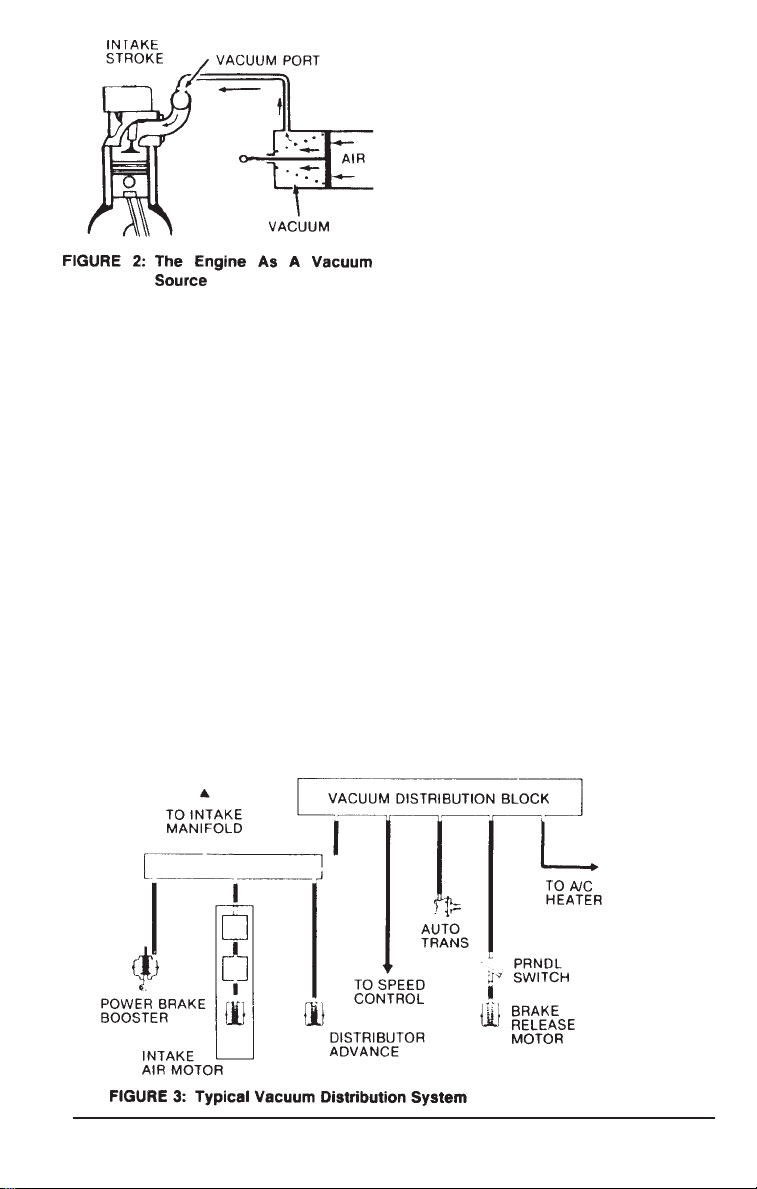

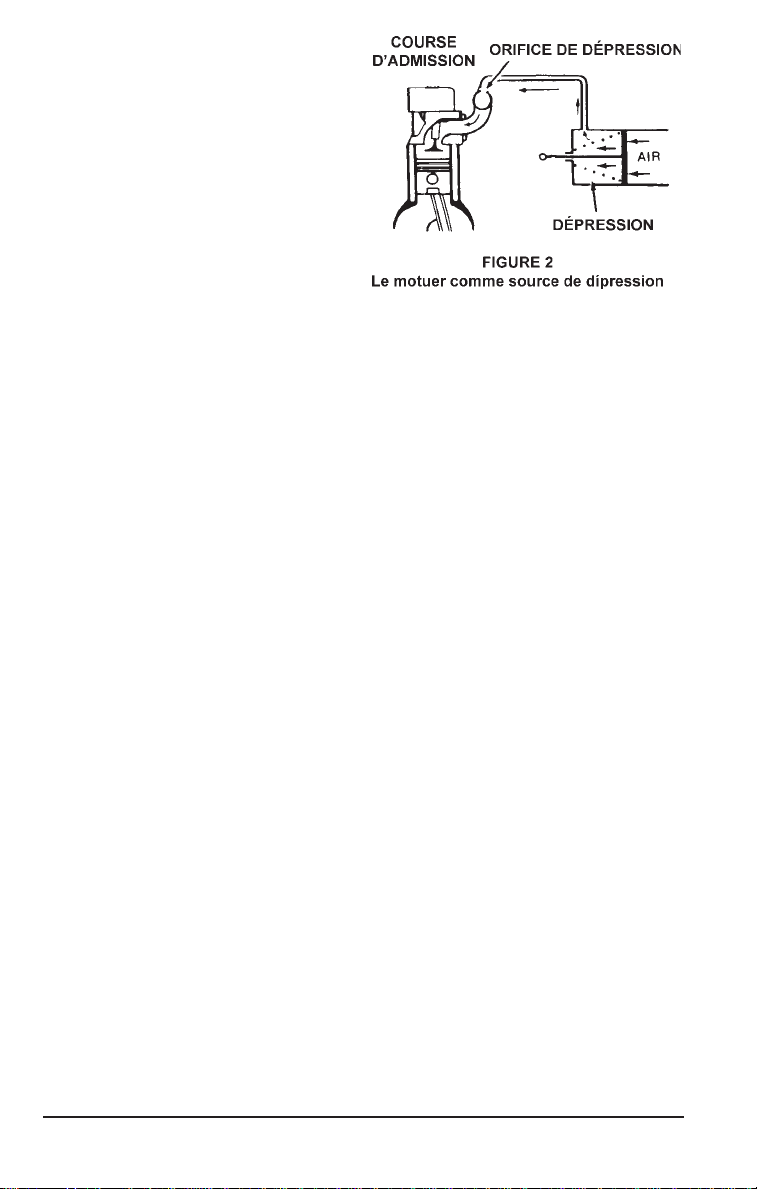

WHY ENGINES CREATE

VACUUM

Vacuum is created when air is withdrawn from a given volume, or a sealed

volume is increased. That is why vacuum

is available in an engine. On the intake

stroke, the piston moves down, this

creates a partial vacuum because the

volume of the cylinder is increased. Air

cannot rush through intake system fast

enough to totally fill the space created

when the piston moves down (FIGURE

2). This is the most common automotive

vacuum supply source.

Page Number - 6

GASOLINE VS. DIESEL

VACUUM

Because a diesel engine does not

produce as much vacuum as a gasoline

engine, a mechanical vacuum pump must

be employed to operate vacuum devices.

The pump is useful in testing devices on

both types of engines.

VACUUM DISTRIBUTION

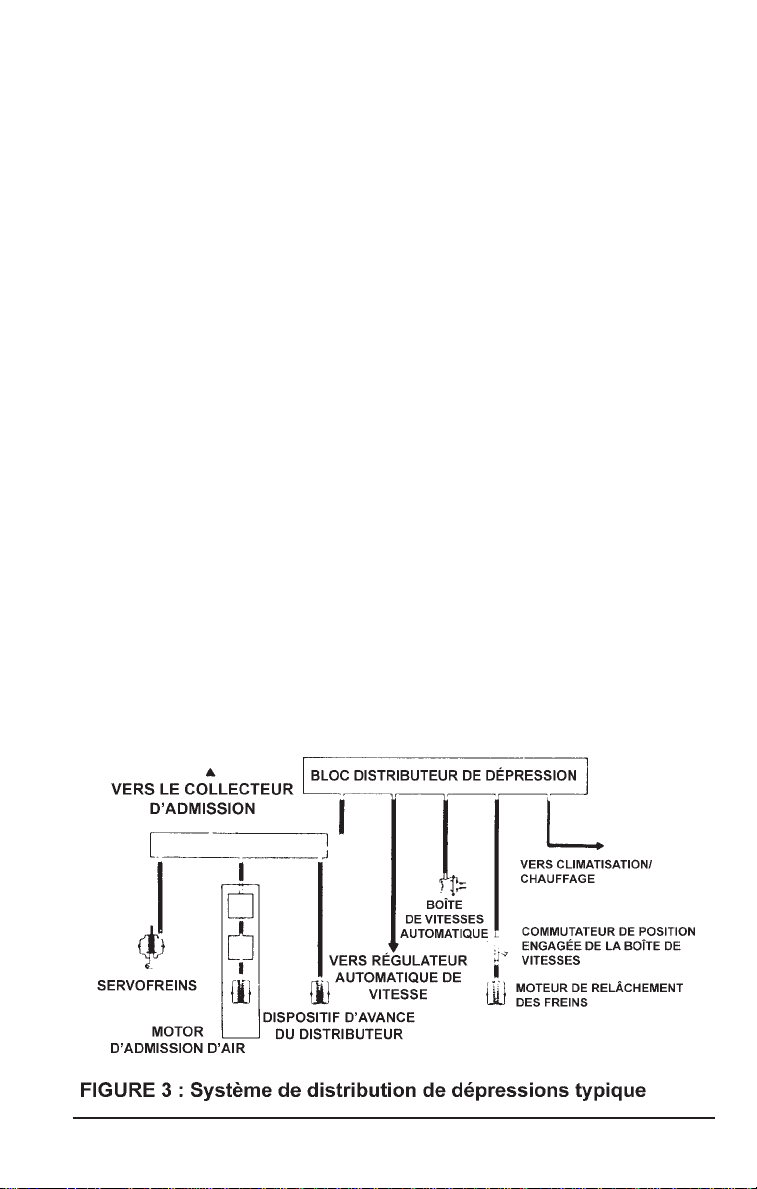

All modern automobiles have a vacuum

distribution system (FIGURE 3),

consisting of lines, hoses, fittings and

vacuum devices. This system must be

leakproof. If it is not, the engine air/fuel

Form 822378

Page 7

mixture will be leaned out by the extra air

entering the system through the leaks,

thus causing problems such as burned

exhaust valves, uneven idle, stalling, preignition, burned spark plugs, etc.

Additionally, any vacuum operated device

affected by the vacuum leak will not

function properly.

A normal gasoline engine should develop

16-22” Hg of intake manifold vacuum at

idle. This is an indication that the engine is

breathing properly. If the vacuum is

lower, the engine is running less

efficiently. The lower the manifold

vacuum, the less efficiently the engine is

running and the lower the gas mileage

will be.

The vacuum distribution system supplies

vacuum to vacuum motors (servos) in the

air conditioning, power brake booster,

speed control servo, emission controls,

manifold absolute pressure (MAP)

sensor, and automatic transmission

control systems. In older vehicles,

vacuum is also supplied to the distributor

vacuum advance or retard mechanism.

These devices can be connected directly

to manifold vacuum, or can be controlled

through electric solenoids, thermostatic

switches, or other vacuum controls.

TROUBLESHOOTING THE

VACUUM SYSTEM

Most vacuum problems can be traced to

leaks, which occur in hoses, connectors,

motor diaphragms or valves. Pinched

lines or clogged valves will also not

allow vacuum flow. Problems can also be

traced to improper mechanical operation

of devices driven by vacuum motors.

The vacuum pump can be used to

measure the amount of vacuum in a

hose. The vacuum gauge feature is very

useful for detecting a fluctuating vacuum

supply or a leaky enables you to check

all types of vacuum operated devices.

On a vacuum motor, for example, the

pump is used to evacuate the diaphragm

chamber, which allows you to check the

mechanical operation of the device as

well as the amount of vacuum, required

to actuate it. Test for leaking diaphragm

by applying 10” Hg vacuum to the device

(FIGURE 4). Observe the gauge to see if

the needle drops after the actuator stops

moving. If the needle continues to drop, a

leaking diaphragm is indicated. If the

diaphragm is okay, the vacuum should

hold for one minute with the needle

steady.

Form 822378

Page Number - 7

Page 8

DIAGNOSING

MECHANICAL ENGINE CONDITIONS

VACUUM GAUGE CHECKS &

DIAGNOSIS

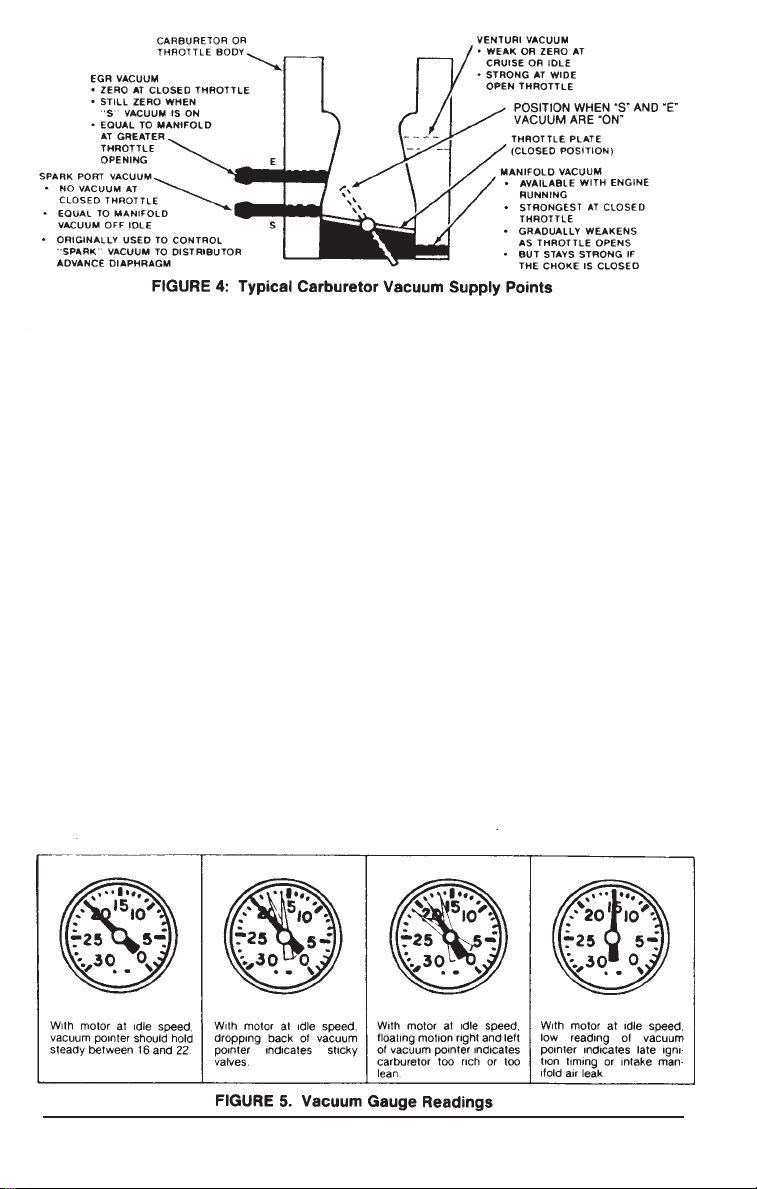

The pump’s vacuum gauge readings give

indications of possible mechanical

problems, but they are not foolproof.

Observe the gauge carefully and follow

the vacuum readings with further tests,

where possible, to confirm your diagnosis.

Do not look for the engine to produce

specific (numerical) amounts of vacuum.

Much more important than specific

numbers is the range of the vacuum

readings and the movement of the needle

(FIGURE 5). Important things to notice

about the needle movement are HOW the

needle moves (in a smooth or jerky

manner, erratic, etc.), what direction it

moves, whether movement is regular or

varying, and how far the needle moves.

The following gives some examples of

what to look for and the meanings of a

variety of vacuum gauge reading should

be 16-22” Hg and steady.

Normal Engine

Run engine at idle and connect the pump

to an intake manifold vacuum port. Watch

the needle’s movement on the gauge. At

idle, the vacuum gauge reading should be

16-22” HG and steady.

BURNED OR LEAKING

V AL VE SPRING

At idle, burned or leaking valves will

cause the pointer on the gauge to drop to

a low reading and return to normal at a

regular interval. The needle will drop

from 1” Hg at regular intervals whenever

the defective valve attempts to close.

Page Number - 8

Form 822378

Page 9

STICKING VALVE

A sticking valve will exhibit a rapid,

intermittent drop from the normal pointer

indication. This is unklike the regular drop

that characterizes a burned or leaking

valve.

A sticking valve condition may be pinpointed by directly applying a lightweight

oil to each valve guide. When the sticking

valve is reached, the situation will be

temporarily remedied.

WEAK OR BROKEN V ALVE

SPRING

Weak valve springs are indicated when

the pointer of the vacuum pump gauge

fluctuates rapidly between 10” and 21”Hg

at idle. The fluctuations will increase with

engine speed. A broken valve spring will

cause the needle to fluctuate rapidly at a

regular interval. Again this will occur

every time the valve attempts to close.

WORN V A LVE GUIDES

Worn valve guides admit air which upsets

the air/fuel mixture. The vacuum gauge

reading will be lower than normal and will

fluctuate rapidly in a range of about 3”

Hg. As the speed of the engine is

increased, the needle will steady.

LEAKING PISTON RING

Vacuum at idle will be low but steady at

about 12” to 16” Hg. Open the throttle and

allow the engine to pick up speed to

about 2000 RPM. Then, close the throttle

quickly. The pointer should jump 2” to 5”

Hg above its low steady reading. A lesser

gain may indicate faulty rings, and a

complete cylinder leakage or compression

test should be done.

BLOWN CYLINDER HEAD

GASKET

At idle, the vacuum pump gauge pointer

will fluctuate between normal and a low

reading. The needle will drop sharply

about 10” Hg from a normal reading and

return each time the defective cylinder or

cylinders research firing position.

EXHAUST RESTRICTION

TEST

An exhaust restriction will cause normal or

near normal performance at engine idle but

cause very poor engine performance

under load, or at higher speeds.

1) Connect the pump hose to an intake

manifold vacuum fitting. Operate the

engine at idle and note the vacuum

reading and needle movement.

Compare readings and movements

against descriptions listed for burned

valves and late ignition or valve timing.

2) Watch the vacuum gauge as engine

speed is increased to approximately

2500 RPM.

3) An increase in vacuum over that

obtained at idle indicates an exhaust

system that is free of restrictions.

4) If the needle drops toward zero as

engine RPM is increased, either an

exhaust restriction or an over-active

Exhaust Gas Recirculation (EGR) valve

is causing the problem.

5) Test the EGR valve separately. If it is

found to be in good condition, the

problem is a restricted exhaust. Check

and replace if necessary.

INCORRECT IDLE AIR/FUEL

MIXTURE

When the needle on the gauge drifts

slowly back and forth at idle, over a range

of 4” to 5” Hg, the fuel mixture is too rich.

A lean mixture will cause an irregular drop

of the needle over about the same range.

INTAKE MANIFOLD OR AIR

INDUCTION LEAKS

If there are any air leaks in the air induction

system, the pump’s gauge needle will be

about 3” to 9” below normal but will remain

steady.

LATE IGNITION OR VALVE

TIMING

An extremely low but steady reading at

idle indicates late ignition or valve timing, or

a uniformly close setting of the valve lash.

Perform separate tests to determine which

of these problems, if any, have affected

the engine.

Form 822378

Page Number - 9

Page 10

POSITIVE CRANKCASE VENTILA TION SYSTEM

SYSTEM OPERATION

The Positive Crankcase Ventilation (PCV)

system is used on all modern engines to

reduce air pollution by providing a more

complete scavenging of crankcase

vapors. Air is drawn through a filter

located in the air cleaner, through a hose

in the valve cover, into the crankcase,

across and up into the rear of the intake

manifold or opposite valve cover, through

the PCV valve, through a hose, into the

intake manifold. Intake manifold vacuum

draws in all vapors from the crankcase to

be burned in the engine.

When air flow through the carburetor or

throttle body is high, added air from the

PCV system has no effect on engine

operation.

However, at idle, air flow through the

carburetor or throttle body is so low that

any large amount added by the ventilation

system would upset the air/fuel mixture,

causing a rough idle. For this reason, the

PCV valve restricts the ventilation system

flow when intake manifold vacuum is

high.

SERVICE PROCEDURES

After a period of operation, the PCV

valve may become clogged and reduce

the amount of crankcase ventilation. The

PCV valve should be replaced periodically

to prevent the formation of acids in the

crankcase and the build up of excessive

crankcase pressure, which could force

engine oil out past the seals. Use the

following procedure to check the PCV

system using your pump:

1) Inspect the system for kinked, plugged

or deteriorated hoses. Check to be sure

all hoses are connected properly.

Repair as necessary.

2) Connect your pump to an intake

manifold port and check the vacuum

reading of the warmed and idling

engine.

3) Clamp off the vacuum hose to the PCV

valve. The engine speed should

decrease 100 RPM to indicate the loss

of the calibrated air leak into the intake

manifold. The vacuum gauge reading

should increase slightly indicating that

the vacuum leak has been plugged. If

this does not happen, replace the OCV

valve and/or replace any damaged,

plugged or loose hoses.

4) If the engine is idling too slow or is

rough, this may be caused by a clogged

PCV valve or hose. Do not adjust the

idle speed without first checking the

PCV system.

5) After installing a new PCV valve,

always adjust the idle speed, and if

possible, the idle air mixture. The

installation of the wrong valve may

cause too much vapor to flow through

the system if the calibrated bleed is too

large. This will lean out the air/fuel

mixture excessively. If the opening is

too small, the plugging effect will be

nullified, emissions will increase,

crankcase acids will form and oil leaks

may develop. Be sure you get the

correct PCV valve for your car.

EXHAUST GAS RECIRCULA TION (EGR)

An Exhaust Gas Recirculation (EGR) system is used on most modern engines to

reduce Oxides of Nitrogen (NOx) emissions. During the combustion process,

nitrogen, which makes up 80 percent of

the air, will mix with oxygen at temperatures above 2,500° F. During the combustion process, temperatures in the

cylinders go well above 3,500° F

providing for the formation ideal conditions for the formation of Nox.

Page Number - 10

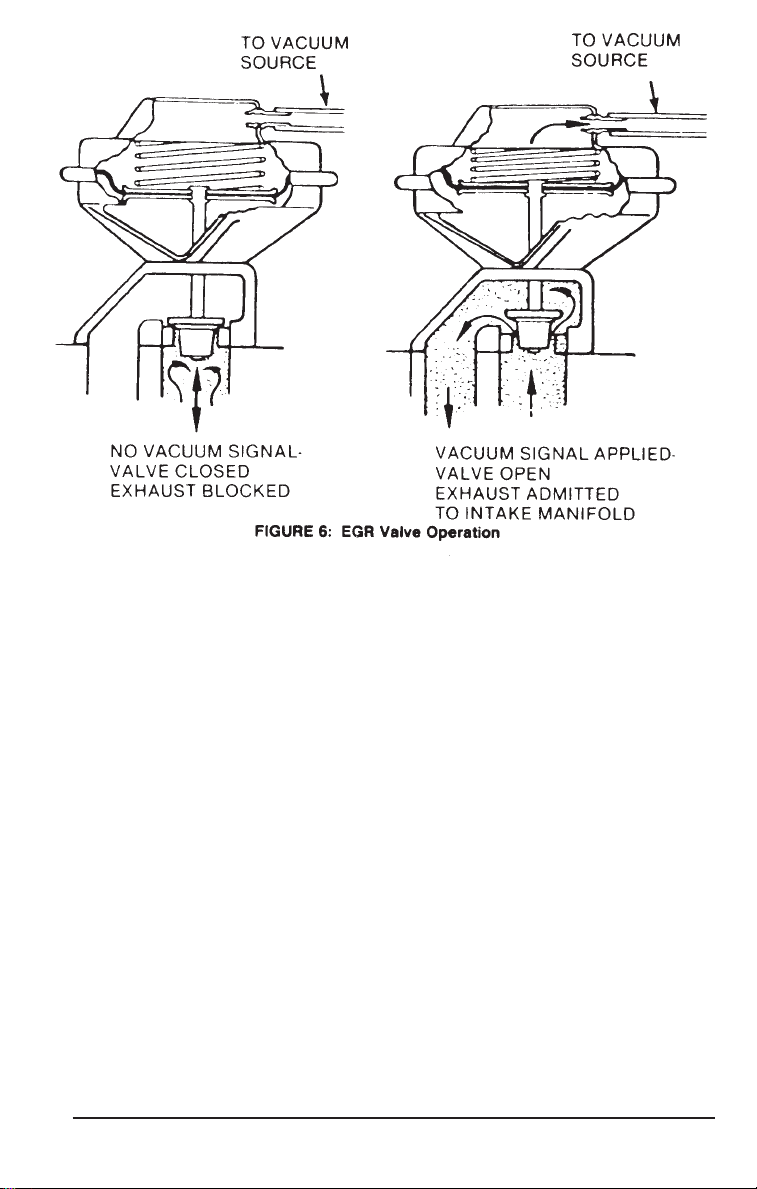

SYSTEM OPERATION

To reduce the formation of NOx, it is

necessary to lower the combustion

temperature. This is most often done by

introducing exhaust gases back into the

combustion chamber through the use of

an EGR valve. The EGR valve (FIGURE 6)

may be operated by ported vacuum from

above the throttle plates or by a sophisticated control system that modulates the

amount of EGR depending on the temperature of the coolant, ambient air temperature, engine speed or load.

Form 822378

Page 11

An EGR valve that does not have a

sophisticated control system must be

fully closed with a vacuum of less than

2” Hg and begin to open with 2-8.5” Hg of

vacuum. At idle and wide-open throttle,

the ported vacuum supply is low and the

valve should be closed.

Some cars have a Back-Pressure

Transducer Valve (BPV) to modulate the

operation of the EGR system. Some cars

have a Venturi Vacuum Amplifier (VVA) to

do the same job. The effect is to modulate

the amount of EGR according to the load

on the engine. To improve cold driveability, most cars are equipped with some

type of vacuum control device to shut off

EGR while the engine is cold.

there is at least 4” to 5” Hg vacuum

available. Remember also that clogged

exhaust passages that lead to or from the

valve can restrict the flow even if the

valve is opening.

An EGR valve that remains open will

cause the engine to idle roughly, die at

idle, and lose power and full-throttle

smoothness. The valve usually fails to

close due to dirt or damage in the valve

seat area. An EGR valve can operate normally with the engine warm but remain

open when the engine is cold. That

condition could be caused by a faulty

thermal switching device that does not

cut off the vacuum supply when the

engine is cold.

EGR systems fail in two ways. Either the

valve may fail due to a fault of its own,

such as a ruptured diaphragm, or due to

a loss of control vacuum. Always check

to be sure that there is vacuum at the

hose connected to the EGR valve, before

replacing the valve. Connect the pump to

the vacuum supply hose at the EGR valve

and check to be sure that at 2000 RPM

Form 822378

SERVICE PROCEDURES GENERAL TEST EXCEPT

GM OR BACK-PRESSURE

CONTROLLED TYPE)

If the symptoms of an engine lead you to

believe that an EGR valve is staying

open, follow this procedure:

Page Number - 11

Page 12

1) Connect a tachometer to the engine

and run the engine at idle speed until it

reaches normal operating temperature. Use the pump to check for at

least 10” Hg vacuum at the valve.

Replace the hose and note the engine

RPM.

2) Remove the vacuum hose from the

valve and notice whether engine RPM

increases.

3) If engine speed does increase, there

may be some type of problem in the

vacuum control circuit. Check the

routing of all vacuum hoses.

4) If engine speed or the quality of idle

changes, remove the valve and check

the pintle and valve seat to make sure

both are clean. If they are not, replace

the valve, gasket and adapter if it is

burned, warped or damaged.

If the engine symptoms lead you to

believe that the EGR valve is staying

closed, follow the procedure below:

1) Operate the engine at idle until it

reaches full operating temperature.

Use the pump to check for the

presence of 10” Hg vacuum at the

valve. Set the engine speed at

approximately 2000 RPM. Plug the

vacuum supply hose. Connect the

vacuum pump to the EGR valve and

apply 10” to 15” Hg vacuum. 2) The

diaphragm should move to the open

position and a decrease in engine

RPM should be noted. If not, the valve

is defective or the manifold passages

are plugged. Release the vacuum on

the EGR valve.

3) The diaphragm should move to the

closed position and an increase in

engine RPM should be noted. Return

the engine to idle and turn it off.

4) Connect the pump to the EGR valve

and test by applying at least 9, Hg of

vacuum to the diaphragm and watch

the gauge carefully for any vacuum

loss.

5) If the valve diaphragm does not move,

or cannot hold vacuum, replace the

EGR valve.

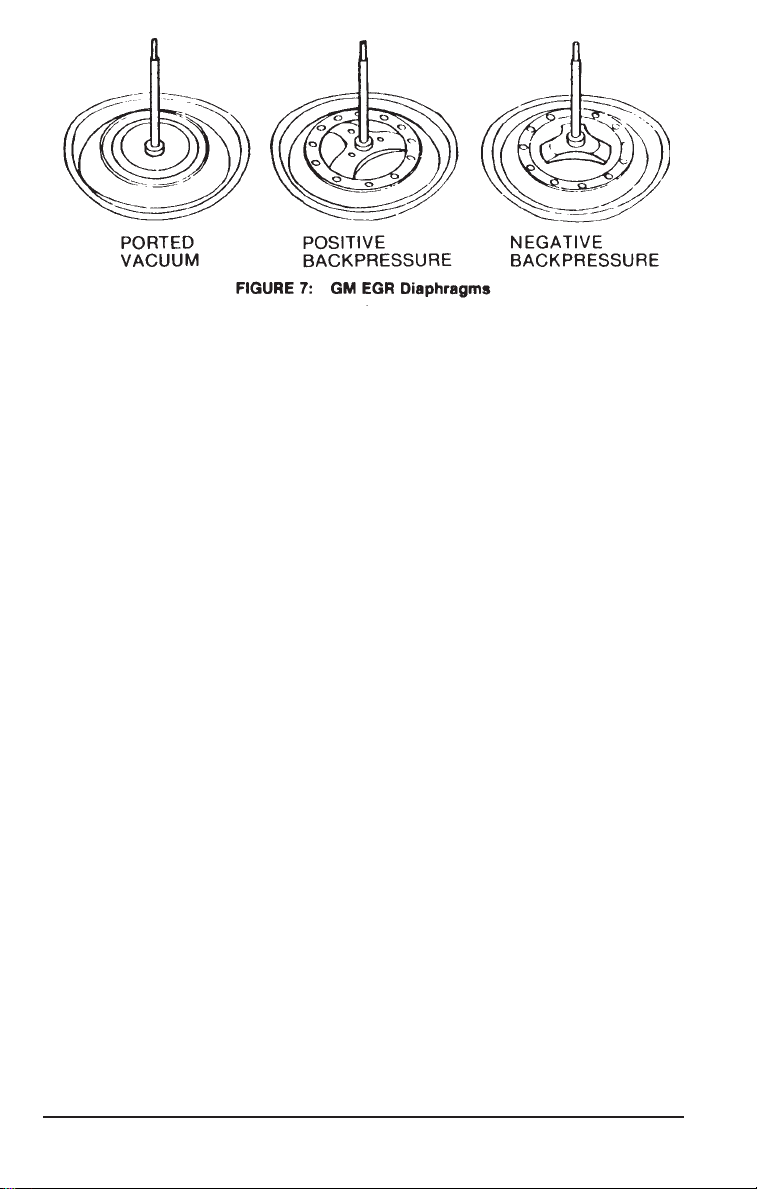

SERVICE PROCEDURES GM

EGR V AL VES

General Motors produces three types of

EGR valves. Each valve can be identified

by the design of its diaphragm plate

(FIGURE 7). The first valve is a ported

vacuum EGR that has only a circular rib

on the back of its diaphragm plate. The

second is a positive back-pressure valve

with X-shaped ribs that are raised only

slightly above the plate. Finally, there is a

negative back-pressure valve with Xshaped ribs raised well above the

diaphragm plate. Both the ported vacuum

and negative back-pressure valves are

tested the same way. A separate test is

listed to check the positive back-pressure

valve.

GM PORTED VACUUM AND

NEGATIVE BACK-PRESSURE EGR TEST

1) Make sure all vacuum hoses are

routed according to the emission

control label.

2) Check the vacuum connection to the

EGR valve for obstructions.

3) Connect the pump between the EGR

valve and the carburetor or vacuum

source. Start engine and run at the

idle until it reaches operating

Page Number - 12

Form 822378

Page 13

temperature (195° F approx). Check

for vacuum at 3000 RPM; it should be

5 Hg minimum.

4) If no vacuum is available in step 3,

check for it between the EGR thermal

vacuum switch (TVS) and the

carburetor. If the vacuum is available

there, replace the TVS.

5) If the vacuum supply between the

EGR and the carburetor is adequate,

connect the pump to the EGR valve

inlet. Depress the valve diaphragm

and apply approximately 10” Hg of

vacuum to the EGR. Release the

diaphragm and record the time it takes

for the diaphragm to return to its

seated position.

6) If it takes less than 20 seconds for the

valve to seat, replace the valve.

GM POSITIVE BACKPRESSURE EGR TEST

1) Follow steps 1 through 4 of the

ported vacuum and negative backpressure EGR test.

2) Remove the EGR valve from the

engine. Connect the pump to the EGR

vacuum inlet and apply 10” Hg of

vacuum. The valve should not open. If

it does, replace the valve.

3) Continue the test by keeping the

vacuum applied and shooting a lowpressure stream of air into the valve’s

exhaust inlet. The valve should now

open. If it does not, replace the valve.

Form 822378

Page Number - 13

Page 14

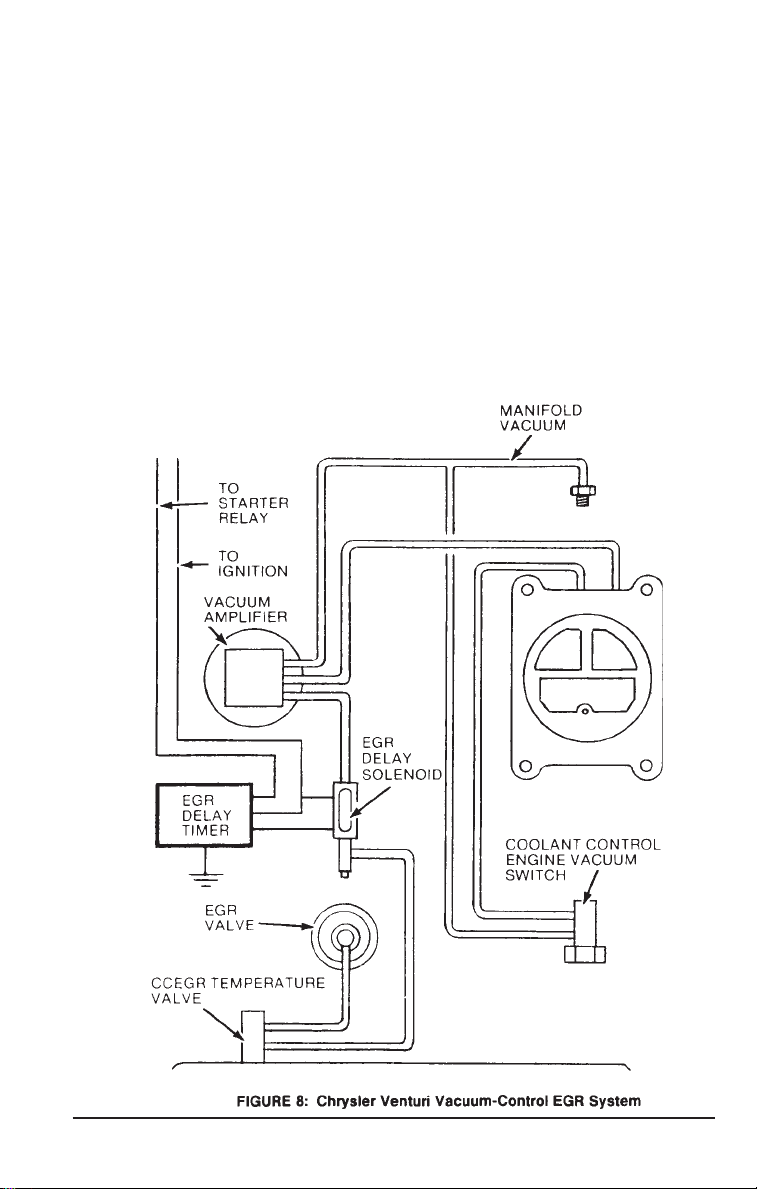

EGR VENTURI VACUUM

AMPLIFIER

Some engines utilize a Venturi Vacuum

Amplifier that uses the weak vacuum signal from the throat of the carburetor to

allow the passage of the stronger intake

manifold vacuum to operate the EGR

valve. On most applications the amplifier

provides a 2” Hg boost to the Venturi signal (FIGURE 8).

SERVICE PROCEDURES

1) Start engine, run at idle until it

reaches normal operating temperature.

2) Make sure the intake manifold hose to

the amplifier is properly connected.

On those systems with a reservoir,

remove the hose from the reservoir

and use a tee connector to join the

hose to the intake manifold vacuum

hose.

3) With separate lengths of hose and

different connectors, bypass any and

all vacuum valves or coolant controlled valves between the amplifier

and the EGR valve.

4) Use a tee connector to attach the

pump into the vacuum line between

the amplifier and EGR valve.

5) Increase engine speed to 1500/2000

RPM and release the throttle. Let the

engine return to idle speed and

remove the vacuum hose at the

carburetor Venturi. The vacuum

reading should be within ± .3” Hg of

the specified boost for that amplifier if

other than zero boost is specified.

Zero boost may read from 0 to .5” Hg.

Replace amplifier if out of specification.

6) Increase engine speed. Watch

vacuum gauge and release accelerator after speed of 1500/2000 RPM is

reached. If the vacuum gauge reading

shows an increase greater than

1” Hg during acceleration period, the

amplifier should be replaced.

7) Remove the pump from the output

vacuum line and reconnect hoses, but

still bypass other valves. Connect the

pump and apply 2” to 4” Hg of vacuum

to port on the amplifier which is

normally connected to intake manifold

vacuum. The EGR valve should

operate and engine idle should drop

or become erratic. If the EGR valve

fails to move, replace the amplifier.

Page Number - 14

Form 822378

Page 15

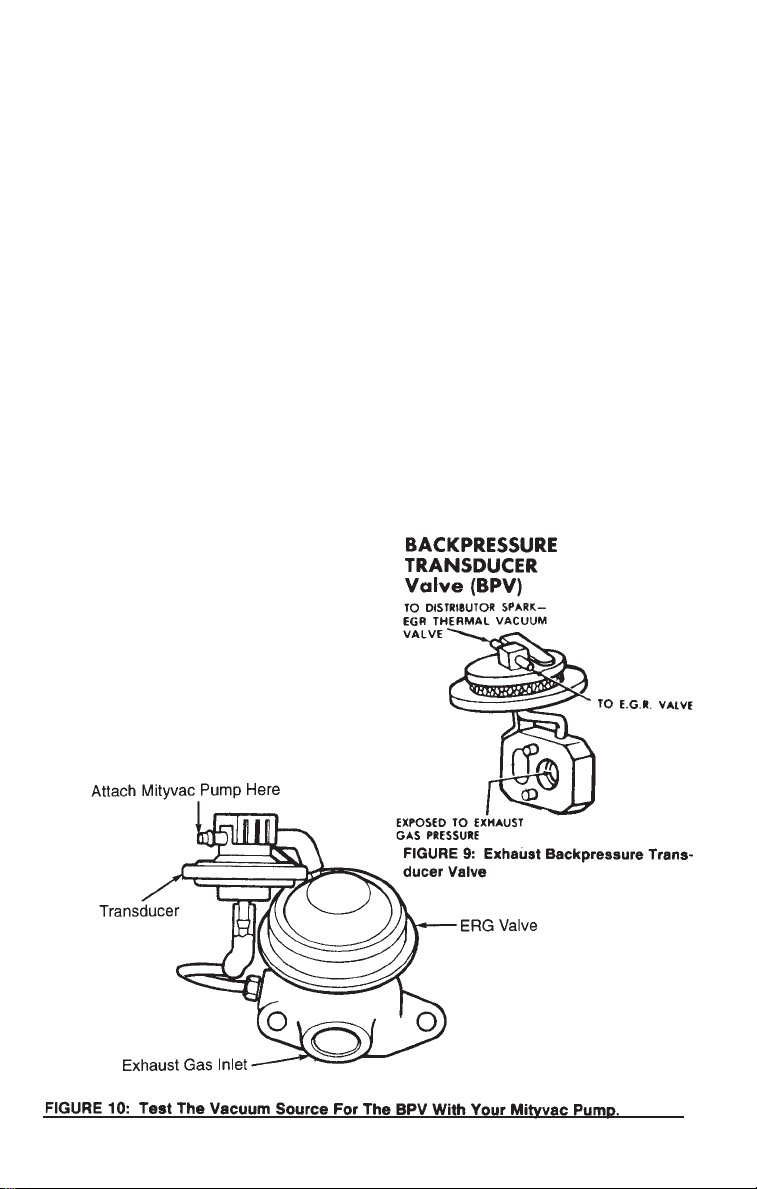

BACK-PRESSURE TRANSDUCER V ALVE (BPV)

OPERATION

The Back-pressure Transducer Valve

(BPV) controls the amount of EGR

according to the load on the engine. An

exhaust pressure probe extends into the

exhaust crossover passageway to

sample the exhaust gas pressure. During

light engine loads, the pressure in the

exhaust passageway is relatively low

while during wide-open throttle operation

(WOT), the pressure is highest. This

pressure signal is transmitted to a

diaphragm in the BPV and is used to

control the amount of vacuum applied to

the EGR valve (FIGURE 9).

SERVICE PROCEDURES

1) Remove the air cleaner and plug the

intake manifold fitting. Start the engine

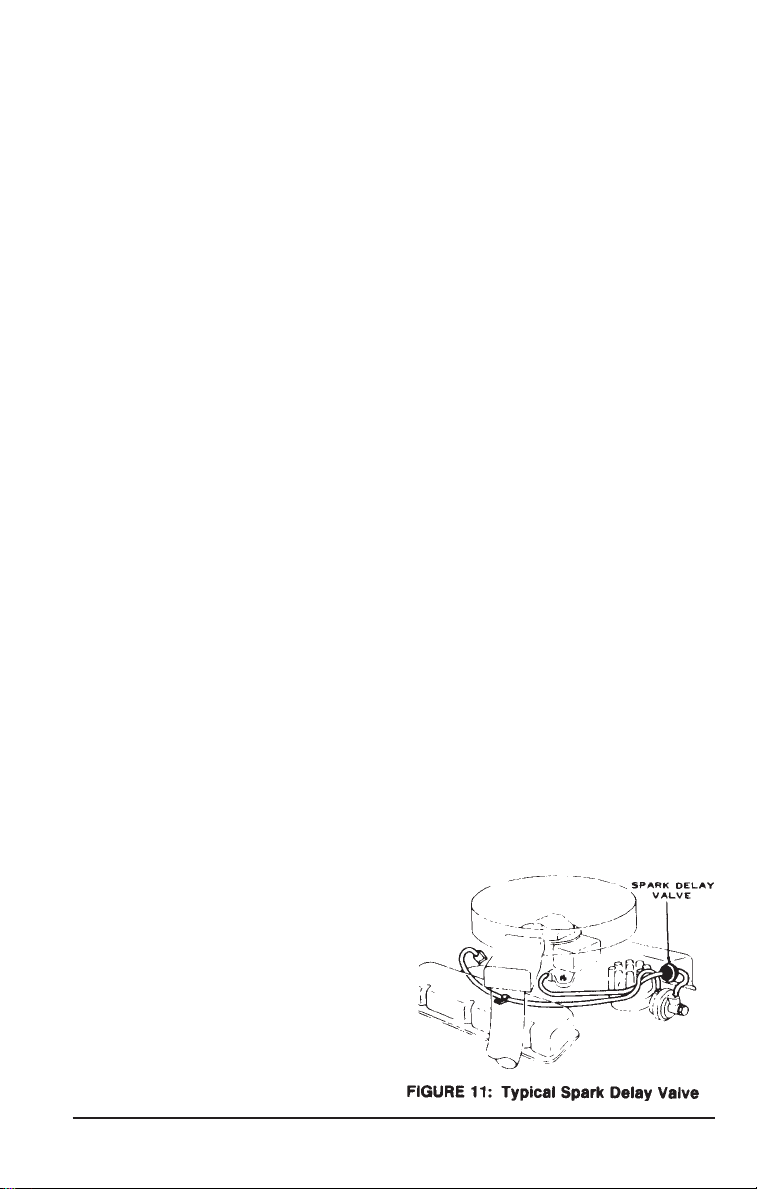

SP ARK DELA Y V ALVE (SDV)

OPERATION

Spark Delay Valves (SDV) are used to

delay vacuum to the distributor vacuum

advance actuator during hard acceleration, to delay the action of the Thermactor

Air Induction Reaction (AIR) system

during prolonged engine idling, and to

delay the application of vacuum to the

automatic choke pulldown diaphragm

during cold engine operation.

A sintered metal valve is installed in the

vacuum advance (outer) diaphragm of

the distributor control unit on some

engines. The purpose of the valve is to

delay the spark advance during rapid

acceleration to minimize the formation of

NOx. The sintered metal is porous and

allows vacuum to bleed through the valve

acting like an orifice of about 0.002” in

diameter. Control is obtained by varying

the number of discs in each valve

assembly so that the time delay features

can be tailored to the engine (FIGURE 11).

and bring it to normal operating

temperature. Position the fast-idle cam

follower on the second step of the

fast-idle cam (to obtain about 1500

RPM), and then note engine speed on

a tachometer, and use the pump to

check the source vacuum at an intake

manifold port (FIGURE 10). Note this

reading.

2) Tee your pump into the vacuum passageway to the BPV and the reading

should be 1-2” Hg of vacuum. Replace

the BPV if it is not within specifications.

3) Leave the vacuum gauge at this

location, remove the hose to the EGR

valve, and plug the hose opening.

Read the vacuum pump gauge, which

should be the same as the intake

manifold vacuum reading. If it is not

within 2” Hg of the source vacuum,

replace the BPV valve.

repaired and must be replaced every

12,000 miles because the pores of the

sintered metal fill with dust, which can

slow the performance of the valve.

NOTE: The spark delay valve is a oneway unit that must be installed with the

Black side facing the carburetor vacuum

port.

To determine if a spark delay valve is

operating correctly, the following service

procedure should be used:

1) With the transmission in neutral, set

the carburetor to the fast-idle

position, remove the spark-delay

valve and tee your vacuum pump into

the hose leading to the carburetor

spark port.

SERVICE PROCEDURES

The time delay of the valve varies with

engine application. The different valves

may be identified by color and part

number. Spark delay valves cannot be

Form 822378

Page Number - 15

Page 16

2) Record the vacuum reading, which

should be between 10-16” Hg.

3) Pinch off the vacuum hose and

observe if the gauge maintains the

vacuum level. If the gauge shows

that the vacuum drops with the hose

pinched off, the gauge or vacuum

hose has an external leak, which

must be corrected.

4) Now, connect the Black side of the

spark-delay valve to the vacuum

hose leading to the carburetor spark

port. Connect a section of vacuum

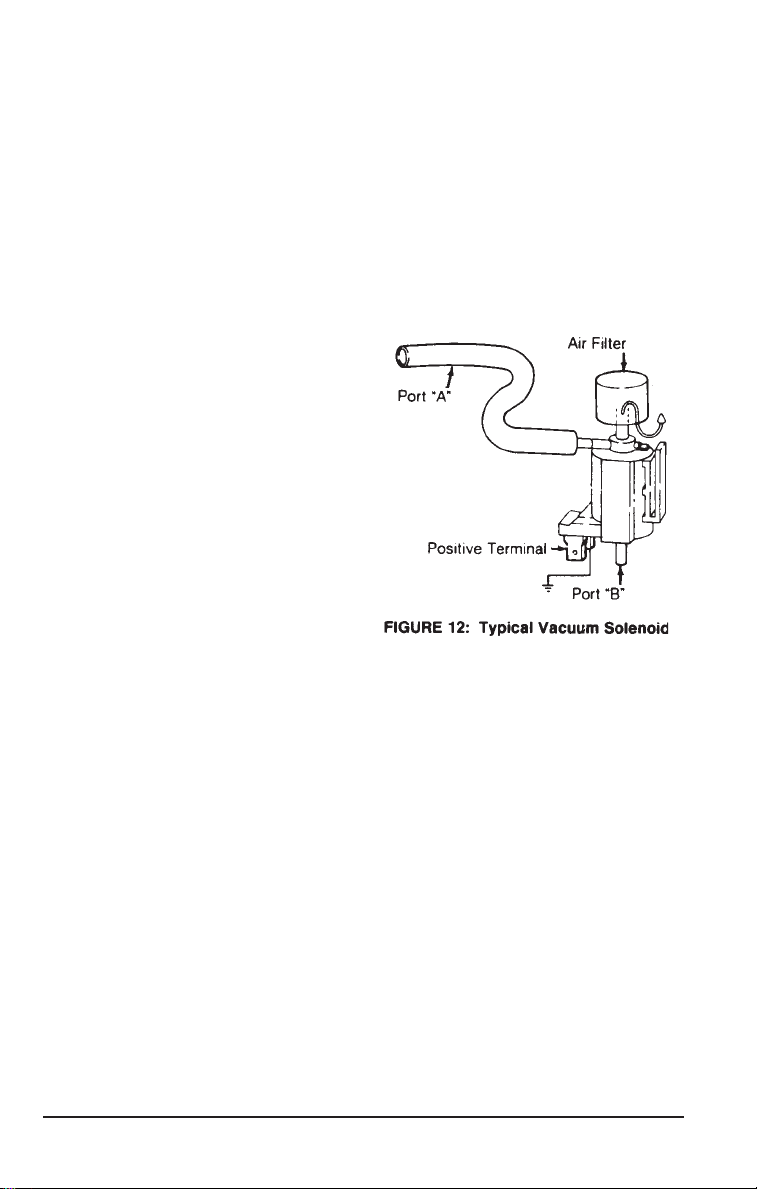

ELECTRICAL/V ACUUM SOLENOID

SERVICE PROCEDURES

1) Disconnect vacuum and electrical

connectors from the solenoid.

Connect the pump to port “B” and

attempt to apply vacuum with pump.

Vacuum should be released through

port “A” (FIGURE 12).

2) Using jumper wires, connect negative

solenoid terminal to ground and apply

12 volts to the positive terminal. Apply

vacuum to port “B”. Vacuum should

hold and not bleed off. If the solenoid

does not hold vacuum, replace

solenoid.

3) With solenoid still energized, move

vacuum pump to port “A”. Attempt to

apply vacuum. Vacuum should be

released through the air filter and no

vacuum should be present at port “B”.

hose to your vacuum pump and

attach the other end to the distributor

end of the spark delay valve.

Observe the time in seconds for the

gauge to reach 6” Hg, with a 10-16”

Hg vacuum source. If the vacuum

reaches the 6” Hg level in less than

two seconds, regardless of type, the

SDV should be replaced. When

checking the valve, care must be

taken to prevent oil or dirt from getting

into the valve as this will impair its

function.

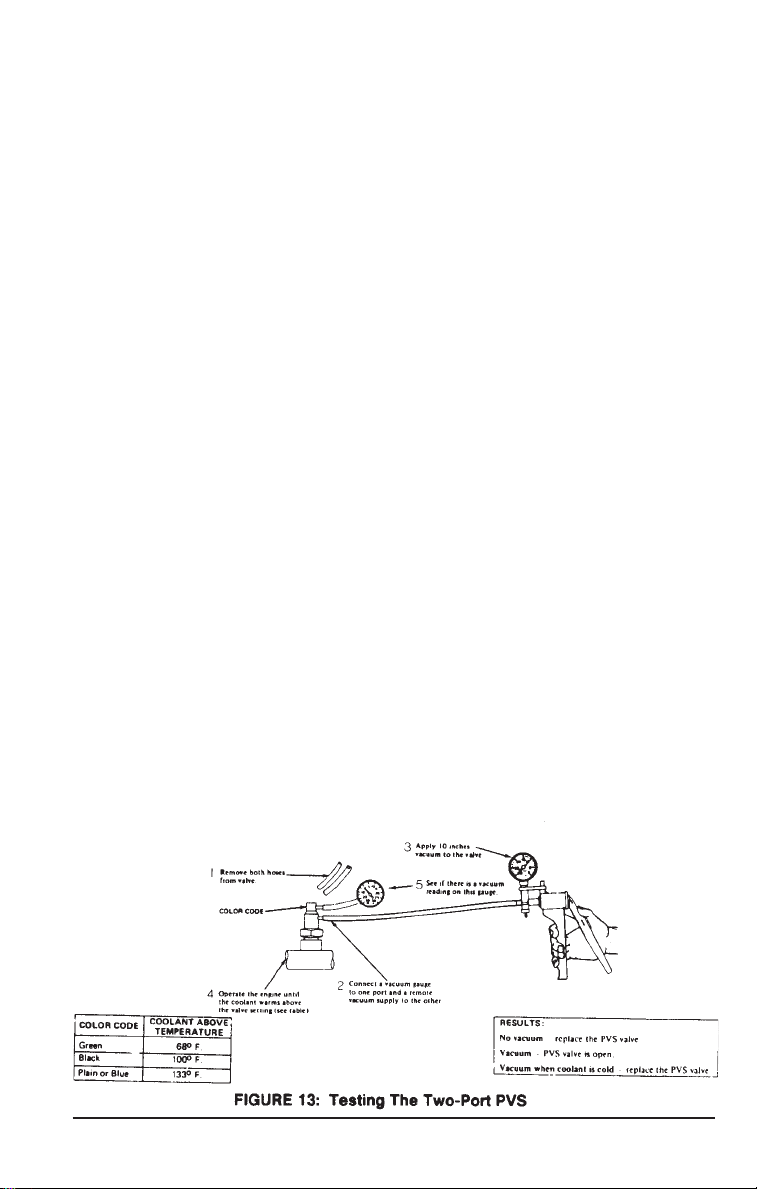

THERMAL-CONTROLLED V ACUUM-SWITCHING V ALVES

SERVICE PROCEDURES

These control valves are called Ported

Vacuum Switches (PVS) when used on

Ford engines. Thermal Ignition Control

(TIC) valves when used on Chrysler

products, and Distributor Thermal

Vacuum-Switches (DTVS) when used on

General Motors engines.

The two-port valve is used to stop EGR

while the engine is cold. This type of

thermal switch is needed to provide good

driveability by limiting the entrance of EGR

until the engine is warmed up.

The three-port valve is commonly called a

cooling system PVS because it switches

the vacuum source to the distributor from

ported to full intake vacuum.

Page Number - 16

The four-port valve has been used in some

Ford engines to bypass the spark delay

valve and cut out the EGR system when the

engine is cold.

SERVICE PROCEDURES

Follow this procedure to test the two-port

vacuum-switching valve:

1) Apply 10” Hg of vacuum to the bottom

port of the valve with your vacuum

pump and measure the results with a

second vacuum gauge as shown in the

accompanying illustration (FIGURE 13).

2) The valves are color coded and the

Green valve should open and pass

vacuum at 68° F, the Black valve at

100° F.

Form 822378

Page 17

3) If full vacuum flows through the valve

when heated, it is okay. If there is no

vacuum flow or there is vacuum flow

when the coolant is cold, replace the

valve.

Follow this procedure to test the threeport vacuum-switching valve:

1) Apply 10” Hg of vacuum with your

vacuum pump to the middle port of the

valve with a vacuum gauge at each

of the other two ports.

2) Refer to the same color-coded valves

and same temperature specifications

as for the two-port valve above. If the

vacuum switches at the specified

temperature, the valve is okay. If there

is no vacuum to the lower port above

the specified temperature, replace the

valve.

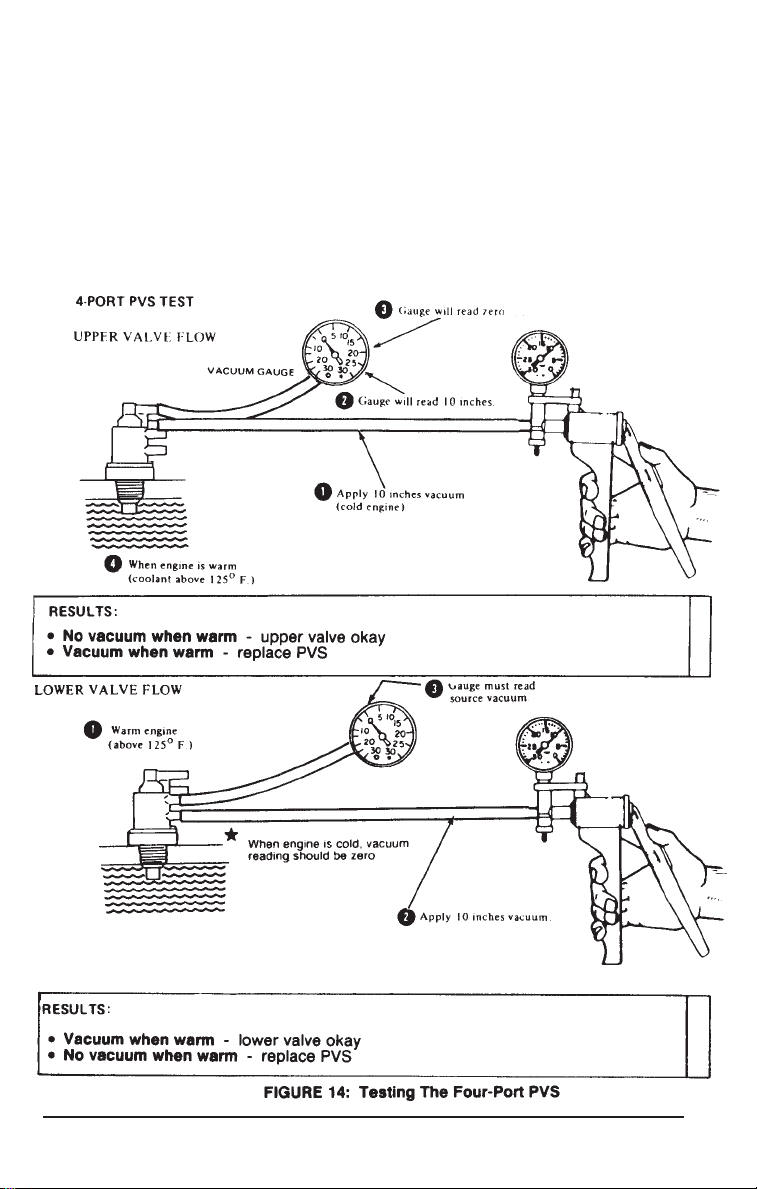

The four-port valve must be tested two

times, once at the top two ports and once

at the bottom two ports as shown in the

accompanying illustration (FIGURE 14).

1) Apply 10” Hg of vacuum with your

vacuum pump to one of the top two

ports. The valve should hold vacuum

when above the specified operating

temperature.

2) If flow occurs when the valve is

warm, replace it.

3) For the lower two ports, vacuum must

pass through the valve only when the

engine is warm; otherwise, replace the

valve.

BRAKE BLEEDING

Many brake systems today feature AntiLock functions and electronic controls.

Many of these systems use a high pressure electric pump to keep the system

pressurized. When bleeding or servicing,

these systems require special procedures and cautions.

Always observe the following precautions when servicing Anti-Lock brake

system:

• ALWAYS wear safety goggles when

servicing high pressure brake

systems.

• ALWAYS depressurize the ABS

system prior to adding fluid or

attempting service or repair.

• Unless instructed to by the manufacturer’s procedure, NEVER open a

bleeder valve or loosen a hydraulic

line while the ABS system is pressurized.

• ONLY use recommended brake fluids.

DO NOT use silicone brake fluid in

ABS equipped vehicles.

• Always refer to an appropriate repair

manual for additional information an

Anti-Lock brake systems.

DEPRESSURIZING ANTILOCK BRAKE

SYSTEMS

Always refer to the vehicle owner’s

manual or appropriate service manual for

additional information on depressurizing

procedure. The procedure will work on

most Anti-Lock brake systems. Ensure

ignition switch is in the OFF position or

disconnect the negative battery cable.

Form 822378

Page Number - 17

Page 18

Pump the brake pedal 25-40 times. A

noticeable change is felt, continue to

pump the pedal a few additional times.

This should eliminate most system

pressure. Open fluid reservoir or brake

lines carefully. Top off reservoir fluid and

reconnect battery cable when finished.

BLEEDING ANTI-LOCK

BRAKE SYSTEMS

Always refer to the vehicle owner’s

manual or appropriate service manual for

manufacturer’s brake bleeding procedure.

The front brakes on most Anti-Lpck brake

systems may be bled in the conventional

manner. Most hydraulic pump/pressure

accumulator units are fitted with a

bleeder valve which must be bled when

the system has lost fluid or is being

replaced. Some vehicles require that the

system be pressurized when the rear

brakes are bled.

Various Asian, European, and domestic

manufacturers use bleeding procedures

which require specialized equipment.

Page Number - 18

Form 822378

Page 19

BRAKE LINE BLEEDING

Most low and soft pedal problems are

caused by air in the hydraulic lines,

which requires bleeding of the hydraulic

system. By using the pump with brake

bleeding accessories, the system can be

bled easily. Follow a wheel-to-wheel

sequence beginning with the wheel

closest to the master cylinder.

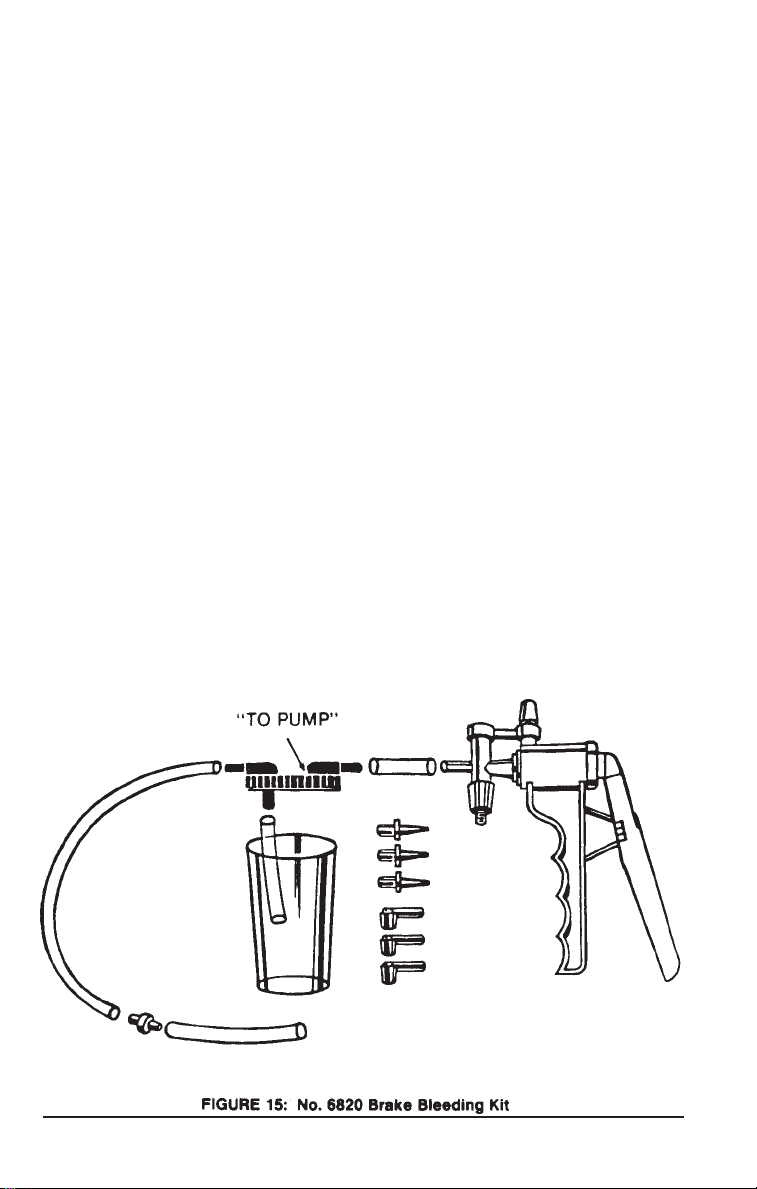

The Kit provides a simple, clean, and

quick method for bleeding the fluid lines in

the automotive brake system. The

creation of a vacuum in the reservoir jar

causes fluid to be drawn into the

reservoir jar. It should be noted that a tiny

stream of bubbles may be noticed in the

hose after all of the air is bled from the

lines. This is caused by air seeping

around the threads of the loosened

bleeder fitting and being drawn back

through the fitting by the suction of the

pump. Once the air is removed from

within the system, these tiny bubbles will

in no way jeopardize the bleeding

operation, since they are present only at

the fitting and do not enter the system. If

you wish, you can put grease or Teflon

tape around the threads of the fitting to

eliminate most of the bubbles.

The correct bleeding procedure follows:

1) Always make certain that the master

cylinder reservoir is filled and that a

supply of new, clean brake fluid of

the proper type is on hand to top off

the reservoir as the fluid level drops

during bleeding. Make sure that all the

bleeding fittings are clean prior to

beginning of the bleeding procedure.

2) Bleed the hydraulic system in the

following order:

a) Master cylinder bleeder fittings, if

equipped. (If installing a new or

rebuilt master cylinder, follow the

bench bleeding procedure which

follows.)

b) Bleeder fittings on the combination

valve, if equipped.

c ) Wheel cylinders and calipers in

succession beginning with the

wheel closest to the master

cylinder, and working to the

farthest one.

NOTE: Wheel balancing sequence varies

among manufacturers. Follow

manufacturer’s recommended

sequence (if known). Procedure

Form 822378

given in this article specifies to begin

bleeding wheel closet to master

cylinder. Regardless of sequence

used, always ensure all air is purged

from system.

3) Slip 1-1/2” of tubing between the

pump and the lid of reservoir jar at

port marked “TO PUMP” (FIGURE 15).

4) Attach 3-1/2” plastic hose to the

bottom of the cap (if not already

attached).

5) Affix at least a 12” piece of tubing to

the other reservoir jar port. Be certain

that the cover of the reservoir jar is

secure, but don’t overtighten.

6) Select the appropriate adapters. The

snap-over adapters (L-shaped) are

different sizes (small, medium, large).

They should fit snugly over the brake

bleeding fitting in order to seal

properly. The tapered adapters fit

inside the thru-hole of fitting and will

generally seal well when inserted

tightly with a pressing and twisting

motion. Attach adapter to reservoir

hose.

7) Place wrench on brake bleeding

fitting; attach adapter and pump

assembly and pump 10-15 times.

NOTE: If bubbles coming out of the

fitting are very small and even in size,

the air is probably coming from within

the system. It is not necessary to

eliminate these bubbles as they do not

affect brake operation. If desired,

these bubbles can generally be

eliminated by placing grease or Teflon

tape around the threads, to act as a

seal.

8) Open fitting slightly, only enough to

cause the fluid to enter jar (usually

1/4 to 1/2 turn).

9) After evacuating about 2” of fluid into

jar, tighten fitting. Keep master

cylinder full.

Repeat all previous steps on all

remaining wheels. If fluid is not drawn

into the jar after opening the fitting,

make certain the lid of the jar is tight.

You will not be able to produce the

necessary vacuum in the jar if the lid

does not fit securely. Occasionally

some dirt will get into the brake line, in

which case the pump may not be

totally effective. If this happens, have

someone touch the brake pedal once

Page Number - 19

Page 20

lightly, with the bleeding valve open,

then proceed to use the pump.

MOTORCYCLE BLEEDING

PROCEDURE

Before bleeding the system, ensure that

1) the brake caliper pistons are free to

move within the calipers.

2) the master cylinder piston is free to

return to the end of its stroke, and

3) inspect the line to ensure that all

fittings are tight.

FRONT BRAKE

1) Pump brake lever to seat caliper pads

against rotor.

2) Cover gas tank with plastic protective

sheet if using DOT 3 fluid (not

necessary if using DOT 5 fluid).

3) Remove master cylinder reservoir cap

and fill reservoir.

4) Attach a 5/32” ID connection hose to

brake bleeding fitting.

5) Pump several times to create vacuum.

Crack bleeder valve with box

wrench, extracting fluid into reservoir.

(Stop and add fluid when master

cylinder begins to get low. Do not

allow air to enter line.) At this point,

all air should be out of system and line

full of fluid. (Note: if air is entering the

pump hose from around bleeder

fitting, remove bleeder fitting and

apply Teflon tape to threaded portion

of bleeder screw only. This will

prevent air seepage around threads

of bleeder screw.)

6) While maintaining vacuum on the

pump line, tighten bleeder fitting.

7) Top off reservoir and reinstall cover.

Check brake by pumping lever several

times. Pedal should have a positive,

solid feel. If not, repeat bleeding

process as more air may have

entered the system. Inspect line to

ensure all fittings are tight. If brake

still feels slack, consult a service

technician.

For dual disc front brakes, repeat

bleeding process as though there are

two separate systems.

REAR BRAKE

Removing all air from the rear brake line is

the same as for the front. The rear brake

reservoir is usually located beneath one

of the side covers.

1) Remove the master cylinder cap and

fill to near full.

2) Attach the pump hose to the bleeder

fitting and pump the handle several

times to create a vacuum.

3) Crack the bleeder with a box wrench.

Because of the short line, most of the

air should be evacuated the first time.

Page Number - 20

Form 822378

Page 21

4) By closing the valve and repeating

the process, all of the air should be

eliminated from the system. Stop and

add more fluid when master cylinder

gets low.

5) Top off and recap the reservoir.

TROUBLESHOOTING

1) If, after bleeding procedure, the brake

continues to be unresponsive, you

may have water in the system, in

which case it will need to be disassembled and cleaned by a qualified

service technician.

2) If the brake squeaks slightly after

bleeding, the disc and pads must be

cleaned.

3) Although DOT 3 fluid is recommended

by most manufacturers, it has a

tendency to collect moisture - which

causes the common discoloration you

see - and that means decreased

efficiency. DOT 5 is silicone based

and does not have the same tendency to collect moisture. It also has a

higher tolerance. DOT 5, however, is

not always easy to find and the two

types of fluid must not be mixed.

4) Rubber hoses are supplied stock on

most motorcycles, but they have a

tendency to expand, which may

result in a spongy brake feel after a

lot of riding. Braided steel line will not

expand like this.

There is also a hose adapter and

5/32” ID hose in the kit for bleeding

hydraulic motorcycle brakes. Be sure

the caliper and master cylinder

pistons are free and all fittings are

tight. Cover the gas tank with rubber

or plastic protective sheet.

Connect the adapter and 5/32” ID

hose to the end of the long tube and

connect to caliper bleeder fitting.

Bleed as with an automobile.

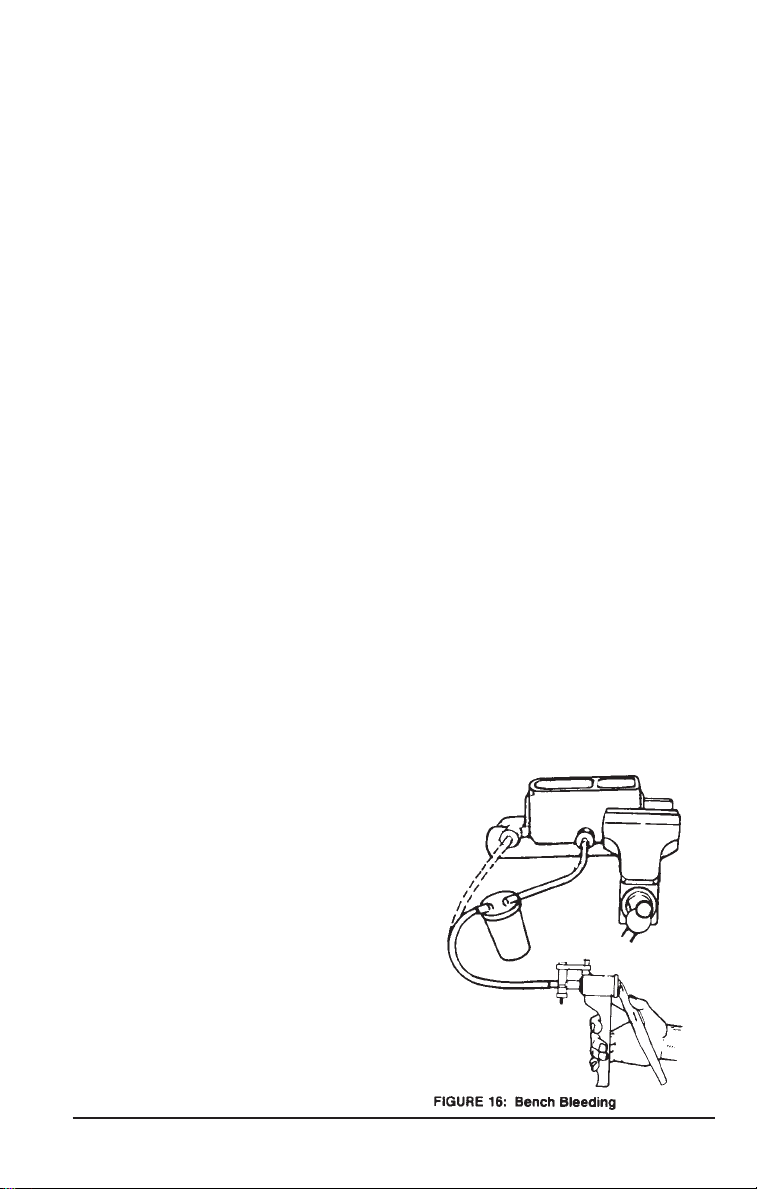

greatly decreases the chance that any

air will be caught in the cylinder upon

reinstallation. This bleeding technique

utilizes this Kit. Follow this procedure:

1) Plug outlet holes of the master

cylinder and gently clamp it in a

vise with the push rod end slightly

elevated. NOTE: Damage may

result if master cylinder is clamped

by the bore or if reservoirs are

clamped too tightly.

2) Fill the master cylinder with an

approved type brake fluid and keep

it filled at all times during the

procedures.

3) Remove a plug from the master

cylinder and attach the proper

adapter to this master cylinder

outlet port. Connect the pump tube

to the reservoir jar and the jar tube

to the adapter (FIGURE 16).

4) Pump the pump and observe air

and fluid flowing into the reservoir

until clear, bubble-free fluid

appears.

5) Plug the outlet tightly and repeat

step 4 on the other outlet ports.

6) Clamp master cylinder in a vise

with the push rod end down

slightly. Slowly slide the master

cylinder push rod back and forth

about 1/8”, until no air bubbles can

be seen in the reservoirs.

7) Remount the master cylinder with

the push rod end up and follow

steps 3 & 4 on all outlet ports. Plug

ports tightly. The master cylinder is

now free of air and ready to install.

BENCH BLEEDNG THE

MASTER CYLINDER

Whenever a master cylinder has been

removed from a vehicle or a new one is

being installed, the master cylinder must

be bench bled. Failure to bench bleed is

the main reason for unsuccessful master

cylinder replacement. Bench bleeding

Form 822378

Page Number - 21

Page 22

DOMESTIC CAR & LIGHT

TRUCK WHEEL LUG NUT

SPECIFICATIONS

Application Ft. Lbs. (N.m)

Domestic Cars

Chrysler Motors & Ford Motor Co.

FWD Models 90-100 (122-136)

RWD Models 85-95 (115-129)

General Motors Corp.

Aluminum Wheels 90-100 (122-136)

Steel Wheels 80-90 (109-122)

Domestic Trucks

Jeep 75-85 (1 02-115)

All Others

1/2” Stud 85-95 (115-129)

9/16” Stud 130-145 (177-197)

5/8” Stud 190-200 (258-272)

IMPORT CAR & LIGHT

TRUCK WHEEL LUG NUT

SPECIFICATIONS

Application Ft. Lbs. (N.m)

Acura & Honda 80 (109)

Audi & BMW 80 (109)

Infiniti & Nissan 72-87 (98-118)

Lexus & Toyota 76 (103)

Mercedes-Benz

190, 300D, 300E, 400E,

500E, C220, C280, E320,

E420 & E500 80 (109)

300SD, 300SE, 400SEL,

500SEL S320, S350,

S420 & S500 111 (150)

Peugeot

Aluminum Wheels 55 (75)

Steel Wheels 45 (61)

Porsche 94 (128)

Volkswagen

Vanagon 123 (167)

All Others 72-95 (98-129)

Volvo

700/900 Series 63 (85)

All Others 80 (109)

All Others

Aluminum Wheels 70-90

Steel Wheels 55-65 (75-88)

LAWN MOWER

APPLICATIONS

1. Priming circuit of the Lawn Boy

and similar engines.

a. Connect pump to the hose

and bulb assembly as shown

in Fig. 17.

b. Seal off vent hole in primer

bulb (if present) with finger

as shown in Fig. 17. Draw a

vacuum on the primer and

hose. The bulb should

collapse and hold a vacuum

until finger is released.

Figure 17

2. Carburator Float Needle and Seat

Assembly.

a. Use dual converter pump and put

selector on pressure.

b. Connect the pump to the fuel inlet.

c. Pressurize to 7 psi minimum.

d. Must hold 7 psi with carburator

inverted as shown on Fig. 18.

Figure 18

Page Number - 22

Form 822378

Page 23

3. Fuel Tank and Fuel Valve Assembly.

a. Use dual converter pump and put

selector on vacuum.

b. Connect pump to the tank outlet.

(See Fig. 19.) Make sure the fuel

valve is closed.

c. Pull a vacuum on the fuel valve.

A good valve will hold a vacuum

without leaking.

d. Put selector on pressure, open

fuel valve (if equiped). Install fuel

cap on tank filler opening.

e. Seal off vent hole in fuel cap and

pump air into fuel tank. Not more

than 2 or 3 psi. A good fuel tank

will hold the air pressure without

leaking. (See Fig. 20.)

Figure 19

Form 822378

Figure 20

Page Number - 23

Page 24

FRANÇAIS

T ABLE DES MA TIÈRES

La pompe ...................................................26

Le système automobile à dépression...........27

Diagnostic des conditions mécaniques

du moteur............................................30

Système de recyclage des gaz du carter....32

Recyclage des gaz d’échappement.............33

Soupapes de délai d’allumage......................38

Électrovalve de dépression de commande

de ralenti.............................................39

thermo-régulées.................................40

Freins...................................................................41

Section Anglaise...........................................2

Section Allemande.......................................48

Section Espagnloe......................................70

Page Number - 24

Form 822378

Page 25

Form 822378

Page Number - 25

Page 26

LA POMPE

La pompe à vide est un outil très polyvalent qui peut être utilisé pour une variété

de tests de systèmes automobiles et une

multitude de tâches utiles. Bien que la

pompe soit évidement utile pour tester des

moteurs d’aspiration, robinets de réglages

et sources d’aspiration, son usage ne se

limite pas à cela. Presque tous les

systèmes qui ont besoin pour fonctionner

de pression, de dépression ou

d’étanchéité appropriées peuvent être

soumis à des essais avec la pompe à vide.

La pompe et ses accessoires permettent

également de transférer des liquides, de

purger les freins et d’exécuter plusieurs

autres tâches. La pompe est aussi

conforme aux spécifications d’outils de

diagnostics, lorsque ces outils sont

spécifiés pour des programmes

d’inspection automobile d’état.

Cette section du manuel décrit la pompe,

ses spécifications, fournit des instructions

sur son mode d’emploi et des conseils

pour garder votre pompe en bon état de

marche.

de vide. C’est un simple levier qui doit être

tiré en arrière pour casser le vide. Cette

action laisse entrer l’air dans le système,

cassant ainsi le vide.

La deuxième méthode utilise un bouton

rotatif à ressort. En tournant lentement le té

de suppression de vide, le vide est cassé

lentement. En tournant le té rapidement, le

vide est cassé rapidement.

BOUCHON DE SÉCURITÉ

Le petit bouchon sur le raccord de pression

est emmanché en force avec un ajustement

serré. Pour l’enlever, il faut tirer en tournant.

Le bouchon empêche les liquides qui sont

entrés accidentellement dans la pompe,

comme le liquide de frein, d’éclabousser les

yeux de l’utilisateur. Pour cette raison, le

bouchon doit être toujours en place lors de

l’utilisation de la pompe, sauf quand vous

utilisez le raccord de pression. La pompe

vous donnera plusieurs années de service

si elle est bien entretenue. Consultez

ENTRETIEN dans cette section.

DESCRIPTION

La pompe à vide manuelle est simple,

précise et facile d’emploi pour de nombreuses applications. Bien que la pompe

soit offerte dans plusieurs versions

différentes, le modèle de base est

composé d’un corps de pompe, d’une

poignée mobile, d’un manomètre

d’aspiration, d’un raccord d’aspiration et

d’un raccord de pression à bouchon de

sécurité. La pompe tient facilement dans la

main, et lorsque vous serrez la poignée,

une dépression est crée au niveau du

raccord d’aspiration. Si l’aspiration de la

pompe est branchée à un système ou à un

récipient fermé, le manomètre indique le

niveau d’aspiration. Si le raccord de

pression est branché au système ou au

récipient, une pression est générée, mais

le manomètre ne la montre pas. Un

manomètre distinct est offert pour indiquer

le niveau de pression.

CASSER LE VIDE

Il existe deux méthodes élémentaires pour

casser le vide à la pompe. La première

méthode utilise la manette de suppression

Page Number - 26

SPÉCIFICA TIONS

Application Mesure

Aspiration maximum

Au niveau de la mer Environ 23 à

25 po Hg (585

à 635 mm Hg)

Volume par course

Modèle standard 16,4 cc.

Modèle réparable 16,4 cc.

Modèle Superpump 32,8 cc.

Modèle Silverline 16,4 cc.

Pression maximum

(Sans assistance)

Modèle standard 48 kPa.

Modèle réparable 83 kPa.

Modèle Superpump 48 kPa.

Modèle Silverline 103 kPa.

Avec assistance

Modèle standard 110 kPa.

Modèle réparable 650 kPa.

Modèle Superpump 83 kPa.

Modèle Silverline> 206 kPa.

Précision du manomètre

15 à 20 po Hg 3%-2%-3%

(381 à 508 mm Hg). de la gamme

complète.

Form 822378

Page 27

DES NÉCESSAIRES D’ENTRETIEN

sont disponibles uniquement pour les

pompes réparables qui sont assemblées

avec des vis visibles. Les pompes non

réparables sont scellées avec des

produits chimiques et ne peuvent pas être

ouvertes sans endommager la pompe.

Aucune réparation ne doit être entreprise

sur ces modèles, à l’exception du graissage. Consultez GRAISSAGE dans cette

section.

UTILISA TION DE LA POMPE

La pompe à vide est facile d’emploi. Dans

la plupart des cas, la pompe est connectée directement à un composant,

utilisée à la place d’une conduite

d’aspiration ou branchée dans un circuit

de mise en dépression avec un raccord en

T. La pompe peut fonctionner comme

instrument d’essai des trois manières

suivantes :

1) Quand la dépression est désirée pour

un essai, serrez simplement la poignée

mobile, comme si vous serriez le poing.

Continuez de pomper jusqu’a ce que le

niveau de dépression désiré soit

indiqué sur le manomètre.

2) La pompe peut être connectée à un

circuit de mise en dépression et être

utilisée pour mesurer le niveau de

dépression actuel, comme le ferait tout

autre manomètre à dépression.

N’appuyez pas plusieurs fois de suite

sur la poignée lorsque la pompe est

utilisée de cette manière car de

mauvaises mesures pourraient en

résulter.

3) En enlevant le bouchon de sécurité et

en connectant le raccord de pression,

la pompe peut aussi fonctionner

comme pompe de pression. La

pression est créée quand la poigné de

la pompe est relâchée de la position

fermée. Pour une pression supplémentaire, appuyez manuellement sur la tige

de la pompe à piston.

ATTENTION : Assurez-vous toujours que

le bouchon de sécurité est en place sauf

si vous utilisez le raccord de pression.

Dans d’autres sections de ce manuel,

vous pouvez trouver des utilisations

spécifiques de la pompe.

ENTRETIEN

Votre pompe est un instrument de mesure

précis, construit solidement. Manipulez-

la avec soin ! Ne faites pas tomber la

pompe et ne la manipulez pas brutalement, car la précision du manomètre peut

en être affectée. Ne posez pas la pompe

sur un moteur chaud et ne l’exposez pas

à une flamme ouverte. Ne laissez pas la

pompe en plastique à l’intérieur d’une

automobile chaude. La pompe pourrait se

déformer. La pompe vous donnera

plusieurs années de service si elle est

bien entretenue.

GRAISSAGE

Le lubrifiant appliqué en usine est une

huile de silicone et doit rester effectif

pendant une longue durée. Si vous avez

besoin de lubrifier votre pompe, utilisez

de l’huile de silicone ou bien, si vous n’en

trouvez pas, un liquide pour les freins à

base silicone DOT 5 (pas DOT 3) ou

même de l’huile végétale alimentaire.

N’utilisez pas de liquide à base de pétrole

ni de lubrifiant aérosol (par exemple WD40, huile de moteur, etc.) car ils peuvent

endommager la pompe.

LE SYSTÈME À

DÉPRESSION

AUTOMOBILE

Form 822378

Page Number - 27

Page 28

Ce manuel traite de la dépression, de son

utilisation dans divers systèmes automobiles et de l’emploi de la pompe à vide

pour contrôler et diagnostiquer ces

systèmes. Cette section explique le

concept de dépression, sa mesure, sa

provenance sur les automobiles, le

système de distribution et d’utilisation de

dépression, et des principes de base de

dépannage.

QU’EST-CE QU’UNE

DÉPRESSION ?

Une dépression est tout simplement de

l’espace vide, et elle peut exister comme

vide partiel ou total. La dépression ne

crée pas de puissance par elle-même. La

puissance pour les accessoires à vide

dépend de la présence de pression

atmosphérique. L’atmosphère exerce une

pression de 101,3 kPa sur tout objet au

niveau de la mer. Si une partie de l’air est

enlevée d’un côté d’un diaphragme (vide

partiel), la pression atmosphérique

exerce une force sur le diaphragme. La

force est égale à la différence de

pression multipliée par l’aire du diaphragme (FIGURE 1). Généralement,

moins il y a d’air dans un espace (vide

plus élevé), plus l’atmosphère cherche à

pénétrer et plus la force créée est

élevée.

MESURE DE LA DÉPRESSION

Aux États-Unis, la dépression est

généralement mesurée en pouces de

mercure (po Hg). Elle peut aussi être

mesurée en millimètres de mercure (mm

Hg) et en kiloPascals (kPa). La pression

atmosphérique supporte une colonne de

mercure dans un manomètre d’environ

765 mm (30 pouces) de haut. Ceci est la

pression barométrique en mm Hg qui varie

selon les variations de la météo. Les

mesures de dépression en mm Hg sont

en réalité des indications de pression

négatives. Par exemple, une dépression

de 765 mm Hg serait un vide complet. La

moitié d’un vide complet serait 382 mm

(15 po) Hg. Un moteur à essence

tournant au ralenti génère normalement

une dépression de 16 à 22 po Hg (400 à

560 mm Hg). Lors des décélérations,

parce que le papillon des gaz est fermé,

la dépression augmente. La pompe

génère environ 25 po Hg (635 mm Hg)

comme indiqué sur le manomètre gradué

en po Hg et kPa.

CRÉA TION DE DÉPRESSION PAR

LES MOTEURS

Une dépression est créée quand de l’air

est retiré d’un certain volume ou bien

lorsqu’un espace scellé est agrandi. C’est

pourquoi une dépression est présente

dans un moteur. Pendant la course

d’admission, le piston descend en créant

un vide partiel car le volume du cylindre

est augmenté. L’air ne peut pas passer

suffisamment vite dans le système

d’admission pour remplir complètement

l’espace créé par le déplacement du

piston (FIGURE 2). C’est la source de

dépression automobile la plus fréquente.

LA DÉPRESSION DU MOTEUR À

ESSENCE ET CELLE DU

MOTEUR DIESEL

Étant donné qu’un moteur diesel ne

produit pas autant de dépression qu’un

moteur à essence, une pompe mécanique

est nécessaire pour opérer les accessoires à dépression. La pompe est aussi

utile pour vérifier les équipements sur les

deux types de moteur.

SYSTÈME DE DISTRIBUTION

DE DÉPRESSION

Toutes les automobiles modernes

présentent un système de distribution de

dépression (FIGURE 3) composé de

conduites, flexibles, raccords et accessoires à dépression. Ce système doit être

étanche. Sinon, le mélange de carburant

et d’air sera appauvri par l’air rentrant par

Page Number - 28

Form 822378

Page 29

les fuites, causant des soupapes

d’échappement et des bougies brûlées,

un ralenti irrégulier, le calage du moteur,

un allumage prématuré, etc. De plus, tous

les instruments commandés par dépression affectés par la fuite ne fonctionneront pas correctement.

Normalement, un moteur à essence

génère une dépression de 16 à 22 po Hg

(400 à 560 mm Hg) dans le collecteur

d’admission au ralenti. Ceci indique que la

dépression du moteur s’effectue correctement. Si elle est moins forte, le moteur

tourne moins efficacement. Plus la

dépression est faible, moins le moteur

tourne efficacement, et plus la consommation kilométrique est élevée. Le

système de distribution de dépression

fournit la dépression aux servomoteurs à

vide dans les systèmes de climatisation,

le servofrein, le servo de régulateur

automatique de vitesse, les contrôles

d’émission, le capteur de pression

absolue du collecteur d’admission, et les

systèmes de commande de la boîte de

vitesses automatique. Dans les véhicules

plus anciens, la dépression est également

fournie au mécanisme à dépression

d’avance ou de retard d’allumage. Ces

instruments peuvent être branchés

directement à l’aspiration du collecteur

d’admission ou commandés par des

solénoïdes, des interrupteurs thermostatiques ou autres commandes à dépression.

DÉPANNAGE DU SYSTÈME À

DÉPRESSION

La plupart des problèmes de dépression

peuvent être attribués à des fuites dans

les flexibles, connecteurs, diaphragmes

ou soupapes. Des conduites pincées ou

des soupapes bouchées ne permettent

pas non plus la circulation de la dépression. Des problèmes peuvent aussi être

causés par le fonctionnement mécanique

incorrect d’un dispositif entraîné par un

moteur à vide.

La pompe à vide permet également de

mesurer le niveau d’aspiration dans un

flexible. Le manomètre est utile pour

détecter une fluctuation de dépression

ou une fuite, et permet de vérifier tous

les types d’accessoires à vide. Sur un

moteur à vide, par exemple, la pompe est

utilisée pour évacuer la chambre du

diaphragme, vous permettant de vérifier

le fonctionnement mécanique du

dispositif ainsi que le niveau de dépression requis pour l’activer. Vérifiez que le

diaphragme n’a pas de fuite en appliquant une dépression de 10 po Hg (254

mm Hg) sur l’équipement. Observez le

manomètre. Si l’aiguille chute lorsque

l’actionneur a fini de bouger, le diaphragme présente une fuite. Si le

diaphragme ne présente pas de fuite, la

dépression doit rester stable pendant

une minute, l’aiguille du manomètre

restant immobile.

Form 822378

Page Number - 29

Page 30

DIAGNOSTIC DES CONDITIONS MÉCANIQUES DU

MOTEUR

VÉRIFICA TIONS ET

DIAGNOSTICS DU MANOMÈTRE

À VIDE

Les mesures du manomètre à vide de la

pompe indiquent les possibilités de

problème mécanique, mais ces diagnostics ne sont pas parfaits. Observez

soigneusement le manomètre et vérifiez

les mesures avec des tests supplémentaires, lorsque c’est possible, pour

vérifier vos diagnostics.

Ne vous attendez pas à ce que le moteur

produise une dépression spécifique. La

plage des mesures du manomètre et le

mouvement de l’aiguille (FIGURE 5) sont

plus importants que ces chiffres

spécifiques. Ce qui est important, c’est

d’observer la MANIÈRE dont l’aiguille

bouge (brusque, progressive, erratique,

etc.), le sens dans lequel elle bouge, si le

mouvement est régulier ou variable, et

l’amplitude de déplacement de l’aiguille.

La figure suivante montre des exemples

de ce qu’il faut rechercher et la signification des mesures de manomètre à vide

qui doivent rester stables, entre 16 et 22

po Hg (400 et 560 mm Hg).

MOTUER NORMAL

Faites tourner le moteur au ralenti et

connectez la pompe à un port d’aspiration

du collecteur d’admission. Regardez le

déplacement de l’aiguille sur le

manomètre. Au ralenti, le manomètre doit

afficher une valeur stable de 16 à 22 po

Hg (400 à 560 mm Hg).

RESSORT DE SOUP APE BRÛLÉE

OU QUI FUIT.

Au ralenti, des soupapes brûlées ou qui

fuient peuvent causer une chute de

l’aiguille du manomètre à une valeur plus

basse avec retour à une valeur normale à

intervalles réguliers. L’aiguille chute de 1

po Hg (25 mm Hg) à intervalles réguliers

quand la soupape défectueuse essaie de

Page Number - 30

Form 822378

Page 31

fermer.

SOUP APE GOMMÉE

Une soupape gommée cause des chutes

rapides et intermittentes de l’aiguille. Ceci

est différent de la descente régulière qui

est indicatrice d’une soupape brûlée ou

fuyante. Une soupape gommée peut être

identifiée en appliquant de l’huile légère

directement sur les guides de soupape.

Lorsque la soupape gommée est atteinte,

l’huile permet de remédier temporairement

à la situation.

RESSORT DE SOUP APE FAIBLE

OU CASSÉ

Un ressort de soupape faible est indiqué

quand l’aiguille du manomètre fluctue

rapidement entre 10 et 21 po Hg (254 et

533 mm Hg) au ralenti. Les fluctuations

augmentent lorsque le régime du moteur

augmente. Un ressort de soupape cassé

cause des fluctuations rapides de

l’aiguille à intervalles réguliers. Ceci se

produit également chaque fois que la

soupape essaie de fermer.

GUIDES DE SOUP APE USÉS

Les guides de soupape usés laissent

entrer de l’air ce qui perturbe le mélange

carburant/air. L’aiguille du manomètre

indique une mesure plus basse que la

normale et fluctue rapidement d’environ 3

po Hg (76 mm Hg). L’aguille devient stable

lorsque le régime du moteur augmente.

FUITE DE SEGMENT DE PISTON

Au ralenti, l’aspiration est basse mais

stable à environ 12 à 16 po Hg (305 à 406

mm Hg). Ouvrez le papillon est laissez le

moteur augmenter de régime jusqu’à 2000

tr/min. Puis, fermez rapidement le papillon.

L’aiguille doit monter rapidement de 2 à 5

po Hg (25 à 127 mm Hg) au-dessus de sa

mesure basse stable. Une augmentation

moins importante peut indiquer des

segments de pistons défectueux et une

vérification complète de fuite des

cylindres ou de compression du moteur

doit être effectuée.

JOINT DE CULASSE CLAQUÉ

Au ralenti, l’aiguille du manomètre de la

pompe à vide fluctue entre une mesure

normale et basse. L’aiguille descend

d’environ 10 po Hg (254 mm Hg) depuis

une mesure normale puis revient à la

position normale chaque fois que les

cylindres défectueux sont en position

d’allumage.

VÉRIFICA TION DE COLMA TAGE

DE L’ÉCHAPPEMENT

Un colmatage de l’échappement affecte

peu la performance du moteur au ralenti,

mais entraîne une très mauvaise performance du moteur sous charge ou à des

régimes plus élevés.

1) Branchez le flexible de la pompe au

raccord d’aspiration du collecteur

d’admission. Faites tourner le moteur

au ralenti et notez le niveau de

dépression et le mouvement de

l’aiguille. Comparez les mesures et les

mouvements aux descriptions

données pour les soupapes brûlées

et la synchronisation tardive de

l’allumage et des soupapes.

2) Surveillez le manomètre pendant que

Form 822378

Page Number - 31

Page 32

le régime du moteur augmente jusqu’à

environ 2500 tr/min.

3) Une augmentation d’aspiration par

rapport au niveau au ralenti indique

que le système d’échappement n’est

pas colmaté.

4) Si l’aiguille chute vers zéro lorsque le

régime du moteur augmente, il y a un

colmatage dans le circuit

d’échappement ou la soupape de

recyclage des gaz d’échappement est

trop active.

5) Vérifiez séparément la soupape de

recyclage des gaz d’échappement. Si

elle est en bon état, le problème est

un circuit d’échappement colmaté.

Vérifiez et remplacez le cas échéant.

MÉLANGE DE CARBURANT ET

D’AIR INCORRECT AU RALENTI

Quand l’aiguille se déplace lentement

avec un mouvement de va-et-vient de 4 à

le moteur.

SYSTÈME DE RECYCLA-

GE DES GAZ DU CARTER

FONCTIONNEMENT DU

SYSTÈME

Le système de recyclage des gaz du

carter (RGC) est utilisé sur tous les

moteurs modernes pour réduire la

pollution atmosphérique en assurant un

balayage plus complet des gaz du carter.

L’air est aspiré au travers d’un filtre situé

dans le filtre à air, d’un flexible dans le

couvercle de soupapes, dans le carter,

en travers et vers le haut dans l’arrière

du collecteur d’admission ou du couvercle de soupapes opposé, à travers la

soupape RGC, au travers d’un flexible, et

dans le collecteur d’admission. Tous les

gaz du carter sont aspirés par le

collecteur d’admission pour brûler dans

le moteur.

Lorsque le débit d’air au travers du

carburateur ou du corps de papillon est

élevé, l’air supplémentaire du système

RGC n’a pas d’effet sur le fonctionnement du moteur.

Cependant, au ralenti le débit d’air au

travers du carburateur ou du corps de

papillon est tellement bas que tout

5 po Hg (101 à 127 mm Hg), le mélange

est trop riche. Un mélange pauvre fait

chuter l’aiguille irrégulièrement sur à peu

près la même plage.

FUITES DU COLLECTEUR

D’ADMISSION OU DE

L ’ADMISSION D’AIR

S’il y a une fuite dans le système

d’admission d’air, l’aiguille de la pompe est

de 3 à 9 po (76 à 228 mm) en dessous de

la normale mais reste stable.

SYNCHRONISA TION TARDIVE

DE L’ALLUMAGE OU DES

SOUP APES

Une mesure très basse mais stable au