Mityvac 04700 User Manual [en, de, es, fr]

USER’S MANUAL

Have Technical Questions?

If you have questions, or require technical

service, please contact our trained service

technicians at:

1-314-679-4200 ext. 4782

Monday - Friday 7:30 am to 4:15 pm CST

Visit our website at www.mityvac.com for

new products, catalogs and instructions for

product use.

Need Service Parts?

To order replacement or service parts, visit

us online at www.mityvacparts.com or call

toll free 1-800-992-9898.

SPECIFICATIONS:

Air Inlet Size: 1/4” NPT

Min. Inlet Air Pressure

Max. Inlet Air Pressure: 120 PSI (8.3 Bar)

: 90 PSI (6.2 Bar)

AirEvac

MODEL 04700

OCT - 2004

Form 823538

Section

- MV28

Page

- 1

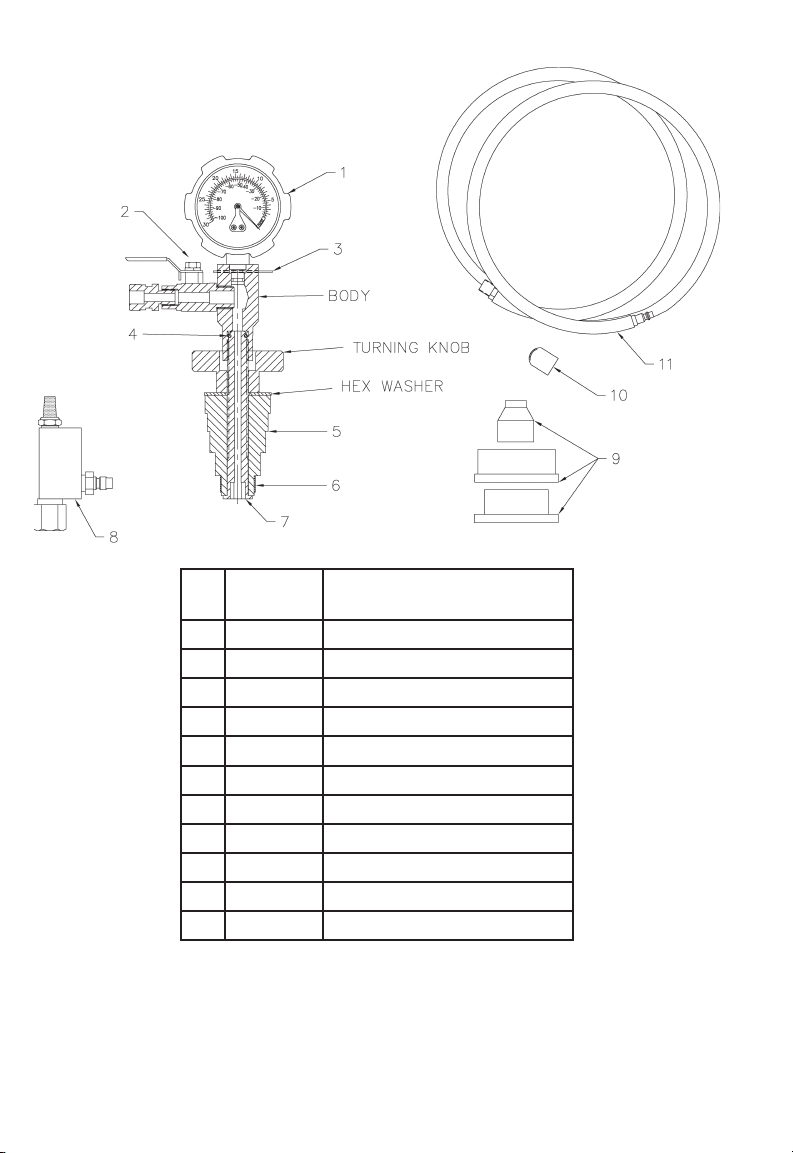

PART

NO.

1 823321 VACUUM GAUGE

2 823484 FLOW CONTROL VALVE

3 823483 RETAINING CLIP

4 823482 O-RING

5 823479 RUBBER ADAPTER KIT

6 823480 METAL RING

7 823481 BRASS BOLT

8 823491 VACUUM PUMP ASSEMBLY

9 823486 RUBBER BUSHING KIT

10 823487 SCREEN CAP

11

823485 HOSE ASSEMBLY

DESCRIPTION

Page Number - 2

Form 823538

CAUTION!

TO AVOID PERSONAL INJURY AND/OR

VEHICLE DAMAGE:

While some precautions are specified in

this manual, and should be noted to avoid

personal injury or vehicle damage, it is

not possible for these cautions to cover all

conceivable ways in which service or testing might be done, or all possible hazardous consequences of each way, nor could

Lincoln possibly know or investigate all

such ways. It is therefore the responsibility

of anyone using this manual or any other

Mityvac product, to satisfy him or herself

completely that neither personal safety nor

vehicle safety will be jeopardized by the service methods selected. Any such injury or

damage is entirely the user’s responsibility.

This device is not to be used in any manner

on the human body.

Instructions for Evacuating the

Cooling System and Checking

for Leaks

Important: This kit is designed for

servicing a variety of vehicles in a

safe, convenient manner. However,

differences in radiator and expansion tank filler necks prevent its use

on every possible make and model.

The procedures below are to serve as

guidelines for the use of this equipment, in addition to these guidelines,

always follow the manufacturer’s recommended procedures when servicing each unique vehicle.

Never remove the radiator cap or

expansion tank cap while the engine

is at operating temperature. Always

allow the engine to cool before removing the radiator cap or expansion tank

cap. The cooling system is under

pressure. Failure to allow the engine

to cool before opening the cooling

system could result in serious injury.

Form 823538

1. Properly position the vehicle for

service access to the radiator or

coolant expansion tank. Turn on the

heater control, and set it to its highest

temperature setting.

2. Thread a ¼” NPT air coupler nipple

(not included) compatible with your

compressed air system, into the

Vacuum Pump Assembly.

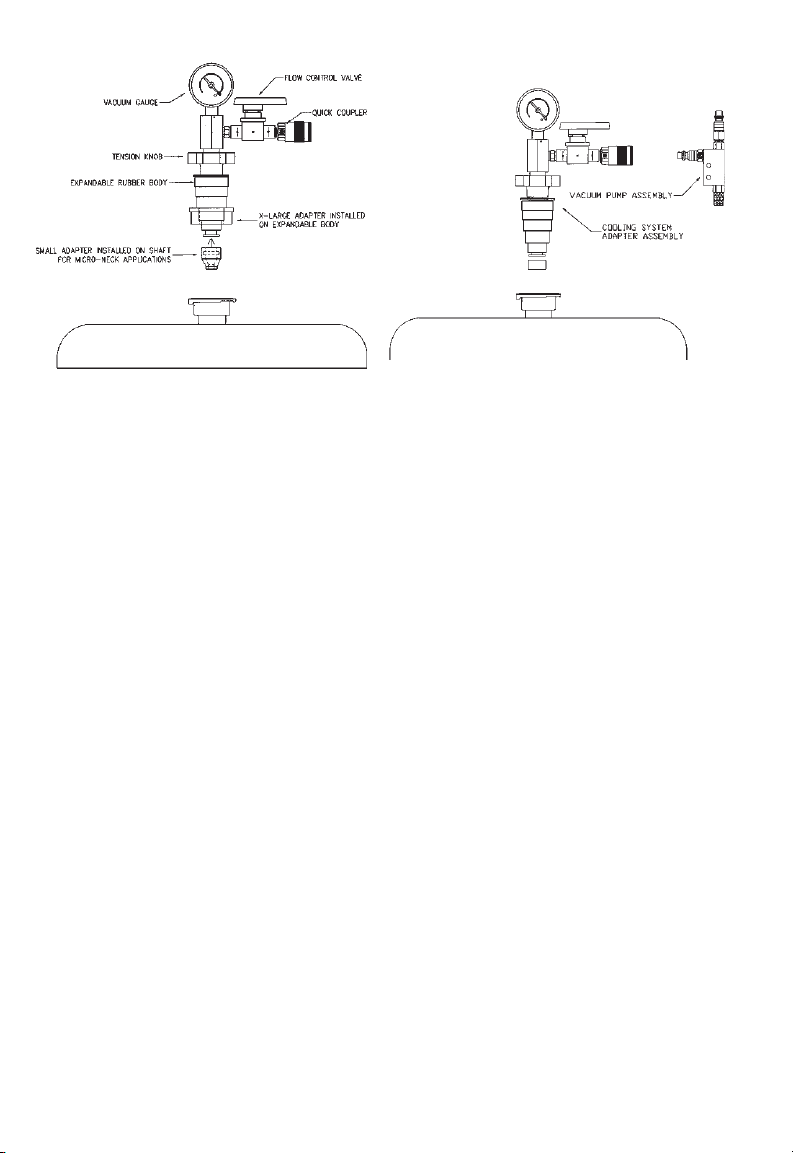

Figure 1

3. After ensuring the engine and cooling

system are cool, cautiously remove

the cap from the radiator or coolant

expansion tank.

4. Turn the tension knob on the Cooling

System Adapter Assembly counterclockwise until all tension has been

relieved from the expandable rubber

body. (See Figure 2.)

5. Insert the expandable rubber body of

the Cooling System Adapter Assem

bly into the filler neck of the radiator

or coolant expansion tank until the

largest possible diameter fits snuggly.

Note: In case none of the diameters

on the expandable rubber body fits

snuggly, two additional bushings

have been provided. These bushings

install over the second step of the

rubber body, and allow a snug fit with

larger diameters fill necks. A third

“micro-neck” rubber adapter has also

been included, and can be installed

onto the head of the shaft on the

adapter, below the expandable rubber

body. (See Figure 2).

Page Number - 3

-

Figure 2

Figure 3

6. Turn the tension knob clockwise to

expand the rubber body until it comes

into firm contact with the interior wall

of the radiator or expansion tank filler

neck.

7. Check the connection by holding the

radiator or expansion tank stable

while carefully attempting to pull up

on the adapter. If the adapter comes

free or is not snug, increase the tension by further rotating the tension

knob.

Caution: Some late-model vehicles

are equipped with radiators or

coolant expansion tanks made of

plastic. Excessive over-tightening

(expansion) of the rubber adapter

could result in cracking the radiator or expansion tank. Use caution

when tightening the expandable

rubber adapter.

8. Utilizing the quick coupler connection,

connect the Vacuum Pump Assembly

to the Cooling System Adapter As

sembly. (See Figure 3.)

9. Connect clean, dry, regulated compressed air between 90 and 120 psi

(6.2 to 8.3 bar), to the Vacuum Pump

Assembly by means of the previously

installed air coupler nipple.

-

10. Turn on the compressed air, and

open the flow control valve on the

Cooling System Adapter Assembly.

The venturi action of the vacuum

pump will make a hissing noise as air

is removed from the cooling system.

If the cooling system is not empty,

coolant may be sucked through the

vacuum pump and sputter from the

muffler.

11. While watching the gauge, allow the

vacuum pump to pull air from the

cooling system until it reaches 24 to

26 in. Hg (81 to 88 kPa). This process should take less than a minute.

Note: As air is evacuated from the

cooling system, it is normal for radiator hoses to collapse. If the system

fails to pull a vacuum, check to see

if there are any overflow hoses that

need to be clamped off in order to

produce a closed system.

12. Once the cooling system has reached

24 to 26 in. Hg (81 to 88 kPa) vacuum, close the valve on the Cooling

System Adapter Assembly, disconnect the air supply, and then discon

nect the Vacuum Pump Assembly.

-

Page Number - 4

Form 823538

13. Watch the gauge for at least 30

seconds. It will maintain the 24 to 26

in. Hg (81 to 88 kPa) reading if the

system does not leak.

14. Follow the procedures below to prop

erly refill the cooling system before

relieving the vacuum from the system.

5. When the vacuum gauge reading

reaches zero (0), the cooling system

is full.

6. Remove the Cooling System Adapter

-

from the radiator or expansion tank

by turning the tension knob counterclockwise.

Refilling the cooling system

1. Follow the procedure above to evacu

ate and check the cooling system for

leaks. If the system has a leak, repair

it and re-evacuate the system.

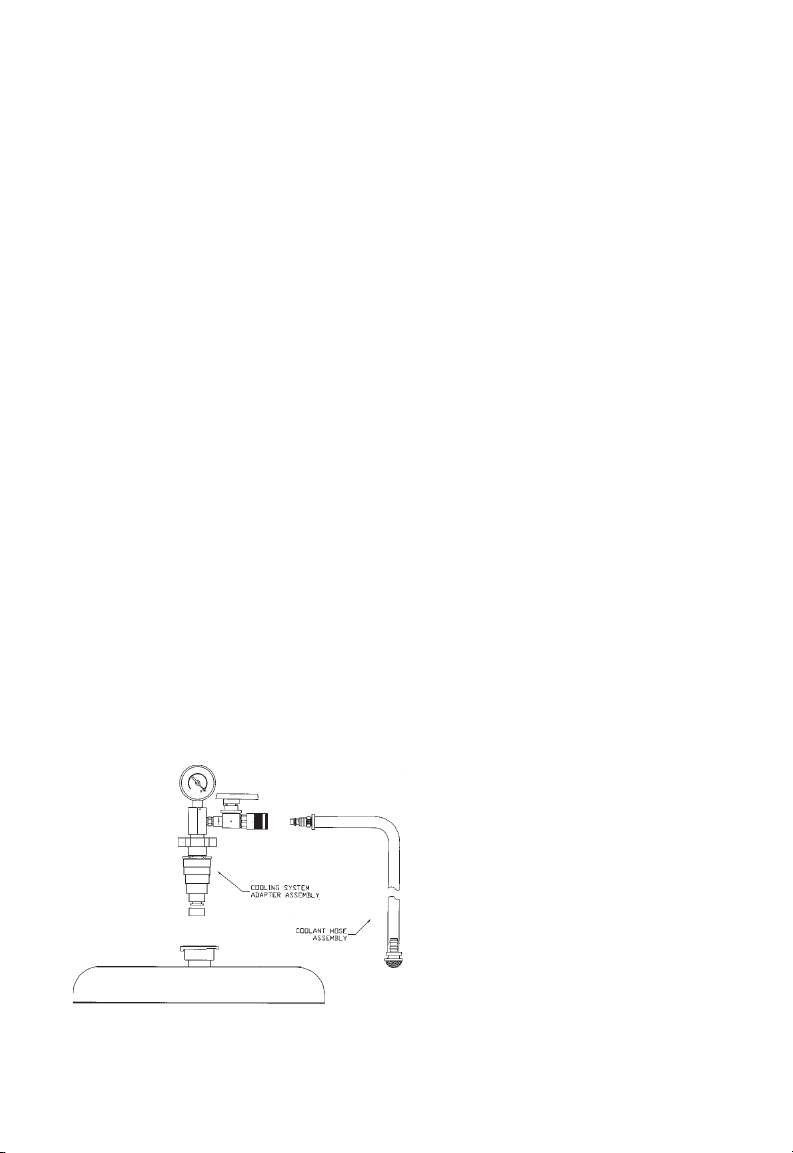

2. With a vacuum of 24 to 26 in. Hg (81

to 88 kPa) on the system, connect the

Coolant Hose Assembly to the Coolant System Adapter Assembly. (See

Figure 4.)

3. Submerse the free end of the coolant

hose into a supply of coolant. Ensure

there is enough coolant to refill the

system, or air will be pulled back into

the system, and the system will not fill

to the proper level.

4. Open the flow control valve on the

Coolant System Adapter Assembly,

and the system will refill with coolant.

Figure 4

7. Start the engine and allow it to reach

operating temperature.

-

8. Top-off the coolant level in the radia

tor or expansion tank as required, and

reinstall the cap.

-

Form 823538

Page Number - 5

MODE D’EMPLOI

Vous Avez des Questions Techniques ?

Si vous avez des questions ou vous

avez besoin de support technique,

merci de bien vouloir appeler nos

techniciens au :

1-314-679-4200 poste 4782

Du lundi au vendredi de 7:30 à 16:15

CST

Allez sur notre site Internet www.

mityvac.com pour voir les nouveaux

produits, les catalogues et les modes

d’emploi.

AirEvac

MODÈLE 04700

Vous Avez Besoin de Pièces Déta

chées ?

Pour commander des pièces de

rechange ou des pièces détachées,

allez sur notre site Internet www.

mityvacparts.com ou appelez notre

numéro vert au 1-800-992-9898.

Caractéristiques Techniques:

Taille de l’admission d’air : 1/4” NPT

Pression minimale de l’admission

d’air : 6,2 bars (90 PSI)

Pression maximale de l’admission

d’air : 8,3 bars (120 PSI)

OCT - 2004 Formulaire 823538 Section – MV28 Page – 1

Page Number - 6

-

Form 823538

Loading...

Loading...