Page 1

DUAL CONVERTER MODEL 06895

and MODEL 04095

DUAL CONVERTER

TM

INST ALLATION INSTRUCTIONS

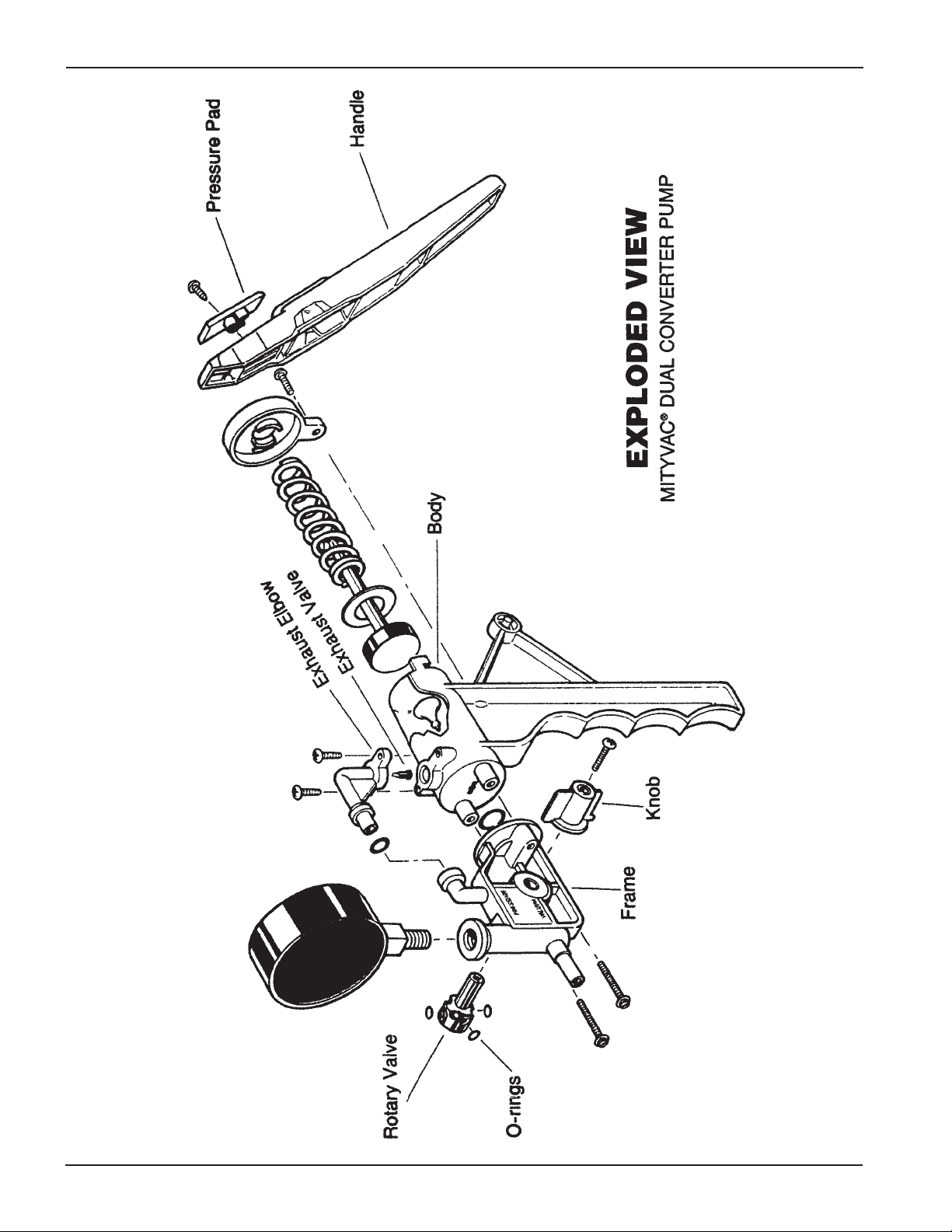

NOTE:READ THROUGH ALL INSTRUCTIONS AND FAMILIARIZE YOURSELF WITH THE PARTS

PRIOR TO INSTALLING YOUR DUAL CONVERTER

1. Make sure the exterior of your pump is cleaned of loose

dirt, grease, oil, etc.

2. Remove the old exhaust fitting

a. For plastic pump: Retain screws

b. For metal pump: Discard screws

3. Remove the old junction

a. For plastic pump: Retain screws

b. For metal pump: Retain screws

4. Install black exhaust valve in elbow. Install the elbow on

the pump. Do not overtighten.

For plastic pump: Use screws retained in step 2a.

For metal pump: Use the two larger screws provided.

TM

a. For plastic Dual Converter

Select the correct exhaust elbow from the Dual

ConverterTM kit. (The elbow marked “M” is for the

metal pump; the one marked “P” is for the plastic

standard pump; the one marked “SP” is for the plastic

SuperpumpTM).

b. For SilverlineTM (metal) Dual ConverterTM (p/n 04095):

Use the exhaust elbow provided in kit.

5. Slip the small O-ring onto elbow. Install the large O-ring

into Dual ConverterTM frame. Slide the Dual Converter

into place on the pump body and elbow. Make sure the

elbow is fully seated and the frame is snug against the

body. Install rear screw (on side away from knob) and

tighten until just snug. Use one of the screws retained in

step 3.

(p/n 06895):

6. Turn knob to “Vacuum” position. (Note the large square

notch on rear side of the black rotary valve is pointing up,

toward elbow.) Remove the screw from knob, then

remove the knob from the shaft.

7. Slowly slide the black rotary valve completely out. Install

front screw. Use the remaining screw retained in step 3.

Tighten until snug. Snug rear screw again.

8. Make sure that all three O-rings are in their recesses,

and carefully push the rotary valve back into place.*

The large square notch must point up toward the elbow.

Replace the knob onto the rotary valve shaft, with the

wide flange pointing toward “Vacuum”. If necessary,

wiggle it slightly to fully seat the knob, then replace the

screw.

Do not overtighten.

9. Install the pressure pad onto the handle.

Note: Silverline

hole, to install pressure pad.

* If the O-rings have become dry, it helps to lightly lubricate

them with Silicone Oil or light grease.

Do Not Use Aerosol Lubricants.

TM

TM

metal pump must have handle screw-

One Lincoln Way

St. Louis, MO 63120-1578

USA

Phone +1.314.679.4200

Fax +1.800.424.5359

Form 822363FEBRUARY 2003

© Copyright 2003

Printed in USA

Web site:

www.lincolnindustrial.com

Page 2

Page Number - 2

Form 822363

Loading...

Loading...