1

Heavy Industrial PC

KUBE-3000 series

User Manual

Version 1.0

2

Table of contents

1.1 Description ............................................................................................................... 3

1.1.1 KUBE-3000 series ................................................................................................ 3

1.2 Ordering data .......................................................................................................... 4

1.2.1 Product ................................................................................................................ 4

1.2.2 Accessories .......................................................................................................... 4

2 Installation ........................................................................................................................ 5

2.1 Wall mount .............................................................................................................. 6

2.1.1 Wall mount .......................................................................................................... 6

2.2 Din rail mount .......................................................................................................... 7

2.2.1 Din rail mount dimension ................................................................................... 8

2.3 Interface ................................................................................................................... 8

2.3.1 I/O port ................................................................................................................ 8

2.3.2 Power connection ............................................................................................... 9

2.3.3 Serial Communication ....................................................................................... 10

2.4 Antenna ................................................................................................................. 11

3 Operation ........................................................................................................................ 12

3.1 LED status .............................................................................................................. 12

4 Maintenance ................................................................................................................... 13

4.1 Service panel.......................................................................................................... 13

4.2 Real time clock battery ......................................................................................... 14

4.3 CMOS/BIOS reset .................................................................................................. 15

4.4 Mass Storage (M.2) ............................................................................................... 16

4.5 Mass Storage (mSATA) .......................................................................................... 17

3

Overview

1.1 Description

MiTwell’s new KUBE series of embedded automation computers are highly rugged

design for heavy industrial application. KUBE series including pocket size, small

size and regular size with different level of processors to meet different kinds of

application in the Industry such as Equipment connectivity, Production process

monitoring, Environment Management, Process Visualization…etc. All models

provides flexible and time-to-market support in variety of applications.

1.1.1 KUBE-3000 series

Compact size, ruggedize fan-less Box PC designed for heavy industrial

application with Intel® Apollo Lake family processor

Futures

Support Extended Temperature and Heavy Industrial EMC

Compact fan-less design, patented thermal solution

Easy for PPC integration by LVDS

Edge LED indication design

Expandable design by multiple interface

Support DIN-Rail, Wall Mounting, VESA Scheme

Removable service panel for easy maintenance

4

1.2 Ordering data

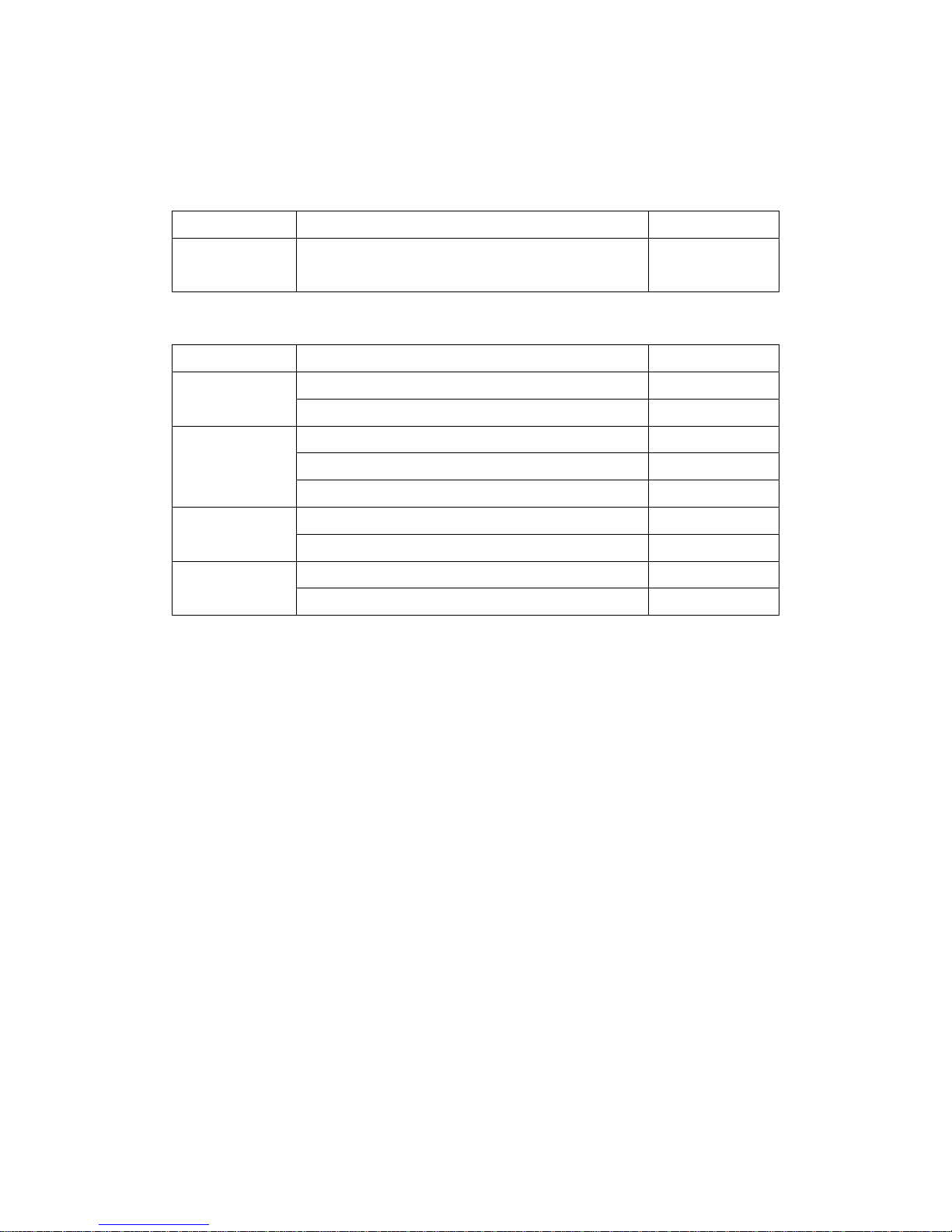

1.2.1 Product

Model No.

Description

Ordering No.

KUBE-3100

Intel® Apollolake Celeron N3350, 4xUSB,

3xCOM, 2xLAN, 24VDC

AS7-3040

1.2.2 Accessories

Catagory

Description

Ordering No.

Video adaptor

DP to VGA video adapter

TBD

DP to DVI-I video adapter

TBD

Mass Storage

(Wide Temp.)

M.2 SSD: 64GB

TBD

M.2 SSD: 128GB

TBD

M.2 SSD: 256GB

TBD

Memory

(KUBE-3000)

DDR3L SO-DIMM 4G

B473D522

DDR3L SO-DIMM 8G

B473D530

Mounting kit

Universal DIN rail adapter

TBD

Wall mounting kit

TBD

5

2 Installation

KUBE series IPC support varies way to mount. Please use the appropriate section

below to mount the IPC.

When installing the KUBE IPC in a cabinet, follow these general rules:

Verify clearances within the cabinet. Typically, leave at least 5 cm (2 in.) on

each side, with 12.7 cm (5 in.) on the connector side.

Drill all holes and make all cuts before beginning installation. Be sure to

protect already

Installed components from shavings during this procedure.

Supporting panels must be at least 14 gauge to provide proper support.

Make sure that there is adequate space around the heat sink to provide

sufficient cooling.

NOTE:

Exceeding the system temperature limits can result in performance degradation

of any or all components. It is therefore important that the ambient

temperature of the installation environment is kept within the system

temperature limits of your KUBE IPC.

6

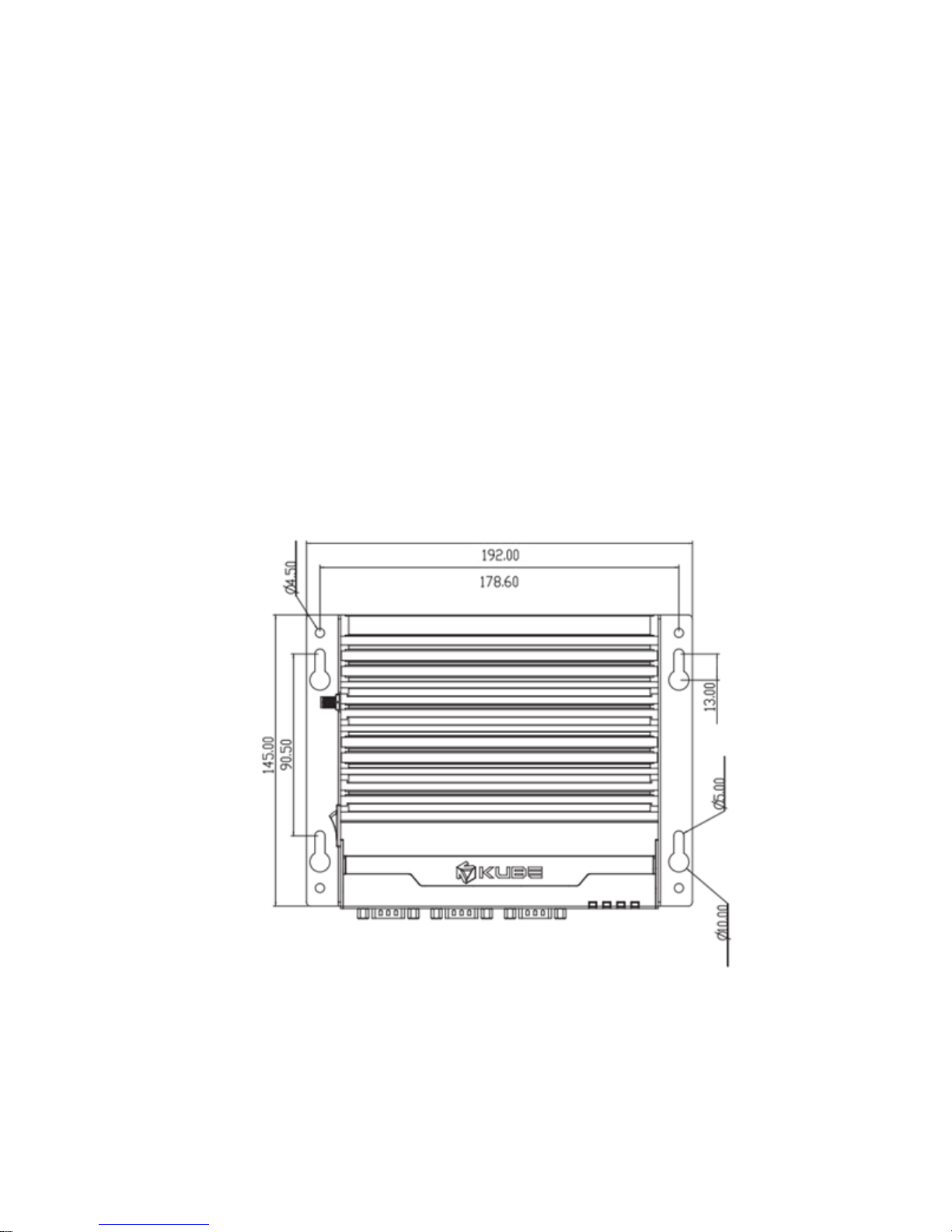

2.1 Wall mount

Installation

1. See the dimensions as below, and mark the locations of the holes on the

mounting surface.

2. Use the correct anchor type for the mounting surface and securely attach the

KUBE IPC to the wall. Ensure that the attaching hardware is in the small section of

the keyholes.

Removal

1. Remove power and disconnect cables to the IPC.

2. Loosen and remove the screws securing the IPC to the mounting surface.

2.1.1 Wall mount

7

2.2 Din rail mount

Install

1. Angle the KUBE IPC so the top edge of the mounting plate hangs on the top

edge of the DIN rail.

2. Rotate the KUBE IPC. down against the lower edge of the DIN rail. Press in until

the latch snaps closed.

Remove

3. Secure the device on the rail with clamps.

4. If necessary to remove, use a screwdriver to release the latch and rotate the

device away from the rail.

8

2.2.1 Din rail mount dimension

Above Din rail mount dimension follow by the Phoenix Contact UTA 107/30

2.3 Interface

2.3.1 I/O port

9

After mounting KUBE IPC, make any necessary cable connections.

The available connectors are:

Ethernet (ETH): Two RJ45 connectors allow the computer to communicate on a

10/100/1000 Base-T Ethernet network.

Serial (COM): Three D-SUB 9 serial ports are available for use. Two ports are set

as RS-232 while one port is configurable as either RS-232, RS-422, or RS-485.

USB (USB): USB devices connect using Type-A connectors. Two ports are USB 2.0

and two are USB 3.0 ports

DisplayPort (DP): These ports connect the KUBE IPC to external digital displays

with a corresponding DisplayPort connector. If needed, you also can use Video

adaptor to other video interface, like DVI, HDMI…etc.

Mini PCIe: This internal slot allows installation of a mini PCIe card (see “Mass

storage” )

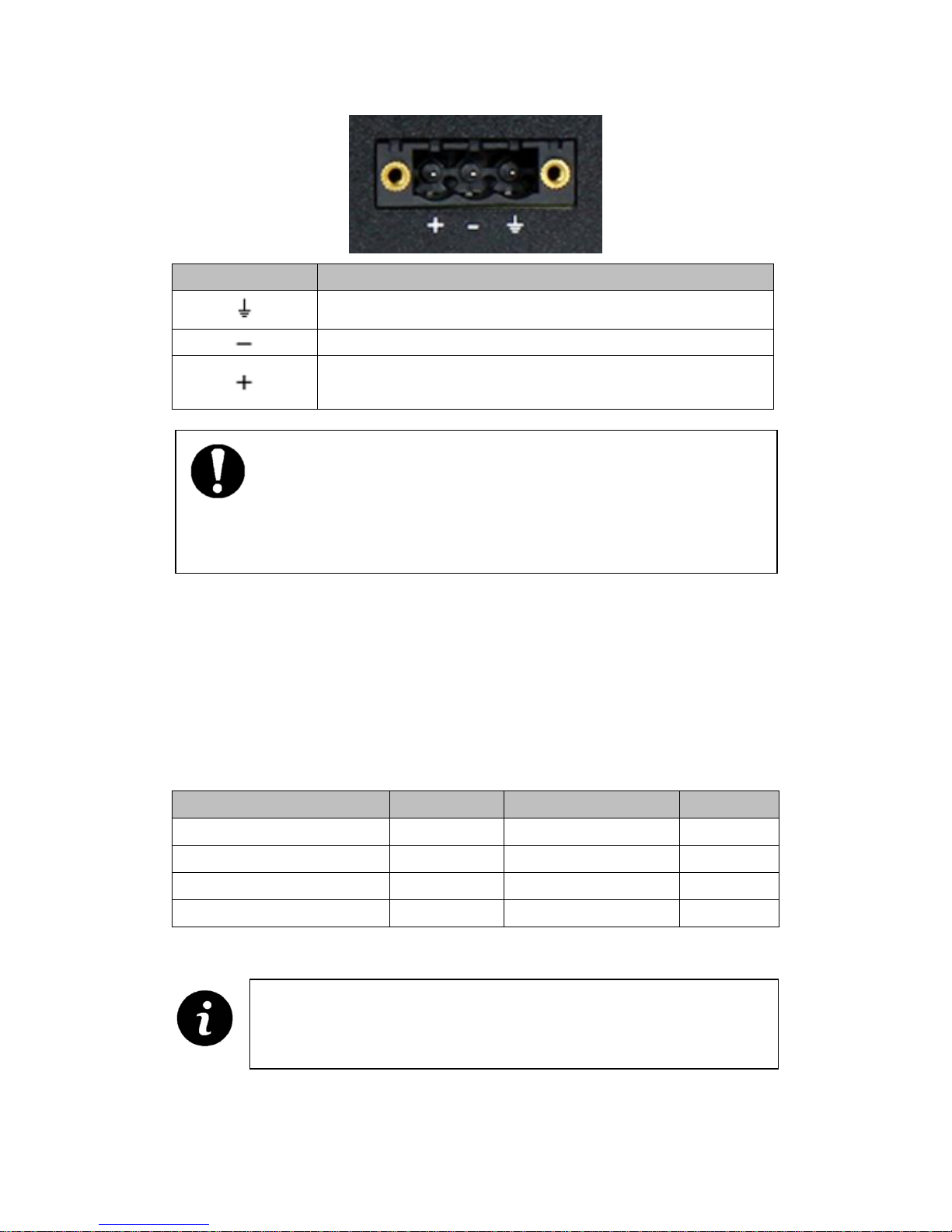

2.3.2 Power connection

A three-position, screw-type connector is provided for connecting power to the KUBE

3000/5000 series IPC.

Connect a power source to the included power connector. This connector supports

wire sizes from 0.2 to 2.5 mm² (24 to 12 AWG). Torque the wire-retaining screws in the

connector to 0.5 Nm (4.4 lbf-in.). Secure the connector to the KUBE IPC chassis.

USB 3.0 ports utilize a blue connector. USB 2.0 ports are black.

10

Pin No.

Description

Ground

0 V DC

24V DC ± 20 ﹪

2.3.3 Serial Communication

One D-SUB 9 connector can be configured to communicate on the RS-232, RS-422, or

RS-485 physical layer. The physical layer is set using the BIOS. The remaining

connectors are limited to RS-232 only. The KUBE-IPC is capable of the following

communication parameters:

Data bits

Parity

Stop bits

RS-232

7/8

None/Even/Odd

1/2

RS-422/485 Autotoggle RTS

8

None

2

RS-422/485 Autotoggle RTS

8

Even/Odd

1/2

RS-422/485 Manual RTS

7/8

None/Even/Odd

1/2

NOTE:

BIOS is set to boot on power, allowing the system to boot as soon as the power

plug is installed. This can be changed in the BIOS.

The table shows the capabilities of the IPC. Configuration of parameters

to communicate with a specific device is typically part of the software

tool performing the communication

11

The function of the pins in the D-SUB 9 connector varies with the different

configuration settings.

D-SUB 9 pin

RS-232

RS-422

RS-485

1

DCD

TXD-

TXD-/RXD-

2

RXD

TXD+

TXD+/RXD+

3

TXD

RXD+

- 4 DTR

RXD-

- 5 GND

GND

GND

6

DSR

- - 7

RTS

- - 8

CTS

- - 9

Ring indicator

-

-

2.4 Antenna

An optional factory-installed mini PCIe card is available to allow the KUBE-IPC to be

placed on a wireless network. Included with the installed card is an antenna (1) that

attaches to a connector on the side of the unit (2).

Since the KUBE IPC is often installed within an enclosure, it may be advisable to install

the antenna on the exterior of the enclosure rather than directly to the IPC. To do this,

an appropriate length antenna cable (3) must be purchased separately.

The antenna or antenna threads onto the KUBE IPC. For external antenna mounting,

route and secure the antenna cable appropriately within the enclosure.

12

3 Operation

3.1 LED status

Four LEDs are provided on the KUBE IPC. These LEDs provide operating

information

LED

Indication

Description

PWR

Green

Power on

SATA

Flashes green

Data storage activity

RUN

Green

Reserved LED for future use

ERROR

Orange / Red

Orange: indicates processor is actively

thermal throttling

Red: indicates processor has shut down due

to overheating.

13

4 Maintenance

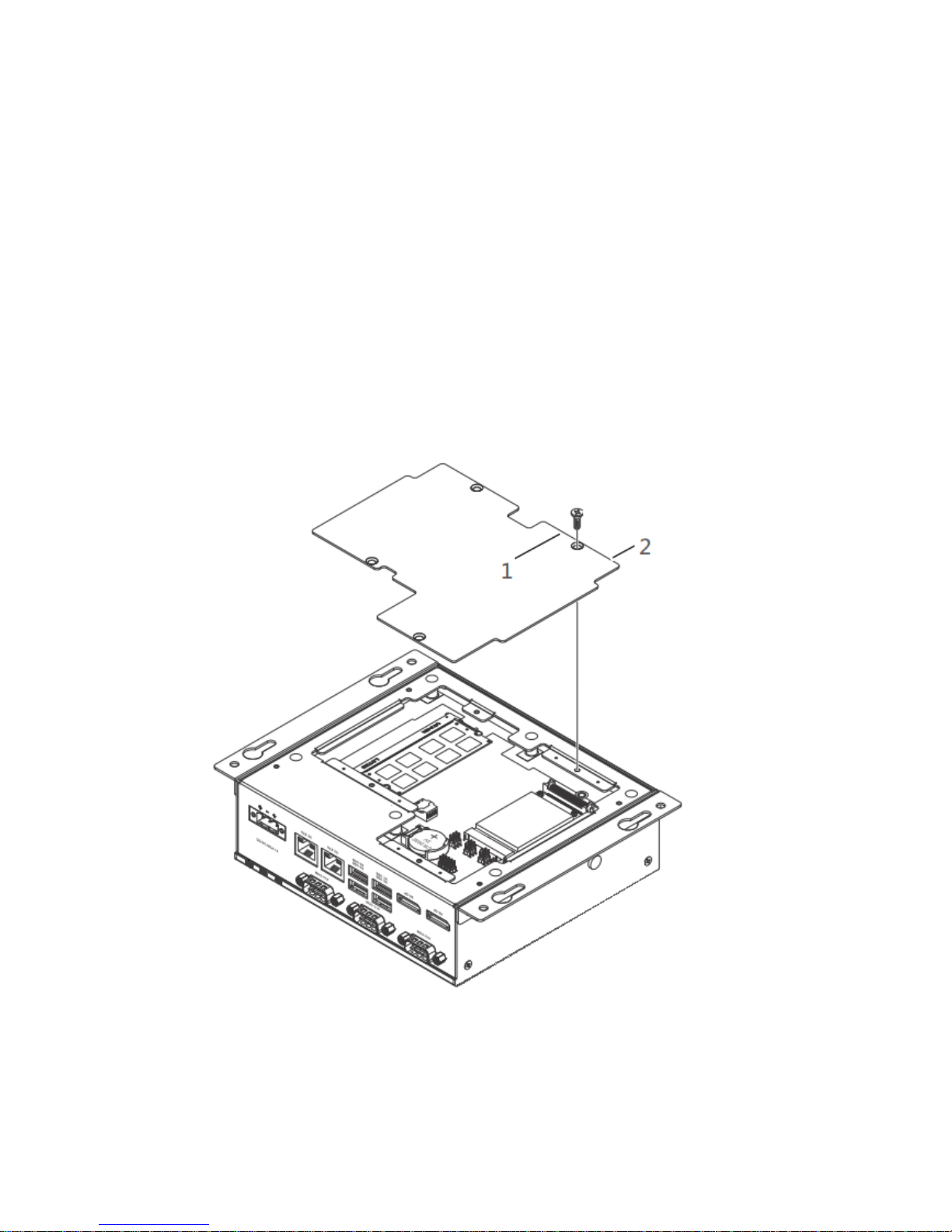

The KUBE-3000/5000 IPC has a removable service panel that allows access to the

mini PCIe card slot, configuration jumpers, and battery.

4.1 Service panel

1. Remove power from the KUBE IPC

2. Disconnect any cables, such as USB, Ethernet, etc., attached to the unit.

3. Place the unit on a flat surface with the heat sink down.

4. Loosen and remove the four screws (1) that hold the service panel (2) to the case

and remove the panel.

14

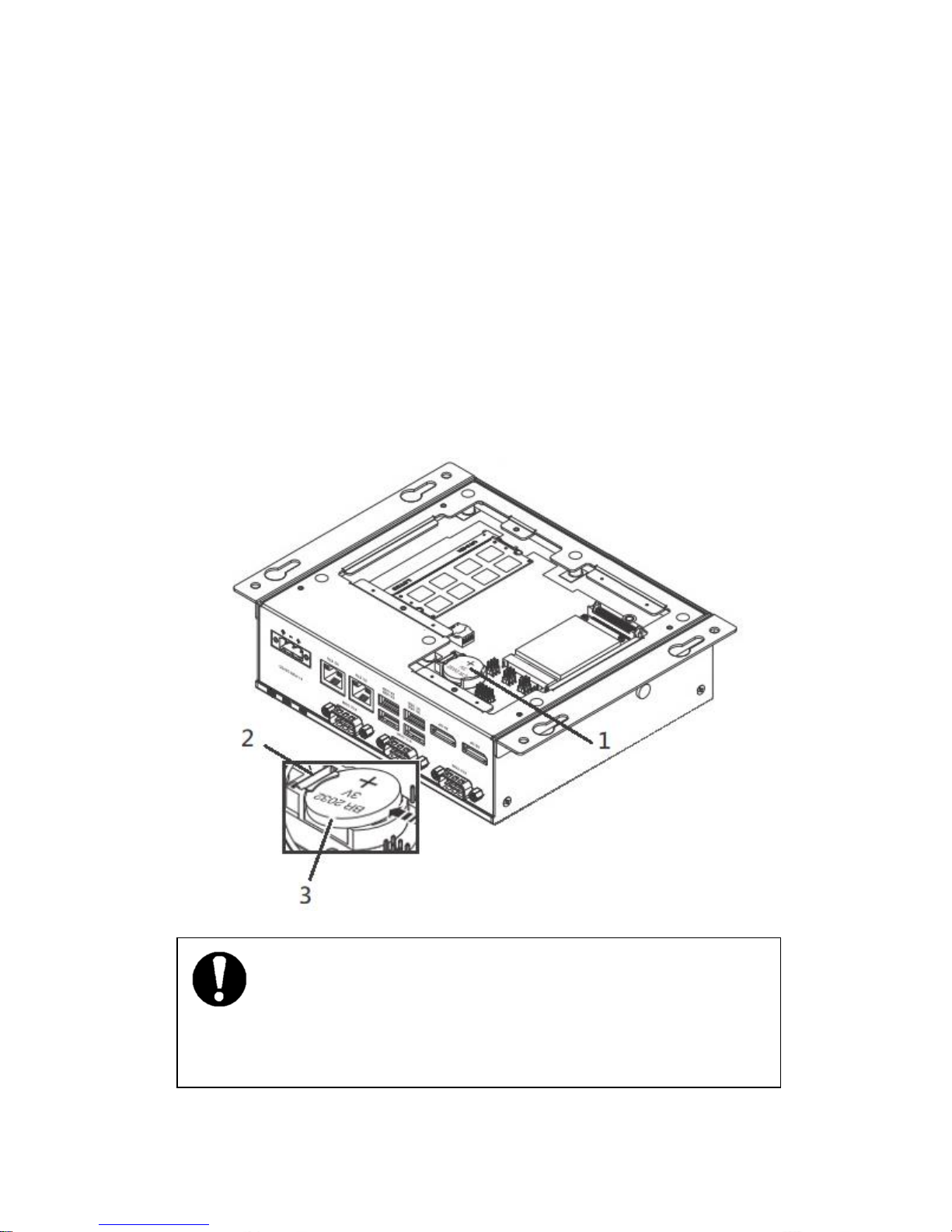

4.2 Real time clock battery

The battery supplies power to the real-time clock (RTC) and maintains the BIOS

settings in the KUBE IPC when the system is not connected to a 24 V DC power source.

If power is removed while the battery is discharged or removed, any user-defined BIOS

settings will be lost, and a “CMOS checksum error” message appears once power is

restored.

To account for user-defined BIOS settings, it is recommended that they be recorded

through photos or a separate document before the battery is depleted or removed.

Store the photos or documents on a different device so they are accessible in the event

of a boot failure. The battery is type BR2032. The battery has a typical life of five years

and may require replacement.

NOTE:

Note the orientation of the battery. One side should have a plus (+) symbol. The

replacement battery must be installed the same way.

15

To replace the battery:

1. Access the battery by removing the service panel.

2. Locate the battery holder (1).

3. To remove the battery, pull the retention clip (2) at the bottom of the battery

housing and the battery (3) will release from the housing.

4. To install a new battery, insert one end under the retention clip. Push the battery

toward the clip until the battery fully drops into the housing.

5. Reset the CMOS and BIOS using the appropriate jumpers

6. Reinstall the service panel or reattach the case to the display panel.

7. Reconnect the power connector and apply power. During the boot process, a

message will appear notifying the user that the CMOS and BIOS settings have been

reset to the factory defaults.

8. During the boot process, press the <F2> key to access the BIOS settings

9. Update the BIOS configuration with any appropriate user-defined requirements.

4.3 CMOS/BIOS reset

The CMOS is a small chip that stores the BIOS settings, date and time, and other

items of the IPC. It is powered by the real-time clock battery and, if the battery is

removed, will likely lose its settings. It can be reset to the factory defaults using a

reset button.

16

To reset the CMOS:

1. Remove the service panel

2. Remove the jumper JPA (1) from pins 1 and 2.

3. Place jumper between pins 2 and 3 for 3 seconds (reset position).

4. Remove jumper from pins 2 and 3, and reinstall on pins 1 and 2 (the run position).

5. Reinstall the service panel or reattach the case to the display panel.

6. Reconnect the power connector and apply power. During the boot process, a

message will appear notifying the user that the CMOS and BIOS settings have been

reset to the factory defaults.

7. During the boot process, press the <F2> key to access the BIOS settings

8. Update the BIOS configuration with any appropriate user-defined requirements.

4.4 Mass Storage (M.2)

The mass storage device is a solid-state drive (SSD) with an M.2 interface in the

chassis. You need to open the cover heatsink to install it.

To replace a drive:

1. Turn off the IPC and disconnect power.

2. Remove the screws on the heat sink

3: Locate the M.2 SSD (2260) and secures the drive in the socket.

4. To install, insert the drive into the connector and secure with the hardware

previously removed.

5. Position the heat sink in place and secure with the hardware previously removed.

Thermal pads between the board and heat sink may cause resistance

when removing the service panel.

NOTE:

Failure to ensure thermal pads are properly positioned may result in performance

loss.

17

4.5 Mass Storage (mSATA)

There is another mass storage option, solid-state drive (SSD) with an mSATA interface

(1) in the back of chassis. You need to open the service panel to install it.

To replace a drive:

1. Turn off the IPC and disconnect power.

2. Remove the screws of back service panel

3: You can see the mSATA socket.

4: Locate the mSATA SSD and secures the drive in the socket.

5. Position the service panel back in place and secure with the hardware previously

removed.

Loading...

Loading...