Digimatic Indicator

Dial Indicator

Dial Test Indicator

Dial Indicator

Application and

Stand

New Products

ID-H

2046S

2109S-10

ID-N / ID-B

Small Tool Instruments and

Data Management

INDEX

Digimatic Indicator

ABSOLUTE Digimatic Indicator ID-S F-2

ABSOLUTE Digimatic Indicator ID-U F-3

ABSOLUTE Digimatic Indicator ID-C F-4 – 9

ABSOLUTE Digimatic Indicator ID-H F-10

ABSOLUTE Digimatic Indicator ID-F F-11

ABSOLUTE Digimatic Indicator ID-N/B F-12

EC Counter F-13

Multi-Unit, Difference/Sum Unit F-13

Dial Indicator

Dial Indicators F-14

Dial Indicators F-15

Dial Indicators F-16 – 18

Dial Indicators F-19, 20, 22 – 26

Special Dial Indicators F-21

Dial Indicators F-27, 28

Dial Indicators F-29

Back Plunger Type Dial Indicator F-30, 31

Hicator, Signal Hicator F-32

Back, Contact Points

(Optional Accessories)

Spindle Lifting Lever and Cable

(Optional Accessories)

Color Spindle Caps

(Optional Accessories)

Limit Stickers

(Optional Accessories)

Dial Indicator Repair Tool Kit F-38

Dial Indicator Crystal Setter F-38

Dial Test Indicators F-39 – 43, 46

Pocket Type Dial Test Indicator F-44, 45

Contact Point and Clamp Holder

(Optional Accessories)

Dial Indicator Application

i-Checker F-48

UDT-2 Dial Gage Tester F-49

Calibration Tester F-49

Thickness Gages F-50 – 53

Light-Weight Dial Thickness Gage F-54

Pocket Thickness Gages F-54

Quick-Mini F-55

Digi-Derm F-56

MU-Gages F-57

Digimatic Caliper Gages F-58 – 62

Dial Tension Gage F-63

V-Block Set F-63

Magnetic V-Block F-63

Bench Gages F-64

Upright Gages F-65

Dial Snap Gages F-66

Snap Gages F-67

Female Screw Thread Comparator F-68

Dial Indicator & Magnetic Stand Set F-68

Stand

Magnetic Stand F-69

Dial Gage Stand F-70

Transfer Stand F-71

Precision Granite Stands F-72

Comparator Stand F-73

Heavy Duty Comparator Stand F-74

F-33 – 35

F-36

F-37

F-37

F-47

Caliper gage

F-1

i>À>ViÊÌÊ>Û`Ê

`ÀiVÌÊvÕiViÊvÊ

V>«}ÊvÀVi

>«}ÊÀ>}i

ä

£ä Óä Îä {ä xä Èä Çä nä ä £ää £Óä £{ä

£ä

£ä xä £ää Óxä xää Çxä £äää £Óxä £xää £Çxä Óäää

ä

£

Ó

Î

{

x

È

Ç

ä

À«Êi}ÌÊV®

/ÕÃ>`ÊÌiÃ

£ä

Óä

Îä

{ä

xä

ä

iÛ>ÌÊ®

ÀÀÀÊ®

,iÃÕÌÊvÊÀi«i>ÌÊ«>VÌÊÌiÃÌ

*ÌiÀÊ`iÛ>Ì

,iÃÕÌÊvÊi`ÕÀ>ViÊÌiÃÌ

Ü`iÀ>}iÊ>VVÕÀ>VÞ

7i}Ì

£xä}

`ÕÀ>ViÊÌiÃÌ}ÊÜÌÊV>

,Ì>ÌÊëii`\Ê£ÓäÀ«

Ó£ä-£äÊ`>Ê`V>ÌÀ

Ó£ä-£äÊ`>Ê`V>ÌÀ

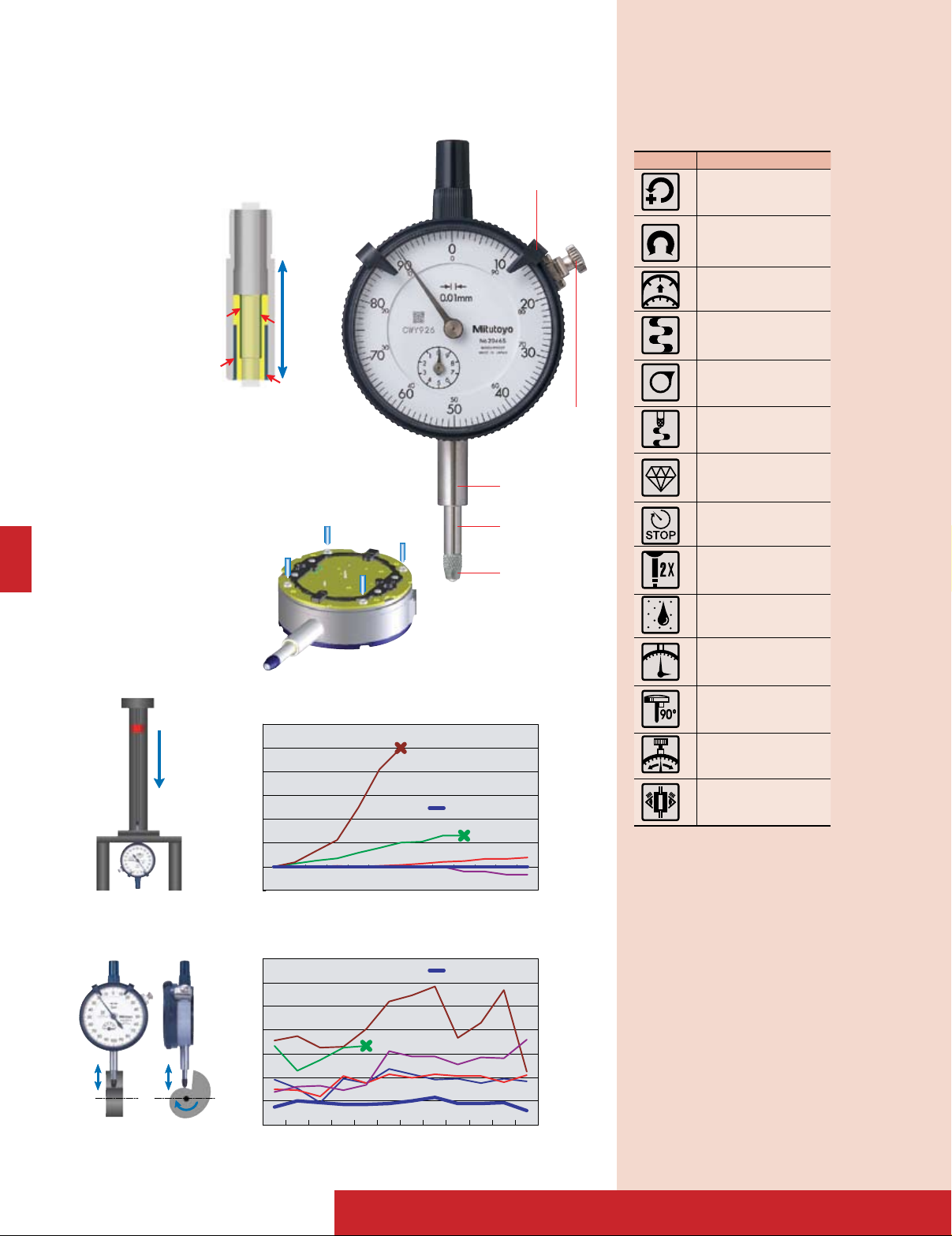

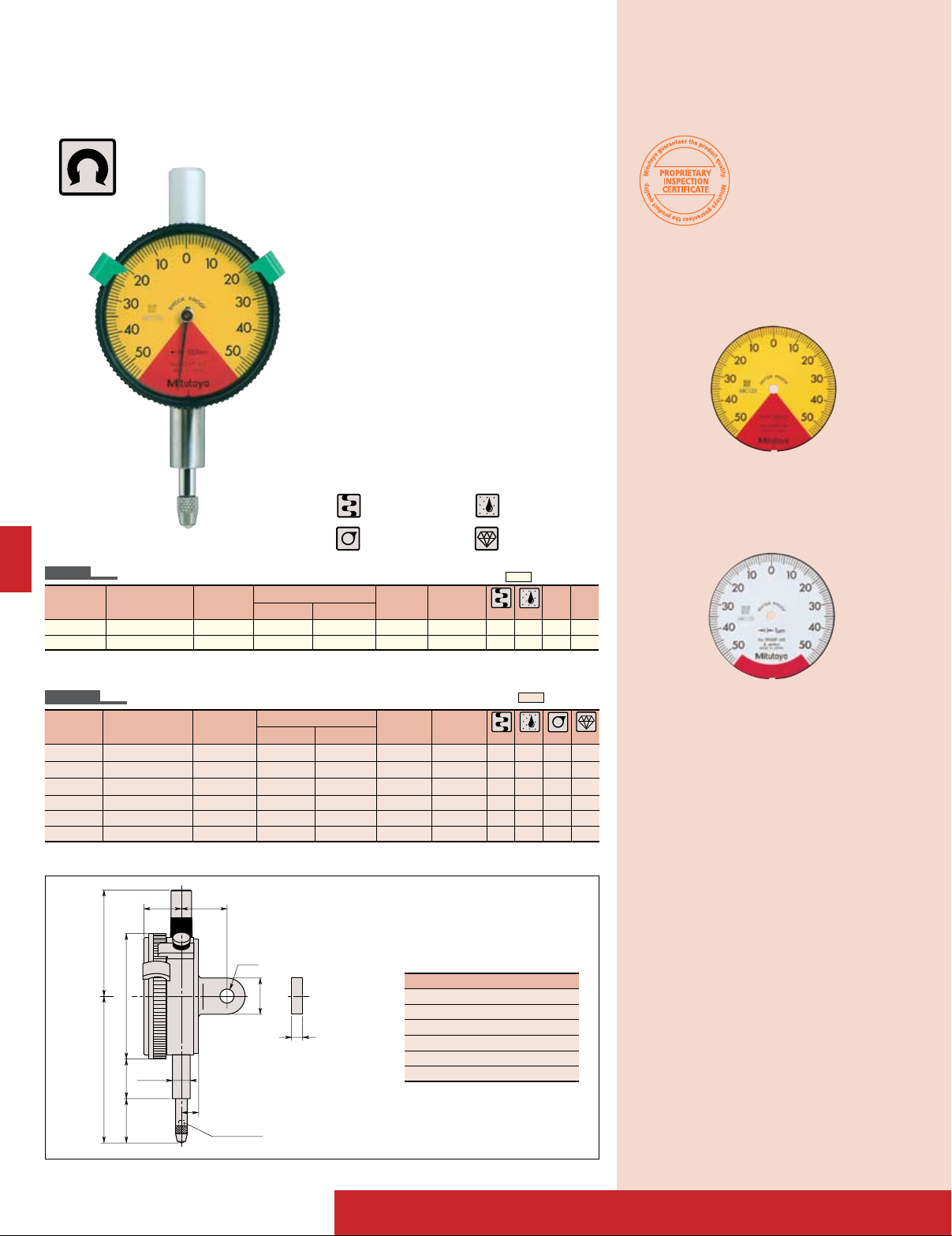

Dial Indicators

FEATURES: S Series

• Revolutionary stem-bush design for trouble

free stem clamping (longer clamping

range).

• No through screw-hole

on the frame for high

dust-resistance.

• Involute curved lifting lever for smooth

movement of spindle and dovetail joint for

tool-less connection.

• Grater rigidity in the bearing plate for

reducing the retracing error (20%) and

4-screw mounting for increasing impact

resistance.

Limit hand

Bezel clamp

Stem

Spindle

Contact point

Description of Icon

Icon Description

Reverse reading type

suitable for depth and step

measurement.

One revolution type for easy

and error-free reading

Double scale spacing type,

easy-on-the-eyes

Shockproof type

Waterproof type

With damper at lowest rest

point

Jeweled bearing type

Peak retaining type

Long stem type

F-14

Dustproof type

With coaxial revolution

counter

Back plunger type

Adjustable hand type

Double-face type

12.5

20

ø6.5

Thickness 5

ø8

0

-0.009

M2.5x0.45

7

A

B 15 ø31

16

30

.49" .75"

ø.26"

Thickness .25"

ø.375"

0

-.001

#4-48 Threads

.28"

A

B .59" ø1.22

.63"

1.18"

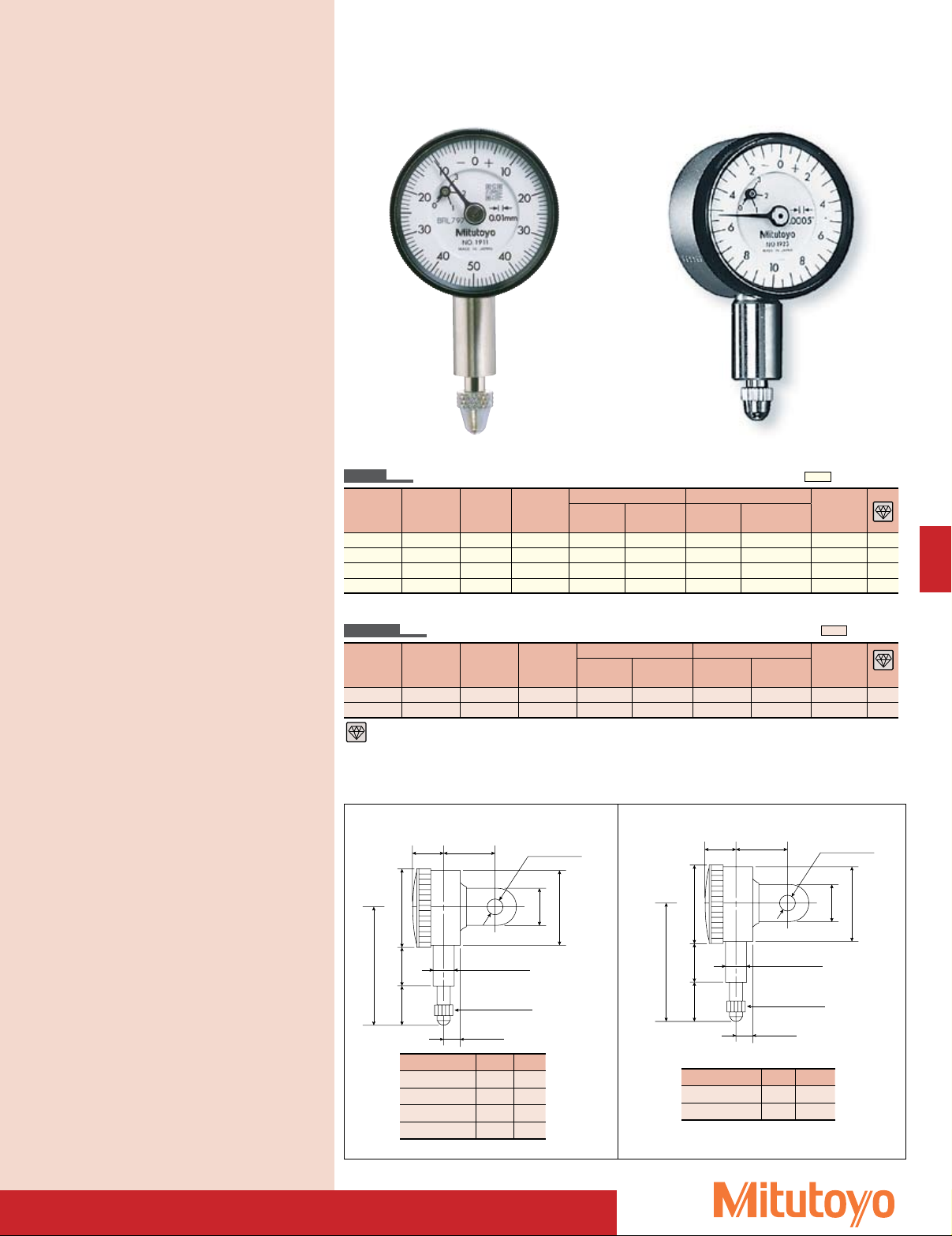

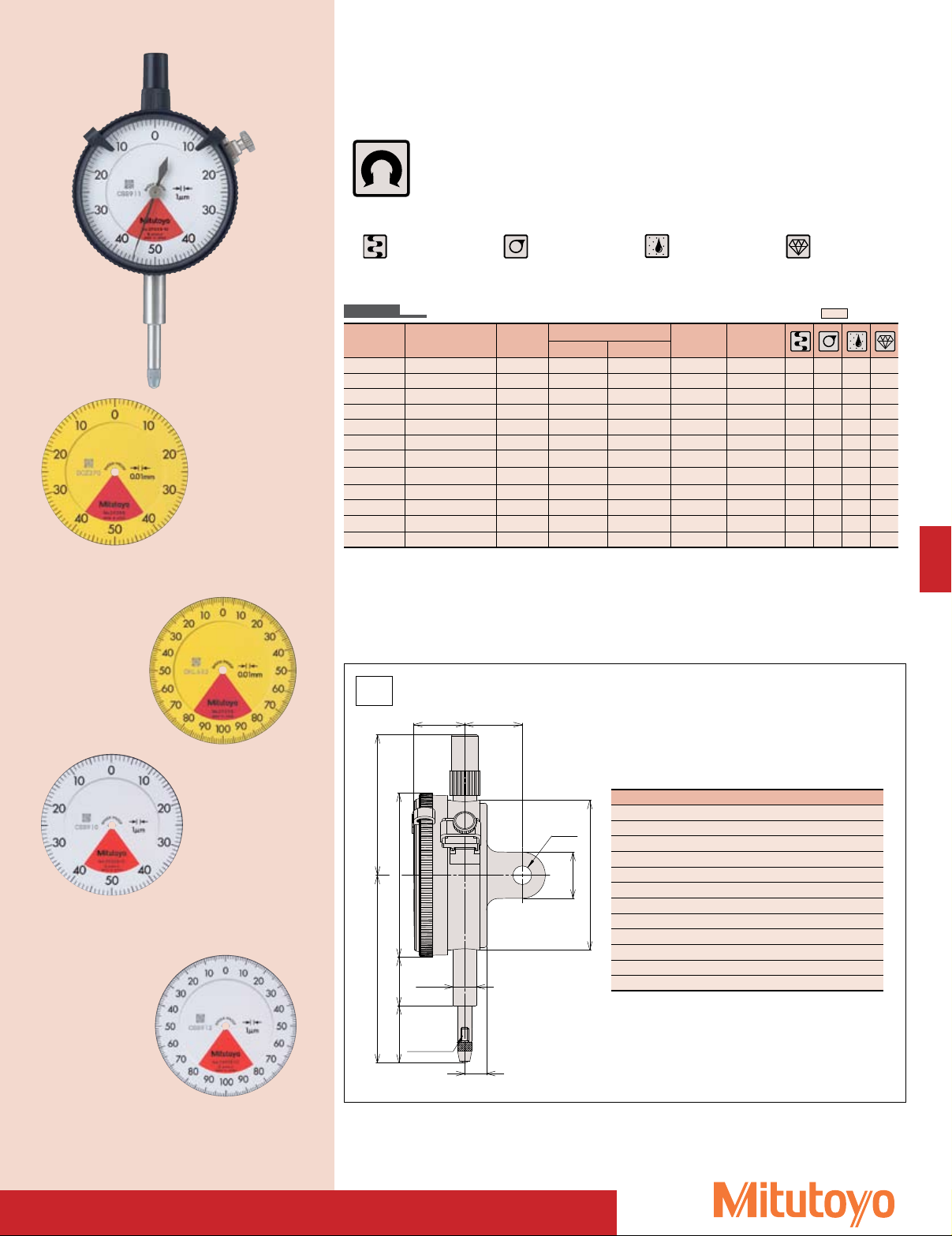

Dial Indicators

SERIES 0 - Compact type

1911

SPECIFICATIONS

Inch

Graduation Range Range/rev Dial reading

.0001” .01” .004” 0-2-0 1927-10 1927B-10 ±.0002” ±.0002”

.0001” .025” .01” 0-5-0 1925-10 1925B-10 ±.0002” ±.0002”

.0005” .05” .02” 0-10-0 1923 1923B ±.0005” ±.0005”

.001” .1” .04” 0-20-0 1921 1921B ±.001” ±.001”

Metric

Graduation Range Range/Rev Dial reading

0.002mm

0.01mm

Jeweled bearing type

0.5mm 0.2mm

2.5mm 1mm

Stem dia. 3/8", #4-48 UNF Thread

Order No. Accuracy

w/ lug Flat-back

Stem ø 8mm, M2.5 x 0.45 Thread

Order No. Accuracy

w/ lug Flat-back

0-100-0 1913-10 1913B-10 ±0.011mm ±0.011mm

0-50-0 1911 1911B ±0.011mm ±0.011mm

First 2.5

Rev

First 2.5

Rev

Overall

Accuracy

Overall

Accuracy

1923

ANSI/AGD type

Measuring

force

1.4N or less

1.4N or less

1.4N or less

1.4N or less

Measuring

force

1.4N or less

1.4N or less

4

4

—

—

ISO/JIS type

4

—

DIMENSIONS

Inch Model

Order Number A B

1927-10 1.46” .26”

1925-10 1.48” .28”

1923 1.51” .31”

1921 1.58” .37”

Unit: Inch Unit: mm

Metric Model

Order Number A B

1911 42 11.5

1913-10 39.5 9

F-15

Dial Indicators

#4-48UNF

16

ø41

13.3

AB

C

ø6.5

6.6

14.5 19

6.35

3/8”

SERIES 1

SPECIFICATIONS

Inch

Graduation Range

.0001" .025" .01" 0-10 1802F-10 1802FB-10

.0001" .025" .01" 0-5-0 1803F-10 1803FB-10

.00025" .05" .02" 0-20 1470F 1470FB

.00025" .05" .02" 0-10-0 1471F 1471FB

.0005" .075" .03" 0-30 1570F-10 1570FB-10

.0005" .075" .03" 0-15-0 1571F-10 1571FB-10

.0005" .1" .04" 0-40 1670F 1670FB

.0005" .1" .04" 0-20-0 1671F 1671FB

.0005" .125" .05" 0-50 1506F 1506FB

.0005" .125" .05" 0-25-0 1507F 1507FB

.001" .125" .05" 0-50 1780F 1780FB

.001" .125" .025" 0-25-0 1781F 1781FB

.001" .25" .1" 0-100 1410F 1410FB

.001" .25" .1" 0-100 1410F-10 1410FB-10

.001" .25" .1" 0-50-0 1411F 1411FB

Metric

Graduation Range

0.002mm 0.5mm 0.2mm 0-20 1010F-11 1010FB-11

0.002mm 0.5mm 0.2mm 0-10-0 1011F-11 1011FB-11

0.01mm 2.5mm 1mm 0-100 1230F-01 1230FB-01

0.01mm 2.5mm 1mm 0-50-0 1231F-01 1231FB-01

0.01mm 5mm 1mm 0-100 1044F-01 1044FB-01

0.01mm 5mm 1mm 0-50-0 1045F-01 1045FB-01

Stem dia. 3/8" #4-48 UNF Thread

Dial

reading

Order No.

(W/Lug) (Flat-back)

Order No.

(W/Lug) (Flat-back)

Range

Dial

/ Rev

reading

Metric - ANSI Standard Stem dia. 3/8"#4-48 UNF Thread yellow dial face

Range

/Rev

ANSI/AGD type

Accuracy

First 2.5 Rev

Overall

Accuracy

Measuring

force

±.0001" ±.0001" 1.4N or less

±.0001" ±.0001" 1.4N or less

±.00025" ±.00025" 1.4N or less

±.00025" ±.00025" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.0005" ±.0005" 1.4N or less

±.001" ±.001" 1.4N or less

±.001" ±.001" 1.4N or less

±.001" ±.001" 1.4N or less

±.001" ±.001" 1.4N or less

±.001" ±.001" 1.4N or less

ANSI/AGD type

Accuracy

First 2.5 Rev

Overall

Accuracy

Measuring

force

±0.002mm - 1.4N or less

±0.003mm - 1.4N or less

±0.01mm - 1.4N or less

±0.01mm - 1.4N or less

±0.01mm ±0.013mm 1.4N or less

±0.01mm ±0.013mm 1.4N or less

4 4

4 4

4

4

4

1411F

4 4

4 4

Shockproof type

DIMENSIONS

Jeweled bearing type

Unit: mm

Order No. A B C

1802F(B)-10 28.1 43.4 9.6

1803F(B)-10 28.1 43.4 9.6

1470F(B) 28.1 42.7 8.9

1471F(B) 28.1 42.7 8.9

1570F(B)-10 28.1 43.4 9.6

1571F(B)-10 28.1 43.4 9.6

1670F(B) 28.1 44.2 10.4

1671F(B) 28.1 44.2 10.4

1506F(B) 28.1 45.2 11.4

1507F(B) 28.1 45.2 11.4

1780F(B) 28.1 45.2 11.4

1781F(B) 28.1 45.2 11.4

1410F(B) 33.2 48.7 14.9

1410F(B)-10 33.2 48.7 14.9

1411F(B) 33.2 48.7 14.9

1010F(B)-11 28.1 43.4 9.6

1011F(B)-11 28.1 43.4 9.6

1230F(B)-01 28.1 44.2 10.4

1231F(B)-01 28.1 44.2 10.4

1044F(B)-01 33.2 46.7 12.9

1045F(B)-01 33.2 46.7 12.9

F-16

Ó°xä°{x

£ääÎ

£È

©{£

ÎÓ°x

©È°x

Ç

£{°x£Î Óä£x

x

£È

Óäΰx

©È°x

Ó°xÝä°{x

x°Î

°x£Ó ©ÎÈ

x

©n

Êä

ä°ää

©n

Êä

ä°ää

Dial Indicators

SERIES 1

1040F 1013F

Metric

Graduation Range

Stem ø 8mm M2.5 X 0.45 Thread

Dial

reading

Order No.

(W/Lug) (Flat-back)

Range

/ Rev

0.001mm 1mm 0.2mm 0-100-0 1109F 1109FB

0.002mm 1mm 0.2mm 0-100-0 1013F 1013FB

0.005mm 3.5mm 0.5mm 0-50 1124F 1124FB

0.01mm 3.5mm 0.5mm 0-50 1040F 1040FB

0.01mm 3.5mm 0.5mm 0-25-0 1041F 1041FB

0.01mm 4mm 1mm 0-50-0 1003B 1003B

0.01mm 5mm 1mm 0-100 1044F 1044FB

0.01mm 5mm 1mm 0-100 1044F-60 1044FB-60

0.01mm 5mm 1mm 0-100 1044F-10 1044FB-10

0.01mm 5mm 1mm 0-50 1045F 1045FB

Shockproof type

Waterproof type

Jeweled bearing type

1045F

Accuracy

First 2.5 Rev

Overall

Accuracy

Measuring

force

±0.001mm ±0.007mm 1.5N or less

±0.002mm ±0.01mm 1.5N or less

±0.005mm ±0.013mm 1.4N or less

±0.01mm ±0.013mm 1.5N or less

±0.01mm ±0.013mm 1.5N or less

±0.01mm ±0.013mm 1.5N or less

±0.01mm ±0.013mm 1.5N or less

±0.01mm ±0.013mm 2N or less

±0.01mm ±0.013mm .4N or less

±0.01mm ±0.013mm 1.4N or less

1003

ISO/JIS type

4 4

4 4

4

4

4

DIMENSIONS

ISO/JIS

Type

Order No. A B C

1040F 46 13 12.5

1041F 46 13 12.5

F-17

1044 47.5 13 14

1044F-10 47.5 13 14

1044F-60 57 11.5 25

1045F 47.5 13 14

1124F 46 13 12.5

1013F 49 13 15.5

1109F 49 13 15.5

Unit: mm

ø

41

32.5 (28.1)

B (13.3)

C (10.9)

A (44.7)

20

(19)

16

(3/8”)

M2.5×0.45

(# 4-48UNF)

5

(6.35)

ø

6.5

7

ø8

0

-0.009

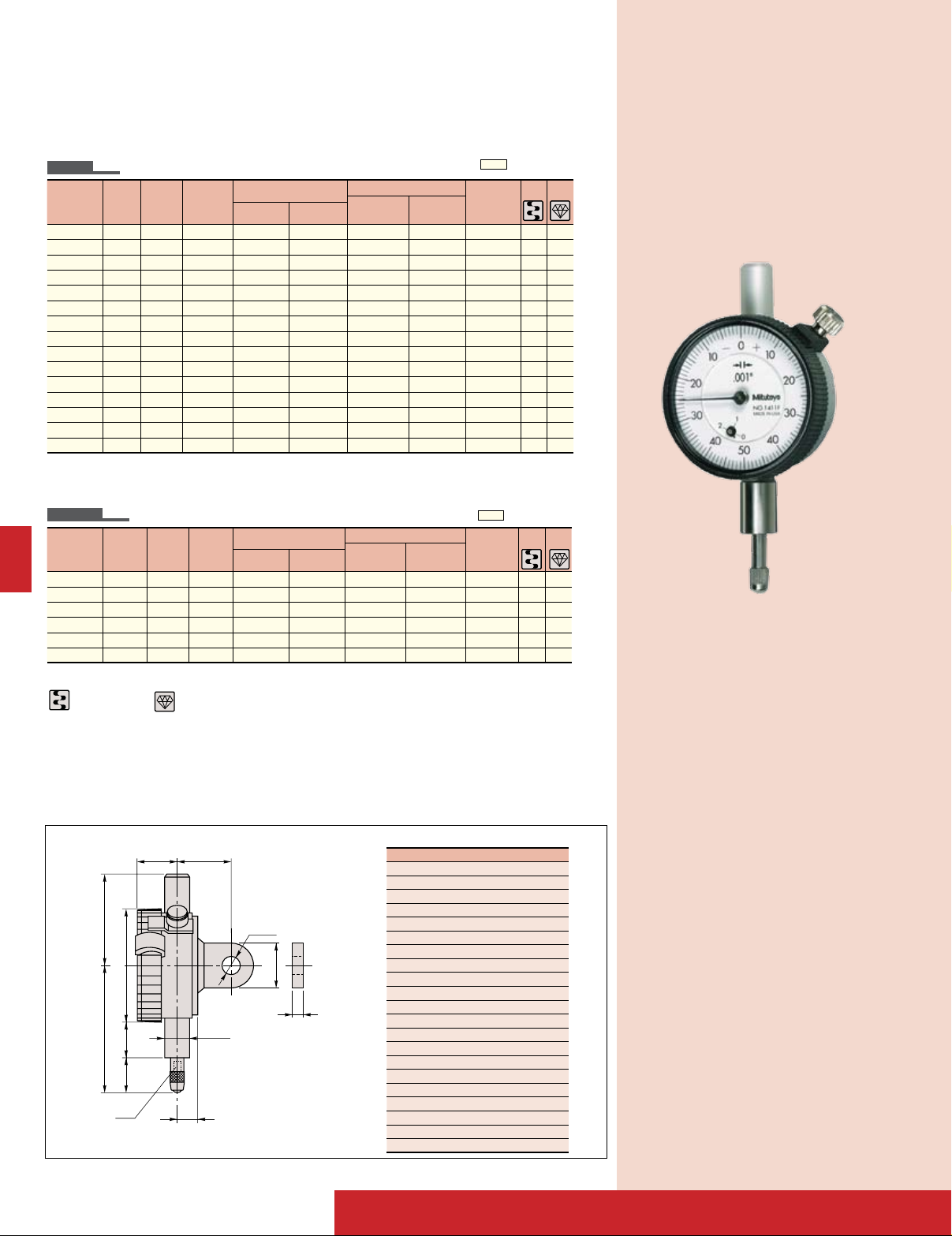

Dial Indicators

Jeweled bearing type

Shockproof type

Waterproof type

Dustproof type

Jeweled bearing type

Waterproof type

SERIES 1 — Compact One Revolution Type for Error-free Reading

Unlike many other dial indicators, the onerevolution dial indicator literally shows the

entire spindle travel or range as one sweep

One revolution type

of the hand, eliminating the possibility of

reading errors due to miscounting the multiple revolutions. With one-revolution dial

indicators, "within tolerance" and "out-oftolerance" can never misinterpreted

An unique shock-proof mechanism is

incorporated, providing improved immunity

to shock due to sudden spindle retraction

caused by high impact.

1929F-62

SPECIFICATIONS

Inch

Graduation

Range

(range/full stroke)

.0001” .006” / .0079” 3-0-3 1910F-72 1910FB-72 ±.0001”

.0005” .04” / .055” 20-0-20 1909F-62 1909FB-62 ±.0005”

Metric

Graduation

Range

(range/full stroke)

0.001mm 0.1mm / 0.14mm 50-0-50 1900F 1900FB ±0.005mm

0.001mm 0.1mm / 0.14mm 50-0-50 1900F-60 1900FB-60 ±0.006mm

0.001mm 0.1mm / 0.14mm 50-0-50 1900F-62 1900FB-62 ±0.006mm

0.01mm 1mm / 1.4mm 50-0-50 1929F 1929FB ±0.011mm

0.01mm 1mm / 1.4mm 50-0-50 1929F-60 1929FB-60 ±0.011mm

0.01mm 1mm / 1.4mm 50-0-50 1929F-62 1929FB-62 ±0.011mm

Stem dia. 3/8", #4-48 UNF Thread

Dial reading

Order No.

w/ lug Flat-back

Stem ø 8mm, M2.5 x 0.45 Thread

Dial reading

Order No.

w/ lug Flat-back

Accuracy

Accuracy

DIMENSIONS

ANSI/AGD type

Measuring

force

1.4N or less

1.4N or less

4 4

4 4

— —

— —

— —

ISO/JIS type

Measuring

force

1.5N or less4— —

1.5N or less4—

1.5N or less

4 4

4 4

—

1.4N or less4— — —

1.4N or less4—

1.4N or less

4 4

4

— —

Unit: mm

1929F

1929F-60

1929F-62

1900F

1900F-60

1900F-62

4

4

—

Optional Accessories

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

F-18

Order No. A B C

1929F 47.5 13 14

1929F-60 55.5 11.5 23.5

1929F-62 47.5 13 14

1900F 53.5 16 17

1900F-60 54.5 11.5 22.5

1900F-62 53.5 16 17

( ): ANSI / AGD type

ø6.5

M2.5×0.45

16

D 20

øC

F E

B

7.6

øH

A

ø8

0

-0.009

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

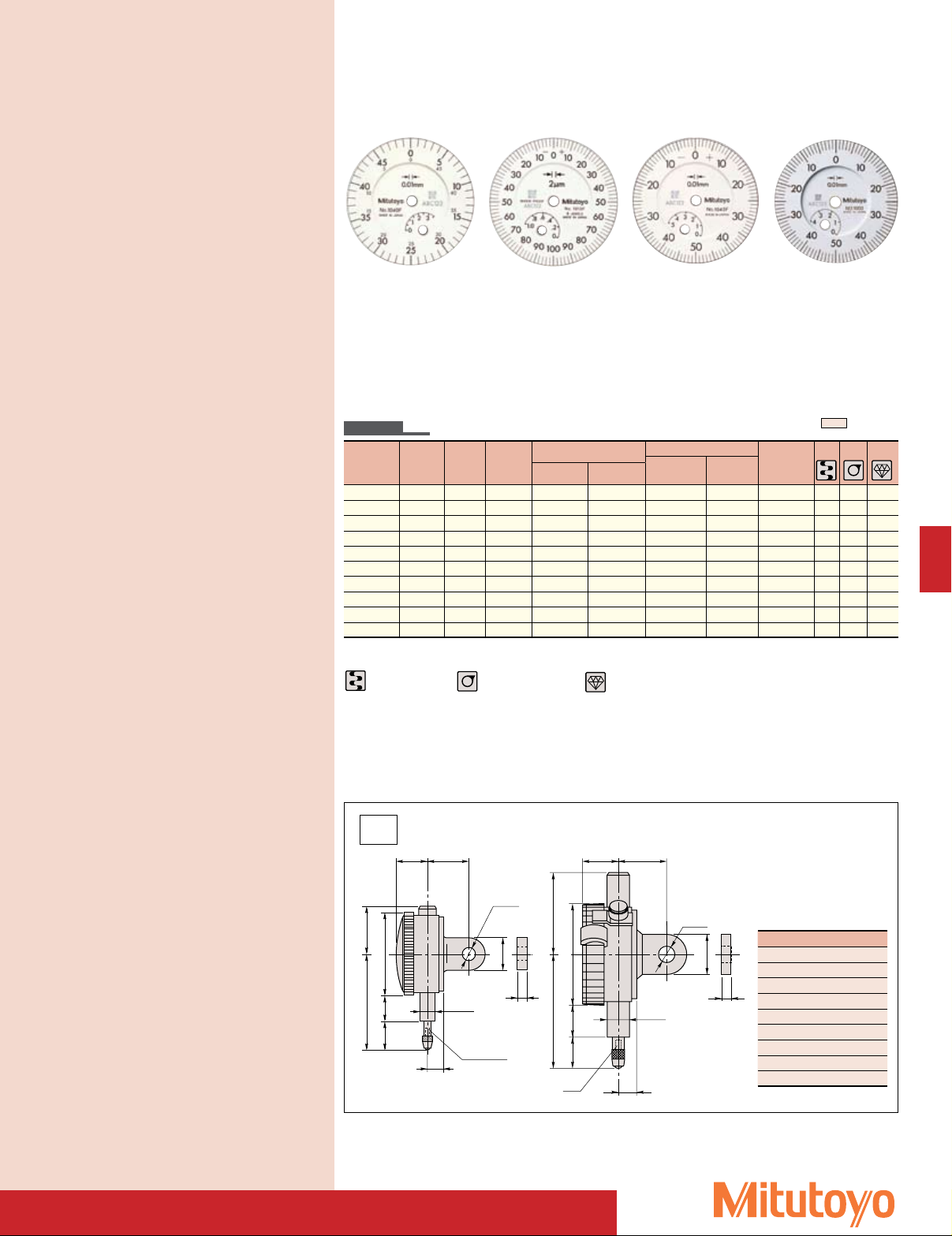

Dial Indicators

SERIES 2 — Standard One Revolution Type for Error-free Reading

One revolution type.

2929S

2929S-60

2929S-62

2900S-10

SPECIFICATIONS

Metric

Graduation

0.001mm 0.08mm / 0.1mm 40-0-40 2900S-10 2900SB-10 ±0.003mm

0.001mm 0.08mm / 0.1mm 40-0-40 2900S-70 2900SB-70 ±0.003mm

0.001mm 0.08mm / 0.1mm 40-0-40 2900S-72 2900SB-72 ±0.003mm

0.001mm 0.16mm / 0.2mm 80-0-80 2901S-10 2901SB-10 ±0.004mm

0.01mm 0.8mm / 1mm 40-0-40 2929S 2929SB ±0.009mm

0.01mm 0.8mm / 1mm 40-0-40 2929S-60 2929SB-60 ±0.009mm

0.01mm 0.8mm / 1mm 40-0-40 2929S-62 2929SB-62 ±0.009mm

0.01mm 1.6mm / 2mm 80-0-80 2959S 2959SB ±0.013mm

0.01mm 0.5mm / 0.7.mm 25-0-25 — 2971* ±0.010mm

0.01mm 1mm / 1.4mm 50-0-50 — 2972* ±0.012mm

0.02mm 1.6mm / 2mm 80-0-80 — 2973* ±0.016mm

0.1mm 4mm / 10mm 2-0-2 2928S 2928SB ±0.040mm

* Flat back type only. (Lug-on-center back is not available.)

Stem ø 8mm, M2.5 x 0.45 Thread

Range

(range/full stroke)

Dial

reading

Order No.

w/ lug Flat-back

Accuracy

DIMENSIONS

ISO/JIS

Type

ISO/JIS type

Measuring

force

1.4N or less4— —

2.0N or less

4 4

2.0N or less4—

1.4N or less4— —

—

4 4

4

4

4

2.0N or less4— — —

2.0N or less

4 4

2.0N or less4—

— —

4

—

1.4N or less4— — —

1.4N or less4—

1.4N or less4—

1.4N or less4—

—

4

—

4

—

4

1.4N or less4— — —

Unit: mm

2900S-10

2900S-70

2900S-72

Optional Accessories

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

2959S

2901S-10

Order No. A B C D E F H

2971 43.2 65.6 55.6 16.2 21 16.8 55

2972 43.2 66.0 55.6 16.2 21 17.2 55

2973 43.2 66.3 55.6 16.2 21 17.5 55

2929S 48.8 65.2 57 17.7 12.3 29.2 52

2929S-62 48.8 65.2 57 17.7 16.9 19.8 52

2929S-60 48.8 70 57 17.7 12.3 29.2 52

2959S 48.8 65.2 57 17.7 16.9 19.8 52

2900S-10 48.8 66 57 17.7 16.9 20.6 52

2900S-72 48.8 66 57 17.7 16.9 20.6 52

2900S-70 48.8 67 57 17.7 12.3 26.2 52

2901S-10 48.8 66.1 57 17.7 16.9 20.7 52

2928S 48.8 65.2 57 17.7 16.9 19.8 52

F-19

Dial Indicators

ø.26”

#4-48 UNF

.63”

D

.75”

øC

E F

B

.3”

A

ø3/8”

SERIES 2 — Standard One Revolution Type for Error-free Reading

FEATURES

• An unique shock-proof mechanism

is incorporated, providing improved

immunity to shock due to sudden spindle

retraction caused by high impact.

• The crystal is hard coated for durability and

scratch resistance.

• Approximately 40% lighter than the

conventional dial indicator.

• Provided with an improved resistance to

shop floor contaminants such as water

and dust.

• Due to the spindle bushing being offset

from the stem, spindle movement will not

be hindered or jammed when clamping

along the stem.

• A pair of limit hands are provided for quick

and easy tolerance judgment (GO/±NG).

SPECIFICATIONS

Inch

Graduation Range

.0001” .008” .01” 4-0-4 2910S-10 2910SB-10 ±.0001”

.0001” .008” .01” 4-0-4 2910S-72 2910SB-72 ±.0001”

.0005” .04” .05” 20-0--20 2909S-62 2909SB-62 ±.0005”

.0005” .02” .028” 10-0-10 — 2976* ±.0005”

.0005” .04” .055” 20-0-20 — 2977* ±.0005”

.001” .06” .079” 30-0-30 — 2978* ±.001”

.001” .08” .1” 40-0-40 2908S 2908SB ±.001”

.001” .08” .1” 40-0-40 2908S-62 2908SB-62 ±.001”

*Flat back type only. (Lug-on-center back is not available.)

Stem 3/8" dia. , #4-48 UNF Thread

Range/full

stroke

Dial reading

Order No.

w/ lug Flat-back

Accuracy

One revolution type.

Measuring

force

1.8N or less

2.5N or less

2.5N or less

1.4N or less

1.4N or less

1.4N or less

1.8N or less

2.5N or less

2908S

ANSI/AGD type

4 4

4 4 4

4 4

4 4

4 4

4 4

4

4 4

Metric

Graduation Range

0.001mm 0.08mm 0.1mm 40-0-40 2900S-73 2900SB-73 ±0.003mm

*Flat back type only. (Lug-on-center back is not available.)

Stem 3/8" dia. , #4-48 UNF Thread Yellow Dial Face

Range/full

stroke)

Dial reading

Order No.

w/ lug Flat-back

DIMENSIONS

Order No. A B C D E F

2976 1.70 2.55 2.19 .64 .62 .83

2977 1.70 2.56 2.19 .64 .64 .83

2978 1.70 2.57 2.19 .64 .65 .83

2908S 1.92 2.08 2.24 .7 .43 .54

2908S-62 1.92 2.08 2.24 .7 .43 .54

2909S-62 1.92 2.04 2.24 .7 .36 .54

2910S-10 1.92 2.02 2.24 .7 .36 .54

2910S-72 1.92 2.02 2.24 .7 .36 .54

2900S-73 1.92 1.99 2.24 .7 .33 .54

Accuracy

Measuring

force

2.0N or less

ANSI/AGD type

4 4 4

2909S-62

Unit: inch

2978

F-20

ø6.5

( ): ANSI / AGD Type

M2.5×0.45M2.5×0.45 (#4-48 UNF)

19.5

(C)

16.9

(13.6)

ø57

ø57

ø57

20 (19)

2048S-10 2046S-80 2940S

17.7

7.6

16

47.4 (A)64.9 (B)

52

ø

ø6.5

M2.5×0.45

15.1

16.919.8

20

17.7

7.6

16

59.8

65.2

52

ø

19.3 16.9

18.1518.15

57.5

64.7

ø8

0

-0.009

ø8

0

-0.009

ø8

(3/8”)

0

-0.009

Special Dial Indicators

SERIES 2

Adjustable hand

2048S-10

Adjustable hand dial gauge

The hand position can be

adjusted independently of

the vertical movement of

the spindle by rotating the

top knob.

SPECIFICATIONS

Peak hold

2046S-80

Peak hold type dial gauge

A mechanism that stops the

pointer and the spindle at the

depressed position where the

Double-face type dial gauge

The displacement of the

spindle can be read from

either the front or rear face.

spindle is depressed makes

the pointer stop and display

the maximum value.

Inch

Graduation Range

.001” .25” .1" 0-100 2919S-10 2919SB-10 ±.001” ±.001"

.001” .25” .1" 0-50-0 2920S-10 2920SB-10 ±.001” ±.001"

.001” .5” .1" 0-100 2915S-10 2915SB-10 ±.001” ±.001"

.001” .5” .1" 0-50-0 2918S-10 2918SB-10 ±.001” ±.001"

Metric

Graduation Range

0.01mm 10mm 1mm 0-100 2048S-11 2048SB-11 ±13μm

Stem dia. 3/8" #4-48 UNF Thread

Range

/ rev

Stem dia. 3/8" #4-48 UNF Thread, Yellow Dial Face

Range

/ rev

Order No. Accuracy

Dial

reading

w/ lug Flat-back

Order No. Accuracy

Dial

reading

w/ lug Flat-back

First 2.5

Rev

First 2.5

Rev

Overall

Accuracy

Overall

±0.013mm

Double-face type

2940S

Measuring

force

1.8N or less

1.8N or less

1.8N or less

1.8N or less

4 4

4 4

4 4 4

4 4 4

Measuring

force

1.4N or less

ANSI/AGD type

ANSI/AGD type

4 4 4

Metric

Graduation Range

0.01mm 10mm 1mm 0-100 2048S-10 2048SB-10 ±0.015mm

0.01mm 10mm 1mm 0-100 2046S-80 2046SB-80 ±0.015mm

0.01mm 10mm 1mm 0-100 2940S — ±0.015mm

DIMENSIONS

Order No. A B C

2915S-10, 2918S-10 52.2 64.1 22

2919S-10, 2920S-10 52.2 57.7 15.6

2048S-11 47.7 59.5 17.4

Unit: mm

Stem ø 8mm, M2.5 x 0.45 Thread

Range

/Rev

Order No.

Dial

reading

w/ lug Flat-back

Accuracy

F-21

Measuring

force

1.4N or less

5.0N or less

3.0N or less

ISO/JIS type

4 4 4

4

4

Unit: mm

Dial Indicators

Waterproof type

Jeweled bearing type

Reverse reading type

Shockproof type

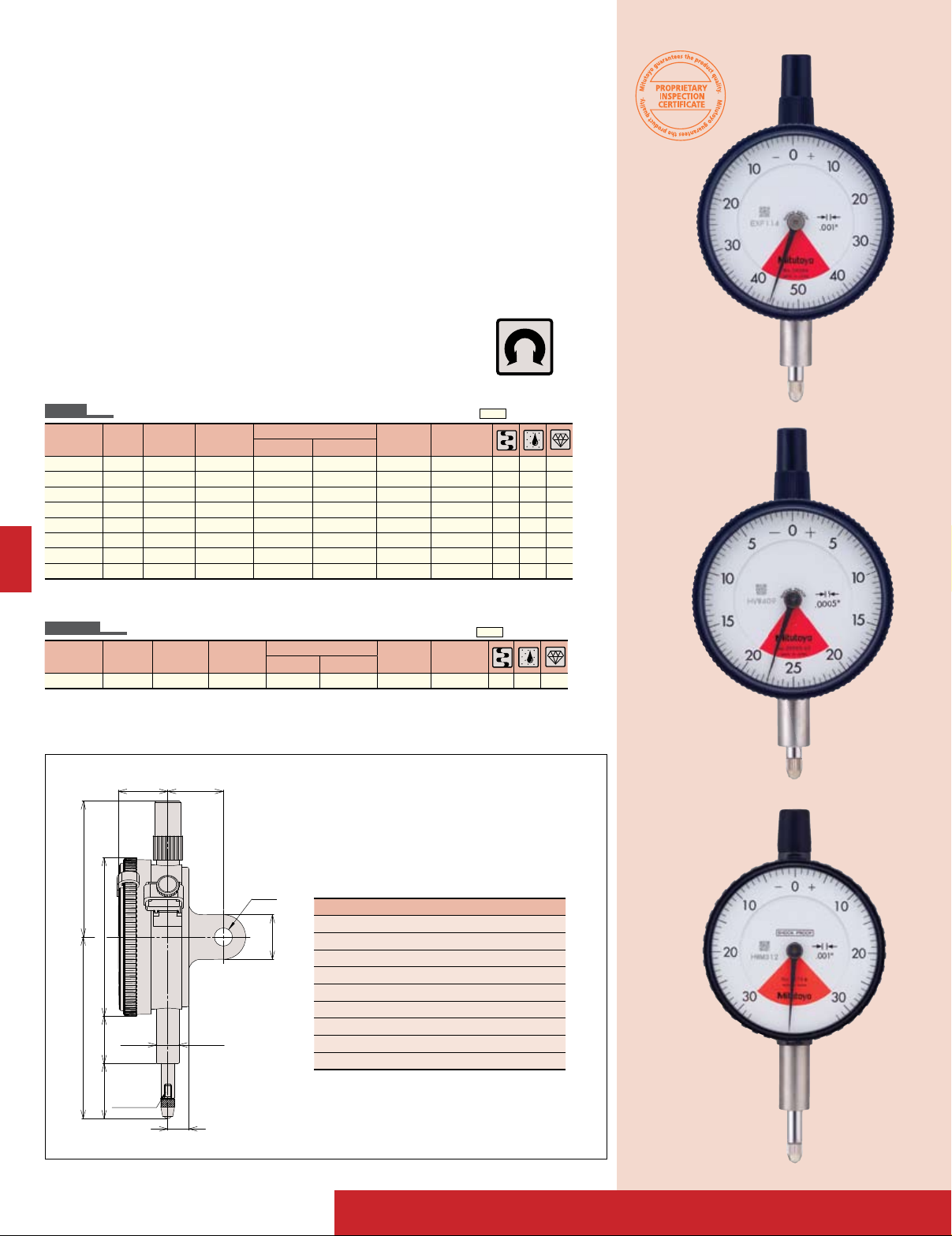

SERIES 2 — Standard Type, Inch Reading

SPECIFICATIONS

Inch

Graduation Range

.0001” .02” .008” 0-4-0 2937S-10 2937SB-10 ±.0001” ±.0001”

.0001” .02” .008” 0-8 2938S-10 2938SB-10 ±.0001” ±.0001”

.0001” .025” .01” 0-10 2802S-10 2802SB-10 ±.0001” ±.0001”

.0001” .025” .01” 0-10 2802S-70 2802SB-70 ±.0001” ±.0001”

.0001” .025” .01” 0-5-0 2803S-10 2803SB-10 ±.0001” ±.0001”

.0001” .025” .01” 0-5-0 2803S-70 2803SB-70 ±.0001” ±.0001”

.0001” .05” .01” 0-10 2804S-10 2804SB-10 ±.0001” ±.0002”

.0001” .05” .01” 0-5-0 2805S-10 2805SB-10 ±.0001” ±.0002”

.0001” .05” .01” 10-0 2905S-10 2905SB-10 ±.0001” ±.0002”

.0001” .05” .01” 0-5-0 2923S-10 2923SB-10 ±.0001” ±.0002”

.0001” .1” .01” 0-10 2806S-10 2806SB-10 ±.0001” ±.0003”

.0001” .1” .01” 0-10 2806S-70 2806SB-70 ±.0001” ±.0003”

.0001” .25” .01” 0-10 2356S-10 2356SB-10 ±.0001” ±.0005”

.0001” .5” .01” 0-10 2358S-10 2358SB-10 ±.0001” ±.0008”

.00025” .05” .02” 0-20 2470S-10 2470SB-10 ±.00025” ±.00025”

.00025” .05” .02” 0-10-0 2471S-10 2471SB-10 ±.00025” ±.00025”

.0005” .1” .04” 0-40 2670S 2670SB ±.0005” ±.0005”

.0005” .1” .04” 0-20-0 2671S 2671SB ±.0005” ±.0005”

.0005” .125” .05” 0-50 2506S 2506SB ±.0005” ±.0005”

.0005” .125” .05” 0-25-0 2507S 2507SB ±.0005” ±.0005”

.0005” .125” .05” 0-25-0 2922S 2922SB ±.0005” ±.0005”

.0005” .4” .04” 0-20-0 2675S 2675SB ±.0005” ±.0015”

.0005” .5” .05” 0-50 2514S 2514SB ±.0005” ±.0015”

.0005” .5” .05” 0-50 2514S-60 2514SB-60 ±.0005” ±.0015”

.0005” 1" .05” 0-50 2776S 2776SB ±.0005” ±.002”

.0005” .1" .05” 0-50 2776S-60 2776SB-60 ±.0005” ±.002”

.001” .125” .05” 0-50 2780S 2780SB ±.001” ±.001”

.001” .125” .05” 0-25-0 2781S 2781SB ±.001” ±.001”

.001” .25” .1” 0-100 2410S 2410SB ±.001” ±.001”

.001” .25” .1” 0-100 2410S-10 2410SB-10 ±.001” ±.001”

.001” .25” .1” 0-100 2410S-60 2410SB-60 ±.001” ±.001”

.001” .25” .1” 0-50-0 2411S 2411SB ±.001” ±.001”

.001” .25” .1” 0-50-0 2411S-10 2411SB-10 ±.001” ±.001”

.001” .25” .1” 0-100 2919S-10 2919SB-10 ±.001” ±.001”

.001” .25” .1” 0-50-0 2920S-10 2920SB-10 ±.001” ±.001”

.001” .5” .1” 0-100 2414S 2414SB ±.001” ±.001”

.001” .5” .1” 0-100 2414S-10 2414SB-10 ±.001” ±.001”

.001” .5” .1” 0-100 2414S-60 2414SB-60 ±.001” ±.001”

.001” .5” .1” 0-50-0 2415S 2415SB ±.001” ±.001”

.001” .5” .1” 0-50-0 2415S-10 2415SB-10 ±.001” ±.001”

.001” 1" .1” 0-100 2416S 2416SB

.001” 1" .1” 0-100

.001” 1" .1” 0-100 2416S-10 2416SB-10

.001” 1" .1” 0-100 2416S-60 2416SB-60

.001” 1" .1” 0-50-0 2417S 2417SB

.001” 1" .1” 100-0 2904S 2904SB

.001” 2" 1” 0-100 2424S-19 2424SB-19

.01” 1" 1” 0-1000 2204S 2204SB

* Black Face

Stem 3/8" dia. ø8mm #4-48 UNF Thread

Order No. Accuracy

Dial

Range

Reading

/ Rev

w/ lug Flat-back First 2.5 Rev Overall

2416S-06* 2416SB-06* ±.001” ±.002” 1.8N or less

±.001” ±.002” 1.8N or less

±.001” ±.002” 1.8N or less

±.001” ±.002” 2.5N or less

±.001” ±.002” 1.8N or less

±.001” ±.002” 1.8N or less

±.001” ±.003” 2.5N or less

±.005” ±.005” 1.8N or less

Measuring

force

2.0N or less

2.0N or less

2.5N or less

2.0N or less

2.5N or less

2.0N or less

2.0N or less

2.0N or less

2.0N or less

2.0N or less

2.0N or less

2.5N or less

2.0N or less

2.0N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

2.5N or less

1.8N or less

2.5N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

2.5N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

1.8N or less

2.5N or less

1.8N or less

1.8N or less

ANSI/AGD type

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4

4 4 4

4 4

4 4

4 4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4 4

2416S

2803S-10

F-22

Optional Accessories

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

ø

6.5

#4-48UNF

16

17.7

19

7.6

57

D C

ø

52

AB

ø9.52

ø3/8”

0

-0.03

ø6.5

#4-48UNF

16

17.7

19 (20.9)

ø57

D C

B

7.6

(9.5)

ø52

A

ø9.52

0

-0.03

ø3/8”

( ): 2424S-19

2424S-19

Dial Indicators

SERIES 2 — Standard Type, Inch Reading

DIMENSIONS

Drawing A

Drawing B

Unit: mm

2 Group Inch

2506S

Order No. A B C D Drawing

2204S(B) 38.9 76.8 13.6 34.7 A

2356S(B)-10 48.8 57.2 13.6 15.1 B

2358S(B)-10 38.9 63.6 13.6 21.5 A

2410S(B) 48.8 57.8 13.6 15.7 B

2410S(B)-10 48.8 57.8 13.6 15.7 B

2410S(B)-60 48.8 62.7 10.6 23.6 B

2411S(B) 48.8 57.8 13.6 15.7 B

2411S(B)-10 48.8 57.8 13.6 15.7 B

2414S(B) 38.9 64.1 13.6 22 A

2414S(B)-10 38.9 64.1 13.6 22 A

2414S(B)-60 48.8 66 10.6 26.9 B

2415S(B) 38.9 64.1 13.6 22 A

2415S(B)-10 38.9 64.1 13.6 22 A

2415S(B)-60 48.8 66 10.6 26.9 B

2416S(B) 38.9 76.8 13.6 34.7 A

2416S(B)-06 38.9 76.8 13.6 34.7 A

2416S(B)-10 38.9 76.8 13.6 34.7 A

2416S(B)-60 66.8 87.2 10.6 48.1 B

2417S(B) 38.9 76.8 13.6 34.7 A

2424S(B)-19 118.5 142.5 54.3 59.7 B

2470S(B)-10 48.8 52.2 13.6 10.1 B

2471S(B)-10 48.8 52.2 13.6 10.1 B

2506S(B) 48.8 54.3 13.6 12.2 B

2507S(B) 48.8 54.3 13.6 12.2 B

2514S(B) 38.9 64.1 13.6 22 A

2923S-10

2514S(B)-60 48.8 66 10.6 26.9 B

2570S(B)-10 48.8 52.9 13.6 10.8 B

2571S(B)-10 48.8 52.9 13.6 10.8 B

Order No. A B C D Drawing

2576S(B)-70 48.8 63.5 10.6 24.4 B

2670S(B) 48.8 53.6 13.6 11.5 B

2671S(B) 48.8 53.6 13.6 11.5 B

2675S(B) 48.8 61.2 13.6 19.1 B

2776S(B) 38.9 76.8 13.6 34.7 A

2776S(B)-60 66.8 87.2 10.6 48.1 B

2780S(B) 48.8 54.3 13.6 12.2 B

2781S(B) 48.8 54.3 13.6 12.2 B

2802S(B)-10 48.8 51.4 13.6 9.3 B

2802S(B)-70 48.8 56.3 10.6 17.2 B

2803S(B)-10 48.8 51.4 13.6 9.3 B

2803S(B)-70 48.8 56.3 10.6 17.2 B

2804S(B)-10 48.8 51.7 13.6 9.6 B

2805S(B)-10 48.8 51.7 13.6 9.6 B

2806S(B)-10 48.8 53.4 13.6 11.3 B

2806S(B)-70 48.8 58.3 10.6 19.2 B

2904S(B) 38.9 76.8 13.6 34.7 A

2905S(B)-10 48.8 51.7 13.6 9.6 B

2914S(B) 38.9 64.1 13.6 22 A

2915S(B)-10 52.2 63.3 13.6 21.2 A

2918S(B)-10 52.2 63.3 13.6 21.2 A

2919S(B)-10 47.7 57.7 13.6 15.6 A

2920S(B)-10 47.7 57.7 13.6 15.6 A

2922S(B) 48.8 54.3 13.6 12.2 B

2923S(B)-10 48.8 51.7 13.6 9.6 B

2937S(B)-10 48.8 51.3 13.6 9.2 B

2938S(B)-10 48.8 51.3 13.6 9.2 B

F-23

Dial Indicators

Waterproof type

Jeweled bearing type

Reverse reading type

Shockproof type

Long stem type

w/ coaxial revolution

counter

w/ damper at

lowest rest point

Double scale spacing

type

SERIES 2 — Metric Standard Type

Series 2 dial indicators are Mitutoyo’s most

popular, and have the widest application.

FEATURES

• Standard 0.01mm graduation dial gauges

having an outer frame with an outside

diameter of 57mm. All types come with

limit pins and an outer frame clamp as

standard.

• The outer clamp and lifting lever (optional)

can be attached to either the right or left

side. These parts can be easily installed and

removed without tools.

• Secured adhesion between the outer frame

and crystal as well as the use of an O-ring

ensure countermeasures against water and

oil permeation via the front face.

• The stem spindle is made of high-strength

quench-hardened stainless steel which

resists strenuous use.

• A carbide contact point is used.

• The grand gear uses stainless steel that is

resistant to wear and deformation.

• Application of a hard coating on the

surface of the crystal makes the gauge

highly scratch- and chemical-resistant.

SPECIFICATIONS

Metric

Graduation Range

0.001mm

0.001mm

0.001mm

0.001mm

0.001mm

0.001mm

0.001mm

0.001mm

0.001mm

0.005mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

0.01mm

*Use in a vertical position only (contact point downward).

Stem dia. ø8mm M2.5 x 0.45 Thread

Range

Dial reading

/ Rev

1mm (0.1mm) 0-100

1mm (0.1mm) 0-100

1mm (0.2mm) 0-100-0

1mm (0.2mm) 0-100-0

1mm (0.2mm) 0-100-0

1mm (0.2mm) 0-100-0

2mm (0.2mm) 0-100-0

5mm (0.2mm) 0-100-100

5mm (0.2mm) 0-100-0

5mm (0.5mm) 0-50

5mm (1mm)

5mm (1mm)

5mm (1mm)

5mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

10mm (1mm)

20mm (1mm)

20mm (1mm)

20mm (1mm)

20mm (1mm)

30mm (1mm)

30mm (1mm)

30mm (1mm)

30mm (1mm)

0-100 2044S 2044SB ±0.012mm

0-100 2044S-09 2044SB-09 ±0.013mm

0-100 2044S-60 2044SB-60 ±0.012mm

0-50-0 2045S 2045SB ±0.012mm

0-100 2046S 2046SB ±0.013mm

0-100 2046SY 2046SYB ±0.013mm

0-100 2046SH 2046SHB ±0.08mm

0-100 — 2046SLB ±0.013mm

0-100 2046S-09 2046SB-09 ±0.015mm

0-100 2046S-60 2046SB-60 ±0.013mm

0-100 2046S-69 2046SB-69 ±0.015mm

0-100 2046S-15 2046SB-15 ±0.013mm

0-100 2310S-10 2310SB-10 ±0.015mm

100-0 2902S 2902SB ±0.013mm

0-50-0 2047S 2047SB ±0.013mm

0-100 2050S 2050SB ±0.020mm

0-100 2050S-60 2050SB-60 ±0.020mm

0-100 2050S-19 2050SB-19 ±0.020mm

0-100 2320S-10 2320SB-10 ±0.020mm

0-100 2052S 2052SB ±0.025mm

0-100 2052S-19 2052SB-19 ±0.025mm

0-100 2330S-10 2330SB-10 ±0.025mm

100-0 2952S 2952SB ±0.025mm

Order No.

w/ lug Flat-back

2110S-10 2110SB-10

2110S-70 2110SB-70

2109S-10 2109SB-10

2109SH-10 2109SHB-10

— 2109SLB-10

2109S-70 2109SB-70

2113S-10 2113SB-10

2118S-10 2118SB-10

2119S-10 2119SB-10

2124S-10 2124SB-10

Accuracy

±0.005mm

±0.005mm

±0.005mm

±0.003mm

±0.005mm

±0.005mm

±0.007mm

±0.010mm

±0.010mm

±0.012mm

Measuring

force

1.5N or less

2.0N or less

1.5N or less

1.5N or less

1.5N or less

2.0N or less

1.5N or less

1.5N or less

1.5N or less

1.5N or less

1.4N or less

1.4N or less

2.5N or less

1.4N or less

1.4N or less

1.4N or less

1.4N or less

1.4N or less

1.4N or less

2.5N or less

2.5N or less

0.8N or less*

1.4N or less

1.4N or less

1.4N or less

2.0N or less

2.5N or less

2.0N or less

2.0N or less

2.5N or less

2.5N or less

2.5N or less

2.5N or less

ISO/JIS type

4 4 4

4 4 4 4

4 4

4 4

4 4 4

4 4 4

4 4

4

4

4

4

4

4

4

4

4

4 4

4

4 4

4

4

4 4 4

4 4 4

4 4 4

4 4 4

4 4

2046S

2046S-60

2046S

2046SH

2046S-09

2046S-15

2046S-80

2046SLB

2046SY

2046S-60

2046S-69

4

4

2047S

F-24

ø6.5

M2.5×0.45

16

17.7 20

ø57

C B

A

7.6

ø52

48.8

10

12.5

5

1.65

30°

ø8

0

-0.009

ø

6.5

M2.5 x 0.45

16

17.7

20

7.6

57

D C

ø

52

AB

ø8

0

-0.009

2902S

2310S-10

Dial Indicators

SERIES 2 — Metric Standard Type

DIMENSIONS

ISO/JIS

Type

Unit: mm

Order No. A B C

2124S-10 60.3 16.9 14.9

2110S-10 66.5 16.9 21.1

2110S-70 67.5 12.3 26.7

2109S-10 60.5 16.9 15.1

2109SH-10 60.5 16.9 15.1

2109SLB-10 80.5 36.9 15.1

2109S-70 65.3 12.3 24.5

2113S-10 61 16.9 15.6

2118S-10 60.3 16.9 14.9

2119S-10 60.3 16.9 14.9

2044S 65.2 16.9 19.8

2044S-09 65.2 16.9 19.8

2044S-60 70 12.3 29.2

2045S 65.2 16.9 19.8

2046S 65.2 16.9 19.8

2046SH 65.2 16.9 19.8

2046SLB 85.2 36.9 19.8

2046S-09 65.2 16.9 19.8

2046S-60 70 12.3 29.2

2046S-69 70 12.3 29.2

2046S-15 65.2 16.9 19.8

2310S-10 65.2 16.9 19.8

2902S 65.2 16.9 19.8

2047S 65.2 16.9 19.8

2044S

2044S-60

2044S-09

Optional Accessories

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

ISO/JIS

Unit: mm

Type

Order No. A B C D

2050S 38.8 75.2 16.9 29.8

2045S

2050S-60 59.8 87.2 12.3 46.4

2050S-19 38.8 75.2 16.9 29.8

2320S-10 38.8 75.2 16.9 29.8

2052S 38.8 88.7 16.9 43.3

2052S-19 38.8 88.7 16.9 43.3

2330S-10 38.8 88.7 16.9 43.3

2952S 38.8 88.7 16.9 43.3

F-25

Dial Indicators

ø6.5

#4-48UNF

16

17.7 19

ø57

C

13.6

(10.6)

B

7.6

ø52

A

10

12.5

6.35

1.65

30°

ø9.52

(3/8”)

0

-0.03

( ): water proof type

SERIES 2 — ANSI / AGD Type Metric Dial Indicator

SPECIFICATIONS

Metric

Graduation Range

0.001mm 1mm 0.2mm 0-10-0 2109S-11 2109SB-11 ±0.003mm ±0.004mm 1.5N or less

0.001mm 5mm 0.2mm 0-10-0 2119S-11 2119SB-11 ±0.007mm ±0.01mm 1.5N or less

0.002mm 0.5mm 0.2mm 0-20 2010S-11 2010SB-11 ±0.003mm ±0.003mm 1.5N or less

0.002mm 0.5mm 0.2mm 0-20 2010S-71 2010SB-71 ±0.003mm ±0.003mm 2.5N or less

0.002mm 0.5mm 0.2mm 0-10-0 2011S-11 2011SB-11 ±0.003mm ±0.003mm 1.5N or less

0.002mm 0.5mm 0.2mm 0-10-0 2011S-71 2011SB-71 ±0.003mm ±0.003mm 2.5N or less

0.005mm 5mm 0.5mm 0-25-0 2125S-71 2125SB-71 ±0.01mm ±0.012mm 2.5N or less

0.01mm 2.5mm 1mm 0-100 2230S-01 2230SB-01 ±0.01mm ±0.01mm 1.4N or less

0.01mm 2.5mm 1mm 0-100 2231S-01 2231SB-01 ±0.01mm ±0.01mm 1.4N or less

0.01mm 5mm 1mm 0-100 2044S-01 2044SB-01 ±0.01mm ±0.01mm 1.4N or less

0.01mm 5mm 1mm 0-100 2044S-61 2044SB-61 ±0.01mm ±0.01mm 2.5N or less

0.01mm 10mm 1mm 0-100 2046S-01 2046SB-01 ±0.01mm ±0.013mm 1.4N or less

0.01mm 10mm 1mm 0-100 2046S-11 2046SB-11 ±0.01mm ±0.013mm 1.4N or less

0.01mm 10mm 1mm 0-100 2046S-61 2046SB-61 ±0.01mm ±0.013mm 2.5N or less

0.01mm 10mm 1mm 0-50-0 2047S-01 2047SB-01 ±0.01mm ±0.013mm 1.4N or less

0.01mm 10mm 1mm 100-0 2902S-01 2902SB-01 ±0.01mm ±0.013mm 1.4N or less

0.01mm 20mm 1mm 0-100 2050S-01 2050SB-01 ±0.01mm ±0.02mm 2.0N or less

0.01mm 20mm 1mm 0-100 2050S-11 2050SB-11 ±0.01mm ±0.02mm 2.0N or less

0.01mm 25mm 1mm 0-100 2056S-01 2056SB-01 ±0.01mm ±0.025mm 2.5N or less

Stem dia. 3/8", #4-48 UNF Thread Yellow Dial Face

Range /

Rev

Order No. Accuracy

Dial

reading

w/ lug Flat-back First 2.5 Rev Overall

Measuring

force

ANSI/AGD type

4 4

4

4 4

4 4

4 4

4 4

4 4

4

4

4

4

DIMENSIONS

Unit: mm

Order No. A B C

2109S-11 48.8 51.4 9.3

2119S-11 48.8 55.8 13.7

2010S-11 48.8 51.4 9.3

2010S-71 48.8 56.3 17.2

2011S-11 48.8 51.4 9.3

2011S-71 48.8 56.3 17.2

2125S-71 48.8 60.7 21.6

2230S-01 48.8 53.6 11.5

2231S-01 48.8 53.6 11.5

2044S-01 48.8 56.1 14.0

2044S-61 48.8 61.0 21.9

2046S-01 48.8 61.1 19.0

2046S-11 48.8 61.1 19.0

2046S-61 48.8 66.0 26.9

2047S-01 48.8 61.1 19.0

2902S-01 48.8 61.1 19.0

2050S-01 38.8 71.1 29.0

2050S-11 38.8 71.1 29.0

2056S-01 38.8 76.1 34.0

F-26

21

19.1

21.5

ø92

18.9

ø71

9

61.2

84

16

M2.5×0.45

4046S

M2.5×0.45

D

21 (19)

16

17.7

ø78

C

ø71

A

B

9

5

(6.35)

ø8

0

-0.009

ø8

0

-0.009

ø6.5

±0.1

M2.5×0.45

(#4-48 UNF) (#4-48 UNF)

D

21 (19)

16

17.7

ø78

C

ø71

A

B

9

(8.9) (8.9)

(3/8”) (3/8”)

5

(6.35)

ø6.5

±0.1

ø6.5

±0.1

ø8

0

-0.009

3046S

Dial Indicators

SERIES 3 — Large Dial Face and Long Stroke Type

• Dial gages with a large-diameter

(78mm / 3.07”) graduation face

to ease reading.

• All types come with limit pins and

an outer frame clamp as standard.

3058S-19

3047S

3050S

3052S-19

3109S-10

3416S

DIMENSIONS

Unit: mm

( ): ANSI / AGD Type

F-27

Order No. A B C D

3052S(B)-11 72.9 102.4 25.9 37.5

3058S(B)-11 81.9 147.1 50.6 57.5

3414S(B) 51.3 73.4 12.6 21.8

3415S(B) 51.3 73.4 12.6 21.8

3416S(B) 51.3 86.1 12.6 34.5

3417S(B) 51.3 86.1 12.6 34.5

3424S(B)-19 84 149.3 50.6 59.7

3426S(B)-19 120.9 198.1 73.9 85.2

3428S(B)-19 141.9 243.9 94.9 110.0

3570S(B)-10 61.2 62.1 12.6 10.5

3571S(B)-10 61.2 62.1 12.6 10.5

3780S(B) 61.2 63.9 12.6 12.3

3781S(B) 61.2 63.9 12.6 12.3

3802S(B)-10 61.2 59.7 12.6 8.1

3803S(B)-10 61.2 59.7 12.6 8.1

3046S(B) 61.2 75.5 15.9 20.6

3047S(B) 61.2 75.5 15.9 20.6

3050S(B) 52.6 94.0 25.9 29.1

3060S(B)-19 120.9 202.3 73.9 89.4

3062S(B)-19 141.9 243.3 94.9 109.4

3109S(B)-10 61.2 79.3 25.9 14.1

Dial Indicators

w/ coaxial revolution

Jeweled bearing type

Shockproof type

w/ damper at lowest

rest point

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

Jeweled bearing type

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

Jeweled bearing type

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

Jeweled bearing type

SERIES 3 — Large Dial Face

SPECIFICATIONS

Inch

Graduation Range

Range

/rev

.0001” .025” .01” 0-10

.0001” .025” .01” 0-5-0

.0005” .075” .03” 0-30

.0005” .075” .03” 0-15-0

.001” .125” .05” 0-50

.001” .125” .05” 0-25-0

.001” .5” .1” ±0-100

.001” .5” .1” 0-50-0

.001” 1” .1” ±0-100

.001” 1” .1” 0-50-0

.001” 2” .1” ±0-100

.001” 3” .1” ±0-100

.001” 4” .1” ±0-100

Stem 3/8" DIA. #4-48 UNF Thread

Order No.

Dial

reading

W/ lug Flat-back

3802S-10 3802SB-10

3803S-10 3803SB-10

3570S-10 3570SB-10

3571S-10 3571SB-10

3780S 3780SB

3781S 3781SB

3414S 3414SB

3415S 3415SB

3416S 3416SB

3417S 3417SB

3424S-19 3424SB-19

3426S-19 3426SB-19

3428S-19 3428SB-19

Accuracy

First 2.5 Rev

Overall

accuracy

Measuring

force

±.0001” ±.0001” 2.0N or less

±.0001” ±.0001” 2.0N or less

±.0005” ±.0005” 1.8N or less

±.0005” ±.0005” 1.8N or less

±.001” ±.001” 1.8N or less

±.001” ±.001” 1.8N or less

±.001” ±.001” 1.8N or less

±.001” ±.001” 1.8N or less

±.001” ±.002” 1.8N or less

±.001” ±.002” 1.8N or less

±.001” ±.003” 3.0N or less

±.001” ±.005” 3.0N or less

±.001” ±.005” 3.2N or less

ANSI/AGD type

4 4

4 4

4

4

4 4 4

4 4 4

4 4 4

Metric

Graduation Range

Stem 3/8" DIA. #4-48 UNF Thread, Yellow dial face

Range

Dial

/rev

reading

0.01mm 30mm 1mm ±0-100

0.01mm 50mm 1mm ±0-100

Metric

Graduation Range

Stem ø 8mm M2.5x0.45 Thread

Range

Dial

/rev

reading

0.001mm 1mm 0.2mm 0-10-0

0.01mm 10mm 1mm 0-100

0.01mm 10mm 1mm 0-50-0

0.01mm 20mm 1mm 0-100

0.01mm 30mm 1mm 0-100

0.01mm 50mm 1mm 0-100

0.01mm 80mm 1mm 0-100

0.01mm 100mm 1mm 0-100

*use in a vertical position only

Order No.

W/ lug Flat-back

3052S-11 3052SB-11

3058S-11 3058SB-11

Accuracy

First 2.5 Rev

±0.01mm ±0.03mm 2.5N or less

±0.01mm ±0.04mm 3.0N or less

Order No.

W/ lug Flat-back

3109S-10 3109SB-10

3046S 3046SB

3047S 3047SB

3050S 3050SB

3052S-19 3052SB-19

3058S-19 3058SB-19

3060S-19* 3060SB-19*

3062S-19* 3062SB-19*

Overall

accuracy

Accuracy

Measuring

Force

Measuring

Force

±0.004mm 1.5N or less

±0.015mm 1.4N or less

±0.015mm 1.4N or less

±0.020mm 2.0N or less

±0.025mm 2.5N or less

±0.035mm 3.0N or less

±0.045mm 3.0N or less

±0.050mm 3.2N or less

ANSI/AGD type

4 4 4

4 4 4

ISO/JIS type

4 4

4

4 4 4

4 4 4

4 4 4

4 4 4

F-28

21

19.1

21.5

ø92

18.9

ø71

9

61.2

84

16

M2.5×0.45

4046S

M2.5×0.45

D

21 (19)

16

17.7

ø92

C

ø71

A

B

9

5

(6.35)

ø8

0

-0.009

ø8

0

-0.009

ø6.5

±0.1

M2.5×0.45

(#4-48 UNF) (#4-48 UNF)

D

21 (19)

16

17.7

ø92

C

ø71

A

B

9

(8.9) (8.9)

(3/8”) (3/8”)

5

(6.35)

ø6.5

±0.1

ø6.5

±0.1

ø8

0

-0.009

Dial Indicators

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

Jeweled bearing type

Waterproof type

Jeweled bearing type

Shockproof type

Dustproof type

Jeweled bearing type

SERIES 4 — Large Dial Face

• Dial gauges with a large-diameter

(92mm / 3.62”) graduation face to ease

reading.

• All types come with limit pins and an

outer frame clamp as standard.

4046S

4887S-19

Inch

Graduation Range

.0001” .025” .01” 0-10

.0001” .025” .01” 0-5-0

.0005” .075” .03” 0-30

.001” .25” .1” ±0-100

.001” 3” .1” ±0-100

Metric

Graduation Range

0.01mm 10mm 1mm 0-100

DIMENSIONS

Stem 3/8" DIA. #4-48 UNF Thread

Range

/rev

Order No.

Dial

reading

W/ lug Flat-back

4802S-10 4802SB-10

4803S-10 4803SB-10

4570S-10 4570SB-10

4410S 4410SB

4887S-19 4887SB-19

Stem ø 8mm M2.5x0.45 Thread

Range

/rev

Order No.

Dial

reading

W/ lug Flat-back

4046S 4046SB

ANSI/AGD type

Accuracy

First 2.5 Rev

±.0001” ±.0001” 2.0N or less

±.0001” ±.0001” 2.0N or less

±.0005” ±.0005” 1.8N or less —

Overall

accuracy

Measuring

Force

4 4

4 4

4

—

—

—

±.001” ±.001” 1.8N or less — — —

±.001” ±.005” 3.0N or less

Accuracy

First 2.5 Rev

accuracy

Overall

Measuring

force

± 0.01mm ± 0.015mm 1.4N or less

Order No. A B C D

4046S(B) 61.2 84.0 18.9 19.1

4410S(B) 61.2 74.3 12.9 15.4

4570S(B)-10 61.2 69.4 12.9 10.5

4802S(B)-10 61.2 67 12.9 8.1

( ): ANSI / AGD Type

4803S(B)-10 61.2 67 12.9 8.1

4887S(B)-19 120.9 198.1 66.9 85.2

4 4 4

ISO/JIS type

4 4

Unit: mm

F-29

Back Plunger Type Dial Indicators

One revolution type

Shockproof type

Jeweled bearing type

SERIES 1 and 2

Mitutoyo's back plunger type dial indicators

are built with the measuring spindles on

the back of the units. This type of indicator

offers the same precision and durability

as all other Mitutoyo dial indicators, and

operates very effectively with optional

holding bars.

• Back plunger type dial gauges are suitable

for mounting onto leveling machine tool

tables or inspection jigs, and for use in small

spaces where the graduations of standard

dial gauges are difficult to see.

• Model No. 1960, which uses Mitutoyo's

proprietary shock-proofing mechanism, has

excellent durability and shock resistance.

SPECIFICATIONS

Inch

Graduation Range

.001” .04” .05”* 20-0-20 1961 ±.001” 1.4N or less

.001” .1” .1” 0-100 1156 ±.001” 2.1N or less

.001” .1” .1” 0-50-0 1157 ±.001” 2.1N or less

.001” .2” .05” 0-50 1166 ±.001” 1.4N or less

.001” .2” .05” 0-25-0 1167 ±.001” 1.4N or less

.001” .2” .05” 50-0 1168 ±.001” 1.4N or less

*Full stroke

Metric

Graduation Range

0.01mm 1mm 1.27mm* 50-0-50 1960 ±0.014mm 1.4N or less

0.01mm 5mm 1mm 0-100 1160 ±0.016mm 1.4N or less —

0.01mm 5mm 1mm 100-0 1162 ±0.016mm 1.4N or less

0.01mm 5mm 1mm 0-100 1180-6 ±0.016mm 1.5N or less with arm

0.01mm 5mm 1mm 0-100 1180-7 ±0.016mm 1.5N or less with arm

0.01mm 5mm 1mm 0-100 1180-8 ±0.016mm 1.5N or less with arm

Series 1

Stem 3/8" dia. , #4-48 UNF Thread

Range

/ Rev

Series 1

Range

/ Rev

Dial

reading

Stem ø8mm, M2.5x0.45 Thread

Dial

reading

Order No. Accuracy

Order No. Accuracy

Measuring

force

Measuring

force

4 4

4 4

ANSI/AGD type

4

Remarks

4

(ø6x42mm)

(ø6.35x42mm)

(ø8x42mm)

ISO/JIS type

—

—

Optional Accessories

136567: Holding bar (ø6mm, L=81mm)

21AAA166: Holding bar (ø6mm, L=42mm)

(Standard with 1180-6)

136568: Holding bar (ø8mm, L=81mm)

21AAA168: Holding bar (ø8mm, L=42mm)

(Standard with 1180-8)

124625: Holding bar (.25” DIA, L=3.19”)

21AAA167: Holding bar (.25” DIA, L=1.65”)

(Standard with 1180-7)

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

Inch

Graduation Range

.0001” .008” .01” 4-0-4 2991 ±.0002” 1.5N or less

.0005” .04” .05” 20-0-20 2961 ±.0005” 1.8N or less

Metric

Graduation Range

0.001mm 0.14” 0.14” 50-0-50 2990 ±0.0065mm 1.5N or less

0.01mm 1.27” 1.27” 50-0-50 2960F ±0.014mm 1.4N or less

Series 2

Series 2

Stem 3/8" dia. , #4-48 UNF Thread

Range/full

stroke

Stem ø8mm, M2.5x0.45 Thread

Range

stroke

Dial reading Order No. Accuracy

/full

Dial reading Order No. Accuracy

Measuring

force

Measuring

force

F-30

ANSI/AGD type

4 4 4

4 4

ISO/JIS type

4 4 4

4 4

21.5AB

øD

C

ø39

ø4

L

ø35

22

Holding bar (optional)

M2.5x0.45 (#4-48 UNF)

ø8

(3/8”)

0

-0.009

M2.5×0.45

ø39

21.59.5

13.8

ø4

øD

L

Holding bar

27.8

ø35

E

ø55.6

12.8 23.7 28

M2.5x0.45

(#4-48 UNF)

(#4-48 UNF)

ø8

0

-0.009

(3/8”)

(3/8”)

ø8

0

-0.009

øD

ø58

4521.517.5

59

ø51

25

L

M2.5x0.45

Holding bar (optional)

( ): ANSI / AGD type

1180-6

1180-7

1180-8

Back Plunger Type Dial Indicators

ø.375"

ø.250"

(ø 6.35)

(ø9.52 )

0

-0.001

0

-0.009

3.86" (98)

1.63" (41.5)

3.19" (81)

#4-48 THREADS

.87"

(22)

1.85" (47)

SERIES 1 and 2

1180-6

Holding bar (optional)

1960

1156

DIMENSIONS

Order No. A B C

1160 25.0 13.8 43.3

1162 25.0 13.8 43.3

1166 25.0 13.0 42.5

1167 25.0 13.0 42.5

1168 25.0 13.0 42.5

1960 28.7 12.8 46.0

1961 25.0 10.9 40.4

Unit: inch (mm)

2960F

2991

Unit: mm

1156, 1157

2990

29060F

F-31

£

©xÈ

©Èä°ÇÓä

ÎÊ{ä°n®ÈÈ

£x°Ç

xÓ{Èä£

xÓ{ÈäÓ

xÓ{ÈäÎ

xÓ{xää

xÓ{xä£

©n

Êä

ä°ää

©n

Êä

ä°ää

ÈÈ {Ç

Ó°xÝä°{x

£

©Èä°ÇÓä

©xÈ

Hicators, Signal Hicators

SERIES 524 — High Accuracy One-Revolution Dial Indicator

FEATURES

The Hicator is Mitutoyo's ultra-sensitive,

one-revolution dial indicator. The spindle is

made of highly durable stainless steel, and

this device features jeweled bearings for

extreme sensitivity as well as a shock-proof

and dust-proof structure.

Hicator

524-501

SPECIFICATIONS

Metric

Graduation Order No.* Range Dial reading Spindle travel Accuracy Measuring force Remarks

0.001mm 524-501 ±0.05mm 50-0-50 3mm ±1μm 1.2N or less w/ spindle lifting cable

0.0005mm 524-500 ±0.03mm 30-0-30 3mm ±0.5μm 1.2N or less w/ spindle lifting cable

*Flat back

Hicator

• The maximum, minimum, or runout value

can be displayed during measurement.

• The Hicator is capable of probing measure-

ments up to 0.0005mm.

• Connected to an optional Signal Box, the

Signal Hicator can output limit signals to

perform GO/±NO-GO judgment.

• Splash-proof structure.

• Lug-on-center back is optional.

Signal Hicator

524-601

ISO/JIS type

Optional Accessories

524-001: Signal box (100V AC)

524-001A: Signal box (120V AC)

––––––: Backs (See page F-33.)

––––––: Contact points (See page F-34.)

Metric

Graduation Order No.* Range Dial reading Spindle stroke Accuracy Measuring force Remarks

0.01mm 524-603 ±0.5mm 50-0-50 3mm ±5μm 1.2N or less w/ 2m signal cable

0.002mm 524-602 ±0.1mm 100-0-100 3mm ±1.5μm 1.2N or less w/ 2m signal cable

0.001mm 524-601 ±0.05mm 50-0-50 3mm ±1μm 1.2N or less w/ 2m signal cable

*Flat back

Signal Hicator

DIMENSIONS

ISO/JIS

Type

F-32

ISO/JIS type

ABSOLUTE Digimatic Indicator ID-C

SERIES 543 — with Green/Red LED and

GO/NG Signal Output Function

Unit: mm

FEATURES

• With the max./min. value holding function, the signal ID-C

can output the signal of the GO/±NG judgment result

against the peak values set. Substitute for the mechanical/

electrical contact, the judgment is carried out by calculating

the measurement data obtained. This provides high

reliability with no deterioration of the contact point and

volume adjustment.

Backs

8

ø44

a

ø12.7

M6 X1 (#1/4 - 28UNF)

11.7

28

ø12.7

22.2

12.7

32

M6 X1 (#1/4 - 28UNF)

5.3(6.4)

50.2

7

18.5

ø7.1

ø10.5

38

25.5

38

16

12

ø6.5

ø20

45

°

45°

6.35

16

12

(11.5)

ø6.5

ø20

45

°

45

°

5 (6.35)

Unit: mm

Unit: mm

Unit: mm

Unit: mm

Unit: mm

Unit: mm

Unit: mm

Unit: mm

Unit: mm

6.4

60

°

30

9.7

A

From A

2.5

Optional Accessory for Digimatic and Dial Indicators

There are two ways to support Digimatic

and dial indicators; by either holding the

stem or the lug on the back of the indicator. The back of the indicator may need to

be replaced for special applications. A wide

variety of backs are available for Mitutoyo

Digimatic and dial indicators.

Application

SPECIFICATIONS

Description Order No.

Flat Back 191559:

Lug-on-Center Back 190561:

Magnetic Back — Special order 900928 900929

Back with Offset Lug — Special order 101167 100837

Series 0

(ø31mm)

1003

(ø36mm)

a=1.0

137906:

for 1003

a=1.0

Metric type

190139:

Inch type

137905:

for 1003

Series 1

(ø41mm)

101211: a=2.2

136872: for water-

proof type

191559: for 1911,

1913-10

101210: metric type

101307: inch type

190561: for 1911,

1913-10

Series 2

(ø57mm)

101039: a=2.5

21AZB231: for

water-proof

of S type

101040: metric

type

101306: inch

type

21AZB230: for

water-proof

of S type

Series 3, 4

(ø77, 91mm)

100836: a=3.0

100691: metric type

100797: inch type

Back with Post

Back with

Screw Mount

Adjustable Back — 136025: M6x1

— 193172 101169 100839

— 193173: M6x1,

193174:

#1/4-28UNF,

129721:

#1/4-28UNF

136023: M6x1

193174:

#1/4-28UNF

136026: M6x1

101168:

1/4-28UNF

136024: M6x1

100840:

#1/4-28UNF

136027: M6x1

100838:

#1/4-28UNF

Back with Dovetail — — 900008 Special order

Back with Adjustable

Bracket

— — 901963: Set No.

129902:

Dovetail

Rack Back

901964:

Dovetail bracket

for rack back

—

( ): ANSI / AGD Type

F-33

.16" Rad. (4 Rad.)

25

°

Contact Points

Optional Accessories for Digimatic and Dial Indicators and Linear Gages

Needle point, Carbide tipped

ø.118" (ø3mm)Ball Point

4-48UNF

L Carbbide Sapphire Ruby Plastic

.28" — — — 902018

.3" 131262 131263 131264 —

.6" 131265 131266 131267 —

1" 131268 131269 131270 —

M2.5 x 0.45mm

L Carbbide Sapphire Ruby Plastic

7.3mm 901312* — — 901994

8mm 120045 120046 120047 —

15mm 120049 120050 120051 —

25mm 120053 120054 120055 —

*Furnished with standard metric dial indicators.

Shell type point

4-48UNF

L Order No.

3/32"(.094") 193697

5/32"(.156") 101184

1/4"(.25") 21AAA031*

3/8"(.375") 21AAA032

1/2"(.5") 101185

5/8"(.625") 21AAA033

3/4"(.75") 101186

7/8"(.875") 21AAA034

1" 101187

1/4

1

"(1.25") 21AAA035

1/2

1

"(1.5")

3/4

1

"(1.75") 21AAA037

2" 21AAA038

1/4

2

"(2.25") 21AAA039

1/2

2

"(2.5") 21AAA040

3/4

2

"(2.75") 21AAA041

3" 21AAA042

*Furnished with standard Inch and Metric ANSI Dial Indicators.

21AAA036

ø.16 Ball Point

4-48UNF

Order No.

900032

M2.5 x 0.45mm

L Order No.

5mm 101386

10mm 101118

15mm 137393

20mm 101387

25mm 101388

ø1.8mm Ball Point

M2.5 x 0.45mm

101122

Needle point

4-48UNF

L Order No.

.6” 21AAA030

1” 21AAA046

11/2” 21AAA047

2” 21AAA048

M2.5 x 0.45mm

L Order No.

15mm 101121

17mm 137413

Flat Point

4-48UNF

D L Order No.

Ø1/2” 3/8” 101188

Ø3/8” 3/8” 101189

M2.5 x 0.45mm

D L Order No.

Ø10mm 10mm 101117

Flat Point,

Carbide Tip

4-48UNF

D d L Order No.

Ø.2” Ø.17” .2” 131259

Ø.27” Ø.25” .4” 131260

Ø.41” Ø.37” .4” 131261

M2.5 x 0.45mm

D d L Order No.

Ø5.2mm Ø4.3mm 5mm 120041

Ø7mm Ø6.5mm 10mm 120042

‚10.5mm Ø9.5mm 10mm 120043

Spherical Point,

Carbide Tip

4-48UNF

D d Radius L Order No.

ø.2" ø.17" .2" .2" 131273

ø.27" ø.16" .16" .4" 131274

ø.41" ø.37" .4" .4" 131275

M2.5 x 0.45mm

D d Radius L Order No.

ø5.2mm ø4.3mm 5mm 5mm 120058

ø7mm ø6.5mm 7mm 10mm 120059

ø10.5mm ø9.5mm 10mm 10mm 120060

4-48UNF

D L Order No.

ø.018" .12" 131281

ø.04" .12" 131280

ø.06" .5" 131279

ø.078" .04" 131271

M2.5 x 0.45mm

D L Order No.

ø0.45mm 2.5mm 120066

ø1mm 2.5mm 120065

ø1.5mm 13mm 120064

ø2mm 1mm 120056

ø2mm 8mm 137257

ø.2" (ø5mm) Flat Point

4-48UNF

L Order No.

5/16” 133017

1/2” 21AAA043

3/4 21AAA044

1 21AAA045

M2.5 x 0.45mm

L Order No.

8mm 131365

Knife edge point,

Carbide tipped

4-48UNF

Order No.

131282

M2.5 x 0.45mm

Order No.

120067

Spherical point

4-48UNF

D L Radius Order No.

ø.5" .125" .28" 101205

ø.375" .09375" .35" 101204

M2.5 x 0.4 5mm

D L Radius Order No.

ø10mm 5mm 7mm 101119

F-34

Contact Points

Optional Accessories for Digimatic and Dial Indicators and Linear Gages

Extension Rod

60˚ Conical point

4-48UNF

L Order No.

1/2” 101190

L Order No.

10mm 101120

90˚ Conical point

4-48UNF

L Order No.

1/4” 101191

Blade Point,

Carbide Tip

M2.5 x 0.45mm

M2.5 x 0.45mm

L Order No.

5mm 101385

90˚ Conical point, Carbide tipped

4-48UNF

L Order No.

.3” 131283

4-48UNF

L Order No.

.08” 131272

M2.5 x 0.45mm

L Order No.

2mm 120057

M2.5 x 0.45mm

L Order No.

8mm 120068

Roller Point

4-48UNF

L Order No.

1/2” 139167

1” 301655

2” 301657

4” 301659

Point Conversion

Order No.

21AAA011

Lever Point

M2.5 x 0.45mm

L Order No.

10mm 303611

20mm 303612

30mm 303613

100mm 303614

Order No.

21AAA012

4-48UNF

D T Order No.

.08” .016” 131276

.08” .024” 131277

.16” .04” 131278

M2.5 x 0.45mm

D T Order No.

2mm 0.4mm 120061

2mm 0.6mm 120062

4mm 1mm 120063

Interchangeable

Contact Point Set

(4-48 UNF)

Set Order No. 21AZA034

Individual No. Description

101184 Shell Type Point 5/32”

101185 Shell Type Point 1/2”

101186 Shell Type Point 3/4”

101187 Shell Type Point 1”

101188 Flat Point ø1/2”

101189 Flat Point ø3/8”

101190 60° Conical Point

101191 90° Conical Point

101204 Spherical Point ø3/8”

21AAA030 Needle Point .6”

4-48UNF

Order No.

901991

M2.5 x 0.45mm

Order No.

901954

Interchangeable

Carbide Contact Point Set

(4-48 UNF)

Set Order No. 21AZA035

Individual No. Description

131260 Flat Point ø1/4”

131274 Spherical Point ø1/4”

131279 Needle Point ø.06” 1/2” Long

131262 Ballpoint ø.118”

131271 Needle Point ø.078” .04” Long

4-48UNF

Order No.

900393

M2.5 x 0.45mm

Order No.

900391

Interchangeable Contact

Point Set (M2.5x0.45)

Set Order No. 7822

Individual No. Description

131365 Flat Point (ø5mm)

101117 Flat Point (ø10mm)

101121 Needle Point

101119 Spherical Point

101118 Shell Type Point

101387 Shell Type Point

F-35

-VÀiÜ

Ó°x®

-«`iÊvÌ}

>Li

-«`i

Spindle Lifting Lever and Cable

Optional Accessories for Digimatic and Dial Indicators

Spindle Lifting Lever

• The Spindle Lifting Lever is attached to

the top end of the spindle for improved

inspection efficiency when using a dial

indicator mounted on a stand.

21AZB149

Use for S type Series 2, 3, and 4 dial indicators

(up to 10mm/.4”).

21AZB150

Use for S type Series 2 and 3 dial indicators (from

10mm/.4” up to 20mm/.8”).

21AZB151

Lifting lever for S type thickness gage.

Application

Use for Series 1 dial indicators.(up 5mm / .25")

Set Order No. Lever Screw Screw Thread

21BZA610 900527 101047 4-48 UNF

21BZA205 900527 101171 M2.5 x 0.45

Use for Series 2 dial indicators (up to 10mm/.4”)

Set Order No. Lever Screw Screw Thread

902794 900525 101047 4-48 UNF

902011 900525 101171 M2.5 x 0.45

Spindle Lifting Cable

901975: with auto-stop function

540774: without auto-stop function

Lifting range: 10mm

Cable length: 300mm

Spindle Lifting Knob

137693

Applicable spindle diameter; 4.8mm

Use for Series 2 dial indicators (up to 10mm/.4”)

Set Order No. Lever Screw Screw Thread

21BZA613 21BZA612 101047 4-48 UNF

902100 21BZA612 101171 M2.5 x 0.45

Use for Series 2 dial indicators (up to 20mm/.8”)

and Series 3 and 4 dial indicators (up to 10mm/.4”)

Set Order No. Lever Screw Screw Thread

903425 903307 192753 4-48 UNF

903424 903307 192686 M2.5 x 0.45

F-36

Color Spindle Caps

Optional Accessories for Digimatic and Dial Indicators

8 colors of spindle caps are available for dial

indicators with a range of 10mm or less.

SPECIFICATIONS

Color Order No.

(normal)

Black 193051 193595

White 193051W 193595W

Red 193051R 193595R

Green 193051G 193595G

Blue 193051B 193595B

Yellow 193051Y 193595Y

Orange 193051D 193595D

Pink 193051P 193595P

Dark blue 193051S 193595S

Order No.

(water-resistant)

Limit Stickers

Optional Accessories for Digimatic and Dial Indicators

FEATURES

• Stuck on the dial face or crystal of a Series

2 dial indicator (55.6mm or 57mm bezel

dia.) to indicate tolerance limits.

136420: Red (10-sheet/set) 136421: Green (10-sheet/set) 136422: Yellow (10-sheet/set)

F-37

Dial Indicator Repair Tool Kit

Optional Accessories for Digimatic and Dial Indicators

Mitutoyo offers a tool set designed to let

you perform simple repairs to your Mitutoyo

dial indicator, and a device that lets you

reset the indicator crystals.

8

10

9

7

1 2 3

16 17 18

19 20

Order No. 7823

Set Configuration

(1) 901171: Molykote (lubricant)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

4

6

14

13

5

15

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

Optional Accessories

For Hand Remover

126630: Interchangeable Pin, 0.8mm DIA.

126630B: Interchangeable Pin, 0.5mm DIA.

126630C: Interchangeable Pin, 1.6mm DIA.

901172: Lubricating oil

901173: Screwdriver (Phillips)

901174: Screwdriver (Phillips/flat blade)

129729: Tweezers

901175: Pin-vise

901176: Brush

901177: Brush

901177: Brush

901178: Hammer

129730: Spindle rest

129731: Pin rest

901179: Nippers

901180: Pliers

901181: Hand remover

129732: Pin remover

129733: Punch

129734: Bearing adjuster

129735: Pinion rest

129736: Reamer ø1

901182: Case

11

SPECIFICATIONS

Order No. Description

7823 Dial indicator repair tool kit

12

21

7823

Dial Indicator Crystal Setter

Optional Accessories for Digimatic and Dial Indicators

FEATURES

• Used for fitting a crystal on dial indicators,

dial test indicators, and dial calipers.

With 8 sizes of crystal setting pads

SPECIFICATIONS

Order No. Description

7000 Dial indicator crystal setter

7000

F-38

Loading...

Loading...