Page 1

Operating, Servicing, and Safety

Manual

Model 3000

52" Foot Shear

CAUTION: Read and Understand

These Operating, Servicing, and

Safety Instructions, Before Using

This Machine.

1-800-467-2464

10 Cooperative Way Wright City, MO 63390

P.O. Box 110 Foristell, MO 63348

1-636-745-7757 Fax 1-636-745-2874

www.mittlerbros.com

Page 2

SAFETY

The purpose of the safety section of this manual is to inform operators and maintenance

personnel of the precautions to be taken while operating or servicing the machine. The following

are a few basic guidelines to follow, but as with any type of machinery good judgment and a safe

attitude should be applied at all times.

1. Always wear safety clothing, including eye protection and protective footwear, while operating or

servicing the machine.

2. Keep all body parts and any foreign objects away from the shear blade assembly while in operation.

3. All guards and covers must be in place before operating the machine.

4. Keep the work area around the foot shear clear and clean to avoid slipping or tripping.

5. Do not operate the machine if it has been damaged or is not operating properly.

6. Do not wear jewelry (watches, rings, necklaces, etc.), or loose fitting clothing while operating or

servicing the machine.

7. The machine should only be operated or serviced by properly trained, authorized personnel.

8. Replacement parts should have the same specification and operation as the original parts on the

machine.

9. Before operating the machine, be sure it is set up properly.

11. Do not operate or service any machine while under the influence of drugs or alcohol.

NOTE: THESE SAFETY RULES ARE FOR YOUR BENEFIT TO HELP PREVENT INJURY TO YOURSELF

AND/OR YOUR CO-WORKERS. REVIEW ALL SETUP AND OPERATING PROCEDURES, WHETHER

COVERED OR NOT, IN THIS MANUAL TO HELP INSURE SAFE OPERATION

OF THE MACHINE.

Page 3

Levelling

Spirit

Lift Here

INSTALLATION

UNPACKING

Use caution in handling and movi ng the foot shear . T he foot shear weighs 875 pounds an d is top-heavy.

Handling should be performed with proper equipment such as a fork lift.

• Insert forks UNDER main table to lift and move.

INSTALLATION

Locate the brake in a well-lighted area on a solid level floor.

NOTE: The Foot Shear is provided fully assembled.

BEFORE USING!!!

Machine should be set up on as FLAT

of surface as possible.

Use Levelling Foot Pad Screw to bring

side plates to exactly 90˚. This will bring

the sides to parallel and insure that the

Upper Blade Holder moves up and down

smoothly. Lock the jam-nut on the foot

pad. Check the action of the shear by

carefully depressing the treadle and

checking for binding.

Level

90˚

Screw

• Place Smart Tool, Level, / Angle Finder on vertical frame

and resting on edge guide plate –

see photo.

• Adjust Leveling Mount on each front frame leg until each

side reads 90-degrees to parallel frame, so upper blade

holder moves up & down smoothly.

• Tighten jam nut on Leveling Mount.

• Carefully depress the shear foot treadle to check for

binding.

Page 4

SHEAR BLADE CLEARANCE

CAUTION: CHECK SHEAR BLADE CLEARANCE BEFORE OPERATING FOOT SHEAR

• Depress Foot Treadle and hold on fl oor .

• Place 0.003” feeler gauge between the upper & lower shear blades – approach blades fro m

machine rear.

• Check Blade Clearance at: 6” from left end / center / 6” from right end.

• NOTE: Blade Clearance is factory set at 0.003”.

GENERAL RULE - BLADE CLEARANCE = 5% - 10% OF MATERIAL THICKNESS.

Aluminum = 5% of material thickness.

Mild steel = 10% of material thickness.

CAUTION: Too Narrow or Too Wide shear blade clearance can cause

blade and/or machine damage.

OPERATION

• Place Metal on table and align with Edge Guide Plate on left side or right side.

• Align metal with edge guide plate scale or marks on metal where metal is to be cut –

Align Both Sides.

• NOTE: Look between infeed guard and Upper Blade Holder Assembly to align marks on metal with

lower shear blade edge.

• Push Foot Treadle down to lower Upper Shear Blade Assembly to cut metal.

NOTE: Push Foot Treadle to floor to insure entire metal width has been cut.

• Release Foot Treadle – Spring Loaded Upper Shear Blade Assembly will move upward to home

position.

Page 5

1/4"

Allen

Bolt

Allen

Bolt

Hex Bolt

Hex Bolt

Hex Bolt

Hex Bolt

Allen

Bolt

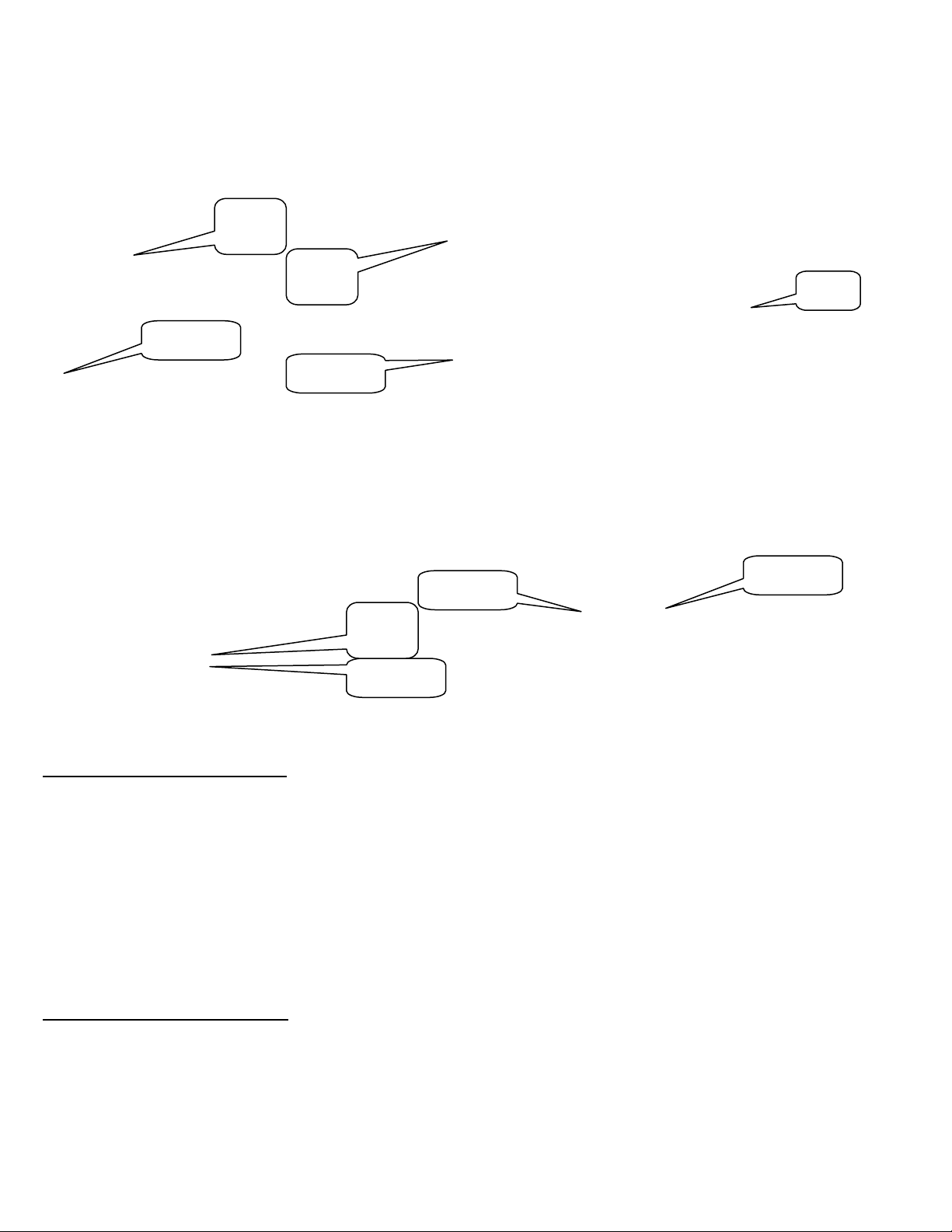

MAINTENANCE

INFEED GUARD ADJUSTMENT

Hex Bolt

SHEAR BLADE ADJUSTMENT

• Loosen four (4) hex head bolts (2 bolts each side) on table underside.

• Loosen jam nut (2) on each side of table front.

• Depress Foot Treadle and hold on fl oor .

Open Shear Blade Clearance

• Turn Allen screw counterclockwise several revolutions to move away from table front.

• Turn hex head jackbolt counterclockwise to move table back and separate upper/lower shear

blades until desired clearance is achieved across shear blades.

• Place desired thickness feeler gauge between the upper & lower shear blades – approach blades

from machine rear.

• Check Blade Clearance at: 6” from left end / center / 6” from right end.

• Turn Allen screws on each side (2) clockwise until screw contacts table front – holds table in

secure position.

• Tighten jam nuts on each side (2).

Close Shear Blade Clearance:

• Turn hex head bolt counterclockwise several revolutions.

• Turn allen screw clockwise to move table forward and close clearance between upper/lower shear

blades until desired clearance is achieved.

• Place desired thickness feeler gauge between the upper & lower shear blades – approach blades

from machine rear.

• Check Blade Clearance at: 6” from left end / center / 6” from right end.

• Tighten jam nuts on each side (2) when desired blade clearance is achieved.

• Turn hex head bolts on each side (2) clockwise until bolt contacts table front.

:

Page 6

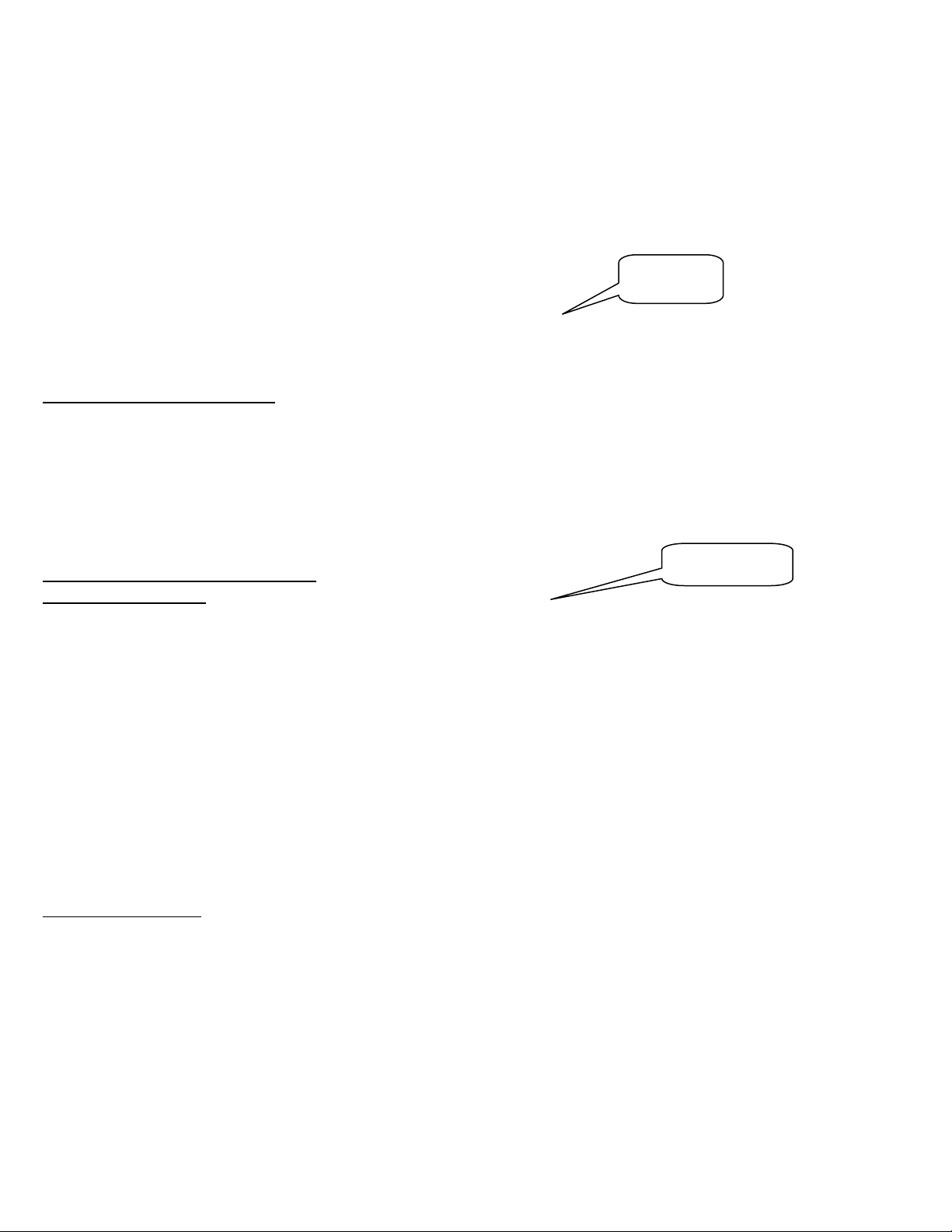

Welded Stop

Jack Bolt

SHEAR BLADE REPLACEMENT:

NOTE: Four (4) 24” long Shear Blades are mounted on machine: 2 Upper Blades / 2 Lower Blades.

Each 24” long Shear Blade has four (4) cutting surfaces. All Shear Blades are interchangeable.

SHEAR BLADE REMOVAL:

CAUTION: SHARP EDGES ON ALL SIDE OF SHEAR BLADE

• Remove five (5) Allen flat head screws to remove 24” long shear blade (1/2 of upper or lower shear

blade).

• Repeat for remaining Shear Blade segments.

SHEAR BLADE INSTALLATION:

Upper Shear Blade:

CAUTION: SHARP EDGES ON ALL SIDE OF SHEAR BLADE

• Place 24” long Shear Blade against welded stop on Upper Shear Holder Assembly.

• Install five (5) Allen flat head screws to install 24” long shear blade (1/2 of upper shear blade).

• Tighten Allen flat head scr ews – five (5).

• Repeat for remaining Shear Blade segment.

Lower Shear Blade:

CAUTION: SHARP EDGES ON ALL SIDE OF SHEAR BLADE

• Place 24” long Shear Blade agai ns t back sid e of Tabl e.

• Install five (5) Allen flat head screws to install 24” long shear blade (1/2 of lower shear bl ad e) .

• Repeat for remaining Shear Blade segment.

• Align Shear Blade Top with Table Top.

• Adjust Shear Blade height with jack bolts under blade.

• Tighten Allen flat head scr ews – nine (9).

• Tighten jack bolt(s) jam nut -- if adjustment was necessary .

Page 7

SPRING TENSION – FOOT TREADLE

Spring Height Adjustment:

Removal:

• Remove cotter pin from foot treadle arm to spring rod.

• Lift Foot Treadle to maximum height.

• Remove Pin that holds spring rod to foot treadle arm.

• Loosen two (2) hex head bolts & nuts holding lower spring bracket to frame.

• Turn jack bolt (under spring bracket) counterclockwise to lower spring bracket and release

spring tension.

• Remove hex head bolts & nuts holding lower spring bracket to frame.

• Remove lower spring bracket and spring.

Installation:

• Install lower spring bracket and spring with spring rod through spring & bracket.

• Install hex head bolts & nuts holding lower spring bracket to frame -- DONOT tighten.

• Turn jack bolt (under spring bracket) clockwise to raise spring bracket and apply spring tension.

Left Spring Height = 5-1/2”

Right Spring Height = 6-3/4”

NOTE: Measurement between bottom of upper flat bracket to top of lower flat bracket.

• Tighten two (2) hex head bolts & nuts holding lower spring bracket to frame.

• Lift Foot Treadle to maximum height.

• Install Pin that holds spring rod to foot treadle arm.

• Install cotter pin into pin holding foot treadle arm to spring rod.

Page 8

LUBRICATION

Lubricate foot treadle arm bearings once per month with good grade grease.

Lubricate upper shear blade slide assembly once per month

with good grade grease.

Lubricate spring rod pin to foot treadle arm with oil once per

month

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

CAUTION: Read and Understand

These Operating, Servicing, and

Safety Instructions, Before Using

This Machine.

1-800-467-2464

10 Cooperative Way Wright City, MO 63390

P.O. Box 110 Foristell, MO 63348

1-636-745-7757 Fax 1-636-745-2874

www.mittlerbros.com

Loading...

Loading...