Page 1

10 Cooperative Way Wright City, MO 63390

(636) 745-7757

Division of Mittler Corp.

P.O. Box 110 Foristell, Missouri 63348

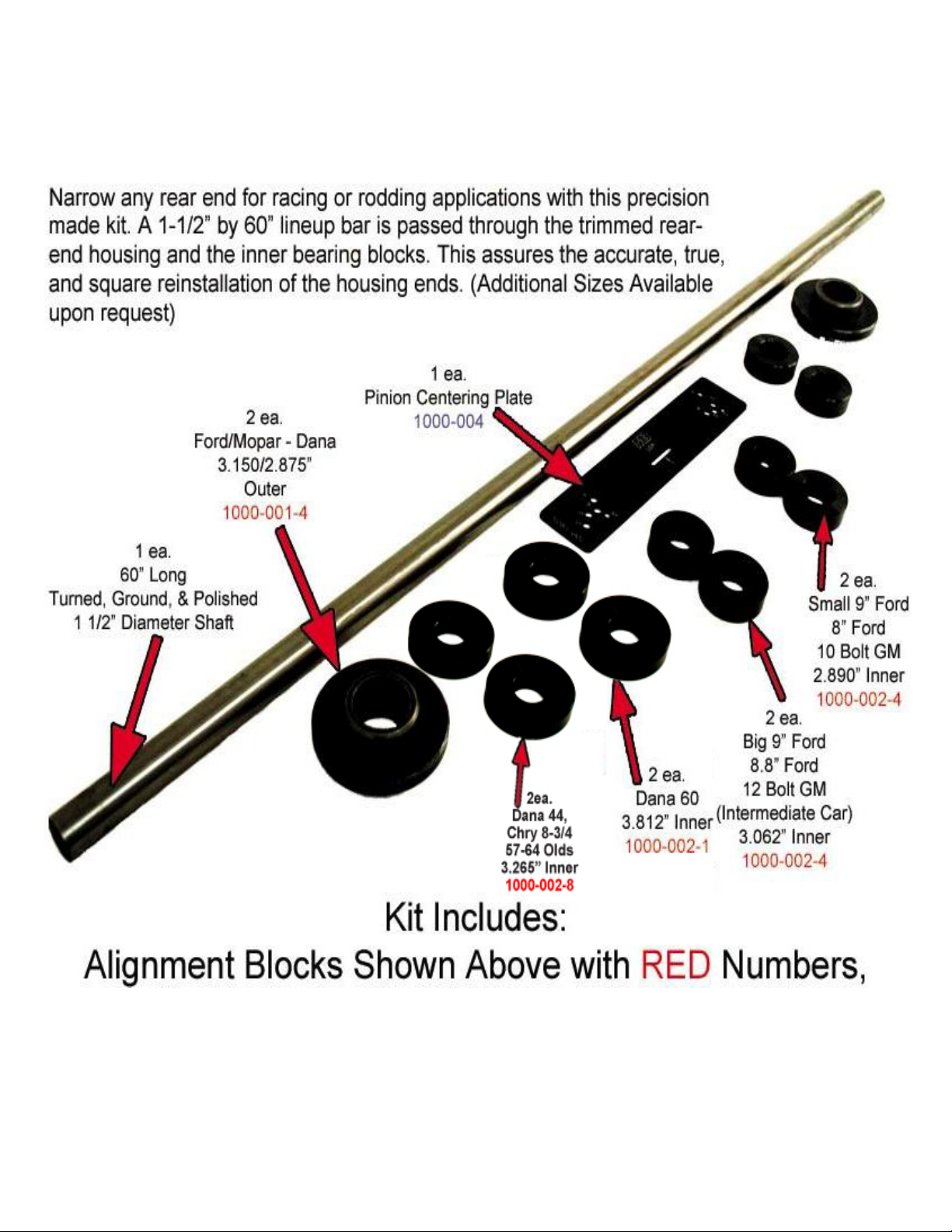

1000-RENK1 REAR END NARROWING KIT

USE OF THIS TOOL REQUIRES BASIC MATH AND WELDING SKILLS

Kit Contents

1ea 1000-001-2 Alignment Shaft - 60" long x 1-1/2" OD

1pr. 1000-001-4 Outer Line Up Ford / Dana

1pr. 1000-001-5 Outer Line Up GM / Ford

1pr. 1000-002-1 Dana 60 Inner Puck 3.812"

1pr. 1000-002-4 Big 9” Ford / GM 12 Bolt Inner Pucks

1pr. 1000-002-2 Small 9” Ford / GM 10 Bolt Inner Pucks

1pr. 1000-002-8 Dana 44 / Chrysler 8-3/4 / 57-64 Olds Inner Pucks

1ea. 1000-004 Pinion Centerline Gauge

SAFETY

• Wear protective clothing suitable for welding.

• Use a welding helmet with the correct shade of filter lens.

• Be sure housings are properly cleaned and degreased to remove flammables.

• Welding sparks can cause fires or explosions. Have a fire extinguisher nearby.

• Breathing welding fumes can be hazardous to your health. Be sure to have adequate ventilation.

PREPERATION

Fax: (636) 745-2874

1. Disassemble and clean housing. Use a good grease cutting solvent to remove the lube residue.

Follow this with warm soapy water, such as from the car wash.

a. On “Drop Out” style housings, such as 9” Ford, you must remove the “Drop Out” and then

clean the housing as described above. We recommend that you get a used “Drop Out”

from a junk yard and use this for your fixture case. This way you will only have minimal

work to re-setup your gears. Place the appropriate pucks into the carrier bearing locations.

Screw the bearing cap bolts finger tight. Slip the bar through the assembly and then tighten

the cap bolts. Remove the shaft.

b. On “One Piece” style housings, such as 12 Bolt & Dana, you will have to remove the ring

gear carrier assembly, be sure to keep track of any shims. With the ring gear carrier

assembly removed clean the housing as described above. Place the appropriate pucks

into the carrier bearing location. Screw the bearing cap bolts finger tight. Slide the bar

through the housing assembly and then tighten the cap bolts.

2. Determine the desired width, pinion offset and cut locations using the supplied work sheet. You

might want to make copies of the work sheet for future jobs. There is an example on the back of

the work sheet. This is a very critical step and care should be taken to get it right. Measure as

many times as needed to be sure that you have all the correct numbers before moving to the next

step.

N:\Product\Product Documentation\1000 Rear End\Narrowing Kit Instructions\1000-RENK1 Instructions.doc Rev1 3-01-2006

Page 2

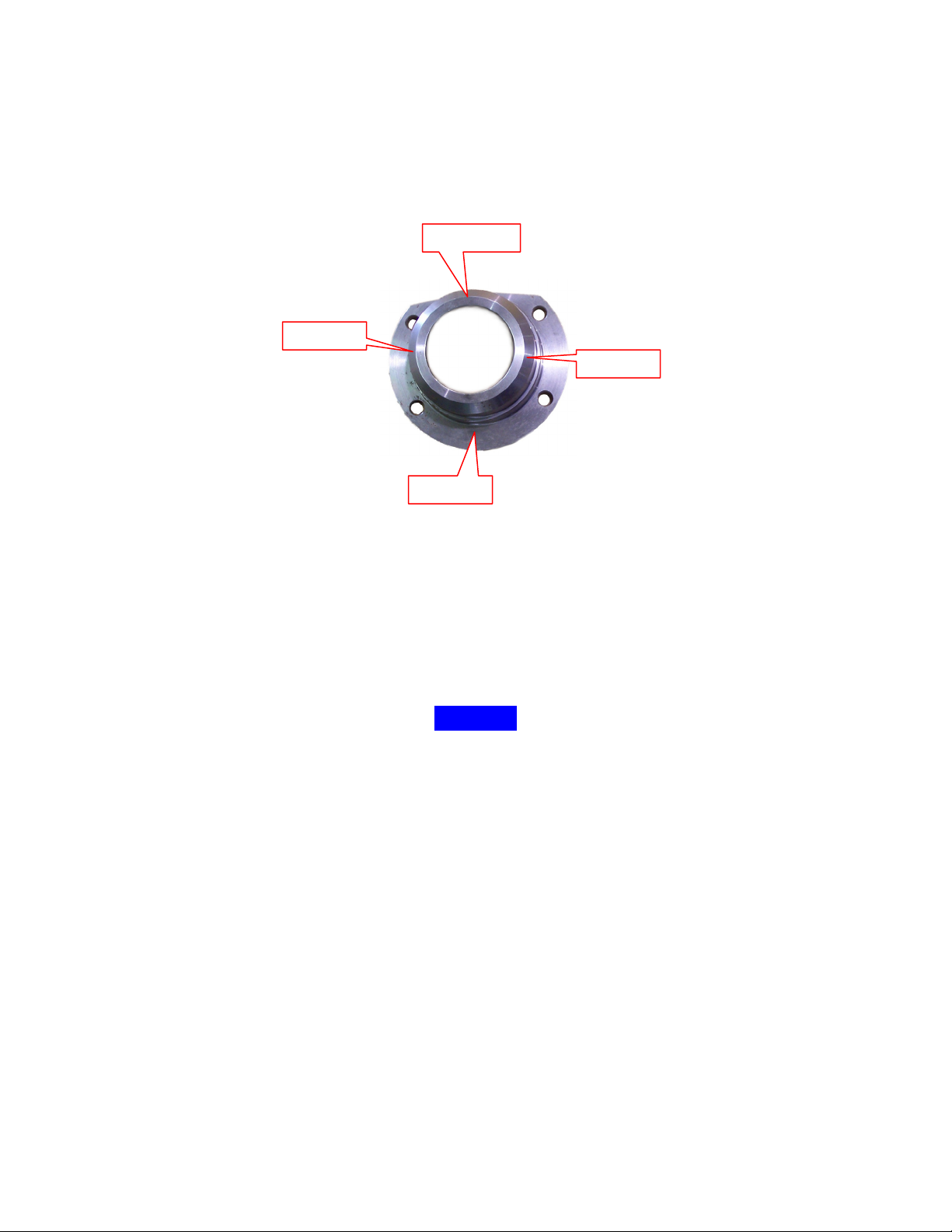

Pinion Centerline

Housing End

Bevel

Outer Puck

Slip Together

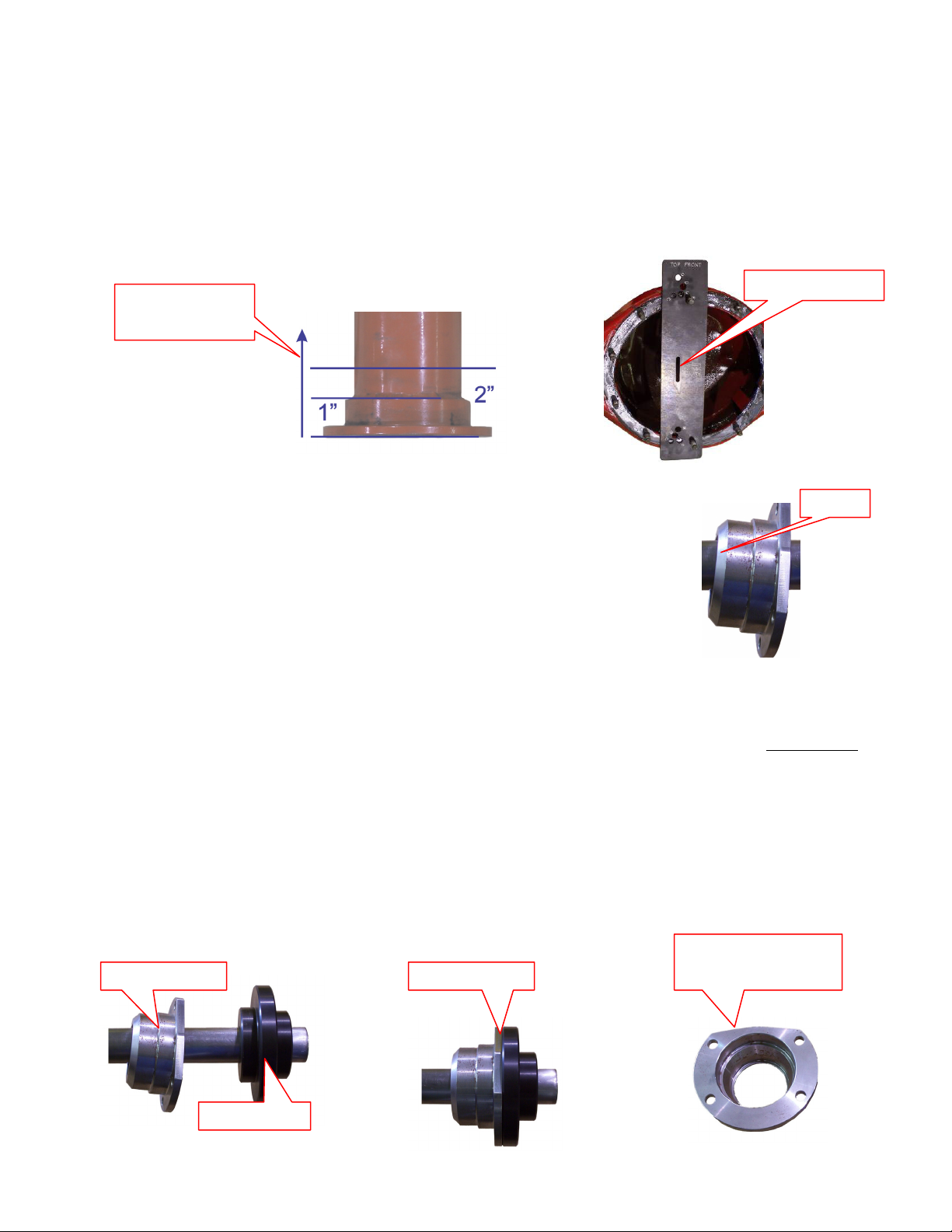

CUTTING

3. After you have determine the desired width, pinion offset and cut locations using the supplied

work sheet you are ready to cut the ends off of your housing. We recommend cutting the

exsisting ends off close to the bearing end between 1” & 2” back from the flange. If there are

seals in the end be sure to cut behind them. The best cuts will be made with a HORIZANTAL

BAND SAW or a CHOP SAW.

Cut 1” or 2” back

from end.

4. Bevel the housing tubes and the housing ends. This will assure a

quality weld joint. The amount of bevel will be determined by the

welding method, MIG or TIG. MIG will require a larger bevel than TIG.

POSITIONING

5. Slide the bar into the housing and through the inner alignment pucks. Be careful not to jam the

bar into the pucks as this may knock them loose or out of alignment. On “Drop Out” style

housings, be sure the carrier assembly is bolted into the housing with a gasket.

6. Slide the housing end onto the shaft followed by the appropriate outer line up puck. Slip the puck

into the housing end and then slide the assembly up to the end of the tube. Be sure to orient the

housing end correctly in relation to the housing. Check that the bolt pattern is aligned correctly for

the brakes you will be using.

Check Bolt Pattern

Check For Top

Page 3

4th Tack

3rd Tack

2nd Tack

1st Tack

WELDING

7. After you are sure that you have the correct dimensions and have the ends oriented correctly they

can be tack welded. We recommend that you tack them in at least 4 places. The tacks should be

located at 90° to each other. Tack both ends of the housing.

8. Double check all your measurements. When you are satisfied that every thing is correct go ahead

and finish weld the ends. We recommend that you weld ¼ of the way around at a time; weld from

tack 1 to tack 3 then tack 4 to tack 2. Move to the other housing end and follow the same

sequence. Now go back to the first end and weld from tack 1 to tack 4 and then tack 2 to tack 3

then move to the other end and complete the welding following the same sequence.

NOTICE

If you are going to be welding on brackets, back braces or other items we strongly suggest that

all of this welding be done prior to putting the housing ends on. By leaving the ends to the last

any heat induced warpage will be compensated for when the ends are installed. This will give

you best possible results and the straightest housing.

9. After all welding is complete let the housing cool to room temperature before handling. DO NOT

artificially cool the welds with water, air or any other method. Cooling to quickly may cause

weld cracking and result in failure.

We appreciate your business and hope that you enjoy your new Mittler Bros. Product. If you have any

questions or concerns please feel free to call us at 1-800-467-2464 for help.

Page 4

Page 5

Page 6

Page 7

Customer:

P

E

0 J2

2

- 0 6

3

2

-

Date:

1-800-467-2464

www.mittlerbros.com

0

.

1

ev.

R

t 0

k Shee

or

W

g Kit

n

rowi

a

N

\

d

En

r

a

0 r

0 Re

1

\

n

n 0

e tatio

cu

o

D

uct

rod

P

ct m

du \

P o

\ r

:

E

Housing Type ____________________________

Tubing End To Tubing End

Housing End To Housing End

Pinion Offset

To Driver Side

Axle Face to Axle Face

e

n

rlin

o

i

in

nte

P

e

C

Pinion Offset To

Passenger Side

Housing End

Thickness

Notes:______________________________________________

Axle Stand Out

Housing End Style ____________________________

Housing End Number ____________________________

Housing End Thickness ____________________________

____________________________________________________

____________________________________________________

____________________________________________________

Page 8

Customer:

Sample

Date:

1-800-467-2464

www.mittlerbros.com

25”

P

E

0 J2

2

- 0 6

3

2

-

0

.

1

ev.

R

t 0

k Shee

or

W

g Kit

n

rowi

a

N

\

d

En

r

a

0 r

0 Re

1

\

n

n 0

e tatio

cu

o

D

uct

rod

P

ct m

du \

P o

\ r

:

E

Housing Type ____________________________

Housing End Style ____________________________

22-1/2”

20-1/2”

Pinion Offset

To Driver Side

Tubing End To Tubing End

Housing End To Housing End

Axle Face to Axle Face

9” Ford

Old Style Big Ford

20-1/2”

e

n

rlin

o

i

in

nte

P

e

C

Pinion Offset To

Passenger Side

18-1/2”

1”

39”

43”

48”

Notes:______________________________________________

1” Pinion offset makes 2” difference

____________________________________________________

23”

Housing End

Thickness

2”

Axle Stand Out

2-1/2”

Housing End Number ____________________________

Housing End Thickness ____________________________

1000-253

2”

in measurement from pinion center

____________________________________________________

to either end

____________________________________________________

Loading...

Loading...