Page 1

MELSEC-QS CC-Link IE Field Network Master/

Local Module

User's Manual

-QS0J71GF11-T2

Page 2

Page 3

SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

The precautions given in this manual are concerned with this product only. For the safety precautions of the

programmable controller system, refer to the user's manual for the CPU module used.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

[Design Precautions]

WARNING

● When a safety programmable controller detects an error in an external power supply or a failure in

programmable controller main module, it turns off all the outputs. Create an external circuit to securely

stop the power of hazard by turning off the outputs. Incorrect configuration may result in an accident.

● To inhibit restart without manual operation after safety functions was performed and outputs were

turned off, create an interlock program which uses a reset button for restart.

● If CC-Link IE Field Network error has been detected, create a sequence program that turns off the

outputs in the program. If the CC-Link IE Field Network is restored with the outputs on, it may

suddenly operate and result in an accident.

[Design Precautions]

CAUTION

● Do not bunch the wires of external devices or communication cables together with the main circuit or

power lines, or install them close to each other. They should be installed 100 mm (3.94 inch) or more

from each other. Not doing so could result in noise that would cause malfunctions.

1

Page 4

[Installation Precautions]

CAUTION

● Use a safety programmable controller in the environment that meets the general specifications

described in the QSCPU User's Manual (Hardware Design, Maintenance and Inspection). Using this

programmable controller in an environment outside the range of the general specifications could

result in electric shock, fire, erroneous operation, and damage to or deterioration of the product.

● While pressing the installation lever located at the bottom of module, insert the module fixing tab into

the fixing hole in the base unit until it stops. Then, securely mount the module with the fixing hole as a

supporting point. Incorrect loading of the module can cause a failure or drop. Secure the module to

the base unit with screws. Tighten the screw in the specified torque range. If the screws are too loose,

it may cause a drop of the screw or module. Overtightening may cause a drop due to the damage of

the screw or module.

● Completely turn off the external supply power used in the system before mounting or removing the

module. Not doing so could result in damage to the product.

● Do not directly touch the module's conductive parts or electronic components. Doing so may cause

malfunctions or a failure.

[Wiring Precautions]

WARNING

● Be sure to shut off all phases of the external supply power used by the system before wiring. Not

completely turning off all power could result in electric shock or damage to the product.

● When energizing or operating the module after installation or wiring, be sure to close the attached

terminal cover. Not doing so may result in electric shock.

2

Page 5

[Wiring Precautions]

CAUTION

● Tighten a module fixing screw within the specified torque range. If the module fixing screw is too

loose, it may cause a drop of the screw or module. Overtightening the screw may cause a drop due to

the damage of the screw or module.

● Be sure there are no foreign substances such as sawdust or wiring debris inside the module. Such

debris could cause a fire, failure, or malfunctions.

● The module has an ingress prevention label on its top to prevent foreign matter, such as wire chips,

from entering the module during wiring. Do not peel this label during wiring. Before starting system

operation, be sure to peel this label because of heat dissipation.

● Be sure to fix the communication cables or power cables by ducts or clamps when connecting them to

the module. Failure to do so may cause damage of the module or cables due to a wobble,

unintentional shifting, or accidental pull of the cables, or malfunctions due to poor contact of the cable.

● When removing the connected communication cables or power cables, do not pull the cable with

grasping the cable part. Pulling the cable connected to a module may result in malfunctions or

damage of the module or cable.

● For the cables to be used in CC-Link IE Field Network, use the ones specified by the manufacturer.

Otherwise, the performance of CC-Link IE Field Network is not guaranteed. As to the maximum

overall cable length and station - to station cable length, follow the specifications described in the

MELSEC-QS CC-Link IE Field Network Master/Local Module User's Manual. If not following the

specification, the normal data transmission is not guaranteed.

3

Page 6

[Startup and Maintenance Precautions]

WARNING

● Turn off all phases of the external supply power used in the system when cleaning the module or

retightening the module fixing screws. Not doing so could result in electric shock.

Tighten a fixing screw within the specified torque range. If the module fixing screw is too loose, it may

cause a drop of the screw or module. Overtightening the screw may cause a drop due to the damage

of the screw or module.

[Startup and Maintenance Precautions]

CAUTION

● Do not disassemble or modify the modules. Doing so could cause a failure, malfunctions, injury, or

fire. If the product is repaired or remodeled by other than the specified FA centers or us, the warranty

is not covered.

● Completely turn off the external supply power used in the system before mounting or removing the

module. Not doing so may result in a failure or malfunctions of the module.

● Restrict the mounting/removal of a module, base unit, and terminal block up to 50 times

(IEC61131-2 compliant), after the first use of the product.

Failure to do so may cause the module to malfunction due to poor contact of connector.

● Before touching the module, always touch grounded metal, etc. to discharge static electricity from

human body, etc. Not doing so may result in a failure or malfunctions of the module.

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste. When disposing of batteries, separate

them from other wastes according to the local regulations. (For details of the Battery Directive in EU

member states, refer to the QSCPU User's Manual (Hardware Design, Maintenance and Inspection).)

4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Although MELCO has obtained the certification for Product's compliance to the international safety

standards IEC61508, EN954-1/ISO13849-1 from TUV Rheinland, this fact does not guarantee that

Product will be free from any malfunction or failure. The user of this Product shall comply with any

and all applicable safety standard, regulation or law and take appropriate safety measures for the

system in which the Product is installed or used and shall take the second or third safety measures

other than the Product. MELCO is not liable for damages that could have been prevented by

compliance with any applicable safety standard, regulation or law.

(2) MELCO prohibits the use of Products with or in any application involving, and MELCO shall not be

liable for a default, a liability for defect warranty, a quality assurance, negligence or other tort and a

product liability in these applications.

(a) power plants,

(b) trains, railway systems, airplanes, airline operations, other transportation systems,

(c) hospitals, medical care, dialysis and life support facilities or equipment,

(d) amusement equipments,

(e) incineration and fuel devices,

(f) handling of nuclear or hazardous materials or chemicals,

(g) mining and drilling,

(h) and other applications where the level of risk to human life, health or property are elevated.

5

Page 8

INTRODUCTION

Thank you for purchasing the Mitsubishi MELSEC-QS series programmable controllers.

This manual describes the overview of the CC-Link IE Field Network, and operating procedure, system configuration,

parameter setting, functions, programming, and troubleshooting of the QS0J71GF11-T2, CC-Link IE Field Network

master/local module (hereafter abbreviated as master/local module).

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the MELSEC-QS series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

COMPLIANCE WITH THE EMC, LOW VOLTAGE, AND

MACHINERY DIRECTIVES

(1) Method of ensuring compliance

To ensure that Mitsubishi programmable controllers maintain EMC, Low Voltage, and Machinery Directives when

incorporated into other machinery or equipment, certain measures may be necessary. Please refer to one of the

following manuals.

• QSCPU User's Manual (Hardware Design, Maintenance and Inspection)

• Safety Guidelines

(This manual is included with the base unit.)

The CE mark on the side of the programmable controller indicates compliance with EMC, Low Voltage, and

Machinery Directives.

(2) For the product

This product complies with the EMC, Low Voltage, and Machinery Directives. Before using this product, please

read this manual, the relevant manuals, the manuals for standard programmable controllers, and the safety

standards carefully and pay full attention to safety to handle the product correctly.

The descriptions are based on the requirements of the Directives and the harmonized standards. However, they

do not guarantee that the entire machinery constructed according to the descriptions complies with the EMC,

Low Voltage, and Machinery Directives.

The manufacture of the machinery must determine the testing method for compliance and declare conformity to

the EMC, Low Voltage, and Machinery Directives.

6

Page 9

RELEVANT MANUALS

(1) Introduction Manual

Read the following manual before designing and constructing a safety system.

Manual name

<manual number (model code)>

Safety Application Guide

<SH-080613ENG, 13JR90>

(2) CC-Link IE Field Network (relevant) manuals

When using CC-Link IE Field Network for the first time, refer to this manual. The following table lists and

describes CC-Link IE Field Network manuals.

Description

Explains the overview, construction method, laying and wiring

examples, and application programs of the safety-related system.

Manual name

<manual number (model code)>

MELSEC-Q CC-Link IE Field Network Master/Local Module

User's Manual

<SH-080917ENG, 13JZ47>

MELSEC-L CC-Link IE Field Network Master/Local Module User’s

Manual

<SH-080972ENG, 13JZ54>

MELSEC-L CC-Link IE Field Network Head Module User's

Manual

<SH-080919ENG, 13JZ48>

CC-Link IE Field Network Ethernet Adapter Module User's Manual

<SH-080939ENG, 13JZ50>

CC-Link IE Field Network Interface Board User's Manual (For

SW1DNC-CCIEF-B)

<SH-080980ENG, 13JZ58>

(3) CPU module user's manual

Manual name

<manual number (model code)>

QSCPU User's Manual (Hardware Design, Maintenance and

Inspection)

<SH-080626ENG, 13JR92>

QSCPU User's Manual (Function Explanation, Program

Fundamentals)

<SH-080627ENG, 13JR93>

QSCPU Programming Manual (Common Instructions)

<SH-080628ENG, 13JW01>

Description

Overview of CC-Link IE Field Network, and specifications, procedures

before operation, system configuration, installation, wiring, settings,

functions, programming, and troubleshooting of the MELSEC-Q series

master/local module

Overview of CC-Link IE Field Network, and specifications, procedures

before operation, system configuration, installation, wiring, settings,

functions, programming, and troubleshooting of the MELSEC-L series

master/local module

Specifications, procedures before operation, system configuration,

installation, wiring, settings, and troubleshooting of the head module

Specifications, procedures before operation, system configuration,

installation, wiring, settings, and troubleshooting of the Ethernet

adapter module

Specifications, procedures before operation, system configuration,

settings, functions, programming, and troubleshooting of the CC-Link

IE Field Network interface board

Description

Explains the specifications of the QSCPU, safety power supply

module, safety base unit, etc.

Explains the functions, programming methods, devices, etc. that are

necessary to create programs with the QSCPU.

Explains how to use the sequence instructions, basic instructions,

application instructions, and QSCPU dedicated instructions.

7

Page 10

(4) Operating manual

Manual name

<manual number (model code)>

GX Developer Version 8 Operating Manual

<SH-080373E, 13JU41>

GX Developer Version 8 Operating Manual (Safety Programmable

Controller)

<SH-080576ENG, 13JU53>

Description

Explains the online functions of GX Developer, such as the

programming, printout, monitoring, and debugging methods.

Explains the functions of GX Developer that are added or changed to

support the safety programmable controller.

8

Page 11

Memo

9

Page 12

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

COMPLIANCE WITH THE EMC, LOW VOLTAGE, AND MACHINERY DIRECTIVES . . . . . . . . . . . . . . . 6

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MANUAL PAGE ORGANIZATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

TERM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CHAPTER 1 CC-Link IE FIELD NETWORK 19

1.1 CC-Link IE Field Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.2 Master/Local Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

CHAPTER 2 PART NAMES 30

CHAPTER 3 SPECIFICATIONS 33

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.3 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.3.1 Using the master/local module as a master station (safety station) . . . . . . . . . . . . . . . . . . . . 35

3.3.2 Using the master/local module as a local station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.4 List of I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.5 List of Buffer Memory Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CHAPTER 4 PROCEDURES BEFORE OPERATION 45

CHAPTER 5 SYSTEM CONFIGURATION 47

5.1 CC-Link IE Field Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.1 Single network system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.1.2 Multi-network system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.2 Network Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

5.2.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.2.2 Hubs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

5.3 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

CHAPTER 6 INSTALLATION AND WIRING 59

6.1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.2 Tests Before Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.2.1 Hardware test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.2.2 Self-loopback test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

6.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4 Tests After Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.4.1 Loop test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.4.2 Cable test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

6.4.3 Communication test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10

Page 13

CHAPTER 7 PARAMETER SETTING 77

7.1 Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.2 Network Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.3 Network Configuration Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.4 Network Operation Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7.5 Refresh Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

7.6 Safety Communication Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.7 Routing Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

CHAPTER 8 FUNCTIONS 96

8.1 Safety Communication Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.1.1 Communication with safety stations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

8.1.2 Error log registration function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

8.1.3 Safety station interlock function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.2 Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

8.2.1 Data flow and link device assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

8.2.2 Link refresh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

8.2.3 Assurance of cyclic data integrity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

8.2.4 Scan synchronization specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8.2.5 Input status setting in case of failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

8.2.6 Output status setting for CPU module STOP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

8.2.7 Cyclic transmission stop and restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

8.3 Transient Transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

8.3.1 Communication within the same network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

8.3.2 Communication with different networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

8.4 Reserved station specification and reserved station function disable . . . . . . . . . . . . . . . . . .119

8.5 Error Invalid Station and Temporary Error Invalid Station Setting Function . . . . . . . . . . . . . .120

8.6 Loopback Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

CHAPTER 9 CC-Link IE FIELD NETWORK DIAGNOSTICS 124

9.1 Diagnostic Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

9.2 Starting Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

9.3 Diagnostic Window. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

9.4 Link Start/Stop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

9.5 Network Event History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .140

9.6 Canceling/Restoring Reserved Station Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

9.7 Setting/Canceling Temporary Error Invalid Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

9.8 Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

CHAPTER 10 DEDICATED INSTRUCTIONS 152

10.1 List of Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

10.2 Precautions for Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .155

10.2.1 Precautions for link dedicated instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

11

Page 14

10.3 Understanding the Documentation on Dedicated Instructions . . . . . . . . . . . . . . . . . . . . . . . . 158

10.4 JP/GP.READ (Reading Data from the Programmable Controller on Another Station) . . . . . .160

10.5 JP/GP.SREAD (Reading Data from the Programmable Controller on Another Station) . . . . . 168

10.6 JP/GP.WRITE (Writing Data to the Programmable Controller on Another Station) . . . . . . . .175

10.7 JP/GP.SWRITE (Writing Data to the Programmable Controller on Another Station) . . . . . . .187

10.8 JP/GP.REQ (Reading/Writing Clock Data) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

CHAPTER 11 PROGRAMMING 209

11.1 Precautions for Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

11.2 Communication Example of when Safety Stations and a Standard Station are Used . . . . . .211

11.2.1 System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

11.2.2 Master station (standard station) settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

11.2.3 Local station (safety station) settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

11.2.4 Checking the network status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

11.2.5 Program example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

11.3 Using Link Special Relay (SB) and Link Special Register (SW) . . . . . . . . . . . . . . . . . . . . . . . 221

CHAPTER 12 TROUBLESHOOTING 235

12.1 Before Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

12.2 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .235

12.3 Checking the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .239

12.4 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .242

12.4.1 Safety communication cannot be established . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

12.4.2 Cyclic transmission cannot be performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

12.4.3 Transient transmission cannot be performed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

12.4.4 Station is disconnected from the network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

12.4.5 Station is repeatedly disconnected and reconnected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

12.4.6 Communication is unstable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

12.5 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .246

12.6 Checking the Master/Local Module Status by System Monitor. . . . . . . . . . . . . . . . . . . . . . . .261

APPENDICES 264

Appendix 1 Details of I/O Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .264

Appendix 1.1 Module failure (X0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Appendix 1.2 Own station data link status (X1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Appendix 1.3 Other stations data link status (X3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Appendix 1.4 Module ready (XF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Appendix 2 Details of Buffer Memory Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

Appendix 2.1 Link device area (buffer memory address: 0 to 18975 (0H to 4A1FH)) . . . . . . . . . 266

Appendix 2.2 RX offset/size information (buffer memory address: 19456 to 19695 (4C00H to 4CEFH))

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Appendix 2.3 RY offset/size information (buffer memory address: 19712 to 19951 (4D00H to 4DEFH))

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Appendix 2.4 RWw offset/size information (buffer memory address: 19968 to 20207 (4E00H to

)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

4EEF

H

12

Page 15

Appendix 2.5 RWr offset/size information (buffer memory address: 20224 to 20463 (4F00H to

)) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

4FEF

H

Appendix 2.6 Own station information (buffer memory address: 20512 to 20536 (5020H to 5038H))

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Appendix 2.7 Other station information (buffer memory address: 20544 to 24383 (5040H to 5F3FH))

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Appendix 3 Link Special Relay (SB) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .273

Appendix 4 Link Special Register (SW) List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Appendix 5 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

Appendix 5.1 Link refresh time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Appendix 5.2 Link scan time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 303

Appendix 5.3 Cyclic transmission delay time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 304

Appendix 5.4 Transmission interval monitoring time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 308

Appendix 5.5 Safety refresh monitoring time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 309

Appendix 5.6 Transmission delay time of dedicated instructions . . . . . . . . . . . . . . . . . . . . . 310

Appendix 6 New and Improved Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .312

Appendix 7 Comparison with an Existing Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .313

Appendix 7.1 Comparison between the CC-Link Safety master module and the master/local

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 313

module

Appendix 7.2 Comparison between the Q series master/local module and the master/local module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 317

Appendix 8 Precautions for When Connecting the MELSEC iQ-R Series Module . . . . . . . . . . . . .320

Appendix 9 Checking the Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . .321

Appendix 10 External Dimension Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .323

INDEX 325

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 329

13

Page 16

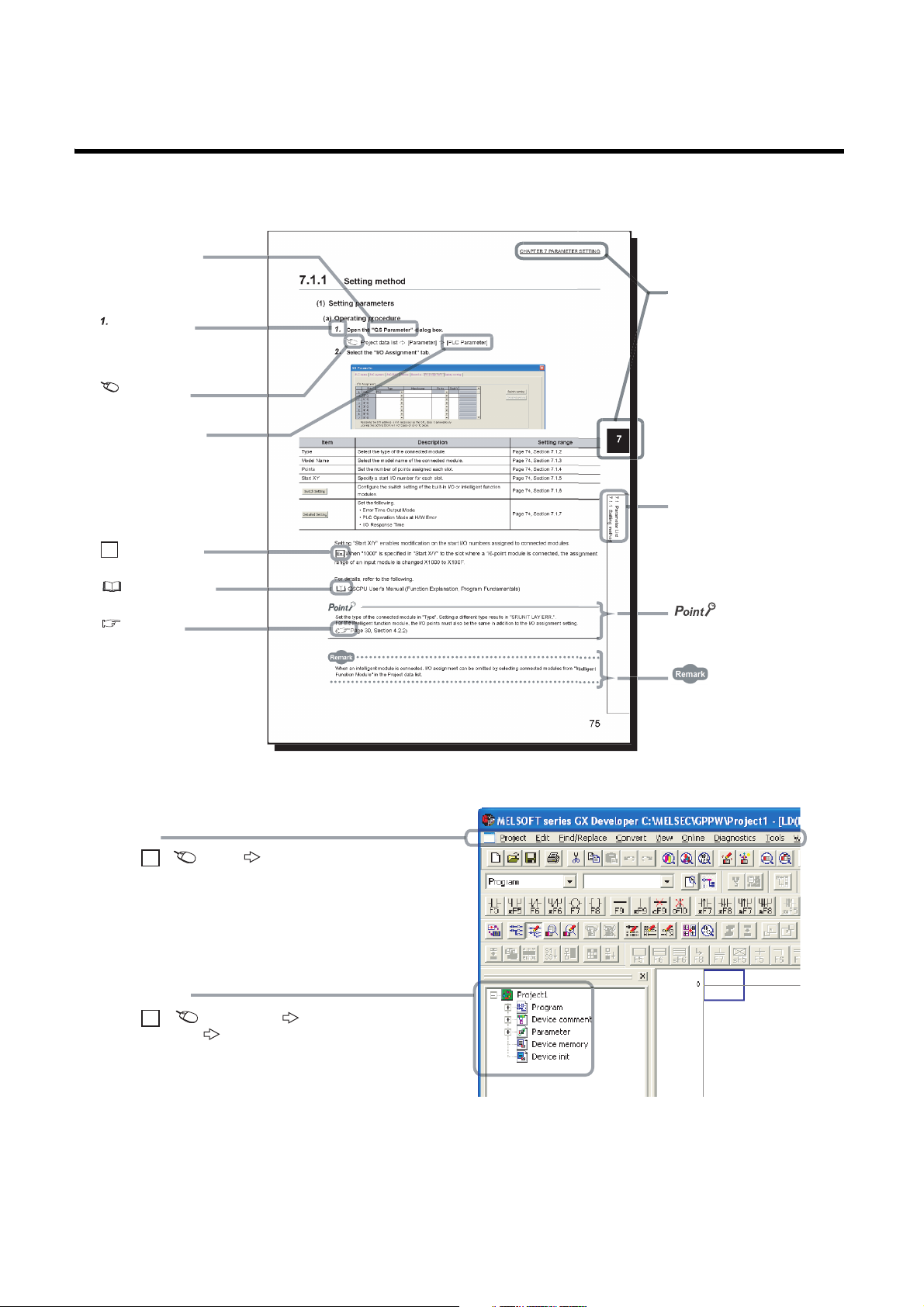

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

window names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

require attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Menu bar

Ex.

Ex.

[PLC parameter]

In the Project data list, expand [Parameter] and

select [PLC parameter].

Project data list

Project data list [Parameter]

In this manual, pages are organized and the symbols are used as shown below.

The following illustration is for explanation purpose only, and should not be referred to as an actual documentation.

14

*1 The mouse operation example is provided below.

Page 17

TERM

Unless otherwise specified, this manual uses the following terms.

Ter m Description

Safety programmable controller

Standard programmable controller

QSCPU Another term for the MELSEC-QS series CPU module

LCPU Another term for the MELSEC-L series CPU module

QCPU Another term for the MELSEC-Q series CPU module

QnACPU Another term for the MELSEC-QnA series CPU module

ACPU Another term for the MELSEC-A series CPU module

System A CPU A CPU module where the system A connector of a tracking cable is connected in a redundant system

System B CPU A CPU module where the system B connector of a tracking cable is connected in a redundant system

Control system CPU A CPU module that controls operations in a redundant system

Standby system CPU A CPU module that stands by in case the control system fails in a redundant system

Control CPU

Programming tool A generic term for GX Works2 and GX Developer

GX Developer

GX Works2

CC-Link IE Field Network A high-speed and large-capacity open field network that is based on Ethernet (1000BASE-T)

CC-Link

Safety CPU module The abbreviation for the QS001CPU safety CPU module

Master/local module

Q series master/local module The abbreviation for the QJ71GF11-T2 CC-Link IE Field Network master/local module

L series master/local module The abbreviation for the LJ71GF11-T2 CC-Link IE Field Network master/local module

CC-Link Safety master module The abbreviation for the QS0J61BT12 CC-Link Safety system master module

Head module The abbreviation for the LJ72GF15-T2 CC-Link IE Field Network head module

Ethernet adapter module The abbreviation for the NZ2GF-ETB CC-Link IE Field Network Ethernet adapter module

CC-Link IE Field Network interface board The abbreviation for the Q81BD-J71GF11-T2 CC-Link IE Field Network interface board

Network module

Intelligent function module

Safety data Data exchanged through safety communication

Safety connection A connection established for safety communication

Safety communication A function to exchange safety data between safety stations on the same network

Standard communication A generic term for cyclic transmission and transient transmission

Cyclic transmission

Transient transmission

Safety station A generic term for a station that performs safety communication and standard communication

Standard station A generic term for a station that performs standard communication

A generic term for a safety CPU module, a safety power supply module, a safety main base unit, a CC-Link Safety

master module, CC-Link Safety remote I/O modules, and a master/local module

A generic term for MELSEC-Q series, MELSEC-L series, MELSEC-QnA series, MELSEC-A series, and MELSECFX series modules (This term is used to distinguish a programmable controller that uses these modules from a

safety programmable controller.)

A CPU module that controls connected I/O modules and intelligent function modules. In a multiple CPU system,

there are multiple CPU modules and each connected module can be controlled by a different CPU module.

The product name of the software package for the MELSEC programmable controllers

A field network system where data processing for control and information can be simultaneously performed at high

speed

The abbreviation for the QS0J71GF11-T2 CC-Link IE Field Network master/local module. This module supports

safety functions.

A generic term for the following modules:

• Module on CC-Link IE Field Network

• CC-Link IE Controller Network module

• Ethernet interface module

• MELSECNET/H module

• MELSECNET/10 module

A MELSEC-Q/L series module that has functions other than input and output, such as an A/D converter module

and D/A converter module

A function by which data are periodically exchanged among stations on the same network using link devices (RX,

RY, RWw, and RWr)

A function of communication with another station, which is used when requested by a dedicated instruction

or a programming tool

15

Page 18

Term Description

A station that controls the entire network. Only one master station can be used in a network.

This station serves as a safety station or a standard station, and can perform cyclic transmission and transient

Master station

Local station

Remote I/O station A station that exchanges I/O signals (bit data) with the master station by cyclic transmission

Remote device station

Intelligent device station

Slave station A generic term for a local station, remote I/O station, remote device station, and intelligent device station

Reserved station A station reserved for future use. This station is not actually connected, but counted as a connected station.

Relay station

Data link Generic term for cyclic transmission and transient transmission

Seamless communication

Routing

Dedicated instruction An instruction that simplifies programming for using functions of intelligent function modules

Link dedicated instruction

Return Processing that restarts data link when a station recovers from an error

Disconnection Processing that stops data link if a data link error occurs

Loopback

Device A device (X, Y, M, D, or others) in a CPU module

Link device A device (RX, RY, RWr, or RWw) in a module on CC-Link IE Field Network

Remote input (RX)

Remote output (RY)

Remote register (RWr)

Remote register (RWw)

Link special relay (SB) Bit data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Link special register (SW) Word data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Link scan (Link scan time)

Link refresh

Baton pass A token to send data over a network

Buffer memory

transmission with all stations.

When set as a safety station, the station can perform safety communication with another safety station on the

same network.

A station that serves as a safety station or a standard station. This station can perform cyclic transmission and

transient transmission with the master station and other local stations.

When set as a safety station, the station can perform safety communication with another safety station on the

same network. The station is controlled by programs in the CPU module or other equivalent modules on the

station.

A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission.

This station responds to a transient transmission request from another station.

A station that exchanges I/O signals (bit data) and I/O data (word data) with another station by cyclic transmission.

This station responds to a transient transmission request from another station and also issues a transient

transmission request to another station.

A station that includes two or more network modules. Data are passed through this station to stations on other

networks.

Communication that allows users to access a different kind of networks without having to consider the differences

as if data were exchanged within one single network.

A process of selecting paths for communication with other networks.

CC-Link IE Field Network requires communication paths to be preset using routing parameters to communicate

with stations on different networks.

A dedicated instruction used for transient transmission with a programmable controller on another station.

This instruction allows a master/local module to communicate with programmable controllers on the same network

(CC-Link IE Field Network) and on other networks (Ethernet, CC-Link IE Controller Network, and MELSECNET/H).

A function that disconnects the station in which an error has occurred, and continues data link with the stations that

are operating normally. Stations connected after the faulty station can also continue data link.

Bit data input from a slave station to the master station (For some areas in a local station, data are input in the

opposite direction.)

Page 103, Section 8.2.1

Bit data output from the master station to a slave station (For some areas in a local station, data are output in the

opposite direction.)

Page 103, Section 8.2.1

Word data input from a slave station to the master station (For some areas in a local station, data are input in the

opposite direction.)

Page 103, Section 8.2.1

Word data output from the master station to a slave station (For some areas in a local station, data are output in the

opposite direction.)

Page 103, Section 8.2.1

Time required for all the stations on the network to transmit data. The link scan time depends on data volume and

the number of transient transmission requests.

Data transfer between a link device in a module on CC-Link IE Field Network and a device in a CPU module. Link

refresh is performed in the END processing of the CPU module's sequence scan.

A memory in an intelligent function module, where data (such as setting values and monitoring values) exchanged

with a CPU module are stored

16

Page 19

Ter m Description

Buffer memory address

RAS

READ The abbreviation for JP.READ and GP.READ

SREAD The abbreviation for JP.SREAD and GP.SREAD

WRITE The abbreviation for JP.WRITE and GP.WRITE

SWRITE The abbreviation for JP.SWRITE and GP.SWRITE

REQ The abbreviation for JP.REQ and GP.REQ

An address that indicates the storage location of data assigned to the buffer memory in an intelligent function

module

The abbreviation for Reliability, Availability, and Serviceability. This term refers to usability of automated

equipment.

17

Page 20

PACKING LIST

QS0J71GF11-T2

MELSEC-QS CC-Link IE Field Network

Master/Local Module

User's Manual (Hardware)

The following items are included in the package of this product. Before use, check that all the items are included.

QS0J71GF11-T2

18

Page 21

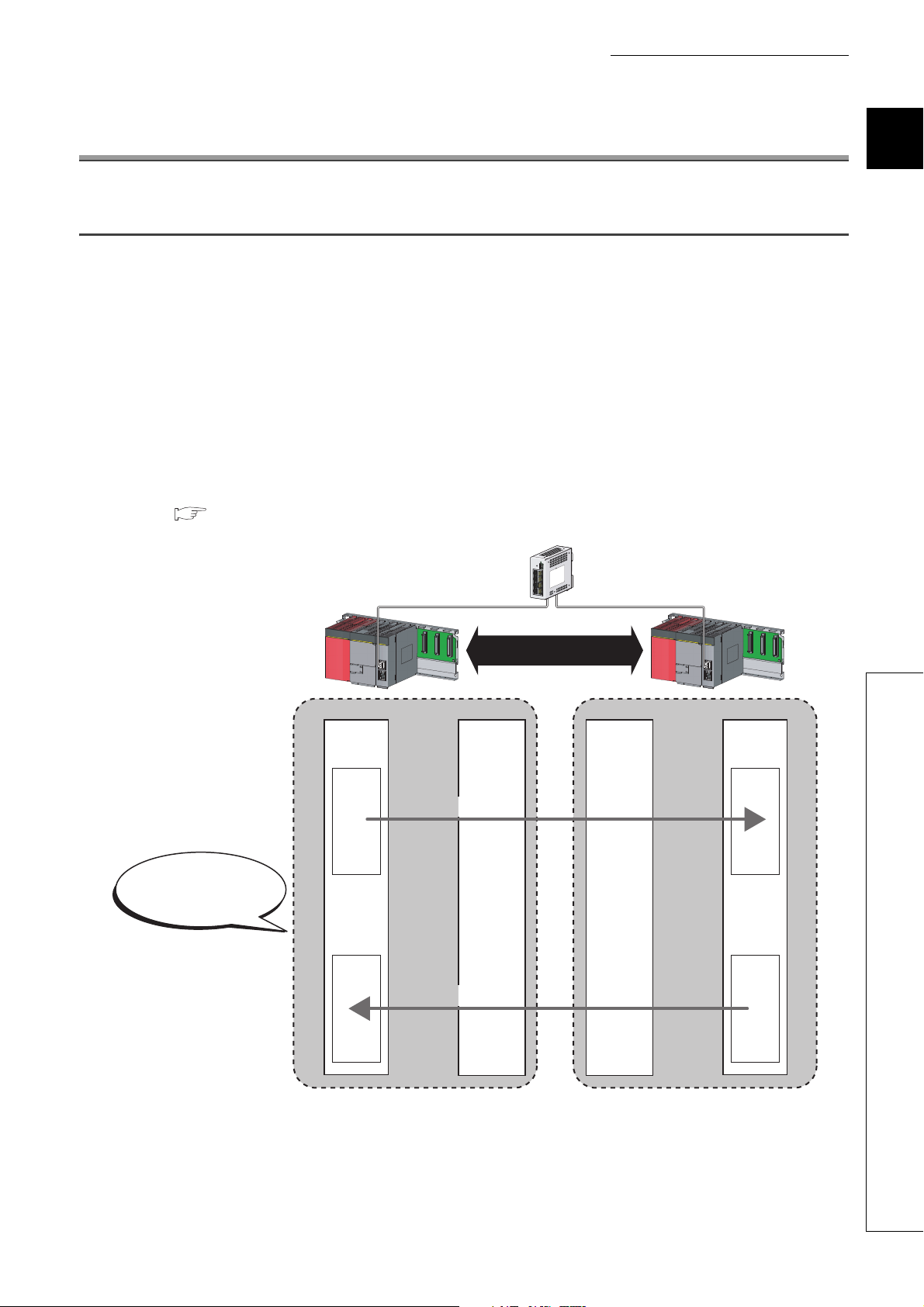

CHAPTER 1 CC-Link IE FIELD NETWORK

Master

station

(safety station)

Local

station

(safety station)

Safety CPU

module

Device

Device

Safety CPU

module

Device

Device

Master station

(safety station)

Local station

(safety station)

1) Safety connection

establishment

2) Safety data transfer

3) Safety data transfer

After safety connection

is established, data

is communicated.

CHAPTER 1 CC-Link IE FIELD NETWORK

1.1 CC-Link IE Field Network

CC-Link IE Field Network is a high-speed and large-capacity open field network that is based on Ethernet

(1000BASE-T).

(1) Data communication

High-speed and large-capacity data communication is available between a master station and slave stations on

CC-Link IE Field Network. A safety station can operate safety communication and standard communication

simultaneously.

(a) Safety communication

Data communication ensuring high safety (safety communication) can be performed.

Data is communicated after a safety connection is established between safety stations on the same network.

( Page 96, Section 8.1)

1

1.1 CC-Link IE Field Network

19

Page 22

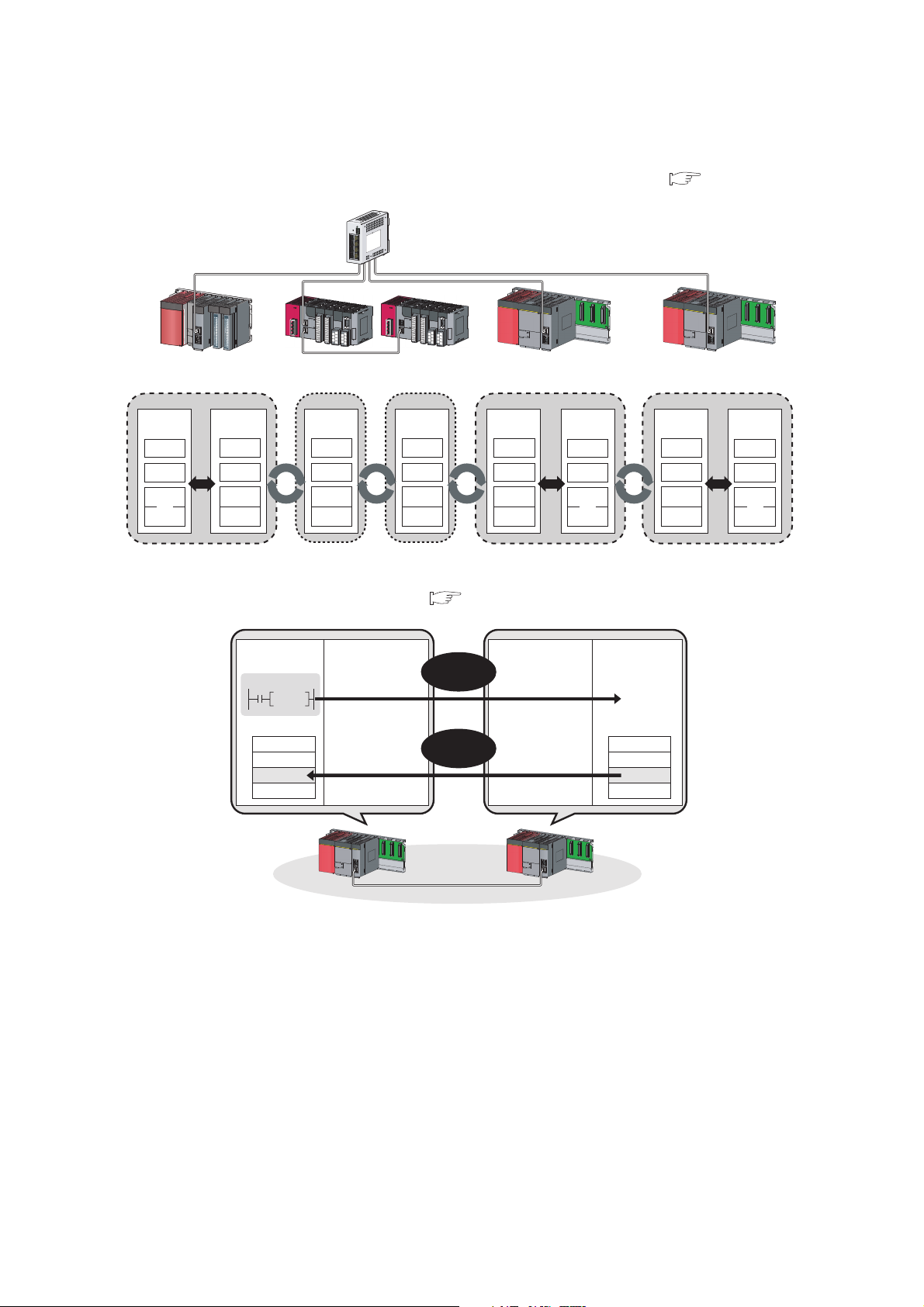

(b) Standard communication

Master

station

(standard station)

CPU module

X

Y

W

RX

RY

RWw

RWr

Local station

(safety station)

Safety

CPU module

Y

X

W

RY

RX

RWr

RWw

RX

RY

RWw

RWr

RX

RY

RWw

RWr

Intelligent

device station

Intelligent

device station

Master station

(standard station)

Local station

(safety station)

Local station

(safety station)

Safety

CPU module

Y

X

W

RY

RX

RWr

RWw

Local station

(safety station)

Intelligent

device station

Intelligent

device station

• Periodic communication (cyclic transmission)

Data is periodically communicated among stations within the same network. ( Page 102, Section 8.2)

• Non-periodic communication (transient transmission)

Data is communicated upon request. ( Page 117, Section 8.3)

Safety

CPU module

Command

Instruction

Device

1234

H

Master station

(safety station)

Read

request

Response

data

Local station

(safety station)

Safety

CPU module

Device

1234

H

20

Page 23

CHAPTER 1 CC-Link IE FIELD NETWORK

Line topology Line topology Line topology

Star topology

(2) 1Gbps communication speed

1Gbps communication speed allows high-speed communication. Also, the takt time can be reduced due to the

improved performance of communication response.

(3) Use of Ethernet cable

A 1000BASE-T-compliant Ethernet is used for the connection interface. The wiring cost can be reduced because

1000BASE-T-compliant Ethernet cables are commercially available. ( Page 56, Section 5.2)

1000BASE-T

(4) Flexible wiring for system arrangements

The network can be wired into star topology, line topology, and ring topology. ( Page 47, Section 5.1.1)

For star topology, a 1000BASE-T compliant switching hub can be used. ( Page 57, Section 5.2.2)

Wiring is highly flexible because a network can consist of a combination of star and line topologies. For example,

the control panels can be connected through a star topology and the production lines through a line topology.

1

1.1 CC-Link IE Field Network

21

Page 24

1.2 Master/Local Modules

Adding a

station

Adding a

station

Safety

station

Safety

station

Standard

station

Standard

station

Safety communication

A master/local module is used to connect a safety programmable controller to CC-Link IE Field Network.

The module is used being mounted on a safety base unit.

The module can be used as the following stations on CC-Link IE Field Network.

• Master station (safety station)

• Local station (safety station)

• Local station (standard station)

(1) Communication that ensures safety (safety communication)

Data communication ensuring high safety (safety communication) can be performed.

Data is communicated after a safety connection is established between safety stations on the same network.

( Page 96, Section 8.1)

(a) Safety stations added on CC-Link IE Field Network

Safety programmable controllers and standard programmable controllers can co-exist on the same network. A

network system with high safety can be easily established by adding safety stations on an existing CC-Link IE

Field Network. ( Page 47, Section 5.1.1)

22

The master/local module has acquired certification of the highest safety level (SIL3 of IEC 61508, Category 4 of EN 654-1,

and Category 4 performance level

"e" of EN ISO 13849-1) applicable to programmable controllers.

Page 25

CHAPTER 1 CC-Link IE FIELD NETWORK

(2) High-speed periodic communication (cyclic transmission)

Since transmission delay time is short, delay caused by the network does not need to be considered (if the link

scan time of each master/local module is shorter than the scan time of the safety CPU module).

Command

High speed

Master/local modules can perform cyclic transmissions in combination with the following functions:

( Page 35, Section 3.3)

• Auto transfer of data between the link devices in the master/local module and the devices in the safety CPU

module

• Cyclic data assurance in units of 32 bits or per station

• Status setting (hold or clear) of input data of standard communication to which a data link error has occurred

• Station reservation for future connection, and others

1

1.2 Master/Local Modules

23

Page 26

(3) Non-periodic communication (transient transmission) with programmable

Command

READ

Device Device

1234

H

1234

H

Safety CPU module Safety CPU module

Master station

(safety station)

Local station

(safety station)

controllers on other stations

(a) Reading or writing data

A master/local module can access programmable controllers on other stations by dedicated instructions.

( Page 152, Section 10.1)

Seamless access of programmable controllers on other networks such as Ethernet, CC-Link IE Controller

Network, MELSECNET/H, and MELSECNET/10 is also possible.

24

Page 27

CHAPTER 1 CC-Link IE FIELD NETWORK

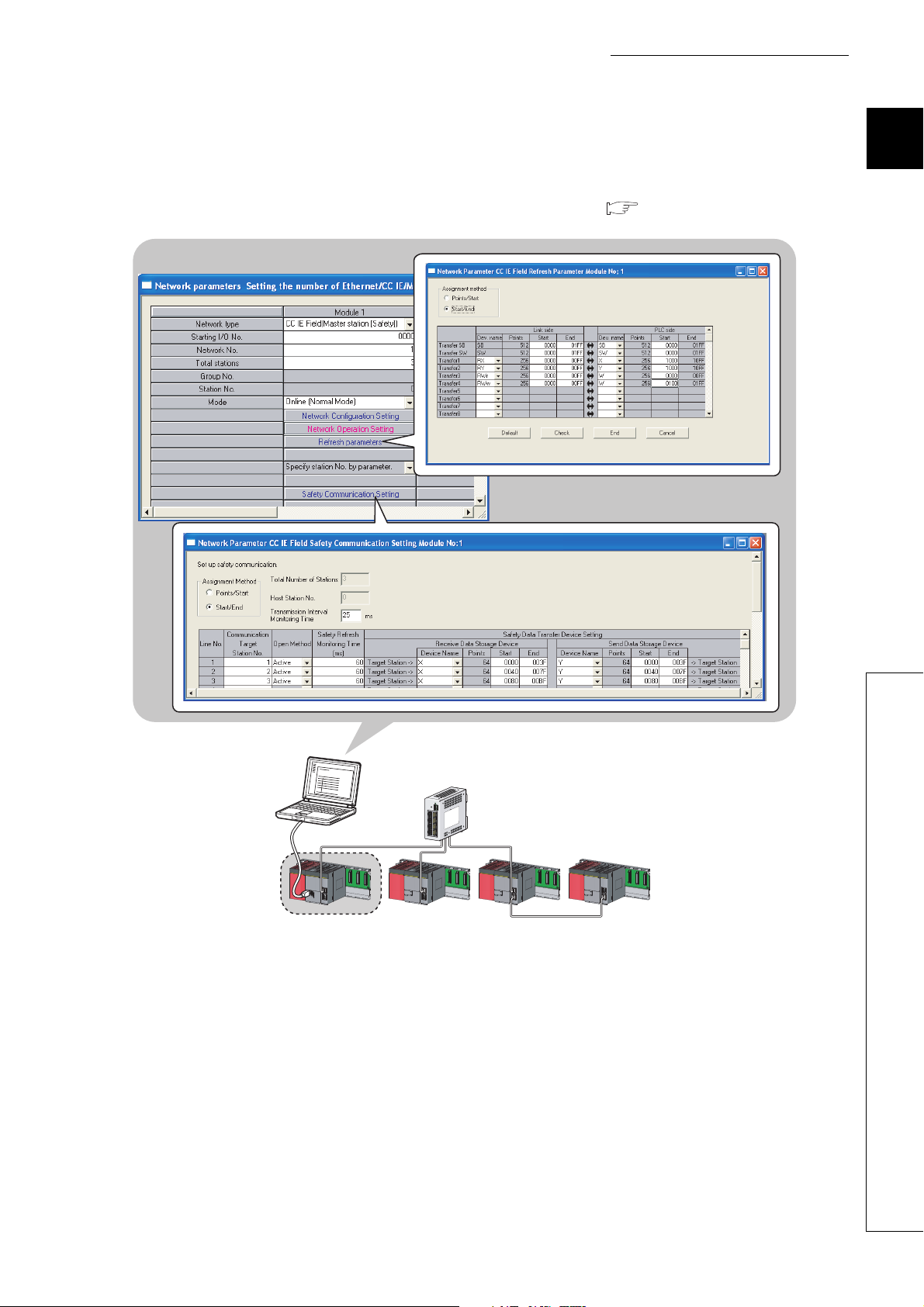

(4) Settings and diagnostics by GX Developer

(a) Setting parameters

Parameters for master/local modules can be set using GX Developer. ( Page 77, CHAPTER 7)

1

1.2 Master/Local Modules

25

Page 28

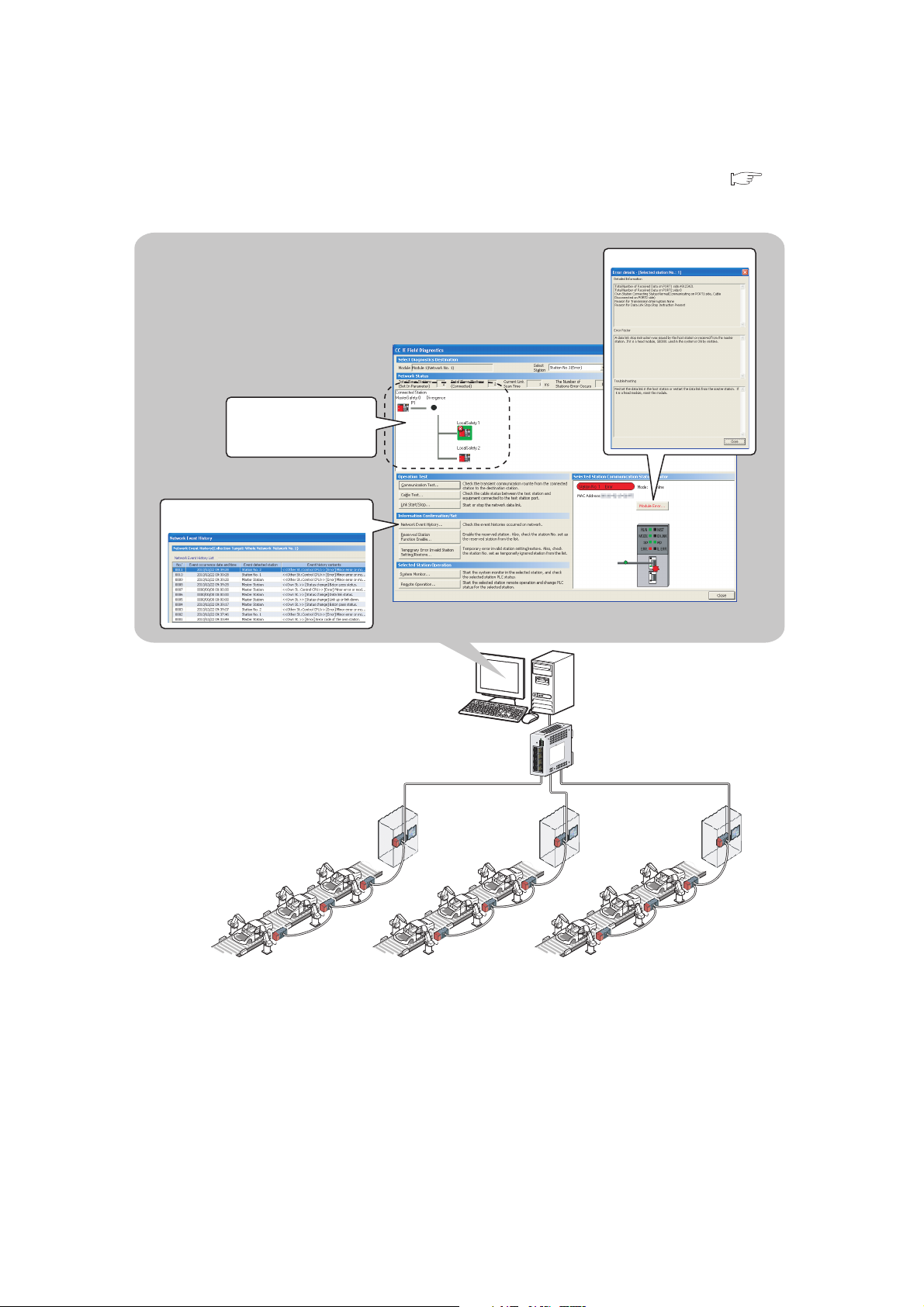

(b) Checking CC-Link IE Field Network status graphically

Displays error details

Displays the network event history

Displays the status of

CC-Link IE Field Network

CC-Link IE Field Network status can be checked using GX Developer. Error locations, error causes, and event

history are displayed on the window. This allows the system to quickly recover from errors. ( Page 124,

CHAPTER 9)

26

Page 29

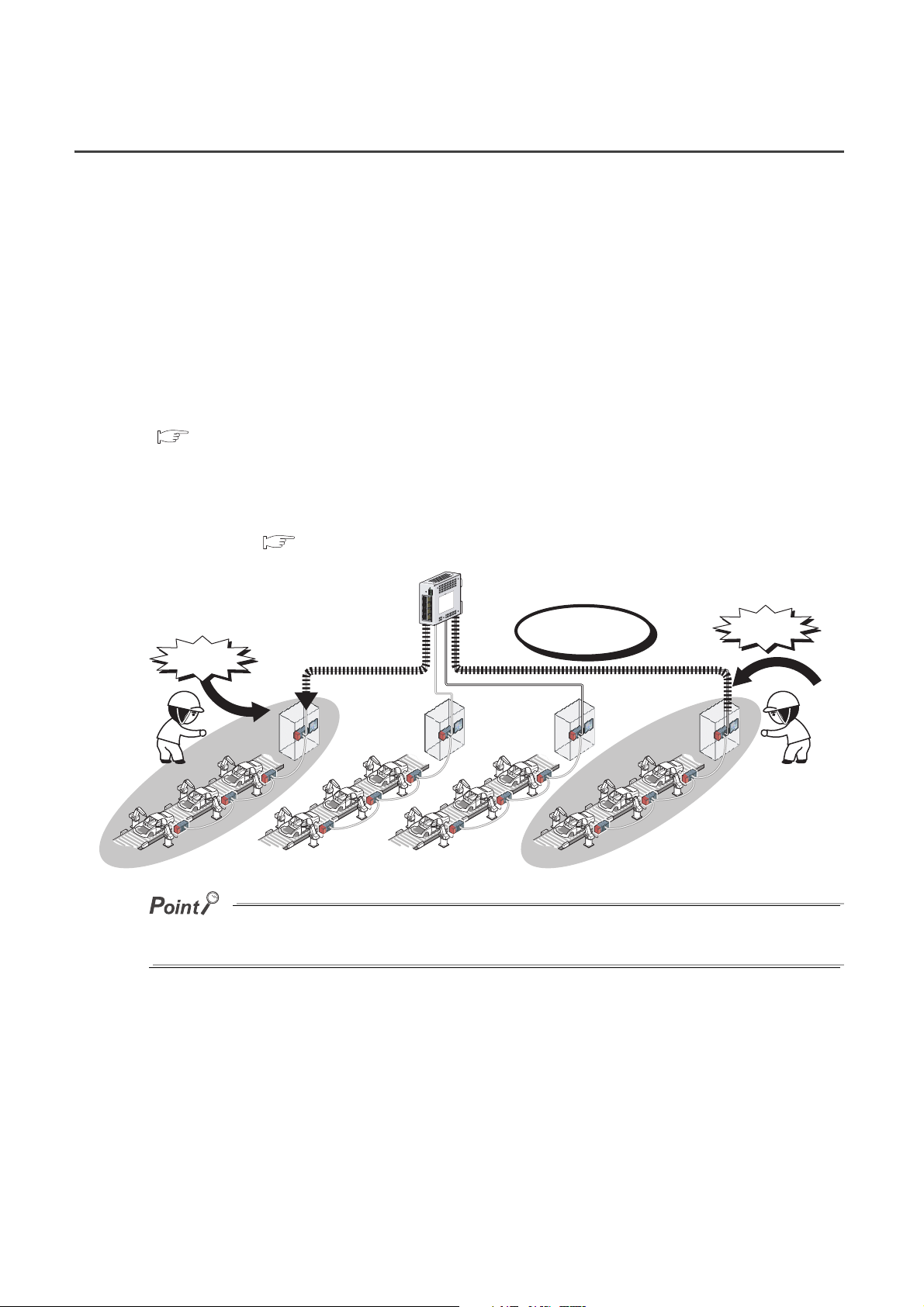

CHAPTER 1 CC-Link IE FIELD NETWORK

GX Developer

CC-Link IE Field Network

CC-Link IE Controller Network

Network No. 2

Network No. 1

(Relay station)

Seamless

access

Systems on other networks

can be tested or monitored.

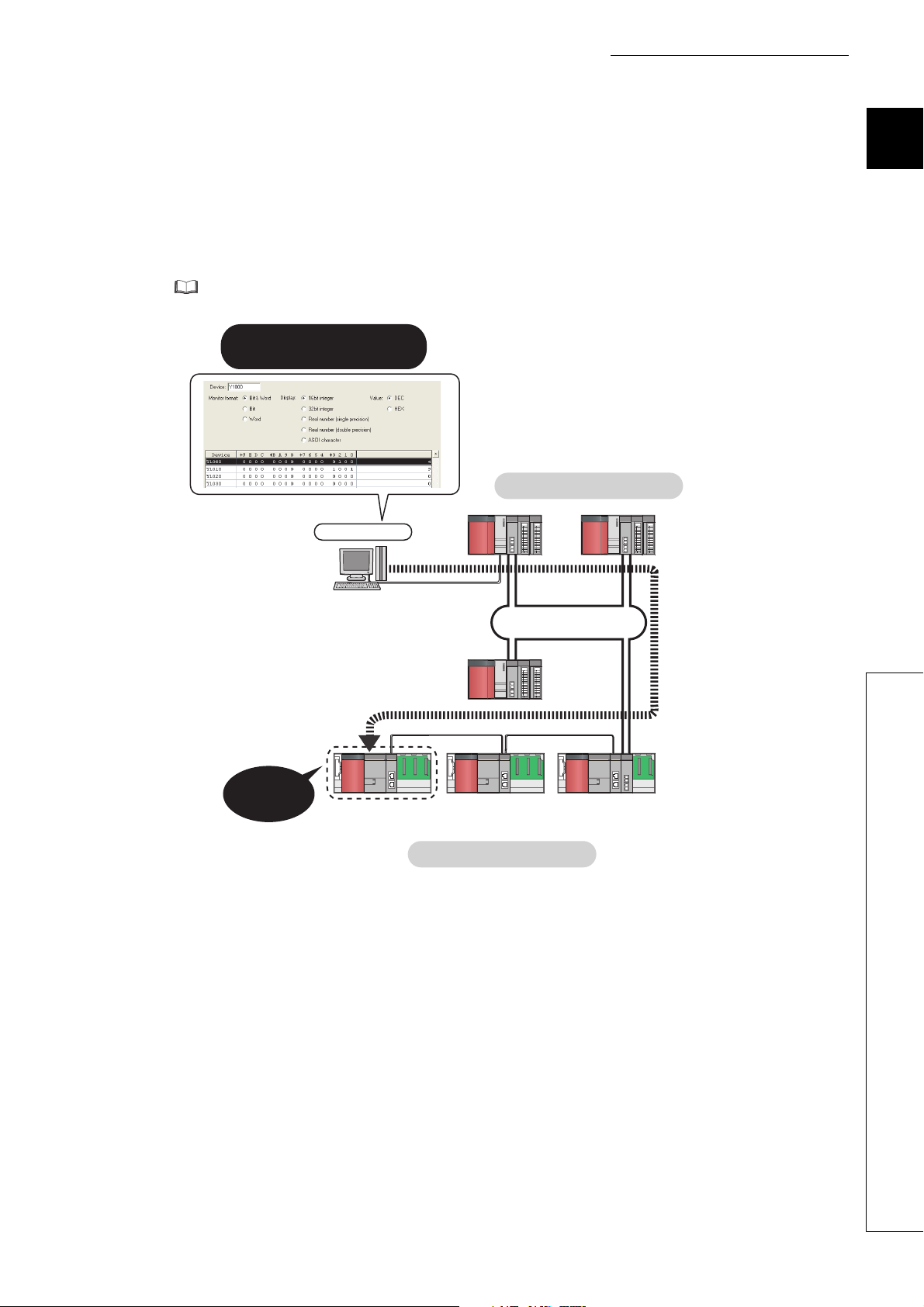

(c) Seamless access to other networks

GX Developer can seamlessly access (test or monitor) systems composed of CC-Link IE Field Network and

other networks. The accessible networks are Ethernet, CC-Link IE Controller Network, MELSECNET/H,

MELSECNET/10, and CC-Link.

Seamless access enables the user to change the access target without modifying the connection between the

personal computer and programmable controller.

For details on access range, refer to the following.

QSCPU User’s Manual (Function Explanation, Program Fundamentals)

1

1.2 Master/Local Modules

27

Page 30

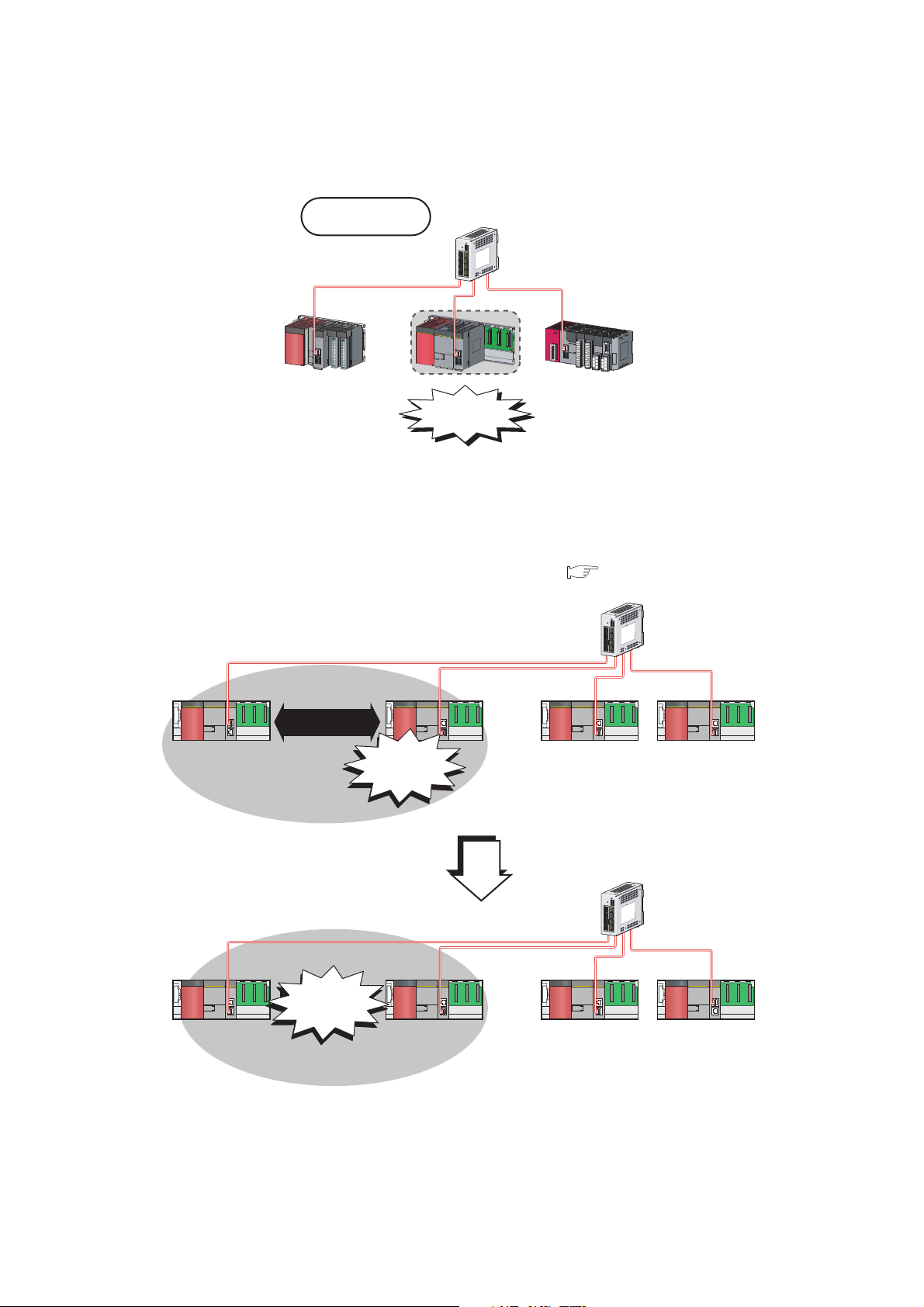

(5) Replacing CC-Link IE Field Network devices without stopping the system

Master station

(safety station)

Station No. 0

Local station

(standard station)

Station No. 1

Local station

(safety station)

Station No. 3

Local station

(standard station)

Station No. 2

Error

Master station

(safety station)

Station No. 0

Local station

(standard station)

Station No. 1

Local station

(safety station)

Station No. 3

Local station

(standard station)

Station No. 2

Communication

disconnection

and interlock

Safety

communication

For star topology, slave stations can be replaced without powering off the whole system.

Star topology

Replacement

(6) RAS function when a communication error occurs

(a) During safety communication

When a communication error occurs between safety stations, communication is automatically disconnected in

order to prevent incorrect input/output from/to the faulty station. ( Page 100, Section 8.1.3)

28

Page 31

CHAPTER 1 CC-Link IE FIELD NETWORK

Master station

(safety station)

Station No. 0

Local station

(standard station)

Station No. 1

Local station

(safety station)

Station No. 3

Local station

(standard station)

Station No. 2

Disconnection

Master station

(safety station)

Station No. 0

Local station

(standard station)

Station No. 1

Local station

(safety station)

Station No. 3

Local station

(standard station)

Station No. 2

Master station

(safety station)

Station No. 0

Local station

(standard station)

Station No. 1

Local station

(safety station)

Station No. 3

Local station

(standard station)

Station No. 2

Error

Standard

communication

Standard

communication

Communication is

automatically

disconnected.

Reconnection

When

recovered

from fault

(b) During standard communication

When a communication error occurs, communication is automatically disconnected in order to prevent

incorrect input/output from/to the faulty station. When the disconnected station gets back to normal operation, it

automatically returns to the network and resumes data link. ( Page 35, Section 3.3.1)

1

1.2 Master/Local Modules

29

Page 32

CHAPTER 2 PART NAMES

1)

2)

3)

This chapter describes the names of each part of the master/local modules.

No. Name Application

RUN LED Indicates the operating status.

ON Operates normally.

OFF A hardware failure or a watchdog timer error has occurred.

MST LED Indicates the station type.

ON Operates as a master station (safety station).

OFF Operates as a local station.

MODE LED Indicates the mode.

ON In online mode.

Flashing In test mode (The module is performing a hardware test, self-loopback test, or loop test.)

1)

D LINK LED Indicates the status of the data link.

SD LED Displays the sending status of data.

RD LED Displays the reception status of data.

OFF In offline mode. (Data link not performed)

ON Data link in operation (cyclic transmission in progress)

Flashing Data link in operation (cyclic transmission stopped)

OFF Data link not performed (disconnected)

ON Sending data.

OFF Data not sent.

ON Receiving data.

OFF Data not received.

30

Page 33

No. Name Application

Ex.

ERR. LED

ON

Flashing A data link faulty station was detected.

OFF Working normally.

L ERR. LED

1)

ON

OFF

ST.NO. Displays the station number of the master/local module.

Indicates the error status of the master/local module. The description of the errors can be confirmed in CC-

Link IE Field Network diagnostics. ( Page 124, CHAPTER 9)

One of the following errors has occurred:

• A stop error occurs in the safety CPU module.

• An error was detected in all stations.

• Modules with same station number exist on the network.

• A network parameter is corrupted.

• The network parameter does not match the installation status. (Reserved station specification, number of

connected stations, network number etc.)

Indicates the error status of the received data and the circuit. When the L ERR. LED is on, you can check

the L ER LED for "P1" or "P2" to see on which port the error was detected.

The description of the errors can be confirmed in CC-Link IE Field Network diagnostics. ( Page 124,

CHAPTER 9)

This LED automatically turns off when the module has received normal data and loopback is completed in

ring topology.

• The module has received abnormal data.

• The module is performing loopback.

• The module has received normal data.

• The module is not performing loopback.

Displays the station number.

CHAPTER 2 PART NAMES

2

Station No. 15

1

1

ON

100

10

OFF Operates as a master station (safety station). (station No. 0)

PORT1 connector for CC-Link IE Field Network (RJ45 connector)

P1

L ER

LED

2)

LINK

LED

P2

L ER LED

LINK LED

3)

Serial number display Displays the serial number printed on the rating plate.

ON

OFF

ON Linkup in progress.

OFF Linkdown in progress.

Connect an Ethernet cable. ( Page 64, Section 6.3)

There are no restrictions on the connection order of the cables for the "P1" connector and "P2" connector.

• The module has received abnormal data.

• The module is performing loopback.

• The module has received normal data.

• The module is not performing loopback.

PORT2 connector for CC-Link IE Field Network (RJ45 connector)

Connect an Ethernet cable. ( Page 64, Section 6.3)

There are no restrictions on the connection order of the cables for the "P1" connector and "P2" connector.

(Same as the "P1" connector)

4

1

10 5+=15

31

Page 34

Remark

For LED indication when the master/local module is in test mode (when the module performs hardware test, self-loopback

test, or loop test), refer to the following.

● Hardware test: Page 60, Section 6.2.1

● Self-loopback test: Page 62, Section 6.2.2

● Loop test: Page 67, Section 6.4.1

32

Page 35

CHAPTER 3 SPECIFICATIONS

CHAPTER 3 SPECIFICATIONS

This chapter describes the specifications, function list, I/O signal, and buffer memory of the master/local module.

3.1 General Specifications

For the general specifications of the master/local module, refer to the following.

QSCPU User's Manual (Hardware Design and Maintenance and Inspection)

3.2 Performance Specifications

Item Specifications

Master station (safety

Number of connectable

stations per network

Number of connectable safety stations per network 32 stations

Maximum number of networks 239

Maximum number of

safety connections per

station

Number of safety inputs/outputs per safety

connection

Maximum link points per network

Maximum link points per

station

station)

Local station (standard

station)

Asynchronous mode 31 connections

Synchronous mode 8 connections

Input 8 words

Output 8 words

RX 16384 points, 2KB

RY 16384 points, 2KB

RWr 8192 points, 16KB

RWw 8192 points, 16KB

RX 16384 points, 2KB

Master station

(safety station)

Local station

RY 16384 points, 2KB

RWr 8192 points, 16KB

RWw 8192 points, 16KB

RX 2048 points, 256 bytes

RY 2048 points, 256 bytes

*1

RWr

RWw

1 station

(Up to 120 slave stations can be connected to the master station (safety station).)

120 stations

1024 points, 2048 bytes

1024 points, 2048 bytes

*2

*2

3

3.1 General Specifications

33

Page 36

Item Specifications

Communication speed 1Gbps

Network topology

Connection cable

Maximum station-to-station

Ethernet

Communication method Token passing method

Number of occupied I/O points 32 points (I/O assignment: Intelligent 32 points)

Internal current consumption (5VDC) 0.85A

External dimensions 98(H) × 27.4(W) × 115(D) [mm]

Weight 0.18kg

*1 The maximum number of points for one master station is listed. A local station can receive data from other stations in

*2 256 points and 512 bytes when "Online (High Speed Mode)" is set

distance

Overall cable distance

Number of cascade

connections

addition to this number of points. ( Page 96, Section 8.1.1)

Line topology, star topology (Coexistence of line topology and star topology is

possible.), and ring topology

An Ethernet cable that meets the 1000BASE-T standard: Category 5e or higher

(double shielded, STP), straight cable ( Page 56, Section 5.2.1)

100m max. (Compliant with ANSI/TIA/EIA-568-B (Category 5e))

( Page 66, Section 6.3 (2))

• Line topology: 12000m

(when cables are connected to 1 master station and 120 slave stations)

• Star topology: Depends on the system configuration.

• Ring topology: 12100m

(when cables are connected to 1 master station and 120 slave stations)

Up to 20

34

Page 37

CHAPTER 3 SPECIFICATIONS

3.3 Function List

3.3.1 Using the master/local module as a master station (safety

station)

(1) Safety communication function

Function Description Reference

Communication with safety stations

Error log registration function

Safety station interlock function

Communication starts among safety stations on the same network

after safety connections are established.

Information on errors occurred in safety stations and errors

occurred in communications among safety stations are transferred

to the safety CPU module and registered as error logs.

If an error occurs in safety communication, this function cuts off the

safety communication and prevents automatic resumption of the

communication.

(2) Cyclic transmission

Function Description Reference

Communication

with other

stations

Device and link

device access

Mode selection for cyclic transmission

Assurance of cyclic data integrity

Scan synchronization specification

Input status setting for data link faulty

station

Output status setting for CPU STOP

Cyclic transmission stop and restart

Communication by

RX and RY

Communication by

RWr and RWw

Link refresh

The master station (safety station) communicates I/O data in units

of bits with other stations.

The master station (safety station) communicates I/O data in units

of words with other stations.

Transfer between the link device of the master/local module and the

device of the safety CPU module is performed automatically.

This mode is selected for optimizing the performance of cyclic

transmission based on the cyclic transmission and transient

transmission frequency.

The mode can be selected from "Online (Normal mode)" and

"Online (High-speed mode)".

The cyclic data integrity is assured in units of 32 bits or station-

based units.

Link scan is set to asynchronous or synchronous with the sequence

scan of the safety CPU module.

Select whether the input data from another station where the data

link error occurred is cleared or held.

When the safety CPU module mounted with a master/local module

is set to STOP, whether cyclic data output is held or cleared can be

selected.

During debugging and other operations, cyclic transmission is

stopped. (Data reception from the slave station and data

transmission from own stations are stopped.) Also, the stopped

cyclic transmission is restarted.

Transient transmission is not stopped.

Page 96, Section 8.1.1

Page 99, Section 8.1.2

Page 100, Section 8.1.3

Page 81, Section 7.3

Page 103, Section 8.2.1

Page 86, Section 7.5

Page 104, Section 8.2.2

Page 79, Section 7.2 (1)

Page 106, Section 8.2.3

Page 112, Section 8.2.4

Page 113, Section 8.2.5

Page 115, Section 8.2.6

Page 116, Section 8.2.7

Page 138, Section 9.4

3

3.3 Function List

3.3.1 Using the master/local module as a master station (safety station)

35

Page 38

(3) Transient transmission

Function Description Reference

Communication within the same

network

Communication with different networks

(4) RAS function

Function Description Reference

Slave station disconnection

Automatic return

Loopback function

Transient transmission is performed to other stations using

dedicated instructions and GX Developer.

By setting the routing parameters (communication path) using GX

Developer in advance, transient transmission can be performed to

stations on different networks through dedicated instructions or GX

Developer. Seamless communication is available with the following

networks.

• Ethernet

• CC-Link IE Controller Network

• MELSECNET/H

• MELSECNET/10

• CC-Link (when using GX Developer)

Only the slave station where an error occurs is disconnected, and

data link continues with the stations that are operating normally.

In a line topology, all stations connected after the faulty station are

disconnected.

When the station disconnected from the network due to a data link

failure recovers, it automatically returns to the network and restarts

data link (for standard communication only).

Only the station where an error occurs is disconnected, and data

link continues with the stations that are operating normally.

All stations after the faulty station are disconnected in line topology.

By using the loopback function with ring topology, data link

continues with the stations that are operating normally.

Page 152, CHAPTER 10

Page 92, Section 7.7

Page 118, Section 8.3.2

Page 121, Section 8.6

(5) Diagnostic function

Function Description Reference

CC-Link IE Field Network diagnostics

Individual unit

diagnostics

Own network

diagnostics

Other network

diagnostics

Hardware test Check the internal hardware of the master/local module. Page 60, Section 6.2.1

Self-loopback test

Loop test

Cable test Check the connection status of the Ethernet cable. Page 74, Section 6.4.2

Communication test

The status of CC-Link IE Field Network can be checked by GX

Developer. The faulty area, cause of the fault and its corrective

action, and event history can be checked in GX Developer.

Check the communication circuit of the transmission system of the

master/local module.

Check the network circuit status and parameter setting status of

each station.

Check whether the communication path for transient transmission

from the own station to the target station is correct.

Page 124, CHAPTER 9

Page 62, Section 6.2.2

Page 67, Section 6.4.1

Page 75, Section 6.4.3

36

Page 39

(6) Other functions

Function Description Reference

Reserved station specification

Temporary cancel of the reserved

station setting

Error invalid station and temporary error

invalid station setting

CHAPTER 3 SPECIFICATIONS

The reserved stations are included in the number of stations that

will be connected to the network in the future without actually

connecting them. Reserved stations are not detected as faulty

stations even though they are not actually connected.

Reserved station specification can be temporarily cancelled without

changing the parameters.

Prevent the master station from detecting a slave station as a faulty

station even if the slave station is disconnected during data link.

This can be used when replacing a slave station during data link, for

instance.

Page 119, Section 8.4

Page 142, Section 9.6

3

Page 120, Section 8.5

Page 146, Section 9.7

3.3 Function List

3.3.1 Using the master/local module as a master station (safety station)

37

Page 40

3.3.2 Using the master/local module as a local station

(1) Safety communication function (using the master/local module as a local

station (safety station))

Function Description Reference

Communication with safety stations

Error log registration function

Safety station interlock function

(2) Cyclic transmission

Function Description Reference

Communication

with other

stations

Device and link

device access

Assurance of cyclic data integrity

Input status setting for data link faulty

station

Output status setting for CPU STOP

Cyclic transmission stop and restart

Communication by

RX and RY

Communication by

RWr and RWw

Link refresh

Communication starts among safety stations on the same network

after safety connections are established.

Information on errors occurred in safety stations and errors

occurred in communications among safety stations are transferred

to the safety CPU module and registered as error logs.

If an error occurs in safety communication, this function cuts off the

safety communication and prevents automatic resumption of the

communication.

I/O data in bit units is communicated between the local station and

other stations.

I/O data in word units is communicated between the local station

and other stations.

Transfer between the link device of the master/local module and the

device of the safety CPU module is performed automatically.

The cyclic data integrity is assured in units of 32 bits or station-

based units.

Select whether the input data from another station where the data

link error occurred is cleared or held.

When the safety CPU module mounted with a master/local module

is set to STOP, whether cyclic data output is held or cleared can be

selected.

During debugging and other operations, cyclic transmission is

stopped. (Data reception from the slave station and data

transmission from own stations are stopped.) Also, the stopped

cyclic transmission is restarted.

Transient transmission is not stopped.

Page 96, Section 8.1.1

Page 99, Section 8.1.2

Page 100, Section 8.1.3

Page 81, Section 7.3

Page 103, Section 8.2.1

Page 86, Section 7.5

Page 104, Section 8.2.2

Page 106, Section 8.2.3

Page 113, Section 8.2.5

Page 115, Section 8.2.6

Page 116, Section 8.2.7

Page 138, Section 9.4

38

Page 41

(3) Transient transmission

Function Description Reference

Communication within the same network

Communication with different networks

(4) Diagnostic function

Function Description Reference

CC-Link IE Field Network diagnostics

Individual unit

diagnostics

Own network

diagnostics

Other network

diagnostics

Hardware test Check the internal hardware of the master/local module. Page 60, Section 6.2.1

Self-loopback test

Loop test

Cable test Check the connection status of the Ethernet cable. Page 74, Section 6.4.2

Communication test

CHAPTER 3 SPECIFICATIONS

Transient transmission is performed to other stations using

dedicated instructions and GX Developer.

By setting the routing parameters (communication path) using GX

Developer in advance, transient transmission can be performed to

stations on different networks through dedicated instructions or GX

Developer. Seamless communication is available with the following

networks.

• Ethernet

• CC-Link IE Controller Network

• MELSECNET/H

• MELSECNET/10

• CC-Link (when using GX Developer)

The status of CC-Link IE Field Network can be checked by GX

Developer. The faulty area, cause of the fault and its corrective

action, and event history can be checked in GX Developer.

Check the communication circuit of the transmission system of the

master/local module.

Check the network circuit status and parameter setting status of

each station.

Check whether the communication path for transient transmission

from the own station to the target station is correct.

Page 152, CHAPTER 10

Page 92, Section 7.7

Page 118, Section 8.3.2

Page 124, CHAPTER 9

Page 62, Section 6.2.2

Page 67, Section 6.4.1

Page 75, Section 6.4.3

3.3.2 Using the master/local module as a local station

3

3.3 Function List

39

Page 42

3.4 List of I/O Signals

This section lists I/O signals for the safety CPU module.

The I/O signal assignment of when the start I/O number of the master/local module is "0000" (the module is mounted

to the 0 slot of the safety main base unit) is shown below.

The device X is an input signal from the master/local module to the safety CPU module. The device Y is an output

signal from the safety CPU module to the master/local module.

Signal direction: Master/local module Safety CPU

module

Signal direction: Safety CPU module Master/local

module

Device number Signal name Device number Signal name

X0 Module failure Y0

X1 Own station data link status Y1

X2 Use prohibited Y2

X3 Other stations data link status Y3

X4

X5 Y5

X6 Y6

X7 Y7

X8 Y8

X9 Y9

XA YA

XB YB

XC YC

XD YD

XE YE

XF Module ready YF

X10

X11 Y11

X12 Y12

X13 Y13

X14 Y14

X15 Y15

X16 Y16

X17 Y17

X18 Y18

X19 Y19

X1A Y1A

X1B Y1B

X1C Y1C

X1D Y1D

X1E Y1E

X1F Y1F

Use prohibited

Use prohibited

Y4

Y10

Use prohibited

40

Page 43

CHAPTER 3 SPECIFICATIONS

● Do not use (turn on) any "use prohibited" signals as an input or output signal to the safety CPU module.

Doing so may cause malfunction of the programmable controller system.

● For details on the I/O signals, refer to "I/O Signals". ( Page 264, Appendix 1)

3

3.4 List of I/O Signals

41

Page 44

3.5 List of Buffer Memory Addresses

The buffer memory is used to exchange data between the master/local module and the safety CPU module.

The buffer memory values are defaulted when the power is turned off or the safety CPU module is reset.

Address

(Decimal

Name

(Hexadecimal))

0 to 1023

(0 to 3FF

)

H

1024 to 2047

to 7FFH)

(400

H

2048 to 10239

to 27FFH)

(800

H

10240 to 18431

(2800

to 47FFH)

H

Link device area

18432 to 18463

to 481FH)

(4800

H

18464 to 18975

to 4A1FH)

(4820

H

18976 to 19455

to 4BFFH)

(4A20

H

System area

19456

)

(4C00

H

19457

)

(4C01

H

to to

RX offset/size information

19694

(4CEE

)

H

19695

)

(4CEF

H

19696 to 19711

to 4CFFH)

(4CF0

H

System area

19712

)

(4D00

H

19713

)

(4D01

H

to to

RY offset/size information

19950

(4DEE

)

H

19951

)

(4DEF

H

19952 to 19967

to 4DFFH)

(4DF0

H

System area

Remote input (RX)

Remote output (RY)

Remote register (RWw)

Remote register (RWr) Read

Link special relay (SB)

Link special register (SW)