Page 1

Air-Conditioners For Building Application

HEAT SOURCE UNIT

PQHY-P72·96TGMU-A

For use with R410A

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

GB

F

Page 2

5

[Fig. 5.0.1]

>

8 m

=

[26 ft]

6

6.1

[Fig. 6.1.1]

45

<

40°

=

>

8 m

=

[26 ft]

[1-25/32]

990 [39]

900 [35-7/16]

B

A

550 [21-21/32]

570 [22-15/32]

602 [23-23/32]

7

[Fig. 7.1.1]

[Fig. 7.4.1]

Side piping

Top piping

7.1

D

B

A

C

F

G

A

G

C

B

F

A Water circulation pipe

B Close valve

C Close valve

D Water outlet

7.4

A Heat source unit

B 4-ø14 [9/16] (Anchoring hole)

C (Top view)

C

16

[21/32]

[Fig. 6.1.2]

E

D Anti-vibration pad etc.

E Concrete base

D

E

6.2

E

H

D

H

E Refrigerant piping

F Y-type strainer

G Water inlet

H Drain pipe

[Fig. 6.2.1]

550

600

A Piping space (for side piping)

B Heat source unit

C Service space (front side)

D (Top view)

[Fig. 6.2.2]

[21-21/32]

[23-5/8]

A

400

[15-3/4] 990 [39]

D

400

[15-3/4]

990 [39]

E

B

C

400

[15-3/4]

TB8

3

4

A Short-circuit wire (Connected before delivery from manufacturer)

B Pump interlock circuit connection

A

63PW

B

2

F

E Piping space (for top piping)

F Piping space (for side piping)

G Heat source unit

H (Front view)

G

H

Page 3

8

A

B

1

3

[Fig. 8.2.1]

8.2

A

A

B C D

a

B

b c d

C

CCC

1

234

e

A (Unit: mm [in])

Å Heat source model

P72

P96

ı Liquid pipe

ø9.52 [3/8]

* ø9.52 [3/8]

Ç Gas pipe

ø19.05 [3/4]

ø22.2 [7/8]

* ø12.7 [1/2] for over 90m [295 ft]

B, C, D (Unit: mm [in])

Î Total capacity of indoor units

~ 54

55 ~ 72

73 ~

ı Liquid pipe

ø9.52 [3/8]

ø9.52 [3/8]

ø9.52 [3/8]

Ç Gas pipe

ø15.88 [5/8]

ø19.05 [3/4]

ø22.2 [7/8]

a, b, c, d, e (Unit: mm [in])

‰ Model number

06,08,12,15,18

24,27,30,36,48,54

72

96

ı Liquid pipe

ø6.35 [1/4]

ø9.52 [3/8]

ø9.52 [3/8]

ø9.52 [3/8]

Ç Gas pipe

ø12.7[1/2]

ø15.88 [5/8]

ø19.05 [3/4]

ø22.2 [7/8]

A

C

5

Ï Downstream unit model total

Ó 4-Branching header

(Downstream unit

model total

CMY-Y104-G

A

B

a

1

~ 72

73 ~ 400

<

=

200)

b

c d e

CC

2

CC

345

¬ 8-Branching header

(Downstream unit

model total

CMY-Y108-G

D

C

<

=

400)

A Heat source unit

B First branch

C Indoor unit

D Cap

Ì Branch kit model

CMY-Y102S-G

CMY-Y102L-G

Ô

10-Branching header

(Downstream unit

model total

CMY-Y1010-G

<

=

650)

9

[Fig. 9.2.1]

[Fig. 9.2.3]

A Close-packed packing

B Hollow packing

9.2

[Fig. 9.2.2]

<A> [Ball valve (Low press. side/flanged type)] <B> [Ball valve (High press. side/flared type)]

<C> This figure shows the valve

in the fully open state.

E

B

OS

SO

A

C

D

J

K

A Valve stem

B Stopper pin

C Packing (Accessory)

D Connecting pipe (Accessory)

E Open (Operate slowly)

F Cap

G Service port

E

G

F

H

I

H Flare nut

I ø9.52 [3/8] (PQHY-P72)

ø9.52 [3/8] (PQHY-P96)

J ø19.05 [3/4] (PQHY-P72)

ø22.2 [7/8] (PQHY-P96)

K Field piping

3

Page 4

C

A

B

D

E

9.3

[Fig. 9.3.1]

A

C

[Fig. 9.3.3]

G

H

J

A Nitrogen gas

B To indoor unit

C System analyzer

D Lo knob

E Hi knob

F Ball valve

G Liquid pipe

H Gas pipe

I Heat source unit

J Service port

F

B

B

C

LO

D

B In case of the cylinder having no syphon pipe.

HI

E

I

[Fig. 9.3.2]

9.4

D

EN

F

A

LO

B

HI

C

O

G

H

I

K

J

L

A

A : Syphon pipe

M

A System analyzer

B Lo knob

C Hi knob

D Ball valve

E Liquid pipe

F Gas pipe

G Service port

H Three-way joint

I Valve

J Valve

K R410A cylinder

L Scale

M Vacuum pump

N To indoor unit

O Heat source unit

[Fig. 9.4.1]

A Steel wire B Piping

C Asphaltic oily mastic or asphalt

D Heat insulation material A

E Outer covering B

[Fig. 9.4.4]

<A> Inner wall (concealed)

A B

A : Sleeve B : Heat insulating material

C : Lagging D : Caulking material

E : Band F : Waterproofing laye

G : Sleeve with edge H: Lagging material

I : Mortar or other incombustible caulking

J : Incombustible heat insulation material

<B> Outer wall

D

C

A B

A

B

C

D

E

E

B

E

A

D

A Liquid pipe B Gas pipe

C Electric wire D Finishing tape

E Insulator

<C> Outer wall (exposed)

E

<D> Floor (waterproofing)

B

I

[Fig. 9.4.3][Fig. 9.4.2]

<E> Roof pipe shaft

D

F

G

<F> Penetrating portion on fire

limit and boundary wall

D

I

J

B

G

B

H

F

A

1m1m

[3.28 ft][3.28 ft]

10

10.2

[Fig. 10.2.1]

A : Power source

L1 L2 L3 M1M2 M1M2 S

TB1

AB

TB3 TB7

C

B : Transmission line

C : Ground screw

4

Page 5

10.3

BA

C

~208–230 V

BA

~208–230 V

E EDE E

[Fig. 10.3.1]

<A> Change the jumper connec-

tor from CN41 to CN40

<B> SW2-1:ON

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON

[Fig. 10.3.2]

<A> Change the jumper connec-

tor from CN41 to CN40

<B> SW2-1:ON

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON

A : Group 1

B : Group 3

C : Group 5

D : Shielded wire

E : Sub remote

controller

( ) Address

L1

OC

CN40

(51)

TB3

M1 M2

M1 M2 S

TB7

D

L2

OC

CN40

(52)

TB3

M1 M2

M1 M2 S

TB7

System

L6

controller

M1M2S

A B C

IC

(01)

TB5

M1 M2 S

r1

AB AB AB

(101)

RC

L3

IC

(02)

TB5

M1 M2 S

IC

(04)

TB5

M1 M2 S

IC

(03)

TB5

M1 M2 S

L5

r4

AB

(103)

RC

IC

(05)

TB5

M1 M2 S

r3

r2

(105)

(155)

RC

M1 M2 S

E

IC

(07)

TB5

L4

IC

(06)

TB5

M1 M2 S

RC

L1

OC

CN40

(51)

TB3

M1 M2

M1 M2 S

TB7

D

L2

OC

CN40

(52)

TB3

M1 M2

M1 M2 S

TB7

System

L6

controller

M1M2

S

A B C

IC

(01)

TB5 TB15

M1 M2 12S

c2

MA

L3

IC

(02)

TB15

TB5

12

M1 M2 S

IC

(04)

TB5

M1 M2 S

c1

IC

(03)

TB5

TB15

M1 M2 S

12

AB

IC

(05)

TB15

TB5

12

M1 M2 S

ABABAB

c2

MAMAMA

E

L4

IC

(07)

TB15

TB5

12

M1 M2 S

IC

(06)

c2

TB15

TB5

12

M1 M2 S

c1

c4

c3

c1

[Fig. 10.4.1]

A : Switch (breakers for wiring and current leakage)

B : Breakers for current leakage

C : Heat source unit

D : Pull box

E : Indoor unit

10.4

5

Page 6

Contents

1. Safety precautions ...................................................................................... 6

1.1. Before installation and electric work .......................................... 6

1.2. Precautions for devices that use R410A refrigerant .................. 6

1.3. Before getting installed .............................................................. 7

1.4. Before installation electrical work .............................................. 7

1.5. Before starting the test run ........................................................ 7

2. About the product ....................................................................................... 7

3. Specifications .............................................................................................. 7

4. Confirmation of parts attached ................................................................... 8

5. Lifting method ............................................................................................. 8

6. Installation of unit and service space .......................................................... 8

6.1. Installation ................................................................................. 8

6.2. Service space ............................................................................ 8

7. Water pipe installation ................................................................................. 8

7.1. Precautions during installation .................................................. 8

7.2. Insulation installation ................................................................. 8

7.3. Water processing and water quality control............................... 8

7.4. Pump interlock........................................................................... 9

1. Safety precautions

GB

1.1. Before installation and electric work

s Before installing the unit, make sure you read all the “Safety

precautions”.

s The “Safety precautions” provide very important points re-

D

garding safety. Make sure you follow them.

Symbols used in the text

FINL EPGRRUTR

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit label.)

<Color: yellow>

Warning:

Carefully read the labels affixed to the main unit.

Warning:

• Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric shock,

or fire.

• Install the unit in a place that can withstand its weight.

- Inadequate strength may cause the unit to fall down, resulting in injuries.

• Use the specified cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fire.

• Prepare for rain and other moisture and earthquakes and install the unit

at the specified place.

- Improper installation may cause the unit to topple over and result in injury.

• Always use an filter and other accessories specified b y Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper installation

by the user may result in water leakage, electric shock, or fire.

• Never repair the unit. If the air conditioner must be repaired, consult the

dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fire may

result.

• If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a flame, poisonous gases will

be released.

• Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fire may

result.

• Have all electric work done by a licensed electrician according to “Electric Facility Engineering Standard” and “Interior Wire Regulations”and

the instructions given in this manual and always use a special circuit.

6

8. Refrigerant piping installation ..................................................................... 9

8.1. Caution ...................................................................................... 9

8.2. Refrigerant piping system .......................................................... 9

9. Additional refrigerant charge ..................................................................... 10

9.1. Calculation of additional refrigerant charge ............................. 10

9.2. Precautions concerning piping connection and

valve operation ........................................................................ 10

9.3. Airtight test, evacuation, and refrigerant charging ................... 11

9.4. Thermal insulation of refrigerant piping ................................... 11

10. Wiring ........................................................................................................ 12

10.1. Caution .................................................................................... 12

10.2. Control box and connecting position of wiring ......................... 12

10.3. Wiring transmission cables ...................................................... 12

10.4. Wiring of main power supply and equipment capacity ............ 14

11. Test run ..................................................................................................... 14

11.1. The following phenomena do not represent trouble

(emergency) ............................................................................ 14

12.Information on rating plate ......................................................................... 14

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result.

• Securely install the heat source unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may enter

the heat source unit and fire or electric shock may result.

• When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant (R410A) specified on the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the refrig-

erant cycle may malfunction and the unit may be damaged.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration from exceeding the safety limit

even if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the safety

limit from being exceeded. Should the refrigerant leak and cause the safety

limit to be exceeded, hazards due to lack of oxygen in the room could result.

• When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock, or

fire may result.

• After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

• Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

and operated forcibly, or parts other than those specified by Mitsubishi Electric are used, fire or explosion may result.

• To dispose of this product, consult your dealer.

• The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Following standards may be applicable if local regulation are not available.

• Pay a special attention to the place, such as a basement, etc. where refrigeration gas can stay, since refrigeration is heavier than the air.

1.2. Precautions for devices that use R410A

refrigerant

Caution:

• Do not use the existing refrigerant piping.

- The old refrigerant and refrigerator oil in the existing piping contains a large

amount of chlorine which may cause the refrigerator oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

• Use refrigerant piping made of phosphorus deoxidized copper and copper alloy seamless pipes and tubes. In addition, be sure that the inner

and outer surfaces of the pipes are clean and free of hazardous sulphur ,

oxides, dust/dirt, shaving particles, oils, moisture, or an y other contaminant.

- Contaminants on the inside of the refrigerant piping may cause the refriger-

ant residual oil to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor trouble may result.

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerator

oil to coat flares and flange connections.

- The refrigerator oil will degrade if it is mixed with a large amount of mineral

oil.

Page 7

• Use liquid refrigerant to fill the system.

- If gas refrigerant is used to seal the system, the composition of the refrigerant in the cylinder will change and performance may drop.

• Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerator oil to deteriorate.

• Use a vacuum pump with a reverse flow check valve.

- The vacuum pump oil may flow back into the refrigerant cycle and cause the

refrigerator oil to deteriorate.

• Do not use the following tools that are used with conventional refrigerants.

(Gauge manifold, charge hose, gas leak detector , reverse flow c heck valve,

refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerator oil are mixed in the R410A,

the refrigerant may deteriorated.

- If water is mixed in the R410A, the refrigerator oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for conven-

tional refrigerants will not react to it.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Be especially careful when managing the tools.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant may deteriorate.

1.3. Before getting installed

Caution:

• Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

• Do not use the air conditioner where food, pets, plants, precision instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

• Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can significantly reduce the performance of

the air conditioner or damage its parts.

• When installing the unit in a hospital, communication station, or similar

place, provide sufficient protection against noise.

- The inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air conditioner

to operate erroneously, or fail to operate. On the other hand, the air conditioner may affect such equipment by creating noise that disturbs medical

treatment or image broadcasting.

• Do not install the unit on a structure that may cause leakage.

- When the room humidity exceeds 80 % or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage work

together with the heat source unit, as required.

1.4. Before installation electrical work

Warning

When installing or relocating the unit, make sure that no substance other

than the specified refrigerant (R410A) enters the refrigerant circuit.

Any presence of foreign substance such as air can cause abnormal pressure rise or explosion.

Caution:

• Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

2. About the product

• The reverse phase of L lines (L1, L2, L3) can be detected (Error cord: 4103),

but the reverse phase of L lines and N line can be not be detected.

- The some electric parts should be damaged when power is supplied under

the miss wiring.

• Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fire.

• Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

• Use power line cables of sufficient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fire.

• Use only a circuit breaker and fuse of the specified capacity.

- A fuse or circuit breaker of a larger capacity or a steel or copper wire may

result in a general unit failure or fire.

• Do not wash the air conditioner units.

- Washing them may cause an electric shock.

• Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal injury

or property damage.

• Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

• Be very careful about product transportation.

- Only one person should not carry the product if it weighs more than 20 kg

[45 LBS].

- Some products use PP bands for packaging. Do not use any PP bands for a

means of transportation. It is dangerous.

- When transporting the heat source unit, support it at the specified positions

on the unit base. Also support the heat source unit at four points so that it

cannot slip side ways.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause

stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which was not torn apart,

they face the risk of suffocation.

1.5. Before starting the test run

Caution:

• Turn on the power at least 12 hours before starting operation.

- Star ting operation immediately after turning on the main power switch can

result in severe damage to internal parts. Keep the power switch turned on

during the operational season.

• Do not touch the switches with wet fingers.

- Touching a switch with wet fingers can cause electric shock.

• Do not touch the refrigerant pipes during and immediately after operation.

- During and immediately after operation, the refrigerant pipes are may be hot

and may be cold, depending on the condition of the refrigerant flowing through

the refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

• Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

• Do not turn off the power immediately after stopping operation.

- Always wait at least five minutes before turning off the power. Otherwise,

water leakage and trouble may occur.

• Do not touch the surface of the compressor during servicing.

- If unit is connected to the supply and not running, crank case heater at

compressor is operating.

GB

D

FINL EPGRRUTR

• This unit uses R410A-type refrigerant

• Piping for systems using R410A may be different from that for systems using

conventional refrigerant because the design pressure in systems using R410A

is higher. Refer to Data Book for more information.

• Some of the tools and equipment used for installation with systems that use

other types of refrigerant cannot be used with the systems using R410A. Refer

to Data Book for more information.

3. Specifications

Model

Noise level

Net weight

Allowable pressure

Refrigerant

Indoor units

Operation temperature

Maximum water pressure

Rated water volume

Allowable water volume

Total capacity

Model / Quantity

PQHY-P72TGMU-A PQHY-P96TGMU-A

46 dB <A> 47 dB <A>

266 kg [588 LBS] 269 kg [594 LBS]

R410A: 7.0 kg [15 LBS 7 oz] R410A: 8.0 kg [17 LBS 11 oz]

P06 ~ P96 / 1 ~ 13 P06 ~ P96 / 1 ~ 16

3

/h [1204 G/h] 5.76 m3/h [1521 G/h]

4.56 m

3

3.9 ~ 6.8 m

/h [1030 ~ 1795 G/h] 4.5 ~ 7.2 m3/h [1181 ~ 1901 G/h]

• Do not use the existing piping, as it contains chlorine, which is found in conventional refrigerating machine oil and refrigerant. This chlorine will deteriorate

the refrigerant machine oil in the new equipment. The existing piping must not

be used as the design pressure in systems using R410A is higher than that in

the systems using other types of refrigerant and the existing pipes may burst.

HP: 4.15 MPa [601 psi], LP: 2.21 MPa [320 psi]

50 ~ 130 %

Water temperature: 10˚C ~ 45˚C [50˚F ~ 113˚F]

1.0 MPa [145 psi]

7

Page 8

4. Confirmation of parts attached

1 Connecting pipe × 1 (Connecting pipe is fixed with the unit.) 2 Packing (inside ø23 [29/32 in], outside ø35 [1-13/32 in]) × 1

3 Bushing × 2

5. Lifting method

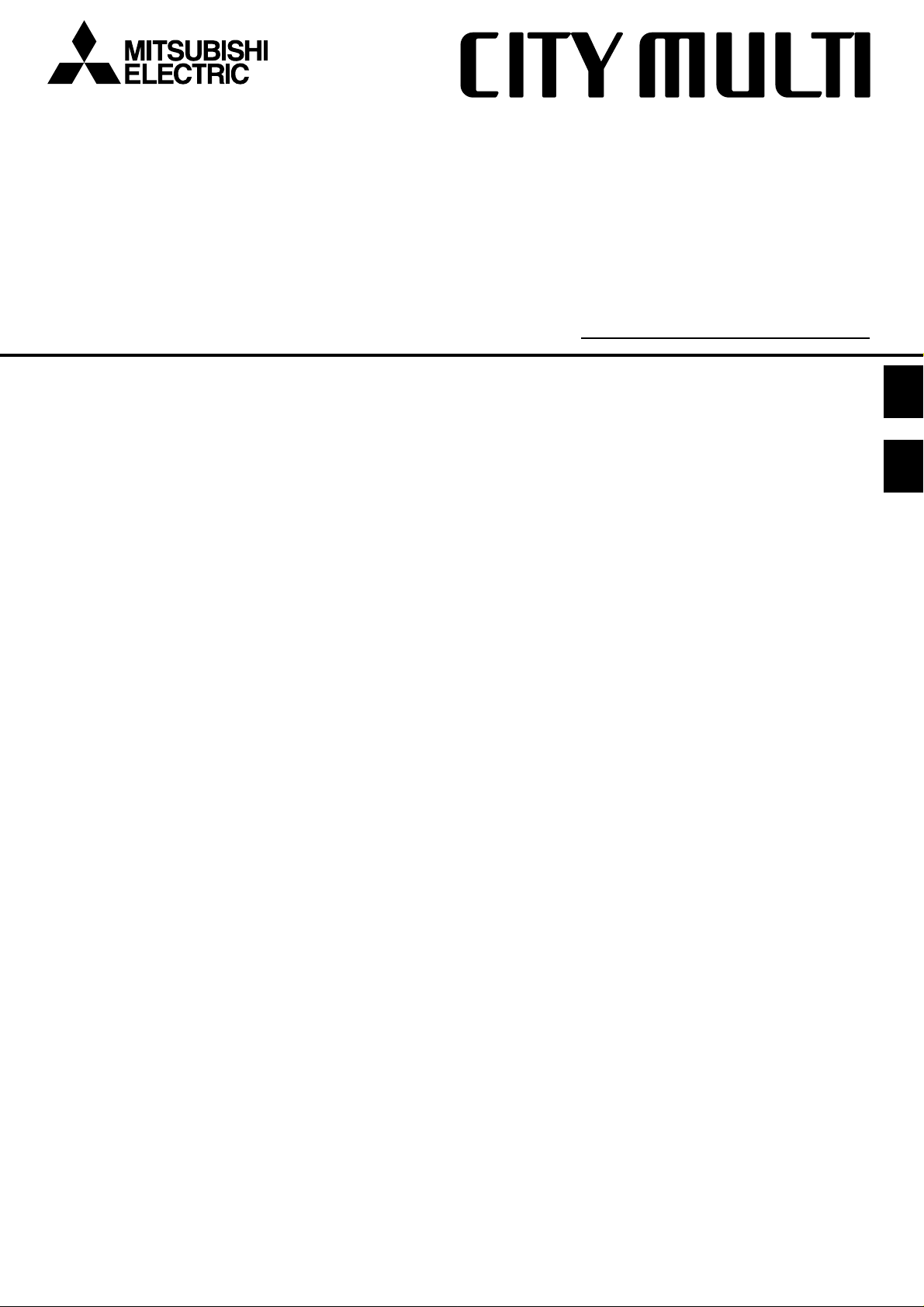

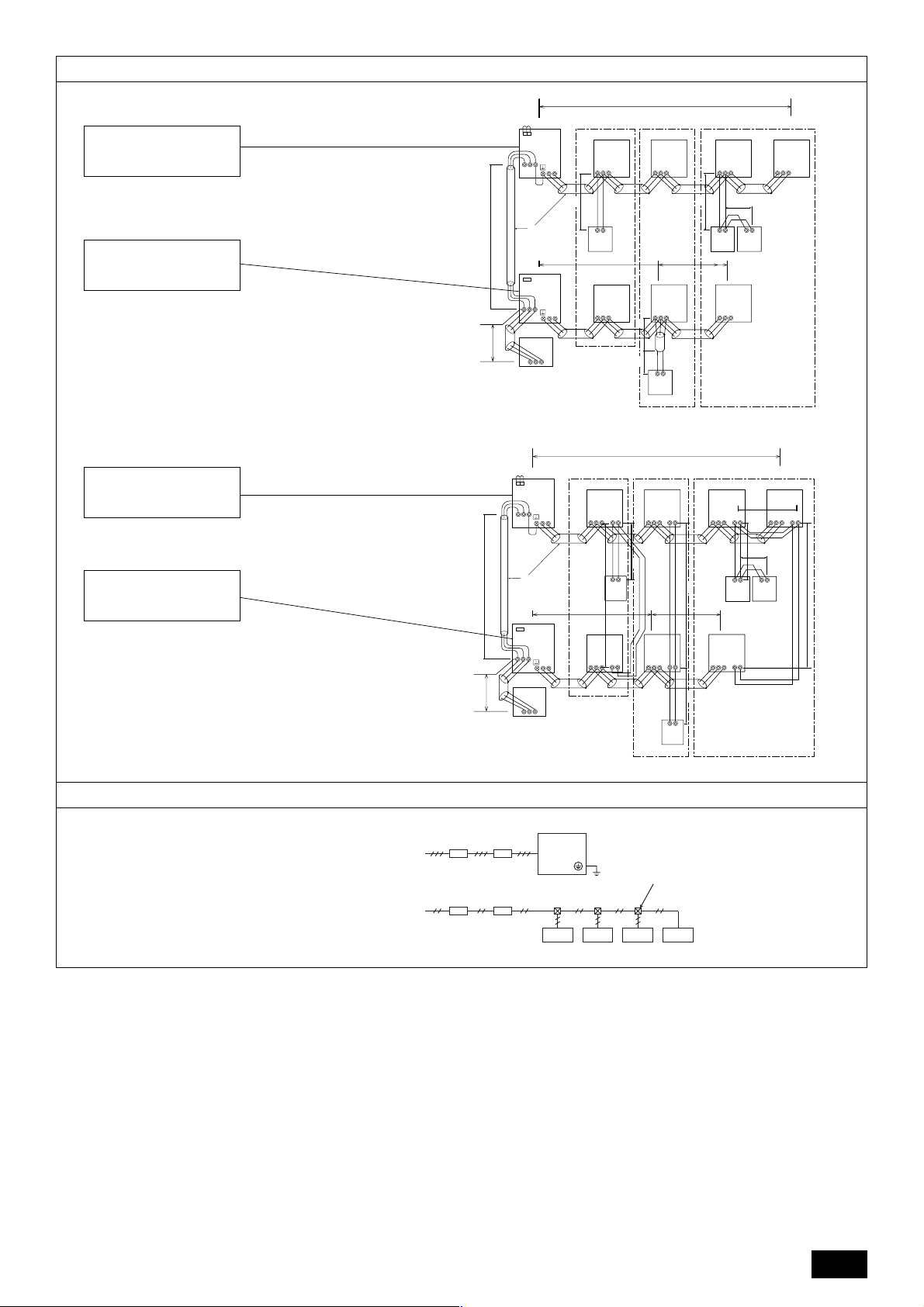

[Fig. 5.0.1] (P.2)

Caution:

Be very careful when carrying the product.

- Do not have only one person to carry product if it is more than 20 kg [46 LBS].

- PP bands are used to pack some products. Do not use them as a mean for transportation because they are dangerous.

- Tear plastic packaging bag and scrap it so that children cannot play with it. Otherwise plastic packaging bag may suffocate children to death.

- When carrying the heat source unit, be sure to support it at four points. Carrying with 3-point support may make the heat source unit unstable, resulting in it falling.

6. Installation of unit and service space

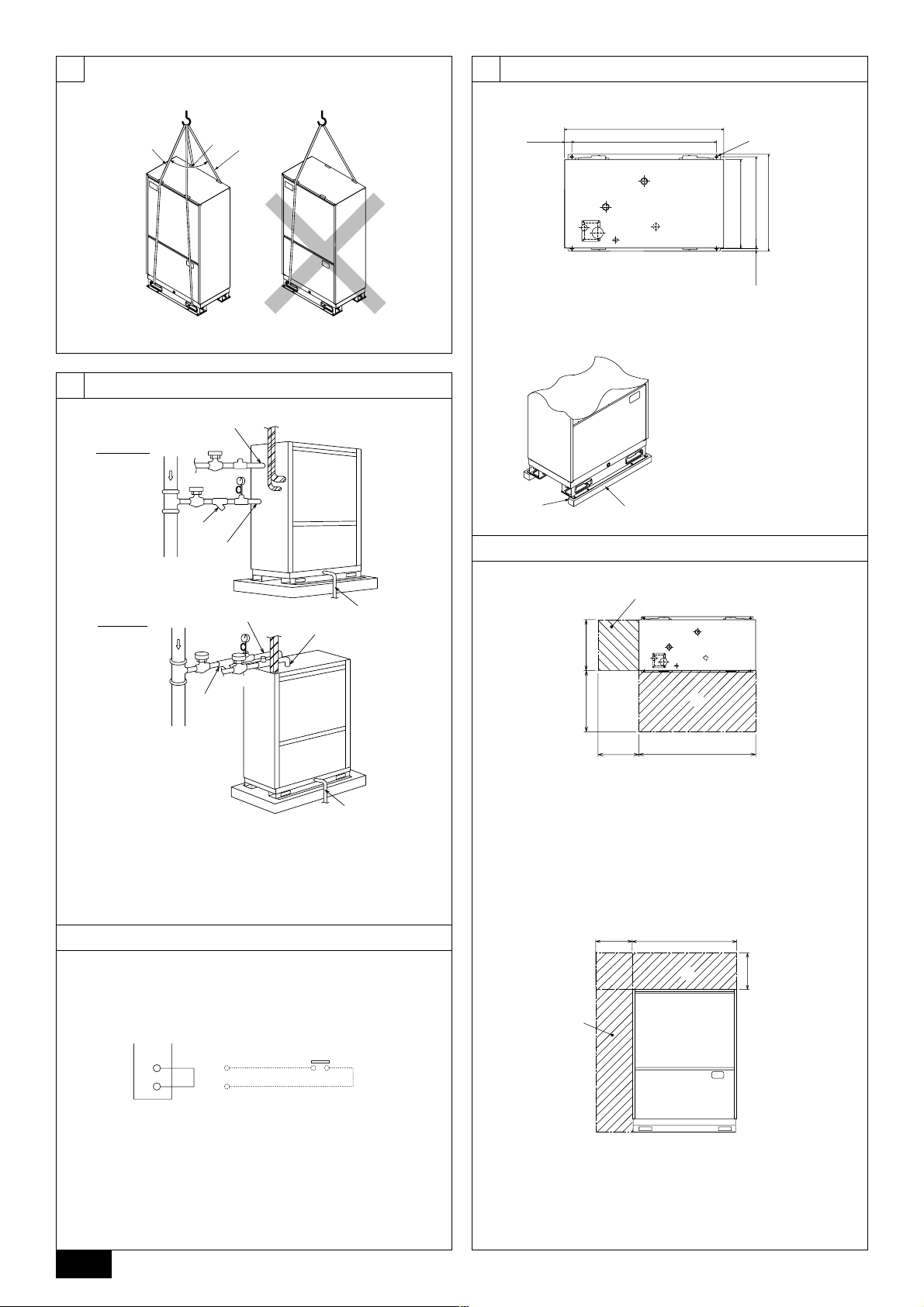

6.1. Installation

• Using the anchoring holes shown below, firmly bolt the unit to the base.

GB

[Fig. 6.1.1] (P.2)

A Heat source unit B 4-ø14 [9/16] (Anchoring hole)

C (Top view)

Bases and anti-vibration

D

• Be sure to install unit in a place strong enough to withstand its weight. If the

base is unstable, reinforce with a concrete base.

• The unit must be anchored on a level surface. Use a level to check after

installation.

• Anti-vibration pads must be placed under the base of the unit.

FINL EPGRRUTR

• If the unit is installed near a room where noise is a problem, using an antivibration stand on the base of the unit is recommended.

[Fig. 6.1.2] (P.2)

D Anti-vibration pad etc. E Concrete base

7. Water pipe installation

• City Multi WY Series pipes are similar to other air-conditioning pipes, however,

please observe the following precautions during installation.

7.1. Precautions during installation

• Use the reverse-return method to insure proper pipe resistance to each unit.

• To insure easy maintenance, inspection, and replacement of the unit, use a

proper joint, valve, etc. on the water intake and outlet port. In addition, be sure

to install a strainer on the water intake pipe. (In order to maintain the heat

source unit, a strainer on the circulating water inlet is necessary.)

* An example of the heat source unit installation is shown in the diagram be-

low.

• Install a suitable air vent on the water pipe. After sending water through the

pipe, be sure to vent the excess air.

• Compressed water may form in the low-temperature sections of heat source

unit. Use a drainage pipe connected to the drain valve at the base of the unit to

drain the water.

• There is a water vent plug in the center of the heat exchanger water inlet head

at the middle of the unit. Use this for maintenance, etc.

In addition, do not allow any of the unit’s electrical parts (such as the solenoid

valve coil or compressor power supply) to become wet.

• Install a back flow-prevention valve on the pump and a flexible joint to prevent

excess vibration.

• Use a sleeve to protect the pipes where they go through a wall.

• Use metal fittings to secure the pipes, and install them so that they have maximum protection against breakage and bending.

• Do not confuse the water intake and outlet valves.

• This unit doesn’t have any heater to prevent freezing within tubes. When the

water flow is stopped on low ambient, take out the water from tubes.

• The unused knockout holes should be closed and the opening of refrigerant

pipes, water pipes, power source and transmission wires should be filled with

putty and so on to prevent from rain. (field construction)

Example of heat source unit installation (using left piping)

8

Warning:

• Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a personal

injury.

• Have installation work in order to protect against earthquake.

Any installation deficiency may cause unit to fall down, resulting in a

personal injury.

6.2. Service space

• Please allow for the following service spaces after installation.

(All servicing can be performed from the front of the unit)

[Fig. 6.2.1] (P.2)

A Piping space (for side piping) B Heat source unit

C Service space (front side) D (Top view)

[Fig. 6.2.2] (P.2)

E Piping space (for top piping) F Piping space (for side piping)

G Heat source unit H (Front view)

[Fig. 7.1.1] (P.2)

A Water circulation pipe B Close valve

C Close valve D Water outlet

E Refrigerant piping F Y-type strainer

G Water inlet H Drain pipe

7.2. Insulation installation

With City Multi WY Series piping, as long as the temperature range of the circulating water is kept to average temperatures year-round (30 °C [86 °F] in the summer,

20 °C [68 °F] in the winter), there is no need to insulate or otherwise protect indoor

piping from exposure. You should use insulation in the following situations:

• Any heat source piping.

• Indoor piping in cold-weather regions where frozen pipes are a problem.

• When air coming from the outside causes condensation to form on piping.

• Any drainage piping.

7.3. Water pr ocessing and water quality con-

trol

To preserve water quality, use the closed type of cooling tower for WY. When the

circulating water quality is poor, the water heat exchanger can develop scales,

leading to a reduction in heat-exchange power and possible corrosion of the heat

exchanger. Please pay careful attention to water processing and water quality control

when installing the water circulation system.

• Removal of foreign objects or impurities within the pipes.

During installation, be careful that foreign objects, such as welding fragments,

sealant particles, or rust, do not enter the pipes.

• Water Quality Processing

1 Depending on the quality of the cold-temperature water used in the air-

conditioner, the copper piping of the heat exchanger may become corroded.

We recommend regular water quality processing.

Cold water circulation systems using open heat storage tanks are

particularly prone to corrosion.

When using an open-type heat storage tank, install a water-to-water heat

exchanger, and use a closed-loop circuit on the air conditioner side. If a

water supply tank is installed, keep contact with air to a minimum, and

keep the level of dissolved oxygen in the water no higher than 1mg/r.

Page 9

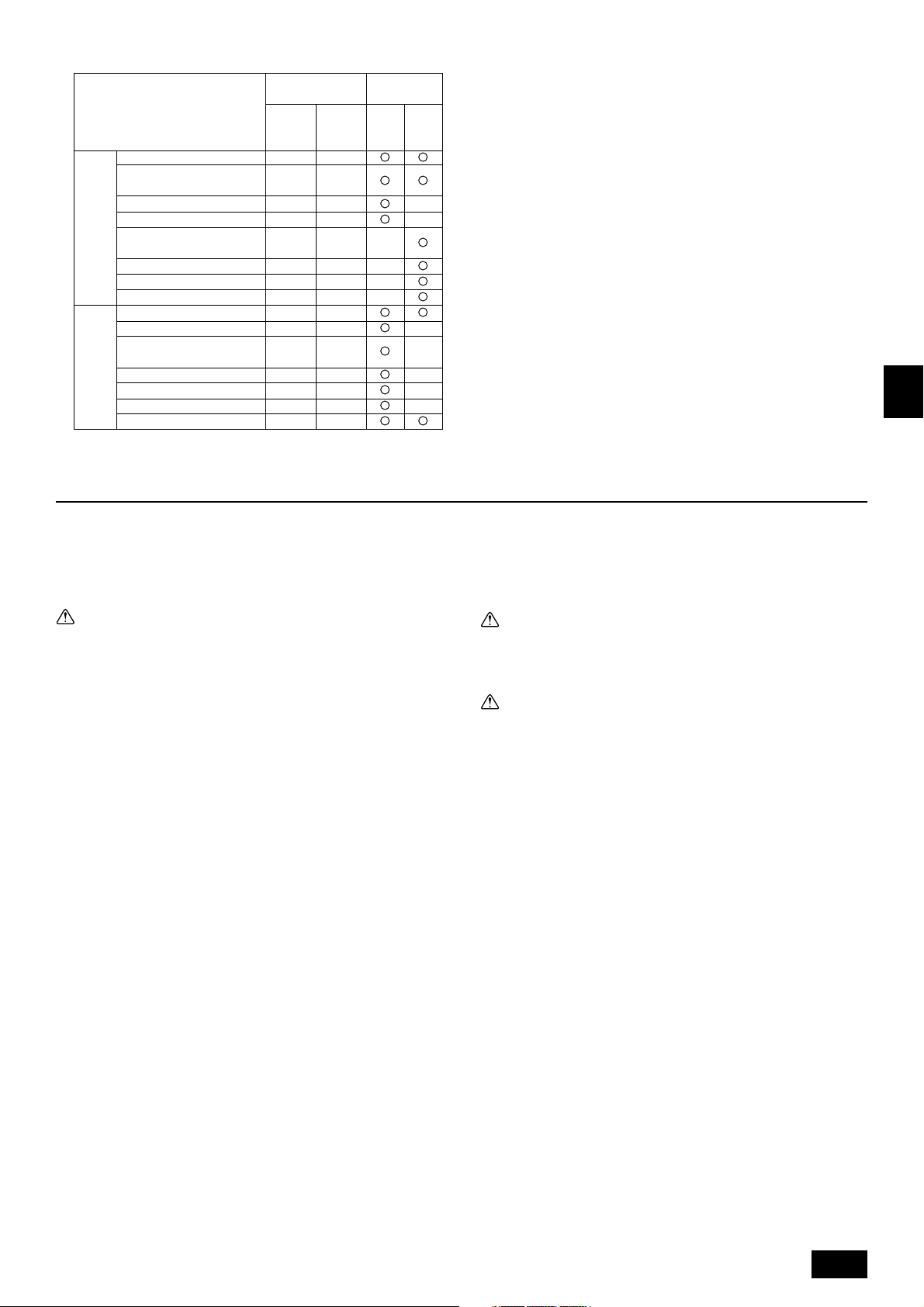

2 Water quality standard

Lower mid-range

temperature water system

2-

/r)

/r)

3

/r)

2

2-

/r)

+

/r)

4

/r)

2

Recirculating

water

[20<T<60°C]

[68<T<140°F]

7.0 ~ 8.0

30 or less

[300 or less]

50 or less

50 or less

50 or less

70 or less

50 or less

30 or less

1.0 or less

1.0 or less

not to be

detected

0.3 or less

0.25 or less

0.4 or less

–

Make-up

water

7.0 ~ 8.0

30 or less

[300 or less]

50 or less

50 or less

50 or less

70 or less

50 or less

30 or less

0.3 or less

0.1 or less

not to be

detected

0.1 or less

0.3 or less

4.0 or less

Items

pH (25˚C) [77°F]

Electric conductivity

Chloride ion (mg Cl-/r)

Sulfate ion (mg SO4

Standard

Acid consumption (pH4.8)

items

Total hardness (mg CaCO

Calcium hardness (mg CaCO3/r)

Ionic silica (mg SiO

Refer-

Iron (mg Fe/r)

ence

Copper (mg Cu/r)

items

Sulfide ion (mg S

Ammonium ion (mg NH

Residual chlorine (mg Cl/r)

Free carbon dioxide (mg CO

Ryzner stability index

Reference : Guideline of Water Quality for Refrigeration and Air Conditioning

Equipment. (JRA GL02E-1994)

(mS/m) (25°C) [77°F]

(µ s/cm) (25°C) [77°F]

(mg CaCO3/r)

Tendency

Corrosive

–

8. Refrigerant piping installation

Scale-

forming

3 Please consult with a water quality control specialist about water quality

control methods and water quality calculations before using anti-corrosive

solutions for water quality management.

4 When replacing a previously installed air conditioning device (even when

only the heat exchanger is being replaced), first conduct a water quality

analysis and check for possible corrosion.

Corrosion can occur in cold-water systems even if there has been no prior

signs of corrosion.

If the water quality level has dropped, please adjust water quality sufficiently before replacing the unit.

7.4. Pump interlock

The heat source unit may become damaged if it is operated with no water circulating through the pipes.

Be sure to interlock unit operation and the water-circuit pump. Use the terminal

blocks for interlocking (TB8-3, 4) that can be found on the unit.

In the case of a pump interlock circuit signal connection to the TB8-3, 4, remove

the short-circuit wire. Also, to prevent mistaken error detection, resulting from a

poor connection, in the pressure valve 63PW, use a low maintained current of 5mA

or less.

[Fig. 7.4.1] (P.2)

A Short-circuit wire (Connected before delivery from manufacturer)

B Pump interlock circuit connection

GB

D

Connecting the piping is a terminal-branch type in which refrigerant piping from

the heat source unit is branched at the terminal and connected to each of the

indoor units.

The method of pipe connection is as follows: flare connection for the indoor units, gas

pipes for heat source units, flare connection for P72 and brazed connection for P96 ~

P168; liquid pipes, flare connection. Note that the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas from leaking while

using fire or flame. If the refrigerant gas comes in contact with a flame from

any source, such as a gas sto ve, it breaks down and generates a poisonous

gas which can cause gas poisoning. Never weld in an unventilated room.

Always conduct an inspection for gas leakage after installation of the refrigerant piping has been completed.

8.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes.

1 Use the following materials for refrigeration piping.

• Material: Use refrigerant piping made of phosphorus deoxidized copper.

In addition, be sure that the inner and outer surfaces of the pipes are clean

and free of hazardous sulphur, oxides, dust/dirt, shaving particles, oils,

moisture, or any other contaminant.

2 Commercially available piping often contains dust and other materials. Always

blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the piping

during installation.

4 Reduce the number of bending portions as much as possible, and make bend-

ing radius as big as possible.

5 Always observe the restrictions on the refrigerant piping (such as rated length,

the difference between high/low pressures, and piping diameter). Failure to do

so can result in equipment failure or a decline in heating/cooling performance.

6 Either a lack or an excess of refrigerant causes the unit to make an emergency

stop. Charge the system with an appropriate amount of refrigerant. At such a

time, always properly charge the unit. When servicing, always check the notes

concerning pipe length and amount of additional refrigerant at both locations,

the refrigerant volume calculation table on the back of the service panel and

the additional refrigerant section on the labels for the combined number of

indoor units.

7 Use liquid refrigerant to fill the system.

8 Never use refrigerant to perform an air purge. Always evacuate using a vacuum

pump.

9 Always insulate the piping properly. Insufficient insulation will result in a de-

cline in heating/cooling performance, water drops from condensation and other

such problems.

0 When connecting the refrigerant piping, make sure the ball valve of the heat

source unit is completely closed (the factory setting) and do not operate it until

the refrigerant piping for the heat source and indoor units has been connected,

a refrigerant leakage test has been performed and the evacuation process has

been completed.

A Residues in commercially available antioxidants may have adverse effects on

the equipment. Braze only with non-oxide brazing material. The use of other

brazing material may result in compressor damage.

(Refer to item 9.2. for detailed information on pipe connections and valve operations.)

B Never perform heat source unit piping connection work when it is raining.

Warning

When installing and moving the unit, do not charge it with refrigerant other

than the refrigerant specified on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to malfunction and result in severe damage.

Caution:

• Use a vacuum pump with a reverse flow check valve.

- If the vacuum pump does not have a reverse flow check valve, the vacuum

pump oil may flow back into the refrigerant cycle and cause deterioration of

the refrigerator oil and other trouble.

• Do not use the tools shown below used with conventional refrigerant.

(Gauge manifold, charge hose, gas leak detector, check v alve, refrigerant

charge base, vacuum gauge, refrigerant recovery equipment)

- Mixing of conventional refrigerant and refrigerator oil may cause the refrig-

erator oil to deteriorate.

- Mixing of water will cause the refrigerator oil to deteriorate.

- R410A refrigerant does not contain any chlorine. Therefore, gas leak detec-

tors for conventional refrigerants will not react to it.

• Manage the tools more carefully than normal.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerator oil will dete-

riorate.

• Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerator oil

in the existing piping will cause the new refrigerant to deteriorate.

• Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate and

the compressor may fail.

• Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

• Do not use special detergents for washing piping.

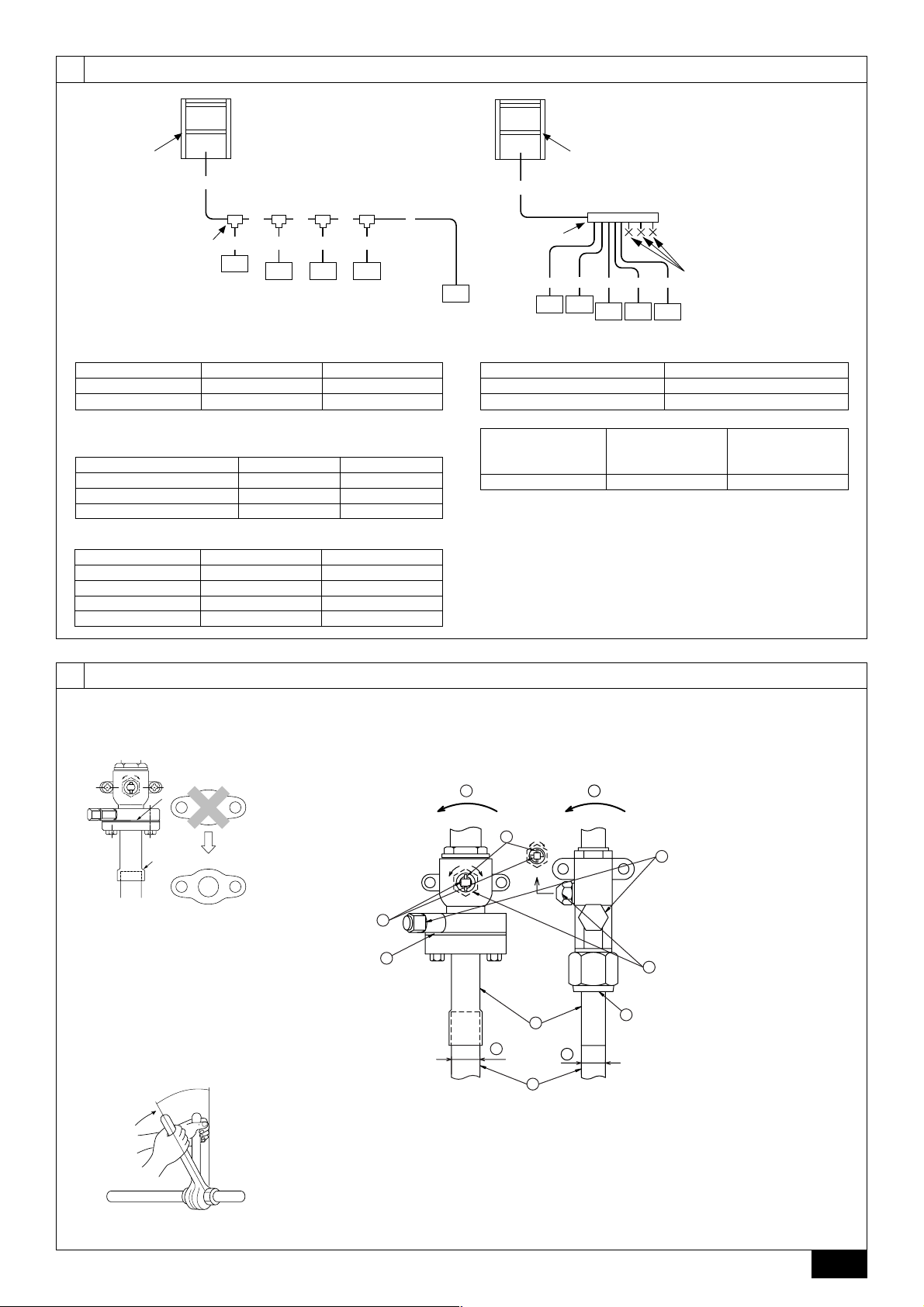

8.2. Refrigerant piping system

Connection Example

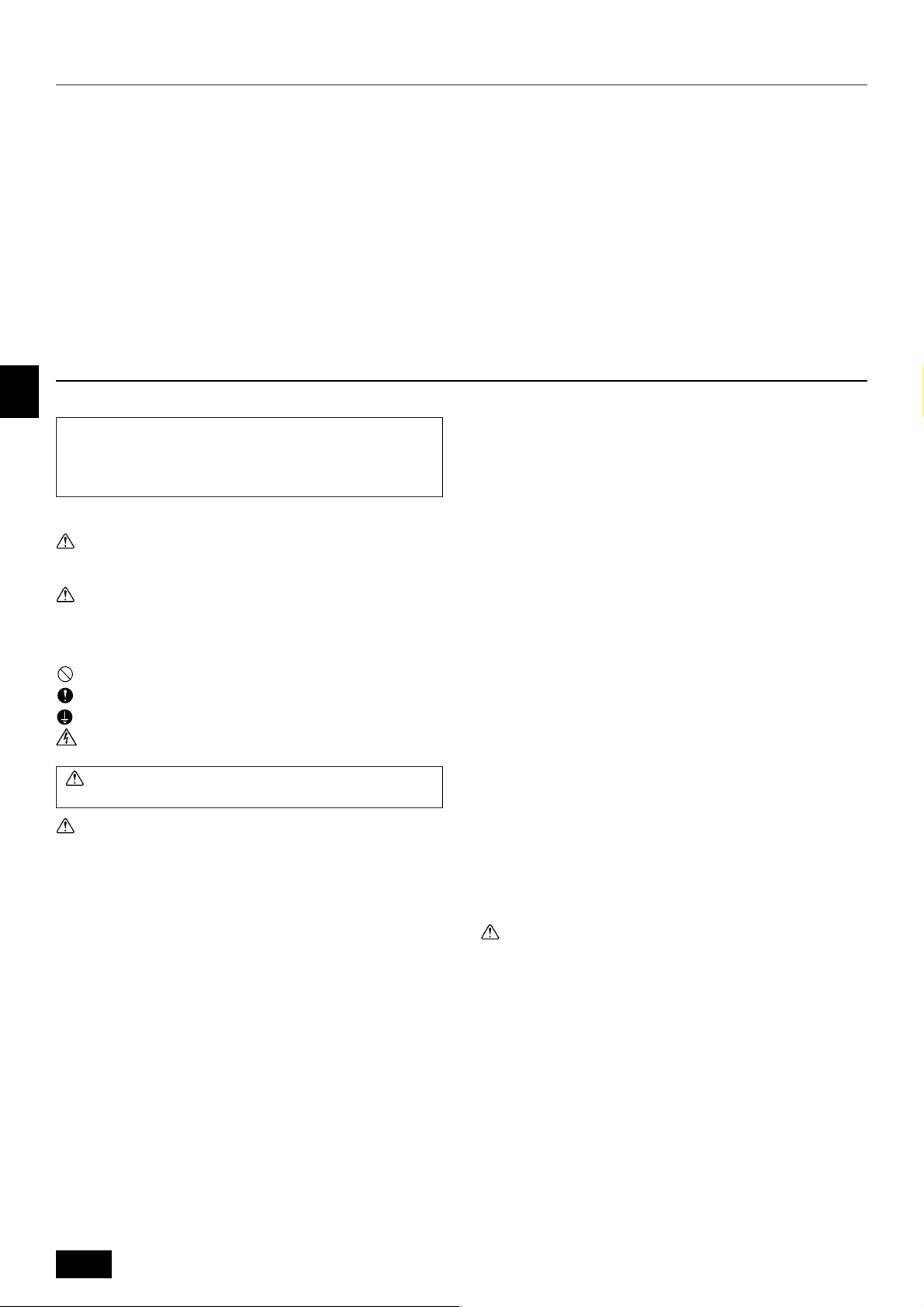

[Fig. 8.2.1] (P.3)

Å Heat source model ı Liquid pipe

Ç Gas pipe Î Total capacity of indoor units

‰ Model number Ï Downstream unit model total

Ì Branch kit model

Ó 4-Branching header (Downstream unit model total

¬ 8-Branching header (Downstream unit model total

Ô 10-Branching header (Downstream unit model total

A Heat source unit B First branch

C Indoor unit D Cap

<

=

<

=

200)

400)

<

=

650)

9

FINL EPGRRUTR

Page 10

9. Additional refrigerant charge

B

At the time of shipping, the heat source unit is charged with the refrigerant. As this

charge does not include the amount needed for extended piping, additional charging for each refrigerant line will be required on site. In order that future servicing

may be properly provided, always keep a record of the size and length of each

refrigerant line and the amount of additional charge by writing it in the space provided on the heat source unit.

9.1. Calculation of additional refrigerant

charge

• Calculate the amount of additional charge based on the length of the piping

extension and the size of the refrigerant line.

• Use the table to the below as a guide to calculating the amount of additional

charging and charge the system accordingly.

• If the calculation results in a fraction of less than 0.1 kg [4 oz], round up to the

next 0.1 kg [4 oz]. For example, if the result of the calculation was 8.48 kg

[277.4 oz], round the result up to 8.5 kg [280 oz].

<Additional Charge>

Additional

refrigerant charge

GB

(kg) [oz]

Liquid pipe size

Total length of

ø12.7 [1/2]

=+++ α

(m) × 0.12 (kg/m)

(in) × 1.29 (oz/ft)

Liquid pipe size

Total length of

ø9.52 [3/8]

(m) × 0.06 (kg/m)

(in) × 0.65 (oz/ft)

Liquid pipe size

Total length of

ø6.35 [1/4]

(m) × 0.024 (kg/m)

(in) × 0.26 (oz/ft)

<Example>

D

Indoor 1: 24 A: ø9.52 [3/8] 40 m [131 ft] a: ø9.52 [3/8] 10 m [32 ft]

2: 36 B: ø9.52 [3/8] 10 m [32 ft] b: ø9.52 [3/8] 5 m [16 ft]

3: 15 C: ø9.52 [3/8] 15 m [49 ft] c: ø6.35 [1/4] 10 m [32 ft]

4: 12 D: ø9.52 [3/8] 10 m [32 ft] d: ø6.35 [1/4] 10 m [32 ft]

5: 24 e: ø9.52 [3/8] 10 m [32 ft]

The total length of each liquid line is as follows:

FINL EPGRRUTR

ø9.52 [3/8]: A + B + C + D + a + b + e = 40 [131] + 10 [32] + 15 [49] + 10 [32]

+ 10 [32] + 5 [16] + 10 [32]

= 100 m [292 ft]

ø6.35 [1/4]: c + d = 10 [32] + 10 [32] = 20 m [64 ft]

Therefore,

<Calculation example>

Additional refrigerant charge

= 100 [292] × 0.06 [0.65] + 20 [64] × 0.024 [0.26] + 2.0 [71] = 8.5 kg [280 oz]

Value of α

Total capacity of connecting indoor units α

Models 31 to 60 1.5 kg [53 oz]

Models 61 to 126 2.0 kg [71 oz]

9.2. Precautions concerning piping connec-

tion and valve operation

• Conduct piping connection and valve operation accurately.

• Flange type side connecting pipe is assembled in factory before shipment.

1 For brazing to the connecting pipe with flange, remove the connecting pipe

with flange from the ball valve, and braze it outside of the unit.

2 During the time when removing the connecting pipe with flange, remove

the seal attached on the rear side of this sheet and paste it onto the flange

surface of the ball valve to prevent the entry of dust into the valve.

3 The refrigerant circuit is closed with a round, close-packed packing upon

shipment to prevent gas leak between flanges. As no operation can be

done under this state, be sure to replace the packing with the hollow packing attached at the piping connection.

4 At the mounting of the hollow packing, wipe off dust attached on the flange

sheet surface and the packing. Coat refrigerating machine oil (Ester oil,

ether oil or alkylbenzene [small amount]) onto both surfaces of the packing.

[Fig. 9.2.1] (P.3)

A Close-packed packing

B Hollow packing

• After evacuation and refrigerant charge, ensure that the handle is fully open. If

operating with the valve closed, abnormal pressure will be imparted to the

high- or low-pressure side of the refrigerant circuit, giving damage to the compressor, four-way valve, etc.

• Determine the amount of additional refrigerant charge by using the formula,

and charge refrigerant additionally through the service port after completing

piping connection work.

• After completing work, tighten the service port and cap securely not to gener-

ate gas leak.

At the

conditions

below:

• Flare machining dimension for systems using R410A is larger than that for

systems using other types of refrigerant in order to increase the air tightness.

• Refer to the table on the below for flare machining dimensions, and follow the

regulations set forth by the local authorities. Seal off the opening of the pipe

with a closure material (not supplied) to keep small animals from entering the

pipe if that is a concern.

flare machining dimension (mm)

outer diameter

A

ø6.35

ø9.52

ø12.70

ø15.88

ø19.05

size in inches

1/4"

3/8"

1/2"

5/8"

3/4"

dimension A

R410A

9.1

13.2

16.6

19.7

24.0

flare nut size (mm)

outer diameter

ø6.35

ø9.52

ø12.70

ø15.88

ø19.05

size in inches

1/4"

3/8"

1/2"

5/8"

3/4"

dimension B

R410A

17.0

22.0

26.0

29.0

36.0

[Fig. 9.2.2] (P.3)

<A> [Ball valve (Gas side/flanged type)]

<B> [Ball valve (Liquid side/flared type)]

<C> This figure shows the valve in the fully open state.

A Valve stem

[Fully closed at the factory, when connecting the piping, when evacuating, and

when charging additional refrigerant. Open fully after the operations above are

completed.]

B Stopper pin [Prevents the valve stem from turning 90° or more.]

C Packing (Accessory)

[Manufacturer: Nichiasu corporation]

[Type: T/#1991-NF]

D Connecting pipe (Accessory)

[Use packing and securely install this pipe to the valve flange so that gas leakage

will not occur. (Tightening torque:40 N·m [400kg·cm]) Coat both surfaces of the

packing with refrigerating machine oil. (Ester oil, ether oil or alkylbenzene [small

amount])]

E Open (Operate slowly)

F Cap, copper packing

[Remove the cap and operate the valve stem. Always reinstall the cap after operation is completed. (Valve stem cap tightening torque: 23 ~ 27 N·m [230 ~ 270

kg·cm])]

G Service port

[Use this port to evacuate the refrigerant piping and add an additional charge at

the site.

Open and close the port using a double-ended wrench.

Always reinstall the cap after operation is completed. (Service port cap tightening

torque: 12 ~ 15 N·m [120 ~ 150 kg·cm)]

H Flare nut

[Tightening torque: Refer to the following table.

Loosen and tighten this nut using a double-ended wrench.

Coat the flare contact surface with refrigerating machine oil (Ester oil, ether oil or

alkylbenzene [small amount])]

I ø9.52 [3/8] (PQHY-P72)

ø9.52 [3/8] (PQHY-P96)

J ø19.05 [3/4] (PQHY-P72)

ø22.2 [7/8] (PQHY-P96)

K Field piping

Appropriate tightening torque by torque wrench:

Copper pipe external dia. (mm [in]) Tightening torque (N·m / kg·cm)

ø6.35 [1/4] 14 to 18 / 140 to 180

ø9.52 [3/8] 35 to 42 / 350 to 420

ø12.7 [1/2] 50 to 57.5 / 500 to 575

ø15.88 [5/8] 75 to 80 / 750 to 800

ø19.05 [3/4] 100 to 140 / 1000 to 1400

Tightening angle standard:

Pipe diameter (mm [in]) Tightening angle (°)

ø6.35 [1/4], ø9.52 [3/8] 60 to 90

ø12.7 [1/2], ø15.88 [5/8] 30 to 60

ø19.05 [3/4] 20 to 35

[Fig. 9.2.3] (P.3)

10

Page 11

Note:

If a torque wrench is not available, use the following method as a standard:

When you tighten the flare nut with a wrench, you will reach a point where

the tightening torque will abruptly increase. Turn the flare nut beyond this

point by the angle shown in the table above.

Caution:

• Always remove the connecting pipe from the ball valve and braze it outside the unit.

- Brazing the connecting pipe while it is installed will heat the ball valve and

cause trouble or gas leakage. The piping, etc. inside the unit may also be

burned.

• Use ester oil, ether oil or alkylbenzene (small amount) as the refrigerating machine oil to coat flares and flange connections.

- The refrigerating machine oil will degrade if it is mixed with a large amount of

mineral oil.

• Keep the ball valve closed until refrigerant charging to the pipes to be

added on site has been completed. Opening the valve before charging

the refrigerant may result in unit damage.

• Do not use a leak detection additive.

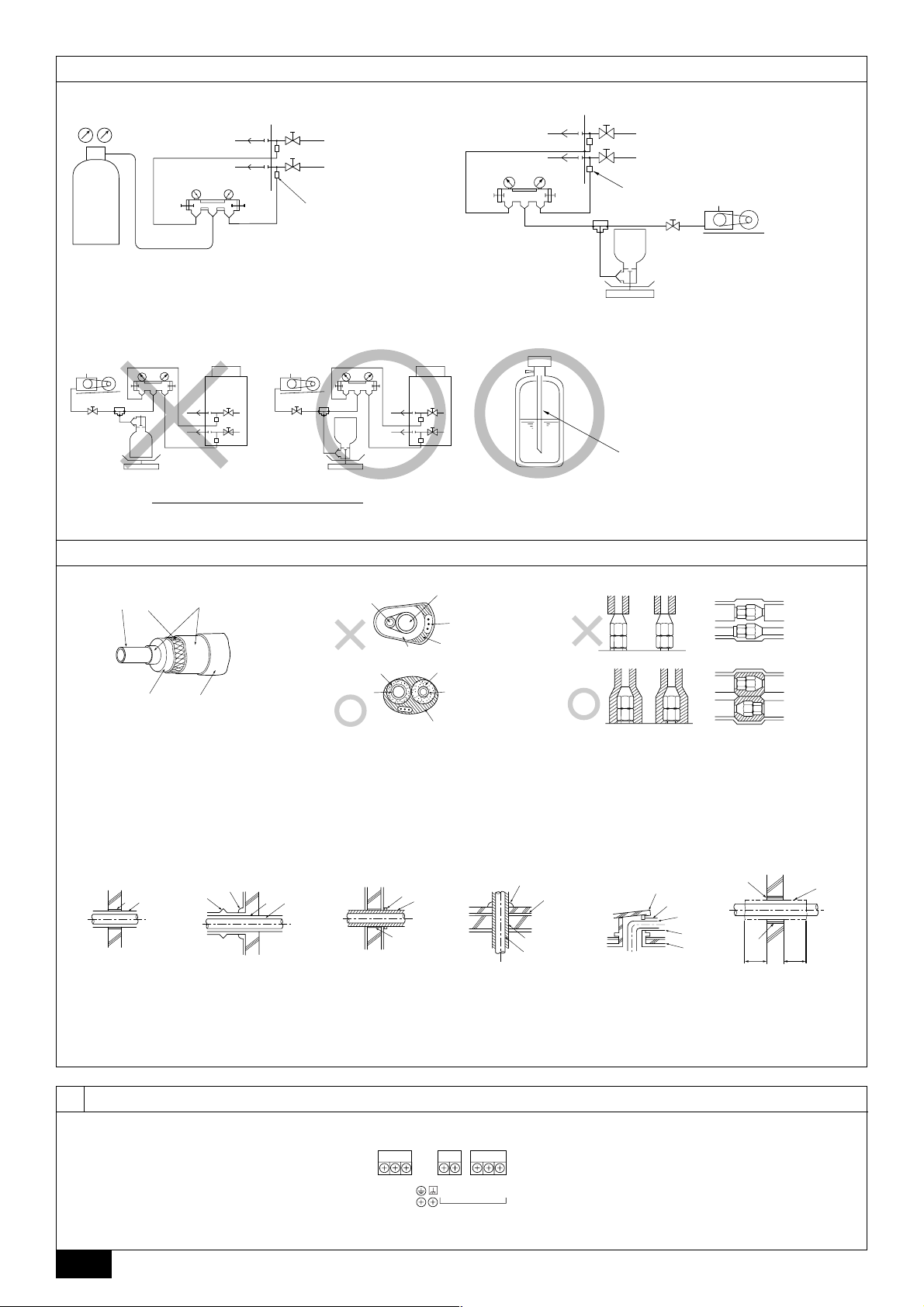

9.3. Airtight test, evacuation, and refrigerant

charging

1 Airtight test

Perform with the ball valve of the heat source unit closed, and pressurize the

connection piping and the indoor unit from the service port provided on the ball

valve of the heat source unit. (Always pressurize from both the Gas pipe and

the Liquid pipe service ports.)

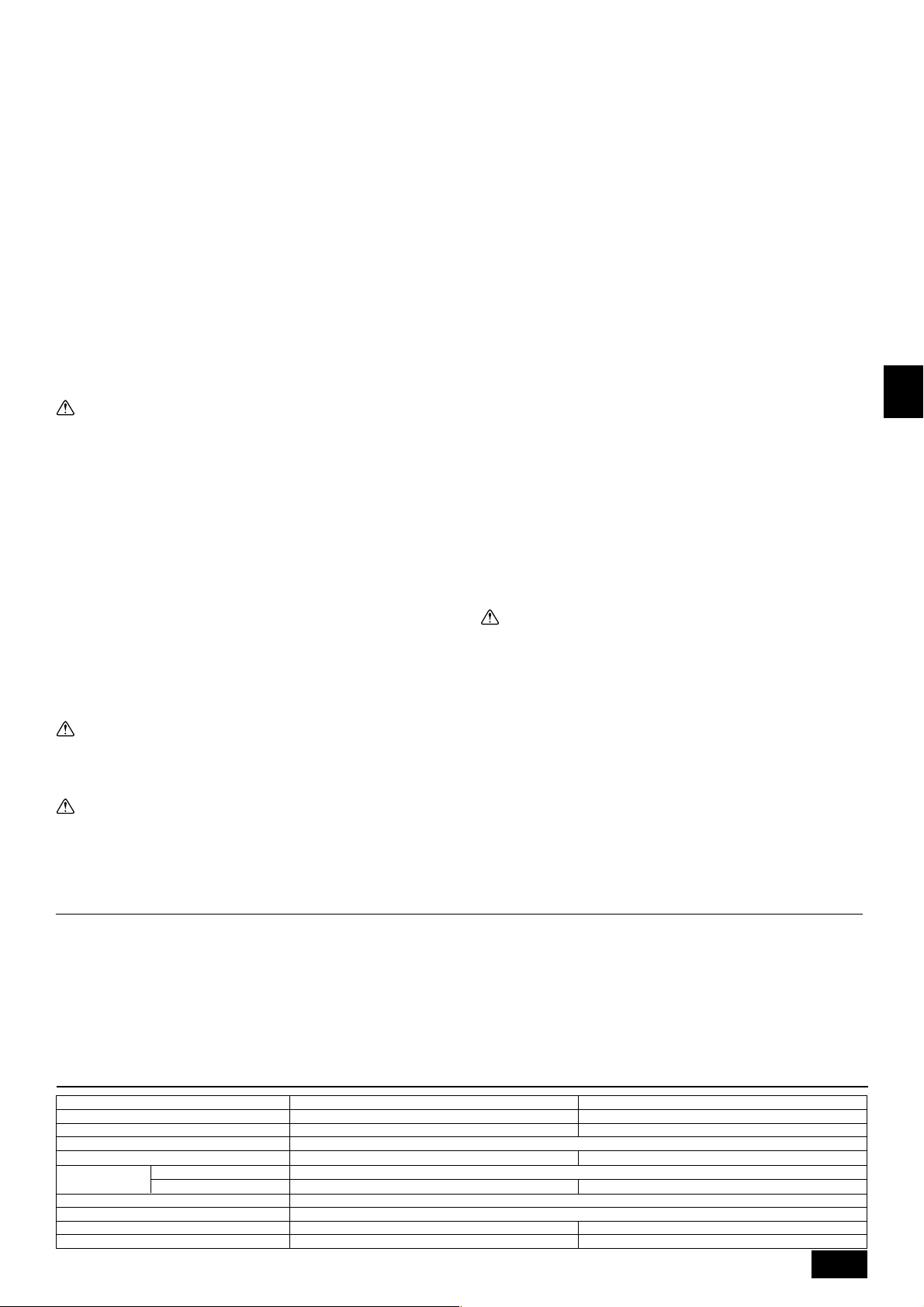

[Fig. 9.3.1] (P.4)

A Nitrogen gas B To indoor unit C System analyzer

D Lo knob E Hi knob F Ball valve

G Liquid pipe H Gas pipe I Heat source unit

J Service port

Observe the following restrictions when conducting an air tightness test to prevent

negative effects on the refrigerating machine oil. Also, with nonazeotropic refrigerant (R410A), gas leakage causes the composition to change and affects performance. Therefore, perform the airtightness test cautiously.

Airtight test procedure

1. Nitrogen gas pressurization

(1) After pressurizing to the design pressure (4.15 MPa [601 psi]) using nitrogen gas, allow it to

stand for about one day. If the pressure does not drop, airtightness is good.

However, if the pressure drops, since the leaking point is unknown, the following bubble test

may also be performed.

(2) After the pressurization descr ibed above, spray the flare connection parts, brazed parts, flanges,

and other parts that may leak with a bubbling agent (Kyuboflex, etc.) and visually check for

bubbles.

(3) After the airtight test, wipe off the bubbling agent.

2. Pressurization using refrigerant gas and nitrogen gas

(1) Pressurizing to a gas pressure of approximately 0.2 MPa [29 psi], pressurize to the design

pressure (4.15 MPa [601 psi]) using nitrogen gas.

However, do not pressurize at one time. Stop during pressurization and check that the pressure does not drop.

(2) Check for gas leaks by checking the flare connection parts, brazed parts, flanges, and other

parts which may leak using an R410A compatible electric leak detector.

(3) This test may be used together the with bubble type gas leak test.

Caution:

Only use refrigerant R410A.

- The use of other refrigerant such as R22 or R407C, which contains chlorine, will

deteriorate the refrigerating machine oil or cause the compressor to malfunction.

2 Evacuation

Evacuate with the ball valve of the heat source unit closed and evacuate both

the connection piping and the indoor unit from the service port provided on the

ball valve of the heat source unit using a vacuum pump. (Always evacuate from

the service port of both the gas pipe and the liquid pipe.) After the vacuum

reaches 650 Pa [abs] [0.0943 psi/5 Torr], continue evacuation for at least one

hour or more.

* Never perform air purging using refrigerant.

[Fig. 9.3.2] (P.4)

A System analyzer B Lo knob C Hi knob

D Ball valve E Liquid pipe F Gas pipe

G Service port H Three-way joint I Valve

J Valve K R410A cylinder L Scale

M Vacuum pump N To indoor unit O Heat source unit

Note:

• Always add an appropriate amount of refrigerant. Also always seal the

system with liquid refrigerant. T oo m uch or too little refrigerant will cause

trouble.

• Use a gauge manifold, charging hose, and other parts for the refrigerant

indicated on the unit.

• Use a graviometer. (One that can measure down to 0.1 kg [4 oz])

• Use a vacuum pump with a reverse flow check valve.

(Recommended vacuum gauge: ROBINAIR 14830A Thermistor Vacuum

Gauge)

Also use a vacuum gauge that reaches 65 Pa [abs] [0.00943 psi/0.5 T orr]

or below after operating for five minutes.

3 Refrigerant Charging

Since the refrigerant used with the unit is nonazerotropic, it must be charged in

the liquid state. Consequently, when charging the unit with refrigerant from a

cylinder, if the cylinder does not have a syphon pipe, charge the liquid refrigerant by turning the cylinder upside-down as shown in Fig.9.3.3. If the cylinder

has a syphon pipe like that shown in the picture on the right, the liquid refrigerant can be charged with the cylinder standing upright. Therefore, give careful

attention to the cylinder specifications. If the unit should be charged with gas

refrigerant, replace all the refrigerant with new refrigerant. Do not use the refrigerant remaining in the cylinder.

9.4. Thermal insulation of refrigerant piping

Be sure to give insulation work to refrigerant piping by covering high press. (liquid)

pipe and low press. (gas) pipe separately with enough thickness heat-resistant

polyethylene, so that no gap is observed in the joint between indoor unit and insulating material, and insulating materials themselves. When insulation work is insufficient, there is a possibility of condensation drip, etc. Pay special attention to insulation work to ceiling plenum.

Note:

• When using polyethylene cover as covering material, asphalt roofing shall

• No heat insulation must be provided for electric wires.

Restriction

• If a flammable gas or air (oxygen) is used as the pressurization

gas, it may catch fire or explode.

• Do not use a refrigerant other than that indicated on the unit.

• Sealing with gas from a cylinder will cause the composition of

the refrigerant in the cylinder to change.

• Use a pressure gauge, charging hose, and other parts especially

for R410A.

• An electric leak detector for R22 cannot detect leaks of R410A.

• Do not use a haloid torch. (Leaks cannot be detected.)

[Fig. 9.3.3] (P.4)

A Syphon pipe B In case of the cylinder having no syphon pipe.

[Fig. 9.4.1] (P.4)

A Steel wire B Piping

C Asphaltic oily mastic or asphalt D Heat insulation material A

E Outer covering B

Heat

insulation

material A

Outer

covering B

not be required.

[Fig. 9.4.2] (P.4)

[Fig. 9.4.3] (P.4)

Glass fiber + Steel wire

Adhesive + Heat - resistant polyethylene foam + Adhesive tape

Indoor Vinyl tape

Floor exposed Water-proof hemp cloth + Bronze asphalt

Heat source Water-proof hemp cloth + Zinc plate + Oily paint

A Liquid pipe B Gas pipe C Electric wire

D Finishing tape E Insulator

GB

D

FINL EPGRRUTR

11

Page 12

Penetrations

[Fig. 9.4.4] (P.4)

<A> Inner wall (concealed) <B> Outer wall

<C> Outer wall (exposed) <D> Floor (waterproofing)

<E> Roof pipe shaft

<F> Penetrating portion on fire limit and boundary wall

A Sleeve B Heat insulating material

C Lagging D Caulking material

E Band F Waterproofing laye

G Sleeve with edge H Lagging material

I Mortar or other incombustible caulking

J Incombustible heat insulation material

10. Wiring

When filling a gap with mortar, cover the penetration part with steel plate so that

the insulation material will not be caved in. For this part, use incombustible materials for both insulation and covering. (Vinyl covering should not be used.)

• Insulation materials for the pipes to be added on site must meet the following

specifications:

ø6.35 ~ 25.4 mm

[1/4 to 1 in]

Thickness

* Installation of pipes in a high-temperature high-humidity environment, such as

the top floor of a building, may require the use of insulation materials thicker

than the ones specified in the chart above.

* When certain specifications presented by the client must be met, ensure that

they also meet the specifications on the chart above.

10 mm min.

[13/32 in min]

Pipe size

ø28.58 ~ 38.1 mm

[1-1/8 to 1-1/2 in]

15 mm min.

[19/32 in min]

100 °C [212 °F] min.Temperature Resistance

10.1. Caution

1 Follow ordinance of your governmental organization for technical standard re-

GB

lated to electrical equipment, wiring regulations and guidance of each electric

power company.

2 Wiring for control (hereinafter referred to as transmission line) shall be (5 cm or

more [2 in or more]) apart from power source wiring so that it is not influenced

by electric noise from power source wiring. (Do not insert transmission line

D

and power source wire in the same conduit.)

3 Be sure to provide designated grounding work to heat source unit.

4 Give some allowance to wiring for electrical part box of indoor and heat source

units, because the box is sometimes removed at the time of service work.

FINL EPGRRUTR

5 Never connect the main power source to terminal block of transmission line. If

connected, electrical parts will be burnt out.

6 Use 2-core shield cable for transmission line. If transmission lines of different

systems are wired with the same multiplecore cable, the resultant poor transmitting and receiving will cause erroneous operations.

7 Only the transmission line specified should be connected to the terminal block

for heat source unit transmission.

(Transmission line to be connected with indoor unit : Terminal block TB3 for

transmission line, Other : Terminal block TB7 for centralized control)

Erroneous connection does not allow the system to operate.

8 In the case of connecting with an upper class controller or to conduct group

operation in different refrigerant systems, the control line for transmission is

required between the heat source units.

Connect this control line between the terminal blocks for centralized control.

(2-wire line with no polarity)

When conducting group operation in different refrigerant systems without connecting to the upper class controller, replace the insertion of the short circuit

connector from CN41 of one heat source unit to CN40.

9 Group is set by operating the remote controller.

10.2. Control box and connecting position of

wiring

1. Connect the indoor unit transmission line to transmission terminal block (TB3),

or connect the wiring between heat source units or the wiring with the central

control system to the central control terminal block (TB7).

When using shielded wiring, connect shield ground of the indoor unit transmission line to the ground screw (

tween heat source units and the central control system transmission line to the

shield (S) terminal of the central control terminal block (TB7) shield (S) terminal. In addition, in the case of heat source units whose power supply connector

CN41 has been replaced by CN40, the shield terminal (S) of terminal block

(TB7) of the central control system should also be connected to the ground

screw (

Fix the wiring securely in place with the cable strap at the bottom of the terminal block so that the external force if not applied to the terminal block. External

force applied to the terminal block may damage the block and short-circuit,

ground fault, or fire may result.

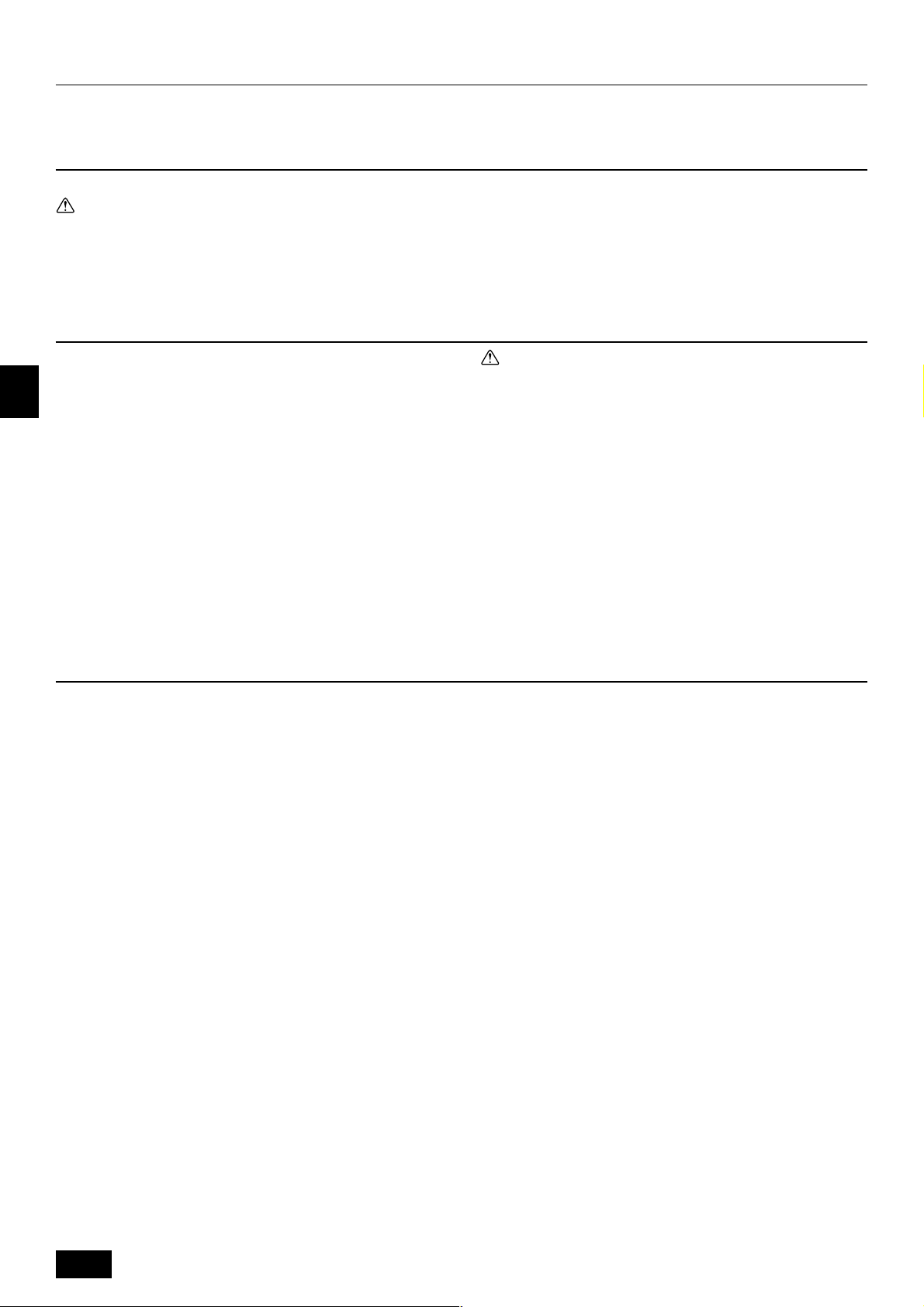

[Fig. 10.2.1] (P.4)

2. Conduit mounting plates (ø27 mm [1-3/32 in]) are being provided. Pass the

power supply and transmission wires through the appropriate knock-out holes,

then remove the knock-out piece from the bottom of the terminal box and connect the wires.

).

A Power source B Transmission line

C Ground screw

) and connect shield ground of the line be-

3. Fix power source wiring to terminal box by using buffer bushing for tensile

force (PG connection or the like).

4. Narrow the opening by using a conduit to keep small animals out.

10.3. Wiring transmission cables

1 Types of control cables

1. Wiring transmission cables

• Types of transmission cables: Shielding wire CVVS or CPEVS or MVVS

• Cable diameter: More than 1.25 mm

• Maximum wiring length: Within 200 m [656 ft]

• Maximum length of transmission lines for centralized control and indoor/out-

door transmission lines (Maximum length via indoor units): 500 m [1640 ft]

MAX

The maximum length of the wiring between power supply unit for transmission

lines (on the transmission lines for centralized control) and each outdoor unit

and system controller is 200 m [656 ft].

2. Remote control cables

• M-NET Remote Controller

Kind of remote control cable

Cable diameter

Remarks

• MA Remote Controller

Kind of remote control cable

Cable diameter

Remarks

* Connected with simple remote controller.

2 Wiring examples

• Controller name, symbol and allowable number of controllers.

Heat source unit controller

Name

Indoor Unit Controller

Remote Controller

Symbol

2

[AWG16]

Sheathed 2-core cable (unshielded)

0.3 to 1.25 mm

(0.75 to 1.25 mm2 [AWG18 to 16])*

When 10 m [32 ft] is exceeded, use cable with

the same specifications as 1. Wiring transmission cables.

Sheathed 2-core cable (unshielded) CVV

0.3 to 1.25 mm

(0.75 to 1.25 mm

Within 200 m [656 ft]

OC

IC

RC

2

[AWG22 to 16]

2

[AWG22 to 16]

2

[AWG18 to 16]))*

Allowable number of controllers

One to twenty four controllers for one OC

Maximum of two per group

12

Page 13

Example of a group operation system with multiple heat source units (Shielding wires and address setting are

necessary.)

<Examples of transmission cable wiring>

[Fig. 10.3.1] M-NET Remote Controller (P.5)

[Fig. 10.3.2] MA Remote Controller (P.5)

<A> Change the jumper connector from CN41 to CN40.

<B> SW2-1:ON

<C> Keep the jumper connector on CN41.

A Group 1 B Group 4 C Group 5 D Shielded wire E Sub remote controller

( ) Address

<Wiring Method and Address Settings>

a. Always use shielded wire when making connections between the heat source unit (OC) and the indoor unit (IC), as well for all OC-OC, and IC-IC wiring intervals.

b. Use feed wiring to connect terminals M1 and M2 and the earth terminal on the transmission cable terminal block (TB3) of each heat source unit (OC) to terminals M1,

M2 and terminal S on the transmission cable block of the indoor unit (IC).

c. Connect terminals 1 (M1) and 2 (M2) on the transmission cable terminal block of the indoor unit (IC) that has the most recent address within the same group to the

terminal block on the remote controller (RC).

d. Connect together terminals M1, M2 and terminal S on the terminal block for central control (TB7) for the heat source unit (OC).

e. On one heat source unit only, change the jumper connector on the control panel from CN41 to CN40.

f. Connect the terminal S on the terminal block for central control (TB7) for the heat source unit (OC) for the unit into which the jumper connector was inserted into CN40

in Step above to the ground terminal

g. Set the address setting switch as follows.

* To set the outdoor unit address to 100, the outdoor address setting switch must be set to 50.

Unit Range Setting Method

IC (Main) 01 to 50 Use the most recent address within the same group of indoor units.

IC (Sub) 01 to 50

Heat source Unit 51 to 100 Use the most recent address of all the indoor units plus 50

M-NET R/C (Main) 101 to 150 Set at an IC (Main) address within the same group plus 100

M-NET R/C (Sub) 151 to 200 Set at an IC (Main) address within the same group plus 150

MA R/C – Unnecessary address setting (Necessary main/sub setting)

h. The group setting operations among the multiple indoor units is done by the remote controller (RC) after the electrical power has been turned on.

in the electrical component box.

Use an address, other than that of the IC (Main) from among the units within the same group of indoor units. This must be

in sequence with the IC (Main)

GB

D

FINL EPGRRUTR

<Permissible Lengths>

1 M-NET Remote controller

• Max length via outdoor units: L

• Max transmission cable length: L

• Remote controller cable length: r

2 MA Remote controller

• Max length via outdoor unit (M-NET cable): L1 + L2 + L3 + L4 and L1 + L2 + L6 = 500 m [1640 ft] (1.25 mm2 [AWG16] or more)

• Max transmission cable length (M-NET cable): L

• Remote controller cable length: c

3 Transmission booster

• Max transmission cable length (M-NET cable): 1 L

• Remote controller cable length: r

1 + L2 + L3 + L4 and L1 + L2 + L3 + L5 and L1 + L2 + L6

1 and L3 + L4 and L3 + L5 and L6 and L2 + L6

1, r2, r3, r4

If the length exceeds 10 m [32 ft], use a 1.25 mm

calculation of the maximum length and overall length.

1 and c1 + c2 + c3 and c1 + c2 + c3 + c4

1, r2

=

If the length exceeds 10 m [32 ft], use 1.25 mm

total extended length and the longest remote length.

10 m [32 ft] (0.3 to 1.25 mm2 [AWG22 to 16])

=

1 and L3 + L4 and L6 and L2 + L6

8 + L1 + L2 + L3 + L5 + L6

2 L

8 + L1 + L2 + L3 + L5 + L7

3 L

8 + L1 + L2 + L4

4 L

6 + L5 + L3 + L4, L4 + L3 + L5 + L7

10 m [32 ft] (0.3 to 1.25 mm2 [AWG22 to 16])

200 m [656 ft] (1.25 mm2 [AWG16])

=

200 m [656 ft] (1.25 mm2 [AWG16] or more)

=

=

200 m [656 ft] (0.3 to 1.25 mm2 [AWG22 to 16])

=

200 m [656 ft] (1.25 mm2 [AWG16])

=

200 m [656 ft] (1.25 mm2 [AWG16])

=

2

[AWG16] shielded cable and calculate the length of that portion (L4 and L7) as within the

500 m [1640 ft] (1.25 mm2 [AWG16] or more)

=

2

[AWG16] shielded wire. The length of this section (L8) should be included in the

200 m [656 ft] (1.25 mm2 [AWG16] or more)

200 m [656 ft] (1.25 mm2 [AWG16])

=

13

Page 14

10.4. Wiring of main power supply and equipment capacity

Schematic Drawing of Wiring (Example)

[Fig. 10.4.1] (P.5)

A Switch (breakers for wiring and current leakage) B Breakers for current leakage C Heat source unit

D Pull box E Indoor unit

Thickness of wire for main power supply, On/Off capacities and system impedance

30

40

15

Breaker for

wiring (NFB)

30

40

15

Breaker for current leakage

30 A 100 mA 0.1sec. or less

40 A 100 mA 0.1sec. or less

20 A 30 mA 0.1sec. or less

Minimum wire thickness (mm2/AWG)

Main cable

Heat source unit

BC controller, indoor unit

1. Use a separate power supply for the heat source unit and indoor unit.

2. Bear in mind ambient conditions (ambient temperature,direct sunlight, rain water,etc.) when proceeding with the wiring and connections.

3. The wire size is the minimum value for metal conduit wiring. The power cord size should be 1 rank thicker consideration of voltage drops.

Make sure the power-supply voltage does not drop more than 10 %.

4. Specific wiring requirements should adhere to the wiring regulations of the region.

5. Power supply cords of parts of appliances for heat source use shall not be lighter than polychloroprene sheathed flexible cord (design 245 IEC57). For

example, use wiring such as YZW.

6. A switch with at least 3.5 mm [0.14 in] contact separation in each pole shall be provided by the Air conditioner installation.

P72

P96

5.3/10

8.4/8

0.41/22

Branch Capacity Fuse

0.41/22

Ground

–

5.3/10

–

8.4/8

0.41/22

Switch (A)

30

40

15

Warning:

• Be sure to use specified wires to connect so that no external force is imparted to terminal connections. If connections are not fixed firmly, it may cause

GB

heating or fire.

• Be sure to use the appropriate type of overcurrent protection switch. Note that generated overcurrent may include some amount of direct current.

Caution:

• A breaker for current leakage must be attached to the power supply. If no earth leakage breaker is installed, it may cause an electric shock.

D

• Do not use anything other than breaker and fuse with correct capacity. Using fuse and wire or copper wire with too lar ge capacity may cause a malfunction

of unit or fire.

11.Test run

FINL EPGRRUTR

11.1. The following phenomena do not represent trouble (emergency)

Phenomenon

Indoor unit does not perform cooling (heating) operation.

The auto vane runs freely.

Fan setting changes during heating.

Fan stops during heating operation.

Fan does not stop while operation has been

stopped.

No setting of fan while start SW has been

turned on.

Indoor unit remote controller shows “HO” or

“PLEASE WAIT” indicator for about five minutes when turning ON universal power supply.

Drain pump does not stop while unit has been

stopped.

Drain pump continues to operate while unit

has been stopped.

Display of remote controller

“Cooling (heating)” flashes

Normal display

Normal display

Defrost display

No lighting

Heat ready

“HO” or “PLEASE WAIT” flashes

Light out

When another indoor unit is performing the heating (cooling) operation,

the cooling (heating) operation is not performed.

Because of the control operation of auto vane, it may change over to horizontal

blow automatically from the downward blow in cooling in case the downward

blow operation has been continued for 1 hour. At defrosting in heating, hot adjusting and thermostat OFF, it automatically changes over to horizontal blow.

Ultra-low speed operation is commenced at thermostat OFF.

Light air automatically changes over to set value by time or piping temperature at

thermostat ON.

The fan is to stop during defrosting.

Fan is to run for 1 minute after stopping to exhaust residual heat (only in heating).

Ultra low-speed operation for 5 minutes after SW ON or until piping temperature

becomes 35 °C [95 °F], low speed operation for 2 minutes thereafter, and then

set notch is commenced. (Hot adjust control)

System is being driven.

Operate remote controller again after “HO” or “PLEASE WAIT” disappear.

After a stop of cooling operation, unit continues to operate drain pump for three

minutes and then stops it.

Unit continues to operate drain pump if drainage is generated, even during a

stop.

Cause

12.Information on rating plate

Refrigerant (R410A)

Model

Allowable pressure (Ps)

Net weight

MANUFACTURER: MITSUBISHI ELECTRIC CORPORATION AIR-CONDITIONING & REFRIGERATION SYSTEMS

WORKS 5-66, TEBIRA, 6-CHOME, WAKAYAMA CITY, JAPAN

P72

7.0 kg [15 LBS 7 oz]

HP: 4.15 MPa [601 psi], LP: 2.21 MPa [320 psi]

266 kg [588 LBS]

14

P96

8.0 kg [17 LBS 11 oz]

269 kg [594 LBS]

Page 15

Table des matières

1. Consignes de sécurité .............................................................................. 15

1.1. Avant l’installation de l’appareil et l’installation électrique ....... 15

1.2. Précautions à prendre avec les dispositifs utilisant le

réfrigérant R410A .................................................................... 16

1.3. Avant de procéder à l’installation ............................................. 16

1.4. Avant de procéder à l’installation électrique ............................ 16

1.5. Avant d’effectuer l’essai ........................................................... 16

2. Le produit .................................................................................................. 17

3. Association aux appareils intérieurs ......................................................... 17

4. Vérification des pièces livrées .................................................................. 17

5. Comment soulever l’appareil .................................................................... 17

6. Installation de l’appareil et espace de service .......................................... 17

6.1. Installation ............................................................................... 17

6.2. Espace de service ................................................................... 17

7. Installation du tuyau d’eau ........................................................................ 17

7.1. Précautions à prendre pendant l’installation ........................... 17

7.2. Mise en place de l’isolation ..................................................... 18

7.3. Traitement de l’eau et contrôle de la qualité de l’eau .............. 18

7.4. Engrenage des pompes .......................................................... 18

1. Consignes de sécurité

1.1. Avant l’installation de l’appareil et l’installation électrique

s Avant d’installer le climatiseur, lire attentivement toutes les

“Consignes de sécurité”.

s Les “Consignes de sécurité” reprennent des points très im-

portants concernant la sécurité. Veillez bien à les suivre.

Symboles utilisés dans le texte

Avertissement:

Précautions à suivre pour éviter tout danger de blessure ou de décès de

l’utilisateur.

Précaution:

Précautions à suivre pour éviter tout endommagement de l’appareil.

Symboles utilisés dans les illustrations

: Indique une action qui doit être évitée.

: Indique des instructions importantes à suivre.

: Indique un élément à mettre à la terre.

: Danger d’électrocuition. (Ce symbole se trouve sur l’étiquette de l’appareil