Page 1

Air-Conditioners

PLA-A·BA

INSTALLATION MANUAL

For safe and correct use, read this manual and the outdoor unit installation manual thoroughly before installing

the air-conditioner unit.

MANUEL D’INSTALLATION

Avant d’installer le climatiseur, lire attentivement ce manuel, ainsi que le manuel d’installation de l’appareil extérieur pour une utilisation sûre et correct.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire

acondicionado.

FOR INSTALLER

POUR L’INSTALLATEUR

PARA EL INSTALADOR

English

Français

Español

Page 2

Contents

1. Safety precautions .....................................................................................2

2. Installation location .................................................................................... 3

3. Installing the indoor unit ............................................................................3

4. Installing the refrigerant piping .................................................................. 5

5. Drainage piping work .................................................................................6

1. Safety precautions

Before installing the unit, make sure you read all the “Safety precautions”.

Please report to your supply authority or obtain their consent before

connecting this equipment to the power supply system.

Warning:

Describes precautions that must be observed to prevent danger of injury or

death to the user.

Caution:

Describes precautions that must be observed to prevent damage to the unit.

Warning:

• Ask a dealer or an authorized technician to install the unit.

• For installation work, follow the instructions in the Installation Manual and

use tools and pipe components specifi cally made for use with refrigerant

specifi ed in the outdoor unit installation manual.

• The unit must be installed according to the instructions in order to mini-

mize the risk of damage from earthquakes, typhoons, or strong winds. An

incorrectly installed unit may fall down and cause damage or injuries.

•

The unit must be securely installed on a structure that can sustain its weight.

• If the air conditioner is installed in a small room, measures must be taken

to prevent the refrigerant concentration in the room from exceeding the

safety limit in the event of refrigerant leakage. Should the refrigerant leak

and cause the concentration limit to be exceeded, hazards due to lack of

oxygen in the room may result.

6. Electrical work ...........................................................................................7

7. Test run ....................................................................................................13

8. System control ........................................................................................16

9. Installing the grille ....................................................................................16

10. Easy maintenance function .....................................................................18

After installation work has been completed, explain the “Safety Precautions,” use,

and maintenance of the unit to the customer according to the information in the

Operation Manual and perform the test run to ensure normal operation. Both the

Installation Manual and Operation Manual must be given to the user for keeping.

These manuals must be passed on to subsequent users.

: Indicates a part which must be grounded.

Warning:

Carefully read the labels affi xed to the main unit.

• Ventilate the room if refrigerant leaks during operation. If refrigerant comes

into contact with a fl ame, poisonous gases will be released.

• All electric work must be performed by a qualifi ed technician according to

local regulations and the instructions given in this manual.

• Use only specifi ed cables for wiring.

• The terminal block cover panel of the unit must be fi rmly attached.

• Use only accessories authorized by Mitsubishi Electric and ask a dealer or

an authorized technician to install them.

• The user should never attempt to repair the unit or transfer it to another

location.

• After installation has been completed, check for refrigerant leaks. If refrigerant leaks into the room and comes into contact with the fl ame of a heater

or portable cooking range, poisonous gases will be released.

1.1. Before installation (Environment)

Caution:

•

Do not use the unit in an unusual environment. If the air conditioner is installed in areas exposed to steam, volatile oil (including machine oil), or sulfuric gas, areas exposed to high salt content such as the seaside, the performance can be signifi cantly reduced and the internal parts can be damaged.

• Do not install the unit where combustible gases may leak, be produced,

fl ow, or accumulate. If combustible gas accumulates around the unit, fi re or

explosion may result.

• Do not keep food, plants, caged pets, artwork, or precision instruments in

the direct airfl ow of the indoor unit or too close to the unit, as these items

can be damaged by temperature changes or dripping water.

1.2. Before installation or relocation

Caution:

• Be extremely careful when transporting the units. Two or more persons are

needed to handle the unit, as it weighs 20 kg, 40 lbs or more. Do not grasp

the packaging bands. Wear protective gloves as you can injure your hands

on the fi ns or other parts.

• Be sure to safely dispose of the packaging materials. Packaging materials,

such as nails and other metal or wooden parts may cause stabs or other

injuries.

1.3. Before electric work

Caution:

• Be sure to install circuit breakers. If not installed, electric shock may result.

• For the power lines, use standard cables of suffi cient capacity. Otherwise, a

short circuit, overheating, or fi re may result.

• When installing the power lines, do not apply tension to the cables.

• When the room humidity exceeds 80% or when the drainpipe is clogged,

water may drip from the indoor unit. Do not install the indoor unit where

such dripping can cause damage.

• When installing the unit in a hospital or communications offi ce, be prepared

for noise and electronic interference. Inverters, home appliances, highfrequency medical equipment, and radio communications equipment can

cause the air conditioner to malfunction or breakdown. The air conditioner

may also affect medical equipment, disturbing medical care, and communications equipment, harming the screen display quality.

•

Thermal insulation of the refrigerant pipe is necessary to prevent condensation.

If the refrigerant pipe is not properly insulated, condensation will be formed.

• Place thermal insulation on the pipes to prevent condensation. If the drainpipe is installed incorrectly, water leakage and damage to the ceiling, fl oor,

furniture, or other possessions may result.

• Do not clean the air conditioner unit with water. Electric shock may result.

• Tighten all fl are nuts to specifi cation using a torque wrench. If tightened

too much, the fl are nut can break after an extended period.

•

Be sure to ground the unit. If the unit is not properly grounded, electric shock

may result.

•

Use circuit breakers (ground fault interrupter, isolating switch (+B fuse), and

molded case circuit breaker) with the specifi ed capacity. If the circuit breaker

capacity is larger than the specifi ed capacity, breakdown or fi re may result.

1.4. Before starting the test run

Caution:

• Turn on the main power switch more than 12 hours before starting operation. Starting operation just after turning on the power switch can severely

damage the internal parts.

• Before starting operation, check that all panels, guards and other protective

parts are correctly installed. Rotating, hot, or high voltage parts can cause

injuries.

2

• Do not operate the air conditioner without the air fi lter set in place. If the air

fi lter is not installed, dust may accumulate and breakdown may result.

• Do not touch any switch with wet hands. Electric shock may result.

• Do not touch the refrigerant pipes with bare hands during operation.

•

After stopping operation, be sure to wait at least fi ve minutes before turning

off the main power switch. Otherwise, water leakage or breakdown may result.

Page 3

2. Installation location

Refer to the outdoor unit installation manual.

3. Installing the indoor unit

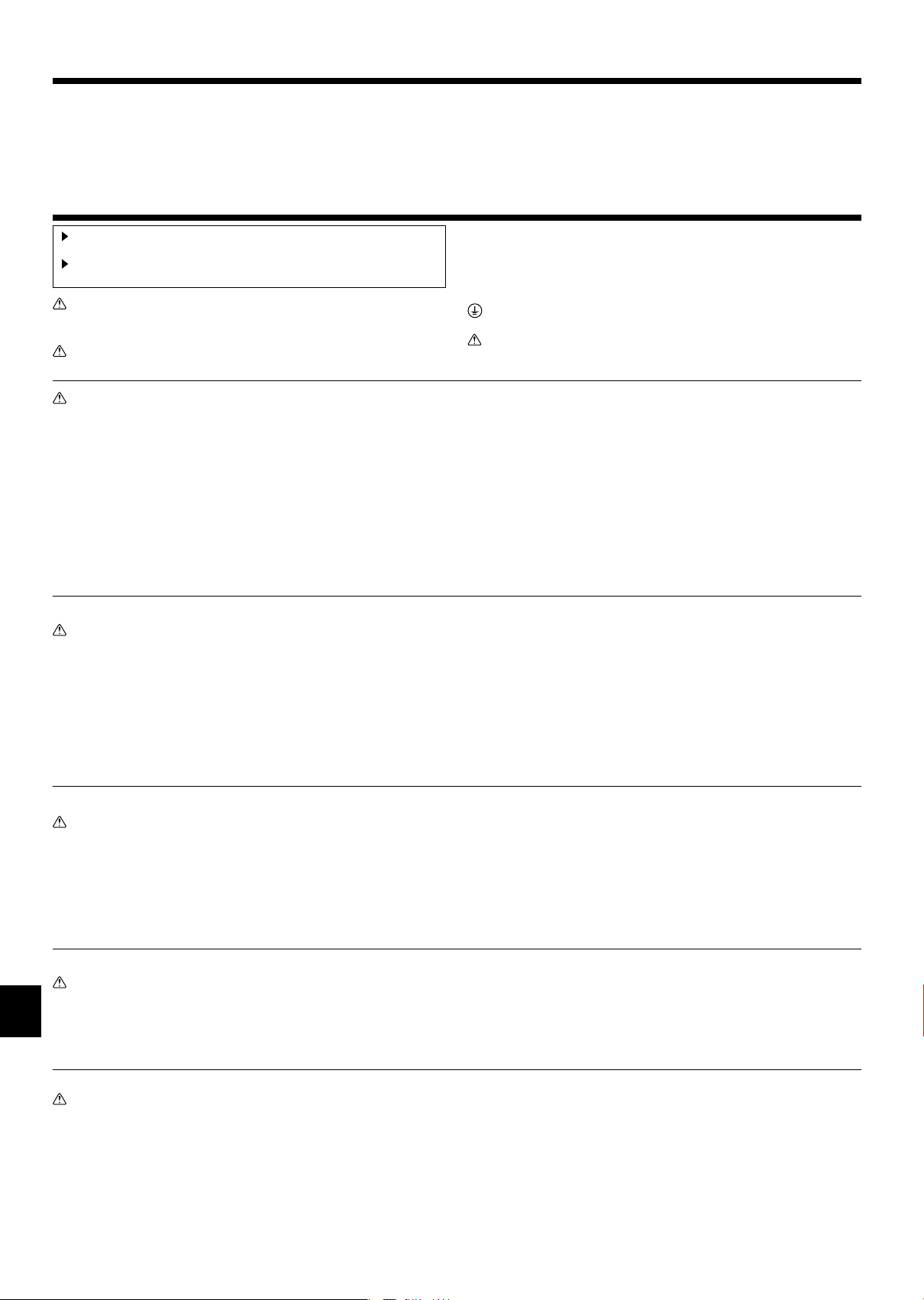

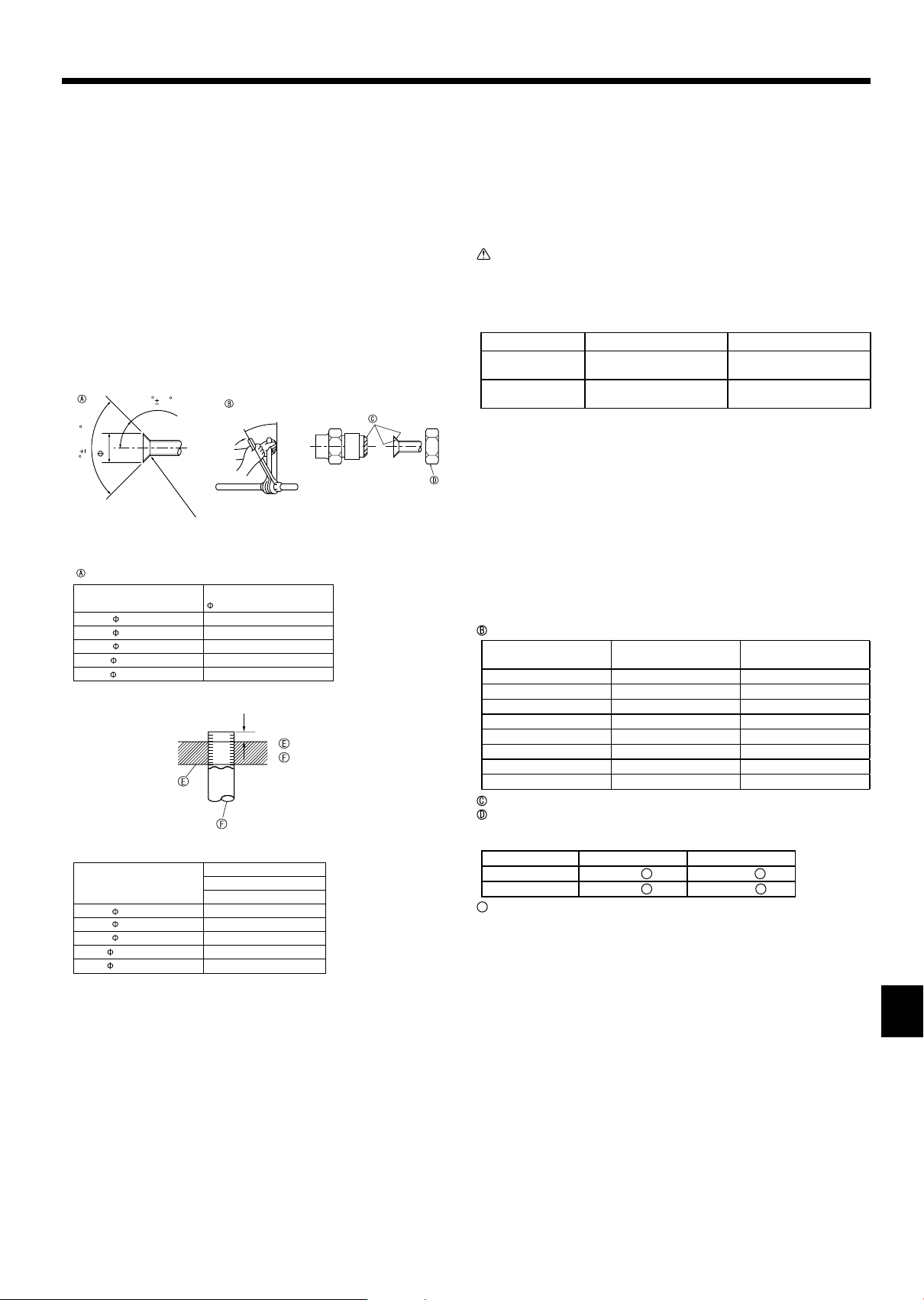

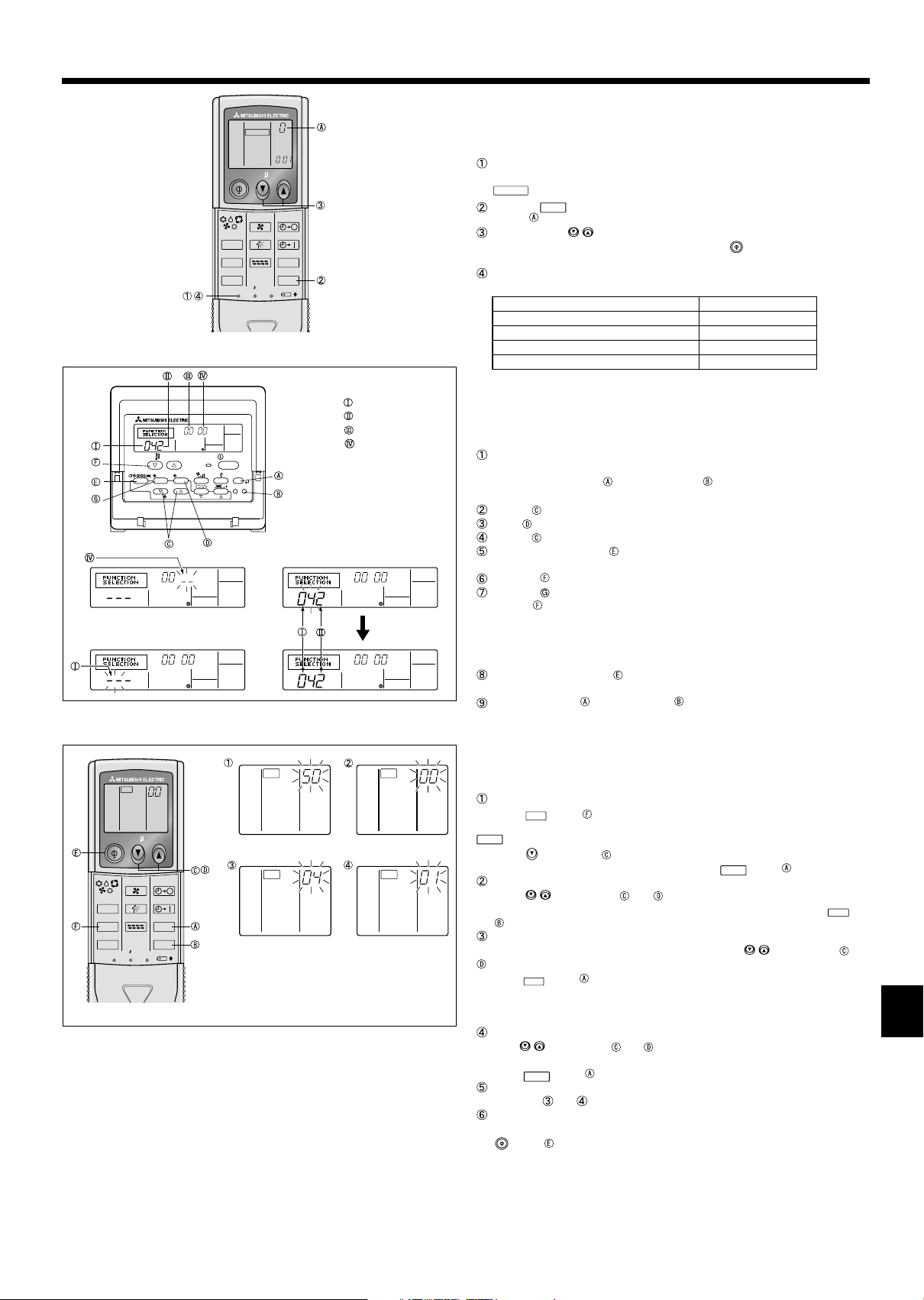

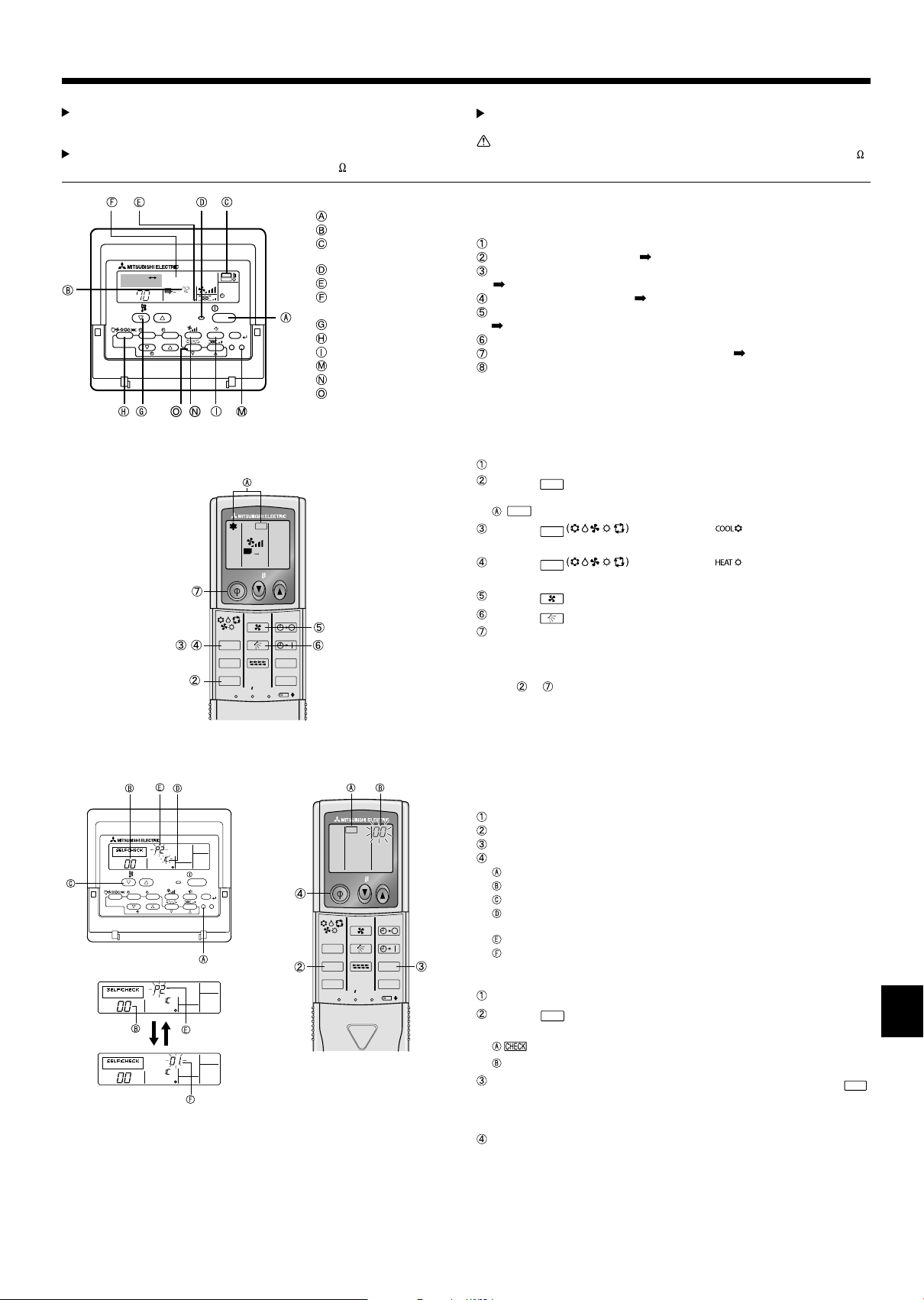

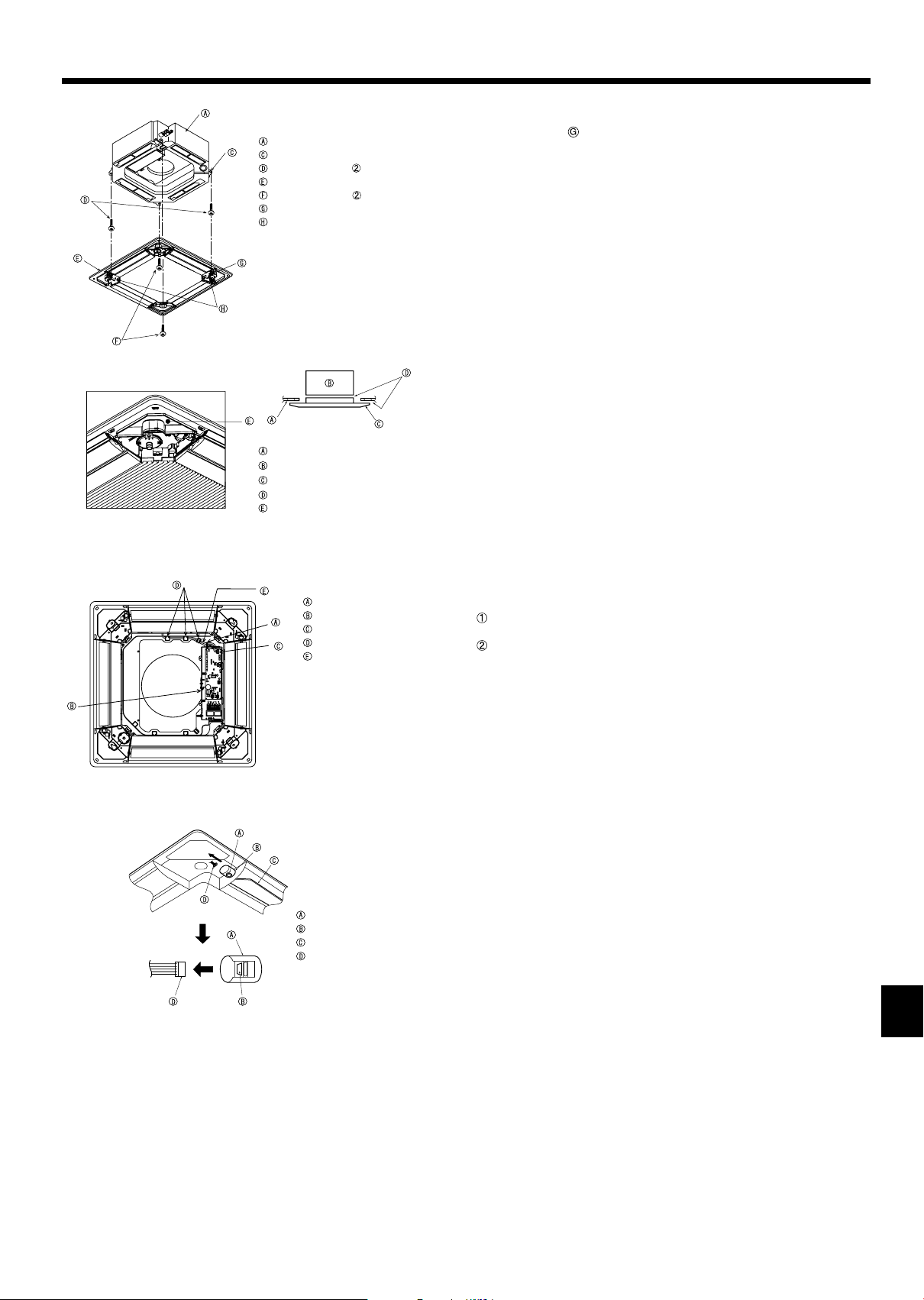

3.1. Check the indoor unit accessories (Fig. 3-1)

The indoor unit should be supplied with the following accessories.

Accessory name Q'ty

Installation template 1

Washers (with insulation)

Washers (without insulation)

Pipe cover (for refrigerant piping joint)

Small diameter

Large diameter

Band 8

Screw with washer (M5 × 25) for mounting grille 4

Drain socket 1

Insulation 1

4

4

1

1

A

3-17/32

6-11/16

5-1/2

*

Fig. 3-1

25/32 to 1-25/32 25/32 to 1-25/32

6-5/16

33-1/16

5-29/32

3-17/32

5-5/16

+3/16

0

11/16

37-3/8

33-27/32 to 35-13/16

31-7/8

6-5/16

7-3/8

33-1/16

Min. 98-7/16

Fig. 3-2

Models

15/16

7-15/32

*

B

2-3/8

11-3/16 14-27/32

*

A12, A18, A24, A30 80, 3-5/32

A36, A42 85, 3-11/32

Fig. 3-3

6-5/16

-3/16

23-13/16

6-5/16

4-1/8

1-15/16

*

*

to 2-3/4

+3/16

Min. 19-11/16

A

25/32 to

1-25/32

(5/16)(5/16)

+1-3/8

24-13/32

37-3/8

33-27/32 to 35-13/16

25/32 to

1-25/32

C

D

0

1-3/8

11/16

74, 2-29/32

77, 3-1/32

(inch)

(mm, inch)

B

3.2. Ceiling openings and suspension bolt installation

locations (Fig. 3-2)

Caution:

Install the indoor unit at least 2.4m (94-1/2inch) above fl oor or grade level.

For appliances not accessible to the general public.

• Using the installation template (top of the package) and the gauge (supplied as

an accessory with the grille), make an opening in the ceiling so that the main unit

can be installed as shown in the diagram. (The method for using the template and

the gauge is shown.)

* Before using, check the dimensions of template and gauge, because they

change due to fl uctuations of temperature and humidity.

* The dimensions of ceiling opening can be regulated within the range shown

in Fig.3-2; so center the main unit against the opening of ceiling, ensuring

that the respective opposite sides on all sides of the clearance between them

becomes identical.

• Use M10 (3/8") suspension bolts.

* Suspension bolts are to be procured at the fi eld.

• Install securely, ensuring that there is no clearance between the ceiling panel &

grille, and between the main unit & grille.

Outer side of main unit Grille

Bolt pitch

Ceiling opening Multi function casement (option)

Outer side of Grille

* Note that the space between ceiling panel of the unit and ceiling slab, etc. must be 10 to 15 mm,

25/64 to 19/32 inch.

When the optional multi-functional casement is installed, add 135 mm, 5-5/16

*

inch to the dimensions marked on the fi gure.

Ceiling

Entire periphery

(mm, inch)

Models C D

A12, A18, A24, A30 241, 9-1/2" 258, 10-3/16"

A36, A42 281, 11-1/16" 298, 11-3/4"

3.3. Refrigerant and drainage piping locations of

indoor unit

The fi gure marked with * in the drawing represent the dimensions of the main unit

excluding those of the optional multi function casement. (Fig. 3-3)

Drain pipe

Ceiling

Grille

Refrigerant pipe (liquid)

Refrigerant pipe (gas)

Water supply inlet

Main unit

When the optional multi-functional casement is installed, add 135 mm, 5-5/16inch

*

to the dimensions marked on the fi gure.

3

Page 4

3. Installing the indoor unit

3-17/32 3-17/32

3-15/16 3-15/16

70°

13-25/32

*6-7/32

3-15/16

5-1/8

120

6-3/32*6-9/16

*

120

(inch)

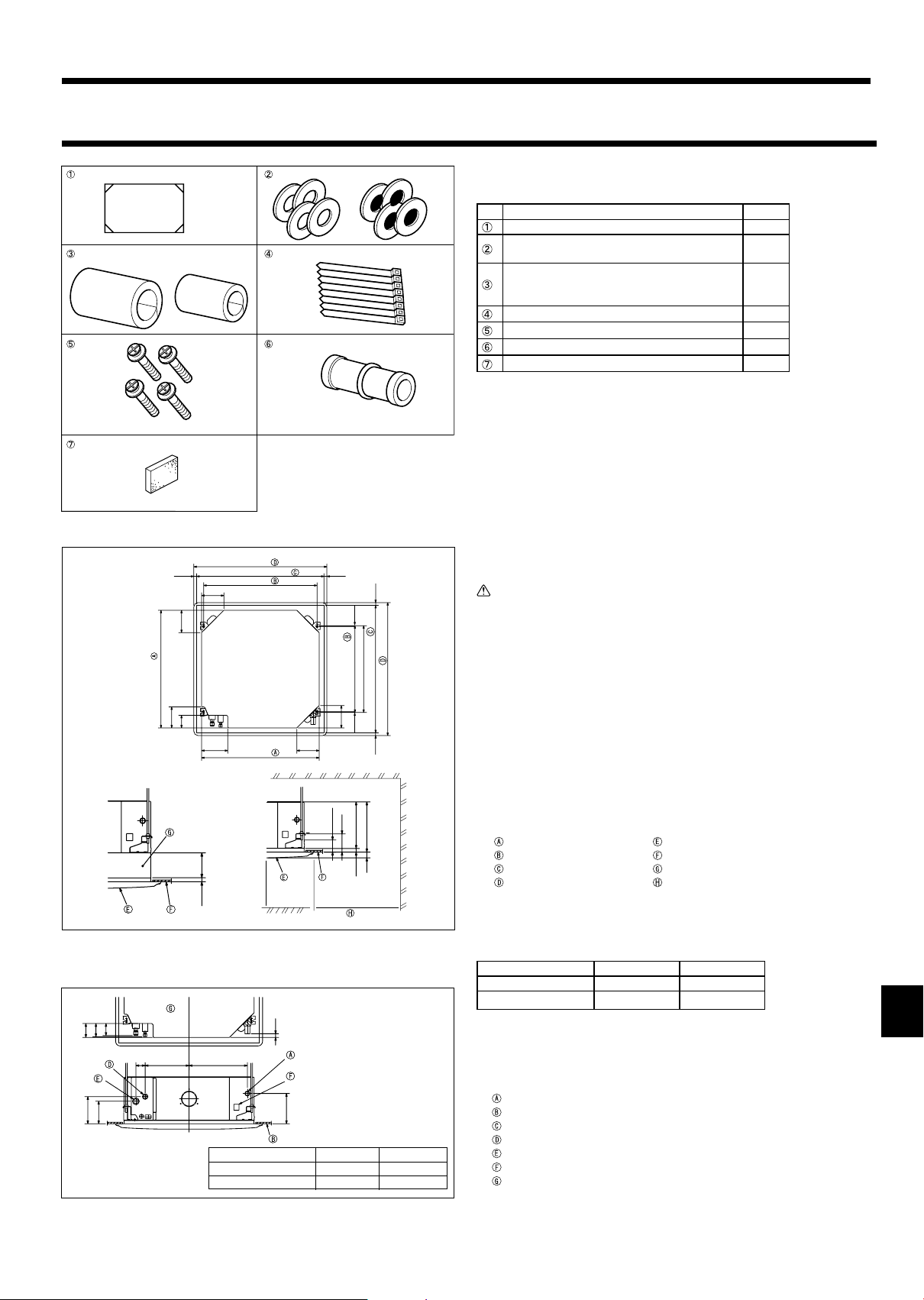

3.4.

Branch duct hole and fresh air intake hole (Fig. 3-4)

At the time of installation, use the duct holes (cut out) located at the positions

shown in Fig3-4, as and when required.

• A fresh air intake hole for the optional multi function casement can also be made.

Note:

The fi gure marked with * in the drawing represent the dimensions of the main

unit excluding those of the optional multi function casement.

When installing the optional multi function casement, add 135 mm, 5-5/16

inch to the dimensions marked on the fi gure.

When installing the branch ducts, be sure to insulate adequately. Otherwise

condensation and dripping may occur.

Branch duct hole 14-ø2.8 mm, ø1/8 inch burring hole

Indoor unit

Fresh air intake hole

Drain pipe

Refrigerant pipe

Branch duct hole diagram

(view from either side)

ø150 mm, ø5-29/32 inch cut out hole

ø175 mm, ø6-7/8 inch burring hole pitch

Fresh air intake hole diagram

3-ø2.8 mm, ø1/8 inch burring hole

ø125 mm, ø4-29/32 inch burring hole pitch

ø100 mm, ø3-15/16 inch cut out hole

Ceiling

Ceiling

Rafter

Beam

Roof beam

+3/16

0

11/16

Fig. 3-6

23-13/16

31-57/64

Min. 1-3/16

4-1/8 (9-29/64)

Fig. 3-4

Use inserts rated at 100-150 kg, 220

-331 lbs each (procure locally)

Suspension bolts M10(3/8") (procure

locally)

Steel reinforcing rod

Fig. 3-5

Suspension bolt

Ceiling

Nut

Washer (with insulation)

Mounting plate

Washer (without insulation)

Check using the Installation gauge

+3/16

0

A=11/16

Main unit

Ceiling

Gauge

Ceiling opening dimensions

Fig. 3-8

Unit

Grille

Pillar

(inch)

(inch)

Fig. 3-7

Main unit

Ceiling

Installation template (top ofthe

package)

Screw withwasher(Accessory)

3.5. Suspension structure (Give site of suspension

strong structure) (Fig. 3-5)

• The ceiling work differs according to the construction of the building. Building

constructors and interior decorators should be consulted for details.

(1) Extent of ceiling removal: The ceiling must be kept completely horizontal and

the ceiling foundation (framework: wooden slats and slat holders) must be rein-

forced in order to protect the ceiling from vibration.

(2) Cut and remove the ceiling foundation.

(3) Reinforce the ends of the ceiling foundation where it has been cut and add ceil-

ing foundation for securing the ends of the ceiling board.

(4) When installing the indoor unit on a slanted ceiling, attach a pillar between the

ceiling and the grille and set so that the unit is installed horizontally.

Wooden structures

• Use tie beams (single storied houses) or second fl oor beams (two story houses)

as reinforcing members.

• Wooden beams for suspending air conditioners must be sturdy and their sides

must be at least 6 cm, 2-3/8 inch long if the beams are separated by not more

than 90 cm, 35-7/16 inch and their sides must be at least 9 cm, 3-9/16 inch long

if the beams are separated by as much as 180 cm, 70-7/18 inch. The size of the

suspension bolts should be ø10 (3/8"). (The bolts do not come with the unit.)

Ferro-concrete structures

Secure the suspension bolts using the method shown, or use steel or wooden

hangers, etc. to install the suspension bolts.

3.6. Unit suspension procedures (Fig. 3-6)

Suspend the main unit as shown in the diagram.

Figures given in parentheses represent the dimensions in case of installing optional

multi function casement.

1. In advance, set the parts onto the suspension bolts in the order of the washers

(with insulation), washers (without insulation) and nuts (double).

• Fit the washer with cushion so that the insulation faces downward.

• In case of using upper washers to suspend the main unit, the lower washers (with

insulation) and nuts (double) are to be set later.

2. Lift the unit to the proper height of the suspension bolts to insert the mounting

plate between washers and then fasten it securely.

3. When the main unit can not be aligned against the mounting hole on the ceiling,

it is adjustable owing to a slot provided on the mounting plate.

• Make sure that A is performed within 17-22 mm, 11/16 to 7/8 inch. Damage

could result by failing to adhere to this range. (Fig. 3-7)

Caution:

Use the top half of the box as a protective cover to prevent dust or debris

from getting inside the unit prior to installation of the decorative cover or

when applying ceiling materials.

3.7. Confi rming the position of main unit and

tightening the suspension bolts (Fig. 3-8)

• Using the gauge attached to the grille, ensure that the bottom of the main unit is

properly aligned with the opening of the ceiling. Be sure to confi rm this, otherwise

condensation may form and drip due to air leakage, etc.

• Confi rm that the main unit is horizontally levelled, using a level or a vinyl tube

fi lled with water.

• After checking the position of the main unit, tighten the nuts of the suspension

bolts securely to fasten the main unit.

• The installation template (top of the package) can be used as a protective sheet to

prevent dust from entering the main unit when the grilles are left unattached for a

while or when the ceiling materials are to be lined after installation of the unit is fi nished.

* As for the details of fi tting, refer to the instructions given on the Installation tem-

plate.

4

Page 5

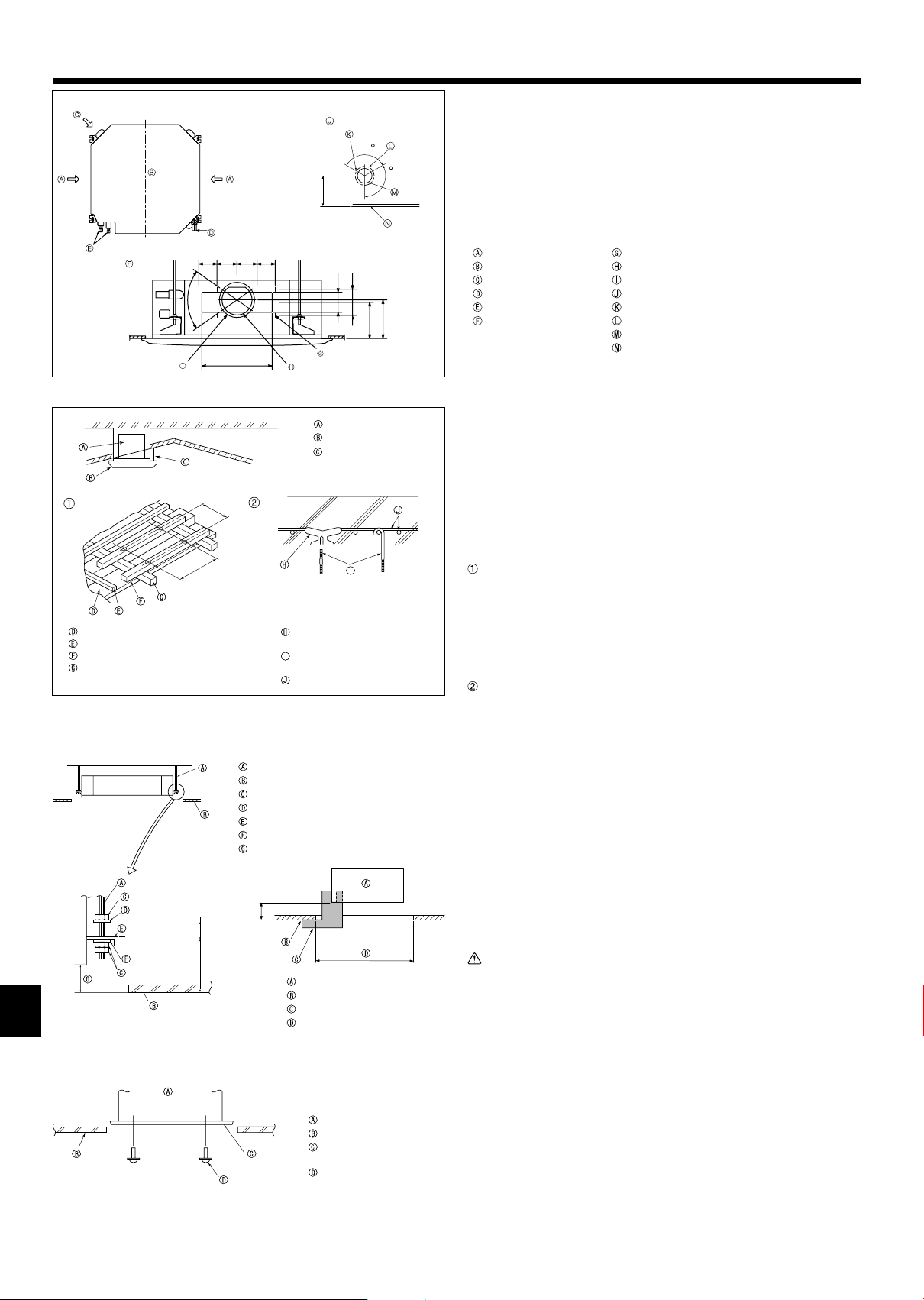

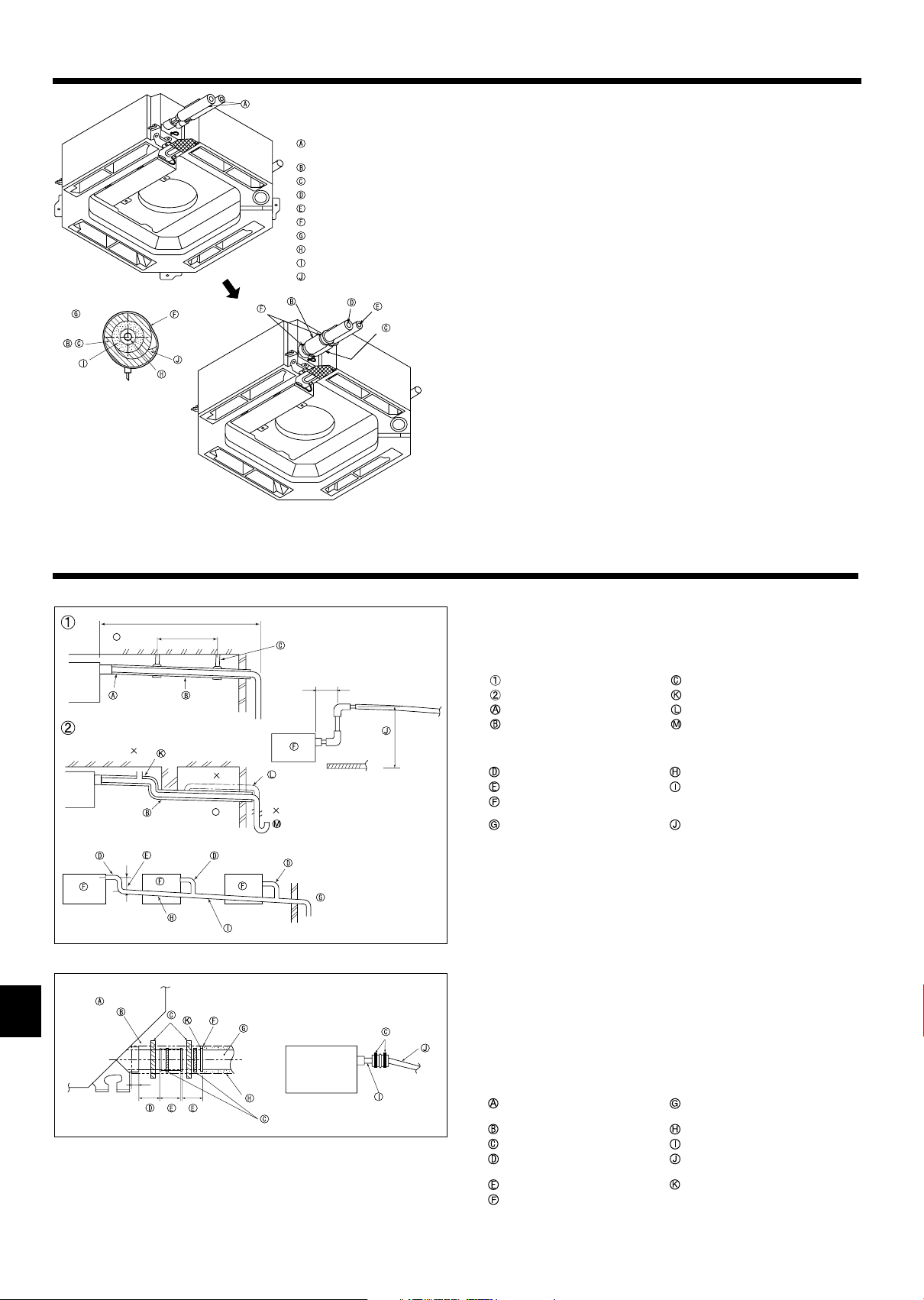

4. Installing the refrigerant piping

45 2

A

90 0.5

Flare cutting dimensions

Copper pipe O.D. Flare dimensions

(mm, inch) A dimensions (mm, inch)

R1/64 to R1/32

Fig. 4-1

6.35, 1/4 8.7 - 9.1, 11/32 - 23/64

9.52, 3/8 12.8 - 13.2, 1/2 - 33/64

12.7, 1/2 16.2 - 16.6, 41/64 - 21/32

15.88, 5/8 19.3 - 19.7, 49/64 - 25/32

19.05, 3/4 23.6 - 24.0, 15/16 - 61/64

B

Die

Copper pipe

4.1. Precautions

For devices that use R410A refrigerant

• Use ester oil, ether oil or alkylbenzene oil (small amount) as the refrigeration oil applied to the fl ared sections.

• Use C1220 copper phosphorus for copper and copper alloy seamless pipes,

to connect the refrigerant pipes. Use refrigerant pipes with the thicknesses

specifi ed in the table below. Make sure the insides of the pipes are clean

and do not contain any harmful contaminants such as sulfuric compounds,

oxidants, debris, or dust.

Warning:

When installing or moving the air conditioner, use only the specifi ed refrigerant (R410A) to charge the refrigerant lines. Do not mix it with any other refrigerant and do not allow air to remain in the lines. Air enclosed in the lines can

cause pressure peaks resulting in a rupture and other hazards.

A12, A18 A24, A30, A36, A42

Liquid pipe

Gas pipe

• Do not use pipes thinner than those specifi ed above.

ø6.35 mm, ø1/4 inch

thickness 0.8mm, 1/32 inch

ø12.7 mm, ø1/2 inch

thickness 0.8mm, 1/32 inch

ø9.52 mm, ø3/8 inch

thickness 0.8mm, 1/32 inch

ø15.88 mm, ø5/8 inch

thickness 1.0mm, 3/64 inch

4.2. Connecting pipes (Fig. 4-1)

• When commercially available copper pipes are used, wrap liquid and gas pipes

with commercially available insulation materials (heat-resistant to 100 °C, 212 °F

or more, thickness of 12 mm, 1/2 inch or more).

• The indoor parts of the drain pipe should be wrapped with polyethylene foam

insulation materials (specifi c gravity of 0.03, thickness of 9 mm, 23/64 inch or

more).

• Apply thin layer of refrigerant oil to pipe and joint seating surface before tighten-

ing fl are nut.

• Use two wrenches to tighten piping connections.

• Use refrigerant piping insulation provided to insulate indoor unit connections. In-

sulate carefully.

Flare nut tightening torque

Copper pipe O.D.

(mm, inch)

ø6.35, 1/4 17, 43/64 14-18, 10-13

ø6.35, 1/4 22, 7/8 34-42, 25-30

ø9.52, 3/8 22, 7/8 34-42, 25-30

ø12.7, 1/2 26, 1-3/64 49-61, 35-44

ø12.7, 1/2 29, 1-9/64 68-82, 49-59

ø15.88, 5/8 29, 1-9/64 68-82, 49-59

ø15.88, 5/8 36, 1-27/64 100-120, 71-86

ø19.05, 3/4 36, 1-27/64 100-120, 71-86

Apply refrigerating machine oil over the entire fl are seat surface.

Use correct fl are nuts meeting the pipe size of the outdoor unit.

Flare nut O.D.

(mm, inch)

Tightening torque

(N-m, ftlbs)

Copper pipe O.D.

mm (inch)

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

15.88 (5/8")

19.05 (3/4")

Fig. 4-2

B (mm, inch)

Flare tool for R410A

Clutch type

1.0 - 1.5, 3/64 - 1/16

1.0 - 1.5, 3/64 - 1/16

1.0 - 1.5, 3/64 - 1/16

1.0 - 1.5, 3/64 - 1/16

1.0 - 1.5, 3/64 - 1/16

Available pipe size

Liquid side ø6.35 ø9.52

Gas side

: Factory fl are nut attachment to the heat exchanger.

A12, A18 A24, A30, A36, A42

ø12.7

ø15.88

5

Page 6

4. Installing the refrigerant piping

Refrigerant pipe and

insulating material

Pipe cover (large)

Pipe cover (small)

Refrigerant pipe (gas)

Refrigerant pipe (liquid)

Band

Cross-sectional view of connection

Pipe

Insulating material

Squeeze

,

4.3. Indoor unit (Fig. 4-3)

Heat insulation for refrigerant pipes:

1 Wrap the enclosed large-sized pipe cover around the gas pipe, making sure that

the end of the pipe cover touches the side of the unit.

2 Wrap the enclosed small-sized pipe cover around the liquid pipe, making sure

that the end of the pipe cover touches the side of the unit.

3 Secure both ends of each pipe cover with the enclosed bands. (Attach the

bands 20 mm, 25/32 inch from the ends of the pipe cover.)

• After connecting the refrigerant piping to the indoor unit, be sure to test the pipe

connections for gas leakage with nitrogen gas. (Check that there is no refrigerant

leakage from the refrigerant piping to the indoor unit.)

4.4. For twin/triple combination

Refer to the outdoor unit installation manual.

Fig. 4-3

5. Drainage piping work

Max. 65 ft

5 to 7 ft

Fig. 5-1

7/16

111

Fig. 5-2

Max. 6 inch

(inch)

5.1. Drainage piping work (Fig. 5-1)

• Use VP25 (O.D. ø32 mm, 1-1/4 inch PVC TUBE) for drain piping and provide

1/100 or more downward slope.

• Be sure to connect the piping joints using a polyvinyl type adhesive.

• Observe the fi gure for piping work.

• Use the included drain hose to change the extraction direction.

Correct piping

Wrong piping

Insulation (9 mm, 23/64 inch or more)

Downward slope (1/100 or more) Odor trap

Grouped piping

O.D. ø32 mm, 1-1/4 inch PVC TUBE Downward slope (1/100 or more)

Make it as large as possible

Indoor unit

Make the piping size large for grouped

piping.

1.Connect the drain socket (supplied with the unit) to the drain port. (Fig. 5-2)

(Fix the tube using PVC adhesive then secure it with a band.)

2.Install a locally purchased drain pipe (PVC pipe, O.D. ø32mm, 1-1/4 inch).

(Fix the pipe using PVC adhesive then secure it with a band.)

3.Insulate the tube and pipe. (PVC pipe, O.D. ø32mm, 1-1/4 inch and socket)

4.Check that drain fl ows smoothly.

5.Insulate the drain port with insulating material, then secure the material with a

band. (Both insulating material and band are supplied with the unit.)

Unit

Insulating material

Band

Drain port (transparent) O.D. ø32 mm, 1-1/4 inch PVC TUBE (Slope

Insertion margin

Matching

Support metal

Air bleeder

Raised

O.D. ø38 mm, 1-1/2 inch PVC TUBE for

grouped piping.(9 mm, 23/64 inch or more

insulation)

Up to 850 mm, 33-7/16 inch

Drain pipe (O.D. ø32mm, 1-1/4inch PVC

TUBE)

Insulating material (purchased locally)

Transparent PVC pipe

1/100 or more)

Drain socket

6

Page 7

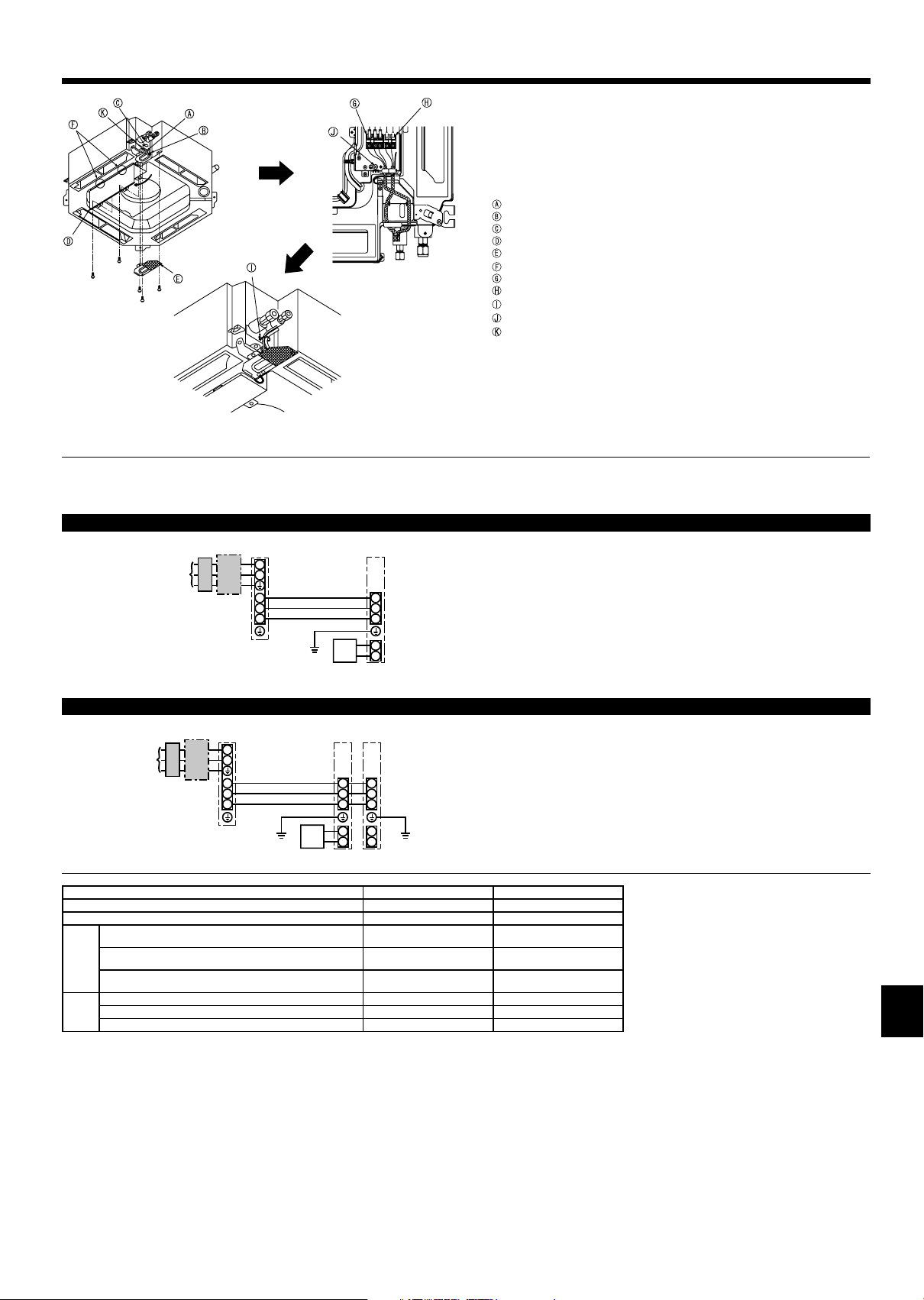

6. Electrical work

Fig. 6-1

6.1.1. Indoor unit power supplied from outdoor unit

The following connection patterns are available.

The outdoor unit power supply patterns vary on models.

D

L

AB C

N

S1

S2

S3

1 System

E

F

6.1. Indoor unit (Fig. 6-1)

1. Remove the electrical wiring service panel.

2. Remove the electrical box cover.

3. Wire the power cable and control cable separately through the respective wiring

entries given in the diagram.

• Do not allow slackening of the terminal screws.

• Leave excess cable so that the electrical box cover can be suspended below the

unit during servicing. (Approx. 50 to 100 mm, 2 to 4 inch)

Entry for control cable

Entry for power

Clamp

Electrical box cover

Service panel for electrical wiring

Temporary hook for

Indoor / Outdoor unit connecting terminals

Remote controller connector

Secure with the clamp

Earth terminal

Conduit

1:1 System

G

S1

S2

S3

1

2

A Outdoor unit power supply

B Ear th leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit earth

F Remote controller

G Indoor unit

electrical box cover

* Affi x label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

Simultaneous twin system

F

GG

S1

S1

S2

S2

S3

S3

2

1

1

2

A Outdoor unit power supply

B Ear th leakage breaker

C Wiring circuit breaker or isolating switch

D Outdoor unit

E Indoor unit earth

F Remote controller

G Indoor unit

E

D

L

ABC

N

S1

S2

S3

E

* Affi x label A that is included with the manuals near each wiring diagram for the indoor and outdoor units.

Indoor unit model PLA-A12, 18, 24, 30 PLA-A36, 42

Minimum circuit ampacity 1A 2A

Maximum rating of overcurrent protective device 15A 15A

Indoor unit-Outdoor unit *1 3 × AWG16 (polar) 3 × AWG16 (polar)

Indoor unit earth 1 × Min. AWG16 1 × Min. AWG16

Wiring

Remote contoroller-Indoor unit *2 2 × AWG22 (Non-polar) 2 × AWG22 (Non-polar)

Wire No. × size

Indoor unit-Outdoor unit S1-S2 *3 AC 208/230 V AC 208/230 V

Indoor unit-Outdoor unit S2-S3 *3 DC24 V DC24 V

rating

Circuit

Remote controller-Indoor unit *3 DC12 V DC12 V

*1. Max. 50 m, 165 ft

*2. The 10m, 30 ft wire is attached in the remote controller accessory. Max. 500 m, 1500ft

*3. The fi gures are NOT always against the ground.

S3 terminal has DC 24 V against S2 terminal. However between S3 and S1, these terminals are not electrically insulated by the transformer or other device.

Notes: 1. Wiring size must comply with the applicable local and national code.

2.

3. Use wires rated 300V or more for the power supply cables and the indoor unit/outdoor unit connecting cables.

Use copper supply wires.

4. Install an earth longer than other cables.

7

Page 8

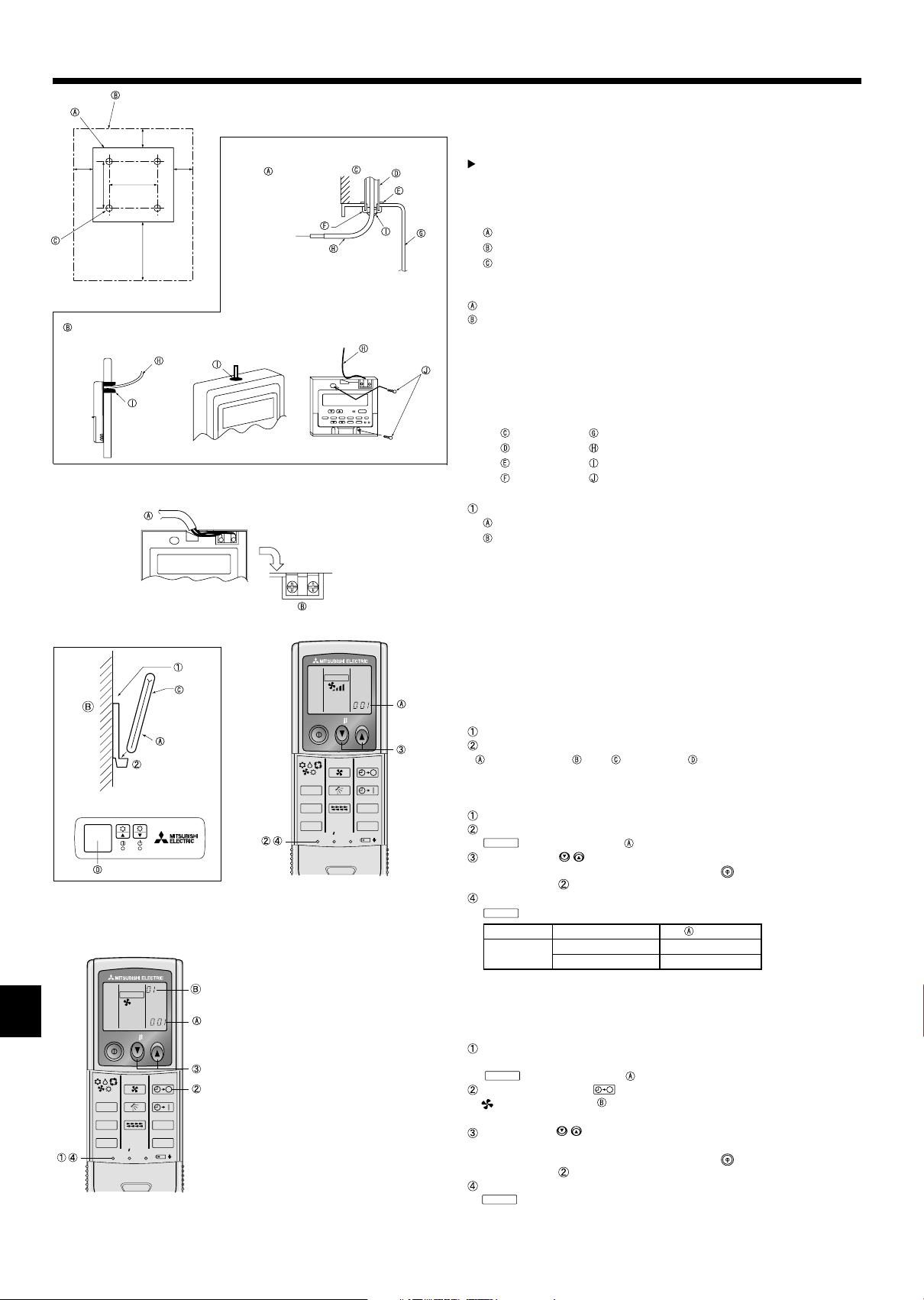

6. Electrical work

1-3/16

1-37/64

3-9/32

Fig. 6-2

B-1. B-2.

Fig. 6-5

MODEL SELECT

ON/OFF TEMP

FAN

VAN E

MODE

CHECK

LOUVER

TEST RUN

RESETSET CLOCK

Fig. 6-7

1-3/161-3/16

4-23/32

AUTO STOP

AUTO START

h

min

Fig. 6-3

Fig. 6-4

BTB

A6

MODEL SELECT

ON/OFF TEMP

FAN

AUTO STOP

VAN E

LOUVER

RESETSET CLOCK

AUTO START

h

min

MODE

CHECK

TEST RUN

Fig. 6-6

6.2. Remote controller

6.2.1. For wired remote controller

1) Installing procedures

(1) Select an installing position for the remote controller. (Fig. 6-2)

The temperature sensors are located on both remote controller and indoor unit.

Procure the following parts locally:

Two piece switch box

Thin copper conduit tube

Lock nuts and bushings

[Fig.6-2]

Remote controller profi le

Required clearances surrounding the remote controller

Installation pitch

(2) Seal the service entrance for the remote controller cord with putty to prevent

possible invasion of dew drops, water, cockroaches or worms. (Fig. 6-3)

For installation in the switch box

For direct installation on the wall, select one of the following:

• Prepare a hole through the wall to pass the remote controller cord (in order to run

the remote controller cord from the back), then seal the hole with putty.

• Run the remote controller cord through the cut-out upper case, then seal the cutout notch with putty.

B-1. To lead the remote controller cord from the back of the controller

B-2. To run the remote controller cord through the upper portion

[Fig.6-3]

Wall Switch box

Conduit Remote controller cord

Lock nut

Seal with putty

Bushing Wood screw

2) Connecting procedures (Fig. 6-4)

Connect the remote controller cord to the terminal block.

To TB5 on the indoor unit

TB6 (No polarity)

3) Two remote controllers setting

If two remote controllers are connected, set one to “Main” and the other to “Sub”.

For setting procedures, refer to “Function selection of remote controller” in the operation manual for the indoor unit.

6.2.2. For wireless remote controller

1) Installation area

• Area in which the remote controller is not exposed to direct sunshine.

• Area in which there is no nearby heating source.

• Area in which the remote controller is not exposed to cold (or hot) winds.

• Area in which the remote controller can be operated easily.

• Area in which the remote controller is beyond the reach of children.

2) Installation method (Fig. 6-5)

Attach the remote controller holder to the desired location using two tapping screws.

Place the lower end of the controller into the holder.

Remote controller Wall Display panel Receiver

• The signal can travel up to approximately 7 meters (in a straight line) within 45

degrees to both right and left of the center line of the receiver.

3) Setting (Fig. 6-6)

Insert batteries.

Press the SET button with something sharp at the end.

MODEL SELECT

4)Automatic fan speed setting (For wireless remote controller) (Fig. 6-7)

(Setting No.02:with automatic fan speed )

blinks and Model No. is lighted.

Press the temp

If you mistook the operation, press the ON/OFF

buttons to set the Model No.

button and operate again

from procedure .

Press the SET button with something sharp at the end.

MODEL SELECT

and Model No. are lighted for three seconds, then turned off.

Indoor Outdoor Model No.

PLA

heat pump models 001

cooling only models 033

It is necessary to set for wireless remote controller only when automatic fan

speed is not set at default setting.

It is not necessary to set for wired remote controller with automatic fan speed at

default setting.

Press the SET button with something sharp at the end.

Operate when display of remote controller is off.

MODEL SELECT

Press the AUTO STOP

blinks and Model No. is lighted.

button.

blinks and setting No. is lighted.

(Setting No.01: without automatic fan speed )

Press the temp.

buttons to set the setting No.02.

If you mistook the operation, press the ON/OFF button and operate again

from procedure .

Press the SET button with something sharp at the end.

MODEL SELECT

and Model No. are lighted for 3 seconds, then turned off.

8

Page 9

6. Electrical work

TEMP.

MENU

ON/OFF

BACK DAY

MONITOR/SET

PAR-21MAA

CLOCK

OPERATION

MODEL SELECT

ON/OFF TEMP

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

Fig. 6-8

ON/OFF

FILTER

CHECK

TEST

CLEAR

Fig. 6-9

AUTO STOP

AUTO START

h

min

Mode number

Setting number

Refrigerant address

Unit number

5) Assigning a remote controller to each unit

Each unit can be operated only by the assigned remote controller.

Make sure each pair of an indoor unit PC board and a remote controller is assigned

to the same pair No.

6) Wireless remote controller pair number setting operation (Fig. 6-8)

Press the SET button with something sharp at the end.

Start this operation from the status of remote controller display turned off.

MODEL SELECT

blinks and Model No. is lighted.

Press the

Pair No.

Press the temp

If you mistook the operation, press the ON/OFF

min

button twice continuously.

“0” blinks.

buttons to set the pair number you want to set.

button and operate again

from procedure 2.

Press the SET button with something sharp at the end.

Set pair number is lighted for three seconds then turned off.

A Pair No. of wireless remote controller Indoor PC board

6.3. Function settings

6.3.1. Function setting on the unit (Selecting the unit functions)

0 Factory setting

1 Cut J41

2 Cut J42

3-9 Cut J41, J42

1) For wired remote controller (Fig. 6-9)

Changing the power voltage setting

• Be sure to change the power voltage setting depending on the voltage used.

Go to the function setting mode.

Switch OFF the remote controller.

Press the FILTER and TEST RUN

buttons simultaneously and

hold them for at least 2 seconds. FUNCTION will start to blink.

Use the buttons to set the refrigerant address (3) to 00.

Press

button and [--] will start to blink in the unit number (4) display.

Use the buttons to set the unit number (4) to 00.

Press the MODE button to designate the refrigerant address/unit number. [--]

will blink in the mode number (1) display momentarily.

Press the buttons to set the mode number (1) to 04.

Press the button and the current set setting number (2) will blink.

Use the

button to switch the setting number in response to the power supply

voltage to be used.

Power supply voltage

230 V : setting number = 1

208 V : setting number = 2

Press the MODE button and mode and the setting number (1) and (2) will

change to being on constantly and the contents of the setting can be confi rmed.

Press the FILTER and TEST RUN buttons simultaneously for at least two

seconds. The function selection screen will disappear momentarily and the air

conditioner OFF display will appear.

CHECK

ON/OFF TEMP

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

AUTO STOP

AUTO START

h

min

CHECK

Fig. 6-10

CHECKCHECK

CHECK

2) For wireless remote controller (Fig. 6-10)

Changing the power voltage setting

• Be sure to change the power voltage setting depending on the voltage used.

Going to the function select mode

Press the

CHECK

button twice continuously.

(Start this operation from the status of remote controller display turned off.)

CHECK

is lighted and “00” blinks.

Press the

toward the receiver of the indoor unit and press the

temp button once to set “50”. Direct the wireless remote controller

h

button .

Setting the unit number

Press the

less remote controller toward the receiver of the indoor unit and press the

temp buttons and to set the unit number “00”. Direct the wire-

min

but-

ton .

Selecting a mode

Enter 04 to change the power voltage setting using the

. Direct the wireless remote controller toward the receiver of the indoor unit and

h

press the

button .

temp buttons and

Current setting number: 1 = 1 beep (one second)

2 = 2 beeps (one second each)

3 = 3 beeps (one second each)

Selecting the setting number

Use the

V). Direct the wireless remote controller toward the sensor of the indoor unit and

press the

To select multiple functions continuously

Repeat steps

temp buttons and to change the power voltage setting to 01 (240

h

button .

and to change multiple function settings continuously.

Complete function selection

Direct the wireless remote controller toward the sensor of the indoor unit and press

the

button .

Note: Whenever changes are made to the function settings after installation

or maintenance, be sure to record the changes with a mark in the “Setting”

column of the Function table.

6.3.2. Function setting on the remote controller

Refer to the indoor unit operation manual.

9

Page 10

6. Electrical work

Function table

Select unit number 00

Mode

Power failure automatic recovery

Indoor temperature detecting

LOSSNAY connectivity

Power voltage

Select unit numbers 01 to 03 or all units (AL [wired remote controller]/07 [wireless remote controller])

Mode

Filter sign

Fan speed

No. of air outlets

Installed options (high-performance fi lter)

Up/down vane setting

*1 When the power supply returns, the air conditioner will start 3 minutes later.

*2 Power failure automatic recovery initial setting depends on the connecting outdoor unit.

Settings

Not available

Available *1

Indoor unit operating average

Set by indoor unit’s remote controller

Remote controller’s internal sensor

Not Supported

Supported (indoor unit is not equipped with outdoor-air intake)

Supported (indoor unit is equipped with outdoor-air intake)

230 V

208 V

Settings

100Hr

2500Hr

No fi lter sign indicator

Silent

Standard

High ceiling

4 directions

3 directions

2 directions

Not supported

Supported

Equipped with vanes (vanes angle setup

Equipped with vanes (vanes angle setup )

Equipped with vanes (vanes angle setup )

Mode no. Setting no.

01 1

2

1

02 2

3

1

03 2

3

04 1

2

Mode no. Setting no.

1

07 2

3

1

08 2

3

1

09 2

3

10 1

2

)

1

11 2

3

Initial setting

Initial setting

setting

setting

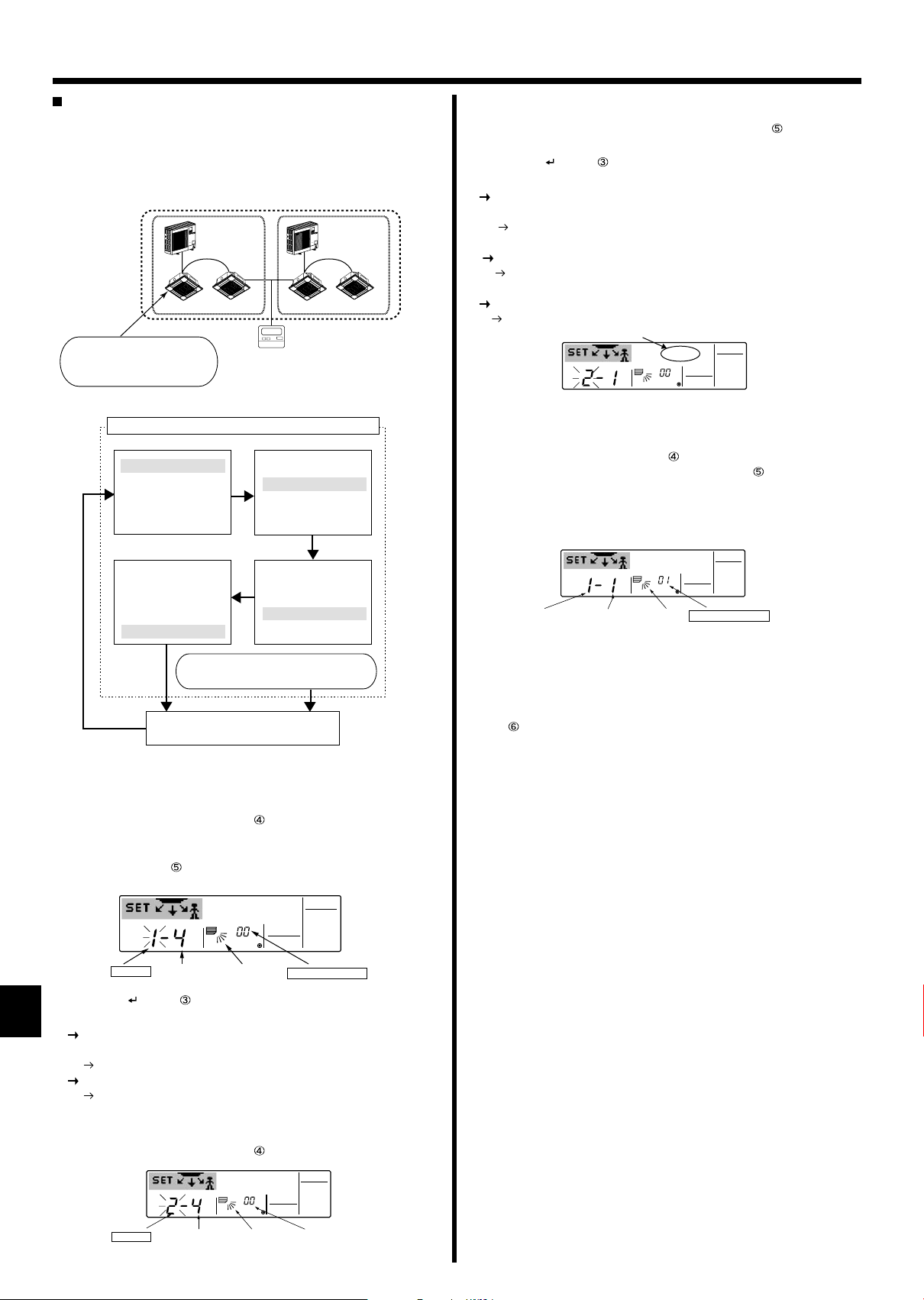

6.3.3 How to set the fi xed up/down air direction (Only for wired remote

controller and PUZ-A/PUY-A•NHA application)

• Only the particular outlet can be fixed to certain direction with the

procedures below. Once fi xed, only the set outlet is fi xed every time air

conditioner is turned on. (Other outlets follow UP/DOWN air direction

setting of the remote controller.)

Explanation of word

• "Refrigerant address No." and "Unit No." are the numbers given to

each air conditioner.

• "Outlet No." is the number given to each outlet of air conditioner.

(Refer to the right.)

• "Up/Down air direction" is the direction (angle) to fi x.

Reset 1

horizontal

2345

Horizontal airflow

Remote controller setting

The airflow direction of

this outlet is controlled by

the airflow direction setting of

remote contoller.

Outlet No.3

Outlet No.2

Note: "0" indicates all outlets.

Downward

Fixed setting

The airflow direction of

this outlet is fixed

in particular direction.

When it is cold because of direct airflow,

the airflow direction can be fixed

horizontally to avoid direct airflow.

Outlet No.4

MITSUBISHI

ELECTRIC

label

Outlet No.1

10

Page 11

6. Electrical work

TEMP.

MENU

BACK DAY

PAR-21MAA

ON/OFF

MONITOR/SET

CLOCK

Mode button (Return button)

Moves between the selected(blinking)

parts.

Unit No. Outlet No.

Operation buttons (During the fi xed airfl ow direction mode)

Press the button with either refrigerant

address No., unit No. or outlet No. blinking, ...

Only the air conditioner with the No. on remote

controller and its outlet are set to the setting 5 of

the airflow direction. (Other outlets are closed.)

It is used to identify the air conditioner and

outlet to set.

Press the button with

Up/Down air direction indicater blinking, ...

Attention

Only the air conditioner with the No. on Remote controller

and its outlet are fixed at "Up/Down air direction"

which is blinking.

This is used only to decide direction conclusively.

Attention: Be careful not to set wrong air conditioner.

ON/OFF

FILTER

CHECK

OPERATION

CLEAR

Up/Down air direction

ON/OFF button

Resets the fixed airflow direction mode.

Fan Speed button

Press for 2

seconds to

change / cancel

"Fixed airflow

TEST

Filter button

(<Enter> button)

Sends the information on

remote controller display.

Check button (Clear button)

·Refer to the next page for details.

Refrigerant addres No.

direction mode".

Set temperature buttons

Changes the selection(No.).

Unit No.

"1-4"

Outlet No.

"1-4"or "0"

Down

Up/Down air direction

5 steps or

cancel

Up

Refrigerant address No.

"00-15"

< Process for setting >

[1] To turn off air conditioner and change the remote

controller to "Fixed airfl ow direction mode"

1.Press ON/OFF button

2.Press Fan Speed button

seconds simultaneously and it becomes the fi xed airfl ow direction

mode after a while.

"Fixed airflow direction mode" display

Air blows downward after it becomes

"fixed airflow direction mode"

[2] To select and identify the outlet to set

1.Press Set Temperature button

blinking. Select outlet No. to set.

Unit No.

to turn off the air conditioner.

and Filter button

to change number with the outlet No.

Outlet No.

Up/Down air direction

Refrigerant addres No.

for more than 2

2.Press Filter

button to send the information on remote controller.

3. Wait for 15 seconds . How does the air conditioner run?

Only the air from the selected outlet blows downward.

Go to step[3].

Air from the wrong outlet blows downward.

Repeat 1 and set again.

All outlets are closed.

The numbers of the air conditioner (refrigerant address No.,

Unit No.) are wrong. Refer to How to fi nd air conditioner No..

[3] To fi x air direction

1.Press Mode button (Return button) to blink Up/Down air direction

indicater.

2.Press Set Temperature button until the direction to set is chosen.

3.Press Filter button to send the information on remote controller to

air conditioner.

4.Wait for 15 seconds . How does the air conditioner run?

Airfl ow direction is set in the selected direction.

The fi xed setting completed (Go to step [4].)

Airfl ow direction is set in the wrong direction.

Repeat 2. and set again.

Outlet No.3

Outlet No.2

Outlet No.4

Outlet No.1

Note: "0" indicates

MITSUBISHI

ELECTRIC

all outlets.

label

Unit No. Outlet No.

Air direction changes

This indicates NO FIXED SETTING(canceled)

Up/Down air direction

Refrigerant addres No.

[4] To cancel "Fixed airfl ow direction mode"

1.Press ON/OFF button to cancel "Fixed airfl ow direction mode".

It is also canceled by pressing Fan Speed button

and Filter button

for more than 2 seconds simultaneously.

2.Do not operate remote controller for 30 seconds after the "Fixed airfl ow

direction mode" is canceled. It does not accept even if it is operated.

11

Page 12

6. Electrical work

How to fi nd air conditioner No.

Each air conditioner has its own refrigerant address No. and unit No.

(Example below).

To fi nd air conditioner No. to set, refer to the procedures below.

Air conditioner No. is found by its airflow direction with the unit No.

changed one after the other.

Flow of procedure

Unit No."1" Unit No."1"Unit No."2" Unit No."2"

As for this air conditioner,

air conditioner No. is "unit No. 1" of

refrigerant address "0".

Check from refrigerant address 00 at first.

Refrigerant

address

No."00"

Remote controller

Refrigerant

address

No."01"

Adjust to the next unit No.with Set Temperature button

.

(refrigerant address No.00 is remained.)

2. Press Filter

button

to send the information on remote controller.

3. Wait for 15 seconds . How does the air conditioner run?

Only air from the outlet which No. displayed on remote controller blows

downward.

No. displayed in remote controller is air conditioner No. (Checking

completed)

All outlets are closed.

Repeat [1] and check. (If all the numbers are checked up to No.4

and is not found, go to [3].)

"Err" is displayed on remote controller.

The refrigerant address does not have further unit No.. (Go to [3].)

Err

[3] To check Unit No. of following refrigerant address No.(Maxmum

refrigerant address No. is 15)

Change to unit No.1 and check

Change to unit No.2 and check

Change to unit No.3 and check

Change to unit No.4 and check

Change to unit No.1 and check

Change to unit No.2 and check

Change to unit No.3 and check

Change to unit No.4 and check

When "Err" is displayed, refrigerant address

does not have further "unit No.".

Change to the next "refrigerant address No..

(Refrigerant No "00"~max. No."15")

Change to unit No.1 and check

Change to unit No.2 and check

Change to unit No.3 and check

Change to unit No.4 and check

Change to unit No.1 and check

Change to unit No.2 and check

Change to unit No.3 and check

Change to unit No.4 and check

<Process to fi nd air conditioner No.>

[1] To check refrigerant address No. and unit No.

1.Press Mode button (Return button)

address No. blinks.

Adjust refrigerant address No.to "00" and unit No."1" with Set

Temperature button

and unit No. or refrigerant

1.Press Mode button (Return button)

to blink refrigerant address No..

Adjust refrigerant No. with Set Temperature button .

* By changing refrigerant address, unit No. and outlet No. turn to initial

display.

2.Go back to [2] and check Unit No. again from Unit No. 1 in order.

Unit No.

Outlet No.

Up/Down air direction

Refrigerant addres No.

To clear fi xed setting

To clear all fi xed setting(reset to factory default), press check button(clear

botton)

for more than 3 seconds in fi xed airfl ow direction mode.

Display of remote controller blinks and the set information is cleared.

Note: This operation clears the fixed setting information of all air

conditioner connected to the remote controller.

Unit No.

2.Press Filter

Outlet No.

button to send the information on remote controller.

Up/Down air direction

Refrigerant addres No.

3. Wait for 15 seconds . How does the air conditioner run?

Only air from the outlet of which No. displayed on remote controller

blows downward.

Refrigerant address No.00 and unit No.1 are the air conditioner No..

All outlets are closed.

Go to step [2].

[2] To check by changing unit No. one after the other

(Maximum unit No. is 4)

1.Press Mode button (Return button)

Unit No.

Outlet No.

and unit No. blinks.

Up/Down air direction

Refrigerant addres No.

12

Page 13

7. Test run

7.1. Before test run

After completing installation and the wiring and piping of the indoor and out-

door units, check for refrigerant leakage, looseness in the power supply or

control wiring, wrong polarity, and no disconnection of one phase in the supply.

Use a 500-volt megohmmeter to check that the resistance between the

power supply terminals and ground is at least 1.0 M

TEST RUN

COOL, HEAT

MENU

BACK DAY

MONITOR/SET

PAR-21MAA

TEMP.

CLOCK

°F

°F

ON/OFF

OPERATION

SIMPLE

ON/OFF

FILTER

CHECK

CLEAR

TEST

.

ON/OFF button

Test run display

Indoor temperature liquid pipe

temperature display

ON/OFF lamp

Power display

Error code display

Test run remaining time display

Set temperature button

Mode selection button

Air direction button

TEST button

Fan Speed button

Louver button

Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1.0 M

7.2. Test run

The following 3 methods are available.

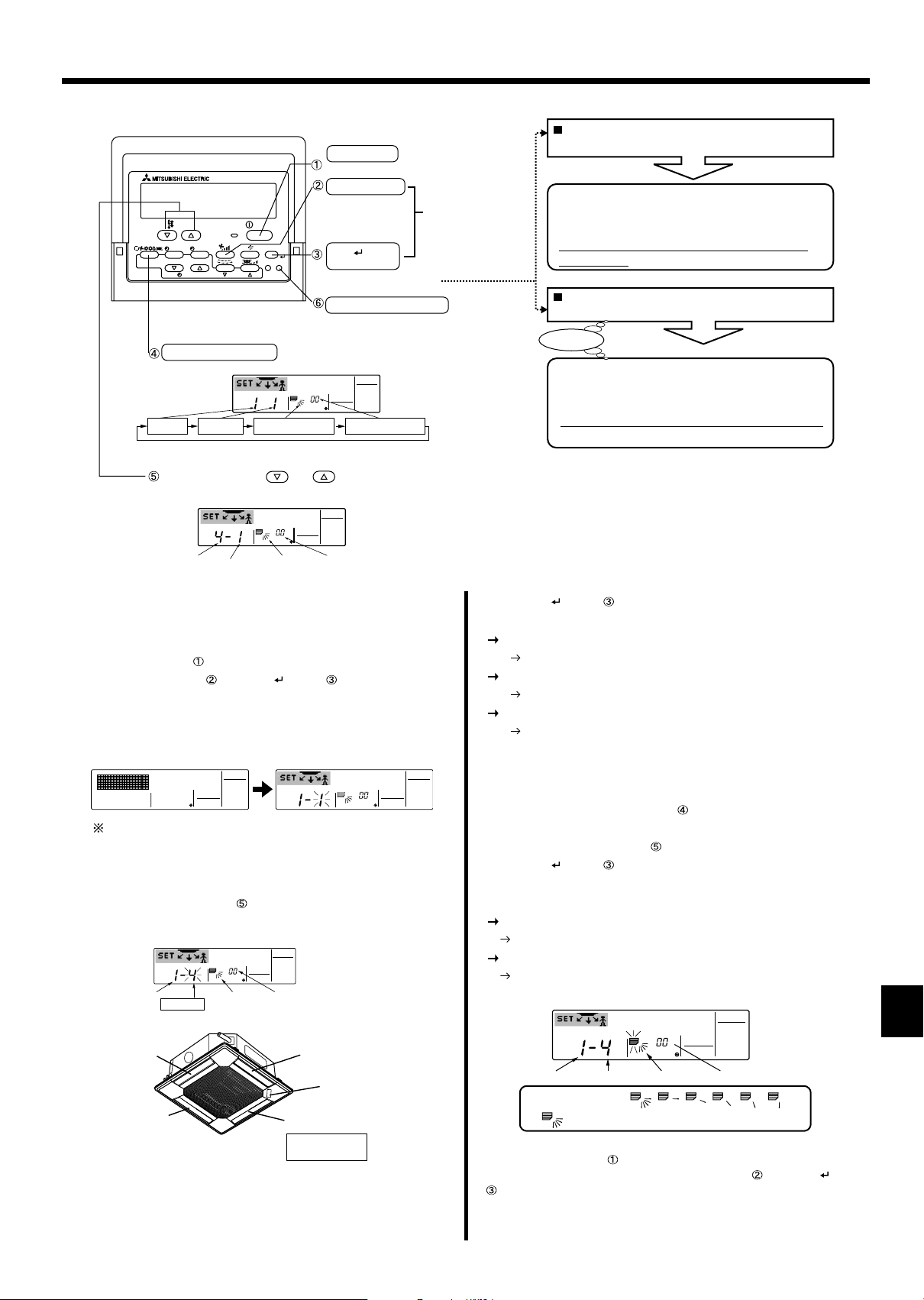

7.2.1. Using wired remote controller (Fig. 7-1)

Turn on the power at least 12 hours before the test run.

Press the [TEST] button twice. “TEST RUN” liquid crystal display

Press the [Mode selection] button and switch to the cooling (or heating) mode.

Make sure that cold (or warm) wind is blown out.

Press the [Fan speed] button. Make sure that the wind speed is switched.

Press the [Air direction button] or [Louver button].

Check operation of the vane or louver.

Check operation of the outdoor unit fan.

Release test run by pressing the [ON/OFF] button. Stop

Register a telephone number.

The telephone number of the repair shop, sales offi ce, etc., to contact if an error

occurs can be registered in the remote controller. The telephone number will be

displayed when an error occurs. For registration procedures, refer to the operation manual for the indoor unit.

.

TEMP.

MENU

BACK DAY

MONITOR/SET

PAR-21MAA

ERROR CODE

ON/OFF

CLOCK

OPERATION

ERROR CODE

ERROR CODE

Fig. 7-3

,

ON/OFF

FILTER

CHECK

CLEAR

Fig. 7-1

ON/OFF TEMP

MODE

CHECK

TEST RUN

Fig. 7-2

TEST

TEST RUN

FAN

VANE

LOUVER

RESETSET CLOCK

AUTO STOP

AUTO START

h

min

CHECK

ON/OFF TEMP

FAN

VANE

MODE

LOUVER

CHECK

TEST RUN

RESETSET CLOCK

Fig. 7-4

AUTO STOP

AUTO START

h

min

7.2.2. Using wireless remote controller (Fig. 7-2)

Turn on the power to the unit at least 12 hours before the test run.

Press the

(Start this operation from the status of remote controller display turned off.)

Press the

cool air is blown out from the unit.

Press the

warm air is blown out from the unit.

Press the

Press the

Press the ON/OFF button to stop the test run.

Note:

• Point the remote controller towards the indoor unit receiver while following

steps

• It is not possible to run the TEST RUN in FAN, DRY or AUTO mode.

TEST RUN

button twice continuously.

and current operation mode are displayed.

TEST RUN

MODE

button to activate mode, then check whether

MODE

button to activate mode, then check whether

FAN

button and check whether fan speed changes.

VANE

button and check whether the auto vane operates properly.

to .

7.2.3. Using SW4 in outdoor unit

Refer to the outdoor unit installation manual.

7.3. Self-check

7.3.1. Wired remote controller (Fig. 7-3)

Turn on the power.

Press the [CHECK] button twice.

Set refrigerant address with [TEMP] button if system control is used.

Press the [ON/OFF] button to stop the self-check.

CHECK button

Refrigerant address

TEMP. button

IC: Indoor unit

OC: Outdoor unit

Check code

Unit address

7.3.2. Wireless remote controller (Fig. 7-4)

Turn on the power.

Press the

(Start this operation from the status of remote controller display turned off.)

While pointing the remote controller toward the unit’s receiver, press the h

button. The check code will be indicated by the number of times that the buzzer

sounds from the receiver section and the number of blinks of the operation

lamp.

Press the ON/OFF button to stop the self-check.

CHECK

button twice.

begins to light.

“00” begins to blink.

13

Page 14

7. Test run

• Refer to the following tables for details on the check codes. (Wireless remote controller)

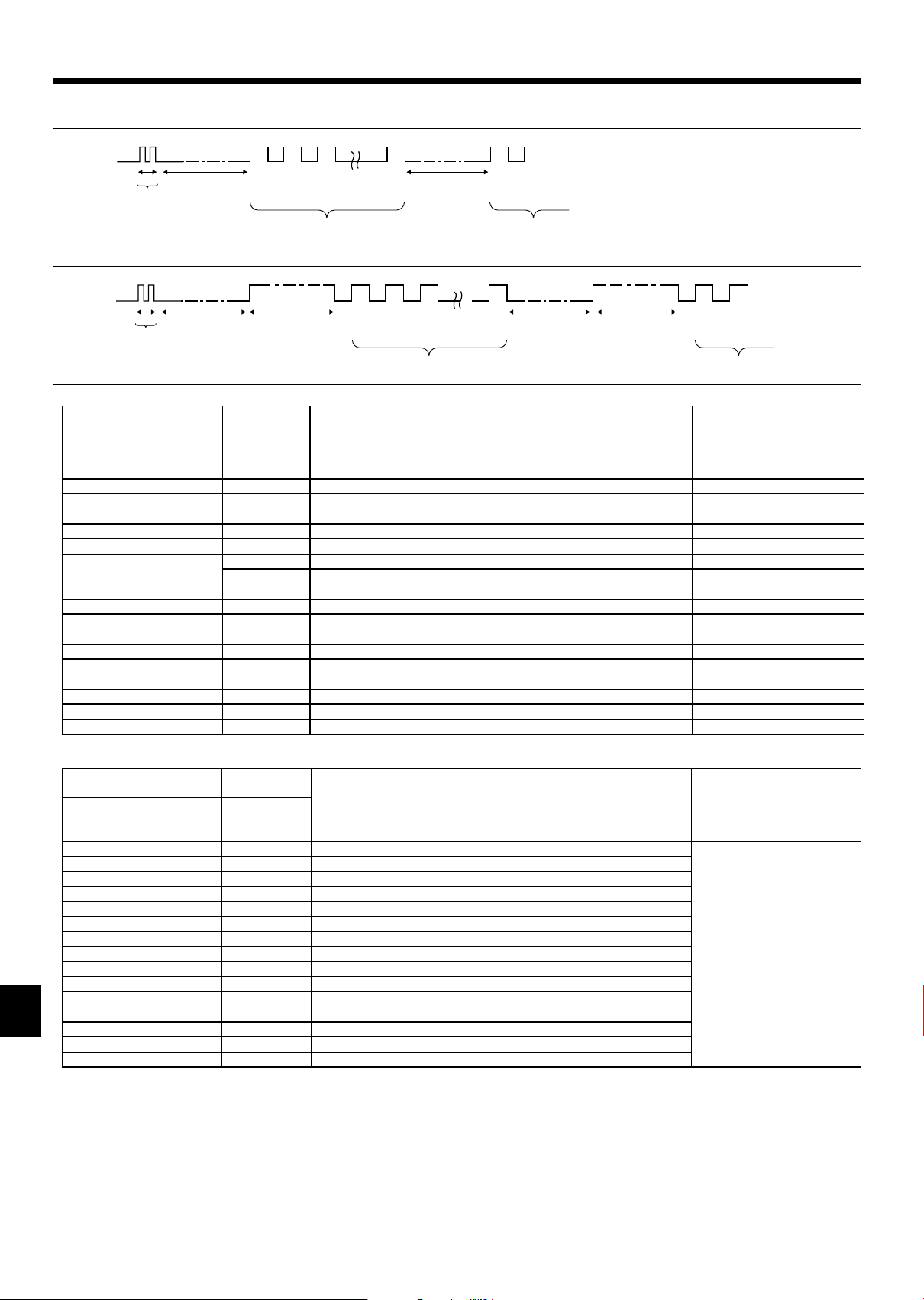

[Output pattern A]

Beeper sounds

OPERATION

INDICATOR

lamp blinking

pattern

[Output pattern B]

Beeper sounds

OPERATION

INDICATOR

lamp blinking

pattern

[Output pattern A] Errors detected by indoor unit

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp blinks

Beep

Off

Self-check

starts

(Start signal

received)

Self-check

starts

(Start signal

received)

Approx. 2.5 sec.On0.5 sec.On0.5 sec.On0.5 sec.

Beep Beep Beep Beep Beep Beep Beep

Off

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.On0.5 sec.

Beep Beep Beep Beep Beep Beep

1st2nd3

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “P5”)

rd

Number of blinks/beeps in pattern indicates the check

code in the following table (i.e., n=5 for “U2”)

th

n

On

0.5 sec.

1st2nd3

Off

Approx. 2.5 sec.On0.5 sec.On0.5 sec.

rd

Wired remote

controller

Check code

(Number of times)

1 P1 Intake sensor error

2

P2 Pipe (TH2) sensor error

P9 Pipe (TH5) sensor error

3 E6, E7 Indoor/outdoor unit communication error

4 P4 Drain sensor error / Float switch connector open

5

P5 Drain pump error

PA Forced compressor error

6 P6 Freezing/Overheating protection operation

7 EE Communication error between indoor and outdoor units

8 P8 Pipe temperature error

9 E4 Remote controller signal receiving error

10 — —

11 — —

12 Fb Indoor unit control system error (memory error, etc.)

No sound E0, E3 Remote controller transmission error

No sound E1, E2 Remote controller control board error

No sound – – – – No corresponding

nd

1st2

Number of blinks/beeps in pattern indicates

the check code in the following table

th

n

On

0.5 sec.

· · · Repeated

nd

1st2

Off

Approx. 2.5 sec.OnApprox. 3 sec.On0.5 sec.On0.5 sec.

Number of blinks/beeps in pattern indicates

the check code in the following table

· · · Repeated

Symptom Remark

[Output pattern B] Errors detected by unit other than indoor unit (outdoor unit, etc.)

Wireless remote controller

Beeper sounds/OPERATION

INDICATOR lamp blinks

Wired remote

controller

Symptom Remark

Check code

(Number of times)

1 E9 Indoor/outdoor unit communication error (Transmitting error) (Outdoor unit)

2 UP Compressor overcurrent interruption

3 U3, U4 Open/short of outdoor unit thermistors

4 UF Compressor overcurrent interruption (When compressor locked)

5 U2 Abnormal high discharging temperature/49C worked/insuffi cient refrigerant

6 U1, Ud Abnormal high pressure (63H worked)/Overheating protection operation

7 U5 Abnormal temperature of heat sink

8 U8 Outdoor unit fan protection stop

9 U6 Compressor overcurrent interruption/Abnormal of power module

For details, check the LED

display of the outdoor controller

board.

10 U7 Abnormality of super heat due to low discharge temperature

11 U9, UH

Abnormality such as overvoltage or voltage shortage and abnormal

synchronous signal to main circuit/Current sensor error

12 — —

13 — —

14 Others Other errors (Refer to the technical manual for the outdoor unit.)

*1 If the beeper does not sound again after the initial two beeps to confi rm the self-check start signal was received and the OPERATION INDICATOR lamp does not come

on, there are no error records.

*2 If the beeper sounds three times continuously “beep, beep, beep (0.4 + 0.4 + 0.4 sec.)” after the initial two beeps to confi rm the self-check start signal was received, the

specifi ed refrigerant address is incorrect.

• On wireless remote controller

The continuous buzzer sounds from receiving section of indoor unit.

Blink of operation lamp

• On wired remote controller

Check code displayed in the LCD.

14

Page 15

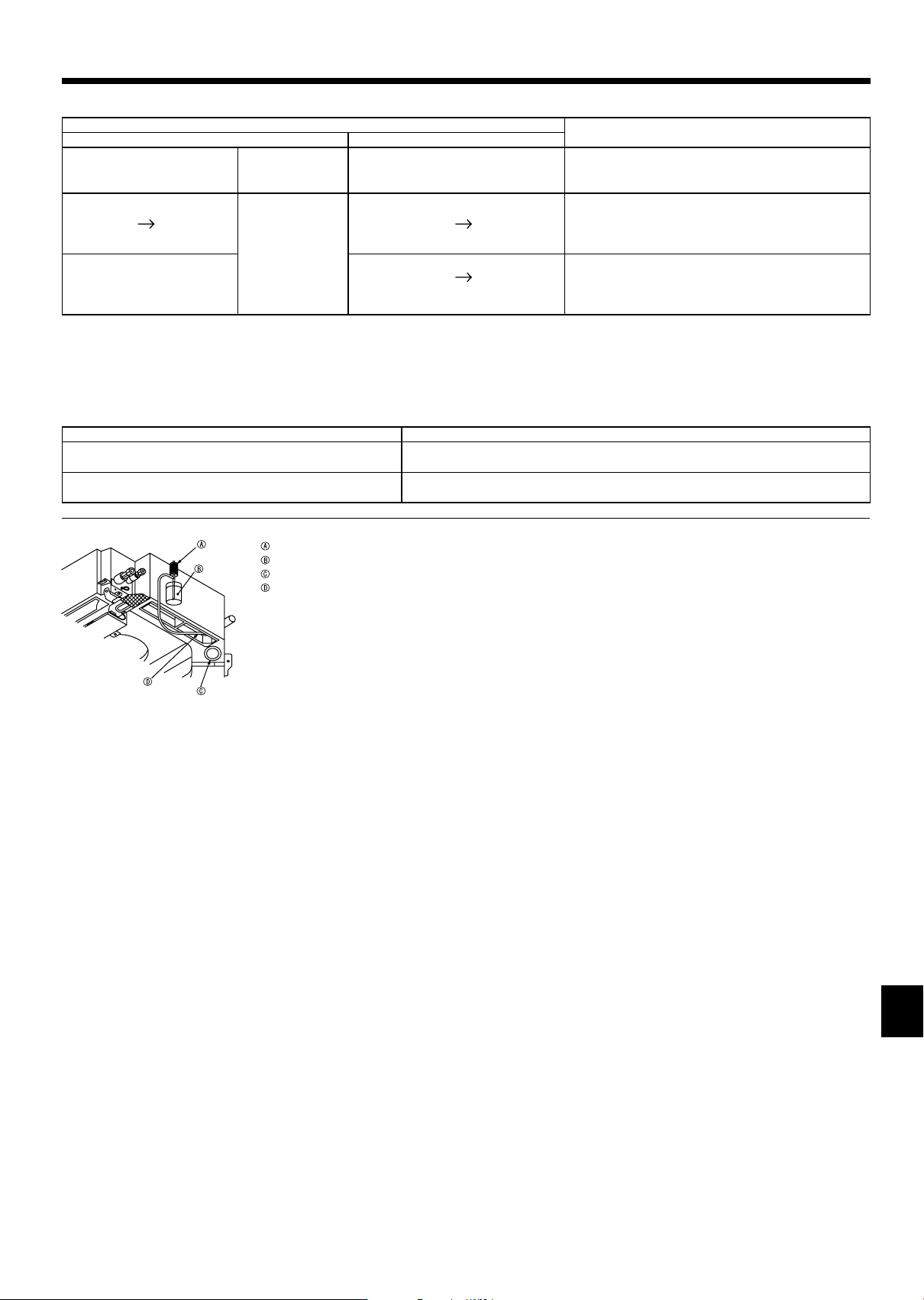

7. Test run

• If the unit cannot be operated properly after the test run has been performed, refer to the following table to remove the cause.

Wired remote controller LED 1, 2 (PCB in outdoor unit

PLEASE WAIT

PLEASE WAIT Error code

Display messages do not appear

even when operation switch is

turned ON

(operation lamp does not light up).

On the wireless remote controller with condition above, following phenomena take place.

• No signals from the remote controller are accepted.

• Operation lamp is blinking.

• The buzzer makes a short ping sound.

Note:

Operation is not possible for about 30 seconds after cancellation of function selection. (Correct operation)

For description of each LED (LED1, 2, 3) provided on the indoor controller, refer to the following table.

LED 1 (power for microcomputer) Indicates whether control power is supplied. Make sure that this LED is always lit.

LED 2 (power for remote controller) Indicates whether power is supplied to the remote controller. This LED lights only in the case of the

LED 3 (communication between indoor and outdoor units) Indicates state of communication between the indoor and outdoor units. Make sure that this LED is

For about 2 minutes

after power-on

Subsequent to about

2 minutes after poweron

Symptom

After LED 1, 2 are lighted, LED 2 is turned

off, then only LED 1 is lighted. (Correct

operation)

Only LED 1 is lighted.

Only LED 1 is lighted. LED 1 blinks

twice, LED 2 blinks once.

indoor unit which is connected to the outdoor unit refrigerant address “0”.

always blinking.

LED 1, 2 blink.

•For about 2 minutes after power-on, operation of the remote

controller is not possible due to system start-up. (Correct

operation)

•Connector for the outdoor unit’s protection device is not

connected.

Reverse or open phase wiring for the outdoor unit’s power

terminal block (L1, L2, GR)

• Incorrect wiring between indoor and outdoor units (incorrect

polarity of S1, S2, S3)

•Remote controller wire short

Cause

Water supply pump

Water (about 1000cc, 1/4 gal)

Drain plug

Pour water through outlet

.

Be carefule not to spray water

into the drain pump mechanism.

7.4. Check of drainage (Fig. 7-5)

• Ensure that the water is being properly drained out and that no water is leaking

from joints.

When electric work is completed.

.

Pour water during cooling operation and check.

When electric work is not completed.

.

Pour water during emergency operation and check.

* Drain pan and fan are activated simultaneously when single phase 220-240V is

turned on to S1 and S2 on terminal block after the connecter (SWE) on controller

board in the electrical branch box is set to ON.

Be sure to turn it back to the former state after work.

15

Page 16

8. System control

Refer to the outdoor unit installation manual.

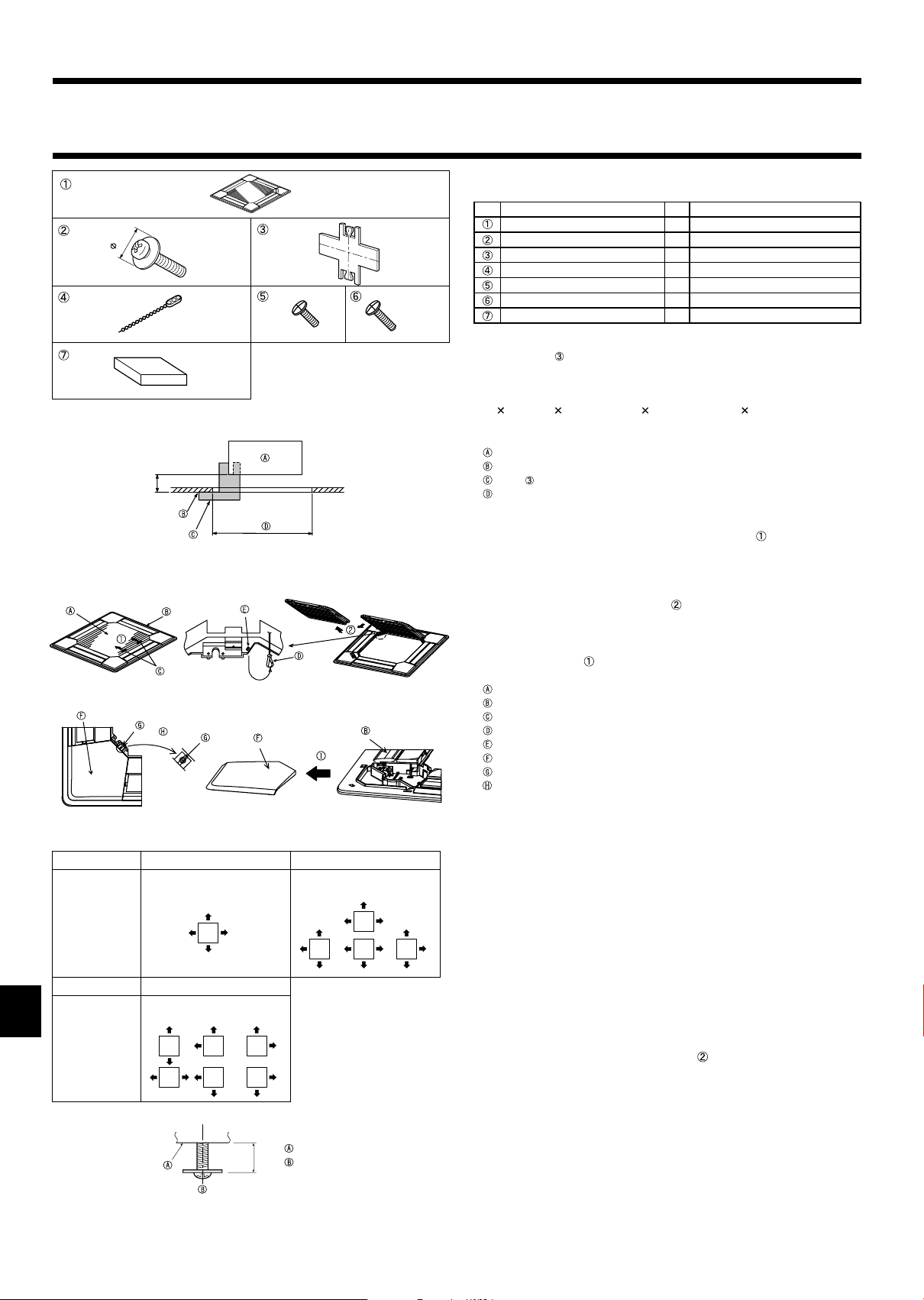

9. Installing the grille

20

Fig. 9-1

+3/16

0

A=11/16

Fig. 9-2

9.1. Checking the contents (Fig. 9-1)

• This kit contains this manual and the following parts.

Accessory name Q’ty Remarks

Grille 1

Screw with captive washer 4 M5 × 0.8 × 25

Gauge 1 (Divided into four parts)

Fastener 3

Screw 4 4 × 8

Screw 1 4 × 12

Wired remote controller 1 for PLP-42BAMD

950 × 950 (mm), 37-3/8 × 37-3/8 (inch)

9.2. Preparing to attach the grille (Fig. 9-2)

• With the gauge supplied with this kit, adjust and check the positioning of the

unit relative to the ceiling. If the unit is not properly positioned relative to the ceiling, it may allow air leaks or cause condensation to collect.

• Make sure that the opening in the ceiling is within the following tolerances:

860

860 - 910 910 mm, 33-7/8 33-7/8 to 35-13/16 35-13/16 inch.

• Make sure that A is performed within 17-22 mm, 11/16-7/8 inch. Damage could

result by failing to adhere to this range.

Main unit

Ceiling

Gauge (inserted into the unit)

Ceiling opening dimensions

9.2.1. Removing the intake grille (Fig. 9-3)

• Slide the levers in the direction indicated by the arrows to open the intake

grille.

• Unlatch the hook that secures the grille.

* Do not unlatch the hook for the intake grille.

• With the intake grille in the “open” position, remove the hinge of the intake grille

from the grille as indicated by the arrows .

Blowout

direction

patterns

Blowout

direction

patterns

Fig. 9-3

Fig. 9-4

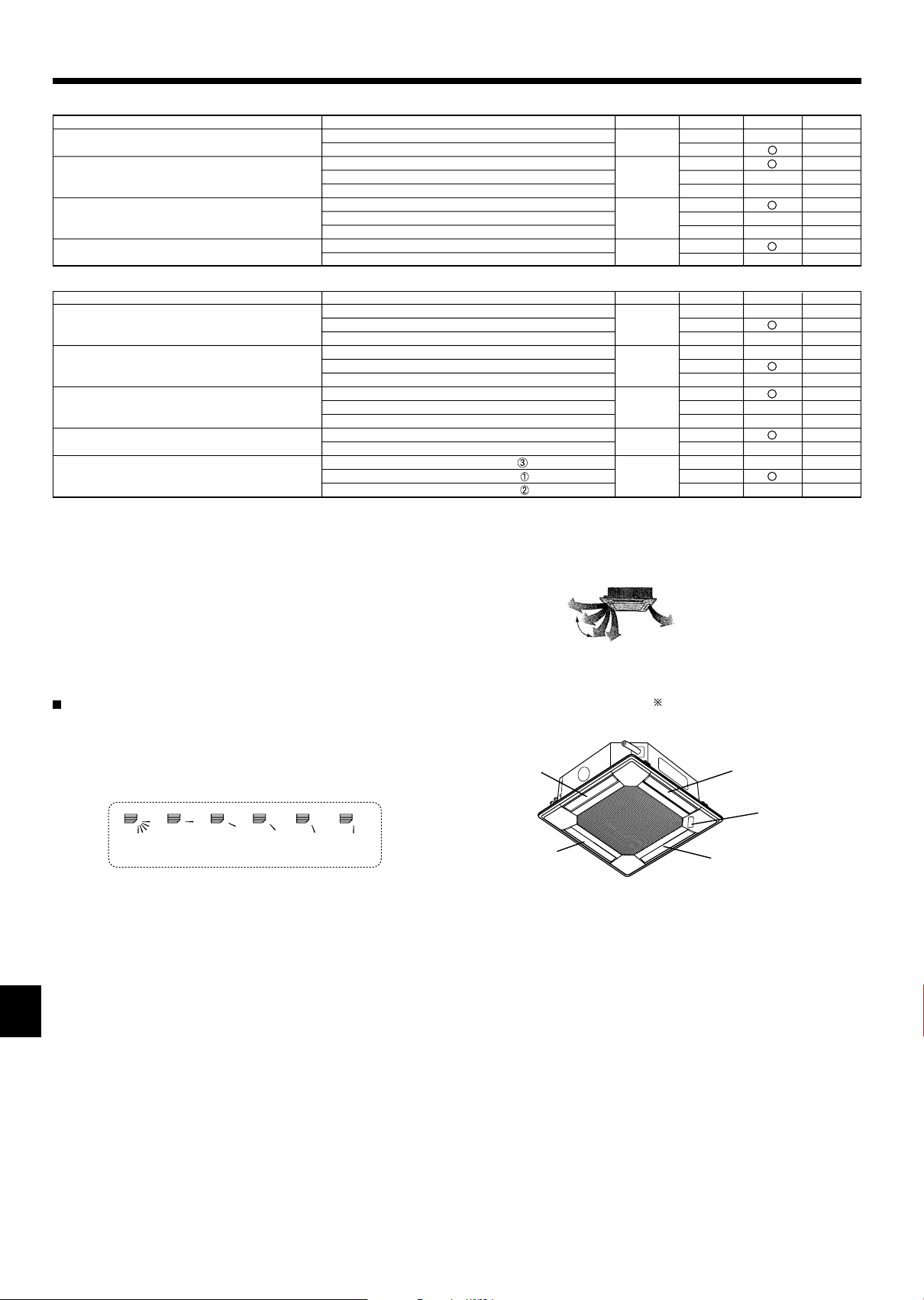

4-directional 3-directional

One pattern: 4 patterns:

Factory setting One air outlet fully closed

2-directional

6 patterns:

Two air outlet fully closed

9.2.2. Removing the corner panel (Fig. 9-4)

• Remove the screw from the corner of the corner panel. Slide the corner panel as

indicated by the arrow

[Fig.9-3] [Fig.9-4]

Intake grille

Grille

Intake grille levers

Grille hook

Hole for the grille’s hook

Corner panel

Screw

Detail

to remove the corner panel.

9.3. Selection of the air outlets

For this grille the discharge direction is available in 11 patterns. Also, by setting the

remote controller to the appropriate settings, you can adjust the air-fl ow and speed.

Select the required settings from the Table 1 according to the location in which you

want to install the unit.

1) Decide on the discharge direction pattern.

2) Be sure to set the remote contoller to the appropriate settings according to the

number of air outlets and the height of the ceiling on which the unit will be installed.

Note:

For 3 and 2-directional, please use the air outlet shutter plate (option).

9.4. Installing the grille

9.4.1. Preparations (Fig. 9-5)

• Install the two enclosed screws with washer in the main unit (at the corner

drain pipe area and at the opposite corner) as shown in the diagram.

16

Table 1

Fig. 9-5

Main unit

Screw with

captive washer

19/32 to 25/32

(inch)

Page 17

9. Installing the grille

Main unit

Corner drain pipe area

Screw with washer (for temporary use)

Grille

Screw with washer

Socket

Bell shaped hole

Fig. 9-6

Ceiling

Main unit

Grille

Make sure that there are no gaps

Adjust the nut of the main unit

using a wrench, etc.

Fig. 9-7

Clamp of the main unit

Electrical box

Indoor controler board

Catch for bell mouth

Lead wire of grille

9.4.2. Temporary installation of the grille (Fig. 9-6)

• Temporarily secure the grille using the bell shaped holes by putting the socket of

the grille marked on the corner drain pipe area of the main unit.

* Make sure that the lead wiring of the grille does not get pinched between the

grille and the main unit.

9.4.3. Securing the grille (Fig. 9-7)

• Secure the grille to the main unit by tightening the previously installed two screws

(with captive washer) as well as the two remaining screws (with captive washer).

* Make sure that there are no gaps between the main unit and the grille or the

grille and the ceiling.

Fixing gaps between the grille and the ceiling

With the grille attached, adjust the height of the main unit to close the gap.

9.4.4. Wire connection (Fig. 9-8)

• Remove the 2 screws fi xing the cover of electrical branch box of the unit and open

the cover.

• Be sure to connect the connector(white, 20-pole) for vane motor of the grille to

CNV connector of contoller board of the unit.

• As for PLP-6BALM, the connector of wireless sensor cable is also connected to

connecor CN90 on indoor controller board.

The lead wire of grille is passed through the catch of bell mouth of the unit perfectly.

The remaining lead wire is tied with clamp of the unit and put the cover of the unit

again with 2 screws.

Note:

Do not put the remaining lead wire in electrical branch box of the unit.

9.5. Locking the up/down airfl ow direction (Fig. 9-9)

The vanes of the unit can be set and locked in up or down orientations depending

upon the environment of use.

• Set according to the preference of the customer.

The operation of the fi xed up/down vanes and all automatic controls cannot be

performed using the remote controller. In addition, the actual position of the vanes

may differ from the position indicated on the remote controller.

Turn off the main power switch.

Injuries or an electrical shock may occur while the fan of the unit is rotating.

Disconnect the connector for the vane motor of the vent that you want to lock.

(While pressing the button, remove the connector in the direction indicated by

the arrow as shown in the diagram.) After removing the connector, insulate it

with tape.

It also can be set by remote controller. Refer to 6.3.3.

Fig. 9-8

Fig. 9-9

9.6. Check

• Make sure that there is no gap between the unit and the grille, or between the

grille and the surface of the ceiling. If there is any gap between the unit and the

grille, or between the grille and the surface of the ceiling, it may cause dew to collect.

• Make sure that the wires have been securely connected.

Button

Vane motor

Up/down vanes

Connector

17

Page 18

9. Installing the grille

9.7. Installing the intake grille (Fig. 9-10 )

Note:

When reinstalling the corner panels (each with a safety wire attached), connect the other end of each safety wire to the grille using a screw (4 pcs,

4

8) as shown in the illustration.

*If the corner panels are not attached, they may fall off while the unit is operating.

• Perform the procedure that is described in “9.2. Preparing to attach the grille” in

reverse order to install the intake grille and the corner panel.

• Multiple units can be installed with grille so that the position of the logo on each

corner panel is consistent with the other units regardless of the orientation of the

intake grille. Align the logo on the panel according to the wishes of the customer

as shown in the diagram to the left. (The position of the grille can be changed.)

Refrigerant piping of the main unit

Drain piping of the main unit

Position of the corner panel when sent from the factory (logo attached).

* Installation in any position is possible.

Position of the levers on the intake grille when sent from the factory.

* Although the clips can be installed in any of four positions, the confi guration shown here is

recommended.(It is not necessary to remove the intake grille when maintenance is performed

on the electric component box of the main unit.)

Receiver (Only PLP-42BALM Panel)

Screw (4ޓ8)ޓ

Corner panel

Safety wire

(Enlarged)

Fig. 9-10

10. Easy maintenance function (For PUZ-A/PUY-A application only)

Display example (Comp discharge temperature 147 )

PAR-21MAA

Maintenance mode operation procedures

(1) Press the

activate the maintenance mode.

(2) Press the TEMP. buttons to set the refrigerant address.

(3) Select the data you want to display.

Compressor

information

MENU

Outdoor unit

information

ON/OFF

Indoor unit

information

* The filter operation time displayed is the number of hours the filter has been

used since the filter reset was performed.

(4) Press the

button for three seconds to

TEST

Cumulative

operation time

Heat exchanger

temperature

Indoor room

temperature

button.

COMP ON

x10 HOURS

OUTDOOR UNIT

H•EXC. TEMP

INDOOR UNIT

INLET TEMP

Display

Display

Display

FILTER

Display

ON/OFF

number

COMP ON

x100 TIMES

Comp discharge

temperature

OUTDOOR UNIT

OUTLET TEMP

Heat exchanger

temperature

INDOOR UNIT

H•EXC. TEMP

Display

MAINTENANCE

Operation

current

COMP ON

CURRENT (A)

Outdoor ambient

temperature

OUTDOOR UNIT

OUTDOOR TEMP

Filter operation

time

INDOOR UNIT

FILTER USE H

By using the maintenance mode, you can display many types of maintenance data

on the remote controller such as the heat exchanger temperature and compressor

current consumption for the indoor and outdoor units.

This function can be used whether the air conditioner is operating or not.

During air conditioner operation, data can be checked during either normal operation or maintenance mode stable operation.

* This function cannot be used during the test run.

* The availability of this function depends on the connecting outdoor unit. Refer to

the brochures.

Stable operation

Using the maintenance mode, the operation frequency can be fixed and the operation can be stabilized. If the air conditioner is stopped, use the following procedure to start this operation.

Press the

Display

button to select the operation mode.

MODE

Stable cooling

operation

COOL

STABLE MODE

Stable heating

operation

HEAT

STABLE MODE

Stable operation

cancellation

STABLE MODE

CANCEL

(5) The data is displayed in .

Display

Waiting for

response

* Repeat steps (2) to (5) to check another data.

(6) Press the

button for three seconds or press the

TEST

deactivate the maintenance mode.

18

(Airflow temperature display example)

Blinking

Approx.

10 sec.

ON/OFF

147

button to

Press the

Waiting for

stable operation

Display

FILTER

button.

Stable

operation

10-20 min.

* You can check the data using steps (3) to (5) of the maintenance mode opera-

tion procedures while waiting for the stable operation.

Page 19

Page 20

Index

1. Consignes de sécurité ............................................................................. 20

2. Emplacement pour l’installation ...............................................................21

3. Installation de l’appareil intérieur ............................................................. 21

4. Installation de la tuyauterie du réfrigérant ............................................... 23

5. Mise en place du tuyau d’écoulement .....................................................24

1. Consignes de sécurité

Avant d’installer le climatiseur, lire attentivement toutes les “Consignes

de sécurité”.

Veuillez consulter ou obtenir l’autorisation de votre compagnie d’élec-

tricité avant de connecter votre système.

Avertissement:

Précautions à suivre pour éviter tout danger de blessure ou de décès de l’utilisateur.

Précaution:

Décrit les précautions qui doivent être prises pour éviter d’endommager l’appareil.

Avertissement:

• Contacter un revendeur ou un technicien agréé pour installer l’appareil.

• Pour l’installation, respecter les instructions du manuel d’installation et

utiliser des outils et des composants de tuyau spécialement conçus pour

une utilisation avec le réfrigérant spécifi é dans le manuel d’installation de l’

appareil extérieur.

• L’appareil doit être installé conformément aux instructions pour réduire les

risques de dommages liés à des tremblements de terre, des typhons ou

des vents violents. Une installation incorrecte peut entraîner la chute de l’

appareil et provoquer des dommages ou des blessures.

L’appareil doit être solidement installé sur une structure pouvant supporter

•

son poids.

• Si le climatiseur est installé dans une petite pièce, certaines mesures doivent être prises pour éviter que la concentration de réfrigérant ne dépasse

le seuil de sécurité en cas de fuite. En cas de fuite de réfrigérant et de

dépassement du seuil de concentration, des risques liés au manque d’oxygène dans la pièce peuvent survenir.

6. Installations électriques ...........................................................................25

7. Marche d’essai ........................................................................................31

8. Contrôle du système ..............................................................................34

9. Installer la grille .......................................................................................34

10. Fonction d’entretien aisé .........................................................................36

Une fois l’installation terminée, expliquer les “Consignes de sécurité”, l’utilisation

et l’entretien de l’appareil au client conformément aux informations du mode d’

emploi et effectuer l’essai de fonctionnement en continu pour garantir un fonctionnement normal. Le manuel d’installation et le mode d’emploi doivent être fournis à l’

utilisateur qui doit les conserver. Ces manuels doivent également être transmis aux

nouveaux utilisateurs.

: Indique un élément qui doit être mis à la terre.

Avertissement:

Prendre soin de lire les étiquettes se trouvant sur l’appareil principal.

• Aérer la pièce en cas de fuite de réfrigérant lors de l’utilisation. Le contact du

réfrigérant avec une fl amme peut provoquer des émanations de gaz toxiques.

• Tout tcavail sur les installations électriques doit être effectué par un technicien qualifi é conformément aux réglementations locales et aux instructions fournies dans ce manuel.

• N’utiliser que les câbles spécifi és pour les raccordements.

• Le couvercle du bloc de sortie de l’appareil doit être solidement fi xé.

• N’utiliser que les accessoires agréés par Mitsubishi Electric et contacter un