Page 1

CC-Link IE Field Network Ethernet Adapter Module

User's Manual

-NZ2GF-ETB

Page 2

Page 3

SAFETY PRECAUTIONS

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING

● Configure safety circuits external to the Ethernet adapter module to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the Ethernet adapter

module. Failure to do so may result in an accident due to an incorrect output or malfunction.

The Ethernet adapter module will stop its operation if it detects an error such as a watchdog timer

error by the self-diagnostic function.

● When changing data from a peripheral device connected to the Ethernet adapter module during

operation, configure an interlock circuit in the program of another station to ensure that the entire

system will always operate safely.

For other controls to a running programmable controller on another station (such as program

modification or operating status change) or the operating status change of the Ethernet adapter

module, read relevant manuals carefully and ensure the safety before the operation. Especially, in the

case of a control from an external device to a remote programmable controller on another station,

immediate action cannot be taken for a problem on the programmable controller due to a

communication failure. To prevent this, configure an interlock circuit on the program on another

station, and determine corrective actions to be taken between the external device and the

programmable controller in case of a communication failure.

● Do not write any data to the "system area" and "write-protect area" (R) of the buffer memory in the

Ethernet adapter module. Doing so may cause malfunction of the Ethernet adapter module.

1

Page 4

[Design Precautions]

CAUTION

● Do not install the communication cables together with the main circuit lines or power cables. Keep a

distance of 100mm or more between them. Failure to do so may result in malfunction due to noise.

[Installation Precautions]

CAUTION

● Use the Ethernet adapter module in an environment that meets the general specifications in this

manual. Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of

the product.

● Do not directly touch any conductive parts and electric components of the Ethernet adapter module.

Doing so can cause malfunction or failure of the Ethernet adapter module.

[Wiring Precautions]

WARNING

● Shut off the external power supply (all phases) used in the system before wiring. Failure to do so may

result in electric shock or cause the Ethernet adapter module to fail or malfunction.

● After wiring, attach the included terminal cover to the module before turning it on for operation. Failure

to do so may result in electric shock.

[Wiring Precautions]

CAUTION

● Individually ground the FG and LG terminals of the programmable controller with a ground resistance

of 100 or less. Failure to so may result in electric shock or malfunction.

● Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when a terminal block screw comes loose,

resulting in failure.

● Check the rated voltage and terminal layout before wiring to the Ethernet adapter module, and

connect the cables correctly. Connecting a power supply with a different voltage rating or incorrect

wiring may cause a fire or failure.

● Securely connect the connector to the Ethernet adapter module.

● Do not install the communication cables together with the main circuit lines or power cables. Failure to

do so may result in malfunction due to noise.

● Place the cables connected to the Ethernet adapter module in a duct or clamp them. If not, dangling

cable may swing or inadvertently be pulled, resulting in damage to the Ethernet adapter module or

cables or malfunction due to poor contact.

2

Page 5

[Wiring Precautions]

CAUTION

● Tighten the terminal block screw within the specified torque range. Undertightening can cause short

circuit, fire or malfunction. Overtightening can damage the screw and/or Ethernet adapter module,

resulting in drop, short circuit, or malfunction.

● When disconnecting the cable from the Ethernet adapter module, do not pull the cable by the cable

part. For the cable with connector, hold the connector part of the cable. Pulling the cable connected to

the Ethernet adapter module may result in malfunction or damage to the module or cable.

● Prevent foreign matter such as dust or wire chips from entering the Ethernet adapter module. Such

foreign matter can cause a fire, failure, or malfunction.

● A protective film is attached to the top of the Ethernet adapter module to prevent foreign matter, such

as wire chips, from entering the module during wiring. Do not remove the film during wiring. Remove it

for heat dissipation before system operation.

● The Ethernet adapter module must be installed in a control panel. Connect the main power supply

through a relay terminal block. Wiring and replacement of the Ethernet adapter module must be

performed by qualified maintenance personnel with knowledge of protection against electric shock.

For wiring methods, refer to "Wiring" in this manual.

[Startup and Maintenance Precautions]

WARNING

● Do not touch any terminal while power is on. Doing so will cause electric shock or malfunction.

● Shut off the external power supply for the system in all phases before cleaning the module or

retightening the terminal block screw. Failure to do so may result in electric shock.

[Startup and Maintenance Precautions]

CAUTION

● Before performing online operations (especially, program modification, forced output, and operating

status change) for the running Ethernet adapter module or programmable controller module on

another station from the peripheral device connected, read relevant manuals carefully and ensure the

safety. Improper operation may damage machines or cause accidents.

● Do not disassemble or modify the Ethernet adapter module. Doing so may cause failure, malfunction,

injury, or a fire.

● Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm away in all directions from the Ethernet adapter module. Failure to do so

may cause malfunction.

● Tighten the terminal block screw within the specified torque range. Undertightening can cause drop of

the component or wire, short circuit, or malfunction. Overtightening can damage the screw and/or

module, resulting in drop, short circuit, or malfunction.

● Before handling the Ethernet adapter module, touch a conducting object such as a grounded metal to

discharge the static electricity from the human body. Failure to do so may cause the Ethernet adapter

module to fail or malfunction.

3

Page 6

[Disposal Precautions]

CAUTION

● When disposing of this product, treat it as industrial waste.

4

Page 7

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

5

Page 8

INTRODUCTION

Thank you for purchasing the CC-Link IE Field Network Ethernet adapter module (hereinafter abbreviated as the

Ethernet adapter module).

This manual describes the operating procedure, system configuration, parameter setting, functions, and

troubleshooting of the Ethernet adapter module.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the Ethernet adapter module to handle it correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and

confirm that it will not cause system control problems.

Please make sure that the end users read this manual.

6

Page 9

RELEVANT MANUALS

(1) CC-Link IE Field Network related manual

When using CC-Link IE Field Network for the first time, refer to the CC-Link IE Field Network Master/Local

Module User's Manual. The following shows the system of CC-Link IE Field Network manuals.

Manual name

<manual number, model code>

MELSEC-Q CC-Link IE Field Network Master/Local Module

User's Manual

<SH-080917ENG, 13JZ47>

MELSEC-L CC-Link IE Field Network Master/Local Module User’s

Manual

<SH-080972ENG, 13JZ54>

MELSEC-QS CC-Link IE Field Network Master/Local Module

User's Manual

<SH-080969ENG, 13JZ53>

CC-Link IE Field Network Interface Board User's Manual (For

SW1DNC-CCIEF-B)

<SH-080980ENG, 13JZ58>

(2) Ethernet related manual

For communications using SLMP, refer to the following manual.

Manual name

<manual number, model code>

SLMP Reference Manual

<SH-080956ENG, 13JV23>

Description

Overview of CC-Link IE Field Network, and specifications, procedures

before operation, system configuration, installation, wiring, settings,

functions, programming, and troubleshooting of the MELSEC-Q series

master/local module

Overview of CC-Link IE Field Network, and specifications, procedures

before operation, system configuration, installation, wiring, settings,

functions, programming, and troubleshooting of the MELSEC-L series

master/local module

Overview of CC-Link IE Field Network, and specifications, procedures

before operation, system configuration, installation, wiring, settings,

functions, programming, and troubleshooting of the MELSEC-QS

series master/local module

Specifications, procedures before operation, system configuration,

settings, functions, programming, and troubleshooting of the CC-Link

IE Field Network interface board

Description

The protocol (SLMP) used for data reading or writing from an external

device to the Ethernet adapter module

7

Page 10

CONTENTS

CONTENTS

SAFETY PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

CONDITIONS OF USE FOR THE PRODUCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

RELEVANT MANUALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MANUAL PAGE ORGANIZATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

TERMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PACKING LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CHAPTER 1 ETHERNET ADAPTER MODULE 16

CHAPTER 2 PART NAMES 22

2.1 Power Supply Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2 CC-Link IE Field Network Part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.3 Ethernet Part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

CHAPTER 3 SPECIFICATIONS 29

3.1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.2.1 Performance specifications of each part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.3 List of the Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.4 Buffer Memory List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.5 SLMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.5.1 Available command list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.5.2 Ranges of accessible devices and buffer memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CHAPTER 4 PROCEDURE BEFORE THE OPERATION 45

4.1 Start-Up Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CHAPTER 5 SYSTEM CONFIGURATION 47

5.1 Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Network Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

5.2.1 CC-Link IE Field Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.2 Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.3 Applicable Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.1 Configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3.2 Software package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

CHAPTER 6 INSTALLATION AND WIRING 52

6.1 Installation Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2.1 Installation precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.2.2 Mounting the module to a control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.3 Mounting the modules on a DIN rail. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3 Testing the Module Before Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

8

Page 11

6.4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4.1 Wiring of the power supply part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.4.2 Ethernet cable wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.4.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.4.4 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

CHAPTER 7 COMMUNICATION OF THE ETHERNET ADAPTER MODULE 66

7.1 SLMP Communication and Cyclic Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.1.1 System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.1.2 Communication details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

7.1.3 Network setting on the configuration computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.1.4 Connection to CC-Link IE Field Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.1.5 Connection to the Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.2 Communication Using the On-demand Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.2.1 System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.2.2 Specifications of send data using the on-demand function . . . . . . . . . . . . . . . . . . . . . . . . . . 89

7.2.3 Applicable range of on-demand data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

7.2.4 How to send on-demand data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

7.2.5 Buffer memories used for the on-demand function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

7.2.6 On-demand data format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

7.2.7 Example of on-demand data sending . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.3 IP Communications over CC-Link IE Field Network (IP Packet Transfer Function) . . . . . . . .105

7.3.1 Deciding the IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.3.2 System configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3.3 Network setting of the configuration computer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

7.3.4 Connection to CC-Link IE Field Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

7.3.5 Connection to Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

7.3.6 Checking communications (IP communication test) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7.3.7 Setting to access a different network address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

7.4 MELSOFT Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

7.4.1 Connection through a hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

7.4.2 Direct connection (simple connection) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

CHAPTER 8 MAINTENANCE AND INSPECTION 137

8.1 Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

8.2 Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

CHAPTER 9 TROUBLESHOOTING 139

9.1 Troubleshooting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

9.2 Checking the Error Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

9.2.1 Error history of CC-Link IE Field Network diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

9.2.2 Ethernet Adapter Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

9.3 Checking the LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

9.3.1 The LED on the power supply part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

9.3.2 The LEDs on the CC-Link IE Field Network part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

9

Page 12

9.3.3 The LEDs on the Ethernet part . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

9.4 Troubleshooting by Symptom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

9.4.1 Cyclic transmission cannot be performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

9.4.2 Transient transmission cannot be performed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

9.4.3 Configuration tool does not start, or communication is not available . . . . . . . . . . . . . . . . . . 152

9.4.4 Configuration tool is not displayed in English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

9.4.5 New function or improved function cannot be used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9.4.6 Communication using SLMP cannot be performed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.4.7 Communications cannot be performed using the IP packet transfer function . . . . . . . . . . . 155

9.5 Error Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

CHAPTER 10 CONFIGURATION TOOL 175

10.1 Starting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.1.1 Preparation before starting the tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

10.1.2 Starting up the configuration tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

10.2 Window Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

10.2.1 Main window structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

10.2.2 Menu bar elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

10.2.3 Toolbar elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

10.3 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

10.3.1 System setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

10.3.2 CC-Link IE Field Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

10.3.3 Ethernet setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

10.3.4 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

10.4 Destination Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .194

10.5 Parameter Writing/Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .195

10.5.1 Parameter writing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10.5.2 Parameter reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

10.6 Device/Buffer Memory Batch Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .196

10.7 Ethernet Adapter Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .198

APPENDICES 200

Appendix 1 Buffer Memory Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .200

Appendix 1.1 Module operation area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Appendix 1.2 Own station information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Appendix 1.3 Ethernet port operation area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Appendix 1.4 Ethernet port error log area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Appendix 1.5 Ethernet port line status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Appendix 1.6 Ethernet port connection status data area . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Appendix 1.7 On-demand function data sending area . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Appendix 2 Link Special Relay (SB) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .212

Appendix 3 Link Special Register (SW) List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Appendix 4 Special Relay (SM) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .215

Appendix 5 Special Register (SD) List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .217

Appendix 6 Resetting Parameters to Factory Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

10

Page 13

Appendix 7 Access Codes and an Attribute Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Appendix 8 EMC and Low Voltage Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Appendix 8.1 Measures to comply with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . 224

Appendix 8.2 Measures to comply with the Low Voltage Directive . . . . . . . . . . . . . . . . . . . . 229

Appendix 9 Processing Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .230

Appendix 9.1 Transmission from the external device to the Ethernet adapter module. . . . . . . . 230

Appendix 9.2 Transmission from the external device to a CPU module through the Ethernet

adapter module

Appendix 10 New Function and Improved Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

Appendix 11 Checking the Serial Number and Function Version . . . . . . . . . . . . . . . . . . . . . . . . . . .234

Appendix 12 External Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .236

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

INDEX 237

REVISIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

11

Page 14

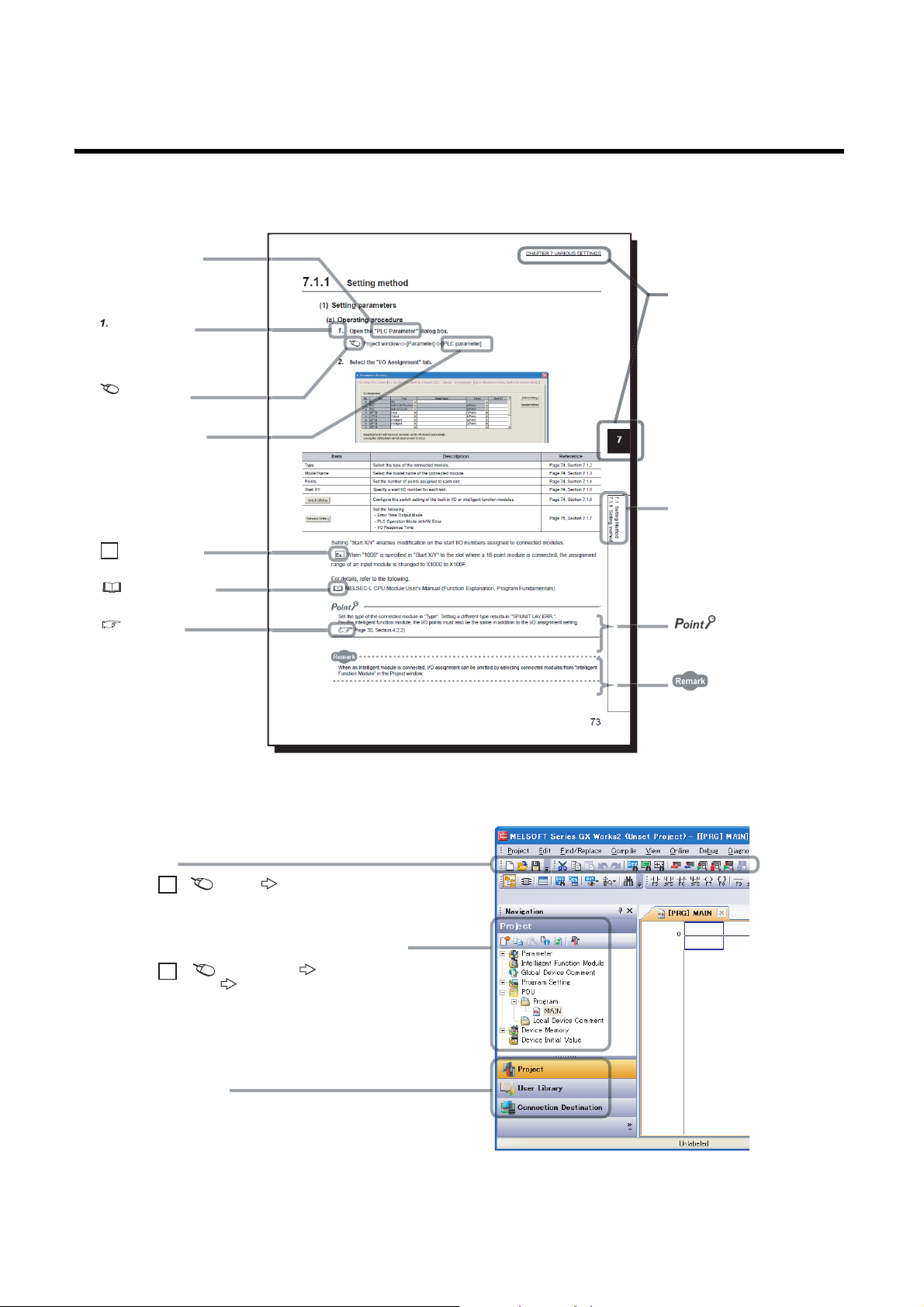

MANUAL PAGE ORGANIZATION

The section of

the current page is shown.

The chapter of

the current page is shown.

"" is used for

screen names and items.

[ ] is used for items

in the menu bar and

the project window.

shows operating

procedures.

shows reference

manuals.

shows notes that

requires attention.

shows mouse

operations.

*1

shows

reference pages.

shows setting or

operating examples.

Ex.

shows useful

information.

A window selected in the view selection area is displayed.

View selection area

[Online] [Write to PLC...]

Select [Online] on the menu bar,

and then select [Write to PLC...].

Project window

[Parameter]

[PLC Parameter]

Select [Project] from the view selection

area to open the Project window.

Menu bar

Ex.

Ex.

In the Project window, expand [Parameter] and

select [PLC Parameter].

In this manual, pages are organized and symbols are used as shown below.

The following page illustration is for explanation purpose only, and is different from the actual pages.

12

*1 The mouse operation example is provided below.

Page 15

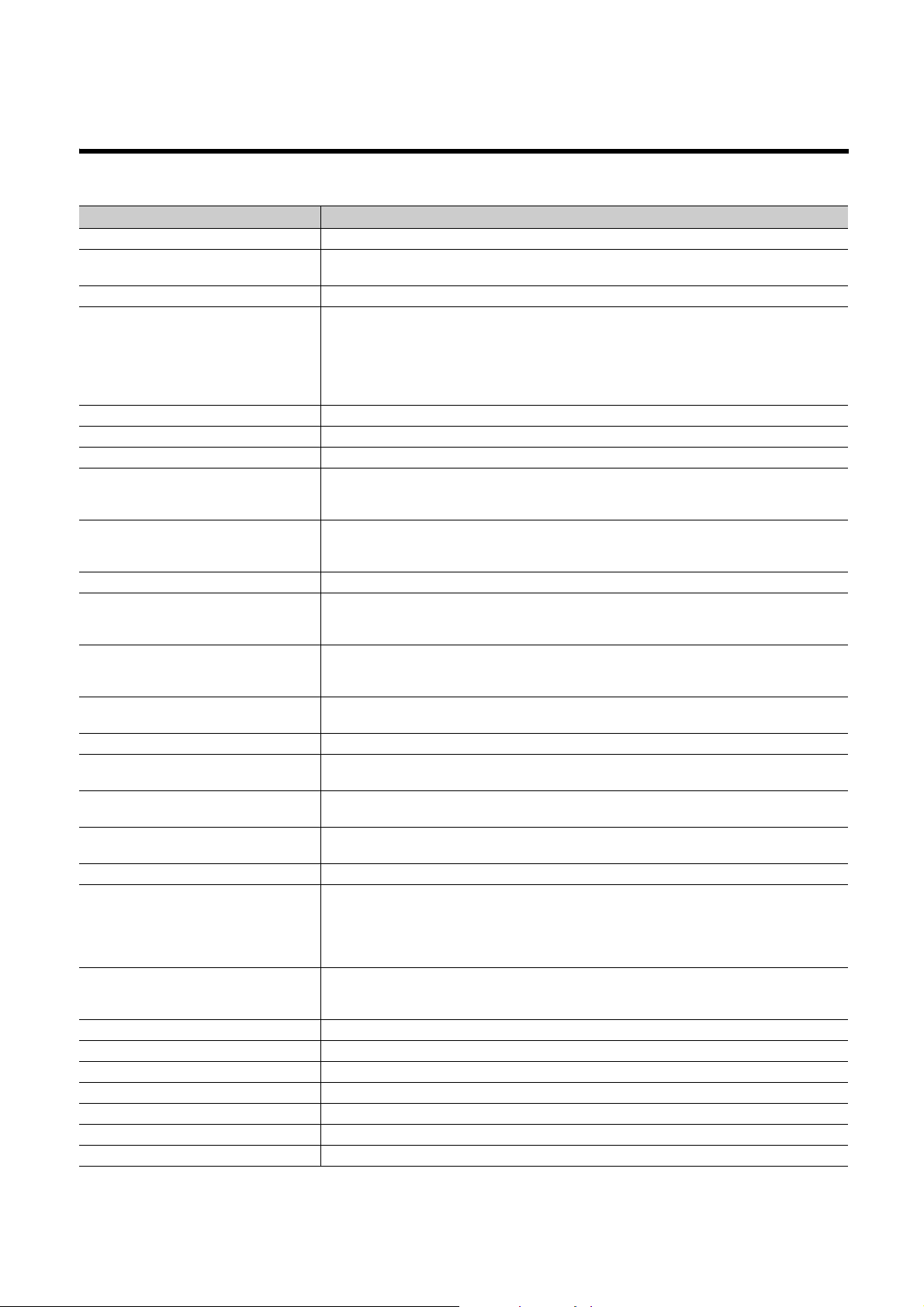

TERMS

Unless otherwise specified, this manual uses the following terms.

Ter m Description

CC-Link IE Field Network A high-speed and large-capacity open field network that is based on Ethernet (1000BASE-T)

Master/local module

Ethernet adapter module The abbreviation for the NZ2GF-ETB CC-Link IE Field Network Ethernet adapter module.

Network module

External device A generic term for devices that send SLMP request messages to an Ethernet adapter module

Configuration tool A software package built in an Ethernet adapter module

GX Works2 The product name of the software package for the MELSEC programmable controllers

Master station

Local station

Remote I/O station A station that exchanges I/O signals (bit data) with the master station by cyclic transmission

Remote device station

Intelligent device station

Slave station

Reserved station A station reserved for future use. This station is not actually connected, but counted as a connected station.

Relay station

Cyclic transmission

Transient transmission

Data link A generic term for cyclic transmission and transient transmission

Routing

SLMP

Request message An SLMP message sent from an external device to an Ethernet adapter module

Response message An SLMP message sent from an Ethernet adapter module to an external device

Dedicated instruction An instruction that simplifies programming for using functions of intelligent function modules

Return A process of restarting data link when a station recovers from an error

Disconnection A process of stopping data link if a data link error occurs

Device A device (X, Y, W, or others) in an Ethernet adapter module

Link device A device (RX, RY, RWr, or RWw) in a module on CC-Link IE Field Network

A generic term for the CC-Link IE Field Network master/local modules: QJ71GF11-T2, QS0J71GF11-T2,

and LJ71GF11-T2

A generic term for the following modules:

• Module on CC-Link IE Field Network

• CC-Link IE Controller Network module

• Ethernet interface module

• MELSECNET/H module

• MELSECNET/10 module

A station that controls the entire network.

This station can perform cyclic transmission and transient transmission with all stations.

Only one master station can be used in a network.

A station that performs cyclic transmission and transient transmission with the master station and other local

stations. The station is controlled by programs in the CPU module or other equivalent modules on the

station.

A station that exchanges I/O signals (bit data) and I/O data (word data) with the master station by cyclic

transmission.

This station responds to a transient transmission request from another station.

A station that exchanges I/O signals (bit data) and I/O data (word data) with the master station by cyclic

transmission. This station responds to a transient transmission request from another station and also issues

a transient transmission request to another station.

A generic term for stations other than a master station: local station, remote I/O station, remote device

station, and intelligent device station

A station that includes two or more network modules. Data are passed through this station to stations on

other networks

A function by which data are periodically exchanged among stations on the same network using link devices

(RX, RY, RWw, and RWr)

A function of communication with another station, which is used when requested by a dedicated instruction

or GX Works2

A process of selecting paths for communication with other networks.

CC-Link IE Field Network requires communication paths to be preset using routing parameters to

communicate with stations on different networks.

An Ethernet adapter module does not require routing parameters. Communications with other networks are

performed according to the routing parameters set to the master station.

The abbreviation for Seamless Message Protocol.

This protocol is used to access an SLMP-compatible device or a programmable controller connected to an

SLMP-compatible device from an external device.

13

Page 16

Ter m Description

Bit data input from a slave station to the master station (For some areas in a local station, data are input in

Remote input (RX)

Remote output (RY)

Remote register (RWr)

Remote register (RWw)

SB (link special relay) Bit data that indicates the operating status and data link status of a module on CC-Link IE Field Network

SW (link special register) Word data that indicates the operating status and data link status of a module on CC-Link IE Field Network

Parameter memory

Buffer memory

RIRD

RIWT

the opposite direction.)

User's manual for the master/local module used

Bit data output from the master station to a slave station (For some areas in a local station, data are output

in the opposite direction.)

User's manual for the master/local module used

Word data input from a slave station to the master station (For some areas in a local station, data are input

in the opposite direction.)

User's manual for the master/local module used

Word data output from the master station to a slave station (For some areas in a local station, data are

output in the opposite direction.)

User's manual for the master/local module used

A flash ROM in an Ethernet adapter module, where the parameters of the Ethernet adapter module are

stored

A memory in an Ethernet adapter module, where data (such as Ethernet port information, setting values,

and monitoring values) are stored

The abbreviation for JP.RIRD and GP.RIRD.

This dedicated instruction is used in programs of the master/local module.

The abbreviation for JP.RIWT and GP.RIWT.

This dedicated instruction is used in programs of the master/local module.

14

Page 17

PACKING LIST

The following items are included in the package of this product. Before use, check that all the items are included.

NZ2GF-ETB

Ethernet adapter module Safety Guidelines (IB-0800463)

15

Page 18

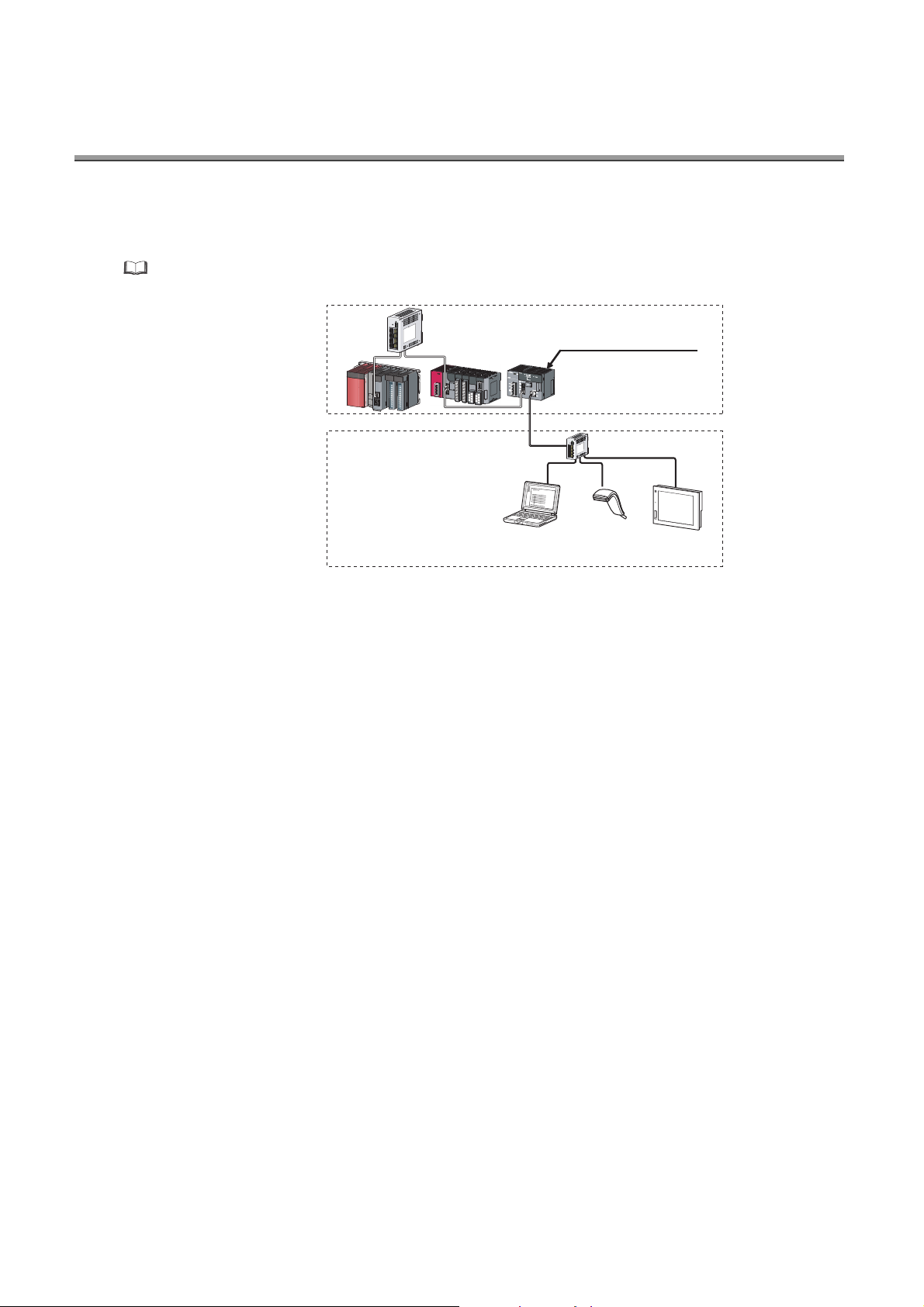

CHAPTER 1 ETHERNET ADAPTER MODULE

Configuration

tool

GOT

Switching hub

Ethernet

CC-Link

IE Field Network

Barcode

reader

Ethernet adapter module

The Ethernet adapter module connects external devices on the Ethernet network to CC-Link IE Field Network.

For details on CC-Link IE Field Network, refer to the following.

User's manual for the master/local module used

16

Page 19

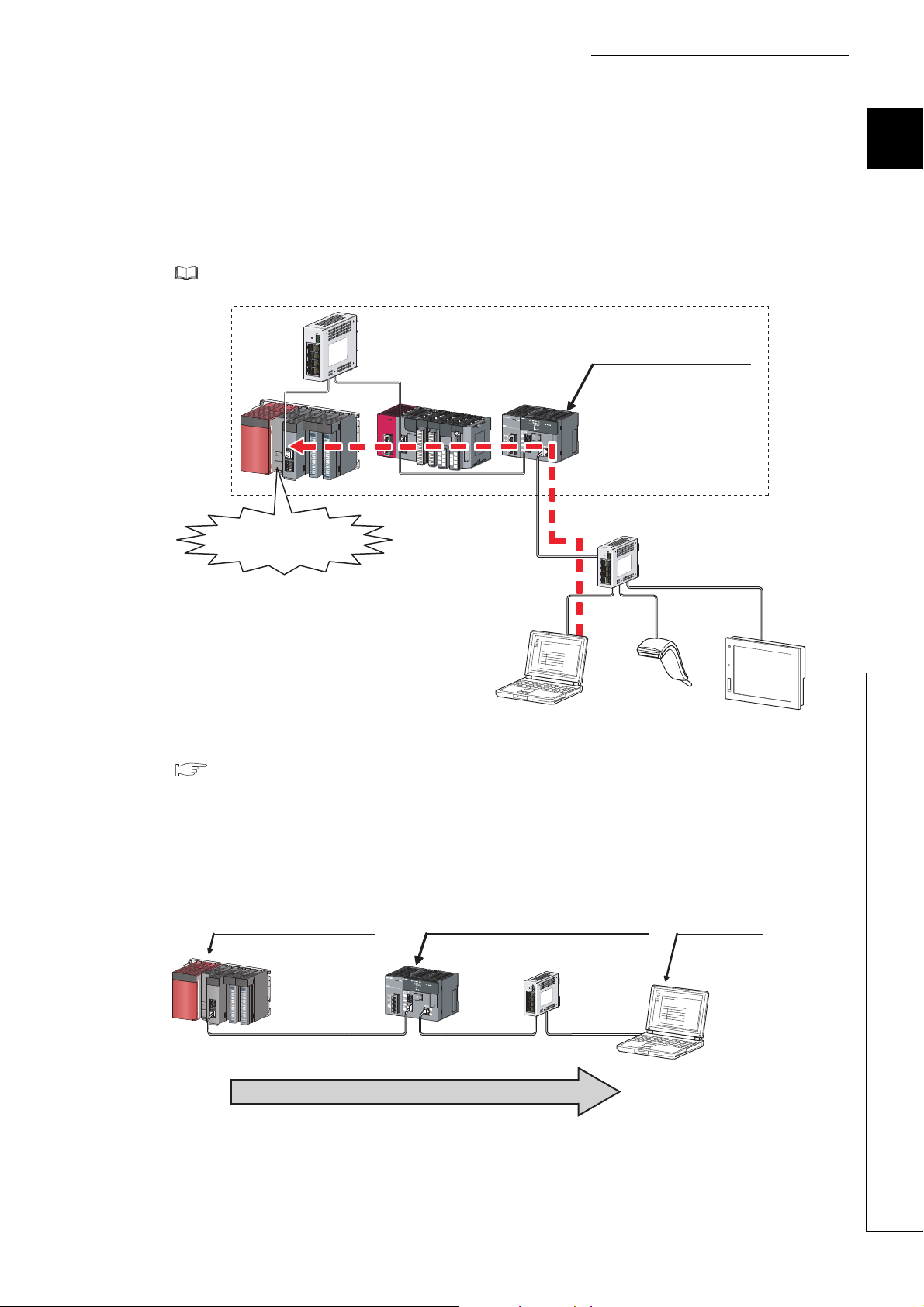

CHAPTER 1 ETHERNET ADAPTER MODULE

Ethernet

Ethernet adapter module (station No. 1)

Master station (station No. 0) External device

CC-Link IE Field Network

(network No. 1)

On-demand data transmission

(1) Communication using SLMP

(a) Data of the programmable controller device can be read/written

Device data can be read or written from an external device to a module on the network where the Ethernet

adapter module is connected. Data reading and writing is also available to the devices of the Ethernet adapter

module. For details on SLMP, refer to the following.

SLMP Reference Manual

Ethernet adapter module

CC-Link

IE Field Network

Device reading

or

writing

Switching hub

SLMP

1

(b) The on-demand function enables data to be sent from the programmable controller

( Page 89, Section 7.2)

Issuing a send request from the CPU module to the Ethernet adapter module allows data to be sent to the

external device.

Events such as link start instruction and read instruction can be notified to an external device.

In addition, data can be simultaneously sent to all the external devices on Ethernet where the Ethernet adapter

module is also connected (broadcast communications).

17

Page 20

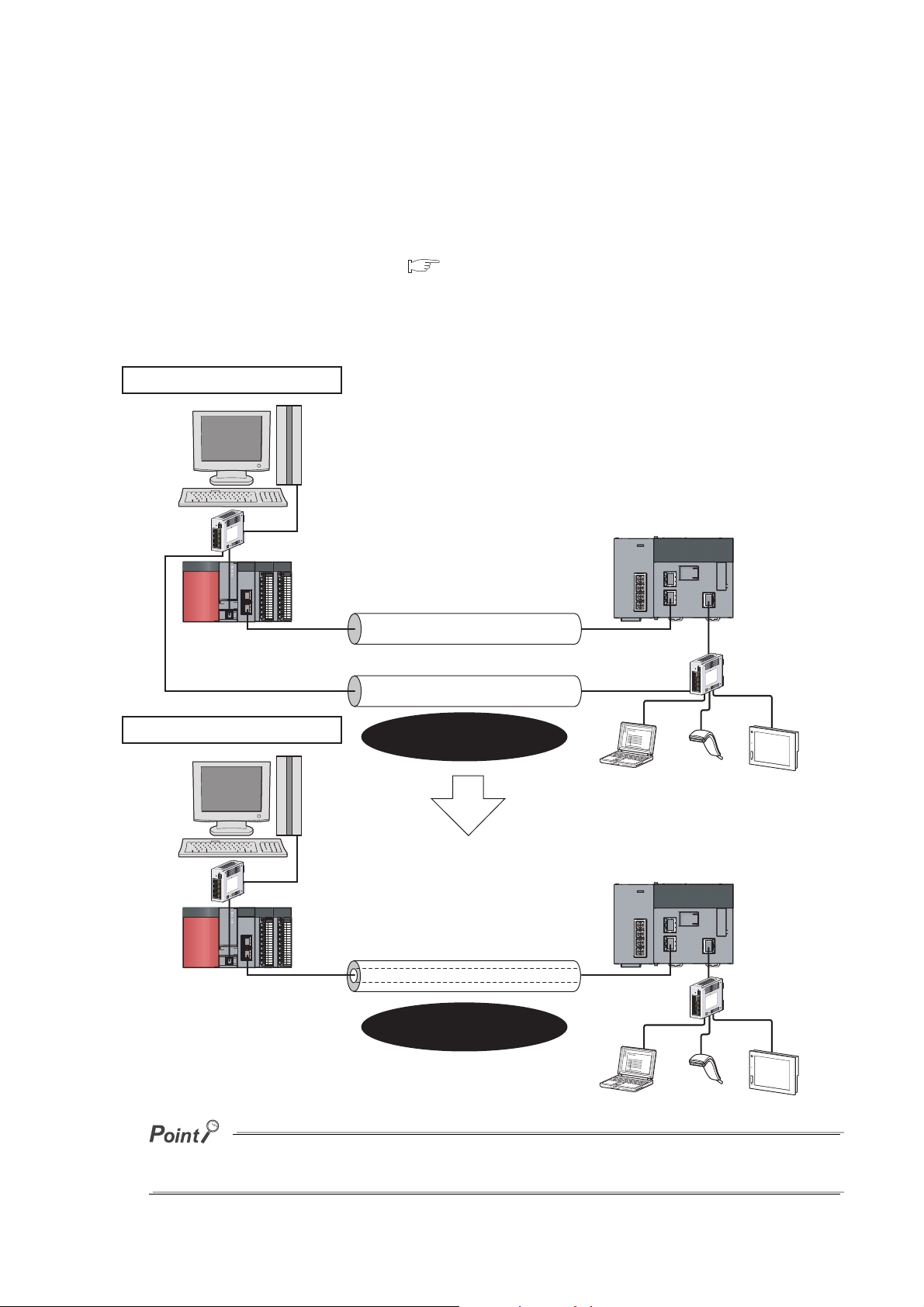

(2) Connection of MC protocol devices

Ethernet

Two networks were required.

CC-Link IE Field Network

Only CC-Link IE Field Network is

required to perform communications.

CC-Link IE Field Network

Ethernet communications (IP packet transfer)

When the IP packet transfer function is used

Conventional way

The message format of SLMP is the same as that of the QnA compatible 3E or 4E frame format of the MC

protocol. Therefore, external devices that support the MC protocol can be connected to CC-Link IE Field Network.

(3) Communications using the specified IP address over CC-Link IE Field Network

(IP packet transfer function) ( Page 105, Section 7.3)

With this function, communications using the specified IP address can be performed over CC-Link IE Field

Network. For example, a personal computer can communicate with the FTP server. Two networks of CC-Link IE

Field Network and Ethernet are not required, resulting in reduced wiring cost.

The IP packet transfer function allows an IP packet to be transferred from an external device to a request destination. An

Ethernet adapter module cannot be used as a request source or a request destination.

18

Page 21

CHAPTER 1 ETHERNET ADAPTER MODULE

Ethernet adapter module

Master station

RWw

Master/local

module

CPU

module

X

Y

W

RX

RY

RWw

RWr

RX

RY

RWr

Ethernet

adapter module

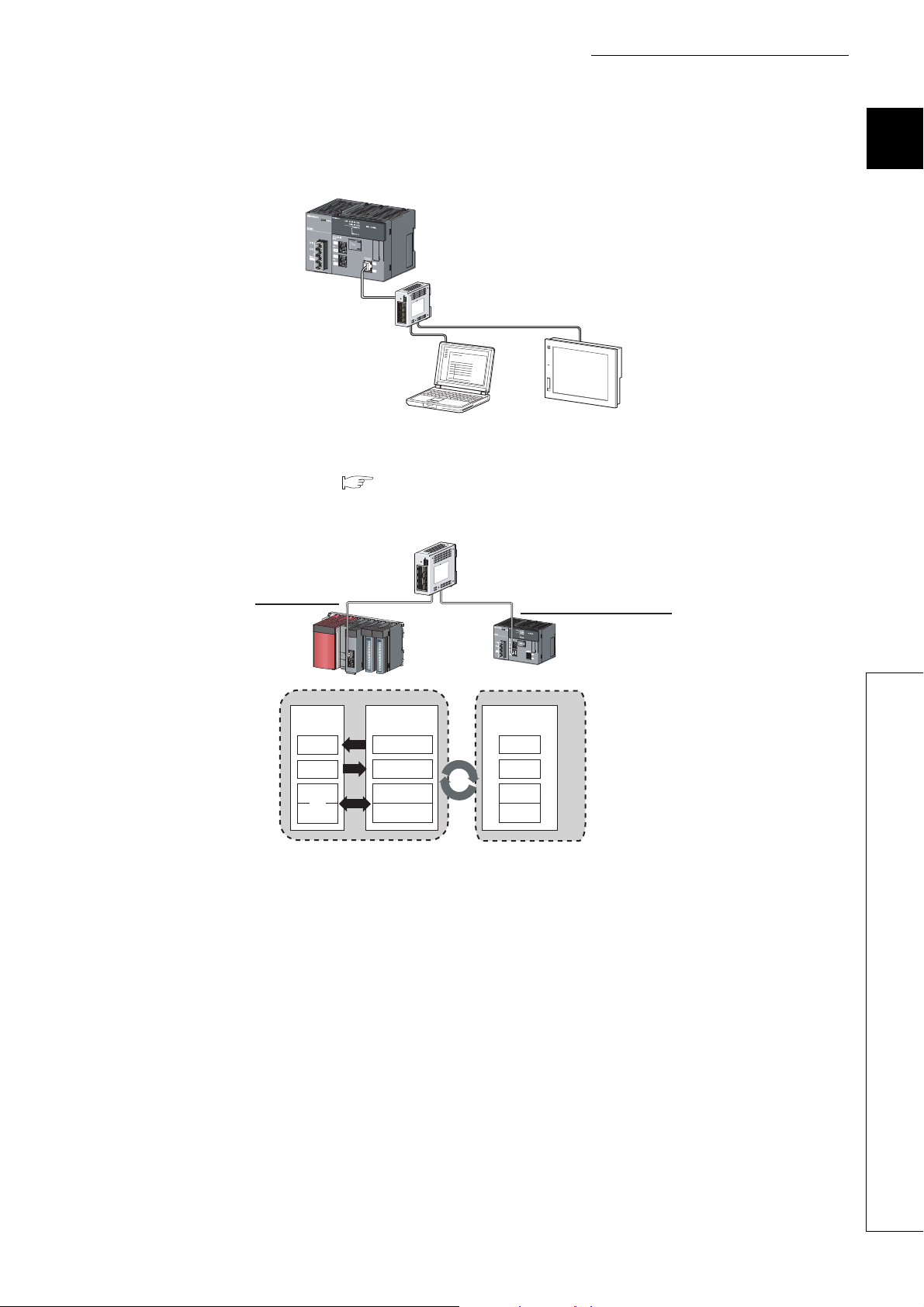

(4) Connection to MELSOFT products or GOTs

The Ethernet adapter module can be also connected to MELSOFT products or GOTs.

Switching hub

MELSOFT

product

GOT

(5) Cyclic transmission ( Page 33, Section 3.2.1 (2))

Data can be periodically exchanged with the master station through link devices (RX, RY, RWr, and RWw).

1

19

Page 22

(6) Transient transmission

Command

REMFR

Device

Buffer memory

1234H

1234H

CPU module Master/local

module

Master station

Ethernet

adapter module

Transient transmission allows direct access from a master or local station to the devices or buffer memory of the

Ethernet adapter module.

Requests from the master or local station to the Ethernet adapter module are made with dedicated instructions.

( User's manual for the master/local module used)

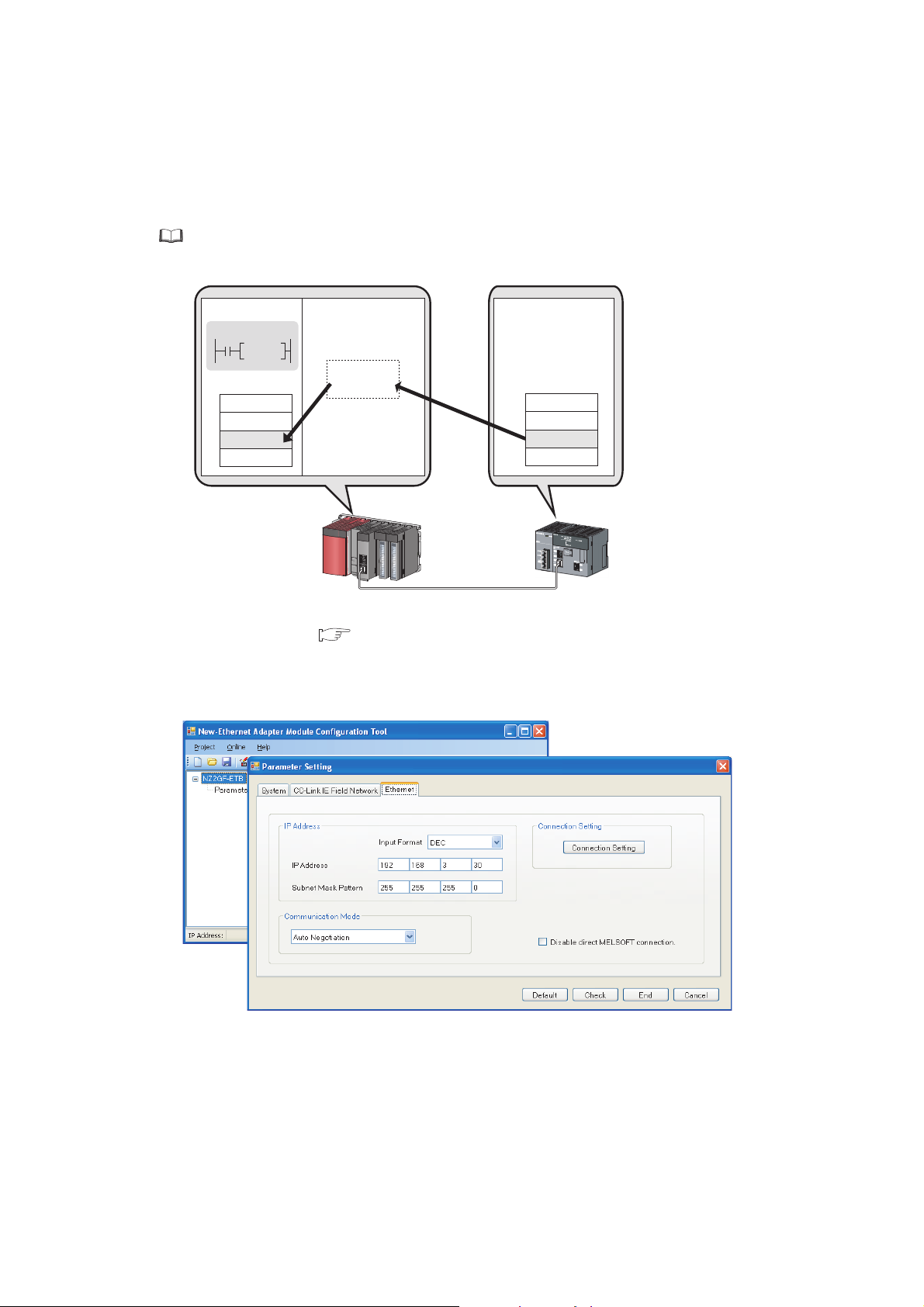

(7) Parameter setting ( Page 184, Section 10.3)

Parameters can be set in the configuration tool incorporated in the Ethernet adapter module. Therefore, there is

no need to create any configuration programs. The configuration tool will be started from a Web browser.

20

Page 23

CHAPTER 1 ETHERNET ADAPTER MODULE

The status of the entire CC-Link IE Field

Network can be monitored.

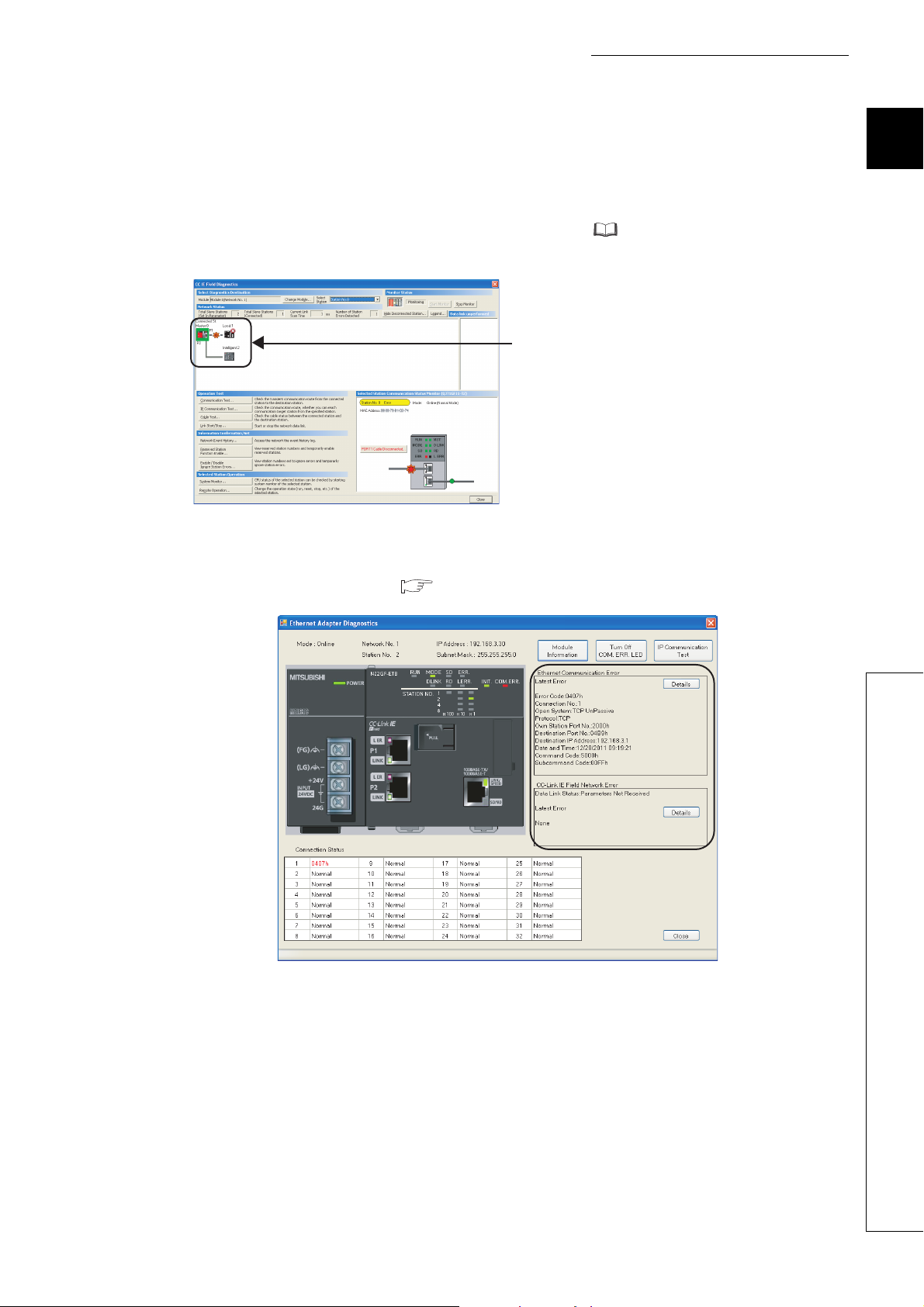

(8) Diagnostics

(a) CC-Link IE Field Network diagnostics

By connecting GX Works2 to a master/local module, the condition of the entire CC-Link IE Field Network can

be viewed on the CC-Link IE Field Network diagnostics dialog box. ( User's manual for the master/local

module used)

(b) Ethernet adapter diagnostics

In the Ethernet Adapter Diagnostics dialog box, the condition, such as an error occurred in communication with

an external device, can be checked. ( Page 198, Section 10.7)

1

21

Page 24

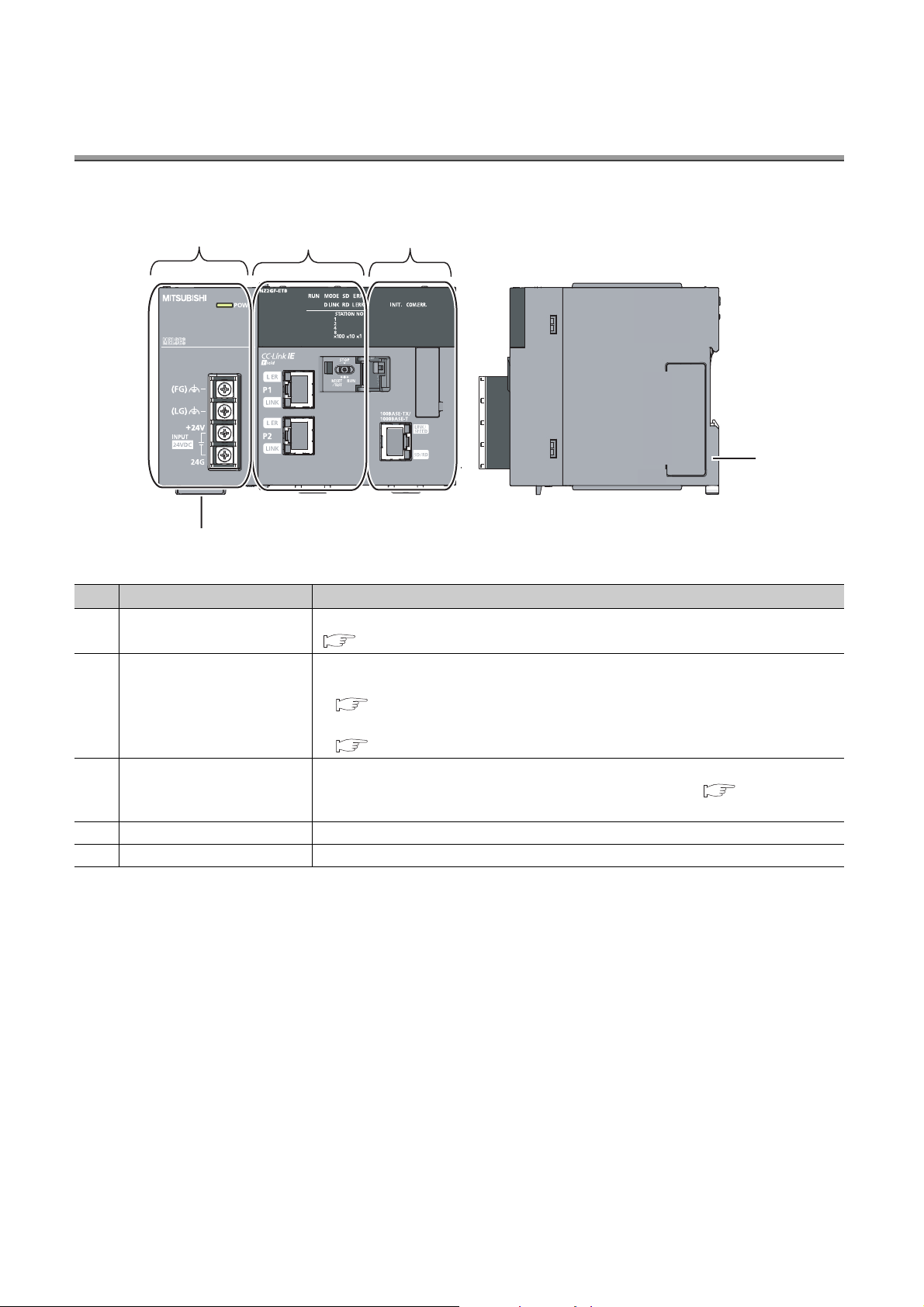

CHAPTER 2 PART NAMES

5)

4)

1) 2) 3)

This chapter describes the Ethernet adapter module parts and their names.

No. Name Description

1) Power supply part

2) CC-Link IE Field Network part

3) Ethernet part

4) Serial number display The serial number on the rating plate is indicated.

5) DIN rail hook This hook is used to mount the module to a DIN rail.

Power is supplied to the Ethernet adapter module through this part. (24VDC)

( Page 23, Section 2.1)

The Ethernet adapter module is connected to CC-Link IE Field Network at this part.

• The communication status of CC-Link IE Field Network is indicated with the LEDs.

( Page 24, Section 2.2 (1))

• The switch on this part is used for controlling the operation of the Ethernet adapter module.

( Page 26, Section 2.2 (2))

The Ethernet adapter module is connected to the Ethernet at this part.

The communication status of the Ethernet is indicated with the LEDs. ( Page 28, Section

2.3)

22

Page 25

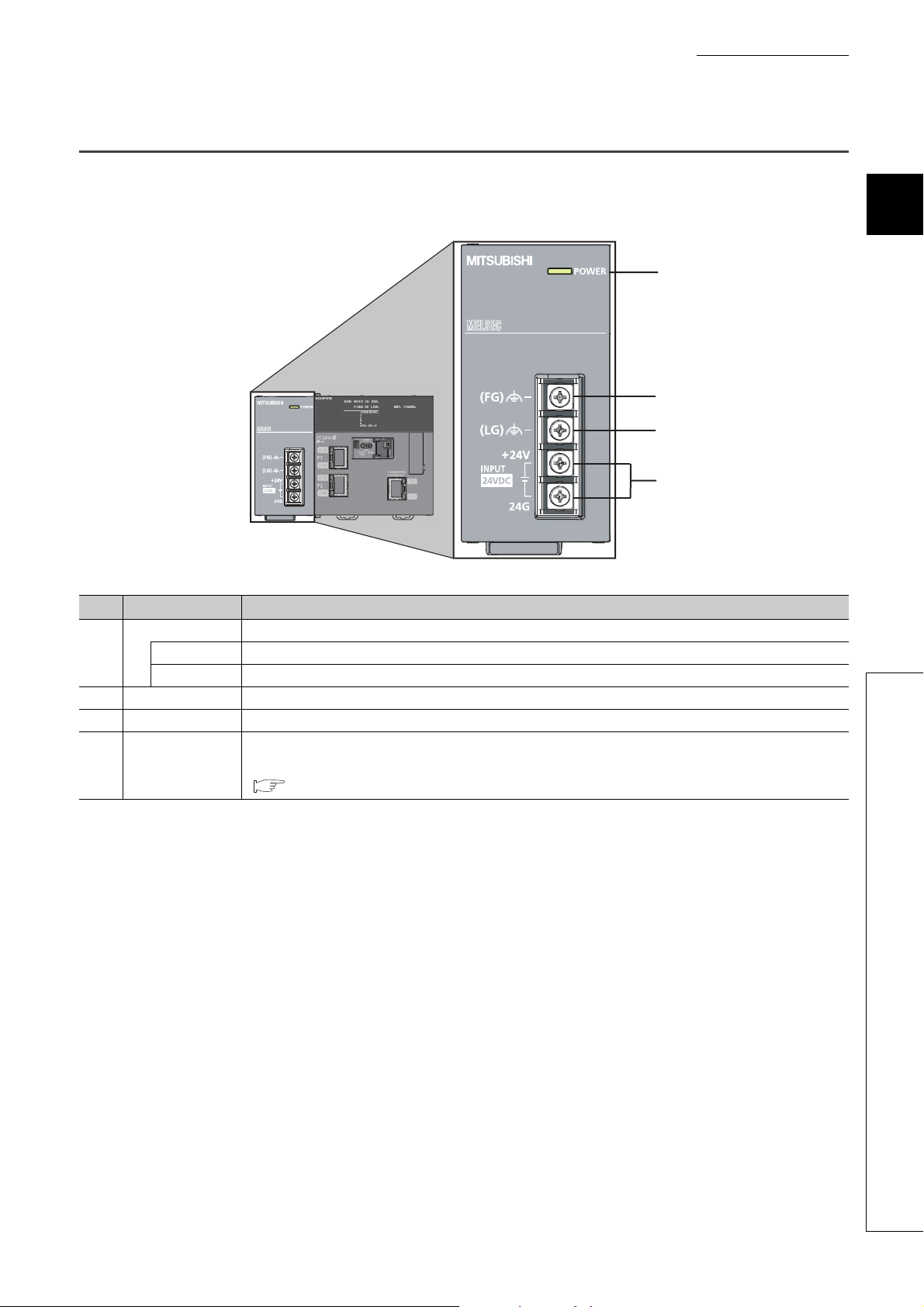

2.1 Power Supply Part

Respective names of the Ethernet adapter module's power supply part are shown below.

CHAPTER 2 PART NAMES

2

1)

2)

3)

4)

No. Name Part

POWER LED Indicates the operating status of the power supply part.

1)

2) FG terminal A ground terminal connected to the shield pattern on the printed circuit board (M3.5 screw)

3) LG terminal A terminal grounded to a power filter (M3.5 screw)

4)

On (green) Normally operating.

Off No power input, power failure, or hardware failure

Power input

terminal

Terminals for power input. (M3.5 screws)

For the specifications of the power supply to be connected, refer to "Performance specifications of each part."

( Page 31, Section 3.2.1 (1))

2.1 Power Supply Part

23

Page 26

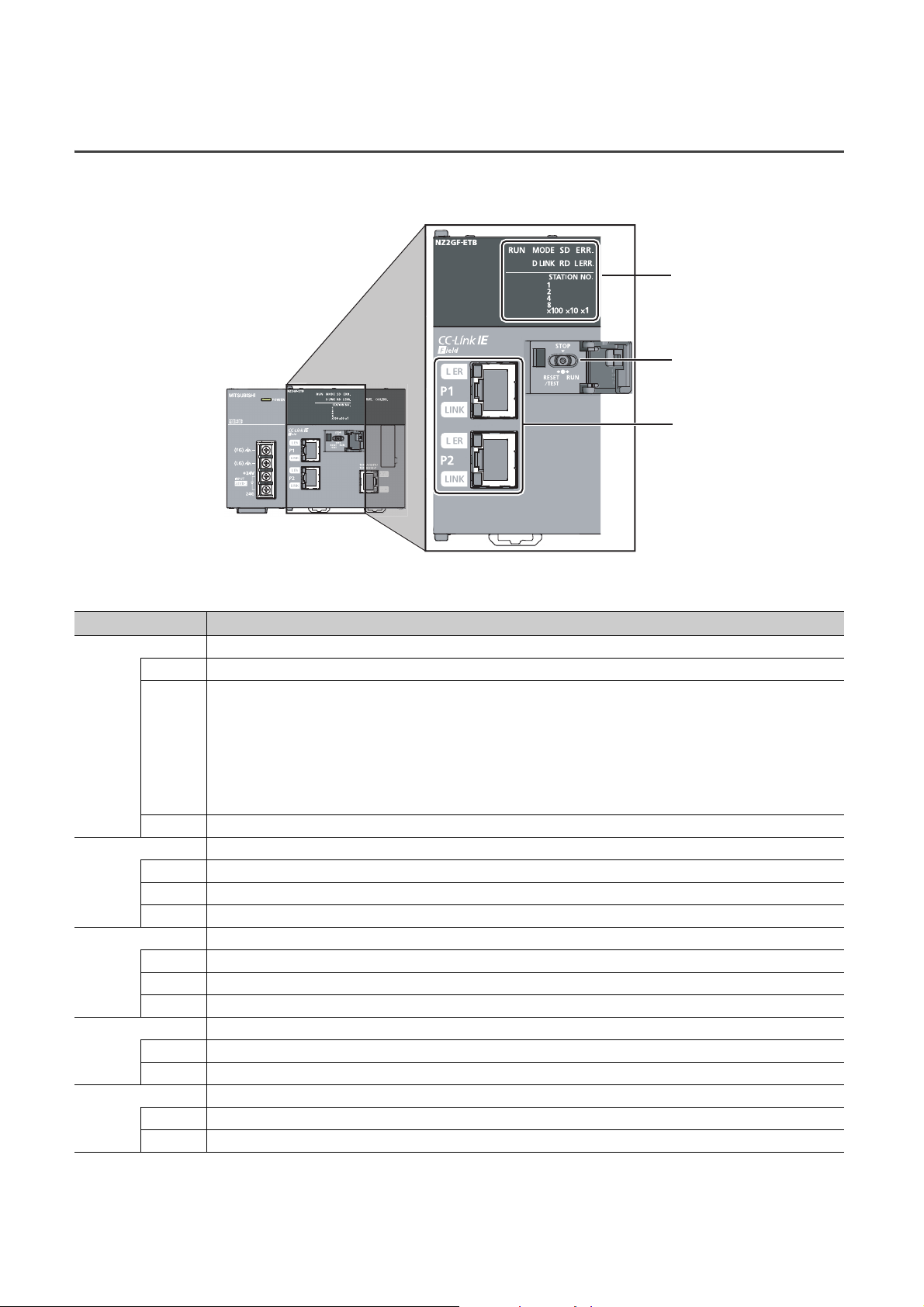

2.2 CC-Link IE Field Network Part

(1)

(2)

(3)

Respective names of the Ethernet adapter module's CC-Link IE Field Network part are shown below.

(1) LEDs

Name Description

RUN LED Indicates the operating status.

On Normally operating. (RUN status)

Normally operating. (STOP status)

• The Ethernet adapter module's switch is set to STOP. (Data transfer among the Ethernet adapter module

devices is stopped.)

Flashing

Off A hardware failure or a watchdog timer error has occurred.

MODE LED Indicates the mode.

On Online mode

Flashing Test mode

Off Offline mode

D LINK LED Indicates the data link status of CC-Link IE Field Network.

On Data link in operation (cyclic transmission in progress)

Flashing Data link in operation (cyclic transmission stopped)

Off Data link not in operation (disconnected) or the module is in offline mode.

SD LED Indicates the data sending status on CC-Link IE Field Network.

On Data being sent

Off No data being sent

RD LED Indicates the data receiving status on CC-Link IE Field Network.

On Data being received

Off No data being received

• The master station is in the STOP status. (Data transfer among the Ethernet adapter module devices is

continued.)

• A remote STOP request is being received.

• The Ethernet adapter module stopped due to an error (except a watchdog timer error).

24

Page 27

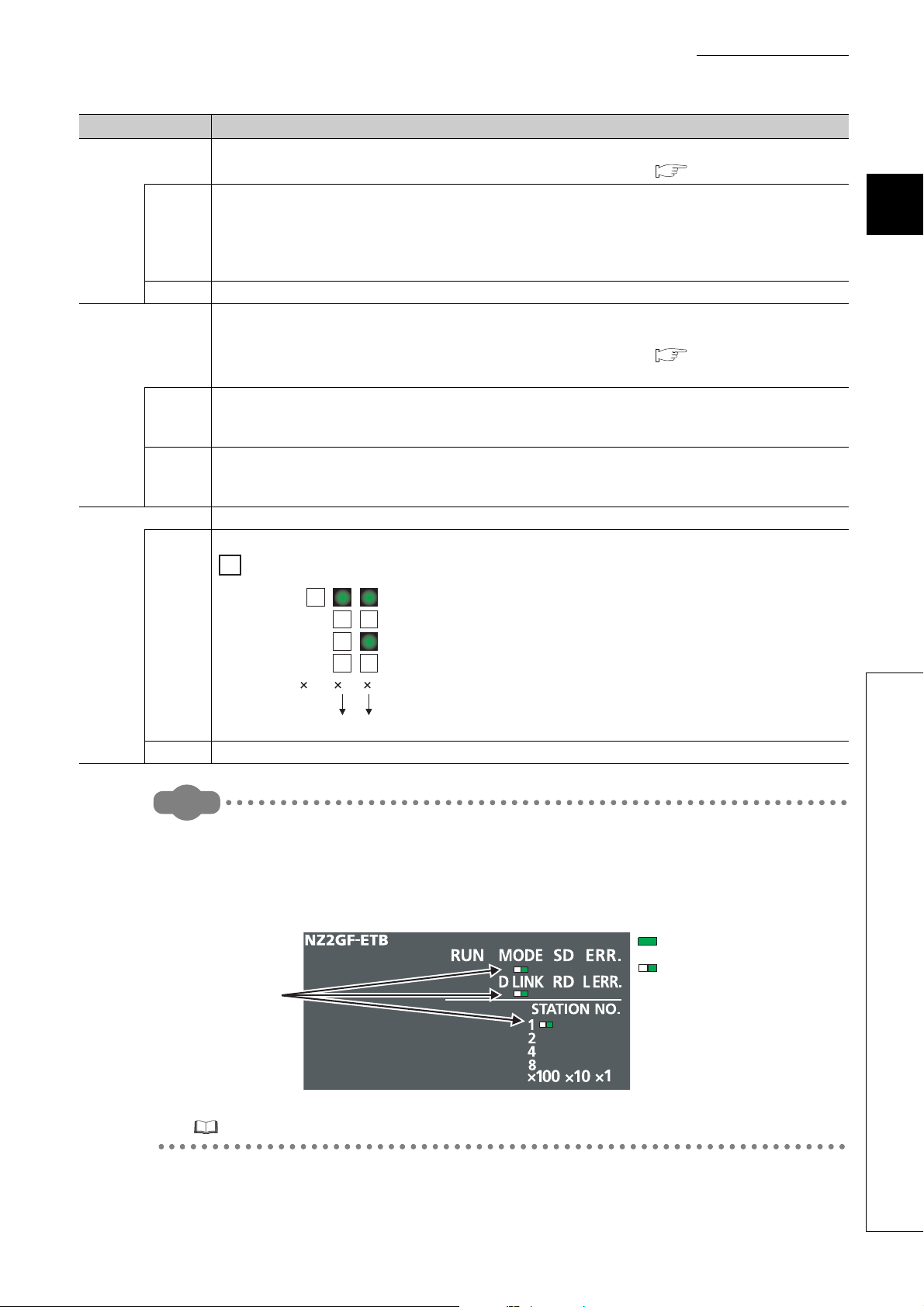

Remark

Name Description

110100

10 5+=15

1

2

8

4

ERR. LED

On

Off Normally operating.

L ERR. LED

On

Off

STATION NO. Indicates the station number of the Ethernet adapter module.

Indicates the error status of the Ethernet adapter module.

The error details can be checked by the CC-Link IE Field Network diagnostics. ( Page 141, Section 9.2.1)

One of the following errors occurred in the Ethernet adapter module.

• Multiple modules with the same station number exist on CC-Link IE Field Network.

• Network parameters for CC-Link IE Field Network is corrupted. Or, there is an error in the reserved station

setting, the number of connected stations, or the network number setting.

• There is an error in the network parameter settings for the Ethernet adapter module.

Indicates the error status of the received data and the line. When this LED is on, check the L ER LED for "P1" or

"P2" to see on which port the error was detected.

The error details can be checked by the CC-Link IE Field Network diagnostics. ( Page 141, Section 9.2.1)

This LED automatically turns off when the module has received normal data and loopback is completed.

• The Ethernet adapter module has received abnormal data.

• The Ethernet adapter module is performing loopback (only the Ethernet adapter module with a serial number

(first five digits) of "12102" or later).

• The Ethernet adapter module has received normal data.

• The Ethernet adapter module does not perform loopback (only the Ethernet adapter module with a serial number

(first five digits) of "12102" or later).

Indicates the station number.

CHAPTER 2 PART NAMES

2

Ex.

Station No.15

On

Off The station number has not been set.

● LED indication during line test execution

While a line test is being performed from the master station, the following LEDs are flashing.

•MODE LED

• D LINK LED

• ×100 LED

Flashing

: On

: Flashing

2.2 CC-Link IE Field Network Part

For execution of the line test, refer to the following.

User's manual for the master/local module used

25

Page 28

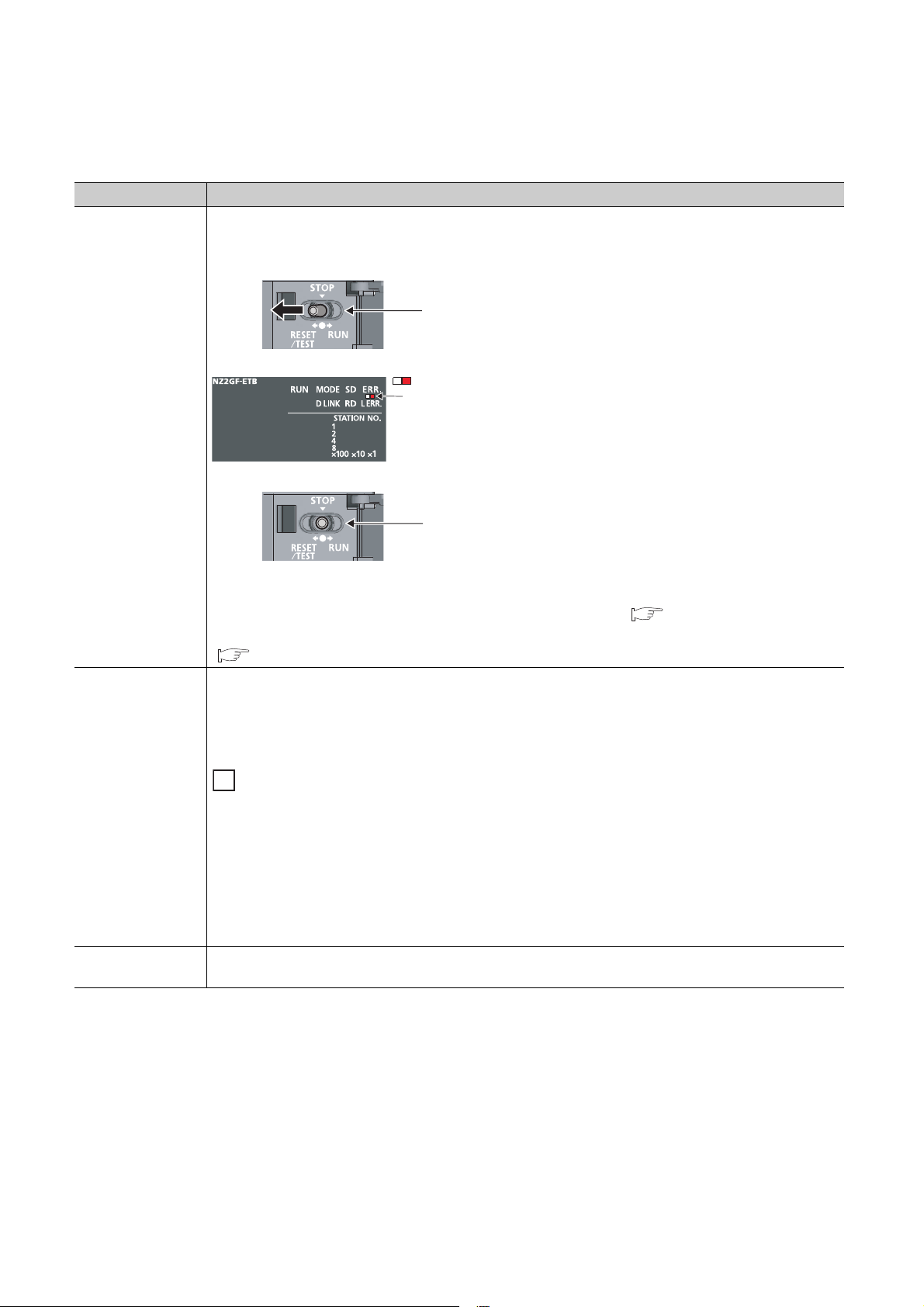

(2) Switch

1. Shift the switch to RESET/TEST for one

second or longer.

Hold the switch and do not release it.

2. Confirm that the ERR. LED flashes

several times and then turns off.

3. Set the switch back to the STOP

position.

The switch will automatically return to the

STOP position when released.

Flashes several times

and then turns off

: Flashing

With this switch, the operation of the Ethernet adapter module can be controlled.

Name Description

The Ethernet adapter module can be reset by the following method.

Set the switch with your fingertip. Using a tool such as a screwdriver may damage the switch.

Switch

RESET/TEST

Switch

You can also switch the Ethernet adapter module to the test mode and reset the parameters to default values.

For switching to the test mode, refer to "Testing the Module Before Wiring." ( Page 57, Section 6.3)

For resetting the parameters to default values, refer to "Resetting Parameters to Factory Default Values."

( Page 222, Appendix 6)

Transfer between the link devices (cyclic data from the master station) and the devices of the Ethernet adapter

module is stopped. (Transfer is stopped while cyclic transmission with the master station is continued.)

This transfer stop can prevent the data exchanged between an external device and the Ethernet adapter module

from being sent to the master and local stations. The STOP switch is used for a purpose, such as debugging

between the Ethernet adapter module and external devices.

STOP

RUN

26

Ex.

Debugging communication data with an external device using the STOP switch

*1

*1 Even if the switch is set to "STOP", the Ethernet adapter module is shown to be in the cyclic transmission status at the

(1) Set the switch to "STOP."

(2) Data transfer between the link devices and devices of the Ethernet adapter module is stopped, and the

Ethernet adapter module is separated from the master station control.

(3) Check if communications are normally performed between the Ethernet adapter module and an external

device. Because transfer is stopped, data exchanged between the Ethernet adapter module and the external

device will not be sent to the master and local stations.

(4) After checking the above, write the parameters to the Ethernet adapter module and start the system

operation.

Cyclic transmission starts between the Ethernet adapter module and the master station. (Data communication

between the Ethernet adapter module and external devices is performed regardless of the switch status.)

master station.

Page 29

(3) Connectors

Name Description

The PORT1 connector for connecting to CC-Link IE Field Network. (RJ45 connector)

P1

L ER

LED

LINK

LED

P2

L ER LED

LINK LED

On

Off

On Linkup in progress

Off Linkdown in progress

Connect an Ethernet cable to this. ( Page 61, Section 6.4.2)

There are no restrictions on the connection order of the cables for the "P1" and "P2" connectors.

• The Ethernet adapter module has received abnormal data.

• The Ethernet adapter module is performing loopback (only the Ethernet adapter module with a serial number

(first five digits) of "12102" or later).

• The Ethernet adapter module has received normal data.

• The Ethernet adapter module does not perform loopback (only the Ethernet adapter module with a serial number

(first five digits) of "12102" or later).

The PORT2 connector for connecting to CC-Link IE Field Network. (RJ45 connector)

Connect an Ethernet cable to this. ( Page 61, Section 6.4.2)

There are no restrictions on the connection order of the cables for the "P1" and "P2" connectors.

(Same as the "P1" connector)

CHAPTER 2 PART NAMES

2

2.2 CC-Link IE Field Network Part

27

Page 30

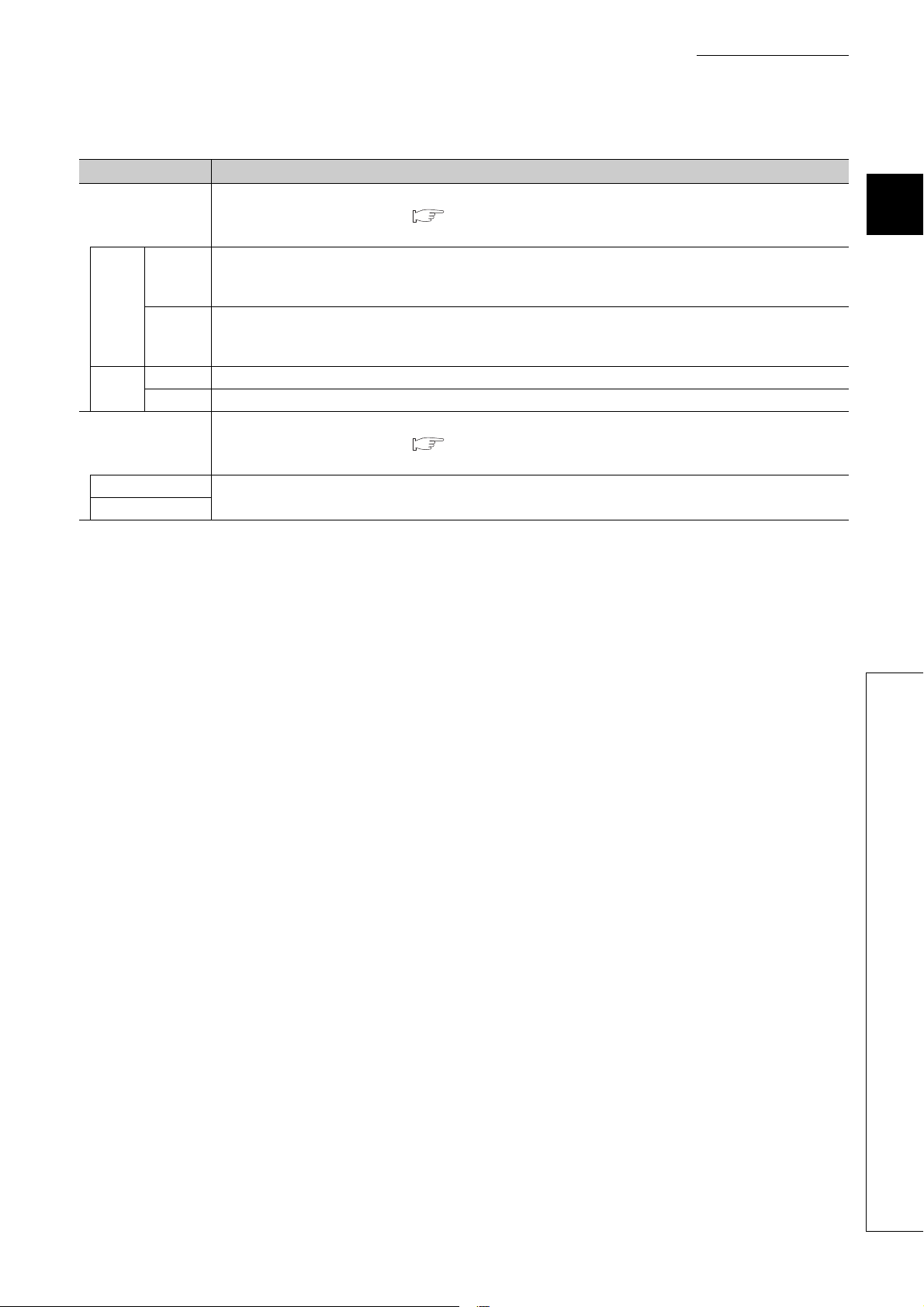

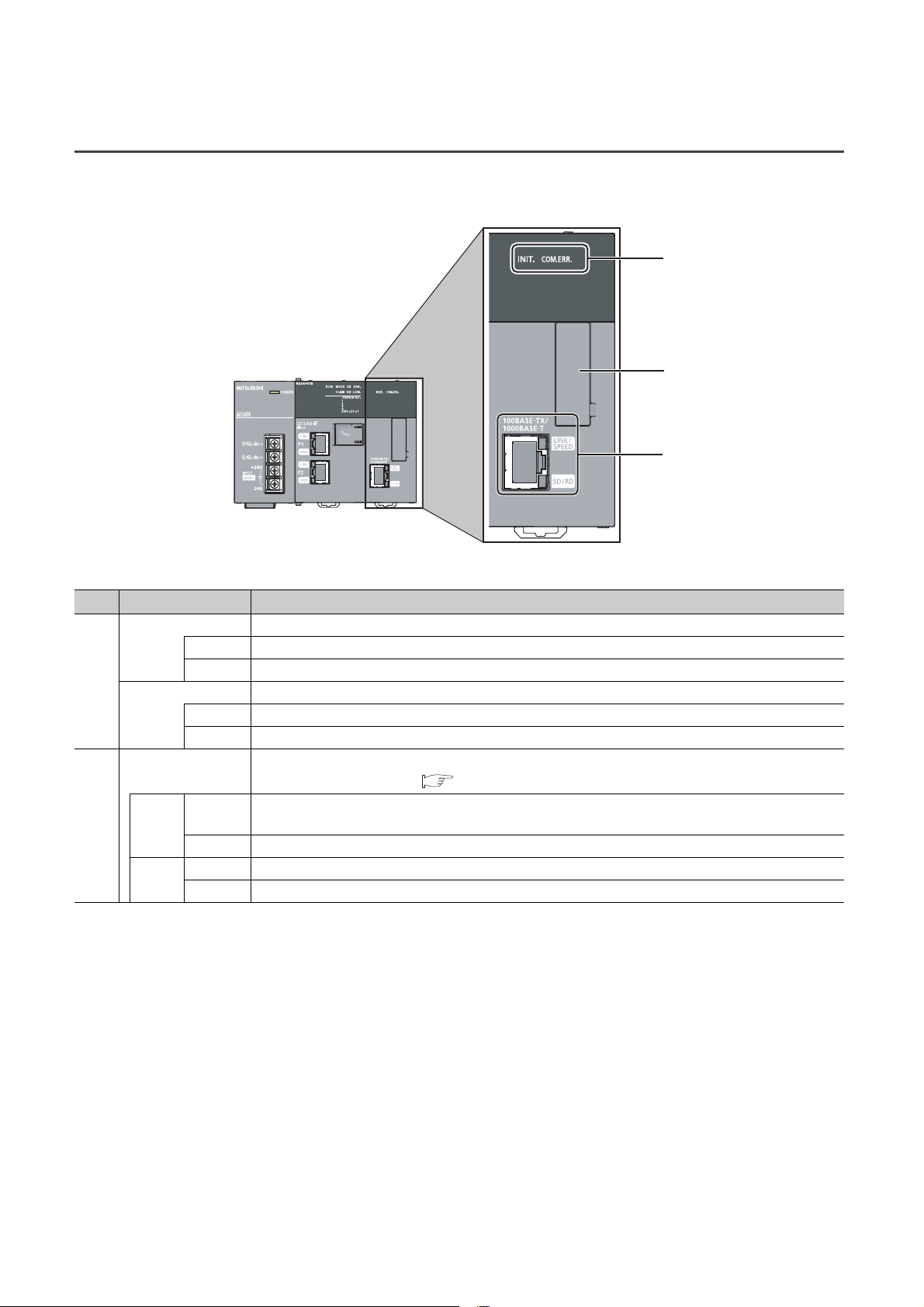

2.3 Ethernet Part

This section describes the names of the Ethernet adapter module's Ethernet part.

*1 Do not remove this sticker since it is used for maintenance.

1)

*1

2)

No. Name Description

INIT. LED Indicates the initial processing status.

On Initial processing completed.

1)

COM.ERR. LED Indicates the Ethernet communication status.

Ethernet port

2)

LINK/

SPEED

SD/RD

Off Initial processing not completed.

On An error occurred in Ethernet communication.

Off Normal Ethernet communication

Connector for Ethernet connection. (RJ45 connector)

Connects an Ethernet cable. ( Page 61, Section 6.4.2)

On

Off Linkdown in progress

On Data being sent or received in Ethernet communication

Off No data transfer in Ethernet communication

• Green: Linkup in progress at 1Gbps

• Orange: Linkup in progress at 100Mbps

28

Page 31

CHAPTER 3 SPECIFICATIONS

This chapter describes the specifications of the Ethernet adapter module.

3.1 General Specifications

Item Specification

Operating ambient

temperature

Storage ambient

temperature

Operating ambient

humidity

Storage ambient

humidity

Compliant with

Vibration resistance

Shock resistance

Operating atmosphere No corrosive gases

Operating altitude

Installation location Inside a control panel

Overvoltage category

Pollution degree

Equipment class Class I

*1

*3

*1 Do not use or store the Ethernet adapter module under pressure equivalent to the atmospheric pressure of an elevation

of 0m or higher. Doing so may cause malfunction. When applying pressure to the module, please consult your local

Mitsubishi representative.

*2 This indicates the section of the power supply to which the equipment is assumed to be connected between the public

power distribution network and the machinery within premises.

Category II applies to equipment for which electric power is supplied from fixed facilities. The surge voltage withstand

level for up to the rated voltage of 300V is 2500V.

*3 This index indicates the degree to which conductive material is generated in terms of the environment in which the

equipment is used.

At pollution level 2, only non-conductive pollution occurs. A temporary conductivity caused by condensing must be

expected occasionally.

JIS B 3502 and

IEC 61131-2

Compliant with JIS B 3502 and IEC 61131-2 (147m/s

*2

Under

intermittent

vibration

Under

continuous

vibration

5 to 95%RH, non-condensing

Frequency

5 to 8.4Hz 3.5mm 10 times each in

8.4 to 150Hz

5 to 8.4Hz 1.75mm

8.4 to 150Hz

0 to 55°C

-25 to 75°C

Constant

acceleration

9.8m/s

4.9m/s

0 to 2000m

II or lower

2 or lower

CHAPTER 3 SPECIFICATIONS

Half amplitude Sweep count

2

2

2

, 3 times each in X, Y, and Z directions)

X, Y, and Z

directions

3

3.1 General Specifications

For compliance with the EMC directive, refer to "EMC and Low Voltage Directives" in this manual.

( Page 224, Appendix 8)

29

Page 32

3.2 Performance Specifications

The following describes the performance specifications of the Ethernet adapter module.

Item Specification

X

Y

Number of device points

Number of writes to the parameter memory Up to 100000 times

Clock function (for display of data such as the

date and time at which an error occurred)

Internal current consumption (24VDC) 0.6A

External dimensions

Weight 0.7kg

W

SB 8192 points, 1KB

SW 8192 points, 16KB

SM 2048 points, 256 bytes

SD 2048 points, 4KB

H90mm

W135mm

D109mm

8192 points, 1KB

(X0 to X1FFF are assigned to RX0 to RX1FFF.)

8192 points, 1KB

(Y0 to Y1FFF are assigned to RY0 to RY1FFF.)

8192 points, 16KB

(1024 points of W0 to W3FF are assigned to RWw0 to RWw3FF.

1024 points of W1000 to W13FF are assigned to RWr0 to RWr3FF.)

Year, month, date, hour, minute, and second (with automatic leap year detection)

When connected to a network, the clock is periodically synchronized with the clock in the

CPU module on the master station via the network. (Initial value: 2000/1/1 00:00:00)

If the Ethernet adapter module is powered off and then on, the clock will restart at the time

the power was turned off. (The clock does not run while the power is off.)

Therefore, the date and time of an error that occurred during initial processing may be

different from the actual date and time.)

30

Page 33

3.2.1 Performance specifications of each part

The performance specifications of each part of the Ethernet adapter module are described below.

CHAPTER 3 SPECIFICATIONS

Power supply

part

CC-Link IE Field

Network part

(1) Power supply part

Item Specification

Input voltage

( Page 32, Section 3.2.1 (1) (a))

Current consumption 0.6A

Inrush current

( Page 32, Section 3.2.1 (1) (b))

Allowable momentary power failure time

( Page 32, Section 3.2.1 (1) (c))

Withstand voltage

Insulation resistance

Noise immunity

Operation status indicator LEDs (Normal: On (green), Error: Off)

Fuse Built-in (not replaceable)

Terminal screw size M3.5

Applicable wire size

Applicable solderless terminal

Applicable tightening torque 0.66 to 0.89N•m

24VDC (-35% to +30%)

100A, 1ms or less

10ms or less

510V AC/min (Altitude: 0 to 2,000m)

Between inputs/LG and outputs/FG

10M or higher by 500VDC insulation resistance tester

(Between inputs/LG and outputs/FG, inputs and LG, outputs and FG)

• By noise simulator of 500Vp-p noise voltage, 1µs noise width, and 25 to 60 Hz noise

frequency

• Noise voltage IEC 61000-4-4, 2kV

0.75 to 2 mm

RAV1.25-3.5, RAV2-3.5, 0.8mm or less in thickness

Two solderless terminals can be connected to one terminal.

2

Ethernet

part

3

3.2 Performance Specifications

3.2.1 Performance specifications of each part

31

Page 34

(a) Input voltage

Input voltage is a voltage at which the power supply part operates normally. If it is outside the specified range,

the Ethernet adapter module may detect an error and stop its operation.

(b) Inrush current

Inrush current is a large current that instantaneously flows into a circuit immediately after power is applied.

Reapplying input power after power-off may cause an inrush current that exceeds the specified value. Allow 5

seconds or more before reapplying input power.

Also, select appropriate fuses or breakers for external circuits, considering the possibility of meltdown, sensing

property, and other items shown in this section.

(c) Allowable momentary power failure time

If a momentary power failure occurs, the system detects an input voltage failure and stops its operation.

Allowable momentary power failure time is the period of time that the system can continue its operation after

power is restored.

If a momentary stop exceeding the allowable momentary power failure time occurs, the operation will be

continued by the load of the power supply part, or will be initially started. When the operation is continued, the

operational behavior is the same as that for the momentary stop within the allowable momentary power failure

time.

32

Page 35

(2) CC-Link IE Field Network part

Item Specification

RWw 8192 points, 16KB

Maximum link points per

network

Maximum link points per

station

Station type Intelligent device station

Station No. 1 to 120

Network No. 1 to 239

Communication method Token passing method

Communication speed 1Gbps

Transmission path

Connection cable

RWr 8192 points, 16KB

RX 16384 points, 2KB

RY 16384 points, 2KB

RWw 1024 points, 2KB

RWr 1024 points, 2KB

RX 2048 points, 256 bytes

RY 2048 points, 256 bytes

Line or star topology (Coexistence of line topology and star topology is possible.), ring

topology

An Ethernet cable that meets the 1000BASE-T standard:

Category 5e or higher, (Double shielded/STP) Straight cable

(

Page 48, Section 5.2.1)

CHAPTER 3 SPECIFICATIONS

3

Maximum station-to-station distance

Overall cable distance

Number of cascade connections Up to 20

Up to 100m (compliant with ANSI/TIA/EIA-568-B (Category 5e)) (

6.4.4 (7))

Line topology: 12000m (when connecting 1 master station and 120 slave stations)

Star topology: Depends on the system configuration

Ring topology: 12100m (when connecting 1 master station and 120 slave stations)

Page 65, Section

3.2 Performance Specifications

3.2.1 Performance specifications of each part

33

Page 36

(3) Ethernet part

Item Specification

For users 32

Number of

connections

Own Station Port No.

Number of simultaneously connectable

modules

Communication speed 1Gbps or 100Mbps

Communication mode Full- or Half-duplex

Transmission system Base band

Connection cable

Maximum distance between switching hub

and node

Number of cascade connections Up to 20

For auto-open 1

For MELSOFT

connection

For 1Gbps

For 100Mbps

*2

3 (TCP connection: 1

1025 to 4999, 5011 to 65534 (0401

Up to 32

An Ethernet cable that meets the 1000BASE-T standard:

Category 5e or higher, (Double shielded/STP) Straight cable

Page 48, Section 5.2.2 (1))

(

An Ethernet cable that meets the 100BASE-TX standard:

Category 5 or higher, (STP) Straight cable

(

Page 48, Section 5.2.2 (1))

Up to 100m

*1

, UDP connection: 1, Direct connection: 1)

to 1387H, 1393H to FFFEH)

H

*1 To use two or more TCP connections for a MELSOFT Connection, user connections can be assigned to MELSOFT

Connection. (

*2 Use of double shielded cables is recommended in a high noise environment.

● When connected to a switching hub, the Ethernet adapter module detects and sets 1000BASE-T or 100BASE-TX and

full-or half- duplex communication mode according to the switching hub. When the connected switching hub does not

support the auto-negotiation function, set the switching hub to the half-duplex communication mode.

● The operation of the following connections is not guaranteed. Check the operation at the user's discretion before use.

• Connections using the Internet (public line)

(Internet connection services by Internet service providers or telecommunications carriers)

• Connections using firewall devices

• Connections using broadband routers

Page 191, Section 10.3.3 (1))

34

Page 37

(a) Communication specifications for TCP connection

Ex.

• Number of resends and resend interval

If the Ethernet adapter module sent a message to an external device and after that did not receive an ACK

from the external device, it will resend the message at the intervals shown below.

Item Specification

Number of resends Up to 3 times

Up to 64 seconds (Varies depending on the line status.)

If the resend fails, the amount of time is doubled. (The maximum value is 64

seconds.)

Resend interval

When the interval for the first resend is 20 seconds;

1st: 20s, 2nd: 40s, 3rd: 64s

If the Ethernet adapter module fails to receive an ACK response from the external device even when it

resends data as many times as the number of resends, it regards that there is no external device, causing

disconnection.

When the connection is disconnected, send a connection establishment request from the external device,

reestablish a connection, and resend a request message.

CHAPTER 3 SPECIFICATIONS

3

• Alive check by KeepAlive

The Ethernet adapter module performs alive check by KeepAlive.

The Ethernet adapter module sends an alive check message in 5 seconds after receiving the last

message from an external device. If no response is returned from the external device for 5 seconds, the

module resends the alive check message. The module resends the message for 7 times at intervals of 5

seconds.

If no response is received for 45 seconds from the last message reception from the external device, the

Ethernet adapter module will close the connection. Allow 45 seconds or longer before opening the same

connection again.

When the external device does not support the TCP KeepAlive function, the connection may be closed.

• Connection establishment request

When a connection establishment request is sent from an external device to the port of the Ethernet

adapter module, where a connection has been already established, the Ethernet adapter module will not

respond. Therefore, if no response is returned even after a connection establishment request is sent to the

Ethernet adapter module, check if the specified port number is correct.

3.2 Performance Specifications

3.2.1 Performance specifications of each part

35

Page 38

3.3 List of the Functions

This section lists the functions of the Ethernet adapter module.

(1) Communications with an external device

Function Description Refer to

Device data can be read or written from an external device to a

Communications from

an external device

Communications

using SLMP

Communication using the specified IP

address over CC-Link IE Field Network

(IP packet transfer function)

Connection to MELSOFT products or

GOTs

Communications from

a CPU module

(on-demand function)

module on the network where the Ethernet adapter module is

connected. Data also can be read or written from/to the Ethernet

adapter module.

Issuing a send request from the CPU module to the Ethernet

adapter module allows data to be sent to the external device.

Events such as link start instruction and read instruction can be

notified to an external device.

In addition, data can be simultaneously sent to all the external

devices on Ethernet where the Ethernet adapter module is also

connected (broadcast communications).

With this function, communications using the specified IP address

can be performed over CC-Link IE Field Network. For example, a

personal computer connected to the Ethernet part can

communicate with another personal computer connected to a Built-

in Ethernet port QCPU.

Two networks of CC-Link IE Field Network and Ethernet are not

required, resulting in reduced wiring cost.

The Ethernet adapter module can be also connected to MELSOFT

products or GOTs.

Page 66, Section 7.1

Page 89, Section 7.2

Page 105, Section 7.3

(2) CC-Link IE Field Network communications

Function Description Refer to

Cyclic transmission

Transient transmission

Data can be periodically exchanged with the master station through

link devices (RX, RY, RWr, and RWw).

The devices or buffer memory of the Ethernet adapter module can

be directly accessed from the master or local station.

Requests from the master or local station to the Ethernet adapter

module are made with dedicated instructions.

(3) Other functions

Function Description Refer to

Device/buffer memory batch monitor

Ethernet adapter diagnostics

The values in the devices and buffer memory of the Ethernet

adapter module can be monitored.

Information such as the latest error that occurred in the Ethernet

adapter module and the status of the communications with an

external device can be checked.

Page 66, Section 7.1

Page 196, Section 10.6

Page 198, Section 10.7

36

Page 39

CHAPTER 3 SPECIFICATIONS

3.4 Buffer Memory List

The buffer memory is used for exchanging data between the Ethernet adapter module and a master/local module or an

external device.

The contents of the buffer memory return to the default state (initial values) when the system is powered off or reset.

Address

(Decimal

(Hexadecimal))

0

)

(0

H

1

)

(1

H

2

)

(2

H

3 to 15

to FH)

(3

H

16 to 18

to 12H)

(10

H

19

)

(13

H

20 to 21

to 15H)

(14

H

22 to 25

to 19H)

(16

H

26 to 28

to 1CH)

(1A

H

29

)

(1D

H

30 to 31

to 1FH)

(1E

H

32 to 33

to 21H)

(20

H

34 to 35

to 23H)

(22

H

36

)

(24

H

37

)

(25

H

38

)

(26

H

39 to 47

to 2FH)

(27

H

48

)

(30

H

49 to 767

to 2FFH)

(31

H

768

)

(300

H

Name

Module LED information

Module operation area

System area

Own station information

(PORT1 and PORT2)

System area

Own station information

(Ethernet port)

System area

Own station information

(Parameters)

System area

Ethernet port operation area

(area for initial processing)

Station No. LED information

Ethernet port LED information

Own station MAC address Read

System area

Own station IP address 0 Read

Own station MAC address Read

System area

Own station IP address 0

Own station subnet mask 0

Mode 0 Read

Network No. 0 Read

Station No. 0 Read

System area

Function check area

Initial processing error code 0 Read

*1

Initial

value

0001

Read/Write Refer to

Read

0

Read

Read

H

Read

Page 201,

Appendix 1.1 (1)

Page 201,

Appendix 1.1 (2)

Page 201,

Appendix 1.1 (3)

Page 202,

Appendix 1.2 (1)

Page 202,

Appendix 1.2 (1)

Page 202,

Appendix 1.2 (2)

Page 202,

Appendix 1.2 (2)

Page 202,

Appendix 1.2 (3)

Page 202,

Appendix 1.2 (3)

Page 203,

Appendix 1.3 (1)

3

3.4 Buffer Memory List

37

Page 40

Address

(Decimal

(Hexadecimal))

769 to 783

to 30FH)

(301

H

784

)

(310

H

785

)

(311

H

786

)

(312

H

787

)

(313

H

788

)

(314

H

789

)

(315

H

790 to 791

to 317H)

(316

H

792

)

(318

H

793

)

(319

H

794 to 795

to 31BH)

(31A

H

796 to 799

to 31FH)

(31C

H

800 to 1295

(320

to 50FH)

H

1296

)

(510

H

1297

)

(511

H

1298

)

(512

H

1299

)

(513

H

1300

)

(514

H

1301

)

(515

H

1302 to 1303

to 517H)

(516

H

1304

)

(518

H

1305

)

(519

H

1306 to 1307

to 51BH)

(51A

H

Name

Initial

value

Read/Write Refer to

System area

Open system 1

Protocol 0

Read

Communication data code 1

Page 203,

Appendix 1.3 (2)

Own Station Port No. 0

Ethernet port operation area

(Connection information area

TCP connection system 0

Read

Connection status 0

Page 203,

Appendix 1.3 (2)

No.1)

System area

Latest error code 0 Read

Destination port No. 0 Read

Page 203,

Appendix 1.3 (2)

Destination IP address 0 Read

System area

Ethernet port operation area

(Connection information area

No.2 to No.32)

Same as Connection information area No.1

Page 204,

Appendix 1.3 (3)

Open system 3

Ethernet port operation area

(Auto-open UDP port area)

Protocol 1

Read

Communication data code 0

Own Station Port No.

1388

H

System area

Connection status 0 Read

Page 204,

Appendix 1.3 (4)

Page 204,

Appendix 1.3 (4)

System area

Latest error code 0

Destination port No. 0

Read

Page 204,

Appendix 1.3 (4)

Destination IP address 0

38

Page 41

CHAPTER 3 SPECIFICATIONS

Address

(Decimal

(Hexadecimal))

1308 to 1311

to 51FH)

(51C

H

1312

)

(520

H

1313

)

(521

H

1314

)

(522

H

1315

)

(523

H

1316

)

(524

H

1317

)

(525

H

1318 to 1319

to 527H)

(526

H

1320

)

(528

H

1321

)

(529

H

1322 to 1323

to 52BH)

(52A

H

1324 to 1327

to 52FH)

(52C

H

1328

)

(530

H

1329

)

(531

H

1330

)

(532

H

1331

)

(533

H

1332

)

(534

H

1333

)

(535

H

1334 to 1335

to 537H)

(536

H

1336

)

(538

H

1337

)

(539

H

1338 to 1339

to 53BH)

(53A

H

1340 to 1343

to 53FH)

(53C

H

Name

Initial

value

Read/Write Refer to

System area

System area

Protocol 1

Communication data code 0

Own Station Port No.

1389

Read

H

Page 205,

Appendix 1.3 (5)

System area

Ethernet port operation area

(MELSOFT application

communication port (UDP/IP)

Connection status 0 Read

Page 205,

Appendix 1.3 (5)

area for the system)

System area

Latest error code 0

Destination port No. 0

Read

Page 205,

Appendix 1.3 (5)

Destination IP address 0

System area

Open system 0

Protocol 0

Ethernet port operation area

(MELSOFT application

communication port (TCP/IP)

area for the system)

Communication data code 0

Own Station Port No.

138A

TCP connection system 0

Connection status 0

Read

H

Page 206,

Appendix 1.3 (6)

System area

Latest error code 0

Destination port No. 0

Read

Page 206,

Appendix 1.3 (6)

Destination IP address 0

System area

3

3.4 Buffer Memory List

39

Page 42

Address

(Decimal

(Hexadecimal))

1344

)

(540

H

1345

)

(541

H

1346

)

(542

H

1347

)

(543

H

1348

)

(544

H

1349

)

(545

H

1350 to 1351

to 547H)

(546

H

1352

)

(548

H

1353

)

(549

H

1354 to 1355

to 54BH)

(54A

H

1356 to 1359

to 54FH)

(54C

H