Page 1

MITSU BIS HI ELECTRIC

MAC Ope ra tor Terminal

Human-Machine-Interface

In stal la tion Manual

MAC 10

MAC 12

MITSU BIS HI ELECTRIC EU RO PE B.V.

FACTORY AU TO MA TI ON

Page 2

Contents

Safety precautions...........................................2

Introduction..................................................... 4

Function overview...........................................5

Installation.......................................................6

A small example............................................10

Overview.......................................................12

Technical data................................................14

Drawings .....................................................A-1

For more detailed information see the

manual for the terminals.

GB

© Mitsubishi Electric Europe B.V. 1997

All examples in this manual are used solely to promote

understanding of how the equipment works and its operati on.

Mitsubishi Electric Europe B.V. takes no responsibility if

these examles are used in real applications.

Because of the great many application areas for this

equipment, the user himself must acquire the appropriate

knowledge needed to use the equipment correctly for

particular applications. Mitsubishi Electric Europe B.V.

absolves itself of all responsibilities for damage and injuries

that may occur during installation or use of this equipment.

Mitsubishi Electric Europe B.V. absolves itself of all

responsibilities for any type of modification made to the

equipment. Only approved spare parts and accessories

manufactured according to specifications of

Mitsubishi Electric Europe B.V. should be used.

The equipment must not be used in an explosive

environment.

1

Page 3

GB

Safety precautions

General

– Check the delivery for transport damage. If

damage is found, advise your supplier.

– The product fulfils the requirements of

article 4 of EMC directive 89/336/EEC.

– Do not use the product in an explosive environment.

– Modifications, changes and additions to the

product are forbidden.

–Use only spare parts approved by

Mitsubishi Electric Europe B.V.

– Read the user instructions carefully before

use.

– This equipment should only be operated by

qualified personnel.

At installation

– The product is constructed for stationary

installation.

– Install the product according to the accompanying installation instructions.

– The product must be grounded according to

the accompanying installation instructions.

– This equipment must be installed by qualified personnel.

– High voltage, signal and supply cables must

be separated.

– The product should not be mounted in direct

sunlight.

In use

– Keep the equipment clean.

– Emergency stop and other safety functions

should not be controlled from the terminal.

– Do not touch the keys, displays, etc. with

sharp objects.

2

Page 4

Service and maintenance

– The agreed warrenty applies.

– Clean the display and face with a soft cloth

and mild detergent.

– Repairs should be made by qualified person-

nel.

At disassembly and scrapping

– Local regulations apply concerning recycling of products or part.

– Please note that the lithium battery, electrolyte condenser and display contain hazardous

substances.

GB

3

Page 5

GB

Introduction

This leaflet describes the operator´s panels

MAC 10/MTA-10 and MAC 12/MTA-12.

Hereafter these products are referred to as the

terminal. In the manual we refer to the software

package MAC Programmer/SW-MTA for DOS

and MAC Programmer+/SW-MTA-WIN for

Windows. Hereafter these products are referred

to as the PC software.

The terminal is operator’s panel in a family of

terminals developed to satisfy the demands

made for man-machine communication.

The functions built into the terminal include

among other things the possibility to display

text with dynamic indication, maneuvring

objects and time channel control. MAC 12/

MTA-12 also include function for datalogging

and recipes.

A terminal is programmed from a PC with the

PC software. The programmed projec t is s t ored

in the terminal. Terminals hav e for the most part

an object-orientated way of working which

makes them easy to use.

4

Page 6

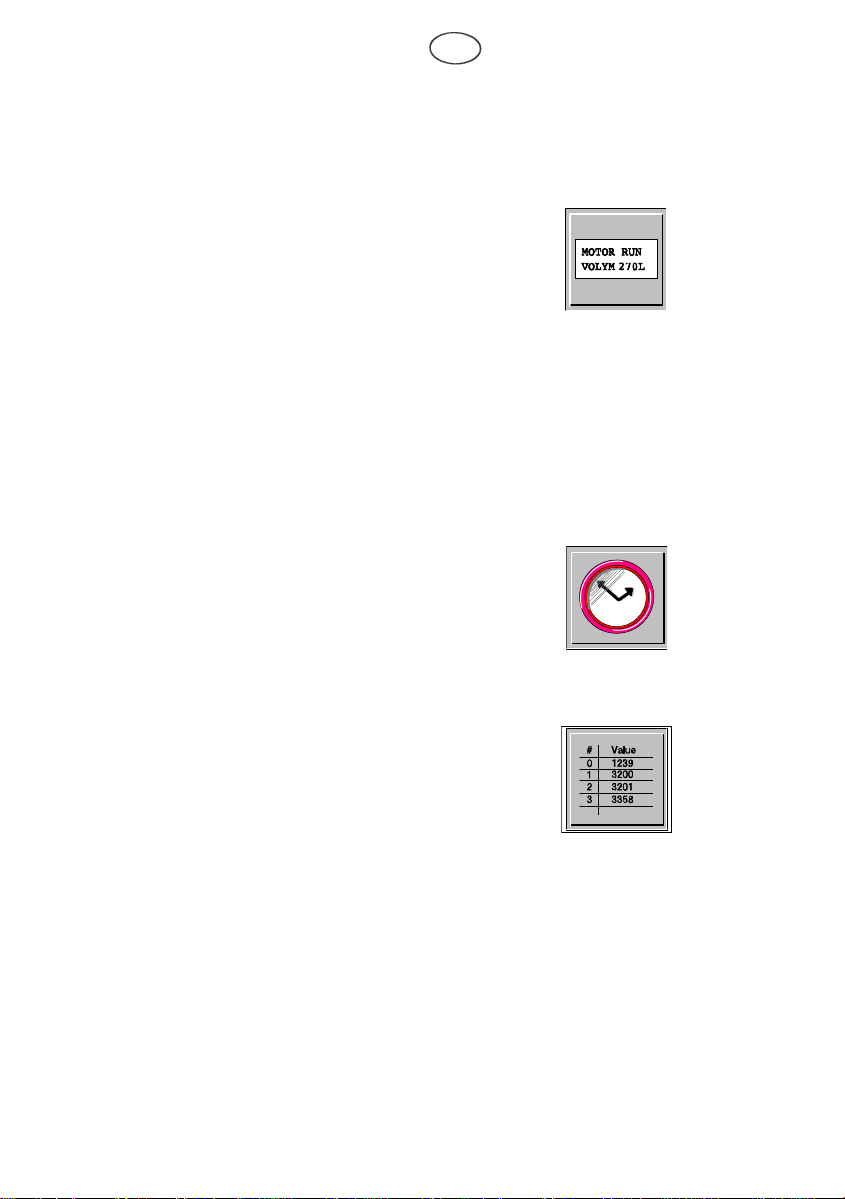

Summary of functions

3

12

9

6

Textblock

Textblock is used to build up dialogs. A Textblock can consist of an arbitrary number of text

lines of up to 16 characters long.

Static text

Static text is text written in textblock which is

not changed when executing the program.

Dynamic objects

Dynamic objects are fields in the text which are

linked to the signals in the PLC system. There

are 7 types of dynamic object: digital, analog,

jump, date/time, bar graph, multiple choice

object and text object.

Time channels

Time channels make it possible to set a digital

signal ON or OFF controlled by the real time

clock, that is, to enable you to ensure that a certain function is ON during certain periods of the

day.

GB

Data logging/recipes

Only valid for MAC 12/MTA-12. A part of the

project memory can be set aside for logging

data and storing recipes.

5

Page 7

MITSUBISH I

MELSEC FX0

GB

Installation

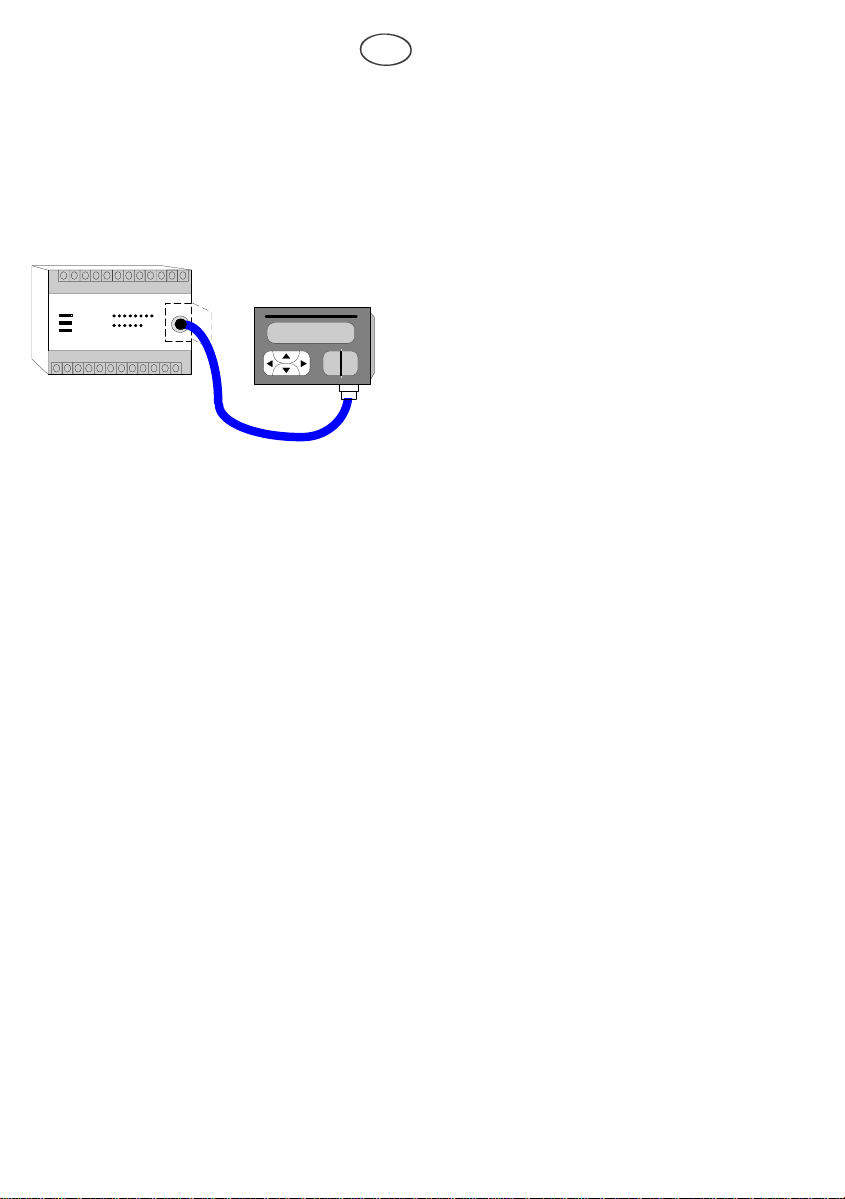

The terminals are connected to FX0, FX0N or

FX PLC system.

Connection to a FX0/FX0N PLC system

Connect the MAC 10/12-CAB (8-pin MINIDIN) cable to the outlet in the bottom of the terminal. The cable is straight; the contact at each

end is compatible with both the terminal and the

PLC system. The cable has a maximum length

of 3 m and the communication speed is 9600

baud. The terminal is powered by the PLC

system via the cable supplied. If a longer cable

is required, the terminal must be powered from

a source other than the PLC system.

6

Page 8

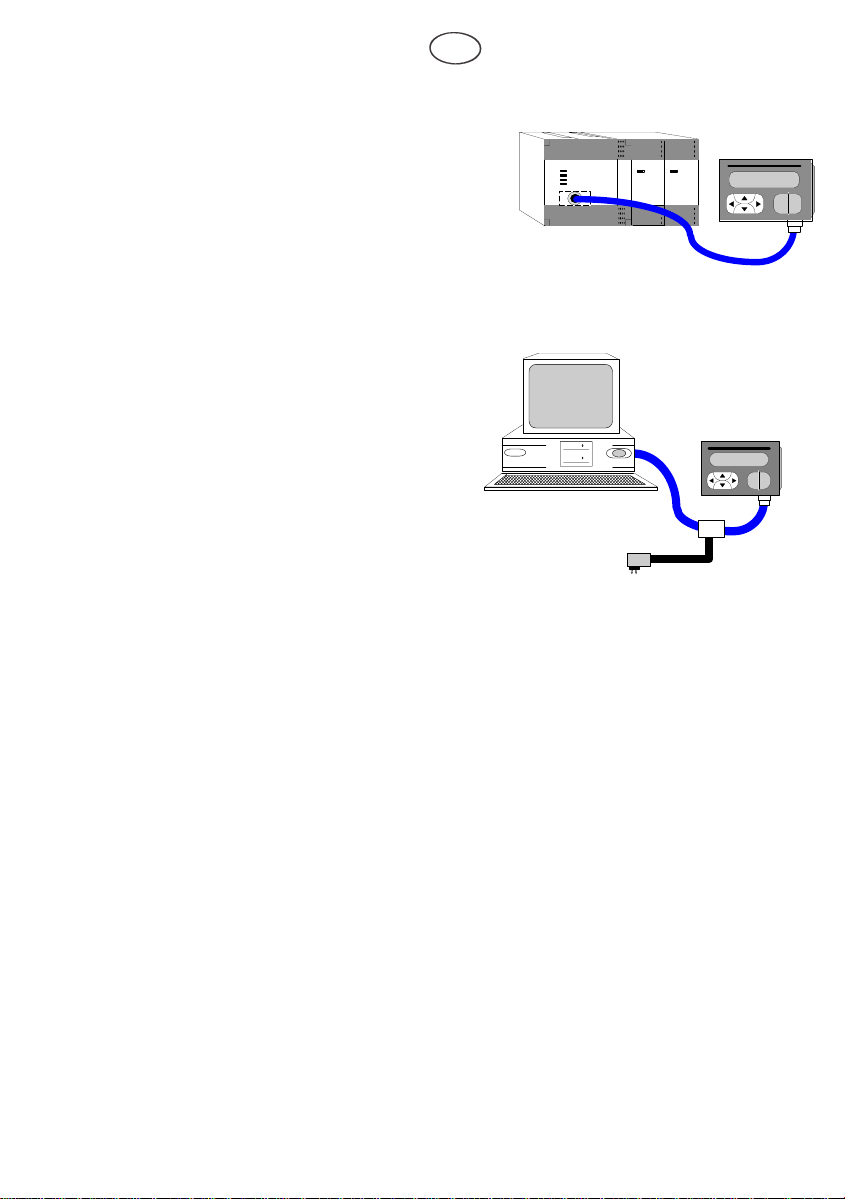

Connection to a FX PLC system

The terminal is connected to a FX PLC system

using the FX-20P-CABN cable. The cable has a

macimum length of 3 meter and the communication speed i 9600 baud.

The terminal is powered by the PLC system via

the cable. If a longer cable is required, the terminal must be powered from a source other than

the PLC system.

Connection to a personal computer

The terminal is connected to a personal computer using a SC06N adapter. The maximum cable

length is 3 meter and the communication speed

is 9600 baud.

Programming from personal computer

You program the terminal with the PC software

installed on a personal computer. The terminal

will enter the ”Communication with MP” mode

if you keep the keys [←] [-] pressed during terminal power up.

The PC software can also be used to make a

backup of the terminal project.

GB

MITSUBISHI

MELSEC FX

7

Page 9

GB

Keyboard

The terminal keyboard incorporates 6 membrane keys which are used to performe the following functions:

Set manoeuvrable digital object (ON).

Increase value of manoeuvrable analog object.

Execute jump.

Select/execute choice from a multiple choice

object.

Reset manoeuvrable digital object (OFF).

Decreace value of manoeuvrable analog object.

Move up one line.

If the first line of time channel settings return to

previous level.

Move to next field (position).

Move to previous field (position).

Move down one line.

8

Page 10

Settings

All settings for the terminal must be done in the

PC software. It is assumed that the PC software

for Windows is installed on your PC and that

you have started up with a new project. See the

PC software maunal for further details.

A number of basic settings have to be entered

before using the terminal. The settings are

entered in the PC software. The following settings are necessary:

Choice of PLC system

You must choose to which PLC system the terminal is to be connected. Select

menu File. In the dialogue box Project settings

you select PLC system and type of terminal.

Choice of character set and menu language

The majority of languages have letters which

are specific to that language. Various menu languages can be chosen. Select

settings

in the menu Setup and then select

required character set and menu language.

This manual assumes that English has been

chosen as menu language.

New

Country

in the

GB

9

Page 11

GB

A small example

The following section gives a small example of

how to start creating applications quickly. The

example follows the whole sequence from building up an application to executing to the PLC

system. The terminal must be connected to a

personal computer with the PC software. In this

example we shall make a textblock which shows

the status of the X0 input.

Start the PC software. First we have to create a

project. Select New in the File menu. In the dialogue box displayed you select terminal type

and PLC system. Then press OK. (See Settings).

The Block list will now be displayed. Select

New to create a textblock. Now the Block header is displayed.

In this example we shall define a textblock.

1. Enter the number of the block here, in this

case 0.

2. Click on the button Status...

10

3. Mark th e alternative Put cursor at first

man. object.

4. Press OK.

5. Press OK to begin editing the block. A field

will be shown.

6. Select D igital text in the Object menu.

7. First enter which I/O signal the object is to

illustrate. Do this by entering the required

address, in this case X0, after the text Digital signal. Press the Ta b key to move the

cursor to the next field.

8. Enter the text which will be displayed when

the signal is 0, in this example OFF. Press

the Tab key.

9. Enter the text which will be displayed when

Page 12

the signal is 1, in this example ON.

10. Press OK to close the dialog box. The dynamic object is now shown by # and two - on

the screen.

When the program is ready you can connect the

terminal to the PLC system.

GB

11

Page 13

GB

Overview

Mode selection

Keep the keys shown to the left pressed during

terminal power-up to enter the mode Communication with MP. The terminal normally enters

Run mode during power-up.

For a complete list of other modes possible see

User´s manual for the terminal.

Dynamic objects

The following dynamic text objects can be used

in block and linked to the stated types of

signals.

Digital Digital object (2 states).

Analog Analog object as value.

Bar graph Porportional filling of analog

object.

Multichoice Digital object (8 states).

Text Text strings from PLC.

Jump Jump to block.

Date/time Date and/or time.

12

Page 14

System block

Certain blocks are reserved for special purposes:

0

990

991

992-999

Main menu

Reserved for compatibility with

other terminals

Time channels

Reserved for compatibility with

other terminals

GB

13

Page 15

GB

Technical data

Front panel

Width 96 x height 72 x depth 3 mm.

Mounting depth

MAC 10/MTA-10: Max 37 mm.

MAC 12/MTA-12: Max 41 mm.

Mounting holes

92 ±1 mm x 68 ±1 mm.

Front panel seal

IP 65

Rear panel seal

IP 20

Front panel material

1,5 mm anodized aluminium and membrane

keyboard. Overlay film of polyester with backside printing.

Container material

Black varnished steel.

Weight

230 g

PLC system connection

8-pol Mini-DIN contact.

Cable to PLC system

4 pair cable, shielded.

Display

MAC 10/MTA-10:

LCD display (liquid crystal), Supertwist 1 lines

of 16 characters each. 8 mm character height.

The contrast adjustable with potentiometer

inside.

MAC 12/MTA-12:

LCD display (liquid crystal), Supertwist 2 lines

of 16 characters each. 5 mm character height.

The contrast adjustable with potentiometer

inside.

14

Page 16

Real time clock

Minimum 10 years lifetime.

Supply voltage

+5 VDC from PLC system CPU port via communication cable.

Internal logic voltage

+5 VDC ±5%.

Power consumption

MAC 10/MTA-10: 70 mA.

MAC 12/MTA-12: 150 mA.

Ambient temperature

0º to +50ºC

Storage temperature

-20º to +60ºC

Air humidity

Max 90% without condensation.

Interference test

Interference tested for external noise according

to: EN 50081-1 emission and EN 50082-2

immunity.

The product have passed and comply with specifications of the above tests. The product must

only be used for applications covered by these

standards.

EMC-tests on the terminal

G & L Beijer Electronics AB confirm that the

terminals conforms with the essential protection

requirements in article four of the directive

89/336/EEC.

GB

15

Page 17

GB

16

Page 18

A-1

Page 19

A-2

Page 20

A-3

Page 21

A-4

Page 22

A-5

Page 23

A-6

Page 24

A-7

Page 25

A-8

Page 26

MITSU BIS HI ELECTRIC

MITSU BIS HI ELECTRIC EU RO PE B.V.

FACTORY AU TO MA TION

GOT HA ER STR. 8, D- 40880 RA TIN GEN

TEL.: (0 21 02) 4 86- 10 , FAX: (0 21 02) 4 86-1 12

Loading...

Loading...