Page 1

Building Air-Conditioners Control System

Model : LMAP03U

Contents

Safety precautions····················································1,2

1

.Parts Include ····························································3

2

.Specifications···························································3

2

-1 External View ···················································3

2

-2 Enviroment Specifications ·······························3

2

-3 Connected Air Conditioning Equipment ··········4

2

-4 LONWORKS®Network Specifications ················4

2

-5 List of LM ADAPTER Functions·······················4

3.Installation ·······························································5

3

-1 Locally Procured Parts·····································5

3

-2 Installation Method···········································6

3

-3 Wiring Methods ················································7

3

-4 Electrical Wiring ···············································8

4

.Sysyem Settings·····················································10

4

-1 If not used together with system controller·····10

4

-2 If used together with system controller···········11

4

-3

Initialization Settings of LONWORKS®Network

···12

5

.Confirming Operation·············································13

5

-1 Flow of Onsite Adjustments····························13

5

-2

Preparation Material for Onsite Adjustments

·····13

5

-3 Preparation and Setting ·································13

5

-4 Test Run·························································14

6

.Troubleshooting······················································14

6

-1 Abstract··························································15

6

-2 Troubleshooting ·············································16

6

-3 Error Code list ················································18

Appendix : Test run check sheet······························19

Before using the unit, please read this Installation

Manual carefully to ensure correct operation. Store this

Installation Manual in a location that is easy to find.

Echelon®,LON®,LONWORKS®,Neuron®,3150®and the

Echelon logo are trademarks of Echelon Corporation

registered in the United States and other countries.

LonMaker™ and the Lon Users logo are trademarks of

Echelon Corporation.

Installation Manual

LM ADAPTER

Page 2

Page 3

1

Safety Precautions

• Before instralling this unit,make sure you read all the “Safety Precautions”.

• This manual describes the installation of LM ADAPTER and wiring to the outdoor unit.

• Please read the installation manual of air-conditioning units with regards to the installation method of air-conditioning units.

• The “Safety Precautions” provide very important points regarding safety. Make sure you follow them.

Symbols and Terms

Statements identify condition or practices that could result in personal injury or loss of life.

Statements identify condition or practices that could result in damage to the unit or other

property.

Symbols used in the illustrations

: Indicates a part which must be grounded.

: Beware of electric shock.(This symbol is displayed on the main unit label) <Color: Yellow>

For servicing,shut down the power supply for LM ADAPTER.

WARNING

WARNING

CAUTION

Ask your dealer or technical representative to install.

Any deficiency cased by your own installation may result in an

electric shock and fire.

Ensure that installation work is done correctly following

that installation manual.

Any deficiency caused by installation may result in an electric

shock or fire.

Install in a place which is strong enough to withstand the

weight of the unit

Any lack of the strength may cause the unit to fall down,

resulting in a personal injury.

Any deficiency caused by installation may result in an electric

shock, fire or incorrect operation.

All electrical work must be performed by a licenced

technician, according to local regulations and the

instructions given in this manual.

Any lack of electric circuit or any deficiency caused by

installation may result in an electric shock or fire.

Wire and connect using the desired cables securely so

that any external force exerted on the cable is not

imparted on to the terminal connections.

Imperfect connection and fixed may result in heating or fire.

Securely install the cover (panel) of the LM ADAPTER.

If the cover (panel) is not installed properly, dust or water may

enter the unit and fire or electric shock may result.

Never modify or repair the unit by yourself.

Any deficiency caused by your modification or repair may

result in an electric shock or fire. Consult with your distributor

for repair.

Do not move and re-install the unit yourself.

Any deficiency caused by installation may result in an electric

shock or fire. Ask your distributor or special vender for moving

and installation.

Make sure that the unit is powered by a dedicated line.

Other appliances connected to the same line could cause an

overload.

Make sure that there is a main power switch.

A ready accessible breaker for power source line helps

reduce the risk of electric shocks.Installation of a breaker is

mandatory in same areas.

If it is assumed that moisture advances into the unit,

such as the time of rainy weather, do not perform any

work on electric circuits.

It may become the cause of damage of a fire and the unit by

an electric shock or corrosion.

• After reading this installation manual, keep it in a place where the final user can see it anytime he or she wants to it.

When someone moves, repairs or uses the LM ADAPTER, make sure that this manual is forwarded to the final user.

Page 4

2

CAUTION

Do not install the unit where combustible gas may leak.

If the gas leaks and accumulates around the unit, an

explosion may result.

Do not use in any special environment.

Using in any place exposed to oil(including machine oil),

steam and sulfuric gas may deteriorate the performances

significantly or given damage to the component parts.

When installing the unit in a hospital, communication

station, or similar place, provide sufficient protection

against noise.

Inverter equipment, private power generator, high-frequency

medical equipment, or radio communication equipment may

cause the air conditioner to operate erroneously, or fail to

operate. On the other hand, the air conditioner may affect

such equipment by creating noise that disturbs medical

treatment or image broadcasting.

Do not wash with water.

Doing so may cause an electric shock or a malfunction.

Do not install in any steamy place such as bath room or

kitchen.

Avoid any place where moisture is condensed into dew.

Doing so may cause an electric shock or a malfunction.

Do not touch any PCB(Printed Circuit Board) with your

hand or tools. Do not allow dust to collected on the PCB.

Doing so may cause an electric shock or fire.

Do not install in any place where acidic or alkaline

solution or special spray or other similar substances are

used.

Doing so may cause an electric shock or a malfuction.

Do not install in any place at a temperature of more then

43 ˚C (109˚F) or less than -15˚C (5˚F) .

It may become the cause of modification and failure.

Safely dispose of the packing materials.

Tear apart and throw away plastic packaging bags so that

children will not play with them. If children play with a plastic

bag which was not torn apart, they face the risk of suffocation.

Be sure to shut off the power source of the unit and all

the other units to connected to the unit before wiring.

Doing so may cause an electric shock or a malfunction.

Use only an earth leakage breaker and fuse of the

specified capacity.

If no earth leakage breaker is installed, it may cause an

electric shock.

Using fuse and wire or copper wire with too large a capacity

may cause a malfunction to the unit or fire.

Do not band together or install in the same metal pipe,

the power supply line and transmission line.

Doing so may cause a malfunction of unit.

This appliance must be grounded.

Make sure to install a grounding line. Do not connect the

grounding line to gas or water pipes, lightning conductors or

telephone grounding lines. Improper grounding may cause an

electric shock.

Wire so that it wires do not received any tension.

Tension may caused wire breakage, heating or fire.

Use standard wires in compliance with the current

capacity.

A failure to do this may result in an electric leakage, heating

or fire.

Never connect the power source to the transmission line.

Doing so may caused a malfunction or a failture.

Do not touch the switches with wet fingers.

Touching a switch with wet fingers can cause electric shock.

Page 5

3

1. Parts Include

2. Specifications

Verify that the following parts are appended to the product.

2-2 Environment Specifications

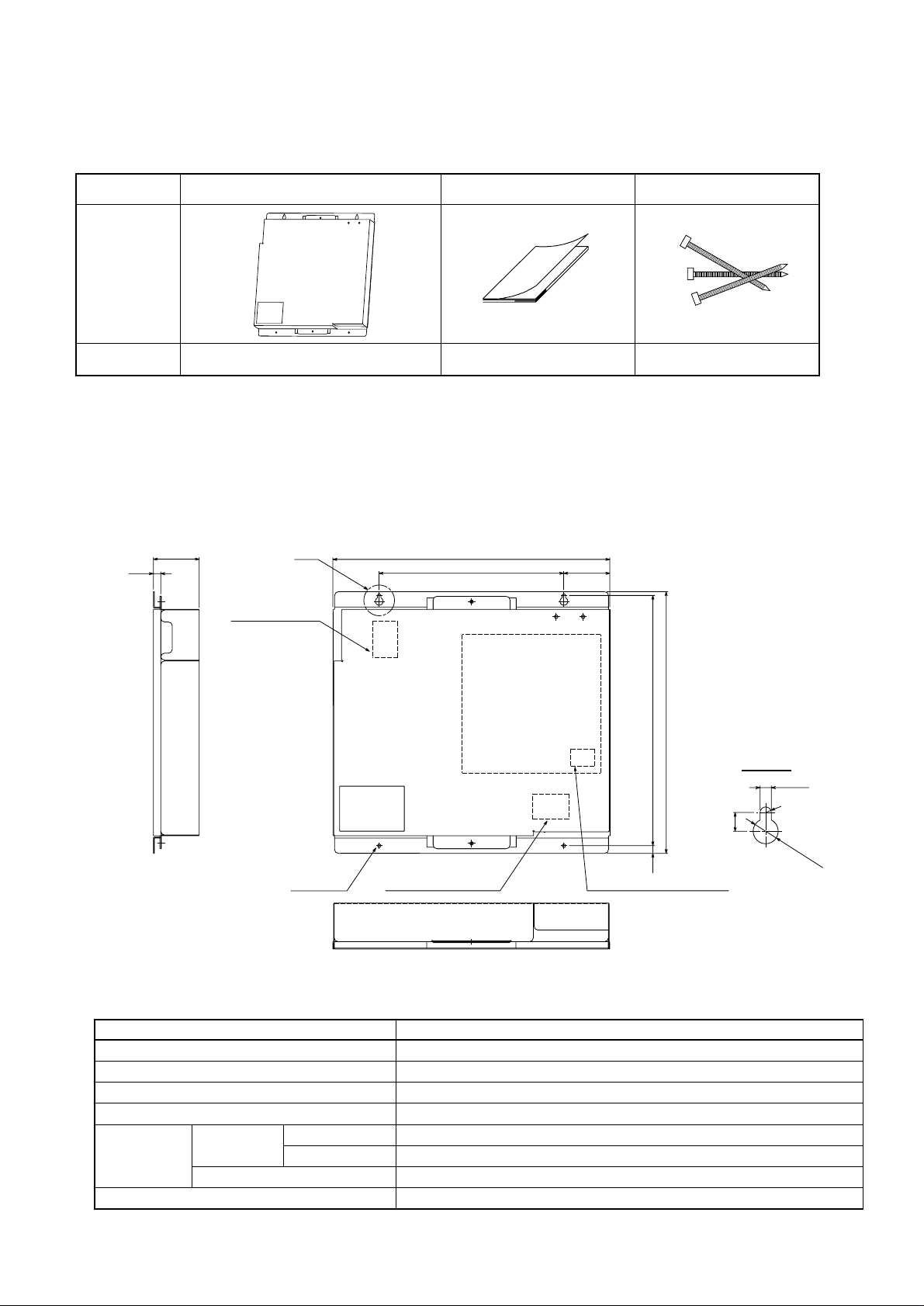

2-1 External View

Name

Shape

Quantity

Main Unit

Binding band

1

3

Installation manual

1

· The external interface file (XIF) is necessary for the product.

Upon verifying the 16-digit program ID (PID) which is bonded on the board, please contact your dealer.

9.6

(3/8)

59.6(2 3/8)

TB1

Power supply terminal

360(14 3/16)A

60(2 3/8)240(9 1/2)

2-ø4.5 hole

(2-ø3/16 hole)

Item

Dimensions

Net Weight

Power Source

Current Consumption

Operation

Temperature

Environment

Humidity

Installation Environment

Operating Range

Storage Range

325(12 13/16)

340(13 7/16)

Detail of A

4.5(3/16)

R

7.5

TB2

M-NET transmission terminal

10

TB21

LONWORKS® transmission terminal

(13/32)

(5/16)

Unit : mm (in)

ø10(

ø13/32)

Description

340 (H) x 360 (W) x 59.6 (D) mm / 13 7/16 (H) x 14 3/16 (W) x 2 3/8 (D) in

3.4 kg / 7 1/2 lb

~ 208 - 230V (60 Hz)

50 mA (Maximum)

-15 to 43˚C / 5 to 109˚F

-20 to 60˚C / -4 to 140˚F

30 to 95 RH (No condensation)

In the control panel box

Page 6

4

2-3 Connected Air Conditioning Equipment

2-4 L

ONWORKS

®

Network Specifications

* The proper communication is not obtainable when communication intervals exceed its performance,

assure sufficeint intervals.

* ACK Service is recommended for the network service.

* Detailed specifications for the LONWORKS®network can be found in “ FTT-10A Free Topology Transceiver

User's Guide ” by Echelon Corporation.

Item Description

Connected Equipment

Number of Units LM ADAPTER can control 50 indoor units (including LOSSNAY)

Item Description

TMPN3150 (10MHz)

Neuron CHIP

FTT-10A (Free Topology 78kbps)

Network Transceiver

Performance

2.5 inputs/second

Average communication capacity

50 inputs/second (for one second)

Peak communication capacity

MITSUBISHI ELECTRIC Multiple split type air conditioners CITY MULTI

Split-type air conditioners Mr.SLIM

Heat recovery ventilators LOSSNAY

(* For details of the connected models, please contact your dealer.)

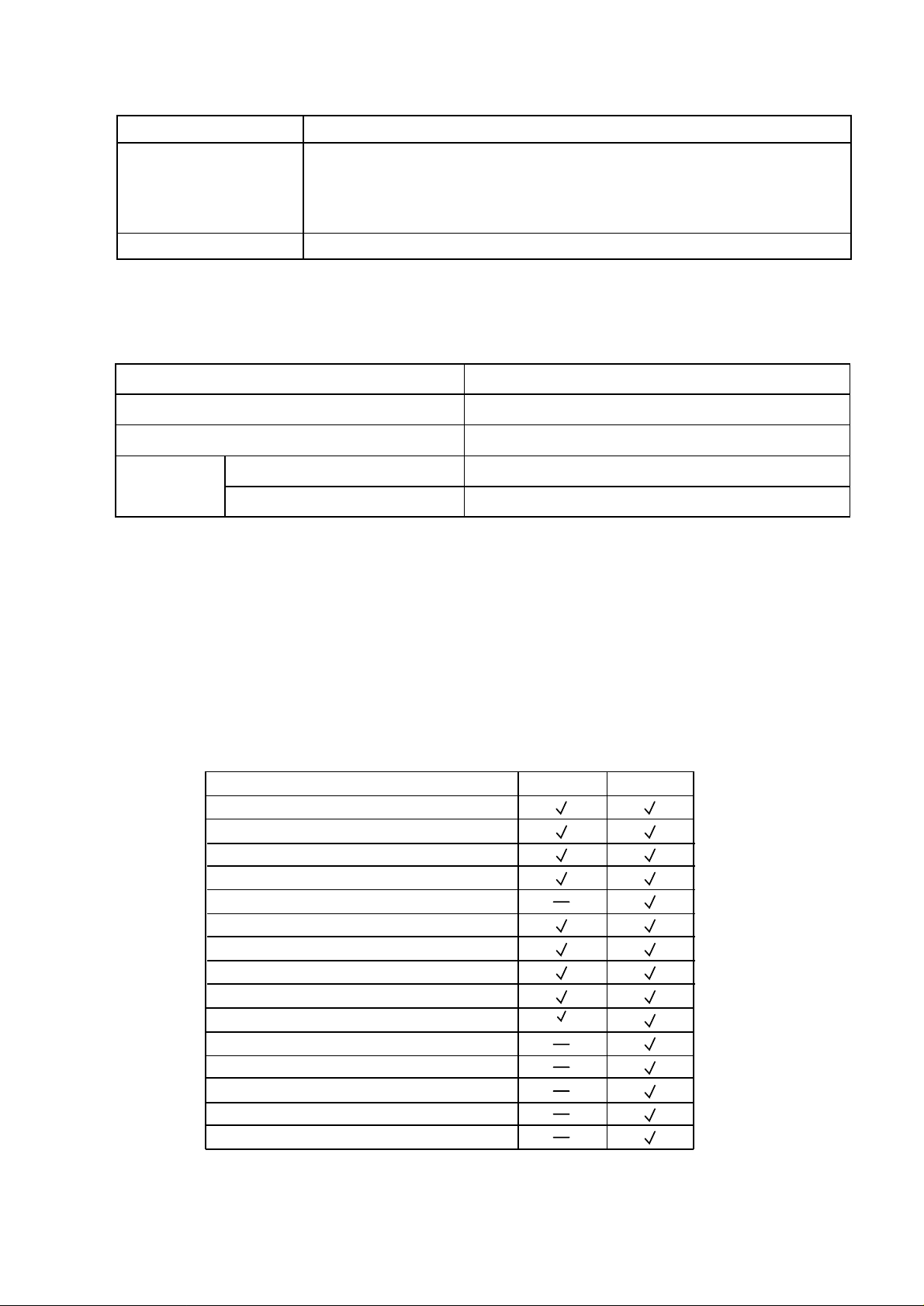

2-5 List of LM ADAPTER Functions

Functions

Name

On/Off

Set Point from network (Both cool and heat)

Mode

Fanspeed

Indoor temperature state

Local Prohibit On/Off

Local Prohibit mode

Local Prohibit SetPoint

Thermostat Off

Filter sign

Thermo On/Off state

Model Size

Alarm state

Error Code

Error Address

input output

(Reset)

Page 7

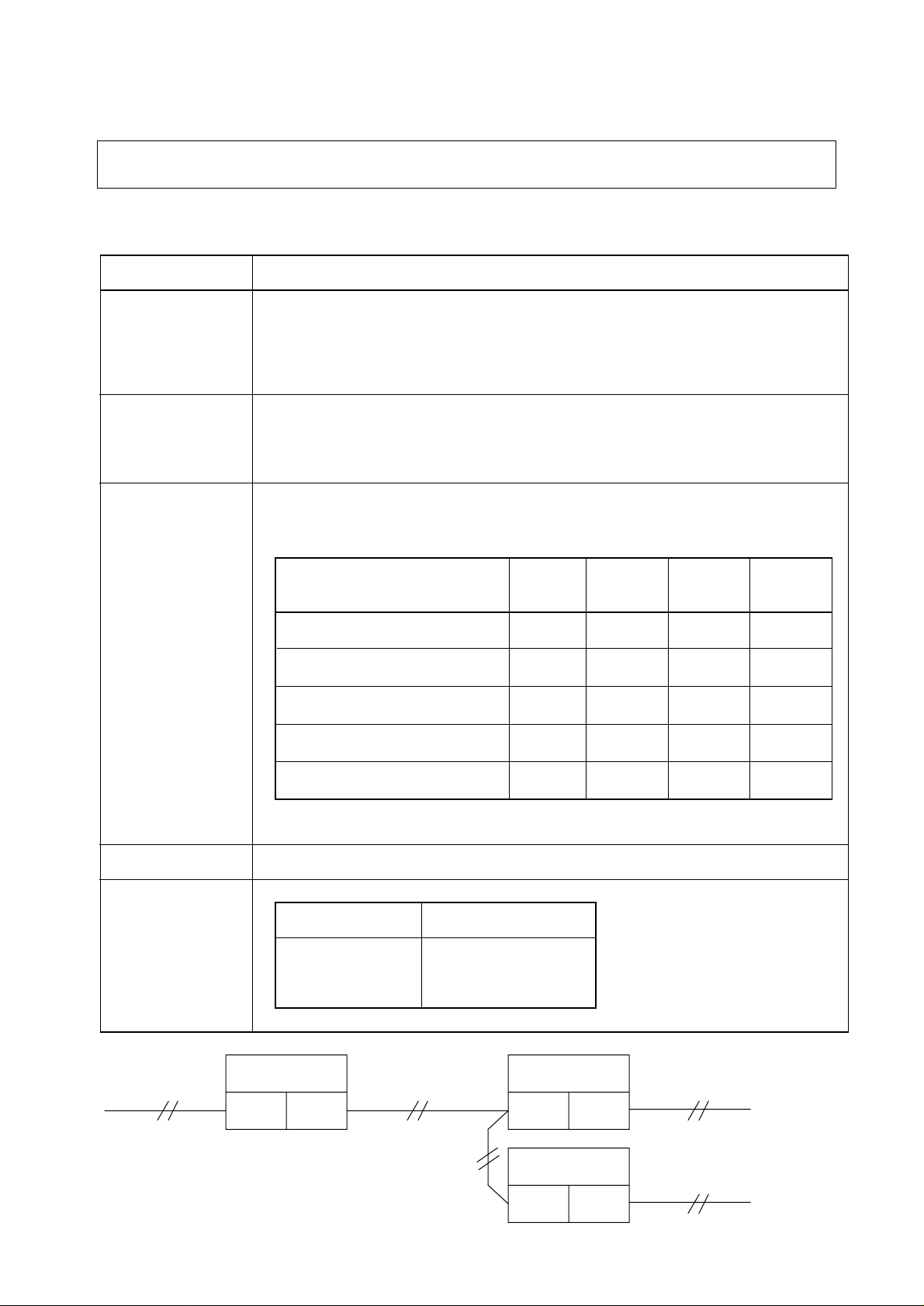

3. Installation

<Notes>

Prepare the following prior to installing the unit.

Read and understand the contents of Chapter 1 “Safety Precautions ” before performing the installation.

3-1 Locally Procured Parts

5

Locally procured parts

Power wire

and ground wire

M-NET

transmission wire

L

ONWORKS

®

Network

transmission wire

Contents

Use sheathed vinyl cord or wire.

Wire type

………

Wire should not be lighter than ordinary PVC sheathed flexible cord IEC 60227

(designation 60227 IEC 53)

Wire size

………

0.75mm

2

to 1.25mm2 (AWG18 to 16)

Use the sheathed vinyl cord or wire.

Wire type

Wire size

………

………

CPEVS, CVVS or equivalent"

Solid wire : ø1.2mm to ø1.6mm

Twist type : 1.25mm

2

to 2mm2 (AWG16 to 14)

Use the wire which is recommended by Echelon Corporation.

For details, refer to “FTT-10A Free Topology Transceiver User's Guide”.

For reference, Cable Types and Typical Parameters.

Cable type

Belden 85102, single twisted pair,

standed 19/29, unshielded, 150˚C

Belden 8471, single twisted pair,

standed 19/29, unshielded, 60˚C

Level IV 22AWG, twisted pair,

typically solid & unshielded

JY(St) Y 2X2X0.8, 4-wire herical twist,

solid, shielded

Wire

dia /AWG

1.3mm/16

1.3mm/16

0.65mm/22

0.8mm/20.4

Rloop

Ω/km

28

28

106

73

nF/km

56

72

49

98

C

Vprop

% of C

62

55

67

41

TIA568A category 5 24AWG, twisted pair

If a shielded cable is used, the shield should be connected to earth ground via a single 470kΩ,

1/4 W, ≤10%, metal film resistor to prevent static charge build-up.

0.51mm/24

168

46

58

Screw To install the main body, prepare four M4 screws which are suitable for the installation area.

Main Power Switch

(Circuit Breaker)

Breaker for wiring

3A

Breaker for Current Leakage

3A 30mA

0.1 sec or less

Use a breaker with a contact distance of 3mm or more.

LONWORKS®

LM ADAPTER

network transmission line

TB21 TB2

M-NET transmission line

(Centralized control line)

Outdoor unit

TB7 TB3

M-NET transmission line

(Indoor / outdoor transmission line)

Outdoor unit

TB7 TB3

M-NET transmission line

(Indoor / outdoor transmission line)

Page 8

6

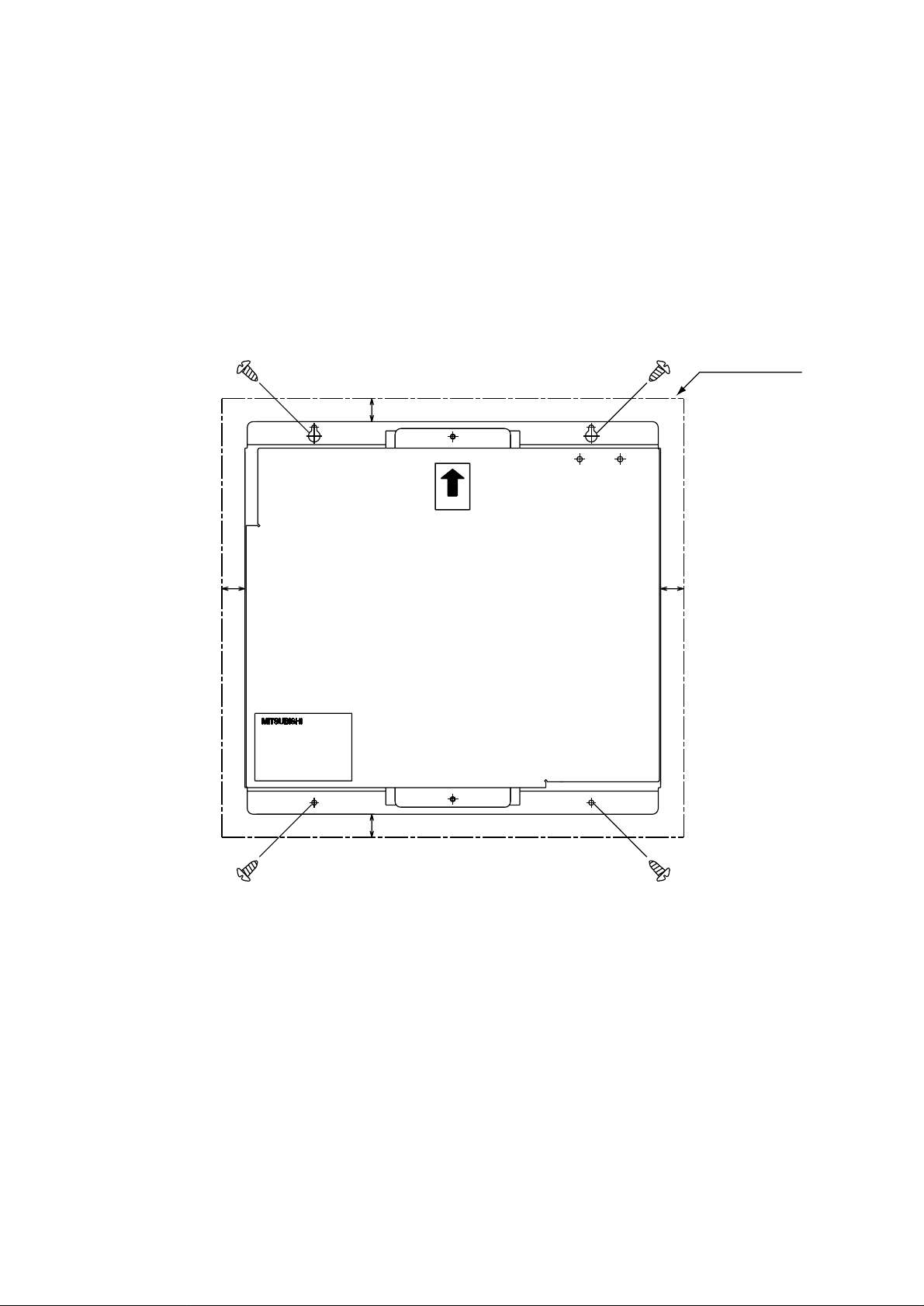

3-2 Installation Method

• LM ADAPTER is not waterproof type.

• LM ADAPTER shall be installed in a control panel box (steel : thickness 1 mm (3/64 in) or more).

Please prepare the control panel box in consideration with installation space as shown in the Fig.

(Install in an area capable of withstanding a 3.4 kg (7 1/2 lb) load.)

The unit shall be also installed in vertical direction only indicated by arrow making on the cover as shown in the

Fig.

• Use M4 screws as shown in Fig. below to fix the product.

To prevent the product from falling, make sure to fix at four places.

Installation space

20

(13/16)(13/16)

UP

20

(13/16)

20

20

(13/16)

Unit : mm (in)

Page 9

7

3-3 Wiring Methods

Use wire clamps provided to secure the wires and prevent external force from being conveyed by the wire to

the wire connections.

* External force could cause deformation or damage to the terminal blocks.

Use a small screwdriver to connect diameter 0.2 to 2.5 mm2(AWG24 to 12) cable for

terminal block (TB21) on the unit. Tightening torque is 0.5 to 0.6 Nm. Up to two wires can

be connected to one terminal block.

For LONWORKS®transmission wire

Connect LONWORKS®signal wire

to “1”, “2” or “3”, “4” of signal wire

terminal block (TB21).

• TB21-“1” and “3” as well as “2”

and “4” of TB21 are connected

inside the circuit board.

Connect the power supply

wires and grounding wire

to “L1”, “L2” and

“grounding” of terminal

block (TB1).

Connect M-NET signal wire to “A”

and “B” of terminal block (TB2).

• Connect the M-NET

transmission wire to

transmission terminal block

(TB7) of the centralized control.

Attach the appended binding band to the power wire and transmission wire, and fasten it, positioning the

area at inner side than the wire clamp.

Make sure that the ground wire is longer than the other wires.

Note1

For power wire and M-NET transmission wire

Note1

Note1

Note1

L1

L2

CN71

CN21

CN32

CN33

CN31

P.B.

CN45

CN65

CN605

CN405

L.B.

CNS3

CNL12

CN702

TB21

LON TB21

4

31

2

Grounding wire

Binding band

Power wire 35mm (1 3/8 in )

M-NET 20mm (13/16 in )

8mm (5/16 in)

20mm

(13/16 in)

SAUPB

80mm (3 3/16 in)

Binding band

Page 10

8

P.B.

L.B.

TB1

PE

L1

L2

Main Power Switch 3A

Unit Body

Unit Body

CN31

313

AC250V

2A T

ZNR2

F

1

T2

CN33

DSA1

ZNR1

Unit Body

7

3

1

5

CN71

SWL

(Service

Switch)

(Service

LEDL

LED)

1

3

4

3

2

1

5

6

CN45

T1

CN65

2

1

CN21

3

1

CN32

1

2

3

4

CNL12

CN605

5

4

3

2

1

LED402

(5VM)

LED502

(3150RST)

6

4

3

2

1

M-NET

Power Supply

CN40

(WDT)

LED009

LED201

CN41

(18007RST)

SW71

(Termination Switch)

12

ON

OFF

312

TO M-NET transmission line

(Centralized control line)

CNS3

AB

TB2

13

CN405

CN702

1

2

Unit Body

LONWORKS® transmission line

TB21

S

12

4

SW4

101

OFF

ON

OFF

ON

SW2

SW1

16

SW3

61

ON

OFF

0

1

5

2

3

4

6

7

8

9

0

1

5

2

3

4

6

7

8

9

SWU1

(1st digit)

SWU2

(2nd digit)

LED001

LED002

LED003

LED004

(Wink)

Power supply

~208-230V 60Hz

3-4 Electrical Wiring

Transformer

Switch Function selection

M-NET address switch

Tremination selection switch

(

LONWORKS

®

)

SYMBOL EXPLANATION

Power circuit boardP.B

L.B LM ADAPTER main board

F

SWU1, 2

Service switch (

LONWORKS

®

)SWL

Fuse AC250V 2A T

NAMESYMBOL

SW1, 2, 3

T1.2

SW71

LONWORKS

®

transmission line

Grounding terminal

M-NET transmission line

Power source

LED

TB21

Power Supply switch connectorCN40/CN41

TB2

TB1

Maintenance LED

Use LED001 as Wink

(

LONW

ORKS

®

) at SW2-1 ˜ 6 OFF

LED001 ˜ 004

Status LED

LED009/201/502/402

Service LED (LONWORKS® )LEDL

NAMESYMBOL

Terminal

block

Service pin

(Service switch)

Service LED

(LEDL)

Power supply terminal

LM ADAPTER main

circuit board

LON connection

terminal

M-NET terminal

Power supply circuit board

Power supply transformer

[ Top Cover Removed ]

Service pin

(Service switch)

Service LED

(LEDL)

[ Exterior of LM ADAPTER ]

Page 11

9

Note: Function switch setting of LM ADAPTER is different according to the management item of the

equipment connected with LONWORKS®. Carefully set the system.

Explanation of function switch

Switch name Function

SW1-1

Function switch

of local prohibit

SW1-2

Used together with

system controller switch

SW1-3

Indoor temperature

state interval switch

SW1-4 Reset filter sign/

Select enable/

disable operation

duration

SW1-5 Function switch

of LOSSNAY

SW1-7 Function switch

of SNVT_switch

SW1-8 Select enable/

disable forced

thermo OFF

SW1-9 Indoor units

test run switch

SW3-2 Initialization

switch of air

conditioner units

ON

local prohibit effective

OFF

local prohibit invalidity

used together with system controller

ON

not used together with system controller

OFF

Transmission interval

ON

(1minutes or more)

Transmission interval

OFF

(10 minutes or more)

ON

Enable

OFF

Disable

ON

LOSSNAY is operated

LONW

from

LOSSNAY interlocks

OFF

ORKS

®

with the indoor unit

ON

SNVT Standard

OFF

Original

ON

Enable forced thermo OFF

OFF

Disable forced thermo OFF

ON

ON(test run) is transmitted

to the indoor units

OFF

OFF is transmitted and

indoor units stop test run

ON

Connected cancellation

command is transmitted

to the indoor units

OFF

None

Note

Operation local prohibit nv input from

LONWORKS

Operation local prohibit nv input from

LONWORKS

®

becomes Effective when switch is ON.

®

becomes invalid when switch is OFF.

Factory

setting

OFF

OFF

*number of indoor units that should

OFF

be connected is 30 or less

When “ON”, the reset filter sign input and the

OFF Before power

operation duration output are enabled.

When “OFF”, the reset filter sign input and

the operation duration output are disabled.

is operation from

LONW

ORKS

®

.

OFFPlease turn on the switch when LOSSNAY

Please turn off the switch when LOSSNAY

interlocks with the indoor units.

When “ON”, the specifications of the nv using

OFF Before power

the SNVT_switch comply with the SNVT Standards.

When “OFF”, the nv using t

he SNVT_switch

has original specifications.

“ON”, the forced thermo OFF nv

OFFWhen

input/output are enabled.

When “OFF”, the forced thermo OFF nv

input/output are disabled.

OFF Always

OFF Always

Set timingSW

Before power

supply

Before power

supply

Before power

supply

supply

Before power

supply

supply

Before power

supply

EPROM

(Program ID)

Neuron ID

Host CPU

Power supply LED

(LED402)

CN 40

M-NET transmission

power supply on

Maintenance LED

LED001 , LED002

( )

LED003 , LED004

CN 41

M-NET transmission

power supply off

(Factory setting)

M-NET address switch

(Factory setting: 47)

LON transceiver: FTT-10A

LON LED

(LED502)

[ LM ADAPTER Main Circuit Board (L.B) ]

Function selection switch

(Factory setting: All OFF)

CPU power supply LED

(LED009)

M-NET LED

(LED201)

Neuron Chip

LON connection terminal

Page 12

10

4. System Settings

<Notes>

This chapter only describes the system settings of this product.

For the installation work and electrical work, refer to the last chapter “ 3. Installation ”.

Read and understand the contents of Chapter 1 “Safety Precautions ” before performing the installation.

4-1 If not used together with system controller.

The system setting is different depending on the system configuration connected.

Check the system configuration.

1. When the system controllers are not used together.

2. When the system controllers are used together.

Switch the short-circuit connector

from CN41 to CN40.

LM ADAPTER

TB2

CN41

CN40

M-NET address 201 to 250 [factory setting 247]

(* Setting of position 100 not required.)

E

Shielded line ground

ON

OFF

M-NET transmission line

(Centralized control line)

SW1-2 [OFF]

12345678910

Iteam

M-NET address of LM ADAPTER

LM ADAPTER power switch connector

Combined switch for LM ADAPTER / system controller

OC central control (SC) on/off switch

OC power supply connector

as is

OC

CN41

TB7

as is

TB7

TB3

OC

CN41

TB3

Setting

SWU2, 1 [201 to 250]

CN41 to CN40 (supplies power)

SW1 - 2 [OFF] (Not used together with system controller)

SW2 -1 [OFF] (No central control)

CN41 as is (power not supplied)

❇ OC : Outdoor Unit

: Switch Position

SW2-1 [OFF]

ON

OFF

123456789

M-NET transmission line

(Indoor/outdoortransmission line)

SW2-1 [OFF]

ON

OFF

12345678910

M-NET transmission line

(Indoor/outdoortransmission line)

Factory setting

CN41

CN41

10

247

OFF

OFF

(Note 1) Change the LM ADAPTER power supply switch connector CN41 to CN40.

(Note:2)When connecting LOSSNAY, settings must be made in the LM ADAPTER.

1) Do not sequence LOSSNAY to the air conditioner. (Independent LOSSNAY)

Or when operation is to be controlled from

LONWORKS

®

(BMS etc.) connected to the LOSSNAY remote controller.

LOSSNAY selection switch. (SW1-5)[ON]

2) When sequencing LOSSNAY to the air conditioner (sequenced LOSSNAY), and not controlling operation

from

LONWORKS

®

.

(BMS etc.)

LOSSNAY selection switch. (SW1-5)[OFF]

When sequencing LOSSNAY to the air conditioner, the indoor unit and LOSSNAY sequence must be

registered from the remote controller.(Refer to the remote controller installation manual for details on registering.)

(Note 3)When changing the system configuration, such as the M-NET address, always carry out the following steps.

1) Turn the LM ADAPTER service switch (SW2-1) [ON].

Change the LM ADAPTER system information delete switch (SW3-2) from [OFF] to [ON].

2) When erasing the system information, the maintenance LED “System Information Erase LED (LED001)” will turn ON.

3) When the system information has been erased, the maintenance LED “System Information Erase LED (LED001)”

will turn OFF, and the maintenance LED “System Information Erase Complete LED (LED002)” will turn ON.

4) Turn the LM ADAPTER service switch (SW2-1) [OFF].

Change the LM ADAPTER system information delete switch (SW3-2) from [ON] to [OFF].

5) Turn the LM ADAPTER power OFF.

6) Make changes to change the unit system.(Addition of indoor unit, change of M-NET address, change of group, etc.)

7) To change the LM ADAPTER M-NET address and settings, carry out the changing work.

8) Turn the LM ADAPTER power ON.

(Note 4)Refer to the “System Design and Construction Manual” for the outdoor unit for details on the M-NET wiring length.

(Note 5)Set the M-NET address so that it is not duplicated with other units.

Page 13

11

4-2 If used together with system controller.

Centralized controller

(system controller)

❇ OC : Outdoor Unit

: Switch Position

as is

LM ADAPTER

M-NET transmission line

(Centralized control line)

CN41

CN40

TB2

E

Shielded line ground

SW1-2 [ON]

ON

OFF

12345678910

M-NET address 201 to 250 [factory setting 247]

(* Setting of position 100 not required.)

as is

TB7

TB7

OC

OC

CN41

CN41

TB3

ON

OFF

TB3

SW2-1 [OFF]

ON

OFF

12345678910

M-NET transmission line

(Indoor/outdoortransmission line)

SW2-1 [ON]

12345678910

M-NET transmission line

(Indoor/outdoortransmission line)

Item

M-NET address of LM ADAPTER

LM ADAPTER power switch connector

Combined switch for LM ADAPTER / system controller

OC central control (SC) on/off switch

OC power supply connector

Setting

SWU2, 1 [201 to 250]

CN41 as is (power not supplied)

SW1 - 2 [ON] (Used together with system controller)

SW2 -1 [ON] (Central control)

CN41 as is (power not supplied)

Factory setting

247

CN41

OFF

OFF

CN41

(Note:1) When connecting LOSSNAY, register the sequence must be registered from the shared system controller.

(Note 2) When changing the system configuration, such as the M-NET address, system controller being shared

must be registered or changed.

(Note 3) Refer to the “System Design and Construction Manual” for the outdoor unit for details on the M-NET wiring length.

(Note 4) Set the M-NET address so that it is not duplicated with other units.

Page 14

12

4-3 Initialization Settings of LONWORKS®Network

(1) System Specifications

• Up to 64 FTT-10/FTT-10A transceivers are allowed per network segment.

• LPT-10 transceivers may be used on network segments with FTT-10/FTT-10A transceivers, but are

subject to additional constraints, particularly on distance.

See the LPT-10 Use's Guide for more information.

• The average temperature of the wire must not exceed +55˚C (+131˚F), although individual segments of

wire may be as hot as +85˚C (+185˚F).

The free topology transmission specification includes two components which must both be met for proper

system operation. The distance from each transceiver to all other transceiver and to the termination

(including the LPI-10 termination, if used) must not exceed maximum node-to-node distance.

If multiple paths exist, e.g., a loop topology, then the longest path should be used for the calculations.

The maximum total wire length is the total amount of wire connected per segment.

For details, refer to “ FTT-10A Free Topology Transceiver User's Guide ” of Echelon Corporation.

For reference, the system specifications and Transmission specifications are described.

(2) Transmission Specifications

Doubly-Terminated Bus Topology Specifications

Free Topology Specifications

Maximum bus length

Belden 85102 2700(8858)

Belden 8471 2700(8858)

Level IV 22AWG 1400(4593)

JY(St)Y 2X2X0.8 900(2953)

TIA Category 5 900(2953)

Units

meters (feet)

Maximum node-to-node distance

Belden 85102 500(1640)

Belden 8471 400(1312)

Level IV 22AWG 400(1312)

JY(St)Y 2X2X0.8 320(1050)

TIA Category 5 250(820)

Maximum total wire length

500(1640)

500(1640)

500(1640)

500(1640)

450(1476)

Units

meters (feet)

Page 15

13

5. Confirming Operation

5-1 Flow of Onsite Adjustments

Test run by unit and local remote controller

……

Test run by LM ADAPTER

Test run from the

LONWORKS

Refer to 5-4 (2)

®

network

……

Refer to 5-4 (1)

……

Refer to 5-4 (3)

There are the following two methods to perform a test run from the LONWORKS® network.

1

Test run by

LONWORKS

®

tools

If the bindings to other machines have not been performed, use the LONWORKS® tools as described by the procedure

given in 5-4 (3) and confirm that operation can be performed from a

2

Test run from building management system

LONWORKS

If the bindings to other machines have been performed, or if you do not have the

management system test run procedure to confirm that operation can be performed from the

®

network.

LONWORKS

®

tools, follow the building

LONWORKS

5-2 Preparation Material for Onsite Adjustments

(1) Preparation material for onsite adjustment

Tester

Onsite adjustment tools (

* LONWORKS

The

®

tools

LONWORKS

• LONWORKS

®

tools are listed below. Contact your dealer for more information.

®

network interface (PCC-10 PC card etc.)

LONWORKS

®

tools, M-NET onsite adjustment tools)

• Cables for the above interface

• nodeutil (Free software from Echelon)

(2) Reference materials

LM ADAPTER Installation Manual

LM ADAPTER Network Variable Specifications

5-3 Preparation and Settings

(1) Perform the previous operations described in Chapter 3 “Installation” ,Chapter 4 “System Settings”.

(2)If being used together with system controller, perform the installation and electrical installation for system controller.

(3) Perform the initial processing for the LM ADAPTER.

1

Turn on the power supply for LM ADAPTER.

2

If being used together with system controller, perform the initialization settings.

3

The units will be idle until the LM ADAPTER initialization has been completed (LED002 goes out).

* This requires approximately 5 to 10 minutes.(If being used together with system controller, it will be approximately

3 minutes after the completion of the initialization settings.)

If you connect the power to the LM ADAPTER before connecting the power supply to the units, the LED002 might stay lit.

If this case arises, reset the power supply to the LM ADAPTER.

4

Confirm that the LM ADAPTER’S maintenance LED (LED003, 004) are not lit.

* If the LM ADAPTER’S maintenance LED (LED003, 004) are lit, refer to the next chapter “6. Troubleshooting”.

(Note 1) Always refer to the previous chapter “4. System settings” before changing the system configuration,

such as the M-NET address.

* After confirming the above details, always refer to the following section “ 5-4 Test Run ” and make confirmations

with trial operations.

(Note 2) Turn all of the switches in the service switch (SW2) [OFF] to confirm the ON/OFF status of the above maintenance

LED (LED002, LED003 and LED004).

®

network.

(4) After confirming the above, always perform the test run as described in the next section “5-4. Test Run”.

Page 16

14

5-4 Test Run

Perform the test run according to the test procedure of the test run check list.

(1) Test run of units by local remote controller

1

Perform the test run of the units by using the local remote controller or system controller.

* Confirm that all units are running normally.

(2) Test-operation of the indoor unit from LM ADAPTER

1

Turn on SW1-9 of LM ADAPTER.

* If there is even one indoor unit that is not running,the LM ADAPTER may not correctly recognize the indoor unit.

Refer to the next chapter “ Troubleshooting ”.

2

Finally turn OFF SW1-9, and verify that all indoor units are stopped.

(3) Test-operation of the indoor unit from

LONWORKS

If there is any tool which corresponds to LONWORKS

the follwing procedure.

1

Set the LM ADAPTER in config .

If LM ADAPTER has been already bounded to another model (the service LED is not ON), don't apply any new binding.

2

During the test operation, use “ nv1n Reguest ON/OFF ” to verify that the indoor unit can be operated.

For details of “ nv1n Reguest ON/OFF ” , refer to the following.

nv1n Request ON/OFF command input

network input SNVT_switch nviOnOff_n;

This input network variable is used to allow On request or Off request of the indoor unit to be

changed via the network.

When the ventilator (LOSSNAY) Interlocks with the indoor unit, it becomes the same operation as

the indoor unit.

®

®

,verify that it can be operated from LONWORKS

®

network according to

Valid range (SW1-7 OFF)

value field: not used

state field: 0 = indoor unit or ventilator unit is “ OFF ”

state field: 1 = indoor unit or ventilator unit is “ ON ”

: Else = Indoor unit or ventilator unit is “ OFF ”

_n: ------------ Indoor unit address (M-NET)

* Refer to the index in the table below when performing update and poll (confirm state) of the

network variable for the

ON/OFF Reguest

index

1

2

LONWORKS

nviOnOff_001

nviOnOff_002

®

tools (nodeutil etc.).

ON/OFF run state

nv name nv name

index

51

52

nvoOnOff_001

nvoOnOff_002

::::

49

nviOnOff_049

50

nviOnOff_050

3

Finally put the LM ADAPTER in the unconfig, and end the test operation.

Contact your dealer for details on trial operation from the

99

nvoOnOff_049

100

nvoOnOff_050

LONWORKS

®

network.

Page 17

15

6. Troubleshooting

6-1 Abstract

If LM ADAPTER does not properly operate, first check the following contents.

Item

LED009

(WDT)

LED402

(5VM)

LED502

(3150RST)

LED201

(18007RST)

Normal state Contents to check

ON

ON

OFF

OFF

Service LED —

LED002 OFF

LED003 OFF

Check the Main Power Switch to the LM ADAPTER is not turned off, any

connectors (CN605, CN65, CN32, CN33, CN31, CN71) are disconnected

and for a blown fuse (F).

Check the Main Power Switch to the LM ADAPTER is not turned off, any

connectors (CN405, CN45, CN21, CN31, CN71) are disconnected

and for a blown fuse (F).

The LM ADAPTER’S initial processing has not been completed.

Wait for 15 minutes after the power supply is turned on (Until the initializing process

is completed).

The LM ADAPTER’S initial processing has not been completed.

Wait for 2 minutes after the power supply is turned on (Until the initializing process

is completed).

It blinks when it is not binding.

At this time, operation is unavailable from the network side from L

Binding the equipment which corresponds to L

ONWORKS

®

network.

ONWORKS

®

.

If it is ON when the dip switch SW2 are all OFF, the LM ADAPTER is incompletely initialized.

Wait for 15 minutes after the power supply is turned on (Until the initializing process

is completed).

If it is ON when the dip switch SW2 are all OFF, check the setting of the switches and

so on, and turn on the power supply again.

LED004 OFF

CN40/41 —

SW71 —

M—NET

Address switch

—

SWU1, SWU2

Dip switch

SW1, SW2,

—

SW3

If it is ON when the dip switch SW2 are all OFF, there may be trouble at the indoor unit.

Check the connection and setting of all indoor units.

If the power supply unit is connected, insert the jumper connector to CN41.

If the power supply unit is not connected, insert the jumper connector to CN40.

L

ONWORKS

According to the system design of L

®

The switch sets the termination of LONWORKS®

ONWORKS

®

network, check whether it is properly

network.

set or not.

If system controller is used, check whether M-NET address is overlapped or not.

Initial setting of LM ADAPTER is 247.

Check whether system controller is present or not (SW1-2), and whether the

independent/combined LOSSNAY (SW1-5) is properly set or not.

Moreover, verify that all other switches are all off.

Page 18

16

6-2 Troubleshooting

No.

Error content Cause Checking method and remedy

LED002 is ON

1

2

The air conditioner

unit does not operate

even by performing

a test run using the

LM ADAPTER’S

SW1-9.

switch

(1) It takes time for the initial processing

to complete (normal).

(2)Setting on M-NET side is not properly

completed.

(3) M-NET power supply switch has not

been set.

(4) The power supply to the air conditio ner unit is disconnected.

(1)The LM ADAPTER is not completely

initialized.

(2)Setting on M-NET side is not properly

completed.

(3)If system controller is used together

LM ADAPTER is not registered to

system controller.

It can take about 15 minutes for the initial processing

to complete. Wait until the initial processing finishes.

Verify that the test operation of the air conditioner is

properly completed. Verify that M-NET transmission

line is properly connected.

Follow the instructions in “4. System Setting” and

check the power supply unit setting, and the LM

ADAPTER power supply switch connector setting.

Verify

that the air conditioner unit power supply is

not disconnected.

* Use a tester to check the voltage of the terminal

(TB2). DC17-30 V

Turn OFF all SW2. After verifying that LED002 is

OFF, test the operation again.

Verify that the test operation of the air conditioner is

properly completed. Verify that M-NET transmission

line is properly connected.

In system controller, register LM ADAPTER as the

sub system controller.

3

The LOSSNAY unit

does not operate

even by performing

a test run using the

LM ADAPTER’S

switch SW1-9.

4

Even if it is operated

with the remote

controller/system

controller, it is not

informed to the host

on LON side.

(1)The LM ADAPTER is not completely

initialized.

(2)Setting on M-NET side is not properly

completed.

(3)If system controller is used in

combination, LM ADAPTER is not

registered to system controller.

(4)The independent/combined

LOSSNAY of LM ADAPTER is not

set.

(1)The LM ADAPTER is not completely

initialized.

(2)Setting on M-NET side is not properly

completed.

(3)If system controller is used in

combination, LM ADAPTER is not

registered to system controller.

(4)L

ONWORKS

®

network transmission

line is not properly connected.

(5)The termination of L

ONWORKS

®

network is not properly set.

Refer to 2-(1).

Refer to 2-(2).

Refer to 2-(3).

Turn on SW1-5 of LM ADAPTER, and reset the

power supply.

Refer to 2-(1).

Refer to 2-(2).

Refer to 2-(3).

Check for disconnection on TB21, short-circuit and

wire breakage on the network wire and so on.

Verify that the termination of LONWORKS® network is

properly set according to the system design.

(6) Binding of L

not properly ended.

ONWORKS

®

network is

Apply the binding again.

Page 19

17

(1)The LM ADAPTER is not completely

initialized.

(2)Setting on M-NET side is not properly

completed.

(3)If system controller is used together

LM ADAPTER is not registered to

system controller.

(4)The independent/combined

LOSSNAY of LM ADAPTER is not

set.

(5)L

ONWORKS

®

network transmission

wire is not properly connected.

(6)The termination of L

ONWORKS

®

network is not properly set.

(7) Binding of L

ONWORKS

®

network is

not properly ended.

Refer to 2-(1).

Refer to 2-(2).

Refer to 2-(3).

Refer to 3-(4).

Refer to 4-(4).

Refer to 4-(5).

Refer to 4-(6).

Error content Cause Checking method and remedy

Independent/combi

ned LOSSNAY can

not be operated

from the LON side.

(1)The LM-ADAPTER is not completely

initialized.

(2)Setting on M-NET side is not properly

completed.

(3)If system controller is used together

LM ADAPTER is not registered to

system controller.

(4)L

ONWORKS

®

network transmission

wire is not properly connected.

(5)The termination of L

ONWORKS

®

network is not properly set.

(6) Binding of L

ONWORKS

®

network is

not properly ended.

Refer to 2-(1).

Refer to 2-(2).

Refer to 2-(3).

Refer to 4-(4).

Refer to 4-(5).

Refer to 4-(6).

Air conditioner can

not be operated

from the LON side.

5

6

7

8

Prohibit local remote

controller operation

cannot be set from

the LON side.

Forced thermo OFF

cannot be set from

the LON side.

(1) Perform the LM ADAPTER’S prohibit

local remote controller operation

setting.

(1) Perform the LM ADAPTER’S forced

thermo OFF setting.

Turn on SW1-8 of LM ADAPTER, and reset the power

supply.

Turn on SW1-1 of LM ADAPTER, and reset the power

supply.

Page 20

18

6-3 Error code list

Error

code

6600

6601

6607

7702

7703

Display of trouble

M-NET remote controller,

MA remote controller,

system controller

M-NET remote controller,

MA remote controller,

system controller

M-NET remote controller,

MA remote controller,

system controller or

building control system

M-NET remote controller,

MA remote controller,

system controller

M-NET remote controller,

MA remote controller,

system controller

Error content Symptom Cause

M-NET

duplication

error

M-NET polarity

not set error

No ACK error

M-NET connection

error (no connection

to indoor unit or

LOSSNAY unit)

M-NET connection

error (no connection

to master system

controller)

• If it has been

confirmed that a unit

with the same M-NET

address is transmitting.

• When discrimination

of the polarity of the

M-NET transmission

wire.

•

If there is no response

(ACK) from the

recipient after a

transmission.

Could not connect to

any indoor units or

LOSSNAY units.

DIP SW1-2 is OFF and

the system con

connected.

DIP SW1-2 is ON and

the system controller is

not connected.

troller is

• If there are two or more

units with the same

M-NET address at the

unit and controller.

• Interrupted power supply,

Connectors (CN405,

CN45, CN21, CN71).

Damage to transformer

(T2).

• Interrupted power supply

for M-NET transmission

wire.

•

If recipient of transmission

is LM ADAPTER.

• Defect in transmission

line (TB2)between

LM ADAPTER.

• Interrupted power

LM ADAPTER

power supply (TB1).

• Blown fuse (F1) in

LM ADAPTER

disconnection on the

loose connector

(CN605, CN65, CN32,

CN33, CN31).

•

Damage transformer in

LM ADAPTER

Damage circuit board

(L.B, P.B).

• Power supply is not

connected to indoor unit

or LOSSNAY unit.

• M-NET transmission

cable is not connected.

• Power supply is not

connected to M-NET

transmission cable.

• M-NET transmission

cable is not connected.

• Power supply is not

connected to M-NET

transmission cable.

• The DIP SW1-2 setting is

different to the system

configuration.

(T1, T2).

Checking method and remedy

• Check that there are no

duplicate addresses.

After correcting

problem, reset power

supply.

• Check for defects. Once

corrected, reset the

power supply.

• Check these areas.

After correcting

problem, reset power

supply.

• Check these areas.

After correcting

problem, reset power

supply.

• Check these areas.

After correcting

problem, reset power

supply.

7705

M-NET remote controller,

MA remote controller,

system controller

Initialization error

Initialization of the LM

ADAPTER failed.

Damage in LM ADAPTER.

Reset the power supply.

If the same error occurs

again, the controller is

faulty.

Page 21

19

Appendix : Test run check sheet

Test run check sheet

Test run of units (SW1-9)

Unit

address

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

* Check the building control system functions beforehand and check off each operation as it is tested.

For the check list, you can either copy this sheet or make a new check list based on this sheet.

Operation from LONW

ON OFF

®

ORKS

network

Operation

temperature

mode

Set

Confirmation of operating status

ON OFFON OFF

Operation

mode

Set

temperature

Error

Intake

temperature

MEMO

Page 22

Page 23

Page 24

WT03760X01

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide resonable protection against harmful inter ference in a residential installation. This equipment generates, uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more

of the following measures:

-- Reorient or relocate the receiving antenna.

-- Increase the separation between the equipment and receiver.

-- Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

-- Consult the dealer or an experienced radio / TV technician for help.

HEAD OFFICE MITSUBISHI DENKI BLDG.MARUNOUCHI TOKYO 100-0005 TELEX J24532 CABLE MELCO TOKYO

Loading...

Loading...