Mitsumi electronic H55K, FR-CVL-H7.5K, FR-CV-H7.5K, FR-CVL-7.5K, FR-CV-7.5K User Manual

...Page 1

TRANSISTORIZED INVERTER

FR-CV

INSTRUCTION MANUAL

POWER REGENERATION

COMMON CONVERTER

FR-CV-7.5K to 30K(-AT)

FR-CV-37K, 55K

FR-CV-H7.5K to H30K(-AT)

FR-CV-H37K, H55K

FR-CVL-7.5K to 55K

FR-CVL-H7.5K to H55K

OUTLINE

INSTALLATION

AND WIRING

PROTECTIVE

FUNCTIONS

1

2

3

SPECIFICATIONS

4

Page 2

Thank you for choosing this Mitsubishi transistorized inverter option unit. This instruction manual provides

handling information and precations for use of the equipment. Before using the inverter option, always read

this instruction manual carefully to use the equipment to its optimum.

Please forward this instruction manual to the end user.

This instruction manual uses the International System of Units (SI). The measuring units in the yard and

pound system are indicated in parentheses as reference values.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read through the instruction

manual and appended documents carefully and can use the equipment correctly.In this instruction manual, the

safety instruction levels are classified into "WARNING" and "CAUTION"

.

WARNING

CAUTION

Note that even the level may lead to a serious consequence according to conditions. Please

follow the instructions of both levels because they are important to personnel safety.

1. Electric Shock Prevention

CAUTION

Assumes that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

Assumes that incorrect handling may cause hazardous conditions, resulting in

medium or slight injury, or may cause physical damage only.

WARNING

z While power is on or when the inverter is running, do not open the terminal block cover. You may get an

electric shock.

z Do not run the inverter with the terminal block cover removed. Otherwise, you may access the exposed

high-voltage terminals or the charging part of the circuitry and get an electric shock.

z Before starting wiring or inspection, switch off power, check to make sure that the charge lamp is off, wait

for at least 10 minutes after the power supply has been switched off, and check that there are no residual

voltage using a tester or the like. The capacitor is charged with high voltage for some time after power off

and it is dangerous.

z Earth (ground) the inverter.

z Any person who is involved in wiring or inspection of this equipment should be fully competent to do the

work.

z Always install the inverter before wiring. Otherwise, you may get an electric shock or be injured.

z Perform setting dial and key operations with dry hands to prevent an electric shock.

z Do not subject the cables to scratches, excessive stress, heavy loads or pinching. Otherwise, you may get

an electric shock.

2. Fire Prevention

CAUTION

z Mount the power regeneration common converter unit and dedicated stand-alone reactor unit to

incombustible material. Mounting it to or near combustible material can cause a fire.

z Do not connect a resistor directly to the DC terminals P/L+, N/L-. This could cause a fire.

3.Injury Prevention

CAUTION

z Apply only the voltage specified in the instruction manual to each terminal to prevent damage etc.

z Ensure that the cables are connected to the correct terminals. Otherwise damage etc. may occur.

z Always make sure that polarity is correct to prevent damage etc.

z While power is on and for some time after power-off, do not touch the power regeneration common

converter unit and dedicated stand-alone reactor unit as they are hot and you may get burnt.

zWhen changing the fan, take care not to get injured.

A-1

Page 3

4. Additional Instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.

1) Transportation and installation

CAUTION

zWhen carrying products, use correct lifting gear to prevent injury.

zDo not stack the inverter option boxes higher than the number recommended.

zEnsure that installation position and material can withstand the weight of the inverter.

z Do not operate if the power regeneration common converter is damaged or has parts missing.

z When carrying the inverter option, do not hold it by the terminal block cover or setting dial; it may fall off or

fail.

z Do not stand or rest heavy objects on the inverter option.

z Check the inverter option mounting orientation is correct.

z Prevent screws, wire fragments, other conductive bodies, oil or other flammable substances from entering

the power regeneration common converter.

z Do not drop the power regeneration common converter, or subject it to impact.

z Use the inverter option under the following environmental conditions. Using it outside the operating range

can cause the power regeneration common converter to become faulty.

Ambient

temperature

Ambient

humidity

Storage

temperature

Ambience Indoors (free from corrosive gas, flammable gas, oil mist, dust and dirt)

Environment

Altitude, vibration

*Temperature applicable for a short time, e.g. in transit.

-10°C to +50°C (14°F to 122°F) (non-freezing)

90%RH or less (non-condensing)

-20°C to +65°C* (-4°F to 149°F)

Maximum 1000m (3280.80feet) above sea level for standard operation.

After that derate by 3% for every extra 500m (1640.40feet) up to

2500m (8202.00feet) (91%). 5.9m/s

2

or less

2) Operation

WARNING

z Do not modify the equipment.

zDo not perform parts removal which is not instructed in this manual. Doing so may lead to fault or damage

of the product.

3) Maintenance, inspection and parts replacement

CAUTION

z Do not carry out a megger (insulation resistance) test on the control circuit of the power regeneration

common converter unit.

4) Emergency stop

CAUTION

z When the breaker on the power regeneration common converter input side trips, check for the wiring fault

(short circuit), damage to internal parts of the power regeneration common converter, etc. Identify the

cause of the trip, then remove the cause and power on the breaker.

5) Disposing of the inverter

CAUTION

z Treat as industrial waste

6) General instructions

Many of the diagrams and drawings in this instruction manual show the inverter without a cover, or partially

open. Never operate the inverter in this like. Always replace the cover and follow this instruction manual

when operating the inverter.

A-2

Page 4

CONTENTS

1 OUTLINE 1

1.1 Pre-Operation Information .....................................................................................2

1.1.1 Precautions for operation .......................................................................................................... 2

1.2 Basic Configuration................................................................................................ 4

1.2.1 Basic configuration .................................................................................................................... 4

1.3 Structure ................................................................................................................ 5

1.3.1 Appearance and structure ......................................................................................................... 5

1.3.2 Removal and reinstallation ........................................................................................................ 6

1.3.3 Structure of the power regeneration common converter ........................................................... 8

2 INSTALLATION AND WIRING 9

2.1 Installation............................................................................................................ 10

2.1.1 Instructions for installation ....................................................................................................... 10

2.2 Wiring................................................................................................................... 12

2.2.1 Terminal connection diagram .................................................................................................. 12

2.2.2 Wiring of the main circuit ......................................................................................................... 14

2.2.3 Wiring of the control circuit ...................................................................................................... 21

2.2.4 Design information................................................................................................................... 22

CONTENTS

2.3 Operation .............................................................................................................23

2.3.1 Pre-operation checks............................................................................................................... 23

2.3.2 Power-on and operation .......................................................................................................... 23

2.4 Other wiring.......................................................................................................... 24

2.4.1 Power harmonics..................................................................................................................... 24

2.4.2 Noise types and reduction techniques..................................................................................... 25

2.4.3 Peripheral devices ................................................................................................................... 26

2.4.4 Instructions for UL and cUL ..................................................................................................... 28

3 PROTECTIVE FUNCTIONS 29

3.1 Errors (Alarms)..................................................................................................... 30

3.1.1 Error (alarm) definitions ........................................................................................................... 30

3.1.2 Alarm symptoms and check points.......................................................................................... 31

3.2 Precautions for Maintenance and Inspection....................................................... 32

3.2.1 Precautions for maintenance and inspection........................................................................... 32

3.2.2 Check items............................................................................................................................. 32

3.2.3 Periodic inspection .................................................................................................................. 32

3.2.4 Insulation resistance test using megger .................................................................................. 33

3.2.5 Pressure test ........................................................................................................................... 33

3.2.6 Daily and Periodic Inspection .................................................................................................. 34

3.2.7 Replacement of parts .............................................................................................................. 36

3.2.8 Measurement of main circuit voltages, currents and power .................................................... 40

i

Page 5

4 SPECIFICATIONS 43

4.1 Standard Specifications ....................................................................................... 44

4.1.1 Model specifications ................................................................................................................ 44

4.1.2 Internal block diagram ............................................................................................................. 47

4.1.3 Outline drawings...................................................................................................................... 48

ii

Page 6

CHAPTER 1

OUTLINE

This chapter gives information on the basic "outline" of this

product.

Always read the instructions in this chapter before using the

equipment.

1.1 Pre-Operation Information ......................... 2

1.2 Basic Configuration.................................... 4

1.3 Structure ...................................................... 5

1

2

3

4

1

Page 7

Pre-Operation Information

1.1 Pre-Operation Information

1.1.1 Precautions for operation

Incorrect handling might cause the inverter option to operate improperly, its life to be reduced considerably, or at the

worst, the inverter option to be damaged. Handle the power regeneration common converter properly in accordance

with the information in each section as well as the precautions and instructions of this manual to use it correctly.

This manual is written for the power regeneration common converter FR-CV.

For handling information on the inverter, stand-alone options, etc., refer to the corresponding manuals.

(1) Unpacking and product check

Unpack the power regeneration common converter and check the capacity plate on the front cover and the rating

plate on the inverter side face to ensure that the product agrees with your order and the inverter is intact.

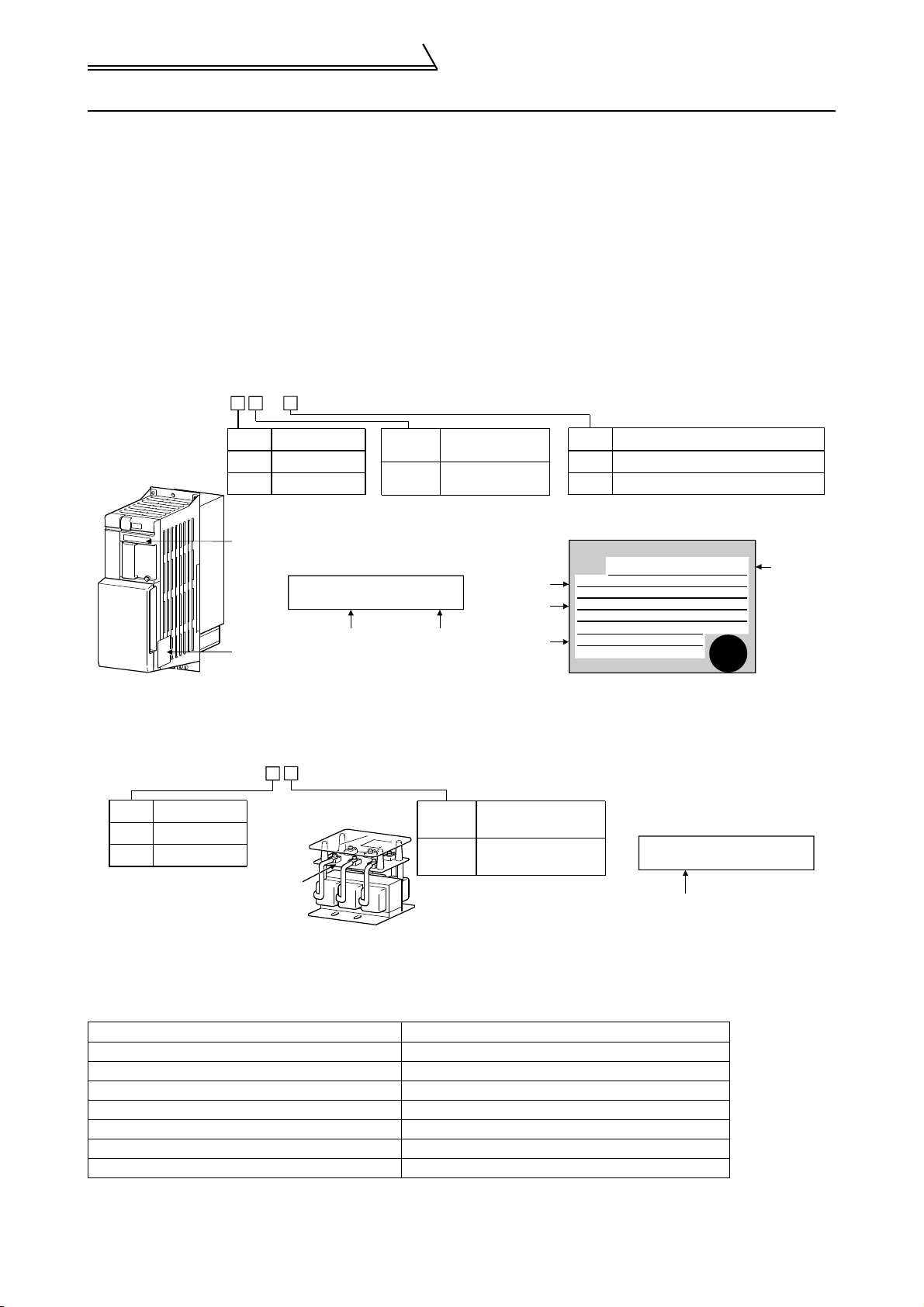

1) Definition of the power regeneration common converter type

FR-CV- K-

Symbol

None

H

Voltage class

200V class

400V class

Symbol

7.5 to 55

Applicable Inverter

Capacity

Indicates capacity

in "kW".

Capacity plate

Capactiy plate

FR-CV-11K

Converter type Serial number

Rating plate

Input rating

Output rating

Serial number

2) The power regeneration common converter accessory

Instruction manual

3) Definition of the dedicated stand-alone reactor

Remember to prepare the dedicated stand-alone reactor as it must be installed.

FR-CVL- K

Symbol

None

H

Voltage class

200V class

400V class

Capacity plate

Symbol

7.5 to 55

Applicable Converter

Capacity

Indicates capacity

in "kW".

Symbol

Heat sink outside mounting structure

None

Enclosure inside installation structure

AT

Structure

Rating plate

MITSUBISHI

MODEL

FR-CV-11K

XXXXX

INPUT :

XXXXX

OUTPUT :

SERIAL :

INVERTER

PASSED

Capacity plate

FR-CVL-11K

Reactor type

Converter

type

If you have found any discrepancy, damage, etc., please contact your sales representative.

(2) Confirmation of the peripheral device types

The dedicated stand-alone reactor must be installed.

Power regeneration common converter Dedicated stand-alone reactor (required)

FR-CV-7.5K(-AT) FR-CVL-7.5K

FR-CV-11K(-AT) FR-CVL-11K

FR-CV-15K(-AT) FR-CVL-15K

FR-CV-22K(-AT) FR-CVL-22K

FR-CV-30K(-AT) FR-CVL-30K

FR-CV-37K FR-CVL-37K

FR-CV-55K FR-CVL-55K

Note: 400Vclass devices have capacity numbers preceded by H in their type codes.

2

Page 8

Pre-Operation Information

(3) Installation

To operate the power regeneration common converter with high performance for a long time, install the inverter in a

proper place, in the correct direction, and with proper clearances. (Refer to page 10.)

(4) Wiring

Connect the power supply, inverter and control signals to the terminal block. Note that incorrect connection may

damage the power regeneration common converter , inverter and peripheral devices. (Refer to page 10.)

1

OUTLINE

3

Page 9

Basic Configuration

1.2 Basic Configuration

1.2.1 Basic configuration

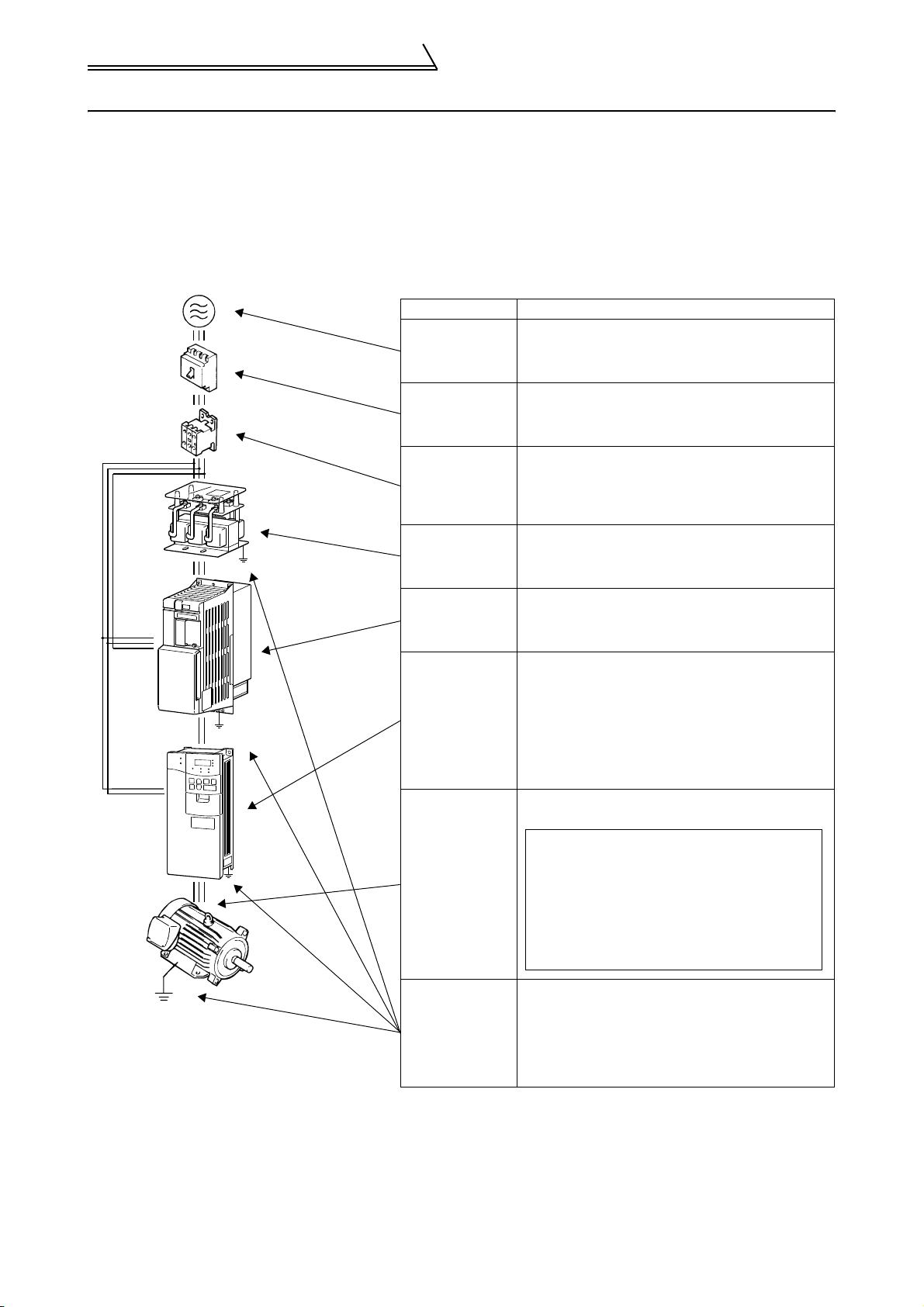

The following devices are required to operate the power regeneration common converter. Proper peripheral devices

must be selected and correct connections made to ensure proper operation. Incorrect system configuration and

connections can cause the inverter to operate improperly, its life to be reduced considerably, and in the worst case,

the inverter to be damaged.

Please handle the product properly in accordance with the information in each section as well as the precautions

and instructions of this manual. (For connections of the peripheral devices, refer to the corresponding manuals.)

Name Description

Use the power supply within the permissible power

(ELB)

or

(NFB)

(MC)

Dedicated Stand-alone

reactor (FR-CVL)

Earth(Ground)

Power regeneration

common converter

(FR-CV)

Earth

(Ground)

Power supply

Earth leakage

circuit breaker

(ELB) or no-fuse

breaker(NFB)

Magnetic

contactor

Installation of

dedicated

stand-alone

reactor

Power

regeneration

common

converter

Inverter

supply specifications of the power regeneration

common converter.

(Refer to page 44.)

The breaker should be selected with care since a

large inrush current flows in the power regeneration

common converter at power on. (Refer to page 26.)

Install the magnetic contactor to ensure safety.

When installed, do not use it to start or stop the

inverter. It might reduce the power regeneration

common converter life.

(Refer to page 26.)

For power coordination, always install the

dedicated stand-alone reactor.

Incorrect wiring might lead to power regeneration

common converter damage. The control signal lines

should be kept away from the main circuit to protect

them from noise.

•Use the compatible inverter.

•The inverter life is influenced by ambient

temperature.The ambient temperature should be

as low as possible within the permissible range.

This must be noted especially when the inverter is

installed in an enclosure .

•Incorrect wiring might lead to inverter damage.The

control signal lines should be kept away from the

main circuit to protect them from noise.

Do not connect a power capacitor, surge suppressor

or radio noise filter to the output side.

Note: Note that when an electromagnetic

contactor (MC) and a no-fuse breaker

(NFB) are installed, switching off the

inverter during operation, then on again

will cause a starting current to flow,

affecting the inverter and motor. When

installing a no-fuse breaker (NFB) on the

output side, contact the NFB manufacturer

for selection of no-fuse breaker.

To prevent an electric shock, always ground the

dedicated stand-alone reactor, power regeneration

common converter, motor and inverter.

The grounding cable provided for reduction of

induction noise from the power line of the inverter is

recommended to be wired by returning it to the

grounding terminal of the inverter.

Earth(Ground)

Earth

(Ground)

Devices

connected to the

output

Earth(Ground)

Note: If connected to the inverter, the power factor improving DC reactor (FR-BEL) does not produce an effect on

power factor improvement. In addition, do not use the power factor improving AC reactor (FR-BAL) since

using it may degrade the power regeneration function.

4

Page 10

1.3 Structure

r

r

)

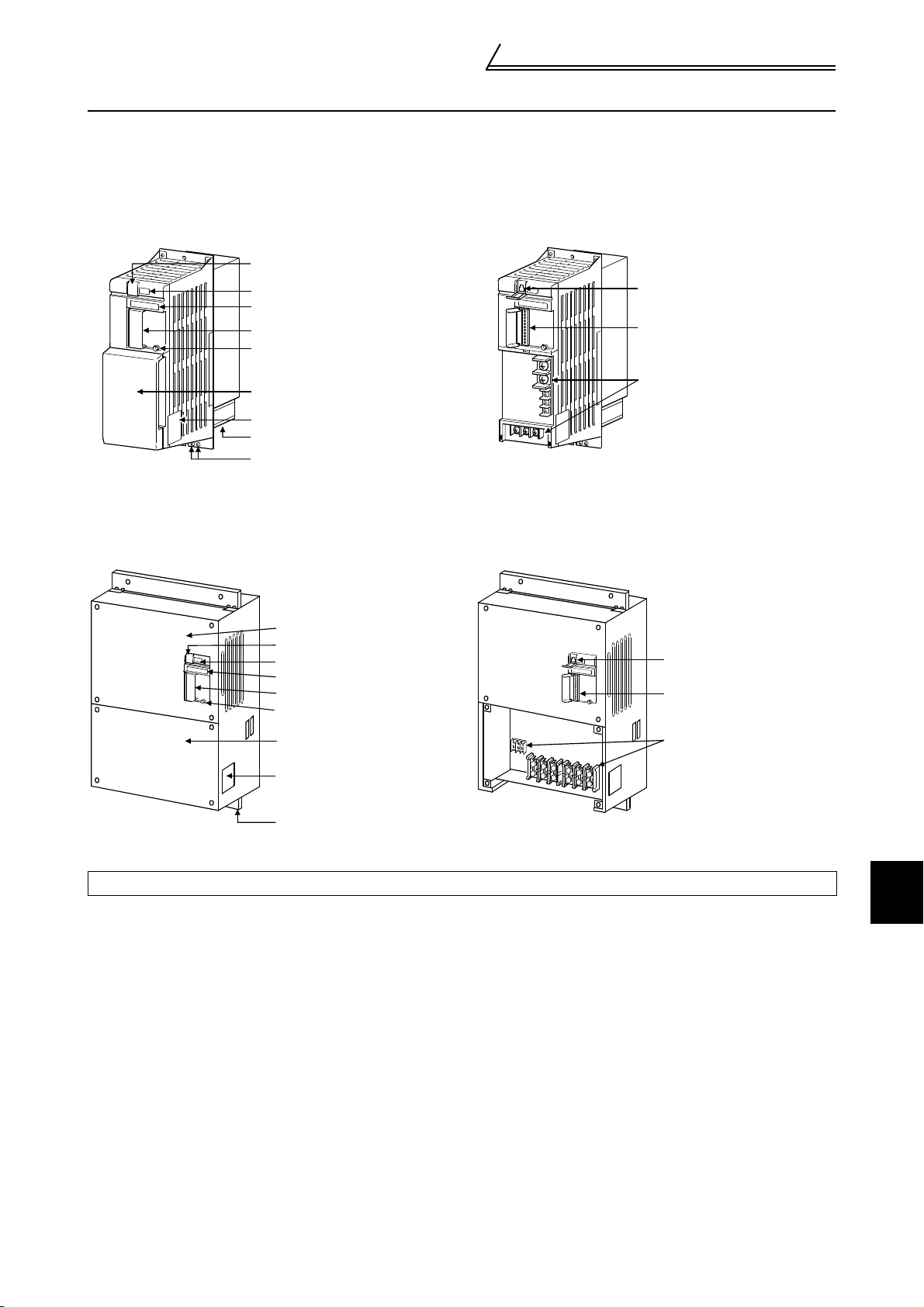

1.3.1 Appearance and structure

FR-CV-7.5K to 30K (-AT), FR-CV-H7.5K to H30K (-AT)

(1) Front view (2) Without front cover

Connector cover for manufacturer

setting

LED display

Capacity plate

Control circuit terminal block cove

CHARGE lamp

Connector for manufacturer

setting (Note)

Control circuit terminal block

Structure

Main cricuit terminal block cover

Main circuit terminal block

Rating plate

Cooling fan

Earth screws

FR-CV-37K/55K, FR-CV-H37K/H55K

(1) Front view (2) Without front cover

Front cover

Maker setting connector cover

LED display

Capacity plate

Control circuit terminal block cove

CHARGE lamp

Main circuit terminal block cover

Rating plate

Fix ture

Maker setting connector (Note

Control circuit terminal block

Main circuit terminal block

Note: Keep the connector for manufacturer setting open.

1

OUTLINE

5

Page 11

Structure

1.3.2 Removal and reinstallation

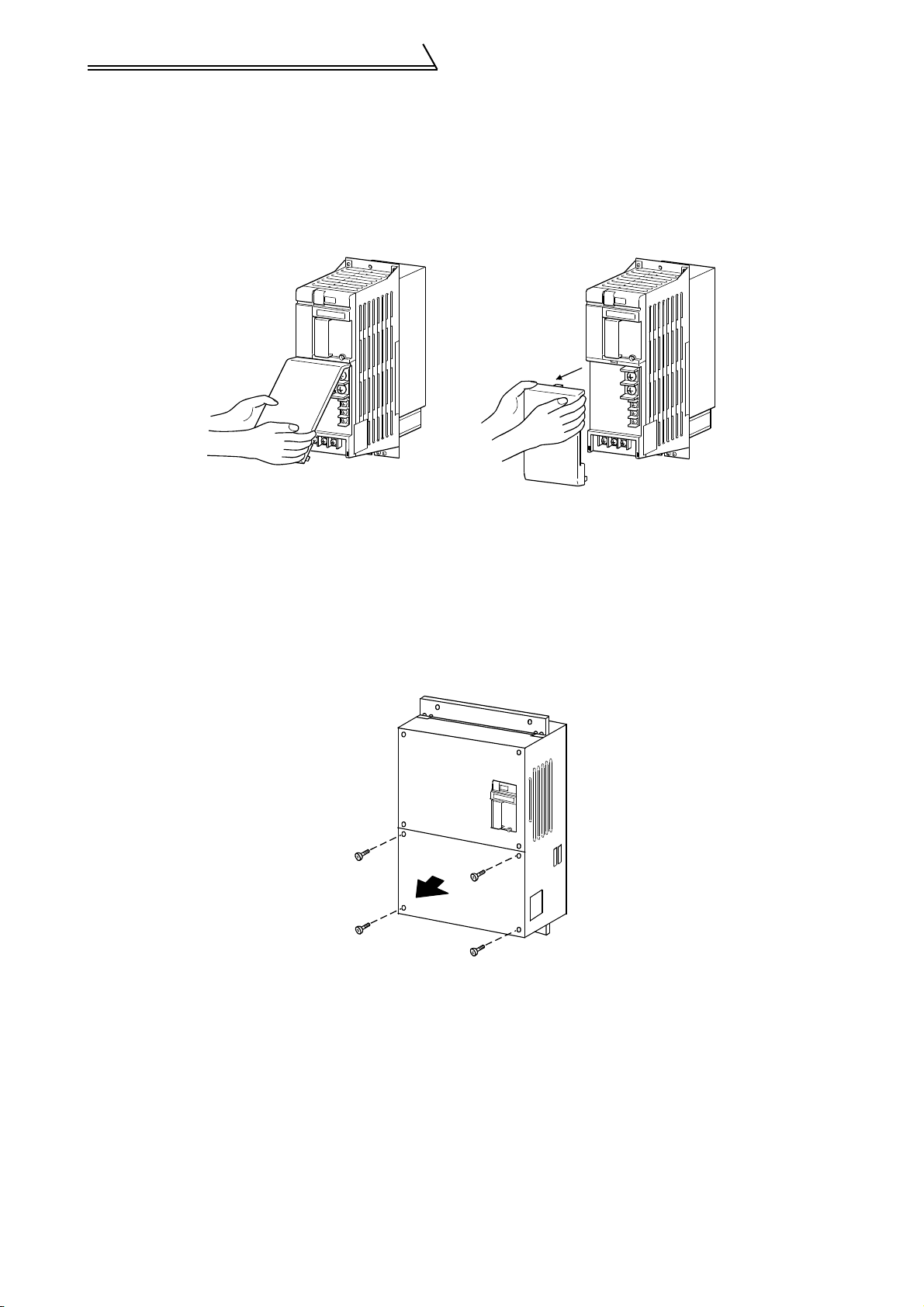

(1) Main circuit terminal block cover

FR-CV-7.5K to 30K (-AT), FR-CV-H7.5K to H30K(-AT)

zRemoval

1)Hold both ends of the cover bottom and pull it toward you.

2)When the bottom of the cover has come off, hold both ends of the cover top and pull it toward you.

zReinstallation

1)Insert the catch at the cover top into the socket in the unit.

2)Using the part of the catch as a support, securely press the catches at both ends of the cover bottom to

the unit.

FR-CV-37K/55K, FR-CV-H37K/H55K

zRemoval

1)Remove the installation screws at the top of the main circuit terminal block cover.

zReinstallation

1)Fix the main circuit terminal block cover with the installation screws.

6

Page 12

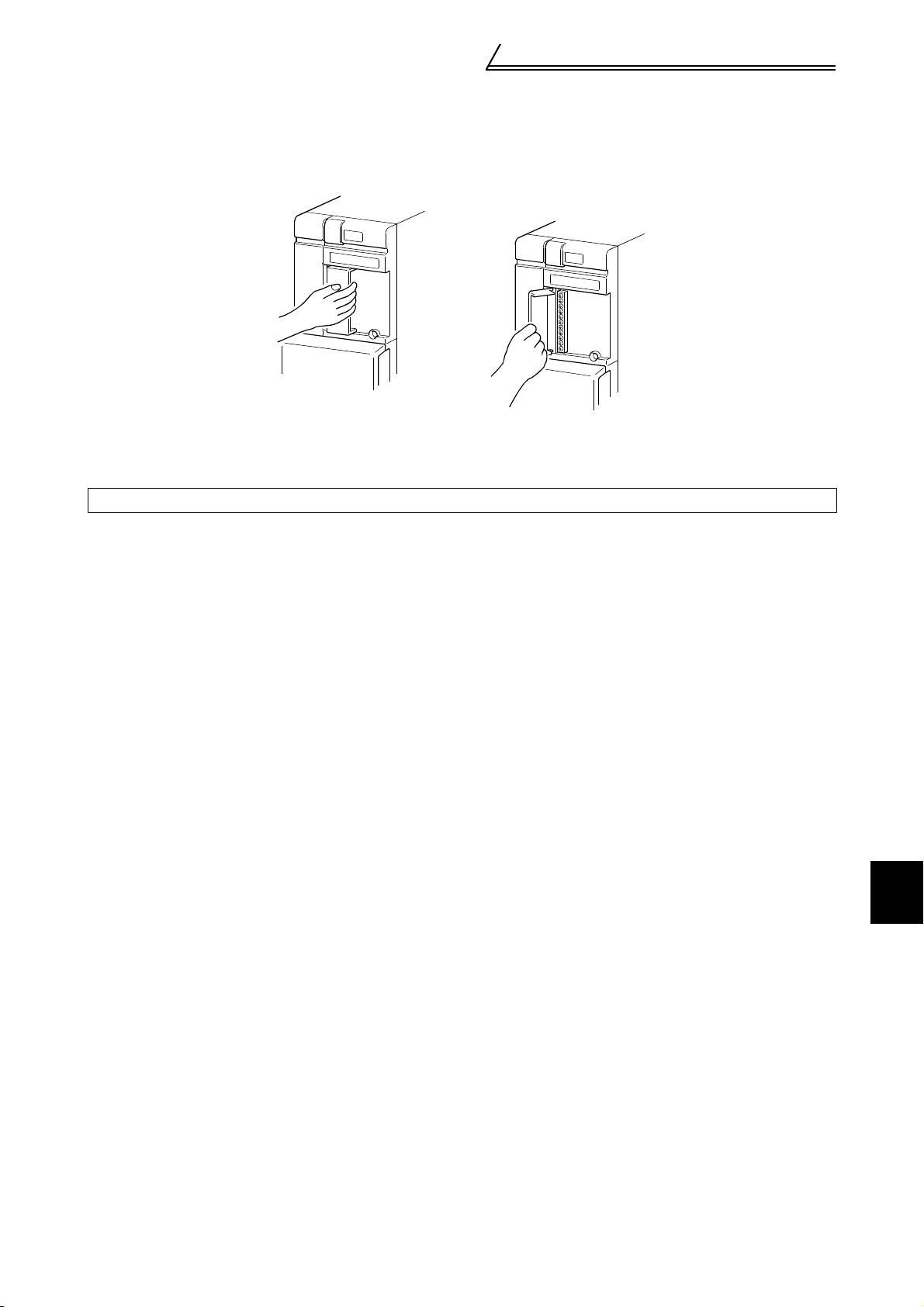

(2) Control circuit terminal block cover

zOpening

1)Hold the right end of the cover and pull it toward you.

2)The cover opens, with the left-hand side of the cover acting as a support.

zClosing

1)Securely press the right end of the cover against the unit.

Note: Make sure that the cover has been fitted securely.

Structure

1

OUTLINE

7

Page 13

Structure

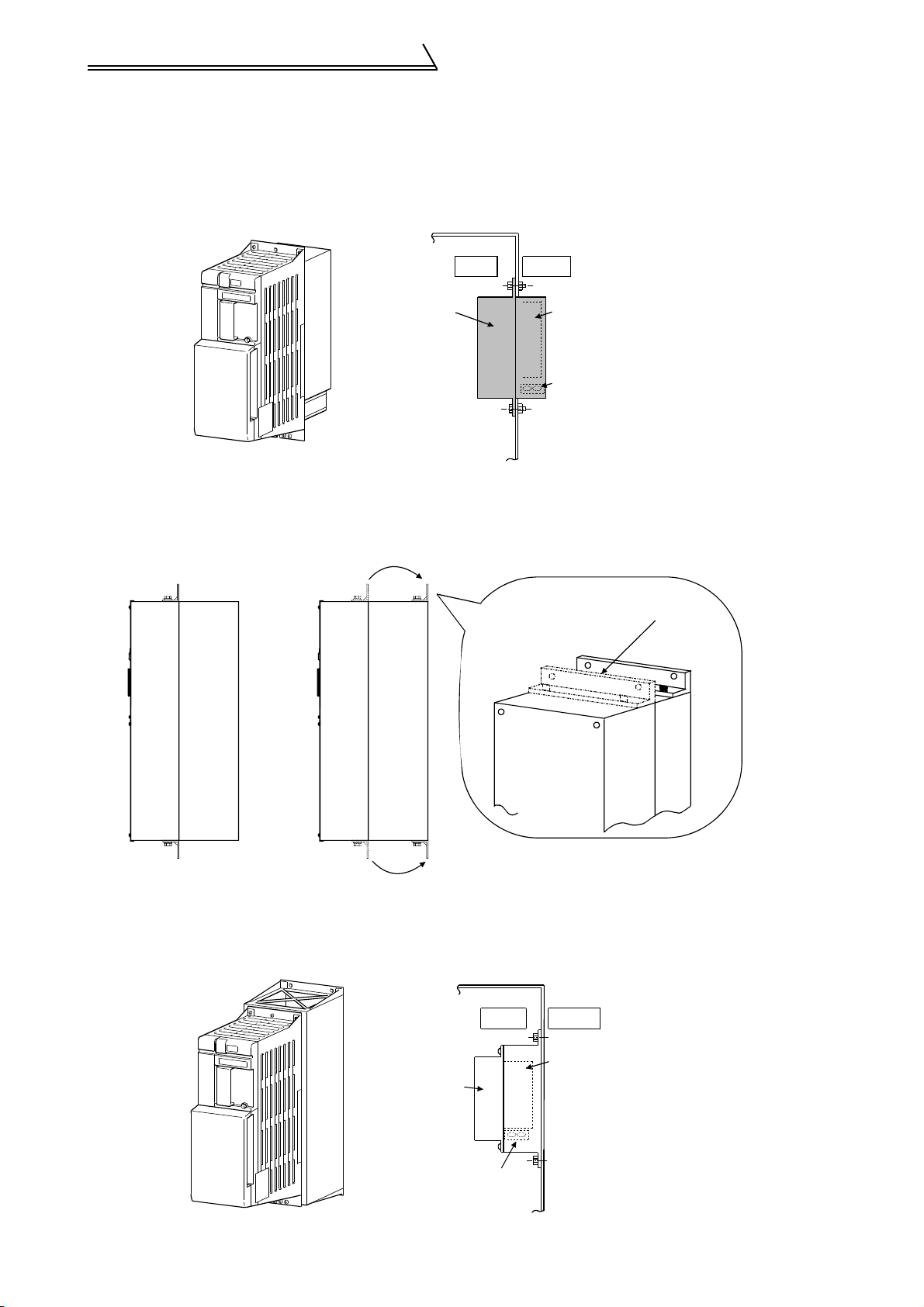

1.3.3 Structure of the power regeneration common converter

The power regeneration common converter is available in two types: a heat sink outside mounting structure model

and an enclosure inside installation structure model.

(1) Heat sink outside mounting structure model (FR-CV-7.5K to 55K, FR-CV-H7.5 to H55K)

Enclosure

Inside

Power regeneration

common converter

Outside

Heat

sink

Cooling

fan

The FR-CV-37K, 55K and FR-CV-H37K, H55K can be used either as a heat sink outside mounting structure model

or an enclosure inside installation structure model by changing its mounting foot position. It is shipped from the

factory as a heat sink outside mounting structure model. Change the mounting foot position as shown below for

installation.

Factory-set mounting

foot position

Heat sink outside mounting

(At factory shipment)

Enclosure inside installation

(2) Enclosure inside installation structure model

(FR-CV-7.5K to 30K-AT, FR-CV-H7.5K to H30K-AT)

Enclosure

Power regeneration

common converter

Cooling fan

8

Inside

Outside

Heat

sink

Page 14

CHAPTER 2

INSTALLATION AND WIRING

This chapter gives information on the basic "Installation and

wiring" of this product.

Always read the instructions in this chapter before using the

equipment.

2.1 Installation ................................................... 10

2.2 Wiring........................................................... 12

2.3 Operation ..................................................... 23

2.4 Other wiring................................................. 24

1

2

3

4

9

Page 15

Installation

2.1 Installation

2.1.1 Instructions for installation

1) Handle the unit carefully.

The power regeneration common converter uses plastic parts. Handle it gently to protect it from damage. Also,

hold the unit with even strength and do not apply too much strength to the terminal block cover alone.

2) Install the inverter in a place where it is immune to vibration. (5.9 m/s

Also note the cart, press, etc.

3) Note on ambient temperature

The power regeneration common converter life is under great influence of ambient temperature. Exercise care

so that the ambient temperatures of the installation place do not fall out of the permissible range (-10°C to

+50°C (14°F to 120°F)). Make sure that the ambient temperatures are within the permissible range at the

measurement positions given in 3) on the next page. It is important to check that not only the ambient

temperatures of the power regeneration common converter but also those of the inverter contained in the same

enclosure fall within the permissible range.

4) Notes on installation surface

The power regeneration common converter will be very hot (maximum about 150°C (302°F)).

The power regeneration common converter (heat sink outside mounting structure model) can be reduced in the

enclosure inside temperature by mounting its heat sink outside the enclosure. Cut the mounting area according

to the panel cutting dimensions. Since the cooling section located outside the enclosure has a cooling fan, do

not use the equipment in the environment that has water drops, oil mists, dust particles, etc. For installation in

an enclosure, use the enclosure inside installation structure model of the power regeneration common

converter and install it on an incombustible (e.g. metal) mounting surface.

Also leave sufficient clearances around the inverter.

5) Avoid high temperature and high humidity.

Avoid direct sunlight and places of high temperature and high humidity.

2

or less)

6) Avoid places where the inverter option is exposed to oil mist, flammable gases, fluff, dust, dirt etc.

Install the inverter option in a clean place or inside a "totally enclosed" panel which does not accept any

suspended matter.

7) Note the cooling method when the power regeneration common converter and inverter is installed in an

enclosure.

When two or more power regeneration common converters and inverters are installed or a ventilation fan is

mounted in an enclosure, the inverters and ventilation fan must be installed in proper positions with extreme

care taken to keep the ambient temperatures of the power regeneration common converters and inverters

below the permissible value. If they are installed in improper positions, the ambient temperatures of the power

regeneration common converters and inverters will rise and ventilation effect will be reduced.

8) Install the power regeneration common converter and inverter securely in the vertical direction with screws or

bolts.

9) Install the dedicated stand-alone reactor (FR-CVL) on horizontal plane. Failure to observe this may lead to

damage of the reactor.

10

Page 16

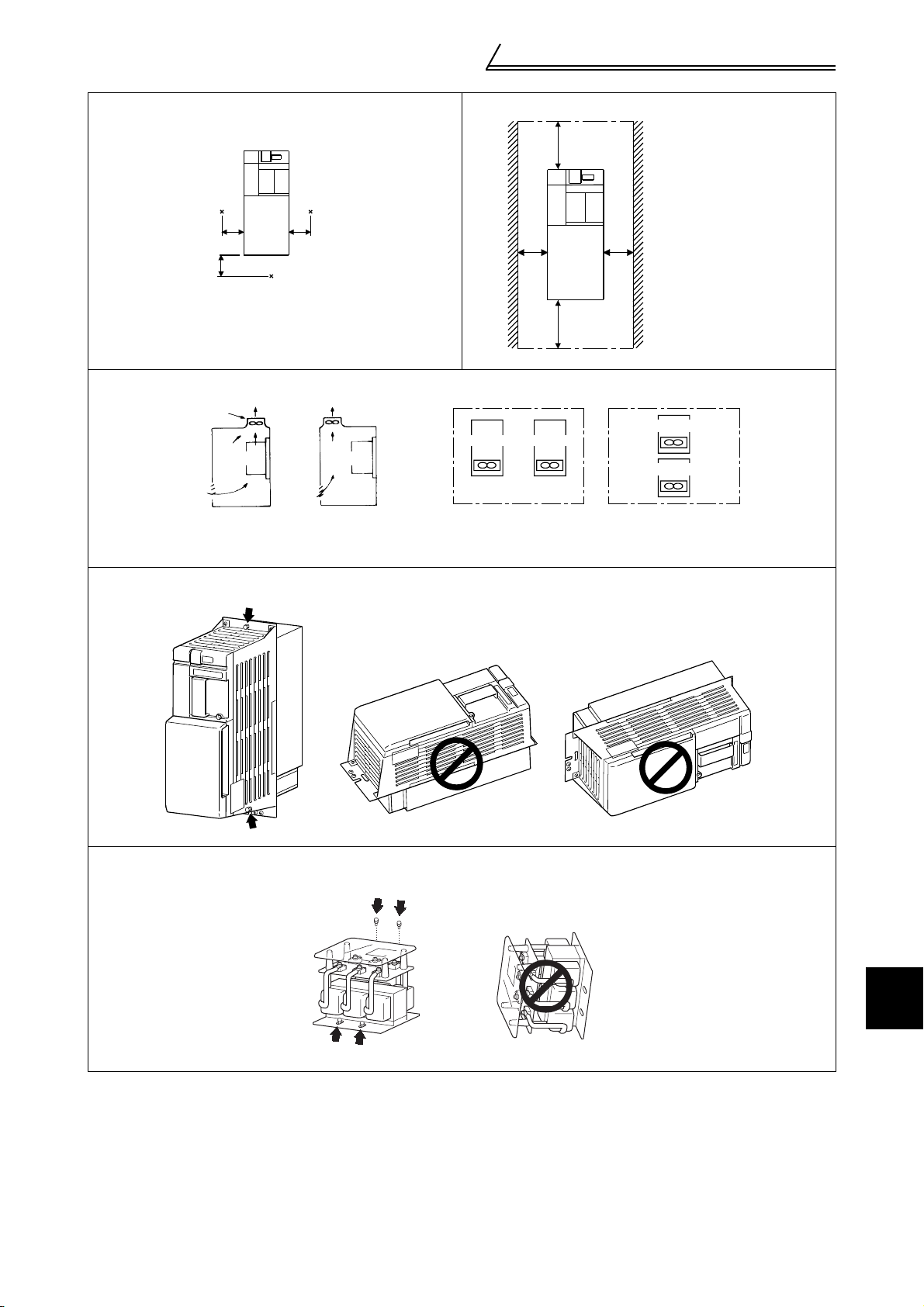

3) Note on ambient temperature 4) Clearances around the inverter

p

10cm

(3.94 inches)

or more

Measurement

position

5cm

(1.97 inches)

5cm

(1.97 inches)

FR-CV

5cm

(1.97 inches)

Measurement

osition

or moer

5cm (1.97 inches)

FR-CV

10cm

(3.94 inches)

or more

or moer

5cm (1.97 inches)

7) For installation in an enclosure

Ventilation

fan

Converter

(Correct example)

Position of Ventilation Fan

Converter

(Incorrect example)

Converter

Built-in cooling fan

Converter

(Correct example)

Accommodation of two or more inverters

Converter

Converter

(Incorrect example)

Installation

Clearances required to

change the cooling fan of

the enclosure inside

installation structure model

(-AT). (Refer to page 36 for

fan replacement.)

8) Vertical mounting

Power regeneration common converter

9) Horizontal plane installation

Dedicated stand-alone reactor

INSTALLATION AND WIRING

2

11

Page 17

Wiring

2.2 Wiring

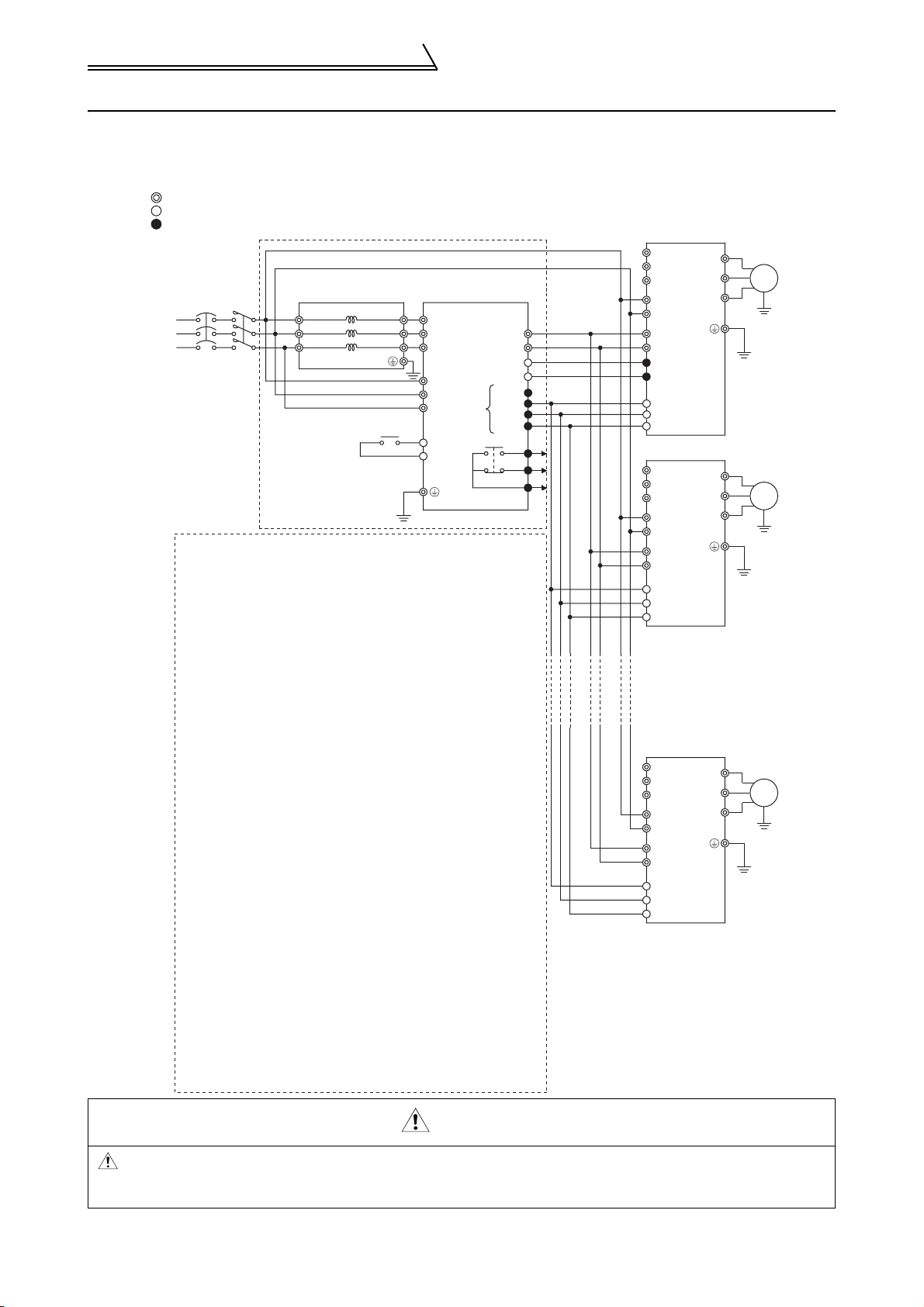

2.2.1 Terminal connection diagram

Main circuit terminal

Control circuit input terminal

Control circuit output terminal

MCNFB

R

S

T

3-phase

AC power supply

Note : 1. Never connect a power supply to the inverter terminals R, S, T.

Such a connection, even if accidental, will damage the inverter

and power regeneration common converter.

2. Match the polarities of the P and N terminals by connecting

terminal P of the inverter to terminal P of the power

regeneration common converter and terminal N of the inverter

to terminal N of the power regeneration common converter as

shown in the connection example. Incorrect matching of

the polarities of the P and N terminals will result in damage

to the inverter.

Do not remove a jumper across terminal P/+ and P1.

3. For the FR-A700, F700, A500, F500 and V500 series, remove

the jumpers across terminals R-R1 and S-S1, and connect

power supply to terminals R1, S1 for the control circuit. For the

FR-E700, D700, E500, S500, C500 and F500J series, the

inverter does not have terminals R1, S1. So you do not need to

make this connection.

4. When wiring the dedicated stand-alone reactor and power

regeneration common converter as well as when wiring

the power supply and terminals R/L11, S/L21, T/MC1, strictly

observe the wiring order as shown in the connection example

(match phase sequence of the power supply).

A wrong connection will damage the power regeneration

common converter.

Do not insert an MCCB nor MC. The power regeneration

common converter functions abnormally.

5. Make sure terminals R/L11, S/L21, T/MC1 are connected to

the power supply. Running the inverter without connecting

these terminals will damage the power regeneration common

converter.

6. Since power to the inverter is supplied by terminals P and N,

set Pr.30 to 2 (for use with a high power factor converter, power

regeneration common converter) for the FR-A700, F700, A500,

F500 and V500 series. This setting disables the built-in brake

resistor.

7. For the FR-A700, F700, E700, D700, A500, F500 and V500

series inverter, assign the X10 signal to any of input terminals to

use the inverter.

8. You can connect up to six inverters to one power regeneration

common converter.

9. Use sink logic (factory setting) when the FR-CV is connected.

The FR-CV cannot be connected when source logic is selected.

FR-CVL

(Note 4)

R/L11

S/L21

T/L31

R2/L12

S2/L22

T2/L32

(Note 5)

(Note 4)

R2/L1

S2/L2

T2/L3

R/L11

S/L21

T/MC1

RES

SD

FR-CV

P/L+

N/L-

RDYA

RDYB

RS0

SE

Open collector

outputs

P24

SD

A

B

C

FR-A720

R/L1

S/L2

(Note 1)

T/L3

R1/L11

(Note 3)

S1/L21

P/+

(Note 2)

N/PC

SD

(Note 7)

X10 (MRS)

RES

SD

FR-A720

R/L1

(Note 1)

S/L2

T/L3

R1/L11

(Note 3)

S1/L21

P/+

(Note 2)

N/-

(Note 7)

X10 (MRS)

RES

SD

FR-A720

R/L1

(Note 1)

S/L2

T/L3

R1/L11

(Note 3)

S1/L21

P/+

(Note 2)

N/-

(Note 7)

X10 (MRS)

RES

SD

U

V

W

U

V

W

U

V

W

IM

IM

IM

CAUTION

Be sure to connect terminal RDY of the FR-CV to the X10 or MRS signal assigned terminal of the

inverter, and connect terminal SE of the FR-CV to terminal SD of the inverter. Without proper

connecting, FR-CV will be damaged.

12

Page 18

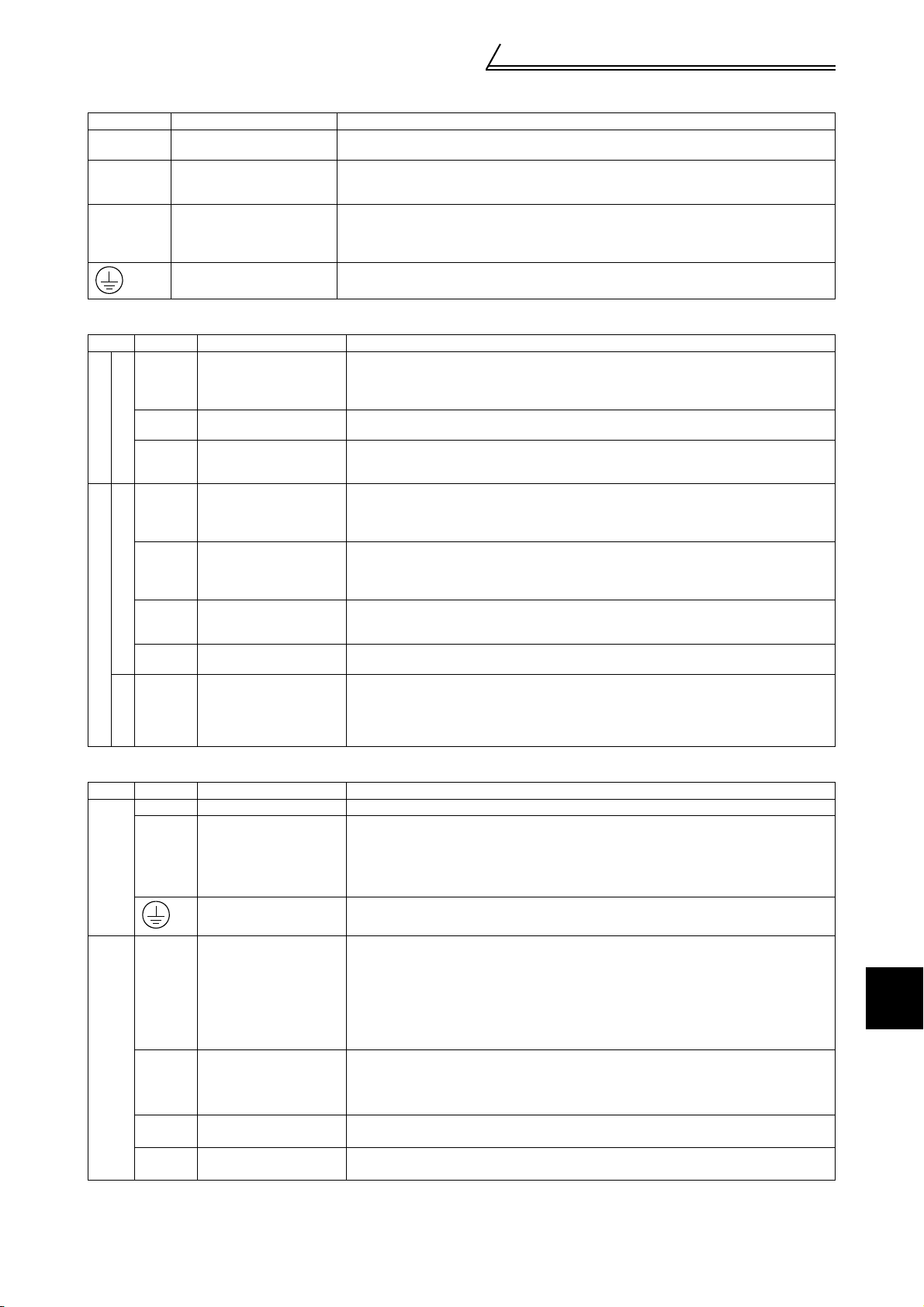

(1) Description of main circuit terminals

Symbol Terminal Name Description

R2/L1, S2/

L2,T2/L3

P/L+, N/L- DC power output

R/L11, S/

L21, T/MC1

AC power input Connect to the dedicated stand-alone reactor terminals R2/L12, S2/L22, T2/L32.

Connect to the inverter terminals P, N, and keep the inverter terminals R, S, T open.

For the FR-A700, F700, A500, F500 or V500 series, set 2 (for use of high power

factor converter, power regeneration common converter) in Pr.30.

Power supply phase

detection

Ground Securely connect to the earth.

Terminals for power supply phase, power voltage detection and control power input.

Connect to the dedicated stand-alone reactor terminals R/L11, S/L21, T/L31.

Running the inverter without connecting these terminals will damage the power

regeneration common converter.

(2) Description of control circuit terminals

Type Symbol Terminal Name Description

Used to input 24VDC power for alarm output relay drive and reset drive signal

P24 24VDC input

RES Reset

Input signals

SD

Power input, contact

RDYA Ready output

RDYB

Open collector

RSO Converter reset

Output signals

SE

A, B, C Alarm output

Contact

24VDC power common

Contact input common

Inverter

operation enable

Open collector output

common

drive. Connect to the inverter terminal PC. When you do not use the inverter

terminal PC, prepare a 24VDC power supply.

Permissible input voltage fluctuation: 22V to 26VDC

Used to reset the activated protective circuit. Turn the terminals RES-SD on for

longer than 0.1 seconds, then turn them off.

Connect the common of the 24VDC power supply.

Shorting the terminal RES and this terminal inputs the reset signal.

Outputs a signal when the power regeneration common converter is ready to

operate.

This output has opposite logic to RDYB.

Permissible load 24V 0.1ADC

Outputs a signal when the power regeneration common converter is faulty or the

reset signal is input. Connect to the X10 (MRS) signal of the inverter. This output

has opposite logic to RDYA.

Permissible load 24V 0.1ADC

Outputs the reset signal to the inverter when the reset signal is input to the power

regeneration common converter. Connect to the inverter terminal RES.

Permissible load 24V 0.1ADC

Common to the terminals RDYA, RDYB and RSO. Connect to the inverter

terminal SD.

Change-over outputs which indicate that the protective function of the power

regeneration common converter was activated to stop the output.

Alarm: No continuity across B-C (continuity across A-C), normal: Continuity across

B-C (no continuity across A-C)

Permissible load 230V 0.3AAC, 30V 0.3ADC

Wiring

(3) Description of inverter connection terminals

Type Symbol Terminal Name Description

P, N DC power input Connect to the power regeneration common converter terminals P/L+, N/L-.

For the FR-A700, F700, A500, F500 or V500 series, remove the jumpers across

R1, S1

Main circuit

X10

(MRS)

RES Converter reset

Control circuit

PC 24VDC power

SD Contact input common

Control circuit power

input

Ground Securely connect to the earth.

Output stop

Note: When used as the 24V power, the terminal PC cannot prevent a sneak path for transistor output.

the inverter terminals R-R1 and S-S1, and input external power to these terminals.

For the FR-E500, S500, C500 or F500J series, the inverter does not have the

terminals R1, S1 so uses the DC power input from the terminals P, N as the control

power.

Shuts off the inverter output when the power regeneration common converter is

faulty or the converter reset signal is input. Connect to the power regeneration

common converter terminal RDYB. For the FR-A700, F700, E700, D700, A500,

F500 or V500 series, assign the X10 signal to any of the input terminals. For the

FR-E500, S500, C500 or F500J series, use the terminal MRS as you cannot

assign the X10 signal. If the terminal MRS is already used, assign another MRS

signal to any of the input terminals.

When the reset signal is input to the power regeneration common converter, the

reset signal is also input to the inverter. Connect to the power regeneration

common converter terminal RSO. For the D700, S500, C500 and F500J series,

assign the RES signal to any one of the input terminals.

24V 0.1ADC power. Connect to the power regeneration common converter

terminal P24.(Note)

Common to the contact input terminals. Also acts as a common to the 24V

0.1ADC power (terminal PC).

INSTALLATION AND WIRING

2

13

Page 19

Wiring

2.2.2 Wiring of the main circuit

(1) Wiring instructions

1) Crimping terminals with insulation sleeves are recommended for use with the power and inverter cables.

2) Strictly observe the order of wiring in the connection example when performing wiring between the dedicated

stand-alone reactor and power regeneration common converter and wiring between the power supply and

terminals R/L11, S/L21, T/MC1. (Match the phase sequence of the power supply.) Incorrect connection will

damage the power regeneration common converter.

3) Make sure to connect the terminal R/L11, S/L21, T/MC1 to the power supply.

Running the inverter without connecting the terminals will damage the power regeneration common converter.

4) Connect a DC power supply between the power regeneration common converter and inverter with correct

polarity.

5) After wiring, wire off-cuts must not be left in the power regeneration common converter.

Wire off-cuts can cause an alarm, failure or malfunction. Always keep the power regeneration common

converter clean.

When drilling mounting holes in a control box etc., exercise care to prevent chips and other foreign matter from

entering the power regeneration common converter.

6) Electromagnetic wave interference

The input/output (main circuit) of the power regeneration common converter and inverter includes harmonic

components, which may interfere with the communication devices (such as AM radios) used near the power

regeneration common converter and inverter. In this case, install the FR-BIF optional radio noise filter (for use

in the input side only) or FR-BSF01 or FR-BLF line noise filter to minimize interference.

7) When rewiring after operation, make sure that the CHARGE lamp has gone off, and when more than 10

minutes have elapsed after power-off, check with a meter that the voltage is zero. After that, start rewiring work.

For some time after power-off, there is a dangerous voltage in the capacitor.

8) Be sure to connect terminal RDY of the FR-CV to the X10 or MRS signal assigned terminal of the inverter, and

connect terminal SE of the FR-CV to terminal SD of the inverter. Without proper connecting, FR-CV will be

damaged.

Notes on Grounding

z To prevent an electric shock, the dedicated stand-alone reactor, power regeneration common converter, inverter and

motor must be grounded.

z Use the dedicated ground terminal to ground the power regeneration common converter. (Do not use the screws in

the case, chassis, etc.)

z Use the reactor mounting screw to earth the dedicated stand-alone reactor.

Use the screw in the marked .

z The ground cable should be as thick as possible. Its gauge should be equal to or larger than those indicated in the

following table. The grounding point should be as near as possible to the power regeneration common converter to

minimize the ground cable length.

(Unit: mm

Capacity

7.5kW (10HP) 5.5 3.5

11kW, 15kW (15HP, 20HP) 14 8

22kW to 37kW

(30 to 50HP)

55kW (75HP) 38 22

Ground Cable Gauge

200V class 400V class

22 14

2

)

14

Page 20

Wiring

(2) Terminal block layout of the power circuit

In the main circuit of the power regeneration common converter, the terminals are arranged as shown below:

FR-CV-7.5K/11K(-AT) FR-CV-15K(-AT), FR-CV-H7.5K/H11K/H15K(-AT)

L+

<DC power output

terminals>

Connect to inverter

P and N terminals.

P

N

<Supply phase detection

terminals>

Connect to FR-CVL R,S and

T terminals (main supp ly).

<AC power supply input termin als>

Connect to FR-CVL R2, S2 and T2

terminals (secondary side).

R2 S2 T2

L+

L-

R

S

T

L11

L21

MC1

Screw size

(M6)

Screw size

(M4)

<DC power output

terminals>

Connect to inverter

P and N terminals.

<Supply phase detection

terminals>

Connect to FR-CVL R, S and

T terminals (main supply).

<AC power supply input terminals>

Connect to FR-CVL R2, S2 and T2

terminals (secondary side).

R2 S2 T2

P

Screw size

L-

N

R

L11

S

L21

MC1

T

Screw size

(M6)

(M4)

L1 L2 L3

Screw size

(M4)

Screw size

(M5)

FR-CV-22K/30K(-AT), FR-CV-H22K/H30K(-AT)

<DC power output terminals>

Connect to inverter P and N

terminals.

<Supply phase detection terminals>

Connect to FR-CVL R, S and T

terminals (main supply).

<AC power supply input terminals>

Connect to FR-CVL R2, S2 and T2

terminals (secondary side).

Screw size

(M5)

P

N

L+

L-

RTL11

S

L21

MC1

Screw size

(M5)

L1 L2 L3

Screw size

(M5)

Screw size

(M6)

Screw size

(M4)

R2 S2 T2

L1 L2 L3

15

INSTALLATION AND WIRING

2

Screw size

(M8)

Screw size

(M8)

Page 21

Wiring

FR-CV-37K

FR-CV-55K

Screw size

T/MC1

R/L11

S/L21

<Supply phase detectio n

terminals>

Connect to FR-CVL R, S and

T terminals (main supply)

Screw size

(M8)

Screw size

R/L11 S/L21 T/MC1

(M4)

(M4)

R2/L1 S2/L2

T2/L3

<AC power supply input termin als>

Connect to FR-CVL R2, S2, and T2

terminals (secondary side)

Screw size

(M10)

N/L-

<DC power output terminals>

Connect to invertor P and

N terminals

P/L+

<Supply phase detect ion

terminals>

Connect to FR-CVL R, S and

T terminals (main supply)

Screw size

FR-CV-H37K/H55K

Screw size (M4)

R/L11

<Supply phase detection terminals>

Connect to FR-CVL R, S and T

terminals (main supply)

4-55

(M8)

S/L21

T/MC1

C172D295H03

R2/L1 S2/L2 T2/L3 N/L- P/L+

<AC power supply input

terminals>

Connect to FR-CVL R2,

S2,and T2 terminals

(secondary side)

<DC power output

terminals>

Connect to invertor P

and N terminals

Screw size

(M12)

R2/L1 S2/L2 T2/L3

<AC power supply input terminals>

Connect to FR-CVL R2, S2 and T2

terminals (secondary side)

N/L- P/L+

<DC power output terminals>

Connect to inverter P and N

terminals

C172C295H02

Screw size

(M8)

Screw size

(M8)

16

Page 22

Wiring

(3) Cables, crimping terminals, etc.

Refer to the following for the cables, crimping terminals and terminal tightening torques used for the power

regeneration common converter.

MCNFB

3-phase

AC power supply

1)

FR-CVL

R/L11

S/L21

T/L31

4)

R2/L12

S2/L22

T2/L32

5)

FR-CV

2)

R2/L1

S2/L2

T2/L3

R/L11

S/L21

T/MC1

P/L+

N/L-

3)

(Note 3)

FR-A720

R/L1

S/L2

T/L3

R1/L11

S1/L21

P/

+

N/-

FR-A720

R/L1

S/L2

T/L3

R1/L11

S1/L21

P/

+

N/-

U

V

W

U

V

W

IM

IM

Note: 1. The cables used should be 75°C (167F°) copper cables.

2. Tighten the terminal screws to the specified torques.

Undertightening can cause a short or misoperation.

Overtightening can cause the screws and unit to be damaged, resulting in a short or misoperation.

3. Do not insert the NFB between terminals P - N (P/L+ - P/+, N/L- - N/-).

FR-A720

R/L1

S/L2

T/L3

R1/L11

S1/L21

P/

+

N/-

U

V

W

IM

INSTALLATION AND WIRING

2

17

Page 23

Wiring

)

1) Connection of power supply and dedicated stand-alone reactor

Dedicated

MCNFB

stand-alone reactor (FR-CVL

1)

R/L11

S/L21

T/L31

R2/L12

S2/L22

T2/L32

Dedicated

Stand-Alone

Terminal Name

Reactor Model

FR-CVL-7.5K

FR-CVL-11K M5 2.5 14-5 14 6

FR-CVL-15K M6 4.4 22-6 22 4

FR-CVL-22K M6 4.4 38-6 38 2

FR-CVL-30K M6 4.4 60-6 60 1/0

FR-CVL-37K M10 14.7 100-10 100 4/0

FR-CVL-55K M10 14.7 150-10 150 MCM300

FR-CVL-H7.5K M5 2.5 3.5-5 3.5 12

FR-CVL-H11K M5 2.5 5.5-5 5.5 10

FR-CVL-H15K M5 2.5 14-5 14 6

FR-CVL-H22K M6 4.4 22-6 22 4

FR-CVL-H30K M6 4.4 22-6 22 4

FR-CVL-H37K M8 7.8 38-8 38 2

FR-CVL-H55K M8 7.8 60-8 60 1/0

R/L11, S/L21,

T/L31

Termi nal

Screw Size

M5 2.5 14-5 14 6

Tightening

Torque N•m

Crimping

Termi nals

mm

Cables

2

AWG

Note: Wire the cables so that the phase sequence is always identical to those of the wiring in 2) and 4).

Connection in wrong phase sequence will damage the power regeneration common converter.

2) Connection of dedicated stand-alone reactor and power regeneration common converter

Dedicated

stand-alone reactor (FR-CVL)

R/L11

S/L21

T/L31

R2/L12

S2/L22

T2/L32

2)

FR-CV

R2/L1

S2/L2

T2/L3

10m

(32.81 feet)

maximum

Dedicated

Stand-Alone

Terminal Name

Reactor Model

FR-CVL-7.5K

FR-CVL-11K M5 2.5 14-5 14 6

FR-CVL-15K M6 4.4 22-6 22 4

FR-CVL-22K M6 4.4 38-6 38 2

FR-CVL-30K M6 4.4 60-6 60 1/0

FR-CVL-37K M10 14.7 100-10 100 4/0

FR-CVL-55K M10 14.7 150-10 150 MCM300

FR-CVL-H7.5K M5 2.5 3.5-5 3.5 12

FR-CVL-H11K M5 2.5 5.5-5 5.5 10

FR-CVL-H15K M5 2.5 14-5 14 6

FR-CVL-H22K M6 4.4 22-6 22 4

FR-CVL-H30K M6 4.4 22-6 22 4

FR-CVL-H37K M8 7.8 38-8 38 2

FR-CVL-H55K M8 7.8 60-8 60 1/0

R2/L12, S2/L22,

T2/L32

Termi nal

Screw Size

M5 2.5 14-5 14 6

Tightening

Torque N•m

Crimping

Termi nals

mm

Cables

2

AWG

18

Page 24

Wiring

Power

Regeneration

Common

Terminal Name

Terminal

Screw Size

Tightening

Tor q u e N•m

Crimping

Terminals

mm

Cables

2

AWG

Converter Model

FR-CV-7.5K

FR-CV-11K M5 2.5 14-5 14 6

FR-CV-15K M5 2.5

FR-CV-22K M8 7.8 38-8 38 2

FR-CV-30K M8 7.8

FR-CV-37K M10 14.7 100-10 100 4/0

FR-CV-55K M12 24.5 150-12 150 MCM300

FR-CV-H7.5K M5 2.5 3.5-5 3.5 12

FR-CV-H11K M5 2.5 5.5-5 5.5 10

FR-CV-H15K M5 2.5 14-5 14 6

FR-CV-H22K M8 7.8 22-8 22 4

FR-CV-H30K M8 7.8 22-8 22 4

FR-CV-H37K M8 7.8 38-8 38 2

FR-CV-H55K M8 7.8 60-8 60 1/0

R2/L1, S2/L2,

T2/L3

M5 2.5 14-5 14 6

22-S6

(Note 2)

CB60-S8

(Note 2)

22 4

60 1/0

Note: 1. Wire the cables so that the phase sequence is always identical to those of the wiring in 1) and 4).

Connection in wrong phase sequence will damage the power regeneration common converter.

2. Manufactured by J.S.T.

3) Connection of power regeneration common converter and inverter

FR-A520

R

S

T

R1

S1

P/+

N/-

R2/L1

S2/L2

T2/L3

R/L11

S/L21

T/MC1

FR-CV

P/L+

N/L-

3)

5m (16.40 feet)

maximum

Note: Do not insert the NFB between terminals P - N (P/L+ - P/+, N/L- - N/-).

Do not remove a jumper across terminal P/+ and P1.

Power

Regeneration

Common

Terminal Name

Terminal

Screw Size

Tightening

Tor q u e N•m

Crimping

Terminals

mm

Cables

2

AWG

Converter Model

FR-CV-7.5K

FR-CV-11K M6 4.4 14-6 14 6

FR-CV-15K M6 4.4 22-6 22 4

FR-CV-22K M6 4.4

FR-CV-30K M6 4.4

FR-CV-37K M10 14.7 100-10 100 4/0

FR-CV-55K M12 24.5 150-12 150 MCM300

FR-CV-H7.5K M6 4.4 3.5-6 3.5 12

FR-CV-H11K M6 4.4 5.5-6 5.5 10

FR-CV-H15K M6 4.4 14-6 14 6

FR-CV-H22K M6 4.4 22-6 22 4

FR-CV-H30K M6 4.4 22-6 22 4

FR-CV-H37K M8 7.8 38-8 38 2

FR-CV-H55K M8 7.8 60-8 60 1/0

P/L+, N/L-

M6 4.4 14-6 14 6

38-S6

(Note 2)

CB60-S6

(Note 2)

38 2

60 1/0

19

INSTALLATION AND WIRING

2

Page 25

Wiring

«Example of connecting two or more inverters»

You can connect up to six inverters to one power regeneration common converter. The capacity of the power

regeneration common converter should always be greater than the sum of the connected inverter capacities or

the sum of rated inverter currents.

zWhen connecting several inverters, pay attention to the selection of the cables sizes since junction terminals or

jumper cables are used to wire the terminals P, N of the inverters. Make selection so that the inverter

capacities are added in order, starting with the one of the remotest inverter.

zWhen connecting several inverters, connect the inverters in order of larger capacities.

zSpecific example

R2/L1

S2/L2

T2/L3

R/L11

S/L21

T/MC1

P/L+

N/L-

FR-CV-22K

FR-A720-11K

3)

Overall wiring length

=5m (16.40 feet) maximum

P/+

N/-

FR-A720-5.5K

P/+

N/-

FR-A720-3.7K

P/+

N/-

First inverter: Choose 38mm assuming

that the converter capacity

is 22K according to the sum

of inverter capacities,

11K+5.5K+3.7K=20.2K.

Second inverter: Choose 14mm assuming

that the converter capacity is

11K according to the sum of

inverter capacities,

5.5K+3.7K=9.2K.

Third inverter: Choose 3.5mm according to

the inverter capacity, 3.7K.

2

2

2

Note: 1. Correctly connect the terminals P/L+, N/L- with the inverter terminals P, N.

Wrong connection will damage the power regeneration common converter.

2. Do not insert the NFB between terminals P - N (P/L+ - P/+, N/L- - N/-, P/+ - P/+, N/- - N/-).

3. Manufactured by J.S.T.

4) Connection of power supply and power regeneration common converter (power supply phase detection

terminals)

R/L11

S/L21

T/L31

R2/L12

S2/L22

T2/L32

R2/L1

S2/L2

T2/L3

Dedicated

Stand-Alone

Reactor Model

FR-CVL-7.5K

4)

10m (32.81 feet) maximum

Terminal Name

R/L11

S/L21

T/MC1

mm

Cables

2

Termi nal

Screw Size

Tightening

Torque N•m

Crimping

Termi nals

M5 2.5 1.25-5 1.25 16

AWG

FR-CVL-11K M5 2.5 1.25-5 1.25 16

FR-CVL-15K M6 4.4 1.25-6 1.25 16

FR-CVL-22K M6 4.4 1.25-6 1.25 16

FR-CVL-30K M6 4.4 1.25-6 1.25 16

FR-CVL-37K M10 14.7 1.25-10 1.25 16

FR-CVL-55K M10 14.7 1.25-10 1.25 16

FR-CVL-H7.5K M5 2.5 1.25-5 1.25 16

R/L11, S/L21,

T/L31

FR-CVL-H11K M5 2.5 1.25-5 1.25 16

FR-CVL-H15K M5 2.5 1.25-5 1.25 16

FR-CVL-H22K M6 4.4 1.25-6 1.25 16

FR-CVL-H30K M6 4.4 1.25-6 1.25 16

FR-CVL-H37K M8 7.8 1.25-8 1.25 16

FR-CVL-H55K M8 7.8 1.25-8 1.25 16

20

Page 26

Wiring

Power

Regeneration

Common

Terminal Name

Terminal

Screw Size

Tightening

Tor q u e N•m

Crimping

Terminals

mm

Cables

2

AWG

Converter Model

FR-CV-7.5K

FR-CV-11K M4 1.5 1.25-4 1.25 16

FR-CV-15K M4 1.5 1.25-4 1.25 16

FR-CV-22K M4 1.5 1.25-4 1.25 16

FR-CV-30K M4 1.5 1.25-4 1.25 16

FR-CV-37K M4 1.5 1.25-4 1.25 16

FR-CV-55K M4 1.5 1.25-4 1.25 16

FR-CV-H7.5K M4 1.5 1.25-4 1.25 16

FR-CV-H11K M4 1.5 1.25-4 1.25 16

FR-CV-H15K M4 1.5 1.25-4 1.25 16

FR-CV-H22K M4 1.5 1.25-4 1.25 16

FR-CV-H30K M4 1.5 1.25-4 1.25 16

FR-CV-H37K M4 1.5 1.25-4 1.25 16

FR-CV-H55K M4 1.5 1.25-4 1.25 16

R/L11, S/L21,

T/MC1

M4 1.5 1.25-4 1.25 16

Note: 1. Wire the cables so that the phase sequence of the wiring in 4) is always identical to those of the wiring in

1) and 2).

Connection in wrong phase sequence will damage the power regeneration common converter.

2. To prevent a malfunction due to noise, run the cables away from the main circuit wiring.

3. Running the inverter without connecting terminals R/L11, S/L21 and T/MC1 to the power supply will

damage the power regeneration common converter.

5) Connection of power supply and inverter

When the model used is the one whose control power is input from R1 and S1, control circuit power must be

input to R1 and S1 of the inverter. At this time, remove the jumpers across R-R1, S-S1.

Cable size: 0.75mm

2

to 2mm

2

FR-A720

R/L1

S/L2

T/L3

R1/L11

S1/L21

P/

+

N/-

(Note1)

(Note2)

Dedicated

stand-alone reactor (FR-CVL)

R/L11

S/L21

T/L31

R2/L12

S2/L22

T2/L32

R2/L1

S2/L2

T2/L3

R/L11

S/L21

T/MC1

5)

FR-CV

P/L+

N/L-

Note: 1. Never connect a power supply to the inverter terminals R, S, T. Accidental connection will damage the

inverter and power regeneration common converter.

2. For the FR-A700, F700, A500, F500 or V500 series, disconnect the jumpers across terminals R-R1, SS1 and connect the control power supply to terminals R1, S1. For the FR-E700, D700, E500, S500,

C500 or F500J series, there are no terminals R1, S1 and you need not make the above connection.

2.2.3 Wiring of the control circuit

(1) Wiring instructions

1) The terminals SD, SE are common to the I/O signals and are isolated from each other. Must not be earthed

(grounded).

2) Shielded or twisted cables must be used for connection to the control circuit terminals, and also run away from

the main and power circuits (including the 200V relay sequence circuit).

3) The input signals to the control circuit are micro currents. When contacts are required, use two or more parallel

micro signal contacts or a twin contact to prevent a contact fault.

4) It is recommended to use the cables of 0.3mm

terminals.

2

to 0.75mm2 gauge for connection to the control circuit

INSTALLATION AND WIRING

2

21

Page 27

Wiring

(2) Terminal block layout

In the control circuit of the power regeneration common converter, the terminals are arranged as shown below:

A

B

C

P24

RES

SD

SD

RDYB

RSO

RDYA

SE

(3) Wiring procedure

1) For the wiring of the control circuit, strip the sheaths of the cables and use them as they are. Over-stripping

may cause a short circuit with the neighboring cable.Under-stripping may cause cable disconnection.

_

7mm (0.28inch) 1mm (0.04inch)

+

2) When using bar terminals or solid cables for wiring, use those of not more than 0.9mm (0.04inch) in diameter.

If the diameter is greater than 0.9mm (0.04inch), the screw threads may be damaged when tightened.

3) Loosen the terminal screw and insert the cable into the terminal.

4) Tighten the screw to the specified torque.

Undertightening can cause cable disconnection or malfunction.Overtightening can cause the screw or unit to

be damaged, resulting in a short circuit or malfunction.

Tightening torque: 0.25N•m to 0.49N•m

*Use a screwdriver of No. 0.

Note: Wire the stripped cable after twisting it to prevent it from becoming loose.

2.2.4 Design information

1) If the machine must be prevented from restarting at recovery of power after a power failure, provide a magnetic

contactor in the primary side of the power regeneration common converter and also make up a sequence that

will not turn on the start signal of the inverter.

If the start signal (start switch) of the inverter is held, the inverter will automatically restart at recovery of power.

2) Configure up a circuit that will always turn off the main circuit power supply terminals R2/L1, S2/L2, T2/L3 as

soon as the power supply phase detection terminals R/L11, S/L21, T/MC1 turn off.

3) Since the input signals to the control circuit are on a low level, use two parallel micro signal contacts or a twin

contact for contact inputs to prevent a contact fault.

4) Do not apply a voltage directly to the alarm output signal terminals (A, B, C).

Always apply a voltage to these terminals via a relay coil, lamp, etc.

5) Make sure that the specifications and rating match the system requirements.

3) Low-level signal contacts

Low-level signal contacts

Twin contact

22

Page 28

Operation

2.3 Operation

2.3.1 Pre-operation checks

When installation and wiring are over, make the following checks prior to power-on.

1) Check the wiring for incorrect connection. Especially check that the phase sequence and polarity of the main

circuit wiring are correct.

2) Check for a short circuit caused by wire off-cuts.

3) Check for loose terminal screws.

4) Make sure that the machine is free of damage.

5) Set the parameter values to match the operating machine system environment.

For the FR-A700, F700, A500, F500 or V500 series, set 2 (high power factor converter, power

regeneration common converter) in Pr. 30 "Regenerative function selection".

6) Perform test operation after making sure that safety is ensured if the machine should become out of control.

7) Perform test operation and make sure that the machine operates safely under light load at a low frequency.

After that, start operation.

Note: Do not conduct an insulation resistance test with a megger in the power regeneration common converter.

2.3.2 Power-on and operation

Before switching power on, check the following:

z Installation check

Make sure that the inverter is installed correctly in a proper location. (Refer to page 10.)

• Wiring check

Make sure that the main and control circuits are wired correctly.

Make sure that the options and peripheral devices are selected and connected correctly.

(Refer to page 12.)

z Switch power on.

Power-on is complete when the CHARGE lamp is lit correctly and the LED displays correct data.

The LED display gives the following indications at power-on.

LED

Display

Power on

Converter

status

Note:

If the cooling fan has stopped due to a fault, the LED display shows a flickering . (400V class only)

During initialization

During alarm

detection

If the DC voltage is higher than

the input power supply voltage

at power-on, regenerative

operation is performed.

At this time, the bottom

segment flickers.

Flicker

During normal

operation

(Driving status)

(Refer to page 30.)

z Start operation.

Turn on the start signal of the inverter. The motor accelerates to a given speed. At this time, the LED display of

the power regeneration common converter shows .

INSTALLATION AND WIRING

Turn off the start signal of the inverter. The motor decelerates to a stop. The LED display of the power

regeneration common converter shows according to the magnitude of the regenerative energy.

LED

Display

Converter

status

During driving operation

(During stop)

Flicker

Flicker

During regenerative operation

When the regeneration converter performs

switching operation, the bottom segment flickers.

Note: When the power regeneration common converter is regenerating power, the dedicated stand-alone reactor

generates sound but it is not a fault.

23

2

Page 29

Other wiring

r

2.4 Other wiring

2.4.1 Power harmonics

Power harmonics may be generated from the power regeneration common converter, affecting generators, power

capacitors, etc. Power harmonics are different in generation source, frequency and transmission path from radio

frequency (RF) noise and leakage currents.

z The differences between harmonics and RF noise indicated below:

Item Harmonics RF Noise

Frequency

Environment To wire paths, power impedance Across spaces, distance, laying paths

Quantitative understanding Logical computation is possible

Generated amount

Immunity of affected device

z Safeguard

The harmonic current generated from the power regeneration common converter to the power supply differs

according to various conditions such as the wiring impedance, whether a power factor improving reactor is used or

not, and output frequency and output current on the load side.

For the output frequency and output current, the adequate method is to obtain them under rated load at the

maximum operating frequency.

Normally 40th to 50th degrees or

less, (up to 3kHz or less)

Approximately proportional to load

capacity

Specified in standards for each

device.

High frequency (several 10kHz to 1GHz order)

Occurs randomly, quantitative understanding is

difficult.

According to current fluctuation rate (larger

with faster switching)

Differs according to maker’s device

specifications.

Do not insert power factor

improving DC reactor

Power factor

improving AC

reactor

NFB

Do not insert power factor

improving AC reactor

Dedicated

stand-alone

reactor

Power regeneration

common converter

Power factor improving

DC reactor

Inverter

Do not insert power factor

improving capacitor

Moto

IM

Note: A power factor improving capacitor or surge suppressor on the inverter’s output may overheat or be

damaged due to the harmonics of the inverter output. Also, when an overcurrent flows in the inverter, the

overcurrent protection is activated, Hence, when the motor is driven by the inverter, do not install a capacitor

or surge suppressor on the inverter’s output. Do not use the power factor improving AC reactor (FR-BAL)

since using it may degrade the power regeneration function.

24

Page 30

Other wiring

2.4.2 Noise types and reduction techniques

Some noises enter the power regeneration common converter causing it to misoperate and others are radiated by

the power regeneration common converter causing misoperation of peripheral devices. Though the power

regeneration common converter is designed to be insusceptible to noise, it handles low-level signals, so it requires

the following basic measures to be taken. Also, since the inverter chops the output at a high carrier frequency, it

could generate noise. If these noises cause peripheral devices to misoperate, measures should be taken to

suppress the noise. The measures differ slightly depending on noise propagation paths.

1) Basic measures

• Do not run the power cables (I/O cables) and signal cables of the power regeneration common converter in

parallel with each other and do not bundle them.

• Use twisted shielded cables for the detector connection and control signal cables and connect the sheathes

of the shielded cables to terminal SD.

• Ground the power regeneration common converter and inverter, motor, etc. at one point.

2) Measures against noises which enter and cause misoperation of the power regeneration common converter

When devices which generate many noises (which use magnetic contactors, magnetic brakes, many relays, for

example) are installed near the power regeneration common converter and the inverter may be effected by

noise, the following measures must be taken:

• Provide surge suppressors for devices that generate noise to suppress noise.

• Fit data line filters to signal cables.

• Ground the shields of the detector connection and control signal cables with cable clamp metal.

3) Measures against noise which is radiated by the power regeneration common converter causing misoperation

of peripheral devices.

Power regeneration common converter-generated noise is largely classified into those radiated by the cables

connected to the power regeneration common converter and power regeneration common converter main

circuit (I/O), those electromagnetically and electrostatically inducted to the signal cables of the peripheral

devices close to the main circuit power supply, and those transmitted through the power supply cables.

Power regeneration

converter generated

noise

Air-propagated

noise

Magnetic induction

noise

Static induction

noise

Cable-propagated

noise

Noise directly radiated

by power regeneration

common converter

Noise radiated by

power cables

Noise radiated by

motor cables

Path 4), 5)

Path 6)

Noise propagated

through power cables

Noise from ground

cable due to

leakage current

Path 1)

Path 2)

Path 3)

Path 7

Path 8

5)

7)

ReceiverInstrument

2)

1)

3)

Motor

7)

Power regeneration

common converter

+

Inverter

4)

IM

6)

Sensor

2)

power supply

Sensor

3)

Telephone

8)

Noise Path Measures

When devices which handle low-level signals and are susceptible to misoperation due to noise (such as

instruments, receivers and sensors) are installed near the power regeneration common converter and

their signal cables are contained in the same panel as the inverter or are run near the power regeneration

common converter, the devices may be affected by air-propagated noises and the following measures

must be taken:

(1) Install easily affected devices as far away as possible from the power regeneration common

1) 2) 3)

converter.

(2) Run easily affected signal cables as far away as possible from the power regeneration common

converter.

(3) Do not run the signal cables and power cables (power regeneration common converter I/O cables) in

parallel with each other and do not bundle them.

(4) Inset line noise filters into I/O and radio noise filters into input side to suppress cable-radiated noises.

(5) Use shielded cables for signal cables and power cables and run them in individual metal conduits to

reduce further effects.

INSTALLATION AND WIRING

2

25

Page 31

Other wiring

Noise Path Measures

When the signal cables are run in parallel with or bundled with the power cables, magnetic and static

induction noise may be propagated to the signal cables to effect the devices and the following measures

must be taken:

(1) Install easily affected devices as far away as possible from the power regeneration common

converter.

4) 5) 6)

7)

8)

(2) Run easily affected signal cables as far away as possible form the power regeneration common

converter.

(3) Do not run the signal cables and power cables (power regeneration common converter I/O cables) in

parallel with each other and do not bundle them.

(4) Use shielded cables for signal cables and power cables and run them in individual metal conduits to

reduce further effects.

When the power supplies of the peripheral devices are connected to the power supply of the power

regeneration common converter within the same line, power regeneration common converter-generated

noise may flow back through the power supply cables to misoperate the devices and the following

measures must be taken:

(1) Install the radio noise filter (FR-BIF) to the power cables (input cables) of the power regeneration

common converter.

(2) Install the line noise filter (FR-BLF, FR-BSF01) to the power cables (I/O cables) of the power

regeneration common converter.

When a closed loop circuit is formed by connecting the peripheral device wiring to the power regeneration

common converter, leakage current may flow through the ground cable of the power regeneration

common converter to affect the device. In such a case, disconnection of the ground cable of the device

may cause the device to operate properly.

2.4.3 Peripheral devices

(1) Selection of peripheral devices

Refer to the following list and prepare appropriate peripheral devices:

1) 200V class

Power Regeneration

Common Converter Type

FR-CV-7.5K (-AT) 7.5 (10) 17 100AF 60A S-N35

FR-CV-11K (-AT) 11 (15) 20 100AF 75A S-N50

FR-CV-15K (-AT) 15 (20) 28 225AF 125A S-N65

FR-CV-22K (-AT) 22 (30) 41 225AF 175A S-N95

FR-CV-30K (-AT) 30 (40) 52 225AF 225A S-N125

FR-CV-37K 37 (50) 66 400AF 250A S-N150

FR-CV-55K 55 (75) 100 400AF 400A S-N220

2) 400V class

Power Regeneration

Common Converter Type

FR-CV-H7.5K (-AT) 7.5 (10) 17 30AF 30A S-N20

FR-CV-H11K (-AT) 11 (15) 20 50AF 50A S-N20

FR-CV-H15K (-AT) 15 (20) 28 100AF 60A S-N25

FR-CV-H22K (-AT) 22 (30) 41 100AF 100A S-N50

FR-CV-H30K (-AT) 30 (40) 52 225AF 125A S-N65

FR-CV-H37K 37 (50) 66 225AF 150A S-N80

FR-CV-H55K 55 (75) 100 225AF 200A S-N125

Applicable Capacity

(kW (HP))

Applicable Capacity

(kW (HP))

Power Supply

Capacity (kVA)

Power Supply

Capacity (kVA)

Rated current of

Circuit Breaker

Rated current of

Circuit Breaker

Magnetic

Contactor

Magnetic

Contactor

Note: 1. For installations in the United States or Canada, the circuit breaker must be inverse time or

instantaneous trip type.

2. When the breaker on the primary side of the power regeneration common converter tripped, check for

wiring fault (e.g.short circuit), damage to internal parts of the inverter (power regeneration common

converter), etc. Identify the cause of the breaker trip, then power on the breaker after removing the

cause of the trip.

26

Page 32

Other wiring

r

(2) Selection the rated sensitivity current for the earth leakage circuit breaker

When using the earth leakage circuit breaker with the inverter circuit, select its rated sensitivity current as follows,

independent of the carrier frequency setting:

z Breaker for harmonic and surge

Rated sensitivity current:

lΔn ≥ 10 × (lg

1 + lgn + lg2 + lgm)

z Standard breaker

Rated sensitivity current:

lΔn ≥ 10 × {lg

lg

1, lg2 : leakage currents of cable path during

1 + lgn + 3 × (lg2+lgm)}

commercial power supply operation

lgn* : leakage current of noise filter on power

regeneration common converter input

side

lgm : leakage current of motor during

commercial power supply operation

<Example>

2

5m

22mm

×

(16.40 feet)

Noise

NV

Ig1 Ign Ig2 Igm

Power regeneration

filter

common converter

+

Inverter

15K

2

22mm

×

(98.43 feet)

30m

φ

3

IM

200V

15kW (20HP)

Example of leakage current

per 1km in cable path during

commercial power supply

operation when the CV

cable is routed in metal

conduit (200V 60Hz)

120

100

80

60

40

20

Leakage current (mA)

0

23.5

8142230386080

5.5

Cable size (mm )

Leakage current example

of 3-phase induction moto

during commercial power

supply operation

(200V 60Hz)

2.0

1.0

0.7

0.5

0.3

0.2

Leakage current (mA)

150

100

2

0.1

1.5 3.7

2.2

5.5 18.5

Motor capacity (kW)

7.5 152211373055

45

Leakage current Ig1 (mA)

Breaker for

Harmonic and Surge

50

5m (16.40 feet)

× =0.25

1000m (3280.80 feet)

Standard Breaker

Leakage current Ign (mA) 0 (without noise filter)

Leakage current Ig2 (mA)

Motor leakage current Igm (mA)

Total leakage current (mA)

Rated sensitivity current (mA) ( ≥Ig × 10)

50

1000m (3280.80 feet)

0.57

2.32 6.46

30 100

30m (98.43 feet)

× =1.50

Note: 1. The NV should be installed to the primary (power supply) side of the power regeneration common

converter.

2. Ground fault in the secondary side of the inverter can be detected at the running frequency of 120Hz or

lower.

3. In the connection neutral point grounded system, the sensitivity current becomes worse for ground

faults in the inverter secondary side. Hence, the protective grounding of the load equipment should be

10Ω or less.

4. When the breaker is installed on the secondary side of the inverter, it may be unnecessarily operated by

harmonics if the effective value is less than the rating. In this case, do not install it since the eddy current

and hysteresis loss increase and the temperature rises.

5. The following models are standard breakers

BV-C1, BC-V, NVB, NV-L, NV-G2N, NV-G3NA, and NV-2F type leakage current relays (except for

NV-ZHA), AA neutral wire, NV with open phase protection

The following models are breakers for harmonic and surge

NV-C/NV-S/MN series, NV30-FA, NV50-FA, BV-C2, leakage current alarm breaker(NF-Z), NV-ZHA,

NV-H

INSTALLATION AND WIRING

2

* Be careful of the leakage current value of the noise filter installed on the power regeneration common

converter input side.

27

Page 33

Other wiring

2.4.4 Instructions for UL and cUL

(Standards to comply with: UL 508C, CSA C22.2 No. 14)

(1) Installation

The equipment has been approved as a product for use in an enclosure.

Design the enclosure so that the ambient temperature, humidity and ambience of the power regeneration common

converter will satisfy the above specifications. (Refer to page 44.)

(2) Branch circuit protection

For installation in United States, branch circuit protection must be provided, in accordance with the National

Electrical Code and any applicable local codes.

For installation in Canada, branch circuit protection must be provided in accordance with the Canada Electrical

Code and any applicable provincial codes.

(3) Short circuit ratings

Suitable For Use in A Circuit Capable of Delivering Not More Than 10kA rms Symmetrical Amperes, 500V

Maximum.

(4) Wiring of the power supply and motor

Screw the cables wired to the input (R, S, T) and output (P, N) terminals and control circuit of the power

regeneration common converter to the specified tightening torque using UL-recognized, 75°C or higher rated

copper wires and round crimping terminals. Crimp the crimping terminals with the crimping tool recommended by

the terminal maker.

28

Page 34

CHAPTER 3

PROTECTIVE FUNCTIONS

This chapter explains the "protective functions" of this

product.

Always read the instructions before using the equipment.

3.1 Errors (Alarms)............................................ 30