Page 1

INVERTER

Option unit

FR-PU07

FR-PU07BB

INSTRUCTION MANUAL

Parameter unit

PRE-OPERATION INSTRUCTIONS

FUNCTIONS

FUNCTION MENU

OPERATION

CHECK FIRST WHEN YOU

HAVE A TROUBLE

SPECIFICATIONS

1

2

3

4

5

6

Page 2

Thank you for choosing the Mitsubishi inverter option unit.

This instruction manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this instruction manual

and appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this instruction manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Assumes that incorrect handling

WARNING

CAUTION

Note that the CAUTION level may lead to a serious

consequence according to conditions. Please follow the

instructions of both levels because they are important to

personnel safety.

may cause hazardous conditions,

resulting in death or severe injury.

Assumes that incorrect handling

may cause hazardous conditions,

resulting in medium or slight injury,

or may cause physical damage

only.

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• Do not run the inverter with the front cover removed.

Otherwise, you may access exposed high voltage terminals

or charging devices and get an electric shock.

• Before starting wiring or inspection, check that the operation

panel indicator is OFF, wait for at least 10 minutes after the

power supply has been switched OFF, and check that there

are no residual voltage using a tester or the like. The

capacitor is charged with high voltage for some time after

power OFF and it is dangerous.

• Any person who is involved in the wiring or inspection of this

equipment should be fully competent to do the work.

• Always install the inverter before wiring. Otherwise, you may

get an electric shock or be injured.

• Operate the keys with dry hands to prevent an electric shock.

A-1

Page 3

2. Additional Instructions

To prevent injury, damage or product failure, please note the

following points.

(1) Transportation and mounting

CAUTION

• Do not install and operate the parameter unit (FR-PU07/FR-

PU07BB) if it is damaged or has parts missing.

• Do not stand or rest heavy objects on this equipment.

• Check the inverter mounting orientation is correct.

• The parameter unit (FR-PU07/FR-PU07BB) is a precision

device. Do not drop it or subject it to impact.

•

Use the inverter under the following environmental conditions:

Surrounding

air

temperature

Ambient

humidity

Storage

temperature

Ambience

Environment

Altitude,

vibration

*Temperatures applicable for a short time, e.g. in transit.

-10°C to +50°C (non-freezing)

90%RH or less (non-condensing)

-20°C to +65°C*

Indoors (free from corrosive gas,

flammable gas, oil mist, dust and dirt)

Maximum 1000m above seal level,

2

or less at 10 to 55Hz (directions

5.9m/s

of X, Y, Z axes)

(2) Test operation and adjustment

CAUTION

• Before starting operation, confirm and adjust the parameters.

A failure to do so may cause some machines to make

unexpected motions.

(3) Usage

WARNING

• Since pressing key may not stop output depending on

the function setting status, provide a circuit and switch

separately to make an emergency stop (power OFF,

mechanical brake operation for emergency stop, etc).

•

Make sure that the start signal is off before resetting the inverter

alarm. A failure to do so may restart the motor suddenly.

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• When parameter clear or all parameter clear is performed,

each parameter returns to the factory setting. Re-set the

required parameters before starting operation.

(4) Corrective actions for alarm

CAUTION

• Provide safety backup devices, such as an emergency brake,

to protect machines and equipment from hazard if the

parameter unit (FR-PU07/FR-PU07BB) becomes faulty.

A-2

Page 4

(5) Disposal

CAUTION

• Treat as industrial waste.

(6) General instruction

All illustrations given in this manual may have been drawn with

covers or safety guards removed to provide in-depth

description. Before starting operation of the product, always

return the covers and guards into original positions as specified

and operate the equipment in accordance with the manual.

3. Safety Precautions for Alkaline Battery

When using an alkaline battery, read the instruction manuals

carefully before using them.

4. Safety Precautions for Nickel Metal Hydride Battery

When using a nickel metal hydride battery and charger, read the

instruction manuals carefully before using them.

A-3

Page 5

— CONTENTS —

INTRODUCTION 1

1 PRE-OPERATION INSTRUCTIONS 2

1.1 Supporting inverter models ..............................................................................................................2

1.2 Unpacking and Product Confirmation .............................................................................................4

1.2.1 Unpacking confirmation..................................................................................................................................4

1.2.2 Appearance and parts identification ...............................................................................................................5

1.2.3 Explanation of keys ........................................................................................................................................7

1.3 Installation and Removal of FR-PU07 ..............................................................................................9

1.3.1 Direct installation to the inverter (A700/F700 series)......................................................................................9

1.3.2 Removal from the inverter (A700/F700 series).............................................................................................10

1.3.3 Installation using the connection cable (FR-CB2) ........................................................................................11

1.3.4 Removal when the connection cable (FR-CB2) is used ...............................................................................13

1.4 Connection and Removal of FR-PU07BB ......................................................................................14

1.4.1 Before using FR-PU07BB in the battery mode.............................................................................................14

1.4.2 Instructions for the FR-PU07BB (battery mode)...........................................................................................17

1.4.3 Connecting to FR-A700/F700 using the connection cable (FR-CB2)...........................................................18

1.4.4 Connecting to FR-E700 using the connection cable (FR-CB2)....................................................................19

1.4.5 Removal when the connection cable (FR-CB2) is used ...............................................................................19

1.5 Parameters to be Checked First .....................................................................................................20

1.5.1 PU display language selection (Pr. 145) ......................................................................................................20

I

Page 6

1.5.2 PU buzzer control (Pr. 990)..........................................................................................................................20

1.5.3 PU contrast adjustment (Pr. 991) .................................................................................................................21

2 FUNCTIONS 22

2.1 Monitoring Function ........................................................................................................................22

2.1.1 Display overview...........................................................................................................................................22

2.1.2 Using "SHIFT" to change the main monitor..................................................................................................25

2.1.3 Setting the power-ON monitor (the first priority monitor)..............................................................................26

2.1.4 Using "READ" to change the main monitor ..................................................................................................27

2.1.5 Using the parameter to change the monitor (Pr. 52) ....................................................................................28

2.2 Frequency Setting............................................................................................................................30

2.2.1 Direct setting.................................................................................................................................................30

2.2.2 Step setting...................................................................................................................................................31

2.2.3 Precautions for frequency setting .................................................................................................................32

2.3 Setting and Changing the Parameter Values ................................................................................33

2.3.1 Specifying the parameter number to change the set value ..........................................................................33

2.3.2 Selecting the parameter from functional list to change the set value ........................................................... 34

2.3.3 Selecting the parameter from parameter list to change the set value..........................................................36

2.3.4 Selecting the parameter from User List to change the set value..................................................................37

2.3.5 Precautions for setting write.........................................................................................................................38

2.4 User Group Function .......................................................................................................................39

2.4.1 Registering the parameters to user group....................................................................................................40

2.4.2 Deleting the parameters from user group.....................................................................................................41

2.4.3 Confirming the parameters registered to user group....................................................................................41

II

Page 7

2.5 Calibration of the Meter (Frequency Meter)...................................................................................42

2.5.1 Calibration of the FM terminal ......................................................................................................................42

2.5.2 Calibration of the AM terminal.....................................................................................................................43

2.6 Adjustment of the Frequency Setting Signals "Bias" and "Gain" ..............................................46

2.6.1 Adjustment procedure ..................................................................................................................................46

3 FUNCTION MENU 53

3.1 Overview of Function Menu ............................................................................................................53

3.1.1 Function menu..............................................................................................................................................53

3.1.2 Function menu transition..............................................................................................................................55

3.2 Operation Procedures for Functions .............................................................................................59

3.2.1 Monitor function............................................................................................................................................59

3.2.2 Selection of PU operation (direct input)........................................................................................................60

3.2.3 Selection of the PU Jog operation mode ......................................................................................................61

3.2.4 Parameters...................................................................................................................................................62

3.2.5 Parameter clear............................................................................................................................................65

3.2.6 Alarm history.................................................................................................................................................67

3.2.7 Alarm clear ...................................................................................................................................................68

3.2.8 Inverter reset ................................................................................................................................................69

3.2.9 Troubleshooting............................................................................................................................................70

3.2.10 Terminal assignment (Selectop)...................................................................................................................74

3.2.11 Option...........................................................................................................................................................75

3.2.12 Multiple copies..............................................................................................................................................76

3.3 Other Precautions ............................................................................................................................81

III

Page 8

3.3.1 Precautions for parameter unit operation ....................................................................................................81

4OPERATION 82

4.1 How to Select the Operation Mode.................................................................................................82

4.1.1 Switching from External operation mode [EXT] to PU operation mode [PU]................................................82

4.1.2 Switching from PU operation mode [PU] to External operation mode [EXT]................................................82

4.1.3 Switching to the External / PU combined operation mode ...........................................................................83

4.2 How to Operate PU Operation ........................................................................................................84

4.2.1 Normal operation..........................................................................................................................................84

4.2.2 PU Jog operation..........................................................................................................................................85

4.3 Combined Operation (Operation Using External Input Signals and PU) ....................................86

4.3.1 Entering the start signal from outside and setting the running frequency from the PU (Pr. 79 = 3) .............86

4.3.2 Entering the running frequency from outside and making start and stop from the PU (Pr. 79 = 4)..............87

4.3.3 Entering the start signal and multi-speed signal from outside and

setting multiple speeds from the parameter unit...........................................................................................88

5 CHECK FIRST WHEN YOU HAVE A TROUBLE 89

5.1 Troubleshooting...............................................................................................................................89

6 SPECIFICATIONS 91

6.1 Standard Specifications ..................................................................................................................91

6.2 Outline Drawing and Panel Cutting Drawing.................................................................................93

IV

Page 9

6.2.1 FR-PU07 outline dimension drawings..........................................................................................................93

6.2.2 FR-PU07BB outline dimension drawings .....................................................................................................94

APPENDIX 95

Appendix 1 Disposing of the equipment in the EU countries...............................................................95

V

Page 10

INTRODUCTION

This product is a unit for setting inverter functions (parameters) and has the following features.

· An operation panel can be removed and a parameter unit can be connected.

· Setting such as direct input method with a numeric keypad, operation status indication, and help function are

usable.

· Eight languages can be displayed.

· Parameter setting values of maximum of three inverters can be stored.

REMARKS

Features only for FR-PU07BB

· Parameter check and setting change are available without connecting a power supply to the inverter.

· Since the shape is specially designed for portable use, it is easy to work with FR-PU07BB in hand.

CAUTION

To use a parameter unit with battery pack (FR-PU07BB) outside Japan, order a "FR-PU07BB-L" (parameter

unit type indicated on the package has L at the end).

Since batteries may conflict with laws in countries to be used (new EU Directive on batteries and

accumulators, etc.), batteries are not enclosed with an FR-PU07BB.

The parameter unit screen displays in this instruction manual are examples used with the FR-A700 series.

1

Page 11

1 PRE-OPERATION INSTRUCTIONS

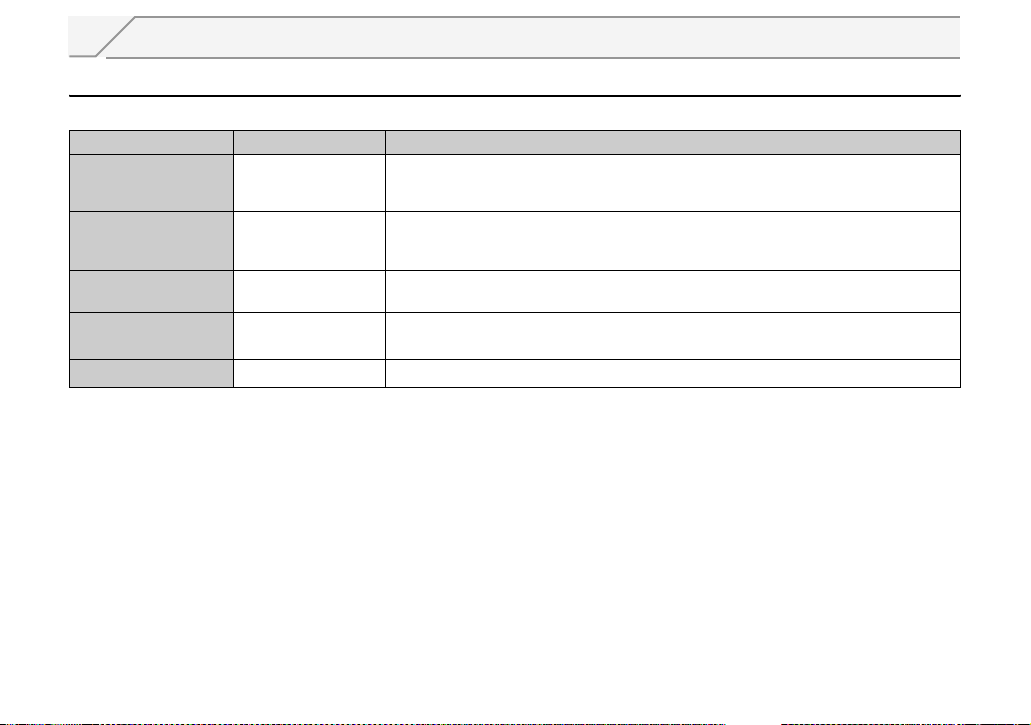

1.1 Supporting inverter models

• FR-PU07/FR-PU07BB supporting models

Model FR-PU07 FR-PU07BB *4

A700 series

F700 series

E700 series

D700 series

500 series

*1 If a product assembled before the above date is connected when the inverter power is OFF, "MITSUBISHI" appears on

the liquid crystal display screen and it is inoperative.

If a product assembled before the above date is connected when the inverter power is ON, "PU07BB/COMPATIBILITY/

ERROR" appears on the liquid crystal display screen and it is inoperative.

*2 If a product assembled before the above date is connected, "PU07BB/COMPATIBILITY/ERROR" appears on the liquid

crystal display screen and it is inoperative regardless of ON/OFF of the inverter power.

*3 Some parameter names displayed are different from those of the FR-PU07.

*4 The FR-PU07 can not be directly connected to the inverter.

{

{

{ *4

{ *4

{ *3, *4

(The FR-A700-EC/-CHT have not been compatible yet but will be compatible in future.)

(The FR-F700-EC/-CHT have not been compatible yet but will be compatible in future.)

(The FR-D700 series have not been compatible yet but will be compatible in future.)

(Products assembled in and after January 2008.) *1

(Products assembled in and after January 2009.) *1

(Products assembled in and after July 2007.) *2

{

{

{

×

×

2

Page 12

Unpacking and Product Confirmation

zSERIAL number

For product assembled date, check the SERIAL number indicated on the inverter rating plate or package.

z SERIAL number check

Refer to the inverter manual for the location of the rating plate.

Rating plate example

Symbol Year Month Control number

The SERIAL consists of 1 version symbol, 2 numeric characters or 1 numeric character and 1 alphabet

letter indicating year and month, and 6 numeric characters indicating control number.

Month is indicated as 1 to 9, X (October), Y (November), and Z (December).

{ { {{{{{{

TC{{{A{{{G{{ TC number

SERIAL (Serial No.)

1

3

Page 13

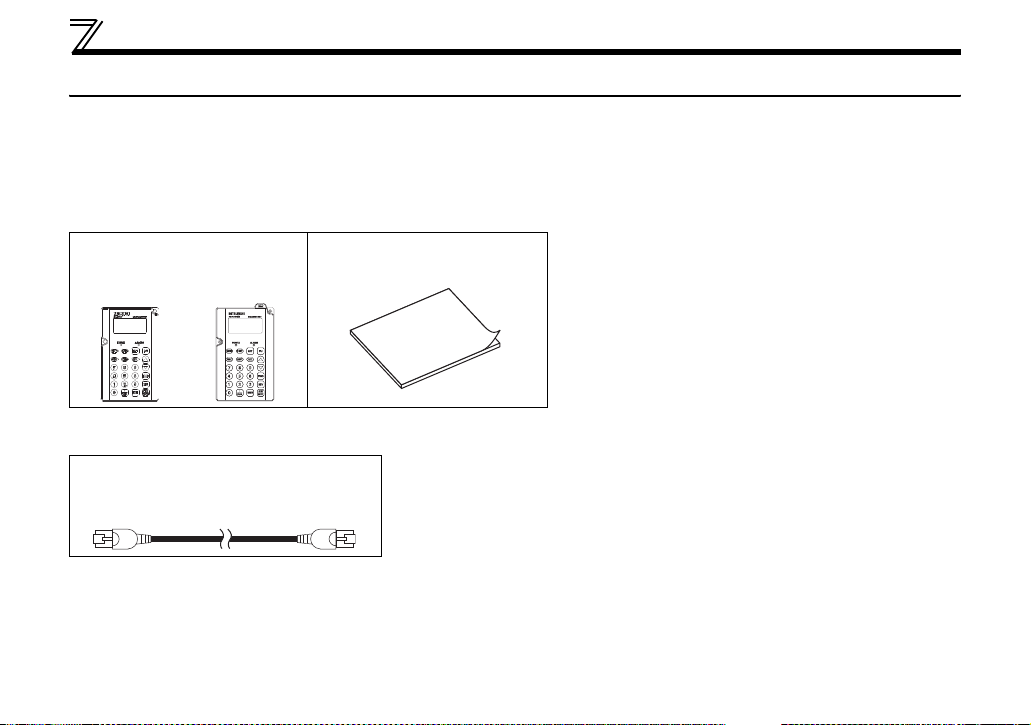

Unpacking and Product Confirmation

1.2 Unpacking and Product Confirmation

Take the parameter unit out of the package, check the unit name, and confirm that the product is as you

ordered and intact.

1.2.1 Unpacking confirmation

Check the enclosed items.

· FR-PU07/FR-PU07BB common

Parameter unit

............................................1

FR-PU07 FR-PU07BB

· FR-PU07BB only

Connection cable (FR-CB203)

...........................................................1

* Batteries are not enclosed. Please prepare them separately.

Instruction manual

............................................1

INSTRUCTION MANUAL

4

Page 14

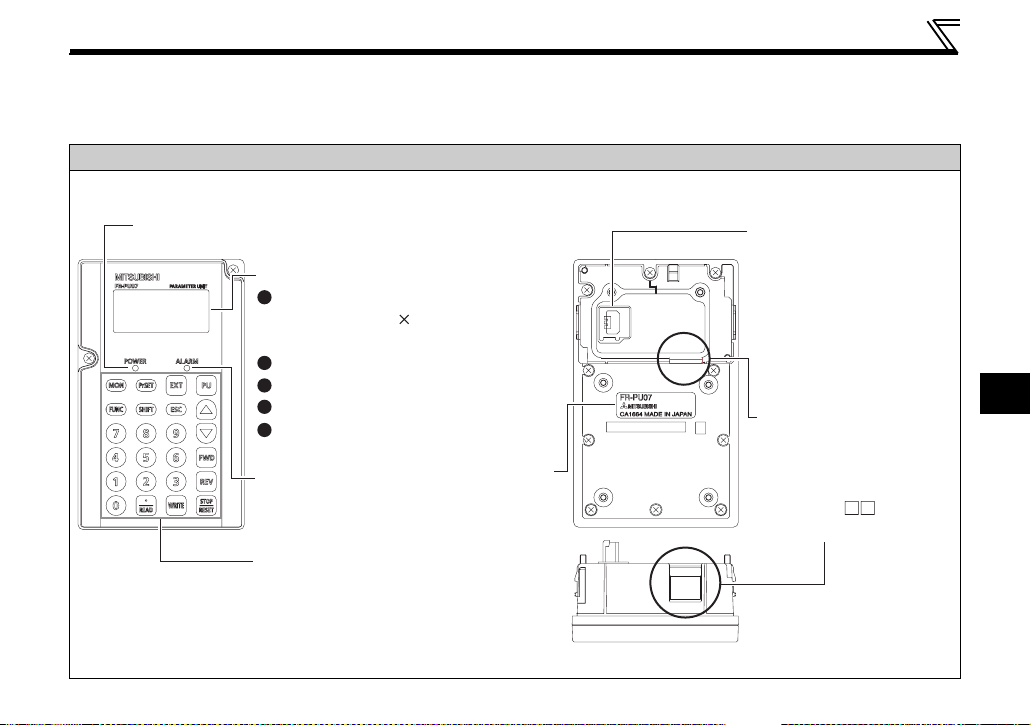

Unpacking and Product Confirmation

1.2.2 Appearance and parts identification

Unpack the parameter unit, check the name plate on the back, and make sure that the product has not

been damaged before using.

FR-PU07

Front

POWER lamp

Lit when the power turns ON.

READ:List

60.00

STF FWD PU

Hz

Monitor

Liquid crystal display

(16 characters 4 lines with

backlight)

Interactive parameter setting

Help function

Trouble shooting guidance

Monitor (frequency, current,

power, etc.)

ALARM lamp

Lit to indicate an inverter

alarm occurrence.

Operation keys

(Refer to page 7)

Rating plate

Rear

Bottom

Connector for inverter

directly

Connector to the inverter.

Connect directly to PU

connector of the inverter.

(Refer to page 9)

Connector for PU

cable

Connect using the

connection cable

(FR-CB2 ).

(Refer to page 11)

1

5

Page 15

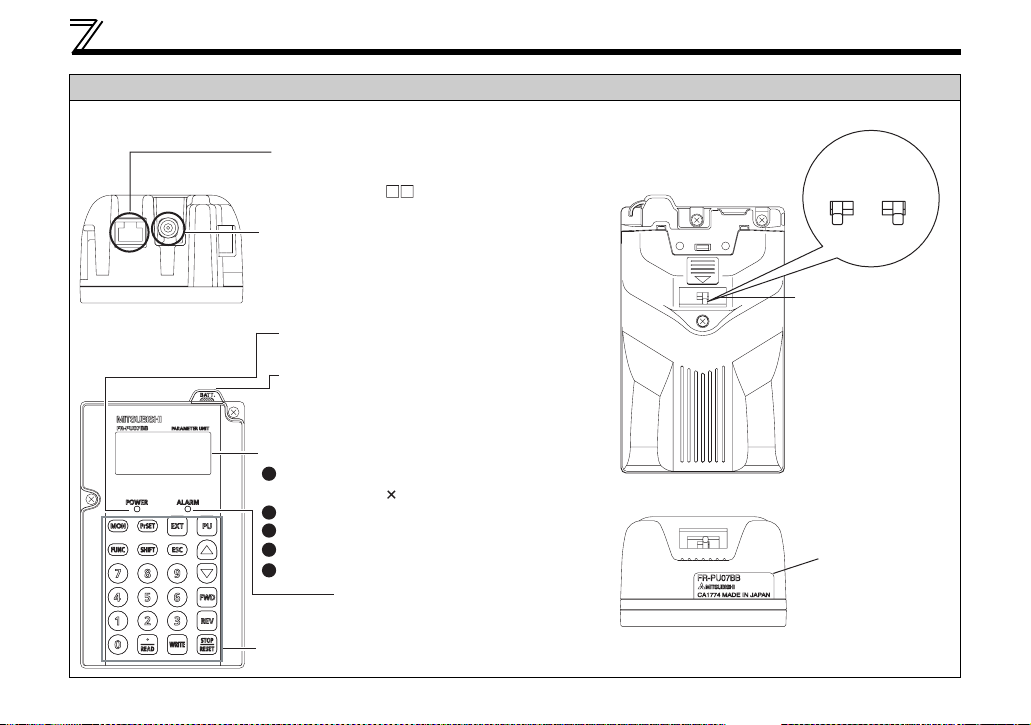

Unpacking and Product Confirmation

FR-PU07BB

Front

READ

0.00

STF FWD PU

Top

:List

Hz

Connector for PU cable

Connect using the connection

cable (FR-CB2

(Refer to page 18, 19)

)

Connector for AC adapter

Pull out the protective cover toward you

to remove and then connect

the AC adapter (sold separately).

(Refer to page 15)

POWER lamp

Lit when the power turns ON.

Battery exhaustion warning lamp

When a battery is low, the lamp color

changes from green to orange.

(Refer to page 91 for details.)

Monitor

Liquid crystal display

(16 characters 4 lines with backlight)

Interactive parameter setting

Help function

Trouble shooting guidance

Monitor (frequency, current, power, etc.)

Rear

Power supply

switch

OFFON

Power supply

switch

Set to ON when

using in the battery

mode.

Rating plate

ALARM lamp

Lit to indicate an inverter

Operation keys

fault occurrence.

Bottom

6

Page 16

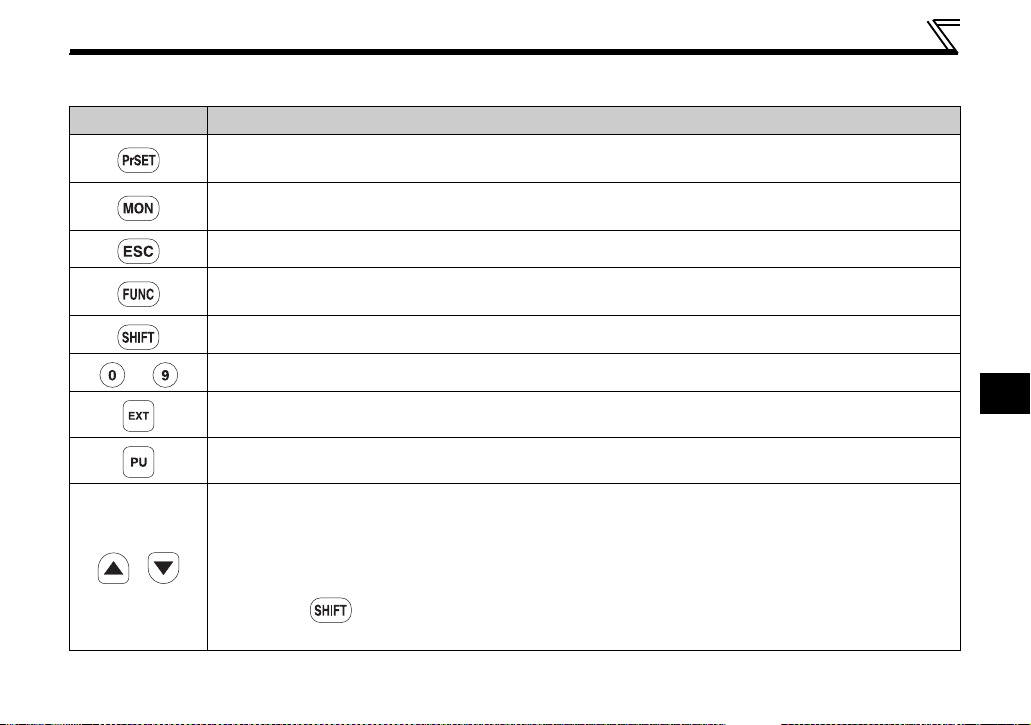

1.2.3 Explanation of keys

Key Description

Used to select the parameter setting mode.

Press to select the parameter setting mode.

Used to display the first priority screen.

Used to display the output frequency when making an initial setting.

Operation cancel key.

Used to display the function menu.

A variety of functions can be used on the function menu.

Used to shift to the next item in the setting or monitoring mode.

Unpacking and Product Confirmation

to

/

Used to enter a frequency, parameter number or set value.

Used to select the External operation mode.

Used to select the PU operation mode to display the frequency setting screen.

· Used to keep on increasing or decreasing the running frequency. Hold down to change the

frequency.

· Press either of these keys on the parameter setting mode screen to change the parameter setting

value sequentially.

· On the selecting screen, these keys are used to move the cursor.

· Hold down and press either of these keys to advance or return the display screen one

page.

1

7

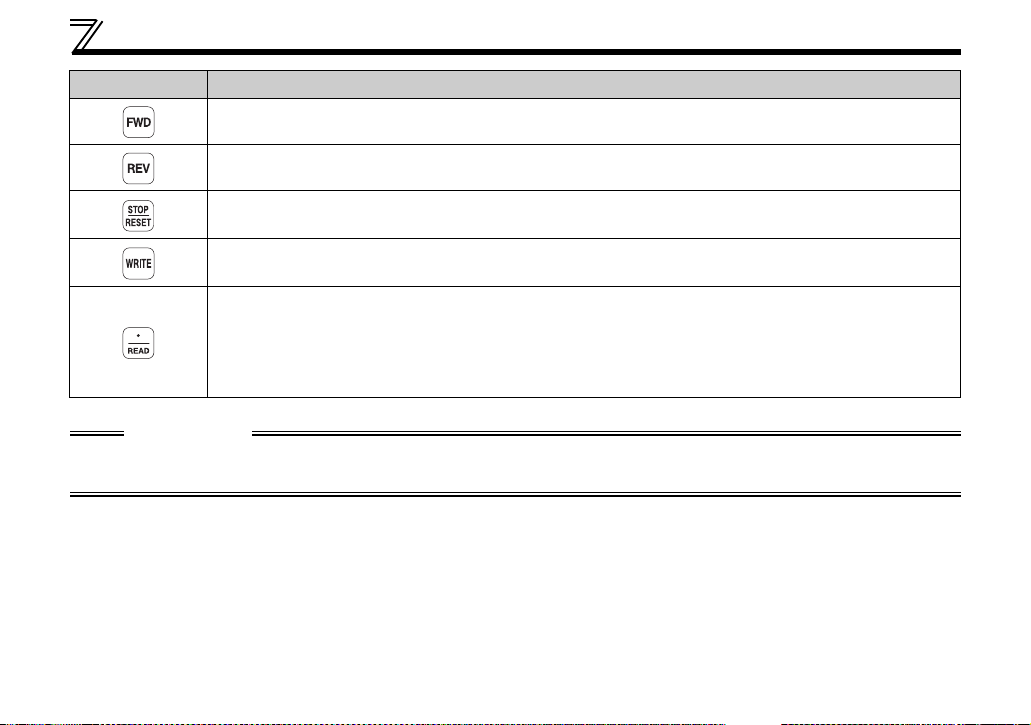

Page 17

Unpacking and Product Confirmation

Key Description

Forward rotation command key.

Reverse rotation command key.

· Stop command key.

· Used to reset the inverter when a fault occurs.

· Used to write a set value in the setting mode.

· Used as a clear key in the all parameter clear or alarm history clear mode.

· Used as a decimal point when entering numerical value.

· Used as a parameter number read key in the setting mode.

· Used as an item select key on the menu screen such as parameter list or monitoring list.

· Used as an alarm definition display key in the alarm history display mode.

· Used as a command voltage read key in the calibration mode.

CAUTION

· Do not use a sharp-pointed tool to push the keys.

· Do not press your fingers against the display.

8

Page 18

Installation and Removal of FR-PU07

1.3 Installation and Removal of FR-PU07

To ensure safety, install or remove FR-PU07 after switching the power of the inverter OFF.

FR-PU07 cannot be directly installed to the FR-E700, D700 inverter.

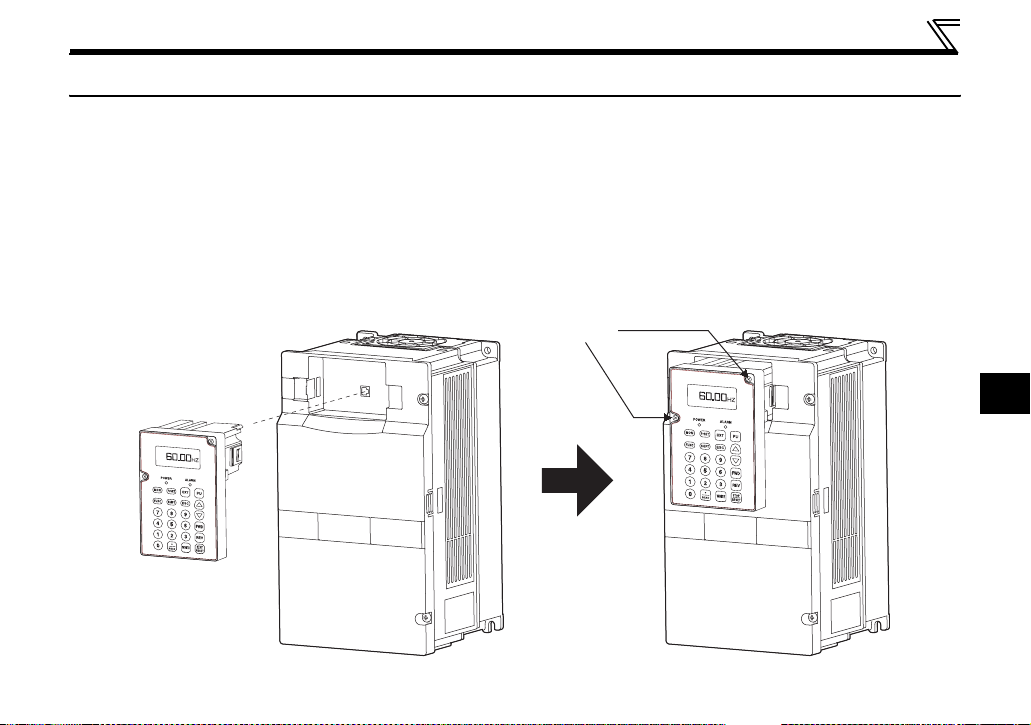

1.3.1 Direct installation to the inverter (A700/F700 series)

(1) Remove the operation panel (FR-DU07).

(2) Insert the parameter unit straight and fit it securely.

(3) Tighten the two screws on the parameter unit to fix the unit to the inverter.

Fixed screw

S

T

F

F

W

D

P

U

S

T

F

F

W

D

P

U

1

9

Page 19

Installation and Removal of FR-PU07

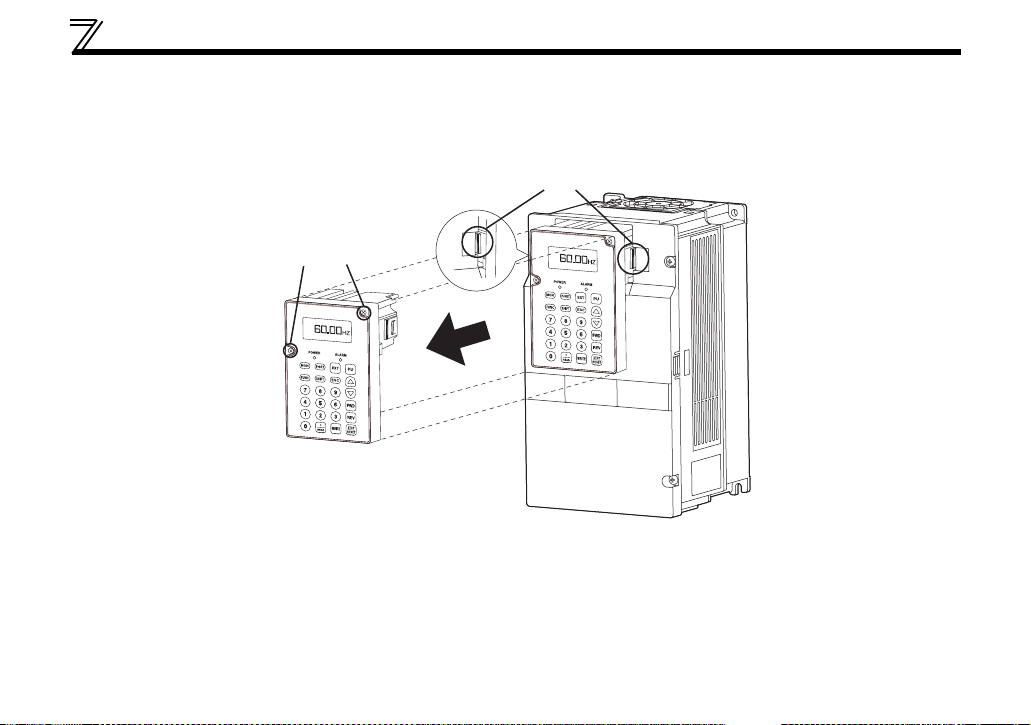

1.3.2 Removal from the inverter (A700/F700 series)

Loosen the fixed screws, hold down the right and left hooks of the FR-PU07, and then pull the parameter

unit toward you.

Press the hooks.

10

Fixed screw

S

T

F

F

W

D

P

U

S

T

F

F

W

D

P

U

Page 20

Installation and Removal of FR-PU07

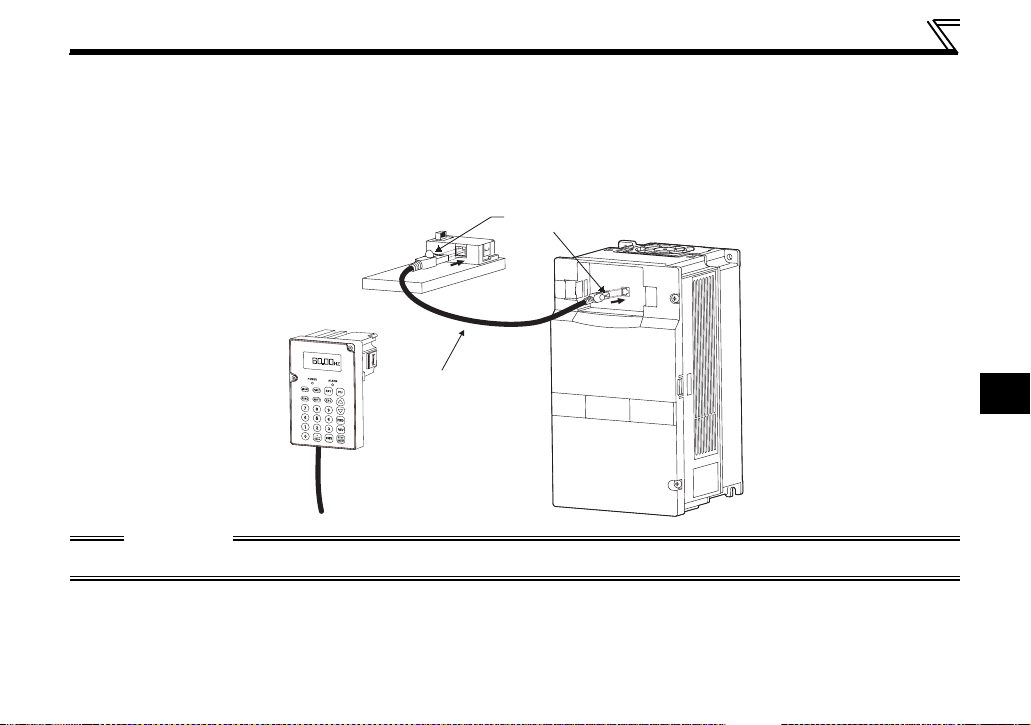

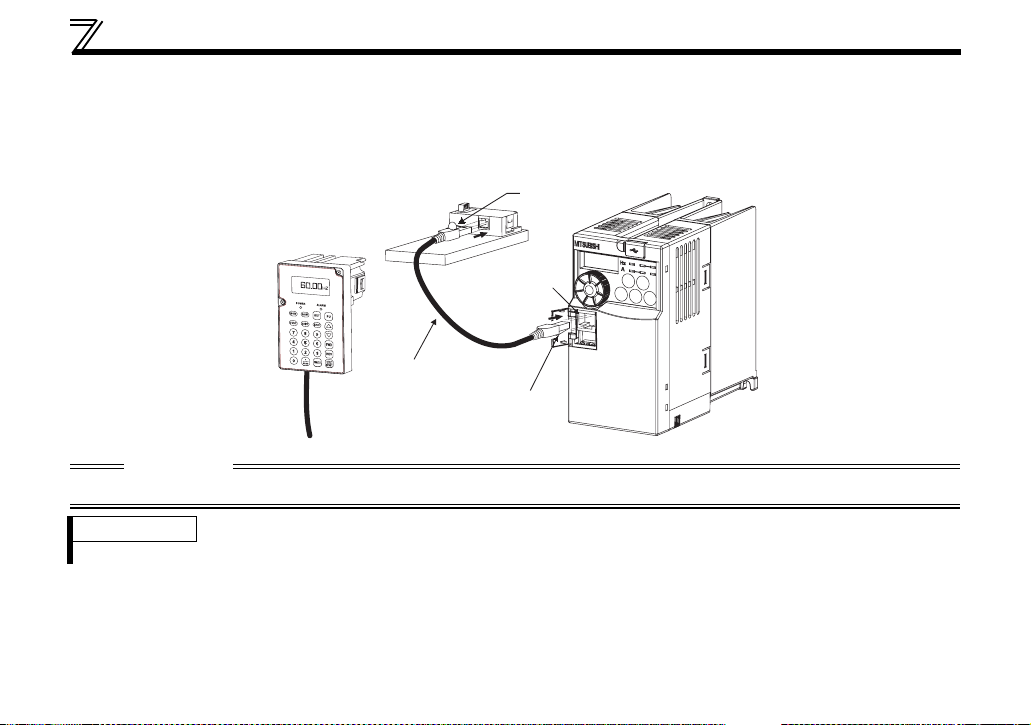

1.3.3 Installation using the connection cable (FR-CB2)

•For the FR-A700/FR-F700

(1) Remove the operation panel (FR-DU07).

(2) Securely insert one end of connection cable into the PU connector of the inverter and the other

end into the connection connector of FR-PU07 along the guides until the stoppers are fixed.

FR-PU07

STF FWD PU

Connection cable

Stopper

CAUTION

Do not connect the connection cable when the front cover is removed.

1

11

Page 21

Installation and Removal of FR-PU07

•For FR-E700

(1) Open the PU connector cover.

(2) Securely insert one end of connection cable into the PU connector of the inverter and the other

end into the connection connector of FR-PU07 along the guides until the stoppers are fixed.

FR-PU07

STF FWD PU

Connection cable

Stopper

PU connector

Stopper

CAUTION

Do not connect the connection cable when the front cover is removed.

REMARKS

For details of the connection cable (FR-CB2), refer to the connection cable (FR-CB2) instruction manual.

12

Page 22

Installation and Removal of FR-PU07

r

•For FR-D700

(1) Remove the inverter front cover. (For the removal of the front cover, refer to the inverter

manual.)

(2) Securely insert one end of connection cable into the PU connector of the inverter and the

other end into the connection connector of FR-PU07 along the guides until the stoppers

are fixed.

PU connector

STF FWD PU

FR-PU07

Stoppe

1

Stopper

Connection cable

CAUTION

Do not connect the connection cable when the front cover is removed.

REMARKS

For details of the connection cable (FR-CB2), refer to the connection cable (FR-CB2) instruction manual.

1.3.4 Removal when the connection cable (FR-CB2) is used

Hold down the tab (stopper) at the cable end and gently pull the plug.

13

Page 23

Connection and Removal of FR-PU07BB

1.4 Connection and Removal of FR-PU07BB

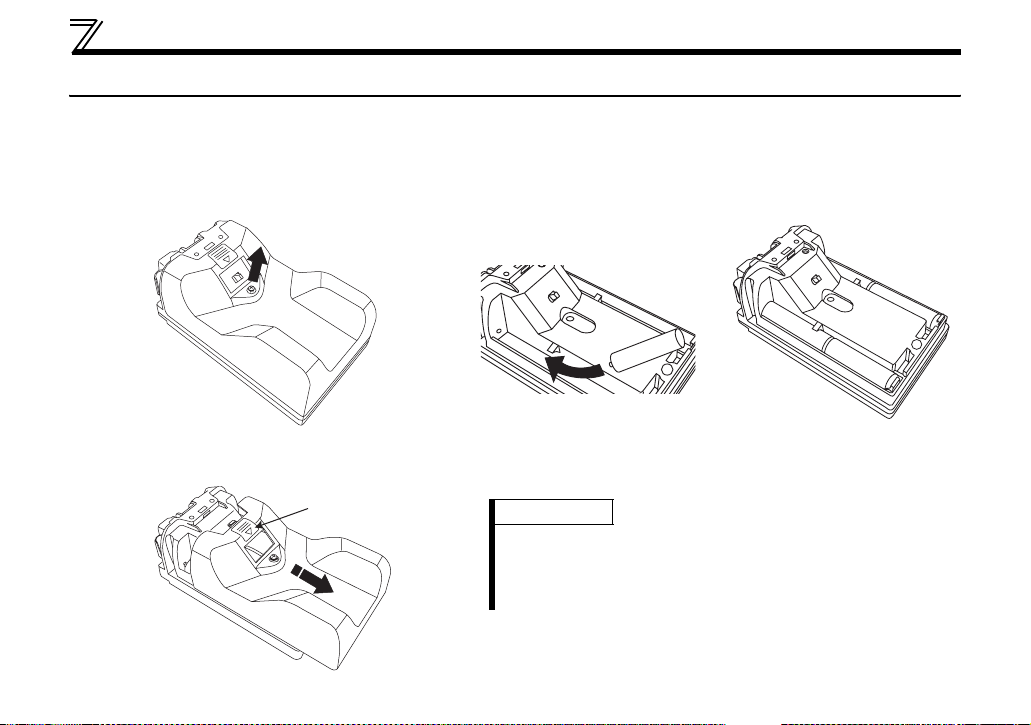

1.4.1 Before using FR-PU07BB in the battery mode

For the power supply of FR-PU07BB, a battery and an AC adapter (sold separately) are available.

(1) When using a battery

1) Loosen the screw of the FR-PU07BB rear side. 3) Place batteries as shown below.

㧗

٤

٤

٤

2) Pushing the hook, slide the cover in the direction

of arrow to open.

㧗

٤

4) Close the cover and tighten the screw.

٤

㧗

٤

㧗

٤

٤

٤

㧗

٤

14

Hook

REMARKS

· Use commercially available AA nickel metal hydride

batteries or AA alkaline batteries (four pieces).

· Batteries are not enclosed. Please prepare them

separately.

Page 24

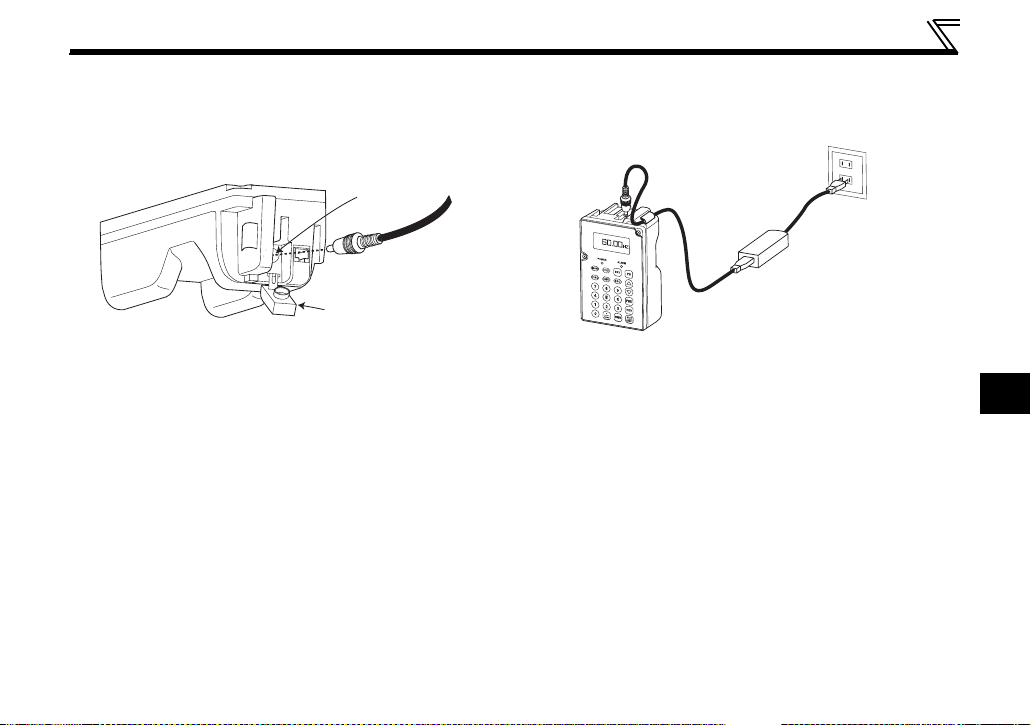

(2) When using an AC adapter

1) Pull out the protective cover toward you to remove

and then insert the output plug of an AC adapter

(sold separately) into the AC adapter connector.

Connector

Protective cover

Connection and Removal of FR-PU07BB

2) Connect the AC adapter (sold separately) to a AC power

supply.

STF FW

D PU

1

15

Page 25

Connection and Removal of FR-PU07BB

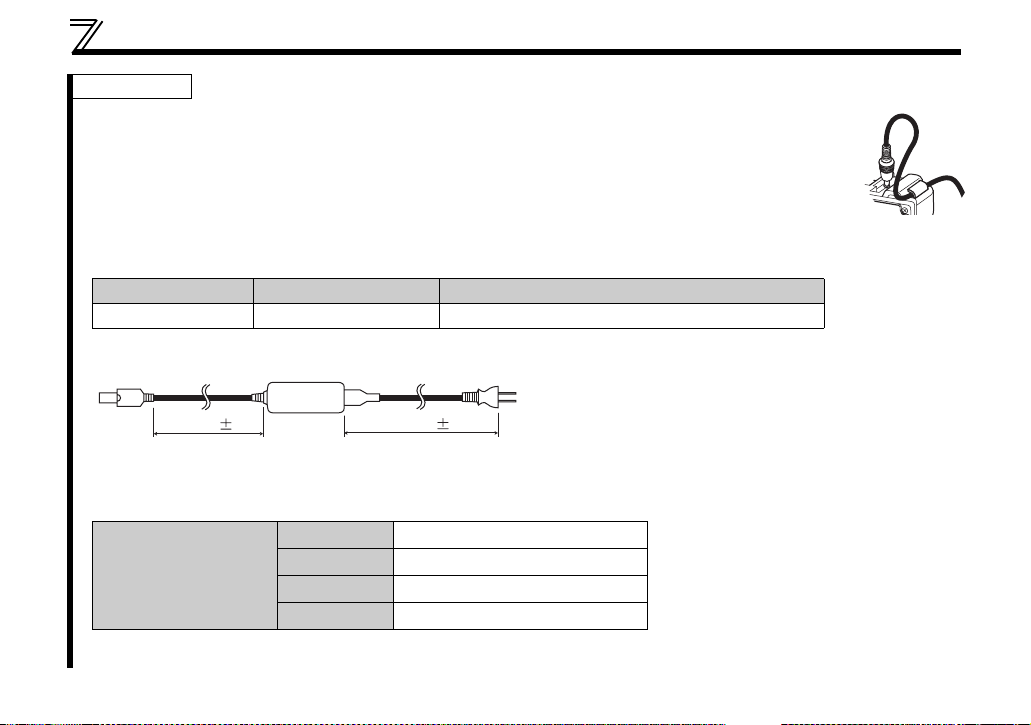

REMARKS

· Disconnection of the connector can be prevented by catching the cable with the hook of the

parameter unit.

· When using a rechargeable battery, use the rechargeable battery charged with the charger specified

by the battery manufacturer. Battery charging is not available with FR-PU07BB even when using an

AC adapter.

· AC adapter (option for exclusive use in Japan)

Use the following adapter to use the FR-PU07BB with single phase 100V power supply.

Product name Model Manufacturer

AC adapter TAS2900-PUA Mitsubishi Electric System & Service Co., Ltd.

AC adapter cable length

1950mm 100

1500mm 50

General specifications

Refer to the specifications below for an adapter to use the FR-PU07BB with AC power supply.

Rated voltage 5.0VDC ± 5% or less

Output specifications

· If batteries are left in the FR-PU07BB when using an AC adapter, batteries may become discharged.

Rated current 2A or more

Polarity Plus polarity in the center.

Connector Conforms to EIAJ RC-5320A

16

Page 26

Connection and Removal of FR-PU07BB

1.4.2 Instructions for the FR-PU07BB (battery mode)

(1) Functions available when using in the battery mode

Description Remarks

Parameter

change

Functions of

the function

menu

· Parameter read

· Parameter write

· For monitor, only frequency setting monitor is available

· PU Operation (Only switching between PU/PU Jog

modes is available, not operational)

· Parameter (list, initial value, changed value, read)

· Parameter clear

· Read/clear of the faults history

· Inverter reset

· Troubleshooting

· Read of software version

· Output terminal monitor

· Frequency direct setting

· Copy/verification function

(2) FM/AM calibration parameter (Pr.900, Pr.901) cannot be set (calibrated).

(3) For following calibration parameters, only the adjusting method without application of analog voltage

(current) is available.

FR-A700 FR-F700 FR-E700

Pr. 902 to Pr. 905, Pr. 917 to Pr.

920, Pr. 932, Pr. 933

Pr. 902 to Pr. 905 Pr. 902 to Pr. 905, Pr. 922, Pr. 923

(4) Operation by the FR-E700 series operation panel is invalid.

Only PRM LED of the operation panel lit at this time.

(5) Do not use the FR Configurator. FR Configurator may not function properly.

· Parameter read/write for plug-in option can be

done in battery mode independently of whether

the plug-in option is mounted or not.

· Monitor value other than frequency setting

monitor is always "0".

· The ON/OFF status of the input signal for the

terminal assignment monitor cannot be

displayed.

· Option fitting status monitor cannot be

displayed.

1

17

Page 27

Connection and Removal of FR-PU07BB

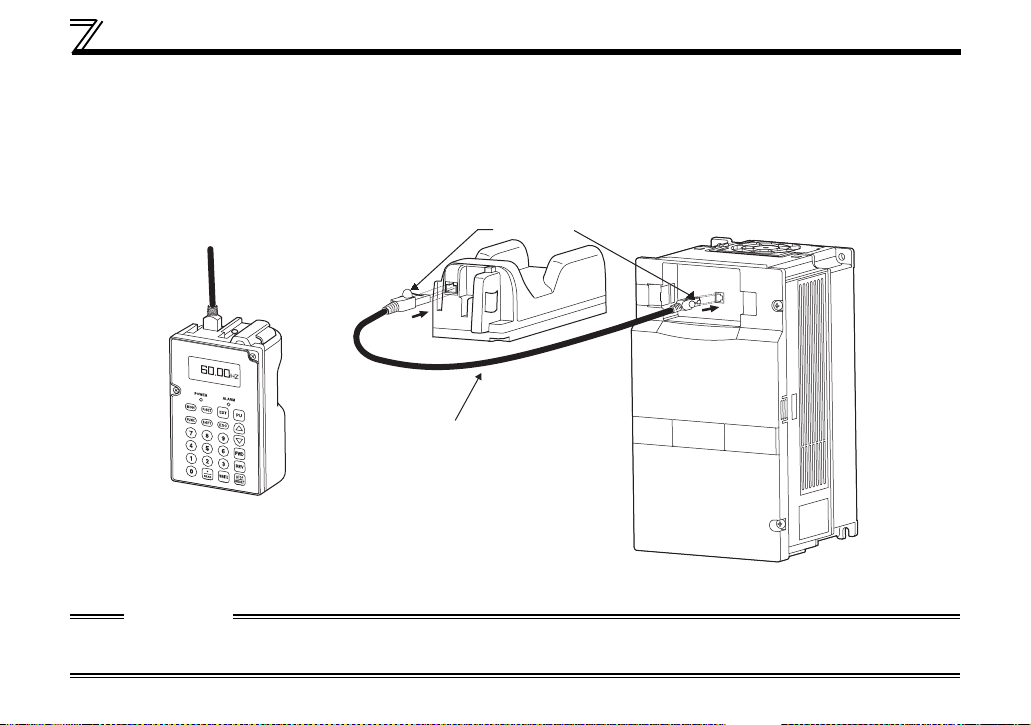

1.4.3 Connecting to FR-A700/F700 using the connection cable (FR-CB2)

(1) Remove the operation panel (FR-DU07).

(2) Insert one end of connection cable securely into the PU connector of the inverter and the other end into

the connection connector of FR-PU07BB along the cable guides until the stoppers are fixed.

(3) When using in the battery mode, turn ON the power supply switch of FR-PU07BB.

ALARM lamp of the inverter flickers in the battery mode.

Stopper

FR-PU07BB

ST

F FW

D

PU

Connection cable (FR-CB2) *

* A connection cable (FR-CB203 (wiring length is 3m)) is enclosed. The cable length when using a connection cable

other than the enclosed should be 3m maximum.

CAUTION

· Connect the connection cable only when the front cover is installed.

· Do not subject the connection cables to scratches, excessive stress, heavy loads or pinching.

18

Page 28

Connection and Removal of FR-PU07BB

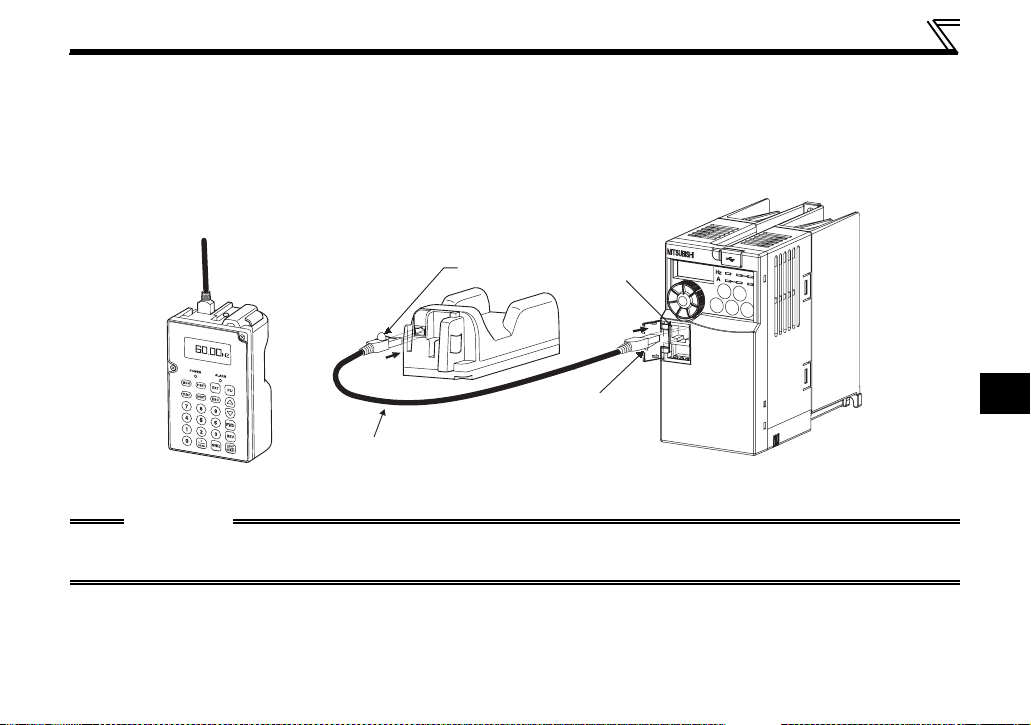

1.4.4 Connecting to FR-E700 using the connection cable (FR-CB2)

(1) Open the PU cover of the inverter.

(2) Insert one end of connection cable securely into the PU connector of the inverter and the other end into

the connection connector of FR-PU07BB along the cable guides until the stoppers are fixed.

(3) When using in the battery mode, turn ON the power supply switch of FR-PU07BB.

FR-PU07BB

Stopper

STF FWD PU

Connection cable (FR-CB2) *

* A connection cable (FR-CB203 (wiring length is 3m)) is enclosed. The cable length when using a connection cable

other than the enclosed should be 3m maximum.

PU connector

Stopper

CAUTION

· Connect the connection cable only when the front cover is installed.

· Do not subject the connection cables to scratches, excessive stress, heavy loads or pinching.

1.4.5 Removal when the connection cable (FR-CB2) is used

Hold down the tab (stopper) at the cable end and gently pull the plug.

19

1

Page 29

Parameters to be Checked First

1.5 Parameters to be Checked First

Change the following parameter settings as required.

For the changing procedures, refer to page 33.

1.5.1 PU display language selection (Pr. 145)

By setting the Pr. 145 PU display language selection value, you can select the language displayed on the

parameter unit.

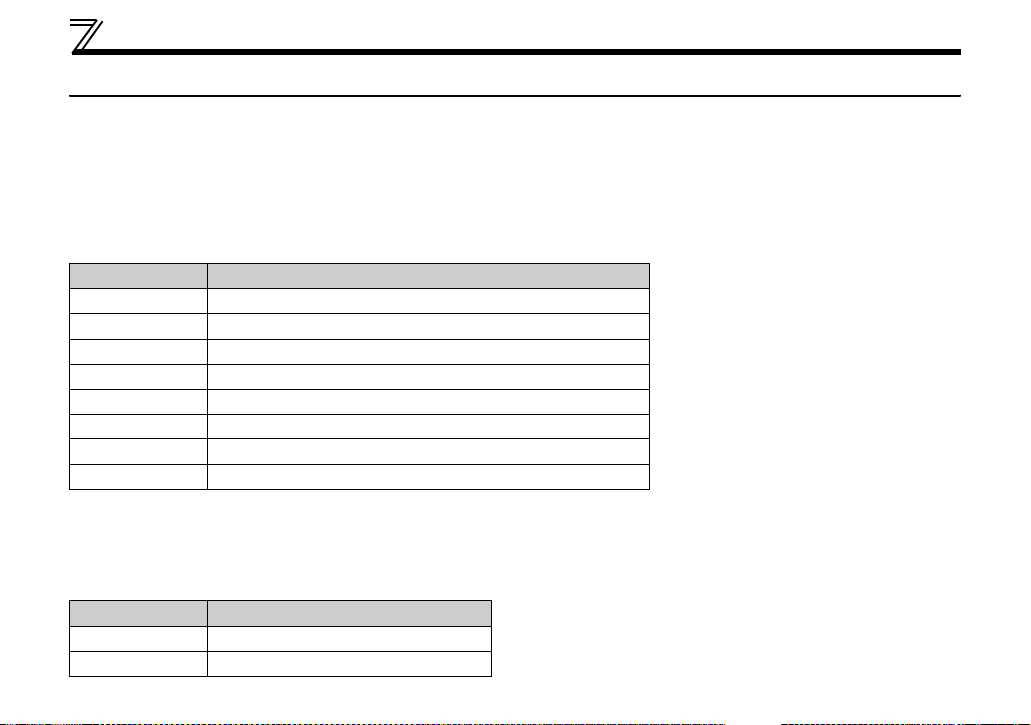

Pr. 145 Setting Display Language

0 (initial value) Japanese

1* English

2German

3French

4Spanish

5Italian

6Swedish

7Finnish

* When the inverter is NA or EC model, the initial value is "1" (English).

1.5.2 PU buzzer control (Pr. 990)

By setting the Pr. 990 PU buzzer control value, you can select to either generate or mute the "beep" which

sounds when you press any of the parameter unit keys.

Pr. 990 Setting Description

0 No buzzer sound

1 (initial value) Buzzer sound generated

20

Page 30

Parameters to be Checked First

1.5.3 PU contrast adjustment (Pr. 991)

By setting the Pr. 991 PU contrast adjustment value, you can adjust the contrast for the display panel of the

parameter unit.

Pr. 991 Setting Description

0 to 63

「0」「63」

Light

「58」

Initial value

Dark

1

21

Page 31

2 FUNCTIONS

2.1 Monitoring Function

2.1.1 Display overview

(1) Main monitor

READ

120.00

STF FWD PU

:List

OL

Hz

(2) Rotation direction indication

(1) Main monitor

Shows the output frequency, output current, output

voltage, alarm history and other monitor data.

· Using to change to the next screen (Refer to

page 25)

· Using to change to the next screen (Refer to

page 59 )

· Using the parameter "PU main display data

selection" (Refer to page 28 )

22

(3) Operating status indication

(2) Rotation direction indication

Display the direction (forward rotation/reverse

rotation) of the start command.

STF : Forward rotation

STR : Reverse rotation

--- : No command or both STF and STR ON

(3) Operating status indication

Display the running status of the inverter.

STOP : During stop

FWD : During forward rotation

REV : During reverse rotation

JOGf : During Jog forward rotation

JOGr : During Jog reverse rotation

ARAR : At fault occurrence

Page 32

READ

120.00

STF FWD PU

(4) Operating mode indication

(4) Operation mode indication

Displays the status of the operation mode.

EXT : External operation mode

PU : PU operation mode

EXTj : External Jog mode

PUj : PU Jog mode

NET : Network operation mode

PU+E : External/PU combined operation mode

(5) Unit indication

Shows the unit of the main monitor.

:List

OL

Hz

Monitoring Function

(6) Warning indication

(5) Unit indication

(6) Warning indication

Displays an inverter warning.

The warning type varies with the inverter model.

Refer to the inverter instruction manual for details.

OL : Overcurrent stall prevention

oL : Overvoltage stall prevention

RB : Regenerative brake pre-alarm

TH : Electronic thermal relay function pre-alarm

ZC : Zero current detection

PS : PU stop

FN : Fan fault

MT : Maintenance signal output

SL : Speed limit

CF : SSCNET communication error

CP : Parameter copy

Nothing is displayed when there is no inverter

warning.

2

23

Page 33

Monitoring Function

REMARKS

· Standby mode function

When FR-PU07BB gets into the standby mode, the backlight of the parameter unit turns OFF, and POWER LED

remains lit.

<Switching conditions>

·When the FR-PU07BB is left in the power-ON status for one minute without connecting to the inverter.

·When FR-PU07BB is connected to the inverter and the inverter remains in the reset status for one minute.

<Recovery conditions>

·When FR-PU07BB is connected to the inverter.

·When the reset of the inverter connected to FR-PU07BB is canceled.

24

Page 34

Monitoring Function

r

2.1.2 Using

"SHIFT"

to change the main monitor

When "0" (initial value) is set in the Pr. 52 DU/PU main display data selection, simply pressing calls 6

different monitor screens in sequence.

Switch power

ON or press

Output frequency monitor Output current monitor

First priority monitor and

top two monitors among

output current, output

frequency, and output voltage

are displayed in rows

When the first priority

monitor is other than

output frequency, output

current and output voltage

When output frequency

is the first priority

monitor (Initial setting)

READ:List

0.00Hz

--- STOP EXT

0.00Hz

0.00A

0.0V

--- STOP EXT

3-step monitor

READ:List

0.0%

--- STOP EXT

(Example: When electric thermal relay function load

factor is set as the first priority monitor)

When the first priority

monitor is other than output

frequency, output current

When output current is

the first priority monitor

0.00A

--- STOP EXT

OTHERS

<READ>

and output voltage

READ:List

When output voltage is

the first priority monitor

READ:List

0.0

--- STOP EXT

V

Output voltage monito

ALARM HISTORY

<READ>

Alarm history monitorSelective monitor

1 UVT 5

2 OC1 6

3 7

4 8

2

25

Page 35

Monitoring Function

2.1.3 Setting the power-ON monitor (the first priority monitor)

Set the monitor which appears first when power is switched ON or is pressed.

• When you press during any monitor screen other than ALARM HISTORY being displayed, that

screen is set as the power-ON screen and will be displayed first.

26

Page 36

Monitoring Function

2.1.4 Using

"READ"

to change the main monitor

Press to display the monitoring list while the main monitor is displayed.

Select a monitor from the monitoring list to change the main monitor.

Example: Select the output current peak value monitor.

1

Press .

The parameter unit is in the

monitoring mode.

2

Press .

The monitoring list appears.

3

Press / to move

the cursor to "Peak I".

Hold down

or to shift one

screen.

4

Press . *1

The output current peak is

displayed.

5

Press . *2

The screen in step 4) is set as

the first priority monitor.

and press

1 Frequency

2 Current

3 Voltage

4 Alarm His

9 Br.Duty %

10 Therm O/L

11 Peak I

12 DC Peak V

Subsequently press

monitor screen.

READ:List

0.00A

--- STOP PU

READ:List

0.00A

--- STOP EXT

to call another

*1 The selected monitor is not set as the first priority

monitor yet when only was pressed. Hence,

the selected monitor is erased from memory as

soon as the power is switched OFF or another

operation mode is selected. In this case, the item

must be selected again. When you press to

select the first priority screen, the selected item is

stored in memory.

*2 Pressing sets the selected "output current

peak" to be displayed in the first priority monitor

when switched to the monitoring mode from other

operation modes. To give first priority to another

monitor screen, press with that monitor screen

being displayed. (Refer to page 26)

REMARKS

· The setting can be also made from the function

menu. For details refer to page 53.

· When "Current monitor" or "Power monitor" is selected,

note that any current or power not more than 5% of the

rated inverter current cannot be detected and displayed.

Example:When a small motor is rotated with a large-

capacity inverter (a 0.4kW motor is used with a

55kW inverter), the power monitor keeps

displaying 0kW and is inoperative.

2

27

Page 37

Monitoring Function

2.1.5 Using the parameter to change the monitor (Pr. 52)

To change the third monitor (output voltage monitor), set Pr. 52 DU/PU main display data selection.

(Note that setting "17" (load meter) *2, "18" (Motor excitation current) *1 *2, and "24" (Motor load ratio)

change the output current monitor.

"Output voltage monitor" monitor displays from the first priority monitor using .

*1 Cannot be monitored for the FR-F700 series.

*2 Cannot be monitored for the FR-E700, D700 series.

REMARKS

Refer to the instruction manual of each inverter for monitor description.

28

Page 38

Monitoring Function

Factory setting

* The monitor displayed at powering ON is the first priority monitor. Refer to page 26 for the setting method

of the first priority monitor.

First priority monitor

READ:List

0.00

--- STOP EXT

(Output frequency monitor) (Output current monitor) (Output voltage monitor)

Hz

First

Second monitor Third monitor

READ:List

--- STOP EXT

1)

0.00

Second

A

--- STOP EXT

2)

READ:List

0.00

Third

V

1) For the set value of "17, 18, 24", their monitors are displayed at the second monitor instead of output

current monitor.

First priority monitor

Output frequency monitor

Monitor of the set value "17, 18, 24"

2) For the set value of "19 to 23, 25

Second monitor

·····

", their monitors are displayed at the third monitor instead of output

Third monitor

Output voltage monitor

voltage monitor.

2

First monitor

Output frequency monitor

Second monitor

Output current monitor

Third monitor

Monitor of the set value "19 to 23, 25 "

REMARKS

The setting range of Pr. 52 DU/PU main display data selection differs according to the inverter.

Refer to the inverter instruction manual for details.

.....

29

Page 39

Frequency Setting

60.00Hz

2.2 Frequency Setting

The frequency in PU operation mode and External/PU combined operation mode (Pr. 79 = "3") can be set.

REMARKS

When changing the operation mode from External operation mode to PU operation mode, operation mode can not be

changed if the external starting signal (STF or STR) is ON.

2.2.1 Direct setting

Directly enter a frequency setting using to .

• Operation procedure (Changing from 0Hz setting to 60Hz setting)

1

Press .

The frequency setting screen

appears.

2

Press and .

Enter 60Hz. *

3

Press .

The 60Hz setting is complete.

* If you entered an incorrect value, press to

return to the pre-entry state.

Freq Set

SET 0.00Hz

0~400Hz

Freq Set

SET 0.00Hz

60.00Hz

0~400Hz

Freq Set

SET

60.00Hz

Completed

30

Page 40

Frequency Setting

60.00Hz

2.2.2 Step setting

Change frequency continuously using / .

You can change the frequency only while you press / . Since the frequency changes slowly at first, this setting

can be used for fine adjustment.

1

Press .

The frequency setting screen

appears.

2

Press / to enter

a desired value (60.00Hz).

You can set any value

between the maximum

frequency (Pr. 1 ) and

minimum frequency (Pr. 2 ).

3

Press .

The 60Hz setting is complete.

SET 0.00Hz

0~400Hz

SET 0.00Hz

0~400Hz

SET

Completed

Freq Set

Freq Set

60.00Hz

Freq Set

60.00Hz

REMARKS

Change of frequency can be made during operation by

the step setting. However, pressing / at

monitor mode may cause actual set frequency to be

higher/lower from the indicated frequency on the

monitor. When performing the step setting at monitor

mode, make sure that output frequency is following the

set frequency.

2

31

Page 41

Frequency Setting

2.2.3 Precautions for frequency setting

1) Pr. 79 Operation mode selection must have been set to switch to the PU operation. (Refer to the inverter

instruction manual for details of Pr. 79 .)

2) In the monitor mode, you cannot make the direct setting (Refer to page 30) to set the running frequency.

Perform the step setting (Refer to page 31) and press , or press to display the frequency setting

screen before frequency setting.

Frequency setting screenDeselect monitor modeMonitor mode

READ:List

30.00Hz

STF FWD PU

Freq Set

SET 0.00Hz

0~400Hz

32

Page 42

Setting and Changing the Parameter Values

180.0S

2.3 Setting and Changing the Parameter Values

Using the FR-PU07/FR-PU07BB allows you to read the parameter of inverter or change the set value

easily. Refer to the inverter instruction manual for details of the parameters.

2.3.1 Specifying the parameter number to change the set value

Example: When changing 5s to 180s at the Pr. 8

Deceleration time setting

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

(You need not press when

the parameter unit is already in

the PU operation mode.)

2

Press .

The parameter unit is in the

parameter setting mode.

3

Press .

Enter the desired parameter

number.

4

Press .

The present setting appears.

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

SETTING MODE

8

8 Dec.T1

5.0S

0~3600

Freq Set

Pr.NO.

<READ>

(1) Direct setting

5

Press .

Enter the desired value.

Or

(2)Step setting

*

8 Dec.T1

5.0S

180S

0~3600

Press .

Display "180" using .

6

Press .

The set value is changed.

7

Press to display the

next parameter.

8 Dec.T1

180.0S

Completed

9 Set THM

2.55A

0~500

* If you entered an incorrect value, press to return

to the pre-entry state.

2

33

Page 43

Setting and Changing the Parameter Values

2.3.2 Selecting the parameter from functional list to change the set value

Example: When changing 5s to 180s at the Pr. 8

Deceleration time setting

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Select the screen using

and move the cursor to

"Appl.Grp".

4

Press .

The function list appears.

Select a function.

5

Point the cursor to "Acc.Dec"

using .

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

1 Basic Func

2 F Command

3 Acc.Dec

4 V/F pattern

1 Basic Func

2 F Command

3 Acc.Dec

4 V/F pattern

6

Press .

A function list regarding

acceleration/deceleration is

displayed.

Select a function.

7

Using , point the

cursor to " Accl/Decl T".

8

Press .

A parameter list regarding

acceleration/deceleration

time is displayed.

When moving the cursor to

9

"Dec.T1" using and

pressing , the present set

value is called.

1 Accl/Decl T

2 Accl/Decl P

3 Brake Seq

1 Accl/Decl T

2 Accl/Decl P

3 Brake Seq

7 Acc.T1

8 Dec.T1

16 JOG T

20 Acc/DecF

8 Dec.T1

5.0S

0~3600

34

Page 44

(1) Direct setting

180.0S

10

Press .

Enter the desired value.

Or

(2)Step setting

*

8 Dec.T1

5.0S

180S

0~3600

Press .

Display "180" using .

11

Press .

The set value is changed.

12

Press to display the next parameter.

* If is pressed when an incorrect setting value is

input, the display returns to the list display "8".

8 Dec.T1

180.0S

Completed

Setting and Changing the Parameter Values

2

35

Page 45

Setting and Changing the Parameter Values

180.0S

2.3.3 Selecting the parameter from parameter list to change the set value

Example: When changing 5s to 180s at the Pr. 8

Deceleration time setting

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

Change the screen using

3

.

Select a parameter list.

4

Using , point the

cursor to "Pr.List".

5

Press .

Select the parameter list.

The list of the parameters can

be read appears.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

0 Trq.Bst1

1 Max.F1

2 Min.F1

3 VFbaseF1

Select the parameter.

6

When moving the cursor

using and pressing

at "Dec.T1", the present

set value is called.

(1) Direct setting

7

Press .

Enter the desired value.

*

Or

(2)Step setting

8 Dec.T1

5.0S

0~3600

8 Dec.T1

5.0S

180S

0~3600

Press .

Display "180" using .

8

Press .

The set value is changed.

9

Press to display the next parameter.

8 Dec.T1

180.0S

Completed

* If is pressed when an incorrect setting value is

input, the display returns to the list display "5".

36

Page 46

Setting and Changing the Parameter Values

180.0S

2.3.4 Selecting the parameter from User List to change the set value

If a parameter is registered to User List, the parameter can be read from User List and changed. (For

registering the user group, refer to page 39 .)

Example: When changing 5s to 180s at the Pr. 8

Deceleration time setting

1

Press .

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

8 Dec.T1

75 RES Mode

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

Change the screen using

3

.

Select a User List.

4

Using , point the

cursor to "User List".

5

Press .

The list of the parameters

registered to User List

appears.

Freq Set

Select the parameter.

6

When moving the cursor

using and pressing

at "Dec.T1", the present

set value is called.

(1) Direct setting

7

Press .

Enter the desired value.

*

Or

(2) Step setting

8 Dec.T1

5.0S

0~3600

8 Dec.T1

5.0S

180S

0~3600

Press .

Display "180" using .

8

Press .

The set value is changed.

9

Press to display the next parameter.

8 Dec.T1

180.0S

Completed

* If is pressed when an incorrect setting value is

input, the display returns to the list display "5".

2

37

Page 47

Setting and Changing the Parameter Values

2.3.5 Precautions for setting write

· Perform parameter setting change during an inverter stop basically in the PU operation mode or

combined operation mode. The parameter setting can not be changed in the External operation mode or

during inverter operation. (Read is performed independently of the operation mode.) Note that some

parameters can be written even in the External operation mode or during operation. Therefore, refer to

the inverter manual.

·As Pr. 77 Parameter write selection = "0" in the initial setting, parameter can be written only during an

inverter stop. (Read is allowed even during operation.) Note that some parameters can be written

always. Refer to the inverter manual for details of Pr. 77.

· In addition to the above case, setting write cannot be performed when:

1) The parameter number selected does not exist in the parameter list; or

2) The value entered is outside the setting range.

· When write cannot be performed and the "Setting Err." appears, press and make setting once more.

(Example: For Pr. 7 Acceleration time )

7 Acc.T1

Setting Error

20000S

<ESC>

38

Page 48

User Group Function

2.4 User Group Function

· User group function is a function to display only parameters necessary for setting.

· Among all parameters, maximum 16 parameters can be registered to the user group. When "1" is set in

Pr. 160, only parameters registered in the user group can be accessed for reading and writing. (The

parameters not registered to the user group cannot be read.)

REMARKS

FR-D700 does not have the user group function.

2

39

Page 49

User Group Function

2.4.1 Registering the parameters to user group

Register.

1

Press .

The parameter unit is in the

parameter setting mode.

Read the parameters.

2

Enter the parameter

number to be registered to

the user group with the

number keys and press

to read the parameter

setting.

Set the parameters.

3

When changing the set

value, enter a new value

with the number keys and

press to write.

When not changing the

setting value, press to

display the setting completion

screen.

4

Press .

The selecting screen

appears.

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

8 Dec.T1

5.0S

0~3600

8 Dec.T1

5.0S

180S

0~3600

Add Pr.

User List

Yes:Add

No :Cancel

5

When moving the cursor to "YES" and pressing

, the registration is executed.

The parameter setting

6

screen appears. To

continue parameter

registration, repeat the

operation from step 2.

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

40

Page 50

User Group Function

2.4.2 Deleting the parameters from

user group

1

Press .

The parameter unit is in the

parameter setting mode.

Select "User List".

2

Using / , point the

cursor to "3 User List" and

press

Select the parameter to be

3

.

deleted.

Using / , point the

cursor to the parameter to be

deleted and press

Delete.

4

The screen of delete

confirmation appears. When

pointing the cursor to "Yes" and

pressing , the parameter is

deleted.

.

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

1 Max.F1

2 Min.F1

3 VFbaseF1

7 Acc.T1

Delete Pr.

User List

Yes:Delete

No :Cancel

To continue deleting

5

parameter, repeat the

operation from step 3.

1 Max.F1

2 Min.F1

7 Acc.T1

8 Dec.T1

2.4.3 Confirming the parameters registered to user group

1

Press .

The parameter unit is in the

parameter setting mode.

Select "User List".

2

Using / , point the

cursor to "3 User List" and

press

Read the parameter.

3

.

You can confirm the

parameters registered to

the user group.

REMARKS

If the parameter is not registered to the user group,

"User List Setting Err." will be displayed. Press to

return to the screen of step 1.

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

1 Appl.Grp

2 Pr.List

3 User List

4 Param Copy

1 Max.F1

2 Min.F1

3 VFbaseF1

7 Acc.T1

2

41

Page 51

Calibration of the Meter (Frequency Meter)

2.5 Calibration of the Meter (Frequency Meter)

The functions vary with the inverter. (Refer to the inverter instruction manual for details of the parameters.)

2.5.1 Calibration of the FM terminal

Parameter

Pr. 900 FM terminal calibration

Pr. 54 FM terminal function selection

Pr. 55 Frequency monitoring reference

This section provides the way to calibrate the fullscale of meter connected to terminal FM using the

parameter unit.

• Calibrating the meter at the running frequency of

60Hz

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

42

3

Enter and

press

The preset frequency is

displayed.

4

Enter and press

.

.

60Hz is set.

5

Press .

Forward rotation is performed

at 60Hz. You need not

connect the motor.

6

Using / , adjust

the meter pointer to a

predetermined position.

The meter pointer moves. (It

takes a long time before the

pointer moves.)

900 FM Tune

Run Inverter

0.00Hz

PU

900 FM Tune

Run Inverter

60Hz

PU

900 FM Tune

MntrF 60.00Hz

<WRITE>PU

Page 52

Calibration of the Meter (Frequency Meter)

7

Press .

Calibration is complete.

8

Press to return to the

main monitor screen.

900 FM Tune

Completed

<MONITOR>

READ:List

60.00Hz

STF FWD PU

REMARKS

When FR-PU07BB is used in the battery mode (the

inverter power is OFF), this parameter cannot be set

(calibrated).

2.5.2 Calibration of the AM terminal

Parameter

Pr. 901 AM terminal calibration

Pr. 158 AM terminal function selection

Pr. 55 Frequency monitoring reference

Pr. 56 Current monitoring reference

This section provides a way to calibrate the meter

connected to terminal AM using the parameter unit.

(1) Calibration procedure 1

(Example: To calibrate the meter at the

running frequency of 60Hz)

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Enter and

press

The preset frequency is

displayed.

.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

901 AM Tune

Run Inverter

0.00Hz

PU

2

43

Page 53

Calibration of the Meter (Frequency Meter)

21

4

Enter and press

.

60Hz is set.

5

Press .

Forward rotation is performed

at 60Hz. You need not

connect the motor.

6

Using / , adjust the meter pointer to a

901 AM Tune

Run Inverter

60Hz

PU

901 AM Tune

MntrF 60.00Hz

<WRITE>PU

predetermined position.

The meter pointer moves. (It takes a long time before

the pointer moves.)

7

Press .

Calibration is complete.

8

Press to return to the

main monitor screen.

901 AM Tune

Completed

<MONITOR>

60.00Hz

STF FWD PU

44

READ:List

(2) When calibrating output current

For the output current or another item, which does

not easily point 100% value during operation,

adjust the reference voltage output, then select the

item to be displayed.

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Enter and

press

The present Pr. 158 setting

appears.

4

Enter and press .

The setting of reference

voltage output is complete.

5

Press .

The parameter unit is in the

parameter setting mode.

.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

158 AM set

1

158 AM set

21

Completed

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

Page 54

Calibration of the Meter (Frequency Meter)

2

6

Enter and

press

The present Pr. 901 setting

appears.

7

Enter and press

.

.

The setting of maximum

running frequency is

complete.

8

Press .

Forward rotation is performed

at 60Hz.

You need not connect the

motor to make adjustment.

9

Using / , adjust the

voltage across terminals

AM-5 and press .

Setting is complete.

The output voltage displayed

is the value at 100% output.

This voltage is not stored if

you do not press .

901 AM Tune

Run Inverter

0.00Hz

PU

901 AM Tune

Run Inverter

60Hz

PU

901 AM Tune

MntrF 1000

<WRITE>PU

901 AM Tune

Completed

<MONITOR>

10

Press .

The parameter unit is in the

parameter setting mode.

11

Enter and

press

The present Pr. 158 setting

appears.

12

Enter and press .

The setting of output current

is complete.

The output current for 10VDC

is the setting value of Pr. 56

Current monitoring reference

(initial value: rated inverter

current).

.

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

158 AM set

21

158 AM set

2

Completed

REMARKS

When FR-PU07BB is used in the battery mode (the

inverter power is OFF), this parameter cannot be set

(calibrated).

2

45

Page 55

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

2.6 Adjustment of the Frequency Setting Signals "Bias" and "Gain"

The functions vary with the inverter model. (Refer to the inverter instruction manual for details of the

functions.)

2.6.1 Adjustment procedure

There are three ways to adjust the bias and gain of the frequency setting voltage (current).

(1) Adjust only the bias and gain frequencies and not adjust the voltage (current) (Refer to page 47)

(2) Adjust any point by applying a voltage across terminals 2-5 (starting a current across terminals 4-5)

(Refer to page 49)

(3) Adjust any point without a voltage being applied across terminals 2-5 (without a current being applied

across terminals 4-5) (Page 51)

REMARKS

When using FR-PU07BB in the battery mode, only Adjustment procedure (3) is available for the following calibration

parameters.

FR-A700 FR-F700 FR-E700

Pr. 902 to Pr. 905, Pr. 917 to Pr.

920, Pr. 932, Pr. 933

Parameter

Pr. 902 Terminal 2 frequency setting bias frequency

Pr. 903 Terminal 2 frequency setting gain

Pr. 904 Terminal 4 frequency setting bias frequency

Pr. 905 Terminal 4 frequency setting gain

Pr. 902 to Pr. 905 Pr. 902 to Pr. 905, Pr. 922, Pr. 923

46

Page 56

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

V

10.00Hz

(1) Adjust only the bias and gain frequencies and

not adjust the voltage

• Setting of the frequency setting voltage bias

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Enter and

press .

The present Pr. 902 setting

appears.

4

Enter .

Voltage need not be applied

across terminals 2-5.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

902 Ext2bias

0.00Hz

Set<WRITE>

Ext<READ>

902 Ext2bias

10Hz

Set<WRITE>

5

Press .

The bias frequency is set at

10Hz.

f

10Hz

0

If the voltage is being applied

across terminals 2- 5 at this

time, the bias setting is as

shown above.

902 Ext2bias

10.00Hz

Completed

2

47

Page 57

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

V

50.00Hz

• Setting of the frequency setting voltage gain

6

Press .

The present setting appears.

7

Enter .

Voltage need not be applied

across terminals 2-5.

8

Press .

The bias frequency is set at

50Hz.

At this time, set the gain on

the assumption that the 5V

(10V) in the inverter is the set

voltage.

f

50Hz

10Hz

0

(10V)

5V

903 Ext2gain

60.00Hz

Set<WRITE>

Ext<READ>

903 Ext2gain

50Hz

Set<WRITE>

903 Ext2gain

50.00Hz

Completed

The adjustment of the frequency setting voltage

bias and gain is complete.

REMARKS

1 The current input (Pr. 904) can also be adjusted

using a similar procedure.

2The Pr. 903 Terminal 2 frequency setting gain remains

unchanged if the Pr. 20 Acceleration/deceleration

reference frequency setting is changed.

48

Page 58

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

(2) Adjust any point by application of voltage to

across terminals 2-5

• Setting of the frequency setting voltage bias

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Enter .

4

Press twice.

The present Pr. 902 setting

appears.

When the set voltage is

changed, the % value also

changes.

This example assumes that a

1V voltage is applied.

The value selected in Pr. 73

(5V in this example) is 100%.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

SETTING MODE

Pr.No.

902

<READ>

902 Ext2bias

5.00Hz

0.5%

Ext 20.0%

1) The previous

setting is

displayed.

2) The present set

voltage across

terminals 2-5 is

displayed in %.

5

Enter .

Set the bias frequency at

10Hz.

f

10Hz

0

6

Press .

The cursor ( ) moves to the

set voltage.

Apply a 0V voltage.

7

In this example, 0V is applied

as 10Hz is set for 0V.

(Indicated % on the right

changes.)

8

1)

2)

Press .

The bias frequency is set at

10Hz for 0V input.

Setting is completed as

shown below:

f

10Hz

0

1V

V

V

902 Ext2bias

10.00Hz

0.5%

EXT 20.0%

902 Ext2bias

10.00Hz

0.5%

Ext - 0.2%

902 Ext2bias

10.00Hz

0.5%

Ext - 0.2%

902 Ext2bias

10.00Hz

- 0.2%

Completed

0.0% of analog input

value may not be

displayed in some

cases.

2

49

Page 59

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

• Setting of the frequency setting voltage gain

9

Press , then .

The present Pr. 903 setting

appears.

When the set voltage is

changed, the % value also

changes.

The value selected in Pr. 73

(5V in this example) is 100%.

903 Ext2gain

60.00Hz

97.1%

Ext 80.0%

1) The previous

setting is

displayed.

2) The present set

voltage across

terminals 2-5 is

displayed in %.

10

Enter .

11

Press .

The cursor ( ) moves to the

set voltage.

Apply a 5V voltage.

12

In this example, 5V is applied

to set 50Hz for 5V input.

903 Ext2gain

50Hz

97.1%

Ext 80.0%

903 Ext2gain

50.00Hz

97.1%

Ext 80.0%

903 Ext2gain

50.00Hz

97.1%

Ext 80.0%

13

Press .

The gain frequency is set at

1)

2)

50Hz for 5V input.

Setting is completed as

shown below:

f

50Hz

10Hz

0

(0%)

(100%)

5V

903 Ext2gain

50.00Hz

99.6%

Completed

The value displayed

may not be just

100.0% in some

cases.

V

The adjustment of the frequency setting voltage

bias and gain is complete.

REMARKS

1 The current input (Pr. 904, Pr. 905 ) can also be

adjusted using a similar procedure.

2The Pr. 903 Terminal 2 frequency setting gain remains

unchanged even if the Pr. 20 Acceleration/

deceleration reference frequency setting is changed.

3 A narrow calibration (command) value set using Pr.

902 and Pr. 903 (Pr. 904 and Pr. 905) will result in "Incr

I/P" and disable write.

50

Page 60

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

)

)

(3) Adjust any point without application of voltage

to across terminals 2-5

• Setting of the frequency setting voltage bias

1

Press .

The frequency setting screen

appears, and operation mode

changes to PU operation mode.

2

Press .

The parameter unit is in the

parameter setting mode.

3

Enter .

4

Press twice.

The present Pr. 902 setting

appears.

When the set voltage is

changed, the % value also

changes.

The value selected in Pr. 73

(5V in this example) is 100%.

Freq Set

SET 0.00Hz

0~400Hz

SETTING MODE

0~9:Ser Pr.NO.

Select Oper

SETTING MODE

Pr.No.

902

<READ>

902 Ext2bias

5.00Hz

0.5%

Ext -0.5%

1) The previous

setting is

displayed.

2) The present set

voltage across

terminals 2-5 is

displayed in %.

1

2

5

Enter .

Set the bias frequency at

10Hz.

6

Press .

The cursor ( ) moves to the

set voltage.

Voltage need not be applied

across terminals 2-5.

7

Enter .

Input 0V to set bias.

8

Press .

The bias frequency is set at

10Hz.

Setting is completed as

shown below:

f

10Hz

0

902 Ext2bias

10Hz

-0.5%

Ext -0.5%

902 Ext2bias

10.00Hz

-0.5%

Ext -0.5%

902 Ext2bias

10.00Hz

- 0%

Ext -0.5%

2

902 Ext2bias

10.00Hz

0.0%

Completed

V

51

Page 61

Adjustment of the Frequency Setting Signals "Bias" and "Gain"

• Setting of the frequency setting voltage gain

9

Press , then .

The present Pr. 903 setting

value appears.

When the set voltage is

changed, the % value also

changes.

The value selected in Pr. 73

(5V in this example) is 100%.

10

Enter .

Set the gain frequency at

50Hz.

11

Press .

The cursor ( ) moves to the

set voltage.

Voltage need not be applied

across terminals 2-5.

12

Enter .

Input 5V to set gain.

903 Ext2gain

60.00Hz

97.1%

Ext 80.0%

1) The previous

setting is

displayed.

2) The present set

voltage across

terminals 2-5 is

displayed in %.

903 Ext2gain

50Hz

97.1%

Ext 80.0%

903 Ext2gain

50.00Hz

97.1%

Ext 80.0%

903 Ext2gain

50.00Hz

100.0%

Ext 80.0%

13

Press .

The gain frequency is set at

1)

2)

50Hz.

Setting is completed as

shown below: