Page 1

When installing or relocating the unit, check

that no substance other than the specified

refrigerant (R410A) enters the refrigerant circuit.

¡Any presence of foreign substance or air can cause abnormal

pressure rise or explosion.

¡For your safety, thoroughly read the following instructions prior to installation.

Safety Precautions

¡Thoroughly read the following “Safety Precautions” to ensure proper installation.

¡Observe the following important safety precautions at all times.

¡Hazards that can occur from incorrect handling are classified by the symbols below:

Mitsubishi Electric Air Conditioner CITY MULTI

Twinning Kit Installation Manual

WARNING

CAUTION

WARNING

Incorrect handling can result in death or serious injury.

Incorrect handling can result in bodily injury and/or structure damage.

❈

See the Installation Manual that came with the outdoor unit for installation instructions.

CAUTION

Only a dealer or qualified technician should

perform installation.

¡Improper installation may result in refrigerant gas leakage

and equipment damage.

Do not make any modifications or alterations.

Consult your dealer for repair.

¡Improper installation may result in water leakage, electric shock,

or fire.

In the event of a refrigerant leak, thoroughly

ventilate the room.

¡If refrigerant leaks and comes in contact with an open flame,

toxic gases will be generated.

Properly install all parts according to the

instructions in the Installation Manual.

¡If the wrong twinning pipe or wrong size connecting pipe is

used, air conditioning performance will suffer.

After installation, check for a refrigerant leak.

¡If leaked refrigerant comes in contact with a heat source,

such as a fan heater, stove, or electric grill, toxic gases will be

generated.

Properly dispose of packing materials.

¡Plastic bags can pose suffocation and choking hazards: keep

them out of the reach of children. Tear the plastics bags

before disposing of them.

Do not touch the refrigerant pipes and

refrigerant circuit components with bare

hands during and immediately after operation.

¡During or immediately after operation, certain parts of the unit

such as pipes and compressor may be either very cold or hot,

depending on the state of the refrigerant in the unit at the

time. To reduce the risk of frostbites and burns, do not touch

these parts with bare hands.

1

CMY-R100VBK, CMY-R200VBK

WT05221X02

Page 2

1. Confirming the Package Contents

The following items are included with the Twinning Kit (CMY-R100VBK, CMY-R200VBK). Verify that all items are present before

starting installation.

❈ Always use the twinning pipes included in the kit when preparing the twinning kit.

If the pipes field-supplied do not fit the parts in the kit, use the accessory piping parts listed below.

(1) Package contents

Model

CMY-R100VBK

CMY-R200VBK

1

1

1

1

2

1

1

-

1

1

-

1

3

1

3

1

1

1

1

Low-pressure

twinning kit

2

High-pressure

twinning pipe

3

Fixing screw

4

Elbow pipe

Ø22.2 [7/8]

5

Elbow pipe

Ø28.58 [1-1/8]

6

Elbow pipe

Ø31.75 [1-1/4]

7

High-pressure pipe

(for routing through

the bottom)

8

High-pressure pipe

(for routing through

the front)

9

Pipe cover

Model

CMY-R100VBK

CMY-R200VBK

2

1

-

-

1

-

1

1

-

1

-

1

-

1

-

1

-

BCD E

FU-PIPE

ID25.4 [1]

G

U-PIPE

ID19.05 [3/4]

-ID25.4 [1]

HSaddle

2

-

0

1

1

IPacking

1

-

A

1

1

J

Fixing plate

2

2

K

Installation Manual

(this booklet)

L

Insulation cover

MCable tie

OD19.05 [3/4]

-ID15.88 [5/8]

OD22.2 [7/8]

-ID19.05 [3/4]

OD19.05 [3/4]

-ID22.2 [7/8]

OD22.2 [7/8]

-ID28.58 [1-1/8]

OD28.58 [1-1/8]

-ID22.2 [7/8]

OD31.75[1-1/4]

-ID34.93 [1-3/8]

(2) List of field-supplied parts

· Refrigerant pipes other than the ones provided in the kit

· Heat-resistant insulation material (for field-supplied refrigerant pipes)

· Insulation cover tape

Package unit name

Outdoor Twinning Kit

Component unit name

Outdoor unit 1

Outdoor unit 2

BC controller ~ Twinning pipe

High-pressure

Low-pressureAB

A0

B0

C0

D0

E0

F0

PURY-**Y(S)HM

PURY-**Y(S)HMU

PURY-**T(S)HMU

A0

P450

P500

P550

P600

P650

P700

P750

P800

EP400

EP450

EP500

EP550

EP600

P144

P168

P192

P216

P240

P144

P168

P192

P216

P240

B0

P250

P250

P300

P300

P350

P400

P400

P400

EP200

P250

EP300

EP300

EP300

P72

P96

P96

P120

P120

P72

P96

P96

P120

P120

C0

P200

P250

P250

P300

P300

P300

P350

P400

EP200

EP200

EP200

P250

EP300

P72

P72

P96

P96

P120

P72

P72

P96

P96

P120

D0

CMY-R100VBK

CMY-R200VBK

CMY-R100VBK

CMY-R100VBK

CMY-R100VBK

F0

Twinning pipe ~ Outdoor unit

Low-pressure

E or F

A3

B3

C3

D3

E3

PURY-**YHM

PURY-**YHMU

PURY-**THMU

A1

A2

A3

P200

Ø15.88

(*)

Ø19.05(*

)

EP200

Ø15.88

(*)

Ø19.05(*

)

P72

Ø15.88

(*)

Ø19.05(*

)

P72

Ø15.88

(*)

Ø19.05(*

)

B1

B2

B3

P250

Ø19.05

Ø22.2

EP300

Ø19.05

Ø22.2

P96

Ø19.05

Ø22.2

P96

Ø19.05

Ø22.2

C1

C2

C3

P300

Ø19.05

Ø22.2

(

*

A)

-

-

-

P120

Ø19.05

Ø28.58

P120

Ø19.05

Ø28.58

D1

D2

D3

P350

Ø19.05

Ø28.58

-

-

-

-

-

-

-

-

-

E1

E2

E3

P400

Ø22.2

(*)

Ø28.58

-

-

-

-

-

-

-

-

-

-

Unit model

A1

B1

C1

D1

E1

High-pressure

C or D

A2

B2

C2

D2

E2

(

Unit : mm [in

] )

(

Unit : mm [in

] )

*

A : In case of CMY-R200VBK

Ø34.93

(*)

[1-3/8]

E0

Ø22.2

[7/8]

Ø22.2

[7/8]

Ø22.2

[7/8]

Ø22.2

[7/8]

Ø28.58

(*)

[1-1/8]

Ø28.58

[1-1/8]

Ø28.58

[1-1/8]

Ø28.58

[1-1/8]

Ø28.58

[1-1/8]

Ø28.58

(*)

[1-1/8]

Ø28.58

(*)

[1-1/8]

Ø28.58

(*)

[1-1/8]

Ø28.58

(*)

[1-1/8]

[5/8]

[3/4]

[5/8]

[3/4]

[5/8]

[3/4]

[5/8]

[3/4]

[3/4]

[7/8]

[3/4]

[7/8]

[3/4]

[7/8]

[3/4]

[7/8]

[3/4]

[7/8]

[3/4]

[1-1/8]

[3/4]

[1-1/8]

[3/4]

[1-1/8]

[7/8]

[1-1/8]

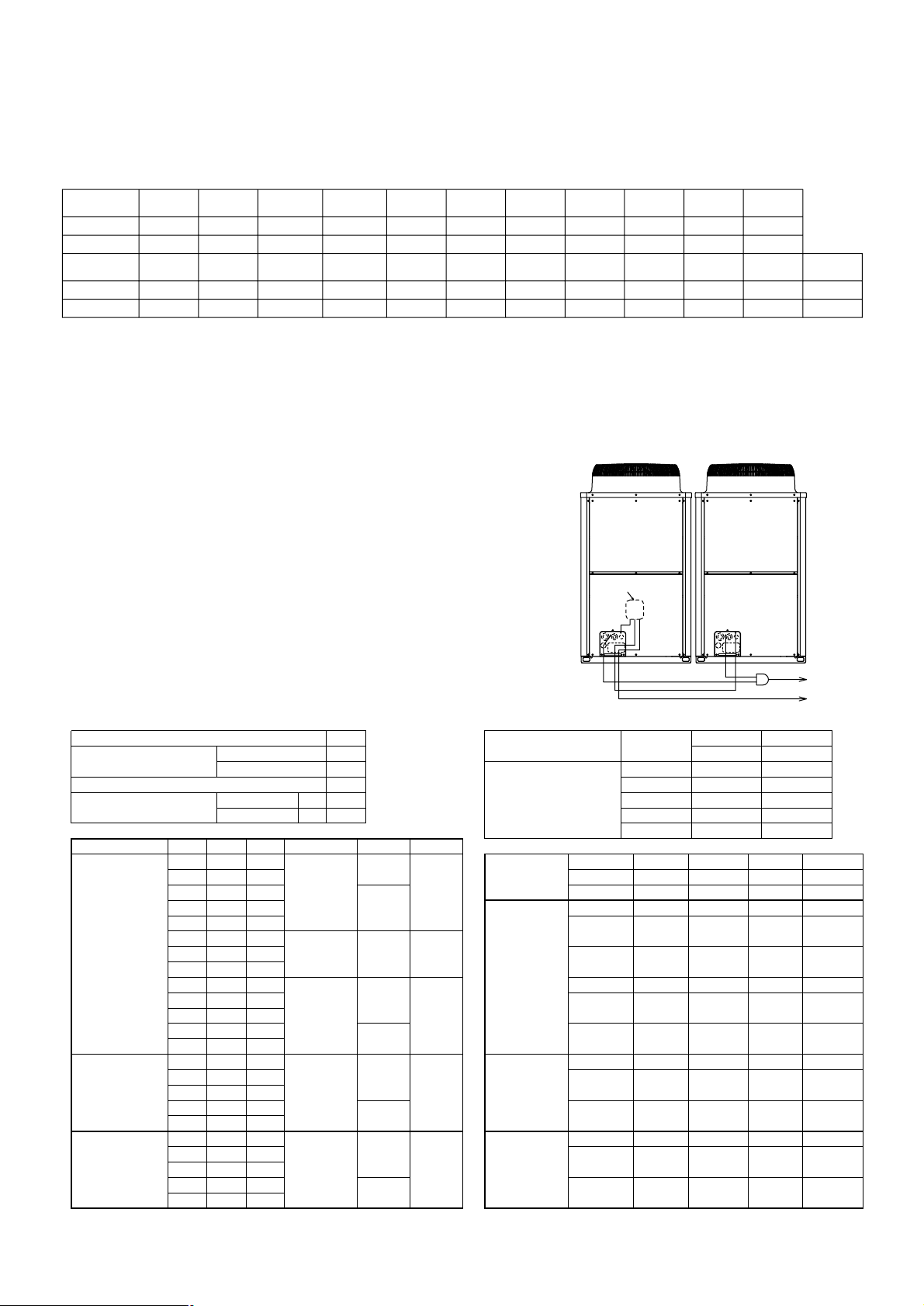

2. Selecting the Correct Size Refrigerant Pipes and Using the Twinning Kit

(1) Pipe size

1 Field-supply the pipes to be connected to the kit.

2 Choose the correct size pipe using the table below. Connect the field-

supplied pipe to the twinning kit for the sizes in the table that are marked

with an asterisk (*).

3 If the pipe was cut with a pipe cutter, remove the burrs and eliminate

foreign materials before connecting.

❈

On the low-pressure side, the twinning kit connects to the pipes field-

supplied inside the outdoor unit.

The distributor on the low-pressure side must be placed in the outdoor unit

that has a larger capacity index of the two, regardless of the relative

positions of the outdoor units or their addresses.

If the distributor is placed in the outdoor unit that has a smaller capacity,

refrigerant will not be properly distributed and compressor failure may result.

( If outdoor units that have the same capacity are used in combination, the

distributor can be placed in either outdoor unit.)

Twinning pipe (high pressure)

Twinning Kit (low pressure)

C

E

D

A

B

To BC controller

To BC controller

Outdoor unit 2

Outdoor unit 1

F

2

See reverse.

Page 3

(3) Routing the pipe through the bottom

(1) Braze item

7 high-pressure pipe to the stop valve so that the

dimples on the pipe are parallel to the edge of the cutout hole.

Expand the end of the field-supplied pipes, and braze them

to item

7 high-pressure pipe.

(2) Attach item

1 low-pressure twinning kit to the sheet metal of the

control valve with item

3 screw, and braze it to the control valve.

(3) Braze item

5 or 6 elbow pipe to the field-supplied pipe first,

and then braze it to item

1 low-pressure twinning kit.

(4) Flare the field-supplied pipe end, and braze the pipe to the

low-pressure pipe in the middle.

(5) Wrap the pipe in front of item

1 low-pressure twinning kit with item

9 pipe cover, and attach compressor cables to item 9 pipe cover with

item

M cable tie to keep them out of direct contact with the pipes.

Twinning pipe on the high-pressure side

±15˚

Slope of the twinning pipe is at an angle within ±15˚ to the horizontal plane.

Note. Refer to the figure below for the installation position of the twinning pipe.

3

(4) Routing the pipe through the front

(1) Braze item

8 high-pressure pipe to the control valve.

(2) Attach item

1 low-pressure twinning kit to the sheet metal of the

control valve with item

3 screw, and braze it to the control valve.

(3) Braze item

5 or 6 elbow pipe to the field-supplied pipe first,

and then braze it to item

1 low-pressure twinning kit.

(4) Braze either item

4 or 5 elbow pipe to the low-pressure pipe in

the middle.

(5) Wrap the pipe in front of item

1 low-pressure twinning kit with

item

9 pipe cover, and attach compressor cables to item 9 pipe

cover with item

M cable tie to keep them out of direct contact

with the pipes.

1

3

5,6

Field-supplied pipes

Field-supplied

pipes

Connect the pipe so that the

dimples on the 7 high pressure

pipe are on an imaginary line

parallel to the edge of the

cutout hole.

9

Wrap the pipe cover here.

Attach compressor cables to

Pipe cover with Cable tie

to keep them out of direct

contact with the pipes.

1

3

5,6

4,5

8

Field-supplied pipes

9

Wrap the pipe cover here.

Attach compressor cables to

Pipe cover with Cable tie

to keep them out of direct

contact with the pipes.

· Before heating the pipes, place a wet towel on the control valve to

keep its temperature below 120

˚C [248˚F]

.

· Direct the flame away from the cables and sheet metals inside the

unit so as not to burn them.

CAUTION

· Before heating the pipes, place a wet towel on the control valve to

keep its temperature below 120

˚C [248˚F]

.

· Direct the flame away from the cables and sheet metals inside the

unit so as not to burn them.

CAUTION

(2) Low-pressure twinning kit in CMY-R100VBK

Use either

F or G in table 1,(1) Package Contents

depending on the size of the pipe at the control valve on

the unit to be combined with. Attach items

H, I, and J

to the stop valve sheet metal and then to the low-pressure

twinning kit to hold it into place.

1. Attach item

J to the stop valve sheet metal.

2. Attach the packing and saddle.

3. Secure the low pressure twinning kit.

F or G

1

H,I,J

33

Section to be brazed field-supplied

Stop valve

(5) Slope of twinning pipes (high-pressure side only)

Make sure the slope of the twinning pipes are at an angle

within ±15˚ to the horizontal plane.

If the slope exceeds the specified angle, the unit may be

damaged.

Page 4

WT05221X02

4. Insulation Cover Installation

Install the insulation cover on the twinning kit after brazing the pipes and twinning kit.

Insulate all refrigerant pipes. Insulate the high-pressure and low-pressure pipes separately, and pipes located inside the unit as well as

the outside. Use heat-resistant insulation material (Heat resistant : at least 120˚C [248˚F], Thickness: high-pressure = 10 mm [13/32 in],

low-pressure = 20 mm [13/16 in] ). Position the edges of the insulation cover and heat-resistant insulation material so as not to leave a

gap, and then wrap the exterior perimeter of the pipe joints and middle with tape (field-supplied).

Downward slope

To BC controller

High-pressure twinning pipe

100mm [4 in]

or more

A B

Upward slope

To BC controller

Total pipe length = A + B < 5m [16-7/16 ft]

Tape (field-supplied)

Overlap margin of the tape

Insulation cover Heat-resistant insulation material (field-supplied)

Insulation covers can shrink.

Overlap the tape as shown in the left

figure so that there will be no gap in

between the insulation cover or

field-installed insulation material.

field-supplied pipe

Heat-resistant insulation material (field-supplied)

Heat-resistant insulation material (field-supplied)

field-supplied pipe

field-supplied pipe

2High-pressure

twinning pipe

LInsulation cover

Tape (field-supplied)

To be gap free

To be gap free

4

See reverse.

3. Pipe Connection Example

Connect the pipes between outdoor units,

using the figure below as a reference.

Main low-pressure pipe (field-supplied)

Main high-pressure pipe (field-supplied)

2High-pressure twinning pipe

Low-pressure connecting pipe

(field-supplied)

High-pressure connecting pipe

(field-supplied)

1Low-pressure twinning kit

·

If high-pressure twinning pipe is installed above the base of the

outdoor unit, it should be no more than 200mm [7-7/8 in].

Outdoor unit 2Outdoor unit 1

High-pressure

twinning pipe

200mm max.

To indoor unit

5. Miscellaneous Notes

Secure the field-supplied pipes with a pipe cover and a cable tie in place to keep them from coming in contact with other pipes as

necessary.

(7) Pipe connection (high-pressure side)

Make sure pipes from the twinning pipe to the outdoor unit are sloped downwards.

(6) The length of the straight pipe between indoor units and the twinning pipe (high-pressure pipe)

Use the pipes supplied in the twinning kit, and make sure the section of the field-supplied pipe that connects to the twinning

pipe has at least 500 mm [19-11/16 in] of straight section. (The section of the field-supplied pipe that connects to the twinning

pipe must have at least 500 mm [19-11/16 in] of straight section.) If the straight section is less than 500 mm [19-11/16 in],

it may result in equipment damage.

Loading...

Loading...