Page 1

Digital-Analog Converter Module type AJ65BT64DAV/DAI User's Manual

Page 2

Page 3

• SAFETY PRECAUTIONS •

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full

attention to safety to handle the product correctly.

The instructions given in this manual are concerned with this product. Refer to the user's manual of the

CPU module to use for a description of the programmable controller system safety instructions.

In this manual, the safety precautions are classified into two levels: "

WARNING

CAUTION

Under some circumstances, failure to observe the precautions given under "

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

[Design Precautions]

WARNING" and " CAUTION".

CAUTION" may lead to

WARNING

• Install a safety circuit external to the programmable controller that keeps the entire system safe

even when there are problems with the external power supply or the programmable controller.

Otherwise, trouble could result from erroneous output or erroneous operation.

(1) The status of analog output changes depending on the setting of various functions that

control the analog output. Take sufficient caution when setting for those functions.

For details of analog output status, refer to Section 3.4.5 ”Combinations of various functions”

(2) Normal output may not be obtained due to malfunctions of output elements or the internal

circuits. So build an external monitoring circuit that will monitor any single outputs that could

cause serious trouble.

!

CAUTION

• Do not bunch the control wires or communication cables with the main circuit or power wires, or

install them close to each other.

They should be installed 100mm(3.94inch) or more from each other.

Not doing so could result in noise that would cause erroneous operation.

• At power ON/OFF, voltage or current may instantaneously be output from the output terminal of

this module.

In such case, wait until the analog output becomes stable to start controlling the external device.

A - 1

Page 4

[Installation Precautions]

!

CAUTION

• Use the module in the environment given in the general specifications of this Manual.

Using this programmable controller in an environment outside the range of the general

specifications could result in electric shock, fire, erroneous operation, and damage to or

deterioration of the product.

• For protection of the switches, do not remove the cushioning material before installation.

• Securely fix the module with a DIN rail or mounting screws. Tighten the screws within the

specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Do not directly touch the module's conductive parts or electronic components.

Touching the conductive parts could cause an operation failure or give damage to the module.

[Wiring Precautions]

!

CAUTION

Shut off the external power suppy for the system in all phases before wiring.

Failure to do so may result in damage to the product.

• Be sure to ground the FG terminals to the protective ground conductor. Not doing so could result

in erroneous operation.

Use applicable solderless terminals and tighten them with the specified torque. If any solderless

spade terminal is used, it may be disconnected when the terminal screw comes loose, resulting

in failure.

• When wiring in the programmable controller, be sure that it is done correctly by checking the

product's rated voltage and the terminal layout.

Connecting a power supply that is different from the rating or incorrectly wiring the product could

result in fire or damage.

• Tighten the terminal screws with the specified torque.

If the terminal screws are loose, it could result in short circuits, fire, or erroneous operation.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

• Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause fires, damage, or erroneous operation.

• Do not install the control lines together with the communication cables, or bring them close to

each other. Failure to do so may cause malfunctions due to noise.

• When connecting the communication and power supply cables to the module, always run them

in conduits or clamp them.

Not doing so can damage the module and cables due to loose, moved or accidentally pulled

cables or can cause a malfunction due to a cable connection fault.

A - 2

Page 5

[Wiring Precautions]

!

CAUTION

When disconnecting the communication and power supply cables from the module, do not hold

and pull the cable part.

Disconnect the cables after loosening the screws in the portions connected to the module.

Pulling the cables connected to the module can damage the module and cables or can cause a

malfunction due to a cable connection fault.

[Starting and Maintenance Precautions]

!

CAUTION

• Do not touch the terminals while power is on. Doing so may cause malfunctioning.

• Be sure to shut off all phases of the external power supply used by the system before cleaning

or retightening the terminal screws.

Not doing so can cause the module to fail or malfunction.

• Do not disassemble or modify the modules.

Doing so could cause trouble, erroneous operation, injury, or fire.

Do not drop or apply strong shock to the module. Doing so may damage the module.

Be sure to shut off all phases of the external power supply used by the system before mounting

or dismounting the module to or from the panel.

Not doing so could result in damage to the product.

Do not install/remove the terminal block more than 50 times after the first use of the product.

(IEC 61131-2 compliant)

• Before touching the module, always touch grounded metal, etc. to discharge static electricity

from human body.

Failure to do so can cause the module to fail or malfunction.

[Disposal Precautions]

!

CAUTION

• When disposing of this product, treat it as industrial waste.

A - 3

Page 6

• CONDITIONS OF USE FOR THE PRODUCT •

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major or

serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of the

PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT LIMITED

TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT, WARRANTY, TORT,

PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR LOSS OR DAMAGE TO

PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR USED IN APPLICATION NOT

INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS, OR WARNING CONTAINED IN

MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY MANUALS, TECHNICAL BULLETINS AND

GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

y Nuclear Power Plants and any other power plants operated by Power companies, and/or any other

cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

y Railway companies or Public service purposes, and/or any other cases in which establishment of a

special quality assurance system is required by the Purchaser or End User.

y Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as Elevator

and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation, Equipment for

Recreation and Amusement, and Safety devices, handling of Nuclear or Hazardous Materials or

Chemicals, Mining and Drilling, and/or other applications where there is a significant risk of injury to

the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT is

limited only for the specific applications agreed to by Mitsubishi and provided further that no special

quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 4

Page 7

REVISIONS

* The manual number is given on the bottom left of the back cover.

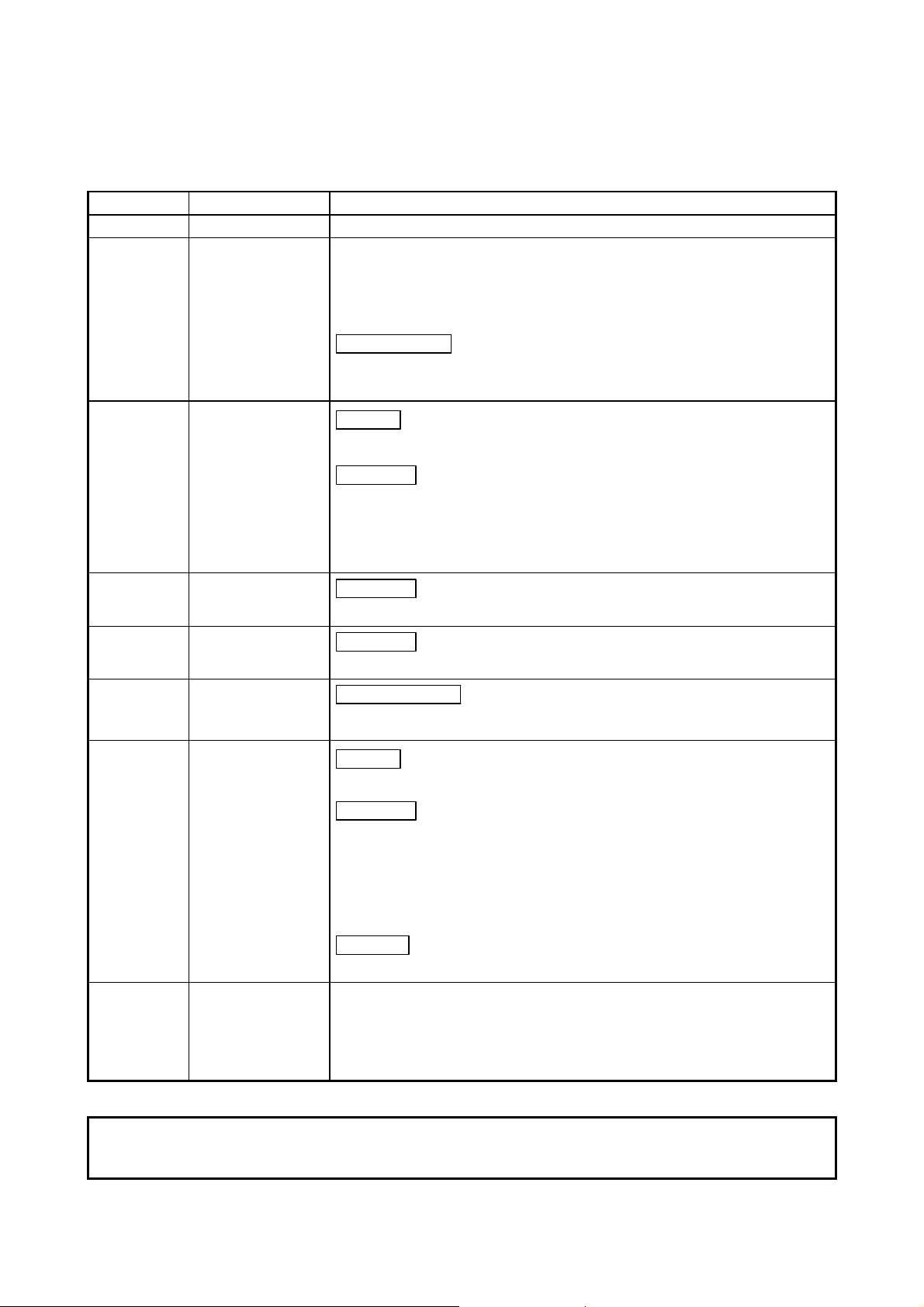

Print Date * Manual Number Revision

Jan., 1997 SH(NA)-3615-A First printing

Jun., 2000 SH(NA)-3615-B Addition of Q series types

Chapter 2, Section 3.2, Section 3.4.1, Section 3.6.3, Section 4.2,

Section 6.2

Sep., 2004 SH(NA)-3615-C

Jul., 2005 SH(NA)-3615-D

Oct., 2006 SH(NA)-3615-E

Dec., 2006 SH(NA)-3615-F

Dec., 2010 SH(NA)-3615-G

Partial changes

Section 1.1(3), Section 3.1, Section 3.2, Section 3.4.5, Section 4.1,

Section 4.6.2, Section 4.7.2, Section 5.2

Addition

Conformation to the EMC Directive and Low Voltage Instruction

Correction

SAFETY PRECAUTIONS, About this Manual, Chapter 1, Chapter 2,

Section 3.1, Section 3.2, Section 3.6.4, Section 3.6.5, Section 4.1,

Section 4.4, Section 4.6, Section 4.6.1, Section 4.6.2, Section 4.7.2,

Chapter 5, Section 6.2

Correction

SAFETY PRECAUTIONS

Correction

SAFETY PRECAUTIONS, Section 4.2

Partial correction

Chapter 2(1), Section 3.5.1, Chapter 5

Addition

CONDITIONS OF USE FOR THE PRODUCT

Correction

SAFETY PRECAUTIONS, Chapter 1, Section 1.1, Chapter 2,

Section 3.1 to Section 3.5, Section 3.5.2, Section 3.6.1, Section 3.6.2,

Section 4.1, Section 4.3, Section 4.6.2, Section 4.7.1, Section 5.1,

Section 5.1, Section 5.2, Section 5.3, Section 5.6, Chapter 6,

Section 6.1, Section 6.2, Appendix 2

Delection

Section 4.6.1

Japanese Manual Version SH-3600-I

This manual does not imply guarantee or implementation right for industrial ownership or implementation

of other rights. Mitsubishi Electric Corporation is not responsible for industrial ownership problems caused

by use of the contents of this manual.

© 1997 MITSUBISHI ELECTRIC CORPORATION

A - 5

Page 8

Introduction

Thank you for purchasing the Mitsubishi MELSEC-A Series General Purpose Programmable Controller.

Before using the equipment, plese read this manual carefully to develop full familiarity with the functions and

performance of the graphic operation terminal you have purchased, so as to ensure correct use.

Please forward a copy of this manual to the end user.

Table of Contents

1. OVERVIEW 1- 1 to 1- 2

1.1 Features ................................................................................................................................................... 1- 1

2. SYSTEM CONFIGURATION 2- 1 to 2- 2

3. SPECIFICATIONS 3- 1 to 3-14

3.1 General Specification............................................................................................................................... 3- 1

3.2 Performance Specification....................................................................................................................... 3- 2

3.3 I/O Conversion Characteristics................................................................................................................ 3- 4

3.3.1 Offset value and gain value........................................................................................................... 3- 4

3.3.2 I/O conversion characteristics ....................................................................................................... 3- 4

3.4 Various Functions to Control the Analog Output .................................................................................... 3- 8

3.4.1 Function to specify hold or clear of the analog output when the programmable controller

CPU is in the STOP status (HOLD/CLEAR setting) .................................................................... 3- 8

3.4.2 Function to specify executing or not executing the D/A conversion processing

(Analog output enable/disable flag).............................................................................................. 3- 8

3.4.3 Function to specify enabling or prohibiting of the analog value external output

(Analog output enable/prohibit setting) ........................................................................................ 3- 8

3.4.4 Offset/gain setting.......................................................................................................................... 3- 8

3.4.5 Combinations of various functions ................................................................................................ 3- 8

3.5 I/O Signals to the Master Station............................................................................................................ 3-10

3.5.1 I/O signal list ................................................................................................................................. 3-10

3.5.2 Functions of the I/O signals.......................................................................................................... 3-11

3.6 Remote Register ..................................................................................................................................... 3-12

3.6.1 Allocation of the remote register .................................................................................................. 3-12

3.6.2 Digital value setting area for channels 1 through 4 ..................................................................... 3-13

3.6.3 Analog output enable/prohibit channel ........................................................................................ 3-13

3.6.4 Set value checking code storage area for channels 1 through 4 ............................................... 3-14

3.6.5 Error code..................................................................................................................................... 3-14

A - 6

Page 9

4. SETUP AND PREPARATION BEFORE OPERATION 4- 1 to 4- 8

4.1 Precautions When Handling .................................................................................................................... 4- 1

4.2 Name of Each Part................................................................................................................................... 4- 2

4.3 Offset/Gain Setting................................................................................................................................... 4- 4

4.4 Station Number Setting............................................................................................................................ 4- 5

4.5 Facing Direction of the Module Installation ............................................................................................. 4- 5

4.6 Data link Cable Wiring ............................................................................................................................. 4- 6

4.6.1 CC-Link dedicated cable connections ..........................................................................................4- 6

4.7 Wiring........................................................................................................................................................ 4- 7

4.7.1 Precautions when wiring ...............................................................................................................4- 7

4.7.2 Wiring between the AJ65BT-64DAV/DAI and external devices .................................................. 4- 7

5. PROGRAMMING 5- 1 to 5-18

5.1 Programming Procedure.......................................................................................................................... 5- 1

5.2 Conditions of Program Example.............................................................................................................. 5- 2

5.3 Program Example for Use of the QCPU (Q mode)................................................................................. 5- 4

5.4 Program Example for Use of the QnACPU............................................................................................ 5-10

5.5 Program Example for Use of the ACPU/QCPU (A mode) (dedicated instructions) ............................. 5-12

5.6 Program Example for Use of the ACPU/QCPU (A mode) (FROM/TO instructions) ............................ 5-16

6. TROUBLESHOOTING 6- 1 to 6- 2

6.1 Error Code List ......................................................................................................................................... 6- 1

6.2 Troubleshooting ....................................................................................................................................... 6- 1

6.2.1 When a communication fault occurs between the master station and this module .................... 6- 2

APPENDIX App- 1 to App- 2

Appendix 1 External Dimensions of the AJ65BT-64DAV .........................................................................App- 1

Appendix 2 External Dimensions of the AJ65BT-64DAI...........................................................................App- 2

A - 7

Page 10

About this Manual

The following are manuals related to this product.

Request for the manuals as needed according to the chart below.

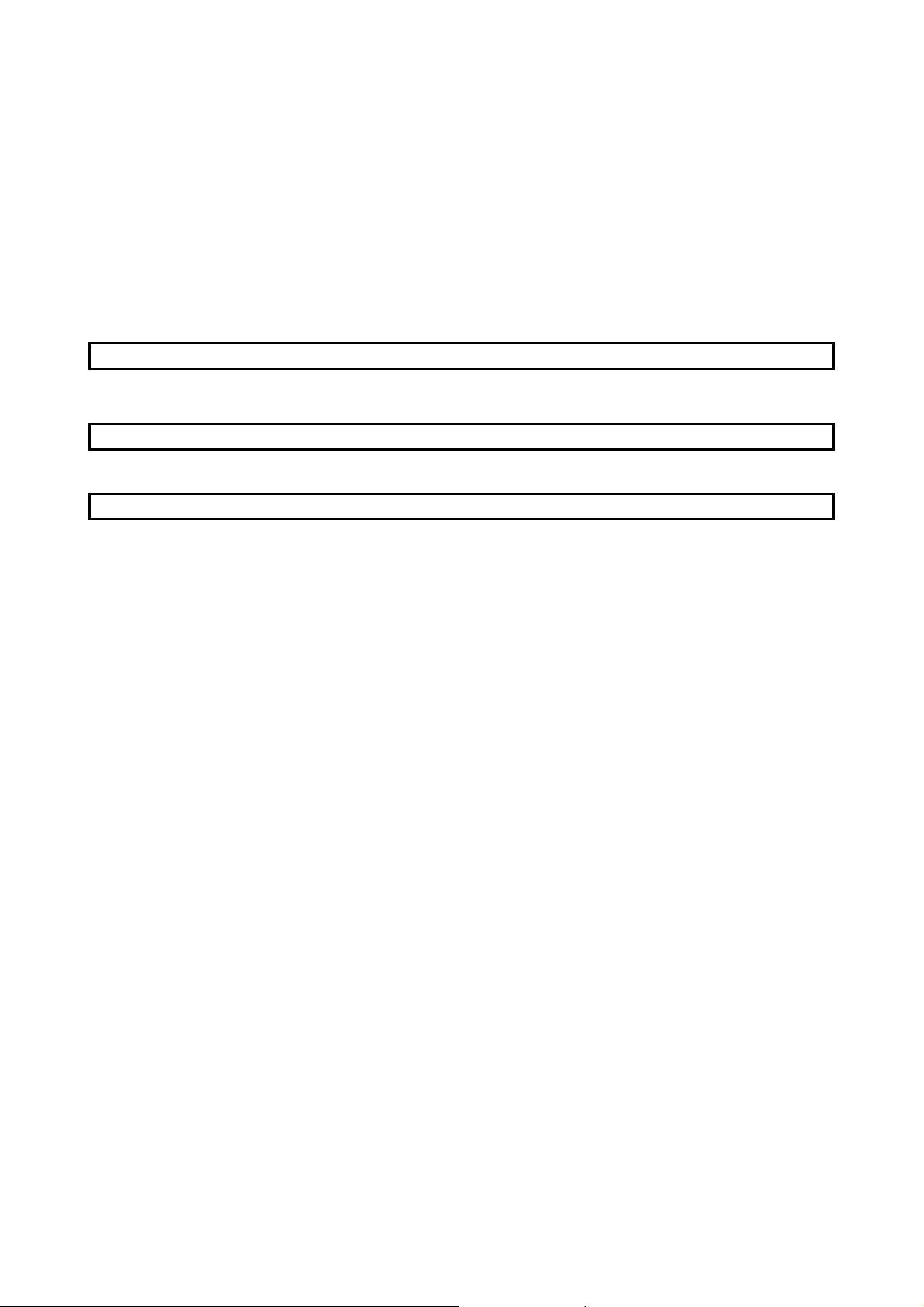

Related Manuals

Manual Name

Manual No.

(Type code)

CC-Link System Master/Local Module Type AJ61BT11/A1SJ61BT11 User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61BT11 and A1SJ61BT11. (Optionally available)

CC-Link System Master/Local Module Type AJ61QBT11/A1SJ61QBT11 User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the AJ61QBT11 and A1SJ61QBT11. (Optionally available)

CC-Link System Master/Local Module User's Manual

Describes the system configuration, performance specifications, functions, handling, wiring and

troubleshooting of the QJ61BT11N. (Optionally available)

MELSEC-L CC-Link System Master/Local Module User's Manual

Describes the system configuration, Performance specifications, functions, handling, wiring and

troubleshooting of the L26CPU-BT and LJ61BT11. (Optionally available)

Compliance with the EMC and Low Voltage Directives

(1) For programmable controller system

To configure a system meeting the requirements of the EMC and Low Voltage

Directives when incorporating the Mitsubishi programmable controller (EMC and

Low Voltage Directives compliant) into other machinery or equipment, refer to

the "EMC AND LOW VOLTAGE DIRECTIVES" chapter of the User's Manual for

the CPU module used.

The CE mark, indicating compliance with the EMC and Low Voltage Directives,

is printed on the rating plate of the programmable controller.

IB-66721

(13J872)

IB-66722

(13J873)

SH-080394E

(13JR64)

SH-080895ENG

(13JZ41)

(2) For the product

For the compliance of this product with the EMC and Low Voltage Directives,

refer to the "CC-Link module" section in the "EMC AND LOW VOLTAGE

DIRECTIVES" chapter of the User's Manual for the CPU module used.

A - 8

Page 11

MEMO

A - 9

Page 12

1. OVERVIEW MELSEC-A

1. OVERVIEW

1

1.1 Features

This user's manual describes the specification and handling of AJ65BT-64DAV digital analog voltage

conversion module (abbreviated as AJ65BT-64DAV from here on) and AJ65BT-64DAI digital analog

current conversion module (abbreviated as AJ65BT-64DAI from here on), which is used as the remote

device station for the CC-Link system.

(1) AJ65BT-64DAV

This is a module which converts the digital values (16-bit encoded binary value) set in the

programmable controller CPU to analog values (-10V to 0V to 10V voltage), and performs an

external output to four channels.

(2) AJ65BT-64DAI

This is a module which converts the digital values (16-bit encoded binary value) set in the

programmable controller CPU to analog values (4mA to 20mA current), and performs an external

output to four channels.

In this manual, the name which refers to both AJ65BT-64DAV and AJ65BT-64DAI is abbreviated as

“AJ65BT-64DAV/DAI.”

The AJ65BT-64DAV/DAI has the following features:

(1) One module can provide four channels of D/A conversion.

The AJ65BT-64DAV/DAI can produce output of analog values (voltage/current) to four external

devices.

(2) The analog-output enable/prohibit setting is possible for each channel.

The sequence program can specify whether to enable or prohibit analog output to the external

devices after the D/A conversion for each channel.

Analog output from the channel where the analog output is prohibited will be 0V or 0mA.

(3) You can make the analog output hold/clear setting at a programmable controller CPU stop or link

error occurrence (all channels batch).

Using the HOLD/CLR terminal, you can select whether to hold or clear the analog output at the

instant the programmable controller CPU is set to a STOP status or a link error occurs.

(4) Offset and gain setting

When a fine I/O conversion characteristic is required, the offset and gain setting of each channel

can be set without a volume control, enabling to modify the I/O conversion characteristic as

desired.

1-1

Page 13

1. OVERVIEW MELSEC-A

MEMO

1

1-2

Page 14

2. SYSTEM CONFIGURATION MELSEC-A

2. SYSTEM CONFIGURATION

2

(1) Applicable master modules

For available master modules, visit the CC-Link Partner Associations (CLPA) website at:

http://www.cc-link.org/

Remark

Check the specifications of the master module before use.

2-1

Page 15

2. SYSTEM CONFIGURATION MELSEC-A

MEMO

2

2-2

Page 16

3. SPECIFICATIONS MELSEC-A

3. SPECIFICATIONS

The general specifications, performance specifications, and I/O characteristics of the

AJ65BT-64DAV/DAI are explained.

3.1 General Specification

3

Usage ambient

temperature

Storage ambient

temperature

Usage ambient humidity 10 to 90%RH, no condensation

Storage ambient humidity 10 to 90%RH, no condensation

Vibration durability

Shock durability

Usage environment No corrosive gas

Usage height *

Installation area Within the control board

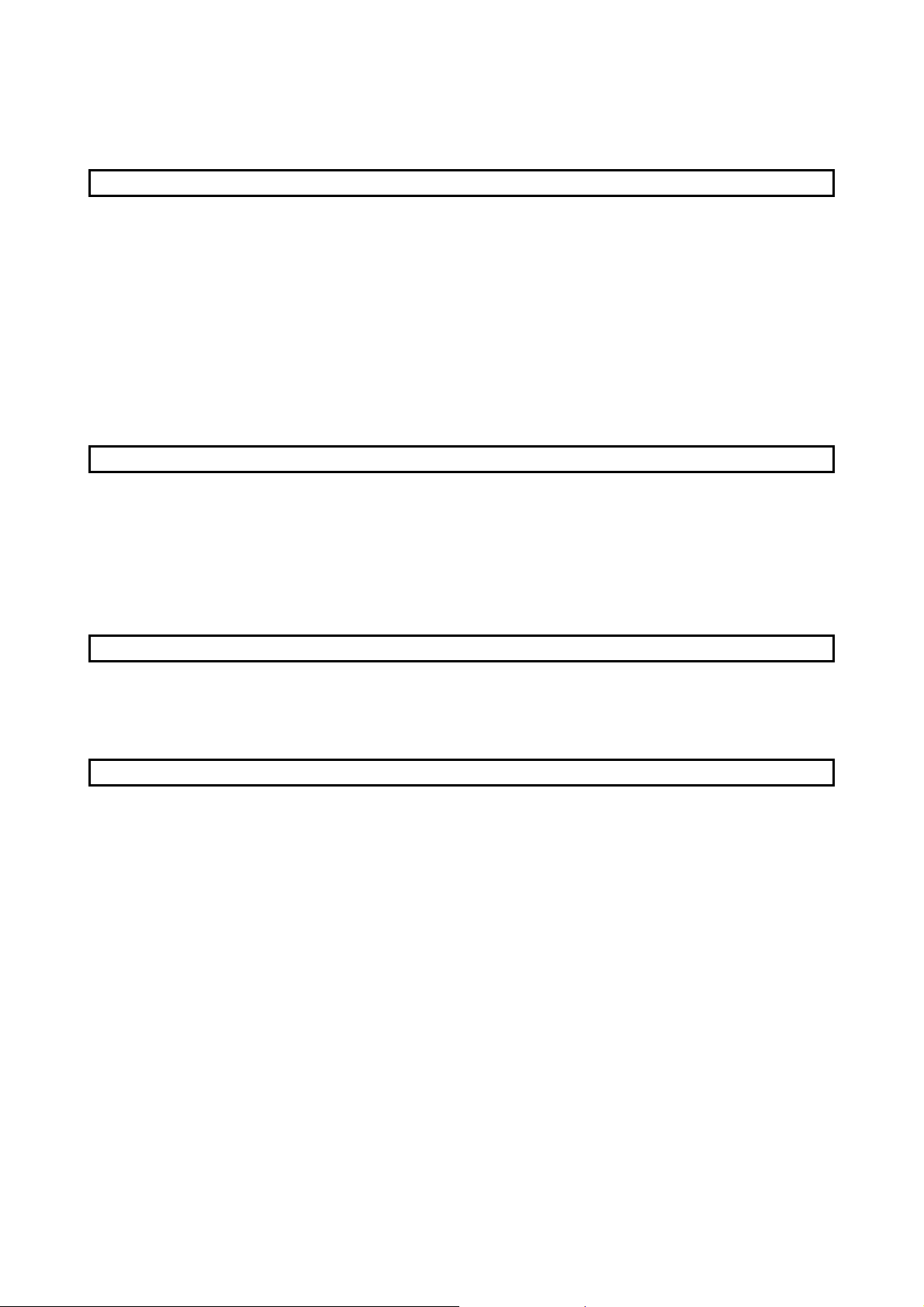

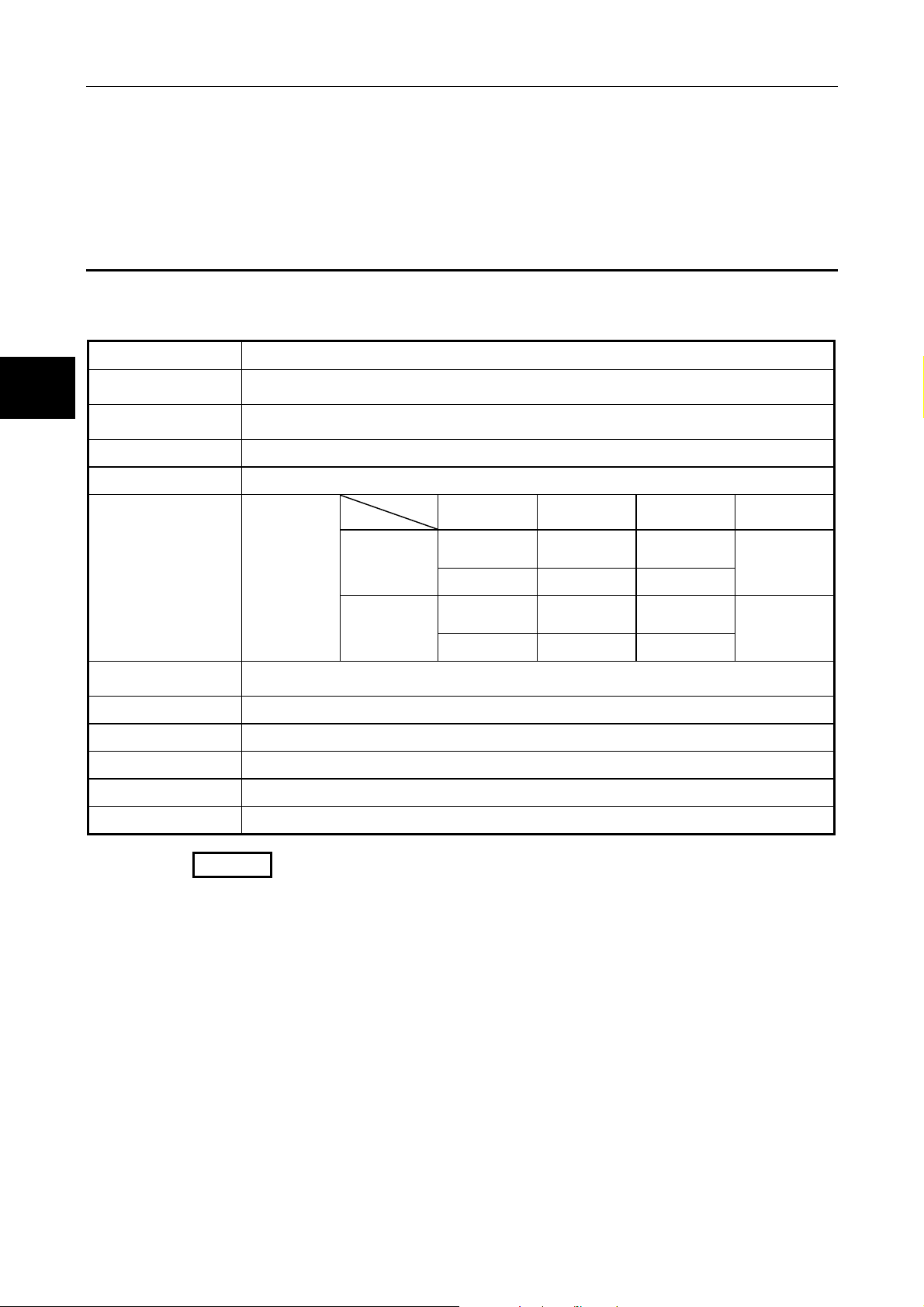

The general specifications of the AJ65BT-64DAV/DAI are shown in Table 3.1.

Item Specification

Conforming to

JIS B 3502,

IEC 61131-2

1

Table 3.1 General specification

0 to 55°C

-20 to 75°C

Frequency Acceleration Amplitude

For intermittent

vibration

For continuous

vibration

5 to 9Hz —

2

9 to 150Hz 9.8m/s

5 to 9Hz —

9 to 150Hz 4.9m/s

Conforming to JIS B 3502, IEC 61131-2

2

(147m/s

, 3 times each in XYZ directions)

Less than 2000 m (Less than 6562 ft.)

—

2

—

3.5mm

(0.14 inches)

1.75mm

(0.069 inches)

Number of

sweeps

10 times in

each X, Y, and

Z direction

—

Over-voltage category *2 Less than II

Pollution rate *3 Less than 2

Remark

*1 Do not operate or store the programmable controller in the environment where the pressure

applied is equal to greater than the atmospheric pressure at the altitude of 0m.

Doing so may cause a malfunction. Please consult our branch office when the programmable

controller is to be operated under pressure.

*2 Indicates the location where the device is connected from the public cable network to the device

structure wiring area.

Category II applies to the devices to which the power is supplied from a fixed equipment.

Surge withstand voltage for devices with up to 300V of rated voltage is 2500V.

*3 This is an index which indicates the degree of conductive object generation in the environment

where the device is used. Level 2 is an environment where only nonconductive objects are

formed with some chances of temporary conductivity generation due to occasional condensation.

3-1

Page 17

3. SPECIFICATIONS MELSEC-A

3.2 Performance Specification

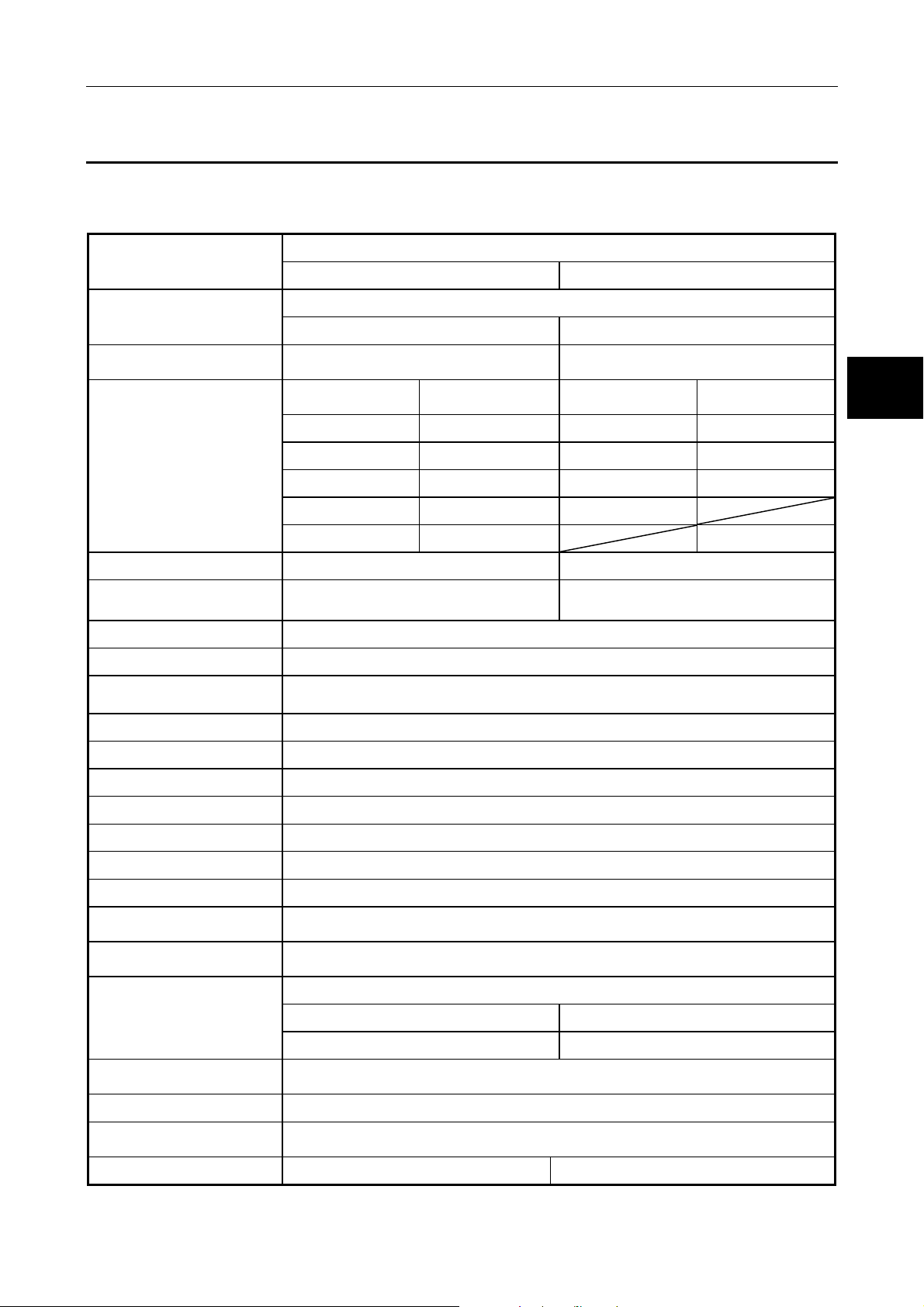

The performance specification of the AJ65BT-64DAV/DAI is shown Table 3.2:

Table 3.2 Performance specification

Item

Digital input value

Analog conversion value

I/O characteristics

Maximum resolution *1 5mV 4μA

Total accuracy *2

(accuracy for the maximum value)

Maximum conversion speed *3 Max. 1ms per channel (4ms per 4 channels)

Output short-circuit protection Yes

Insulation system

Analog output points 4 channels per module

(External load resistance: 2kΩ to 1MΩ)

Digital input value

AJ65BT-64DAV AJ65BT-64DAI

16-bit encoded binary (valid bit: 12 bits)

-2048 to 2047 0 to 4095

Voltage: -10 to 10VDC

Analog conversion

value

2000 10V 4000 20mA

1000 5V 2000 12mA

0 0V 0 4mA

-1000 -5V

-2000 -10V

± 1% (± 100mV) ± 1% (±200

Across output channels: Non-insulated

Across external supply power and analog output: Transformer insulated

Specification

Current: 4 to 20mADC

(External load resistance: 0 to 600Ω)

Digital input value

Analog conversion

value

μ

A)

3

Offset/gain adjustment Yes (user setting or factory setting)

CC-Link station type Remote device station

Number of occupied stations 2 stations

Connector terminal block 27-point terminal block (M3.5 × 7 screws)

Supported cable size 0.75 to 2.00mm2

Supported solderless terminal RAV 1.25-3.5 (according to JIS C 2805), RAV 2-3.5

Module installation screw

Supported DIN rail

External supply power

Current consumption:0.18A (at 24VDC) Current consumption:0.27A (at 24VDC)

Noise resistance

Dielectric withstand voltage Power and communication systems batch-Analog output batch, 500VAC, one minute

Insulation resistor

Weight 0.4kg 0.4kg

Measured using a noise simulator with 1μs of noise amplitude and 25 to 60Hz of noise frequency.

M4 x 0.7mm x 16mm or larger screw (tightening torque 0.78 to 1.18N⋅m)

Installable with the DIN rail.

TH35-7.5Fe, TH35-7.5Al,TH35-15Fe

(conforming to JIS C 2812)

24V DC (20.4V DC to 26.4V DC)

Inrush current: 1.5A, within 0.67ms Inrush current: 3.2A, within 0.43ms

Noise voltage: 500Vp-p

Power and communication systems batch-Analog output batch, 500VDC

10MΩ or more at the insulation resistance tester

3-2

Page 18

3. SPECIFICATIONS MELSEC-A

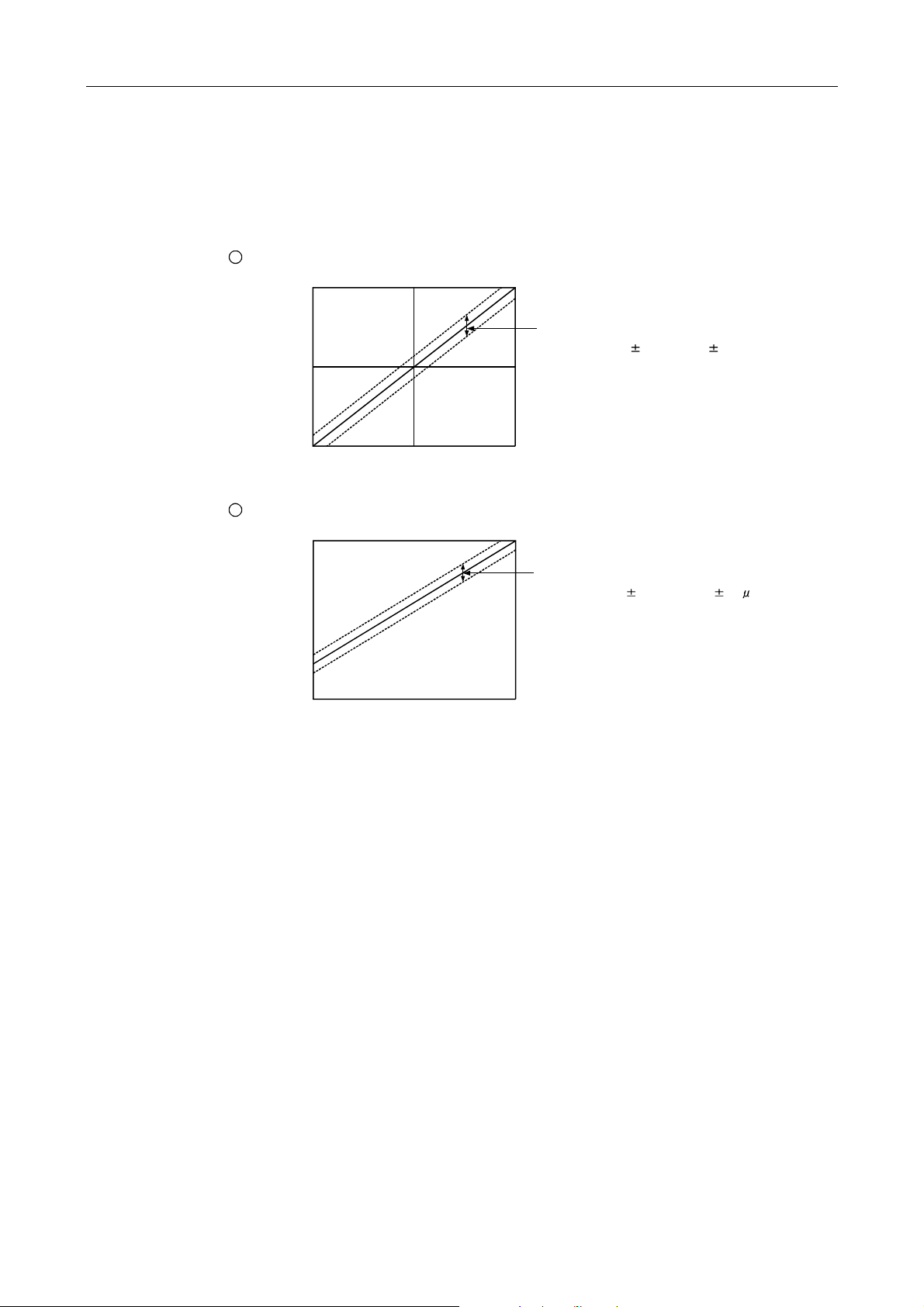

(

*1 Maximum resolution of analog value

The maximum resolution of analog value means the variation of analog value when the digital

value changes for "1".

*2 Total accuracy

The total accuracy is the accuracy of the maximum analog output value.

1

The overall accuracy of the AJ65BT-64 DAV is the accuracy for 10V.

+10V

e

u

l

a

v

t

u

p

t

0V

u

o

g

o

l

a

n

A

-10V

-2000 20000

Digital input value

Depending on the operating environment

the ambient temperature, noise), it fluctuates

within a range of 1.0% of 10V ( 100mV).

2

The overall accuracy of the AJ65BT-64 DAI is the accuracy for 20mA.

20mA

e

u

l

a

v

t

u

p

t

u

o

g

o

l

a

n

4mA

A

0mA

0 4000

Digital input value

Depending on the operating environment

(the ambient temperature, noise), it fluctuates

within a range of 1.0% of 20mA ( 200 A).

*3 Maximum conversion speed

The maximum conversion speed means the time required to read the digital value written in the

buffer memory, execute the D/A conversion, and output the specified analog value. It takes the

longest (1ms) to produce the maximum analog output value when the current output is the

minimum, and to produce the minimum analog output value when the current output is the

maximum.

3-3

Page 19

3. SPECIFICATIONS MELSEC-A

A

3.3 I/O Conversion Characteristics

The I/O conversion characteristics of the AJ65BT-64DAV/DAI are explained.

3.3.1 Offset value and gain value

(1) Offset value

This is an analog value (voltage or current value) produced by the AJ65BT-64DAV/DAI when the

digital value set by the programmable controller CPU is "0".

(2) Gain value

This is an analog value (voltage or current value) produced by the AJ65BT-64DAV/DAI when the

digital value set by the programmable controller CPU is "2000" for AJ65BT-64DAV, and "4000"

for AJ65BT-64DAI.

(3) The factory-set offset and gain values are as follows:

AJ65BT-64DAV AJ65BT-64DAI

Offset value 0V 4mA

Gain value 10V 20mA

(4) The offset value and gain value can be set separately for each channel in the test mode.

3.3.2 I/O conversion characteristics

(1) When AJ65BT-64DAV is used:

(V)

15

10

e

5

g

a

t

l

o

v

t

u

0

p

t

u

o

g

o

l

a

-5

n

A

-10

-15

-2000

-2048

0

Digital input value

Offset value Gain value

nalog output

practical range

2000

2047

Figure 3.1 I/O conversion characteristics of the AJ65BT-64DAV

1

How to calculate the analog output value:

The resolution of AJ65BT-64DAV can be set arbitrarily by modifying the settings of the offset

value and gain value.

How to calculate the analog value resolution and the analog output value for a given digital

input value when the settings of the offset value and gain value are changed is shown next.

3-4

Page 20

3. SPECIFICATIONS MELSEC-A

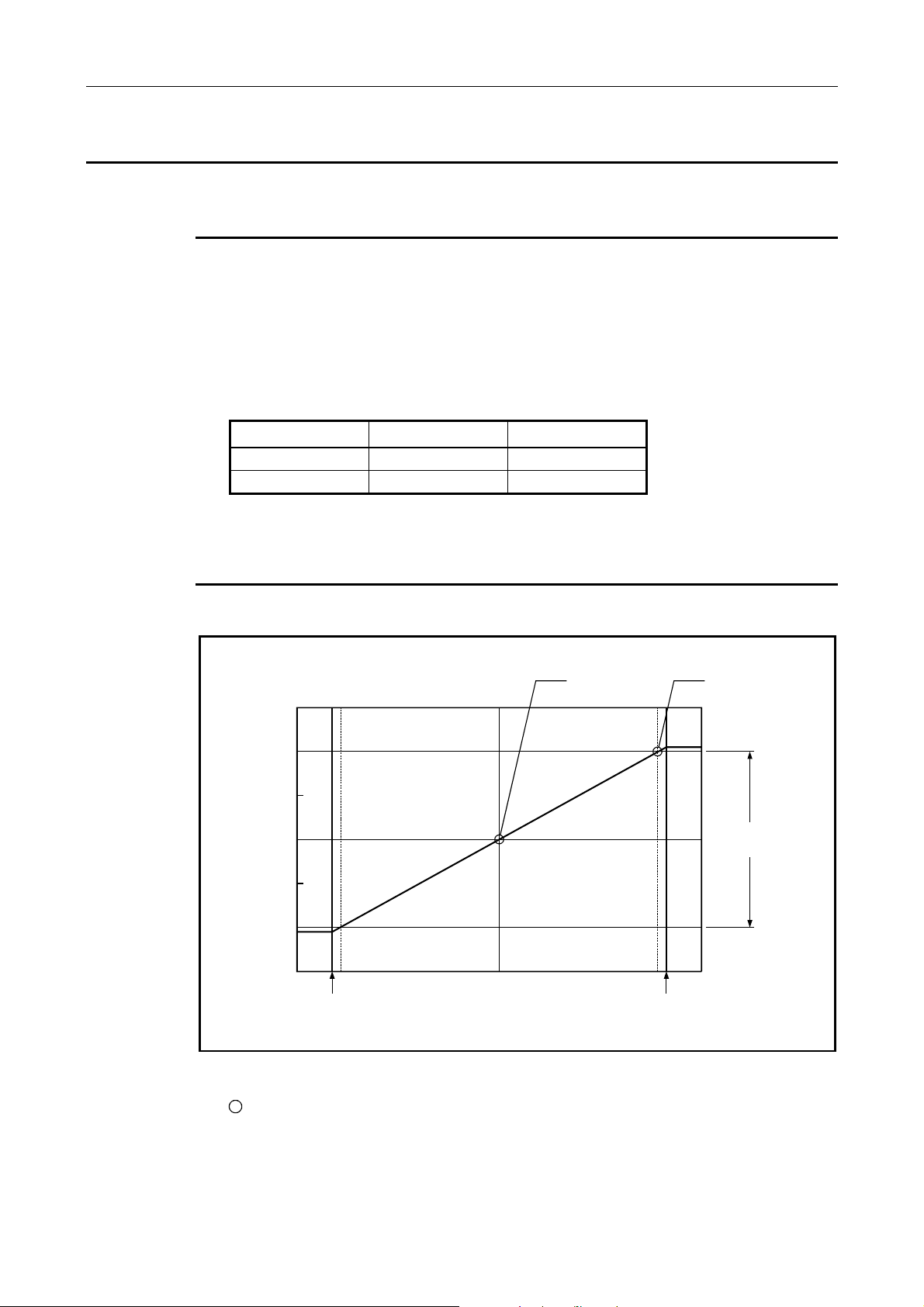

The I/O conversion characteristics are shown in

the graph on the right when the offset value and

the gain value are set as in the following table:

Number Offset value Gain value

(Analog output) = (Analog resolution) × (Digital input value) + (Offset value)

(Analog resolution) =

(Gain value) - (Offset value)

2000

2

The following graph shows the I/O characteristics when the offset and gain values of the

AJ65BT-64DAV are changed:

1

0V 10V

2

-10V 10V

3

4V 8V

Example

The analog output voltage for the characteristic graphs 1 to 3 becomes as below, when the digital

input value is at 1000 and 500:

Number Digital input value Analog output voltage

1

2

3

1000 5.0V

500 2.5V

1000 0V

500 -5.0V

1000 6.0V

500 5.0V

Figure 3.2 I/O conversion characteristics of AJ65BT-64DAV

3-5

Page 21

3. SPECIFICATIONS MELSEC-A

(2) When AJ65BT-64DAI is used:

(mA)

20

t

n

15

e

r

r

u

c

t

u

10

p

t

u

o

g

o

l

5

a

n

A

0

0 4000

Figure 3.3 I/O conversion characteristics of AJ65BT-64DAI

1

How to calculate the analog value

The resolution of AJ65BT-64DAI can be set arbitrarily by modifying the settings of the offset

value and gain value.

How to calculate the analog value resolution and the analog output value for a given digital

input value when the settings of the offset value and gain value are changed is shown.

(Analog output) = (Analog resolution) × (Digital input value) + (Offset value)

(Analog resolution) =

Offset value

Digital input value

(Gain value) - (Offset value)

4000

4095

Gain value

Analog output

practical range

3-6

Page 22

3. SPECIFICATIONS MELSEC-A

2

The following graph shows the I/O characteristic when the offset and gain values of the

AJ65BT-64DAI are changed:

The I/O conversion characteristics are shown in

the graph on the right when the offset value and

the gain value are set as in the following table:

Number Offset value Gain value

1

10mA 20mA

2

4mA 20mA

3

6mA 16mA

(mA)

t

n

e

r

r

u

c

t

u

p

t

u

o

g

o

l

a

n

A

20

15

10

Analog

output

practical

5

0

range

0

Digital input value

Example

The analog output voltage for the characteristic graphs 1 to 3 becomes as below, when the digital

input value is at 2000 and 1000:

Number Digital input value Analog output voltage

1

2

3

2000 15mA

1000 12.5mA

2000 12mA

1000 8mA

2000 11mA

1000 8.5mA

Figure 3.4 I/O conversion characteristics of AJ65BT-64DAI

4000

4095

3-7

Page 23

3. SPECIFICATIONS MELSEC-A

3.4 Various Functions to Control the Analog Output

Various functions to control the analog output of the AJ65BT-64DAV/DAI are explained.

3.4.1 Function to specify hold or clear of the analog output when the

programmable controller CPU is in the STOP status (HOLD/CLEAR

setting)

Using this function, the HLD/CLR terminal on the module front panel can be used to set whether to

retain or clear (i.e. to output the offset) the analog output value immediately before the programmable

controller CPU enters the STOP status or before the AJ65BT-64DAV/DAI stops the D/A conversion

due to an error. All channels are set simultaneously. (Including a time when link communications are

shut off)

3.4.2 Function to specify executing or not executing the D/A conversion processing (Analog output enable/disable flag)

Using this function, whether to output the D/A conversion value or the offset value can be selected for

each channel by turning on or off the Analog output enable/disable flag from the programmable

controller program.

However, the D/A conversion time (conversion speed) is constant regardless of the setting of the

Analog output enable/disable flag.

ON: D/A conversion value OFF: Offset value

3.4.3 Function to specify enabling or prohibiting of the analog value external output (Analog output enable/prohibit setting)

Using this function, whether to enable or prohibit the external output of the analog signal can be

specified for each channel by writing "0" or "1" to the remote register's address from the

programmable controller program.

1: 0V/0mA 0: D/A conversion value or offset value

3.4.4 Offset/gain setting

When a fine I/O conversion characteristic is required, the I/O conversion characteristics can be

modified arbitrarily by setting the offset and gain of each channel without a volume control, after

entering the test mode by short-circuiting the test mode terminal. When it is not necessary, turning

on the RYn4, which is the I/O signal to the master station, selects the factory-configured offset and

gain values.

Factory-configured values:

AJ65BT-64DAV........ Offset value 0V, Gain value 10V

AJ65BT-64DAI ......... Offset value 4mA, Gain value 20mA

3.4.5 Combinations of various functions

By combining the functions explained above, the analog output when the programmable controller

CPU is in the RUN status and when a module error occurs can be set as desired, as shown in Table

3.3.

Select each function depending on the analog output status of your choice.

3-8

Page 24

3. SPECIFICATIONS MELSEC-A

Table 3.3 Analog output status combination list

Setting

combination

Execution

status

Analog output status when the programmable

controller CPU is in the RUN status

Analog output status when the programmable

controller CPU is in the STOP status

Analog output status when the programmable

controller CPU is in the error status

Analog output status when an error has

occurred in the AJ65BT-64DAV/DAI

Analog output status when a WDT error (*)

has occurred in the AJ65BT-64DAV/DAI

Analog output status when the L.RUN LED is

turned off (when link communications are

shut off)

Analog output status after reset

HOLD/CLEAR setting CLEAR HOLD

Analog output enable

signal

Analog output

enable/disable flag

(*) WDT error ...........indicates the abnormal operation time by the programmable controller. The

Enable (on) Prohibit (off) Enable (on)/Prohibit (off)

Enable (0) Prohibit (1) Enable (0) Prohibit (1) Enable (0) Prohibit (1)

Output of the

analog value

after D/A

conversion

from the digital

value specified

by the

programmable

controller CPU

Offset value 0V/0mA

Offset value 0V/0mA

Output of the

maximum or

minimum

analog value

Offset value 0V/0mA

Output of the

analog value

after D/A

conversion

from the digital

value specified

by the

programmable

controller CPU

0V/0mA

0V/0mA

0V/0mA

Offset

value

Offset

value

Offset

value

Offset

value

Offset

value

Offset

value

0V/0mA

0V/0mA

0V/0mA

0V/0mA

0V/0mA

0V/0mA

0V/0mA

Output of the

analog value

after D/A

conversion

from the

digital value

specified by

the

programmable

controller CPU

Analog value

before the

programmable

controller CPU

stop is

retained.

Analog value

before the

CPU error is

retained.

Output of the

maximum or

minimum

analog value

Analog value

before the

LINK ERR is

retained.

Output of the

analog value

after D/A

conversion

from the

digital value

specified by

the

programmable

controller CPU

0V/0mA

0V/0mA

0V/0mA

0V/0mA

0V/0mA

0V/0mA

elapsed time for one scan by the program is monitored, and a WDT error results

when it does not finish within the scheduled time.

3-9

Page 25

3. SPECIFICATIONS MELSEC-A

3.5 I/O Signals to the Master Station

Assignment of the I/O signals and function of each signal are explained.

3.5.1 I/O signal list

The AJ65BT-64DAV/DAI uses 32 input points and 32 output points for exchanging signals with the

master station.*1 The allocation of the I/O signals and the name of each signal are listed in Table 3.4.

An RX device indicates an input signal from the AJ65BT-64DAV/DAI to the master module, and a RY

device indicates an output signal from the master module to the AJ65BT-64DAV/DAI.

Table 3.4 I/O signals

Signal direction:

AJ65BT-64DAV/DAI→Master

Device No. Signal name Device No. Signal name

RXn0 RYn0

RYn1

to

RXnF

RX (n+1) 0

to

RX (n+1) 7

RX (n+1) 8

RX (n+1) 9 Initial data setting complete flag RY (n+1) 9 Initial data setting request flag

RX (n+1) A Error status flag RY (n+1) A Error reset request flag

RX (n+1) B Remote READY

RX (n+1) C

to

RX (n+3) F

Initial data processing request

Unusable

Unusable

flag

Unusable

n: The address allocated to the master station in the station number setting

RYn2

RYn3

RYn4 Offset/gain value selection

RYn5

to

RYnF

RY (n+1) 0

to

RY (n+1) 7

RY (n+1) 8

RY (n+1) B

to

RY (n+3) F

Signal direction:

Master→AJ65BT-64DAV/DAI

CH.1 Analog output

enable/disable flag

CH.2 Analog output

enable/disable flag

CH.3 Analog output

enable/disable flag

CH.4 Analog output

enable/disable flag

Unusable

Unusable

Initial data processing complete

flag

Unusable

*1 Although the number of occupied stations for the AJ65BT-64DAV/DAI is

2, inputs, RX(n+2) 0 to RX(n+3)F, are not used.

However, devices for inputs, RX(n+2) 0 to RX(n+3)F, and outputs,

RY(n+2) 0 to RY(n+3) F, are reserved in the master module or CPU

module. When creating a program, pay attention to device allocation.

Point

If a device not allowed to use is turned on/off from the sequence program, the function of the

AJ65BT-64DAV/DAI is not guaranteed.

3-10

Page 26

3. SPECIFICATIONS MELSEC-A

3.5.2 Functions of the I/O signals

Functions of the I/O signals of the AJ65BT-64DAV/DAI are shown in Table 3.5.

Table 3.5 Descriptions of the I/O signals

Device number Signal Name Description

RX (n+1) 8

RX (n+1) 9

RX (n+1) A Error status flag

RX (n+1) B Remote READY

RYn0

to

RYn3

RYn4

RY (n+1) 8

RY (n+1) 9

RY (n+1) A

Initial data

processing request

flag

Initial data setting

complete flag

CH.

analog output

enable/disable flag

Offset/gain value

selection

Initial data

processing complete

flag

Initial data

processing request

flag

Error reset request

flag

The ON and OFF timing of each flag for the initial data processing request, processing complete,

setting complete, and the setting request by the AJ65BT-64DAV/DAI:

After the power is turned on or after the hardware reset, the initial data

processing request flag is turned on by the AJ65BT-64DAV/DAI in order to

request the initial data setting. It is turned off when the initial data setting

is complete (i.e. initial data processing complete flag RY(n+1)8 is turned

on).

When there is an initial data setting request (i.e. RY(n+1)9 is turned on), it

is turned on by the initial data setting completion. When the initial data

setting request flag is turned off after the initial data setting completion, the

initial data setting complete flag is also turned off.

This is turned on when an error other than the WDT error occurs on the

AJ65BT-64DAV/DAI.

This is turned on when the initial data setting is complete and the

AJ65BT-64DAV/DAI is in the READY status, after the power is turned on or

after the hardware reset. It is turned off during the test mode.

(This is used to interlock the read and write from the master module.)

These are the analog value output enable signals for channels 1 through 4.

The analog output value from the corresponding channel is enabled when

turned on.

Turn it off to prohibit the output of the analog value.

"User settings" or "factory settings" of the offset and gain values are

selected by switching the RYn4. To select the factory setting, keep the

RYn4 set to on.

After the power is turned on or after the hardware reset, the initial data

processing is executed by the initial data processing request, and this flag

is turned on after the processing is completed.

Turn this on to set or modify the initial data.

When the error reset request flag (RY(n+1)A) is turned on, the error status

flag (RX(n+1)A) is turned off and the error code of the remote register write

area is cleared (0000

H).

3-11

Page 27

3. SPECIFICATIONS MELSEC-A

3.6 Remote Register

The AJ65BT-64DAV/DAI has a remote register (does not have backup) for data communication with

the master module. The remote register allocation and data structure are described below.

3.6.1 Allocation of the remote register

The allocation of the remote register is shown in Table 3.6.

Table 3.6 Allocation of the remote register

Write area

Read area

(M→R)

(R→M)

Address Description Initial value

RWwm CH.1 digital value setting 0

RWwm+1 CH.2 digital value setting 0

RWwm+2 CH.3 digital value setting 0

RWwm+3 CH.4 digital value setting 0

RWwm+4

RWwm+5

RWwm+6

RWwm+7

RWrn CH.1 set value check code 0

RWrn+1 CH.2 set value check code 0

RWrn+2 CH.3 set value check code 0

RWrn+3 CH.4 set value check code 0

RWrn+4 Error code 0 Section 3.6.5

RWrn+5

RWrn+6

RWrn+7

m, n: The address set for the master station in the station number setting.

Analog output enable/disable

setting

Unusable

Unusable

0 Section 3.6.3

Reference

section

Section 3.6.2

Section 3.6.4

Point

Do not execute read or write to the remote register that is not allowed to use. When a read or

write is executed, the function of the AJ65BT-64DAV/DAI is not guaranteed.

3-12

Page 28

3. SPECIFICATIONS MELSEC-A

3.6.2 Digital value setting area for channels 1 through 4

(1) This area is used to write the digital value for the D/A conversion from the programmable

controller CPU.

(2) The digital values at all channels become "0" in the following conditions:

(a) After the power is turned on, when the remote READY (RX(n+1)B) is turned on.

(b) After the reset of the programmable controller CPU, when the remote READY (RX(n+1)B) is

turned on.

(3) The digital value can be set as 16-bit signed binary data and within the available setting range of

the digital value resolution.

If a value beyond the range of the digital value resolution is set, the data in Table 3.7 is applied

for the D/A conversion.

In addition, the checking code is stored in the set value checking code storage area (addresses

from RWrn to RWrn+3).

Table 3.7 Available setting range of the digital value

Digital value for the D/A conversion

when the value beyond the range is set

2048 or higher: 2047

-2049 or lower: -2048

4096 or higher: 4095

-1 or lower: 0

AJ65BT-64DAV

AJ65BT-64DAI

Model Name Available setting range

-2048 to 2047

(Practical range: -2000 to 2000)

0 to 4095

(Practical range: 0 to 4000)

3.6.3 Analog output enable/prohibit channel

(1) Enable or prohibit of the external output of the analog value from each channel is set in this area.

(2) Output is prohibited at all channels in the following conditions:

(a) When the power is turned on.

(b) When the power is reset.

Note that when initial data processing is finished, (module ready turns on, and) the output is

enabled at all channels with the default values of 0.

(3) Enable/prohibit of the external output is set to 0 or 1 for each channel.

(a) 0 ............ Enabled

(b) 1 ............ Prohibited

(4) Configuration of the output enable/prohibit area for each channel is as follows:

3-13

Page 29

3. SPECIFICATIONS MELSEC-A

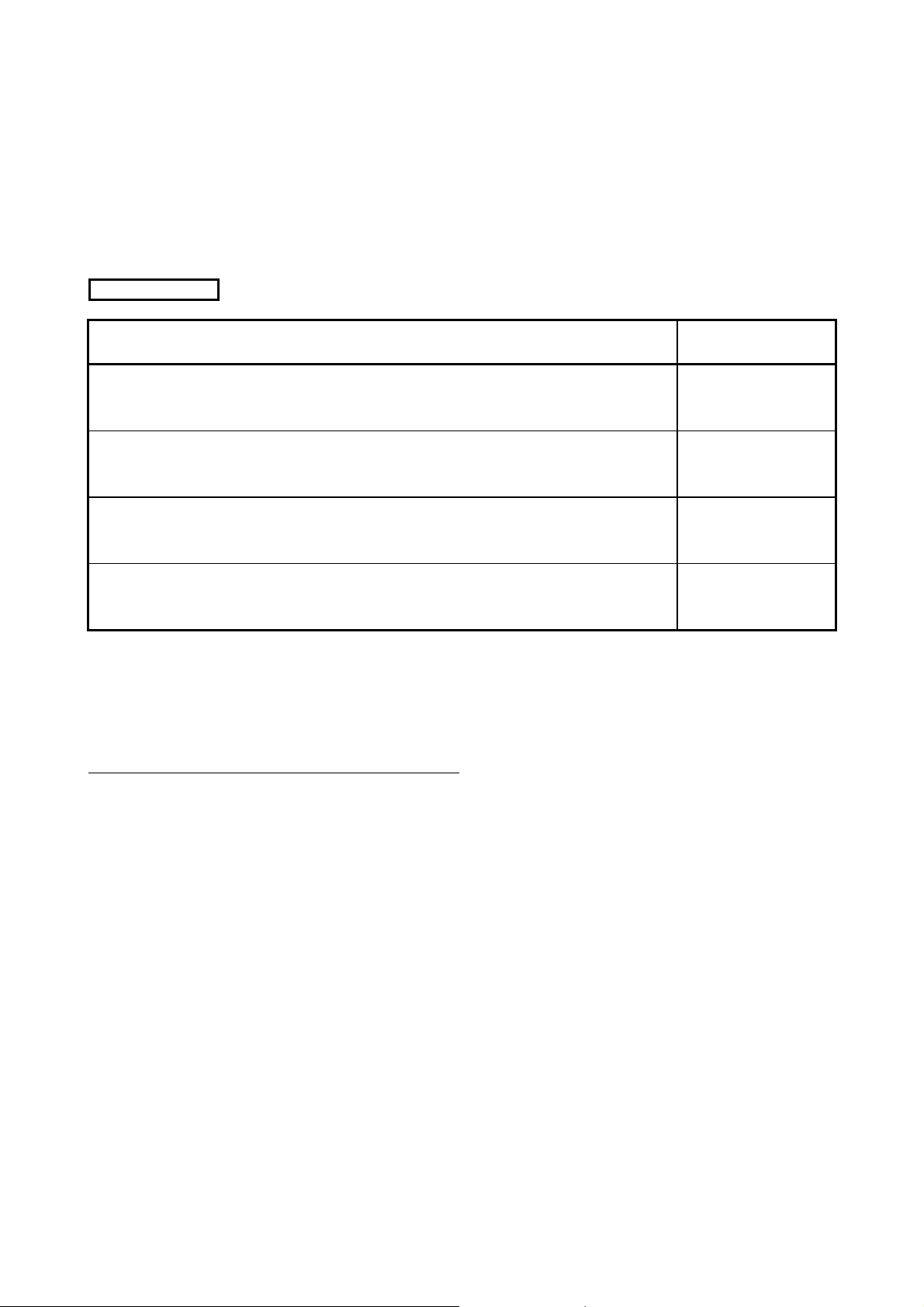

3.6.4 Set value checking code storage area for channels 1 through 4

This area is used to check if the digital value is within or out of the setting range. One of the following

checking codes is stored when the digital value lower or higher than the setting range is set.

Check code list

Check code Description

000FH A digital value which exceeds the setting range was set.

00F0H A digital value which is below the setting range was set.

Both a digital value below the setting range and digital value exceeding the setting

range were set.

00FFH

(1) The check code once stored is not reset even if the set value is set to within the valid setting

allowed range.

(2) The storage area or the set value check code is reset by turning on the error reset request flag

(RY (n+1) A).

3.6.5 Error code

For example, the 00FF

range is written, and then, without the check code being reset, a digital value that

falls short of the valid range is written.

H check code is stored if a digital value exceeding the valid

(1) If an error occurs when starting the module or writing data to the AJ65BT-64DAV/DAI (the RUN

LED flashes), the following error code is stored in the error code (RWrn+4) in the

AJ65BT-64DAV/DAI remote register.

Error code list

Error code Error description Processing

The set digital value is outside the

11

999

(2) When multiple errors occurred, the error code of the first error is stored, but the other errors are

not stored.

(3) The error code reset is performed by turning on the error reset request flag (RY (n+1) A).

When the error code is “999”, however, it cannot be reset because the hardware of the module is

faulty.

setting range.

The

indicates the channel number

where the error occurred.

The offset/gain setting values stored in

2

PROM became faulty.

E

The indicates the channel number where the error occurred.

Correct the digital value to within the setting

range.

Power-cycle the AJ65BT-64DAV/DAI again.

If this recurs, the module may be faulty.

Consult your local servicing company, dealer

or our branch office.

3-14

Page 30

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

4. SETUP AND PREPARATION BEFORE

4.1 Precautions When Handling

4

OPERATION

The precautions when handling the AJ65BT-64DAV/DAI are described below:

CAUTION

z Do not touch any terminal while power is on.

Doing so may cause malfunction.

z Be sure there are no foreign substances such as sawdust or wiring debris inside the module.

Such debris could cause fires, damage, or erroneous operation.

z Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

z Do not directly touch the module's conductive parts or electronic components.

Touching the conductive parts could cause an operation failure or give damage to the module.

z Do not drop or apply strong shock to the module.

Doing so may damage the module.

z Do not remove the module print board from the case.

This may cause breakdowns.

z Tighten the terminal screws with the specified torque.

If the terminal screws are loose, it could result in short circuits, fire, or erroneous operation.

z When disposing of this product, treat it as industrial waste.

z If the terminal screws are loose, it could result in short circuits, fire, or erroneous operation.

Using this programmable controller in an environment outside the range of the general

specifications could result in electric shock, fire, erroneous operation, and damage to or

deterioration of the product.

z For protection of the switches, do not remove the cushioning material before installation.

z Securely fix the module with a DIN rail or mounting screws. Tighten the screws within the

specified torque range.

Undertightening can cause drop of the screw, short circuit, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or

malfunction.

z Be sure to shut off all phases of the external power supply used by the system before mounting

or dismounting the module to or from the panel.

Not doing so could result in damage to the product.

z Before touching the module, always touch grounded metal, etc. to discharge static electricity

from human body.

Failure to do so can cause the module to fail or malfunction.

(1) Tighten the screws such as module installation screws with the following torque :

Module installation screw (M4 screw) 0.78 to 1.18 N·m

Terminal block terminal screw (M3.5 screw) 0.59 to 0.88 N·m

Terminal block installation screw (M4 screw) 0.78 to 1.18 N·m

(2) When using the DIN rail adapter, install the DIN rail by making sure of the following:

(a) Applicable DIN rail models (conforming to JIS C 2812)

TH35-7.5Fe

TH35-7.5Al

TH35-15Fe

(b) DIN rail installation screw interval

(3) Refer to the Master Module user's manual for the name, specification, and manufacturers of

When installing the DIN rail, tighten the screws with less than 200mm (7.87 inch) pitches.

supported cables for the use with AJ65BT-64DAV/DAI.

Screw location Tightening torque range

4-1

Page 31

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

4.2 Name of Each Part

The name of each part in the AJ65BT-64DAV/DAI is described.

MITSUBISHI

MELSEC

AJ65BT-64DA

PW

RUN

L RUN

L ERR.

SD

RD

STATION NO.B RATE

X10 X1

0

0

OFFSET

GAIN

1

9

2

8

3

7

456

GAIN. RESET

SET

DOWN

0

1

2

3

456

1

2

3

4

CH.

1

2

3

4

Number Name Description

1

Station number

setting switch

2

B RATE (Transfer

baud rate) setup

switch

↓ ×10 The AJ65BT-64DAV/DAI station number

↓ ×1 is set within the range 1 to 63. (Factory shipment setting : 00)

Setting number Transfer baud rate

0 156kbps(Factory shipment setting)

1 625kbps

2 2.5Mbps

3 5Mbps

4 10Mbps

4

Unused (When a value other than 0 to 4 is set, L ERR. LED turns on, and results in a

communication error.)

3

CH. (CHANNEL)

selection switch

4

OFFSET/GAIN

(Offset/gain)

setting switch

Select the channel to perform offset adjustment or gain adjustment.

(Positions other than 1 to 4 are not processed.)

The switch to set the offset/gain values during test mode.

(1) OFFSET position : Calibration mode for the offset value

(2) GAIN position : Calibration mode for gain value

(3) SET position : When the switch is set from the OFFSET/GAIN position,

which are modes to record offset/gain value to the SET

position, to the SET position, the offset/gain value is

recorded.

5

UP/DOWN switch The switch to adjust the analog output value for the offset/gain of the specified

channel. The analog output value increases/decreases by turning on the UP/DOWN

switch.

6

RESET switch Resets the H/W.

Initializes the AJ65-BT-64DAV/DAI I/O signals, remote register, and operation

processing. When the switch is turned on, AJ65BT-64DAV/DAI initial data

processing request flag turns on.

4-2

Page 32

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

Number Name Description

7

Operation status

display LED

8

Terminal block

PW LED On : When the power is on

Off : When the power is shut off

RUN LED

Normal

mode

On : Normal operation

Flashing : W rite data error

Off : 24VDC power shutoff or watchdog

timer error

Test mode Flashing : Flashes in 0.5 second intervals

when the offset/gain setting switch

is at OFFSET or GAIN. Flashes in

0.1 second intervals when

exceeding the upper or lower limits

of the allowable setting using the

UP/DOWN switch.

Off : W hen the offset/gain setting switch

is at SET.

L RUN LED On : Normal communication

Off : Communication interrupted (timeout error)

SD LED On : Data being transferred

RD LED On : Data being received

L ERR. LED On : When the baud rate or the station number

setting is out of range.

Flashing at regular intervals :

When the baud rate or station number setting is

changed after power-on or reset.

Flashing at irregular intervals :

When you forgot fitting the termination resistors

or the module or CC-Link dedicated cable is

affected by noise.

Off : Normal communication

AJ65BT-64DAV

1 3 5 7 9 111315171921232527

DA DG

2 4 6 8 10 12 14 16 18 2 0 22 24 26

+24V 24G

+24V 24G

DB SLD (FG) TEST TEST

HLD/

CLR

HLD/

CLR

CH1/

V+

COM COM COM COM

COM COM COM COM

CH2

V+

CH3

V+

CH4

V+

AJ65BT-64DAI

1 3 5 7 9 111315171921232527

DA DG

2 4 6 8 10 12 14 16 18 20 22 24 26

+24V 24G

+24V 24G

DB SLD (FG) TEST TEST

HLD/

CLR

HLD/

CLR

CH1/

I+

COM COM COM COM

COM COM COM COM

CH2

I+

CH3

I+

CH4

HLD/CLR setting terminal

....HOLD is set by shorting between terminals, and CLEAR is set by releasing.

Test mode setting terminal

....By shorting between terminals, the system enters the test mode

I+

4-3

Page 33

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

4.3 Offset/Gain Setting

When changing the I/O conversion characteristics, follow the procedure below.

4-4

Page 34

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

Point

(1) Set the offset and gain values in the actual usage state.

(2) The offset and gain values are stored in the AJ65BT-64DAV/DAI, and are not erased even

the power supply is shut off.

(3) Perform the offset/gain setting when the programmable controller CPU is stopped. When in

the test mode, D/A conversion is stopped for all channels, so use the remote READY signals

as an interlock.

(4) Perform the offset/gain setting in the range from DC -10 to +10V or from 4 to +20mA. When

the setting exceeds this range, the maximum resolution or total precision may not be in the

range indicated in the performance specification.

4.4 Station Number Setting

By the AJ65BT-64DAV/DAI station number setting, the addresses to store the control I/O signal data

and read/write data are determined.

For details, refer to the user's manual of the master module used.

4.5 Facing Direction of the Module Installation

Panel

M

I

T

S

U

B

I

S

H

I

M

I

T

S

U

B

I

S

H

I

I

H

S

I

B

U

S

T

I

M

When the module is installed next to the panel When the module is installed on the panel

4-5

Page 35

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

4.6 Data link Cable Wiring

The wiring of the CC-Link dedicated cable which connects the AJ65BT-64DAV/DAI and the master

module is described.

4.6.1 CC-Link dedicated cable connections

The CC-Link dedicated cable connections between the AJ65BT-64DAV/DAI and master module are as

follows:

4-6

Page 36

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

4.7 Wiring

Precautions when wiring the AJ65BT-64DAV/DAI and how to wire to the external devices are

explained.

4.7.1 Precautions when wiring

To obtain maximum performance from the functions of AJ65BT-64DAV/DAI and improve the system

reliability, an external wiring with high durability against noise is required.

The precautions performing external wiring for the AJ65BT-64DAV/DAI are shown below:

(1) Use separate cables for the AC and AJ65BT-64DAV/DAI external input signals, in order not to be

affected by the AC side surge or conductivity.

(2) Do not bunch the control wires or load cables from other than the programmable controller with

the wires to the module, or install them close to each other. Doing this makes the wiring easy to

accept the noise, surge or induction effects.

(3) Perform a one-point grounding for the shielded line or the shield of the shielded cable.

4.7.2 Wiring between the AJ65BT-64DAV/DAI and external devices

(1) Wiring example of the AJ65BT-64DAV and external devices is shown in Figure 4.1.

*1 Use a two-core twist shielded line for the wiring.

*2 When noise or ripple generates within the external wiring, connect a condenser with about

0.1 to 0.47μF (25V or higher voltage-resistant product) to the input terminal of the external

device.

Figure 4.1 Wiring example of the AJ65BT-64DAV and external devices

4-7

Page 37

4. SETUP AND PREPARATION BEFORE OPERATION MELSEC-A

(2) Wiring example of the AJ65BT-64DAI and external devices is shown in Figure 4.2.

*1 Use a two-core twist shielded line for the wiring.

*2 When noise or ripple generates within the external wiring, connect a condenser with about

0.1 to 0.47μF (25V or higher voltage-resistant product) to the input terminal of the external

device.

Figure 4.2 Wiring example of the AJ65BT-64DAI and external devices

Remark

Though you can perform the jumper wiring of the common line on the external device side, the

commons are connected also inside this module.

When wiring, be careful of sneak currents on the external device side.

4-8

Page 38

5. PROGRAMMING MELSEC-A

5. PROGRAMMING

The programming procedure, basic read/write programs, and program examples for the

AJ65BT-64DAV/DAI are described.

When applying any of the program examples introduced in this chapter to the actual system, verify the

applicability and confirm that no problems will occur in the system control.

Refer to the user's manual of the master module used for the master module, to Section 3.6 for the

remote registers, and to the AnSHCPU/AnACPU/AnUCPU/QCPU (A mode) Programming Manual

(Dedicated Instructions) for details of the dedicated instructions.

5.1 Programming Procedure

Create programs for executing the digital-analog conversion of the AJ65BT-64DAV/DAI in the

following procedure.

5

*1 When using the QCPU (Q mode), you can use the remote device station initialization procedure

*2 The remote device station initialization procedure registration function cannot be used to make

registration function to make settings. When using the ACPU, QCPU (A mode) or QnACPU, use

the sequence program to make settings.

settings.

Use the sequence program to make settings.

5-1

Page 39

5. PROGRAMMING MELSEC-A

5.2 Conditions of Program Example

The program examples in this chapter are created under the following conditions.

(1) System configuration

(2) Relationships between programmable controller CPU, master module and AJ65BT-64DAV

5

5-2

Page 40

5. PROGRAMMING MELSEC-A

POINT

Some CPU modules may not accept the devices used in the program example in this

chapter. For the setting ranges of the devices, refer to the user's manual of the CPU

module used.

For the A1SHCPU, for example, devices X100, Y100 and later are unusable. Use such

devices as B and M.

(3) Initial settings

Setting Item Settings

Offset/gain value selection Factory setting

Analog output enable/disable setting (RWw4) Channels 1, 2, 3, 4: enable

(4) Other settings

Setting Item Settings

CH.1 digital value setting (RWw0) 50

CH.2 digital value setting (RWw1) 100

CH.3 digital value setting (RWw2) 200

CH.4 digital value setting (RWw3) 3000

CH.1 analog output enable/disable flag (RY00) Enable

CH.2 analog output enable/disable flag (RY01) Enable

CH.3 analog output enable/disable flag (RY02) Enable

CH.4 analog output enable/disable flag (RY03) Enable

5-3

Page 41

5. PROGRAMMING MELSEC-A

5.3 Program Example for Use of the QCPU (Q mode)

The program examples in this section are created under the following conditions.

GX Developer is used to set the network and automatic refresh parameters.

Using the remote device station initialization procedure registration function facilitates initial settings.

(1) Parameter setting

(a) Network parameter setting

(b) Automatic refresh parameter setting

5-4

Page 42

5. PROGRAMMING MELSEC-A

(2) Initial setting by remote device station initialization procedure registration

(a) Setting the target station number

Set the station number to which initial setting will be made.

Set the target station number to "1".

(b) Setting the procedure registration

When the initial data processing request flag (RX18) turns on and the remote device station

initialization procedure registration (SB0D) is set, the following data are registered to the

AJ65BT-64DAV.

Procedure Execution Condition Execution

Offset/gain value selection (RY04) is turned on (factory setting).

Analog output enable/disable setting: channels 1, 2, 3, 4: enable

Initial data processing request flag (RX18) turns on

Initial data processing request flag (RX18) turns off Initial data processing complete flag (RY18) is turned off.

Initial data setting complete flag (RX19) turns on Initial data setting request flag (RY19) is turned off.

(c) Setting results

The setting results are shown below.

(RWw4: 0000

Initial data processing complete flag (RY18) is turned on.

Initial data setting request flag (RY19) is turned on.

H)

POINT

(1) If the remote device station initialization procedure registration directive (SB000D)

is turned off after the initial processing, all RY signals that were turned on within the

initial procedure registration turn off. Hence, turn on the "CH.

analog output

enable/disable flag (RYn0, RYn1, RYn2, RYn3)" in the sequence program.

(2) When the initial setting (analog output enable/disable setting (RWwm+4)) has been

changed, the remote device station initialization procedure registration function

cannot be used.

Change the initial setting in the sequence program.

(3) For the case where the remote device station initialization procedure registration

function is not used but a sequence program is used to make setting, refer to the

user's manual of the used master module.

5-5

Page 43

5. PROGRAMMING MELSEC-A

(3) Program example

5-6

Page 44

5. PROGRAMMING MELSEC-A

*1: When making remote device station initialization procedure registration to multiple stations,

correct the program within the dotted line 1) as shown below.

[System configuration]

[Corrected program]

RX(m+1)B and RX(n+1)B are remote READY.

RX(m+1)8 and RX(n+1)8 are initial data processing request flags.

Insert the remote READY and initial data processing request flags for all the stations, to which the

remote device station initialization procedure registration has been made, into the program.

5-7

Page 45

5. PROGRAMMING MELSEC-A

[Usage in combination with other remote device stations]

(1) Depending on the remote device stations to be used, the program enclosed by the dotted

line 1) has two programming patterns as shown in the above and the below figures.

(To check which pattern can be used, refer to the manual for the remote device to be used.)

[System configuration]

[Corrected program]

RX(p+1)9 and RX(q+1)9 are initial data setting completion flags.

RX(p+1)8 and RX(q+1)8 are initial data processing request flags.

5-8

Page 46

5. PROGRAMMING MELSEC-A

(2) When using the program enclosed by the dotted line 1) in combination with other remote

device stations, correct the program as shown below.

[System configuration]

[Corrected program]

Note that the master module can register the initialization procedure of only the specified

station out of the multiple remote device stations.

The master module supporting this function is the QJ61BT11N which serial No's first 5

digits is 08032 or later.

Fro details, refer to the CC-Link System Master/Local Module User's Manual,

"CHAPTER 4 FUNCTIONS"

*2: Before the communication program is executed with remote device stations, the program

enclosed by the dotted line 1) enables the initial setting by using the SB0D (remote device station

initialization procedure registration instruction) and SB5F (completion status of remote device

station initialization procedure). Initialization processing can’t be made only by the parameter

setting of GX Developer.

*3: The program enclosed by the dotted line 2) is necessary only when the initial settings are

changed.

5-9

Page 47

5. PROGRAMMING MELSEC-A

5.4 Program Example for Use of the QnACPU

GX Developer is used to set the network and automatic refresh parameters.

(1) Parameter setting

(a) Network parameter setting

(b) Automatic refresh parameter setting

POINT

When the QnACPU is used, using "Y" as the remote output (RY) refresh device of the

automatic refresh parameter may not hold the analog value even for the HOLD setting.

For the HOLD setting, use "M" or "B" as the remote output (RY) refresh device.

5-10

Page 48

5. PROGRAMMING MELSEC-A

(2) Program example

*Checking of AJ65BT-64DAV status

Reads data link status

AJ65BT-64DAV dat a

link normal

AJ65BT-64DAV dat a

link normal

*Initial settings

*1

*Changing of Initial settings

Initial setting c hange

*Processing at initial settings

*Setting of digital values

Digital

value

setting

*Analog output enable/disable specification

Analog

output

enable

*Processing at error occurence

Error reset

Offset/gain value selection

(RY04)

Analog output enab le/

disable setting (RWw4)

Turns on initial data proc edure

completion flag ( RY18)

Turns on initial d ata setting

request flag (RY19)

Offset/gain value sel ection

(RY04)

Analog output ena ble/

disable setting (RWw4)

Turns on initial data setting

request flag (RY19)

Turns off initial data procedure

completion flag (RY18)

Turns off initial data sett ing

request flag (RY19)

CH.1 digital value setting

(RWw0): 50

CH.2 digital value setting

(RWw1): 100

CH.3 digital value setting

(RWw2): 200

CH.4 digital value setting

(RWw3): 300

Turns on CH.1 analog output

enable/disable flag ( RY00)

Turns on CH.2 analog output

enable/disable flag ( RY01)

Turns on CH.3 analog output

enable/disable fla g (RY02)

Turns on CH.4 analog output

enable/disable fla g (RY03)

Reads CH. Check code

(RWr0, RWr1, RWr2, RWr3)

Reads error codes (RWr4)

Turns on error reset

request flag (RY1A)

Turns off error reset

request flag (RY1A)

*1: The program enclosed by the dotted line is necessary only when the initial settings are changed.

5-11

Page 49

5. PROGRAMMING MELSEC-A

,

5.5 Program Example for Use of the ACPU/QCPU (A mode) (dedicated instructions)

A sequence program is used to set the network and automatic refresh parameters.

(1) Program example

*Setting of network parameters using RLPA dedicated instruction

Synchronizat ion mode:

invalid

Number of conne cted

modules:1

AJ65BT-64DAV station

information (remote de vice

station, 2 stations occupied

station No.1)

Dedicated instruction

(RLPA)

Starting I/O number of

master module

Parameter storage

starting device

*Setting of automatic refresh parameters using RRPA dedicated instruction

Device which turns on 1

scan at completion

Reads parame ter status

at abnormal completion

5-12

Page 50

5. PROGRAMMING MELSEC-A

Sets RX starting num ber

Sets "X"

Sets X400

Sets 32points

Sets RY starting num ber

Sets "Y"

Sets Y400

Sets 32points

Sets RW starting number

Sets "D"

Sets D200

Sets 264points

Sets SB starting num ber

Sets "B"

Sets B0

Sets 512points

Sets SW starting num ber

Sets "W"

Sets W0

Sets 512points

Dedicated instruction

(RRPA)

Starting I/O n umber of

master module

Parameter storage

starting devic e

5-13

Page 51

5. PROGRAMMING MELSEC-A

*Checking of AJ65BT-64DAV status

Reads data link status

AJ65BT-64DAV data

link normal

AJ65BT-64DAV data

link abnormal

*Initial settings

*1

*Changing of initial settings

Initial setting change

*Processing at initial settings

*Setting of digital values

Digital

value

setting

*Analog output enable/disable specification

Analog

output

enable

Offset/gain value selection

(RY04)

Analog output enable/

disable s ettin g (RWw4)

Turns on initial data

processing completion

flag (RY18)

Turns on initial data setting

request flag (RY19)

Offset/gain value selection

(RY04)

Analog output enable/

disable setting (RWw4)

Turns on initial data setting

request flag (RY19)

Turns off initial data

processing completion

flag (RY18)

Turns off initial data setting

request flag (RY19)

CH.1 digital value setting

(RWw0): 50

CH.2 digital value setting

(RWw1): 100

CH.3 digital value setting

(RWw2): 200

CH.4 digital value setting

(RWw3): 300

Turns on CH.1 analog output

enable/disable flag (RY00)

Turns on CH.2 analog output

enable/disable flag (RY01)

Turns on CH.3 analog output

enable/disable flag (RY02)

Turns on CH.4 analog output

enable/disable flag (RY03)

*1: The program enclosed by the dotted line is necessary only when the initial settings are changed.

5-14

Page 52

5. PROGRAMMING MELSEC-A

)

*Processing at error occurence

Reads CH. Check code

(RWr0, RWr1, RWr2, RWr3

Reads error code(RWr4)

Error reset

Turns on error reset

request flag (RY1A)

Turns off error reset

request flag (RY1A)

5-15

Page 53

5. PROGRAMMING MELSEC-A

5.6 Program Example for Use of the ACPU/QCPU (A mode) (FROM/TO instructions)

5-16

Page 54

5. PROGRAMMING MELSEC-A

*

*Initial settings

Offset/gain value selection

(RY04)

Analog output enable/disable

setting (RWw4 )

Writes to the master station

Turns on initial data procedure

completion flag (RY18 )

Turns on initial data setting

request flag (RY19)

1

*Changing of Initial settings

*Processing at initial settings

*Setting of digital values

Initial setting change

Digital

value

setting

Offset/gain v alue selection

(RY04)

Analog output en able/

disable setting (RWw4 )

Writes to the master stati on

Turns on initial data setting

request flag (RY19)

Turns off initial data procedure

completion flag (RY18 )

Turns off initial data setting

request flag (RY19)

CH.1 digital value setti ng

(RWw0): 50