Mitsubishi Heavy Industries SRK52CF-BN, SRK71CF-BN, SRK52CF-BP, SRK71CF-BP Technical Manual

-

3

-

WALL MOUNTED TYPE

ROOM AIR-CONDITIONER

TECHNICAL MANUAL

Collection data

Manual No. ’06

.

SRK-T

.

062

(Split system, air cooled cooling only type)

SRK52CF-BN, 71CF-BN

SRK52CF-BP, 71CF-BP

-

1

-

CONTENTS

1. GENERAL INFORMATION .............................................................................. 1

1.1 Specific features ....................................................................................... 1

1.2 How to read the model name ................................................................... 1

2. SELECTION DATA .......................................................................................... 2

2.1 Specifications ........................................................................................... 2

2.2 Range of usage & limitations .................................................................. 6

2.3 Exterior dimensions ................................................................................. 6

2.4 Piping system ........................................................................................... 8

2.5 Selection chart .......................................................................................... 9

3. ELECTRICAL DATA ........................................................................................ 10

3.1 Electrical wiring ........................................................................................ 10

4. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ................... 14

4.1 Operation control function by remote control switch ........................... 14

4.2 Unit ON/OFF button .................................................................................. 16

4.3 Power blackout auto restart function ..................................................... 16

4.4 Custom cord switching procedure ......................................................... 17

4.5 Flap and louver control ............................................................................ 17

4.6 Comfortable timer setting ........................................................................ 18

4.7 Sleep timer operation ............................................................................... 18

4.8 Outline of cooling operation .................................................................... 19

4.9 Outline of dehumidifying operation ........................................................ 20

4.10 Outline of automatic operation................................................................ 21

4.11 Set temperature selection ........................................................................ 21

4.12 Outline of fan operation ........................................................................... 22

4.13 Regulation of outdoor air flow................................................................. 22

4.14 Stop mode ................................................................................................. 23

4.15 External control (remote display)/control of input signal ..................... 24

4.16 Operation permission/prohibition control.............................................. 25

4.17 Protective control function ...................................................................... 25

4.18 List of indoor unit jumper selections...................................................... 28

5. APPLICATION DATA ....................................................................................... 29

5.1 Selection of location for installation ....................................................... 30

5.2 Installation of indoor unit ......................................................................... 31

5.3 Installation of outdoor unit ...................................................................... 34

5.4 Refrigerant piping ..................................................................................... 34

5.5 Test run ...................................................................................................... 36

5.6 Precautions for wireless remote control installation and operation ........ 36

5.7 Installation of wired remote control and super link

adapter (SC-AD-ER) (Optional parts) ...................................................... 37

6. MAINTENANCE DATA .................................................................................... 44

6.1 Troubleshooting procedures for electrical equipment ......................... 44

6.2 Servicing.................................................................................................... 52

-

1

-

Power supply

Series No.

Cooling only type

Product capacity

Wall mounted type

Split type room air-conditioner

1.2 How to read the model name

Example : SR K 52 C F - BN

TIMER lightRUN light

Error of signal transmission

1 GENERAL INFORMATION

1.1 Specific features

The “MITSUBISHI HEAVY INDUSTRIES, LTD.” room air-conditioner: SRK series are of split and wall mounted type and the unit

consists of indoor unit and outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling equip-

ment with operation control switch and the outdoor unit is composed of condensing unit with compressor.

(1) Remote control flap & louver

The flap & louver can be automatically controlled by operating wireless remote control.

¡Flap swing : The flaps swing up and down successively.

¡Louver swing : The louvers swing left and right successively.

¡Multi-directional Air Flow : Activating both up/down air swing and left/right air swing at the same time results in a multi-

directional air flow.

¡Memory flap : Once the flap & louver position is set, the unit memorizes the position and continues to operate

at the same position from the next time.

(2) Automatic operation

When the remote control switch is set on “auto(

) ”, it will either automatically decide operation mode such as cooling and

thermal dry, or operate in the operation mode before it has been turned to automatic control.

(3) Self diagnosis function

¡ We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows.

Room temperature sensor error

Indoor fan motor error

Heat exchanger sensor error

2 time flash

6 time flash

TIMER light

ON

Outdoor heat exchanger sensor

error

Discharge pipe temp. sensor error

Outdoor temperature sensor error

2 time flash

4 time flash

RUN light

keeps flashing

1 time flash

Trouble of outdoor unit

Over heat of compressor

2 time flash

5 time flash

RUN light

ON

6 time flash

(up/down air scroll and

left/right air scroll)

1 time flash

BN: 1 Phase 220-240V 50Hz

BP: 1 Phase 220V 60Hz

-

2

-

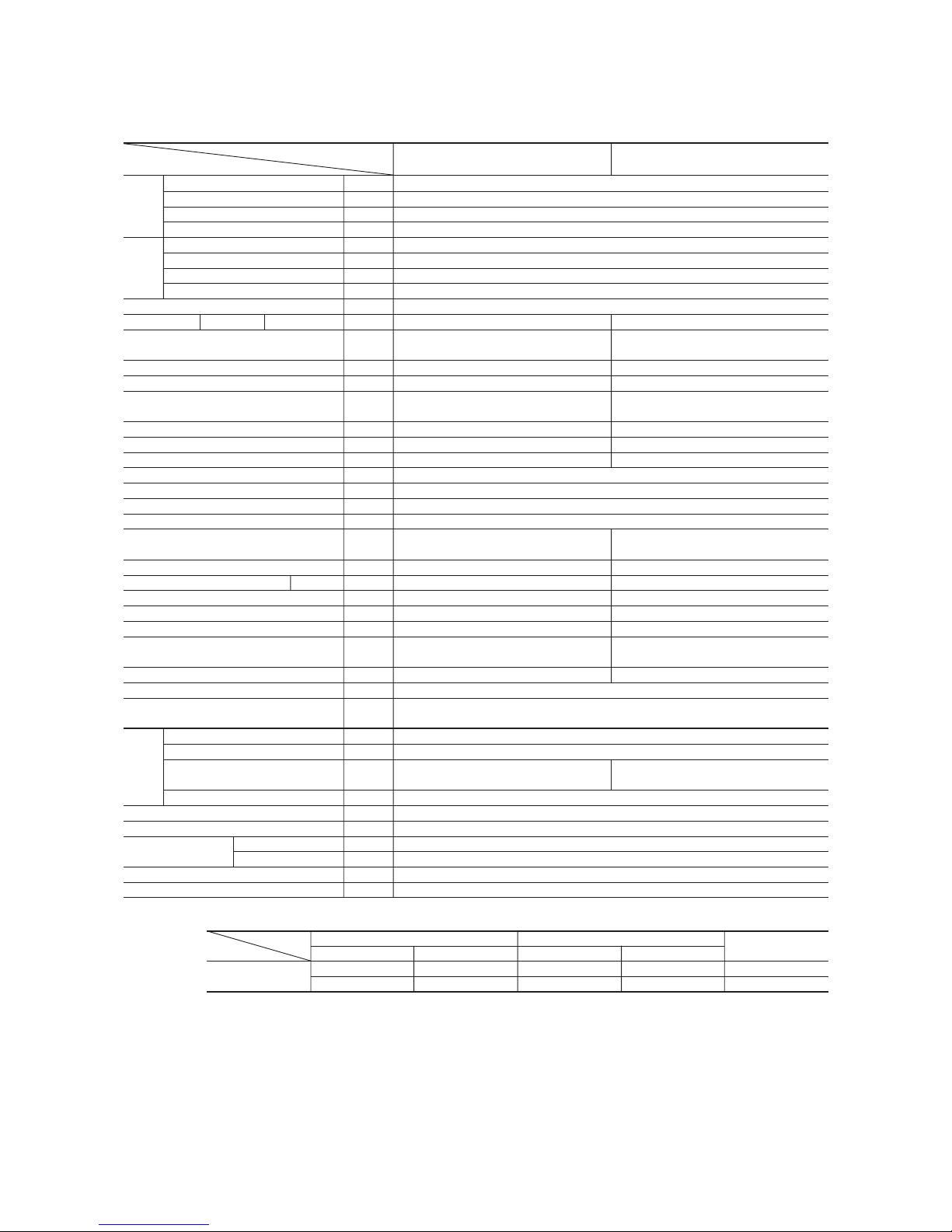

Item

Model

SRK52CF-BN SRC52CF-BN

Cooling capacity kW 5.4 / 5.4

Cooling power input kW 1.76 / 1.91

Energy efficiency ratio Btu/hW 10.47 / 9.66

Rating current A 8.8 / 8.7

Cooling capacity kW 5.0 / 5.0

Cooling power input kW 2.06 / 2.20

Energy efficiency ratio Btu/hW 8.29 / 7.75

Rating current A 10.3 / 10.1

Power source 1 Phase, 220-240V, 50Hz

Noise level Cooling Sound level dB Hi 43, Me 40, Lo 37 49

Exterior dimensions

Height × Width × Depth

mm

318 × 1098 × 248 640 × 850 × 290

Color Yellowish white Stucco white

Net weight kg 15 46

Refrigerant equipment

Compressor type & Q’ty

– 2KS314D5AB04 (Rotary type) × 1

Motor kW – 1.5

Starting method – Line starting

Heat exchanger Slit fins & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control Capillary tubes + Electric expansion valve

Refrigerant

(3)

kg R22 1.25 (Pre-Charged up to the piping length of 7m)

Refrigerant oil R 0.67 (ATMOS NM56M or SUNISO 4DGID)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 46 35

Air flow (at High) (Cooling)

CMM

20 38

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ15.88 (5/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.70m

Gas line: 0.63m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts Wired-Remote control

Notes (1) The data are measured at the following conditions.

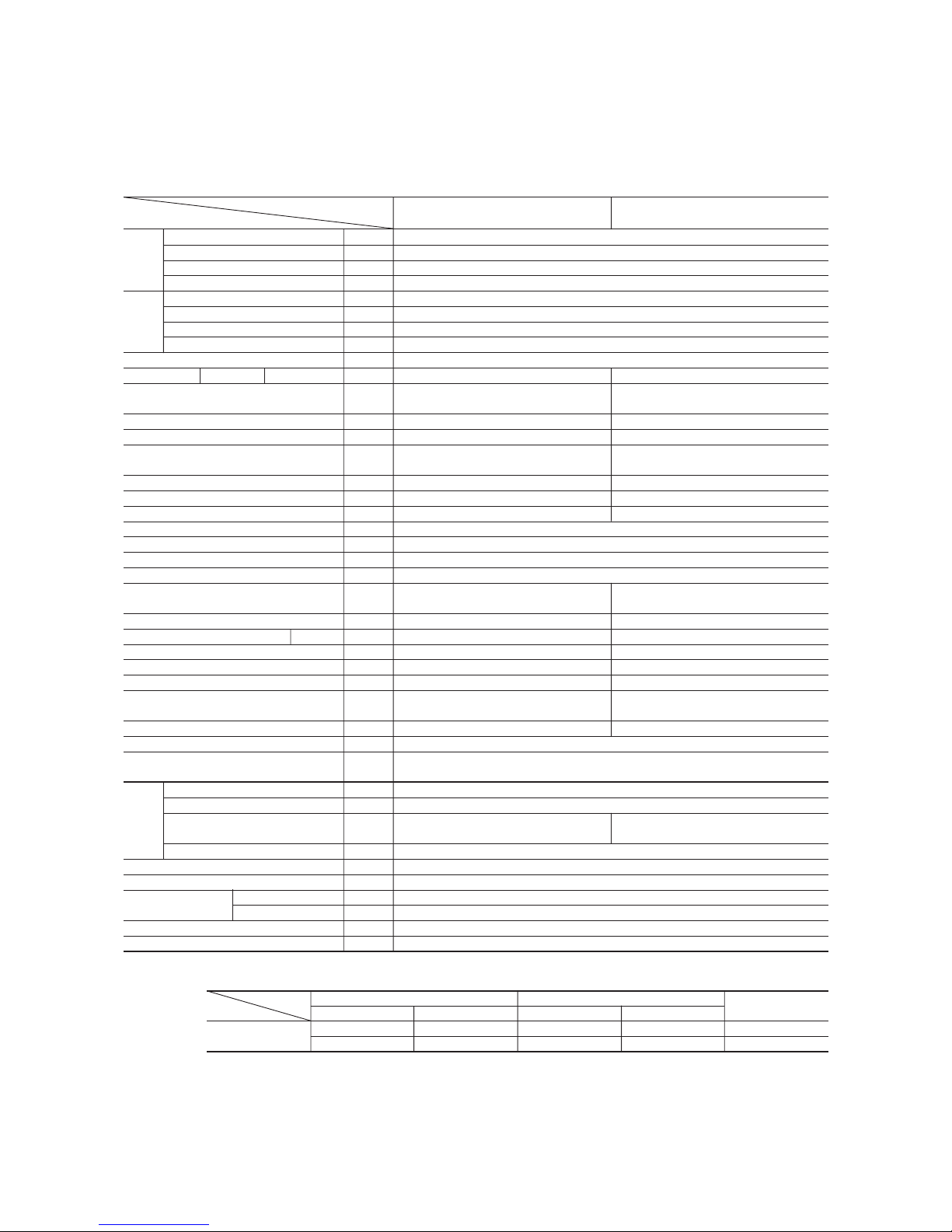

2. SELECTION DATA

2.1 Specifications

Model SRK52CF-BN (Indoor unit)

SRC52CF-BN (Outdoor unit)

(2) The operation data are applied to the 220/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7 to 25m, add 25g refrigerant per meter.

ISO-T1

(JIS)

Refrigerant

piping

Compressor: overheat protection, Frost protection, Serial signal error protection, Indoor fan motor error

protection

(220/240V)

ISO-T3

(SASO)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling

27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

29ºC 19ºC 46ºC 24ºC

ISO-T3, SASO 385/386

The piping length is 7.5m.

-

3

-

Item

Model

SRK71CF-BN SRC71CF-BN

Cooling capacity kW 7.03 / 7.03

Cooling power input kW 2.12 / 2.27

Energy efficiency ratio Btu/hW 11.33 / 10.58

Rating current A 10.6 / 10.4

Cooling capacity kW 6.3 / 6.3

Cooling power input kW 2.48 / 2.60

Energy efficiency ratio Btu/hW 8.67 / 8.26

Rating current A 12.4 / 11.9

Power source 1 Phase, 220-240V, 50Hz

Noise level Cooling Sound level dB Hi 45, Me 42, Lo 39 55

Exterior dimensions

Height × Width × Depth

mm

318 × 1098 × 248 750 × 880 × 340

Color Yellowish white Stucco white

Net weight kg 15 67

Refrigerant equipment

Compressor type & Q’ty

–

2JS386D5BC02 (Rotary type) × 1

Motor kW – 1.8

Starting method – Line starting

Heat exchanger Slit fins & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control Capillary tubes + Electric expansion valve

Refrigerant

(3)

kg R22 1.75 (Pre-charged up to the piping length of 7m)

Refrigerant oil R 0.7 (ATMOS NM56M or SUNISO 4GDID)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 46 85

Air flow (at High) (Cooling) CMM 20.5 60

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ15.88 (5/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.70m

Gas line : 0.63m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts Wired-Remote control

Notes (1) The data are measured at the following conditions.

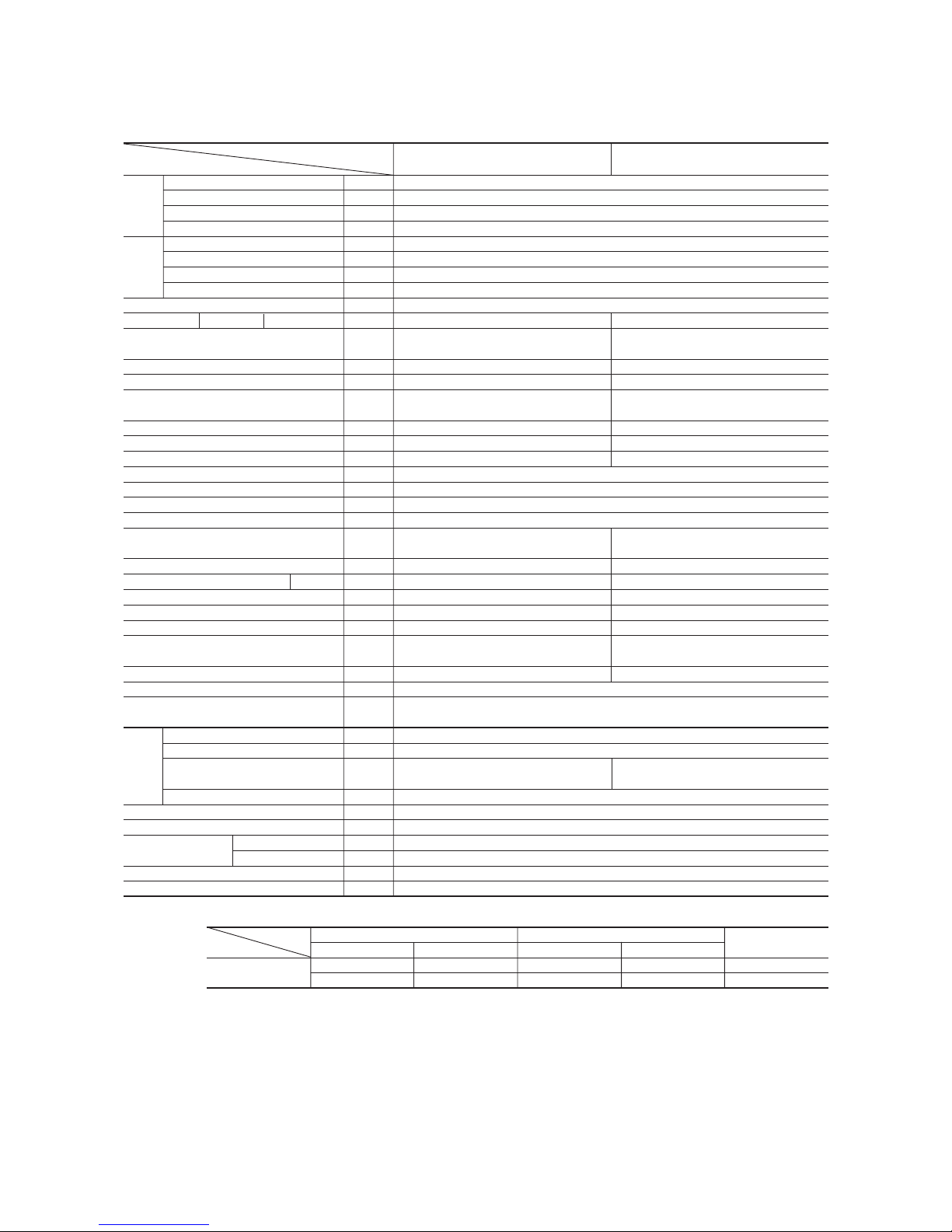

Model SRK71CF-BN (Indoor unit)

SRC71CF-BN (Outdoor unit)

(2) The operation data are applied to the 220/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7 to 25m, add 25g refrigerant per meter.

Refrigerant

piping

Compressor: overheat protection, Frost protection, Serial signal error protection, Indoor fan motor error

protection

(220/240V)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling

27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

29ºC 19ºC 46ºC 24ºC

ISO-T3, SASO 385/386

The piping length is 7.5m.

ISO-T1

(JIS)

ISO-T3

(SASO)

-

4

-

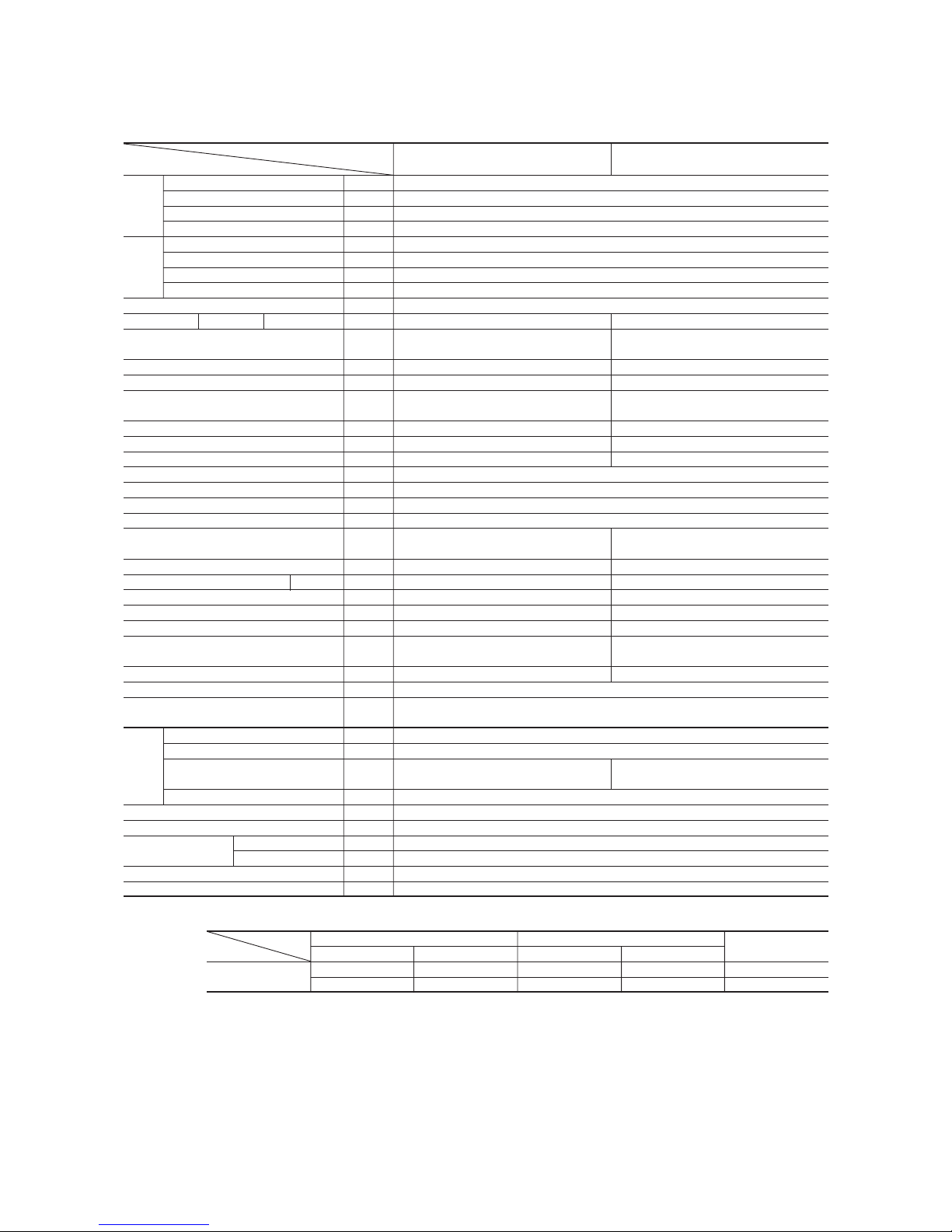

Item

Model

SRK52CF-BP SRC52CF-BP

Cooling capacity kW 5.4

Cooling power input kW 1.76

Energy efficiency ratio Btu/hW 10.47

Rating current A 8.8

Cooling capacity kW 5.0

Cooling power input kW 2.06

Energy efficiency ratio Btu/hW 8.29

Rating current A 10.3

Power source 1 Phase, 220V, 60Hz

Noise level Cooling Sound level dB Hi 43, Me 40, Lo 37 49

Exterior dimensions

Height × Width × Depth

mm

318 × 1098 × 248 640 × 850 × 290

Color Yellowish white Stucco white

Net weight kg 15 46

Refrigerant equipment

Compressor type & Q’ty

– 2KS252H5AB04 (Rotary type) × 1

Motor kW – 1.2

Starting method – Line starting

Heat exchanger Slit fins & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control Capillary tubes + Electric expansion valve

Refrigerant

(3)

kg R22 1.25 (Pre-Charged up to the piping length of 7m)

Refrigerant oil R 0.65 (ATMOS NM56M or SUNISO 4GDID)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 46 29

Air flow (at High) (Cooling)

CMM

20 38

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ15.88 (5/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.70m

Gas line: 0.63m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts Wired-Remote control

Notes (1) The data are measured at the following conditions.

Model SRK52CF-BP (Indoor unit)

SRC52CF-BP (Outdoor unit)

(2) The operation data are applied to the 220V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7 to 25m, add 25g refrigerant per meter.

ISO-T1

(JIS)

Refrigerant

piping

Compressor: overheat protection, Frost protection, Serial signal error protection, Indoor fan motor error

protection

(220V)

ISO-T3

(SASO)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling

27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

29ºC 19ºC 46ºC 24ºC

ISO-T3, SASO 385/386

The piping length is 7.5m.

-

5

-

Item

Model

SRK71CF-BP SRC71CF-BP

Cooling capacity kW 7.03

Cooling power input kW 2.12

Energy efficiency ratio Btu/hW 11.33

Rating current A 10.6

Cooling capacity kW 6.3

Cooling power input kW 2.48

Energy efficiency ratio Btu/hW 8.67

Rating current A 12.4

Power source 1 Phase, 220V, 60Hz

Noise level Cooling Sound level dB Hi 45, Me 42, Lo 39 55

Exterior dimensions

Height × Width × Depth

mm

318 × 1098 × 248 750 × 880 × 340

Color Yellowish white Stucco white

Net weight kg 15 67

Refrigerant equipment

Compressor type & Q’ty

–

2JS318H5AB02(Rotary type) × 1

Motor kW – 1.5

Starting method – Line starting

Heat exchanger Slit fins & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control Capillary tubes + Electric expansion valve

Refrigerant

(3)

kg R22 1.75 (Pre-charged up to the piping length of 7m)

Refrigerant oil R 0.7 (ATMOS NM56M or SUNISO 4GDID)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 46 73

Air flow (at High) (Cooling) CMM 20.5 60

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ15.88 (5/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.70m

Gas line : 0.63m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source supply Terminal block (Screw fixing type)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts Wired-Remote control

Notes (1) The data are measured at the following conditions.

Model SRK71CF-BP (Indoor unit)

SRC71CF-BP (Outdoor unit)

(2) The operation data are applied to the 220V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7 m connecting piping.

(Purging is not required even in the short piping.)

If the piping length is longer, when it is 7 to 25m, add 25g refrigerant per meter.

Refrigerant

piping

Compressor: overheat protection, Frost protection, Serial signal error protection, Indoor fan motor error

protection

(220V)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling

27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

29ºC 19ºC 46ºC 24ºC

ISO-T3, SASO 385/386

The piping length is 7.5m.

ISO-T1

(JIS)

ISO-T3

(SASO)

-

6

-

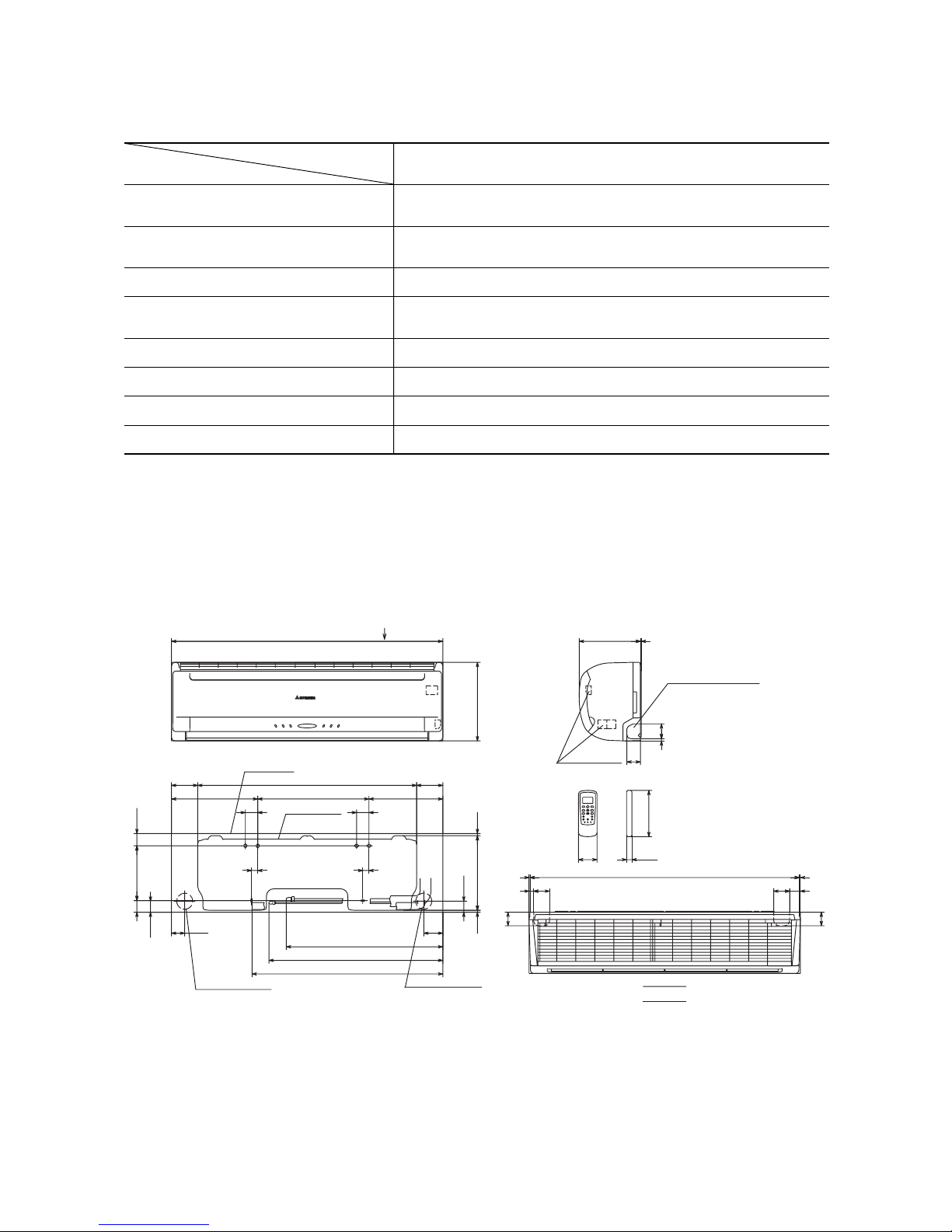

2.2 Range of usage & limitations

2.3 Exterior dimensions

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length

All models

Cooling operation: Approximately 21 to 32 °C

Cooling operation: Approximately 21 to 54 °C

Power source voltage Rating ± 10%

Voltage at starting Min. 85% of rating

Max. 25m

Max. 15m

Frequency of ON-OFF cycle Max. 10 times/h

ON and OFF interval Max. 3 minutes

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Item

Models

(1) Indoor unit

Models SRK52CF-BN, 71CF-BN, 52CF-BP, 71CF-BP

VIEW A

A

17.360

150

4

43.5

55

64

489

Piping hole right (left)

3

248

55

4

19 51.2

55

Terminal block

1090

Unit: mm

318

77

44.5

7.7

299

106

8.5301.8

25

50

Installation board

450

50

25

Piping for Gas (ø15.88) 633.5

44.5

53.5

106

49.5

349

886

221.547

Indoor unit

1098

Piping for Liquid (ø6.35) 703.5

Drain hose 772 (ø16)

Piping hole (ø65)

Piping hole (ø65)

-

7

-

Drain holes

286.4

12

50

290

49.6

43.5

850

203.1

510 136.9

476

Elogated hole

(2-12 x16)

314

12

328

Terminal block

Service valve (Liquid)

ø6.35 (1/4'')

Service valve (Gas)

ø15.88 (5/8'')

Ground

terminal

124

34.6

20˚

20˚

42.7

100.3

15

640

14

(2) Outdoor unit

Models SRC52CF-BN, 52CF-BP

Models SRC71CF-BN, 71CF-BP

Unit: mm

38019

24

750

103.5 48.5

580

880

418

340

88

150 150

27

32

310223

47.561

61

2-R7.5

60

15

Drain holes

Service valve(Gas)

Flare fitting ø15.88(5/8")

Service valve (Liquid)

Flare fitting ø6.35(1/4")

Terminal block

30°

165.5 25

Unit: mm

-

8

-

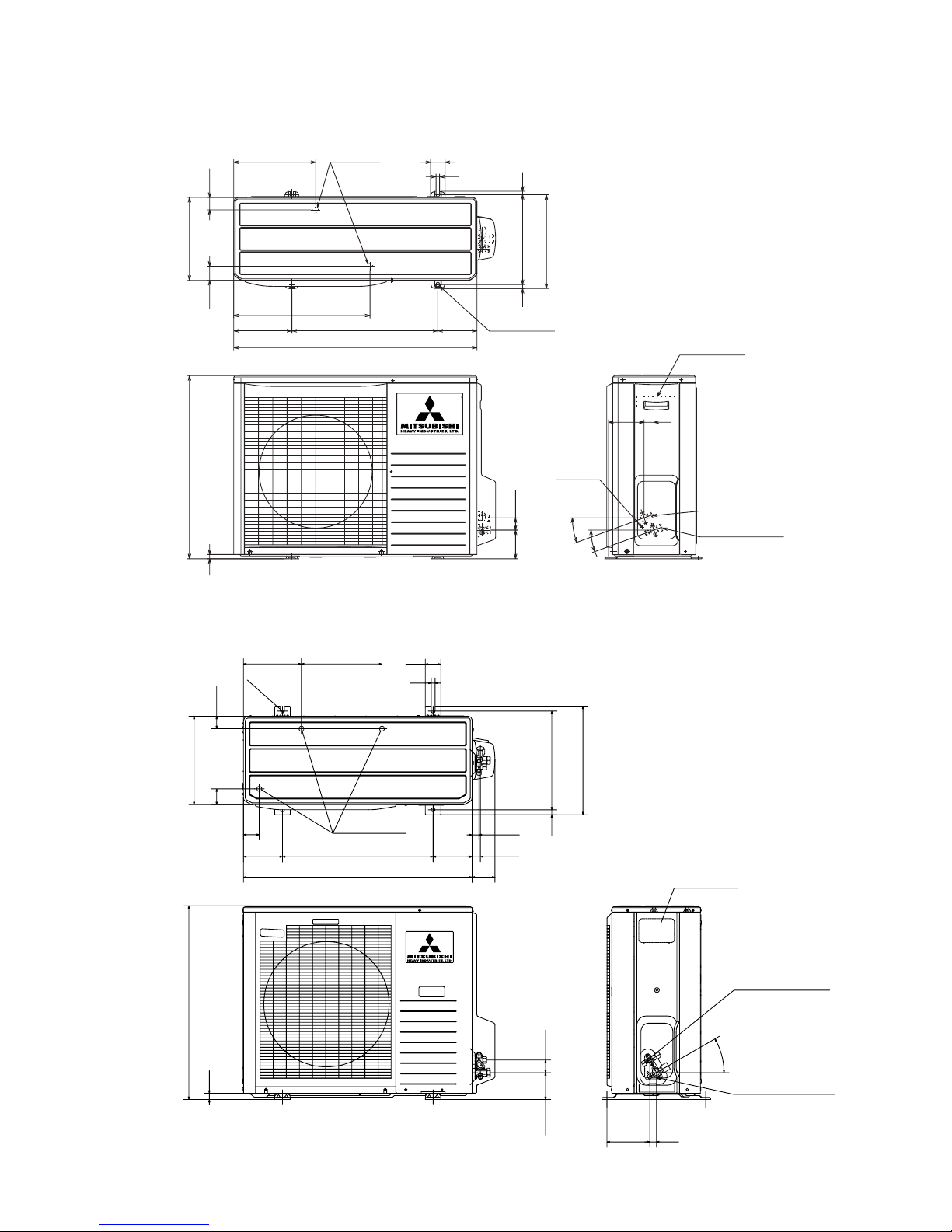

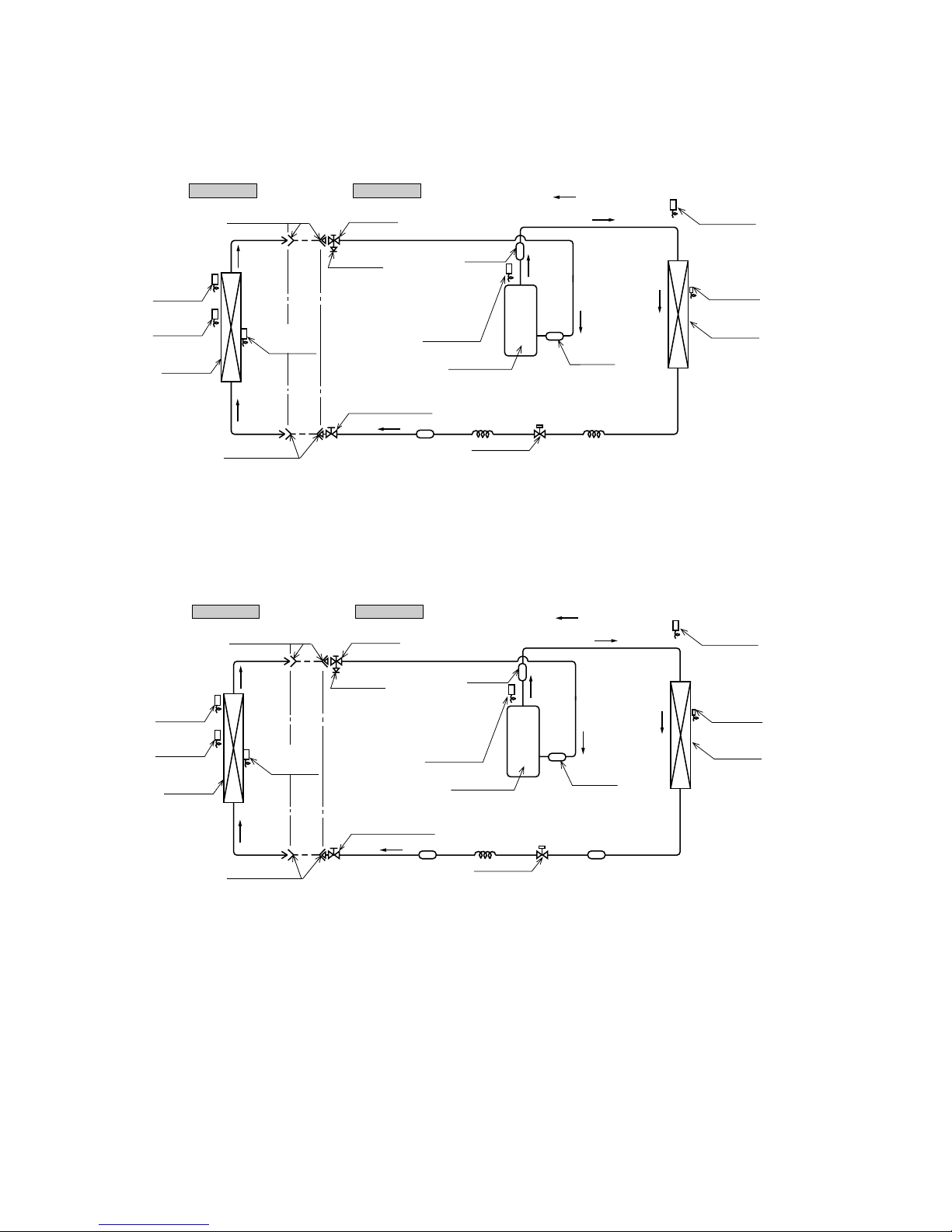

2.4 Piping system

Models SRK52CF-BN, 52CF-BP

Models SRK71CF-BN, 71CF-BP

Outdoor unitIndoor unit

Room temp.

sensor

Humidity

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø

6.35

Piping

(Gas)

ø15.88

Check joint

Service valve (Liquid)

Flare connecting

Discharge pipe

temp. sensor

Cooling cycle

Muffler

*

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube Capillary tube

Strainer

Accumulator

Service valve

(Gas)

Electronic

expansion valve

* except for 52CF-BN

Outdoor unitIndoor unit

Room temp.

sensor

Humidity

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø

6.35

Piping

(Gas)

Check joint

Service valve (Liquid)

Flare connecting

Discharge pipe

temp. sensor

Cooling cycle

Muffler

*

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Strainer

Accumulator

Service valve

(Gas)

Electronic

expansion valve

ø

15.88

* except for 71CF-BP

-

9

-

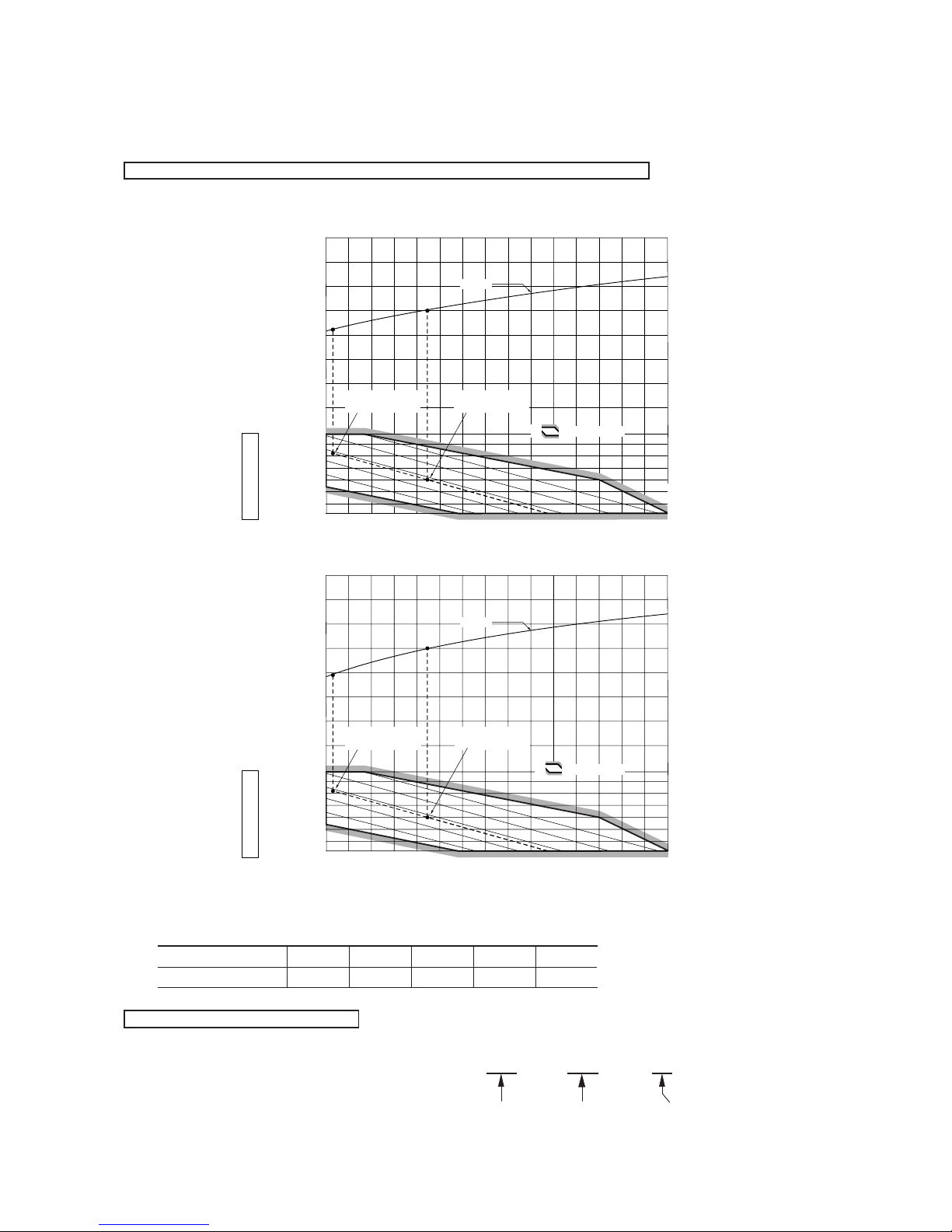

2.5 Selection chart

Correct the cooling capacity in accordance with the conditions as follows. The net cooling capacity can be obtained in the following way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

(1) Coefficient of cooling capacity in relation to temperatures

Piping length [m]

Cooling

7

1.0

10

0.99

15

0.975

20

0.965

25

0.95

How to obtain the cooling capacity

Example : The net cooling capacity of the model SRK71CF-BN with the piping length of 15m, indoor wet-bulb temperature at 19.0˚C

and outdoor dry-bulb temperature 35˚C is Net cooling capacity = 7030 ✕ 0.975 ✕ 1.0 = 6854 W

SRK71CF-BN

Length 15m

Factor by air

temperatures

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling capacity in relation to the one way piping length between the indoor and outdoor units.

16 18 20 22

21

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

45

50

54

24

Indoor air W.B. temperature °C W.B.

Cooling

Applicable range

Coefficient of cooling

capacity in

relation to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

ISO-T3

Standard Condition

ISO-T1

Standard Condition

16 18 20 22

21

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

45

50

54

24

Indoor air W.B. temperature °C W.B.

Cooling

Applicable range

Coefficient of cooling

capacity in

relation to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

ISO-T3

Standard Condition

ISO-T1

Standard Condition

S SRK52CF-BN, 52CF-BP

S SRK71CF-BN, 71CF-BP

-

10

-

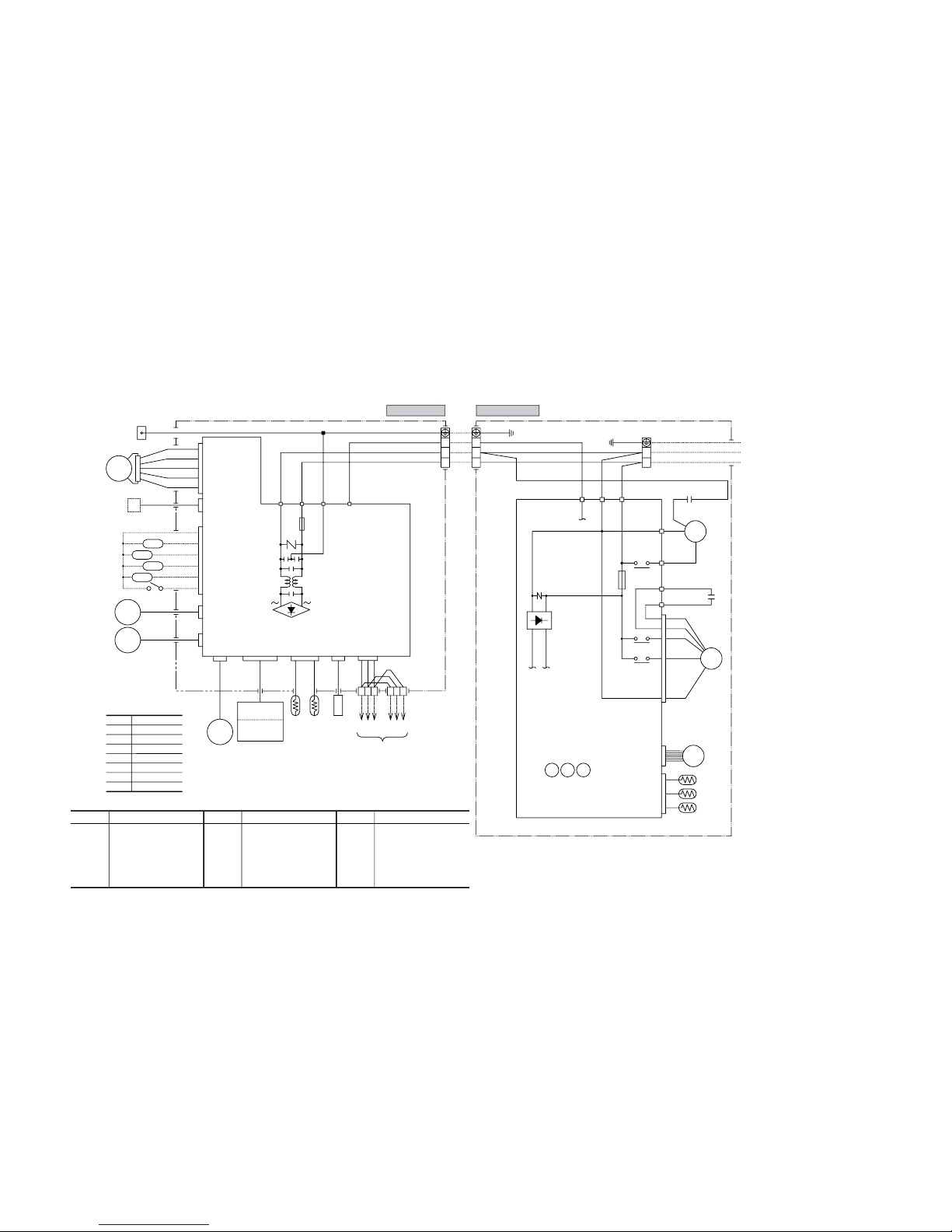

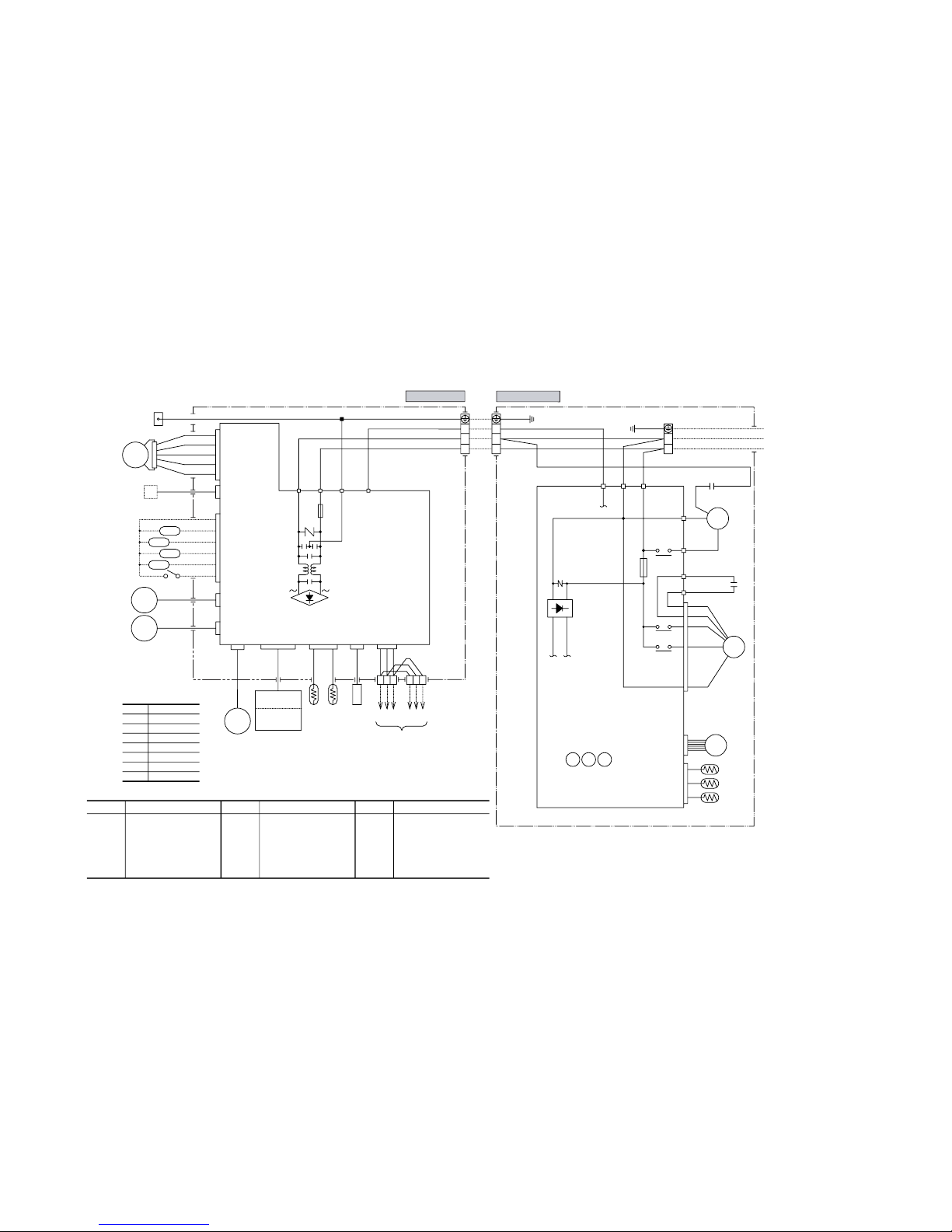

3 ELECTRICAL DATA

3.1 Electrical wiring

Model SRK52-CF-BN

DS

+

~

-

~

J

N

L

CC

11

9

7

3

5

CNU

JEM-A

CNB

CNE CNF

CNM

CNX

CNY

CNT

Option

XR1

XR2

XR3

XR4

XR5

CNG

SM

LM1

LM2

HA

J

RD

Y/GN

G

Y/GN

BK

2/N

1

WH

3

2/N

1

3

L

N

RD

Y/GN

BK

R/LS/N

WH

WH

RD

BK

1

3

Y

BL

4

5

6

ZNR

ZNR

F

250V

3.15A

F

250V

3.15A

Terminal block

TB TB

XZ

Y

XZ

Y

RD

WH

BK

BK

Color symbol

Meaning of marks

Symbol

CM

F

FM

I

FM

O

SM

LM

1,2

Th

1

Th

2

Compressor motor

Fuse

Fan motor(Indoor)

Fan motor(Outdoor)

Flap motor

Louver motor

Room temp.sensor

Heat exch.sensor(Indoor unit)

Capacitor for CM

Capacitor for FM

O

Terminal block

Operation indication (DC12)

Heating indication (DC12)

ON indication for CM(DC12)

Check indication (DC12)

Distant operation

Humidity sensor

Heat exch.sensor(Outdoor unit)

Outdoor air temp.sensor

Discharge pipe temp.sensor

Varistor

Electronic expansion valve

Diode stack

Auxiliary relay

Th

3

Th

4

Th

5

Th

6

ZNR

EEV

DS

52

X1~4

CC

CF

O

TB

XR1

XR2

XR3

XR4

XR5

Parts name

BL

OR

Y/G

Black

Blue

Orange

Yellow/Green

WH White

RD Red

GR Green

Y Yellow

Parts name Parts nameSymbol Symbol

BK

WH

RD

WH

RD

WH

OR

Y

RD

BL

WH

BK

Y

Y

CM2

CM1

W

V

U

52X1

52X3

52X4

Heat

exchanger

To wired

remote

control

(Option)

Power Source

1 Phase

220-240V 50Hz

R-AMP

Wireless

Display

Printed circuit

board

Printed circuit

board

CNU

CNE

CNG

FM

I

CM

52X

1

52X

3

52X

4

EEV

FMo

CF

O

Th4

Th5

Th6

Outdoor unit

Indoor unit

Th3Th2Th1

-

11

-

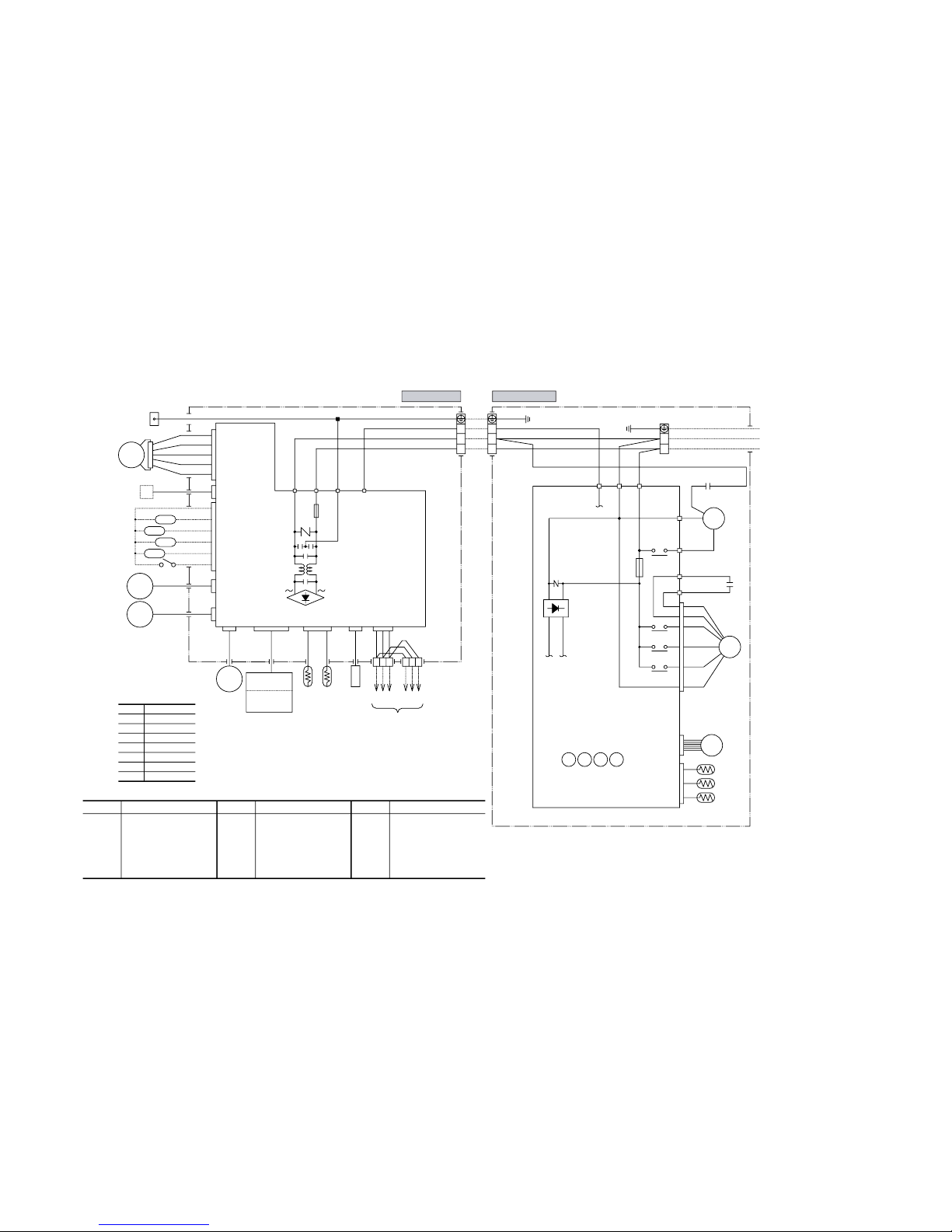

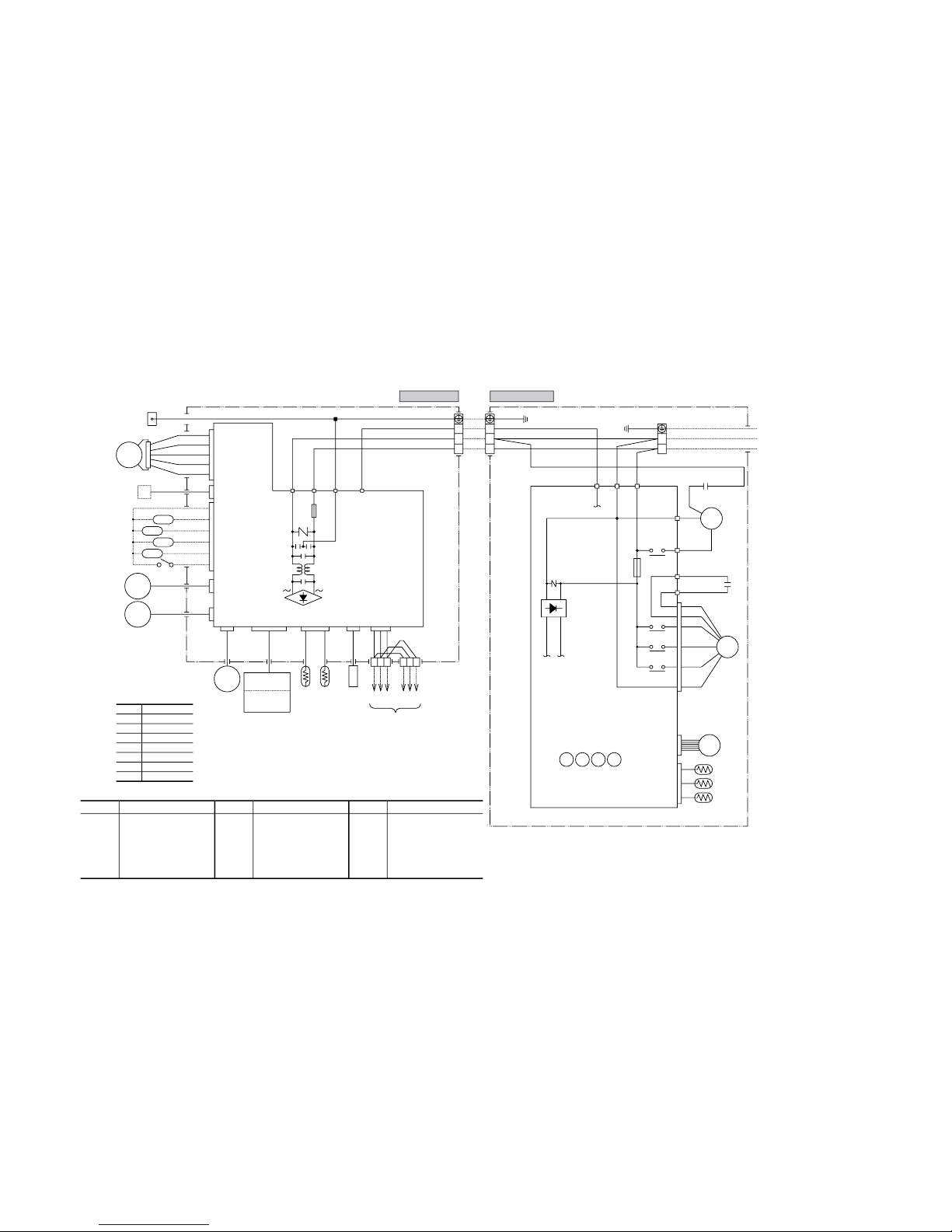

Model SRK71CF-BN

DS

+

-

J

N

L

CC

11

9

7

3

1

5

Option

XR1

XR2

XR3

XR4

XR5

CNE CNFCNM

CNX

CNY

CNT

CNG

SM

LM1

LM2

Heat

HA

J

RD

Y/GN

G

Y/GN

BK

2/N

1

WH

3

2/N

1

3

L

N

RD

Y/GN

BK

R/LS/N

WH

WH

RD

BK

1

3

Y

BL

4

5

6

exchanger

ZNR

ZNR

F

250V

3.15A

F

250V

3.15A

Terminal block

TB TB

XZ

Y

XZ

Y

RD

WH

BK

BK

Color symbol

Meaning of marks

Symbol

CM

F

FM

I

FM

O

SM

LM

1,2

Th

1

Th

2

Compressor motor

Fuse

Fan motor(Indoor)

Fan motor(Outdoor)

Flap motor

Louver motor

Room temp.sensor

Heat exch.sensor(Indoor unit)

Capacitor for CM

Capacitor for FM

O

Terminal block

Operation indication (DC12)

Heating indication (DC12)

ON indication for CM(DC12)

Check indication (DC12)

Distant operation

Humidity sensor

Heat exch.sensor(Outdoor unit)

Outdoor air temp.sensor

Discharge pipe temp.sensor

Varistor

Electronic expansion valve

Diode stack

Auxiliary relay

Th

3

Th

4

Th

5

Th

6

ZNR

EEV

DS

52

X1~5

CC

CF

O

TB

XR1

XR2

XR3

XR4

XR5

Parts name

BL

OR

Y/G

Black

Blue

Orange

Yellow/Green

WH White

RD Red

GR Green

Y Yellow

Parts name Parts nameSymbol Symbol

BK

WH

RD

WH

RD

WH

OR

Y

RD

BL

BK

WH

BK

Y

Y

CM2

CM1

W

V

U

52X1

52X3

52X4

52X5

Power Source

1 Phase

220-240V 50Hz

To wired

remote

control

(Option)

R-AMP

Wireless

Display

board

Printed circuit

Printed circuit

board

CNU

JEM-A

CNB

CNU

CNE

CNG

FM

I

CM

EEV

FMo

CF

O

52X

1

52X

3

52X

4

52X

5

Th4

Th5

Th6

Outdoor unit

Indoor unit

Th3Th2Th1

~~

-

12

-

Model SRK52CF-BP

DS

+

~

-

~

J

N

L

CC

11

9

7

3

5

CNU

JEM-A

CNB

CNE CNF

CNM

CNX

CNY

CNT

Option

XR1

XR2

XR3

XR4

XR5

CNG

SM

LM1

LM2

HA

J

RD

Y/GN

G

Y/GN

BK

2/N

1

WH

3

2/N

1

3

L

N

RD

Y/GN

BK

R/LS/N

WH

WH

RD

BK

1

3

Y

BL

4

5

6

ZNR

ZNR

F

250V

3.15A

F

250V

3.15A

Terminal block

TB TB

XZ

Y

XZ

Y

RD

WH

BK

BK

Color symbol

Meaning of marks

Symbol

CM

F

FM

I

FM

O

SM

LM

1,2

Th

1

Th

2

Compressor motor

Fuse

Fan motor(Indoor)

Fan motor(Outdoor)

Flap motor

Louver motor

Room temp.sensor

Heat exch.sensor(Indoor unit)

Capacitor for CM

Capacitor for FM

O

Terminal block

Operation indication (DC12)

Heating indication (DC12)

ON indication for CM(DC12)

Check indication (DC12)

Distant operation

Humidity sensor

Heat exch.sensor(Outdoor unit)

Outdoor air temp.sensor

Discharge pipe temp.sensor

Varistor

Electronic expansion valve

Diode stack

Auxiliary relay

Th

3

Th

4

Th

5

Th

6

ZNR

EEV

DS

52

X1~4

CC

CF

O

TB

XR1

XR2

XR3

XR4

XR5

Parts name

BL

OR

Y/G

Black

Blue

Orange

Yellow/Green

WH White

RD Red

GR Green

Y Yellow

Parts name Parts nameSymbol Symbol

BK

WH

RD

WH

RD

WH

OR

Y

RD

BL

WH

BK

Y

Y

CM2

CM1

W

V

U

52X1

52X3

52X4

Heat

exchanger

To wired

remote

control

(Option)

Power Source

1 Phase

220V 60Hz

R-AMP

Wireless

Display

Printed circuit

board

Printed circuit

board

CNU

CNE

CNG

FM

I

CM

52X

1

52X

3

52X

4

EEV

FMo

CF

O

Th4

Th5

Th6

Outdoor unit

Indoor unit

Th3Th2Th1

-

13

-

Model SRK71CF-BP

DS

+

-

J

N

L

CC

11

9

7

3

1

5

Option

XR1

XR2

XR3

XR4

XR5

CNE CNFCNM

CNX

CNY

CNT

CNG

SM

LM1

LM2

Heat

HA

J

RD

Y/GN

G

Y/GN

BK

2/N

1

WH

3

2/N

1

3

L

N

RD

Y/GN

BK

R/LS/N

WH

WH

RD

BK

1

3

Y

BL

4

5

6

exchanger

ZNR

ZNR

F

250V

3.15A

F

250V

3.15A

Terminal block

TB TB

XZ

Y

XZ

Y

RD

WH

BK

BK

Color symbol

Meaning of marks

Symbol

CM

F

FM

I

FM

O

SM

LM

1,2

Th

1

Th

2

Compressor motor

Fuse

Fan motor(Indoor)

Fan motor(Outdoor)

Flap motor

Louver motor

Room temp.sensor

Heat exch.sensor(Indoor unit)

Capacitor for CM

Capacitor for FM

O

Terminal block

Operation indication (DC12)

Heating indication (DC12)

ON indication for CM(DC12)

Check indication (DC12)

Distant operation

Humidity sensor

Heat exch.sensor(Outdoor unit)

Outdoor air temp.sensor

Discharge pipe temp.sensor

Varistor

Electronic expansion valve

Diode stack

Auxiliary relay

Th

3

Th

4

Th

5

Th

6

ZNR

EEV

DS

52

X1~5

CC

CF

O

TB

XR1

XR2

XR3

XR4

XR5

Parts name

BL

OR

Y/G

Black

Blue

Orange

Yellow/Green

WH White

RD Red

GR Green

Y Yellow

Parts name Parts nameSymbol Symbol

BK

WH

RD

WH

RD

WH

OR

Y

RD

BL

BK

WH

BK

Y

Y

CM2

CM1

W

V

U

52X1

52X3

52X4

52X5

Power Source

1 Phase

220V 60Hz

To wired

remote

control

(Option)

R-AMP

Wireless

Display

board

Printed circuit

Printed circuit

board

CNU

JEM-A

CNB

CNU

CNE

CNG

FM

I

CM

EEV

FMo

CF

O

52X

1

52X

3

52X

4

52X

5

Th4

Th5

Th6

Outdoor unit

Indoor unit

Th3Th2Th1

~~

-

14

-

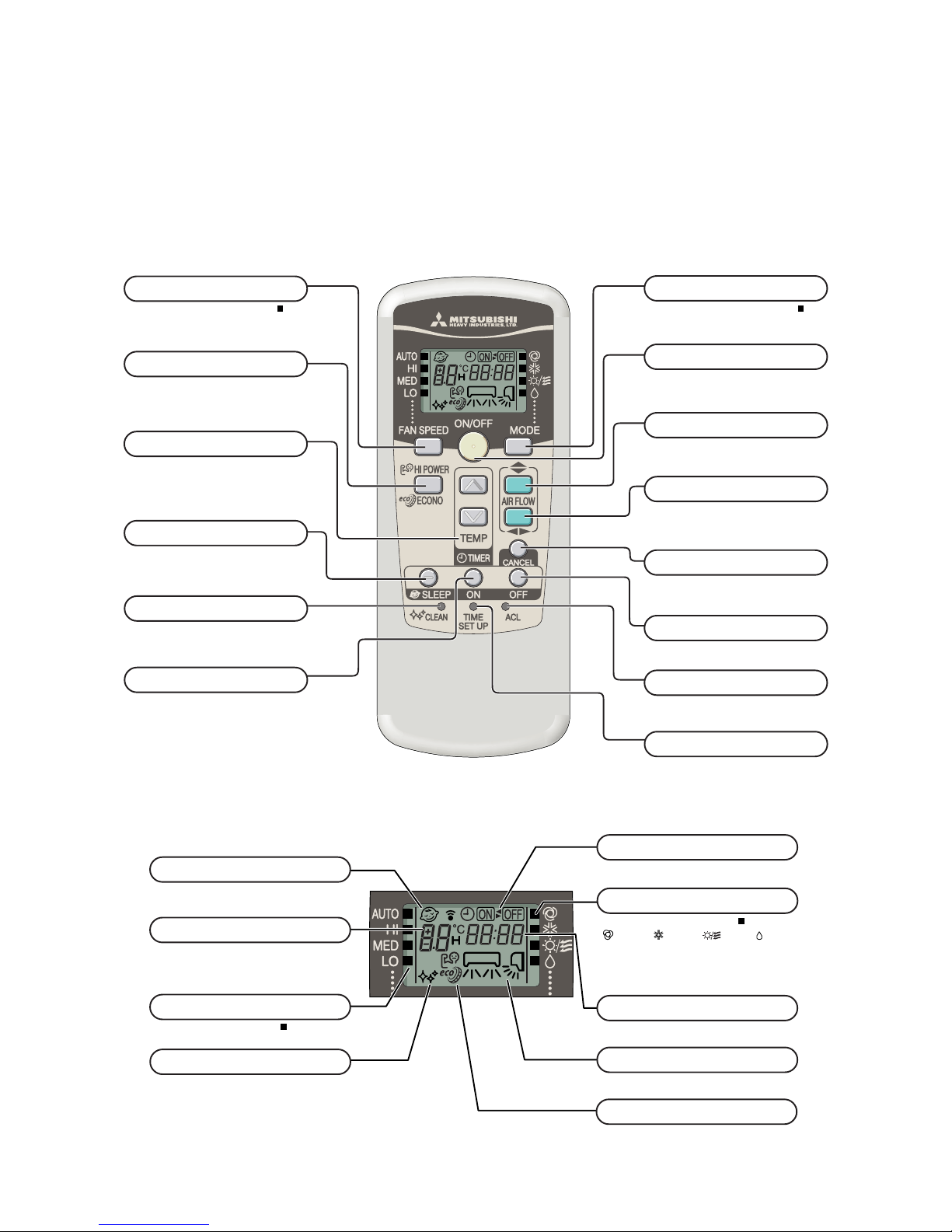

S Indication section

Models All models

S Operation section

4. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

4.1 Operation control function by remote control switch

(1) Wireless remote control

FAN SPEED button

Each time the button is pushed, the indicator is switched over in turn.

• The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pushed, the indicator is switched over in turn.

ON/OFF (luminous) button

Press for starting operation, press again for

stopping.

HI POWER/ECONO button

This button changes the HIGH POWER/

ECONOMY mode.

AIR FLOW (UP/DOWN) button

This button changes the air flow (up/down)

mode.

TIME SET UP switch

This switch for setting the time.

SLEEP button

This button selects SLEEP operation.

CLEAN switch

This switch changes the CLEAN mode.

ON TIMER button

This button selects ON TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

OFF TIMER button

This button selects OFF TIMER operation.

RESET switch

Switch for resetting microcomputer.

OPERATION MODE indicator

Indicates selected operation with lamp.

[ (Auto) • (Cool) • (Fan) • (Dry)]

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with lamp.

CLEAN indicator

Indicates during CLEAN operation.

SLEEP indicator

Indicates during SLEEP operation.

ON/OFF TIMER indicator

Indicates during ON/OFF TIMER operation.

TIME indicator

Indicates present time or timer setting time.

AIR FLOW indicator

Shows selected flap and louver mode.

AIR FLOW (LEFT/RIGHT) button

This button changes the air flow (left/right)

mode.

CANCEL button

This button cancels the ON timer, OFF

timer, and SLEEP operation.

HI POWER/ ECONO MODE indicator

Indicates during High power/economy mode

operation.

-

15

-

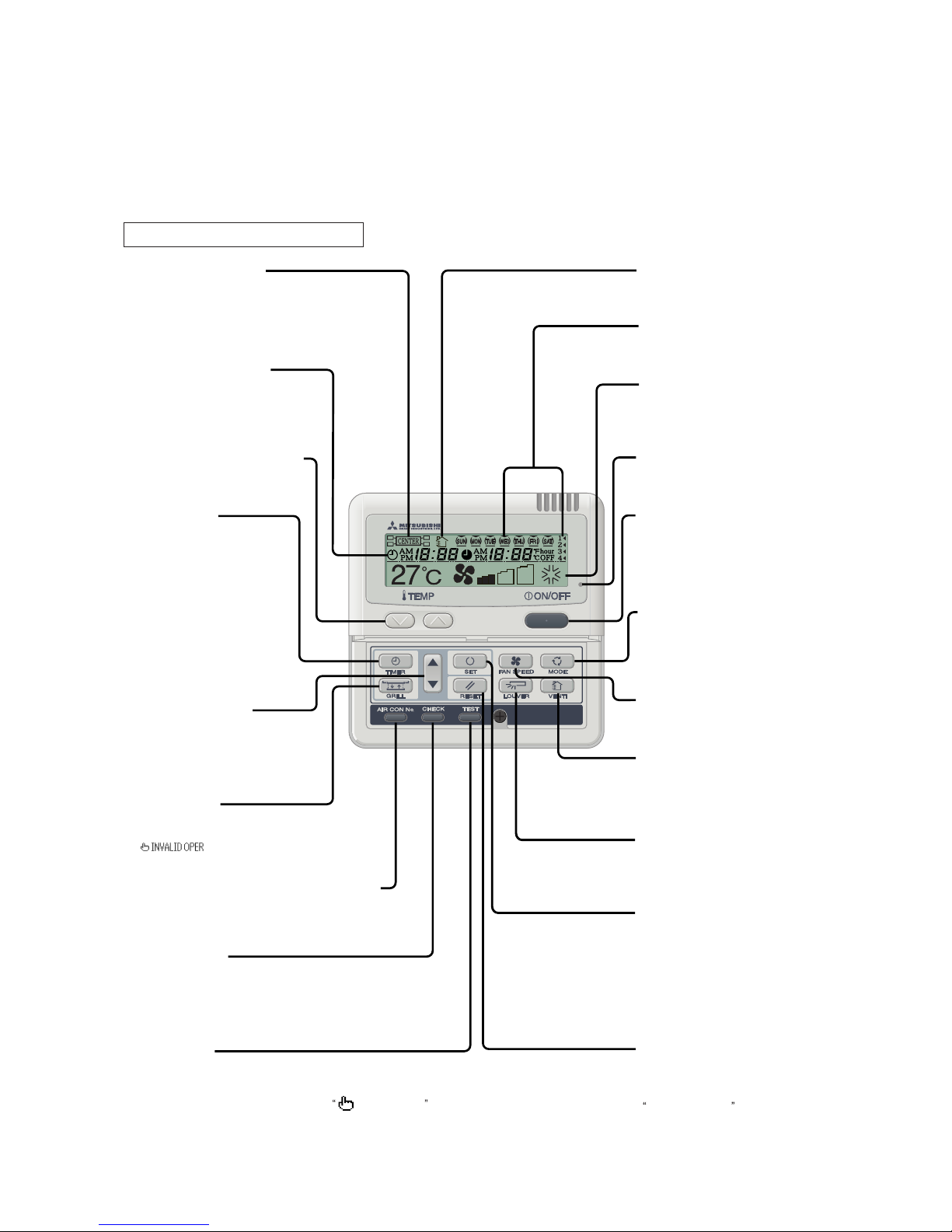

(2) Wired remote control (Optional parts)

The figure below shows the remote control with the cover opened. Note that all the items that may be displayed in the liquid crystal display

area are shown in the figure for the sake of explanation.

Characters displayed with dots in the liquid crystal display area are abbreviated.

Pull the cover downward to open it.

Weekly timer display

Displays the settings of

the weekly timer.

[Vent indicator]

Indicates operation in the

ventilation mode.

Operation/Stop switch

This switch is used to operate and

stop the air conditioning system.

Press the switch once to operate

the system and press it once again to

stop the system.

MODE switch

This switch is used to switch between

operation modes.

(The clean operation cannot be selected.)

Operation setting display area

Displays setting temperature,

airflow volume, operation mode and

operation message.

Operation/Check indicator light

During operation: Lit in green

In case of error: Flashing in red

FAN SPEED switch

This switch is used to set the

airflow volume.

(AUTO, HI POWER or ECONO

cannot be selected.)

SET switch

This switch is used to apply the timer

operation setting.

This switch is also used to make silent

mode operation settings.

[RESET switch]

Press this switch while making settings

to go back to the previous operation.

This switch is also used to reset the

FILTER CLEANING message display.

(Press this switch after cleaning the air filter.)

Central control display

Displayed when the air conditioning

system is controlled by the option controller.

Timer operation display

Displays the settings related to

timer operation.

AIR CON No. (Air conditioning system No.) switch

Displays the number of the connected

air conditioning system.

("00" appears.)

[CHECK switch]

This switch is used at servicing.

[TEST switch]

This switch is used during test operation.

Temperature setting switches

These switches are used to set

the temperature of the room.

[VENT switch]

Switch that operates the

connected ventilator.

Timer setting switches

These switches are used to set

the timer mode and time.

TIMER switch

This switch is used to select

a timer mode.

(The comfortable timer or sleep

operation cannot be selected.)

[GRILL switch]

This switch has no function.

When this switch is pressed,

(Invalid Operation)

is displayed, but it does not mean a failure.

LOUVER switch

This switch is used to operate/stop

the swing louver.

(UP/down swing only)

* If you press any of the switches above and INVALID OPER is display, the switch has no function.

But it does not mean a failure.

Note (1) The SRK models don't support the switches and functions displayed in [ ].

Loading...

Loading...