Mitsubishi Heavy Industries SRK63ZE-S1, SRK25ZD-S1, SRK35ZD-S1, SRK50ZD-S1, SRK71ZE-S1 Technical Manual

...

-

3

-

INVERTER WALL MOUNTED TYPE ROOM AIR-CONDITIONER

( Split system, air to air heat pump type )

SRK20ZD-S1, SRK25ZD-S1, SRK35ZD-S1, SRK50ZD-S1

SRK63ZE-S1, SRK71ZE-S1

WALL MOUNTED TYPE ROOM AIR-CONDITIONER

( Split system, air to air heat pump type )

SRK20HD-S1, SRK28HD-S1, SRK40HD-S1

SRK20HC-S2, SRK28HC-S2, SRK40HC-S2

SRK50HE-S1, SRK56HE-S1

SRK63HE-S1, SRK71HE-S1

WALL MOUNTED TYPE ROOM AIR-CONDITIONER

( Split system, air cooled cooling only type )

SRK20CD-S1, SRK28CD-S1, SRK40CD-S1

SRK20CC-S1, SRK28CC-S1, SRK40CC-S1

SRK50CE-S1, SRK56CE-S1

SRK63CE-S1, SRK71CE-S1

Manual No. ’06

.

SRK-T

.

050

updated September 29, 2009

TABLE OF CONTENTS

1. INVERTER WALL MOUNTED TYPE ROOM AIR-CONDITIONER

(Split system, air to air heat pump type) ...................................................................... 001

2. WALL MOUNTED TYPE ROOM AIR-CONDITIONER

(Split system, air to air heat pump type) ...................................................................... 137

3. WALL MOUNTED TYPE ROOM AIR-CONDITIONER

(Split system, air cooled cooling only type) ................................................................. 261

-

1

-

1.1 SRK20ZD-S1

SRK25ZD-S1

SRK35ZD-S1

SRK50ZD-S1 ............................................................ 2

1.2 SRK63ZE-S1

SRK71ZE-S1............................................................. 70

1. INVERTER WALL MOUNTED TYPE

ROOM AIR-CONDITIONER

Split system, air to air

heat pump type

( )

-

2

-

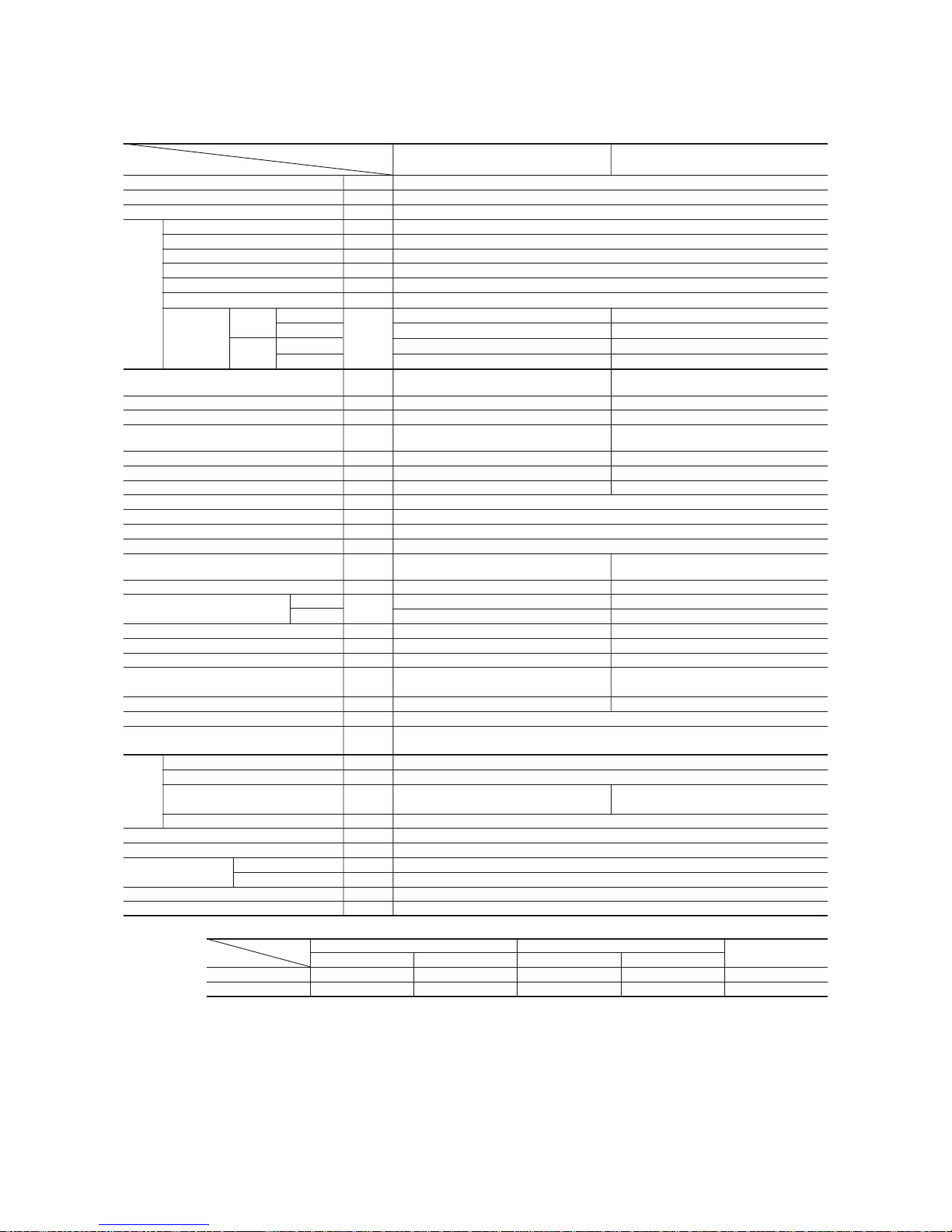

CONTENTS

1.1.1 GENERAL INFORMATION....................................................................... 3

(1) Specific features.................................................................................... 3

(2) How to read the model name................................................................ 3

1.1.2 SELECTION DATA.................................................................................... 4

(1) Specifications ........................................................................................ 4

(2) Range of usage & limitations ............................................................... 8

(3) Exterior dimensions.............................................................................. 8

(4) Piping system ........................................................................................ 10

(5) Selection chart....................................................................................... 11

1.1.3 ELECTRICAL DATA ................................................................................. 12

(1) Electrical wiring..................................................................................... 12

1.1.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............ 14

(1) Operation control function by remote control switch ....................... 14

(2) Unit ON/OFF button............................................................................... 15

(3) Power blackout auto restart function.................................................. 15

(4) Flap control............................................................................................ 16

(5) Comfortable timer setting..................................................................... 16

(6) Outline of heating operation ................................................................ 17

(7) Outline of cooling operation ................................................................ 19

(8) Outline of dehumidifying operation..................................................... 20

(9) Outline of automatic operation ............................................................22

(10) Economical operation ........................................................................... 22

(11) Protective control function................................................................... 22

1.1.5 APPLICATION DATA ................................................................................ 28

(1) Selection of location for installation ................................................... 29

(2) Installation of indoor unit .....................................................................30

(3) Installation of outdoor unit ................................................................... 32

(4) Refrigerant piping ................................................................................. 32

(5) Test run................................................................................................... 34

(6) Precautions for wireless remote controller installation and

operation ................................................................................................35

1.1.6 MAINTENANCE DATA .............................................................................36

(1) Troubleshooting procedures for electrical equipment ...................... 36

(2) Servicing ................................................................................................ 54

1.1.7 REFRIGERANT PIPING INSTALLATION/SERVICING MANUAL

FOR AIR CONDITIONERS USING R410A............................................... 55

(1) Outline ....................................................................................................55

(2) Refrigerant piping installation ............................................................. 56

(3) Installation, removal and servicing ..................................................... 62

(4) Refrigerant recovery ............................................................................. 67

-

3

-

Over heat of compressor

Error of signal transmission

Outdoor fan motor error

1.1.1 GENERAL INFORMATION

(1) Specific features

The “MITSUBISHI HEAVY INDUSTRIES, LTD” room air-conditioner: SRK series are of split and wall mounted type and the unit

consists of indoor unit and outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling or

heating equipment with operation control switch and the outdoor unit is composed of condensing unit with compressor.

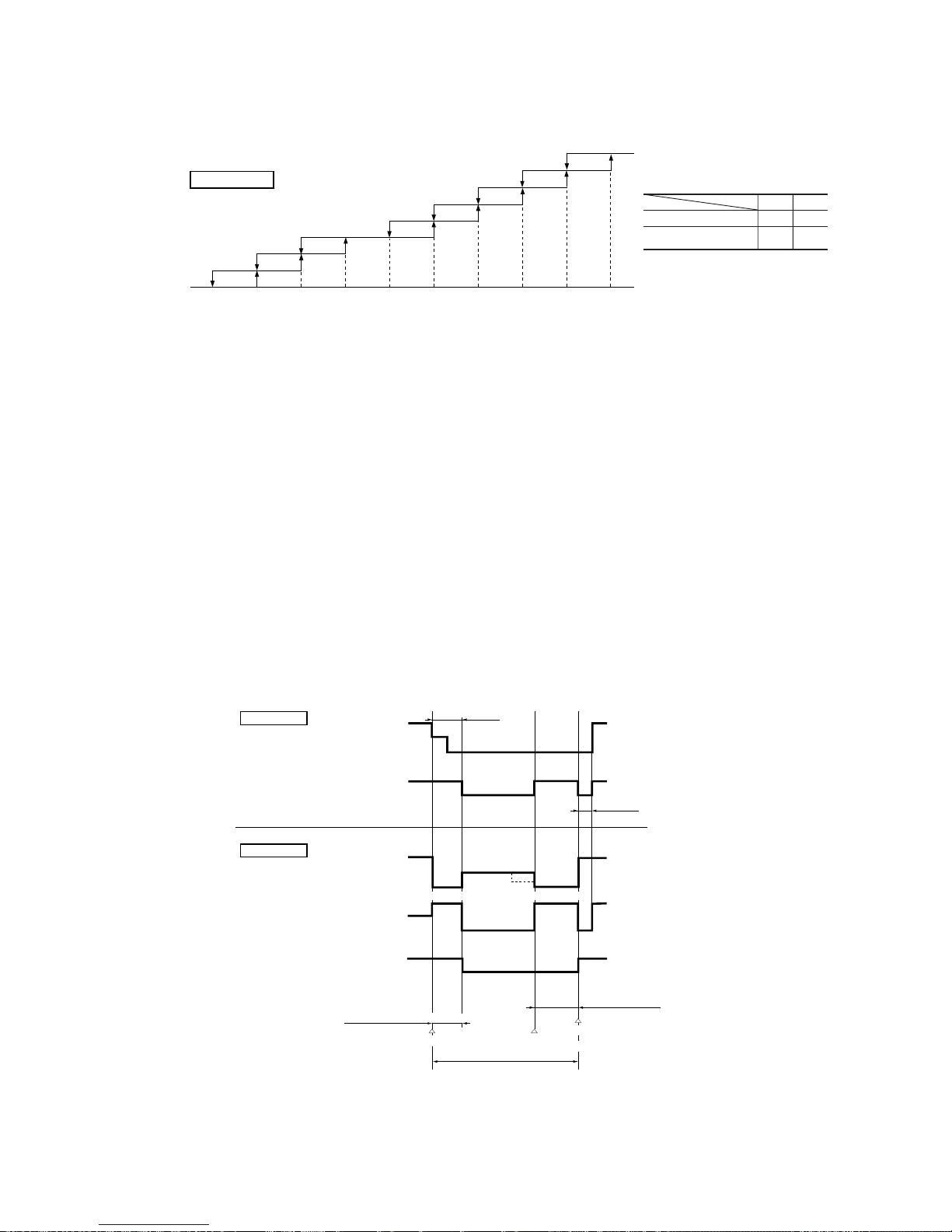

(a) Inverter (Frequency converter) for multi-steps power control

¡ Heating/Cooling

The rotational speed of a compressor is changed in step in relation to varying load, interlocked with the indoor and outdoor unit

fans controlled to change frequency, thus controlling the capacity.

¡ Allowing quick heating/cooling operation during start-up period. Constant room temperature by fine-tuned control after the

unit has stabilized.

(b) Fuzzy control

¡ Fuzzy control calculates the amount of variation in the difference between the return air temperature and the setting temperature

in compliance with the fuzzy rules in order to control the air capacity and the inverter frequency.

(c) Remote control flap

The flap can be automatically controlled by operating wireless remote control.

¡ Air scroll (AUTO): Flap operation is automatically control.

¡ Swing: This will swing the flap up and down.

¡ Memory flap: Once the flap position is set, the unit memorizes the position and continues to operate at the same position from

the next time.

(d) Self diagnosis function

¡ We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows.

Outdoor heat exchanger liquid

pipe sensor error

Discharge pipe sensor error

Outdoor temperature sensor error

2 time flash

4 time flash

RUN light

keeps flashing

1 time flash

Trouble of outdoor unit

Over current

Current cut

2 time flash

3 time flash

RUN light

ON

1 time flash

5 time flash

TIMER light

R410A models

Series No.

Inverter type

Product capacity

Wall mounted type

Split type room air-conditioner

(2) How to read the model name

Example : SR K 35 Z D - S1

Room temperature sensor error

Indoor fan motor error

Heat exchanger sensor error

2 time flash

6 time flash

TIMER light

ON

1 time flash

RUN light

Rotor lock

6 time flash

7 time flash

2 time flash

RUN light

2 time flash

-

4

-

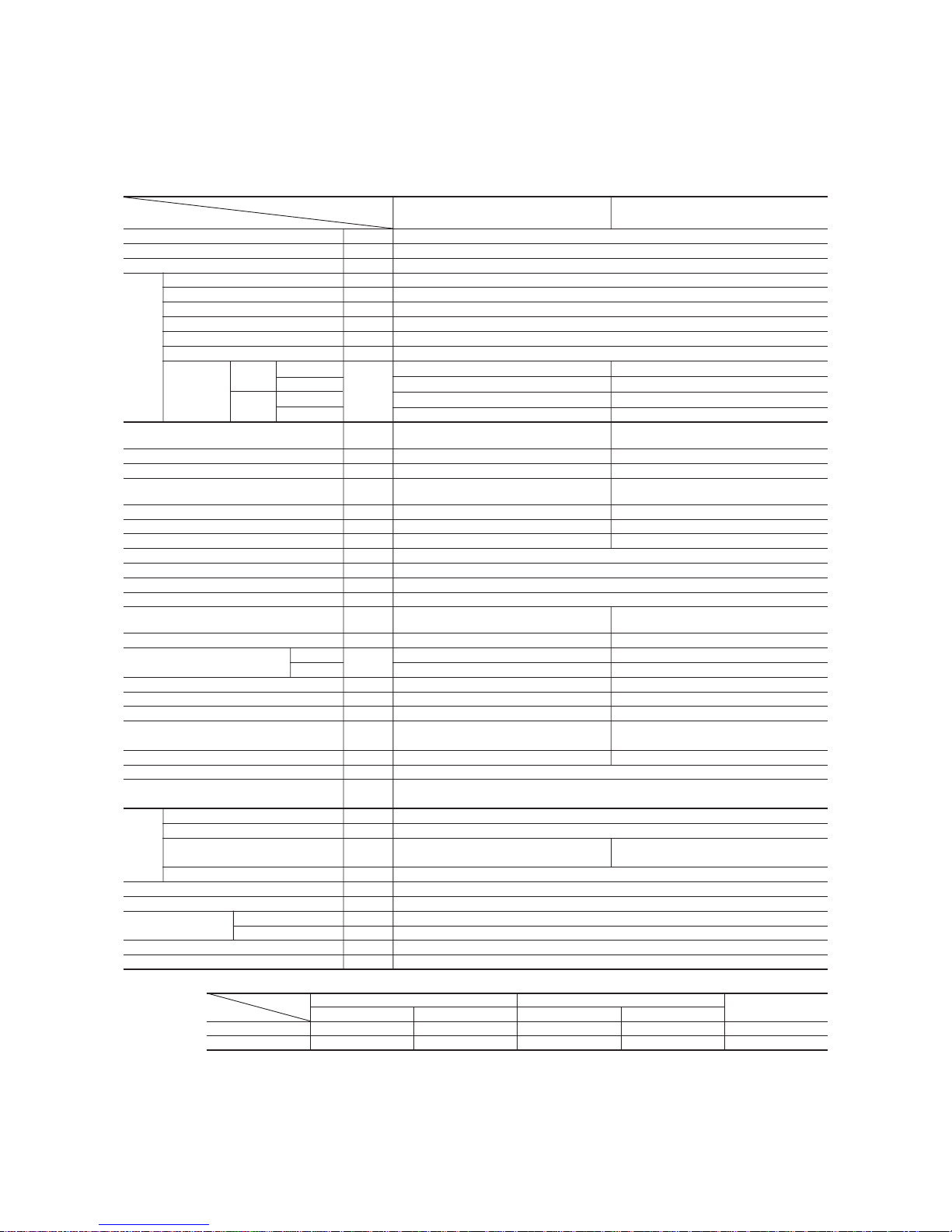

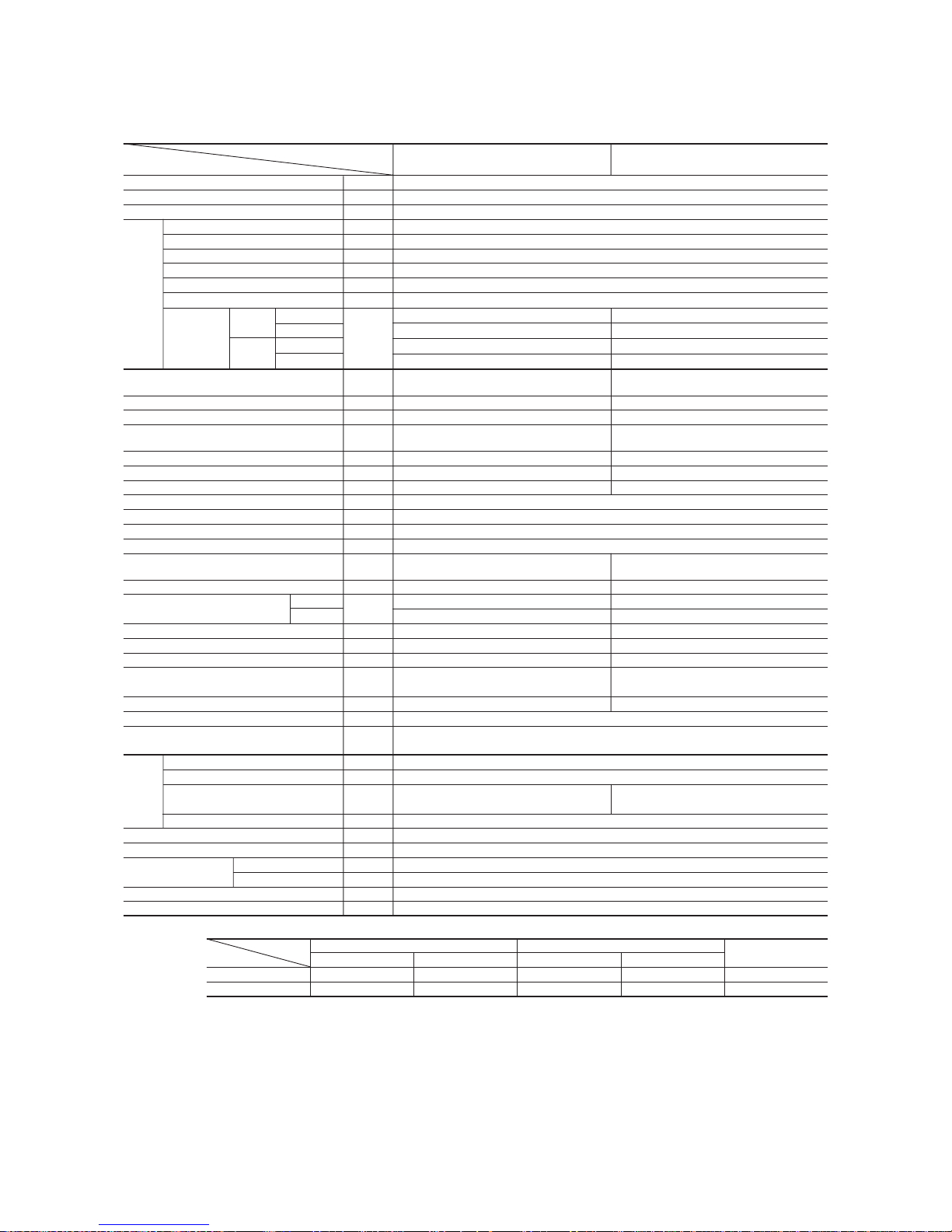

Item

Model

SRK20ZD-S1 SRC20ZD-S1

Cooling capacity

(1)

W 2000 (500~2800)

Heating capacity

(1)

W 2700 (500~4600)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 0.44 (0.1~0.91)

Running current (Cooling) A 2.4/2.3/2.2

Heating input kW 0.62 (0.09~1.27)

Running current (Heating) A 3.0/2.9/2.8

Inrush current A 3.0/2.9/2.8

COP Cooling: 4.55 Heating: 4.35

Cooling

Sound level Hi 36, Me 29, Lo 21 44

Noise level

Power level

dB

52 58

Heating

Sound level Hi 38, Me 32, Lo 25 47

Power level 54 61

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 9.0 32

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 0.9 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 29 24

(Cooling) 7.2 30

Air flow (at High)

(Heating)

CMM

8.3 25

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.47 m

Gas line : 0.40 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter x1, Photocatalytic washable deodorizing filter x1)

Optional parts –

Notes (1) The data are measured at the following conditions.

1.1.2 SELECTION DATA

(1) Specifications

Model SRK20ZD-S1 (Indoor unit)

SRC20ZD-S1 (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

5

-

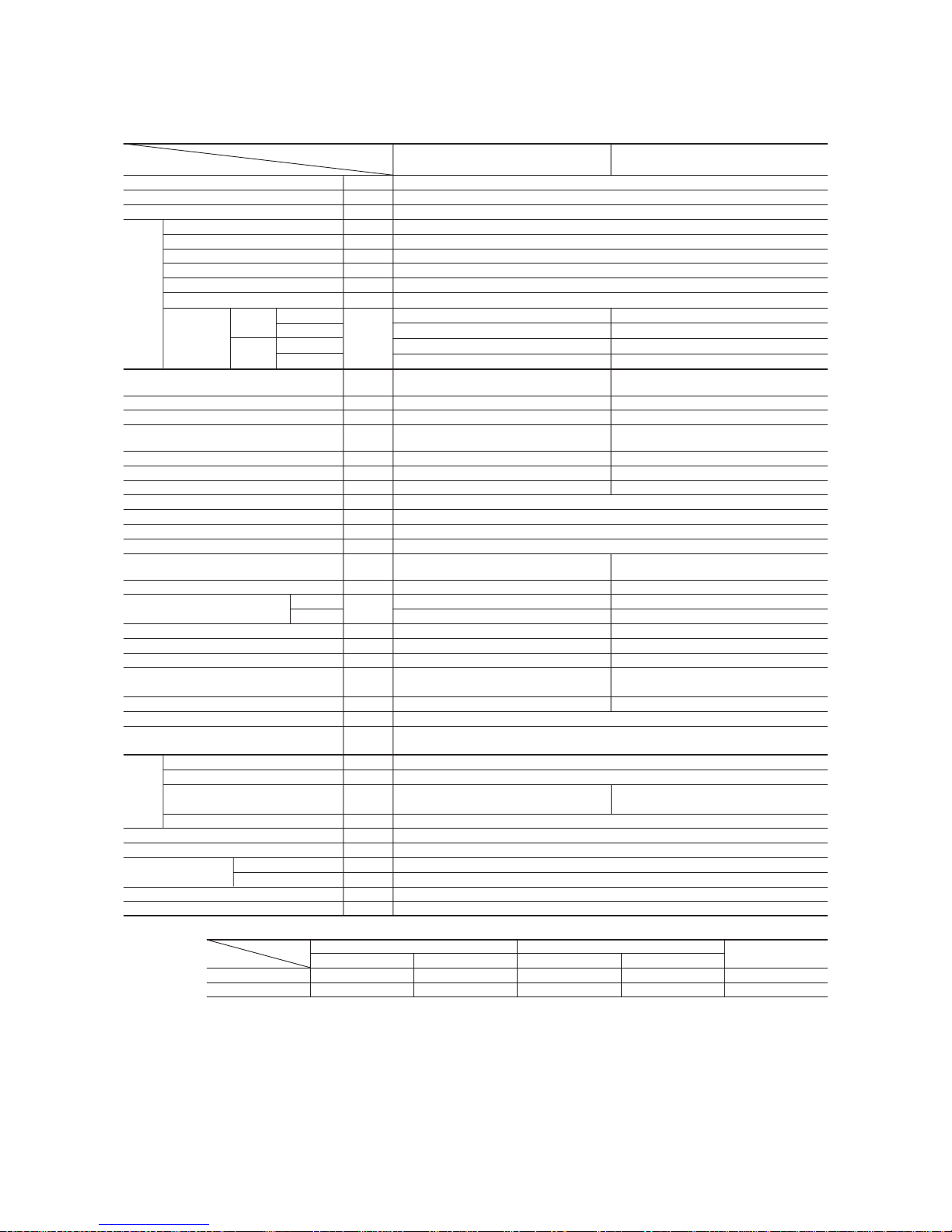

Item

Model

SRK25ZD-S1 SRC25ZD-S1

Cooling capacity

(1)

W 2500 (500~3000)

Heating capacity

(1)

W 3400 (500~4800)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 0.62 (0.1~0.97)

Running current (Cooling) A 3.1/3.0/2.9

Heating input kW 0.94 (0.09~1.30)

Running current (Heating) A 4.5/4.3/4.1

Inrush current A 4.5/4.3/4.1

COP Cooling: 4.03 Heating: 3.62

Cooling

Sound level Hi 37, Me 30, Lo 22 44

Noise level

Power level

dB

53 58

Heating

Sound level Hi 39, Me 33, Lo 26 47

Power level 55 61

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 9.0 32

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 0.9 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 29 24

(Cooling) 8.0 30

Air flow (at High)

(Heating)

CMM

8.7 25

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.47 m

Gas line : 0.40 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter x1, Photocatalytic washable deodorizing filter x1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK25ZD-S1 (Indoor unit)

SRC25ZD-S1 (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

6

-

Item

Model

SRK35ZD-S1 SRC35ZD-S1

Cooling capacity

(1)

W 3500 (500~3900)

Heating capacity

(1)

W 4500 (500~5100)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 1.09 (0.1~1.22)

Running current (Cooling) A 5.4/5.2/5.0

Heating input kW 1.24 (0.09~1.32)

Running current (Heating) A 5.9/5.7/5.4

Inrush current A 5.9/5.7/5.4

COP Cooling: 3.21 Heating: 3.63

Cooling

Sound level Hi 41, Me 32, Lo 23 48

Noise level

Power level

dB

58 62

Heating

Sound level Hi 45, Me 36, Lo 27 50

Power level 59 64

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 9.0 35

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 [Rotary type] × 1

Motor kW – 0.90

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.1 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 29 24

(Cooling) 8.9 34

Air flow (at High)

(Heating)

CMM

10.3 34

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.47 m

Gas line : 0.40 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter x1, Photocatalytic washable deodorizing filter x1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK35ZD-S1 (Indoor unit)

SRC35ZD-S1 (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

7

-

Model SRK50ZD-S1 (Indoor unit)

SRC50ZD-S1 (Outdoor unit)

Item

Model

SRK50ZD-S1 SRC50ZD-S1

Cooling capacity

(1)

W 5000 (600~5300)

Heating capacity

(1)

W 6300 (600~7900)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 1.66 (0.12~2.1)

Running current (Cooling) A 7.6/7.3/7.0

Heating input kW 1.96 (0.11~2.71)

Running current (Heating) A 9.0/8.6/8.2

Inrush current A 9.0/8.6/8.2

COP Cooling: 3.01 Heating: 3.21

Cooling

Sound level Hi 48, Me 42, Lo 26 48

Noise level

Power level

dB

61 61

Heating

Sound level Hi 46, Me 40, Lo 34 50

Power level 62 64

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 640 × 850 × 290

Color Cool white Stucco white

Net weight kg 9.0 43

Refrigerant equipment

Compressor type & Q’ty

– 5CS102XFA [Scroll type] × 1

Motor kW – 1.5

Starting method – Line starting

Heat exchanger Slit fins + Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.35 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.36 (RB68A)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 29 34

(Cooling) 11.5 42

Air flow (at High)

(Heating)

CMM

13.0 42

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.47 m

Gas line : 0.40 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Natural enzyme filter x1, Photocatalytic washable deodorizing filter x1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is longer, when it is 15 to 25m, add 20 g refrigerant per meter.

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

8

-

(2) Range of usage & limitations

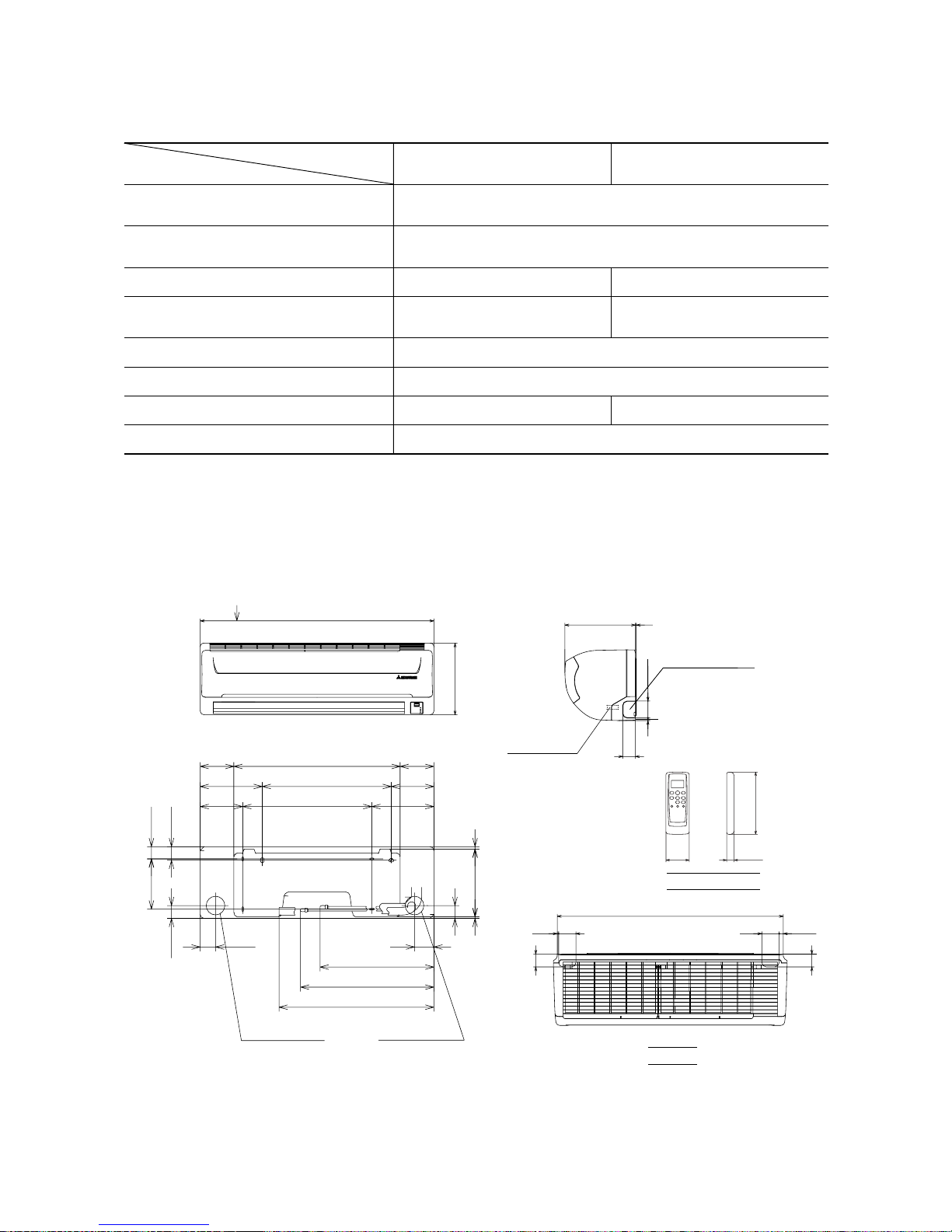

(3) Exterior dimensions

(a) Indoor unit

Models SRK20ZD-S1, 25ZD-S1, 35ZD-S1, 50ZD-S1

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length Max. 15m

SRK20ZD-S1, 25ZD-S1, 35ZD-S1 SRK50ZD-S1

Cooling operation : Approximately 21 to 32˚C

Heating operation : Approximately 15 to 30˚C

Cooling operation : Approximately 21 to 43˚C

Heating operation : Approximately

-

5 to 21˚C

Power source voltage Rating ± 10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle

Max. 7 times/h

(Inching prevention 5 minutes)

Max. 4 times/h

(Inching prevention 10 minutes)

ON and OFF interval Max. 3 minutes

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Max. 10m (Outdoor unit is higher)

Max. 10m (Outdoor unit is lower)

Max. 25m

Max. 15m (Outdoor unit is higher)

Max. 15m (Outdoor unit is lower)

Item

Models

VIEW A

117.5

580 117.5

148.5

216.5216.5

8.2

44.5

236.1

5.7

450

450

67.5

42.7

47.2

175

44.5

216.5216.5

148.5

53.5

Piping for Gas

Drain hose 540 (ø16)

Piping for Liquid 465.1 (ø6.35)

Piping hole (ø65)

Piping hole (ø65)

( )

20,25,35: ø9.52

50:

ø

12.7

397.1

45

14.5

60

788

5

60

45

815

A

250

Unit: mm

Piping hole right(left)

Terminal block

9

60

45

3

249

150

18

56

Remote controller

-

9

-

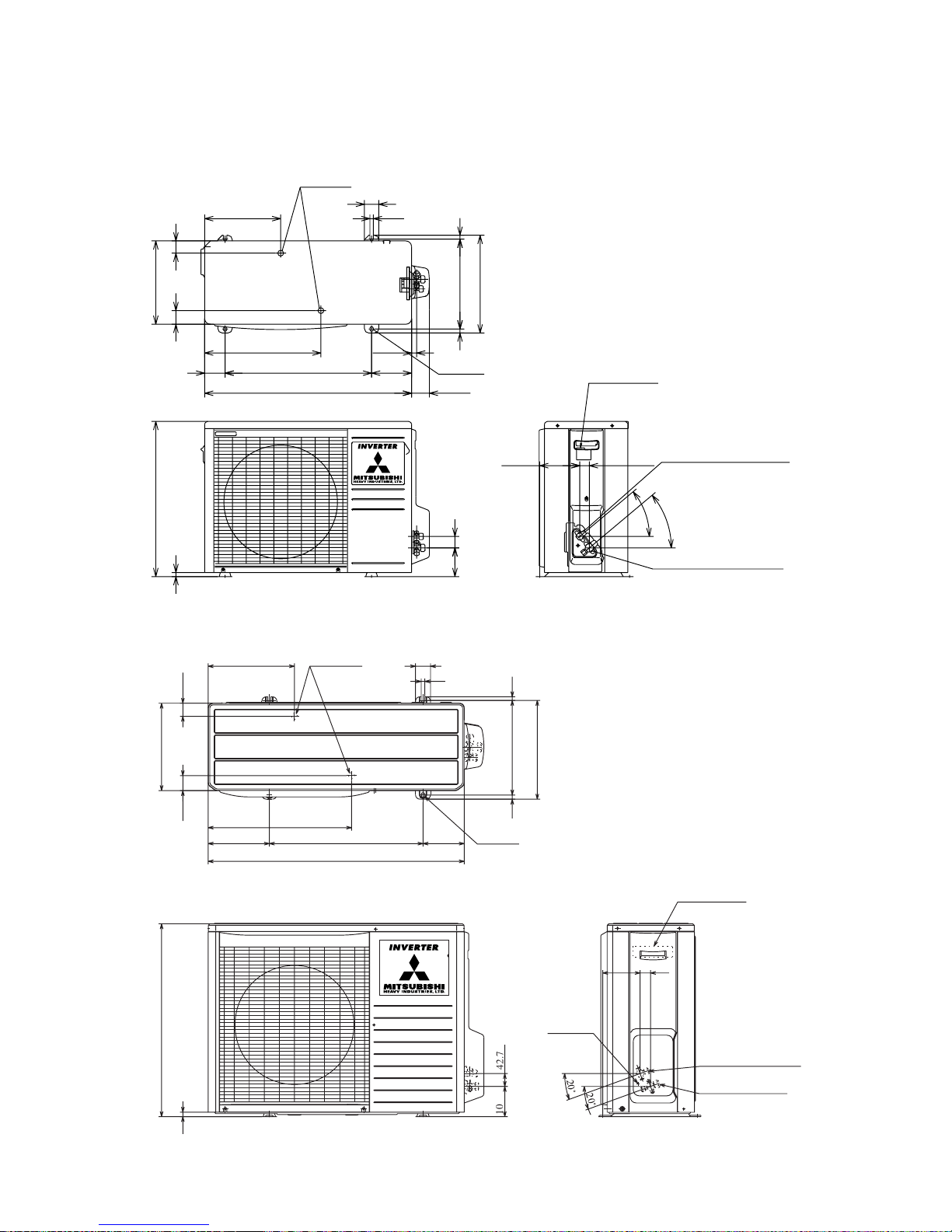

(b) Outdoor unit

Models SRC20ZD-S1, 25ZD-S1, 35ZD-S1

Drain holes

286.4

12

50

290

49.6

43.5

850

203.1

510 136.9

476

2-16x12

314

12

328

Terminal block

Service valve (Liquid)

ø6.35 (1/4'')

Service valve (Gas)

ø12.7 (1/2'')

Ground

terminal

124

34.6

20û

20û

42.7

100.3

15

640

14

Model SRC50ZD-S1

Unit: mm

290

540

14.4

47.4 42.6

264.5

71

404.5

510

720

17.8

Drain holes

50

12

39.7

99.9

340

312.5

13.5

14

139

2-16 x12

61.9

139.3 33.3

Flare connection ø6.35 (1/4")

Service valve (Liquid)

40

˚

40

˚

Flare connecting ø9.52 (3/8")

Service valve (Gas)

Terminal block

-

10

-

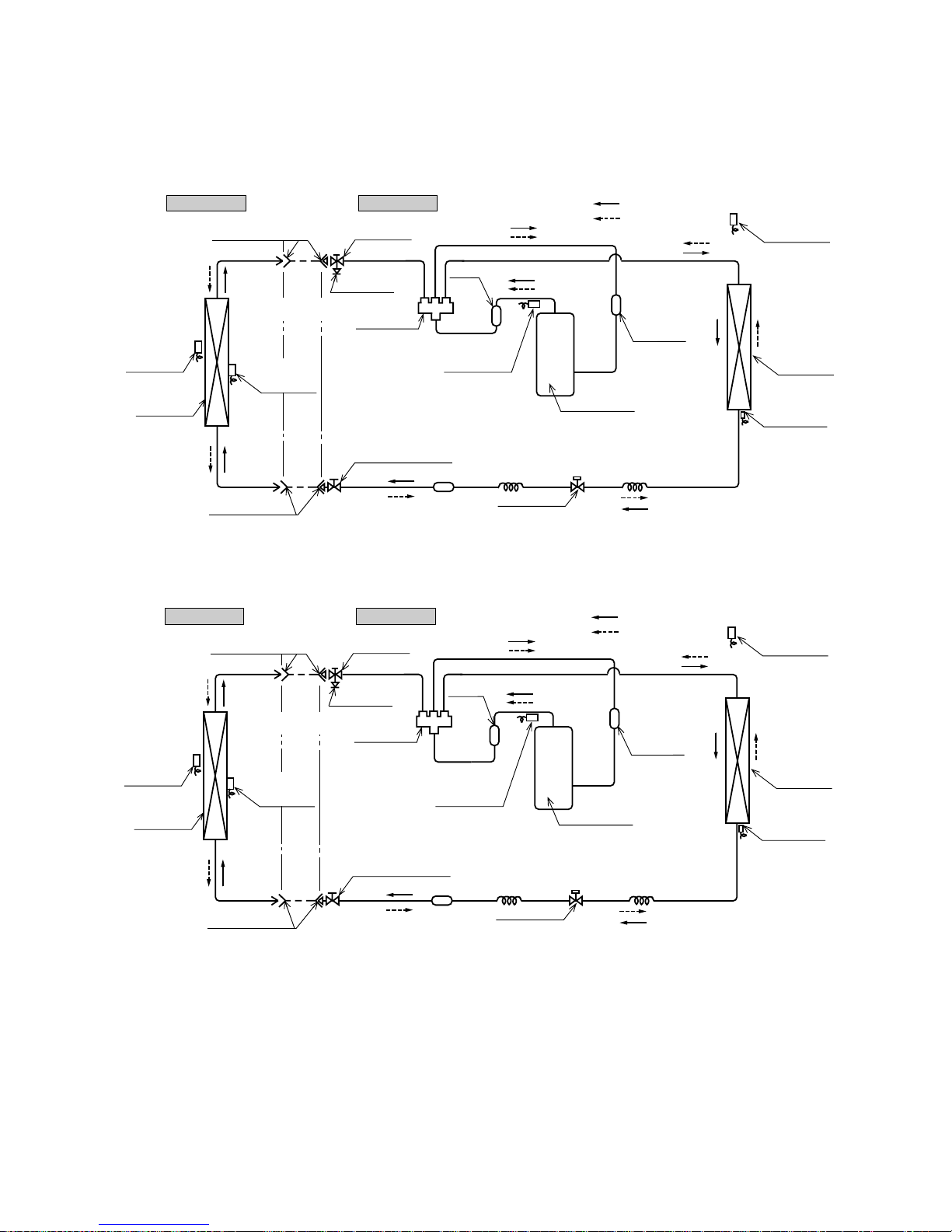

(4) Piping system

Models SRK20ZD-S1, 25ZD-S1, 35ZD-S1

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connection

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

4 way valve

Service valve (Liquid)

Flare connetion

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Accumulator

Service valve

(Gas)

Electronic

expansion valve

Piping

(Gas)

ø9.52

Model SRK50ZD-S1

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connection

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

4 way valve

Service valve (Liquid)

Flare connection

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Strainer

Service valve

(Gas)

Capillary tube

Electronic

expansion valve

Piping

(Gas)

ø12.7

Muffler

Capillary tube

Muffler

-

11

-

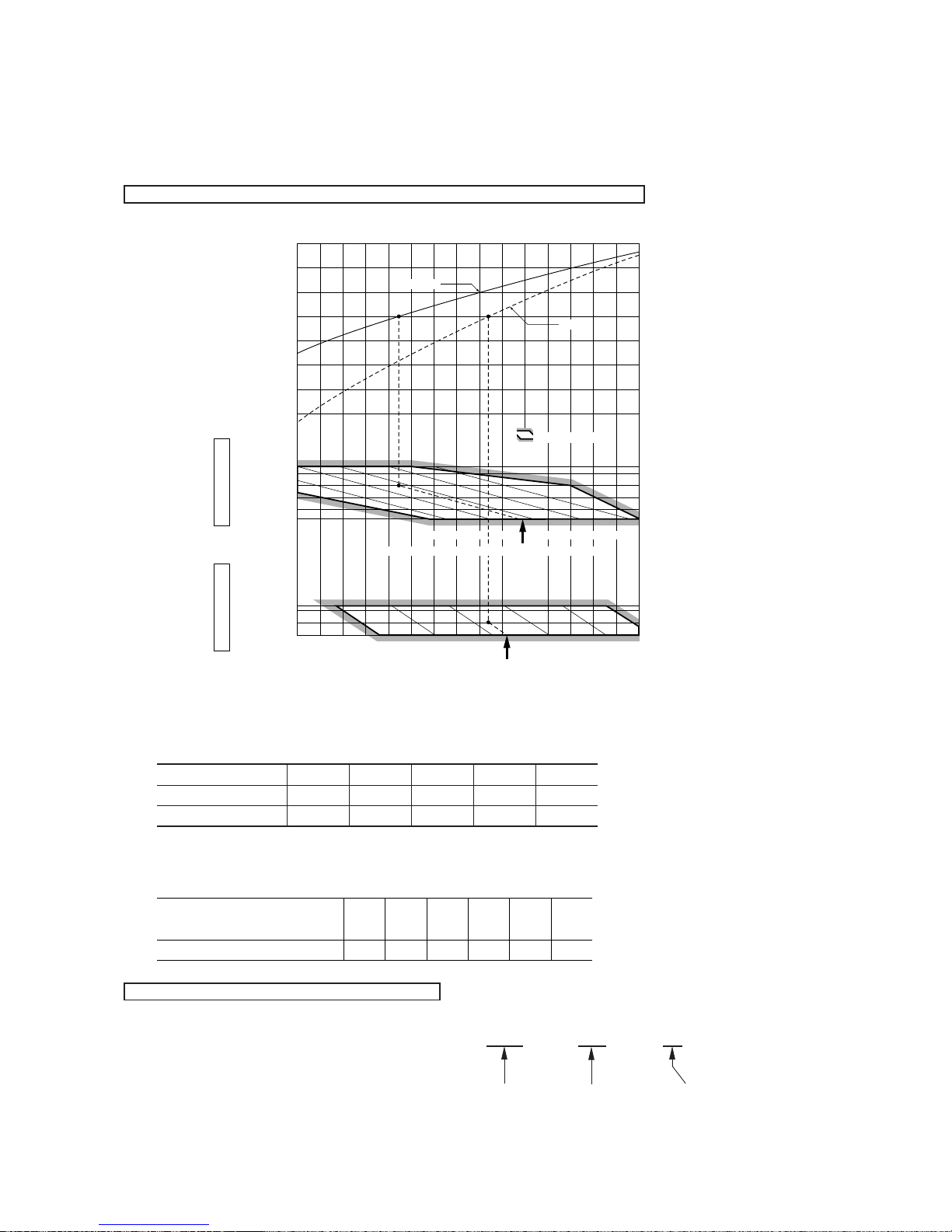

(5) Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

(a) Coefficient of cooling and heating capacity in relation to temperatures

(b) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way piping length between the indoor and outdoor

units.

(c) Correction relative to frosting on outdoor heat exchanger during heating

In additions to the foregoing corrections (a), (b) the heating capacity needs to be adjusted also with respect to the frosting on the

outdoor heat exchanger.

How to obtain the cooling and heating capacity

Example : The net cooling capacity of the model SRK20ZD-S1 with the piping length of 15m, indoor wet-bulb temperature at 19.0˚C

and outdoor dry-bulb temperature 35˚C is Net cooling capacity = 2000 ✕ 0.975 ✕ 1.0 = 1950 W

Length 15m

Factor by air

temperatures

15

ISO-T1 Standard ConditionOutdoor air W.B. temperature ˚C W.B.

1005-5

16 18 20 22 24

20

ISO-T1 Standard ConditionIndoor air W.B. temperature ˚C W.B.

Heating

Applicable range

27

25

20

15

21

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

Cooling

Heating operation

Indoor air D.B.

temperature

˚C D.B.

Cooling operation

Outdoor air D.B.

temperature

˚C D.B.

Coefficient of cooling &

Heating capacity in

relation to temperature

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

Air inlet temperature of

outdoor unit in ˚C WB

Adjustment coefficient

-5

0.91-30.88-10.8610.8730.9251.00

SRK20ZD-S1

-

12

-

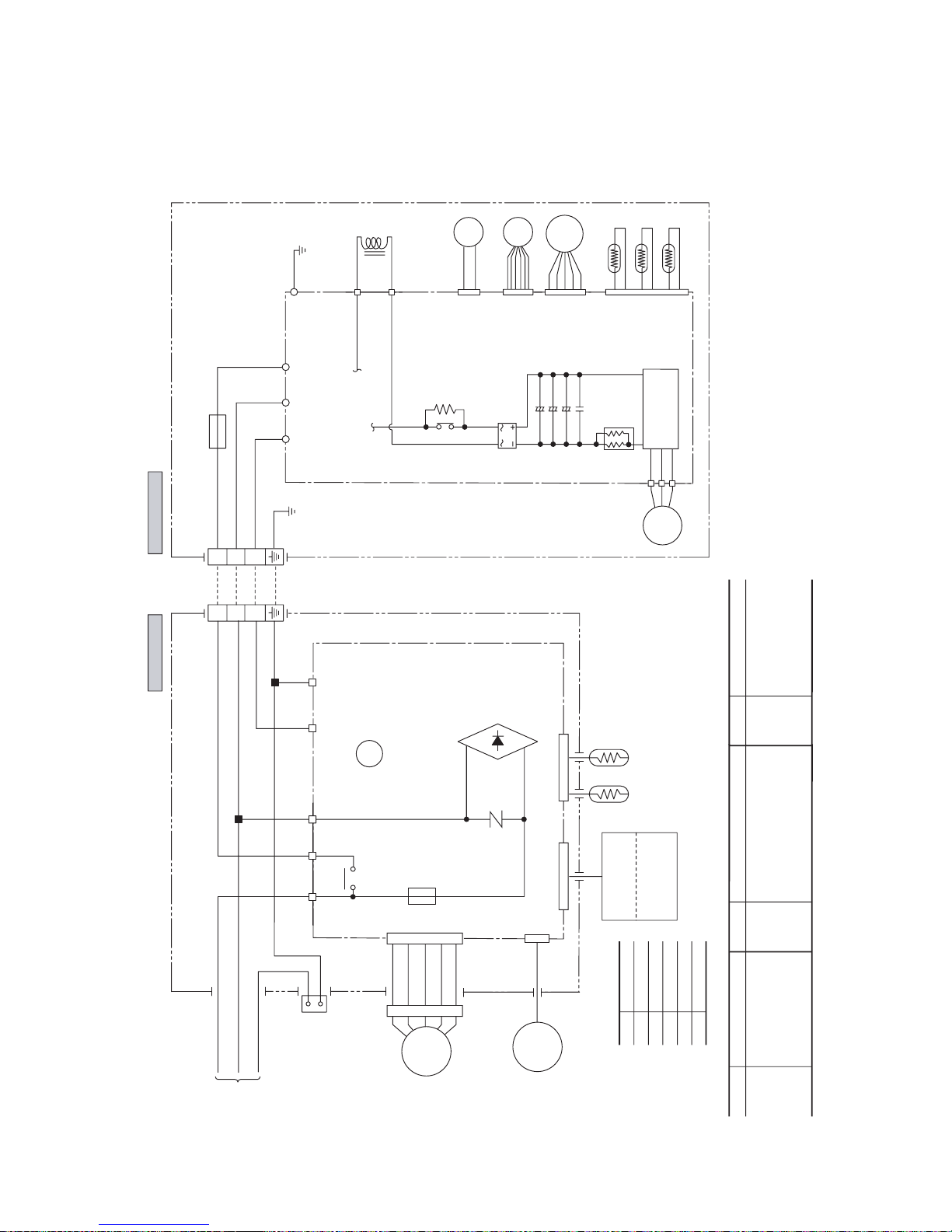

1.1.3 ELECTRICAL DATA

(1) Electrical wiring

Models SRK20ZD-S1, 25ZD-S1, 35ZD-S1

Power source

1 Phase

220/230/240V 50Hz

Outdoor unit

Indoor unit

HEAT

EXCHANGER

Printed circuit

board

Printed circuit board

BR

BL

Y/GN

BK

WH

RD

RD

1

3

4

5

6

CNU

BK

WH

Y

BL

TB TB

F2 (250V 20A)

F1

250V

3.15A

BK

WH

RD

U

V

W

BK

C2 S.IN R.IN

Re

G

WH

RD

Y/GN

N

ZNR

CNM

CNE CNG

52C3

52C

52C4

J

Th4

Th1 Th2

Th5

Th6

CNB

CNE

CNA

CND

1

2

3

NP

Power

transistor

20S

52C

EEV

FMo

DS

CM

1

2

3

( )

FM

I

SM

Display

Wireless

R-Amp

Black

Brown

Red

Blue

White

Yellow/Green

BK

BR

RD

BL

WH

Y/GN

Color symbol

Meaning of marks

Symbol

Parts name

CM

Compressor motor

F

Fuse

FM

I

F

Fan motor (Indoor)

FMo

F

an motor (Outdoor)

SM

RE

Flap motor

Reactor

Symbol

Parts name

Th

1

Room temp. sensor

Th

2

Heat exchanger

sensor

(Indoor unit)

Th

4

Heat exchanger

sensor

(Outdoor unit)

Th

5

Outdoor air temp. sensor

Th

ZNR

6

Dischar

Varistor

ge pipe temp. sensor

Symbol

Parts name

20S

4 way valve (coil)

52C

Magnetic contactor

DS

Diode stack

EEV

Electronic expansion valve

-

13

-

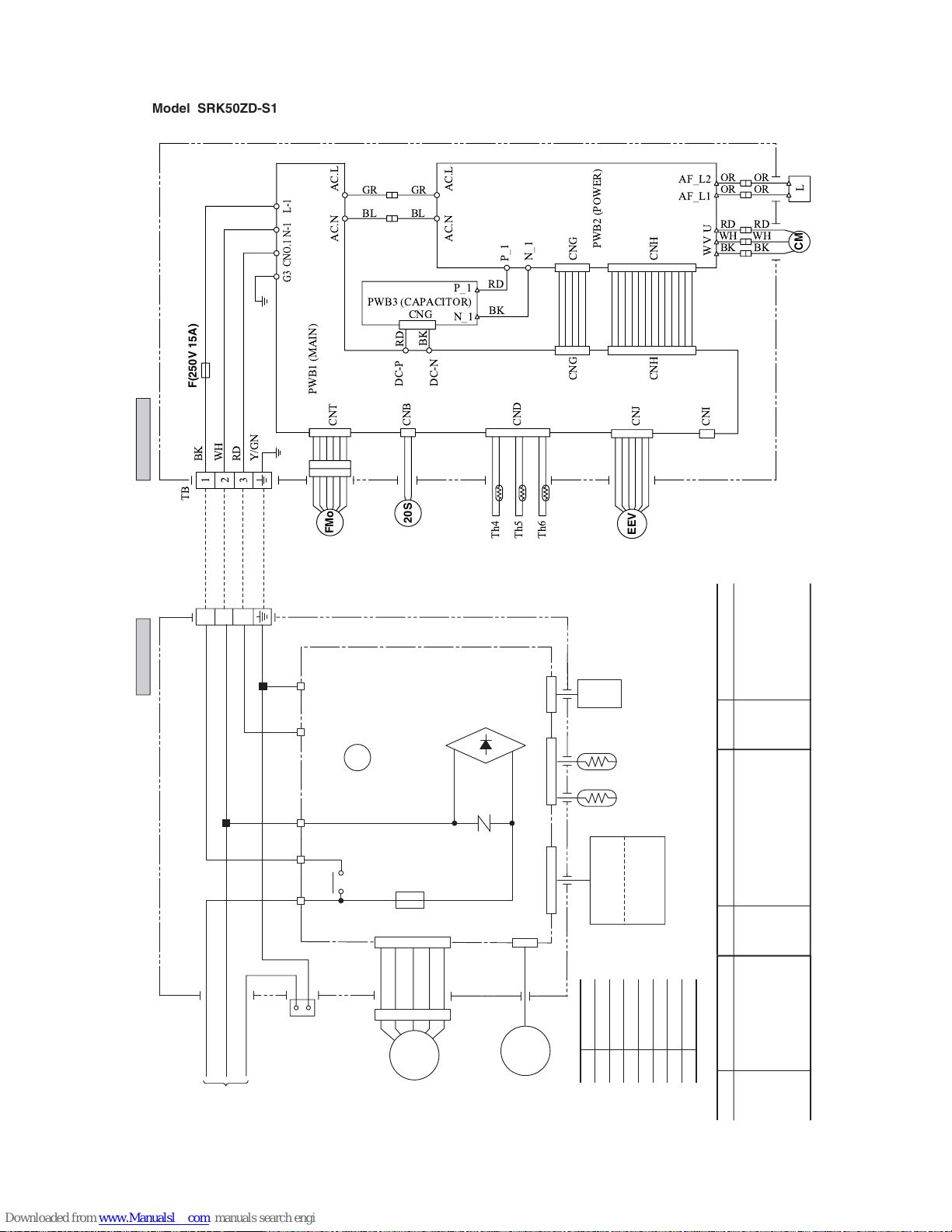

Power source

1 Phase

220/230/240V 50Hz

Outdoor unit

Indoor unit

HEAT

EXCHANGER

Printed circuit board

BRBLY/GN

BK

WH

RD

RD

BK

WH

Y

BL

TB

F1

250V

3.15A

N

ZNR

CNM

CNE CNG CNF

52C3

52C

52C4

J

52C

1

2

3

( )

FM

I

SM

Display

Wireless

R-Amp

Th1 Th2

Th3

13456

CNU

Black

Brown

Red

Blue

White

Yellow/Green

BKBRRD

BL

Orange

OR

Green

GR

WH

Y/GN

Color symbol

Meaning of marks

Symbol

Parts name

CFo

Capacitor for FMo

CM

Compressor motor

F

Fuse

FM

I

F

Fan motor (Indoor)

FMo

F

an motor (Outdoor)

SM

RL

L

Flap motor

Inspection lamp

Inductor

Symbol

Parts name

Th

1

Room temp. sensor

Th

2

Heat exchanger sensor (Indoor unit)

Th

3

Humidity sensor

Th

4

Heat exchanger sensor (Outdoor unit)

Th

5

Outdoor air temp. sensor

Th

6

Discharge pipe temp. sensor

Symbol

Parts name

ZNR

Varistor

20S

4 way valve (coil)

52C

Magnetic contactor

DS

Diode stack

EEV

Electronic expansion valve

EEV

FMo

20S

F(250V 15A)

CM

!

"#

Model SRK50ZD-S1

-

14

-

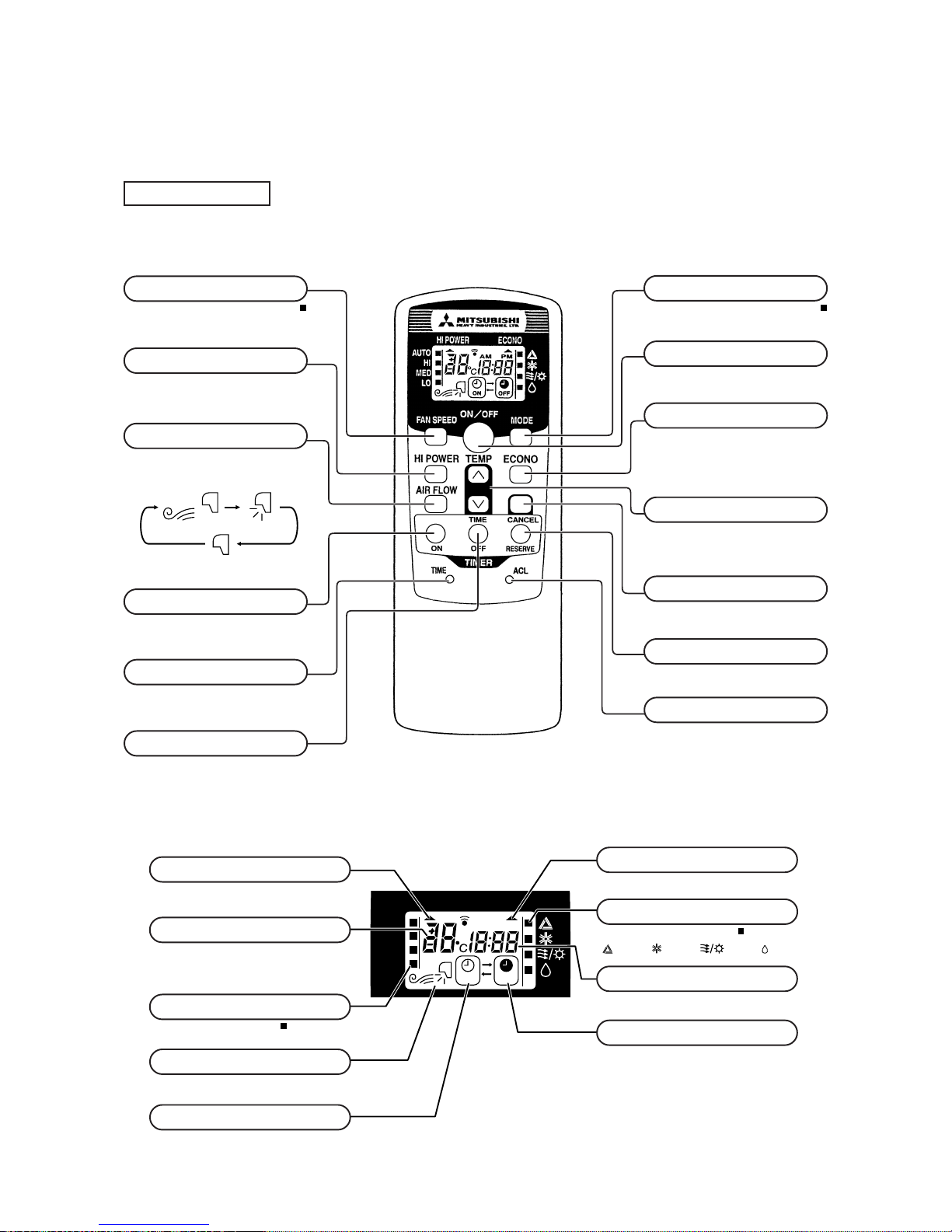

LO

MED

HI

AUTO

HI POWER

ECONO

ON OFF

AM PM

FAN SPEED button

Each time the button is pushed, the

indicator is switched over in turn.

• The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pushed, the

indicator is switched over in turn.

AIR FLOW button

This button changes the flap mode. When

pressed, this button changes the mode in the

following order:

ON/OFF button

Press for starting operation, press again for

stopping.

HI POWER button

This button changes the HI POWER mode.

ECONOMY button

This button changes the ECONOMY mode.

RESET switch

Switch for resetting microcomputer.

ON TIMER button

This button selects ON TIMER operation.

TIME switch

This switch for setting the time.

OFF TIMER button

This button selects OFF TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

CANCEL button

This button cancels the ON timer and OFF

timer.

RESERVE button

This button sets the present time and

TIMER time.

S Indication section

OPERATION MODE indicator

Indicates selected operation with lamp.

[

(Auto) • (Cool) • (Heat) • (Dry)]

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with lamp.

AIR FLOW indicator

Shows selected flap mode.

HI POWER MODE indicator

Indicates during Hi power mode operation.

ECONOMY MODE indicator

Indicates during economy mode operation.

ON TIMER indicator

Indicates during ON TIMER operation.

TIME indicator

Indicates present time or timer setting time.

OFF TIMER indicator

Indicates OFF TIMER operation.

Models All models

Remote controller

S Operation section

1.1.4

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

(1) Operation control function by remote control switch

(Air scroll) (Swing)

(Flap stopped)

-

15

-

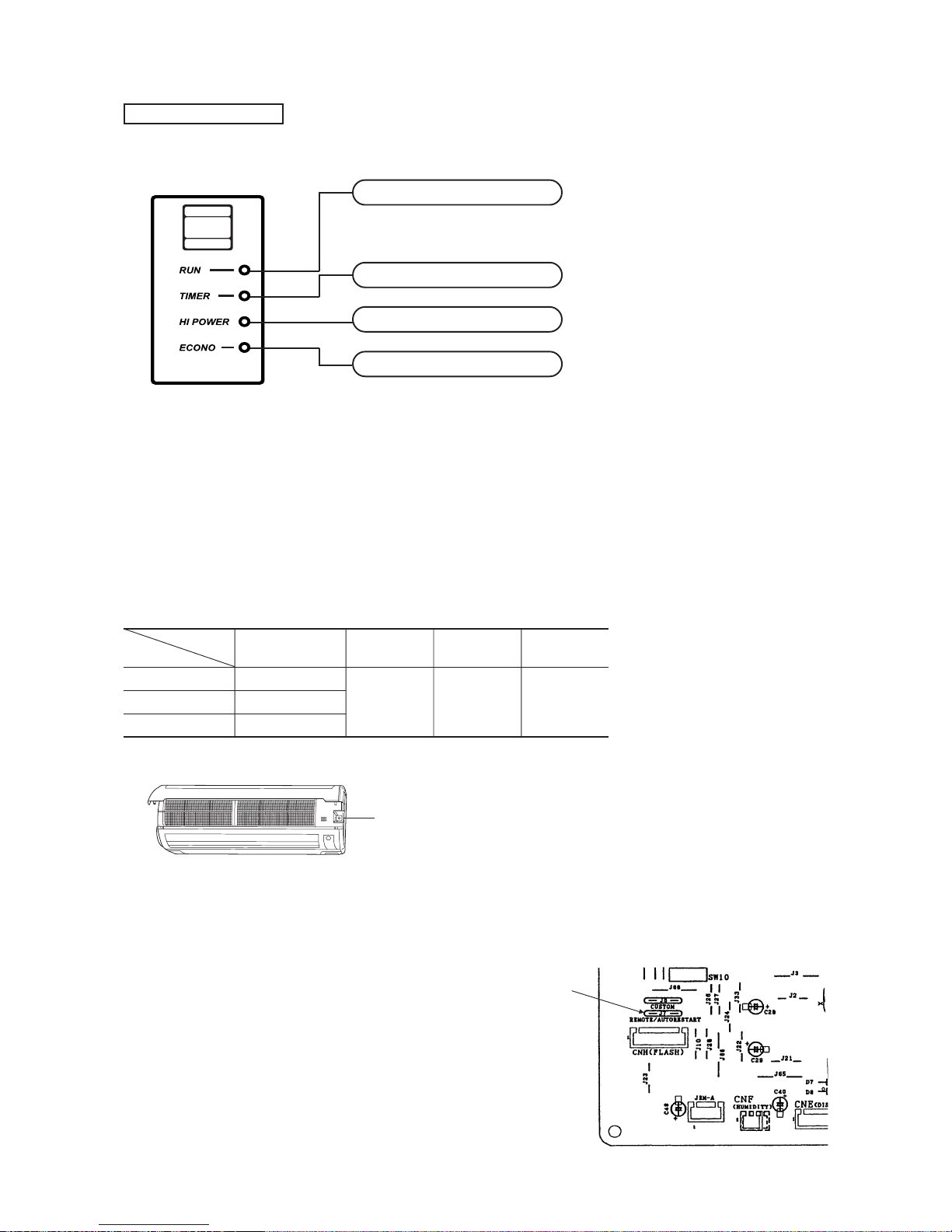

Unit indication section

Models SRK20ZD-S1, 25ZD-S1, 35ZD-S1, 50ZD-S1

(2) Unit ON/OFF button

When the remote controller batteries become weak, or if the remote controller is lost or malfunctioning, this button may be used to turn

the unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by sensor),

whether to go into the cooling, thermal dry or heating modes.

Function

Room temperature

Operation mode

setting

Fan speed Flap Timer switch

Cooling About 25ºC

Thermal dry About 25ºC Auto Auto Continuous

Heating About 26ºC

Unit ON/OFF button

ECONOMY light (orange)

Illuminates during ECONOMY operation.

TIMER light (yellow)

Illuminates during TIMER operation.

HI POWER light (green)

Illuminates during HI POWER operation.

RUN (HOT KEEP) light (green)

• Illuminates during operation.

• Flashes at air flow stop due to the ‘HOT KEEP’.

(3) Power blackout auto restart function

(a) Power blackout auto restart function is a function that records the operational status of the air-conditioner immediately prior to it

being switched off by a power cut, and then automatically resumes operations at that point after the power has been restored.

(b) The following settings will be cancelled:

(i) Timer settings

(ii) High-power operations

Notes (1) The power blackout auto restart function is set at on when the air-conditioner is shipped from the

factory. Consult with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3)

If the jumper wire (J7) “REMOTE/AUTORESTART” is cut, auto restart is disabled. (See the diagram

at right)

Models SRK20ZD-S1, 25ZD-S1, 35ZD-S1, 50ZD-S1

Jumper wire (J7)

-

16

-

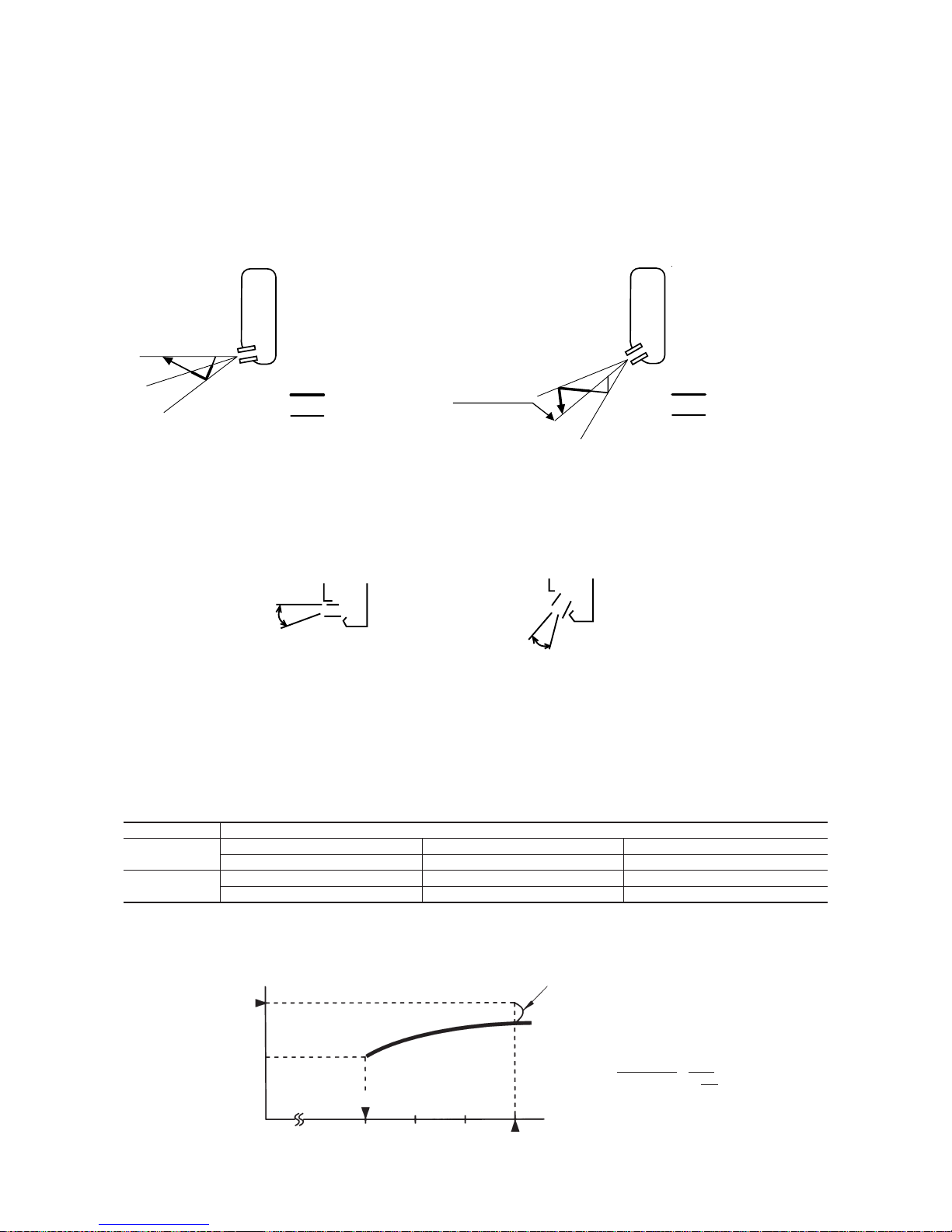

(4) Flap control

Control the flap by AIRFLOW button on the wireless remote control.

(a) Air scroll (AUTO)

The flap will be automatically set to the angle of air flow best to operation.

(i) Starting time of operation

(c) Swing flap

Flap moves in upward and downward directions continuously.

(ii) When not operating

The flap returns to the position of air flow directly below, when operation has stopped.

(b) Memory flap

While the flap is operating if the AIRFLOW button is pushed once, it stops swinging at an angle.

As this angle is memorized in the microcomputer, the flap will be automatically set to the angle when next operation is started.

¡ Recommendable stopping angle of the flap

Corrects the starting time of next operation by

calculating the temperature difference.

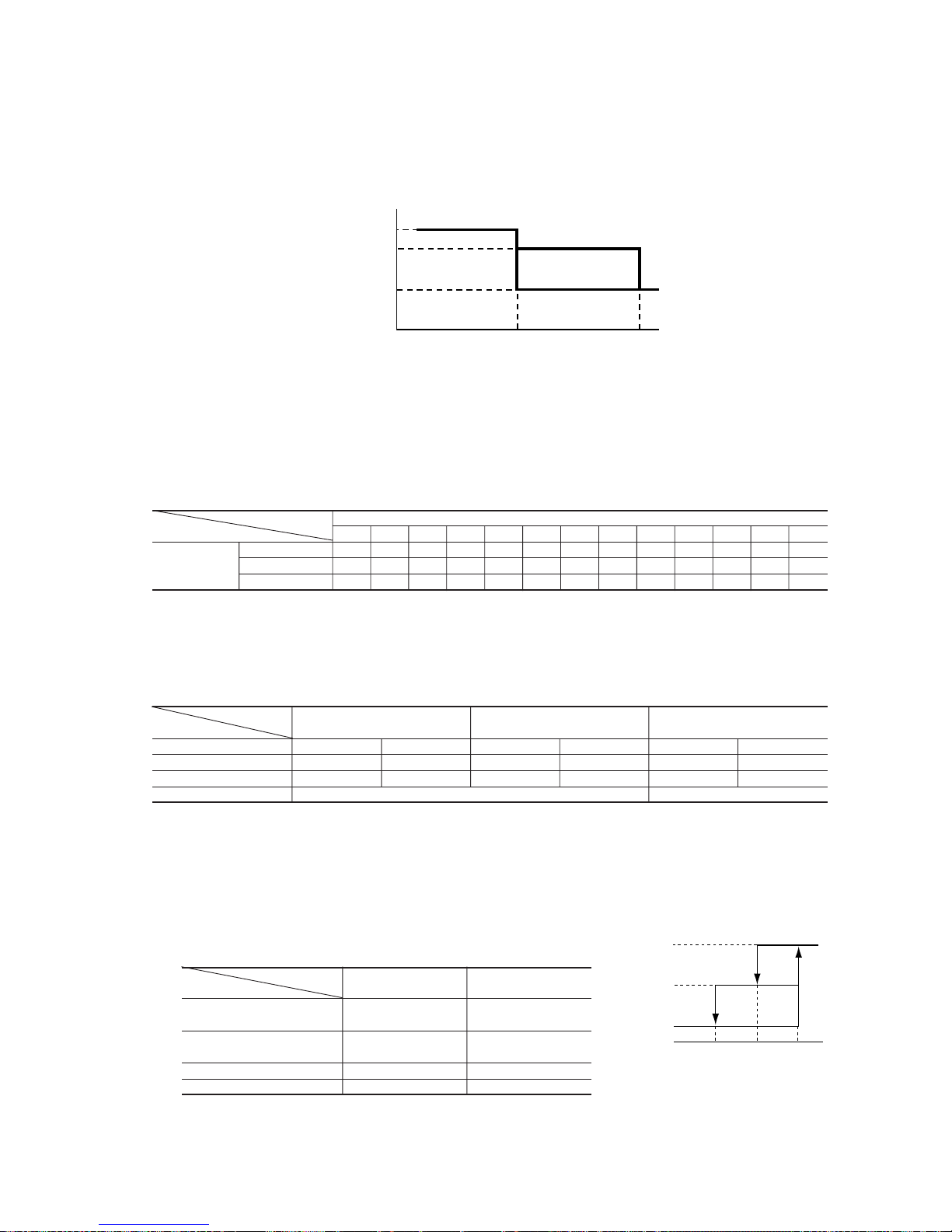

(Example) Heating

Setting temperature

Room temperature

Operation starting time

Time

Setting time

15 min. 10 min. 5 min.

earlier earlier earlier

¡ If the difference (= Setting temperature – Room tempera-

ture) is 4ºC, the correction value is found to be +5 minutes from the table shown above so that the starting time

of next operation is determined as follows:

15 min. earlier + 5 min. = 20 min. earlier

↑↑

Current operation Correction value

start time

s

During cooling and

t

dry operation

Thick line : Rapid movement

Thin line : Slow movement

Stops for approximately

5 seconds in the

horizontal position.

s

During heating

t

operation

Stops for approximately

5 seconds in this

position.

Thick line : Rapid movement

Thin line : Slow movement

Horizontal

blowing

COOL•DRY

Slant forward

blowing

HEAT

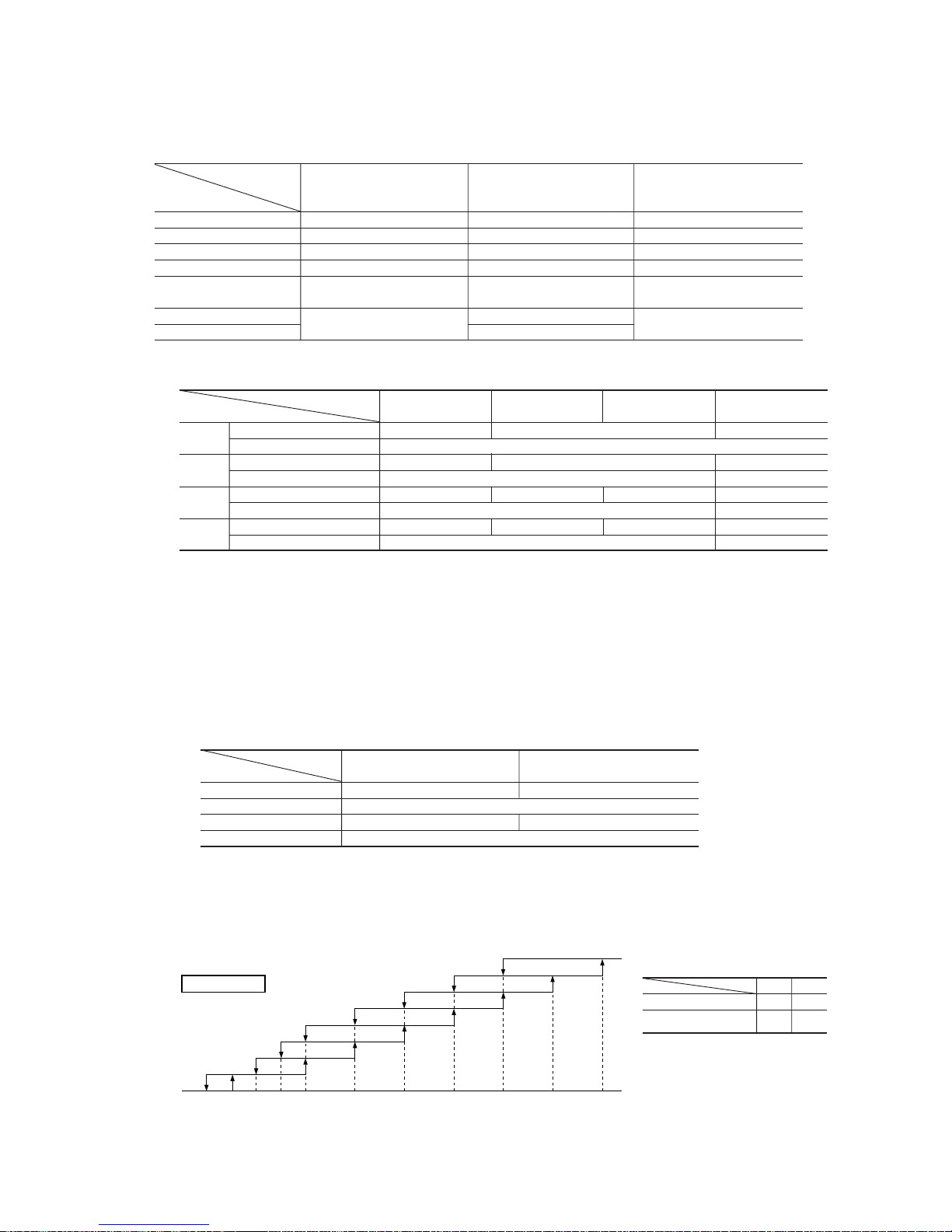

(5) Comfortable timer setting

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in auto mode operation

is selected, the comfortable timer starts and determines the starting time of next operation based on the initial value of 15 minutes and the

relationship between the room temperature at the setting time (temperature of room temperature sensor) and the setting temperature.

(Max. 60 minutes)

Operation mode Operation start time correction value (Min.)

3 < Room temp. – Setting temp. 1 < Room temp. – Setting temp.

=

<

3 Room temp. – Setting temp.

=

<

1

At cooling

+5 No change –5

3 < Setting temp. – Room temp. 2 < Setting temp. – Room temp.

=

<

3 Setting temp. – Room temp.

=

<

2

At heating

+5 No change –5

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature sensor (Th1).

(2) This function does not operate when in the Dry or Auto Dry mode.

However, the operation in item (1) does operate in the Auto Dry mode.

(3) During the comfortable timer operation, both the RUN light and TIMER light illuminate and the TIMER light goes off after expiration of the timer, ON setting

time.

-

17

-

(iii) Hot keep operation

If the hot keep operation is selected during the heating operation, the indoor blower is controlled based on the temperature of

the indoor unit heat exchanger (detected with Th2, indoor unit heat exchanger sensor) to prevent blowing of cool wind.

Note (1) Refer to the table shown above right for the values A and B.

¡ Normal mode (Normal heating operation, operation after HI POWER completion)

Indoor heat exchanger temp. (˚C)

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

AB

20~35: 23°C

50: 20°C

28 29.5 31.5 34 36 37.5 39 40

1st speed

3rd speed

4th speed

5th speed

6th speed

7th speed

OFF

Indoor fan

(c) Details of control at each operation mode (pattern)

(i) Fuzzy operation

Deviation between the room temperature setting correction temperature and the suction air temperature is calculated in

accordance with the fuzzy rule, and used for control of the air capacity and the inverter speed.

(ii) Heating thermostat operation

¡ Operating conditions

If the speed obtained with the fuzzy calculation drops below -24 rps during the heating fuzzy operation, the operation

changes to the heating thermostat operation.

¡ Detail of operation

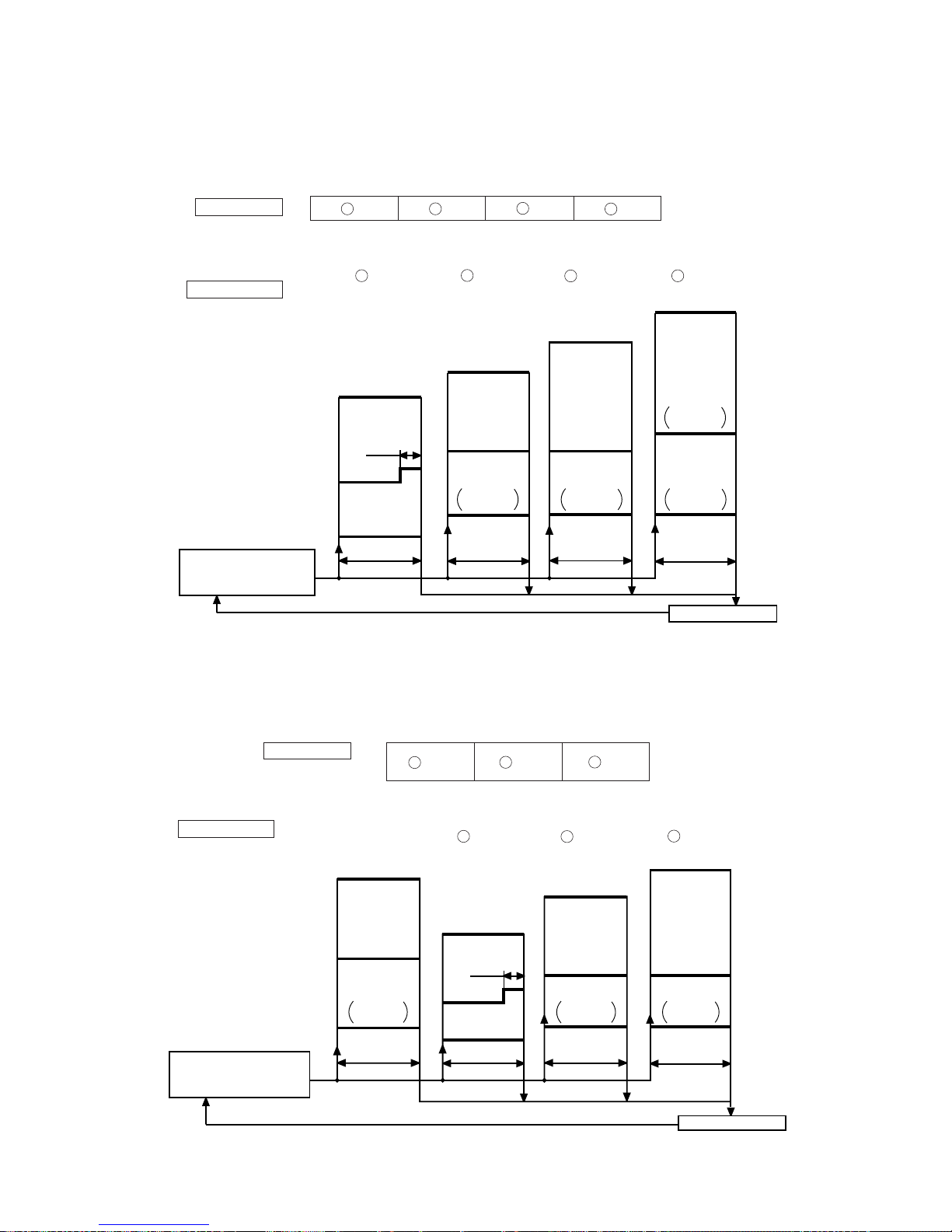

(6) Outline of heating operation

(a) Operation of major functional components in heating mode

(b) Air flow selection

(i) Speed of inverter changes within the range of selected air flow.

(ii) When the defrosting, protection device, etc. is actuated, operation is performed in the corresponding mode.

(iii) Outdoor unit blower operates in accordance with the inverter command speed.

Model

SRK20, 25, 35ZD-S1 SRK50ZD-S1

Item

Inverter speed 0rps [Comp. stopped] 10 rps [10sec.] → 0rps [Comp. stopped]

Indoor fan Hot keep normal mode → 1st speed

Outdoor fan Stop 2nd speed [1min.] → stop

Flap Horizontal

Auto

HI

MED

LO

Item

Indoor fan motor ON ON OFF

Flaps ON or OFF ON or OFF Stop position control

Display Lights up Lights up Lights up or flashes

52C ON ON OFF after stop mode

Outdoor fan motor

OFF (20, 25, 35 type)

ON

OFF (20, 25, 35 type)

Depending on the stop mode (50 type) Depending on the stop mode (50 type)

4-way valve

Depending on the stop mode

ON

Depending on the stop mode

Electronic expansion valve Depending on the EEV control

When the inverter

speed is 0rps

When the inverter speed

is other than 0rps

When the inverter speed is 0rps

due to an anomalous stop

Functional

components

(20, 25, 35 only)

8th speed

(20, 25, 35 only)

9th speed

Model

SRK20ZD-S1 SRK25ZD-S1 SRK35ZD-S1 SRK50ZD-S1

Air flow selection

Inverter command speed 30~100rps 30~102rps 15~120rps

Air flow Depends on inverter command speed.

Inverter command speed 30~100rps 30~102rps 15~120rps

Air flow 8th speed fixed 6th/7th speed

Inverter command speed 30~72rps 30~72rps 30~76rps 15~62rps

Air flow 6th speed fixed 4th/5th speed

Inverter command speed 30~42rps 30~42rps 30~46rps 15~38rps

Air flow 4th speed fixed 3rd speed fixed

-

18

-

Notes (1) Refer to the table shown above right for the values A and B.

Note (2) Values in ( ) are for type 20, 25, 35.

¡ Hot keep M mode [During HI POWER operation (for 15 min.)]

Indoor heat exchanger temp. (˚C)

AB2931 32 34 36 43

(40)

(43) (47)

1st speed

3rd speed

4th speed

5th speed

6th speed

7th speed

OFF

Indoor fan

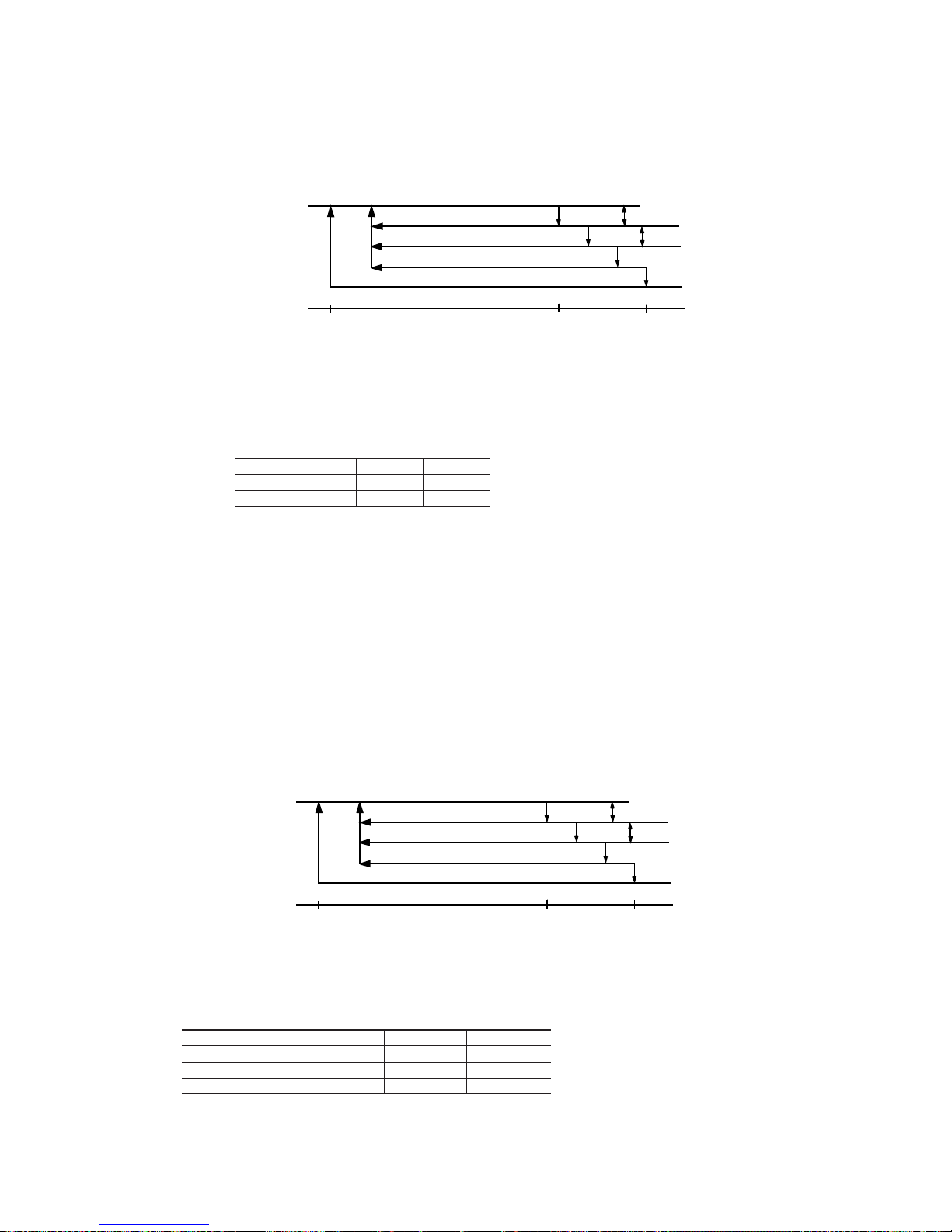

(iv) Defrosting operation

1) Starting conditions (Defrosting operation can be started only when all of the following conditions are met.)

1 After start of heating operation → When it elapsed 35 minutes. (Accumulated operation time)

2 After end of defrosting operation → When it elapsed 35 minutes. (Accumulated compressor operation time)

3 Outdoor unit heat exchanger sensor (Th4) temperature → When the temperature has been below –5ºC for 3 minutes

continuously.

4 When the temperature difference between the outdoor air sensor temperature and the outdoor unit heat exchanger

sensor temperature exceeded 20. 25 type: 7.0°C, 35 type: 5.0°C, 50 type: 4.0°C

5 During continuous compressor operation

In addition, when the speed command from the indoor controller of the indoor unit during heating operation has

counted 0 rps 10 times or more and all conditions of 1, 2 and 3 above are satisfied (note that when the temperature

for Th4 is -5°C or less: 62 rps or more, -4°C or less: less than 62 rps), defrost operation is started.

2) Operation of functional components during defrosting operation

¡ 20, 25, 35 type

Indoor fan

RUN light

Corresponding

to speed

OFF

ON

Flashing

(Hot keep)

Outdoor fan

Inverter

command

Fuzzy calculated

value

70 rps

0

Corresponding

to speed

OFF

OFF

ON

(1)

4-way valve

Final defrost operation

Defrost control

Hot keep

Indoor unit

Outdoor unit

60 sec.

Hot keep

50 sec.

Normal heating operation restored

Defrost end

(Th4

>

=

13˚C, 10 minutes)

Defrost operation

Defrost operation

preparation

6th speed 6th speed

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

8th speed

9th speed

(20, 25, 35 only)

(20, 25, 35 only)

Note (1) When outdoor unit heat exchanger sensor (Th4) temperature becomes 2°C or higher, inverter command changes 70 rps to 50

rps.

-

19

-

(v) Heating “HI POWER” operation (HI POWER button on remote controller: ON)

Operation is maintained for 15 minutes with a higher blow out air temperature.

¡ Detail of operation

Model

SRK20ZD-S1 SRK25, 35ZD-S1 SRK50ZD-S1

Item

Inverter speed 100 rps 102 rps 120 rps

Indoor fan Hot keep M mode (max 8th speed) Hot keep M mode (max 7th speed)

Outdoor fan 4th speed 2nd speed

Notes (1) Room temperature is not adjusted during the HI POWER operation.

(2) Protective functions will actuate with priority even during the HI POWER operation.

3) Ending conditions (Operation returns to the heating cycle when either one of the following is met.)

1 Outdoor heat exchanger sensor (Th4) temperature: 13ºC or higher (50 type: 20°C or higher)

2 Continued operation time of defrosting → For more than 10 min.

Indoor fan

RUN light

Corresponding

to speed

OFF

ON

Flashing

(Hot keep)

Outdoor fan

Inverter

command

Fuzzy calculated

value

70 rps

(1)

0

Corresponding

to speed

OFF

OFF

ON

4-way valve

Final defrost operation

Defrost control

Hot keep

Indoor unit

Outdoor unit

75 sec.

Hot keep

60 sec.

Normal heating operation restored

Defrost end

(Th4

>

=

20°C, 10 minutes)

Defrost operation

Defrost operation

preparation

2nd speed 2nd speed

(7) Outline of cooling operation

(a) Operation of major functional components in Cooling mode

¡ 50 type

Item

Indoor fan motor ON ON OFF

Flaps ON or OFF ON or OFF Stop position control

Display Lights up Lights up Lights up or flashes

52C ON ON OFF after stop mode

Outdoor fan motor

OFF (20, 25, 35 type)

ON

OFF (20, 25, 35 type)

Depending on the stop mode (50 type) Depending on the stop mode (50 type)

4-way valve

Depending on the stop mode

ON

Depending on the stop mode

Electronic expansion valve Depending on the EEV control

When the inverter

speed is 0rps

When the inverter speed

is other than 0rps

When the inverter speed is 0rps

due to an anomalous stop

Functional

components

Note (1) When outdoor unit heat exchanger sensor (Th4) temperature becomes 7°C or higher, inverter instruction changes 70 rps to 50

rps.

-

20

-

(c) Detail of control in each mode (Pattern)

(i) Fuzzy operation

During the fuzzy operation, the air flow and the inverter speed are controlled by calculating the difference between the room

temperature setting correction temperature and the suction air temperature.

(ii) Cooling thermostat operation

1) Operating conditions

During the cooling fuzzy operation or when the speed obtained by the fuzzy calculation is less than -24 rps.

2) Detail of operation

(b) Air flow selection

(i) Speed of inverter changes within the range of selected air flow.

(ii) When any protective function actuates, the operation is performed in the mode corresponding to the function.

(iii) Outdoor blower is operated in accordance with the inverter command speed.

(iii) Cooling “HI POWER” operation (HI POWER button on remote controller: ON)

The unit is operated continuously for 15 minutes regardless of the setting temperature.

1) Detail of operation

Model

SRK20, 25, 35ZD-S1 SRK50ZD-S1

Item

Inverter speed 0 rps [Comp. stopped] 10rps [10sec.] → 0rps [Comp. stopped]

Indoor fan Corresponds to fan speed switch.

Outdoor fan Stop 2nd speed [1min.] → stop

Notes (1) Protective functions will actuate with priority even during the “HI POWER” operation.

(2) Room temperature is not adjusted during the “HI POWER” operation

(8) Outline of dehumidifying operation

(a) After operating the indoor blower for 20 seconds from immediately after the start of operation, the indoor temperature is checked

and, based on the result of check, the cooling oriented dehumidifying or heating oriented dehumidifying is selected.

Heating oriented dehumidifying Cooling oriented dehumidifying

Low –3 High

Room temperature - Setting temperature (deg)

Cooling or heating oriented dehumidifying is selected again one hour after the first selection of the cooling or heating oriented

dehumidifying.

Auto

HI

MED

LO

Model

SRK20ZD-S1 SRK25ZD-S1 SRK35ZD-S1 SRK50ZD-S1

Air flow selection

Inverter command speed 20~60rps 20~70rps 20~98rps 15~90rps

Air flow Depends on inverter command speed.

Inverter command speed 20~60rps 20~70rps 20~98rps 15~90rps

Air flow 7th speed fixed 5th~7th speed

Inverter command speed 20~52rps 20~58rps 15~60rps

Air flow 5th speed fixed 3rd~5th speed

Inverter command speed 20~34rps 20~38rps 15~30rps

Air flow 2nd speed fixed

Model

SRK20ZD-S1 SRK25ZD-S1 SRK35ZD-S1 SRK50ZD-S1

Item

Inverter speed 60 70 98 90

Indoor fan 7th speed

Outdoor fan 4th speed 2nd speed

-

21

-

D range C range B range A range

(ii) Heating oriented dehumidifying

After interrupting the compressor operation for 3 minutes (by the 3-minute timer) following the determination of heating

oriented dehumidifying, the unit begins in the heating operation. If the room temperature exceeds the setting temperature by

2ºC or more, the unit checks the room temperature at 5-minute intervals and, depending on the result, determines the range

of heating oriented dehumidifying operation.

Operation range

DCBA

Low –1 0 +2 High

Room temperature – Setting temperature (deg)

(D) (C) (C) (B)

OFF

3rd speed

25 sec.

OFF

0

20, 25, 35 type : 38

50 type : 24

20, 25, 35 type : 50

50 type : 40

50 type :

4th speed

20, 25, 35 type : 30

50 type : 15

5th speed

2nd speed

1st speed

50 type :

1st speed

50 type :

1st speed

50 type :

1st speed

Inverter speed

Indoor fan

Outdoor fan

Determination of cooling

oriented dehumidifying

operation range

Temperature check

5 min. 5 min. 5 min. 5 min.

Operation pattern

OLM

Low –1 0 High

Room temperature – Setting temperature (deg)

Operation range

Heating operation O range L range M range

4th speed

OFF

3rd speed

OFF

4th speed

2nd speed

1st speed

20, 25, 35 type : 38

50 type : 28

20, 25, 35 type : 30

50 type : 15

20, 25, 35 type : 48

50 type : 44

0

50 type :

1st speed

50 type :

1st speed

25 sec.

50 type :

1st speed

Inverter speed

Indoor fan

Outdoor fan

Determination of heating

oriented dehumidifying

operation range

Temperature check

5 min. 5 min. 5 min.

Depends on

the operation

condition

Operation pattern

Note (1) Figures in the parentheses

( ) show the values at

economical operation.

Note (1) Figures in the parentheses

( ) show the values at

economical operation.

(b) Outline of control

(i) Cooling oriented dehumidifying

Room temperature is checked at 5-minute intervals after selecting the cooling or heating oriented dehumidifying in order to

determine the operation range.

(O) (L) (L)

-

22

-

(9) Outline of automatic operation

(a) Determination of operation mode

The unit checks the room temperature and the outdoor air temperature after operating the indoor and outdoor blowers for 20

seconds, determines the operation mode and the room temperature setting correction value, and then begins in the automatic

operation.

Heating

Dehumidifying

Cooling

Room temperature (˚C)

Outdoor temperature (˚C)

27.5

25.5

19.5

18

30

(b) The unit checks the temperature every hour after the start of operation and, if the result of check is not same as the previous

operation mode, changes the operation mode.

(c) When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is selected

during heating, cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(d) Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals of

the wireless remote controller and the setting temperature.

Signals of wireless remote controller (Display)

–6 –5 –4 –3 –2 –1 ±0+1+2+3+4+5+6

Setting

Cooling 19 20 21 22 23 24 25 26 27 28 29 30 31

temperature

Dehumidifying 19 20 21 22 23 24 25 26 27 28 29 30 31

Heating 20 21 22 23 24 25 26 27 28 29 30 31 32

(10) Economical operation

(ECONO button on remote controller: ON)

(a) The set temperature is raised by 1.5ºC (0.5ºC every one hour) at cooling operation and lowered by 2.5ºC (Steps of 1ºC, 1ºC and

0.5ºC every one hour) at heating operation to continue the operation with the following contents.

(b) Detail of operation

(11) Protective control function

(a) Frost prevention for indoor heat exchanger (During cooling or dehumidifying)

(i) Operating conditions

1) Indoor heat exchanger temperature (detected with Th2) is lower than 5ºC.

2) 10 minutes after reaching the inverter command speed except 0 rps.

(ii) Detail of anti-frost operation

5°C or lower 2.5°C or lower

Item

Upper limit speed

20, 25 : 44 rps

0rps

35, 50 : 70 rps

Indoor fan Depends on operation mode

20, 25, 35: Max 2nd

50: 2nd

Outdoor fan Depends on operation mode OFF

4-way valve OFF Depends on stop mode

(iii) Reset conditions: The indoor heat exchanger temperature (Th2) is 8ºC or higher after 5 minutes of operation following

control of the inverter command speed upper limit.

Model

SRK20, 25ZD-S1 SRK35ZD-S1 SRK50ZD-S1

Item

Operation mode Cooling Heating Cooling Heating Cooling Heating

Inverter command speed 20~52rps 20~72rps 20~58rps 20~76rps 15~60rps 15~62rps

Indoor fan 2nd, 5th speed 4th, 6th speed 2nd, 5th speed 4th, 6th speed 3rd~5th speed 4th, 5th speed

Outdoor fan 3rd speed 1st speed

Indoor heat exchanger

temperature

Indoor heat exchanger

temperature (°C)

2.5 5 8

0 rps

Upper

limit

speed

Inverter

command

speed

-

23

-

(b) Indoor fan motor protection

When the air conditioner is operating and the indoor fan motor is turned ON, if the indoor fan motor has operated at 300 rpm or

under for more than 30 seconds, the unit enters first in the stop mode and then stops the entire system.

TIMER light illuminates simultaneously and the RUN light flashing 6 times at each 8-second.

(c) Dew condensation prevention control [Cooling (including automatic), cooling oriented dehumidifying operation)

◆ SRK20, 25, 35ZD-S1

(i) Operating conditions: When compressor is kept ON for 30 min. after the unit starts operation.

(ii) Operation contents

(iii) Reset conditions: When compressor is off. (ex. thermo becomes OFF, operation mode is changed)

◆ SRK50ZD-S1

(i) Operating conditions: When the following conditions are met after 20 minutes or more of continuous operation after

operation starts.

1 The command speed is 28 rps or higher

2 The humidity sensor value is 68% or higher

(ii) Operation contents

(iii) Reset conditions: When either of the following conditions is satisfied.

1 The command speed is lower than 28 rps.

2 The humidity sensor value is less than 63%.

(d) Prevention of continuous low speed operation: For oil return to compressor

(i) Operating conditions: When command speed of less than 30(26) rps continues for 8(60) minutes

(ii) Detail of operation: The unit is operated at command speed of 30 rps forcibly for 15 seconds. (The indoor and outdoor

fans are not changed.)

Notes (1) When the command of exceeding 30 rps is directed during 30 rps forced operation, the unit follows it.

Note (2) Values in ( ) are for Type 50.

(e) Compressor protection start

(i) When the indoor unit calculated speed is 64 rps or over at operation start, the unit is operated with 64 rps for 1 minute and 45

seconds. (All models) After that when the calculated speed is 96 rps or over, the unit is operated with 96 rps for 5 minutes

then moved to command speed. (50 type only)

(ii) At thermo operation (OFF → ON) this control is not executed.

(iii) The indoor unit fan corresponds to the command speed of each operation mode.

Note (1) When the calculated speed is less than 64 rps, the unit is started with low load starting described in article (f).

(f) Low load starting

(i) When the unit is started with calculated speed of less than 60(30) rps, it is operated with 60(30) rps for 80(60) seconds, then

the operation is moved to the command speed.

(ii) The indoor fan corresponds to the operation mode.

Cooling: Speed corresponding to the command speed of air flow switching

Dehumidification: Speed decided in the operation region

Heating: The lower one between the speed corresponding to the command speed and the hot keep speed

Note (1) Values in ( ) are for Type 50.

Type

SRK20ZD-S1 SRK25ZD-S1 SRK35ZD-S1

Item

Upper limit speed 60 rps 62 rps 86 rps

Type

SRK50ZD-S1

Item

Fan Speed Medium Indoor fan speed 4th speed

Fan Speed Low Indoor fan speed 4th speed

Other Settings Indoor fan speed Corresponding to command speed

Humidity (%)

68 73

50 rps

30 rps

Inverter command speed at upper limit

-

24

-

(g) Inching prevention

When the compressor goes into the thermo operation within 10(5) minutes since operation start or becomes various dehumidifying

operations, the operation is continued with the command speed of 20(15) rps forcibly.

Note (1) Values in ( ) are for Type 50.

(h) Current safe

(i) Purpose: Current is controlled not to exceed the upper limit of the setting operation current.

(ii) Detail of operation: Input current to the converter is monitored with the current sensor fixed on the printed circuit board

of the outdoor unit and, if the operation current value reaches the limiting current value, the inverter speed is reduced.

If the mechanism is actuated when the speed of outdoor unit is less than 30 rps, the compressor is stopped immediately.

Operation starts again after a delay time of 3 minutes.

(i) Current cut

(i) Purpose: Inverter is protected from overcurrent.

(ii) Detail of operation: Output current from the converter is monitored with a shunt resistor and, if the current exceeds the

setting value, the compressor is stopped immediately. Operation starts again after a delay time of 3 minutes.

(j) Heating overload protective control

(i) Operating conditions : When the unit is operating with the outdoor unit speed other than 0 rps or when the outdoor air

temperature (detected by Th5) rose beyond 17ºC for 30 seconds continuously.

(ii) Detail of operation

1) Indoor fan speed is raised forcibly by 1 step.

2) Taking the upper limit of control speed range at 60 rps, if the output speed obtained with the fuzzy calculation exceeds the

upper limit, the upper limit value is maintained.

3) The outdoor fan is set on 2nd speed. (20, 25, 35 types only)

4) The lower limit of control speed is set to 40(35) rps and even if the calculated result becomes lower than that after fuzzy

calculation, the speed is kept to 40(35) rps. However, when the thermo becomes OFF, the speed is reduced to 0 prs.

(iii) Reset conditions: When the outdoor air temperature drops below 16ºC.

Note (1) Values in ( ) are for Type 50.

(k) Cooling overload protective control

(i) Operating conditions: When the outdoor unit is operating with the speed of other than 0 rps, or when the outdoor air

temperature (detected by Th5) becomes 41ºC or over for 30 seconds continuously.

(ii) Detail of operation

1) Outdoor fan is stepped up by 3(1) speed step.

2) The lower limit of control speed is set to 30 rps and even if the calculated result becomes lower than that after fuzzy

calculation, the speed is kept to 30 rps. However, when the thermo becomes OFF, the speed is reduced to 0 rps.

3) The upper limit of control speed is 72 rps.

(iii) Restoration condition: When the outdoor air temperature becomes 40ºC or less

Note (1) Values in ( ) are for Type 50.

(l) Freezing cycle system protective control

(i) Operating conditions: When both of following conditions have continued for more than 5 minutes later than 5 minutes

after the start of operation.

1) Command speed is higher than 60 rps

2) During cooling, dehumidifying: Indoor heat exchanger temperature - Room temperature > –4ºC

During heating: Indoor heat exchanger temperature - Room temperature < 6ºC

(ii) Detail of operation

The command speed repeats 30 minutes at 30rps ↔ 2 minutes at 62 rps.

(iii) Restoration conditions: When the condition becomes outside of either conditions 1) or 2) shown above

Note (1) This control is valid when the room air temperature is in the range of 10 to 40ºC at cooling and dehumidification operation and 0 to 40ºC at heating

operation.

-

25

-

Notes (1) When the discharge pipe temperature is in the range of 100(90) to 125(110)ºC, the speed is reduced by 4 rps.

(2) When the discharge pipe temperature is raised and continues operation for 20 seconds without changing, then the speed is reduced again by 4 rps.

(3) If the discharge pipe temperature is still 90 (80) ºC or greater but less than 100 (90) ºC even when the inverter command speed is maintained for 3

minutes when the temperature is 90 (80) ºC or greater but less than 100 (90) ºC, the speed is raised by 2 rps and kept at that speed for 3 minutes. This

process is repeated until the command speed is reached.

(4) Lower Limit Speed

Cooling Heating

20, 25, 35 type 20 30

50 type 22 38

(5) Values in ( ) are for Type 50.

2) If the temperature of 125 (110)ºC is detected by the sensor on the discharge pipe, then the compressor will stop immediately.

When the discharge pipe temperature drops and the time delay of 3 minutes is over, the unit starts again within 1 hour but

there is no start at the third time.

(n) Serial signal transmission error protection

(i) Purpose: Prevents malfunction resulting from error on the indoor ↔ outdoor signals.

(ii) Detail of operation: When the indoor unit controller ↔ outdoor unit controller signals cannot be received, the compressor

is stopped immediately. Once the operation stops, it does not start any more.

(TIMER light on the indoor unit flashing at the same time.)

(o) High pressure control

(i) Purpose: Prevents anomalous high pressure operation during heating.

(ii) Detector: Indoor unit heat exchanger sensor (Th2)

(iii) Detail of operation:

(m) Compressor overheat protection

(i) Purpose: It is designed to prevent deterioration of oil, burnout of motor coil and other trouble resulting from the compressor

overheat.

(ii) Detail of operation

1) Speeds are controlled with temperature detected by the sensor mounted on the discharge pipe.

Discharge pipe temperature (˚C)

Lower limit

(4)

After lapse of 3 min. or over

(3)

After lapse of 3 min. or over

(3)

After lapse of 3 min. or over

(3)

4 rps

4 rps

(1)

0 rps

(Example) Fuzzy

90

(80)

100

(90)

125

(110)

Notes (1) RPSmin: The lower one between the outdoor unit speed and the command speed

Note (2) Values in ( ) are for Type 50.

¡ Temperature list

ABC

RPSmin < 40(88) 48 (48.5) 53 (56) 58 (61)

40(88)

<

=

RPSmin < 50(108)

48 (44) 53 (51.5) 58 (56.5)

50(108)

<

=

RPSmin 48.5 (39) 56 (46.5) 61 (51.5)

(Example) Fuzzy

Indoor unit heat exchanger temperature (˚C)

Lower limit

speed 20(35)rps

After lapse of 20 Sec. or over

(2)

After lapse of 20 Sec. or over

(2)

After lapse of 20 Sec. or over

(2)

B

C

8 rps

(1)

8 rps

0 rps

A

Notes (1) When the indoor unit heat exchanger temperature is in the range of B~C ºC, the speed is reduced by 8 rps at each 20 seconds. When the temperature is C

ºC or over for 1 minute continuously, the inverter is stopped.

(2) When the indoor unit heat exchanger temperature is in the range of A~B ºC, if the inverter command speed is been maintained and the operation has

continued for more than 20 seconds at the same speed, it returns to the normal heating operation.

(3) Indoor blower retains the fan tap when it enters in the high pressure control. Outdoor blower is operated in accordance with the speed.

Unit : ºC

-

26

-

(p) Heating low outdoor temperature protective control (50 type only)

◆ <I>

(a) Operating conditions: When the outdoor air temperature sensor (Th5) is 4ºC or lower continues for 5 minutes while the

outdoor speed is other than 0 rps.

(b) Operation content: When the command speed is less than 22 rps, the command speed is forcibly set at 22 rps.

(c) Reset conditions: When the outdoor air temperature sensor (Th5) becomes 6ºC or higher.

◆ <II >

(a) Operating conditions: When the outdoor air temperature sensor (Th5) is 0ºC or lower continuously for 5 minutes while

the outdoor speed is other than 0 rps.

(b) Operation content: The outdoor fan motor speed is raised to the next higher speed. (Upper limit 2nd speed)

(c) Reset conditions: When the outdoor air temperature sensor (Th5) becomes 2ºC or higher.

◆ <III>

(a) Operating conditions: When the temperature sensed by the outdoor heat exchanger sensor (Th4) becomes –10ºC or

lower continuously for 1 minute.

(b) Operation content: When the command speed upper limit is set at 70 rps.

(c) Reset conditions: When the temperature sensed by the outdoor heat exchanger sensor (Th4) becomes -7ºC or higher.

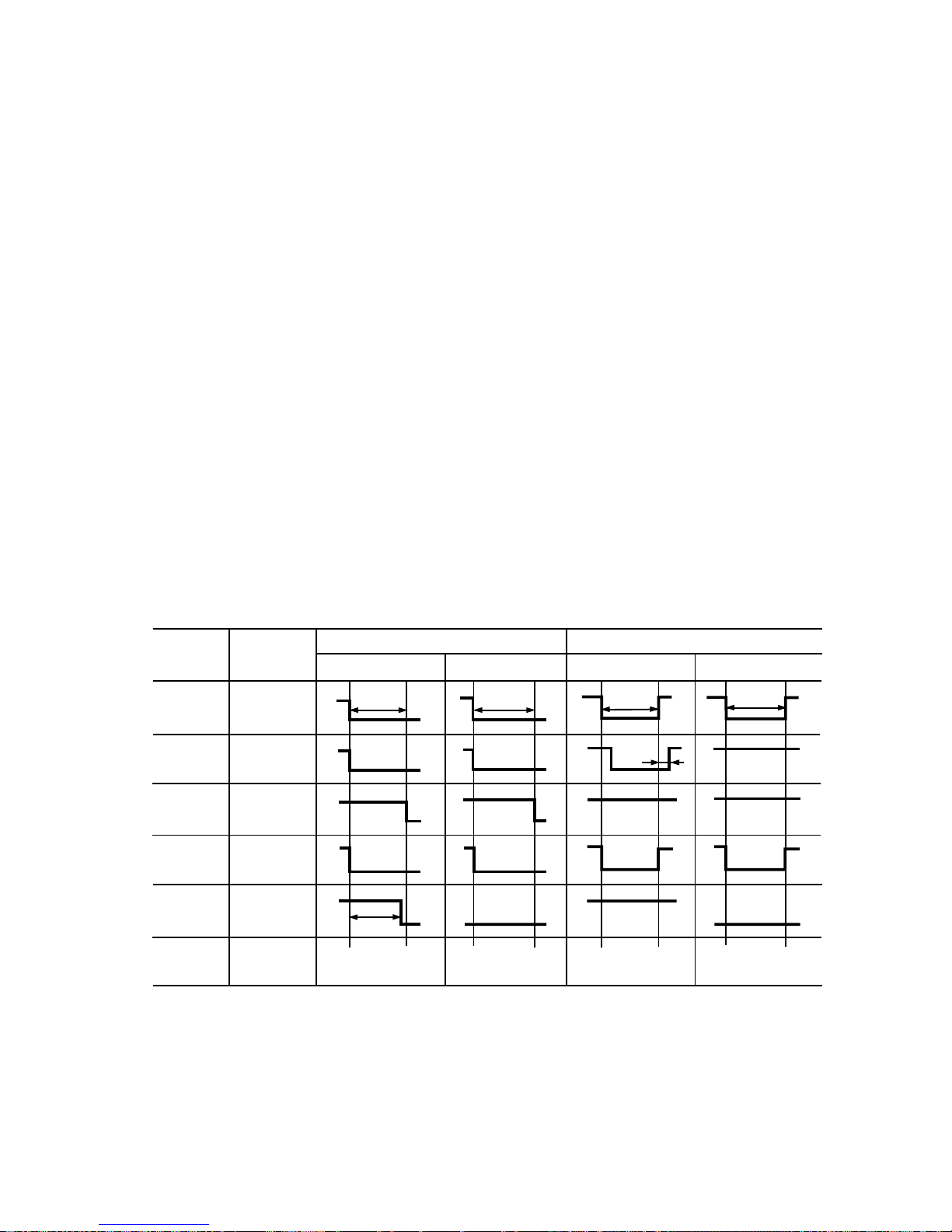

(q) Stop mode

(i) Operating conditions: When the operation mode is changed, when the dehumidifying operation is changed from the

heating oriented mode to the cooling oriented mode or vice versa, or when the inverter speed turns to 0 rps. [When 0 rps is

commanded from the indoor unit controller, or when an outdoor protective function is actuated]

(ii) Detail of operation

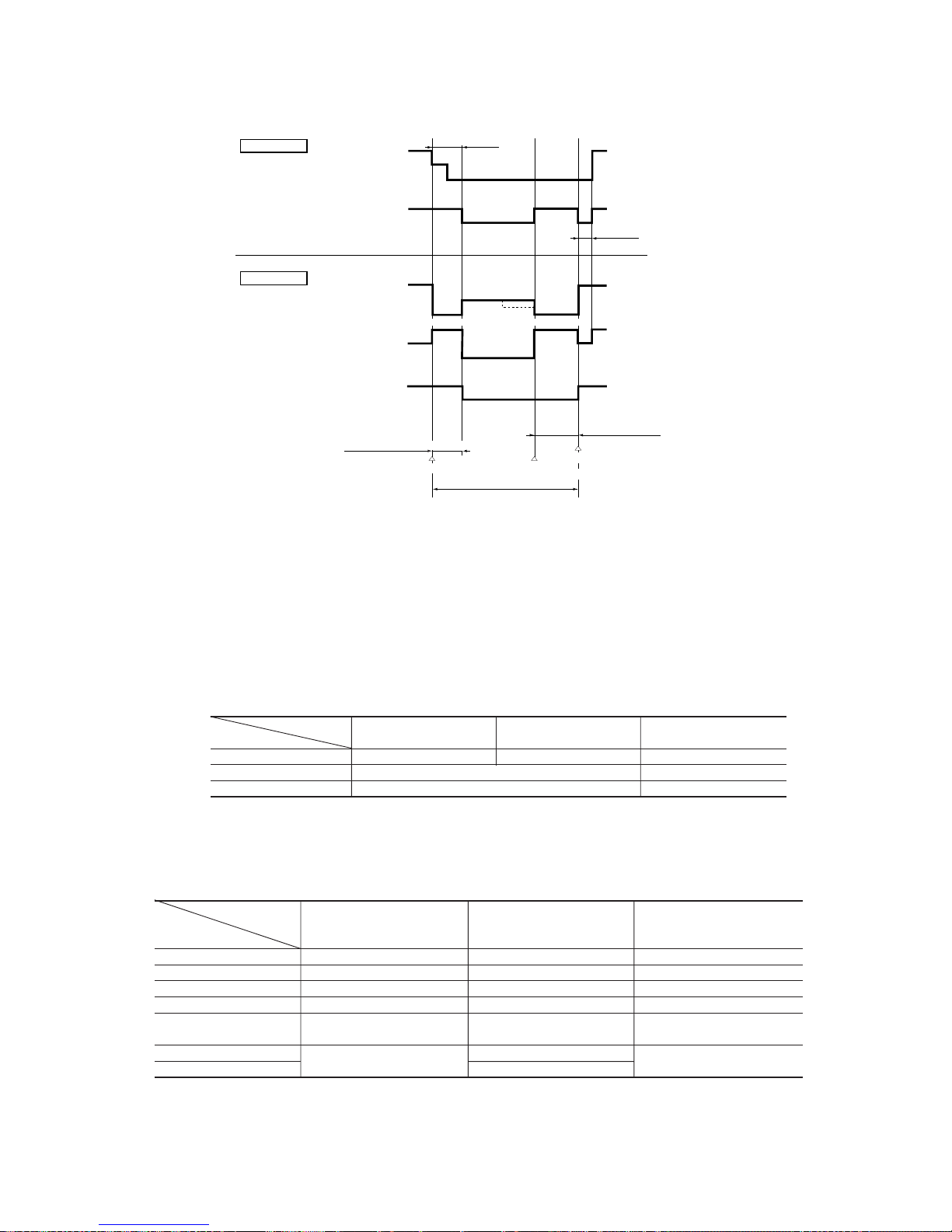

◆ 20, 25, 35 type

When stopped by indoor unit controller When stopped or reset by outdoor unit protective function

Function Operation

Heating, heating Cooling, cooling Heating, heating Cooling, cooling

oriented dehumidifying oriented dehumidifying oriented dehumidifying oriented dehumidifying

Stop Full stop Stop Full stop Stop Restart Stop Restart

(0 rps command) (0 rps command) (0 rps command) (0 rps command)

Inverter

speed

Indoor

fan

Indoor

power

relay

Outdoor

fan

4-way

valve

(Command

speed)

0

(Speed

dependent)

OFF

ON

OFF

3 min.

(1)

3 min.

(1)

2 min. 2 min.

55 sec. 55 sec.

Hot keep

2 min.55sec.

ON

OFF

ON

OFF

1st speed

-

27

-

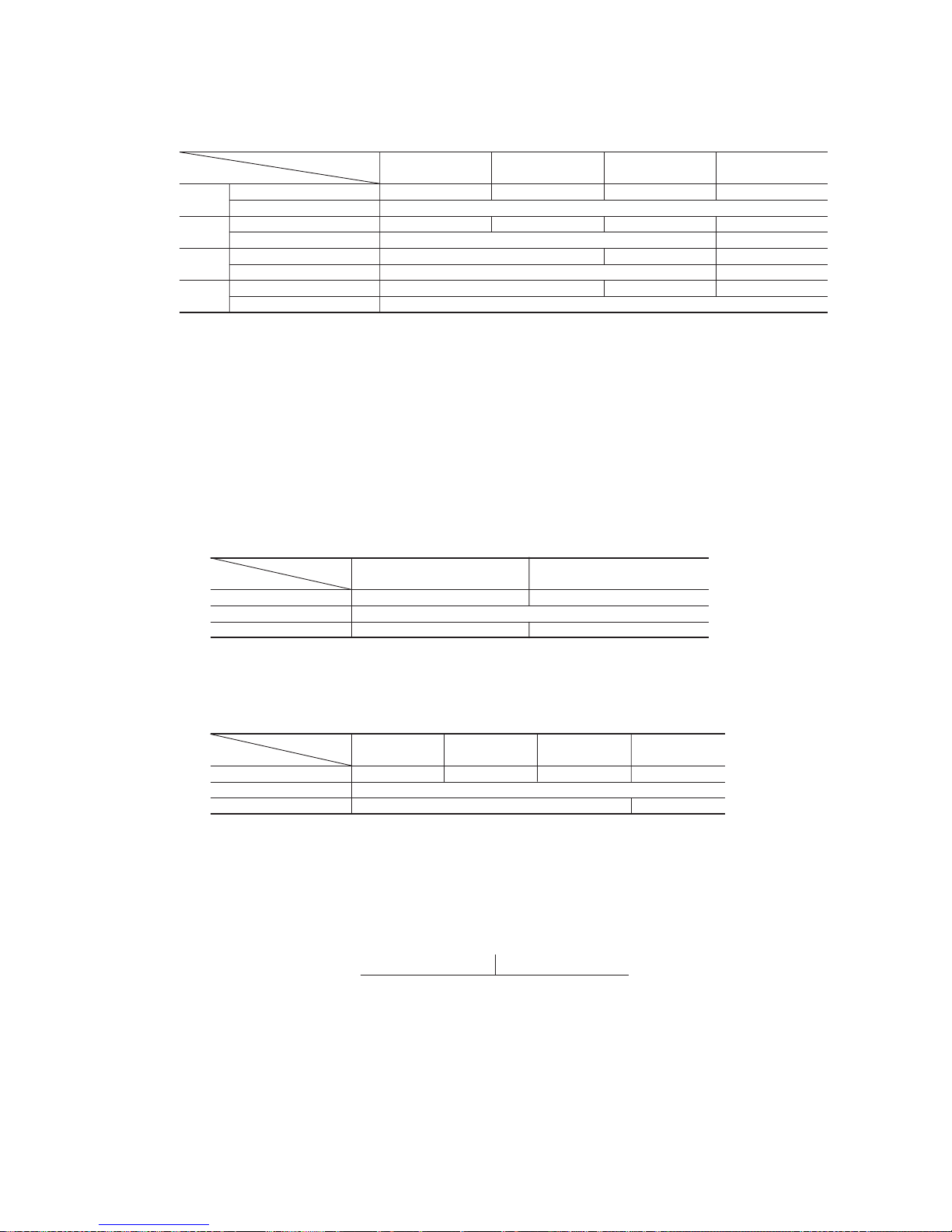

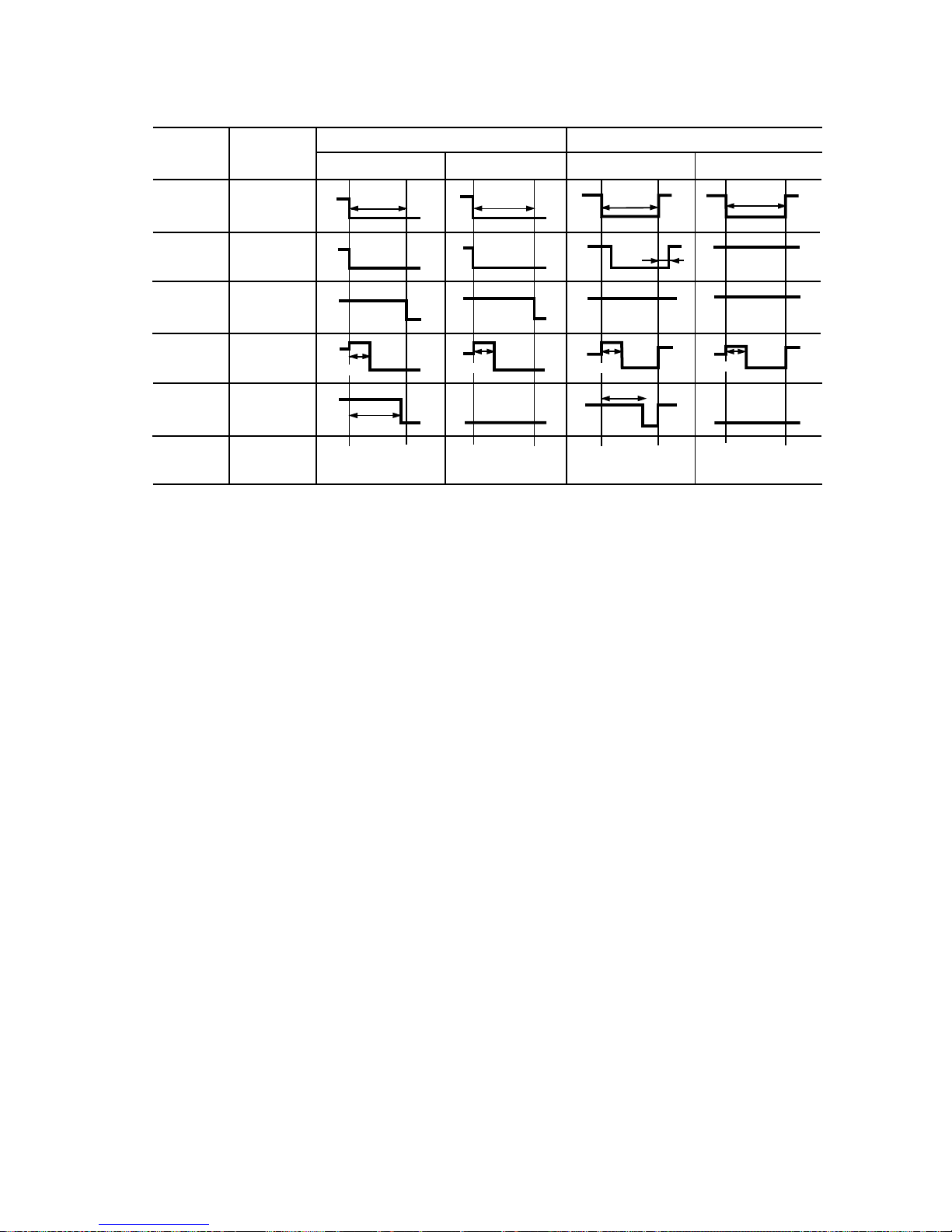

◆ 50 type

Note (1) When the start delay of compressor of indoor unit controller is actuated and the operation is reset, it takes 2 minutes and 55 seconds.

When stopped by indoor unit controller When stopped or reset by outdoor unit protective function

Function Operation

Heating, heating Cooling, cooling Heating, heating Cooling, cooling

oriented dehumidifying oriented dehumidifying oriented dehumidifying oriented dehumidifying

Stop Full stop Stop Full stop Stop Restart Stop Restart

(0 rps command) (0 rps command) (0 rps command) (0 rps command)

Inverter

speed

Indoor

fan

Indoor

power

relay

Outdoor

fan

4-way

valve

(Command

speed)

0

(Speed

dependent)

OFF

ON

OFF

3 min.

(1)

3 min.

(1)

3 min.

2 min.

55 sec.

Hot keep

2 min.55sec.

ON

OFF

ON

OFF

2nd speed 2nd speed

2nd speed

2nd speed

1 min.

1 min.

1 min.

1 min.

1st speed

2 min.55sec.

-

28

-

1.1.5 APPLICATION DATA

SAFETY PRECAUTIONS

¡ Please read these “Safety Precautions” first then accurately execute the installation work.

¡ Though the precautionary points indicated herein are divided under two headings,

WARNING and CAUTION , those points

which are related to the strong possibility of an installation done in error resulting in death or serious injury are listed in the

WARNING section. However, there is also a possibility of serious consequences in relationship to the points listed in the

CAUTION section as well. In either case, important safety related information is indicated, so by all means, properly observe all

that is mentioned.

¡ After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please explain

operating methods as well as maintenance methods to the user (customer) of this equipment, based on the owner’s manual.

Moreover, ask the customer to keep this sheet together with the owner’s manual.

WARNING

¡ To disconnect the appliance from the mains supply this appliance must be connected to the mains by means of

a circuit breaker or a switch (use a recognized 16A) with a contact separation of at least 3mm.

¡ The appliance shall be installed in accordance with national wiring regulations.

¡ This system should be applied to places as households, residences and the like. Application to inferior environ-

ment such as engineering shop could cause equipment malfunction.

¡ Please entrust installation to either the company which sold you the equipment or to a professional contractor.

Defects from improper installations can be the cause of water leakage, electric shocks and fires.

¡ Execute the installation accurately, based on following the installation manual. Again, improper installations can

result in water leakage, electric shocks and fires.

¡ For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insuffi-

cient, injury can result from a falling of the unit.

¡ For electrical work, please see that a licensed electrician executes the work while following the safety standards

related to electrical equipment, and local regulations as well as the installation instructions, and that only

exclusive use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks

and fires.

¡ Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted

to the terminal connection part, through properly securing it improper connection or securing can result in heat

generation or fire.

¡ Ta ke care that wiring does not rise upward ,and accurately install the lid/service panel.It’s improper installation

can also result heat generation or fire.

¡ When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the

designated refrigerant within the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

¡ Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this

company can result in water leakage, electric shock, fire and refrigerant leakage.

¡ Ventilate the work area when refrigerant leaks during the operation.

Coming in contact with fire, refrigerant could generate toxic gas.

¡ Confirm after the foundation construction work that refrigerant does not leak.

If coming in contact with fire of a fan heater, a stove or movable cooking stove, etc., refrigerant leaking in the

room could generate toxic gas.

¡ In joining pipes, do not use conventional (R22) pipng flare nuts, etc. The use of conventional pipng materials may

lead to the rapture of piping due to higher pressure used for the refrigerant cycle and possible personal injury.

(Use only piping material designed specifically for R410A)

CAUTION

¡ Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone

ground wire.

Improper placement of ground wires can result in electric shock.

¡ The installation of an earth leakage breaker is necessary depending on the established location of the unit.

No installing an earth leakage breaker may result in electric shock.

¡ Do not install the unit where there is a concern about leakage of combustible gas.

The rare even of leaked gas collecting around the unit could result in an outbreak of fire.

¡ For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it

to prevent condensation. Inadequate plumbing can result in water leakage and water damage to interior items.

¡ Do not place objects near the outdoor unit or allow leaves to gather around the unit. If there are objects or leaves

around the outdoor unit, small animals may enter unit and contact electrical parts resulting in break down,

emission of smoke or flame.

Loading...

Loading...