Mitsubishi Heavy Industries SRK25ZSX-S, SRK35ZSX-S, SRK20ZS-SB, SRK25ZS-SB, SRK20ZS-S Technical Manual

...

Manual No.'17•SRK-T-203

updated April 10, 2017

TECHNICAL MANUAL

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air to air heat pump type)

SRK20ZSX-S

25ZSX-S

35ZSX-S

50ZSX-S

60ZSX-S

'17 • SRK-T-203

'10 • SRK-T-105

CONTENTS

1. SPECIFICATIONS ........................................................................................ 3

2. EXTERIOR DIMENSIONS

......................................................................... 8

(1) Indoor units .......................................................................................... 8

(2) Outdoor units ....................................................................................... 9

(3) Remote control

..................................................................................... 11

3. ELECTRICAL WIRING .............................................................................. 13

(1) Indoor units .......................................................................................... 13

(2) Outdoor units ....................................................................................... 14

4. NOISE LEVEL ............................................................................................ 16

5. PIPING SYSTEM ...................................................................................... 21

6. RANGE OF USAGE & LIMITATIONS

7. CAPACITY TABLES

8. APPLICATION DATA

................................................................................... 24

.................................................................................. 26

..................................................... 22

(1) Installation of indoor unit ...................................................................... 26

(2) Installation of outdoor unit .................................................................. 30

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............... 34

(1) Operation control function by wireless remote control

(2) Unit ON/OFF button

........................................................................... 35

....................... 34

......................................................................... 35(3) Auto restart function

(4) Installing two air-conditioners in the same room

............................... 35

(5) Selection of the annual cooling function .............................................. 36

(6) Heating only function ........................................................................... 36

(7) High power operation ........................................................................... 36

(8) Economy operation

.............................................................................. 37

(9) Airflow direction adjustment .................................................................... 37

(10) 3D auto operation

(11) Timer operation

........................................................................... 38

.................................................................................. 39

(12) Silent operation .................................................................................... 40

(13) Night setback operation

..................................................................... 40

(14) Airflow range setting ........................................................................... 40

(15) Display brightness adjustment

(16) Auto OFF operation

............................................................................ 41

............................................................... 41

(17) Outline of heating operation

(18) Outline of cooling operation

(19) Outline of dehumidifying (DRY) opertaion

(20) Outline of automatic operation

(21) Protective control function

............................................................... 41

............................................................... 43

........................................... 43

............................................................... 44

................................................................... 44

-

-

1

'17 • SRK-T-203

'13 • SRK-T-135

10. MAINTENANCE DATA

(1) Cautions

............................................................................................. 51

............................................................................... 51

(2) Items to check before troubleshooting ................................................. 51

(3) Troubleshooting procedure

(4) Troubleshooting procedure (If the air-conditioner runs)

(5) Self-diagnosis table ............................................................................. 53

(If the air-conditioner does not run at all)

..................... 52

(6) Service mode (Trouble mode access function) ................................... 54

(7) Inspection procedures corresponding to detail of trouble .................... 62

Phenomenon observed after shortcircuit, wire breakage on sensor

(8)

(9) Checking the indoor electrical equipment

........................................... 67

......... 67

(10) How to make sure of wireless remote control ...................................... 69

(11) Inspection procedure for blown fuse on the indoor and outdoor PCB .... 69

(12) Outdoor unit inspection points .............................................................. 70

11. INDOOR UNIT DISASSEMBLY PROCEDURE

12. OPTION PARTS

(1) Wired remote control (RC-E5)

(2) Interface kit (SC-BIKN-E)

........................................................................................... 79

.............................................................. 79

..................................................................... 85

............................................ 73

(3) Superlink E board (SC-ADNA-E) .......................................................... 89

........ 51

13. TECHNICAL INFORMATION

■How to read the model name

Example: SRK 20 Z

SX-S

....................................................................... 91

Series code

Inverter type

Product capacity (Cooling capacity : 2.0kW)

Model name SRK : Wall mounted type

SRC : Outdoor unit

-

-

2

'17 • SRK-T-203

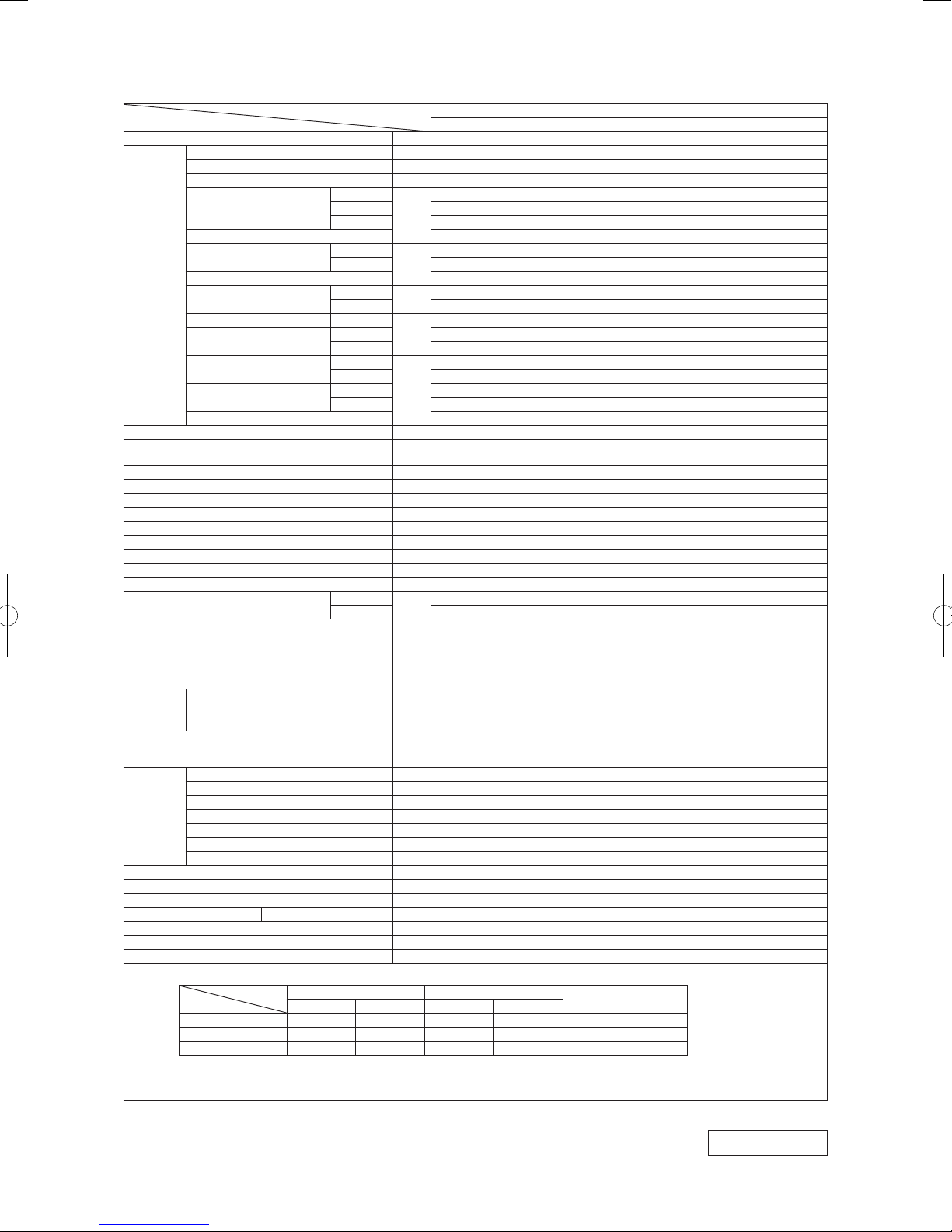

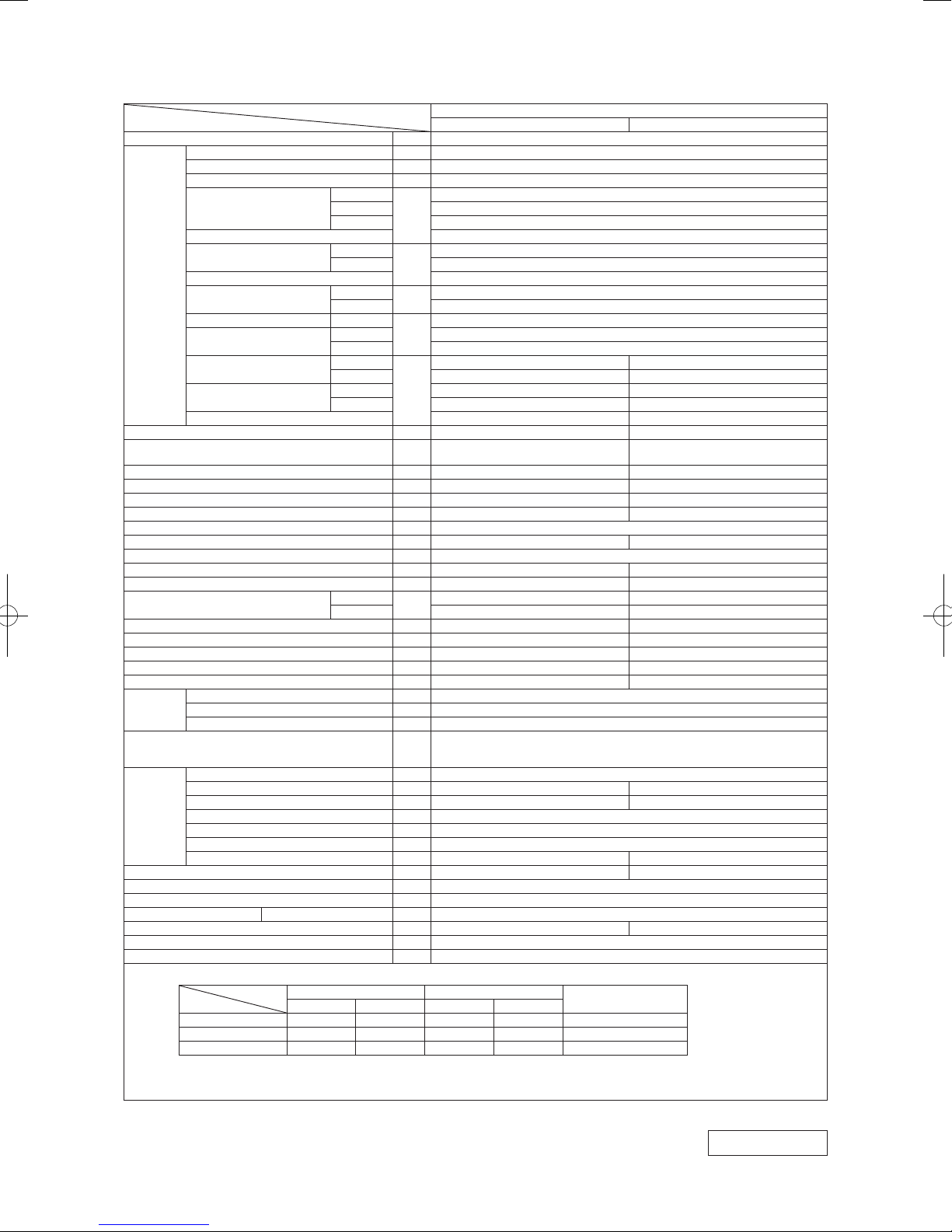

1. SPECIFICATIONS

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 305 x 920 x 220 640 x 800 (+71) x 290

Exterior appearance

(Equivalent color)

Net weight kg 13 43.0

Compressor type & Quantity — RMT5111MCE2(Twin rotary type) x 1

Compressor motor (Starting method) kW — 0.75 (Inverter driven)

Refrigerant oil (Amount, type) ℓ — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.45 in outdoor unit (Incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 2.5

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit (SC-BIKN-E)

Nominal cooling capacity (range) kW 2.0 ( 0.9(Min.) - 3.2 (Max.))

Nominal heating capacity (range) kW 2.7 ( 0.8(Min.) - 5.3 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.92

Running current

Inrush current, max current 2.5 Max. 9

Power factor

EER Cooling 6.25

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:33 / Heating:38

Remote control Wireless - remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, ECO: Blue

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.48 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 (Outdoor unit is higher) / Max.15 (Outdoor unit is lower)

Drain hose Hose connectable (VP 16) Holes φ20 x 5 pcs

Cooling

Heating 0.47 (0.14 - 1.36)

Heating (H2) —

Cooling

Heating 2.6 / 2.5 / 2.4 (220/ 230/ 240V)

Cooling

Heating 81

Heating 5.74

Heating (H2) —

Cooling

Heating 53 58

Cooling Hi: 38 Me: 31 Lo: 24 ULo: 19 43

Heating Hi: 38 Me: 32 Lo: 25 ULo: 19 44

Cooling

Heating Hi: 12.2 Me: 10.3 Lo: 7.2 ULo: 5.4 31.0

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK20ZSX-S Outdoor unit SRC20ZSX-S

53 56

Munsell : (8.0Y 9.3/0.1), RAL : 9003

Hi: 11.3 Me: 9.1 Lo: 6.0 ULo: 5.0 31.0

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Fine snow

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

Item

DB WB DB WB

SRK20ZSX-S

0.32 (0.16 - 0.74)

1.9 / 1.8 / 1.7 (220/ 230/ 240V)

76

Munsell : (4.2Y 7.5/1.1), RAL : 7004

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

RWA000Z269

-

-

3

'17 • SRK-T-203

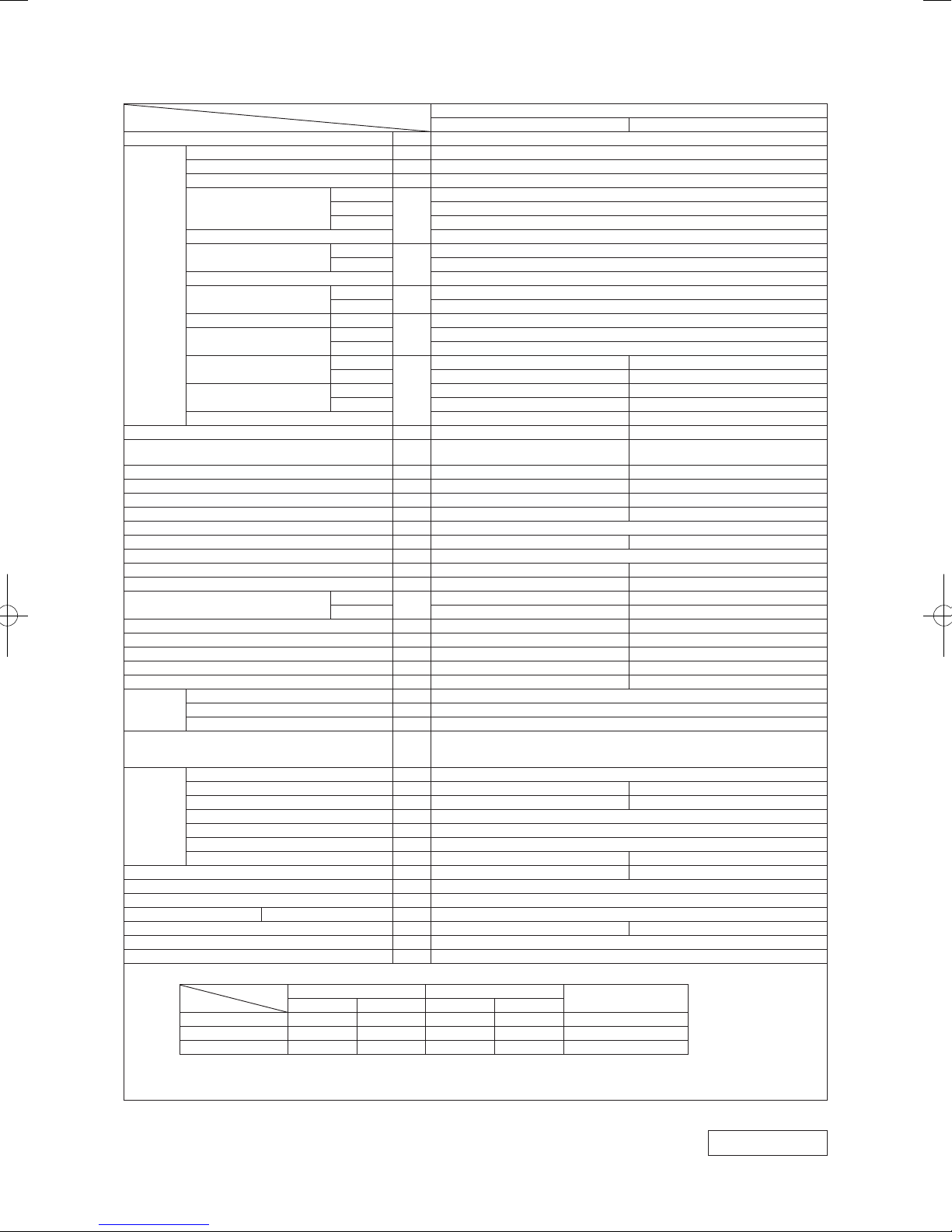

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 305 x 920 x 220 640 x 800 (+71) x 290

Exterior appearance

(Equivalent color)

Net weight kg 13 43.0

Compressor type & Quantity — RMT5111MCE2(Twin rotary type) x 1

Compressor motor (Starting method) kW — 0.75 (Inverter driven)

Refrigerant oil (Amount, type) ℓ — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.45 in outdoor unit (Incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.0

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit (SC-BIKN-E)

Nominal cooling capacity (range) kW 2.5 ( 0.9(Min.) - 3.7 (Max.))

Nominal heating capacity (range) kW 3.2 ( 0.8(Min.) - 5.8 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.92

Running current

Inrush current, max current 3.0 Max. 9

Power factor

EER Cooling 5.68

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:35 / Heating:39

Remote control Wireless - remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, ECO: Blue

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.48 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 (Outdoor unit is higher) / Max.15 (Outdoor unit is lower)

Drain hose Hose connectable (VP 16) Holes φ20 x 5 pcs

Cooling

Heating 0.59 (0.14 - 1.54)

Heating (H2) —

Cooling

Heating 3.2 / 3.0 / 2.9 (220/ 230/ 240V)

Cooling

Heating 85

Heating 5.42

Heating (H2) —

Cooling

Heating 56 58

Cooling Hi: 39 Me: 33 Lo: 25 ULo: 19 44

Heating Hi: 40 Me: 34 Lo: 27 ULo: 19 45

Cooling

Heating Hi: 12.8 Me: 11.0 Lo: 7.8 ULo: 5.4 31.0

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK25ZSX-S Outdoor unit SRC25ZSX-S

55 57

Munsell : (8.0Y 9.3/0.1), RAL : 9003

Hi: 12.2 Me: 10.0 Lo: 6.7 ULo: 5.0 31.0

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Fine snow

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

Item

DB WB DB WB

SRK25ZSX-S

0.44 (0.16 - 0.89)

2.5 / 2.4 / 2.3 (220/ 230/ 240V)

80

Munsell : (4.2Y 7.5/1.1), RAL : 7004

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

RWA000Z269

-

-

4

'17 • SRK-T-203

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 305 x 920 x 220 640 x 800(+71) x 290

Exterior appearance

(Equivalent color)

Net weight kg 13 43.0

Compressor type & Quantity — RMT5111MCE2(Twin rotary type) x 1

Compressor motor (Starting method) kW — 0.90 (Inverter driven)

Refrigerant oil (Amount, type) ℓ — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.45 in outdoor unit (Incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.3

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit (SC-BIKN-E)

Nominal cooling capacity (range) kW 3.5 ( 0.9(Min.) - 4.3 (Max.))

Nominal heating capacity (range) kW 4.3 ( 0.8(Min.) - 6.6 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 1.92

Running current

Inrush current, max current 4.3 Max. 9

Power factor

EER Cooling 4.49

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:38 / Heating:43

Remote control Wireless - remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, ECO: Blue

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.48 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max.25

Vertical height diff. between O.U. and I.U. m Max.15 (Outdoor unit is higher) / Max.15 (Outdoor unit is lower)

Drain hose Hose connectable (VP 16) Holes φ20 x 5 pcs

Cooling

Heating 0.90 (0.14 - 1.89)

Heating (H2) —

Cooling

Heating 4.4 / 4.3 / 4.1 (220/ 230/ 240V)

Cooling

Heating 92

Heating 4.78

Heating (H2) —

Cooling

Heating 58 62

Cooling Hi: 43 Me: 35 Lo: 26 ULo: 19 48

Heating Hi: 41 Me: 35 Lo: 28 ULo: 19 47

Cooling

Heating Hi: 13.9 Me: 11.8 Lo: 8.6 ULo: 5.4 31.0

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK35ZSX-S Outdoor unit SRC35ZSX-S

58 61

Munsell : (8.0Y 9.3/0.1), RAL : 9003

Hi: 13.1 Me: 10.8 Lo: 7.3 ULo: 5.0 36.0

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Fine snow

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

Item

DB WB DB WB

SRK35ZSX-S

0.78 (0.16 - 1.26)

3.9 / 3.7 / 3.6 (220/ 230/ 240V)

91

Munsell : (4.2Y 7.5/1.1), RAL : 7004

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

RWA000Z269

-

-

5

'17 • SRK-T-203

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 305 x 920 x 220 640 x 800 (+71) x 290

Exterior appearance

(Equivalent color)

Net weight kg 13 45

Compressor type & Quantity — RMT5113MCE2(Twin rotary type) x 1

Compressor motor (Starting method) kW — 1.50 (Inverter driven)

Refrigerant oil (Amount, type) ℓ — 0.45 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.50 in outdoor unit (Incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 5.0

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit (SC-BIKN-E)

Nominal cooling capacity (range) kW 5.0 ( 1.0(Min.) - 5.8 (Max.))

Nominal heating capacity (range) kW 6.0 ( 0.6(Min.) - 8.1 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 2.90

Running current

Inrush current, max current 5.0 Max. 15

Power factor

EER Cooling 3.85

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless - remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, ECO: Blue

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2" )

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.48 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max.30

Vertical height diff. between O.U. and I.U. m Max.20 (Outdoor unit is higher) / Max.20 (Outdoor unit is lower)

Drain hose Hose connectable (VP 16) Holes φ20 x 5 pcs

Cooling

Heating 1.36 (0.18 - 2.43)

Heating (H2) —

Cooling

Heating 6.2 / 6.0 / 5.7 (220/ 230/ 240V)

Cooling

Heating 99

Heating 4.41

Heating (H2) —

Cooling

Heating 62 63

Cooling Hi: 44 Me: 39 Lo: 31 ULo: 22 50

Heating Hi: 46 Me: 41 Lo: 33 ULo: 23 49

Cooling

Heating Hi: 17.3 Me: 14.3 Lo: 9.8 ULo: 6.2 33.0

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK50ZSX-S Outdoor unit SRC50ZSX-S

59 63

Munsell : (8.0Y 9.3/0.1), RAL : 9003

Hi: 14.3 Me: 12.4 Lo: 7.8 ULo: 5.4 39.0

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Fine snow

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

Item

DB WB DB WB

SRK50ZSX-S

1.30 (0.19 - 1.80)

6.0 / 5.7 / 5.5 (220/ 230/ 240V)

99

Munsell : (4.2Y 7.5/1.1), RAL : 7004

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

RWA000Z269

-

-

6

'17 • SRK-T-203

Item

Power source 1 Phase, 220 - 240V, 50Hz / 220V, 60Hz

Operation

data

Exterior dimensions (Height x Width x Depth) mm 305 x 920 x 220 640 x 800(+71) x 290

Exterior appearance

(Equivalent color)

Net weight kg 13 45

Compressor type & Quantity — RMT5113MCE2(Twin rotary type) x 1

Compressor motor (Starting method) kW — 1.50 (Inverter driven)

Refrigerant oil (Amount, type) ℓ — 0.45 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.50 in outdoor unit (Incl. the amount for the piping of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Quantity Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 42 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (Washable) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor)

Electric heater — —

Operation

control

Safety equipments

Installation

data

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 5.0

Interconnecting wires Size x Core number 1.5mm

IP number IPX0 IPX4

Standard accessories

Option parts Interface kit (SC-BIKN-E)

Nominal cooling capacity (range) kW 6.1 ( 1.0(Min.) - 6.8 (Max.))

Nominal heating capacity (range) kW 6.8 ( 0.6(Min.) - 8.7 (Max.))

Heating capacity (H2) kW —

Power consumption

Max power consumption 2.90

Running current

Inrush current, max current 5.0 Max. 15

Power factor

EER Cooling 3.37

COP

Sound power level

Sound pressure level

Silent mode sound pressure level — Cooling:42 / Heating:43

Remote control Wireless - remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, ECO: Blue

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ12.7 (1/2" )

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.48 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max.30

Vertical height diff. between O.U. and I.U. m Max.20 (Outdoor unit is higher) / Max.20 (Outdoor unit is lower)

Drain hose Hose connectable (VP 16) Holes φ20 x 5 pcs

Cooling

Heating 1.67 (0.18 - 2.86)

Heating (H2) —

Cooling

Heating 7.7 / 7.3 / 7.0 (220/ 230/ 240V)

Cooling

Heating 99

Heating 4.07

Heating (H2) —

Cooling

Heating 63 64

Cooling Hi: 46 Me: 41 Lo: 33 ULo: 22 52

Heating Hi: 46 Me: 42 Lo: 34 ULo: 23 52

Cooling

Heating Hi: 17.8 Me: 13.7 Lo: 10.9 ULo: 6.2 39.0

Model

kW

A

%

dB(A)

3

m

/min

Indoor unit SRK60ZSX-S Outdoor unit SRC60ZSX-S

62 65

Munsell : (8.0Y 9.3/0.1), RAL : 9003

Hi: 16.3 Me: 13.4 Lo: 8.9 ULo: 5.4 41.5

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection( High pressure control ), Cooling overload protection

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Fine snow

Compressor overheat protection, Overcurrent protection,

2

x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

Notes (1) The data are measured at the following conditions.

Indoor air temperature Outdoor air temperature

Operation

Cooling 27˚C 19˚C 35˚C 24˚C ISO5151-T1

Heating 20˚C — 7˚C 6˚C ISO5151-H1

Heating (H2) 20˚C — 2˚C 1˚C ISO5151-H2

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

Item

DB WB DB WB

SRK60ZSX-S

1.81 (0.19 - 2.50)

8.3 / 7.9 / 7.6 (220/ 230/ 240V)

99

Munsell : (4.2Y 7.5/1.1), RAL : 7004

Rubber sleeve (for fan motor & compressor)

The pipe length is 5m.

Standards

Stucco white

RWA000Z269

-

-

7

'17 • SRK-T-203

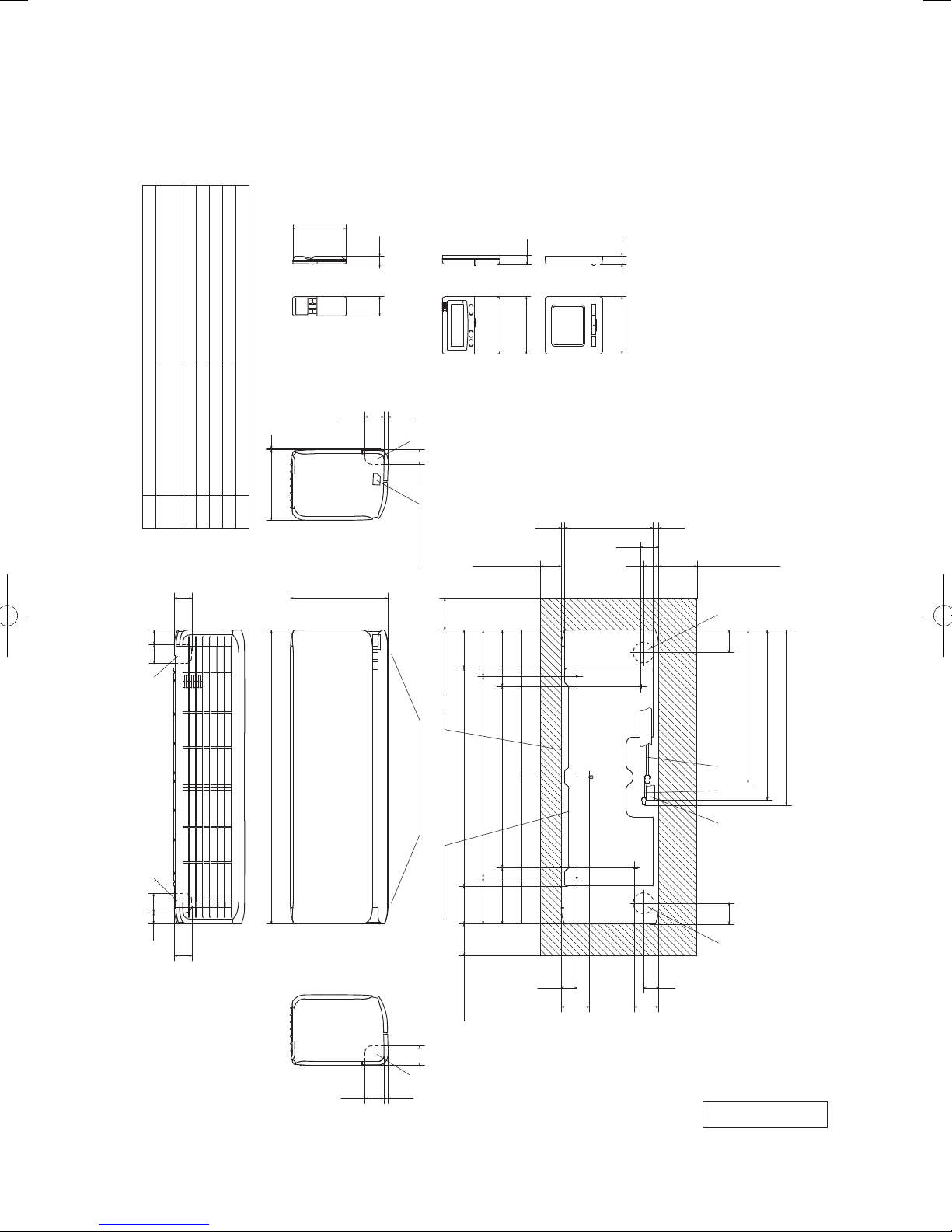

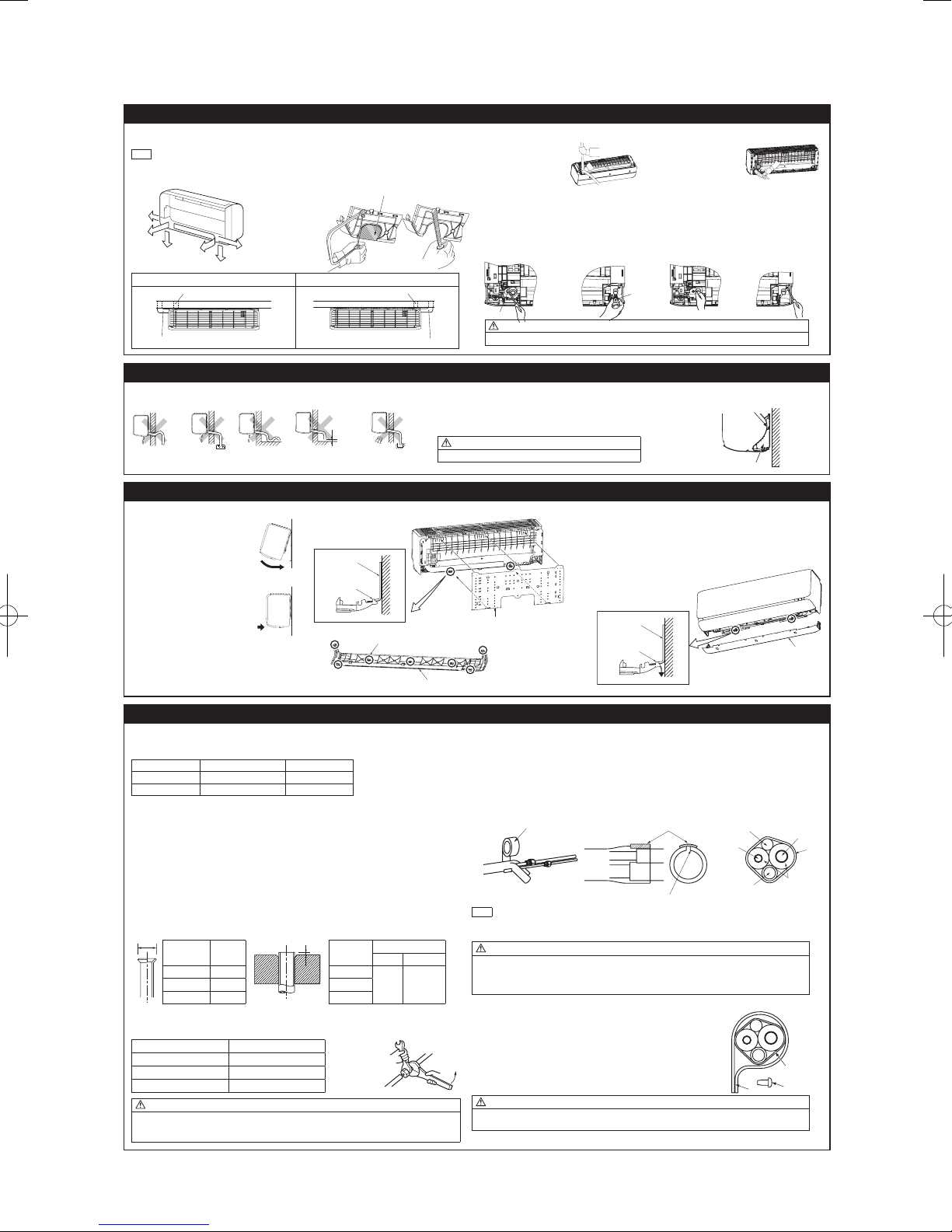

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK20ZSX-S, 25ZSX-S, 35ZSX-S, 50ZSX-S, 60ZSX-S

167

19

Unit:mm

SRK 20,25,35 φ9.52(3/8")(Flare)

Content

Gas piping

A

Symbol

60 45

Wireless remote control

SRK 50,60 φ12.7(1/2")(Flare)

VP16

φ6.35(1/4")(Flare)

(φ65)

(φ65)

Liquid piping

Hole on wall for right rear piping

Hole on wall for left rear piping

Outlet for piping

Drain hose

220 3

B

55

F

ECD

60 24

59.512.5

305

(Option)

Wired remote control

FF

45

Terminal block

100

118.5118.5 683

(Service space)

Unit

□120

10.3277.317.4

65120

(Service space)

□120 19

Notes(1)The model name label is attached

on the right side of the unit.

(2)To connect the wired remote control,

the interface kit(SC-BIKN-E) is required.

56.4

47

(Service space)

533

548

SRK 50,60 486

SRK 20,25,35 480

920

F F

6035

55

Outlet for downward piping

61

59.512.5

(Refer to the top view)

145 630 145

Installation board

100

(Service space)

-

-

8

176 568 176

460 460

48.6

88.6

Space for installation and service when viewing from the front

65 70

D B AE C

47

76.6

RLF000Z201

'17 • SRK-T-203

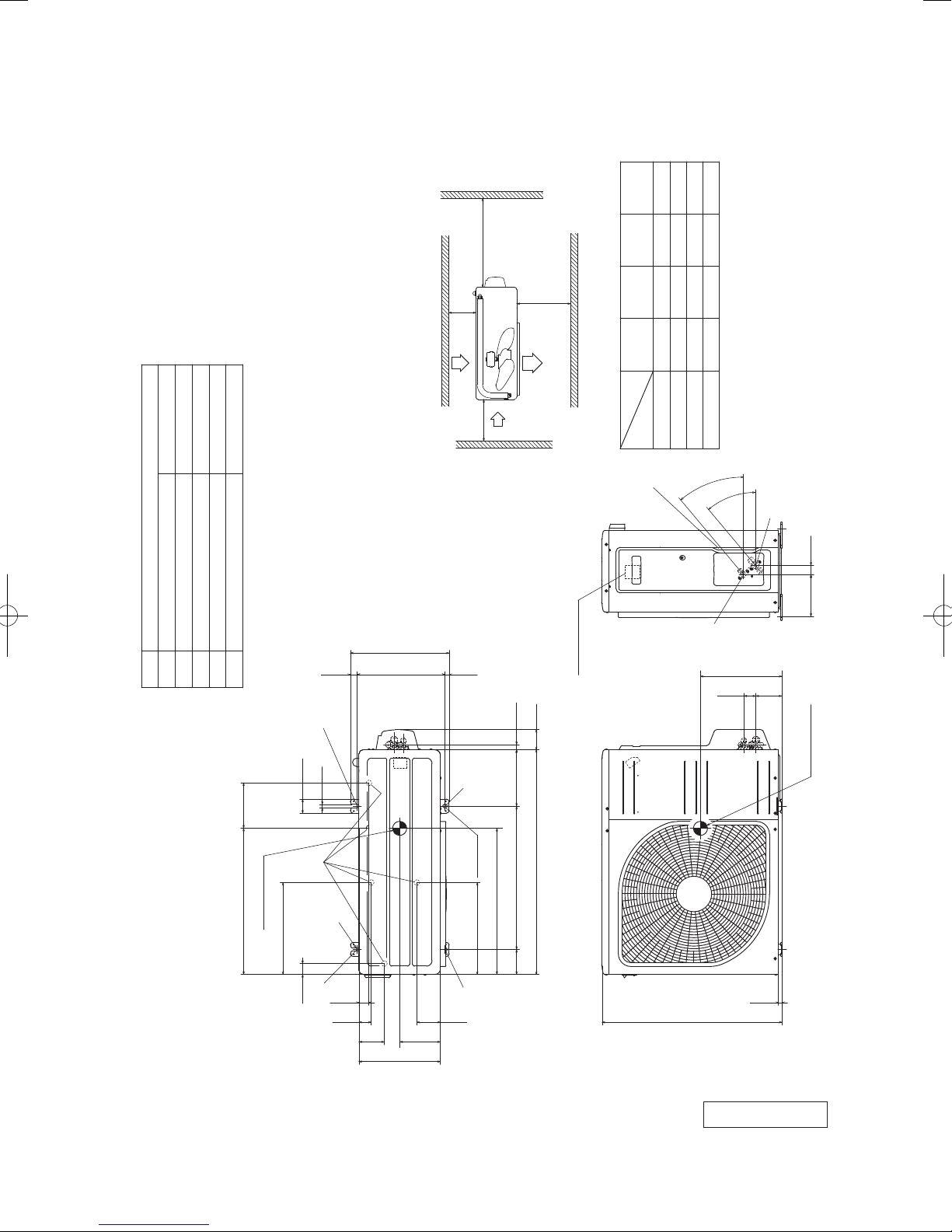

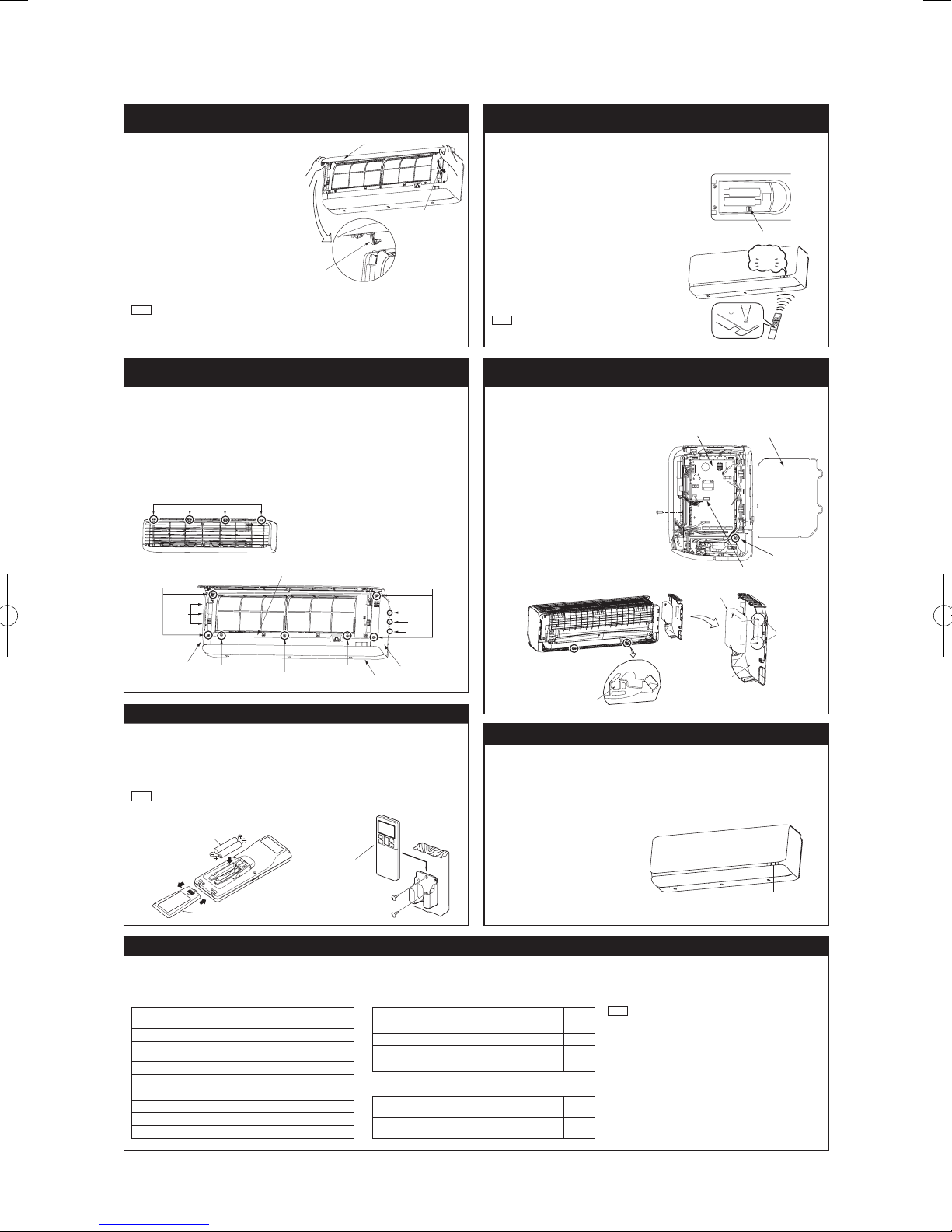

(2) Outdoor units

Models SRC20ZSX-S, 25ZSX-S, 35ZSX-S

φ9.52(3/8")( Flare)

Content

A Service valve connection(Gas side)

Symbol

M10-12×4 places

φ20×5 places

φ6.35(1/4")( Flare)

Drain discharge hole

Service valve connection(Liquid side)

E Anchor bolt hole

D

B

C Pipe/cable draw-out hole

L4

Service

space

( )

Inlet

17.9

L1

Outlet

71.2

L3

Inlet

L2

Notes

( 1) The unit must not be surrounded by walls on the four sides.

( 2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

( 3) If the unit is installed in the location where there is a possibility of

strong winds, place the unit such that the direction of air from the

outlet gets perpendicular to the wind direction.

( 4) Leave 200mm or more space above the unit.

( 5) The wall height on the outlet side should be 1200mm or less.

( 6) The model name label is attached on the right side of the unit.

351.6

24.3312.514.8

Ⅳ

180

Ⅲ

280

280

I Ⅱ

Open

Minimum installation space

installation

L1

Examples

Size

C

Terminal block

Open

Open

75

100

L2

80

80

80

100

L3

40°

Open

Unit:mm

250

Open

250

L4

40°

A

33.5148.4

B

290

93 42.5

12

50.6

520.6 161

Center of gravity

327.3

38.6

E

D E

2-12X16

2-R

E

35.6

43.5

90.6

290

327.3

E

83.5

145

800

Slot hole

520

89 510 201

640

Center of gravity

12.4

RCT000Z019

-

-

9

'17 • SRK-T-203

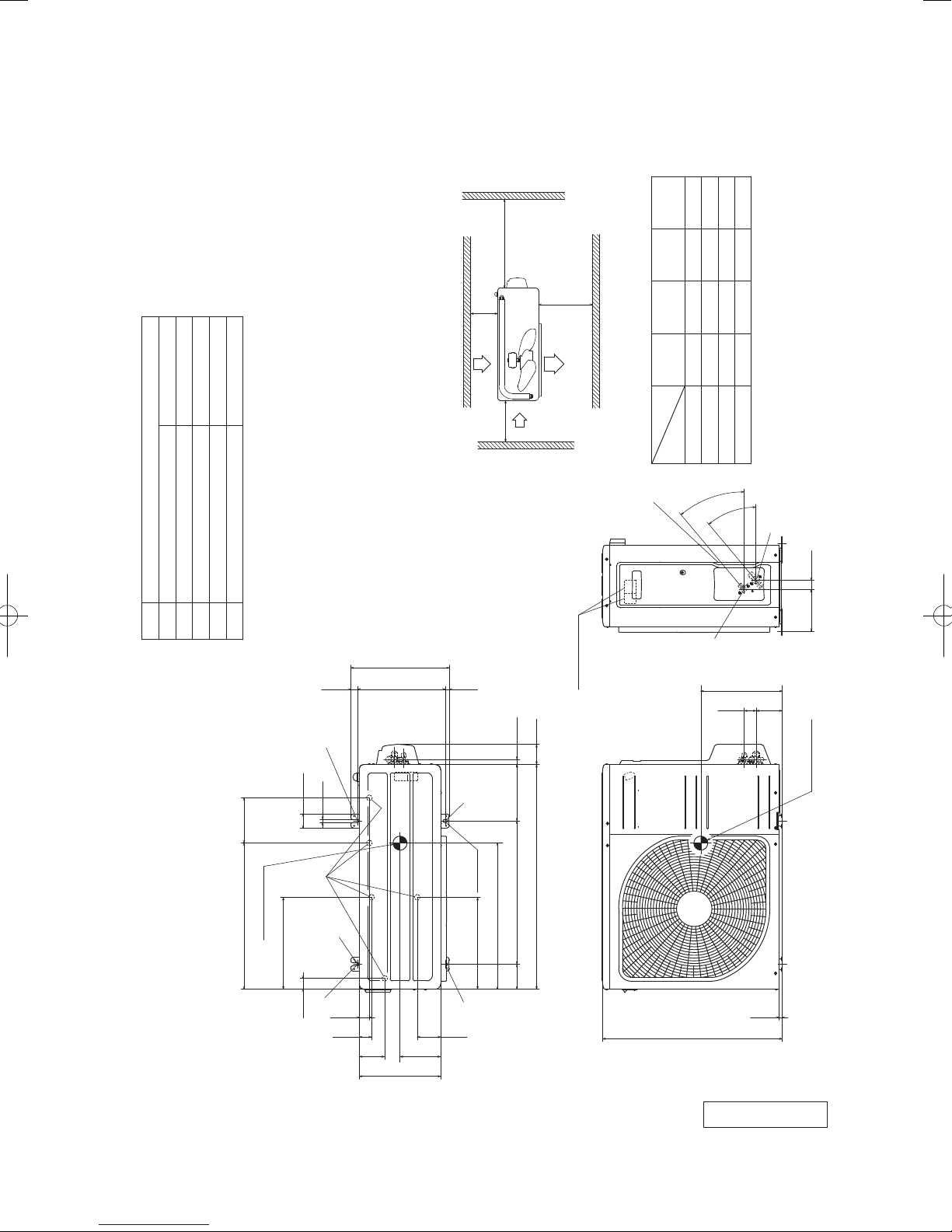

Model SRC50ZSX-S, 60ZSX-S

φ12.7(1/2")(Flare)

Content

A Service valve connection(Gas side)

Symbol

M10-12×4 places

φ20×5 places

φ6.35(1/4")(Flare)

Service valve connection(Liquid side)

Drain discharge hole

E Anchor bolt hole

D

B

C Pipe/cable draw-out hole

L4

Service

space

( )

L3

Inlet

L2

Notes

(1) The unit must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) If the unit is installed in the location where there is a possibility of

strong winds, place the unit such that the direction of air from the

outlet gets perpendicular to the wind direction.

(4) Leave 200mm or more space above the unit.

(5) The wall height on the outlet side should be 1200mm or less.

(6) The model name label is attached on the front side of the unit.

351.6

24.3312.514.8

E

17.9

L1

Outlet

Inlet

Terminal block

71.2

Ⅳ

Ⅲ

I Ⅱ

Minimum installation space

installation

Examples

Size

C

180

Open

280

Open

75

280

100

Open

L2

L1

40°

40°

80

80

80

100

L3

Open

250

Open

250

L4

B

290

Unit:mm

A

33.5148.4

93 42.5

12

50.6

520.6 161

Center of gravity

327.3

38.6

E

D

2-12X16

2-R

E

35.6

43.5

90.6

290

327.3

E

83.5

145

800

Slot hole

520

89 510 201

640

Center of gravity

12.4

RCT000Z020

-

-

10

'17 • SRK-T-203

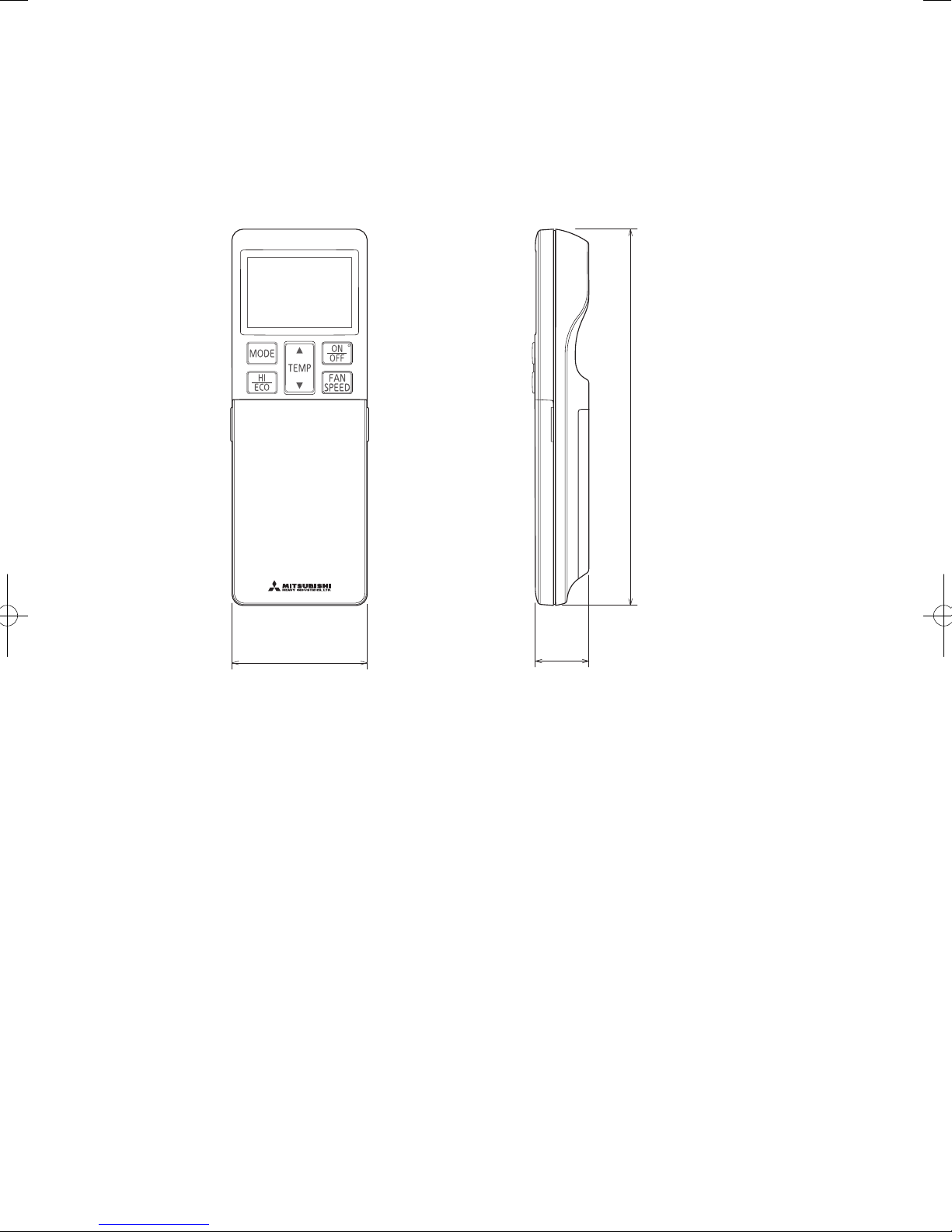

(3) Remote control

(3) Remote control

Wireless remote control

Unit : mm

167

60

26

-

11

-

'17 • SRK-T-203

(b) Wired remote control (option parts)

Interface kit (SC-BIKN-E) is required to use the wired remote control.

Wiring outlet

Cut off the upper thin part of remote control lower case with a nipper or knife,

Exposed mounting

0.3mm2×2 cores.

In case of pulling out

from upper left

L C D

48

In case of pulling out

from center

TEMP ON/OFF

and grind burrs with a file etc.

In case of pulling out

from upper left

Upper

Board

X Y

In case of pulling out

from center

Lower case

Lower part

Sheath

Upper cace

Upper part

Upper

Sheath

Upper cace

Board

YX

X, Y Terminal block

Attach M3 screw

□120

with washer

Pearl whiteExterior appearance

(Munsell color) (N8.5) near equivalent

Embedded mounting

Wall surface

Wiring

Electrical box

(Not included)

19

Remote

control

outline

Wiring oulet

12×7 Slot hole

Lower

In case of pulling out from

The peeling-off length of sheath

Pulling out from upper left

X wiring : 215mm

Y wiring : 195mm

Wiring

upper left

Pulling out from center

X wiring : 170mm

Y wiring : 190mm

Remote control installation dimensions

83.5

120

46

23

44

42

11.5 11

Installation hole

9.5×5 Slot hole (4 places)

Tighten the screws after

cutting off the thin part of

screw mounting part.

120

45

(1) Installation screw for remote control

M4 screw (2 pieces)

Lower

In case of pulling out from center

Wiring

The peeling-off length

of sheath

Unit:mm

Wiring specifications

(1) If the prolongation is over 100m, change to the size below.

But, wiring in the remote control case should be under 0.5mm

the case according to wire connecting. Waterproof treatment is necessary at the wire connecting

section. Be careful about contact failure.

Length Wiring thickness

100 to 200m

Under 300m

Under 400m

Under 600m

0.5mm

0.75mm

1.25mm

2.0mm

2

×2 cores

2

×2 cores

2

×2 cores

2

×2 cores

-

12

2

. Change the wire size outside of

-

PJZ000Z295

'17 • SRK-T-203

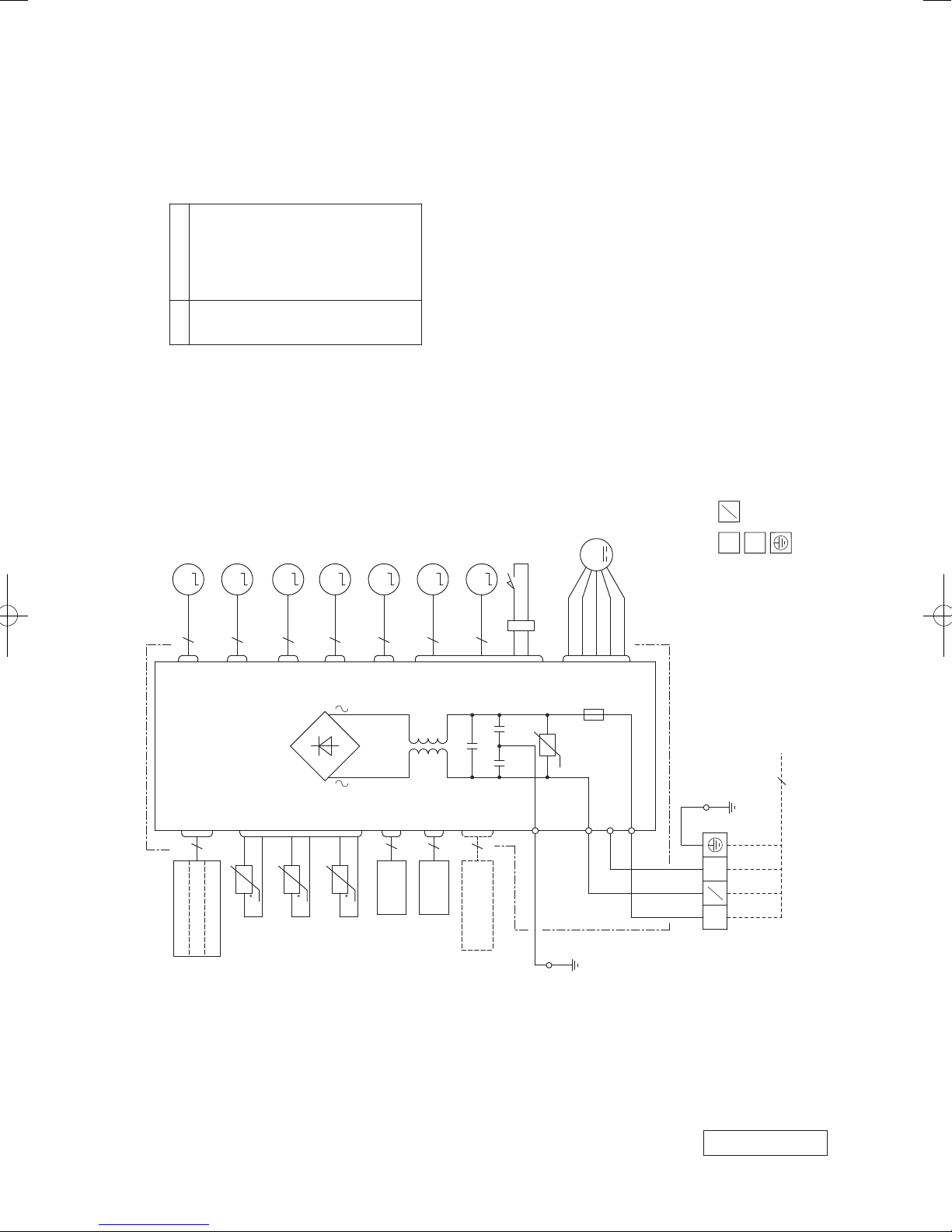

3. ELECTRICAL WIRING

(1) Indoor units

Models SRK20ZSX-S, 25ZSX-S, 35ZSX-S, 50ZSX-S, 60ZSX-S

ConnectorCNE

DescriptionItem

CNF

CNG

CNJ

CNL

CNM

CNP

CNS

CNU

CNX

CNY

CNZ

LEFT

MOTOR

LOUVER

M

RIGHT

MOTOR

LOUVER

M

FLAP

MOTOR

M

LEFT

FLAP

LOWER

RIGHT

LOWER

MOTOR

M

FLAP

UPPER

MOTOR

M

INLET

MOTOR

M

LEFT

INLET

MOTOR

M

INLET

RIGHT

SW

LIMIT

PANEL

FAN

MOTOR

M

N

2

1

3

5

DISPLAY

5

CNL

BOARD

CIRCUIT

PRINTED

CNE

7

BACK-UP SW

WIRELESS RECEIVER

5

CNZ

CNX

DIODE

STACK

t

SENSOR

ROOM TEMP.

5

CNG

t

SENSOR 1

HEAT EXCHANGER

5

CNY

CNM

CNF

2

t

HUMIDITY

SENSOR 2

HEAT EXCHANGER

5

CNJ

3

MOTION

SENSOR

5

CNP

CNS

5

INTERFACE KIT

SENSOR

G2

YELLOW/GREEN

RED

WHITE

BLACK

345

1

CNU

FUSE

U

VARISTOR

S/N

WHITE

HEAT

BLUE

YELLOW

6

250V

3.15A

J

L

RED

BLACK

EXCHANGER

Power source

YELLOW/GREEN

N

2

1 3

T

BLOCK

TERMINAL

POWER WIRES

SIGNAL WIRE

EARTH WIRE

[ ]

220V 60Hz

1 Phase

TO OUTDOOR UNIT

220-240V 50Hz

4

HEAT

EXCHANGER

-

13

RWA000Z412

-

'17 • SRK-T-203

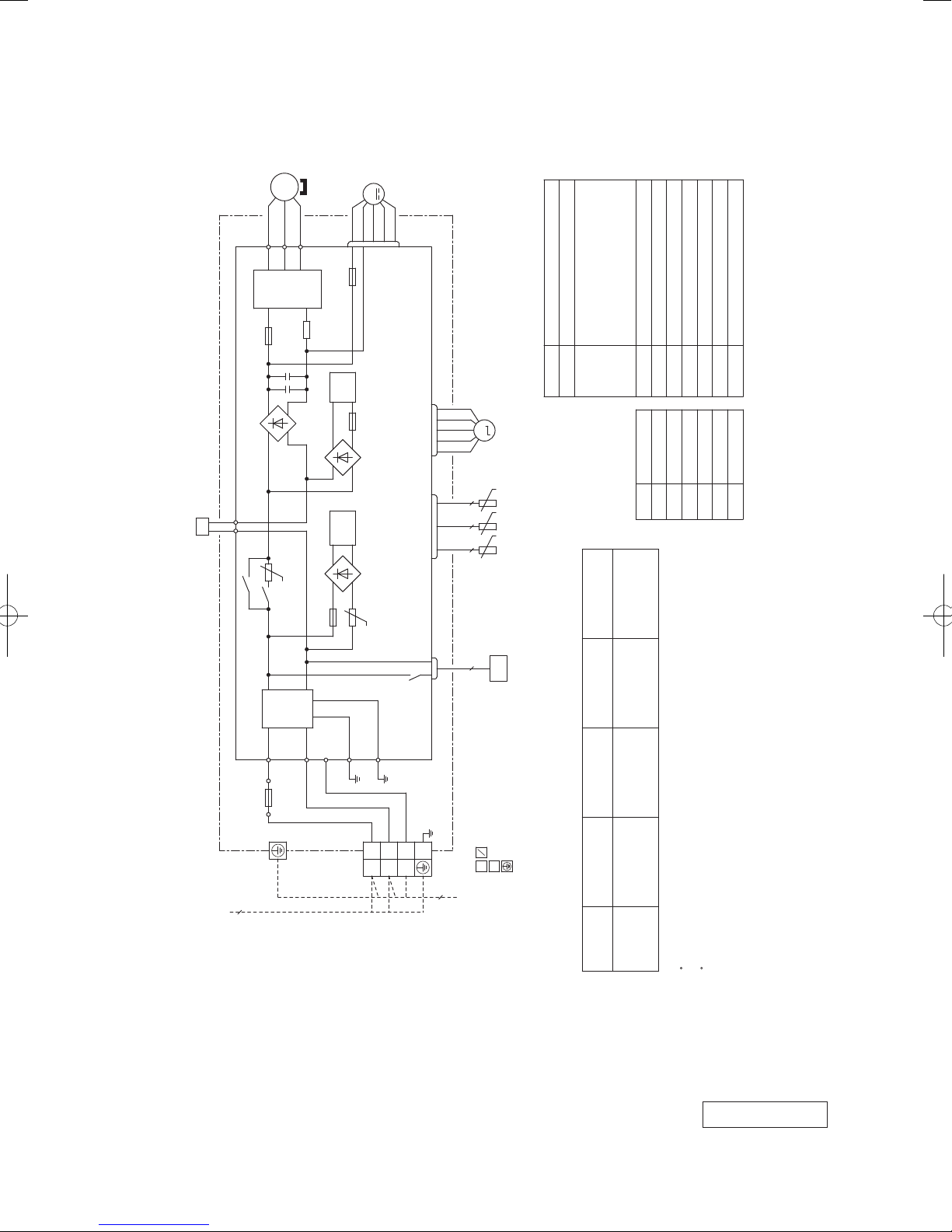

(2) Outdoor units

Models SRC20ZSX-S, 25ZSX-S, 35ZSX-S

CM

MS

3~

(BK)

(WH)

(RD)

U

V

W

UP

V

W

POWER

TRANSISTOR

PCB ASSY PCB1

F2

N

250V 20A

F3

T 1A L 250V

M

(WH)

CNFAN

FMo

+

+

+

DIODE

STACK2

~

L

T1 T2

(YE) (OR)

t゜

NOISE

FILTER

R.IN

(BK)

F7

250V 15A

-

~

PAM

CIRCUIT

F4

250V 10A

+

STACK1

~

+

STACK4

~

F1

C-2

(RD)

-

~

POWER

CIRCUIT

SWITCHING

-

~

t゜

F 3.15A L 250V

G1

(YG)

G2

(YG)

DIODE

DIODE

S.IN

(WH)

(RD)

(WH)

(BK)

CNTH CNEEV

CN20S

M

EEV

t゜

22

TH4TH2 TH3

t゜

t゜

2 2

20S

Item Description

CNEEV

CN20S Connector

20S 4 way valve(coil)

Meaning of marks

Connecting cable

wire size x number*

(m)

Power cable length

wire size x number*(A)

EEV Electric expansion valve(coil)

CM Compressor motor

CNTH

CNFAN

Mark Color

BK Black

Color marks

x 4

2

x 3 22 1.5mm

2

TH4 Discharge pipe temp. sensor

TH3 Outdoor air temp. sensor

TH2 Heat exchanger sensor

L Reactor

FMo Fan motor

Yellow/Green

RD Red

WH White

OR Orange

YE Yellow

YG

3

220V 60Hz

Power source

1 Phase

220-240V 50Hz

TB1

BLOCK

TERMINAL

(BK)

(YG)

3

L 1

N 2

4

]

N

2

1

3

POWER WIRES

SIGNAL WIRE

EARTH WIRE

TO INDOOR UNIT

[

9

MAX running current Power cable

Model name

Power cable, indoor-outdoor connecting wires

SRC20ZSX-S

Switchgear or circuit breaker capacity should be chosen according to national or regional electricity

The power cable specifications are based on the assumption that a metal or plastic conduit is used

with no more than three cables contained in a conduit and a voltage drop is 2%. For an installation

SRC35ZSX-S

SRC25ZSX-S 2.0mm

The wire numbers include earth wire(Yellow/Green)*regulations.

falling outside of these conditions, please follow the national or regional electricity regulations.

RWC000Z297

-

-

14

'17 • SRK-T-203

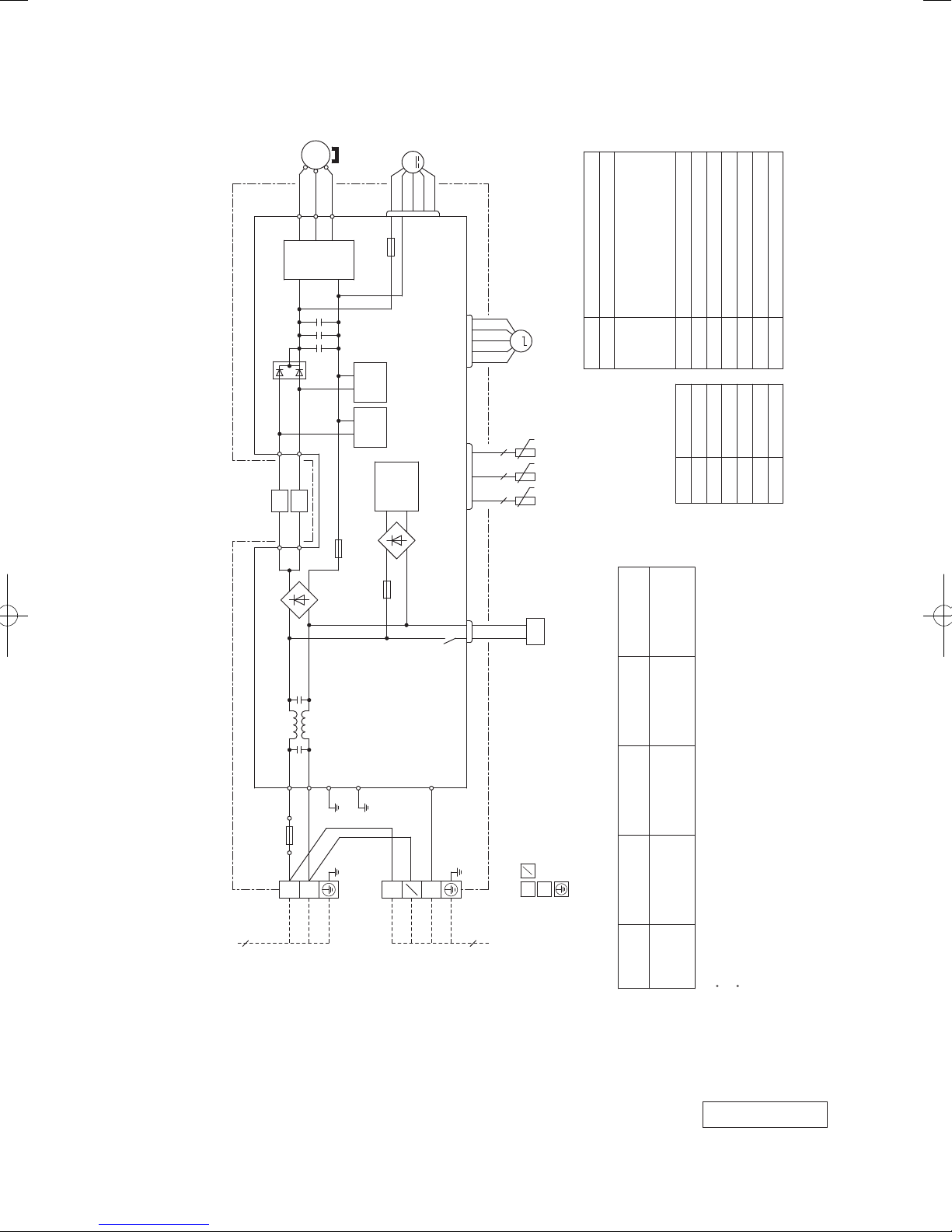

Models SRC50ZSX-S, 60ZSX-S

(RD)

UP

POWER

TRANSISTOR

MS

(WH)

VWU

CM

3~

(BK)

V

W

N

F3

T 1A L 250V

M

(WH)

CNFAN

FMo

+

++

T2

T12

(BL)

(YE)

L1

L2

(BL)

(YE)

T1

T11

+

-

DIODE

STACK1

~

~

PCB ASSY PCB1

F8

PAM

PAM

DIODE

250V 20A

CIRCUIT

CIRCUIT

SWITCHING

+

STACK2

~

F1

POWER

CIRCUIT

-

~

F 3.15A L 250V

(RD)

(WH)

(BK)

CNTH CNEEV

CN20S

M

EEV

Item Description

20S Solenoid coil for 4 way valve

CNFAN

CNEEV

CN20S Connector

EEV Electric expansion valve(coil)

CM Compressor motor

CNTH

TH3 Discharge pipe temp. sensor

TH2 Outdoor air temp. sensor

TH1 Heat exchanger sensor

L1,2 Reactor

FMo Fan motor

Meaning of marks

t゜

t゜

t゜

2 2 2

TH1 TH2 TH3

20S

Connecting cable

Power cable length

Color

BK Black

Mark

Color marks

x 4

2

wire size x number*

(m)

BL Blue

RD Red

YE Yellow

WH White

Yellow/Green

YG

S.IN

R.IN

(BK)

(WH)

F4

250V 20A

(BK)

N

L

TB1

BLOCK 1

TERMINAL

3

220V 60Hz

220-240V 50Hz

Power source

1 Phase

wire size x number*(A)

MAX running current Power cable

Model name

SRC50ZSX-S

x 3 13 1.5mm

2

2.0mm

15

SRC60ZSX-S

Switchgear or circuit breaker capacity should be chosen according to national or regional electricity

The power cable specifications are based on the assumption that a metal or plastic conduit is used

with no more than three cables contained in a conduit and a voltage drop is 2%. For an installation

The wire numbers include earth wire(Yellow/Green)*regulations.

falling outside of these conditions, please follow the national or regional electricity regulations.

G1

G2

(YG)

(YG)

(WH)

(YG)

BLOCK 2

TERMINAL

(BK)

TB2

C-2

(RD)

]

N

N

1

2

(YG)

3

4

2

3

1

POWER WIRES

SIGNAL WIRE

EARTH WIRE

TO INDOOR UNIT

Power cable, indoor-outdoor connecting wires

[

RWC000Z298

-

-

15

'17 • SRK-T-203

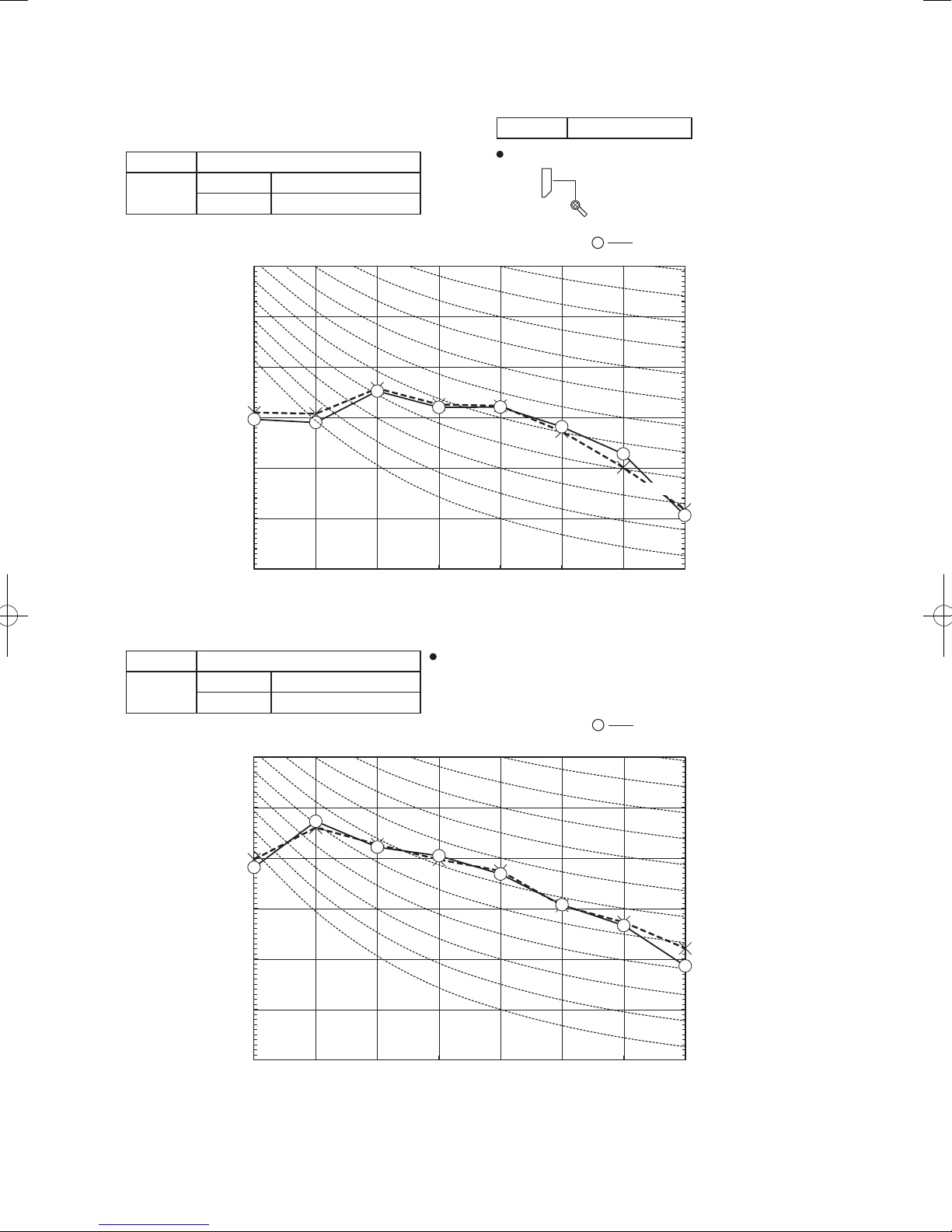

Mid octave band frequency (Hz)

N50

N30

N40

N60

N2

Mid octave band frequency (Hz)

N50

N40

N20

N30

Mike position: at highest noise level in position as mentioned below

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

4. NOISE LEVEL

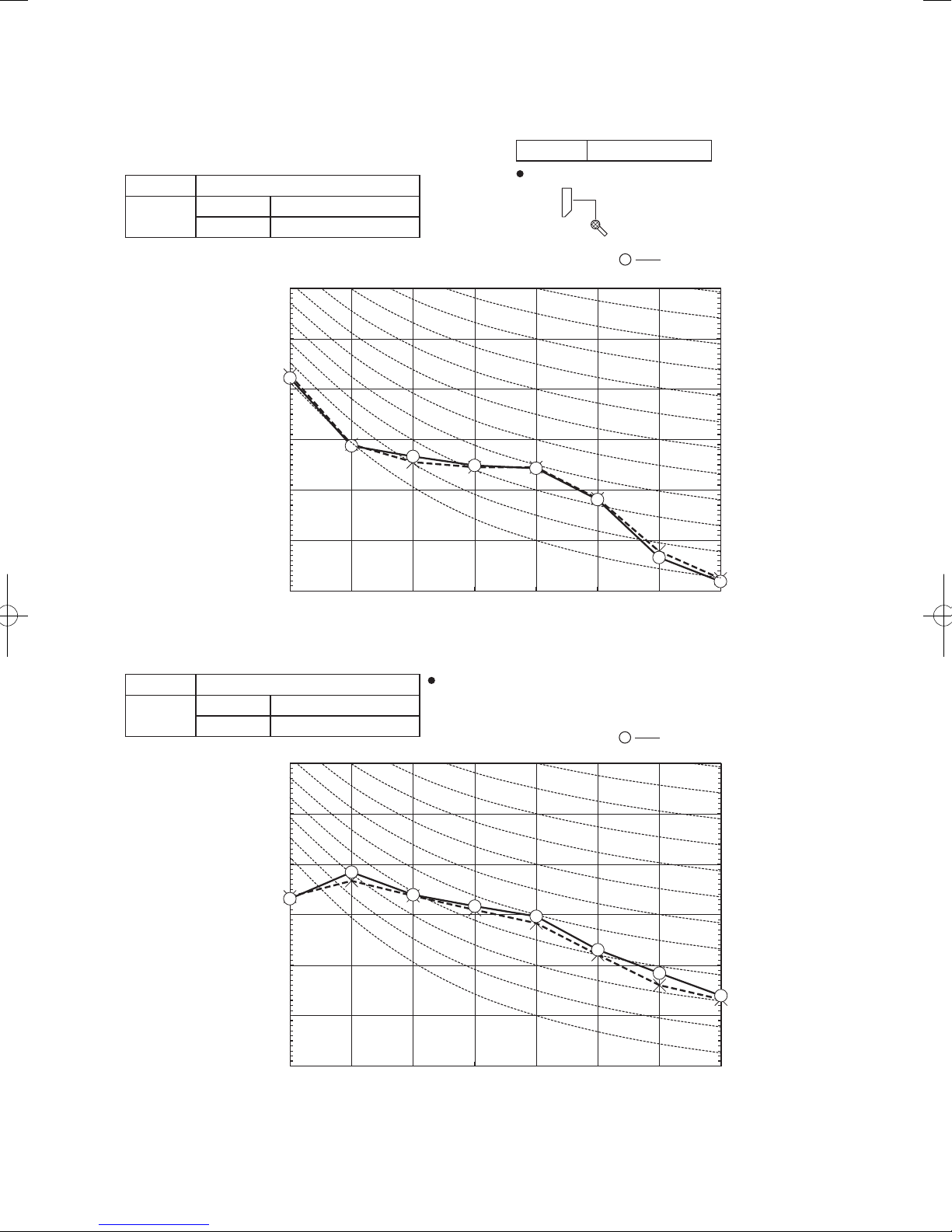

Model SRK20ZSX-S

(Indoor Unit)

Model SRK20ZSX-S

Noise

Level

Cooling 38 dB(A)

Heating 38 dB(A)

Condition ISO5151 T1/H1

1m

0.8m

×

......

Unit

Cooling,

Mike position

(Center & Low points)

Heating

70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

(Outdoor Unit)

Model SRC20ZSX-S

Noise

Level

Cooling 43 dB(A)

Heating 44 dB(A)

70

Distance from front side 1m

......

×

Cooling, Heating

70

N70

60

50

40

30

20

0

10

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

-

16

60

N60

50

40

30

20

10

-

'17 • SRK-T-203

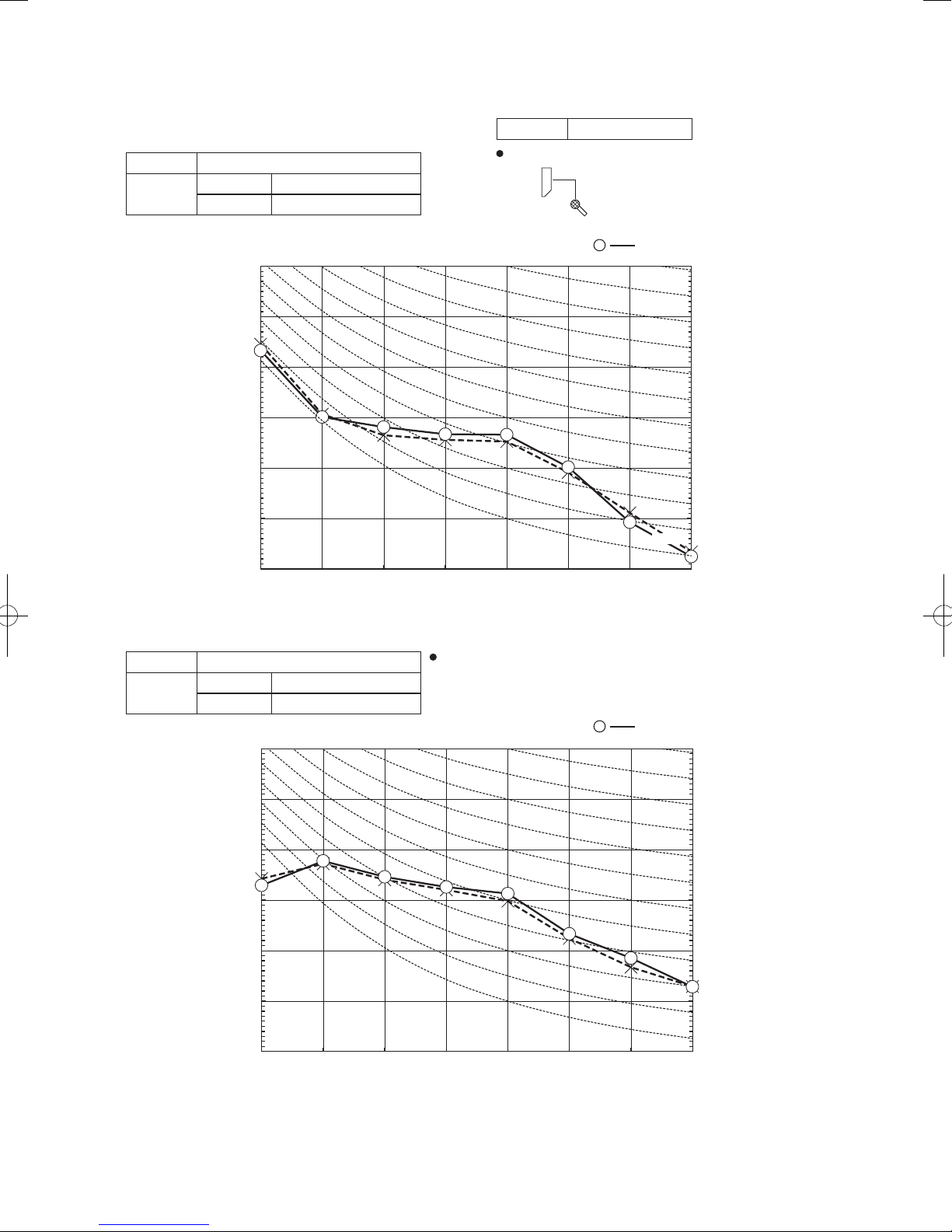

Model SRK25ZSX-S

Mid octave band frequency (Hz)

Mid octave band frequency (Hz)

Mike position: at highest noise level in position as mentioned below

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

(Indoor Unit)

Model SRK25ZSX-S

Noise

Level

Cooling 39 dB(A)

Heating 40 dB(A)

70

Condition ISO5151 T1/H1

1m

0.8m

×

......

Unit

Cooling,

Mike position

(Center & Low points)

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

(Outdoor Unit)

Model SRC25ZSX-S

Noise

Level

Cooling 44 dB(A)

Heating 45 dB(A)

70

Distance from front side 1m

......

×

Cooling, Heating

60

N60

50

N50

40

N40

30

N30

20

N20

10

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

-

17

60

N60

50

N50

40

N40

30

N30

20

N20

10

-

'17 • SRK-T-203

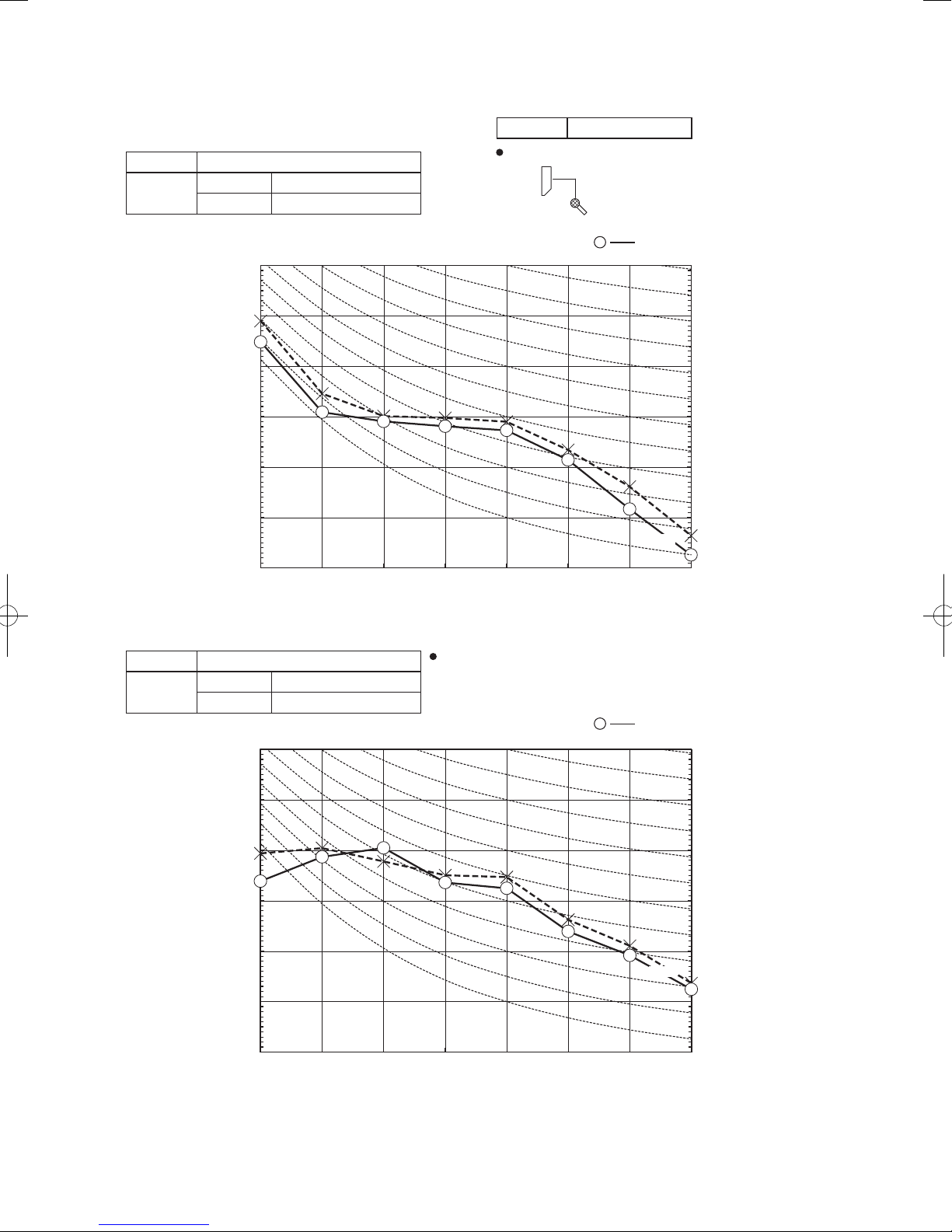

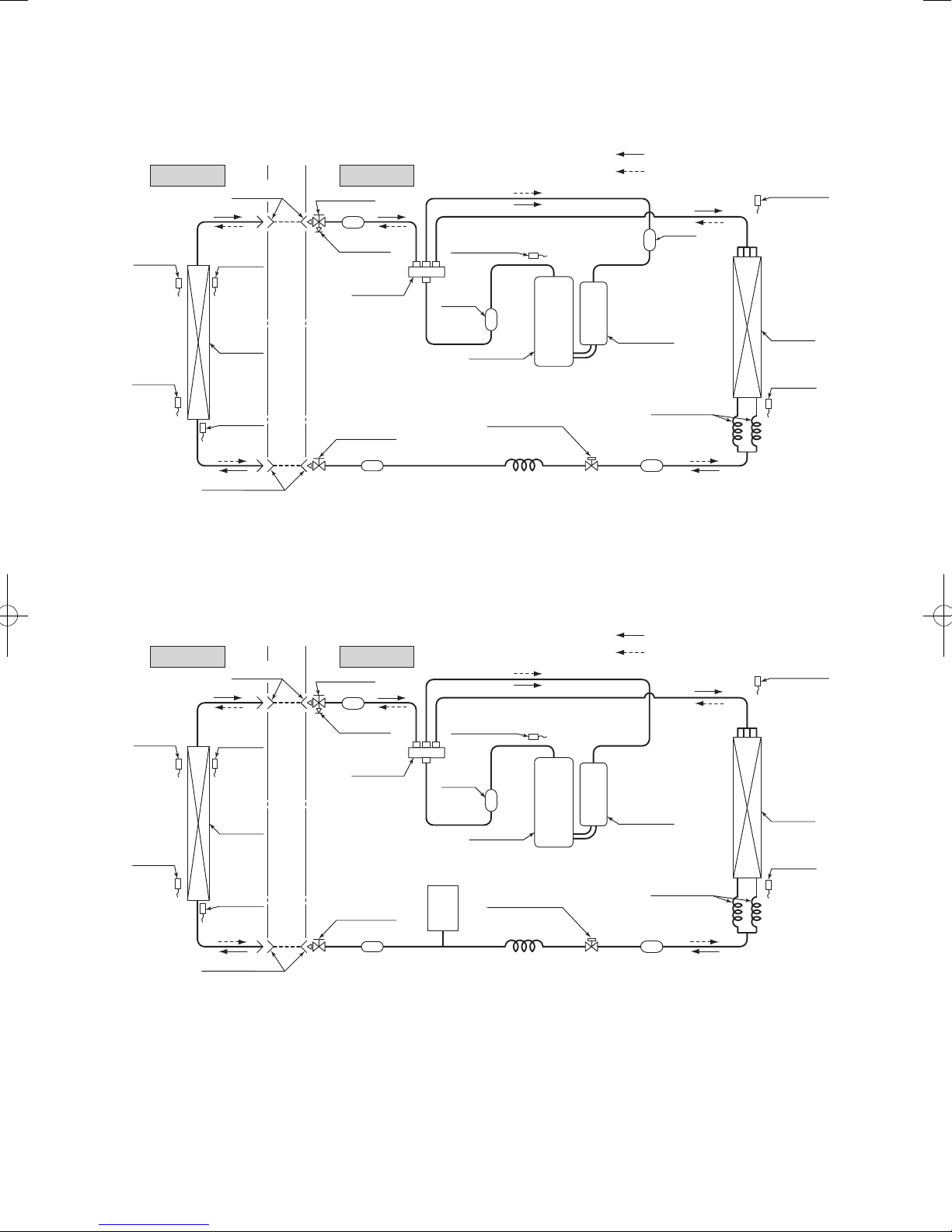

Model SRK35ZSX-S

Mid octave band frequency (Hz)

Mike position: at highest noise level in position as mentioned below

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

(Indoor Unit)

Model SRK35ZSX-S

Noise

Level

Cooling 43 dB(A)

Heating 41 dB(A)

70

Condition ISO5151 T1/H1

1m

0.8m

×

......

Unit

Cooling,

Mike position

(Center & Low points)

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

(Outdoor Unit)

Model SRC35ZSX-S

Noise

Level

Cooling 48 dB(A)

Heating 47 dB(A)

70

Distance from front side 1m

......

×

Cooling,

60

N60

50

N50

40

N40

30

N30

20

N20

10

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

Mid octave band frequency (Hz)

-

18

60

N60

50

N50

40

N40

30

N30

20

N20

-

'17 • SRK-T-203

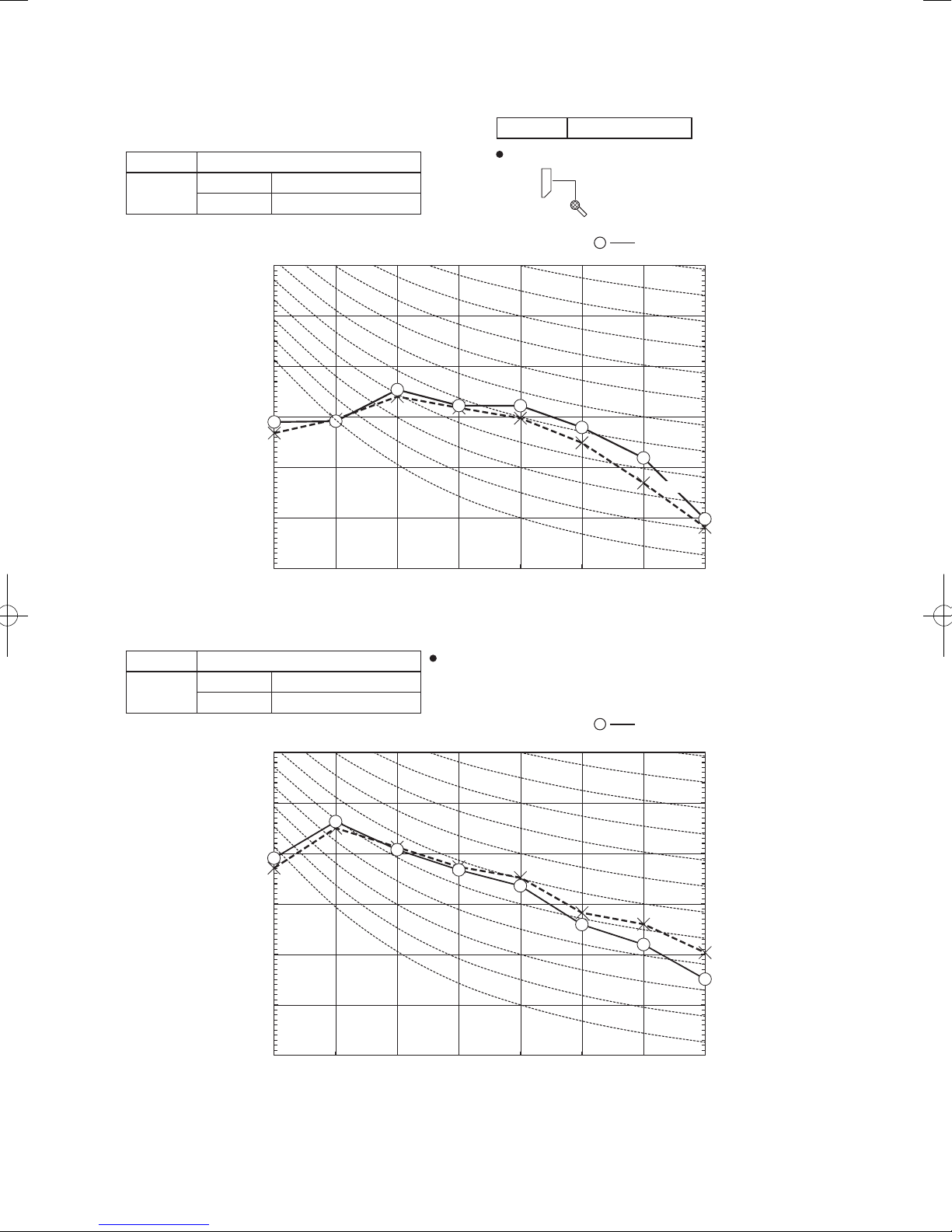

Mike position

Model SRK50ZSX-S

Mike position: at highest noise level in position as mentioned below

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

(Indoor Unit)

Model SRK50ZSX-S

Noise

Level

Cooling 44 dB(A)

Heating 46 dB(A)

70

Condition ISO5151 T1/H1

1m

0.8m

×

......

Unit

Cooling,

Mike position

(Center & Low points)

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

(Outdoor Unit)

Model SRC50ZSX-S

Noise

Level

Cooling 50 dB(A)

Heating 49 dB(A)

70

Mid octave band frequency (Hz)

Distance from front side 1m

......

×

Cooling,

60

N60

50

N50

40

N40

30

N30

20

N20

10

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

Mid octave band frequency (Hz)

-

19

60

N60

50

N50

40

N40

30

N30

20

N20

10

-

'17 • SRK-T-203

Model SRK60ZSX-S

Mid octave band frequency (Hz)

Mid octave band frequency (Hz)

Mike position: at highest noise level in position as mentioned below

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

(Indoor Unit)

Model SRK60ZSX-S

Noise

Level

Cooling 46 dB(A)

Heating 46 dB(A)

70

Condition ISO5151 T1/H1

1m

0.8m

×

......

Unit

Cooling,

Mike position

(Center & Low points)

Heating

N70

70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

(Outdoor Unit)

Model SRC60ZSX-S

Noise

Level

Cooling 52 dB(A)

Heating 52 dB(A)

70

Distance from front side 1m

......

×

Cooling,

60

N60

50

N50

40

N40

30

N30

20

N20

10

Heating

70

N70

60

50

Pa)

-5

40

(Standard 2×10

30

Sound pressure level (dB)

20

10

63 125 250 500 1000 2000 4000 8000

-

20

60

N60

50

N50

40

N40

30

N30

20

N20

10

-

'17 • SRK-T-203

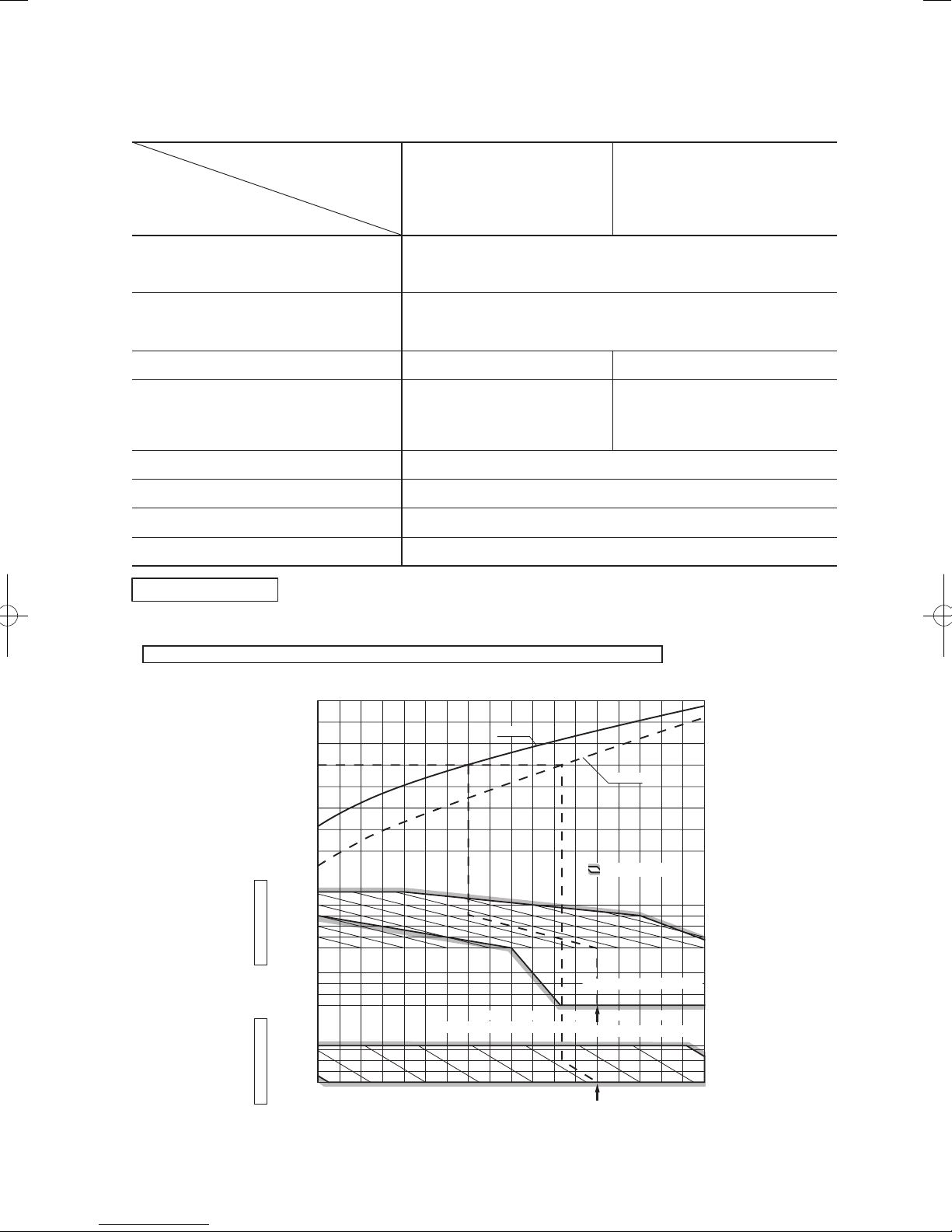

5. PIPING SYSTEM

Models SRK20ZSX-S, 25ZSX-S, 35ZSX-S

Indoor unit

Room temp.

sensor

(Th1)

Humidity

sensor

(Th3)

Flare

connection

Heat

exchanger

sensor

(Th2

2)

Heat

exchanger

Heat

exchanger

sensor

1)

(Th2

Gas pipe

(φ9.52)

Liquid

pipe

(φ6.35)

Outdoor unit

Service valve

Gas

)

(

Muffler

Check joint

4-way valve

Service valve

(Liquid)

Discharge pipe

temp. sensor

(TH3)

Muffler

Compressor

Electronic

expansion valve

(EEV)

Capillary tube

Cooling cycle

Heating cycle

Accumulator

Capillary tube

Muffler

Outdoor air

temp. sensor

(TH2)

Heat

exchanger

Heat

exchanger

sensor

(TH1)

Flare connection

Models SRK50ZSX-S,60ZSX-S

Indoor unit

Room temp.

sensor

(Th1)

Humidity

sensor

(Th3)

Flare

connection

Heat

exchanger

sensor

(Th2

2)

Heat

exchanger

Heat

exchanger

sensor

1)

(Th2

Gas pipe

(φ12.7)

Liquid

pipe

(φ6.35)

Service valve

Strainer Muffler

Outdoor unit

Gas

)

(

Muffler

Check joint

4-way valve

Service valve

(Liquid)

Muffler

Receiver

Discharge pipe

temp. sensor

(TH3)

Compressor

Electronic

expansion valve

Capillary tube

(EEV)

Cooling cycle

Heating cycle

Accumulator

Capillary tube

Outdoor air

temp. sensor

(TH2)

Heat

exchanger

Heat

exchanger

sensor

(TH1)

Flare connection

Strainer

-

21

Muffler

-

'17 • SRK-T-203

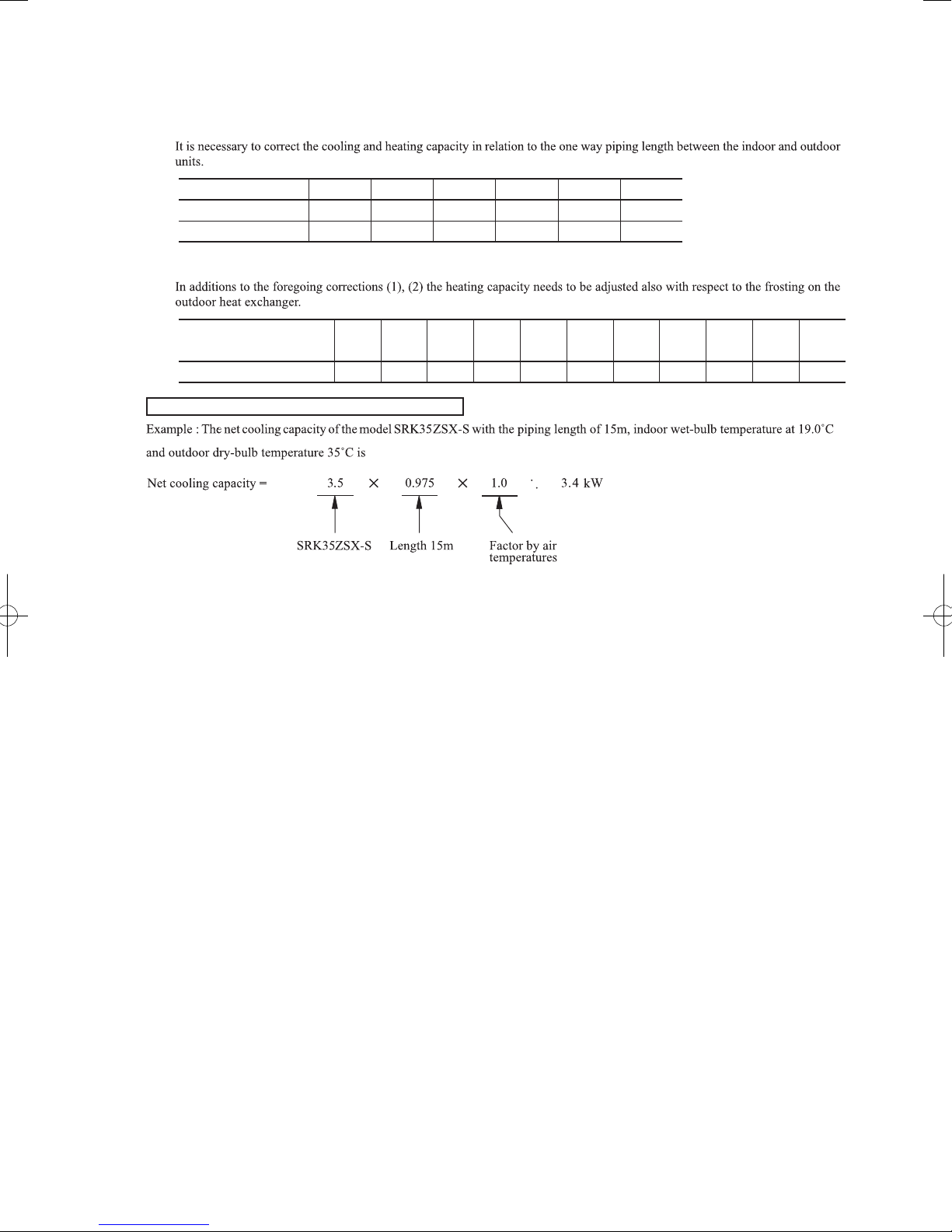

6. RANGE OF USAGE & LIMITATIONS

RANGE OF USAGE & LIMITATIONS

Models

SRK20, 25, 35ZSX-S

SRK50, 60ZSX-S

Item

Indoor return air temperature

(Upper, lower limits)

Outdoor air temperature

(Upper, lower limits)

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Cooling operation : Approximately 18 to 32℃ D.B.

Heating operation : Approximately 10 to 30℃ D.B.

(Refer to the selection chart)

Cooling operation : Approximately -15 to 46℃ D.B.

Heating operation : Approximately -20 to 24℃ D.B.

(Refer to the selection chart)

Max. 25m Max. 30m

Max. 15m

(Outdoor unit is higher)

Max. 15m

(Outdoor unit is lower)

(Outdoor unit is lower)

Max. 20m

(Outdoor unit is higher)

Max. 20m

Power source voltage Rating ±10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle

Max. 4 times/h

(Inching prevention 10 minutes)

ON and OFF interval Min. 3 minutes

Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification ×Correction factors as follows.

(1) Coefficient of cooling and heating capacity in relation to temperatures

1.3

&

1.2

1.1

1.0

0.9

0.8

Coefficient of cooling

Heating capacity in

relation to temperature

0.7

0.6

46

40

35

30

°C D. B.

25

temperature

20

Outdoor air D.B.

Cooling operation

0

-5

-10

-15

27

25

20

15

°C D. B.

10

temperature

Indoor air D.B.

Heating operation

Indoor air W.B. temperature °C W.B

-15-20 -10 -5 0 5 10 15

Cooling

Depends on installed situation

.

ISO-T1 Standard Condition

Outdoor air W.B. temperature °C W.B.

ISO-T1 Standard Condition

Heating

Applicable range

26

24

2220181614

-

22

-

'17 • SRK-T-203

'09•SRK-DB-087D

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

Piping length [m]

Cooling

Heating

(3) Correction relative to frosting on outdoor heat exchanger during heating

Air inlet temperature of

outdoor unit in °C WB

Adjustment coefficient

How to obtain the cooling and heating capacity

7

1.0

1.0

-20

0.95 1.00

10

0.99

1.0

-15

0.95 0.95

-10

15

0.975

1.0

20

0.965

1.0

0.94-90.93-70.91-50.88-30.86

=

25

0.95

1.0

30

0.935

1.0

-1 1

0.8730.92

5 or more

-

23

-

'17 • SRK-T-203

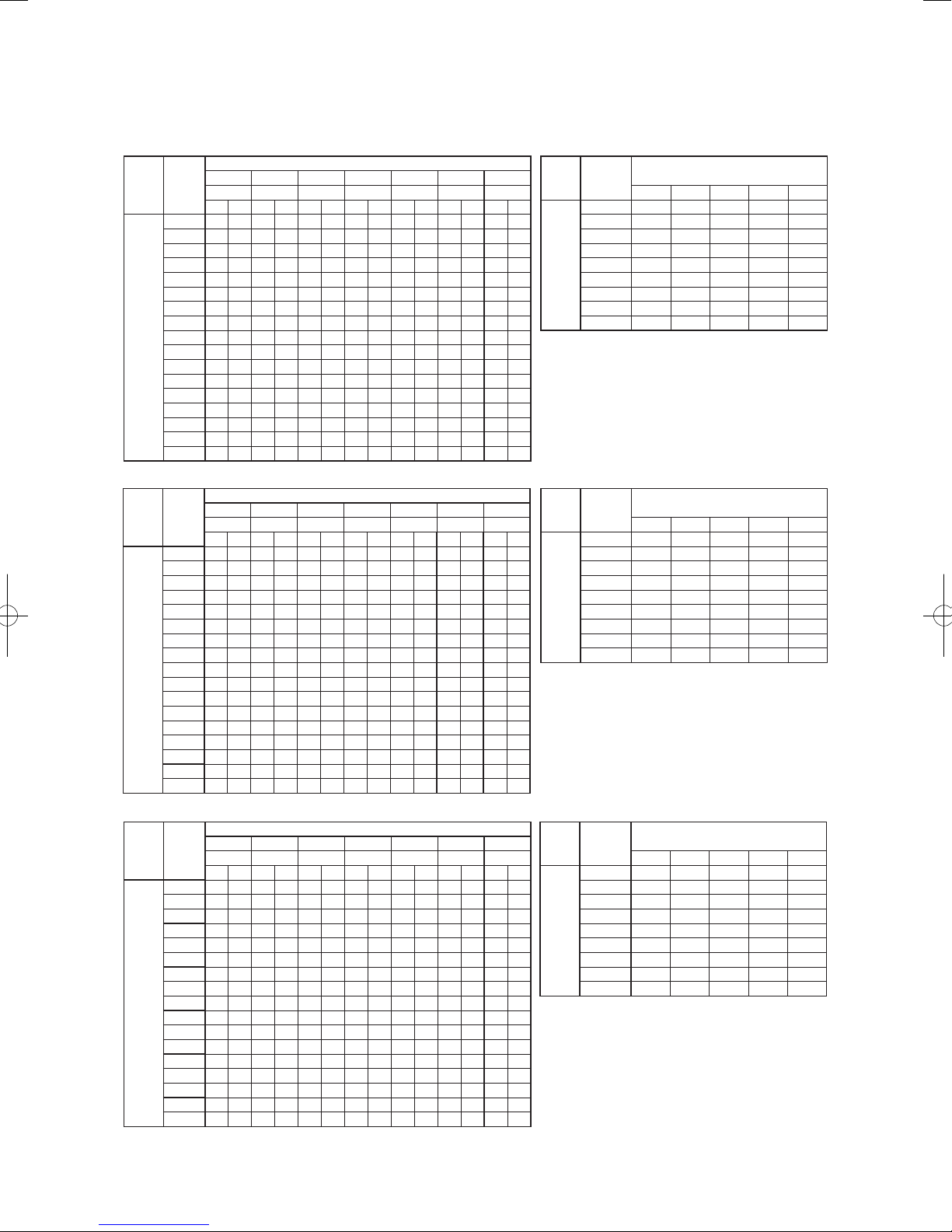

7. CAPACITY TABLES

Model SRK20ZSX-S

Outdoor

Air flow

air temp.

10 2.25 2.12 2.36 2.09 2.45 2.19 2.49 2.17 2.53 2.14 2.60 2.26 2.67 2.21

12 2.21 2.10 2.32 2.07 2.41 2.18 2.45 2.16 2.50 2.14 2.58 2.26 2.65 2.20

14 2.17 2.06 2.28 2.05 2.38 2.17 2.42 2.15 2.47 2.12 2.55 2.24 2.62 2.20

16 2.13 2.02 2.24 2.03 2.34 2.15 2.39 2.13 2.43 2.11 2.52 2.23 2.59 2.17

18 2.08 1.98 2.19 2.01 2.30 2.14 2.35 2.12 2.40 2.10 2.49 2.22 2.56 2.16

20 2.04 1.94 2.15 2.00 2.26 2.13 2.31 2.11 2.36 2.09 2.45 2.20 2.53 2.15

22 1.99 1.89 2.10 1.97 2.22 2.11 2.28 2.10 2.32 2.08 2.42 2.19 2.50 2.14

24 1.94 1.85 2.05 1.95 2.18 2.07 2.24 2.09 2.28 2.07 2.38 2.18 2.47 2.14

Hi

11.3

26 1.90 1.80 2.01 1.91 2.14 2.03 2.20 2.07 2.24 2.05 2.35 2.17 2.43 2.13

3

/min)

(m

28 1.85 1.75 1.96 1.86 2.09 1.99 2.15 2.05 2.20 2.04 2.31 2.16 2.40 2.12

30 1.79 1.70 1.90 1.81 2.05 1.94 2.11 2.01 2.16 2.02 2.27 2.15 2.36 2.11

32 1.74 1.65 1.85 1.76 2.00 1.90 2.07 1.96 2.12 2.00 2.23 2.12 2.32 2.10

34 1.69 1.60 1.80 1.71 1.95 1.85 2.02 1.92 2.07 1.97 2.19 2.08 2.28 2.09

35 1.66 1.58 1.77 1.68 1.93 1.83 2.00 1.90 2.05 1.94 2.17 2.06 2.26 2.08

36 1.63 1.55 1.74 1.65 1.90 1.81 1.98 1.88 2.02 1.92 2.15 2.04 2.24 2.08

38 1.58 1.50 1.68 1.60 1.85 1.76 1.93 1.83 1.98 1.88 2.11 2.00 2.20 2.07

39 1.55 1.47 1.66 1.57 1.83 1.74 1.91 1.81 1.95 1.85 2.08 1.98 2.18 2.06

Model SRK25ZSX-S

Outdoor

Air flow

air temp.

10 2.82 2.64 2.95 2.60 3.06 2.75 3.11 2.72 3.16 2.70 3.26 2.83 3.34 2.76

12 2.77 2.62 2.90 2.58 3.01 2.74 3.07 2.71 3.12 2.68 3.22 2.82 3.31 2.73

14 2.71 2.58 2.85 2.56 2.97 2.71 3.03 2.69 3.08 2.66 3.18 2.80 3.28 2.72

16 2.66 2.53 2.80 2.54 2.92 2.70 2.98 2.67 3.04 2.65 3.15 2.79 3.24 2.71

18 2.60 2.47 2.74 2.52 2.88 2.68 2.94 2.66 2.99 2.63 3.11 2.76 3.20 2.70

20 2.55 2.42 2.68 2.49 2.83 2.66 2.89 2.64 2.95 2.62 3.07 2.75 3.17 2.69

22 2.49 2.37 2.63 2.47 2.78 2.64 2.84 2.62 2.90 2.60 3.02 2.73 3.13 2.68

24 2.43 2.31 2.57 2.44 2.72 2.59 2.80 2.60 2.85 2.58 2.98 2.72 3.08 2.67

Hi

12.2

26 2.37 2.25 2.51 2.38 2.67 2.54 2.74 2.59 2.80 2.56 2.93 2.71 3.04 2.66

3

/min)

(m

28 2.31 2.19 2.44 2.32 2.61 2.48 2.69 2.56 2.75 2.55 2.89 2.69 3.00 2.64

30 2.24 2.13 2.38 2.26 2.56 2.43 2.64 2.51 2.70 2.53 2.84 2.68 2.95 2.63

32 2.18 2.07 2.31 2.20 2.50 2.37 2.58 2.46 2.64 2.51 2.79 2.65 2.90 2.62

34 2.11 2.00 2.25 2.13 2.44 2.32 2.53 2.40 2.59 2.46 2.74 2.60 2.85 2.61

35 2.08 1.97 2.21 2.10 2.41 2.29 2.50 2.38 2.56 2.43 2.71 2.58 2.83 2.60

36 2.04 1.94 2.18 2.07 2.38 2.26 2.47 2.35 2.53 2.40 2.69 2.55 2.80 2.59

38 1.97 1.87 2.11 2.00 2.32 2.20 2.41 2.29 2.47 2.35 2.63 2.50 2.75 2.58

39 1.94 1.84 2.07 1.97 2.28 2.17 2.38 2.26 2.44 2.32 2.61 2.48 2.72 2.57

Cooling Mode

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Cooling Mode

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Heating Mode (HC) (kW)(kW)

outdoor

Air flow

air temp.

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

-15˚CWB 1.66 1.63 1.59 1.55 1.52

-10˚CWB 1.88 1.85 1.82 1.78 1.74

-5˚CWB 2.04 2.01 1.97 1.94 1.91

0˚CWB 2.13 2.10 2.07 2.04 2.01

Hi

12.2

(m

Air flow

12.8

(m

5˚CWB 2.72 2.69 2.67 2.62 2.58

3

/min)

6˚CWB 2.76 2.73 2.70 2.67 2.63

10˚CWB 2.94 2.91 2.89 2.85 2.82

15˚CWB 3.20 3.17 3.14 3.11 3.08

20˚CWB 3.43 3.41 3.39 3.35 3.32

Heating Mode (HC) (kW)(kW)

outdoor

air temp.

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

-15˚CWB 1.97 1.93 1.88 1.84 1.80

-10˚CWB 2.23 2.19 2.16 2.10 2.06

-5˚CWB 2.41 2.38 2.33 2.30 2.27

0˚CWB 2.53 2.49 2.45 2.42 2.38

Hi

5˚CWB 3.22 3.19 3.17 3.10 3.06

3

/min)

6˚CWB 3.27 3.24 3.20 3.16 3.12

10˚CWB 3.48 3.45 3.42 3.38 3.34

15˚CWB 3.79 3.75 3.73 3.69 3.65

20˚CWB 4.07 4.04 4.02 3.97 3.94

indoor air temp

indoor air temp

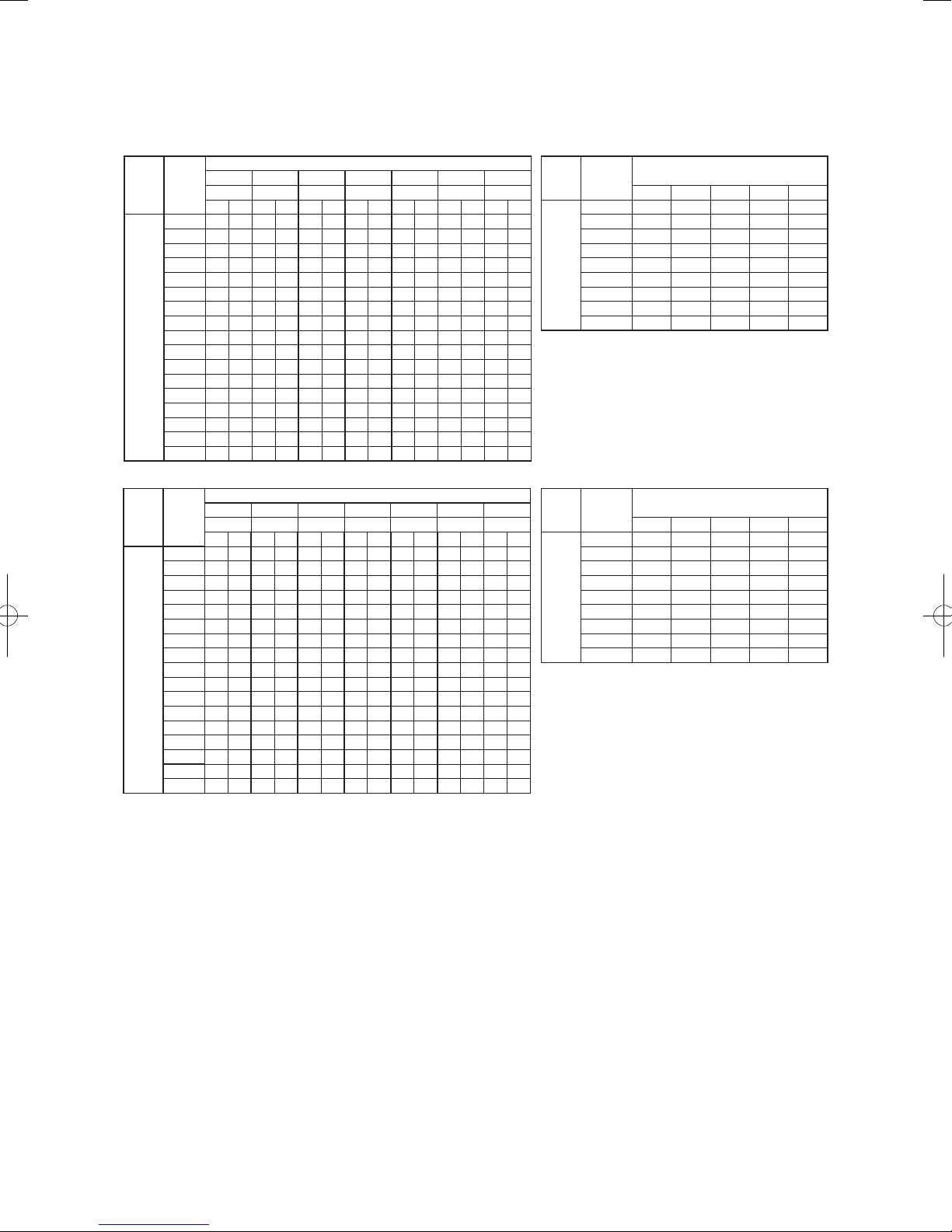

Model SRK35ZSX-S

Outdoor

Air flow

air temp.

10 3.94 3.46 4.13 3.40 4.28 3.57 4.35 3.53 4.43 3.49 4.56 3.64 4.68 3.55

12 3.87 3.42 4.06 3.37 4.22 3.55 4.29 3.51 4.37 3.47 4.51 3.62 4.63 3.53

14 3.80 3.39 3.99 3.34 4.16 3.52 4.24 3.49 4.31 3.45 4.46 3.61 4.59 3.52

16 3.72 3.36 3.91 3.31 4.09 3.50 4.18 3.46 4.25 3.43 4.40 3.59 4.54 3.50

18 3.65 3.32 3.84 3.28 4.03 3.47 4.11 3.44 4.19 3.40 4.35 3.57 4.49 3.49

20 3.57 3.28 3.76 3.24 3.96 3.44 4.05 3.41 4.13 3.38 4.29 3.55 4.43 3.47

22 3.49 3.24 3.68 3.20 3.89 3.42 3.98 3.39 4.06 3.36 4.23 3.53 4.38 3.46

24 3.40 3.20 3.59 3.17 3.81 3.39 3.91 3.36 3.99 3.33 4.17 3.51 4.32 3.44

Hi

13.1

26 3.32 3.15 3.51 3.13 3.74 3.35 3.84 3.34 3.92 3.31 4.11 3.49 4.26 3.42

3

/min)

(m

28 3.23 3.07 3.42 3.10 3.66 3.32 3.77 3.30 3.85 3.28 4.04 3.47 4.20 3.40

30 3.14 2.98 3.33 3.06 3.58 3.29 3.70 3.28 3.78 3.25 3.98 3.44 4.13 3.37

32 3.05 2.90 3.24 3.02 3.50 3.26 3.62 3.25 3.70 3.22 3.91 3.42 4.06 3.36

34 2.95 2.81 3.14 2.98 3.41 3.23 3.54 3.22 3.62 3.19 3.84 3.39 4.00 3.33

35 2.91 2.76 3.10 2.94 3.37 3.20 3.50 3.20 3.58 3.18 3.80 3.38 3.96 3.32

36 2.86 2.72 3.05 2.90 3.33 3.16 3.46 3.19 3.54 3.17 3.76 3.37 3.92 3.31

38 2.76 2.62 2.95 2.80 3.24 3.08 3.38 3.16 3.46 3.14 3.69 3.35 3.85 3.29

39 2.71 2.57 2.90 2.75 3.20 3.04 3.33 3.15 3.42 3.12 3.65 3.34 3.81 3.28

Cooling Mode

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Indoor air temp

-

24

Heating Mode (HC) (kW)(kW)

outdoor

Air flow

air temp.

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

-15˚CWB 2.65 2.59 2.53 2.48 2.42

-10˚CWB 2.99 2.94 2.90 2.83 2.77

-5˚CWB 3.24 3.20 3.13 3.10 3.05

0˚CWB 3.40 3.35 3.29 3.25 3.20

Hi

13.9

3/m

(m

Notes(1) These data show average statuses.

5˚CWB 4.33 4.28 4.26 4.17 4.11

in)

6˚CWB 4.40 4.35 4.30 4.25 4.19

10˚CWB 4.68 4.63 4.60 4.54 4.49

15˚CWB 5.09 5.04 5.01 4.95 4.91

20˚CWB 5.47 5.42 5.40 5.34 5.29

Depending on the system control, there may be ranges where the operation

is not conducted continuously.

These data show the case where the operation frequency of a compressor is

fixed.

(2) Capacities are based on the following conditions.

Corresponding refrigerant piping length :7m

Level difference of Zero.

(3) Symbols are as follows.

TC : Total cooling capacity (kW)

SHC : Sensible heat capacity (kW)

HC : Heating capacity (kW)

indoor air temp

-

'17 • SRK-T-203

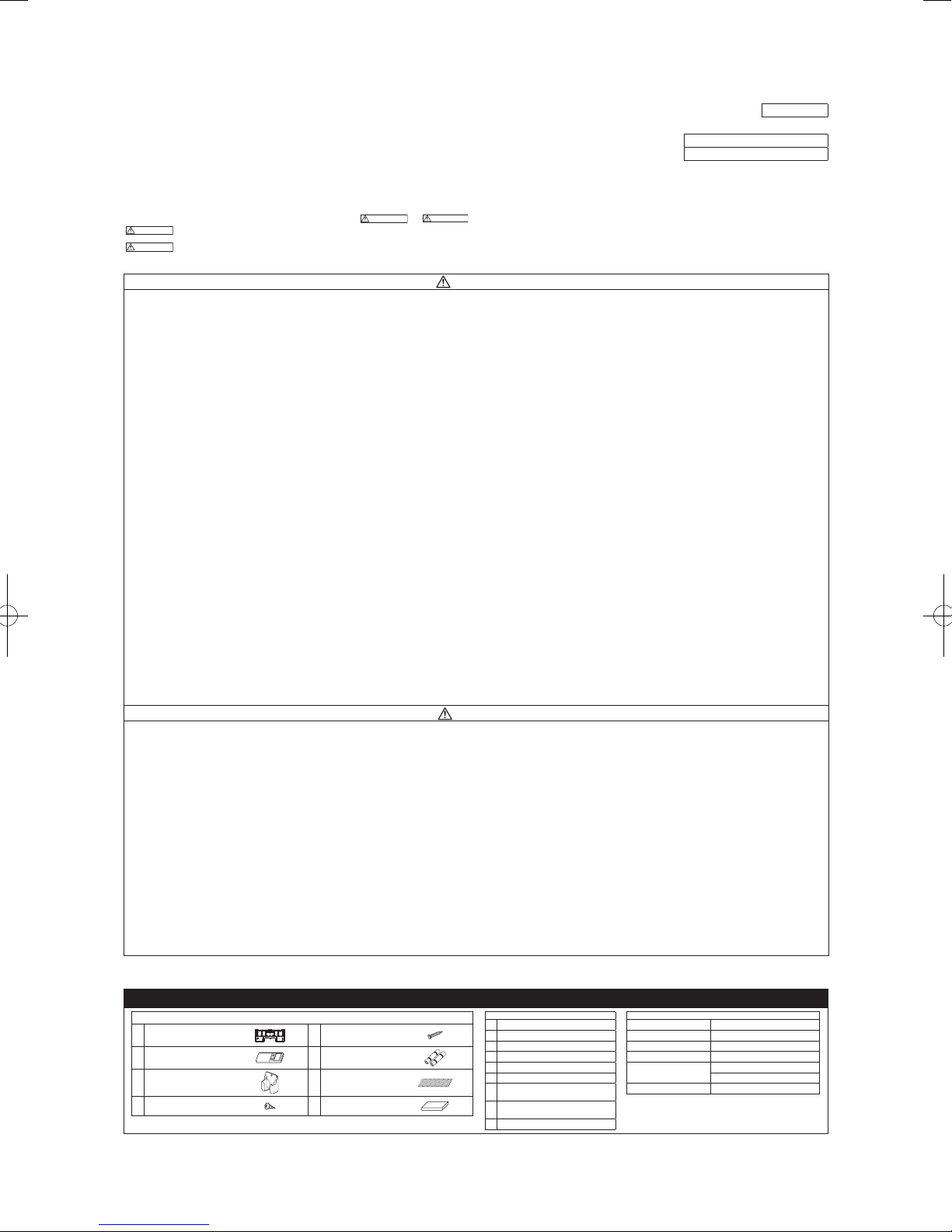

Model SRK50ZSX-S

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

Outdoor

Air flow

air temp.

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

10 5.63 4.45 5.90 4.37 6.11 4.54 6.22 4.48 6.32 4.42 6.51 4.57 6.69 4.43

12 5.53 4.40 5.80 4.32 6.03 4.50 6.14 4.45 6.25 4.39 6.44 4.54 6.62 4.40

14 5.43 4.34 5.70 4.28 5.94 4.47 6.05 4.42 6.16 4.36 6.37 4.51 6.55 4.38

16 5.32 4.29 5.59 4.23 5.85 4.43 5.96 4.38 6.08 4.33 6.29 4.48 6.48 4.36

18 5.21 4.24 5.48 4.18 5.75 4.39 5.88 4.34 5.99 4.29 6.21 4.45 6.41 4.33

20 5.10 4.18 5.37 4.13 5.65 4.35 5.78 4.31 5.90 4.26 6.13 4.42 6.33 4.31

22 4.98 4.13 5.25 4.08 5.55 4.30 5.69 4.26 5.80 4.21 6.05 4.39 6.25 4.28

24 4.86 4.07 5.14 4.02 5.45 4.25 5.59 4.22 5.71 4.18 5.96 4.36 6.17 4.25

Hi

14.3

26 4.74 4.01 5.01 3.97 5.34 4.21 5.49 4.18 5.61 4.14 5.87 4.33 6.08 4.23

3

/min)

(m

28 4.61 3.95 4.89 3.91 5.23 4.16 5.39 4.14 5.50 4.10 5.78 4.30 5.99 4.20

30 4.49 3.89 4.76 3.86 5.11 4.12 5.28 4.10 5.40 4.06 5.68 4.26 5.90 4.17

32 4.35 3.82 4.63 3.80 5.00 4.07 5.17 4.05 5.29 4.02 5.58 4.22 5.81 4.13

34 4.22 3.76 4.49 3.74 4.88 4.01 5.06 4.01 5.18 3.98 5.48 4.19 5.71 4.10

35 4.15 3.73 4.42 3.70 4.82 3.99 5.00 3.99 5.12 3.95 5.43 4.17 5.66 4.08

36 4.08 3.70 4.35 3.67 4.76 3.96 4.94 3.96 5.06 3.93 5.37 4.15 5.61 4.07

38 3.94 3.63 4.21 3.61 4.63 3.91 4.82 3.91 4.94 3.88 5.27 4.11 5.50 4.04

39 3.87 3.60 4.14 3.58 4.57 3.89 4.76 3.89 4.88 3.86 5.21 4.09 5.45 4.02

Model SRK60ZSX-S

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

Outdoor

Air flow

air temp.

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

10 6.87 5.29 7.19 5.21 7.46 5.38 7.58 5.30 7.72 5.23 7.94 5.38 8.16 5.21

12 6.75 5.23 7.07 5.14 7.35 5.33 7.48 5.26 7.62 5.19 7.86 5.35 8.08 5.18

14 6.62 5.17 6.95 5.08 7.24 5.28 7.38 5.22 7.52 5.15 7.77 5.31 8.00 5.15

16 6.49 5.10 6.82 5.02 7.13 5.23 7.28 5.18 7.42 5.11 7.68 5.27 7.91 5.12

18 6.36 5.03 6.69 4.96 7.02 5.18 7.17 5.13 7.31 5.06 7.58 5.24 7.82 5.09

20 6.22 4.96 6.55 4.89 6.89 5.13 7.06 5.08 7.20 5.02 7.48 5.20 7.73 5.06

22 6.08 4.89 6.41 4.83 6.77 5.07 6.94 5.01 7.08 4.96 7.38 5.16 7.63 5.03

24 5.93 4.81 6.27 4.76 6.64 5.00 6.82 4.97 6.96 4.91 7.27 5.13 7.53 4.99

Hi

16.3

26 5.78 4.74 6.12 4.69 6.51 4.95 6.70 4.92 6.84 4.86 7.16 5.08 7.42 4.95

3

/min)

(m

28 5.63 4.66 5.96 4.62 6.38 4.89 6.57 4.86 6.71 4.82 7.05 5.04 7.31 4.92

30 5.47 4.59 5.81 4.55 6.24 4.83 6.44 4.81 6.58 4.76 6.93 5.00 7.20 4.88

32 5.31 4.51 5.65 4.48 6.10 4.78 6.31 4.76 6.45 4.71 6.81 4.95 7.08 4.85

34 5.15 4.43 5.48 4.40 5.95 4.72 6.17 4.71 6.31 4.66 6.68 4.91 6.96 4.81

35 5.07 4.39 5.40 4.36 5.88 4.69 6.10 4.68 6.24 4.63 6.62 4.89 6.90 4.78

36 4.98 4.35 5.31 4.32 5.80 4.65 6.03 4.65 6.17 4.61 6.56 4.86 6.84 4.76

38 4.81 4.27 5.14 4.25 5.65 4.59 5.89 4.59 6.03 4.55 6.42 4.81 6.71 4.72

39 4.72 4.23 5.05 4.21 5.57 4.56 5.81 4.57 5.95 4.53 6.36 4.79 6.65 4.70

Cooling Mode

Indoor air temp

Cooling Mode

Indoor air temp

Heating Mode (HC) (kW)(kW)

outdoor

Air flow

air temp.

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

-15˚CWB 3.69 3.61 3.53 3.45 3.38

-10˚CWB 4.18 4.10 4.05 3.95 3.86

-5˚CWB 4.52 4.46 4.37 4.32 4.25

0˚CWB 4.74 4.67 4.59 4.54 4.47

Hi

17.3

(m

Air flow

17.8

(m

Notes(1) These data show average statuses.

5˚CWB 6.04 5.97 5.94 5.82 5.74

3

/min)

6˚CWB 6.14 6.07 6.00 5.92 5.85

10˚CWB 6.52 6.46 6.42 6.34 6.27

15˚CWB 7.10 7.04 6.99 6.91 6.85

20˚CWB 7.63 7.57 7.53 7.45 7.39

Heating Mode (HC) (kW)(kW)

outdoor

air temp.

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

-15˚CWB 4.18 4.09 4.00 3.92 3.83

-10˚CWB 4.73 4.65 4.59 4.47 4.38

-5˚CWB 5.13 5.05 4.95 4.90 4.82

0˚CWB 5.38 5.30 5.20 5.14 5.07

Hi

5˚CWB 6.85 6.77 6.73 6.60 6.51

3

/min)

6˚CWB 6.96 6.88 6.80 6.71 6.63

10˚CWB 7.39 7.32 7.28 7.18 7.11

15˚CWB 8.05 7.98 7.92 7.83 7.76

20˚CWB 8.65 8.58 8.54 8.44 8.37

Depending on the system control, there may be ranges where the operation

is not conducted continuously.

These data show the case where the operation frequency of a compressor is

fixed.

(2) Capacities are based on the following conditions.

Corresponding refrigerant piping length :7m

Level difference of Zero.

(3) Symbols are as follows.

TC : Total cooling capacity (kW)

SHC : Sensible heat capacity (kW)

HC : Heating capacity (kW)

indoor air temp

indoor air temp

-

25

-

'17 • SRK-T-203

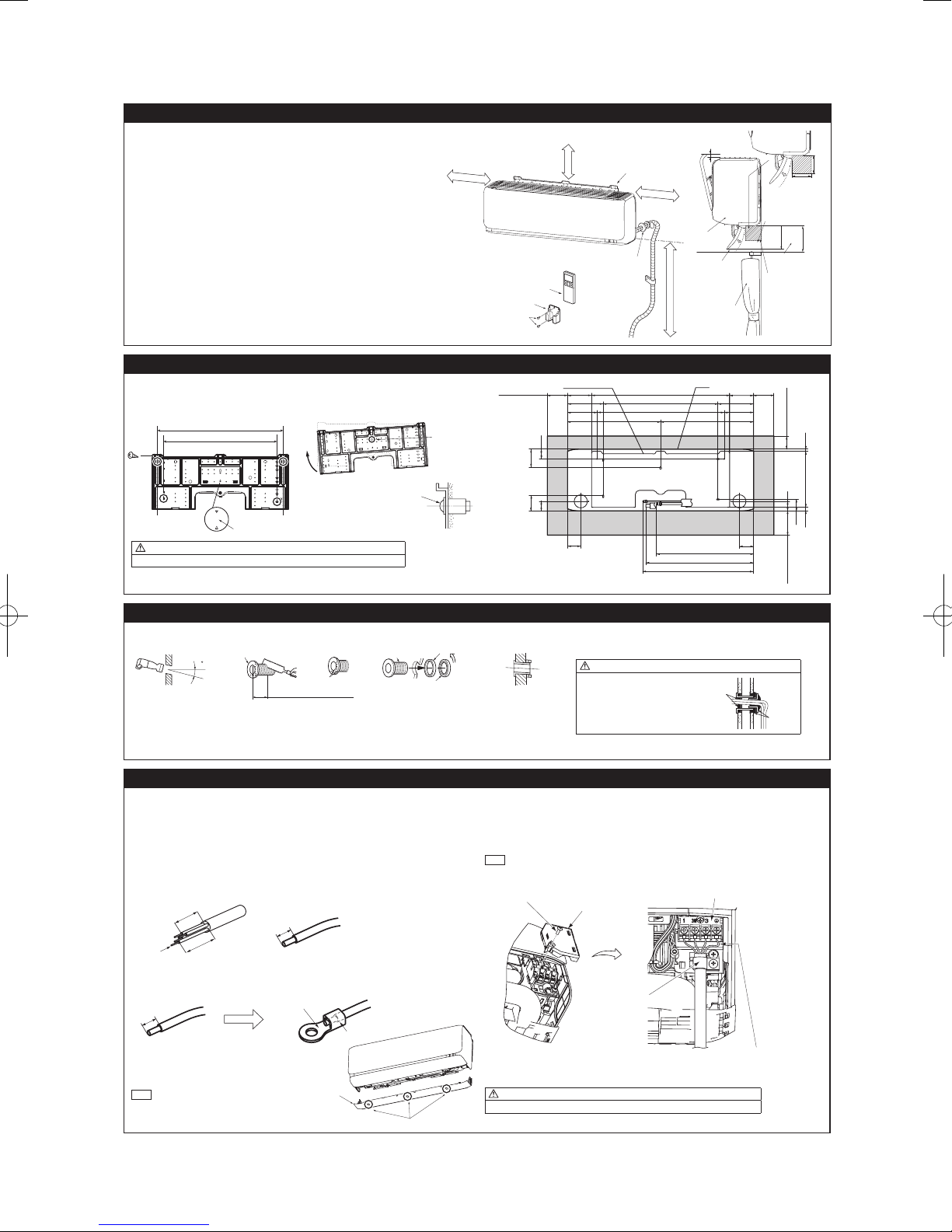

WARNING

CAUTION

WARNING

CAUTION

8. APPLICATION DATA

(1) Installation of indoor unit

•

This installation manual deals with an indoor unit installation only. For an outdoor unit installation, refer to page 30.

• Before installation, read the “SAFETY PRECAUTIONS” carefully and strictly follow it during the installation work in order to protect yourself.

•

The precautionary items mentioned below are distinguished into two levels,

Indicates a potentially hazardous situation which, if not avoided, can result in serious con-

sequences such as death or severe injury.

Indicates a potentially hazardous situation which, if not avoided, can result in personal inju-

Both mention the important items to protect your health and safety. Therefore, strictly follow them by any means.

• Be sure to use only for residential purpose.

If this unit is installed in inferior environment such as machine shop, vehicle (like ship), warehouse,

• Installationmustbe carriedoutbythequalied installercompletelyinaccor-

Installationbynon qualiedpersonorincorrect installationcancauseserious troublessuchaswater

•

Impropersafetymeasurescanresultinpersonalinjury.

• Usetheoriginalaccessoriesandthespeciedcomponentsfortheinstallation.

Usingpartsotherthanthoseprescribedmaycausewaterleak,electricshock,reandpersonalinjury.

•

Ifleaked gasesaccumulate around theunit, itcan causere resultingin propertydamage andper-

• When installing the unit in small rooms, make sure that refrigerant density

If refrigerant density exceeds the limit, consult the dealer and install the ventilation system.

Otherwise lack of oxygen can occur resulting in serious accident.

• Install the unit in a location where unit will remain stable, horizontal and free

Unsuitableinstallationlocationcancausetheunittofallresultinginmaterialdamageandpersonalinjury.

• Do not run the unit with removed panels or protections.

Touchingrotatingequipments, hot surfacesor highvoltage parts cancause personal injurydue to

• ThisunitisdesignedspecicallyforR410A.

Usinganyotherrefrigerantcancauseunitfailureandpersonalinjury.

• DonotventR410Aintoatmosphere.

R410AisauorinatedgreenhousegaswithaGlobalWarmingPotential(GWP)=2088.

• Make sure that no air enters the refrigerant circuit when the unit is installed

If air enters the refrigerant circuit, the pressure in the refrigerant circuit will become too high, which

• Besuretousetheprescribedpipes,arenutsandtoolsforR410A.

Usingexistingparts(forR22orR407C)can causerefrigerantcircuitburstresultinginunit failureand

• Be sure to connect both liquid and gas connecting pipes properly before op-

Do not open the liquid and gas service valves before completing piping work,

If the compressor is operated when connecting pipes are not connected and service valves are open,

• Besuretotightenthearenutstospeciedtorqueusingthetorquewrench.

Tighteningarenutswithexcesstorquecancauseburstandrefrigerantleakageafteralongperiod.

• Take care when carrying the unit by hand.

Iftheunitweightismorethan20kg,itmustbecarriedbytwoormorepersons.

Do not carry the unit by the plastic straps. Always use the carry handle.

• Do not install the outdoor unit in a location where insects and small animals

Insectsandsmallanimalscanentertheelectricalpartsandcause damageresultinginreorperson

• If the outdoor unit is installed at height, make sure that there is enough space

Insufcientspacecanresultinpersonalinjuryduetofallingfromtheheight.

• Do not install the unit near the location where neighbours are bothered by

It can affect surrounding environment and cause a claim.

• Do not install in the locations where unit is directly exposed to corrosive

It can cause corrosion of heat exchanger and damage to plastic parts.

• Do not install the unit close to the equipments that generate electromagnetic

Equipment such as inverters, standby generators, medical high frequency equipments and telecom-

The system can also affect medical equipment and telecommunication equipment, and obstruct its

ry or property damage.

etc., it can malfunction.

dance with the installation manual.

leak,electricshock,reandpersonalinjury.

Be sure to wear protective goggles and gloves while performing installation work.

Donotinstalltheunitnearthelocationwhereleakageofammablegasescanoccur.

sonalinjury.

does not exceed the limit (Reference: ISO5149) in the event of leakage.

of any vibration transmission.

entrapment, burn or electric shock.

and removed.

cancauseburstandpersonalinjury.

personalinjury.

erating the compressor.

and evacuation.

air can be sucked into the refrigerant circuit which can cause anomalous high pressure resulting in

burstorpersonalinjury.

can inhabit.

alinjury.Instructtheusertokeepthesurroundingsclean.

for installation, maintenance and service.

noise or air generating from the unit.

gases (like sulphide gas, chloride gas), sea breeze or salty atmosphere.

waves and/or high-harmonic waves.

munication equipments can affect the system, and cause malfunctions and breakdowns.

functionorcausejamming.

SAFETY PRECAUTIONS

and

•Be sureto conrmno operation problemon theequipment after completingthe installation. Ifunusual

noise can be heard during the test run, consult the dealer.

• Be sure to explain the operating methods as well as the maintenance methods of this equipment to the

.

user according to the user’s manual.

• Be sure to keep the installation manual together with user’s manual at a place where it is easily accessible to the user any time. Moreover, ask the user to hand the manuals to a new user, whenever required.

WARNING

• During pump down work, be sure to stop the compressor before closing ser

vice valves and removing connecting pipes.

If the connecting pipes are removed when the compressor is in operation and service valves are

open, air can be sucked into the refrigerant circuit which can cause anomalous high pressure result

inginburstorpersonalinjury.

• In the event of refrigerant leakage during installation, be sure to ventilate the

working area properly.

Iftherefrigerantcomesintocontactwithnakedames,poisonousgaseswillbeproduced.

• Electricalwork mustbe carriedoutbythequalied electrician,strictlyinac-

cordance with national or regional electricity regulations.

Incorrectinstallationcancauseelectricshock,reorpersonalinjury.

• Make sure that earth leakage breaker and circuit breaker of appropriate ca

pacities are installed.

Circuitbreaker should beable to disconnectall poles underover current.Absence ofappropriate

breakerscancauseelectricshock,personalinjuryorpropertydamage.

• Be sure to switch off the power source in the event of installation, mainte

nance or service.

Ifthepowersourceisnotswitchedoff,thereisariskofelectricshock,unitfailureorpersonalinjury.

• Be sure to tighten the cables securely in terminal block and relieve the ca-

bles properly to prevent overloading the terminal blocks.

Looseconnectionsorcablemountingscancauseanomalousheatproductionorre.

• Do not process, splice or modify the power cable, or share the socket with

other power plugs.

Improperpower cableorpower plugcancause reor electricshockdue topoorconnection, insuf

cient insulation or over-current.

• Do not perform any change in protective device or its setup condition yourself.

Changingprotectivedevicespecicationscancauseelectricshock,reorburst.

• Be sure to clamp the cables properly so that they do not touch any internal

component of the unit.

Ifcablestouchanyinternalcomponent,itcancauseoverheatingandre.

• Be sure to install service cover properly.

Improperinstallationcancauseelectricshockorreduetointrusionofdustorwater.

• Be sure to use the prescribed power and connecting cables for electrical work.

Usingimpropercablescancauseelectricleak,anomalousheatproductionorre.

• This appliance must be connected to main power source by means of a cir

cuit breaker or switch with a contact separation of at least 3mm.

Improperelectricalworkcancauseunitfailureorpersonalinjury.

•

Whenpluggingthisunit,aplugconformingtothenormIEC60884-1mustbeused.

Usingimproperplugcancauseelectricshockorre.