Mitsubishi Heavy Industries SRK20ZFX-S, SRC25ZFX-S, SRK35ZFX-S, SRK25ZFX-S, SRC35ZFX-S Technical Manual

...

-

3

-

INVERTER WALL MOUNTED TYPE

ROOM AIR-CONDITIONER

( Split system, air to air heat pump type )

SRK20ZFX-S, 25ZFX-S, 35ZFX-S, 50ZFX-S

TECHNICAL MANUAL

Collection data

Manual No. ’06

.

SRK-T

.

051

-

1

-

CONTENTS

1. GENERAL INFORMATION ........................................................................... 1

1.1 Specific features .................................................................................... 1

1.2 How to read the model name ................................................................ 1

2. SELECTION DATA........................................................................................ 2

2.1 Specifications ........................................................................................ 2

2.2 Range of usage & limitations ............................................................... 6

2.3 Exterior dimensions .............................................................................. 6

2.4 Piping system ........................................................................................ 8

2.5 Selection chart ....................................................................................... 9

3. ELECTRICAL DATA ..................................................................................... 10

3.1 Electrical wiring ..................................................................................... 10

4. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ................12

4.1 Operation control function by remote control switch ........................ 12

4.2 Unit ON/OFF button ...............................................................................13

4.3 Power blackout auto restart function................................................... 13

4.4 Custom cord switching procedure ....................................................... 14

4.5 Flap and louver control .........................................................................14

4.6 Comfortable timer setting .....................................................................15

4.7 Sleep timer operation ............................................................................15

4.8 Outline of clean operation..................................................................... 15

4.9 Outline of heating operation ................................................................. 16

4.10 Outline of cooling operation ................................................................. 18

4.11 Outline of dehumidifying operation .....................................................19

4.12 Outline of automatic operation............................................................. 21

4.13 ECONOMY operation ............................................................................. 21

4.14 Protective control function ...................................................................22

5. APPLICATION DATA .................................................................................... 29

5.1 Selection of location for installation .................................................... 30

5.2 Installation of indoor unit ...................................................................... 31

5.3 Installation of outdoor unit ................................................................... 34

5.4 Refrigerant piping .................................................................................. 34

5.5 Test run ................................................................................................... 36

5.6 Precautions for wireless remote control installation and operation...... 36

6. MAINTENANCE DATA.................................................................................. 37

6.1 Troubleshooting procedures for electrical equipment ....................... 37

6.2 Servicing................................................................................................. 57

7. REFRIGERANT PIPING INSTALLATION/SERVICING MANUAL

FOR AIR CONDITIONERS USING R410A .................................................. 58

7.1 Outline .................................................................................................... 58

7.2 Refrigerant piping installation .............................................................. 59

7.3 Installation, removal and servicing ...................................................... 65

7.4 Refrigerant recovery.............................................................................. 70

-

1

-

Over heat of compressor

Error of signal transmission

Outdoor fan motor error

1 GENERAL INFORMATION

1.1 Specific features

The “MITSUBISHI HEAVY INDUSTRIES, LTD.” room air-conditioner: SRK series are of split and wall mounted type and the unit

consists of indoor unit and outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling or

heating equipment with operation control switch and the outdoor unit is composed of condensing unit with compressor.

(1) Inverter (Frequency converter) for multi-steps power control

¡ Heating/Cooling

The rotational speed of a compressor is changed in step in relation to varying load, interlocked with the indoor and outdoor unit

fans controlled to change frequency, thus controlling the capacity.

¡ Allowing quick heating/cooling operation during start-up period. Constant room temperature by fine-tuned control after the

unit has stabilized.

(2) Fuzzy control

¡ Fuzzy control calculates the amount of variation in the difference between the return air temperature and the setting tempera-

ture in compliance with the fuzzy rules in order to control the air capacity and the inverter frequency.

(3) Remote control flap & louver

The Flap & louver can be automatically controlled by operating wireless remote control.

¡ Flap swing : The flaps swing up and down successively.

¡ Louver swing : The louvers swing left and right successively.

¡ Memory flap : Once the Flap & louver position is set, the unit memorizes the position and continues to operate

at the same position from the next time.

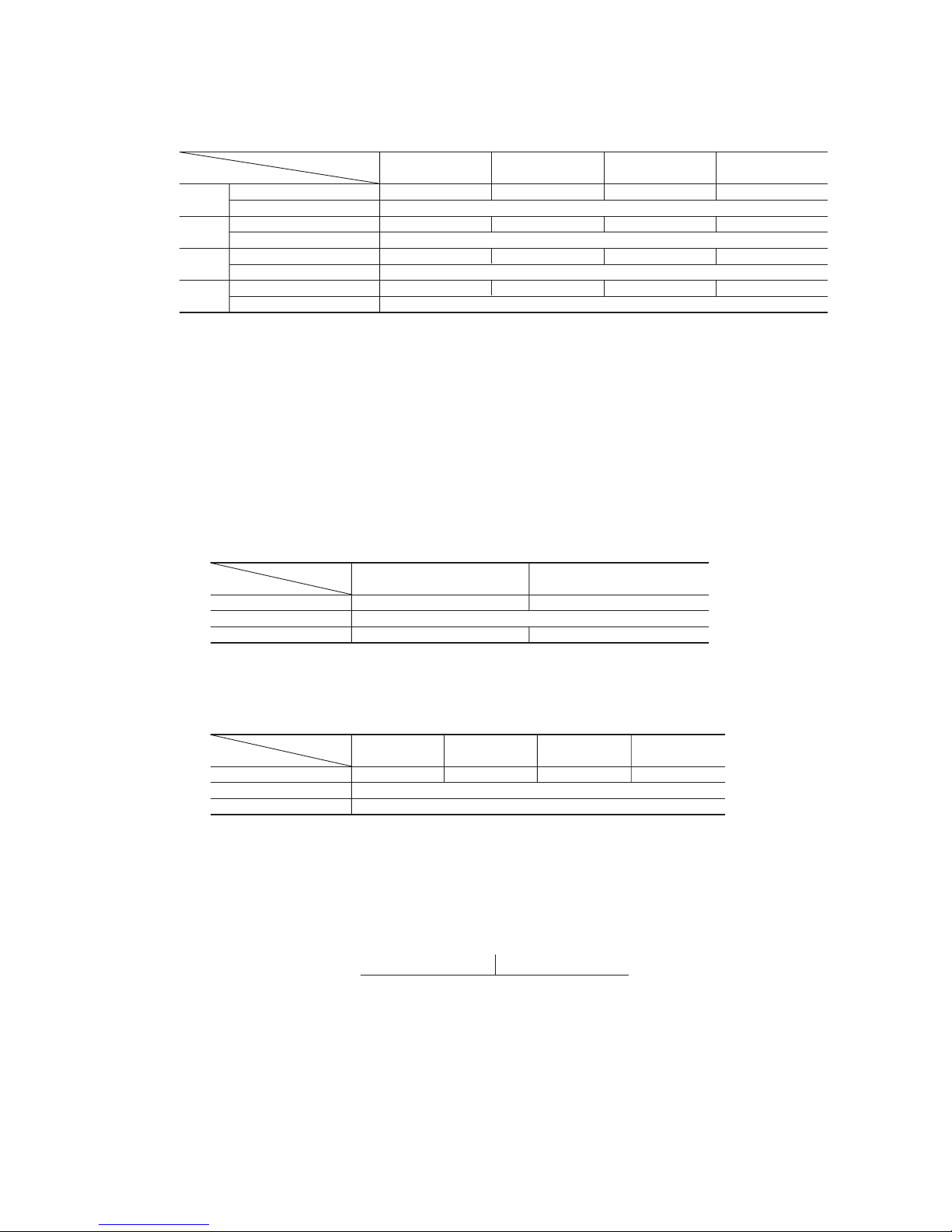

(4) Self diagnosis function

¡ We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows.

Outdoor heat exchanger sensor

error

Discharge pipe sensor error

Outdoor air temperature sensor

error

2 time flash

4 time flash

RUN light

keeps flashing

1 time flash

Trouble of outdoor unit

Over current

Current cut

2 time flash

3 time flash

RUN light

ON

1 time flash

5 time flash

TIMER light

Room temperature sensor error

Indoor fan motor error

Heat exchanger sensor error

2 time flash

6 time flash

TIMER light

ON

1 time flash

RUN light

Rotor lock

6 time flash

7 time flash

2 time flash

RUN light

2 time flash

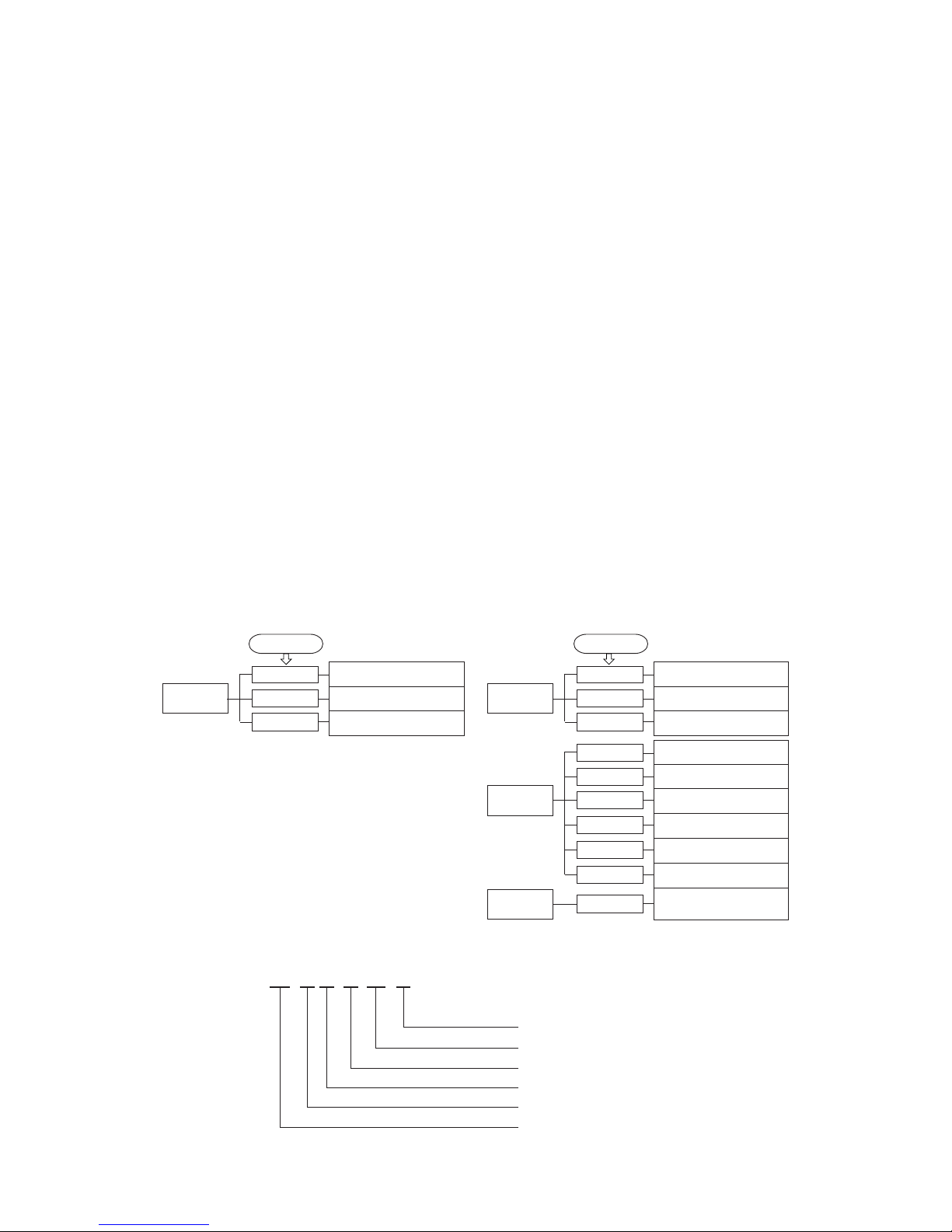

1.2 How to read the model name

Example : SR K 35 Z FX - S

R410A models

Series No.

Inverter type

Product capacity

Wall mounted type

Split type room air-conditioner

-

2

-

2 SELECTION DATA

2.1 Specifications

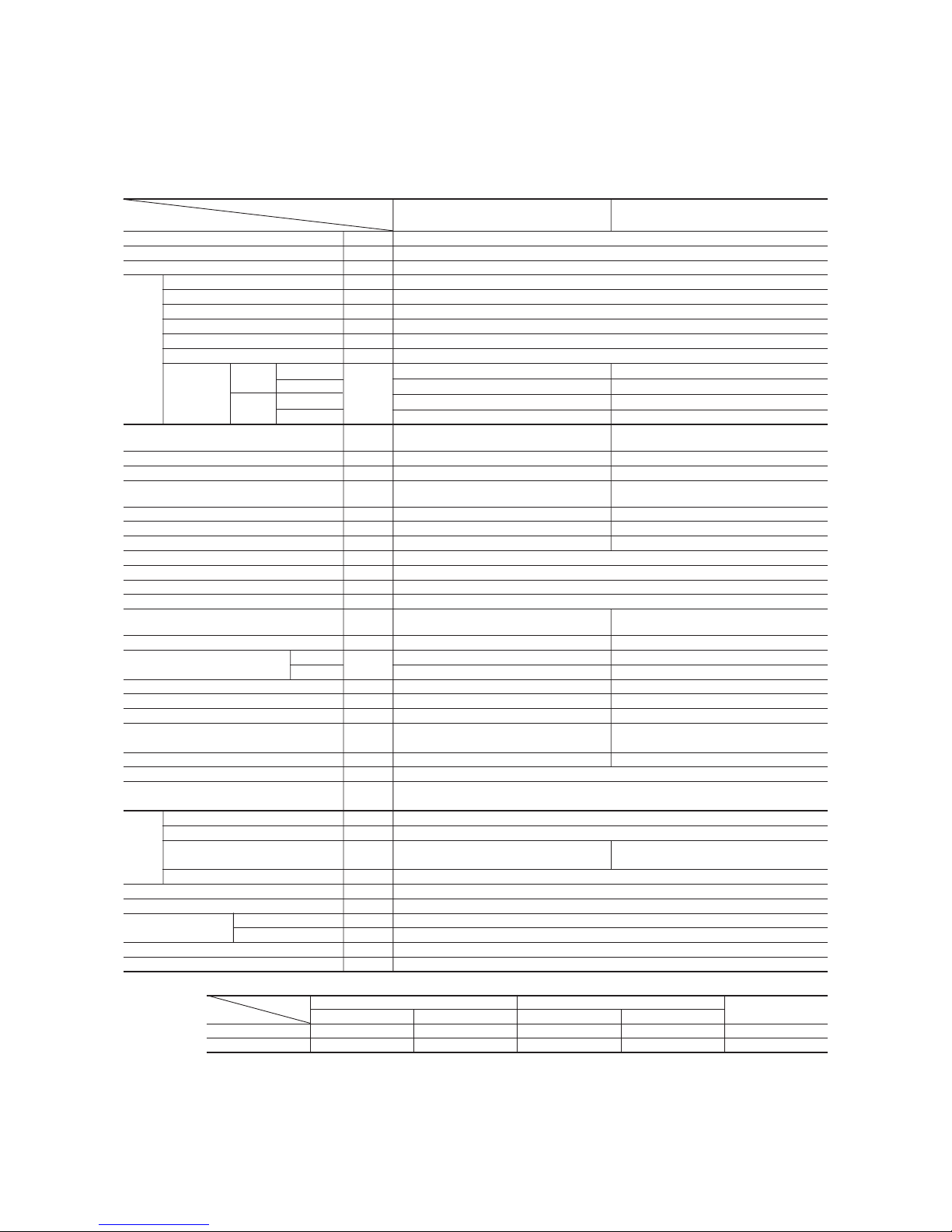

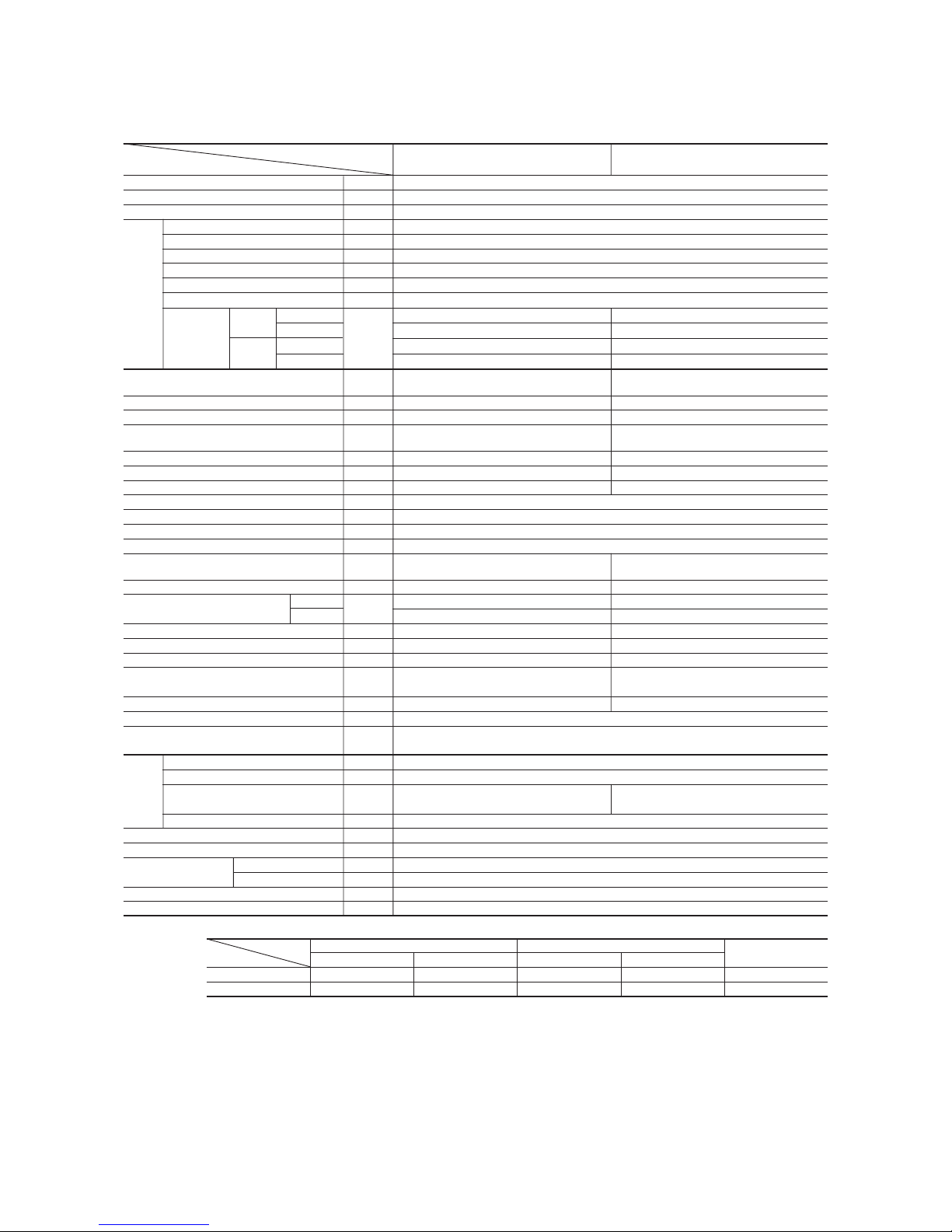

Model SRK20ZFX-S (Indoor unit)

SRC20ZFX-S (Outdoor unit)

Item

Model

SRK20ZFX-S SRC20ZFX-S

Cooling capacity

(1)

W 2000 (500~2800)

Heating capacity

(1)

W 2400 (500~4600)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 0.37 (0.1~0.91)

Running current (Cooling) A 2.1/2.0/1.9

Heating input kW 0.44 (0.09~1.27)

Running current (Heating) A 2.5/2.4/2.3

Inrush current A 2.5/2.4/2.3

COP Cooling: 5.41 Heating: 5.45

Cooling

Sound level Hi 42, Me 34, Lo 21 44

Noise level

Power level

dB

57 57

Heating

Sound level Hi 42, Me 35, Lo 25 43

Power level 58 55

Exterior dimensions

Height × Width × Depth

mm

298 × 840 × 259 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 12 35

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 27 24

(Cooling) 11.8 30

Air flow (at High)

(Heating)

CMM

12 25

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.54 m

Gas line : 0.47 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Allergen clear filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

3

-

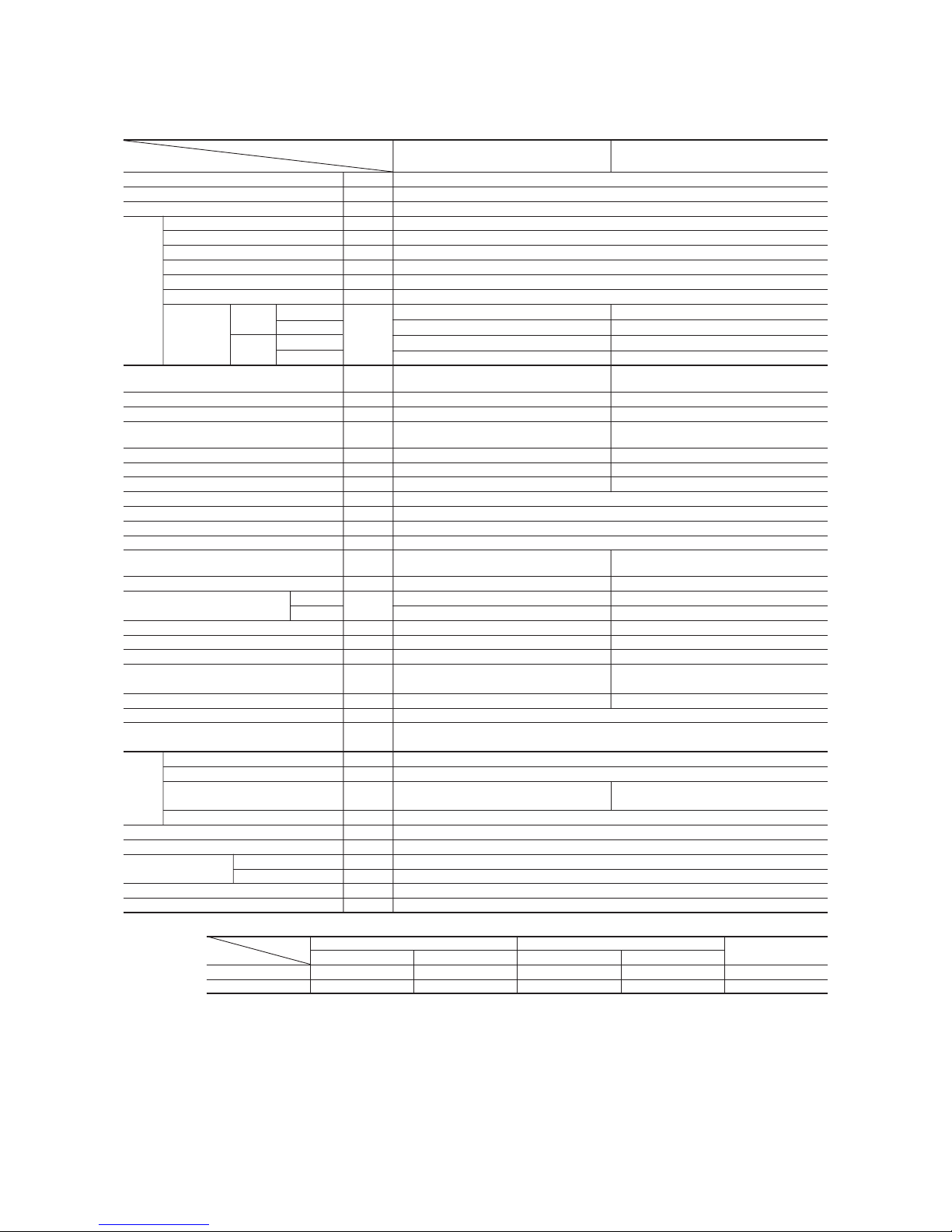

Item

Model

SRK25ZFX-S SRC25ZFX-S

Cooling capacity

(1)

W 2500 (500 ~ 3000)

Heating capacity

(1)

W 3000 (500 ~ 5000)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 0.50 (0.10 ~ 0.64)

Running current (Cooling) A 2.5/2.4/2.3

Heating input kW 0.59 (0.09 ~ 1.16)

Running current (Heating) A 2.9/2.8/2.7

Inrush current A 2.9/2.8/2.7

COP Cooling: 5.00 Heating: 5.08

Cooling

Sound level Hi 43, Me 34, Lo 21 45

Noise level

Power level

dB

58 58

Heating

Sound level Hi 43, Me 36, Lo 26 47

Power level 59 59

Exterior dimensions

Height × Width × Depth

mm

298 × 840 × 259 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 12 35

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 27 24

(Cooling) 11.8 30

Air flow (at High)

(Heating)

CMM

12 27

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot light RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.54 m

Gas line : 0.47 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Allergen clear filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

Model SRK25ZFX-S (Indoor unit)

SRC25ZFX-S (Outdoor unit)

-

4

-

Item

Model

SRK35ZFX-S SRC35ZFX-S

Cooling capacity

(1)

W 3500 (500 ~ 3900)

Heating capacity

(1)

W 4200 (500 ~ 5100)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 0.87 (0.10 ~ 0.98)

Running current (Cooling) A 4.2/4.0/3.8

Heating input kW 1.00 (0.09 ~ 1.19)

Running current (Heating) A 4.9/4.7/4.5

Inrush current A 4.9/4.7/4.5

COP Cooling: 4.02 Heating: 4.20

Cooling

Sound level Hi 44, Me 35, Lo 22 47

Noise level

Power level

dB

59 60

Heating

Sound level Hi 44, Me 37 , Lo 27 50

Power level 60 63

Exterior dimensions

Height × Width × Depth

mm

298 × 840 × 259 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 12 35

Refrigerant equipment

Compressor type & Q’ty

– RM-B5077MD1 [Rotary type] × 1

Motor kW – 0.90

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.2 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.35 (MA68)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 27 24

(Cooling) 12 30

Air flow (at High)

(Heating)

CMM

12.2 27

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot light RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.54 m

Gas line : 0.47 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Allergen clear filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK35ZFX-S (Indoor unit)

SRC35ZFX-S (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

5

-

Model SRK50ZFX-S (Indoor unit)

SRC50ZFX-S (Outdoor unit)

Item

Model

SRK50ZFX-S SRC50FX-S

Cooling capacity

(1)

W 5000 (600~5300)

Heating capacity

(1)

W 6000 (600~7900)

Power source 1 Phase, 220-240V, 50Hz

Cooling input kW 1.56 (0.12~2.1)

Running current (Cooling) A 7.5/7.2/6.9

Heating input kW 1.66 (0.11~2.71)

Running current (Heating) A 7.9/7.6/7.3

Inrush current A 7.9/7.6/7.3

COP Cooling: 3.21 Heating: 3.61

Cooling

Sound level Hi 45, Me 38, Lo 26 48

Noise level

Power level

dB

60 61

Heating

Sound level Hi 47, Me 39, Lo 24 50

Power level 62 65

Exterior dimensions

Height × Width × Depth

mm

298 × 840 × 259 640 × 850 × 290

Color Cool white Stucco white

Net weight kg 12 43

Refrigerant equipment

Compressor type & Q’ty

– 5CS102XFA [Scroll type] × 1

Motor kW – 1.5

Starting method – Line starting

Heat exchanger Slit fins + Louver fins & inner grooved tubing Straight fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Refrigerant

(3)

kg R410A 1.35 (Pre-Charged up to the piping length of 15m)

Refrigerant oil R 0.36 (RB68A)

Deice control Microcomputer control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 27 34

(Cooling) 12.5 42

Air flow (at High)

(Heating)

CMM

13.5 42

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote control –

Room temperature control Microcomputer thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line: 054 m

Gas line : 0.47 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Allergen clear filter × 1, Photocatalytic washable deodorizing filter × 1)

Optional parts –

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15 m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is longer, when it is 15 to 25m, add 20 g refrigerant per meter.

Operation data

(1)

Refrigerant

piping

Compressor overheat protection, Heating overload protection (High pressure control), Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection, Cooling overload protection

The piping length is 7.5m.

(220/230/240V)

-

6

-

2.2 Range of usage & limitations

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length Max. 15m

SRK20ZFX-S, 25ZFX-S, 35ZFX-S SRK50ZFX-S

Cooling operation: Approximately 21 to 32°C

Heating operation: Approximately 15 to 30°C

Cooling operation: Approximately -15 to 43°C

Heating operation: Approximately -5 to 21°C

Power source voltage Rating ± 10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle

ON and OFF interval Max. 3 minutes

Max. 4 times/h

(Inching prevention: 10 min.)

Max. 7 times/h

(Inching prevention: 5 min.)

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Max. 10m (Outdoor unit is higher)

Max. 10m (Outdoor unit is lower)

Max. 25m

Max. 15m (Outdoor unit is higher)

Max. 15m (Outdoor unit is lower)

Item

Models

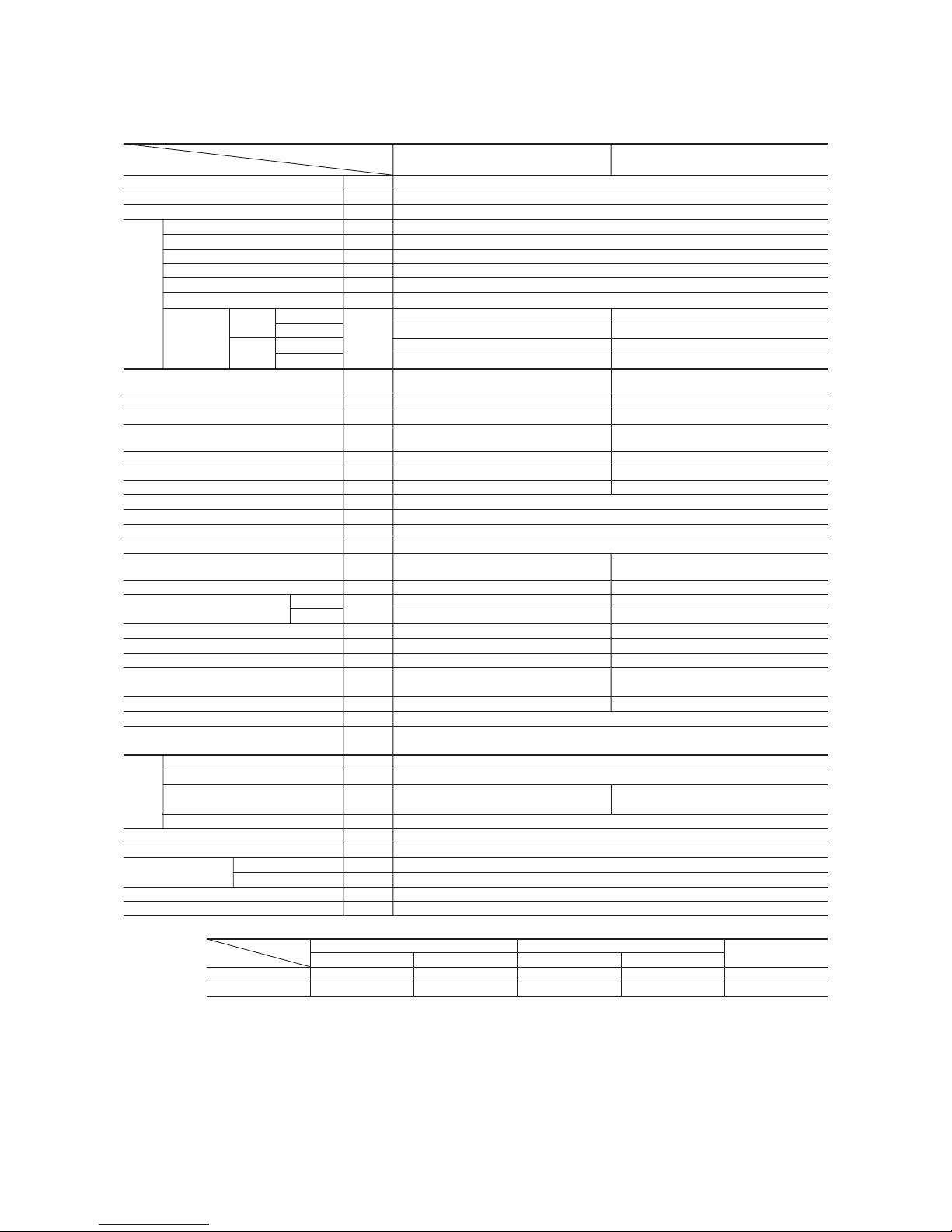

2.3 Exterior dimensions

(1) Indoor unit

Models All models

840

298

A

Piping hole right

259

9

44

right: 67

left : 60

3

60

60

14.5

813

603

44

44

60

60

VIEW A

44.5

47.5220.5

50

207.5

73.5

53.5

Piping hole (ø65)

Piping hole (ø65)

Indoor unit

Installating board

Drain hose 515 (ø16)

Piping for gas 533.5

)(

20,25,35: ø9.52

50: ø12.7

Piping for liquid 603.5 (ø6.35)

63.5

8.5

5.3

284.2

44.5

73.5

182.5

50

450

693

25

-

7

-

(2) Outdoor unit

Models SRC20ZFX-S, 25ZFX-S, 35ZFX-S

Unit: mm

290

540

14.4

47.4 42.6

264.5

71

404.5

510

720

17.8

Drain holes

50

12

39.7

99.9

340

312.5

13.5

14

139

2-16 x12

61.9

139.3 33.3

Flare connection ø6.35 (1/4")

Service valve (Liquid)

40

°

40

°

Flare connecting ø9.52 (3/8")

Service valve (Gas)

Terminal block

Drain holes

286.4

12

50

290

49.6

43.5

850

203.1

510 136.9

476

2-16 × 12

314

12

328

Terminal block

Service valve (Liquid)

ø6.35 (1/4'')

Service valve (Gas)

ø12.7 (1/2'')

Ground

terminal

124

34.6

20˚

20˚

42.7

100.3

15

640

14

Model SRC50ZFX-S

-

8

-

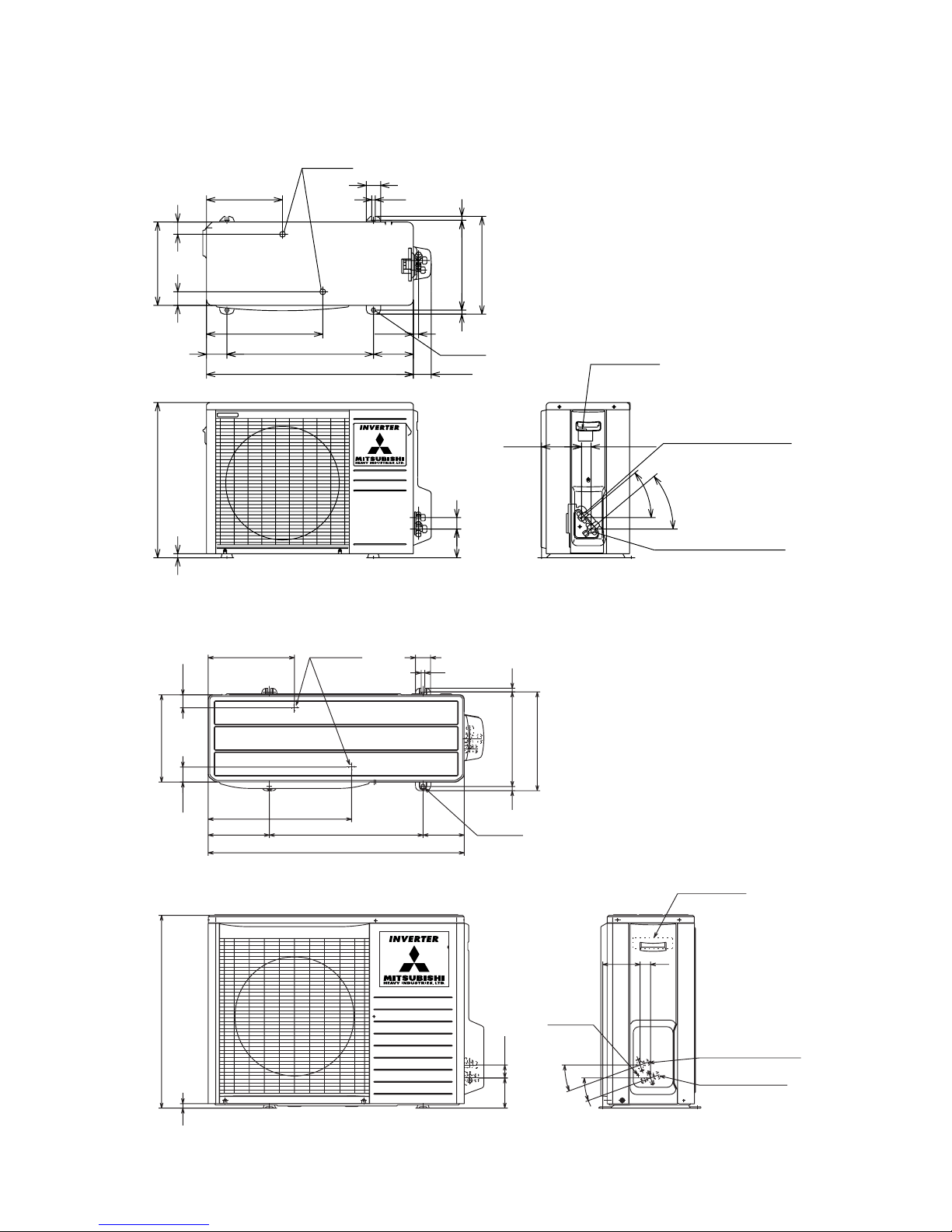

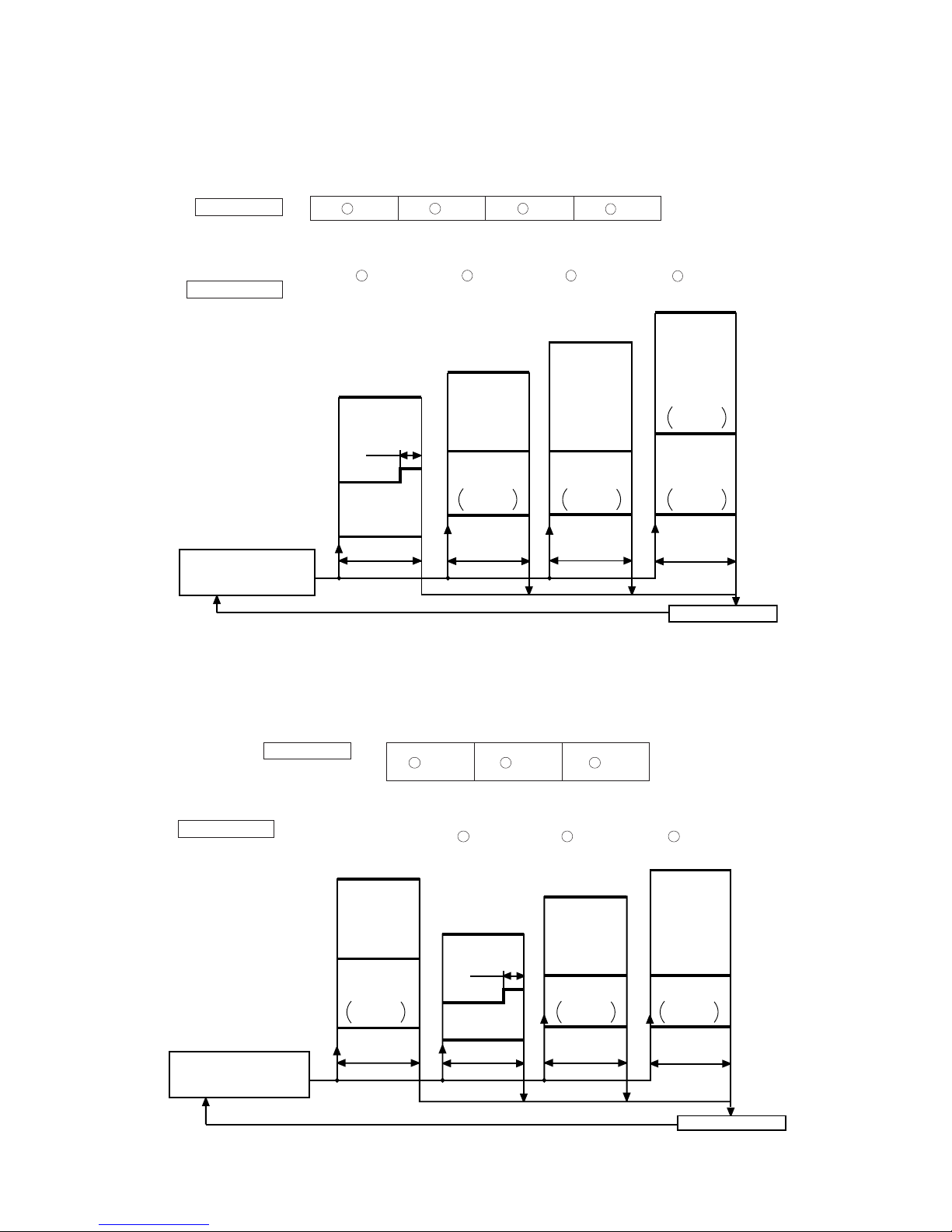

2.4 Piping system

Models SRK20ZFX-S, 25ZFX-S, 35ZFX-S

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connection

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

4 way valve

Service valve (Liquid)

Flare connetion

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Accumulator

Service valve

(Gas)

Electronic

expansion valve

Piping

(Gas)

ø9.52

Model SRK50ZFX-S

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connection

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

4 way valve

Service valve (Liquid)

Flare connection

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Outdoor air

temp. sensor

Heat

exchanger

Heat exchanger

sensor

Compressor

Capillary tube

Strainer

Strainer

Service valve

(Gas)

Capillary tube

Electronic

expansion valve

Piping

(Gas)

ø12.7

Muffler

Capillary tube

-

9

-

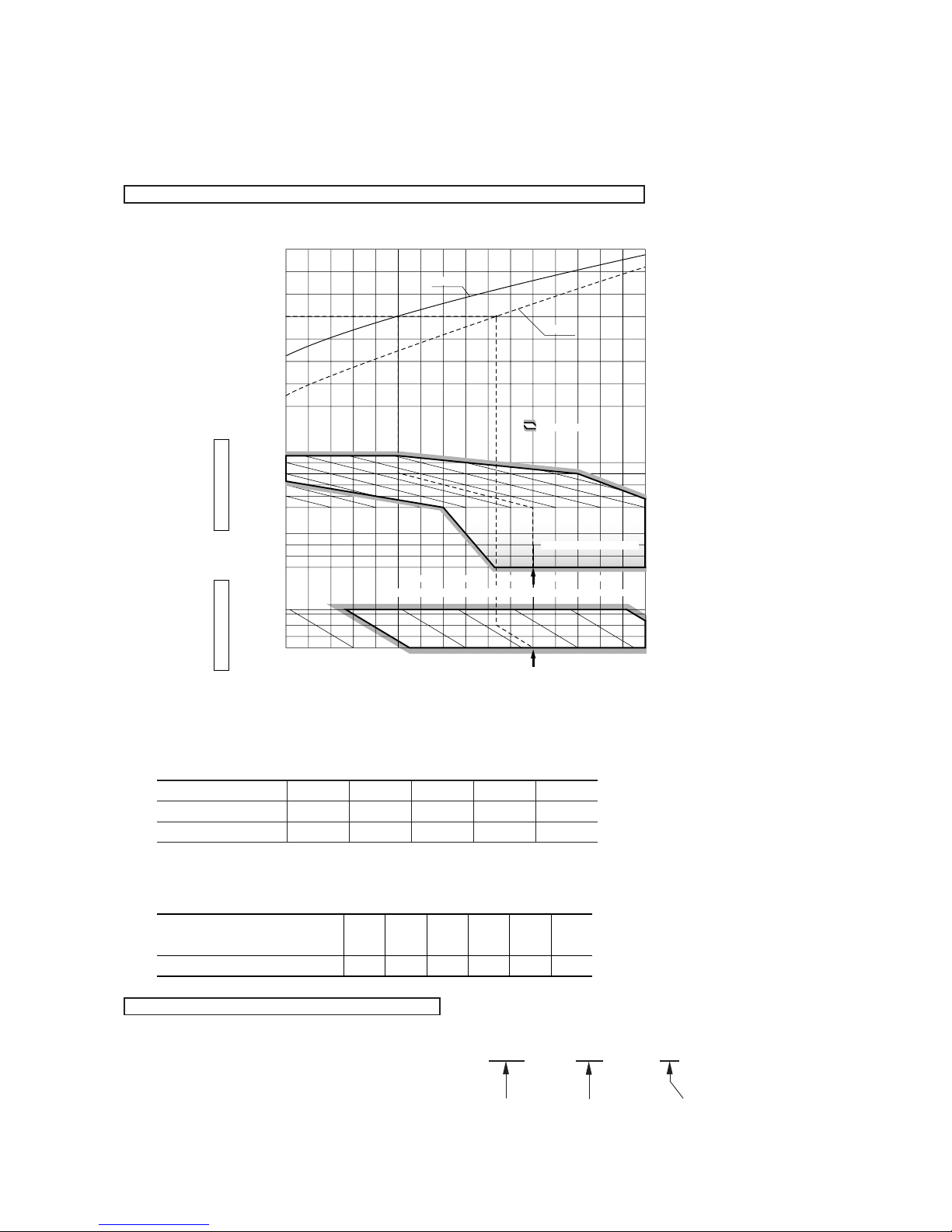

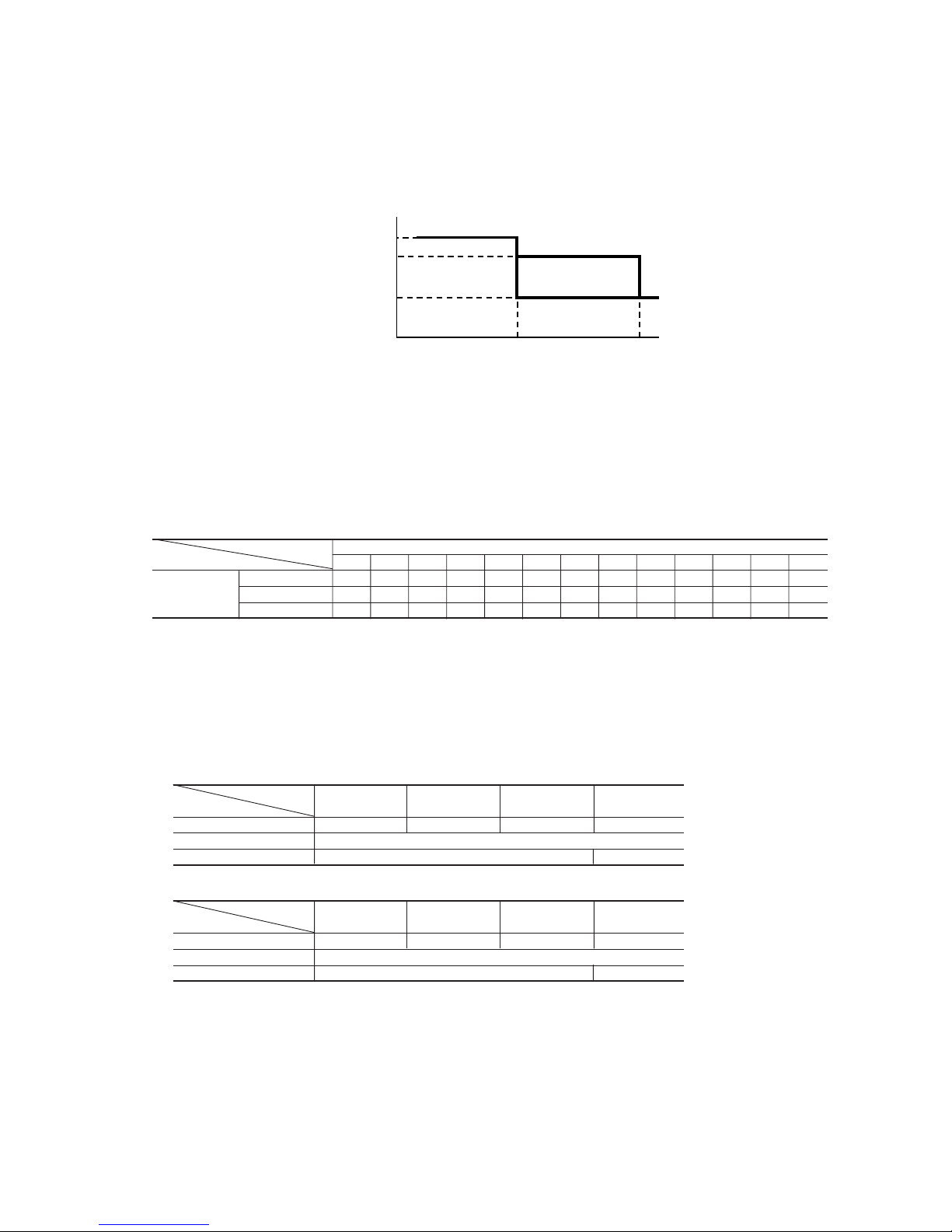

2.5 Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification ✕ Correction factors as follows.

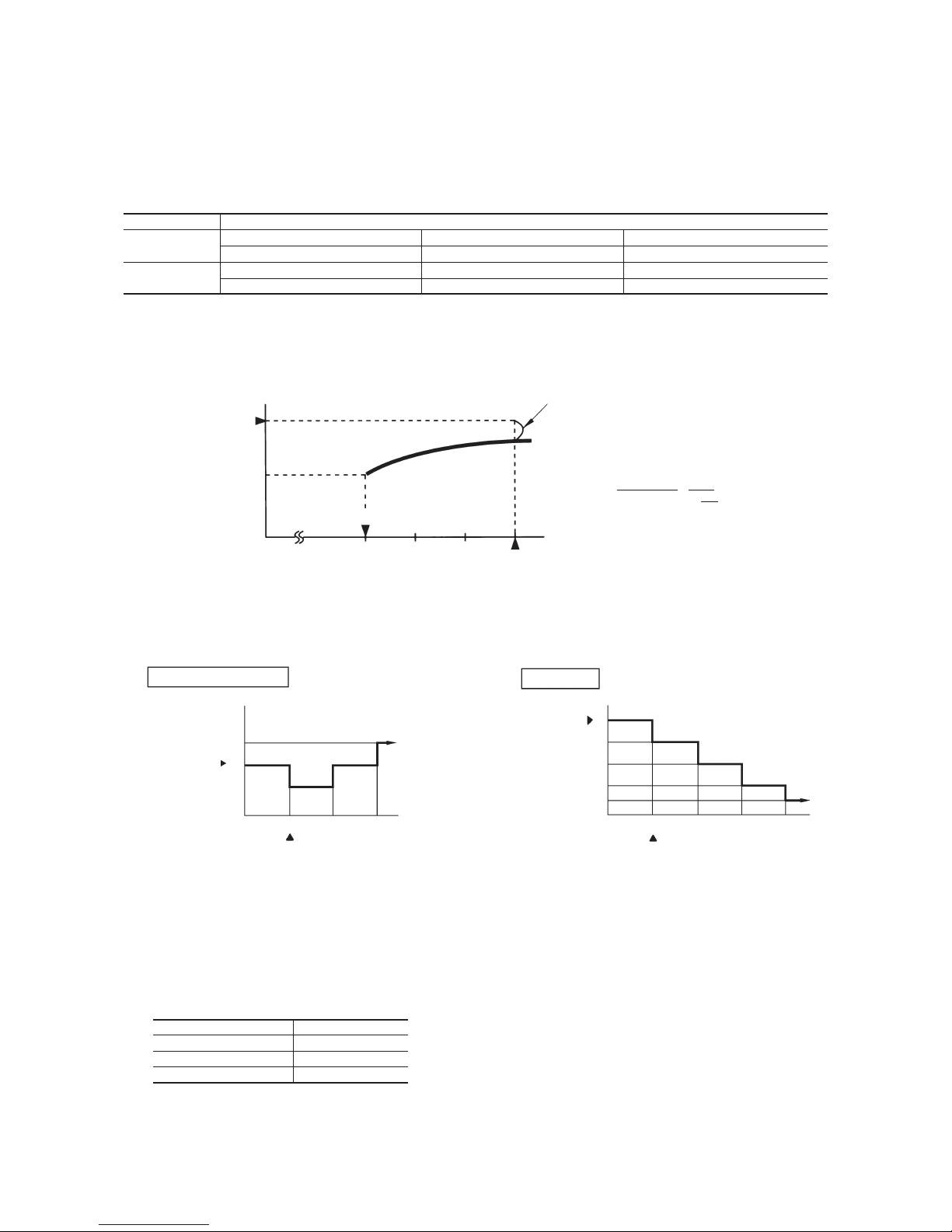

(1) Coefficient of cooling and heating capacity in relation to temperatures

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way piping length between the indoor and outdoor

units.

(3) Correction relative to frosting on outdoor heat exchanger during heating

In additions to the foregoing corrections (1), (2) the heating capacity needs to be adjusted also with respect to the frosting on the

outdoor heat exchanger.

How to obtain the cooling and heating capacity

Example : The net cooling capacity of the model SRK35ZFX-S with the piping length of 15m, indoor wet-bulb temperature at 19.0˚C

and outdoor dry-bulb temperature 35˚C is Net cooling capacity = 3500 ✕ 0.975 ✕ 1.0 = 3413 W

SRK35ZFX-S Length 15m

Factor by air

temperatures

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

Coefficient of cooling &

Heating capacity in

relation to temperature

Heating operation

Indoor air D.B.

temperature

°C D. B.

Cooling operation

Outdoor air D.B.

temperature

°C D. B.

10

15

20

25

27

20

25

30

35

40

43

15010-5-10-15 5

24

26

2220181614

Applicable range

Cooling

Heating

ISO-T1 Standard Condition

Indoor air W.B. temperature °C W.B.

Depends on installed situation

Outdoor air W.B. temperature °C W.B.

ISO-T1 Standard Condition

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

Air inlet temperature of

outdoor unit in ˚C WB

Adjustment coefficient

-5

0.91-30.88-10.8610.8730.9251.00

-

10

-

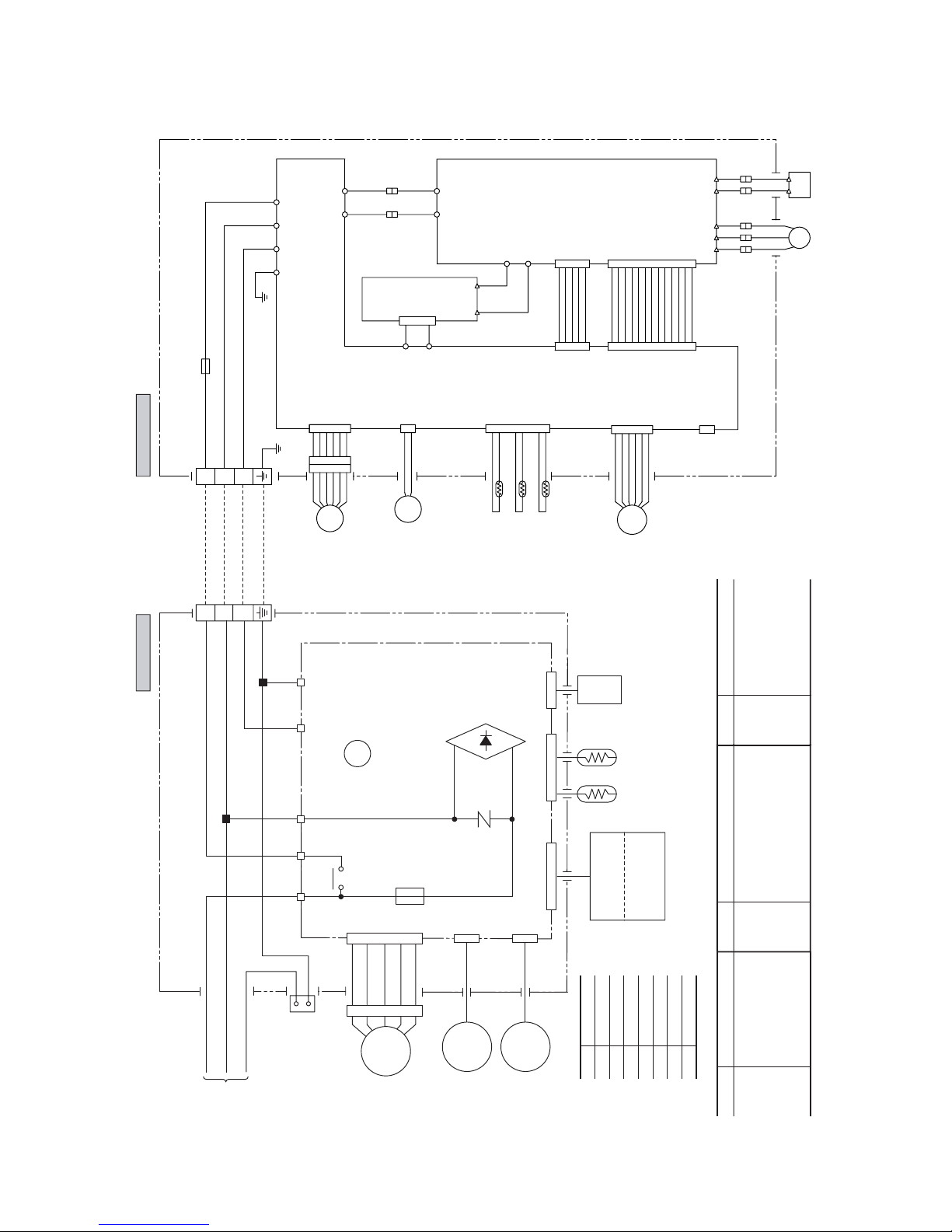

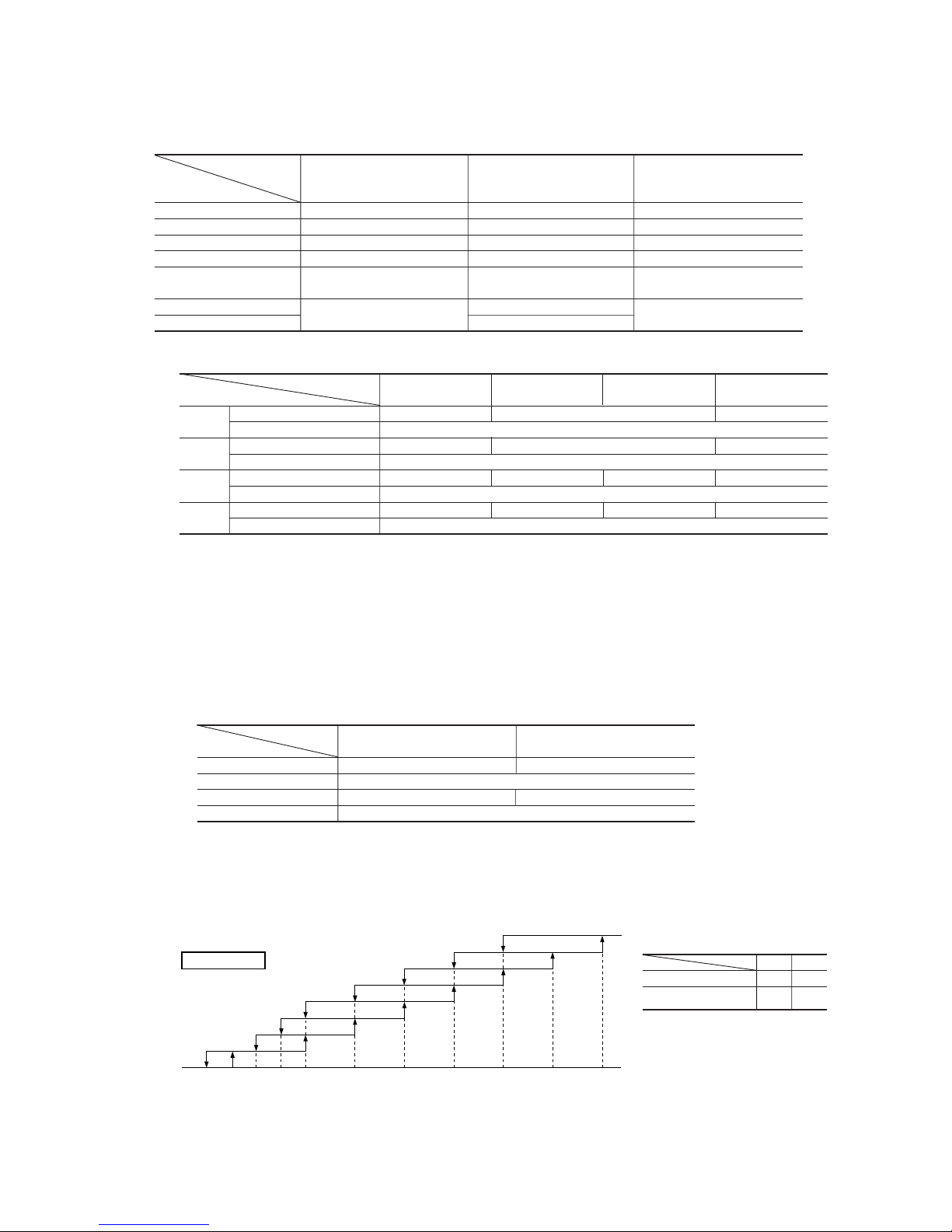

3 ELECTRICAL DATA

3.1 Electrical wiring

Models SRK20ZFX-S, 25ZFX-S, 35ZFX-S

Power source

1 Phase

220-240V 50Hz

Outdoor unit

Indoor unit

HEAT

EXCHANGER

Printed circuit

board

Printed circuit board

BR

BL

Y/GN

BK

WH

RD

RD

1

3

4

5

6

CNU

BK

WH

Y

BL

TB TB

F2 (250V 20A)

F1

250V

3.15A

BK

WH

RD

U

V

W

BK

C2 S.IN R.IN

Re

G

WH

RD

Y/GN

N

ZNR

CNM

CNE CNG

52C3

52C

52C4

J

Th4

Th1 Th2

Th5

Th6

CNB

CNE

CNA

CND

1

2

3

NP

Power

transistor

20S

52C

EEV

FMo

DS

CM

1

2

3

( )

FM

I

SM

CNX

LM

Display

Wireless

R-Amp

Black

Brown

Red

Blue

White

Yellow/Green

BK

BR

RD

BL

WH

Y/GN

Color symbol

Meaning of marks

Symbol

Parts name

CM

Compressor motor

F

Fuse

FM

I

Fan motor (Outdoor)

Fan motor (Indoor)

FMo

FSM

LM

Flap motor

Louver motor

Symbol

Parts name

Th

1

Room temp. sensor

Th

2

Heat exchanger sensor (Indoor unit)

Th

4

Heat exchanger sensor (Outdoor unit)

Th

5

Outdoor air temp. sensor

Th

6

Discharge temp. sensor

Symbol

Parts name

20S

4 way valve (coil)

RE

Reactor

ZNR

Varistor

52C

Magnetic contactor

DS

Diode stack

EEV

Electronic expansion valve

-

11

-

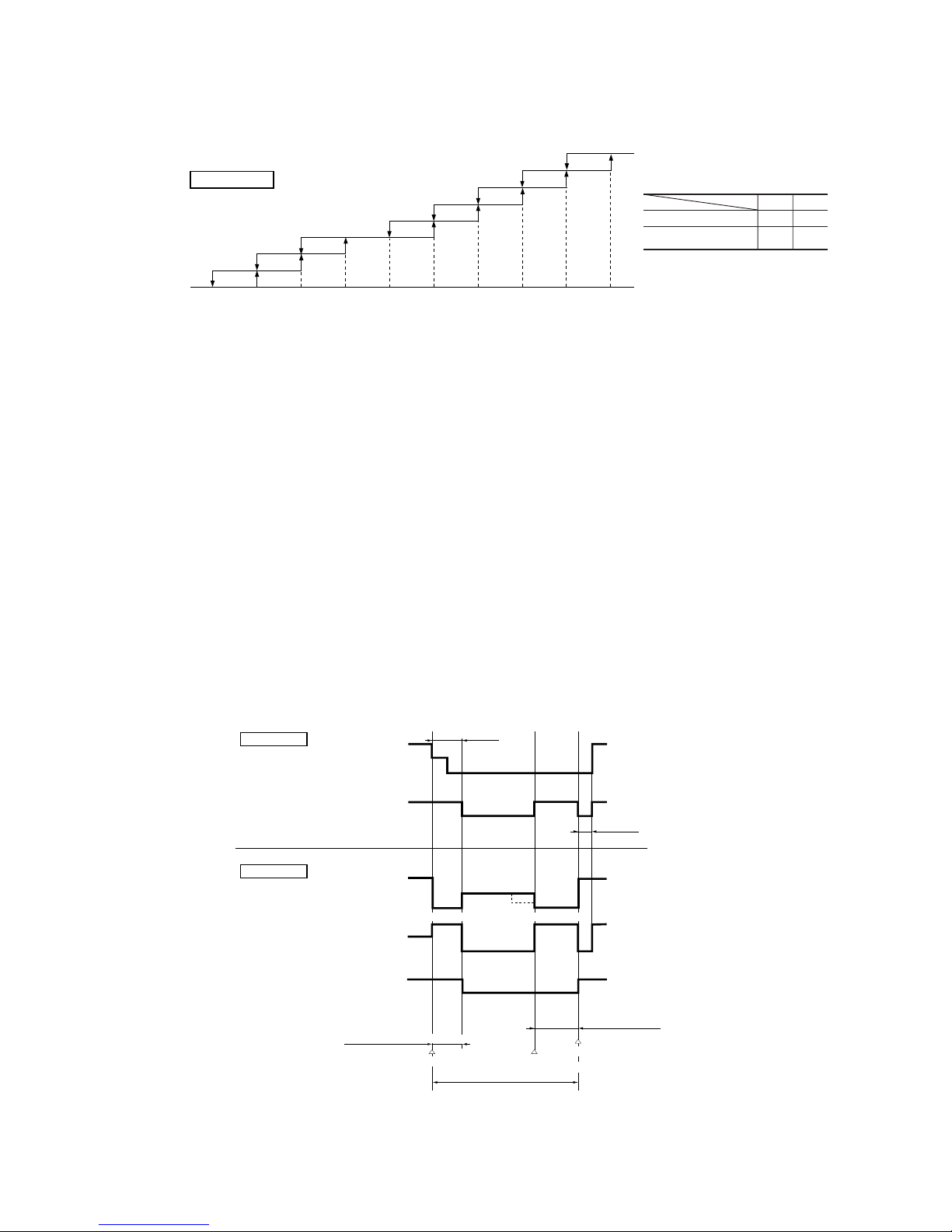

Power source

1 Phase

220-240V 50Hz

Outdoor unit

Indoor unit

HEAT

EXCHANGER

Printed circuit board

BRBLY/GN

BK

WH

RD

RD

BK

WH

Y

BL

TB

F1

250V

3.15A

N

ZNR

CNM

CNE CNG CNF

52C3

52C

52C4

J

52C

1

2

3

( )

FM

I

SM

CNX

LM

Display

Wireless

R-Amp

Th1 Th2

Th3

13456

CNU

Black

Brown

Red

Blue

White

Yellow/Green

BKBRRD

BL

Orange

OR

Green

GR

WH

Y/GN

Color symbol

Meaning of marks

Symbol

Parts name

CFo

Capacitor for FMo

CM

Compressor motor

F

Fuse

FM

I

Fan motor (Outdoor)

Fan motor (Indoor)

FMo

FSM

LM

L

Flap motor

Louver motor

Inductor

Symbol

Parts name

Th

1

Room temp. sensor

Th

2

Heat exchanger sensor (Indoor unit)

Th

3

Humidity sensor

Th

4

Heat exchanger sensor (Outdoor unit)

Th

5

Outdoor air temp. sensor

Th

6

Discharge pipe temp. sensor

Symbol

Parts name

ZNR

Varistor

20S

4 way valve (coil)

52C

Magnetic contactor

DS

Diode stack

EEV

Electronic expansion valve

N_1

P_1

BK

RD

N_1

P_1

DC-N

DC-P

PWB3 (CAPACITOR)

BK

RD

CNG

PWB1 (MAIN)

PWB2 (POWER)

EEV

Th4

Th5

Th6

CNT

TB

CNJ

CND

CNB

FMo

20S

F(250V 15A)

BK

1

L-1

AC.N

AC.N AC.L

AC.L

BL

GR

BL

GR

L

AF_L2

AF_L1

OR

OR

V

CM

W

BK

RD

WH

OR

OR

BK

RD

WH

U

CNH

CNG

G3

CNH

CNG

RD

Y/GN

CNI

WH

2

N-1

3

CNO.1

Model SRK50ZFX-S

-

12

-

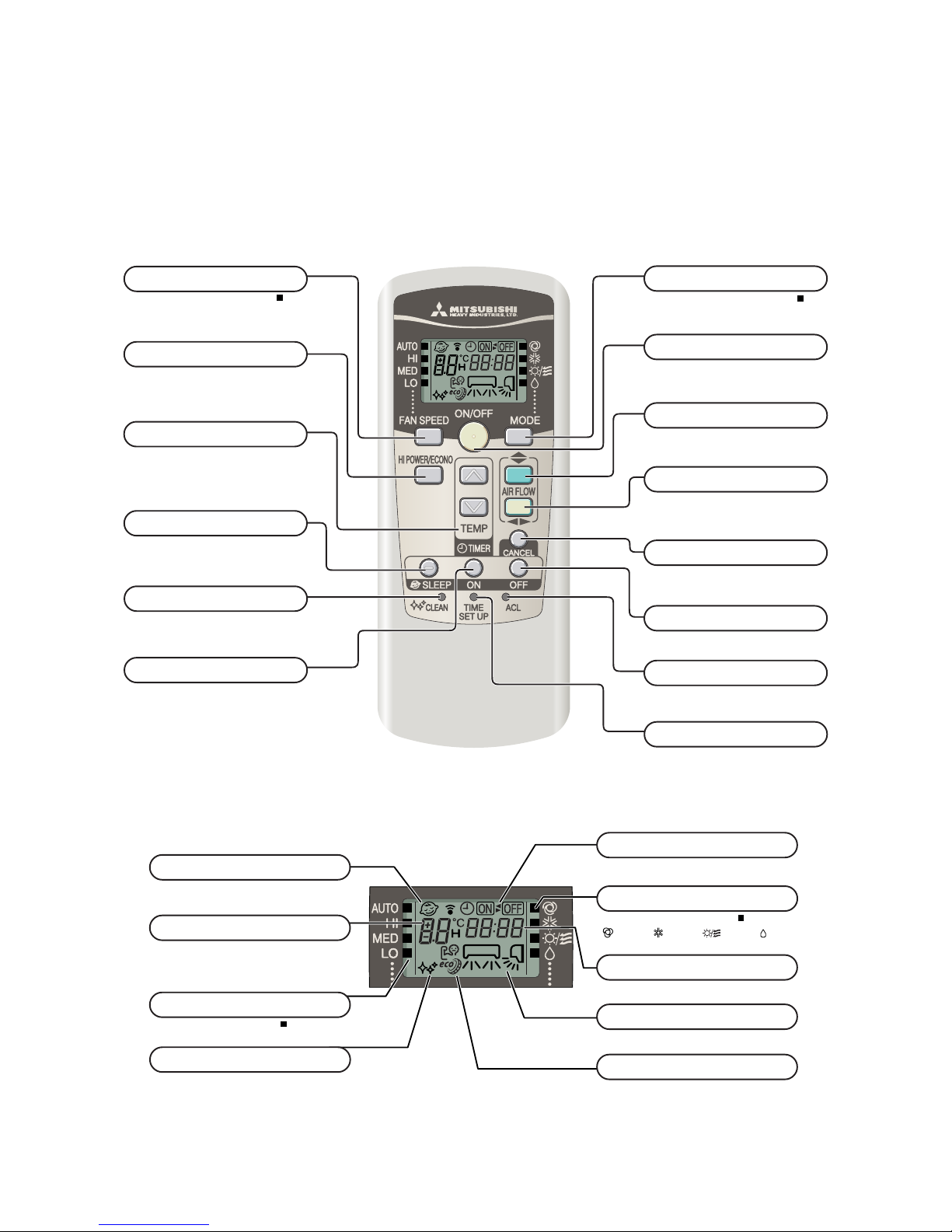

S Indication section

Models All models

S Operation section

4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

4.1 Operation control function by remote control switch

Wireless remote control

FAN SPEED button

Each time the button is pushed, the indicator is switched over in turn.

• The above illustration shows all controls, but in practice

only the relevant parts are shown.

OPERATION MODE select button

Each time the button is pushed, the indicator is switched over in turn.

ON/OFF (luminous) button

Press for starting operation, press again for

stopping.

HI POWER/ECONO button

This button changes the HIGH POWER/

ECONOMY mode.

AIR FLOW (UP/DOWN) button

This button changes the air flow (up/down)

mode.

TIME SET UP switch

This switch for setting the time.

SLEEP button

This button changes to SLEEP operation.

CLEAN switch

This switch changes the CLEAN mode.

ON TIMER button

This button selects ON TIMER operation.

TEMPERATURE button

This button sets the room temperature.

(This button changes the present time and

TIMER time.)

OFF TIMER button

This button selects OFF TIMER operation.

RESET switch

Switch for resetting microcomputer.

OPERATION MODE indicator

Indicates selected operation with lamp.

[

(Auto) • (Cool) • (Heat) • (Dry)]

TEMPERATURE indicator

Indicates set temperature.

(Does not indicate temperature when operation

mode is on AUTO)

FAN SPEED indicator

Indicates set air flow rate with lamp.

CLEAN indicator

Indicates during CLEAN operation.

SLEEP indicator

Indicates during SLEEP operation.

ON/OFF TIMER indicator

Indicates during ON/OFF TIMER operation.

TIME indicator

Indicates present time or timer setting time.

AIR FLOW indicator

Shows selected flap and louver mode.

AIR FLOW (LEFT/RIGHT) button

This button changes the air flow (left/right)

mode.

CANCEL button

This button cancels the ON timer, OFF

timer, and SLEEP operation.

HI POWER/ ECONO MODE indicator

Indicates during High power/economy mode operation.

-

13

-

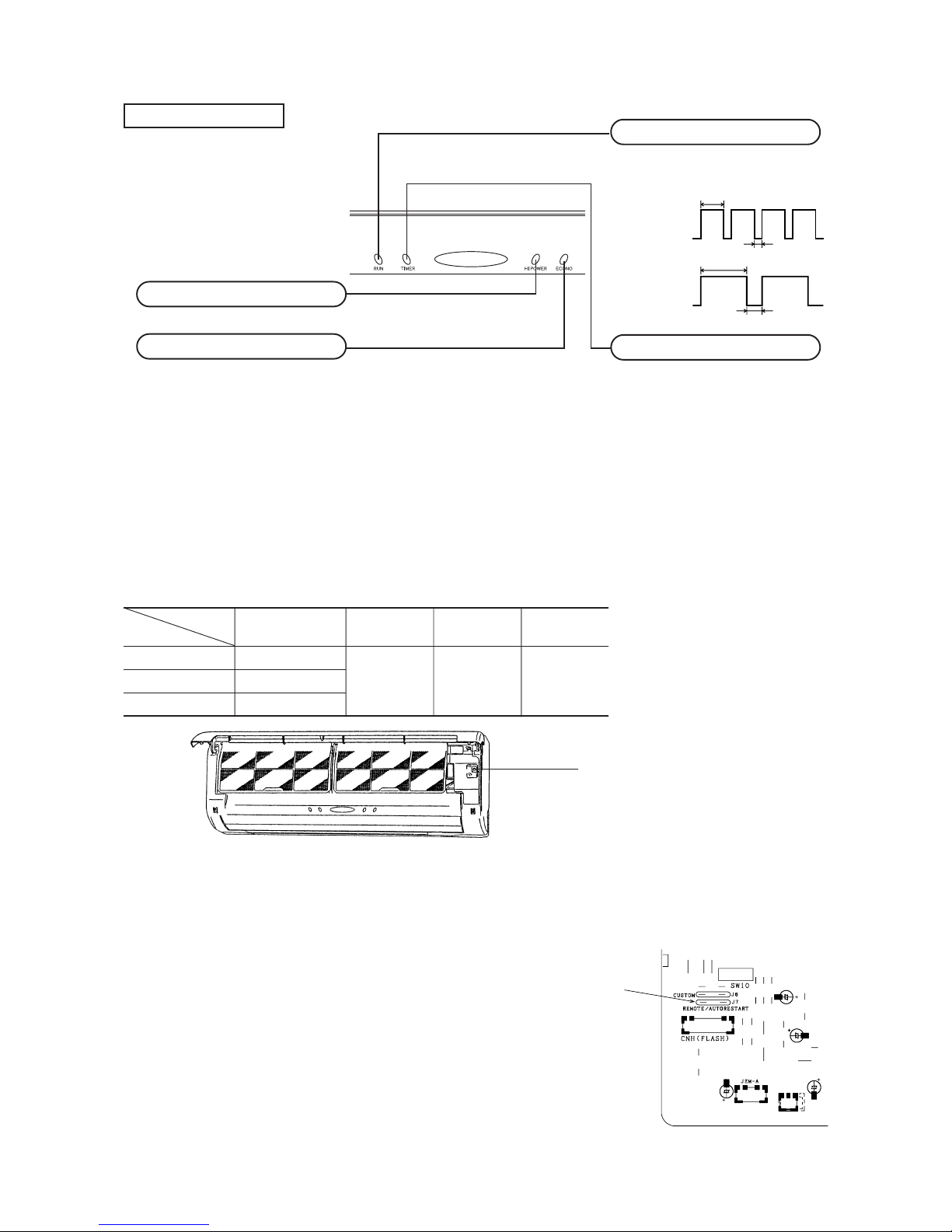

4.2 Unit ON/OFF button

When the remote control batteries become weak, or if the remote control is lost or malfunctioning, this button may be used to turn the

unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by sensor),

whether to go into the cooling, thermal dry or heating modes.

Function

Room temperature

Operation mode

setting

Fan speed Flap Timer switch

Cooling About 25ºC

Thermal dry About 25ºC Auto Auto Continuous

Heating About 26ºC

4.3 Power blackout auto restart function

(1) Power blackout auto restart function is a function that records the operational status of the air-conditioner immediately prior to it

being switched off by a power cut, and then automatically resumes operations at that point after the power has been restored.

(2) The following settings will be cancelled:

(a) Timer settings

(b) High-power operations

Notes (1) The power blackout auto restart function is set at on when the air-conditioner is shipped from the factory.

Consult with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3)

If the jumper wire (J7) “REMOTE/AUTORESTART” is cut, auto restart is disabled. (See the diagram at right)

Unit ON/OFF button

Jumper wire (J7)

Unit indication section

Models All models

ECONOMY light (orange)

Illuminates during ECONOMY operation.

TIMER light (yellow)

Illuminates during TIMER operation.

HI POWER light (green)

Illuminates during HIGH POWER operation.

RUN (HOT KEEP) light (green)

• Illuminates during operation.

• Brinks at air flow stop due to the ‘HOT KEEP’

and ‘CLEAN’ operation.

ON

OFF

ON

1.5 sec.

0.5 sec.

1 sec.

3 sec.

OFF

HOT KEEP

CLEAN

operation

-

14

-

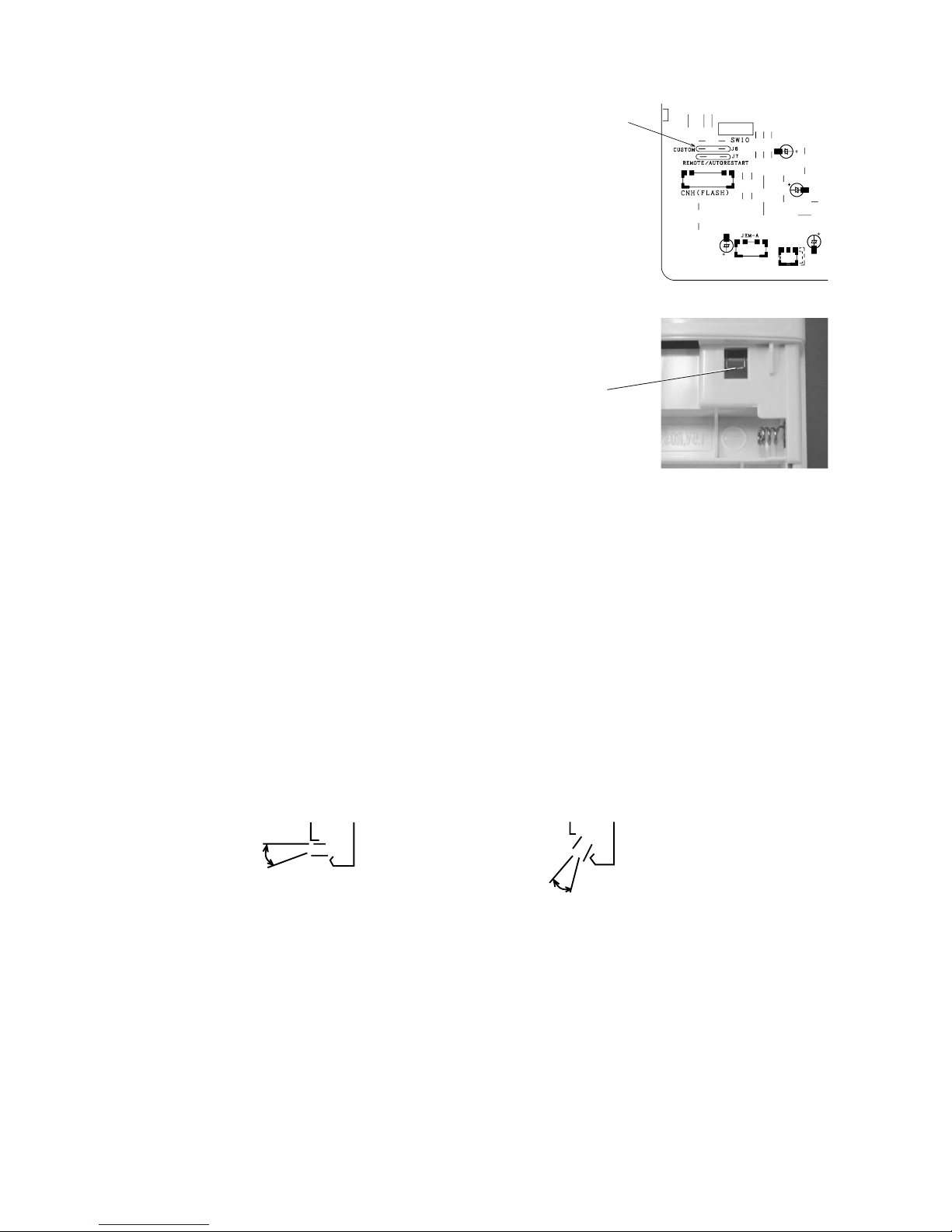

4.4 Custom cord switching procedure

If two wireless remote controls are installed in one room, in order to prevent wrong operation due to

mixed signals, please modify the printed circuit board in the indoor unit’s control box and the remote

control using the following procedure. Be sure to modify both boards. If only one board is modified,

receiving (and operation) cannot be done.

(1) Modifying the indoor unit’s printed circuit board

Ta ke out the printed circuit board from the control box and cut off jumper wire (J6) using wire cutters.

After cutting of the jumper wire, take measures to prevent contact with the other the lead wires, etc.

(2) Modifying the wireless remote control

1) Remove the battery.

2) Cut the jumper wire shown in the figure at right.

Jumper wire (J6)

Slant forward

blowing

HEAT

4.5 Flap and louver control

Control the flap and louver by AIRFLOW

(UP/DOWN) and

(LEFT/RIGHT) button on the wireless remote control.

(1) Swing flap

Flap moves in upward and downward directions continuously.

(2) Swing louver

Louver moves in left and right directions continuously.

(3) When not operating

The flap returns to the position of air flow directly below, when operation has stopped.

(4) Memory flap (Flap or Louver stopped)

When you press the AIRFLOW (UP/DOWN or LEFT/RIGHT) button once while the flap or louver is operating, it stops swinging

at an angle. Since this angle is memorized in the microcomputer, the flap or louver will automatically be set at this angle when the

next operation is started.

¡ Recommendable stopping angle of the flap

Horizontal

blowing

COOL•DRY

Cut

-

15

-

4.8 Outline of clean operation

COOL,DRY,AUTO (COOL,DRY); after operation has stopped, the moisture inside the dryer air conditioner, controls the production of

fungus etc.

(1) Operating condition

‘Clean’ is switched ON, when the air conditioner receives a STOP signal.

(2) Detail of operation

(3) Reset condition

When control finishes 120 minutes after the Clean operation starts. When the stop signal is received from the remote control.

Inverter command speed 0 rps

Indoor fan motor 1st Speed

Outdoor fan motor OFF

Flap and louver Fully closed

(Example) Heating

Setting temperature

Room temperature

4.6 Comfortable timer setting

If the timer is set at ON when the operation select switch is set at the cooling or heating, or the cooling or heating in auto mode operation

is selected, the comfortable timer starts and determines the starting time of next operation based on the initial value of 15 minutes and the

relationship between the room temperature at the setting time (temperature of room temperature sensor) and the setting temperature.

(Max. 60 minutes)

Operation mode Operation start time correction value (Min.)

3 < Room temp. – Setting temp. 1 < Room temp. – Setting temp. ≤ 3 Room temp. – Setting temp. ≤ 1

At cooling

+5 No change –5

3 < Setting temp. – Room temp. 2 < Setting temp. – Room temp. ≤ 3 Setting temp. – Room temp. ≤ 2

At heating

+5 No change –5

Notes (1) At 5 minutes before the timer ON time, operation starts regardless of the temperature of the room temperature sensor (Th1).

(2) This function does not operate when in the Dry or Auto Dry mode.

However, the operation in item (1) does operate in the Auto Dry mode.

(3) During the comfortable timer operation, both the RUN light and TIMER light illuminate and the TIMER light goes off after expiration of the timer, ON setting

time.

Corrects the starting time of next operation by

calculating the temperature difference.

Operation starting time

Time

Setting time

15 min. 10 min. 5 min.

earlier earlier earlier

¡ If the difference (= Setting temperature – Room tempera-

ture) is 4ºC, the correction value is found to be +5 minutes from the table shown above so that the starting time

of next operation is determined as follows:

15 min. earlier + 5 min. = 20 min. earlier

↑↑

Current operation Correction value

start time

=

=

=

=

Timer operation

(time)

Start

Timer operation

(time)

Temperature

setting (˚C)

Start

Temperature

setting (˚C)

Heating

Cooling, DRY

4.7 Sleep timer operation

Pressing the SLEEP button causes the temperature to be controlled as shown in the following chart with respect to the set temperature.

+

1.0

0

-1.0

0 1.0 2.0

0

-1.0

-2.0

-3.0

-6.0

0 0.5 1.0 2.0

-

16

-

Model

SRK20ZFX-S, 25ZFX-S, 35ZFX-S SRK50ZFX-S

Item

Inverter speed 0rps [Comp. stopped] 10 rps [10sec.] → 0rps [Comp. stopped]

Indoor fan Hot keep normal mode → 1st speed

Outdoor fan Stop 6th speed [1min.] → stop

Flap and louver Horizontal, center

Model

SRK20ZFX-S SRK25ZFX-S SRK35ZFX-S SRK50ZFX-S

Air flow selection

Inverter command speed 30~94rps 30~102rps 20~120rps

Air flow Depends on inverter command speed.

Inverter command speed 30~94rps 30~102rps 20~120rps

Air flow 8th speed fixed

Inverter command speed 30~66rps 30~72rps 30~76rps 20~80rps

Air flow 6th speed fixed

Inverter command speed 30~38rps 30~42rps 30~46rps 20~38rps

Air flow 4th speed fixed

(c) Hot keep operation

If the hot keep operation is selected during the heating operation, the indoor blower is controlled based on the temperature of

the indoor unit heat exchanger (detected with Th2, indoor unit heat exchanger sensor) to prevent blowing of cool wind.

¡ Normal mode (Normal heating operation, operation after HI POWER completion)

Note (1) Refer to the table shown above right for the values A and B.

Indoor heat exchanger temp. (˚C)

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

AB

20~35: 23°C

50: 20°C

28 29.5 31.5 34 36 37.5 39 40

1st speed

3rd speed

4th speed

5th speed

6th speed

7th speed

OFF

Indoor fan

4.9 Outline of heating operation

(1) Operation of major functional components in heating mode

(2) Air flow selection

(a) Speed of inverter changes within the range of selected air flow.

(b) When the defrosting, protection device, etc. is actuated, operation is performed in the corresponding mode.

(c) Outdoor unit blower operates in accordance with the inverter command speed.

(3) Details of control at each operation mode (pattern)

(a) Fuzzy operation

Deviation between the room temperature setting correction temperature and the suction air temperature is calculated in

accordance with the fuzzy rule, and used for control of the air capacity and the inverter speed.

(b) Heating thermostat operation

¡ Operating conditions

If the speed obtained with the fuzzy calculation drops below -24 rps during the heating fuzzy operation, the operation

changes to the heating thermostat operation.

¡ Detail of operation

Auto

HI

MED

LO

Item

Indoor fan motor ON ON OFF

Flap and louver ON or OFF ON or OFF Stop position control

Display Lights up Lights up Lights up or flashes

52C ON ON OFF after stop mode

Outdoor fan motor

OFF (20, 25, 35 type)

ON

OFF (20, 25, 35 type)

Depending on the stop mode (50 type) Depending on the stop mode (50 type)

4-way valve

Depending on the stop mode

ON

Depending on the stop mode

Electronic expansion valve Depending on the EEV control

When the inverter

speed is 0rps

When the inverter speed

is other than 0rps

When the inverter speed is 0rps

due to an anomalous stop

Functional

components

8th speed

(20, 25, 35 only)

9th speed

-

17

-

Notes(1) Refer to the table shown above right for the values A and B.

(2) Values in ( ) are for type 20, 25, 35.

¡ Hot keep M mode [During HI POWER operation (for 15 min.)]

Indoor heat exchanger temp. (˚C)

AB2931 32 34 36 43

(40)47(43)

(47)

1st speed

3rd speed

4th speed

5th speed

6th speed

7th speed

OFF

Indoor fan

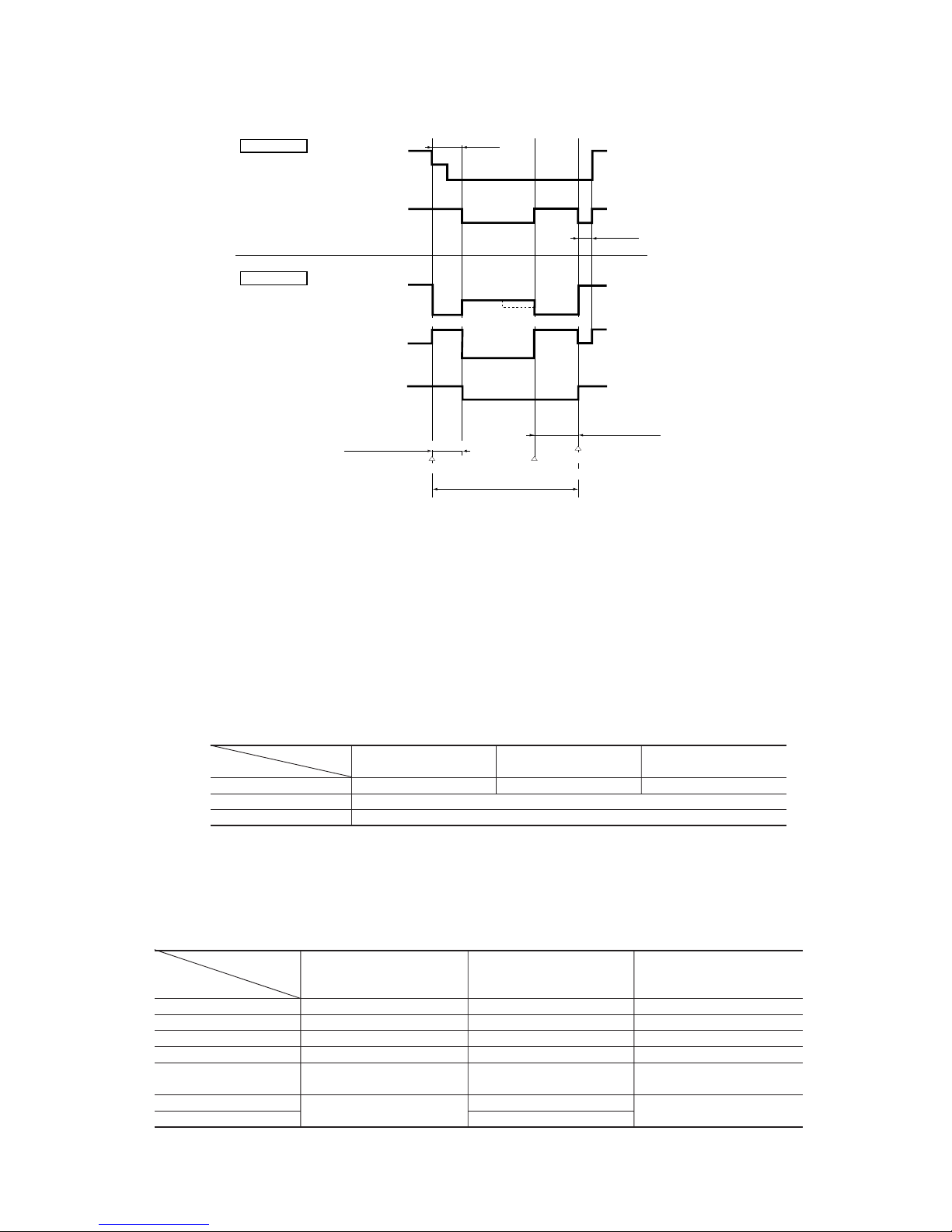

(d) Defrosting operation

(i) Starting conditions (Defrosting operation can be started only when all of the following conditions are met.)

1 After start of heating operation → When it elapsed 35 minutes. (Accumulated operation time)

2 After end of defrosting operation → When it elapsed 35 minutes. (Accumulated compressor operation time)

3 Outdoor unit heat exchanger sensor (Th4) temperature → When the temperature has been below –5ºC for 3 minutes

continuously.

4 When the temperature difference between the outdoor air sensor temperature and the outdoor unit heat exchanger

sensor temperature exceeded 20. 25 type: 7.0°C, 35 type: 5.0°C, 50 type: 4.0°C

5 During continuous compressor operation

In addition, when the speed command from the indoor controller of the indoor unit during heating operation has

counted 0 rps 10 times or more and all conditions of 1, 2 and 3 above are satisfied (note that when the temperature

for Th4 is -5°C or less: 62 rps or more, -4°C or less: less than 62 rps), defrost operation is started.

(ii) Operation of functional components during defrosting operation

¡ 20, 25, 35 type

Indoor fan

RUN light

Corresponding

to speed

OFF

ON

Flashing

(Hot keep)

Outdoor fan

Inverter

command

Fuzzy calculated

value

70 rps

0

Corresponding

to speed

OFF

OFF

ON

(1)

4-way valve

Final defrost operation

Defrost control

Hot keep

Indoor unit

Outdoor unit

60 sec.

Hot keep

50 sec.

Normal heating operation restored

Defrost end

(Th4

>

=

13˚C, 10 minutes)

Defrost operation

Defrost operation

preparation

6th speed 6th speed

¡ Values of A, B

AB

At 0 rps command 22 25

Other than 0 rps

17 19

command

8th speed

9th speed

(20, 25, 35 type only)

Note (1) When outdoor unit heat exchanger sensor (Th4) temperature becomes 2°C or higher, inverter command changes 70 rps to 50 rps.

-

18

-

(iii) Ending conditions (Operation returns to the heating cycle when either one of the following is met.)

1 Outdoor heat exchanger sensor (Th4) temperature: 13ºC or higher (50 type: 13°C or higher) for 30 seconds

continuously

2 Continued operation time of defrosting → For more than 10 min.

(e) Heating “HIGH POWER” operation (HI POWER button on remote control: ON)

Operation is maintained for 15 minutes with a higher blow out air temperature.

¡ Detail of operation

Model

SRK20ZFX-S SRK25, 35ZFX-S SRK50ZFX-S

Item

Inverter speed 94 rps 102 rps 120 rps

Indoor fan Hot keep M mode (max 8th speed)

Outdoor fan 6th speed

Notes (1) Room temperature is not adjusted during the HIGH POWER operation.

(2) Protective functions will actuate with priority even during the HIGH POWER operation.

Indoor fan

RUN light

Corresponding

to speed

OFF

ON

Flashing

(Hot keep)

Outdoor fan

Inverter

command

Fuzzy calculated

value

70 rps

(1)

0

Corresponding

to speed

OFF

OFF

ON

4-way valve

Final defrost operation

Defrost control

Hot keep

Indoor unit

Outdoor unit

75 sec.

Hot keep

60 sec.

Normal heating operation restored

Defrost end

(Th4

>

=

13°C, 10 minutes)

Defrost operation

Defrost operation

preparation

6th speed

6th speed

4.10 Outline of cooling operation

(1) Operation of major functional components in cooling mode

¡ 50 type

Item

Indoor fan motor ON ON OFF

Flap and louver ON or OFF ON or OFF Stop position control

Display Lights up Lights up Lights up or flashes

52C ON ON OFF after stop mode

Outdoor fan motor

OFF (20, 25, 35 type)

ON

OFF (20, 25, 35 type)

Depending on the stop mode (50 type) Depending on the stop mode (50 type)

4-way valve

Depending on the stop mode

ON

Depending on the stop mode

Electronic expansion valve Depending on the EEV control

When the inverter

speed is 0rps

When the inverter speed

is other than 0rps

When the inverter speed is 0rps

due to an anomalous stop

Functional

components

Note (1) When outdoor unit heat exchanger sensor (Th4) temperature becomes 7°C or higher, inverter instruction changes 70 rps to 50 rps.

-

19

-

(2) Air flow selection

(a) Speed of inverter changes within the range of selected air flow.

(b) When any protective function actuates, the operation is performed in the mode corresponding to the function.

(c) Outdoor blower is operated in accordance with the inverter command speed.

(3) Detail of control in each mode (Pattern)

(a) Fuzzy operation

During the fuzzy operation, the air flow and the inverter speed are controlled by calculating the difference between the room

temperature setting correction temperature and the suction air temperature.

(b) Cooling thermostat operation

(i) Operating conditions

During the cooling fuzzy operation or when the speed obtained by the fuzzy calculation is less than -24 rps.

(ii) Detail of operation

Model

SRK20ZFX-S SRK25ZFX-S SRK35ZFX-S SRK50ZFX-S

Item

Inverter speed 65 rps 74 rps 86 rps 92 rps

Indoor fan 7th speed

Outdoor fan 6th speed

Model

SRK20ZFX-S SRK25ZFX-S SRK35ZFX-S SRK50ZFX-S

Air flow selection

Inverter command speed 20~65rps 20~74rps 20~86rps 20~92rps

Air flow Depends on inverter command speed.

Inverter command speed 20~65rps 20~74rps 20~86rps 20~92rps

Air flow 7th speed fixed

Inverter command speed 20~44rps 20~56rps 20~58rps 20~62rps

Air flow 5th speed fixed

Inverter command speed 20~30rps 20~34rps 20~38rps 20~30rps

Air flow 2nd speed fixed

(c) Cooling “HIGH POWER” operation (HI POWER button on remote control: ON)

The unit is operated continuously for 15 minutes regardless of the setting temperature.

1) Detail of operation

Model

SRK20ZFX-S, 25ZFX-S, 35ZFX-S SRK50ZFX-S

Item

Inverter speed 0 rps [Comp. stopped] 10rps [10sec.] → 0rps [Comp. stopped]

Indoor fan Corresponds to fan speed switch.

Outdoor fan Stop 6th speed [1min.] → stop

Notes (1) Protective functions will actuate with priority even during the “HIGH POWER” operation.

(2) Room temperature is not adjusted during the “HIGH POWER” operation

4.11 Outline of dehumidifying operation

(1) After operating the indoor blower for 20 seconds from immediately after the start of operation, the indoor temperature is checked

and, based on the result of check, the cooling oriented dehumidifying or heating oriented dehumidifying is selected.

Heating oriented dehumidifying Cooling oriented dehumidifying

Low –3 High

Room temperature - Setting temperature (deg)

Cooling or heating oriented dehumidifying is selected again one hour after the first selection of the cooling or heating oriented

dehumidifying.

Auto

HI

MED

LO

-

20

-

D range C range B range A range

(b) Heating oriented dehumidifying

After interrupting the compressor operation for 3 minutes (by the 3-minute timer) following the determination of heating

oriented dehumidifying, the unit begins in the heating operation. If the room temperature exceeds the setting temperature by

2ºC or more, the unit checks the room temperature at 5-minute intervals and, depending on the result, determines the range

of heating oriented dehumidifying operation.

Operation range

D C B A

Low –1 0 +2 High

Room temperature – Setting temperature (deg)

(D) (C) (C) (B)

OFF

5th speed

25 sec.

OFF

0

20, 25, 35 type : 38

50 type : 24

20, 25, 35 type : 50

50 type : 40

50 type :

4th speed

20, 25, 35 type : 30

50 type : 20

5th speed

2nd speed

1st speed

50 type :

4th speed

50 type :

4th speed

50 type :

4th speed

Inverter speed

Indoor fan

Outdoor fan

Determination of cooling

oriented dehumidifying

operation range

Temperature check

5 min. 5 min. 5 min. 5 min.

Operation pattern

O L M

Low –1 0 High

Room temperature – Setting temperature (deg)

Operation range

Heating operation O range L range M range

4th speed

OFF

OFF

4th speed

2nd speed

1st speed

20, 25, 35 type : 38

50 type : 28

20, 25, 35 type : 30

50 type : 20

20, 25, 35 type : 48

50 type : 44

0

50 type :

4th speed

50 type :

4th speed

25 sec.

50 type :

4th speed

5th speed

Inverter speed

Indoor fan

Outdoor fan

Determination of heating

oriented dehumidifying

operation range

Temperature check

5 min. 5 min. 5 min.

Depends on

the operation

condition

Operation pattern

Note (1) Figures in the parentheses

( ) show the values at

ECONOMY operation.

Note (1) Figures in the parentheses

( ) show the values at

ECONOMY operation.

(2) Outline of control

(a) Cooling oriented dehumidifying

Room temperature is checked at 5-minute intervals after selecting the cooling or heating oriented dehumidifying in order to

determine the operation range.

(O) (L) (L)

-

21

-

4.12 Outline of automatic operation

(1) Determination of operation mode

The unit checks the room temperature and the outdoor air temperature after operating the indoor and outdoor blowers for 20

seconds, determines the operation mode and the room temperature setting correction value, and then begins in the automatic

operation.

Heating

Dehumidifying

Cooling

Room temperature (˚C)

Outdoor temperature (˚C)

27.5

25.5

19.5

18

30

(2) The unit checks the temperature every hour after the start of operation and, if the result of check is not same as the previous

operation mode, changes the operation mode.

(3) When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is selected

during heating, cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(4) Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals of

the wireless remote control and the setting temperature.

Signals of wireless remote control (Display)

–6 –5 –4 –3 –2 –1 ±0+1+2+3+4+5+6

Setting

Cooling 19 20 21 22 23 24 25 26 27 28 29 30 31

temperature

Dehumidifying 19 20 21 22 23 24 25 26 27 28 29 30 31

Heating 20 21 22 23 24 25 26 27 28 29 30 31 32

4.13 ECONOMY operation

(ECONO button on remote control: ON)

(1) The set temperature is raised by 1.5ºC (0.5ºC every one hour) at cooling operation and lowered by 2.5ºC (Steps of 1ºC, 1ºC and

0.5ºC every one hour) at heating operation to continue the operation with the following contents.

(2) Detail of operation

◆ Heating

◆ Cooling

Model

SRK20ZFX-S SRK25ZFX-S SRK35ZFX-S SRK50ZFX-S

Item

Inverter command speed 30~66rps 30~72rps 30~76rps 20~66rps

Indoor fan 4th, 6th speed

Outdoor fan 5th speed 4th, 5th speed

Model

SRK20ZFX-S SRK25ZFX-S SRK35ZFX-S SRK50ZFX-S

Item

Inverter command speed 20~42rps 20~52rps 20~58rps 20~42rps

Indoor fan 2nd, 5th speed

Outdoor fan 5th speed 4th speed

Loading...

Loading...