Mitsubishi Heavy Industries SRK25QA-S, SRK35QA-S, SRC25QA-S, SRC35QA-S Technical Manual

-1-

Mitsubishi Heavy Industries Air Conditioners

Technical Manual

Manual Number: 2011 No. W1-01

Variable Frequency Wall Mounted Type

Room Air Conditioners

(Split system, heat pump type)

SRK25QA-S/SRC25QA-S

SRK35QA-S/SRC35QA-S

(R410A Refrigerant Used)

MITSUBISHI HEAVY INDUSTRIES, LTD.

-2-

Table of Contents

1. GENERAL INFORMATION……..…………………………….……1

1.1 Features…………………………………………………………..…1

1.2 Model identification………………………………………………1

2 MODEL SELECTION…………………………………………………2

2.1 Model function..…………..…….……..………………………..……2

2.2 Range of usage……………………………………………..………4

2.3 Outline drawing…..………………………………………………..…4

2.4 Cooling cycle system diagram….…………………..…………...…5

2.5 Performance curve……………………………………………………6

3 ELECTRICAL WIRING DIAGRAM………………………………….7

4 NAME OF EACH PART AND ITS FUNCTION……………….….….9

4.1 NAME OF EACH PART………………..………….………………9

4.2 Emergency “ON/OFF” button (back-up switch) …........………..12

4.3 Automatic restart……………..…………..………………………..12

4.4 Flap control………..…………..……..……………………………..12

4.5 Comfort timer setting……..……..……..…………………………..14

4.6 Outline of heating operation.……..………………………….……..15

4.7 Outline of cooling operation ............................................................ 17

4.8 Outline of drying operation ................................................. 18

4.9 Outline of automatic operation ..........................................................20

4.10 Economical operation.....................................................................20

4.11 Air blowing operation.......................................................................20

4.12 CLEAN operation control...................................................21

4.13 EEV control.....................................................................................21

5 INSTALLATION................................................................................22

5.1 Selection of installation location.................................................24

5.2 Installation of indoor unit..................................................................25

5.3 Installation of outdoor unit...............................................................28

-3-

5.4 Pipe connection.................................................................................28

5.5 Precautions for wireless remote controller operation........................30

5.6 Standard running data........................................................................31

6 MAINTENANCE................................................................................32

6.1 Electrical parts failure diagnosis method............................................32

6.2 Servicing.............................................................................................56

7 SERVICING MANUAL.......................................................................57

8 MOUNT ASSEMBLY………………………….................................72

8.1 Indoor unit.........................................................................................72

8.2 Outdoor unit......................................................................................80

-1-

1 GENERAL INFORMATION

1.1 Features

(1) Inverter

● Heating/cooling

The rotate speed of the compressor is changed steplessly in relation to varying load, and is

linked with the fans of indoor and outdoor units controlled by the changes of frequency, thus

controls the power.

● Allowing quick heating/cooling operation during start-up period.

The room temperature is kept constant through fine-tuned control after the machine is

stabilized.

(2) Fuzzy control: According to the fuzzy control technology, the room temperature and humidity,

etc. are obtained through dynamic analysis to accurately regulate the rotate

speeds of the compressor and the fan to realize precise temperature control.

(3) Life: Actual service life: over 20,000 hours; Working life: over 100,000 hours; On/off of relay:

over 100,000 times; Continuous on of LED: over 50,000 hours; On/off of emergency

switch: over 10,000 times.

(4) Self diagnosis function: We will continuously provide the best services for our customers

through devices judging abnormal operation, as follows:

The air conditioner indicates the error of the indoor and outdoor sensors (thermistors) only when

it is in the stop mode. Error indication is removed after restart.

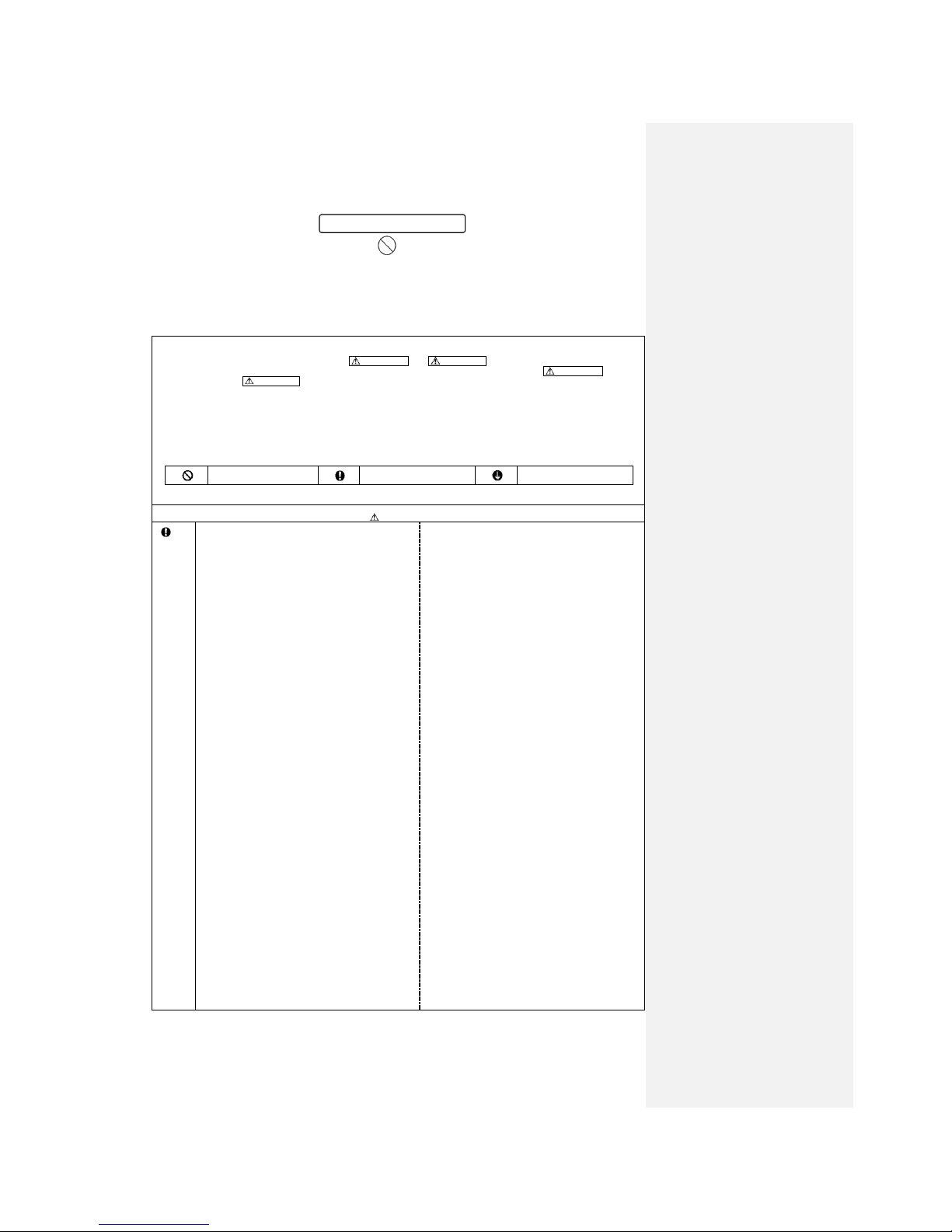

1.2 Model identification

R410A Refrigerant used

Master pattern change code

Master pattern

Capacity

Wall mounted type (C is the code for outdoor unit.)

Split type room air conditioner

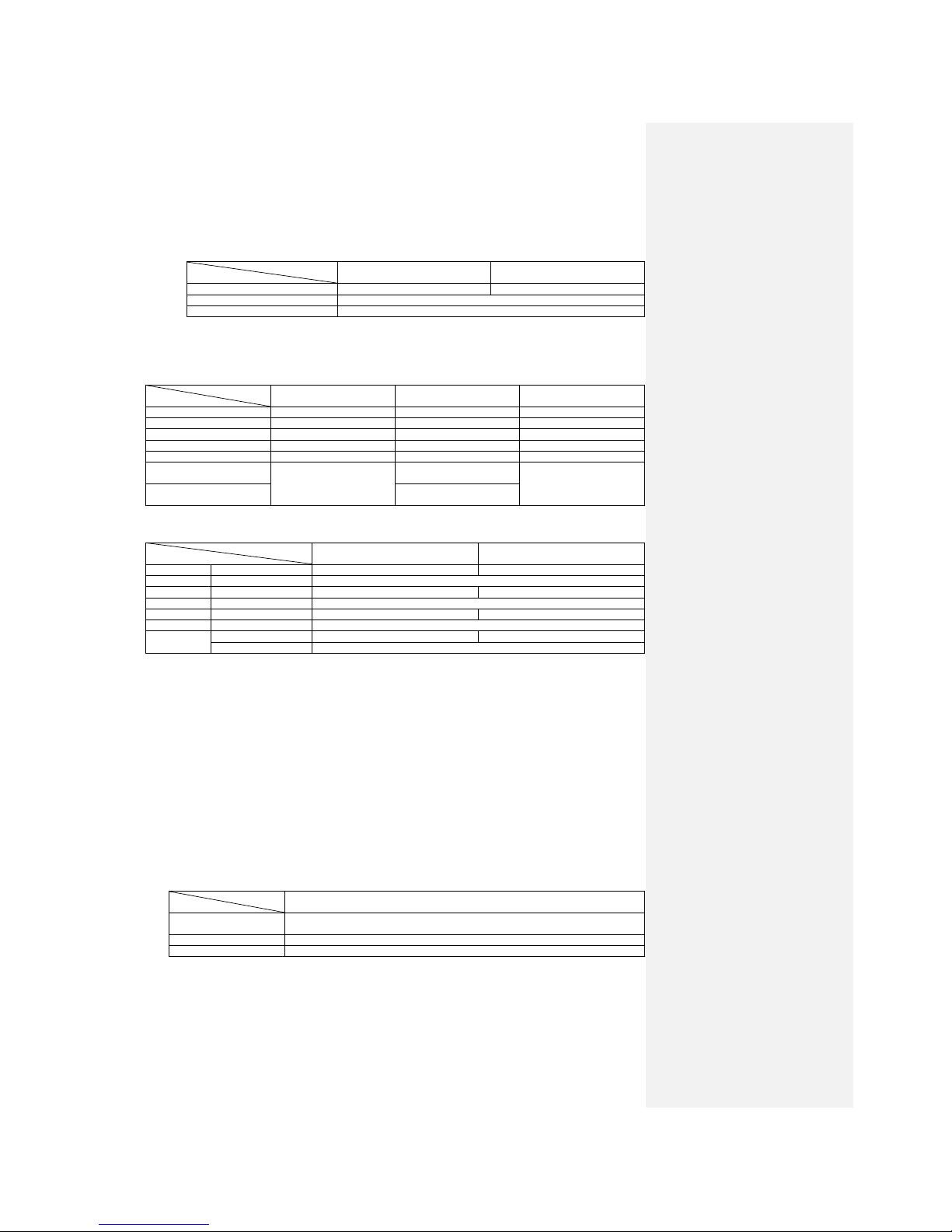

TIMER lamp

ON

RUN lamp

keeps flashing

RUN lamp

ON

RUN lamp

Flash 2 times

RUN lamp

Flash 1 time

Flash 2 times

Flash 5 times

Flash 6 times

TIMER lamp

Flash 1 time

Flash 2 times

Flash 4 times

Flash 1 time

Flash 2 times

Flash 3 times

Flash 4 times

Flash 5 times

Flash 6 times

Flash 2 times

Failure Causes

Heat exchanger sensor error

Room temperature sensor error

Abnormal voltage input

Indoor fan motor error

Outdoor unit temperature sensor

error

Outdoor unit heat exchanger liquid

pipe sensor error

Vent-pipe sensor error

Current cut

Outdoor unit error

Safe current

Power transistor error

Compressor over heat protection

Signal transmission error

Rotor lock

Heat exchanger sensor wire break, poor connector connection

Room temperature sensor wire break, poor connector connection

Voltage too high or too low

Failure of fan motor, poor connector connection

Outdoor unit sensor wire break, poor connector connection

Heat exchanger liquid pipe sensor wire break, poor connector

connection

Vent-pipe sensor wire break, poor connector connection

Compressor blockage, compressor output open-phase, power short

circuit, control valve closed

Power-cut, compressor wire break

Vent-pipe sensor wire break, poor connector connection

Compressor not rotating (dead lock)

Overload, over current

Failure of power transistor

Insufficient refrigerant, failure of vent-pipe sensor, control valve

closed

Failure of power supply, signal cable break, failure of

indoor/outdoor unit control device

Failure of compressor

Compressor open-phase

Failure of outdoor unit control device

-2-

2 MODEL SELECTION

2.1 Model function

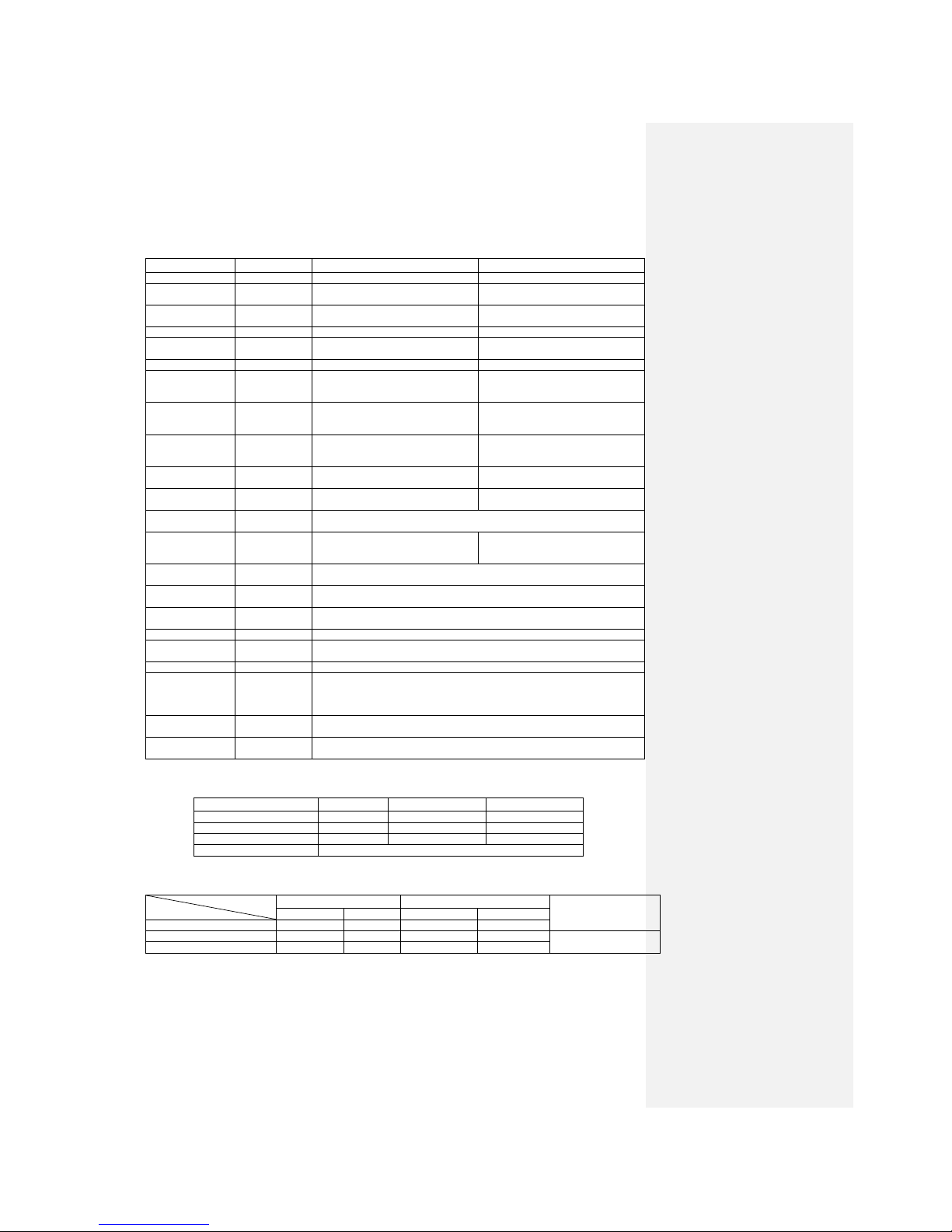

2.1.1 Model: SRK25QA–S (Indoor unit)

SRC25QA–S (Outdoor unit)

Item

Unit

Indoor unit SRK25QA–S

Outdoor unit SRC25QA–S

Net weight

kg

9

31

Machine

dimension

mm

790×222×268

780×290×540

Package

dimension

Length× Width

×Height

830×340×280

920×380×590

Color White

Ash-colored

Fan

Through-flow type, AS resin + glass

fiber

Axial flow type, AS resin + glass

fiber

Air flow

m3/h

550

1830

Noise in cool

room

dB(A)

Hi/Me/Lo:

37/30/23(completely mute,

SPL)

45(completely mute, SPL)

Noise in warm

room

dB(A)

Hi/Me/Lo:

37/32/28(completely mute,

SPL)

48(completely mute, SPL)

Fan motor

Nominal value

16W, 4-step capacitor type

asynchronous motor, insulation

grade E

25W, AC motor, insulation grade B

Power of motor

W (reference

value)

40

50

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.0mm2, 250V, 10A, 2m, w/o plug

Heat exchanger

Spiral, hydrophilic, 3-folded,

16-section, 2-row, 452-fin, 1-2

circuit

Spiral, hydrophilic, 20-section,

1-row, 621-fin, 2-1 circuit

Compressor

Nominal value

THACOM RM - B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.65mm) + hush pipe

Refrigerant

g

R-410A, 850g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

Mpa

Max.: 4.1, Min.: 1.47

Air filter

Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, outdoor unit 1, Drain elbow 1,

Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

2500

3200

Power

W

700

870

Energy efficiency ratio

3.57

3.68

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

-3-

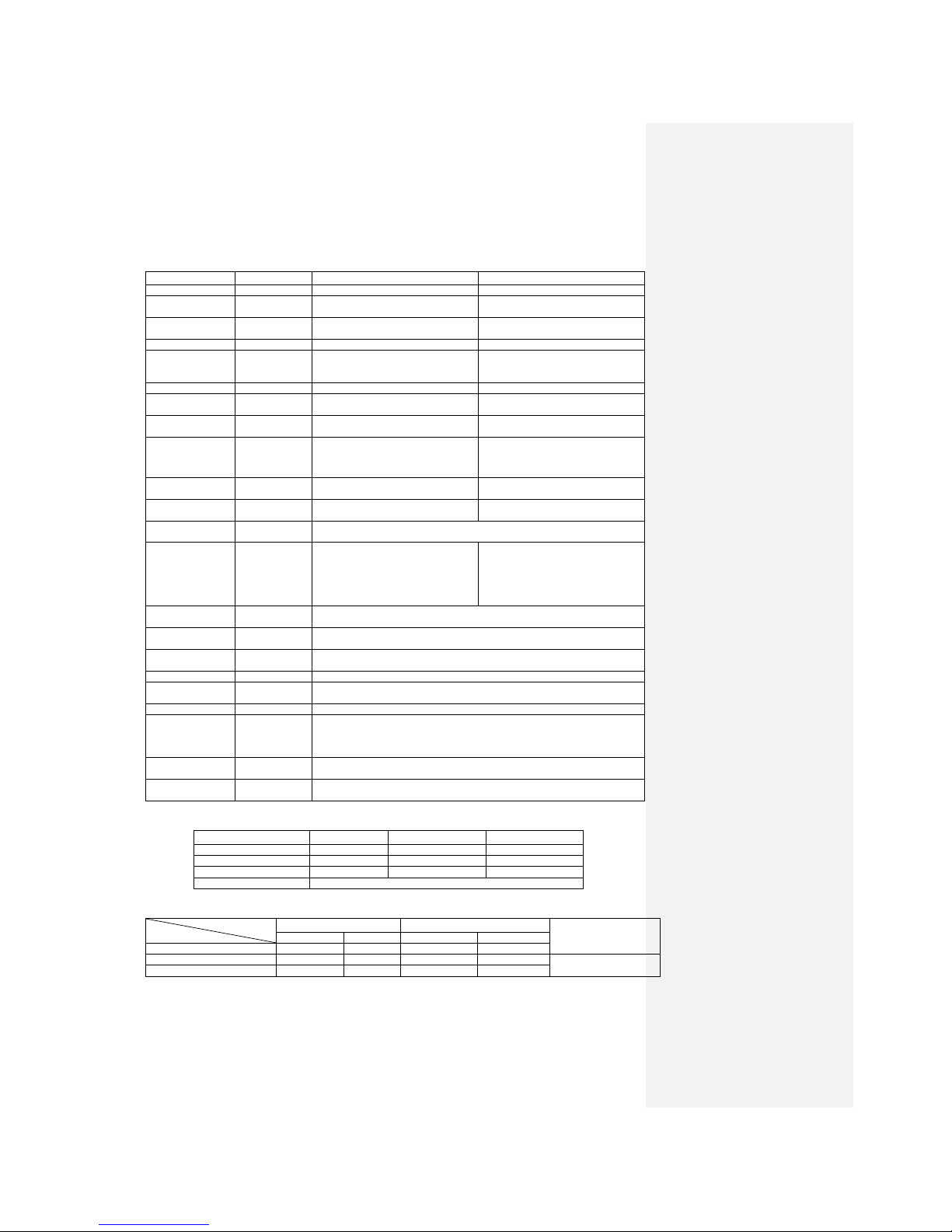

2.1.2 Model: SRK35QA–S (Indoor unit)

SRC35QA–S (Outdoor unit)

Item

Unit

Indoor unit SRK35QA–S

Outdoor unit SRC35QA–S

Net weight

kg

9.5

35

Machine

dimension

mm

790×222×268

780×290×540

Package

dimension

Length× Width

×Height

830×340×280

920×380×590

Color White

Ash-colored

Fan

Through-flow type, AS resin + glass

fiber

Axial flow type, AS resin + glass

fiber (embedded damping spindle

sleeve)

Air flow

m3/h

520

1940

Noise in cool

room

dB(A)

Hi/Me/Lo: 40/33/25

47

Noise in warm

room

dB(A)

Hi/Me/Lo: 39/35/27

48

Fan motor

Nominal value

16W, 4-step capacitor type

asynchronous motor, insulation

grade E

24W, DC motor, insulation grade E

Power of motor

W (reference

value)

40

20

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.0mm2, 250V, 10A, 2m, w/o plug

Heat exchanger

Spiral, hydrophilic, 3-folded,

16-section, 2-row, 452-fin, 1-4

circuit

Child heat exchanger: Spiral,

hydrophilic, 1-row, 4-section,

408-fin

Spiral, hydrophilic, 20-section,

2-row, 1221-fin, 2-1 circuit

Pf1.4

Compressor

Nominal value

THACOM RM - B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.5mm) + hush pipe

Refrigerant

g

R-410A, 900g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

MPa

Max.: 4.15, Min.: 1.47

Air filter

Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, outdoor unit 1, Drain elbow 1,

Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

3500

4000

Power

W

1020

1100

Energy efficiency ratio

3.43

3.64

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

-4-

(Purging is not required even for the short piping.)

2.2 Range of usage

Please use the air conditioners within the following range of usage, otherwise the protector will be

triggered.

Cooling Operation

Heating Operation

Outdoor temperature

About 18℃~43℃

About -15~24℃

Room temperature

About18℃~32℃

About below 30℃

Indoor humidity

About below 80%

25~35 Models

Max. piping one-way length

Within 15 m

Vertical height difference

Within 5 m

Additional R410A Refrigerant

Not required

Voltage

Rating ±10%

Starting voltage

At least 85% of rating

Switching frequency

Max. 10 times per hour

Time interval between stop and start

Min. 3 min

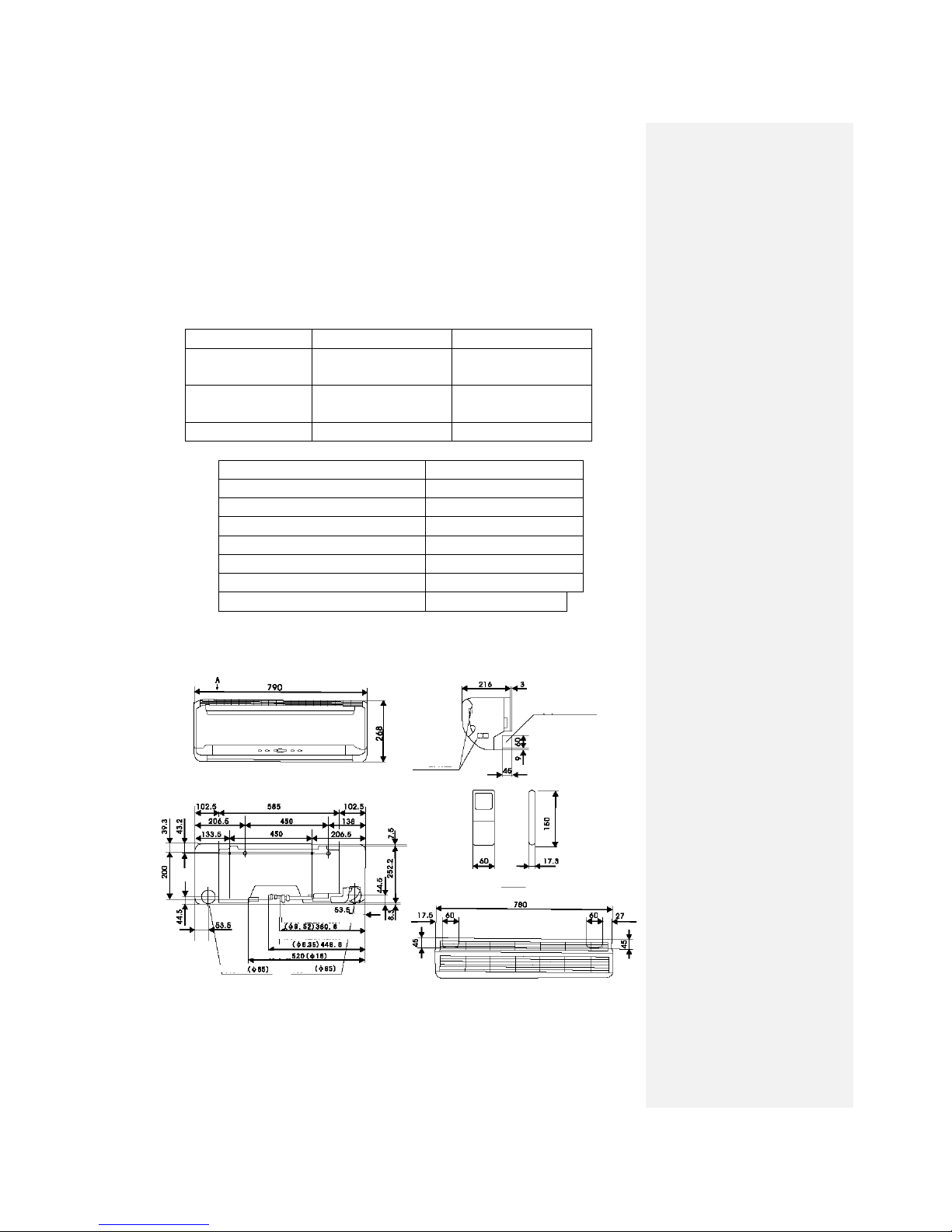

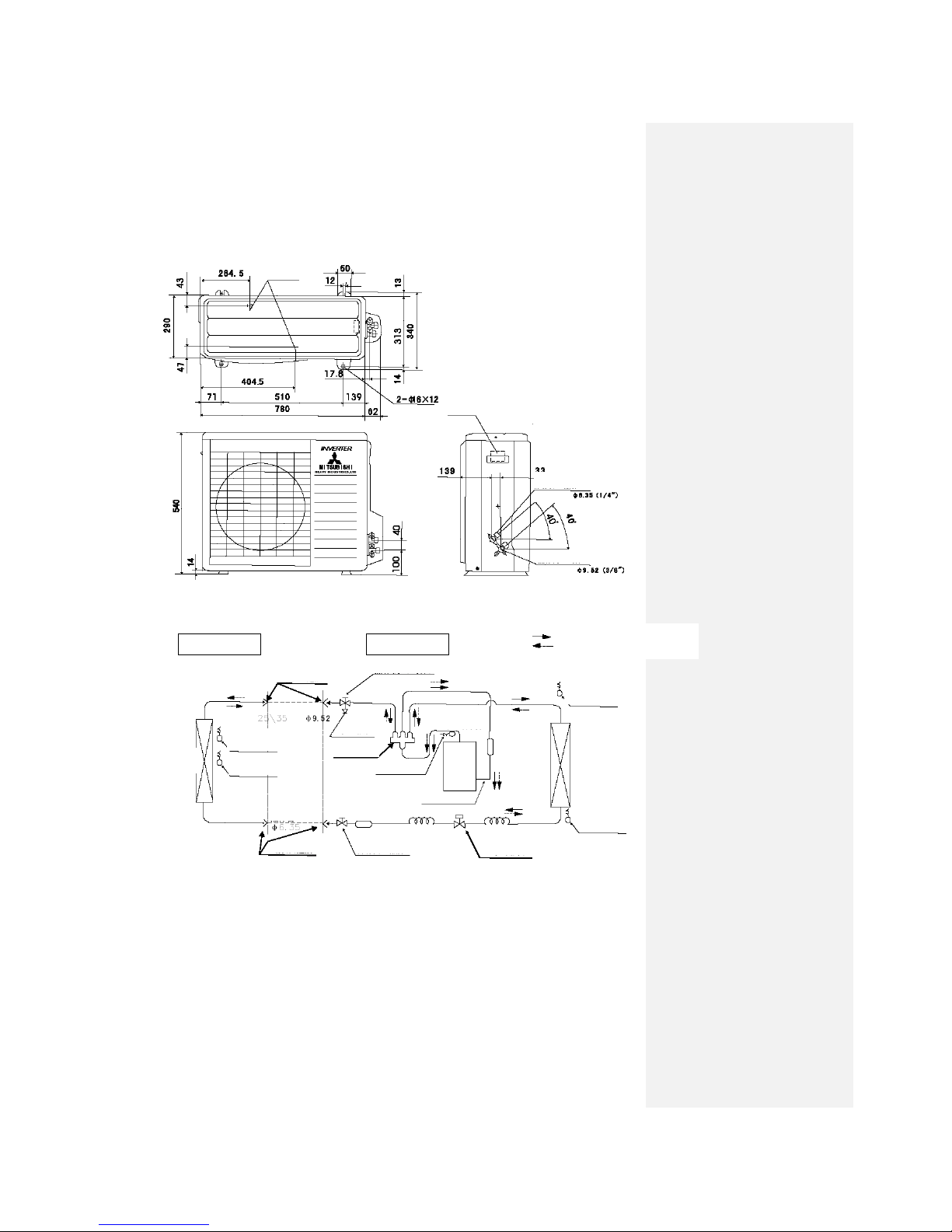

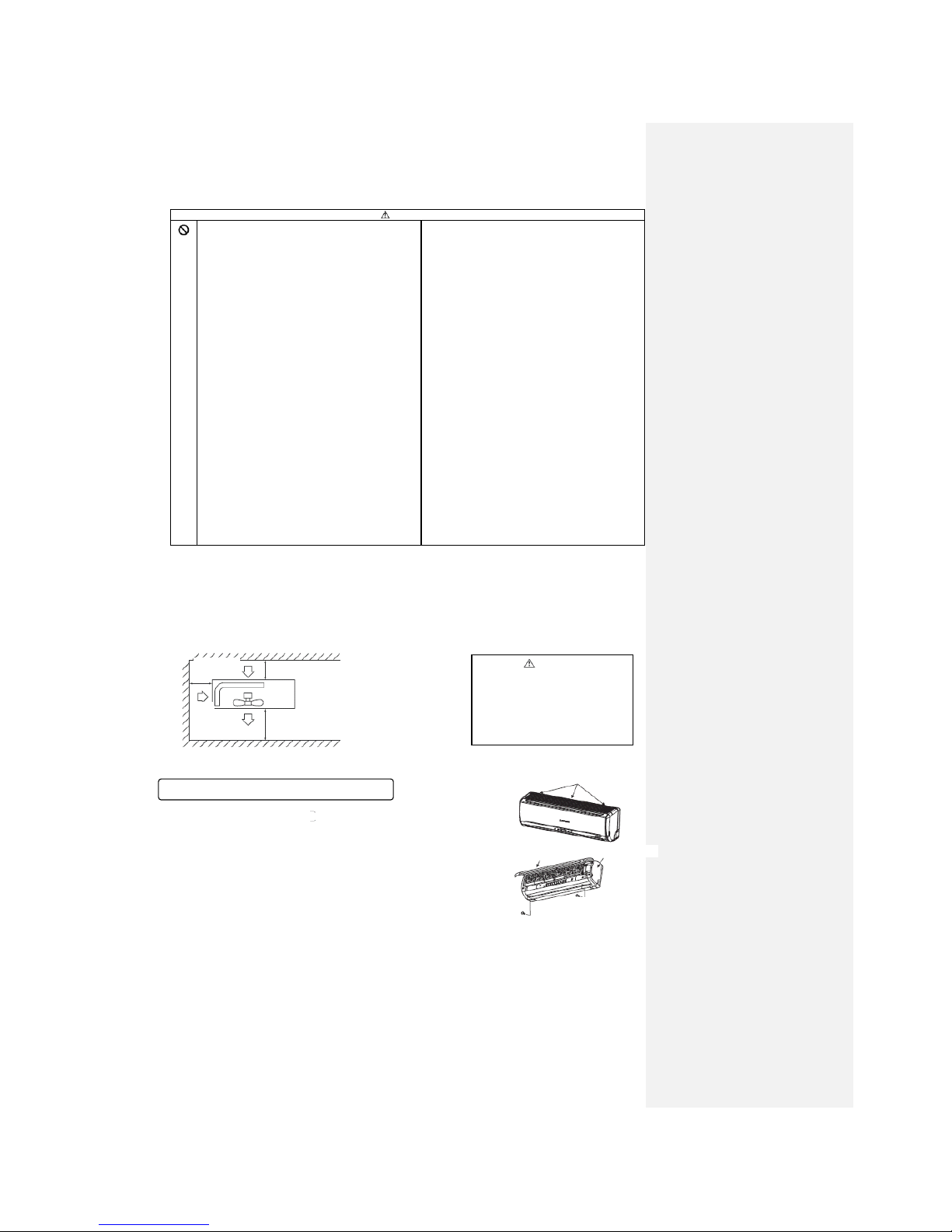

2.3 Outline drawing

(1) Indoor unit: SRK25QA–S/ SRK35QA–S Unit: mm

Piping hole right (left)

Terminal block

Remote controller

Flare connecting (Gas)

Flare connecting (Liquid)

Drainage pipe

Piping hole

Piping hole

VIEW A

-5-

(2) Outdoor unit: SRC25QA-S/ SRC35QA-S Unit: mm

2.4 Cooling cycle system diagram

Models: QA-S Series

Note (1)……line is piping for site construction.

Drain holes

Terminal block

Flare connecting

Flare connecting

Operation valve (Gas)

Indoor unit

Outdoor unit

Circulation of cooling

Circulation of heating

Flare connecting

Operation valve (Gas)

Outdoor air

temp. sensor

Air heat

exchanger

Heat exchanger

sensor

Gas liquid

separator

Compressor

Discharge pipe sensor

4-way valve

Check joint

Gas pipe Note (1)

model

Air heat

exchanger

Inlet air temp.

sensor

Air heat

exchanger sensor

Liquid pipe

Flare connecting

Filter

Electronic expansion valve

Hush pipe

Hush pipe

Operation valve (Liquid)

Refrigerant inlet pipe

Refrigerant outlet

pipe

-6-

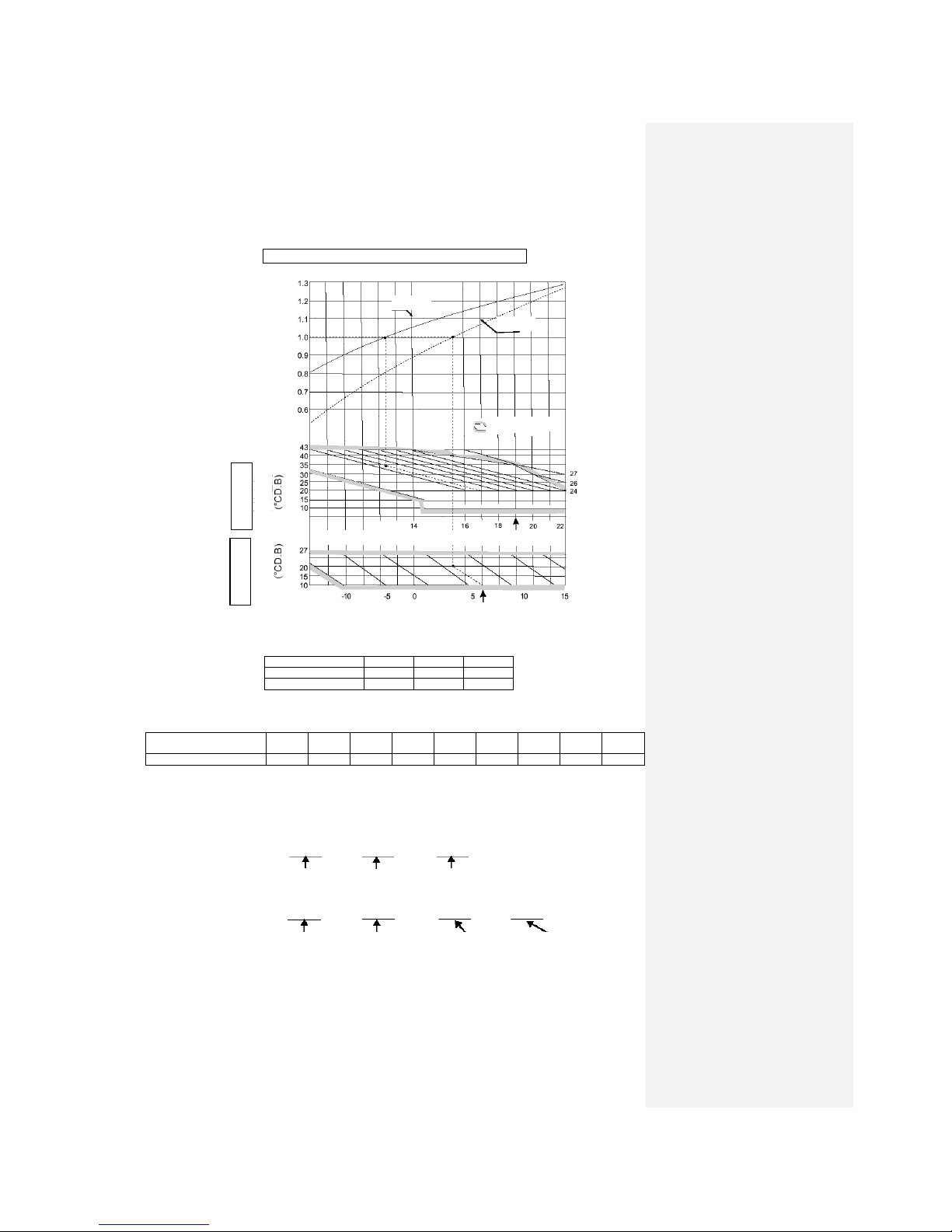

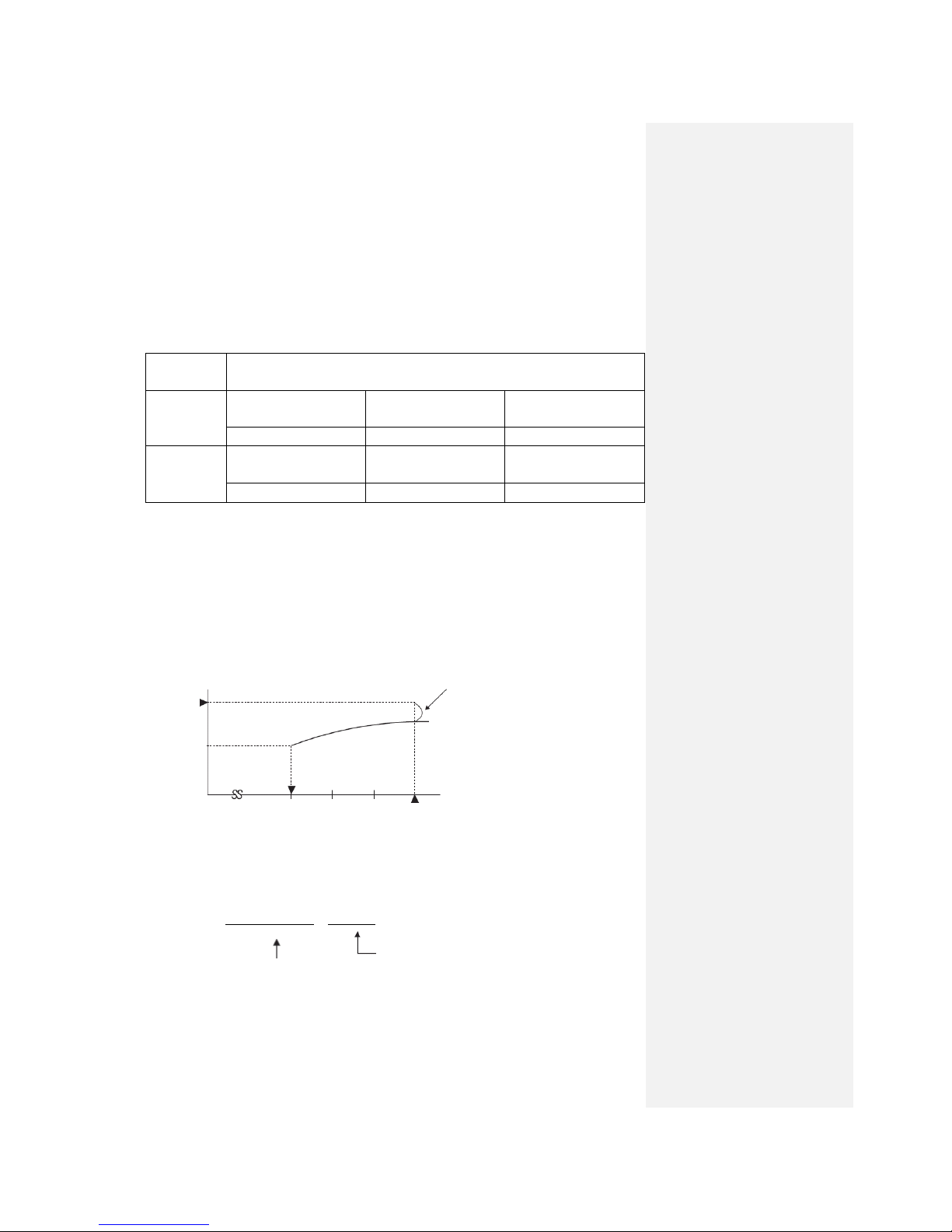

2.5 Performance curve

The cooling and heating capacities are measured in the following conditions. The actual capacity

can be obtained with the following formula.

Actual capacity = Rating capacity x Correction factor

(1) Capacity correction according to indoor and outdoor temperatures:

Outdoor air W.B. temperature (°C W.B.) ISO-T1 Standard

⑵ Capacity correction according to one way length of refrigerant piping:

It is necessary to correct the cooling and heating capacity according to the one way length of

refrigerant piping.

Piping length (m)

7

10

15

Cooling

1.0

0.99

0.975

Heating

1.0

1.0

1.0

⑶ Capacity correction according to frosting on outdoor heat exchanger during heating:

In additions to the foregoing corrections (1) and (2), the heating capacity also needs to be

corrected according to the frosting on the outdoor heat exchanger.

Air inlet temperature of

outdoor unit

-10

-9

-7

-5

-3

-1 1 3

5

Frosting correction factor

0.95

0.94

0.93

0.91

0.88

0.86

0.87

0.92

1.00

⑷ Example of cooling and heating capacity calculation:

The actual cooling capacity of model SRK25QA-S with the one way piping length of 25m at the

indoor wet-bulb temperature of 19℃ and outdoor dry-bulb temperature of 35℃in summer or

indoor dry-bulb temperature of 20℃, outdoor dry-bulb temperature of 1℃and indoor wet-bulb

temperature of -1℃ in winter is

Actual cooling capacity = 2500 x 1.0 x 0.95 ≈ 2375W

Nominal cooling Temp. correction Piping length

capacity factor correction factor

Actual heating capacity = 3200 x 0.81 x 0.95 x 0.86 ≈ 2118W

Nominal heating Temp. correction Piping length Frosting

capacity factor correction factor correction factor

Cooling

Heating

Accommodation

Cooling operation

Heating operation

Indoor air D.B.

temperature

Outdoor air D.B.

temperature

Indoor air W.B. temperature (°C W.B.) ISO-T1 Standard

Correction factor of cooling & heating

capacity in relation to temperature

-7-

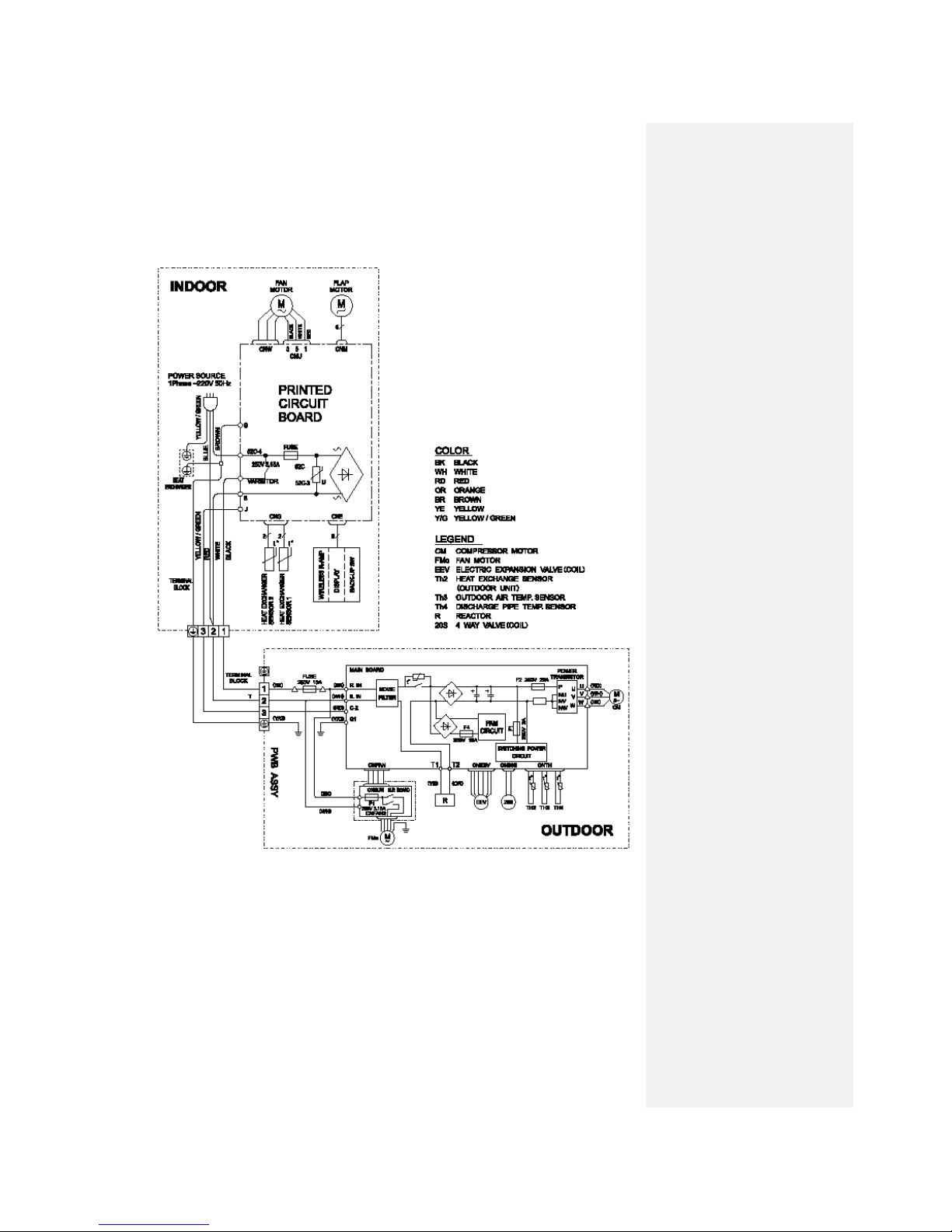

3 ELECTRICAL WIRING DIAGRAM

3.1 Circuit diagram: 25QA-S

-8-

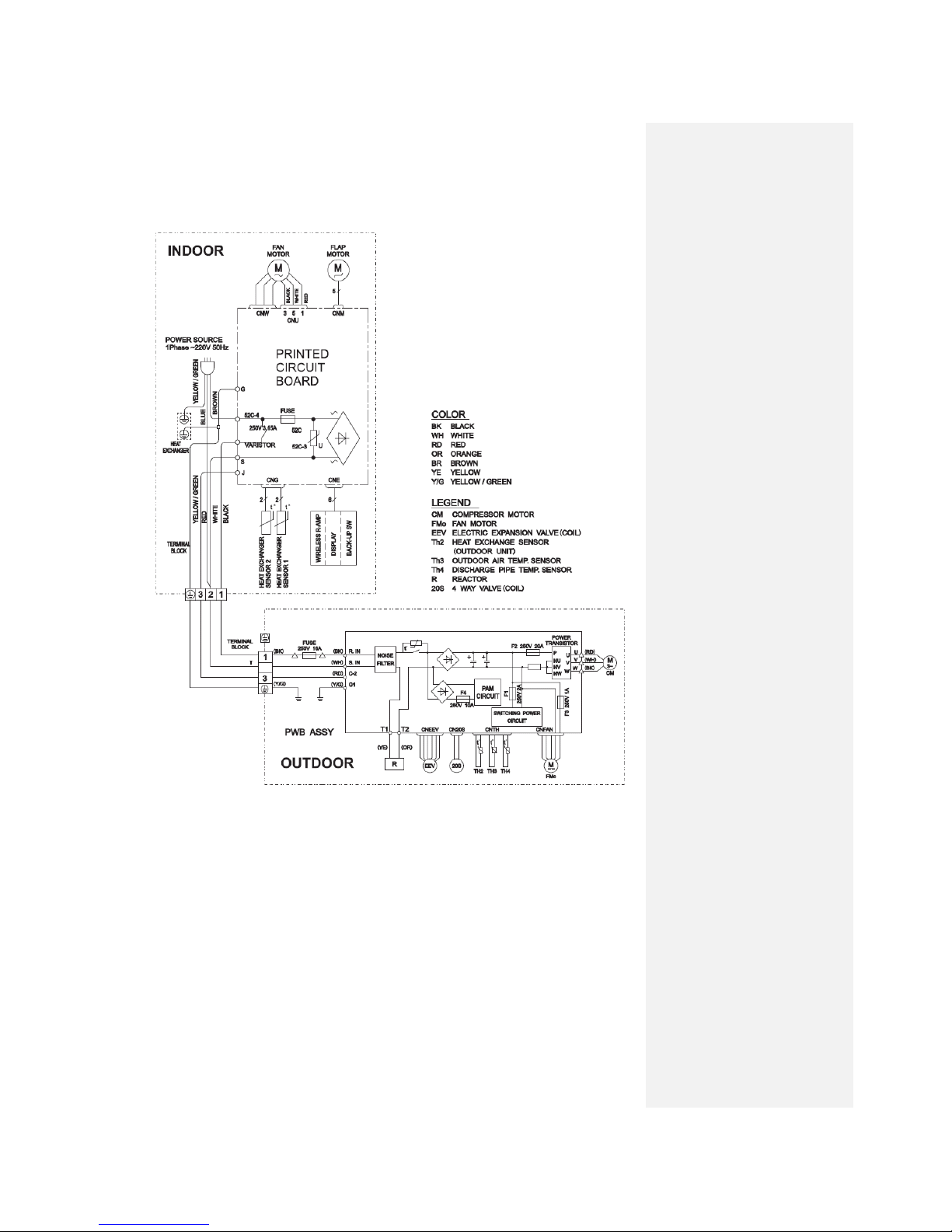

3.2 Circuit diagram: 35QA-S

-9-

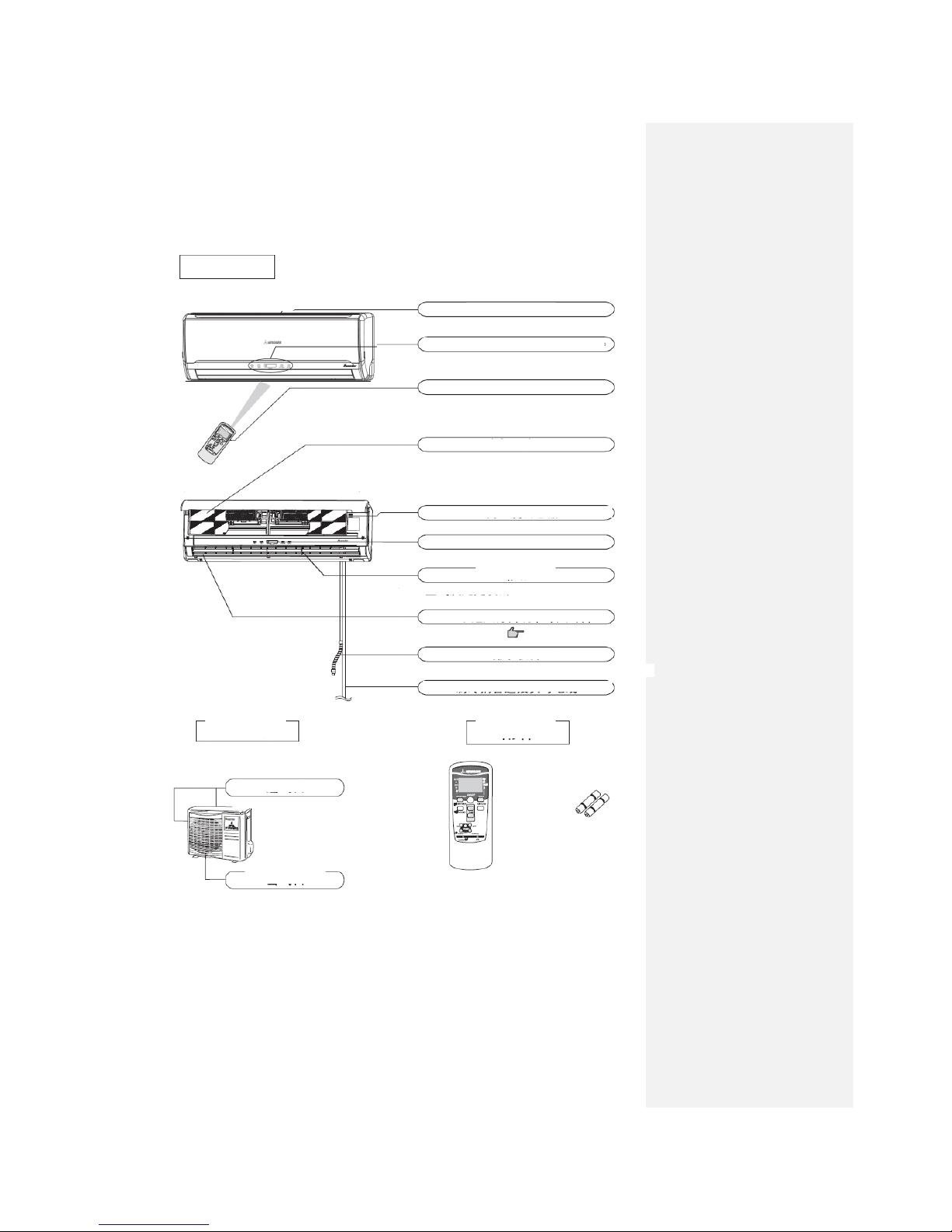

4 NAME OF EACH PART AND ITS FUNCTION

4.1 Name of each part

Indoor unit

Air inlet panel

Draws in the indoor air.

Unit indication section and remote control signal receiver

Wireless remote control

Air filter

Removes dust or dirt from the inlet air

Room temperature detector

Unit operation switch

Air blows from here.

Up/down air direction flap

Page 11

Drain hose

Drains water from the dehumidified air.

Refrigerant piping connection electric flex

Outdoor unit

Accessories

Air inlet

Air out

(on side&rear suface)

Battery

Wireless remote controller

Air outlet

-10-

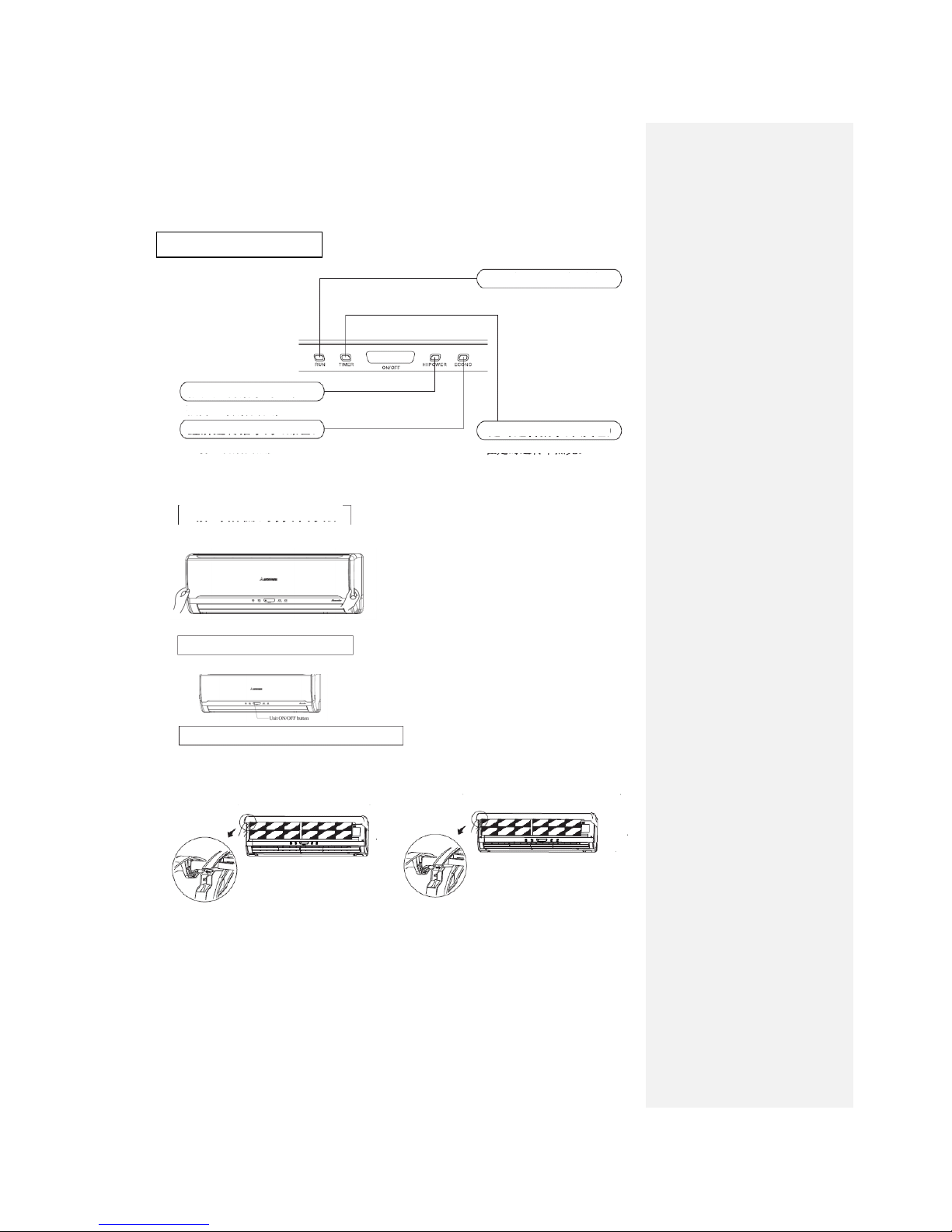

Indication section of air conditioner

RUN lamp (green)

ON during running and

mould-proof running

TIMER lamp (yellow)

ON during timing operation

HI POWER lamp (green)

ON during Hi Power running

Opening the air inlet grille

Put your hands on the indentations on both sides, raise the grille towards yourself, and stop at the

opening position of about 60°.

Closing the air inlet grille

Gently push both sides and then gently push the central portion.

Removing and mounting the air inlet grille

To remove the air inlet grille to clean the inside,

open it at the position of about 65° and pull it

towards yourself to remove the grille.

To mount the air inlet grille, insert the mounting

arm in the pin roll on the main frame and close the

grille.

ECONO lamp (green)

ON during ECONO running

-11-

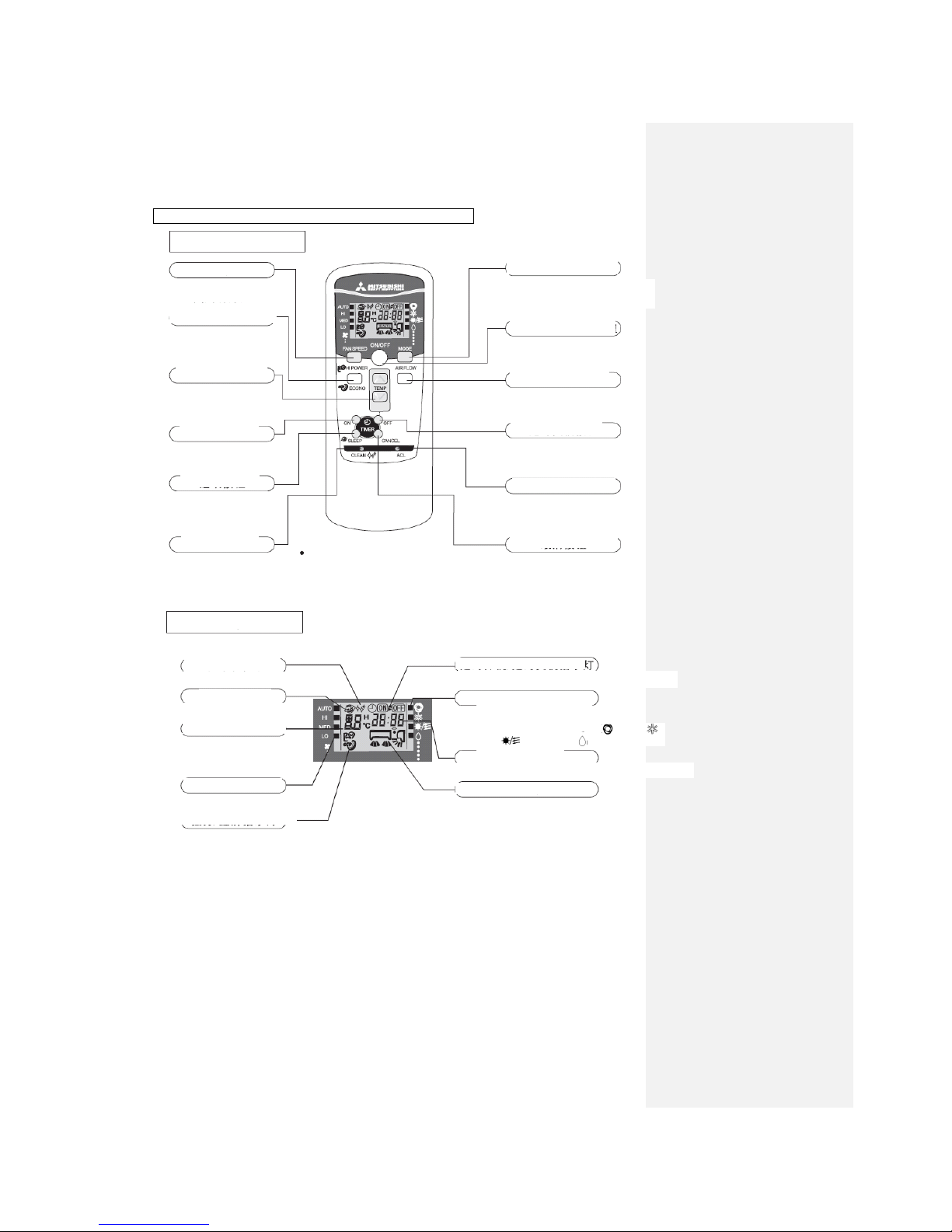

Operation and indication section for remote control

Operation section

FAN SPEED button

Each time the button is pushed ■indicator is

switched over in turn.

HI POWER/ECONOMY button

TEMPERATURE button

This button sets the room temperature.(press the button to select the

current time and timing time)

ON TIMER button

This button sets the ON timer Times.

CLEAN button

Indication section

SLEEP indicator

Indicates during SLEEP mode

TEMPERATURE indicator

FAN SPEED indicator

Indicates set air flow rate with■ lamp.

HI POWER/ECONOMY indicator

Display in the HI POWER/ ECONOMY operation mode respectively.

OPERATION MODE select button

Each time the button is pushed ■

indicator is switched over in turn.

ON/OFF button

Press for starting operation press again for stopping.

AIR FLOW button

This button sets the swaying

OFF TIMER button

CANCEL button

The button is used to cancel the timing

ONtimer/OFF timer and SLEEP operation.

Indicates during ON/OFF TIMER mode operation.

Operation mode indicator

Indicates selected operation with lamp.

Time display lamp

Display the current time or the time

■ is used to indicate the mode selected: [ (AUTO)

(COOLING) (HEATING) (DRYING)]

Display the swaying way of the wind guide blade.

The above illustration shows all

controls,but in practice only the

relevant parts are shown.

CLEAN indicator

ON/OFF (luminous) button

This button changes the HI POWER /ECONOMY mode.

SLEEP button

This button changes the

“SLEEP” mode.

This button changes the “CLEAN” mode.

RESET switch

Switch for resetting microcomputer.

This button sets the OFF timer

Times.

Indicates set temperature.

(Does not indicate temperature

when operation mode is on AUTO)

Air supply display lamp

-12-

4.2 Emergency “ON/OFF” button (back-up switch)

When the battery of the remote controller runs out or the remote controller is lost or

malfunctioning, this switch can be used to turn the unit on and off.

(1) Operation method

Press the switch once to place the unit in the AUTO mode. Push it once more to turn the unit off.

(2) Detail of operation

The system operates in the COOL, DRY or HEAT mode according to the room temperature

(temperature at the temperature detection point).

Note: To repair or move the machine, push and hold the switch for more than 5 seconds to set to

the cooling mode automatically.

Function

Operating mode

Set temperature

Fan speed

Flap

Timer

conversion

COOL

About 24℃

Automatic

Automatic

Continuous

DRY

About 24℃

HEAT

About 26℃

Emergency “ON/OFF” button on the equipment

4.3 Automatic restart due to power cut:

(1) This function can rapidly record the operation state immediately before the air conditioner is

switched off due to power failure, and will resume operation automatically after the power

supply is restored.

(2) This function is set to Active by default.

(3) Operation state memorized immediately before power cut includes:

● Indoor operation switching (cool room · warm room · drying · automatic · air flow, stop)

● Air flow

● Power Save

● Set temperature

● Air direction

(4) After automatic restart due to power cut, the following settings will be canceled:

Timing operation, HI POWER operation, CLEAN operation

(5) Priority of start:

Compressor 3 min. delayed start control > Automatic restart due to power cut

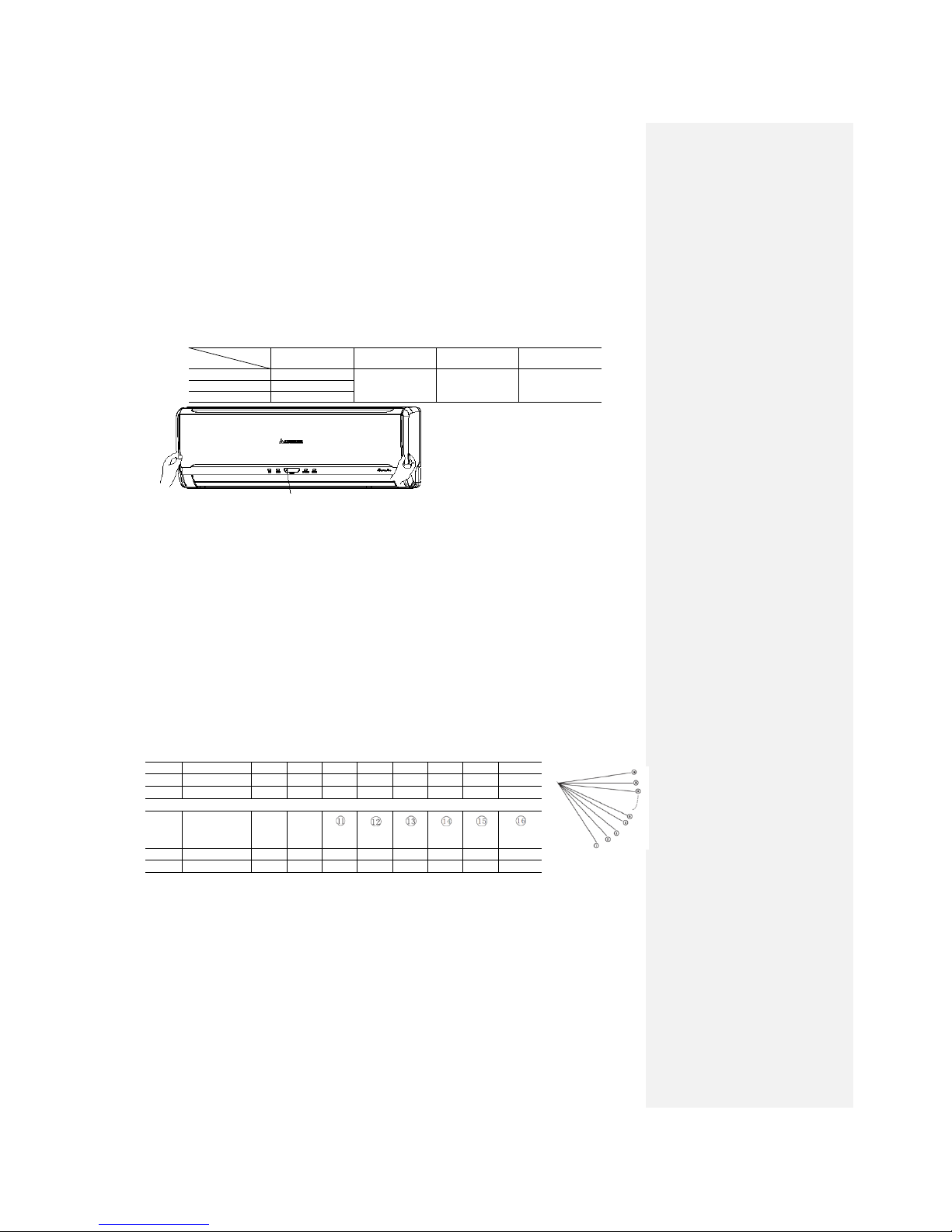

4.4 Flap control

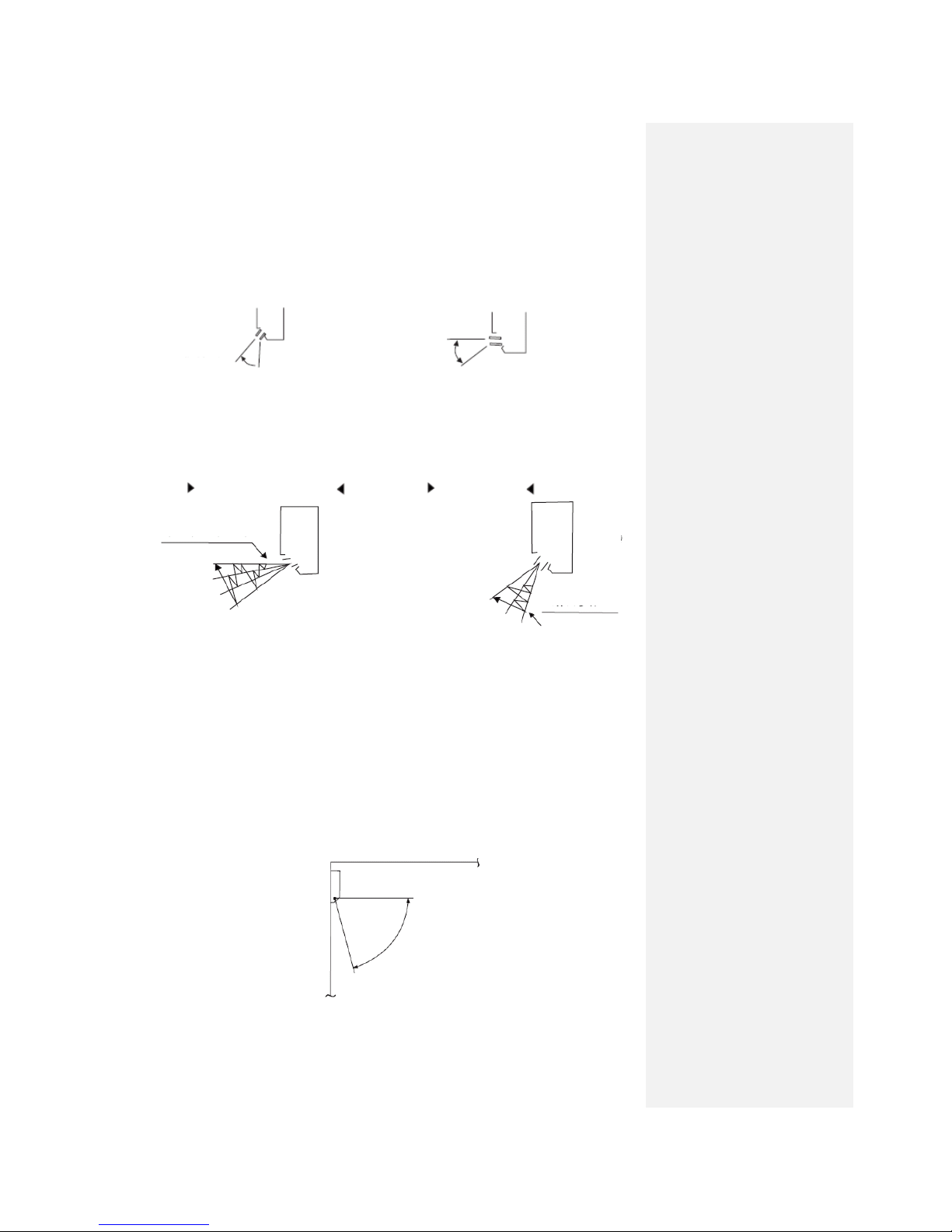

(1) Swing of vertical flap (SM1)

The vertical flap continuously swings upward and downward.

Set the angle and pulse count (0° for horizontal)

① ② ③ ④ ⑤ ⑥ ⑦

⑧

SM1

Angle

75°

70°

65°

60°

55°

50°

45°

40°

Pulse count

0

57

114

171

228

284

341

398

⑨

⑩

SM1

Angle

32°

30°

25°

20°

15°

10°

5°

-24° Pulse count

489

512

569

626

683

739

796

1274

Note: Max control range: 1274 pulse.

(2) Non-operating period

When the machine stops, the vertical flap fully closes.

-13-

(3) Flap memorizing function (where the vertical or horizontal flap stops)

When you press the AIR FLOW (Up/Down or Left/Right) button, the flap will operate at the

angle set. As this angle is memorized in the microcomputer, the flap will automatically operate

at the same angle next time the machine is started.

● Recommended angle of flap

(4) Flap control

The flap is controlled with the FLAP button on the remote controller.

(a) Automatic direction

The flap is automatically set to the best air flow angle in an operating mode.

1) Start time of operation

COOL and DRY operation HEAT operation

The flap moves repeatedly as The flap moves repeatedly as

shown in the above figure. shown in the above figure.

● In the HEAT mode, when the climator

(thermostat) functions or the DRY

operation is in progress, it becomes

horizontal automatically.

2) Non-operating period

When the machine stops, the flap fully closes.

(b) Flap memorizing function

As this angle is memorized in the microcomputer, the flap will automatically operate at the

angle next time the machine is started.

(c) Swing

As shown in the figure below, the flap swings upward/downward and to the left/right

continuously.

HEAT

(Slant forward

blowing)

COOL, DRY

(Horizontal

blowing)

Stops here for 1

minute

Swing

Swing

Stops here for 3

min. and 50 sec.

-14-

4.5 Comfort timer setting

If, in the COOL or HEAT mode or Automatic COOL or HEAT mode, the timer is set to ON, the

Comfort Timer functions.

The initial value is 15 minutes. The start time for next operation is determined according to the

relationship between the room temperature (sensor) at the time of setting and the set temperature

(max. 60 minutes).

Operating

mode

Correction value at the start of operation (minute)

COOL

3 < room temperature -

set temperature

1 < room temperature -

set temperature ≤ 3

room temperature - set

temperature ≤ 1

+5

No change

-5

HEAT

3 < room temperature -

set temperature

2 < room temperature -

set temperature ≤ 3

room temperature - set

temperature ≤ 2

+5

No change

-5

Notes: (1) The room temp. sensor (Th1) commences operation 5 minutes before the timer is ON,

regardless of the temperature.

(2) In the DRY or Automatic DRY mode, the function does not work.

However, in the Automatic DRY mode, the operation described in (1) commences.

(3) During the comfort reservation operation, the RUN lamp and TIMER lamp light up.

After expiration of the timer, the TIMER lamp goes off.

(Example) HEAT

Detect the temperature difference to compensate the start time of next operation.

15 min 10 min 5 min time set

earlier earlier earlier

● If the difference between the set temperature and room temperature is 4℃, according to the

above table, the correction value is +5 minutes, therefore, the start time of next operation is:

15 minutes earlier + 5 minutes = 20 minutes earlier

Compensation value

Start time of current operation

Set temp,

Room temp.

Time

-15-

4.6 Outline of heating operation

(1) Operation of functional components

Item

Functional

component

Instruction frequency 0

Instruction frequency

other than 0

Changed to a value other

than 0 due to abnormal

stop

Indoor fan motor

ON

ON

OFF

Swinging flap

ON or OFF

ON or OFF

Stop position control

Indication

Light up

Light up

Light up or flash

52C relay

ON

ON

OFF in Stop mode

Outdoor fan motor

Depending on Stop mode

ON

Depending on Stop mode

4-way valve

Depending on Stop mode

ON (Indoor continuous

instructions-1)

Depending on Stop mode

EEV

Depending on EEV

control

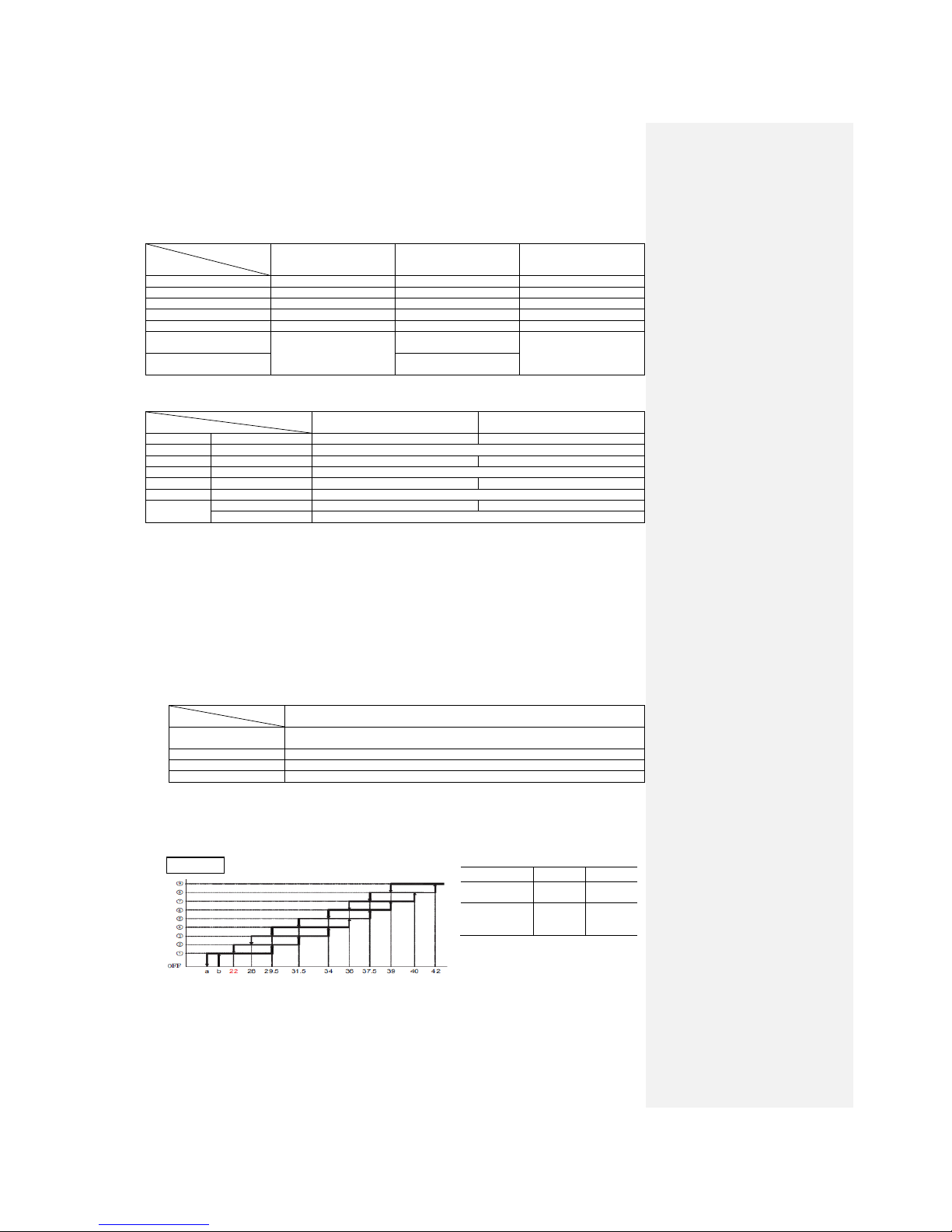

(2) Air flow switching

(a) The inverter instruction frequency changes within the range of selected air flow.

Model

Air flow switching

SRK25QA-S

SRK35QA-S

AUTO

Frequency

30-110 rps

30-112 rps

Air flow

Corresponding to frequency

HI

Frequency

30-110 rps

30-112 rps

Air flow

8th speed

ME

Frequency

30-72 rps

30-78 rps

Air flow

5th speed

LO

Frequency

30-42 rps

30-50 rps

Air flow

3rd speed

(b) When the defrosting or protection device is actuated, operation is performed in the

corresponding mode.

(c) Outdoor fan operates in accordance with the instruction frequency.

(3) Details of control in each operating mode

(a) Fuzzy operation

Deviation between the room temperature setting compensation value and the suction air

temperature is calculated in accordance with the fuzzy rule, and used for control of the air

flow and the inverter frequency.

(b) Heating constant temperature operation (HEAT operation)

● Operating conditions

If the frequency obtained with the fuzzy calculation drops below -24 rps during the heating

fuzzy operation, the operation changes to the heating constant temperature operation.

● Detail of operation

Model

Item

SRK25QA-S, SRK35QA-S

Inverter instruction

frequency

0 rps [Comp. stopped]

Indoor fan

Heat-retaining (normal operating mode)→1st speed (OFF)

Outdoor fan

According to the stop mode

Flap

According to the HEAT and DRY flap control

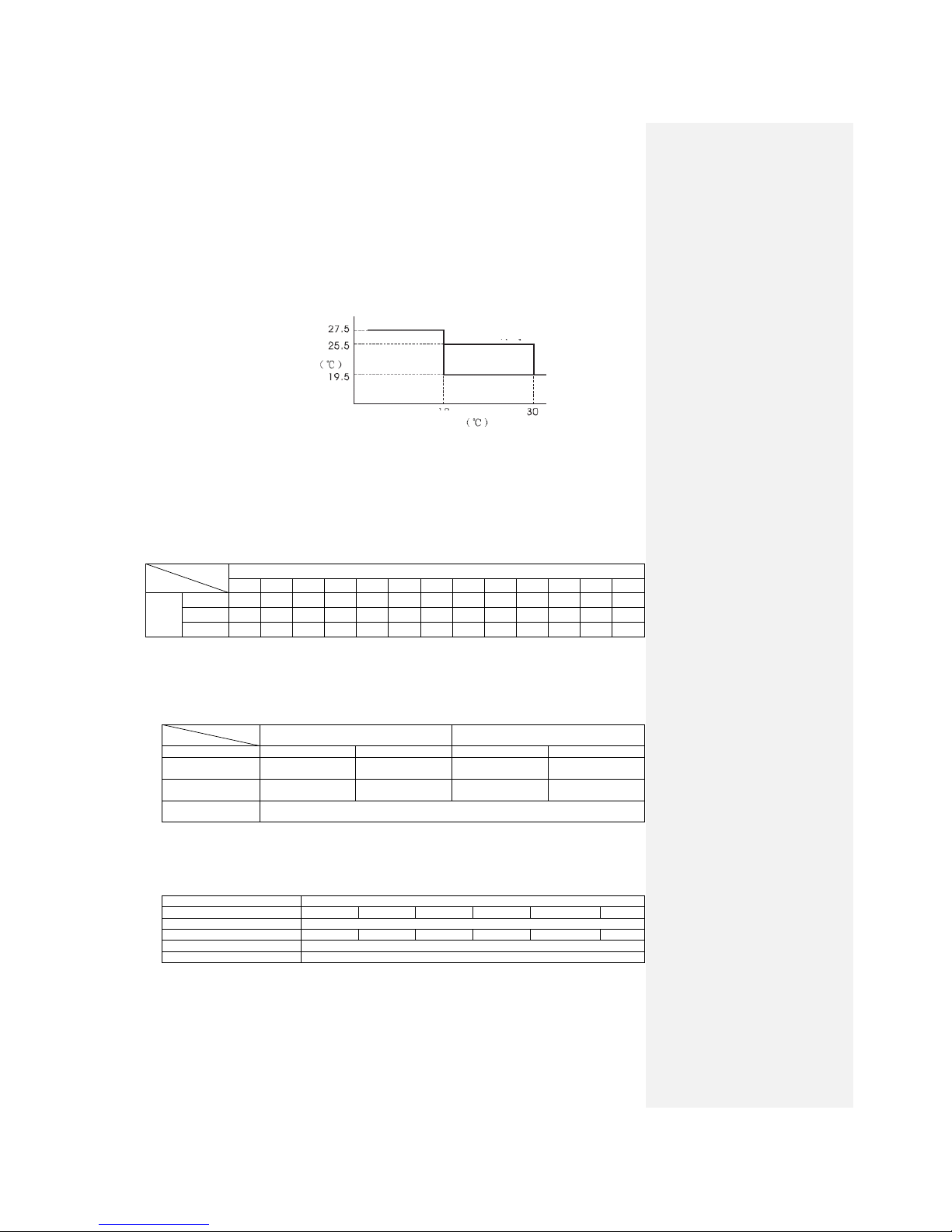

(c) Heat-retaining operation

During the heating operation, the indoor fan is controlled based on the temperature of the

outdoor heat exchanger (measured by indoor heat exchanger sensor) to prevent cool wind

from blowing.

● Normal operation (Usual heating operation, HI POWER operation)

Temp. of indoor heat exchanger (°C)

Note: (1) For the values of A and B, see the above table.

● Values of A, B

A B

At 0 rps

instruction

22

25

Other than 0

rps

instruction

10

15

Indoor fan

Fan speed

-16-

● Heat-retaining M mode (automatic, economical operation (15 minutes))

Temp. of indoor heat exchanger (°C)

Note: (1) For the values of A and B, see the above table.

● Values of A, B

A B

At 0 rps

instruction

22

25

Other than 0

rps

instruction

10

15

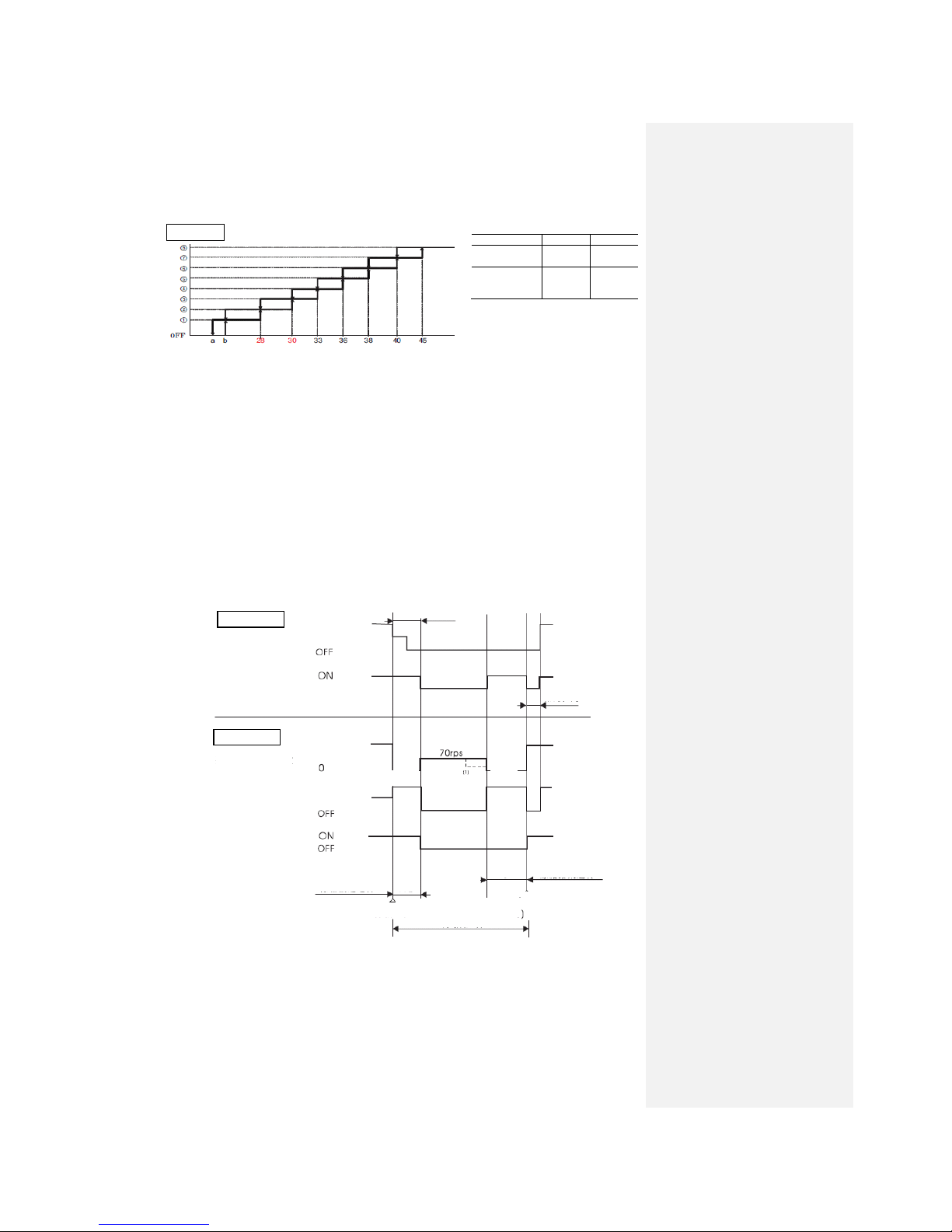

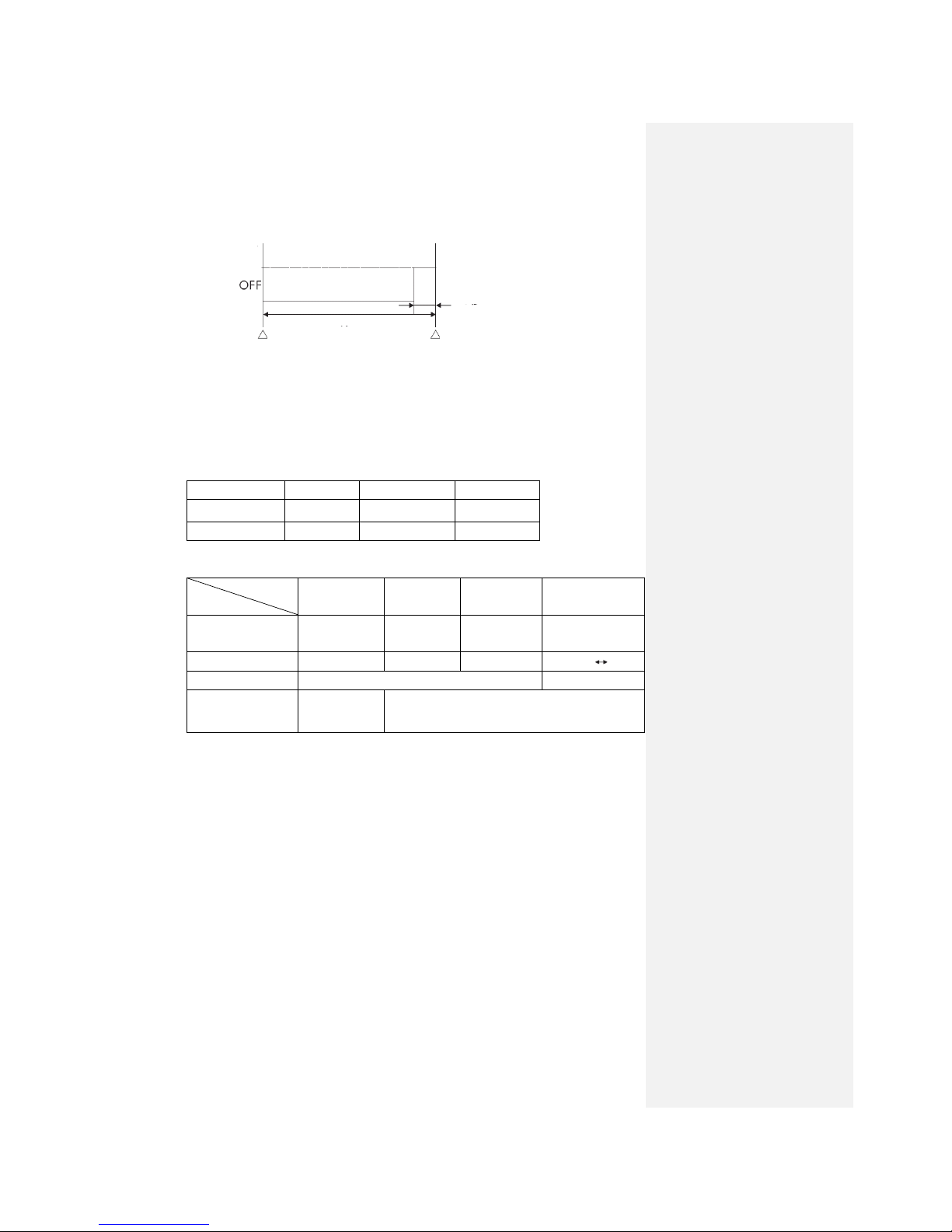

(d) Defrosting operation

1) Starting conditions (The defrosting operation is started only when all of the

following conditions are met.)

① 35 minutes after start of heating operation (accumulated operation time).

② 35 minutes after end of defrosting operation (accumulated compressor operation

time).

③ The temperature measured by the outdoor heat exchanger liquid pipe sensor (Th4) has

been below –5ºC for 3minutes continuously.

④ Temperature measured by outdoor air temp. sensor (Th5) - Temperature measured by

outdoor heat exchanger liquid pipe sensor (Th4) > 5ºC.

⑤ During compressor operation. (However, the defrosting can’t operate within 10

minutes after the compressor commences operation.)

In addition, if the count exceeds 10 times when the inverter frequency of the indoor

controller is 0 rps during heating operation, only ①, ② and ③ should be satisfied.

(However, the temperature measured by Th4 is below -5°C when the frequency is

above 62 rps and below -4°C when the frequency is below 62 rps.)

2) Operation of functional components during defrosting operation

● 25, 35 models

Note: When the temperature measured by the outdoor heat exchanger sensor (Th4) becomes 2 ºC or higher,

the inverter instruction frequency changes from 70 rps to 50 rps.

3) Ending conditions (Operation returns to the heating operation when either of the

following is met.)

① Temperature measured by outdoor heat exchanger sensor (Th4): 13ºC or higher

② Continued operation time of defrosting: More than 10 min.

Indoor fan

Fan speed

Indoor

Corresponding

speed

Heat-retaining

Indoor fan

RUN lamp

Flashing

(Heat-retaining)

Heat-retaining

Outdoor

Fuzzy calculated

value

Inverter

instruction

frequency

Outdoor fan

4-way valve

Corresponding

speed

Defrosting operation

preparation

Defrosting operation

50 sec.

60 sec.

6th

speed

6th

speed

Final defrosting operation

Normal heating operation

Defrosting control

Defrosting end

(Th4≥13C, 10 min

-17-

(e) HI POWER Heating operation (HI POWER button on remote controller: ON)

High rotate speed operation for15 minutes.

● Detail of operation

Model

Item

SRK25QA-S

SRK35QA-S

Inverter instruction frequency

110

112

Indoor fan

Heat-retaining mode (max. 9th speed)

Outdoor fan

Corresponding to instruction frequency

Notes: (1) Room temperature can’t be adjusted during the HI POWER operation.

(2) Priority is given to actuation of protective device even during the HI POWER operation.

4.7 Outline of cooling operation

(1) Operation of functional components

Item

Functional component

Instruction frequency 0

Instruction frequency

other than 0

Becomes 0 due to

abnormal stop

Indoor fan motor

ON

ON

OFF

Swinging flap

ON or OFF

ON or OFF

Stop position control

Indication

Light up

Light up

Light up or flash

52C relay

ON

ON

OFF in Stop mode

Outdoor fan motor

Depending on Stop mode

ON

Depending on Stop mode

4-way valve

Depending on Stop mode

OFF (Indoor continuous

instructions-0)

Depending on Stop mode

EEV

Depending on EEV

control

(2) Air flow switching

(a) The inverter instruction frequency changes within the range of selected air flow.

Model

Air flow switching

SRK25QA-S

SRK35QA-S

AUTO

Frequency

20~92 rps

20~106 rps

Air flow

Corresponding to frequency

HI

Frequency

20~92 rps

20~106 rps

Air flow

6th speed

ME

Frequency

20~55 rps

20~66 rps

Air flow

4th speed

LO

Frequency

20~34 rps

20~38 rps

Air flow

2nd speed

(b) When the protection device is actuated, operation is performed in the corresponding mode.

(c) Outdoor fan operates in accordance with the instruction frequency.

(3) Details of control in each operating mode

(a) Fuzzy operation

Deviation between the room temperature setting compensation value and the suction air

temperature is calculated in accordance with the fuzzy rule, and used for control of the air

flow and the inverter frequency.

(b) Cooling constant temperature operation

● Operating conditions

If the frequency obtained with the fuzzy calculation drops below -24 rps during the

cooling fuzzy operation, the operation changes to the cooling constant temperature

operation.

● Detail of operation

Model

Item

SRK25QA-S, SRK35QA-S

Inverter instruction

frequency

0 rps [Comp. stopped]

Indoor fan

According to the Indoor Fan Operating Mode Table (corresponding to fan speed)

Outdoor fan

Stop

-18-

(c) HI POWER Cooling operation (HI POWER button on remote controller: ON)

Unrelated to set temperature. Continuous operation for15 minutes.

● Detail of operation

Model

Item

SRK25QA-S

SRK35QA-S

Inverter instruction frequency

92

106

Indoor fan

7th speed

Outdoor fan

Corresponding to instruction frequency

Notes: (1) Room temperature can’t be adjusted during the HI POWER operation.

(2) Priority is given to actuation of protective device even during the HI POWER operation.

4.8 Outline of drying operation

(1) After the fan commences operation (1st speed for indoor fan, 3rd speed for outdoor fan) within

20 seconds after the start of operation, the room temperature TION, the outdoor air temp. sensor

TO and set temperature SP are checked to determine whether to use cooling & drying or heating

& drying.

● TION > SP-3 or TO ≥ 19℃: cooling & drying

● TION ≤ SP-3 or TO < 19℃: heating & drying

Cooling & drying or heating & drying is selected again one hour after selection.

(2) Outline of control

(a) Cooling & drying

● Room temperature TION, set temperature SP and value of humidity sensor are checked

every 5 minutes after the cooling & drying is selected to determine the operation range of

drying.

● Operation ranges are shown in the table below:

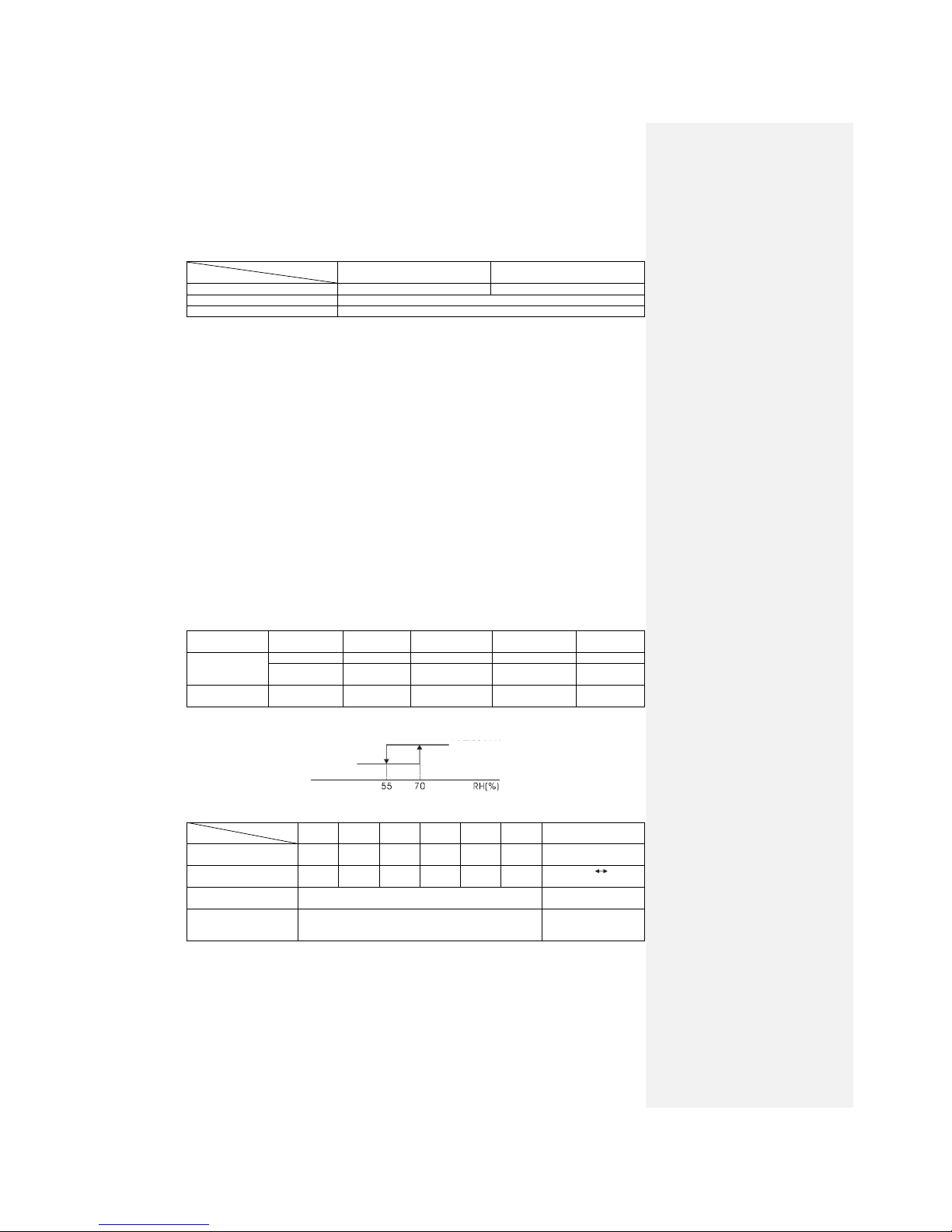

Humidity

range

TION<SP-1

SP-1≤TION<SP

SP≤TION<SP+2

SP+2≤TION

Normal

operation

Low humidity

Range I

Range C

Range B

Range A

High

humidity

Range I

Range F

Range E

Range D

Economical

type

Range I

Range C

Range C

Range E

● The range of humidity sensor is judged according to the following:

● The operations of the components in the operation range of cooling & drying are as

follows:

Operation range

Functional component

A B C D E F I

Instruction frequency

HZ

34

26

20

40

26

20 0 Rotate speed of indoor

fan

4th

speed

2nd

speed

2nd

speed

4th

speed

2nd

speed

2nd

speed

1st speed OFF

Rotate speed of

outdoor fan

Corresponding to instruction frequency

OFF

4-way valve

OFF (indoor continuous instructions - 0)

OFF F (indoor

continuous

instructions - 0)

● When the set temperature change signal is received, the original range will be continued till

finished; in the next 5 minutes, the room temperature TION, set temperature SP and value

of humidity sensor are checked to determine the new operation range.

● When a range other than Range I is switched to Range I, the control is as follows:

(A) According to the Stop mode (B);

High humidity range

Low humidity range

-19-

(B) Prevent Range I in jiggle operation from changing to Range C operation.

-20-

● Operation of Range I:

(b) Heating & drying

After heating & drying is determined, heating operation begins 3 minutes (3 min. timer)

after the stop of the compressor. When the room temperature TION is higher than the set

temperature SP by more than 2℃, the room temperature TION and set temperature SP are

checked every 5 minutes to determine the operation range of heating & drying.

● Operation ranges are shown in the table below:

TION<SP-1

SP-1≤TION<SP

SP≤TION

Usual operation

Range O

Range L

Range M

Economical type

Range O

Range L

Range M

● The operations of the components in the operation range of cooling & drying are as

follows:

Operation range

Functional component

Heating

operation

M L O

Instruction frequency

HZ

40

26

20

0

Indoor fan

5th speed

2nd speed

2nd speed

1st speed OFF

Outdoor fan

Corresponding to instruction frequency

OFF

4-way valve

OFF (indoor

continuous

instructions - 1)

OFF F (indoor continuous instructions - 0)

● During the heating operation, the protection functions of defrosting operation and high

pressure control are effective. (This is also the case for usual heating operation.)

● If, during the operation of this control range, the set temperature TP change signal is received

and the heating operation of heating & drying is changed immediately, TION judgment will

be conducted. For other operations, it operates in the range before temperature confirmation

every 5 minutes and in the new range after judgment.

● When a range other than Range O is switched to Range O, the control is as follows:

(A) According to the Stop mode;

(B) Prevent Range O in jiggle operation from changing to Range L operation.

●Range O operation is the same as Range I operation of cooling & drying.

● No heat-retaining is conducted during heating operation.

1st speed

Indoor fan

25 sec.

Temperature and humidity check

5 min.

Temperature and humidity check

-21-

4.9 Outline of automatic operation

(1) Determination of operating mode

After the indoor and outdoor fans operate at the 2nd sped and 3rd speed respectively for 20

seconds, the system checks the room temperature and outdoor air temperature to determine the

operating mode and the room temperature setting compensation value, and then enters the

automatic operation.

(2) The unit checks the temperature every hour after the start of operation and, if the result of

check is not the same as the previous operating mode, it will change the operating mode.

(3) When the unit is started again within one hour after the stop of automatic operation or when

the automatic operation is selected during heating, cooling or drying operation, the unit will

operate in the original operating mode.

(4) Set temperature can be adjusted within the following range. There is the relationship as shown

below between the signals of the wireless remote controller and the set temperature.

Signals of wireless remote controller (indication)

-6

-5

-4

-3

-2

-1 0 +1

+2

+3

+4

+5

+6

Set

temp.

Cooling

18

19

20

21

22

23

24

25

26

27

28

29

30

Drying

18

19

20

21

22

23

24

25

26

27

28

29

30

Heating

20

21

22

23

24

25

26

27

28

29

30

31

32

4.10 Economical operation (ECONO button on remote controller: ON)

(1) When the ECONO button is pressed, the power is controlled for gentle operation in the status

which is not too cold or too hot. In this case, the temperature in the Cooling mode is higher

than the set temperature by 1.5ºC (increasing 0.5ºC per hour), and the temperature in the

Heating mode is lower than the set temperature by 2.5ºC (decreasing 0.5ºC per hour).

Model

Item

SRK25QA-S

SRK35QA-S

Operating mode

Cooling

Heating

Cooling

Heating

Inverter instruction

frequency

20~46 rps

20~60 rps

20~62 rps

20~76 rps

Rotate speed of

indoor fan

2nd, 4th speed

3rd, 5th speed

2nd, 4th speed

3rd, 5th speed

Rotate speed of

outdoor fan

3rd speed

4.11 Air blowing operation

(1) When the fresh air signal from the remote controller is received, the fresh air operation begins.

(2) The so-called “fresh air operation” refers to the air blowing operation in the whole machine

with filter.

Air flow switching

Automatic

Hi

Me

Lo

Economical

Instruction frequency HZ

0

Rotate speed of indoor fan

6th speed

5th speed

4th speed

3rd speed

2nd speed

Rotate speed of outdoor fan

-

4-way valve

Same as cooling

(3) In this control, the continuous transmission error protection function can be neglected.

(4) In the fresh air operation, all timing functions are effective.

Cooling

Drying

Heating

Room temperature

Outdoor temperature

-22-

4.12 CLEAN operation control

About CLEAN operation:

In the cooling and drying mode, when the unit is turned off, the fan of the indoor unit will

continue to run for 120 minutes to discharge the water from the unit for the purpose of

mould-proof.

CLEAN setting

Example: Setting of CLEAN operation when the unit is turned off after cooling operation.

1: When the air conditioner is in the stop mode, press the ON/OFF button.

2: Press the MODE button to set the cooling mode.

3: Press the CLEAN button and CLEAN indication on the display will light up.

Cancelation of CLEAN operation

Press the CLEAN button and CLEAN indication on the display will disappear.

.

4.13 Electronic expansion valve (EEV) control function

(1) General control range: 0~470 pulse.

(2) The open loop control and area control are combined for EEV control.

-23-

5 Installation

○ Use this system only for household and

residence.

○ This appliance must be installed according to the national wiring regulation.

○ A 2-level switch must be used for the fixed wiring of the power supply and its disconnection

clearance must be at least 3mm.

○ If the outdoor unit may tip over or move and drop from the original installation location, use

trip bolts or string to secure it in place.

○ The liquid pipe and gas pipe in the piping should be insulated with thermal insulation.

SAFETY PRECAUTIONS

• Please read this “SAFETY PRECAUTIONS” carefully before the installation work in order to ensure correct installation.

• T he precautions described below are divided into WARNING and CAUTION. The matters with possibilities leading to

serious consequences such as death or serious personal injury due to erroneous handling are listed in the WARNING, however

the matters listed in CAUTION may sometimes lead to serious accidents. These are very important precautions for safety. Be

sure to observe all of them without fail.

• For qualified installing personnel, take precautions in respect to themselves by using suitable protective clothing, groves, etc., and then

perform the installation works.

• Please pay attention not to fall down the tools, etc. when installing the unit at the high position.

• If unusual noise can be heard during operation, consult the local dealer.

• Be sure to confirm no anomaly on the equipment by commissioning after completed installation and explain the operating methods as

well as the maintenance methods of this equipment to the user according to the owner’s manual.

• Symbols which appear frequently in the text have the following meaning:

Strictly prohibited

Observe instructions

Provide proper earthing

• Keep the installation manual together with owner’s manual at a place where any user can read. Moreover if necessary, ask to hand

them to a new user.

WARNING

• Installation must be carried out by the qualified

installer and only the specified optional components

should be used.

If you install the system by yourself, it may cause serious

trouble such as water leaks, electric shocks, fire and

personal injury, as a result of a system malfunction.

• Install the system in full accordance with the

instruction manual.

Incorrect installation may cause bursts, personal injury,

water leaks, electric shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such

as machine shop etc., it can cause malfunction.

• Use the original accessories and the specified

components for installation.

If parts other than those prescribed by us are used, it may

cause drop of machine, water leaks, electric shocks, fire,

refrigerant leakage, insufficient performance, poor control,

and personal injury.

• Install the unit in a location with good support and

ensure the unit is stable when installed, so that it can

withstand earthquakes and strong winds.

Unsuitable installation locations can cause the unit to fall

and cause material damage and personal injury.

• Ventilate the working area well in the event of

refrigerant leakage during installation.

If the refrigerant comes into contact with naked flames,

poisonous gas is produced.

• When the equipment is to be installed in a small room,

take preventive measures to avoid refrigerant leakage

exceeding the density limit.

Consult with the installation professionals about the

preventive measures. If the density is greater than the limit

of refrigerant, it may cause serious accidents such as

refrigerant leakage, shortage of oxygen, etc.

• Confirm there is no refrigerant leakage after the

installation.

If the refrigerant leaked comes into contact with the fire of

an air blowing type heater, oven, etc., poisonous gas is

produced.

• Use the prescribed pipes, flare nuts and tools for

R410A.

Using conventional parts (for R22) can cause the unit

failure and serious accidents due to burst of the refrigerant

circuit.

• Tighten the flare nut by torque wrench with specified

method.

If the flare nut were tightened with excess torque, this may

cause burst and refrigerant leakage after a long period.

• Do not open the operation valves for liquid line and gas

line until completed refrigerant piping work, air

tightness test and evacuation.

If the compressor is operated when operation valves are

open before the connection of refrigerant piping work is

completed, it can cause frostbite or injury due to rapid

refrigerant leakage, and burst or personal injury due to

anomalously high pressure in the refrigerant circuit into

which air is sucked.

• The electrical installation must be carried out by the

qualified electrician in accordance with “the norm for

electrical work” and “national wiring regulation”, and

the system must be connected to the dedicated circuit.

Power supply with insufficient capacity and incorrect

function done by improper work can cause electric shocks

and fire.

• Be sure to shut off the power before starting electrical

work.

Failure to shut off the power can cause electric shocks,

unit failure or incorrect function of equipment.

• Be sure to use the cables conformed to safety standard

and cable ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous

heat production or fire.

• This appliance must be connected to main power

supply by means of a circuit breaker or switch

(fuse:16A) with a contact separation of at least 3mm.

• If the appliance has a plug, the plug must comply with

IEC 60884-1.

• Use the prescribed cables for electrical connection,

tighten the cables securely in terminal block and

relieve the cables correctly to prevent overloading the

terminal block.

Loose connections or cable mountings can cause

anomalous heat production or fire.

• Arrange the wiring in the control box so that it cannot

be pushed up further into the box. Install the case and

service panel correctly.

Incorrect installation may result in overheating and fire.

• Be sure to mount the service panel.

Incorrect mounting can cause electric shocks or fire due to

intrusion of dust or water.

• Be sure to switch off the power supply before

installation, inspection or servicing.

If the power supply is not shut off, there is a risk of

electric shocks, unit failure or personal injury due to the

unexpected start of fan.

Precautions for installation

-24-

WARNING

• To recover refrigerant, stop the compressor before closing the valve and disconnecting the refrigerant piping.

If the refrigerant piping is disconnected before the compressor stops and when the service valve is opened, it can cause

frostbite or injury due to rapid refrigerant leakage, and burst or personal injury due to anomalously high pressure in the

refrigerant circuit into which air is sucked

• Do not put the drainage pipe directly into drainage

channels where poisonous gases such as sulphide gas

can occur.

Poisonous gases will flow into the room through drainage

pipe and seriously affect the user’s health and safety.

• Never connect the power cord to the central socket.

Never use extended wires or share a socket with other

electrical appliances.

This may cause fire or electric shocks due to defective

contact, poor insulation and over-current etc.

• Do not discharge R410A to the atmosphere. R410A is a

fluoride greenhouse gas and can cause global warming

if it is discharged to the atmosphere.

• Ensure that no air enters in the refrigerant circuit

when the unit is installed and removed.

If air enters in the refrigerant circuit, the pressure in the

refrigerant circuit becomes too high, which can cause

burst and personal injury.

• Do not bundle or wind the power cord. Or, do not

deform the power plug by treading it.

This may cause electric shocks, heating or fire.

• Do not run the unit with removed panels or

protections.

Touching rotating equipments, hot surfaces or high

voltage parts can cause personal injury due to entrapment,

burn or electric shocks.

• Do not perform any change of protective device itself

or its setup condition.

The forced operation by short-circuiting protective device

of pressure switch and temperature controller or the use of

non specified component can cause fire or burst.

• Carry out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line, liquid line, lightning conductor or telephone line’s ground lead. Incorrect

grounding can cause unit faults such as electric shocks due to short-circuiting. Never connect the ground lead to the gas

line as gas leakage can cause explosion or fire.

CAUTION

• Use the circuit breaker with correct breaking capacity

at all electrodes.

If a wrong breaker is used, it can cause the unit

malfunction and fire.

• Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause

fire or electric shocks.

• Secure a space for installation, inspection and

maintenance specified in the manual.

Insufficient space can result in accident such as personal

injury due to falling from the installation place.

• After maintenance, all wi ring, wiring ties and the like,

should be returned to their original state and wiring

route, and the necessary clearance from all metal parts

should be secured.

• Take care when carrying the unit by hand.

If the unit weighs more than 20kg, it must be carried by

two or more persons. Do not carry by the plastic straps,

always use the carry handle when carrying the unit by

hand. Use gloves to minimize the risk of cuts by the

aluminum fins.

• Dispose of any packing materials correctly.

Any remaining packing materials can cause personal

injury as it contains nails and wood. And to avoid danger

of suffocation, be sure to keep the plastic wrapper away

from children and to dispose after tearing it up.

• Be sure to insulate the refrigerant pipes so as not to

condense the ambient air moisture on them.

Insufficient insulation can cause condensation, which can

lead to moisture damage on the ceiling, floor, furniture

and any other valuables.

• When the air conditioner is operating (cooling &

drying operation) and the ventilator installed in the

room is also running, there is the possibility that drain

water may backflow as the room enters the negative

pressure state. Therefore, set up the opening port to let

air enter the room to provide appropriate ventilation

(for example, open the door a little). In addition, just

as above, set up the opening port if the room enters the

negative pressure state due to the aerator for the high

rise apartment etc.

• Install isolator or disconnect switch on the power

supply wiring in accordance with the local codes and

regulations.

• Do not install the unit in the locations listed below.

• Locations where carbon fiber, metal powder or any

powder is floating.

• Locations where any substances that can affect the unit

such as sulphide gas, chloride gas, acid and alkaline can

occur.

• Vehicles and ships.

• Locations where cosmetic or special sprays are often

used.

• Locations with direct exposure to oil mist and steam

such as kitchen and machine plant.

• Locations where an y machines which generate high

frequency harmonics.

• Locations with salty atmospheres such as coastlines.

• Locations with heavy snow.

• Locations where the unit is exposed to chimney smoke.

• Locations at high altitude (more than 1000m high).

• Locations with ammonic atmospheres.

• Locations where heat radiation from other heat source

can affect the unit.

• Locations without good air circulation.

• Locations with any obstacles which can prevent inlet

and outlet air of the unit.

• Locations where short circuit of air can occur (in case of

multiple units installation).

• Locations where strong air blows against the vent of

outdoor unit. It can cause remarkable decrease in

performance, corrosion and damage of components,

malfunction and fire.

-25-

CAUTION

• Do not install the outdoor unit in the locations listed

below.

• Locations where discharged hot air or operating sound of

the outdoor unit can bother neighborhood.

• Locations where outlet air of the outdoor unit blows

directly to animals or plants. The outlet air may cause

adverse impact on plants, etc.

• Locations where vibration and operation sound

generated by the outdoor unit can affect seriously (on the

wall or at the place near bed room).

• Locations where vibration can be amplified and

transmitted due to insufficient strength of structure.

• Locations where an equipment affected by high

harmonics is placed (TV set or radio receiver is placed

within 5m).

• Locations where drainage cannot run off safely. It can

affect surrounding environment and cause a complaint.

• Do not install the unit where corrosive gas (such as

sulfurous acid gas etc.) or combustible gas (such as

thinner and petroleum gases) can accumulate or

collect, or where volatile combustible substances are

handled.

Corrosive gas can cause corrosion of heat exchanger,

breakage of plastic parts and etc. And combustible gas can

cause fire.

• Do not use the base flame for outdoor unit which is

corroded or damaged due to long periods of operation.

Using an old and damaged base flame can cause the unit

falling down and cause personal injury.

• Do not touch the suction or a luminum fin on the

outdoor unit.

This may cause injury.

• Do not install the outdoor unit in a location where

insects and small animals can inhabit.

Insects and small animals can enter the electric parts and

cause damage or fire. Instruct the user to keep the

surroundings clean.

• Do not i nstall nor use the system close to the

equipment that generates electromagnetic fields or

high frequency harmonics.

Equipment such as inverters, standby generators, medical

high frequency equipments and telecommunication

equipments can affect the system, and cause malfunctions

and breakdowns. The system can also affect medical

equipment and telecommunication equipment, and

obstruct its function or cause jamming.

• Do not use any materials other than a fuse with the

correct rating in the location where fuses are to be

used.

Connecting the circuit with copper wire or other metal

thread can cause unit failure and fire.

• Do not touch any buttons with wet hands.

It can cause electric shocks.

• Do not touch any refrigerant pipes with your hands

when the system is in operation.

During operation the refrigerant pipes become extremely

hot or extremely cold depending on the operating

condition, and it can cause burn injury or frost injury.

• Do not put anything on the outdoor unit and operating

unit.

This may cause damage of the object or injury due to the

fall of the object.

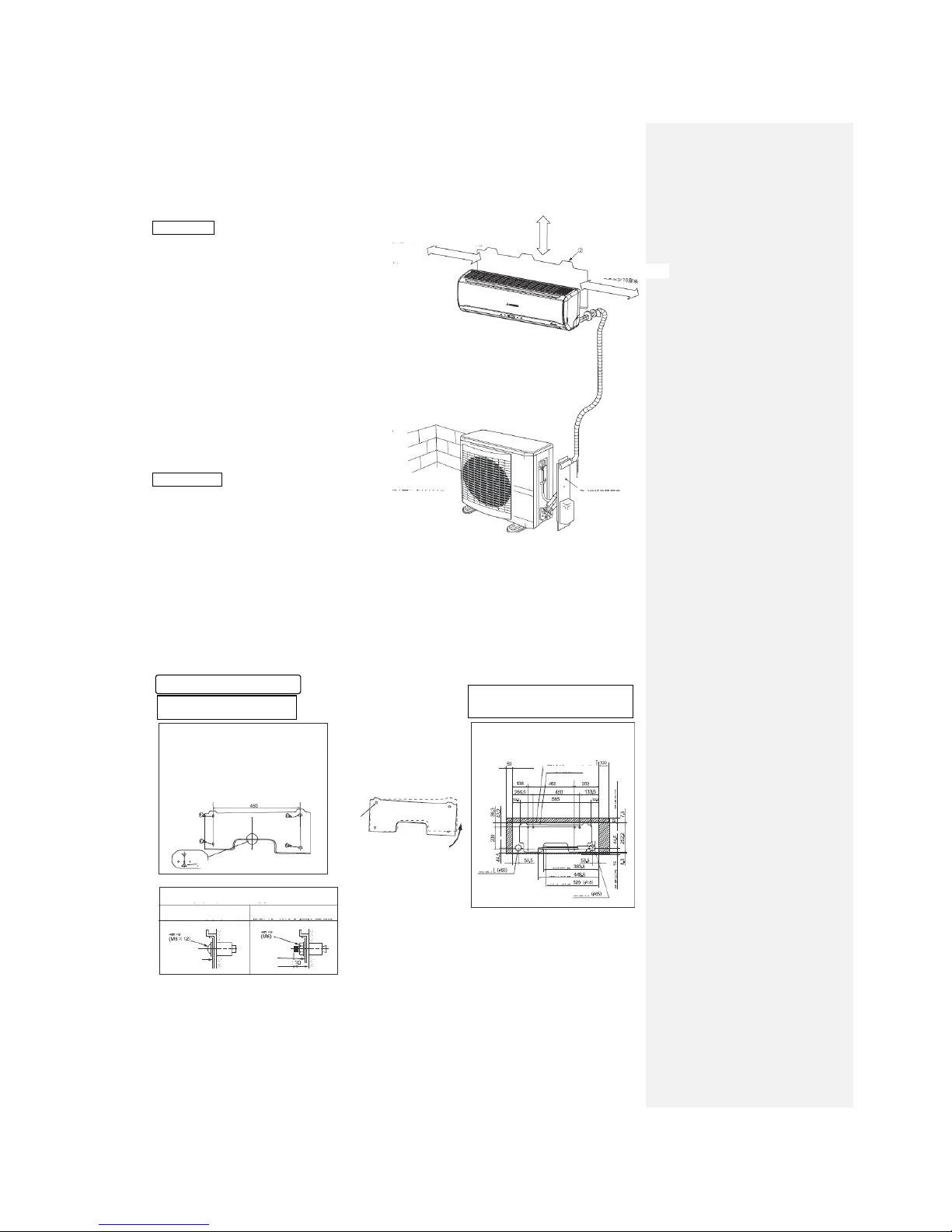

5.1 Selection of installation location

○ The appliance must be installed at a location with the air intake and vents being 10cm away

from walls.

(In case the fence is 1.2m or above in height, or is overhead, the sufficient space between the

unit and walls shall be secured.)

○ When the unit is installed, the space of the following dimension shall be secured.

Air intake

10cm MIN

No obstacles (Service

space for electrical

parts))

Air

intake

Air outlet

60cm MIN

Caution

If the wall is 1.2m or above in

height or there is a ceiling, the

sizes should be greater than

those indicated above.

10cm MIN

How to remove and install the front panel

○ Removal

① Remove the air inlet

grille.

② Remove the 2 screws

securing the front panel.

③ Remove the 3 latches

on the upper part of the

front panel and remove the

front panel from the unit.

○ Installation

① Remove the air filter.

② Cover the unit with the

front panel.

③ Tighten the 2 screws to

secure the front panel.

④ Mount the air filter.

⑤ Mount the air inlet grille.

Latches

Front panel

Air inlet grille

Screw

Screw

-26-

Selection of installation location

Indoor unit

○ Where there are no obstructions and where

cool air and warm air can blow in the

room.

○ Where the indoor unit or wall does not

vibrate and where is strong.

○ Where there is adequate space for servicing.

(The space mentioned below is safe.)

○ Where wire and pipe mounting is

convenient.

○ Where direct sunlight and strong light do

not hit the unit.

○ Where water from the unit can drain easily.

○ Where there is at least 1 meter distance

from the TV set or radio. (Otherwise, it

may interfere with TV reception or produce

noise.)

Outdoor unit

○ Where rain, snow and sunlight do not

directly hit the unit, and where there is

enough air circulation.

○ Where blasts of cold or hot air and noise do

not bother the neighbors.

○ Where there are installation and servicing conditions.

○ A location where vibrations are not enhanced and where is strong.

※ Please avoid the following locations.

○ A location near the room, etc. to prevent the operating noise from causing trouble.

○ Where there are possibilities of flammable gas leaks.

○ Where there is constant exposure to harsh winds.

5.2 Installation of indoor unit

At least 6.5 cm from ceiling

Mounting plate

At least 10 cm from wall

At least 5 cm from wall

Electric component

service panel

Mountng of mounting plate

Fixing the mounting plate

Firstly find the position of

support or columella in the wall.

Check that the mounting location

is level and then fix the unit

more securely.

Plane mating mark

○ In the loose state, use

four screws to adjust

the mounting plate

horizontally.

Standard

hole

○ Turn the mounting

plate with the standard

hole as the center to

make it level.

Setting the relationship between

plate and indoor unit

Installation space

(Indoor unit) (Front view)

Service space

Indoor unit

Service

space

Mounting plate

Pipe

hole

Gas piping

Liquid piping

Drainage

Pipe hole

Service space

Service space

Fixing on the concrete wall

Using nut retainer

Using screw retainer

Mounting plate

Mounting

plate

Nut

Nut

Max.

-27-

Installation of indoor unit

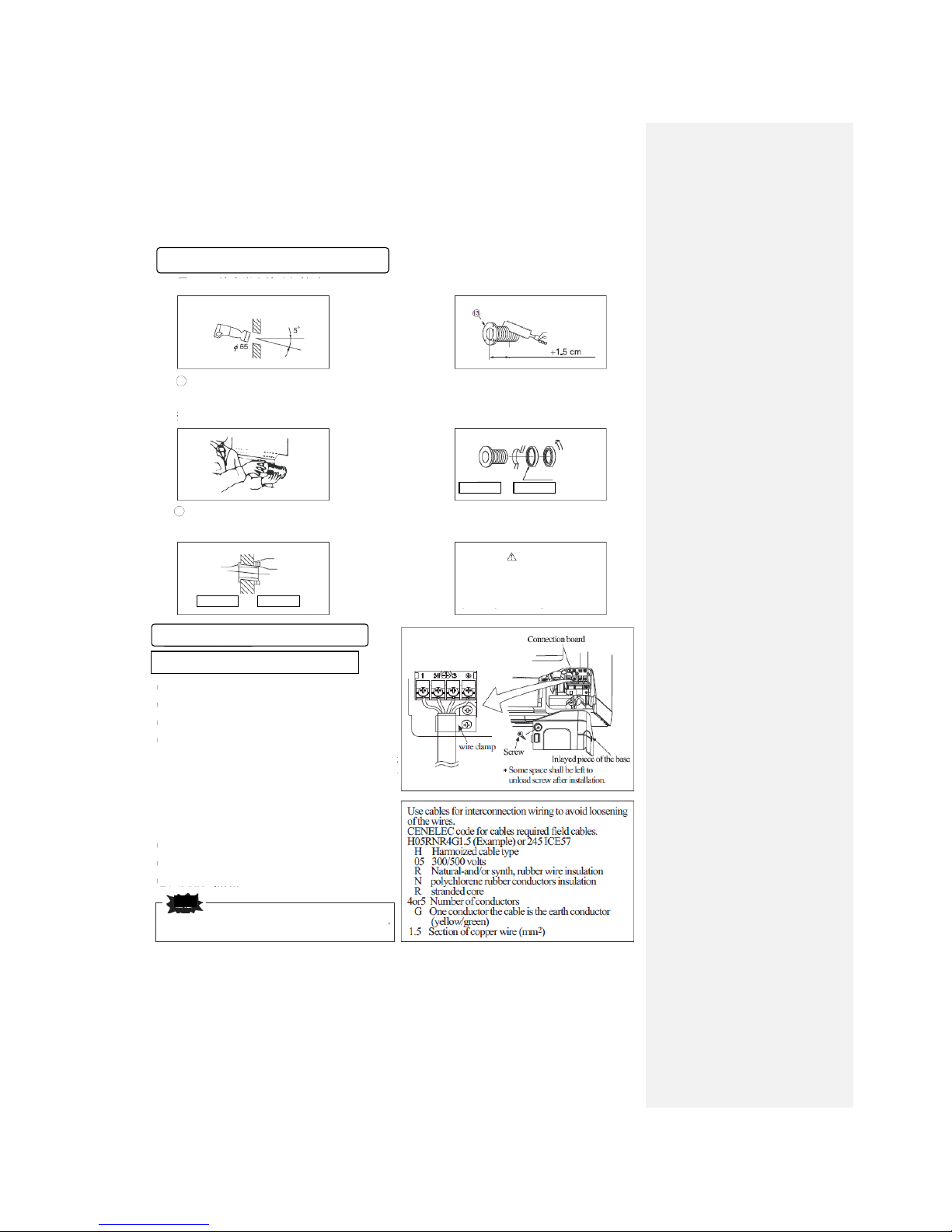

Drilling holes and securing sleeve (optional)

Drilling a hole with Φ65 whole core drill

Indoor

Outdoor

Adjusting the length of the sleeve

Top

Thickness of wall

Use the whole core drill to drill a hole.

Mounting the sleeve.

○ If the rear pipe is pulled out, cut the

lower part and right side of the axle

collar

Sleeve Declined plate Sealing ring

Turn to

tighten

Indoor

Outdoor

Putty

Insert the sleeve.

Sketch of state after mounting

Sleeve

Indoor

Outdoor

Declined

flange

Sealing ring

Caution

Drill a hole at an angle of 5°

Preparation for installation of indoor unit

Preparation for mounting of electric wire

① Open the air inlet grille.

② Remove the cover.

③Remove the wire clamp.

④ Connect the electric wire to the connection board

securely.

1) Connect the electric wire to the connection board

securely. If the electric wire is not fixed

completely, the contacting will be poor, thus

causes risk, as the connection board may heat

which causes fire.

2) Please note that the number of terminals of the

indoor and outdoor connections should not be

confused.

3) Use the wire clamp to connect the electric wire.

⑤ Connect the electric wire through the wire clamp.

⑥ Secure the cover.

⑦ Close the air inlet grille.

In case of failure of wiring connection, the indoor unit will stop running,

the RUN lamp will light up, and the TIMER lamp will flash.

Caution

Loading...

Loading...