Mitsubishi Heavy Industries SRK28HD, SRK40HD Technical Manual

WALL MOUNTED TYPE

ROOM AIR-CONDITIONER

(Air to air heat pump type)

R22 use models

SRK28HD

SRK40HD

TECHNICAL MANUAL

& PARTS LIST

DRAFT

INDOOR UNIT

Models SRK28HD, SRK40HD

OUTDOOR UNIT

Model SRC28HD

REMOTE CONTROLLER

Model SRC40HD

-

1

-

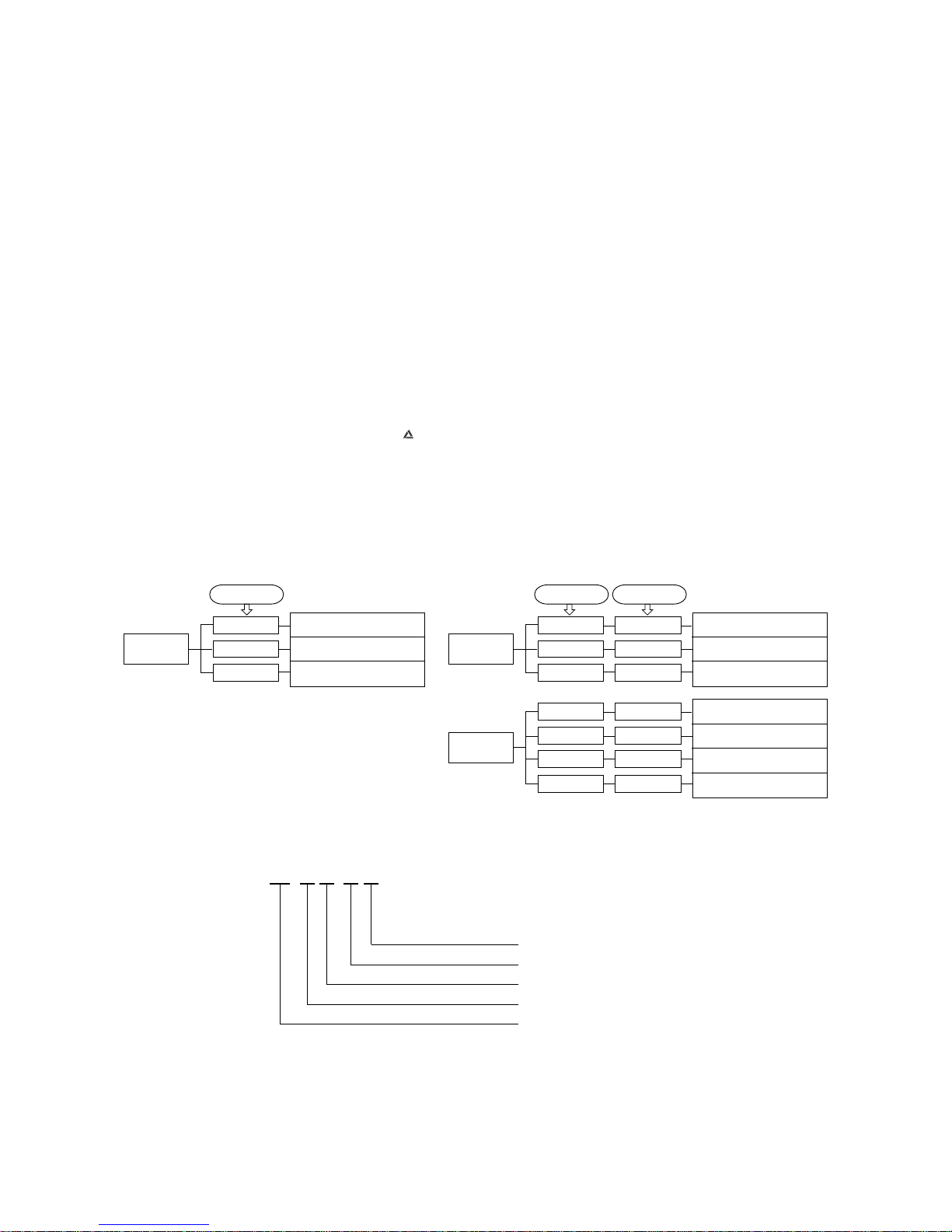

Serial signal transmission error

1 GENERAL INFORMATION

1.1 Specific features

The “Mitsubishi Daiya” room air-conditioner: SRK series are of split and wall mounted type and the unit consists of indoor unit and

outdoor unit with refrigerant precharged in factory. The indoor unit is composed of room air cooling or heating equipment with operation control switch and the outdoor unit is composed of condensing unit with compressor.

(1) Remote control flap

The flap can be automatically controlled by operating wireless remote controller.

¡ Air scroll: Flap operation is automatically control.

¡ Swing: This will swing the flap up and down.

¡ Memory flap: Once the flap position is set, the unit memorizes the position and continues to operate at the same position from

the next time.

(2) Automatic Operation

When the remote control switch is set on “auto( ) ”, it will either automatically decide operation mode such as cooling, heating

and thermal dry, or operate in the operation mode before it has been turned to automatic control.

(3) Self diagnosis function

¡ We are constantly trying to do better service to our customers by installing such judges that show abnormality of operation as

follows.

Series No.

Heat pump type

Product capacity

Wall mounted type

Split type room air-conditioner

1.2 How to read the model name

Example : SR K 40 H D

Room temperature thermistor error

Indoor fan motor error

Heat exchanger thermistor error

2 time flash

6 time flash

TIMER lamp

ON

1 time flash

Outdoor unit heat exchanger

thermistor error

Discharge pipe thermistor error

Outdoor temperature thermistor

error

2 time flash

4 time flash

RUN lamp

keeps flashing

1 time flash

OFF

OFF

OFF

Outdoor unit error

Compressor overheat

Current cut

2 time flash

5 time flash

RUN lamp

ON

1 time flash

2 time flash

5 time flash

1 time flash

6 time flash 6 time flash

RUN lamp TIMER lamp Outdoor (LED)

-

2

-

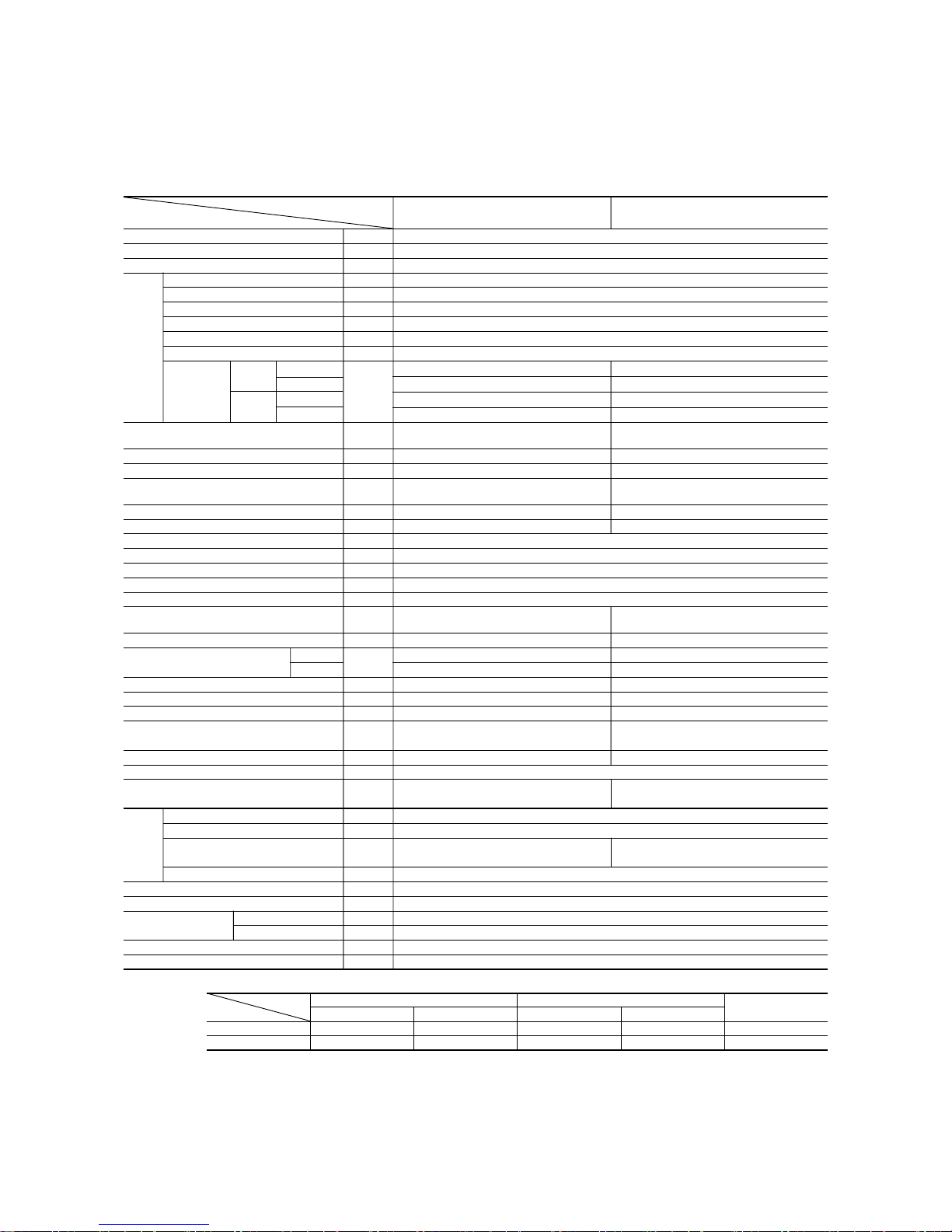

Item

Model

SRK28HD SRC28HD

Cooling capacity

(1)

W

Heating capacity

(1)

W

Power source 1 Phase, 220/230/240V, 50Hz

Cooling input kW

Running current (Cooling) A

Heating input kW

Running current (Heating) A

Inrush current A

COP

Cooling

sound level

Noise level

Power level

dB

(55) (60)

Heating

sound level

Power level (56) (60)

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 540 × 720 × 290

Color Cool white Stucco white

Net weight kg 9.0 32

Refrigerant equipment

Compressor type & Q’ty

– 2PS164D5BF02 (Rotary type) × 1

Motor kW – 0.75

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 0.8 (Pre-Charged up to the piping length of 7.5m)

Refrigerant oil R 0.35 (SUNISO 4GDID or ATMOS M60)

Deice control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 14 15

(Cooling) 8.0 30

Air flow (at High)

(Heating)

CMM

8.5 30

Air filter, Q’ty Polypropylene net (washable) × 2–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ9.52 (3/8″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Gas line : 0.33 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

2 SELECTION DATA

2.1 Specifications

Model SRK28HD (Indoor unit)

SRC28HD (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

If the piping length is longer, when it is less than 10 m, add 20 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.

Operation data

(1)

Refrigerant

piping

Frost protection, Serial signal error protection

Fan motor error protection

The piping length is 7.5m.

Compressor overheat protection, Overcurrent protection, Serial signal error protection

-

3

-

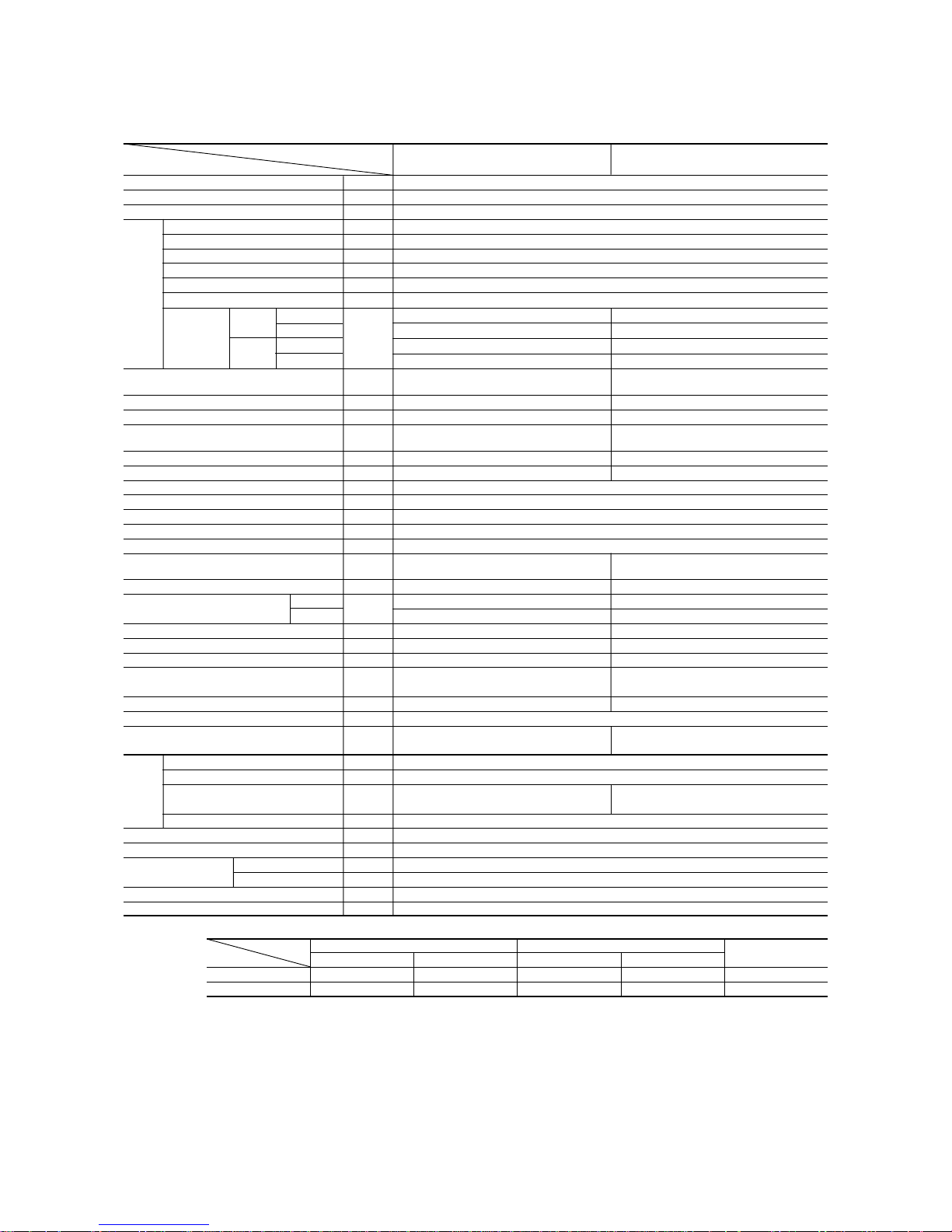

Item

Model

SRK40HD SRC40HD

Cooling capacity

(1)

W

Heating capacity

(1)

W

Power source 1 Phase, 220/230/240V, 50Hz

Cooling input kW

Running current (Cooling) A

Heating input kW

Running current (Heating) A

Inrush current A

COP

Cooling

sound level

Noise level

Power level

dB

(56) (63)

Heating

sound level

Power level (57) (64)

Exterior dimensions

Height × Width × Depth

mm

250 × 815 × 249 640 × 850 × 290

Color Cool white Stucco white

Net weight kg 9.0 41

Refrigerant equipment

Compressor type & Q’ty

– (RM5517GNE4)

Motor kW – 1.3

Starting method – Line starting

Heat exchanger Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Refrigerant

(3)

kg R22 (Pre-Charged up to the piping length of 7.5m)

Refrigerant oil R 0.6 (BARREL FREEZE 32SAM)

Deice control MC control

Air handling equipment

Fan type & Q’ty

Tangential fan × 1 Propeller fan × 1

Motor W 14 35

(Cooling) 9.0 38

Air flow (at High)

(Heating)

CMM

9.5 38

Air filter, Q’ty

Polypropylene net (washable) × 2

–

Shock & vibration absorber – Cushion rubber (for compressor)

Electric heater ––

Operation control

Operation switch

Wireless-Remote controller –

Room temperature control MC. Thermostat –

Pilot lamp RUN (Green), TIMER (Yellow), HI POWER (Green), ECONO (Orange)

Safety equipment

O.D mm (in) Liquid line: φ6.35 (1/4″) Gas line: φ12.7 (1/2″)

Connecting method Flare connecting

Attached length of piping Liquid line: 0.4 m

Gas line : 0.33 m

–

Insulation Necessary (Both sides)

Drain hose Connectable

Power source cord 2.5 m (3 cores with Earth)

Size × Core number 1.5 mm2 × 4 cores (Including earth cable)

Connection wiring

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Optional parts –

Notes (1) The data are measured at the following conditions.

Model SRK40HD (Indoor unit)

SRC40HD (Outdoor unit)

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27ºC 19ºC 35ºC 24ºC ISO-T1, JIS C9612

Heating 20ºC – 7ºC 6ºC ISO-T1, JIS C9612

(2) The operation data are applied to the 220/230/240V districts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 7.5 m connecting piping.

If the piping length is longer, when it is less than 10 m, add 20 g refrigerant per meter and when it is 10 to 15 m, add 30 g refrigerant per meter.

Operation data

(1)

Refrigerant

piping

The piping length is 7.5m.

Frost protection, Serial signal error protection

Fan motor error protection

Compressor overheat protection, Overcurrent protection, Serial signal error protection

Loading...

Loading...