Mitsubishi Heavy Industries SRK20ZMXA-S, SRK25ZMXA-S, SRK50ZMXA-S, SRK35ZMXA-S, SRK20ZMX-S Technical Manual

...

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air to air heat pump type)

SRK20ZMXA-S

SRK25ZMXA-S

SRK35ZMXA-S

SRK50ZMXA-S

SRK60ZMXA-S

Manual No.'14

•

SRK-T-155

-

1

-

'14 • SRK-T-155

TECHNICAL MANUAL

-

2

-

'14 • SRK-T-155

'10 • SRK-T-105

CONTENTS

1. SPECIFICATIONS ........................................................................................ 4

(2) Outdoor units ....................................................................................... 10

..................................................... 23

(3) Remote control

..................................................................................... 12

......................................................................... 9

(1) Indoor units .......................................................................................... 9

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING .............................................................................. 14

(1) Indoor units .......................................................................................... 14

4. NOISE LEVEL ............................................................................................ 17

(2) Outdoor units ....................................................................................... 15

6. RANGE OF USAGE & LIMITATIONS

................................................................................... 25

7. CAPACITY TABLES

5. PIPING SYSTEM ...................................................................................... 22

.................................................................................. 27

8. APPLICATION DATA

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............... 47

(10) Timer operation

.................................................................................. 52

(9) 3D auto operation

........................................................................... 51

............................... 48

(1) Operation control function by wireless remote control

(8) Flap and louver control ...................................................................... 50

(5) Selection of the annual cooling function .............................................. 49

(4) Installing two air conditioners in the same room

......................................................................... 48(3) Auto restart function

(2) Unit ON/OFF button

........................................................................... 48

....................... 47

(11) Silent mode .................................................................................... 52

(13) Installation location setting ........................................................... 52

(12) Night setback .................................................................................. 52

(14) Outline of heating operation ................................................................ 53

(16) Outline of dry (dehumidifying) opration .............................................. 55

(15) Outline of cooling operation ............................................................... 54

(1) Installation of indoor unit ...................................................................... 27

(2) Installation of outdoor unit .................................................................. 31

(7) Economy operation

.............................................................................. 49

(6) High power operation ........................................................................... 49

(17) Outline of automatic operation ........................................................... 55

(18) Protective control function

................................................................... 56

(19) DRED

................................................................................................... 64

-

3

-

'14 • SRK-T-155

(10) How to make sure of wireless remote control ...................................... 83

(12) Outdoor unit inspection points .............................................................. 84

(11) Inspection procedure for blown fuse on the indoor and outdoor PCB .... 83

(8)

Phenomenon observed after shortcircuit, wire breakage on sensor

......... 81

(9) Checking the indoor electrical equipment

........................................... 81

■How to read the model name

Example: SRK 20 Z

Series code

Inverter type

Product capacity (Cooling capacity : 2.0kW)

Model name SRK : Wall mounted type

SRC : Outdoor unit

MXA-S

........................................................................................... 87

11. OPTION PARTS

.............................................................. 87

..................................................................... 93

(1) Wired remote control (RC-E5)

(2) Interface kit (SC-BIKN-E)

(3) Super link E board (SC-ADNA-E) .......................................................... 97

(6) Service mode (Trouble mode access function) ................................... 68

(7) Inspection procedures corresponding to detail of trouble .................... 76

..................... 66

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

........ 65

(2) Items to check before troubleshooting ................................................. 65

(5) Self-diagnosis table ............................................................................. 67

............................................................................... 65

(1) Cautions

............................................................................................. 65

10. MAINTENANCE DATA

-

4

-

'14 • SRK-T-155

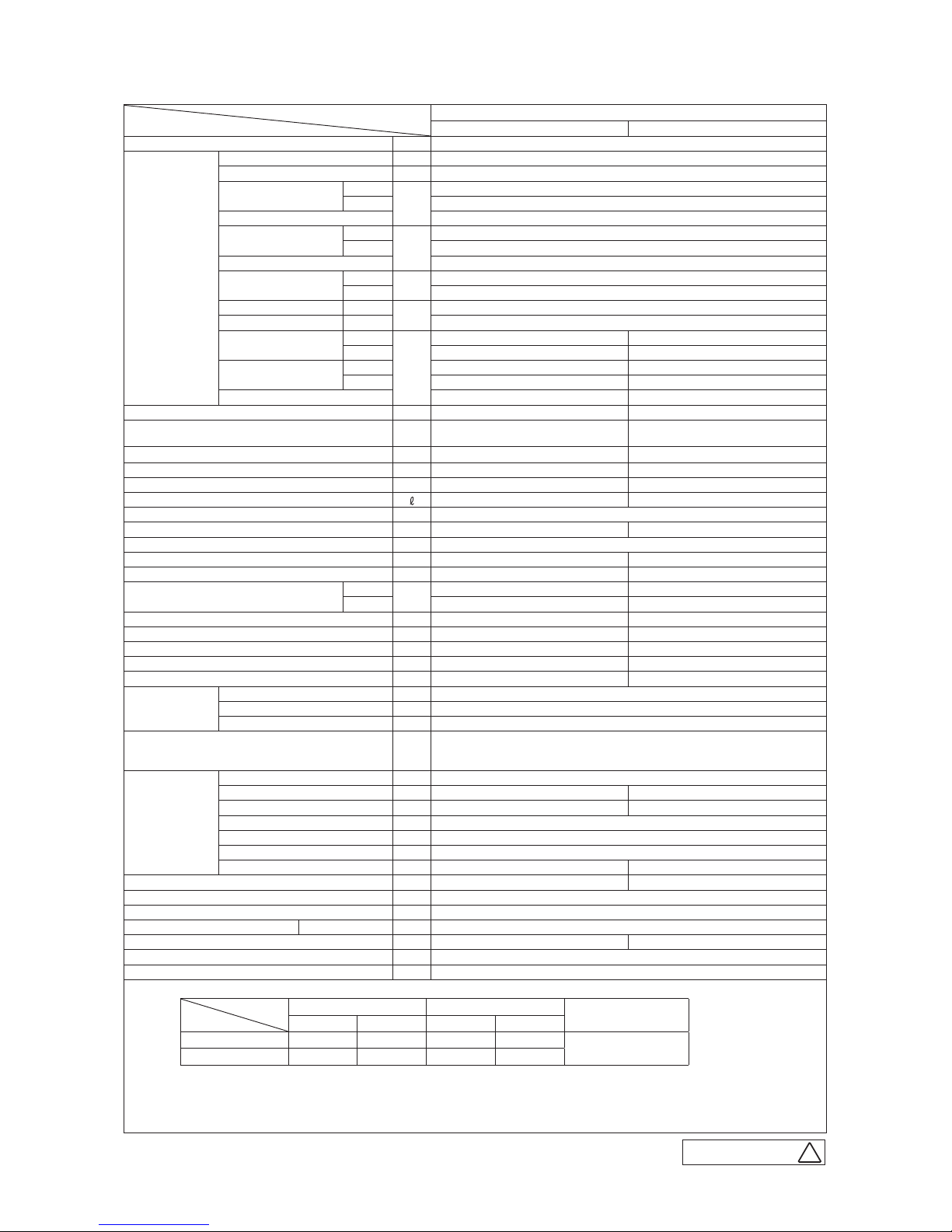

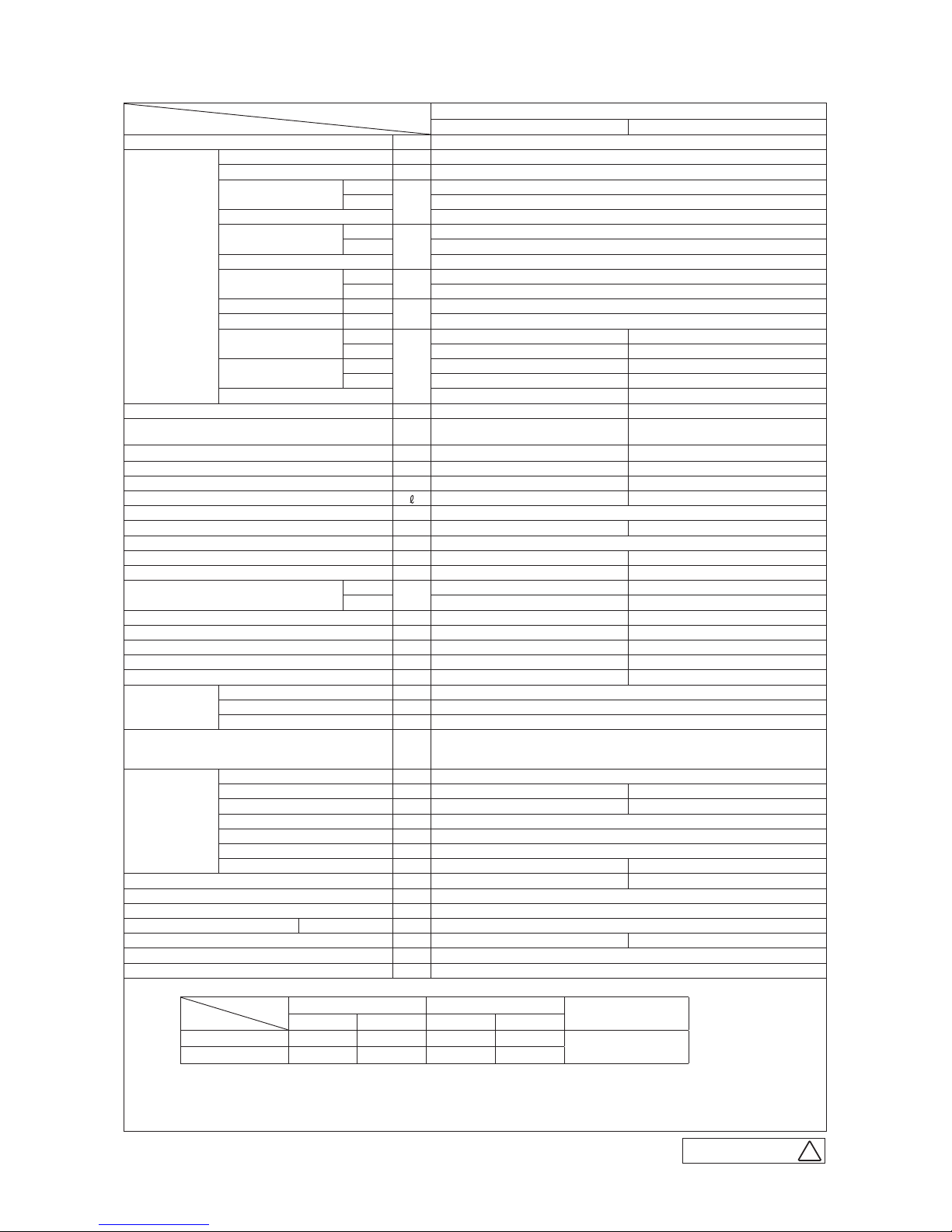

1. SPECIFICATIONS

Model

Item

SRK20ZMXA-S

Indoor unit SRK20ZMXA-S Outdoor unit SRC20ZMXA-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 2.0 ( 0.9 (Min.) - 3.1 (Max.))

Nominal heating capacity (range) kW 2.5 ( 0.9 (Min.) - 4.3 (Max.))

Power

consumption

Cooling

kW

0.35 ( 0.19 - 0.70 )

Heating 0.45 ( 0.23 - 1.00 )

Max power consumption 1.65

Running

current

Cooling

A

1.9 / 1.8 / 1.7 (220/ 230/ 240 V)

Heating 2.4 / 2.3 / 2.2 (220/ 230/ 240 V)

Inrush current, max current 2.4 / 2.3 / 2.2 (220/ 230/ 240 V) Max. 8

Power factor

Cooling

%

85

Heating 86

EER Cooling 5.71

COP Heating 5.56

Sound power level

Cooling

dB(A)

53 60

Heating 54 59

Sound pressure level

Cooling Hi: 39 Me: 30 Lo: 24 ULo: 21 47

Heating Hi: 38 Me: 33 Lo: 25 ULo: 21 47

Silent mode sound pressure level — Cooling:40 / Heating:42

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780(+62) x 290

Exterior appearance

( Munsell color )

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 13.5 35

Compressor type & Q'ty — RM-B5077MDE1( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.2 in outdoor unit (incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 11.5 Me: 8.0 Lo: 6.3 ULo: 5.0 29.5

Heating Hi: 12.0 Me: 9.5 Lo: 7.0 ULo: 6.3 27.0

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net ( washable ) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green, ECONO: Blue

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.49 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 15

Vertical height diff. between O.U. and I.U.

m Max. 10 (Outdoor unit is higher) / Max. 10 (Outdoor unit is lower)

Drain hose

Hose connectable ( VP 16 ) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 2.4 / 2.3 / 2.2 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Option parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) This air-conditioner is compliant with DRED (AS/NZS 4755.3.1), and can operate with DRM1, 2 or 3, and is equipped with a terminal

block for DRED.

The pipe length is 7.5m.

C

RWA000Z252

-

5

-

'14 • SRK-T-155

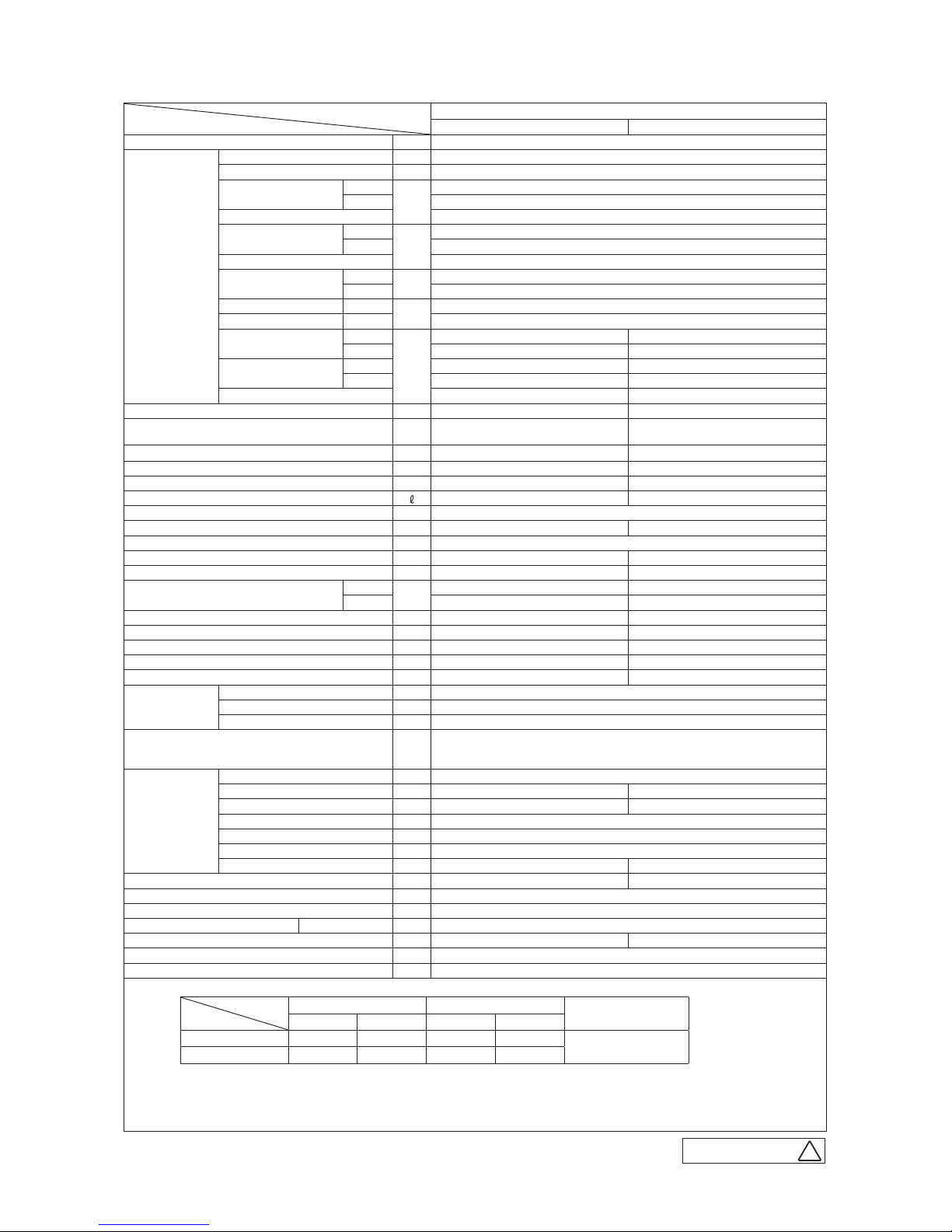

Model

Item

SRK25ZMXA-S

Indoor unit SRK25ZMXA-S Outdoor unit SRC25ZMXA-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 2.55 ( 0.9 (Min.) - 3.2 (Max.))

Nominal heating capacity (range) kW 3.13 ( 0.9 (Min.) - 4.7 (Max.))

Power

consumption

Cooling

kW

0.49 ( 0.19 - 0.82 )

Heating 0.595 ( 0.23 - 1.12 )

Max power consumption 1.65

Running

current

Cooling

A

2.5 / 2.4 / 2.3 (220/ 230/ 240 V)

Heating 3.1 / 2.9 / 2.8 (220/ 230/ 240 V)

Inrush current, max current 3.1 / 2.9 / 2.8 (220/ 230/ 240 V) Max. 8

Power factor

Cooling

%

90

Heating 88

EER Cooling 5.20

COP Heating 5.26

Sound power level

Cooling

dB(A)

55 60

Heating 58 60

Sound pressure level

Cooling Hi: 41 Me: 31 Lo: 25 ULo: 22 47

Heating Hi: 41 Me: 34 Lo: 27 ULo: 21 47

Silent mode sound pressure level — Cooling:41 / Heating:42

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780(+62) x 290

Exterior appearance

( Munsell color )

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 13.5 35

Compressor type & Q'ty — RM-B5077MDE1( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.75 ( Inverter driven )

Refrigerant oil (Amount, type) — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.2 in outdoor unit (incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 12.5 Me: 9.0 Lo: 6.3 ULo: 5.0 29.5

Heating Hi: 13.0 Me: 10.0 Lo: 7.5 ULo: 6.3 27.0

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net ( washable ) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green, ECONO: Blue

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.49 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 15

Vertical height diff. between O.U. and I.U.

m Max. 10 (Outdoor unit is higher) / Max. 10 (Outdoor unit is lower)

Drain hose

Hose connectable ( VP 16 ) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 3.1 / 2.9 / 2.8 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Option parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) This air-conditioner is compliant with DRED (AS/NZS 4755.3.1), and can operate with DRM1, 2 or 3, and is equipped with a terminal

block for DRED.

The pipe length is 7.5m.

C

RWA000Z252

-

6

-

'14 • SRK-T-155

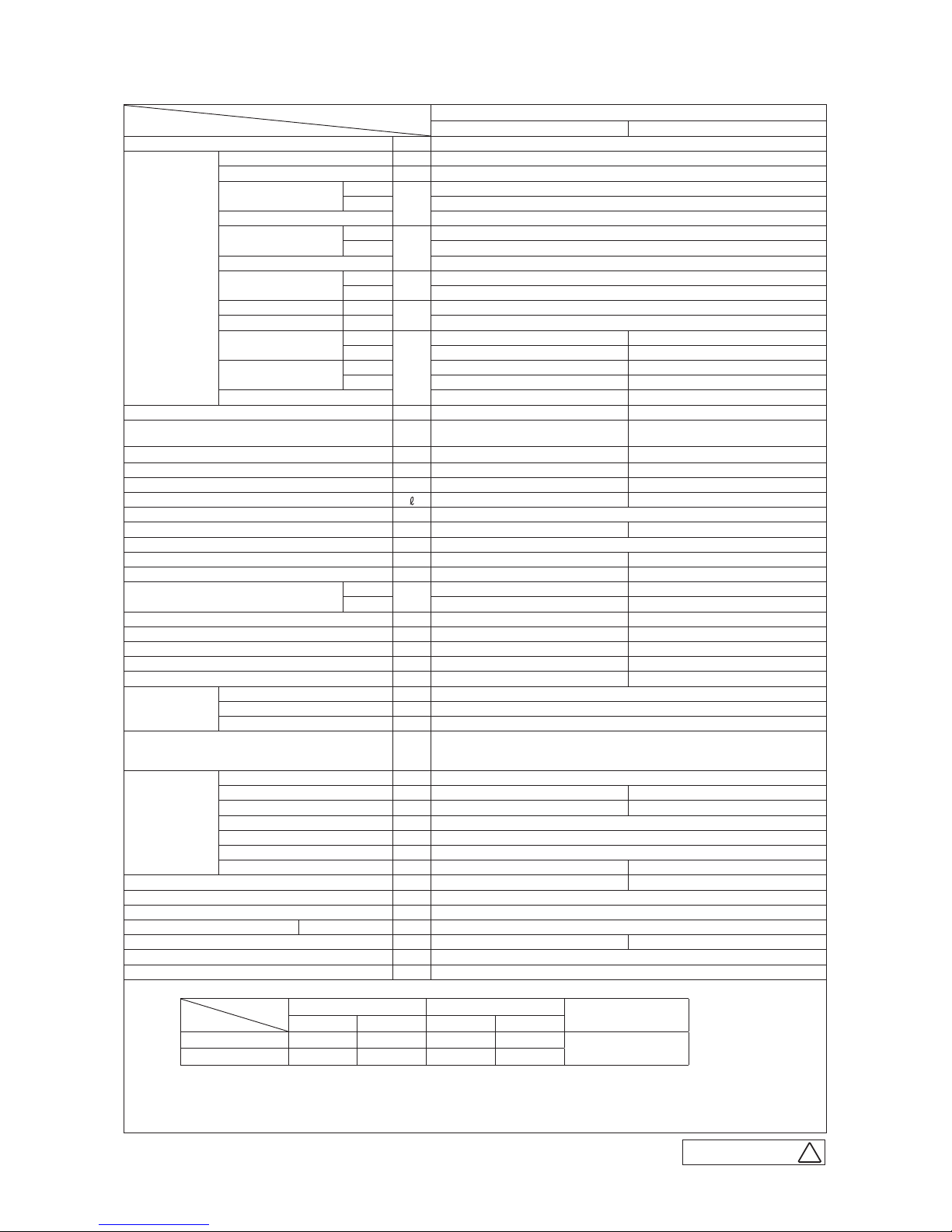

Model

Item

SRK35ZMXA-S

Indoor unit SRK35ZMXA-S Outdoor unit SRC35ZMXA-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 3.5 ( 0.9 (Min.) - 4.1 (Max.))

Nominal heating capacity (range) kW 4.3 ( 0.9 (Min.) - 5.1 (Max.))

Power

consumption

Cooling

kW

0.845 ( 0.19 - 1.01 )

Heating 0.960 ( 0.23 - 1.35 )

Max power consumption 1.65

Running

current

Cooling

A

4.0 / 3.8 / 3.6 (220/ 230/ 240 V)

Heating 4.6 / 4.4 / 4.2 (220/ 230/ 240 V)

Inrush current, max current 4.6 / 4.4 / 4.2 (220/ 230/ 240 V) Max. 8

Power factor

Cooling

%

97

Heating 95

EER Cooling 4.14

COP Heating 4.48

Sound power level

Cooling

dB(A)

58 63

Heating 59 62

Sound pressure level

Cooling Hi: 43 Me: 33 Lo: 25 ULo: 22 50

Heating Hi: 42 Me: 35 Lo: 27 ULo: 22 50

Silent mode sound pressure level — Cooling:45 / Heating:43

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 595 x 780(+62) x 290

Exterior appearance

( Munsell color )

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 13.5 35

Compressor type & Q'ty — RM-B5077MDE1( Rotary type ) x 1

Compressor motor (Starting method) kW — 0.90 ( Inverter driven )

Refrigerant oil (Amount, type) — 0.35 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.2 in outdoor unit (incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 30 x1 (Direct drive) 24 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 13.5 Me: 9.5 Lo: 6.5 ULo: 5.0 32.5

Heating Hi: 14.0 Me: 11.0 Lo: 8.0 ULo: 6.5 29.5

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net ( washable ) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green, ECONO: Blue

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ9.52 (3/8")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.49 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 15

Vertical height diff. between O.U. and I.U.

m Max. 10 (Outdoor unit is higher) / Max. 10 (Outdoor unit is lower)

Drain hose

Hose connectable ( VP 16 ) Holes φ20 x 2 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 4.6 / 4.4 / 4.2 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Option parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) This air-conditioner is compliant with DRED (AS/NZS 4755.3.1), and can operate with DRM1, 2 or 3, and is equipped with a terminal

block for DRED.

The pipe length is 7.5m.

C

RWA000Z252

-

7

-

'14 • SRK-T-155

Model

Item

SRK50ZMXA-S

Indoor unit SRK50ZMXA-S Outdoor unit SRC50ZMXA-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 5.0 ( 1.1 (Min.) - 5.8 (Max.))

Nominal heating capacity (range) kW 6.0 ( 0.6 (Min.) - 7.7 (Max.))

Power

consumption

Cooling

kW

1.30 ( 0.2 - 1.80 )

Heating 1.36 ( 0.2 - 2.43 )

Max power consumption 2.9

Running

current

Cooling

A

6.0 / 5.7 / 5.5 (220/ 230/ 240 V)

Heating 6.2 / 6.0 / 5.7 (220/ 230/ 240 V)

Inrush current, max current 6.2 / 6.0 / 5.7 (220/ 230/ 240 V) Max. 15

Power factor

Cooling

%

99

Heating 99

EER Cooling 3.85

COP Heating 4.41

Sound power level

Cooling

dB(A)

60 63

Heating 64 63

Sound pressure level

Cooling Hi: 47 Me: 40 Lo: 27 ULo: 25 54

Heating Hi: 48 Me: 40 Lo: 33 ULo: 26 50

Silent mode sound pressure level — Cooling:45 / Heating:45

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 640 x 800(+71) x 290

Exterior appearance

( Munsell color )

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 13.5 45.5

Compressor type & Q'ty — RMT5113MCE2( Twin Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) — 0.45 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.5 in outdoor unit (incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 30 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 13.5 Me: 11.0 Lo: 8.0 ULo: 7.0 39.0

Heating Hi: 17.0 Me: 14.5 Lo: 10.5 ULo: 8.0 33.0

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net ( washable ) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green, ECONO: Blue

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.49 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 30

Vertical height diff. between O.U. and I.U.

m Max. 20 (Outdoor unit is higher) / Max. 20 (Outdoor unit is lower)

Drain hose

Hose connectable ( VP 16 ) Holes φ20 x 5 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 6.2 / 6.0 / 5.7 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Option parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) This air-conditioner is compliant with DRED (AS/NZS 4755.3.1), and can operate with DRM1, 2 or 3, and is equipped with a terminal

block for DRED.

The pipe length is 7.5m.

C

RWA000Z252

-

8

-

'14 • SRK-T-155

Model

Item

SRK60ZMXA-S

Indoor unit SRK60ZMXA-S Outdoor unit SRC60ZMXA-S

Power source 1 Phase, 220 - 240V, 50Hz

Operation

data

Nominal cooling capacity (range) kW 6.0 ( 1.1 (Min.) - 6.8 (Max.))

Nominal heating capacity (range) kW 6.8 ( 0.6 (Min.) - 8.2 (Max.))

Power

consumption

Cooling

kW

1.86 ( 0.2 - 2.50 )

Heating 1.67 ( 0.2 - 2.70 )

Max power consumption 2.9

Running

current

Cooling

A

8.5 / 8.2 / 7.8 (220/ 230/ 240 V)

Heating 7.7 / 7.3 / 7.0 (220/ 230/ 240 V)

Inrush current, max current 8.5 / 8.2 / 7.8 (220/ 230/ 240 V) Max. 15

Power factor

Cooling

%

99

Heating 99

EER Cooling 3.23

COP Heating 4.07

Sound power level

Cooling

dB(A)

62 64

Heating 64 64

Sound pressure level

Cooling Hi: 51 Me: 41 Lo: 29 ULo: 25 54

Heating Hi: 48 Me: 41 Lo: 34 ULo: 27 54

Silent mode sound pressure level — Cooling:45 / Heating:45

Exterior dimensions (Height x Width x Depth) mm 309 x 890 x 220 640 x 800(+71) x 290

Exterior appearance

( Munsell color )

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 13.5 45.5

Compressor type & Q'ty — RMT5113MCE2( Twin Rotary type ) x 1

Compressor motor (Starting method) kW — 1.50 ( Inverter driven )

Refrigerant oil (Amount, type) — 0.45 (DIAMOND FREEZE MA68)

Refrigerant (Type, amount, pre-charge length) kg R410A 1.5 in outdoor unit (incl. the amount for the piping of 15m )

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Fan motor (Starting method) W 30 x1 (Direct drive) 34 x1 (Direct drive)

Air flow

Cooling

m3/min

Hi: 14.5 Me: 12.5 Lo: 8.5 ULo: 7.0 41.5

Heating Hi: 17.5 Me: 15.0 Lo: 11.0 ULo: 8.5 39.0

Available external static pressure Pa 0 0

Outside air intake Not possible —

Air filter, Quality / Quantity Polypropylene net ( washable ) x 2 —

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber sleeve (for fan motor & compressor)

Electric heater — —

Operation

control

Remote control Wireless remote control

Room temperature control Microcomputer thermostat

Operation display RUN: Green, TIMER: Yellow, HI POWER: Green, 3D AUTO: Green, ECONO: Blue

Safety equipments

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connection Flare connection

Attached length of piping m Liquid line : 0.55 / Gas line : 0.49 —

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length m Max. 30

Vertical height diff. between O.U. and I.U.

m Max. 20 (Outdoor unit is higher) / Max. 20 (Outdoor unit is lower)

Drain hose

Hose connectable ( VP 16 ) Holes φ20 x 5 pcs

Drain pump, max lift height mm — —

Recommended breaker size A 16

L.R.A. (Locked rotor ampere) A 8.6 / 8.2 / 7.9 (220/ 230/ 240 V)

Interconnecting wires Size x Core number 1.5mm2 x 4 cores (Including earth cable) / Terminal block (Screw fixing type)

IP number IPX0 IPX4

Standard accessories

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Option parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO5151-T1

Heating 20˚C — 7˚C 6˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) Sound level indicates the value in an anechoic chamber. During operation these values are somewhat higher due to ambient conditions.

(4) Select the breaker size according to the own national standard.

(5) This air-conditioner is compliant with DRED (AS/NZS 4755.3.1), and can operate with DRM1, 2 or 3, and is equipped with a terminal

block for DRED.

The pipe length is 7.5m.

C

RWA000Z252

-

9

-

'14 • SRK-T-155

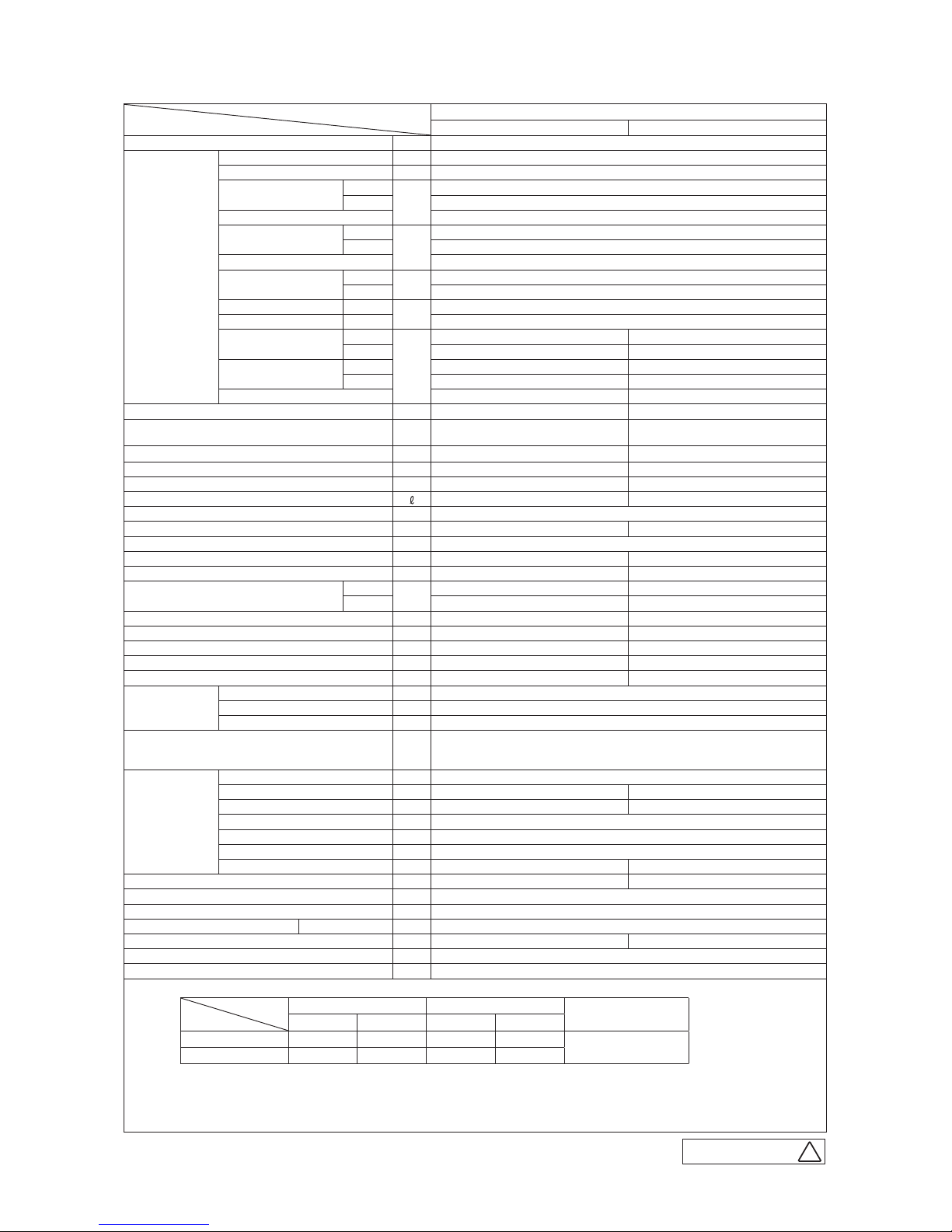

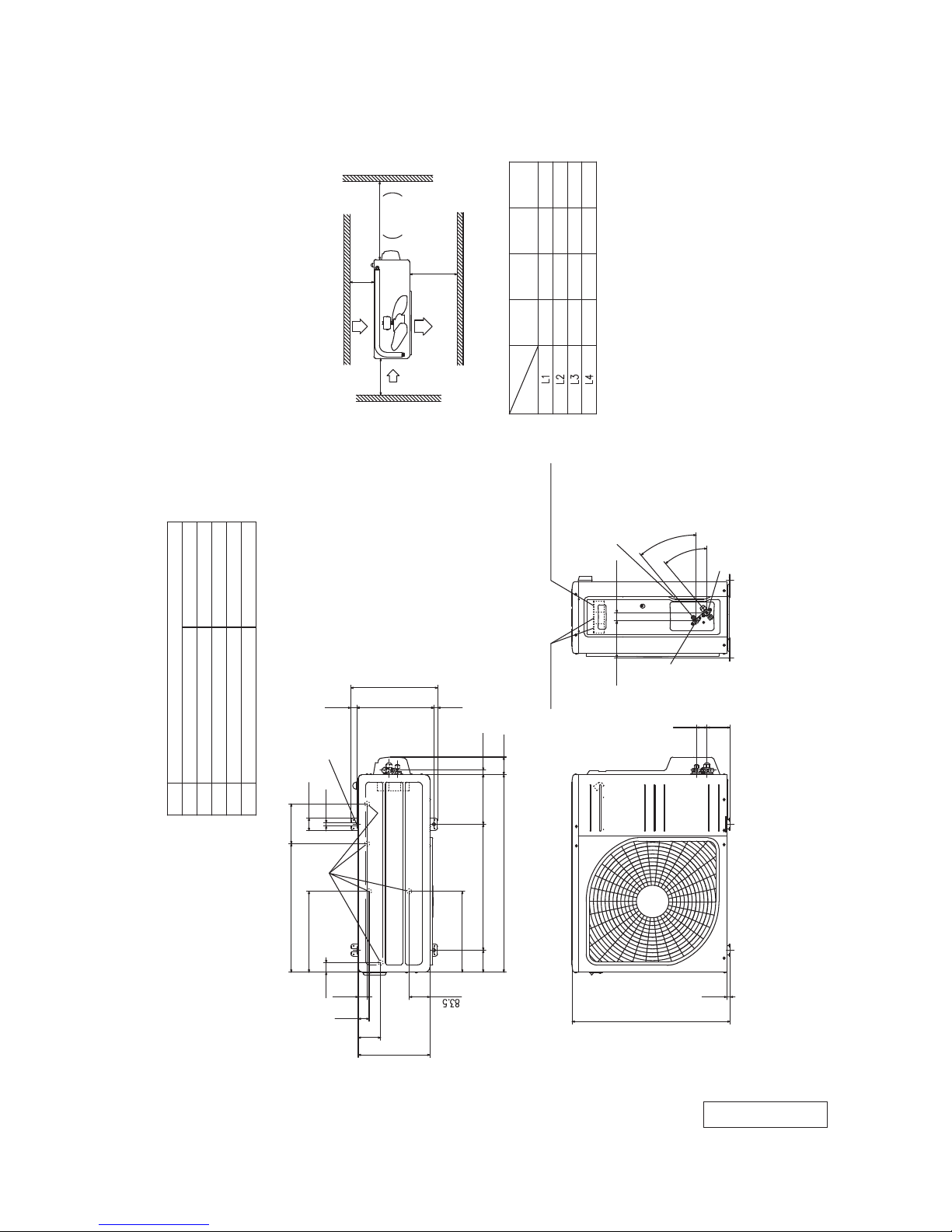

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK20ZMXA-S, 25ZMXA-S, 35ZMXA-S, 50ZMXA-S, 60ZMXA-S

RKY000Z056

26

59.9

46.5

61.5

881.9

20.959.9

46.5

61.5

890

309

Outlet for down piping

(Refer to the above view)

Installation plate

(Service space)

120

220

50

48.9222.5

650

450

35 35

48

58

D

A

E

B

120 100

220

Unit

491.1

520.8

559.1

C

Space for installation and service when viewing from the front

48

5.7

295.4

15 (Service space)

7.9

70

(Service space)

(Service space)

Terminal block

9 61.5

46.5

61.5

F

3220

G

Hole on wall for right rear piping

Hole on wall for left rear piping

Outlet for wiring

Drain hose

F

E

C

D

VP16

(φ65)

(φ65)

Outlet for piping (on both side)

G

Symbol

Content

Gas pipingA

Liquid pipingB

φ6.35(1/4")(Flare)

φ12.7(1/2")(Flare)

Model 50,60

φ9.52(3/8")(Flare)

Model 20,25,35

Wireless remote control

Wired - remote control

(Option)

120

19

Unit:mm

Notes(1)The model name label is attached

on the underside of the panel.

(2)It takes the interface kit (SC-BIKN-E)

to connect the wired remote control.

-

10

-

'14 • SRK-T-155

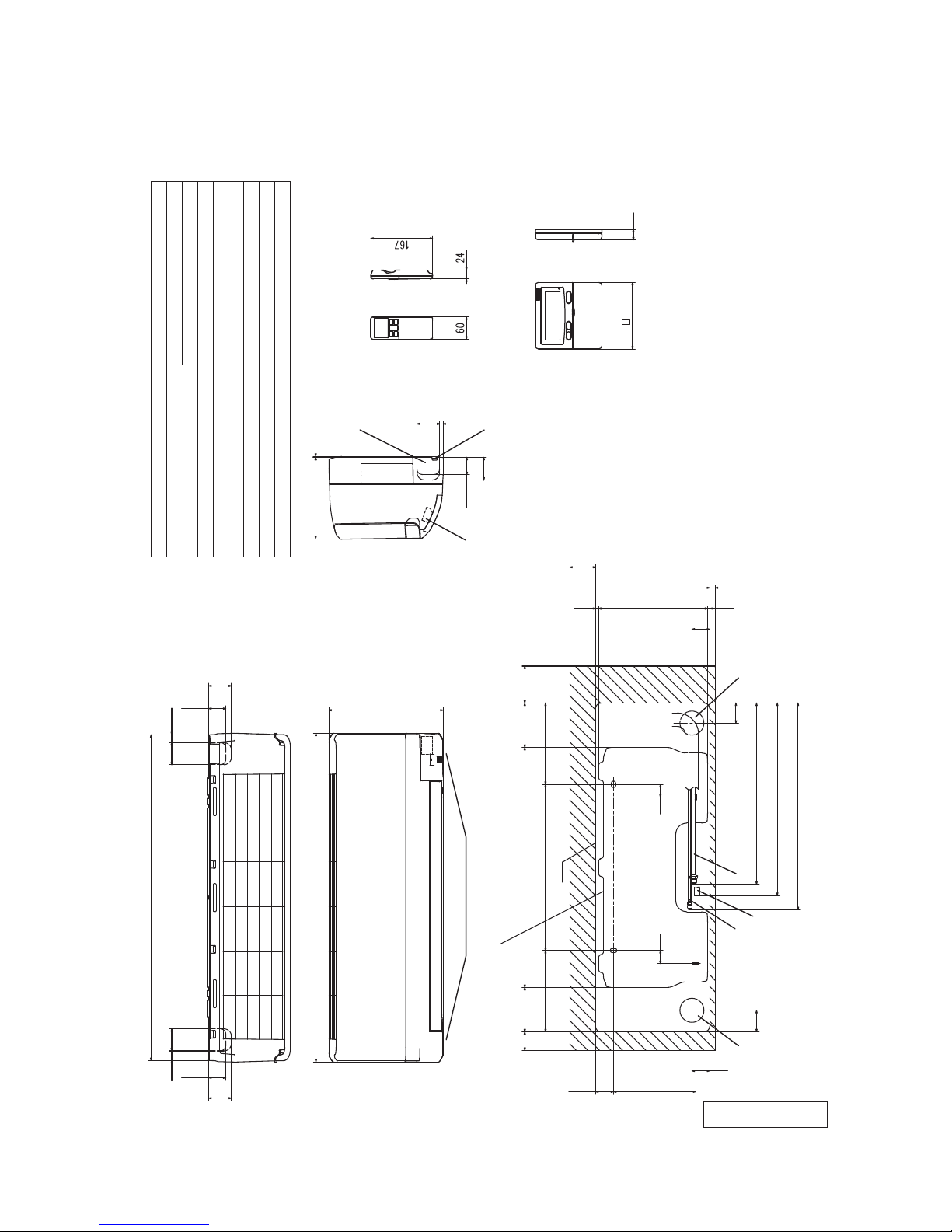

(2) Outdoor units

Models SRC20ZMXA-S, 25ZMXA-S, 35ZMXA-S

RCV000Z018

63.469.4

290

390.6

50.6

12

E

D

111.6

390.6

510

780

158.4

14.8

17.9

61.9

312.5 24.3

351.6

φ

9.52(3/8")(Flare)

Content

C

Pipe/cable draw-out hole

E

Anchor bolt hole

Drain discharge hole

Symbol

B

A

Service valve connection(gas side)

M10×4places

Service valve connection(liquid side)

φ

6.35(1/4")(Flare)

D

φ

20×2places

595

15.8

97.7

42.5

138.4

B

Terminal block

Terminal block

(For DRED AS/NZS 4755)

33.5

C

40°

40°

A

Notes

(1) It must not be surrounded by walls on the four sides.

(2)The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6)The model name label is attached on the lower right corner of the front panel.

Service

space

L2

Intake

Intake

L3

Outlet

L1

L4

Minimum installation space

Examples of

installation

Dimensions

L2L3L4

L1

I II III IV

100

100

250

Open

280

Open

80

75

Open

250

80

280

180

Open

80

Open

Unit:mm

-

11

-

'14 • SRK-T-155

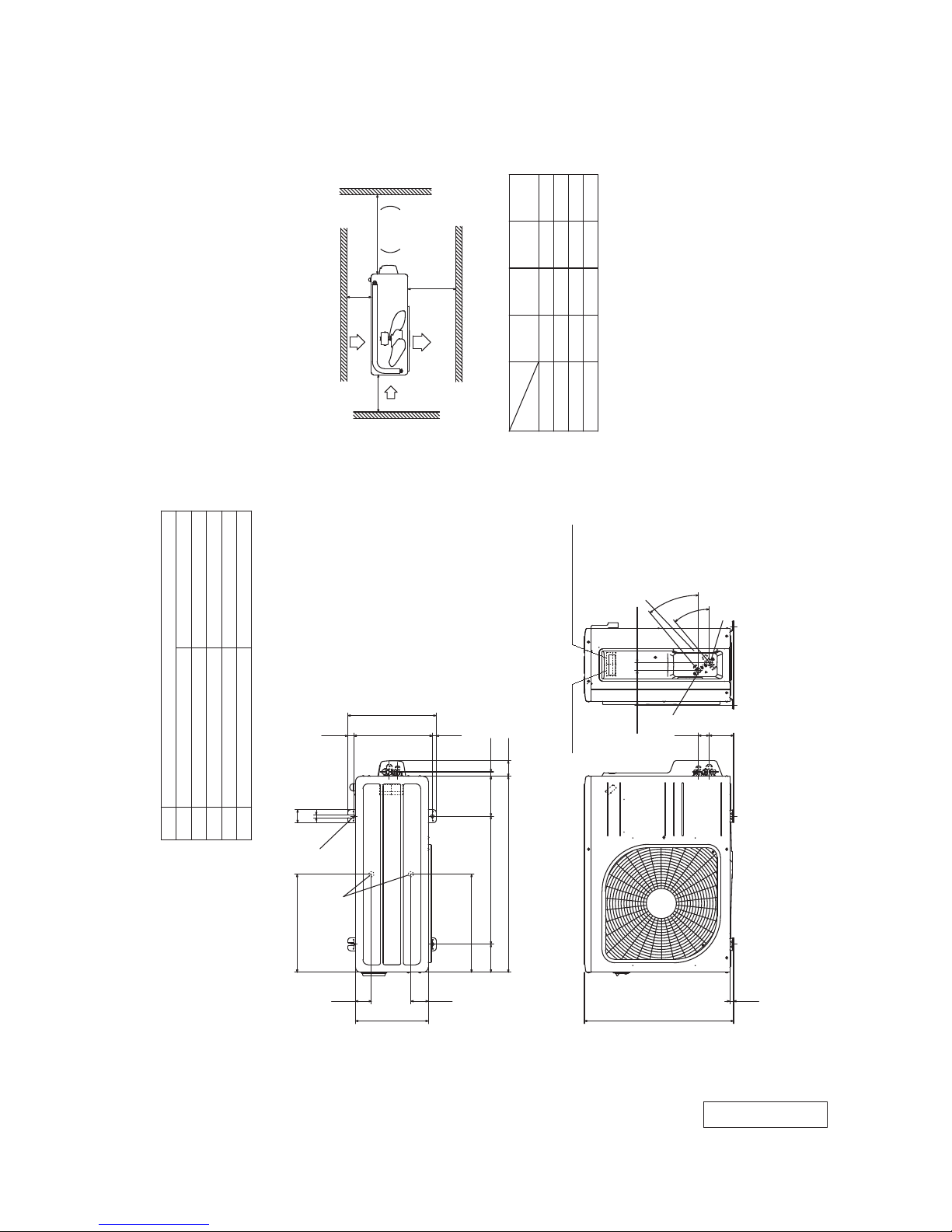

RCT000Z008

Models SRC50ZMXA-S, 60ZMXA-S

290

90.6

43.5

35.6

38.6

327.3

520.6

161

50.6

12

E

89

327.3

510

800

201

71.2

17.9

14.8

312.5

351.6

24.3

640

12.4

93

42.5

Terminal block

Terminal block

(For DRED AS/NZS 4755)

148.4

33.5

C

40°

40°

B

A

L2

Intake

Outlet

Intake

L3

L4

L1

Service

space

Examples of

Dimensions

installation

I II III IV

100

100

250

Open

Open

250

80

280 280

Open

80

75

180

Open

80

Open

Unit:mm

Minimum installation space

Content

C

Pipe/cable draw-out hole

D

E

Anchor bolt hole

Drain discharge hole

Symbol

B

A

Service valve connection(gas side)

M10×4places

Service valve connection(liquid side)

φ12.7(1 / 2" ( ) Flare)

φ

20×5places

φ6.35(1 / 4" ( ) Flare)

Notes

(1) It must not be surrounded by walls on the four sides.

(2)The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6)The model name label is attached on the right side of the unit.

D

-

12

-

'14 • SRK-T-155

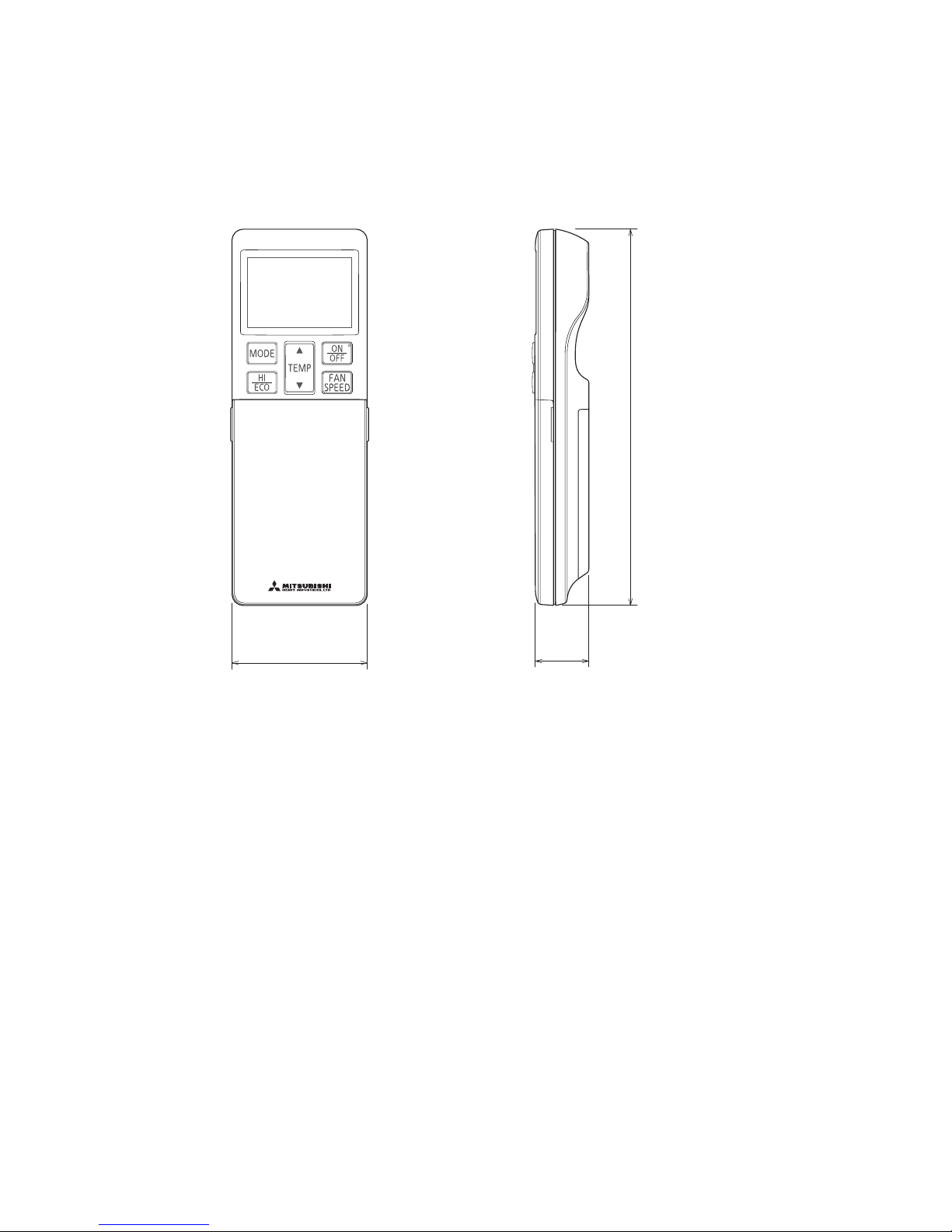

(3) Remote control

Unit : mm

60

26

167

(a) Wireless remote control

-

13

-

'14 • SRK-T-155

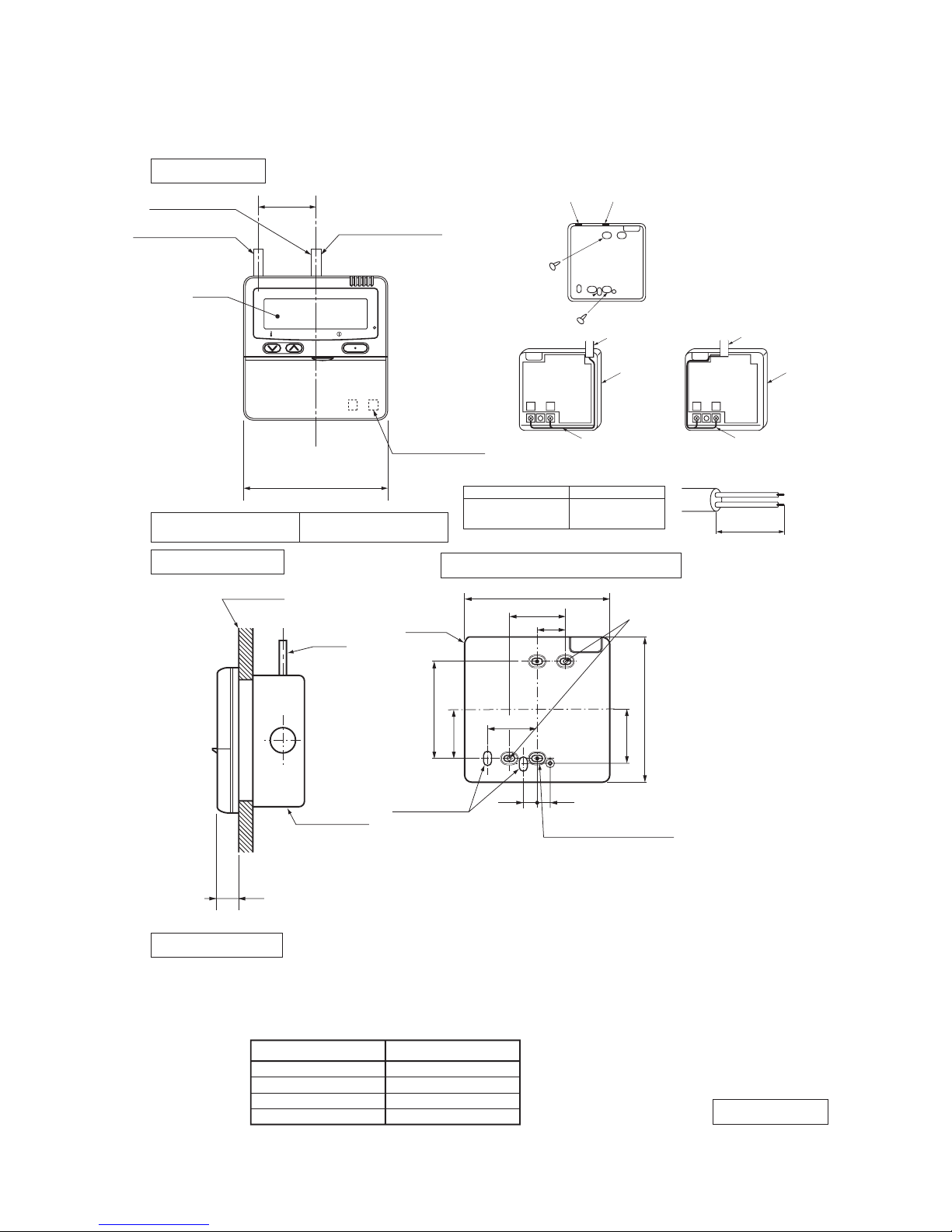

(b) Wired remote control (option parts)

Interface kit (SC-BIKN-E) is required to use the wired remote control.

PJZ000Z295

TEMP ON/OFF

48

□120

L C D

Wall surface

Wiring

Electrical box

(Not included)

19

Wiring specifications

Exposed mounting

23

46

11.5 11

Remote

control

outline

120

45

83.5

42

120

Remote control installation dimensions

Wiring oulet

Installation hole

12×7 Slot hole

9.5×5 Slot hole (4places)

(1) Installation screw for remote control

M4 Screw (2 pieces)

44

(1) If the prolongation is over 100m, change to the size below.

But, wiring in the remote control case should be under 0.5mm2. Change the wire size outside of

the case according to wire connecting. Waterproof treatment is necessary at the wire connecting

section. Be careful about contact failure.

Length Wiring thickness

100 to 200m

0.5mm2×2 cores

0.75mm2×2 cores

1.25mm2×2 cores

2.0mm2×2 cores

Under 300m

Under 400m

Under 600m

Upper part

Lower part

Lower case

Sheath

Upper cace

Board

Wiring

Upper

Lower

X Y

Sheath

Upper cace

Board

Wiring

Upper

Lower

YX

Tighten the screws after

cutting off the thin part of

screw mounting part.

Embedded mounting

Pearl WhiteExterior appearance

(Munsell color) (N8.5) near equivalent

The peeling-off length of sheath

The peeling-off length

of sheath

In case of pulling out from

upper left

In case of pulling out

from upper left

In case of pulling out

from upper left

X wiring : 170mm

Y wiring : 190mm

Pulling out from center

X wiring : 215mm

Y wiring : 195mm

Pulling out from upper left

In case of pulling out from center

In case of pulling out

from center

In case of pulling out

from center

Wiring outlet

Cut off the upper thin part of remote control lower case with a nipper or knife,

and grind burrs with a file etc.

0.3mm2×2 cores.

X, Y Terminal block

Attach M3 screw

with washer

Unit:mm

-

14

-

'14 • SRK-T-155

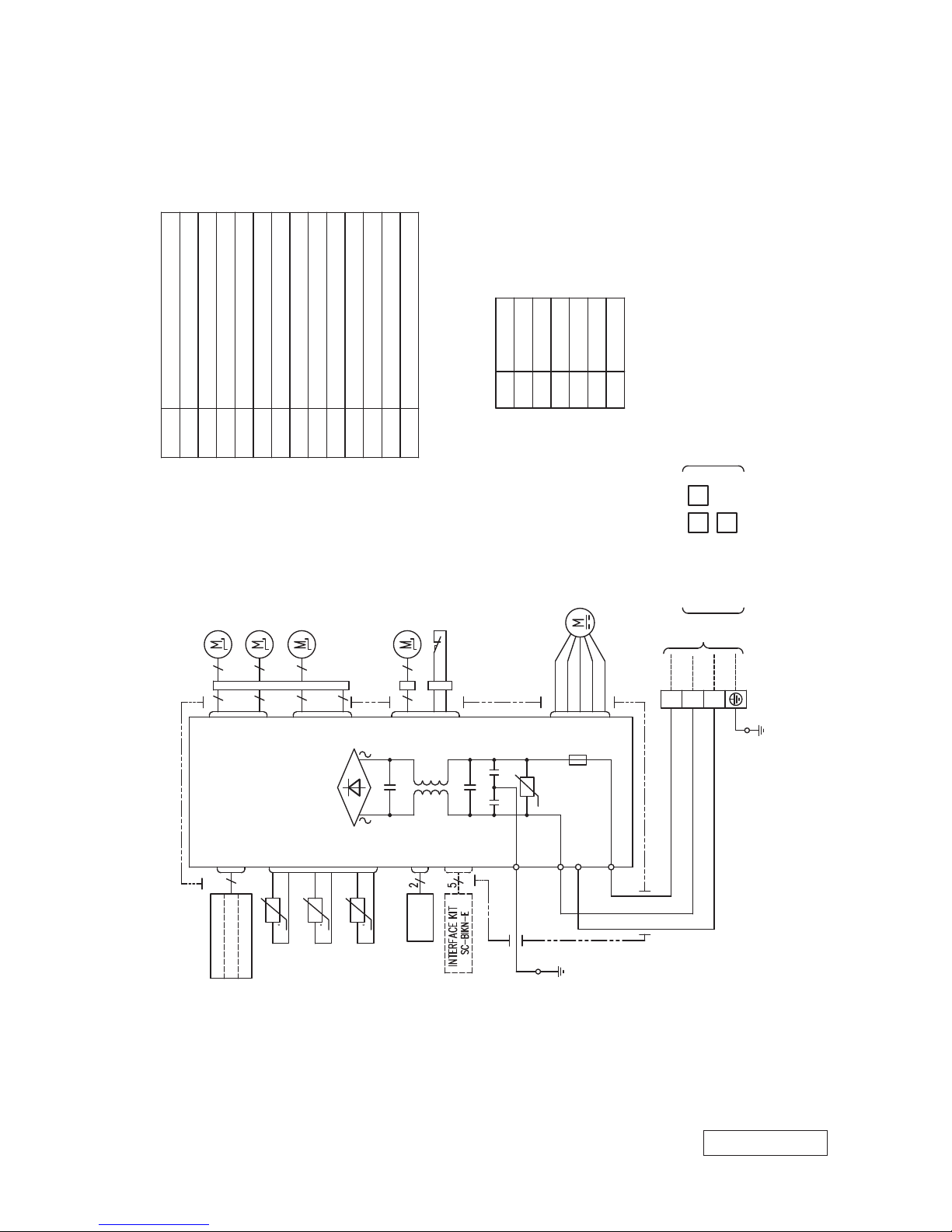

3. ELECTRICAL WIRING

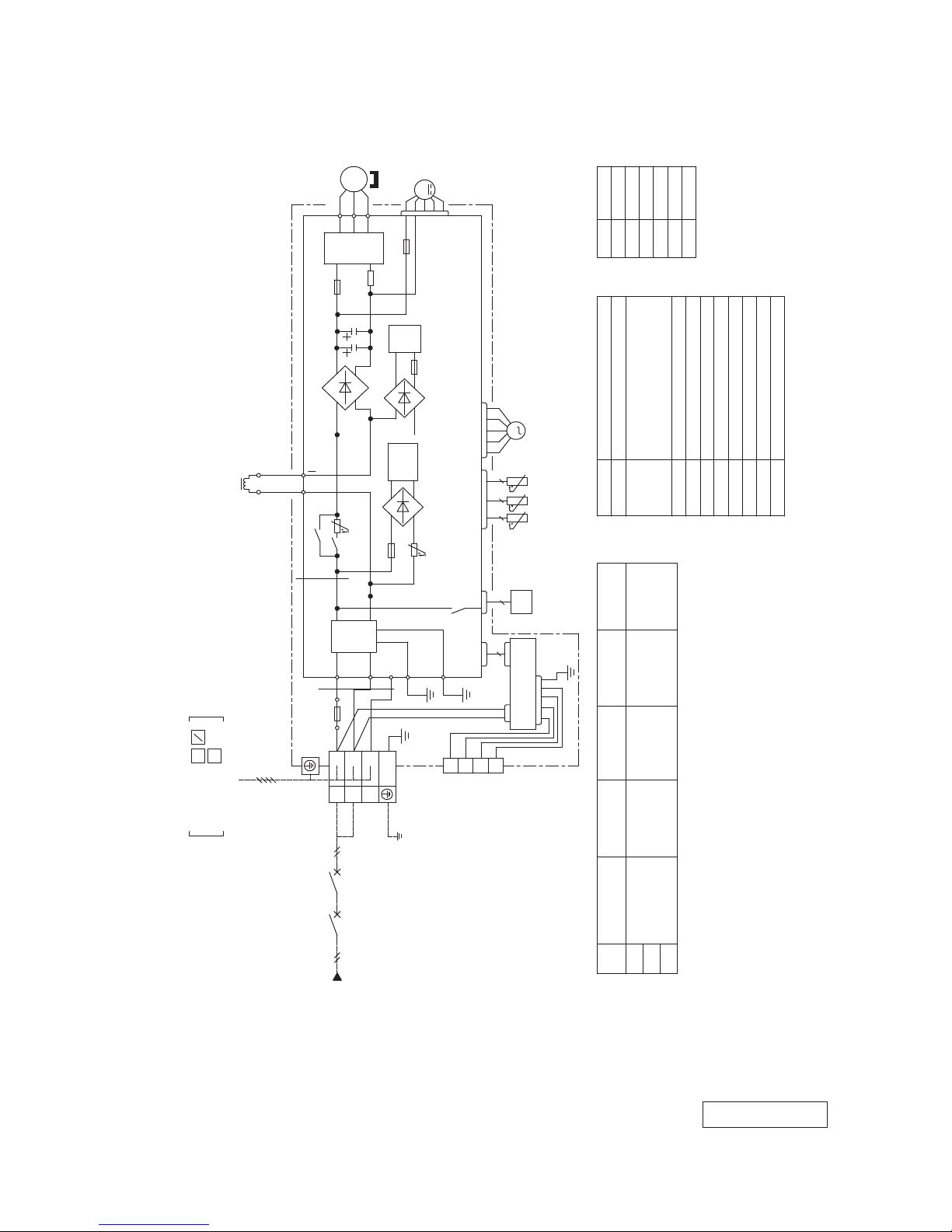

(1) Indoor units

Models SRK20ZMXA-S, 25ZMXA-S, 35ZMXA-S, 50ZMXA-S, 60ZMXA-S

RWA000Z256

WIRELESS RECEIVER

BACK-UP SW

DISPLAY

12

Th1

t

t

t

Th2

1

Th2

2

Th3

CNG

CNE

BOARD

CIRCUIT

PRINTED

CNX1

CNX2

DS

G

CNY

CNF

CNS

Y/G

S/N

WH

JRD

L

BK

HEAT

EXCHANGER

CNU

VaU

250V

3.15A

F

13456

5 5

5 5

5

5

5

5 5

LM

1

LM

2

SM

LS

IM

RDWHBKBLY

FM

I

Power source

1 phase 220 - 240 V 50Hz

TO OUTDOOR UNIT

1

2/N

3

T

HEAT

EXCHANGER

POWER WIRES

SIGNAL WIRE

1

2/N

3

Connector

DescriptionItem

CNE-CNY

Heat exch. sensor

Humidity sensor(50,60 only)

Fan motor

Room temp. sensor

Flap motor

Th1

Th2

1,2

Th3

Diode stack

DS

Fuse

F

FM

I

Terminal blockT

Louver motor

LM

1,2

SM

Limit switchLS

Inlet motor

IM

VaristorVa

Color Marks

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow/GreenY/G

YellowY

ColorMark

-

15

-

'14 • SRK-T-155

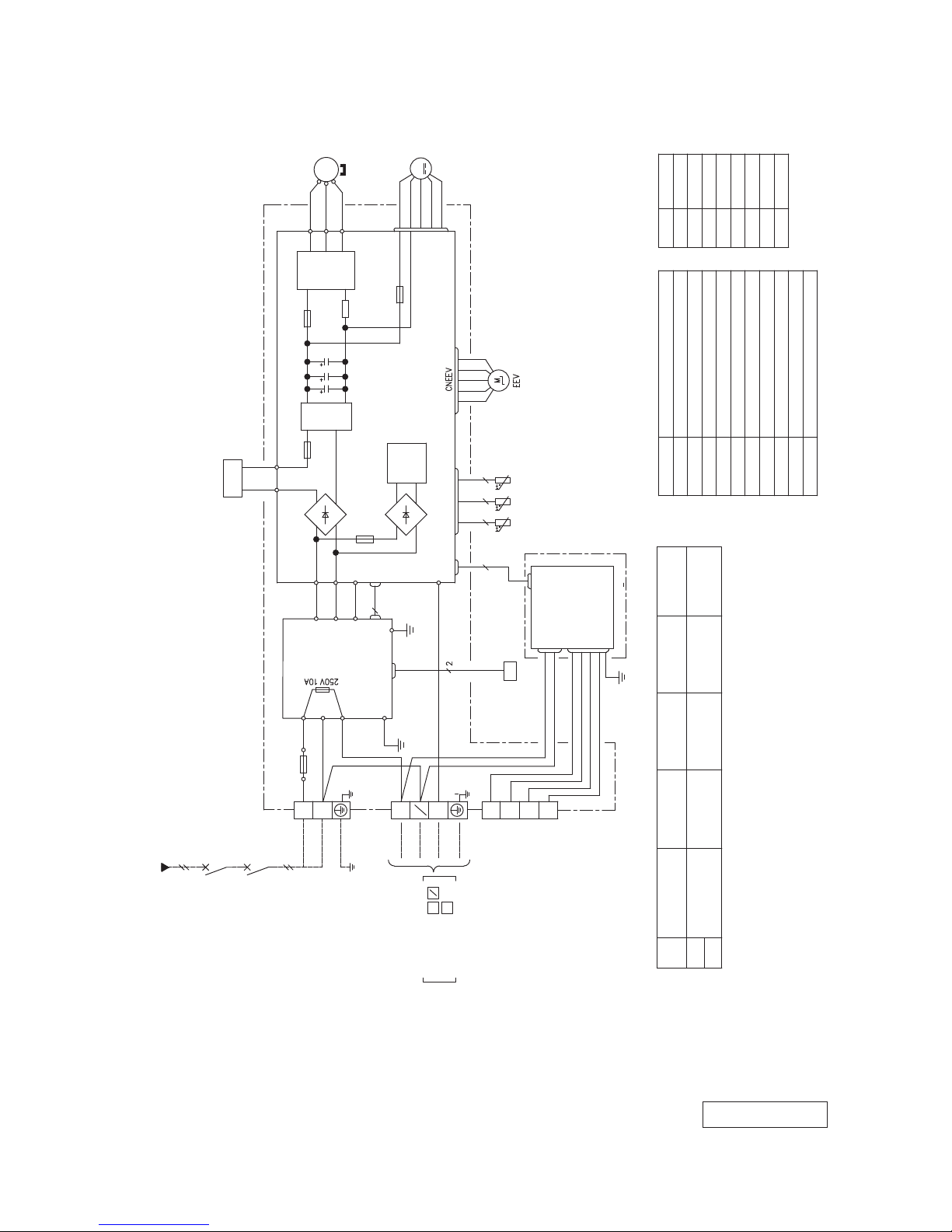

(2) Outdoor units

Models SRC20ZMXA-S, 25ZMXA-S, 35ZMXA-S

RWC000Z271

TO INDOOR UNIT

SIGNAL WIRE

POWER WIRES

3

1

2

N

POWER SOURCE

〜220ー240V50Hz/〜220V60Hz

TB1

TERMINAL

BLOCK

L

N

132

(BK)

250V 15A

(Y/G)

(BK)

(WH)

R.IN

(Y/G)

(Y/G)

(RD)

C-2G1G2

S.IN

FILTER

NOISE

TB2

TERMINAL

BLOCK

D1D2D3

C

(YE)

(RD)

(BL)

(BK)

(WH)

CNPOWER

CNDRED

(BK)

CNDRM

(Y/G)

PWB ASSY

PWB2

CNDRM

4

20S

2

CN20S

F1

250V 3.15A

(OR

)

(Y)

L

T1

T2

CIRCUIT

POWER

SWITCHING

F4

250V 10A

CIRCUIT

PAM

PWB ASSY PWB1

TRANSISTOR

POWER

250V 20A

F2

(BK)

(WH)

(RD)

W

V

U

W

V

U

N

P

M

3〜

CM

CNFAN

FMo

M

F3 250V 1A

CNTH CNEEV

2 2 2

TH2 TH3 TH4

EEV

M

The specifications shown in the above table are for units without heaters. For units with heaters, refer

to the installation instructions or the construction instructions of the indoor unit.

Switchgear of Circuit breaker capacity which is calculated from MAX. over current should be chosen

along the regulations in each country.

The cable specifications are based on the assumption that a metal or plastic conduit is used with no

more than three cables contained in a conduit and a voltage drop is 2%. For an installation falling

outside of these conditions, please follow the internal cabling regulations. Adapt it to the regulation

in effect in each country.

Power cable, indoor-outdoor connecting wires

MAX running current

(A)

20

Model

25

35

9(ZMA)

8(ZMXA)

Power cable size

(mm

2

)

2.0 32

Power cable length

(m)

indoor-outdoor

wire size x number

Earth wire size

(mm

2

)

1.51.5mm

2

x 3

DescriptionItem

Connector

Electric expansion valve(coil)

EEV

Fan motorFMo

ReactorL

Terminal blockTB1,2

Compressor motor

CM

Solenoid valve for 4 way valve20S

Heat exchanger sensor(outdoor unit)

TH2

Outdoor air temp.sensorTH3

TH4

Discharge pipe temp.sensor

CN20S

CNTH

CNEEV

CNFAN

Color

RD

Mark

OrangeORYellow/Green

Y/G

Black

BK

Yellow

Y

WhiteWH

Red

•

•

•

-

16

-

'14 • SRK-T-155

Models SRC50ZMXA-S, 60ZMXA-S

RWC000Z268

CN20S

POWER SOURCE

〜220-240V 50Hz

TB1

TERMINAL

BLOCK

N

L

(BK)

FUSE

250V 20A

(BK)

(WH)

(BR)

(Y/G)

PWB ASSY(SUB)

(WH)

TB2

BLOCK

TERMINAL

1

3

2

N

(Y/G)

TO INDOOR UNIT

POWER WIRES

SIGNAL WIRE

3

1

TB3

BLOCK

TERMINAL

D1D3D2

C

(BK)

(WH)

(YE)

(RD)

(BL)

(BK)

(Y/G)

20S

CNDRM

CNPOWER

CNDRED

PWB ASSY(DRED)

TH2 TH4TH3

2 2 2

4

CNDRM CNTH

(RD)

C-2

S

R

IN

IN

OUT

R

F10

(Y/G)

G1

CN20S

(Y/G)

R

O

O

S

S-1

CNMAIN

G3

(BK)

(WH)

(WH)

(BK)

4

SRS-2

CNSUB

F1

250V 3.15A

CIRCUIT

SWITCHING

POWER

250V 20A

ACTIVE

FILTER

UNIT

PWB ASSY(MAIN)

F8

250V 20A

F2

TRANSISTOR

POWER

P

N

W

V

U

W

V

U

2

N

R

(OR

)

(YE)

T2

T1

F3 250V 1A

CNFAN

(BK)

(WH)

(RD)

MS

3〜

CM

M

FMo

Power cable, indoor-outdoor connecting wires

Model

MAX running current Power cable size

(mm

2

)(A)

Power cable length

(m)

indoor-outdoor

wire size x number

Earth wire size

(mm

2

)

15 2.0 18 1.5mm

2

x 3 1.5

50

60

The specifications shown in the above table are for units without heaters. For units with heaters, refer

to the installation instructions or the construction instructions of the indoor unit.

Switchgear of Circuit breaker capacity which is calculated from MAX. over current should be chosen

along the regulations in each country.

The cable specifications are based on the assumption that a metal or plastic conduit is used with no

more than three cables contained in a conduit and a voltage drop is 2%. For an installation falling

outside of these conditions, please follow the internal cabling regulations. Adapt it to the regulation

in effect in each country.

Description

Item

Connector

CNEEV〜CN20S

Electric expansion valve(coil)

EEV

Fan motor

FMo

ReactorRTerminal blockTB1,2,3

Compressor motor

CM

Solenoid valve for 4 way valve

20S

Heat exchanger sensor(outdoor unit)

TH2

Outdoor air temp.sensor

TH3

TH4

Discharge pipe temp.sensor

Mark

BK

BRORRDWHYEBLY/G Yellow/Green

Blue

Yellow

White

Red

Orange

Brown

Boack

Color

•

•

•

-

17

-

'14 • SRK-T-155

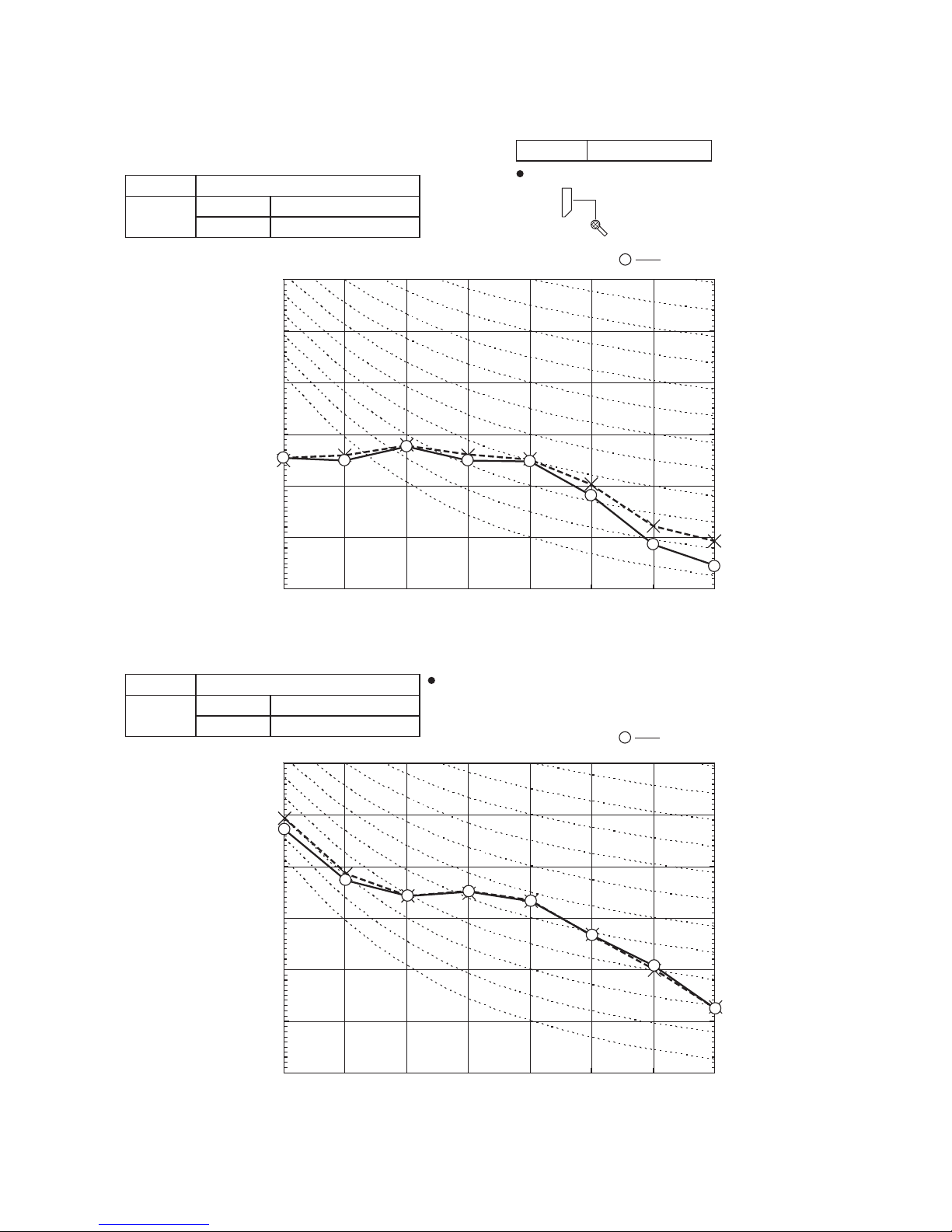

(Indoor Unit)

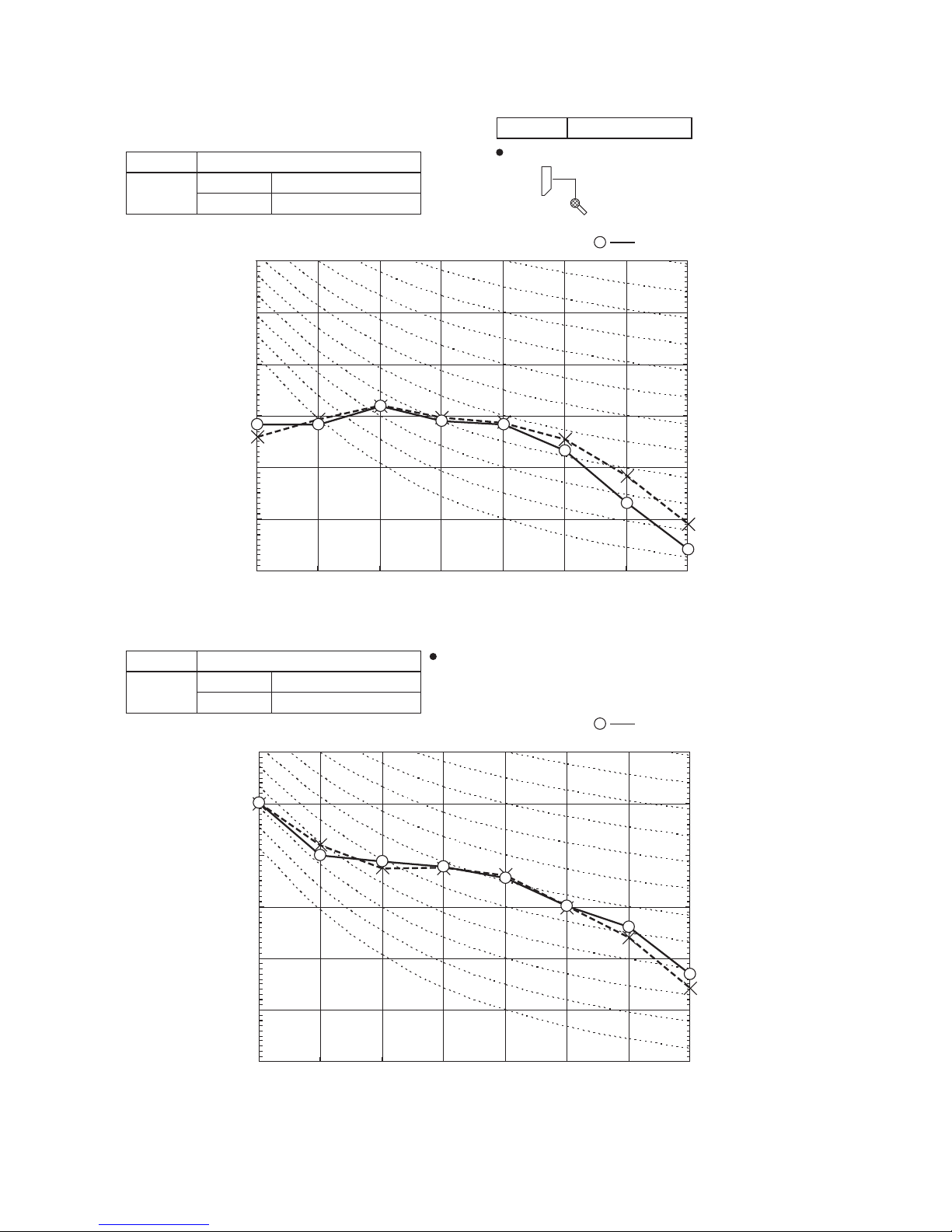

Model SRK20ZMXA-S

Noise

Level

Cooling 39 dB(A)

Heating 38 dB(A)

×

......

Cooling, Heating

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

(Outdoor Unit)

Model SRC20ZMXA-S

Noise

Level

Cooling 47 dB(A)

Heating 47 dB(A)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N40

N60

N70

N20

N30

×

......

Cooling, Heating

Condition ISO-T1,JIS C 9612

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

4. NOISE LEVEL

Model SRK20ZMXA-S

-

18

-

'14 • SRK-T-155

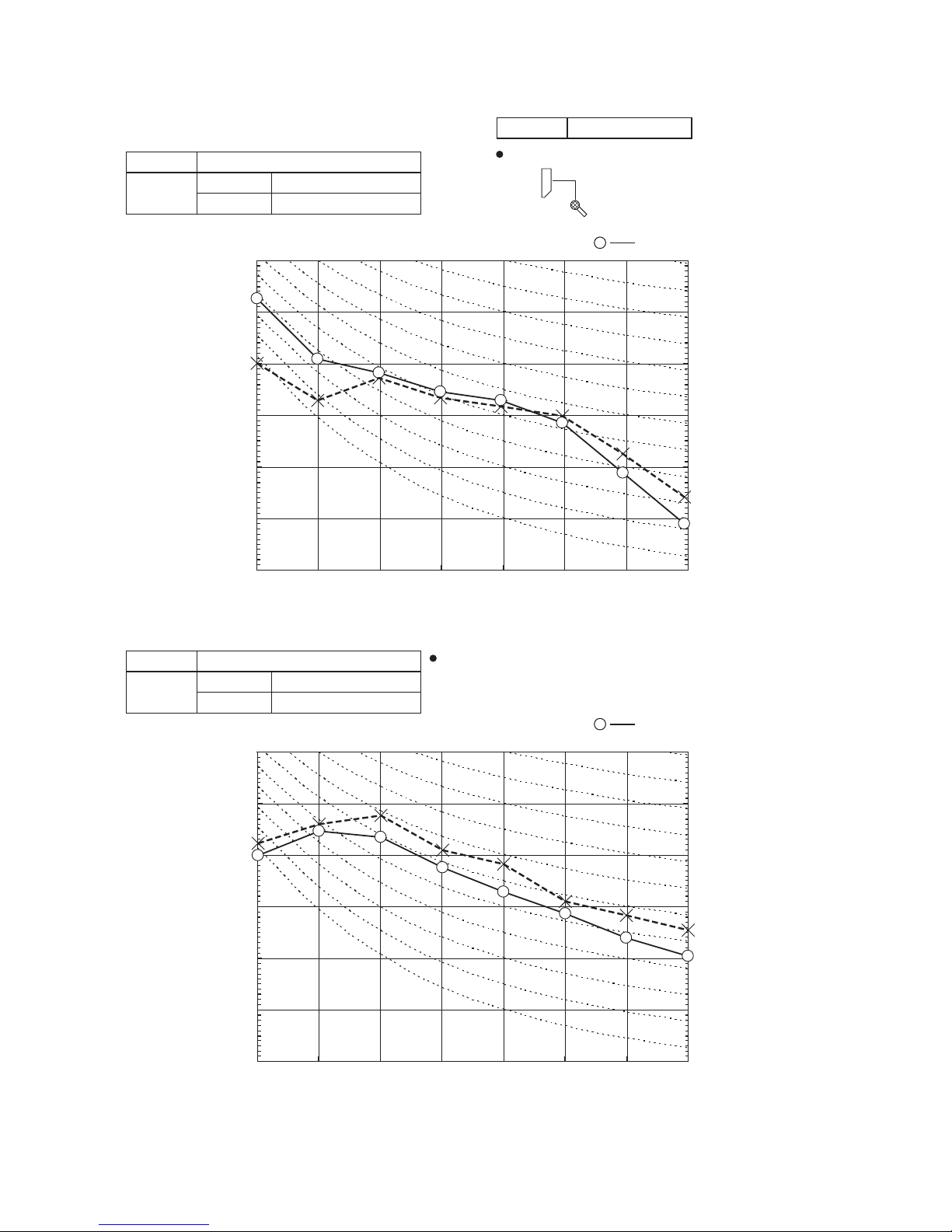

(Indoor Unit)

Model SRK25ZMXA-S

Noise

Level

Cooling 41 dB(A)

Heating 41 dB(A)

×

......

Cooling, Heating

Model SRK25ZMXA-S

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

(Outdoor Unit)

Model SRC25ZMXA-S

Noise

Level

Cooling 47 dB(A)

Heating 47 dB(A)

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N40

N60

N70

N20

N30

×

......

Cooling, Heating

Condition ISO-T1,JIS C 9612

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

-

19

-

'14 • SRK-T-155

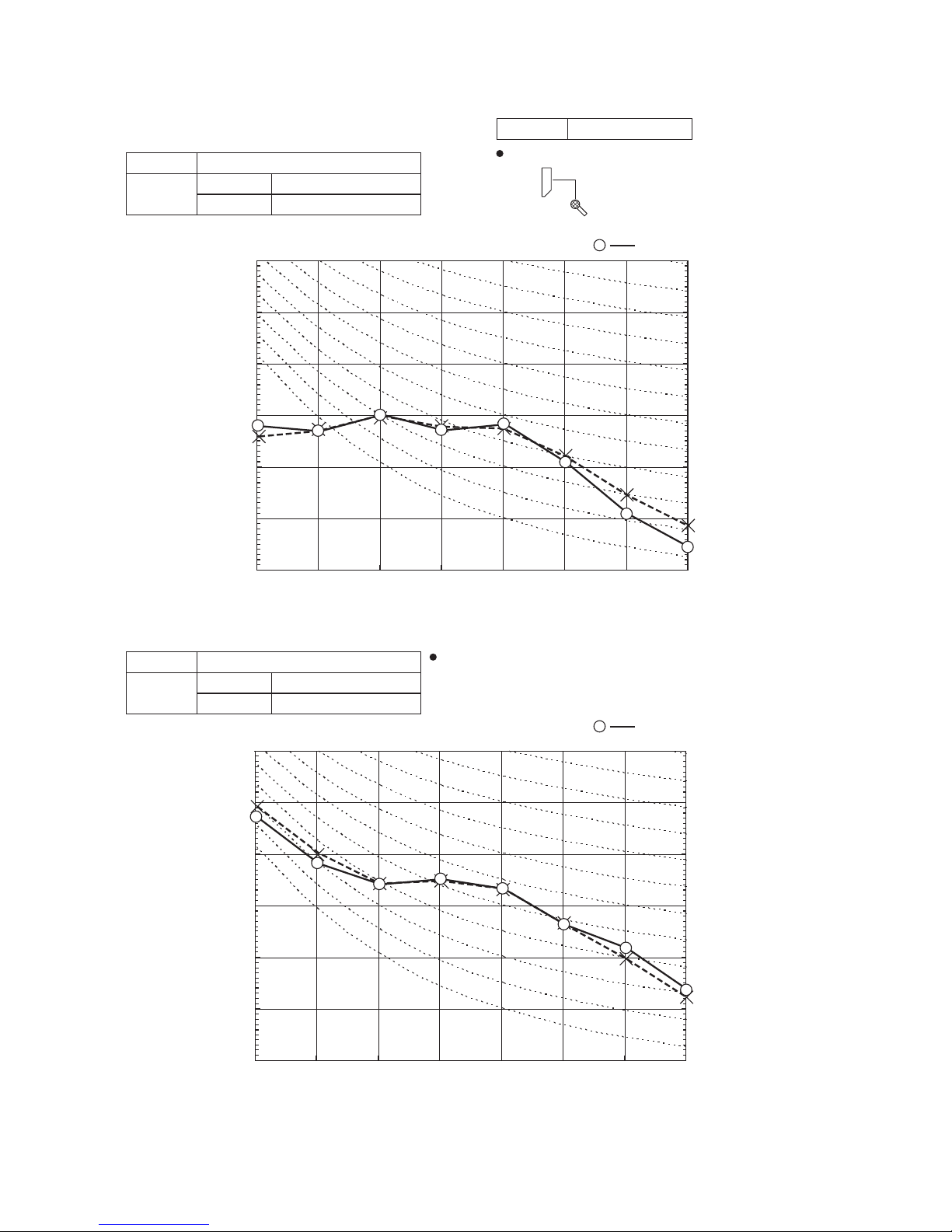

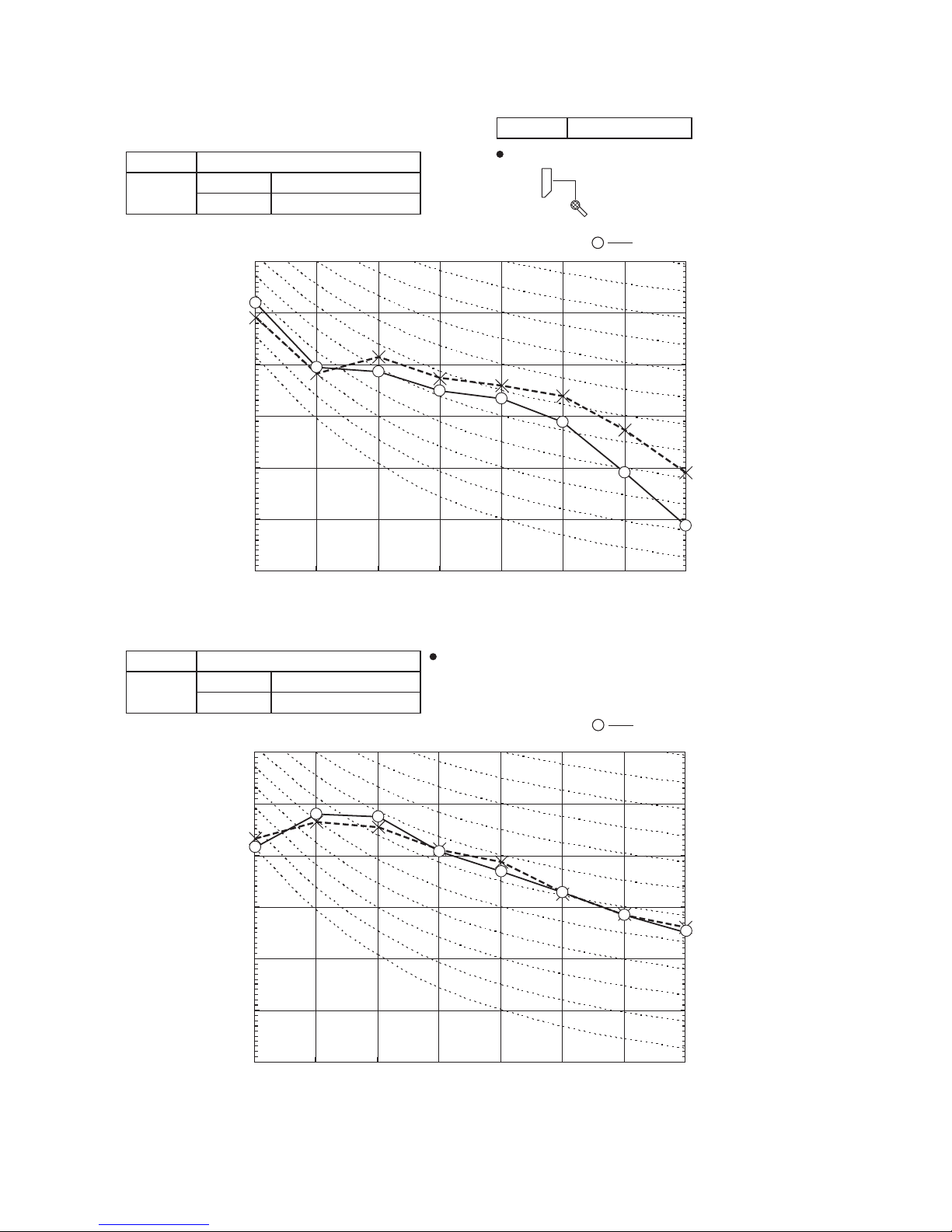

(Indoor Unit)

Model SRK35ZMXA-S

Noise

Level

Cooling 43 dB(A)

Heating 42 dB(A)

×

......

Cooling, Heating

Model SRK35ZMXA-S

(Outdoor Unit)

Model SRC35ZMXA-S

Noise

Level

Cooling 50 dB(A)

Heating 50 dB(A)

×

......

Cooling, Heating

Condition ISO-T1,JIS C 9612

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

-

20

-

'14 • SRK-T-155

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

(Indoor Unit)

Model SRK50ZMXA-S

Noise

Level

Cooling 47 dB(A)

Heating 48 dB(A)

×

......

Cooling, Heating

Model SRK50ZMXA-S

(Outdoor Unit)

Model SRC50ZMXA-S

Noise

Level

Cooling 54 dB(A)

Heating 50 dB(A)

×

......

Cooling, Heating

Condition ISO-T1, JIS C 9612

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

-

21

-

'14 • SRK-T-155

(Indoor Unit)

Model SRK60ZMXA-S

Noise

Level

Cooling 51 dB(A)

Heating 48 dB(A)

×

......

Cooling, Heating

Model SRK60ZMXA-S

(Outdoor Unit)

Model SRC60ZMXA-S

Noise

Level

Cooling 54 dB(A)

Heating 54 dB(A)

×

......

Cooling, Heating

Condition ISO-T1, JIS C 9612

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

Mid Octave Band frequency (Hz)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa )

10

20

30

40

50

60

70

N50

N30

N40

N60

N70

N20

Mike position: at highest noise level in position as mentioned below

Distance from front side 1m

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

Mike position

0.8m

1m

Unit

Mike position

(Center & Low points)

-

22

-

'14 • SRK-T-155

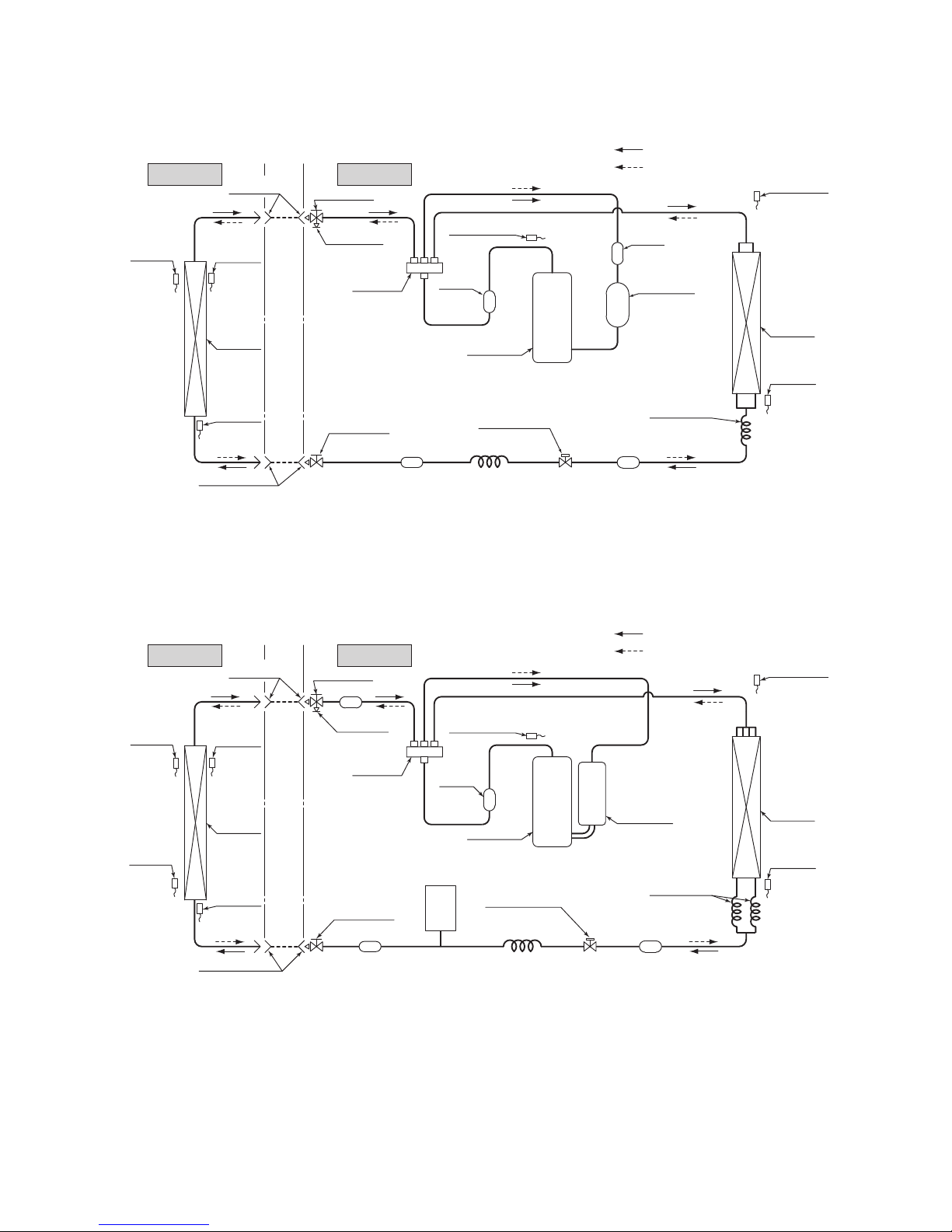

Models SRK50ZMXA-S,60ZMXA-S

Indoor unit

Outdoor unit

Flare

connection

Flare connection

Liquid

pipe

(φ6.35)

Gas pipe

(φ12.7)

Service valve

Heat

exchanger

Heat

exchanger

sensor

Electronic

expansion valve

(Liquid)

Strainer

Receiver

Muffler

Capillary tube

Outdoor air

temp. sensor

Muffler

Compressor

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Check joint

4way valve

Service valve

Heat

exchanger

sensor

(Th2

2)

(TH3)

Room temp.

sensor

(Th1)

Humidity

sensor

(Th3)

(Th2

1)

(

Gas

)

(TH2)

Heat

exchanger

sensor

(TH1)

(EEV)

Capillary tube

Heat

exchanger

Accumulator

Strainer

Models SRK20ZJX-S, 25ZJX-S, 35ZJX-S

Indoor unit

Outdoor unit

Flare

connection

Flare connection

Liquid

pipe

(φ6.35)

Gas pipe

(φ9.52)

Service valve

Heat

exchanger

Heat

exchanger

sensor

Electronic

expansion valve

(Liquid)

Strainer Muffler

Capillary tube

Outdoor air

temp. sensor

Muffler

Muffler

Compressor

Accumulator

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Check joint

4way valve

Service valve

Heat

exchanger

sensor

(Th22)

(TH3)

Room temp.

sensor

(Th1)

(Th21)

(

Gas

)

(TH2)

Heat

exchanger

sensor

(TH1)

(EEV)

Capillary tube

Heat

exchanger

Model SRK50ZJ-S

Indoor unit

Outdoor unit

Flare

connection

Flare connection

Liquid

pipe

(φ6.35)

Gas pipie

(φ12.7)

Service valve

Heat

exchanger

Heat

exchanger

sensor

Electronic

expansion valve

(Liquid)

Strainer

Receiver

Muffler

Capillary tube

Outdoor air

temp. sensor

Muffler

Muffler

Compressor

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Check joint

4way valve

Service valve

Heat

exchanger

sensor

(Th3)

(TH3)

Room temp.

sensor

(Th1)

(Th2)

(

Gas

)

(TH2)

Heat

exchanger

sensor

(TH1)

(EEV)

Capillary tube

Heat

exchanger

Humidity

sensor

(HD)

Models SRK20ZMXA-S, 25ZMXA-S, 35ZMXA-S

5. PIPING SYSTEM

-

23

-

'14 • SRK-T-155

RANGE OF USAGE & LIMITATIONS

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length

Power source voltage Rating ±10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle

Max. 4 times/h

(Inching prevention 10 minutes)

ON and OFF interval Min. 3 minutes

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Max. 15m Max. 30m

Max. 10m

(Outdoor unit is higher)

Max. 10m

(Outdoor unit is lower)

Max. 20m

(Outdoor unit is higher)

Max. 20m

(Outdoor unit is lower)

Item

Models

SRK20,25,35ZMXA-S

Cooling operation : Approximately 18 to 32℃ D.B.

Heating operation : Approximately 10 to 30℃ D.B.

(Refer to the selection chart)

Cooling operation : Approximately -15 to 46℃ D.B.

Heating operation : Approximately -15 to 24℃ D.B.

(Refer to the selection chart)

Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification ×Correction factors as follows.

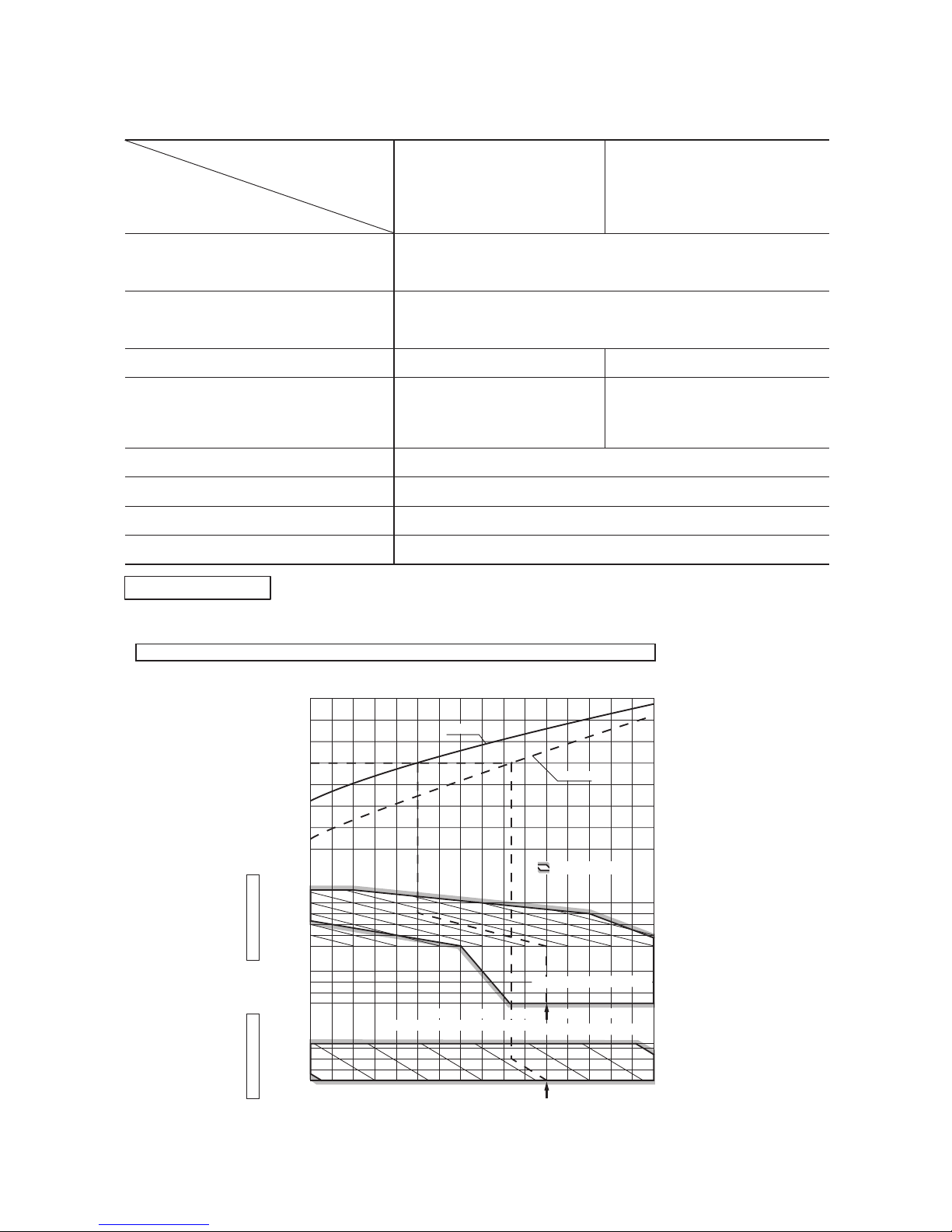

(1) Coefficient of cooling and heating capacity in relation to temperatures

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

24

26

20

25

30

35

40

46

10

15

20

25

27

Outdoor air W.B. temperature °C W.B.

-15 -10 -5 0 5 10 15

.

Cooling operation

Outdoor air D.B.

temperature

°C D. B.

Coefficient of cooling

&

heating capacity in

relation to temperature

Heating operation

Indoor air D.B.

temperature

°C D. B.

ISO-T1 Standard Condition

Depends on installed situation

ISO-T1 Standard Condition

2220181614

Indoor air W.B. temperature °C W.B

Applicable range

Cooling

Heating

SRK50,60ZMXA-S

6. RANGE OF USAGE & LIMITATIONS

-

24

-

'14 • SRK-T-155

'09•SRK-DB-087D

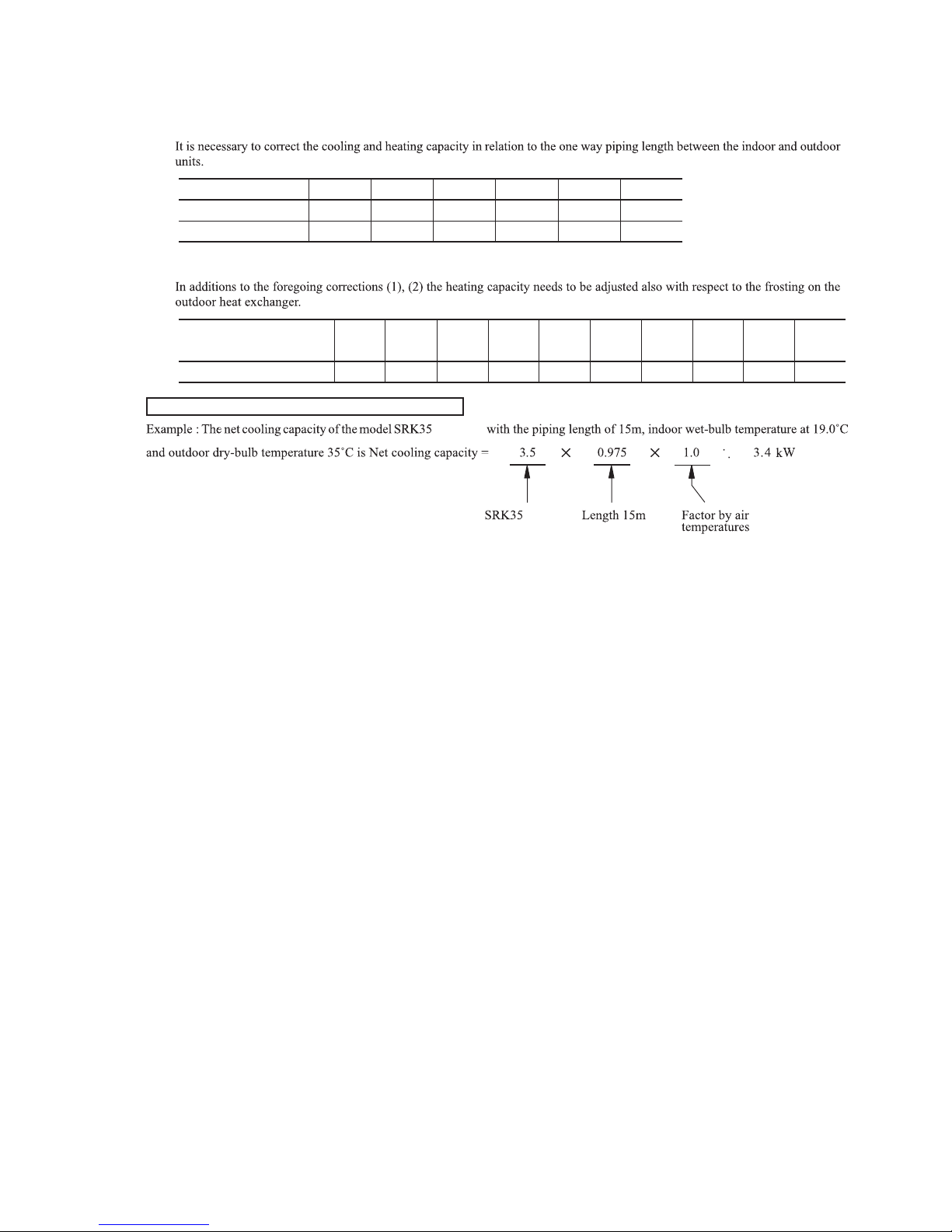

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

(3) Correction relative to frosting on outdoor heat exchanger during heating

How to obtain the cooling and heating capacity

=

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

30

0.935

1.0

Air inlet temperature of

outdoor unit in °C WB

Adjustment coefficient

-15

0.95 0.95 0.94 0.93 0.91 0.88 0.86 0.87 0.92 1.00

-10 -9 -7 -5 -3 -1 1 3

5 or more

ZMXA-S

ZMXA-S

-

25

-

'14 • SRK-T-155

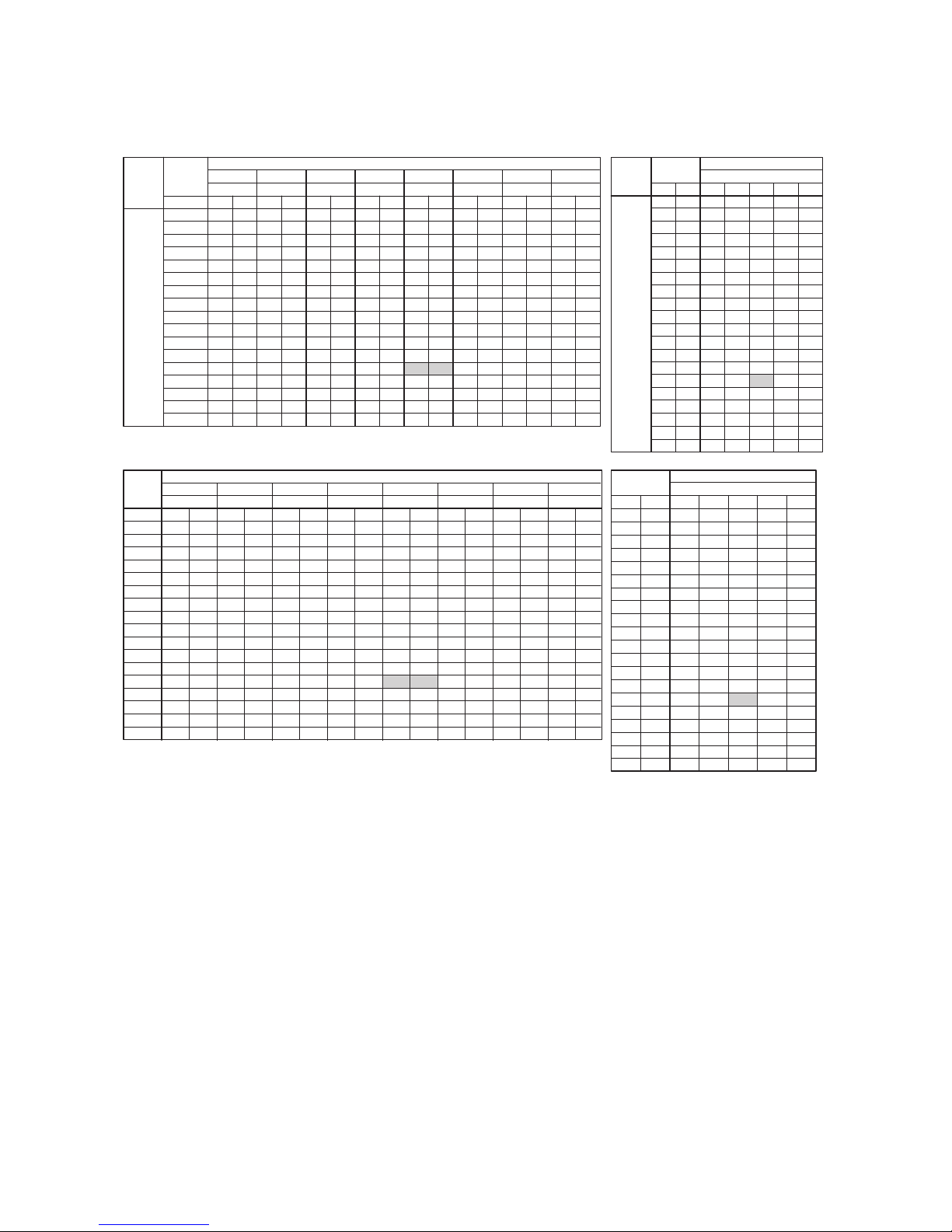

7. CAPACITY TABLES

Model SRK20ZMXA-S

Cooling Mode

Air flow

Outdoor

air temp.

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Hi

11.5

(m3/min)

10 2.25 2.14 2.36 2.11 2.45 2.24 2.49 2.21 2.53 2.19 2.60 2.30 2.67 2.24

12 2.21 2.10 2.32 2.09 2.41 2.22 2.45 2.20 2.50 2.18 2.58 2.29 2.65 2.24

14 2.17 2.06 2.28 2.07 2.38 2.21 2.42 2.19 2.47 2.17 2.55 2.28 2.62 2.23

16 2.13 2.02 2.24 2.05 2.34 2.19 2.39 2.18 2.43 2.15 2.52 2.27 2.59 2.22

18 2.08 1.98 2.19 2.03 2.30 2.17 2.35 2.16 2.40 2.14 2.49 2.26 2.56 2.21

20 2.04 1.94 2.15 2.02 2.26 2.15 2.31 2.15 2.36 2.13 2.45 2.25 2.53 2.20

22 1.99 1.89 2.10 2.00 2.22 2.11 2.28 2.13 2.32 2.12 2.42 2.23 2.50 2.19

24 1.94 1.85 2.05 1.95 2.18 2.07 2.24 2.11 2.28 2.10 2.38 2.23 2.47 2.18

26 1.90 1.80 2.01 1.91 2.14 2.03 2.20 2.09 2.24 2.08 2.35 2.21 2.43 2.18

28 1.85 1.75 1.96 1.86 2.09 1.99 2.15 2.05 2.20 2.05 2.31 2.19 2.40 2.16

30 1.79 1.70 1.90 1.81 2.05 1.94 2.11 2.01 2.16 2.04 2.27 2.16 2.36 2.15

32 1.74 1.65 1.85 1.76 2.00 1.90 2.07 1.96 2.12 2.01 2.23 2.12 2.32 2.14

34 1.69 1.60 1.80 1.71 1.95 1.85 2.02 1.92 2.07 1.97 2.19 2.08 2.28 2.13

35 1.66 1.58 1.77 1.68 1.93 1.83 2.00 1.90 2.05 1.94 2.17 2.06 2.26 2.12

36 1.63 1.55 1.74 1.65 1.90 1.81 1.98 1.88 2.02 1.92 2.15 2.04 2.24 2.11

38 1.58 1.50 1.68 1.60 1.85 1.76 1.93 1.83 1.98 1.88 2.11 2.00 2.20 2.09

39 1.55 1.47 1.66 1.57 1.83 1.74 1.91 1.81 1.95 1.85 2.08 1.98 2.18 2.07

Air flow

outdoor

air temp.

indoor air temp

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

Hi

12.0

(m3/min)

-15˚CWB 1.54 1.51 1.47 1.44 1.41

-10˚CWB 1.74 1.71 1.69 1.64 1.61

-5˚CWB 1.89 1.86 1.82 1.80 1.77

0˚CWB 1.98 1.95 1.91 1.89 1.86

5˚CWB

2.52 2.49 2.48 2.43 2.39

6˚CWB

2.56 2.53 2.50 2.47 2.44

10˚CWB 2.72 2.69 2.68 2.64 2.61

15˚CWB

2.96 2.93 2.91 2.88 2.85

20˚CWB

3.18 3.15 3.14 3.10 3.08

Heating Mode (HC) (kW)(kW)

Model SRK25ZMXA-S

Cooling Mode

Air flow

Outdoor

air temp.

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Hi

12.5

(m3/min)

10 2.87 2.69 3.01 2.65 3.12 2.80 3.17 2.77 3.23 2.74 3.32 2.88 3.41 2.81

12 2.82 2.67 2.96 2.63 3.07 2.78 3.13 2.75 3.19 2.73 3.28 2.86 3.38 2.80

14 2.77 2.63 2.90 2.61 3.03 2.76 3.09 2.74 3.14 2.69 3.25 2.85 3.34 2.79

16 2.71 2.58 2.85 2.58 2.98 2.74 3.04 2.70 3.10 2.68 3.21 2.84 3.31 2.78

18 2.66 2.52 2.80 2.56 2.93 2.71 3.00 2.69 3.05 2.66 3.17 2.82 3.27 2.77

20 2.60 2.47 2.74 2.54 2.88 2.69 2.95 2.67 3.01 2.65 3.13 2.81 3.23 2.75

22 2.54 2.41 2.68 2.51 2.83 2.67 2.90 2.65 2.96 2.63 3.08 2.80 3.19 2.74

24 2.48 2.36 2.62 2.48 2.78 2.64 2.85 2.64 2.91 2.61 3.04 2.78 3.15 2.72

26 2.42 2.30 2.56 2.43 2.72 2.59 2.80 2.62 2.86 2.60 2.99 2.76 3.10 2.71

28 2.35 2.24 2.49 2.37 2.67 2.53 2.75 2.60 2.81 2.58 2.95 2.75 3.06 2.70

30 2.29 2.17 2.43 2.31 2.61 2.48 2.69 2.56 2.75 2.56 2.90 2.74 3.01 2.69

32 2.22 2.11 2.36 2.24 2.55 2.42 2.64 2.50 2.70 2.54 2.85 2.70 2.96 2.67

34 2.15 2.04 2.29 2.18 2.49 2.36 2.58 2.45 2.64 2.51 2.79 2.65 2.91 2.65

35 2.12 2.01 2.26 2.14 2.46 2.33 2.55 2.42 2.61 2.48 2.77 2.63 2.89 2.65

36 2.08 1.98 2.22 2.11 2.43 2.30 2.52 2.39 2.58 2.45 2.74 2.60 2.86 2.64

38 2.01 1.91 2.15 2.04 2.36 2.24 2.46 2.34 2.52 2.39 2.69 2.55 2.81 2.60

39 1.97 1.88 2.11 2.01 2.33 2.21 2.43 2.31 2.49 2.36 2.66 2.52 2.78 2.59

Air flow

outdoor

air temp.

indoor air temp

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

Hi

13.0

(m3/min)

-15˚CWB 1.93 1.88 1.84 1.80 1.76

-10˚CWB 2.18 2.14 2.11 2.06 2.02

-5˚CWB 2.36 2.33 2.28 2.25 2.22

0˚CWB 2.47 2.44 2.40 2.37 2.33

5˚CWB 3.15 3.12 3.10 3.04 2.99

6˚CWB 3.20 3.17 3.13 3.09 3.05

10˚CWB

3.40 3.37 3.35 3.30 3.27

15˚CWB 3.70 3.67 3.65 3.61 3.57

20˚CWB

3.98 3.95 3.93 3.88 3.85

Heating Mode (HC) (kW)(kW)

Note(1) These data show average statuses.

Depending on the system control, there may be ranges where the operation is

not conducted continuously.

These data show the case where the operation frequency of a compressor is

fixed.

(2) Capacities are based on the following conditions.

Corresponding refrigerant piping length :7m

Level difference of Zero.

(3) Symbols are as follows.

TC : Total cooling capacity (kW)

SHC : Sensible heat capacity (kW)

HC : Heating capacity (kW)

Model SRK35ZMXA-S

Cooling Mode

Air flow

Outdoor

air temp.

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

Hi

13.5

(m3/min)

10 3.94 3.47 4.13 3.42 4.28 3.59 4.35 3.55 4.43 3.51 4.56 3.66 4.68 3.55

12 3.87 3.44 4.06 3.39 4.22 3.56 4.29 3.53 4.37 3.49 4.51 3.65 4.63 3.53

14 3.80 3.40 3.99 3.36 4.16 3.54 4.24 3.50 4.31 3.47 4.46 3.61 4.59 3.52

16 3.72 3.37 3.91 3.32 4.09 3.51 4.18 3.48 4.25 3.44 4.40 3.59 4.54 3.50

18 3.65 3.33 3.84 3.29 4.03 3.48 4.11 3.45 4.19 3.42 4.35 3.57 4.49 3.49

20 3.57 3.30 3.76 3.25 3.96 3.46 4.05 3.43 4.13 3.39 4.29 3.55 4.43 3.47

22 3.49 3.26 3.68 3.22 3.89 3.43 3.98 3.40 4.06 3.37 4.23 3.53 4.38 3.45

24 3.40 3.22 3.59 3.19 3.81 3.40 3.91 3.38 3.99 3.35 4.17 3.51 4.32 3.44

26 3.32 3.15 3.51 3.14 3.74 3.37 3.84 3.35 3.92 3.32 4.11 3.49 4.26 3.42

28 3.23 3.07 3.42 3.11 3.66 3.34 3.77 3.32 3.85 3.30 4.04 3.47 4.20 3.40

30 3.14 2.98 3.33 3.07 3.58 3.31 3.70 3.29 3.78 3.26 3.98 3.45 4.13 3.38

32 3.05 2.90 3.24 3.03 3.50 3.27 3.62 3.26 3.70 3.24 3.91 3.43 4.06 3.36

34 2.95 2.81 3.14 2.99 3.41 3.24 3.54 3.23 3.62 3.21 3.84 3.40 4.00 3.34

35 2.91 2.76 3.10 2.94 3.37 3.20 3.50 3.22 3.58 3.20 3.80 3.39 3.96 3.33

36 2.86 2.72 3.05 2.90 3.33 3.16 3.46 3.20 3.54 3.18 3.76 3.38 3.92 3.32

38 2.76 2.62 2.95 2.80 3.24 3.08 3.38 3.18 3.46 3.15 3.69 3.36 3.85 3.30

39 2.71 2.57 2.90 2.75 3.20 3.04 3.33 3.16 3.42 3.14 3.65 3.34 3.81 3.29

Air flow

outdoor

air temp.

indoor air temp

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

Hi

14.0

(m3/m in)

-15˚CWB 2.65 2.59 2.53 2.48 2.42

-10˚CWB 2.99 2.94 2.90 2.83 2.77

-5˚CWB 3.24 3.20 3.13 3.10 3.05

0˚CWB 3.40 3.35 3.29 3.25 3.20

5˚CWB

4.33 4.28 4.26 4.17 4.11

6˚CWB 4.40 4.35 4.30 4.25 4.19

10˚CWB 4.68 4.63 4.60 4.54 4.49

15˚CWB 5.09 5.04 5.01 4.95 4.91

20˚CWB

5.47 5.42 5.40 5.34 5.29

Heating Mode (HC) (kW)(kW)

-

26

-

'14 • SRK-T-155

Indoor air temperature Indoor air temperature

Outdoor

air temp.

Outdoor

air temp.

Air flow

Hi

13.5

(m

3

/min)

18˚CDB 21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

˚CDB

12˚CWB 14˚CW B 16˚CWB 18˚CWB 19˚CWB 20˚CW B 22˚CWB 24˚CW B

˚CDB ˚CWB

16 18 20 22 24

TC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

-19.8

-20

11

-17.7

-18

13

-15.7

-16

15

-13.5

-14

17

-11.5

-12

19 -9.5 -10

21 -7.5 -8

23 -5.5 -6

25 -3.0 -4

27 -1.0 -2

29 1.0 0

31 2.0 1

33 3.0 2

35 5.0 4

37 7.0 6

39 9.0 8

41 11.5 10

43 13.5 12

15.5 14

16.5 16

˚CDB SHC

Heating Mode (HC)

Model SRK50ZMXA-S

Cooling Mode

4.22 3.46 4.45 3.72 4.56 3.69 4.69 3.66 4.94 3.86 5.19 3.78 3.13 3 .07 3.02 2.96 2 .90

2.29 2.86 2.81 2.75 2.69

4.32 3.50 4.56 3.77 4.68 3.73 4.81 3.70 5.07 3.90 5.32 3.82 3.33 3 .28 3.23 3.

17 3.11

4.42 3.54 4.68 3.81 4.80 3.78 4.93 3.75 5.19 3.94 5.45 3.86 3.56 3 .50 3.45 3.39 3 .34

4.53 3.59 4.79 3.86 4.92 3.83 5.06 3.80 5.32 3.98 5.58 3.90 3.78 3 .73 3.67 3.62 3 .56

4.62 3.63 4.89 3.90 5.02 3.86 5.19 3.84 5.51 4.05 5.84 3.98 4.00 3 .95 3.90 3.84 3 .78

4.76 3.69 4.99 3.94 5.13 3.91 5.32 3.89 5.70 4.11 6.09 4.06 4.22 4 .17 4.12 4.06 4 .01

4.81 3.71 5.04 3.96 5.19 3.93 5.37 3.91 5.73 4.13 6.10 4.07 4.31 4 .26 4.21 4.17 4 .12

4.66 3.87 4.86 3.74 5.10 3.98 5.25 3.95 5.42 3.93 5.76 4.14 6.11 4.07 4.39 4.35 4.31 4.27 4 .23

4.70 3.89 4.91 3.76 5.16 4.01 5.31 3.98 5.46 3.95 5.75 4.13 4.47 4.44 4.41 4.37

4.33

4.62 3.85 4.83 3.72 5.08 3.97 5.23 3.95 5.38 3.92 5.68 4.11 4.56 4.53 4.50 4.47 4.44

4.54 3.81 4.75 3.69 5.00 3.94 5.15 3.92 5.30 3.89 5.60 4.08 4.60 4.58 4.55 4.52 4.50

4.04 3.45 4.31 3.70 4.67 3.65 4.93 3.91 5.08 3.89 5.23 3.86 5.53 4.06 4.89 4.87 4.84 4 .81 4.78

4.11 3.49 4.30 3.70 4.59 3.62 4.85 3.88 5.00 3.86 5.15 3.83 5.45 4.03 5.48 5.45 5.42 5 .39 5.35

4.04 3.45 4.23 3.67 4.52 3.59 4.77 3.85 4.92 3.83 5.07 3.80 5.37 4.00 6.07 6.04 6.00 5 .96 5.92

3.97 3.42 4.16 3.63 4.45 3.56 4.70 3.82 4.85 3.80 4.99 3.77 5.29 3.97 6.38 6.34 6.30 6 .25 6.21

3.90 3.39 4.09 3.60 4.38 3.53 4.62 3.79 4.77 3.77 4.92 3.74

5.21 3.95 6.69 6.64 6.59 6 .55 6.50

3.83 3.35 4.01 3.56 4.30 3.49 4.55 3.76 4.69 3.74 4.84 3.72 5.13 3.92 7.07 7.01 6.95 6 .85 6.80

7.45 7.37 7.30 7.15 7.10

7.63 7.56 7.48 7.31 7.25

Air flow

Hi

17.0

(m

3

/min)

(kW) (kW)

Heating Mode (HC)

Cooling Mode

(kW) (kW)

Note(1) These data show average statuses.

Note(1) Depending on the system control, there may be ranges where the operation is not conducted continuously.

Note(1) These data show the case where the operation frequency of a compressor is fixed.(Cooling only)

(2) Capacities are based on the following conditions.

(2) Corresponding refrigerant piping length :7m

(2) Level difference of Zero.

(3) Symbols are as follows.

TC : Total cooling capacity (kW)

SHC : Sensible heat capacity (kW)

HC : Heating capacity (kW)

Model SRK60ZMXA-S

Indoor air temperature

Indoor air temperature

Outdoor

air temp.

Outdoor

air temp.

18°CDB 21°CDB 23°CDB 26°CDB 27°CDB 28°CDB 31°CDB 33°CDB

°CDB

12°CWB 14°CWB 16°CWB 18°CWB 19°CWB 20°CWB 22°CWB 24°CWB

°CDB °CWB

16 18 20 22 24

TC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

11

13

15

-13.5

-14

-15.7

-16

-17.7

-18

-19.8

-20

17

-11.5

-12

19

-9.5

-10

21

-7.5

-8

23

-5.5

-6

25

-3.0

-4

27

-1.0

-2

29

1.0

0

31

2.0

1

33

3.0

2

35

5.0

4

37

7.0

6

39

9.0

8

41

11.5

10

43

13.5

12

15.5

14

16.5 16

°CDB

SHC

5.07 3.95 5.34 4.23 5.47 4.19 5.63 4.16 5.93 4.36 6.23 4.27

5.19

4.01 5.47 4.28 5.62 4.25 5.77 4.21 6.08 4.41 6.39 4.33

5.31

4.06 5.61 4.34 5.76 4.30 5.92 4.27 6.23 4.47 6.54 4.37

4.03 3.97 3.91 3.85 3.78

5.43

4.11 5.75 4.40 5.91 4.36 6.07 4.32 6.38 4.52 6.70 4.42

4.28 4.22 4.16 4.10 4.04

5.54

4.16 5.87 4.45 6.03

4.41

6.22 4.38 6.61 4.60

7.00 4.52

4.53 4.47 4.41 4.35 4.29

5.71

4.24 5.98 4.49 6.15 4.46 6.38 4.44 6.84 4.68 7.31 4.62

4.79 4.73 4.67 4.60 4.54

5.77

4.27 6.05 4.52 6.22 4.49 6.44 4.47 6.88 4.70

7.32 4.63

4.88 4.83 4.78 4.72 4.67

5.59 4.44

5.83

4.29 6.12 4.55 6.30 4.52 6.50 4.49 6.92 4.71

7.33 4.63

4.98 4.93 4.88 4.84 4.79

5.64 4.47

5.89

4.32 6.19 4.58 6.37 4.55 6.55 4.51 6.90 4.70

5.07 5.03 4.99 4.95 4.91

5.55 4.42

5.80

4.28 6.10 4.54 6.28 4.51 6.45 4.47 6.81 4.67

5.17 5.13 5.10 5.07 5.03

5.45 4.38

5.70

4.24 6.00 4.50 6.18 4.47 6.36 4.44 6.72 4.64

5.21 5.19 5.16 5.13 5.10

4.85 3.97

5.17 4.24

5.61

4.19 5.91 4.46 6.09 4.43 6.27 4.40 6.63 4.61

5.55 5.52 5.49 5.45 5.42

4.93 4.01 5.16 4.23

5.51

4.15 5.82 4.43 6.00

4.40

6.18 4.37 6.54 4.57

6.21 6.18 6.14 6.10 6.07

4.84 3.97 5.07 4.19

5.43

4.11 5.73 4.39 5.91 4.36 6.09 4.33 6.44 4.54

6.88 6.84 6.80 6.76 6.71

4.76 3.93 4.99 4.15

5.34

4.07 5.64 4.35 5.82 4.33 5.99 4.29 6.35 4.51

7.23 7.18

7.14

7.09 7.04

4.68 3.89 4.90 4.11

5.25

4.03 5.55 4.31 5.72 4.29 5.90 4.26 6.25 4.47

7.58 7.53 7.47 7.42 7.37

4.60 3.85 4.82 4.07 5.16 3.99 5.46 4.28 5.63 4.25 5.81 4.23 6.15 4.44

8.01 7.94 7.88 7.77 7.71

8.44 8.36 8.28 8.11 8.04

8.65 8.56 8.48 8.28 8.21

-

27

-

'14 • SRK-T-155

R410A REFRIGERANT USED

WALL TYPE AIR CONDITIONER

INSTALLATION MANUAL FOR INDOOR UNIT

RKY012A011

WARNING

• Installation must be carried out by the qualified installer.

If you install the system by yourself, it may cause serious trouble such as

water leaks, electric shocks, fire and personal injury, as a result of a system

malfunction. Do not carry out the installation and maintenance work except

the by qualified installer.

• Install the system in full accordance with the installation manual.

Incorrect installation may cause bursts, personal injury, water leaks, electric

shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such as machine shop

and etc., it can cause malfunction.

• Use the original accessories and the specified components for

installation.

If parts other than those prescribed by us are used, It may cause water

leaks, electric shocks, fire and personal injury.

• Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause

material damage and personal injury.

• Ventilate the working area well in the event of refrigerant leakage

during installation.

If the refrigerant comes into contact with naked flames, poisonous gas is

produced.

• When installing in small rooms, take prevention measures not to

exceed the density limit of refrigerant in the event of leakage,

referred by the formula (accordance with ISO5149).

If the density of refrigerant exceeds the limit, please consult the dealer and

install the ventilation system, otherwise lack of oxygen can occur, which

can cause serious accident.

• After completed installation, check that no refrigerant leaks from

the system.

If refrigerant leaks into the room and comes into contact with an oven or

other hot surface, poisonous gas is produced.

• Use the prescribed pipes, flare nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and

serious accidents due to burst of the refrigerant circuit.

• Tighten the flare nut by torque wrench with specified method.

If the flare nut were tightened with excess torque, this may cause burst and

refrigerant leakage after a long period.

• The electrical installation must be carried out by the qualified

electrician in accordance with “the norm for electrical work” and

“national wiring regulation”, and the system must be connected to

the dedicated circuit.

Power supply with insufficient capacity and incorrect function done by

improper work can cause electric shocks and fire.

• Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks, unit failure or

incorrect function of equipment.

• Be sure to use the cables conformed to safety standard and cable

ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous heat production

or fire.

• This appliance must be connected to main power supply by means

of a circuit breaker or switch (fuse:16A) with a contact separation of

at least 3mm.

• When plugging this appliance, a plug conforming to the norm

IEC60884-1 must be used.

• Use the prescribed cables for electrical connection, tighten the

cables securely in terminal block and relieve the cables correctly to

prevent overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat

production or fire.

• Arrange the wiring in the control box so that it cannot be pushed up

further into the box. Install the service panel correctly.

Incorrect installation may result in overheating and fire.

• Be sure to switch off the power supply in the event of installation,

inspection or servicing.

If the power supply is not shut off, there is a risk of electric shocks, unit

failure or personal injury due to the unexpected start of fan.

• Be sure to wear protective goggles and gloves while at work.

• Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause electric shocks.

CAUTION

• Use the circuit breaker of correct capacity. Circuit breaker should

be the one that disconnect all poles under over current.

Using the incorrect one could cause the system failure and fire.

• Install isolator or disconnect switch on the power supply wiring in

accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

• Be sure to install indoor unit properly according to the installation

manual in order to run off the drainage smoothly.

Improper installation of indoor unit can cause dropping water into the room

and damaging personal property.

• Install the drainage pipe to run off drainage securely according to

the installation manual.

Incorrect installation of the drainage pipe can cause dropping water into the

room and damaging personal property.

• Be sure to install the drainage pipe with descending slope of 1/100

or more, and not to make traps and air-bleedings.

Check if the drainage runs off securely during commissioning and ensure

the space for inspection and maintenance.

• Secure a space for installation, inspection and maintenance

specified in the manual.

Insufficient space can result in accident such as personal injury due to

falling from the installation place.

• For installation work, be careful not to get injured with the heat

exchanger, piping flare portion or screws etc.

• Be sure to insulate the refrigerant pipes so as not to condense the

ambient air moisture on them.

Insufficient insulation can cause condensation, which can lead to moisture

damage on the ceiling, floor, furniture and any other valuables.

• When perform the air conditioner operation (cooling or drying opera-

tion) in which ventilator is installed in the room. In this case, using the