Mitsubishi Heavy Industries SRK20MA-S, SRC20MA-S, SRK25MA-S, SRC25MA-S, SRK35MA-S Technical Manual

...

- 1 -

Mitsubishi Heavy Industries Air Conditioners

Technical Manual

Manual Number: 2011 No. W2-01

Variable Frequency Wall Mounted Type

Room Air Conditioners

(Split system, heat pump type)

SRK20MA-S/SRC20MA-S

SRK25MA-S/SRC25MA-S

SRK35MA-S/SRC35MA-S

SRK50MA-S/SRC50MA-S

(R410A Refrigerant Used)

MITSUBISHI HEAVY INDUSTRIES, LTD.

- 2 -

Table of Contents

1. GENERAL INFORMATION…………..……………………….……1

1.1 Features……………………………………..……………………..…1

1.2 Model identification………………………………………………1

2 MODEL SELECTION…………………………………………………2

2.1 Model function..…………..…….……..………………………..……2

2.2 Range of usage……………………………………………..………6

2.3 Outline drawing……………………………..……………………..…6

2.4 Cooling cycle system diagram…….………………..…………...…8

2.5 Performance curve……………………………………………………9

3 ELECTRICAL WIRING DIAGRAM……………………………….10

4 NAME OF EACH PART AND ITS FUNCTION………….12

4.1 Name of each part………………………….......…………………....15

4.2 Emergency switch………………………….......…………………....15

4.3 Automatic restart……………..…………..………………………..15

4.4 Key lock………….…………..……..……………………………..15

4.5 CLEAN operation………………...……..…………………………..15

4.6 SLEEP operation……..……..…………………………….……..16

4.7 Timing off………...............................................................16

4.8 Timing on ...........................................................................17

4.9 Programmed timer........................................................................17

4.10 Current time setting.....................................................................18

4.11 HI POWER operation....................................................................18

4.12 JET operation.........................................................................18

4.13 POWER SAVE operation.................................................................19

4.14 Air direction adjustment..............................................................19

4.15 Area setting…......................................................................20

4.16 Installation location setting.............................................................20

4.17 Outline of automatic operation..................................................20

- 3 -

4.18 Outline of drying operation..................................................21

4.19 Outline of defrosting operation.................................................21

4.20 Outline of vertical and horizontal flaps control................................23

4.21 Outline of electronic expansion valve (EEV) control.....................24

4.22 Outline of compressor control.........................................24

4.23 Outline of outdoor fan control.........................................24

4.24 Outline of indoor fan control.........................................25

5 INSTALLATION................................................................................27

5.1 Selection of installation location.................................................29

5.2 Installation of indoor unit..................................................................30

5.3 Installation of outdoor unit...............................................................33

5.4 Pipe connection.................................................................................33

5.5 Precautions for wireless remote controller operation.........................35

5.6 Standard running data........................................................................36

6 MAINTENANCE................................................................................37

6.1 Electrical parts failure diagnosis method.....................................37

6.2 Servicing.............................................................................................58

7 SERVICING MANUAL.......................................................................59

8 MOUNT ASSEMBLY…………………………...........................74

8.1 Indoor unit.........................................................................................74

8.2 Outdoor unit......................................................................................90

- 1 -

1 GENERAL INFORMATION

1.1 Features

(1) Inverter

● Heating/cooling

The rotate speed of the compressor is changed steplessly in relation to varying load, and is linked

with the fans of indoor and outdoor units controlled by the changes of frequency, thus controls

the power.

● Allowing quick heating/cooling operation during start-up period.

The room temperature is kept constant through fine-tuned control after the machine is stabilized.

(2) Fuzzy control: According to the fuzzy control technology, the indoor temperature and humidity,

etc. are obtained through dynamic analysis to accurately regulate the rotate speeds

of the compressor and the fan to realize precise temperature control.

(3) Comfort: 3D air blowing, sleep mode, and other air blowing modes.

(4) Humanization: Room temperature displaying, key lock, concentrated/area air blowing.

(5) Life: Actual service life: over 20,000 hours; Working life: over 100,000 hours; On/off of relay:

over 50,000 times; Continuous on of LED: over 50,000 hours; On/off of emergency switch:

over 10,000 times.

(4) Self diagnosis function: We will continuously provide the best services for our customers through

devices judging abnormal operation, as follows:

Indoor indication

Error

RUN lamp

TIMER lamp

Temp.

indication

Indoor

unit

Sensors

Indoor heat exchanger sensor error

1 time/8 sec.

ON

06

Indoor inlet air (room temp.) sensor error

2 times/8 sec.

--

Others

Indoor fan motor error

6 times/8 sec.

16

Display communication error

--

--

00

Outdoor unit

Sensors

Outdoor temp. sensor error

Continuous

flashing

1 time/8 sec.

38

Outdoor heat exchanger (liquid pipe)

sensor error

2 times/8 sec.

37

Vent-pipe sensor error

4 times/8 sec.

39

Others

Power cut for current protection

ON

1 time/8 sec.

42

Failure of outdoor unit

2 times/8 sec.

59

Current safety

3 times/8 sec.

58

Failure of power module

4 times/8 sec.

51

Compressor over heat protection

5 times/8 sec.

36

Serial signal transmission error

6 times/8 sec.

05

Outdoor fan motor error

7 times/8 sec.

48

Cool room high pressure protection

control

Continuous

flashing

35

Controllable silicon voltage error

5 times/8 sec.

ON

47

Cooling circulation system protection

7 times/8 sec.

57

Locked-rotor/rotor lock

2 times/8 sec.

2 times/8 sec.

60

The air conditioner indicates the error of the indoor and outdoor sensors (thermistors) only when it is

in the stop mode. Error indication is removed after restart.

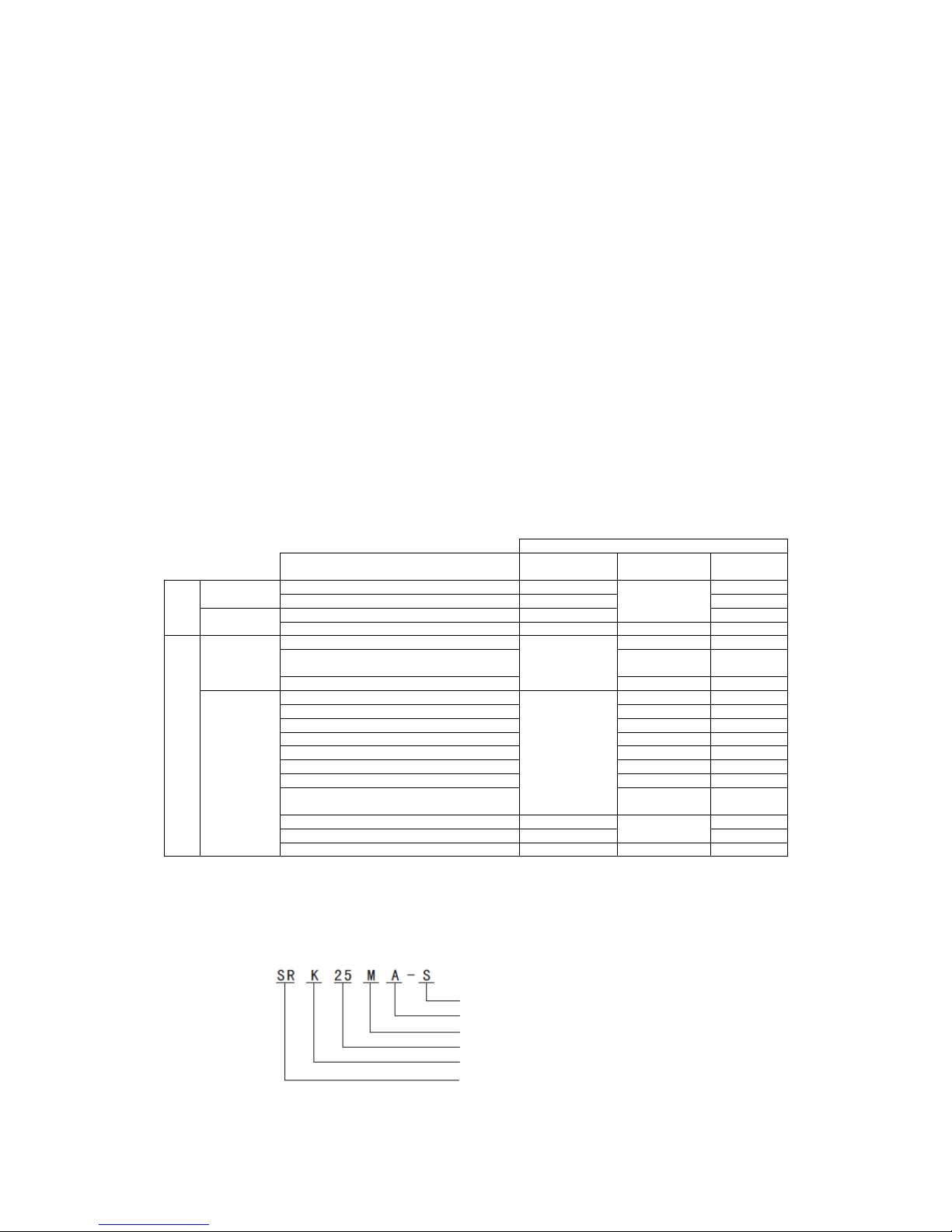

1.2 Model identification

For example:

R410A Refrigerant used

Master pattern change code

Master pattern

Capacity

Wall mounted type (C is the code for outdoor unit.)

Split type room air conditioner

- 2 -

2 MODEL SELECTION

2.1 Model function

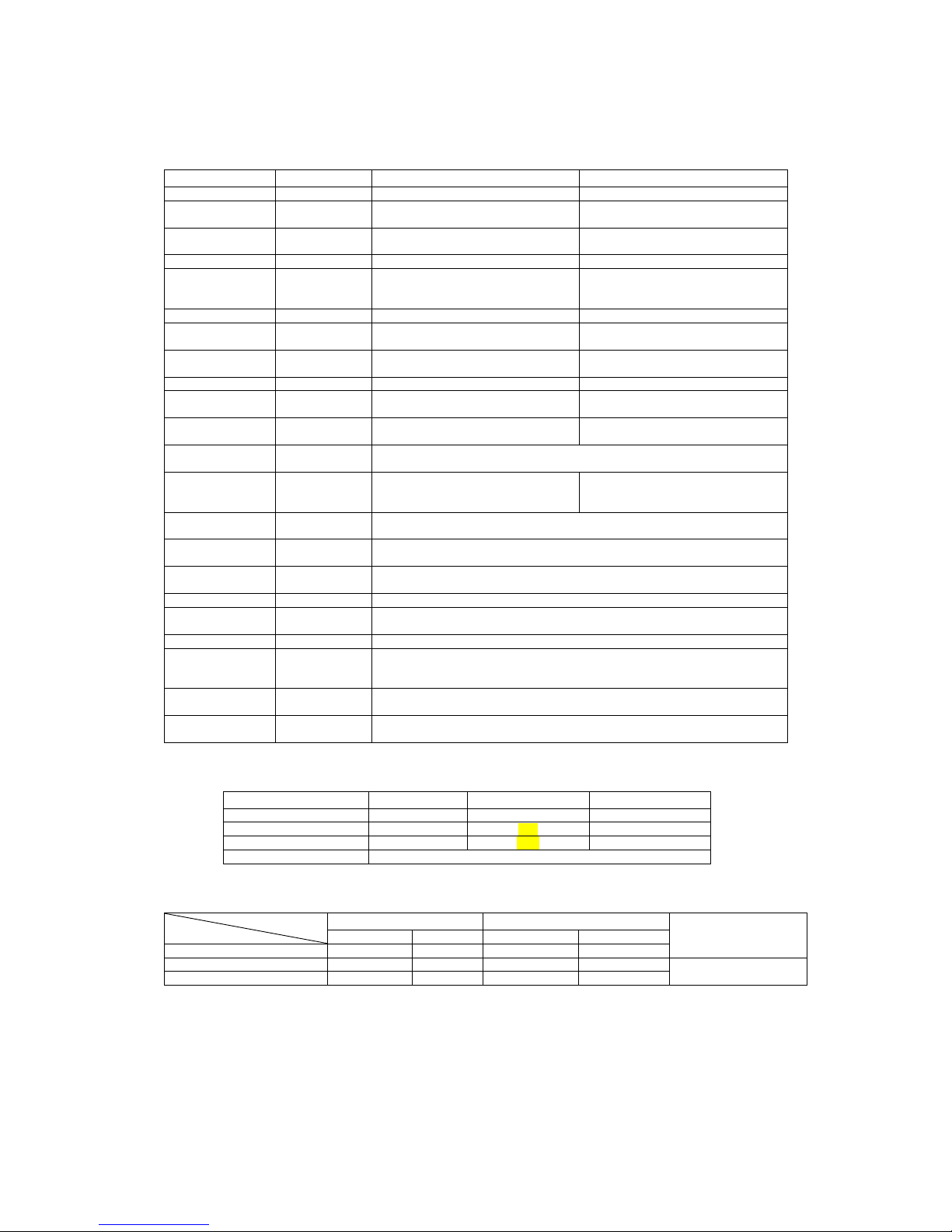

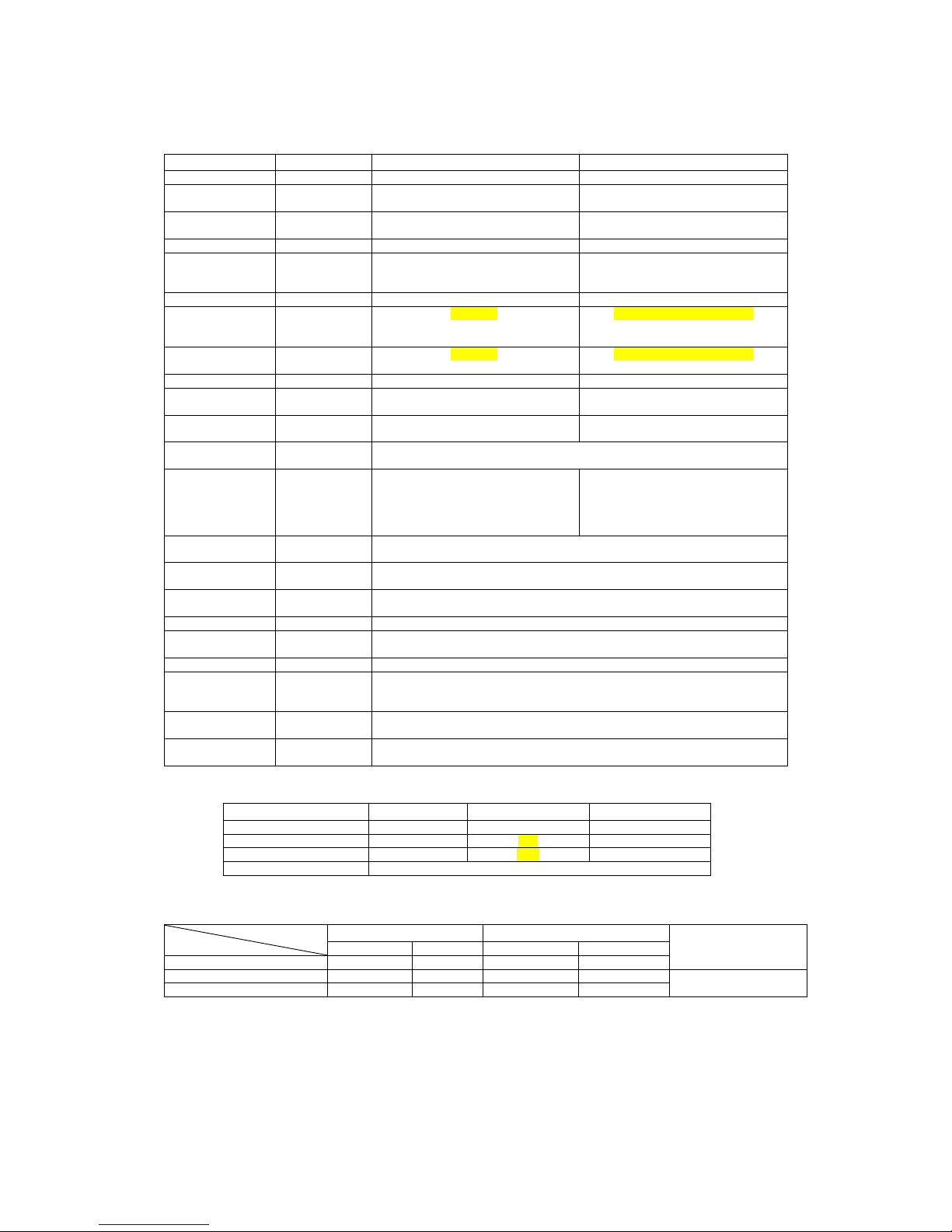

2.1.1 Model: SRK20MA–S (Indoor unit)

SRC20MA–S (Outdoor unit)

Item

Unit

Indoor unit SRK20MA–S

Outdoor unit SRC20MA–S

Net weight

kg

10

32

Machine

dimension

mm

798×230×294

780×290×540

Package

dimension

Length×

Width ×Height

850×365×310

920×380×590

Color White

Ash-colored

Fan

Through-flow type, AS resin +

glass fiber

Axial flow type, AS resin + glass

fiber (embedded damping spindle

sleeve)

Air flow

m3/h

600

1800

Noise in cool

room

dB(A)

Hi/Me/Lo: 37/27/21(completely

mute, SPL)

43(completely mute, SPL)

Noise in warm

room

dB(A)

Hi/Me/Lo: 37/28/24(completely

mute, SPL)

45(completely mute, SPL)

Fan motor

Nominal value

33W, DC motor, insulation grade E

24W, DC motor, insulation grade E

Power of motor

W (reference

value)

19

20

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.0mm2, 250V, 10A, 2m, w/o plug

Heat exchanger

Spiral, hydrophilic, 4-folded,

15-section, 2-row, 528-fin, 1-2

circuit

Spiral, hydrophilic, 20-section,

1-row, 621-fin, 2-1 circuit

Compressor

Nominal value

THACOM RM-B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.5mm) + hush pipe

Refrigerant

g

R-410A, 900g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

Mpa

Max.: 4.15, Min.: 1.47

Air filters

Lysozyme filter + Antibacterial deodorizing filter + Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, filter components 2, outdoor unit

1, Drain elbow 1, Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

2000

2700

Power

W

450

600

Energy efficiency ratio

4.44

4.50

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

- 3 -

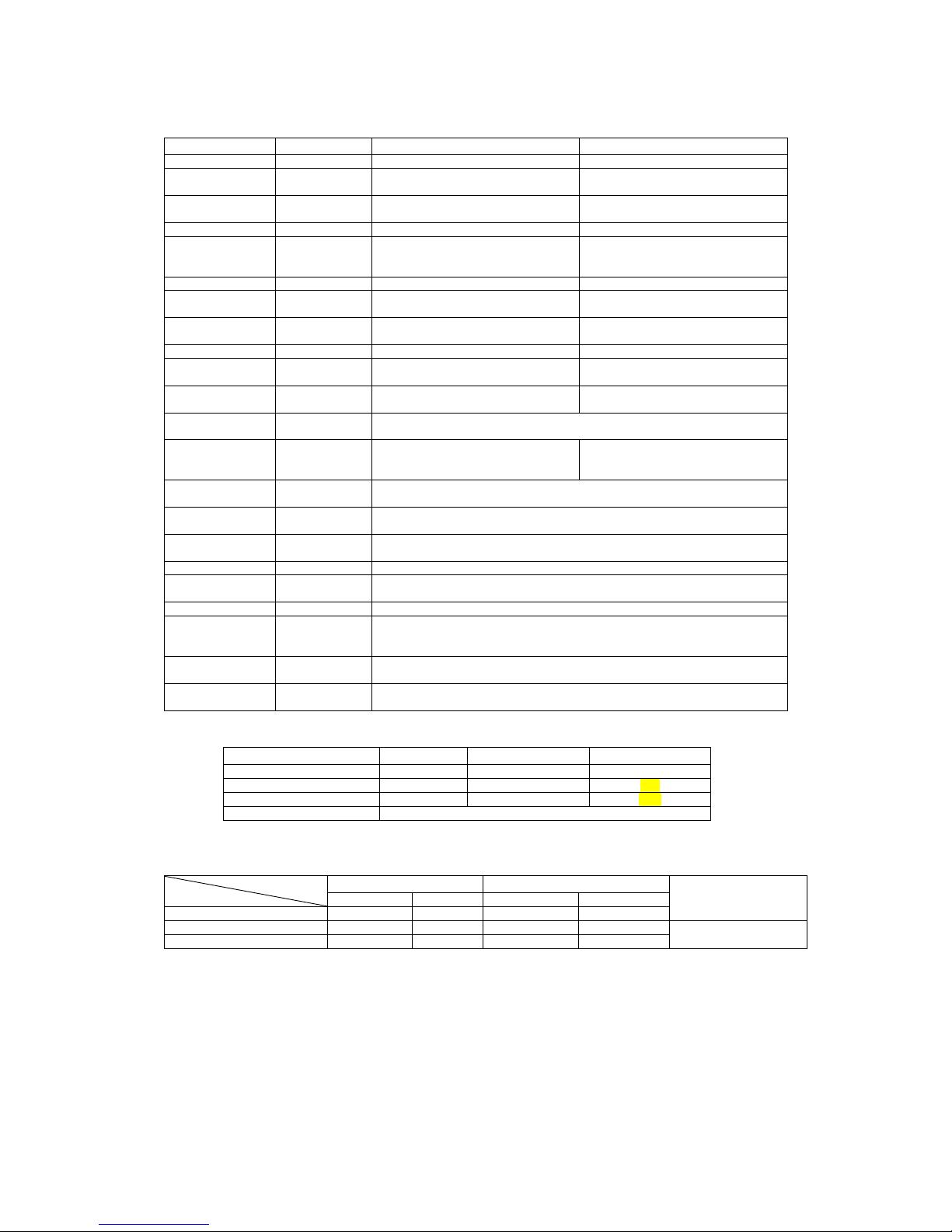

2.1.2 Model: SRK25MA–S (Indoor unit)

SRC25MA–S (Outdoor unit)

Item

Unit

Indoor unit SRK25MA–S

Outdoor unit SRC25MA–S

Net weight

kg

10

32

Machine

dimension

mm

798×230×294

780×290×540

Package

dimension

Length×

Width ×Height

850×365×310

920×380×590

Color White

Ash-colored

Fan

Through-flow type, AS resin +

glass fiber

Axial flow type, AS resin + glass

fiber (embedded damping spindle

sleeve)

Air flow

m3/h

600

1800

Noise in cool

room

dB(A)

Hi/Me/Lo: 37/27/22(completely

mute, SPL)

44(completely mute, SPL)

Noise in warm

room

dB(A)

Hi/Me/Lo: 38/29/23(completely

mute, SPL)

45(completely mute, SPL)

Fan motor

Nominal value

33W, DC motor, insulation grade E

24W, DC motor, insulation grade E

Power of motor

W (reference

value)

19

20

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.0mm2, 250V, 10A, 2m, w/o plug

Heat exchanger

Spiral, hydrophilic, 4-folded,

15-section, 2-row, 528-fin, 1-2

circuit

Spiral, hydrophilic, 20-section,

1-row, 621-fin, 2-1 circuit

Compressor

Nominal value

THACOM RM - B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.5mm) + hush pipe

Refrigerant

g

R-410A, 900g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

Mpa

Max.: 4.15, Min.: 1.47

Air filters

Lysozyme filter + Antibacterial deodorizing filter + Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, filter components 2, outdoor unit

1, water elbow 1, Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

2500

3200

Power

W

680

790

Energy efficiency ratio

3.68

4.05

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

- 4 -

2.1.2 Model: SRK35MA–S (Indoor unit)

SRC35MA–S (Outdoor unit)

Item

Unit

Indoor unit SRK35MA–S

Outdoor unit SRC35MA–S

Net weight

kg

10.5

35

Machine

dimension

mm

798×230×294

780×290×540

Package

dimension

Length×

Width ×Height

850×365×310

920×380×590

Color White

Ash-colored

Fan

Through-flow type, AS resin +

glass fiber

Axial flow type, AS resin + glass

fiber (embedded damping spindle

sleeve)

Air flow

m3/h

600

1870

Noise in cool

room

dB(A)

Hi/Me/Lo: 39/31/23(completely

mute, SPL)

46(completely mute, SPL)

Noise in warm

room

dB(A)

Hi/Me/Lo: 41/34/23(completely

mute, SPL)

50(completely mute, SPL)

Fan motor

Nominal value

33W, DC motor, insulation grade E

24W, DC motor, insulation grade E

Power of motor

W (reference

value)

19

20

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.0mm2, 250V, 10A, 2m, w/o plug

Heat exchanger

Parent: Spiral, hydrophilic,

4-folded, 15-section, 2-row,

528-fin, Pf1.2

Child: Spiral, hydrophilic,

4-section, 1-row, 452-fin, Pf1.4

Spiral, hydrophilic, 20-section,

2-row, 1221-fin, 2-1 circuit, Pf1.4

Compressor

Nominal value

THACOM RM - B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.5mm) + hush pipe

Refrigerant

g

R-410A, 900g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

Mpa

Max.: 4.15, Min.: 1.47

Air filters

Lysozyme filter + Antibacterial deodorizing filter + Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, filter components 2, outdoor unit

1, Drain elbow 1, Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

3500

4000

Power

W

960

1100

Energy efficiency ratio

3.65

3.64

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

- 5 -

2.1.2 Model: SRK50MA–S (Indoor unit)

SRC50MA–S (Outdoor unit)

Item

Unit

Indoor unit SRK50MA–S

Outdoor unit SRC50MA–S

Net weight

kg

10.5

43

Machine

dimension

mm

798×230×294

850×290×640

Package

dimension

Length×

Width ×Height

850×365×310

990×395×700

Color White

Ash-colored

Fan

Through-flow type, AS resin +

glass fiber

Axial flow type, AS resin + glass

fiber (embedded damping spindle

sleeve)

Air flow

m3/h

720

2400

Noise in cool

room

dB(A)

Hi/Me/Lo: 44/34/25(completely

mute, SPL)

50(completely mute, SPL)

Noise in warm

room

dB(A)

Hi/Me/Lo: 48/34/25(completely

mute, SPL)

50(completely mute, SPL)

Fan motor

Nominal value

33W, DC motor, insulation grade E

24W, DC motor, insulation grade E

Power of motor

W (reference

value)

19

20

Power of electric

control

W (reference

value)

2

7.5

Power supply and

power cord

Single-phase, 220V, 50Hz and 3-core, 1.5mm2, 250V, 16A, 2m, w/o plug

Heat exchanger

Parent: Spiral, hydrophilic,

4-folded, 15-section, 2-row,

528-fin, Pf1.2

Child: Spiral, hydrophilic,

4-section, 1-row, 452-fin, Pf1.4

Spiral, hydrophilic, 24-section,

2-row, 1334-fin, 4-1 circuit, Pf1.2

Compressor

Nominal value

THACOM RM - B5077MDE2, 527W, DC frequency conversion

compressor, insulation grade E

Refrigerating

machine oil

ml

300, DIAMOND FREEZE MA68

Refrigerant

controller

Electronic expansion valve (Φ1.5mm) + hush pipe

Refrigerant

g

R-410A, 1250g, addition/reduction not needed within the use range of 15m

Operating

pressure limit

Mpa

Max.: 4.15, Min.: 1.47

Air filters

Lysozyme filter + Antibacterial deodorizing filter + Mould-proof air filter

Accessories and

quantity

Indoor unit 1, mounting plate 1, tapping screw 5, battery 2, use and

installation manual 1, remote controller 1, filter components 2, outdoor unit

1, Drain elbow 1, Water shutoff plug 1

Operation control

devices

Wireless remote controller, electronic thermostat controlling room

temperature, microcomputer controlling defrosting

Safety devices

Serial signal protection, fan error protection, compressor over heat

protection, high voltage protection, over current protection, etc.

* The nominal values of “Noise in cool room” and “Noise in warm room” in the above table are tested in a dead

room.

Item

Unit

Rating cooling

Rating heating

Capacity

W

5000

5800

Power

W

1560

1600

Energy efficiency ratio

3.21

3.63

Energy efficiency grade

Grade A (European norm)

Note (1) The data are measured at the following conditions. The pipe length is 5m.

Item

Operation

Indoor air temperature

Outdoor air temperature

Standards

DB

WB

DB

WB

Cooling

27℃

19℃

35℃

24℃

Heating

20℃

—

7℃

6℃

Low temperature Heating

20℃ — 2℃

1℃

(2) The operation data are applied to the 220Vdistricts respectively.

(3) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

- 6 -

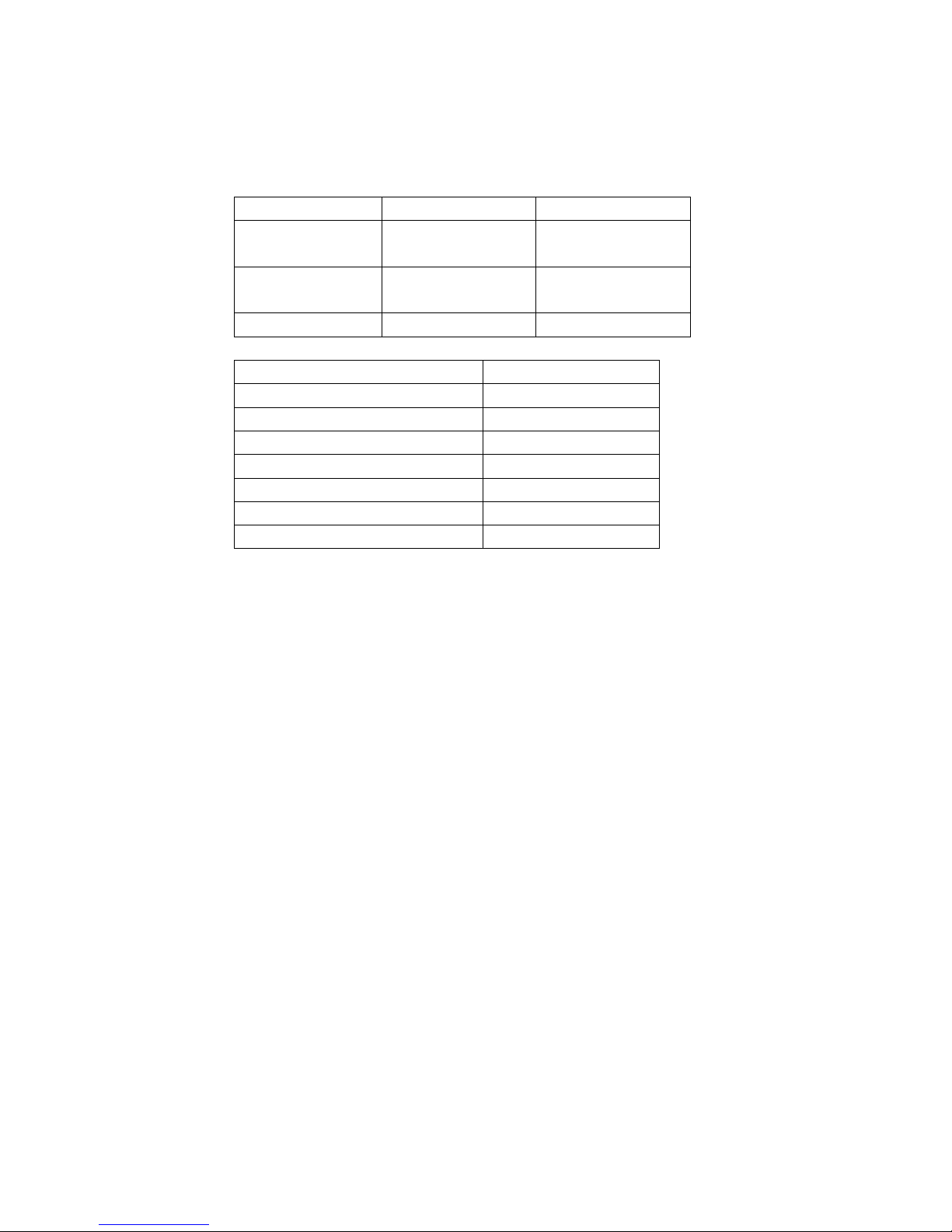

2.2 Range of usage

Please use the air conditioners within the following range of usage, otherwise the protector will be

triggered.

Cooling Operation

Heating Operation

Outdoor temperature

About 18℃~43℃

About -15~24℃

Indoor temperature

About18℃~32℃

About below 30℃

Indoor humidity

About below 80%

20~50 Models

Max. piping one-way length

Within 15 m

Vertical height difference

Within 5 m

Additional R410A Refrigerant

Not required

Voltage

Rating ±10%

Starting voltage

At least 85% of rating

Switching frequency

Max. 10 times per hour

Time interval between stop and start

Min. 3 min

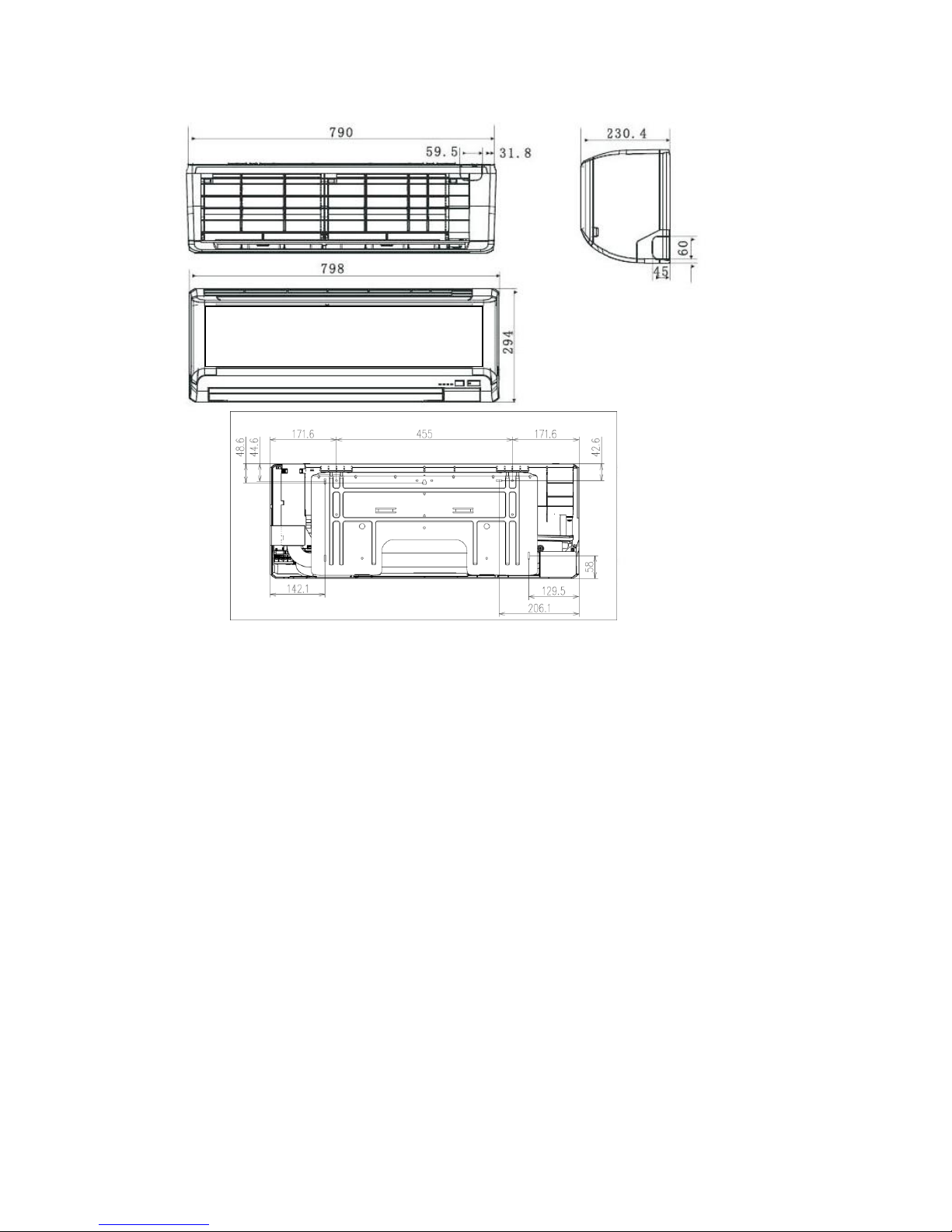

2.3 Outline drawing

(1) Indoor unit: MA-S Series Unit: mm

- 7 -

- 8 -

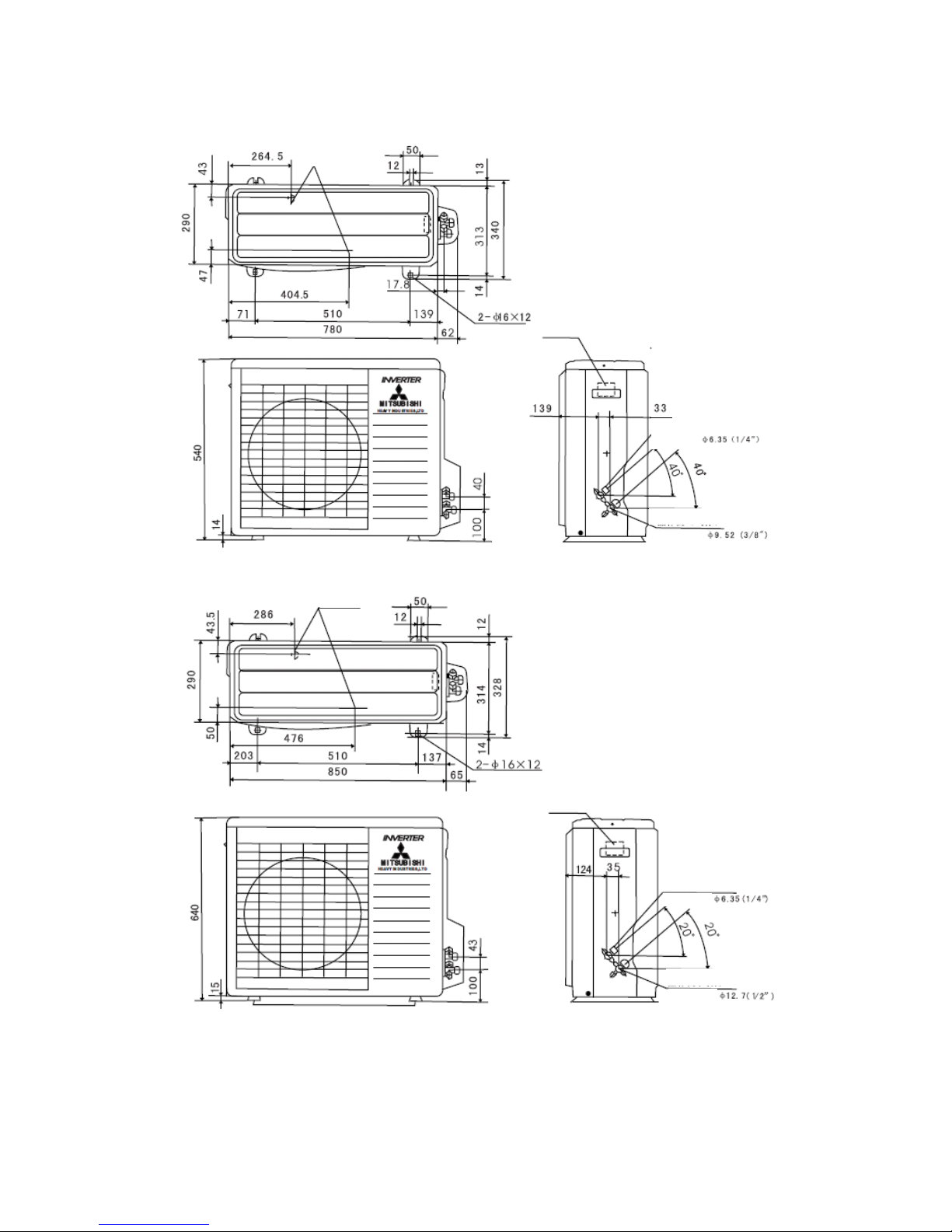

(2) Outdoor unit: SRC20MA-S/ SRC25MA-S/ SRC35MA-S Unit: mm

(3) Outdoor unit: SRC50-MA-S Unit: mm

Drainage pipes

Junction box

Operation valve (Liquid)

Flare connecting

Operation valve (Gas)

Flare connecting

Drain holes

Terminal block

Operation valve (Liquid)

Flare connecting

Operation valve (Gas)

Flare connecting

- 9 -

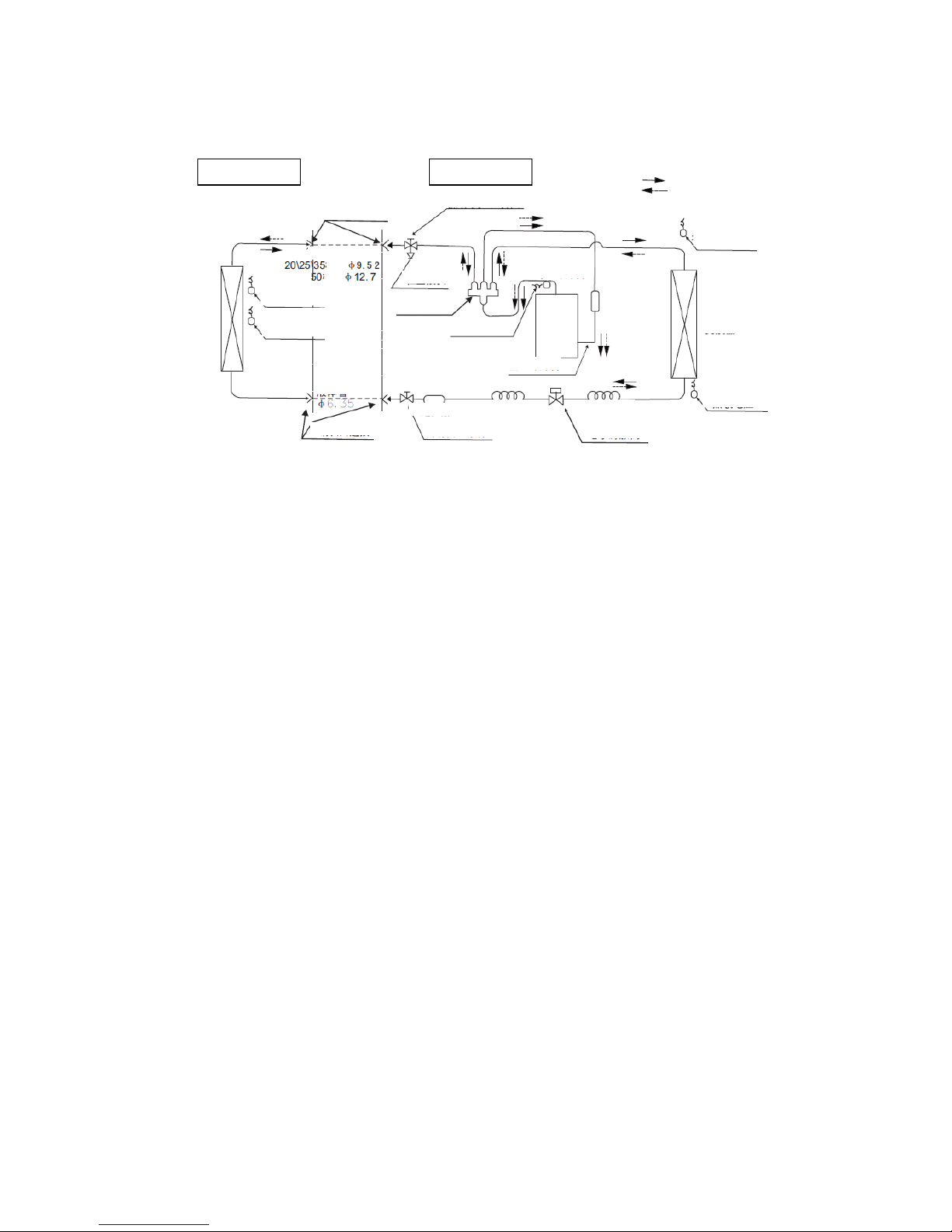

2.4 Cooling cycle system diagram

Models: MA-S Series

Note (1)……line is piping for site construction.

Indoor unit

Outdoor unit

Circulation of cooling

Circulation of heating

Flare connecting

Operation valve (Gas)

Outdoor air

temp. sensor

Air heat

exchanger

Heat exchanger

sensor

Gas liquid

separator

Compressor

Discharge pipe sensor

4-way valve

Check joint

Gas pipe Note (1)

model

Air heat

exchanger

Inlet air temp.

sensor

Air heat exchanger

sensor

Liquid pepe

Flare connecting

Filter

Electronic expansion valve

Hush pipe

Hush pipe

Operation valve (Liquid)

Refrigerant inlet pipe

Refrigerant outlet

pipe

model

- 10 -

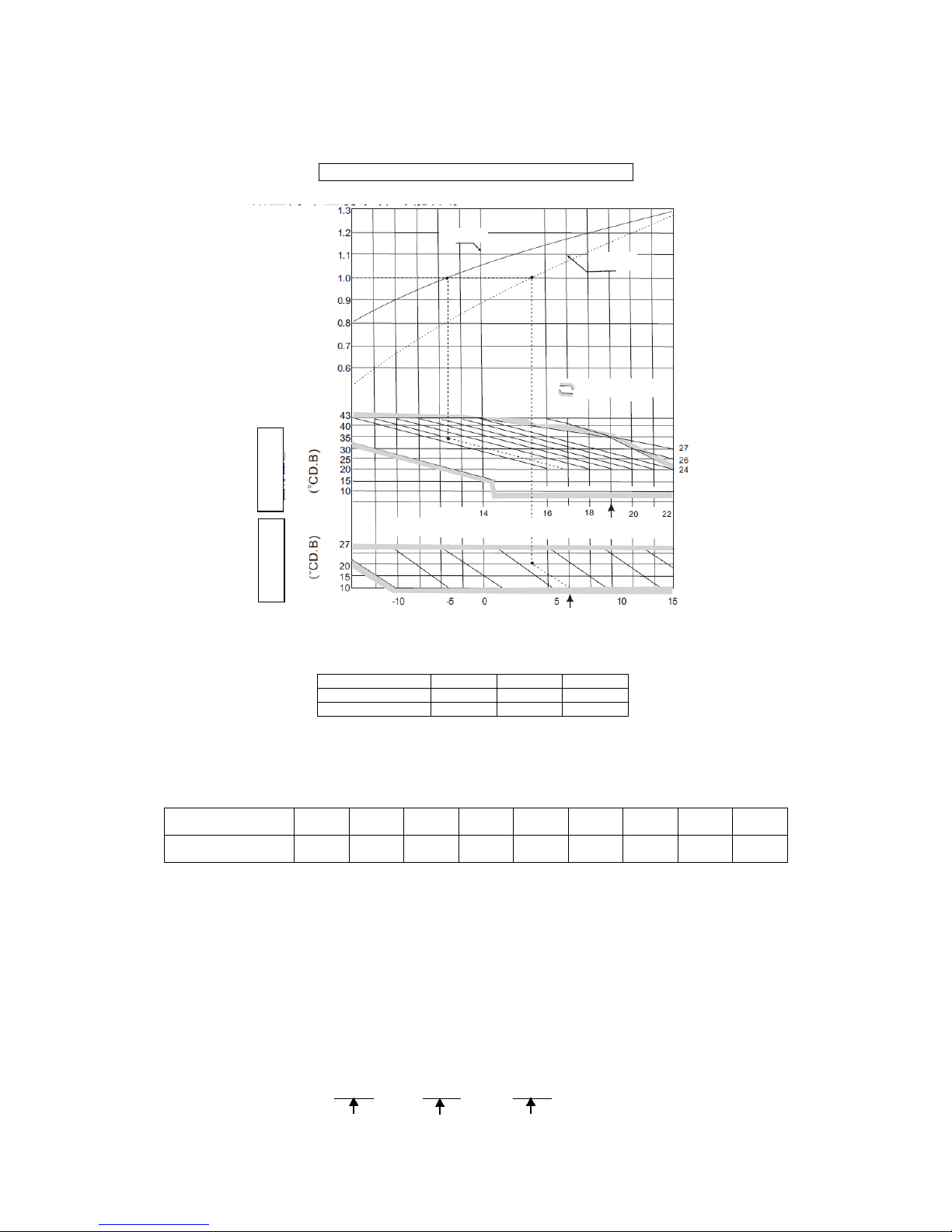

2.5 Performance curve

The cooling and heating capacities are measured in the following conditions. The actual capacity can

be obtained with the following formula.

Actual capacity = Rating capacity x Correction factor

(1) Capacity correction according to indoor and outdoor temperatures:

Outdoor air W.B. temperature (°C W.B.) ISO-T1 Standard

⑵ Capacity correction according to one way length of refrigerant piping:

It is necessary to correct the cooling and heating capacity according to the one way length of refrigerant

piping.

Piping length (m)

7

10

15

Cooling

1.0

0.99

0.975

Heating

1.0

1.0

1.0

⑶ Capacity correction according to frosting on outdoor heat exchanger during heating:

In additions to the foregoing corrections (1) and (2), the heating capacity also needs to be corrected

according to the frosting on the outdoor heat exchanger.

Air inlet temperature

of outdoor unit

-10

-9

-7

-5

-3

-1 1 3 5 Frosting correction

factor

0.95

0.94

0.93

0.91

0.88

0.86

0.87

0.92

1.00

⑷ Example of cooling and heating capacity calculation:

The actual cooling capacity of model SRK50MA-S with the one way piping length of 25m at the

indoor wet-bulb temperature of 19℃ and outdoor dry-bulb temperature of 35℃in summer or indoor

dry-bulb temperature of 20℃, outdoor dry-bulb temperature of 1℃and indoor wet-bulb temperature of

-1℃ in winter is

Actual cooling capacity = 5000 x 1.0 x 0.95 ≈ 4750W

Cooling

Heating

Accommodation

Correction factor of cooling & heating

capacity in relation to temperature

Cooling operation

Heating operation

Indoor air D.B.

temperature

Outdoor air D.B.

temperature

Indoor air W.B. temperature (°C W.B) ISO-T1 Standard

- 11 -

Nominal cooling Temp. correction Piping length

capacity factor correction factor

Actual heating capacity = 5800 x 0.81 x 0.95 x 0.86 ≈ 3838W

Nominal heating Temp. correction Piping length Frosting

capacity factor correction factor correction factor

- 12 -

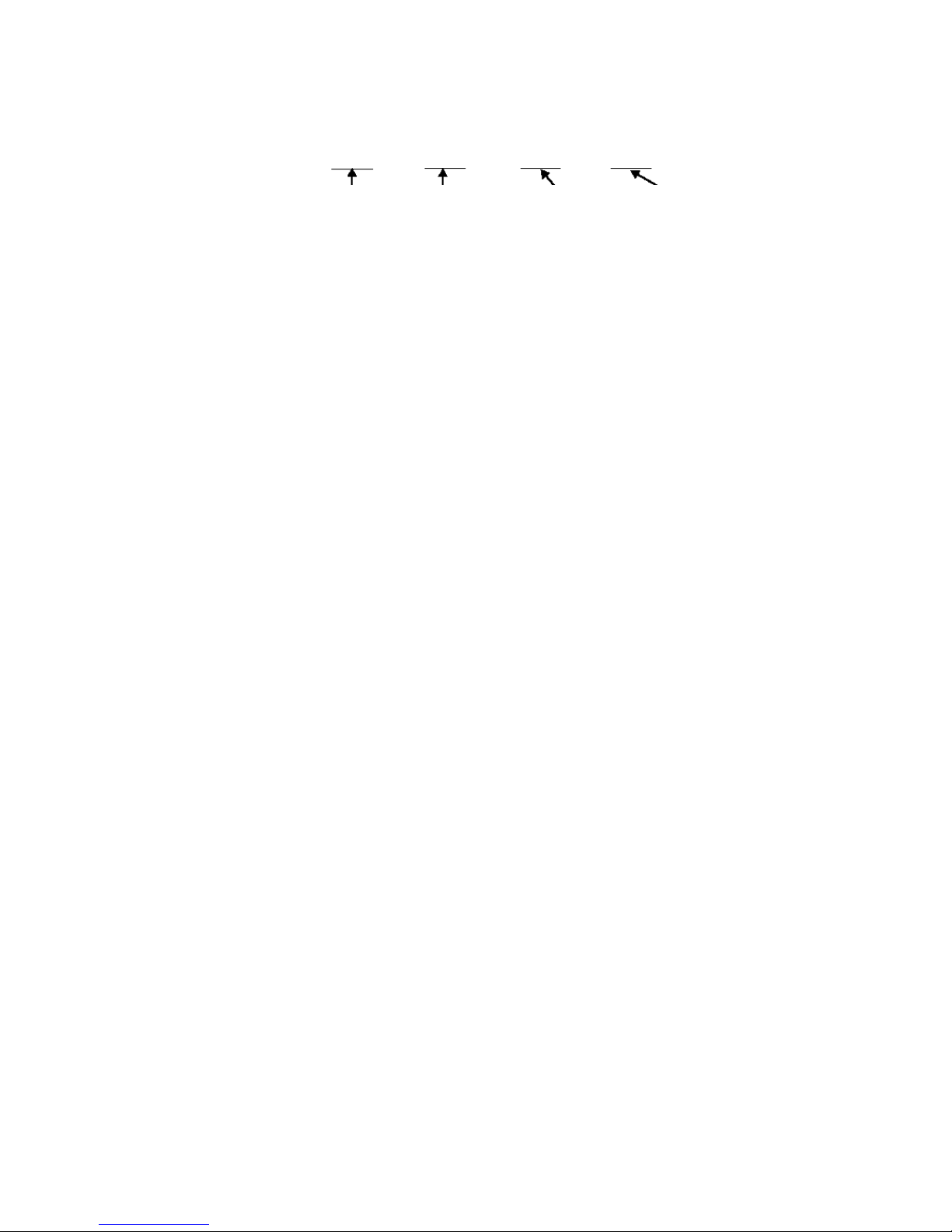

3 ELECTRICAL WIRING DIAGRAM

3.1 Circuit diagram: 20, 25, 35MA-S

- 13 -

3.2 Circuit diagram: 50MA-S

- 14 -

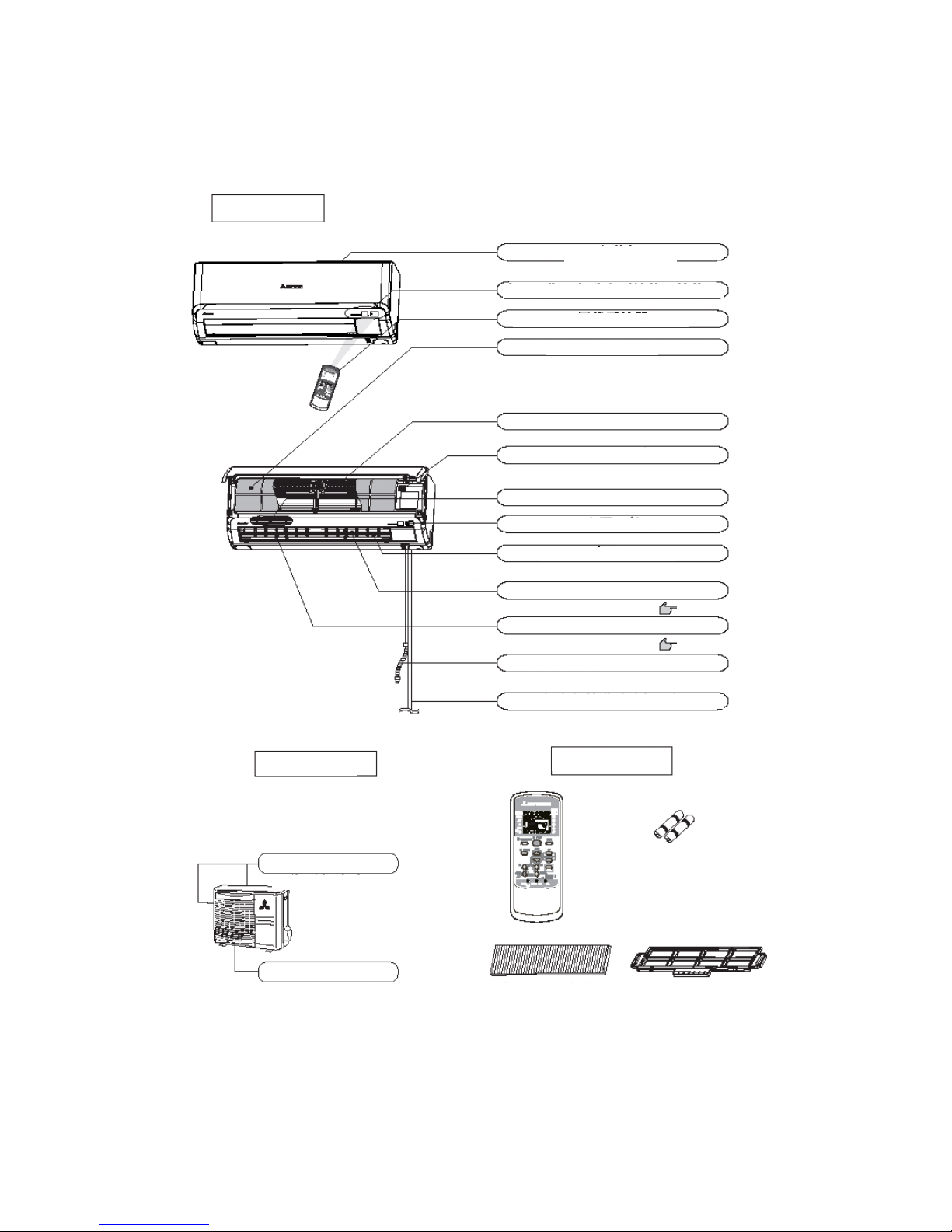

4 NAME OF EACH PART AND ITS FUNCTION

4.1 Name of each part

Indoor unit

Suctions air in the room

Wireless remote controller

Air filter

Page 19

Filter

Indoor fan

Power switch

Vent

Air blows from here.

Up/down air direction flap

Page 11

Left/right air direction flap

Page 11

Drainage pipe

Drains water removed from air

Refrigerant pipe joint and electric wire

Outdoor unit

Accessories

Air inlet

Vent

(on the side and back)

Batteries

Wireless remote controller

Filter retainer (2 pcs)

Lysozyme filter and

antibacterial deodorizing filter

Indication section of A/C and signal receiver of remote controller

Air inlet panel

Draws in the indoor air.

Removes dust or dirt from the inlet air

Room temperature detector

- 15 -

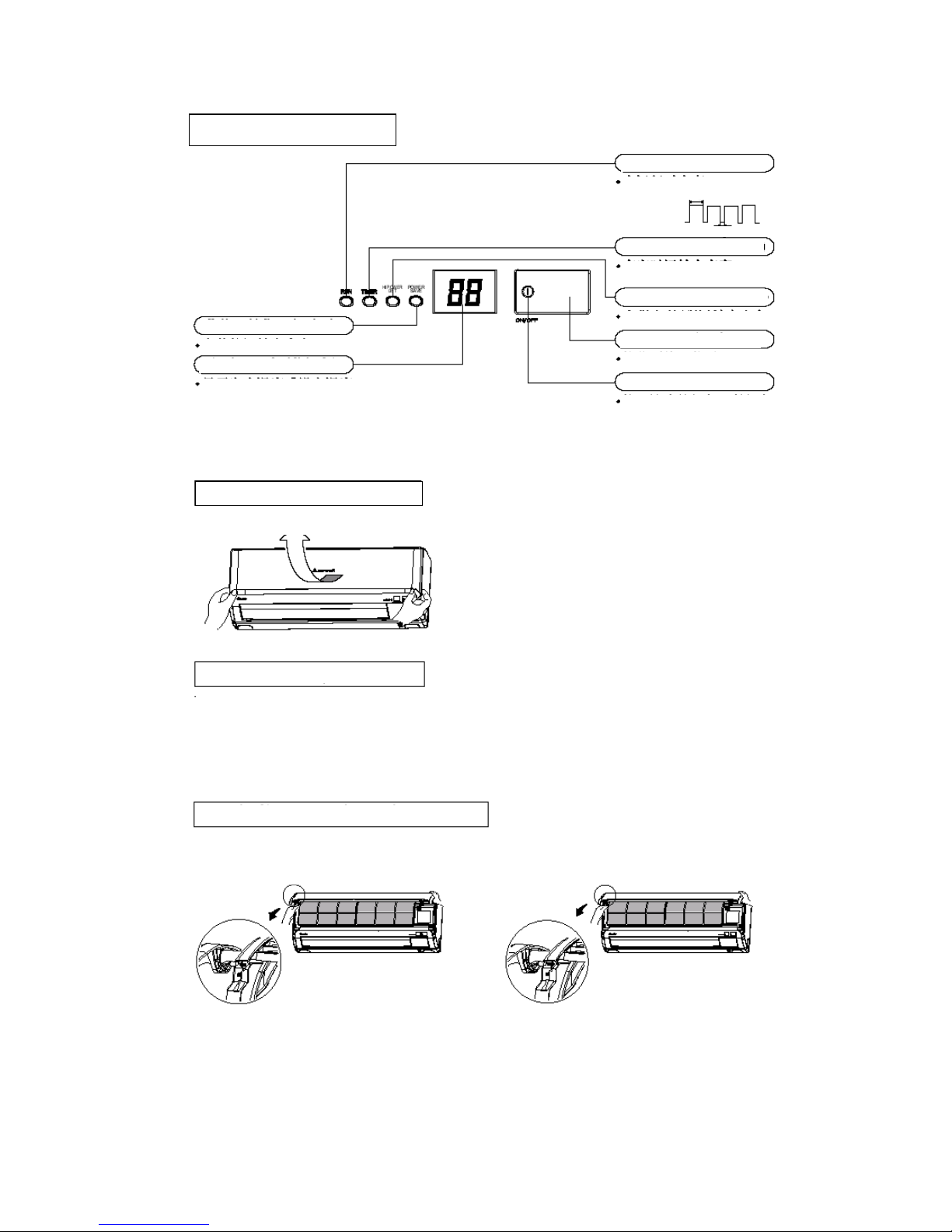

Indication section of air conditioner

RUN lamp (green)

ON during running

Heat-retaining

Running

Stop

1.5 sec.

0.5 sec.

ON during HI POWER/JET running

TIMER lamp (yellow)

ON during timing operation

HI POWER/JET lamp (green)

Receiving part of remote controller

Receives signals from remote controller

ON/OFF button

Press this button to begin

running; press it again to stop

running.

POWER SAVE lamp (green)

ON during Power Save running

Temp. displaying lamp (olivine)

It displays the room temperature or

set temperature. (Each time the

remote controller is pressed, the

temperature set with the remote

controller flashes for 10 seconds,

and then the room temperature is

displayed.

Opening the air inlet grille

Put your hands on the indentations on both sides, raise the grille towards yourself, and stop at the opening position of

about 60°.

Closing the air inlet grille

Gently push both sides and then gently push the central portion.

Removing and mounting the air inlet grille

To remove the air inlet grille to clean the inside, open it

at the position of about 65° and pull it towards yourself

to remove the grille.

To mount the air inlet grille, insert the mounting arm

onto the pin roll and close the grille.

- 16 -

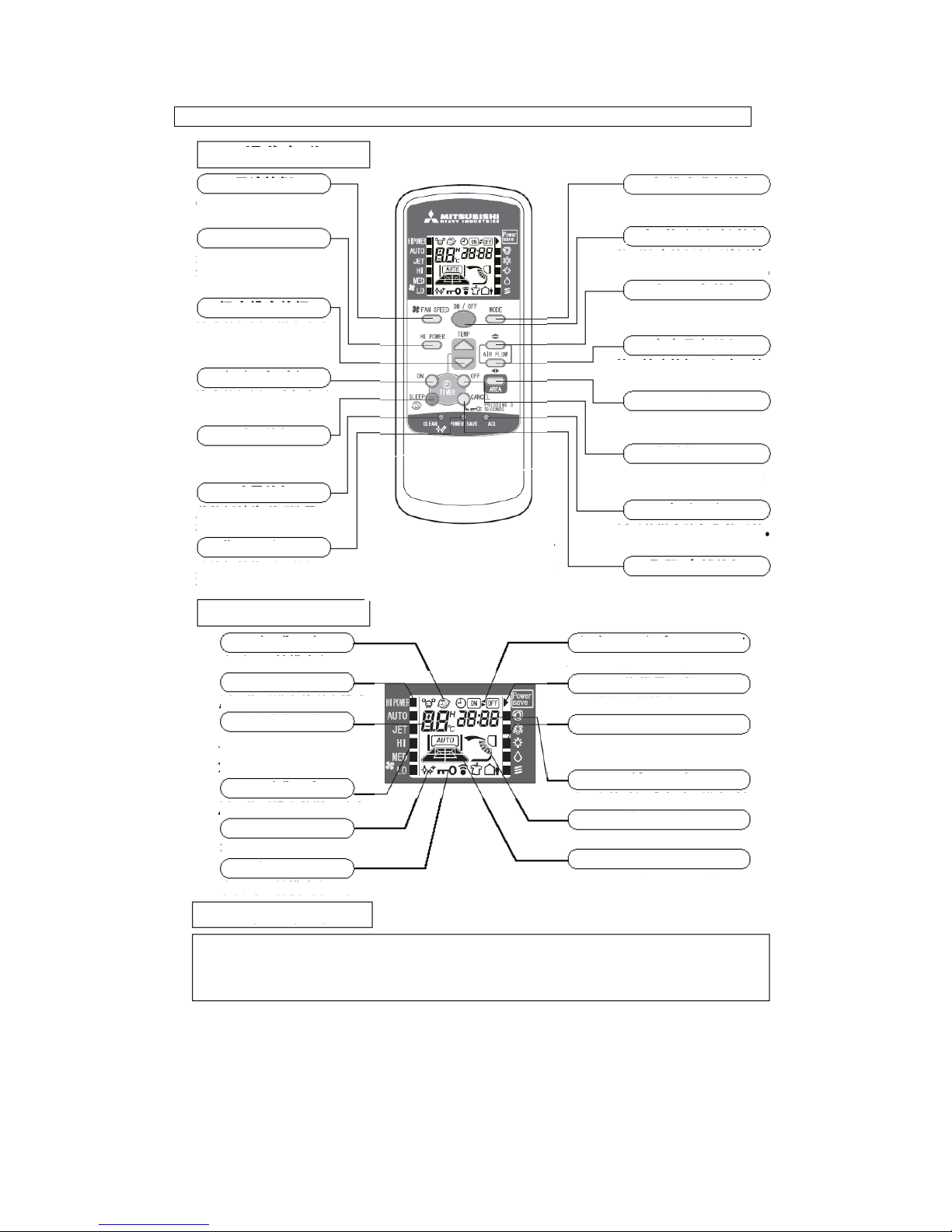

Operation and indication section for remote control

Operation section

FAN SPEED button

Each time this button is pressed,

■ displaying changes in order.

HI POWER button

This button is used to change

the HI POWER mode.

TEMP button

This button is used to set the room

temp. (or select the current time

and set time for timing operation.)

TIMER ON button

This button is used to select

the Timing ON operation.

SLEEP button

Press this button to switch to

the SLEEP operation.

CLEAN button

Press this button to switch to

the CLEAN mode.

POWER SAVE button

Press this button to switch to the

POWER SAVE mode.

Displaying section

SLEEP indicator

Appears in the SLEEP mode

HI POWER indicator

■ is used to indicate the HI POWER mode

TEMP indicator

Displays the set temperature

(No temperature is displayed in

the AUTO mode.

FAN SPEED indicator

■ is used to indicate the fan speed set.

CLEAN indicator

Appears in the CLEAN mode

KEY LOCK indicator

Appears in the CLEAN mode

Transmission method

MODE button

Each time this button is pressed, ■

displaying changes in order.

ON/OFF (luminous) button

Press this button to begin running;

press it again to stop running.

Up/Down air direction button

Press this button and the air flap begins

to swing upwards and downwards.

Left/Right air direction button

Press this button and the air flap begins to

swing to the left and the right.

AREA button

Press this button to set the air

regulation area in the room.

TIMER OFF button

This button is used to select the

Timing OFF operation.

ACL switch

Used to reset the microcomputer

CANCEL/KEY LOCK button

Press this button to cancel Timing ON/OFF

and SLEEP operations; press and hold it for 3

seconds to lock the functional keys.

Timing ON/ Timing OFF indicator

Appears in the Timing ON/ Timing OFF mode

Power Save indicator

Indicates the POWER SAVE mode

MODE indicator

■ is used to indicate the mode selected:

[AUTO/ COOLING/ HEATING/ DRYING/ BLOW]

TIME indicator

Displays the current time or the set time of the timer

AIR FLOW indicator

Displays the swinging mode of the flap

AREA indicator

Displays the air regulation area in the room

When the remote controller is pointed at the air conditioner, press a button on the remote controller and the signal will be

transmitted to the air conditioner. When the signal is received correctly, the air conditioner will issue the receiving sound. The

effective linear distance of transmission of the remote controller is 5 meters. The transmission head of the remote controller

should be pointed at the receiving head, otherwise, the receiving may be impacted.

● The above figure shows all

control contents for convenient

explanation. However, in actual

use, only related contents are

displayed.

- 17 -

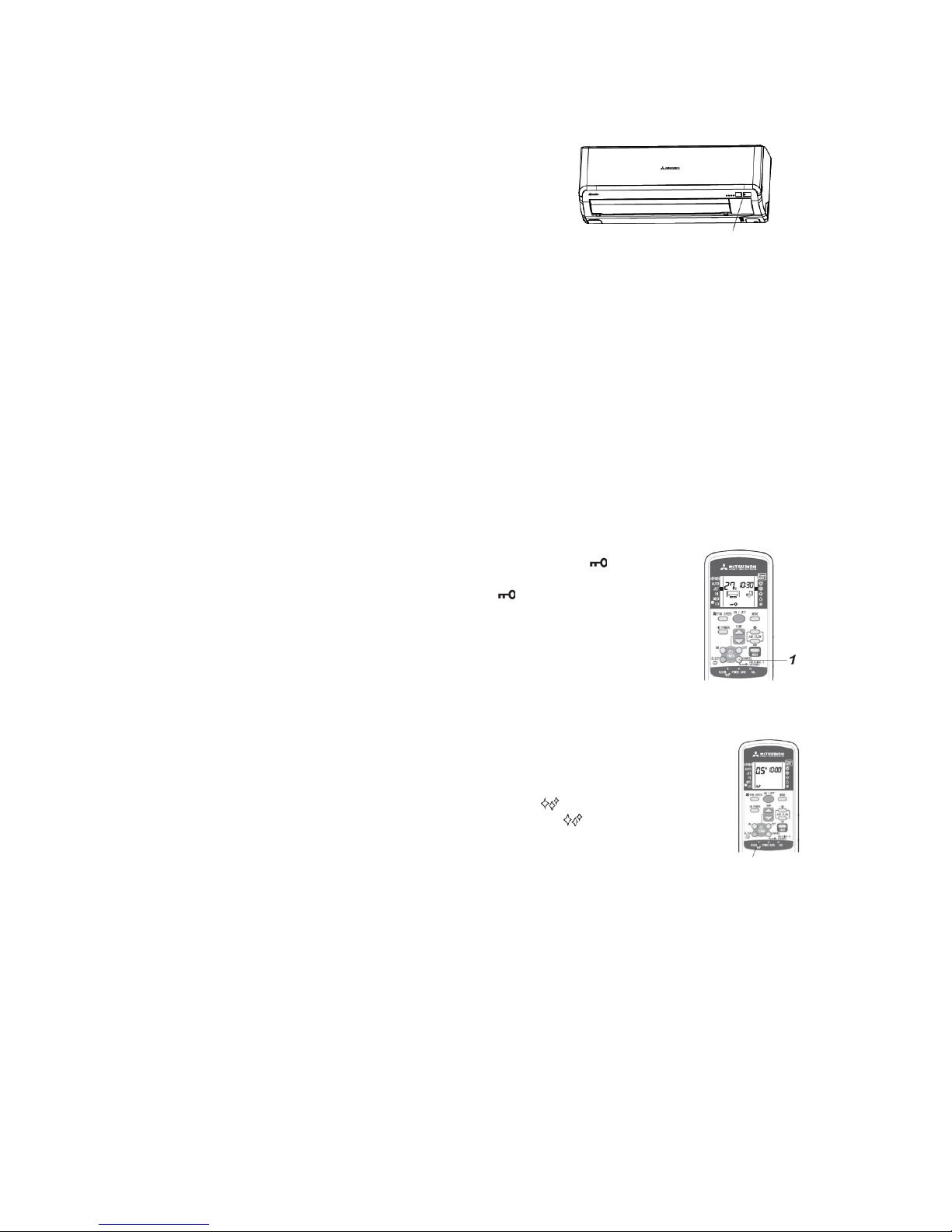

4.2 Emergency switch:

(1) When the remote controller is not used, the emergency operation switch “ON/OFF” button

can be used to turn on/off the machine.

(2) Press the “ON/OFF” button to begin operation. Press it

again to stop.

(3) Operation items:

● Operating mode: Automatic

● Fan speed: Automatic

● Air direction: Automatic

(4) Note:

Press and hold it for over 5 seconds to set to the cooling mode automatically.

4.3 Automatic restart due to power cut:

(1) This function can rapidly record the operation state immediately before the air conditioner is

switched off due to power failure, and will resume operation automatically after the power

supply is restored.

(2) This function is set to Active by default.

(3) Operation state memorized immediately before power cut includes:

● Indoor operation switching (cool room · warm room · drying · automatic · air flow, stop)

● Air flow

● Power Save

● Set temperature

● Air direction

(4) After automatic restart due to power cut, the following settings will be canceled:

Timing operation, HI POWER operation, CLEAN operation

(5) Priority of start:

Compressor 3 min. delayed start control > Automatic restart due to power cut

4.4 Key lock:

(1) The key lock setting prevents misoperation.

(2) Press and hold the KEY LOCK button for over 3 seconds and will appear

on the remote controller, which means the function is enabled; press and hold

the KEY LOCK button for over 3 seconds and on the remote controller

will disappear, which means the function is disabled

(3) When the function is enabled, only the ON/OFF button can be operated, and

the settings of temperature, air flow, air direction, etc. can’t be changed.

(4) When the function is enabled in the JET/ HI POWER operating mode, the

operation and action are valid before the air conditioner stops and become

invalid when the air conditioner operates again.

(5) The key lock function can’t be set in the CLEAN operation and various timing operations.

4.5 CLEAN operation:

(1) CLEAN operation: In the automatic, cooling and drying operating modes, when the

air conditioner is turned off, the fan of the indoor unit will continue to run for 30

minutes to dry the moisture in the indoor unit and inhibit the growth of mould and

bacteria. However, mould, bacteria, stain, etc. attached can’t be removed.

(2) Press the CLEAN button on the remote controller and will appear, which

means the CLEAN function is enabled; press it again and will disappear,

which means the CLEAN operation is disabled.

(3) After the CLEAN function is enabled, in the automatic/cooling/drying mode, press

the ON/OFF button to stop the operation of the air conditioner. In such case, the

RUN lamp will go off; the CLEAN indicator on the remote controller will light up; and the

CLEAN operation will run for about 30 minutes.

(4) During the CLEAN operation, press the ON/OFF button and the CLEAN operation will stop.

(5) According to the relative humidity, the rotate speed of the fan will be selected automatically

(including 3 rotate speeds) and will not be changed during the operation.

(6) When Air Flow, Timing On and SLEEP Operation stop, the CLEAN operation can’t run.

(7) During the CLEAN operation, press the SLEEP button and the CLEAN operation will be

switched to the SLEEP operation.

(8) The CLEAN function is disabled by default. Users need to set it according to the above steps.

ON/OFF button of the equipment

CLEAN

- 18 -

4.6 SLEEP operation:

(1) SLEEP operation: This function prevents the temperature in the cooling operation from

becoming too low and the temperature in the heating operation from

becoming too high; regulates the room temperature automatically as

time goes by; and stops automatically after the time set.

(2) Operation method:

① If the SLEEP button is pressed during the operation of the air

conditioner, and the run time, such as , will appear.

There are 11 options, including 1-10 hours (interval of 10 hours)

and OFF.

② If the SLEEP button is pressed when the air conditioner is in the

stop mode, the air conditioner will execute the previous

operation settings and stop after the time set.

(3) Making correction based on the set temperature and regulating the

room temperature automatically:

① During cooling operation:

Beginning (-1℃), 1 hour later (±0℃), 2 hours later (+1℃);

② During heating operation:

Beginning (-1℃), 30 minutes later (-2℃), 1 hour later (-1℃), 2 hours later (-6℃); 4 hours

later (-3℃)

(4) The set time of SLEEP operation can be changed with the SLEEP button at any time. Since

the remote controller receives the change signal, the air conditioner continues to run

according to the changed set time.

(5) When the operation switch change signal is received during the SLEEP operation, the air

conditioner will control the sleep setting according to the operation switching and the

temperature correction value in the elapsed time will be retained.

(6) When the set temperature change signal is received during the SLEEP operation, the

temperature correction value will be recalculated.

(7) When the air conditioner is set to automatic control (fuzzy automatic) and the indoor

operating mode (cool room · drying · warm room) is set, the SLEEP operation begins. The

change of cool room · drying · warm room state arising from the automatic control (fuzzy

automatic) is made only when the set temperature is changed. (In other words, the operating

mode judgment according to the operation judgment timing is not executed.)

(8) Priority of sleep timing operation

① Set temperature correction: HI POWER operation > Setting correction temperature

② Timing: Sleep timing run > HI POWER run

4.7 Timing OFF:

(1) Timing OFF: The timing OFF operation begins when the Timing OFF

signal is received from the remote controller and stops after the set time.

(2) Operation method:

① When the air conditioner is in the stop mode, press the ON/OFF

button;

② When the air conditioner is running, press the TIMER OFF button

and the Timing OFF indicator will flash;

③ Press the or button to set the OFF time (unit: 10

minutes);

④ Within 60 seconds, press the TIMER OFF button and the indicator

will change from flashing to a fixed state. The setting is finished;

⑤ The TIMER lamp (yellow) of the indoor unit lights up.

(3) Use the TIMER OFF button to set a new Timing OFF time at any time.

(4) During the Timing OFF operation, all setting change signals from the remote controller are

accepted.

(5) During the Timing OFF operation, when the Timing ON signal is received, the operation will

become the programmed timing operation and the remaining Timing OFF time will be

retained.

(6) During the Timing OFF operation, when the Sleep signal is received, the Timing OFF

operation will be canceled (and the remaining time will be canceled too) and the operation

will be switched to the SLEEP operation. (In other words, the SLEEP operation can’t be used

with the Timing OFF function.)

(7) To cancel the Timing OFF function, press the Cancel button and the TIMER lamp will go

off.

Sleep

timing

Timing

OFF

- 19 -

4.8 Timing ON:

(1) Timing ON: The air conditioner begins to detect the room temperature 60 minutes before

the set time and commences operation 5-60 minutes in advance according to the difference

between the room temperature and the set temperature to make the room temperature reach

the best value at the set time.

(2) Operation method:

① To set the Timing ON operation, whether the air conditioner is running is not considered.

② Press the TIMER ON button and the Timing ON lamp will flash;

③ Press the or button to set the ON time (unit: 10 minutes);

④ Within 60 seconds, press the TIMER ON button and the lamp will change from flashing

to a fixed state. The setting is finished;

⑤ The TIMER lamp (yellow) of the indoor unit lights up.

(3) Composition of Timing ON operation:

(4) Notes:

① The air conditioner commences operation 5-60 minutes before the set time.

② When the time reaches the set time, the TIMER lamp (yellow) will go off;

③ During the Timing ON operation, the current time is not displayed.

(5) Use the TIMER ON button to set a new Timing ON time at any time and the air conditioner

will enter the stand-by state or warm-up running state after the changed set time.

(6) When the Timing OFF signal is received, the air conditioner will run in the timing mode with

an earlier set time.

(7) During the Timing ON operation and stand-by, when the operation switching, mode

switching or set temperature change signal is received from the remote controller, only the

changed content will be accepted.

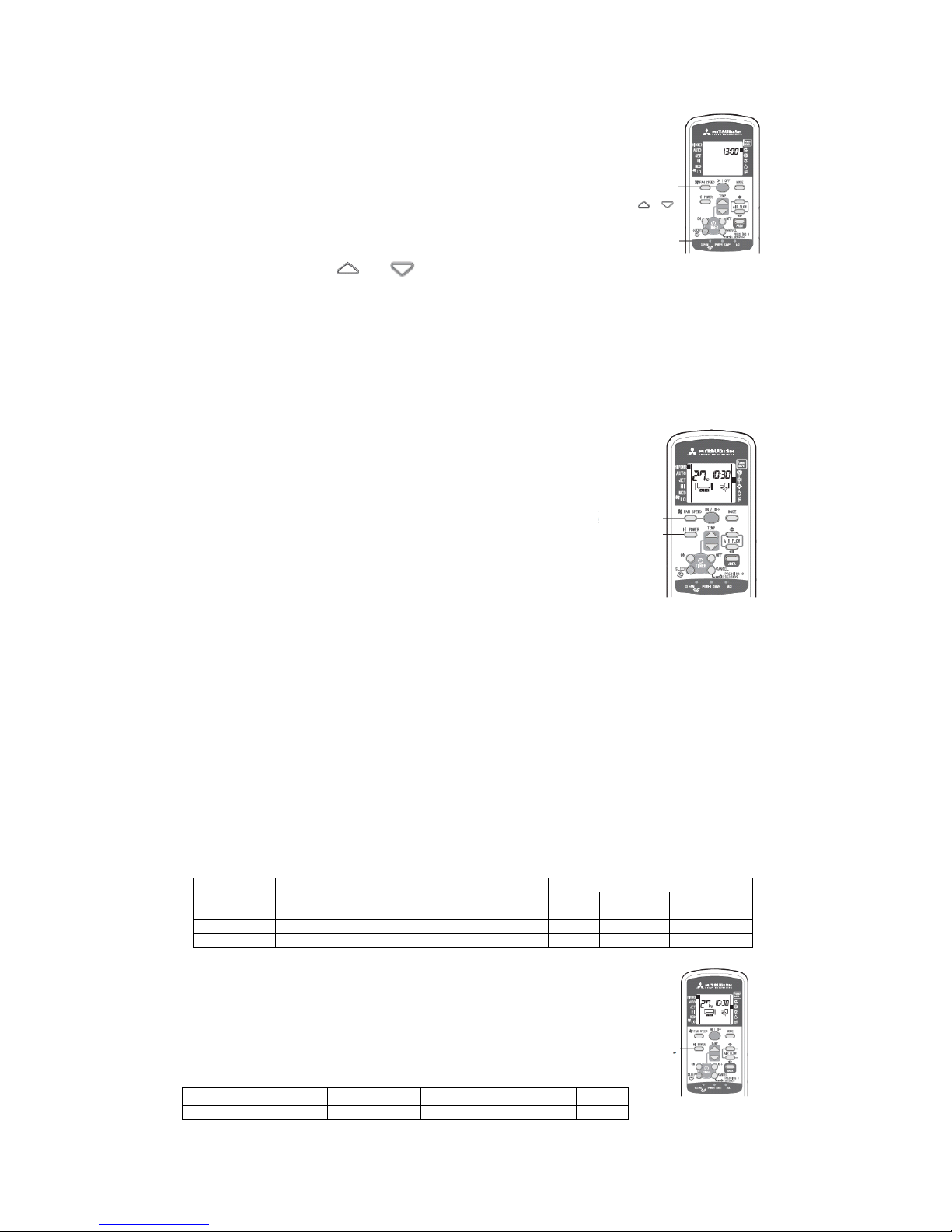

4.9 Programmed timer:

(1) Timing operations include Timing ON and Timing OFF. Once the function is enabled, the

operation begins. As long as the ON/OFF button is not pressed, the air conditioner will begin

operation at the same time everyday till the stop time.

(2) Operation method:

For example, to set the air conditioner to turn on at 8:00 and turn off at 22:30,

① Step 1: By referring to “4.9 Timing ON”, set it to ;

② Step 2: By referring to “4.8 Timing OFF”, set it to ;

③ When the TIMER lamp (yellow) lights up, the setting is finished;

④ The time will be displayed on the remote controller;

⑤ The displaying will change with the operation state: Stop( ),

Run.( )

(3) Repeated running:

(4) Notes:

① The operation becomes programmed running only when both the Timing On and Timing

OFF signals are received;

② The Timing ON and Sleep combined operation is executed once only and will not

become programmed operation.

(5) Use the TIMER ON or OFF button to set new ON time.

Timing ON

RUN Lamp

TIMER Lamp

Running state of compressor

Lamp lights up

Lamp lights up

Stop

△Timing ON signal

Timing ON stand-by

Warm-up running

(MAX 1 hour)

△Timing ON set time

Timing ON running

Timing ON run

Timing ON run

Timing ON run

Timing OFF run

Timing OFF run

Timing OFF

setting

Timing OFF

set time

Timing ON

set time

24 hours

Timing ON

set time

24 hours

Timing OFF

set time

24 hours

Timing OFF

set time

- 20 -

4.10 Current time setting:

(1) After inserting the batteries, the current time is set to 13:00

automatically.

In time setting, all contents displayed on the remote controller

are reset.

(2) Operation method:

For example, to set to 11:30,

① Step 1: Use the pen point to press the ACL switch and the

TIMER lamp will flash. Here you can set the current time;

② Step 2: Press the or button to set the current time to 11:30;

③ Within 60 seconds, press the ON/OFF button and the lamp will change from flashing to a

fixed state, thus the setting is finished.

(3) Notes:

① Timing operation is set according to the current time;

② The time on the remote controller changes according to the setting of current time.

4.11 HI POWER operation

(1) HI POWER operation: Press the HI POWER button to enable the HI POWER operation, that

is, the cooling or heating function runs continuously for 15 minutes with the fan speed set to

High.

(2) Operation method:

① Step 1: In the Automatic, Cooling or Heating mode, press

the ON/OFF button;

② Step 2: Press the HI POWER button to switch to the HI

POWER mode, and the indoor unit will commence HI

POWER or JET operation 5 seconds after receiving the

signal.

(3) The HI POWER mode is canceled in one of the following

cases:

① The HI POWER button is pressed again;

② The operating mode is changed;

③ After 15 minutes;

④ The FAN SPEED button is pressed;

⑤ The system enters the Timing operation.

(4) Notes:

① During the HI POWER operation, the room temperature is not controlled.

② The HI POWER operation is not supported during the drying and programmed timer

operation.

③ The Shower and Warm Feet modes can’t be used with the HI POWER mode.

④ During the Timing ON operation, the HI POWER operation commences only after the

time reaches the ON time.

⑤ During the timing operation, the HI POWER operation can be set only after the timing

setting is finished.

(5) Setting difference between HI POWER and JET operations:

“O” means the option can be set; “X” means the option can’t be set.

Operating mode

Settings

Auto Cooling Heating Drying

Air flow

Temp.

Fan

speed

Air

direction

HI POWER

X

X X X O JET O X O

O

4.12 JET operation:

(1) JET operation: The system runs at the maximum fan speed to rapidly

achieve cooling or heating.

(2) Operation method: Press the FAN SPEED button to switch to the JET

mode.

(3) Note: JET operation has no time limit.

★ In the Cooling or Heating mode, the fan speeds corresponding to the

various modes are as follows:

Mode

Auto

JET

HI POWER

Standard

Econo

Fan Speed

Auto

Ultra high

Hi

Me

Lo

ON/OFF

ACL

ON/OFF

HI POWER

FAN SPEED

- 21 -

4.13 POWER SAVE operation:

(1) The Power Save function regulates the frequency of the compressor, etc. and

reduces the current value during operation, thus reduces the cooling/heating

capacity to save energy.

(2) Operation method: Point the remote controller at the air conditioner and use the

pen point to press the POWER SAVE button to make point at Power Save

. The Power Save operation is enabled.

(3) Notes:

① The Power Save operation is set to disabled by default;

② When Power Save is enabled, other operations following it (except reset and CLEAN

operation) are valid.

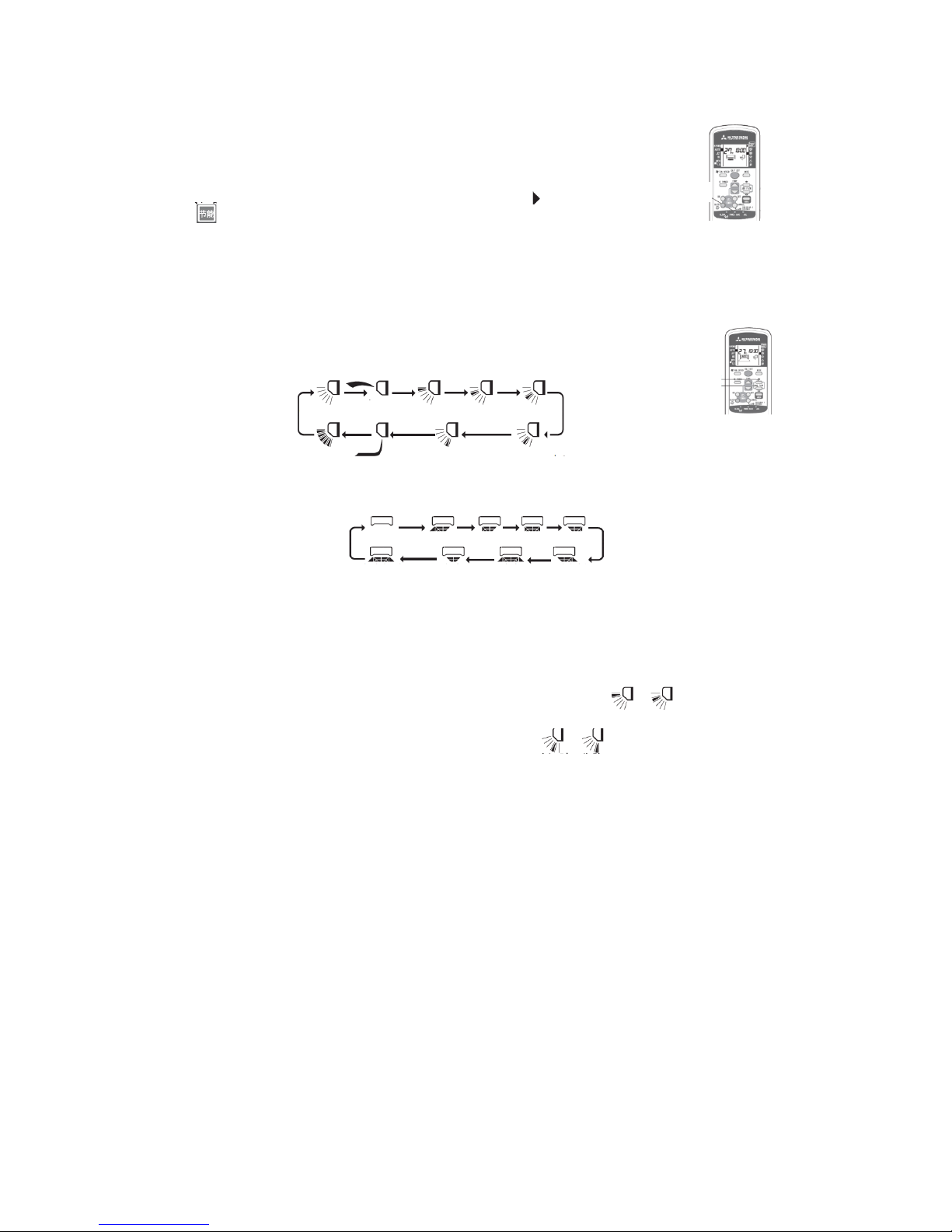

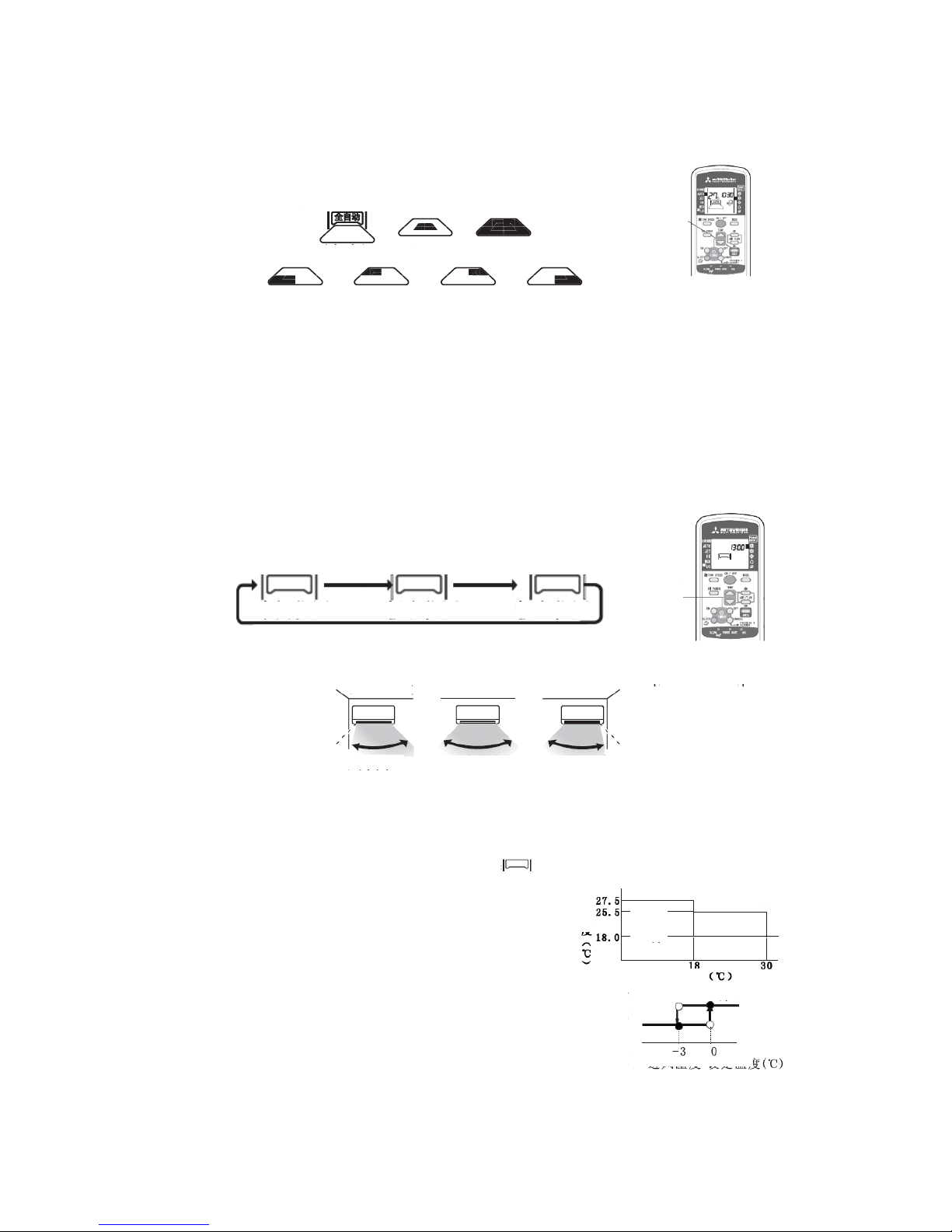

4.14 Air direction regulation:

(1) Operation method:

● Step 1: Press the ON/OFF button to run the air conditioner;

② Step 2: Press the Up/Down AIR FLOW button, as shown in the figure

below, to regulate the up/down direction of the vertical flap;

(Up/down swing) (Warm Feet)

③ Step 3: Press the Left/Right AIR FLOW button, as shown in the figure below, to regulate

the left/right air direction of the horizontal flap:

(2) Notes:

① Cool Air Shower (for cooling only): Through air direction regulation, cool air can be

blown everywhere in the room;

② Warm Feet (for heating only): Through air direction regulation, warm air can be even

blown to the bottom of feet;

(3) Use suggestions:

① Avoid directly blowing to the body for a long time;

② During cooling and drying, the up/down air direction is set to to prevent too

much cool air from going down;

③ During heating, the up/down air direction is set to to prevent too much warm

air from going up.

(4) Notes:

① When the Heating mode is enabled (that is, the heating operation begins), in order to

prevent cool air from blowing, the flap will move to the level position, in which case, the

air direction can’t be set. When warm air begins to blow, the air flap will be restored to

the set position, in which case, the air direction can be set.

② During the heating operation, when the room temperature is higher than the set

temperature, or during the defrosting operation, when the flap is at the level position, the

air direction can’t be set. The air direction can be set only when warm air begins to blow.

③ In the Cool Air Shower or Warm Feet mode, the horizontal flap will be at the level

position.

④ In the Cooling or Drying mode, avoid blowing downwards for a long time, otherwise,

condensation may appear on the air outlet grille and drip down;

⑤ Never attempt to regulate the air flap or regulating port manually, otherwise, the control

angle may change and the flap can’t be fully closed.

⑥ Flap memorizing function (stop of flap): When the flap is swinging, press the AIR

FLOW (Up/Down or Left/Right) button once, it will stop at that angle. As this angle is

memorized in the microcomputer, the flap will automatically operate at the same angle

next time the machine is started.

Power

Save

Up/Down

Left/Right

(Swing stops) (Cool Air Shower)

(Swing stops) (Leftmost) (Left) (Level) (Right)

(Left/right swing) (Fixed point) (Wide-angle) (Rightmost)

- 22 -

4.15 Area setting:

(1) The area setting function is used to regulate the indoor air and the air in the specific area in

the room.

(2) Operation method: When the air conditioner is running, press the AREA

button, as needed, to switch to the desired area.

(3) The area indications are as follows:

(Bottom left) (Top left) (Top right) (Bottom right)

(4) Cancelation: Press the Up/Down or Left/Right button to regulate the air direction.

(5) Notes:

① In the AUTO mode, the HI POWER and JET modes are not supported;

② After the Area setting is canceled, when the air conditioner is started again, the air

direction before the Area setting will be displayed.

4.16 Installation location setting:

(1) The installation location setting function is used to consider the installation location of air

conditioner and regulate the maximum space of the left/right air flow.

(2) Operation method:

① Switch on the air conditioner and let it stay in the stop mode;

If it is running, press the ON/OFF button to stop;

② Press and hold both the Up/Down and Left/Right buttons for over 5 seconds, and the

installation location will flash on the display;

③ Press the Left/Right button to regulate to the desired position;

whenever the Left/Right button is pressed, the displaying changes in

the following order:

④ Within 1 minute, press the ON/OFF button again to send a signal to

the air conditioner and the air conditioner will memorize the installation location.

(3) The installation location and air direction range of the air conditioner are as follows:

(4) Notes:

① After the installation location is set again, even when the plug is unplugged, the air

conditioner will also memorize the installation location;

② During operation, the installation location can’t be set;

③ After the installation location is set, if the air conditioner is reset or the batteries are

replaced, the remote controller will display , i.e. the installation location

memorized by the air conditioner.

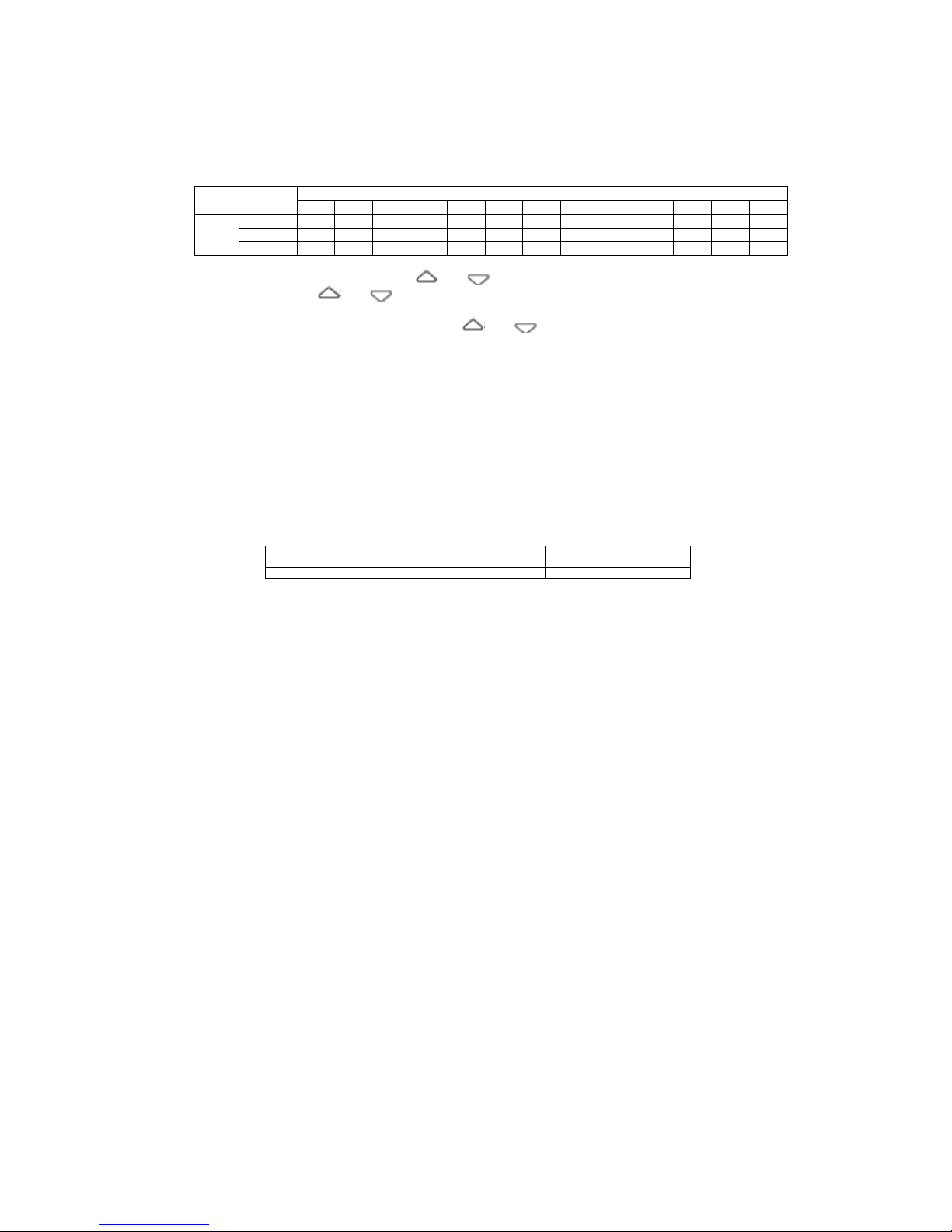

4.17 Outline of automatic operation:

(1) Determination of operating mode:

After the indoor and outdoor fans operate at the 2nd speed

and 4th speed respectively for 20 seconds, the system will

check the room temperature, humidity and outdoor

temperature to automatically select the cooling, heating or

drying mode and the room temperature compensation

value, and operate automatically. (Note: Here, the vertical

flap stops at the level position and the horizontal flap

stops at the central position.)

(2) The system checks the temperature every hour after the

operation begins. When the operating mode is judged to be different from the previous one,

the operating mode will be changed;

Area

setting

(Central)

(Central)

(Full)

Area

setting

Press and

hold both

buttons

for 5 sec.

Central

Rightmost

Lefttmost

(About 30° from front

direction)

(About 30° from front

direction)

Central

Left

Right

Right

Left

Air direction

range

Cooling

Drying

Heating

Area A

Room

temp

Judgement

conditon

forArea A

Heating

Cooling

Air inlet temp. – set temp.

Outdoor temp.

- 23 -

(3) If the air conditioner is started again within 1 hour after the automatic operation stops, or it is

converted to automatic operation in the heating, cooling or drying mode, it will operate in the

previous mode.

(4) The temperature can be set in the following range. The relationship between the signals of

the wireless remote controller and the set temperature is as follows:

Signals of wireless remote controller (displaying)

-6

-5

-4

-3

-2

-1 0 +1

+2

+3

+4

+5

+6

Set

temp

Cooling

18

19

20

21

22

23

24

25

26

27

28

29

30

Drying

18

19

20

21

22

23

24

25

26

27

28

29

30

Heating

20

21

22

23

24

25

26

27

28

29

30

31

32

(5) Operation of remote controller:

① In the AUTO mode, press the or button to regulate 6 levels of temperature;

② Each time the or button is pressed, the temperature will be switched in the

following order: -6 ~ -5 ~ -4 ~ -3 ~ -2 ~ -1 ~ ±0 ~ +1 ~ +2 ~ +3 ~ +4 ~ +5 ~ +6

③ When -6 or +6 is displayed, press the or button and the displaying will not

change;

④ The set temperature of ±0 in AUTO mode is: Cooling 24℃, Heating 26 ℃, Drying

24℃.

4.18 Outline of drying operation:

(1) Judgment of operation state:

① After the indoor and outdoor fans run at the 2nd speed and 3rd speed respectively for 20

minutes. the system checks the room temperature (Tai) and outdoor temperature (Th0-A)

to determine the operation state. (Note: Here, the vertical flap stops at the level position

and the horizontal flap stops at the central position.)

② The system checks the temperature every hour after the operation begins. When the

operating mode is judged to be different from the previous one, the operating mode will

be changed.

③ Judgment of operating mode:

Tai and TS (setting correction temperature), Th0-A relationship

Operating mode

Tai > TS-3 or Th0-A ≥ 19℃

Slightly cool heating & drying

Tai ≤ TS-3 or Th0-A < 19℃

Slightly warm heating & drying

(2) Notes:

① After the operating mode is judged, the system decides the running range according to

the room temperature and setting correction temperature every 5 minutes;

② Slightly cool heating & drying includes four running ranges, all of which are cooling

operations;

③ Slightly warm heating & drying includes four running ranges, in which three are cooling

operations and one is heating operation.

4.19 Outline of defrosting operation:

(1) Beginning conditions:

Case 1 (The defrosting running begins when all of the following conditions are met):

① After the heating begins and the defrosting ends, the accumulated running time of the

compressor exceeds 45 minutes;

② The outdoor heat exchanger sensor (Th0-R) meets one of the following conditions:

A) Accumulated running time of compressor < 150 minutes, Th0-R ≤ -5℃;

B) Accumulated running time of compressor ≥ 150 minutes, Th0-R ≤ -3.5℃;

③ The outdoor heat exchanger sensor (Th0-R) and the outdoor air temp. sensor (Th0-A)

meet one of the following conditions:

A) When outdoor air temp. sensor Th0-A ≥ 0℃:

Accumulated running time of compressor < 150 minutes, (Th0-A) - (Th0-R) ≥ 7.0;

B) When outdoor air temp. sensor Th0-A ≥ 0℃:

Accumulated running time of compressor ≥ 150 minutes, (Th0-A) - (Th0-R) ≥ 4.0;

C) When outdoor air temp. sensor -15℃ ≤Th0-A < 0℃:

Accumulated running time of compressor < 150 minutes, (Th0-A) - (Th0-R) ≥ 4/15 *

(Th0-A) + 7;

D) When outdoor air temp. sensor -15℃ ≤ Th0-A < 0℃:

Accumulated running time of compressor ≥ 150 minutes, (Th0-A) - (Th0-R) ≥ 4/15 *

(Th0-A) + 6;

E) When outdoor air temp. sensor Th0-A < -15℃: (Th0-A) - (Th0-R) ≥ -5.0;

④ The compressor runs for over 7 minutes continuously.

Case 2: Low load running (The defrosting running begins when all of the following conditions

are met):

① After the heating begins and the defrosting ends, the accumulated running time of the

compressor is 45 minutes with air flow controlled;

- 24 -

② The outdoor heat exchanger sensor (Th0-R) meets one of the following conditions:

A) When the actual rotate speed of the compressor N ≥ 62 rps: Th0-R ≤ -5℃;

B) When the actual rotate speed of the compressor N < 62 rps: Th0-R ≤ -4℃;

③ Outdoor air temp. sensor (Th0-A): Th0-A ≤ 3℃;

④ The compressor runs for over 7 minutes continuously.

(2) Ending conditions:

135 seconds after the system is switched to the defrosting mode, the defrosting running is

canceled when one of the following conditions is met:

① Outdoor heat exchanger sensor (Th0-R): Th0-R ≥ 13℃;

② The elapsed time of defrosting running is 15±0.5 min.

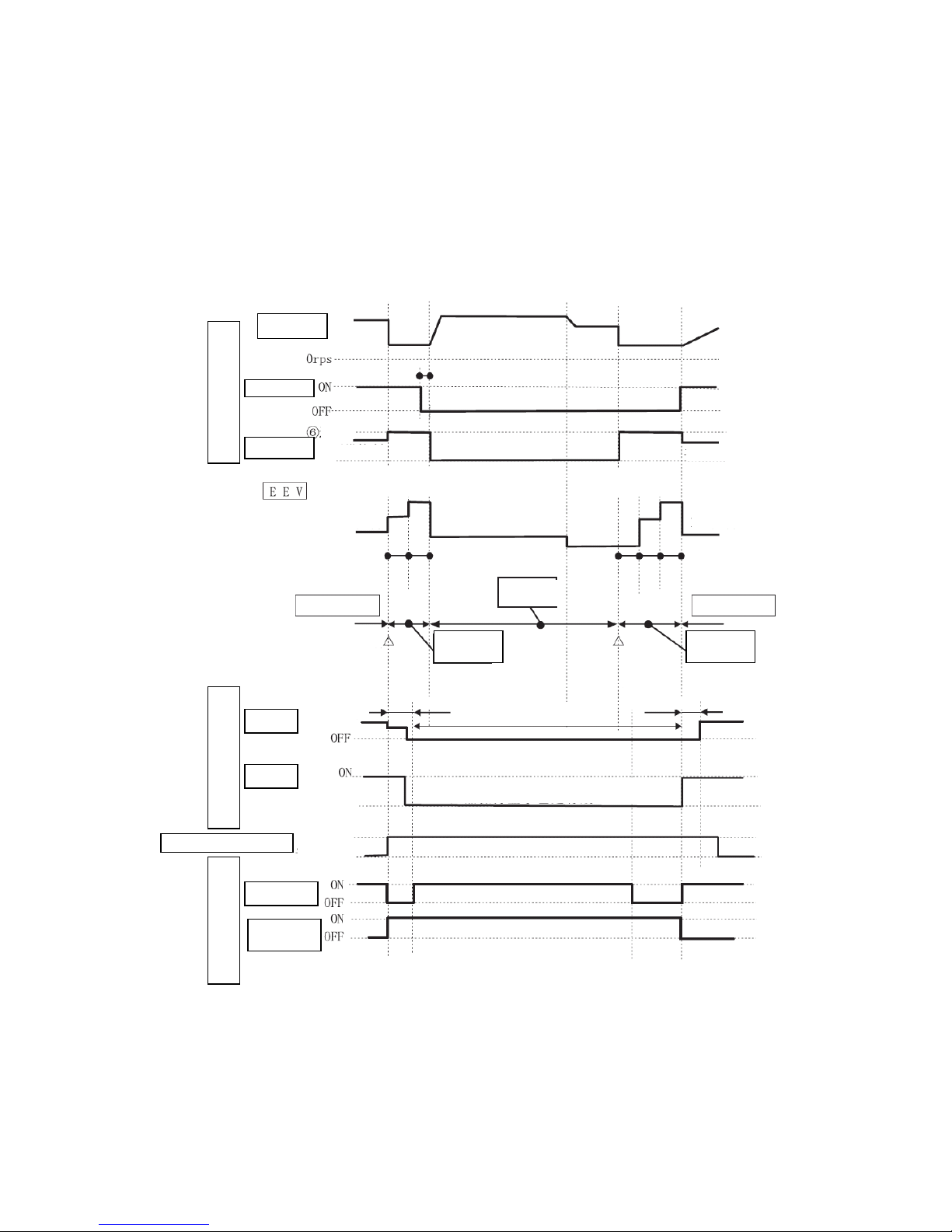

(3) Operation time pattern of various functional parts in defrosting control:

Defrosting

Compressor

4-way valve

Outdoor fan

Operation of outdoor

functional parts

5 sec.

speed

Usual control

Usual control

Enter

EEV openng

EEV control

EEV openng

EEV control

End running

EEV openng

Usual heating

Usual heating

Defrosting

running state

Beginning

conditions met

Enter defrosting

running

Ending

conditions

met

End defrosting

running

Heat-retaining

Heat-retaining

Heat-retaining

ineffective

Indoor fan

RUN lamp

Operation of indoor

functional parts

Indoor → outdoor

communication

Verhical/horizontal flap

Response

Flahsing

(heat-retaining)

Control

Set position

In the defrosting control, even when the compressor

displays OFF, the heat-retaining displaying is effective.

Singnal of

compressor

Defrosting

singnal

- 25 -

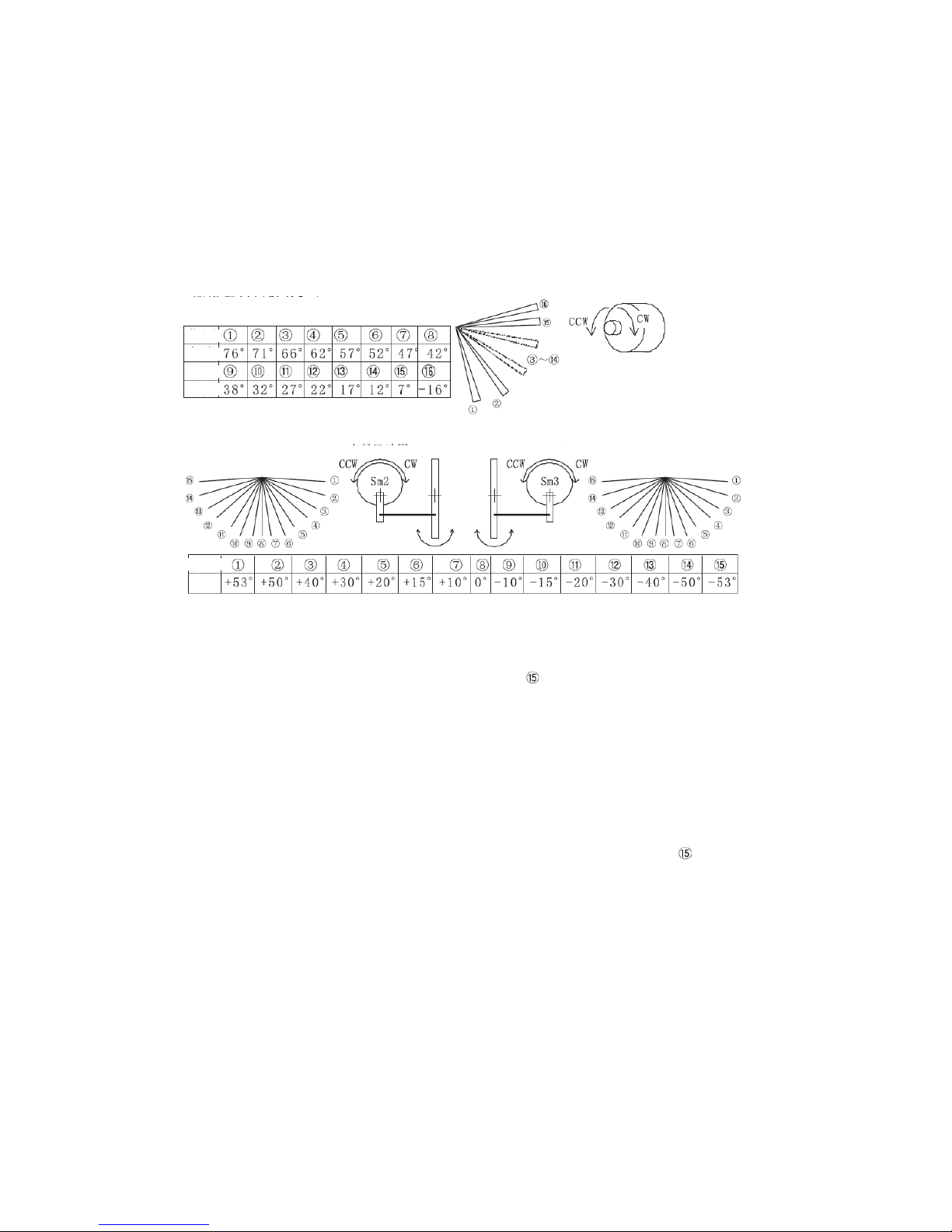

4.20 Outline of vertical and horizontal flaps control:

(1) Overview:

Sm1: Vertical flap (mounted on the right side when you face the appliance);

Sm2: Left horizontal flap (mounted on the left side when you face the appliance);

Sm3: Right horizontal flap (mounted on the right side when you face the appliance);

(2) Vertical flap Sm1:

The level set is 0℃.

(3) Horizontal flaps Sm2 and Sm3:

(4) Reference position control:

① Beginning condition: This control is executed only when the air conditioner begins to run.

It is not executed when the operating mode is switched and the flap mode is changed.

② Control: This control ends when the vertical flap Sm1 moves to position ① and the

horizontal flaps Sm2 and Sm3 move to position . The flaps stop at the position set with

the remote controller or the preset position memorized.

(4) Control of vertical flap and horizontal flaps at the start of heating, stop of heating and for

defrosting:

To avoid blowing cool air during heating before the indoor heat exchanger is fully warmed.

① Beginning condition (when one of the following conditions is met):

A) The indoor running mode is switched from a mode other than Heating to the Heating

mode, and the temperature measured by the indoor heat exchanger sensor is < 28℃;

B) During the Heating mode, the compressor displays OFF;

C) During the Heating mode, the defrosting signal is received.

② Control: This control ends when the vertical flap Sm1 moves to position and the

horizontal flaps Sm2 and Sm3 move to position ⑧.

③ Ending conditions (when one of the following conditions is met):

A) The indoor running mode is switched from a mode other than Heating to the Heating

mode, and the temperature measured by the indoor heat exchanger sensor is ≥ 28℃;

B) In the Heating mode, the compressor is changed from OFF to ON, and the

temperature measured by the indoor heat exchanger sensor is ≥ 28℃;

C) In the Heating mode, the defrosting signal is canceled, and the temperature measured

by the indoor heat exchanger sensor is ≥ 28℃;

D) When this control is canceled, the flap position before the control is restored.

④ Notes:

A) This control is not executed in the JIS mode;

B) This control is not executed when the temperature measured by the indoor heat

exchanger sensor is approximately below -28℃ (disconnection of sensor).

Position

Position

Angle

Angle

Relationship between rotation direction

of motor and state of vertical flap

Vertical flap closed → CCW of motor

Vertical flap opened → CW of motor

Position

Angle

For left flap

For right flap

Wide-angle

Wide-angle

Fixed point direction

- 26 -

4.21 Outline of electronic expansion valve (EEV) control:

(1) Overview:

① Initial control: When the power is ON and the reference position is determined, the EEV opening is

widened within 5 minutes to let the refrigerant return, thus makes the low pressure rise easily and

avoid misdiagnosis of insufficient refrigerant and poor EEV operation as the low pressure can’t rise

after decline;

② Open loop control: After the initial control, when the temperature measured by the sensor, etc. are

unstable, the EEV opening is set according to the balance of the compressor;

③ Area control: During quasi-steady running and steady running, the EEV opening is set according to

the extent of over heat of exhaust, mainly aiming at the measure for the deviation due to open loop

control;

④ Stop control: The EEV opening is set according to the stop control;

⑤ Negative pressure countermeasure control: When the mode is switched from a mode other than

Heating to the Heating mode, the compressor is changed from OFF to ON, and the outdoor

temperature is too low (temperature measured by discharge pipe sensor (Th0-D) - temperature

measured by outdoor air temp. sensor (Th0-A) < 10℃), this control is executed for 8 minutes to

avoid negative pressure risk;

⑥ Throttle correction control of cooling & drying: Five minutes after the area control, when the actual

rotate speed of the compressor is below 24 rps and the temperature measured by the outdoor air

temp. sensor (Th0-A) meets the condition 25℃≤ Th0-A < 38℃ and the temperature measured by

the indoor heat exchanger sensor (Th1-RX) is above 10℃, this control is executed to increase the

latent heat capacity in cooling;

⑦ Condensation prevention control: When the actual rotate speed of the compressor is above 32 rps

and the value measured by the humidity sensor (HS) is above 68% for 30 minutes continuously, this

control is executed to make the actual rotate speed of the compressor reduce to below 32 rps or

make the value measured by HS reduce to below 63%.

(2) Priority of various EEV controls:

Stop control > Defrosting control > Indoor issued fixed opening control > Initial control > Protective

control > Open loop control and area control

(3) Except the special situations such as reference position control, etc., others are controlled within the

pulse range of 41-47.

4.22 Outline of compressor control:

(1) Overview of ON/OFF of cooling and heating running:

① When the outdoor running mode is Cooling or Heating, the compressor has stopped for over 3

minutes, and the compressor running signal from the indoor unit is received, the compressor will be

turned on;

② When the compressor is ON, the rotate speed of the compressor is fuzzily calculated using the

temperature of the indoor inlet air, the temperature set with the remote controller, the setting

correction temperature, etc., and the outdoor unit sends the compressor ON signal, the value of

fuzzy calculation, the actual rotate speed, etc. to the indoor unit;

③ When the outdoor running mode is Cooling or Heating, the compressor has run for over 5 minutes,

and the compressor stop signal from the indoor unit is received, the compressor will be turned off;

④ When the compressor is OFF, the outdoor unit sends the compressor OFF signal, the value of fuzzy

calculation, the actual rotate speed, etc. to the indoor unit;

⑤ In defrosting control, the compressor OFF conditions are not judged.

(2) Running range: 20-120 rps (varying depending on the model).

(3) In order to prevent the oil level of the compressor from falling and ensure that oil is supplied to the

pump of the compressor normally, enable the protection against temporary rise of rotate speed of

compressor.

(4) In order to guarantee the pressure difference for switching the 4-way valve, enable the low load for

temporary rise of rotate speed of compressor.

(5) With respect to the change rate of the actual rotate speed of the compressor, the instructed rotate speed

from the outdoor inverter to the compressor and the temperature measured by the outdoor heat

exchanger sensor (during cooling) or the temperature measured by the indoor heat exchanger sensor

(during heating) should be observed to decide the rise/fall speed of the compressor (2 rps, 1/2 rps) and

finally make the compressor operate in the appropriate working state.

4.23 Outline of outdoor fan control:

(1) The settings of rotate speed of the outdoor fan are as follows:

Speed position

① ② ③ ④ ⑤ ⑥ ⑦

⑧

Rotate speed

(rpm)

20MA-S

150

240

570

630

720

780

840

920

25 MA-S

150

240

570

630

720

780

840

920

35 MA-S

150

240

570

640

750

840

900

950

50 MA-S

150

290

520

650

700

750

800

850

- 27 -

(2) Priority of rotate speed control:

Error response control > Outdoor fan control in compressor soft start control > Outdoor fan

control in defrosting control > Outdoor fan control/indoor forcing outdoor fan running

control in stop mode > Outdoor fan control at start > Outdoor fan control at the low outdoor

temperature in cooling > Outdoor fan control under overload in cooling > Delayed speed

position switching > Outdoor fan control under overload in heating > Speed position control

(3) Error response control:

When the outdoor fan runs at a speed below 75 rpm for over 30 seconds, the inverter will

immediately stop output to the fan and indicate results of self-diagnosis; if this occurs 3

times, it will send the error code to the indoor unit; if the speed exceeds 75 rpm once before

the 3 times, recount will be conducted.

(4) The minimum rotate speed of the outdoor fan in the compressor soft start control is speed

④.

(5) In the defrosting control, the rotate speed of the outdoor fan is OFF or speed ⑥.

(6) Outdoor fan control in the stop mode:

When the actual rotate speed of the compressor is 0, the outdoor fan continues to run at speed

③ for 1 minute or 2 minutes and 55 seconds and then stop.

(7) Indoor forced running control:

When the outdoor fan running start signal is received from the indoor unit, the operation at

the fan speed received will begin, and this control is unrelated to the running mode,

compressor instruction and protection stop (except outdoor fan error, low voltage). This

control is canceled when the outdoor fan running cancel signal is received from the indoor

unit.

(8) At start, the outdoor fan operates according to the speed position control; when the

compressor is started and in the ON state in the cooling mode and the outdoor temperature is

below 22℃, it will run at speed ② or ① for 30 seconds.

(9) Outdoor fan control of low outdoor temperature in cooling, overload in cooling, low outdoor

temperature in heating and overload in heating:

① In the cooling or heating mode, when the compressor is in the ON state and the

temperature measured by the outdoor air temp. sensor meets the control conditions, this

control will begin.

② This control is canceled when either of the above conditions is not met.

③ According to the temperature measured by the outdoor heat exchanger liquid pipe sensor

and the temperature measured by the outdoor air temp. sensor, the rotate speed of the

outdoor fan is decreased (to as low as speed ② or ①) or increased (up to speed ⑧).

(10) Delayed speed position switching control:

When the outdoor fan is changed from a high speed position to a low one, the switching is

generally delayed for 60 seconds. If it is changed to a high speed position within 60 seconds,

the delay will be canceled and it is converted to the high speed position immediately. If the

outdoor fan is changed to OFF, there will be no delay and it will stop immediately.

(11) The speed position control is generally between speed ③ and ⑧.

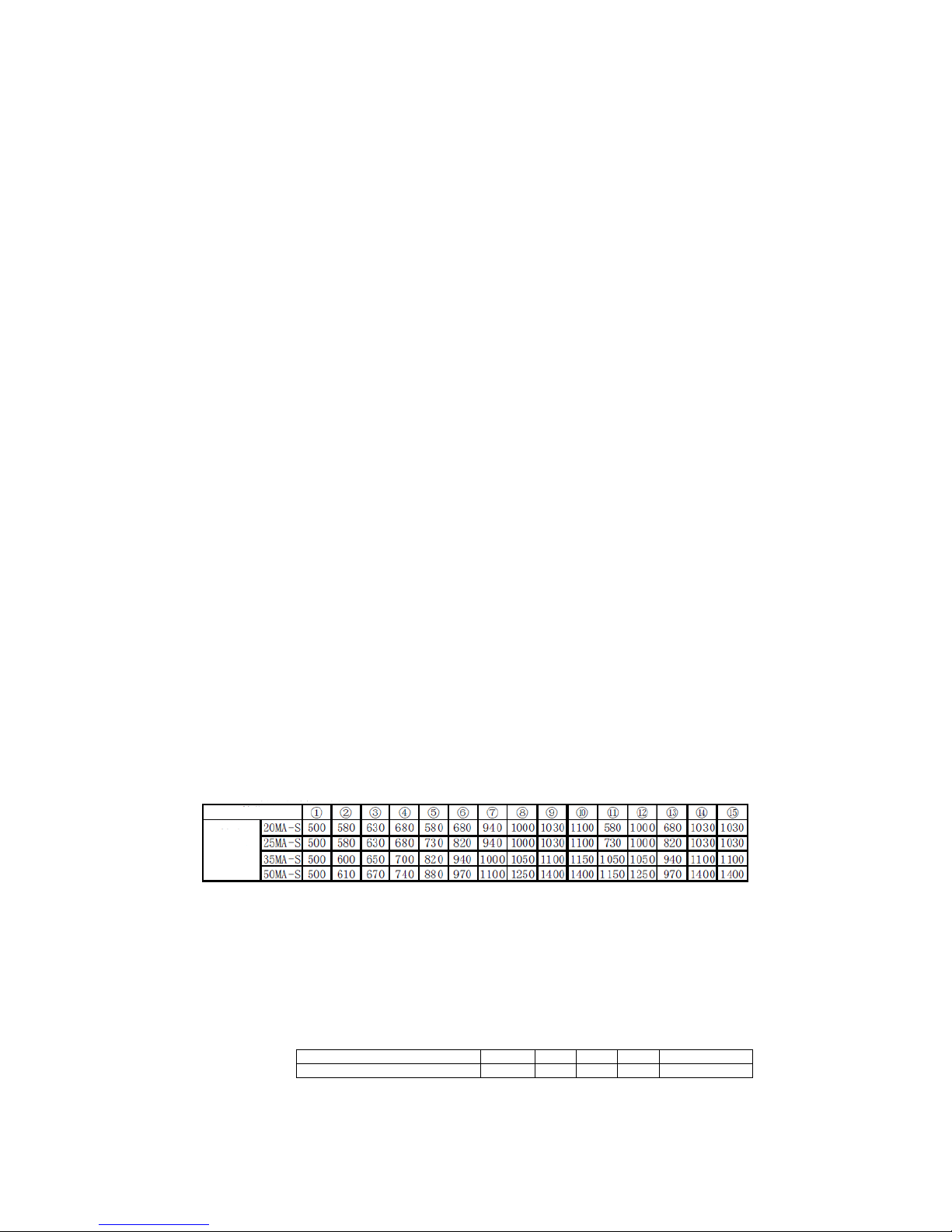

4.24 Outline of indoor fan control:

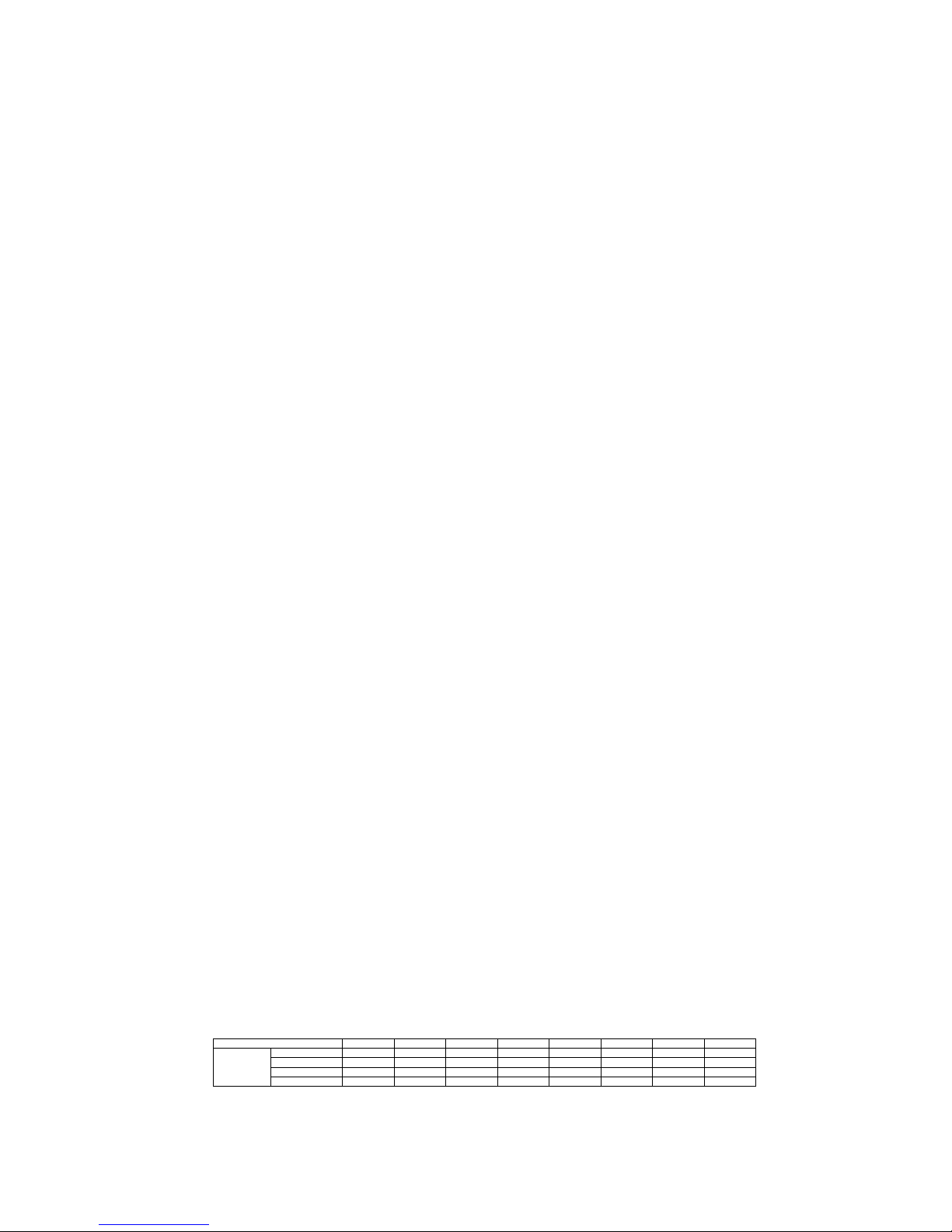

(1) The settings of rotate speed of the indoor fan are as follows:

(2) Priority of rotate speed switching:

HI POWER > AUTO/HI/ME/LO

(3) Error response control:

When the indoor fan runs at a speed below 75 rpm for over 30 seconds, the air conditioner

will fully stop to indicate the results of self-diagnosis.

(4) When the indoor fan is started and runs for 1 second under the initial voltage at the speed of

300 rpm, the system will compare with the signal from the fan to correct the rotate speed to

the determined one.

(5) Rate of rotate speed adjustment: 80 rpm for increase and 10 rpm for decrease.

(6) The speed positions corresponding to the fan speeds are as follows:

Air flow switching

AUTO

HI

ME

LO

HI POWER

Speed position of indoor fan

⑤ ⑥ ⑤ ④ ⑦

Speed position

Rotate

speed

(rpm)

- 28 -

(7) The relationship between the rotate speed of heat-retaining during heating and the

temperature measured by the indoor heat exchanger sensor Th1-R1 is as follows:

Speed position of indoor fan

Temperature measured by the

indoor heat exchanger sensor

When the compressor displays ON

When the compressor displays OFF

- 29 -

5 Installation

○ Use this system only for household and

residence.

○ This appliance must be installed according to the national wiring regulation.

○ A 2-level switch must be used for the fixed wiring of the power supply and its disconnection

clearance must be at least 3mm.

○ If the outdoor unit may tip over or move and drop from the original installation location, use

trip bolts or string to secure it in place.

○ The liquid pipe and gas pipe in the piping should be insulated with thermal insulation.

SAFETY PRECAUTIONS

• Please read this “SAFETY PRECAUTIONS” carefully before the installation work in order to ensure correct installation.

• The precautions described below are divided into WARNING and CAUTION. The matters with possibilities leading to

serious consequences such as death or serious personal injury due to erroneous handling are listed in the WARNING, however

the matters listed in CAUTION may sometimes lead to serious accidents. These are very important precautions for safety. Be

sure to observe all of them without fail.

• For qualified installing personnel, take precautions in respect to themselves by using suitable protective clothing, groves, etc., and then

perform the installation works.

• Please pay attention not to fall down the tools, etc. when installing the unit at the high position.

• If unusual noise can be heard during operation, consult the local dealer.

• Be sure to confirm no anomaly on the equipment by commissioning after completed installation and explain the operating methods as

well as the maintenance methods of this equipment to the user according to the owner’s manual.

• Symbols which appear frequently in the text have the following meaning:

Strictly prohibited

Observe instructions

Provide proper earthing

• Keep the installation manual together with owner’s manual properly. Moreover if necessary, ask to hand them to a new user.

WARNING

• Installation must be carried out by the qualified

installer and only the specified optional components

should be used.

If you install the system by yourself, it may cause serious

trouble such as water leaks, electric shocks, fire and

personal injury, as a result of a system malfunction.

• Install the system in full accordance with the

instruction manual.

Incorrect installation may cause bursts, personal injury,

water leaks, electric shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such

as machine shop etc., it can cause malfunction.

• Use the original accessories and the specified

components for installation.

If parts other than those prescribed by us are used, it may

cause drop of machine, water leaks, electric shocks, fire,

refrigerant leakage, insufficient performance, poor control,

and personal injury.

• Install the unit in a location with good support and

ensure the unit is stable when installed, so that it can

withstand earthquakes and strong winds.

Unsuitable installation locations can cause the unit to fall

and cause material damage and personal injury.

• Ventilate the working area well in the event of

refrigerant leakage during installation.

If the refrigerant comes into contact with naked flames,

poisonous gas is produced.

• When the equipment is to be installed in a small room,

take preventive measures to avoid refrigerant leakage

exceeding the density limit.

Consult with the installation professionals about the

preventive measures. If the density is greater than the limit

of refrigerant, it may cause serious accidents such as

refrigerant leakage, shortage of oxygen, etc.

• Confirm there is no refrigerant leakage after the

installation.

If the refrigerant leaked comes into contact with the fire of

an air blowing type heater, oven, etc., poisonous gas is

produced.

• Use the prescribed pipes, flare nuts and tools for

R410A.

Using conventional parts (for R22) can cause the unit

failure and serious accidents due to burst of the refrigerant

circuit.

• Tighten the flare nut by torque wrench with specified

method.

If the flare nuts were tightened with excess torque, this

may cause burst and refrigerant leakage after a long

period.

• Do not open the operation valves for liquid line and

gas line until completed refrigerant piping work, air

tightness test and evacuation.

If the compressor is operated when operation valves are

open before the connection of refrigerant piping work is

completed, it can cause frostbite or injury due to rapid

refrigerant leakage, and burst or personal injury due to

anomalously high pressure in the refrigerant circuit into

which air is sucked.

• The electrical installation must be carried out by the

qualified electrician in accordance with “the norm for

electrical work” and “national wiring regulation”, and

the system must be connected to the dedicated circuit.

Power supply with insufficient capacity and incorrect

function done by improper work can cause electric shocks

and fire.

• Be sure to shut off the power before starting electrical

work.

Failure to shut off the power can cause electric shocks,

unit failure or incorrect function of equipment.

• Be sure to use the cables conformed to safety standard

and cable ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous

heat production or fire.

• This appliance must be connected to main power

supply by means of a circuit breaker or switch

(fuse:16A) with a contact separation of at least 3mm.

• If the appliance has a plug, the plug must comply with

IEC 60884-1.

• Use the prescribed cables for electrical connection,

tighten the cables securely in terminal block and