Mitsubishi Heavy Industries SRK05CM, SRK05CM-3, SRK09CM-3, SRK09CM-4, SRK09CM-5 Technical Manual

...

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONERS

(Split system, air cooled cooling only type)

SRK05CM, 05CM-3

SRK05CMP-3

SRK09CM-3, 09CM-4, 09CM-5

SRK09CMP-3, 09CMP-4

SRK12CM-3, 12CM-4, 12CM-5

Manual No.'13•SRK-T-141

-

1

-

'13•SRK-T-141

TECHNICAL MANUAL

-

2

-

'13•SRK-T-141

'10 • SRK-T-099

CONTENTS

1. SPECIFICATIONS .................................................................................... 4

(2) Outdoor units ...................................................................................... 17

(3) Wireless remote control

...................................................................... 19

........................................................................ 15

(1) Indoor units ......................................................................................... 15

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING ............................................................................. 20

(1) Indoor units ......................................................................................... 20

(2) Outdoor units ...................................................................................... 21

....................................................... 24

5. RANGE OF USAGE & LIMITATIONS

4. PIPING SYSTEM ..................................................................................... 23

............................................................................... 26

6. APPLICATION DATA

7. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ........... 40

(6) Timer operation

................................................................................. 43

(5) Flap control ....................................................................................... 43

...................................................... 42(4) Custom cord switching procedure

........................................................................ 42(3) Auto restart function

(2) Unit ON/OFF button

.......................................................................... 42

(1) Operation control function by remote control

..................................... 40

(8) Outline of automatic operation .......................................................... 44

(7) Outline of cooling operation .............................................................. 44

(9) Protective control function

.................................................................. 45

.............................................................................. 46

.................... 47

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

....... 46

(1) Cautions

............................................................................................ 46

(2) Items to check before troubleshooting ................................................ 46

(5) Self-diagnosis table ............................................................................ 47

(6) Inspection procedures corresponding to detail of trouble ................... 48

8. MAINTENANCE DATA

-

3

-

'13•SRK-T-141

'10 • SRK-T-099

(7)

Phenomenon observed after shortcircuit, wire breakage on sensor

........ 49

■How to read the model name

Example: SRK 05 C

Series code

Cooling only type

Product capacity

Model name SRK : Wall mounted type

SRC : Outdoor unit

MP

(8) How to make sure of wireless remote control ..................................... 50

-

4

-

'13•SRK-T-141

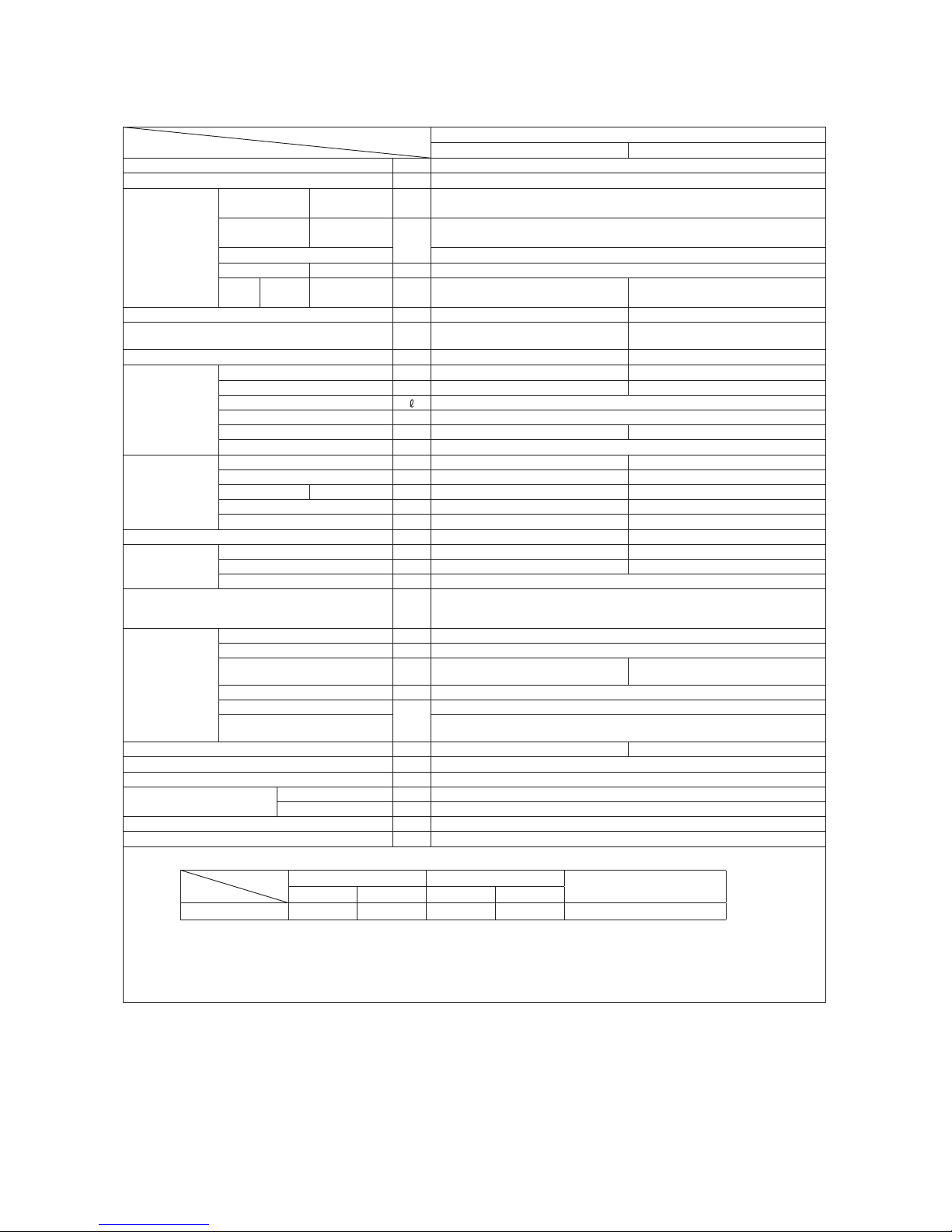

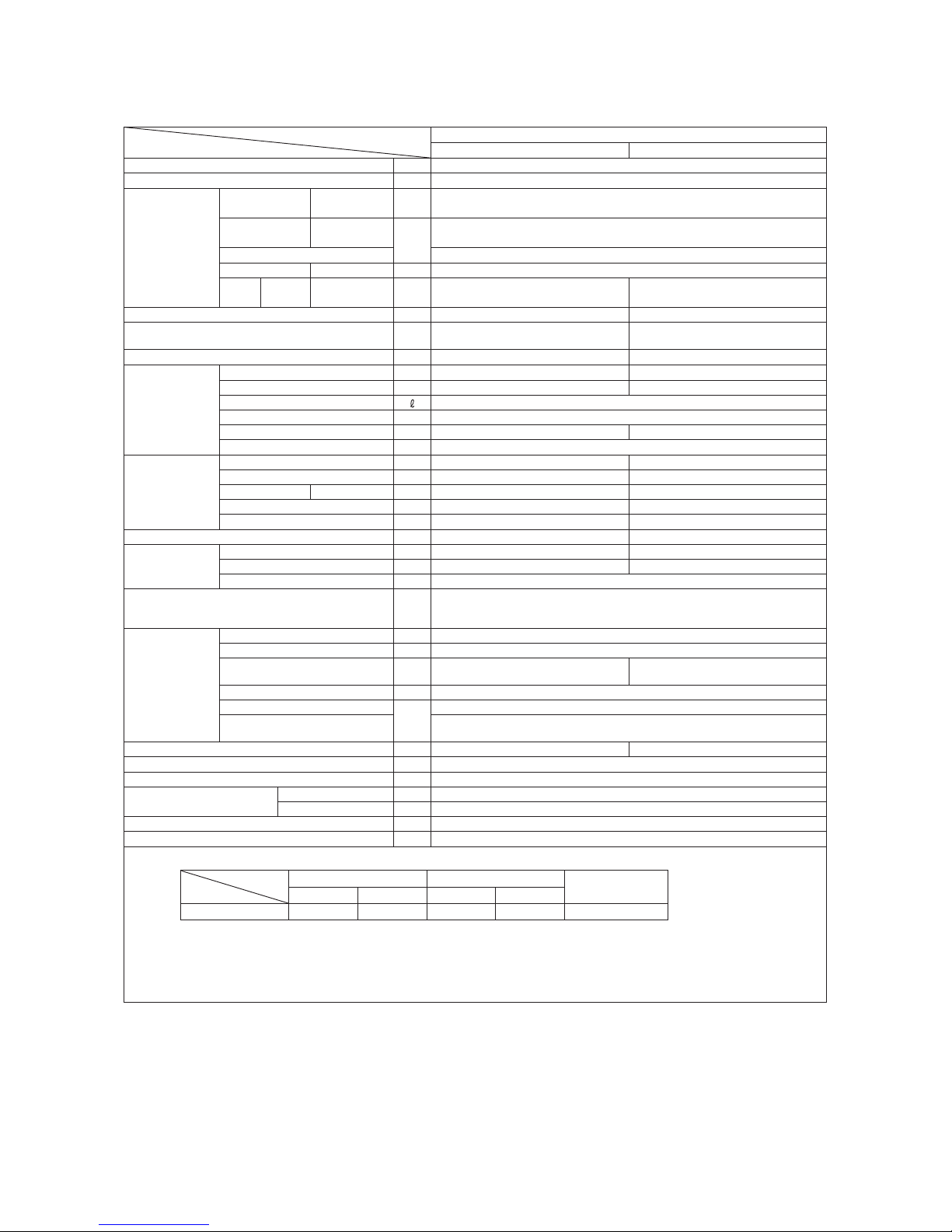

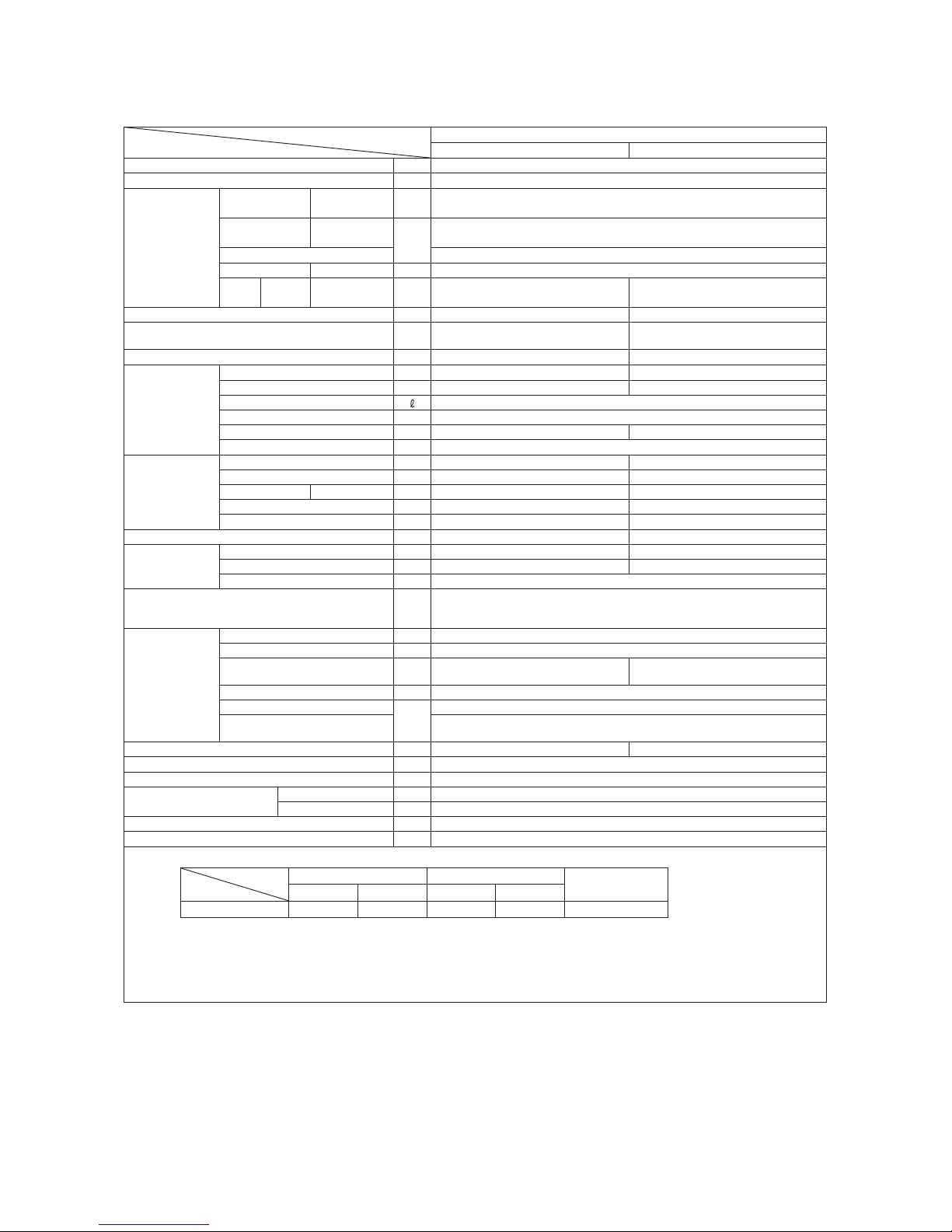

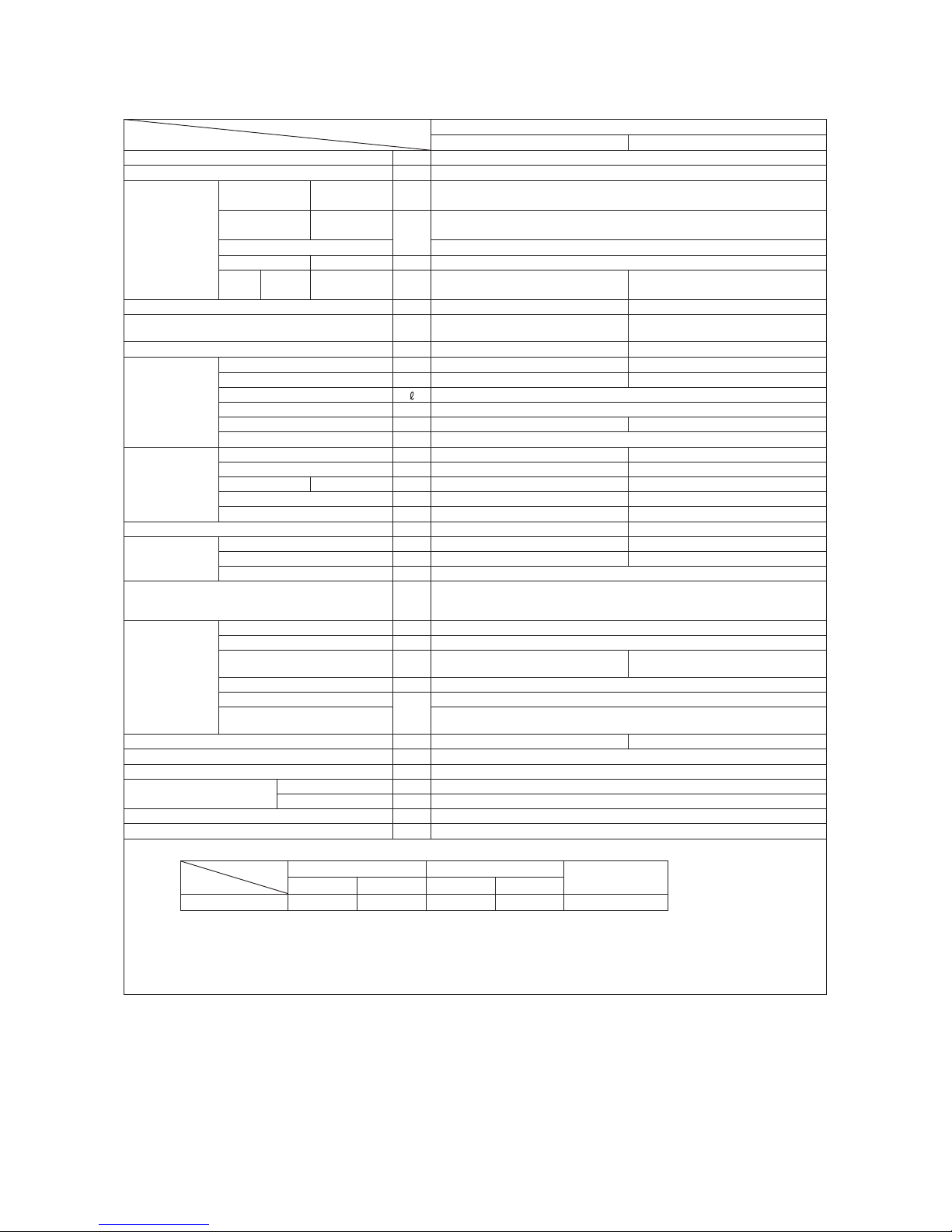

1. SPECIFICATIONS

Model

Item

SRK05CM

Indoor unit SRK05CM Outdoor unit SRC05CM

Cooling capacity (1) W 1500

Power supply 1 Phase, 220V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.42

Running

current

Cooling

A

2.0

Inrush current 9.5

COP Cooling 3.57

Noise

level

Cooling Sound level dB(A) 42 47

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 19

Refrigerant

equipment

Compressor type & Q'ty — RMC201A009 (Rotary type) x 1

Motor (Starting method) kW — 0.35 (PSC)

Refrigerant oil 0.29 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.40 (Pre-Charged up to the piping length of 7.5m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 220V districts.

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 7.5m to 15m, additional refrigerant is 10g per each 1m longer than 7.5m.

The pipe length is 7.5m.

-

5

-

'13•SRK-T-141

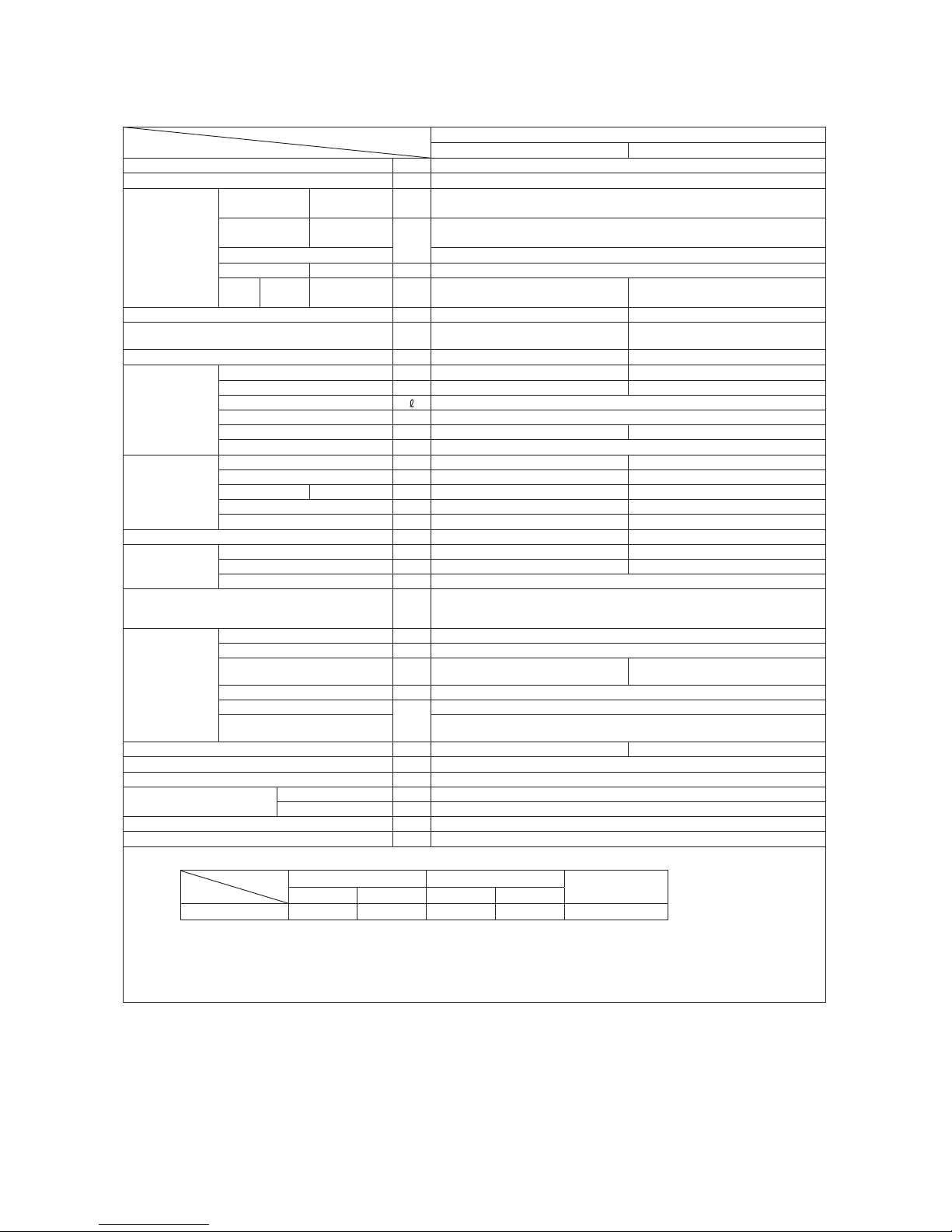

Model

Item

SRK05CM-3

Indoor unit SRK05CM-3 Outdoor unit SRC05CM-3

Cooling capacity (1) W 1465

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.375

Running

current

Cooling

A

1.8

Inrush current 9.5

COP Cooling 3.91

Noise

level

Cooling Sound level dB(A) 42 48

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 20

Refrigerant

equipment

Compressor type & Q'ty — RMC201A055 (Rotary type) x 1

Motor (Starting method) kW — 0.35 (PSC)

Refrigerant oil 0.23 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.45 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

6

-

'13•SRK-T-141

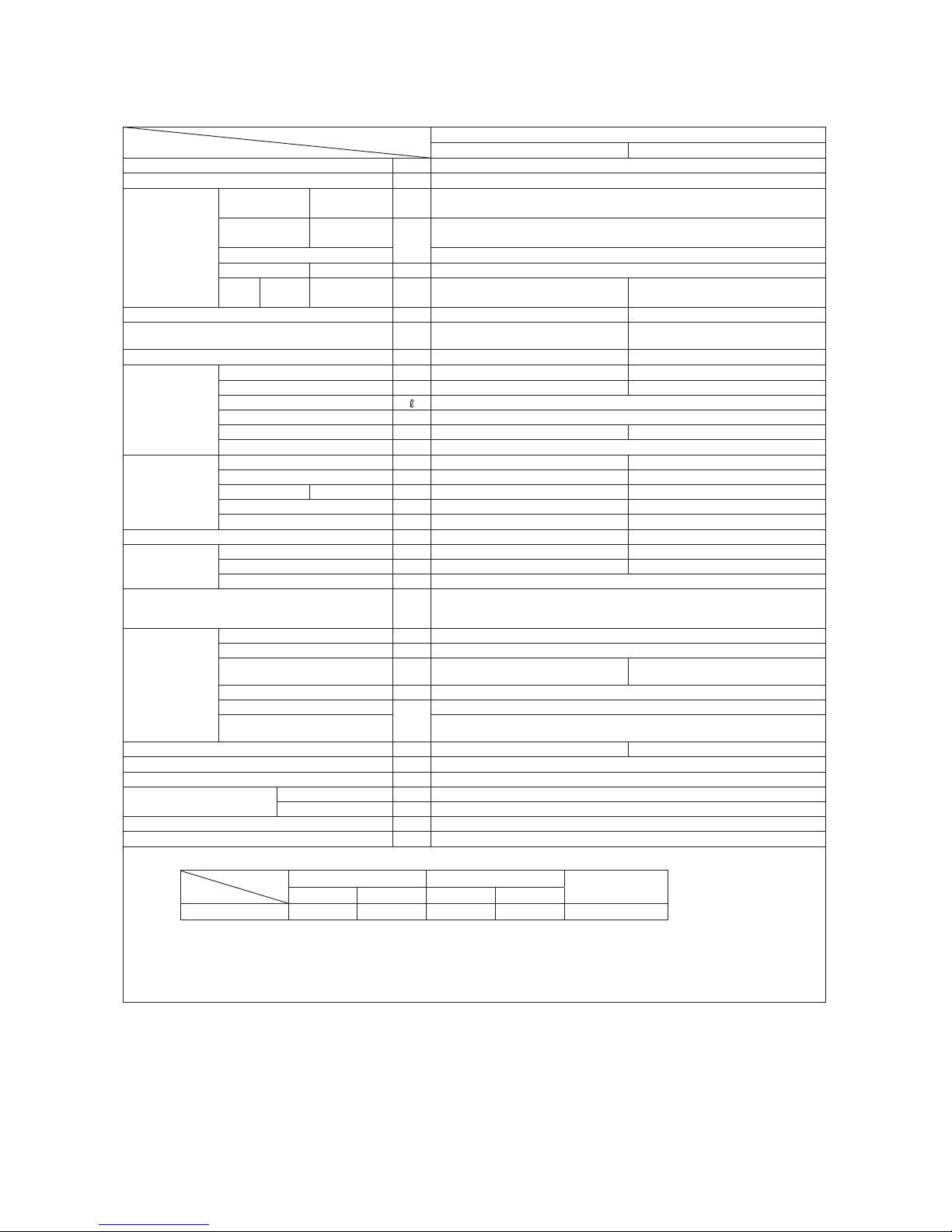

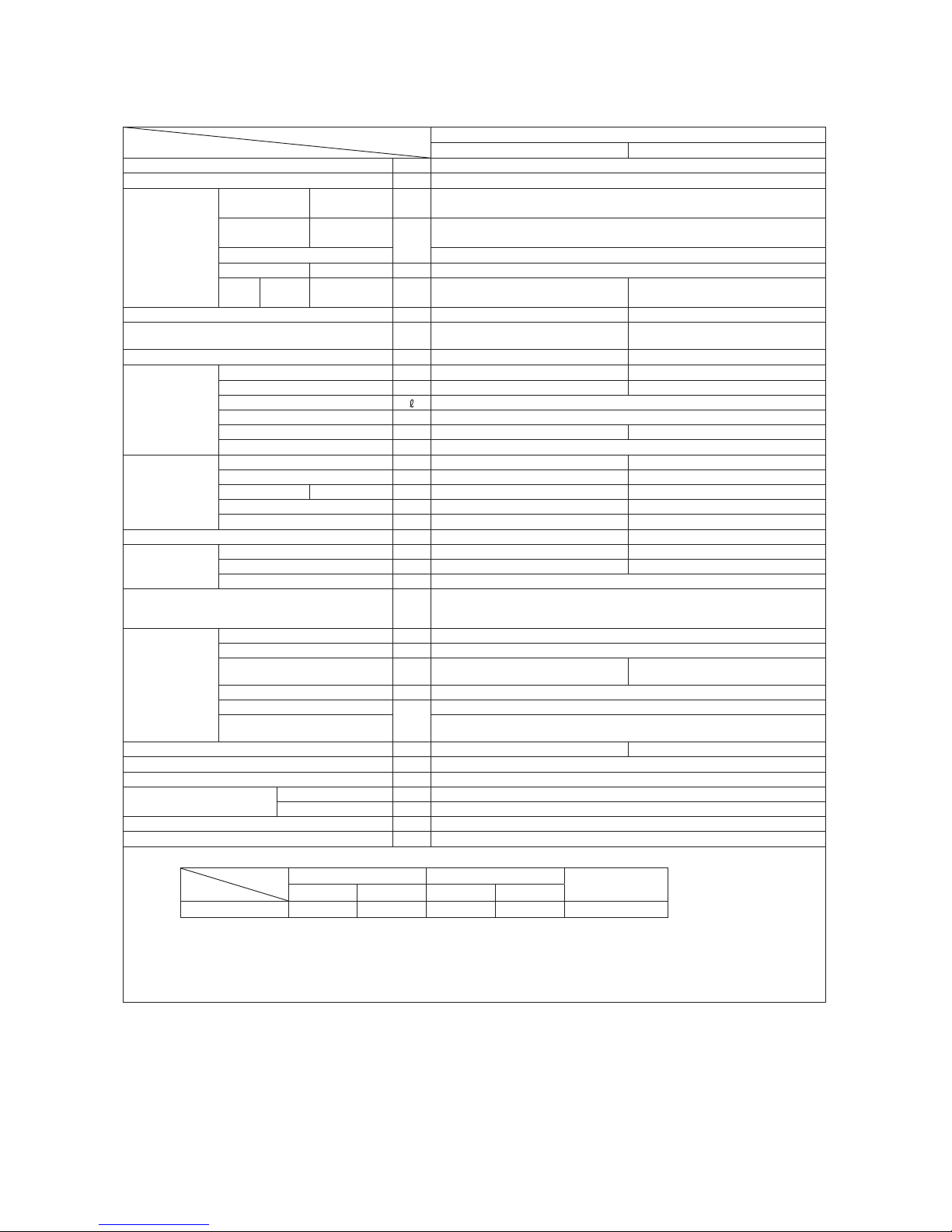

Model

Item

SRK05CMP-3

Indoor unit SRK05CMP-3 Outdoor unit SRC05CMP-3

Cooling capacity (1) W 1465

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.49

Running

current

Cooling

A

2.3 / 2.2

Inrush current 9.5

COP Cooling 2.99

Noise

level

Cooling Sound level dB(A) 42 47

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 19

Refrigerant

equipment

Compressor type & Q'ty — RMC201A009 (Rotary type) x 1

Motor (Starting method) kW — 0.35 (PSC)

Refrigerant oil 0.29 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.34 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 8.5 20.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

7

-

'13•SRK-T-141

Model

Item

SRK09CM-3

Indoor unit SRK09CM-3 Outdoor unit SRC09CM-3

Cooling capacity (1) W 2638

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.90

Running

current

Cooling

A

4.2 / 4.0

Inrush current 21.0

COP Cooling 2.93

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 22.5

Refrigerant

equipment

Compressor type & Q'ty — RMC201A054 (Rotary type) x 1

Motor (Starting method) kW — 0.7 (PSC)

Refrigerant oil 0.28 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.45 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9.0 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

8

-

'13•SRK-T-141

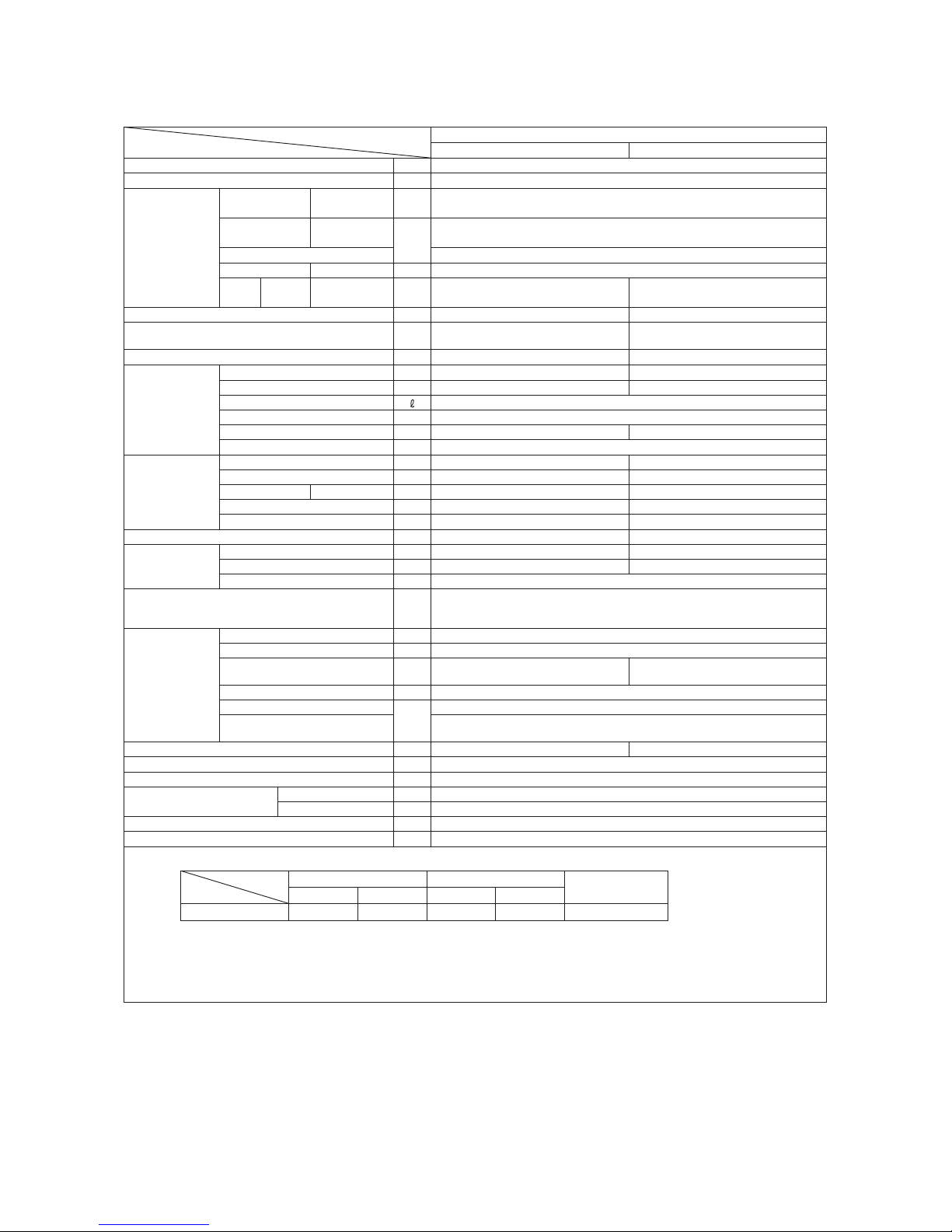

Model

Item

SRK09CM-4

Indoor unit SRK09CM-4 Outdoor unit SRC09CM-4

Cooling capacity (1) W 2638

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.90

Running

current

Cooling

A

4.2 / 4.0

Inrush current 21.0

COP Cooling 2.93

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 22.5

Refrigerant

equipment

Compressor type & Q'ty — RMC201A054 (Rotary type) x 1

Motor (Starting method) kW — 0.7 (PSC)

Refrigerant oil 0.28 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.45 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9.0 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

9

-

'13•SRK-T-141

Model

Item

SRK09CM-5

Indoor unit SRK09CM-5 Outdoor unit SRC09CM-5

Cooling capacity (1) W 2638

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.90

Running

current

Cooling

A

4.2 / 4.0

Inrush current 21.0

COP Cooling 2.93

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 22.5

Refrigerant

equipment

Compressor type & Q'ty — RMC201A054 (Rotary type) x 1

Motor (Starting method) kW — 0.7 (PSC)

Refrigerant oil 0.28 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.45 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9.0 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

10

-

'13•SRK-T-141

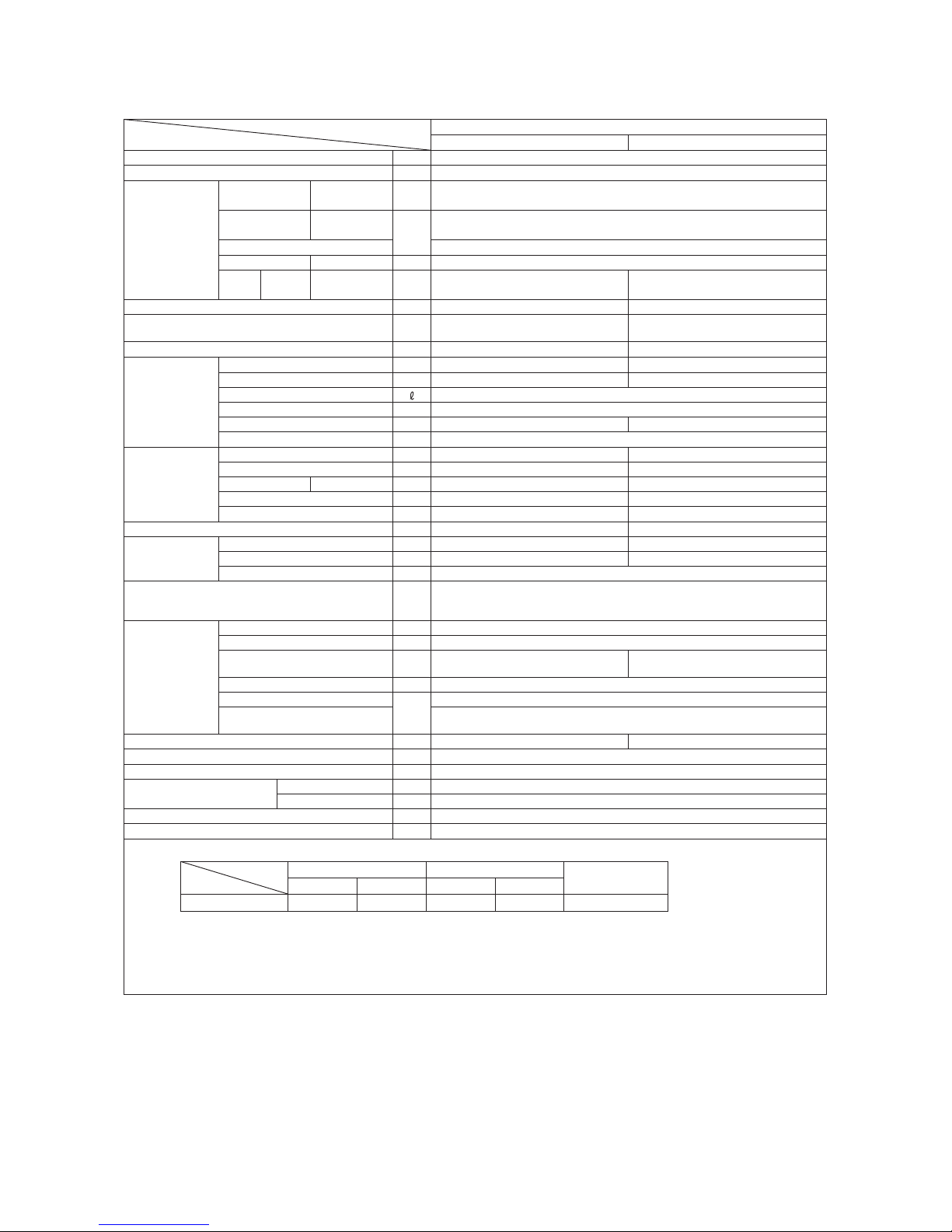

Model

Item

SRK09CMP-3

Indoor unit SRK09CMP-3 Outdoor unit SRC09CMP-3

Cooling capacity (1) W 2500

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.925

Running

current

Cooling

A

4.7 / 4.6

Inrush current 21.0

COP Cooling 2.70

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 22

Refrigerant

equipment

Compressor type & Q'ty — RMC201A054 (Rotary type) x 1

Motor (Starting method) kW — 0.7 (PSC)

Refrigerant oil 0.28 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.41 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9.0 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

11

-

'13•SRK-T-141

Model

Item

SRK09CMP-4

Indoor unit SRK09CMP-4 Outdoor unit SRC09CMP-4

Cooling capacity (1) W 2500

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.925

Running

current

Cooling

A

4.7 / 4.6

Inrush current 21.0

COP Cooling 2.70

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 615 x 210 435 x 645 (+50) x 275

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 6 22

Refrigerant

equipment

Compressor type & Q'ty — RMC201A054 (Rotary type) x 1

Motor (Starting method) kW — 0.7 (PSC)

Refrigerant oil 0.28 (SUNISO 4GSI or ATMOS NM56M)

Refrigerant (3) kg R22 0.41 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 22

Air flow Cooling m3/min 9.0 23.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.46

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 10

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

12

-

'13•SRK-T-141

Model

Item

SRK12CM-3

Indoor unit SRK12CM-3 Outdoor unit SRC12CM-3

Cooling capacity (1) W 3517

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 1.09

Running

current

Cooling

A

5.1

Inrush current 25.0

COP Cooling 3.23

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 29

Refrigerant

equipment

Compressor type & Q'ty — RMC201A056 (Rotary type) x 1

Motor (Starting method) kW — 0.92 (PSC)

Refrigerant oil 0.38 (SUNISO 4GSI or ATMOS NM56)

Refrigerant (3) kg R22 0.58 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 10.0 32.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 15

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

13

-

'13•SRK-T-141

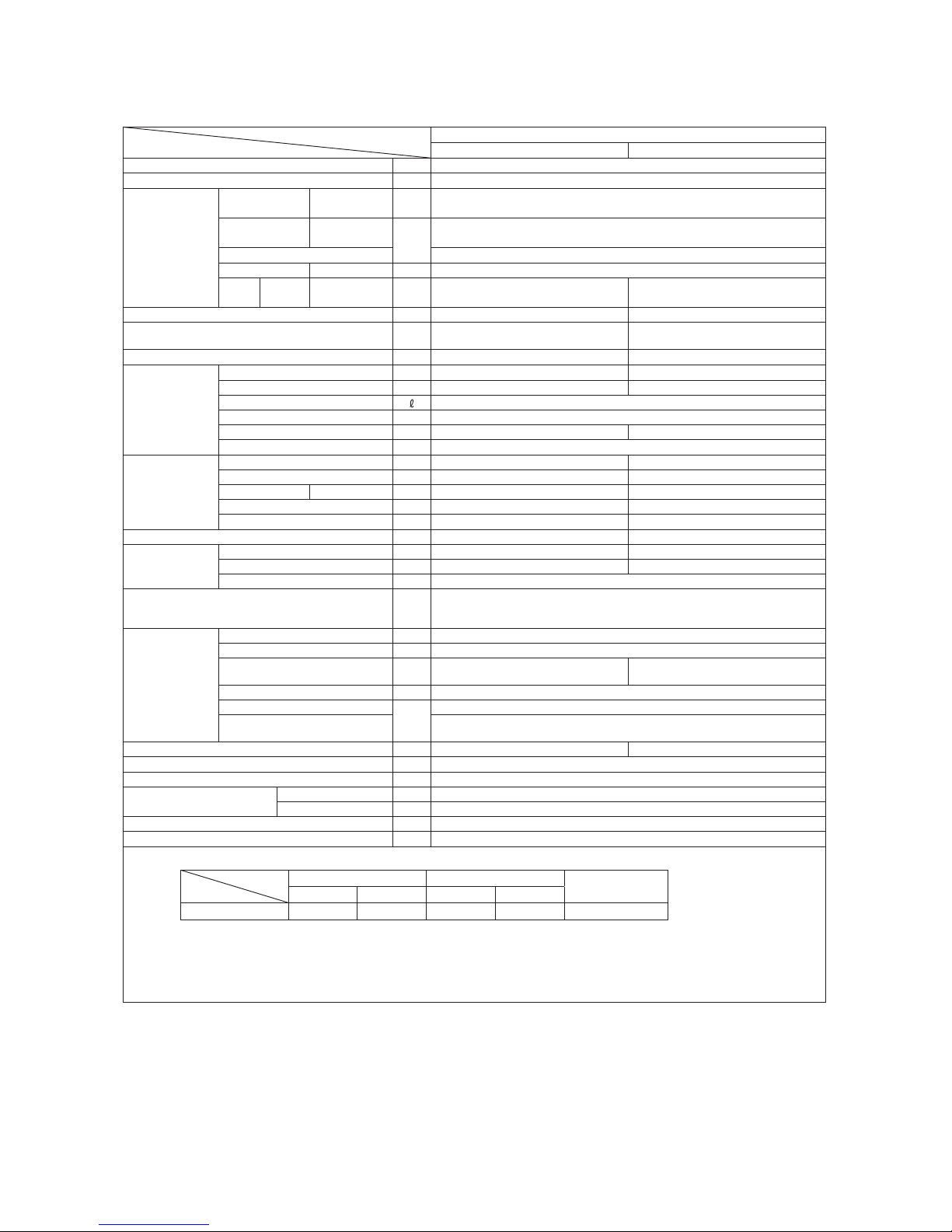

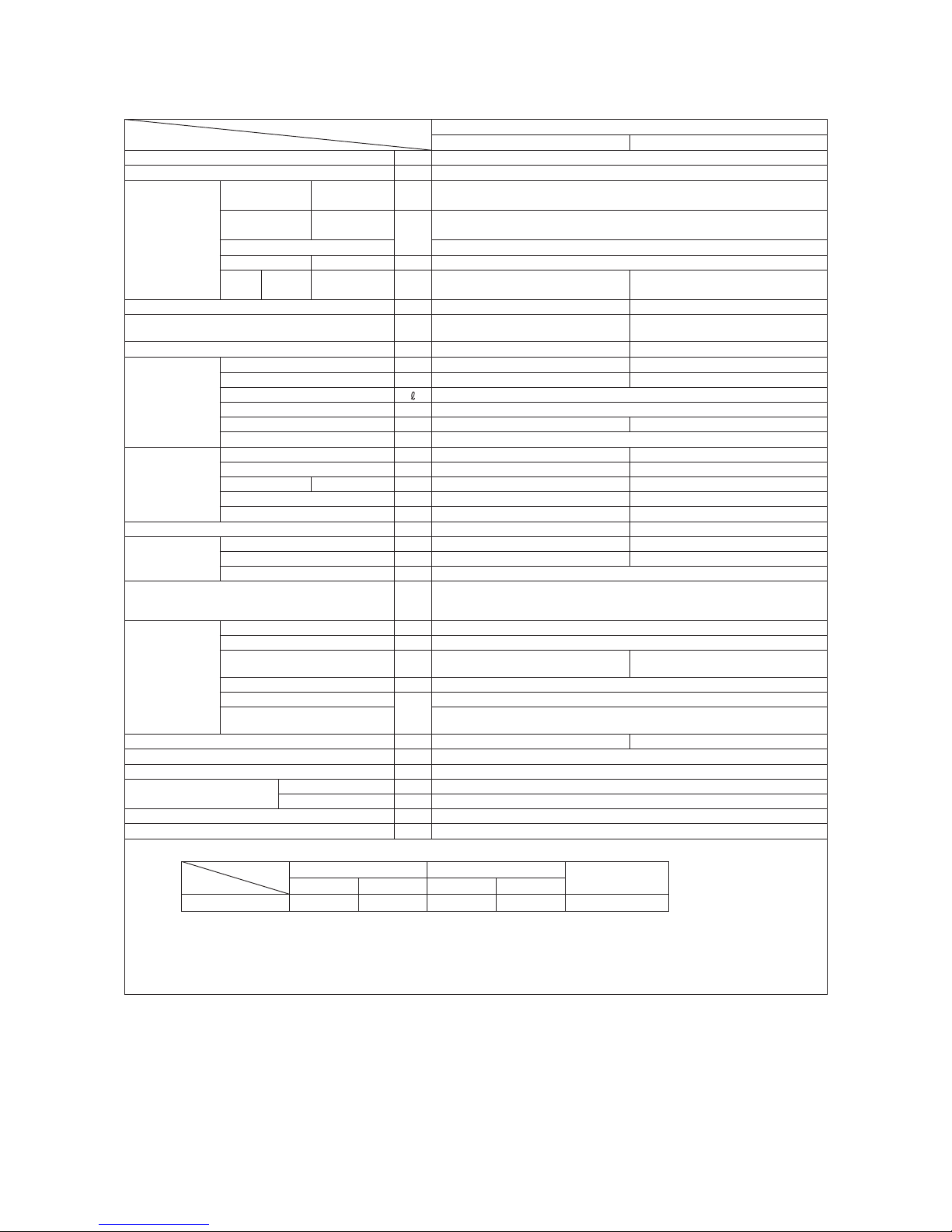

Model

Item

SRK12CM-4

Indoor unit SRK12CM-4 Outdoor unit SRC12CM-4

Cooling capacity (1) W 3517

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 1.09 / 1.11

Running

current

Cooling

A

5.1 / 5.0

Inrush current 25.0

COP Cooling 3.23 / 3.17

Noise

level

Cooling Sound level dB(A) 43 50 / 51

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 29

Refrigerant

equipment

Compressor type & Q'ty — RMC201A056 (Rotary type) x 1

Motor (Starting method) kW — 0.92 (PSC)

Refrigerant oil 0.38 (SUNISO 4GSI or ATMOS NM56)

Refrigerant (3) kg R22 0.58 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 10.0 32.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 15

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220 / 230V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

14

-

'13•SRK-T-141

Model

Item

SRK12CM-5

Indoor unit SRK12CM-5 Outdoor unit SRC12CM-5

Cooling capacity (1) W 3517

Power supply 1 Phase, 220 - 240V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 1.09

Running

current

Cooling

A

5.1

Inrush current 25.0

COP Cooling 3.23

Noise

level

Cooling Sound level dB(A) 43 50

Exterior dimensions (Height x Width x Depth) mm 262 x 769 x 210 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 7 29

Refrigerant

equipment

Compressor type & Q'ty — RMC201A056 (Rotary type) x 1

Motor (Starting method) kW — 0.92 (PSC)

Refrigerant oil 0.38 (SUNISO 4GSI or ATMOS NM56)

Refrigerant (3) kg R22 0.58 (Pre-Charged up to the piping length of 5.0m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Cross flow fan x 1 Propeller fan x 1

Motor W 17 25

Air flow Cooling m3/min 10.0 32.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 1 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.45

Gas line : 0.41

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable —

Recommended breaker size A 15

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included) Mounting kit

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C ISO-T1, JIS C 9612

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220V districts.

(4) The refrigerant quantity to be charged includes the refrigerant in 5.0m connecting piping.

(Purging is not required even for the short piping.)

If the piping length is 5m to 15m, additional refrigerant is 10g per each 1m longer than 5m.

The pipe length is 5.0m.

-

15

-

'13•SRK-T-141

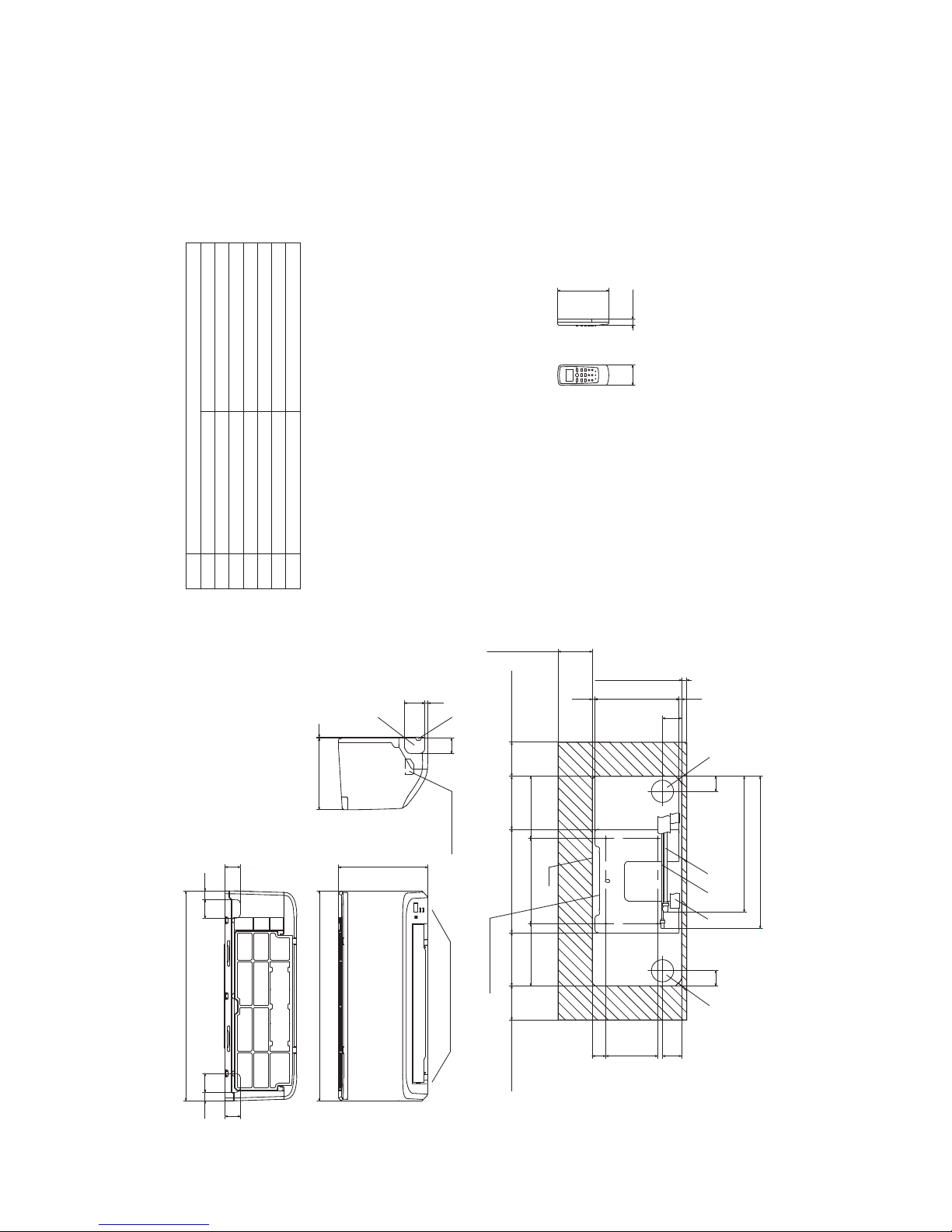

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models SRK05CM, 05CM-3

SRK05CMP-3

SRK09CM-3, 09CM-4, 09CM-5

SRK09CMP-3, 09CMP-4

Note(1)Themodelnamelabelisattached

ontheundersideofthepanel.

60

150

17.3

2555

45

55

45

25

615

615

262

3210

45

609

44

56

247.1

(Servicespace)

15

7.2 7.7

44

56 40152.1

100

(Servicespace)

155.4

181.9 250 181.9

100

(Servicespace)

303 155.4

Unit

100

(Servicespace)

445.9

398.2

Installationplate

Unit:mm

Wirelessremotecontrol

Spaceforinstallationandservicewhenviewingfromthefront

Holeonwallforrightrearpiping

Holeonwallforleftrearpiping

Outletforwiring

Drainhose

Liquidpiping

F

ECD

B

Symbol

(φ65)

VP16

φ6.35(1/4")(Flare)

Content

(φ65)

Outletforpiping(onbothside)

G

Outletfordownpiping

(Refertotheaboveview)

D E AB C

Gaspiping

A

φ9.52(3/8")(Flare)

G

F

Terminalblock

-

16

-

'13•SRK-T-141

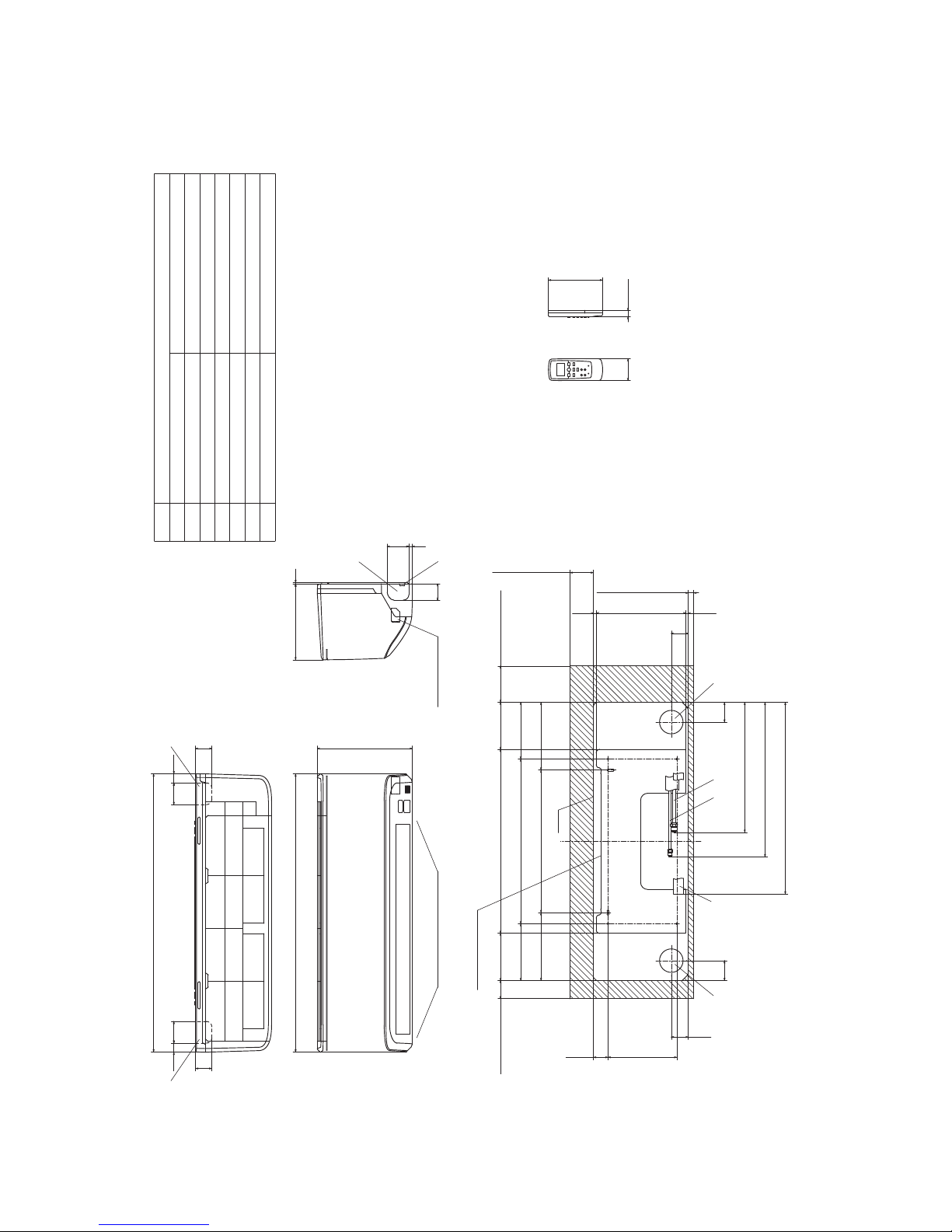

G

Terminal block

F

GG

Unit:mm

Wireless remote control

Outlet for down piping

(Refer to the above view)

Space for installation and service when viewing from the front

D E C

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

ECD

B

Symbol

A

(φ65)

VP16

φ6.35(1/4")(Flare)

Content

(φ65)

Outlet for piping(on both side)

G

φ12.7(1/2")(Flare)

AB

Note(1)The model name label is attached

on the underside of the indoor unit.

60

150

17.3

190 40.1

47

130.5 508 130.5

157 455 157

187.5 394 187.5

47

7.6247.5

6.9

(Service space)

65

(Service space)

15

50

(Service space)

100

(Service space)

55

409

449

530

55

Installation plate

Unit

6025 60 25

768.1

45

45

769

262

45

609

210 3

Models SRK12CM-3, 12CM-4, 12CM-5

-

17

-

'13•SRK-T-141

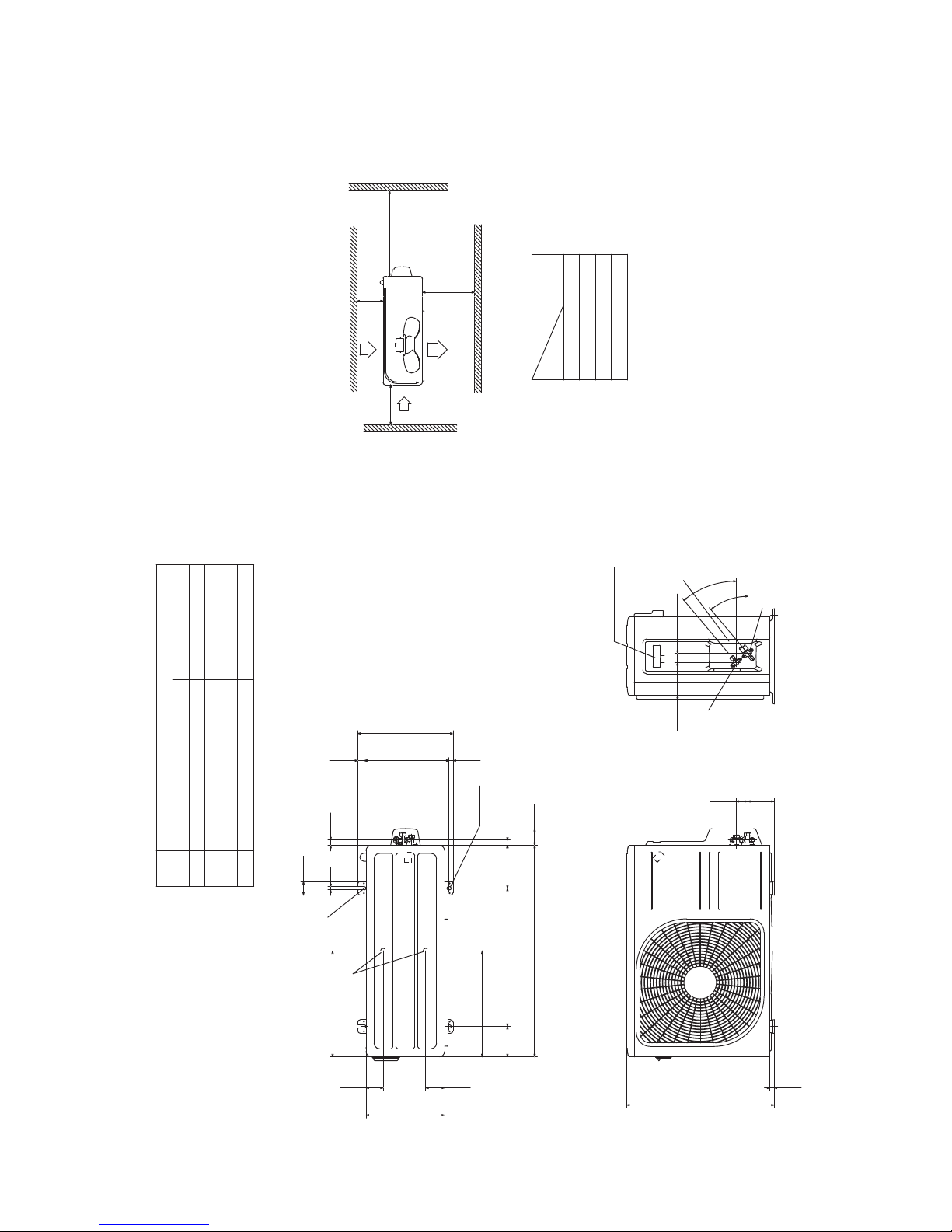

(2) Outdoor units

Models SRC05CM, 05CM-3

SRC05CMP-3

SRC09CM-3, 09CM-4, 09CM-5

SRC09CMP-3, 09CMP-4

)eralF()"8/3(25.9φ

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10×4places

φ20×2places

Service valve connection(liquid side)

)eralF()"4/1

(

53.6φ

Minimum installation space

Notes

.sedisruofllanosllawybdednuorrusebtontsumtI)1(

(2)The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3)Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicular ly

to the dominant wind direction.

(4)Leave 1m or more space above the unit.

(5)A wall in front of the blower outlet must not exceed the unit height.

(6)The model name label is attached on the right side of the unit.

L2

L3

L4

L1 600

100

100

Examples of

Dimensions

Unit:mm

mm

installation

Outlet

Intake

L3

L1

L2

Intake

Service

space

( )

L4

Open

322

50

40

12

135

275

120.5

74.5 480 91 19.7

694.2

16.8304.414.8

336

2-16x12

Terminal block

147.2

2

0

°

2

0

°

86.3 43.2

16.5

437

E

D

BCA

-

18

-

'13•SRK-T-141

Models SRC12CM-3, 12CM-4, 12CM-5

)eralF()"4/1(53.6φ

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10×4places

φ20×2places

Service valve connection(liquid side)

)eralF()"2/1(7.21φ

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

( )

Notes

.sedisruofllanosllawybdednuorrusebtontsumtI)1(

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the unit height.

(6) The model name label is attached on the right side of the unit.

L4

L2

L3

L4

L1

100

100

600

Open

Examples of

Dimensions

installation

15.8

543.8

390.6

390.6

63.469.4

290

111.6 510 158.4

780 61.9

18.9

14.8

351.6

2-16x12

312.5 24.3

50.6

12

97.7 42.5

Terminal block

40

°

4

0

°

138.4 33.5

19.9

D

E

A

C

B

Unit:mm

mm

-

19

-

'13•SRK-T-141

(3) Wireless remote control

Unit: mm

60

17.3

150

Models All model

Unit: mm

17.3

150

-

20

-

'13•SRK-T-141

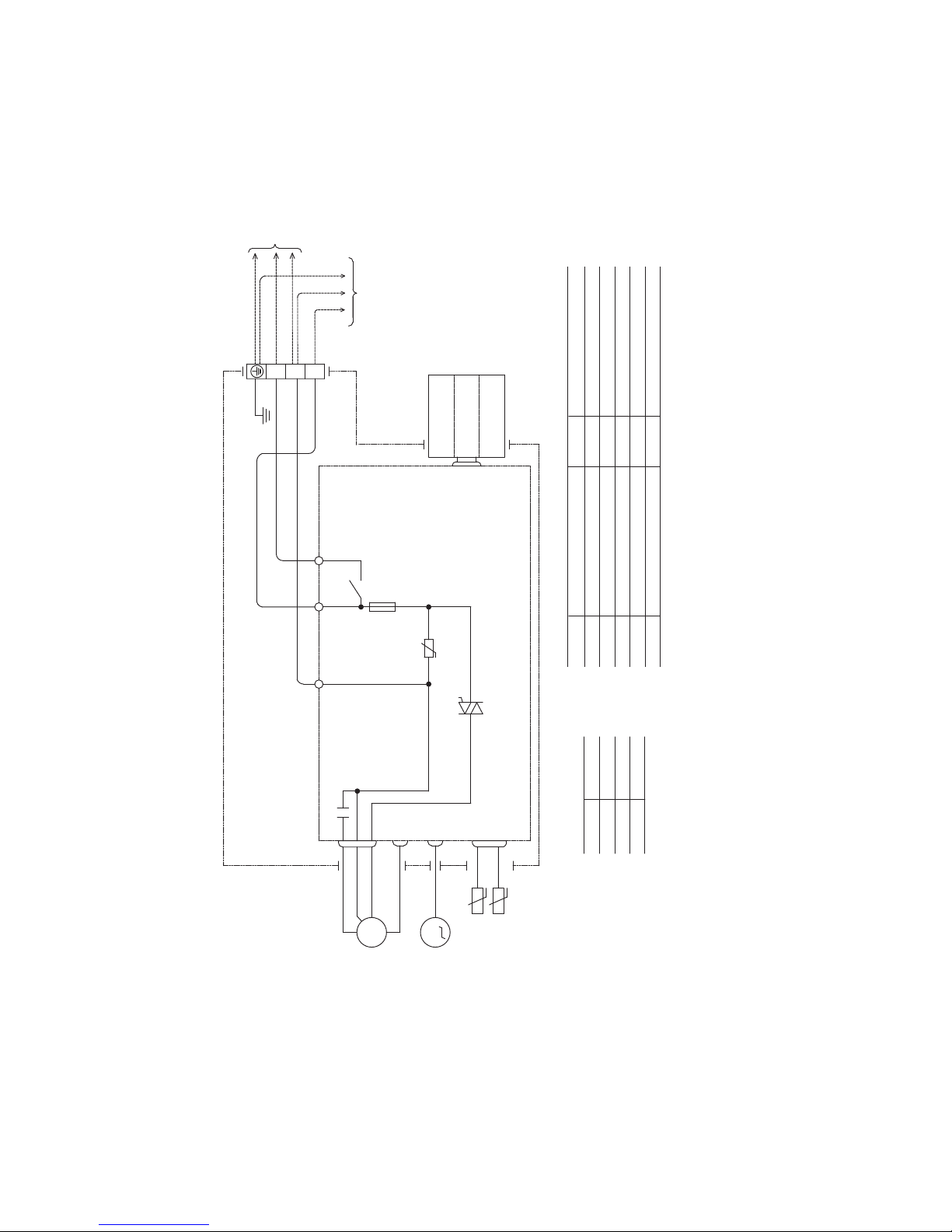

3. ELECTRICAL WIRING

(1) Indoor units

Models All model

Printed circuit board

Wireless

R-Amp

Display

CNE

WHRDBK

M

CNW

IC15

ZNR

153

CNU

CF

I

L 52C-3

52C

F

250V 3.15A

CONTROL BOX

Back up Sw

CNG

CNM

N

1〜

FM

I

T1

t°

t°

Th1

Th2

2/N

L

1

Symbol

Meaning of Marks

Parts name Symbol Parts name

Capacitor forCF

IFMI

FM

ZNR

FM

I

Fuse

Fan motor

Flap motor

Varistor

F

Th2

T1

Room temp. thermistor

Heat exchanger thermistor

Terminal block

Th1

BK

Color symbol

BL

Black

Blue

RD

WH

Red

White

BL

WH

BK

Power source

220/230/240V 50Hz

TO

OUTDOOR

UNIT

U

MFM

-

21

-

'13•SRK-T-141

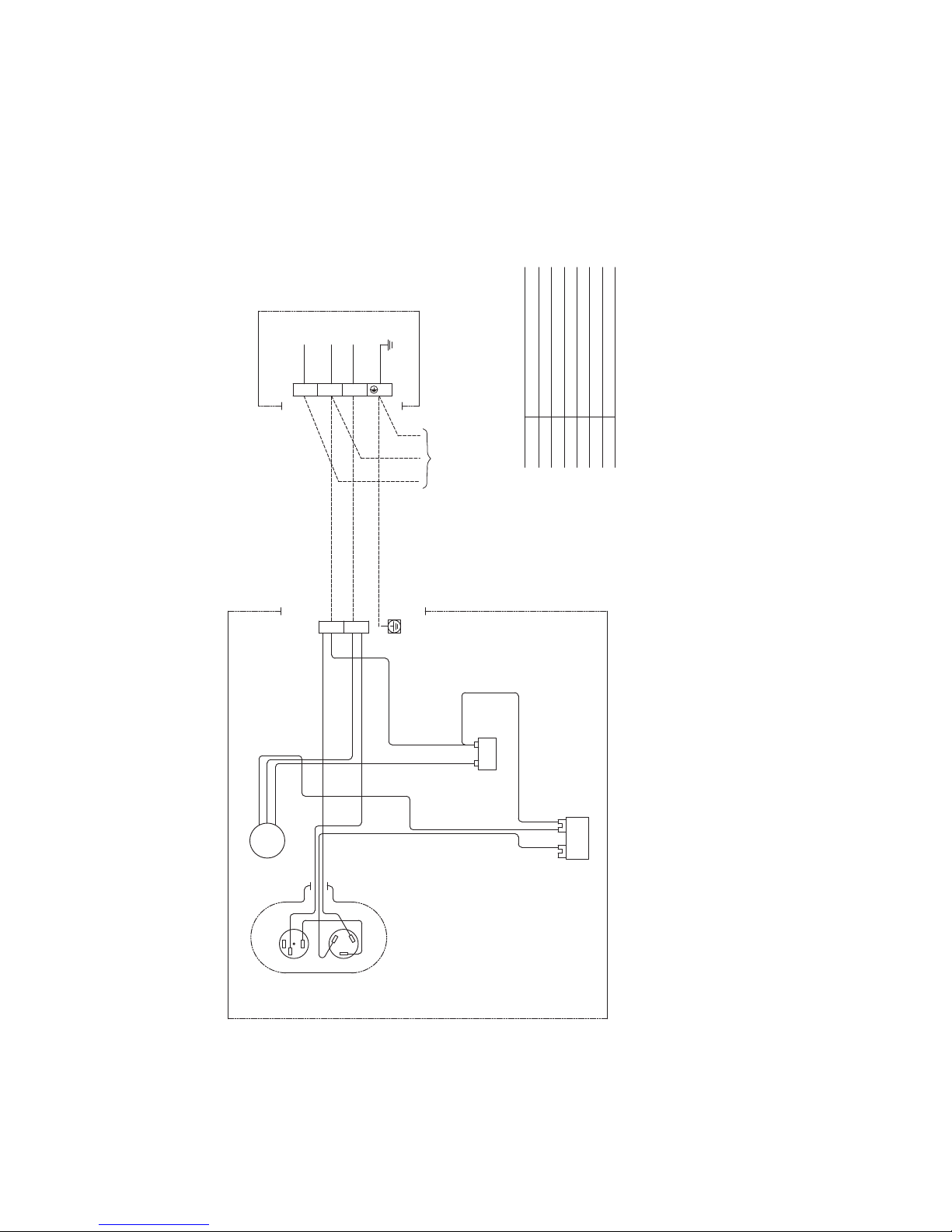

(2) Outdoor units

Models SRC05CM, 05CM-3

SRC05CMP-3

SRC09CM-3, 09CM-4, 09CM-5

SRC09CMP-3, 09CMP-4

Power source

220-240V 50Hz

INDOOR UNIT

FMo

BLACK

ORANGE

WHITE

RED

Cc

ORANGE

CFo

ORANGE

WHITE

WHITE

BLACK

BLACK

WHITE

1 2

T1

WHITE

CM

BLACK

BLACK

51C

2

3

1

RED

C

S

R

T2

WHITE

CAPACITOR

L

1

2/N

ORANGE

Symbol

Meaning of Marks

Parts name

Capacitor for CMCc

Capacitor for FMoCFo

Compressor motorCM

Fan motorFMo

Motor protector for CM51C

Terminal blockT1,T2

OUTDOOR UNIT

-

22

-

'13•SRK-T-141

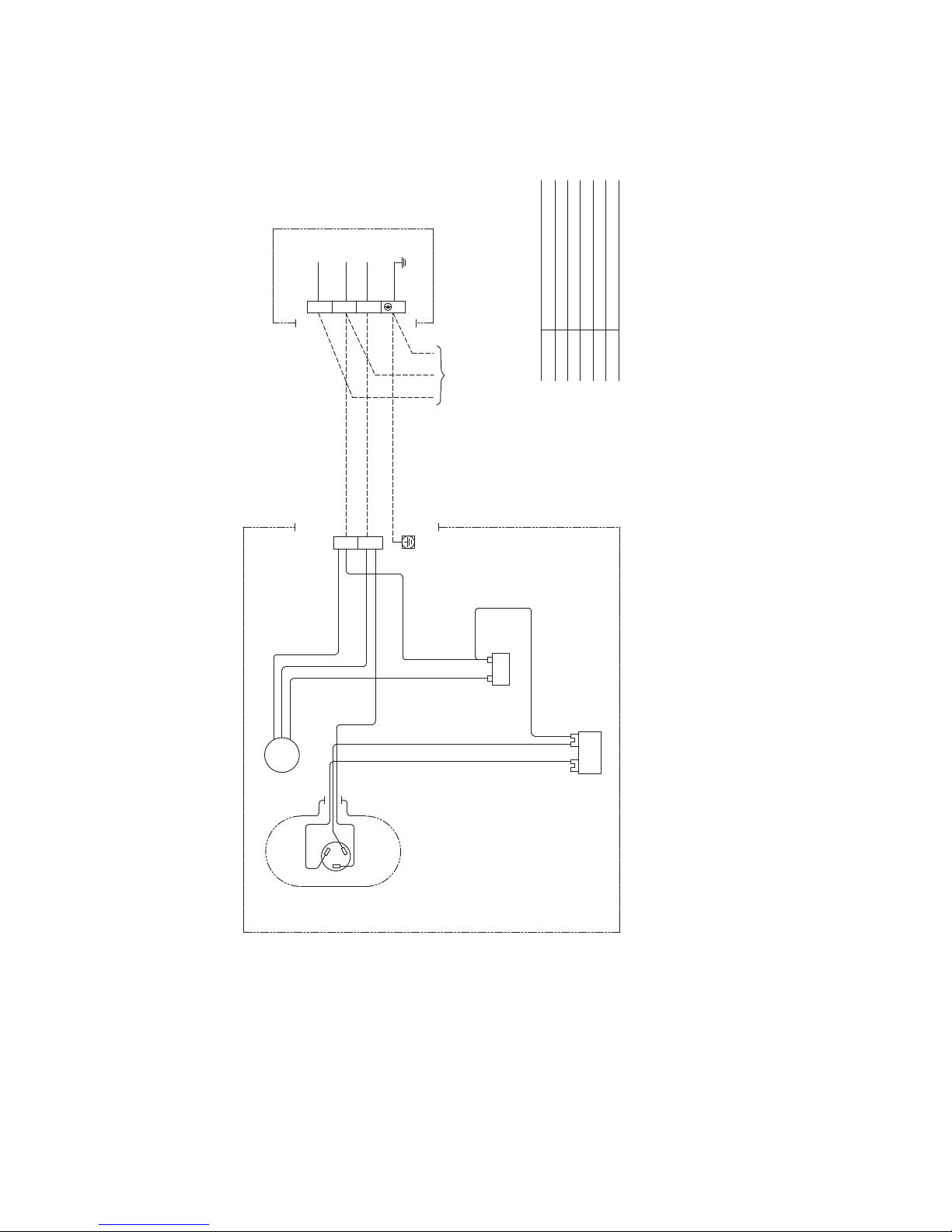

Models SRC12CM-3, 12CM-4, 12CM-5

Symbol

Meaning of Marks

Parts name

Capacitor for CMCc

Capacitor for FMoCFo

Compressor motorCM

Fan motorFMo

Terminal blockT1,T2

Powersource

220-240V50Hz

INDOORUNIT

BLACK

ORANGE

WHITE

RED

Cc

ORANGE

CFo

ORANGE

WHITE

WHITE

BLACK

BLACK

WHITE

1 2

T1

WHITE

CM

BLACK

RED

C

S

R

T2

WHITE

CAPACITOR

L

1

2/N

ORANGE

OUTDOORUNIT

BLACK

FMo

-

23

-

'13•SRK-T-141

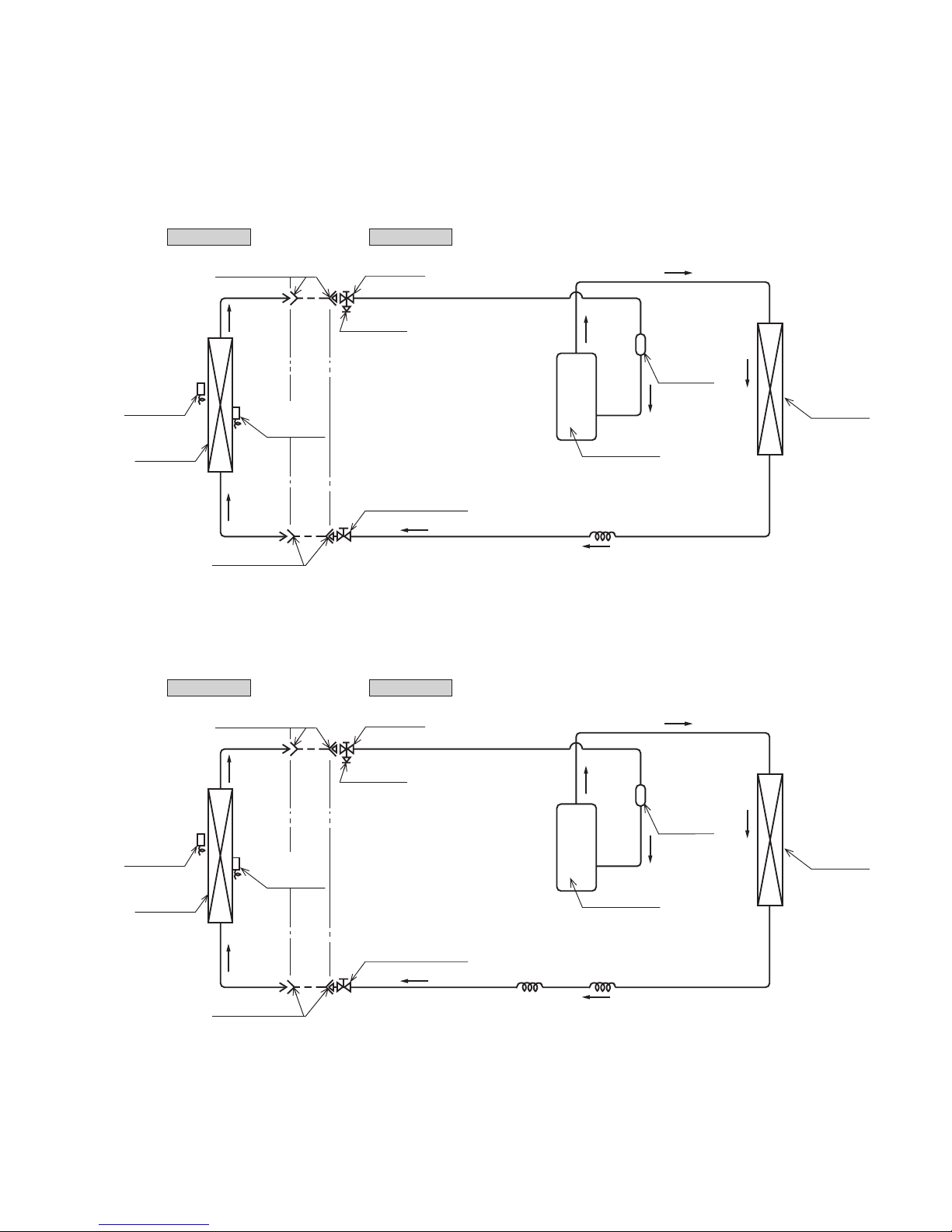

4. PIPING SYSTEM

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

Service valve (Liquid)

Flare connecting

Heat

exchanger

Compressor

Accumulator

Service valve

(Gas)

Capillary tube

ø9.52

Piping

(Gas)

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

Service valve (Liquid)

Flare connecting

Heat

exchanger

Compressor

Capillary tube

Accumulator

Service valve

(Gas)

Capillary tube

Piping

(Gas)

ø12.7

Models SRK05CM, 05CM-3

SRK05CMP-3

SRK09CM-3, 09CM-4, 09CM-5

SRK09CMP-3, 09CMP-4

Models SRK12CM-3, 12CM-4, 12CM-5

-

24

-

'13•SRK-T-141

5. RANGE OF USAGE & LIMITATIONS

Net capacity = Capacity shown on specification Correction factors as follows.

(1) Coefficient of cooling capacity in relation to temperatures

All model

Models

Item

Indoor return air temperature

(

Upper, lower limits

)

Outdoor air temperature

(

Upper, lower limits

)

Refer to the selection chart

Refrigerant line (one way) length

Max. 15m

Max. 5m (Outdoor unit is higher

)

Max. 5m (Outdoor unit is lower

)

Min. 3 minutes

Max. 10 times/h

Min. 85% of rating

Vertical height difference between

outdoor unit and indoor unit

Power source voltage

Voltage at starting

Frequency of ON−OFF cycle

ON and OFF interval

Rating 10%

14 16 18 20 22

15

20

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

24

ISO-T1 Standard ConditionIndoor air W.B. temperature °C W.B.

Cooling

Applicable range

Coefficient of cooling

capacity in relation

to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

-

25

-

'13•SRK-T-141

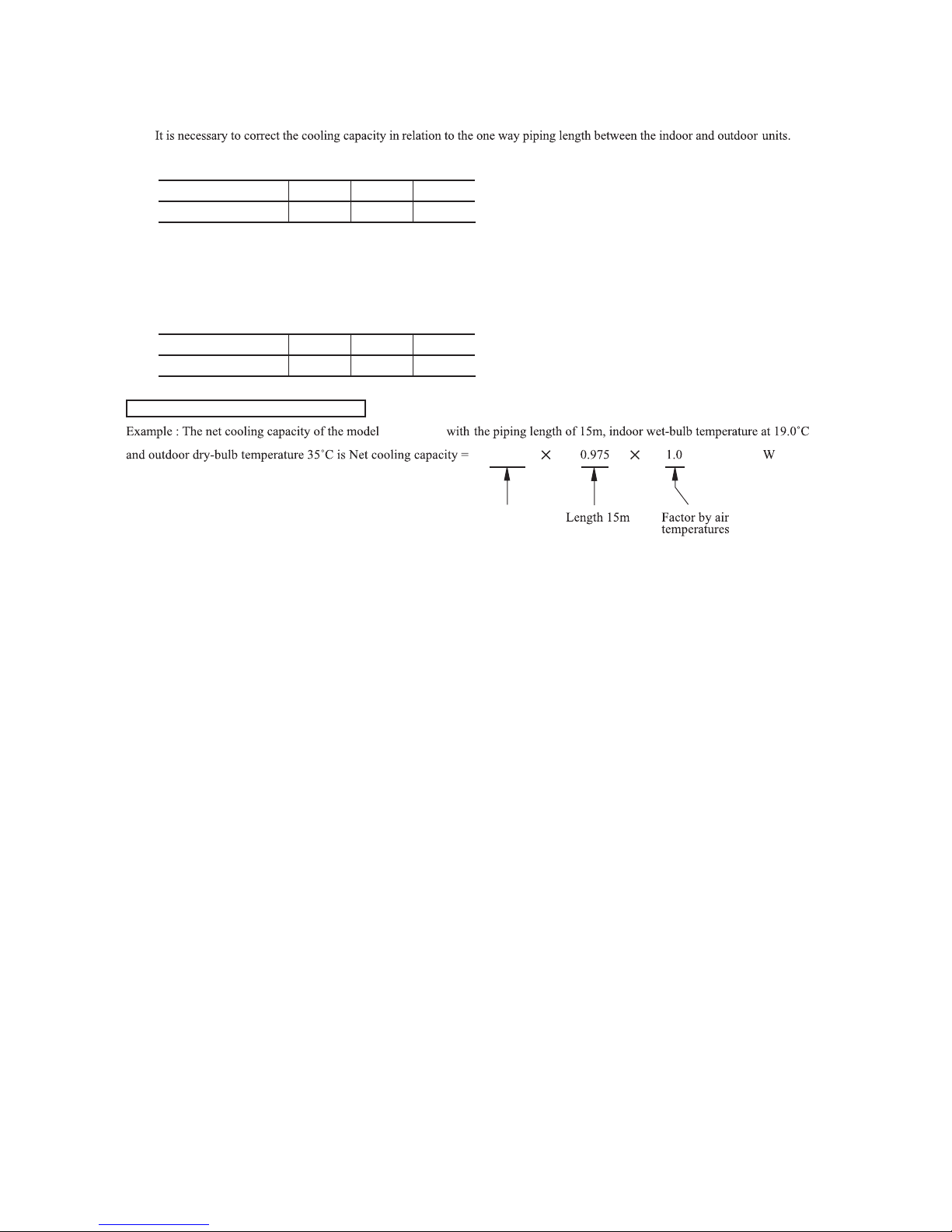

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

How to obtain the cooling capacity

Model SRK05CM

=

Piping length [m]

Cooling

7.5

1.0

10

0.99 0.975

15

Models SRK05CM-3

SRK05CMP-3

SRK09CM-3, 09CM-4, 09CM-5

SRK09CMP-3, 09CMP-4

SRK12CM-3, 12CM-4, 12CM-5

Piping length [m]

Cooling

5

1.0

10

0.985 0.97

15

1500

SRK05CM

SRK05CM

1463

-

26

-

'13•SRK-T-141

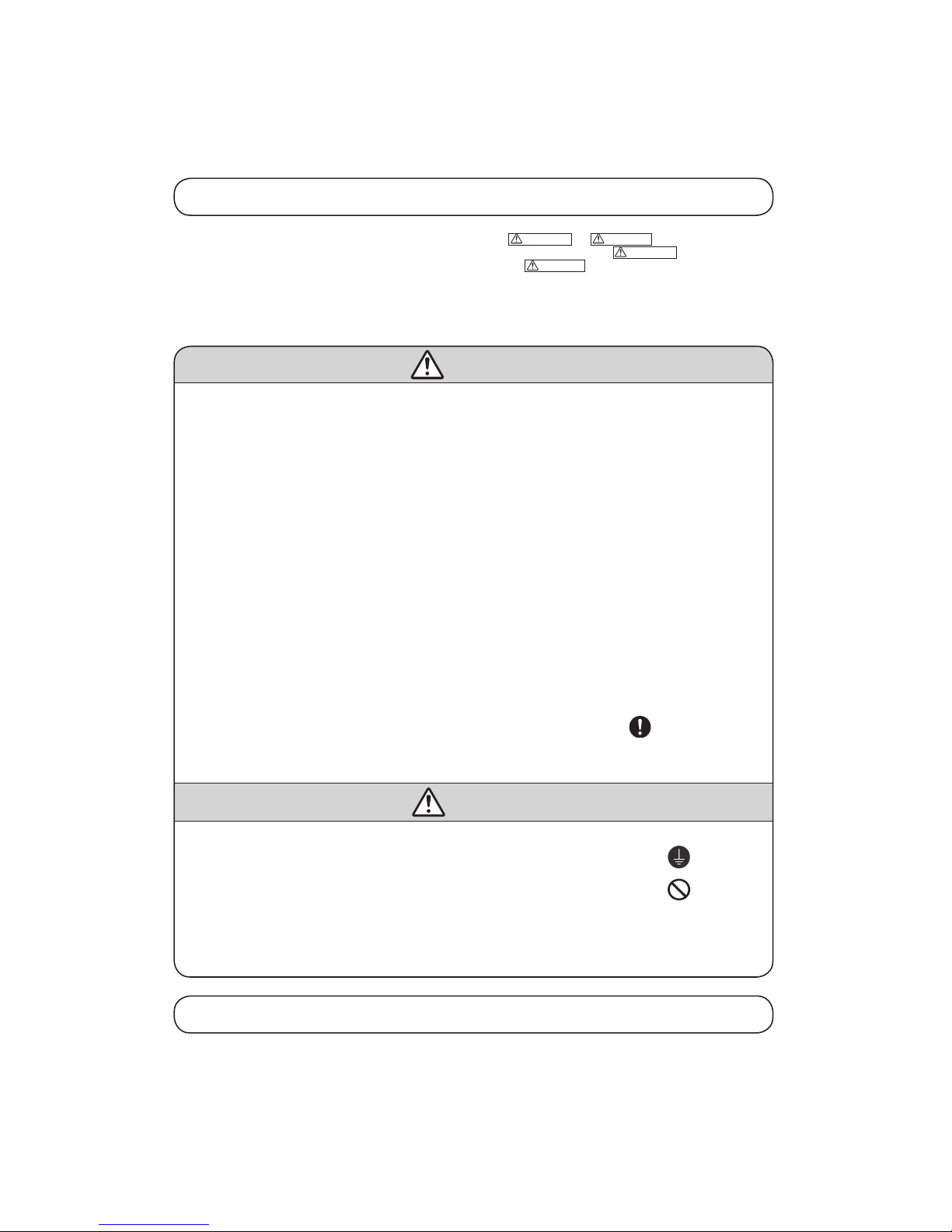

Safety precautions

• Please read these “Safety Precautions” first then accurately execute the installation work.

• Though the precautionary points indicated herein are divided under two headings,

WARNING

and

CAUTION

, those points which are related

to the strong possibility of an installation done in error resulting in death or serious injury are listed in the

WARNING

section. However, there

is also a possibility of serious consequences in relationship to the points listed in the

CAUTION

section as well. In either case, important safety

related information is indicated, so by all means, properly observe all that is mentioned.

• After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please explain operating methods as

well as maintenance methods to the user (customer) of this equipment, based on the owner’s manual.

Moreover, ask the customer to keep this sheet together with the owner’s manual.

WARNING

• To disconnect the appliance from the mains supply this appliance must be connected to the mains by means of a circuit breaker or a switch (use a

recognized 10A) with a contact separation of at least 3mm.

• The appliance shall be installed in accordance with national wiring regulations.

• This systemshould be applied to placesas households, residences and thelike. Application to inferiorenvironment such as engineering shopcould

cause equipment malfunction.

• Please entrust installation to either the company which sold you the equipment or to a professional contractor. Defects from improper installations

can be the cause of water leakage, electric shocks and fires.

• Execute the installation accurately, based on following the installation manual. Again, improper installations can result in water leakage, electric

shocks and fires.

• For installation, confi rm that the installation site can suf ficiently support heavy weight. When strength is insuf fi

cient, injury can result from a

falling of the unit.

• For electrical work, please see that a licensed electrician executes the work while following the safety standards related to electrical equipment,

and local regulations as well as the installation instructions, and that only exclusive use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks and fires.

• This equipmentmust be installed with earth leakage circuit breaker (ELCB). Otherwise, it may causeelectrical shock and fire incase of equipment

breakdown.

• Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to the terminal connection part,

through properly securing it improper connection or securing can result in heat generation or fire.

• Take care that wiring does not rise upward, and accurately install the lid/service panel. It’s improper installation can also result heat generation or

fire.

• When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated refrigerant (R22) within

the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

• Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this company can result in water

leakage, electric shock, fire and refrigerant leakage.

• Ventilate the work area when refrigerant leaks during the operation.

Coming in contact with fire, refrigerant could generate toxic gas.

• Confirm after the foundation construction work that refrigerant does not leak.

If coming in contact with fire of a fan heater, a stove or movable cooking stove, etc., refrigerant leaking in the room could generate toxic gas.

CAUTION

• Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone ground wire.

Improper placement of ground wires can result in electric shock.

• The installation of an earth leakage breaker is necessary depending on the established location of the unit.

No installing an earth leakage breaker may result in electric shock.

• Do not install the unit where there is a concern about leakage of combustible gas.

The rare even of leaked gas collecting around the unit could result in an outbreak of fire.

• For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to prevent condensation.

Inadequate plumbing can result in water leakage and water damage to interior items.

• Install the outdoor unit so that the aluminum fins on the air heat exchanger cannot be touched. Failure to observe this may result in injury.

• Do not place objects near the outdoor unit or allow leaves to gather around the unit. If there are objects or leaves around the outdoor unit, small

animals may enter unit and contact electrical parts resulting in break down, emission of smoke or flame.

Cautions for installation

① The system should be applied to places as households, residences and the like.

② The equipment shall be installed in accordance with national wiring regulations.

③ The connection to the fixed wiring of the mains supply must be made via a double pole isolating switch with a contact gap of at least

3mm in each pole.

④ When the outdoor unit has a possibility of being overturned or being displaced and fall from its original installation position, the outdoor

unit should be fixed in its position by use of anchor bolts or wires.

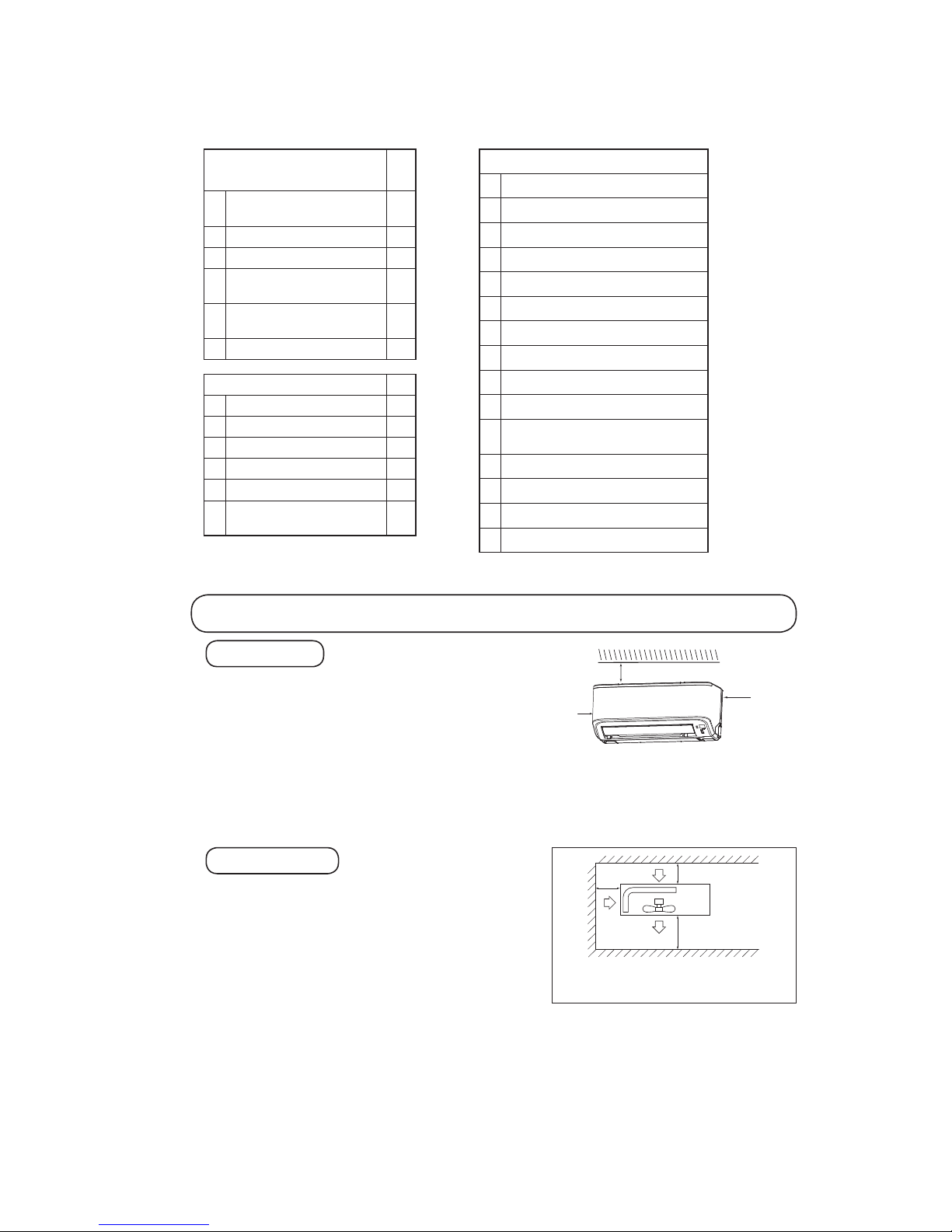

6. APPLICATION DATA

Models SRK05CM, 05CM-3 SRK09CM-3, 09CM-4, 09CM-5

SRK05CMP-3 SRK09CMP-3, 09CMP-4

-

27

-

'13•SRK-T-141

① A place where good air circulation can be obtained and where rain,

snow or sunshine will not directly strike the unit.

② A place where discharged hot air or unit’s operating sound will not be a

nuisance to the neighborhood.

③ A place where servicing space can be secured.

④ A place where vibration will not be enlarged.

*Avoid installing in the following places.

•A place near the bedroom and the like, so that the operation noise will

cause no trouble.

•A place where there is possibility of flammable gas leakage.

•A place exposed to strong wind.

•In a salt-laden atmosphere or a place where the generation of oil mist, vapor or fume is expected.

⑤ Blowing out port and suction port on the back side of the unit can be installed at a distance of 10cm from walls.

(In case the barrier is 1.2m or above in height, or is overhead, the sufficient space between the unit and wall shall be secured.)

⑥ When the unit is installed, the space of the following dimension and above shall be secured.

OUTDOOR UNIT

Selection of installation location

① Where there is no obstructions to the air flow and where the cooled

air can be evenly distributed.

② A solid place where the unit or the wall will not vibrate.

③ A place where there will be enough space for servicing. (Where

space mentioned right can be secured)

④ Where wiring and the piping work will be easy to conduct.

⑤ The place where receiving part is not exposed to the direct rays of

the sun or the strong rays of the street lighting.

⑥ A place where it can be easily drained.

⑦ A place separated at least 1m away from the television or the

radio.

(To prevent interfence to images and sounds.)

INDOOR UNIT

Standard accessories

(Installation kit)

Accessories for indoor unit

Q’ty

①

Installation board

(Attached to the rear of the indoor unit)

1

②

Wireless remote control 1

③

Remote control holder 1

④

Tapping screws

(for installation board 4dia. by 25mm)

5

⑤

Wood screw

(for remote control switch holder 3.5dia. by 16mm)

2

⑥

Battery [R03 (AAA, Micro) 1.5V]

2

Option parts Q’ty

ⓐ

Sealing plate 1

ⓑ

Sleeve 1

ⓒ

Inclination plate 1

ⓓ

Putty 1

ⓔ

Drain hose (extention hose) 1

ⓕ

Piping cover

(for insulation of connection piping)

1

Necessary tools for the installation work

1 Plus headed driver (Phillips screwdriver)

2 Knife

3 Saw

4 Tape measure

5 Hammer

6 Spanner wrench

7

Torque wrench

( )

14.0 ~ 61.0N · m

(1.4 ~ 6.1kgf · m)

8 Hole core drill (65mm in diameter)

9 Wrench key (Hexagon) [4m/m]

10 Vacuum pump

11

Vacuum pump adapter

(Anti-reverse flow type)

( )

Designed specifically

for R22

12

Gauge manifold

( )

Designed specifically

for R22

13

Charge hose

( )

Designed specifically

for R22

14

Flaring tool set

( )

Designed specifically

for R22

15

Gas leak detector

( )

Designed specifically

for R22

Note (1) If the wall is higher than 1.2 m or a ceiling is present,

distances larger thanindicated in the above table must

be provided.

Air intake

Air outlet

No obstacles

(Service space

for electrical

parts)

Air

intake

10 cm

MIN

60 cm MIN

10 cm MIN

Left

side

10 cm

10 cm

Right

side

10 cm

-

28

-

'13•SRK-T-141

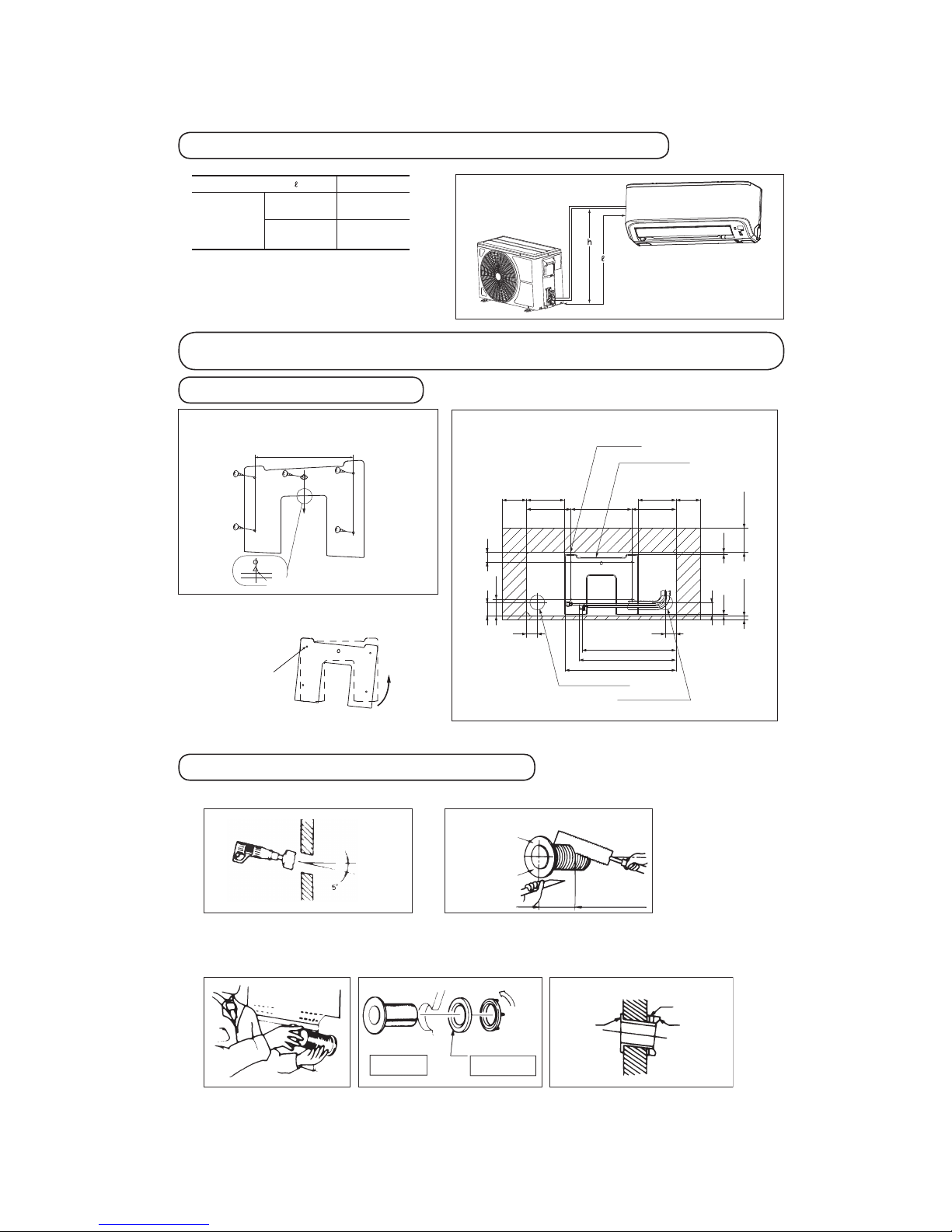

Installation of indoor unit

Installation of installation board

• Adjustment of the installation board inthe horizontal

direction is to be conducted with five screws in a

temporary tightened state.

• Adjust so that board will be level byturning the

board with the standard hole as the center.

Standard hole

Limitations for one way piping length and vertical height difference

One way piping length ( )

15 m

Vertical height

difference (h)

Outdoor

unit is lower

5 m

Outdoor

unit is higher

5 m

Look f or the inside wall structu res (Int ersediate support or

pillar and firaly install the uni t after l evel surface has be en

checked.)

Mating mark fo r level surface

250

* Leave extra space on the right side to enable removal of the lid screw.

INSTALLATION SPACE (INDOOR UNIT) (FRONT VIEW)

Unit : mm

Drilling of holes and fixture sleeve (Option parts)

Drill a hole with Ø65 whole core drill

Install the sleeve

Adjusting sleeve length

Note (1) Drill a hole with incline of 5 degree from

indoor side to outdoor side.

Wall thickness

+ 1.5 cm

Cut off the sleeve

collar that can be

seen from beneath

the unit.

Cut off the sleeve

collar in case of

drawing piping out

to rear.

Indoor side

Indoor side

Indoor side

View of sleeve when installed

Outdoor side

Outdoor side

Outdoor side

(Inserting sleeve) (*Sleeve + *Inclined + *Sealing plate)

Paste

Sleeve

Turn to

tighten

In cli ne d

flange

Seali ng

plate

Space for

service

Space for

service

Space for

service

Space for

service*

Indoor unit

181.9181.9

44

44

40

56

69.9

15

56

100

7.2 7.7

250

Installation board

Piping for Gas 398.2

Piping for Liquid 445.9

Drain hose 386.3 (

Ø16)

Piping hole (

Ø65)

Piping hole (Ø65)

100

100

155.4

155.4

-

29

-

'13•SRK-T-141

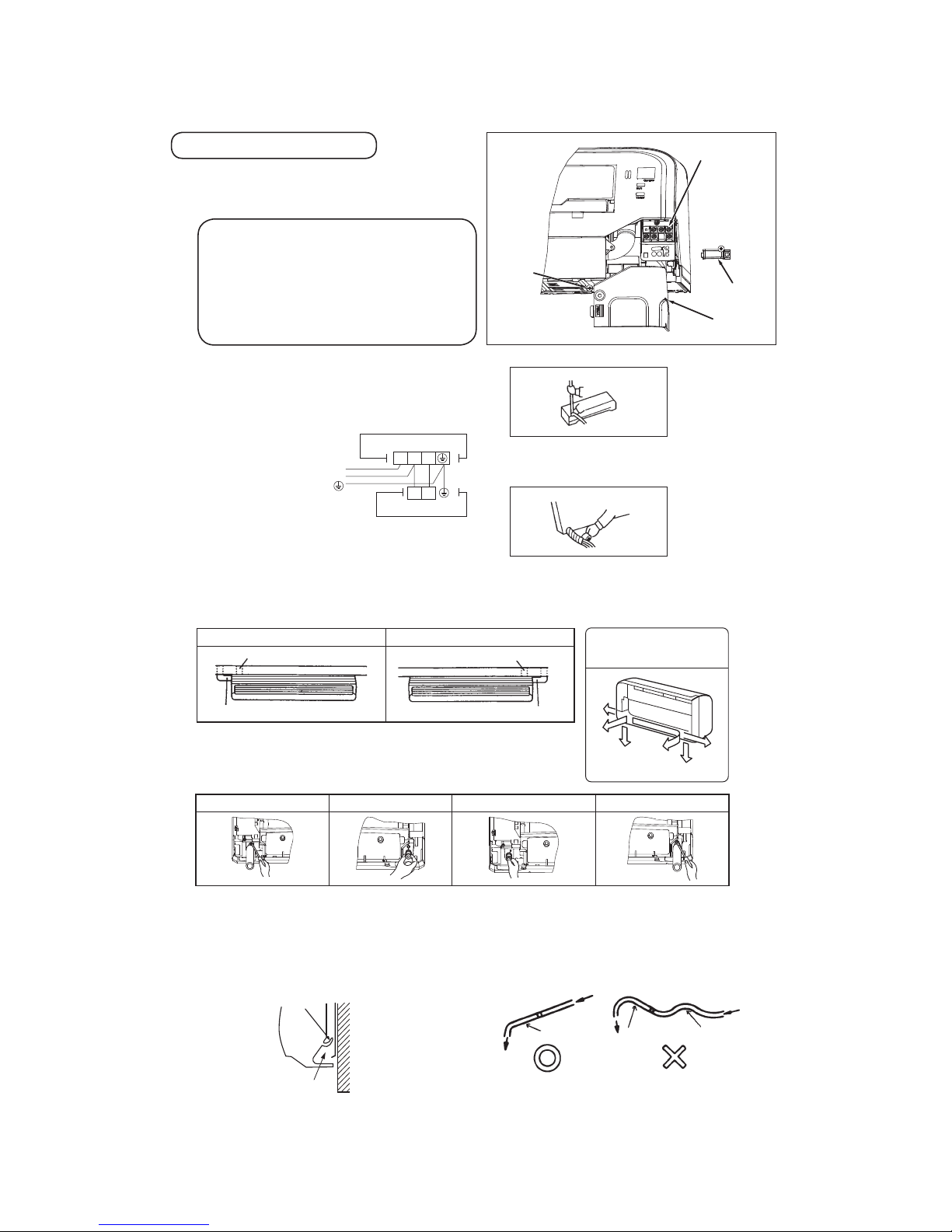

Preparation of indoor unit

① Mounting of connecting wires

ⓐ Remove the lid.

ⓑRemove the wiring clamp.

ⓒConnect the connecting wire securely to the terminal block.

Use cable for interconnection wiring to avoid loosening of the wires.

CENELEC code for cables Required field cables.

75CEI542ro)elpmaxE(5.1G4RNR50H

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Standed core

srotcudnocforebmuN5ro4

G

One conductor of the cables is the earth conductor (yellow/green)

1.5 Section of copper wire (mm2)

• Connect the connection wire securely to the terminal block. If

the wire is not affixed completely, contact will be poor, and it

is dangerous as the terminal block may heat up and catch fire.

• Take care not to confuse the t erminal numbers for p ower

source indoor and outdoor connections.

•

Earthlead wireshall be longerthan theother lead wiresfor theelectrical

safety in case of the slipping out of the cord from the anchorage.

• The earth line of power cord must be properly earthed.

L

N

Connecting diagram.

Power supply

source

Terminal on the indoor unit

L 2/N

2

N

L

1

1

Terminal on the outdoor unit

• Affix the connection wire using the wiring clamp.

ⓓFix the connecting wire by wiring clamp.

ⓔAttach the lid.

② Shaping the pipe

③ Taping of the exterior

• Hold the bottom of the pipe and change its direction

before stretching it and shaping it.

• Tape only the portion that runs through the wall.

Always tape the crossover wires with the pipe.

④ Cautions when piping from the left and the rear center of the unit

[ Top View ]

• R emov e th e sc rew an d

pull th e drain hose, w hile

twisting.

• Re move i t wi th ha nd o r

pliers.

• I nser t th e d rai n c ap w hic h

was removed at procedure “2”

se cure ly us ing a hex ago nal

wrench etc.

Note: Be careful that if it is not

inserted securely, water leakage

may occur.

• Insert the drain hose securely,

pus h t he dr ain h ose wh ile

twisting. Install the screw.

Note: Be careful that if it is

not ins erted secure ly, water

leakage may occur.

Piping is possible in the rear,

left, left rear, l eft dow nward,

right or downward direction.

• Do not place the power supply cords above the gutter, because the

air conditioner is structuredin a way where condensation on theback

side is collected in to the drain pan before drainage.

• Do not make traps in the drain hose line.

Declining slope

Inverted slipe

Trap

* Leave space to allow

removal of this screw

after installation.

[ Drain hose changing procedures ]

Pipe

Drain hose

Terminal block

Screw*

Clamp

Lid

Left Side Piping Right Side Piping

Left rear piping

Left side piping

Right rear piping

Right side piping

Right

Left

Left rear

Rear

Downward

Left downward

1. Remove the drain hose. 2. Remove the drain cap. 3. Insert the drain cap. 4. Connect the drain hose.

Gutter

Pipes storage area

Wall

Loading...

Loading...