Mitsubishi Heavy Industries SRK10CMV, SRK-13CMS-2, SRK13CMV, SRK19CMS, SRK25CMS Technical Manual

...

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONER

(Split system, air cooled cooling only type)

SRK10CMV, 13CMV

SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2

SRK19CMS, 25CMS

Manual No.'12•SRK-T-137

-

1

-

'12•SRK-T-137

TECHNICAL MANUAL

1. SRK10CMV, 13CMV

SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2 ............................................. 2

2. SRK19CMS, 25CMS................................................... 38

-

2

-

'12•SRK-T-137

( )

1. SRK10CMV, 13CMV

SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONER

Split system, air cooled

cooling only type

'10 • SRK-T-099

CONTENTS

1.1 SPECIFICATIONS .................................................................................... 5

(2) Outdoor units .................................................................................... 10

(3) Wireless remote control

.................................................................... 11

........................................................................ 9

(1) Indoor units ......................................................................................... 9

1.2 EXTERIOR DIMENSIONS

1.3 ELECTRICAL WIRING ............................................................................. 12

(1) Indoor units ......................................................................................... 12

(2) Outdoor units ...................................................................................... 14

....................................................... 16

1.5 RANGE OF USAGE & LIMITATIONS

1.4 PIPING SYSTEM ..................................................................................... 15

............................................................................... 18

1.6 APPLICATION DATA

1.7 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ........... 25

(6) 3D auto operation

............................................................................. 29

(7) Timer operation

................................................................................. 30

(5) Flap and louver control ..................................................................... 28

...................................................... 27(4) Custom cord switching procedure

........................................................................ 27(3) Auto restart function

(2) Unit ON/OFF button

.......................................................................... 27

(1) Operation control function by remote control

..................................... 25

(8) Installation location setting ................................................................. 30

(10) Outline of automatic operation .......................................................... 31

(9) Outline of cooling operation .............................................................. 31

(11) Protective control function

.................................................................. 32

.............................................................................. 33

.................... 34

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

....... 33

(1) Cautions

............................................................................................ 33

(2) Items to check before troubleshooting ................................................ 33

(5) Self-diagnosis table ............................................................................ 34

(6) Inspection procedures corresponding to detail of trouble ................... 35

1.8 MAINTENANCE DATA

-

3

-

'12•SRK-T-137

'10 • SRK-T-099

CONTENTS

1.1 SPECIFICATIONS .................................................................................... 5

(2) Outdoor units .................................................................................... 10

(3) Wireless remote control

.................................................................... 11

........................................................................ 9

(1) Indoor units ......................................................................................... 9

1.2 EXTERIOR DIMENSIONS

1.3 ELECTRICAL WIRING ............................................................................. 12

(1) Indoor units ......................................................................................... 12

(2) Outdoor units ...................................................................................... 14

....................................................... 16

1.5 RANGE OF USAGE & LIMITATIONS

1.4 PIPING SYSTEM ..................................................................................... 15

............................................................................... 18

1.6 APPLICATION DATA

1.7 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ........... 25

(6) 3D auto operation

............................................................................. 29

(7) Timer operation

................................................................................. 30

(5) Flap and louver control ..................................................................... 28

...................................................... 27(4) Custom cord switching procedure

........................................................................ 27(3) Auto restart function

(2) Unit ON/OFF button

.......................................................................... 27

(1) Operation control function by remote control

..................................... 25

(8) Installation location setting ................................................................. 30

(10) Outline of automatic operation .......................................................... 31

(9) Outline of cooling operation .............................................................. 31

(11) Protective control function

.................................................................. 32

.............................................................................. 33

.................... 34

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

....... 33

(1) Cautions

............................................................................................ 33

(2) Items to check before troubleshooting ................................................ 33

(5) Self-diagnosis table ............................................................................ 34

(6) Inspection procedures corresponding to detail of trouble ................... 35

1.8 MAINTENANCE DATA

-

4

-

'12•SRK-T-137

'10 • SRK-T-099

(9) How to make sure of wireless remote control ..................................... 37

(7)

Phenomenon observed after shortcircuit, wire breakage on sensor

........ 36

(8) Checking the indoor electrical equipment

.......................................... 36

■How to read the model name

Example: SRK 10 C

Series code

Cooling only type

Product capacity

Model name SRK : Wall mounted type

SRC : Outdoor unit

MV

-

5

-

'12•SRK-T-137

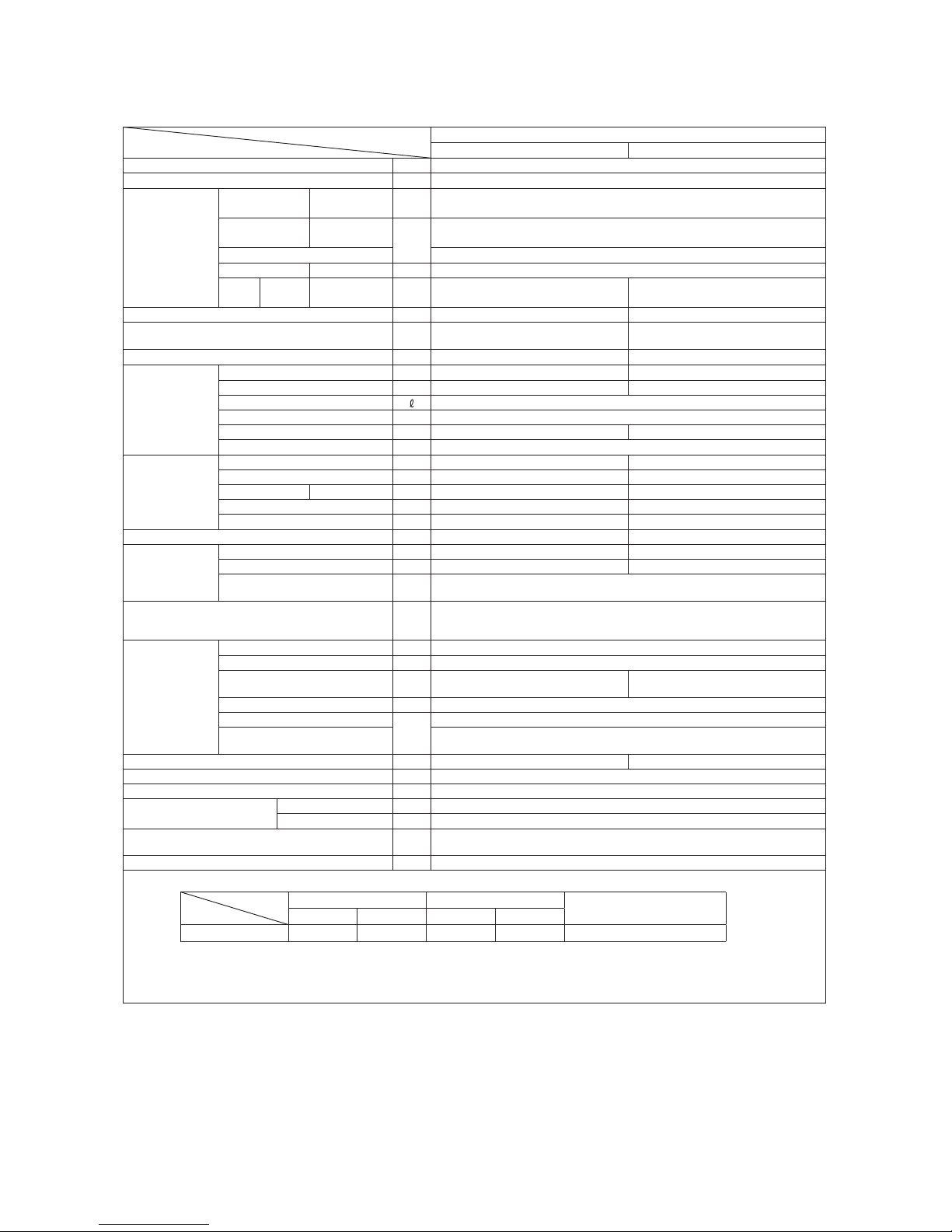

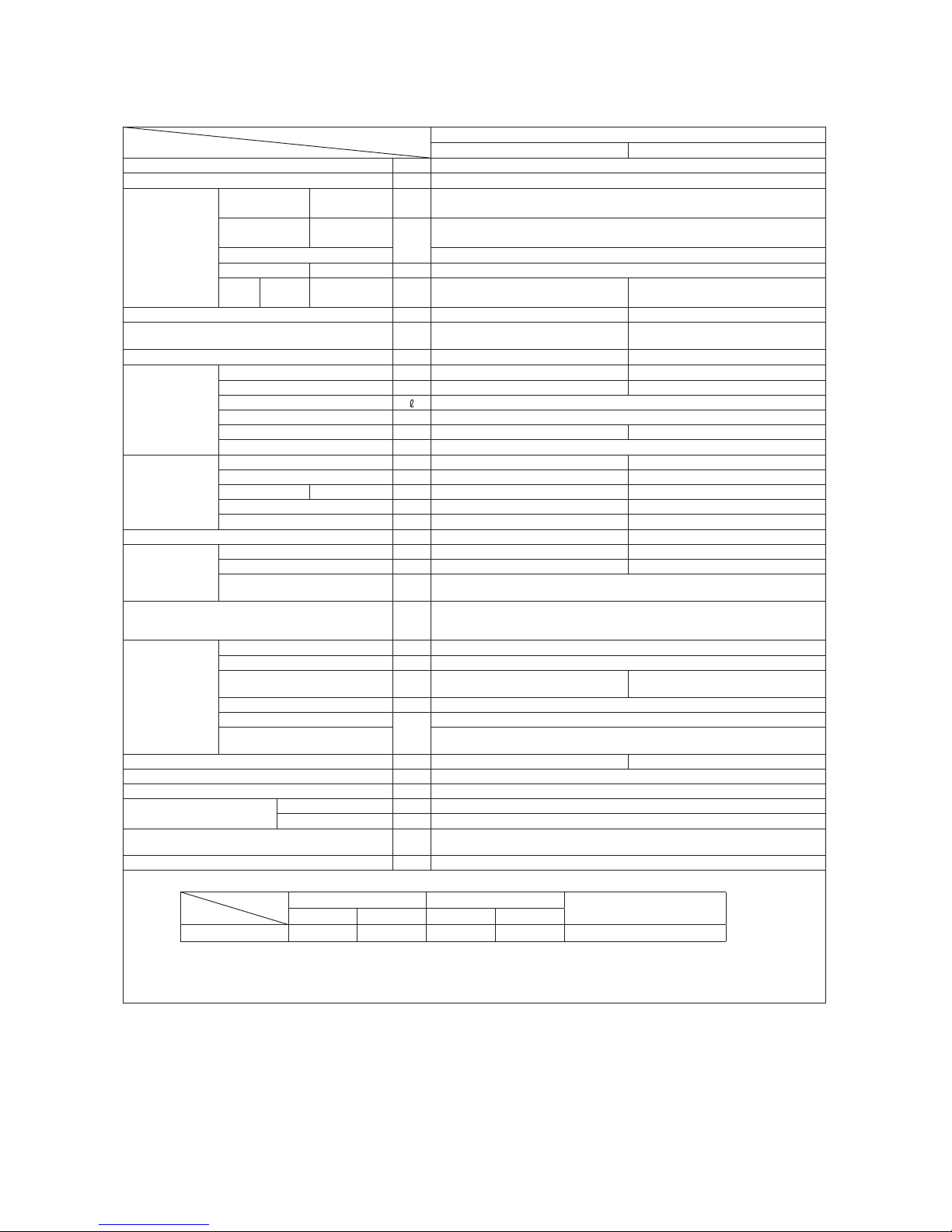

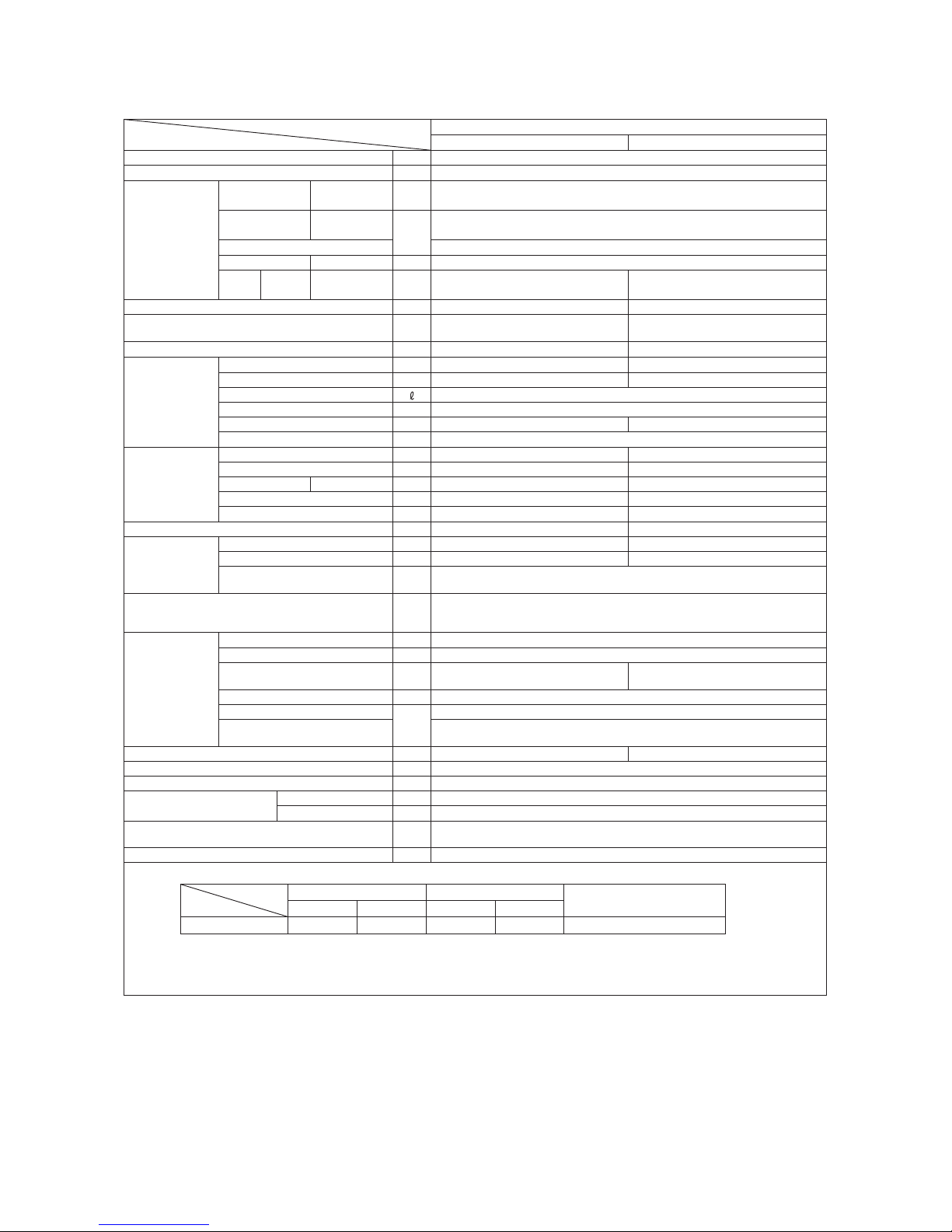

1.1 SPECIFICATIONS

Model

Item

SRK10CMV

Indoor unit SRK10CMV Outdoor unit SRC10CMV

Cooling capacity (1) W 2800

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.77

Running

current

Cooling

A

3.5

Inrush current 18

COP Cooling 3.57

Noise

level

Cooling Sound level dB(A) 40 45

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 28

Refrigerant

equipment

Compressor type & Q'ty — RMC201A011 (Rotary type) x 1

Motor (Starting method) kW — 0.69 (Line starting)

Refrigerant oil 0.35 (SUNISO 4GSI or ATMOS NM56)

Refrigerant (3) kg R22 0.58 (Pre-Charged up to the piping length of 7.5m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 16 14.5

Air flow Cooling m3/min 10.0 26.5

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

ECONO : Orange

Safety devices

Frost protection, Fan motor error protection,

Internal thermostat (for Compressor)

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.4

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2.5m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit

,

Clean filter (Natural enzyme filterx1, Photocatalytic washable deodorizing filterx1)

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

-

6

-

'12•SRK-T-137

Model

Item

SRK13CMV

Indoor unit SRK13CMV Outdoor unit SRC13CMV

Cooling capacity (1) W 3600

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 1.00

Running

current

Cooling

A

4.7

Inrush current 29

COP Cooling 3.60

Noise

level

Cooling Sound level dB(A) 40 49

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 36

Refrigerant

equipment

Compressor type & Q'ty — RMC201A012 (Rotary type) x 1

Motor (Starting method) kW — 1.10(Line starting)

Refrigerant oil 0.45 (BARREL FREEZE 32SAM)

Refrigerant (3) kg R22 0.86 (Pre-Charged up to the piping length of 7.5m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 16 25

Air flow Cooling m3/min 10.0 29.5

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

ECONO : Orange

Safety devices

Frost protection, Fan motor error protection,

Internal thermostat (for Compressor)

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.40

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2.5m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit

,

Clean filter (Natural enzyme filterx1, Photocatalytic washable deodorizing filterx1)

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

-

7

-

'12•SRK-T-137

Model

Item

SRK10CMS(-2)

Indoor unit SRK10CMS(-2) Outdoor unit SRC13CMS(-2)

Cooling capacity (1) W 2800

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 0.77

Running

current

Cooling

A

3.5

Inrush current 18

COP Cooling 3.57

Noise

level

Cooling Sound level dB(A) 40 45

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 28

Refrigerant

equipment

Compressor type & Q'ty — RMC201A011 (Rotary type) x 1

Motor (Starting method) kW — 0.69 (Line starting)

Refrigerant oil 0.35 (SUNISO 4GSI or ATMOS NM56)

Refrigerant (3) kg R22 0.58 (Pre-Charged up to the piping length of 7.5m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 16 15

Air flow Cooling m3/min 10.0 26.5

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green

Safety devices

Frost protection, Fan motor error protection,

Internal thermostat (for Compressor)

Installation

data

Refrigerant piping size (O.D) mm Liquid line: φ6.35 (1/4") Gas line: φ9.52 (3/8")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.4

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2.5m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit

,

Clean filter (Natural enzyme filterx1, Photocatalytic washable deodorizing filterx1)

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

-

8

-

'12•SRK-T-137

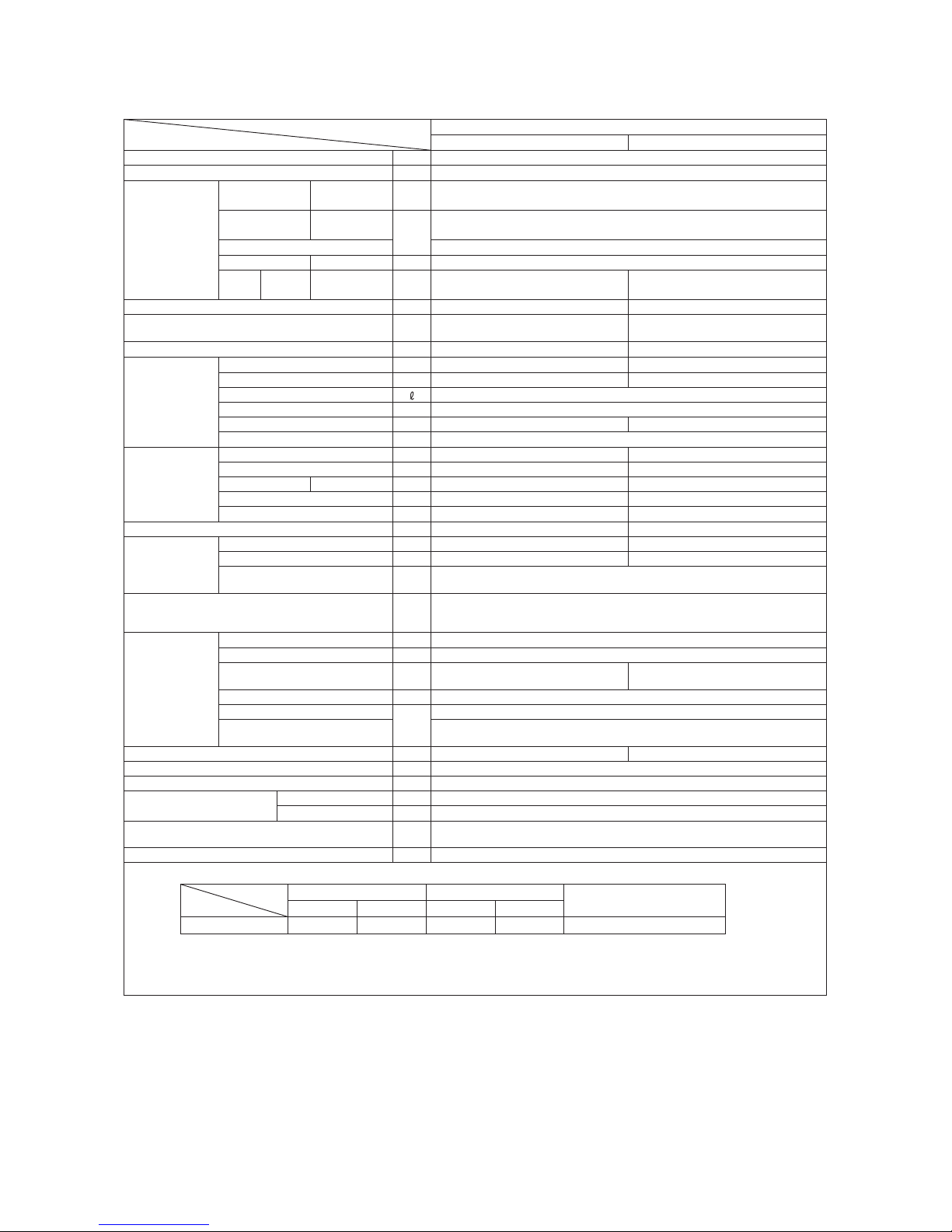

Model

Item

SRK13CMS(-2)

Indoor unit SRK13CMS(-2) Outdoor unit SRC13CMS(-2)

Cooling capacity (1) W 3600

Power supply 1 Phase, 220 V, 50Hz

Operation

data (1)

Power

consumption

Cooling kW 1.00

Running

current

Cooling

A

4.7

Inrush current 29

COP Cooling 3.60

Noise

level

Cooling Sound level dB(A) 40 49

Exterior dimensions (Height x Width x Depth) mm 268 x 790 x 213 540 x 780 (+62) x 290

Exterior appearance

(Munsell color)

Fine snow

(8.0Y 9.3/0.1) near equivalent

Stucco white

(4.2Y 7.5/1.1) near equivalent

Net weight kg 8.5 36

Refrigerant

equipment

Compressor type & Q'ty — RMC201A012 (Rotary type) x 1

Motor (Starting method) kW — 1.10(Line starting)

Refrigerant oil 0.45 (BARREL FREEZE 32SAM)

Refrigerant (3) kg R22 0.86 (Pre-Charged up to the piping length of 7.5m)

Heat exchanger Louver fins & inner grooved tubing Louver fins & inner grooved tubing

Refrigerant control Capillary tubes

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 16 25

Air flow Cooling m3/min 10.0 29.5

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display

RUN : Green, TIMER : Yellow, HI POWER : Green,

3D AUTO : Green

Safety devices

Frost protection, Fan motor error protection,

Internal thermostat (for Compressor)

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

connecting method Flare connecting

Attached length of piping m

Liquid line : 0.40

Gas line : 0.33

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 15

Vertical height difference between

outdoor unit and indoor unit

Max.5 (Outdoor unit is higher)

Max.5 (Outdoor unit is lower)

Drain hose Connectable (VP 16) —

Power cable 2.5m (3 Cores wih Earth)

Recommended breaker size A 20

Connection wiring

Size x Core number 1.5mm2 x 3 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit

,

Clean filter (Natural enzyme filterx1, Photocatalytic washable deodorizing filterx1)

Option parts —

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C JIS C 9612, TISI 1155, 2134, 812

(2) This air-conditioner is manufactured and tested in conformity with the TISI.

(3) The operation data are applied to the 220V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 7.5m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

-

9

-

'12•SRK-T-137

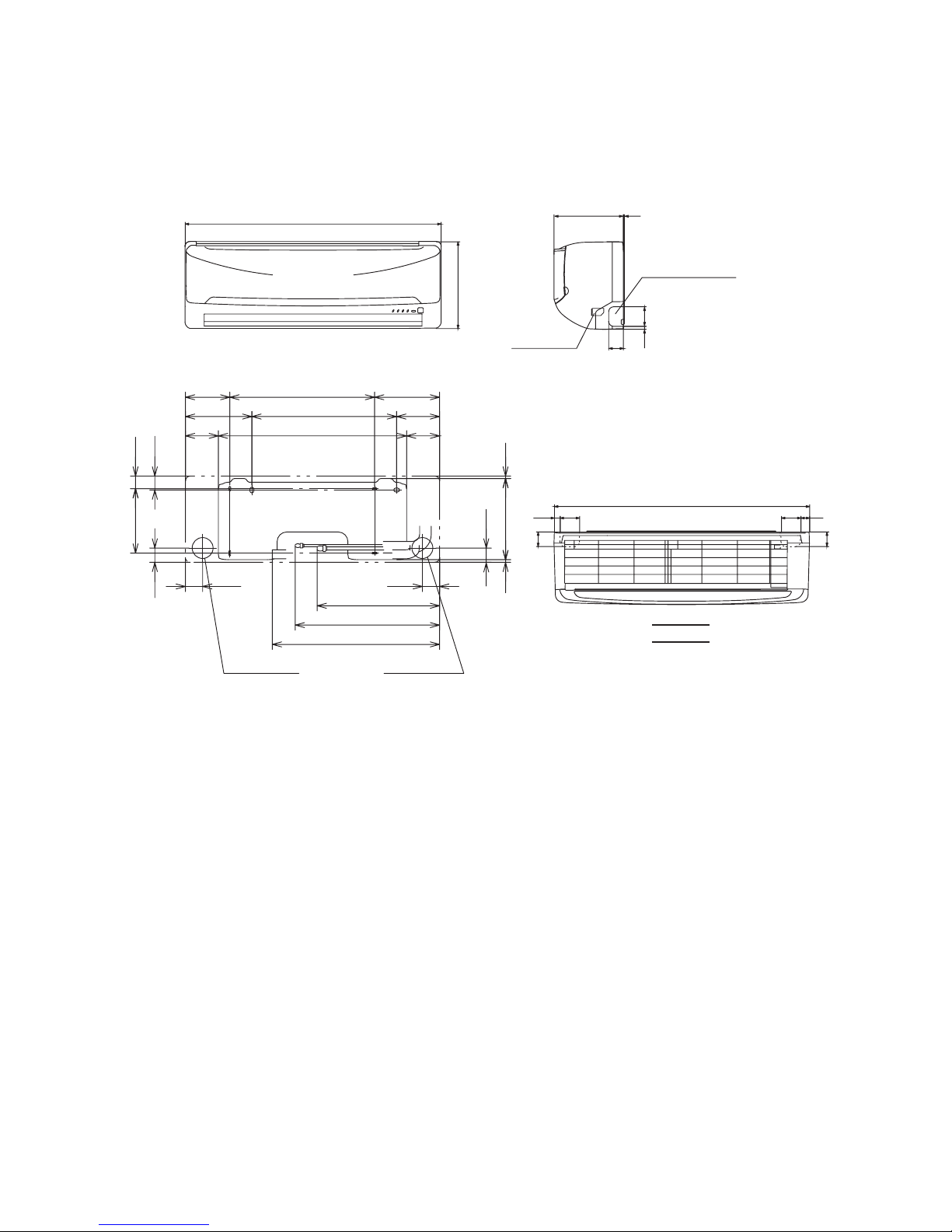

1.2 EXTERIOR DIMENSIONS

(1) Indoor units

Models All model

Piping hole (ø65)

( )

Piping hole (ø65)

53.5

380.6

Piping for Liquid 448.6 (ø6.35)

10 :ø9.52

13 :ø12.7

Piping for Gas

Drain hose 520 (ø16)

53.5

44.5

252.2

7.5

8.3

102.5

585

102.5

133.5450206.5

202450138

44.5

43.2

39.3

200

45

45

60

17.5

60

27

788

Terminal block

Piping hole right (left)

9

213 3

45

60

268

790

→

A

VIEW A

Unit:mm

-

10

-

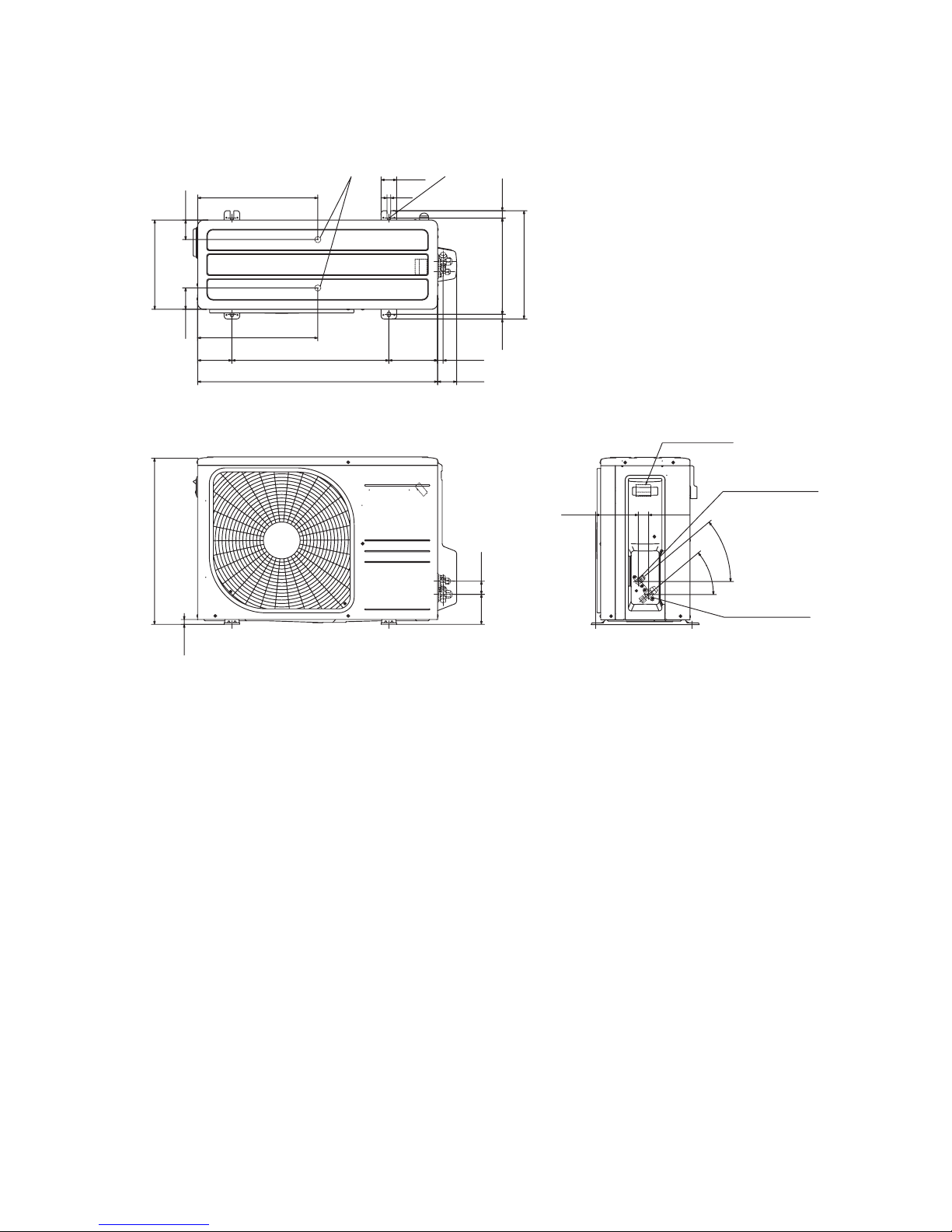

'12•SRK-T-137

(2) Outdoor units

Models All model

63.4

390.6

390.6

69.4

111.6 510 158.4

780 61.9

17.9

14.8 312.5 24.3

351.6

50.6

12

290

15.8

540

97.7 42.5

40°

40°

138.4 33.5

Anchor bolt holeDrain discharge holes

Terminal block

Service valve (Liquid)

Flare connection

ø6.35(1/4")

Service valve (Gas)

Flare connection

10: ø9.52(3/8")

13: ø12.7(1/2")

Unit:mm

-

11

-

'12•SRK-T-137

(3) Wireless remote control

Unit: mm

60

17.3

150

Unit: mm

60

17.3

150

Models SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2

Models SRK10CMV, 13CMV

Unit: mm

17.3

150

Unit: mm

17.3

150

-

12

-

'12•SRK-T-137

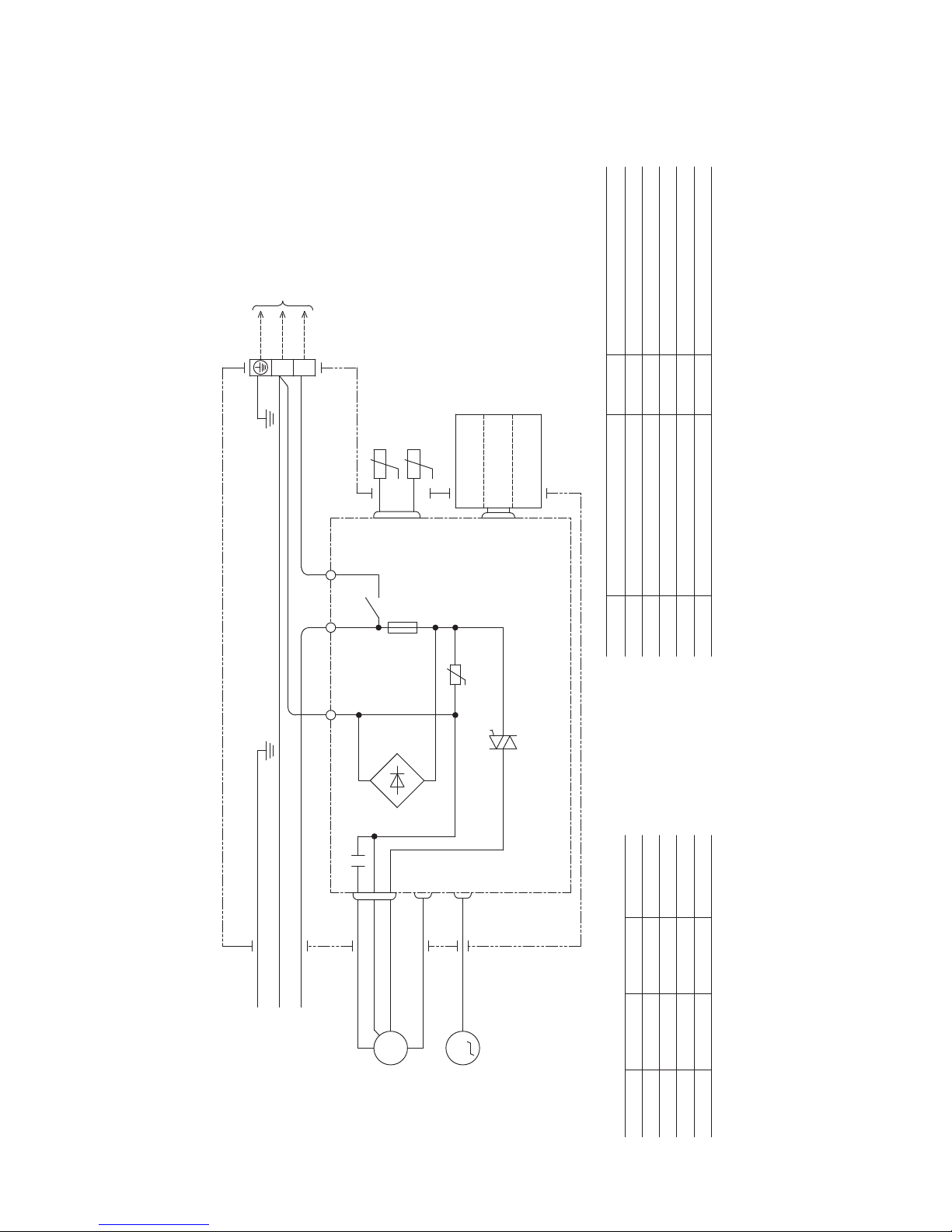

1.3 ELECTRICAL WIRING

U

MFM

BK

Color symbol

BL

BR

LB

YE

RD

YG

WH

Red

Yellow/Green

White

Black

Blue

Brown

Light blue

Yellow

Symbol

Meaning of Marks

Parts name Symbol Parts name

Capacitor forCF

I

FMIFM

ZNR

FM

I

Fuse

Fan motor

Flap motor

Varistor

Th2

T

Room temp. thermistor

Heat exchanger thermistor

Terminal block

F

Th1

Power source

220/230/240V 50Hz

YG

LB

BR

Printed circuit board

T

YG

BL

BR

WH

BK

TO

OUTDOOR

UNIT

Th1

Th2

Wireless

R-Amp

Display

CNE

CNG

YEWHRD

M

CNW

IC15

ZNR

153

CNU

CF

I

52C-4 52C-3

52C

F

250V 3.15A

CONTROL BOX

1

2

Back up Sw

CNM

N

t°

1~

FM

I

t°

(1) Indoor units

Models SRK10CMV, 13CMV

-

13

-

'12•SRK-T-137

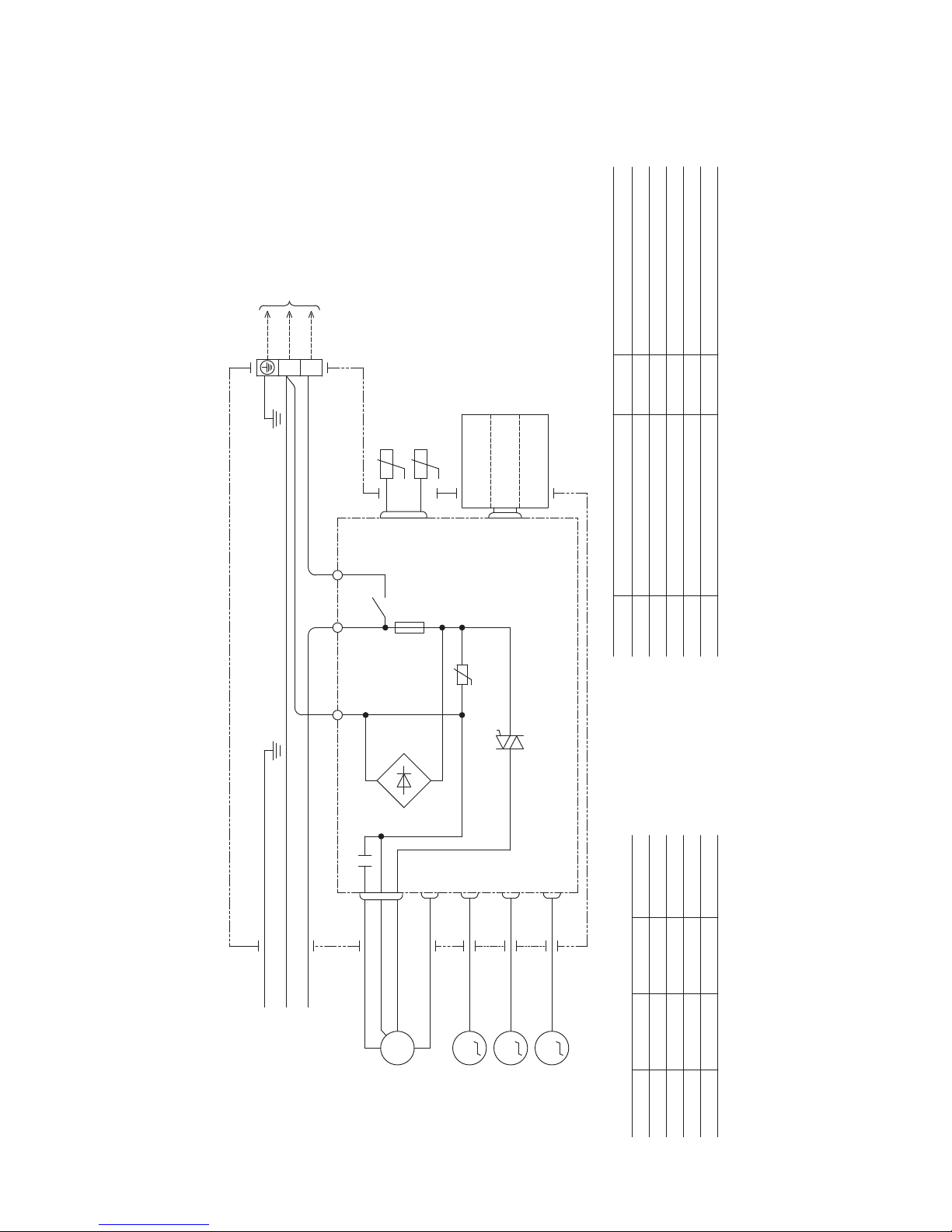

Models SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2

U

M

M

M

LM

LM

FM

BK

Color symbol

BL

BR

LB

YE

RD

YG

WH

Red

Yellow/Green

White

Black

Blue

Brown

Light blue

Yellow

Symbol

Meaning of Marks

Parts name Symbol Parts name

Capacitor forCF

I

FMIFM

ZNR

FM

I

Fuse

Fan motor

Flap motor

Varistor

Louver motor(RIGHT)LM

Th2

T

Room temp. thermistor

Heat exchanger thermistor

Terminal block

F Th1

Power source

220/230/240V 50Hz

YG

LB

BR

Printed circuit board

T

YG

BL

BR

WH

BK

TO

OUTDOOR

UNIT

Th1

Th2

Wireless

R-Amp

Display

CNE

CNG

YEWHRD

M

CNW

CNY

IC15

ZNR

153

CNU

CF

I

52C-4 52C-3

52C

F

250V 3.15A

CONTROL BOX

1

2

Back up Sw

CNX

CNM

N

R

Louver motor(LEFT)LM

L

t°

1~

R

L

FM

I

t°

-

14

-

'12•SRK-T-137

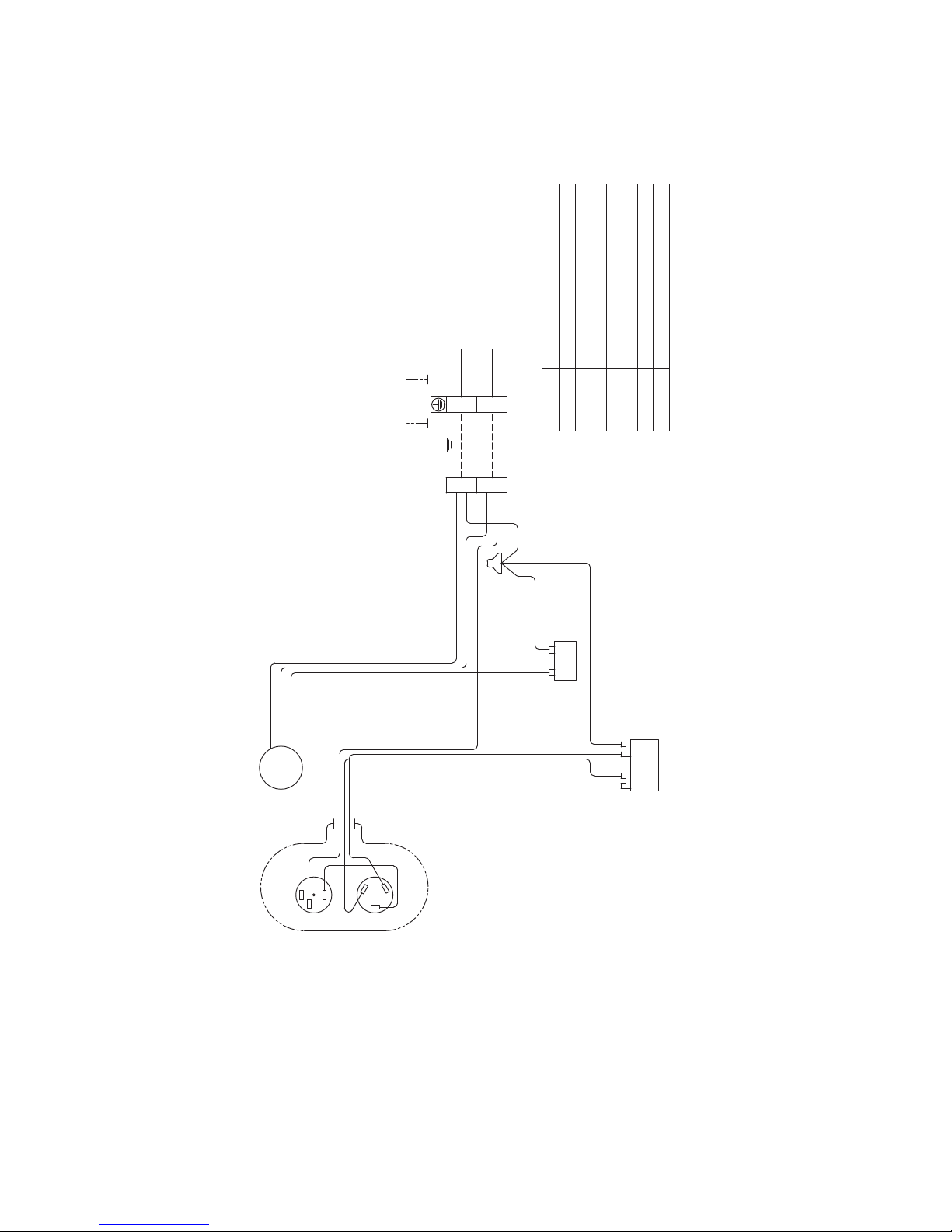

(2) Outdoor units

Models All model

Symbol

Meaning of Marks

Parts name

Capacitor for CMCc

Capacitor for FMoCFo

Compressor motorCM

Fan motorFMo

Motor protector for CM51C

Terminal blockT

ConnectorSh

1

Power source

220-240V 50Hz

INDOOR

UNIT

FMo

BLACK

ORANGE

WHITE

RED

WHITE

Cc

ORANGE

CFo

WHITE

ORANGE

WHITE

WHITE

BLACK

BLACK

WHITE

1 2

T

WHITE

CM

BLACK

BLACK

51C

2

3

1

RED

C

S

R

Sh

1

T

WHITE

1 2

CAPACITOR

-

15

-

'12•SRK-T-137

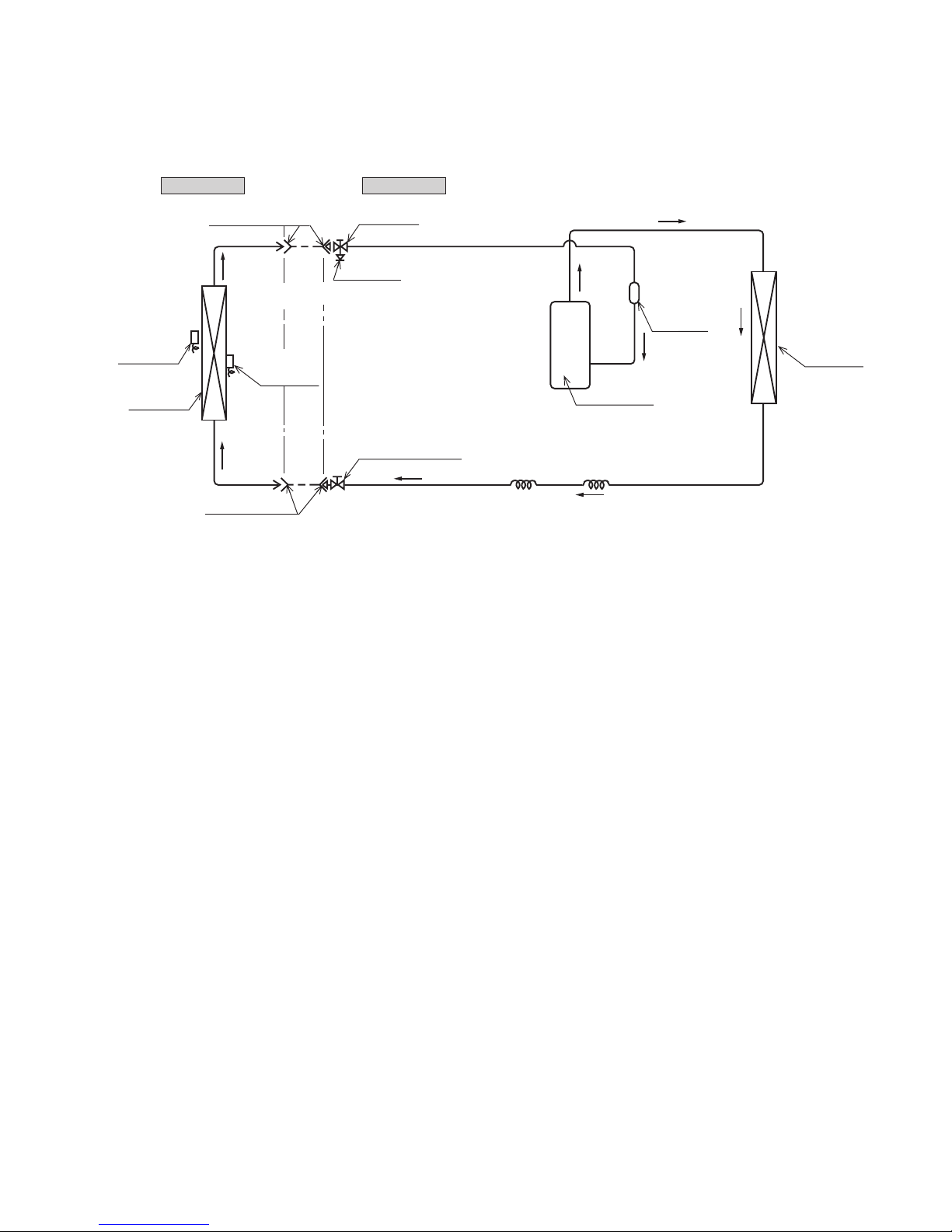

1.4 PIPING SYSTEM

Outdoor unitIndoor unit

Room temp.

sensor

Heat

exchanger

Flare connecting

Heat

exchanger

sensor

Piping

(Liquid)

ø6.35

Check joint

Service valve (Liquid)

Flare connecting

Heat

exchanger

Compressor

Capillary tube

Accumulator

Service valve

(Gas)

Capillary tube

10 : ø9.52

Piping

(Gas)

13 : ø12.7

( )

Models All model

-

16

-

'12•SRK-T-137

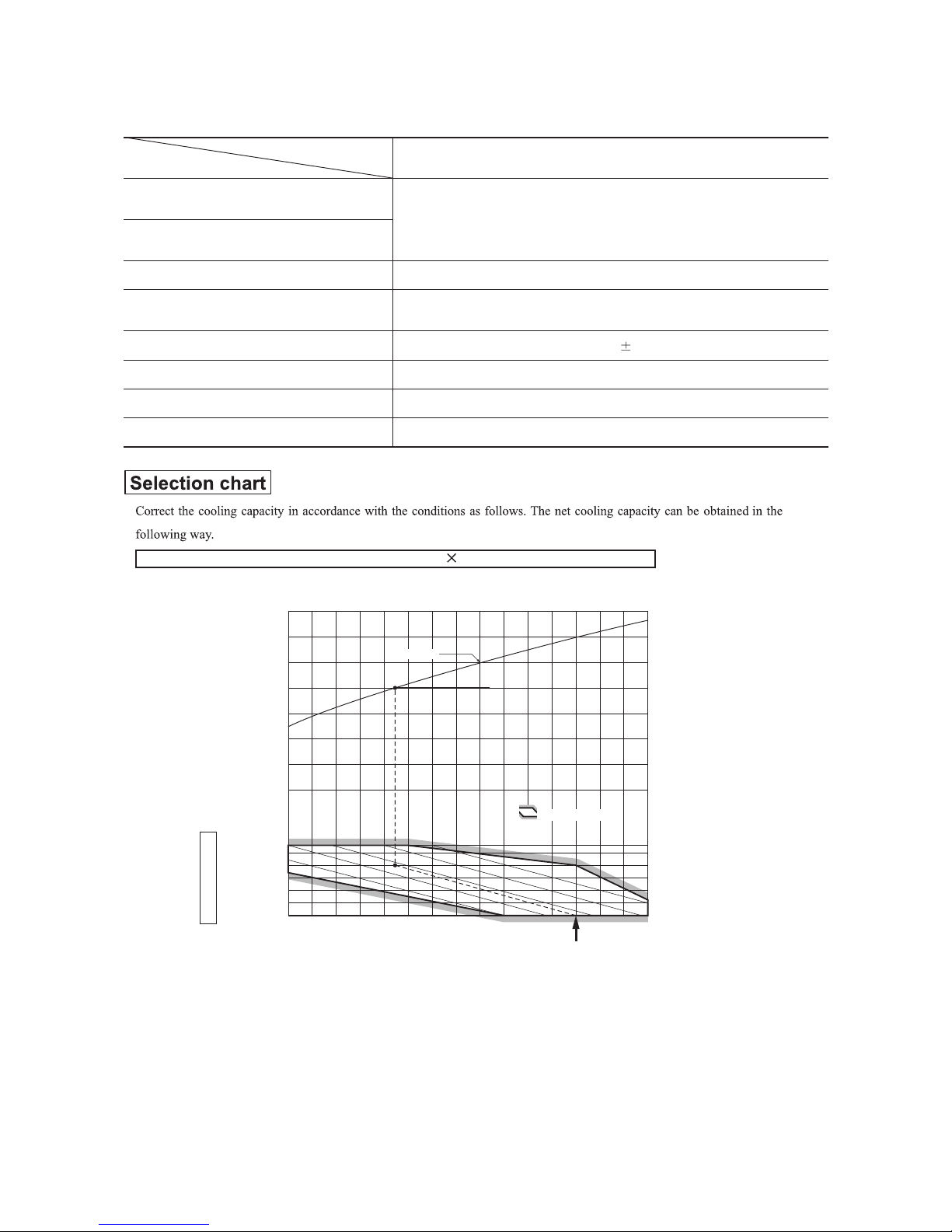

1.5 RANGE OF USAGE & LIMITATIONS

Net capacity = Capacity shown on specification Correction factors as follows.

(1) Coefficient of cooling capacity in relation to temperatures

All model

Models

Item

Indoor return air temperature

(

Upper, lower limits

)

Outdoor air temperature

(

Upper, lower limits

)

Refer to the selection chart

Refrigerant line (one way) length

Max. 15m

Max. 5m (Outdoor unit is higher

)

Max. 5m (Outdoor unit is lower

)

Min. 3 minutes

Max. 10 times/h

Min. 85% of rating

Vertical height difference between

outdoor unit and indoor unit

Power source voltage

Voltage at starting

Frequency of ON−OFF cycle

ON and OFF interval

Rating 10%

14 16 18 20 22

15

20

25

30

35

40

0.6

0.7

0.8

0.9

1.0

1.1

1.2

1.3

43

24

ISO-T1 Standard ConditionIndoor air W.B. temperature °C W.B.

Cooling

Applicable range

Coefficient of cooling

capacity in relation

to temperature

Cooling operation

Outdoor air D.B.

temperature

°C D.B.

-

17

-

'12•SRK-T-137

(2) Correction of cooling capacity in relation to one way length of refrigerant piping

How to obtain the cooling capacity

=

Piping length [m]

Cooling

7

1.0

10

0.99 0.975

15

3600

SRK13CMV

SRK13CMV

3510

-

18

-

'12•SRK-T-137

1.6 APPLICATION DATA

Safety precautions

• Please read these “Safety Precautions” first then accurately execute the installation work.

• Though the precautionary points indicated herein are divided under two headings, WARNING and CAUTION , those points which are

related to the strong possibility of an installation done in error resulting in death or serious injury are listed in the WARNING section. However,

there is also a possibility of serious consequences in relationship to the points listed in the CAUTION section as well. In either case, important

safety related information is indicated, so by all means, properly observe all that is mentioned.

• After completing the installation, along with confirming that no abnormalities were seen from the operation tests, please expla in operating methods

as well as maintenance methods to the user (customer) of this equipment, based on the owner’s manual.

Moreover, ask the customer to keep this sheet together with the owner’s manual.

WARNING

• To disconnect the appliance from the mains supply this appliance must be connected to the mains by means of a circuit breaker or a switch (use

a recognized 20A) with a contact separation of at least 3mm.

• The appliance shall be installed in accordance with national wiring regulations.

• This system should be applied to places as households, residences and the like. Application to inferior environment such as engineering shop

could cause equipment malfunction.

• Please entrust installation to either the company which sold you the equipment or to a professional contractor. Defects from improper installations can be the cause of water leakage, electric shocks and fires.

• Execute the installation accurately, based on following the installation manual. Again, improper installations can result in water leakage,

electric shocks and fires.

• For installation, confirm that the installation site can sufficiently support heavy weight. When strength is insufficient, injury can result from a

falling of the unit.

• For electrical work, please see that a licensed electrician executes the work while following the safety standards related to electrical equipment,

and local regulations as well as the installation instructions, and that only exclusive use circuits are used.

Insufficient power source circuit capacity and defective installment execution can be the cause of electric shocks and fires.

• Accurately connect wiring using the proper cable, and insure that the external force of the cable is not conducted to the terminal connection

part, through properly securing it improper connection or securing can result in heat generation or fire.

• Take care that wiring does not rise upward, and accurately install the lid/service panel. It’s improper installation can also result heat generation

or fire.

• When setting up or moving the location of the air conditioner, do not mix air etc. or anything other than the designated refrigerant (R22) within

the refrigeration cycle.

Rupture and injury caused by abnormal high pressure can result from such mixing.

• Always use accessory parts and authorized parts for installation construction. Using parts not authorized by this company can result in water

leakage, electric shock, fire and refrigerant leakage.

• Ventilate the work area when refrigerant leaks during the operation.

Coming in contact with fire, refrigerant could generate toxic gas.

• Confirm after the foundation construction work that refrigerant does not leak.

If coming in contact with fire of a fan heater, a stove or movable cooking stove, etc., refrigerant leaking in the room could generate toxic gas.

CAUTION

• Execute proper grounding. Do not connect the ground wire to a gas pipe, water pipe, lightning rod or a telephone ground wire.

Improper placement of ground wires can result in electric shock.

• The installation of an earth leakage breaker is necessary depending on the established location of the unit.

No installing an earth leakage breaker may result in electric shock.

• Do not install the unit where there is a concern about leakage of combustible gas.

The rare even of leaked gas collecting around the unit could result in an outbreak of fire.

• For the drain pipe, follow the installation manual to insure that it allows proper drainage and thermally insulate it to prevent condensation.

Inadequate plumbing can result in water leakage and water damage to interior items.

• Install the outdoor unit so that the aluminum fins on the air heat exchanger cannot be touched. Failure to observe this may result in injury.

• Do not place objects near the outdoor unit or allow leaves to gather around the unit. If there are objects or leaves around the outdoor unit, small

animals may enter unit and contact electrical parts resulting in break down, emission of smoke or flame.

Cautions for installation

① The system should be applied to places as households, residences and the like.

② The equipment shall be installed in accordance with national wiring regulations.

③ The connection to the fixed wiring of the mains supply must be made via a double pole isolating switch with a contact gap of at least

3mm in each pole.

④ When the outdoor unit has a possibility of being overturned or being displaced and fall from its original installation position , the

outdoor unit should be fixed in its position by use of anchor bolts or wires.

-

19

-

'12•SRK-T-137

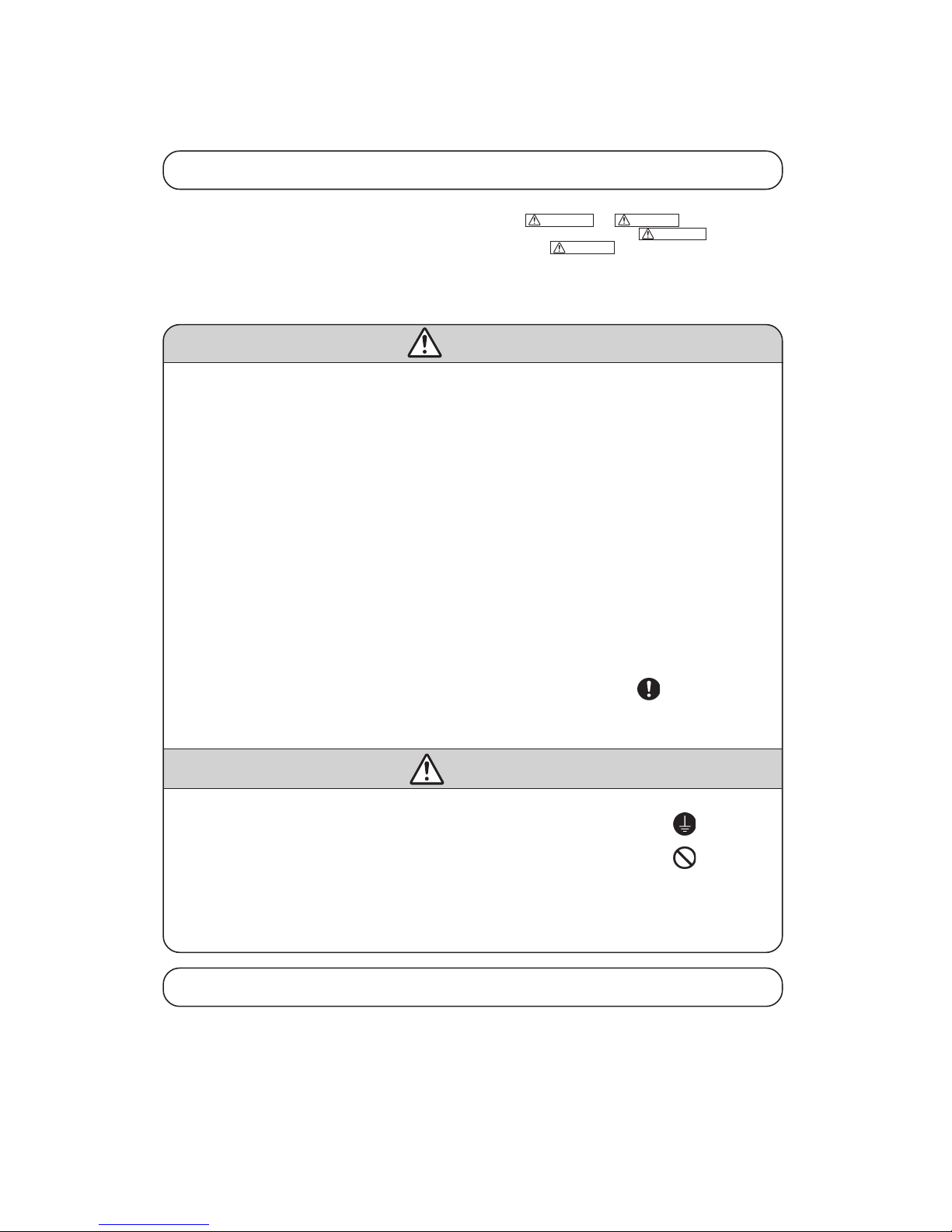

Necessary tools for the installation work

1 Plus headed driver (Phillips screwdriver)

2 Knife

3 Saw

4 Tape measure

5 Hammer

6 Spanner wrench

7 Torque wrench

8 Hole core drill (65mm in diameter)

9 Wrench key (Hexagon)

[4m/m]

10 Vacuum pump

11

Vacuum pump adapter

(Anti-reverse flow type)

12 Gauge manifold

13 Charge hose

14 Flaring tool set

15 Gas leak detector

( )

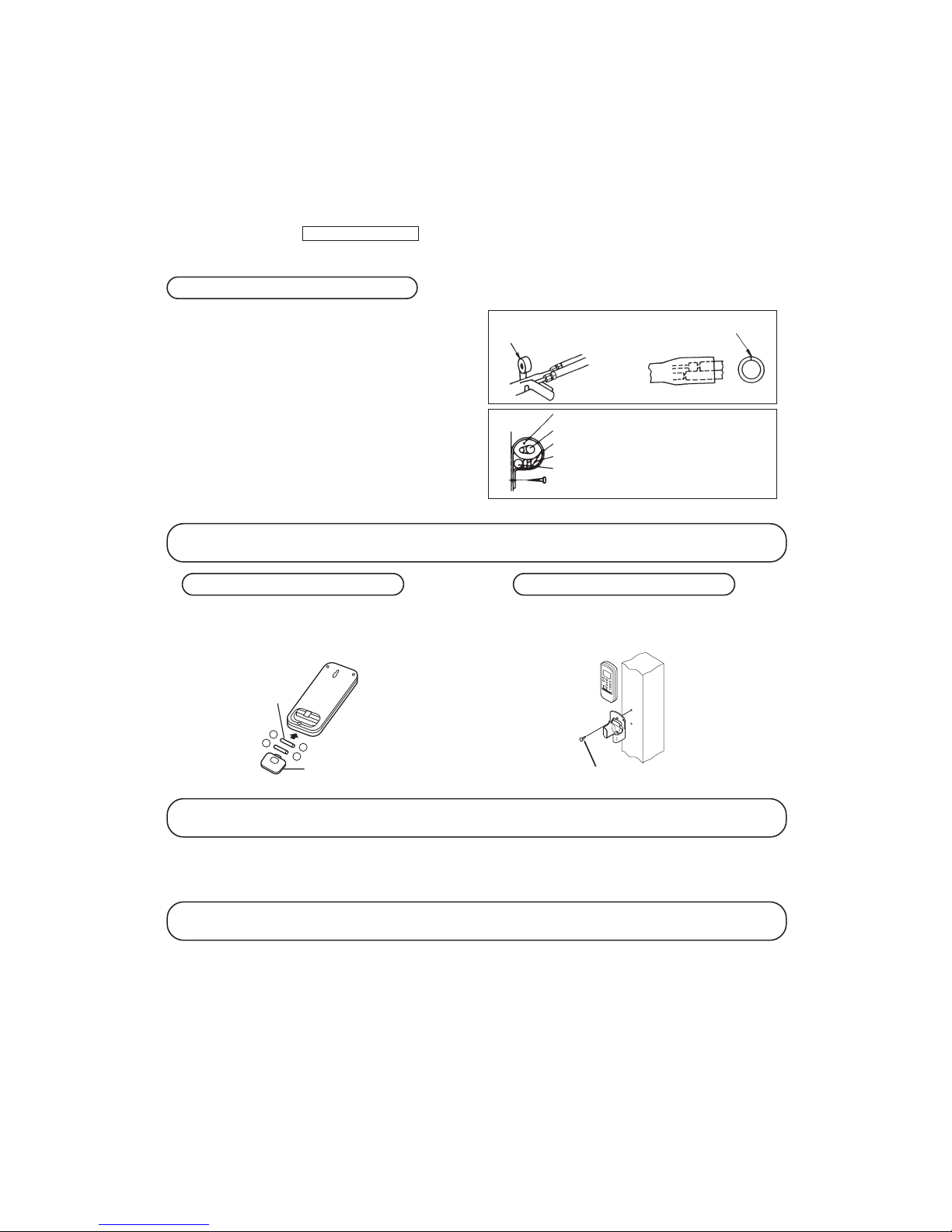

Standard accessories

(Installation kit) Q’ty

Accessories for indoor unit

①

Installation board

1

(Attached to the rear of the indoor unit)

② Wireless remote control 1

③ Remote contorol holder 1

④

Tapping screws

5

(for installation board 4dia. by 25mm)

⑤

Wood screw

2

(for remote contorol switch holder 3.5dia. by 16mm)

⑥

Baterry [R03 (AAA, Micro) 1.5V]

2

⑦ Air-cleaning filters 2

⑧

Filter holders

2

(Attached to the front panel of the indoor unit)

Option parts Q’ty

ⓐ 1etalp gnilaeS

ⓑ 1eveelS

ⓒ Inclination plate 1

ⓓ 1yttuP

ⓔ Drain hose (extention hose) 1

ⓕ

Piping cover (for insulation of

1

connection piping)

① A place where good air circulation can be obtained and where rain,

snow or sunshine will not directly strike the unit.

② A place where discharged hot air or unit’s operating sound will not

be a nuisance to the neighborhood.

③ A place where servicing space can be secured.

④ A place where vibration will not be enlarged.

*Avoid installing in the following places.

•A place near the bedroom and the like, so that the operation noise

will cause no trouble.

•A place where there is possibility of flammable gas leakage.

•A place exposed to strong wind.

•In a salt-laden atmosphere or a place where the generation of oil mist, vapor or fume is expected.

⑤ Blowing out port and suction port on the back side of the unit can be installed at a distance of 10cm from walls.

(In case the barrier is 1.2m or above in height, or is overhead, the sufficient space between the unit and wall shall be secured.)

⑥ When the unit is installed, the space of the following dimension and above shall be secured.

OUTDOOR UNIT

Note (1) If the wall is h igher than 1.2 m or a ceiling is

present, distances larger than indicated in the above

table must be provided.

Selection of installation location

① Where there is no obstructions to the air flow and where the

cooled air can be evenly distributed.

② A solid place where the unit or the wall will not vibrate.

③ A place where there will be enough space for servicing. (Where

space mentioned right can be secured)

④ Where wiring and the piping work will be easy to conduct.

⑤ The place where receiving part is not exposed to the direct rays of

the sun or the strong rays of the street lighting.

⑥ A place where it can be easily drained.

⑦ A place separated at least 1m away from the television or the ra-

dio.

(To prevent interfence to images and sounds.)

INDOOR UNIT

Left

side

Right

side

14.0 ~ 61. 0N · m

(1.4 ~ 6.1 kgf · m)

( )

Designed s pecifically

for R22

( )

Designed s pecifically

for R22

( )

Designed s pecifically

for R22

( )

Designed s pecifically

for R22

( )

Designed s pecifically

for R22

10 cm

5 cm

10 cm

-

20

-

'12•SRK-T-137

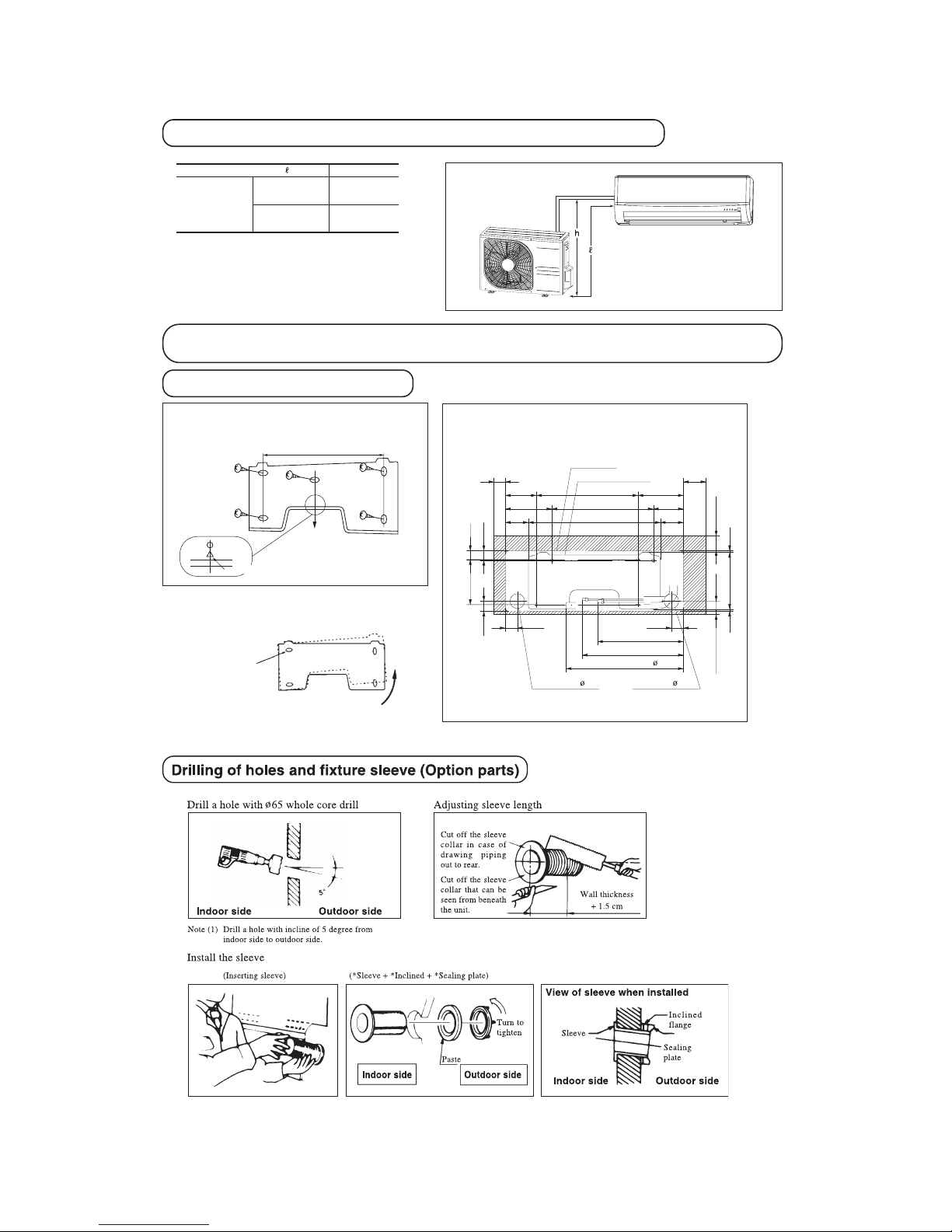

Installation of indoor unit

Installation of installation board

• Adjustment of the installation board in the horizontal

direction is to be conducted with five screws in a

temporary tightened state.

• Adjust so that board will be level by turning

the board with the standard hole as the center.

Standard hole

Look for the inside wall structures (Intersediate support or

pillar and firaly install the unit after level surface has been

checked.)

Mating mark for level surface

450

INSTALLATION SPACE (INDOOR UNIT) (FRONT VIEW)

Unit : mm

Piping hole( 65) Piping hole( 65)

Installation board

Indoor unit

53.5

Piping for Gas 380.6

Piping for Liquid 448.6

Drain hose 520( 16)

53.5

Space

for service*

Space

for service

44.5

252.2

7.5

8.3

Space for

service

50

Space for

service

100

102.5

585

102.5

133.5

450206.5

202450138

44.5

43.2

39.3

200

100

15

Limitations for one way piping length and vertical height difference

One way piping length ( ) 15 m

Outdoor

unit is lower

5 m

Outdoor unit

is higher

5 m

Vertical height

difference (h)

* Leave extra space on the right side to enable removal of the lid screw.

-

21

-

'12•SRK-T-137

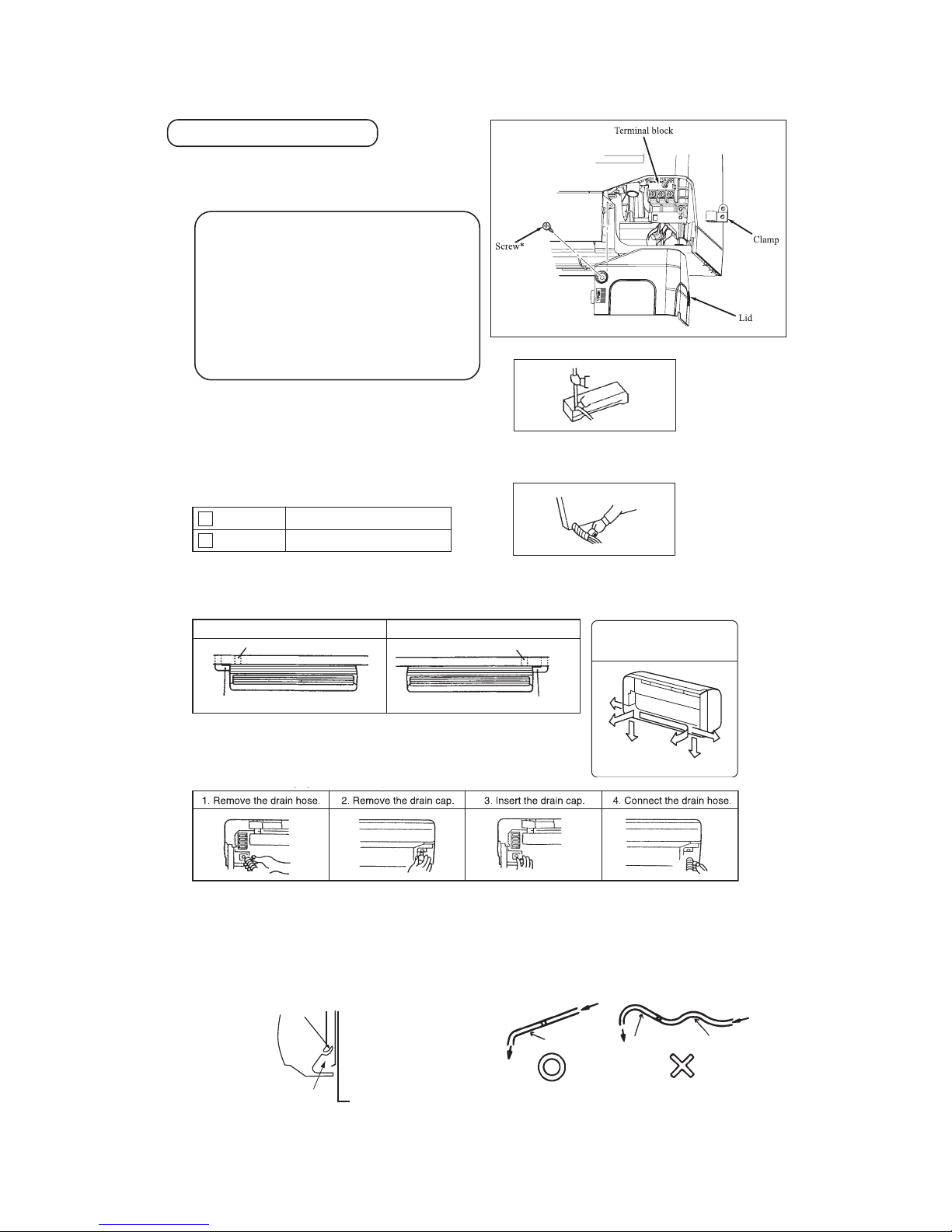

Preparation of indoor unit

Pipe

Drain hose

① Mounting of connecting wires

ⓐ Remove the lid.

ⓑ Remove the wiring clamp.

ⓒ Connect the connecting wire securely to the terminal block.

Use cable for interconnection wiring to avoid loosening of the

wires.

CENELEC code for cables Required field cables.

H05RNR3G1.5 (Example) or 245IEC57

H Harmonized cable type

05 300/500 volts

R Natural-and/or synth. rubber wire insulation

N Polychloroprene rubber conductors insulation

R Standed core

4or5 Number of conductors

G One conductor of the cables is the earth conductor (yel-

low/green)

1.5 Section of copper wire (mm

2

)

• Connect the connection wire securely to the terminal block.

If the wire is not affixed completely, contact will be poor,

and it is dangerous as the terminal block may heat up and

catch fire.

• Take care not to confuse the terminal numbers for indoor and

outdoor connections.

• Affix the connection wire using the wiring clamp.

ⓓ Fix the connecting wire by wiring clamp.

ⓔ Attach the lid.

ⓕ Close the air inlet panel.

For power supply, indoor outdoor

For power supply, indoor outdoor

1 Brown

2 Blue

② Shaping the pipe

③ Taping of the exterior

• Hol d the bottom of the pipe and change its direction befor e stretching it and shap ing it.

• Tap e only the p ortion that runs throug h the wall .

Always ta pe the cros sover wires with the p ipe.

④ Cautions when piping from the left and the rear center of the unit

[ Top View ]

• L oose n and r emov e the

spring-typ e clamp.

• Rem ove with your hand or

a pair of pliers.

• Use a hexagonal wrench to

correctly insert the drain cap

which was removed in 2.

Caution: Be careful because

if th e cap i s not i nse rted

pro perty , water l eak may

occur.

• Lo osen the spring-type clamp

and sec urely inse rt the drai n

hose.

Caution: Be care ful because if

the drai n hos e is not i nsert ed

properly, wa ter leak ma y occur.

gnipiP ediS thgiRgnipiP ediS tfeL

Right rear pipingLeft rear piping

gnipip edis thgiRgnipip edis tfeL

Left downward

Right

Rear

Downward

Left rear

Left

Piping is possible in the rear,

left, left rear, left downward,

right or downward direction.

• Do not place t he power su pply cords above the gutter, bec ause the

air conditioner is structur ed i n a way wh ere condensati on o n th e

back side is collect ed in to th e drain pan before dra inage.

• Do not make tr aps in the drain hose line.

Declining slope

Inverted s lipe

Trap

* Leave space to allow

removal of this screw

after installation.

[ Procedure for exchanging the drain hose ]

Wall

Gutter

Pipes storage area

-

22

-

'12•SRK-T-137

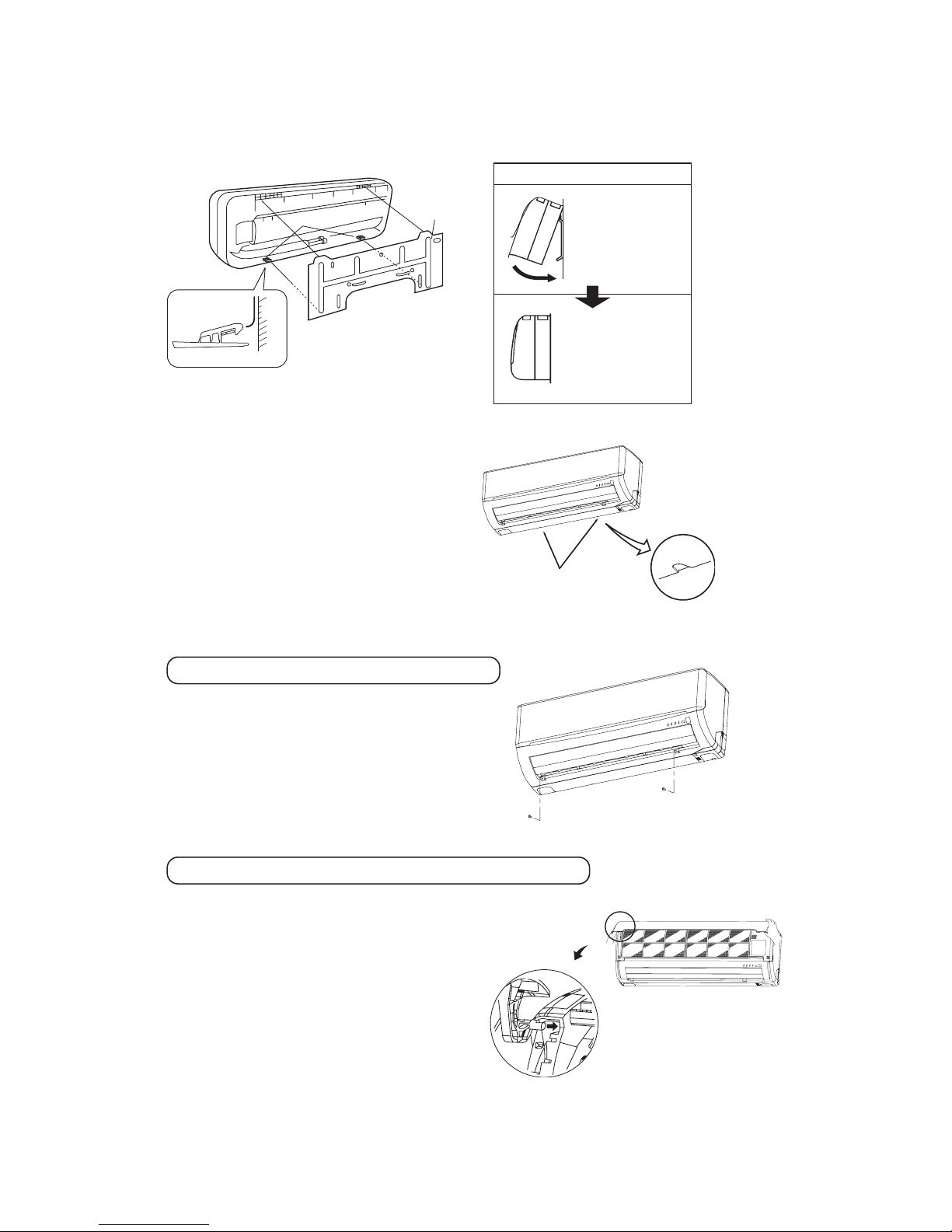

Installing steps

1.Hook the upper part

of the indoor unit to

the installation board.

2.The unit can be installed

simply by gently pushing in the lower part.

⑤ Securing the indoor unit to the installation board

Wall

Indoor un it base low er latch

Installati on board

Latch (2 l ocations)

Installati on

board

Indoor uni t

•

How to remove the indoor unit from the installation board

① Push up at the marked portion of the indoor unit base

lower latch, and slightly pull it toward you.

(both right and left hand sides)

(The indoor unit base lower latch can be removed

from the installation board)

② Push up the indoor unit upward. So the indoor unit

will be removed from the installation board.

Removal and installation of the front panel

Open/close and detachment/attachment of air inlet panel

Set screw s

① Removing

• Remove the 2 set screws.

• Mov e the lower part of the panel forward and push

upwards to remove. (Remove the 3 latches in the upper

section.)

② Fitting

• Do remove the air filter.

• Cover the body with the front panel.

• Push the circled portion at the front.

• Tighten the 2 set screws.

• Fit the air filter. Carry out in the above order.

① To open, pull the panel at both ends of lower part and

rel ease lat ches, then pull up th e panel unt il you feel

resistance. (The air inlet panel stops at approx. 60˚ open

position.)

② To close, hold the panel at both ends of lower part to lower

downward and push it slightly until the latch works, then

push the center portion slightly.

③ To remove, pull up the panel to the position shown in right

illustration and pull it toward you.

④ To install, insert the air inlet panel arm into the slot on the

front panel from the position shown in right illustration,

hold the panel at both ends of lower part, lower it downward

slow ly, then push it slightly until the latch works and

further push the center portion slightly.

The marke d portion o f the

indoor un it base low er latch

-

23

-

'12•SRK-T-137

1 2

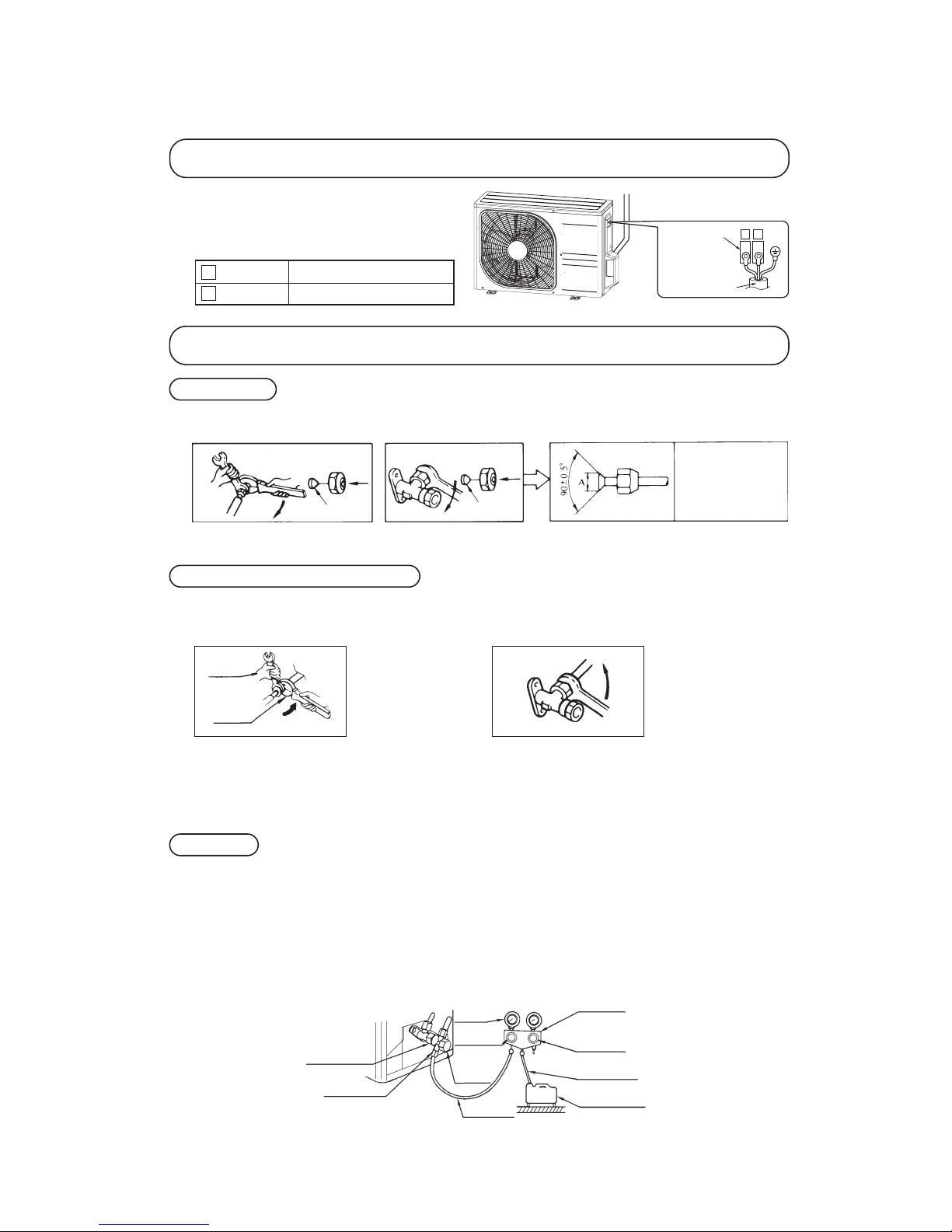

Installation of outdoor unit

For power supply, indoor outdoor

For power supply, indoor outdoor

1 Brown

2 Blue

① Make sure that the unit is stable in installation. Fix the unit

to stable base.

② Perfrom wiring, making wire terminal numbers conform to

terminal numbers of indoor unit terminal block.

Terminal block

Interconne cting wi re

Connection of refrigerant pipings

Preparation

Connection of refrigerant piping

Air purge

Keep the openings of the pipes covered with tapes etc. to prevent dust, sand, etc. from entering them.

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~61N·m (4.9~6.1kgf·m)

• Use one more spanner to fix the valve.

① Tighten all flare nuts in the pipings both indoor and outside wall so as not to cause leak.

② Connect service valve, charge hose, manifold valve and vacuum pump as is illustrated below.

③ Open manifold valve handle Lo to its full width, and perform vacuum or evacuation.

Continue the vacuum or evacuation operation for 15 minutes or more and check to see that the vacuum gauge reads – 0.1 MPa

(– 76 cmHg).

④ After completing vacuum operation, fully open service valve (Both gas and liquid sides) with hexagon headed wrench.

⑤ Detach the charge hoses.

⑥ Check for possible leakage of gas in the connection parts of both indoor and outdoor.

• Remo ve the flar ed nuts.

(on both liquid and gas sides)

• Rem ove the fla red nuts.

(on both l iquid and ga s sides)

• Inst all the remov ed flared nuts t o the pipes to be connected, th en flare t he pipes.

Dimension A

Liquid si de

(ø6.35): 9.0 dia

Gas side

(ø9.52): 13.0 di a

(ø12.7): 16.2 d ia

Press

Remove

Remove

(Do not

turn)

Spanner

for fixing

the piping )

Torque

wrench

• Specified torquing value:

Liquid side (ø6.35) : 14~18N·m (1.4~1.8kgf·m)

Gas side (ø9.52) : 34~42N·m (3.4~4.2kgf·m)

Gas side (ø12.7) : 49~61N·m (4.9~6.1kgf·m)

① Indoor unit side

② Outdoor unit side

① Indoor unit side ② Outdoor unit side

• Connect firmly gas and liquid side

pipings by Torque wrench.

• Connect firmly gas and liquid side

pipings by Torque wrench.

• Always use a Torque wrench and back up spanner to tighten the flare nut.

Manifol d

Valve

-76 cm Hg

Handle Lo

(pressure )

Charge ho se

Stop valv e

(Two-way valve)

Service p ort

Stop value

(Three- way

value)

Compound

(Gauge)

Pressure

gauge

Handle Hi

(pressure)

Charge ho se

Vacuum pu mp

-

24

-

'12•SRK-T-137

When refrigerant piping exceeds 7.5m conduct additional refrigerant charge after refrigerant sweeping.

7.5m over 15m:Additional charge amount per meter = 10g/m

[Example]

How much amount of additional charge for 15m piping?

(15 – 7.5)m × 10g/m=75g 75g for additional charge

♦ Additional refrigerant charge

Installation of wireless remote control

Insulation of connecting portion

Mounting method of battery

Earthing work

① Cover the connection portion of the refrigerant piping with the

pipe cover and seal them.

If neglecting to do so, moisture occurs on the piping and water

will drip out.

② Finishing and fixing

ⓐ Tie up the piping with wrapping tape, and shape it so that it con-

forms to which the pipe is attached.

ⓑ Fix them with clamps as right figure.

Vinyl tap e

To c over the c onnecting portion with insulation mate rials, cut upper porti on and then seal

it with i nsulation m aterials.

Cover th e exterior portion with cov ering ta pe and sh ape the piping so it

will m atch the contou rs of the route

that the piping to take . Al so fi x th e

wiring and pipi ngs to the wall with

clamps.

Insulation

Refrigeran t piping

Electrica l wiring

Covering tape

Drain hos e

Tapping s crew

-

-

+

+

• Uncover the wireless remote control, and mount the batteries [R03(AAA, Micro)×2 pieces] in the body regularly.

(Fit the poles with the indication marks, ⊕ & ⊖without

fail)

• Earth work shall be carried out without fail in order to prevent electric shock and noise generation.

• The connection of the earth cable to the following substances causes dangerous failures, therefore it shall never be done.

City water pipe, Town gas pipe, TV antenna, lightning conductor, telephone line, etc.

Trial run and operation

① Conduct trial run after confirming that there is no gas leaks.

② When conducting trial run set the remote control thermostat to continuous operation position. However when the power source is cut

off or when the unit’s operation switch is turned off or was turned to fan operation position, the unit will not go into opera tion in

order to protect the compressor.

③ Explain to the customer on the correct usage of the air-conditioner in simple layman’s terms.

④ Make sure that drain flows properly.

Battery

Cover

Fixing to pillar or wall

• Conventionally, operate the wireless remote control by

holding in your hand.

• Avoid installing it on a clay wall etc.

Screws

-

25

-

'12•SRK-T-137

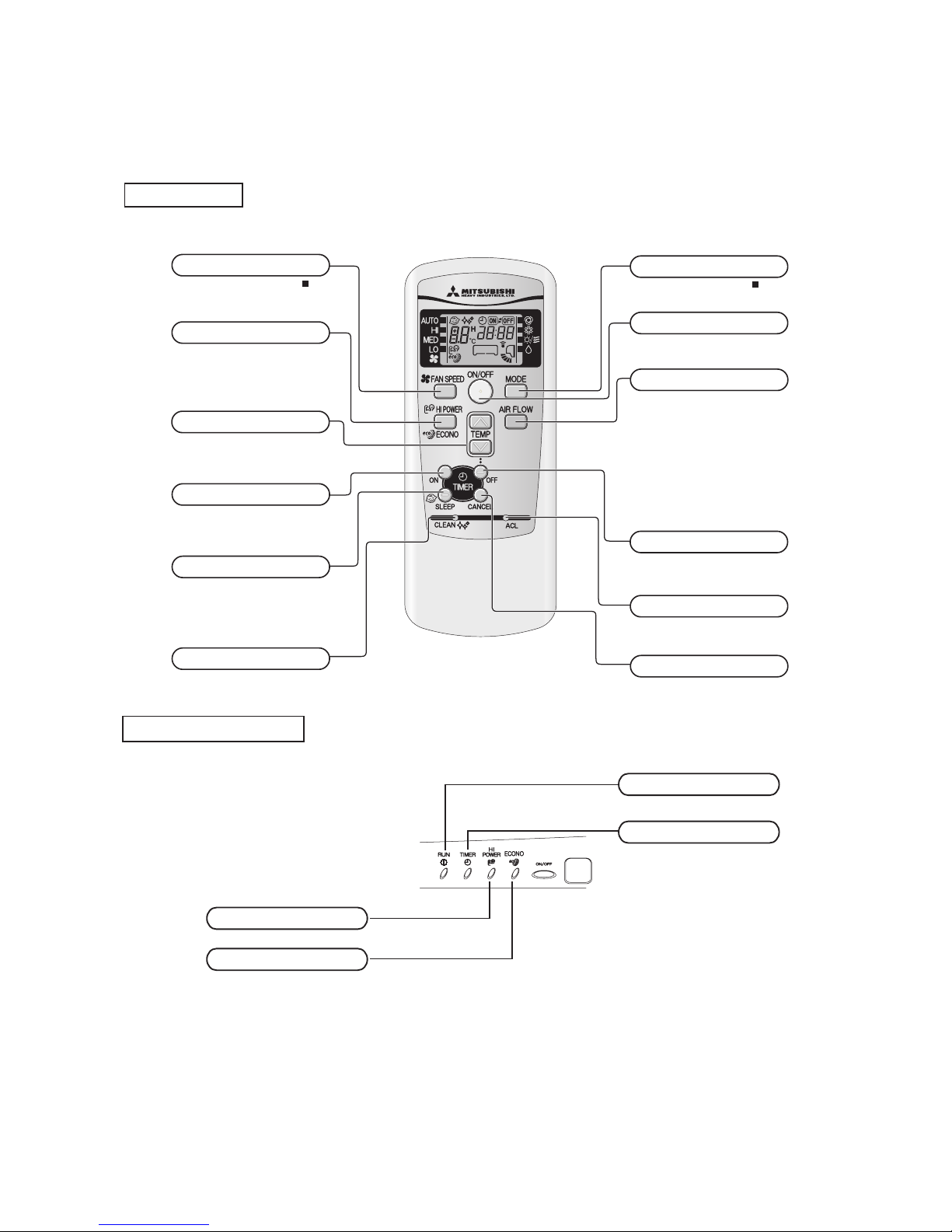

Remote control

1.7

OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

(1) Operation control function by remote control

◆

Operation section

Models SRK10CMV, 13CMV

ECONO light (orange)

Illuminate s during ECO NOMY operati on.

HI POWER light (green)

Illuminate s during H IGH POWER opera tion.

RUN light (green)

Illuminate s during o peration

and CLEAN operation.

TIMER light (yellow)

Illuminate s during TIM ER operatio n.

FAN SPEED button

Each time the button i s pushed, th e

indicator is switche d over in t urn.

HI POWER/ECONO button

This butt on changes the HIGH PO WER/

ECONOMY mo de.

TEMPERATURE Button

This butt on sets the room tempe rature.

(This but ton changes the presen t time and

TIMER time .)

ON TIMER button

This butt on selects ON TIMER op eration.

SLEEP button

This butt on changes to SLEEP op eration.

CLEAN switch

This swic h changes t he CLEAN mo de.

OPERATION MODE select button

Each time the button pushed, th e

indicator is switched over in turn .

ON/OFF (luminous) button

Press for starting o peration, p ress agian

for stoppi ng.

AIR FLOW (UP/DOWN) button

This butto n changes th e air flow ( up/

down) mode .

• The above illustration shows all controls, but in practi ce

only the r elevant parts a re shown.

OFF TIMER button

This butto n selects OFF TIMER o peration.

CANCEL button

This butt on cancels the ON time r, OFF

timer, and SLEEP opera tion.

RESET switch

Switch fo r resetting microcompu ter and

setting t ime.

Unit display section

-

26

-

'12•SRK-T-137

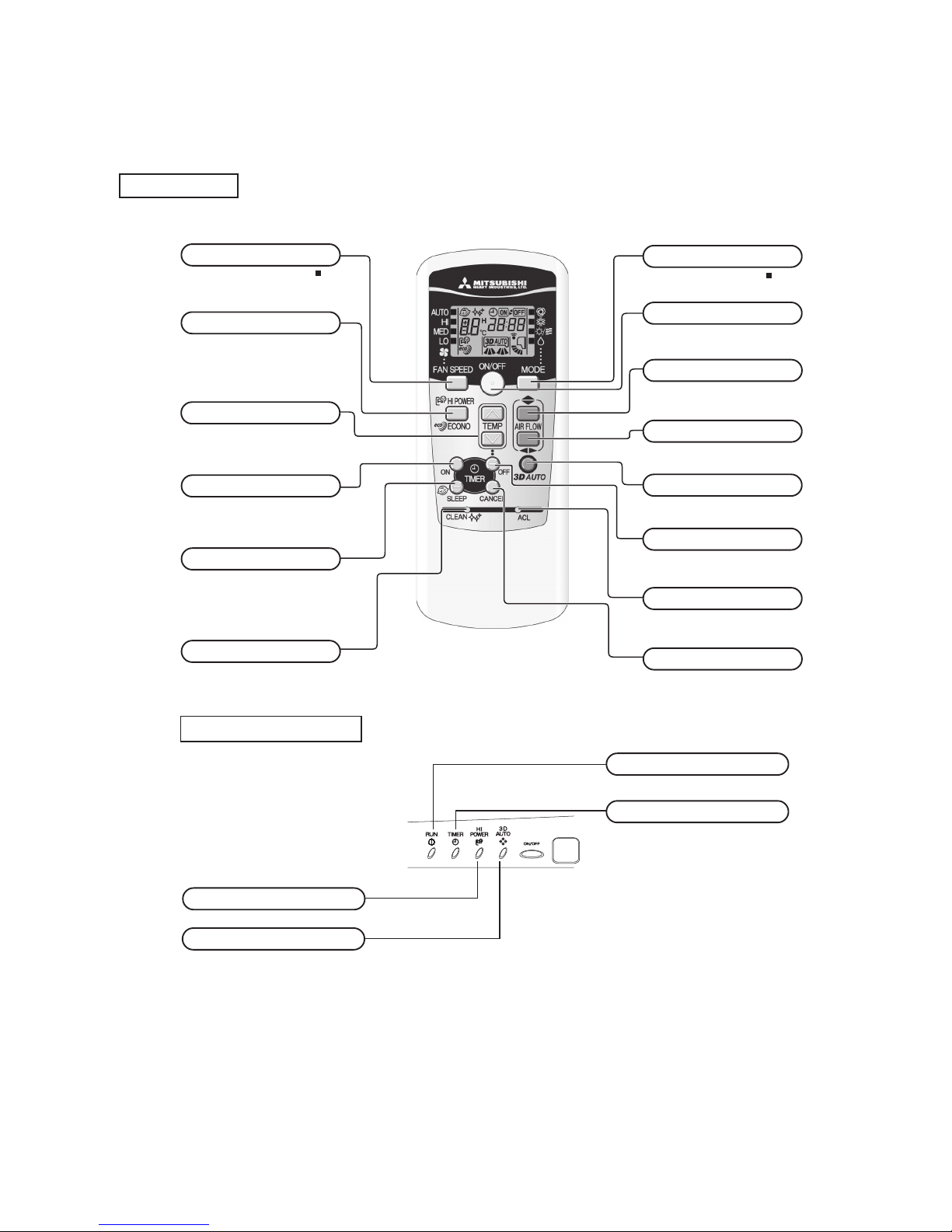

◆

Operation section

Unit display section

Models SRK10CMS, 13CMS

SRK10CMS-2, 13CMS-2

3D AUTO light (green)

Illuminate s during 3D AUTO operation.

HI POWER light (green)

Illuminate s during HI GH POWER opera tion.

RUN light (green)

Illuminate s during op eration

and CLEAN operation.

TIMER light (yellow)

Illuminate s during TIM ER operatio n.

Operation and indication section for remote control

Operation section

SRK10YJV-S

SRK13YJV-S

FAN SPEED button

Each time the button is pushed, the

indicator is switched ov er in turn.

v

The above illustratio n shows all controls, but in practice

only the r elevant par ts are show n.

OPERATION MODE select button

Each time the button push ed, the

indicator is switched ove r in turn.

ON/OFF (luminous) button

Press for sta rting operat ion, press again

for stoppi ng.

HI POWER/ECONO button

This butt on ch anges th e HIG H POW ER/

ECONOMY mo de.

AIR FLOW (UP/DOWN) button

This butto n changes t he air flow (up/down) mode .

This butto n changes t he air flow (left/righ t) mode.

SLEEP button

This butto n changes t o SLEEP ope ration.

CLEAN switch

This switc h changes t he CLEAN mo de.

ON TIMER button

This butto n selects O N TIMER ope ration.

AIR FLOW (LEFT/RIGHT) button

3D AUTO button

Thi s b utto n set s 3D AUTO ope ratio n.

Thi s b utto n can cels the ON t imer, OFF

timer, and SLE EP operatio n.

CANCEL button

RESET switch

Switch for resetting microcomput er and

setting ti me.

OFF TIMER button

This butto n selects O FF TIMER op eration.

TEMPERATURE button

This butto n sets the room temper ature.

(This butt on changes the pre sent time a nd

TIMER time .)

Remote control

-

27

-

'12•SRK-T-137

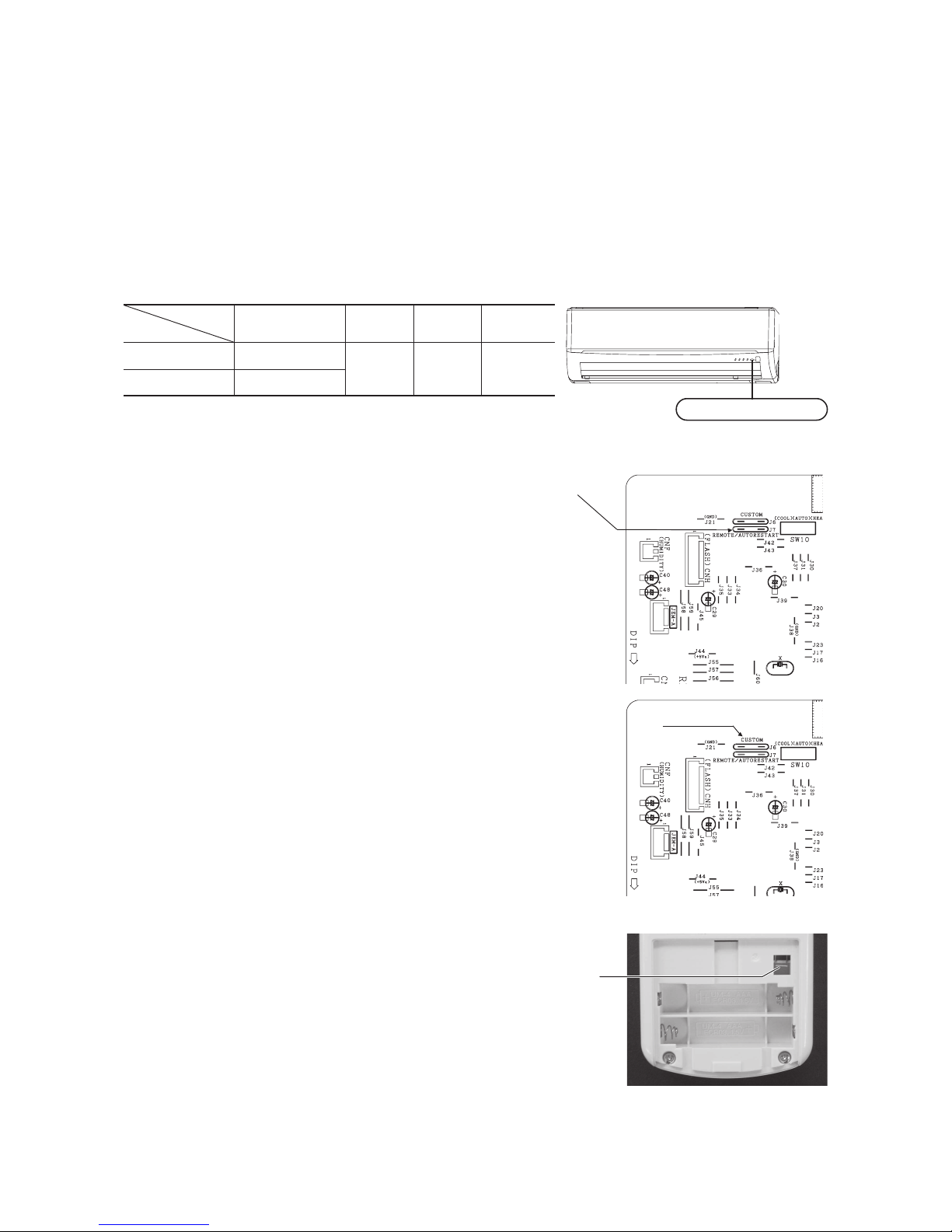

(2) Unit ON/OFF button

When the remote control batteries become weak, or if the remote control is lost or malfunctioning, this button may be used to turn the

unit on and off.

(a) Operation

Push the button once to place the unit in the automatic mode. Push it once more to turn the unit off.

(b) Details of operation

The unit will go into the automatic mode in which it automatically determines, from room temperature (as detected by sensor),

whether to go into the cooling or thermal dry modes.

(3) Auto restart function

(a) Auto restart function records the operational status of the air-conditioner immediately prior to be switched off by a power cut,

and then automatically resumes operations after the power has been restored.

(b) The following settings will be cancelled:

(i) Timer settings

(ii) HIGH POWER operations

Notes (1) Auto restart function is set at on when the air-conditioner is shipped from the factory. Consult

with your dealer if this function needs to be switched off.

(2) When power failure ocurrs, the timer setting is cancelled. Once power is resumed, reset the timer.

(3)

If the jumper wire (J7) “AUTO RESTART” is cut, auto restart is disabled. (See the diagram at right)

(4) Custom cord switching procedure

If two wireless remote control are installed in one room, in order to prevent wrong operation

due to mixed signals, please modify the printed circuit board in the indoor unit’s control box

and the remote control using the following procedure. Be sure to modify both boards. If

only one board is modied, receiving (and operation) cannot be done.

(a) Modifying the indoor unit’s printed circuit board

Take out the printed circuit board from the control box and cut off jumper wire (J6)

using wire cutters.

After cutting of the jumper wire, take measures to prevent contact with the other the lead

wires, etc.

(b) Modifying the wireless remote control

(i) Remove the battery.

(ii) Cut the jumper wire shown in the gure at right.

Cut

Function

Operation mode

Room temperature

setting

Fan speed

Flap

Timer switch

COOL

About 23ºC

Auto Auto Continuous

DRY

About 24ºC

Jumper wire (J7)

Jumper wire (J6)

Unit ON/OFF button

In emergen cies, this button c an be used for turni ng on/off the unit when

remote con trol is not availab le.

Page 15

RUN light (green)

Illuminate s during operation

and CLEAN operation.

TIMER light (yellow)

Illuminate s during TIMER oper ation.

Unit ON/OFF button

-

28

-

'12•SRK-T-137

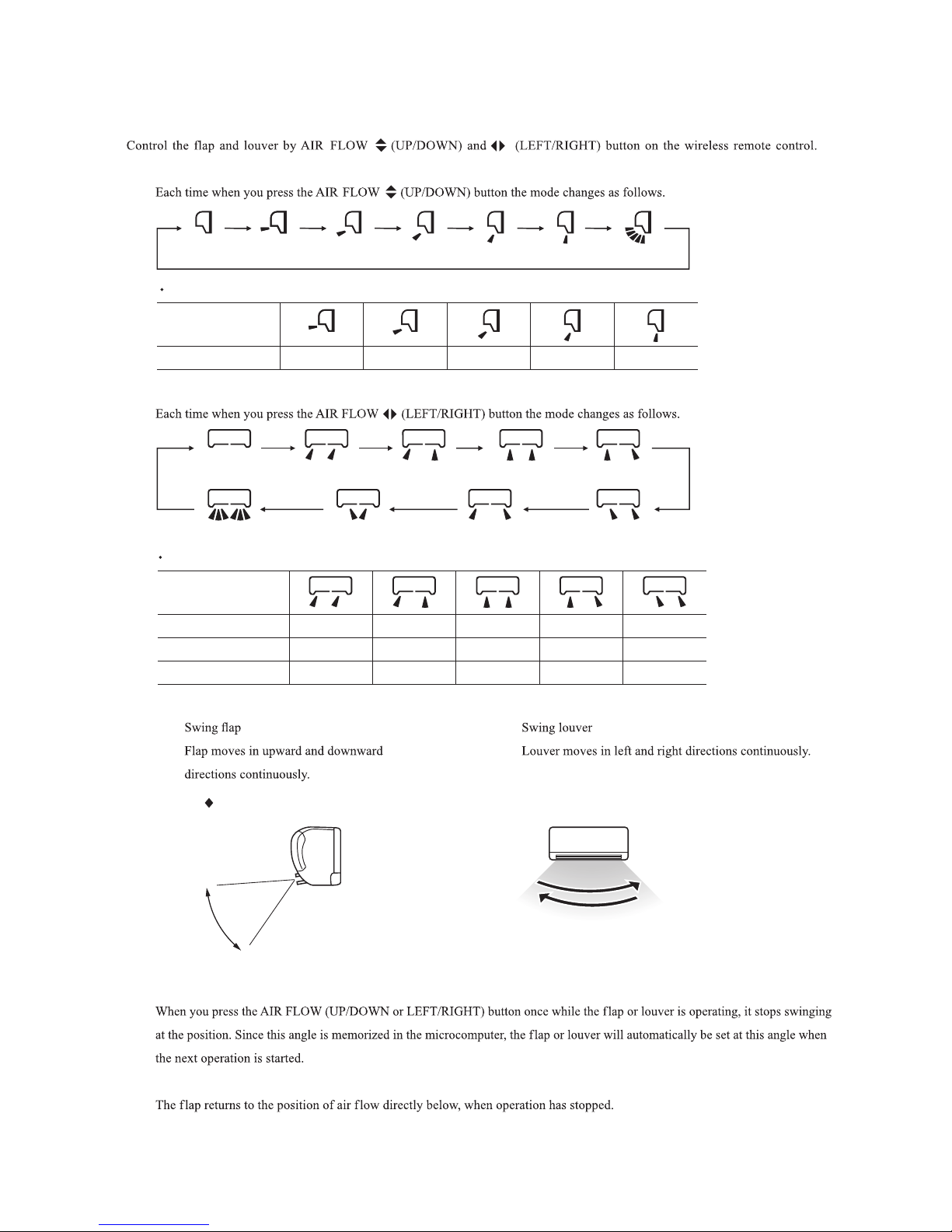

(5) Flap and louver control (Louver control function only CMS and CMS-2 models)

(a) Flap

(b) Louver

(c) Swing

(i)

(d) Memory flap (Flap or Louver stopped)

(e) When not operating

COOL , DRY, FAN

Remote control

display

Approx. 10° Approx. 20° Approx. 30°

(Swing)

(Flap stopped)

Approx. 45° Approx. 60°

Angle of Flap from Horizontal

Center installation

Remote control

display

Right end installation

Left end installation

Angle of Louver

Left Approx. 45°

Left Approx. 45°

Left Approx. 20°

Left Approx. 30°

Center

Left Approx. 20°

Right Approx. 20°

Center

Right Approx. 45°

Right Approx. 20°

Left Approx. 20°

Center

Right Approx. 20° Right Approx. 30° Right Approx. 45°

(Louver stopped)

(Swing) (Spot) (Wide)

In COOL, DRY, FAN operation

Approx.

10°

Approx. 60°

(ii)

-

29

-

'12•SRK-T-137

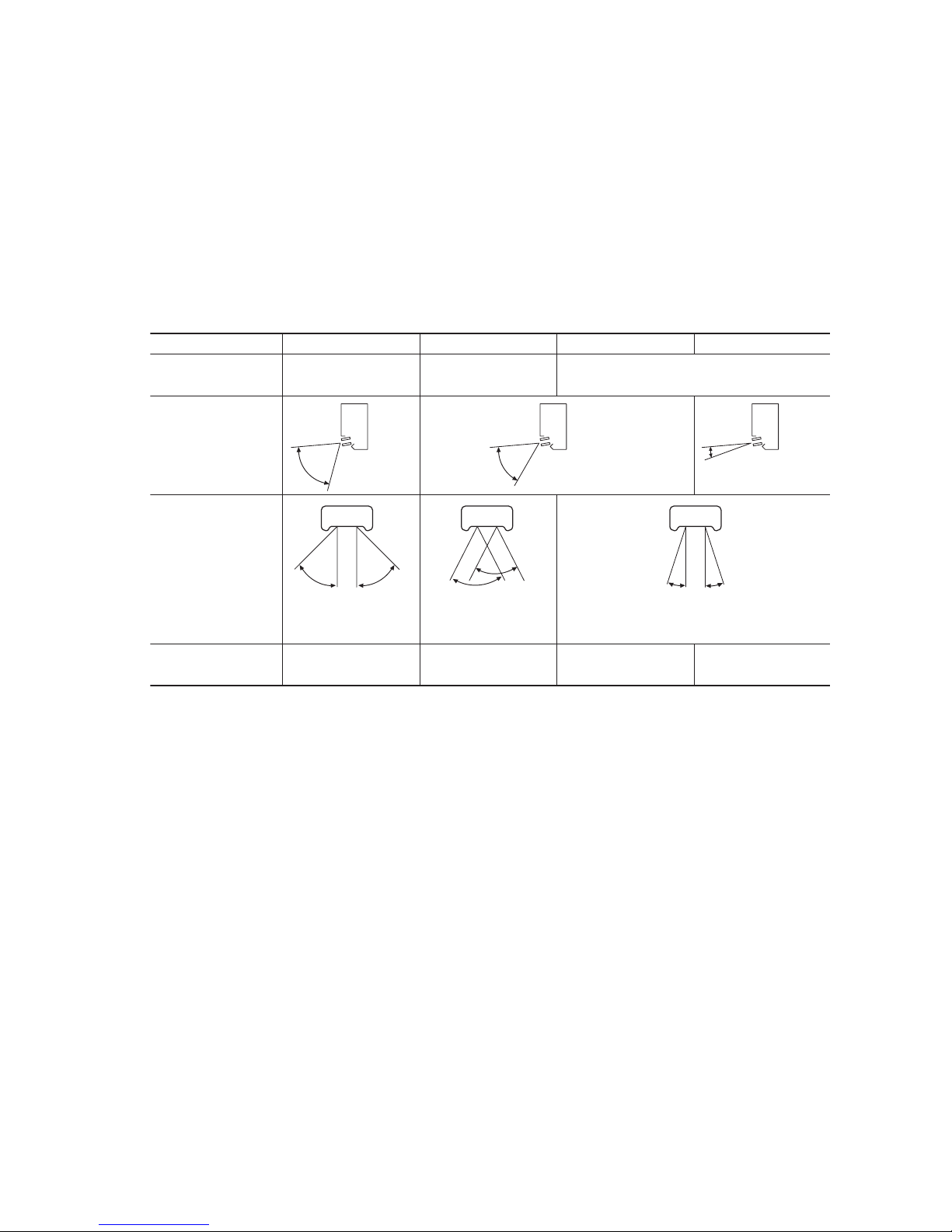

(6) 3D auto operation (only CMS and CMS-2 models)

Operation step

Flap

Louver

Conditions for

jumping to next STEP

Fan speed Setting fan speed

_

20 cycle 60 cycle 60 cycle

Auto : HIGH POWER

Other than Auto: Setting fan speed

Setting fan speed

STEP1 STEP2 STEP3 STEP4

Left louver

The left louver and right louver

operate in the same direction

left and right.

The left louver and right louver

operate in opposite directions to

each other on the left and right sides.

The left louver and right louver operate in opposite directions to

each other on the left and right sides.

Right louver

Left louver Right louver

Left louver Right louver

1.4.6 3D auto operation

(only SRK10CJV-2, 13CJV-2)

Control the flap and louver by 3D AUTO button on the wireless remote control.

Fan speed and air flow direction are automatically controlled, allowing the entire room to efficiently conditioned.

(a) Detail of operation

(i) Perform STEP1 → STEP2 → STEP3 → STEP4 one time.

(ii) After performing STEP4 in (i) above, the next steps to be carried out are determined by the difference between the room

temperature and the setting temperature.

1) Room temperature – Setting temperature > 5ºC: STEP2 STEP3 →→ STEP4 are performed.

2) Room temperature – Setting temperature

<

5ºC: STEP3

=

→

STEP4 are performed.

-

30

-

'12•SRK-T-137

(b) Sleep timer operation

(7) Timer operation

(a) Comfortable timer setting (ON timer)

(c) OFF timer operation

(8) Installation location setting (only CMS and CMS-2 models)

(a) Setting

(i)

If the air conditioning unit is running, press the ON/OFF button to stop.

(ii) Press the AIR FLOW (UP/DOWN) button and the

AIR FLOW

(LEFT/RIGHT) button together for 5 seconds

or more.

(iii) Setting the air-conditioning installation location.

(iv) Press the ON/OFF button.

Airf low range Airf low rangeAirf low range

(Left End Installation) (Center Installation) (Right End Installation)

(Center Installation) (Right End Installation) (Left End Installation)

(i), (iv)

(ii)

(iii)

-

31

-

'12•SRK-T-137

27.5

25.5

19.5

18

30

(9) Outline of cooling operation

(a) Operation of major functional components in Cooling mode

(b) Fan speed switching

ON OFF OFF

ON

OFF OFF

ON ON ON

Thermostat ON Thermostat OFF Failure

Cooling

Compressor

Indoor fan motor

Outdoor fan motor

Auto fan control

Speed 5

Speed 3

Speed 2

Model

Fan speed

All model

Auto

MED

HI

LO

(10) Outline of automatic operation

(a) Determination of operation mode

The unit checks the indoor air temperature and the outdoor air temperature, determines the operation mode, and then begins in

the automatic operation.

Dehumidifying

Cooling

Indoor air temperature (˚C)

Outdoor air temperature (˚C)

(b)

The unit checks the temperature every 30 minutes after the start of operation and, if the result of check is not same as the previ

-

ous operation mode, changes the operation mode.

(c)

When the unit is started again within one hour after the stop of automatic operation or when the automatic operation is selected

during cooling or dehumidifying operation, the unit is operated in the previous operation mode.

(d)

Setting temperature can be adjusted within the following range. There is the relationship as shown below between the signals of

the wireless remote control and the setting temperature.

Signals of wireless remote control (Display)

–6 –5 –4 –3 –2 –1

±

0 +1 +2 +3 +4 +5 +6

Setting

Cooling

17 18 19 20 21 22 23 24 25 26 27 28 29

temperature

Dehumidifying

18 19 20 21 22 23 24 25 26 27 28 29 30

-

32

-

'12•SRK-T-137

(11) Protective control function

(a) Frost prevention for indoor heat exchanger (During cooling or dehumidifying)

(i) Operating conditions

1) Indoor heat exchanger temperature (Th2) is lower than 2.5ºC.

2) 3 minutes elapsed after the start of operation.

(ii) Detail of frost prevention operation

Compressor OFF

Indoor fan Protects the fan tap just before frost prevention control.

Outdoor fan Depending on the stop mode

(iii) Reset condition: Indoor heat exchanger temperature (Th2) is higher than 8ºC.

(b) Indoor fan motor protection

When the airconditioner is operating and the indoor fan motor is turned ON, if the indoor fan motor has operated at 300 rpm or

under for more than 30 seconds, the unit enters first in the stop mode and then stops the entire system.

TIMER light illuminates simultaneously and the RUN light flashing 6-time at each 8-second.

(c) 3 minutes forced operation

When the compressor begins operating the thermal operation is not effective for 3 minutes, so operation continues as is in the

operation mode. (After 3 minutes has passed the thermal operation is effective.)

However, stopping the compressor via a stop signal or protection control has priority.

(d) Abnormality of outdoor unit

When the indoor heat exchanger temperature does not fall to 25°C or below for 40 minutes after 5 minutes have elapsed since

the compressor operation start, the abnormality stop occurs. (RUN light : ON, TIMER light : 2-time flash)

(e) Sensor disconnection (room temperature, indoor heat exchanger

)

(i) Room temperature sensor

If the temperature detected by the room temperature sensor is – 20ºC or lower continuously for 15 seconds or longer while

operation is stopped, an error indication is displayed. (RUN light: 2-time flash, TIMER light: ON)

(ii) Indoor heat exchanger temperature sensor

If the temperature detected by the indoor heat exchanger temperature sensor is –20ºC or lower continuously for 15 seconds

or longer while operation is stopped, an error indication is displayed.

(RUN light : 1-time flash, TIMER light : ON)

-

33

-

'12•SRK-T-137

1.8 MAINTENANCE DATA

(1) Cautions

(a) If you are disassembling and checking an air conditioner, be sure to turn off the power before beginning. When working on

indoor units, let the unit sit for about 1 minute after turning off the power before you begin work. When working on an outdoor

unit, there may be an electrical charge applied to the main circuit (electrolytic condenser), so begin work only after discharg-

ing this electrical charge (to DC 10 V or lower).

(b) When taking out printed circuit boards, be sure to do so without exerting force on the circuit boards or package components.

(c) When disconnecting and connecting connectors, take hold of the connector housing and do not pull on the lead wires.

(2) Items to check before troubleshooting

(a) Have you thoroughly investigated the details of the trouble which the customer is complaining about?

(b) Is the air conditioner running? Is it displaying any self-diagnosis information?

(c) Is a power supply with the correct voltage connected?

(d) Are the control lines connecting the indoor and outdoor units wired correctly and connected securely?

(e) Is the outdoor unit’s service valve open?

(3) Troubleshooting procedure (If the air conditioner does not run at all)

If the air conditioner does not run at all, diagnose the trouble using the following troubleshooting procedure. If the air condi-

tioner is running but breaks down, proceed to troubleshooting step (4).

Important

When all the following conditions are met, we say that the air conditioner will not run at all.

(a) The RUN light does not light up.

(b) The aps do not open.

(c) The indoor unit fan motors do not run.

(d) The self-diagnosis display does not function.

YES

YES

YES

NO

NO

NO

NO

YES

Troubleshooting procedure (If the air conditioner does not run at all)

Is the cor rec t v olt age

connected for the power

supply?

With the power off, do

the aps open manually,

then close again when

the power is turned on?

Is the r e a re c e pt i o n

sound emitted from the

unit when it is operated

by the remote control?

Replace the indoor PCB and

perform an operation check.

Make sure the correct voltage is connected, then perform an operation check.

Is the current fuse on the indoor unit PCB blown?

Proceed to the indoor PCB

check.

Proceed to the wireless remote

control troubleshooting procedure.

If the package components

are not damaged, replace

the fuse and perform an operation check again.

* If the voltage is correct, it will be

within the following voltage range.

AC 198 ~ 264 V

-

34

-

'12•SRK-T-137

(4) Troubleshooting procedure (If the air conditioner runs)

NO

NO

NO

NO

YES

YES

YES

YES

Note (1) Even in cases where only intermittent stop data are generated, the air conditioning system is normal. However, if the same protective operation recurs

repeatedly (3 or more times), it will lead to customer complaints. Judge the conditions in comparison with the contents of the complaints.

Conrm the contents of the customer complaint.

Check the self-diagnosis display.

Eliminate the cause of the trouble and perform an

operation check.

Replace the faulty component, then perform an

operation check.

Identify the faulty component by using the check

procedure corresponding to the content of the trouble.

The cause of the trouble can

be specically identied.

See below.

NO

YES

(5) Self-diagnosis table

When this air conditioner performs an emergency stop, the reason why the emergency stop occurred is displayed by the ashing of

display lights. If the air conditioner is operated using the remote control 3 minutes or more after the emergency stop, the trouble

display stops and the air conditioner resumes operation.

(1)

Notes (1) The air conditioner cannot be restarted using the remote control for 3 minutes after operation stops.

When a heat exchanger sensor wire disconnection is detected while operation is

stopped. (If a temperature of –20ºC or lower is detected for 15 seconds, it is

judged that the wire is disconnected.)

(Not displayed during operation.)

When a room temperature sensor wire disconnection is detected while operation

is stopped. (If a temperature of –20ºC or lower is detected for 15 seconds, it is

judged that the wire is disconnected.)

(Not displayed during operation.)

• Broken heat exchanger sensor

wire, poor connector

connection

• Indoor PCB is faulty

• Broken room temperature

sensor wire, poor connector

connection

• Indoor PCB is faulty

When conditions for turning the indoor unit’s fan motor on exist during air

conditioner operation, an indoor unit fan motor speed of 300 rpm or lower is

measured for 30 seconds or longer. (The air conditioner stops.)

• Defective fan motor, poor

connector connection

ON

1-time

flash

ON

2-time

flash

ON

6-time

flash

When there is an emergency stop caused by trouble in the outdoor unit, or the

input current value is found to be lower than the set value.

(The air conditioner stops.)

• Broken compressor wire

• Compressor blockage

•

52C relay in indoor PCB is faulty

• Improper wire connection

between indoor and outdoor

2-time

flash

ON

Indoor unit display panel

Cause Display (flashing) condition

RUN

light

TIMER

light

Heat exchanger

sensor error

Room

temperature

sensor error

Indoor fan

motor error

Trouble of

outdoor unit

Description

of trouble

-

35

-

'12•SRK-T-137

(6) Inspection procedures corresponding to detail of trouble

Sensor error

[Broken sensor wire,

connector poor connection]

Is connector connection good?

YES

YES

NO

NO

Replace PCB.

Correct connection.

Replace sensor.

Is sensor resistance value good?

(Short circuit)

(Broken wire)

◆

S ensor tempe r ature char a cteri s tics

(Room temp., indoor heat exchanger temp.)

Temperature (˚C)

Resistance (k

Ω

)

30

25

20

15

10

5

30

20

10

40 50 60

70

0

-

10

Indoor fan motor error

[Defective fan motor, connector poor

connection, defective indoor PCB]

Is connector connection good?

YES

NO

Is the output of the indoor unit

PCB normal?

Power supply reset

Correct connector connection

Is normal state restored?

Malfunction by temporary

noise

NO

Replace fan motor (If anomaly

persiste after replacing fan motor,

replace indoor PCB)

YES

Replace indoor PCB

NO

-

36

-

'12•SRK-T-137

Trouble of outdoor unit

[Compressor malfunction of

insufficient gas (refrigerant)]

Does compressor operation?

Is capacitor for compressor normal?

Replace compressor.

Replace heat exchanger sensor

Insufficient gas

Is refrigerant amount normal?

Is heat exchanger sensor resistance

value good?

Is connector for compressor connection

good?

Does trouble persist after charging gas?

Clogged capillary tube or strainer,

defective EEV, etc.

Replace capacitor for compressor.

Correct connection

Check if there are any places where

gas is leaking

YES

YES

NO NO

NO

NO

NO

NO

YES

YES

YES

YES

(8) Checking the indoor electrical equipment

(a) Indoor PCB check procedure

Is there voltage at power source?

(AC 220/230/240V)

Replace PCB

Inspect power source.

If the packag e co mponents

are not damaged, replace the

fuse and perform an operation

check again.

Is the fuse burnt out? (3.15 A)

NO

YES

NO

YES

(7) Phenomenon observed after shortcircuit, wire breakage on sensor

(a) Indoor unit

Phenomenon

Sensor

Shortcircuit

Broken wire

Cooling

Release of continuous compressor operation command

Cooling

System can be operated normally.

Operation

mode

Continuous compressor operation command is not released.

Continuous compressor operation command is not released.

(Anti-frosting)

Heat exchanger

sensor

Room temperature

sensor

-

37

-

'12•SRK-T-137

(9) How to make sure of wireless remote control

(1)

Is remote

contro l norm al?

YES

Again pushing

operating switch

Operating the unit?

NO

Does ON/OFF button

of indoor unit operates?

Operating the unit.

NO

NO

YES

YES

Remote control

defects

Abnormality is not

found.

Replace the display

of indoor unit.

Control problem on

main unit

Is the unit

operable with remote

control?

Defective remote

control

NO

YES

Normal

Note (1) Check method of remote control

(a) Press the reset switch of the remote control.

(b) If all LCD are displayed after one (1) display, it is basically normal.

-

38

-

'12•SRK-T-137

( )

2. SRK19CMS, 25CMS

WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONER

Split system, air cooled

cooling only type

'10 • SRK-T-099

CONTENTS

2.1 SPECIFICATIONS .................................................................................. 41

(2) Outdoor units .................................................................................... 44

(3) Wireless remote control

.................................................................... 45

...................................................................... 43

(1) Indoor units ....................................................................................... 43

2.2 EXTERIOR DIMENSIONS

2.3 ELECTRICAL WIRING ........................................................................... 46

(1) Indoor units ....................................................................................... 46

(2) Outdoor units .................................................................................... 47

...................................................... 50

2.5 RANGE OF USAGE & LIMITATIONS

2.4 PIPING SYSTEM ...................................................................................... 49

.............................................................................. 52

2.6 APPLICATION DATA

2.7 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ........... 61

(6) 3D auto operation

............................................................................. 64

(7) Timer operation

................................................................................. 65

...................................................... 62

(1) Operation control function by remote control

(5) Flap and louver control ..................................................................... 63

(4) Custom cord switching procedure

........................................................................ 62(3) Auto restart function

(2) Unit ON/OFF button

.......................................................................... 62

..................................... 61

(8) Installation location setting ................................................................. 65

(10) Outline of automatic operation .......................................................... 66

(9) Outline of cooling operation .............................................................. 66

(11) Protective control function

.................................................................. 67

..................... 70

............................................................................. 69

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

....... 69

(1) Cautions

............................................................................................ 69

(2) Items to check before troubleshooting ................................................ 69

(5) Self-diagnosis table ............................................................................ 71

(6) Inspection procedures corresponding to detail of trouble ................... 72

2.8 MAINTENANCE DATA

-

39

-

'12•SRK-T-137

'10 • SRK-T-099

CONTENTS

2.1 SPECIFICATIONS .................................................................................. 41

(2) Outdoor units .................................................................................... 44