Mitsubishi Heavy Industries RMA502A001, RKX502A007B, RKW502A200D, RKW502A200B, RKX502A001C Service Support Handbook

...

SERVICE

SUPPORT

HANDBOOK

www.dwgeire.ie

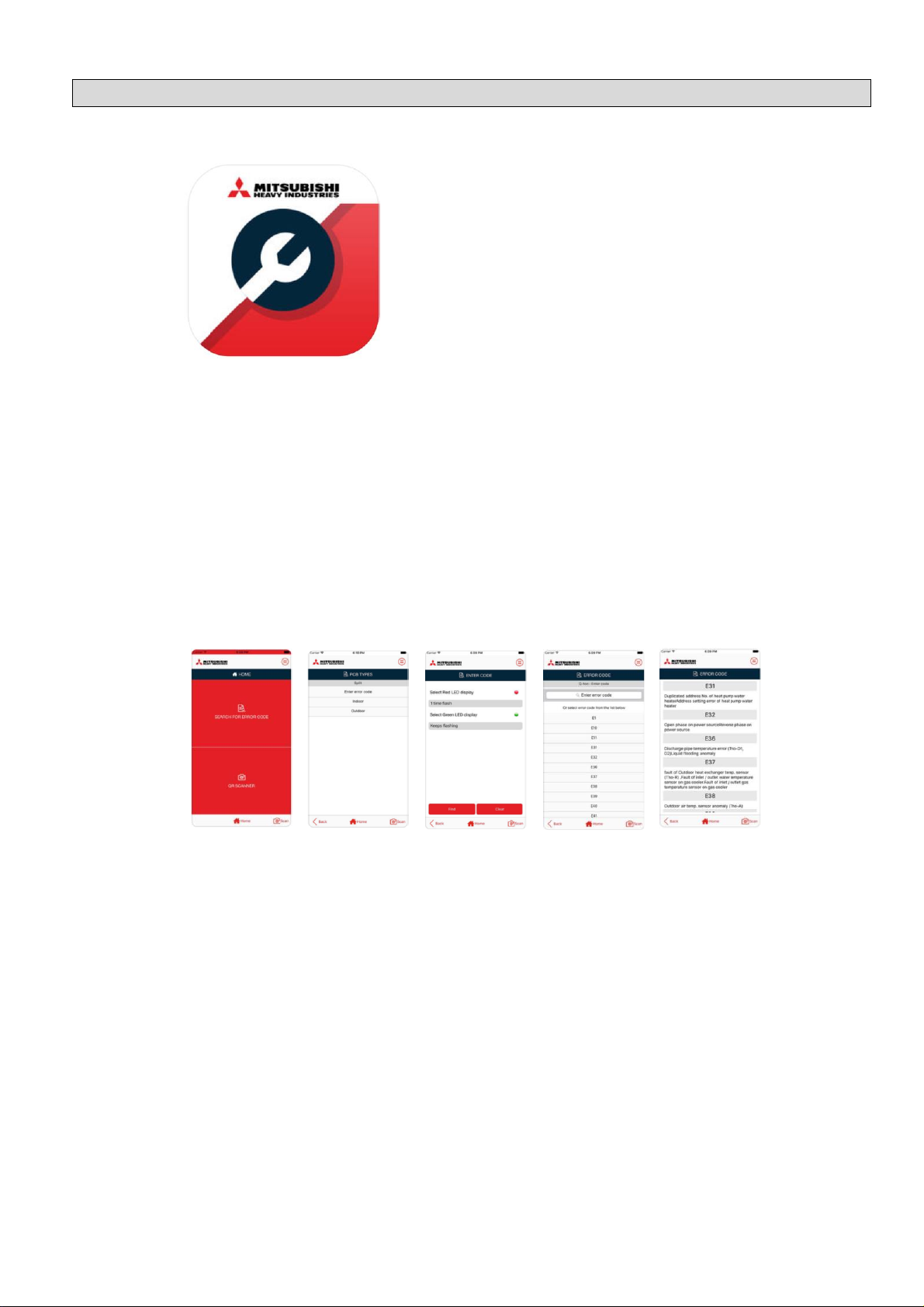

MHI e-service

DCSL Software Ltd

Free

Compatibility

Iphone or Ipad on IOS9.3 or later Android devices on 4.3 or later.

Screenshots

Description

MHI e-service is an application that enables users to make a quick search of the meaning

of error codes that may appear when there is a malfunction in "Mitsubishi Heavy Industries

Thermal Systems, Ltd" Air conditioning system, and the probable cause of the

malfunction.

In addition this application enables you to scan unit's QR code and search the meaning

of error codes depending on the model type.

The application covers "Mitsubishi Heavy Industries Thermal Systems, Ltd" Air conditioning

systems: Split (RAC & PAC), VRF, Q-ton & A2W.

The MHI e-service app is a free download available from Google Play for Android devices

(4.03 or later), or the Apple App Store for IOS devices (IOS9.3 or later).

MHI e-service app

WARNING

The information contained in this ‘Service Support Handbook’ is intended for use by

qualified service technicians familiar with safety procedures and equipped with the

proper tools and test instruments. Additionally, the information presented here is not a

replacement for, nor a substitute to the Manufacturers Technical Manuals.

MHI Air Conditioners contain pressurized refrigerants that are harmful to the atmosphere

so all refrigeration works must be performed by a qualified "F-Gas" registered person.

Please do not remove any covers, or attempt any repair or measurement on any MHI

LTD. product, unless you are suitably qualified and licensed to do so.

Repairs made by unqualified persons can result in hazards to you and others.

Technical Assistance is available Monday to Friday

between the hours of 08:00 and 17:00

on 03301 235 598

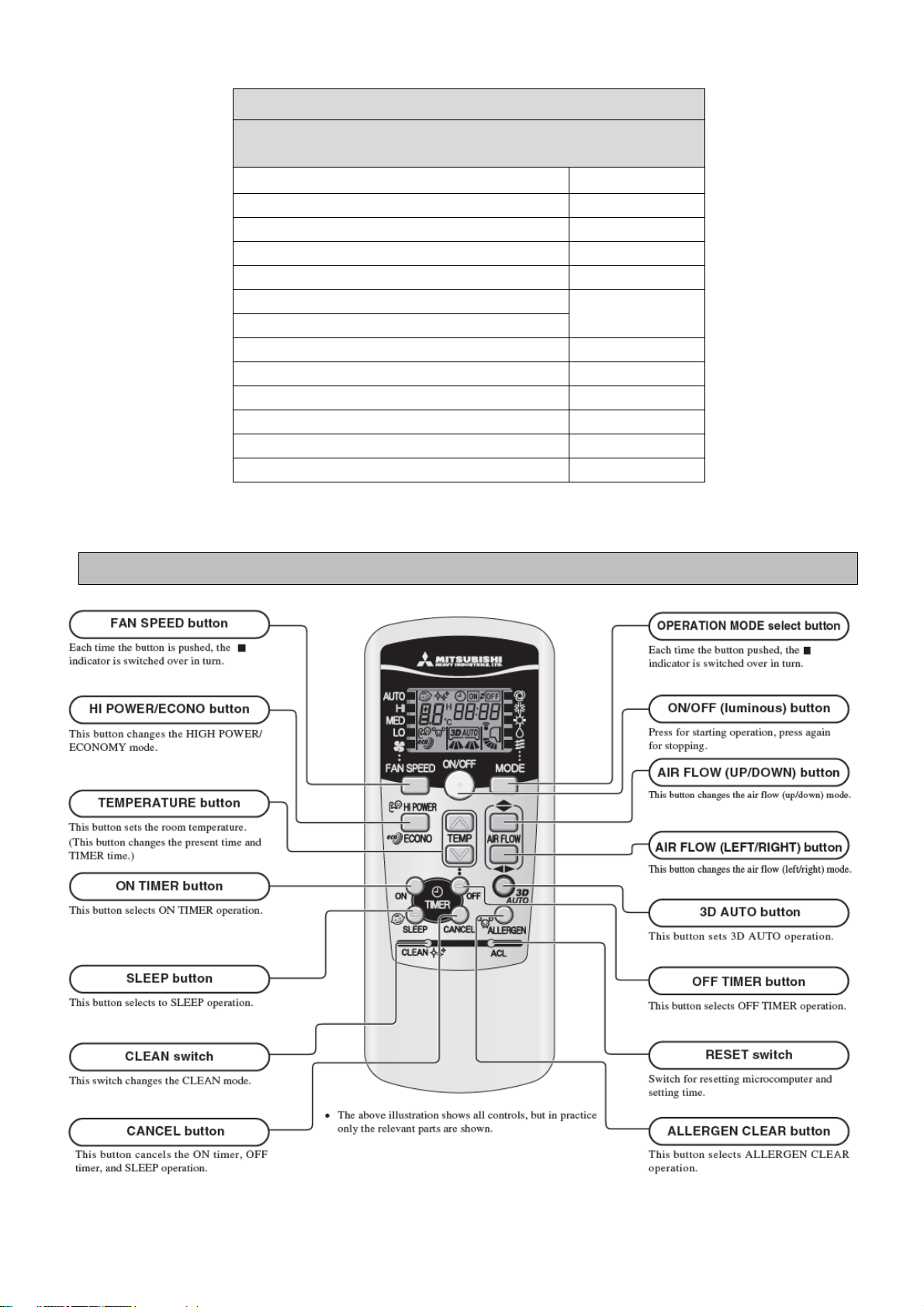

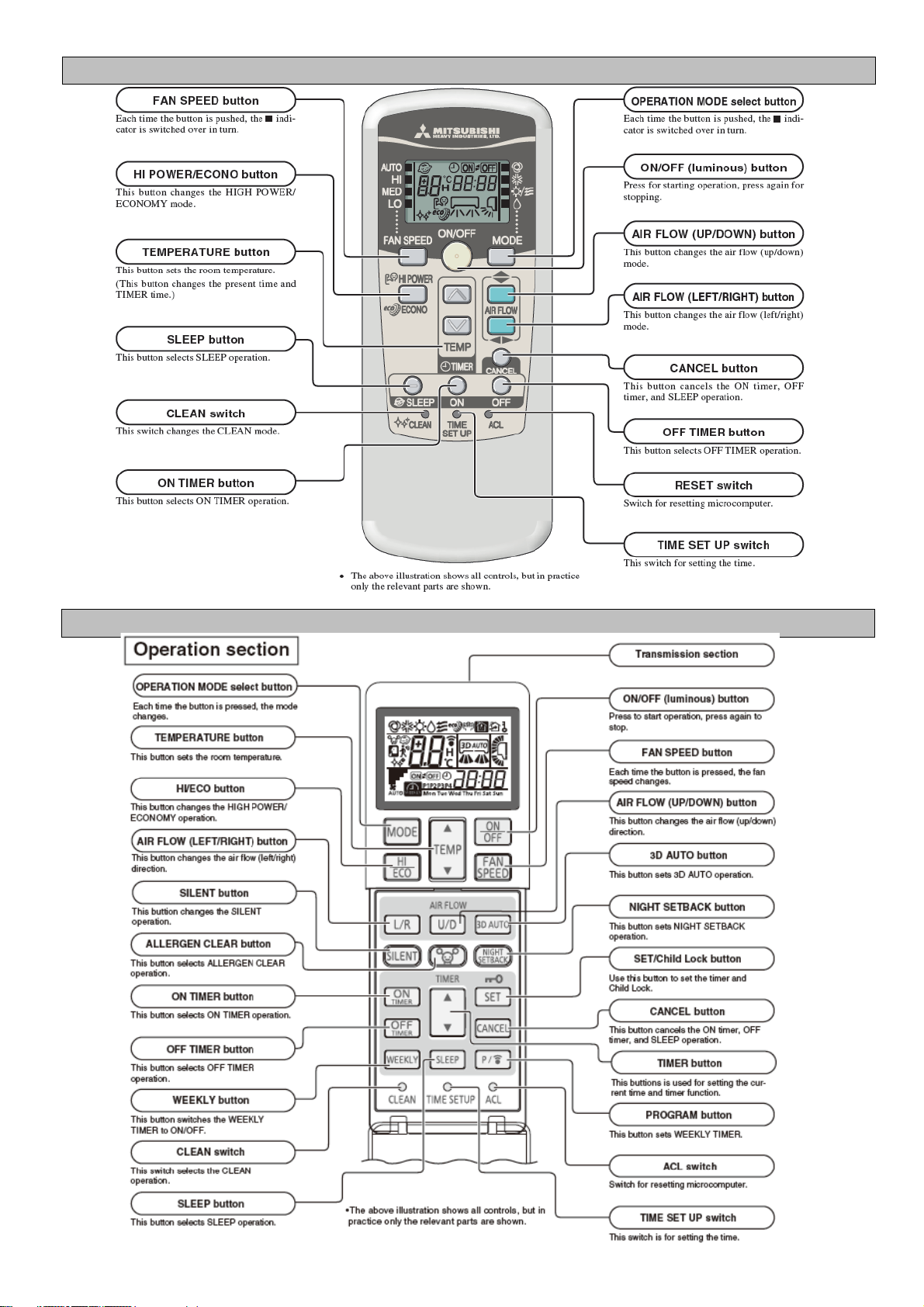

Hi-Wall Mounted Split Systems - Remote Controls of SRK

Before Proceeding to RAC Self Diagnosis Information,

ensure the correct Remote Control is being used.

Indoor Model

Remote Control

SRK--HC-S, HC-S1, HD-S, ZD-S, SKM--ZD-S

RMA502A001

SRK--HG-S

RKX502A007B

SRK--ZE-S, SRK--ZE-S1, SRK--ZR-S

RKW502A200D

SRK--ZFX-S, SRK--ZGX-S

RKW502A200B

SRK--ZG-S, ZHX-S, ZIX-S

RKX502A001C

SRK--ZJ-S, ZJ-S1, ZJX-S, ZJX-S1

SRK--ZM-S, SRK--ZMX-S, SRK--ZR-S

RLA502A701R

SRK--ZS-S

RLA502A701L

SRK--ZSX-S

RLA502A700K

SRF--ZMX-S

RLA502A700C

SRK--ZMP-S

RKX502A001P

SRK--ZSP-S

RKX502A007P

RKX502A001C

RKW502A200

RLA502A701R

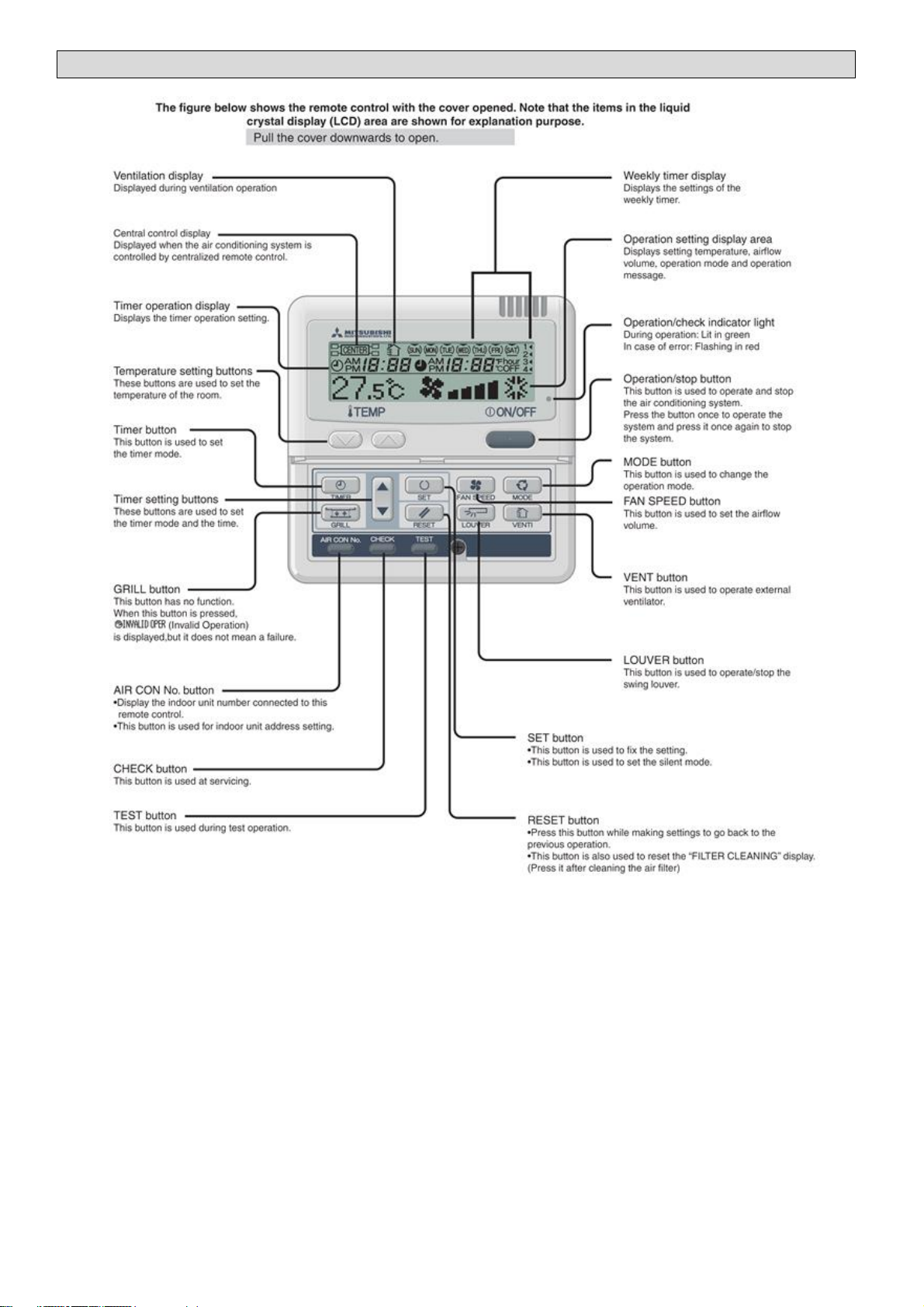

RC-E5 Layout

To access the RC-E5 Remote Controls Operation Data function, press the "CHECK" button on the MASTER remote control.

On 'Operation data' press the "SET" button.

If 'I/U No' is displayed select the unit number required, using the "/\" and "\/" buttons above the "CHECK" button, then

press the "SET" button

All navigation is carried out using the "/\" and "\/" buttons above the "CHECK" button.

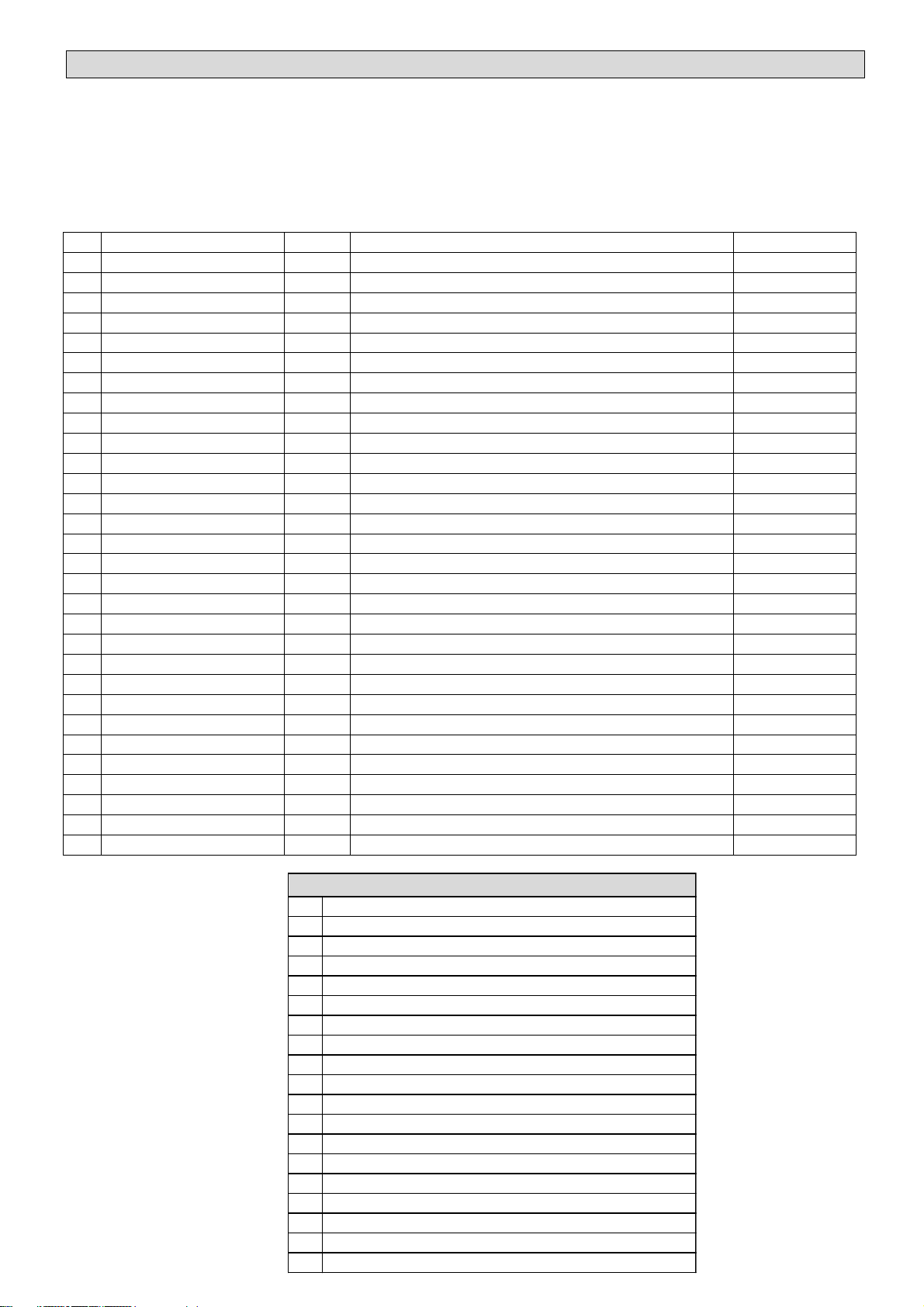

RAC Unit

Compatibility

01

MODE

Current operation mode

ok

02

SET TEMP

°C

Set temperature

ok

03

RETURN AIR

°C

Return air sensor temperature

ok

04

SENSOR

°C

Remote control sensor temperature

ok

05

THI-R1

°C

Indoor heat exchanger sensor (on U bend)

ok

06

THI-R2

°C

Indoor heat exchanger sensor (on Capillary)

ok

07

THI-R3

°C

Indoor heat exchanger sensor (on suction header)

-

08

I/U FANSPEED

Indoor unit fan speed

-

09

DEMAND

Hz

Required frequency

-

10

ANSWER

Hz

Response frequency

-

11

I/U EEV

PULSE

Pulse rate of KX indoor unit expansion valve

-

12

TOTAL I/U RUN

Hr

Total running hours of the indoor unit

-

21

OUTDOOR

°C

Outdoor air temperature

ok

22

THO-R1

°C

Outdoor unit heat exchanger sensor

ok

23

THO-R2

°C

Outdoor unit heat exchanger sensor

-

24

COMP

Hz

Compressor frequency

ok

25

HP

MPa

High pressure (x10=Bar)

-

26

LP

Mpa

Low pressure (x10=Bar)

-

27

Td

°C

Discharge Pipe Temperature

ok

28

COMP BOTTOM

°C

Compressor base temperature

-

29

CT

Amp

Current

ok

30

TARGET SH

°C

Target Super Heat

-

31

SH

°C

Super Heat temperature

-

32

TDSH

°C

Compressor discharge pipe super heat

ok

33

PROTECTION No

Protection state number of the compressor

-

34

O/U FANSPEED

Outdoor unit fan speed

ok

35

63H1

63H1 High pressure switch on/off

-

36

DEFROST

Defrost control on/off

ok

37

TOTAL COMP RUN

Hr

Total running hours of compressor

-

38

O/U EEV1

PULSE

Pulse rate of the outdoor unit expansion valve EEVC

ok

39

O/U EEV2

PULSE

Pulse rate of the outdoor unit expansion valve EEVH

-

No. Contents of display

0 Normal

1 Discharge pipe temperature protection control

2 Discharge pipe temperature anomaly

3 Current safe control of inverter primary current

4 High pressure protection control

5 High pressure anomaly

6 Low pressure protection control

7 Low pressure anomaly

8 Anti-frost prevention control

9 Current cut

10 Power transistor protection control

11 Power transistor anomaly (Overheat)

12 Compression ratio control

13 14 Condensation prevention control

15 Current safe control of inverter secondary current

16 Stop by compressor rotor lock

17 Stop by compressor startup failure

Details of 33 Compressor Protection Status

RC-E5 OPERATION DATA

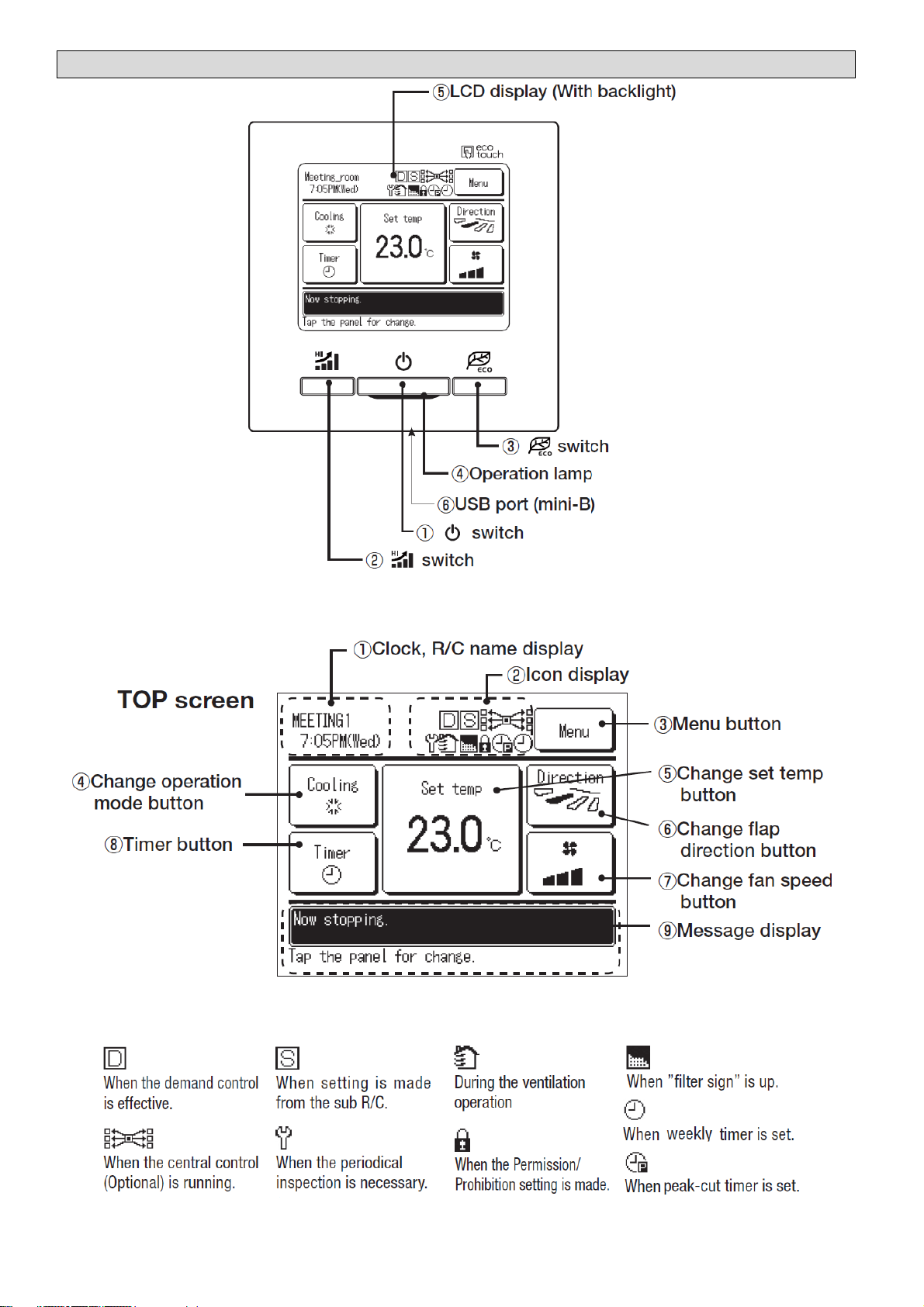

Touch panel control, which is operated by tapping the LCD screen with a finger, is employed for all functions except

1 On/Off switch, 2 Hi Power switch and 3 ECO switch.

RC-EX1 & EX1A Layout

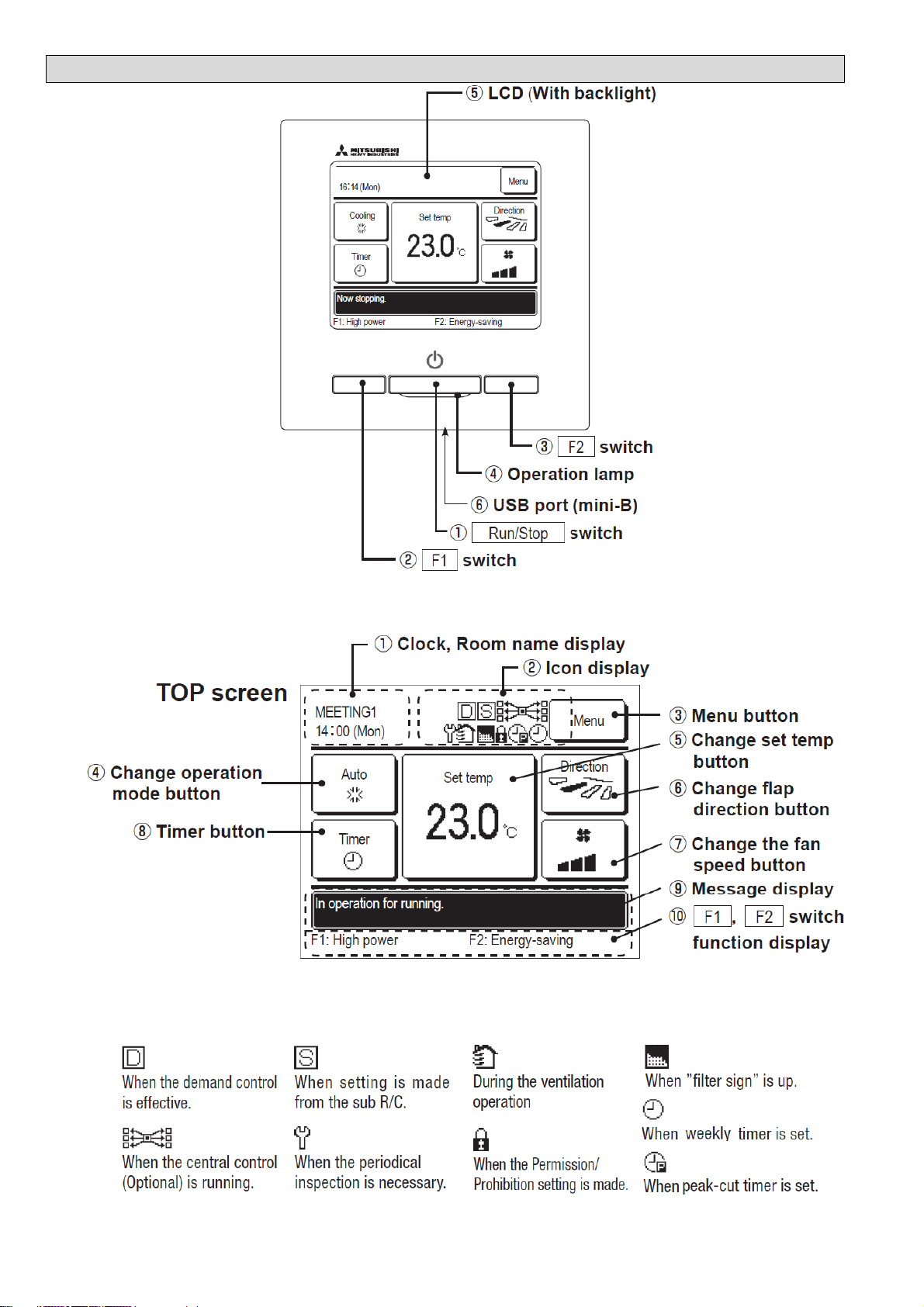

Touch panel control, which is operated by tapping the LCD screen with a finger, is employed for all functions except

1 On/Off switch, 2 Hi Power switch and 3 ECO switch.

RC-EX3 Layout

To access the RC-EX Remote Controls Operation Data function, press MENU on the MASTER remote control Front Screen.

Then press NEXT followed by SERVICE (RC-EX3 only) and SERVICE & MAINTENANCE. Enter the service pass code, press SET

then press OPERATION DATA. You can then select the indoor unit you want to view.

RAC Unit

Compatibility

01

MODE

Current operation mode

ok

02

SET TEMP

°C

Set temperature

ok

03

RETURN AIR

°C

Return air sensor temperature

ok

04

SENSOR

°C

Remote control sensor temperature

ok

05

THI-R1

°C

Indoor heat exchanger sensor (on U bend)

ok

06

THI-R2

°C

Indoor heat exchanger sensor (on Capillary)

ok

07

THI-R3

°C

Indoor heat exchanger sensor (on suction header)

-

08

I/U FANSPEED

Indoor unit fan speed

-

09

DEMAND

Hz

Required frequency

-

10

ANSWER

Hz

Response frequency

-

11

I/U EEV

PULSE

Pulse rate of KX indoor unit expansion valve

-

12

TOTAL I/U RUN

Hr

Total running hours of the indoor unit

-

21

OUTDOOR

°C

Outdoor air temperature

ok

22

THO-R1

°C

Outdoor unit heat exchanger sensor

ok

23

THO-R2

°C

Outdoor unit heat exchanger sensor

-

24

COMP

Hz

Compressor frequency

ok

25

HP

MPa

High pressure (x10=Bar)

-

26

LP

Mpa

Low pressure (x10=Bar)

-

27

Td

°C

Discharge Pipe Temperature

ok

28

COMP BOTTOM

°C

Compressor base temperature

-

29

CT

Amp

Current

ok

30

TARGET SH

°C

Target Super Heat

-

31

SH

°C

Super Heat temperature

-

32

TDSH

°C

Compressor discharge pipe super heat

ok

33

PROTECTION No

Protection state number of the compressor

-

34

O/U FANSPEED

Outdoor unit fan speed

ok

35

63H1

63H1 High pressure switch on/off

-

36

DEFROST

Defrost control on/off

ok

37

TOTAL COMP RUN

Hr

Total running hours of compressor

-

38

O/U EEV1

PULSE

Pulse rate of the outdoor unit expansion valve EEVC

ok

39

O/U EEV2

PULSE

Pulse rate of the outdoor unit expansion valve EEVH

-

No. Contents of display

0 Normal

1 Discharge pipe temperature protection control

2 Discharge pipe temperature anomaly

3 Current safe control of inverter primary current

4 High pressure protection control

5 High pressure anomaly

6 Low pressure protection control

7 Low pressure anomaly

8 Anti-frost prevention control

9 Current cut

10 Power transistor protection control

11 Power transistor anomaly (Overheat)

12 Compression ratio control

13 14 Condensation prevention control

15 Current safe control of inverter secondary current

16 Stop by compressor rotor lock

17 Stop by compressor startup failure

Details of 33 Compressor Protection Status

RC-EX OPERATION DATA

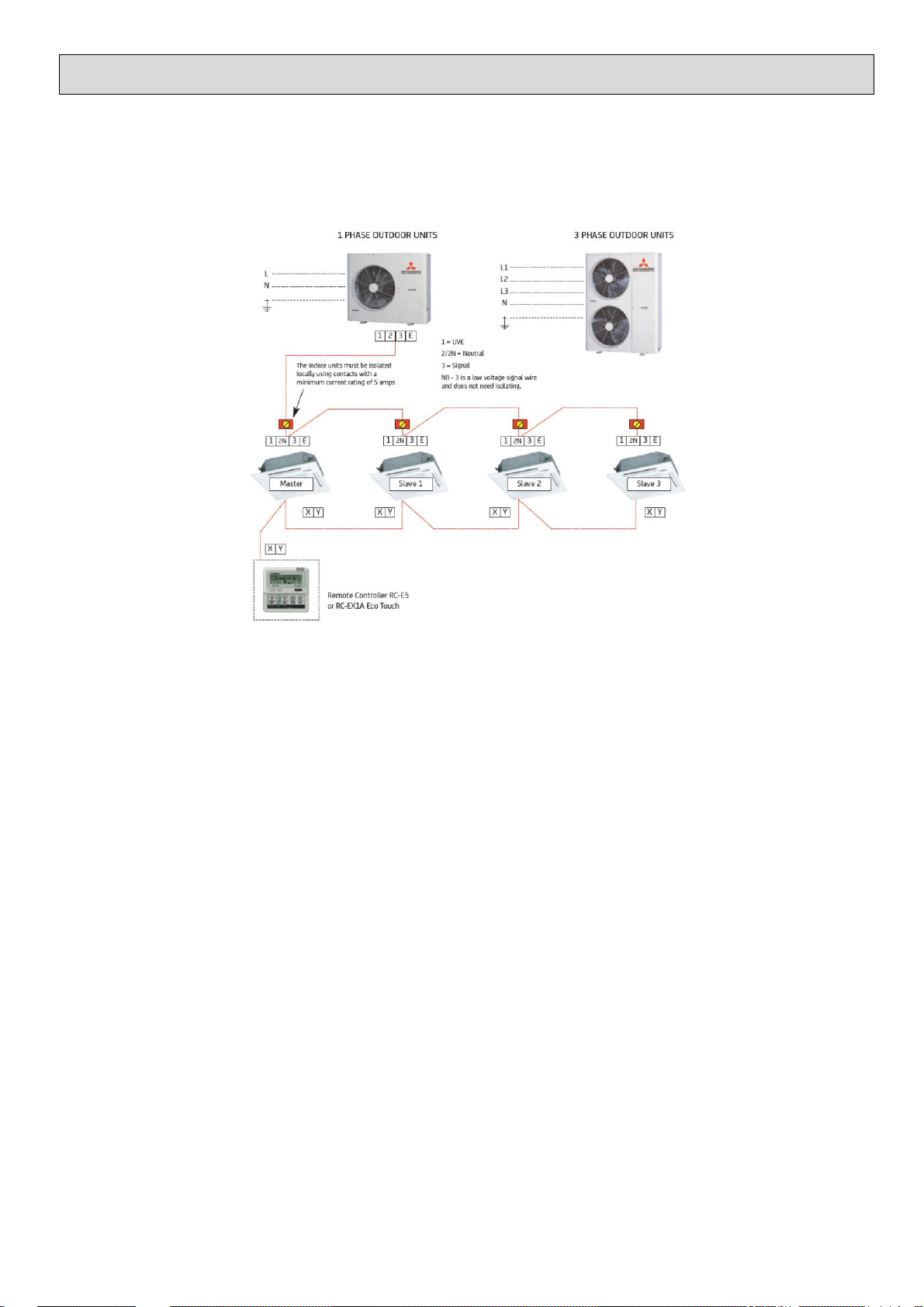

Master/ Slave and Group Settings

Master / Slave Settings

All split system indoor units are supplied set up as a master unit as default and this only needs changing when the system being

installed is a multisplit system, excluding SCM or KX systems, comprising of 2 to 4 RAC or PAC indoor units running off a

PAC single split outdoor unit. The remote control wires and all wires of the interconnecting cable go to each indoor unit

including the slave units.

When using RAC SRK indoor units, excluding ZMP/ZSP models, on a multisplit each indoor unit needs an SC-BIKN-E

interface to allow the installation of the wired remote control and setup of the master slave settings.

SYSTEM TYPE PAC Indoor Units SC-BIKN-E Interface

Unit SW5-1 SW5-2 SW3-1 SW3-2

Single Twin Triple Quad MASTER OFF OFF OFF OFF

Twin Triple Quad SLAVE 1 OFF ON OFF ON

Triple Quad SLAVE 2 ON OFF ON OFF

Quad SLAVE 3 ON ON ON ON

All indoor units on a multisplit system must be in the same space and operate off a single wired remote control as there is no

refrigerant control in the indoor units.

Group Settings

When multiple systems need to be controlled off a single RC-EX1A, RC-EX3 or RC-E5 wired remote control each system

needs to be given a different address. The system addressing is set on PAC unit indoor boards using SW2 or on RAC indoor

units via SW1 on the SC-BIKN-E interface. Upto 16 indoor units can be connected to a wired remote and that includes

multiplit systems using PAC outdoor units.

System Indoor Outdoor System Unit Group Address Master Slave

Unit Unit Type Switch Setting Switch #1 #2

1 FDT FDC Split Master SW2 0 SW5 OFF OFF

2 FDT FDC Quad Master SW2 1 SW5 OFF OFF

FDT Slave 1 SW2 1 SW5 OFF ON

FDT Slave 2 SW2 1 SW5 ON OFF

FDT Slave 3 SW2 1 SW5 ON ON

3 SRK FDC Twin Master SW1 2 SW3 OFF OFF

SRK Slave 1 SW1 2 SW3 OFF ON

4 FDUM FDC Split Master SW2 3 SW5 OFF OFF

Refrigerant Piping Information

RAC CURRENT MODELS

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A

SRC25ZMP-S, 10 15 10 10 0.655 20 1/4" (6.35) 3/8" (9.52) 16

SRC35ZMP-S 15 15 10 10 0.810 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC45ZMP-S 15 25 15 15 1.200 20 1/4" (6.35) 1/2" (12.7) 16

SRC25ZM-S 15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC35ZM-S 15 15 10 10 1.050 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC50ZM-S 15 25 15 15 1.350 20 1/4" (6.35) 1/2" (12.7) 16

FDC100VNP 15 30 20 20 2.550 60 3/8" (9.52) 5/8" (15.88) 32

SRC20_35ZMX-S 15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC50_60ZMX-S 15 30 20 20 1.500 20 1/4" (6.35) 1/2" (12.7) 16

SRC63ZR-S 15 30 20 20 1.550 20 1/4" (6.35) 1/2" (12.7) 16

SRC71ZR-S 15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88) 20

SRC80ZR-S 15 30 20 20 1.900 25 1/4" (6.35) 5/8" (15.88) 20

SRC20_25ZS-S 15 20 10 10 0.750 20 1/4" (6.35) 3/8" (9.52) 16

SRC35ZS-S 15 20 10 10 0.950 20 1/4" (6.35) 3/8" (9.52) 16

SRC50ZS-S 15 25 15 15 1.250 20 1/4" (6.35) 1/2" (12.7) 20

SCM Multi Splits

For SCM Systems the maximum one way piping length to an indoor unit is 25 metres.

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A

SCM40ZS-S 30 30 15 15 1.900 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM45ZS-S 30 30 15 15 1.900 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM50ZS-S 40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52) 25

SCM45ZM-S 30 30 15 15 2.000 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM60ZM-S 40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52) 25

SCM80ZM-S 40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52) 25

SCM100_125ZM-S 50 90 20 20 6.000 20 5x 1/4" (6.35) 5x 3/8" (9.52) 32

PAC Splits - CURRENT MODELS

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A(/ph)

FDC71VNP 15 30 20 20 1.600 20 1/4" (6.35) 1/2" (12.7) 20

FDC90VNP 15 30 20 20 2.100 20 1/4" (6.35) 5/8" (15.88) 20

FDC100VNP 15 30 20 20 2.550 60 3/8" (9.52) 5/8" (15.88) 32

FDC100VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC125VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC140VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC71VNX 30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88) 25

FDC100VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC125VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC140VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC100VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC125VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC140VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC100VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC125VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC140VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC200VSA 30 70 30 15 5.600 60 3/8" (9.52) 7/8" (22.22) 32

FDC250VSA 30 70 30 15 7.200 120 1/2" (12.7) 1-1/8" (28.58) 32

Refrigerant Piping Information

Historic Models

Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm)

15 15 10 10 0.900 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.100 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.050 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.150 N/A 1/4" (6.35) 3/8" (9.52)

15 25 15 15 1.350 20 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52)

15 30 20 20 1.400 20 1/4" (6.35) 1/2" (12.7)

15 30 20 20 1.500 20 1/4" (6.35) 1/2" (12.7)

15 30 20 20 1.900 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

20 30 15 15 1.600 20 2x 1/4" (6.35) 2x 3/8" (9.52)

30 40 15 15 2.200 20 3x 1/4" (6.35) 3x 3/8" (9.52)

40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52)

30 30 15 15 2.000 N/A 2x 1/4" (6.35) 2x 3/8" (9.52)

40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52)

40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52)

50 90 20 20 6.000 20 5x 1/4" (6.35) 5x 3/8" (9.52)

30 40 30 15 1.550 20 1/4" (6.35) 1/2" (12.7)

30 40 30 15 1.750 20 1/4" (6.35) 5/8" (15.88)

30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88)

30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88)

30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88)

30 70 30 15 5.400 60 3/8" (9.52) 7/8" (22.22)

30 70 30 15 7.200 120 1/2" (12.7) 7/8" (22.22)

FDC71VN

FDC200VS

FDC250VS

SCM80ZG-S

SCM45ZJ-S

SCM60ZJ-S,S1

SCM80ZJ-S,S1

SCM100,125ZJ-S,S1

FDCVA151,201HEN

FDCVA251HEN

FDCVA302HENR,AR

FDCVA402_602HENR,AR

SRC20,25,35,ZIX,ZJX-S,ZJX-S1

SRC50,60ZFX,ZGX,ZHX,ZIX

SRC50,60ZJX-S

SRC63_71-S,S1

SRC63,71,80,ZK-S

SRC63ZM-S

SRC71_80ZM-S

SCM45ZG-S

SCM60ZG-S

Model

SRC20_25ZD,ZF,ZG

SRC20_325ZGX-S

SRC20,25ZJ-S

SRC35ZD,ZG

SRC35ZJ-S

SRC20ZJ-S1

SRC25,35ZJ-S1

SRC50ZD,ZG,ZJ-S,ZJ-S1

SRK

SRR/ SRF

SRC

Description of Trouble Possible Cause

Run Light

Timer

Light

Green Amber

Red LED

- - - E1 Error of wi red remote Broken wi re, fa ulty indoor P.C.B., faul ty control le r.

OFF Flas hing - E21 Li mit Switch error

Defe ctive limi t switch, ai r inlet pane l s et, I/D

control PCB

1x ON - - He at excha nger s ens or (1) error

Broken he at e xcha nger sensor (1) wire, poor

conne ction

2x ON - E7 Room temperature sens or

Broken room temperature s ens or wi re, poor

conne ction

2x 2x 7x E60 Rotor l ock

Fa ulty compressor, open pha se on compres sor,

faulty outdoor P.C.B.

3x ON - - He at excha nger s ens or (2) error

Broken he at e xcha nger sensor (2) wire, poor

conne ction

4x ON - E9 Drai n Fa ult

Float s witch a ctivated, faulty pump, faulty PCB,

faulty float s witch

5x ON 2x E47 Active Fil ter volta ge e rror Defe ctive Active Fi lter, incorrect power supply

6x ON - E16 I ndoor fan motor e rror Fa ult indoor fan motor, poor connecti on

7x ON 2x E57

Refri geration system prote ctive

control

Service valve clos ed, refrigerant i nsufficient

7x 1x 4x E40

Service valve (ga s s ide) cl osed,

defe ctive outdoor PCB

Output current of i nverter excee ds specifi cation

Fla shing 1x 8x E38 Outdoor ai r temp s ens or Broken s ensor wi re, poor connection

Fla shing 2x 8x E37 Outdoor heat excha nger s ens or Broken s ensor wi re, poor connecti on

Fla shing 4x 8x E39 Dis charge pipe sensor Broken s ensor wi re, poor connection

ON 1x 1x E42 Current Cut

Compressor locki ng, open pha se on compres sor

output, s hort ci rcuit on power transis tor, clos ed

service valve, EEV not opening

ON 2x 2x E59 Trouble of outdoor unit

Broken compre ssor wi re, broke n powe r trans is tor,

broken discharge s ensor wire/poor connection,

compress or bl ockage

ON 3x 3x E58 Current s afe stop

Overload protection, over cha rged, compres sor

locking

ON 4x 1x E51 Power Trans is tor error Faul ty power trans is tor

ON 5x 5x E36 Over heat of compres sor

Low on gas, faulty di scharge pipe senor, cl osed

service valve

ON 6x 6x E3 / E5 Error of s ignal tra nsmi ssi on

Defe ctive powe r suppl y, broken si gnal wire,

faulty indoor/outdoor P.C.B.

ON 7x ON E48 Fa ulty outdoor fa n motor Fa ulty condenser fa n motor, poor conne ction

ON Fla shing 2x E35 Cooling High Press ure Protection

Overload protection, over cha rged, broken

outdoor he at e xcha nger sensor wire, closed

service valve

Outdoor

Control

PCB,

Wired

Remote

Control

Inverter RAC

Outdoor Unit

ZD, ZE, ZE-S1, ZG, ZJ, ZJ-S1,ZM, ZR, ZS, ZFX, ZGX, ZHX, ZIX, ZJX, ZJX-S1,ZMX, ZSX

Indoor Unit Display

RAC FAULT CODES

ZD, ZE, ZE-S1, ZG, ZJ, ZJ-S1,ZM, ZMP, ZR, ZS, ZFX, ZGX, ZHX, ZIX, ZJX, ZJX-S1,ZMX, ZSX

ZIX, ZJX, ZJX-S1,ZMX

Inverter RAC

Indoor Unit

SRK ZJX-S, ZJX-S1 ZK-S

SRR

SRF

FDTC

FDUM

FDEN

SCM

Run Light

Timer

Light

Green Amber

Red LED

- - - E1

Error of wired remote Control

- - 1 E41

Power transistor overheat

- - 2 E40

High pressure error

- - 4 E45

Outd oor main or sub PCB

communication error

- - 8 E54

High pressure sensor

-

Flashing - E21 Limit switch error

1x ON OFF -

Indoor heat excha nger sensor (1)

error

2x ON OFF -

Room temperature sensor

2x 2x 7x E60

Rotor lock

3x ON OFF -

Heat ex chan ger sensor 2 error

4x ON OFF E9

Drain error

5x ON 2x E47

Activ e filter voltage error

6x ON OFF E16

Indoor fan motor error

7x ON 2x E57

Refrigerant cycle system protective

control

Flashing 1x 8x E38 Outdoor air temperature sensor

Flashing 2x 8x E37 Outdoor heat exchanger sensor

Flashing 4x 8x E39 Discharge pipe sensor

Flashing 5x 8x E53 Outdoor suction sensor

ON 1x x1 E42

Current Cut

ON 2x 2x E59

Trouble of outdoor unit

ON 3x 3x E58

Current safe stop

ON 4x 1x E51

Power transistor error

ON 5x 5x E36

Ov er heat of compressor

ON 6x 6x E5

Error of signal transmission

ON 7x Flashing E48

Outd oor fan motor or main PCB

ON Flashing 2x E35

Cooling High Pressure Protection

Faulty pow er transistor or sensor.

Outd oor sub or main PCB faulty, poor connection of wires

betw een outdoor PCBs

Faulty high pressure sensor, faulty control PCB.

Broken sensor wire, poor connection, faulty outdoor PCB

Broken sensor wire, poor connection, faulty outdoor sub

PCB

Faulty compressor, open pha se on compressor, faulty

outdoor P.C.B.

Defective limit switch, air inlet panel set, I/D control PCB

Faulty high pressure sensor, faulty control PCB, poor air

circulation.

Broken wire, faulty indoor P.C.B., faulty controller.

Defective Activ e Filter, incorrect power supply

Faulty indoor fan motor, poor connection

Closed serv ice v alve, insufficient refrigerant

Broken sensor wire, poor connection, faulty outdoor PCB

Broken sensor wire, poor connection, faulty outdoor PCB

Ov erload protection, ov er charged, broken outdoor heat

exchanger sensor wire, closed serv ice v alv e

Broken heat exchanger sensor (1) wire, poor connection

Broken room temperature sensor wire, poor connection

Broken heat exchanger sensor 3 wire, poor connection

Blocked drain, faulty float switch, faulty d rain pump

faulty inv erter PCB, faulty main PCB or faulty fan motor

Low on gas, faulty discharge pipe senor, closed service

v alv e

Defective power supply, broken signal wire, faulty

indoor/outdoor P.C.B.

Faulty condenser fan motor or faulty main P CB

Compressor locking, open phase on compressor output,

short circuit on power transistor, closed service v alv e

Broken compressor wire, broken power transistor, broken

discharge sensor wire or poor connection, compressor

Ov erload protection, ov er charged, compressor locking

Possible Cause

Description of Trouble

Inverter Mul ti

Outdoor

ZJ-S, ZJ-S1, ZM-S

Indoor Unit Display

Outdoor

Control

PCB,

Wired

Remote

Control

ZJ-S,ZJ-S1,ZM-S,ZMX-S

ZJ-S

ZJX-S, ZJX-S1,ZMX-S

VD,VF, VF/1

VF, VF/1

VD, VF, VF/1

Inverter Multi

Indoor

RAC MULTISPLIT FAULT CODES - Current and Previous Models

SKM

SRRM

STM

SCM

Run Light

Timer

Light

Green Amber

Red LED

- - - E1 Error of wired remote

Broken wire, faulty indoor P.C.B., faulty

controller.

1x ON OFF E6

Indoor heat exchanger sensor (1) error

Broken heat exchanger sensor (1) wire, poor

connection

2x ON OFF E7 Room temperature sensor

Broken room temperature sensor wire, poor

connection

2x 2x 7x E60 Rotor lock

Faulty compressor, open phase on

compressor, faulty outdoor P.C.B.

4x ON OFF E9 Drain error

Blocked drain, fault y float swit ch, faulty drain

pump

5x ON OFF E6

Indoor heat exchanger sensor (2) error

Broken heat exchanger sensor (2) wire, poor

connection

6x ON OFF E16 Indoor fan motor error Fault indoor fan motor, poor connecti on

7x ON OFF E6

Closed serv ice valv e, indoor

heat exchanger sensor (1)

Closed serv ice valv e, indoor heat exchanger

disconnected or open circuit

Flashing 1x Flashing E38 Outdoor air temperat ure sensor Broken sensor wire, poor connection

Flashing 2x Flashing E37 Outdoor heat exchanger sensor Broken sensor wire, poor connecti on

Flashing 4x

4 sec

on/off

E39 Discharge pipe sensor Broken sensor wire, poor connection

Flashing 5x Flashing E53 Compressor suct ion sensor Broken sensor wire, poor connecti on

Flashing 6x Flashing E41 Power transistor sensor error Broken sensor wire, poor connection

ON 1x 1x E42 Current Cut

Compressor locki ng, open pha se on compres sor

output, s hort ci rcuit on power transis tor, clos ed

service valve

ON 2x 2x E59 Trouble of outdoor unit

Broken compressor wire, broken power

transist or, broken discharge sensor wire or

ON 3x 3x E58 Current safe st op

Overload protecti on, over charged,

compressor locking

ON 4x 4x E41 Power transistor error Broken power transistor

ON 5x 5x E36 Ov er heat of compressor

Low on gas, fault y discharge pipe senor,

closed serv ice v alv e

ON 6x 6x E5 Error or signal transmission

Defect iv e power supply, broken signal wire,

faulty indoor/outdoor P.C.B.

ON 7x ON E48 Fault y outdoor fan motor Faulty condenser fan motor, poor connecti on

Inverter Multi

Outdoor

ZD-S, ZF-S, ZG-S

Indoor Unit Display

Outdoor

Control

PCB,

Wired

Remote

Control

Description of Trouble

Possible Cause

RAC MULTISPLIT FAULT CODES - Historic Models

ZD, ZF, ZG

ZE, ZF

ZE, ZF

Inverter Multi

Indoor

RED GREEN (1) RED GREEN (1)

Off Flashing Off Flashing - Normal Operati on

Off Off 2x Off Indoor unit power supply

Power OFF, broken wire, blown fuse, broken

transformer wire

Remote cont rol ler wires Poor or wrong connection, broken wire

Remote cont rol ler Faulty Remote controller

Communicati on error

(indoor-outdoor)

Faulty interconnect wiring, faulty PCB

Remote Control ler

Improper set t ing of master and slave by

Remote Control ler

E1 Off Flashing Off Flashing

Communicati on error

(indoor-remot e control)

Poor or wrong connection, broken wire,

intrusion of noise, faulty indoor PCB or

2x Flashing 2x Flashing

Indoor - Outdoor

communication fault

Poor connection, incorrect wiri ng, indoor or

outdoor PCB

Elect rical Noise CPU Runaway on Outdoor cont rol PCB

Outdoor Control PCB

Faulty Outdoor Control PCB

(Communicat ion Circuit)

2x Flashing Off Off Outdoor Control PCB Faulty Outdoor Control PCB or Power supply

E6 1x Fl ashing Off Flashing

Indoor heat exchanger

temp sensor

Faulty sensor, poor connecti on, faulty

indoor PCB

E7 1x Fl ashing Off Flashing

Indoor ret urn air temp

sensor

Faulty sensor, poor connecti on, faulty

indoor PCB

E8 1x Fl ashing Off Flashing

Indoor heat exchanger

temp sensor

Heating overload, faulty sensor, faulty

indoor PCB

E9 1x Fl ashing Off Flashing Fl oat swit ch activ at ed

Blocked drain, fault y pump, fault y indoor

PCB, faulty float switch

E10 Off Flashing Off Fl ashing

No. of indoor units

connected

Too many units connected to 1 cont rol ler

(MAX 16)

E14 3x Flashing Off Flashing Remote controll er Fault

No master assigned to slav es, incorrect

wiri ng, broken wire between master &

E16 1x Flashing Off Flashing Indoor fan motor

Faulty Indoor fan motor, poor connection,

faulty indoor PCB

E18 1x Flashing Off Flashing Address Setti ng Error

Address sett ing error of master and slav e

indoor units

E19 1x Flashing Off Flashing Mode Setting Incorrect mode sett ing

E20 1x Flashing Off Flashing Indoor fan motor

Fan motor speed fault or fault y indoor

Power PCB

E21 1x Flashing Off Flashing Panel Li mit Swit ch error

Defect iv e limit switch, air inlet panel set,

I/D control PCB

E28 Off Flashing Off Fl ashing

Remote Control ler temp

sensor

Faulty Remote controller t emp sensor

FDU

VF, VF/1, VG

FDUM

1, 1R, V, VD, VF, VF/1

PAC SELF-DIAGNOSIS INFORMATION

FDT

V, VD, VF, VF/1, VG

FDTC

V, VD, VF, VF/1,

Inverter

PAC

Indoor

Units

FDEVGFDEN

V, VD, VF, VF/1

Flashing

Off

Flashing

2x

E5

FDF

VD

Indoor PCB LEDs

Outdoor unit LEDs

Error Code

Description of Fault

Possible Cause

No Error

Code

"W AIT" or

"INS PECT I/U"

3x

Flashing

Off

Off

Flashing

2x

Flashing

Flashing

FDCVA

FDC

RED GREEN (1) RED GREEN (1) INV LED

E33 Off Flashing 1x Flashing - Power supply Anomalous current on inver ter primary side

E34 Off Flashing 1x Flashing Flashing Power supply

Phase open circuit , faulty outdoor control

PCB (3 Phase model)

E35 Off Flashing 1x Flashing Flashing

Outdoor heat exchanger

thermist or

Over heat of condenser, fault y thermistor,

faulty outdoor PCB

E36 Off Flashing 1x Flashing Flashing Discharge pipe thermist or

High discharge temp, fault y sensor, faulty

outdoor control PCB

E37 Off Flashing 1x Flashing Flashing

Outdoor heat exchanger

thermist or

Poor connection, broken wire, faulty

thermist or, faulty PCB

E38 Off Flashing 1x Flashing Flashing Outdoor ambient air sensor

Poor connection, broken wire, faulty

thermist or, faulty PCB

E39 Off Flashing 1x Flashing Flashing Discharge pipe thermist or

Poor connection, broken wire, faulty

thermist or, faulty PCB

E40 Off Flashing 1x Flashing Flashing High Press ure Error

Activ at ion of HP swit ch (63H1), closed

serv ice valv e, faulty PCB (63H1 Circuit )

E41 Off Flashing 1x Flashing 2 or 6x Power Transi st or ov erheat Short circuit of air flow, faulty Inverter PCB

E42 Off Flashing 1x Flashing 1 or 5x Current Cut

Closed serv ice valve, faulty outdoor

control PCB

E45 Off Flashing 1x Flashing Flashing

Communicati on Error -

Invert er t o Control PCB

Poor Connection, faulty control or inv ert er

PCBs

E47 Off Flashing 1x Flashing 7x

Control PCB, Power

transist or

Anomalous inv ert er ov er voltage

E48 Off Flashing 1x Flashing Flashing Condenser fan motor Fault y fan motor or outdoor PCB

E49 Off Flashing 1x Flashing Flashing Low Pressure Error

Closed serv ice valve, short of gas, faulty LP

sensor, fault y outdoor cont rol PCB

E51 Off Flashing 1x Flashing 2 or 6x Inv erter Error Fault y Inverter PCB

E53 Off Flashing 1x Flashing Flashing S uction pipe thermist or

Poor connection, broken wire, faulty

thermist or, faulty PCB

E54 Off Flashing 1x Flashing Flashing Low Pressure S ensor Error

Closed serv ice valve, short of gas, faulty LP

sensor, fault y outdoor cont rol PCB

E55 Off Flashing 1x Flashing Flashing

Under-dome temp

thermist or

Poor connection, broken wire, faulty

thermist or, faulty PCB

E57 Off Flashing 1x Flashing Flashing Low Pressure Error Insufficient refri gerant

E59 Off Flashing 5x Flashing Off or 4x Compressor start up error Fault y power supply, fault y inverter circuit .

E60 Off Flashing 1x Flashing - Compressor Fault y compressor, faulty inv ert er circuit.

E75 Off Flashing Off Flashing -

Central Control ler

communication error

Poor connection, broken wire, faulty

controller

Error Code

Description of Fault

Possible Cause

Inverter PAC

Outdoor

PAC SELF-DIAGNOSIS INFORMATION

HEN, HENR, HENAR

VN, VNP, VS, VSA, VNX,VSX

Indoor PCB LEDs

Outdoor unit LEDs

SRC

Run Light Timer Light

Green Amber

Red LED

Installation, operation stat us Higher outdoor heat exchanger temp

Outdoor heat exchanger temp

sensor

Faulty outdoor heat exchanger temp sensor

Outdoor control PCB

Faulty outdoor control PCB (temperature

sensor input circuit )

Installation, operation stat us Higher discharge temperature

Discharge pipe temperature

sensor

Faulty discharge pipe sensor

Outdoor control PCB

Faulty outdoor control PCB (temperature

sensor input circuit )

Outdoor heat exchanger temp

sensor

Faulty outdoor heat exchanger temp sensor,

broken wire or poor connecti on

Outdoor control PCB

Faulty outdoor control PCB (temperature

sensor input circuit )

Outdoor air temperat ure sensor

Faulty outdoor air t emp sensor, broken wire or

poor connection

Outdoor control PCB

Faulty outdoor control PCB (temperature

sensor input circuit )

Discharge pipe temperature

sensor

Faulty discharge pipe sensor, broken wire,

poor connection

Outdoor control PCB

Faulty outdoor control PCB (temperature

sensor input circuit )

Outdoor control PCB,

compressor

Current cut (anomalous compressor ov er

current )

Installation, operation stat us S ervice valv e cl osi ng operati on

E47 Off Fl ashing 2x

Outdoor control PCB, power

transist or

Anomalous inv ert er ov er current

Outdoor fan motor Faulty outdoor fan motor

Outdoor control PCB Faulty outdoor control PCB

E51 Off Fl ashing 1x

Power transistor, outdoor control

PCB

Power transistor error

Operation stat us Shortage of refrigerant

Installation stat us Serv ice v alv e closed

E58 Off Fl ashing 3x Current safe st op

Overload operation, over charge,

compressor locking

E59 Off Fl ashing 2x Compressor, outdoor control PCB Anomalous compressor start up

E60 Off Fl ashing 7x Compressor Anomalous compressor rot or lock

E57

Off

Flashing

2x

Error Code

Location of trouble

Description of trouble

8x

Flashing

Off

E39

1x

Flashing

Off

E42

E48

Off

Flashing

Flashing

E35

2x

Flashing

Off

E36

Off

Flashing

5x

E37

8x

Flashing

Off

E38

Off

Flashing

8x

PAC SELF-DIAGNOSIS INFORMATION

Inverter PAC

Outdoor

ZHX-S, ZIX-S, ZJX-S,ZMX-S, ZSX-S

Indoor Unit Display

Outdoor

Control

PCB,

KX High Wall Indoor Units on Wireless Remote Control

When fitted with the wi reless remote control kit the high wall uni ts do not show the error code on an digital readout. The error code is indicated in the follow ing manner.

FDK15-56KXE6 FDK71KXE6 FDK15-56KXZE1 FDK71-90KXZE1

The 'TIMER/CHECK' LED on the KX6 indoor units will fl ash continously to indicate there is a fault.

On both the KX6 and the KXZE1 high wall units the actual error code is indicated by the numbe r of flashes (0.5s on/0.5s off) in a 10 second period of the 'CHECK1' / 'RUN/CHECK1' (tens) and the 'CHECK2' / 'TIMER / CHECK2' (ones) LEDs.

ie An E39 High Discharge fault would be indicated as follows

KX6 KXZE1 Flash Rate

On Off

CHECK1 RUN/CHECK1

(Orange (Green)

CHECK2 TIMER/CHECK2

(Orange) (Orange)

0.5s

0.5s

0.5s

0.5s

Error Code

O/D 7

segment

display

Green Red Green Red Location of Trouble P robable Causes

E1

keeps

flashing

stays off

keeps

flashing

stays off

Communication error (indoor-

remote control)

Poor or wrong connection, broken wire, intrusion

of noise, faulty indoor PCB or remote control

E2

keeps

flashing

keeps

flashing

keeps

flashing

stays off Duplicated indoor unit ad dress

Number of connected indoor units exceeds the

limitation, duplicat ed indoor unit address,

indoor control PWB anomaly.

E3

keeps

flashing

2x or stays

off

keeps

flashing

stays off Outdoor unit signal line error

Power not sup plied to the O /D unit, mismatch

of pairing between I/D and O/D units, indoor

control PWB anomaly, Outdoor control PWB

anomaly, M issing local wiring.

E5

keeps

flashing

2xor stays

off

keeps

flashing

2x

Communication error during

operation

Unit a ddress number setting error, remote

control wires broken, poor

connection/disconnection of remote control

wires, indoor control PWB anomaly

E6

keeps

flashing

1 x

keeps

flashing

stays off

Indoor heat exchanger

thermistor anomaly

Anomalous connection of I/D heat exchanger

temperature thermistor, I/D heat exchanger

thermistor anomaly, I/D control PWB anomaly

E7

keeps

flashing

1x

keeps

flashing

stays off

Indoor return air temperature

thermistor anomaly

Anomalous connection of I/D return air

temperature thermistor, I/D return air thermistor

anomaly, I/D control PWB anomaly

E9

keeps

flashing

1x

keeps

flashing

stays off Drainage trouble

I/D control PWB anomaly, Mistake in setting of

float switch, mistake in setting of optional

equipment, mistake in drain piping, drain motor

anomaly, disconnection/breakage of drain

motor wires

E10

keeps

flashing

stays off

keeps

flashing

stays off

Excessiv e number of indoor

units (more than 17 units) by

controlling one remote control

Excessiv e number of I/D units, remote control

anomaly

E11

keeps

flashing

stays off

keeps

flashing

stays off

Address setting error between

master and slav e indoor units

IU add ress has been set using the "Master IU

add ress set" function of remote control

E12

keeps

flashing

keeps

flashing

keeps

flashing

stays off

Address setting error by mixed

setting method

Automatic address setting and manual address

setting method are mixed when setting add ress

of indoor units

E16

keeps

flashing

1x

keeps

flashing

stays off

Indoor fan motor anomaly

(FDT, FDTC, FDTW, FDTS, FDU,

FDUM, FDK, FDUT71, FDFW

series)

I/D fan motor anomaly, foreign matter at

rotational area of fan propeller, fan motor

anomaly, dust on control PWB, blown fuse,

external noise, surge

E18

keeps

flashing

1x

keeps

flashing

stays off

Address setting error of master

and slav e indoor units

Address setting error of the master indoor unit,

no power to the master indoor unit, no

connection of super link signal wires between

master and slav e indoor unit

E19

keeps

flashing

1x

keeps

flashing

stays off

Indoor unit operation check

drain motor check mode

anomaly

Mistake in SW 7-1 setting due to forgetting to

turn off SW7-1 after indoor operation check

KX SELF-DIAGNOSIS INFORMATION

FDCA----HKXE4_HXKRE4. FDC----KXEN6, KXE6, KXRE6, KXZE1, KXZPE1,

KXZRE1

Inverter KX

LED Display

Indoor PCB

Outdoor PCB

KX SELF-DIAGNOSIS INFORMATION

Error Code

O/D 7

segment

display

Green Red Green Red Location of Trou ble P robable Causes

E20

keeps

flashing

1x

keeps

flashing

stays off

Indoor fan motor speed

anomaly (FDT, FDTC, FDTW,

FDTS, FDU, FDUM , FDK, FDUT71,

FDFW series)

I/D fan motor anomaly, foreign matter at

rotational area of fan propeller, fan motor

anomaly, dust on control PWB, blown fuse,

external noise, surge

E21

keeps

flashing

1x

keeps

flashing

stays off

Defective panel switch

operation (FDT)

Defective panel switch, d isconnection of wiring,

defectiv e I/D control PWB

E22

keeps

flashing

2x

keeps

flashing

stays off

Wrong connection with

Outd oor unit

Unmatched pa iring of 1.5kW KX indoor and KX6

/KXR6 outdoor unit, Indoor control PCB

anomaly, Outdoor control PCB anomaly

E28

keeps

flashing

stays off

keeps

flashing

stays off

Remote control temperature

thermistor anomaly (Thc)

Anomalous connection of remote control

temperature thermistor, remote control

temperature thermistor anomaly, remote control

PWB anomaly

E30

keeps

flashing

stays off

keeps

flashing

1x

Unmatched connection of

indoor and outdoor unit

Indoor control PCB anomaly, Outdoor control

PCB anomaly

E31

keeps

flashing

stays off

keeps

flashing

1x

Duplicated out door unit

add ress number

Mistake in ad dress setting of outdoor units, more

than 129 I/D units connected, no setting of

master/slav e setting switch for combination use

E32

keeps

flashing

stays off

keeps

flashing

2x

Open L3 phase on pow er

supply a t primary side

Anomalous power supp ly at primary side,

outdoor control PWB anomaly

E36-1

keeps

flashing

stays off

keeps

flashing

1x

Discharge pipe temperature

error, Tho-D1

E36-2

keeps

flashing

stays off

keeps

flashing

2x

Discharge pipe temperature

error, Tho-D2

E36-3

keeps

flashing

stays off

keeps

flashing

3x Liquid flooding anomaly KX6 product only

E37-1

keeps

flashing

stays off

keeps

flashing

1x

Outd oor heat excha nger

temperature thermistor

anomaly, Tho-R1

E37-2

keeps

flashing

stays off

keeps

flashing

2x

Outd oor heat excha nger

temperature thermistor

anomaly, Tho-R2

E37-3

keeps

flashing

stays off

keeps

flashing

3x

Outd oor heat excha nger

temperature thermistor

anomaly, Tho-R3

E37-4

keeps

flashing

stays off

keeps

flashing

4x

Outd oor heat excha nger

temperature thermistor

anomaly, Tho-R4

E37-5

keeps

flashing

stays off

keeps

flashing

5x

Outd oor sub cooling coil

temperature thermistor 1

anomaly, Tho-SC

E37-6

keeps

flashing

stays off

keeps

flashing

6x

Outd oor sub cooling coil

temperature thermistor 2

anomaly, Tho-H

E38

keeps

flashing

stays off

keeps

flashing

1x

Outd oor air temperature

thermistor anomaly, Tho-A

E39-1

keeps

flashing

stays off

keeps

flashing

1x

Discharge pipe temperature

thermistor anomaly, Tho-D1

E39-2

keeps

flashing

stays off

keeps

flashing

2x

Discharge pipe temperature

thermistor anomaly, Tho-D2

E40

keeps

flashing

stays off

keeps

flashing

1x

High Pressure anomaly, 63H1-1,

2 activ ated

Short circuit of airflow at condenser side of heat

exchanger/disturbance of airflow/clogging

filter/fan motor anomaly, disconnection of high

E41-1

keeps

flashing

stays off

keeps

flashing

1x

Power transistor overheat,

CM1

E41-2

keeps

flashing

stays off

keeps

flashing

2x

Power transist or overheat,

CM2

E42-1

keeps

flashing

stays off

keeps

flashing

1x Current cut, CM 1

E42-2

keeps

flashing

stays off

keeps

flashing

2x Current cut, CM 2

Broken thermistor harness or the internal wire of

sensing section, disconnection of thermistor

harness connection, O/D control PWB anomaly

KX SELF-DIAGNOSIS INFORMATION

Inverter KX

LED Display

FDCA----HKXE4_HXKRE4. FDC----KXEN6, KXE6, KXRE6, KXZE1, KXZPE1

Indoor PCB

Outdoor PCB

Compressor anomaly, refrigerant leak, power

transistor module anomaly, anomalous pow er

supply for INV PWB, O/D fan motor anomaly

Discharge pipe temperature anomaly, SV1,2

anomaly, breakage in coil, faulty main body,

O/D control PWB anomaly, insufficient amount

of refrigerant, insufficient airflow v olume, short

circuit of airflow

E39

E37

E36

E41

Anomalous high temperature of power

transistor is detected 5 times within 60 minutes.

Power transistor anomaly, power transistor

temperature thermistor anomaly, inv erter PWB

anomaly, outdoor fan motor anomaly,

anomalous cooling fan motor for inv erter

E42

Error Code

O/D 7

Green Red Green Red Location of Trou ble P robable Causes

E43-1

keeps

flashing

stays off

keeps

flashing

1x

Excessiv e number of indoor

units connected

E43-2

keeps

flashing

stays off

keeps

flashing

2x

Excessiv e total capacity of

connection

E44-1

keeps

flashing

stays off

keeps

flashing

1x Liquid flooding anomaly, CM1

E44-2

keeps

flashing

stays off

keeps

flashing

2x Liquid flooding anomaly, CM2

E45-1

keeps

flashing

stays off

keeps

flashing

1x

Communication error betw een

inv erter PWB and outdoor

control PWB, INV 1

E45-2

keeps

flashing

stays off

keeps

flashing

2x

Communication error betw een

inv erter PWB and outdoor

control PWB, INV 2

E46

keeps

flashing

stays off

keeps

flashing

stays off

Mix ed ad dress setting methods

coexist in the same network

Mistake in the address setting, mistake in the

connection of signal wire

E48-1

keeps

flashing

stays off

keeps

flashing

1x

Outd oor DC fan motor

anomaly, FMO 1

E48-2

keeps

flashing

stays off

keeps

flashing

2x

Outd oor DC fan motor

anomaly, FMO 2

E49

keeps

flashing

stays off

keeps

flashing

1x Low p ressure anomaly

Low pressure sensor (PSL) anomaly, service

v alves closed, EEV anomaly, insufficient

refrigerant amount, clogging at EEV or strainer

E51-1

keeps

flashing

stays off

keeps

flashing

1x

Power transistor overheat,

CM1

E51-2

keeps

flashing

stays off

keeps

flashing

2x

Power transistor overheat,

CM2

E53-1

keeps

flashing

stays off

keeps

flashing

1x

Suction pipe temperature

thermistor anomaly, Tho-S,

CM1

E53-2

keeps

flashing

stays off

keeps

flashing

2x

Suction pipe

temperaturethermistor

anomaly, Tho-S, CM 2

E54-1

keeps

flashing

stays off

keeps

flashing

1x Low p ressure anomaly (PSL)

E54-2

keeps

flashing

stays off

keeps

flashing

2x High pressure anomaly (PSH)

E55-1

keeps

flashing

stays off

keeps

flashing

1x

Und er dome temperature

thermistor anomaly, Tho-C1

E55-2

keeps

flashing

stays off

keeps

flashing

2x

Und er dome temperature

thermistor anomaly, Tho-C2

E56-1

keeps

flashing

stays off

keeps

flashing

1x

Power transistor temperature

anomaly, Tho- P1

E56-2

keeps

flashing

stays off

keeps

flashing

2x

Power transistor temperature

anomaly, Tho- P2

E58-1

keeps

flashing

stays off

keeps

flashing

1x

Anomalous compressor by loss

of synchronism, CM1

E58-2

keeps

flashing

stays off

keeps

flashing

2x

Anomalous compressor by loss

of synchronism, CM2

E59-1

keeps

flashing

stays off

keeps

flashing

1x

Compressor start up failure,

CM1

E59-2

keeps

flashing

stays off

keeps

flashing

2x

Compressor start up failure,

CM2

E48

E53

Broken sensor harness, disconnection of sensor

harness connection, sensor (PSH, PSL) anomaly,

O/D control PWB anomaly, a nomalous

installation conditions, insufficient airflow

v olume, excessive or insufficient refrigerant

amount

E54

Anomalous v oltage of power supply,

anomalous components for refrigerant circuit,

inv erter PWB anomaly, loose connection of

connector or cable, compressor anomaly

(motor or bearing)

KX SELF-DIAGNOSIS INFORMATION

Inverter KX

LED Display

FDCA----HKXE4_HXKRE4. FDC----KXEN6, KXE6, KXRE6, KXZE1, KXZPE1,

KXZRE1

Indoor PCB

Outdoor PCB

Broken thermistor harness or the internal wire of

sensing section, disconnection of thermistor

harness connection, O/D control PWB anomaly

E56

E55

Broken thermistor harness or the internal wire of

sensing section, disconnection of thermistor

harness connection, O/D control PWB anomaly

Broken thermistor harness or the internal wire of

sensing section, disconnection of thermistor

harness connection, O/D control PWB anomaly

Broken or disconnected wire, faulty fan motor,

defectiv e inv erter PWB, defectiv e control PWB,

defectiv e power transistor, defectiv e diode

module, defective surge suppressor resistor

Signal wire anomaly, O/D control PWB

anomaly, INV PWB an omaly, inrush current

prev ention resistor anomaly, defectiv e 52C or

52X, defectiv e diode module

Insufficient time elapsed after the power

supplied b efore compressor start up (unit

started w ithout crankcase heater ON),

compressor anomaly, inv erter PWB anomaly,

power tran sistor anomaly

E58

E59

Mistake in setting of I/D or O/D addresses,

mistake in signal wire connection

E43

KXZ Product only. M ismatching of refrigerant

piping and or signal wiring, overcharging of

refrigerant, anomalous control of superheat,

anomalous circuit of liquid refrigerant by-pa ss,

anomalous refrigerant circuit of sub cooling coil,

under dome temperature Tho-D1, D2 anomaly

E44

E45

E51

Anomalous high temperature of power transistor

is detected 15 minutes continuously. Broken

thermistor harness or the internal wire of sensing

section, disconnection of thermistor harness

connection, O/D control PWB anomaly

Testing Method

1) Setup Procedure

a) Turn off the power to the system.

b) Allow the compressor to cool (if it was greater than 30°C)

c) Remove the terminal cover from the compressor and disconnect the wires U, V and W.

d) With your multimeter set for Ohms (Ω) check the resistances U-V, V-W, U-W.

All three readings should be balanced and less than 1.5Ω

e) Using a Mega meter or the mega Ohms (MΩ) setting on your multimeter test the resistance

of a compressor terminal to Earth, either on an unpainted part of the compressor body or

condensing unit chassis or to an earth terminal in the electrics box.

Alternatively, if you do not have a Mega meter set your multi meter to the highest resistance

setting available to do the test.

The reading should be greater than 1MΩ on a Mega meter or infinity on a multi meter.

2) Diagnosis

If the any of the terminal to terminal readings read infinity or over range then you have an open

circuit winding.

If any of the terminal to terminal readings are less than 0.1Ω then you have a short circuit in the

compressor windings.

If the reading between the compressor terminal and earth is low, ie measured in Ohms, then the

compressor windings are down to earth

If the reading to earth is not 0Ω or is less than 1 MΩ (or infinity on a multi meter) then you could have

moisture in the system so repeat test e) after running the system for 5-10 minutes. Do not wait for the

compressor to cool down for this second test.

Error Code

O/D 7

segment

display

Green Red Green Red Location of Trouble P robable Causes

E60-1

Keeps

flashing

Stays off

Keeps

flashing

1x

Rotor position detection error,

CM1

E60-2

Keeps

flashing

Stays off

Keeps

flashing

2x

Rotor position detection error,

CM2

E61-1

keeps

flashing

stays off

keeps

flashing

1x

Communication error betw een

the master unit an d slav e units,

Slav e unit 1

E61-2

keeps

flashing

stays off

keeps

flashing

2x

Communication error betw een

the master unit an d slav e units,

Slav e unit 2

E63

keeps

flashing

stays off

keeps

flashing

1x

Emergency stop. When a n ON

signal is inputted to th e CNT

terminal of I/D control PWB

Factor for emergency stop

E75

keeps

flashing

stays off

keeps

flashing

stays off

Central control

communications error

Poor connection, broken wire, faulty controller

E85

keeps

flashing

stays off

keeps

flashing

stays off Ind oor unit PCB setting error

The indoor PCB has been replaced but the

links/switches on the replacement hav e not

been configured the same as on the original

PCB, specifically SW8-3/J7 which is currently

open/off and needs to be closed/on.

-

OPE 3

keeps

flashing

stays off

keeps

flashing

stays off

Ma ster/Slav e Outdoor Unit

Control Switch Error

Inv alid combination of outdoor units

-

OPE 7

keeps

flashing

stays off

keeps

flashing

stays off SW4 S etting incorrect

Correct the SW4 settings to match the outd oor

unit model.

-

OPE 10

keeps

flashing

stays off

keeps

flashing

stays off

SW5 setting (Test Run or Pump

down ) in slav e outdoor unit

Reset the SW5 switchs as the required function

can only be initiated in the master outd oor unit

KX4 & KX6 P roduct. If it fails to detect the rotor

position of compressor, after changing ov er to

the operation of compressor rotor position

detection, the compressor stops. It restarts

automatically after 3 minutes delay. If this

anomaly occurs 4 times within 15 minutes after

the initial detection, error is displayed

E60

Signal wire anomaly, O/D control PWB

anomaly, INV PWB an omaly, inrush current

prev ention resistor anomaly

E61

KX SELF-DIAGNOSIS INFORMATION

Inverter KX

LED Display

FDCA----HKXE4_HXKRE4. FDC----KXEN6, KXE6, KXRE6, KXZE1, KXZPE1,

KXZRE1

Indoor PCB

Outdoor PCB

Compressor Windings Resistances

Type A SRC & KX4 Outdoor Units

Testing Method

1) Setup Procedure

a) Turn off the power to the system.

b) Remove the terminal cover from the compressor and disconnect the wires U, V and W.

c) Connect the disconnected wires to the inverter checker U (Red), V (White) and W (Black).

2) Operation for Judgement.

a) Turn on the power to the system and start a test run operation in cooling or heating mode.

b) Check the on/off status of the 6 LED’s of the inverter checker.

c) Judge the Inverter PCB by the ON/OFF status of the 6LED’s of the inverter checker.

d) Stop the test run within within 2 minutes from starting it.

1. RAC 2. PAC

Model Type (FDC***VN, VS, VNX, VSX)

SRC ZG-S, ZGX-S, SCM ZG-S A Capacity Type

SCM100~125ZJ-S1 B 1Ph 3Ph

SRC40~60ZJX-S, SRC63~80ZK-S 71VN/VNX B

SRC20~50ZJ-S/C, SRC25~60ZJX-S/C 71~100VNP C

SRC25~45ZJP-S1, SCM40-80ZJ-S/C 100, 125, 140 B B

SRC40~60ZHX, SRC40~60ZIX-S 200, 250 A

SRC20~50ZJ-S, SRC25~35ZJX-S

SRC25~45ZJP-S, SCM40~80ZJ-S

2. KX

Unit Settings for Inverter Checker Test (FDCA***KXK('R)E4R, FDC***KX('R)E6)

Type A: No special settings required Capacity Type

Type B: Requires dip switch SW10-4 turning ON KX4 KX6

Type C: Connector required to put unit in TEST mode 112, 140, 155 A B

Type D: Not compatible with inverter checker. 224, 280 A B

335 ~680 A B

Inverter Types

Type A: 120° Conduction Control

Type B, C & D: Vector Control

C

D

Test Procedure – Inverter Checker Compatibility

Test Procedure – Using an Inverter Checker

Type B - FDC VN, VS, VNA, VSA, VNX, VSX & KX6 Outdoor Units

Testing Method

1) Setup Procedure

a) Turn off the power to the system.

b) Remove the terminal cover from the compressor and disconnect the wires U, V and W.

c) Connect the disconnected wires to the inverter checker U (Red), V (White) and W (Black).

d) Switch JSW10-4 on the outdoor units inverter PCB ON.

Operation for Judgement

2) a) Turn on the power to the system.

b) About 15seconds after the power was switched on the LEDs should start to cycle 5seconds ON/OFF

c) Check the on/off status of the 6 LED’s of the inverter checker.

d) Judge the Inverter PCB by the ON/OFF status of the 6 LED’s of the inverter checker

e) Switch OFF JSW10-4 on the inverter PCB once test has been completed.

Type C - SRC & FDC VNP Outdoor Units

Testing Method

3) Setup Procedure

f) Turn off the power to the system.

g) Remove the terminal cover from the compressor and disconnect the wires U, V and W.

h) Connect the disconnected wires to the inverter checker U (Red), V (White) and W (Black).

i) With the mains power OFF connect a short connector to CNROM on the PCB linking

pins 2 and 3.

SHORT

CONNECTOR

4) Operation for Judgement

a) Turn on the power to the system.

b) About 15seconds after the power was switched on the LEDs should start to cycle 5seconds ON/OFF

c) Check the on/off status of the 6 LED’s of the inverter checker.

d) Judge the Inverter PCB by the ON/OFF status of the 6 LED’s of the inverter checker

e) Power off and remove the short connector from CNROM once test has been completed.

Test Procedure – Using an Inverter Checker

“WARNING” Power off the unit, waiting a minimum 3 minutes before removing any applicable wiring. Ensure to

measure that the DC voltage has discharged sufficiently before carrying out the below testing.

1 Phase Diode Module

3 Phase Diode Module

Test No. Tester (+) Tester (-) Result using Multimeter Result using Diode Tester

(Red) (Black) (Resistance) (Buzzer)

1 (1) (4) Several MΩ On

2 (2) (4) Several MΩ On

3 (5) (1) Several MΩ On

4 (5) (2) Several MΩ On

5 (4) (1) Several 10MΩ Off

6 (4) (2) Several 10MΩ Off

7 (1) (5) Several 10MΩ Off

8 (2) (5) Several 10MΩ Off

Layout of Diode Module

Measure the resistance of the points (N0. 1-12) as shown in the following table using a circuit tester.

- are the terminal No. shown in the above drawing.

No. Tester (+) Tester (-) Resistance Remarks

(Red) (Black) (Ohm)

1 Several MΩ Upper arm U in normal direction

2 Several MΩ Upper arm V in normal direction

3 Several MΩ Upper arm W in normal direction

4 Several MΩ Lower arm U in normal direction

5 Several MΩ Lower arm V in normal direction

6 Several MΩ Lower arm W in normal direction

7 Several 10MΩ Upper arm U in reverse direction

8 Several 10MΩ Upper arm V in reverse direction

9 Several 10MΩ Upper arm W in reverse direction

10 Several 10MΩ Lower arm U in reverse direction

11 Several 10MΩ Lower arm V in reverse direction

12 Several 10MΩ Lower arm W in reverse direction

<Judgement>

i) If the resistance is 0-several kOhms the diode module could be burnt.

ii) If the resistance is infinity (∞), the diode module could be burnt

# In case that the jugement is i) or ii) above replace the diode module

1

5

Test Procedure – 1PH & 3PH Diode Module

“WARNING” Power off the unit, waiting a minimum 3 minutes before removing any applicable wiring. Ensure to

measure that the DC voltage has discharged sufficiently before carrying out the below testing.

Measure the resistance of the points shown in the following table using a circuit tester.

P, N, U, V and W are the terminal No. shown in the above drawing.

Tester (+) Tester (-) Result using Multimeter

(Red) (Black) (Resistance)

P N OL / Several 10MΩ

N P Several MΩ

P U OL / Several 10MΩ

P V OL / Several 10MΩ

P W OL / Several 10MΩ

N U Several 100kΩ

N V Several 100kΩ

N W Several 100kΩ

U P Several 100kΩ

V P Several 100kΩ

W P Several 100kΩ

U N OL / Several 10MΩ

V N OL / Several 10MΩ

W N OL / Several 10MΩ

<Judgement>

If the resistance is 0- a few kOhms there is a possibility that the elements are damaged

so replace the power transistor.

Test Procedure – 3 PH Transistor Module

“WARNING” Power off the unit,

waiting a minimum 3 minutes before

removing any applicable wiring.

Ensure to measure that the DC

voltage has discharged sufficiently

before carrying out the below

testing.

Measure the resistance points

as per the following table by

Multimeter.

If readings are within

the nominated table

values, it is normal.

From To Reference Resistance Old New

White Red 45 - 50 Ohms Yes Yes

Red Orange 45 - 50 Ohms Yes Yes

Orange White 90 - 100 Ohms Yes Yes

Yellow Brown 45 - 50 Ohms Yes not applicable

Brown Blue 45 - 50 Ohms Yes not applicable

Blue Yellow 90 - 100 Ohms Yes Yes

Yellow Red 45 - 50 Ohms not applicable Yes

Red Blue 45 - 50 Ohms not applicable Yes

Blue Yellow 90 - 100 Ohms not applicable Yes

Test Procedure – Electronic Expansion Valve

Old

New

Lead wires = 6

Lead wires = 5

Inner Circuit of EEV Solenoid Coil

f

Expected Readings of Control PWB VDC Outputs to

DCFM

Expected Readings of DC Fan Motor Circuit Board

Resistances

Multi Meter Test Points for VDC

Multi Meter Test Points for Ω

Multimeter Red

Probe

Multimeter

Black Probe

PCB DC Volts

Multimeter

Black Probe

Multimeter

Red Probe

DCFM PWB Resistance

Value

Vm

Gnd

# 300 ~ 350 Vdc

Vm

Gnd

# > 1 MΩ

Vcc

Gnd

# 15 Vdc

Vcc

Gnd

# > 4 KΩ

Vsp

Gnd

* 2 ~ 7 Vdc

Vsp

Gnd

# > 100 KΩ

Vfg

Gnd

* 2 ~ 7 Vdc

Vfg

Gnd

* All Series – Voltages are only present during operation.

# ZM Series onwards - Voltages are only present

during operation.

# If Resistance Values are ok, confirm with DCFM Tester.

Note: If no resistance value is evident, reverse multimeter

probes and re-test.

Wiring of DC Fan Motor

DC Fan Motor Type

Type A

Type B / C

Type D

Vm

Motor Power Voltage Input

Red

Red

Red

Gnd

Ground

Black

Blue

Black

Vcc

Control Power Voltage Input

White

Brown

White

Vsp

Speed Control Voltage Input

Yellow

Orange

Yellow

Vfg

Revolution Pulse Output

Blue

White

Blue

IMPORTANT NOTE: The current version of the DCFM Tool, Part No: RMA006A012A (short/wide model) can run/test

the Type C fan motor. The original version of the DCFM Tool, Part No: RMA006A012 (long/narrow model) cannot

run/test the Type C fan motor.

DC FAN MOTOR TESTING

Type “A” Fan Motor

Type “B / C” Fan Motor

Type ‘D’ Fan Motor

DC FAN MOTOR TESTING

Type B (RAC)

Type C (PAC)

KX Models

Resistance of motor's coil

Connection Table of Power Lead Wires

Connection Table of Sensor Lead Wires

REV : Reverse turn detection output

Vsp : Speed command output

FG : RPM monitor input

Over C : Over -current error input

Outline of the driver circuit

DC FAN MOTOR TESTING

Refrigerant Pressure Cause

Location Extra Low Low Normal High Extra High

Excessive refrigerant overcharge

Non condensibles in the system

Faulty outdoor fan motor

High Side

Blocked outdoor unit heat exchanger

Liquid flooded outdoor heat exchanger

High indoor return air temperature

Excessive load

Insufficient refigerant

Gas leak

Blockage

Ineffective compressor compression

Liquid refrigerant flooding back from indoor unit

High indoor return air temperature

High ambient temperature

Mixture of non condensibles

Lack of Load

Restricted/Blocked liquid line

Low refrigerant charge

Blocked filter

Indoor fan fault

Dirty indoor unit heat exchanger

Low Side

Mixture of non condensibles

Bypass valve open

TROUBLE SHOOTING REFRIGERATION SYSTEM

High Side

•

High Side

Low Side

High Side

Low Side

High Side

Low Side

Low Side

Low Side

•••

•••

•

•

•

Colour of Compressor oil

Sample Oil State

Number

0 - 1 Normal

2 - 3 Slight moisture contamination

4 - 5 High temperature or high moisture content

6+ Compressor motor burnout

THERMISTOR TEMPERATURE & RESISTANCE CHARACHERISTICS

Indoor Return Air Sensor (THI-A1) Remote Control Temperature Sensor (ThC)

Indoor Heat Exchanger Sensor (THI-R1, R2 & R3)

Outdoor Air Temperature Sensor (THO-A) RAC

Outdoor Heat Exchanger Sensor (THO-R1, R2, R3 & R4)

Outdoor Suction Pipe Sensor (THO-S & THO-H)

Resistance-temperature characteristics

Temperature °C

Resistance KΩ Temperature °C Resistance KΩ

0 65 30 16

1 62 32 15

2 59 34 14

4 53 36 13

6 48 38 12

8 44 40 11

10 40 42 9.9

12 36 44 9.2

14 33 46 8.5

16 30 48 7.8

18 27 50 7.3

20 25 52 6.7

22 23 54 6.3

24 21 56 5.8

26 19 58 5.4

28 18 60 5.0

Outdoor Air Temperature Sensor (THO-A) PAC & KX Outdoor Discharge Pipe Sensor (THO-D1 & THO-D2)

Outdoor Power Transistor Sensor (THO-IP, P1 & P2)

Term

Explanation

Service Mode

The service mode is the mode where service data are displayed by flashing lights when the operations

described below are performed with the indoor controller

Service Data

These are the contents of error displays and protective stops which occurred I the past in the system.

Error display contents and protective stop data from past anomalous operations are saved in the indoor

unit controller's non-volatile memory. There are two types of data, self-diagnosis data and stop data.

Self-Diagnosis

Data

(Error code)

These are the data which display error display (self-diagnosis display) occurred in an indoor unit. Data

are recorded for up to 5 previous occurrences. Data which is older than the 5th previous occurrence

are erased. In addition, data on the temperature of each sensor are recorded when trouble occurs, so

more detailed information can be checked.

Stop Data

(Stop code)

These are the data which display the reason by which a stop occurred when the system performed

protective stops, etc. in the past. If stop data alone are generated, the system restarts automatically.

Data older than the 10th previous occasion are erased.

(Important) In cases where transient stop data only are generated, the system may still be normal.

However, if the same protective stop occurs frequently (3 or more times), it could lead to customer

complaints

Service mode display procedure

Hi-Wall Mounted Inverter Split Systems - SERVICE MODE – SRK (R410A Models only)

Start

Turn off the A/C's power, and then

wait one minute or longer.

Turn the A/C \'s power back on while

pressing the unit ON/OFF button.

Did a buzzer located in

the indoor unit sound?

NO (*1)

*1: If the buzzer does not sound no matter

how many times you repeat the

operation, the unit ON/OFF button may

Within 1 minute after turning the A/C back on, signals

will be sent from the remote control (*2)

*2: Set the remote controls settings on

"cooling operation", "fan speed MED" and

"Set temperature: 21C."

Count the number of times the RUN and TIMER lights flash (*3),

and check the contents of the error, etc. from the table.

Is other data displayed?

NO

Turn off the A/C's power to terminate the

service mode.

Change the remote controls settings based

on the instructions in the table (*4)

*3: To Count the number of flashes in the service mode, count the number of flashes after the light lights up

for 1.5 sec initially (start signal). Do not count start signal.

• In the case of current cut (example: stop code “42”)

The RUN light (10’s digit) flashes 4 times and the TIMER light (1’s digit) flashes 2 times.

4 x 10 + 2 x 10 = 42 > from the table, read the instructions for error code 42, “current cut”.

Run light

Timer light

*4: When in the service mode, when the remote control settings (operation switching, fan speed switching,

temperature setting) are set as shown in the following table and sent to the air conditioner unit, the unit switches to

display of service data.

SELF-DIAGNOSTIC DATA

Remote Control Setting

Contents of Output Data

Operation

Mode

Fan Speed

Cooling

MED

Displays the reason for stopping display in the past (error code).

HI

Displays the room temp sensor reading at the time the error code was displayed in the past.

AUTO

Displays indoor heat exchanger sensor temp at the time the error code was displayed in the

past.

Heating

LO

Displays the remote control information at the time the error code was displayed in the past.

MED

Displays the outdoor air temp sensor reading at the time the error code was displayed in the

past.

HI

Displays the outdoor heat exchanger sensor temp at the time the error code was displayed

in the past.

AUTO

Displays the discharge pipe sensor temp at the time the error code was displayed in the

past.

Remote Control Temp

Setting

When Error Occurred

21ºC

Previous time

22ºC

2nd previous time

23ºC

3rd previous time

24ºC

4th previous time

25ºC

5th previous time

Only for Indoor Heat Exchanger 2 (ZHX, ZIX, ZJ, ZJX, ZK, ZL)

Remote Control

Temp Setting

When error occurred

26ºC

Previous time

27ºC

2nd previous time

28ºC

3rd previous time

29ºC

4th previous time

30ºC

5th previous time

ERROR CODE DATA

Remote Control Setting

Displayed Data

Operation

Switching

Fan Speed

Switching

Temperature

Setting

Cooling

Medium

21ºC

Displays the reason for the stop the previous time an error

code was displayed

22ºC

Displays the reason for the stop 2 times previous time an error

was displayed

23ºC

Displays the reason for the stop 3 times previous time an error

was displayed

24ºC

Displays the reason for the stop 4 times previous time an error

was displayed

25ºC

Displays the reason for the stop 5 times previous time an error

was displayed

STOP DATA

Remote Control Setting

Displayed Data

Operation

Switching

Fan Speed

Switching

Temperature

Setting

Cooling

LO

21ºC

Displays the stop code the previous time when the A/C was

stopped by protective control.

22ºC

2 times previous

23ºC

3 times previous

24ºC

4 times previous

25ºC

5 times previous

26ºC

6 times previous

27ºC

7 times previous

28ºC

8 times previous

29ºC

9 times previous

30ºC

10 times previous

Remote Control Information Tables

Display pattern when in Service Mode

RUN light [i]

Operation switching

Operation switching

when there is an

abnormal stop

TIMER light [ii] Fan

Speed Switching

Fan Speed Switching

when there is an

abnormal stop

0 AUTO 0

AUTO 1

DRY 2

HI 2

COOL 3

MED 3

FAN 4

LO 4

HEAT 6

HI POWER

7 ECONO

If no data is recorded (error code is normal), the information display in the remote control becomes as follows;

• If no data is recorded (error code is normal), the information display in the remote control becomes as follows.

• EXAMPLE - Outdoor air sensor temperature “42 ºC”

When the temperature value is ≧0, the buzzer does not sound. Run light x4 flashes and Timer light flashes twice.

BUZZER Off

RUN LIGHT

TIMER LIGHT

No Buzzer, Run light x 4, Timer light x 2.

Buzzer sound Run light

Timer Light (1’s digit)

(10’s digit )

0 1 2 3 4 5 6 7 8 9

6 -60 -61 -62 -63 -64

5 -50 -51 -52 -53 -54 -55 -56 -57 -58 -59

4 -40 -41 -42 -43 -44 -45 -46 -47 -48 -49

Yes 3 -30 -31 -32 -33 -34 -35 -36 -37 -38 -39