Mitsubishi Heavy Industries RMA502A001, RKX502A007B, RKW502A200D, RKW502A200B, RKX502A001C Service Support Handbook

...

SERVICE

SUPPORT

HANDBOOK

www.dwgeire.ie

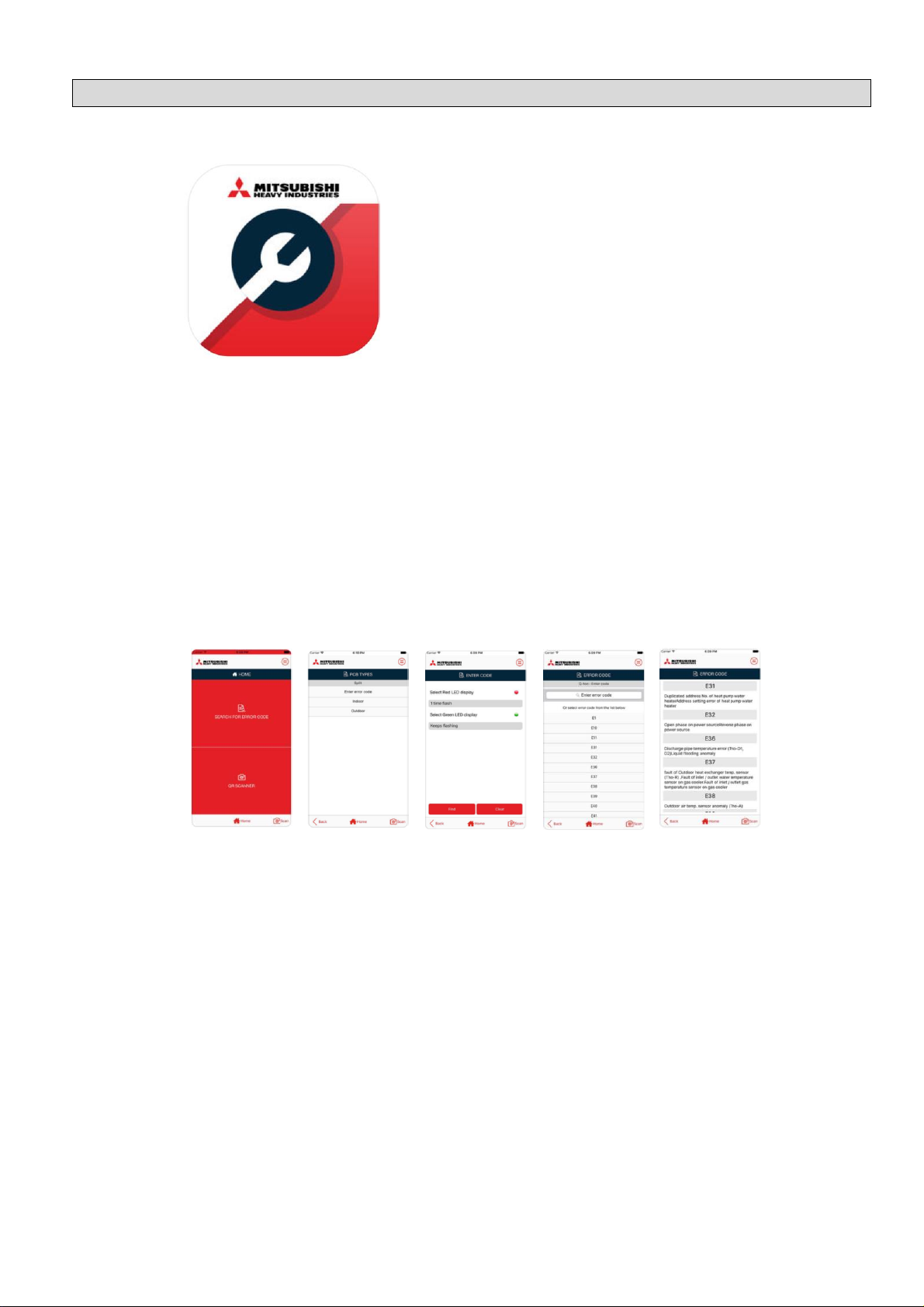

MHI e-service

DCSL Software Ltd

Free

Compatibility

Iphone or Ipad on IOS9.3 or later Android devices on 4.3 or later.

Screenshots

Description

MHI e-service is an application that enables users to make a quick search of the meaning

of error codes that may appear when there is a malfunction in "Mitsubishi Heavy Industries

Thermal Systems, Ltd" Air conditioning system, and the probable cause of the

malfunction.

In addition this application enables you to scan unit's QR code and search the meaning

of error codes depending on the model type.

The application covers "Mitsubishi Heavy Industries Thermal Systems, Ltd" Air conditioning

systems: Split (RAC & PAC), VRF, Q-ton & A2W.

The MHI e-service app is a free download available from Google Play for Android devices

(4.03 or later), or the Apple App Store for IOS devices (IOS9.3 or later).

MHI e-service app

WARNING

The information contained in this ‘Service Support Handbook’ is intended for use by

qualified service technicians familiar with safety procedures and equipped with the

proper tools and test instruments. Additionally, the information presented here is not a

replacement for, nor a substitute to the Manufacturers Technical Manuals.

MHI Air Conditioners contain pressurized refrigerants that are harmful to the atmosphere

so all refrigeration works must be performed by a qualified "F-Gas" registered person.

Please do not remove any covers, or attempt any repair or measurement on any MHI

LTD. product, unless you are suitably qualified and licensed to do so.

Repairs made by unqualified persons can result in hazards to you and others.

Technical Assistance is available Monday to Friday

between the hours of 08:00 and 17:00

on 03301 235 598

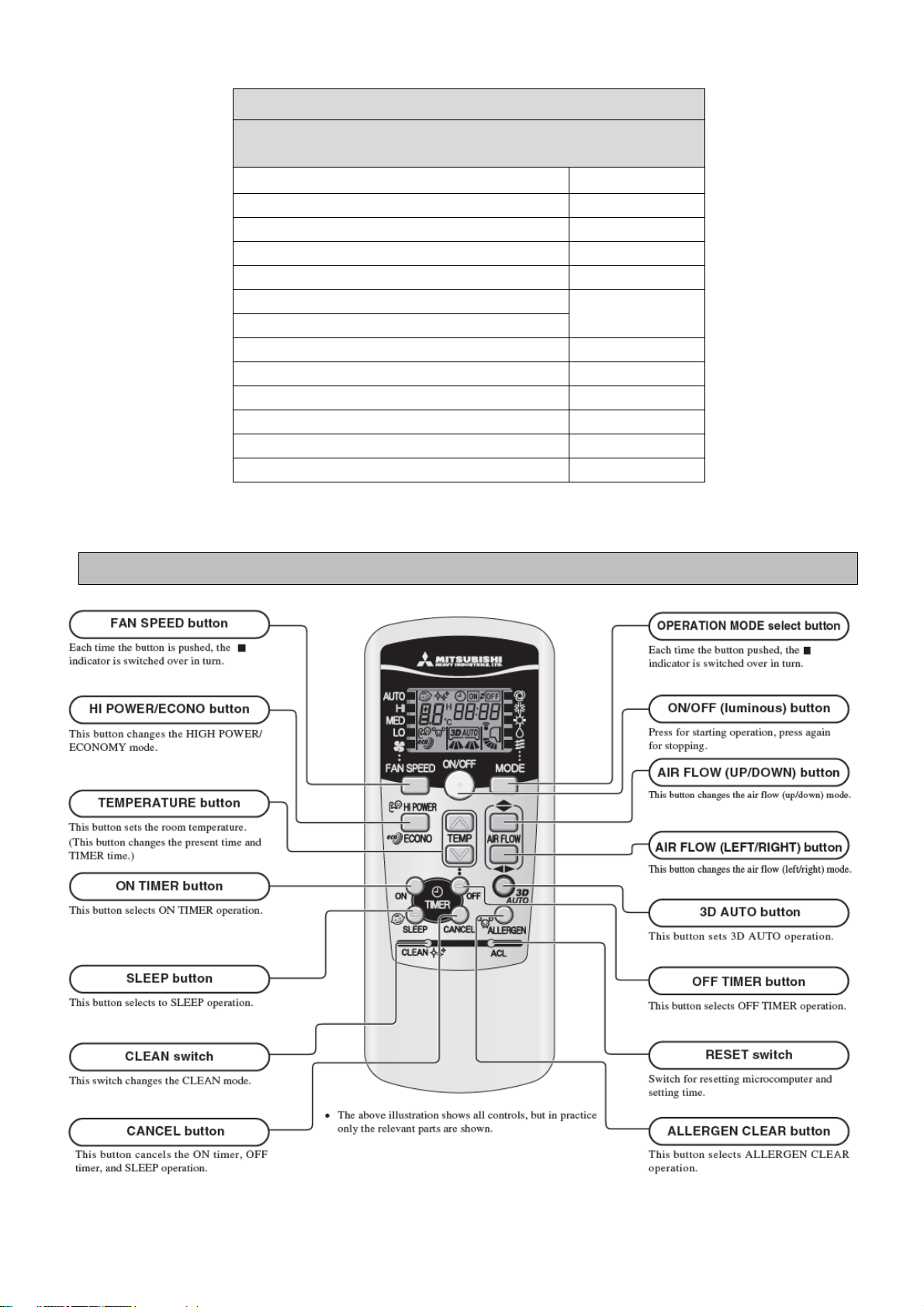

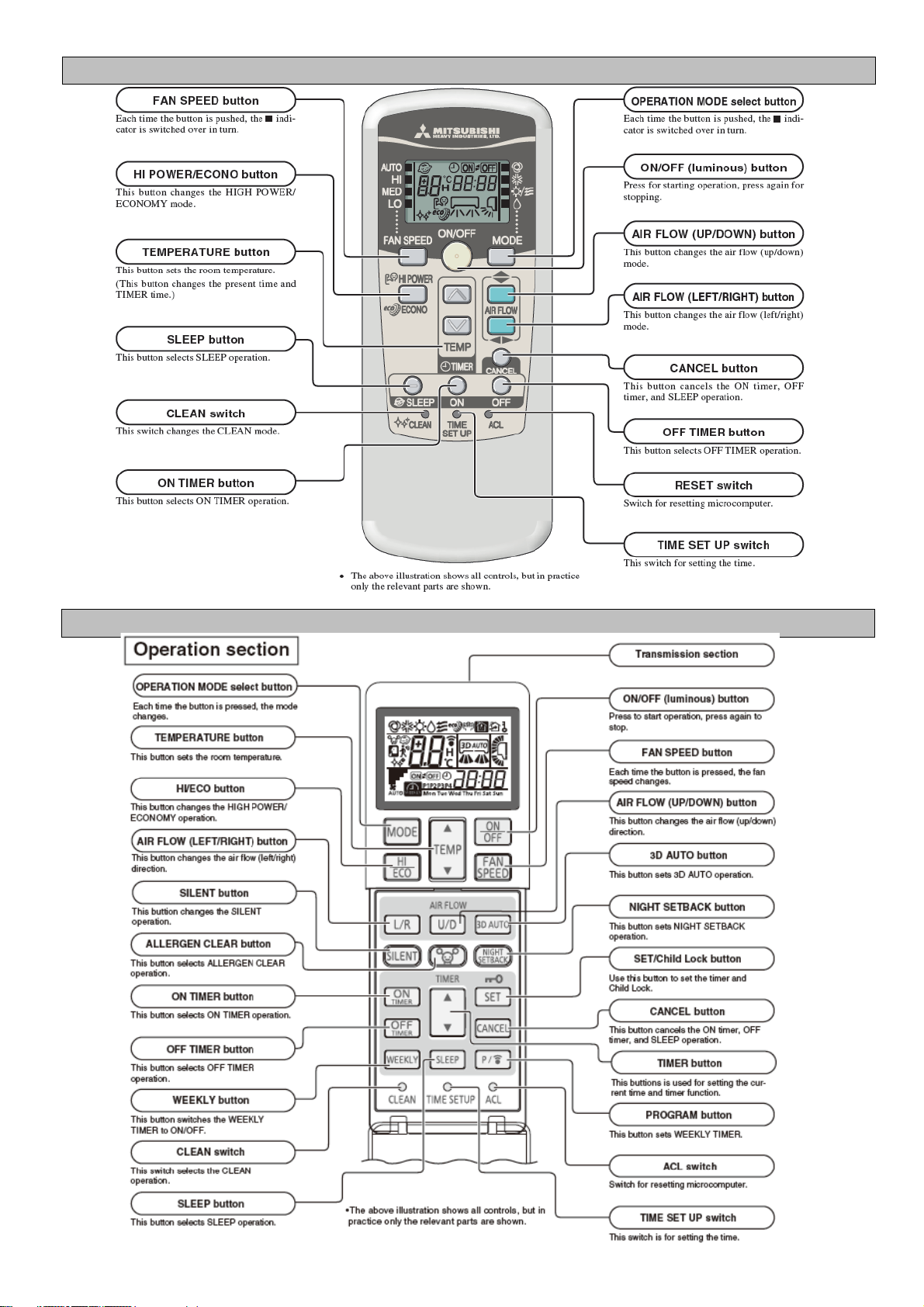

Hi-Wall Mounted Split Systems - Remote Controls of SRK

Before Proceeding to RAC Self Diagnosis Information,

ensure the correct Remote Control is being used.

Indoor Model

Remote Control

SRK--HC-S, HC-S1, HD-S, ZD-S, SKM--ZD-S

RMA502A001

SRK--HG-S

RKX502A007B

SRK--ZE-S, SRK--ZE-S1, SRK--ZR-S

RKW502A200D

SRK--ZFX-S, SRK--ZGX-S

RKW502A200B

SRK--ZG-S, ZHX-S, ZIX-S

RKX502A001C

SRK--ZJ-S, ZJ-S1, ZJX-S, ZJX-S1

SRK--ZM-S, SRK--ZMX-S, SRK--ZR-S

RLA502A701R

SRK--ZS-S

RLA502A701L

SRK--ZSX-S

RLA502A700K

SRF--ZMX-S

RLA502A700C

SRK--ZMP-S

RKX502A001P

SRK--ZSP-S

RKX502A007P

RKX502A001C

RKW502A200

RLA502A701R

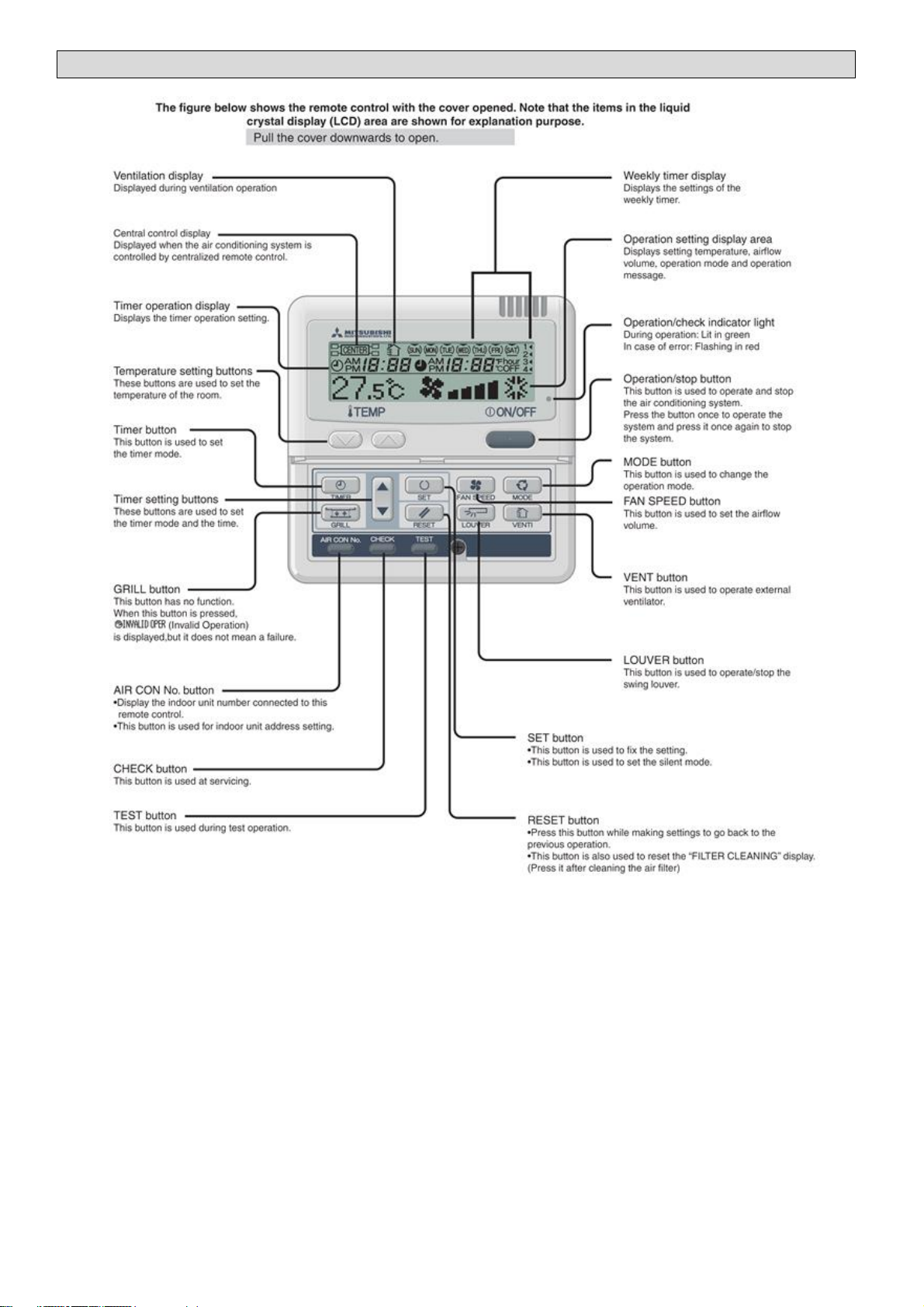

RC-E5 Layout

To access the RC-E5 Remote Controls Operation Data function, press the "CHECK" button on the MASTER remote control.

On 'Operation data' press the "SET" button.

If 'I/U No' is displayed select the unit number required, using the "/\" and "\/" buttons above the "CHECK" button, then

press the "SET" button

All navigation is carried out using the "/\" and "\/" buttons above the "CHECK" button.

RAC Unit

Compatibility

01

MODE

Current operation mode

ok

02

SET TEMP

°C

Set temperature

ok

03

RETURN AIR

°C

Return air sensor temperature

ok

04

SENSOR

°C

Remote control sensor temperature

ok

05

THI-R1

°C

Indoor heat exchanger sensor (on U bend)

ok

06

THI-R2

°C

Indoor heat exchanger sensor (on Capillary)

ok

07

THI-R3

°C

Indoor heat exchanger sensor (on suction header)

-

08

I/U FANSPEED

Indoor unit fan speed

-

09

DEMAND

Hz

Required frequency

-

10

ANSWER

Hz

Response frequency

-

11

I/U EEV

PULSE

Pulse rate of KX indoor unit expansion valve

-

12

TOTAL I/U RUN

Hr

Total running hours of the indoor unit

-

21

OUTDOOR

°C

Outdoor air temperature

ok

22

THO-R1

°C

Outdoor unit heat exchanger sensor

ok

23

THO-R2

°C

Outdoor unit heat exchanger sensor

-

24

COMP

Hz

Compressor frequency

ok

25

HP

MPa

High pressure (x10=Bar)

-

26

LP

Mpa

Low pressure (x10=Bar)

-

27

Td

°C

Discharge Pipe Temperature

ok

28

COMP BOTTOM

°C

Compressor base temperature

-

29

CT

Amp

Current

ok

30

TARGET SH

°C

Target Super Heat

-

31

SH

°C

Super Heat temperature

-

32

TDSH

°C

Compressor discharge pipe super heat

ok

33

PROTECTION No

Protection state number of the compressor

-

34

O/U FANSPEED

Outdoor unit fan speed

ok

35

63H1

63H1 High pressure switch on/off

-

36

DEFROST

Defrost control on/off

ok

37

TOTAL COMP RUN

Hr

Total running hours of compressor

-

38

O/U EEV1

PULSE

Pulse rate of the outdoor unit expansion valve EEVC

ok

39

O/U EEV2

PULSE

Pulse rate of the outdoor unit expansion valve EEVH

-

No. Contents of display

0 Normal

1 Discharge pipe temperature protection control

2 Discharge pipe temperature anomaly

3 Current safe control of inverter primary current

4 High pressure protection control

5 High pressure anomaly

6 Low pressure protection control

7 Low pressure anomaly

8 Anti-frost prevention control

9 Current cut

10 Power transistor protection control

11 Power transistor anomaly (Overheat)

12 Compression ratio control

13 14 Condensation prevention control

15 Current safe control of inverter secondary current

16 Stop by compressor rotor lock

17 Stop by compressor startup failure

Details of 33 Compressor Protection Status

RC-E5 OPERATION DATA

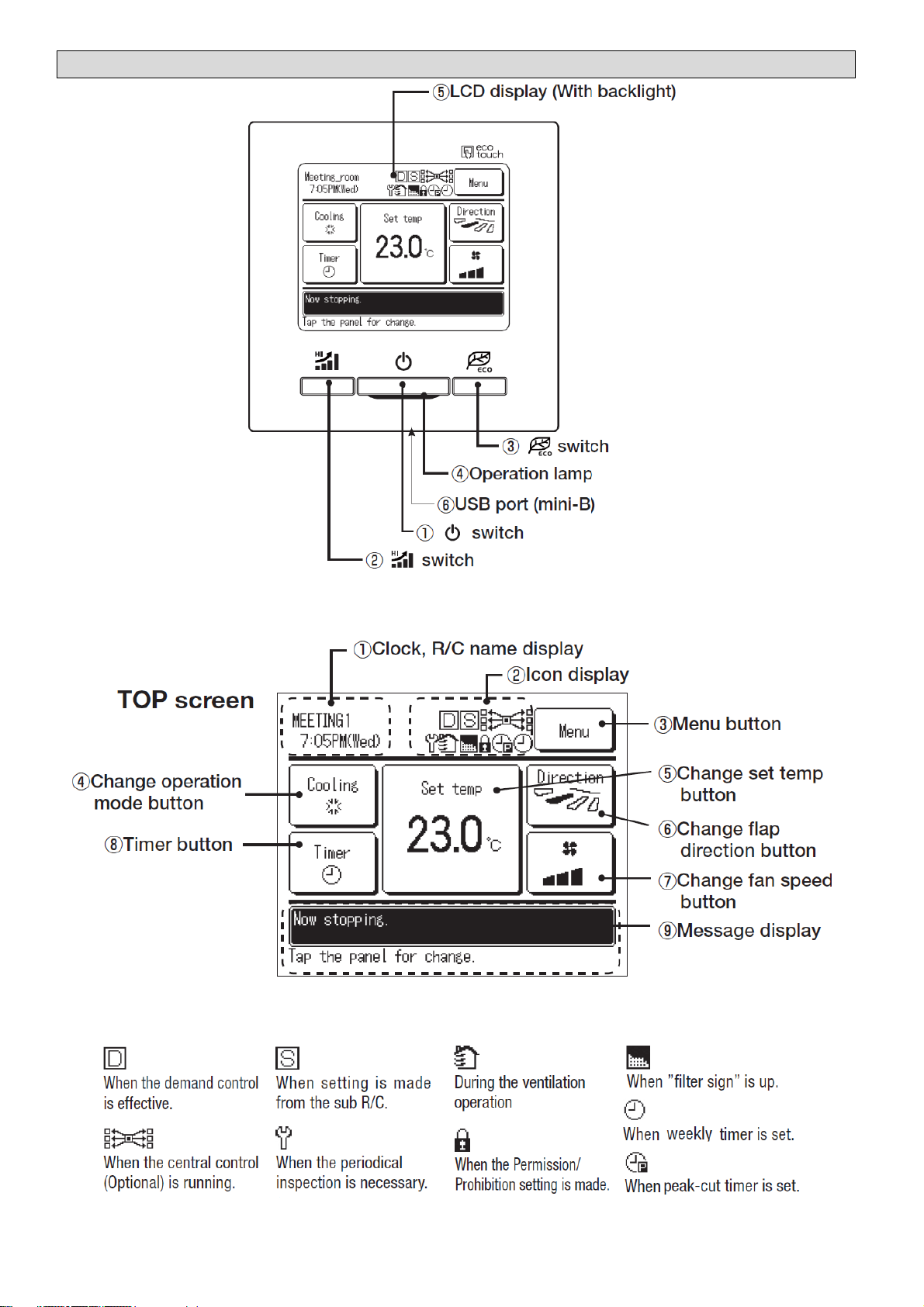

Touch panel control, which is operated by tapping the LCD screen with a finger, is employed for all functions except

1 On/Off switch, 2 Hi Power switch and 3 ECO switch.

RC-EX1 & EX1A Layout

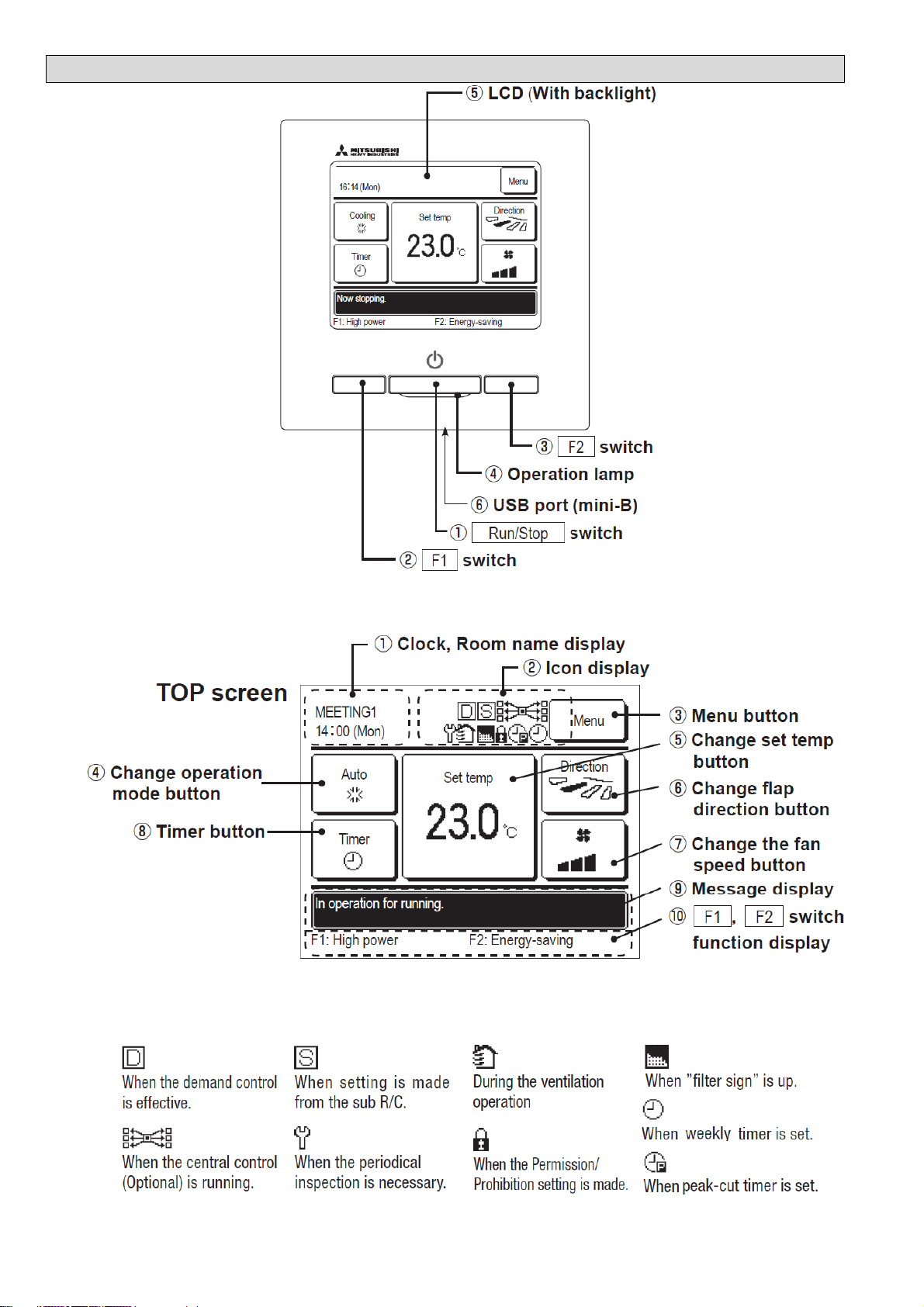

Touch panel control, which is operated by tapping the LCD screen with a finger, is employed for all functions except

1 On/Off switch, 2 Hi Power switch and 3 ECO switch.

RC-EX3 Layout

To access the RC-EX Remote Controls Operation Data function, press MENU on the MASTER remote control Front Screen.

Then press NEXT followed by SERVICE (RC-EX3 only) and SERVICE & MAINTENANCE. Enter the service pass code, press SET

then press OPERATION DATA. You can then select the indoor unit you want to view.

RAC Unit

Compatibility

01

MODE

Current operation mode

ok

02

SET TEMP

°C

Set temperature

ok

03

RETURN AIR

°C

Return air sensor temperature

ok

04

SENSOR

°C

Remote control sensor temperature

ok

05

THI-R1

°C

Indoor heat exchanger sensor (on U bend)

ok

06

THI-R2

°C

Indoor heat exchanger sensor (on Capillary)

ok

07

THI-R3

°C

Indoor heat exchanger sensor (on suction header)

-

08

I/U FANSPEED

Indoor unit fan speed

-

09

DEMAND

Hz

Required frequency

-

10

ANSWER

Hz

Response frequency

-

11

I/U EEV

PULSE

Pulse rate of KX indoor unit expansion valve

-

12

TOTAL I/U RUN

Hr

Total running hours of the indoor unit

-

21

OUTDOOR

°C

Outdoor air temperature

ok

22

THO-R1

°C

Outdoor unit heat exchanger sensor

ok

23

THO-R2

°C

Outdoor unit heat exchanger sensor

-

24

COMP

Hz

Compressor frequency

ok

25

HP

MPa

High pressure (x10=Bar)

-

26

LP

Mpa

Low pressure (x10=Bar)

-

27

Td

°C

Discharge Pipe Temperature

ok

28

COMP BOTTOM

°C

Compressor base temperature

-

29

CT

Amp

Current

ok

30

TARGET SH

°C

Target Super Heat

-

31

SH

°C

Super Heat temperature

-

32

TDSH

°C

Compressor discharge pipe super heat

ok

33

PROTECTION No

Protection state number of the compressor

-

34

O/U FANSPEED

Outdoor unit fan speed

ok

35

63H1

63H1 High pressure switch on/off

-

36

DEFROST

Defrost control on/off

ok

37

TOTAL COMP RUN

Hr

Total running hours of compressor

-

38

O/U EEV1

PULSE

Pulse rate of the outdoor unit expansion valve EEVC

ok

39

O/U EEV2

PULSE

Pulse rate of the outdoor unit expansion valve EEVH

-

No. Contents of display

0 Normal

1 Discharge pipe temperature protection control

2 Discharge pipe temperature anomaly

3 Current safe control of inverter primary current

4 High pressure protection control

5 High pressure anomaly

6 Low pressure protection control

7 Low pressure anomaly

8 Anti-frost prevention control

9 Current cut

10 Power transistor protection control

11 Power transistor anomaly (Overheat)

12 Compression ratio control

13 14 Condensation prevention control

15 Current safe control of inverter secondary current

16 Stop by compressor rotor lock

17 Stop by compressor startup failure

Details of 33 Compressor Protection Status

RC-EX OPERATION DATA

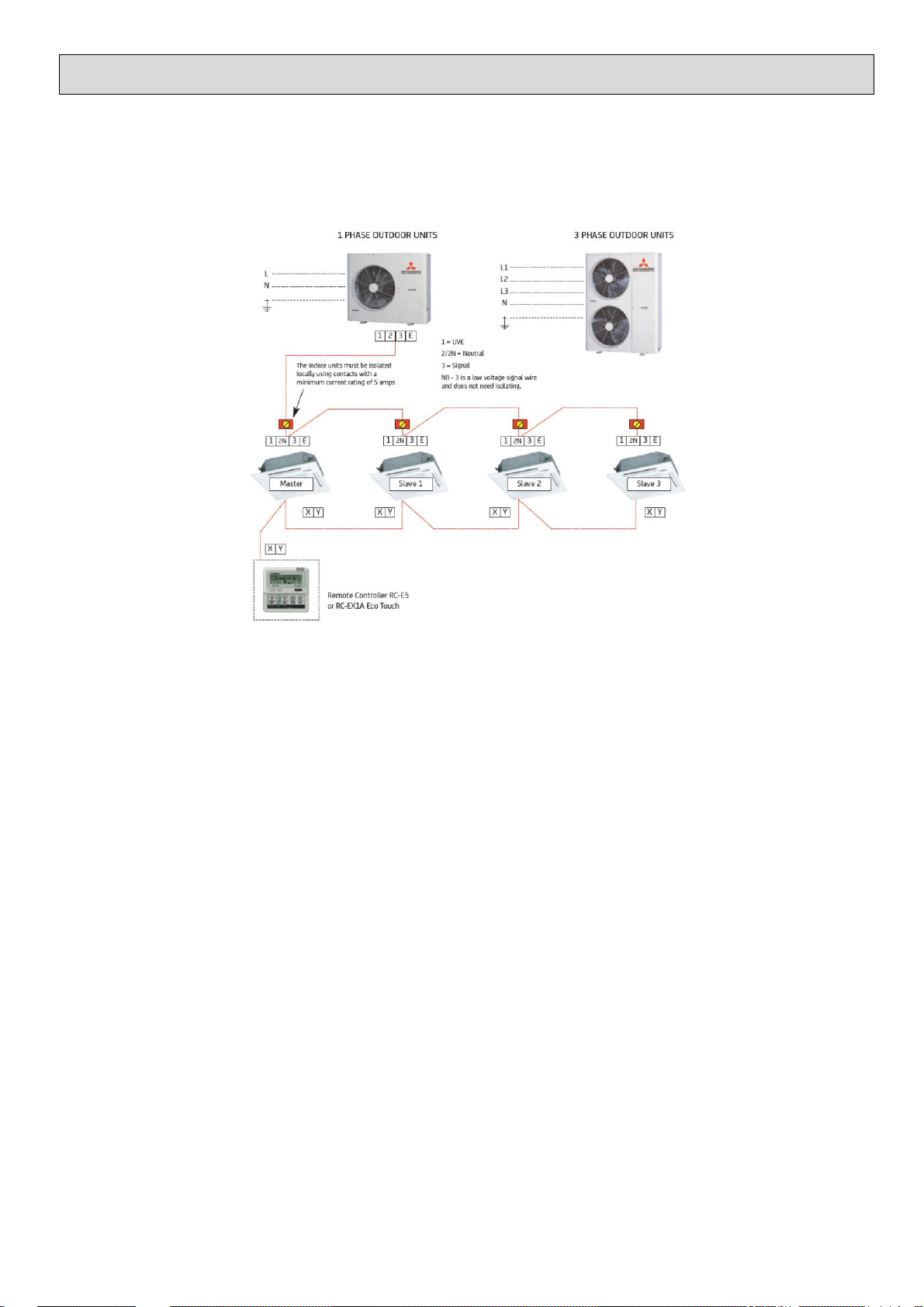

Master/ Slave and Group Settings

Master / Slave Settings

All split system indoor units are supplied set up as a master unit as default and this only needs changing when the system being

installed is a multisplit system, excluding SCM or KX systems, comprising of 2 to 4 RAC or PAC indoor units running off a

PAC single split outdoor unit. The remote control wires and all wires of the interconnecting cable go to each indoor unit

including the slave units.

When using RAC SRK indoor units, excluding ZMP/ZSP models, on a multisplit each indoor unit needs an SC-BIKN-E

interface to allow the installation of the wired remote control and setup of the master slave settings.

SYSTEM TYPE PAC Indoor Units SC-BIKN-E Interface

Unit SW5-1 SW5-2 SW3-1 SW3-2

Single Twin Triple Quad MASTER OFF OFF OFF OFF

Twin Triple Quad SLAVE 1 OFF ON OFF ON

Triple Quad SLAVE 2 ON OFF ON OFF

Quad SLAVE 3 ON ON ON ON

All indoor units on a multisplit system must be in the same space and operate off a single wired remote control as there is no

refrigerant control in the indoor units.

Group Settings

When multiple systems need to be controlled off a single RC-EX1A, RC-EX3 or RC-E5 wired remote control each system

needs to be given a different address. The system addressing is set on PAC unit indoor boards using SW2 or on RAC indoor

units via SW1 on the SC-BIKN-E interface. Upto 16 indoor units can be connected to a wired remote and that includes

multiplit systems using PAC outdoor units.

System Indoor Outdoor System Unit Group Address Master Slave

Unit Unit Type Switch Setting Switch #1 #2

1 FDT FDC Split Master SW2 0 SW5 OFF OFF

2 FDT FDC Quad Master SW2 1 SW5 OFF OFF

FDT Slave 1 SW2 1 SW5 OFF ON

FDT Slave 2 SW2 1 SW5 ON OFF

FDT Slave 3 SW2 1 SW5 ON ON

3 SRK FDC Twin Master SW1 2 SW3 OFF OFF

SRK Slave 1 SW1 2 SW3 OFF ON

4 FDUM FDC Split Master SW2 3 SW5 OFF OFF

Refrigerant Piping Information

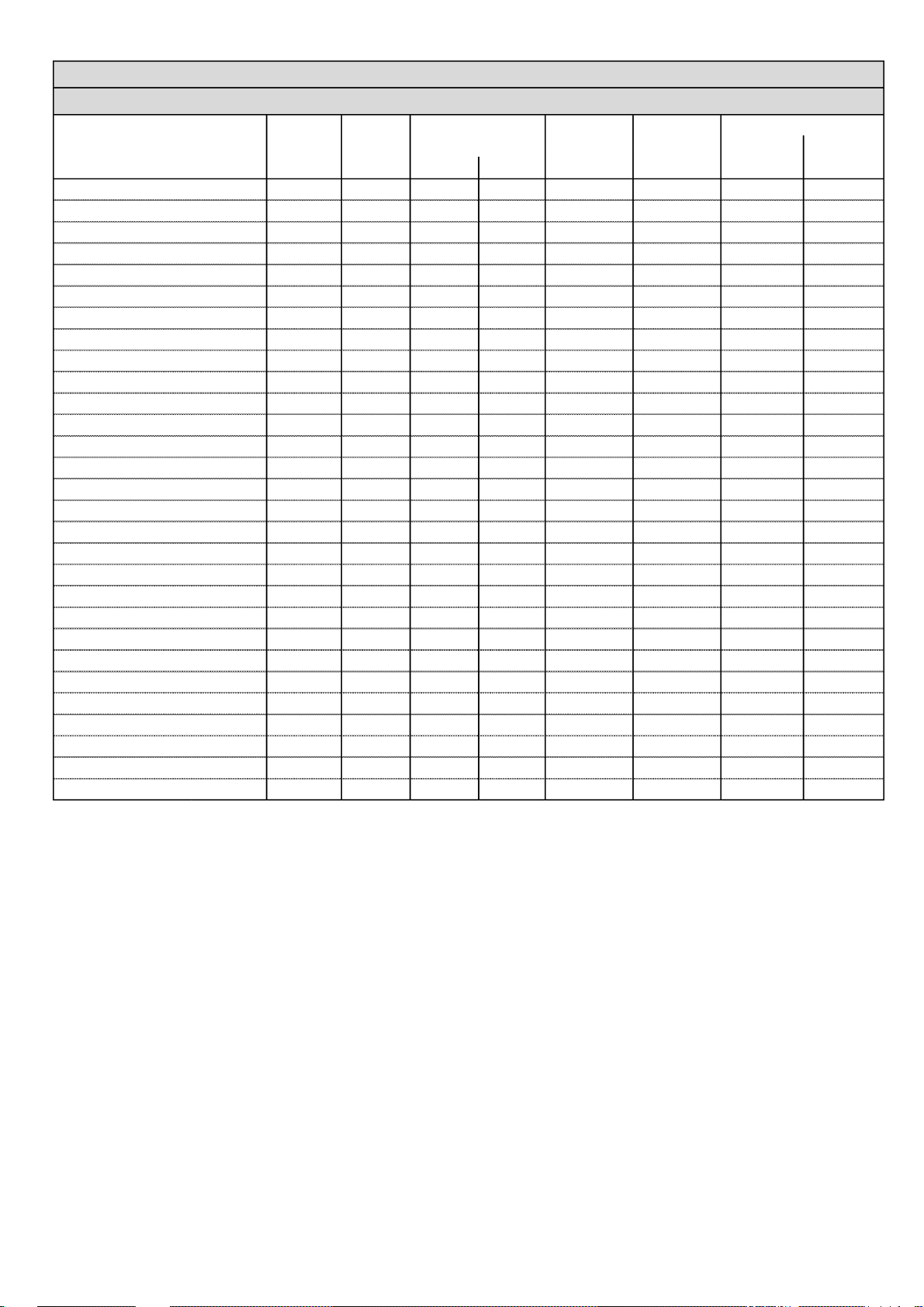

RAC CURRENT MODELS

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A

SRC25ZMP-S, 10 15 10 10 0.655 20 1/4" (6.35) 3/8" (9.52) 16

SRC35ZMP-S 15 15 10 10 0.810 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC45ZMP-S 15 25 15 15 1.200 20 1/4" (6.35) 1/2" (12.7) 16

SRC25ZM-S 15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC35ZM-S 15 15 10 10 1.050 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC50ZM-S 15 25 15 15 1.350 20 1/4" (6.35) 1/2" (12.7) 16

FDC100VNP 15 30 20 20 2.550 60 3/8" (9.52) 5/8" (15.88) 32

SRC20_35ZMX-S 15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52) 16

SRC50_60ZMX-S 15 30 20 20 1.500 20 1/4" (6.35) 1/2" (12.7) 16

SRC63ZR-S 15 30 20 20 1.550 20 1/4" (6.35) 1/2" (12.7) 16

SRC71ZR-S 15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88) 20

SRC80ZR-S 15 30 20 20 1.900 25 1/4" (6.35) 5/8" (15.88) 20

SRC20_25ZS-S 15 20 10 10 0.750 20 1/4" (6.35) 3/8" (9.52) 16

SRC35ZS-S 15 20 10 10 0.950 20 1/4" (6.35) 3/8" (9.52) 16

SRC50ZS-S 15 25 15 15 1.250 20 1/4" (6.35) 1/2" (12.7) 20

SCM Multi Splits

For SCM Systems the maximum one way piping length to an indoor unit is 25 metres.

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A

SCM40ZS-S 30 30 15 15 1.900 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM45ZS-S 30 30 15 15 1.900 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM50ZS-S 40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52) 25

SCM45ZM-S 30 30 15 15 2.000 N/A 2x 1/4" (6.35) 2x 3/8" (9.52) 25

SCM60ZM-S 40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52) 25

SCM80ZM-S 40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52) 25

SCM100_125ZM-S 50 90 20 20 6.000 20 5x 1/4" (6.35) 5x 3/8" (9.52) 32

PAC Splits - CURRENT MODELS

Model Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes MCB

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe Rating

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm) A(/ph)

FDC71VNP 15 30 20 20 1.600 20 1/4" (6.35) 1/2" (12.7) 20

FDC90VNP 15 30 20 20 2.100 20 1/4" (6.35) 5/8" (15.88) 20

FDC100VNP 15 30 20 20 2.550 60 3/8" (9.52) 5/8" (15.88) 32

FDC100VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC125VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC140VN 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 32

FDC71VNX 30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88) 25

FDC100VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC125VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC140VNX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 32

FDC100VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC125VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC140VS 30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88) 20

FDC100VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC125VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC140VSX 30 100 30 15 4.500 60 3/8" (9.52) 5/8" (15.88) 20

FDC200VSA 30 70 30 15 5.600 60 3/8" (9.52) 7/8" (22.22) 32

FDC250VSA 30 70 30 15 7.200 120 1/2" (12.7) 1-1/8" (28.58) 32

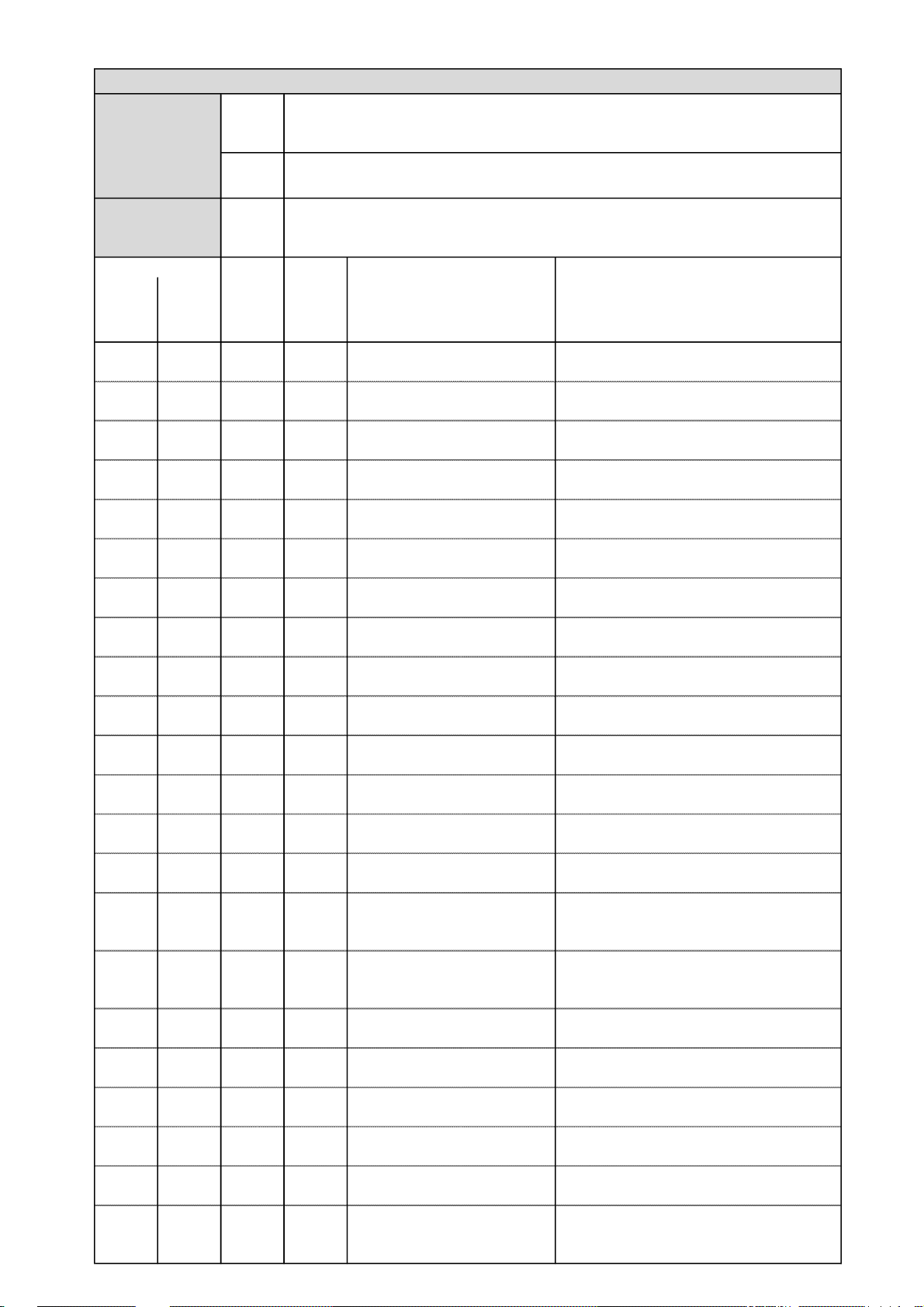

Refrigerant Piping Information

Historic Models

Precharged Maximum Maximum Vertical Factory Additional Pipe Sizes

Piping Piping Piping Length (m) Charge Charge R410A Liquid Pipe Gas Pipe

Length (m) Length (m) O/D Above I/D Above R410A (kg) per m (g/m) "" (mm) "" (mm)

15 15 10 10 0.900 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.100 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.050 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 0.750 N/A 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.150 N/A 1/4" (6.35) 3/8" (9.52)

15 25 15 15 1.350 20 1/4" (6.35) 3/8" (9.52)

15 15 10 10 1.200 N/A 1/4" (6.35) 3/8" (9.52)

15 30 20 20 1.400 20 1/4" (6.35) 1/2" (12.7)

15 30 20 20 1.500 20 1/4" (6.35) 1/2" (12.7)

15 30 20 20 1.900 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

15 30 20 20 1.800 25 1/4" (6.35) 5/8" (15.88)

20 30 15 15 1.600 20 2x 1/4" (6.35) 2x 3/8" (9.52)

30 40 15 15 2.200 20 3x 1/4" (6.35) 3x 3/8" (9.52)

40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52)

30 30 15 15 2.000 N/A 2x 1/4" (6.35) 2x 3/8" (9.52)

40 40 15 15 2.500 N/A 3x 1/4" (6.35) 3x 3/8" (9.52)

40 70 20 20 3.150 20 4x 1/4" (6.35) 4x 3/8" (9.52)

50 90 20 20 6.000 20 5x 1/4" (6.35) 5x 3/8" (9.52)

30 40 30 15 1.550 20 1/4" (6.35) 1/2" (12.7)

30 40 30 15 1.750 20 1/4" (6.35) 5/8" (15.88)

30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88)

30 50 30 15 3.800 60 3/8" (9.52) 5/8" (15.88)

30 50 30 15 2.950 60 3/8" (9.52) 5/8" (15.88)

30 70 30 15 5.400 60 3/8" (9.52) 7/8" (22.22)

30 70 30 15 7.200 120 1/2" (12.7) 7/8" (22.22)

FDC71VN

FDC200VS

FDC250VS

SCM80ZG-S

SCM45ZJ-S

SCM60ZJ-S,S1

SCM80ZJ-S,S1

SCM100,125ZJ-S,S1

FDCVA151,201HEN

FDCVA251HEN

FDCVA302HENR,AR

FDCVA402_602HENR,AR

SRC20,25,35,ZIX,ZJX-S,ZJX-S1

SRC50,60ZFX,ZGX,ZHX,ZIX

SRC50,60ZJX-S

SRC63_71-S,S1

SRC63,71,80,ZK-S

SRC63ZM-S

SRC71_80ZM-S

SCM45ZG-S

SCM60ZG-S

Model

SRC20_25ZD,ZF,ZG

SRC20_325ZGX-S

SRC20,25ZJ-S

SRC35ZD,ZG

SRC35ZJ-S

SRC20ZJ-S1

SRC25,35ZJ-S1

SRC50ZD,ZG,ZJ-S,ZJ-S1

SRK

SRR/ SRF

SRC

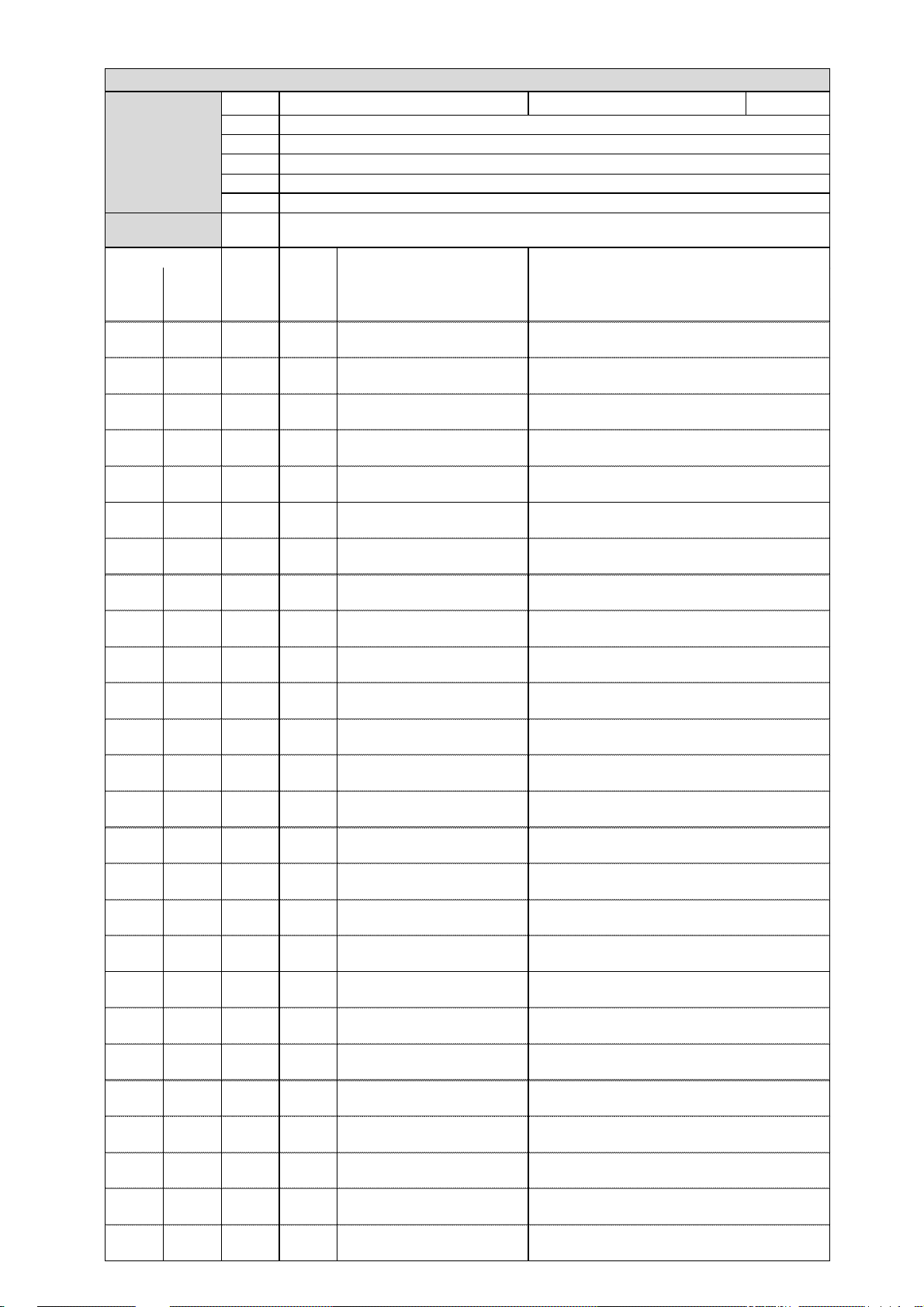

Description of Trouble Possible Cause

Run Light

Timer

Light

Green Amber

Red LED

- - - E1 Error of wi red remote Broken wi re, fa ulty indoor P.C.B., faul ty control le r.

OFF Flas hing - E21 Li mit Switch error

Defe ctive limi t switch, ai r inlet pane l s et, I/D

control PCB

1x ON - - He at excha nger s ens or (1) error

Broken he at e xcha nger sensor (1) wire, poor

conne ction

2x ON - E7 Room temperature sens or

Broken room temperature s ens or wi re, poor

conne ction

2x 2x 7x E60 Rotor l ock

Fa ulty compressor, open pha se on compres sor,

faulty outdoor P.C.B.

3x ON - - He at excha nger s ens or (2) error

Broken he at e xcha nger sensor (2) wire, poor

conne ction

4x ON - E9 Drai n Fa ult

Float s witch a ctivated, faulty pump, faulty PCB,

faulty float s witch

5x ON 2x E47 Active Fil ter volta ge e rror Defe ctive Active Fi lter, incorrect power supply

6x ON - E16 I ndoor fan motor e rror Fa ult indoor fan motor, poor connecti on

7x ON 2x E57

Refri geration system prote ctive

control

Service valve clos ed, refrigerant i nsufficient

7x 1x 4x E40

Service valve (ga s s ide) cl osed,

defe ctive outdoor PCB

Output current of i nverter excee ds specifi cation

Fla shing 1x 8x E38 Outdoor ai r temp s ens or Broken s ensor wi re, poor connection

Fla shing 2x 8x E37 Outdoor heat excha nger s ens or Broken s ensor wi re, poor connecti on

Fla shing 4x 8x E39 Dis charge pipe sensor Broken s ensor wi re, poor connection

ON 1x 1x E42 Current Cut

Compressor locki ng, open pha se on compres sor

output, s hort ci rcuit on power transis tor, clos ed

service valve, EEV not opening

ON 2x 2x E59 Trouble of outdoor unit

Broken compre ssor wi re, broke n powe r trans is tor,

broken discharge s ensor wire/poor connection,

compress or bl ockage

ON 3x 3x E58 Current s afe stop

Overload protection, over cha rged, compres sor

locking

ON 4x 1x E51 Power Trans is tor error Faul ty power trans is tor

ON 5x 5x E36 Over heat of compres sor

Low on gas, faulty di scharge pipe senor, cl osed

service valve

ON 6x 6x E3 / E5 Error of s ignal tra nsmi ssi on

Defe ctive powe r suppl y, broken si gnal wire,

faulty indoor/outdoor P.C.B.

ON 7x ON E48 Fa ulty outdoor fa n motor Fa ulty condenser fa n motor, poor conne ction

ON Fla shing 2x E35 Cooling High Press ure Protection

Overload protection, over cha rged, broken

outdoor he at e xcha nger sensor wire, closed

service valve

Outdoor

Control

PCB,

Wired

Remote

Control

Inverter RAC

Outdoor Unit

ZD, ZE, ZE-S1, ZG, ZJ, ZJ-S1,ZM, ZR, ZS, ZFX, ZGX, ZHX, ZIX, ZJX, ZJX-S1,ZMX, ZSX

Indoor Unit Display

RAC FAULT CODES

ZD, ZE, ZE-S1, ZG, ZJ, ZJ-S1,ZM, ZMP, ZR, ZS, ZFX, ZGX, ZHX, ZIX, ZJX, ZJX-S1,ZMX, ZSX

ZIX, ZJX, ZJX-S1,ZMX

Inverter RAC

Indoor Unit

SRK ZJX-S, ZJX-S1 ZK-S

SRR

SRF

FDTC

FDUM

FDEN

SCM

Run Light

Timer

Light

Green Amber

Red LED

- - - E1

Error of wired remote Control

- - 1 E41

Power transistor overheat

- - 2 E40

High pressure error

- - 4 E45

Outd oor main or sub PCB

communication error

- - 8 E54

High pressure sensor

-

Flashing - E21 Limit switch error

1x ON OFF -

Indoor heat excha nger sensor (1)

error

2x ON OFF -

Room temperature sensor

2x 2x 7x E60

Rotor lock

3x ON OFF -

Heat ex chan ger sensor 2 error

4x ON OFF E9

Drain error

5x ON 2x E47

Activ e filter voltage error

6x ON OFF E16

Indoor fan motor error

7x ON 2x E57

Refrigerant cycle system protective

control

Flashing 1x 8x E38 Outdoor air temperature sensor

Flashing 2x 8x E37 Outdoor heat exchanger sensor

Flashing 4x 8x E39 Discharge pipe sensor

Flashing 5x 8x E53 Outdoor suction sensor

ON 1x x1 E42

Current Cut

ON 2x 2x E59

Trouble of outdoor unit

ON 3x 3x E58

Current safe stop

ON 4x 1x E51

Power transistor error

ON 5x 5x E36

Ov er heat of compressor

ON 6x 6x E5

Error of signal transmission

ON 7x Flashing E48

Outd oor fan motor or main PCB

ON Flashing 2x E35

Cooling High Pressure Protection

Faulty pow er transistor or sensor.

Outd oor sub or main PCB faulty, poor connection of wires

betw een outdoor PCBs

Faulty high pressure sensor, faulty control PCB.

Broken sensor wire, poor connection, faulty outdoor PCB

Broken sensor wire, poor connection, faulty outdoor sub

PCB

Faulty compressor, open pha se on compressor, faulty

outdoor P.C.B.

Defective limit switch, air inlet panel set, I/D control PCB

Faulty high pressure sensor, faulty control PCB, poor air

circulation.

Broken wire, faulty indoor P.C.B., faulty controller.

Defective Activ e Filter, incorrect power supply

Faulty indoor fan motor, poor connection

Closed serv ice v alve, insufficient refrigerant

Broken sensor wire, poor connection, faulty outdoor PCB

Broken sensor wire, poor connection, faulty outdoor PCB

Ov erload protection, ov er charged, broken outdoor heat

exchanger sensor wire, closed serv ice v alv e

Broken heat exchanger sensor (1) wire, poor connection

Broken room temperature sensor wire, poor connection

Broken heat exchanger sensor 3 wire, poor connection

Blocked drain, faulty float switch, faulty d rain pump

faulty inv erter PCB, faulty main PCB or faulty fan motor

Low on gas, faulty discharge pipe senor, closed service

v alv e

Defective power supply, broken signal wire, faulty

indoor/outdoor P.C.B.

Faulty condenser fan motor or faulty main P CB

Compressor locking, open phase on compressor output,

short circuit on power transistor, closed service v alv e

Broken compressor wire, broken power transistor, broken

discharge sensor wire or poor connection, compressor

Ov erload protection, ov er charged, compressor locking

Possible Cause

Description of Trouble

Inverter Mul ti

Outdoor

ZJ-S, ZJ-S1, ZM-S

Indoor Unit Display

Outdoor

Control

PCB,

Wired

Remote

Control

ZJ-S,ZJ-S1,ZM-S,ZMX-S

ZJ-S

ZJX-S, ZJX-S1,ZMX-S

VD,VF, VF/1

VF, VF/1

VD, VF, VF/1

Inverter Multi

Indoor

RAC MULTISPLIT FAULT CODES - Current and Previous Models

Loading...

Loading...