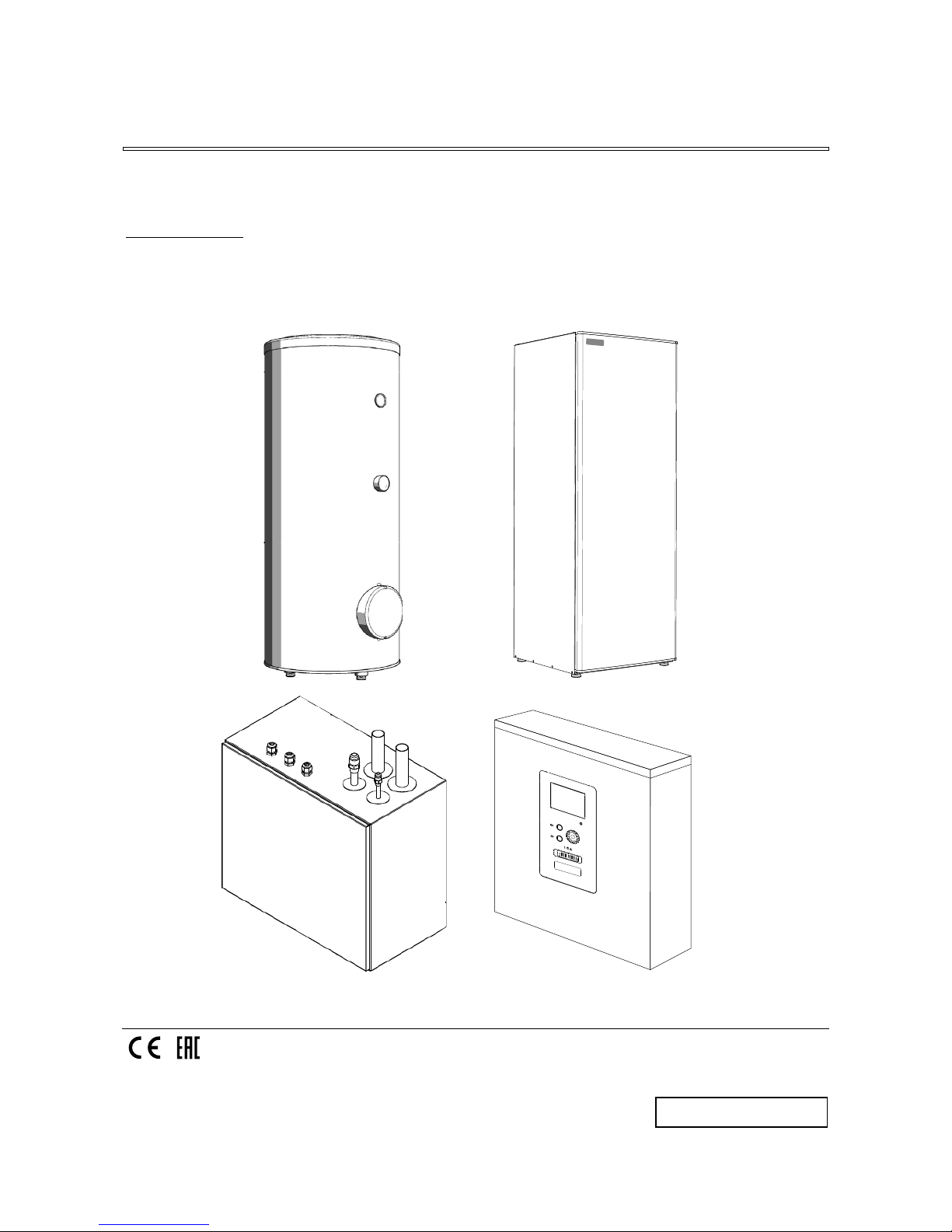

Mitsubishi Heavy Industries HSB60, FDCW60VNX-APT300, HMK60, RC-HY20, RC-HY40 Installation Manual

INSTALLATION MANUAL

MITSUBISHI HEAVY INDUSTRIES

Air to Water Heat Pump

H y drolution (HM)

HSB60/HMK60/FDCW60VNX-A

PT300/RC-HY20/40

P

SC012D085BS

English:Original instruction

This heat pump complies with EMC Directive 2004/108/

EC (replaced by 2014/30/EU on 20/4/2016), LV Directive

2006/95/EC (replaced by 2014/35/EU on 20/4/2016).

CE marking is applicable to the area of 50 Hz power supply.

HK 200S

1

2

1

Safety precautions

2

General information for installer

7

Over view and design

7

Transport and storage

10

Supplied components

10

Assembly

10

Hanging indoor unit

12

Hanging control unit

12

Dimensioning expansion vessel

13

Recommended installation order

13

Pipe installation

14

General

14

Installation diagram

14

HSB60

14

HMK60

15

System requirements

16

Overflow valve

16

Pump capacity diagram

16

Pressure drop in indoor unit

1

7

Dimensions and pipe connections

1

7

HSB60

1

7

HMK60

17

PT300

18

Water circuit

19

Connection to heating system

19

Connection to hot water heater

19

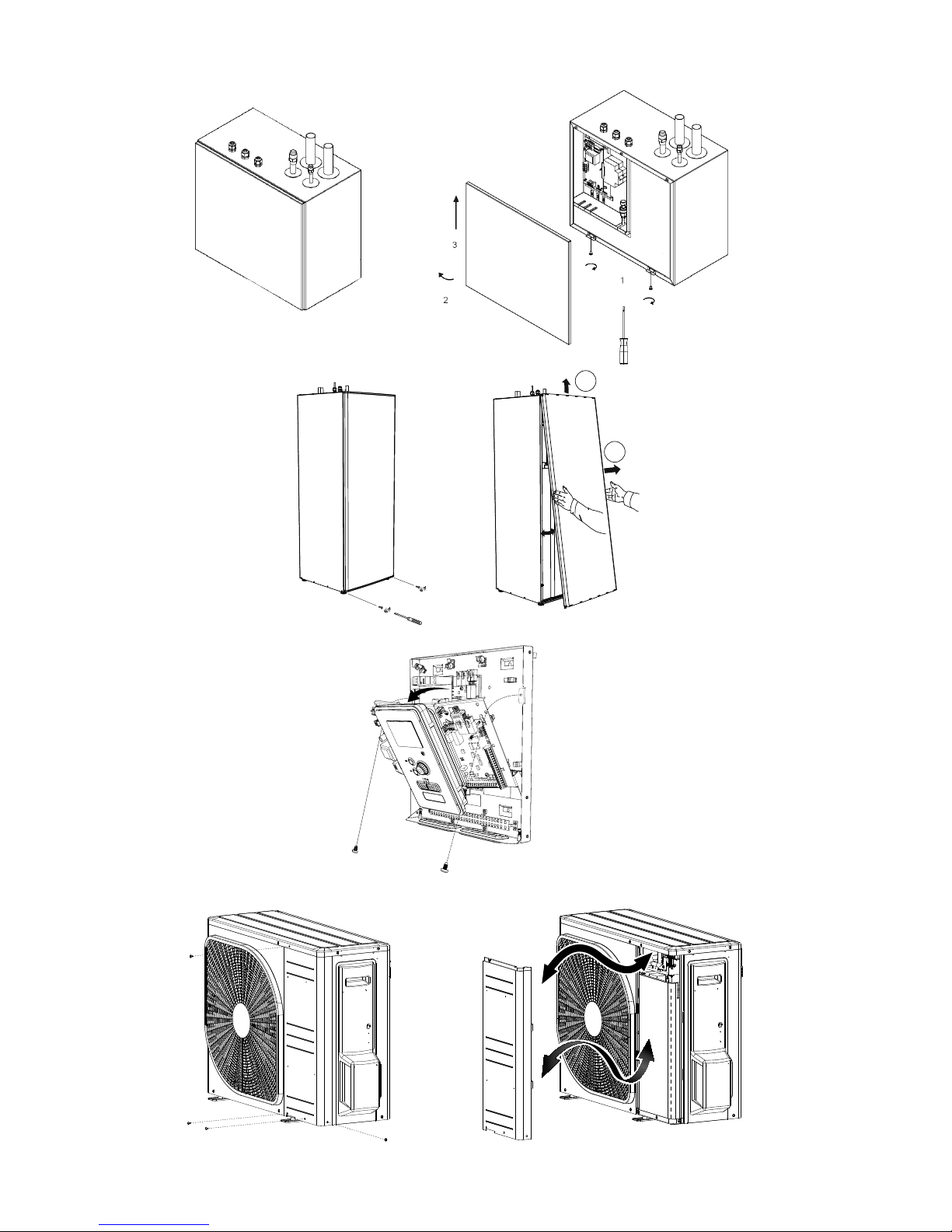

Housing disassembly of tank unit

19

Connecting hot water tank to indoor unit

20

Connecting hot water tank to water main

21

Hot water circulation circuit

22

Connection of external heat source

23

Refrigerant circuit

23

Connecting refrigerant pipes

23

Piping insulation

23

Drain connection

23

Dockings

24

Electrical installation

29

General

29

Electrical components

30

Accessibility, electrical connection for controller

32

Cable lock

34

Connection

34

<HSB60>

34

Power supply

34

Connection between indoor and outdoor unit

34

Connection between indoor unit and controller

35

Cascade connection setting

35

Recommended fuse size for HSB60

35

Recommended cable size for HSB60

35

<HMK60>

35

Circuit breaker

35

Power supply

35

Connection between indoor and outdoor unit

36

Connection between indoor unit and controller

36

Recommended fuse size for HMK60

36

Recommended cable size for HMK60

35

<RC-HY20/40>

36

Power supply

36

Connection between controller and indoor unit

37

HSB60 with RC-HY20

37

HSB60 with RC-HY40

37

HMK60 with RC-HY20

37

HMK60 with RC-HY40

37

Connection between controller and circulation pump (GP12) 38

HSB60 with RC-HY20

38

HSB60 with RC-HY40

38

HMK60 with RC-HY20

39

HMK60 with RC-HY40

39

Connection between controller and 3-way valve (QN10/QN12) 40

HSB60 with RC-HY20

40

HSB60 with RC-HY40

40

HMK60 with RC-HY20

41

HMK60 with RC-HY40

41

Connection between controller and sensors

42

RC-HY20 with HSB60

42

RC-HY20 with HMK60

43

RC-HY40 with HSB60

45

RC-HY40 with HMK60

46

Optional connections

48

RC-HY20

48

Room sensor BT50

48

Step controlled additional heat

48

Connection example with HMK60

49

Relay output for emergency mode

49

Connection example with HMK60

50

External circulation pump

50

AUX inputs/outputs

50

myUpway™

52

RC-HY40

53

Load monitor

53

Room sensor BT50

53

Step controlled additional heat

53

Relay output for emergency mode

53

External circulation pump

53

AUX inputs/outputs

54

myUpway™

55

Commissioning and adjusting

56

Preparation

56

Filling and venting

56

Hot water tank

56

Climate system

56

Inspection of installation

56

Start-up and inspection

57

Before start-up

57

Commissioning with heat pump

57

Commissioning with additional heater only

57

3-way valve operation check

57

AUX function check

57

Cooling mode

57

Cleaning particle filter

57

Secondary adjustment

57

Start guide

58

Heating/cooling curve setting

59

Hot water circulation setting

60

SG ready

61

Control

62

Display unit

62

Menu system

63

Menu list

66

Menu 1 – Indoor climate

66

Menu 2 – Hot water

66

Menu 3 – Info

66

Menu 4 – My system

66

Menu 5 – Service

67

Service

75

Disturbances in comfort

78

Manage alarm

78

Troubleshooting

78

Additional heating only

79

Alarm list

80

Accessories

83

Technical data

84

Dimensions and setting-out coordinates

84

Electrical circuit diagram

85

Table of Contents

2

Safety precautions

Safety precautions

When installing the unit, be sure to check

whether the selection of installation

place, power supply specifications,

usage limitation (piping length, height

differences between indoor and outdoor

units, power supply voltage and etc.) and

installation spaces.

We recommend you to read this

“SAFETY PRECAUTIONS” carefully

before installation in order to gain full

advantage of the functions of the unit

and to avoid malfunction due to

mishandling.

The precautions described below are

divided into

WARNING

and

CAUTION

.

The matters with possibilities leading

to serious consequences such as

death or serious personal injury due

to erroneous handling are listed in

the

WARNING

and the matters with

possibilities leading to personal injury

or damage of the unit due to erroneous

handling including probability leading to

serious consequences in some cases

are listed in

CAUTION

. These are very

important precautions for safety. Be

sure to observe all of them without fail.

Be sure to confirm no anomaly on the

equipment by commissioning after

completed installation and explain the

operating methods as well as the

maintenance methods of this equipment

to the user according to the owner’s

manual.

Keep the installation manual together

with owner’s manual at a place where

any user can read at any time. Moreover

if necessary, ask to hand them to a new

user.

This heat pump complies with EMC

Directive 2014/30/EU.

This appliance is designed for use in a

home environment and can be used by

children aged from 8 years and above and

persons with reduced physical, sensory or

mental capabilities or lack of experience

and knowledge if they have been given

supervision or instruction concerning use

of the appliance in a safe way and

understand the hazards involved. Children

WARNING

Installation must be carried out by

the qualified installer.

If you install the system by yourself, it may cause

serious trouble such as water leaks, electric

shocks, fire and personal injury, as a result of a

system malfunction.

Install the system in full accordance

with the instruction manual.

Incorrect installation may cause bursts, personal

injury, water leaks, electric shocks and fi re.

Use the original accessories and the

specified components for installation.

If parts other than those prescribed by us are used,

It may cause water leaks, electric shocks, fi re and

personal injury.

When installing in small rooms, take

prevention measures not to exceed

the density limit of refrigerant in the

event of leakage.

Consult the expert about prevention measures. If

the density of refrigerant exceeds the limit in the

event of leakage, lack of oxygen can occur, which

can cause serious accidents.

Ventilate the working area well in the

event of refrigerant leakage during

installation.

If the refrigerant comes into contact with naked

fl ames, poisonous gas is produced.

After completed installation, check that

no refrigerant leaks from the system.

If refrigerant leaks into the room and comes into

contact with an oven or other hot surface, poisonous

gas is produced.

shall not play with the appliance. Cleaning

and user maintenance shall not be made

by children without supervision.

This in accordance to applicable parts of

the low voltage directive 2014/35/EU, LVD.

This appliance is also intended for use by

experts or trained users in shops, hotels,

light industry, on farms and in similar

environments. This in accordance to

applicable parts of the machinery directive

2006/42/EC.

CE marking is applicable to the area of 50

Hz power supply.

The emission sound pressure level from

each Indoor and Outdoor unit is under 70

dB(A).

3

the box. Install the service panel correctly.

Incorrect installation may result in overheating

and fi re.

Do not perform brazing work in the

airtight room.

It can cause lack of oxygen.

Use the prescribed pipes, flare nuts

and tools for R410A.

Using existing parts (for R22 or R407C) can

cause the unit failure and serious accidents due to

burst of the refrigerant circuit.

Tighten the flare nut by using double

spanners and torque wrench according

to prescribed method. Be sure not to

tighten the flare nut too much.

Loose fl are connection or damage on the fl are part

by tightening with excess torque can cause burst

or refrigerant leaks which may result in lack of

oxygen.

Do not open the service valves for

liquid line and gas line until completed

refrigerant piping work, air tightness

test and evacuation.

If the compressor is operated in state of opening

service valves before completed connection of

refrigerant piping work, air can be sucked into

refrigerant circuit, which can cause bust or

personal injury due to anomalously high pressure

in the refrigerant.

Do not put the drainage pipe directly into

drainage channels where poisonous

gases such as sulphide gas can occur.

Poisonous gases will fl ow into the room through

drainage pipe and seriously affect the user’s

health and safety.

Only use prescribed optional parts.

The installation must be carried out by

the qualified installer.

If you install the system by yourself, it can cause

serious trouble such as water leaks, electric

shocks, fi re.

Do not run the unit with removed panels

or protections

Touching rotating equipments, hot surfaces or

high voltage parts can cause personal injury due

to entrapment, burn or electric shocks.

Be sure to fix up the service panels.

Incorrect fi xing can cause electric shocks or

fi re due to intrusion of dust or water.

Do not perform any repairs or modifications by yourself. Consult the dealer

if the unit requires repair.

If you repair or modify the unit, it can cause water

Safety precautions

Hang up the unit at the specified points

with ropes which can support the

weight in lifting for portage. And to

avoid jolting out of alignment, be sure to

hang up the unit at 4-point support.

An improper manner of portage such as 3-point

support can cause death or serious personal injury

due to falling of the unit.

Install the unit in a location with good

support.

Unsuitable installation locations can cause the

unit to fall and cause material damage and

personal injury.

Ensure the unit is stable when installed,

so that it can withstand earthquakes

and strong winds.

Unsuitable installation locations can cause the

unit to fall and cause material damage and

personal injury.

Ensure that no air enters in the refrigerant circuit when the unit is installed

and removed.

If air enters in the refrigerant circuit, the pressure

in the refrigerant circuit becomes too high, which

can cause burst and personal injury.

The electrical installation must be

carried out by the qualified electrician

in accordance with “the norm for

electrical work” and “national wiring

regulation”, and the system must be

connected to the dedicated circuit.

Power supply with insufficient capacity and

incorrect function done by improper work can

cause electric shocks and fi re.

Be sure to shut off the power before

starting electrical work.

Failure to shut off the power can cause electric

shocks, unit failure or incorrect function of

equipment.

Be sure to use the cables conformed

to safety standard and cable ampacity

for power distribution work.

Unconformable cables can cause electric leak,

anomalous heat production or fi re.

Use the prescribed cables for electrical

connection, tighten the cables securely

in terminal block and relieve the

cables correctly to prevent overloading the

terminal blocks.

Loose connections or cable mountings can cause

anomalous heat production or fi re.

Arrange the wiring in the control box so

that it cannot be pushed up further into

4

leaks, electric shocks or fi re.

Do not perform any change of protective device itself or its setup condition

The forced operation by short-circuiting protective

device of pressure switch and temperature

controller or the use of non specified component

can cause fi re or burst.

Be sure to switch off the power supply

in the event of installation, inspection

or servicing.

If the power supply is not shut off , there is a risk

of electric shocks, unit failure or personal injury

due to the unexpected start of fan.

Consult the dealer or an expert regarding removal of the unit.

Incorrect installation can cause water leaks,

electric shocks or fi re.

Stop the compressor before disconnecting refrigerant pipes in case of pump

down operation.

If disconnecting refrigerant pipes in state of

opening service valves before compressor

stopping, air can be sucked, which can cause burst

or personal injury due to anomalously high

pressure in the refrigerant circuit.

CAUTION

Carry out the electrical work for ground

lead with care.

Do not connect the ground lead to the gas line,

water line, lightning conductor or telephone line’s

ground lead. Incorrect grounding can cause unit

faults such as electric shocks due to shortcircuiting.

Use the circuit breaker with sufficient

breaking capacity.

If the breaker does not have sufficient breaking

capacity, it can cause the unit malfunction and

fi re.

Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can

cause electric shocks.

Do not use any materials other than a

fuse with the correct rating in the

location where fuses are to be used.

Connecting the circuit with copper wire or other

metal thread can cause unit failure and fi re.

Do not install the unit near the location

where leakage of combustible gases

can occur.

If leaked gases accumulate around the unit, it can

cause fi re.

Do not install the unit where corrosive

gas (such as sulfurous acid gas etc.) or

combustible gas (such as thinner and

petroleum gases) can accumulate or collect,

or where volatile combustible substances

are handled.

Corrosive gas can cause corrosion of heat

exchanger, breakage of plastic parts and etc. And

combustible gas can cause fi re.

Secure a space for installation, inspection and maintenance specified in the

manual.

Insufficient space can result in accident such as

personal injury due to falling from the installation

place.

When the outdoor unit is installed on a

roof or a high place, provide permanent

ladders and handrails along the access

route and fences and handrails around the

outdoor unit.

If safety facilities are not provided, it can cause

personal injury due to falling from the installation

place.

Do not use the indoor unit at the place

where water splashes may occur.

Since the indoor unit is not waterproof, it

can cause electric shocks and fi re.

Do not install or use the system close

to the equipment that generates electromagnetic fields or high frequency

harmonics.

Equipment such as inverters, standby generators,

medical high frequency equipments and

telecommunication equipments can affect the

system, and cause malfunctions and breakdowns.

The system can also aff ect medical equipment and

telecommunication equipment, and obstruct its

function or cause jamming.

Do not install the outdoor unit in a

location where insects and small animals

can inhabit.

Insects and small animals can enter the electric

parts and cause damage or fi re. Instruct the user to

keep the surroundings clean.

Do not use the base flame for outdoor

unit which is corroded or damaged due

to long periods of operation.

Using an old and damage base flame can cause

the unit falling down and cause personal injury.

Do not install the unit in the locations

listed below.

Locations where carbon fi ber, metal powder or

Safety precautions

5

any powder is fl oating.

Locations where any substances that can aff ect

the unit such as sulphide gas, chloride gas, acid

and alkaline can occur.

Vehicles and ships.

Locations where cosmetic or special sprays are

often used.

Locations with direct exposure of oil mist and

steam such as kitchen and machine plant.

Locations where any machines which generate

high frequency harmonics are used.

Locations with salty atmospheres such as

coastlines.

Locations with heavy snow (If installed, be sure

to provide base fl ame and snow hood mentioned

in the manual).

Locations where the unit is exposed to chimney

smoke.

Locations at high altitude (more than 1000m

high).

Locations with ammonic atmospheres.

Locations where heat radiation from other heat

source can aff ect the unit.

Locations without good air circulation.

Locations with any obstacles which can prevent

inlet and outlet air of the unit.

Locations where short circuit of air can occur (in

case of multiple units installation).

Locations where strong air blows against the air

outlet of outdoor unit.

It can cause remarkable decrease in performance,

corrosion and damage of components,

malfunction and fi re.

Do not install the outdoor unit in the

locations listed below.

Locations where discharged hot air or operating

sound of the outdoor unit can bother

neighborhood.

Locations where outlet air of the outdoor unit

blows directly to plants.

Locations where vibration can be amplifi ed and

transmitted due to insufficient strength of

structure.

Locations where vibration and operation sound

generated by the outdoor unit can affect

seriously. (on the wall or at the place near bed

room)

Locations where an equipment aff ected by high

harmonics is placed. (TV set or radio receiver is

placed within 5m)

Locations where drainage cannot run off safely.

It can aff ect surrounding environment and cause a

claim.

Do not install the remote controller at

the direct sunlight.

It can cause malfunction or deformation of the

remote controller.

Do not use the unit for special purposes

such as storing foods, cooling precision

instruments and preservation of

animals, plants or art.

It can cause the damage of the items.

Take care when carrying the unit by

hand.

If the unit weights more than 20kg, it must be

carried by two or more persons. Do not carry by

the plastic straps, always use the carry handle

when carrying the unit by hand. Use gloves to

minimize the risk of cuts by the aluminum fi ns.

Dispose of any packing materials correctly.

Any remaining packing materials can cause

personal injury as it contains nails and wood. And

to avoid danger of suff ocation, be sure to keep the

plastic wrapper away from children and to dispose

after tear it up.

Pay attention not to damage the drain

pan by weld spatter when welding

work is done near the indoor unit.

If weld spatter entered into the indoor unit during

welding work, it can cause pin-hole in drain pan

and result in water leakage. To prevent such

damage, keep the indoor unit in its packing or

cover it.

Be sure to insulate the refrigerant pipes

so as not to condense the ambient air

moisture on them.

Insufficient insulation can cause condensation,

which can lead to moisture damage on the ceiling,

fl oor, furniture and any other valuables.

Be sure to perform air tightness test

by pressurizing with nitrogen gas after

completed refrigerant piping work.

If the density of refrigerant exceeds the limit in

the event of refrigerant leakage in the small room,

lack of oxygen can occur, which can cause serious

accidents.

Do not touch any buttons with wet hands.

It can cause electric shocks.

Do not shut off the power supply immediately after stopping the operation.

Wait at least 5 minutes, otherwise there is a risk

of water leakage or breakdown.

Do not control the system with main

power switch.

It can cause fi re or water leakage. In addition, the

Safety precautions

6

Safety precautions

fan can start unexpectedly, which can cause

personal injury.

Do not touch any refrigerant pipes

when the system is in operation.

During operation the refrigerant pipes become

extremely hot or extremely cold depending the

operating condition, and it can cause burn injury

or frost injury.

Notabilia for units designed for R410A

Only use R410A refrigerant. R410A is the

refrigerant whose pressure is 1.6 times as high as

that of conventional refrigerant.

The size of charging port of service valve and

check joint for R410A are altered from that for

conventional refrigerant in order to prevent the

system being charged with the incorrect

refrigerant by mistake. And the protruding

dimension of pipe for flare processing and flare

nut size for R410A are also altered from that for

conventional refrigerant in order to reinforce

strength against the pressure for R410A.

Accordingly the dedicated tools for R410A listed

in the below mentioned table should be prepared

for installation and servicing.

Dedicated tools for R410A

a) Gauge manifold

b) Charge hose

c) Electronic scale for refrigerant charge

d) Torque wrench

e) Flare tool

f) Protrusion control gauge for copper pipe

g) Vacuum pump adapter

h) Gas leak detector

Do not use charging cylinder. Using charging

cylinder may alter the composition of refrigerant,

which results in making the performance of the

system worse.

Refrigerant must be charged always in liquid state

from the bottle.

7

General information for the installer

General information for installer

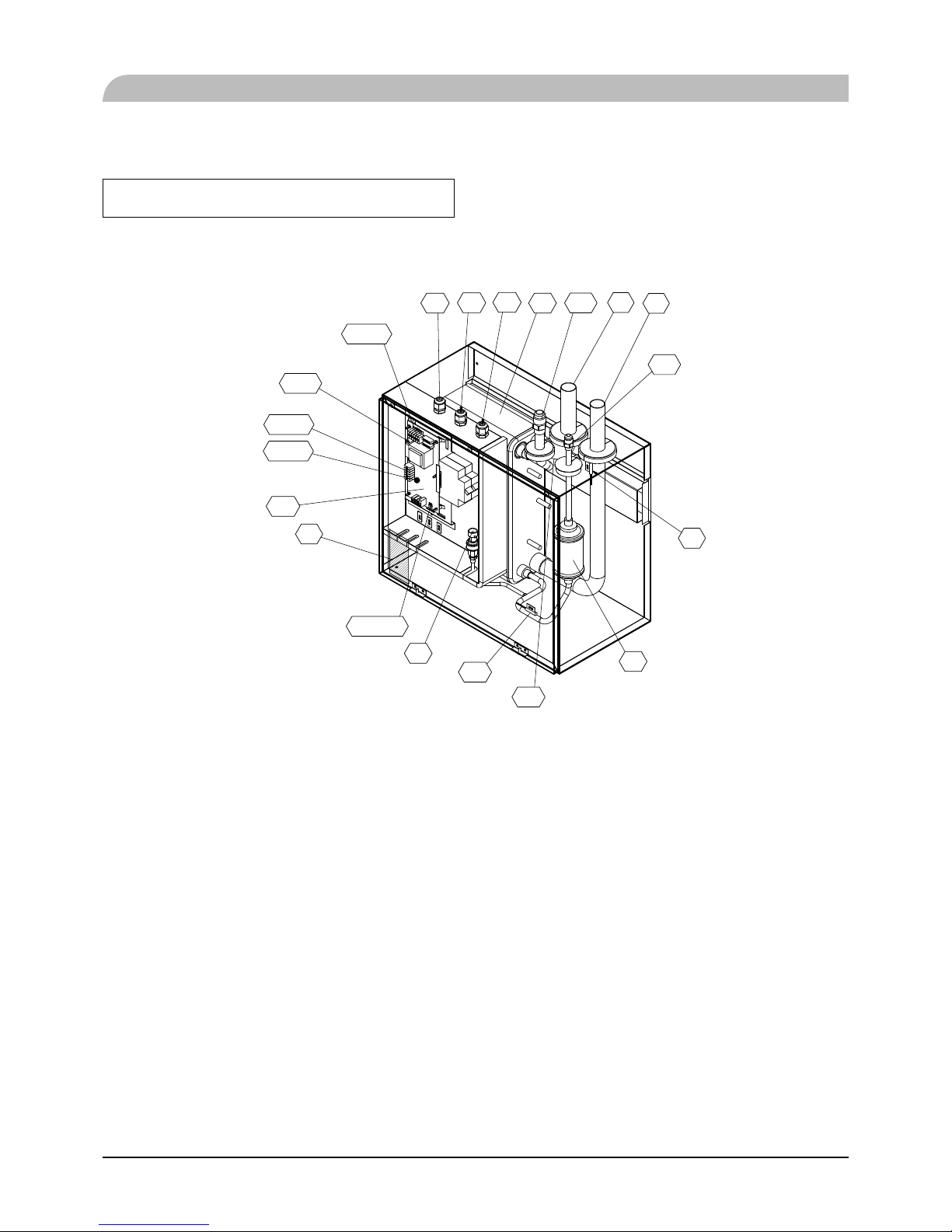

Over view and design

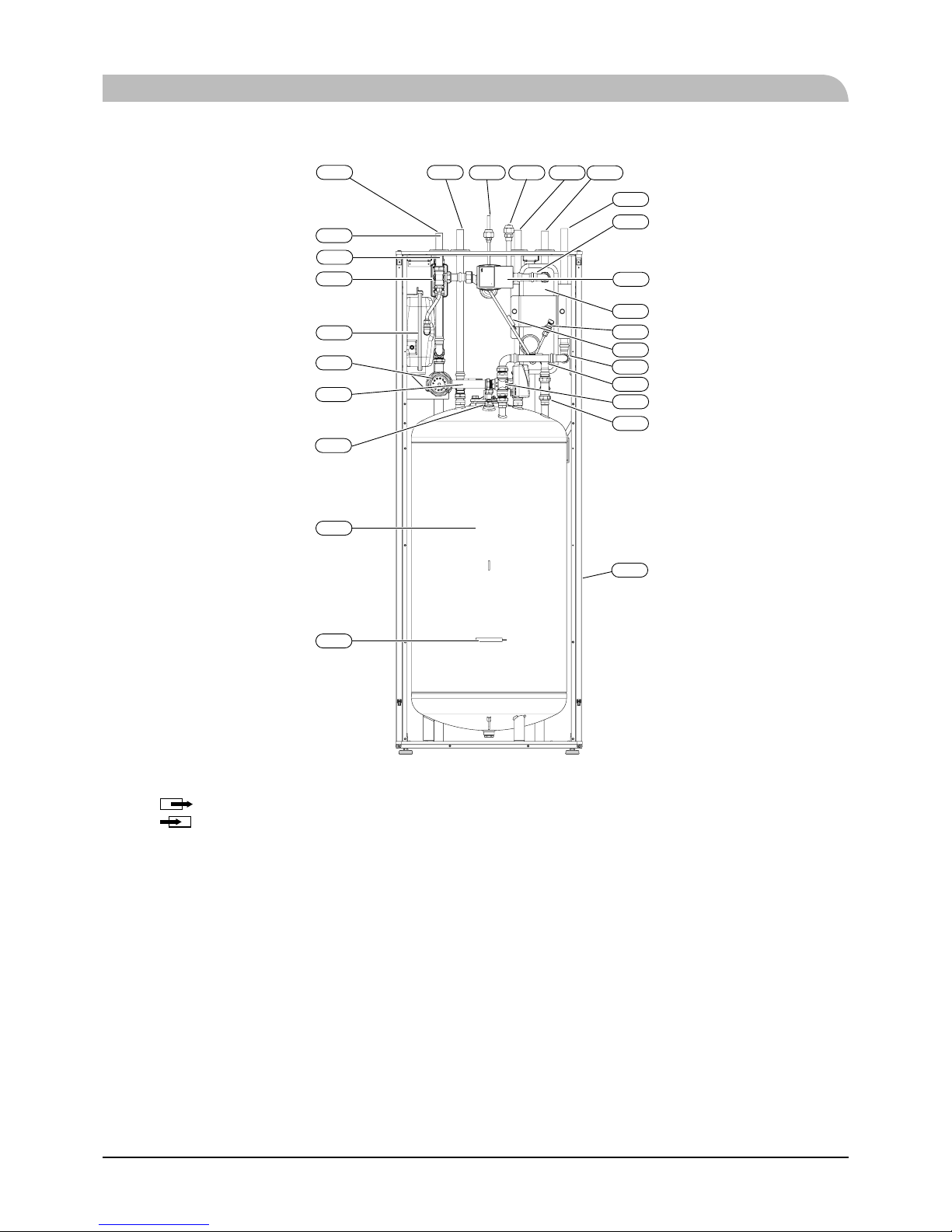

HSB60

XL1

XL2

XL1 3

XL14

HZ2

EP2

PF3

UB1

UB2

UB3

BT15

BT3

BP4

AA2 3

AA23-X100

AA2 3 - X4

AA23-S3

A23-F3

AA2 3 - X1

BT12

Pipe connections

XL1(Red mark) Climate system supply

XL2 (Blue mark) Climate system return

XL14 Connection, gas line

XL13 Connection, liquid line

Valves etc.

EP2 Heat exchanger

HQ1 Particle fi lter (supplied)

HZ2 Drying fi lter

Electrical components

AA23 Communication board

AA23-F3 Fuse for external heating cable

AA23-S3 DIP switch, addressing of outdoor unit

AA23-X1 Terminal block, incoming supply, connection

of KVR

AA23-X4 Terminal block, communication with indoor

module / control module

AA23-X100 Terminal block, communication outdoor

module

For outdoor unit installation information, see Installation

manual for Outdoor unit.

Sensor, thermostats

BP4 Pressure sensor, high pressure

BT3 Temperature sensor, heating medium, return

BT12 Temperature sensor, condenser, supply

BT15 Temperature sensor, fl uid pipe

Miscellaneous

UB1 Cable gland

UB2 Cable gland

UB3 Cable gland

8

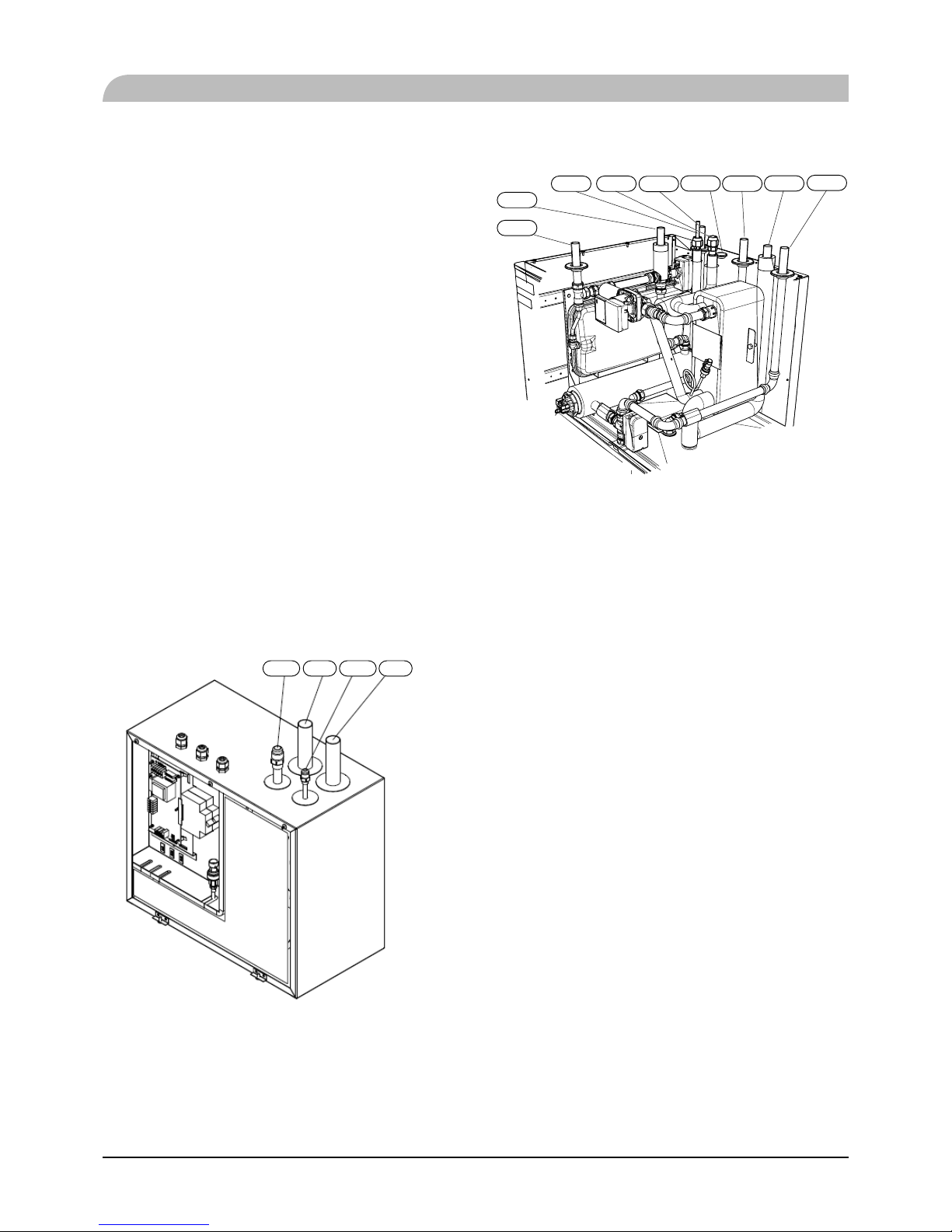

HMK60

XL10

XL11

QN12

QN10

GP12

EP2

CM1

EB1

XL4 XL13

XL14

XL3

XL2

XL1

BP4

EB15

BT15

BT71

BT6

EB2

BT64

BT63

BT7

BT12

BT3

BT25

Pipe connections

XL1

(

)

Connection, heating medium, supply

XL2

(

)

Connection, heating medium, return

XL3 Connection, cold water

XL4 Connection, hot water

XL10 Connection, cooling

XL11 Connection, safety group, manometer

XL13 Connection, liquid cooling medium

XL14 Connection, gas cooling medium

HVAC elements

CM1 Diaphragm expansion vessel, closed

QN10 Isolation valve, domestic hot water/central heating

QN12 Isolation valve, cooling/heating

GP12 Circulation pump

EP2 Heat exchanger

Sensors

BP4 Pressure sensor, high pressure

BT3 Temperature sensor, heating medium return

BT6 Temperature sensor, hot water loading

BT7 Temperature sensor, top of the hot water heater

BT12 Temperature sensor, condenser outlet

BT15 Temperature sensor, liquid

BT25 Temperature sensor, heating medium supply

BT63 Temperature sensor, heating medium supply

downstream the submersible heater

BT64 Temperature sensor, cooling medium supply

BT71 Temperature sensor, heating medium re- turn

Others

EB15 HMK 60

PF3 Serial number

EB2 Domestic hot water tank

General information for the installer

9

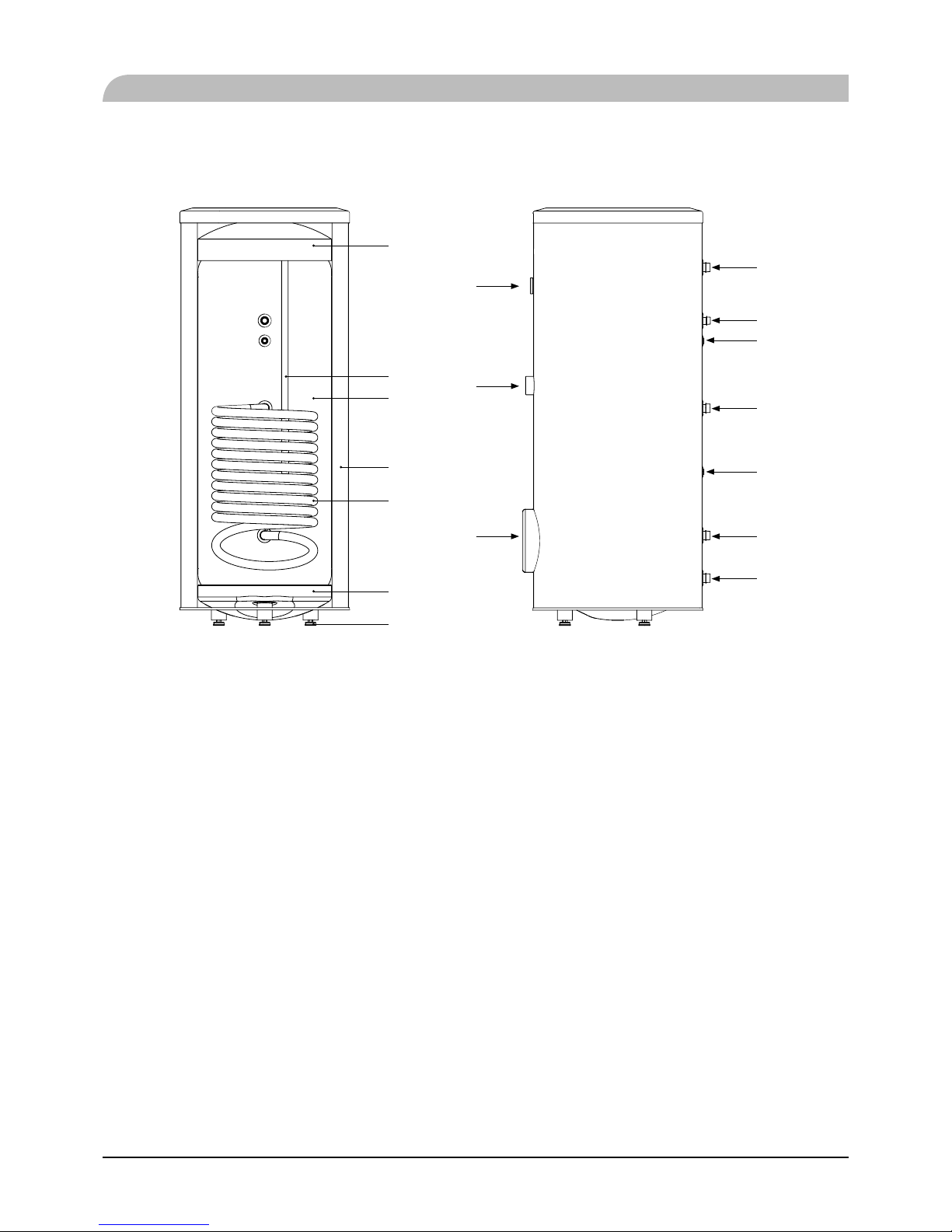

PT300

1

2

3

4

5

6

7

8

9

10

11

12

13

14

13

15

16

Section of the PT300 storage tanks.

1. Upper insulation of the storage tank

2. Protective magnesium anode

3. Enamelled tank

4. Side insulation of the storage tank

5. Coil

6. Lower insulation of the storage tank

7. Adjustable foot

Side view of the PT300 storage tanks.

8. Thermometer

9. Connector pipe for mounting electric heating unit

10. Inspection opening

11. Hot water intake connector pipe

12. Hot water circulation connector pipe

13. Temperature sensor cover

14. Coil supply connector pipe

15. Connection of return line from the coil

16. Cold water supply connector pipe

General information for the installer

10

Transport and storage

Indoor unit and tank unit must be transported and stored

vertically in dry conditions.

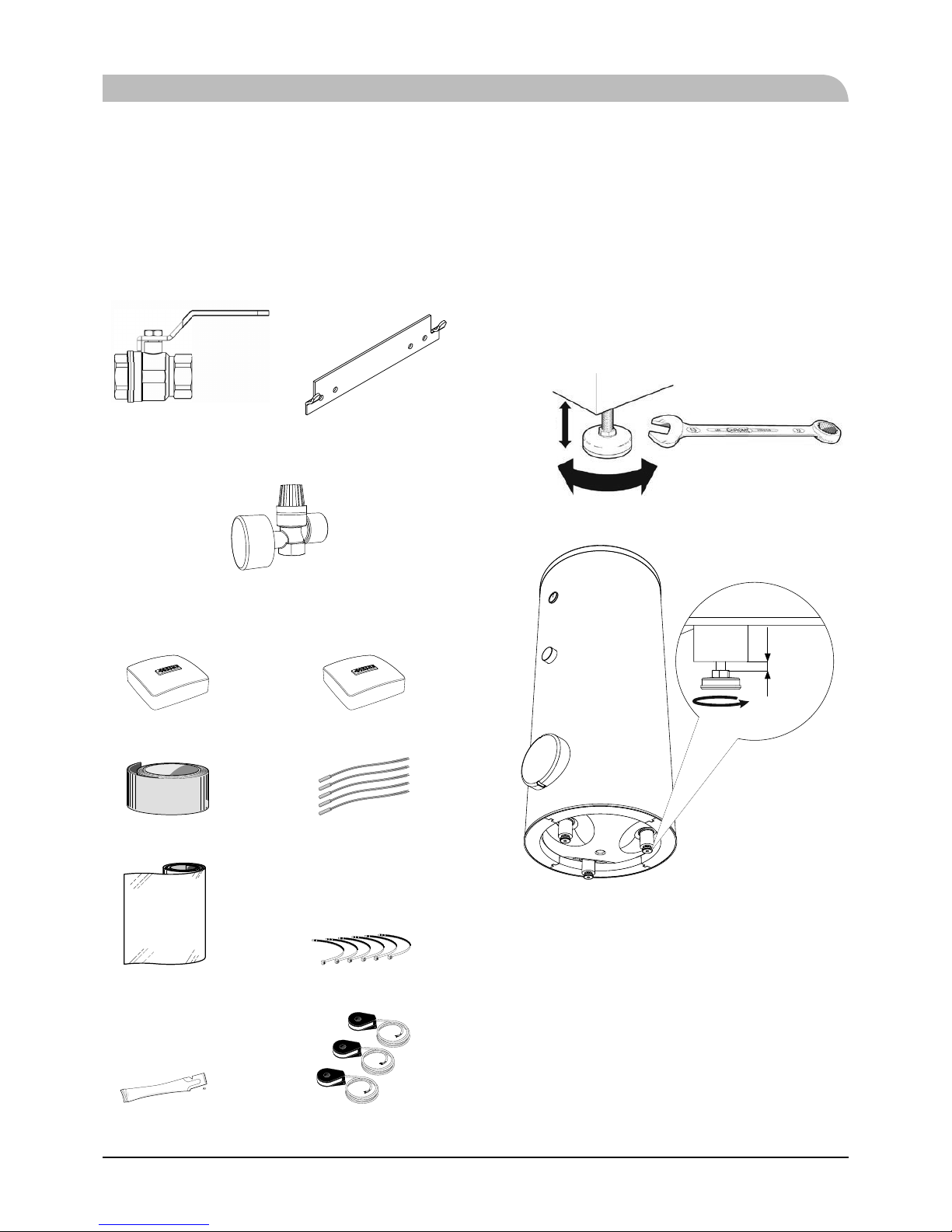

Supplied components

HSB60 Indoor unit

Particle filter R25 (HQ1). Brackets kit

HMK60 Indoor unit with tank

Safety valve with pressure gauge

RC-HY20/40 Control unit

Room sensor (RC-HY40 only)Outside sensor

LEK

Temperature sensorInsulation tape

LEK

Cable tiesAluminium tape

LEK

LEK

LEK

Current sensor (RC-HY40 only)Heating pipe paste

Assembly

■ It is recommended that indoor unit is installed in a room

with existing fl oor drainage, most suitably in a utility room

or boiler room.

■ For indoor unit and control unit, the mounting surface must

be fi rm, fl at and vertical, preferably a concrete wall.

■ Indoor unit with tank and tank unit must be set on a solid

waterproof base that would keep the weight of the unit. The

height-adjusting legs allow for levelling and stable setting.

HMK60

20-40 mm

Wrench size 13

PT300

0-15 mm

■ For indoor unit with tank, floor drain port is required to

connect drain hose in case cooling function is used.

■ Install indoor unit with its back to an outside wall, ideally

in a room where noise does not matter. If this is not

possible, avoid placing it against a wall behind a bedroom

or other room where noise may be a problem.

■ Route pipes so they are not fixed to an internal wall that

backs on to a bedroom or living room.

■ Install indoor unit with tank, tank unit and its pipings to

indoor unit indoors in order to avoid icing.

■ Ensure free space described in the following figures for

future maintenance.

General information for the installer

11

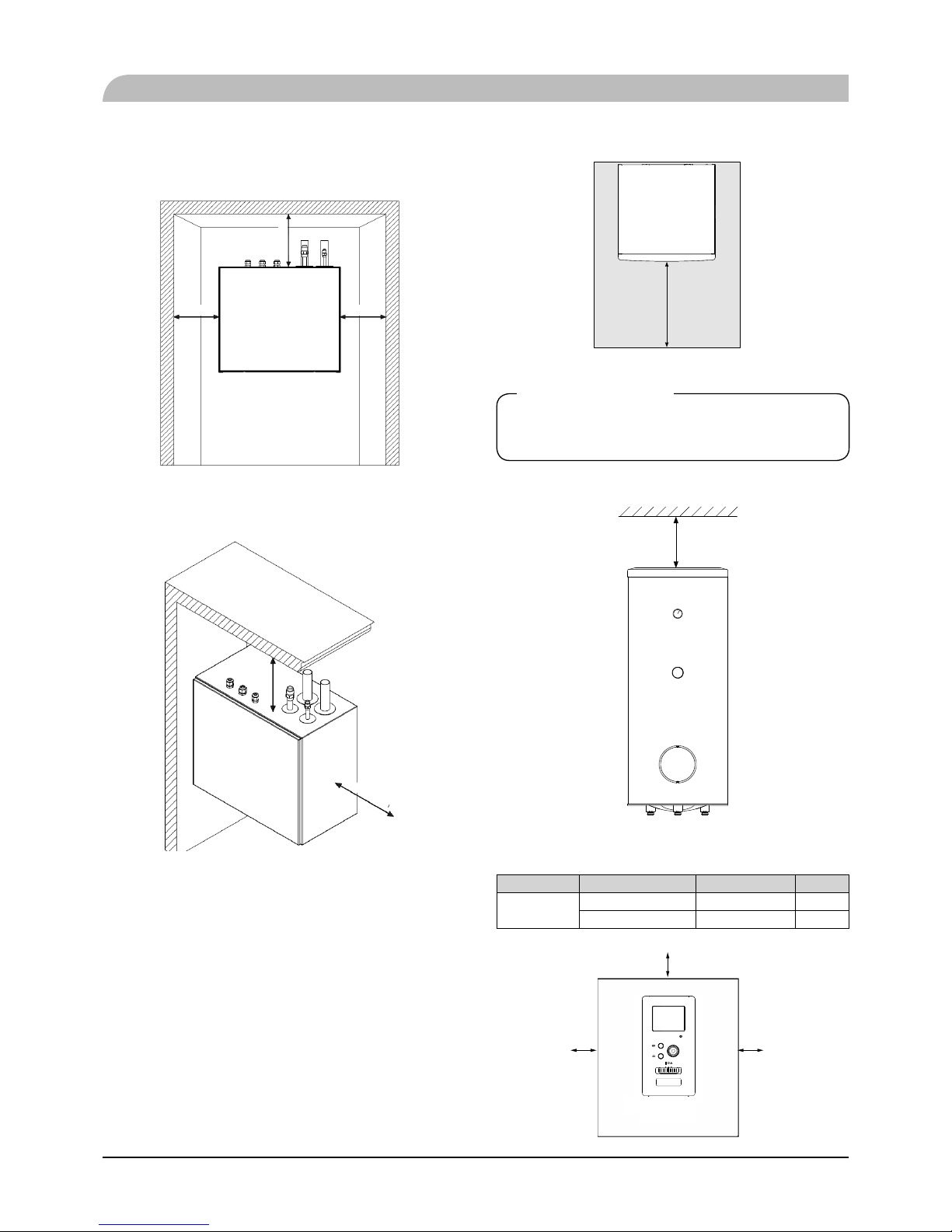

HSB60

Recommendation for positioning on wall

Min. 200mm Min. 200mm

Min. 300mm

Recommendation for positioning in corner

Min. 400mm

Min. 400mm

*Min 800mm is required in front

General information for the installer

HMK60

800 mm

IMPORTANT

For HMK60, leave 10 – 25 mm free space between the indoor

module and the back wall f or cables and piping.

PT300

A

min

A

min

is required on top to replace anode bar, and 500 mm is

required in front to replace immersion heater if equipped.

Application Connector pipe dia. Type of anode A

min

PT300

1" Chain ø26×8 150 mm

¾" Titanium anode 200 mm

RC-HY20/40

100 mm

100 mm 100 mm

12

General information for the installer

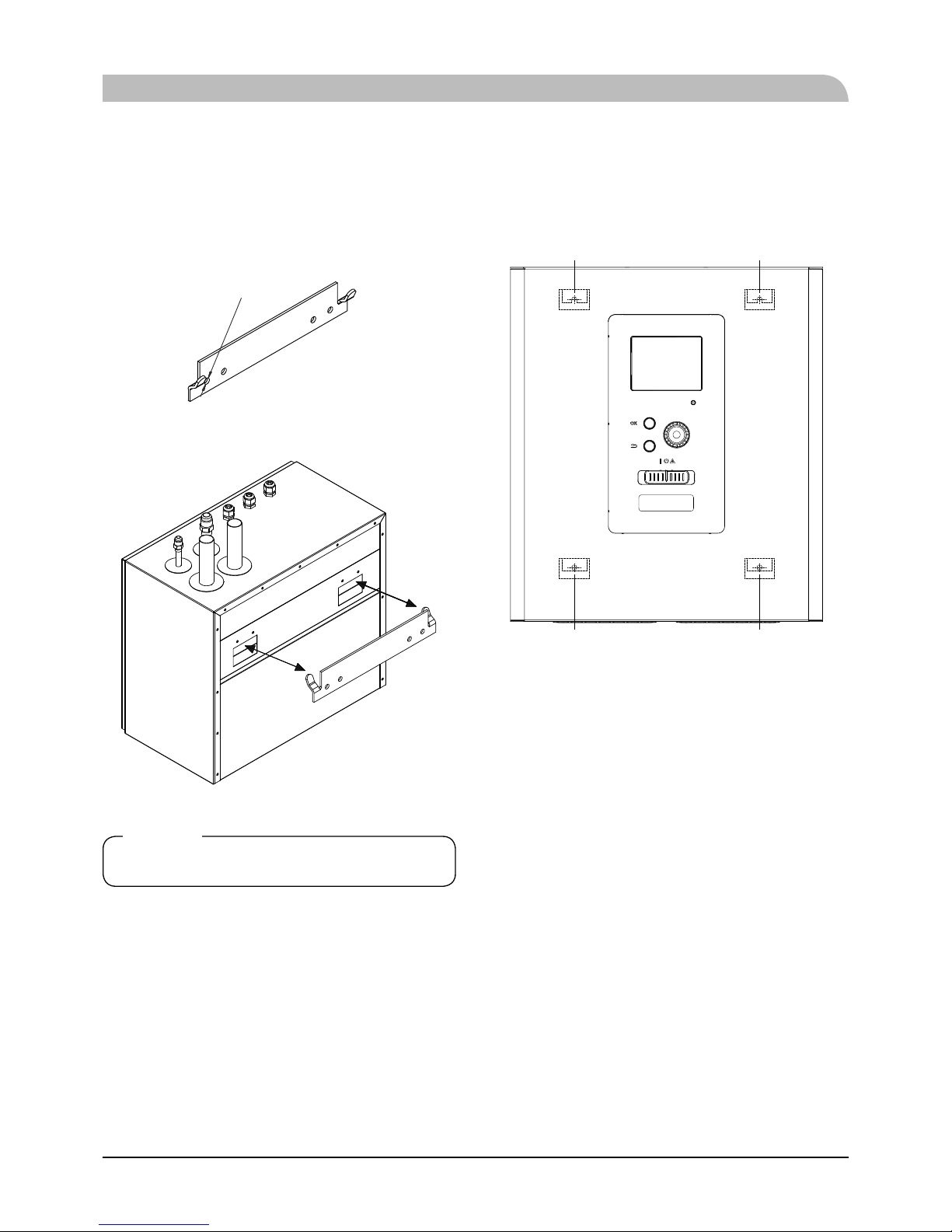

Hanging indoor unit

It is recommended that the split box is installed in a room with

existing fl oor drainage, most suitably in a utility room or boiler

room.

1. The bracket for the split box is mounted to the wall by use

of appropriate screws.

4-ø10

2. Insert HSB60 in the bracket mounted to the wall.

NOTE

Indoor unit weigh 16 kg excluding water inside.

Hanging control unit

Use all mounting points and install control unit upright against

a fl at wall. Make sure whole back surface faces the wall.

Mounting point Mounting point

Mounting point Mounting point

13

Dimensioning expansion vessel

The expansion vessel volume must be at least 5% of total water

volume in the circulation system.

HMK60 is equipped with an expansion vessel with a volume

of 10 liters.

Initial pressure and max height difference

Recommended maximum height diff erence between expansion

vessel and the highest point in the system is 5m.

The initial pressure of the pressure expansion vessel must be

dimensioned according to the maximum height (H) between

the vessel and the highest positioned radiator, see figure. An

initial pressure of 0.5 bar (5 mvp) means a maximum permitted

height diff erence of 5 m.

If the standard initial pressure in the pressure vessel is not high

enough it can be increased by filling via the valve in the

expansion vessel. The expansion vessel’s standard initial

pressure must be entered in the check list on User’s manua1.

Any change in the initial pressure affects the ability of the

expansion vessel to handle the expansion of the water.

Consult local distributor in case height diff erence exceeds 5m.

H

Recommended installation order

1. Hang indoor unit and control unit to appropriate position

and connect indoor unit and tank unit.

2. Connect indoor unit to climate system, cold and hot water

lines as well as any external heat sources. See page 14, 15.

Also see docking descriptions on page 26-28 and further

on.

3. Install refrigerant pipes according to the description on the

Installation manual for outdoor unit.

4. Connect current limiter, any centralised load control and

external contacts as well as the cable between indoor unit

and outdoor unit.

5. Connect incoming electricity to indoor unit and/or outdoor

unit. See page 34-36.

6. Follow the commissioning instructions on page 37-55.

General information for the installer

14

Pipe installation

General

Pipe installation must be carried out in accordance with current

norms and directives.

A following table shows plumbing necessary for each product.

Refrigerant Plumbing

HSB Necessary Necessary

HMK Necessary Necessary

PT ⸺ Necessary

PC-HY ⸺ ⸺

This heat pump system is designed for low or medium

temperature heating system. It is recommended water

temperature must not exceed 55°C on supply and 45°C on

return at lowest design outdoor temperature (DOT) though

indoor unit can operate with a return temperature of up to 65°C

and an outgoing temperature from the unit of 65°C.

Indoor unit is not equipped with shut off valves; these must be

installed outside the heat pump to facilitate any future

servicing.

Indoor unit can be connected to the radiator system, floor

heating system and/or fan convectors.

Safety valve is not equipped with in indoor unit. Make sure to

install safety valve in the circuit.

FDCW60

AA25

P

HSB60

BP4

BT3BT15

BT12

XL14

XL13

XL1

XL2

PT300

Pipe installation

Installation diagram

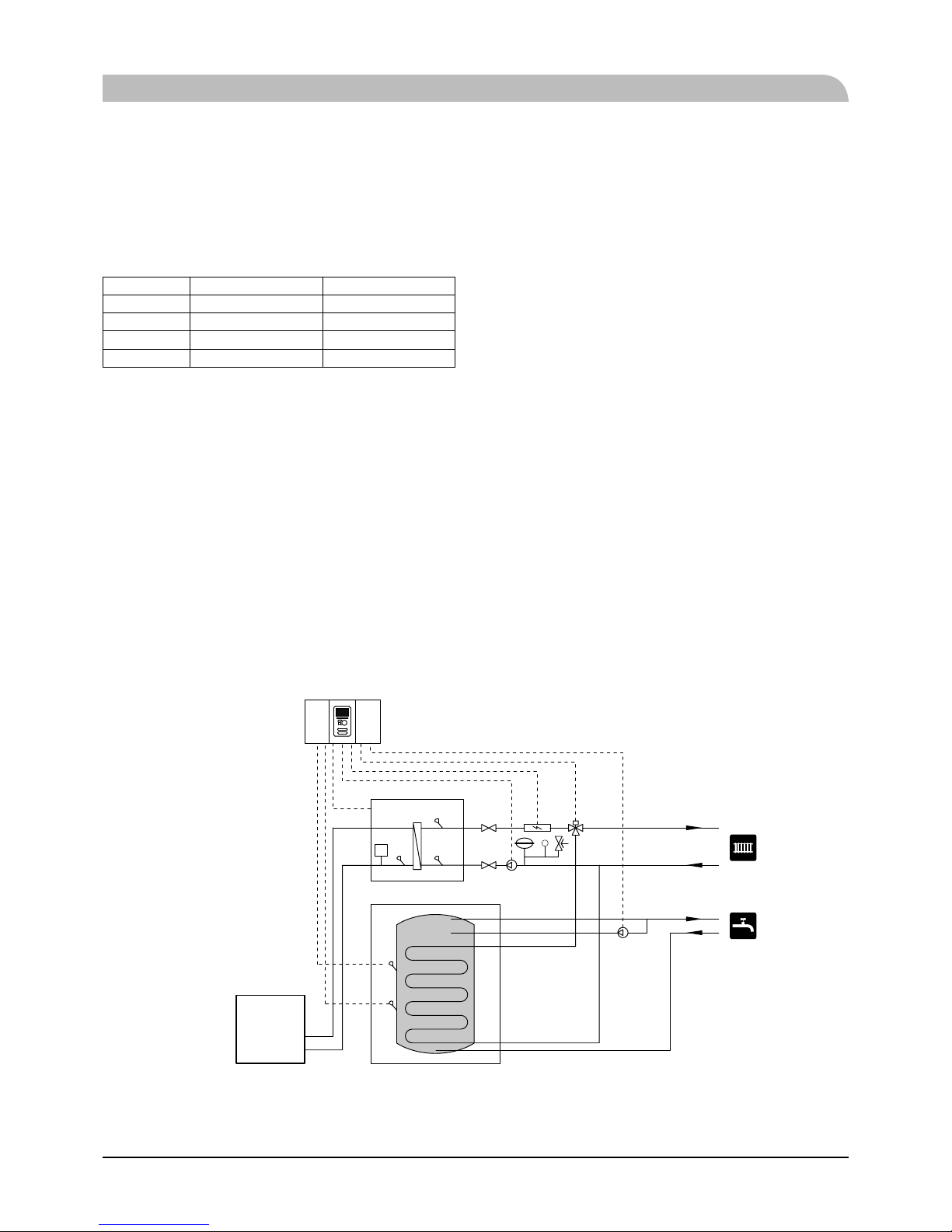

FDCW60VNX-A outdoor unit provides heat for space heating and domestic hot water using free energy in the outdoor air within the

range of low temperature up to -20°C. Connection is diff erent according to the type of indoor unit (see below fi gures). The system is

controlled by RC-HY20 or RC-HY40 control unit.

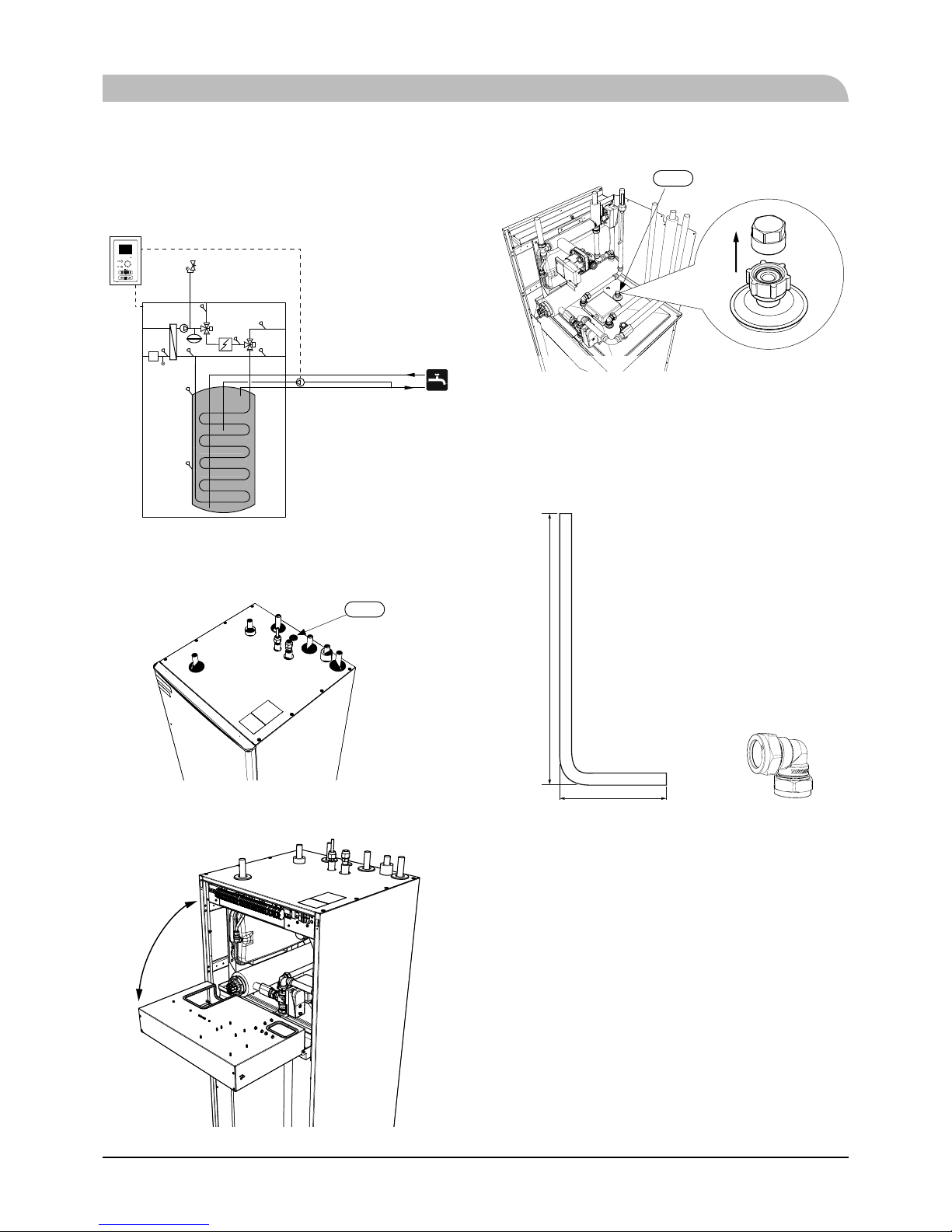

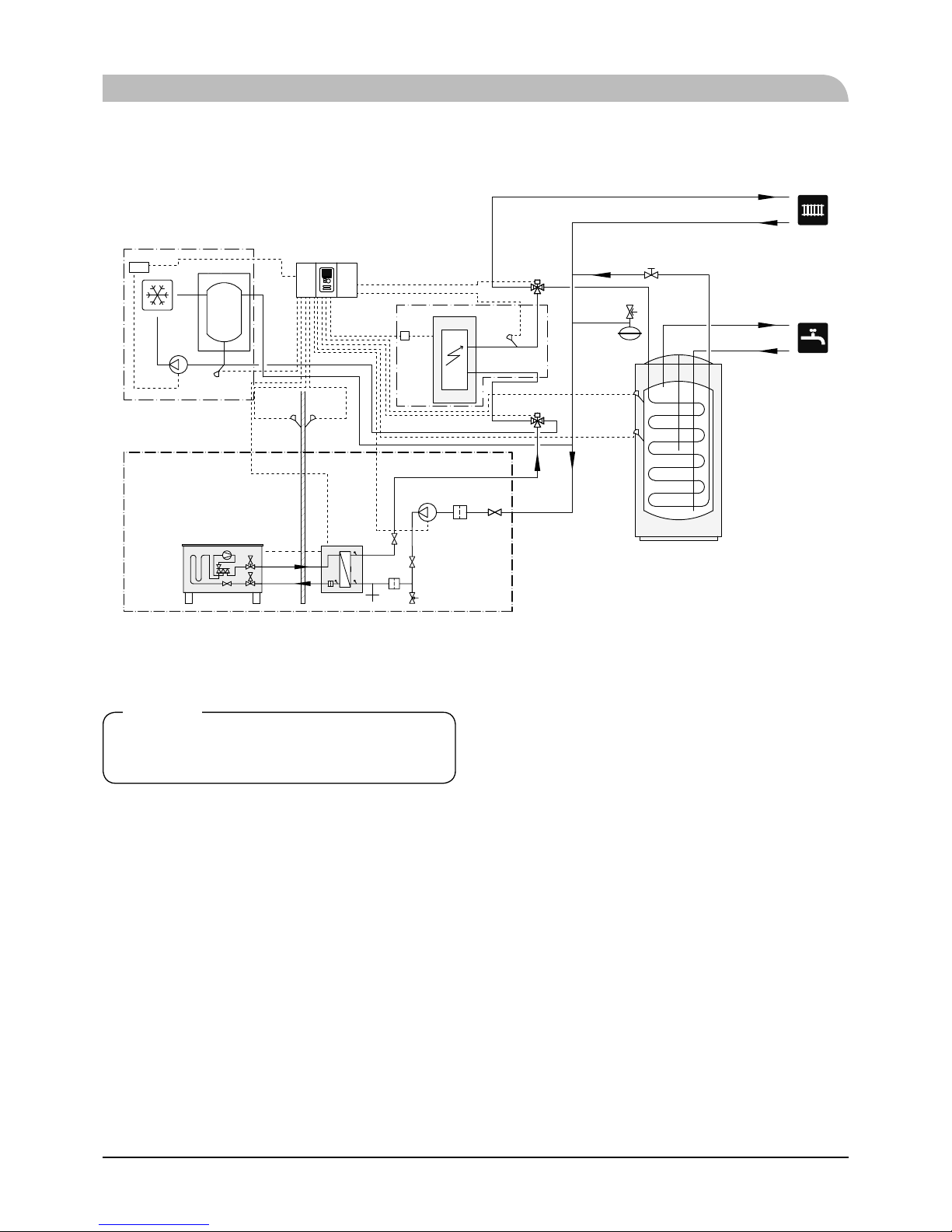

HSB60

HSB60 indoor unit is equipped with plate heat exchanger. It needs to install expansion vessel, shut-off valves, safety valve, electric

heater and circulation pump to make a complete heating system. In case domestic hot water is required, 3 way valve and tank is also

necessary.

15

HMK60

HMK60 indoor unit is equipped with coil water heater, expansion vessel, safety valve, electric heater, plate heat exchanger,

sensors and gauge, and circulation pump.

P

FDCW60

XL10

BP4

EH

XL1

XL11

XL14

XL13

XL2

XL4

XL3

HMK60

Pipe installation

Symbol Meaning Symbol Meaning

Vent

P

Manometer

Cut-off valve Circulation pump

Water tap Particulate fi lter

Non-return valve Compressor

Balancing valve Heat exchanger

Three-way valve Cooling

Safety valve Central heating system

T

Thermometer Domestic hot water

Temperature sensor

Heating systems Floor

heating

Diaphragm expansion

vessel

Cooling system

16

System requirements

The minimum water volume in the climate system is subject to

the values in the table below. If it is not fulfi lled, volume

vessel must be installed.

For more options, see the docking description on Page 24.

(liter)

With underfl oor

cooling application

Without underfl oor

cooling application

HSB60, HMK60,

FDCW60VNX-A

50 20

Overflow valve

NOTE

A free f low is required for all docking options, which

means that an over fl ow val ve must be installed.

The circulation pump may become damaged.

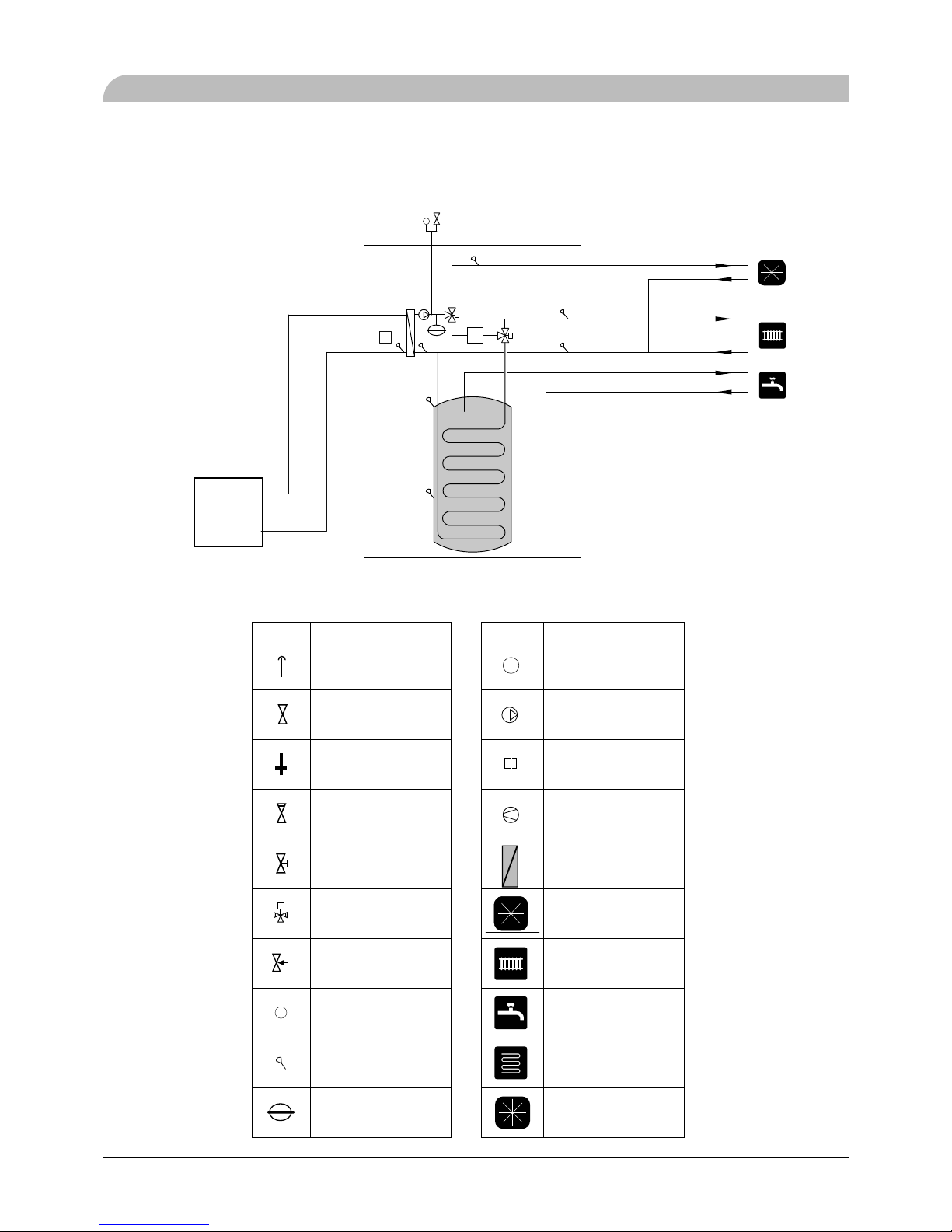

Pump capacity diagram

HSB60

HSB60 is not equipped with circulation pump.

This graph shows the characteristic of CPD11-25/55.

0

10

20

30

40

50

60

70

80

Pressure

[kPa]

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Flow [l / s]

HMK60

Pressure

[kPa]

Flow [l / s]

Pipe installation

17

Pressure drop in indoor unit

HSB60

0

5

10

15

20

25

30

0,0

0,1 0,2 0,3 0,4 0,5 0,6 0,7 0,

8

Tryckfall HBS05

HSB60, 140HSB100

kPa]

Flow [l / s]

HMK60

0

2

4

6

8

10

12

14

16

0 0.2 0.4 0.6

[kPa]

Flow[l/s]

Connection of extra circulation pump

When connecting extra circulation pumps, requirements for

pressure, maximum flow etc must be met. See page 27 for

location.

NOTE

Non-ret urn v alve must be install ed in c ase e xt ra cir culat ion

pump is used. See page 27 for the position.

The circlulation pump may become damaged.

Dimensions and pipe connections

HSB60

XL13

XL1

XL14

XL2

Pipe connections

XL1 (Red mark) Climate system, fl ow ø28 mm

XL2 (Blue mark) Climate system, return ø28 mm

XL14 Gas line refrigerant, fl are ½

XL13 Liquid line refrigerant, fl are ¼

HMK60

600.5

610.5

300

156

93.5 92.5

XL11

XL14

XL1XL2XL3XL5XL4

XL13

PF3

XL10

87

63

55

65

155

44

152

Pipe connections

XL1 Connection, Heating medium supply ø22 mm

XL2 Connection, Heating medium return ø22 mm

XL3 Connection, cold water ø22 mm

XL4 Connection, hot water ø22 mm

XL5 Connection, circulation ø15 mm

XL13 Connection, liquid cooling medium ¼ ࡉ

XL14 Connection, gas cooling medium ½ ࡉ

XL10 Connection, cooling ø22 mm

XL11 Connection, safety valve ø22 mm, manometer

Other information

PF3 Serial number plate

(

)

(

)

Pipe installation

18

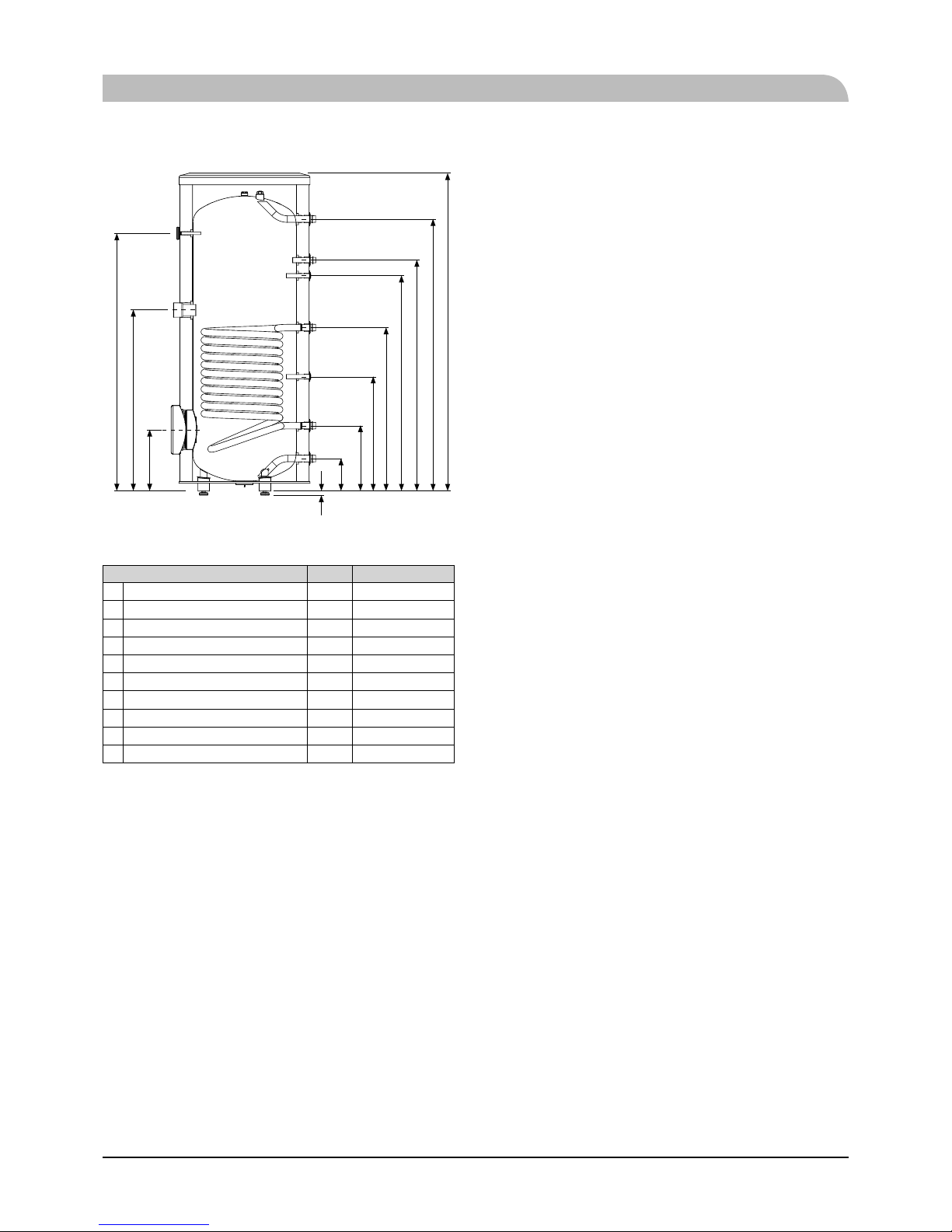

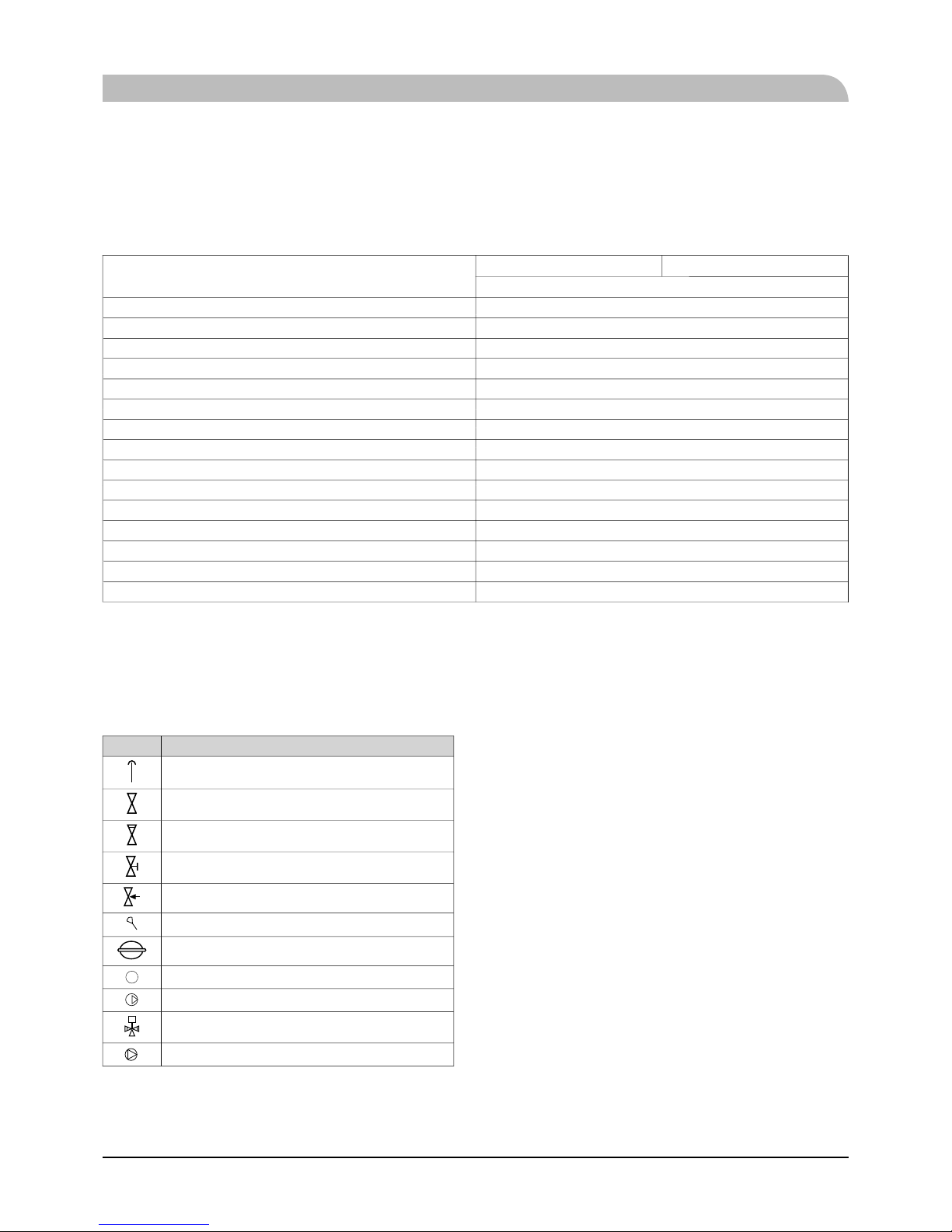

PT300

1634

1398

1187

1107

840

588

336

167

21-0/+15

315

930

1325

F

E

D

N

L

K

J

I

H

G

Connection U/m PT300

D

Inspection opening mm ø120

E

Heating unit connection inch 1½ Female

F

Thermometer enclosure mm ø10 Female

N

Hot water outlet inch 1 Male

L

Hot water circulation inch ¾ Male

K

Temp. sensor enclosure (BT7) mm ø16 Female

J

Coil supply inch 1 Male

I

Temp. sensor enclosure (BT6) mm ø16 Female

H

Return from coil inch 1 Male

G

Cold water input inch 1 Male

Pipe installation

19

Pipe installation

Water circuit

Connection to heating system

Connect XL1 to supply line and X2 to return line from

heating system.

■ All required safety devices and shut-off valves must be

installed as close to the indoor unit as possible.

■ Install bleed valves where necessary, highest point of the

water system in usual case.

■ When connecting to a system with thermostats on all

radiators, install an overfl ow valve or remove some of the

thermostats to ensure suffi cient fl ow.

■ See section Dockings on page 25 for outline diagram.

■ Install a safety valve with manometer on heating circuit and

hot water circuit. (FL2)

For HSB60 install a safety valve for heating circuit on the

water pipe returning to indoor unit since it doesn’t have

port for FL2.

The entire length of the overfl ow water pipe from the safety

valves must be inclined to prevent water pockets and must

also be frost proof.

■ The end of overfl ow water pipe from the safety valves must be

left open to the atmosphere. The water may drip from the pipe.

HSB60

XL14 XL1 XL13 XL2

Install safety valve as close to XL2 as possible.

HMK60

XL9XL8

XL3

XL5 XL4 XL2

XL1

XL10

XL11

Install safety valve FL2 on XL11.

Connection to hot water heater

For HSB60 indoor unit, it is necessary to connect PT300 tank

unit applying 3 way valve in order to use domestic hot water

function.

For HMK60 indoor unit, 180L tank unit is integrated in

indoor unit.

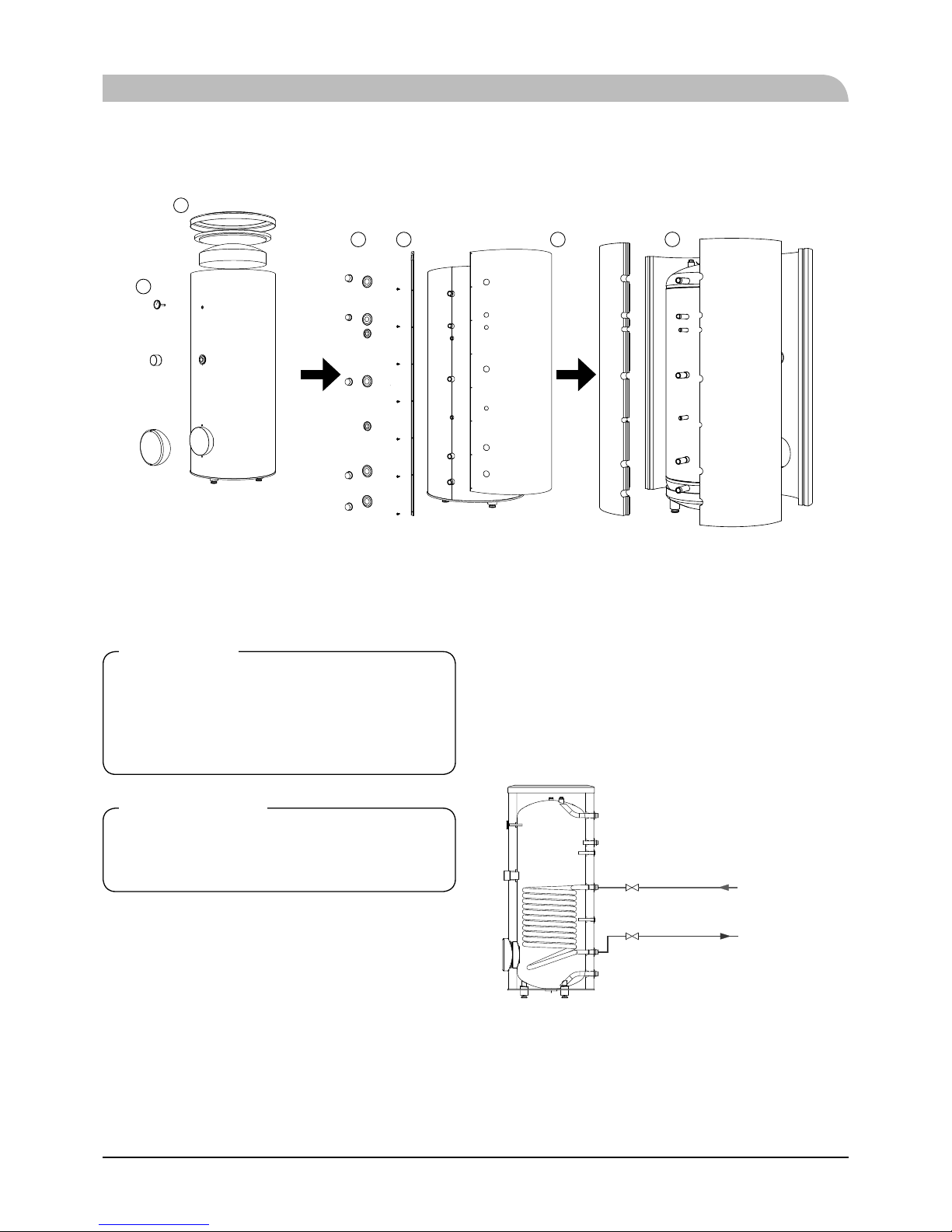

Housing disassembly of tank unit

Removable housing with thermal insulation facilitates transport and installation of the storage tank. Disassembly the housing in the following order (see below fi gure):

1. Remove the Temperature gauge, plug of the heating element connector pipe and blanking plate of the inspection

opening.

2 Remove the upper cover of the housing together with

thermal insulation.

3. Remove the plugs from the connector pipes and black

bushings.

4. Remove the fixing screws and the strip connecting the

housing jacket.

5. Remove the jacket surrounding the tank (housing jacket.)

6. Remove the four-piece thermal insulation.

After the installation of the storage tank in its fi nal location,

reinstall the removed components in the reverse order.

20

Housing and thermal insulation disassembly

1

2

34

5

6

Connecting hot water tank to indoor unit

CAUTION

Instal lation and commis sioning of the storage tank

shall onl y be d one b y ap propri atel y qualif ied install er.

The installer should inform the user of the functions of

the product and provide the necessary in formation on its

safe use.

Information

We recommend installing a strainer in order to protect the

pumps, check valve and the components of the heating

system.

■ Tank and its pipings to indoor unit must be installed

indoors where the temperature wouldn't drop below 15°C

in order to prevent pipings from icing.

■ Maximum piping length between indoor unit and tank is

10 m.

■ Tank unit should be placed on firm, preferably a concrete

fl oor or foundation.

Pipe installation

■ Tank unit can be aligned using the adjustable feet.

■ Protection against overpressure shall be made in accordance

with the relevant regulations.

■ Connect the heating system according to the installation

diagram (see fi gure).

Installation diagram of the PT storage tank with one coil.

1

2

2

supply from heat

pump

1. PT storage tank

2. Cut-off valve

return to heat pump

21

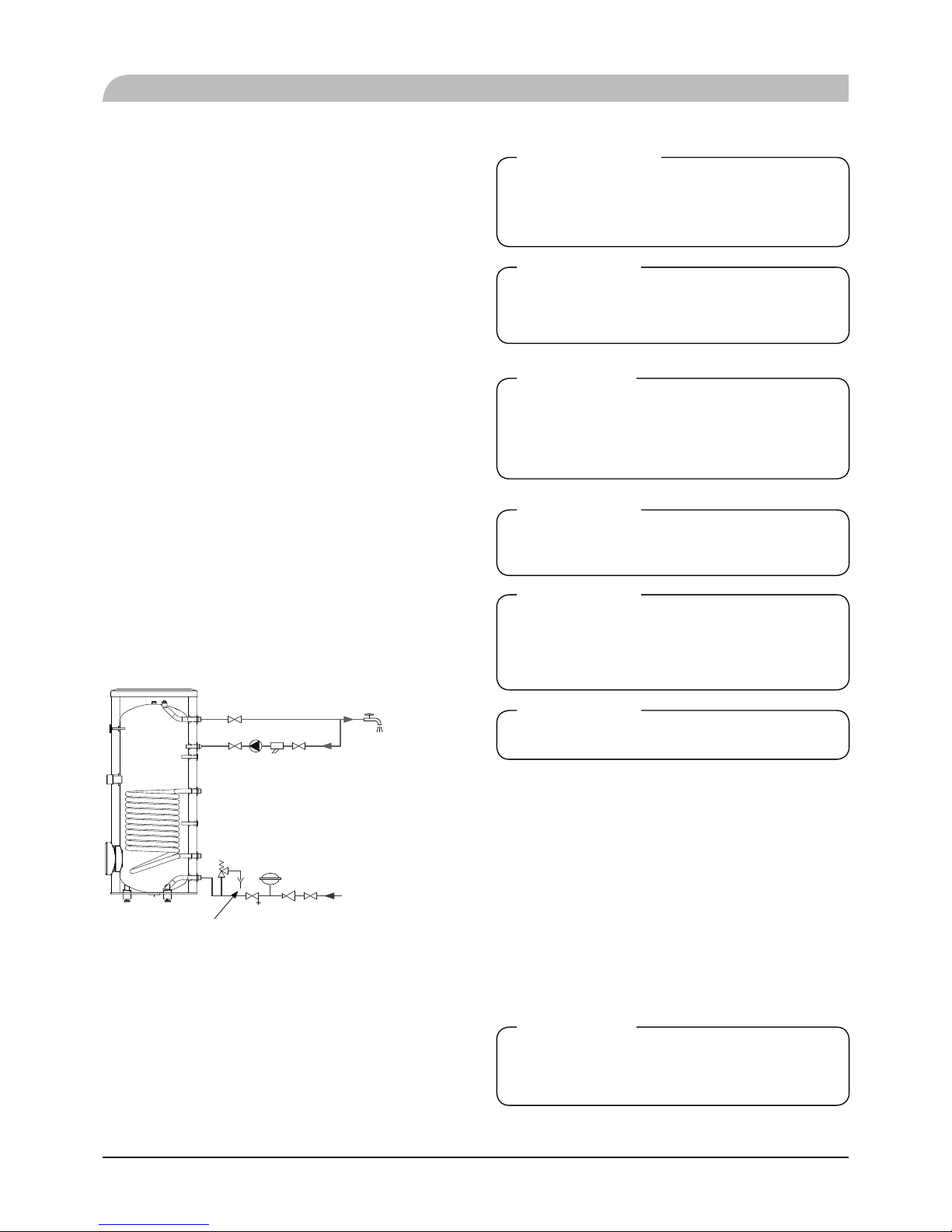

Connecting hot water tank to water main

■ Install a mixing valve if the temperature exceeds 60 °C.

■ It is recommended to install a thermostatic mixing valve

for stable temperature hot water supply.

■ Connect the storage tank to the water supply system of

water pressure at least 1 bar and max 10 bar. Install a

pressure reducer if the pressure at the cold water inlet to the

tank is higher than allowed.

■ Install a safety valve which have a maximum 10.0 bar

opening pressure on the incoming domestic water line

according to outline diagram in order to protect the storage

tank against overpressure. Pressure increases during heating

the water.

■ During heating the water, small and temporary water fl ow

from the safety valve can occur, which indicates that the

pressure has increased above the rated value, which

triggered the valve. This may in no way be prevented.

■ Safety valve drain line should be installed with a decline, in

an environment free of freezing and remain open to the

atmosphere. The manufacturer is not responsible for

fl ooding the room through the safety valve.

■ Blocked safety valve can cause equipment failure. Drain

the outfl ow from the safety valve to the sewerage or drain

grate.

■ See section Dockings on page 25 for outline diagram.

■ Connect the water supply system according to the

installation diagram.

Installation diagram of the PT storage tank with one coil.

1

2

22

2

6

7

38

45

DHW

hot water circulation

(optional)

to sewerage

water supply system

1. PT storage tank

2. Cut-off valve

3. Safety valve

4. Drain valve

5. Pressure reducer (option, if the pressure in the system

exceeds the allowable value)

6. Strainer

7. Hot water circulating pump

8. Hot water expansion vessel

Information

In order to minimi ze t he f low of wate r f ro m the saf ety val ve

associated with the thermal expansion of the liquid, it is

advisable to install a suitable expansion vessel at the cold

water connection (see item 8.)

CAUTION

Installation of the appropriate safety valve in the cold

water supply line protecting the unit against

overpressure is mandatory!

CAUTION

Installation of necking of any kind (such as reducers, dirt pockets,

etc.) and cut-o valves between the storage tank and the safety

valve is not allowed. Only a T-pipe with a drain valve and a T-pipe

with an expansion vessel may be installed in these line sections.

CAUTION

Never block the safety valve or drain line. This can cause

a dangerous overpressure in the storage tank.

CAUTION

When heating water, slight, temporary discharge from

the safety valve can occur. This is a correct safety valve

function. Any attempt to interfere in its operati on can

lead to the danger and destruction of the storage tank.

CAUTION

Never use the equipment with clogged safety valves.

Connection

After the installation and levelling the tank, follow the procedure below (for the connector pipe symbols, refer to page 19):

1. Remove protecting plugs from the connector pipes

2. Connect the hot water intake line (N).

3. Connect the cold water supply line together with the

required safety valves (G).

4. If the system has the hot water circulation system, connect

it to the connector pipe (L). Otherwise, plug the pipe.

5. Connect the supply (J) and return (H) of the heating

medium to the coil.

CAUTION

If there is an electric heating module installed in the

storage tank, ll the tank with water before connecting

it to the electrical installation.

Pipe installation

22

Hot water circulation circuit

Hot water circulation function is available for HMK60 and

PT300.

HMK60

To connect the circulation:

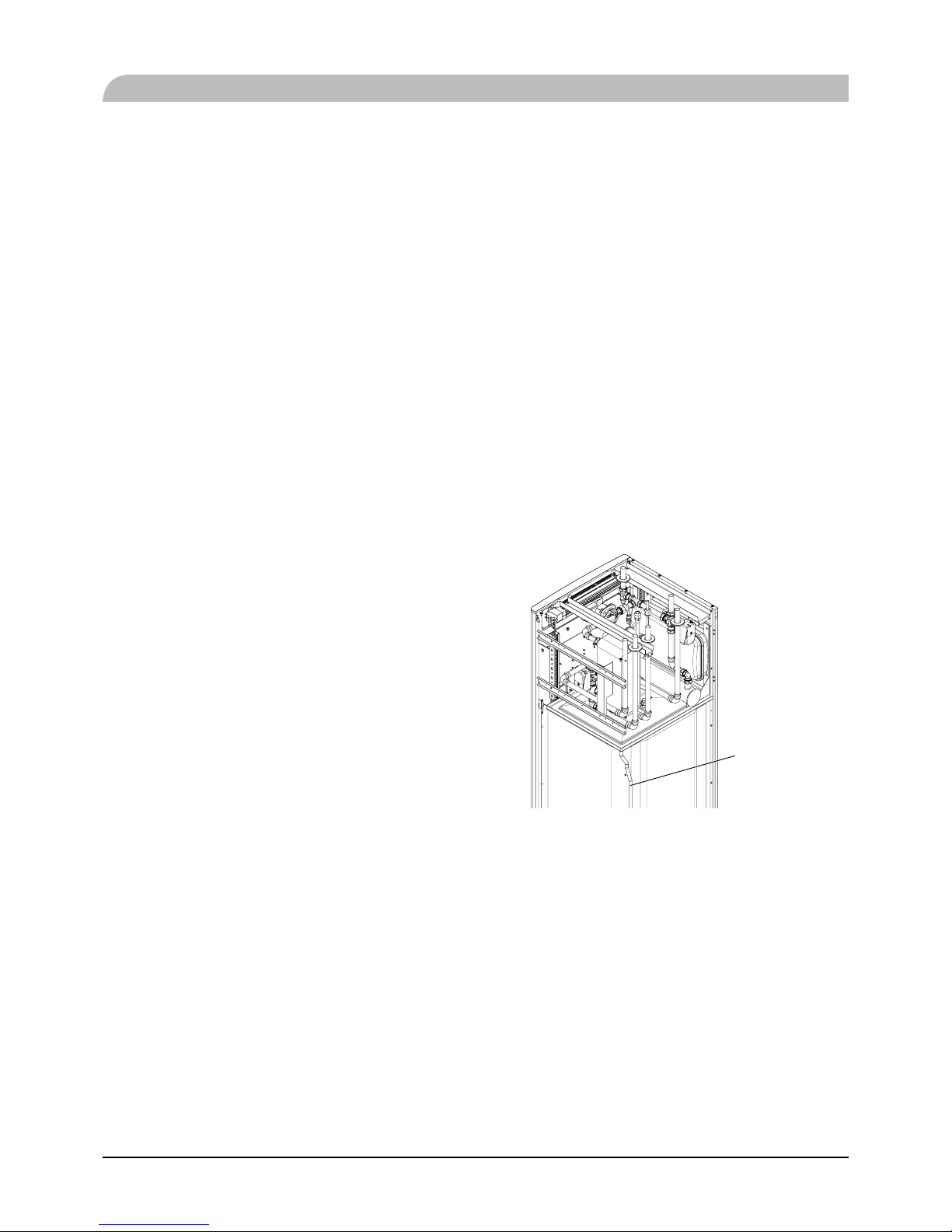

1. Remove the XL5 plug from the top of the housing.

XL5

2. Remove the front panel, then slide the control panel down

to access the hydraulic connections.

3. Remove the plug from the circulation pipe (XL5).

XL5

4. Install the elbow, facing the rear housing, on the circulation

pipe.

5. Connect the pipe to the elbow, with the dimensions shown

in the fi gure below, leading pipe in the top of the housing,

in place of the XL5 plug. Mount the pipe insulation.

520

120

Circulation pipe dimensions (*) Elbow 15x15 (*)

6. At the outlet of the circulation tube, install the circulation

pump and then connect its control to the RC-HY (Chapter 5

Electrical connection).

7. Install the control panel and the front panel.

(*) Prepared on site.

PT300

If the system has the hot water circulation system, connect it to

the port L (see page 19).

Then install the Cut-off valves, circulation pump and strainer.

Pipe installation

23

Connection of external heat source

External heat source, e.g. a gas or oil boiler or electric heater,

can be connected on supply line of heating system (XL1).

Pipe installation

Refrigerant circuit

Connecting refrigerant pipes

See Installation manual for outdoor unit.

Piping insulation

Install insulation on all piping in order to avoid condensation

during cooling operation.

It is also strongly recommended to insulate piping for heating

only application in order to avoid getting burned or reducing

the heating capacity.

The thickness of the insulation should be 20mm where the

relative humidity exceeds 70%.

Drain connection

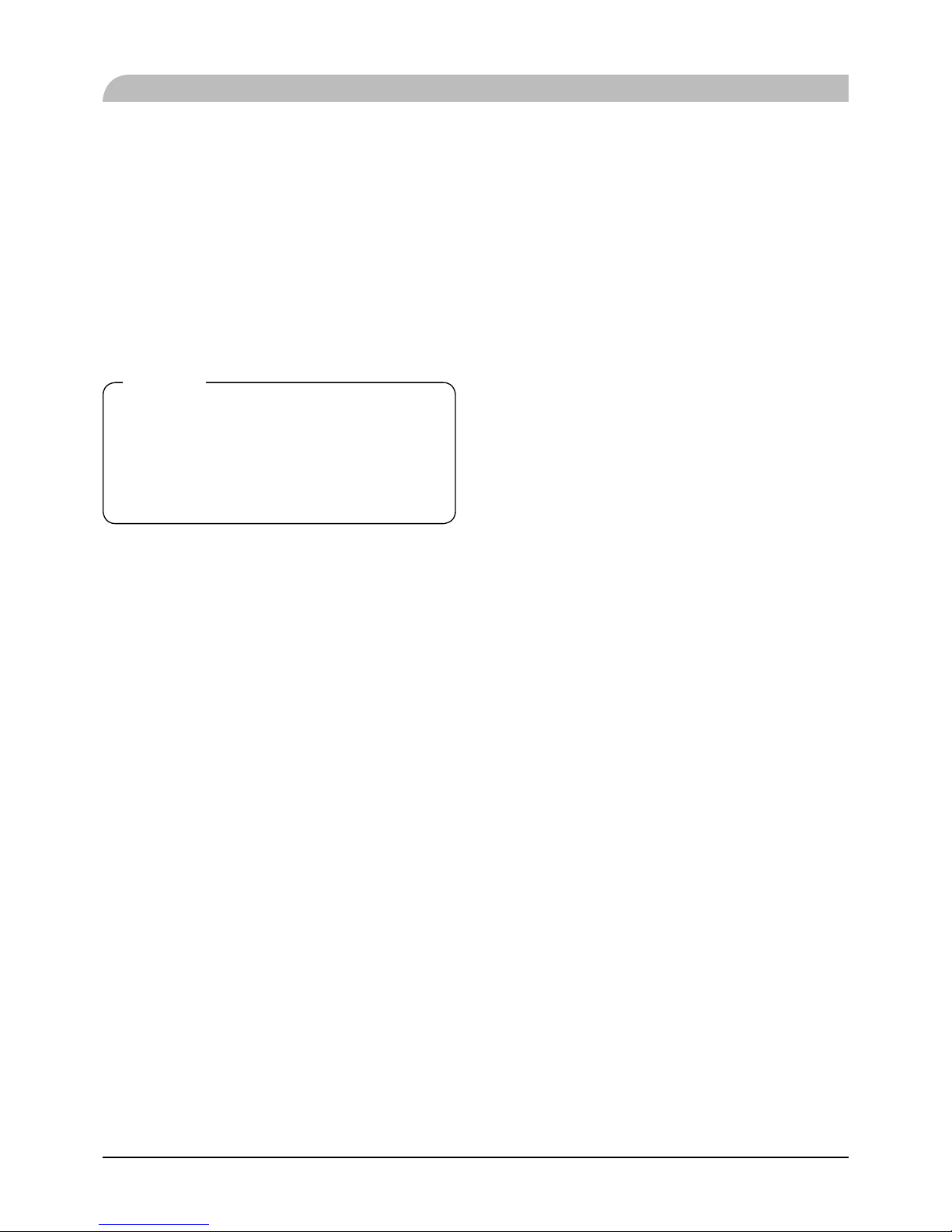

HMK 60 is equipped with a condensate hose in the heat

exchanger section. The hose drains all condensate away from

the device to minimize the risk of damage. If necessary, the

hose can be extended.

Condensate hose

24

Dockings

General

Installation requirements

Hydrolution can be connected in several diff erent ways, some of which are shown on the following pages.

Min flow, climate system

Max flow, climate system

Min flow, climate system, at 100% circulation pump speed

Min volume, climate system during underfloor cooling

Min volume, climate system during heating, cooling

Max supply temp. cooling

Min supply temp. cooling

Max supply temperature with compressor at outdoor temp -15°C

Max temperature from external heat source

Max temperature in indoor unit

Max temperature, climate system

Max pressure, climate system

0.25 MPa (2.5 Bar)

FDCW60VNX-A

HMK60HSB60

65 °C

Highest recommended supply/return temperature

55/45°C

65 °C

65 °C

58 °C

25 °C

7 °C

20 L

50 L

0.29 L/s

0.19 L/s

0.09 L/s

Nominal system flow heating (ѬT=5K)

0.29 L/s (6kW, 7/45°C)

Nominal system flow cooling (ѬT=5K)

0.28 L/s (5.8kW, 35/7°C)

External circulation pump must be used when the pressure drop in the system is greater than the available external pressure. In such

cases, a bypass line with non-return valve must be installed.

Use an overfl ow valve if system fl ow cannot be guaranteed.

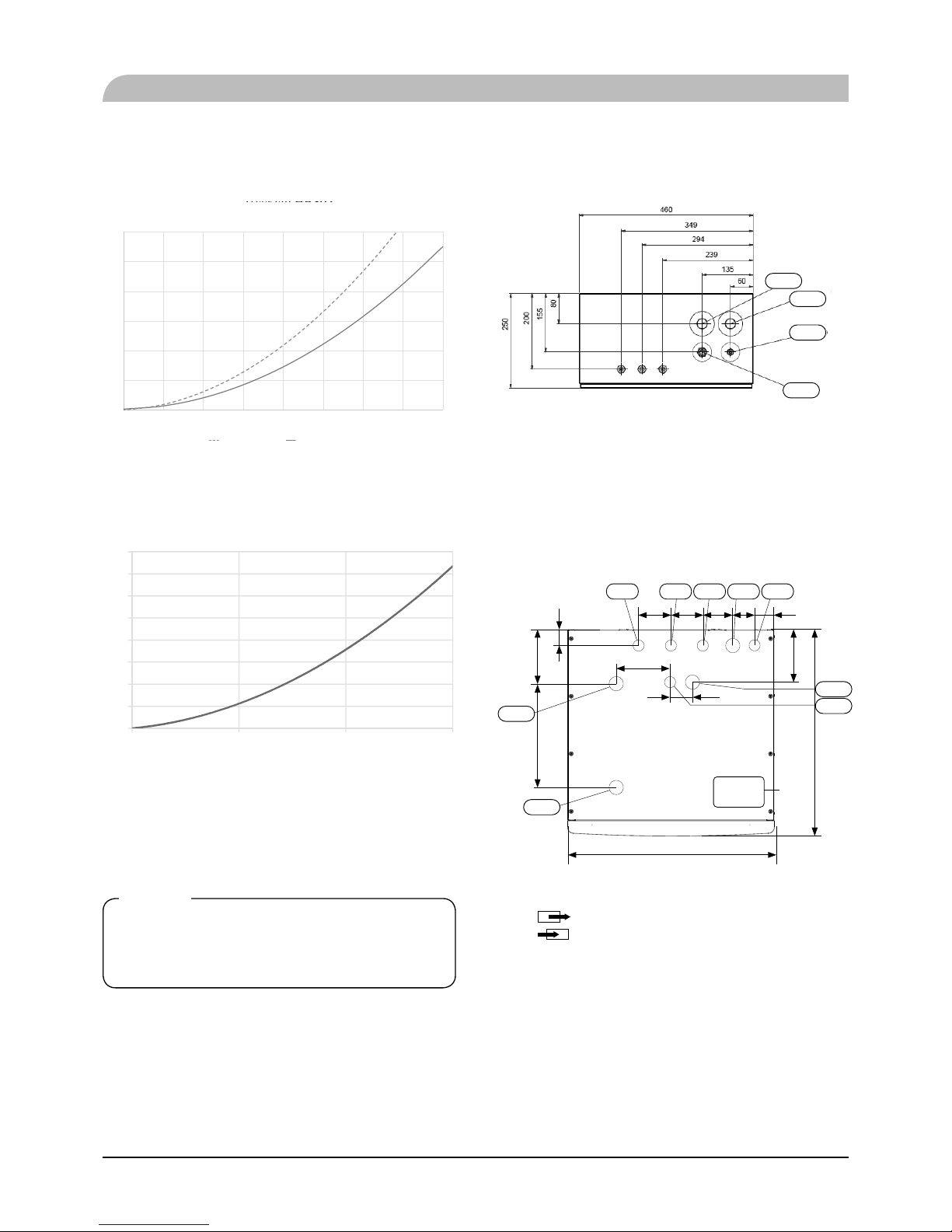

Symbol key

MeaningSymbol

Venting valve

Shut-off valve

Non-return valve

Control valve

Safety valve

Temperature sensor

Expansion vessel

Pressure gauge

P

Circulation pump

Shunt / shuttle valve

Fan

Pipe installation

25

Pipe installation

Docking alternatives

Heating system can be constructed in several different ways

combining indoor unit, tank, control unit and other accessories.

For further option information, see page 84.

In the system example shown on the following page, heating,

hot water as well as cooling operation are available.

Additional heating is helpful on the cold day of the year as the

energy from the air is reduced. It is also recommended as backup in case the heat pump operation is blocked for any reason

(e.g. ambient temperature exceeds the operation limit of heat

pump).

NOTE

The heating medium side and the hot water side must be

f itted w ith the necessar y safet y equipment in accordance

with the applicable regulations.

This is the outline diagram. Actual installations

must be planned according to applicable

standards.

Explanation

AA25 Controller

BT1 Outdoor sensor

1)

BT6 Temperature sensor, hotwater charging

1)

BT7 Temperature sensor, hot water top

1)

BT25 Temperature sensor, external supply line

1)

BT50 Room sensor

BT63 Temperature sensor, external supply line after

electric heater

BT71 Temperature sensor, external return line

1)

GP10 Circulation pump, Heating medium

QN10 Reversing valve, Hot water/Heating medium

2)

EB1 Additional heat

EB1 Immersion heater

KA1 Auxiliary relay/Contactor

2)

EB101 Heat pump system

BP4 Pressure sensor, condensor

3)

BT3 Temperature sensor, return line

3)

BT12 Temperature sensor, condenser supply line

3)

BT15 Temperature sensor, fl uid pipe

3)

EB101 Heat pump

FL10 Safety valve

GP12 Charge pump

2)

HQ1 Particle fi lter

3)

QM1 Drain valve, Heating medium

QM31 Shut-off valve, Heating medium, Flow

QM32 Shut off valve, Heating medium, Return

QM43 Shut-off valve

EQ1 Cooling system

BT64 Temperature sensor, cooling supply line

2)

CP6 Single jacket accumulator tank, cooling

GP13 Circulation pump, cooling

QN12 Reversing valve, Cooling/Heating

2)

Miscellaneous

CM1 Expansion vessel closed, Heating medium

CP5 Buff er vessel

CP10 Accumulator tank with hotwater heating

EB20 Immersion heater

FL2 Safety valve, Heating medium

KA1 Auxiliary relay/Contactor

RN10 Trim valve

1) Included in and supplied with controller

2) Included in and supplied with accessory

3) Included in indoor unit

26

Installation with indoor unit HSB60, tank PT300, controller RC-HY20/40 with step controlled additional heat

before reversing valve for hot water and cooling function (4 pipe system)

-FL2

-CM1

-EB101

-QM43

-GP12

-EB101

-HQ1

-BT1

-AA25

-AA25

-BT50

-AA25

-BT63

-KA1

-EB1

-RN10

-CP10

-AA25-QN10

-AA25-BT7

-AA25-BT6

-GP13

-AA25

-BT64

-EQ1-QN12

-EQ1

-EB1

-CP6-CP6

-QM1

-EZ101

-BT12

-BT3

-BT15

-BP4

-FL10

-QM31

-QM32

-HQ1

-XL14

-XL13

-XL1

-XL2

-EZ102

NOTE

Not all components are shown in this

outl ine di agram.

Controller (AA25) starts and stops the heat pump (EB101) to

meet the heating and hot water demand.

At simultaneous heating and hot water demand, the reversing

valve (AA25-QN10) switches periodically between the climate

system and the water heater/accumulator tank (CP10). When

the hot water heater/accumulator tank is fully charged, the

reversing valve switches to the climate system.

Additional heat (EB1) is turned on automatically when the

heating demand exceeds the heat pump capacity. This is used

for both heating and charging hot water.

The additional heat can also be used for water heater when a

higher temperature is required than the heat pump can produce.

During cooling operation, the reversing valve (EQ1-QN12)

switches to the cooling system (EQ1). If several simultaneous

demands occur while there is a cooling demand, the system

reacts differently. In the event of a hot water demand, the

reversing valve switches back and hot water is produced until

the demand is fulfi lled. In the event of a heating demand, the

reversing valve switches periodically between cooling and

heating. If the cooling demand is met, the reversing valve

switches back to basic mode (heating/hot water).

Pipe installation

27

Pipe installation

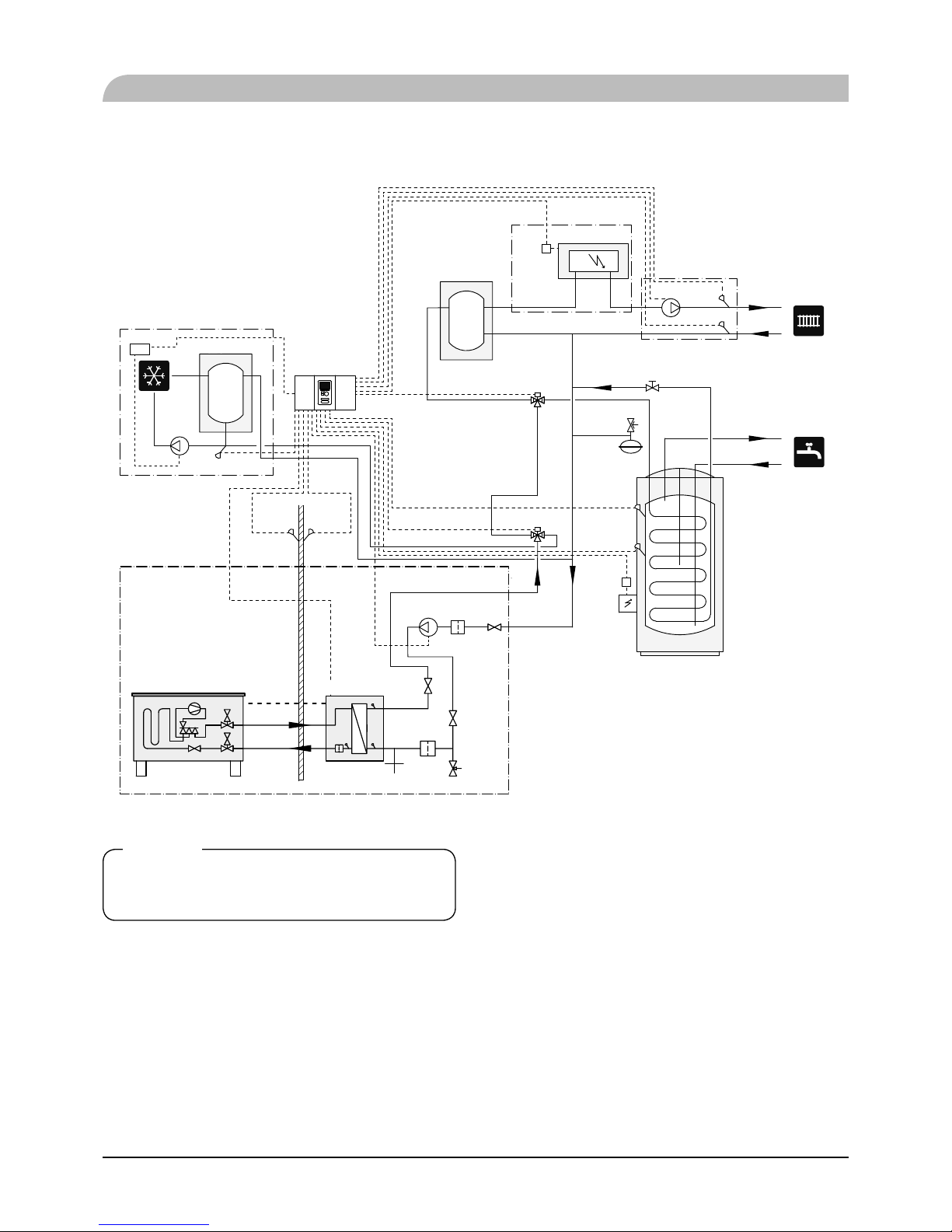

Indoor unit HSB60, tank PT300, controller RC-HY20/40 with step controlled additional heat after reversing

valve for hot water and cooling function (4 pipe system)

-EB20

-KA1

-FL2

-CM1

-EB101

-QM43

-GP12

-EB101

-HQ1

-BT1

-AA25

-AA25 -AA25

-RN10

-CP10

-AA25-QN10

-AA25-BT7

-AA25-BT6

-BT25

-EB1

-CP5

-GP10

-KA1

-BT71

-EB1

-AA25

-GP13

-BT64

-EQ1-QN12

-EQ1

-BT50

-CP6-CP6

-QM1

-EZ101

-BT12

-BT3

-BT15

-BP4

-FL10

-QM31

-QM32

-HQ1

-XL14

-XL13

-XL1

-XL2

-AA25

-EZ102

NOTE

Not all components are shown in this

outl ine di agram.

This installations alternative is suitable for more complex

installations with a focus on comfort.

Controller (AA25) starts and stops the heat pump (EB101) to

meet the heating and hot water demand of the installation.

At simultaneous heating and hot water demand the reversing

valve (AA25-QN10) switches periodically between the climate

system and the water heater/accumulator tank (CP10). When

the hot water heater/accumulator tank is fully charged, the

reversing valve switches to the climate system.

Additional heat (EB1) is turned on, automatically when the

heating demand exceeds the heat pump capacity.

Immersion heater (EB20) in the water heater/accumulator tank

is used during the time to produce hot water if the heat pump is

used for heating at the same time.

The immersion heater (EB20) can also be used if a higher

temperature of hot water is required than the heat pump can

produce.

During cooling operation, the reversing valve (EQ1-QN12)

switches to the cooling system (EQ1). If several simultaneous

demands occur while there is a cooling demand, the system

reacts differently. In the event of a hot water demand, the

reversing valve switches back and hot water is produced until

the demand is fulfi lled. In the event of a heating demand, the

reversing valve switches periodically between cooling and

heating. If the cooling demand is met, the reversing valve

switches back to basic mode (heating/hot water).

28

Pipe installation

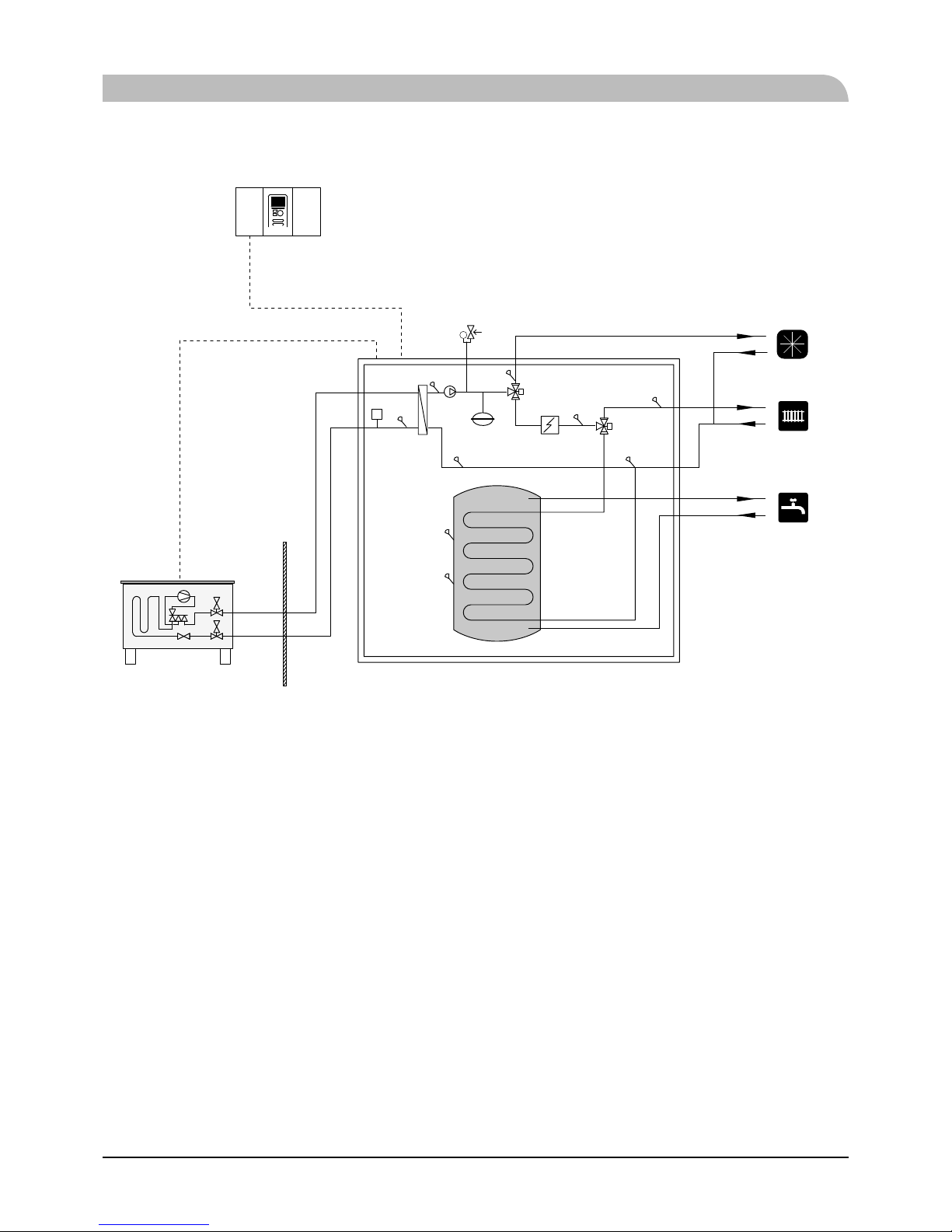

Installation with indoor unit HMK60 for hot water and cooling function (4 pipe system)

P

XL14

XL13

-BP4

-BT15

-BT3

-CM1

-EB1

-BT7

-BT6

BT71

XL4

XL3

XL1

XL2

-QN10

-BT63

-BT64

-QN12

-GP12

-BT12

XL10

-BT25

AA25

-XL14

-XL13

Controller (AA25) starts and stops the heat pump (EB101) to

meet the heating and hot water demand. At simultaneous

heating and hot water demand, the reversing valve (QN10)

swithes periodically between the climate system and the hot

water heater. When the hot water heater is fully charged, the

reversing valve swithes to the climate system.

Additional heat (EB1) is turned on automatically when the

heating demand exceeds the heat pump capacity. This is used

for both heating and charging water heater.

The additional heat can also be used for water heater when a

higher temperature is required than the heat pump can produce.

Cooling is controlled by the sensor BT64, and the reversing

valve (QN12) swithes to the cooling system. If several

simultaneous demands occur while there is a cooling demands,

the system reacts differently. In the event of a hot water

demand, the reversing valve switches back and hot water is

produced until the demand is fulfi lled. In the event of heating

demand, the reversing valve switches periodically between

cooling and heating. If the cooling demand is met, the

reversing valve switches back to basic mode (heating/hot

water).

Loading...

Loading...