Mitsubishi Heavy Industries FDTCVA602HEST2R, FDENVA402HESP2R, FDENVA602HES2R, FDENVA402HES2R, FDENVA502HESP2R Technical Manual

...

TECHNICAL MANUAL

Collection data

Manual No. '07•PAC-T-115D

PACKAGED AIR-CONDITIONER

(Spilit system, Air to air heat pump type)

MULTI-TYPE (V-MULTI)

PACKAGED AIR-CONDITIONER

CEILING RECESSED COMPACT TYPE

FDTCVA402HESP2R FDTCVA602HEST2R

CEILING SUSPENDED TYPE

FDENVA402HES2R

502HES2R

602HES2R

FDENVA402HESP2R

502HESP2R

602HESP2R

FDENVA602HEST2R

SATELLITE DUCTED TYPE

FDUMVA402HES2R

502HES2R

602HES2R

FDUMVA402HESP2R

502HESP2R

602HESP2R

FDUMVA602HEST2R

CEILING RECESSED TYPE

FDTVA402HES2R

502HES2R

602HES2R

FDTVA402HESP2R

502HESP2R

602HESP2R

FDTVA602HEST2R

WALL MOUNTED TYPE

FDKNVA402HESP2R

502HESP2R

FDKNVA602HEST2R

(OUTDOOR UNIT)

FDCVA402HESAR

502HESAR

602HESAR

(INDOOR UNIT)

FDTCA201R FDTA201R

251R

301R

FDUMA202R

252R

302R

FDEN201R

251R

301R

FDKNA201R

251R

DRAFT

-

1

-

TABLE OF CONTENTS

1. PACKAGED AIR-CONDITIONER ........................................................................1

2. MULTI-TYPE (V MULTI) PACKAGED AIR-CONDITIONER .............................. 36

2. MULTI-TYPE (V MULTI)

PACKAGED AIR-CONDITIONER

CONTENTS

1.1 GENERAL INFORMATION ............................................................................... 2

1.1.1 Specific features .......................................................................................... 2

1.1.2 How to read the model name....................................................................... 2

1.2 SELECTION DATA ........................................................................................... 3

1.2.1 Specifications ............................................................................................... 3

(1) Ceiling recessed compact type (FDTC) ........................................................ 3

(2) Ceiling recessed type (FDT) ......................................................................... 5

(3) Ceiling suspended type (FDEN) ................................................................. 12

(4) Satellite ducted type (FDUM)...................................................................... 19

(5) Wall mounted type (FDKN) ......................................................................... 26

1.3 ELECTRICAL DATA ....................................................................................... 29

1.3.1 Electrical wiring .......................................................................................... 29

(1) Indoor unit ................................................................................................... 29

(2) Outdoor unit ................................................................................................ 35

-

2

-

1.1 GENERAL INFORMATION

1.1.1 Specific features

(1) A new refrigerant, R410A, which causes no damage to the earth’s ozone layer, is used. R410A is a pseudoazeotropic refrigerant, so

there is little formation of separate vapor and liquid layers, and it is possible to add refrigerant on-site.

(2) Less refrigerant charge amount due to use of double phase refrigerant flow system. The total refrigerant charge amount has been

reduced by more than 50%.

(3) The microcomputer chip is installed in the indoor unit and outdoor unit. There is no need for the unit to communicate between the

outdoor and indoor units so the unit is more resistant to electromagnetic noise thus the incidence of microcomputer malfunction

has been reduced. The compressor in the outdoor unit has its own self protection function, that reacts according to anomalous high

pressure and excessive high temperature.

(4) There are only three power lines between the outdoor and indoor unit. One cabtyre cable with 3 wires encased in one sheath is

enough for conducting the wiring work between the outdoor unit and the indoor unit. This contributes to simpler wiring work in the

field.

(5) All air supply ports have auto swing louvers. (Only case of FDTC, FDT, FDEN and FDKN models). The indoor fan motor has

three speeds of high, medium and low.

(6) All models have service valves protruding from the outdoor unit for faster flare cannection work in the field.

(7) Compared to the previous models, a single fan is used in the FDCVA402 ~ 602 outdoor unit models, resulting in markedly reduced

weight and greater compactness. In addition, use of an inverter makes these units much more economical compared to the previous

fixed speed units.

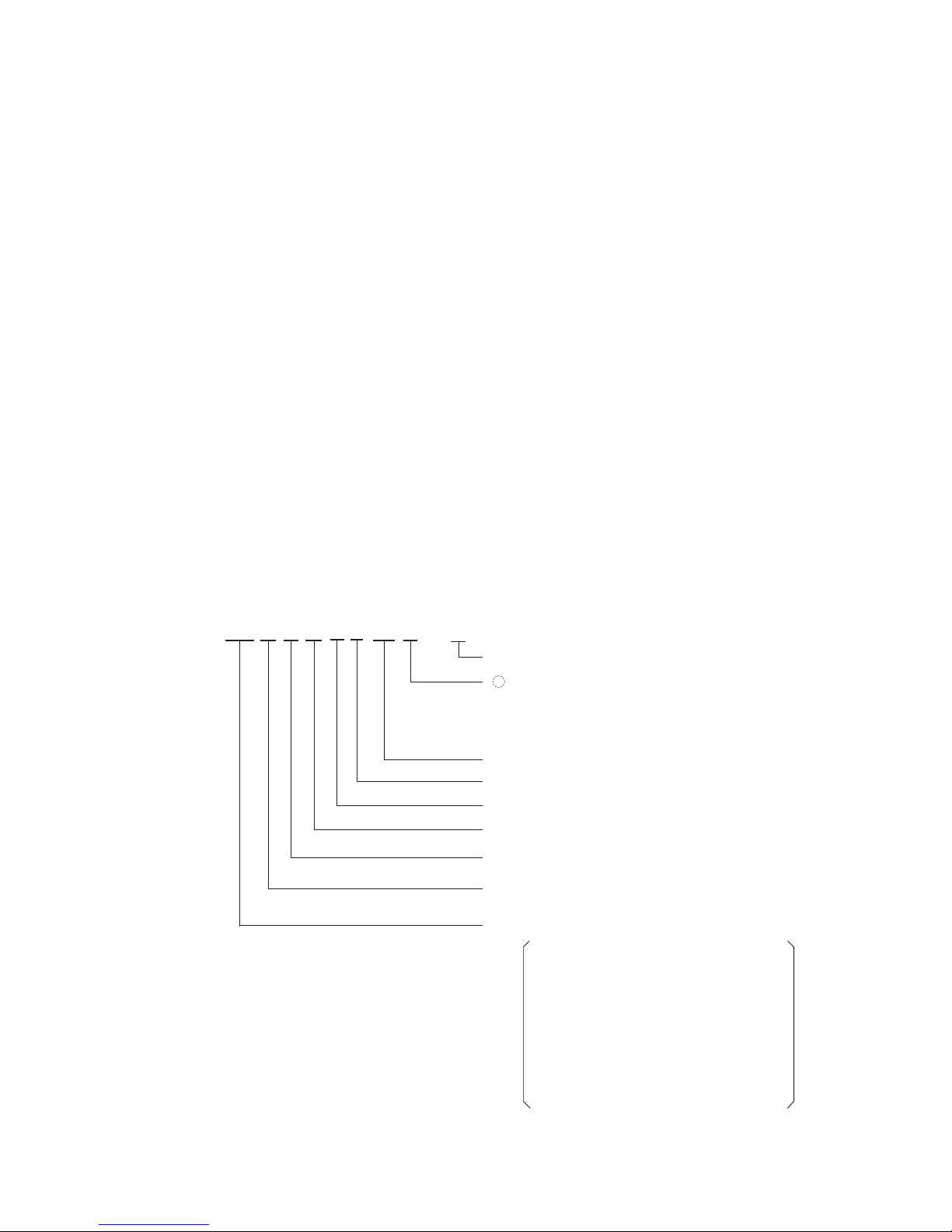

Example: FDT V A 40 2 H ES P 2 R

1.1.2 How to read the model name

RoHS specification

: Single type

Applicable power source ... See the specifications

Heat pump type

Series No.

Product capacity

R410A models

V : Inverter specification

Model name

FDTC :

FDT :

FDEN :

FDUM :

FDKN :

FDC :

Celing recessed compact type unit

with wired remote controller

Celing recessed type unit with wired

remote controller

Celing suspended type unit with wireless remote controller

Satellite ducted type unit with wired

remote controller

Wall mounted type unit with wireless

remote controller

Outdoor unit

P: Twin type

T: Triple type

(blank)

-

3

-

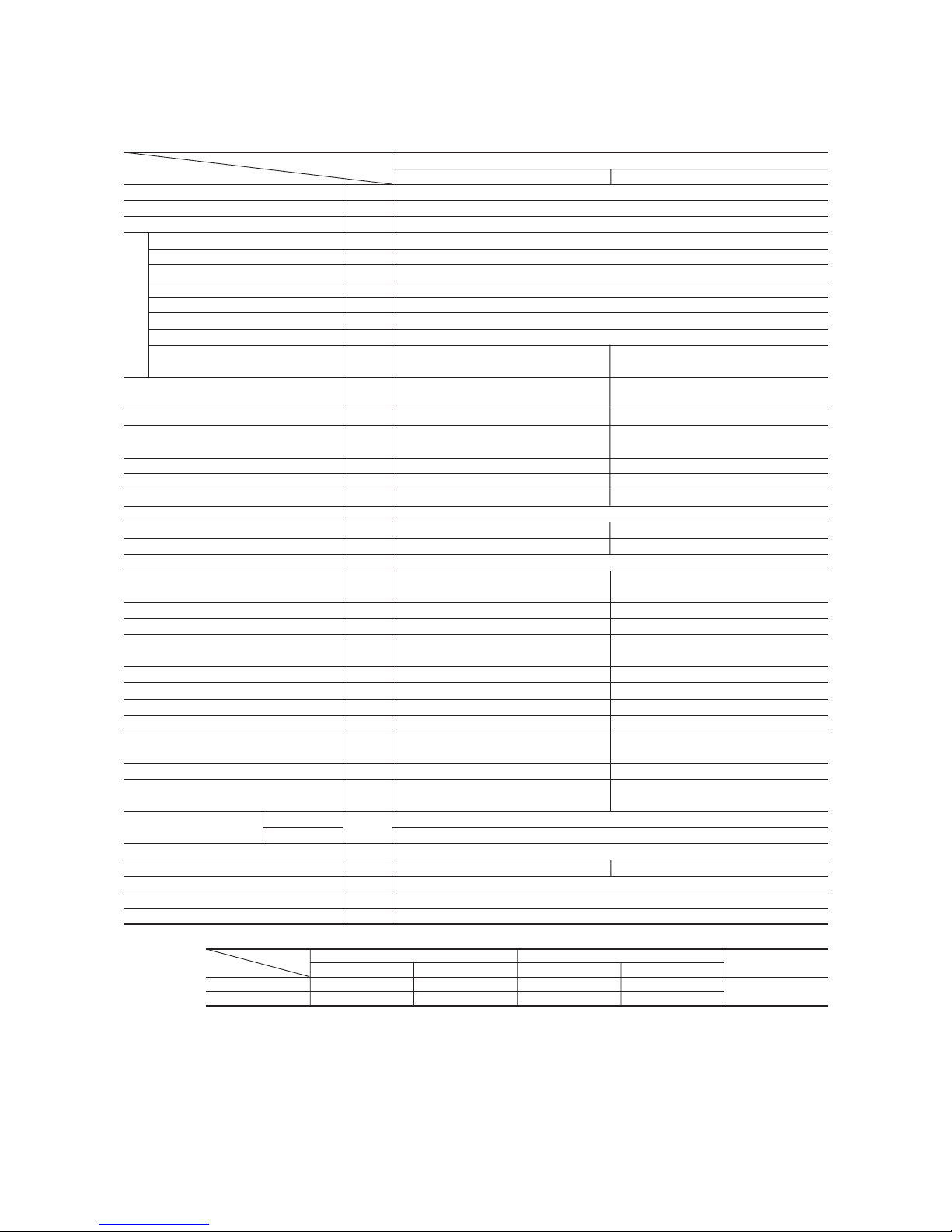

Item

Model

FDTCA201R FDCVA402HESAR

Nominal cooling capacity

(1)

kW 10.0 [6.1~11.2]

Nominal heating capacity

(1)

kW 11.2 [5.6~12.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.84/2.84

Running current (Cooling) A 4.2/4.4

Power factor (Cooling) % 98/98

Heating power consumption kW 3.08/3.08

Running current (Heating) A 4.5/4.8

Power factor (Heating) % 99/97

Inrush current (L.R.A) A 5

Noise level dB(A)

35 52

Exterior dimensions

mm

Unit 248 × 570 × 570

845 × 970 × 370

Height × Width × Depth Panel 35 × 700 × 700

Net weight kg 19.5 (Unit:16 Panel:3.5) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 50 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional:RCND-KIT-HER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data Liquid line mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size Gas line (in) Indoor branch pipe: φ12.7 (1/2″), Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where two indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

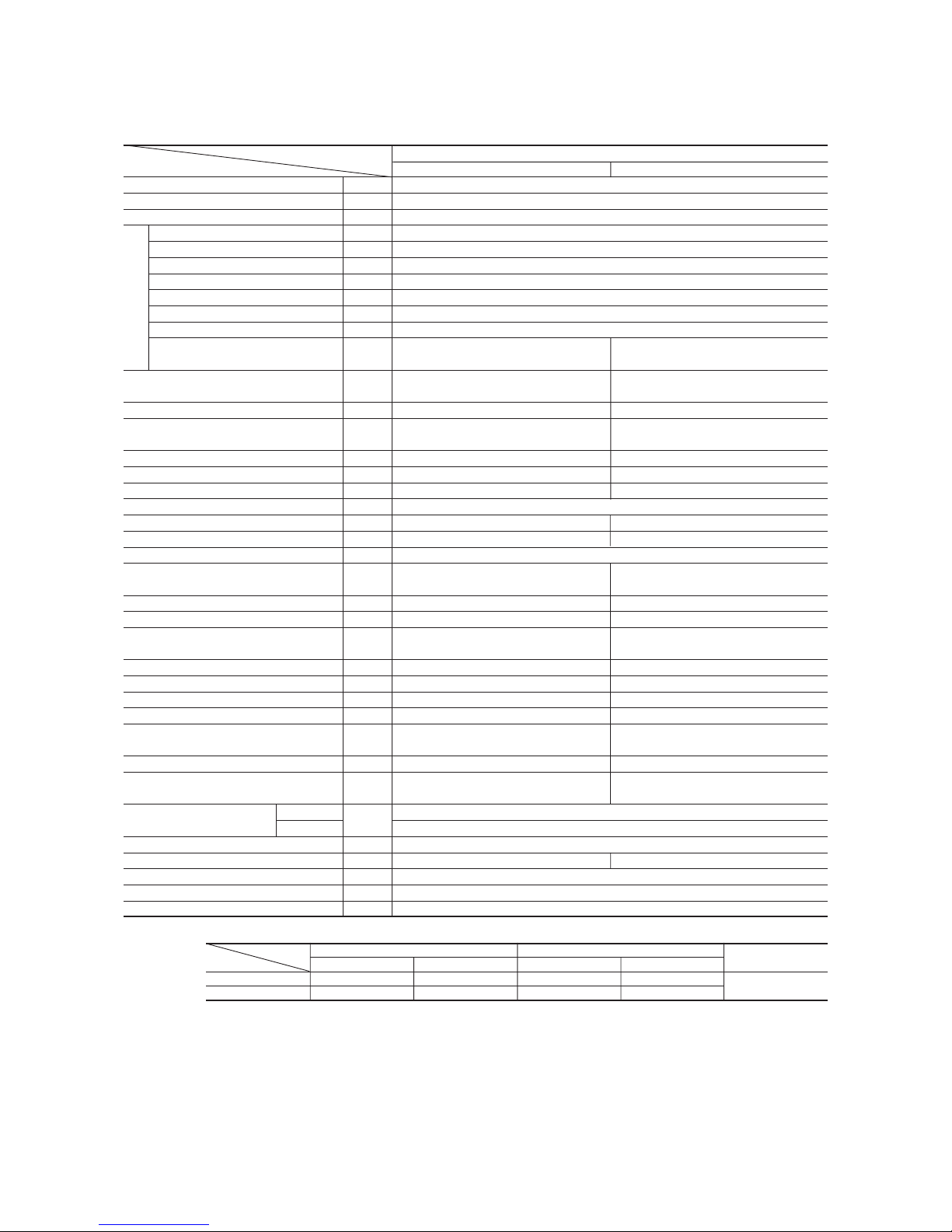

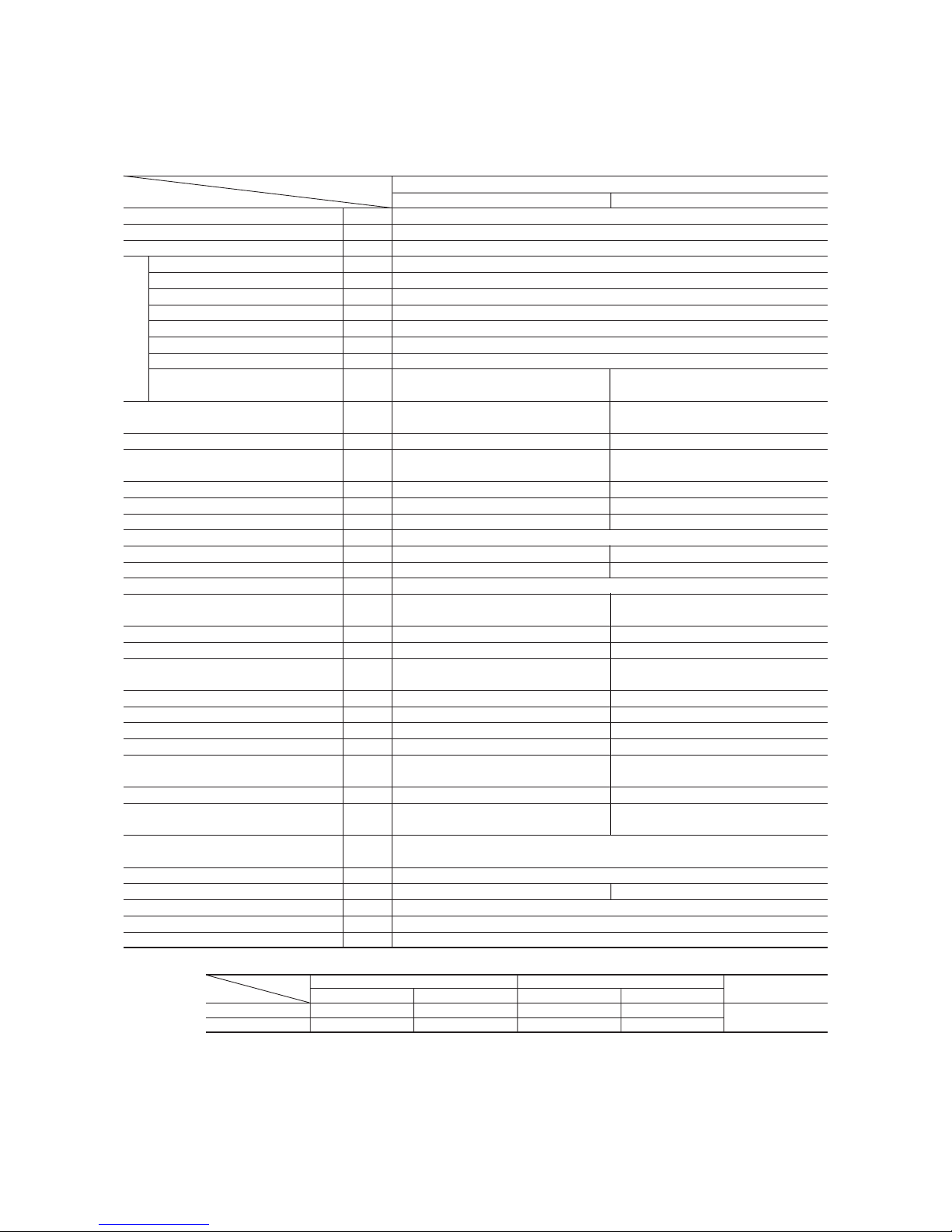

FDTCVA402HESP2R

Powerful mode Hi:46 Me:42 Lo:38

Mild mode Hi:42 Me:38 Lo:35

Powerful mode Hi:13.5 Me:11.5 Lo:10

Mild mode Hi:11.5 Me:10 Lo:8

50

1.2 SELECTION DATA

1.2.1 Specifications

(1) Ceiling recessed compact type (FDTC)

(a) Twin type

Model FDTCVA402HESP2R (Indoor unit: 2 units, Outdoor unit: 1 unit)

-

4

-

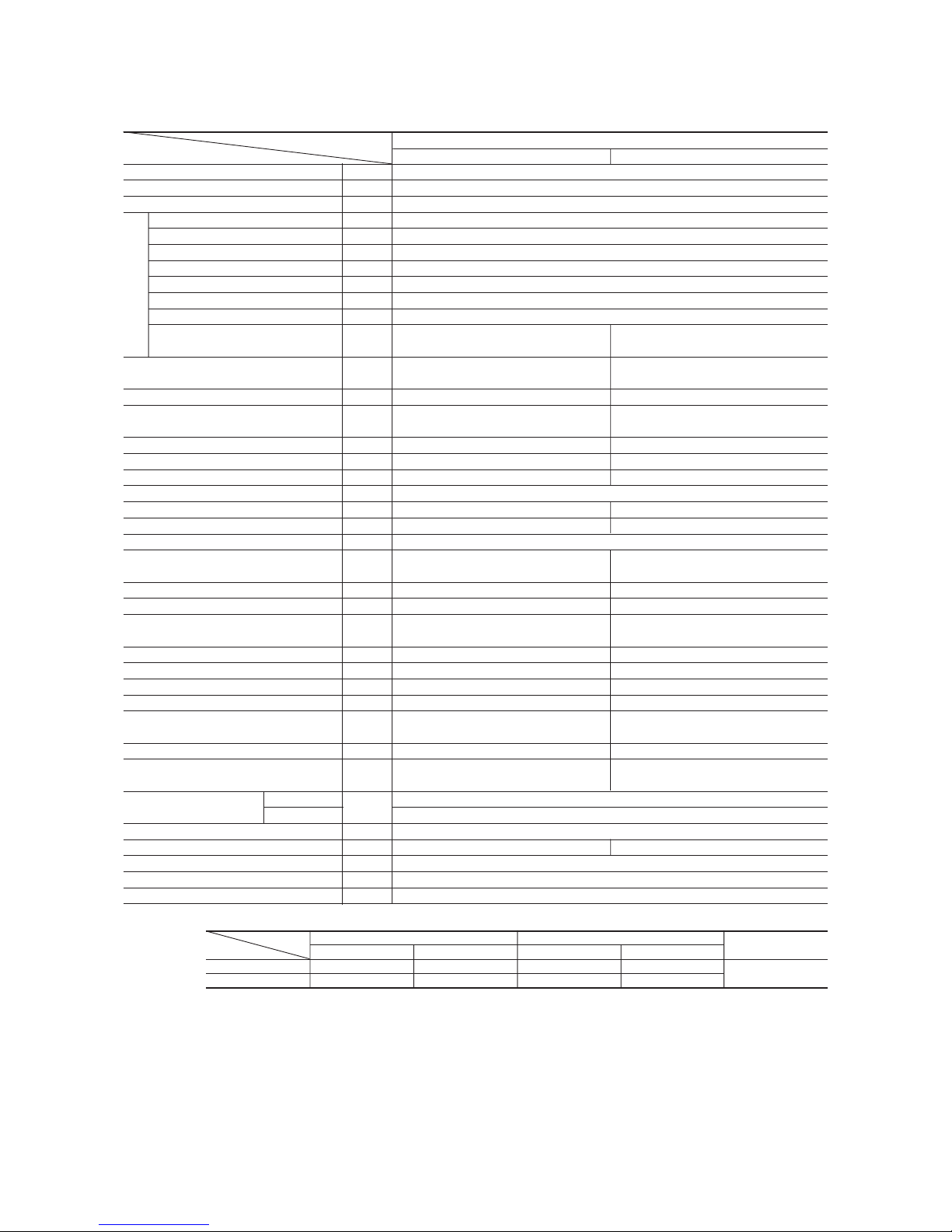

Item

Model

FDTCA201R FDCVA602HESAR

Nominal cooling capacity

(1)

kW 14.0 [6.7~14.8]

Nominal heating capacity

(1)

kW 16.0 [6.3~16.8]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.64/4.64

Running current (Cooling) A 6.8/7.1

Power factor (Cooling) % 98/99

Heating power consumption kW 4.52/4.52

Running current (Heating) A 6.6/7.0

Power factor (Heating) % 99/98

Inrush current (L.R.A) A 5

Noise level dB(A)

552

Exterior dimensions

mm

Unit 248 × 570 × 570

845 × 970 × 370

Height × Width × Depth Panel 35 × 700 × 700

Net weight kg 19.5 (Unit:16 Panel:3.5) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 50 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional:RCND-KIT-HER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data Liquid line mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size Gas line (in) Indoor branch pipe: φ12.7 (1/2″), Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where three indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

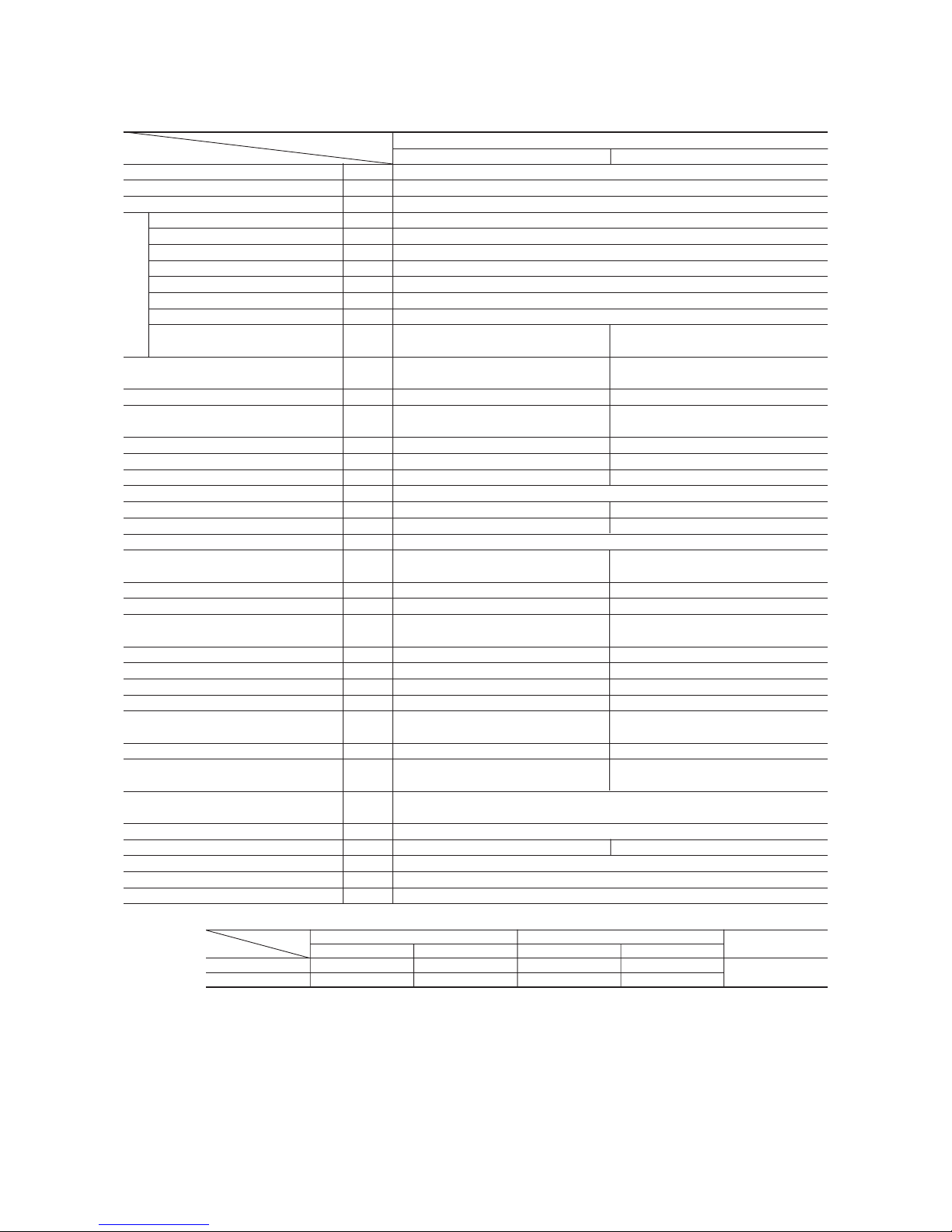

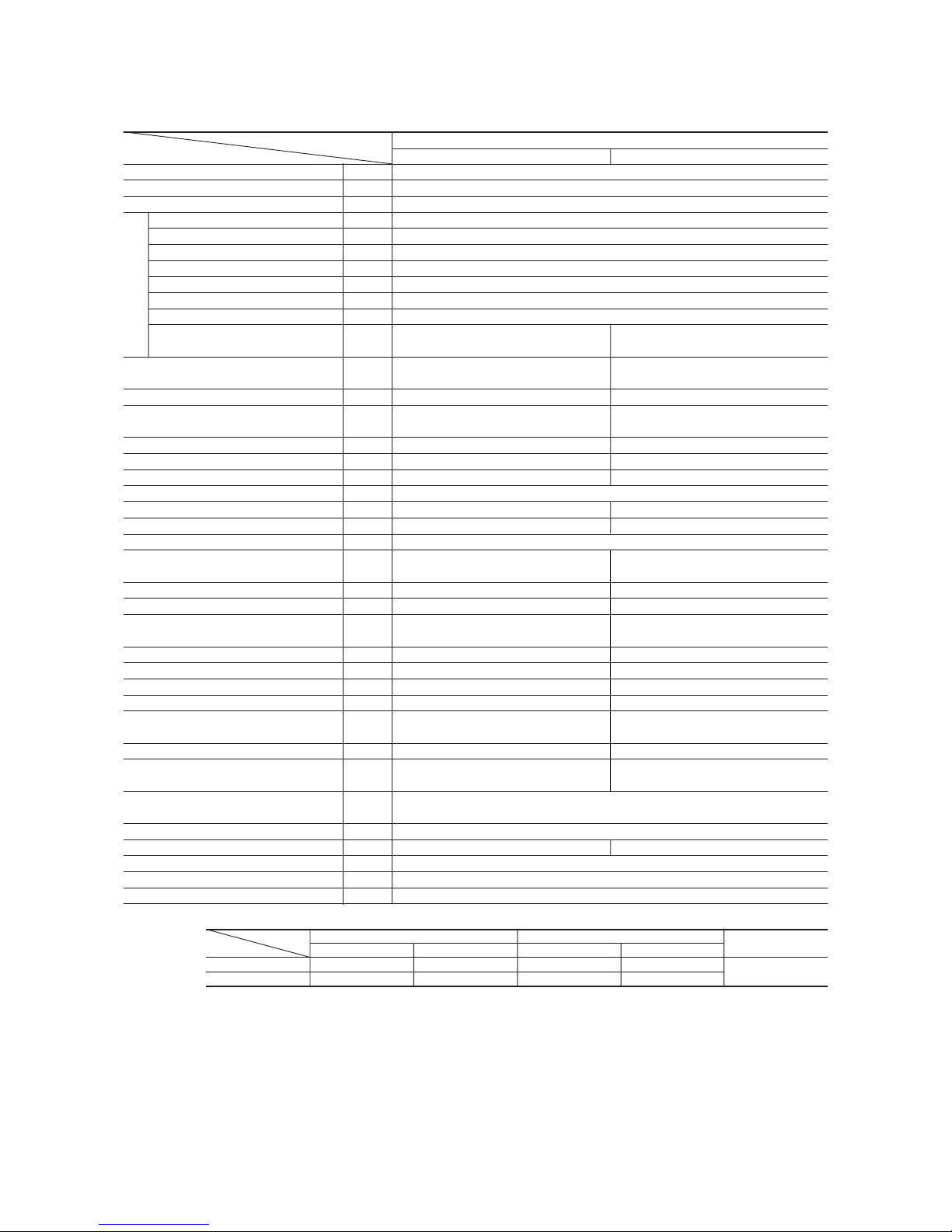

FDTCVA602HEST2R

(b) Triple type

Model FDTCVA602HEST2R (Indoor unit: 3 units, Outdoor unit: 1 unit)

Powerful mode Hi:46 Me:42 Lo:38

Mild mode Hi:42 Me:38 Lo:39

Powerful mode Hi:13.5 Me:11.5 Lo:10

Mild mode Hi:11.5 Me:10 Lo:8

53

-

5

-

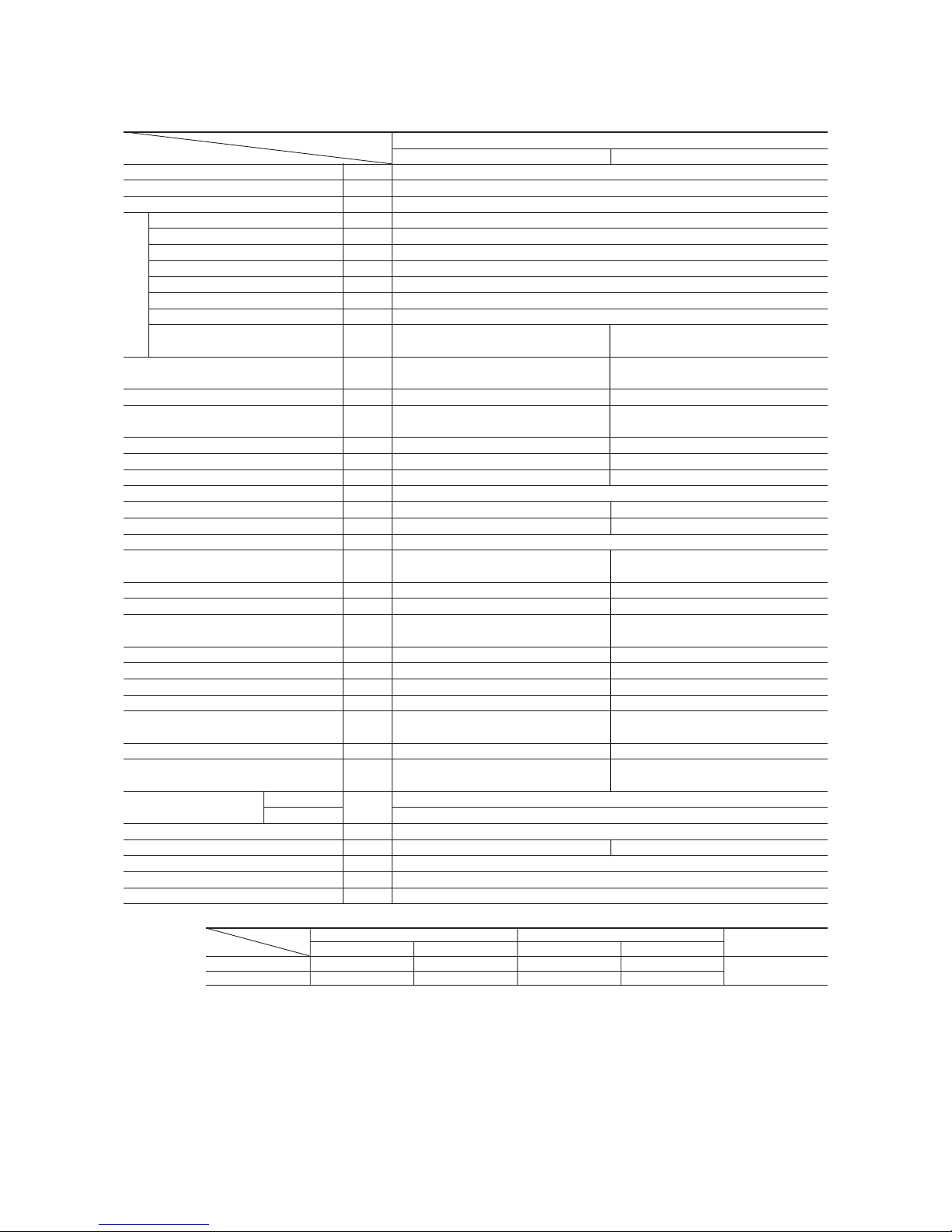

Item

Model

FDTA401R FDCVA402HESAR

Nominal cooling capacity

(1)

kW 10.0 [6.1~11.2]

Nominal heating capacity

(1)

kW 11.2 [5.6~12.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.97

Running current (Cooling) A 4.7

Power factor (Cooling) % 9.1

Heating power consumption kW 2.92

Running current (Heating) A 4.6

Power factor (Heating) % 92

Inrush current (L.R.A) A 5

Noise level dB(A)

35 52

Exterior dimensions

mm

Unit 248 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 19.5 (Unit:16 Panel:3.5) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 40 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional:RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

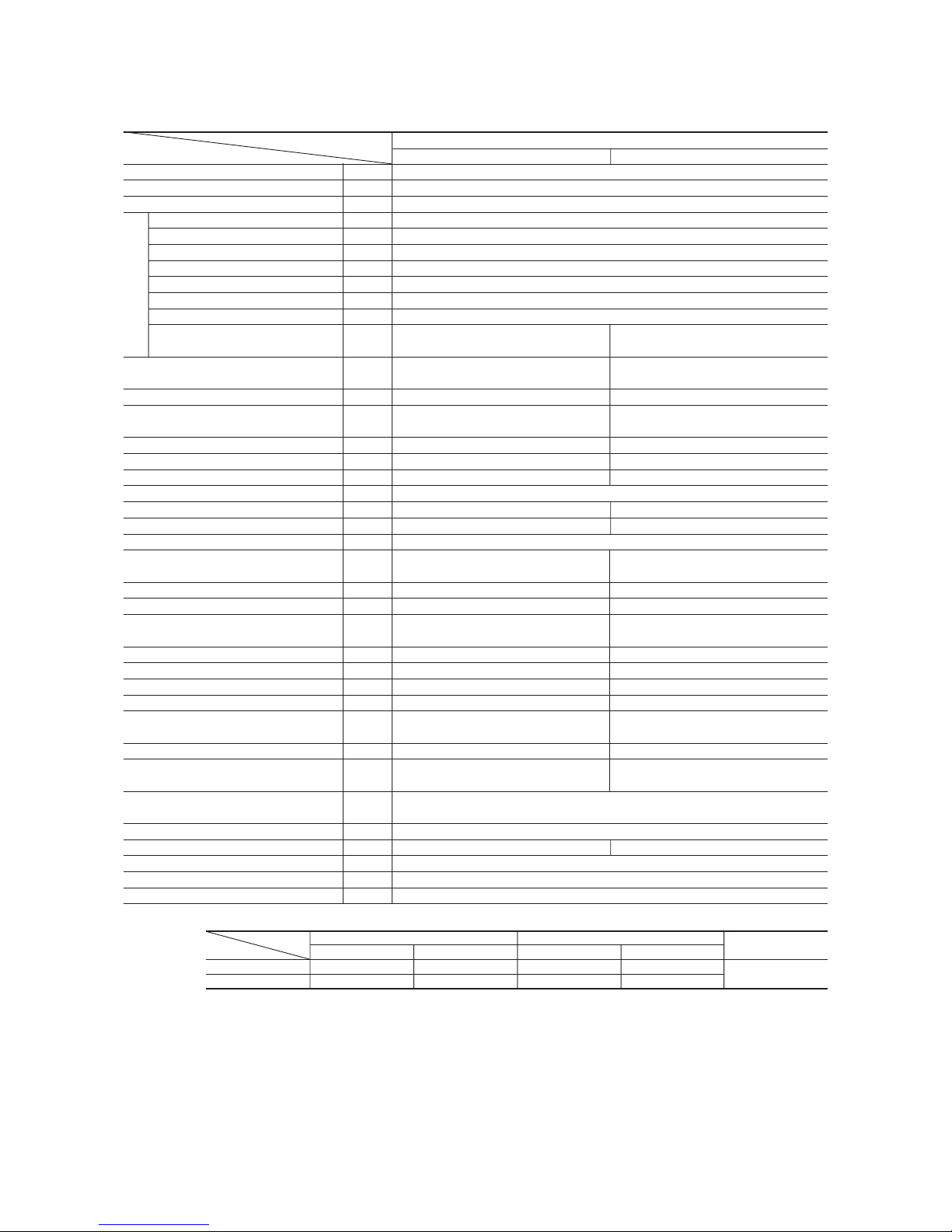

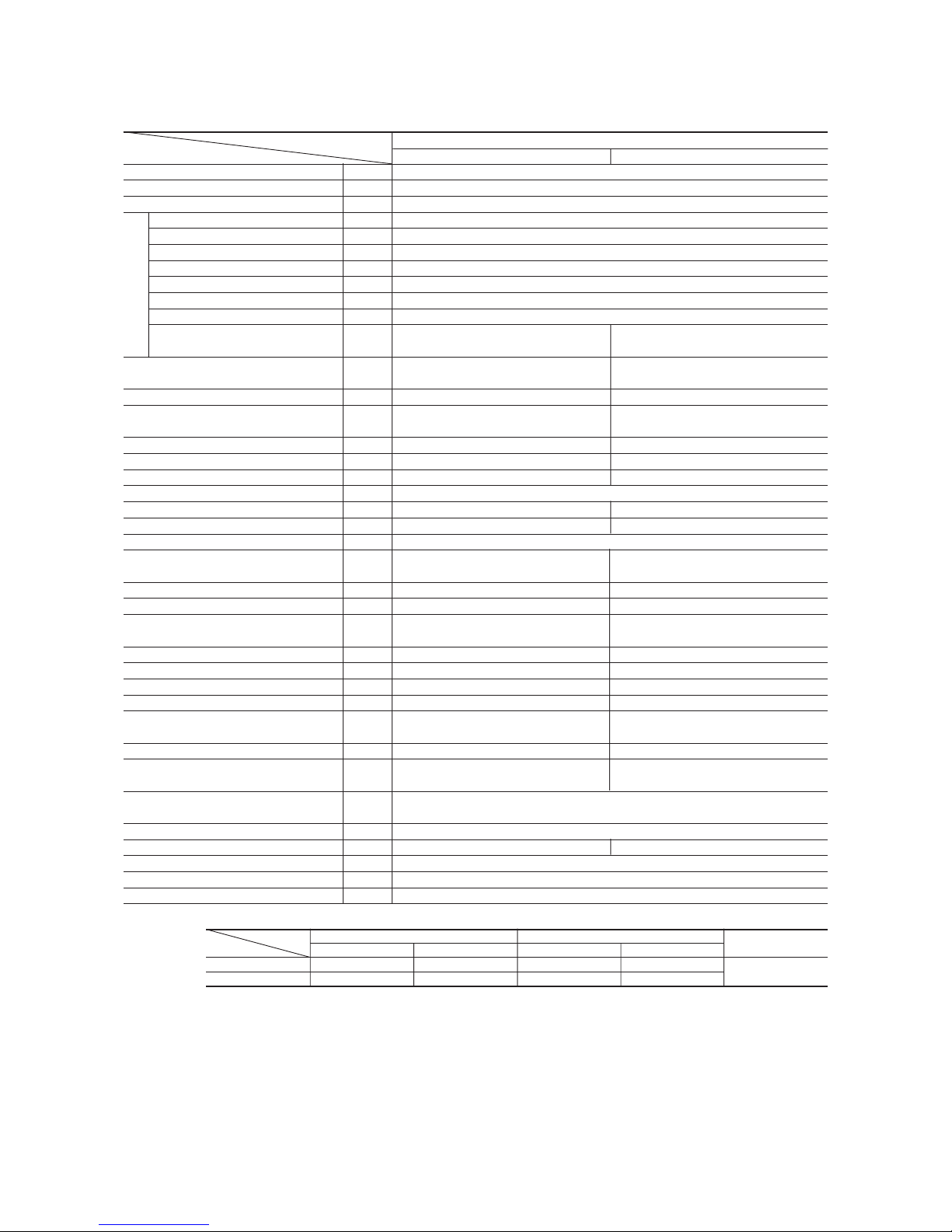

FDTVA402HES2R

Powerful mode Hi:46 Me:43 Lo:41

Mild mode Hi:43 Me:41 Lo:38

Powerful mode Hi:25 Me:22 Lo:20

Mild mode Hi:22 Me:20 Lo:18

50

(2) Ceiling recessed type (FDT)

(a) Single type

Model FDTVA402HES2R

-

6

-

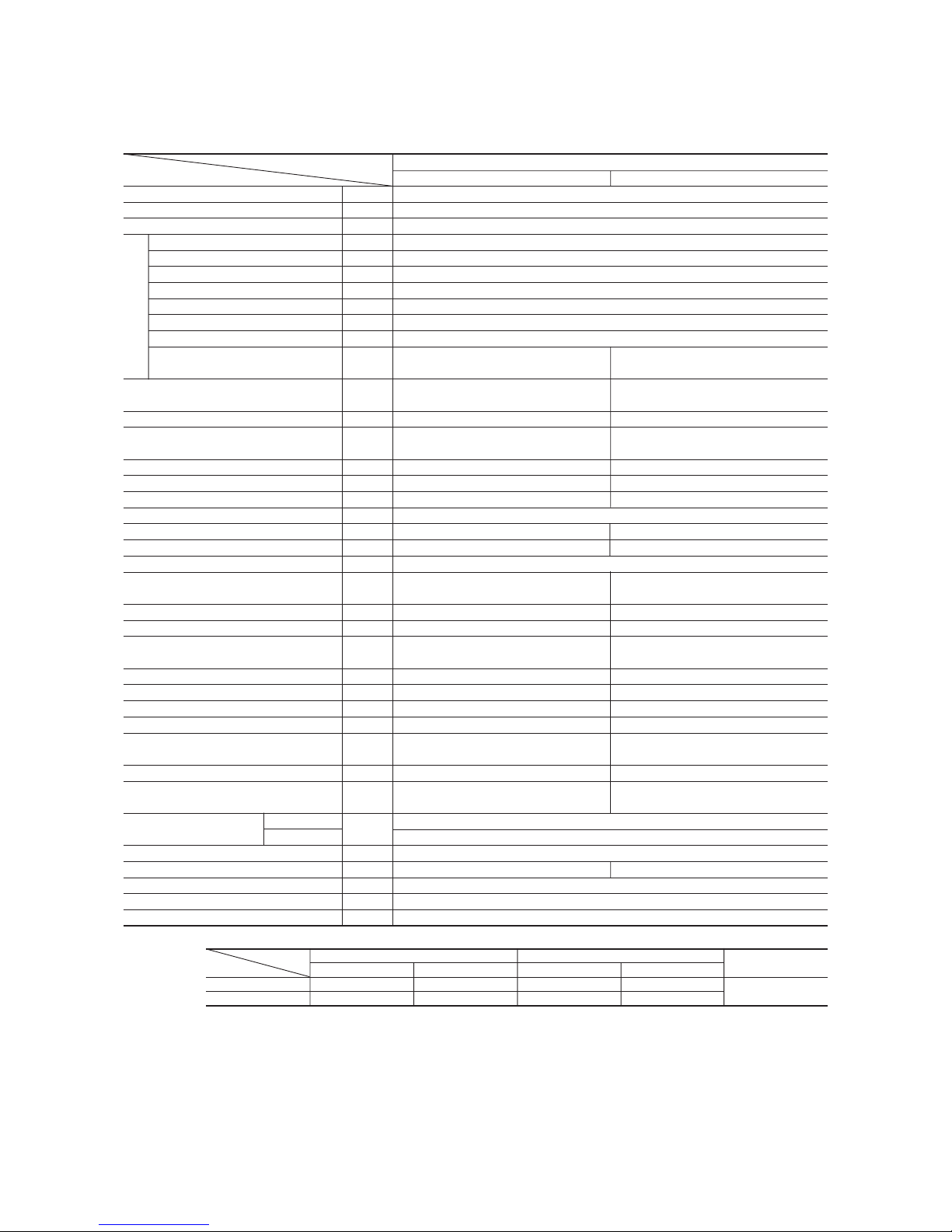

Item

Model

FDTA501R FDCVA502HESAR

Nominal cooling capacity

(1)

kW 12.5 [6.5~14.0]

Nominal heating capacity

(1)

kW 14.0 [6.2~16.0]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.05/4.05

Running current (Cooling) A 5.9/6.3

Power factor (Cooling) % 99/98

Heating power consumption kW 3.97/3.97

Running current (Heating) A 5.8/6.3

Power factor (Heating) % 99/96

Inrush current (L.R.A) A 5

Noise level dB(A)

552

Exterior dimensions

mm

Unit 365 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 38 (Unit:31 Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 120 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA502HES2R

Model FDTAV502HES2R

Powerful mode Hi:48 Me:45 Lo:43

Mild mode Hi:45 Me:43 Lo:40

Powerful mode Hi:32 Me:29 Lo:26

Mild mode Hi:29 Me:26 Lo:23

52

-

7

-

Item

Model

FDTA601R FDCVA602HESAR

Nominal cooling capacity

(1)

kW 14.0 [6.7~14.5]

Nominal heating capacity

(1)

kW 16.0 [6.3~16.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.65/4.65

Running current (Cooling) A 6.8/7.3

Power factor (Cooling) % 99/97

Heating power consumption kW 4.54/4.54

Running current (Heating) A 6.7/7.4

Power factor (Heating) % 98/93

Inrush current (L.R.A) A 5

Noise level dB(A)

Exterior dimensions

mm

Unit 360 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 38 (Unit:31, Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 4 Propeller fan × 1

Motor W 120 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

Model FDTVA602HES2R

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA601HES2R

53

Powerful mode Hi:48 Me:45 Lo:43

Mild mode Hi:45 Me:43 Lo:40

Powerful mode Hi:34 Me:30 Lo:26

Mild mode Hi:30 Me:26 Lo:23

-

8

-

Item

Model

FDTA201R FDCVA402HESAR

Nominal cooling capacity

(1)

kW

Nominal heating capacity

(1)

kW

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.90/2.96

Running current (Cooling) A 5.1/5.5

Power factor (Cooling) % 86/75

Heating power consumption kW 2.54/2.60

Running current (Heating) A 4.6/4.8

Power factor (Heating) % 84/75

Inrush current (L.R.A) A 45

Noise level dB(A)

3

552

Exterior dimensions

mm

Unit 270 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 31 (Unit:24 Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 14 ⳯ 1 120 ⳯ 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size (in) Indoor branch pipe: φ12.7 (1/2″), Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where two indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA402HESP2R

(b) Twin type

Model FDTVA402HESP2R (Indoor unit: 2 units, Outdoor unit: 1 unit)

10.0 [6.1~11.2]

11.2 [5.6~12.5]

2.94/2.96

4.3/4.6

99/98

3.09/3.09

4.5/4.8

99/98

5

50

Powerful mode Hi:18 Me:15 Lo:14

Mild mode Hi:15 Me:14 Lo:13

Powerful mode Hi:36 Me:33 Lo:32

Mild mode Hi:33 Me:32 Lo:31

Liquid line

Gas line

-

9

-

Model FDTVA502HESP2R (Indoor unit: 2 units, Outdoor unit: 1 unit)

Item

Model

FDTA251R FDCVA502HESAR

Nominal cooling capacity

(1)

kW

Nominal heating capacity

(1)

kW

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.90/2.96

Running current (Cooling) A 5.15.5

Power factor (Cooling) % 86/

Heating power consumption kW 2.54/2.60

Running current (Heating) A 4.6/4.8

Power factor (Heating) % 84/

Inrush current (L.R.A) A

Noise level dB(A)

552

Exterior dimensions

mm

Unit 270 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 31 (Unit:24 Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 20 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size (in) Indoor branch pipe, Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where two indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA502HESP2R

12.5 [6.5~14.0]

14.0 [6.2~16.0]

4.29/4.31

6.3/6.7

98/98

4.13/4.15

6.1/6.4

98/99

5

52

Powerful mode Hi:38 Me:35 Lo:33

Mild mode Hi:35 Me:33 Lo:31

Powerful mode Hi:20 Me:17 Lo:15

Mild mode Hi:17 Me:15 Lo:13

Liquid line

Gas line

-

10

-

Item

Model

FDTA301R FDCVA602HESAR

Nominal cooling capacity

(1)

kW 14.0 [7.0~14.5]

Nominal heating capacity

(1)

kW 16.0 [6.3~16.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.69/4.71

Running current (Cooling) A 6.9/7.2

Power factor (Cooling) % 98/99

Heating power consumption kW 4.58/4.60

Running current (Heating) A 6.7/7.1

Power factor (Heating) % 99/98

Inrush current (L.R.A) A 5

Noise level dB(A)

35 52

Exterior dimensions

mm

Unit 270 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 30 × 950 × 950

Net weight kg 31 (Unit:24 Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 20 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size (in) Indoor branch pipe, Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where two indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA602HESP2R

Model FDTVA602HESP2R (Indoor unit: 2 units, Outdoor unit: 1 unit)

Powerful mode Hi:38 Me:35 Lo:33

Mild mode Hi:35 Me:33 Lo:31

Powerful mode Hi:20 Me:17 Lo:15

Mild mode Hi:17 Me:15 Lo:13

53

Liquid line

Gas line

-

11

-

Item

Model

FDTA201R FDCVA602HESAR

Nominal cooling capacity

(1)

kW

Nominal heating capacity

(1)

kW

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.90/2.96

Running current (Cooling) A 5.1/5.5

Power factor (Cooling) % 86/75

Heating power consumption kW 2.54/2.60

Running current (Heating) A 4.6/4.8

Power factor (Heating) % 84/75

Inrush current (L.R.A) A 45

Noise level dB(A)

3

552

Exterior dimensions

mm

Unit 270 × 840 × 840

845 × 970 × 370

Height × Width × Depth Panel 35 × 950 × 950

Net weight kg 31 (Unit:24 Panel:7) 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 14 ⳯ 1 120 ⳯ 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch Wireless kit (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size (in) Indoor branch pipe: φ12.7 (1/2″), Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where three indoor units

are combined and run together.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA602HEST2R

(c) Triple type

Model FDTVA602HEST2R (Indoor unit: 3 units, Outdoor unit: 1 unit)

14.0 [7.0~14.5]

16.0 [6.3~16.5]

4.74/4.77

6.9/7.4

99/98

4.63/4.63

6.8/7.1

98/99

5

53

Powerful mode Hi:18 Me:15 Lo:14

Mild mode Hi:15 Me:14 Lo:13

Powerful mode Hi:36 Me:33 Lo:32

Mild mode Hi:33 Me:32 Lo:31

Liquid line

Gas line

-

12

-

Item

Model

FDENA401R FDCVA402HESAR

Nominal cooling capacity

(1)

kW 10.0 [6.1~11.2]

Nominal heating capacity

(1)

kW 11.2 [5.9~12.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 2.85/2.85

Running current (Cooling) A 4.2/4.4

Power factor (Cooling) % 98/98

Heating power consumption kW 2.97/2.97

Running current (Heating) A 4.3/4.6

Power factor (Heating) % 99/98

Inrush current (L.R.A) A 5

Noise level dB(A)

Exterior dimensions

mm 250 × 1620 × 690 845 × 970 × 370

Height × Width × Depth

Net weight kg 46 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Centrifugal fan × 4 Propeller fan × 1

Motor W 40 × 2 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Unavailable –

Air filter, Q’ty Polypropylene net ×2(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wired remote control switch (Optional: RC-E1R)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP20 (I.D.20mm, O.D.26mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

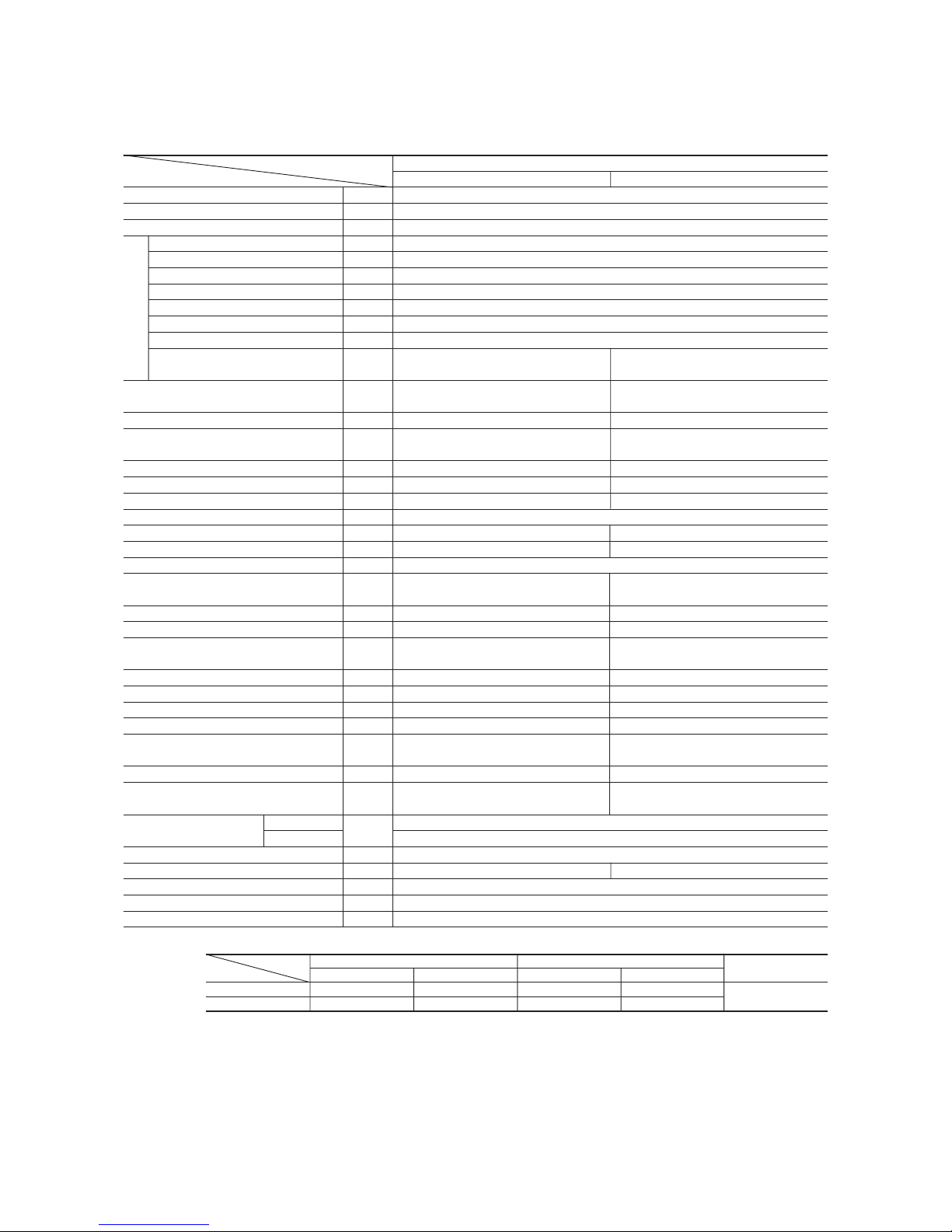

(3) Ceiling suspended type (FDEN)

(a) Single type

Model FDENVA402HES2R

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDENVA402HES2R

50

Powerful mode Hi:46 Me:44 Lo:41

Mild mode Hi:44 Me:41 Lo:39

Powerful mode Hi:29 Me:26 Lo:23

Mild mode Hi:26 Me:23 Lo:21

-

13

-

Item

Model

FDENA501R FDCVA502HESAR

Nominal cooling capacity

(1)

kW 12.5 [6.5~14.0]

Nominal heating capacity

(1)

kW 14.0 [6.2~16.0]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.35/4.35

Running current (Cooling) A 6.4/6.7

Power factor (Cooling) % 98/99

Heating power consumption kW 3.95/3.95

Running current (Heating) A 5.8/6.1

Power factor (Heating) % 98/98

Inrush current (L.R.A) A 5

Noise level dB(A)

Exterior dimensions

mm 250 × 1620 × 690 845 × 970 × 370

Height × Width × Depth

Net weight kg 46 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Centrifugal fan × 4 Propeller fan × 1

Motor W 45 × 2 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Unavailable –

Air filter, Q’ty Polypropylene net ×2(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wired remote control switch (Optional: RC-E1R)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP20 (I.D.20mm, O.D.26mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

Model FDENVA502HES2R

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDENVA502HES2R

52

Powerful mode Hi:48 Me:46 Lo:44

Mild mode Hi:46 Me:44 Lo:43

Powerful mode Hi:31 Me:29 Lo:26

Mild mode Hi:29 Me:26 Lo:23

-

14

-

Item

Model

FDENA601R FDCVA602HESRR

Nominal cooling capacity

(1)

kW 14.0 [6.7~14.5]

Nominal heating capacity

(1)

kW 16.0 [6.3~16.5]

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW 4.95/4.95

Running current (Cooling) A 7.2/7.6

Power factor (Cooling) % 99/99

Heating power consumption kW 4.69/4.69

Running current (Heating) A 6.8/7.2

Power factor (Heating) % 99/99

Inrush current (L.R.A) A 5

Noise level dB(A)

Exterior dimensions

mm 250 × 1620 × 690 845 × 970 × 370

Height × Width × Depth

Net weight kg 46 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Centrifugal fan × 4 Propeller fan × 1

Motor W 45 × 2 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Unavailable –

Air filter, Q’ty Polypropylene net ×2(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wired remote control switch (Optional: RC-E1R)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP20 (I.D.20mm, O.D.26mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

Model FDENVA602HES2R

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDENVA602HES2R

53

Powerful mode Hi:48 Me:46 Lo:44

Mild mode Hi:46 Me:44 Lo:43

Powerful mode Hi:31 Me:29 Lo:26

Mild mode Hi:29 Me:26 Lo:23

-

15

-

Item

Model

FDENA201R FDCVA402HESAR

Nominal cooling capacity

(1)

kW

Nominal heating capacity

(1)

kW

Power source 3 Phase, 380-415V 50Hz/380V 60Hz

Cooling power consumption kW

Running current (Cooling) A

Power factor (Cooling) %

Heating power consumption kW

Running current (Heating) A

Power factor (Heating) %

Inrush current (L.R.A) A

Noise level dB(A)

Exterior dimensions

mm 210 × 1070 × 690 845 × 970 × 370

Height × Width × Depth

Net weight kg 30 74

Refrigerant equipment

– RM-B5125MDE31

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

3.8 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.7 (M-MA68)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Centrifugal fan × 2 Propeller fan × 1

Motor W 30 × 1 120 × 1

Starting method Direct line start Direct line start

Air flow CMM Cooling: 75, Heating: 73

Outside air intake Unavailable –

Air filter, Q’ty Polypropylene net ×2(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wired remote control switch (Optional: RC-E1R)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Anomalous discharge temperature protection.

Installation data mm Indoor branch pipe, Outdoor main pipe: φ9.52 (3/8″)

Refrigerant piping size (in) Indoor branch pipe: φ12.7 (1/2″), Outdoor main pipe: φ15.88 (5/8″)

Connecting method Flare piping

Drain hose Connectable with VP20 (I.D.20mm, O.D.26mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

(b) Twin type

Model FDENVA402HESP2R (Indoor unit: 2 units, Outdoor unit: 1 unit)

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 400V 50Hz or 380V 60Hz.

(4) Values in [ ~ ] show the minimum to maximum range.

(5) Indoor unit specifications show the specifications for one unit. Capacity and running characteristics values are shown for the case where two indoor units

are combined and run together.

(6) If wireless specifications are used, use 1 wireless indoor unit in combination with wired indoor units.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDENVA402HESP2R

50

10.0 [6.1~11.2]

11.2 [5.9~12.5]

2.78/2.78

4.1/4.3

98/98

2.94/2.94

4.3/4.5

99/99

5

Powerful mode Hi:42 Me:39 Lo:38

Mild mode Hi:39 Me:38 Lo:37

Powerful mode Hi:12 Me:11 Lo:9

Mild mode Hi:11 Me:9 Lo:7

Liquid line

Gas line

Loading...

Loading...