Mitsubishi Heavy Industries FDC508HES3, FDC808HES3, FDC1008HES3, FDT208-A, FDT258-A User Manual

...

677

V MULTI

18. MULTI-TYPE(V MULTI)

PACKAGED AIR-CONDITIONER

Split system, Air to air

heat pump type

OUTDOOR UNIT

FDC508HES3

808HES3

1008HES3

INDOOR UNIT

FDT208-A FDR208-A

258-A 258-A

308-A 308-A

408-A 408-A

508-A 508-A

()

677

V MULTI

678

V MULTI

CONTENTS

18.1 GENERAL INFORMATION ......................................................................679

18.1.1 Specific features................................................................................679

18.1.2 How to read the model name............................................................679

18.1.3 Table of models .................................................................................680

18.1.4 Table of system combinations .........................................................680

18.2. SELECTION DATA ...................................................................................681

18.2.1 Specifications ....................................................................................681

18.2.2 Range of usage & limitations ...........................................................688

18.2.3 Exterior dimensions..........................................................................690

18.2.4 Exterior appearance..........................................................................702

18.2.5 Piping system ....................................................................................703

18.2.6 Selection chart...................................................................................705

18.2.7 Characteristic of fan..........................................................................707

18.2.8 Noise level..........................................................................................709

18.3. ELECTRICAL DATA.................................................................................711

18.3.1 Electrical wiring.................................................................................711

18.4. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER............713

18.5. APPLICATION DATA................................................................................713

18.5.1 Installation of indoor unit ................................................................713

18.5.2 Installation of remote controller (Optional parts)...........................713

18.5.3 Installation of outdoor unit...............................................................713

18.6. MAINTENANCE DATA .............................................................................721

679

V MULTI

18.1 GENERAL INFORMATION

18.1.1 Specific features

Ideal for the installation conditions characteristic of larger rooms and L-shaped or other non-standard-shaped rooms, the Multi-Type V

series allows an extensive degree of flexibility in the selection of indoor units. Specifically, the selection of indoor units with differing

capacities and differing or similar types is supported, as is the selection of indoor units with similar capacities and differing types.

Furthermore, a maximum of up to four individual indoor units can be operated in synchrony with a single outdoor unit.

(1) Simaltaneous operation possible in non-standard-shaped rooms or large-sized areas.

(2) Select indoor units of differing capacities and differing or similar types; alternatively, indoor units of similar capacities and differ-

ing types.

(3) Up to four individual indoor units can be connected to single outdoor unit.

(4) Indoor unit.

(i) Ceiling recessed type (FDT)

(a) All air supply ports have auto swing louvers. The indoor fan motor has two speeds of high and low.

(b) All models have service valves protruding from the outdoor unit for faster flare connection work in the field.

(c) Low sound level

Operating noise has been remarkably reduced due to adoption of the crescent turbo fan which cuts off wind-blowing

noise and also console type of cabinet which is highly effective to protect vibration.

(d) 700mm high drain head

Adoption of drain pump with high drain head and high capacity (600cc/min) has made it possible to have maximum

700 mm(from below ceiling drain head.[In case 700mm drain head is required, set it up close to the unit. It is impossible

to do piping on down slope.]

(ii) Cassetteria type (FDR)

(a) Quiet sound design

(i) Noise reducing effect has been improved significantly with the employment of large silent steam fans which are

free from the wind swishing sound, and the special designing of noise shielding and acoustic suction panel.

(ii) Ideal adaptation to the need for quiet sound at conference rooms, offices, etc.

(b) 2 types of optional decorative panel

(i) Optional decorative panel consists of silent panel and a canvas duct panel. [has smaller sizes and is prepared with

canvas duct panel which provides higher drain head.]

(ii) Flexibility of installation is increased with 2 type panels.

(c) External static pressure

High external static pressure type (Refer to the specification in clause 2 for the external static pressure.)

Applicable power source ... See the specifications

Heat pump type

Series No.

Nominal capacity

Model name (FDC: Outdoor unit)

Example: FDC 80 8 H ES 3

18.1.2 How to read the model name

Example: FDT 20 8- A

Series No.

Nominal capacity

Model name

FDT: Ceiling recessed type unit with

wired remote controller

FDR: Cassetteria type unit with wired

remote controller

680

V MULTI

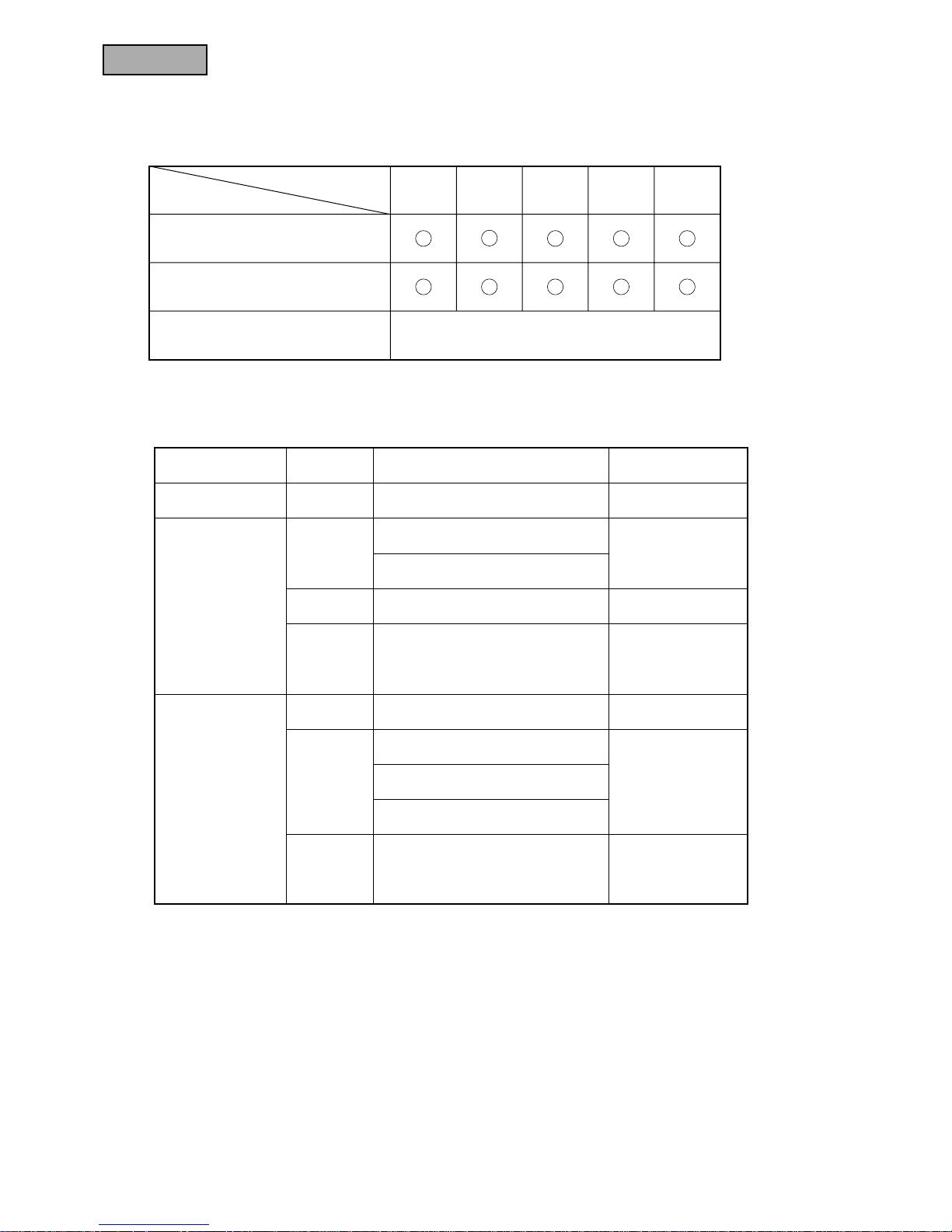

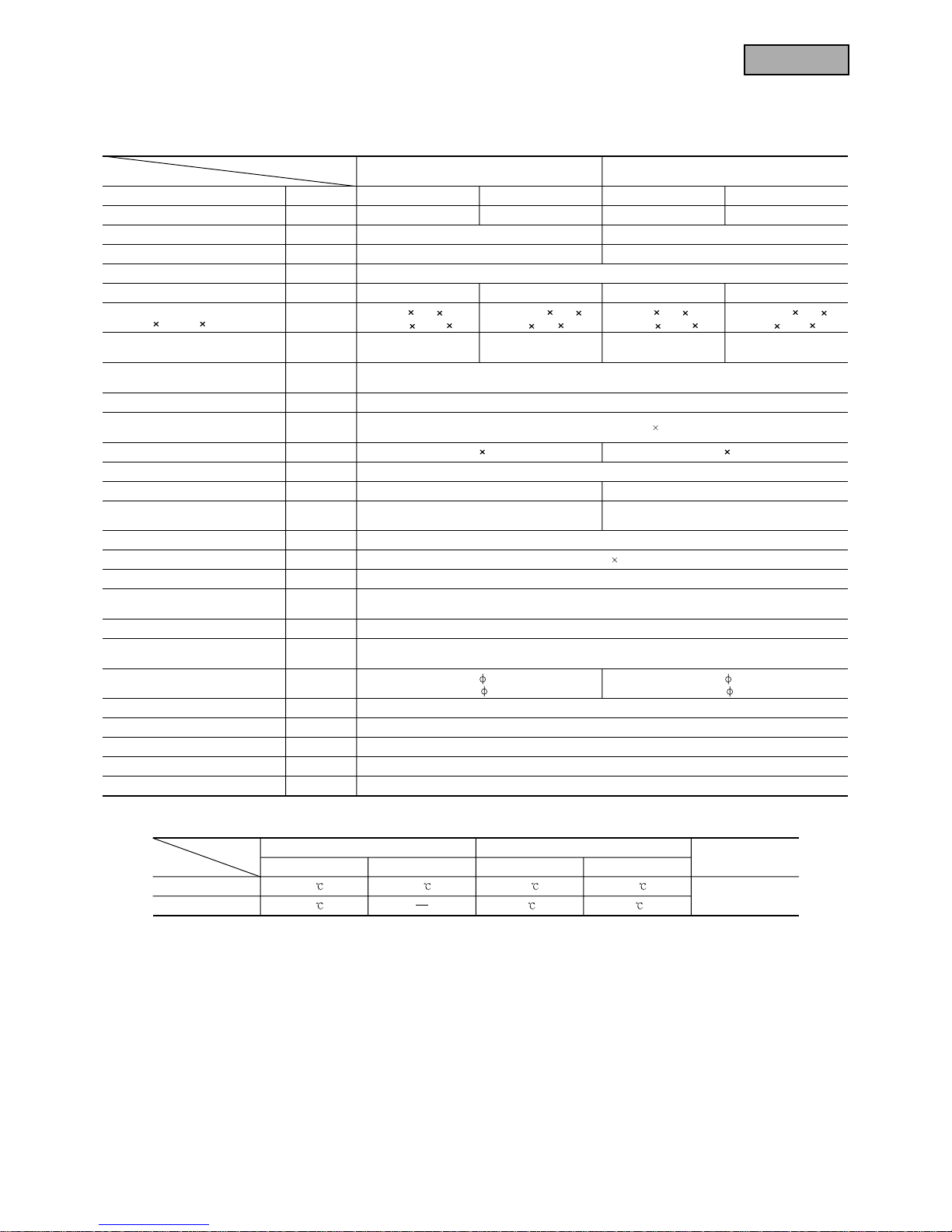

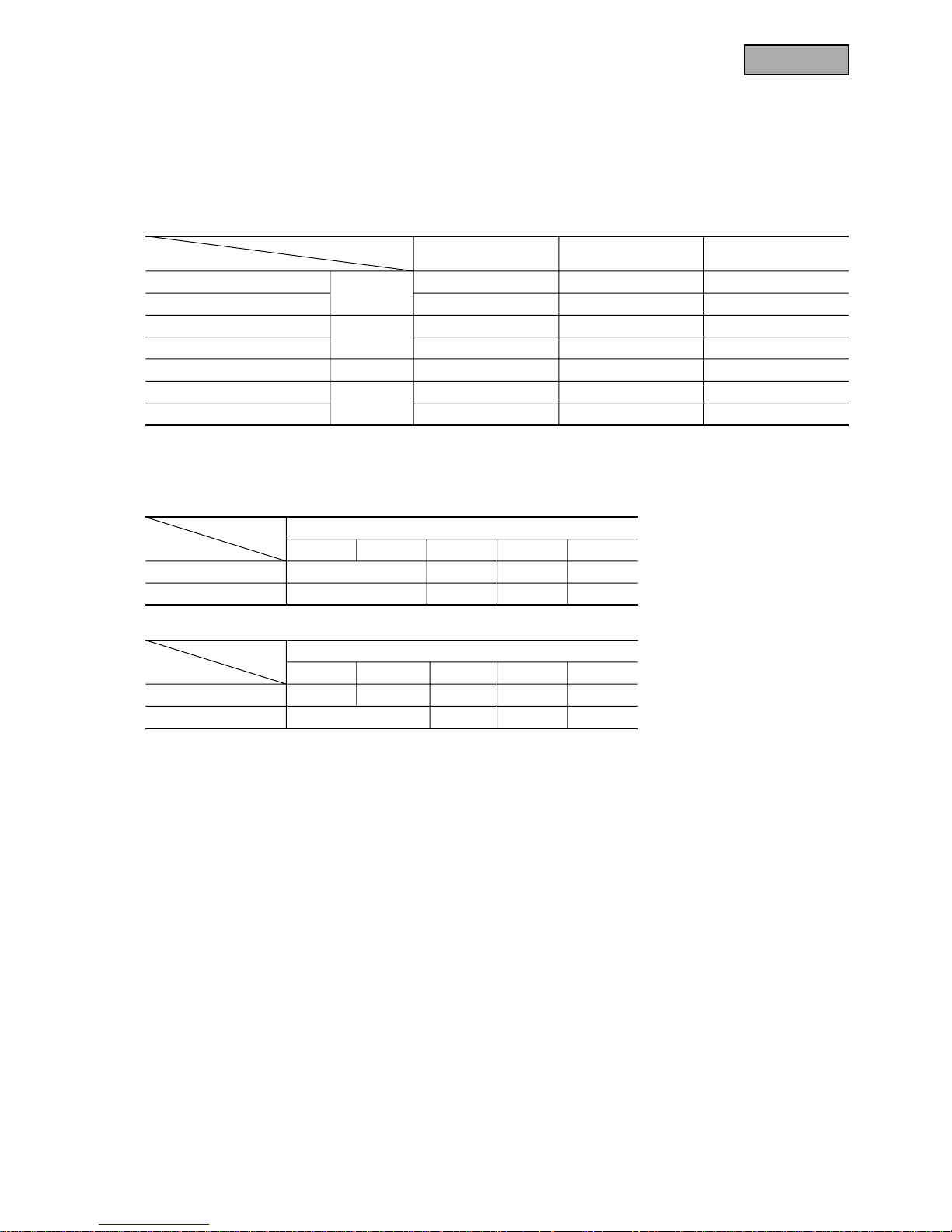

18.1.3 Table of models

Capacity

Model

Ceiling recessed type (FDT)

FDC508HES3

(5 Horse Power)

FDC808HES3

(8 Horse Power)

FDC1008HES3

(10 Horse Power)

Cassetteria type (FDR)

208 258 308 508408

Outdoor unit to be combined(FDC)

18.1.4 Table of system combinations

Indoor unit assembly capacity

Branch pipe set

(Optional)

258+258 DIS-WA

408+408

308+508FDC808HES3

308+308+308 DIS-TB

DIS-WB

508+508 DIS-WB

DIS-WA

º

2set

DIS-WB

º

1set

208+408+408

258+258+508 DIS-TB

Type

Twin

Outdoor unit

FDC508HES3

Triple

Twin

Twin

Double twin

Triple

FDC1008HES3

308+308+408

208+208+208+208

DIS-WA

º

2set

DIS-WB

º

1set

Double twin

258+258+258+258

Notes (1) It is possible to used different models (FDT, FDR) when combining indoor units.

(2) Always use the branch piping set (optional) at branches in the refrigerant piping.

681

V MULTI

Item

Nominal cooling capacity

(

1)

W

W

W

CMM

23(Unit:18 Panel:5)

25 1

Hi: 16 Lo: 11Hi: 14 Lo: 10

dB(A)

mm

Unit:215 700 700

Panel:26 800 800

Nominal heating capacity

(

1)

Power source

Net weight

Refrigerant control

Starting method

Fresh air intake

Air filter, Q'ty

Shock & vibration absorber

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Internal thermostat for fan motor.

Frost protection thermostat

Air handling equipment

Fan type & Q'ty

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Model

FDT208-A

5000

5400

FDT258-A

5700

6100

1 Phase 220/240V 50Hz

Capillary tube

Line starting

Available

Long life filter 1(Washable)

Rubber sleeve(for fan motor)

Flare piping

Connectable with VP25

Necessary (both Liquid & Gas line)

Mounting kit, Drain hose

Decorative Panel

Thermostat by electronics

Turbo fan 1

mm(in)

Safety equipment

Remote control switch (Optional:RCD-H-S-E)

Hi: 38 Lo: 33

Louver fine & inner grooved tubing

30 1

30(Unit:24 Panel:6)

Unit:260 840 840

Panel:30 950 950

Hi: 39 Lo: 35

Liquid line: 6.35 (1/4")

Gas line: 15.88 (5/8")

Liquid line: 9.52 (3/8")

Gas line: 15.88 (5/8")

(1) The data are measured at the following conditions.Notes

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616"UNITARY AIR-CONDITIONERS"

Decorative Panel model (Optional)

Item

Item

Indoor air temperature Outdoor air temperature

Standards

ISO-T1,JIS B8616

Operation

Model

FDT208-A T-PSA-22W-E

FDT258-A T-PSA-32W-E

Panel Part No.

DB WB DB WB

Cooling 27

Heating

20

19 35

7

24

6

kg

18.2 SELECTION DATA

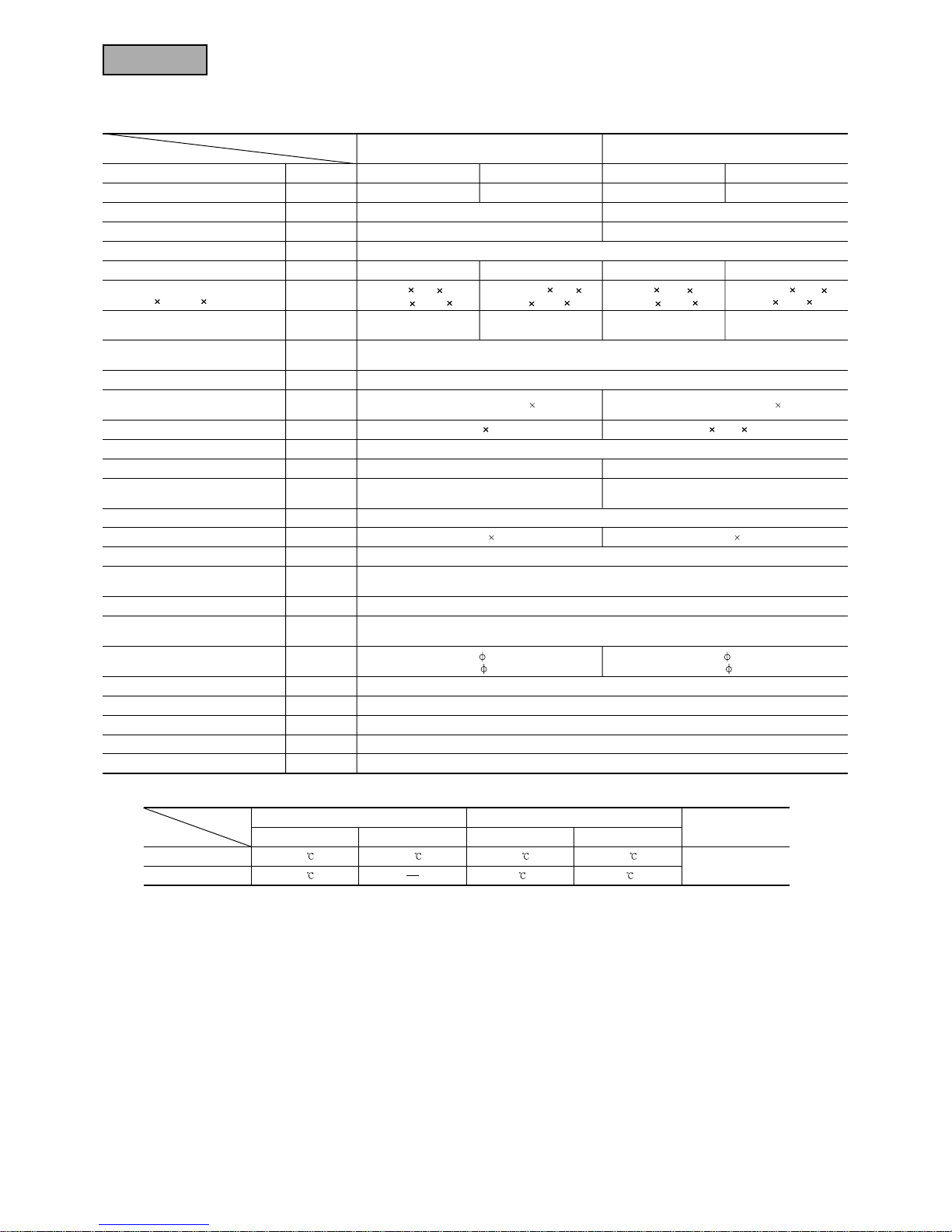

18.2.1 Specifications

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Models FDT208-A, 258-A

682

V MULTI

Item

Nominal cooling capacity

(

1)

W

W

W

CMM

34(Unit:28 Panel:6)30(Unit:24 Panel:6) 36(Unit:30 Panel:6)

80 1

Hi: 17 Lo: 12 Hi: 26 Lo: 19 Hi: 28 Lo: 20

130 1

dB(A)

mm

Nominal heating capacity

(

1)

Power source

Net weight

Refrigerant control

Starting method

Fresh air intake

Air filter, Q'ty

Shock & vibration absorber

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Internal thermostat for fan motor.

Frost protection thermostat

Air handling equipment

Fan type & Q'ty

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Model

FDT308-A

7100

FDT408-A

10000

FDT508-A

12500

8000 11200

1 Phase 220/240V 50Hz

Capillary tube

Line starting

Available

Long life filter 1(Washable)

Rubber sleeve(for fan motor)

Flare piping

Connectable with VP25

Necessary (both Liquid & Gas lines)

Mounting kit, Drain hose

Decorative Panel

Thermostat by electronics

Turbo fan 1

Liquid line: 9.52 (3/8")

Gas line: 15.88 (5/8")

Liquid line: 9.52 (3/8")

Gas line: 19.05 (3/4")

mm(in)

Safety equipment

Remote control switch (Optional:RCD-H-S-E)

Hi: 41 Lo: 35 Hi: 48 Lo: 40

Louver fine & inner grooved tubing

Hi: 49 Lo: 43

14000

30 1

(1) The data are measured at the following conditions.Notes

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616"UNITARY AIR-CONDITIONERS"

Decorative Panel model (Optional)

Item

Item

Indoor air temperature Outdoor air temperature

Standards

ISO-T1,JIS B8616

Operation

Model

FDT308-A, 408-A, 508-A T-PSA-32W-E

Panel Part No.

DB WB DB WB

Cooling 27

Heating

20

19 35

7

24

6

kg

Unit:320 840 840

Panel:30 950 950

Unit:260 840 840

Panel:30 950 950

Models FDT308-A, 408-A, 508-A

683

V MULTI

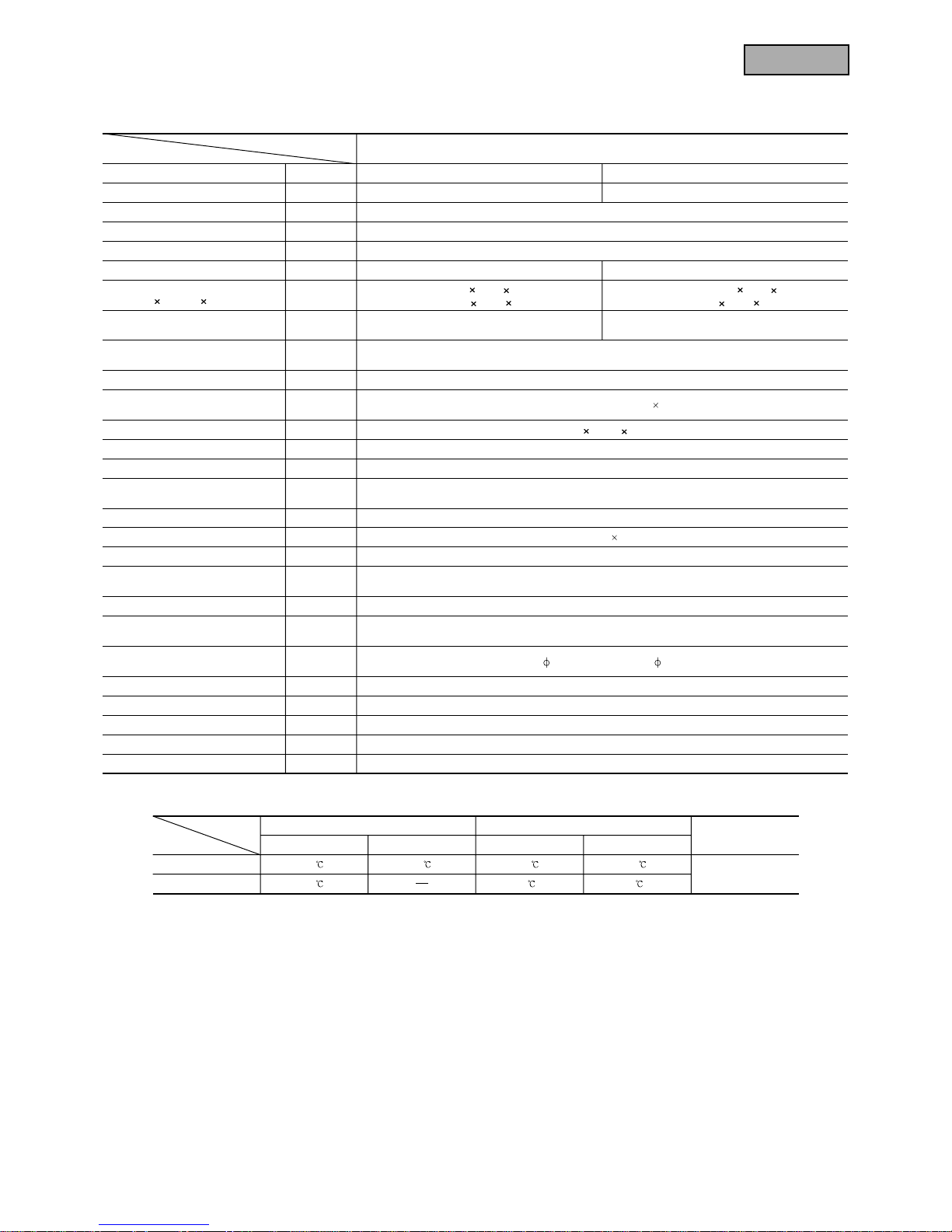

Item

Nominal cooling capacity

(

1)

Panel model (Option)

Decorative panel Silent panel

R-PNLS-26W-E R-PNLC-26W-E R-PNLS-36W-E R-PNLC-36W-E

Canvas panel Canvas panelSilent panel

W

W

W

CMM

kg

Pa

(mmAq)

Standard:50(5), High:85(8.5) Standard:45(4.5), High:80(8.0)

Unit:30

Panel:7

Unit:30

Panel:5

Unit:35

Panel:8

Unit:35

Panel:6

55 1

Hi: 14 Lo: 11 Hi: 18 Lo: 14

90 1

dB(A)

mm

Unit:355 750 635

Panel:10 1040 750

Nominal heating capacity

(

1)

Power source

Net weight

Refrigerant control

Starting method

Fresh air intake

Air filter Q'ty

Shock & vibration absorber

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Internal thermostat for fan motor.

Frost protection thermostat

Air handling equipment

Fan type & Q'ty

Available static pressure

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Model

FDR208-A

5000

FDR258-A

5700

5400

1 Phase 220/240V 50Hz

Capillary tube

Line starting

Available

Polypropylene net 2(Washable)

Rubber sleeve(for fan motor)

Flare piping

Connectable with VP25

Necessary (both Liquid & Gas lines)

Mounting kit, Drain hose

Silent panel, Canvas panel, Canvas duct

Thermostat by electronics

mm(in)

Safety equipment

Remote control switch (Optional:RCD-H-E)

Hi: 43 Lo: 37 Hi: 44 Lo: 38 Hi: 43 Lo: 37 Hi: 44 Lo: 38

Louver fins & inner grooved tubing

6100

Unit:(299+α) 750 635

Panel:10 864 585

Unit:(299+α) 950 635

Panel:10 1064 585

Unit:355 950 635

Panel:10 1240 750

Liquid line: 6.35 (1/4")

Gas line: 15.88 (5/8")

Liquid line: 9.52 (3/8")

Gas line: 15.88 (5/8")

(1)The data are measured at the following conditions.Notes

(2)This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616"UNITARY AIR-CONDITIONERS"

(3)Canvas panel is used in combination with following canvas duct

Canvas duct: HA01503

(4)Add the canvas duct lenght to the unit height for the canvas type.

Item

Indoor air temperature Outdoor air temperature

Standards

ISO-T1,JIS B8616

Operation

DB WB DB WB

Cooling 27

Heating

20

19 35

7

24

6

Multiblade centrifugal fan 2

(b) Cassetteria type (FDR)

Models FDR208-A, 258-A

684

V MULTI

Item

Nominal cooling capacity

(

1)

Panel model (Option)

Decorative panel Silent panel

R-PNLS-36W-E R-PNLC-36W-E R-PNLS-46W-E R-PNLC-46W-E

Canvas panel Canvas panelSilent panel

W

W

W

CMM

kg

Pa

(mmAq)

Standard:45(4.5), High:80(8.0) Standard:50(5.0), High:80(8.0)

Unit:35

Panel:8

Unit:35

Panel:6

Unit:50

Panel:9

Unit:50

Panel:7

Hi: 20 Lo: 15 Hi: 28 Lo: 22

100 1

dB(A)

mm

Unit:355 950 635

Panel:10 1240 750

Nominal heating capacity

(

1)

Power source

Net weight

Refrigerant control

Starting method

Fresh air intake

Air filter Q'ty

Shock & vibration absorber

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Internal thermostat for fan motor.

Frost protection thermostat

Air handling equipment

Fan type & Q'ty

Available static pressure

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Model

FDR308-A

7100

FDR408-A

10000

8000

1 Phase 220/240V 50Hz

Capillary tube

Line starting

Available

Polypropylene net 3(Washable)

Rubber sleeve(for fan motor)

Flare piping

Connectable with VP25

Necessary (both Liquid & Gas lines)

Mounting kit, Drain hose

Silent panel, Canvas panel, Canvas duct

Thermostat by electronics

Liquid line: 9.52 (3/8")

Gas line: 15.88 (5/8")

mm(in)

Safety equipment

Remote control switch (Optional:RCD-H-E)

Hi: 44 Lo: 38 Hi: 45 Lo: 39 Hi:45 Lo: 38 Hi: 46 Lo: 39

Louver fins & inner grooved tubing

11200

Unit:(299+α) 950 635

Panel:10 1064 585

Unit:(350+α) 1370 635

Panel:10 1484 585

Unit:406 1370 635

Panel:10 1660 750

Polypropylene net 2(Washable)

Liquid line: 9.52 (3/8")

Gas line: 19.05 (3/4")

(1)The data are measured at the following conditions.Notes

(2)This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616"UNITARY AIR-CONDITIONERS"

(3)Canvas panel is used in combination with following canvas duct

Canvas duct: HA01503

(4)Add the canvas duct lenght to the unit height for the canvas type.

Item

Indoor air temperature Outdoor air temperature

Standards

ISO-T1,JIS B8616

Operation

DB WB DB WB

Cooling 27

Heating

20

19 35

7

24

6

Multiblade centrifugal fan 2

45 1+90 1

Multiblade centrifugal fan 3

Models FDR308-A, 408-A

685

V MULTI

Item

Nominal cooling capacity

(

1)

Panel model (Option)

Decorative panel Silent panel

R-PNLS-46W-E R-PNLC-46W-E

Canvas panel

W

W

W

CMM

kg

Pa

(mmAq)

Standard:50(5.0), Hi speed:80(8.0)

Unit:52

Panel:9

Unit:52

Panel:7

Hi: 34 Lo: 27

50 1+100 1

dB(A)

mm

Unit:406 1370 635

Panel:10 1660 750

Nominal heating capacity

(

1)

Power source

Net weight

Refrigerant control

Starting method

Fresh air intake

Air filter Q'ty

Shock & vibration absorber

Room temperature control

Connecting method

Drain hose

Insulation for piping

Accessories

Optional parts

Motor

Air flow(Standard)

Exterior dimensions

Height Width Depth

Refrigerant equipment

Heat exchanger

Internal thermostat for fan motor.

Frost protection thermostat

Air handling equipment

Fan type & Q'ty

Available static pressure

Operation control

Operation switch

Installation data

Refrigerant piping size

Noise level

Model

FDR508-A

12500

14000

1 Phase 220/240V 50Hz

Capillary tube

Line starting

Available

Polypropylene net 3(Washable)

Rubber sleeve(for fan motor)

Flare piping

Connectable with VP25

Necessary (both Liquid & Gas lines)

Mounting kit, Drain hose

Silent panel, Canvas panel, Canvas duct

Thermostat by electronics

mm(in)

Safety equipment

Remote control switch (Optional:RCD-H-E)

Hi: 46 Lo: 39 Hi: 47 Lo: 40

Louver fins & inner grooved tubing

Unit:(350+α) 1370 635

Panel:10 1484 585

(1)The data are measured at the following conditions.Notes

(2)This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616"UNITARY AIR-CONDITIONERS"

(3)Canvas panel is used in combination with following canvas duct

Canvas duct: HA01484

(4)Add the canvas duct lenght to the unit height for the canvas type.

Item

Indoor air temperature Outdoor air temperature

Standards

ISO-T1,JIS B8616

Operation

DB WB DB WB

Cooling 27

Heating

20

19 35

7

24

6

Multiblade centrifugal fan 3

Liquid line: 9.52 (3/8"), Gas line: 19.05 (3/4")

Model FDR508-A

686

V MULTI

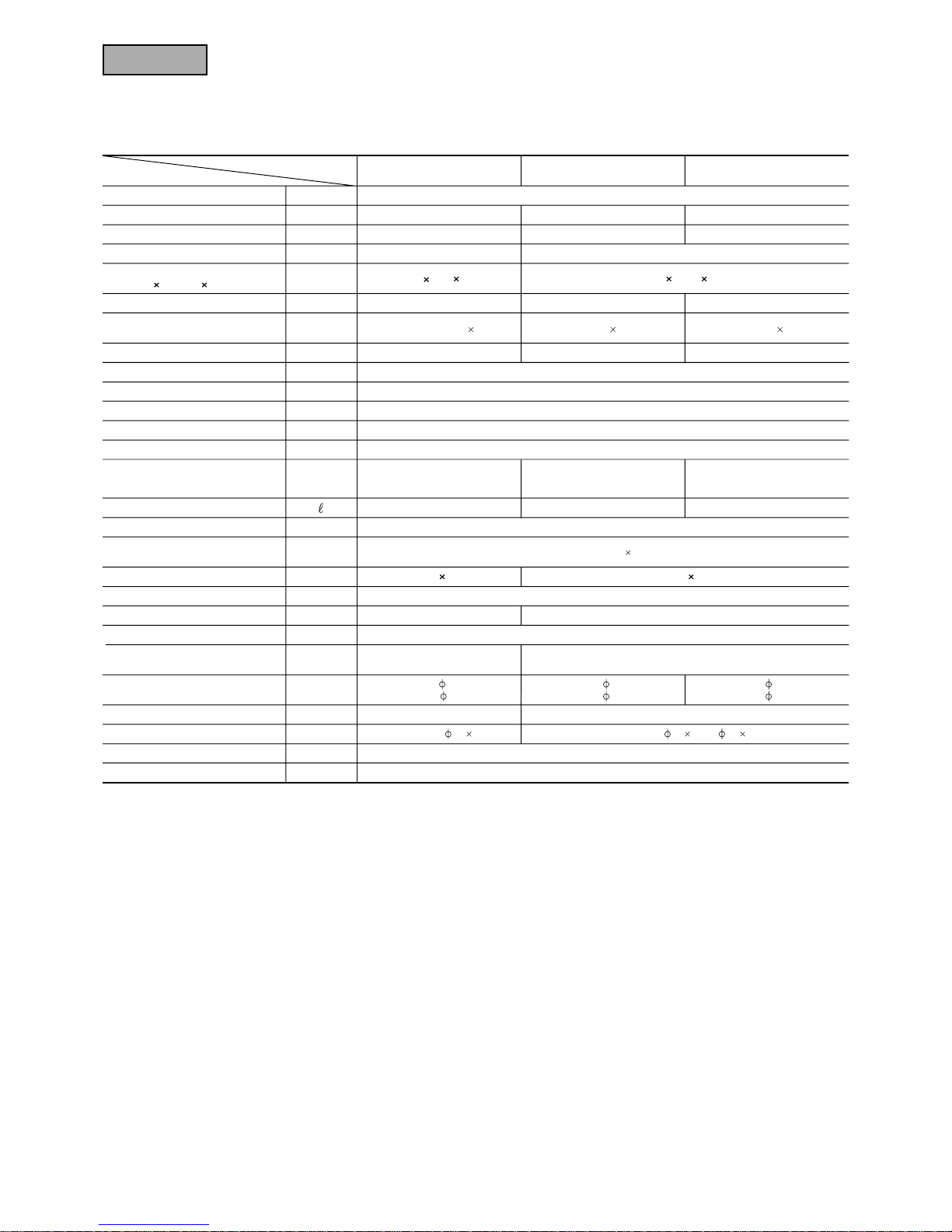

Item

W

W

kg

kW

GU-A5570ES41 1

CB125 1CB90 1

101

dB(A)

W

kg

W

CMM 110 180

mm(in)

mm

Model

FDC1008HES3FDC808HES3

25000

FDC508HES3

12500

14000

20000

21200

3 Phase 380/415V 50Hz

Line starting

Line starting

Flare piping Liquid line: Flare piping Gas line: Brazing

_

Hole for drain( 20 8pcs, 50 1pcs)

Necessary (both Liquid & Gas lines)

5855

28000

195185

3.8 (BARREL FREEZE 32SAM)4.4 (BARREL FREEZE 32SAM)1.6 (BARREL FREEZE 32SAM)

1.9(Pre-charged up to

the piping length of 5m)

5.33(Pre-charged up to

the piping length of 5m)

7.6(Pre-charged up to

the piping length of 5m)

70

3.75

R22

9.0

1250 920 340

1450 1350 600

Nominal cooling capacity

(

1)

Power source

Nominal heating capacity

(

1)

Net weight

Crankcase heater

Heat exchanger

Refrigerant control

Refrigerant

Quantity

Refrigerant oil

Defrost control

Starting method

Exterior dimensions

Height Width Depth

Refrigerant equipment

compressor type & Q’ ty

Noise level

Motor

(1) The cooling and heating capabilities imply the values when the indoor unit of rated capacity is connected under the condition specified in JIS-B8616.

(2) The refrigerant quantity in the connecting pipe is not included Charge it additionally at the site.

Notes

Air handling equipment

Fan type & Q’ty

Motor

Starting method

Air flow(Standard)

Shock & vibration absorber Rubber mount (for compressor)

Internal thermostat for fan motor.

Thermistor for discharge temperature.

Internal thermostat for fan motor.

High pressure protection switch

Safety equipment

Connecting method

Drain

Insulation for piping

Accessories

Installation data

Refrigerant piping size

Capillary tube

IC controlled De-Icer

Slitted fines & bare tubing

Propeller fan 2

65 2 100 2

Liquid line: 9.52 (3/8")

Gas line: 19.05 (3/4")

Hole for drain( 20 3pcs)

Liquid line: 15.88 (5/8")

Gas line: 28.58 (11/8")

Liquid line: 12.7 (1/2")

Gas line: 25.4 (1")

6.5

(2) Outdoor unit

Models FDC508HES3, 808HES3, 1008HES3

687

V MULTI

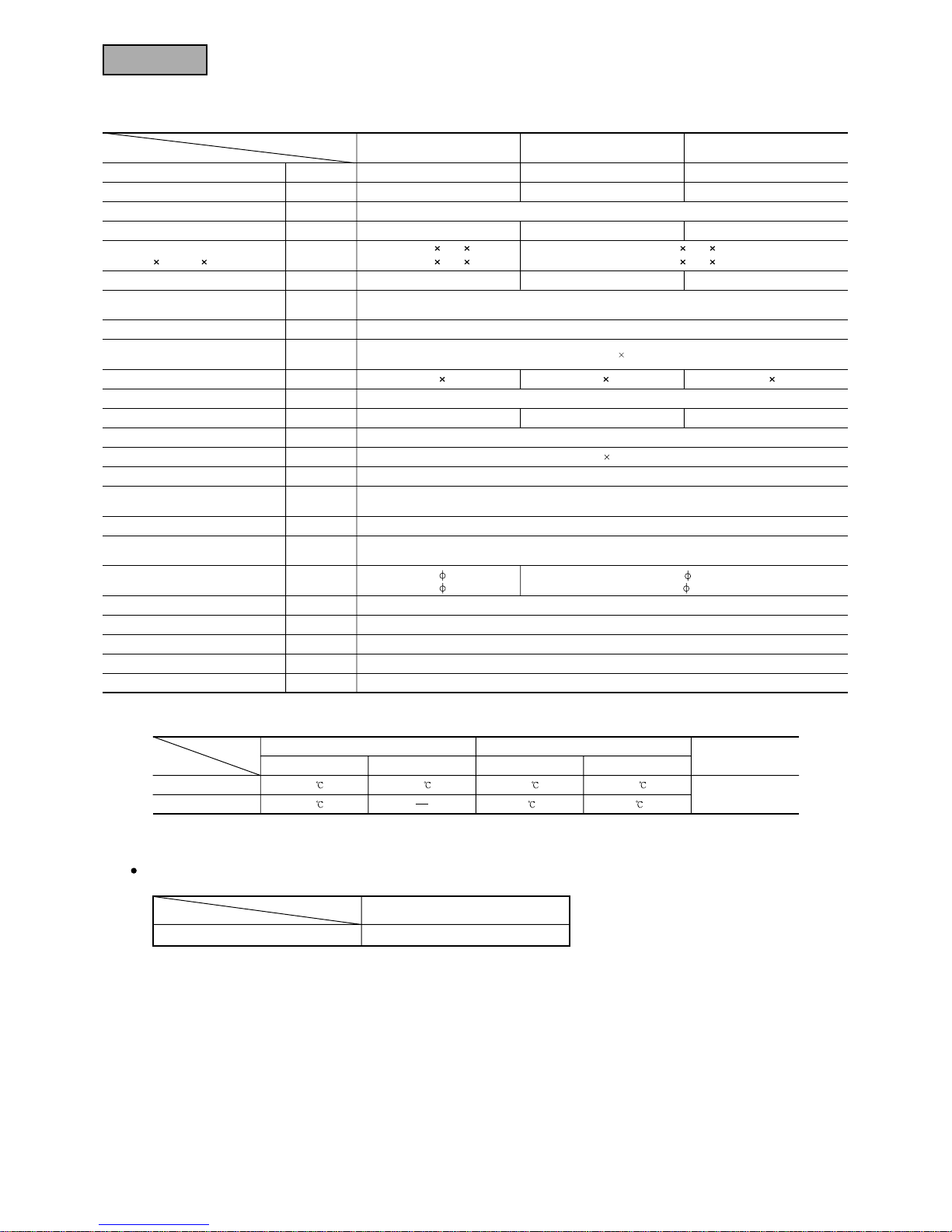

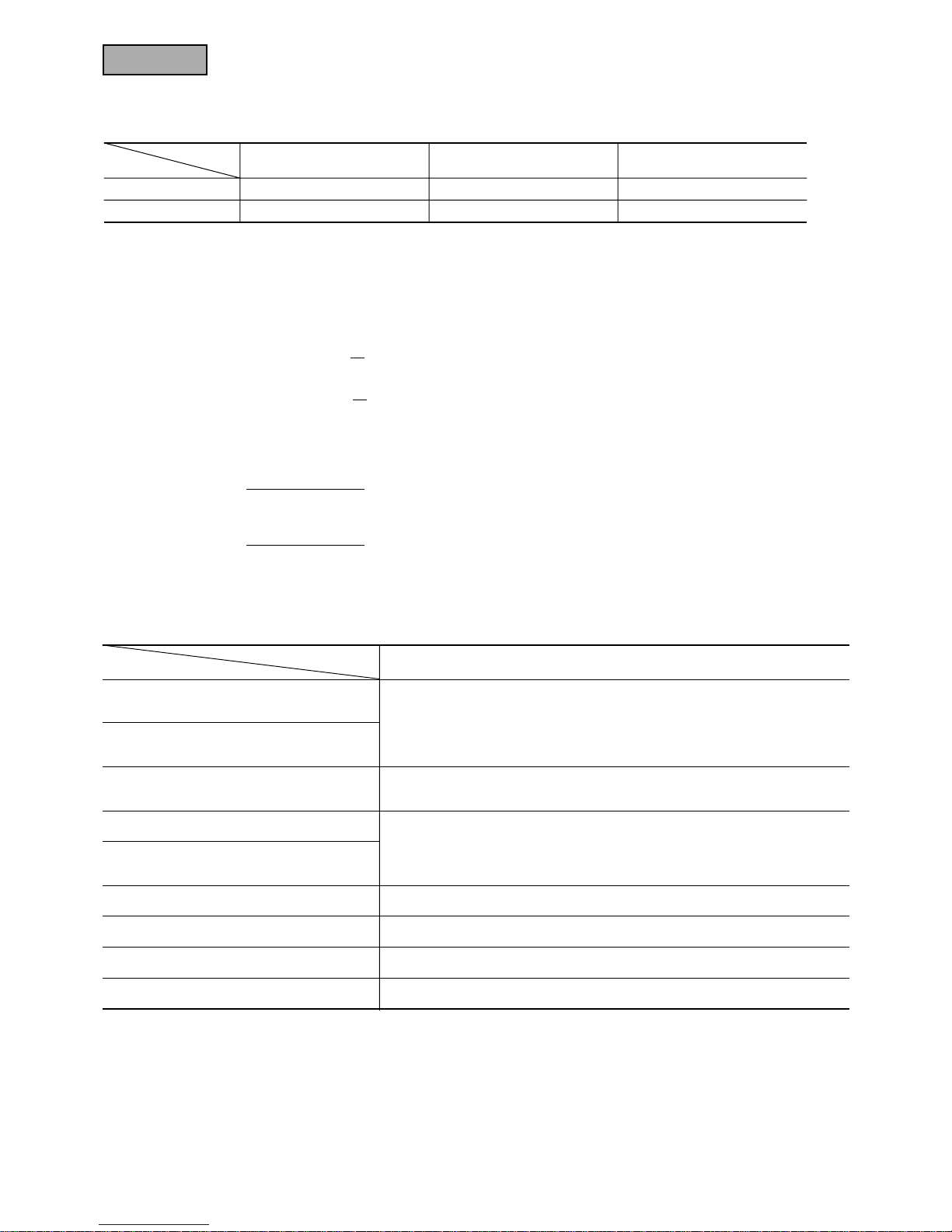

(c) Calculation of total operation characteristics

Since the operation characteristics of series Multi depend on combination of indoor unit, calculate the total operation characteristics of the system by using the formulas below according to specifications of each indoor unit or outdoor unit.

1)Total power input

Total power input (kW) = Power input of outdoor unit + ∑ (Power input of indoor unit)

2)Total running current

Total running current (A) = Running current of outdoor unit + [∑ (Running current of indoor unit) × 2/3]

3)Total power factor

Total power factor (%) = [Total power input (W) / √—3 × Total running current (A) × Power source] × 100

Total operation characteristics = Operation characteristic value of outdoor unit + Operation characteristic value of indoor unit

[Example]

(3) Operation chart

The Multi series is a system that allows for different models and capacities of indoor units to be combined so the individual

operating characteristics of the indoor and outdoor are provided. Use the procedure shown in Item (c) to calculate the combined

operating characteristics.

(a) Operating characteristic of outdoor unit

Cooling input

Heating input

Cooling running current

Heating running current

Inrush current (L.R.A)

Cooling power factor

Heating power factor

(380 V/415 V)

Item

Model

FDC508HES3

5.03/5.28

4.58/4.71

8.6/9.4

8.1/9.0

74

89/78

86/73

8.44/8.54

6.44/6.64

14.2/13.5

11.6/11.2

99

90/88

84/82

11.92/12.02

9.72/9.92

20.0/19.0

16.5/16.0

154

91/88

90/86

FDC808HES3 FDC1008HES3

kW

A

A

%

Note (1) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616 “UNITARY AIR-CONDITIONERS”

(b) Operating characteristic of indoor unit

Item

Model FDT Series

FDT Series

(220 V/240 V)

Power input (kW)

Running current (A)

0.10/0.11

0.5/0.5

0.11/0.12

0.6/0.6

0.21/0.21

1.2/1.2

0.27/0.27

1.4/1.4

208-A 258-A 308-A 408-A 508-A

Item

Model FDR Series

FDR Series

(220 V/240 V)

Power input (kW)

Running current (A)

0.11/0.120.10/0.11

0.5/0.5

0.15/0.16

0.7/0.7

0.19/0.19

0.9/0.9

0.24/0.24

1.2/1.2

208-A 258-A 308-A 408-A 508-A

Notes (1) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

JIS B8616 “UNITARY AIR-CONDITIONERS”

(2) The values shown in the above table are common to both cooling and heating operations.

(Conditions) Operation Voltage ········Indoor unit: 220 V, 50 Hz

Outdoor unit: 380 V, 50 Hz

Operation mode ···········Cooling and Heating

Unit·······························Outdoor unit: FDC808HES3 × 1 unit

Indoor unit: FDT308-A × 1 units, FDT508-A × 1 units

688

V MULTI

1 Total power input (kW)

(Cooling) 8.44 + 0.11+ 0.27 = 8.82 (kW)

(Heating) 6.44 + 0.11+ 0.27 = 6.82 (kW)

2 Total running current (A)

(Cooling) 14.2 + (0.6+1.4 ×

2

) 15.5 (A)

3

(Heating) 11.6 + (0.6 + 1.4 ×

2

) 12.9 (A)

3

3 Total power factor (%)

8.82 × 1000

(Cooling)

√—3 × 15.5 × 380

× 100 86 %

6.82 × 1000

(Heating)

√—3 × 12.9 × 380

× 100 80 %

=

.

.

=

.

.

=

.

.

=

.

.

Item

Model

FDC808HES3 FDT308-A FDT508-A

Operation characteristics of each unit

(Cooling/Heating)

Power input (kW)

Running current (A)

8.44/6.44

14.2/11.6

0.11/0.11

0.6/0.6

0.27/0.27

1.4/1.4

Models All models

18.2.2 Range of usage & limitations

Refer to the following

Model

Item

Indoor return air temperature

(Upper, lower limits)

Outdoor air temperature

(Upper, lower limits)

Indoor unit atmosphere (behind ceiling)

temperature and humidity

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Power source voltage

Voltage at starting

Frequency of ON-OFF cycle

ON and OFF interval

Dew point temperature: 28˚C or less, relative humidity: 80% or less

Refer to the selection chart

Max. 10 times/h

Max. 3 minutes

Min. 85% of rating

Rating ± 10%

All models

689

V MULTI

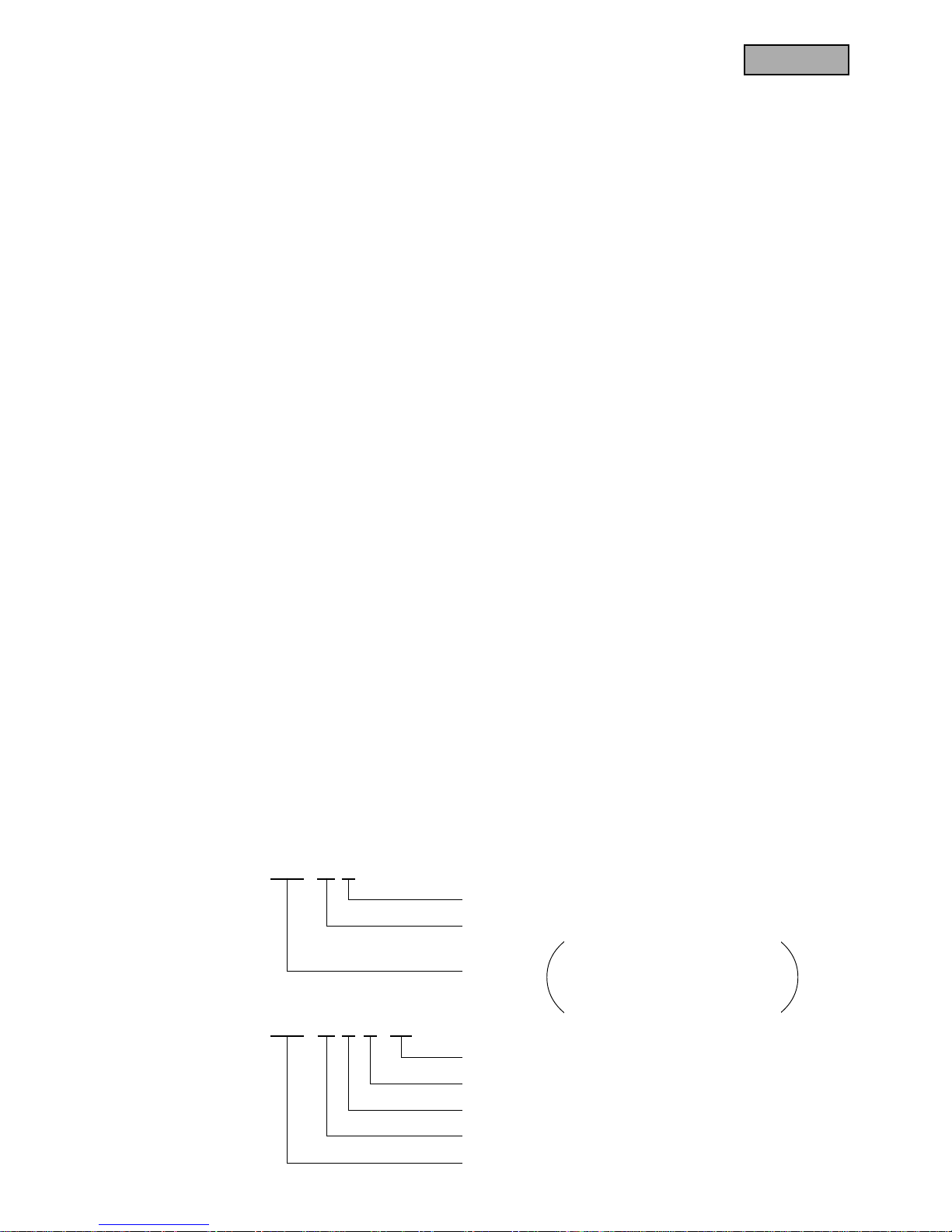

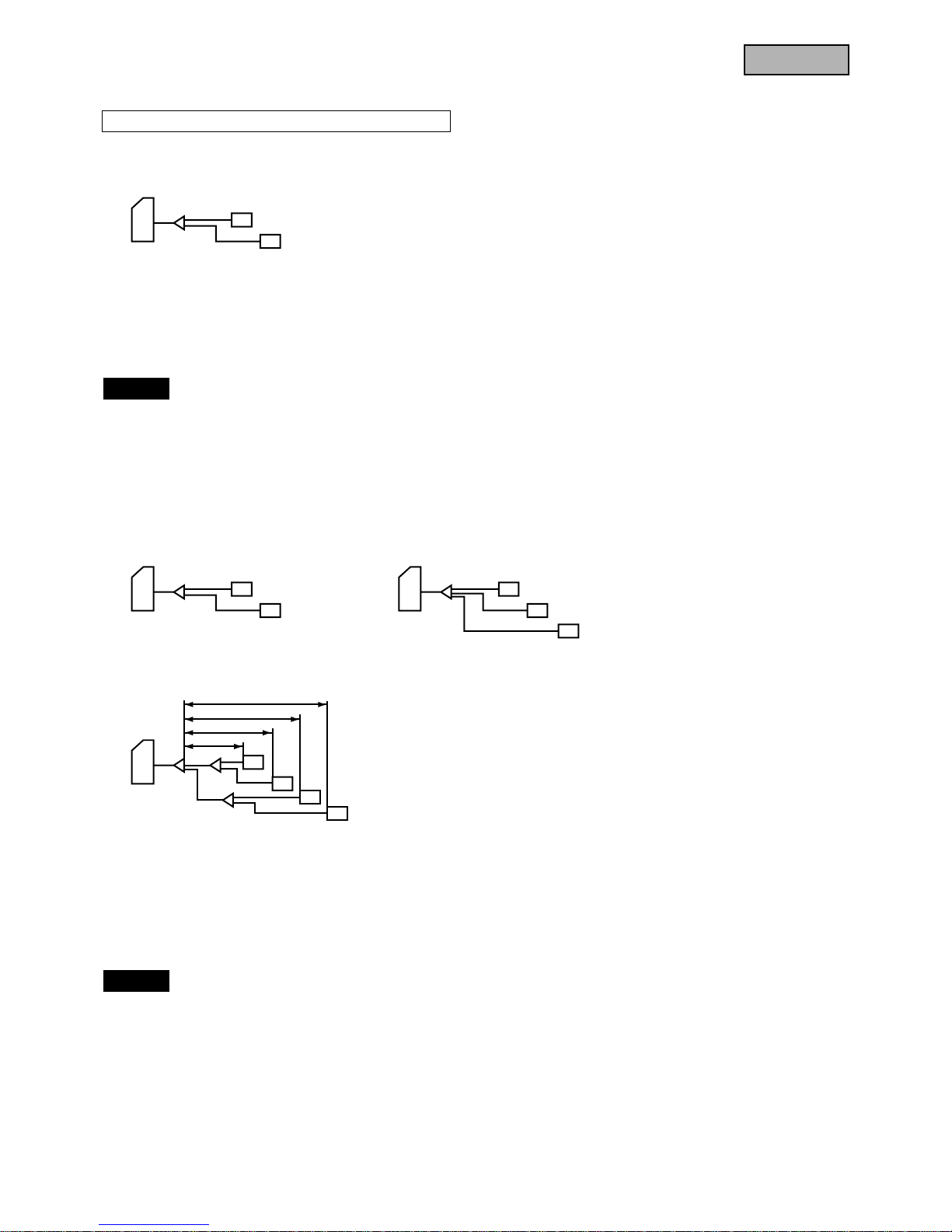

Height and length restrictions for refrigerant piping

(Twin type) (Triple type)

Indoor unit

Indoor unit

Outdoor unit Indoor unitOutdoor unit

A

L

ra

rb

B

Indoor unitOutdoor unit

A

L

ra

rb

B

A

L

ra

rb

rc

B

C

A

L

ra

rArA

rb

rc

rd

rB

rC

rD

r2

r1

B

C

D

Outdoor unit

(Double-twin type)

Models FDC508HES3

Models FDC808, 1008HES3

In the illustration the L is main piping and ra, andrb are branch piping.

In the illustration the L is main piping and ra,rb,rc, andrd are branch piping.

(1) When the capacity of the indoor unit to be connected is 208 or less, be sure to use a pipe diameter of ø9.52 for the

size of the liquid piping of branch piping (between branch and indoor units). (for twin, triple, and double-twin

only) For connections to indoor units (liquid piping side dia. ø6.35) use the different diameter adapter coupling

that is included in the branch piping kit.

(2) For the branch be sure to select the specified branch pipe set (sold separately) and then to follow the directions of

the instruction manual included in the branch pipe set when installing the piping. Be sure to install the branch

piping so that the branch is level.

• One-way pipe length (m) L + ra 50, L+rb 50, L+rc 50, L+rd 50

• Branch pipe length (m) lra – rbl 10, lra – rcl 10, lrb – rcl 10

lra – rdl 10, lrb – rdl 10, lrc – rdl 10

ra 30, rb 30, rc 30, rd 30

rA +rB 15, rC +rD 15

• Vertical height difference between outdoor unit and indoor unit

Outdoor unit is higher Max. 30m

Outdoor unit is lower Max. 15m

• Difference in higher between indoor units Max. 4m

Request

(1) For the branch be sure to select the specified branch pipe set (sold separately) and then to follow the directions

of the instruction manual included in the branch pipe set when installing the piping. Be sure to install the branch

piping so that the branch is level.

Request

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

<

=

• One-way pipe length (m) L +ra +rb 50

• Branch pipe length (m) lra – rbl 10, ra 30, rb 30

• Vertical height difference between outdoor unit and indoor unit

Outdoor unit is higher Max. 30m

Outdoor unit is lower Max. 15m

• Difference in higher between indoor units Max. 1m

<

=

<

=

<

=

<

=

<

=

690

V MULTI

18.2.3 Exterior dimensions

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Model FDT208-A

B→

D

→

C

→

A

→

Gas piping

φ15.88(5/8")

Exhaust air opening

for ducting

Fresh air opening

for ducting

Air outlet grille

Air inlet grille

(Suspension bolts pitch)

(Suspension bolts

pitch)

(Ceiling hole size)

Drain hose(Accessories)

(Connectable with VP25)

Space for installation and service

Holes for

tapping screws

Holes for

tapping screws

Hole for wiring

Control box

Lug for Suspension bolts

Liquid piping

φ6.35(1/4")

(Max. Drain up)

Obstacle

Suspension bolts

(M10 or M8)

295 ~ 325

700 or more

570

359

430

264

304300

515

800

700

161

99

49

or more

26

215

141

295

336

1000

or more

35

110

90

90

50

70 140

80

87

37100

120

740

680

4-φ4

VIEW A

VIEW B

VIEW D

VIEW C

1000

or more

4-φ4

Unit : mm

Decorative Panel

691

V MULTI

Unit : mm

Decorative Panel

VIEW A

VIEW DVIEW C

VIEW B

Space for installation and service

Liquid piping

φ9.52(3/8")

860~890

(Ceiling hole size)

267

310332

675

(Suspension bolts pitch)

637

422

420

400

780

(Suspension bolts pitch )

Fresh air

opening for ducting

Exhaust air

opening for ducting

Drain hose (Accessories)

(Connectable with VP25)

Gas piping

( φ15.88)

(M10 or M8 ×4pcs.)

B→

C

Air inlet grille

Air outlet grille

630

950

295~325

700

or less

(Max. Drain up)

210

137

187

260

30

45

or more

95

Lug for

suspension bolts

Control box

Hole for wiring

Suspension bolts

A

↑

840

1000

1000

Obstacle

or more

or more

55

25

160 33

80

113

140

Holes for

tapping screws

4-φ4

112

100

60

140

42

140

Holes for

tapping screws

6-φ4

D→

↑

Models FDT258-A, 308-A

692

V MULTI

Models FDT408-A, 508-A

Unit : mm

Decorative Panel

VIEW A

VIEW DVIEW C

VIEW B

Space for installation and service

Liquid piping

φ9.52(3/8")

860~890

(Ceiling hole size)

267

310332

675

(Suspension bolts pitch)

637

422

420

400

780

(Suspension bolts pitch )

Fresh air

opening for ducting

Exhaust air

opening for ducting

Drain hose (Accessories)

(Connectable with VP25)

Gas piping

φ19.05(3/4")

(M10 or M8 ×4pcs.)

B→

C

Air inlet grille

Air outlet grille

630

950

295~325

700

or less

(Max. Drain up)

270

137

187

320

30

45

or more

95

Lug for

suspension bolts

Control box

Hole for wiring

Suspension bolts

A

↑

840

1000

1000

Obstacle

or more

or more

55

25

160 93

80

113

140

Holes for

tapping screws

4-φ4

112

100

60

140

42

140

Holes for

tapping screws

6-φ4

D→

↑

693

V MULTI

Silent Panel (Model: R-PNLS-26W-E)

Unit : mm

VIEW C

(Locality)

Drain hose (Accessories)

284

786

(Suspension bolts pitch)

270 275

353433

980

(Ceiling hole size)

137

69

59

75

690

(Ceiling hole size)

(Suspension bolt pitch)

70

45

57

Panel center

71

45

Gas piping

φ15.88 (5/8")

Drain

(Connectable with VP25)

Liquid piping

φ6.35 (1/4")

(I.D. φ14)

Air outlet duct

Control box

405

150

Fresh air opening

(Knock out hole)

295~325

650

250

102

480

80

635

510

465

405

245

φ

200

232

(Max. Drainup)

MIN

320

355~369

40

460

185

320

750

213

163

81

Drain (Natural drainage)

Hole for

humidifier piping

(VP20)

Suspension bolts

(M10 × 4pcs.)

Hole of wiring

(I.D. φ35)

C↓

↑A

B→

VIEW B

VIEW A

Space for installation and service

4-φ 4.0

φ

170

205 213

φ

149

Holes of

tapping screws

90

φ

170

150

Fresh air opening

for ducting

(Knock out hole)

Exhaust air opening for ducting

(Knock out for ducting)

75

45

45

950

45

750

75

45

510

1040

Air inlet

Air inlet

1000

or more

100 or

more

100 or

more

50

or

more

Obstacle

545

(b) Cassetteria type (FDR)

Model FDR208-A

694

V MULTI

Canvas Panel (Model: R-PNLC-26W-E)

Unit : mm

VIEW C

VIEW B

VIEW A

Space for installation and service

Control box

90

45

804

(Ceiling hole size)

69

59

71

9

786

(Suspension bolts pitch)

9

545

(Suspension bolts pitch)

193

45

70

525

(Ceiling hole size)

352

Air outlet duct

Panel center

Drain hose (Accessories)

Liquid piping

φ6.35 (1/4")

Drain

(Connectable with VP25)

Gas piping

φ15.88 (5/8")

(Local Locality)

284

150

405

Fresh air opening

(Knock out hole)

80

φ

170

φ

170

φ

149

Holes of tapping screws

4-φ4.0

205 213

90

Exhaust air opening for ducting

150

774

45

864

45

45

75

345

585

75

45

Air inlet

Air inlet

Fresh air

opening for ducting

1000

or more

100

or

more

100

or

more

50

or

more

Obstacle

(Knock out hole)

(Knock out hole)

C↓

635

Hole for humidifier piping

(I.D.φ14)

295~325

250

Hole of

wiring

(I.D.φ35)

460

260

40

405

465

480

510

149

199

274

299

150~

300

600

35

245

Drain (Natural drainage)

(VP20)

320

750

185

φ

200

130

Canvas duct

(Optional parts)

(Max. Drain up)

Suspension bolts

(M10 × 4pcs.)

A

↑

B→

Drain

(Connectable

with VP25)

Model FDR208-A

695

V MULTI

VIEW C

Silent Panel (Model: R-PNLS-36W-E)

Unit : mm

1180

(Ceiling hole size)

986

(Suspension bolts pitch)

Panel center

Air outlet duct

(Suspension bolts pitch)

690

(Ceiling hole size)

Drain hose (Accessories)

(Locality)

533

57

453

Control box

71

45 45

545

75

70

137

284

69

59

C↓

275

270

500

150

Fresh air opening

(Knock out hole)

950

285

285

165

215

↑A

B→

232

MIN

320

650

Suspension bolts

(M10 × 4pcs.)

φ

200

Gas piping

φ15.88 (5/8")

(Max. Drain up)

295~325

80

81

102

163

213

355~369

Hole

of wiring

(I.D.φ35)

460

250

40

405

465

480

510

635

Drain (Natural drainage)

(VP20)

Hole for

humidifier piping

(I.D.φ14)

VIEW A

VIEW B

Space for installation and service

45

Holes of

tapping screws

4-φ4.0

150

φ

170

φ

170

φ

149

90

Exhaust air opening for ducting

(Knock out hole)

Fresh air opening

for ducting

(Knock out hole)

205

213

Air inlet

Air inlet

1240

1150

45

45

75

45

75

750

510

Obstacle

100

or more

100

or

more

50

or

more

1000

or

more

Liquid piping

φ9.52 (3/8")

Models FDR258-A, 308-A

696

V MULTI

Models FDR258-A, 308-A

697

V MULTI

Models FDR408-A, 508-A

1000

100 100

50

or more

or more or more

or more

Obstacle

205 213

Hole of tapping screws

175 320 320 320

295~325

235

460

Air inlet

Air inlet

80 635

510

480

465

405

155

57 743 663

137

284

69

58

495

76

1370

1600(Ceiling hole size)

690(Ceiling hole size)

Drain hose(Accessories)

(Locality)

Air outlet duct

Fresh air opening

(Knock out hole)

Drain

Gas piping

φ

19.05(3/4")

1660

750

Liquid piping

φ

9.52(3/8")

(Connectable

with VP25)

Hole for

humidifier piping

1406(Suspension bolts pictch)

(Suspension bolts pictch)

(Max.Drain up)

545

MIN276

MIN320

103

81

213

163

650

40

406~420

270 275

45

70

150

45

75

Suspension bolts

(M10 × 4 pcs.)

Drain(Natural drainage)

Fresh air opening

for ducting

(Knock out hole)

Exhaust air opening for ducting

(Knock out hole)

(VP20)

φ

149

90

φ

170

45

1570 45

φ

170

φ200

Panel center

Control box

(I.D.φ35)

(I.D.

φ

14)

Hole of

wiring

4 -

φ

4.0

150

510

75

45

45

75

A

C

B

Space for installation and service

Unit : mm

Silent Panel (Model: R-PNLS-46W-E)

VIEW A

VIEW B

VIEW C

698

V MULTI

205 213

Hole of tapping screws

175 320

130

320

Canvas duct

(Optional parts)

320

295~325

235

460

Air inlet

Air inlet

80

635

510

480

465

405

155

99

284

69

495

71

59

1370

1424(Ceiling hole size)

Drain hose(Accessories)

(Locality)

Air outlet duct

Fresh air opening

(Knock out hole)

Drain

Gas piping

φ

19.05(3/4")

1484

585

Liquid piping

φ

9.52(3/8")

(Connectable

with VP25)

Hole for

humidifier piping

1406(Suspension bolts pictch)

545

(Suspension bolts pictch)

(Max.Drain up)

600

86

200

250

325

350

40

310

45

352 193 45

70

90

150

Suspension bolts

(M10 × 4 pcs.)

Drain(Natural drainage)

Fresh air opening

for ducting

(Knock out hole)

Exhaust air opening for ducting

(Knock out hole)

(VP20)

φ

149

90

φ

170

45 45

1394

φ

170

φ200

Panel center

Control box

(I.D.φ35)

(I.D.

φ

14)

Hole of

wiring

4 -

φ

4.0

150

345

75

45

75

45

525(Ceiling hole size)

A

C

B →

150~300

Space for installation and service

1000

100 100

50

or more

or more or more

or more

Obstacle

Models FDR408-A, 508-A

Unit : mm

Canvas Panel (Model: R-PNLC-46W-E)

VIEW A

VIEW B

VIEW C

699

V MULTI

16

Remote controller mounting dimensions

47

7

Standard Within 0.3 mm

2

× Within 100 m

0.5 mm

2

× Within 200 m

0.75 mm

2

× Within 300 m

1.25 mm

2

× Within 400 m

2 mm

2

× Within 600 m

Allowable rang of wire thickness and length

♦ Usable JIS box, JIS C 8336

⋅ Switch box for 1 piece (without cover)

(use of the mark hole as illustrated on the left)

⋅ Switch box for 2 pieces

(use of the mark hole as illustrated on the left)

(without cover)

(use of the mark hole as illustrated on the left)

(when installing the cover)

Notes (1) Allowable length of remote controller

cable: 600 m

0.3mm2, 3cores (O.D.φ5.6)

LCD display

120

Wall

Wire

(Recessed)

Junction box

(Locally Purchased)

89

83.5

17

120

Remote controller outline

For the passage

after wiring

120

60

46

(2) Remote controller (Optional parts)

Unit : mm

700

V MULTI

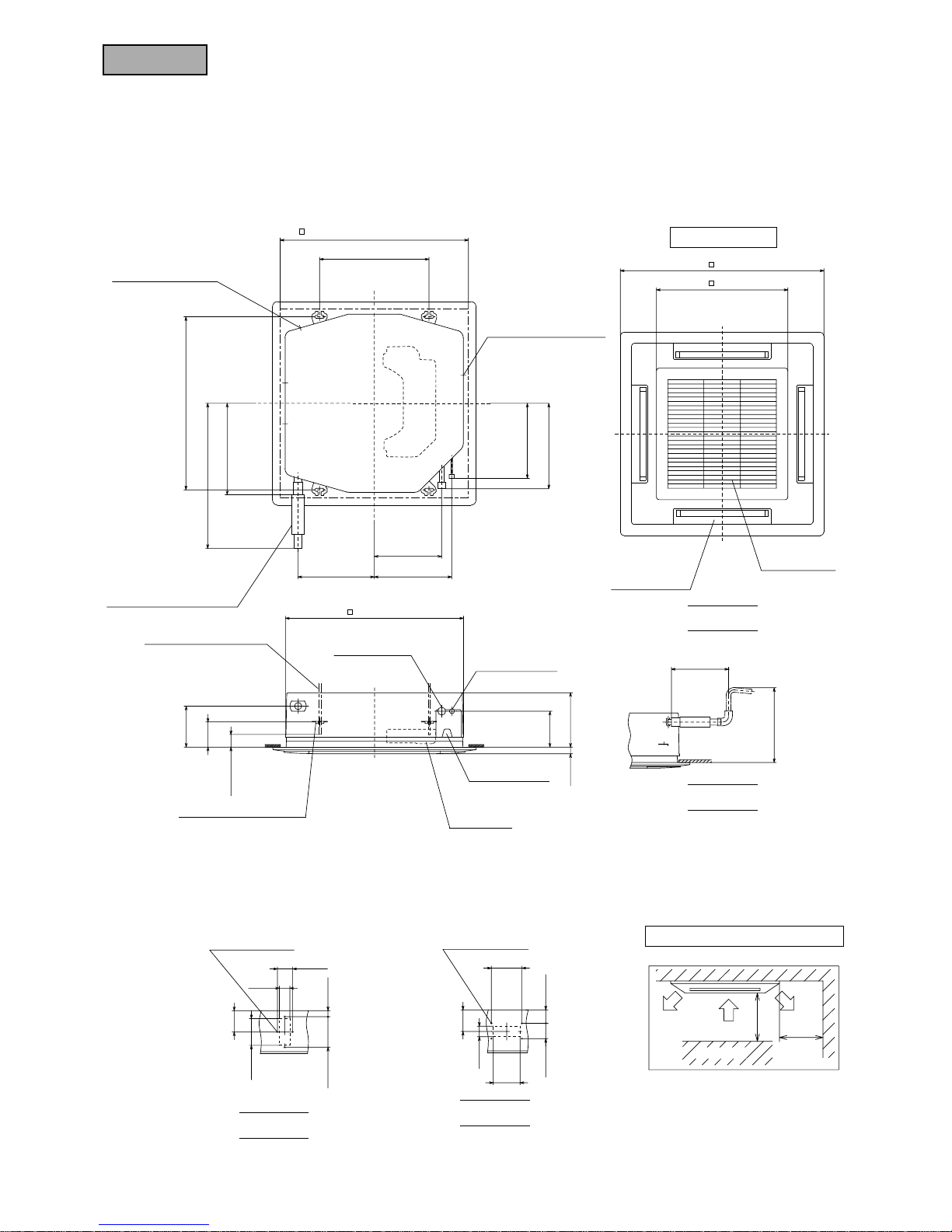

(3) Outdoor unit

Model FDC508HES3

Required space for maintenance and air flow Minimum allowable space to the obstacles

Unit:mm

Mark

123

L1 Open Open 500

L2 300 5 Open

L3 150 300 150

L4 555

Installation

type

Notes

(1) Avoid the location where four sides are entirely

surrounded by walls.

(2) Fix the unit by anchor bolts without fail. Restrict

the protrusion length of anchor bolt to 15 mm

and under.

(3) When strong wind blows against the unit, direct

the discharge port at a right angle to the wind

direction.

(4) Secure the space of 1 m and over at the top of

unit.

(5) Make the height of obstruction wall in front of

discharge port lower than the height of unit.

VIEW A

L

2

L

3

L

4

L

1

Air

inlet

Air inlet

Air outlet

Maintenance

space

50

110

195

555

578

920

10

46

50

48

100

165

580

175

35

15

380 15

15

103

5050

50

50

110

195

50

70

50 15

50

27

50

15

47

295237

15

340

35

55

55

150

40

Gas piping:

φ

19.05 (3/4")

(Flare connecting)

Liquid piping:

φ

9.52 (3/8")

(Flare connecting)

Opening for electric wiring

Holes for drain

(

φ

20 × 3pcs.)

Opening for

electric wiring

Opening for piping

and electric wiring

Opening for piping

and electric wiring

Electric wiring

Opening for piping

and electric wiring

Holes for anchor bolt

(M10 × 4pcs.)

Gas piping:

φ

19.05 (3/4")

(Flare connecting)

Liquid piping:

φ

9.52 (3/8")

(Flare connecting)

Opening for electric wiring

Terminal block

1250

A

Unit: mm

701

V MULTI

Models FDC808HES3, 1008HES3

( )

291.5

119

1350

1450

20

50

Power supply connecting

terminal block

Connect of gas piping

Connect of liquid piping

102

29

22

157

Opening for

exit gas pipimg

Opening for

exit liquid

pipimg

(ø39)

(ø25)

105

80

170

Opening for

exit piping

Opening for

exit wiring

(ø50)

(ø88)

600

105

170

80

Opening for

exit wiring

(ø50)

Opening for

exit piping

(ø88)

1564015

250

850

250

40

157

767

81

532

135

702

283.5

567

283.5

169

395

123

Hole for drain

Downward outlet hole for

piping and wiring

(8-ø20)

Hole for drain

Anchor bolts

(ø50)

(M10 × 4pcs.)

( )

808: ø12.7 (1/2")

1008: ø15.58 (5/8")

( )

70

100

175

110

50

175

240

110

88

123

Dimentions of refrigerant piping

connecting mouth

(Front)

Opening for

exit liquid piping

Rear surface

Connect of liquid piping

(ø50)

Opening for

exit wiring

Opening for exit

gas pipimg

(ø35)

(ø65)

808: ø12.7 (1/2")

1008: ø15.88 (5/8")

Connect of

gas piping

( )

808: ø25.4 (1")

1008: ø28.58 (1 1/8")

808: ø25.4 (1")

1008: ø28.58 (1 1/8")

Wall height H

4

Wall height H

2

L

1

L

3

Wall Height H

3

Wall height H

1

( )

suction

L

4

L

2

I II III

L

1

L

2

L

3

L

4

Open

Not limited

Not limited

Not limited

Not limited

Not limited

Not limited

700 or less

Not limited

Open

300

0

Open

500

300

0

500

0

1000 or less

300

0

Unit:mm

Dimensions

Installation

example

H

1

H

2

H

3

H

4

Notes (1) Make sure to secure the unit with anchor bolts.

(2) When the strong wind blows, place the unit so that dis-

charge outlet faces the wind direction with right angle.

(3) Make sure to allow the space of 1 m or more above the

unit.

(4) Connect the refrigerant piping (both gas side and liquid

side) at local site.

(5) If the wall height H

1

, H3 of installation example III

exceeds the limited value, make sure the value of L

1

, L3

are to be as follows.

L

1

=H1 -500

L

3

= 300 + (H3-700) / 2, however, if L3 exceeds 600, there

is no limit for the wall height H

3

.

Service

space

A

Unit: mm

VIEW A

702

V MULTI

18.2.4 Exterior appearance

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Models All models

Pearl white

(Decorative panel)

(2) Outdoor unit

Model FDC508HES3

Polar white

(b) Cassetteria type (FDR)

Models All models

Silent panel type

Ceramic White

Ceramic White

Canvas-duct panel type

Models FDC808HES3, 1008HES3

Polar white

Type

Item

Panel model Remarks

FDT208-A T-PSA-22W-E

Without swing

FDT258-A~508-A T-PSA-32W-E

703

V MULTI

18.2.5 Piping system

(1) Twin type

Model FDC508HES3

Models FDC808HES3,1008HES3

Thermistor

(Th

I

-R)

Thermistor

(Th

O

-D)

Thermistor

(Th

O

-R)

Solenoid

valve (SV2)

Solenoid

valve (SV1)

Thermistor

(Th

O

-A)

Thermistor

(Th

I

-A)

Heat exchanger

Heat exchanger

High pressure switch (63H

2

)

(For fan motor control)

Strainer

Strainer Strainer

StrainerCapillary

tube

Capillary tube

Capillary tube

Capillary

tube

Capillary

tube

Liquid line

(ø9.52)

Gas line

(ø19.05)

Service valve

(Flare connecting)

Service valve

(Flare connecting)

Cooling cycle

Heating cycle

4way valve

Compressor

Accumulators

Check valve

Check

joint

Check joint

Check joint

Oil separator

Subcooling

coil

Branch

pipe

(Brazing)

(ø9.52)

(ø15.88)

Strainer

Strainer

Capillary

tube

(ø9.52)

(ø15.88)

Flare connecting

Branch pipe

(Brazing)

Flare connecting

Outdoor unitIndoor unitIndoor unit

Heat

exchanger

Thermistor

Capillary tube

Liquid line

Thermistor

Cooling cycle

Heating cycle

4way valve

Muffler

Muffler

Capillary tube

Capillary tube

Accumlator

Heat

exchanger

Lower Upper

(Th

O

-A)

(Th

I

-A)

(Th

I

-R)

Thermistor

Service valve

(Brazing)

Branch

pipe

(Brazing)

Branch

pipe (Brazing)

High pressure switch(63H2)

(For fan motor control)

High pressure

switch(63H

1

)

(For protection)

Check valve

Compressor

Service valve

(Flare connecting)

Thermistor (Th

O

-R)

Only case of FDC808HES3

Thermistor (Th

O

-R)

Only case of FDC1008HES3

Strainer

Strainer

( )

( )( )

Gsa line

Flare connecting

808 : ø25.4

1008 : ø28.58

( )

808 : ø12.7

1008 : ø15.88

Strainer

Strainer

(ø9.52) (ø9.52)

308 : ø15.88

408,508 : ø19.05

308 : ø15.88

408,508 : ø19.05

Outdoor unitIndoor unitIndoor unit

Note (1) Refer to page 715 for piping size after branching.

Note (1) Refer to page 716 for piping size after branching.

704

V MULTI

(2) Triple type

Models FDC808HES3,1008HES3

Note (1) Refer to page 716 for piping size after branching.

Note (1) Refer to page 717 for piping size after branching.

Heat

exchanger

Thermistor

Capillary tube

Liquid line

Thermistor

Cooling cycle

Heating cycle

4way valve

Muffler

Muffler

Capillary tube

Capillary tube

Accumlator

Heat

exchanger

Lower Upper

(Th

O-A)

(Th

I-A)

(Th

I-R)

Thermistor

Service valve

(Brazing)

Branch

pipe

(Brazing)

Branch

pipe(Brazing)

High pressure switch(63H2)

(For fan motor control)

High pressure

switch(63H1)

(For protection)

Check valve

Compressor

Service valve

(Flare connecting)

Thermistor (Th

O-R)

Only case of FDC808HES3

Thermistor (Th

O-R)

Only case of FDC1008HES3

Strainer

Strainer

( )

208~308 : ø15.88

408, 508 : ø19.05

( )

208: ø6.35

258~508 : ø9.52

( )

208~308 : ø15.88

408, 508 : ø19.05

( )

208: ø6.35

258~508 : ø9.52

( )

Gsa line

Flare

connecting

Flare

connecting

808 : ø25.4

1008 : ø28.58

( )

808 : ø12.7

1008 : ø15.88

Strainer

Strainer

208~308 : ø15.88

408, 508 : ø19.05

( )

208: ø6.35

258~508 : ø9.52

( )

Strainer

Strainer

Outdoor unitIndoor unitIndoor unit Indoor unit

Heat

exchanger

Thermistor

Capillary tube

Thermistor

Cooling cycle

Heating cycle

4way valve

Muffler

Muffler

Capillary tube

Capillary tube

Accumlator

Heat

exchanger

Lower Upper

(Th

O

-A)

(Th

I

-A)

(Th

I

-R)

Thermistor

Service valve

(Brazing)

Branch

pipe

(Brazing)

Branch

pipe

(Brazing)

Branch

pipe (Brazing)

Secondary

branch pipe

High pressure switch(63H2)

(For fan motor control)

High pressure

switch(63H1)

(For protection)

Check valve

Compressor

Service valve

(Flare connecting)

Thermistor (Th

O

-R)

Only case of FDC808HES3

Thermistor (Th

O

-R)

Only case of FDC1008HES3

Strainer

Strainer

Flare connecting

Branch pipe

(Brazing)

First branch pipe

Strainer

Strainer

(¿15.88) (¿15.88)

(¿15.88)

Secondary

branch pipe

(¿9.52)

(¿19.05)

First branch

pipe

(¿19.05)

( )

208 : ¿6.35

258 : ¿9.52

( )

208 : ¿6.35

258 : ¿9.52

( )

208 : ¿6.35

258 : ¿9.52

( )

208 : ¿6.35

258 : ¿9.52

(¿15.88) (¿15.88)

Heat

exchanger

Thermistor

Capillary tube

Thermistor

(ThI-A)

(Th

I

-R)

Branch

pipe

(Brazing)

Branch

pipe (Brazing)

Strainer

Strainer

Flare connecting

Gsa line

808 : ¿25.4

1008 : ¿28.58

( )

Liquid line

( )

808 : ¿12.7

1008 : ¿15.88

Strainer

Strainer

Indoor unit

Indoor unit

Indoor unit Indoor unit

(3) Dauble twin type

Models FDC808HES3,1008HES3

705

V MULTI

OFF 2.5MPa (25.5 kgf/cm2) OFF 2.75MPa (28 kgf/cm2)

ON 2.06MPa (21 kgf/cm2) ON 2.16MPa (22 kgf/cm2)

ThI-R

Tho-D

Tho-R

63H2

63H1

Indoor unit

Outdoor unit

Outdoor unit

Outdoor unit

18.2.6 Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specifications × Correction factors as follows.

(1) Coefficient of cooling and heating capacity in relation to temperatures

Outdoor air W.B. temperature (˚CW.B.) ISO-T1 Standard condition

Indoor air W.B. temperature (˚CW.B.)

ISO-T1 Standard condition

Outdoor air D.B.

temperature (˚CD.B.)

Cooling operation

I

ndoor air D.B.

temperature (˚CD.B.)

Heating operation

Coefficient of cooling and heating capacity

in relation to temperatures

Preset point of the protective devices

Parts name Mark

Thermistor

(for protection overloading in heating)

Thermistor

(for frost prevention)

Thermistor

(for detecting discharge pipe temp.)

Thermistor

(for detecting heat

exchange temp.)

High pressure switch

(for controlling FM0)

High pressure switch

(for protection)

OFF 68˚C

ON 61˚C

Equipped

unit

FDC508HES3

OFF 2.5˚C

ON 10˚C

OFF 135˚C

ON 90˚C

OFF 70˚C

ON 60˚C

FDC808HES3, 1008HES3

OFF 2.41MPa (24.5 Kgf/cm2)

ON 1.86MPa (19.0 kgf/cm2)

706

V MULTI

Equivalent piping length

(1)

m 5 10152025303540455055

Heating 1.0 1.0 1.0 1.0 1.0 0.995 0.995 0.99 0.99 0.985 0.985

1.0 0.99 0.975 0.965 0.95 0.94 0.925 0.915 0.9 0.89 0.875

1.0 0.99 0.98 0.97 0.96 0.95 0.94 0.93 0.92 0.91 0.9

(3) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way equivalent piping length between the indoor

and outdoor units.

Note (1) Equivalent piping length can be obtained by calculating as follows.

508 series [φ19.05 (3/4″)] : Equivalent piping length = Real piping length + (0.15 × Number of bends in piping)

808 series [φ25.4 (1″)] : Equivalent piping length = Real piping length + (0.15 × Number of bends in piping)

1008 series [φ28.58 (1 1/8″)] : Equivalent piping length = Real piping length + (0.20 × Number of bends in piping)

[Equivalent piping length < Limitation length of piping + 5m]

(4) When the outdoor unit is located at a lower height than the indoor unit in cooling operation and when the

outdoor unit is located at a higher height than the indoor unit in heating operation, the following values should be

subtracted from the values in the above table.

Cooling

FDC508 type

FDC808, 1008 type

Item

Model

All models

Max. one way piping length 50m

Max. vertical height difference

Outdoor unit is higher 30m

Outdoor unit is lower 15m

Note (1) Values in the table indicate the one way piping length between the indoor and outdoor units.

Height difference between the indoor unit and

outdoor unit in the vertical height difference

5m 10m 15m 20m 25m 30m

Adjustment coefficient 0.01 0.02 0.03 0.04 0.05 0.06

Piping length limitations

How to obtain the cooling and heating capacity

Example : The net cooling capacity of the model FDC808HES3 with the air flow “High”, the piping length of 40m, the outdoor unit

located 5m lower than the indoor unit, indoor wet-bulb temperature at 19.0 ˚C and outdoor dry-bulb temperature 35 ˚C is

Net cooling capacity = 20000 × 1.00 × (0.93 - 0.01) × 1.0 = 18400 w

Factor by air

temperatures

FDC808HES3

Air flow

“High”

Length m.

Height difference 5 m

Item

Air flow

Hi 0.112 0.050 0.065 0.076 0.025

Lo 0.073 0.030 0.030 0.050 0.013

Model

208 type 258 type 308 type 408 type 508 type

(2) Correction of cooling and heating capacity in relation to air flow rate control (fan speed)

Coefficient: 1.00 at High, 0.95 at Low

Table of bypass factor

FDT series

FDR series

Item

Air flow

Hi 0.035 0.035 0.039 0.085 0.035

Lo 0.021 0.020 0.023 0.060 0.023

Model

208 type 258 type 308 type 408 type 508 type

707

V MULTI

18.2.7 Characteristics of fan

• External static pressure table

How to interpret the blower characteristics table

Example : Case of FDR308-A

1 2-spot blowout.....................

Internal resistance increases more

than the standard 3-spot blowout.

Approx. 14 (1.4) Pa (mmAq) at

17m

3

/min.

2 Square duct blowout...........

Internal resistance decreases

more than the standard round

duct (ø200 3-spot). 3 (0.3) Pa

(mmAq) at 17 m

3

/nin. (External

static pressure increases in

reverse.).

3 Decorative panel...................

When the decorative panel is not

used with the ceiling return type,

the part of internal resistance

related to the panel decrease. 3

(0.3) Pa (mmAq) at 17mm

3

/min.

Model FDR258-A

Unit: Pa (mmAq)

FDR208-A

FDR258-A

FDR308-A

FDR408-A

FDR508-A

Type

Air flow

(m

3

/min)

Duct specs.

1 spot closing

(1)

Standard

(2)

Square duct

(3)

Stan-

dard

High

speed

(4)

High

speed

(4)

High

speed

(4)

Stan-

dard

Stan-

dard

14

18

20

28

34

—

30(3)

25(2.5)

40(4)

40(4)

—

65(6.5)

60(6)

70(7)

70(7)

50(5)

45(4.5)

45(4.5)

50(5)

50(5)

85(8.5)

80(8)

80(8)

80(8)

80(8)

50(5)

50(5)

50(5)

50(5)

55(5.5)

90(9)

85(8.5)

85(8.5)

85(8.5)

85(8.5)

Notes (1) 1 spot closing: Round duct flange at center is removed and shield

with a decorative panel (option).

(2) Standard: ø200 ducts are installed at all blowout holes.

(3) Square duct: All round ducts are removed and replaced with special

square duct flanges (option).

(4) When operating at a high speed, invert the connection of white

and red connectors on the flank of control box.

[Standard]3-spot blower

internal resistance

Internal resistance without suction panel

Internal resistance without filter

Square duct blower internal resistance

2-spots blower

internal resistance

•

High

Standard

•

Low

14

40(4)

20(2)

0(0)

–2(–2)

17 20 22

Air flow (m3/min)

Static pressure Pa (mmAq)

Internal resistance without suction panel

Internal resistance without filter

Square duct blower internal resistance

[Standard] 2-spot blower internal resistance

High speed

•

High

High speed

•

Upper limit

High speed

•

Lower limit

High speed

•

Low

Standard

•

Upper limit

Standard

•

Low

Standard

•

High

Static pressure Pa (mmAq)

Lower

limit

Upper

limit

Air flow (m3/min)

10

–20(–2)

0(0)

20(2)

40(4)

60(6)

80(8)

100(10)

120(12)

12 14 15.5

Internal resistance without suction panel

Internal resistance without filter

Square duct blower internal resistance

[Standard] 3-spot blower internal resistance

2-spot blower internal resistance

High speed

•

High

High speed

•

Upper limit

High speed

•

Lower limit

High speed

•

Low

Standard

•

Upper limit

Standard

•

Low

Standard

•

High

Static pressure Pa (mmAq)

Lower

limit

Upper

limit

Air flow (m3/min)

13

–20(–2)

0(0)

20(2)

40(4)

60(6)

80(8)

100(10)

120(12)

14 16 18 20

Model FDR208-A

708

V MULTI

Model FDR308-A Model FDR408-A

Internal resistance without suction panel

Internal resistance without filter

Square duct blower internal resistance

[Standard]

3-spot blower internal resistance

2-spot blower

internal resistance

High speed

•

High

High speed

•

Upper limit

High speed

•

Lower limit

High speed

•

Low

Standard

•

Upper limit

Standard

•

Low

Standard

•

High

Static pressure Pa (mmAq)

Lower

limit

Upper

limit

Air flow (m3/min)

14

–20(–2)

0(0)

20(2)

40(4)

60(6)

80(8)

100(10)

120(12)

17 20 22

Model FDR508-A

Internal resistance without suction panel

Internal resistance without filter

Square duct blower internal resistance

4-spot blower internal resistance [Standard]

3-spot blower

internal resistance

High speed

•

High

High speed

•

Upper limit

High speed

•

Lower limit

High speed

•

Low

Standard

•

Upper limit

Standard

•

Low

Static pressure Pa (mmAq)

Lower

limit

Upper

limit

Air flow (m3/min)

24

–20(–2)

0(0)

20(2)

40(4)

60(6)

80(8)

100(10)

120(12)

3026 34 38

Internal resistance without suction panel

Internal resistance without filter

Square duct blower

internal resistance

[Standard] 4-spot blower internal resistance

3-spot blower internal resistance

High speed

•

High

High speed

•

Upper limit

High speed

•

Lower limit

H

igh speed

•

Low

Standard

•

Upper limit

Standard

•

Low

Standard

•

High

Static pressure Pa (mmAq)

Lower

limit

Upper

limit

Air flow (m3/min)

21

–20(–2)

0(0)

20(2)

40(4)

60(6)

80(8)

100(10)

120(12)

2522 28 31

709

V MULTI

18.2.8 Noise level

Notes (1) The data are based on the following conditions.

Ambient air temperature:

Indoor unit 27˚C DB, 19˚C WB.

Outdoor unit 35˚C DB.

Indoor unit

Measured based on JIS B 8616

Mike position as below

(2) The data in the chart are measured in an unechonic room.

(3) The noise levels measured in the field are usually higher than the data because of reflection.

Outdoor unit

Only case of FDC508

Measured based on JIS B 8616

Mike position: at highest noise level

in position as below

Distance from front side 1 m

Height 1 m

Only case of FDC808, 1008

Mike position: front height is 1 meter.

Model FDT208-A

Noise level 38 dB (A) at HIGH

33 dB (A) at LOW

Model FDT258-A

Noise level 39 dB (A) at HIGH

35 dB (A) at LOW

Model FDT408-A

Noise level 48 dB (A) at HIGH

40 dB (A) at LOW

Model FDT508-A

Noise level 49 dB (A) at HIGH

43 dB (A) at LOW

Mike (center & low points)

Mid octave band frequency (Hz)

N30

N20

N

50

N

60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N

50

N

60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N

30

N20

N50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N

50

N

60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Unit Unit

Silent panel Canvas panel

1.5m

1.5m

Model FDR208-A

Noise level 43 dB (A) at HIGH

37 dB (A) at LOW

Model FDR258-A

Noise level 43 dB (A) at HIGH

37 dB (A) at LOW

Model FDR308-A

Noise level 44 dB (A) at HIGH

38 dB (A) at LOW

Mid octave band frequency (Hz)

N

30

N20

N50

N60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N

30

N20

N

50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N50

N60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

(b) Cassetteria type (FDR)

1) Silent panel

FDT series

FDR series

Model FDT308-A

Noise level 41 dB (A) at HIGH

35 dB (A) at LOW

(1) Indoor unit

(a) Ceiling recessed type (FDT)

710

V MULTI

2) Canvas panel

Model FDR408-A

Noise level 45 dB (A) at HIGH

38 dB (A) at LOW

Model FDR508-A

Noise level 46 dB (A) at HIGH

39 dB (A) at LOW

Mid octave band frequency (Hz)

N

30

N20

N

50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N

30

N20

N

50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Model FDR208-A

Noise level 44 dB (A) at HIGH

38 dB (A) at LOW

Model FDR258-A

Noise level 44 dB (A) at HIGH

38 dB (A) at LOW

Model FDR308-A

Noise level 45 dB (A) at HIGH

39 dB (A) at LOW

Mid octave band frequency (Hz)

N

30

N20

N

50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N

30

N20

N

50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N

30

N20

N50

N

60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

Model FDR408-A

Noise level 46 dB (A) at HIGH

39 dB (A) at LOW

Model FDR508-A

Noise level 47 dB (A) at HIGH

40 dB (A) at LOW

Mid octave band frequency (Hz)

N30

N20

N50

N

60

N

70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N

50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

Model FDC508HES3

Noise level 55 dB (A)

Souud pressure level

(standard 0.0002µbar)

Mid octave band frequency (Hz)

N

3

0

N

2

0

N

5

0

N

6

0

N

7

0

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

4

0

(2) Outdoor unit

Model FDC808HES3

Noise level 58 dB (A)

Model FDC1008HES3

Noise level 58 dB (A)

Mid octave band frequency (Hz)

N30

N20

N50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N40

Sound pressure level

(Standard 0.0002µ bar) dB

Mid octave band frequency (Hz)

N30

N20

N50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

N

40

Sound pressure level

(Standard 0.0002µ bar) dB

711

V MULTI

18.3 ELECTRICAL DATA

18.3.1 Electrical wiring

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Models All models

(b) Cassetteria type (FDR)

Models All models

LM

FM

I

(49FI)

DM

Y / GN

RD

WH

BK

TB

1

2

3

1

2

9

X

1

X

3

X

4

X

7

X

5

X

2

WH

WH

WH

OR OR

RD

RD

BL

BK

BL

BK

WHWHY / GN

CnJ

CnF

1

CF

I

3

87

6

5

L

H

UH

OR

WHWH

RDWH

RD

BR

BR

GR

CnF

1

CnJ

CnR

CnI

CnI

CnR

4

13

X

1

X

2

X

3

X

4

X

7

X

5

Val

CnT

CnH

CnN

CnSCnB

CnN

CnH

2

ThI–A

ThI–R

BK

BK

BK BK

RD

RD

BK

BK

BK

RD

BK

BR

CnW

1

CnW2

CnQ

Tr I

Test

XR1

XR2

XR3