Mitsubishi Heavy Industries BD2g, BS3g User Manual

MANUAL

C/

#:

28000001-UP

28500001-UP

38000001-UP

281 00001-UP

28600001-UP

381 00001-UP

(v

28200001-UP

28700001-UP

38500001-UP

28300001-UP

38600001-UP

MITSUBISHI

TRACTOR

BD2G

TRACTOR

SHOVEL

BS3G

+

MITSUBISHI

I"-

HEAVY

INDUSTRIES,

LTD.

Chassis

and

Engine Serial

Number

Locations

Chassis and engine serial numbers are stamped in locations

and forms shown.

When ordering replacement parts or asking your local

Mitsubishi dealer

to

repair

your

machine, be sure

to

give

these serial numbers and service meter reading .

• BD2G

Engine serial number

(right side

of

machine)

~

MODEL I 1

MACHINE

No.c:::::::J

ENG

INE

No.c:::::::J

MIT.UBISHI

HEAVY

INDuSTRIES,

LTD.

rCK"t1I

JAf'AH

Nameplate

(left side

of

machine)

___

.!::==::!:=:==---L

'.

Chassis serial 'number

(left-side

of

machine)

502615

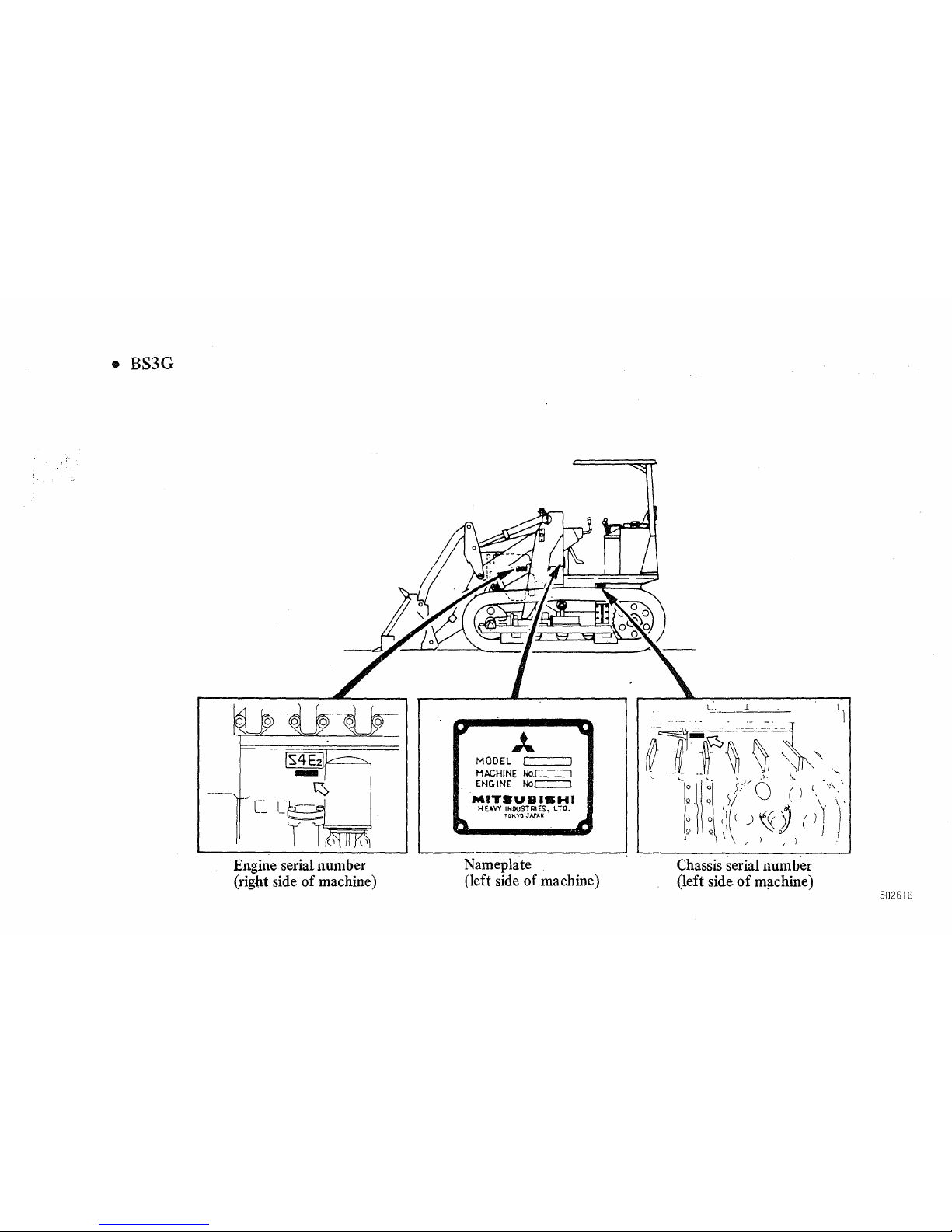

• BS3G

o

Engine serial number

(right side

of

machine)

J...

MODEL I I

MACHINE

No.c::::::J

ENG

IN

E No.c::::=:::J

MIT.UBIBWI

HEAVY INDUSTRIES, LTD.

TOKYO

JAn.No

Nameplate

(left side

of

machine)

Chassis serial number

(left side

of

machine)

502616

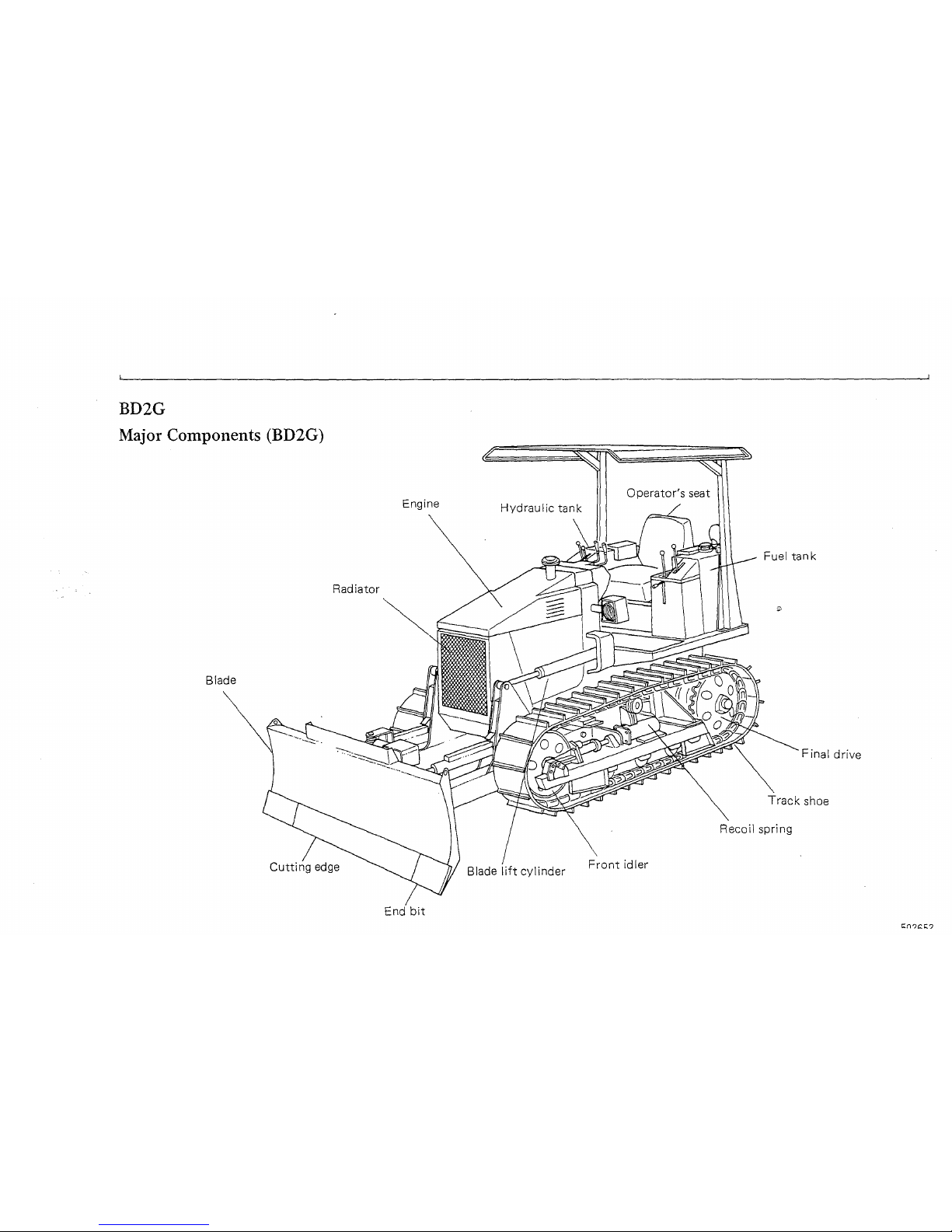

BD2G

Major

Components (BD2G)

Radiator

Blade

Cutting

edge

Engine

Front

idler

bit

Fuel

tank

Final drive

Track

shoe

Recoil spring

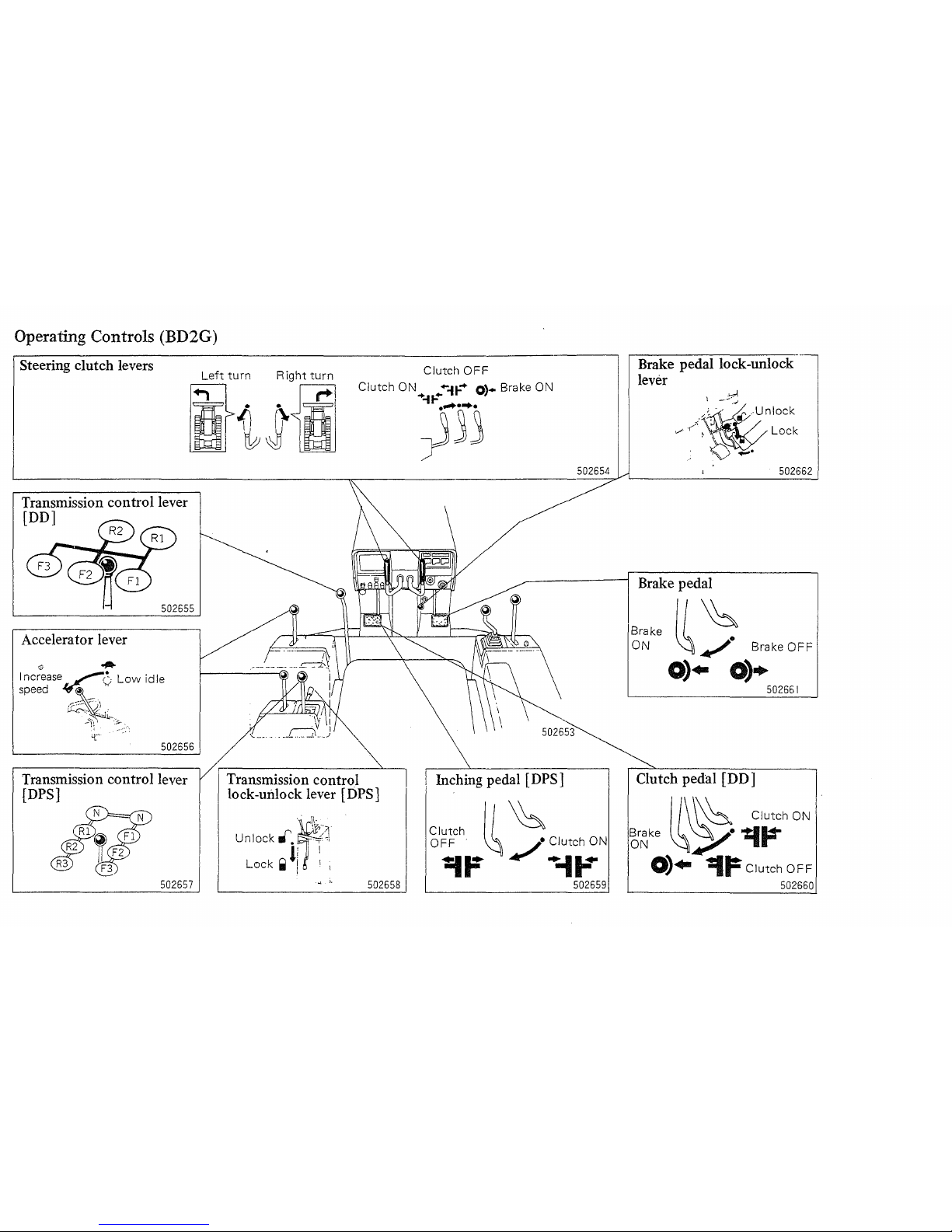

Operating Controls (BD2G)

Steering

clutch

levers

Left

turn

Right

turn

Clutch

OFF

it~\i

Clutch ON

....

n-

....

0'.

Brake ON

......

~..

'I

Transmission

control lever

[DO]

502655

Accelerator

lever

502656

Transmission

control lever

{DPS]

502657

Transmission

control

lock-unlock

lever

[DPS]

..

\\.

Unlock

rtf.~~~}

li

1

Lock

..

! ! I

;

"

..

502658

)33

502654

Inching

pedal

[DPS]

Clutch II

~

OFF

.

~

j.

Clutch ON

~F

.,

+-11-"

502659

Brake

pedal lock-unlock

lever

502662

Brake

pedal

Brake

~~

ON

~.

At'

Brake

OFF

0)"

0)+

502661

Clutch

pedal [DO]

1/\

\h

Clutch ON

~~ke

~~.~~

0)"

-=I~

Clutch

OFF

502660

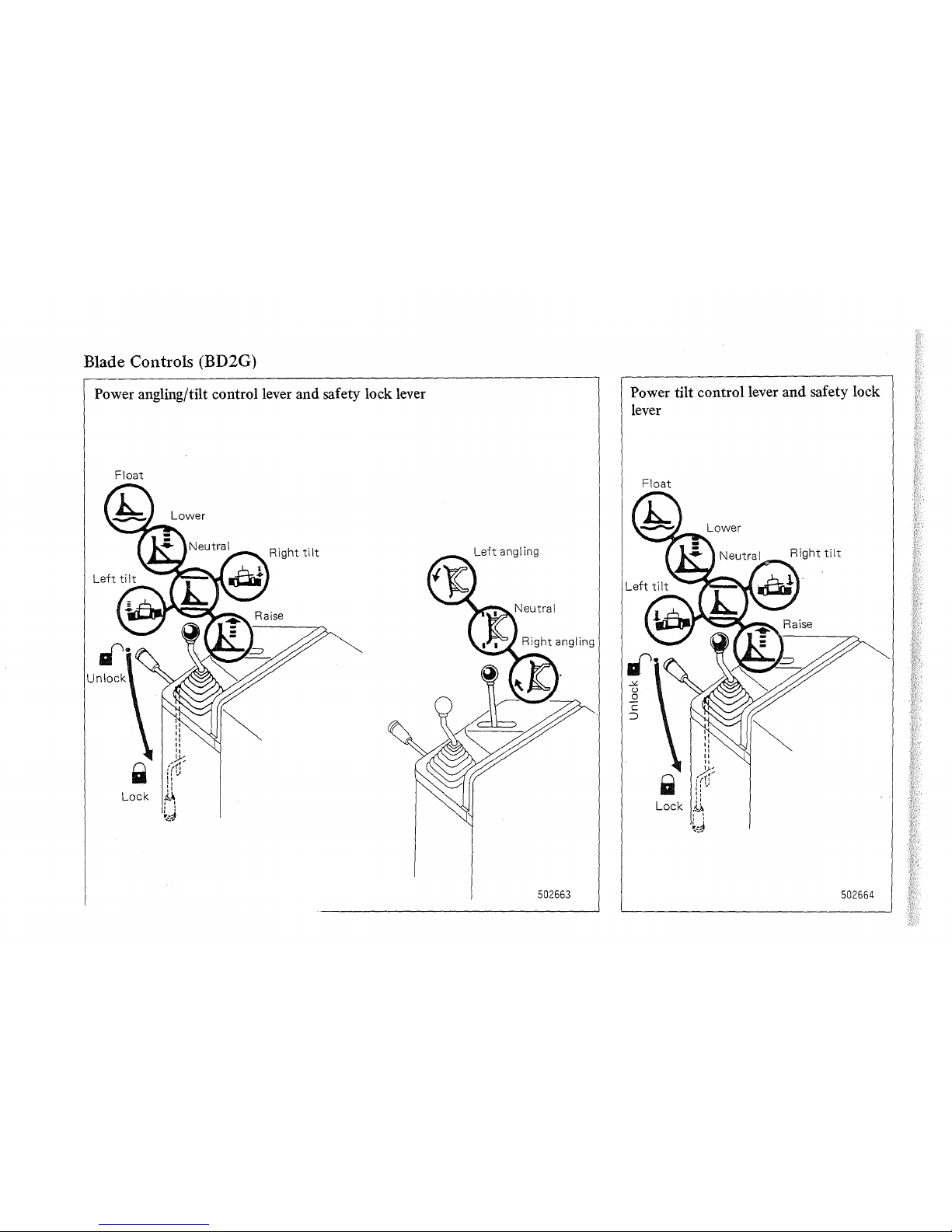

Blade Controls (BD2G)

Power angling/tilt control lever and safety lock lever

Float

502663

Power tilt control lever and safety lock

lever

Float

502664

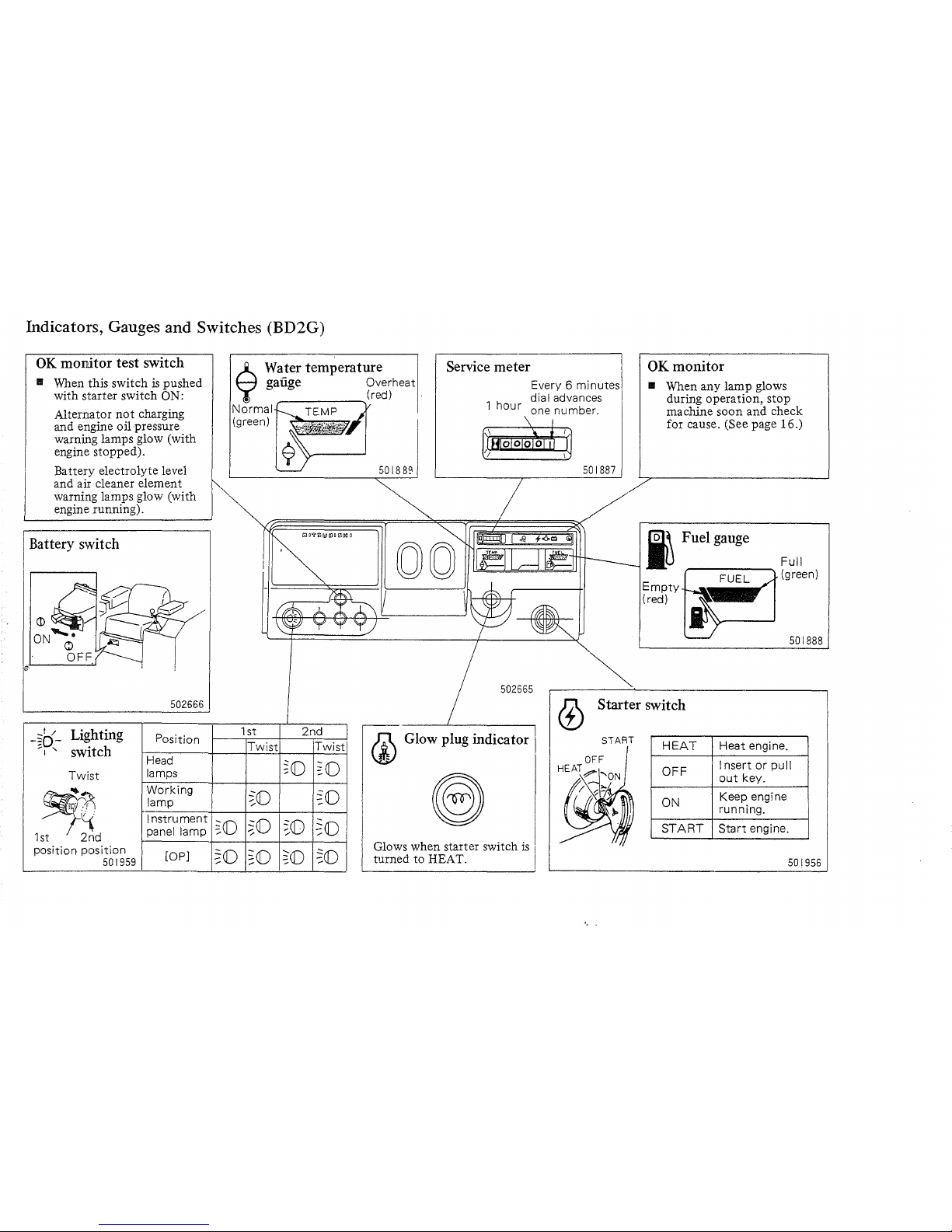

Indicators, Gauges and Switches (BD2G)

OK

monitor test switch

.. When this switch

is

pushed

with starter switch

ON:

Alternator

not

charging

and engine oil pressure

warning lamps glow (with

engine stopped).

Ba

ttery

electrolyte level

and air cleaner element

warning lamps glow (with

engine running).

Battery switch

@i·.L-.---"------<.J

-§o-

Lighting

~I"

switch

Twist

~

1st 2nd

position

position

501959

502666

Position

Head

lamps

Working

lamp

Instrument

panel lamp

rop)

$

Water

temperature

gauge Overheat

.--

______

(red) .

Normal

TEMP

(green)

50

1889

Service meter

Every 6 minutes

dial advances

1

hour

one number.

501887

00

502665

OK

monitor

..

When any lamp glows

during operation, stop

machine soon and check

for cause. (See page 16.)

I Fuel gauge

Empty

(red)

Full

(green)

501888

1st

2nd

(l)

Starter switch

Twist

'Twist

Glow plug indicator

Glows when starter switch

is

I

turned to HEAT.

".

START

HEAT

OFF

ON

START

Heat engine.

I nsert

or

pull

out

key.

Keep engine

running.

Start

engine.

501956

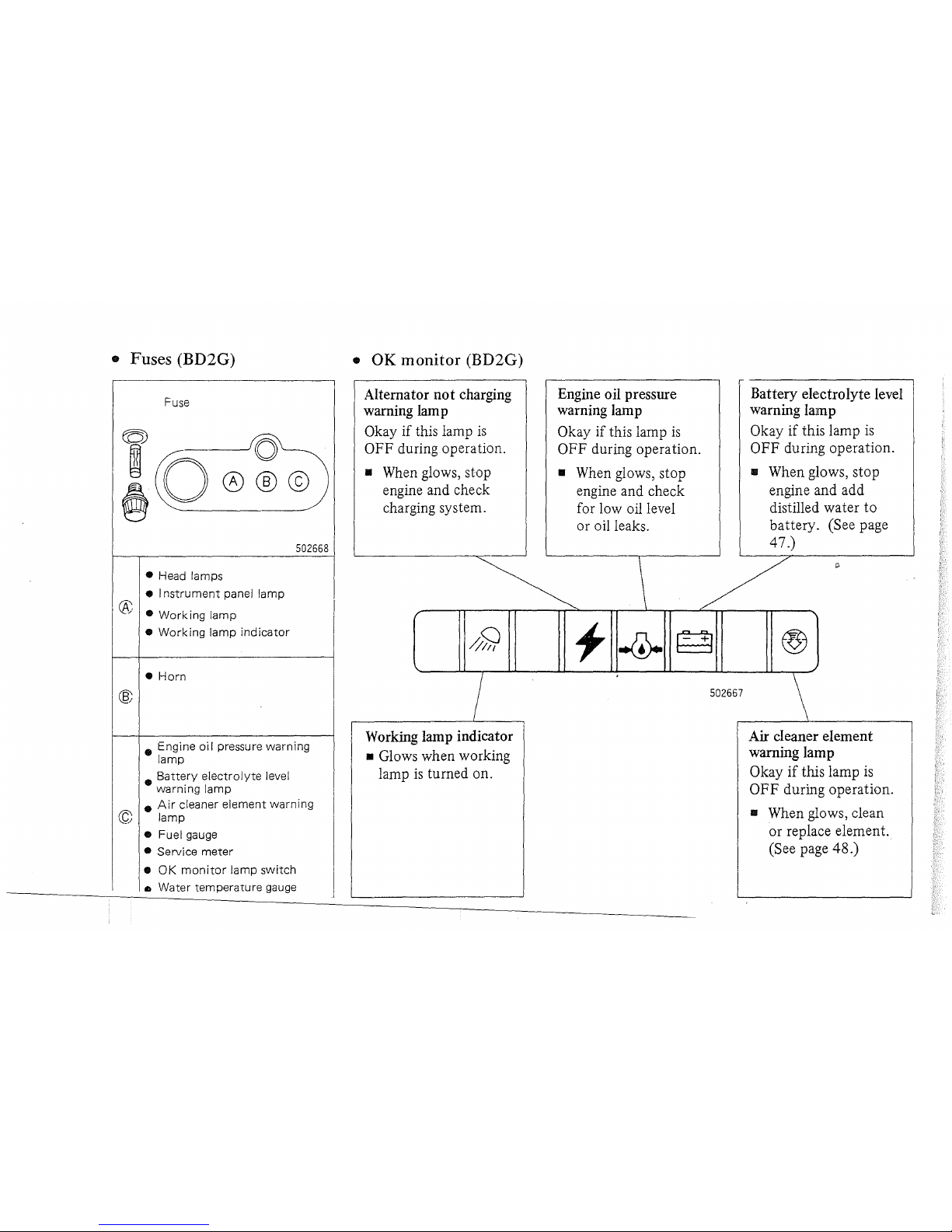

• Fuses (BD2G)

®

Fuse

502668

• Head lamps

• I

nstrument

panel lamp

•

Working

lamp

•

Working

lamp

indicator

•

Horn

• Engine

oil

pressure warning

lamp

•

Battery

electrolyte

level

warning lamp

•

Air

cleaner element warning

© lamp

• Fuel gauge

• Service

meter

•

OK

monitor

lamp

switch

III

Water

temperature

gauge

•

OK

monitor

(BD2G)

Alternator

not

charging

warning lam p

Okay if this lamp

is

OFF during operation.

• When glows, stop

engine and check

charging system.

7

,--------------L-----

1

Working lamp indicator

• Glows when working

lamp

is

turned on.

Engine oil pressure

warning lamp

Okay if this lamp

is

OFF during operation.

• When glows, stop

engine and check

for low oil level

or oil leaks.

Battery electrolyte level

warning lamp

Okay

if

this lamp

is

OFF during operation.

• When glows, stop

engine and add

distilled water

to

battery. (See page

47.)

\ /

502667

\

Air cleaner element

warning lamp

Okay

if

this lamp

is

OFF

during operation.

• When glows, clean

or replace element.

(See page 48.)

Others (BD2G)

Horn

switch

Operator's seat

(fore-aft adjustment)

502669

502670

Operator's seat (turning over)

.-

1:1

---.::::.?\

lL~

\ \

iJF

1---

~

l~//--

'------,--'

I

Seat support

A

WARNING

. Be sure to. support seat after turn-

ing it over.

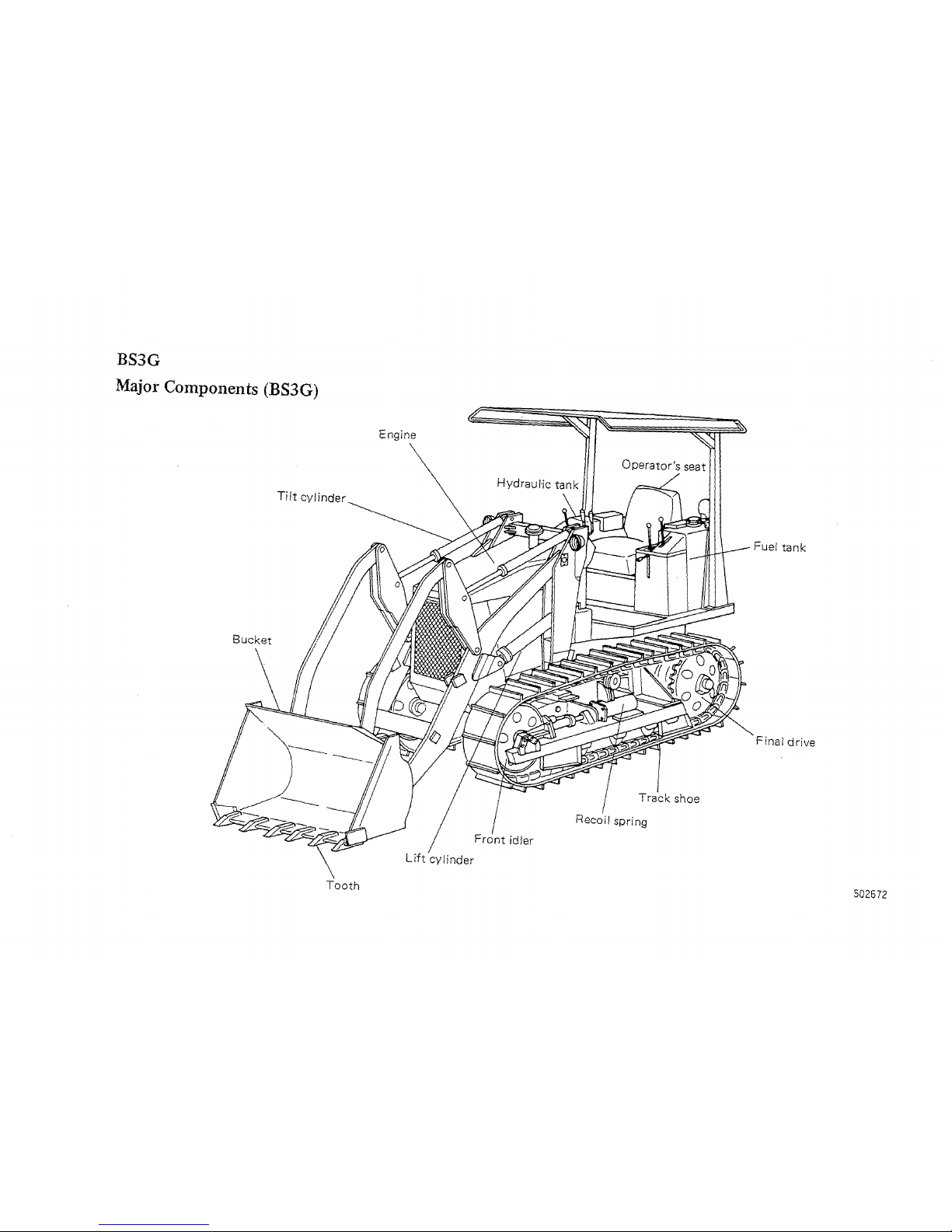

BS3G

Major Components (BS3G)

Engine

Tilt cylinder

Fuel

tank

Bucket

Final

drive

Track

shoe

Tooth

502672

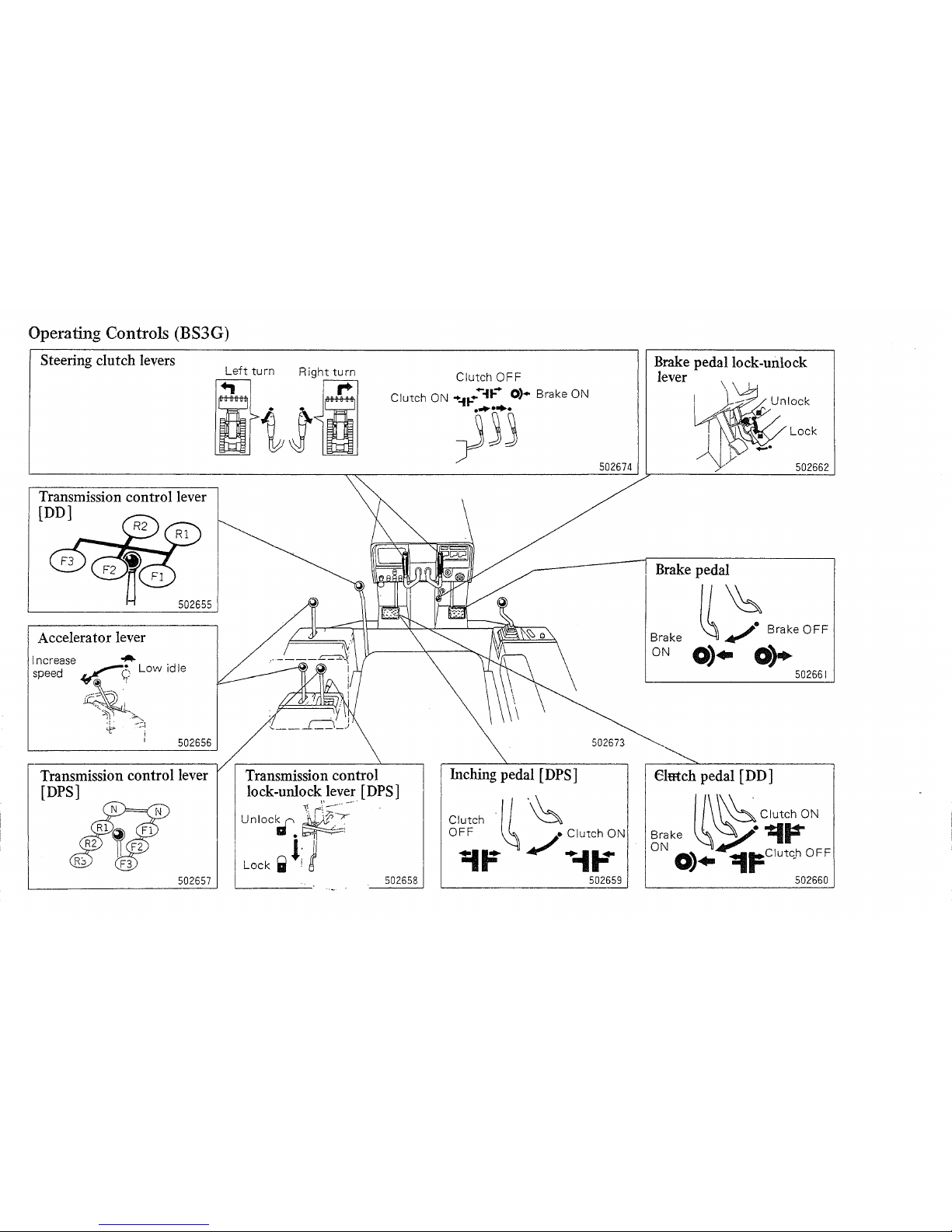

Operating Controls (BS3G)

Steering

clutch

levers

Transmission

control lever

(DD]

502655

Accelerator

lever

502656

Transmission

control lever

(DPS]

502657

Clutch

OFF

Clutch ON

.....

t-

.....

it-

..

0)·

Brake ON

~'Ij

Transmission

control

lock-unlock

lever

[DPS]

\-.

r\'

:;:~--.

-'

unIOc~.~

Lock

..

l;

j

502658

502674

Inching

pedal

[DPS]

Clutch

·11

'~

O~F

~/~-I;~N

502659

Brake

pedal lock-unlock

lever

Lock

502662

Brake

pedal

II

~

8rnk'

OFF

Brake

~..,

ON

0).

o~

502661

Elmch

pedal

[D D ]

~

\

~

Clutch

ON

Brake .

~'0$.../.

'=I~

ON

~~

0).

lIt=Clutc,h

OFF

502660

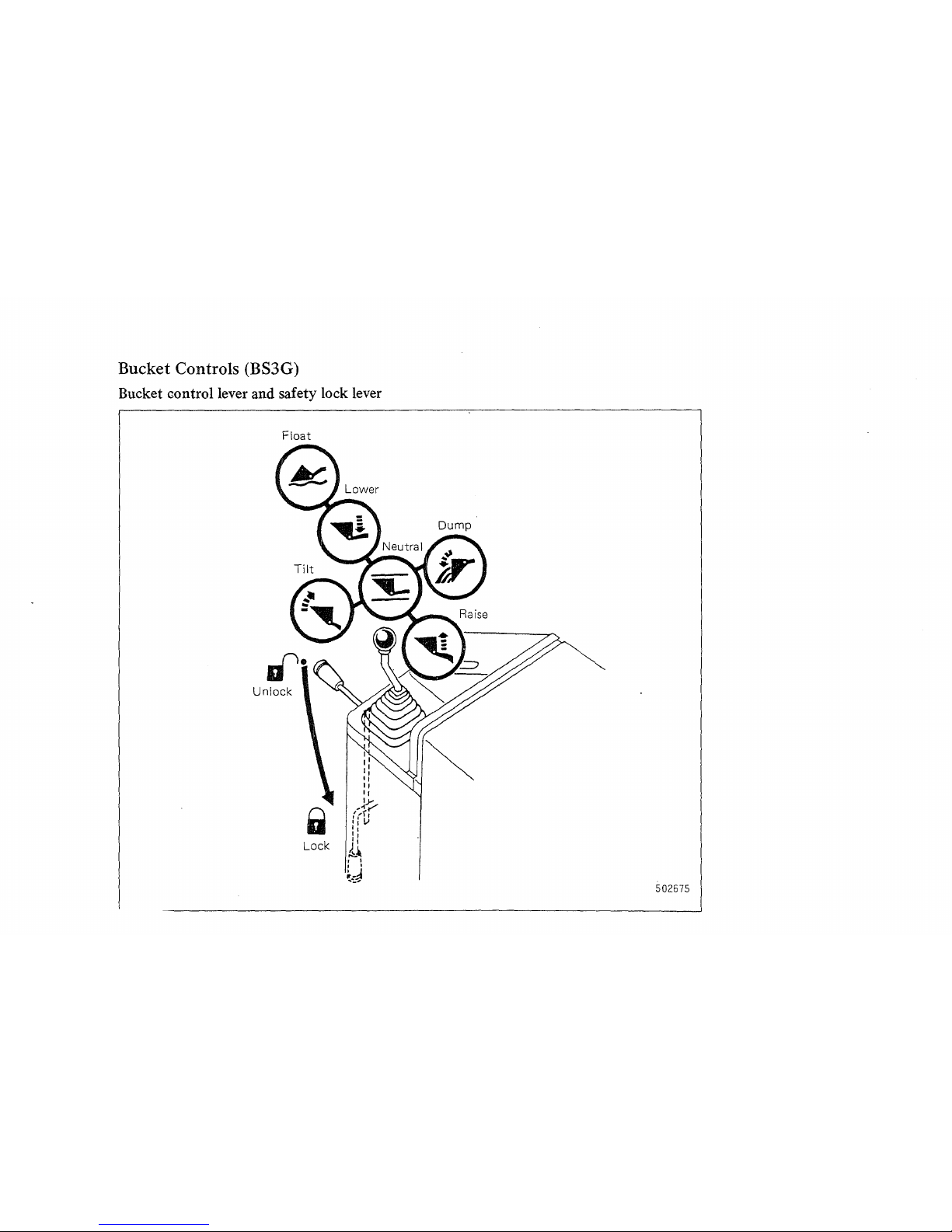

Bucket Controls (BS3G)

Bucket control lever and safety lock lever

Float

502675

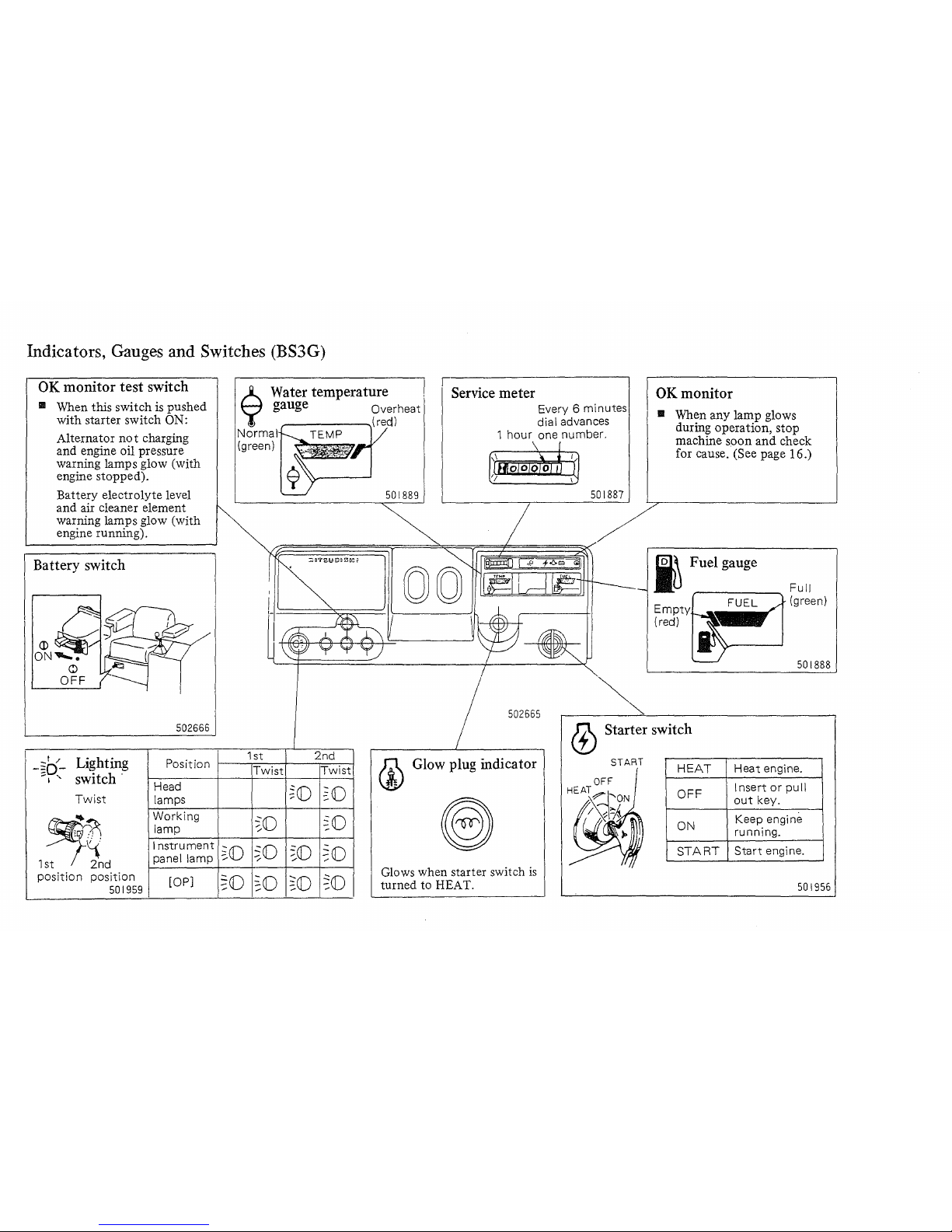

Indicators, Gauges and Switches (BS3G)

OK monitor

test

switch

III When this switch

is

pushed

with starter switch

ON:

Alternator

not

charging

and engine oil pressure

warning lamps glow (with

engine stopped).

Battery electrolyte level

and air cleaner element

warning lamps glow (with

engine running).

Battery switch

502666

_I

/

Lighting

-~D-

Position

-I

"

switch -

Head

Twist

lamps

~

Working

lamp

Instrument

1st

2nd

panel lamp

position

position

lOP]

501959

6 Water temperature ,

);

gauge Overheat

Norma

TEMP

(green)

501889

Service meter

Every 6 minutes

dial advances

1

hour

one number.

501881

502665

OK

monitor

III When any lamp glows

during operation, stop

machine soon

and

check

for cause. (See page 16.)

i Fuel gauge

Empty

(red)

Full

(green)

501888

1 st

2nd

(j)

Starter switch

Twist

Twist

~(j)

~O

~(j)

~O

~(j)

~(j)

,-

~(j)

~O

~(j)

~O

~(j)

~(j)

Glow plug indicator

Glows when starter switch

is

turned to HEAT.

START

HEAT

OFF

ON

START

Heat

engine.

Insert

or

pull

out

key.

Keep engine

running.

Start

engine.

501956

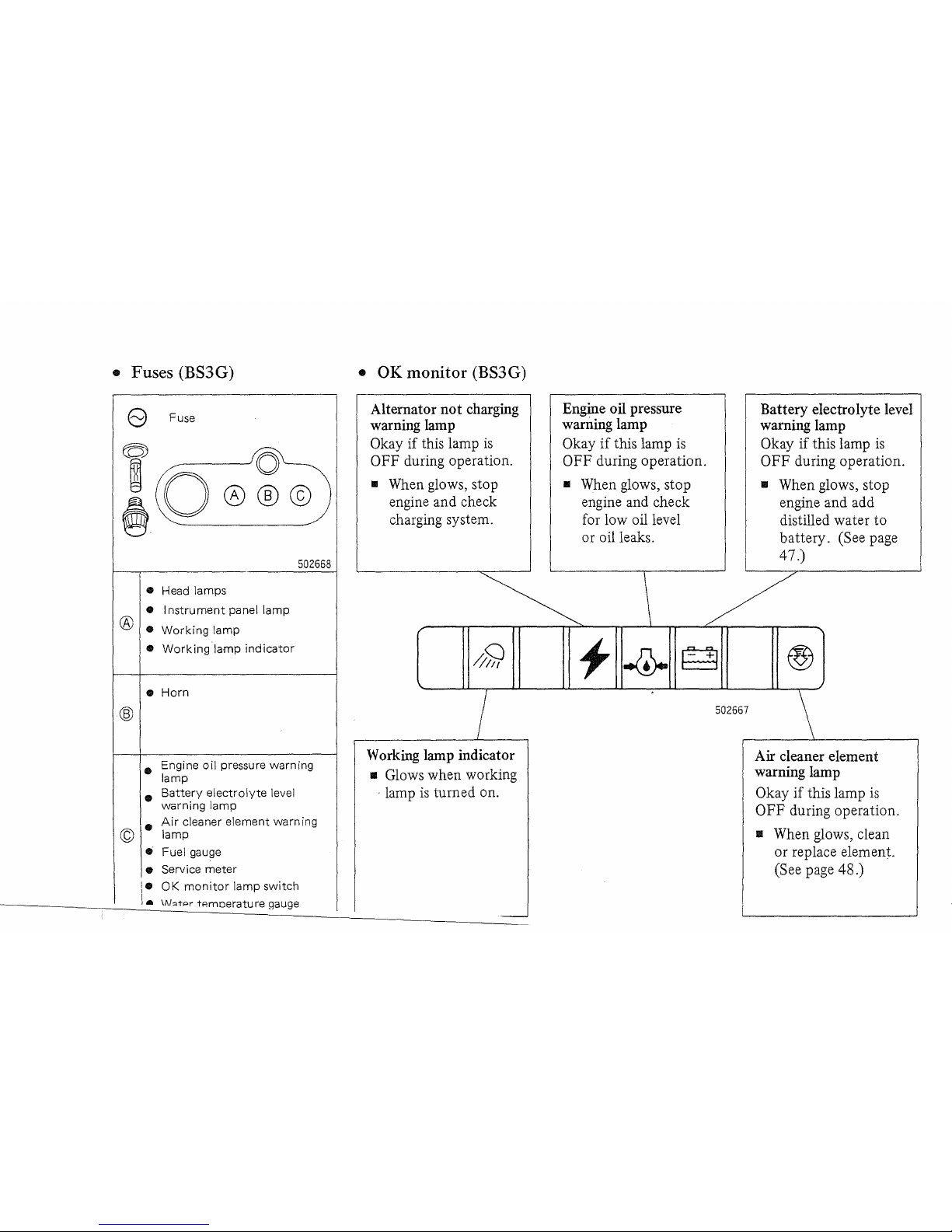

• Fuses (BS3

G)

e Fuse

(Ql~

&0

@@©)

• Head lamps

• I

nstrument

panel

lamp

® •

Working

lamp

•

Working

lamp

indicator

•

Horn

502668

• Engine

oil

pressure warning

lamp

•

Battery

electrolyte

level

warning

lamp

•

Air

cleaner element warning

© lamp

• Fuel gauge

• Service

meter

i.

OK

monitor

lamp

switch

\.

IAbtpr

tAmoerature gauge

•

OK

monitor (BS3G)

Alternator not

charging

warning

lamp

Okay

if

this lamp

is

OFF during operation.

.. When glows, stop

engine and check

charging system.

I

Working

lamp

indicator

II

Glows when working

. lamp

is

turned on.

-

Engine oil

pressure

warning

lamp

Okay

if

this lamp

is

OFF during operation.

.. When glows, stop

engine and check

for low oil level

or oil leaks.

Battery electrolyte level

warning

lamp

Okay if this lamp

is

OFF during operation.

II

When glows, stop

engine and add

distilled water

to

battery. (See page

47.)

\ /

f

502667

\

Air

cleaner element

warning

lamp

Okay

if

this lamp

is

OFF during operation.

II

When glows, clean

or

replace element.

(See page 48.)

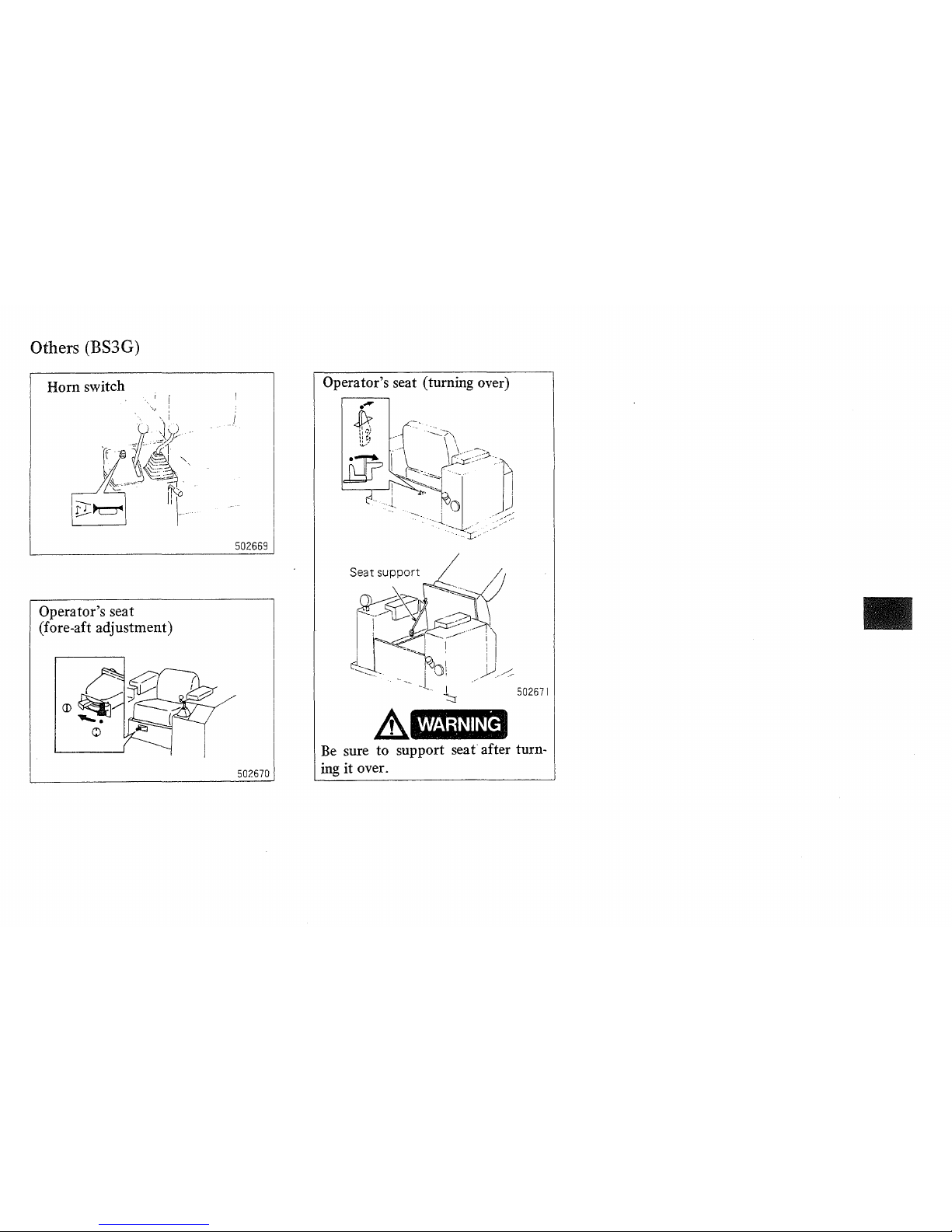

Others (BS3G)

Horn switch

I I

".,1

:

Operator's seat

(fore-aft adjustment)

Operator's seat (turning over)

502669

WARNING

Be

sure to support

seat

after turn-

502670

ing

it

over.

L-

____________________

~~

L-

______________________

__

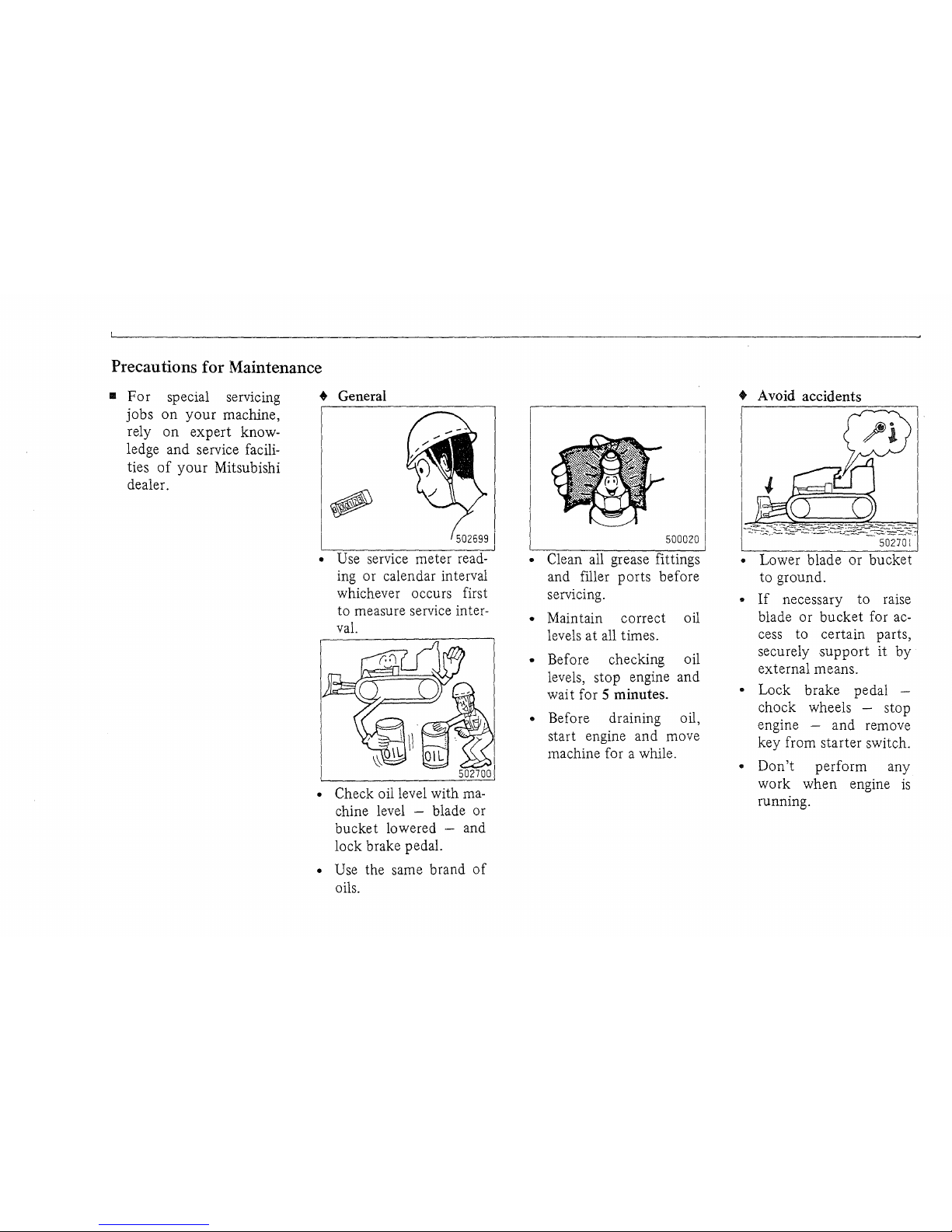

Precautions for Maintenance

..

For

special servlcmg

jobs

on

your

machine,

rely

on

expert

knowledge and service facilities

of

your

Mitsubishi

dealer.

• General

502699

I

• Use service meter reading or calendar interval

whichever occurs first

to measure service interval.

• Check oil level with

machine level - blade or

bucket lowered - and

lock brake pedal.

• Use the same brand

of

oils.

500020

• Clean all grease fittings

and filler ports before

servicing.

• Maintain correct oil

levels

at

all times.

• Before checking oil

levels, stop engine and

wai t for

5 minutes.

• Before draining oil,

start engine and move

machine for a while.

• Avoid accidents

50270

I

• Lower blade

or

bucket

to ground.

•

If

necessary to raise

blade

or

bucket

for access to certain parts,

securely

support

it

by

external means.

• Lock brake pedal chock wheels - stop

engine - and remove

key from starter switch.

•

Don't

perform any

work

when

engine

is

running.

502702

•

Attach

"DO NOT

OP-

ERA

TE"

tag when

servicing, adjusting or

repairing machine.

• Keep

off

personnel

while at

work

on

ma-

chine.

502703

• Start and operate engine only in well ventilated area.

•

Don't

smoke while

servicing fuel system - or

refueling.

o Store oily rags and

other combustible materials in a safe place.

500022

• Before removing radiator

cap or hydraulic

tank cap after operation, wait until machine

cools down

to

avoid

having scalding

hot

coolant or oil blown

out.

Before removing filler

cap, loosen

it

slowly to

relieve pressure.

500024

• Disconnect

battery

cables before servicing

electrical system.

• Battery electrolyte

is

very corrosive.

If

you

drip

it

on

your

skin

or

clothing, flush

it

off

at

once with water.

•

Don't

touch

exhaust

pipe immediately after

shutting down engine.

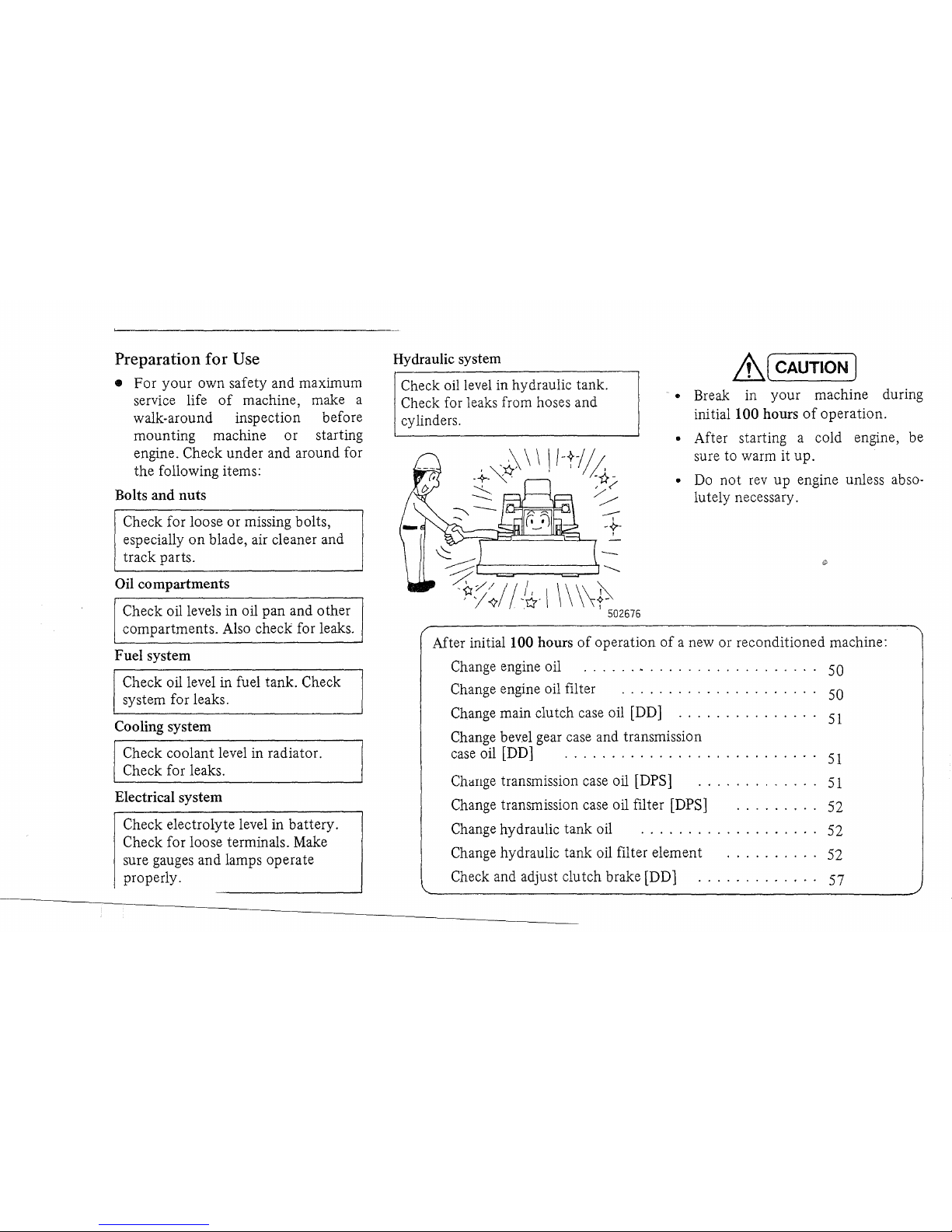

Preparation for Use

• For

your

own safety and maximum

service life

of

machine, make a

walk-around inspection before

mounting machine or starting

engine. Check under and around for

the following items:

Bolts and nuts

Check for loose or missing bolts,

especially

on

blade, air cleaner and

track parts.

Oil compartments

Check oil levels in oil pan and other

compartments. Also check for leaks.

Fuel system

Check oil level in fuel tank. Check

system for leaks.

Cooling system

Check coolant level in radiator.

Check for leaks.

Electrical system

Check electrolyte level in battery.

Check for loose terminals. Make

sure gauges and lamps operate

properly.

Hydraulic system

Check oil level in hydraulic tank .

Check for leaks from hoses and

cylinders.

---

-~.

>==;~~~:::L.,

I

\\

\\~

I 502676

~(

CAUTION)

• Break in your machine during

initiallOO hours

of

operation.

• After starting a cold engine, be

sure to warm it up.

•

Do

not

rev

up

engine unless abso-

lutely necessary.

After

initialI00

hours

of

operation

of

a new or reconditioned machine:

Change engine oil

......

. . . . . . . . . . . . . . . . .

..

50

Change engine oil filter . . . . . . . . . . . . . . . . . . . 50

Change main clutch case oil [DD]

...............

51

Change bevel gear case and transmission

case

oil [DD] . . . . . . . . . . . . . . . . . . . . . . . . .

..

51

ChaIlge transmission case oil [DPS]

..........

.

..

51

Change transmission case oil filter [DPS]

.......

" 52

Change hydraulic tank oil . . . . . . . . . . . . . . . . .

..

52

Change hydraulic tank oil filter element

..........

52

Check and adjust clutch brake [DD]

.............

57

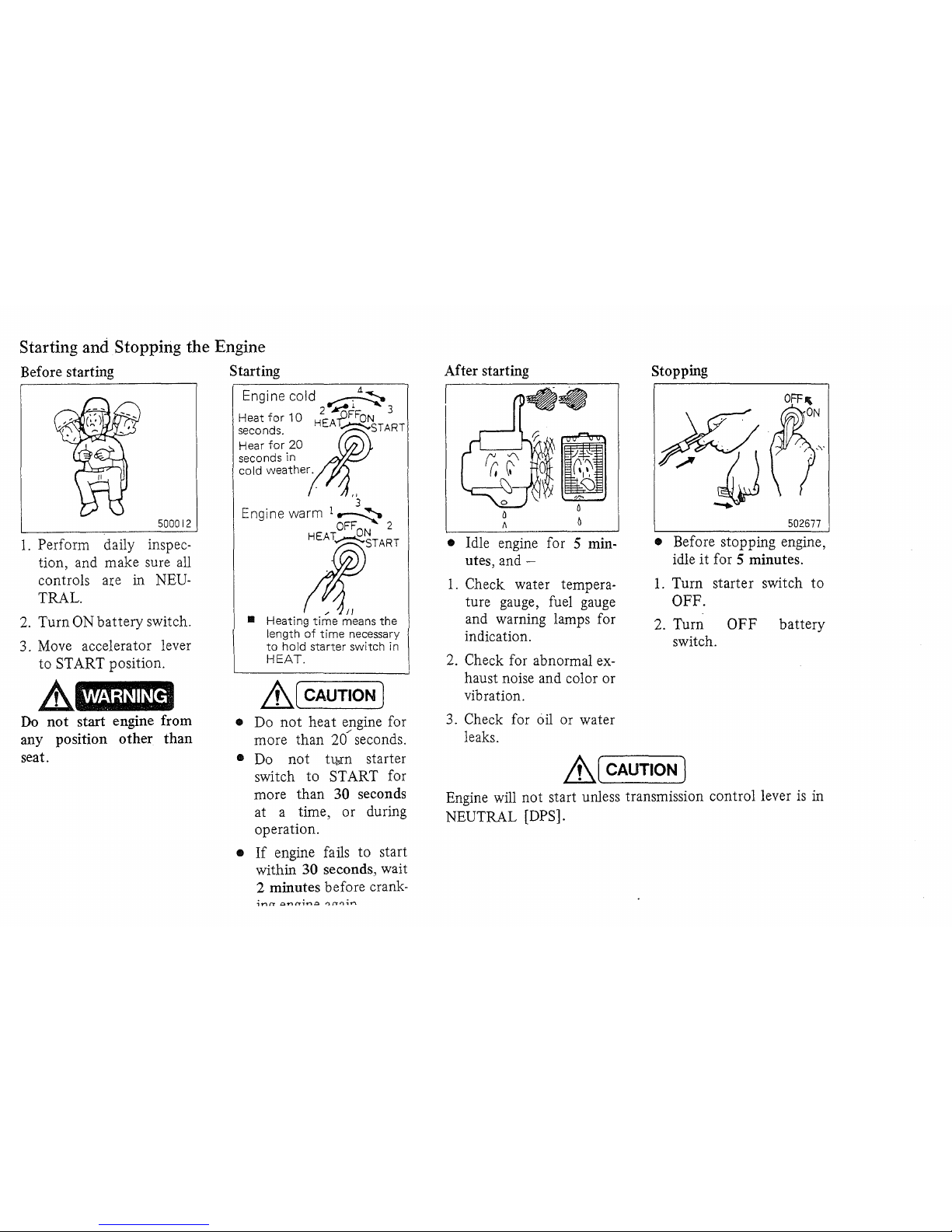

Starting and Stopping the Engine

Before starting

500012

1.

Perform daily inspec-

tion, and make sure all

controls

a:ce

in NEU-

TRAL.

2.

Turn ON battery switch.

3. Move accelerator lever

to START position.

A

WARNING·

Do

not

start engine from

any position other

than

seat.

Starting

Engine cold

~

2"-~1

... 3

Heat

for

10

HEAfFFON

seconds.

;t~START

Hear

for

20

seconds

in

cold

weather.

'3

Engine

warm

1

~

OFF

ON

2

l:START

..

Heating

time

means

the

length

of

time

necessary

to

hold

starter

switch

in

HEAT.

&,,(

CAUTION)

• Do

not

heat engine for

more than

20/ seconds.

•

Do

not

tl¥n

starter

switch to START for

more than

30 seconds

at a time, or during

operation.

•

If

engine fails to start

within

30 seconds, wait

2 minutes before crank-

After starting

• Idle engine for 5 minutes,

and-

1.

Check water temperature gauge, fuel gauge

and warning lamps for

indication.

2.

Check for abnormal

ex-

haust noise and color or

vibration.

3. Check for

oil

or water

leaks.

Stopping

502677

• Before stopping engine,

idle

it

for 5 minutes.

1.

Turn starter switch to

OFF.

2.

Turn

OFF

battery

switch.

&,,(

CAUTION)

Engine will not start unless transmission control lever

is

in

NEUTRAL

[DPS].

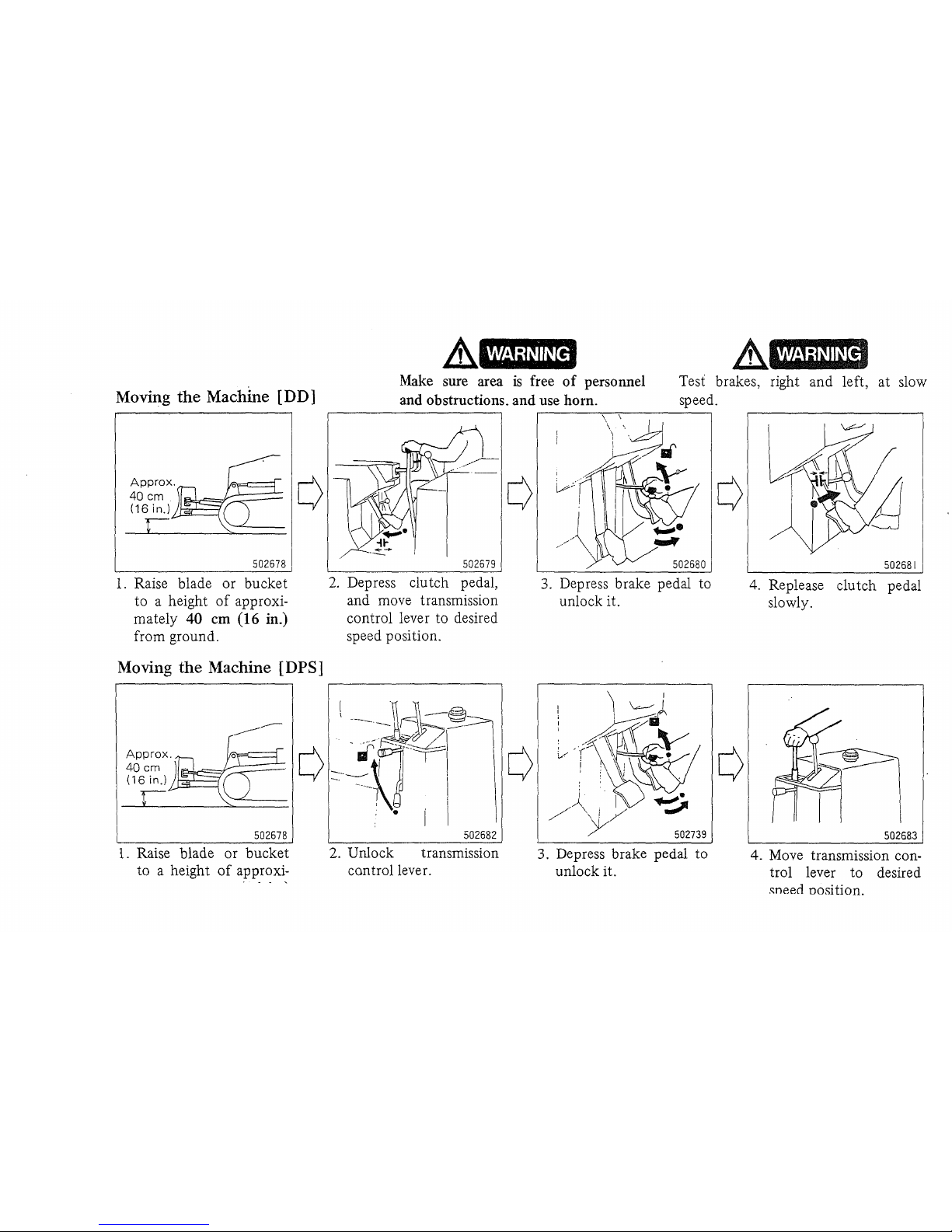

Moving the Machine [D D ]

502678

1.

Raise blade

or

bucket

to

a height

of

approxi-

mately

40

em

(16

in.)

from ground.

Moving the Machine [DPS]

502678

1.

Raise blade

or

bucket

to

a height

of

approxi-

WARNING

.&

Make

sure

area

is

free

of

personnel

and obstructions. and use horn.

Test brakes, right

and

left,

at

slow

speed.

502679

2.

Depress clutch pedal,

and move transmission

control lever to desired

speed position.

502682

2. Unlock transmission

control lever.

3.

Depress brake pedal to

unlock it.

j . I

/--\.

i

./

./

,.

/'

)V

502739

3. Depress brake pedal

to

unlock

it.

502681

4. Replease

clutch

pedal

slowly.

If!

502683

4.

Move transmission control lever

to

desired

."need Dosition.

Loading...

Loading...