<Diode Modules>

.............…..............................…

dual (Half-Bridge)

APPLICATION

Dimension in mm

INTERNAL CONNECTION

Tolerance otherwise specified

E2

G1

(NC)

E2

(NC)

G2

(NC)

Di1

Di2

C1

C2E1

E1

(NC)

Division of Dimension

Tolerance

0.5

to 3

±0.2

over 3

to 6

±0.3

over 6

to 30

±0.5

over 30

to 120

±0.8

over 120

to 400

±1.2

RM400DY-24S

HIGH POWER SWITCHING USE

INSULA TED TYPE

AC Motor Control, Motion/Servo Control, Power supply, etc.

OUTLINE DRAWING & INTERNAL CONNECTION

Forward current IF

Repetitive peak reverse voltage V

Maximum junction temperature T

.....................…

RRM

........................

jmax

4 0 0 A

1 2 0 0 V

1 5 0 °C

●Flat base Type

●Copper base plate

●RoHS Directive compliant

●Recognized under UL1557, File E323585

Publication Date : September 2014

TMH-1105 Ver.1.0

1

<Diode Modules>

RM400DY-24S

INSULATED TYPE

Symbol

Item

Conditions

Rating

Unit

V

RRM

Repetitive peak reverse voltage

-

1200

V

V

Reverse DC blocking voltage

-

960

V

IDC

DC forward current

DC, TC=68 °C

(Note1, 2)

400

Tj=25°C start, VRM=0 V

tw=8.3 ms, Tj=25 °C start,

Value for one cycle of surge current

V

isol

Isolation voltage

Terminals to base plate, RMS, f=60 Hz , AC 1 min

2500

V

T

Storage temperature

-

-40 ~ +125

Limits

Min.

Typ.

Max.

RRM

V

Forward voltage

IF=400 A, Tj=25 °C

(Note3)

-

2.6

3.3

V

trr

Reverse recovery time

VR=600 V, IF=400 A, Tj=25 °C,

- - 250

ns

Qrr

Reverse recovery charge

di/dt=-3500 A/μs, Inductive load

-

16 - μC

R

Internal lead resistance

Main terminal-chip, per Diode, TC=25 °C

-

0.75 - mΩ

Limits

Min.

Typ.

Max.

(Note2)

(Note2, 4)

Limits

Min.

Typ.

Max.

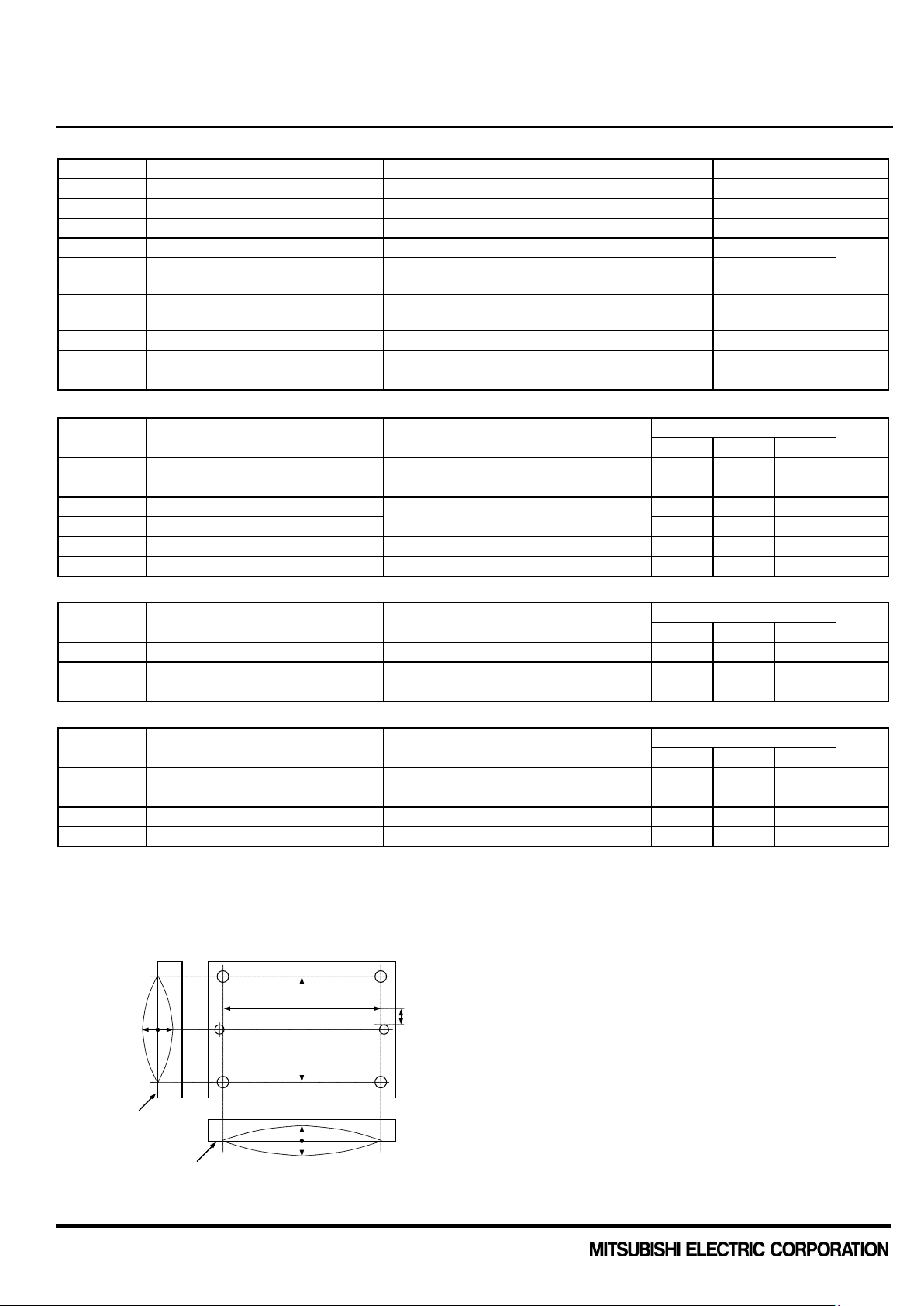

Ms

Mounting to heat sink

M 6 screw

3.5

4.0

4.5

N·m

ec

Flatness of base plate

On the centerline X, Y

(Note5)

-100 - +100

μm

Y

X

+:Convex

-:Concave

3 mm

+:Convex

-:Concave

Mounting

side

Mounting

side

Mounting

side

HIGH POWER SWITCHING USE

MAXI MUM RATINGS (Tj=25 °C, unless otherwise specified)

V

Non-repetitive peak reverse voltage - 1200 V

RSM

R(DC)

I

Surge non-repetitive forward current

FSM

I2t Current square time for fusing

1 cycle of half wave at 60Hz, peak value,

2000

1.66 × 104 A2s

Tj Junction temperature - -40 ~ +150

stg

A

°C

ELECTRICAL CHARACTERISTICS

Symbol Item Conditions

I

Reverse current VR=V

RRM

F

, Tj=125 °C - - 10 mA

Err Reverse recovery energy per pulse Tj=125 °C, Inductive load - 23.5 - mJ

AA'-KK'

Unit

THERMAL RESISTANCE CHARACTERISTICS

Symbol Item Conditions

R

Thermal resistance Junction to case, per Diode

th(j- c)

R

Contact thermal resistance

th(c- s )

Case to heat sink, per 1/2 module,

Thermal grease applied

- - 62 K/kW

- 18 - K/kW

Unit

MECHANICAL CHARACTERISTICS

Symbol Item Conditions

Mt

Mounting torque

Main terminals M 6 screw 3.5 4.0 4.5 N·m

m mass - - 580 - g

Note1. Junction temperature (Tj) should not increase beyond T

2. Case temperature (T

) and heat sink temperature (Ts) are defined on the each surface (mounting side) of base plate and heat sink just under

C

jmax

rating.

the chips. Refer to the figure of chip location.The heat sink thermal resistance should measure just under the chips.

3. Pulse width and repetition rate should be such as to cause negligible temperature rise.

4. Typical value is measured by using thermally conductive grease of λ=0.9 W/(m·K).

5. Base plate (mounting side) flatness measurement points (X, Y) are as follows of the following figure.

Unit

Publication Date : September 2014

TMH-1105 Ver.1.0

2

<Diode Modules>

RM400DY-24S

INSULATED TYPE

CHIP LOCATIO N (Top view)

Dimension in mm, tolerance: ±1 mm

Di1/Di2: DIODE

IF

C2E1

E2

Es2

(NC)

G2

(NC)

Es1

(NC)

G1

(NC)

C1

V

IF

C2E1

E2

Es2

(NC)

G2

(NC)

Es1

(NC)

G1

(NC)

C1

V

VRM

RG

-VGE

+VGE

Load

+

vR

vGE

0

iF

C1

E

C2E1

C

DUT

CM400DY

-24NF

Irr

Qrr=0.5×Irr×trr

0.5×Irr

t

t

rr

iF

0 A

IF

dIF/dt

IFM

vAK

iF

t

0 V

ti

t

VRM

0 A

dIF/dt

HIGH POWER SWITCHING USE

TEST CIRCUIT

Di1 Di2

VEC test circu it

TEST CIRCUIT AND WAVEFORMS

Reverse recovery characteristics test circuit and waveforms

Reverse recovery energy test waveforms

(Integral time instruction drawing)

Publication Date : September 2014

TMH-1105 Ver.1.0

3

<Diode Modules>

RM400DY-24S

INSULATED TYPE

FORWARD CHARACTERISTICS

TRANSIENT THERMAL IMPEDANCE

(TYPICAL)

CHARACTERISTICS

(MAXIMUM)

---------------: Tj=25 °C, - - - - -: Tj=125 °C

R

th(j- c)

=62 K/kW

th(j- c)

FORWARD VO LTAG E VF (V)

TIME (S)

REVERSE RECOVERY CHARACTERISTICS

REVERSE RECOVERY CHARACTERISTICS

(TYPICAL)

(TYPICAL)

VR=600 V, di/dt=-3500 A/μs, Tj=125 °C,

VR=600 V, di/dt=-3500 A/μs, Tj=25 °C,

INDUCTIVE LOAD, PER PULSE

INDUCTIVE LOAD

rr

rr

FORWARD CURRENT IF (A)

FORWARD CURRENT IF (A)

HIGH POWER SWITCHING USE

PERFORMANCE CURVES

(A)

F

FORWARD CURRENT I

NORMALIZED TRANSIENT THERMAL RESISTANCE Z

(A)

(ns), I

t

REVERSE RECOVERY ENERGY (mJ)

Note: The characteristics curves are presented for reference only and not guaranteed by production test, unless otherwise noted.

Publication Date : September 2014

TMH-1105 Ver.1.0

4

<Diode Modules>

RM400DY-24S

INSULATED TYPE

HIGH POWER SWITCHING USE

Keep safety first in your circuit designs!

Mitsubishi Electric Corpor ation puts the maxi mum effort into making se miconductor products better and more

reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors

may lead to personal injury, fire or property damage. Remember to gi ve due consideration to safety when

making your circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary

circuits, (ii) use of non-flam m abl e material or (iii) prevention against any malfunct io n or m ishap.

Notes regarding these ma t er ials

•These materials are intended as a reference to assist our customers in the selection of the Mitsubishi

semiconductor product best suited to the customer's application; they do not convey any license under any

intellectual property right s, or any other rights, belonging to Mitsubishi E lectr ic Corporation or a third party.

•Mitsubishi Electric Corporation assumes no responsibility for any damage, or infringement of any

third-party's rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or

circuit application examples contained in these materials.

•All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are subject

to change by Mitsubishi Elect ric Corporat ion without notice due to product improv ements or ot her reasons. It

is therefore recommended that customers contact Mitsubishi Electric Corporation or an authorized

Mitsubishi Semiconductor product distributor for the latest product information before purchasing a product

listed herein.

The information described here may contain technical inaccuracies or typographical errors. Mitsubishi

Electric Corporation assumes no responsibility for any damage, liability, or other loss rising from these

inaccuracies or errors.

Please also pay attention to information published by Mitsubishi Electric Corporation by various means,

including the Mitsubishi S em iconductor home page (www.MitsubishiElectric.com/semiconductors/).

•When using any or all of the information contained in these materials, including product data, diagrams,

charts, programs, and algorithms, please be sure to evaluate all information as a total system before making

a final decision on the applicability of the information and products. Mitsubishi Electric Corporation assumes

no responsibility for any damage, liability or other loss resulting from the information contained herein.

•Mitsubishi Electric Corporation semiconductors are not designed or manufactured for use in a device or

system that is used under circumstances in which human life is potentially at stake. Please contact

Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor when

considering the use of a product contained herein for any specific purposes, such as apparatus or systems

for transportation, vehi cular, medical, aerospace, nucle ar, or undersea repeater use.

•The prior written approval of Mitsubishi Electric Corporation is necessary to reprint or reproduce in whole or

in part these materials.

•If these products or technologies are subject to the Japanese export control restrictions, they must be

exported under a license from the Japanese government and cannot be imported into a country other than

the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of Japan and/or the country of

destination is prohibited.

•Please contact Mitsubis hi Electr ic Corporat ion or an aut horized M itsubishi S emico nductor pr oduct distri butor

for further details on these materials or the products contai ned therein.

©2014 MITSUBISHI ELECTRIC CORPORATION. ALL RIGHTS RESERVED.

Publication Date : September 2014

TMH-1105 Ver.1.0

5

Loading...

Loading...