<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

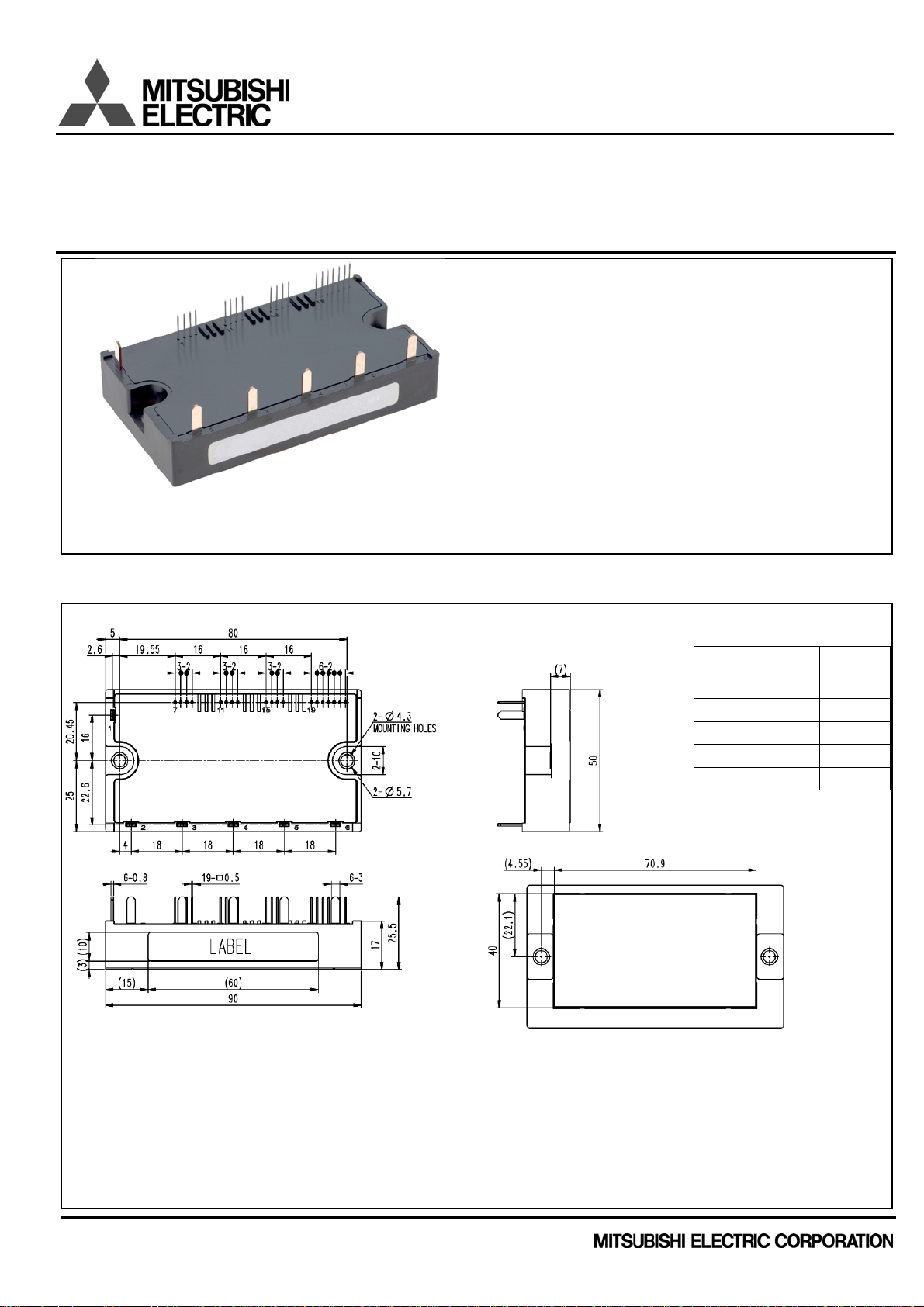

FLAT-BASE TYPE

INSULATED PACKAGE

APPLICATION

General purpose inverter, servo drives and other motor controls

PACKAGE OUTLINES Dimensions in mm

TERMINAL CODE

----CG1AP type----

1.NC, 2.P, 3.N, 4.U, 5.V, 6.W, 7.V

15.V

, 16.WFO, 17.WP, 18.V

WPC

, 19.VNC, 20.VN1, 21.NC, 22.UN, 23.VN, 24.WN, 25.FO

WP1

----CG1APL type----

1.N, 2.P, 3.NC, 4.U, 5.V, 6.W, 7.V

15.V

, 16.WFO, 17.WP, 18.V

WPC

, 19.VNC, 20.VN1, 21.NC, 22.UN, 23.VN, 24.WN, 25.FO

WP1

, 8.UFO, 9.UP, 10.V

UPC

, 8.UFO, 9.UP, 10.V

UPC

FEATURE

a) Adopting Full-Gate CSTBTTM chip.

b) The over-temperature protection which

detects the chip surface temperature of

CSTBT

TM

is adopted.

c) Error output signal is available from

each protection upper and lower arm of IPM.

d) Outputting an error signal corresponding

to the abnormal state (error mode identification)

UL Recognized under UL1557, File No. E323585

This product is compliant with the Restriction of the Use of Certain

Hazardous Substances in Electrical and Electronic Equipment

(RoHS) directive 2011/65/EU.

UP1

UP1

, 11.V

, 11.V

, 12.VFO, 13.VP, 14.V

VPC

, 12.VFO, 13.VP, 14.V

VPC

Tolerance otherwise specified

Division of

Dimension

0.5 to 3 ±0.2

over 3 to 6 ±0.3

over 6 to 30 ±0.5

over 30 to 120 ±0.8

over 120 to 400 ±1.2

,

VP1

,

VP1

Tolerance

APPLICATION NOTE <CMH-11600-A>

Publication date : Nov, 2017

1

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

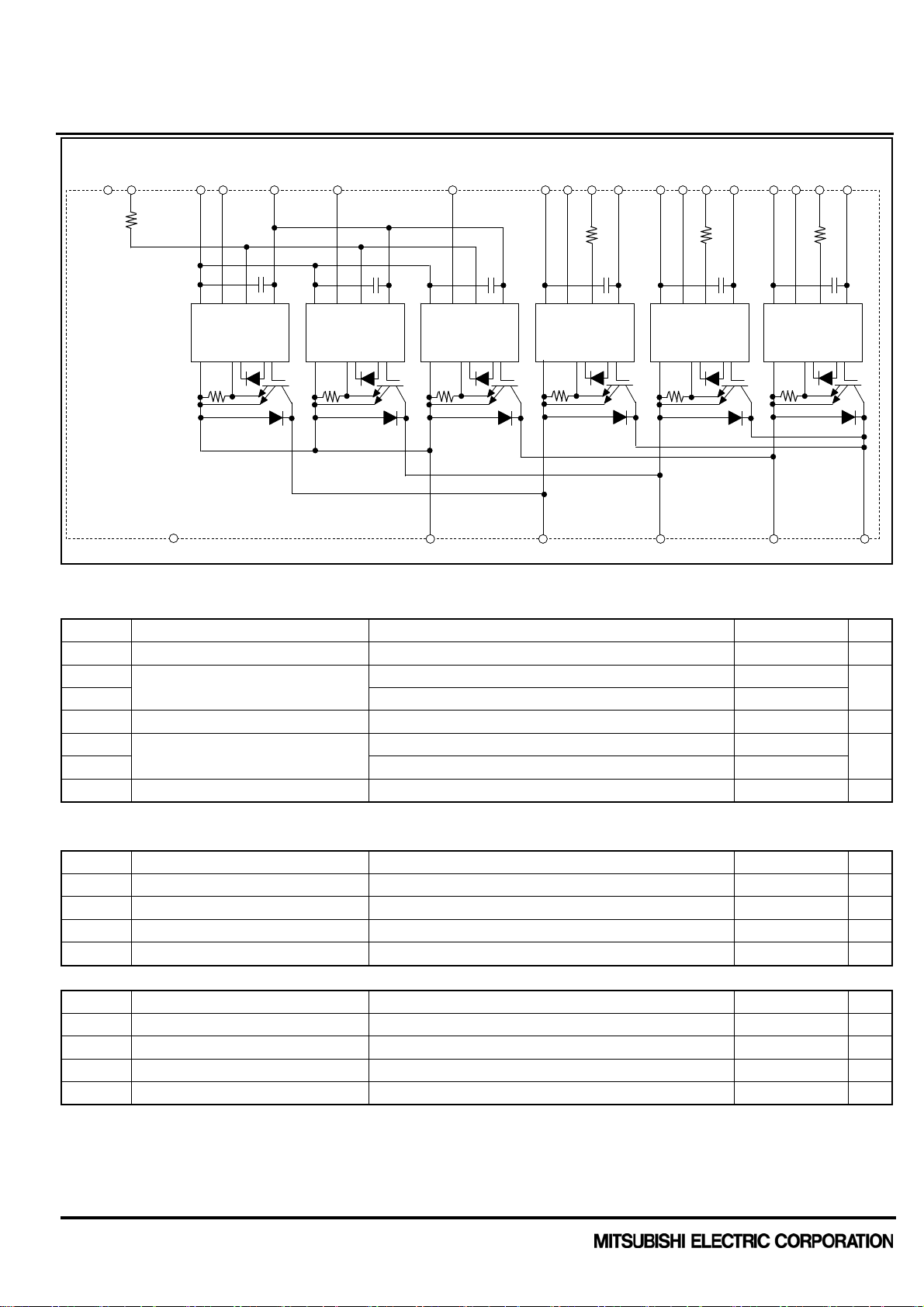

INTERNAL FUNCTIONS BLOCK DIAGRAM

NC Fo

V

NCWN

V

N1

V

N

U

N

V

WPC

V

W

WP1

P

W

Fo

V

V

VPC

V

P

VP1

V

Fo

U

V

UPC

V

P

UP1

U

Fo

1.5k

FoIN

GND

GND

NC

Vcc

Si OT OUT

GND

VccFoINGND

Si OT OUT

GND

VccFoINGND

Si OT OUT

GND Si OT OUT

1.5k

Fo

INGND

Vcc

GND

GND

1.5k

IN

Si OT OUT

VccFo

GND

1.5k

VccFoINGND

Si OT OUT

PUVWN

MAXIMUM RATINGS (Tvj = 25°C, unless otherwise noted)

INVERTER PART

Symbol Parameter Conditions Ratings Unit

V

Collector-Emitter Voltage VD=15 V, V

CES

IC

I

Pulse 200

CRM

P

Total Power Dissipation TC=25 °C 357 W

tot

Collector Current

TC=25 °C 100

IE Emitter Current TC=25 °C 100

I

(Free-wheeling Diode Forward current) Pulse 200

ERM

Tv j Junction Temperature -20 ~ +150 °C

=15 V 650 V

CIN

A

A

*: Tc measurement point is just under the chip.

CONTROL PART

Symbol Parameter Conditions Ratings Unit

VD Supply Voltage Applied between: V

V

Input Voltage Applied between: UP-V

CIN

VFO Fault Output Supply Voltage Applied between: UFO-V

IFO Fault Output Current Sink current at UFO, VFO, WFO, Fo terminals 20 mA

UP1-VUPC

UPC

UPC

, V

, VP-V

, VFO-V

VP1-VVPC

, WP-V

VPC

VPC

, V

WP1-VWPC

, WFO-V

, VN1-VNC 20 V

, UN, VN, WN-VNC 20 V

WPC

, Fo-VNC 20 V

WPC

TOTAL SYSTEM

Symbol Parameter Conditions Ratings Unit

V

Supply Voltage Protected by SC VD =13.5 V~16.5 V, Inverter Part, Tvj=+125°C start 400 V

CC(PROT)

T

Storage Temperature - -40 ~ +125 °C

stg

TC Operating Case Temperature - -20 ~ +125 °C

V

Isolation Voltage 60Hz, Sinusoidal, Charged part to Base plate, AC 1min, RMS 2500 V

isol

*: Tc measurement point is just under the chip.

APPLICATION NOTE <CMH-11600-A>

2

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

THERMAL RESISTANCE

Symbol Parameter Conditions

R

th(j-c)Q

R

th(j-c)D

R

th(c-s)

Note1. If you use this value, R

Thermal Resistance

Junction to case, FWD, per 1 element (Note1) - - 0.56

Contact Thermal Resistance

should be measured just under the chips.

th(s-a)

Note2. Typical value is measured by using thermally conductive grease of λ=0.9W/(m·K), D

Junction to case, IGBT, per 1 element (Note1) - - 0.35

Case to heat sink, per 1 module,

Thermal grease applied (Note.1, 2)

=50 μm.

(C-S)

CHIP LOCATION (Top view) Dimension in mm, torelance: ±1mm

ELECTRICAL CHARACTERISTICS (Tvj= 25°C, unless otherwise noted)

INVERTER PART

Symbol Parameter Conditions

V

=15 V, IC=100 A Tv j=25 °C

D

V

Collector-Emitter Saturation Voltage

CEsa t

V

=0 V, Pulsed, (Fig.1) Tvj =125 °C

CIN

=15 V, IE=100 A, Tv j=25 °C

V

D

VEC Emitter-Collector Voltage

V

= 15 V, pulsed, (Fig.2) Tv j=125 °C

CIN

ton

trr V

t

Tv j=125 °C, - 0.17 0.75

c(on)

t

Inductive Load - 1.0 2.3

off

t

c(off)

I

Collector-Emitter Cut-off Current

CES

Switching Time

(Fig.3, 4) - 0.13 0.4

VD=15 V, V

=300 V, I

CC

V

V

, VD=15 V,

CE=VCES

=15 V (Fig.5)

CIN

=0 V←→15 V, 0.3 0.6 1.2

CIN

=100A, - 0.2 0.65

C

Terminal - - 1.75

Chip - 1.25 -

Terminal - - 2.0

Chip - 1.33 -

Terminal - - 1.95

Chip - 1.40 -

Terminal - - 2.05

Chip - 1.45 -

Tv j =25 °C - - 1

Tv j =125 °C - - 10

Limits

Min. Typ. Max.

- 19.1 - K/kW

Tr** : IGBT

Di** : FWD

Limits

Min. Typ. Max.

Unit

K/W

Unit

V

V

μs

mA

APPLICATION NOTE <CMH-11600-A>

3

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

ELECTRICAL CHARACTERISTICS (Tvj = 25°C, unless otherwise noted)

CONTROL PART

Symbol Parameter Conditions

V

- 4 6

P1-VPC

VN1-VNC - 12 18

ID Circuit Current

=15 V, V

V

D

VD=15 V, V

=15 V

CIN

=0 V←→15 V, VCC=400 V VP1-VPC - 16 19

CIN

IC=0A, Tv j=125 °C, fC≤20kHz VN1-VNC - 48 58

V

Input ON Threshold Voltage Applied between: 1.2 1.5 1.8

th(ON)

V

Input OFF Threshold Voltage UP-V

th(OFF)

UPC

, VP-V

VPC

, WP-V

, UN, VN, WN-VNC 1.7 2.0 2.3

WPC

SC Short Circuit Trip Level -20≤Tvj≤125 °C, VD=15 V (Fig.3, 6) 200 - - A

t

Short Circuit Current Delay Time VD=15 V, Tv j=125 °C (Fig.3, 6) - 2.0 - μs

d(SC)

OT

OT

(hys)

UVt Supply Circuit

UVr Under-Voltage Protection Reset level - 12.5 -

I

FO(H)

I

FO(L)

Over Temperature Protection Detect temperature of IGBT chip surface

Hysteresis - 20 -

-

Fault Output Current V

- 10 15

=15 V, VFO=15 V (Note3)

D

Trip level 150 - -

Trip level 11.0 12.0 12.7

OT

tFO Fault Output Pulse Width VD=15 V (Note3)

UV

SC

Note3. Fault output is given only when the internal SC, OT & UV protections schemes of either upper or lower arm device operate to protect it.

Limits

Min. Typ. Max.

- - 0.01

-

-

-

8.0

4.0

2.0

-

-

-

Unit

mA

V

°C

V

mA

ms

MECHANICAL RATINGS AND CHARACTERISTICS

Symbol Parameter Conditions

Ms Mounting Torque Mounting part screw : M4 1.5 1.7 2.0 N•m

m mass - - 175 - g

Limits

Min. Typ. Max.

Unit

RECOMMENDED CONDITIONS FOR USE

Symbol Parameter Conditions Recommended value Unit

VCC Supply Voltage Applied across P-N terminals ≤ 400 V

VD Control Supply Voltage

V

Input ON Voltage Applied between : ≤ 0.8

CIN(ON)

V

Input OFF Voltage UP-V

CIN(OFF)

f

PWM Input Frequency Using Application Circuit of Fig. 8 ≤ 20 kHz

PWM

t

Arm Shoot-through Blocking Time For IPM’s each input signals (Fig.7) ≥ 2.0 μs

dead

This product is compliant with the Restriction of the Use of Certain Hazardous Substances in Electrical and Electronic

Equipment (RoHS) directive 2011/65/EU.

Note4. With ripple satisfying the following conditions: dv/dt swing ≤ ±5 V/μs, Variation ≤ 2 V peak to peak

Applied between :

V

UP1-VUPC

UPC

, V

, VP-V

VP1-VVPC

VPC

, V

WP1-VWPC,VN1-VNC

, WP-V

WPC

(Note4)

15.0±1.5

, UN, VN, WN-VNC ≥ 9.0

V

V

APPLICATION NOTE <CMH-11600-A>

4

<Intelligent Power Modules>

A

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

PRECAUTIONS FOR TESTING

1. Before applying any control supply voltage (V

supply voltage and each input signal should be kept off state.

After this, the specified ON and OFF level setting for each input signal should be done.

2. When performing “SC” tests, the turn-off surge voltage spike at the corresponding protection operation should not be allowed to

rise above V

rating of the device.

CES

(These test should not be done by using a curve tracer or its equivalent.)

Vcc

Fo

VD( al l )

Fo

Vci n

IN

GND

), the input terminals should be pulled up by resistors, etc. to their corresponding

D

P,(U ,V,W)

V

Vcc

Fo

Ic

VD( al l )

Fo

Vci n

IN

GND

P,(U,V, W)

V

I

E

VD(all)

VD(all)

U,V,W(N)

Vcin

Vcin

Fig.1 V

P

Vcc

Fo

Fo

IN

GND

Vcc

Fo

Fo

IN

GND

U,V,W

V

N

Tes t Fig.2 VEC Test

CEsat

Vcc

Fo

Vcin

Fo

Vcin

Fo

IN

GND

Vcc

Fo

IN

GND

V

I

C

VD(all)

CC

VD(all)

Fig.3 Switching time and SC test circuit Fig.4 Switching time test waveform

P

V

V

U,V, W

N

CC

I

C

VD(all)

Fo

Vci n

Vcc

Fo

IN

GND

Fig.5 I

P,(U,V,W)

V

CE

pulse

U,V,W(N)

Tes t Fig.6 SC test waveform

CES

U,V,W(N)

Fig. 7 Dead time measurement point example

APPLICATION NOTE <CMH-11600-A>

5

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

20k≥10µ

VUP 1

VD

VD

VD

VD

IF

0.1µ

≥

20k≥10µ

IF

0.1µ

≥

20k

IF

0.1µ

≥

20k≥10µ

IF

0.1µ

≥

UFO

UP

VUP C

VVP1

VFO

VP

VVPC

VWP 1

WFO

WP

VWP C

UN

10µ

≥

VN

VN1

WN

VNC

1.5k

1.5k

1.5k

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

Vcc

Fo

IN

GND

OUT

OT

Si

GND

OUT

OT

GND

OUT

OT

Si

GND

OUT

OT

GND

OUT

OT

Si

GND

OUT

GND

Si

Si

OT

Si

P

U

V

W

NC

+

-

M

N

1k

5V

NC

1.5k

Fo

: Interface which is the same as the U-phase

Fig. 8 Application Example Circuit

NOTES FOR STABLE AND SAFE OPERATION ;

• Design the PCB pattern to minimize wiring length between opto-coupler and IPM’s input terminal, and also to minimize the stray capacity

between the input and output wirings of opto-coupler.

• Connect low impedance capacitor between the Vcc and GND terminal of each fast switching opto-coupler.

• Fast switching opto-couplers: t

PLH

, t

≤ 0.8μs, Use High CMR type.

PHL

• Slow switching opto-coupler: CTR > 100%

• Use 4 isolated control power supplies (V

). Also, care should be taken to minimize the instantaneous voltage charge of the power supply.

D

• Make inductance of DC bus line as small as possible, and minimize surge voltage using snubber capacitor between P and N terminal.

APPLICATION NOTE <CMH-11600-A>

6

<Intelligent Power Modules>

Y

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

COLLECTOR-EMITTER SATURATION

VOLTAGE (VS. Ic) CHARACTERISTICS

120

(A)

C

COLLECTOR CURRENT I

100

VD=15V, Chip

80

60

40

20

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4

(TYPICAL)

Tvj=25°C

Tvj=125°C

COLLECTOR-EMITTER SATURATION

VOLTAGE VCEsat (V)

SWITCHING TIME (t

CHARACTERISTICS

10.0

Vcc=300V

V

D

Inductive Load

(TYPICAL)

=15V

Tvj=25°C

Tvj=125°C

, t

)

on

off

FREE WHEELING DIODE FORWARD

110

100

90

80

(A)

E

70

60

50

40

30

20

EMITTER CURRENT I

10

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

EMITTER - COLLECTOR VOLTAGE VEC (V)

1

CHARACTERISTICS

(TYPICAL)

VD=15V, Chip

Tvj=25°C

Tvj=125°C

SWITCHING TIME (t

CHARACTERISTICS

(TYPICAL)

t

c(off)

c(on)

, t

)

c(off)

t

1.0

off

t

on

SWITCHING TIME (μs)

0.1

0 20 40 60 80 100 120

COLLECTOR CURRENT I

(A)

C

0.1

t

c(on)

Vcc=300V

=15V

V

SWITCHING TIME (μs)

0.01

D

Tvj=25°C

Tvj=125°C

Inductive Load

0 20406080100120

COLLECTOR CURRENT IC (A)

SWITCHING ENERGY CHARACTERISTICS

4.0

Vcc=300V

3.5

3.0

2.5

2.0

1.5

1.0

0.5

SWITCHING ENERGY Eon (mJ/pulse)

0.0

=15V

V

D

Inductive Load

0 20 40 60 80 100 120

COLLECTOR CURRENT I

(TYPICAL)

Tvj=25°C

Tvj=125°C

C

(A)

8.0

7.0

Eon

6.0

5.0

4.0

3.0

E

off

2.0

1.0

0.0

FREE WHEELING DIODE REVERSE RECOVER

ENERGY CHARACTERISTICS

SWITCHING ENERGY Eoff (mJ/pulse)

3.0

2.5

2.0

1.5

1.0

0.5

0.0

REVERSE RECOVERY ENERGY (mJ/pulse)

0 20406080100120

(TYPICAL)

Vcc=300V

=15V

V

D

Inductive Load

EMITTER CURRENT IE (A)

Tvj=25°C

Tvj=125°C

APPLICATION NOTE <CMH-11600-A>

7

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

REVERSE RECOVERY TIME (ns)

REVERSE RECOVERY CURRENT (A)

UVt / UVr (V)

FREE WHEELING DIODE REVERSE

RECOVERY CHARACTERISTICS

1000

100

10

Vcc=300V

V

D

Inductive Load

1

0 20 40 60 80 100 120

(TYPICAL)

=15V

Tvj=25°C

Tvj=125°C

EMITTER CURRENT I

E

(A)

t

rr

I

rr

UV TRIP LEVEL VS. Tvj CHARACTERISTICS

20

18

16

14

12

10

8

6

4

2

0

-50 0 50 100 150

(TYPICAL)

UV

UV

r

t

Tvj (°C)

TRANSIENT THERMAL IMPEDANCE

CHARACTERISTICS

(TYPICAL)

VS. fC CHARACTERISTICS

I

70

60

50

40

(mA)

30

D

I

20

10

0

SC TRIP LEVEL VS. Tvj CHARACTERISTICS

2.0

1.8

1.6

1.4

1.2

1.0

SC

0.8

0.6

0.4

(SC of Tvj=25°C is normalized 1)

0.2

0.0

D

(TYPICAL, MAXIMUM)

Vcc=400V

=15V, Tvj=125°C

V

D

TYPICAL

MAXIMUM

0 5 10 15 20 25

N side

P side

fc (kHz)

(TYPICAL)

VD=15V

-50 0 50 100 150

Tvj (°C)

10

1

Zth(j-c)

0.1

0.01

0.001

NORMARIZED TRANSIENT THERMAL IMPEDANCE

0.00001 0.0001 0.001 0.01 0.1 1 10

Single Pulse

IGBT Part;

Per unit base: Rth(j-c)Q=0.35K /W

FWD Part;

Per unit base: Rth(j-c)D=0.56K /W

TIME (s)

APPLICATION NOTE <CMH-11600-A>

8

<Intelligent Power Modules>

PM100CG1AP065/PM100CG1APL065

HIGH POWER SWITCHING USE

INSULATED TYPE

Keep safety first in your circuit designs!

This product is designed for industrial application purpose. The performance, the quality and support level of the product is

guaranteed by “Customer's Std. Spec.”.

Mitsubishi Electric Corporation puts its reasonable effort into making semiconductor products better and more reliable, but there

is always the possibility that trouble may occur with them by the reliability lifetime such as Power Cycle, Thermal Cycle or others,

or to be used under special circumstances(e.g. high humidity, dusty, salty, highlands, environment with lots of organic matter /

corrosive gas / explosive gas, or situation which terminal of semiconductor products is received strong mechanical stress).

In the customer's research and development, please evaluate it not only with a single semiconductor product but also in the

entire system, and judge whether it's applicable. Furthermore, trouble with semiconductors may lead to personal injury, fire or

property damage. Remember to give due consideration to safety when making your circuit designs, with appropriate measures

such as (i) placement of substitutive, auxiliary circuits (e.g. appropriate fuse or circuit breaker between a power supply and

semiconductor products), (ii) use of non-flammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

•These materials are intended as a reference to assist our customers in the selection of the Mitsubishi semiconductor product

best suited to the customer's application; they do not convey any license under any intellectual property rights, or any other

rights, belonging to Mitsubishi Electric Corporation or a third party.

•Mitsubishi Electric Corporation assumes no responsibility for any damage, or infringement of any third-party's rights, originating

in the use of any product data, diagrams, charts, or circuit application examples contained in these materials.

•All information contained in these materials, including product data, diagrams and charts represents information on products at

the time of publication of these materials, and are subject to change by Mitsubishi Electric Corporation without notice due to

product improvements or other reasons. It is therefore recommended that customers contact Mitsubishi Electric Corporation or

an authorized Mitsubishi Semiconductor product distributor for the latest product information before purchasing a product listed

herein.

The information described here may contain technical inaccuracies or typographical errors. Mitsubishi Electric Corporation

assumes no responsibility for any damage, liability, or other loss rising from these inaccuracies or errors.

Please also pay attention to information published by Mitsubishi Electric Corporation by various means, including the Mitsubishi

Semiconductor home page (www.MitsubishiElectric.com/semiconductors/).

•When using any or all of the information contained in these materials, including product data, diagrams, and charts, please be

sure to evaluate all information as a total system before making a final decision on the applicability of the information and

products. Mitsubishi Electric Corporation assumes no responsibility for any damage, liability or other loss resulting from the

information contained herein.

•Mitsubishi Electric Corporation semiconductors are not designed or manufactured for use in a device or system that is used

under circumstances in which human life is potentially at stake. Therefore, this product should not be used in such applications.

Please contact Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor when considering

the use of a product contained herein for any specific purposes, such as apparatus or systems for transportation, vehicular,

medical, aerospace, nuclear, or undersea repeater use.

•In the case of new requirement is available, this material will be revised upon consultation.

•The prior written approval of Mitsubishi Electric Corporation is necessary to reprint or reproduce in whole or in part these

materials.

•If these products or technologies are subject to the Japanese export control restrictions, they must be exported under a license

from the Japanese government and cannot be imported into a country other than the approved destination.

Any diversion or re-export contrary to the export control laws and regulations of Japan and/or the country of destination is

prohibited.

•Please contact Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor for further details

on these materials or the products contained therein.

Generally the listed company name and the brand name are the trademarks or registered trademarks of the respective companies.

Note:

The characteristics curves are presented for reference only and not guaranteed by production test,

unless otherwise noted.

© 2018 MITSUBISHI ELECTRIC CORPORATION. ALL RIGHTS RESERVED.

APPLICATION NOTE <CMH-11600-A>

9

Loading...

Loading...