< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

NSULATED TYPE

I

sevenpack (3φ Inverter+Chopper Brake)

APPLICATION

AC Motor Control, Motion/Servo Control, Power supply, etc.

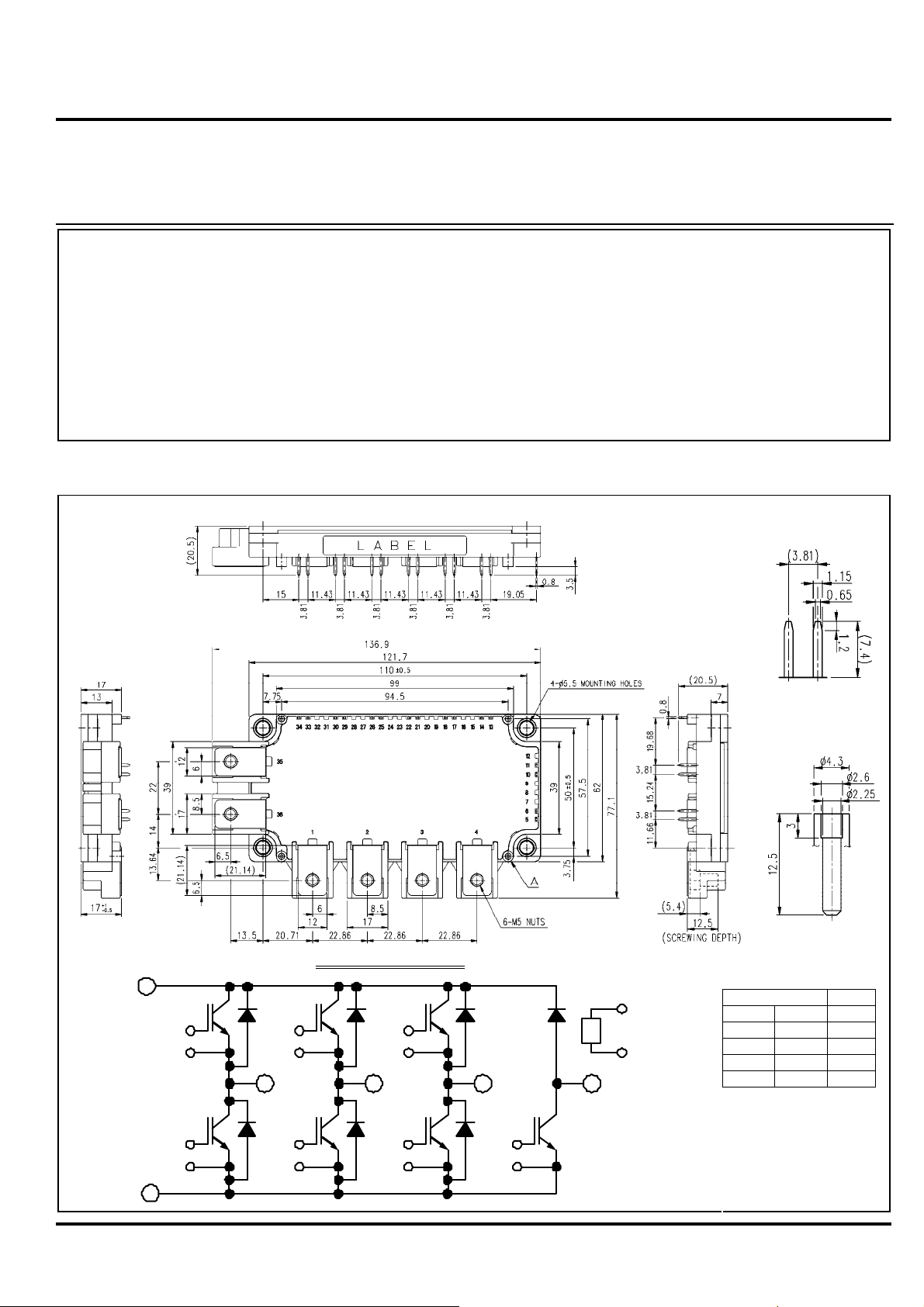

OUTLINE DRAWING & INTERNAL CONNECTION

Collector current I

Collector-emitter voltage V

Maximum junction temperature T

●Flat base Type

●Copper base plate (non-plating)

●Tin plating pin terminals

●RoHS Directive compliant

●Recognized under UL1557, File E323585

.............….......................… 100A

C

......................… 1200V

CES

.............. 175°C

jmax

Dimension in mm

TERMINAL

P(35)

GUP(34)

EUP(33)

U(1)

INTERNAL CONNECTION

GVP(26)

EVP(25)

GWP(18)

EWP(17)

V(2)

W(3)

NTC

W(4)

TH1(10)

TH2(11)

t=0.8

SECTION A

Tolerance otherwise specified

Division of Dimension Tolerance

0.5 to 3 ±0.2

over 3 to 6 ±0.3

over 6 to 30 ±0.5

over 30 to 120 ±0.8

over 120 to 400 ±1.2

The tolerance of size between

terminals is assumed to be ±0.4.

GU N(30 )

EUN(29)

N(3 6)

Publication Date : August 2013

G VP(22)

EVP(21)

GWN (14)

EWN(13)

GB(6)

EB(5)

1

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

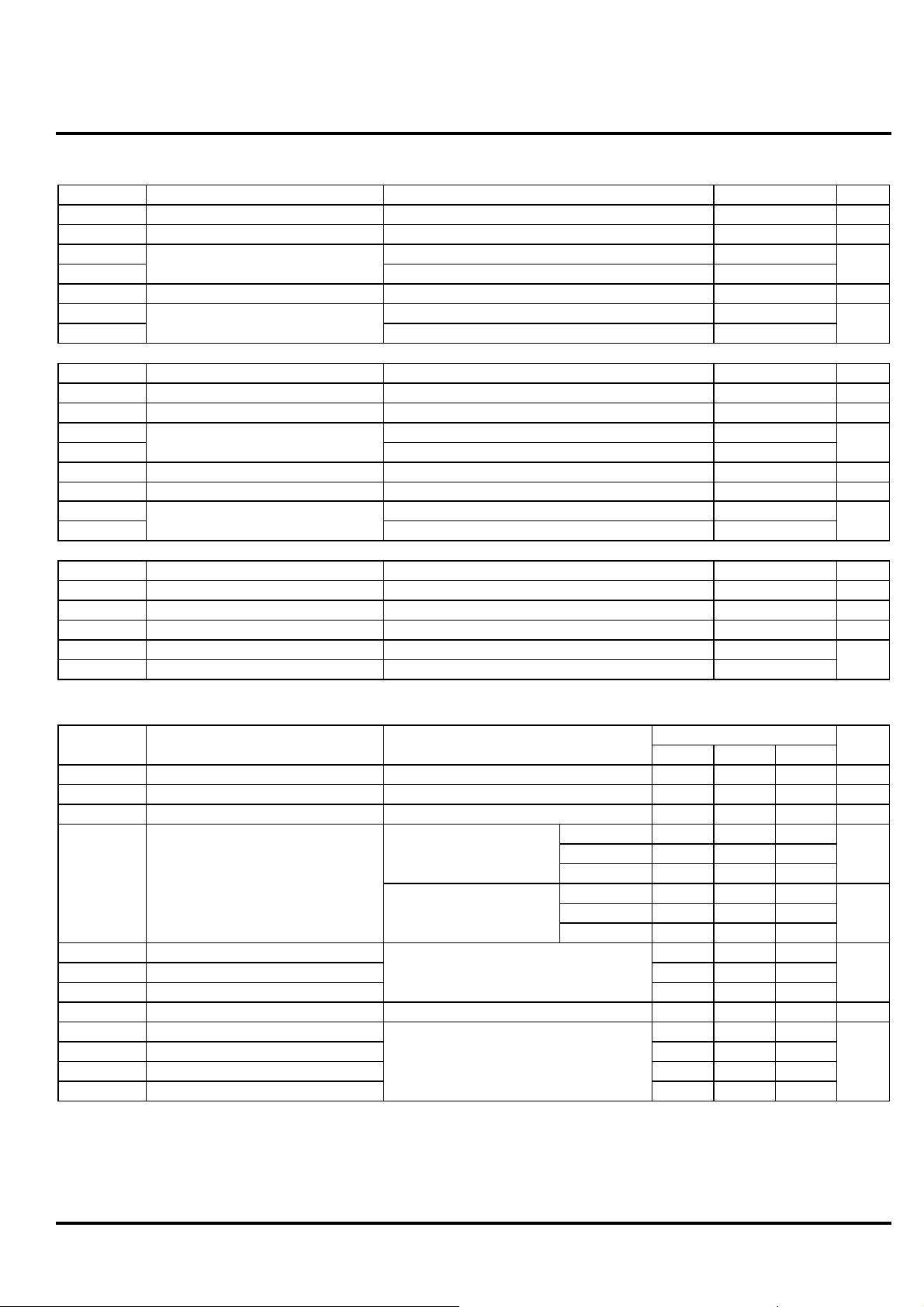

ABSOLUTE MAXIMUM RATINGS (T

INVERTER PART IGBT/DIODE

Symbol Item Conditions Rating Unit

V

Collector-emitter voltage G-E short-circuited 1200 V

CES

V

Gate-emitter voltage C-E short-circuited ± 20 V

GES

IC DC, TC=119 °C

I

CRM

P

Total power dissipation TC=25 °C

tot

(Note1)

IE

I

ERM

BRAKE PART IGBT/DIODE

V

CES

V

GES

IC DC, TC=125 °C

I

CRM

P

tot

V

RRM

IF

I

FRM

MODULE

V

isol

T

jmax

T

Cmax

T

jop

T

stg

(Note1)

Symbol Item Conditions Rating Unit

Collector-emitter voltage G-E short-circuited 1200 V

Gate-emitter voltage C-E short-circuited ± 20 V

Total power dissipation TC=25 °C

Repetitive peak reverse voltage G-E short-circuited 1200 V

Symbol Item Conditions Rating Unit

Isolation voltage Terminals to base plate, RMS, f=60 Hz, AC 1 min 2500 V

Maximum junction temperature Instantaneous event (overload) 175 °C

Maximum case temperature

Operating junction temperature Continuous operation (under switching) -40 ~ +150

Storage temperature - -40 ~ +125

Collector current

Emitter current

Collector current

Forward current

=25 °C, unless otherwise specified)

j

(Note2, 4)

Pulse, Repetitive

(Note2)

100

Pulse, Repetitive

Pulse, Repetitive

(Note2)

50

Pulse, Repetitive

(Note4)

125 °C

(Note3)

(Note2, 4)

750 W

(Note3)

(Note2, 4)

(Note3)

(Note2, 4)

425 W

(Note3)

100

200

200

50

100

100

A

A

A

A

°C

ELECTRICAL CHARACTERISTICS (Tj=25 °C, unless otherwise specified)

INVERTER PART IGBT/DIODE

Symbol Item Conditions

I

Collector-emitter cut-off current VCE=V

CES

I

Gate-emitter leakage current VGE=V

GES

V

Gate-emitter threshold voltage IC=10 mA, VCE=10 V 5.4 6.0 6.6 V

GE(th)

IC=100 A

, G-E short-circuited - - 1.0 mA

CES

, C-E short-circuited - - 0.5 μA

GES

(Note5)

, Tj=25 °C - 1.80 2.25

VGE=15 V, Tj=125 °C - 2.00 -

V

CEsat

Collector-emitter saturation voltage

(Terminal) Tj=150 °C - 2.05 IC=100 A

(Note5)

, Tj=25 °C - 1.70 2.15

VGE=15 V, Tj=125 °C - 1.90 (Chip) T

C

Input capacitance - - 10

ies

V

C

Output capacitance - - 2.0

oes

C

Reverse transfer capacitance

res

=10 V, G-E short-circuited

CE

=150 °C - 1.95 -

j

QG Gate charge VCC=600 V, IC=100 A, VGE=15 V - 233 - nC

t

Turn-on delay time - - 300

d(on)

tr Rise time

t

Turn-off delay time - - 600

d(off)

tf Fall time

V

=600 V, IC=100 A, VGE=±15 V,

CC

R

=6.2 Ω, Inductive load

G

Limits

Min. Typ. Max.

- - 0.17

- - 200

- - 300

Unit

V

V

nF

ns

Publication Date : August 2013

2

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

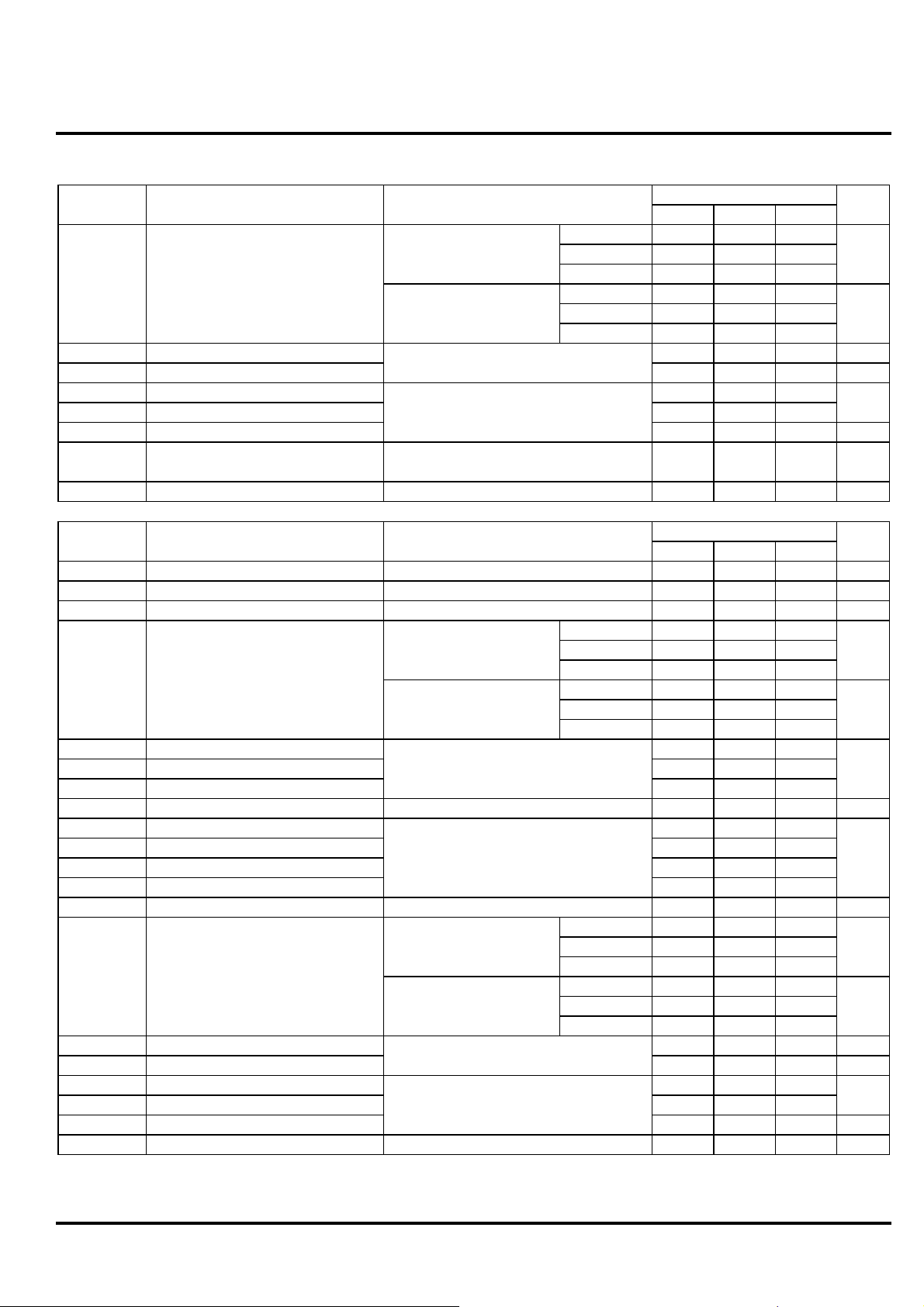

ELECTRICAL CHARACTERISTICS (cont; T

INVERTER PART IGBT/DIODE

Symbol Item Conditions

(Note1)

VEC

(Note1)

t

Reverse recovery time VCC=600 V, IE=100 A, VGE=±15 V, - - 300 ns

rr

(Note1)

Qrr

Eon Turn-on switching energy per pulse VCC=600 V, IC=IE=100 A, - 8.6 E

Err

R

rg Internal gate resistance Per switch - 0 - Ω

BRAKE PART IGBT/DIODE

I

I

V

V

C

C

C

QG Gate charge VCC=600 V, IC=50 A, VGE=15 V - 117 - nC

t

tr Rise time

t

tf Fall time

I

RRM

V

trr Reverse recovery time VCC=600 V, IE=50 A, VGE=±15 V, - - 300 ns

Qrr Reverse recovery charge RG=13 Ω, Inductive load - 2.7 - μC

Eon Turn-on switching energy per pulse VCC=600 V, IC=IE=50 A, - 5.5 E

Err Reverse recovery energy per pulse Inductive load - 4.5 - mJ

rg Internal gate resistance - - 0 - Ω

Reverse recovery charge RG=6.2 Ω, Inductive load - 5.3 - μC

Turn-off switching energy per pulse VGE=±15 V, RG=6.2 Ω, Tj=150 °C, - 10.7 -

off

(Note1)

Reverse recovery energy per pulse Inductive load - 10.2 - mJ

Internal lead resistance

CC'+EE'

Symbol Item Conditions

Collector-emitter cut-off current VCE=V

CES

Gate-emitter leakage current VGE=V

GES

Gate-emitter threshold voltage IC=5 mA, VCE=10 V 5.4 6.0 6.6 V

GE(th)

CEsat

Input capacitance - - 5.0

ies

Output capacitance - - 1.0

oes

Reverse transfer capacitance

res

Turn-on delay time - - 300

d(on)

Turn-off delay time - - 600

d(off)

Repetitive peak reverse current VR=V

F

Turn-off switching energy per pulse VGE=±15 V, RG=13 Ω, Tj=150 °C, - 5.3 -

off

Emitter-collector voltage

Collector-emitter saturation voltage

Forward voltage

=25 °C, unless otherwise specified)

j

IE=100 A

(Note5)

, Tj=25 °C - 1.80 2.25

G-E short-circuited, Tj=125 °C - 1.80 (Terminal) Tj=150 °C - 1.80 IE=100 A

(Note5)

, Tj=25 °C - 1.70 2.15

G-E short-circuited, Tj=125 °C - 1.70 (Chip) T

Main terminals-chip, per switch,

T

=25 °C

C

IC=50 A

(Note4)

, G-E short-circuited - - 1.0 mA

CES

, C-E short-circuited - - 0.5 μA

GES

(Note5)

, Tj=25 °C - 1.80 2.25

VGE=15 V, Tj=125 °C - 2.00 (Terminal) Tj=150 °C - 2.05 IC=50 A

(Note5)

, Tj=25 °C - 1.70 2.15

VGE=15 V, Tj=125 °C - 1.90 (Chip) T

V

=10 V, G-E short-circuited

CE

V

=600 V, IC=50 A, VGE=±15 V,

CC

R

=13 Ω, Inductive load

G

, G-E short-circuited - - 1.0 mA

RRM

IE=50 A

(Note5)

, Tj=25 °C - 1.80 2.25

G-E short-circuited, Tj=125 °C - 1.80 (Terminal) Tj=150 °C - 1.80 IE=50 A

(Note5)

, Tj=25 °C - 1.70 2.15

G-E short-circuited, Tj=125 °C - 1.70 (Chip) T

Limits

Min. Typ. Max.

=150 °C - 1.70 -

j

- - 3.5 mΩ

Limits

Min. Typ. Max.

=150 °C - 1.95 -

j

- - 0.08

- - 200

- - 300

=150 °C - 1.70 -

j

Unit

V

V

mJ

Unit

V

V

nF

ns

V

V

mJ

Publication Date : August 2013

3

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

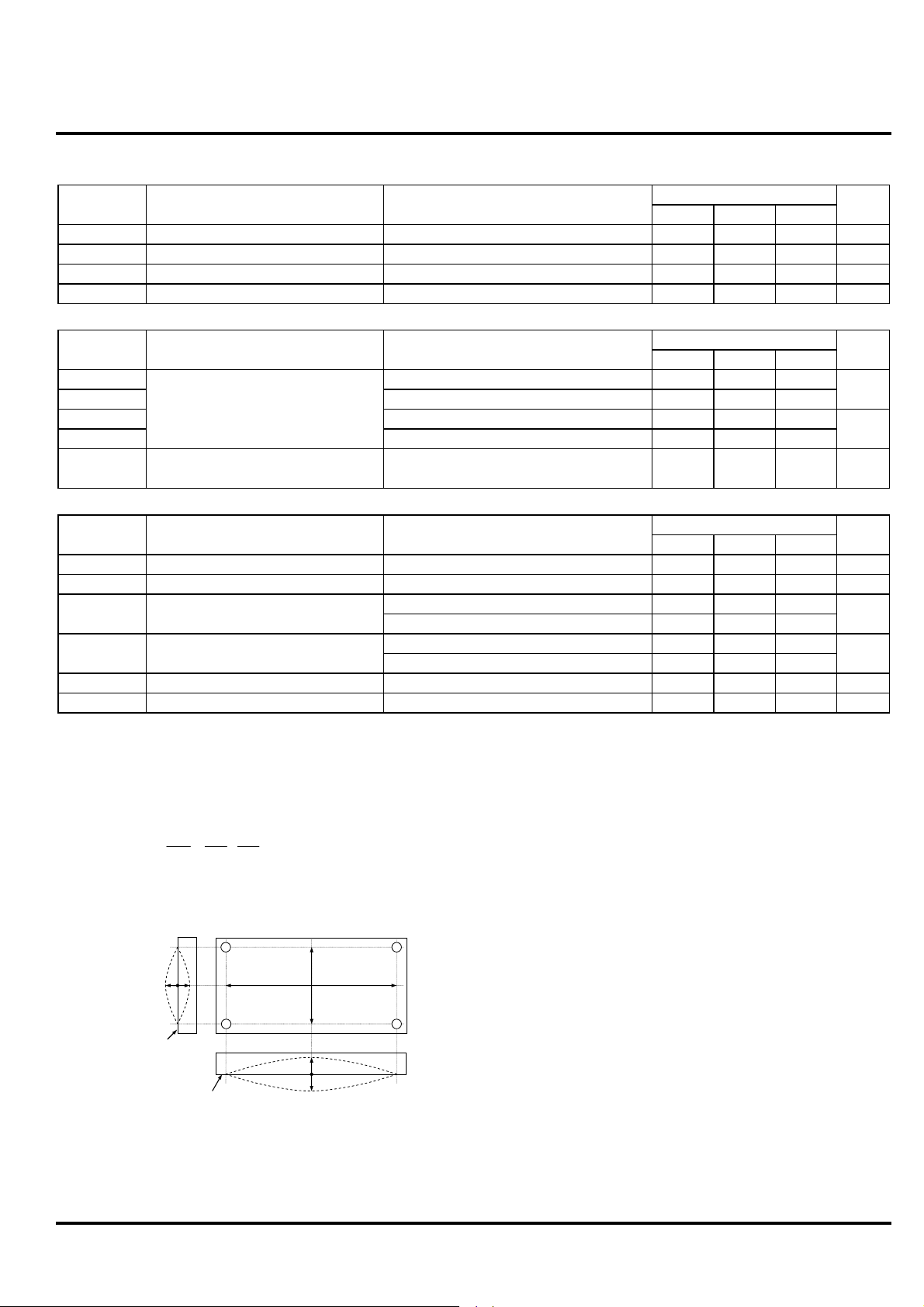

ELECTRICAL CHARACTERISTICS (cont; T

NTC THERMISTOR PART

Symbol Item Conditions

R25 Zero-power resistance TC=25 °C

∆R/R Deviation of resistance R

B

B-constant Approximate by equation

(25/50)

P25 Power dissipation TC=25 °C

THERMAL RESISTANCE CHARACTERISTICS

Symbol Item Conditions

R

R

R

R

R

Junction to case, per Inverter IGBT - - 0.20

th(j-c)Q

Junction to case, per Inverter DIODE - - 0.29

th(j-c)D

Junction to case, per Brake IGBT - - 0.35

th(j-c)Q

th(j-c)D

Contact thermal resistance

th(c-s)

Thermal resistance

(Note4)

=25 °C, unless otherwise specified)

j

(Note4)

4.85 5.00 5.15 kΩ

=493 Ω, TC=100 °C

100

(Note4)

- - 10 mW

(Note4)

-7.3 - +7.8 %

(Note7)

- 3375 - K

Junction to case, per Brake DIODE - - 0.63

(Note4)

Case to heat sink, per 1 module,

(Note7)

Thermal grease applied

Limits

Min. Typ. Max.

Limits

Min. Typ. Max.

- 15 - K/kW

Unit

Unit

K/W

K/W

MECHANICAL CHARACTERISTICS

Symbol Item Conditions

Mt Mounting torque Main terminals M 5 screw 2.5 3.0 3.5 N·m

Ms Mounting torque Mounting to heat sink M 5 screw 2.5 3.0 3.5 N·m

ds Creepage distance

da Clearance

Terminal to terminal 10.25 - Terminal to base plate 12.32 - Terminal to terminal 10.28 - Terminal to base plate 10.85 - -

m mass - - 370 - g

ec Flatness of base plate On the centerline X, Y

(Note8)

±0 - +100 μm

Note1. Represent ratings and characteristics of the anti-parallel, emitter-collector free wheeling diode (DIODE).

2. Junction temperature (T

3. Pulse width and repetition rate should be such that the device junction temperature (T

4. Case temperature (T

) should not increase beyond T

j

) and heat sink temperature (Ts) are defined on the each surface (mounting side) of base plate and heat sink

C

jmax

rating.

) dose not exceed T

j

just under the chips. Refer to the figure of chip location.

5. Pulse width and repetition rate should be such as to cause negligible temperature rise.

Refer to the figure of test circuit.

R

6.

5025

: resistance at absolute temperature T25 [K]; T25=25 [°C]+273.15=298.15 [K]

R

25

: resistance at absolute temperature T50 [K]; T50=50 [°C]+273.15=323.15 [K]

R

50

25

ln(B

)/(

/()

R

11

,

)

TT

502550

7. Typical value is measured by using thermally conductive grease of λ=0.9 W/(m·K).

8. The base plate (mounting side) flatness measurement points (X, Y) are as follows of the following figure.

Limits

Min. Typ. Max.

rating.

jmax

Unit

mm

mm

Y

mounting side

-:Concave

+:Convex

mounting side

+:Convex

mounting side

-:Concave

X

9. Use the following screws when mounting the printed circuit board (PCB) on the stand offs.

"φ2.6×10 or φ2.6×12 self tapping screw"

The length of the screw depends on the thickness (t1.6~t2.0) of the PCB.

Publication Date : August 2013

4

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

RECOMMENDED OPERATING CONDITIONS

Symbol Item Conditions

VCC (DC) Supply voltage Applied across P-N terminals - 600 850 V

V

Gate (-emitter drive) voltage

GEon

RG External gate resistance Per switch

CHIP LOCATION (Top view)

Limits

Min. Typ. Max.

Applied across GB-EB/

G*P-E*P/G*N-E*N (*=U, V, W) terminals

Inverter IGBT 6.2 - 62

Brake IGBT 13 - 130

13.5 15.0 16.5 V

Dimension in mm, tolerance: ±1 mm

Unit

Ω

Tr*P/Tr*N/TrBr: IGBT, Di*P/Di*N: DIODE (*=U/V/W), DiBr: BRAKE DIODE, Th: NTC thermistor

TEST CIRCUIT AND WAVEFORMS

0 V

*: U, V, W

+V

GE

-V

GE

-VGE

RG

vGE

G*P

E*P

G*N

E*N

iE

P

v

GE

0 V

Load

V

*

vCE

+

iC

N

i

CC

C

0 A

t

d(on)

~

~

90 %

0

~

~

90 %

t

iE

IE

0 A

Q

=0.5×Irr×t

rr

t

Irr

10%

t

r

t

d(off)

t

f

t

Switching characteristics test circuit and waveforms trr, Qrr test waveform

i

I

vCE

0.1×I

0

CM

CM

VCC

ti

C

0.1×VCC

i

C

V

CC

0.1×V

t

CC

ICM

v

CE

0.02×I

CM

t0

t

i

iE

0 A

IEM

t

i

IGBT Turn-on switching energy IGBT Turn-off switching energy DIODE Reverse recovery energy

Turn-on / Turn-off switching energy and Reverse recovery energy test waveforms (Integral time instruction drawing)

rr

rr

t

0.5×I

rr

v

EC

V

CC

t

t0 V

Publication Date : August 2013

5

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

TEST CIRCUIT

VGE=15V

34

35

IC

VGE=15V

35

35

VGE=15V

I

C26

18

IC

circuited

Short-

circuited

VGE=15V

Gate-emitter

short-circuited

circuited

V

Short-

GUP

EUP

GUN

EUN

Short-

33

1

30

29

GVP-EVP GVN-EVN,

GWP-EWP , GWN-EWN,

GB-EB

UP / UN IGBT

34

36

P

U

N

35

V

Short-

Short-

GVP

EVP

GVN

EVN

Gate-emitter

Short-

25

2

22

21

GUP-EUP, GUN-EUN,

GWP-EWP , GWN-EWN,

GB-EB

VP / VN IGBT

26

36

P

V

N

35

V

V

CEsat

circuited

VGE=15V

I

C

short-circuited

test circuit

I

E

circuited

circuited

circuited

circuited

V

VGE=15V

IC

short-circuited

circuited

IE

V

Short-

Short-

GWP

EWP

GWN

EWN

Gate-emitter

WP / WN IGBT

Short-

17

3

14

13

GUP-EUP, GUN-EUN,

GVP-EVP, GVN-EVN,

GB-EB

18

36

P

W

N

35

P

V

V

B

VGE=15V

IC

EB

Gate-emitter

short-circuited

GUP-EUP, GUN-EUN,

GVP-EVP, GVN-EVN,

GWP-EWP , GWN-EWN

Brake IGBT

N

I

CGB

35

I

IE

F

33

V

Short-

circuited

1

30

29

36

Short-

circuited

Short-

circuited

Gate-emitter

short-circuited

GUP

EUP

GUN

EUN

GVP-EVP GVN-EVN,

GWP-EWP , GWN-EWN,

GB-EB

UP / UN DIODE VP / VN DIODE WP / WN DIODE

P

V

U

IE

N

Publication Date : August 2013

V

Short-

circuited

Short-

circuited

Short-

circuited

Gate-emitter

short-circuited

25

2

22

21

GVP

EVP

GVN

EVN

GUP-EUP, GUN-EUN,

GWP-EWP , GWN-EWN,

GB-EB

36

P

V

N

V

Short-

circuited

Short-

circuited

V

Short-

circuited

I

E

Gate-emitter

short-circuited

VEC / VF test circuit

6

17

14

13

GWP

EWP

GWN

EWN

GUP-EUP, GUN-EUN,

GVP-EVP, GVN-EVN,

GB-EB

36

P

W

N

3

Short-

circuited

6

5

4

V

36

V

IE

Gate-emitter

short-circuited

GUP-EUP, GUN-EUN,

GVP-EVP, GVN-EVN,

GWP-EWP , GWN-EWN

Brake DIODE

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

INVERTER PART

OUTPUT CHARACTERISTICS

(TYPICAL)

COLLECTOR-EMITTER SATURATION VOLTAGE

CHARACTERISTICS

(TYPICAL)

(A)

C

COLLECTOR CURRENT I

Tj=25 °C

200

VGE=20 V

15 V

150

100

50

0

0246810

13.5 V

12 V

11 V

10 V

9 V

(Chip)

(V)

CEsat

COLLECTOR-EMITTER

SATURATION VOLTAGE V

VGE=15 V

3.5

3

2.5

2

1.5

1

0.5

0

0 50 100 150 200

T

Tj=125 °C

Tj=25 °C

COLLECTOR-EMITTER VOLTAGE VCE (V) COLLECTOR CURRENT IC (A)

COLLECTOR-EMITTER SATURATION VOLTAGE

CHARACTERISTICS

(TYPICAL)

FREE WHEELING DIODE

FORWARD CHARACTERISTICS

(TYPICAL)

=150 °C

j

(Chip)

10

Tj=25 °C

(Chip)

G-E short-circuited

1000

Tj=125 °C

8

(V)

CEsat

6

4

IC=200 A

=100 A

I

C

IC=40 A

100

(A)

E

Tj=150 °C

Tj=25 °C

10

COLLECTOR-EMITTER

2

EMITTER CURRENT I

SATURATION VOLTAGE V

0

6 8 10 12 14 16 18 20

1

0 0.5 1 1.5 2 2.5 3

GATE-EMITTER VOLTAGE VGE (V) EMITTER-COLLECTOR VOLTAGE VEC (V)

(Chip)

Publication Date : August 2013

7

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

INVERTER PART

VCC=600 V, VGE=±15 V, RG=6.2 Ω, INDUCTIVE LOAD

1000

100

SWITCHING CHARACTERISTICS

---------------: T

HALF-BRIDGE

(TYPICAL)

=150 °C, - - - - -: Tj=125 °C

j

t

d(off)

t

f

t

d(on)

SWITCHING CHARACTERISTICS

HALF-BRIDGE

(TYPICAL)

VCC=600 V, VGE=±15 V, IC=100 A, INDUCTIVE LOAD

1000

---------------: T

100

=150 °C, - - - - -: Tj=125 °C

j

tf

t

d(off)

10

SWITCHING TIME (ns)

t

r

1

1 10 100

SWITCHING TIME (ns)

10

1 10 100

t

d(on)

tr

COLLECTOR CURRENT IC (A) EXTERNAL GATE RESISTANCE RG (Ω)

HALF-BRIDGE

SWITCHING CHARACTERISTICS

(TYPICAL)

VCC=600 V, VGE=±15 V, RG=6.2 Ω,

INDUCTIVE LOAD, PER PULSE

100

10

---------------: T

=150 °C, - - - - -: Tj=125 °C

j

100

SWITCHING CHARACTERISTICS

VCC=600 V, VGE=±15 V, IC/IE=100 A,

INDUCTIVE LOAD, PER PULSE

---------------: T

HALF-BRIDGE

(TYPICAL)

=150 °C, - - - - -: Tj=125 °C

j

E

on

E

rr

E

off

1

E

on

SWITCHING ENERGY (mJ)

REVERSE RECOVERY ENERGY (mJ)

0.1

1 10 100

COLLECTOR CURRENT IC (A)

EMITTER CURRENT I

Publication Date : August 2013

E

(A)

10

SWITCHING ENERGY (mJ)

REVERSE RECOVERY ENERGY (mJ)

1

1 10 100

EXTERNAL GATE RESISTANCE R

8

G

(Ω)

E

off

E

rr

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

INVERTER PART

100

10

1

CAPACITANCE (nF)

0.1

CAPACITANCE CHARACTERISTICS

(TYPICAL)

G-E short-circuited, Tj=25 °C

REVERSE RECOVERY CHARACTERISTICS

FREE WHEELING DIODE

(TYPICAL)

VCC=600 V, VGE=±15 V, RG=6.2 Ω, INDUCTIVE LOAD

1000

C

ies

(A)

rr

C

oes

C

res

(ns), I

rr

t

---------------: T

100

=150 °C, - - - - -: Tj=125 °C

j

Irr

trr

0.01

0.1 1 10 100

10

1 10 100

COLLECTOR-EMITTER VOLTAGE VCE (V) EMITTER CURRENT IE (A)

GATE CHARGE CHARACTERISTICS

20

15

(V)

GE

10

5

VCC=600 V, IC=100 A, Tj=25 °C

(TYPICAL)

GATE-EMITTER VOLTAGE V

TRANSIENT THERMAL IMPEDANCE CHARACTERISTICS

(MAXIMUM)

Single pulse, TC=25 °C

R

1

0.1

th(j-c)Q

=0.20 K/W, R

th(j-c)D

th(j-c)

Z

0.01

=0.29 K/W

NORMALIZED TRANSIENT THERMAL RESISTANCE

0

0 100 200 300 400

0.001

0.00001 0.0001 0.001 0.01 0.1 1 10

GATE CHARGE QG (nC) TIME (S)

Publication Date : August 2013

9

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

BRAKE PART

COLLECTOR-EMITTER SATURATION

VOLTAGE CHARACTERISTICS

(TYPICAL)

FORWARD CHARACTERISTICS

CLAMP DIODE

(TYPICAL)

3.5

3

(V)

2.5

CEsat

2

1.5

1

COLLECTOR-EMITTER

VGE=15 V

T

Tj=125 °C

=150 °C

j

Tj=25 °C

(Chip)

G-E short-circuited

100

(V)

F

10

Tj=150 °C

Tj=25 °C

FORWARD VOLTAGE V

SATURATION VOLTAGE V

0.5

0

0 20406080100

1

00.511.522.5

COLLECTOR CURRENT IC (A) FORWARD CURRENT IF (A)

HALF-BRIDGE

SWITCHING CHARACTERISTICS

(TYPICAL)

VCC=600 V, VGE=±15 V, RG=13 Ω, INDUCTIVE LOAD

1000

---------------: T

=150 °C, - - - - -: Tj=125 °C

j

t

d(off)

1000

SWITCHING CHARACTERISTICS

VCC=600 V, IC=50 A, VGE=±15 V, INDUCTIVE LOAD

---------------: T

HALF-BRIDGE

(TYPICAL)

=150 °C, - - - - -: Tj=125 °C

j

(Chip)

Tj=125 °C

3

100

10

SWITCHING TIME (ns)

tf

t

d(on)

tr

1

1 10 100

SWITCHING TIME (ns)

t

f

t

d(off)

100

t

d(on)

t

r

10

10 100 1000

COLLECTOR CURRENT IC (A) EXTERNAL GATE RESISTANCE RG (Ω)

Publication Date : August 2013

10

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

BRAKE PART

10

1

SWITCHING CHARACTERISTICS

VCC=600 V, VGE=±15 V, RG=13 Ω,

INDUCTIVE LOAD, PER PULSE

---------------: T

HALF-BRIDGE

(TYPICAL)

=150 °C, - - - - -: Tj=125 °C

j

E

off

SWITCHING CHARACTERISTICS

HALF-BRIDGE

(TYPICAL)

VCC=600 V, IC/IF=50 A, VGE=±15 V,

INDUCTIVE LOAD, PER PULSE

100

E

rr

---------------: T

10

=150 °C, - - - - -: Tj=125 °C

j

Eon

Eon

SWITCHING ENERGY (mJ)

REVERSE RECOVERY ENERGY (mJ)

0.1

1 10 100

COLLECTOR CURRENT IC (A)

FORWARD CURRENT I

REVERSE RECOVERY CHARACTERISTICS

VCC=600 V, VGE=±15 V, RG=13 Ω, INDUCTIVE LOAD

1000

---------------: T

CLAMP DIODE

(TYPICAL)

=150 °C, - - - - -: Tj=125 °C

j

F

(A)

E

off

SWITCHING ENERGY (mJ)

Err

REVERSE RECOVERY ENERGY (mJ)

1

10 100 1000

EXTERNAL GATE RESISTANCE R

G

TRANSIENT THERMAL IMPEDANCE CHARACTERISTICS

(MAXIMUM)

Single pulse, TC=25 °C

th(j-c)Q

=0.35 K/W, R

R

1

0.1

th(j-c)D

=0.63 K/W

(Ω)

(A)

rr

(ns), I

rr

t

100

10

110100

trr

Irr

th(j-c)

Z

NORMALIZED TRANSIENT THERMAL RESISTANCE

0.01

0.001

0.00001 0.0001 0.001 0.01 0.1 1 10

FORWARD CURRENT IF (A) TIME (S)

Publication Date : August 2013

11

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULATED TYPE

PERFORMANCE CURVES

NTC thermistor part

TEMPERATURE CHARACTERISTICS

(TYPICAL)

100

10

1

RESISTANCE R (kΩ)

0.1

-50 -25 0 25 50 75 100 125

TEMPERATURE T (°C)

Publication Date : August 2013

12

< IGBT MODULES >

CM100RX-24S

HIGH POWER SWITCHING USE

INSULA TED TYPE

Keep safety first in your circuit designs!

Mitsubishi Electric Corporation puts the maximum effort into making semiconductor product s better and more

reliable, but there is always the possibility that trouble may occur with them. Trouble with semiconductors

may lead to personal injury, fire or property damage. Remember to give due consideration to safety when

making your circuit designs, with appropriate measures such as (i) placement of substitutive, auxiliary

circuits, (ii) use of non-flammable material or (iii) prevention against any malfunction or mishap.

Notes regarding these materials

•These materials are intended as a reference to assist our customers in the selection of the Mitsubishi

semiconductor product best suited to the customer's application; they do not convey any license under any

intellectual property rights, or any other rights, belonging to Mitsubishi Electric Corporation or a third party.

•Mitsubishi Electric Corporation assumes no responsibility for any damage, or infringement of any

third-party's rights, originating in the use of any product data, diagrams, charts, programs, algorithms, or

circuit application examples contained in these materials.

•All information contained in these materials, including product data, diagrams, charts, programs and

algorithms represents information on products at the time of publication of these materials, and are subject

to change by Mitsubishi Electric Corporation without notice due to product improvements or other reasons. It

is therefore recommended that customers contact Mitsubishi Electric Corporation or an authorized

Mitsubishi Semiconductor product distributor for the latest product information before purchasing a product

listed herein.

The information described here may contain technical inaccuracies or typographical errors. Mitsubishi

Electric Corporation assumes no responsibility for any damage, liability, or other loss rising from these

inaccuracies or errors.

Please also pay attention to information published by Mitsubishi Electric Corporation by various means,

including the Mitsubishi Semiconductor home page (www.MitsubishiElectric.com/semiconductors/).

•When using any or all of the information contained in these materials, including product data, diagrams,

charts, programs, and algorithms, please be sure to evaluate all information as a total system before making

a final decision on the applicability of the information and products. Mitsubishi Electric Corporation assumes

no responsibility for any damage, liability or other loss resulting from the information containedherein.

•Mitsubishi Electric Corporation semiconductors are not designed or manufactured for use in a device or

system that is used under circumstances in which human life is potentially at stake. Please contact

Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor when

considering the use of a product contained herein for any specific purposes, such as apparatus or systems

for transportation, vehicular, medical, aerospace, nuclear, or undersea repeater use.

•The prior written approval of Mitsubishi Electric Corporation is necessary to reprint or reproduce in whole or

in part these materials.

•If these products or technologies are subject to the Japanese export control restrictions, they must be

exported under a license from the Japanese government and cannot be imported into a country other than

the approved destination.

Any diversion or reexport contrary to the export control laws and regulations of Japan and/or the country of

destination is prohibited.

•Please contact Mitsubishi Electric Corporation or an authorized Mitsubishi Semiconductor product distributor

for further details on these materials or the products contained therein.

© 2013 MITSUBISHI ELECTRIC CORPORATION. ALL RIGHTS RESERVED

Publication Date : August 2013

13

Loading...

Loading...