SECURITY

CODE

Spec. NAME

Customer’s

Std. Spec.

Prepared by K.Kurachi

Checked by

Approved by H.Yamaguchi

DATE 10-Apr.-2008

MITSUBISHI ELECTRIC CORPORATION

R

E

V

HIGH VOLTAGE DIODE MODULE

1. Type Number RM900DB-90S

2. Structure Flat base type (Insulated package, Cu base plate)

3. Application & Customer High power converters & Inverters for traction application

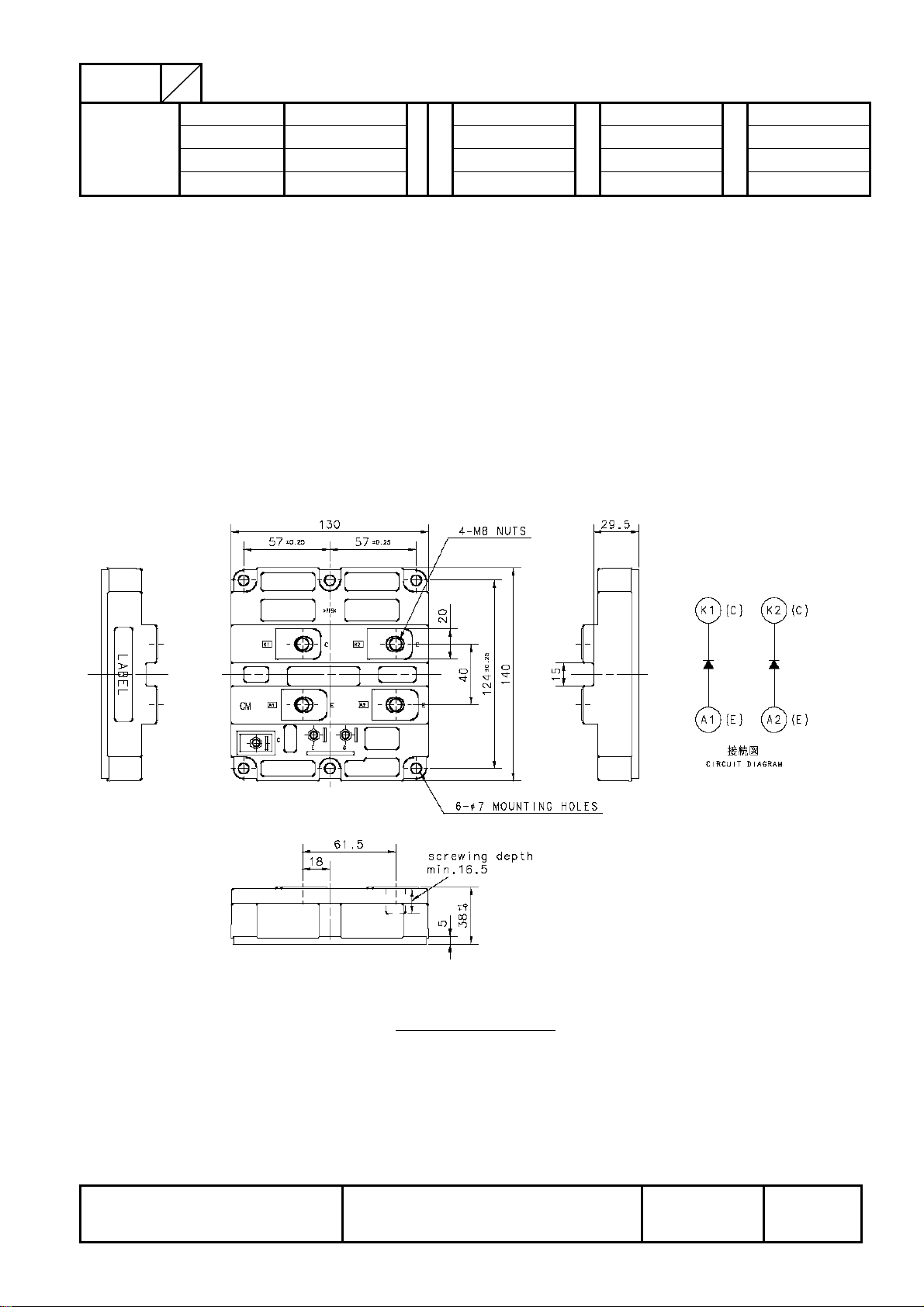

4. Outline See Fig. 1

5. Related Specifications

HIGH VOLTAGE DIODE MODULE

Fig. 1 - Outline drawing

HVM-2018

(HV-SETSU)

PAGE

1 / 11

6. Maximum Ratings

MITSUBISHI ELECTRIC CORPORATION

Item Symbol Conditions Ratings Unit

6.1 Repetitive peak reverse voltage V

6.2 Non-repetitive peak reverse

voltage

6.3 Reverse DC voltage V

6.4 DC forward current IF T

6.5 Surge forward current I

6.6 Surge current load integral I2t

6.7 Isolation voltage V

T

RRM

T

V

RSM

R(DC)

FSM

= 25 °C 4500 V

j

= 25 °C 4500 V

j

Tj = 25 °C 3000 V

= 25 °C 900 A

c

T

= 25 °C start, tw = 8.3 ms

j

Half sign wave

T

= 25 °C start, tw = 8.3 ms

j

6400 A

Half sign wave

iso

Charged part to the baseplate

RMS sinusoidal, 60Hz 1min.

6000 V

170 kA

6.8 Junction temperature Tj — −40 ~ +150 °C

6.9 Storage temperature T

— −40 ~ +125 °C

stg

6.10 Operating temperature Top — −40 ~ +125 °C

V

≤ 3000 V

6.11 Maximum reverse recovery

instantaneous power

—

R

di/dt ≤ 2600A/µs, T

[See Fig.1, Fig.2, 12-5]

= 125 °C

j

900 kW

7. Electrical Characteristics

2

s

Item Symbol Conditions

7.1 Repetitive reverse current I

RRM

7.2 Forward voltage VFM

VRM = V

IF = 900 A

RRM

(Note 1)

Tj = 25 °C

Tj = 125 °C

Tj = 25 °C

Tj = 125 °C

Limits

Min. Typ. Max.

— — 8

— 8 20

— 4.00 —

— 3.60 —

Unit

mA

V

7.3 Reverse recovery time trr — 0.9 — µs

V

= 2250 V, IF = 900 A

7.4 Reverse recovery current Irr — 900 — A

7.5 Reverse recovery charge Qrr — 650 — µC

7.6 Reverse recovery energy E

Note 1: It doesn't include the voltage drop by Internal lead resistance.

rec

R

di/dt = −1800 A/µs

= 125 °C

T

j

[See Fig.1,Fig.2]

— 0.70 — J/P

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

2 / 11

8. Thermal Characteristics

MITSUBISHI ELECTRIC CORPORATION

Item Symbol Conditions

8.1 Thermal resistance R

8.2 Contact thermal resistance R

Note 2: Thermal conductivity is 1W/mK with a thickness of 100µm.

th(j-c)R

th(c-f)

Junction to case

(per 1/2 module)

Case to fin

Conductive grease applied

(per 1/2 module)

(Note 2)

Limits

Min. Typ. Max.

Unit

— — 20.0 K/kW

— 16.0 — K/kW

9. Mechanical Characteristics

Item Symbol Conditions

9.1 Mounting torque —

9.2 Mounting torque —

Main terminal screw : M8

Mounting screw : M6

9.3 Mass — — — 1.5 — kg

9.4 Comparative tracking index CTI — 600 — — —

Limits

Min. Typ. Max.

Unit

7.0 — 13.0 N·m

3.0 — 6.0 N·m

9.5 Clearance — — 19.5 — — mm

9.6 Creepage distance — — 32 — — mm

9.7 Internal inductance L

9.8 Internal lead resistance R

— — 35 — nH

A-K(int)

A-K(int)

Tc = 25 °C — 0.25 — mΩ

10. Shipping Inspection Report Item

Static characteristics : I

Dynamic characteristics : t

Note 3: One shipping inspection report with the above item values is submitted when modules are delivered. The test

conditions are defined in bracket.

RRM

[7.3], Qrr [7.5]

rr

(note 3)

[7.1], VFM [7.2]

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

3 / 11

MITSUBISHI ELECTRIC CORPORATION

∫

∫

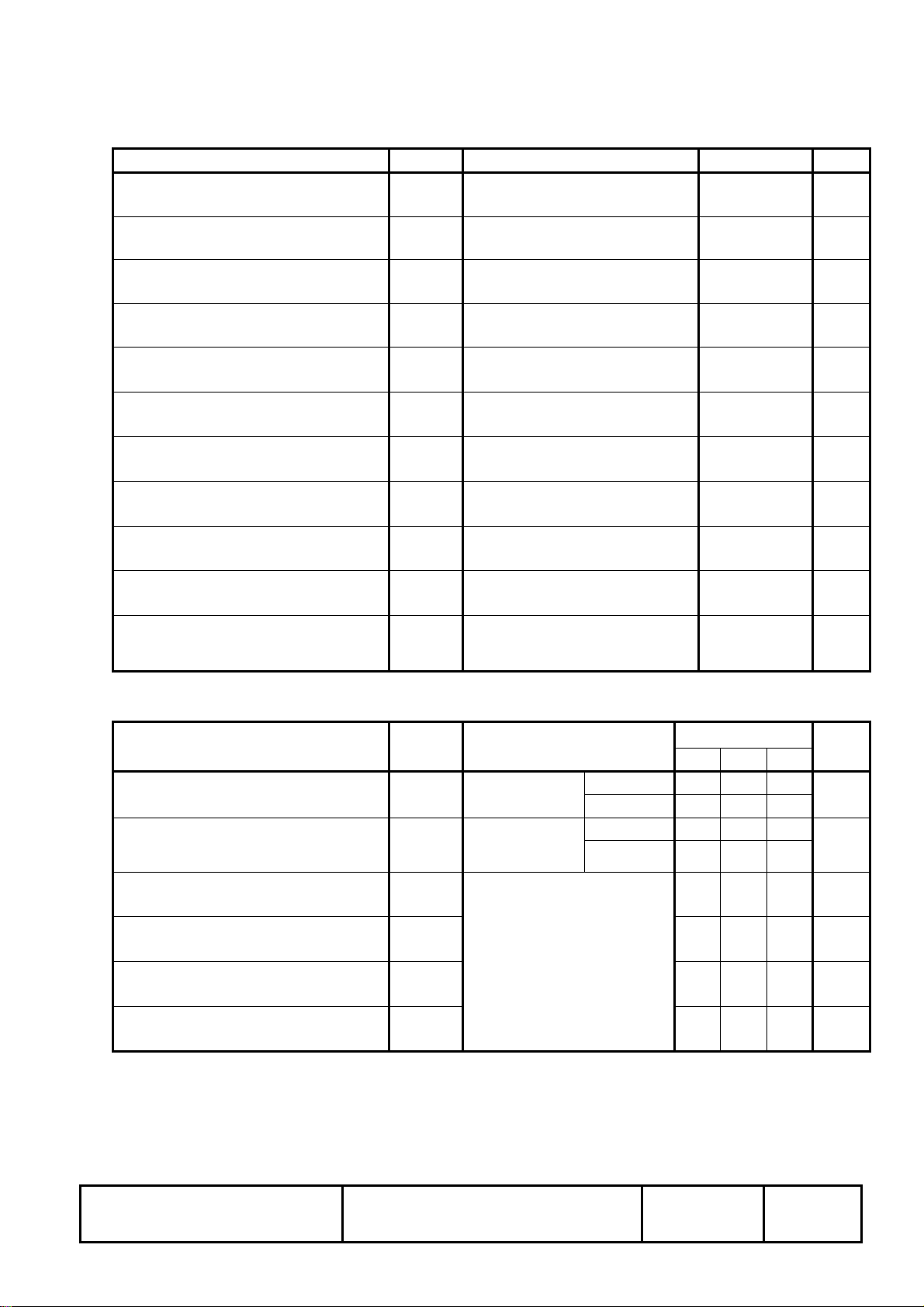

11. Test Circuit & Definition of Switching Characteristics

S1

L

Rg

L

K

LOAD

DUT: diode

L

S2

= 150 nH

C = 2 mF VCC

Diode part: reverse recovery

IF

di/dt

0

0

di

Irr

trr

dt

10%V

CS = 200 uF

A

Fig. 1 – Switching test circuit

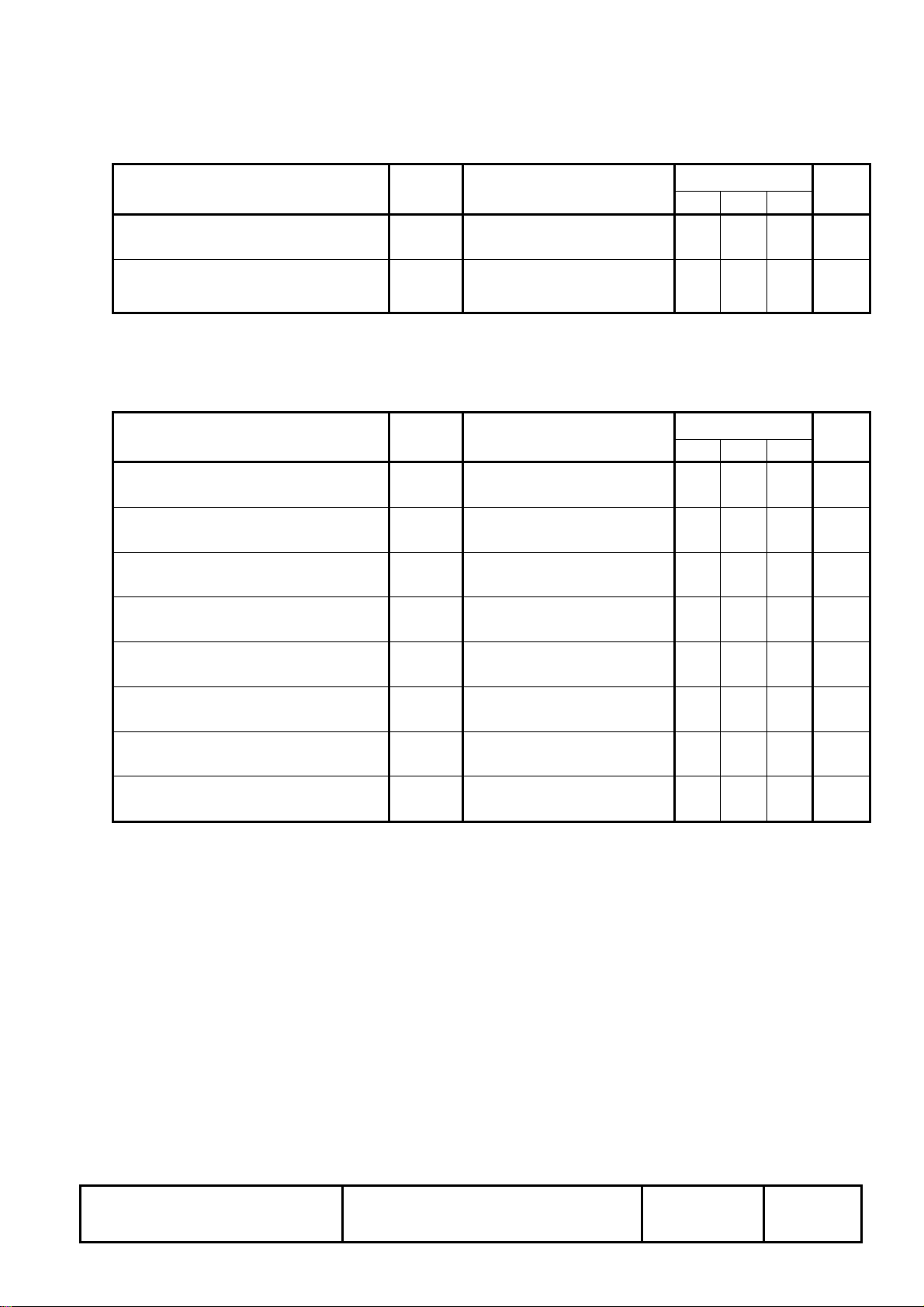

= –

= –

t6

if dt

0

t6

if•vr dt

t5

Qrr

V

R

10%IF

50%Irr

90%Irr

R

Erec

t5

0

t6

Fig. 2 – Definitions of reverse recovery charge & energy

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

4 / 11

MITSUBISHI ELECTRIC CORPORATION

12. Performance curves

12-1 Forward characteristics...................................................................................................6

12-2 Reverse recovery energy characteristics ......................................................................7

12-3 Reverse recovery current characteristics......................................................................8

12-4 Transient thermal impedance characteristics...............................................................9

12-5 Reverse recovery safe operating area .........................................................................10

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

5 / 11

MITSUBISHI ELECTRIC CORPORATION

12-1 Forward characteristics

1800

1600

1400

1200

[A]

F

1000

Tj=125°C Tj=25°C

800

Forward current I

600

400

200

0

012345678

Forward voltage VFM [V]

Forward voltage characteristics (typical)

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

6 / 11

MITSUBISHI ELECTRIC CORPORATION

12-2 Reverse recovery energy characteristics

1.4

1.2

1.0

0.8

0.6

Reverse recovery energy Erec [J/P]

Tj = 125°C, V

= 2250V

R

Ls = 150nH, Inductive load

Integration range: 10%V

~10%IF

R

0.4

0.2

0.0

0 500 1000 1500 2000

Forward current IF [A]

Reverse recovery energy characteristics (typical)

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

7 / 11

MITSUBISHI ELECTRIC CORPORATION

A

12-3 Reverse recovery current characteristics

1400

Tj = 125°C, VR = 2250V

Ls = 150nH,

1200

1000

]

Inductive load

Reverse recovery current Irr [

800

600

400

200

0

0 500 1000 1500 2000

Forward current IF [A]

Reverse recovery current characteristics (typical)

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

8 / 11

MITSUBISHI ELECTRIC CORPORATION

12-4 Transient thermal impedance characteristics

1.2

Rth(j-c) = 20 K/kW

1.0

0.8

0.6

0.4

Normalized transient thermal impedance

0.2

0.0

0.001 0.01 0.1 1 10

Time [sec.]

Transient thermal impedance characteristics

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

9 / 11

MITSUBISHI ELECTRIC CORPORATION

12-5 Reverse recovery safe operating area

2500

2000

[A]

Tj = 125°C, VR ≤ 3000 V

di/dt ≤ 2600A/µs

1500

1000

Reverse recovery current Irr

500

0

0 1000 2000 3000 4000 5000

Reverse recovery safe operating area (RRSOA)

HIGH VOLTAGE DIODE MODULE

Reverse voltage VR [V]

HVM-2018

(HV-SETSU)

PAGE

10 / 11

MITSUBISHI ELECTRIC CORPORATION

Rev.

No.

−

Summary of changes

Original

Signature

& date

K.Kurachi

10-Apr.-2008

HIGH VOLTAGE DIODE MODULE

HVM-2018

(HV-SETSU)

PAGE

11 / 11

Loading...

Loading...