Page 1

Version 7.0 09/10/2010

2010

Service

Manual

DLP PROJECTION HDTV

V43C Chassis

WD-60C10

WD-65C10

WD-73C10

V43+ Chassis

WD-60738

WD-65738

WD-73738

V43 Chassis

WD-60638

WD-65638

WD-73638

V43++ Chassis

WD-65838

WD-73838

WD-82838

WD-82738

CAUTION:

Before servicing this chassis, it is important that the service person read the "SAFETY PRECAUTIONS" and

"PRODUCT SAFETY NOTICE" contained in this manual.

SPECIFICATIONS

• Power Input : AC 120V, 60Hz

• Light Engine : DLP™ (1080p)

• Light Source : 156W

• Antenna Input : RF 75Ω unbalanced

• Tuning : NTSC/ATSC/QAM

: Analog Cable - 1~125

Digital Cable - 1~135

• Speakers : 10W x 2 (V43C, V43, V43+)

: 2W x 16 (V43++)

• See Page 5 for additional specifications.

• Design specifications are subject to change without notice.

• Analog Input

Level (RCA Type)

Y/Video: 1.0 Vp-p, Cr, Cb: 700mVp-p

75Ω unbalanced

: AUDIO IN JACK (RCA Type)

-4.7dBm 43kΩ unbalanced

• Analog Output : AUDIO / SUBWOOFER OUT JACK

Level (RCA Type)

-4.7dBm 4.7kΩ unbalanced

• Digital : AC-3/PCM Digital Audio Output

Inputs/Outputs (RCA Type)

: HDMI™

:

: PC - use HMDI™

:

: Ethernet (V43+, V43++)

: Bluetooth (V43++)

: Composite/Component

USB

Wired IR Input/Output (V43++)

MITSUBISHI DIGITAL ELECTRONICS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618-1904

Copyright © 2010 Mitsubishi Digital Electronics America, Inc.

All Rights Reserved

Page 2

Page 3

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

CONTENTS

INTRODUCTION ................................................................................................................................. 5

Dimensions, weight, power usage, etc. ...........................................................................................5

PRODUCT SAFETY NOTICE .............................................................................................................5

SAFETY PRECAUTIONS.................................................................................................................... 6

DISASSEMBLY & PARTS REPLACEMENT...................................................................................... 7

Back Cover Removal.......................................................................................................................7

Chassis Removal ............................................................................................................................ 8

Rear Terminal Cover Removal ........................................................................................................8

Power Supply Shield Removal.........................................................................................................9

PWB-POWER Removal...................................................................................................................9

Top Chassis Brackets Removal.....................................................................................................10

PWB-MAIN Removal ..................................................................................................................... 10

PWB-BALLAST Removal...............................................................................................................12

Optical Engine Assembly Removal & Disassembly.......................................................................12

Duct Assembly Removal................................................................................................................13

Optical Engine Replacement ......................................................................................................... 15

Projection Lens Replacement........................................................................................................16

Color Wheel Replacement............................................................................................................. 17

Screen Replacement ..................................................................................................................... 18

Mirror Replacement ....................................................................................................................... 24

SERVICE PROCEDURES................................................................................................................. 25

Remote Control..............................................................................................................................25

Option Menu...................................................................................................................................26

Reset and Initialization...................................................................................................................28

LED Indications & Self Diagnostics................................................................................................29

Error Codes....................................................................................................................................30

Error Code Log...............................................................................................................................30

Sound Projector Transducer Test..................................................................................................31

Service Adjustments

Equipment & Test Signals .................................................................................................... 32

Service Menu........................................................................................................................ 32

Horizontal & Vertical Position Adjustment ............................................................................ 34

Index Delay Adjustment........................................................................................................ 35

Manual Geometry Alignment................................................................................................ 36

Data Transfer Functions ................................................................................................................ 40

Using Lead Free Solder.................................................................................................................42

Chip Parts Replacement................................................................................................................43

REPLACEMENT PARTS ..................................................................................................................44

Parts Ordering................................................................................................................................ 44

Critical and Warranty Parts Designation........................................................................................44

Parts Tolerance Codes ..................................................................................................................44

Parts Quick Reference................................................................................................................... 45

Service Parts List........................................................................................................................... 46

Screen Parts ..................................................................................................................................55

Mirror Kits & Preparation................................................................................................................57

CIRCUIT BLOCK DIAGRAMS..........................................................................................................59

SCHEMATIC DIAGRAMS

......................................................................................................................32

Page 3

Page 4

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Digital Light Processing®, Digital Micro Mirror Device and DLP® are Trademarks of Texas Instruments.

HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing, LLC..

Page 4

Page 5

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

INTRODUCTION

This service manual provides service instructions for the V43C, V43, V43+ and V43++ chassis types. The specific

models for each chassis type, dimensions and weight are listed below. Service personnel should read this manual

thoroughly before servicing these chassis.

This service manual includes:

1. Disassembly & replacement instructions for cabinet and chassis components.

2. Replacing the Lenticular Screen, Fresnel Lens and Mirror.

3. Initial setup and troubleshooting.

4. Service adjustments.

5. Using lead free solder.

6. Chip parts replacement procedures.

7. Replacement part Instructions

8. Replacement parts list

9. Circuit block diagrams

10. Schematic diagrams

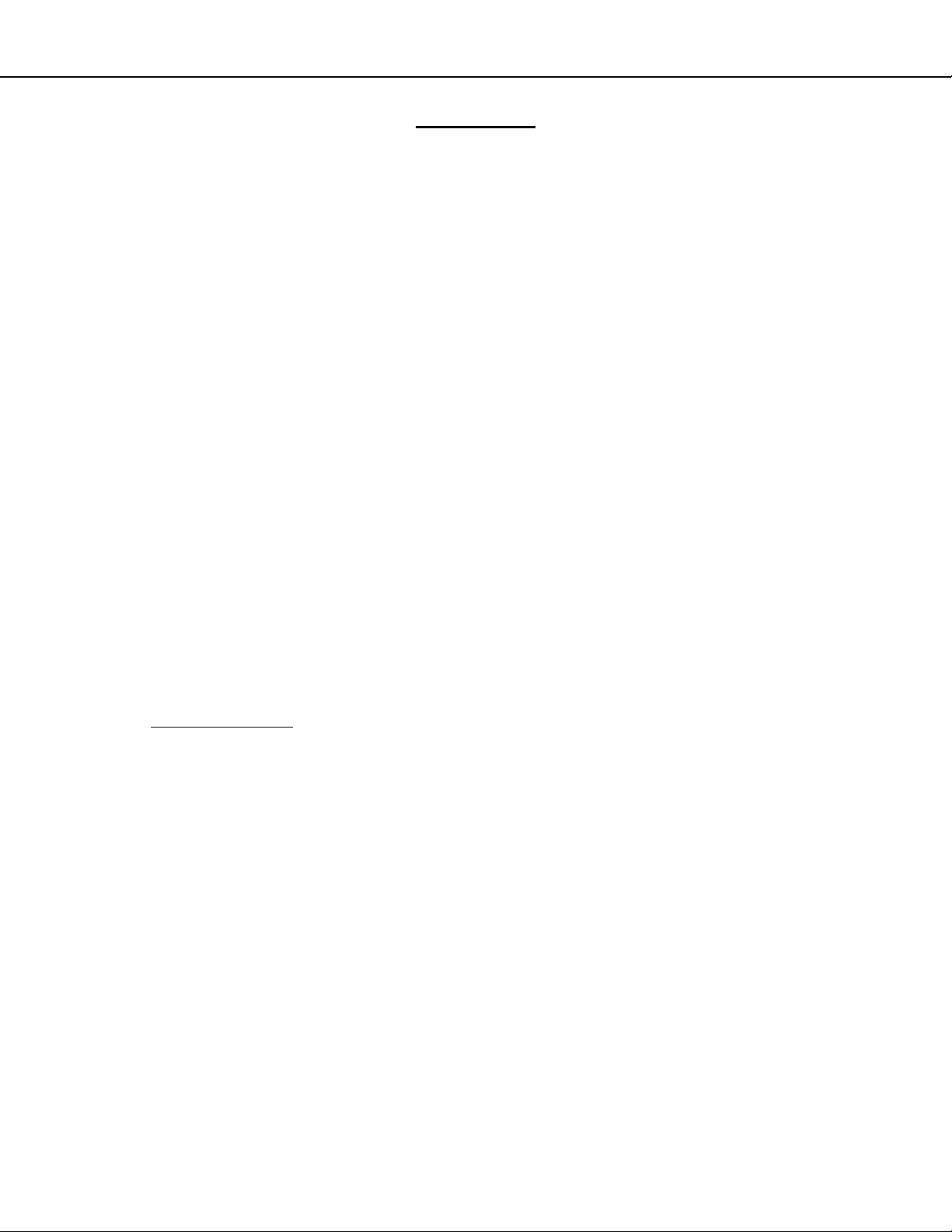

MODEL CHASSIS HEIGHT WIDTH DEPTH WEIGHT

WD-60C10

WD-65C10

WD-73C10

WD-60638

WD-65638

WD-73638

WD-60738

WD-65738

WD-73738

WD-82738

WD-65838

WD-73838

WD-82838

V43C 36.7" 54.7" 14.4" 65.0 lbs 260W

V43C 39.5" 58.2" 15.4" 72.3 lbs 260W

V43C 43.6" 65.2" 17.5" 93.0 lbs 260W

V43 36.7" 54.7" 14.4" 65.0 lbs 260W

V43 39.5" 58.2" 15.4" 72.3 lbs 260W

V43 43.6" 65.2" 17.5" 93.0 lbs 260W

V43+ 36.7" 54.7" 14.4" 65.0 lbs 270W

V43+ 39.5" 58.2" 15.4" 72.3 lbs 270W

V43+ 43.6" 65.2" 17.5" 93.0 lbs 270W

V43+ 48.5" 73.2" 20.0" 139.7 lbs 270W

V43++ 39.5" 58.2" 15.8" 77.2 lbs 290W

V43++ 43.6" 65.2" 17.9" 97.9 lbs 290W

V43++ 48.5" 73.2" 20.4" 147.5 lbs 290W

POWER

USAGE

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in television receivers have special safety related characteristics. These characteristics are often not evident from visual inspection nor can the protection afforded by them necessarily be obtained by using replacement components rated for higher voltage, wattage, etc.

Replacement parts which have special safety characteristics are identified on the schem atic diagrams and parts list

of this service manual. The replacement for any safety part should be identical in value and characteristics.

The PWBs used in this chassis are constructed using Lead-Free Solder. When servicing use

only recommended Lead-Free Solder. Refer to the section “Using Lead Free Solder.”

Page 5

Page 6

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SAFETY PRECAUTIONS

NOTICE:

Observe all cautions and safety related notes located inside the receiver cabinet and on the receiver chassis.

WARNING:

1. Operation of this receiver outside the cabinet or with the cover removed presents a shock hazard from

the receiver's power supplies. Work on the receiver should not be attempted by anyone who is not thoroughly

familiar with the precautions necessary when working on high volta ge equipment.

2. When service is required, observe the original lead dress. Where a short-circuit has occurred, replace those

components that indicate evidence of overheating.

SAFETY PRECAUTION

To protect your eyes, do not look directly into the lamp, or light coming directly from the lamp, lens or

mirror.

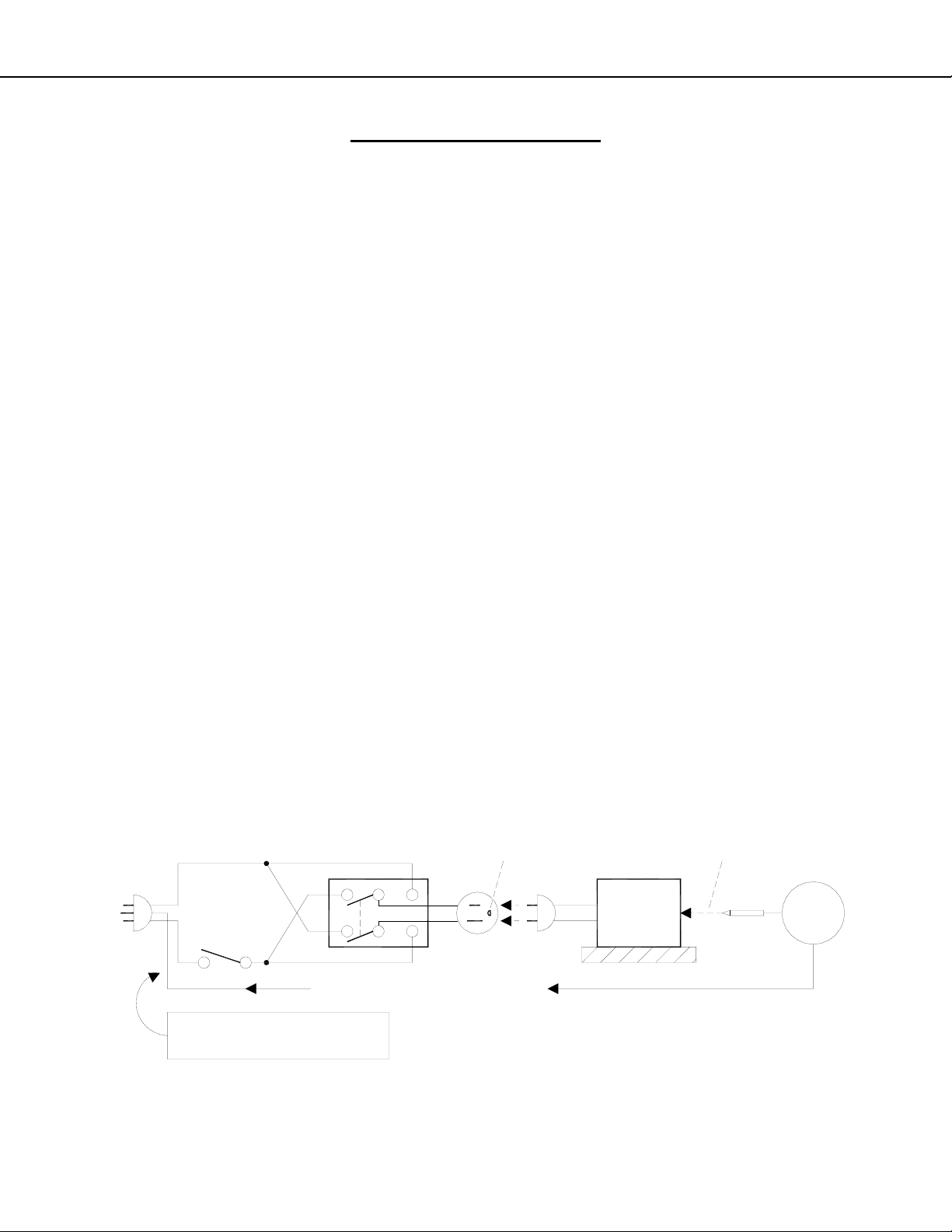

Leakage current check

Before returning the receiver to the customer, it is recommended that leakage current be measured according to the

following methods.

1. Cold Check

With the alternating current (AC) plug removed from the AC source, place a jumper across the two AC plug

prongs. Connect one lead of an ohm meter to the AC plug and touch the other lead to each exposed metal

part (i.e. antennas, handle bracket, metal cabinet, screw heads, metal overlay, control shafts, etc.), particularly

any exposed metal part that has a return path to the chassis. The resistance of the exposed metal parts having a return path to the chassis should be a minimum of 1Meg Ohm. Any resistance below this value indicates an abnormal condition and requires corrective action.

2. Hot Check ...Use the circuit shown below to perform the hot check test.

1. Keep switch S1 open and connect the receiver to the measuring circuit. Immediately after connection,

and with the switching devices of the receiver in their operating positions, measure the leakage current

for both positions of switch S2.

2. Close switch S1, energizing the receiver. Immediately after closing switch S1, and with the switching

devices of the receiver in their operating positions, measure the leakage current for both positions of

switch S2. Repeat the current measurements of items 1 and 2 after the receiver has reached therm al

stabilization. The leakage current must not exceed 0.5 milliampere (mA).

S1

SUPPLY CONNECTOR GROUND

GWG - Green Wire Ground

(Earth Ground)

S2

OPEN

GROUND

L

N

Page 6

TOUCH ALL

EXPOSED

METAL PARTS

RECEIVER

AC MA

METER

INSULATED TABLE

Page 7

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

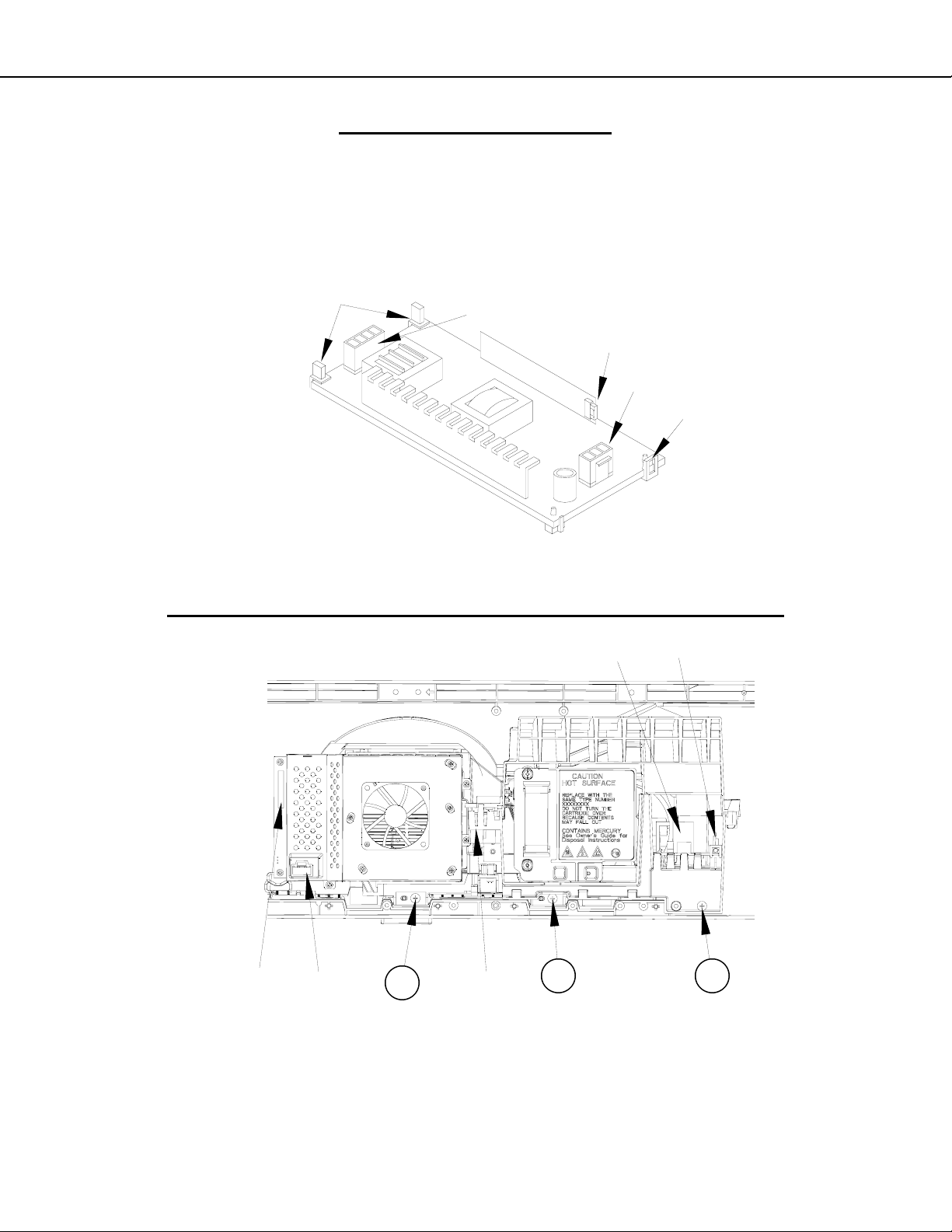

DISASSEMBLY & PARTS REPLACEMENT

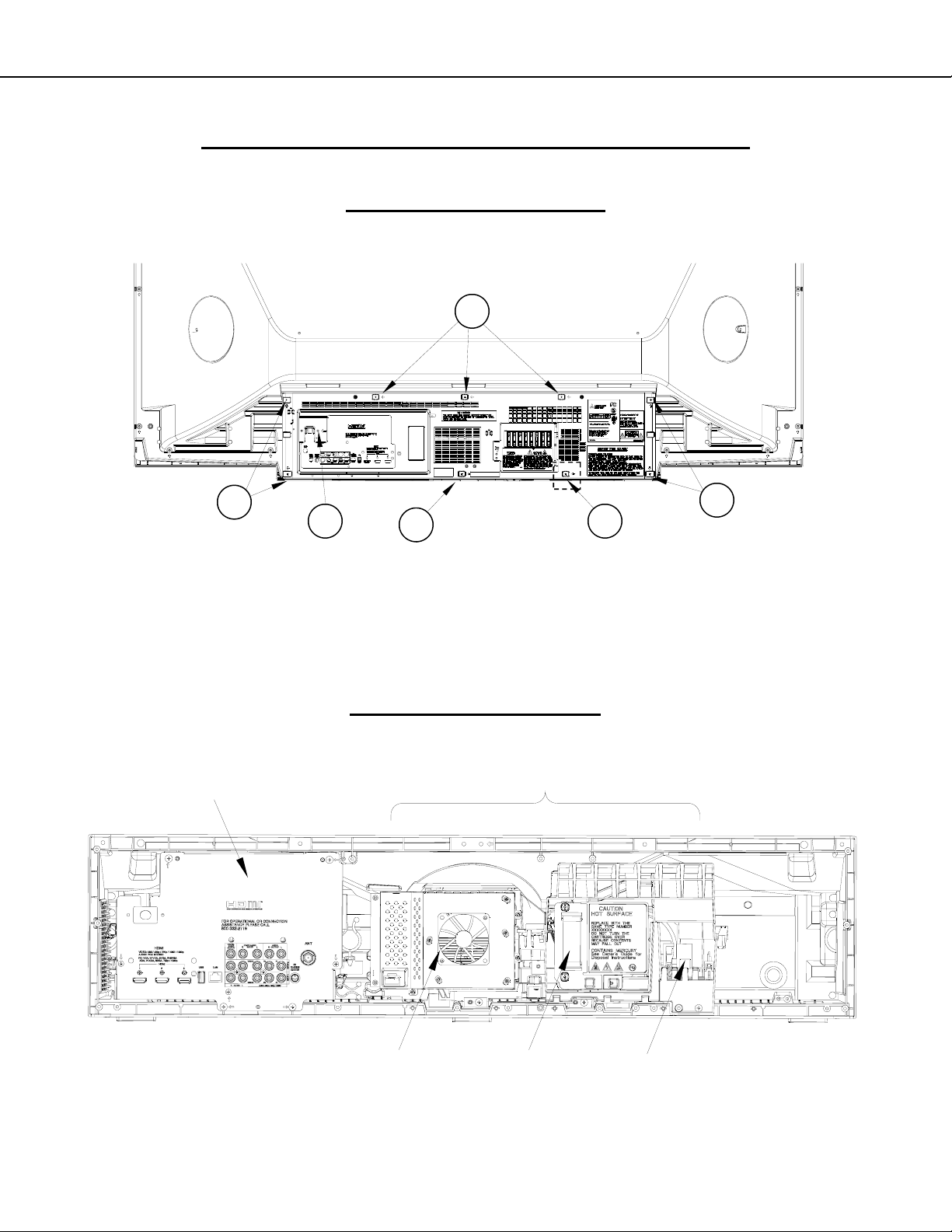

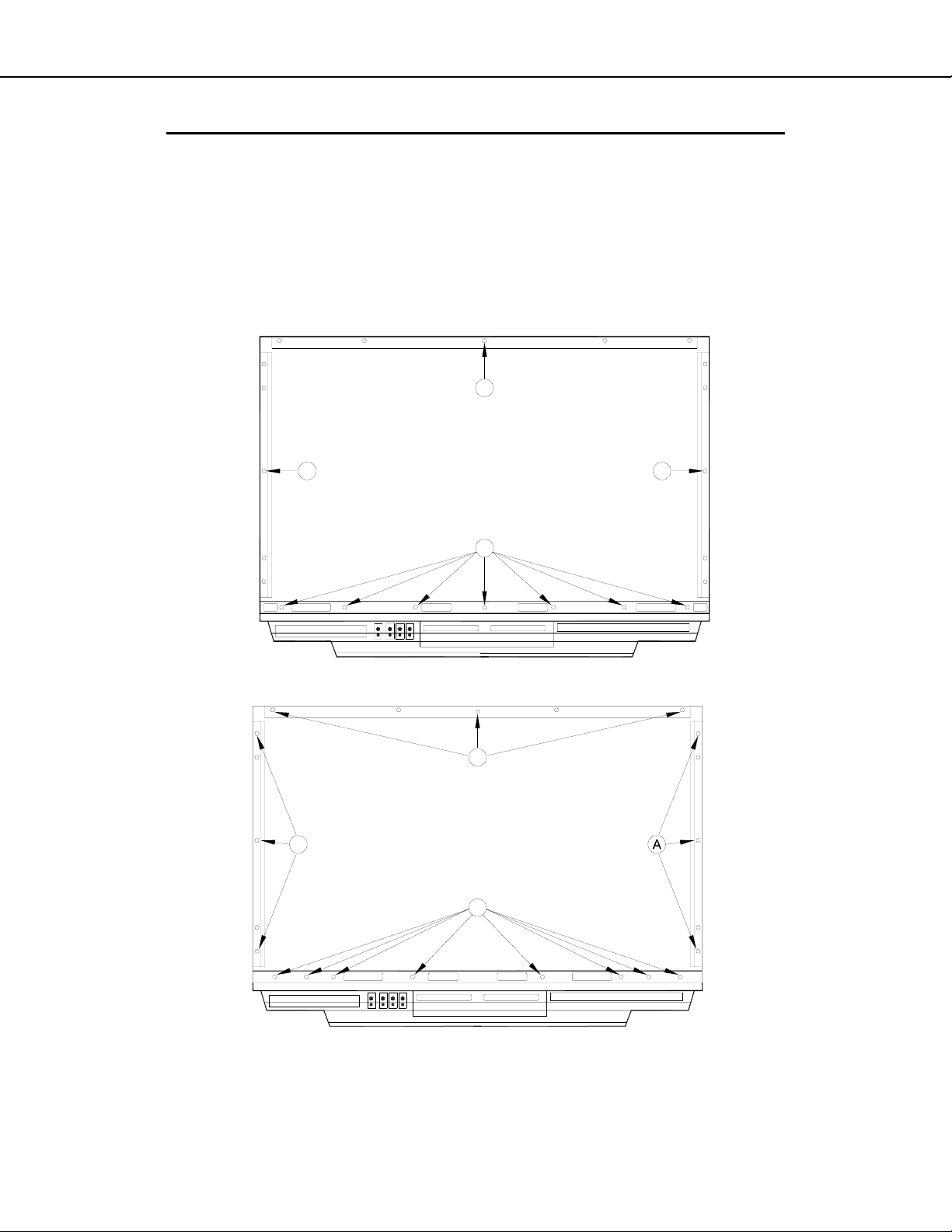

BACK COVER REMOVAL

A

A

A

Back Cover Removal

1. Remove screws (A) from the back cover.

2. Remove the back cover from the TV.

CHASSIS

A

73” & 82” Only

ASSEMBLY LOCATIONS

OPTICAL ENGINE ASSEMBLY

A

A

DMD FAN LAMP PWB-BALLAST

Page 7

Page 8

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

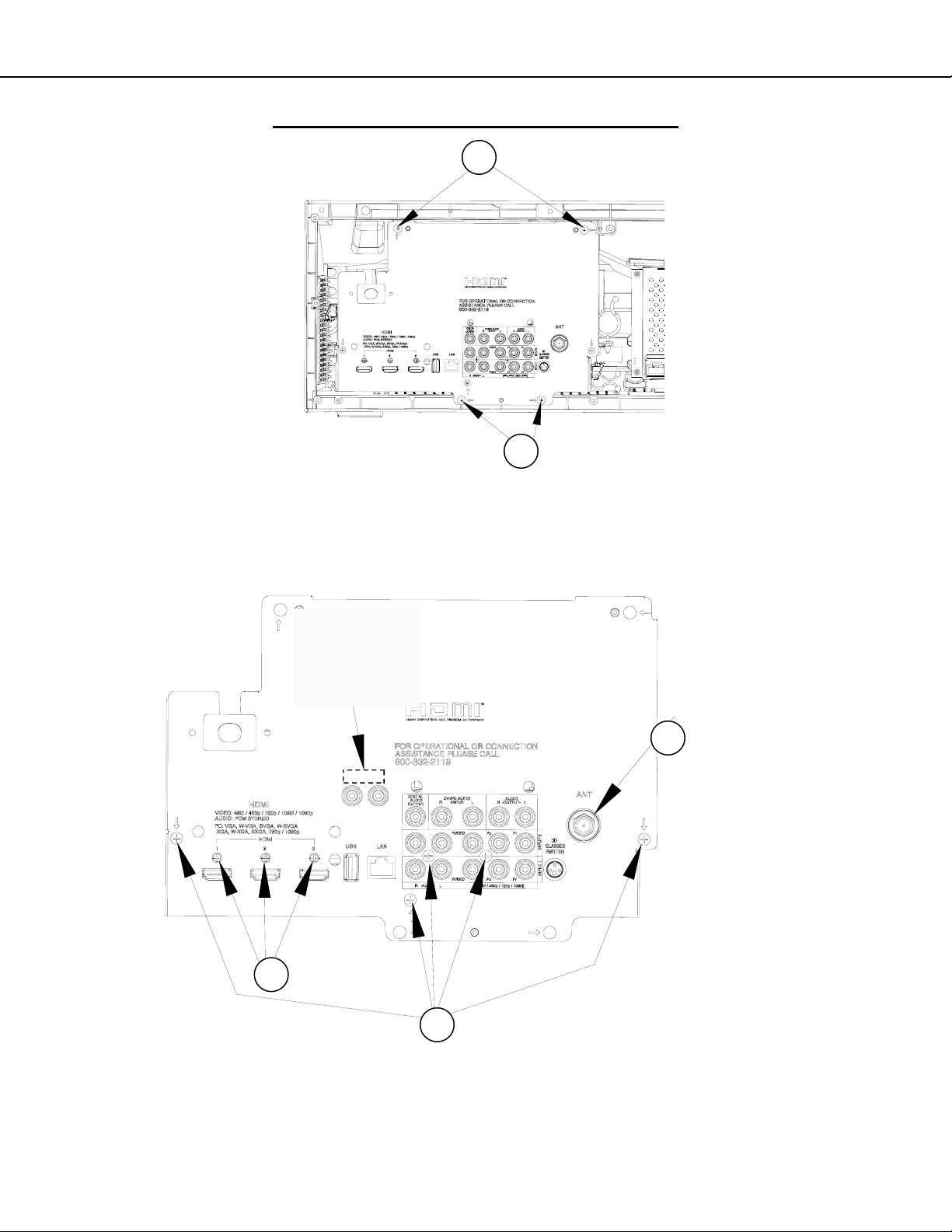

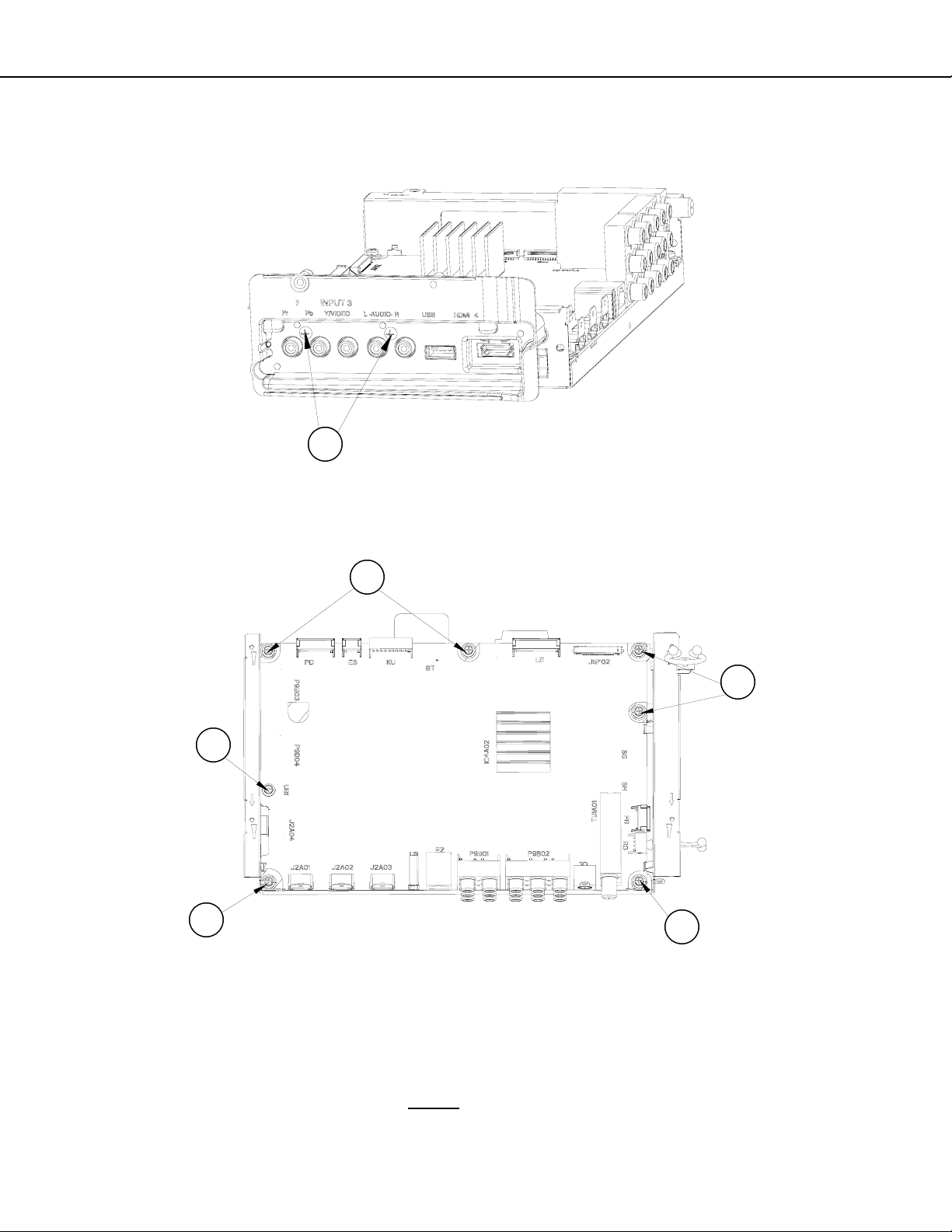

CHASSIS - REMOVAL & DISASSEMBLY

A

A

Chassis Removal

1. Remove screws (A).

2. Disconnect all cables connecting to the chassis.

3. Slide the chassis out of the cabinet.

PWB-AUX

CONNECTOR

(ON REAR)

V43++ Only

A

ANT Location:

V43C, V43 Left Side

V43+, V43++ Right Side

B

Rear Terminal Cover Removal

1. Remove nut (A) from the ANT input.

2. Remove screws (B) and (C).

3. Disconnect the connector to the PWB-AUX (V43++).

4. Remove the Terminal Cover from the chassis.

C

Page 8

Page 9

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

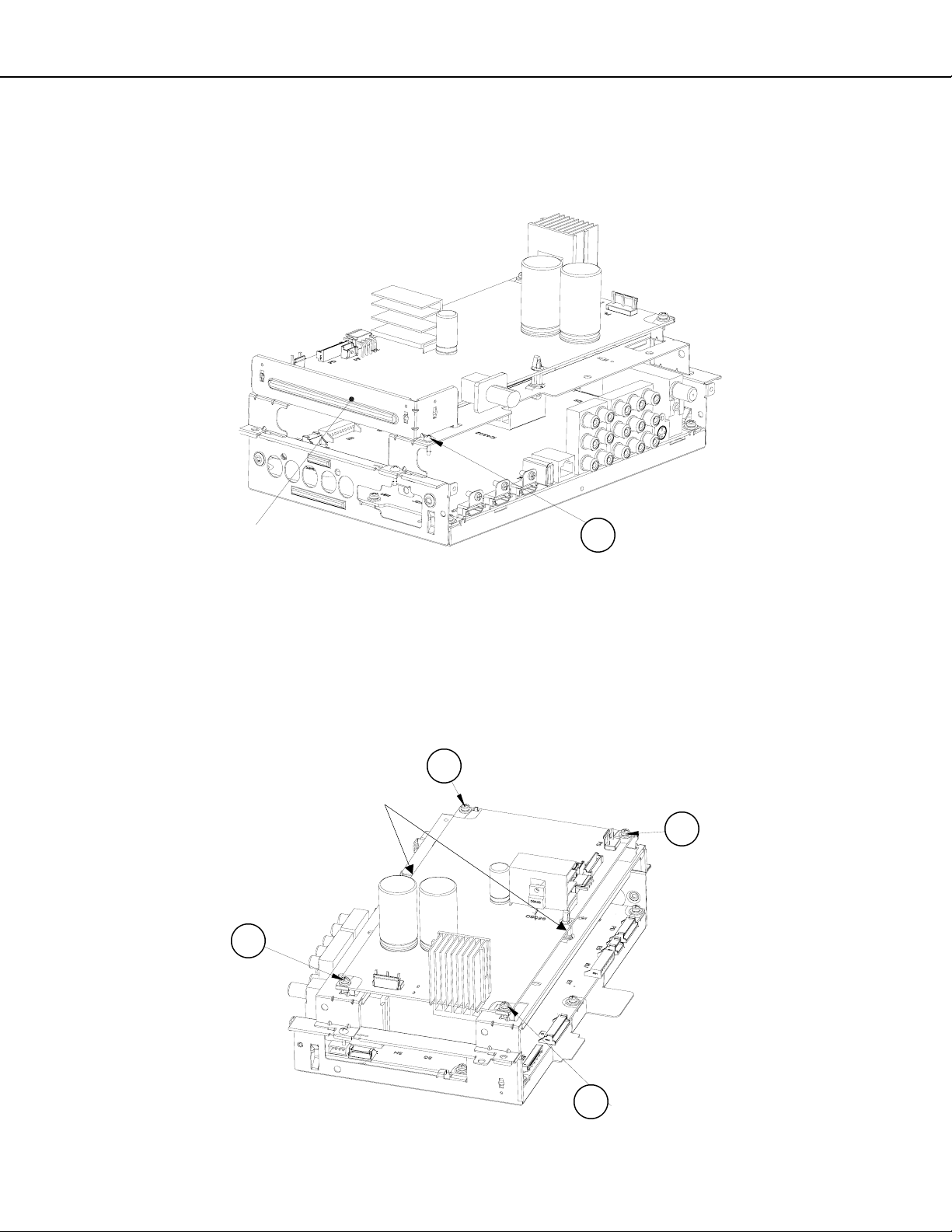

Power Supply Shield Removal

1. Remove screw (A).

POWER SUPPLY SHIELD

PWB-POWER Removal

1. Disconnect all cables from the PWB-POWER.

2. Remove screws (A).

3. Pinch the Retainers to release the PWB.

4. Lift the PWB-POWER from the chassis.

Retainers

(Pinch)

A

A

A

A

Page 9

A

Page 10

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

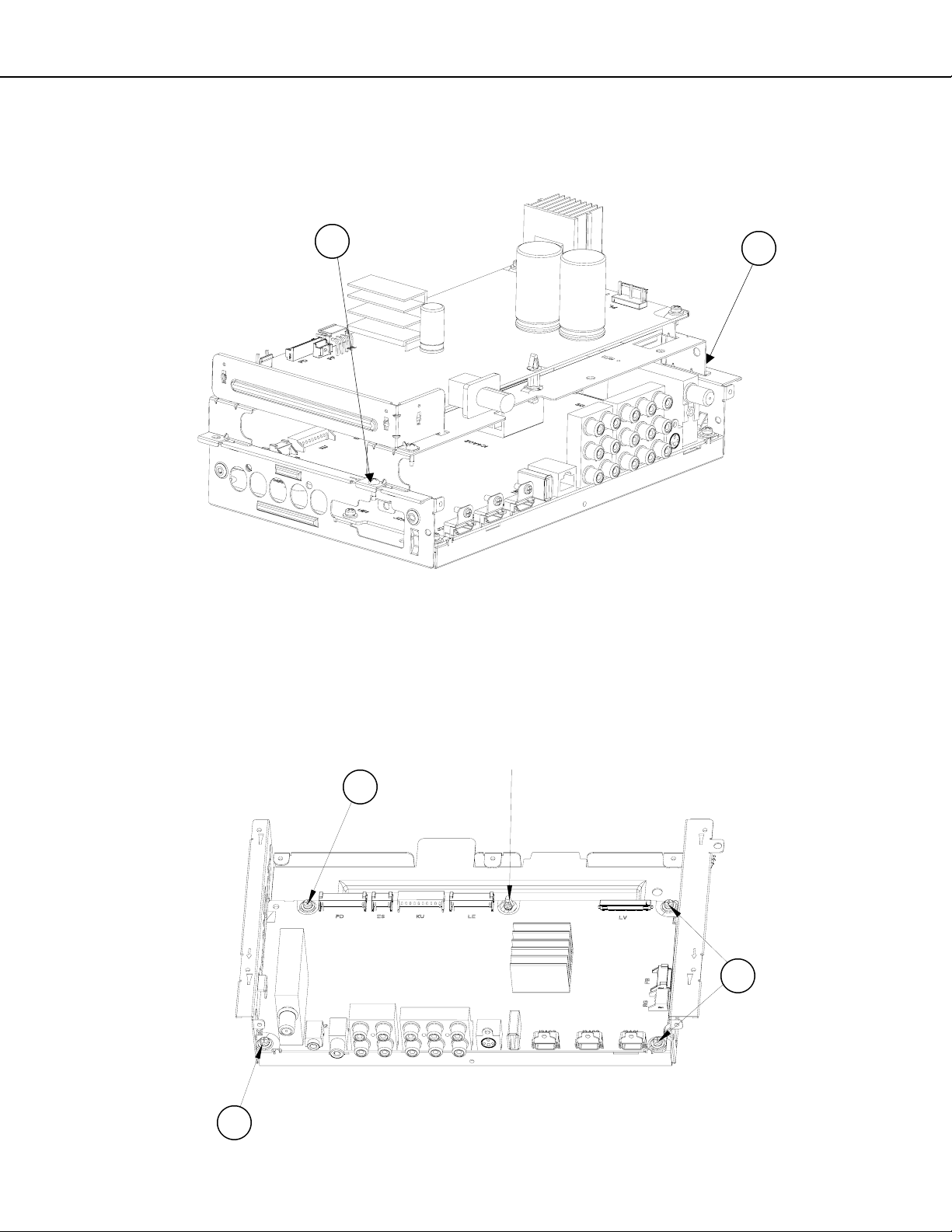

PWB-MAIN ACCESS

1. Remove screws (A).

2. Lift the Power Supply and Mounting Brackets from the chassis.

A

PWB-MAIN Removal (V43)

1. Disconnect all cables to PWB-MAIN.

2. Remove screws (B) from the top of the PWM-MAIN.

3. Pinch the Retainer to release the PWB.

4. Lift the PWB-MAIN out of the chassis.

A

B

Retainer

(Pinch)

B

B

Page 10

Page 11

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

PWB-MAIN Removal (V43+, V43++)

1. Disconnect all cables to PWB-MAIN.

2. Remove screws (A) from the Side Terminals (V43++ only).

A

V43++ Only

3. Remove screws (B) from the top of the PWM-MAIN.

4. Lift the PWB-MAIN out of the chassis.

B

V43+ Only

B

B

B

B

After PWB-MAIN Replacement

See Data Transfer in Service Procedures section.

1. V43C & V43: Perform “Restore Engine Data From Backup.”

2. V43+ & V43++: Perform “Restore Engine Data From Backup” and “Restore Geometry Data From Backup.”

V43+, V43++ IMPORTANT REPLACEMENT NOTE: If the customer has subscribed to VUDU (Internet program

provider), the customer must be instructed to contact VUDU to re-activate their account after the replacement

PWB has been installed. The original PWB cannot

per policy.

be installed in another TV. It must be returned to Mitsubishi

Page 11

Page 12

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

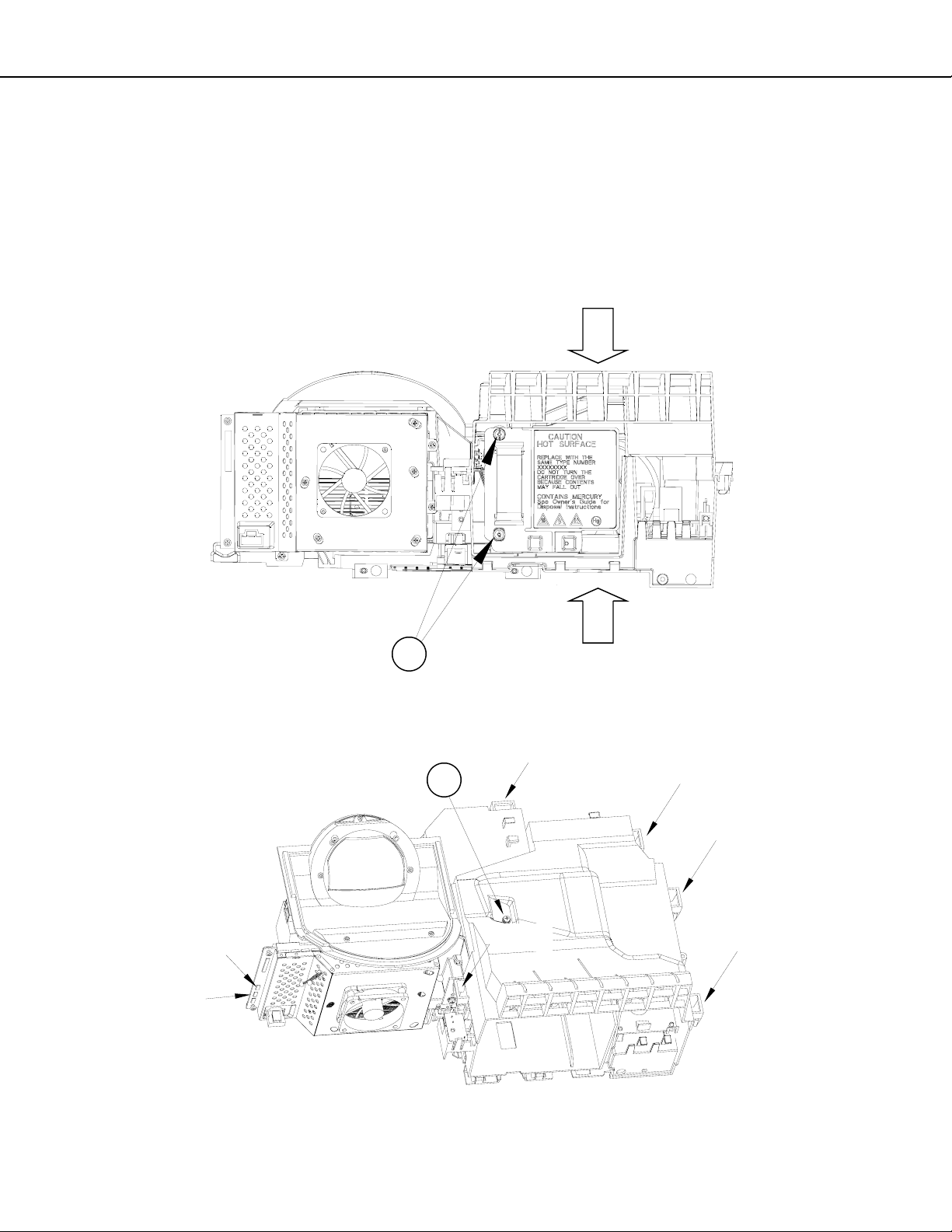

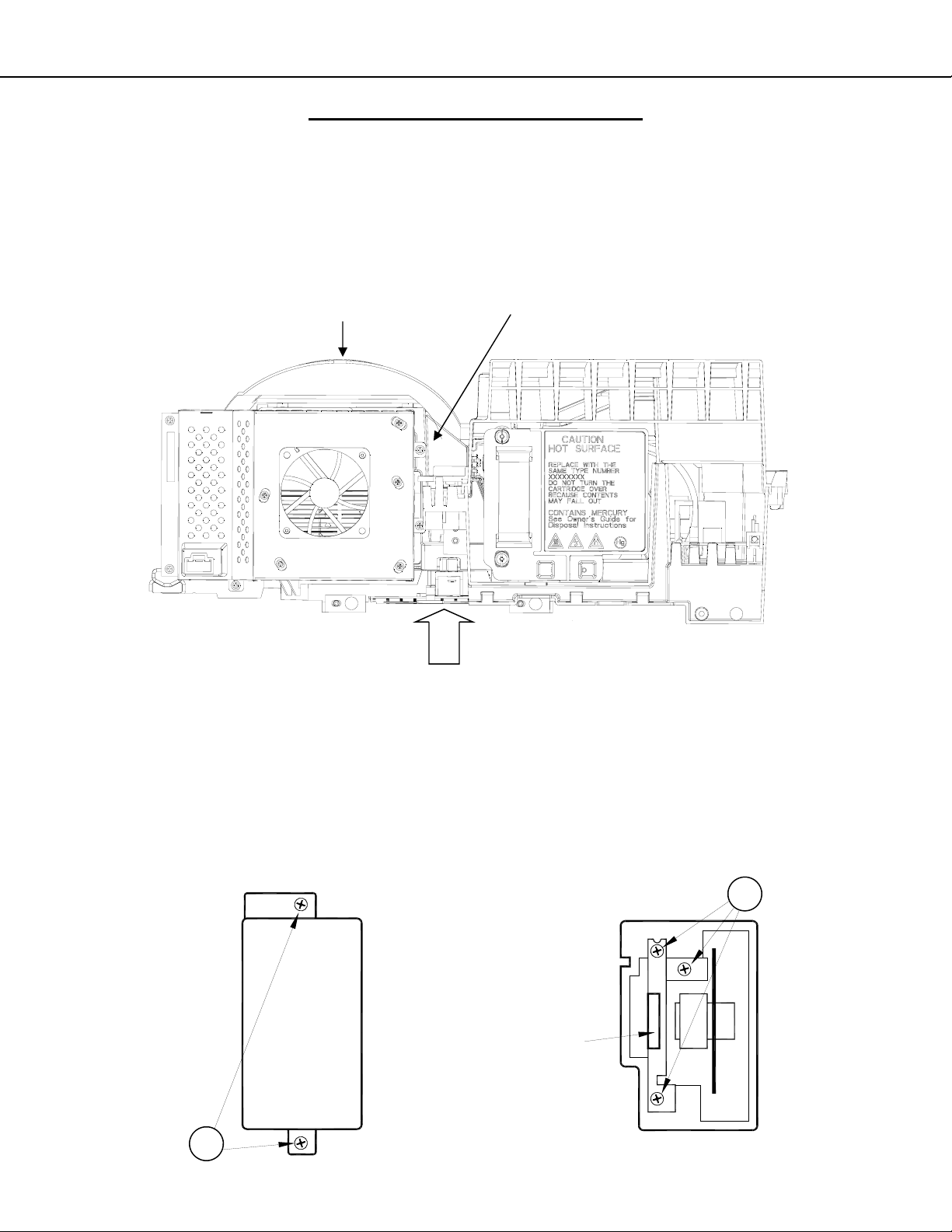

PWB-BALLAST REMOVAL

Note: To remove the PWB-BALLAST, it is not necessary to remove the Engine or Lamp Cartridge.

1. Release the Latch to lift the PWB-BALLAST from the mounting bracket.

2. Slide the PWB-BALLAST out of the Engine Assembly.

3. Disconnect the electrical locking connectors indicated.

4. To reinstall, first connect the connectors. Then slide the PWB under the Retaining Hooks. Then press the rear

edge of the PWB down onto the guide pins to engage the latch.

RETAINING

HOOKS

CJ4 (HV to Lamp)

CJ3 (Lamp Control)

CJ1 (Lamp Power)

LATCH

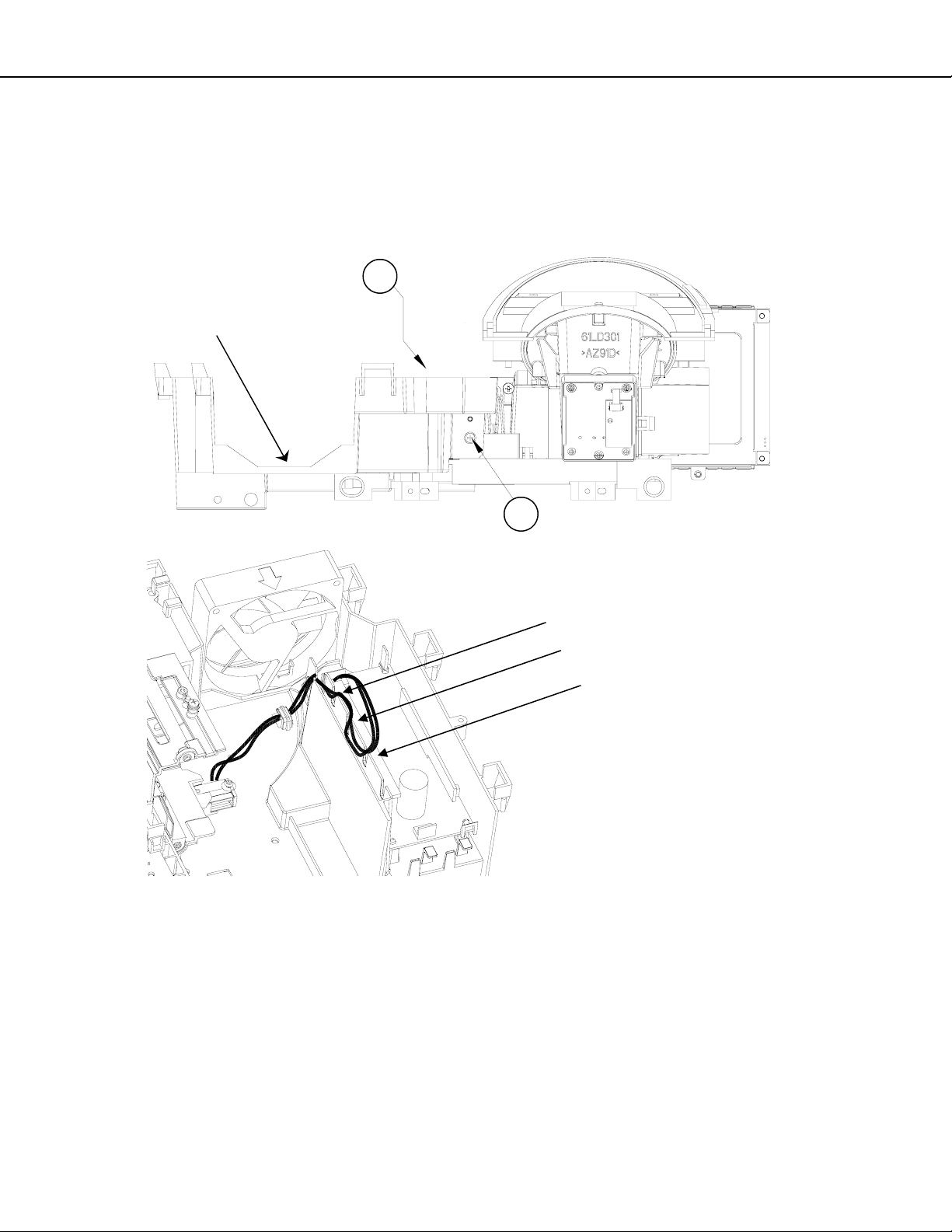

OPTICAL ENGINE ASSEMBLY - REMOVAL & DISASSEMBLY

CJ1 (Lamp Power)

CJ3 (Lamp Control)

J12 (LVDS)

PE

(Engine Power)

A

OPTICAL ENGINE ASSEMBLY REMOVAL

1. Remove 3 screws (A) from the Optical Engine Assembly.

2. Disconnect the electrical locking connectors indicated.

3. Slide the Optical Engine Assembly out of the cabinet.

A A

CD

(Lamp Door Sw)

Page 12

Page 13

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

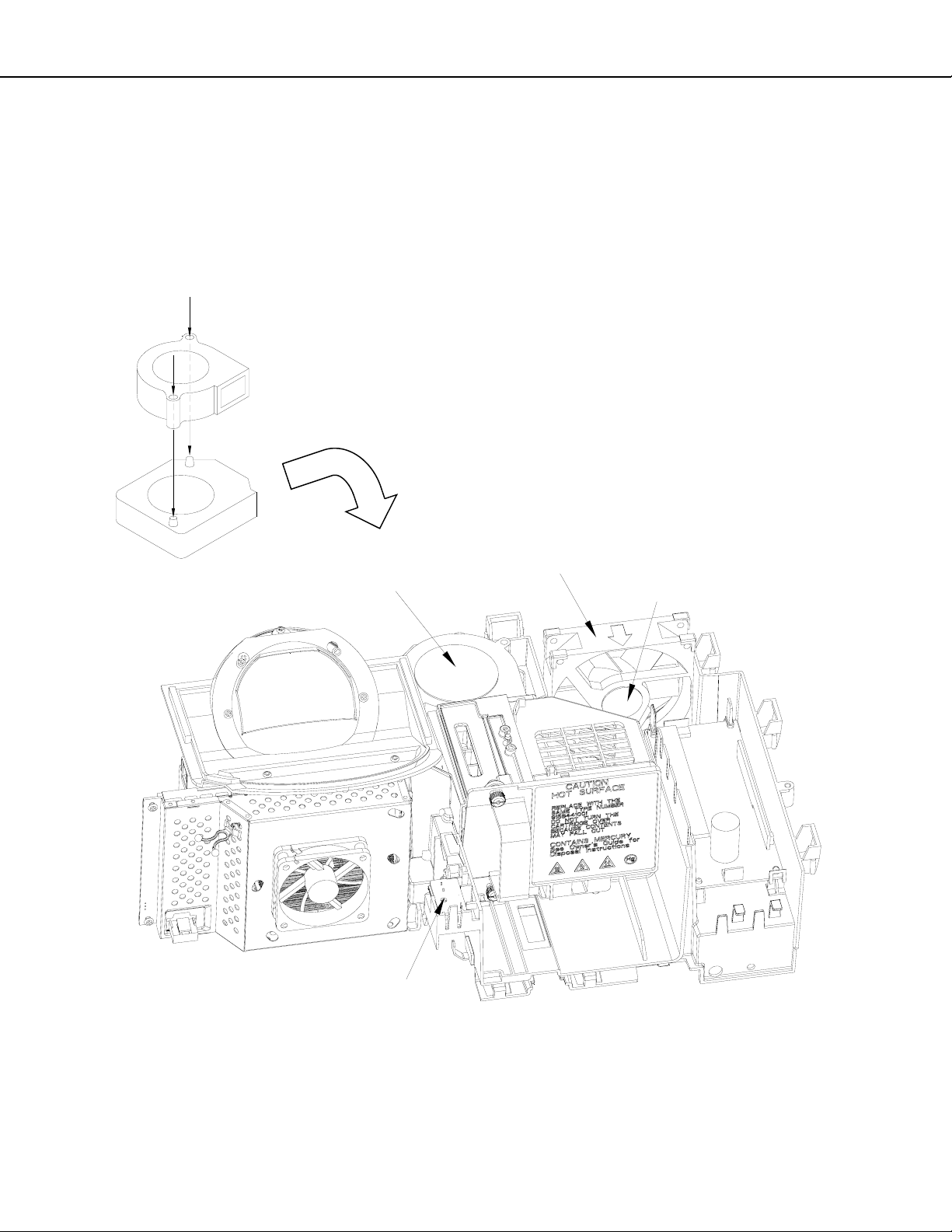

DUCT ASSEMBLY - Removal and Disassembly

Upper Duct Removal

1. Loosen two screws (A) and remove the Lamp Cartridge.

2. Disconnect the Exhaust and Sirocco Fan Connectors (J4 and J8) from the back of the Engine and loosen the

wiring harnesses from the looms.

3. Remove screw (B) from the top of the Upper Duct and release the latches.

4. Remove the Upper Duct from the Optical Engine Assembly.

UPPER DUCT

J8

(Sirocco Fan)

J4

(Exhaust Fan)

A

B

LATCH

LATCH

LOWER DUCT

LATCH

LATCH

LATCH

Page 13

Page 14

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Duct Interior Components

Duct Interior Components are shown below.

Notes:

• The Upper Duct must be removed to replace the Lamp Door Switch PWB, Sirocco Fan and Exhaust Fan.

• When replacing the Optical Engine, transfer all Duct and Duct Interior Components from the old Engine to the

new Engine.

• The Exhaust Fan must be installed so the Label is facing inside the Duct.

• The Sirocco Fan must be installed so the Label is facing up with the Flanges aligned onto the Guide Pins.

Sirocco Fan Flanges

Align Onto Guide Pins

SIROCCO FAN

(Label Facing Up)

PWB-LAMP DOOR SW

EXHAUST FAN

(Label Facing In)

Page 14

Page 15

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Lower Duct Removal

1. Remove the Lamp Cartridge, Upper Duct, Exhaust Fan and Sirocco Fan.

2. Disconnect the HV Lamp Wiring from the Ballast and loosen it from the guides.

3. Remove the 2 screws (C) one in front and one in the rear of the lower duct.

4. Carefully remove the Lower Duct from the Engine.

Not Shown

(Rear of Engine)

HV Lamp Wiring

C

C

HV LAMP WIRING

Dress Through Guides as Shown

OPTICAL ENGINE REPLACEMENT

1. Install Duct Assembly on the new Engine.

2. Connect the HV Lamp Wiring to the Ballast and dress the wiring through the guides as shown.

3. Remove the Protective Lens Cover from the face of the Lens and place it on the old Engine for return.

4. Install the Engine Assembly in the cabinet.

5. After a new Engine is installed, perform the following procedures as described in the Data Transfer section of

the Service Procedures:

• “Restore Index Delay”

• “Save Engine and Geometry Setting to Backup”

5. If needed. perform the Horizontal and Vertical Centering Adjustment and Manual Geometry Alignment as described in the Service Adjustments section of the Service Procedures.

Page 15

Page 16

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

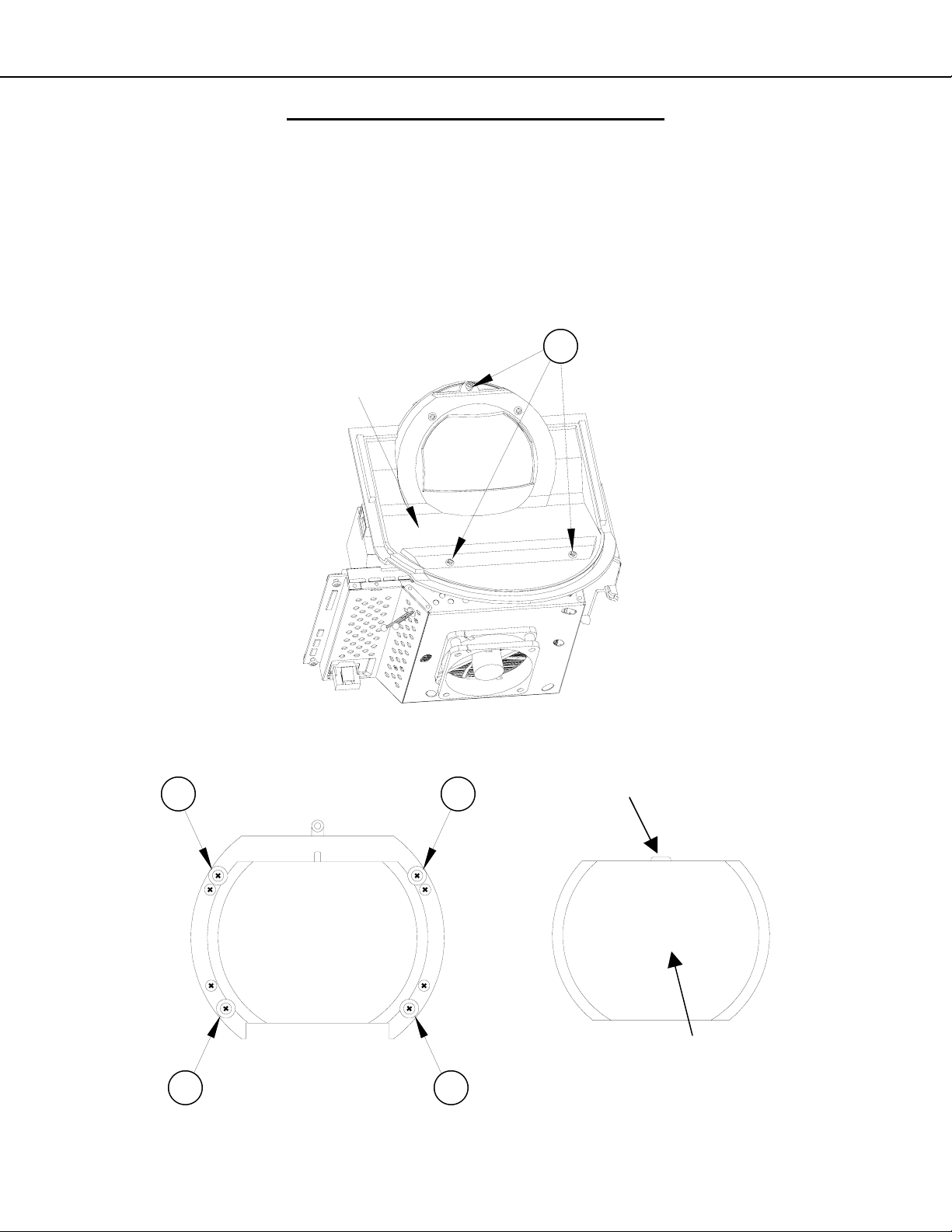

PROJECTION LENS REPLACEMENT

CAUTION: Any dust or fingerprints in the optics can cause abnormalities in the picture.

This procedure should be performed in a dust free environment.

Wear lint free cotton or rubber gloves while performing this procedure.

1. Remove Optical Engine Assembly.

2. Remove screws (A) and remove the Lens Collar.

3. Remove screws (B).

4. Lift out the Projection Lens.

5. Install the replacement lens so the key is oriented towards the top as shown.

A

LENS

COLLAR

B

B

B

B

Page 16

KEY

LENS

Page 17

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

COLOR WHEEL REPLACEMENT

CAUTION: This procedure should be performed in a dust free environment.

Any dust entering into the color wheel compartment can cau se a bnormalities in the picture.

1. Remove the Optical Engine Assembly.

2. Remove the Lens Collar and cover the projection lens to protect it from scratches. See previous page.

3. Disconnect the 2 connectors, J6 & J7, from the front side of the Light Engine. Note the orientation of the

ribbon cable for re-assembly (Silver Contacts towards the Lens).

4. Access the Color Wheel Compartment from the bottom of the Optical Engine

LENS COLLAR

Color Wheel Compartment

5. Remove 2 screws (A) and lift the cover off of the color wheel compartment.

6. Remove the 3 screws (B) from the Color Wheel Assembly.

7. Use the metal Handle to lift the Color Wheel from the compartment.

8. For installation, reverse the procedure above.

CAUTION: Avoid touching or scratching the Color Wheel.

9. After re-assembly, perform the Index Delay Adjustment described in the Service Adjustments section.

IMPORTANT: To prevent damage in return shipping, pack the original color wheel the same way the

replacement part was sent to you.

J6 & J7

(Opposite Side of Formatter PWB)

A

B

HANDLE

Page 17

Page 18

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

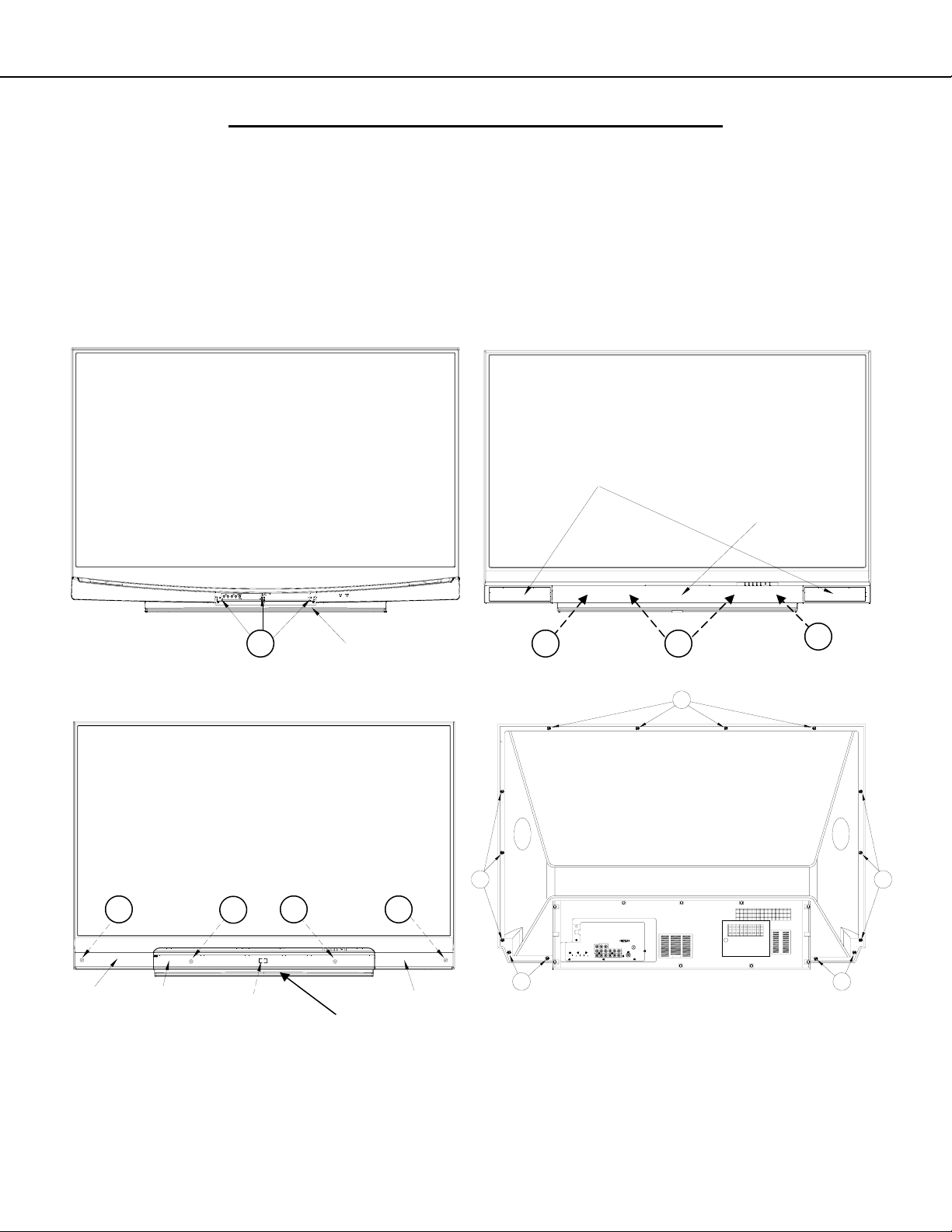

SCREEN REPLACEMENT 60”, 65” & 73” Models

Screen Assembly Removal and Replacement

1. V43C, V43 - Open the front control panel door.

2. V43+, V43++ - Remove the ORNAMENT LEFT & RIGHT first by pinching up and pulling away from the

bottom. Then remove the ORNAMENT CENTER using the same method.

3. Remove screws (A).

4. V43++ - Disconnect the PWB-SBL connector.

5. Remove screws (B) around the rear edge of the screen bezel.

6. During re-assembly replace screws in their original locations.

V43C,V43 (60” 65” 73”)

V43+ (60”)

ORNAMENT LEFT & RIGHT

(Speaker Covers)

V43+ (65” 73”)

A A

A

DOOR

V43++

(73” Only) (73” Only)

A A

A

A

B

A

(65” Only)

ORNAMENT CENTER

B

Number and Location of

Screws Varies by Model

73 INCH

A

(65” Only)

B

ORNAMENT LEFT

PWB-SBL

CONNECTOR

ORNAMENT RIGHT

ORNAMENT

CENTER

(Speaker Cover)

Page 18

B

B

Page 19

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

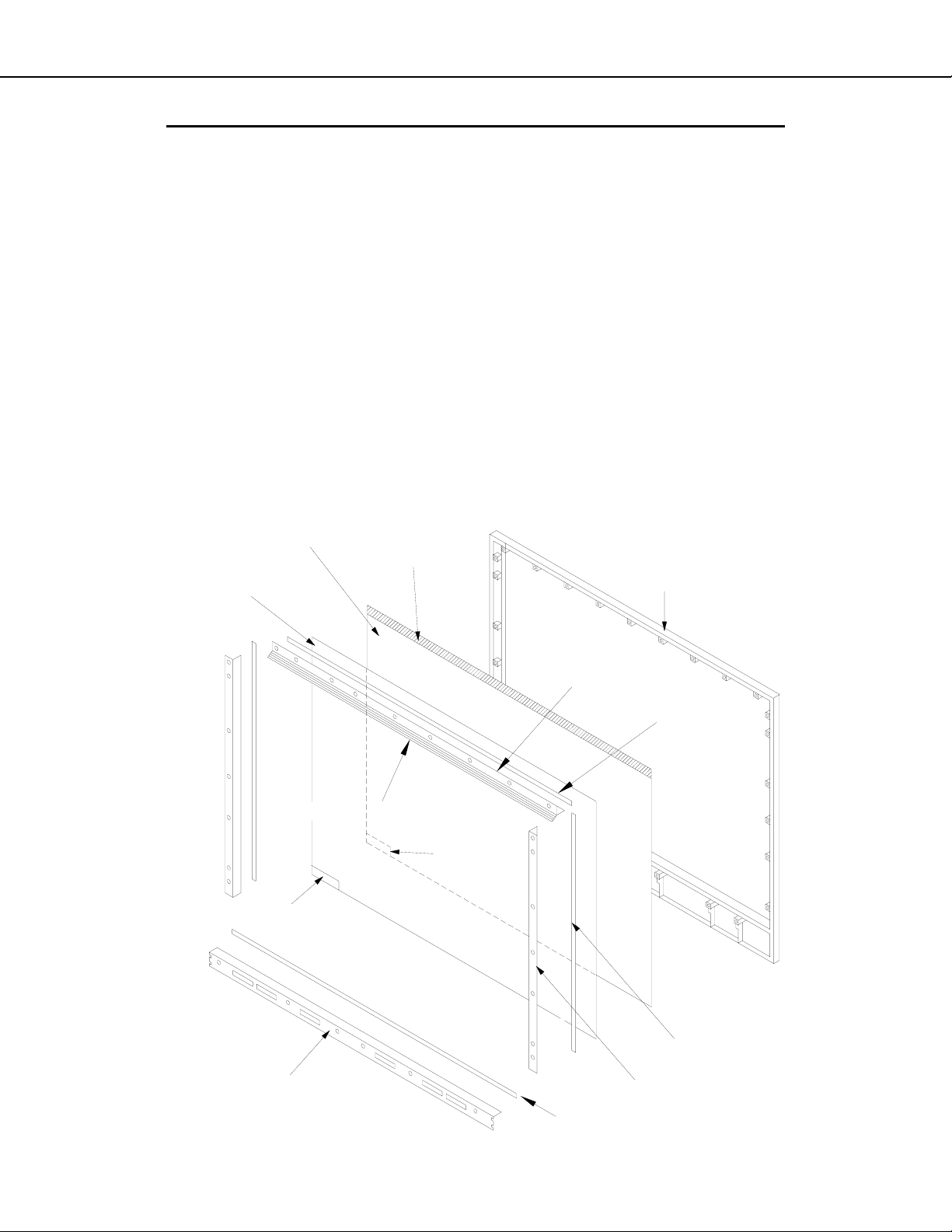

SCREEN REPLACEMENT 60”, 65” & 73” Models (continued)

Screen Removal From the Bezel-Front

1) Remove screws (A) and remove the top, bottom and side rails.

NOTE: The number and location of screws vary by model.

2) Lift the Fresnel Lens and Lenticular screen from the Bezel-Front.

3) During re-assembly replace screws in their original locations.

A

A

AA

A

60 & 65 INCH

(Rear View)

A

A

73 INCH

(Rear View)

A

Example Diagrams. The number and location of screws vary by model.

Page 19

Page 20

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SCREEN REPLACEMENT 60”, 65” & 73” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

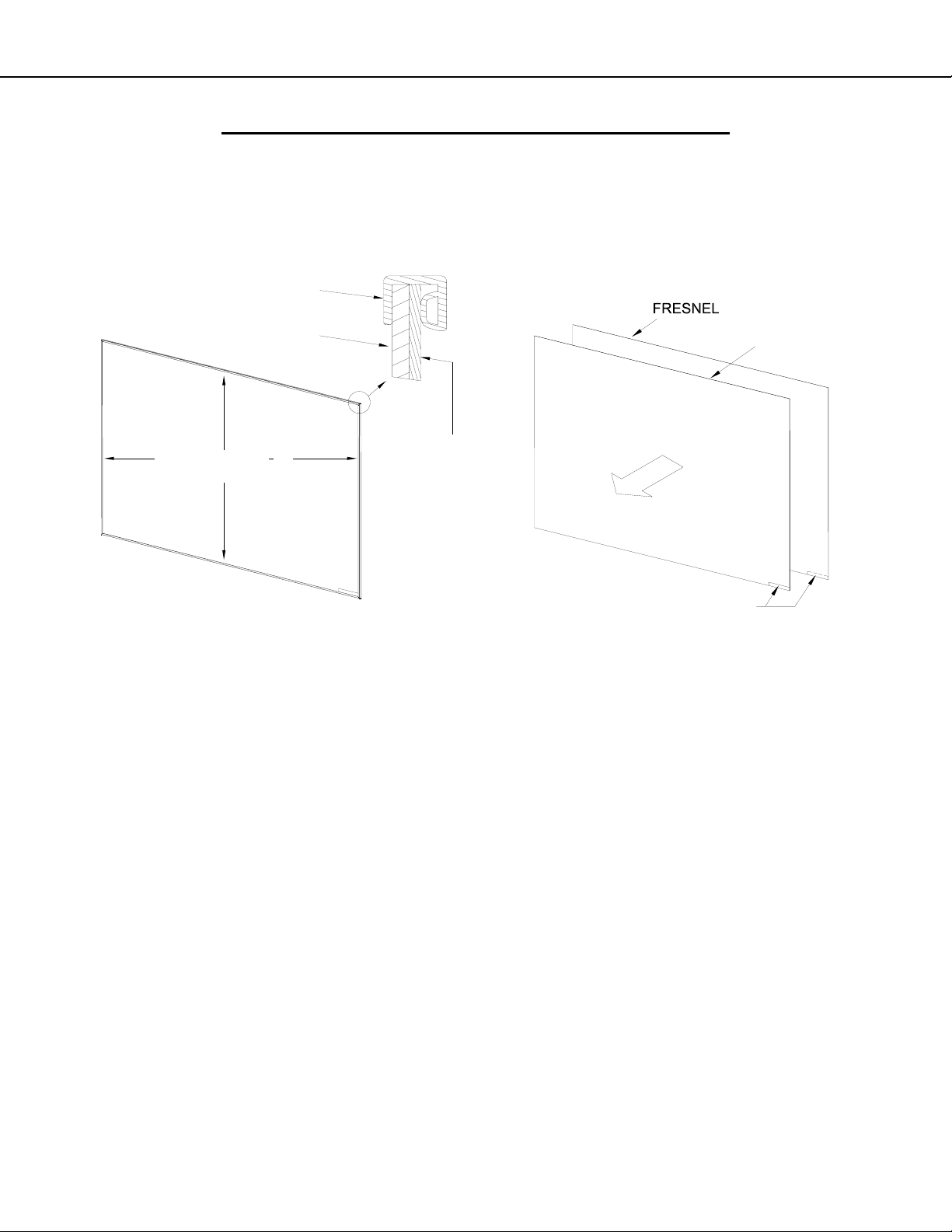

Lenticular Screen and Fresnel Lens Removal

1. After removing the top, bottom and side HOLDER-SCREEN rails and their cushions from the Bezel, lift the

screens as a single unit from the frame.

2. Separate the Lenticular Screen and Fresnel Lens.

Note: When separating the Lenticular Screen from the Fresnel Lens, use caution

while prying the Screen and Lens apart. Use a slot type screw driver, and

remove the pressure sensitive double sided tape.

Lenticular Screen and Fresnel Lens Replacement

1. Apply LENS-TAPE along the rear top edge of the Lenticular Screen.

2. Place the Fresnel Lens on top of the Lenticular Screen, and apply pressure along the top edge.

3. Place the screens in the screen frame and reinstall the cushions, top, bottom and side rails.

NOTE: The Lenticular Screen label must face the front and the Fresnel Lens label face the rear.

4. Reverse the Screen Removal Procedure and insert the screens in the Bezel.

LENTICULAR

LENS

FRESNEL

SCREEN

LENS-TAPE

BEZEL FRONT

HOLDER-SCREEN-T

SPACER-SCREEN-T

COVER-HOLDER-T

LABEL

LABEL

HOLDER-SCREEN-B

SPACER-SCREEN-S

HOLDER-SCREEN-S

SPACER-SCREEN-B

Page 20

Page 21

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

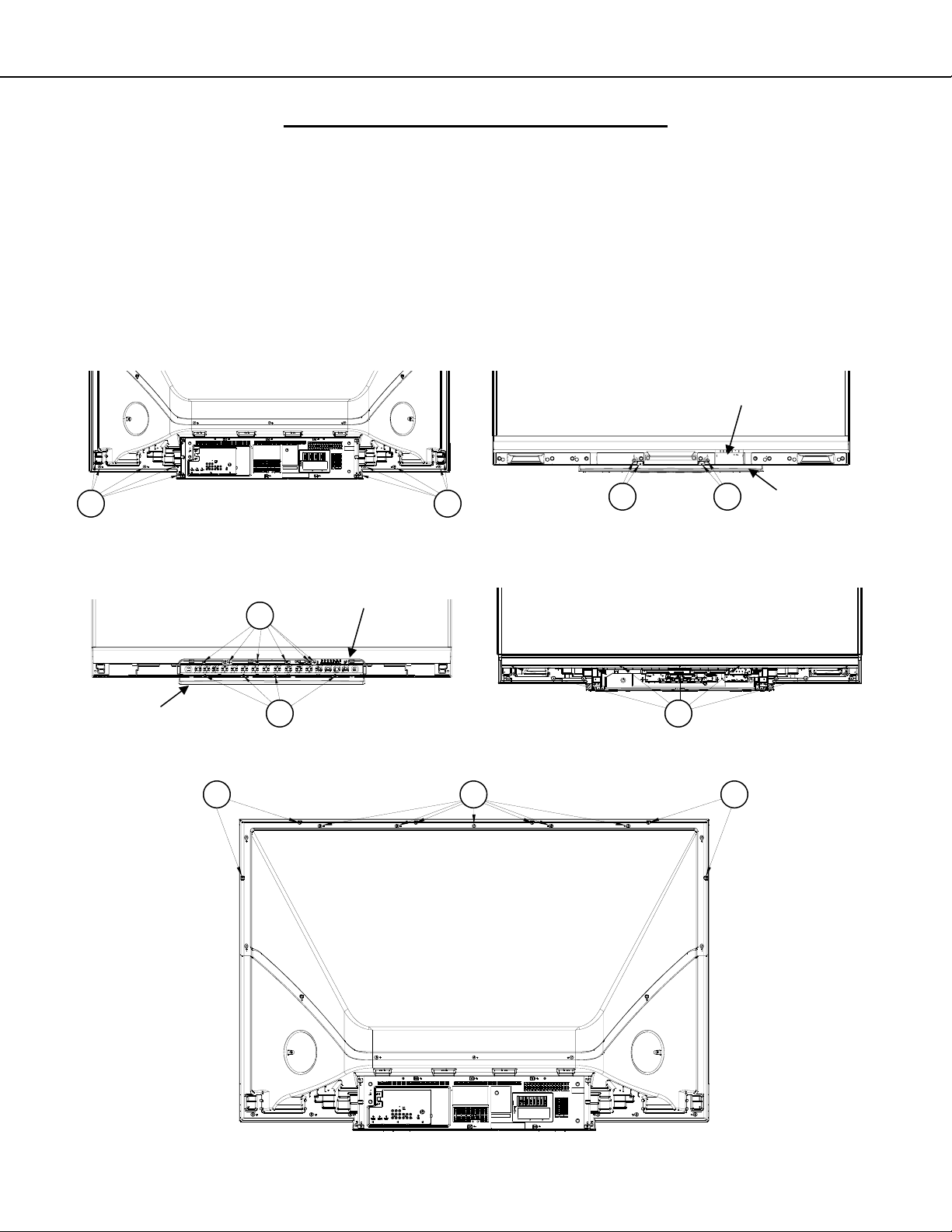

SCREEN REPLACEMENT 82” Models

Screen Assembly Removal

1. Remove screws (A) around the bottom rear edge.

2. Pull off ornamental Front Covers and Speaker Grills.

3. (V43+) Remove the Pedestal and Bezel by removing screws (B).

4. (V43++) Remove the Speaker Box and Pedestal by removing screws (B).

5. Remove screws (C) from the bottom front of the screen assembly.

6. Remove screws (D) from the top rear edge of the cabinet.

NOTE: Leave one screw secure at the top. Then support the assembly to prevent it from falling while

removing the remaining screw.

A A

(V43++)

B

PEDESTAL

D D D

SPEAKERBOX

B

(V43+)

A A

B

C

BEZEL

B B

PEDESTAL

Page 21

Page 22

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SCREEN REPLACEMENT 82” Models (continued)

CAUTION: Wear gloves when handling the Lenticular Screen and Fresnel Lens.

This prevents cuts and finger prints. Do not place Fresnel Lens in the sun.

This may cause fire and heat related injuries.

Lenticular Screen and Fresnel Lens Removal

1. Remove four screws (A) in all four corners of the Screen Bezel.

2. Remove the Screen Bezel components from the Screen/Lens Assembly.

A X4

CORNER-S-T

CORNER-CAP

TOP-L

HOLDER-SCREEN

S-L

CORNER

B-L

SCREEN/LENS

ASSEMBLY

FRONT

HOLDER-SCREEN-B

COVER-HOLDER-T

CORNER-S-T

CORNER-CAP

TOP-R

HOLDER-SCREEN

S-R

LABEL

CORNER

B-R

Page 22

Page 23

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SCREEN REPLACEMENT 82” Models (continued)

Lenticular Screen and Fresnel Lens Disassembly

1. Remove the HOLDER-SCREEN from the top, bottom and sides.

2. Separate the Lenticular Screen and Fresnel Lens.

HOLDER-SCREEN

LENTICULAR

SCREEN

HOLDER-SCREEN

(TOP/BOTTOM)(SIDES)

FRESNEL

LENS

LENS

FRONT

Label Position

(Facing Outside)

Lenticular Screen and Fresnel Lens Replacement

1. Place the Fresnel Lens on top of the Lenticular Screen with the labels facing outside as shown.

2. Install the HOLDER-SCREEN, top, bottom and sides as shown above.

3. Reverse the disassembly procedure to reassemble and install the screen frame assembly.

NOTE: The Lenticular Screen must face the front and the Fresnel Lens must face the rear.

LENTICULAR

SCREEN

Page 23

Page 24

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

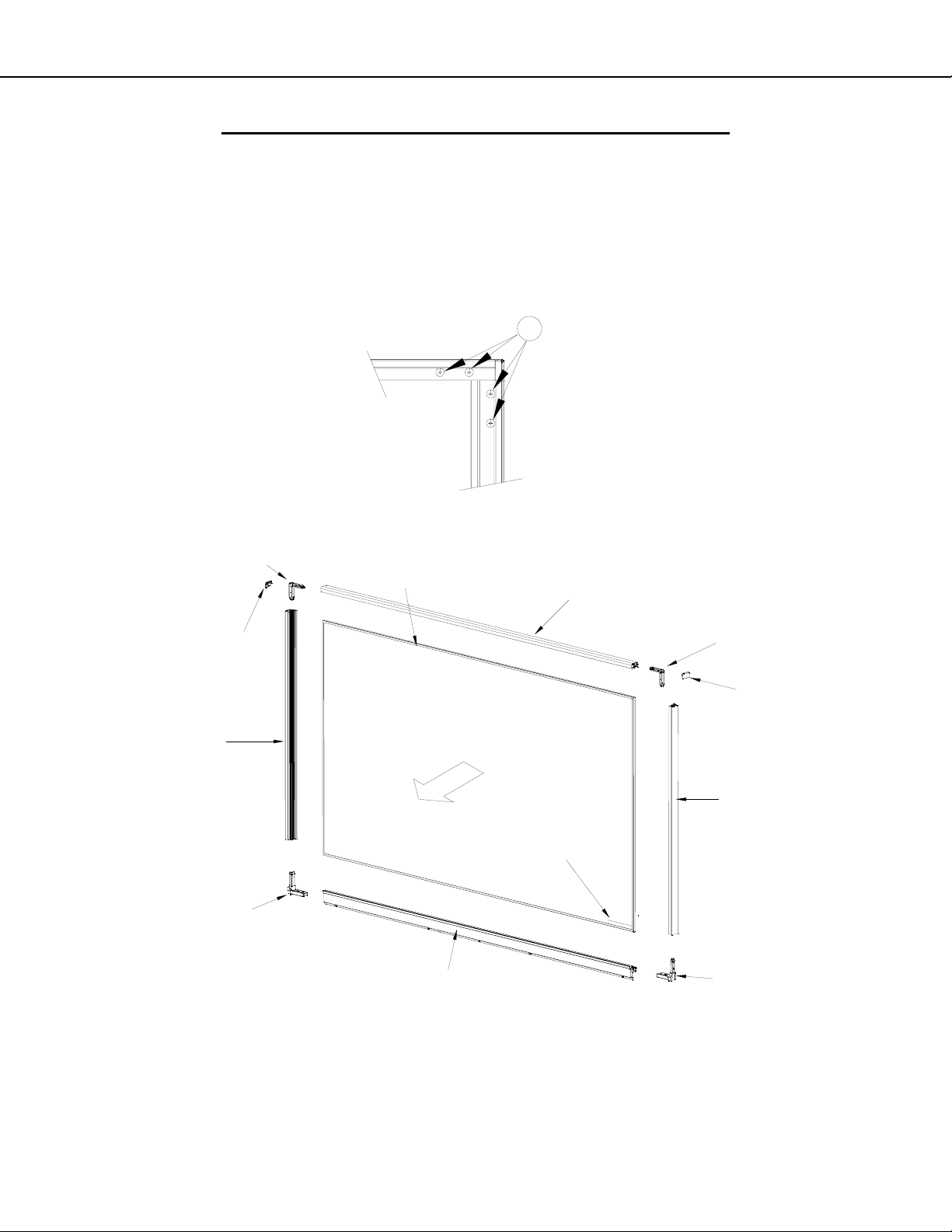

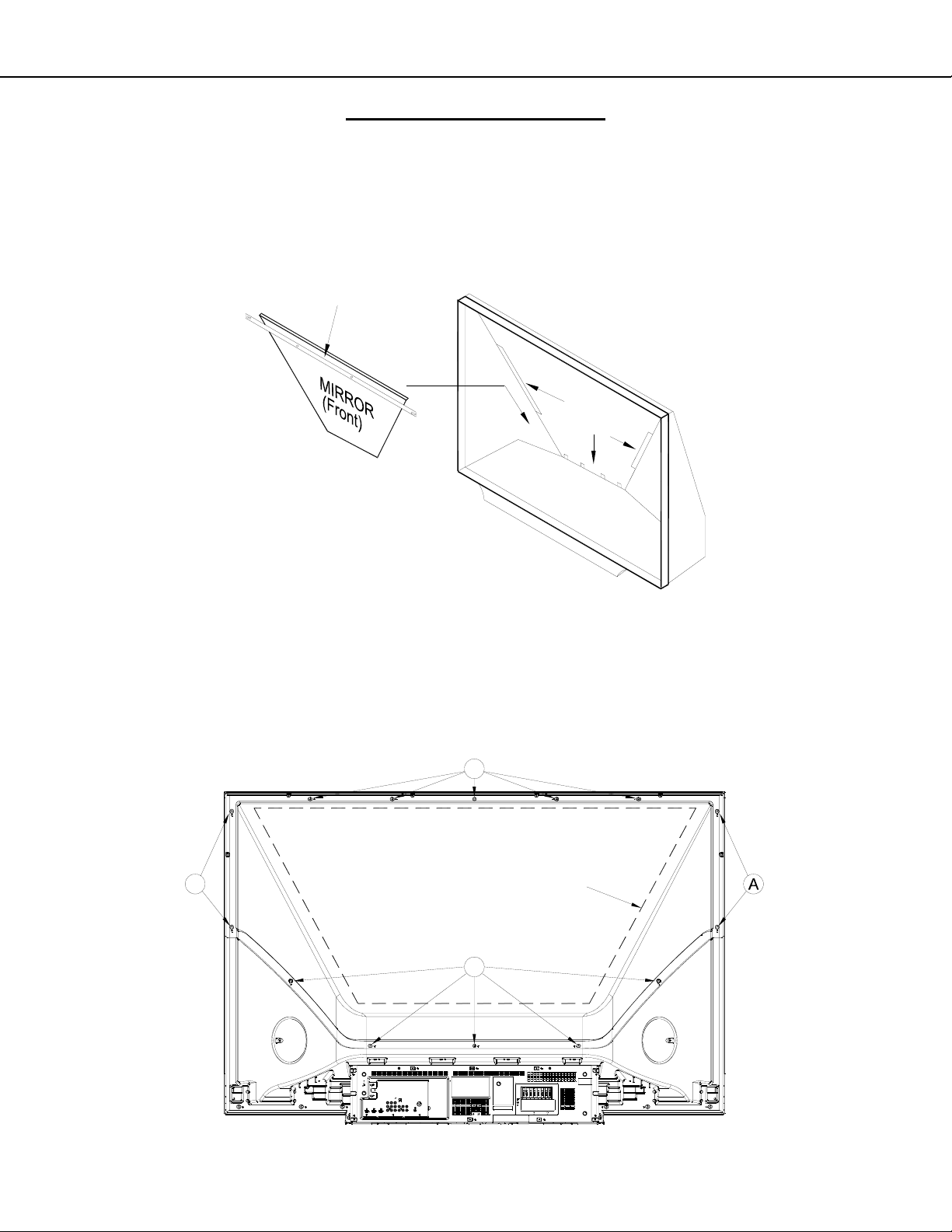

MIRROR REPLACEMENT

MIRROR REPLACEMENT - 60”, 65” & 73” Models

1. To access the Mirror for replacement, remove the Screen Assembly (See Screen Assembly Removal).

2. The Mirror slides down into the Left, Right and Bottom Brackets inside the cabinet.

3. For 73” models, a Top Bracket is installed.

4. See the Mirror Parts section for instructions on preparing a replacement mirror.

TOP BRACKET

(73" Models)

SUPPORT

BRACKETS

MIRROR REPLACEMENT - 82” Models

1. To access the Mirror for replacement, remove screws (A) and lift away the Mirror Cover.

2. The Mirror rests in place below the Mirror Cover.

3. See the Mirror Parts section for instructions on preparing a replacement mirror.

A

A

A

MIRROR

(Below Cover)

Page 24

Page 25

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SERVICE PROCEDURES

NOTE: Service Procedures differ between the V43C & V43 and the V43+ & V43++ chassis. Be sure to follo w the

procedure indicated for the model being serviced.

V43C & V43

WD-60C10 WD-60638

WD-65C10 WD-65638

WD-73C10 WD-73638

WD-82738 WD-82838

V43+ & V43++

WD-60738

WD-65738 WD-65838

WD-73738 WD-73838

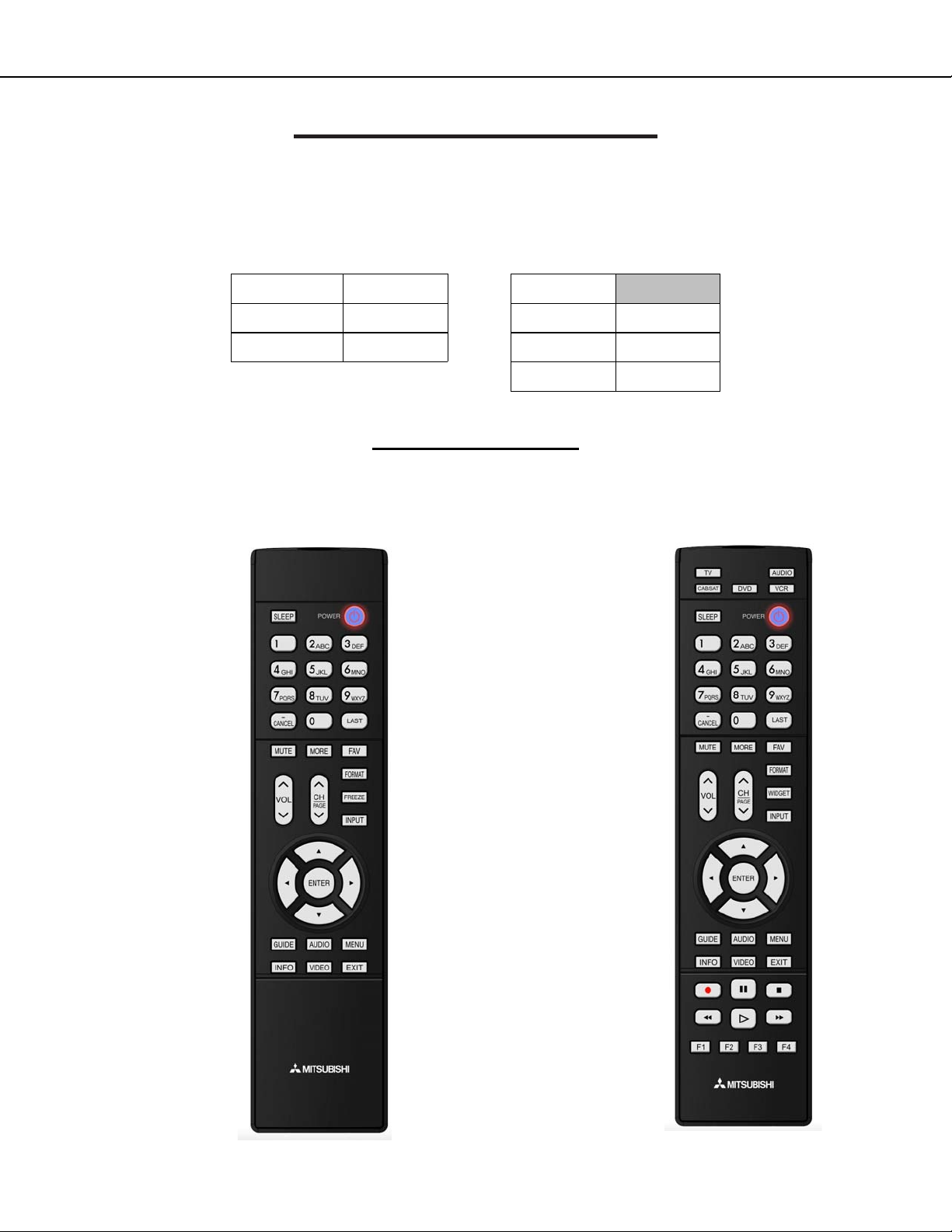

REMOTE CONTROL

REMOTE CONTROL USE FOR SERVICE

Many service functions and adjustments are accessed using the Remote Control.

V43C & V43 V43+ & V43++

Page 25

Page 26

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

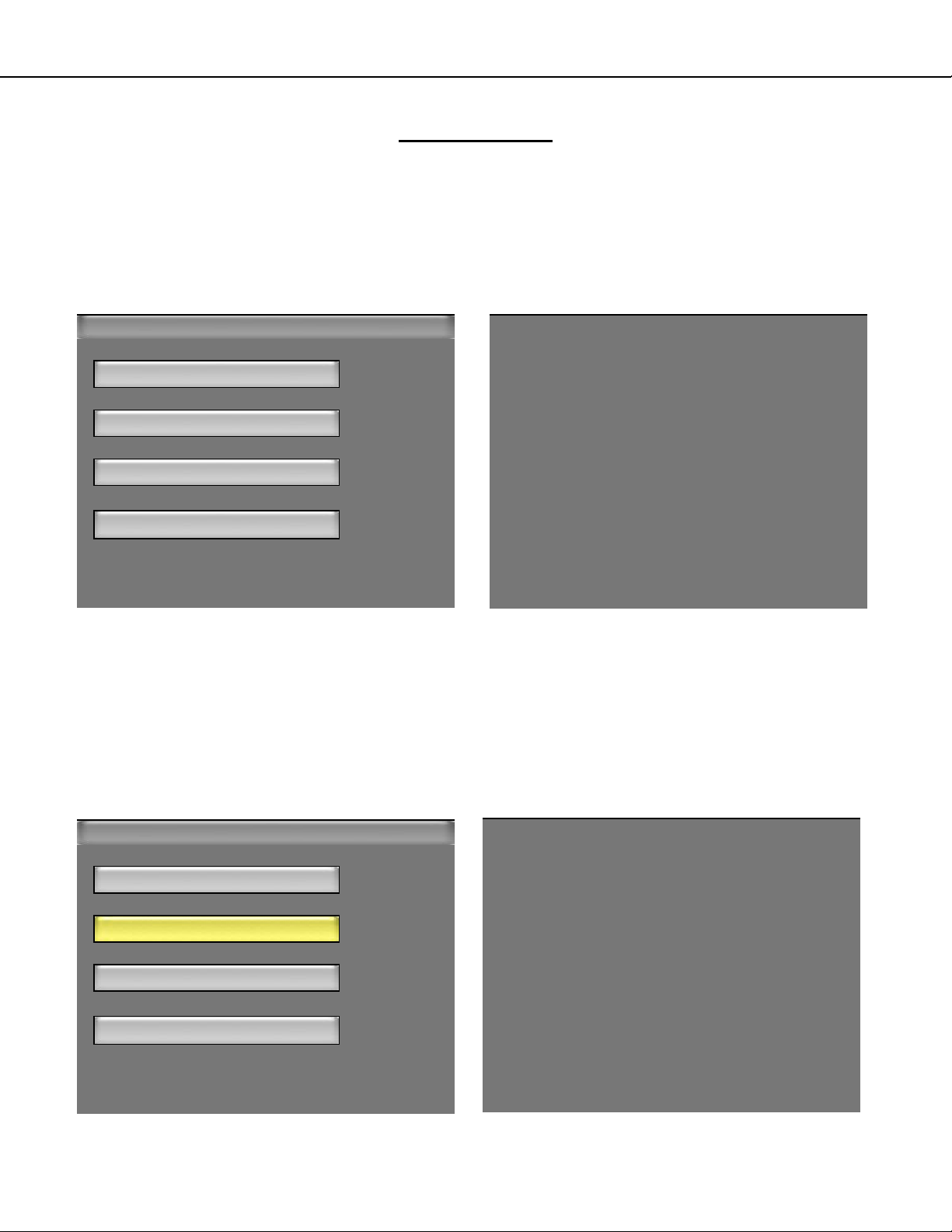

OPTION MENU

OPTION MENU

1. Press the <MENU> button on the remote control.

2. Press the buttons <2-4-7-0>. The scree n will display the Option Menu.

3. The Option Menu for the V43C & V43 differs from the V43+ & V43++ chassis. V43C & V43 Option Menu

items are included in the Service Menu. See below.

V43C & V43 Option / Service Menu

<MENU><2-4-7-0>

Service Menu

1. Information

2. Reset All Settings

3. Calibration

4. Test Pictures

V43+ & V43++ Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

VERSION: Vxx xxx.xx.xx

SERVICE LEVEL INITIALIZATION

Service Level Initialization is used to restore all customer menu, video and audio settings to the original factory default

condition.

1. Enter the Option Menu <MENU><2-4-7-0>

2. V43C & V43 Chassis select “2. Reset All Settings” and <ENTER>. Then confirm “YES” <ENTER>..

V43+ & V43++ Chassis select “Initialize” and <ENTER>.

V43C & V43 Option / Service Menu

<MENU><2-4-7-0>

Service Menu

1. Information

2. Reset All Settings

3. Calibration

4. Test Pictures

VERSION: Vxx xxx.xx.xx

V43+ & V43++ Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

Page 26

Page 27

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

DIGITAL SIGNAL INFORMATION

Information on the currently selected digital channel can be displayed on screen.

1. Enter the Option / Service Menu <MENU><2-4-7-0>

V43C & V43 Option / Service Menu

<MENU><2-4-7-0>

Service Menu

1. Information

2. Reset All Settings

3. Calibration

4. Test Pictures

V43+ & V43++ Option Menu

<MENU><2-4-7-0>

Initialize

Power Restore OFF

Production Mode OFF

Digital Signal Strength <1~9>

NetCommand Software Vxx xxx.xx

Total hours of use 0

VERSION: Vxx xxx.xx.xx

2. V43C & V43 Chassis select “Information” and <ENTER>.

V43+ & V43++ Chassis select “Digital Signal Strength” and <ENTER>.

V43C & V43 Digital Signal Information

“Information” <ENTER>

System Info

Source/Channel Info

Source ID

Source Type: Composite

Source/Channel Status: No Source Signal

RF Band: Air

RF Channel: 0

Frequency: Signal Quality: 0

Video PID: Audio PID: PCR PID: -

Audio/Video Stream Info

Video Resolution: Video Scan Rate: Video Scan Type: Audio Type: PCM

Audio Sample Tate: 48k

V43+ & V43++ Digital Signal Information

“Digital Signal Strength” <ENTER>

Tuner

Frequency(MHz) 749

Signal Level <1~9>

Modulation 8VSB Air

Carrier Lock

SNR

Correctable errors 0

Un Correctable errors 0

Locked

29.09

Page 27

Page 28

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

RESET / INITIALIZATION

SERVICE TIP:

Many symptoms that are customer generated, intermittent or cannot be verified can be resolved by using the various

Reset and Initialization options. Before visiting the customer’s home ask the customer to 1st perform a System Reset by

pressing the <POWER> button on the front panel and holding it for 8 seconds. If this does not resolve the issue, they

can perform an A/V Reset by pressing the <INPUT> + <VOL > buttons on the front panel at the same time and holding

for 10 seconds. Then, if necessary, perform a user level Initialization by pressing <MENU><1-2-3> <ENTE R> with the

remote. The customer should be made aware when settings and/or options will be reset. For more information, see the

chart below.

Reset Name When to use How to use Resulting Action

Remote Control

TV Layer Reset

Remote Control

TV Volume/

Mute functions

Returns the remote control TV layer

to normal operation.

Returns the volume and mute functions of the remote control to TV volume and mute for TV, Cable/Sat,

VCR and DVD layers after the Audio

Lock for AV Receiver feature has

been used.

1)

Set the selector switch to TV position.

2)

Press and hold the <POWER> button until it flashes twice

then release the button.

3)

Enter the code <0-0-9-3-5>.

1)

Set the selector switch to TV position.

2)

Press and hold the <POWER> button until it flashes twice

then release the button.

3)

Enter the code <9-9-3>< VOL >.

Once the valid code has

been entered and confirmed, the remote control

has been reset.

The remote will now operate

the TV's volume and mute

when the slide switch is in

the TV, CABLE/SAT, VCR

or DVD positions.

A/V Memory

Reset, by individual input

A/V Reset, all

inputs

System Reset To reset the TV when it does not turn

Initialize User

Level

Initialize - Service Level

V-Chip Password Bypass

When the audio or video performance

or settings for a single input seem to

be incorrect.

When the audio or video performance

or settings for more than one input

seem to incorrect.

on or off, does not respond to the

remote control, front panel buttons or

has other unusual symptoms.

To reset all customer settings except

V-Chip

To reset all customer settings V43C/V43 <MENU>2-4-7-0>"Reset Settings"

If V-Chip password is not known

<MENU> Audio/Video AV Reset <ENTER>

While viewing the TV, press the front panel buttons <INPUT> +

<VOL > at the same time and hold for 10 seconds.

Press the <POWER> button on the front panel and hold it for 8

seconds.

Press <MENU><1-2-3><ENTER>

V43/V43+<MENU><2-4-7-0> "INITIALIZE" press <ENTER>

Press <LAST>+<9> at the same time.

All Audio and Video settings

for the individual input are

reset except for the Listen

To, Language, Balance and

Closed Caption settings.

All Audio and Video settings

are reset to the factory default settings. No other

menu options are changed.

TV Micro Re-boots. Note:

The changes made during

the current TV-On period

may be lost. All other previous user settings are not

lost.

All customer menu options

and A/V settings except VChip & locked ISF are reset

to factory default.

All customer menu options

and A/V settings are reset

to factory default.

Password will be bypassed.

If in the V-Chip menu, enter

a new password.

Unlock Front

Panel

To unlock the front panel if it has

been locked in the V-Chip Menu.

Press and hold the front panel <ENTER> button for 8 seconds.

Page 28

Front Panel becomes operational. Other V-Chip

settings not changed. Note:

Cannot be performed while

in the Low Power mode and

the set is Off.

Page 29

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

LED INDICATI ONS AND SELF DIAGNOSTICS

The front panel Status LED provides an indication of the set’s operation and the possible cause of a malfunction.

NORMAL INDICATIONS

STATUS LED Indication Condition

Off Off (Standby)

Green Power On

Slow Blinking Green Power Off with Timer Set. Power On normally

Fast Blink Green 80 seconds after Power Off Power Off Lamp cooling. Wait for blinking to

stop to Power On.

Fast Blinking Green 1 to 3 minutes after Power

Restored from AC interrupt, Power On, System

Reset or Software update.

ABNORMAL INDICATIONS

STATUS LED Indication Condition

Steady Red Lamp Failure

Steady Yellow DMD Temperature Excessive

Blinking Yellow Lamp Cover Open

Blinking Red then Blinking Yellow Circuit Failure (See Self Diagnostics)

Boot-up. Wait for blinking to stop to Power On.

SELF DIAGNOSTICS

A blinking red and yellow Status LED will indicate an Error Code that can help determine the cause of a circuit

failure.

• The number of Red blinks indicates the value of the MSD (tens digit) of the Error Code.

• The number of Yellow blinks indicates the value of the LSD (ones digit) of the Error Code.

Example: If the Error Code is “37”, the LED will continuously blink Red three times, followed by blinking Yellow

seven times.

See the following page for a list of Error Codes.

To perform a System Reset, press and hold the Power button for 10 seconds. Or, unplug the set for 10 seconds

then restore power.

Number of Red Blinks Number of Yellow Blinks

3 7

Error Code: 37

Page 29

Page 30

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

ERROR CODES

Error Codes, descriptions and the most likely cause of failure are listed below:

ERROR CODES

Code Description Most Likely Cause

16 LAMP-EN Detection

Check Color Wheel / Check J6 & J7 circuitry /

Engine Failure

Loss of 12V from PWB-POWER to Engine /

17 I2C Communication loss between TV Micro and Engine

Check PE & PE2 circuitry

Engine Failure, PWB-MAIN Failure

Engine will not accept data

18

(ASIC-READY signal from Engine is not detected).

LDVS circuitry

Engine Failure

24 Sirocco fan (Lamp fan) rotation not detected. Check Sirocco Fan / Check J8 circuitry

Lamp turns Off while the TV is playing.

34

Lamp Failure

Lamp Cartridge Failure

Lamp Enable signal from engine is lost.

36 Exhaust Fan rotation not detected. Check Exhaust Fan / Check J4 circuitry

37 Engine (DMD) fan rotation not detected. Check DMD Fan / Check J5 circuitry

44 LVDS cable between PWB-MAIN and Engine not detected. Check LVDS Cable & circuitry

48 PON-SHORT 3.3V or 5V switched supply short PWB-MAIN Failure

Loss of 340V from PWB-POWER to Ballast /

Check PL & CJ1 circuitry

57 Ballast communication problem (ballast to chassis)

Loss of communications between PWB-MAIN

and Ballast / Check FB & CJ3 circuitry

Ballast Failure

Lamp did not turn on at P-ON sequence

(No Lamp inserted)

66

(Disconnected cable between ballast and lamp)

(Lamp-Enable goes to PWB-MAIN but not to Ballast)

Check CJ4 circuitry

No Lamp Inserted.

HV connection or lead wire to lamp.

Lamp Cartridge Failure

ERROR CODE LOG (V43+ & V43++)

The Error Code Log may be helpful to retrieve the code for an error that occurred in the past.

Press MENU to Exit

Error Code Log Definitions

• PAGE - Current page number

• CURRENT TIME - total hours of operational

use.

• USAGE TIME - usage hours when the error

occurred.

• CODE - the specific Error Code that occurred.

• STATUS: HAPPENED - Indicates an error

was recorded.

Press <CANCEL> to erase the Log.

Error Code Log

<MENU><3-5-6-4>

***** PAGE (001/001) *****

CURRENT TIME: 01455 HOURS

USAGE TIME CODE STATUS

00413 HRS 44 HAPPENED

00716 HRS 57 HAPPENED Press Up to Previous Page

Press Down to Next Page

Press Right to Top Page

Press Left to Last Page

Press CANCEL to Erase

NOTE: The Error Code Log is intended as a reference tool and

is not meant to be used as a final determination of a defective part.

Page 30

Page 31

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SOUND PROJECTOR TRANSDUCER TEST (V43++)

This procedure will test will each of the TV’s speakers individually using an internal tone generator.

1. Press the <MENU> button on the remote control. The Customer Menu will appear.

2. Press the <2-4-5-7> buttons. The Service Menu will appear.

3. Press the <0> button. The Data Transfer & Geometry Menu will appear. See below.

4. Use the <TS> buttons to select “SOUND PROJECTOR TRANSDUCER TEST” and press <ENTER>. The

Sound Projector Transducer Test Menu will be displayed. A tone will automatically cycle from one

speaker to the next as indicated on screen. Follow the instructions to manually cycle the tone.

5. Press <EXIT> to exit.

Data Transfer & Geometry Menu <MENU><2-4-5-7>< 0>

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

SOUND PROJECTOR TRANSDUCER TEST

Page 31

Page 32

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

SERVICE ADJUSTMENTS

Service Adjustments include Adjustment Procedures and Data Transfer Function s.

Electrical Adjustments (there are no mechanical adjustments)

• Horizontal and Vertical Centering Adjustment

• Index Delay Adjustment

• Geometry Alignment

• Data Transfer Functions

Test Equipment and Test Patterns

• Remote Control

• Internally generated Test Patterns

• No external test equipment or pattern generators are required.

SERVICE MENU

The Service Menu is used for all service adjustments.

Service adjustments can only be performed using the remote control.

1. Activating the Service Menu

V43C & V43

For the V43C & V43 chassis, all service functions except Data Transfer are inclu ded under the Service Menu.

1. Press the <MENU> button on a remote control. (The Customer Menu will appear.)

2. Press the buttons <2-4-7-0>. (The Service Menu will appear.)

V43+ & V43++

1. Press the <MENU> button on a remote control. (The Customer Menu will appear.)

2. Press the buttons <2-4-5-7>. (The Service Menu will appear.)

V43C & V43 Service Menu

<MENU><2-4-7-0>

Service Menu

1. Information

2. Reset All Settings

3. Calibration

4. Test Pictures

V43+ & V43++Service Menu

<MENU> <2-4-5-7>

SERVICE

TVM

1. HVPOS

Page 32

-3

4

Page 33

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

2. Test Pattern Activation

V43C & V43

1. When in the Service Menu select “Test Picture” <ENTER> <0,1,2,3,4 or 5> to select specific patterns.

2. When in the Service Menu select “Calibration” <ENTER> <1-1-1-1>. Use <CH U> and <CH V> to toggle

between patterns.

V43+ & V43++

1. When in the Service Menu, press Play <Z> to activate the internal test patterns (no indication will be dis-

played initially). Use FWD <XX> and RWD <WW> to toggle between patterns.

2. Press Play <Z> a second time and use FWD <XX> and RWD <WW> to access additional patterns.

3. Press Play <Z> again to toggle back to the previous patterns.

3. Adjustment Overview—Specific adjustment procedures follow.

V43C & V43

When in the Service Menu select “Calibration” <ENTER> followed by the code for the adjustment desired.

<MENU><2-4-7-0> “Calibration” <ENTER>

CODE ADJUSTMENT

2846 Horizontal & Vertical Position

2580 Index Delay

1397 Geometry

V43+ & V43++

1. When in the Service Menu use the <VIDEO> button to toggle to adjustment desired indicated by the

number and abbreviation displayed on screen.

2. For Geometry, from the Service Menu press <0> and select “Manual Geometry Alignment” <ENTER>.

<MENU><2-4-5-7><VIDEO>

ABBREVIATION ADJUSTMENT

1. HVPOS Horizontal & Vertical Position

60. IDL Index Delay

4. Adjusting Data

After selecting an adjustment item, use the Navigation arrows or other buttons indicated in the adjustment

procedure to perform the adjustment.

5. Saving Data

Press <ENTER> to save the adjustment data.

V43C & V43, The Status LED will turn red for about 1 second.

V43+ & V43++, The menu display will turn red for approximately one second.

Note: If the circuit adjustment mode is terminated without pressing <ENTER>, changes in adjustment data

are not saved.

6. Exiting the Service Menu

Press <EXIT> to quit.

Page 33

Page 34

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

ADJUSTMENT PROCEDURES

V43C & V43

Horizontal and Vertical Position Adjustment

1. Enter the Service Menu <MENU><2-4-7-0> .

2. Select “Calibration” <ENTER>. The raster will blank out.

3. Enter the H & V Position adjustment by pressing <2-8-4-6>. The geometry pattern below will be displayed

and the STATUS LED will blink Green at a 1 second interval during the alignment..

4. Use the Navigation <TSWX> buttons to center the display.

5. Press <ENTER> to save the adjustment data. The STATUS LED will turn Red while the data is saved.

V43+ & V43++

Horizontal and Vertical Position Adjustment

1. Enter the Service Menu <MENU><2-4-5-7> .

2. Select the Geometry Test Pattern shown Play <Z> Rewind <WW> x2.

3. If necessary, use the <VIDEO> button to select the adjustment, “1.HVPOS”.

4. After selecting the HVPOS adjustment item, use the Navigation <TSWX> buttons to center the display.

5. Press <ENTER> to save the adjustment data. The on-screen display will flash red while the data is saved.

V43C & V43 Vertical & Horizontal Position Adjustment

<MENU><2-4-7-0> “Calibration” <ENTER><2-8-4-6>

V43 & V43+ Vertical & Horizontal Position Adjustment

<MENU><2-4-5-7> <Z> <WW> <WW>

Adjustment

SERVICE

TVM

Data (HPOS)

1.HVPOS

-3

4

Data (VPOS)

Page 34

Page 35

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Index Delay Adjustment (Perform after color wheel replacement)

V43C & V43

1. Enter the Service Menu <MENU><2-4-7-0> .

2. Select “Calibration” <ENTER>. The raster will blank out.

3. Enter the Index Delay adjustment by pressing <2-5-8-0>. The ramp pattern below will be displayed and the

STATUS LED will blink Green at a 1 second interval during the alignment..

4. Use the Navigation <TS> buttons to adjust the ramp pattern color bars for the smoothest transition from

dark to bright.

5. Press <ENTER> to save the adjustment data. The STATUS LED will turn Red while the data is saved.

V43C & V43 Index Delay Adjustment

<MENU><2-4-7-0> “Calibration” <ENTER><2-5-8-0>

Index Delay Adjustment (Perform after color wheel replacement)

V43+ & V43++

1. Enter the Service Menu <MENU><2-4-5-7> .

2. Select the Ramp Pattern shown below <Z><WW> x3.

3. Use the <VIDEO> button to select the adjustment, “60.IDL”

4. After selecting the IDL adjustment item, use the Navigation <TS> buttons to adjust the ramp pattern color

bars for the smoothest transition from dark to bright.

5. Press <ENTER> to save the adjustment data. The on-screen display will turn red while the data is saved.

V43+ & V43++ Index Delay Adjustment

<MENU><2-4-5-7> <Z> <WW> <WW> <WW> <VIDEO>

Adjustment

SERVICE

TVM

Data

60.IDL

201

Page 35

Page 36

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Manual Geometry Alignment

V43C & V43

1. Entering the Manual Geometry Alignment Mode

1. Activate the Service Menu <MENU><2-4-7-0>.

2. Select “Calibration” <ENTER>. A “dot pattern” will be displayed.

. Enter the Manual Geometry Alignment mode by pressing <1-3-9-7>. The Manual Geometry Alignment Pattern

will appear. See 2. Manual Geometry Alignment procedure on next page.

V43C & V43 Option / Service Menu

<MENU><2-4-7-0>

Service Menu

1. Information

2. Reset All Settings

3. Calibration

4. Test Pictures

Manual Geometry Alignment

V43+ & V43++

1. Entering the Manual Geometry Alignment Mode

1. Activate the Service Mode <MENU><2-4-5-7>.

2. From the Service Menu, press the <0> button. The Data Transfer & Geometry Menu will appear.

3. Use the <TS> buttons to select “MANUAL GEOMETRY ALIGNMENT” <ENTER>. The Manual Geometry

Alignment Pattern will appear. See 2. Manual Geometry Alignment procedure on next page.

Data Transfer & Geometry Menu

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

Warning

- Only use "SAVE ENGINE AND GEOMETRY SETTING TO BACKUP"

after Optical Engine replacement.

<MENU><2-4-5-7><0>

Page 36

Page 37

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

C

r

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

V43C & V43 Manual Geometry Alignment

<MENU><2-4-7-0> “Calibration” <ENTER><1-3-9-7>

V43 & V43+ Manual Geometry Alignment

<MENU><2-4-5-7><0> “MANUAL GEOMETRY ALIGNMENT”<ENTER>

All Models

2. Manual Geometry Alignment

Note: To remove all geometry correction, while the Geometry Alignment Pattern is displayed, press <1> then

<ENTER>. This will null all correction data. Then re-enter the Manual Geometry Alignment mode.

Note: To restore the original factory geometry data from backup:

• V43C & V43: Exit the Service Menu and press <MENU><2-4-5-7><5-5-5-5>.

• V43+ & V43++: From the Data Transfer & Geometry Menu <MENU><2-4-5-7><0>, select “RESTORE GE-

OMETRY DATA FROM BACKUP” <ENTER>.

+

urso

+

Adjustment Points

(16 Total)

Align Cursor + Flush With Bezel Edge

Phase 1 - 16 Point Geometry Alignment

1. 16 Adjustment Points are indicated by white dots around the edge of the raster. The adjustment position is

indicated by a + cursor.

2. Starting from the upper left corner, use the <WTSX> buttons to align the + at each point in a straight line,

flush with the bezel as a reference. See example above.

Note: Only the cursor will move. The Geometry Pattern will not change.

3. After adjusting each point, use the (V43C & V43 <CH U>) (V43+ & V43++ <XX>) button to shift the cursor to

the next point clockwise and repeat until all 16 points have been adjusted.

4. After all 16 points are adjusted and the cursor is returned to the original starting point, press <ENTER>.

Correction will be automatically calculated and saved and the Manual Geometry Alignment will be terminated.

5. Re-activate the Manual Geometry Alignment. The geometry pattern will appear with the corrections applied. If

Geometry is acceptable, press <EXIT> to quit. To touchup the raster geometry, proceed to Phase 2.

Phase 2 - Geometry Touch-up Alignment

1. If additional correction is necessary after performing the Manual Geometry Alignment, re-enter the Manual

Geometry Alignment mode.

2. Use the (V43C & V43 <CH U> or <CH V>) (V43+ & V43++ <WW> or <XX>) button to shift the cursor to

the point needing correction.

3. Use the <WTSX> buttons to indicate the direction and amount of correction necessary at the particular

point. Note: Only the cursor will move. The Geometry Pattern will not change.

4. Press the <INFO> button to apply the correction. The Geometry Pattern will now show the correction.

5. Repeat steps 2, 3 and 4 as needed.

6. Press <ENTER> to save your changes. The Manual Geometry Alignment will be terminated.

7. Press <EXIT> to exit the alignment mode. Or, to proceed to Phase 3, re-enter the Geometry Alignment

mode

Page 37

Page 38

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Phase 3 - 4:3 and 16:9 Alignment

1. With the Manual Geometry Alignment activated, press <VIDEO> to enter the 4:3 Alignment Mode. The pattern below will be displayed.

Note: Pressing <VIDEO> will toggle between the 4:3,16:9 (top & b ottom) and 16 Point Geometry Alignment

modes.

2. In the 4:3 Alignment Mode, pressing (V43C & V43 <CH U> or <CH V>) (V43+ & V43++ <WW> or <XX>) will

cause the geometry pattern to be displayed with 11 preset amounts of correction. Toggle through them until

you find the one with the straightest Blue 4:3 Lines. It may help to count the patterns as you cycle through

them. When you find the pattern with the straightest Blue 4:3 Lines, press <VIDEO>. The Top 16:9 Alignment Mode will then be activated as indicated by the Top Red 16:9 Line displayed in the pattern.

4:3 MODE

Select Straightest Blue Lines

3. In the Top 16:9 Alignment Mode, pressing (V43C & V43 <CH U> or <CH V>) (V43+ & V43++ <WW> or

<XX>) will cause the geometry pattern to be displayed with 15 different preset amounts of correction to the

Top Red 16:9 Line. Toggle through them until you find the one with the straightest Top Red 16:9 Line. Again,

count the patterns as you cycle through them. When you find the pattern with the straightest line, press

<VIDEO>. The Bottom 16:9 Alignment Mode will then be activated as indicated by the Bottom Red 16:9 Line

displayed in the pattern.

4:3 MODE

Select Straightest Red Line (Top)

Page 38

Page 39

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

4. In the Bottom 16:9 Alignment Mode, pressing (V43C & V43 <CH U> or <CH V>) (V43+ & V43++ <WW> or

<XX>) will cause the geometry pattern to be displayed with 15 different preset amounts of correction to the

Bottom Red 16:9 Line. Toggle through them until you find the one with the straightest Bottom Red 16:9

Line. Again, count the patterns as you cycle through them. When you find the pattern with the straightest

line, press <ENTER> to exit and save the 4:3 and 16:9 data.

5. Select the Geometry Test Pattern (See HVPOS). If Geometry is acceptable, press <EXIT> to quit.

4:3 MODE

Select Straightest Red Line (Bottom)

Page 39

Page 40

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

DATA TRANSFER FUNCTIONS

Data Transfer

Service Data is duplicated and stored in separate EEPROMs in two locations.

• PWB-MAIN - Working Service Data for TV operation

• OPTICAL ENGINE - Backup Service Data

The Optical Engine also includes data for the Index Delay setting for color wheel timing determined at the factory.

The PWB-MAIN also includes User and/or ISF settings. The User/ISF data is not backed up on the Engine. However if

used, it can be backed up onto a USB flash drive.

Data Transfer Procedures should be followed…

• After PWB-MAIN Replacement:

1. Restore Engine Data From Backup (Includes Geometry Data in V43C & V43)

2. Restore Geometry Data From Backup. (V43+ V43++)

3. Restore ISF Settings From Flash Drive. (V43+ V43++) (Only if backup USB flash drive is available).

• After OPTICAL ENGINE Replacement:

1. Restore Index Delay.

2. Save Engine and Geometry Setting to Backup

Data Transfer Procedure:

V43C & V43

Data Transfer is accomplished by code command rather than on-screen menus.

1. Press <MENU> - Customer Menu will appear

2. Press <2-4-5-7> - No indication will be displayed.

3. Press the four digit Code for the desired date transfer function. The STATUS LED will turn red while the data

is being transferred.

4. Press <EXIT> to quit.

<MENU> <2-4-5-7> <CODE>

TRANSFER FUNCTION CODE WHEN TO USE

Restore Engine Data From Backup 5555 After PWB-Main Replacement

Restore Index Delay 0000 After Optical Engine Replacement

Save Engine and Geometry Settings to Backup 9999 After Optical Engine Replacement

Page 40

Page 41

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Data Transfer Procedure:

V43+ & V43++

1. Enter the Service Mode <MENU><2-4-5-7> Select the Data Transfer & Geometry Menu <0>

Note: Besides MANUAL GEOMETRY ALIGNMENT, six data transfer choices are listed on screen.

• RESTORE ENGINE DATA FROM BACKUP - copies backup factory adjustments HVPOS, White Balance

• RESTORE GEOMETRY DATA FROM BACKUP - copies backup factory Geometry Alignment data from

• RESTORE INDEX DELAY - copies factory Index Delay Adjustment data from the Optical Engine to the

• SAVE ENGINE AND GEOMETRY SETTING TO BACKUP - copies all working data from the PWB-MAIN

• BACKUP AND RESTORE ISF SETTINGS - allows the ISF (ADV) video settings to be backed up and

• RED ONLY AND GREEN ONLY - displays the video in red or green only during ISF Calibration.

2. Use the <TS> buttons to select the item and press <ENTER>.

3. Follow on-screen instructions if given.

4. Press <EXIT> to quit.

Data Transfer & Geometry Menu

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RES TORE INDEX DELAY

SAVE ENG IN E AND G E OM E TRY S ETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

Warning

after Optical E ngi ne repl ac em ent.

and Index Delay from the Optical Engine to the PWB-MAIN.

the Optical Engine to the PWB-MAIN.

PWB-MAIN.

into backup memory on the Optical Engine.

restored using an external USB flash drive.

Data Transfer & Geometry Menu <MENU><2-4-5-7>< 0>

- Only use "SAVE ENGINE AND GEOMETRY SETTING TO BACKUP"

RESTORE ENGINE DATA FROM BACKUP

RESTORE GEOMETRY DATA FROM BACKUP

MANUAL GEOMETRY ALIGNMENT

RESTORE INDEX DELAY

SAVE ENGINE AND GEOMETRY SETTING TO BACKUP

BACKUP AND RESTORE ISF SETTINGS

RED ONLY AND GREEN ONLY

<MENU><2-4-5-7><0>

Page 41

Page 42

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

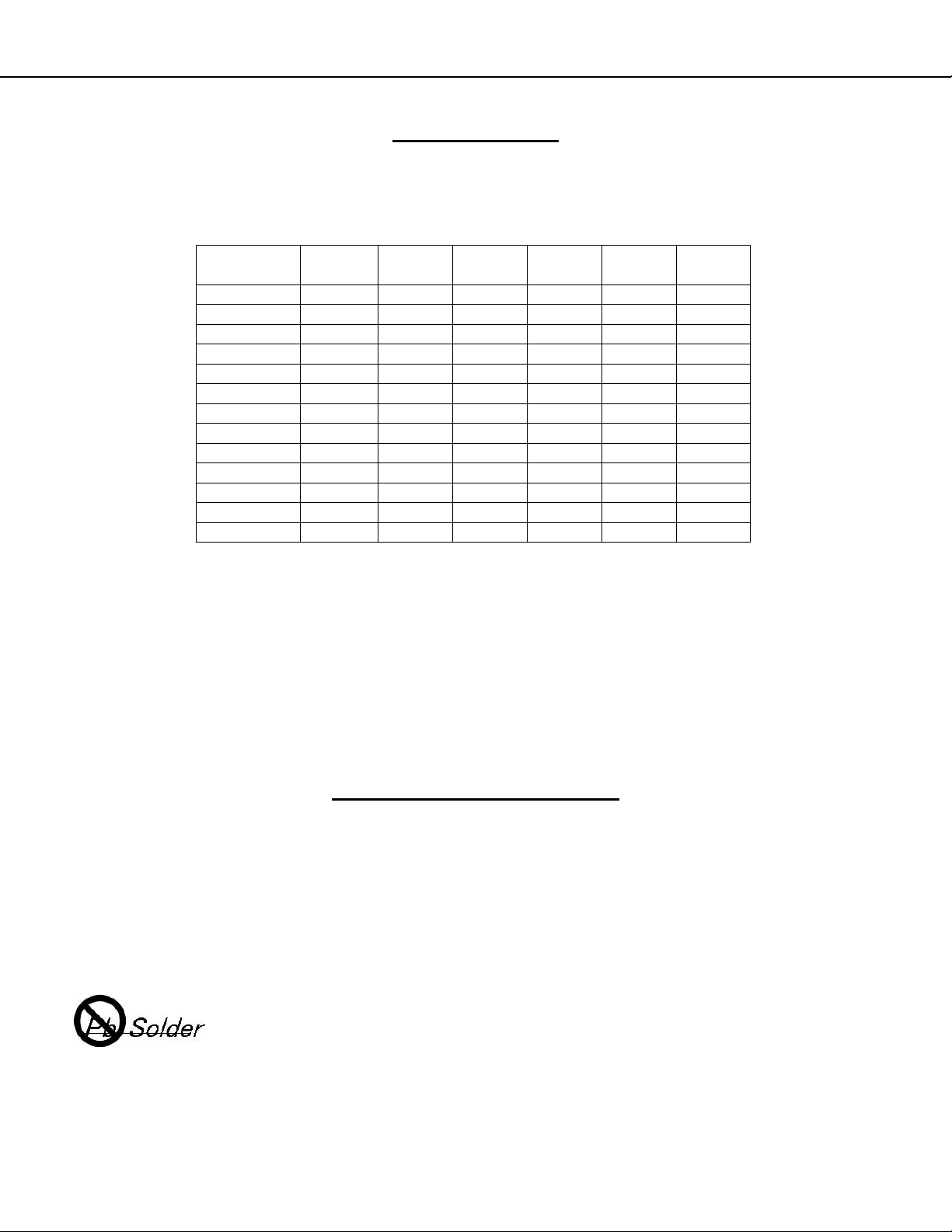

Using Lead Free Solder

Pb Solder

The symbol shown above indicates Lead (Pb) Free Solder was used during the construction of PWBs. Only Lead Free

Solder should be used when servicing these PWBs.

Solder must be compatible with that used by the manufacturer. Leaded solder can not be used on PWBs manufactured

with Pb-free solder. The Mitsubishi standard for service requires the use of Tin-Silver-Copper (Sn-96.5, Ag-3.0, Cu-0.5).

It can be obtained through the Parts Department.

Order part number: PB FREE SOLDER

Lead Free Solder has a higher melting point, and does not “wet” as well as leaded solder. This means it does not adhere as readily to the solder iron tip, and the surface to be soldered. To counteract this, the flux used is more corrosive.

The following cautions must be taken when using Pb Free Solder.

• Higher temperatures can cause the PWB to warp, detaching surface mount components.

• Higher temperatures may cause thermal damage to components.

• Higher temperatures can cause plastics such as connectors, relays, LEDs, electrolytic capacitors to melt or warp.

• Higher temperatures can cause surface oxidation resulting in poor solder spread-ability and wet-ability.

• The flux is more corrosive.

• The time required for a good solder connection may take longer.

• Poor wet-ability can cause solder balls.

• Higher temperatures can cause flux spattering.

• Soldering iron tip life is shortened.

• Dull finish solder joints (not shiny) can appear to be a “cold” solder joint.

In general a tip temperature of 700° F will usually provide good results.

Displays used to indicate Pb-free

PWBs will be marked, indicating the level of Pb-free construction. Table 1 defines the levels by phase and shows the

different symbols that will be displayed on the PWB. Additionally, a PWB constructed using Pb-free solder may be simply

marked LFS.

When possible, the indication will be placed close to the part number that is screened onto the PCB (not the part label).

Pb-Free

Phase Definition Display

Phase-1 PCB's constructed using

Pb-free solder.

Pb Solder

Phase-2 Solder, PCB surface

Phase-3 Solder, PCB surface

finishing and component

lead plating is Pb-free.

Components may have

internal Pb.

finishing and components

are Pb-free. (100% Pbfree)

Table 1: Pb-Free Phases and Symbols

Pb Joints

Pb PCA

Page 42

Short Display (When the

area is too small)

Pb S

Pb J

Pb P

Page 43

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

Chip Parts Replacement

Some resistors, shorting jumpers (0 Ohm resistors), ceramic capacitors, transistors and diodes are chip parts. The following precautions should be taken when replacing these part s.

Cautions:

1. Use a fine tipped, well insulated soldering iron and tweezers.

2. Melt the solder and remove the chip parts carefully so as not to tear the copper foil from the printed circuit

board.

3. Discard removed chips; do not reuse them.

4. Do not apply heat for more than 3 (three) seconds to new chip parts.

5. Avoid using a rubbing stroke when soldering

6. Take care not to scratch, or damage the chip parts when soldering.

7. Supplementary cementing is not required.

Chip Parts Removal (Resistors, Capacitors, etc.)

1. Grasp the part with tweezers.

2. Melt the solder at both sides alternately, and remove one side of the part with a twisting motion.

3. Melt the solder at the other side and remove the part.

Chip Parts Removal (Transistors)

1. Melt the solder of one lead and lift the side of that lead upward.

2. Simultaneously melt the solder of the other two leads and lift the part from the PCB.

Replacement

1. Pre-solder the contact points on the circuit pattern.

2. Press the part downward with tweezers and apply the soldering iron as shown.

Page 43

Page 44

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

REPLACEMENT PARTS

Parts Ordering

To expedite delivery of replacement parts orders, specify the following:

1. Model Number/Serial Number

2. Part Number and description

3. Quantity

Note: Unless complete information is supplied, delay in processing of orders will result.

Safety Critical Parts Designation

Safety Critical Components are indicated in the Parts List by Bol d Type and a

schematic diagrams by a red hatch and a

Parts Tolerance Codes

Refer to the following chart for tolerance characteristics of electrical components.

symbol.

symbol, and in the

MARKBCDFGJK

Tolerance % ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2 ± 5 ± 10

MARK M N V X Z P Q

Tolerance %

MARK M N V X Z

Tolerance (pF) ± 0.1 ± 0.25 ± 0.5 ± 1 ± 2

± 20 ± 30 ± 10 + 40 + 80 + 100 + 30

-20 -20 - 0 -10

Page 44

Page 45

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

[ # ] Model Legend: (a) WD-60638, (b) WD-60738, (c) WD-60C10, (d) WD-65638, (e) WD-65738, (f) WD-65838, (g) WD-65C10,

(h) WD-73638, (i) WD-73738, (j) WD-7383 8, (k) WD-73C10, (l) WD-82738, (m) WD-82838

[] Safety Critical Part - Use exact replacement only

Parts Quick Reference

Description Part Number #

ASSY-PWB-POWER 934C370001 acdghk

ASSY-PWB-POWER 934C370002 beil

ASSY-PWB-POWER 934C370003 fjm

ASSY-PWB-MAIN 934C369001 acdghk

ASSY-PWB-MAIN 934C381001 beil

ASSY-PWB-MAIN 934C381002 fjm

ASSY-PWB-SOUND 934C382001 fjm

ASSY-PWB-CONTROL 934D110001 aceil

ASSY-PWB-CONTROL 934D110002 bdghk

ASSY-PWB-PREAMP 934D112001 ac

ASSY-PWB-PREAMP 934D112002 dghk

ASSY-PWB-PREAMP 934D112003 b

ASSY-PWB-PREAMP 934D112004 eil

ASSY-PWB-SW-LAMP 934D113001

ASSY-PWB-AUX 934D123001 fjm

ASSY-PWB-BALLAST 938P178010

ASSY-SBL-MODULE 938P181010 fjm

BLUETOOTH-MODULE 938P177010 fjm

LAMP-CARTRIDGE 915B441001

ASSY-OPTICAL-ENGINE 938P174010 abc

ASSY-OPTICAL-ENGINE 938P174020 deg

ASSY-OPTICAL-ENGINE 955B378006 f

ASSY-OPTICAL-ENGINE 938P174040 hik

ASSY-OPTICAL-ENGINE 955B378007 j

ASSY-OPTICAL-ENGINE 938P174060 l

ASSY-OPTICAL-ENGINE 955B378008 m

COLOR-WHEEL 938P179010

LENS-PROJECTION 491P245010

SCREEN-LENTICULAR 491P241010 abc

SCREEN-LENTICULAR 491P241020 defg

SCREEN-LENTICULAR 491P217060 hijk

SCREEN-LENTICULAR 491P231010 lm

LENS-FRESNEL 491P242040 abc

LENS-FRESNEL 491P242050 defg

LENS-FRESNEL 491P218030 hijk

LENS-FRESNEL 491P232010 lm

MIRROR 60”

MIRROR 65” KIT-MIR V43 65

MIRROR 73” KIT-MIR V43 73

MIRROR 82” KIT-MIR V43 82

KIT-MIR V43 60 abc

Page 45

defg

hijk

lm

Page 46

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

[ # ] Model Legend: (a) WD-60638, (b) WD-60738, (c) WD-60C10, (d) WD-65638, (e) WD-65738, (f) WD-65838, (g) WD-65C10,

(h) WD-73638, (i) WD-73738, (j) WD-7383 8, (k) WD-73C10, (l) WD-82738, (m) WD-82838

[] Safety Critical Part - Use exact replacement only

Ref P/N Part Name & Description

IC1B01 271P349010 IC - MIC2005-0.5YM6

IC1B05 271P349010 IC - MIC2005-0.5YM6 befijlm

IC1B06 276P578020 IC-C-MOS - MM3376A33NRE fjm

IC2A01 276P726020 IC-C-MOS - 276P726 befijlm

IC2A01 276P829010 IC-C-MOS - PS331QFN64G acdghk

IC3A00 271P348010 IC - YDA164 abcdeghikl

IC3C00 276P741010 IC-C-MOS - AK4420ETP beil

IC3F01 276P515010 IC-C-MOS - DIR9001PWR fjm

IC3G01 276P513010 IC-C-MOS - D708E001BRFP266 fjm

IC3H01 276P827010 IC-C-MOS - K4S641632N fjm

IC3J01 271P326020 IC - NJM2831F05 fjm

IC3J02 271P355010 IC - NJM2781V fjm

IC3J03 271P345010 IC - NJM2753V fjm

IC3J04 276P503010 IC-C-MOS - AK5358AETP fjm

IC3L01 276P828010 IC-C-MOS - PCM1681PWPR fjm

IC3L02 276P828010 IC-C-MOS - PCM1681PWPR fjm

IC3L03 276P741010 IC-C-MOS - AK4420ETP fjm

IC3L05 276P741010 IC-C-MOS - AK4420ETP fjm

IC3M01 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3M02 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3M03 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3M04 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3N01 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3N02 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3N03 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3N04 276P831010 IC-C-MOS - TPA2017D2V2RTJR fjm

IC3P01 271P254010 IC - ISL6545ACBZ-TS2698 fjm

IC4A01 276P742020 IC-C-MOS - PST8428NR befijlm

IC4A01 276P823010 IC-C-MOS - BCM35143 acdghk

IC4A02 276P687030 IC-C-MOS - BCM3549SLKFSB5G befijlm

IC4A02 276P744010 IC-C-MOS - NT5TU64M16DG-AC acdghk

IC4A03 276P551010 IC-C-MOS - AT24C02BN-SH-T acdghk

IC4A04 276P825010 IC-CMOS - MX25L6405DMI-12G acdghk

IC4A05 271P345010 IC - NJM2753V acdghk

IC4A06 276P578040 IC-C-MOS - MM3376A18NRE acdghk

IC4A07 276P578030 IC-C-MOS - MM3376A10NRE acdghk

IC4A08 271P319020 IC - MM1701JHBE acdghk

IC4A09 276P578020 IC-C-MOS - MM3376A33NRE acdghk

IC4F01 276P744010 IC-C-MOS - NT5TU64M16DG-AC befijlm

IC4F02 271P033020 IC - LP2996LQNOPB befijlm

IC4F03 276P744010 IC-C-MOS - NT5TU64M16DG-AC befijlm

IC4G01 271P251040 IC - MM1662FHBE befijlm

IC4K01 276P832020 IC-C-MOS - NAND2GW3B2DZA6E befijlm

IC5A01 276P722010 IC-C-MOS - UPD808526F1

IC5A02 271P319010 IC - MM1701AHBE

IC5A03 271P319010 IC - MM1701AHBE

IC7A01 276P576010 IC-C-MOS - UPD78F1178GF(S)

IC7A03 276P578020 IC-C-MOS - MM3376A33NRE

IC7E01 276P519010 IC-C-MOS - 74HC132DB fjm

IC8300 276P525010 IC-C-MOS - MAX4489ASA+T fjm

INTEGRATED CIRCUITS

acdfghjkm

#

Ref P/N Part Name & Description

IC9010 267P324010 HIC - STR-W6756

IC9020 271P142010 IC - RT9H301C

IC9030 271P315010 HIC - STR-A6159

IC9031 271P142010 IC - RT9H301C

IC9A01 271P254010 IC - ISL6545ACBZ-TS2698

IC9A02 270P950010 IC - NJM78M09DL1A(TE1) befijlm

IC9A02 271P254010 IC - ISL6545ACBZ-TS2698 acdghk

IC9A03 271P254010 IC - ISL6545ACBZ-TS2698 acdghk

IC9A03 271P323010 IC - ISL8014IRZ-T befijlm

IC9A04 271P323010 IC - ISL8014IRZ-T befijlm

IC9A04 276P578020 IC-C-MOS - MM3376A33NRE acdghk

IC9A05 271P323010 IC - ISL8014IRZ-T befijlm

IC9A06 271P321010 IC - PST8242NR

IC9A07 271P321010 IC - PST8242NR

IC9A08 276P578020 IC-C-MOS - MM3376A33NRE befijlm

IC9G80 271P349010 IC - MIC2005-0.5YM6

CHIP Type Transistors (Listed by Part No.)

TRANSISTORS

#

D2A11 262P904070 DIODE-CHIP - DZ2J051M0L

D2A12 262P830010 D-CHIP - MC2850-T111-1

D2A13 262P830010 D-CHIP - MC2850-T111-1

D2A21 262P904070 DIODE-CHIP - DZ2J051M0L

D2A22 262P830010 D-CHIP - MC2850-T111-1

D2A23 262P830010 D-CHIP - MC2850-T111-1

D2A31 262P904070 DIODE-CHIP - DZ2J051M0L

D2A32 262P830010 D-CHIP - MC2850-T111-1

D2A33 262P830010 D-CHIP - MC2850-T111-1

D2A41 262P904070 DIODE-CHIP - DZ2J051M0L fjm

D2A42 262P830010 D-CHIP - MC2850-T111-1 fjm

D2A43 262P830010 D-CHIP - MC2850-T111-1 fjm

D4A05 262P830010 D-CHIP - MC2850-T111-1 befijlm

D4A06 262P830010 D-CHIP - MC2850-T111-1 befijlm

D4A07 262P830010 D-CHIP - MC2850-T111-1 befijlm

Part No. Description

261P805010 FDV301N

261P842080 2SC3052-T112-1E;F

261P844010 RT1N436C-T112-1

261P845010 RT1P241C-T1112-1

261P874010 FDS8896

261P875010 FDS8984

261P876010 FDS6298

261P877010 FDC655BN

261P878010 RT3Y97M-T111-1

261P881010 2SB1424T100R

261P889010 ISA1235AC1-T112A-1E,1F

261P918010 FDS6910

DIODES

Page 46

Page 47

MODELS: WD-60C10 / WD-65C10 / WD-73C10 / WD-60638 / WD-65638 / WD-73638 /

WD-60738 / WD-65738 / WD-73738 / WD-82738 / WD-65838 / WD-73838 / WD-82838

[ # ] Model Legend: (a) WD-60638, (b) WD-60738, (c) WD-60C10, (d) WD-65638, (e) WD-65738, (f) WD-65838, (g) WD-65C10,

(h) WD-73638, (i) WD-73738, (j) WD-7383 8, (k) WD-73C10, (l) WD-82738, (m) WD-82838

[] Safety Critical Part - Use exact replacement only

Ref P/N Part Name & Description

D4A07 262P852010 D-CHIP - BAT54S acdghk

D4A08 262P830010 D-CHIP - MC2850-T111-1 acdghk

D4A08 262P830010 D-CHIP - MC2850-T111-1 befijlm

D4A09 262P830010 D-CHIP - MC2850-T111-1 acdghk

D7A03 262P830010 D-CHIP - MC2850-T111-1 befijlm

D7A04 262P828020 D-CHIP - MC2836-T112-1

D7E00 262P830010 D-CHIP - MC2850-T111-1 fjm

D8000 264P584020 DIODE-LE - SML1216W-C,D acefijlm

D8200 264P584020 DIODE-LE - SML1216W-C,D bdghk

D8300 262P828010 D-CHIP - MC2838-T112-1 fjm

D8301 268P100010 DIODE-PHOTO - SFH235FA fjm

D9005 262P170010 DIODE - SARS01

D9006 262P203070 DIODE - UF4007

D9008 262P201060 DIODE - 1N4006

D9009 262P201060 DIODE - 1N4006

D9010 262P201060 DIODE - 1N4006

D9011 262P201060 DIODE - 1N4006

D9013 262P084010 DIODE - 31DQ06

D9014 264P774020 DIODE - MTZJ4.7A,B,CQLF

D9015 262P085010 DIODE - 11EFS2N-TA2B5

D9023 262P085010 DIODE - 11EFS2N-TA2B5

D9024 262P085010 DIODE - 11EFS2N-TA2B5

D9026 262P208010 DIODE - FCHS10A12-15A

D9031 262P210010 DIODE - 30PHA20-FC5

D9207 262P200010 DIODE - D6SB80-7001

D9A01 262P904020 DIODE-CHIP - DZ2J140M0L befijlm