Mitsubishi TM-RFM006C20, TM-RFM002C20, TM-RFM006E20, TM-RFM012E20, TM-RFM018E20 User Manual

...Page 1

Direct Drive Motor

Mitsubishi Electric AC Servo System

User's Manual

-TM-RFM

-TM-RG2M

-TM-RU2M

Page 2

Page 3

SAFETY INSTRUCTIONS

WARNING

Indicates that incorrect handling may cause hazardous conditions, resulting in

death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous conditions, resulting in

medium or slight injury.

Indicates what must not be done. For example, "No Fire" is indicated by .

Indicates what must be done. For example, grounding is indicated by .

(Please read the instructions carefully before using the equipment.)

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you have read

through this manual, Installation guide, and appended documents carefully. Do not use the equipment until you have a full

knowledge of the equipment, safety information and instructions.

In this manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

Note that the CAUTION level may lead to a serious consequence depending on conditions.

Please follow the instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

In this manual, instructions at a lower level than the above, instructions for other functions, and so on are classified into

"POINT".

After reading this guide, keep it accessible to the operator.

[Installation/wiring]

WARNING

● To prevent an electric shock, turn off the power and wait for 15 minutes or more before starting wiring

and/or inspection.

● To prevent an electric shock, ground the direct drive motor securely.

● To prevent an electric shock, any person who is involved in wiring should be fully competent to do the

work.

● To prevent an electric shock, do not attempt to wire the direct drive motor until it has been installed.

● To prevent an electric shock, do not touch the conductive parts.

[Installation/wiring]

CAUTION

● To prevent injury, do not touch the rotor of the direct drive motor during operation.

● To prevent injury, transport the products correctly according to their mass.

[Maintenance]

WARNING

● To prevent an electric shock, any person who is involved in inspection should be fully competent to do

the work.

1

Page 4

DISPOSAL OF WASTE

Please dispose this product and other options according to your local laws and regulations.

CABLES USED FOR WIRING

The wiring cables mentioned in this User's Manual are selected based on the ambient temperature of 40 °C.

U.S. CUSTOMARY UNITS

U.S. customary units are not shown in this manual. Convert the values if necessary according to the following table.

Quantity SI (metric) unit U.S. customary unit

Mass 1 [kg] 2.2046 [lb]

Length 1 [mm] 0.03937 [inch]

Torque 1 [N•m] 141.6 [oz•inch]

-4

Moment of inertia 1 [(× 10

Load (thrust load/axial load) 1 [N] 0.2248 [lbf]

Temperature N [°C] × 9/5 + 32 N [°F]

kg•m2)] 5.4675 [oz•inch2]

2

Page 5

CONTENTS

SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

DISPOSAL OF WASTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CABLES USED FOR WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

U.S. CUSTOMARY UNITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

CHAPTER 1 INTRODUCTION 5

1.1 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Parts identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Instructions on storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 Design Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.6 Instructions on maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

CHAPTER 2 INSTALLATION 7

2.1 Equipment configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Mounting direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Load mounting/dismounting precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Permissible load for the rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Protection from oil and water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Inspection items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Periodic inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Parts having life. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Machine accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.9 Flange size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.10 Restrictions when using this product at altitude exceeding 1000 m and up to 2000 m . . . . . . . . . . . . . . . 12

2.11 Magnetic shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

CONTENTS

CHAPTER 3 CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING 13

3.1 Selection of connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Wiring connectors (connector configurations A/B/C/D/E). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHAPTER 4 CONNECTOR DIMENSIONS 16

CHAPTER 5 CONNECTION OF SERVO AMPLIFIER AND DIRECT DRIVE MOTOR 21

5.1 Precautions for wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Direct drive motor power cable wiring diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Selection example of wires. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

CHAPTER 6 Wiring option 24

6.1 Connector set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Combinations of connector sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connector list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Encoder connector set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Combinations of encoder cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fabrication of the encoder cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Shield procedure of CN2, CN2A, CN2B, and CN2C side connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.3 Absolute position storage unit MR-BTAS01 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3

Page 6

CHAPTER 7 TM-RFM SERIES 37

7.1 Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 Combinations of servo amplifier and direct drive motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1-axis servo amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Multi-axis servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.3 Specification list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

TM-RFM series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.4 Torque characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.5 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TM-RFM002C20, TM-RFM004C20, TM-RFM006C20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

TM-RFM006E20, TM-RFM012E20, TM-RFM018E20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

TM-RFM012G20, TM-RFM048G20, TM-RFM072G20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

TM-RFM040J10, TM-RFM120J10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

CHAPTER 8 TM-RG2M SERIES/TM-RU2M SERIES 47

8.1 Model designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.2 Combinations of servo amplifier and direct drive motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

1-axis servo amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Multi-axis servo amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.3 Specification list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

TM-RG2M series/RU2M series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

8.4 Torque characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.5 Installation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.6 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

TM-RG2M002C30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

TM-RG2M004E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

TM-RG2M009G30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

TM-RU2M002C30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

TM-RU2M004E30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

TM-RU2M009G30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

CHAPTER 9 COMPLIANCE WITH EACH REGION 55

9.1 Compliance with CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

For compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.2 Compliance with UL/CSA standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

CHAPTER 10 APPENDIX 58

10.1 Fabrication of the encoder cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

REVISIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

TRADEMARKS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

4

Page 7

1 INTRODUCTION

Precautions

*2

*1

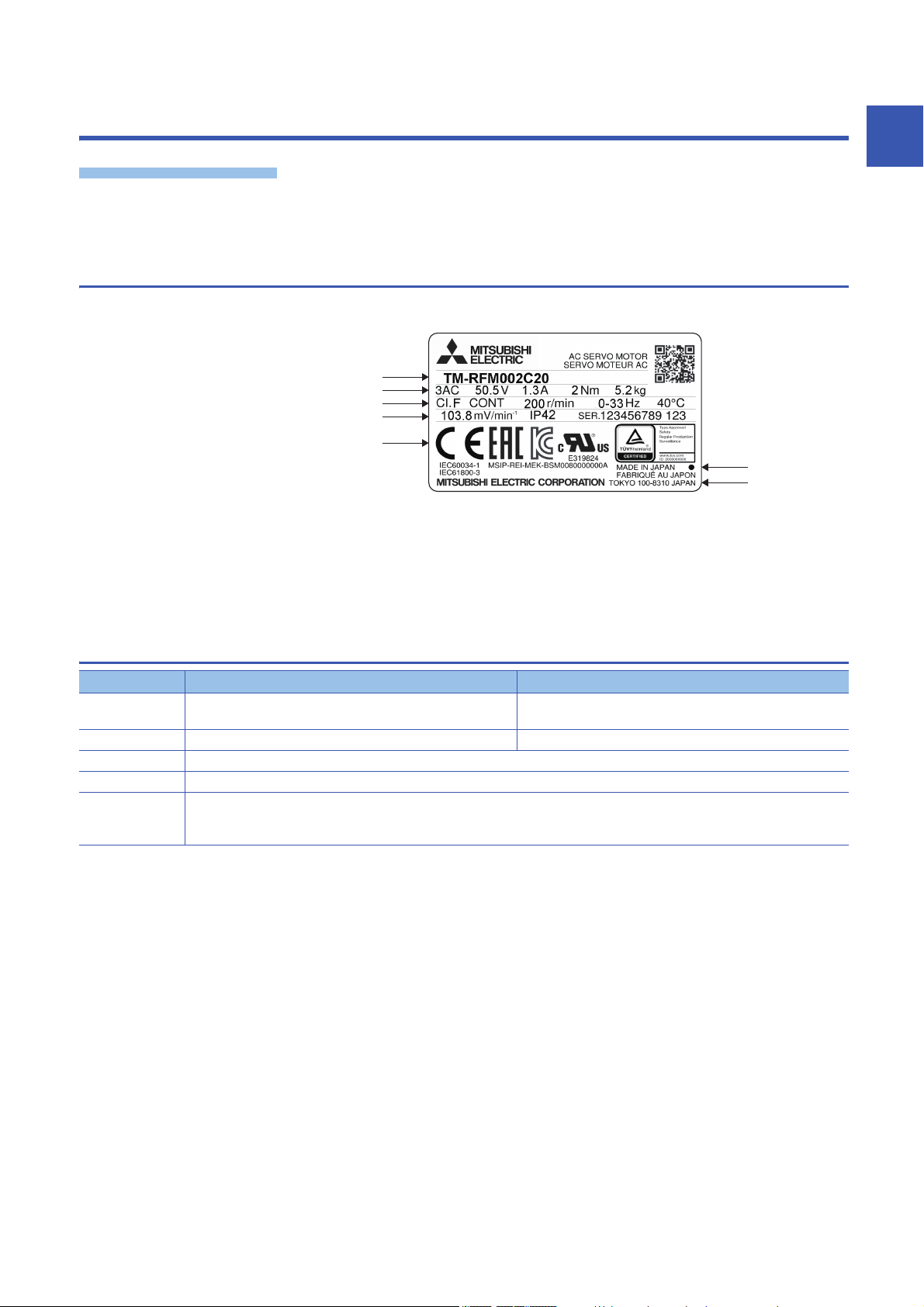

Induced voltage constant, IP rating, serial number

Model

Input power, rated torque, mass

Insulation class, rated speed, maximum ambient temperature

Country of origin

Manufacturer

• Use direct drive motors manufactured after June 2019.

• MR-J5-_G_-RJ and MR-J5-_A_-RJ will be available in the future.

1.1 Rating plate

The following shows an example of the rating plate for explanation of each item.

*1 Production year and month of the direct drive motor are indicated in a serial number on the rating plate.

The year and month of manufacture are indicated by the last two digits of the year and one digit of the month [1 to 9, X (10), Y (11), and

Z (12)].

For January 2012, the Serial No. would be "SER. _ _ _ _ _ _ _ _ _ 121".

*2 Certified products by the Authorized Bodies are marked.

The mark depends on the related Authorized Bodies.

1

1.2 Environment

Operation Storage/transportation

Ambient

temperature

Ambient humidity 10 %RH to 80 %RH (non-condensing) 10 %RH to 90 %RH (non-condensing)

Ambience

Altitude 2000 m or less

Vibration

resistance

*1 Do not use in an environment where there is exposure to oil mist, oil, and water.

*2 Refer to the following for restrictions on using this product at an altitude exceeding 1000 m and up to 2000 m.

*3 Do not place the direct drive motor near magnetic sources, such as a magnet. If it is unavoidable, block the magnetic force by installing

*1*3

Page 12 Restrictions when using this product at altitude exceeding 1000 m and up to 2000 m

a shielding plate or others.

0 ˚C to 40 ˚C (non-freezing) -15 ˚C to 70 ˚C (non-freezing)

Indoors (no direct sunlight); no corrosive gas, inflammable gas, oil mist or dust

*2

Refer to the following.

Page 39 Specification list

Page 49 Specification list

1 INTRODUCTION

1.1 Rating plate

5

Page 8

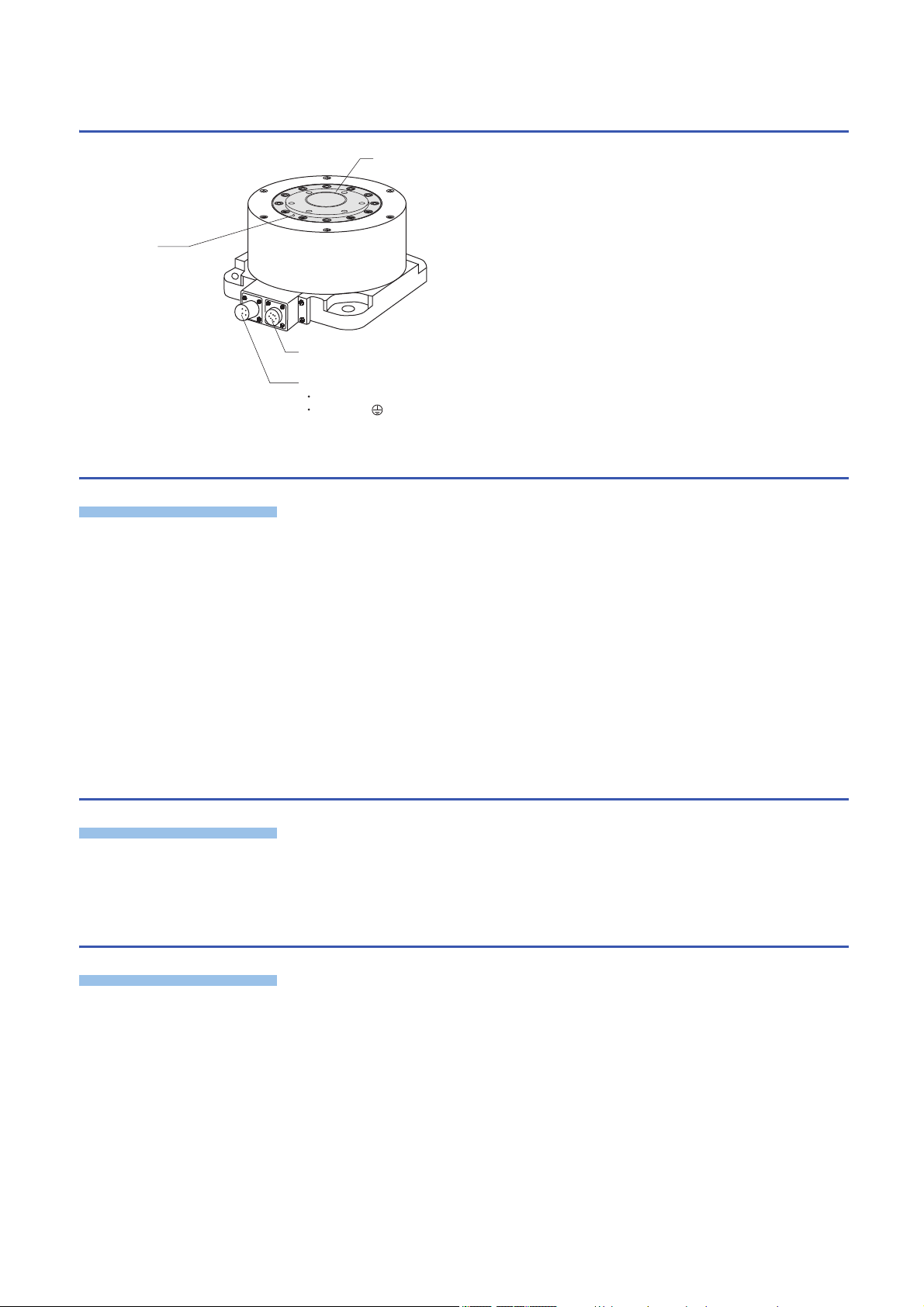

1.3 Parts identification

Precautions

Precautions

Precautions

Rotor (output shaft)

Encoder connector

Power connector

Power supply (U/V/W)

Grounding ( )

Z-phase mark

1.4 Instructions on storage

Note the following when storing the direct drive motor for an extended period of time (guideline: three months or longer).

• Always store the linear servo motor indoors, in a clean and dry place.

• When storing in a dusty and humid area, take measures such as covering the whole product.

• If the insulation resistance of the winding decreases, check how to store the equipment.

• Although the servo motor has been given rust prevention treatment with paint and preventive oil before shipment, rust may

still appear depending on the storage period and conditions. If the servo motor is to be stored for longer than six months,

apply rust prevention oil again, especially on the machine surfaces of the rotating parts and others.

• Before using the product after an extended storage, hand-turn the rotor (output shaft) of the direct drive motor, and check to

ensure that there is no abnormality.

• When the product has been stored for an extended period of time, contact your local sales office.

1.5 Design Instructions

• If a hazardous condition is suspected at the time of stoppage and product malfunction, provide an external braking system

as a prevention.

1.6 Instructions on maintenance

• For repair and parts replacement, contact your local sales office.

6

1 INTRODUCTION

1.3 Parts identification

Page 9

2 INSTALLATION

Precautions

• The cables should not be damaged, stressed, loaded, or pinched.

• Install the direct drive motor on incombustible material. Installing them directly or close to combustibles will lead to smoke

or a fire.

• Provide an adequate protection to prevent screws and other conductive matter, oil and other combustible matter from

entering the direct drive motor.

• Direct drive motor may be hot depending on the operating method. Take safety measures such as providing covers.

• Stacking in excess of the specified number of product packages is not allowed.

• Do not hold the cables, connectors, rotor, or encoder when carrying the direct drive motor. Otherwise, it may drop.

• Install the direct drive motor in a load-bearing place in accordance with the user’s manual.

• The equipment must be installed in the specified direction.

• Use the product within the specified environment. For the environment, refer to the specifications of the direct drive motor.

• Securely fix the direct drive motor to the machine. If attached insecurely, the motor may come off during operation.

• Do not install or operate a direct drive motor, which has been damaged or has any parts missing.

• To prevent a malfunction on the encoder, do not apply shocks, e.g. hit with a hammer, when coupling the rotor of the direct

drive motor.

• To prevent the rotor from being damaged, do not subject the rotor of the direct drive motor to more than the permissible

load.

• To prevent a connection failure, malfunction, or others, do not strike the connector.

• Be sure to measure the vibration level with the direct drive motor mounted on the machine. A great vibration may cause

early damage to a bearing and encoder. The great vibration may also cause the poor connector connection or screw

looseness.

• For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform with a

measurement device to check that no vibration occurs. If the vibration occurs due to high gain, the vibration may cause

early damage to the direct drive motor.

• To illustrate details, the equipment in the diagrams of this manual may have been drawn without covers and safety guards.

When the equipment is operated, the covers and safety guards must be installed as specified. Operation must be

performed in accordance with this user’s manual.

• To prevent the vibration during direct drive motor operation, or the cause of the damage to the bearings and encoder, the

balance level of the load needs to be as even as possible. To prevent malfunction, do not use the direct drive motor where

the shaft-through portion may be subject to pressure (e.g. compressed air).

• Take safety measures such as providing covers to avoid accidentally touching the rotor of direct drive motor during

operation.

• Do not get on or put heavy load on the equipment.

• Do not drop or strike the direct drive motor.

• To prevent a fire or injury from occurring in case of an earthquake or other natural disasters, securely install, mount, and

wire the linear servo motor in accordance with the user’s manual.

• To prevent an electric shock or a fire, do not disassemble, repair, or modify the product. Disassembled, repaired, and/or

modified products are not covered under warranty.

• When coupling a load to the direct drive motor, make sure to align and center the load on the motor flange rabbet.

Particularly, when a rigid coupling is used, even a slight center deviation may reduce position accuracy or damage the rotor.

2

2 INSTALLATION

7

Page 10

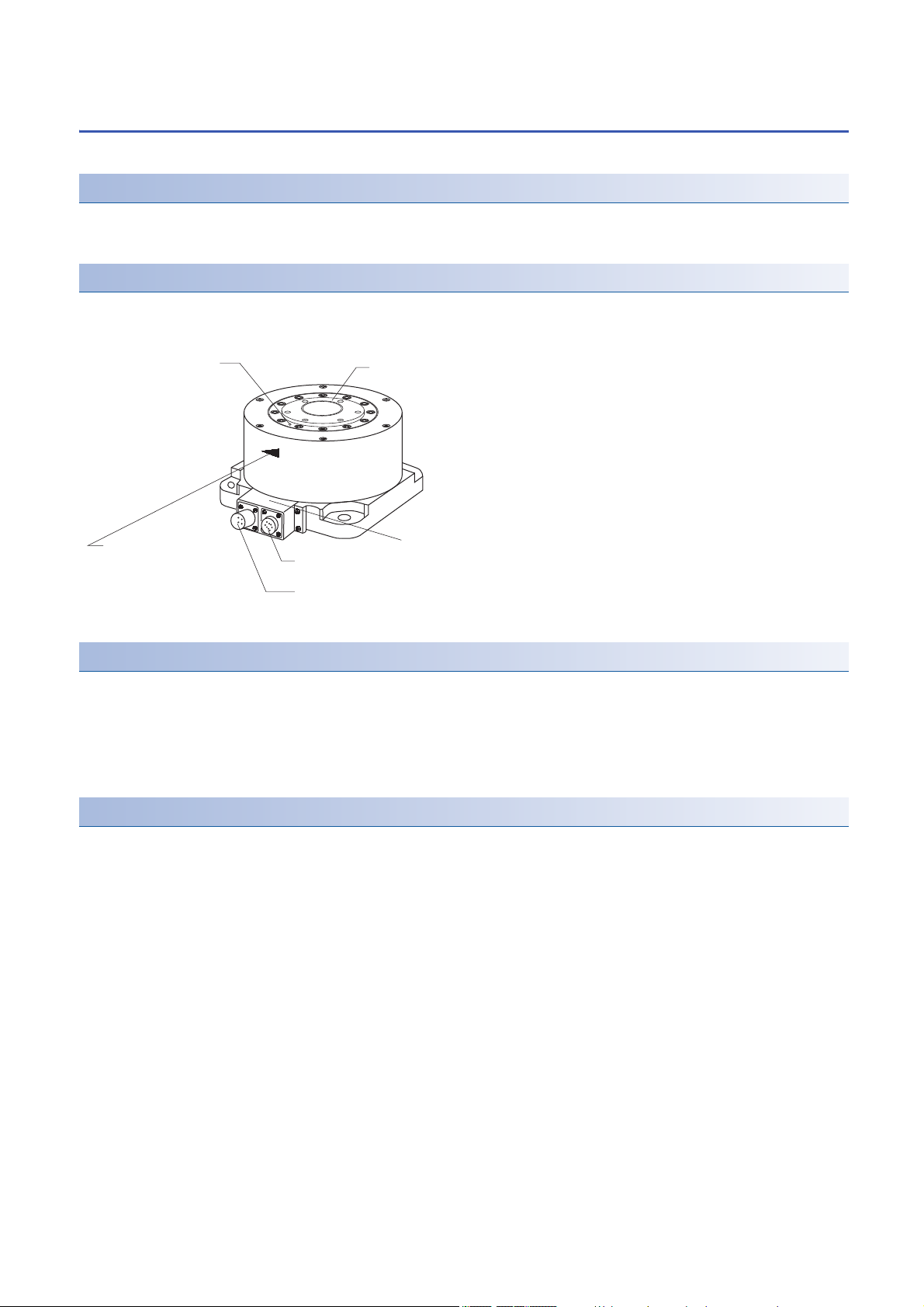

2.1 Equipment configuration

Z-phase pulse is on

(Z-phase mark passing)

when the Z-phase mark

on the rotor end of the

direct drive motor is in

the connector area.

Rotor (output shaft)

Encoder connector

Connector mounting part

Power connector

Z-phase mark

The following shows the configuration of a direct drive motor. When using the direct drive motor, note the following.

Minimum oscillation angle

For a direct drive motor that performs a rotating oscillating motion within 70 °, rotate the motor more than 90 ° at least once a

day to keep the bearings lubricated.

Z-phase position

Z-phase pulse is on (Z-phase mark passing) when the Z-phase mark on the rotor end of the direct drive motor is in the

connector area. Keep the Z-phase position visible even after the direct drive motor is installed to a machine.

Precautions for Z-phase mark passing

After power on, the Z-phase mark of the direct drive motor must pass the connector area once. In a system which prevents

the direct drive motor from making a full rotation or more, install the direct drive motor in a position where the Z-phase mark

can pass over the connector area.

In order to turn the Z-phase pulse, Z phase mark needs to be rotated ±15° or more with respect to the center of the connector

mounting part.

For vertical axis (lift)

For the system where the unbalanced torque occurs, such as a vertical axis system (lift), use the direct drive motor in the

absolute position detection system. In the absolute position detection system, the absolute position is established when the Z-

phase mark passes the connector area once. Therefore, at system startup, make the Z-phase mark pass over the connector

area, and switch the servo amplifier's power supply from off to on.

If the direct drive motor can be rotated manually, make the Z-phase mark pass over the connector area while only the servo

amplifier's control circuit power supply is on. After that, switch the servo amplifier's power supply from off to on.

If the direct drive motor cannot be rotated manually, detect the magnetic poles while the torque is balanced, then run the direct

drive motor in the test mode to make its Z-phase mark pass over the connector area. After that, switch the servo amplifier's

power supply from off to on. After the Z-phase mark passes over the connector area once, magnetic poles detection is not

required.

8

2 INSTALLATION

2.1 Equipment configuration

Page 11

2.2 Mounting direction

The mounting direction of the direct drive motor is shown in the following table.

Direct drive motor series Mounting direction

TM-RFM

TM-RG2M

TM-RU2M

All directions

2.3 Load mounting/dismounting precautions

• To prevent a malfunction on the encoder, the rotor must not be hammered during assembling.

• The direction of the encoder on the direct drive motor cannot be changed.

• When mounting the direct drive motor, use spring washers and others, and fully tighten the screws so that they do not

become loose due to vibration.

2

2.4 Permissible load for the rotor

Do not use rigid coupling, as it may damage the rotor.

For the permissible rotor load specific to the direct drive motor, refer to the following.

Page 39 Specification list

• When coupling a load to the direct drive motor, the load applied to the rotor must be within the permissible load.

• The load, which exceeds the permissible load, can cause the bearing life to reduce and the rotor to break.

• The load indicated in this section is static load in a single direction and does not include eccentric load. Make eccentric load

as small as possible. Not doing so can cause the direct drive motor to be damaged.

2 INSTALLATION

2.2 Mounting direction

9

Page 12

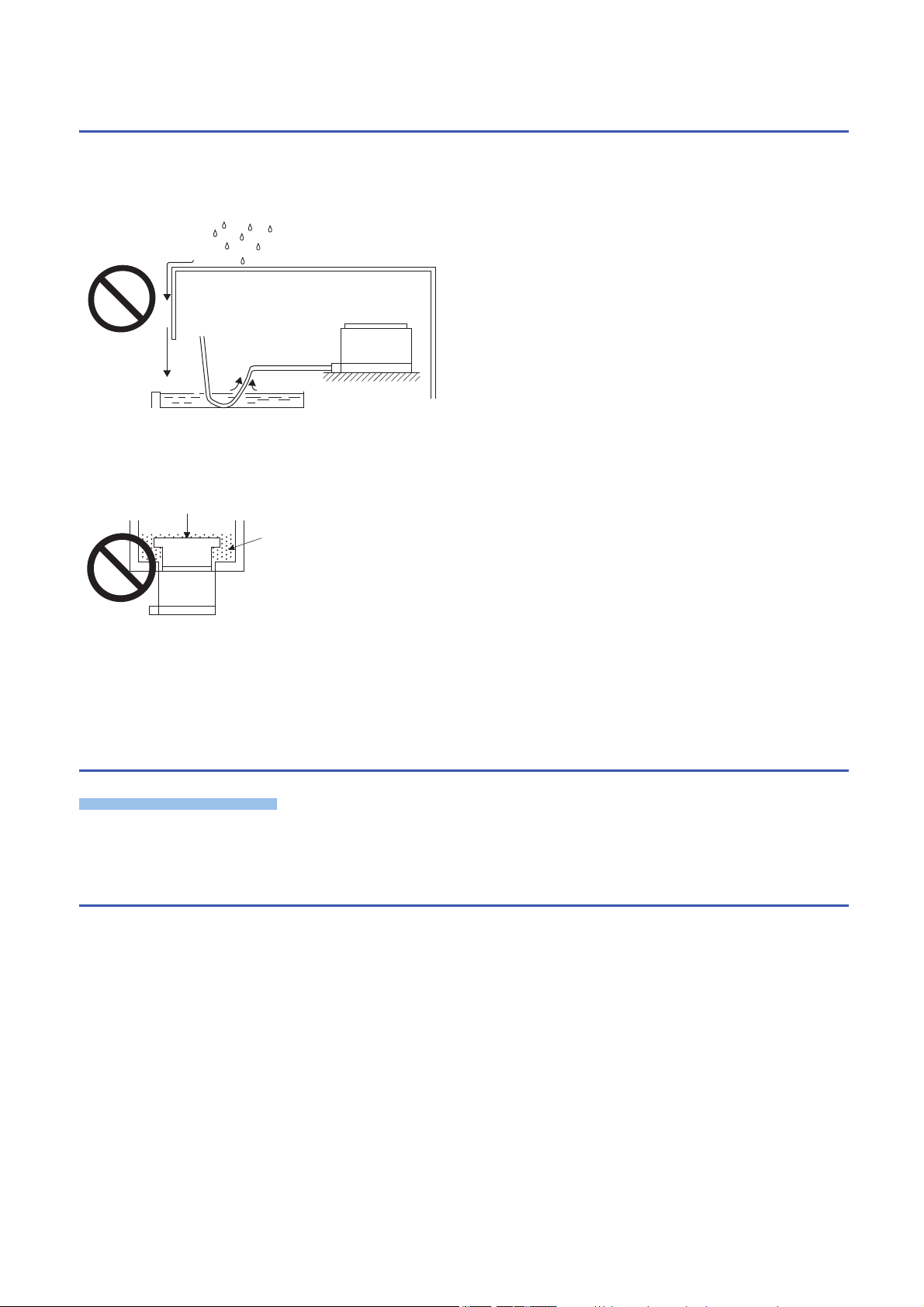

2.5 Protection from oil and water

Precautions

Cover

Oil/water pool

Capillary action

Direct drive motor

Lubricating oil

Rotary table or others

Direct drive motor

Provide adequate protection to prevent foreign matter such as oil and water from entering the rotor of the direct drive motor.

When mounting the direct drive motor, consider the items in this section.

• Do not use the rotary servo motor with its cable soaked in oil or water.

• Provide measures so that the direct drive motor is not exposed to oil and water entering from the machine side, rotating

table, etc.

• If liquid such as cutting oil drops on the direct drive motor, the sealant, packing, cable and others may be affected

depending on the liquid type.

• In the environment where the direct drive motor is exposed to oil mist, steam, oil, water, grease, and/or the like, a standard

specification direct drive motor cannot be used. Provide dust proof and waterproof measures on the machine side.

2.6 Inspection items

• To prevent malfunction, do not perform insulation resistance test on the direct drive motor.

• Do not disassemble and/or repair the equipment on customer side.

Periodic inspection

Perform the following inspections.

• Check the bearings and the like for unusual noise.

• Check the cables and the like for scratches or cracks. Especially when the junction cable is movable, perform periodic

inspection according to operating conditions.

• Check the power connector and encoder connector connections for looseness.

10

2 INSTALLATION

2.5 Protection from oil and water

Page 13

2.7 Parts having life

d

A

c

bA

a

A

φ_

φ_

The life of the following parts is listed below. If any fault is found in the parts, replace them immediately because their life

varies. For parts replacement, contact your local sales office.

Part name Guideline of life Remark

Bearings 20,000 hours to 30,000 hours The Guideline of Life field gives the reference time.

Encoder 20,000 hours to 30,000 hours

Absolute position storage unit (option) 20,000 hours to 30,000 hours

When the motor is run at rated speed and at rated load, bearings should be changed in 20,000 to 30,000 hours as a guideline.

As this differs depending on the operating conditions, the bearings must also be changed if unusual noise or vibration occurs

during inspection.

If any fault is found before this time is reached, the part must be

changed.

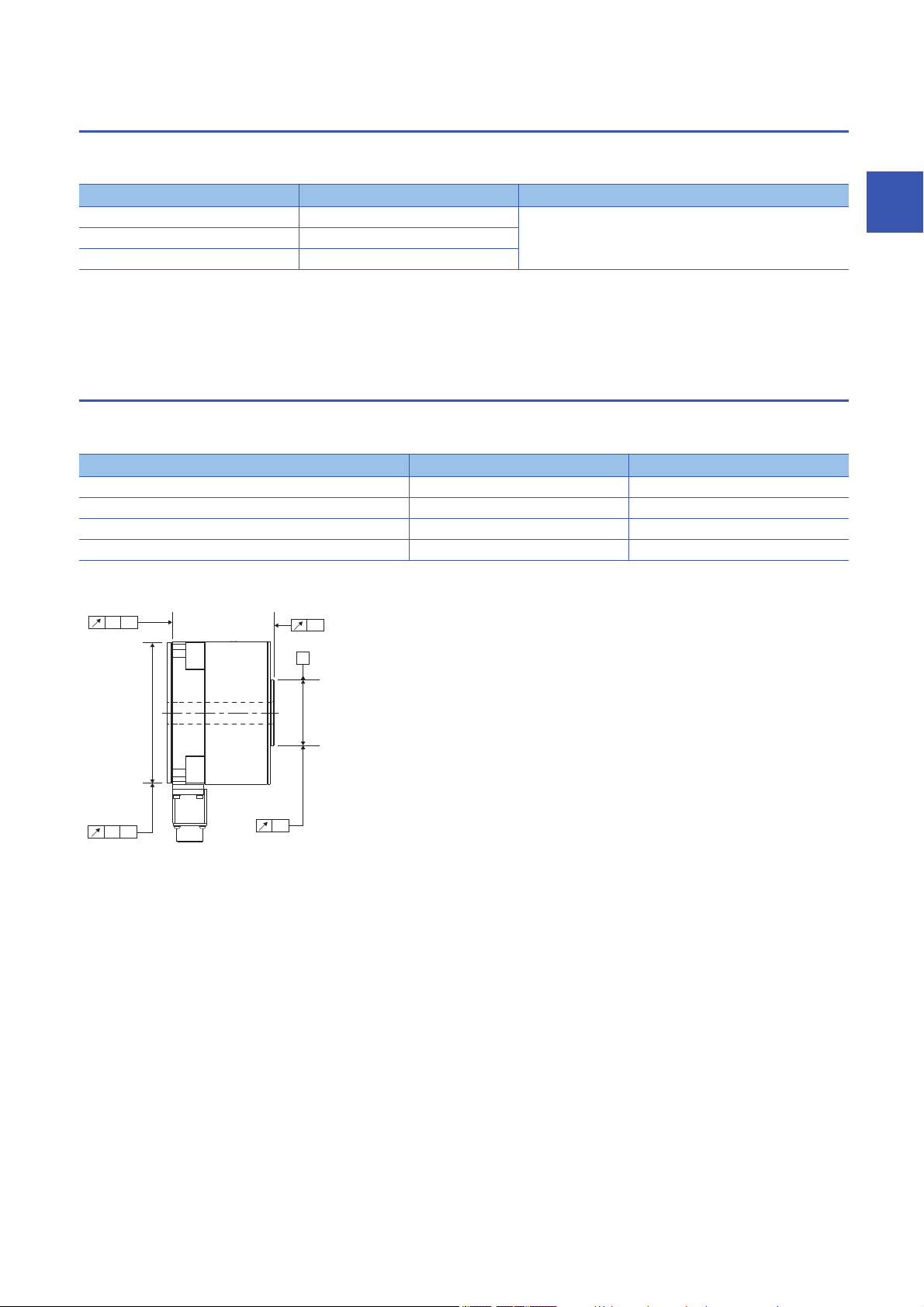

2.8 Machine accuracy

The following table indicates the machine accuracy of the rotor (output shaft) and the mounting area of the direct drive motor

(except special products).

Item Measuring position Accuracy [mm]

Runout of mounting surface to rotor (output shaft) a 0.05

Runout of fitting outer diameter of mounting surface b 0.07

Runout of rotor (output shaft) c 0.04

Runout of rotor (output shaft) end d 0.02

2

Reference diagram

2 INSTALLATION

2.7 Parts having life

11

Page 14

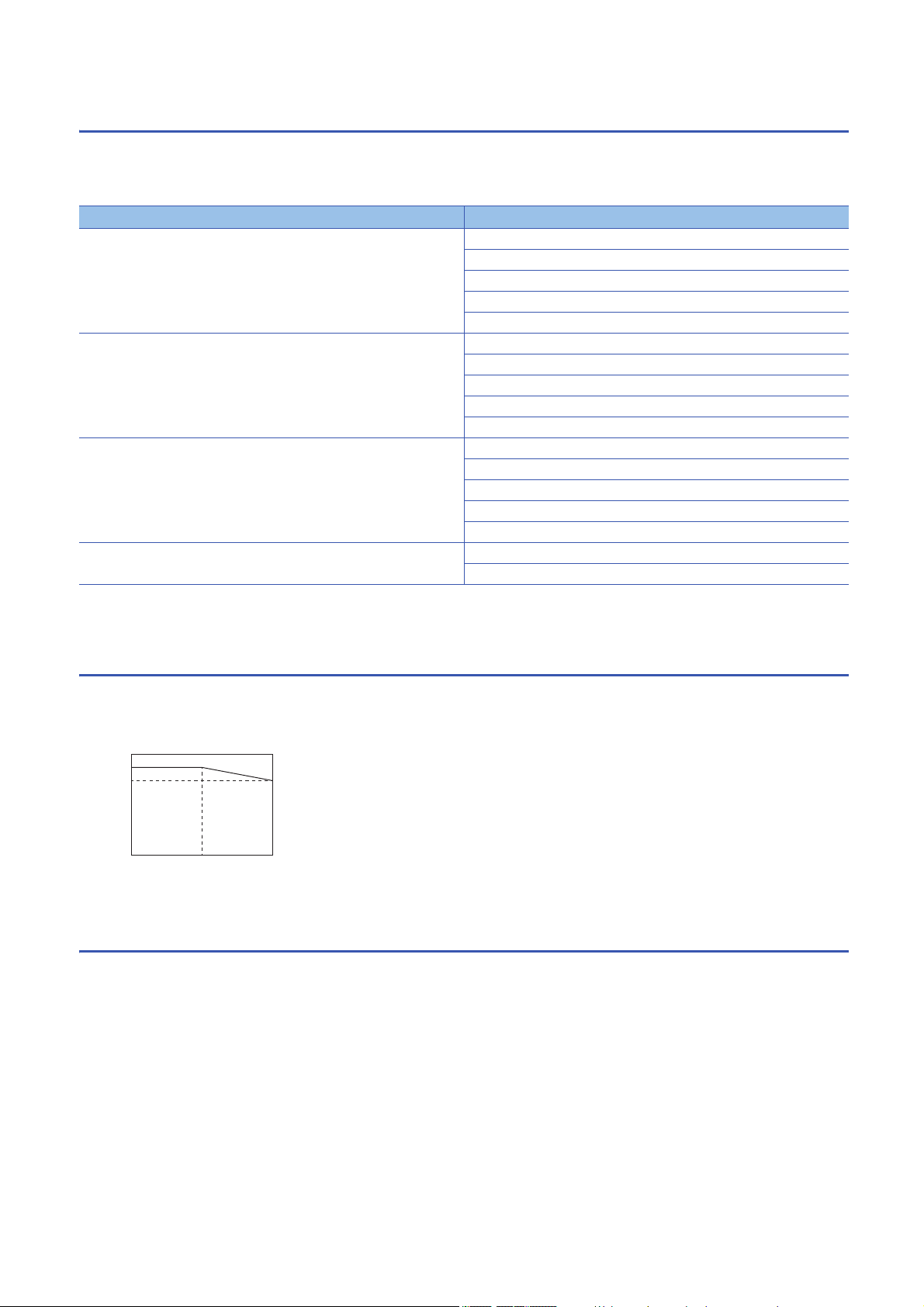

2.9 Flange size

0

20001000

95

100

0

[%]

[m]

Altitude

Derating rate

The rated torque of the direct drive motor is the continuous permissible torque value that can be generated when the direct

drive motor is mounted on the flange specified in this table, made of aluminum, and used in the environment of 0 ˚C to 40 ˚C

ambient temperature.

Flange size [mm] Direct drive motor

400 × 400 × 20 TM-RG2M002C30

TM-RU2M002C30

TM-RFM002C20

TM-RFM004C20

TM-RFM006C20

550 × 550 × 35 TM-RG2M004E30

TM-RU2M004E30

TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

650 × 650 × 35 TM-RG2M009G30

TM-RU2M009G30

TM-RFM012G20

TM-RFM048G20

TM-RFM072G20

750 × 750 × 45 TM-RFM040J10

TM-RFM120J10

2.10 Restrictions when using this product at altitude

exceeding 1000 m and up to 2000 m

As heat dissipation effects decrease in proportion to the decrease in air density, use the product within the effective load ratio

and regenerative load ratio shown in the following figure.

2.11 Magnetic shielding

Do not place the direct drive motor near magnetic sources, such as a magnet. If it is unavoidable, block the magnetic force by

installing a shielding plate or others.

12

2 INSTALLATION

2.9 Flange size

Page 15

3 CONNECTORS USED FOR DIRECT DRIVE

Precautions

MR-BTAS01

Power connector

Encoder connector

Absolute position storage unit

Servo amplifier-side

connector

Encoder-side

connector

MOTOR WIRING

• The IP rating indicated is the connector's protection against ingress of dust and water when the connector is connected to a

servo amplifier, direct drive motor, or absolute position storage unit.

• If the IP rating of the connector, servo amplifier, direct drive motor, and absolute position storage unit varies, the overall IP

rating depends on the lowest IP rating of all components.

3.1 Selection of connectors

Use the connector configuration products given in the table as the connectors for connection with the direct drive motor. Refer

to the following for the compatible connector configuration products.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

3

Direct drive motor Wiring connector

For power supply For encoder Absolute position storage unit (option)

Servo amplifier side Encoder side

TM-RFM_C20 Connector configuration B Connector configuration A Connector configuration A Connector configuration E

TM-RFM_E20

TM-RFM_G20 Connector configuration C

TM-RFM040J10 Connector configuration D

TM-RFM120J10

TM-RG2M002C30 Connector configuration B

TM-RU2M002C30

TM-RG2M004E30

TM-RU2M004E30

TM-RG2M009G30

TM-RU2M009G30

*1 Used in the absolute position detection system

*1

3 CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3.1 Selection of connectors

13

Page 16

3.2 Wiring connectors (connector configurations A/B/

Plug Cord clamp

Plug

Cable clamp

C/D/E)

Connector

configuration

Feature Plug (Hirose Electric) Recommended cable (Bando

Densen)

Typ e Plug Cord clamp Model Cable OD

A IP67 Straight RM15WTPZK-12S JR13WCCA-8(72) 20276

VSVPAWG#23×6P

KB-0492

*1 The connector to be mated.

*2 Supplier: Toa Electric Industrial

Connector

configuration

Feature Plug (DDK) Cable clamp Direct drive motor

Typ e Model Cable OD [mm]

(reference)

BIP67

EN

compliant

General

environment

*1

Straight CE05-6A14S-2SD-D

Applicable wire size: AWG 22 to 16

D/MS3106B14S-2S

Applicable wire size: AWG 22 to 16

4 to 8 ACS-08RL-MS14F

8 to 12 ACS-12RL-MS14F

5 to 8.3 YSO14-5 to 8

8.3 to 11.3 YSO14-9 to 11

7.9 or less

(Bushing ID)

*2

Direct drive motor

encoder connector or

absolute position

[mm]

(reference)

8.2 RM15WTRZB-12P(72)

Model

(Nippon Flex)

(Nippon Flex)

(Daiwa Dengyo)

(Daiwa Dengyo)

D/MS3057-6A

storage unit

connector (servo

amplifier side)

power supply

connector

CE05-2A14S-2PD-D

*1

*2

*1 Not comply with EN.

*2 The connector to be mated.

14

3 CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3.2 Wiring connectors (connector configurations A/B/C/D/E)

Page 17

Connector

Plug Cable clamp

Plug Cable clamp

Plug Cord clamp

configuration

CIP67

Feature Plug (DDK) Cable clamp (DDK) Direct drive motor

Typ e Model Cable OD [mm]

EN

compliant

General

environment

*1

Straight CE05-6A18-10SD-D-BSS

*1 Not comply with EN.

*2 The connector to be mated.

Applicable wire size: AWG 14 to 12

D/MS3106B18-10S

Applicable wire size: AWG 14 to 12

Model

(reference)

8.5 to 11 CE3057-10A-2-D CE05-2A18-10PD-D

10.5 to 14.1 CE3057-10A-1-D

14.3 or less

(Bushing ID)

D/MS3057-10A

power supply

connector

*2

3

Connector

configuration

Feature Plug (DDK) Cable clamp (DDK) Direct drive motor

Typ e Model Cable OD [mm]

(reference)

DIP67

EN

compliant

General

environment

*1

Straight CE05-6A22-22SD-D-BSS

Applicable wire size: AWG 10 to 8

D/MS3106B22-22S

Applicable wire size: AWG 10 to 8

9.5 to 13 CE3057-12A-2-D CE05-2A22-22PD-D

12.5 to 16 CE3057-12A-1-D

15.9 or less

(Bushing ID)

*1 Not comply with EN.

*2 The connector to be mated.

Connector

configuration

Feature Plug (Hirose Electric) Recommended cable (Bando

Densen)

Typ e Plug Cord clamp Model Cable OD

E IP67 Straight RM15WTPZ-12P(72) JR13WCCA-8(72) 20276

VSVPAWG#23×6P

KB-0492

*1 The connector to be mated.

*2 Supplier: Toa Electric Industrial

*2

Model

D/MS3057-12A

power supply

connector

Absolute position

storage unit

connector (encoder

*1

[mm]

side)

(reference)

8.2 RM15WTRZB-12S(72)

*2

3 CONNECTORS USED FOR DIRECT DRIVE MOTOR WIRING

3.2 Wiring connectors (connector configurations A/B/C/D/E)

15

Page 18

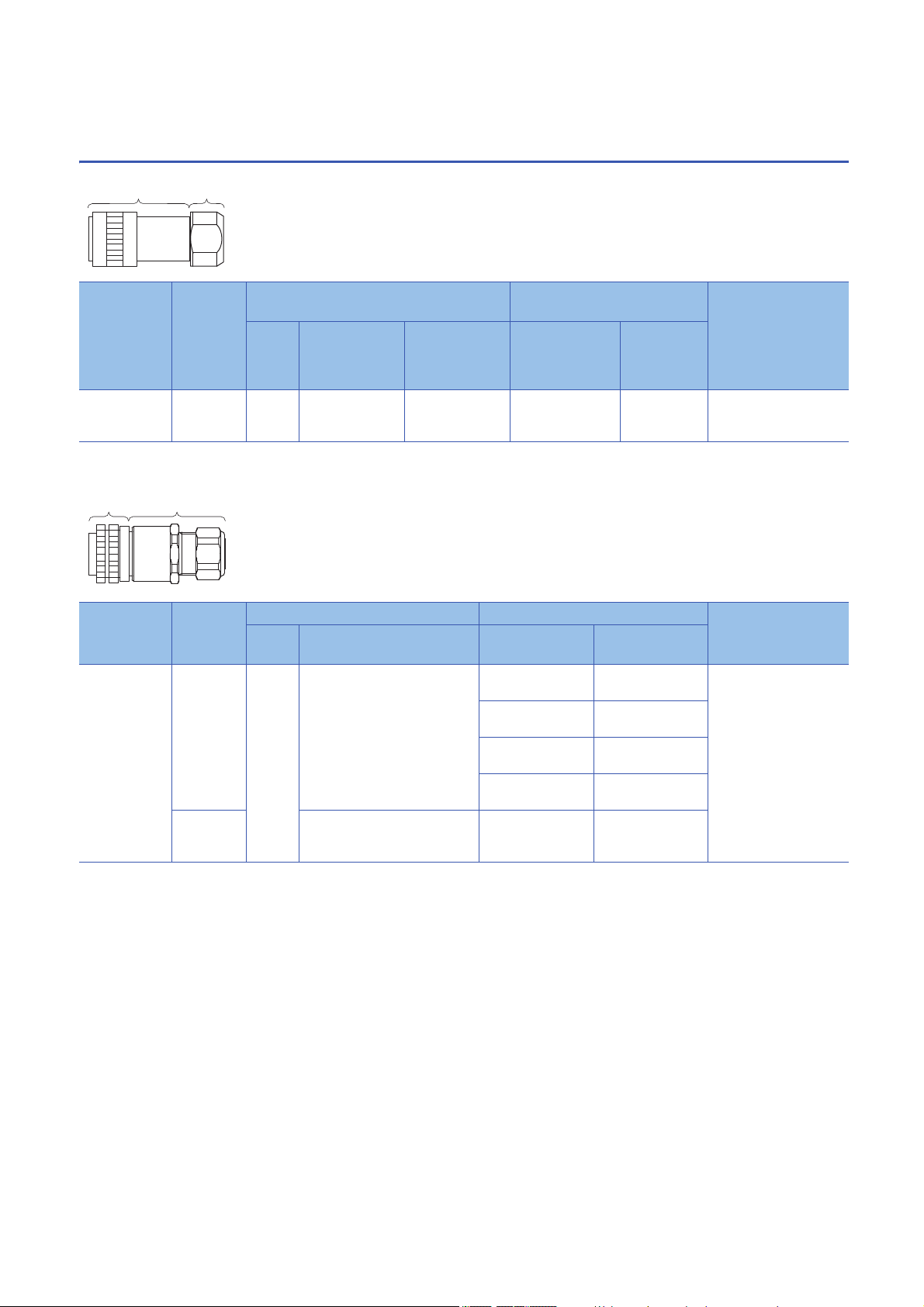

4 CONNECTOR DIMENSIONS

M19 × 1

M16 × 0.75

36.3

φ21.5

φ15.2

Spanner hook gap dimension: 18

[Unit: mm]

7.5

φ20

M16 × 0.75

8

Spanner hook gap dimension: 17

[Unit: mm]

The following shows the dimensions of the connectors used for wiring the direct drive motor.

Hirose Electric

■RM15WTPZK-12S/RM15WTPZ-12P(72)

Model Connector configuration

RM15WTPZK-12S A

RM15WTPZ-12P(72) F

*1 Refer to the following for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

■JR13WCCA-8(72)

Refer to the following connector configuration A and F for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

*1

16

4 CONNECTOR DIMENSIONS

Page 19

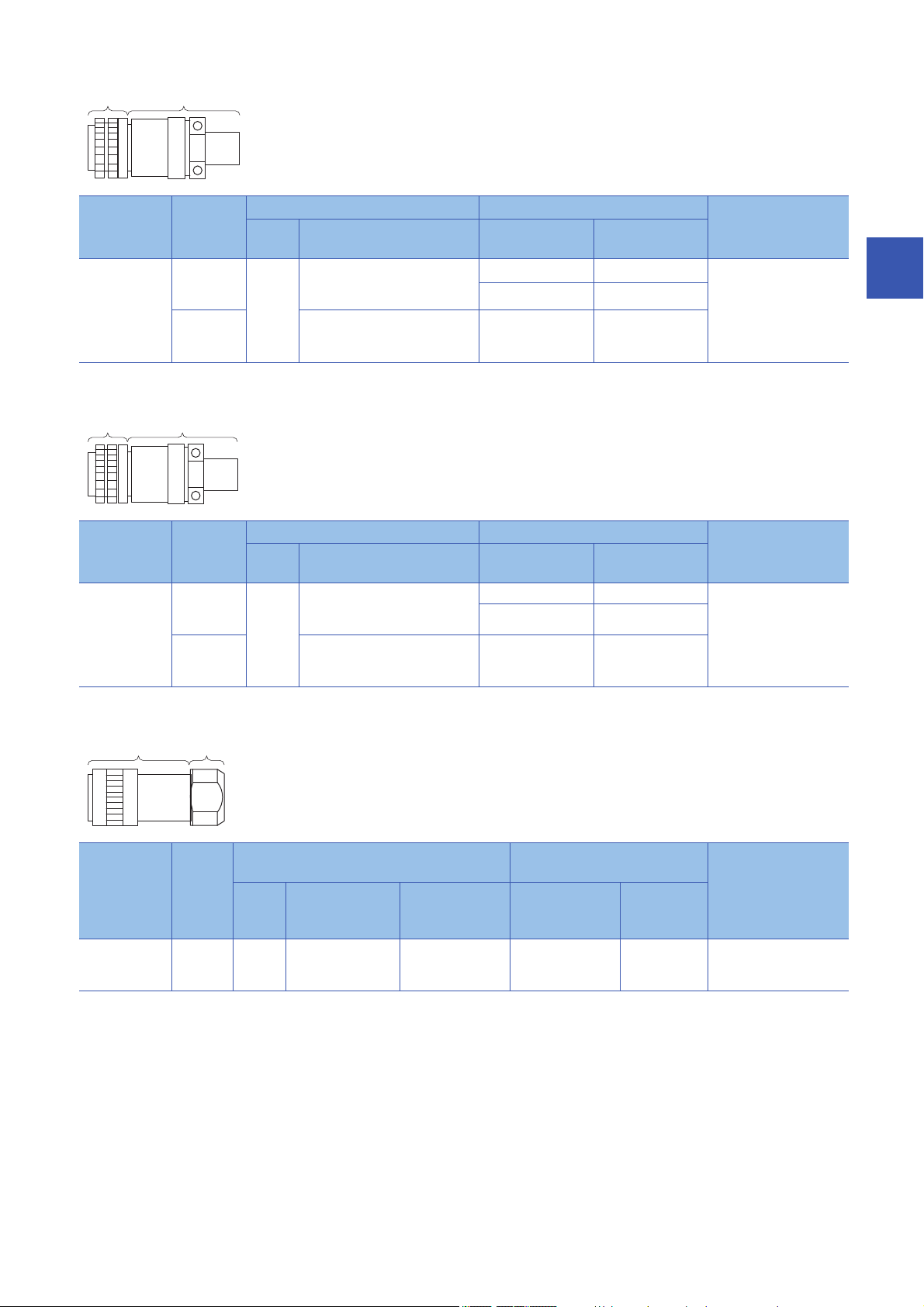

DDK

24.0 ± 1

8.46 ± 0.5

5.6 ± 0.1

7/8-20UNEF-2B

(13.2)

3/4-20UNEF-2A

φ28.57

0

-0.38

φ17.0 ± 0.25

[Unit: mm]

Positioning key

φC

φB

ADW

Positioning key

[Unit: mm]

+0

-0.38

B

■CE05-6A14S-2SD-D

Refer to the following connector configuration B for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

■CE05-6A18-10SD-D-BSS, CE05-6A22-22SD-D-BSS, CE05-6A32-17SD-D-BSS

4

Model A C ± 0.8 D or less W Connector

configuration

CE05-6A18-10SD-D-BSS 1 1/8-18UNEF-2B 34.13 32.1 57 1-20UNEF-2A C

CE05-6A22-22SD-D-BSS 1 3/8-18UNEF-2B 40.48 38.3 61 1 3/16-18UNEF-2A D

CE05-6A32-17SD-D-BSS 2-18UNS-2B 56.33 54.2 79 1 3/4-18UNS-2A E

*1 Refer to the following for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

*1

4 CONNECTOR DIMENSIONS

17

Page 20

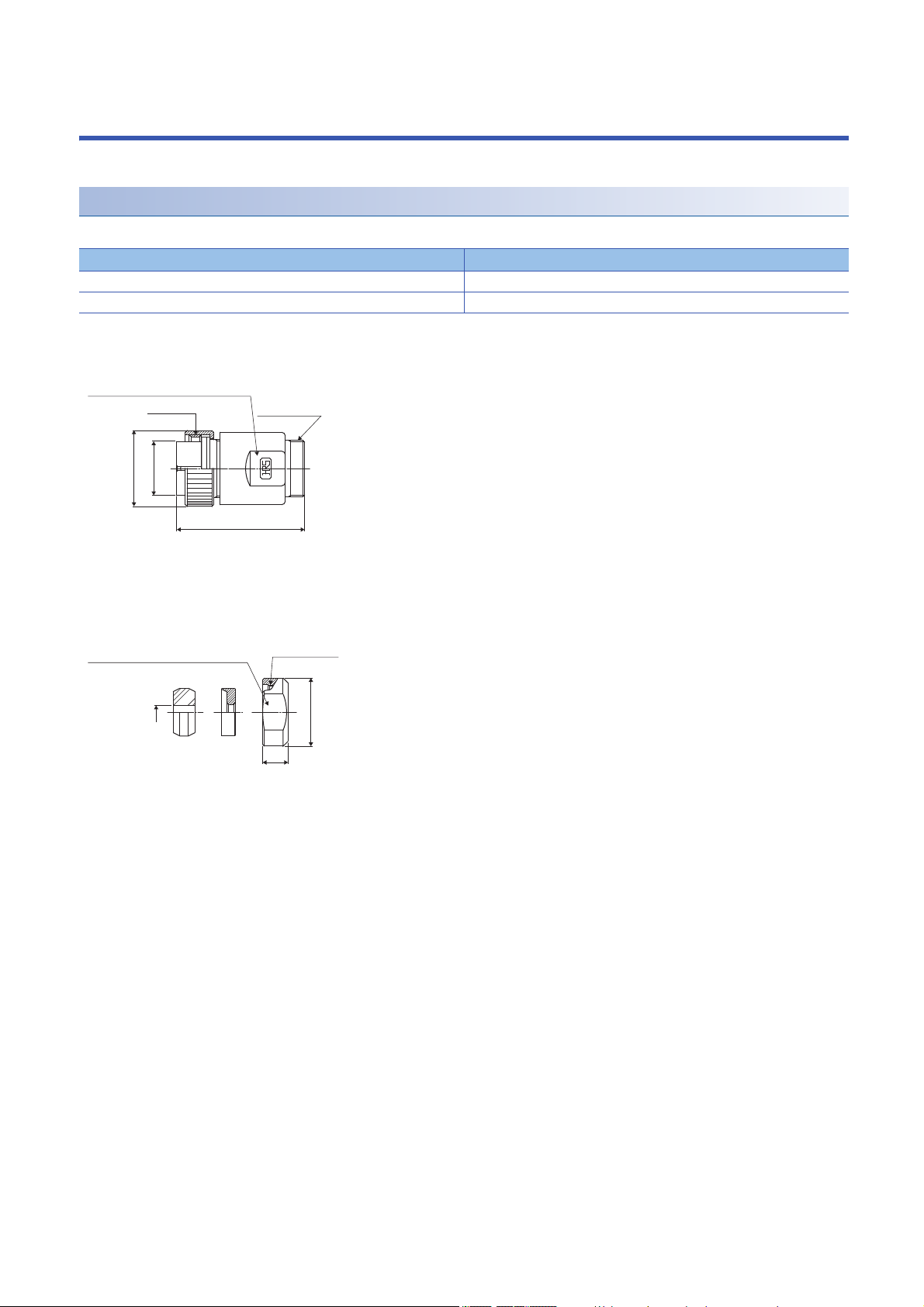

■CE3057-10A-1-D, CE3057-10A-2-D, CE3057-12A-1-D, CE3057-12A-2-D, CE3057-20A-1-D

φE

φB

φF

(D)

C

1.5

A ± 0.7

G ± 0.7

(Bushing OD)

V-thread

[Unit: mm]

(Bushing ID)

φQ

0

-0.38

A

V

J ± 0.12

L or shorter

W or longer

Y or shorter

[Unit: mm]

Model Applicable

shell size

CE3057-10A-1-D18 23.8 30.1 10.3 (41.3) 15.9 14.1 31.7 1-20UNEF-2BCE3420-10-1 10.5 to 14.1 C

CE3057-10A-2D

CE3057-12A-1-D22 23.8 35 10.3 (41.3) 19 16.0 37.3 1 3/16-

CE3057-12A-2D

CE3057-20A-1-D32 27.8 51.6 11.9 (43.0) 32.0 23.8 51.6 1 3/4-

A B C (D) E F G V Enclosed

bushing

model

11.0 CE3420-10-2 8.5 to 11

CE342012-1 12.5 to 16 D

18UNEF-2B

13.0 CE342012-2 9.5 to 13

CE3420-20-1 22.0 to 23.8 E

18UNS-2B

Applicable

cable OD

(reference)

*1 Refer to the following for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

■D/MS3106B14S-2S, D/MS3106B18-10S, D/MS3106B22-22S, D/MS3106B32-17S

Connector

configuration

*1

18

Model A J L Q V W Y Connector

D/MS3106B14S-2S 7/8-20UNEF 13.49 42.88 28.57 3/4-20UNEF 8.00 30 B

D/MS3106B18-10S 1 1/8-18UNEF 18.26 52.37 34.13 1-20UNEF 9.53 42 C

D/MS3106B22-22S 1 3/8-18UNEF 18.26 56.57 40.48 1 3/16-18UNEF 9.53 50 D

D/MS3106B32-17S 2-18UNS 18.26 61.92 56.33 1 3/4-18UNS 11.13 66 E

*1 Refer to the following for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

4 CONNECTOR DIMENSIONS

configuration

*1

Page 21

■D/MS3057-6A, D/MS3057-10A, D/MS3057-12A, D/MS3057-20A

1.6

V

A ± 0.7

φB ± 0.7

G ± 0.7

Effective thread length C

φD (Cable clamp ID)

φE (Bushing ID)

[Unit: mm]

A

L

Hexagonal

width across

corners φD3

Hexagonal width

across corners φD1

Hexagonal

width across

edges D

Hexagonal width

across edges D2

O-ring

[Unit: mm]

Model Shell size A B C D E G V Bushing Connector

configuration

D/MS3057-6A 14S 22.2 24.6 10.3 11.2 7.9 27.0 3/4-20UNEF AN3420-6 B

D/MS3057-10A 18 23.8 30.1 10.3 15.9 14.3 31.7 1-20UNEF AN3420-10 C

D/MS3057-12A 22 23.8 35.0 10.3 19.0 15.9 37.3 1 3/16-18UNEF-2A AN3420-12 D

D/MS3057-20A 32 27.8 51.6 11.9 31.7 23.8 51.6 1 3/4-18UNS AN3420-20 E

*1 Refer to the following for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

Daiwa Dengyo

Model Applicable cable ODA Length L

before

tightening

YSO14-5 to 8 4 to 8.3 3/4-20UNEF-2B44 23 25 26 28 B

YSO14-9 to 11 7 to 11.3

*1 Refer to the following connector configuration B for the connector configuration.

Width

across

flats D

Width

across

corners

D1

Width

across

flats D2

Width

across

corners

D3

Connector

configuration

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

*1

4

*1

4 CONNECTOR DIMENSIONS

19

Page 22

Nippon Flex

E' × F' × G'

A15

E

G

F

φd

L

(2) *1

L

(1) *1

Screw C

[Unit: mm]

Model Screw C Applicable

cable OD

ACS08RLMS14F

ACS12RLMS14F

3/420UNEF2B

3/420UNEF2B

4.0 to 8.0 7 15.0 20 22.0 6 22 24.2 6 46 41 B

8.0 to 12.0 7 15.0 24 26.4 6 36 28.6 6 46 41

A φd Tightening nut Nipple body L L1 Connector

E

Two face

width

F

Width

across

corners

G

Number

of

corners

E'

Two face

width

F'

Width

across

corners

G'

Number

of

corners

*1 (1) indicates the reference dimension before assembling, and (2) indicates the reference dimension after assembling.

*2 Refer to the following connector configuration B for the connector configuration.

Page 14 Wiring connectors (connector configurations A/B/C/D/E)

configuration

*2

20

4 CONNECTOR DIMENSIONS

Page 23

5 CONNECTION OF SERVO AMPLIFIER AND

Precautions

U

M

V

W

U

V

W

U

M

V

W

U

V

W

Servo amplifier Servo amplifier Direct drive motorDirect drive motor

DIRECT DRIVE MOTOR

• Insulate the conductive parts of the terminals.

• To prevent an unexpected operation of the direct drive motor, wire the equipment correctly and securely.

• Make sure to connect the cables and connectors by using the fixing screws and the locking mechanism. Otherwise, the

cables and connectors may be disconnected during operation.

• Do not install a power capacitor, surge killer, or radio noise filter (optional FR-BIF) on the power wire of the direct drive

motor.

• To prevent an abnormal operation and a malfunction of the direct drive motor, connect the servo amplifier power output (U/

V/W) to the direct drive motor power input (U/V/W) directly. Do not connect a magnetic contactor and others between them.

• When the wires are not tightened enough to the terminal block, the wires or terminal block may generate heat because of

the poor contact. Be sure to tighten the wires with specified torque.

• Use the direct drive motor with the specified servo amplifier.

• Do not modify the equipment.

• To prevent malfunction, eliminate static electricity before wiring, switch operation, or others.

• To prevent failure and malfunction, only the power/signal specified in the user’s manual should be connected to each

terminal.

• We recommend using HIV wires to connect the servo amplifier to the direct drive motor. Therefore, the recommended wire

sizes may differ from those of the used wires for the previous direct drive motors.

5

5 CONNECTION OF SERVO AMPLIFIER AND DIRECT DRIVE MOTOR

21

Page 24

5.1 Precautions for wiring

Precautions

*1

Cabinet

Direct drive motor

PE terminal

Servo

amplifier

U

V

W

U

V

W

M

*1

Direct drive motorServo amplifier

30 m or less

• To avoid a malfunction, connect the power phases (U/V/W) of the servo amplifier and the direct drive motor correctly.

• To prevent a malfunction, do not connect AC power supply directly to the direct drive motor.

Refer to the following for the encoder cable.

Page 24 Wiring option

This section explains the connection of the direct drive motor power (U/V/W). Use of the optional connector is recommended

for connection between the servo amplifier and direct drive motor. Refer to the following for details of the options.

Page 24 Wiring option

For grounding, connect the grounding lead wire from the servo motor to the protective earth (PE) terminal of the servo

amplifier, and then connect the wire from the servo amplifier to the ground via the protective earth of the cabinet. Do not

connect the wire directly to the protective earth (PE) terminal of the cabinet.

*1 The number of PE terminals of the servo amplifier differs depending on the type of servo amplifier.

5.2 Direct drive motor power cable wiring diagram

To wire to the servo amplifier, use connectors packed with the servo amplifier or optional connectors. For connectors, refer to

"Wiring CNP1, CNP2, and CNP3" in the following manual.

MR-J5 User's Manual (Hardware)

Fabricate a cable as shown below.

Refer to the following for the wires used for the cable.

Page 23 Selection example of wires

*1 This grounding is for the MR-J5 1-axis servo amplifier. For MR-J5 multi-axis servo amplifier, ground it to CNP3_ connector.

22

5 CONNECTION OF SERVO AMPLIFIER AND DIRECT DRIVE MOTOR

5.1 Precautions for wiring

Page 25

5.3 Selection example of wires

Wires indicated in this section are separated wires.

Selection conditions of wire size are as follows.

• Construction condition: Single wire set in midair

• Wiring length: 30 m or shorter

Wire size selection examples for the 600 V Grade heat-resistant polyvinyl chloride insulated wire (HIV wire) are indicated

below.

TM-RFM SERIES

Direct drive motor Wire [mm2]

U/V/W/

TM-RFM002C20 1.25 (AWG 16)

TM-RFM004C20

TM-RFM006C20

TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

TM-RFM012G20

TM-RFM048G20 3.5 (AWG 12)

TM-RFM072G20

TM-RFM040J10 1.25 (AWG 16)

TM-RFM120J10 3.5 (AWG 12)

5

TM-RG2M series and TM-RU2M series

Direct drive motor Wire [mm2]

U/V/W/

TM-RG2M002C30 0.75 (AWG 18)

TM-RU2M002C30

TM-RG2M004E30

TM-RU2M004E30

TM-RG2M009G30

TM-RU2M009G30

5 CONNECTION OF SERVO AMPLIFIER AND DIRECT DRIVE MOTOR

5.3 Selection example of wires

23

Page 26

6 Wiring option

Precautions

Precautions

• To prevent malfunction and a fire, use the specified peripheral equipment and options.

• To prevent an electric shock, fire, or injury, correctly wire options and peripheral equipment, etc. in the correct combination.

• We recommend using HIV wires to wire the servo amplifiers, direct drive motors, options, and peripheral equipment.

Therefore, the recommended wire sizes may differ from those of the used wires for the previous direct drive motors.

6.1 Connector set

For the connectors used with this direct drive motor, please purchase the options indicated in this section.

When fabricating an encoder cable, refer to the following.

Page 58 Fabrication of the encoder cable

• The IP rating indicated is the connector's protection against ingress of dust and water when the connector is connected to a

servo amplifier, direct drive motor, or absolute position storage unit. If the IP rating of the connector, servo amplifier, direct

drive motor, and absolute position storage unit varies, the overall IP rating depends on the lowest IP rating of all

components.

24

6 Wiring option

6.1 Connector set

Page 27

Combinations of connector sets

(4)

(4) (5)

(1)

(2) (3)

CNP3

CN2

TM-RFM

TM-RG2M

TM-RU2M

MR-BTAS01

*2

CN4

CN2

CN4

*1

Encoder

connector

Power

connector

For incremental system

For absolute position detection system

For absolute position detection system

Absolute position storage unit

MR-J5 1-axis

servo amplifier

Direct drive motor

Battery unit

MR-BT6VCASE and

MR-BAT6V1 battery

Battery

MR-J5 1-axis

servo amplifier

MR-J5 1-axis servo amplifier

6

*1 Connectors for 3.5 kW or less.

*2 To configure the absolute position detection system, connect to battery unit and absolute position storage unit. Refer to the following for

absolute position storage unit.

Page 36 Absolute position storage unit MR-BTAS01

For the battery, refer to "Battery" in the following manual.

MR-J5 User's Manual (Hardware)

6 Wiring option

6.1 Connector set

25

Page 28

MR-J5 multi-axis servo amplifier

(4)

(4) (5)

(1)

(2) (3)

TM-RFM

TM-RG2M

TM-RU2M

MR-BTAS01

*1

*2

*2

CNP3A

CNP3B

CNP3C

CN2B

CN2A

CN2C

CN4

CN4

Encoder

connector

Power

connector

For incremental system

For absolute position detection system

For absolute position detection system

Absolute position storage unit

Direct drive motor

MR-J5 multi-axis

servo amplifier

Battery unit

MR-BT6VCASE and

MR-BAT6V1 battery

MR-J5 multi-axis

servo amplifier

*1 To configure the absolute position detection system, connect to battery unit and absolute position storage unit. Refer to the following for

absolute position storage unit.

Page 36 Absolute position storage unit MR-BTAS01

For the battery, refer to "Battery" in the following manual.

MR-J5 User's Manual (Hardware)

*2 This connection is for the MR-J5 3-axis servo amplifier.

26

6 Wiring option

6.1 Connector set

Page 29

Connector list

No. Product

name

(1) Power

connector set

(2) Power

connector set

(3) Power

connector set

(4) Encoder

connector set

Model Description Connectable

direct drive

motor

MR-PWCNF

MR-PWCNS4

MR-PWCNS5

MR-J3DDCNS

Plug: CE05-6A14S-2SD-D (DDK)

Cable clamp: YSO14-9 to 11 (Daiwa Dengyo)

Applicable cable

Applicable wire size: 0.3 mm

Cable OD: 8.3 mm to 11.3 mm

Plug: CE05-6A18-10SD-D-BSS

Cable clamp: CE3057-10A-1-D

(DDK)

Applicable cable

Applicable wire size: 2 mm

Cable OD: 10.5 mm to 14.1 mm

Plug: CE05-6A22-22SD-D-BSS

Cable clamp: CE3057-12A-1-D

(DDK)

Applicable cable

Applicable wire size: 5.5 mm

Cable OD: 12.5 mm to 16 mm

2

to 1.25 mm2 (AWG 22 to 16)

2

to 3.5 mm2 (AWG 14 to 12)

2

to 8 mm2 (AWG 10 to 8)

For TM-RFM_C20

For TM-RFM_E20

For TMRG2M_C30

For TMRG2M_E30

For TMRG2M_G30

For TMRU2M_C30

For TMRU2M_E30

For TMRU2M_G30

For TM-RFM_G20 IP67

For TMRFM040J10

For TMRFM120J10

IP67

Remark

IP67

EN

compliant

EN

compliant

6

IP67

EN

compliant

(5) Encoder

connector set

MR-J3DDSPS

For connection between servo amplifier and direct drive motor

For connection between servo amplifier and absolute position storage unit

Refer to the following for details.

Page 28 Encoder connector set

IP67

For connection between absolute position storage unit and direct drive

motor

Refer to the following for details.

Page 28 Encoder connector set

6 Wiring option

6.1 Connector set

27

Page 30

6.2 Encoder connector set

The encoder cable should be fabricated by the customer. Refer to the following for fabrication.

Page 28 MR-J3DDCNS

Page 28 MR-J3DDSPS

Page 29 Combinations of encoder cables

For fabrication, refer to the following wiring diagram.

Page 30 Fabrication of the encoder cable

Fabricate the encoder cable to be 50 m or shorter between the servo amplifier and the direct drive motor.

To configure the absolute position detection system, connect to battery unit and absolute position storage unit. Refer to the

following for absolute position storage unit.

Page 36 Absolute position storage unit MR-BTAS01

For the battery, refer to "Battery" in the following manual.

MR-J5 User's Manual (Hardware)

MR-J3DDCNS

This connector set is used to fabricate an encoder cable for the incremental system or the absolute position detection system

(between the servo amplifier and the absolute position storage unit).

Applicable wire size: 0.25 mm

■Servo amplifier-side connector

2

to 0.5 mm2 (AWG 23 to 20)

Receptacle: 36210-0100PL

Shell kit: 36310-3200-008

(3M)

or

Connector set: 54599-1019

(Molex)

■Encoder-side connector or absolute position storage unit-side (connected from servo

amplifier) connector

Plug: RM15WTPZK-12S

Cord clamp: JR13WCCA-8(72)

(Hirose Electric)

MR-J3DDSPS

This connector set is used to fabricate an encoder cable for the absolute position detection system (between the absolute

position storage unit and the direct drive motor).

Applicable wire size: 0.25 mm

2

to 0.5 mm2 (AWG 23 to 20)

28

6 Wiring option

6.2 Encoder connector set

Page 31

■Absolute position storage unit-side connector

CN2B

CN2A

CN2

CN2C

(1) (2)

TM-RFM

TM-RG2M

TM-RU2M

*2

*1

Or

MR-J5 multi-axis

servo amplifier

MR-J5 1-axis

servo amplifier

Encoder cable A

50 m or less

Direct drive motor

Plug: RM15WTPZ-12P(72)

Cord clamp: JR13WCCA-8(72)

(Hirose Electric)

■Encoder-side connector

Plug: RM15WTPZK-12S

Cord clamp: JR13WCCA-8(72)

(Hirose Electric)

Combinations of encoder cables

For incremental system

6

*1 Refer to the following for details.

Page 30 Detail of the encoder cable A connector

*2 This connection is for the MR-J5 3-axis servo amplifier.

6.2 Encoder connector set

6 Wiring option

29

Page 32

For absolute position detection system

CN2B

CN2A

CN2

CN2C

(3) (4)

TM-RFM

TM-RG2M

TM-RU2M

(5)

(6)

MR-BTAS01

*4

*3

*2

*1

Or

MR-J5 multi-axis

servo amplifier

MR-J5 1-axis

servo amplifier

Encoder cable B

20 m or less

Encoder cable C

Absolute position

storage unit

Direct drive motor

4

MRR

2

LG

8

6

1

P5

5

10

3

MR

7

9

THM2

THM1

1P53

MR

7 9

4

MRR

2

LG

86 10

5

THM2

THM1

*1 Refer to the following for details.

Page 32 Detail of the encoder cable B connector

*2 Refer to the following for details.

Page 33 Detail of the encoder cable C connector

*3 This connection is for the MR-J5 3-axis servo amplifier.

*4 If 20 m is exceeded, contact your local sales office.

Fabrication of the encoder cable

Detail of the encoder cable A connector

■CN2, CN2A, CN2B, and CN2C side connector (1)

Receptacle: 36210-0100PL

Shell kit: 36310-3200-008

(3M)

View from the wiring side.

Connector set: 54599-1019

(Molex)

View from the wiring side.

*1 Do not connect anything to the pins shown with a diagonal line. Refer to the following.

Page 35 Shield procedure of CN2, CN2A, CN2B, and CN2C side connectors

* 1

* 1

30

6 Wiring option

6.2 Encoder connector set

Page 33

■Encoder-side connector (2)

1

MRR

3

54

2

MR

7

6

12

THM1

9 8

P5

LG

10

11

FG

THM2

P5

LG

1

2

MR

MRR

3

4

6

9

5

7

8

10

LG

MR

MRR

P5

THM1THM1

116 THM2THM2

5FGSD

(1) CN2, CN2A, CN2B, and

CN2C side connector

(2) Encoder-side

connector

Plate

Straight plug: RM15WTPZK-12S

Cord clamp: JR13WCCA-8(72)

(Hirose Electric) Recommended cable: 20276 VSVPAWG#23×6P

KB-0492

(Bando Densen)

*2

View from the wiring side.

* 1

*1 Do not connect anything to the pins shown with a diagonal line.

*2 Supplier: Toa Electric Industrial

Encoder cable A cable internal wiring diagram

Refer to the following table for the required wires to fabricate the encoder cable.

Core size [mm2] Conductor resistance of one core [Ω/km] Cable OD [mm]

0.25 63.6 or less 8.2

6

6 Wiring option

6.2 Encoder connector set

31

Page 34

Detail of the encoder cable B connector

4

MRR

BAT

2

LG

8

6

1

P5

5

10

3

MR

7

9

THM2

THM1

1P53

MR

7 9

4

MRR

BAT

2

LG

86 10

5

THM2

THM1

1

MRR

BAT

3

54

2

MR

7

6

12

THM1

9 8

P5

LG

10

11

FG

THM2

■CN2, CN2A, CN2B, and CN2C side connector (3)

Receptacle: 36210-0100PL

Shell kit: 36310-3200-008

(3M)

View from the wiring side.

* 1

Connector set: 54599-1019

(Molex)

View from the wiring side.

*1 Do not connect anything to the pins shown with a diagonal line. Refer to the following.

Page 35 Shield procedure of CN2, CN2A, CN2B, and CN2C side connectors

* 1

■Absolute position storage unit-side connector (4)

Straight plug: RM15WTPZK-12S

Cord clamp: JR13WCCA-8(72)

(Hirose Electric) Recommended cable: 20276 VSVPAWG#23×6P

KB-0492

(Bando Densen)

*2

32

View from the wiring side.

* 1

*1 Do not connect anything to the pins shown with a diagonal line.

*2 Supplier: Toa Electric Industrial

6 Wiring option

6.2 Encoder connector set

Page 35

Encoder cable B cable internal wiring diagram

P5

LG

1

2

MR

MRR

3

4

6

9

5

7

8

10

LG

MR

MRR

P5

THM1THM1

116 THM2THM2

29 BAT

5FG

BAT

SD

(3) CN2, CN2A, CN2B, and

CN2C side connector

(4) Absolute position storage

unit side connector

Plate

1

MR

2

MRR

3

5LG4

BAT

7612

THM1

98

P5

10

11

FG

THM2

VB

When the distance between the servo amplifier and the direct drive motor is within 20 m

*1

*1 If 20 m is exceeded, contact your local sales office.

Refer to the following table for the required wires to fabricate the encoder cable.

Core size [mm2] Conductor resistance of one core [Ω/km] Cable OD [mm]

0.25 63.6 or less 8.2

Detail of the encoder cable C connector

■Absolute position storage unit-side connector (5)

Straight plug: RM15WTPZ-12P(72)

Cord clamp: JR13WCCA-8(72)

(Hirose Electric)

Recommended cable: 20276 VSVPAWG#23×6P

KB-0492

(Bando Densen)

View from the wiring side.

*1 Do not connect anything to the pins shown with a diagonal line.

*2 Supplier: Toa Electric Industrial

*2

* 1

6

6 Wiring option

6.2 Encoder connector set

33

Page 36

■Encoder-side connector (6)

1

MR

2

MRR

3

5

LG

4

BAT

7

6

12

THM1

9 8

P5

10

11

FG

THM2

VB

P5

LG

9

10

MR

MRR78

6

9

6

BAT

7

8

10

2

LG

MR

MRR

BAT

P5

THM1THM1

1111 THM2THM2

11VBVB

2

FG 5 FG5

(5) Absolute position storage

unit side connector

(6) Encoder-side

connector

Straight plug: RM15WTPZK-12S

Cord clamp: JR13WCCA-8(72)

(Hirose Electric)

Recommended cable: 20276 VSVPAWG#23×6P

KB-0492

(Bando Densen)

*2

View from the wiring side.

* 1

*1 Do not connect anything to the pins shown with a diagonal line.

*2 Supplier: Toa Electric Industrial

Encoder cable C cable internal wiring diagram

When the distance between the servo amplifier and the direct drive motor is within 20 m

*1 If 20 m is exceeded, contact your local sales office.

Refer to the following table for the required wires to fabricate the encoder cable.

Core size [mm2] Conductor resistance of one core [Ω/km] Cable OD [mm]

0.25 63.6 or less 8.2

*1

34

6 Wiring option

6.2 Encoder connector set

Page 37

Shield procedure of CN2, CN2A, CN2B, and CN2C side

Screw

Cable

Ground plate

connectors

For CN2, CN2A, CN2B, and CN2C side connectors, securely connect the external conductor of the shielded cable to the

ground plate and fix it to the connector shell.

6

6 Wiring option

6.2 Encoder connector set

35

Page 38

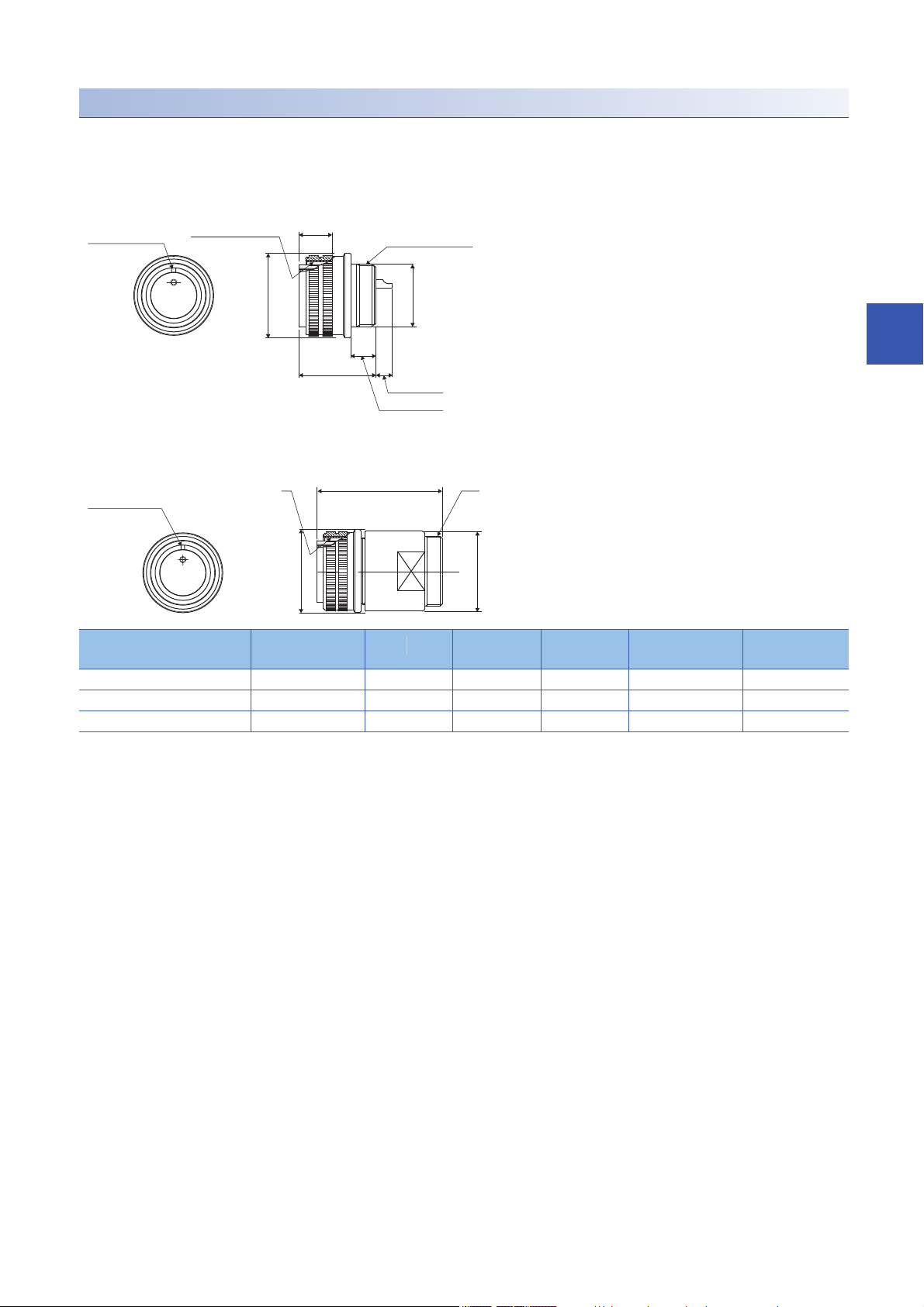

6.3 Absolute position storage unit MR-BTAS01

Precautions

63

81

RM15WTRZB-12S(72)

*1

*1

RM15WTRZB-12P(72)

20

45.2

6

R3

5

5

30

22

69.855

79.8

6

R3

15

19 19

16

20

45.2

(Encoder-side)

Mounting surface A

Mounting screw size

M5

Mass: 0.26 kg

[Unit: mm]

Mounting surface B

(Servo amplifier-side)

2-φ6 Mounting hole

• If the absolute position storage unit MR-BTAS01 is replaced, the absolute position is erased. For details, refer to "Absolute

position detection system" in the following manual.

MR-J5 User's Manual (Hardware)

• If the encoder cable is disconnected, [AL. 025 Absolute position erased] occurs.

Connection method with the encoder cable

Page 30 For absolute position detection system

Dimensions

*1 When mounting the unit outside the cabinet, fix the mounting surface A with four screws. When mounting the unit inside the cabinet, the

Environment

The following table indicates the environment for the absolute position storage unit.

Item Environment

Ambient temperature Operation 0 ˚C to 55 ˚C (non-freezing)

Ambient humidity Operation 10 %RH to 90 %RH (non-condensing)

Ambience Indoors (no direct sunlight), free from corrosive gas, flammable gas, oil mist, dust, dirt, oil and water

Altitude 2000 m or less

Vibration

resistance

mounting surface B can be fixed with two screws.

Storage -20 ˚C to 65 ˚C (non-freezing)

Storage 10 %RH to 90 %RH (non-condensing)

When mounting

surface A fixed

When mounting

surface B fixed

X, Y, Z: 49 m/s

X, Y, Z: 5.9 m/s

2

2

36

6 Wiring option

6.3 Absolute position storage unit MR-BTAS01

Page 39

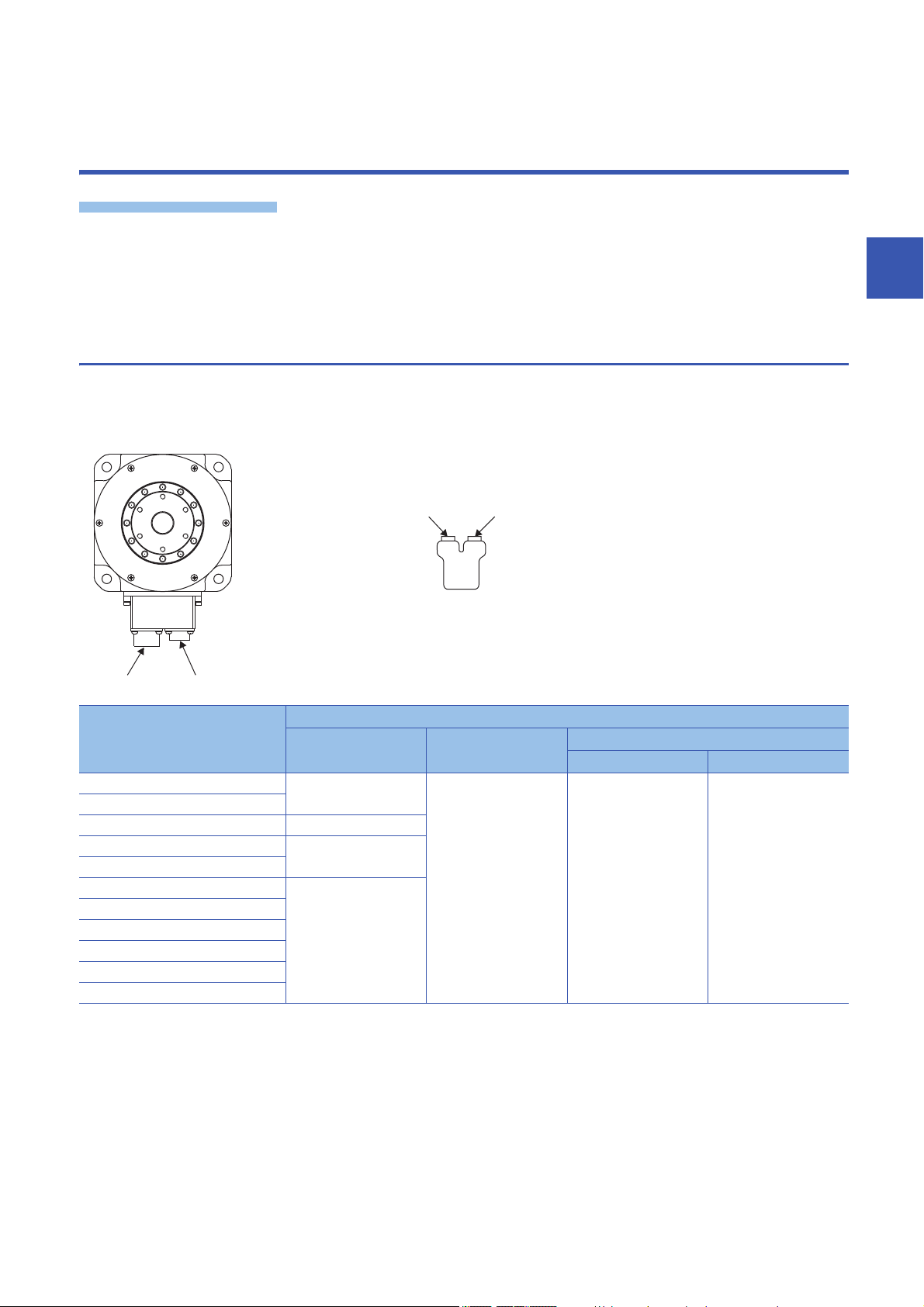

7 TM-RFM SERIES

10 100

C φ130

E

φ180

G

φ230

J

φ330

002 2

004 4

006 6

012 12

018 18

040

40

048 48

072 72

120 120

20 200

02C20TM-RFM 0

Rated speed

Symbol

Motor OD (frame OD)

Symbol

Symbol

Rated torque

Series

Rated speed [r/min]

Dimensions [mm]

Rated torque [N•m]

Z-phase mark

Appearance

This chapter provides information on the direct drive motor specifications and characteristics. When using the TM-RFM series

direct drive motor, always read the Safety Instructions in the beginning of this manual in addition to this chapter.

7.1 Model designation

The following describes model designation. Not all combinations of the symbols are available.

7

7 TM-RFM SERIES

7.1 Model designation

37

Page 40

7.2 Combinations of servo amplifier and direct drive

motor

1-axis servo amplifier

: Standard torque

Direct drive motor Servo amplifier MR-J5-_

20G/A 40G/A 60G/A 70G/A 100G/A 350G/A

TM-RFM002C20

TM-RFM004C20

TM-RFM006C20

TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

TM-RFM012G20

TM-RFM048G20

TM-RFM072G20

TM-RFM040J10

TM-RFM120J10

Multi-axis servo amplifier

: Standard torque

Direct drive motor Servo amplifier MR-J5W2- Servo amplifier MR-

J5W3-

22G 44G 77G 1010G 222G 444G

TM-RFM002C20

TM-RFM004C20

TM-RFM006C20

TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

TM-RFM012G20

TM-RFM040J10

38

7 TM-RFM SERIES

7.2 Combinations of servo amplifier and direct drive motor

Page 41

7.3 Specification list

TM-RFM series

Item TM-RFM SERIES

002C20 004C20 006C20 006E20 012E20 018E20

Motor OD (frame OD) [mm] φ130 φ180

Power supply capacity Refer to "Power supply capacity and generated loss" in the following manual.

*1

Continuous running duty

Maximum torque [N•m] 6 12 18 18 36 54

Rated speed [r/min]

Maximum speed [r/min] 500

Instantaneous permissible speed [r/min] 575

Power rate at continuous rated torque [kW/s] 3.7 9.6 16.1 4.9 12.9 21.8

Rated current [A] 1.3 2.2 3.2 3.0 3.8 6.0

Maximum current [A] 3.9 6.6 9.6 9.0 12 18

Moment of inertia J [× 10

Recommended load to motor inertia ratio

Absolute accuracy [s]

Speed/position detector

Thermistor Built-in

Insulation class 155 (F)

Structure Totally enclosed, natural cooling (IP rating: IP42)

Vibration resistance

Vibration rank

Rotor permissible load

Mass [kg] 5.2 6.8 8.4 11 15 18

*1

*5

*6

Rated output [W] 42 84 126 126 251 377

Rated torque [N•m] 2 4 6 6 12 18

-4

kg•m2] 10.9 16.6 22.4 74.0 111 149

*2

*8

*3

*7

Moment load [N•m] 22.5 70

Axial load [N] 1100 3300

MR-J5 User's Manual (Hardware)

200

50 times or less

±15 ±12.5

20-bit encoder common to absolute position and incremental systems

(resolution per direct drive motor revolution: 1048576 pulses/rev)

X: 49 m/s2 Y: 49 m/s

V10

2

7

7 TM-RFM SERIES

7.3 Specification list

39

Page 42

Item TM-RFM SERIES

012G20 048G20 072G20 040J10 120J10

Motor OD (frame OD) [mm] φ230 φ330

Power supply capacity Refer to "Power supply capacity and generated loss" in the following manual.

*1

Continuous running duty

Rated output [W] 251 1005 1508 419 1257

Rated torque [N•m] 12 48 72 40 120

Maximum torque [N•m] 36 144 216 120 360

Rated speed [r/min]

*1

Maximum speed [r/min] 500 200

Instantaneous permissible speed [r/min] 575 230

Power rate at continuous rated torque [kW/s] 6.0 37.5 59.3 9.4 40.9

Rated current [A] 3.6 11 16 4.3 11

Maximum current [A] 11 33 48 13 33

-4

Moment of inertia J [× 10

Recommended load to motor inertia ratio

Absolute accuracy [s]

Speed/position detector

kg•m2] 238 615 875 1694 3519

*2

*8

*3

Thermistor Built-in

Insulation class 155 (F)

Structure Totally enclosed, natural cooling (IP rating: IP42)

Vibration resistance

Vibration rank

Rotor permissible load

*5

*6

*7

Moment load [N•m] 93 350

Axial load [N] 5500 16000

Mass [kg] 17 36 52 53 91

MR-J5 User's Manual (Hardware)

200 100

50 times or less

±12.5 ±10

20-bit encoder common to absolute position/incremental systems (resolution per direct drive

motor revolution: 1048576 pulses/rev)

X: 49 m/s2 Y: 49 m/s

2

X: 24.5 m/s2 Y: 24.5 m/s

V10

2

40

7 TM-RFM SERIES

7.3 Specification list

Page 43

*1 When the power supply voltage drops, the output and the rated speed cannot be guaranteed.

X

Y

Measuring position

F

L

F

L

F

A

(External force)

(External force)

Axial load = F + mass of load Axial load = F + mass of load

Moment load = F × L

Axial load = mass of load

Moment load = F × (L + A)

(External force)

Bearings

*2 If the load to motor inertia ratio exceeds the indicated value, contact your local sales office.

*3 To configure the absolute position detection system, connect to battery unit and absolute position storage unit. Refer to the following for

absolute position storage unit.

Page 36 Absolute position storage unit MR-BTAS01

For the battery, refer to "Battery" in the following manual.

MR-J5 User's Manual (Hardware)

*4 Penetration area of the rotor and the connector area are excluded. IP classifies the degrees of protection provided against the intrusion

of solid objects and water in electrical enclosures.

*5 The vibration direction is as shown in the figure. The numerical value indicates the maximum value. When the direct drive motor stops,

fretting is likely to occur at the bearing. Therefore, suppress the vibration to about the half of the permissible value.

*6 V10 indicates that the amplitude of a direct drive motor alone is 10 μm or less. The following figure shows the direct drive motor

mounting position for measurement and the measuring position.

*7 The axial and moment loads, which are applied to the direct drive motor's rotor (output shaft) during operation, must be maintained to be

equal to or below the permissible value. The following figure shows an example of the load applied during operation.

Direct drive motor Motor OD [mm] Dimension A [mm]

TM-RFM002C20

TM-RFM004C20

TM-RFM006C20

TM-RFM006E20

TM-RFM012E20

TM-RFM018E20

TM-RFM012G20

TM-RFM048G20

TM-RFM072G20

TM-RFM040J10

TM-RFM120J10

φ130 19.1

φ180 20.2

φ230 24.4

φ330 32.5

*8 Absolute accuracy changes depending on the mounting condition of the load and the surrounding environment.

7

7 TM-RFM SERIES

7.3 Specification list

41

Page 44

7.4 Torque characteristics

: 3-phase 200 VAC and 1-phase 230 VAC

: 1-phase 200 VAC

[TM-RFM004C20]

100 200 300 400

500

0

0

4

8

16

12

Speed [r/min]

Short-duration

running range

Continuous

running range

Torque [N•m]

[TM-RFM006E20]

100

200

300 400 5000

0

6

12

24

18

Speed [r/min]

Short-duration

running range

Continuous

running range

Torque [N•m]

[TM-RFM018E20]

0 100 200 300 400 500

0

20

40

60

Speed [r/min]

Short-duration

running range

Continuous

running range

Torque [N•m]

[TM-RFM048G20]

100 200 300 400

500

0

0

40

80

160

120

Speed [r/min]

Short-duration

running range

Continuous

running range

Torque [N•m]

[TM-RFM040J10]

100 2000

0

40

80

140

120

Speed [r/min]

Short-duration

running range

Continuous

running range

Torque [N•m]

For the machine where the unbalanced torque occurs, such as a vertical axis system (lift), use the absolute

position detection system.

Page 8 For vertical axis (lift)

The unbalanced torque of the machine should be kept at 70 % or lower of the motor's rated torque.

The single-phase power input is for TM-RFM002C20, TM-RFM004C20, TM-RFM006C20, TM-RFM006E20, TM-RFM012E20,

TM-RFM018E20, TM-RFM012G20, and TM-RFM040J10.

[TM-RFM002C20]

8

6

4

Short-duration

running range

Torque [N•m]

2

Continuous

running range

0

100 200 300 400 500

0

Speed [r/min]

[TM-RFM012E20]

40

30

Short-duration

20

running range

Torque [N•m]

10

Continuous

running range

0

100 200 300 400

0

Speed [r/min]

500

[TM-RFM006C20]

24

18

Short-duration

12

running range

Torque [N•m]

6

Continuous

running range

0

100 200 300 400

0

Speed [r/min]

[TM-RFM012G20]

40

30

Short-duration

20

running range

Torque [N•m]

10

Continuous

running range

0

100 200 300 400

0

Speed [r/min]

500

500

[TM-RFM072G20]

240

180

Short-duration

running range

120

Torque [N•m]

60

Continuous

running range

0

100 200 300 400

0

42

Speed [r/min]

7 TM-RFM SERIES

7.4 Torque characteristics

500

[TM-RFM120J10]

400

300

200

Short-duration

running range

Torque [N•m]

100

Continuous

running range

0

100 2000

Speed [r/min]

Page 45

7.5 Dimensions

indicates the rotor.

CBD

A

U

φ20

12

16 15

(PE)

□130

L

5 29 3.5

45°

φ150

60°

3

111.5

φ128h7

φ60h7

φ77.5

φ130

116.9

B

62

A

17

16

RM15WTRZB-12P(72)

CE05-2A14S-2PD-D

W

V

φ170

φ50±0.1

4-φ9 mounting hole

Use hexagon socket

head cap screw.

6-M5

Screw hole depth 8

Power connector

output shaft side

Detailed view of A

Encoder connector

Power connector

Arrow B

[Unit: mm]

Since the actual dimensions may be approximately 3 mm larger than the drawing dimensions at a maximum, allow some

margin when designing the machine side.

TM-RFM002C20, TM-RFM004C20, TM-RFM006C20

Model Variable dimensions L

TM-RFM002C20 58.5

TM-RFM004C20 75.5

TM-RFM006C20 92.5

7

7 TM-RFM SERIES

7.5 Dimensions

43

Page 46

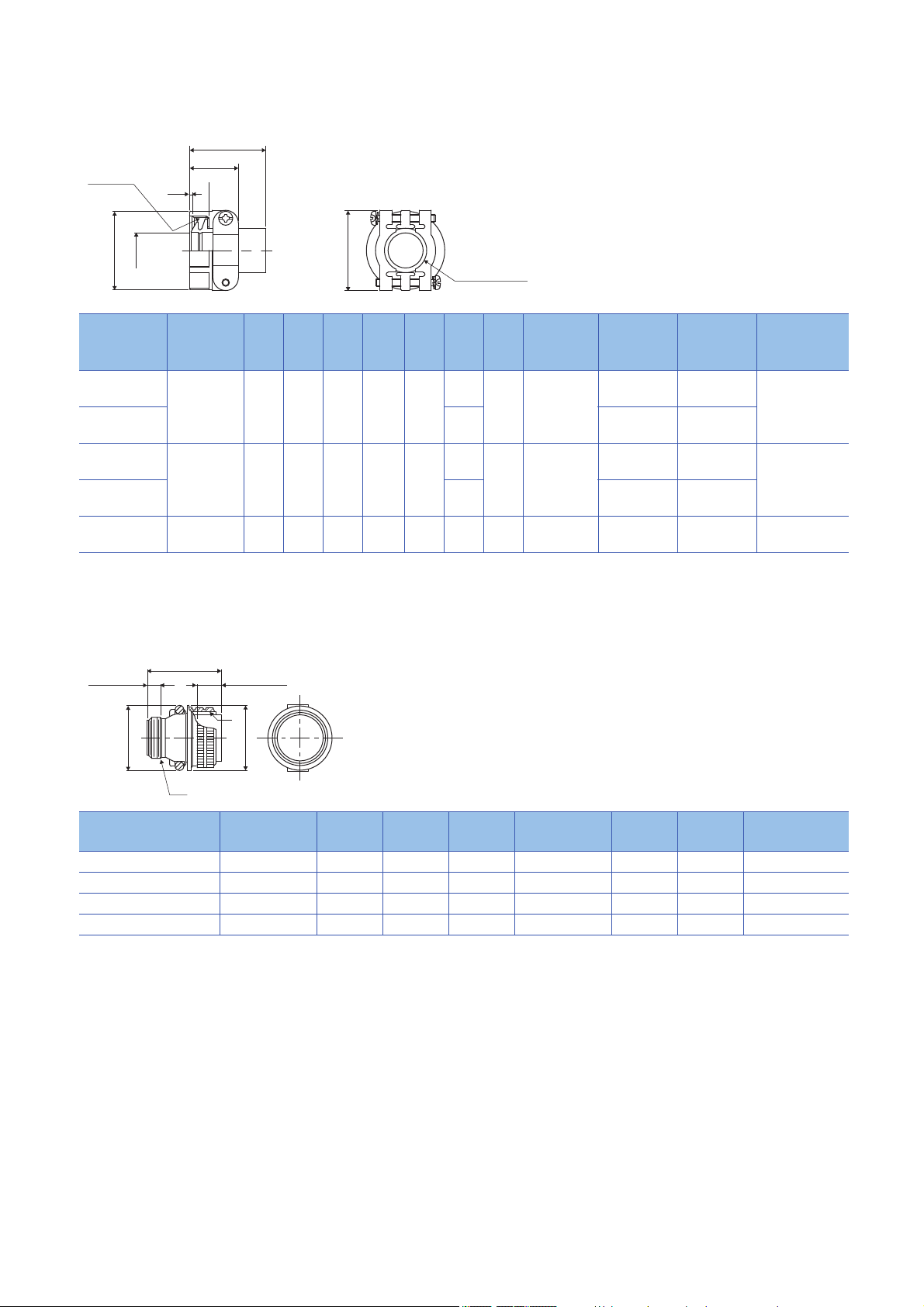

TM-RFM006E20, TM-RFM012E20, TM-RFM018E20

16

15

(PE)

□180

29

L

A

3.5

5

3

18

φ235

136.5

141.9

B

RM15WTRZB-12P(72)

CE05-2A14S-2PD-D

62

16

φ178h7

φ100h7

φ47

φ180

φ124

W

V

U

17

45°

φ20

5

60°

φ

90±0.1

CBD

A

[Unit: mm]

Encoder connector

Arrow B

Power connector

output shaft side

Detailed view of A

6-M5

Screw hole depth 8

4-φ14 mounting hole

Use hexagon socket

head cap screw.

Power connector

Model Variable dimensions L

TM-RFM006E20 62

TM-RFM012E20 83

TM-RFM018E20 104

44

7 TM-RFM SERIES

7.5 Dimensions

Page 47

TM-RFM012G20, TM-RFM048G20, TM-RFM072G20

20

295

16

(PE)

A

W

V

19.5

U

□230

4

3

L

φ290

166.5

B

15

21.5

14.5

70

RM15WTRZB-12P(72)

CE05-2A18-10PD-D

177.5

φ206h7

φ62

φ130h7

φ164

φ230

115

45°

φ260

60°

φ120±0.1

CBD

A

[Unit: mm]Arrow B

Power connector

Encoder connector

Power connector

output shaft side

2×2-M10 screw hole depth19.5

Detailed view of A

6-M6

screw hole depth10

4-φ14 mounting hole

Use hexagon socket

head cap screw.

Model Variable dimensions L

TM-RFM012G20 69

TM-RFM048G20 144

TM-RFM072G20 194

7

7 TM-RFM SERIES

7.5 Dimensions

45

Page 48

TM-RFM040J10, TM-RFM120J10

5