Page 1

General-Purpose AC Servo

J3 Series

SSCNET Interface Direct Drive Servo

MODEL (Servo Amplifier)

MR-J3- B-RJ080W

MODEL (Direct Drive Motor)

TM-RFM

INSTRUCTION MANUAL

Page 2

Safety Instructions

Please read the instructions carefully before using the equipment.

To use the equipment correctly, do not attempt to install, operate, maintain, or inspect the equipment until you

have read through this Instruction Manual, MR-J3documents carefully. Do not use the servo amplifier and direct drive motor until you have a full knowledge of

the equipment, safety information and instructions.

In this Instruction Manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

CAUTION

Note that the CAUTION level may lead to a serious consequence according to conditions. Please follow the

instructions of both levels because they are important to personnel safety.

What must not be done and what must be done are indicated by the following diagrammatic symbols.

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in medium or slight injury to personnel or may cause physical

damage.

B Servo amplifier Instruction Manual, and appended

: Indicates what must not be done. For example, "No Fire" is indicated by

: Indicates what must be done. For example, grounding is indicated by

In this Instruction Manual, instructions at a lower level than the above, instructions for other functions, and so

on are classified into "POINT".

After reading this Instruction Manual, keep it accessible to the operator.

.

.

A - 1

Page 3

1. To prevent electric shock, note the following

WARNING

Before wiring or inspection, turn off the power and wait for 15 minutes or more until the charge lamp turns

off. Then, confirm that the voltage between P(

Otherwise, an electric shock may occur. In addition, always confirm from the front of the servo amplifier,

whether the charge lamp is off or not.

Connect the servo amplifier and direct drive motor to ground.

Any person who is involved in wiring and inspection should be fully competent to do the work.

Do not attempt to wire the servo amplifier and direct drive motor until they have been installed. Otherwise,

it may cause an electric shock.

Operate the switches with dry hand to prevent an electric shock.

The cables should not be damaged, stressed, loaded, or pinched. Otherwise, it may cause an electric

shock.

During power-on or operation, do not open the front cover of the servo amplifier. Otherwise, it may cause

an electric shock.

Do not operate the servo amplifier with the front cover removed. High-voltage terminals and charging area

are exposed and you may get an electric shock.

Except for wiring or periodic inspection, do not remove the front cover even of the servo amplifier if the

power is off. The servo amplifier is charged and you may get an electric shock.

To prevent an electric shock, always connect the protective earth (PE) terminal (marked ) of the servo

amplifier to the protective earth (PE) of the cabinet.

When using a residual current device (RCD), select type B.

To avoid an electric shock, insulate the connections of the power supply terminals.

2. To prevent fire, note the following

) and N( ) is safe with a voltage tester and others.

CAUTION

Install the servo amplifier, direct drive motor and regenerative resistor on incombustible material. Installing

them directly or close to combustibles will lead to a fire.

Always connect a magnetic contactor between the power supply and the main circuit power supply of the

servo amplifier (L

side of the servo amplifier’s power supply. If a magnetic contactor is not connected, continuous flow of a

large current may cause a fire when the servo amplifier malfunctions.

When a regenerative resistor is used, use an alarm signal to switch main power off. Otherwise, a

regenerative transistor fault or the like may overheat the regenerative resistor, causing a fire.

Provide adequate protection to prevent screws and other conductive matter, oil and other combustible

matter from entering the servo amplifier and direct drive motor.

Always connect a molded-case circuit breaker to the power supply of the servo amplifier.

, L2, and L3), and configure the wiring to be able to shut down the power supply on the

1

A - 2

Page 4

3. To prevent injury, note the following

CAUTION

Only the voltage specified in the Instruction Manual should be applied to each terminal, Otherwise, a burst,

damage, etc. may occur.

Connect the terminals correctly to prevent a burst, damage, etc.

Ensure that polarity ( , ) is correct. Otherwise, a burst, damage, etc. may occur.

The servo amplifier heat sink, regenerative resistor, direct drive motor, etc. may be hot while power is on

or for some time after power-off. Take safety measures, e.g. provide covers, to prevent accidental contact

of hands and parts (cables, etc.) with them.

During operation, never touch the rotor of the direct drive motor. Otherwise, it may cause injury.

4. Additional instructions

The following instructions should also be fully noted. Incorrect handling may cause a fault, injury, electric shock,

etc.

(1) Transportation and installation

CAUTION

Transport the products correctly according to their mass.

Stacking in excess of the specified number of products is not allowed.

Do not carry the direct drive motor by holding the cables, rotor, encoder or connector.

Do not hold the front cover to transport the servo amplifier. The servo amplifier may drop.

Install the servo amplifier in a load-bearing place in accordance with the Instruction Manual.

Do not get on or put heavy load on the equipment.

The servo amplifier and direct drive motor must be installed in the specified direction.

Leave specified clearances between the servo amplifier and cabinet inside walls or other equipment.

Otherwise, it may cause a malfunction.

Do not install or operate the servo amplifier and direct drive motor which has been damaged or has any

parts missing.

Do not block intake and exhaust areas of the servo amplifier. Otherwise, it may cause a malfunction.

Do not drop or strike servo amplifier or direct drive motor. Isolate from all impact loads.

Securely attach the direct drive motor to the machine. If you attach it insecurely, the direct drive motor may

come off during operation.

Measure a direct drive motor, and check the motor vibration level. A great vibration may cause the early

damage of a bearing, encoder, and brake. The great vibration may also cause the poor connector

connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and the speed waveform by

using a measurement device, and then check that no vibration occurs. If the vibration occurs due to high

gain, the vibration may cause the early damage of the direct drive motor.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotor of the direct drive

motor during operation.

Never hit the rotor of the direct drive motor, especially when coupling the direct drive motor to the machine.

Otherwise, the encoder may malfunction.

A - 3

Page 5

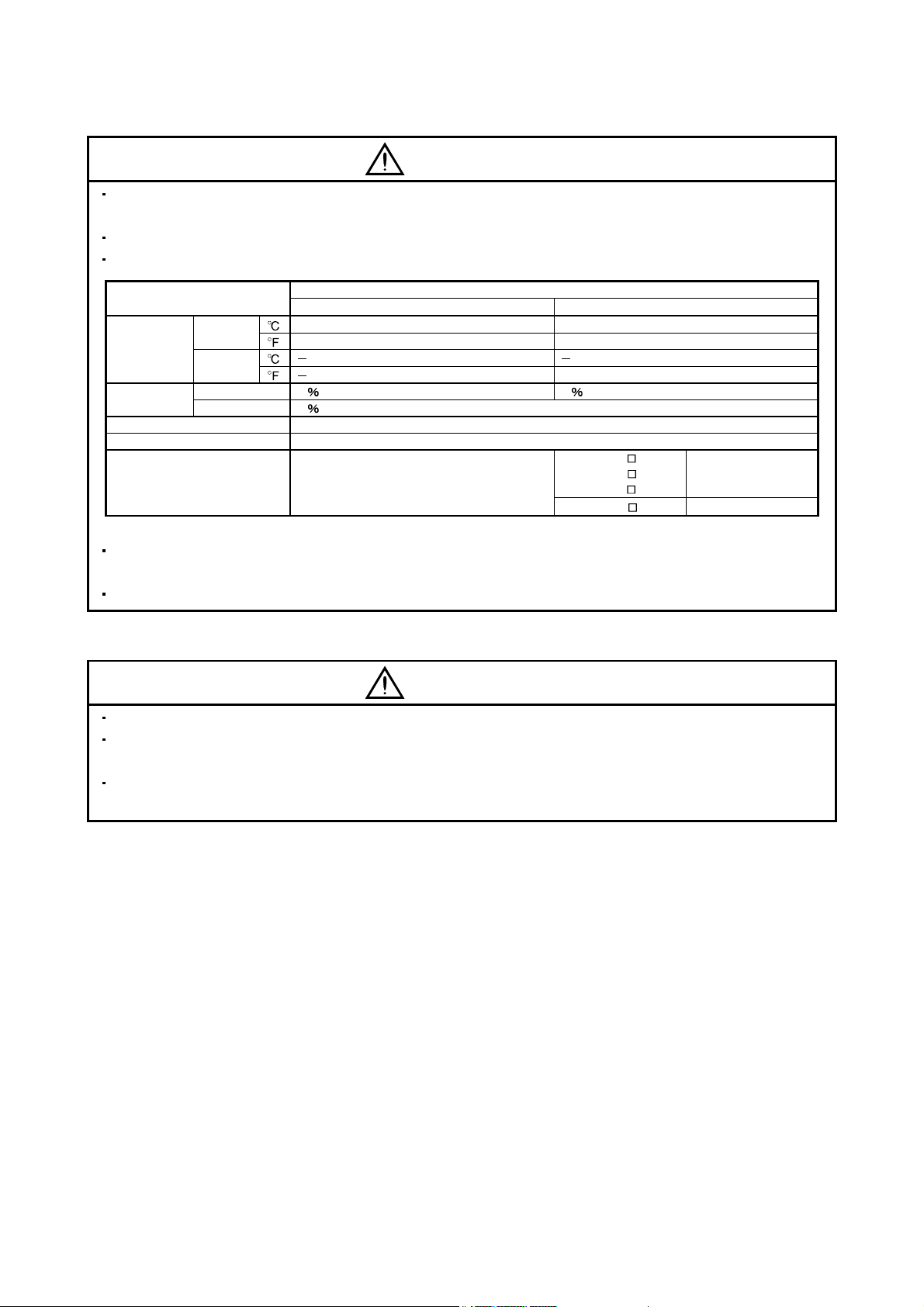

CAUTION

Do not subject the rotor of the direct drive motor to more than the permissible load. Otherwise, the rotor

may break.

When the equipment has been stored for an extended period of time, contact your local sales office.

When you keep or use it, please fulfill the following environment.

Environment

[] 0 to 55 (non-freezing) 0 to 40 (non-freezing)

Ambient

temperature

[] 20 to 65 (non-freezing) 15 to 70 (non-freezing)

Ambient

Operation 90 RH or less (non-condensing) 80 RH or less (non-condensing)

humidity

Ambience Indoors (no direct sunlight) Free from corrosive gas, flammable gas, oil mist, dust and dirt

Altitude Max. 1000m above sea level

Vibration resistance

When treating the servo amplifier and direct drive motor be careful about the edged parts such as the

corners of the servo amplifier and direct drive motor.

The servo amplifier must be installed in the metal cabinet.

(2) Wiring

Item

Operation

Storage

Storage 90

[ ] 32 to 131 (non-freezing) 32 to 104 (non-freezing)

[ ] 4 to 149 (non-freezing) 5 to 158 (non-freezing)

Servo amplifier Direct drive motor

RH or less (non-condensing)

2

at 10 to 55Hz

5.9 m/s

(directions of X, Y and Z axes)

TM-RFM C20

TM-RFM

TM-RFM

TM-RFM

E20

G20

J10 X, Y: 24.5 m/s2

X, Y: 49 m/s

2

CAUTION

Wire the equipment correctly and securely. Otherwise, the direct drive motor may operate unexpectedly.

Do not install a power capacitor, surge killer or radio noise filter (FR-BIF option) between the direct drive

motor and servo amplifier.

To avoid a malfunction, connect the wires to the correct phase terminals (U, V, and W) of the servo

amplifier and direct drive motor.

A - 4

Page 6

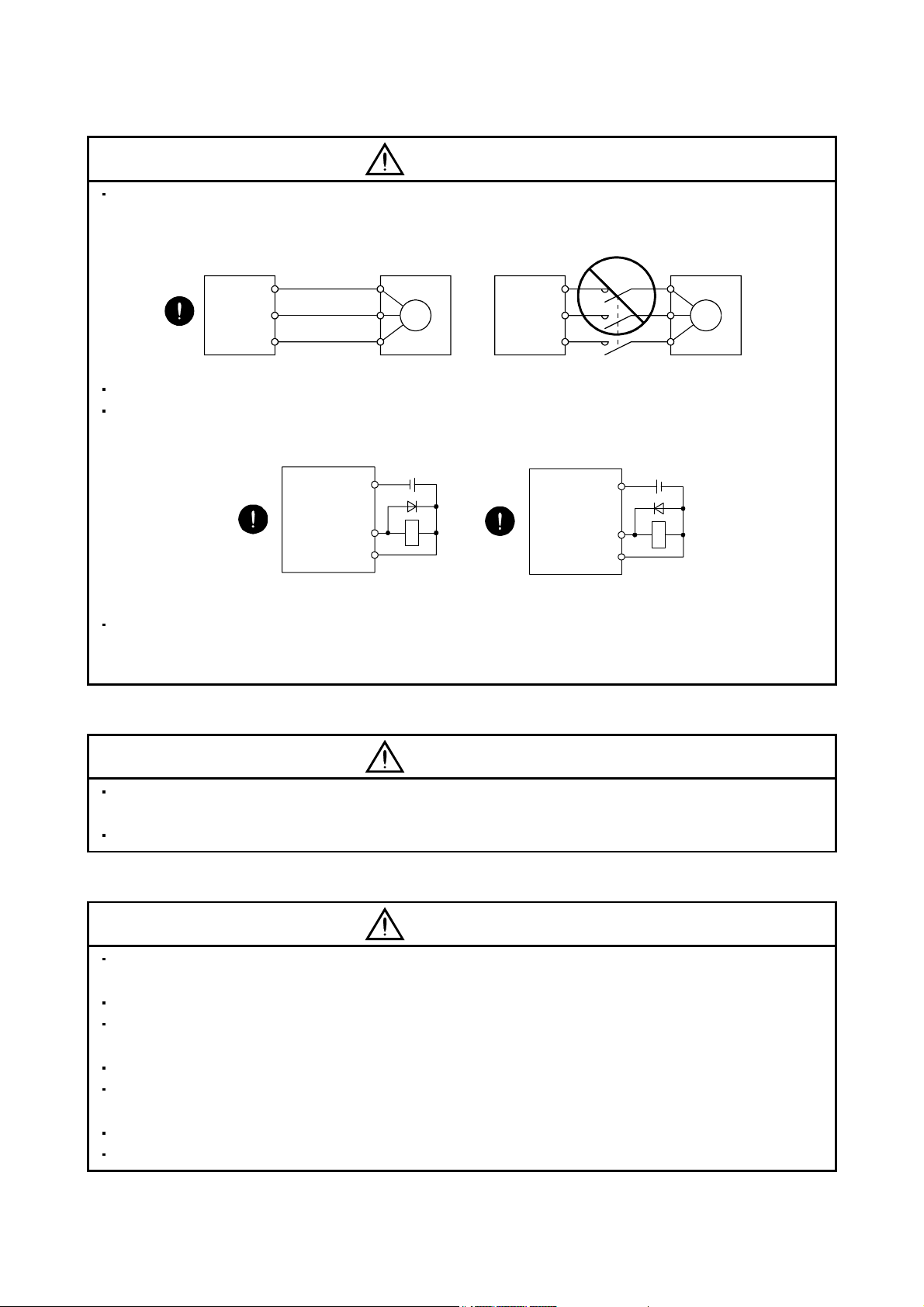

CAUTION

Connect the servo amplifier power supply output (U, V, and W) to the direct drive motor power supply input

(U, V, and W) directly. Do not let a magnetic contactor, etc. intervene. Otherwise, it may cause a

malfunction.

Servo amplifier

U

V

W

Direct drive motor

U

V

M

W

Servo amplifier Direct drive motor

U

V

W

U

V

M

W

Do not connect AC power directly to the direct drive motor. Otherwise, it may cause a malfunction.

The surge absorbing diode installed on the DC relay for control output should be fitted in the specified

direction. Otherwise, the emergency stop and other protective circuits may not operate.

Servo amplifier

DOCOM

Control output

signal

DICOM

For sink output interface

24VDC

RA

Servo amplifier

24VDC

DOCOM

Control output

signal

DICOM

For source output interface

RA

When the cable is not tightened enough to the terminal block (connector), the cable or terminal block

(connector) may generate heat because of the poor contact. Be sure to tighten the cable with specified

torque.

(3) Test run adjustment

CAUTION

Before operation, check the parameter settings. Improper settings may cause some machines to perform

unexpected operation.

The parameter settings must not be changed excessively. Operation will be instable.

(4) Usage

CAUTION

Provide an external emergency stop circuit to ensure that operation can be stopped and power switched

off immediately.

Any person who is involved in disassembly and repair should be fully competent to do the work.

Before resetting an alarm, make sure that the run signal of the servo amplifier is off to prevent an accident.

A sudden restart is made if an alarm is reset with the run signal on.

Do not modify the equipment.

Use a noise filter, etc. to minimize the influence of electromagnetic interference.

Electromagnetic interference may be given to electronic equipment used near the servo amplifier.

Burning or breaking a servo amplifier may cause a toxic gas. Do not burn or break a servo amplifier.

Use the servo amplifier with the specified direct drive motor.

A - 5

Page 7

(5) Corrective actions

CAUTION

When it is assumed that a hazardous condition may take place at the occur due to a power failure or a

product fault, use a direct drive motor with an external brake mechanism for the purpose of prevention.

When any alarm has occurred, eliminate its cause, ensure safety, and deactivate the alarm before

restarting operation.

Design the machine in order to avoid sudden restarting in case of after an instantaneous power failure.

(6) Maintenance, inspection and parts replacement

CAUTION

With age, the electrolytic capacitor of the servo amplifier will deteriorate. To prevent a secondary accident

due to a fault, it is recommended to replace the electrolytic capacitor every 10 years when used in general

environment.

Please contact your local sales office.

(7) Storage

CAUTION

Note the following points when storing the direct drive motor for an extended period of time (guideline: three

or more months).

Always store the direct drive motor indoors in a clean and dry place.

If it is stored in a dusty or damp place, make adequate provision, e.g. cover the whole product.

If the insulation resistance of the winding decreases, reexamine the storage method.

Though the direct drive motor is rust-proofed before shipment using paint or rust prevention oil, rust may

be produced depending on the storage conditions or storage period.

If the direct drive motor is to be stored for longer than six months, apply rust prevention oil again especially

to the machined surfaces of the rotor, etc.

Before using the product after storage for an extended period of time, hand-turn the direct drive motor rotor

(output shaft) to confirm that nothing is wrong with the direct drive motor.

When the equipment has been stored for an extended period of time, contact your local sales office.

(8) General instruction

To illustrate details, the equipment in the diagrams of this Specifications and Instruction Manual may have

been drawn without covers and safety guards. When the equipment is operated, the covers and safety

guards must be installed as specified. Operation must be performed in accordance with this Specifications

and Instruction Manual.

A - 6

Page 8

DISPOSAL OF WASTE

Please dispose a servo amplifier, battery (primary battery) and other options according to your local laws and

regulations.

EEP-ROM life

The number of write times to the EEP-ROM, which stores parameter settings, etc., is limited to 100,000. If the

total number of the following operations exceeds 100,000, the servo amplifier may fail when the EEP-ROM

reaches the end of its useful life.

Write to the EEP-ROM due to parameter setting changes

Write to the EEP-ROM due to device changes

Precautions for Choosing the Products

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of Mitsubishi;

machine damage or lost profits caused by faults in the Mitsubishi products; damage, secondary damage,

accident compensation caused by special factors unpredictable by Mitsubishi; damages to products other

than Mitsubishi products; and to other duties.

COMPLIANCE WITH THE CE MARKING

Refer to Appendix 5 for the compliance with CE marking.

<<About the manuals>>

This Instruction Manual and the following manuals are required if you use this direct drive servo for the first

time. Always purchase them and use the direct drive servo safely.

A - 7

Page 9

Relevant manuals

Manual name Manual No.

MELSERVO-J3 Series Instructions and Cautions for Safe Use of AC Servos IB(NA)0300077

MELSERVO-J3 Series MR-J3- B Servo Amplifier Instruction Manual SH(NA)030051

This Instruction Manual describes the functions unique to the SSCNET

Therefore, when using the MR-J3-

B-RJ080W, refer to the SSCNET Interface MR-J3- B Servo

Interface Direct Drive Servo.

Amplifier Instruction Manual as well. However, the following items are not described in this Instruction

Manual. For details of these items, refer to the MR-J3-

Item MR-J3- B Servo Amplifier Instruction Manual

INSTALLATION CHAPTER 2

STARTUP CHAPTER 4

GENERAL GAIN ADJUSTMENT CHAPTER 6

SPECIAL ADJUSTMENT FUNCTIONS CHAPTER 7

OPTIONS AND AUXILIARY EQUIPMENT CHAPTER 11

B Servo Amplifier Instruction Manual.

<<Wiring>>

Wires mentioned in this instruction manual are selected based on the ambient temperature of 40

(104 ).

A - 8

Page 10

CONTENTS

1. FUNCTIONS AND CONFIGURATION 1 - 1 to 1 -12

1.1 Summary .................................................................................................................................................. 1 - 1

1.2 Servo amplifier standard specifications................................................................................................... 1 - 3

1.3 Function list .............................................................................................................................................. 1 - 4

1.4 Model code definition ............................................................................................................................... 1 - 5

1.5 Combinations of servo amplifiers and direct drive motor........................................................................ 1 - 5

1.6 Parts identification .................................................................................................................................... 1 - 6

1.7 Configuration including auxiliary equipment............................................................................................ 1 - 9

2. DIRECT DRIVE MOTOR 2 - 1 to 2 -34

2.1 Rating plate .............................................................................................................................................. 2 - 1

2.2 Parts identification .................................................................................................................................... 2 - 1

2.3 Installation ................................................................................................................................................2 - 2

2.3.1 Equipment configuration ................................................................................................................... 2 - 3

2.3.2 Installation orientation ....................................................................................................................... 2 - 4

2.3.3 Load remove precautions ................................................................................................................. 2 - 4

2.3.4 Permissible load for the rotor ............................................................................................................ 2 - 4

2.3.5 Protection from oil and water ............................................................................................................ 2 - 5

2.3.6 Inspection ..........................................................................................................................................2 - 6

2.3.7 Life ..................................................................................................................................................... 2 - 6

2.3.8 Machine accuracies .......................................................................................................................... 2 - 7

2.3.9 Flange surface size ........................................................................................................................... 2 - 7

2.4 Connectors used for direct drive motor wiring ........................................................................................ 2 - 8

2.4.1 Selection of connectors..................................................................................................................... 2 - 8

2.4.2 Wiring connectors (Connector configurations A

2.4.3 Connector outline drawings ............................................................................................................. 2 -11

2.5 TM-RFM series direct drive motor .......................................................................................................... 2 -15

2.5.1 Model code definition .......................................................................................................................2 -15

2.5.2 Specification list ................................................................................................................................ 2 -16

2.5.3 Torque characteristic........................................................................................................................ 2 -19

2.5.4 Outline dimension drawings............................................................................................................. 2 -20

2.5.5 Connection of servo amplifier and direct drive motor ..................................................................... 2 -32

B C D E F) .............................................. 2 - 9

3. SIGNALS AND WIRING 3 - 1 to 3 -12

3.1 Precautions for this chapter .....................................................................................................................3 - 2

3.2 Input power supply circuit ........................................................................................................................ 3 - 2

3.2.1 Selection example of wires ............................................................................................................... 3 - 3

3.2.2 Connection example ......................................................................................................................... 3 - 4

3.3 I/O signal connection example ................................................................................................................ 3 - 7

3.4 Connector and signal arrangements ....................................................................................................... 3 - 9

3.5 Internal connection diagram ................................................................................................................... 3 -10

3.5.1 Incremental system .......................................................................................................................... 3 -10

3.5.2 Absolute position detection system .................................................................................................3 -11

1

Page 11

4. OPERATION AND FUNCTIONS 4 - 1 to 4 -18

4.1 Startup ...................................................................................................................................................... 4 - 1

4.2 Magnetic pole detection ........................................................................................................................... 4 - 2

4.2.1 Preparation for the magnetic pole detection .................................................................................... 4 - 2

4.2.2 Driving when magnetic pole is detected........................................................................................... 4 - 3

4.2.3 Magnetic pole detection method setting........................................................................................... 4 - 6

4.2.4 Setting the magnetic pole detection voltage level of the position detection method ...................... 4 - 6

4.2.5 Magnetic pole detection method using MR Configurator................................................................. 4 - 8

4.3 Operation from the controller .................................................................................................................. 4 -10

4.3.1 Operation method............................................................................................................................. 4 -10

4.3.2 Servo system controller setting........................................................................................................ 4 -11

4.4 Servo control error detection function .................................................................................................... 4 -16

5. PARAMETERS 5 - 1 to 5 -12

5.1 Parameter write inhibit (Parameter No.PA19)......................................................................................... 5 - 1

5.2 Basic setting parameters (No.PA

5.2.1 Parameter list .................................................................................................................................... 5 - 2

5.2.2 List of details...................................................................................................................................... 5 - 3

5.3 Gain/Filter parameters (No.PB

5.3.1 Parameter list .................................................................................................................................... 5 - 5

5.4 Extension setting parameters (No.PC

5.4.1 Parameter list .................................................................................................................................... 5 - 6

5.5 I/O setting parameters (No.PD

5.5.1 Parameter list .................................................................................................................................... 5 - 7

5.6 Special setting parameters (No.PS

5.6.1 Parameter list .................................................................................................................................... 5 - 8

5.6.2 List of details...................................................................................................................................... 5 - 9

).................................................................................................... 5 - 2

) ....................................................................................................... 5 - 5

) ............................................................................................ 5 - 6

) ....................................................................................................... 5 - 7

) ................................................................................................ 5 - 8

6. TROUBLESHOOTING 6 - 1 to 6 - 8

6.1 Alarms and warning list ............................................................................................................................ 6 - 1

6.2 Remedies for alarms ................................................................................................................................ 6 - 2

6.3 Remedies for warnings ............................................................................................................................ 6 - 6

7. SERVO AMPLIFIER OUTLINE DRAWINGS 7 - 1 to 7 - 6

8. CHARACTERISTICS 8 - 1 to 8 - 4

8.1 Overload protection characteristics .........................................................................................................8 - 1

8.2 Dynamic brake characteristics................................................................................................................. 8 - 3

8.2.1 Dynamic brake operation .................................................................................................................. 8 - 3

8.2.2 The dynamic brake at the load inertia moment ratio........................................................................8 - 4

9. OPTIONS FOR DIRECT DRIVE SERVO 9 - 1 to 9 -12

9.1 Cable/connector sets ...............................................................................................................................9 - 1

2

Page 12

9.1.1 Combinations of cable and connector set ........................................................................................9 - 2

9.1.2 Encoder connector set ......................................................................................................................9 - 4

9.2 Absolute position storage unit MR-BTAS01........................................................................................... 9 -10

APPENDIX App.- 1 to App.- 8

App. 1 Parameter list..................................................................................................................................App.- 1

App. 2 Signal layout recording paper ........................................................................................................App.- 3

App. 3 Handling of AC servo amplifier batteries for the United Nations Recommendations on the

Transport of Dangerous Goods ....................................................................................................App.- 3

App. 4 Symbol for the new EU Battery Directive ......................................................................................App.- 5

App. 5 Compliance with the CE marking...................................................................................................App.- 6

3

Page 13

MEMO

4

Page 14

1. FUNCTIONS AND CONFIGURATION

1. FUNCTIONS AND CONFIGURATION

1.1 Summary

To meet high-accuracy and high-efficiency requirements in areas including semiconductor and liquid crystal

related machines, and surface mount device placement machines, a system with a direct drive motor in a drive

axis has been increased. The direct drive servo system includes the following features.

(1) Performance

(a) Since load is directly coupled to the direct drive motor, gear reducer and transmission elements can be

(2) Mechanism

eliminated, offering greater rigidity and torque.

(b) The high-resolution encoder contributes to high-accuracy control.

(c) Due to the gearless structure, error caused by backlash can be eliminated, offering high-accuracy

operation and shorter settling time.

(d) Because of no reduction gear or others, the direct drive motor does not deteriorate with time.

(a) The motor's low profile design contributes to compact construction and a low center of gravity for

enhanced machine stability.

(b) The motor has an inner rotor with hollow shaft which enables cables and pipes to be passed through.

(c) Lubrication and maintenance due to abrasion is not required.

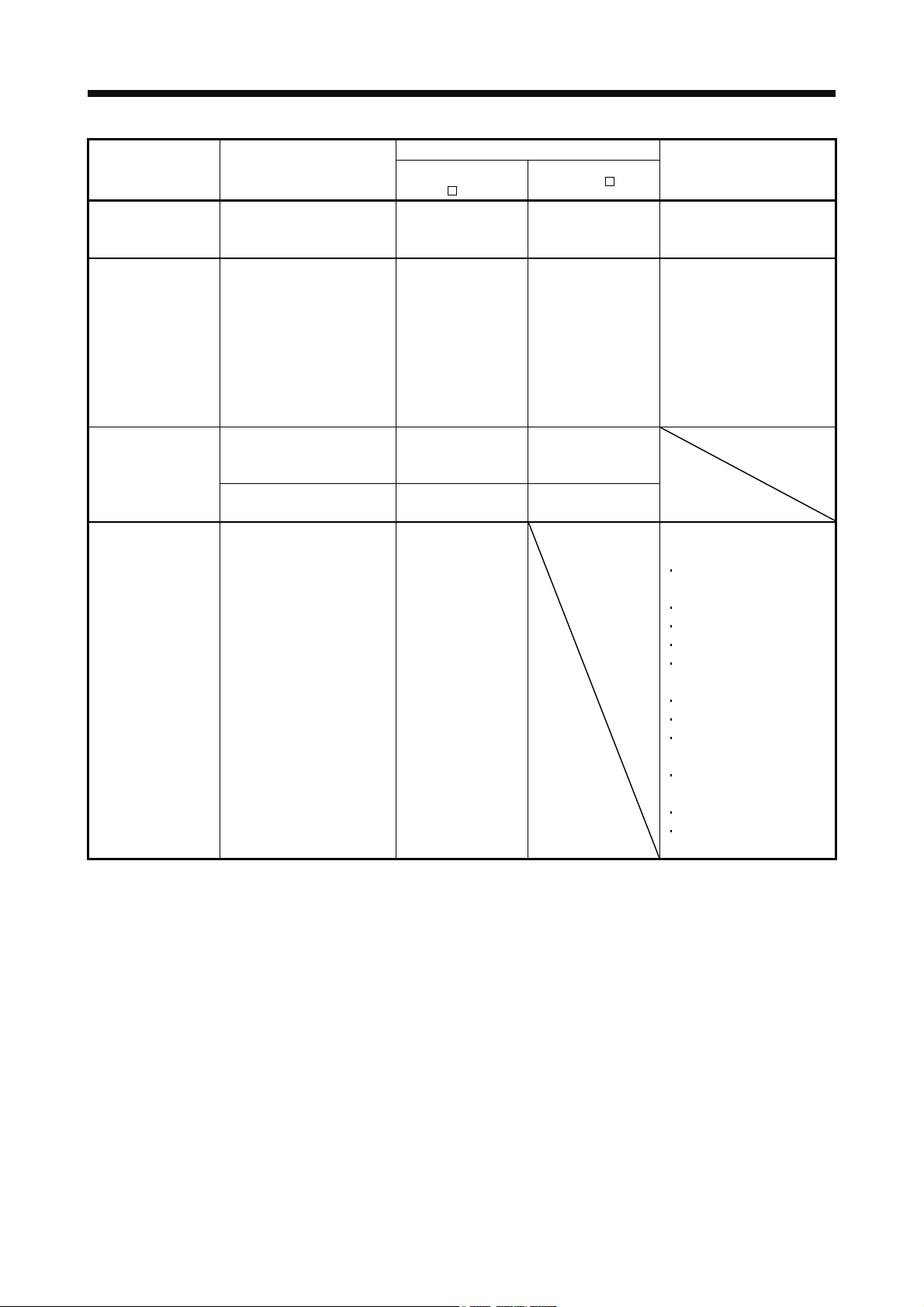

The following shows the differences between the direct drive servo and the MR-J3-

B.

1 - 1

Page 15

1. FUNCTIONS AND CONFIGURATION

Classification Item

(MR-J3-

External I/O signal Stroke limit input signal

(FLS, RLS)

Motor pole adjustment Magnetic pole detection

operation

Absolute position

detection system

Alarm/warning Alarm/warning designed

Battery for absolute position

encoder

(MR-J3BAT)

Absolute position storage unit

(MR-BTAS01)

exclusively for the direct drive

servo

Required (when

magnetic pole is

detected)

Required Not required (adjusted

Required Required

Required Not required

Addition Alarm/warning which is added

Differences

Direct drive servo

B-RJ080W)

MR-J3-

Not required Automatically turns on in the

at shipment)

B

parameter setting.

Automatically executed at the

first servo-on after turning the

power on.

For the absolute position

detection system, the

magnetic polarity detection

can be made invalid in the

setting of parameter No.PS01.

(Refer to section 4.2.2 (2).)

or the contents is changed

Remarks

Encoder combination error

(1F)

Encoder error2 (20)

Encoder error3 (21)

Absolute position erase (25)

Initial magnetic pole

detection error (27)

Encoder counter error (2B)

Servo control error (42)

Direct drive motor overheat

(46)

Battery cable disconnection

warning (92)

Battery warning (9F)

Direct drive motor overheat

warning (E2)

1 - 2

Page 16

1. FUNCTIONS AND CONFIGURATION

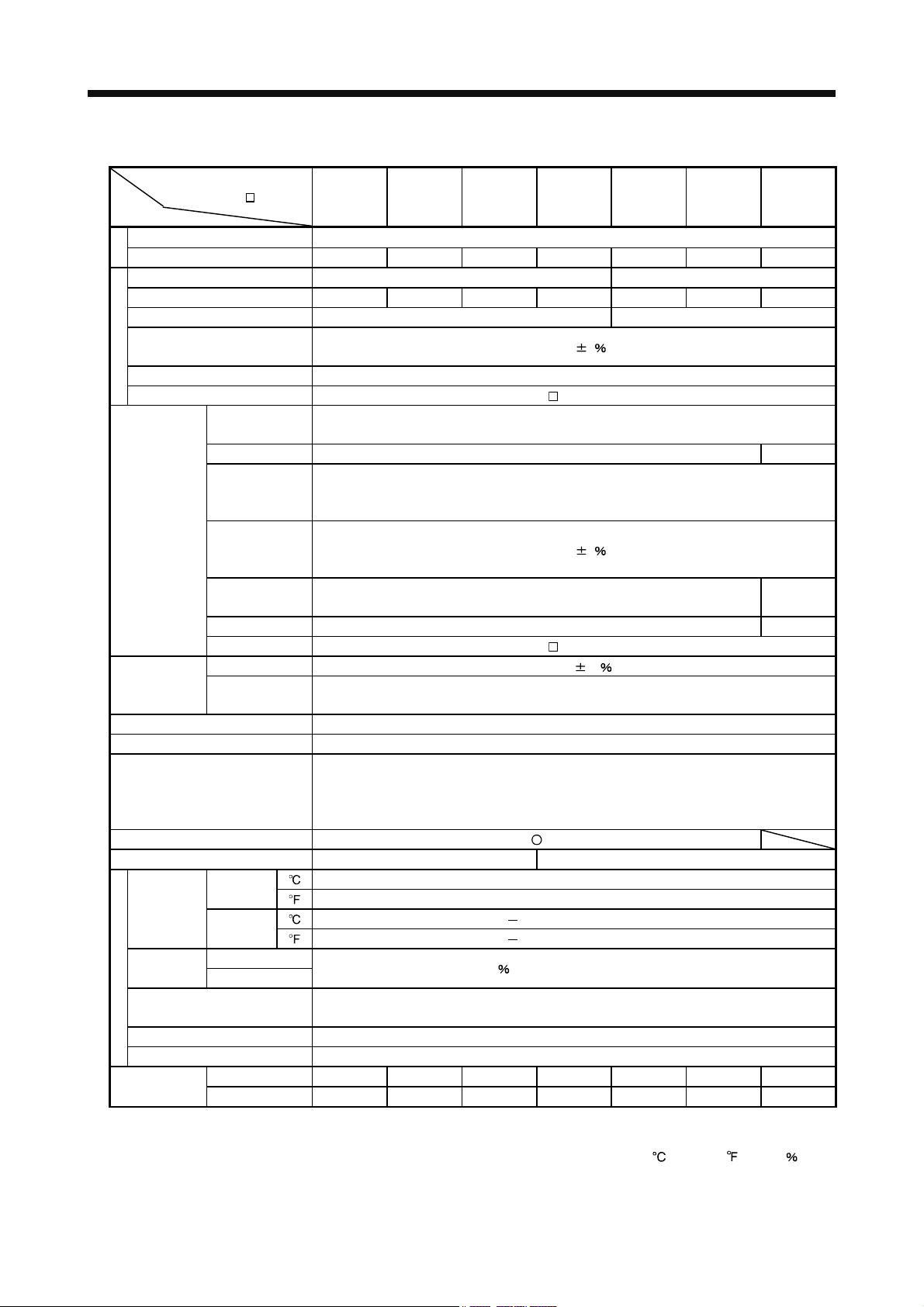

1.2 Servo amplifier standard specifications

Servo amplifier

MR-J3-

Item

Rated voltage 3-phase 170VAC

Output

Rated current [A] 1.5 2.8 3.2 5.8 6.0 17.0 28.0

Voltage/frequency 3-phase or 1-phase 200 to 230VAC, 50/60Hz 3-phase 200 to 230VAC, 50/60Hz

Rated current [A] 1.5 2.6 3.2 3.8 5.0 16.0 21.7

Permissible voltage fluctuation 3-phase or 1-phase 170 to 253VAC 3-phase 170 to 253VAC

Permissible frequency

fluctuation

Power supply capacity Refer to section 2.5.2

Main circuit power supply

Inrush current Refer to section 10.5 "MR-J3- B Servo Amplifier Instruction Manual"

Control circuit

power supply

Interface power

supply

Control system Sine-wave PWM control, current control system

Dynamic brake Built-in

Protective functions

Close mounting (Note 2)

Structure Natural-cooling, open (IP rating: IP00) Force-cooling, open (IP rating: IP00)

Ambient

temperature

humidity

Ambient

Environmental conditions

Altitude Max. 1000m above sea level

Vibration resistance 5.9m/s2 10 to 55Hz (directions of X, Y and Z axes)

Mass

Note 1. 0.15A is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number of

I/O points.

2. When closely mounting servo amplifiers, operate them at the ambient temperatures of 0 to 45

smaller effective load ratio.

-RJ080W

Voltage,

frequency

Rated current [A] 0.2 0.3

Permissible

voltage

fluctuation

Permissible

frequency

fluctuation

Power

consumption [W]

Input 30W 45W

Inrush current Refer to section 10.5 "MR-J3-

Voltage 24VDC 10

Power supply

capacity [A]

Operation

Storage

Operation Ambient

Storage

Indoors (no direct sunlight)

[ ] (Note 2) 0 to 55 (non-freezing)

[

[ ] 20 to 65 (non-freezing)

[

[kg] 0.8 1.0 1.0 1.4 1.4 2.3 4.6

20B 40B 60B 70B 100B 350B 500B

Within

5

1-phase 200 to 230VAC, 50/60Hz

1-phase 170 to 253VAC

Within

5

30 45

B Servo Amplifier Instruction Manual"

(Note 1) 0.15

Overcurrent shut-off, regenerative overvoltage shut-off, overload shut-off (electronic thermal

relay), direct drive motor overheat protection, encoder error protection, regenerative error

protection, undervoltage, instantaneous power failure protection, overspeed protection,

excessive error protection, magnetic pole detection protection, servo control error protection

] (Note 2) 32 to 131 (non-freezing)

] 4 to 149 (non-freezing)

RH or less (non-condensing)

90

Free from corrosive gas, flammable gas, oil mist, dust and dirt

[lb] 1.8 2.2 2.2 3.1 3.1 5.1 10

(32 to 113 ) or at 75 or

1 - 3

Page 17

1. FUNCTIONS AND CONFIGURATION

1.3 Function list

The following table lists the functions of this servo. For details of the functions, refer to the reference field.

Function Description Reference

Absolute position detection

system

Gain changing function You can switch between gains during rotation and gains during stop or use an

Advanced vibration

suppression control

Adaptive filter Servo amplifier detects mechanical resonance and sets filter characteristics

Low-pass filter Suppresses high-frequency resonance which occurs as servo system response

Machine analyzer function Analyzes the frequency characteristic of the mechanical system by simply

Machine simulation Can simulate machine motions on a personal computer screen on the basis of

Gain search function Personal computer with MR Configurator changes gains automatically and

Robust disturbance

compensation

Advanced Gain search Advanced Gain search automatically searches for the optimum parameter for

Slight vibration suppression

control

Auto tuning Automatically adjusts the gain to optimum value if load applied to the direct drive

Brake unit Used when the regenerative option cannot provide enough regenerative power.

Power regenerative converter Used when the regenerative option cannot provide enough regenerative power.

Regenerative option Used when the built-in regenerative resistor of the servo amplifier does not have

Alarm history clear Alarm history is cleared.

Output signal selection

(Device settings)

Output signal (DO) forced

output

Test operation mode JOG operation positioning operation DO forced output. However, MR

Analog monitor output Servo status is output in terms of voltage in real time.

MR Configurator

(C2 or later)

Merely setting a home position once makes home position return unnecessary

at every power-on. A battery (MR-J3BAT) and an absolute position storage unit

(MR-BTAS01) are required.

input device to change gains during operation.

This function suppresses vibration at the arm end or residual vibration.

automatically to suppress mechanical vibration.

is increased.

connecting MR Configurator installed personal computer and servo amplifier.

MR Configurator is necessary for this function.

Make sure to execute the machine analyzer function after the magnetic pole

detection. If the magnetic pole detection is not executed, this function may not

operate properly.

the machine analyzer results. MR Configurator is necessary for this function.

searches for overshoot-free gains in a short time. MR Configurator is necessary

for this function.

This function provides better disturbance response in case of low response level

due to high load inertia moment ratio for the roll send axis.

MR Configurator is necessary for this function.

settle time to be short.

The gain can be adjusted by setting sequentially in accordance with wizard

screens.

MR Configurator is necessary for this function.

Suppresses vibration of 1 pulse produced at a direct drive motor stop.

motor rotor varies.

Can be used the 5kW or more servo amplifier.

Can be used the 5kW or more servo amplifier.

sufficient regenerative capability for the regenerative power generated.

The pins that output the output devices, including the malfunction (ALM) and the

dynamic brake interlock (DB), can be changed to certain pins of the CN3

connectors.

Output signal can be forced on/off independently of the servo status. Use this

function for output signal wiring check, etc.

Configurator is necessary for positioning operation.

Using a personal computer, parameter setting, test operation, status display,

etc. can be performed.

1 - 4

Chapter 9

MR-J3-

Amplifier Instruction

Manual

MR-J3-

Amplifier Instruction

Manual

B Servo

B Servo

Page 18

1. FUNCTIONS AND CONFIGURATION

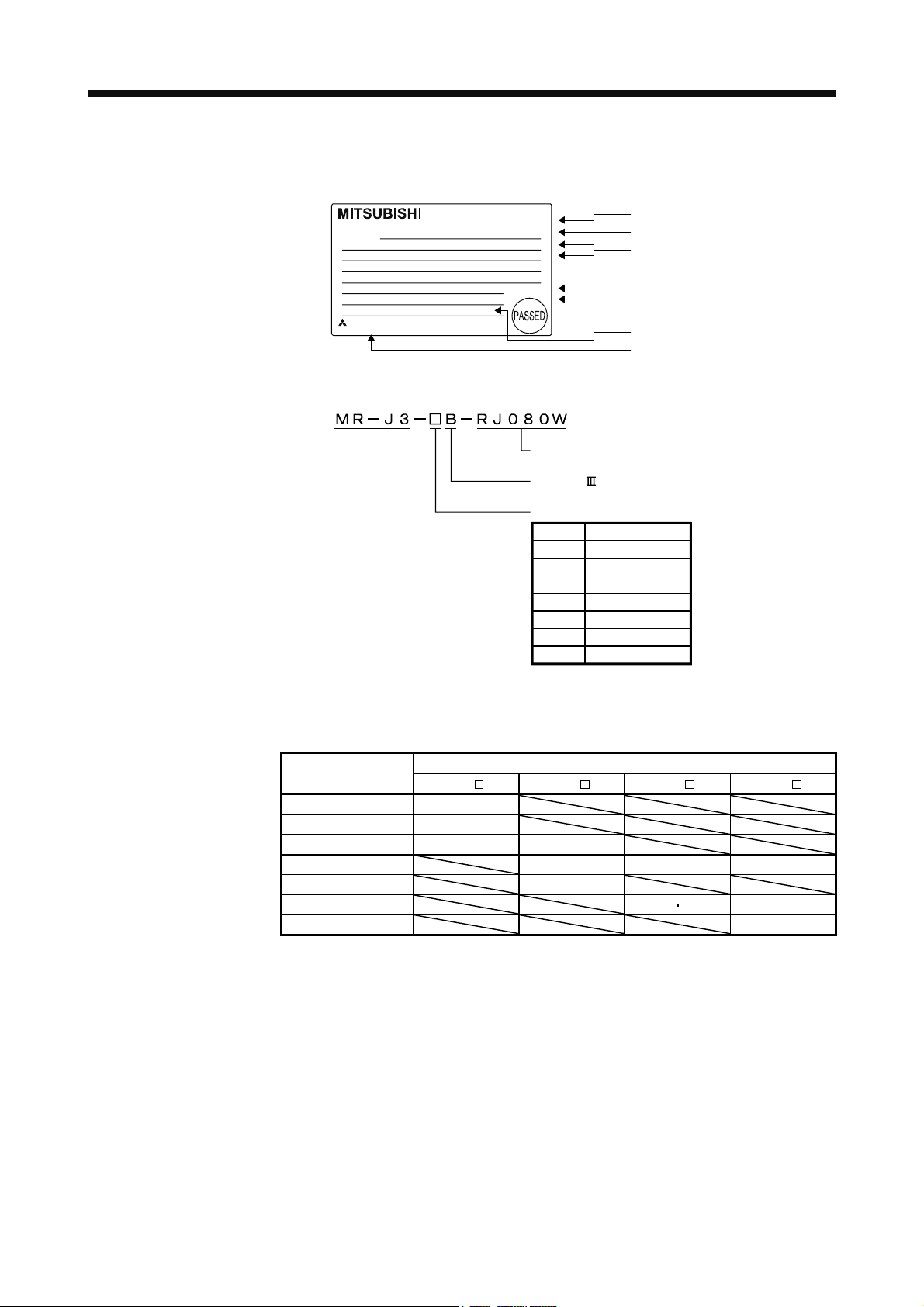

1.4 Model code definition

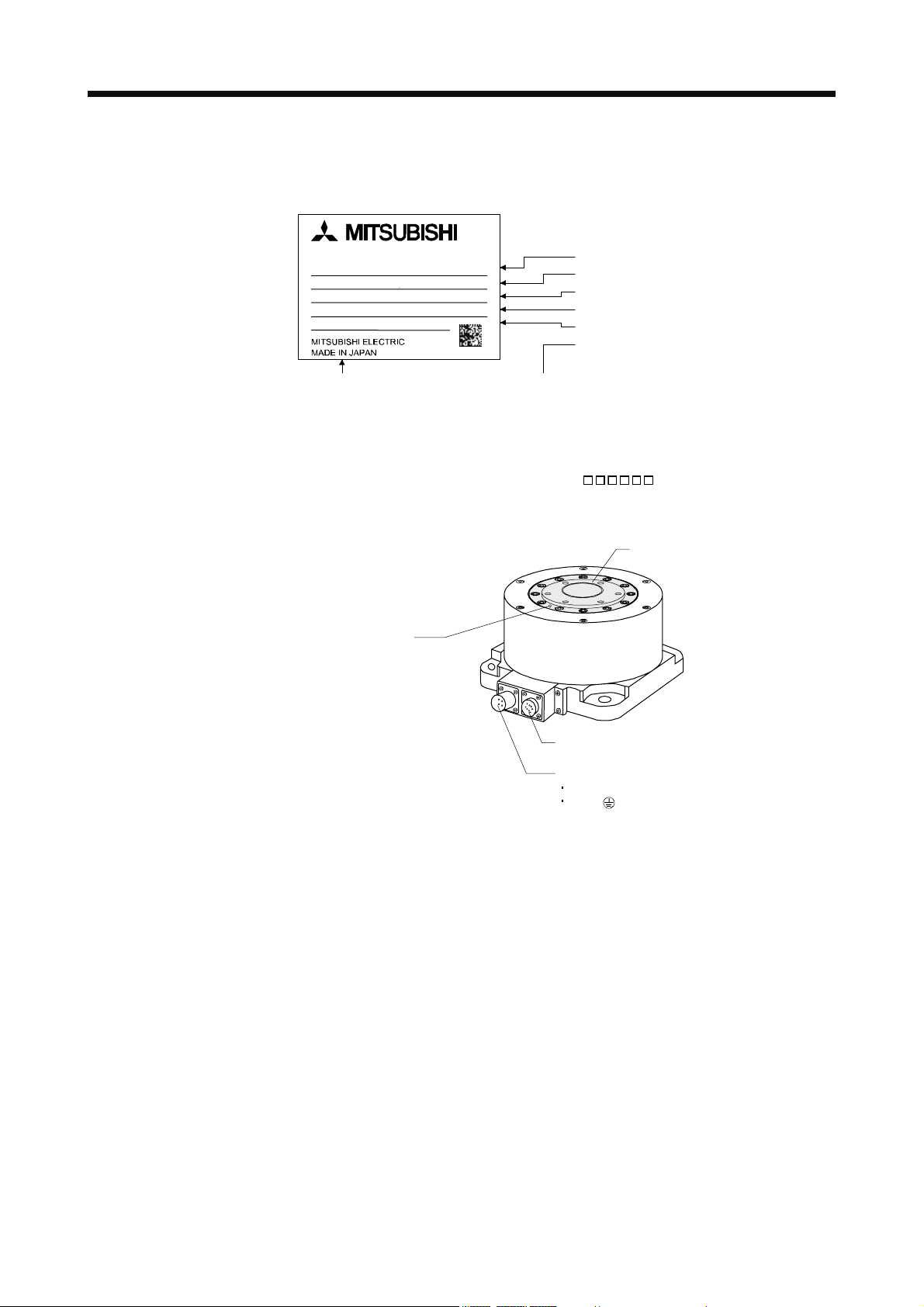

(1) Rating plate

MODEL

(2) Model

MR-J3-20B-RJ080W

200W

:

POWER

1.5A 3PH+1PH200-230V 50Hz

:

INPUT

OUTPUT

SERIAL

KCC-REI-MEK-TC300A***G51

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

3PH+1PH200-230V 60Hz

2.2A 1PH200-230V 50Hz/60Hz

170V 0-360Hz 1.5A

:

A18001050

:

Series name

AC SERVO

DATE: 2012-11

The year and month of manufacture

Model

Capacity

Applicable power supply

Rated output current

Serial number

KC mark number

Country of origin

Direct drive motor compatible

SSCNET Interface

Rated output

Symbol

Rated output [kW]

20 0.2

40 0.4

60 0.6

70 0.75

100 1

350 3.5

500 5

1.5 Combinations of servo amplifiers and direct drive motor

The following table lists combinations of servo amplifiers and direct drive motors.

Servo amplifier

Direct drive motor

TM-RFM

C20 TM-RFM E20 TM-RFM G20 TM-RFM J10

MR-J3-20B-RJ080W 002

MR-J3-40B-RJ080W 004

MR-J3-60B-RJ080W 006 006

MR-J3-70B-RJ080W 012 012 040

MR-J3-100B-RJ080W 018

MR-J3-350B-RJ080W 048 072 120

MR-J3-500B-RJ080W 240

1 - 5

Page 19

1. FUNCTIONS AND CONFIGURATION

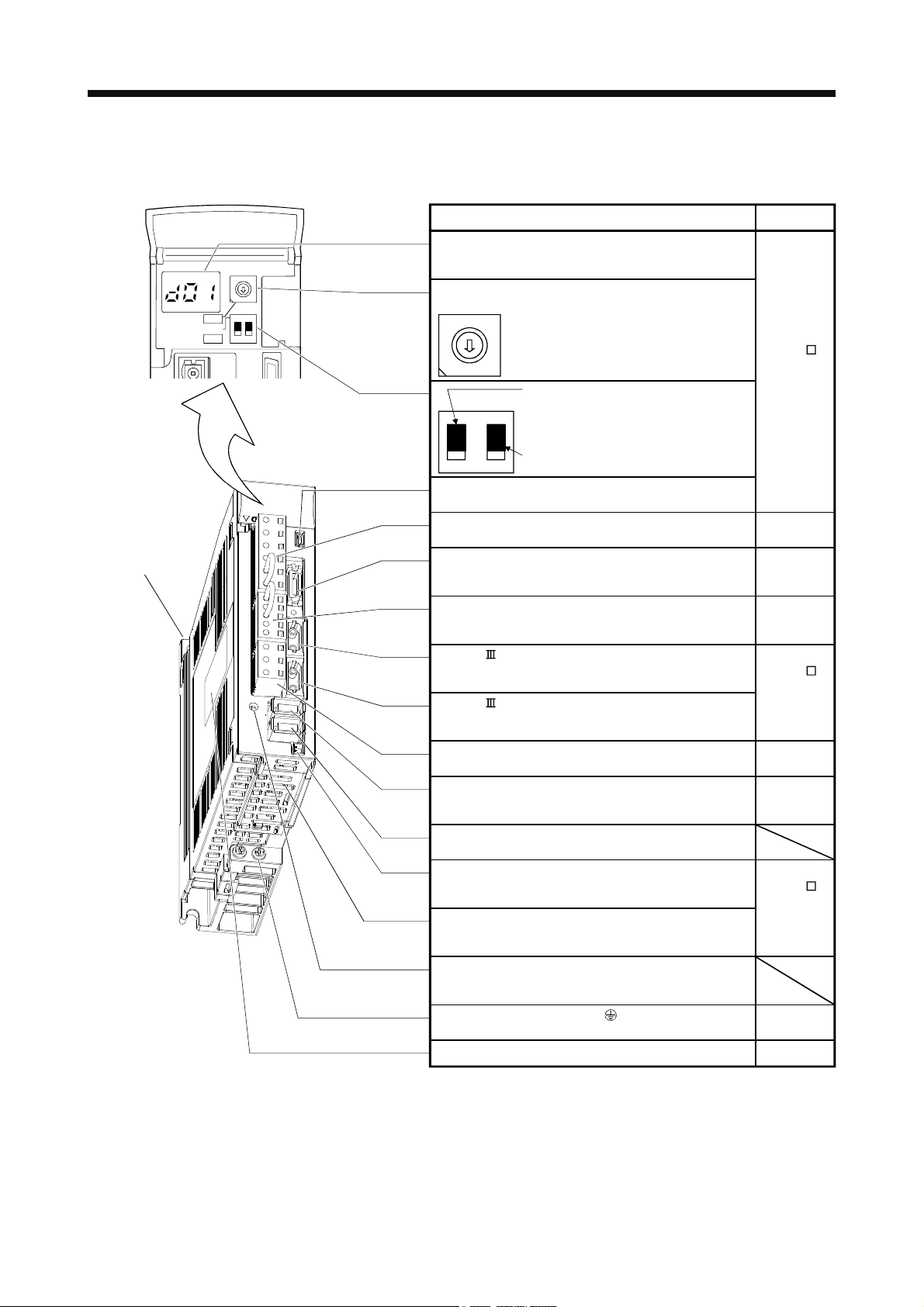

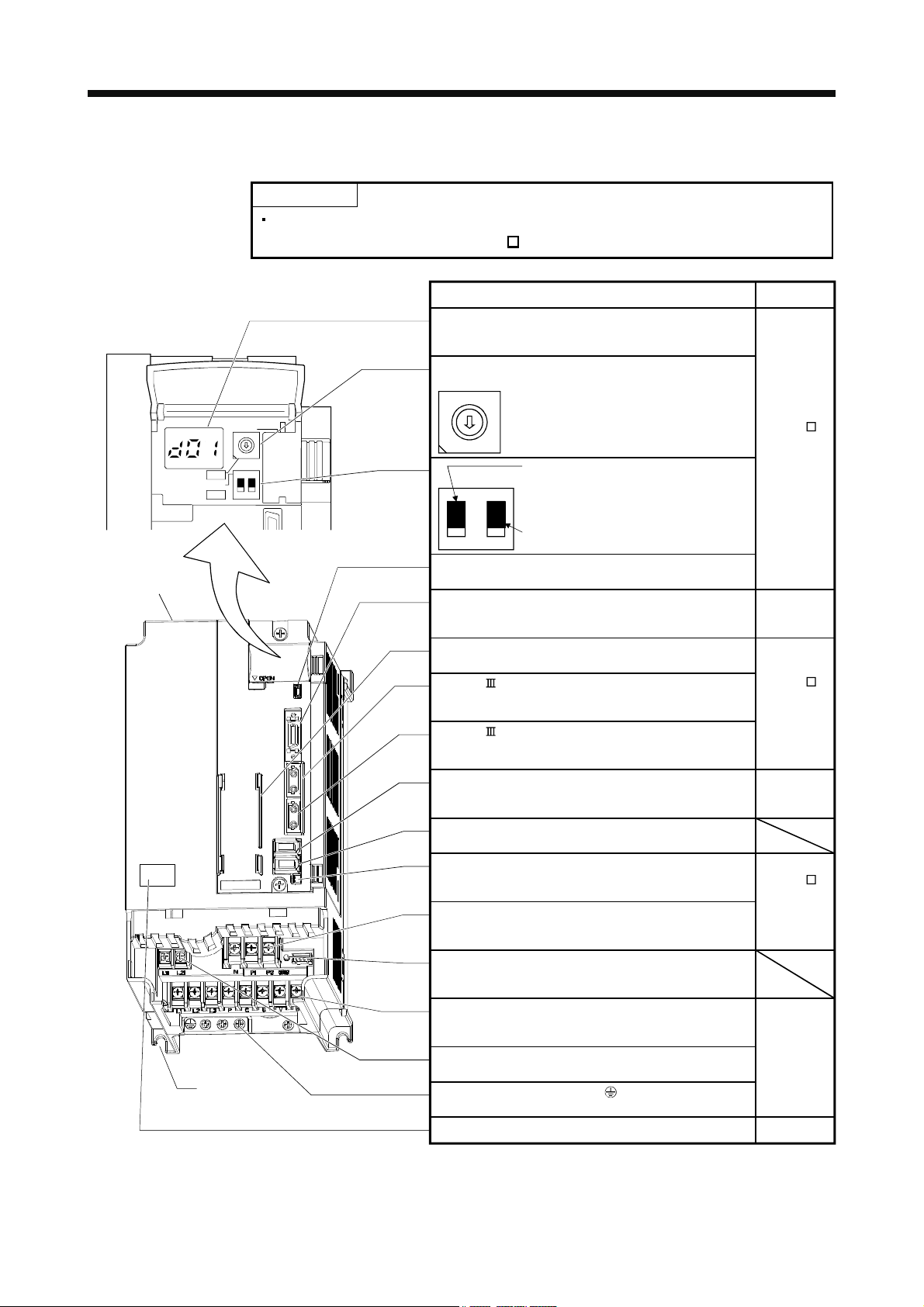

1.6 Parts identification

(1) MR-J3-100B-RJ080W or less

Fixed part

(2 places)

SW1

TEST

SW2

7

6

5

4

3

2

ON 4E

12

Name/Application

Detailed

explanation

Display

The 3-digit, seven-segment LED shows the servo

8

9

A

B

C

D

E

F

1

0

status and alarm number.

Rotary axis setting switch (SW1)

SW1

8

Used to set the axis No. of servo amplifier.

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

Refer to the

MR-J3- B

Servo

Amplifier

SW2

Test operation select switch (SW2-1)

Used to perform the test operation

Instruction

Manual.

mode by using MR Configurator.

For manufacturer setting (Be sure to set

to the "Down" position).

2

1

USB communication connector (CN5)

Connect the personal computer.

Main circuit power supply connector (CNP1)

Connect the input power supply.

Section 3.2

I/O signal connector (CN3)

Used to connect digital I/O signals.

Section 3.3

More over an analog monitor is output.

Control circuit connector (CNP2)

Connect the control circuit power supply/regenerative

Section 3.2

option.

SSCNET cable connector (CN1A)

Used to connect the servo system controller or the front

axis servo amplifier.

SSCNET cable connector (CN1B)

Used to connect the rear axis servo amplifier. For the final

axis, puts a cap.

Direct drive motor power output connector (CNP3)

Connect the direct drive motor.

Encoder connector (CN2)

Used to connect the direct drive motor encoder.

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

Chapter 2

Section 3.2

Chapter 2

Section 3.4

Chapter 9

Connector for manufacturer setting (CN2L)

Not used for this servo amplifier.

Battery connector (CN4)

Used to connect the battery for absolute position data

backup.

Battery holder

Install the battery MR-J3BAT.

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

Charge lamp

Lit to indicate that the main circuit is charged. While this

lamp is lit, do not reconnect the cables.

Protective earth (PE) terminal ( )

Ground terminal.

Rating plate

Section 3.2

Section 1.4

1 - 6

Page 20

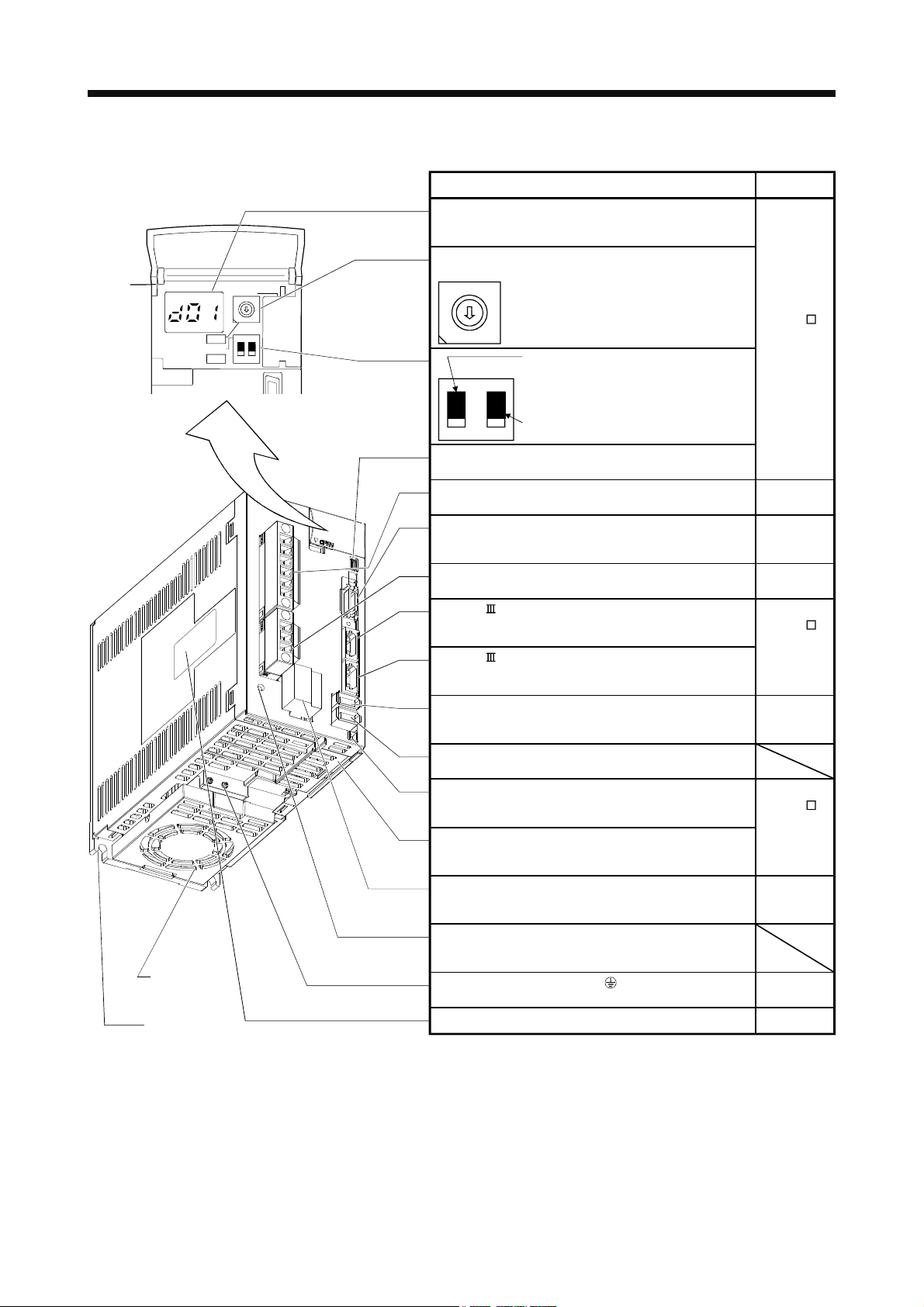

1. FUNCTIONS AND CONFIGURATION

(2) MR-J3-350B-RJ080W

Cooling fan

Fixed part

(3 places)

SW1

TEST

SW2

7

6

5

4

3

2

ON 4E

12

Name/Application

Detailed

explanation

Display

The 3-digit, seven-segment LED shows the servo

status and alarm number.

Rotary axis setting switch (SW1)

SW1

8

Used to set the axis No. of servo amplifier.

9

7

8

9

A

B

C

D

E

F

1

0

A

6

B

5

C

4

D

3

E

2

F

1

0

SW2

Test operation select switch (SW2-1)

Used to perform the test operation

mode by using MR Configurator.

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

For manufacturer setting (Be sure to set

to the "Down" position).

2

1

USB communication connector (CN5)

Connect the personal computer.

Main circuit power supply connector (CNP1)

Connect the input power supply.

Section 3.2

I/O signal connector (CN3)

Used to connect digital I/O signals.

Section 3.3

More over an analog monitor is output.

Direct drive motor power output connector (CNP3)

Connect the direct drive motor.

SSCNET cable connector (CN1A)

Used to connect the servo system controller or the front

axis servo amplifier.

SSCNET cable connector (CN1B)

Used to connect the rear axis servo amplifier. For the final

axis, puts a cap.

Encoder connector (CN2)

Used to connect the direct drive motor encoder.

Chapter 2

Section 3.2

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

Chapter 2

Section 3.4

Chapter 9

Connector for manufacturer setting (CN2L)

Not used for this servo amplifier.

Battery connector (CN4)

Used to connect the battery for absolute position data

backup.

Battery holder

Install the battery MR-J3BAT.

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

Control circuit connector (CNP2)

Connect the control circuit power supply/regenerative

Section 3.2

option.

Charge lamp

Lit to indicate that the main circuit is charged. While this

lamp is lit, do not reconnect the cables.

Protective earth (PE) terminal ( )

Ground terminal.

Rating plate

Section 3.2

Section 1.4

1 - 7

Page 21

1. FUNCTIONS AND CONFIGURATION

(3) MR-J3-500B-RJ080W

POINT

The servo amplifier is shown without the front cover. For removal of the front cover,

refer to section 1.7.2 of the MR-J3-

B Servo Amplifier Instruction Manual.

Cooling fan

8

7

6

5

4

3

2

1

ON 4E

SW1

TEST

12

SW2

Fixed part

(4 places)

Name/Application

Detailed

explanation

Display

The 3-digit, seven-segment LED shows the servo

status and alarm number.

Rotary axis setting switch (SW1)

SW1

8

Used to set the axis No. of servo amplifier.

9

7

A

6

B

5

C

4

D

3

9

A

B

C

D

E

F

0

2

F

1

0

SW2

E

Test operation select switch (SW2-1)

Used to perform the test operation

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

mode by using MR Configurator.

For manufacturer setting (Be sure to set

to the "Down" position).

21

USB communication connector (CN5)

Connect the personal computer.

I/O signal connector (CN3)

Used to connect digital I/O signals.

Section 3.3

More over an analog monitor is output.

Battery holder

Install the battery MR-J3BAT.

SSCNET cable connector (CN1A)

Used to connect the servo system controller or the front

axis servo amplifier.

SSCNET cable connector (CN1B)

Used to connect the rear axis servo amplifier. For the final

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

axis, puts a cap.

Encoder connector (CN2)

Used to connect the direct drive motor encoder.

Chapter 2

Section 3.4

Chapter 9

Connector for manufacturer setting (CN2L)

Not used for this servo amplifier.

Battery connector (CN4)

Used to connect the battery for absolute position data

backup.

Power factor improving DC reactor terminal block (TE3)

Used to connect the power factor improving DC reactor.

Refer to the

MR-J3- B

Servo

Amplifier

Instruction

Manual.

Charge lamp

Lit to indicate that the main circuit is charged. While this

lamp is lit, do not reconnect the cables.

Main circuit terminal block (TE1)

Used to connect the input power supply and direct drive

motor.

Control circuit terminal block (TE2)

Section 3.2

Used to connect the control circuit power supply.

Protective earth (PE) terminal ( )

Ground terminal.

Rating plate

Section 1.4

1 - 8

Page 22

1. FUNCTIONS AND CONFIGURATION

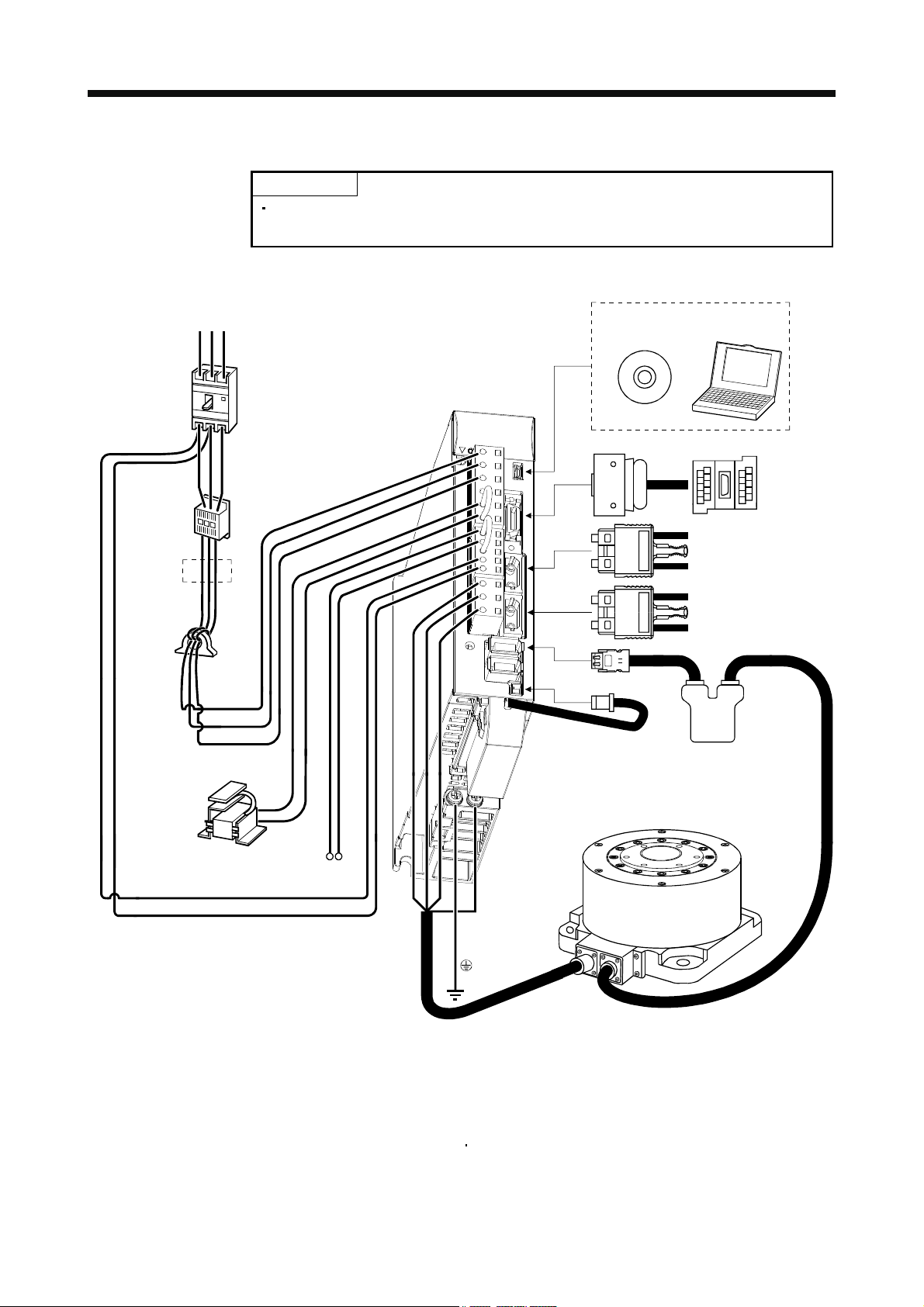

1.7 Configuration including auxiliary equipment

POINT

Equipment other than the servo amplifier and direct drive motor are optional or

recommended products.

(1) MR-J3-100B-RJ080W or less

(Note 3)

Power supply

Molded-case

circuit breaker

(MCCB) or fuse

Magnetic

contactor

(MC)

(Note 2)

Line noise

filter

(FR-BSF01)

R S T

Personal

computer

Junction

terminal

block

Servo system

controller or Front axis

servo amplifier CN1B

Rear servo amplifier

CN1A or Cap

Servo amplifier

U

V

W

MR Configurator

CN5

CN3

CN1A

CN1B

CN2

1

L

L

2

L3

(Note 2)

Power factor

improving DC

reactor

(FR-BEL)

Note 1. The battery (option) and absolute position storage unit (option) are used for the absolute position detection system. (Refer to chapter

9.)

2. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used. When

not using the power factor improving DC reactor, short P

3. A 1-phase 200V to 230VAC power supply may be used with the servo amplifier of MR-J3-70B-RJ080W or less.

For 1-phase 200V to 230VAC, connect the power supply to L

specification.

P1

P2

PC

Regenerative option

L

11

L

21

and P2.

1

and leave L3 open. Refer to section 1.2 for the power supply

1L2

CN4

(Note 1)

Battery

MR-J3BAT

Direct drive motor

(Note 1)

Absolute

position

storage unit

MR-BTAS01

1 - 9

Page 23

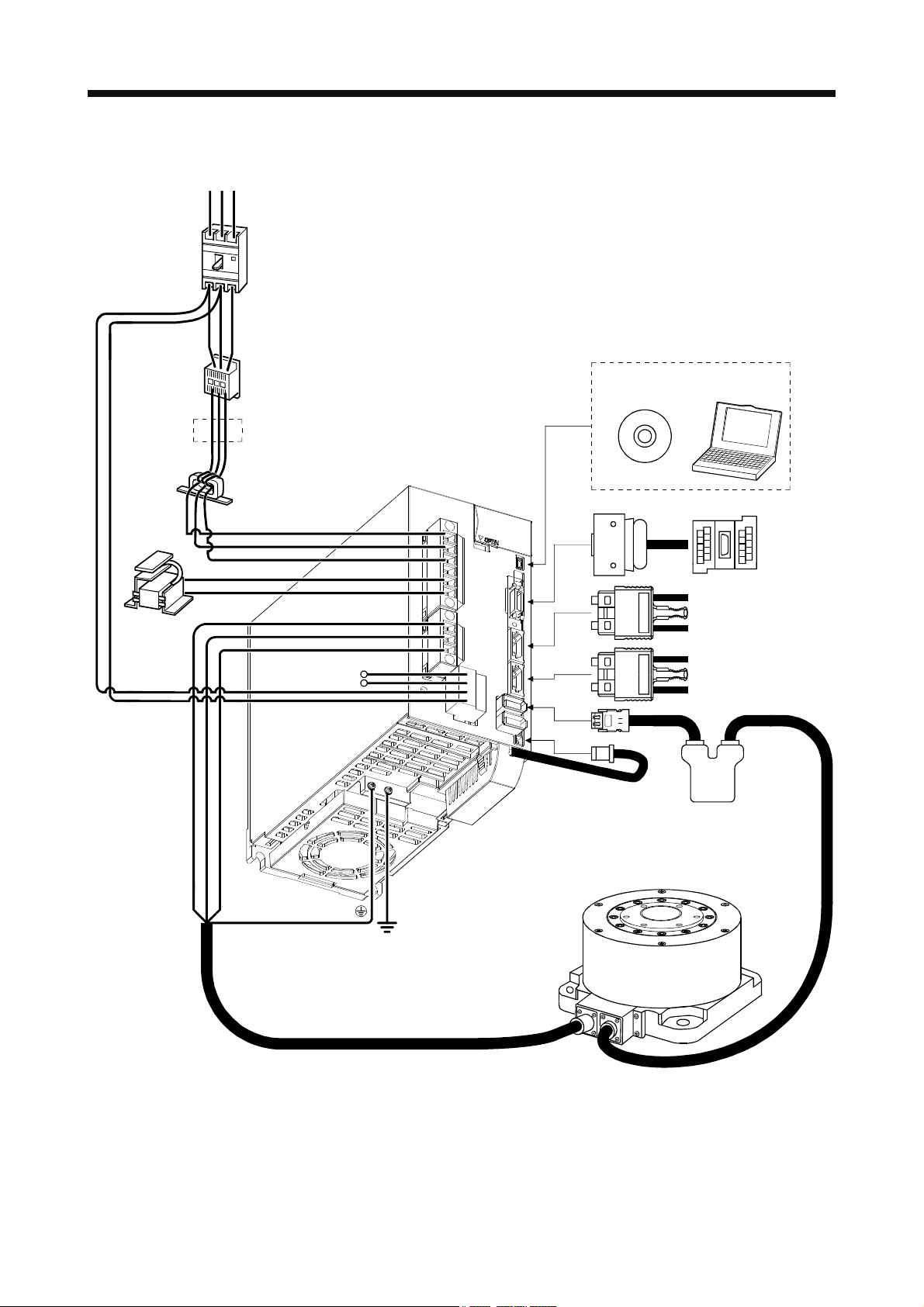

1. FUNCTIONS AND CONFIGURATION

(2) MR-J3-350B-RJ080W

(Note 3)

Power supply

Molded-case

circuit breaker

(MCCB) or fuse

Magnetic

contactor

(MC)

(Note 2)

Line noise

filter

(FR-BLF)

(Note 2)

Power factor

improving DC

reactor

(FR-BEL)

L

11

L

21

R S T

P

P2

L

L

L

1

1

2

3

Regenerative option

Personal

MR Configurator

computer

CN5

Servo amplifier

CN3

Junction

terminal

block

CN1A

P

CN1B

C

Servo system

controller or Front axis

servo amplifier CN1B

Rear servo amplifier

CN1A or Cap

CN2

CN4

(Note 1)

(Note 1)

Battery

MR-J3BAT

Absolute

position

storage unit

MR-BTAS01

Direct drive motor

U

V

W

Note 1. The battery (option) and absolute position storage unit (option) are used for the absolute position detection system. (Refer to chapter

9.)

2. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used. When

not using the power factor improving DC reactor, short P

3. Refer to section 1.2 for the power supply specification.

and P2.

1

1 - 10

Page 24

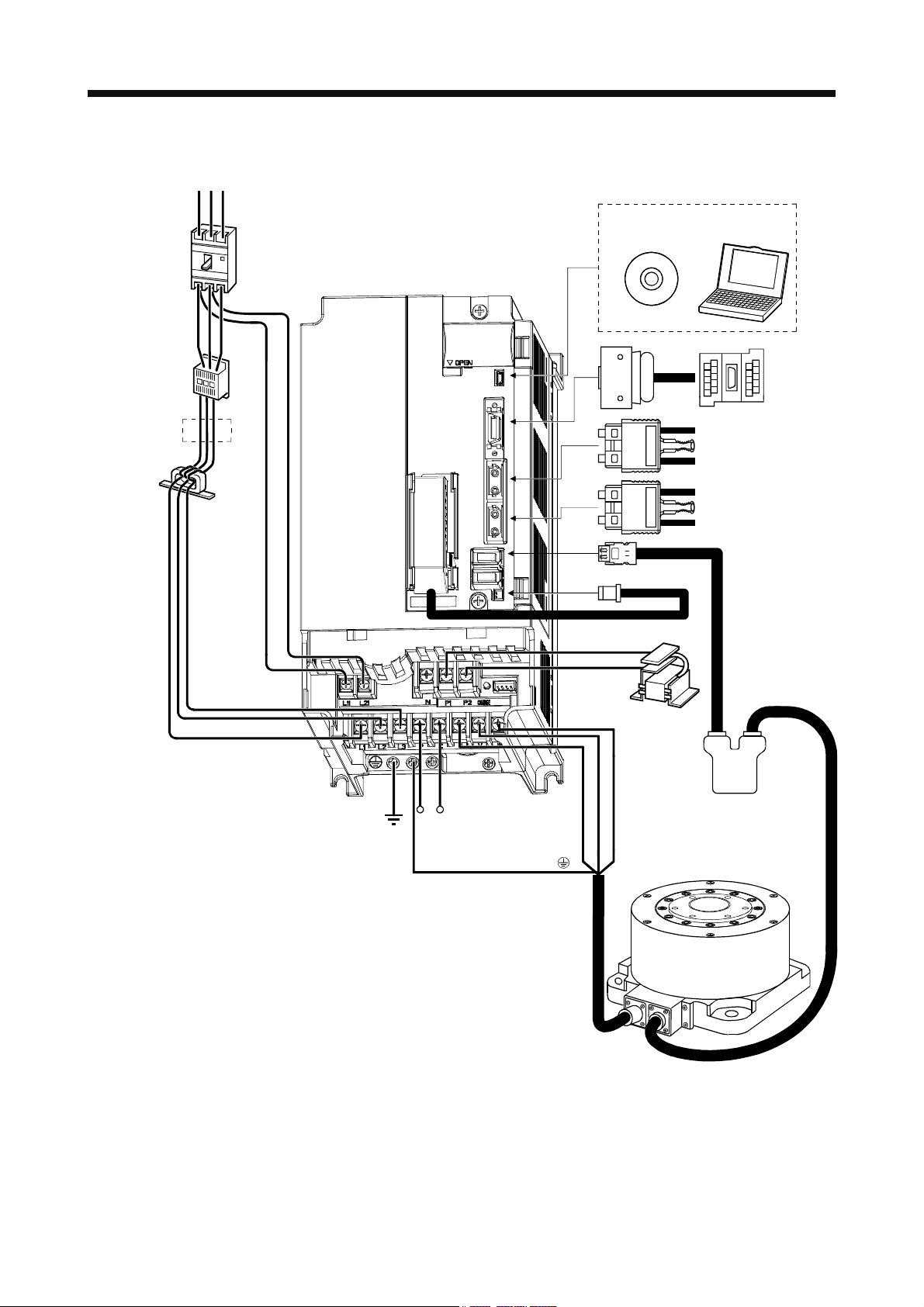

1. FUNCTIONS AND CONFIGURATION

(3) MR-J3-500B-RJ080W

(Note 3)

Power supply

Molded-case

circuit breaker

(MCCB) or fuse

Magnetic

contactor

(MC)

(Note 2)

Line noise

filter

(FR-BLF)

R S T

Servo amplifier

(Note 1)

Battery

MR-J3BAT

CN5

CN3

CN1A

CN1B

CN2

CN4

MR Configurator

Personal

computer

Junction

terminal

block

Servo system

controller or Front axis

servo amplifier CN1B

Rear servo amplifier

CN1A or Cap

L21

L11

L

3

L2

L1

CP

Regenerative option

P1

P

2

UVW

(Note 2)

Power factor

improving DC

reactor

(FR-BEL)

Direct drive motor

(Note 1)

Absolute position

storage unit

MR-BTAS01

Note 1. The battery (option) and absolute position storage unit (option) are used for the absolute position detection system. (Refer to chapter

9.)

2. The power factor improving AC reactor can also be used. In this case, the power factor improving DC reactor cannot be used. When

not using the power factor improving DC reactor, short P

3. Refer to section 1.2 for the power supply specification.

and P2.

1

1 - 11

Page 25

1. FUNCTIONS AND CONFIGURATION

MEMO

1 - 12

Page 26

2. DIRECT DRIVE MOTOR

2. DIRECT DRIVE MOTOR

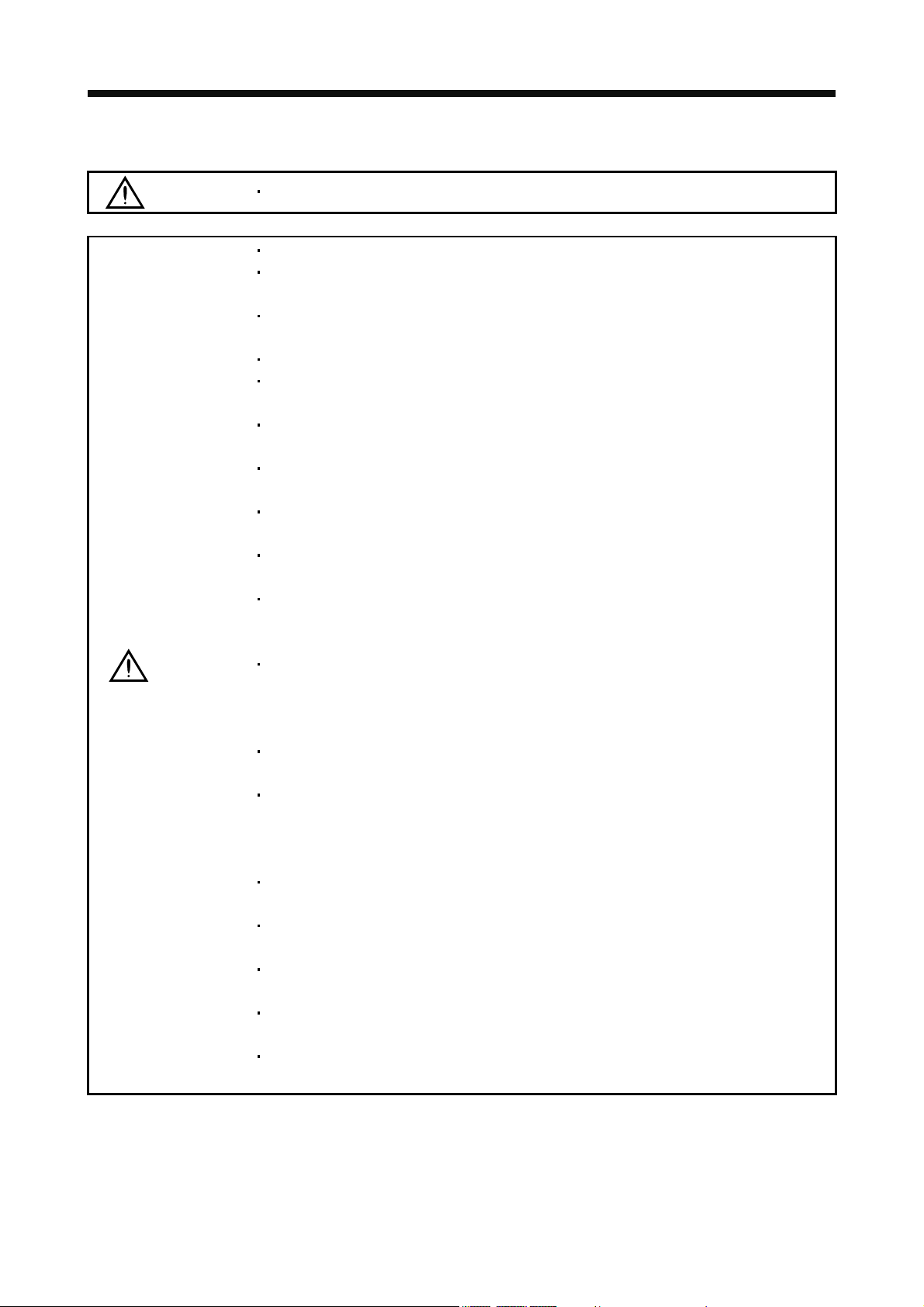

2.1 Rating plate

2.2 Parts identification

AC DIRECT DRIVE MOTOR

TM-RFM002C20

INPUT 3AC 45.7V 1.2A

TORQUE 2Nm

200r/min IP42CI.F 5.2kg

SER.No. 000000 12Y

Note. Production year and month of the direct drive motor are indicated in a serial number on the

rating plate.

The year and month of manufacture are indicated by the last two digits of the year and one

digit of the month [1 to 9, X(10), Y(11), and Z(12)].

For Nov. 2012, the Serial No. is like, "SER. No.

Z-phase mark

Model

Input power supply

Rated output

Rated speed, IP rating, Insulation class, Mass

Serial number (Note)

Country of origin

12Y".

Rotor (output shaft)

Encoder connector

Power supply connector

Power supply (U, V, and W)

Earth ( )

2 - 1

Page 27

2. DIRECT DRIVE MOTOR

2.3 Installation

WARNING

CAUTION

To prevent electric shock, ground each equipment securely.

Stacking in excess of the limited number of product packages is not allowed.

Install the equipment on incombustible material. Installing it directly or close to

combustibles will lead to a fire.

Install the equipment in a load-bearing place in accordance with this Instruction

Manual.

Do not get on or put heavy load on the equipment to prevent injury.

Use the equipment within the specified environmental condition range.

Refer to the specifications of the direct drive motor series.

Do not subject the direct drive motor to drop impact or shock loads as they are

precision equipment.

Do not install or operate the direct drive motor which has been damaged or has any

parts missing.

Do not carry the direct drive motor by holding the cables, rotor, encoder or

connector. Otherwise, a fault or injury may occur.

Securely fix the direct drive motor to the machine. If fixed insecurely, the direct drive

motor will come off during operation, leading to injury.

Measure a direct drive motor, and check the motor vibration level. A great vibration

may cause the early damage of a bearing, encoder, and brake. The great vibration

may also cause the poor connector connection or bolt looseness.

For the gain adjustment at the equipment startup, check the torque waveform and

the speed waveform by using a measurement device, and then check that no

vibration occurs. If the vibration occurs due to high gain, the vibration may cause the

early damage of the direct drive motor.

When coupling the rotor end of the direct drive motor, do not subject the rotor end to

impact, such as hammering. The encoder may become faulty.

When coupling a load to the direct drive motor, make sure to align and center the

load on the motor flange rabbet. Particularly, when the rigid coupling is used, the

slight center deviation may cause the decline of the position accuracy, and may

cause the rotor damage.

Balance the load to the extent possible. Failure to do so can cause vibration during

direct drive motor operation or damage the bearings and encoder.

Take safety measures, e.g. provide covers, to prevent accidental access to the rotor

of the direct drive motor during operation.

Do not subject the direct drive motor rotor to more than the permissible load.

Otherwise, the rotor may break, leading to injury.

When the product has been stored for an extended period of time, contact your local

sales office.

When treating the direct drive motor, be careful about the edged parts such as the

corners of the direct drive motor.

2 - 2

Page 28

2. DIRECT DRIVE MOTOR

2.3.1 Equipment configuration

This section explains the system configuration with a direct drive motor. Note the following points when using a

direct drive motor.

(1) Minimum oscillation angle

If the direct drive motor rotates repeatedly by a small angle (by 70° or less), make the direct drive motor

rotate by 90° or more at least once a day in order to keep the bearing lubricated.

(2) Z-phase position

A Z-phase pulse turns on (Z-phase mark passing) when the Z-phase mark on the rotor end of the direct

drive motor passes over the connector area. Keep the Z-phase position visible even after the direct drive

motor is installed to a machine.

Z-phase mark

Rotor (output shaft)

Z-phase pulse turns

on when the Z-phase

mark passes over

the connector area.

Encoder connector

Power supply connector

(3) Precautions for Z-phase mark passing

After power on, the Z-phase mark of the direct drive motor must pass the connector area once. In a system

which prevents the direct drive motor from making a full rotation, install the direct drive motor in a position

where the Z-phase mark can pass over the connector area.

(4) Vertical axis (lift)

For the system where the unbalanced torque occurs, such as a vertical axis system (lift), use the motor in

the absolute position detection system. In the absolute position detection system, the absolute position is

established when the Z-phase mark passes the connector area once.

At the system startup, make the Z-phase mark pass over the connector area, and switch the servo

amplifier's power supply from off to on.

If the direct drive motor can be rotated manually, make the Z-phase mark pass over the connector area

while only the servo amplifier's control power supply is on. After that, switch the servo amplifier's power

supply from off to on.

If the direct drive motor cannot be rotated manually, detect the magnetic poles while the torque is balanced,

then run the direct drive motor in the test mode to make its Z-phase mark pass over the connector area.

After that, switch the servo amplifier's power supply from off to on.

After the Z-phase mark passes through the connector area once, magnetic pole detection is not required.

2 - 3

Page 29

2. DIRECT DRIVE MOTOR

2.3.2 Installation orientation

The following table indicates the installation orientation of the direct drive motor.

Direct drive motor series Direction of installation

TM-RFM May be installed in any direction.

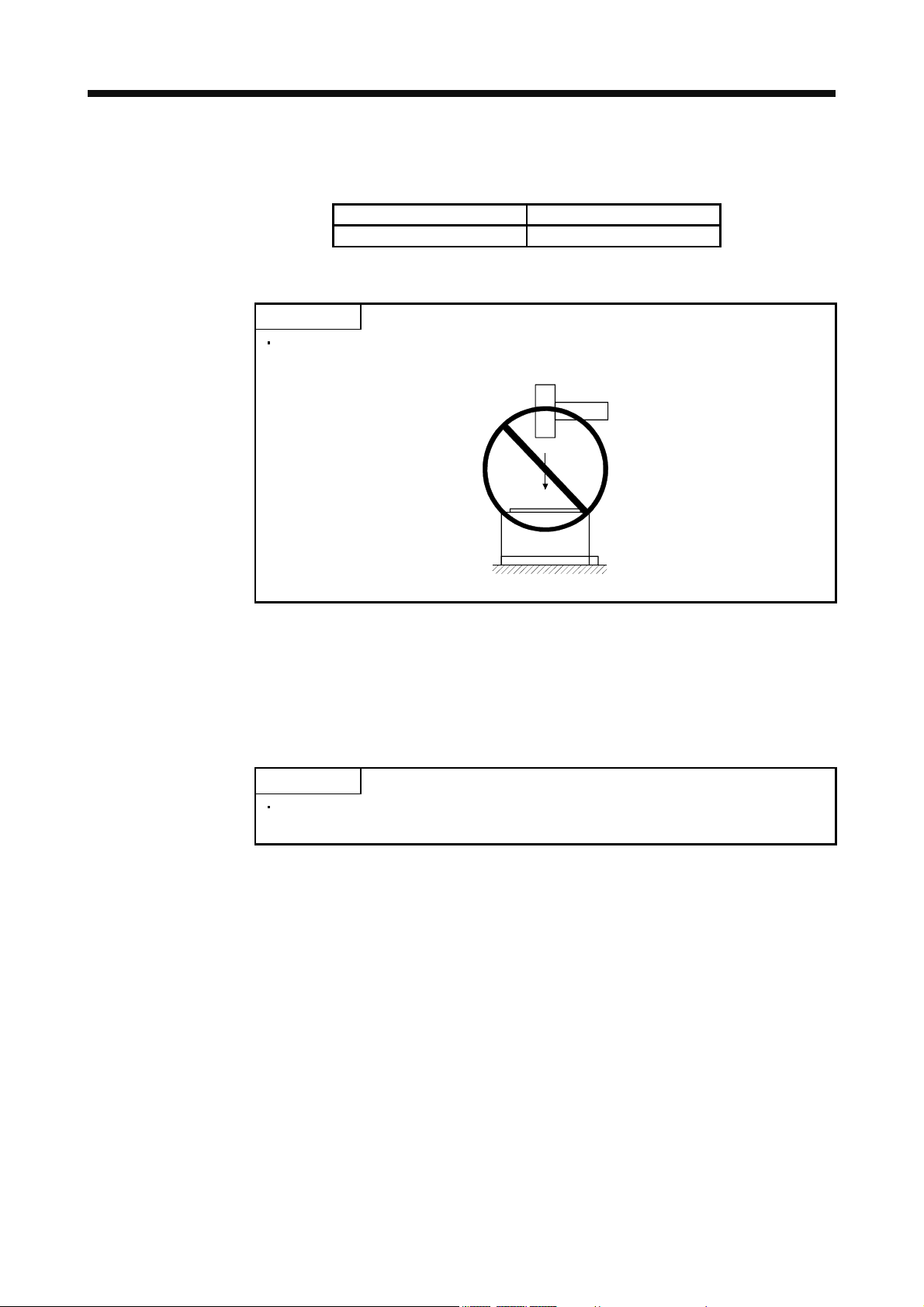

2.3.3 Load remove precautions

POINT

During assembling, the rotor end must not be hammered. Doing so can cause the

encoder to fail.

(1) The orientation of the encoder on the direct drive motor cannot be changed.

(2) For installation of the direct drive motor, use spring washers, etc. and fully tighten the bolts so that they do

not become loose due to vibration.

2.3.4 Permissible load for the rotor

POINT

Because the rigid coupling may damage the rotor, make sure to align and center

the load on the rotor.

For the permissible rotor load specific to the direct drive motor, refer to section 2.5.2.

(1) When coupling a load to the direct drive motor, the load applied to the rotor must be under the permissible

load.

(2) Excess of the permissible load can cause the bearing life to reduce and the rotor to break.

(3) The load indicated in this section is static load in a single direction and does not include eccentric load.

Make eccentric load as small as possible. Not doing so can cause the direct drive motor to be damaged.

2 - 4

Page 30

2. DIRECT DRIVE MOTOR

2.3.5 Protection from oil and water

Provide adequate protection to prevent foreign matter, such as oil and water from entering the direct drive motor

rotor. When installing the direct drive motor, consider the items in this section.

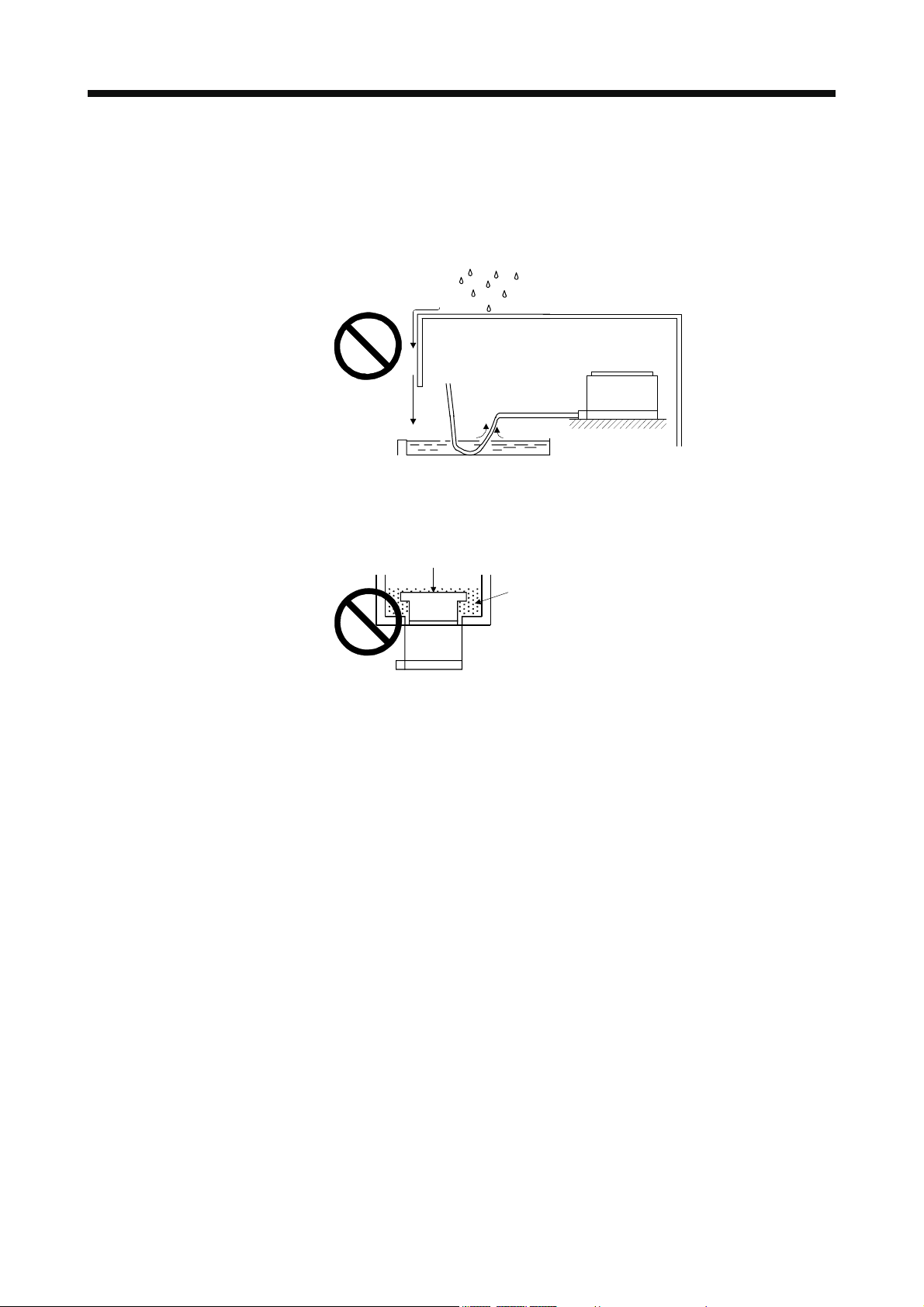

(1) Do not use the direct drive motor with its cable soaked in oil or water.

Cover

Direct drive motor

Oil/water pool

Capillary phenomenon

(2) Provide measures so that the direct drive motor is not exposed to oil and water entering from the machine

side, rotating table, etc.

Rotating table etc.

Lubricating oil

Direct drive motor

(3) If the direct drive motor is exposed to cutting fluid, etc., the sealant, packing, cable and others may be

affected depending on the fluid type.

(4) In the environment where the direct drive motor is exposed to oil mist, oil, water, grease and/or like, a

standard specification direct drive motor may not be usable. Provide measures to prevent dust and/or water

on the machine side.

2 - 5

Page 31

2. DIRECT DRIVE MOTOR

2.3.6 Inspection

Before starting maintenance and/or inspection, turn off the power and wait for 15

minutes or more until the charge lamp turns off. Then, confirm that the voltage

between P(

WARNING

electric shock may occur. In addition, always confirm from the front of the servo

amplifier, whether the charge lamp is off or not.

To avoid the risk of electric shock, only qualified personnel should attempt

inspections. For repair, contact your local sales office.

CAUTION

Do not disassemble and/or repair the equipment on customer side.

It is recommended to make the following checks periodically.

(a) Check the direct drive motor bearings, etc. for unusual noise.

(b) Check the cables and the like for scratches and cracks. Especially when the junction cable is movable,

perform periodic inspection according to operating conditions.

(c) Check the direct drive motor rotor (output shaft) and coupling for misalignment.

(d) Check the power supply connector and encoder connector tightening for looseness.

2.3.7 Life

) and N( ) is safe with a voltage tester and others. Otherwise, an

The following parts must be replaced periodically as listed below. If any part is found faulty, it must be replaced

immediately even when it has not yet reached the end of its life, which depends on the operating method and

environmental conditions. For parts replacement, please contact your local sales office.

Parts name Guideline of life Remarks

Bearings 20,000 to 30,000 hours

Encoder 20,000 to 30,000 hours

Absolute position

storage unit (option)

Battery MR-J3BAT

(option)

20,000 to 30,000 hours

5,000 hours

(battery life with power off)

The Guideline of Life field gives the reference time. If any fault is found

before this time is reached, the parts must be replaced.

When the direct drive motor is run at rated speed under rated load, bearings should be exchanged in 20,000 to

30,000 hours as a guideline. This differs on the operating conditions. The bearings must also be replaced if

unusual noise or vibration is found during inspection.

2 - 6

Page 32

2. DIRECT DRIVE MOTOR

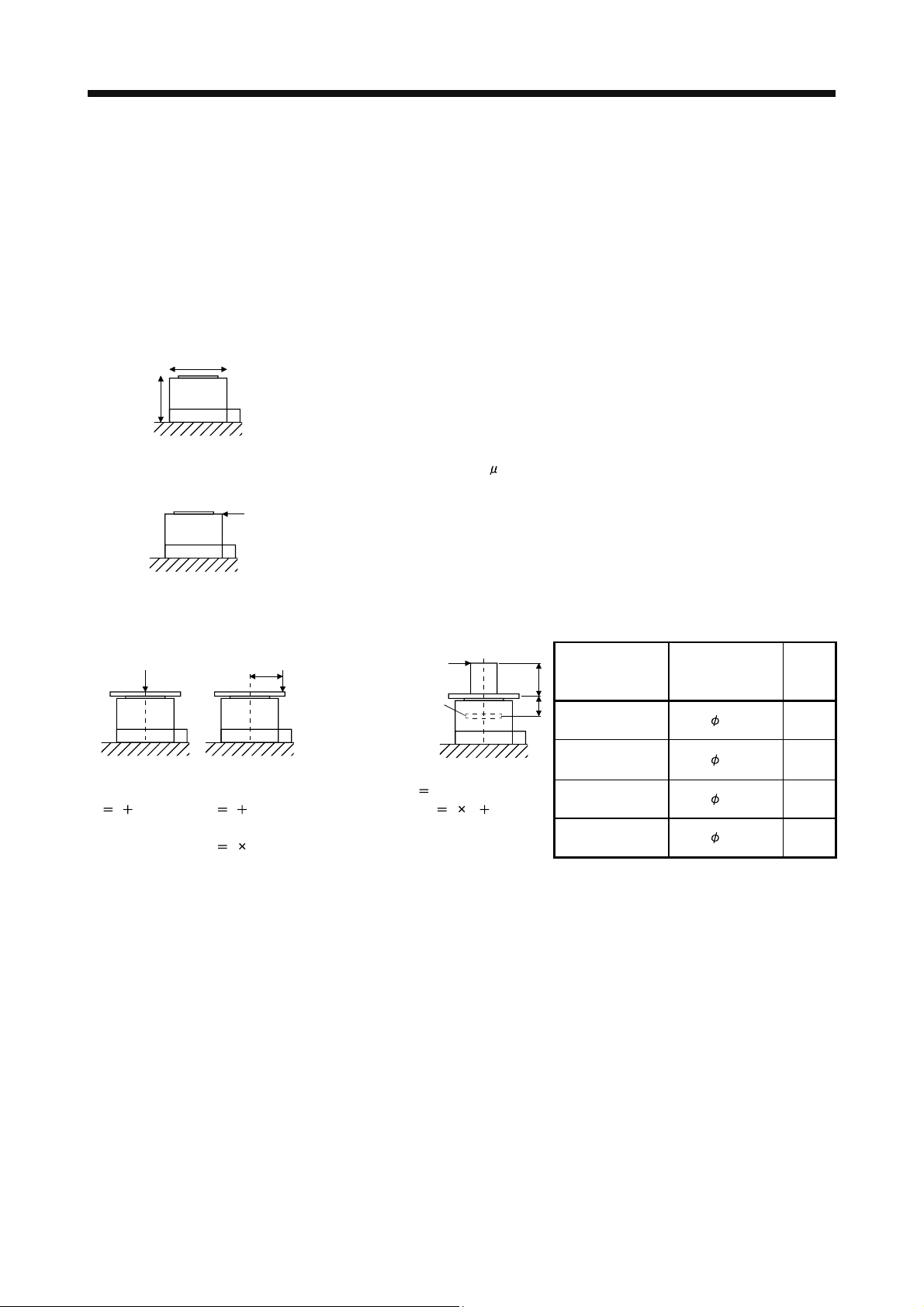

2.3.8 Machine accuracies

The following table indicates the machine accuracies of the direct drive motor around the rotor (output shaft) and

mounting. (except the optional products)

Item Measured part Accuracy [mm]

Runout of flange surface about rotor (output shaft) a 0.05

Runout of fitting outer diameter of flange surface b 0.07

Runout of rotor (output shaft) c 0.04

Runout of rotor (output shaft) end d 0.02

Reference diagram

2.3.9 Flange surface size

The rated torque of the direct drive motor indicates the permissible continuous torque value that can be

generated at the specific ambient temperature (0 to 40

aluminum surface shown in this table.

Flange surface

size [mm]

002C20

400 400 20 004C20

006C20

006E20

450 450 12 012E20

018E20

012G20

550 550 12 048G20

072G20

040J10

750 750 45 120J10

240J10

). The direct drive motor is installed on the specified

Direct drive motor

TM-RFM

2 - 7

Page 33

2. DIRECT DRIVE MOTOR

2.4 Connectors used for direct drive motor wiring

POINT

The IP rating indicated is the connector's protection against ingress of dust and

water when the connector is connected to a servo amplifier, direct drive motor and

absolute position storage unit. If the IP rating of the connector, servo amplifier,

direct drive motor and absolute position storage unit vary, the overall IP rating

depends on the lowest IP rating of all components.

2.4.1 Selection of connectors

Use the connector configuration products given in the table as the connectors for connection with the direct drive

motor. Refer to section 2.4.2 for the compatible connector configuration products.

Power supply connector Encoder connector

Servo amplifier

side connector

Absolute position storage unit

Encoder side

connector

MR-BTAS01

Wiring connector

Direct drive motor

TM-RFM C20

TM-RFM E20

TM-RFM G20 Connector configuration C

TM-RFM040J10

TM-RFM120J10

TM-RFM240J10 Connector configuration E

Note. This absolute position storage unit is required for configuring absolute position detection system.

For power supply For encoder

Connector configuration B

Connector configuration D

Connector configuration A Connector configuration A Connector configuration F

Absolute position storage unit (Option) (Note)

Servo amplifier side Encoder side

2 - 8

Page 34

2. DIRECT DRIVE MOTOR

2.4.2 Wiring connectors (Connector configurations A

B C D E F)

Plug

Plug (Hirose Electric) Recommended cable (Bando Densen)

Connector

configuration

A IP67 Straight RM15WTPZK-12S JR13WCCA-8(72)

Feature

Type Plug Cord clamp Model name

clamp

Note 1. The connector to be mated.

Cord

2. Purchase from Toa Electric Industry Co. Ltd., Nagoya Branch

Plug Cable clamp

Plug (DDK) Cable clamp

Connector

configuration

B

Feature

4 to 8

IP67

EN compliant

8.3 to 11.3

General environment

(Note 1)

Type Model name

CE05-6A14S-2SD-D

Straight

Applicable wire size: AWG 22 to 16

D/MS3106B14S-2S

Applicable wire size: AWG 22 to 16

Note 1. Not comply with the EN.

2. The connector to be mated.

Cable clampPlug

20276

VSVPAWG#23×6P

KB-0492 (Note 2)

Overall

diameter of

cable

[mm]

(Reference)

8 to 12

5 to 8.3

7.9 or less

(bushing ID)

Overall

diameter of

cable

[mm]

(Reference)

8.2 RM15WTRZB-12P(72)

Model name

ACS-08RL-MS14F

(Nippon Flex)

ACS-12RL-MS14F

(Nippon Flex)

YSO14-5 to 8

(Daiwa Dengyo)

YSO14-9 to 11

(Daiwa Dengyo)

D/MS3057-6A

Direct drive motor encoder

connector or absolute

position storage unit

connector

(servo amplifier side)

(Note 1)

Direct drive motor power

supply connector (Note 2)

CE05-2A14S-2PD-D

Connector

configuration

C

Feature

EN compliant

General environment

(Note 1)

Note 1. Not comply with the EN.

2. The connector to be mated.

Plug (DDK) Cable clamp (DDK)

Type Model name

CE05-6A18-10SD-D-BSS

Straight

Applicable wire size: AWG 14 to 12

D/MS3106B18-10S

Applicable wire size: AWG 14 to 12

2 - 9

Overall

diameter of

cable

[mm]

(Reference)

8.5 to 11 CE3057-10A-2-D IP67

10.5 to 14.1 CE3057-10A-1-D

14.3 or less

(bushing ID)

Model name

D/MS3057-10A

Direct drive motor power

supply connector (Note 2)

CE05-2A18-10PD-D

Page 35

2. DIRECT DRIVE MOTOR

Connector

configuration

D

Note 1. Not comply with the EN.

2. The connector to be mated.

Feature

EN compliant

General environment

(Note 1)

Type Model name

Straight

Cable clampPlug

Plug (DDK) Cable clamp (DDK)

Overall

diameter of

cable

[mm]

(Reference)

CE05-6A22-22SD-D-BSS

Applicable wire size: AWG 10 to 8

D/MS3106B22-22S

Applicable wire size: AWG 10 to 8

Cable clampPlug

9.5 to 13 CE3057-12A-2-D IP67

12.5 to 16 CE3057-12A-1-D

15.9 or less

(bushing ID)

Model name

D/MS3057-12A

Direct drive motor power

supply connector (Note 2)

CE05-2A22-22PD-D

Plug (DDK) Cable clamp (DDK)

Connector

configuration

E

Feature

IP67

EN compliant

General environment

(Note 1)

Type Model name

CE05-6A32-17SD-D-BSS

Straight

Applicable wire size: AWG 6 to 4

D/MS3106B32-17S

Applicable wire size: AWG 6 to 4

Note 1. Not comply with the EN.

2. The connector to be mated.

Cord

Plug

Plug (Hirose Electric)

Connector

configuration

F IP67 Straight RM15WTPZ-12P(72) JR13WCCA-8(72)

Feature

Type Plug Cord clamp Model name

clamp

Note 1. The connector to be mated.

2. Purchase from Toa Electric Industry Co. Ltd., Nagoya Branch

diameter of

(Reference)

23.8 or less

(bushing ID)

20276

VSVPAWG#23×6P

KB-0492 (Note 2)

Overall

cable

[mm]

22 to 23.8 CE3057-20A-1-D

Recommended cable

(Bando Densen)

Model name

D/MS3057-20A

Overall

diameter of

cable

[mm]

(Reference)

8.2 RM15WTRZB-12S(72)

Direct drive motor power

connector (Note 2)

CE05-2A32-17PD-D

Absolute position storage

unit connector

(encoder side) (Note 1)

2 - 10

Page 36

2. DIRECT DRIVE MOTOR

2.4.3 Connector outline drawings

The connector outline drawings for wiring the direct drive motor are shown below.

(1) Hirose Electric

(a) RM15WTPZK-12S

RM15WTPZ-12P(72)

Model Connector configuration (Note)

RM15WTPZK-12S A

RM15WTPZ-12P(72) F

Note. For the connector configuration, refer to section 2.4.2.

Spanner hook gap dimension: 18

M16 0.75M19 1

[Unit: mm]

(b) JR13WCCA-8(72)

For the connector configuration, refer to the connector configuration A and F of section 2.4.2.

(2) DDK

(a) CE05-6A14S-2SD-D

For the connector configuration, refer to the connector configuration B of section 2.4.2.

36.3

Spanner hook gap dimension: 17

Positioning key

7/8-20UNEF-2B

M16 0.75

7.5

(13.2)

[Unit: mm]

[Unit: mm]

3/4-20UNEF-2A

24.0 1

5.6 0.1

8.46 0.5

2 - 11

Page 37

2. DIRECT DRIVE MOTOR

(b) CE05-6A18-10SD-D-BSS

CE05-6A22-22SD-D-BSS

CE05-6A32-17SD-D-BSS

Positioning key

[Unit: mm]

A

D

W

Model A B

CE05-6A18-10SD-D-BSS 1 1/8-18UNEF-2B 34.13 32.1 57 1-20UNEF-2A C

CE05-6A22-22SD-D-BSS 1 3/8-18UNEF-2B 40.48 38.3 61 1 3/16-18UNEF-2A D

CE05-6A32-17SD-D-BSS 2-18UNS-2B 56.33 54.2 79 1 3/4-18UNS-2A E

Note. For the connector configuration, refer to section 2.4.2.

0

C 0.8 D or less W

0.38

Connector configuration

(c) CE3057-10A-1-D

CE3057-10A-2-D

CE3057-12A-1-D

CE3057-12A-2-D

CE3057-20A-1-D

V-Thread

B

(D)

A 0.7

C

1.5

F

(Bushing inner diameter)

G 0.7

(Bushing outer diameter)

(Note)

[Unit: mm]

E

Model

CE3057-

10A-1-D

CE3057-

10A-2-D

CE3057-

12A-1-D

CE3057-

12A-2-D

CE3057-

20A-1-D

Note. For the connector configuration, refer to section 2.4.2.

Applicable

shell size

18 23.8 30.1 10.3 (41.3) 15.9

22 23.8 35 10.3 (41.3) 19

32 27.8 51.6 11.9 (43.0) 32.0 23.8 51.6 1 3/4-18UNS-2B CE3420-20-1 22.0 to 23.8 E

A B C (D) E F G V

14.1 CE3420-10-1 10.5 to 14.1

11.0

16.0 CE3420-12-1 12.5 to 16

13.0

31.7 1-20UNEF-2B

1 3/16-18UNEF-

37.3

2B

2 - 12

Enclosed

bushing type

CE3420-10-2 8.5 to 11

CE3420-12-2 9.5 to 13

Range of

applicable cables

(Reference)

Connector

configuration

(Note)

C

D

Page 38

2. DIRECT DRIVE MOTOR

(d) D/MS3106B14S-2S

D/MS3106B18-10S

D/MS3106B22-22S

D/MS3106B32-17S

W

Y or less

[Unit: mm]

L or less

J 0.12

A

Q

D/MS3106B14S-2S 7/8-20UNEF 13.49 42.88 28.57 3/4-20UNEF 8.00 30 B

D/MS3106B18-10S 1 1/8-18UNEF 18.26 52.37 34.13 1-20UNEF 9.53 42 C

D/MS3106B22-22S 1 3/8-18UNEF 18.26 56.57 40.48 1 3/16-18UNEF 9.53 50 D

D/MS3106B32-17S 2-18UNS 18.26 61.92 56.33 1 3/4-18UNS 11.13 66 E

Note. For the connector configuration, refer to section 2.4.2.

(e) D/MS3057-6A

D/MS3057-10A

D/MS3057-12A

D/MS3057-20A

V

Model name A J L Q V W Y

A 0.7

Effective thread length C

1.6

V

B 0.7

E (Bushing inner diameter)

D (Cable clamp inner diameter)

G 0.7

Connector

configuration

(Note)

[Unit: mm]

Model name Shell size A B C D E G V Bushing

D/MS3057-6A 14S 22.2 24.6 10.3 11.2 7.9 27.0 3/4-20UNEF AN3420-6 B

D/MS3057-10A 18 23.8 30.1 10.3 15.9 14.3 31.7 1-20UNEF AN3420-10 C

D/MS3057-12A 22 23.8 35.0 10.3 19.0 15.9 37.3 1 3/16-18UNEF-2A AN3420-12 D

D/MS3057-20A 32 27.8 51.6 11.9 31.7 23.8 51.6 1 3/4-18UNS AN3420-20 E

Note. For the connector configuration, refer to section 2.4.2.

Connector

configuration

(Note)

2 - 13

Page 39

2. DIRECT DRIVE MOTOR

(3) Daiwa Dengyo

[Unit: mm]

O-ring

A

across flats D

Hexagonal width

Hexagonal width

across corners D1

L

across flats D2

Hexagonal width

Hexagonal width

across corners D3

Model name

Applicable

cable OD

YSO14-5 to 8 4 to 8.3

YSO14-9 to 11 7 to 11.3

Length before

A

tightening

L

Width

across

flats

3/4-20UNEF-2B 44 23 25 26 28 B

Width

across

corners

D

D1

Width

across

flats

D2

Width

across

corners

D3

Note. For the connector configuration, refer to the section 2.4.2.

(4) Nippon Flex

(Note 1)

(Note 1) L1

A15

d

(1)

L

(2)

E

G

F

E' × F' × G'

Model name Screw C

ACS-08RLMS14F

ACS-12RLMS14F

3/4-20UNEF-2B 4.0 to 8.0 7 15.0 20 22.0 6 22 24.2 6 46 41

3/4-20UNEF-2B 8.0 to 12.0 7 15.0 24 26.4 6 36 28.6 6 46 41

Applicable

cable OD

Screw C

A d

Tightening nut Nipple body

E

Two-

face

width

F

Width

across

corners

G

Number

of

corners

E'

Twoface

width

F'

Width

across

corners

G'

Number

of

corners

L L1

Note 1. (1) Indicates the reference dimension before assembling, and (2) indicates the reference dimension after assembling.

2. For the connector configuration, refer to section 2.4.2.

Connector

configuration

(Note)

[Unit: mm]

Connector

configuration

(Note 2)

B

2 - 14

Page 40

2. DIRECT DRIVE MOTOR

2.5 TM-RFM series direct drive motor

This section provides information on the specifications and characteristics of the direct drive motor. When using

the TM-RFM series direct drive motor, always read the Safety Instructions in the beginning of this manual in

addition to this section.

2.5.1 Model code definition